Resistor heat resistance detection device for high-temperature area of electronic equipment

A technology for electronic equipment and heat resistance, which is applied in the field of resistance heat resistance detection devices, can solve the problems of large influence on the service life of the resistance, poor uniformity of heating on the surface of the resistance to be measured, and low accuracy of detection data, so as to avoid detection data. Inaccurate, enriching the performance of comprehensive indicators, reducing the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

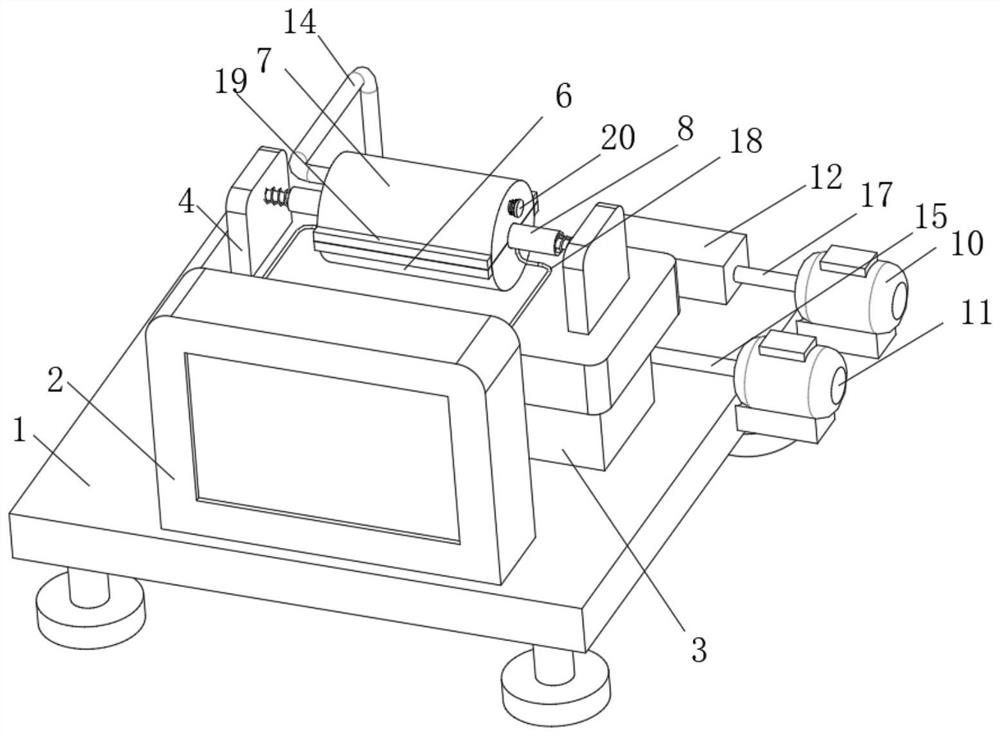

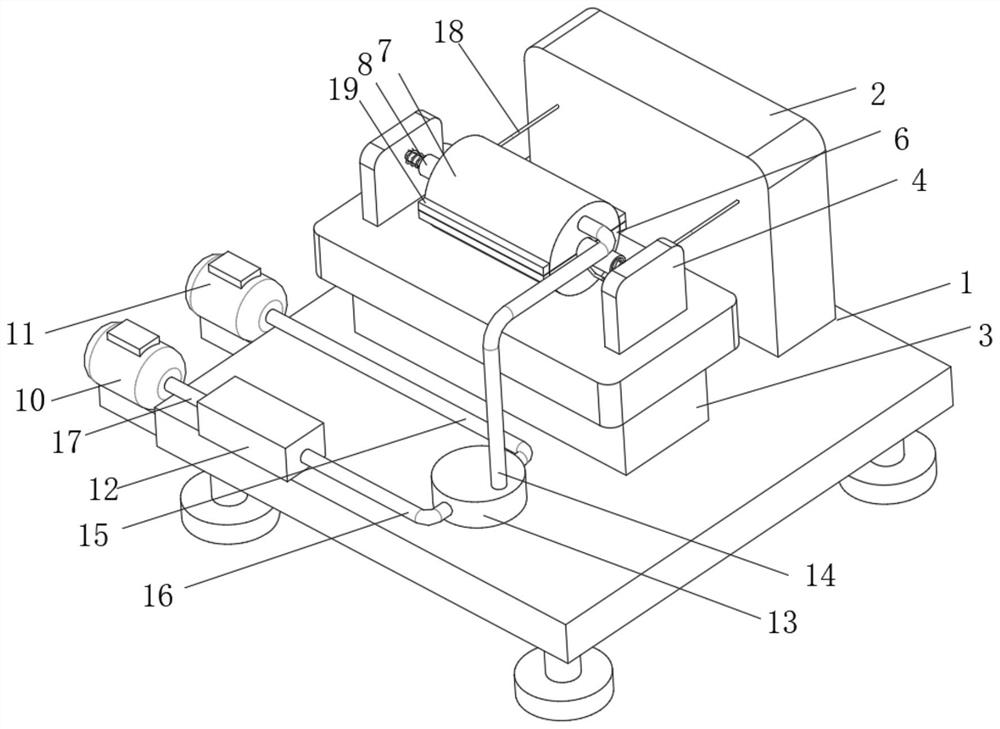

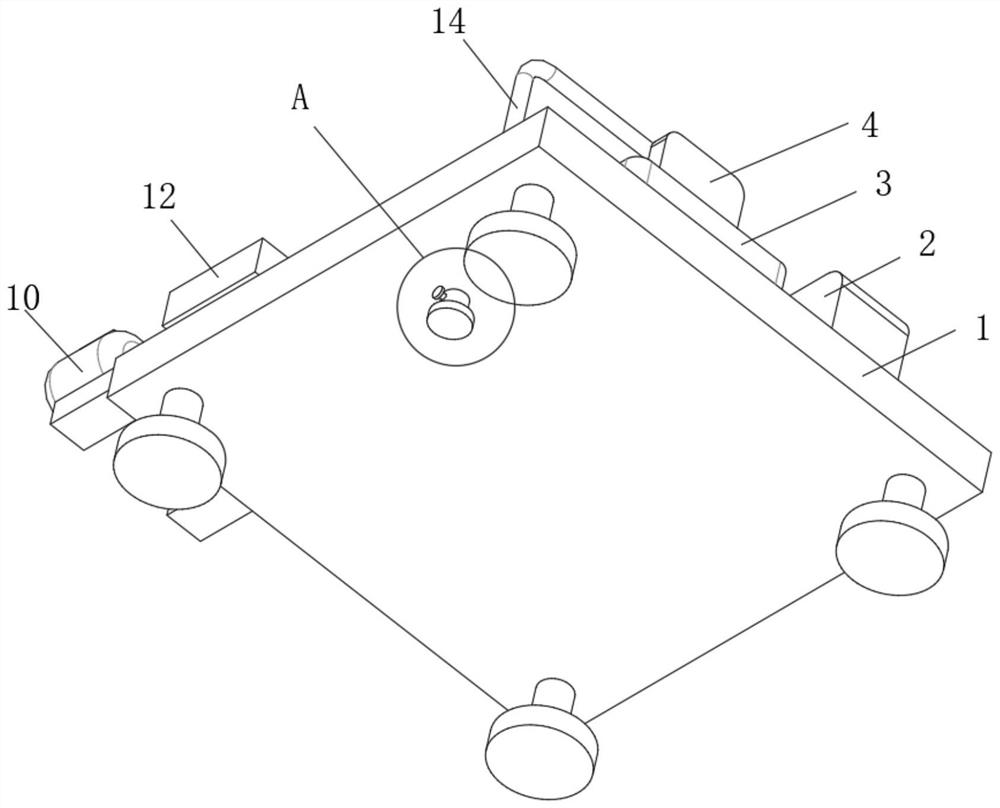

[0038] The first embodiment: as Figure 1-Figure 10 As shown, when testing the heat resistance performance, when the upper case 7 and the lower case 6 are separated, pull the pull rod 86 on the power connection mechanism 8, so that the two groups of power connection mechanisms 8 are far away, and place the resistor 9 in the On one side of the power connection mechanism 8, loosen the pull rod 86 to realize clamping and fixing, place the upper casing 7 above the lower casing 6, and install it with the installation mechanism 19, start the No. 1 air pump 10, and the No. 1 air pump 10 pumps in The gas enters the heating box 12 through the No. 3 pipe 17, starts the heating pipe 21 in the heating box 12, the gas heats up in the heating box 12 and enters the inside of the distribution mechanism 13 through the No. 1 pipe 15, and makes the high-temperature gas pass through The connecting pipe 14 enters the detection space surrounded by the upper casing 7 and the lower casing 6, and the r...

no. 2 example

[0042] The second embodiment: as Figure 1-Figure 7 As shown, the clamping sleeve 83 of the electrical connection mechanism 8 is sleeved in the arc groove on the top surface of the lower housing 6, and the fixed rod 81 and the No. 1 spring 82 fixedly installed on the side of the side plate 4 are sleeved in the clamping sleeve. In 83, the elastic effect of the No. 1 spring 82 is used to make the resistor 9 push the pull rod 86 and drive the clamping sleeve 83 to move when the resistor 9 is installed, so that the resistor 9 is effectively clamped between the two sets of clamping sleeves 83, and through the The end face of the clamping sleeve 83 is equipped with a connecting plate 85, and the connecting plate 85 is electrically connected to the connecting wire 18, so that the resistor 9 hovers between the lower casing 6 and the upper casing 7 after being clamped, and the outer surface of the resistor 9 Not in contact with the power connection mechanism 8, so that when hot air and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com