Patents

Literature

774 results about "Transverse vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for separating particles by size

InactiveUS7108137B2Easy to manufactureLow costWater/sewage treatment with mechanical oscillationsParticle size analysisUltrasonic radiationHigh pressure

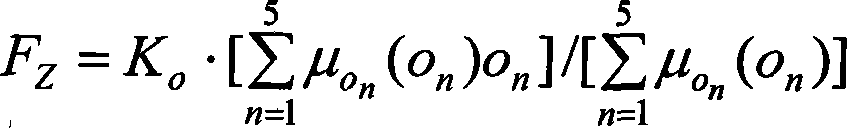

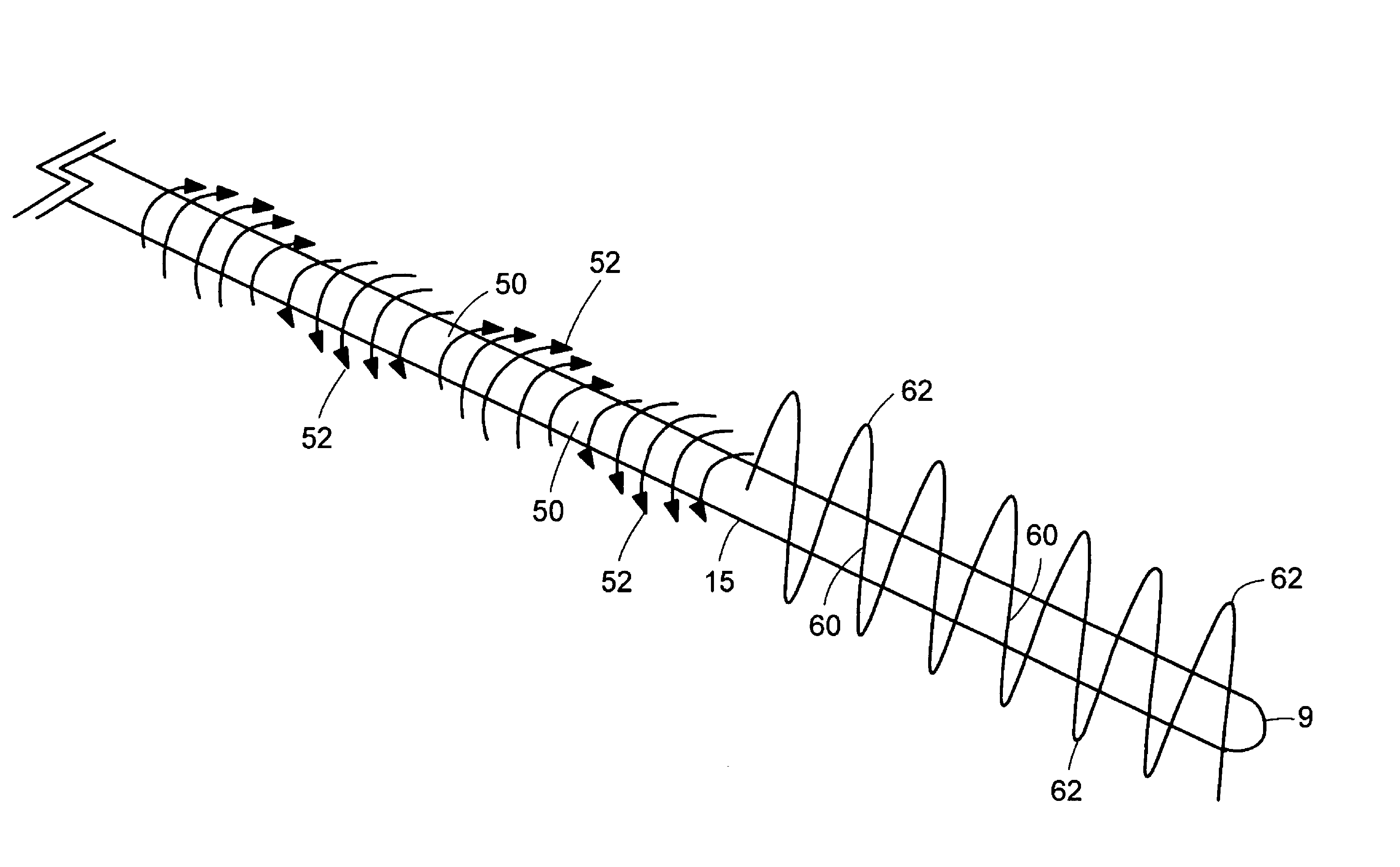

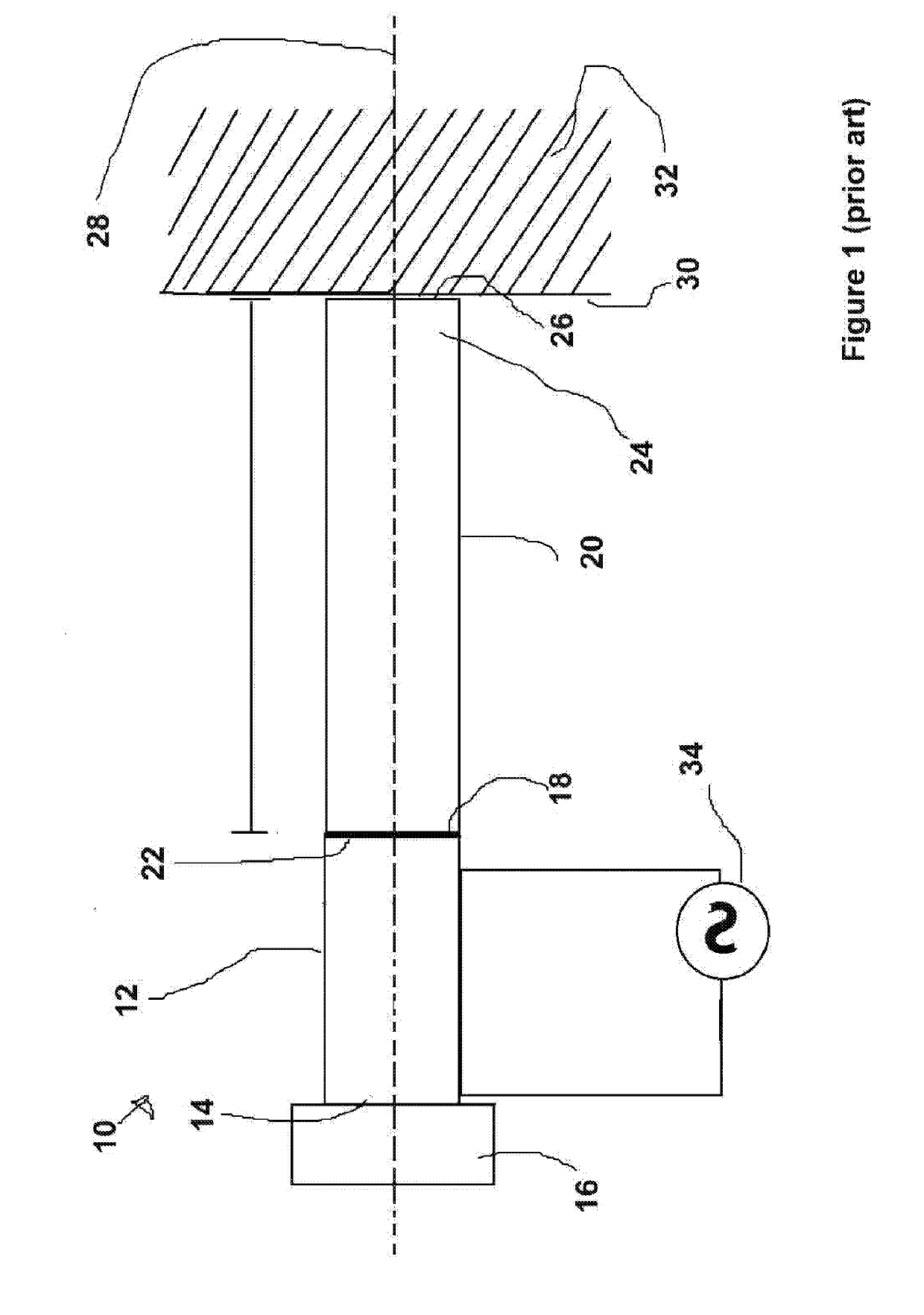

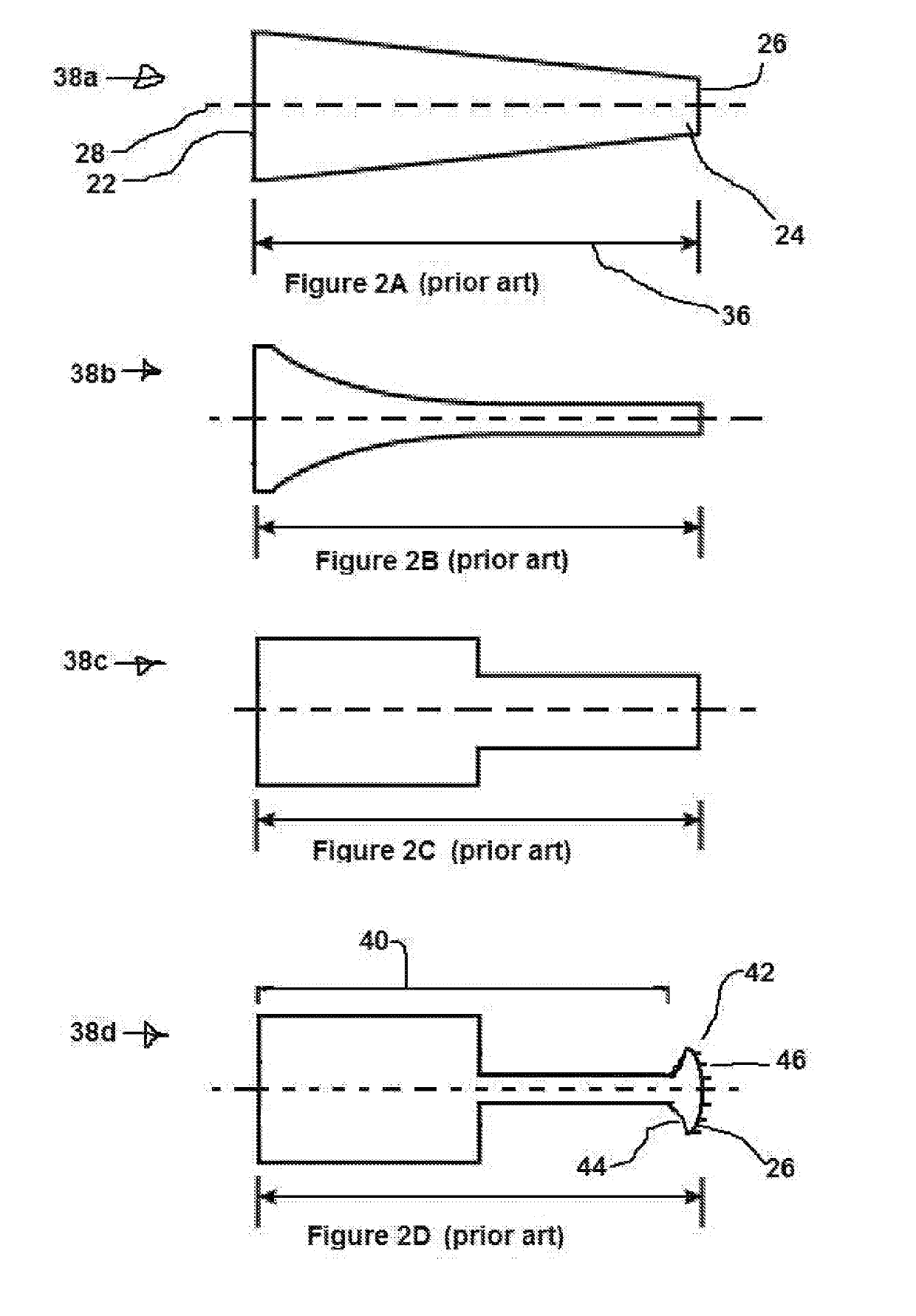

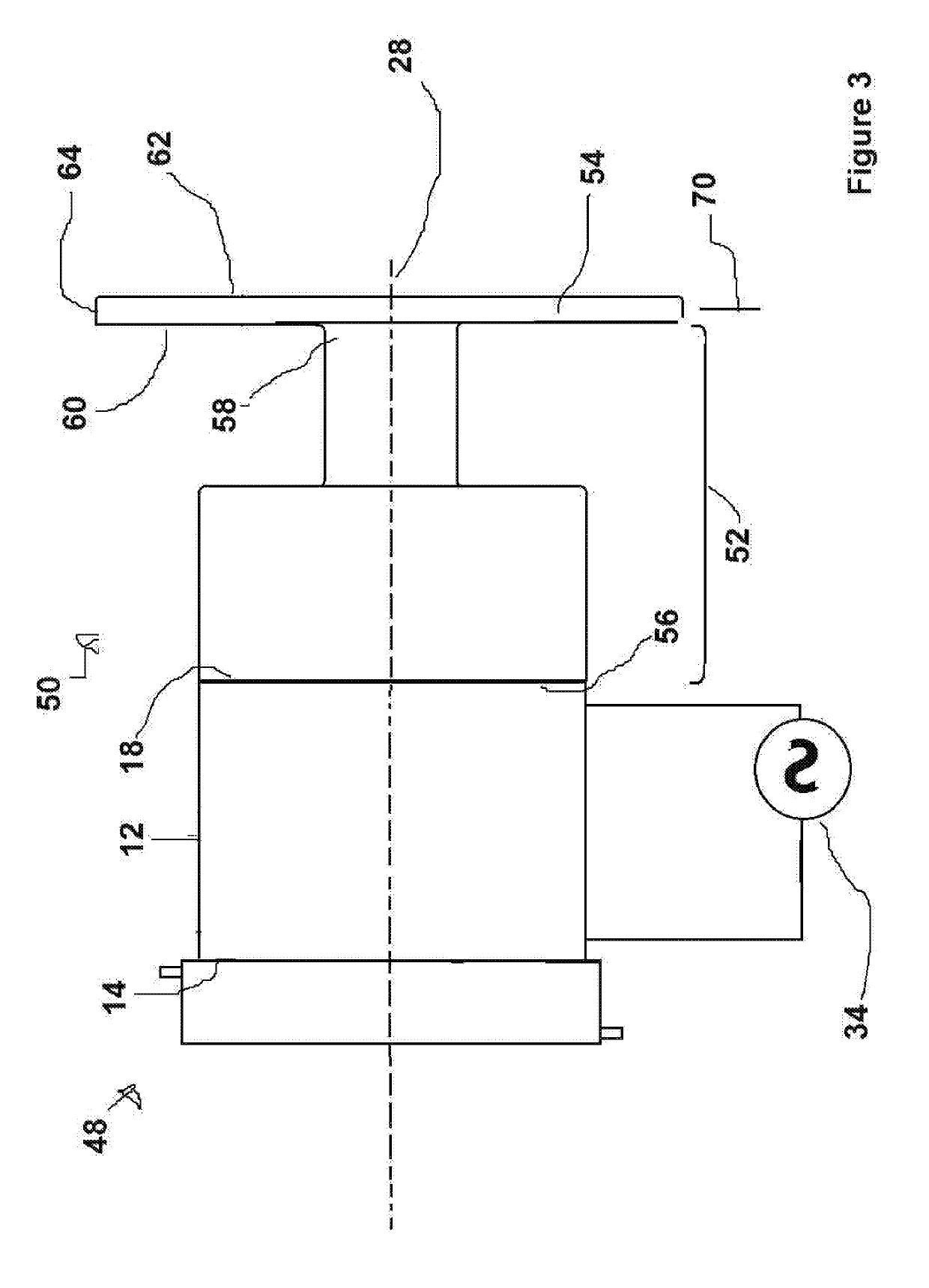

A method and apparatus for separating a mixture of particles of various sizes in a capillary tube into groups by size using multiple forces of controlled amplitude. Ultrasonic radiation at a first selected frequency is applied to set up a standing pressure wave in the capillary tube, resulting in a first aggregating force which causes particles of all sizes to aggregate at positions within the capillary tube which correspond to nodes or anti-nodes of the standing wave. Transverse vibrations are also applied to the capillary tube. The frequency of the ultrasonic radiation is adjusted to reduce the magnitude of the first aggregating force. Inertial forces resulting from the transverse vibrations then cause the particles to separate by size. The apparatus and method allows a mixture of particles to be separated by size quickly, without requiring the use of high voltages.

Owner:WISCONSIN ALUMNI RES FOUND

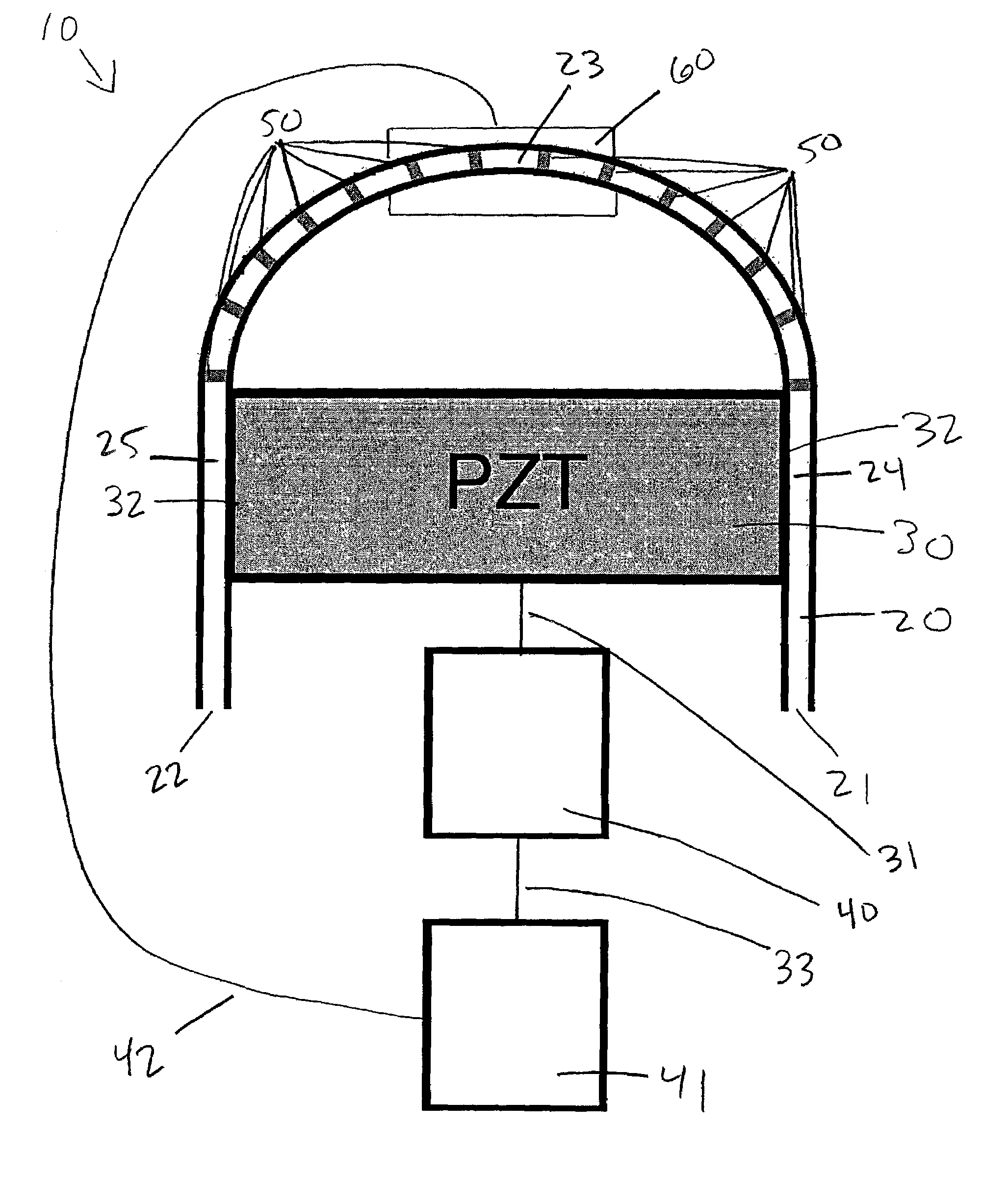

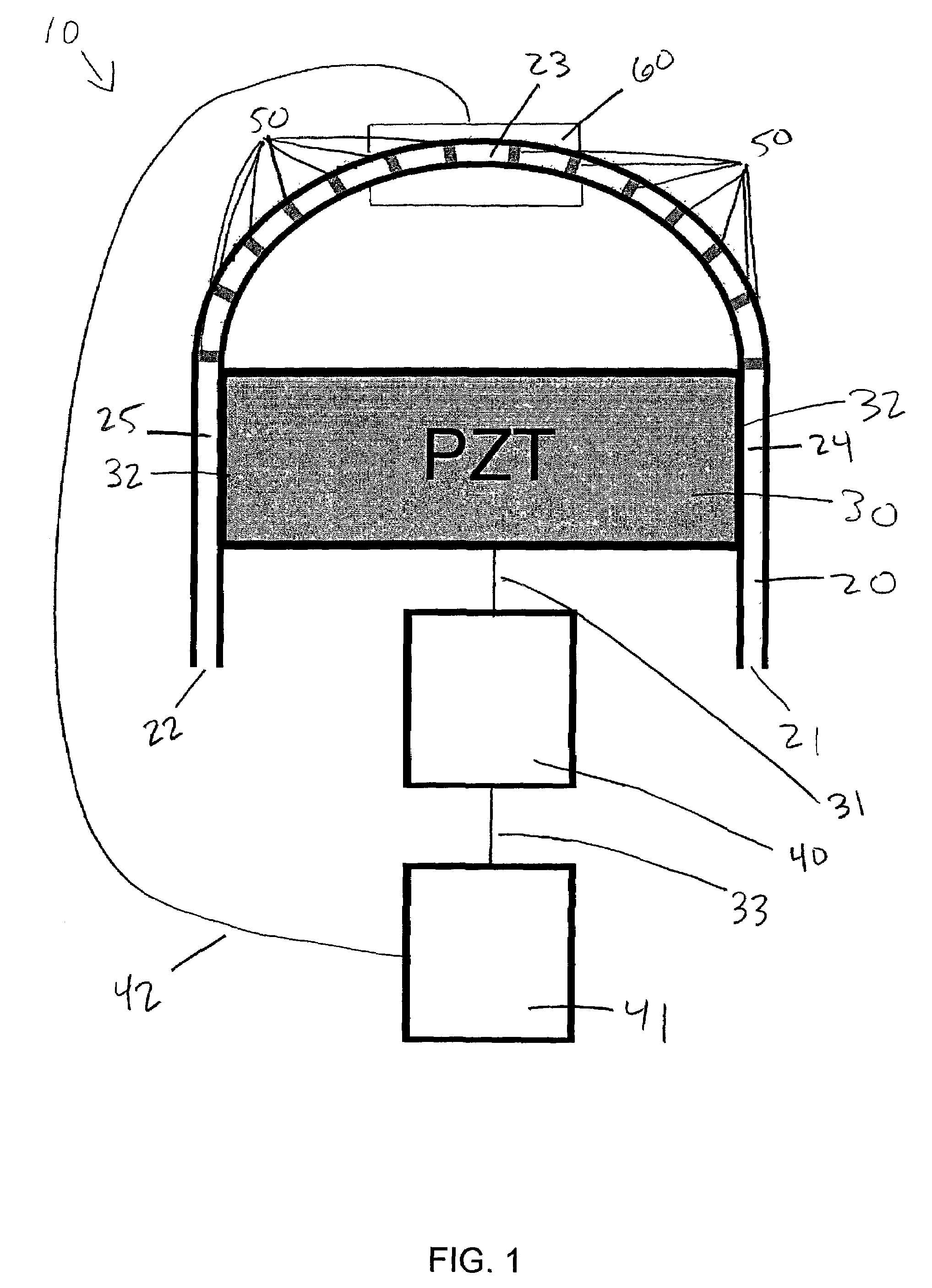

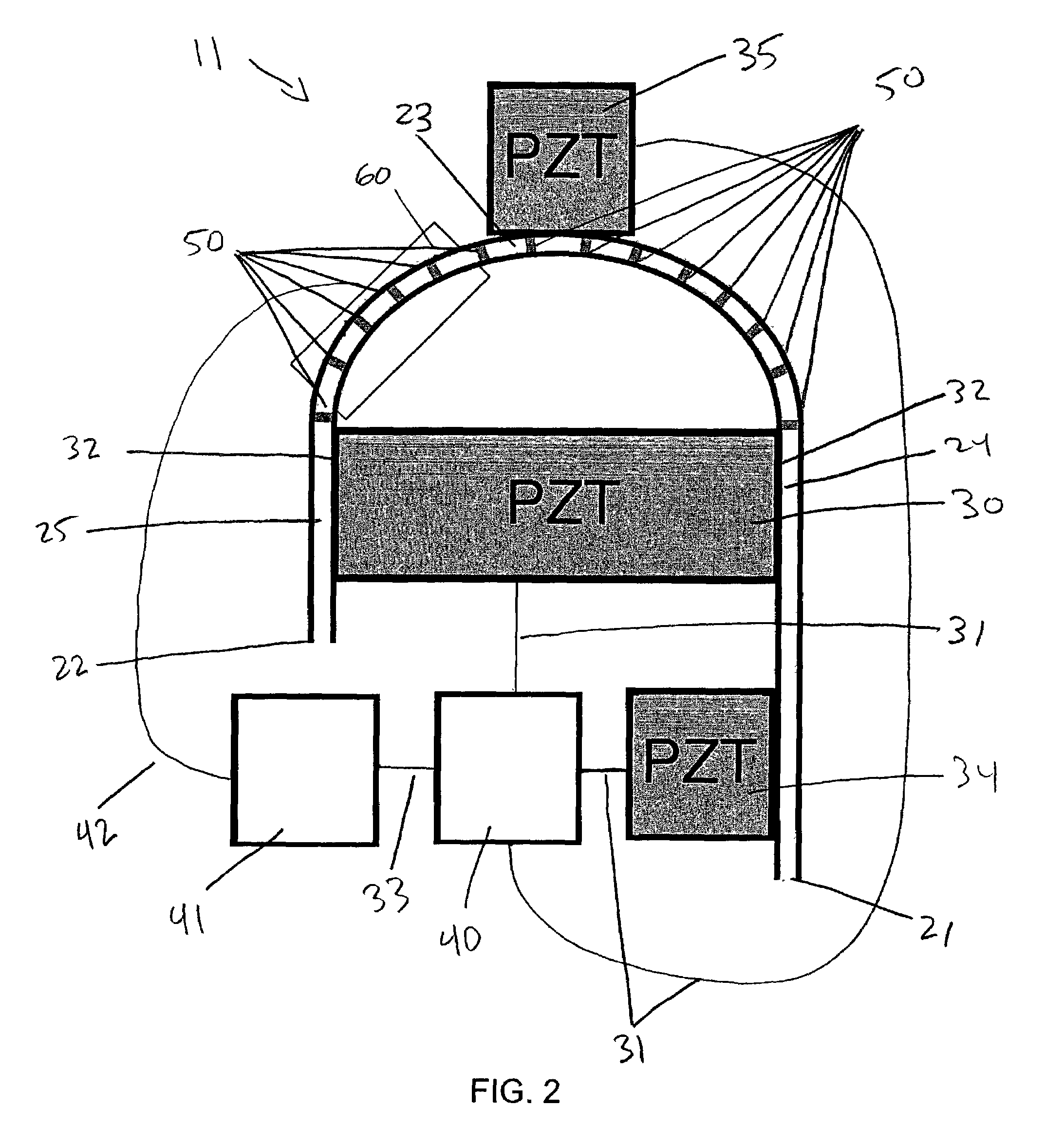

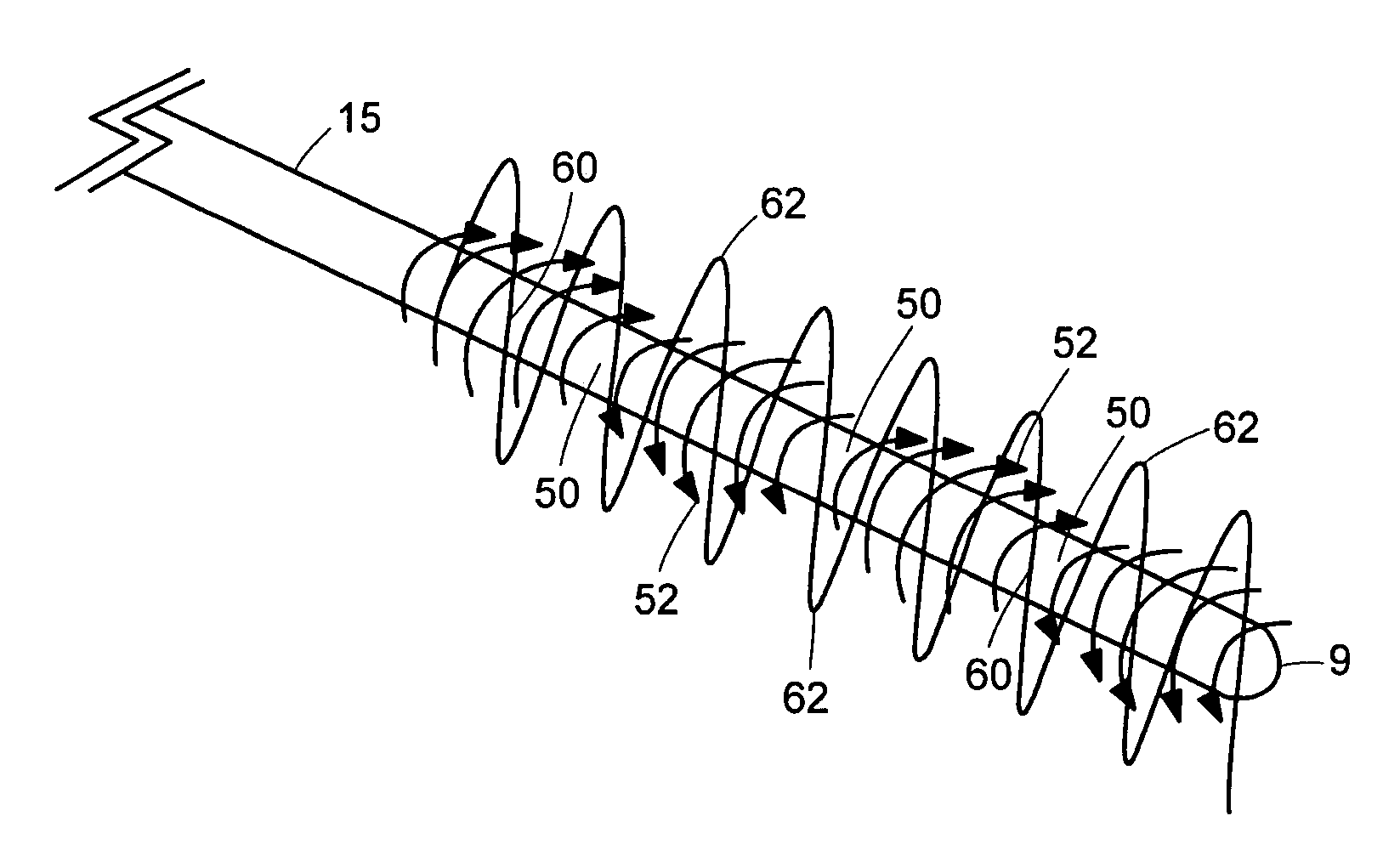

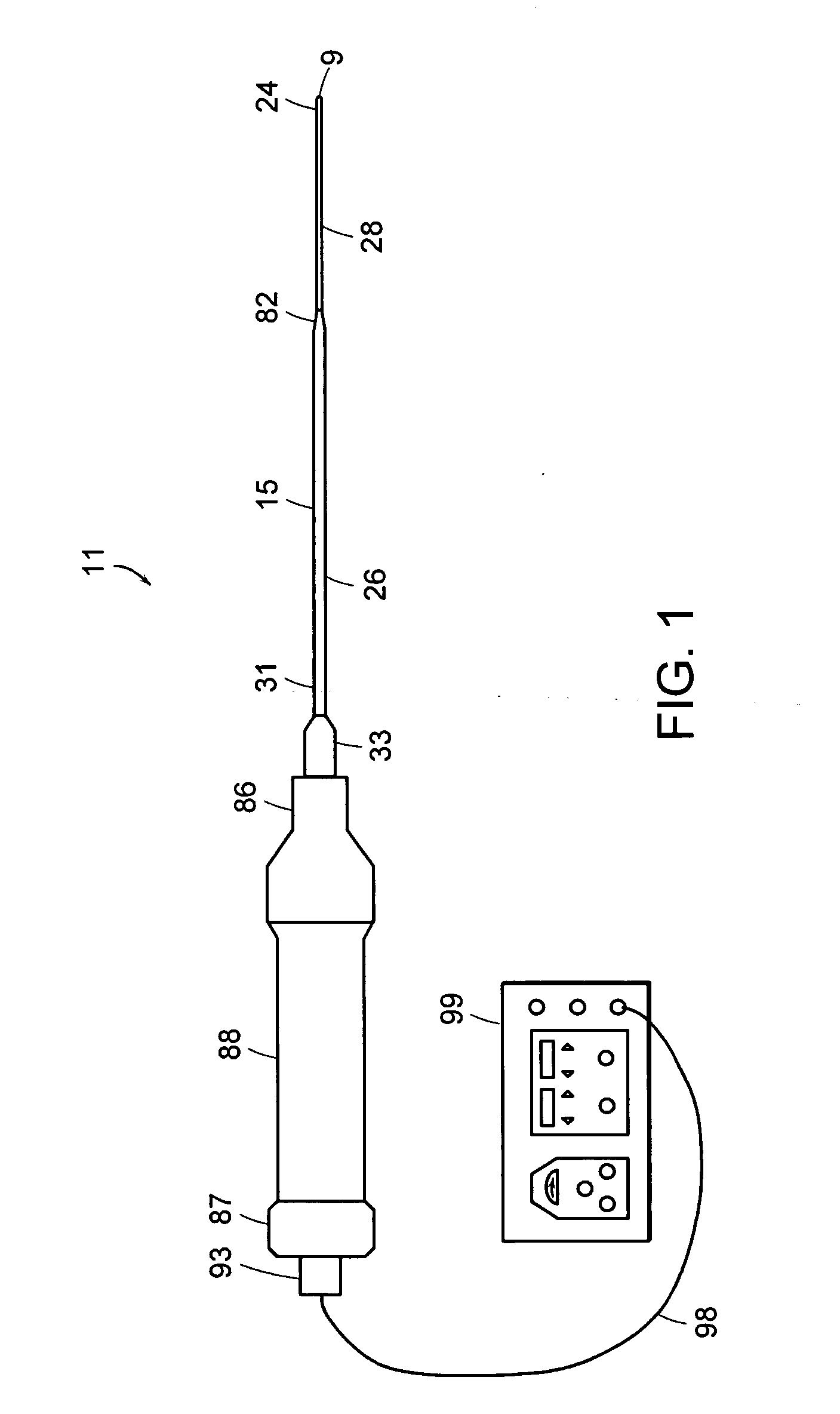

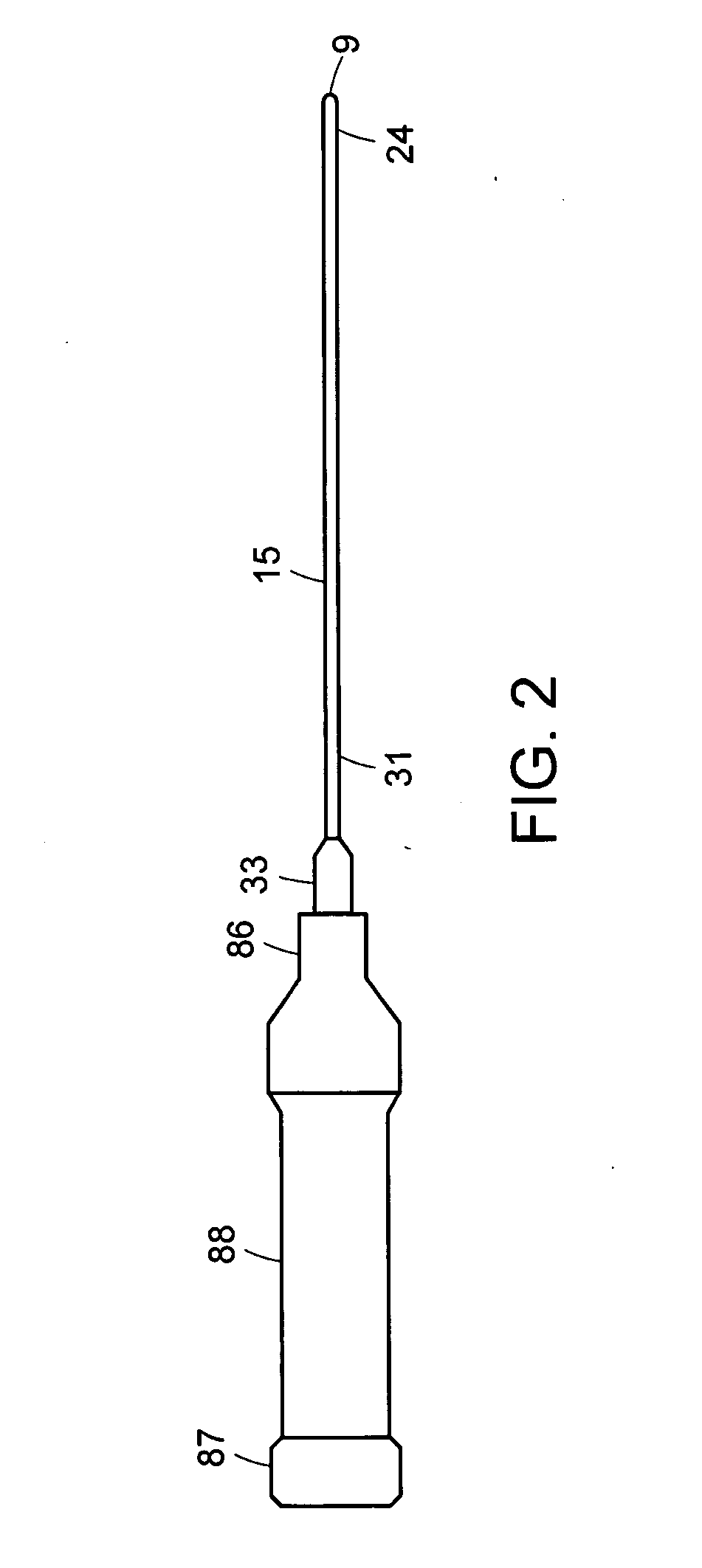

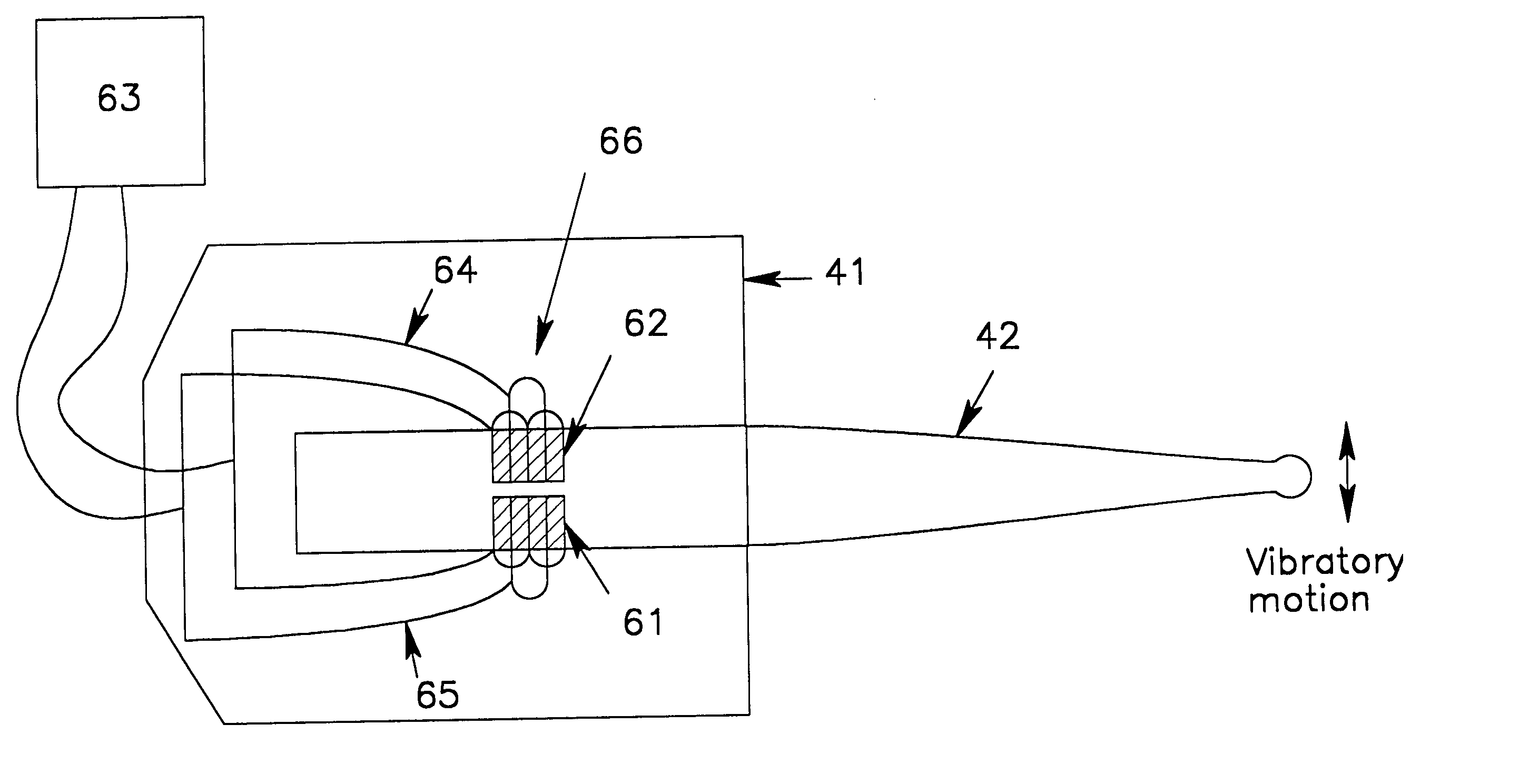

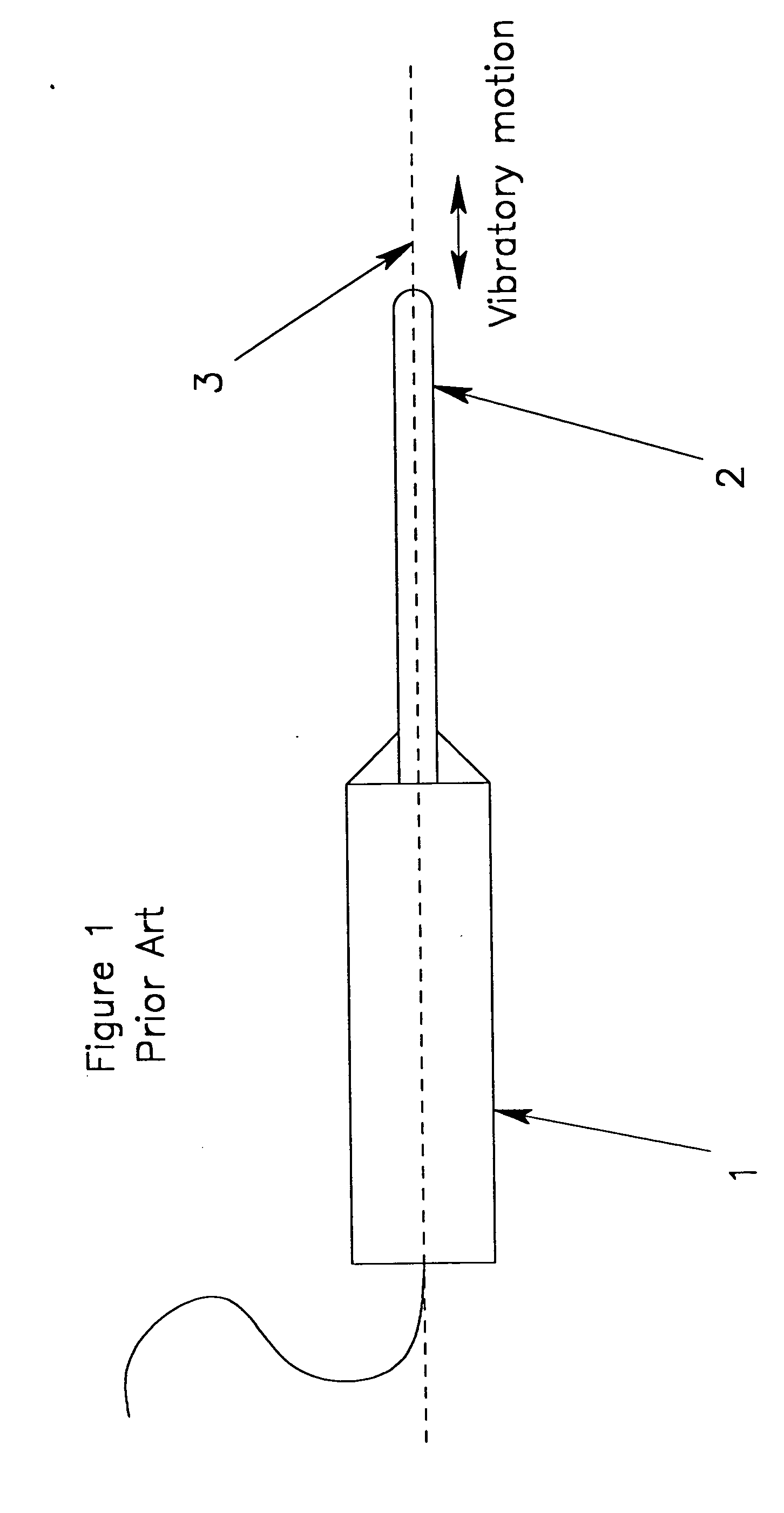

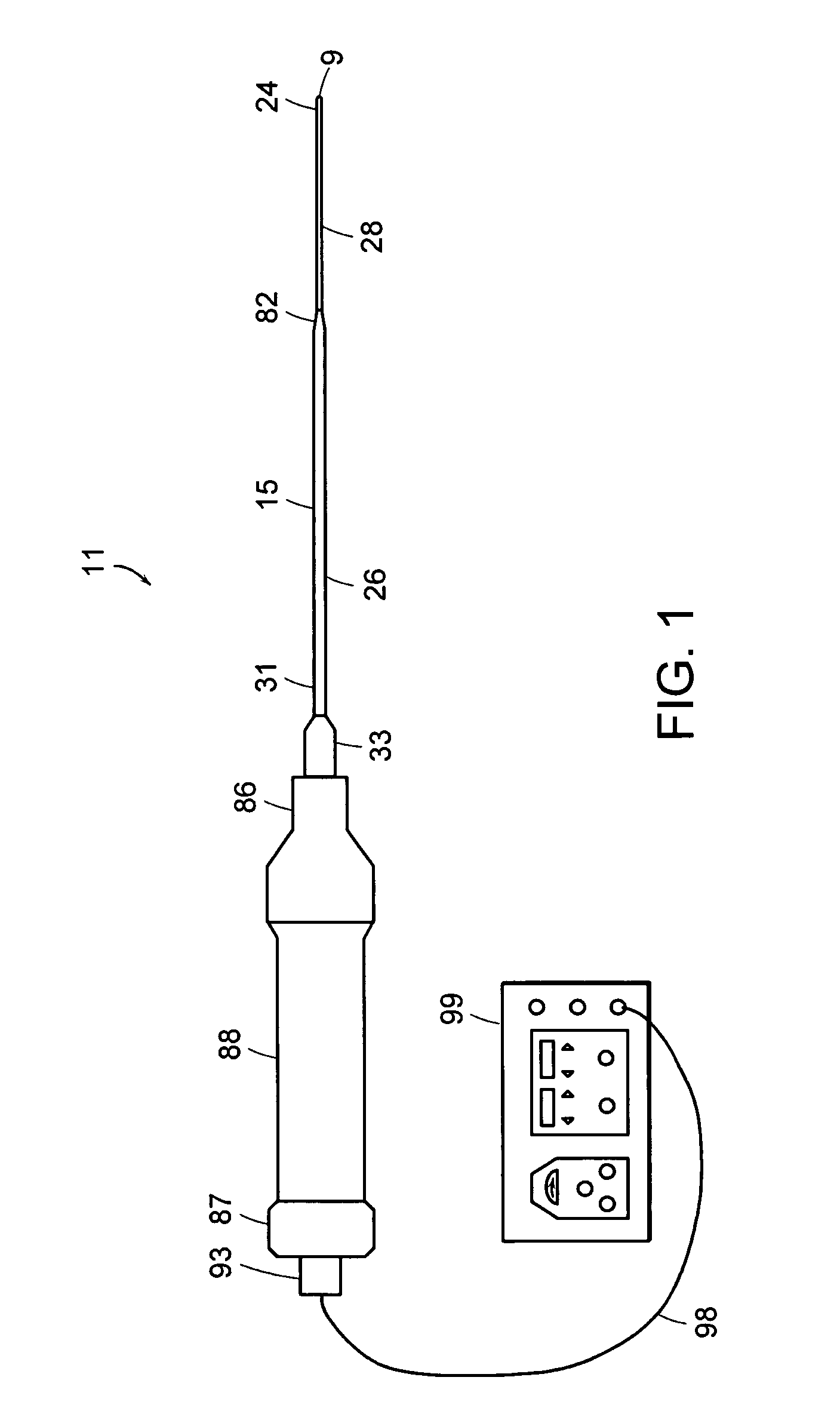

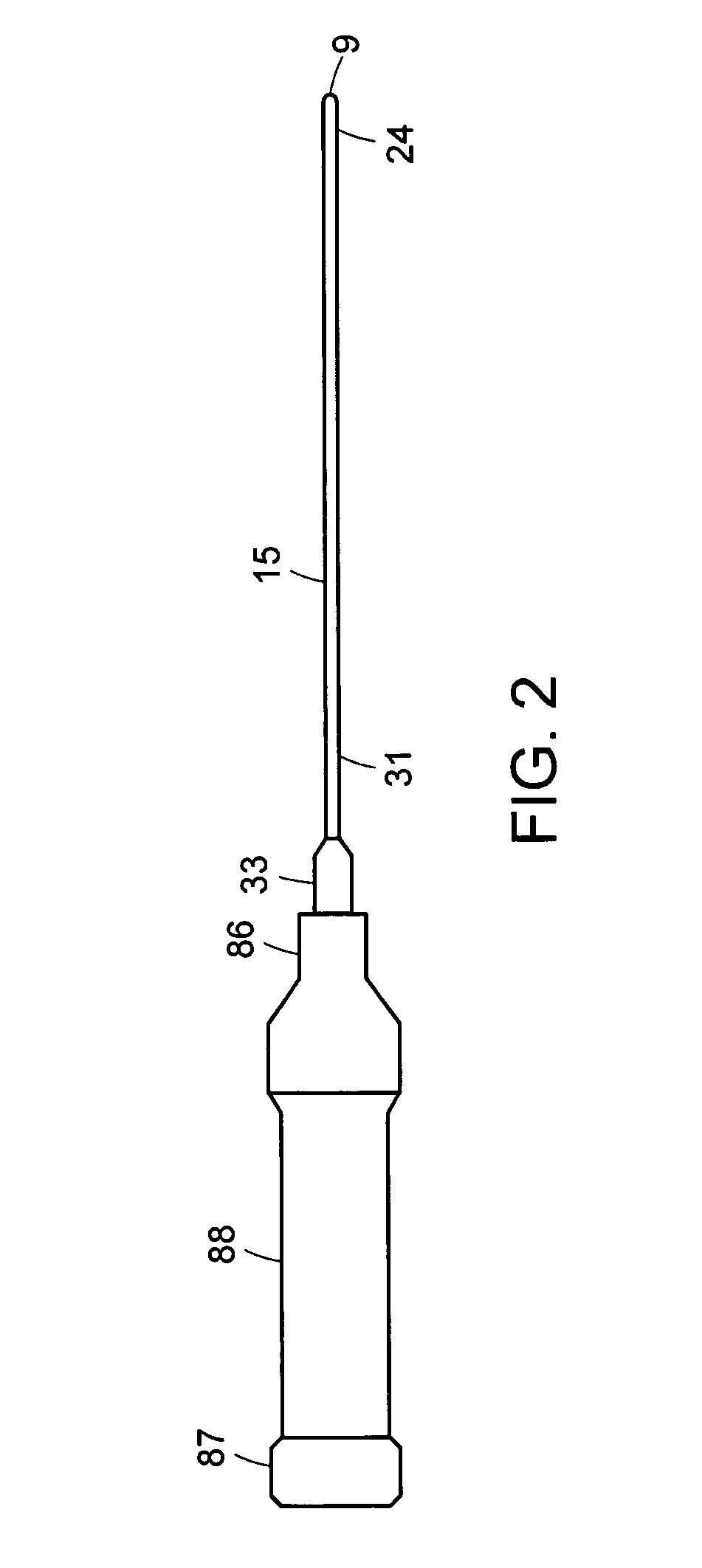

Apparatus and method for an ultrasonic medical device operating in torsional and transverse modes

InactiveUS20050187513A1Effective timeSimple, user-friendlySurgeryChiropractic devicesCavitationTransducer

The present invention provides an apparatus and a method for an ultrasonic medical device operating in a torsional mode and a transverse mode. An ultrasonic probe of the ultrasonic medical device is placed in communication with a biological material. An ultrasonic energy source is activated to produce an electrical signal that drives a transducer to produce a torsional vibration of the ultrasonic probe. The torsional vibration produces a component of force in a transverse direction relative to a longitudinal axis of the ultrasonic probe, thereby exciting a transverse vibration along the longitudinal axis causing the ultrasonic probe to undergo both a torsional vibration and a transverse vibration. The torsional vibration and the transverse vibration cause cavitation in a medium surrounding the ultrasonic probe to ablate the biological material.

Owner:CYBERSONICS

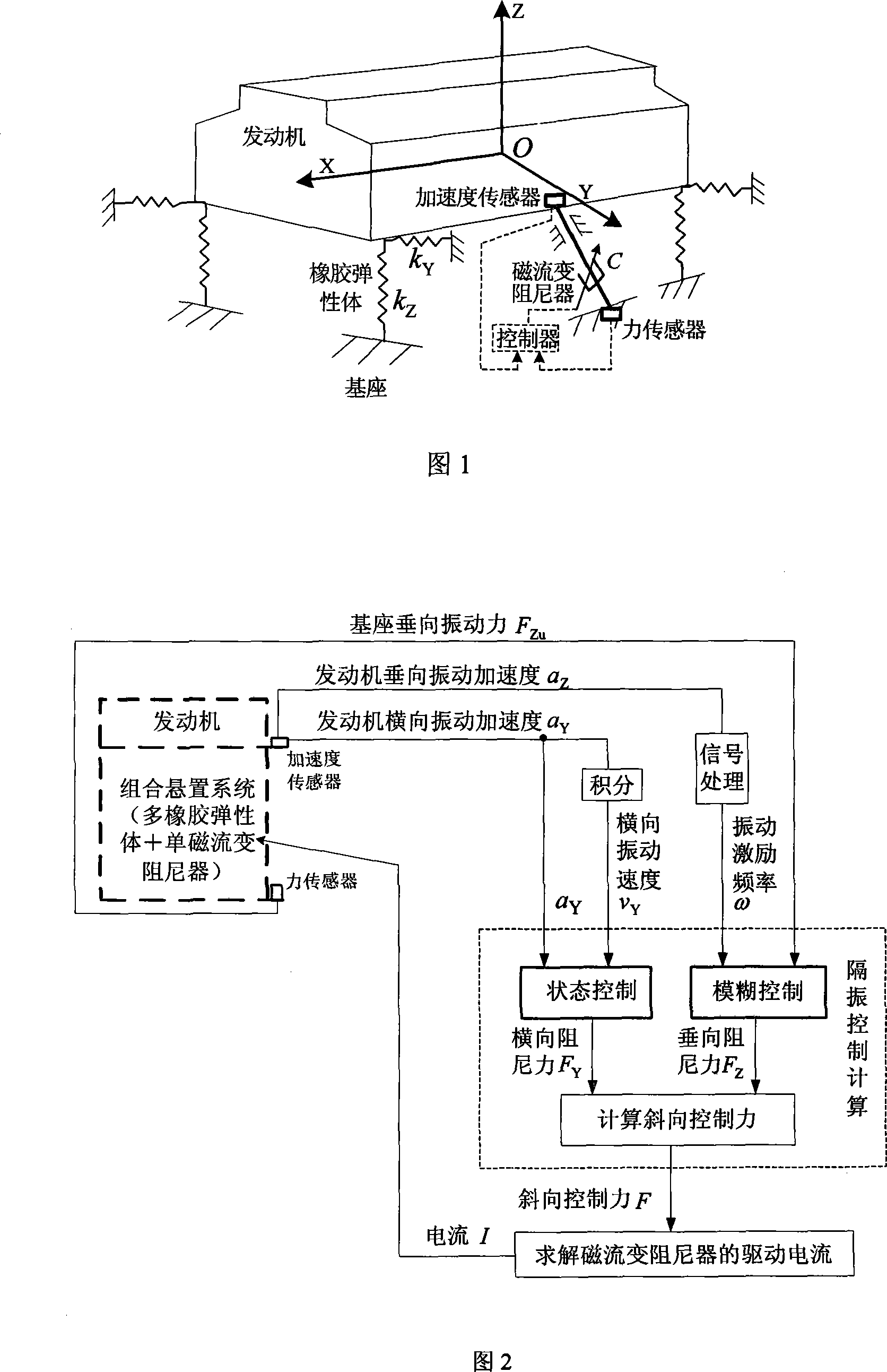

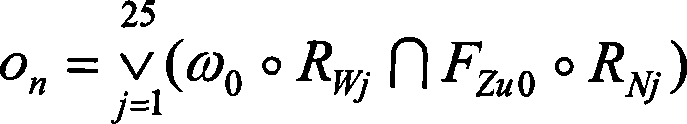

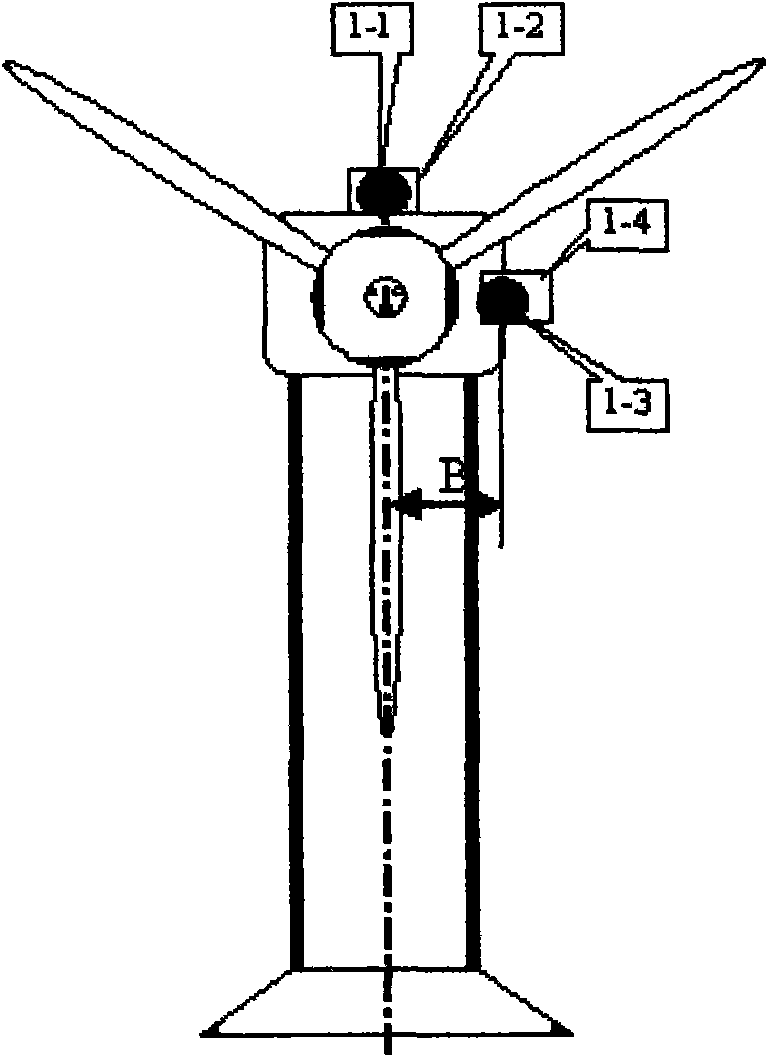

Engine vibration isolation system based on combined suspension and its control method

InactiveCN101220845AEffective vibration isolationChange the strength of the magnetic fieldNon-rotating vibration suppressionPower plants being motor-drivenVertical vibrationElastomer

The invention provides an engine vibration isolation system which is based on a combination suspension and a control method, relating to the automatic control technical field. The invention forms the combination suspension by a plurality of passive rubber elastomers and a single controllable magneto-rheological damper which is obliquely arranged between the middle part of the engine and a base; an acceleration sensor and a force sensor respectively extract the vertical and transverse vibration acceleration of the engine body and the vertical vibration force of the base, so as to calculate the vibration excitation frequency and the transverse vibration speed of the engine; an engine vertical vibration isolation fuzzy control rule and a transverse damping state control rule are established in a controller, and an oblique control force of the magneto-rheological damper is calculated; the driving current of the magneto-rheological damper is determined by an oblique control force, the damping force of the combination suspension is adjusted in real-time, the transmission of the vibration energy of the engine is restricted. The invention can lead to effective vibration isolation of the engine in wide-frequency range, reduces the self vibration of the engine, and improves the durability and the riding comfort of a carrier.

Owner:CHONGQING UNIV

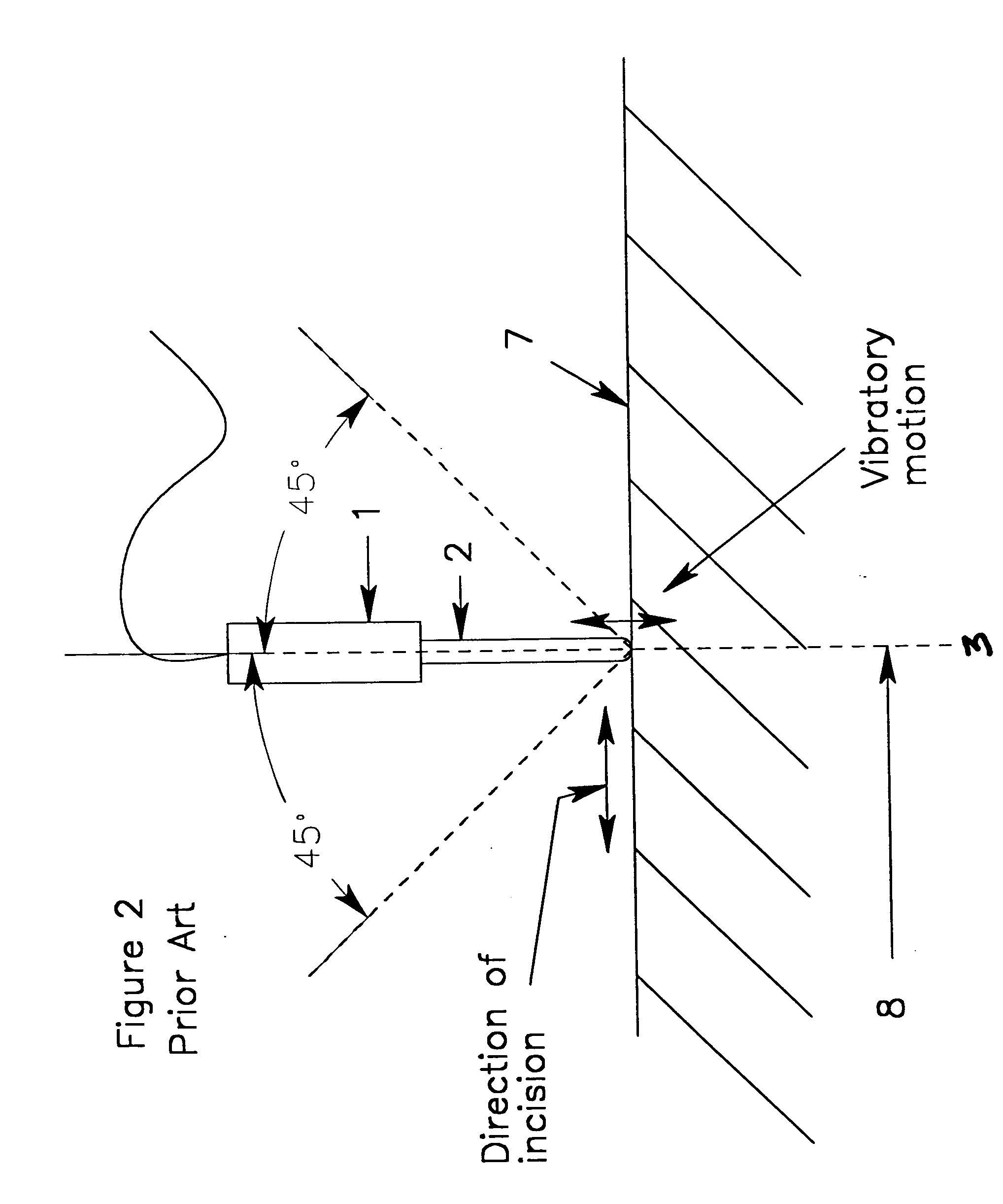

Ultrasonic cutting and coagulation knife using transverse vibrations

An ultrasonic frequency surgical dissecting device including a handpiece with a surgical blade that vibrates in a direction transverse to a long axis passing through the handpiece and blade for improved cutting and coagulation

Owner:SOUND SURGICAL TECH

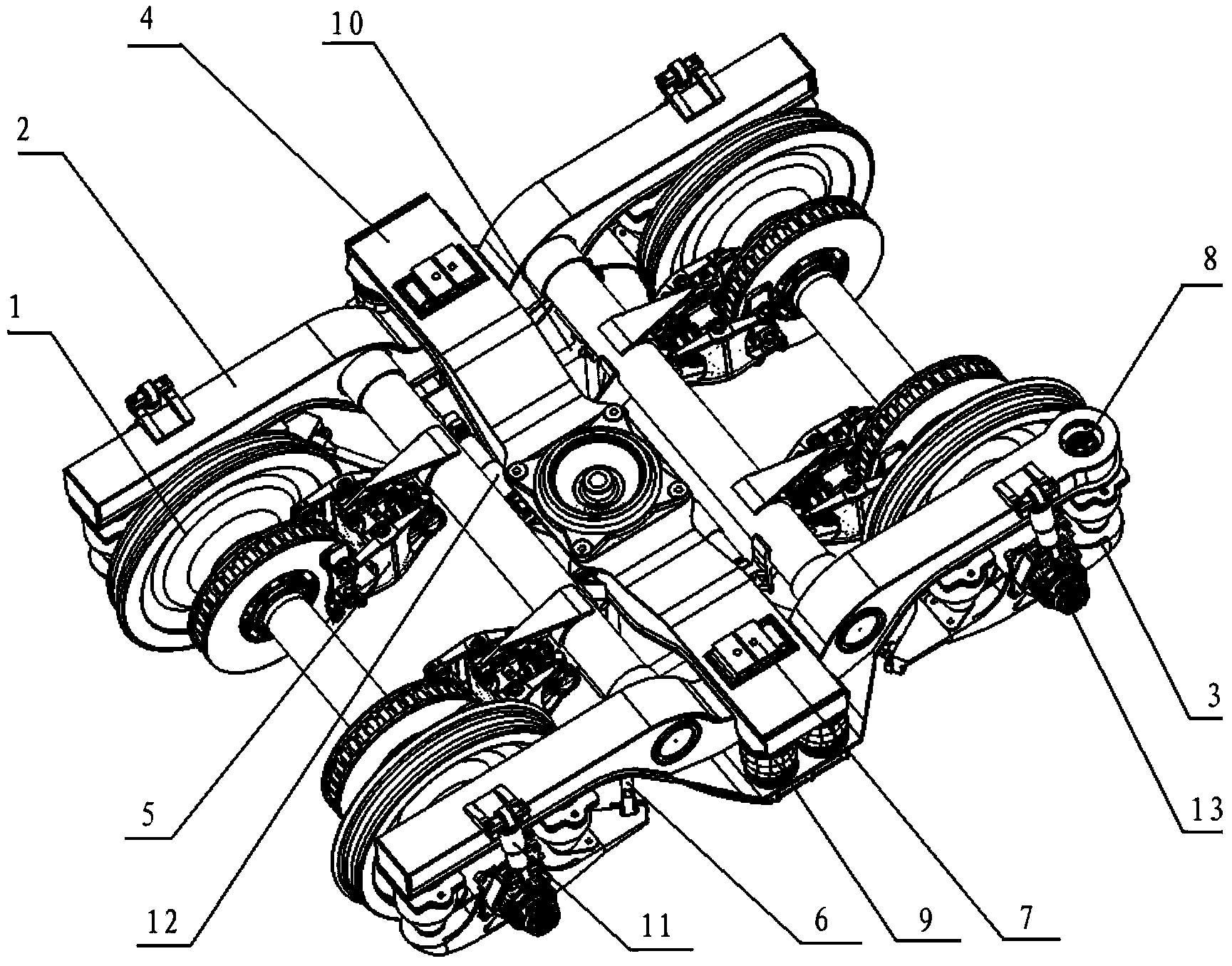

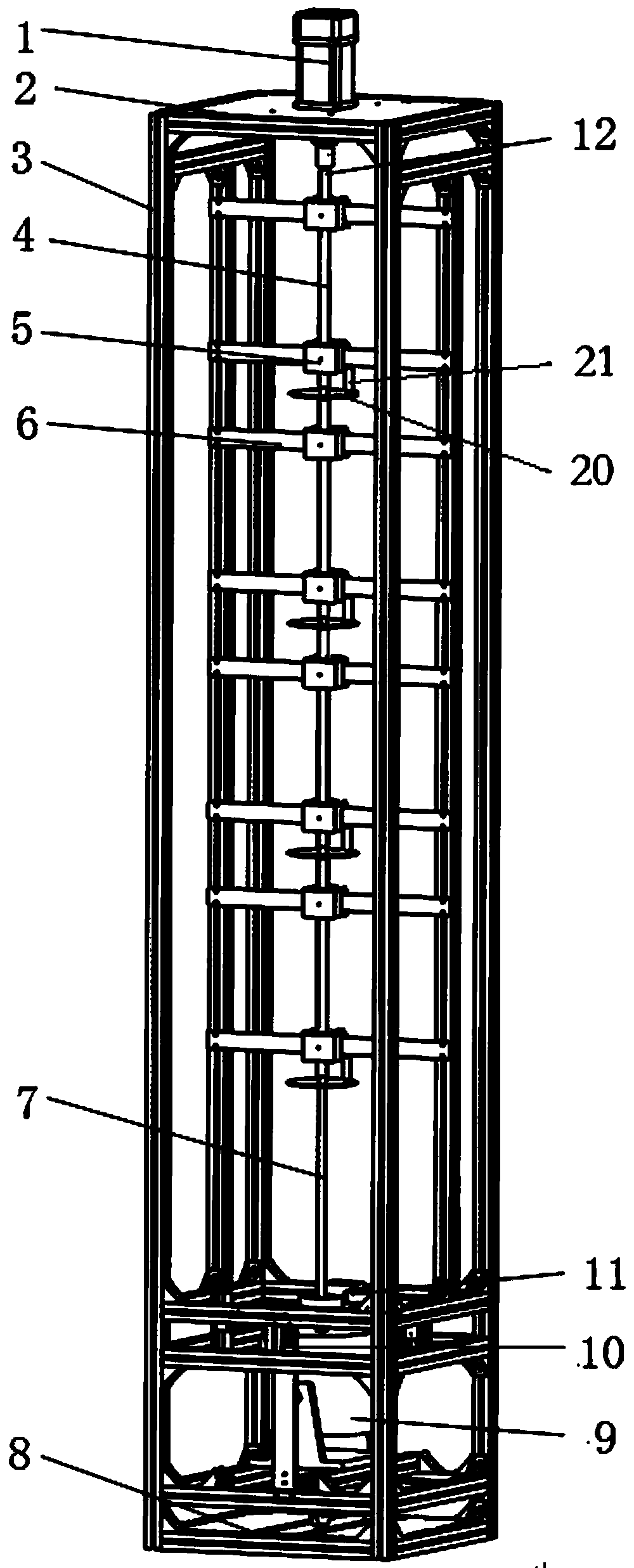

Friction liner-hoisting steel wire rope dynamic friction drive test device and friction liner-hoisting steel wire rope dynamic friction drive test method

ActiveCN104122198AImproved dynamic friction transmission characteristicsGood effectUsing mechanical meansMaterial analysisLongitudinal vibrationDynamical friction

The invention discloses a friction liner-hoisting steel wire rope dynamic friction drive test device and a friction liner-hoisting steel wire rope dynamic friction drive test method. The device comprises a base frame, a driving mechanism, a friction drive mechanism, a surrounding angle adjusting mechanism, a shock excitation mechanism, a steel wire rope and a condition monitoring mechanism, wherein the base frame comprises a stand column, a lower support platform and an upper support platform; the driving mechanism comprises a motor and a torque sensor; the friction drive mechanism comprises a friction wheel and a brake device; the surrounding angle adjusting mechanism comprises a C bracket and an adjusting wheel; the shock excitation mechanism comprises a transverse shock excitation mechanism and a longitudinal shock excitation mechanism; the condition monitoring mechanism comprises a steel wire rope tension monitoring device, a dynamic contact monitoring device, a steel wire rope vibration monitoring device and a micro-slippage monitoring device. After the device and the method are adopted, the dynamic friction drive characteristic between a friction liner and a hoisting steel wire rope can be simulated in a friction hoisting system when the hoisting steel wire rope is in a dynamic coupling vibration state, so that various changes in the friction drive process under the actions of transverse vibration, longitudinal vibration and transverse and longitudinal coupled vibration can be researched.

Owner:CHINA UNIV OF MINING & TECH

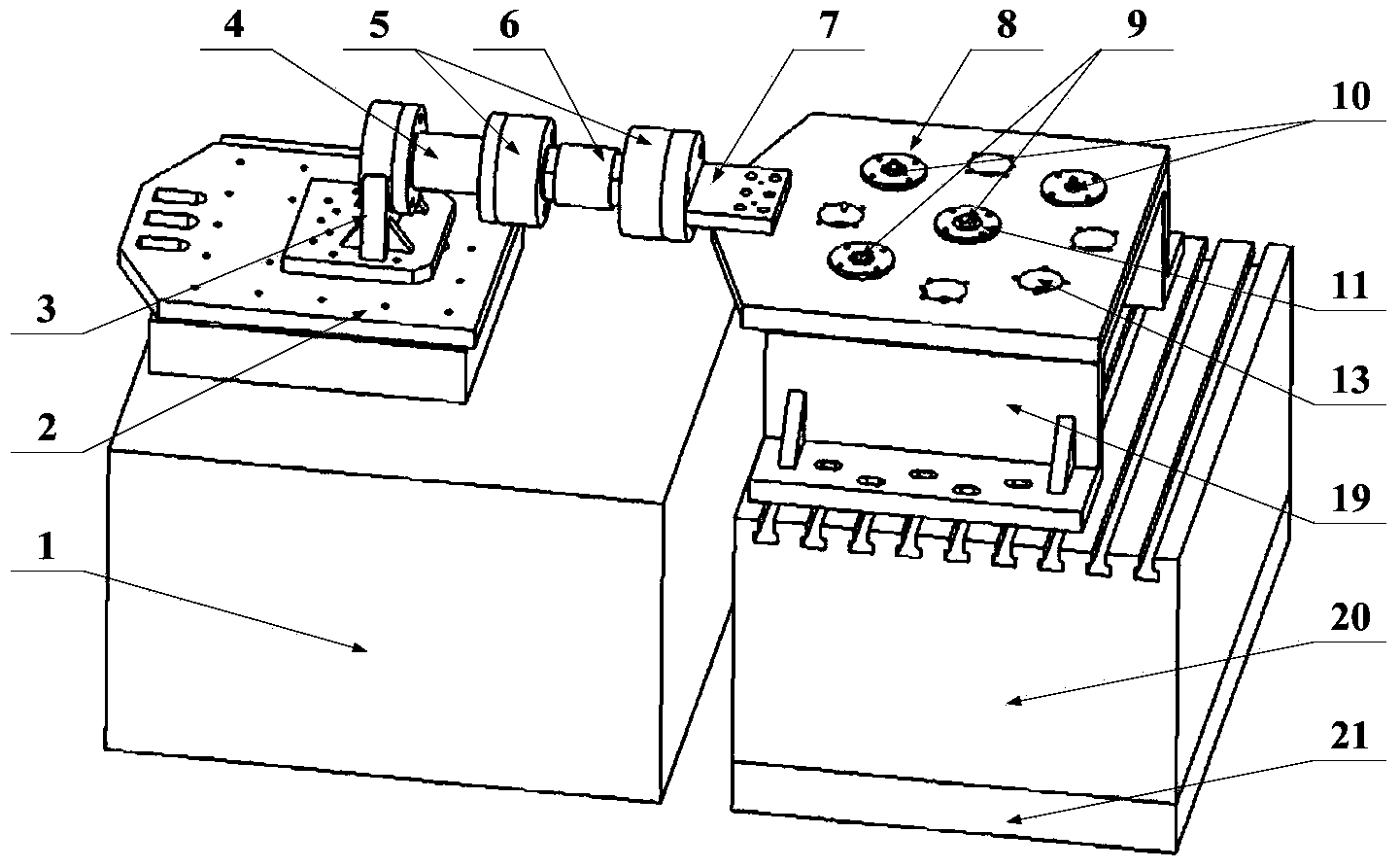

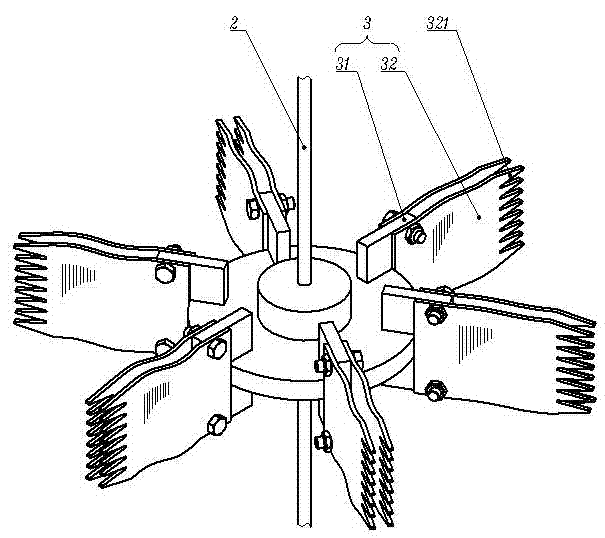

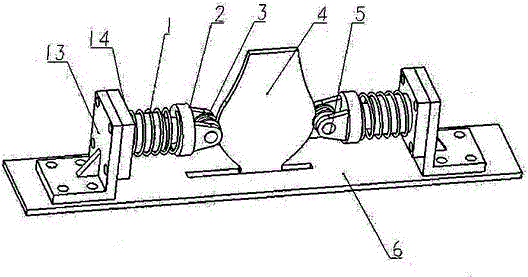

Threaded fastener transverse vibration test device and method

ActiveCN103954419ARealize high frequency vibrationRealize stepless amplitude modulationVibration testingEngineeringEngineering technician

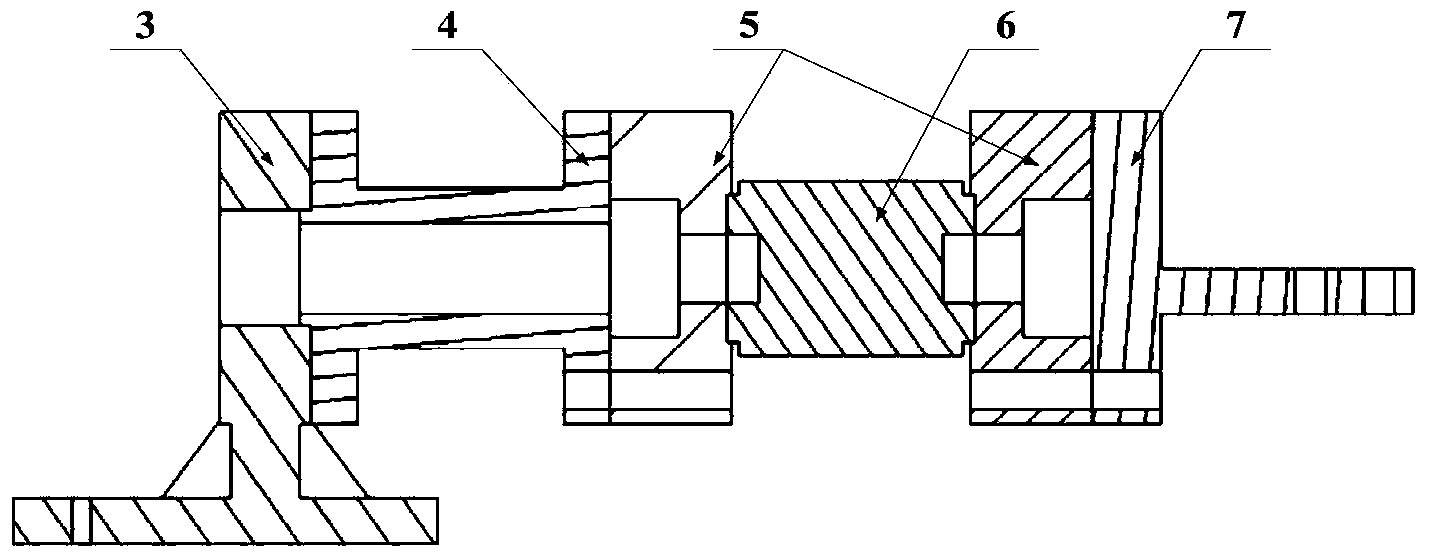

The invention discloses a threaded fastener transverse vibration test device and method. The device comprises a transverse vibration platform, a transmission system, a clamp system, an installation base and a measuring device; one end of the transmission system is fixed to the vibration platform through a bolt, and the other end of the transmission system is fixed to a movable plate in the clamp system; a fixed base of the clamp system is fastened to the installation base through a T-shaped groove; the transmission system is provided with a pull pressure sensor, and the clamp system is provided with a gasket type force sensor. The device and method can simulate high-frequency vibration, achieve electrodeless amplitude modulation, monitor changes of transverse shear force and axial pre-tightening force of a threaded fastener in a vibration process in real time, and test the anti-loose characteristic of single bolts and bolt sets (distributed in a linear, rectangular and circular mode) with different specifications. The device and method provide a basis platform and data support for engineering technicians to analyze anti-loose performance of various threaded fasteners and assess effectiveness of various anti-loose methods.

Owner:XI AN JIAOTONG UNIV +1

Low-cost mountainous-area expressway tunnel entrance vehicle speed control facility designing method

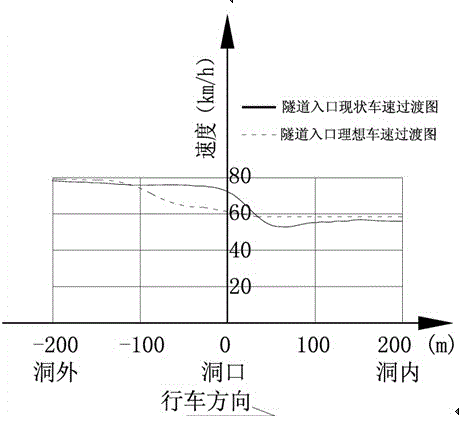

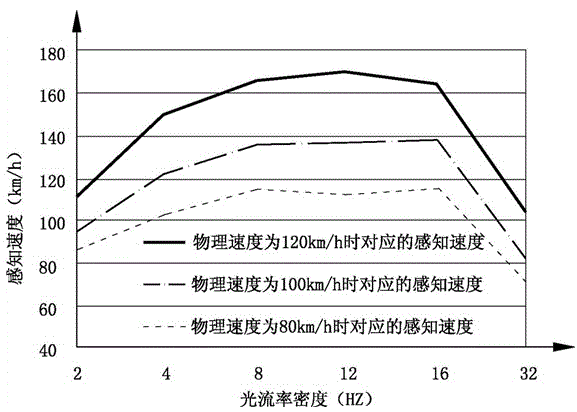

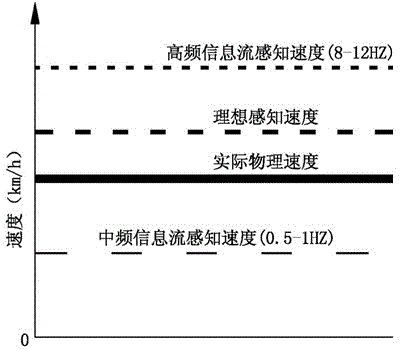

InactiveCN102720148AImprove instant perception speedImprove sense of directionTraffic signalsRoad signsPolygonal lineIntermediate frequency

The invention discloses a low-cost mountainous-area expressway tunnel entrance vehicle speed control facility designing method which comprises the following steps of: setting red-and-white mark lines and road-side road surface and in-road lane line raised road signs on the side wall of the tunnel entrance, the lower edge of curb and the plane of the overhauling way at a space of 1.5-3m to form a high-frequency vision information flow; setting intermediate-frequency information at the tunnel entrance in the advancing direction every 20-30m, setting 3 layers of delineators on each side wall of the tunnel from top to bottom, setting a side wall vertical mark line and 2 side wall white broken lines, and setting a transverse staggered vision mark line and 2 white broken lines on the road surface to form an intermediate-frequency vision information flow; and forming a retroreflection illumination system from the retroreflecting materials by use of the high and intermediate-frequency vision information. Road-side road surface raised road signs and transverse deceleration mark lines (consisting of transverse vibration mark lines and transverse staggered vision mark lines) are arranged in front of the tunnel entrance, and the longitudinal space of the transverse deceleration mark lines turns smaller at first and then becomes stable to form a tunnel pre-deceleration system. The retroreflection illumination system and the deceleration system form the tunnel entrance vehicle speed control facility which realizes reasonable transition of the vehicle speed at the tunnel entrance and is suitable for the mountainous-area expressway tunnel entrance with the speed limit of 60-80km / h.

Owner:WUHAN UNIV OF TECH

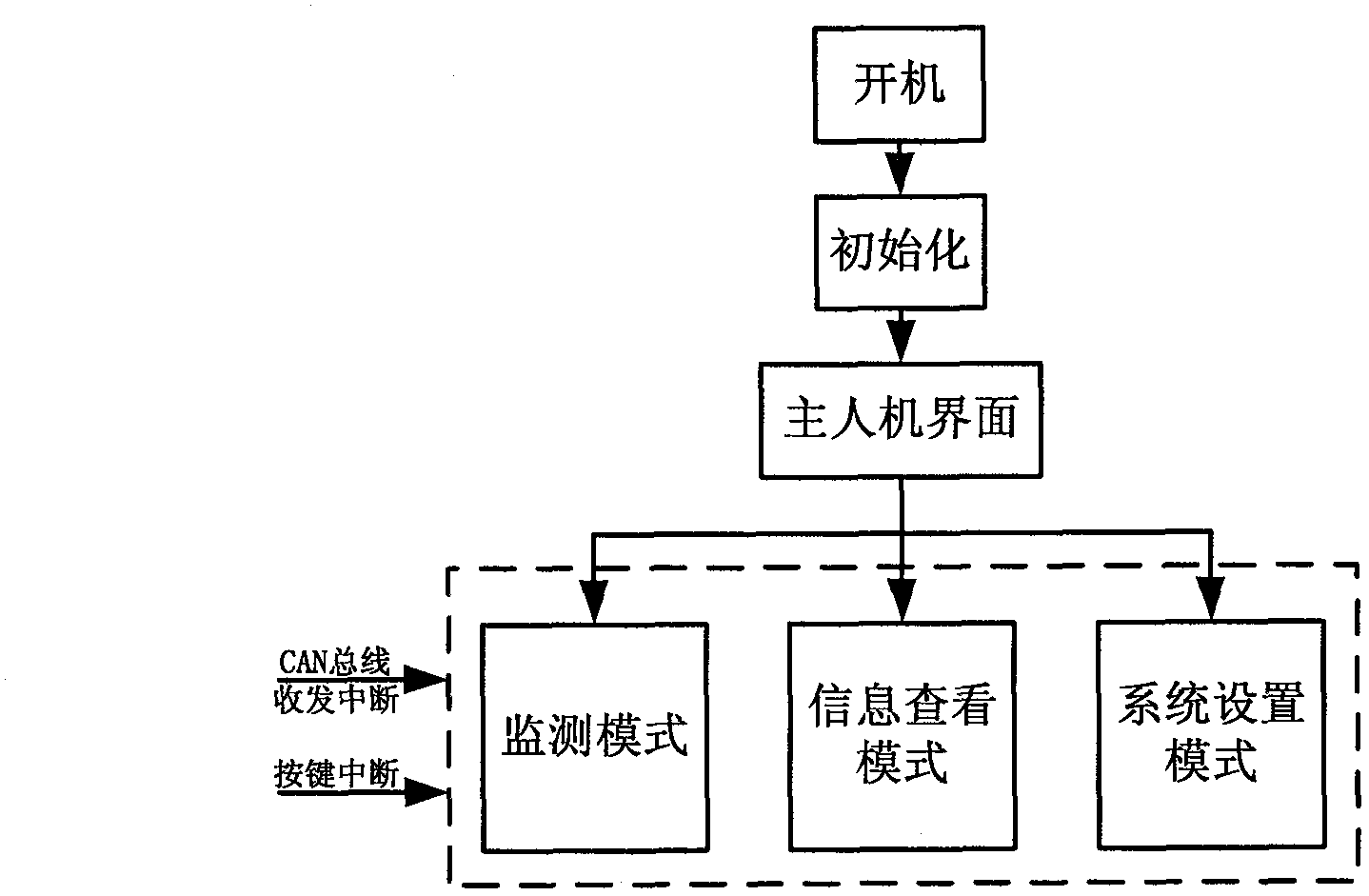

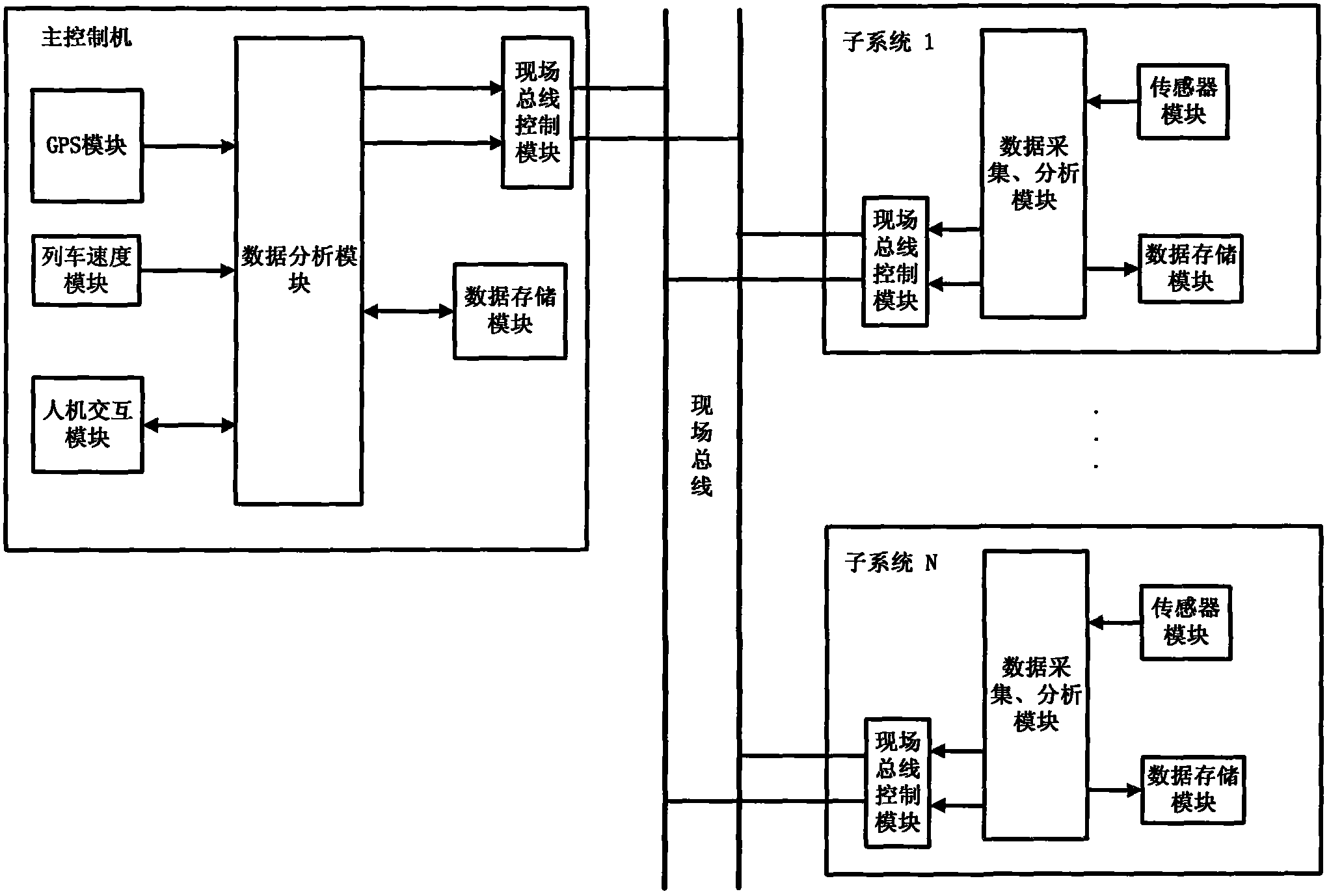

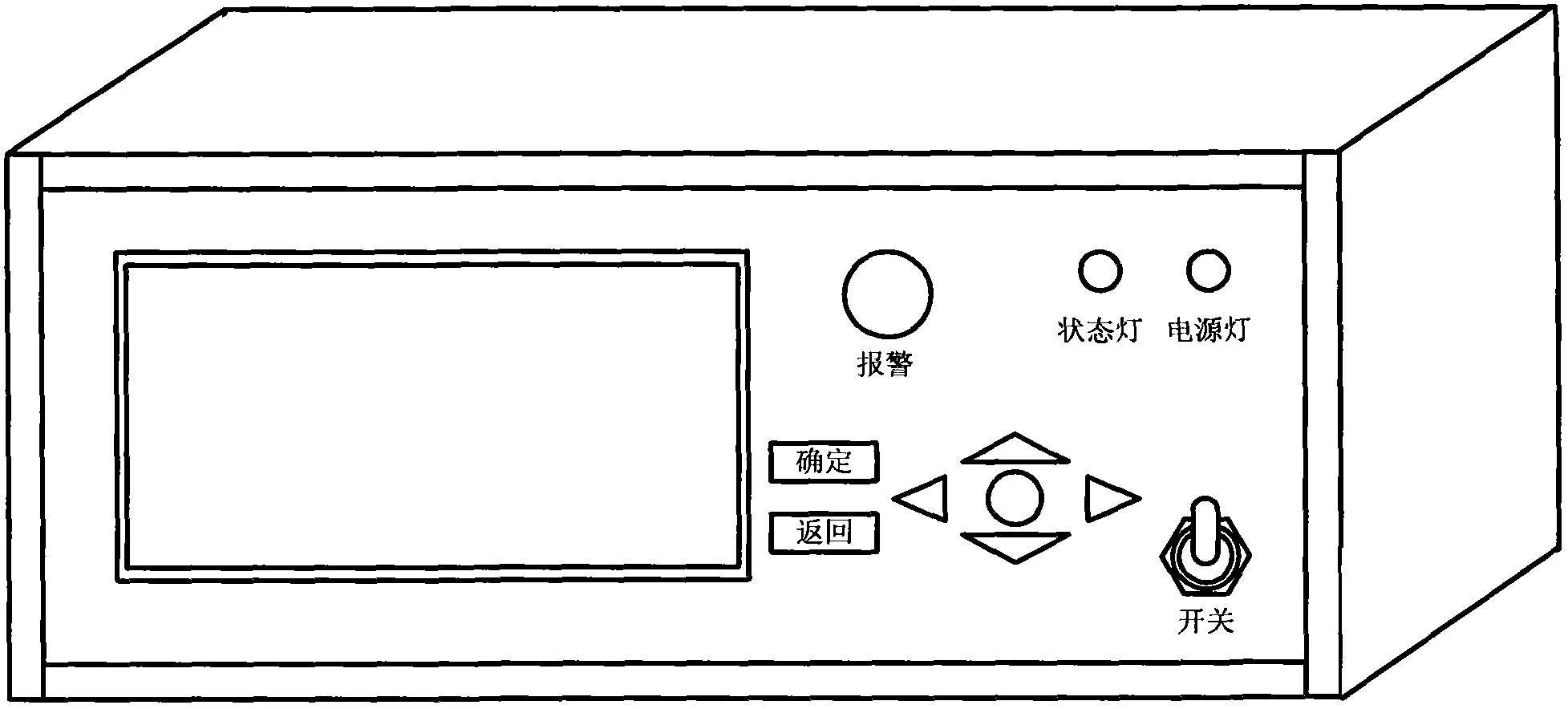

Method and device for detecting snaking motion instability of high speed train bogie

InactiveCN102706569AAccurate monitoring of snaking motion stabilityNot affectedRailway vehicle testingBogieInstability

The invention relates to a device for detecting snaking motion instability of a high speed train bogie, which is used for monitoring on-line whether snaking motion instability of the bogie appears during the travel of a high speed train. The device provided by the invention comprises a main controller system and a sub-detection system. The main controller system mainly comprises a man-machine interaction module, a GPS (global position system) module, a data analysis record module and a field bus control module. The sub-detection system mainly comprises a sensor module, a data acquisition module, a data analysis module, a field bus control module and a data storage module. A main controller and the sub-detection system are subjected to data communication through a field bus. The sub-detection system monitors the transverse vibration state of the bogie in real time to judge whether the snaking motion instability appears and transmits instability information to the main controller through a field bus; and the main controller completes analysis of the instability information, combines with the GPS module and a clock module to correctly provide time and space synchronizing information at the moment of the occurrence of instability, then gives out a warning signal and stores the fault information.

Owner:SOUTHWEST JIAOTONG UNIV

Multifunctional fastener testing machine

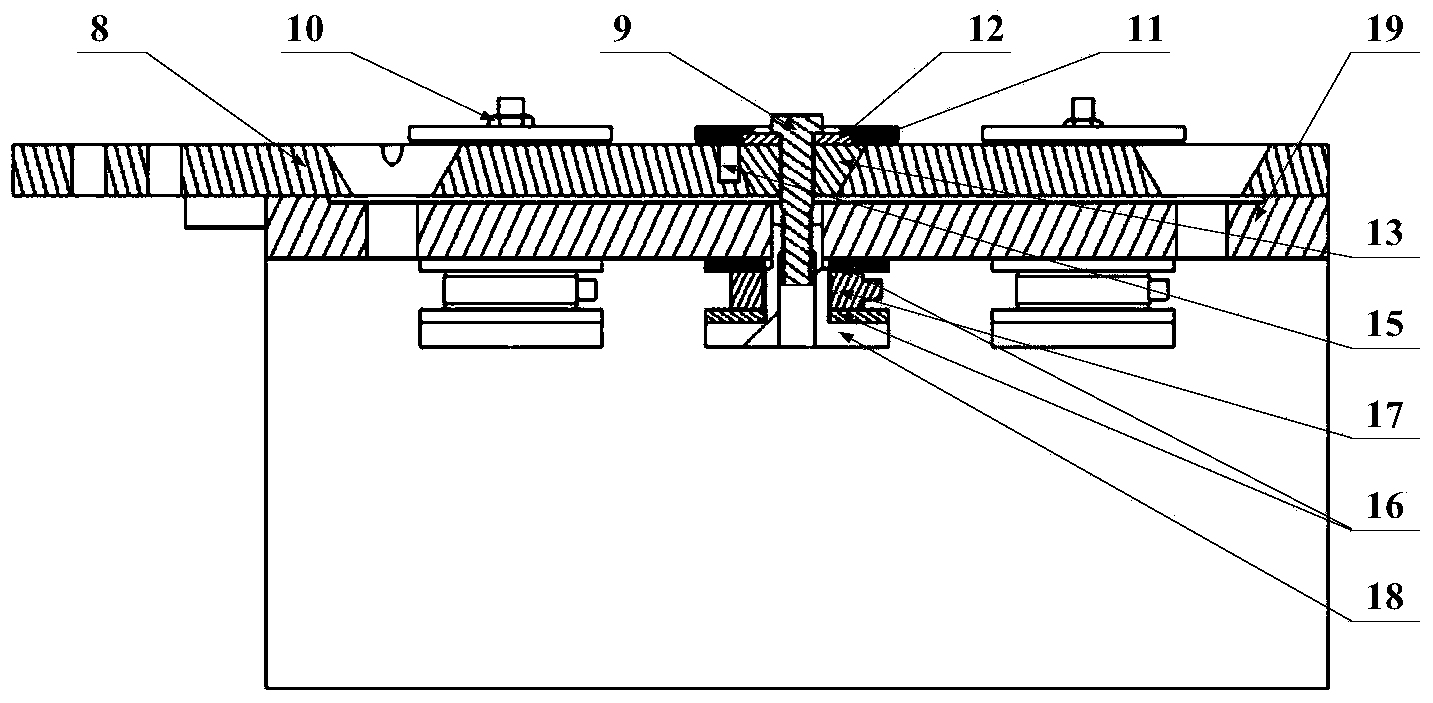

ActiveCN105784304AChange the ambient temperatureSimple drive structureVibration testingCouplingMultiple sensor

The invention provides a multifunctional fastener testing machine, belongs to the field of mechanical testing equipment, and relates to the multifunctional fastener testing machine. According to the testing machine, multiple sensors and vibration exciters are cooperatively adopted to test torque, force and displacement of a tested piece. A guide rail is installed on a base. The output shaft of a speed regulating motor installed on the guide rail is connected with a coupler. One end of a toque rotating speed sensor is connected with the coupler, and the other end is fixedly connected with a sleeve. The sleeve clamps the tested fastener. An intermediate connecting clamp plate is fixedly installed on the base. A transverse vibration exciter installed at the left part of the base is connected with an axial force sensor through threads. The other end of the axial force sensor is installed at the left end of the intermediate connecting clamp plate. The testing machine can perform pre-tightening loading and loading of vibration load on the same tested fastener without changing the state so that the measured data are enabled to be more accurate. The vibration exciters are adopted so that the structure is simplified, space is saved and test accuracy is enhanced.

Owner:DALIAN UNIV OF TECH

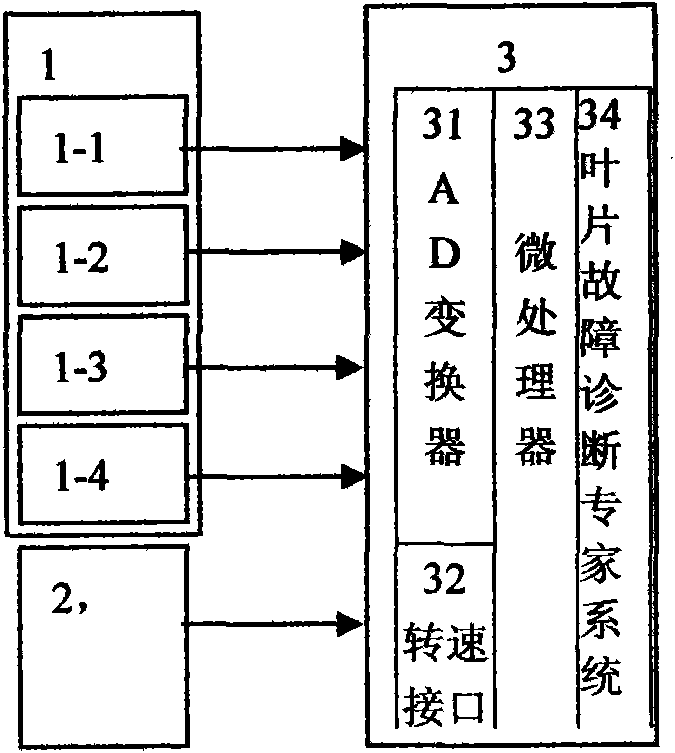

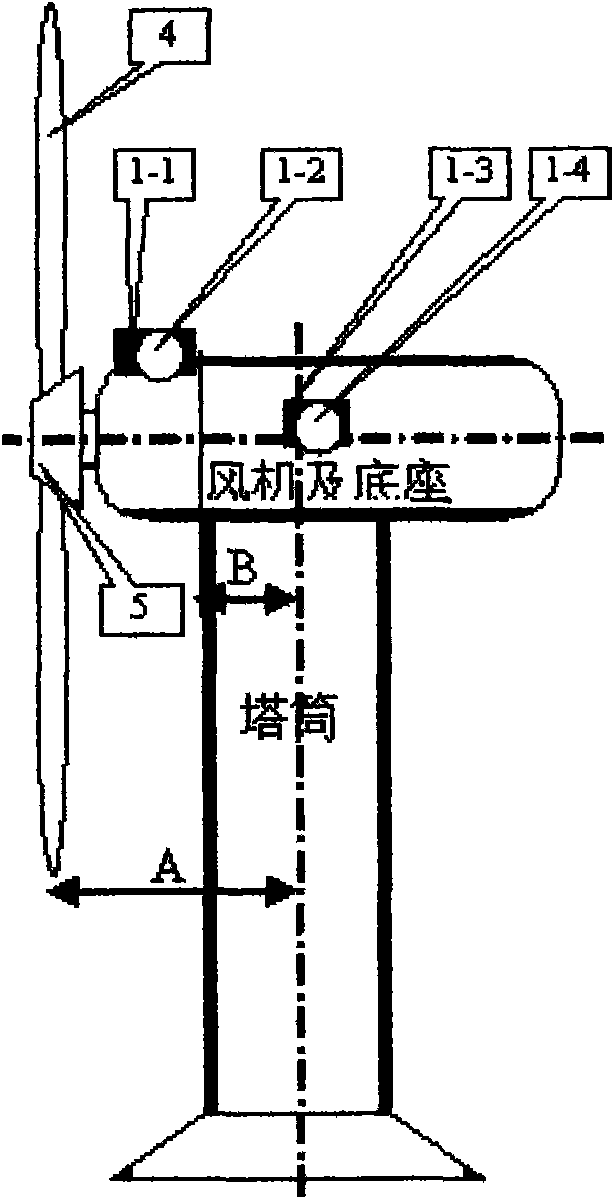

Fault indirect diagnosis technique of rotating blade

A fault indirect diagnosis technique of a rotating blade comprises a vibration impact sensor group which is installed on a static component of a blade machine, senses the vibration and impact caused by aerodynamic force and forcible touch and wear of rotor blades relative to static components and includes a rotational speed sensor for detecting operation frequency of the blade machine and a blade fault diagnosis device for analyzing signals reflecting blade fault information in the signals of the vibration sensor group relative to a signal rule of the rotational speed sensor, wherein the signals of the vibration impact sensor group including at least two vibration impact sensors and the signals of the rotational speed sensor with each rotator corresponding to one are connected to the blade fault diagnosis device, and blade fault diagnostician system software which is arranged in a microprocessor installed in the blade fault diagnosis device is used for diagnosing blade faults through vibration signals and rotational speed signals. The FFT analysis of the transverse vibration shock P of the blade machine in operation, the axial vibration shock Y of the blade machine and the torsional vibration NZ of a hanging or support device of the blade machine, and the analysis of the rotational speed frequency FN of the rotor are performed for recognizing blade faults by combining a computer technique with an electric sensor and the fault diagnostician system software. Various defects of prior art can be overcome.

Owner:北京唐智科技发展有限公司

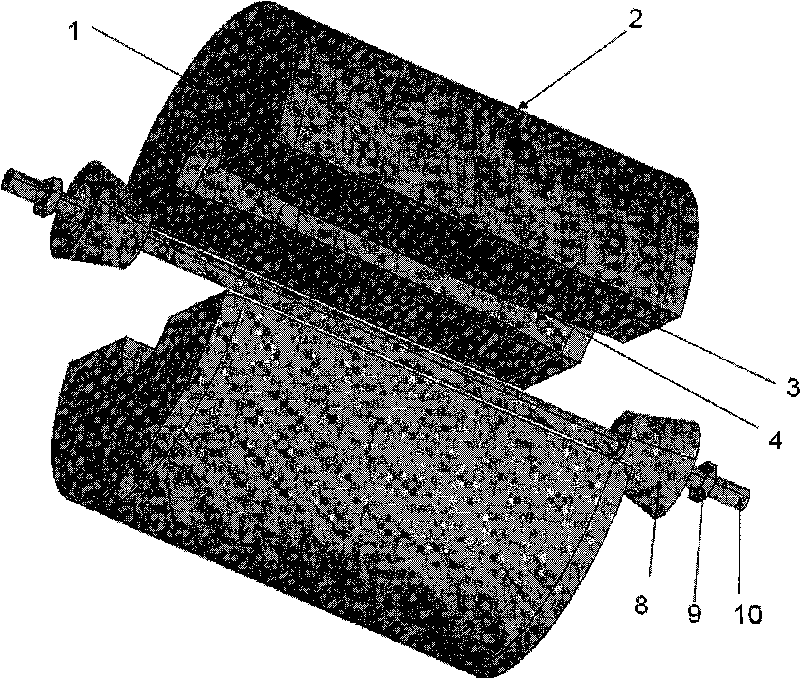

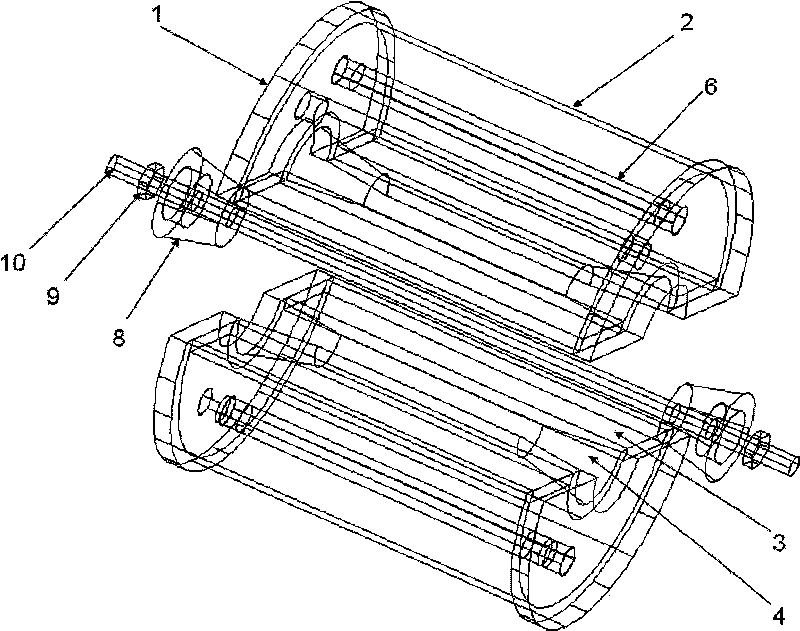

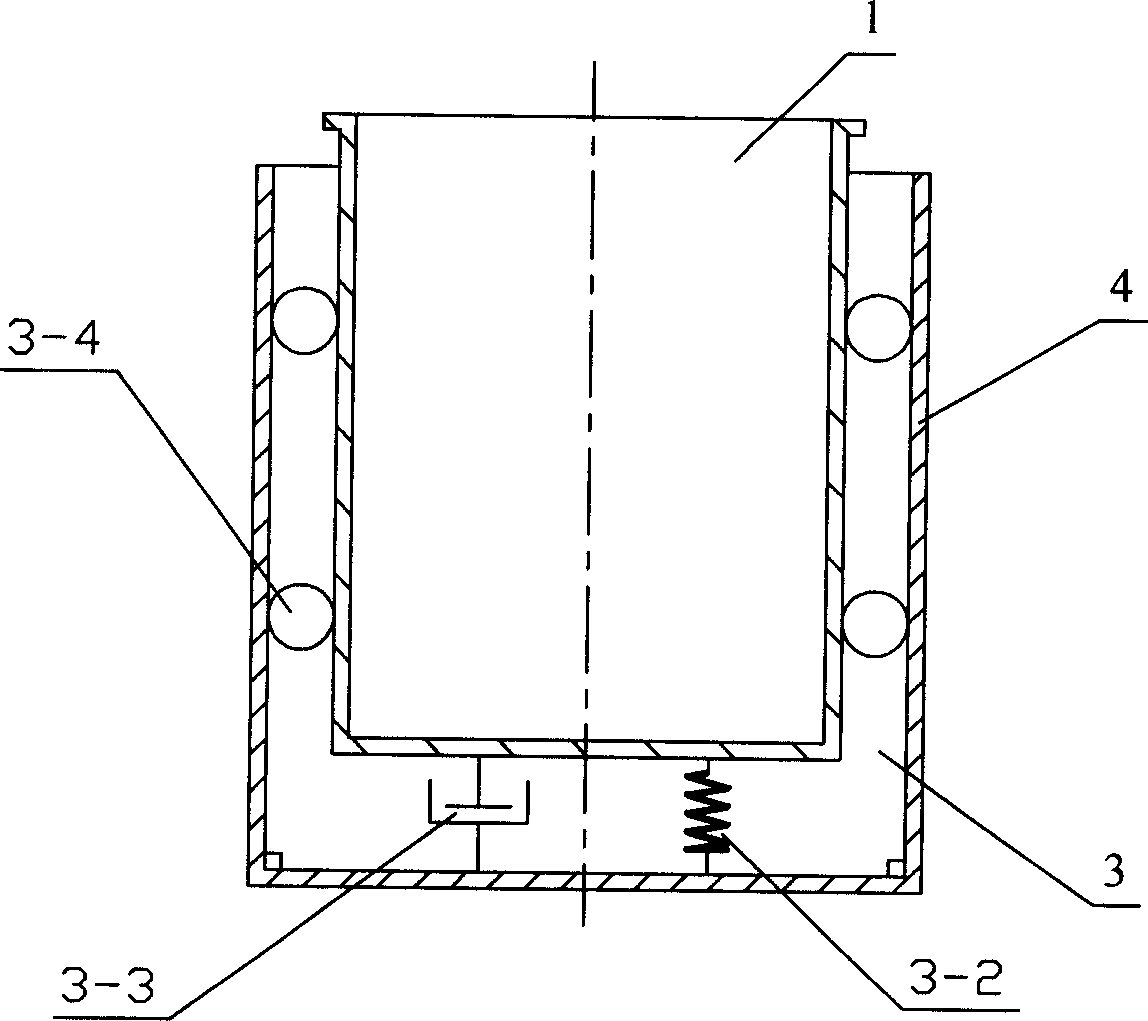

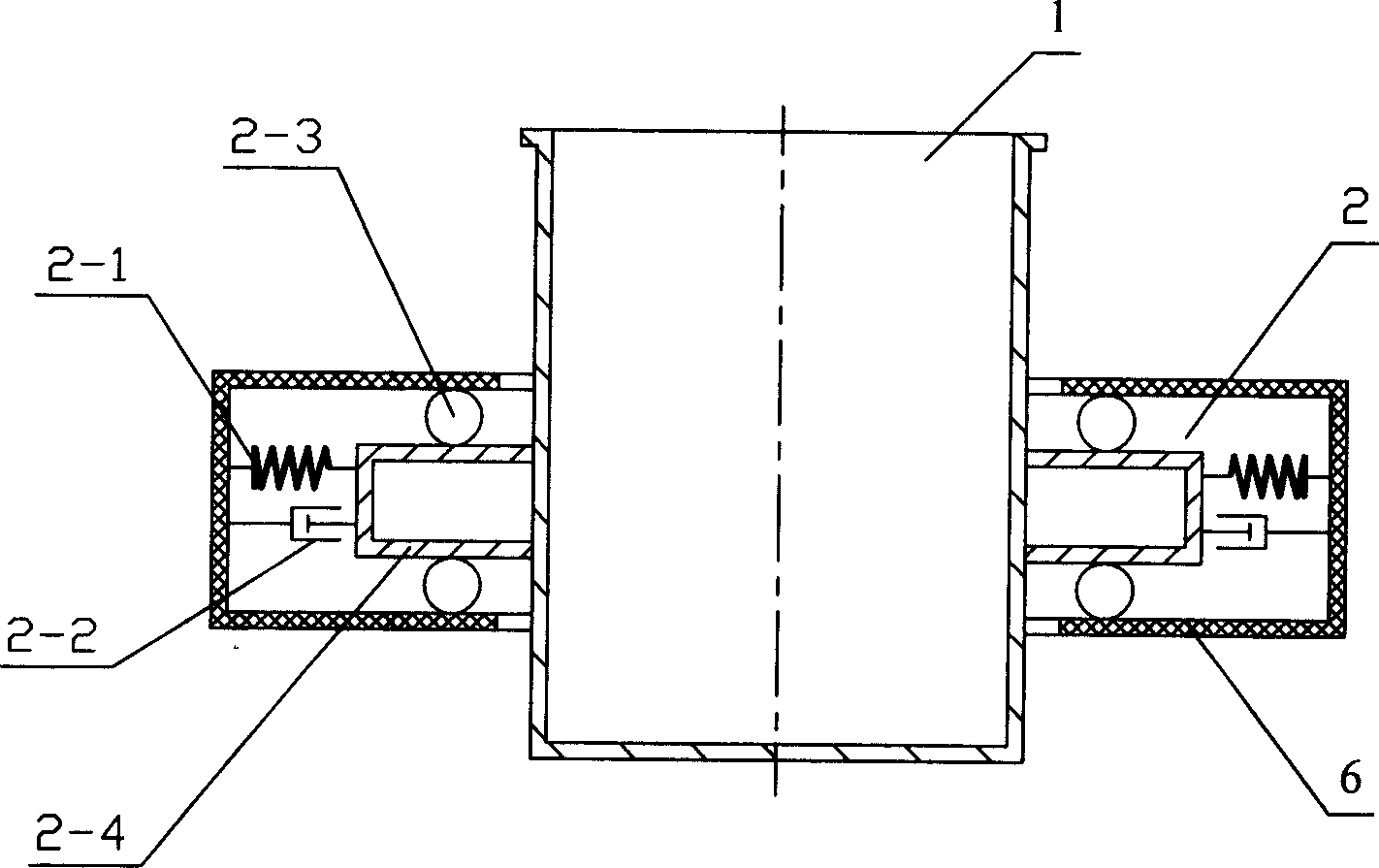

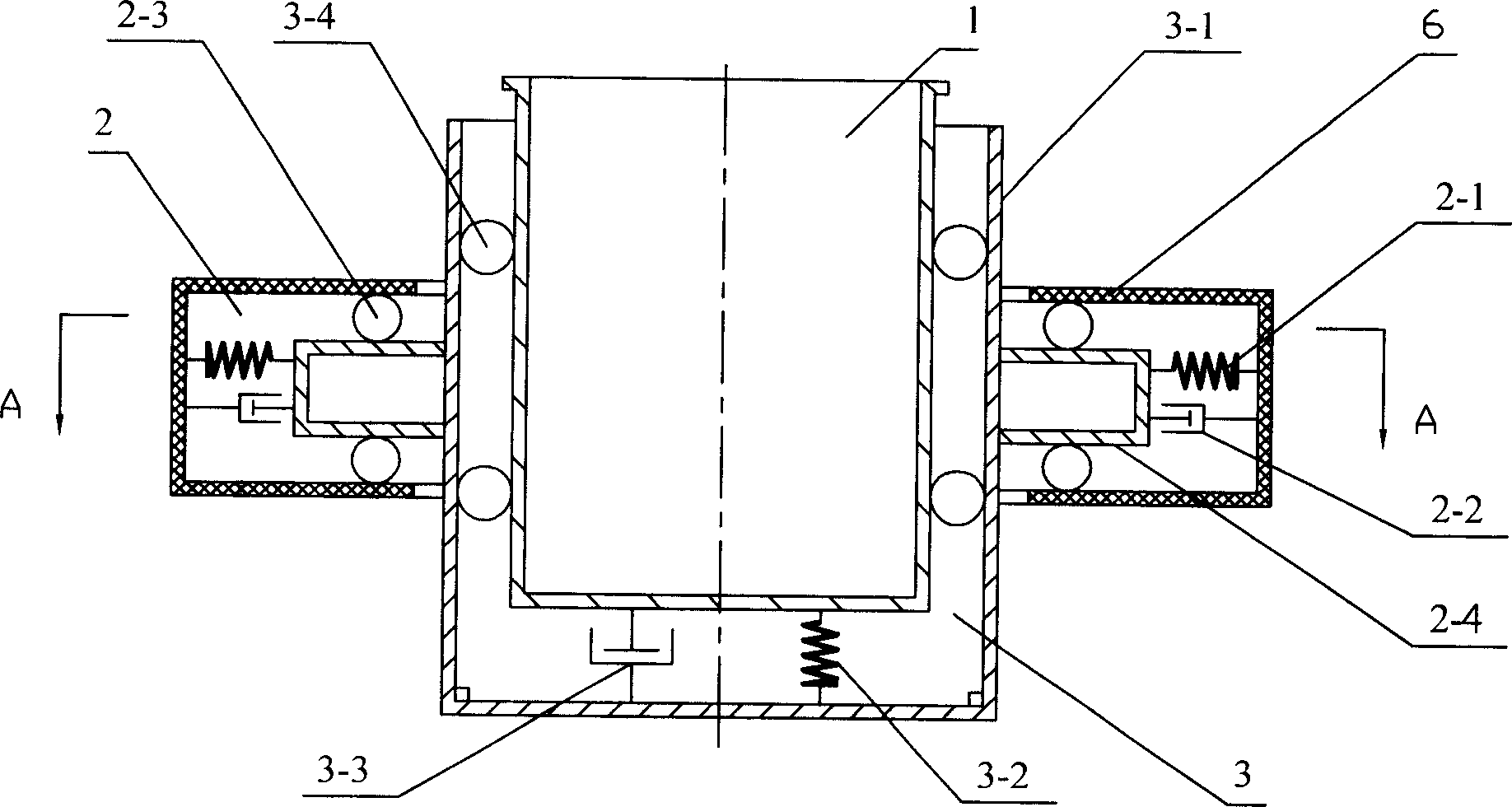

Hollow shafting particle damper

InactiveCN101725656AGuaranteed symmetric distributionSave spaceFriction dampersInterior spaceLongitudinal vibration

The invention relates to a hollow shafting particle damper, which is used for comprehensively controlling shafting vibrations. The hollow shafting particle damper comprises two identical semi-cylindrical damping units and a positioning device, wherein the positioning device is positioned between the two semi-cylindrical damping units and is used for fixing the two semi-cylindrical damping units in a hollow shaft. The damper can effectively control the torsional vibration, transverse vibration and longitudinal vibration of a shafting, and is a comprehensive control device for the vibration of the shafting in three directions. The damper is arranged in the shafting so as to effectively make use of the inner space of the shafting and save cost and space.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

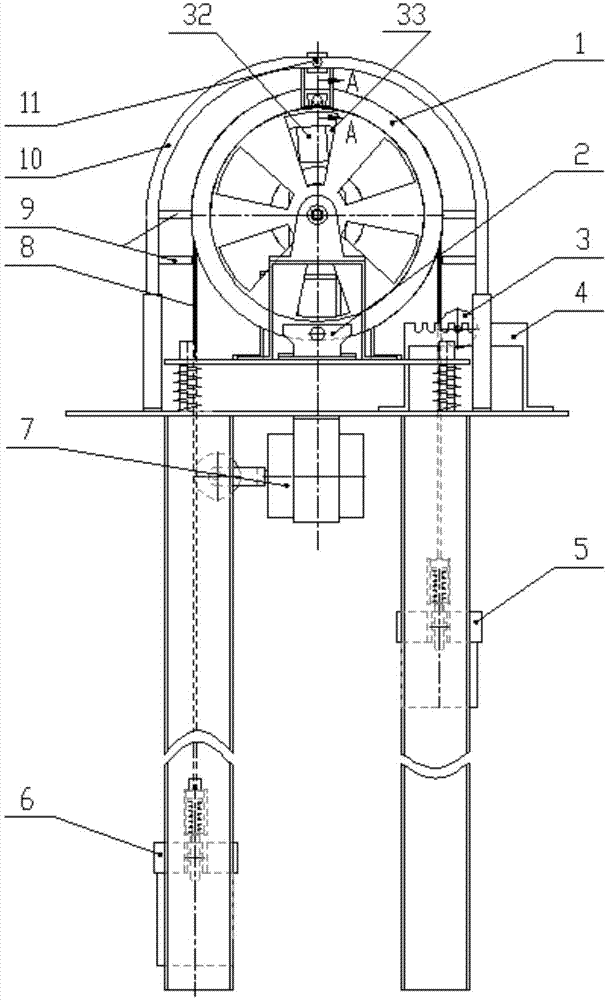

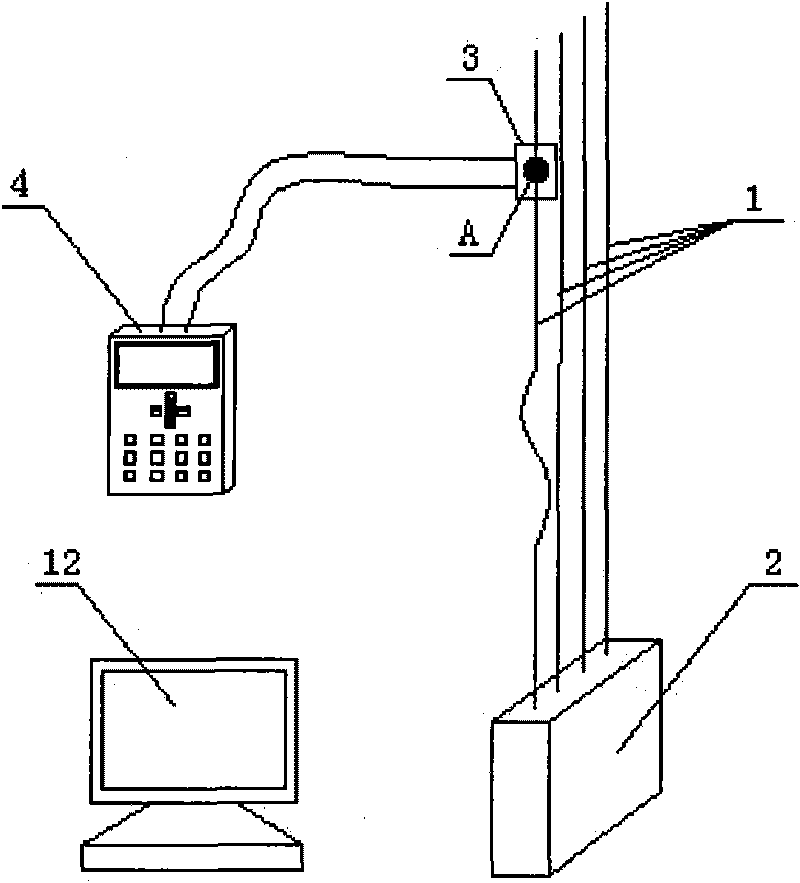

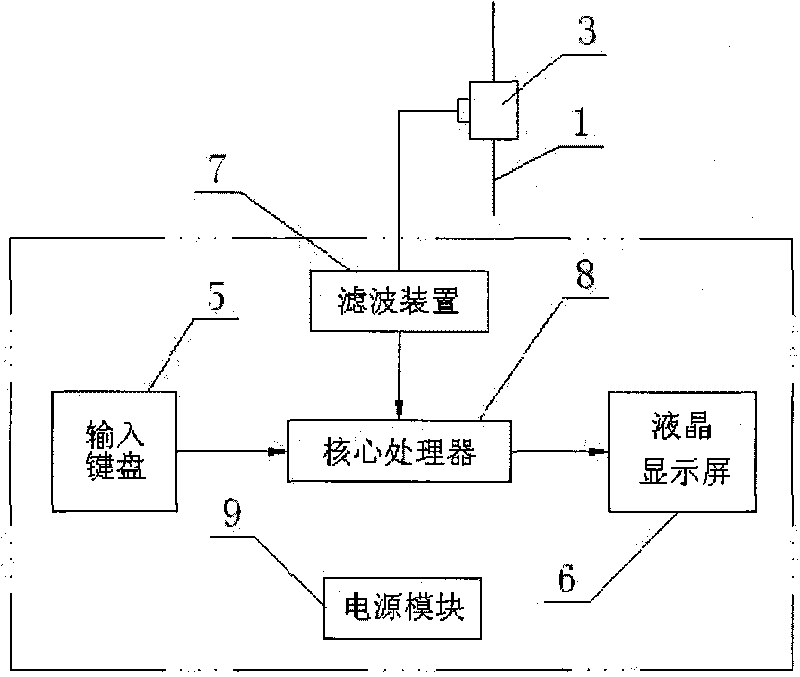

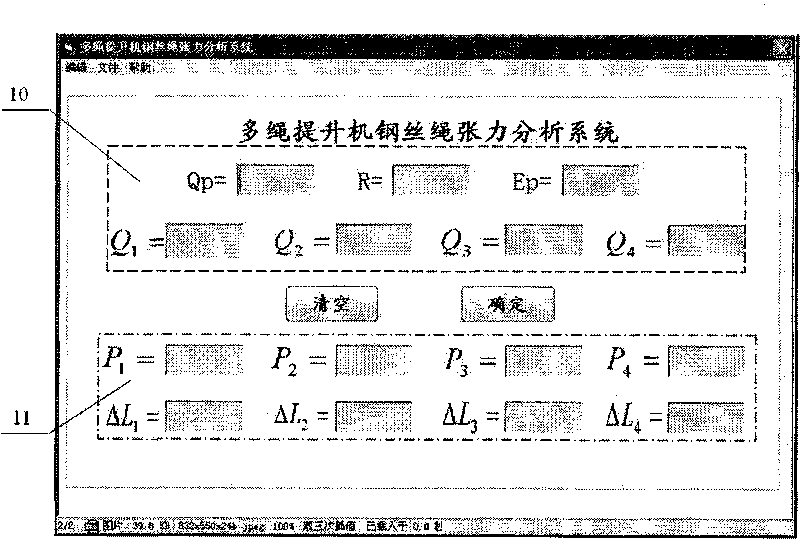

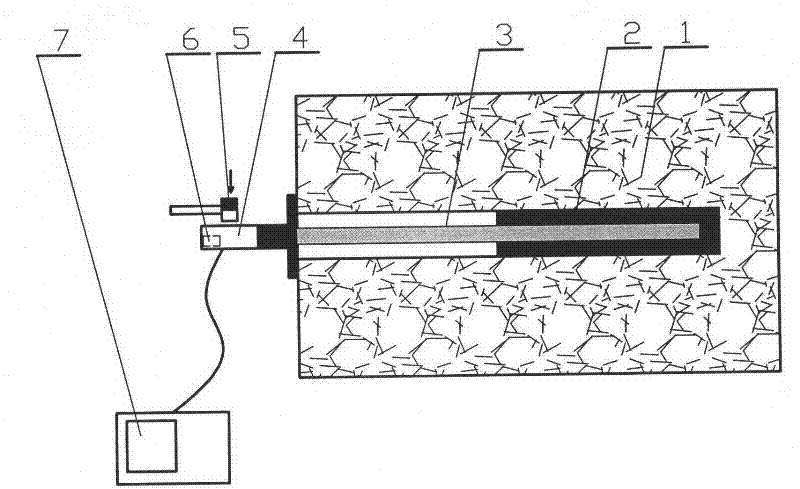

Multi-rope winder steel wire rope tension test method and device thereof

InactiveCN101726383AImprove detection accuracyEasy to archiveTension measurementTransducerEngineering

The invention relates to a multi-rope winder steel wire rope tension test method and a device thereof. The method comprises the following steps: firstly fixing an acceleration transducer on steel wire ropes to be tested and connecting with a tension measuring device, then beating the steel wire ropes vertically to generate transverse vibration, collecting the diffusion cycle t of the vibration wave on the steel wire ropes by the acceleration transducer, then inputting the steel wire rope length L, steel wire rope density rho and correction coefficient beta in the tension measuring device of the steel wire ropes to obtain the terminal load Qi of each steel wire rope, and then inputting the average load Qp, diameter R, elastic modulus Ep and the measured terminal load Qi of the steel wire ropes in a tension analysis system to calculate the rate of deviation Pi and adjustment value Delta Li of each steel wire rope. The method and device of the invention can accurately measure the tension of the steel wire rope and analyze the degree of uniformity between a plurality of steel wire ropes to obtain the adjustment value and manage and maintain the steel wire rope, thus prolonging the service life of the steel wire rope, preventing accidents to happen and having an important use value.

Owner:TAIYUAN UNIV OF TECH

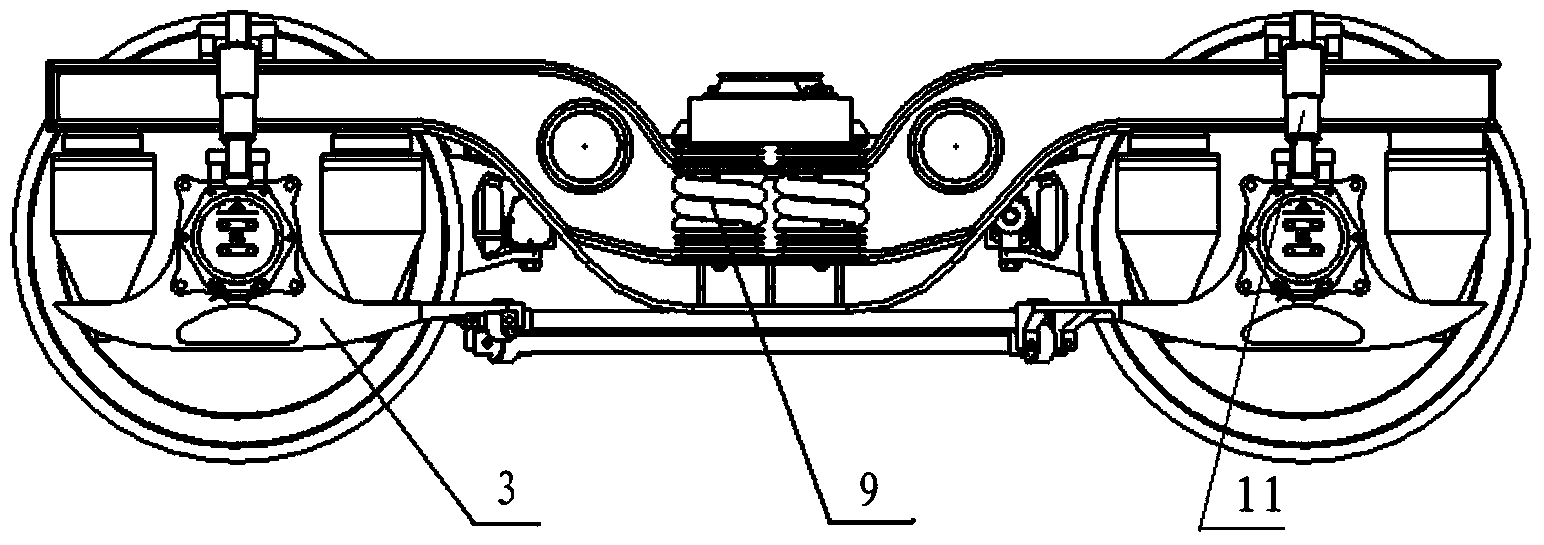

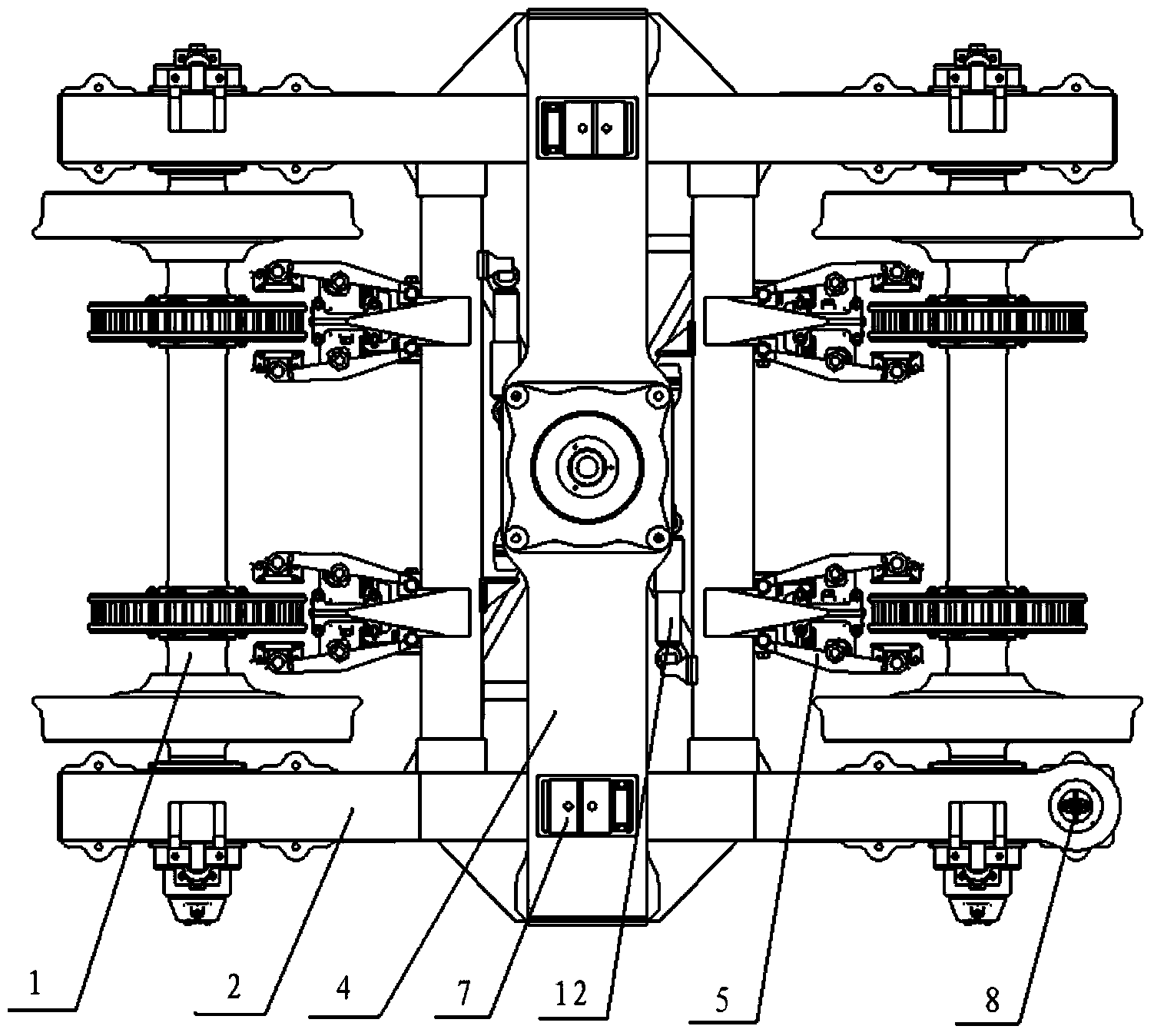

Rapid freight car radial bogie

InactiveCN103661464AReduce forceReduce lateral vibration accelerationBogie-underframe connectionsAxle-boxes mountingBogieTruck

The invention discloses a rapid freight car radial bogie. The rapid freight car radial bogie comprises an axle assembly, a frame, a swing bolster, a braking device, central suspension devices, a radial device, a side bearing device arranged on the swing bolster and an axle box suspension device, wherein the frame is installed on the axle assembly through the axle box suspension device, the two ends of the swing bolster are fixedly installed in the middle of the frame respectively through the central suspension devices, the frame is composed of two side beams and parallel cross beams connected with the side beams, and bearing platforms where the central suspension devices are installed are arranged outside the middle portions of the side beams. The rapid freight car radial bogie structure obviously reduces wheel-rail wear and wheel-rail noise, reduces wheel-rail acting force, reduces vehicle transverse vibration acceleration and improves vehicle operation lateral stability, straight line stability and curve line negotiating capacity. The unsprung mass of the bogie is reduced, the speed of the bogie is high, vehicle braking performance is improved, wheel-rail wear and wheel-rail noise are small, vehicle operation stability is good, and stability and safety are high.

Owner:CRRC MEISHAN

Apparatus and method for an ultrasonic medical device operating in torsional and transverse modes

InactiveUS7794414B2Simple, user-friendlyEffective timeSurgeryChiropractic devicesCavitationTransducer

Owner:CYBERSONICS

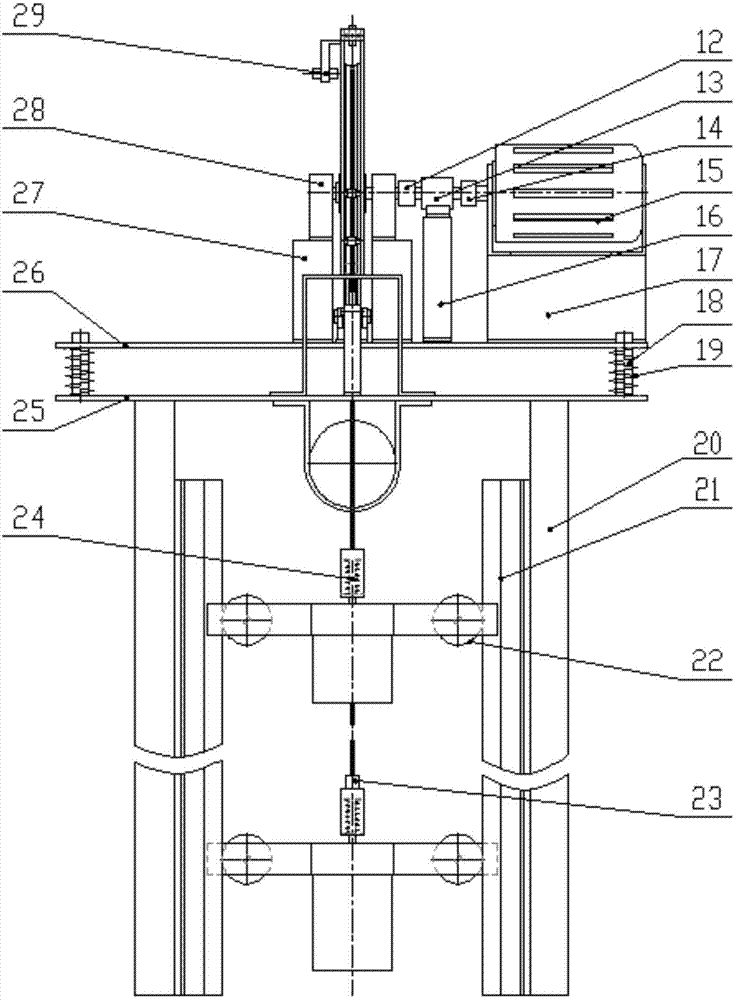

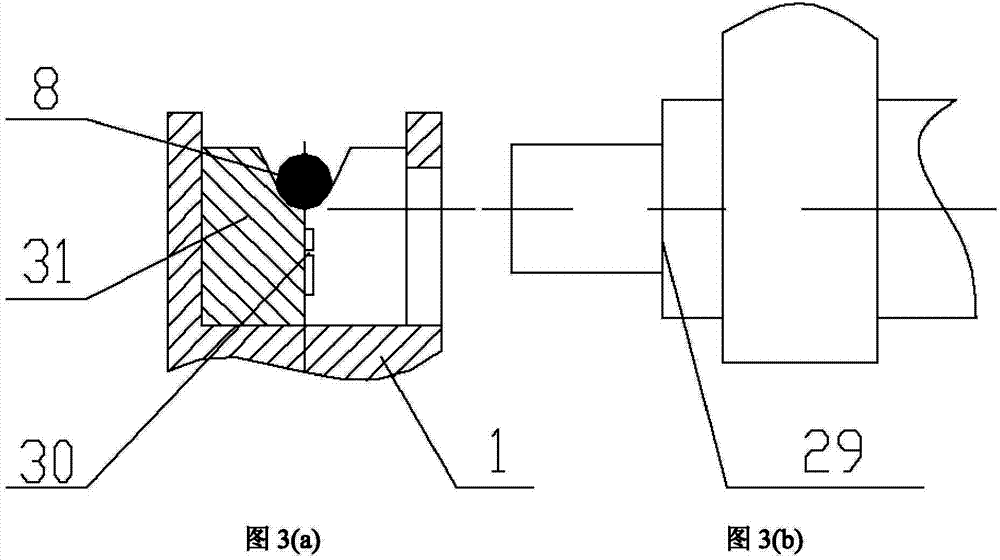

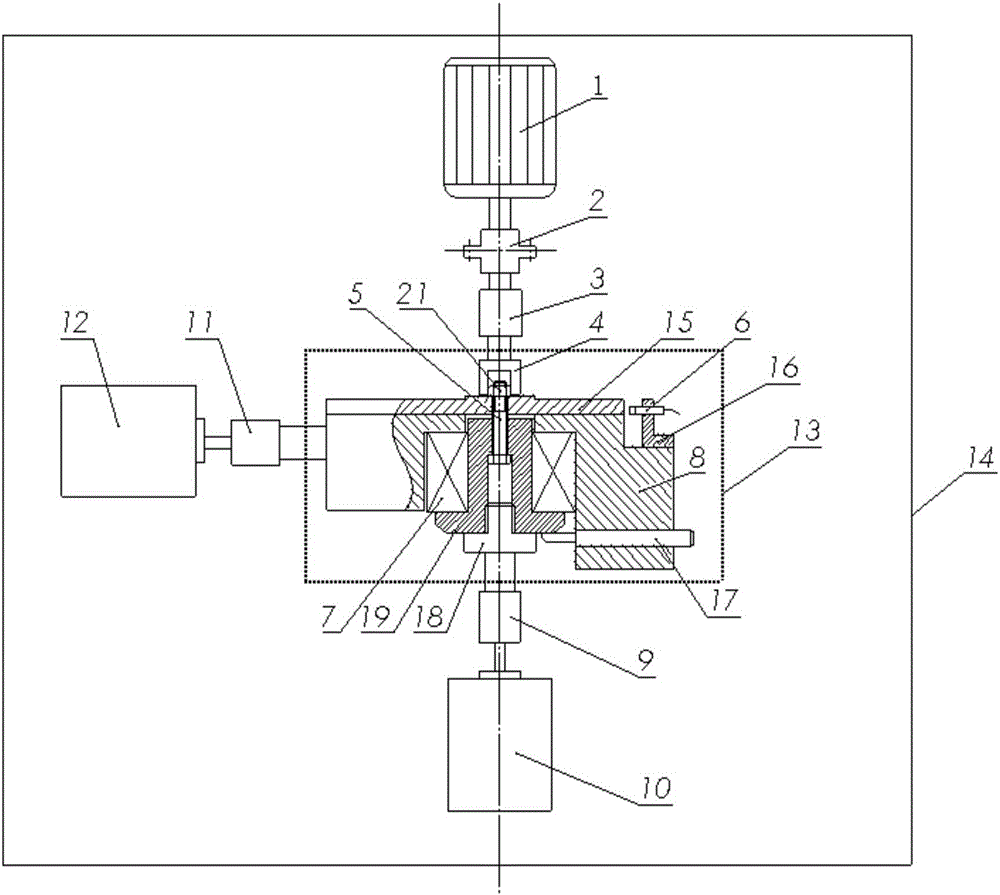

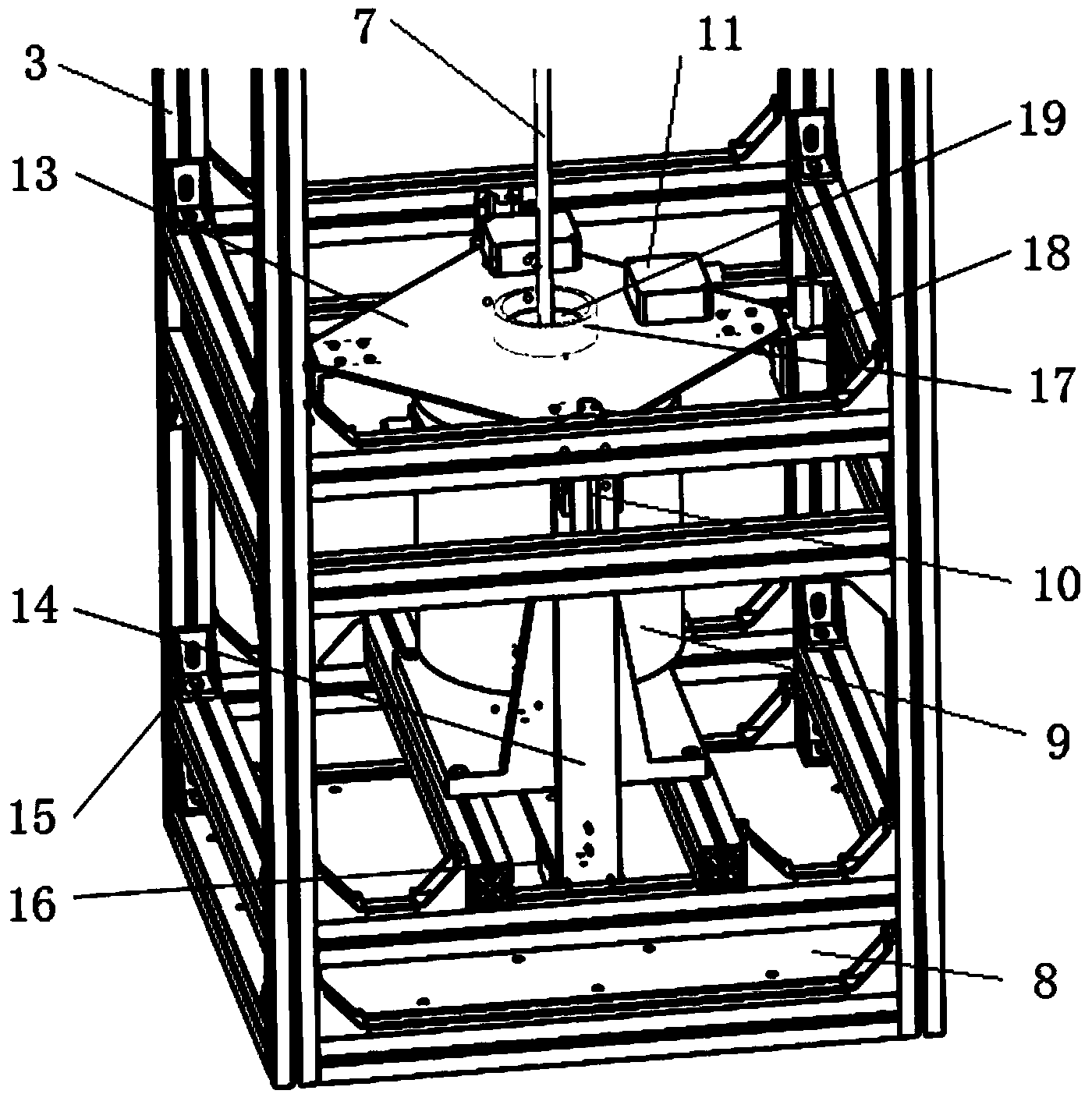

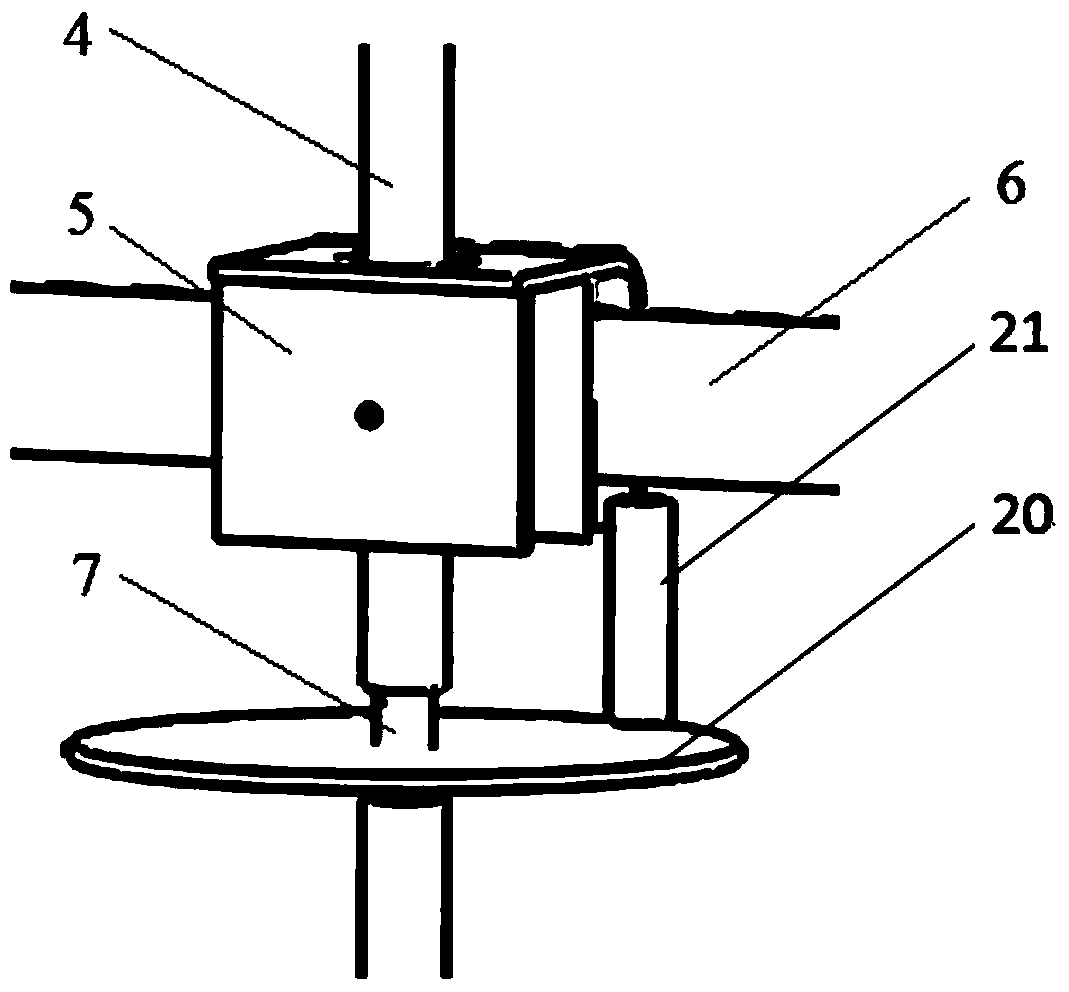

Experimental device for researching drill column dynamic characteristic

InactiveCN103712790AResearch is accurate and feasibleMachine part testingCircular discElectric machinery

The invention relates to an experimental device for researching a drill column dynamic characteristic. The experimental device comprises a main machine frame, a well-wall-simulating assembly, a rotary assembly, a disc assembly, an excitation assembly, a weighing assembly and a detecting device. The well-wall-simulating assembly comprises an organic glass tube, a fixing clamping and a clamp mounting plate. The rotary assembly is provided with a motor, a driver, a coupler, a thin steel column and a top mounting plate, the rotary assembly penetrates through the whole main machine frame, the disc assembly comprises a disc and a cylinder, the disc is arranged on a floating platform, and the disc conducts rotary movement in the cylinder. An exciter in the excitation assembly excites the bottom of the disc according to the input signal type to simulate interaction of a drill head and rocks at the bottom of a borehole. The detecting device comprises a whirling motion track and a transverse vibration and longitudinal vibration detecting device. The experimental device for researching the drill column dynamic characteristic can simulate the vibration and deformation situations of a drill column and determine the parameters of the rotating speed, the bit pressure similarity ratio and the like according to the dynamic similarity ratio and the geometric similarity ratio.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Integrated shock absorbing vibrating isolation device for stellite

InactiveCN1911734ASo as not to damageLower launch costsCosmonautic vehiclesCosmonautic partsStellite alloyIsolating mechanisms

Owner:郑钢铁 +3

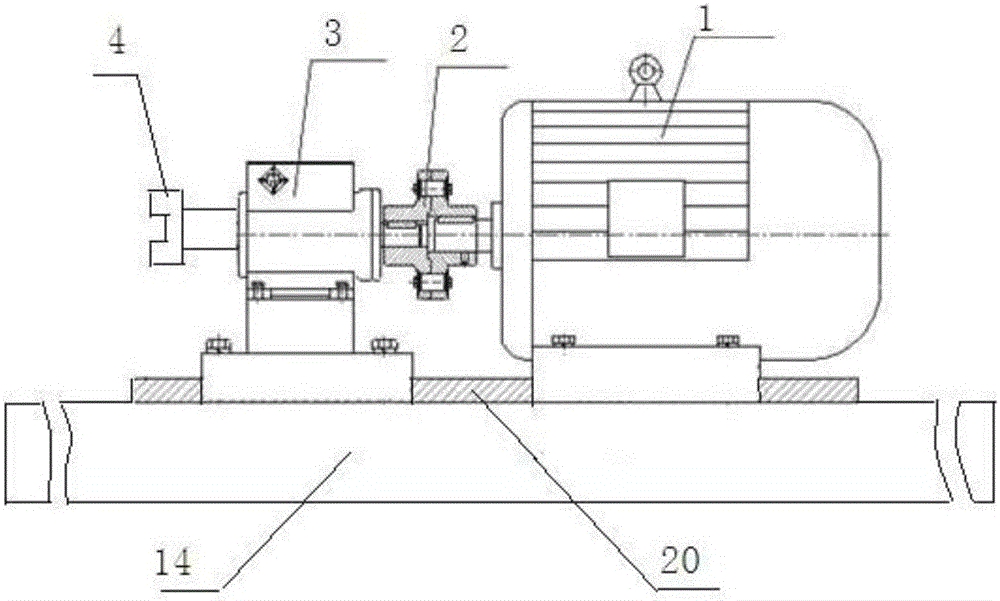

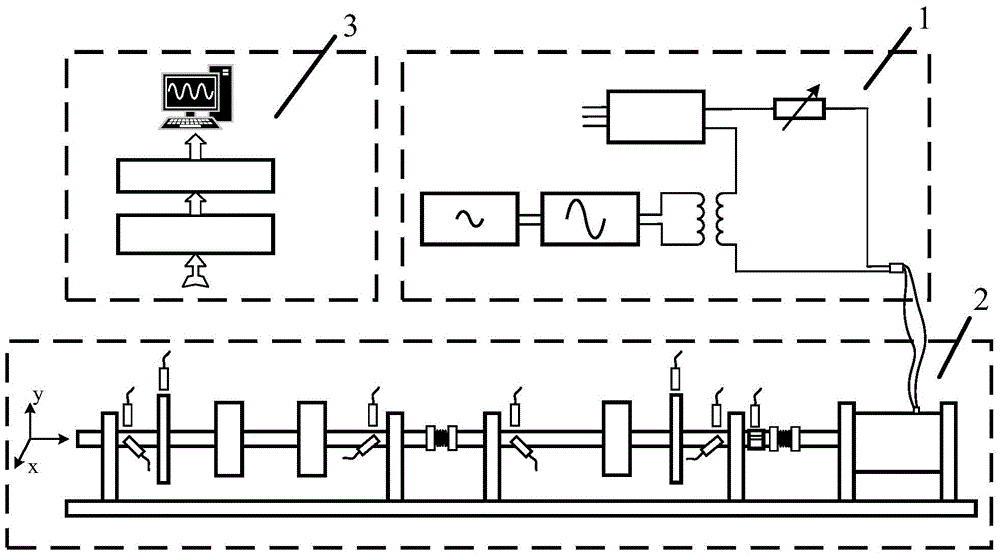

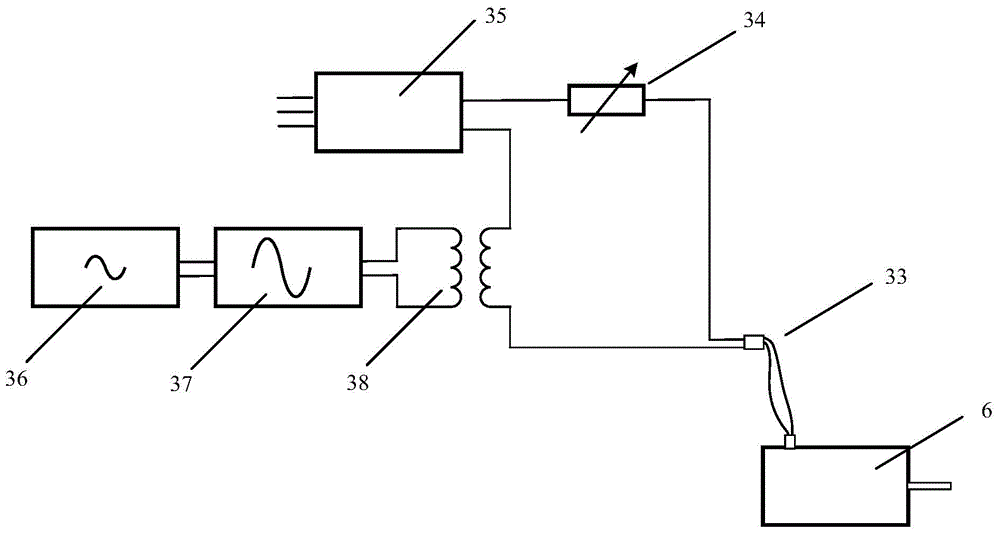

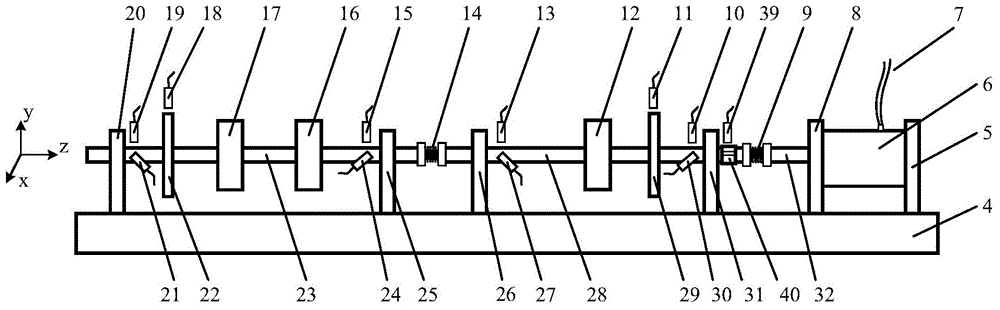

Rotor torsional vibration excitation and vibration analyzing experimental system

ActiveCN103558003AReal-time monitoring of lateral vibrationReal-time monitoring of torsional vibrationVibration testingAudio power amplifierTransformer action

The invention discloses a rotor torsional vibration excitation and vibration analyzing experimental system, and belongs to the technical field of rotating machine experimental devices. The rotor torsional vibration excitation and vibration analyzing experimental system comprises a multi-span rotor test bed, a rotor torsional vibration exciting device and a rotor vibration monitoring and analyzing system. In the rotor torsional vibration exciting device, an alternating signal generated by a signal generator is processed by a power amplifier and a transformer and then is overlapped with an output signal of a direct current voltage stabilization linear power source, and the overlapped signals serve as the input of a direct current motor to enable the direct current motor to output fluctuation torque. A rotor of the multi-span rotor test bed generates torsional vibration under the excitation of the fluctuation torque, and the rotor transverse vibration and rotor torsional vibration are monitored by the rotor vibration monitoring and analyzing system. The excitation and measuring of the torsional vibration of the rotor system can be finished under the condition of a laboratory, and the rotor torsional vibration excitation and vibration analyzing experimental system can be used for studying the relation between the transverse vibration and the torsional vibration when the rotor system is excited by the torsional vibration, and analyzing the characters of the rotor system excited by the torsional vibration. The rotor torsional vibration excitation and vibration analyzing experimental system is easy to achieve and complete in function, and is mainly used for the fields of rotating machine scientific researches and teaching.

Owner:TSINGHUA UNIV

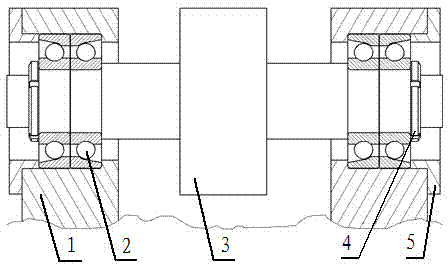

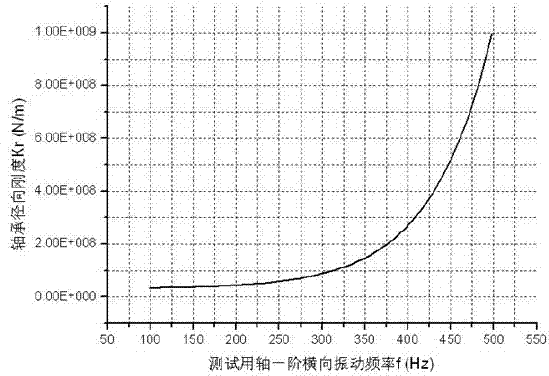

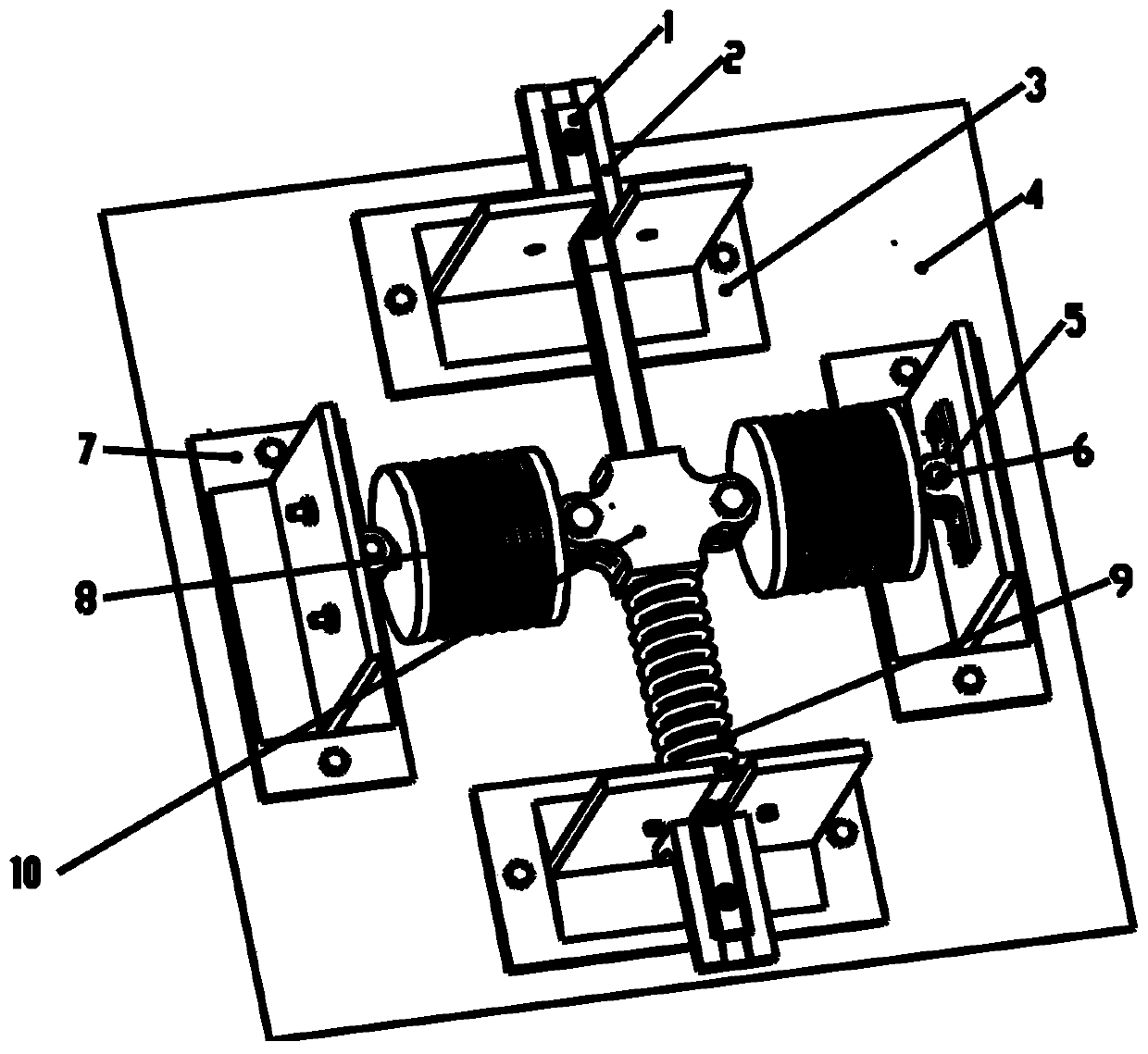

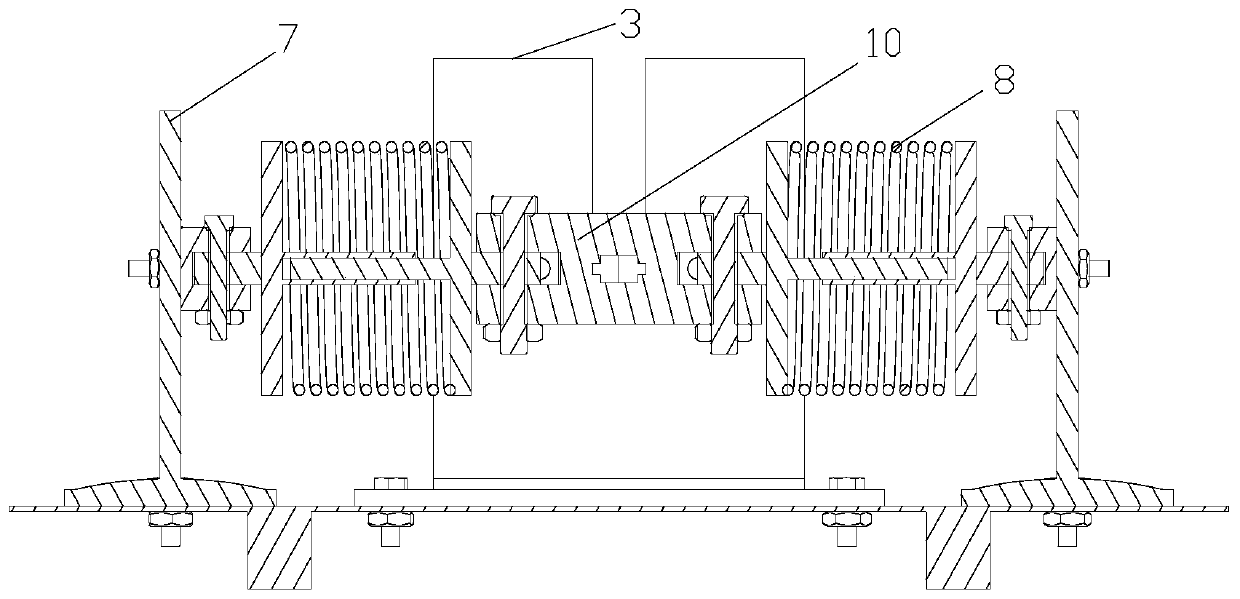

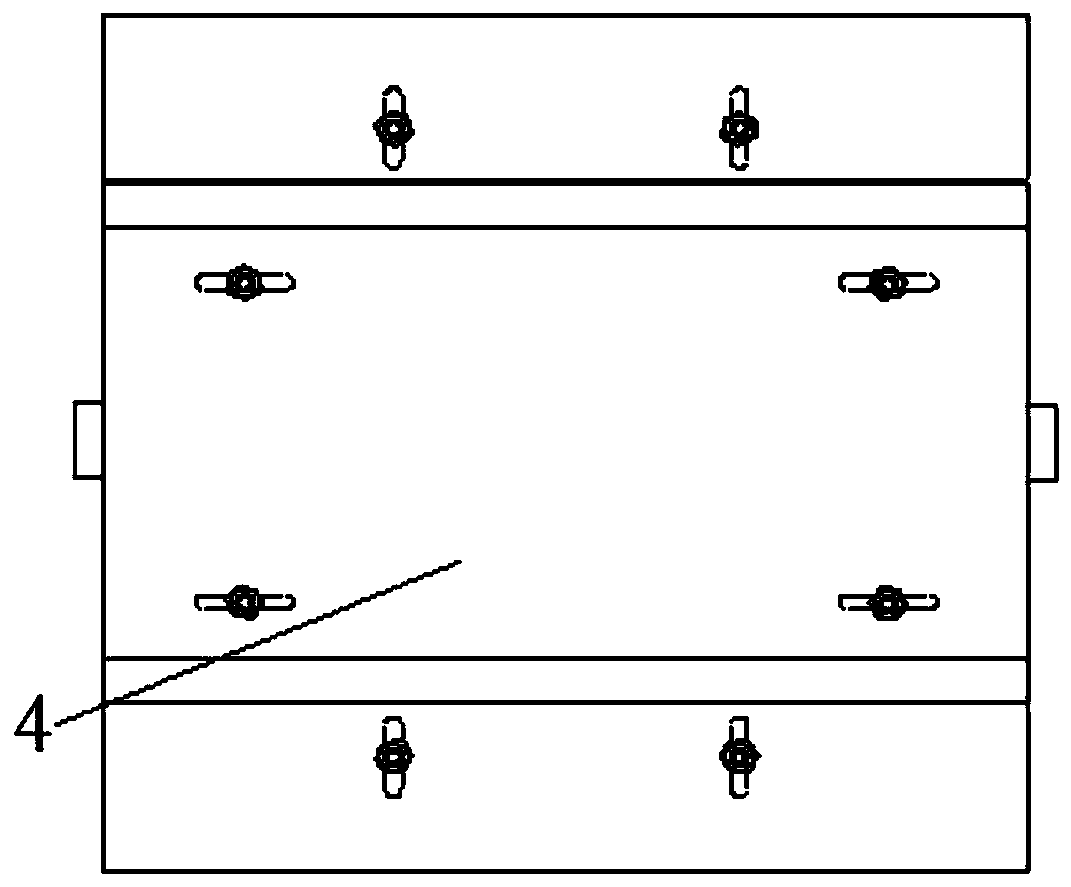

Dynamic measurement method for radial stiffness and axial stiffness of bearing

InactiveCN102889990AMeasuring Radial StiffnessMeasuring Axial StiffnessMachine bearings testingMeasurement testPhysical system

The invention belongs to the technical field of mechanical measurement and is applicable to measurement of radial stiffness and axial stiffness of bearings. The measurement principle is based on a relationship between the bearing stiffness and inherent vibration frequency of a shaft for test. The method comprises the following steps of: in the process of measuring the radial stiffness of the bearing, solving a function relationship between the radial stiffness of the bearing and the first-order transverse vibration frequency of a shaft for test, building a physical system among the shaft for test, a measured bearing and a rigid support, measuring the first-order radial vibration inherent frequency of the shaft for test, and finally, calculating the radial stiffness of the bearing according to a function relationship between the inherent vibration frequency and the radial stiffness of the bearing; and in the process of measuring the axial stiffness of the bearing, solving the mass of the shaft for test, building a physical system among the shaft for test, the measured bearing and the rigid support, measuring the first-order axial vibration inherent frequency of the shaft for test, and finally, calculating the axial stiffness of the bearing according to a relationship between the vibration inherent frequency and the axial stiffness of the bearing.

Owner:马会防

Nonlinear energy trap vibration absorbing device for whole satellite vibration suppression

InactiveCN109780130ATroubleshooting Cubic Stiffness PropertiesCubic Stiffness Properties PureNon-rotating vibration suppressionBroadbandEngineering

The invention discloses a nonlinear energy trap vibration absorbing device for whole satellite vibration suppression. The nonlinear energy trap vibration absorbing device comprises two geometric linear springs, a supporting linear spring, a mass block, a guide rail, a bracket and a bottom plate; the vibration absorbing device is installed along the wall of an adapter cone shell; and the mass blockmoves along the guide rail to drive the three linear springs to move to achieve the relatively-pure cubic stiffness characteristic, and a nonlinear energy trap device is formed to achieve the vibration absorption effect. The nonlinear energy trap vibration absorbing device is arranged on the wall of the adapter cone shell of a satellite, the linear springs are guided in the direction of the guiderail, and the longitudinal and transverse vibration suppression effect is achieved; and meanwhile, the nonlinear energy trap device is simple in structure and easy to adjust and install and has the advantages that the robustness is good, effective broadband vibration suppression can be achieved and an external power supply is not needed.

Owner:XIAN UNIV OF TECH

Dynamic and static pressure composite gas bearing with internal pi shaped air wedge groove

InactiveCN101691879AImprove bearing capacityImprove reliabilityBearing componentsBearingsCouplingGas supply

The invention provides a dynamic and static pressure composite gas bearing with an internal pi shaped air wedge groove, which relates to bearing technology, and belongs to a gas bearing with a novel structural form for supporting an ultrahigh speed rotary machine. The gas bearing is structurally characterized in that the inner surface of the bearing adopts pi shaped air wedge groove design, dynamic and static pressure composite design, and dynamic and static pressure design of a thrust surface; the thrust surface adopts spiral pressurizing groove design; and the inner surface and the thrust surface are provided with a static pressure gas supply hole respectively. The gas bearing overcomes the defects of the coupling and mutual interference between static pressure and dynamic pressure, overcomes the defect that the dynamic pressure effects at two ends of the bearing are inconsistent, not only remarkably improves the bearing capacity and rotating speed of the bearing, but also greatly reduces the axial and transverse vibration of a rotor journal, and improves the stability and reliability of a rotor system. Therefore, the gas bearing has the advantages of simple structure, high bearing capacity, stable operation and high reliability, and further widens the application range of the gas bearing.

Owner:DALIAN UNIV OF TECH

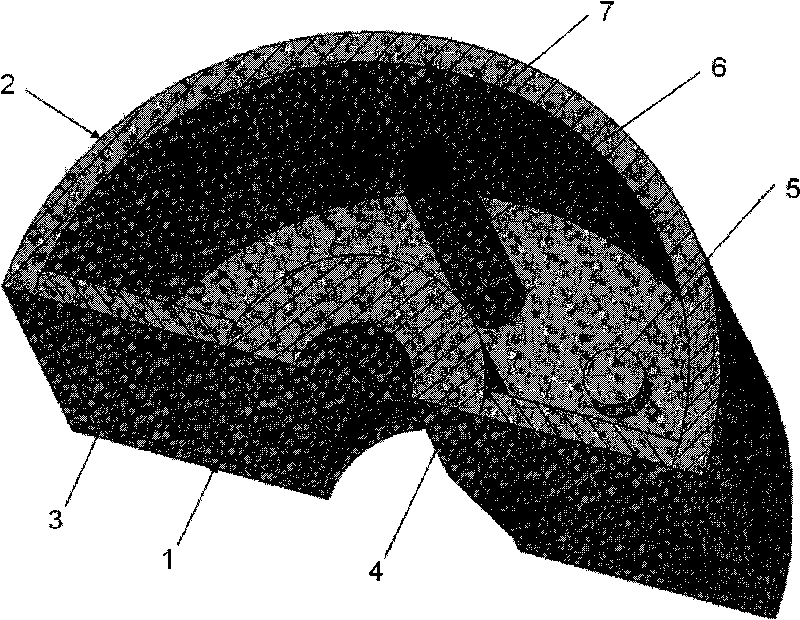

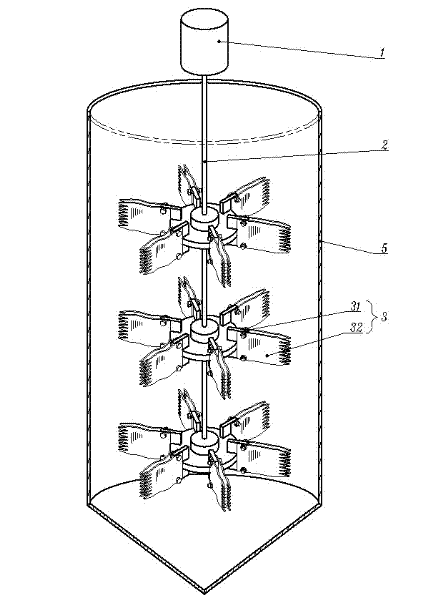

Combined type stirring impeller for increasing leaching rate of manganese metal electrolyte

InactiveCN102191372AHigh extraction rateThe effect of improving the extraction rateRotary stirring mixersImpellerManganese

The invention discloses a combined type stirring impeller for increasing the leaching rate of manganese metal electrolyte. The stirring impeller is provided with a plurality of layers which are fixedly arranged on a stirring shaft coaxial with a manganese metal electrolyte leaching tank; and each blade of each layer of stirring impeller is a combined type impeller which is formed by connecting a rigid blade section close to the stirring shaft and a flexible blade section far away from the stirring shaft. The rigid blade section is in a flat-plate shape; and the flexible blade section is a flexible slice or two flexible slices which are clamped at both sides of the rigid blade section. The tail end of the flexible blade section can be comb-shaped if necessary. The flexible blade section of the combined impeller can keep on doing extremely reliable transverse vibration in ore pulp. The combined type stirring impeller has more obvious effects on the aspects of saving energy sources and increasing the leaching rate of the manganese metal electrolyte. When the combined type stirring impeller is applied, the accuracy requirements on the layer numbers and the interlayer spacing of the stirring impeller and the length of the rigid blade section of the stirring impeller are extremely reduced. Therefore, the combined type stirring impeller has the advantage of obviously reducing the comprehensive cost.

Owner:CHONGQING UNIV

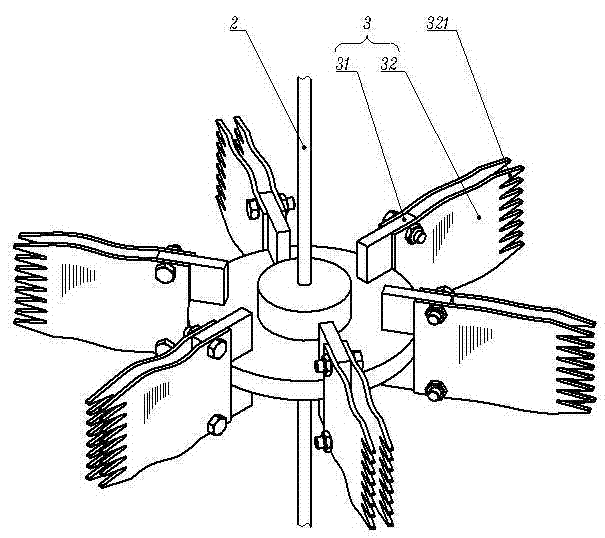

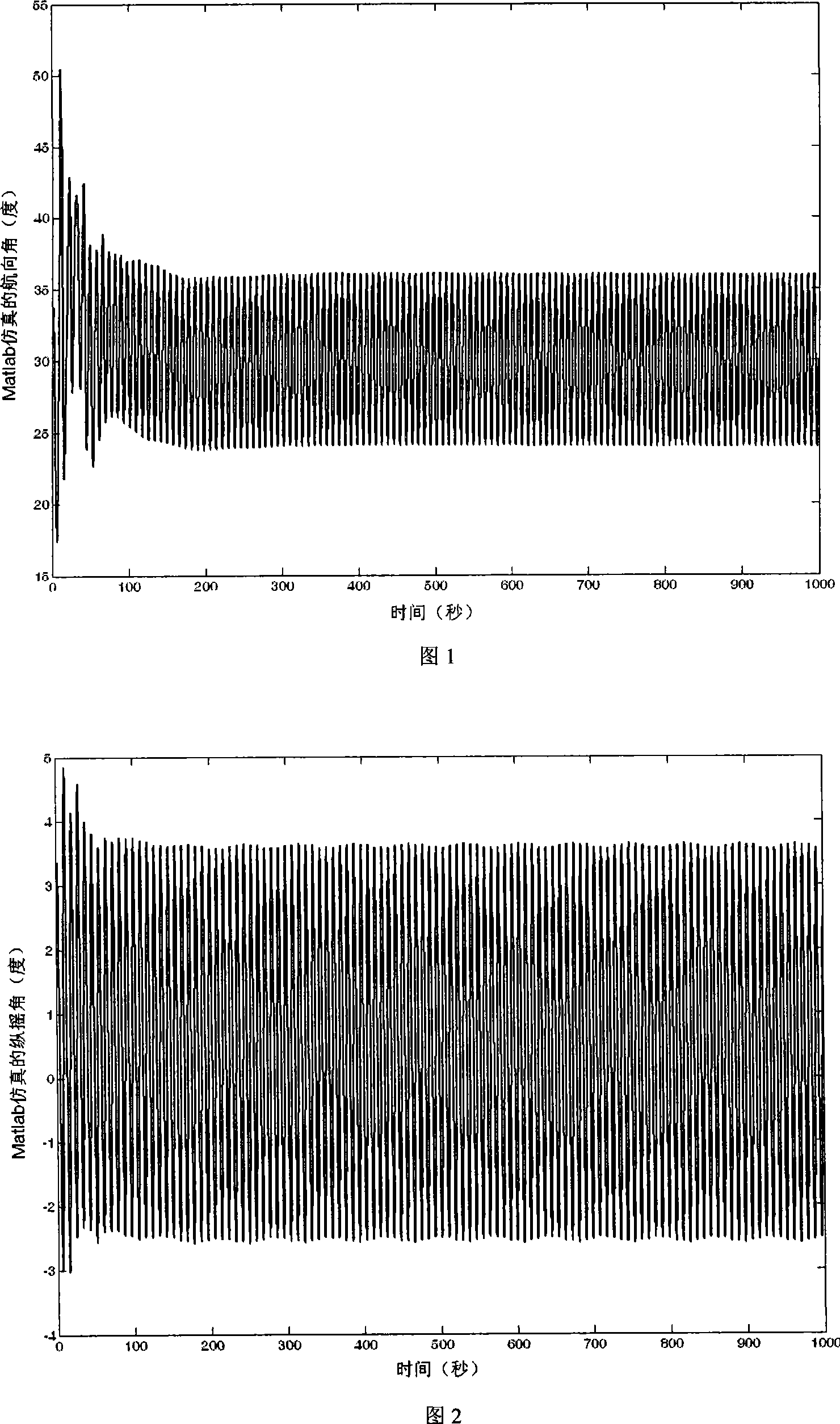

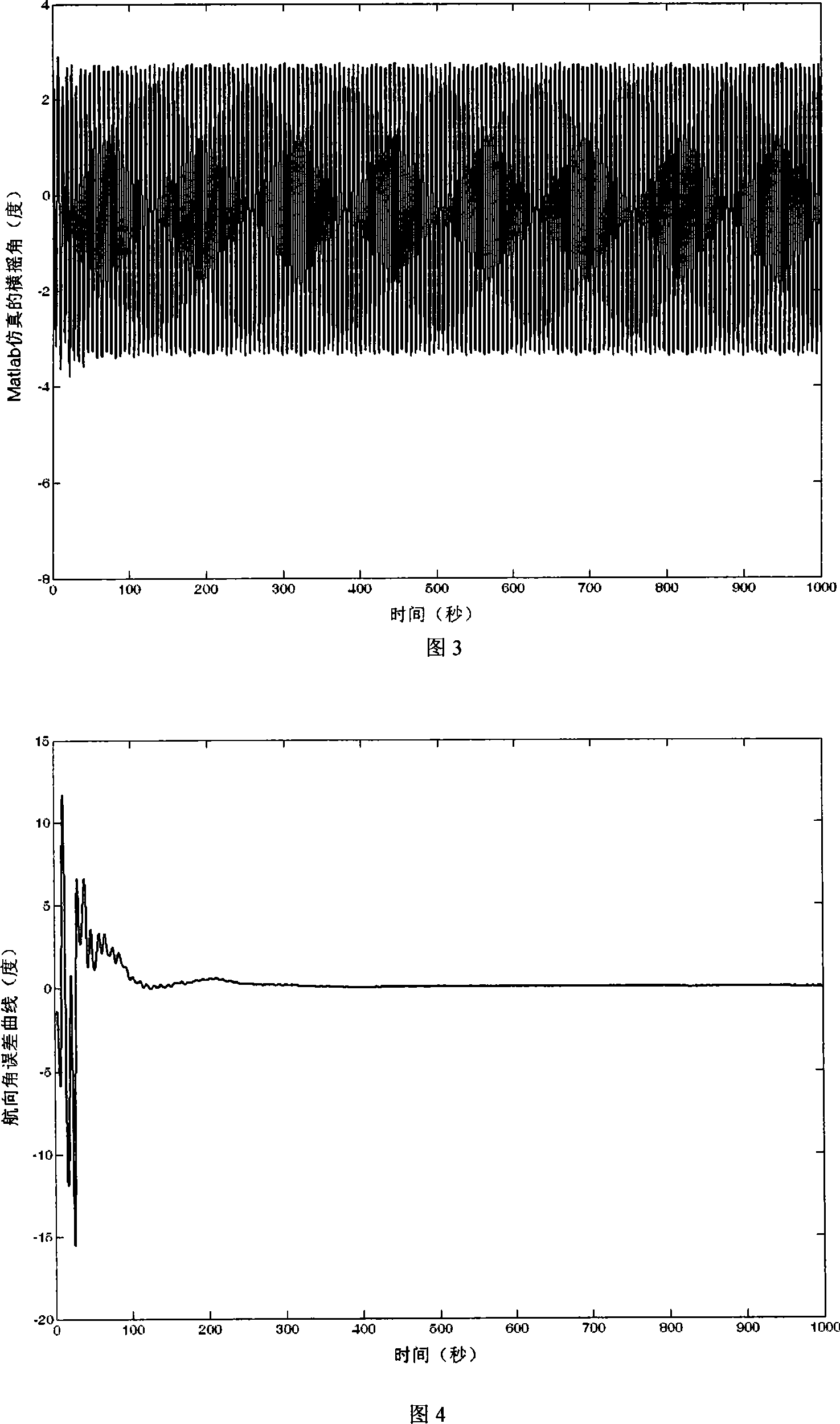

Marine fiber optic gyroscope attitude heading reference system mooring extractive alignment method under the large heading errors

InactiveCN101162147AHigh precisionImprove alignment accuracyNavigation by speed/acceleration measurementsSagnac effect gyrometersFiberVertical vibration

The invention provides an accurate aligning method for berthing ship-used fiber peg-top strapdown attitude system in large misalignment angle. For a ship-used fiber peg-top strapdown attitude system in berthing condition, on the base that coarse alignment is performed according to collected information of the output of peg-top and the acceleration output (because of very big longitudinal vibration, transverse vibration, vertical vibration), a converting array between a carrier coordinate system and a calculating geography coordinate system is built to determine quaternion error; a kalman filtering equation using the quaternion error and the speed error as state variables and a measuring equation using speed error as measuring variable are built; by the quaternion error and the quaternion corresponding to the attitude array in first time, the quaternion corresponding to converting array between the carrier coordinate system and an inertia system is figured out for original aligning. In the invention, the system equation is still linear for large misalignment angle, relatively mature kalman filtering is used for filtering estimating, a high accuracy and a good reliability are attained; the invention is not sensitive to the three vibrations in ship berthing condition, thus a high aligning accuracy is got.

Owner:HARBIN ENG UNIV

Sonotrode

ActiveUS20190091490A1Ultrasound therapySurgical instruments for heatingReduced subcutaneous fatLongitudinal vibration

Disclosed are methods and devices for treatment of subcutaneous fat by simultaneously transdermally inducing both ultrasonic transverse vibrations and ultrasonic longitudinal vibrations in subcutaneous tissue, for example for reduction of subcutaneous fat.

Owner:ALMA LASERS LTD

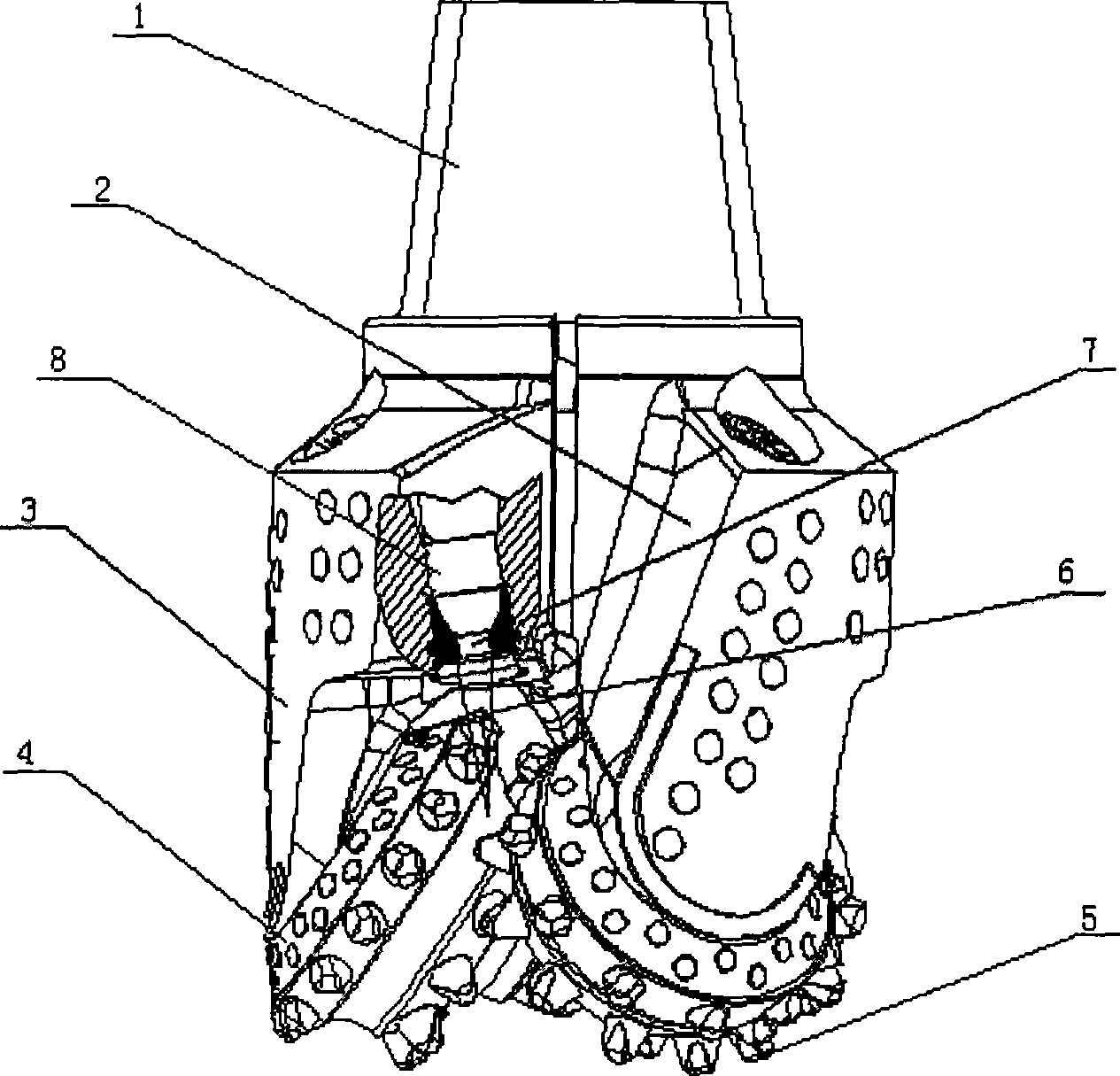

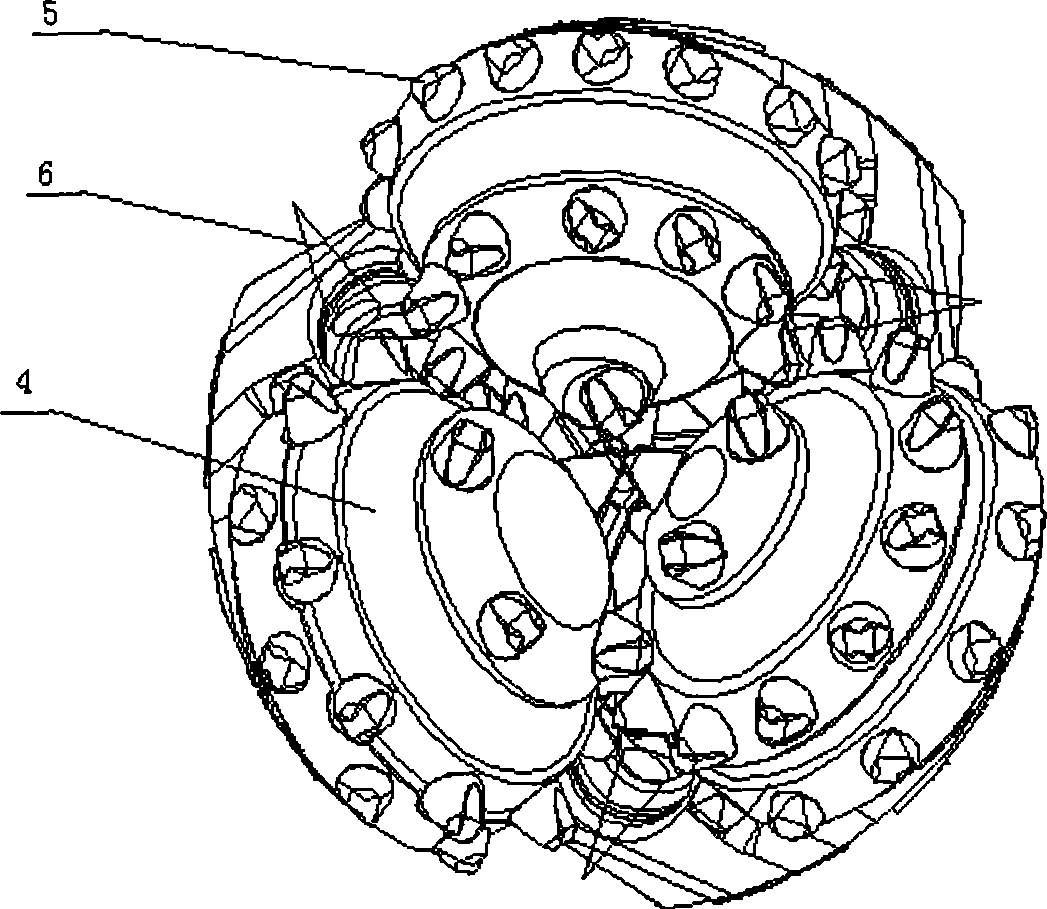

Three-cone bit for horizontal well and hard formation well

InactiveCN101382045AImprove stabilityImprove cooling effectDrill bitsDrilling rodsWell drillingCooling effect

The invention relates to a tricone bit for a horizontal well and a hard formation well. The tricone bit comprises three palms and cones arranged on the lower ends of the palms. The upper parts of the three palms are integrated to form a bit body, nozzle holders are arranged between the palms of the bit body, and nozzles are arranged in the jet orifices of the nozzle holders. The invention is characterized in that radius holding teeth are arranged on the back upper parts of the backs of the palms to form radius holding planes on the upper parts of the palms, and the front side faces of the palms deflect backwardly integrally. The radius holding points arranged on the back upper parts of the backs of the palms strengthen the drilling stability of the bit and reduce transverse vibration. And therefore, the bit is not easily deviated when drilling a horizontal well, thereby improving the effective service life of the tricone bit. The front side faces of the palms backs deflect backwardly integrally, thereby promoting the up returning of the rock debris with the slurry, and facilitating the improvement of the drilling efficiency. The jet direction of each nozzle is led to the front side of a next cone, thereby reinforcing the cleaning of the bottom of the well and the cooling effect of the cone teeth, and bringing about relatively longer service life and higher mechanical drilling speed for the tricone bit.

Owner:SINOPEC OILFIELD EQUIP CORP

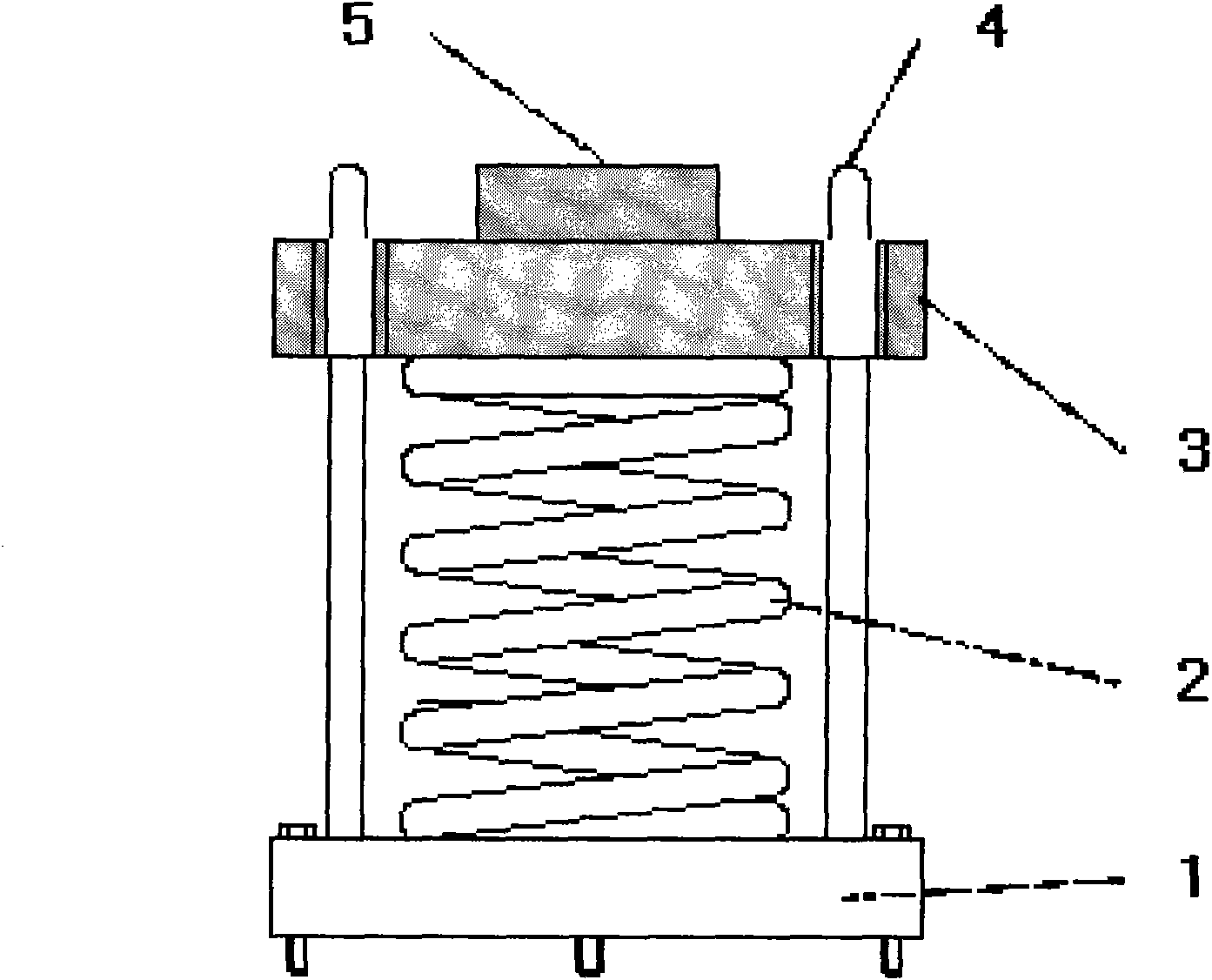

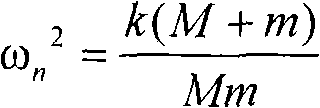

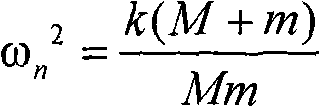

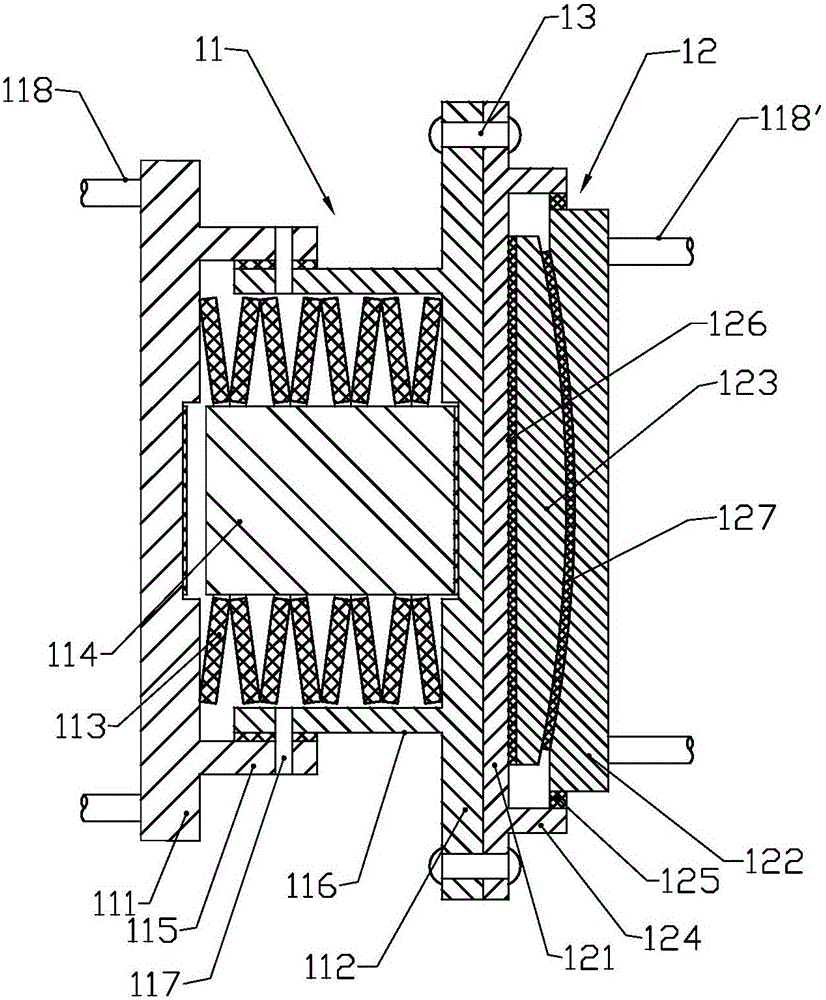

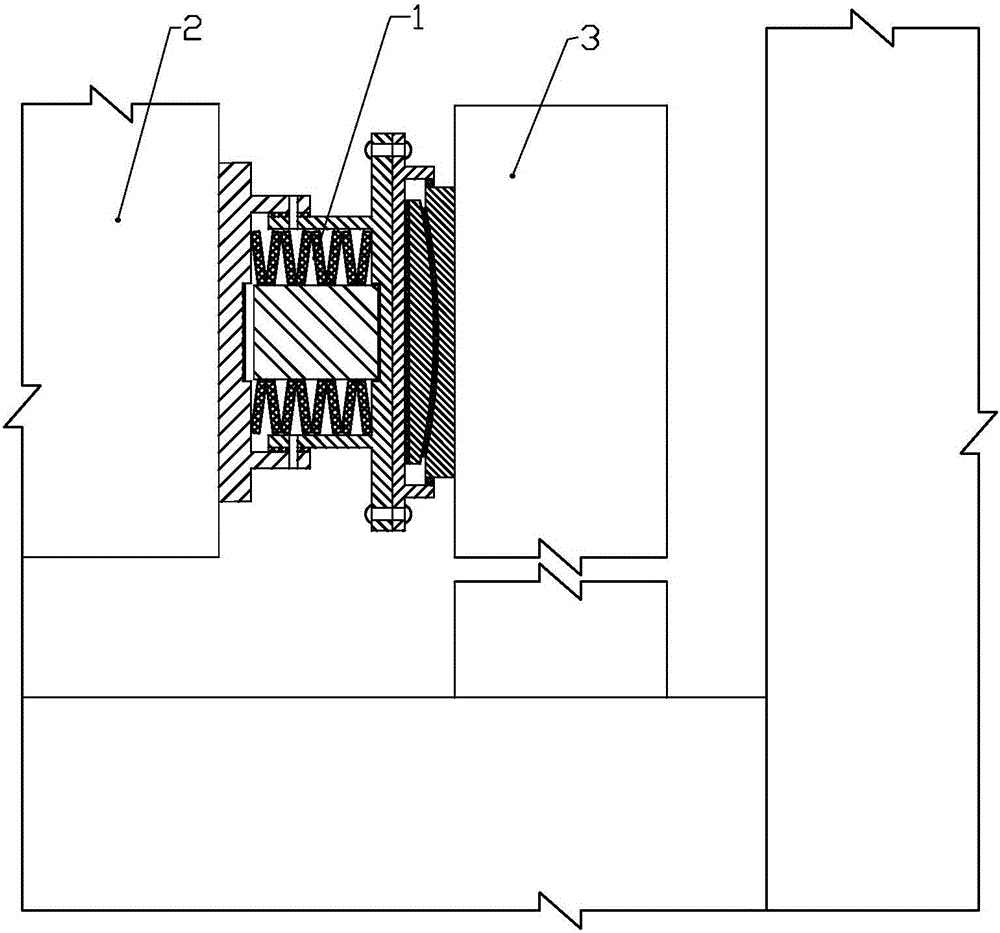

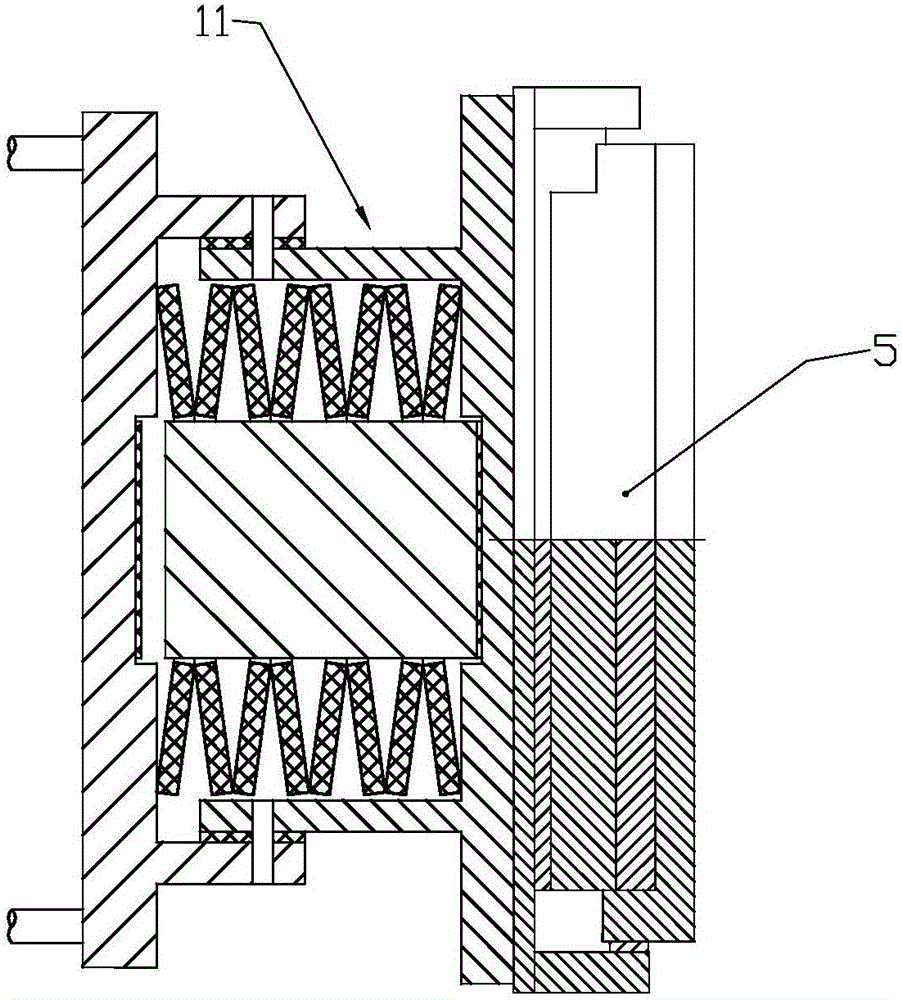

Vibration enhanced device of electric vibration table

The invention provides a vibration enhanced device of electric vibration table, comprising a substrate and a test bed; the device is characterized in that: a spring is connected between the substrate and the test bed; a rigid guide bar leading the test bed surface to do vertical movement is installed between the substrate and the test bed; an additional mass block is placed at the center of the test bed; selection of the rigidity of the spring and the resonance frequency of the spring quality system satisfy the following relationship: omega n2=k(M+m) / Mm. Compared with the prior art, the technical proposal is easier to be implemented, and can effectively limit the transverse vibration and conveniently control the vibration enhanced frequency. The vibration enhanced ability can arrive more than 10 times. The technical proposal and the method can be used in various dynamic test apparatuses for enhancing the vibration acceleration or displacement and providing special dynamic excitation source.

Owner:希蒙电子国际有限公司

Bridge shock reduction and isolation supporting base and cable-stayed bridge and suspension bridge supporting structure

ActiveCN105887668AIncrease inputIncrease the lateral stiffness of the structureBridge structural detailsCable stayedTower

The invention discloses a bridge shock reduction and isolation supporting base and a cable-stayed bridge and suspension bridge supporting structure. The bridge supporting base comprises a left part and a right part, the left part is a transverse disk spring assembly, the right part is a transverse one-way movable supporting base, the left part and the right part are connected in series and connected into an integrated structure through a connecting piece, and a plurality of C-type mild steel dampers can be evenly arranged between a first plate and a second plate in the circumferential direction. The invention discloses application of the bridge supporting base to a cable-stayed bridge and a suspension bridge. After the bridge shock reduction and isolation supporting base is adopted, the transverse vibration period of the structure can be effectively prolonged, and deformation of a disk spring can also consume part of earthquake energy, so that bridge tower transverse seismic response can be remarkably reduced, the amplitude reaches 20-30%, and design difficulty and building cost are effectively reduced.

Owner:SHANDONG TRAFFIC PLANNING DESIGN INST

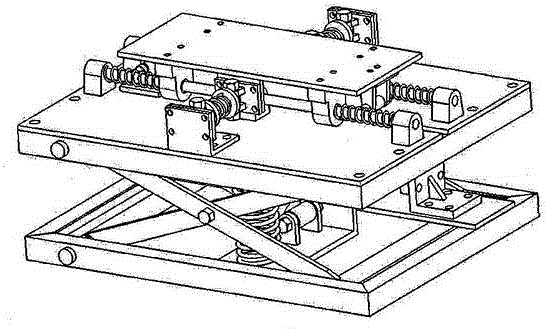

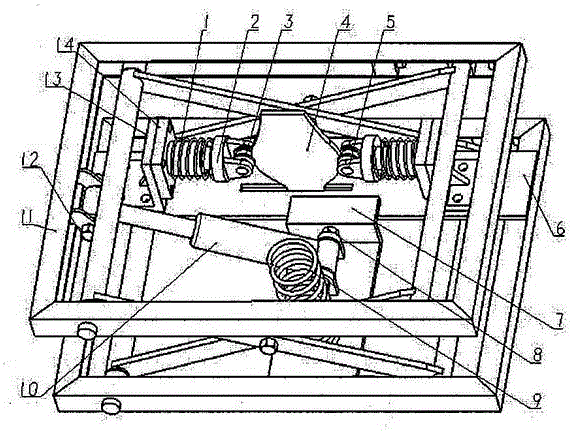

Two-dimensional nonlinear vibration-isolating suspension frame of seats of off-road vehicle

InactiveCN104401240AExtended Isolation DimensionsWith two-dimensional vibration isolationVibration suppression adjustmentsSeat suspension devicesVertical vibrationEngineering

The invention discloses a two-dimensional nonlinear vibration-isolating suspension frame of seats of an off-road vehicle. The two-dimensional nonlinear vibration-isolating suspension frame consists of a vertical vibration-isolating part and a transverse vibration-isolating part, which are respectively used for achieving vibration isolating effects in the vertical direction and the transverse direction, and are fixed by virtue of a bolt. The two-dimensional nonlinear vibration-isolating suspension frame has vibration isolating effects in the vertical direction and the transverse direction, adopts the non-linear vibration isolating principle, and is suitable for various off-road vehicles, especially the off-road vehicles, such as excavators, with very great transverse vibration.

Owner:JILIN UNIV

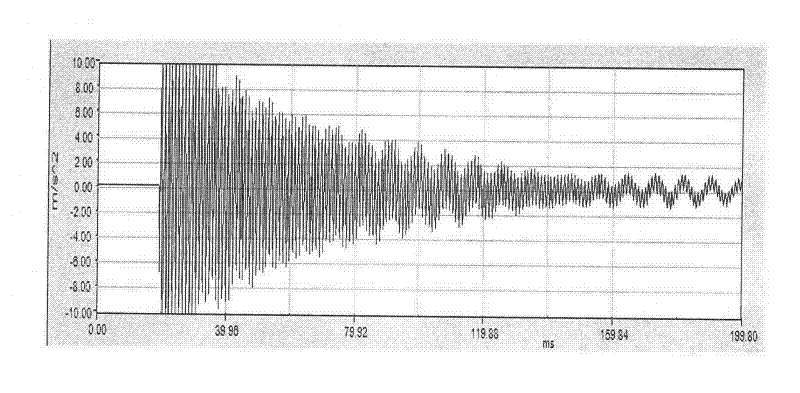

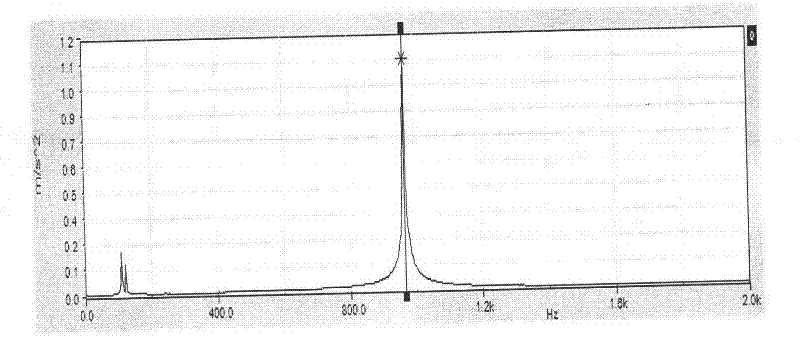

Non-destructive testing method for natural frequency of transverse vibration of non-fully grouted anchoring bolt in coal mine

InactiveCN102207404AMonitor stabilityEasy to install and connectVibration measurement in solidsFrequency spectrumVibration acceleration

The invention relates to a non-destructive testing method for the natural frequency of transverse vibration of a non-fully grouted anchor bolt in coal mine, which comprises the testing steps that: an exposed end of the anchor bolt is connected with a sensor connecting device and a sensor; nominal exciting force is applied to the sensor connecting device via a small hammer so that the anchor bolt generates transverse vibration; the vibration acceleration of the anchor bolt is acquired by the sensor and an acceleration signal is transmitted to a tester; the tester converts the received acceleration analog signal into an acceleration digital signal and stores the acceleration digital signal; simultaneously, the acquired signal is subjected to spectrum analysis to obtain the natural frequency of the anchoring system of the tested anchor bolt, and the resultant natural frequency of the transverse vibration of the anchor bolt is closely correlated with the axial stress of the anchor bolt and the bonding state between the anchoring section of the anchor bolt and coal. The device disclosed by the invention is simple and convenient in installation and connection, short in testing time required and capable of implementing large-area testing for the anchor bolt in a tunnel and monitoring the stability of the overall tunnel.

Owner:江苏中矿立兴能源科技有限公司

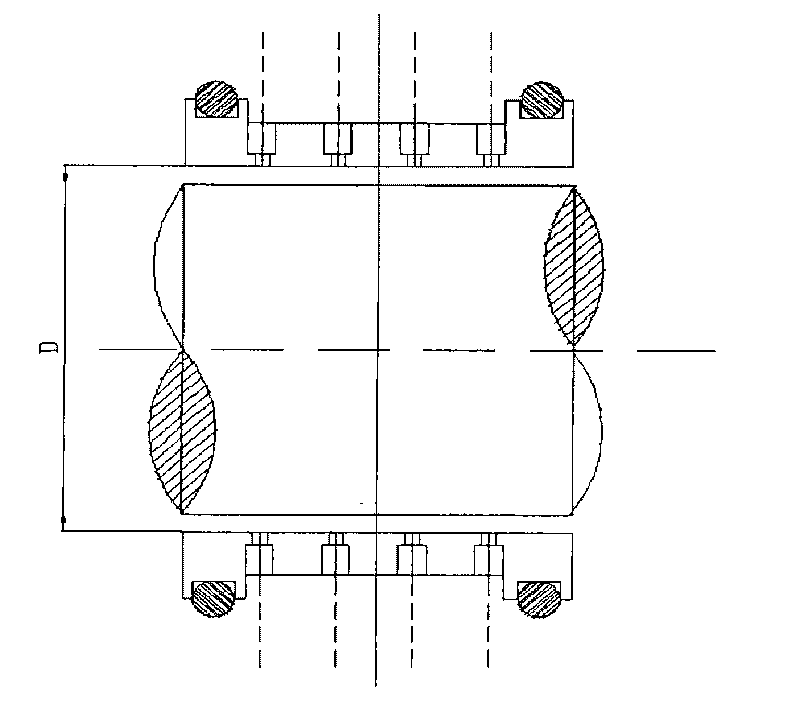

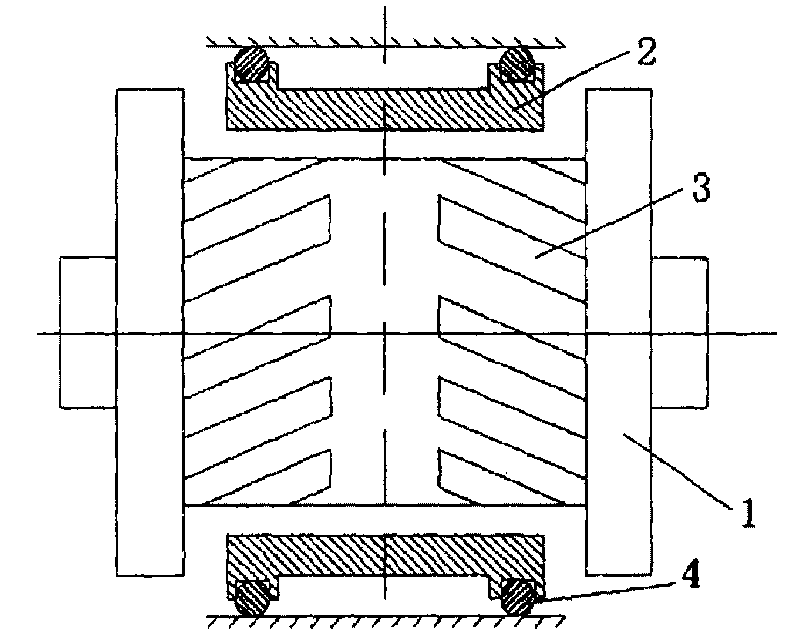

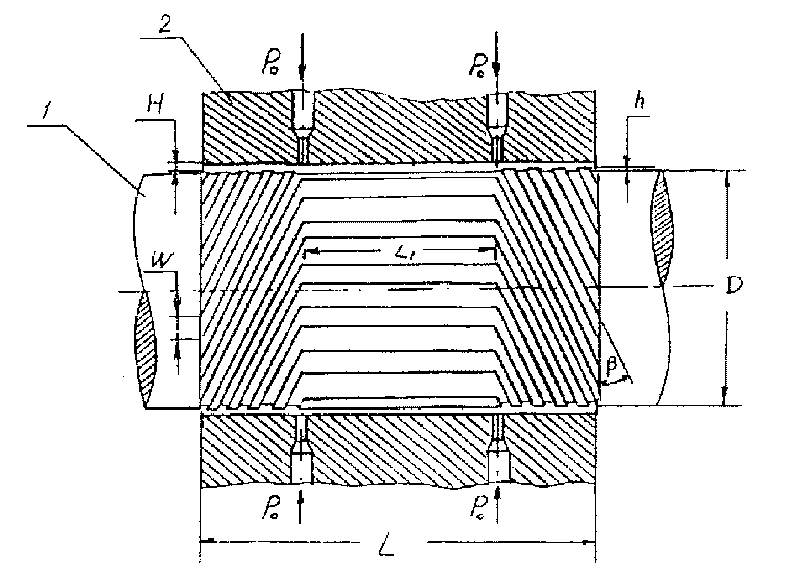

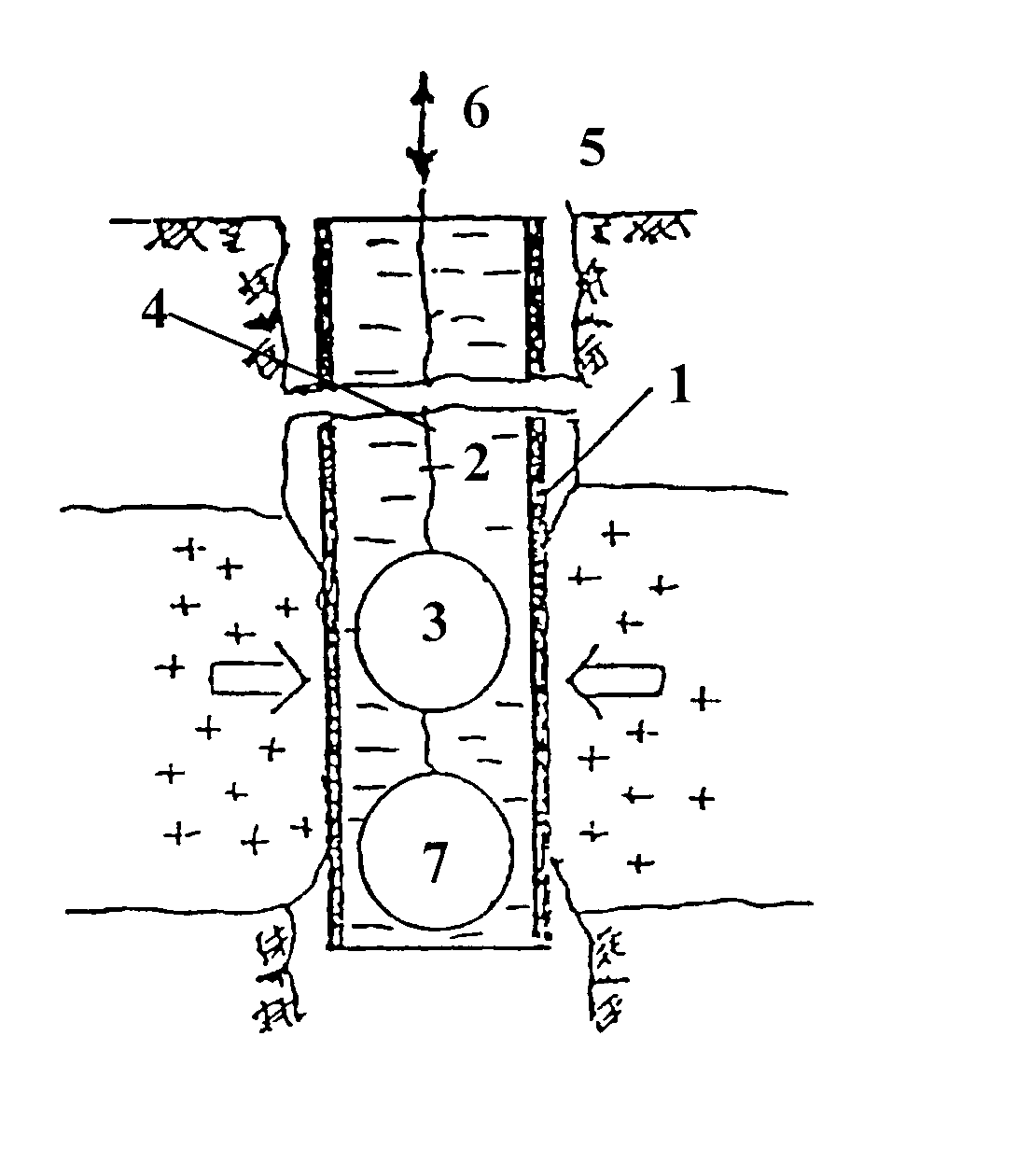

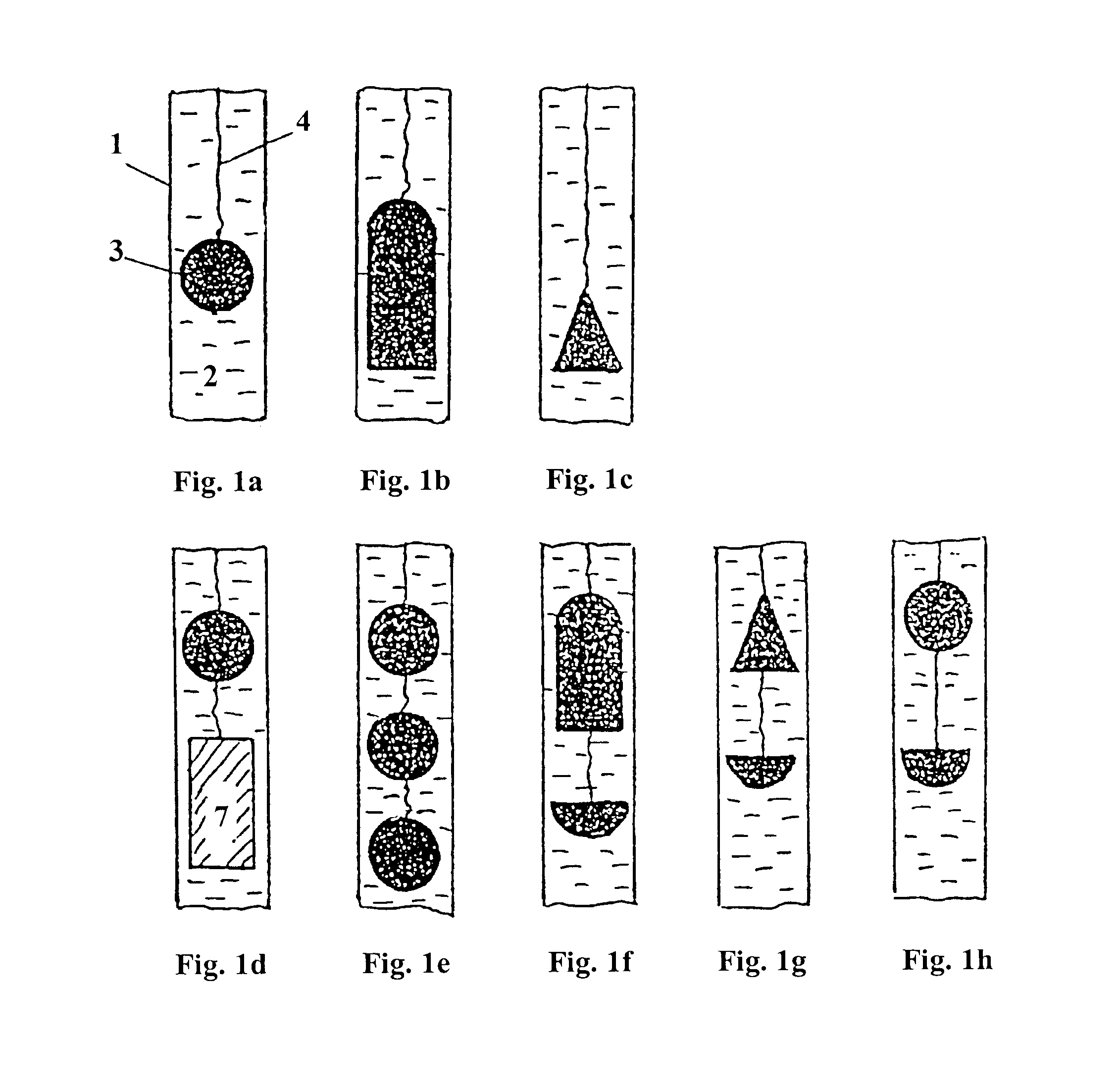

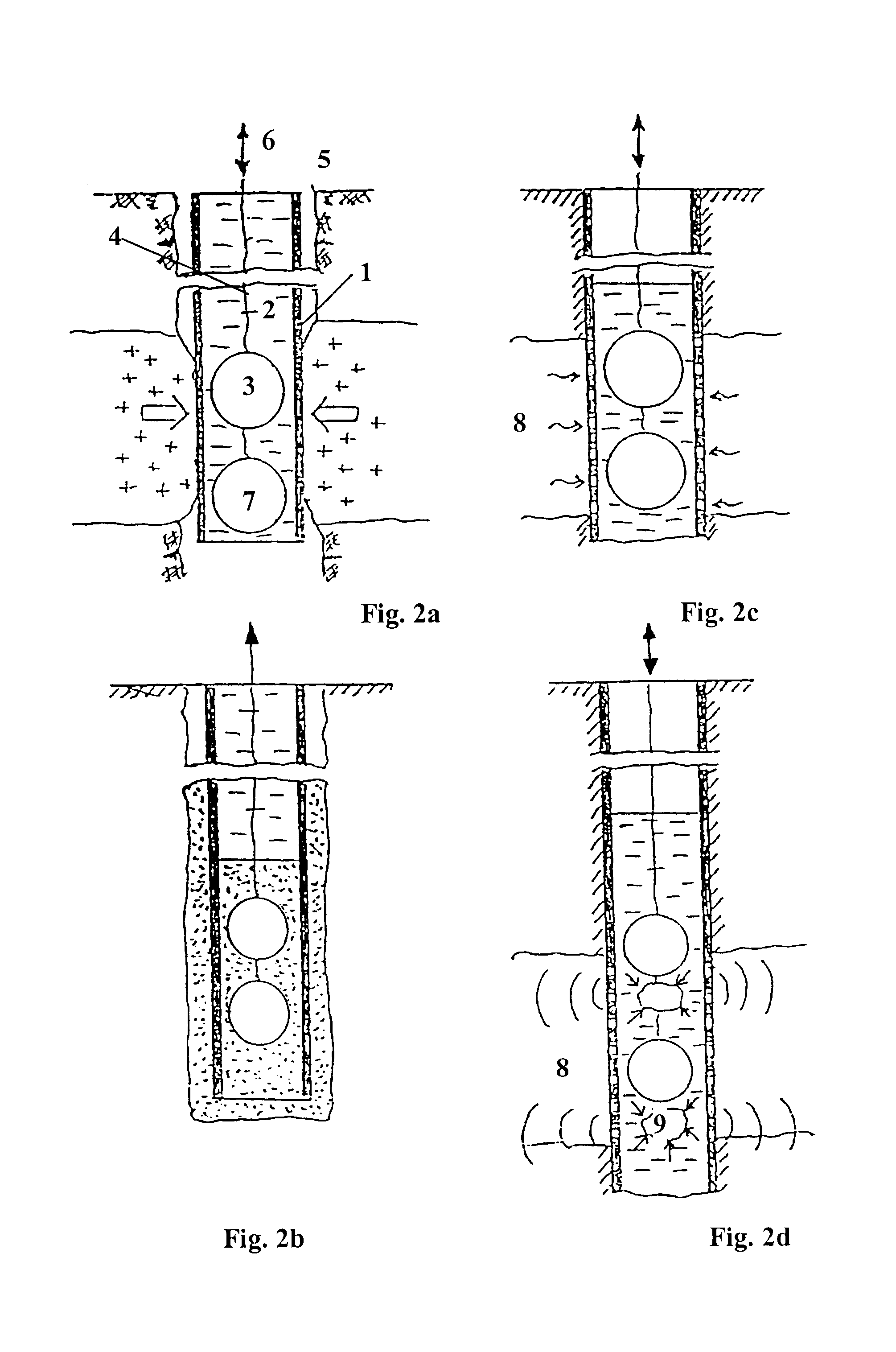

Method and device for exciting transversal oscillations of a pipe string in a borehole

Method and devices for freeing stuck pipes in wells in the absence of circulation or intensifying of inflow of fluids from a productive rock, for cleaning plugged well screens, and for improving quality of cementing of casing pipes in wells. Transverse vibrations are excited in a column of tubes in the well by axial motion of a hammer or hammers suspended inside the column of tubes on a flexible suspension support. The hammers have a maximum cross-section which is 0.90-0.98 times the inner diameter of the tubes. The hammers oscillate in a radial direction and hit the wall of tubes when the flexible suspension is pulled, thus exciting transverse vibrations in the column of tubes. The strength and repetition rate of hits can be varied depending on the speed of axial motion of the hammers, weight of a load placed under the hammers, number or shape of the hammers, spacing between the hammers, and the density or viscosity of a liquid filling the well.

Owner:BIP TECH

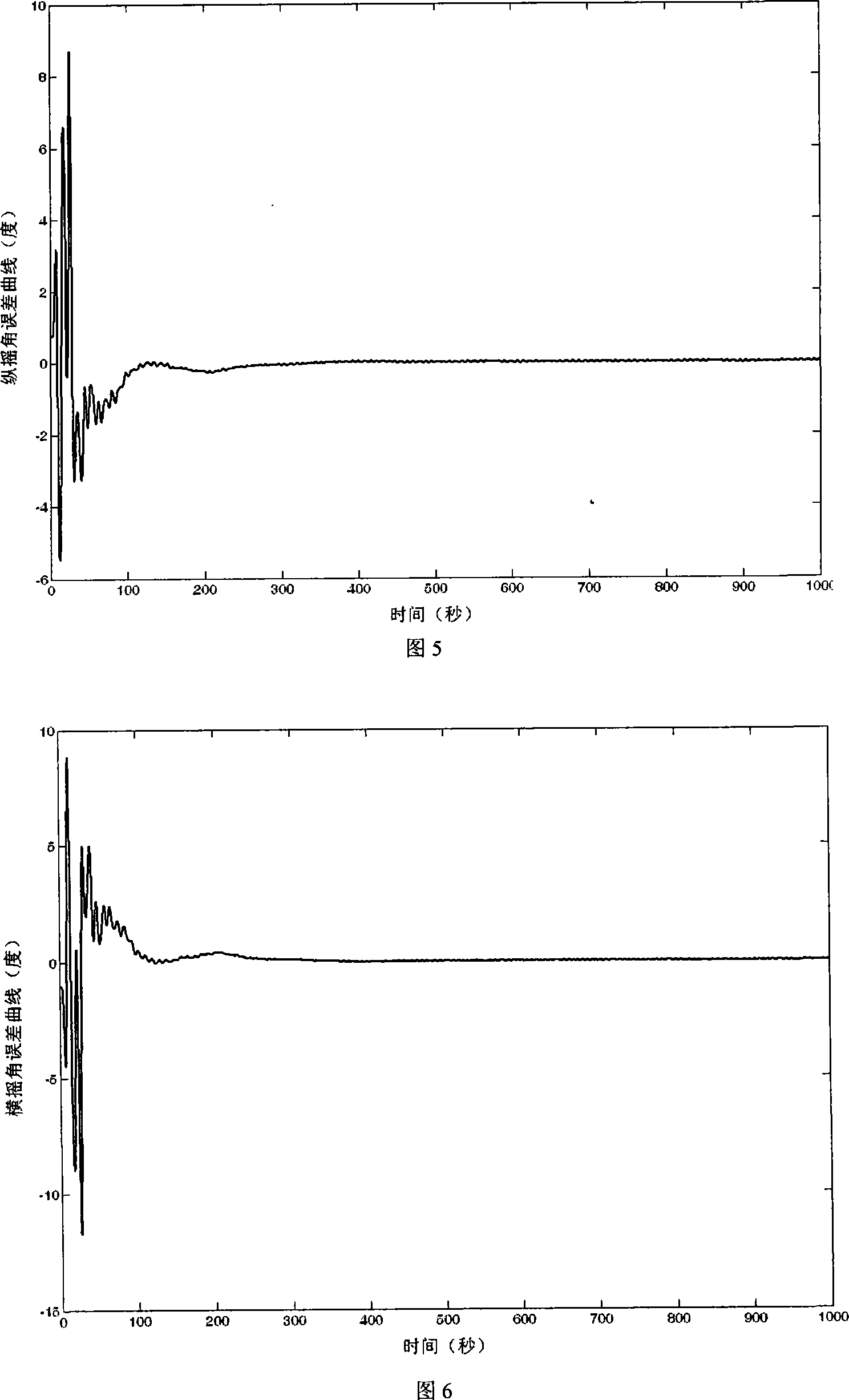

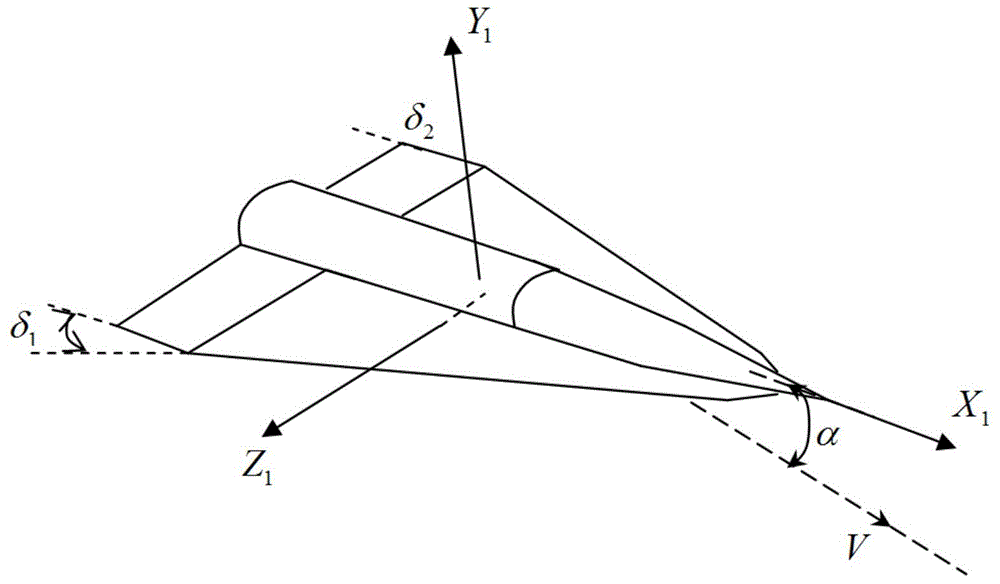

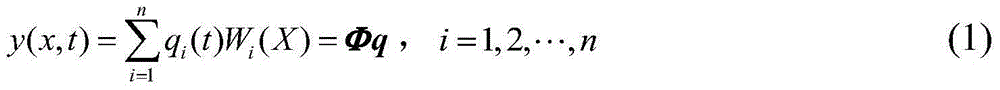

Elastic motion modeling method of trailing edge rudder gliding aircraft

ActiveCN105629725AGuarantee task progressIncrease awarenessAdaptive controlElastic vibrationEngineering

The invention belongs to the technical field of aircraft elastic motion modeling, and specifically relates to an elastic motion modeling method of a trailing edge rudder gliding aircraft. The method comprises the following steps: (1) converting an elastic body transverse free vibration into superposition of various mutually independent main vibrations by utilizing modal orthogonality; (2) according to a linear small disturbance hypothesis, under the action of external forces, still describing the transverse vibration of an elastic body approximatively by utilizing modal superposition, and determining a vibration mode function by structural characteristics (rigidity and quality distribution) of the elastic body and a boundary condition of the elastic body; (3) establishing a vibration differential equation according to the d'almbert's principle and other methods; and (4) analyzing the external forces, which comprise an aerodynamic force, a rudder surface control force, a posture jet pipe control force, a rudder surface swinging inertia force and the like, influencing an elastic vibration of the gliding aircraft. A traditional elastic motion modeling method is corrected and improved.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com