Multifunctional fastener testing machine

A fastener and testing machine technology, applied in the field of multifunctional fastener testing machines, can solve the problems of large test uncertainty and inability to guarantee, and achieve the effects of saving space, improving accuracy, and simplifying the driving structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

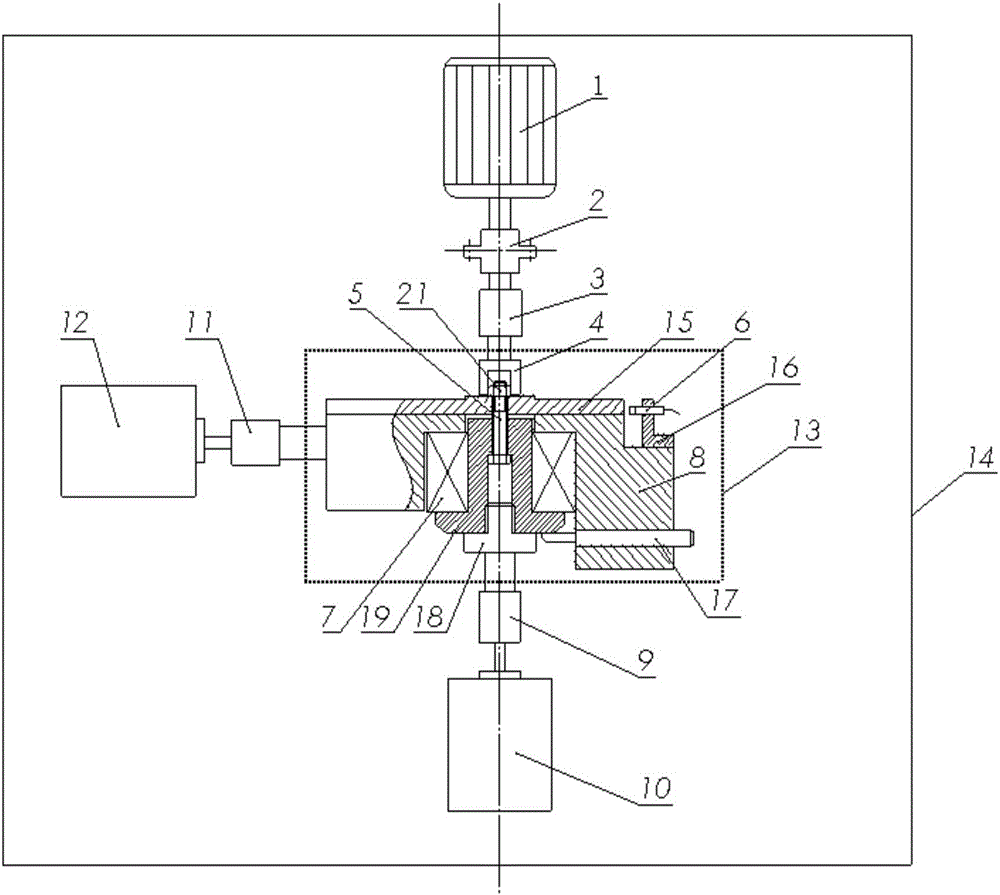

[0009] The specific implementation manner of the present invention will be described in detail in conjunction with the accompanying drawings and technical solutions.

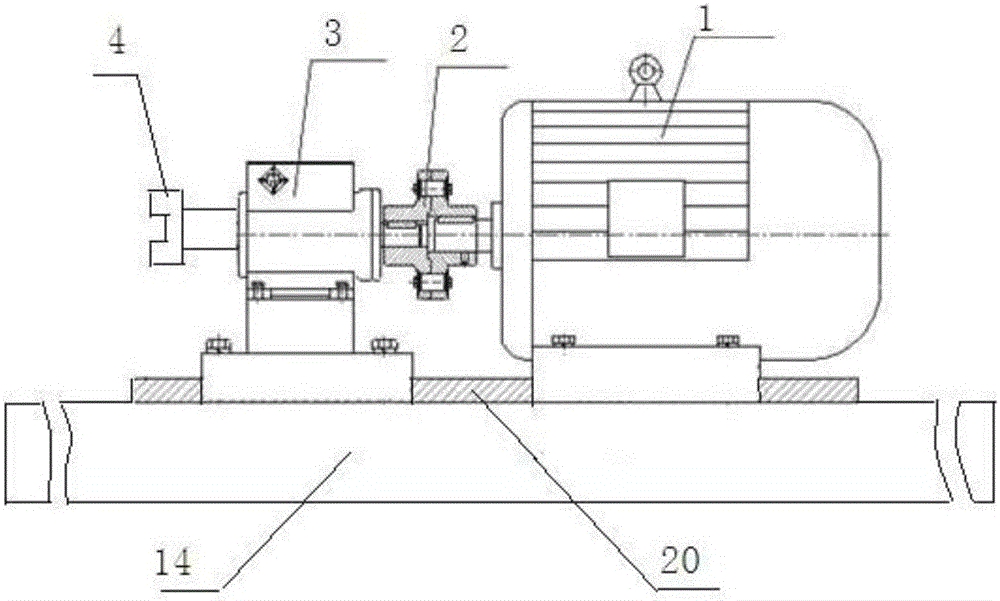

[0010] attached figure 1 Among them, the multifunctional fastener testing machine has a base 14, and the guide rail 20 is fixedly installed on the base 14. The speed-regulating motor 1 is installed on the guide rail 20, and the position of the speed-regulating motor 1 on the abutment 14 can be adjusted to facilitate installation, and tighten the fastener 5 to be tested, such as figure 2 shown.

[0011] The speed-regulating motor 1 installed on the guide rail 20 is used to provide the speed and torque required for the test in real time; the other end of the coupling 2 connected to the speed-regulating motor 1 is equipped with a torque speed sensor 3, which is used to measure The output speed and real-time torque of speed-regulating motor 1. The transverse vibrator 12 and the connected axial force sensor 11 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com