Patents

Literature

331results about How to "Simple drive structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

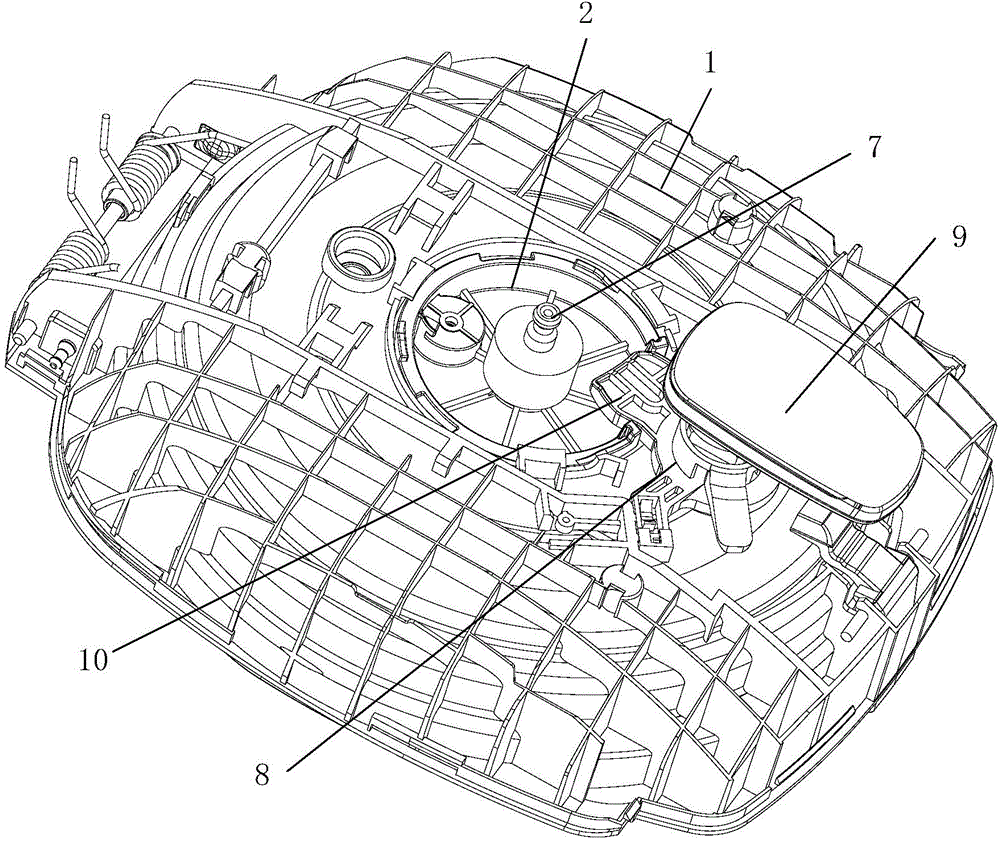

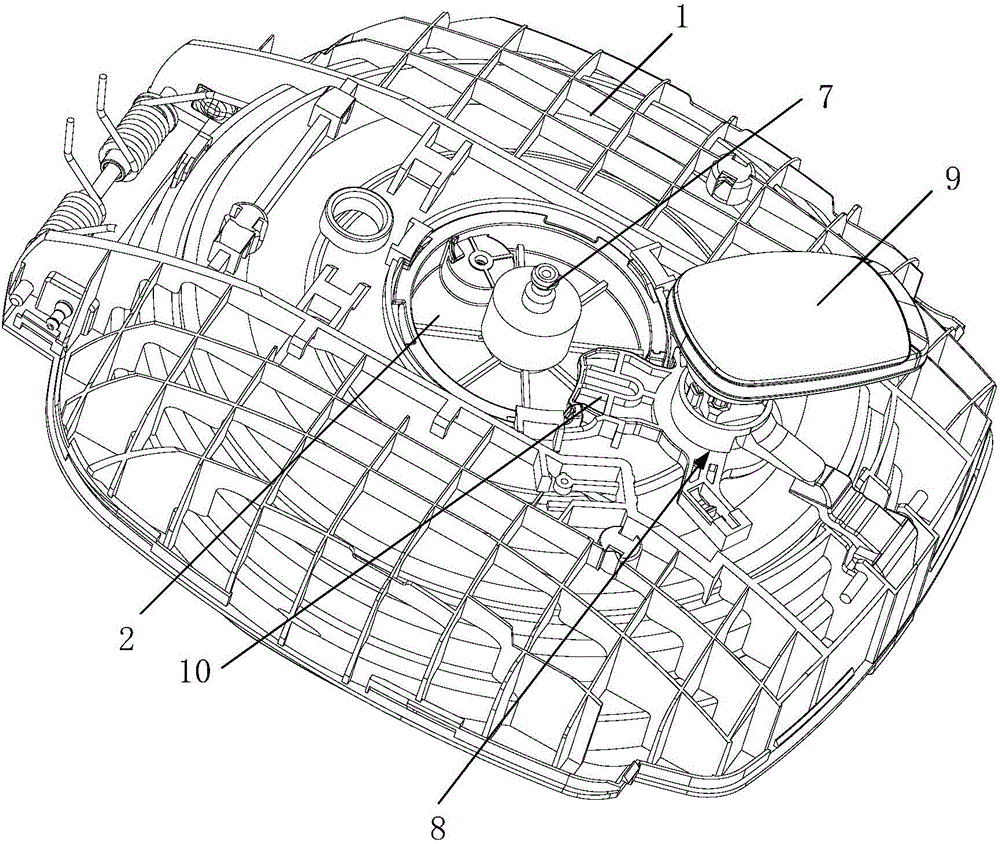

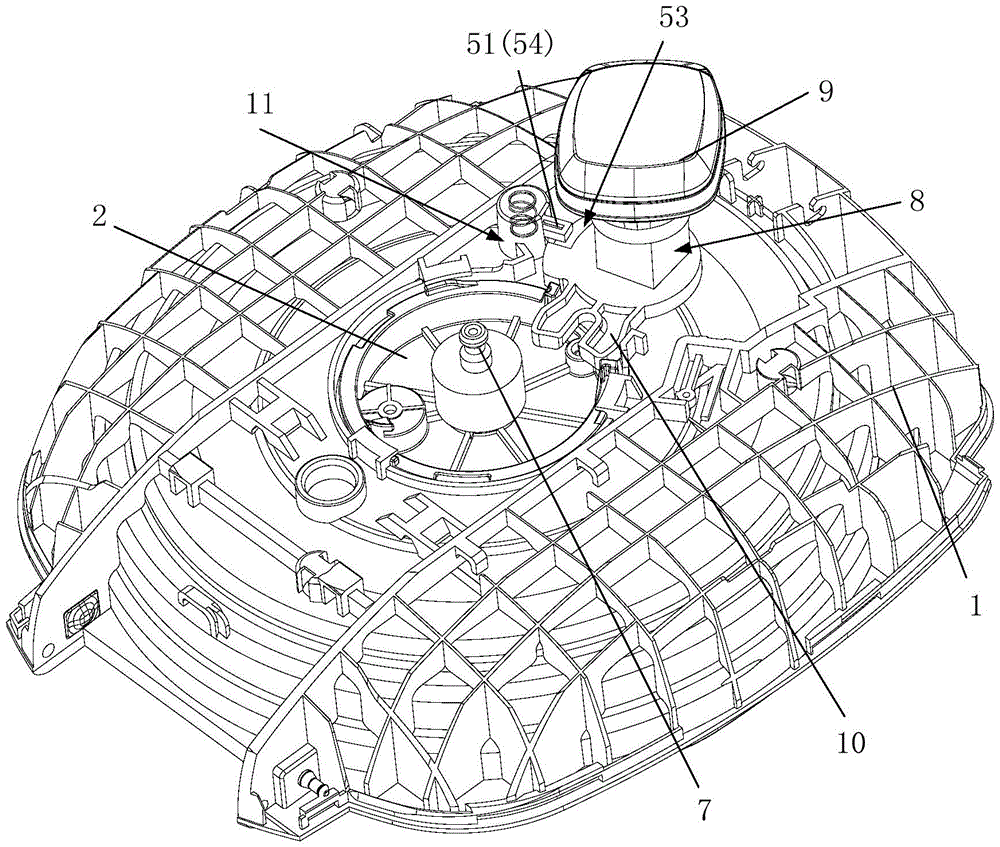

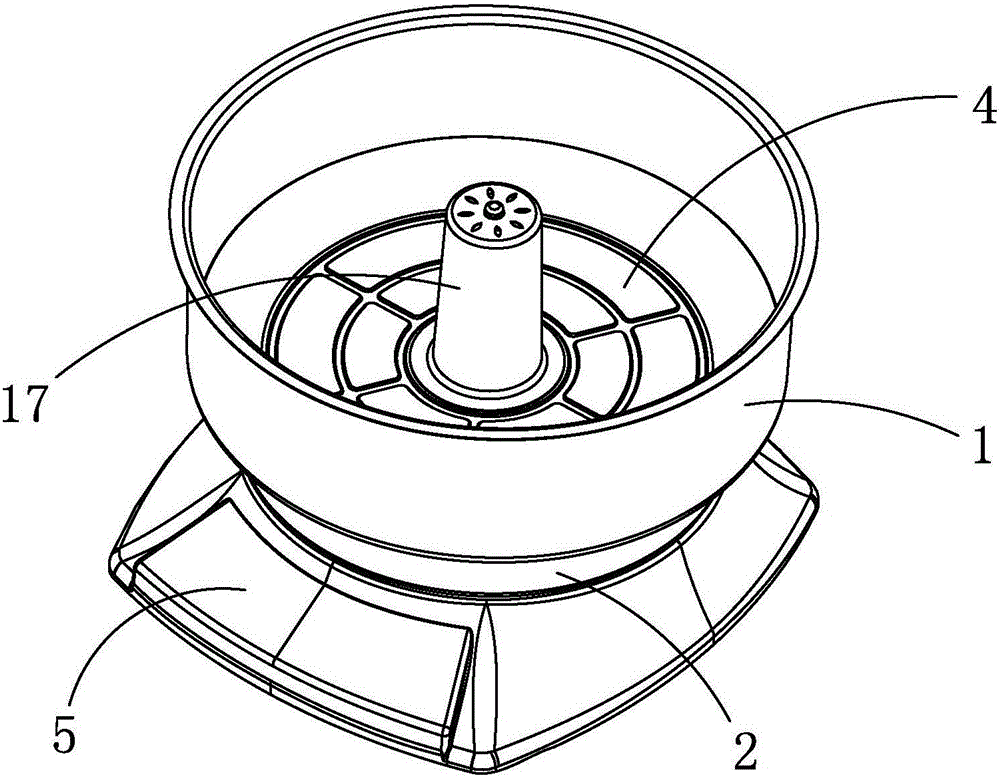

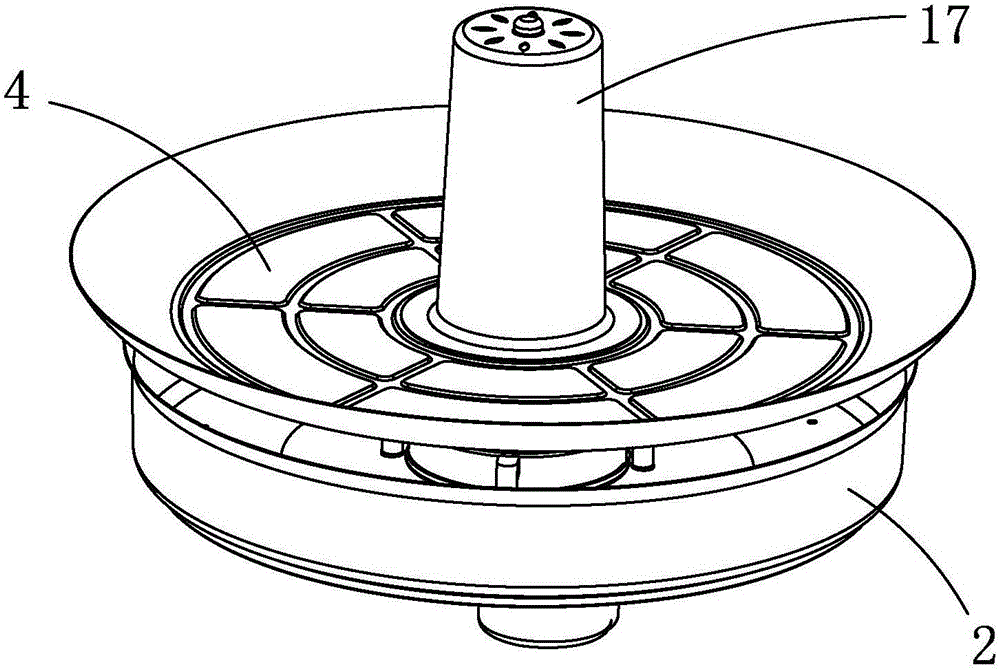

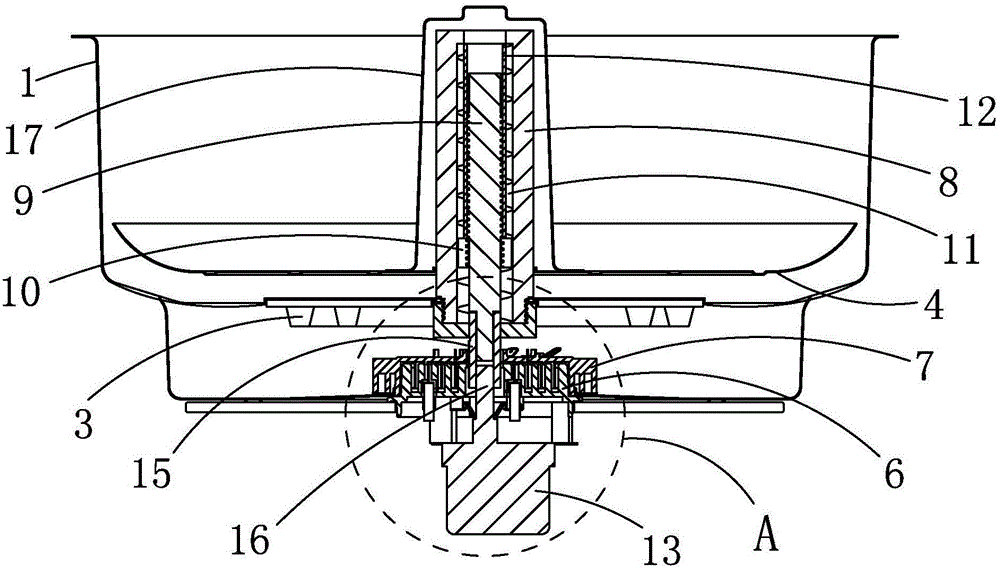

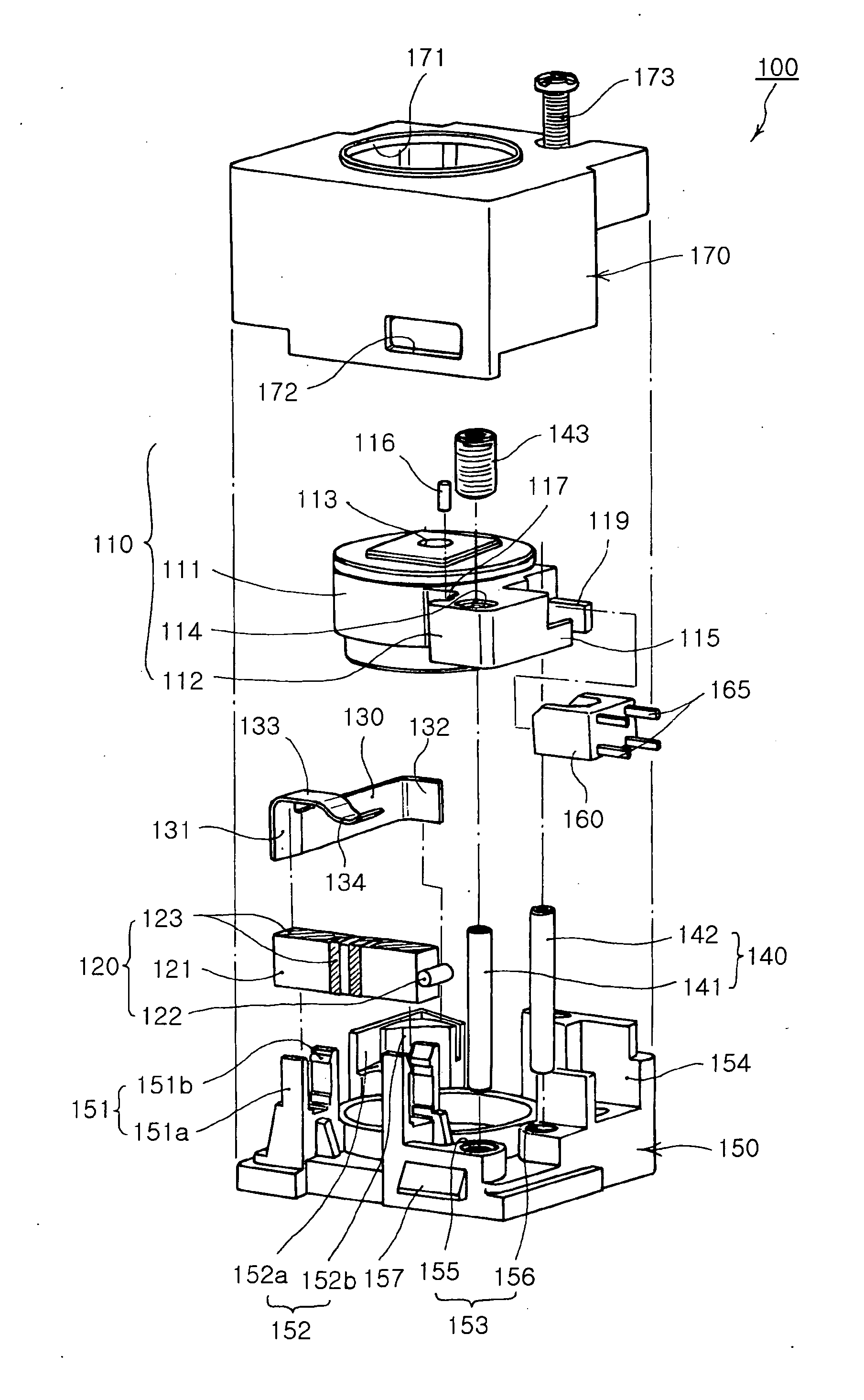

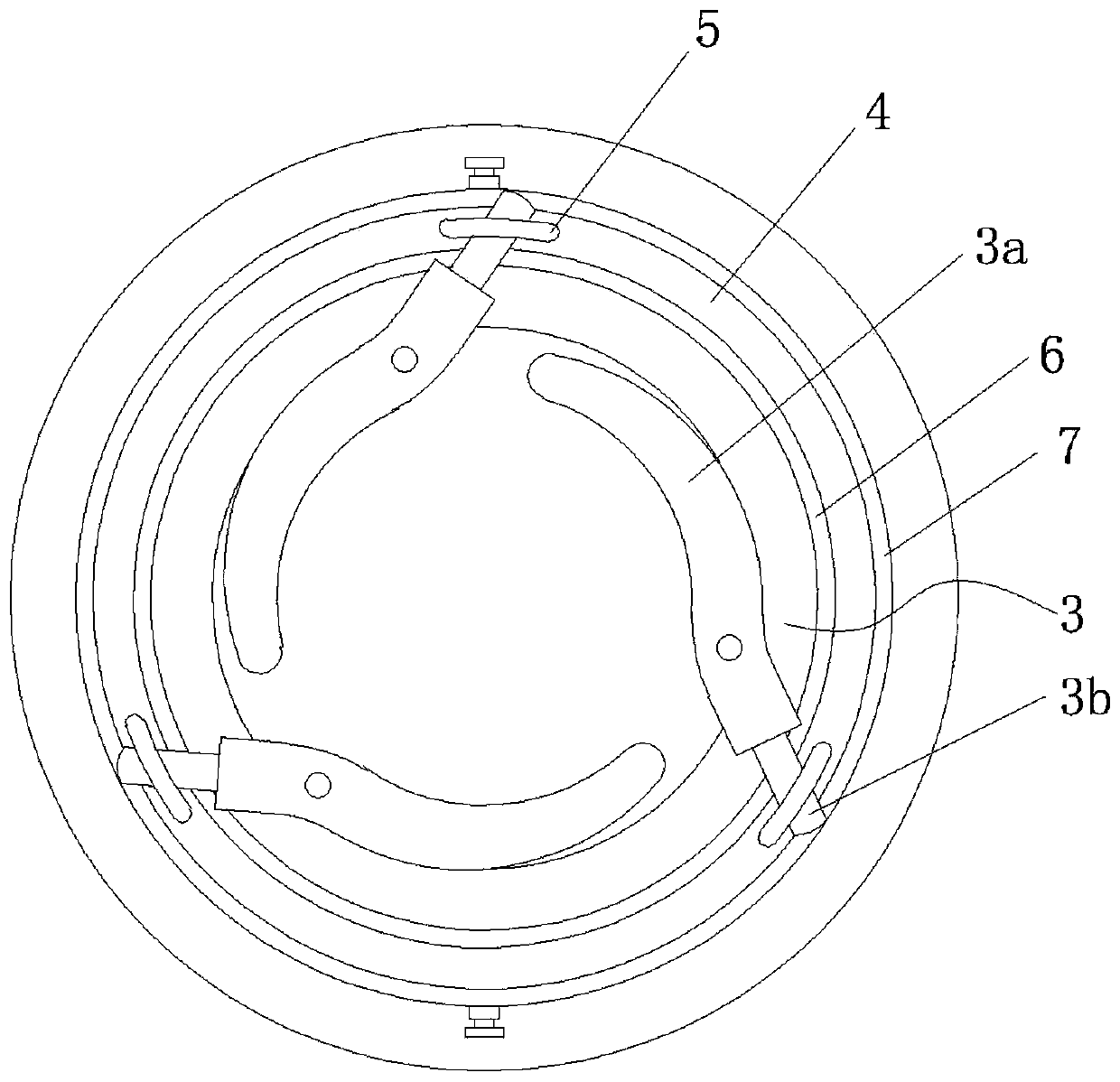

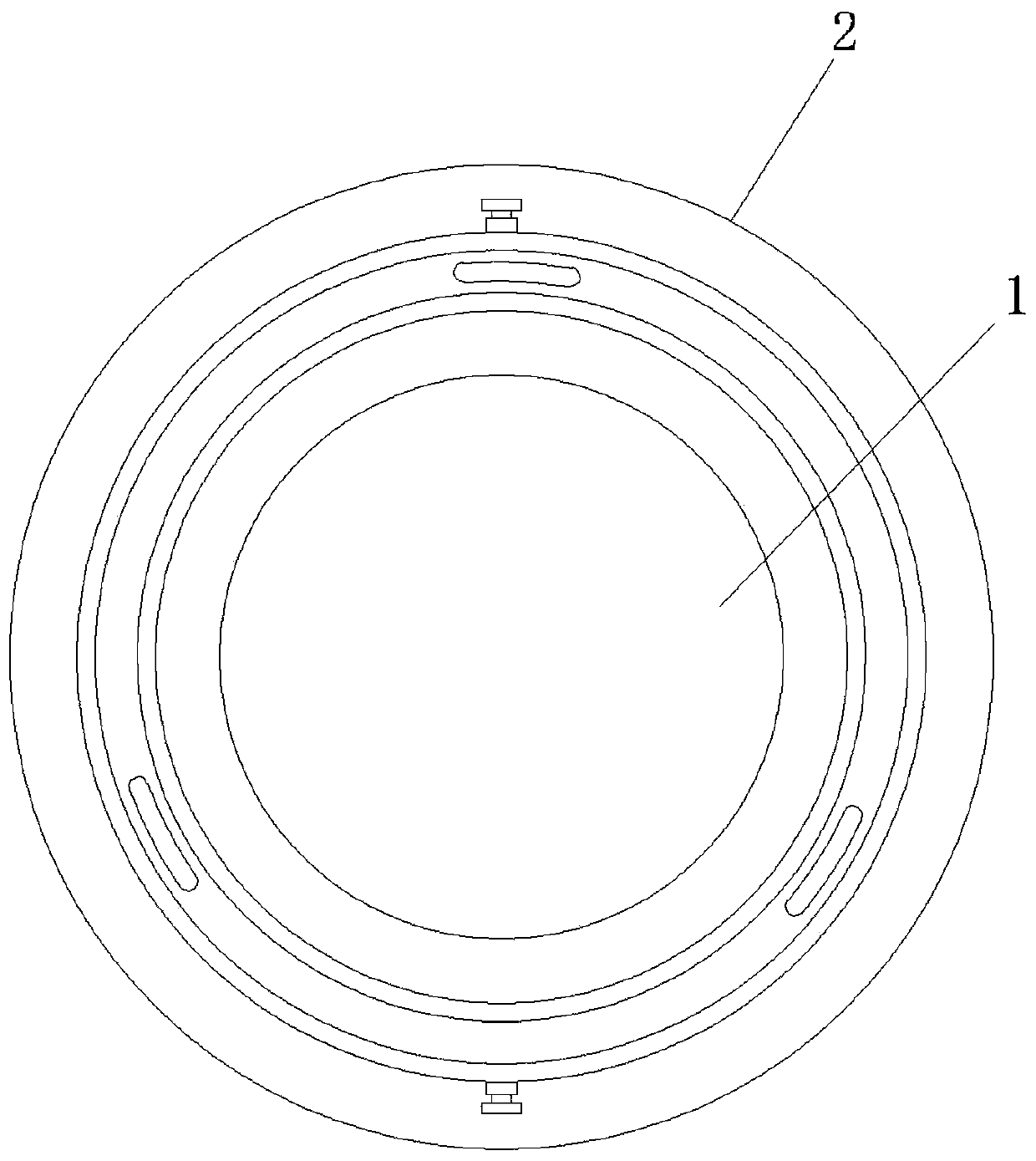

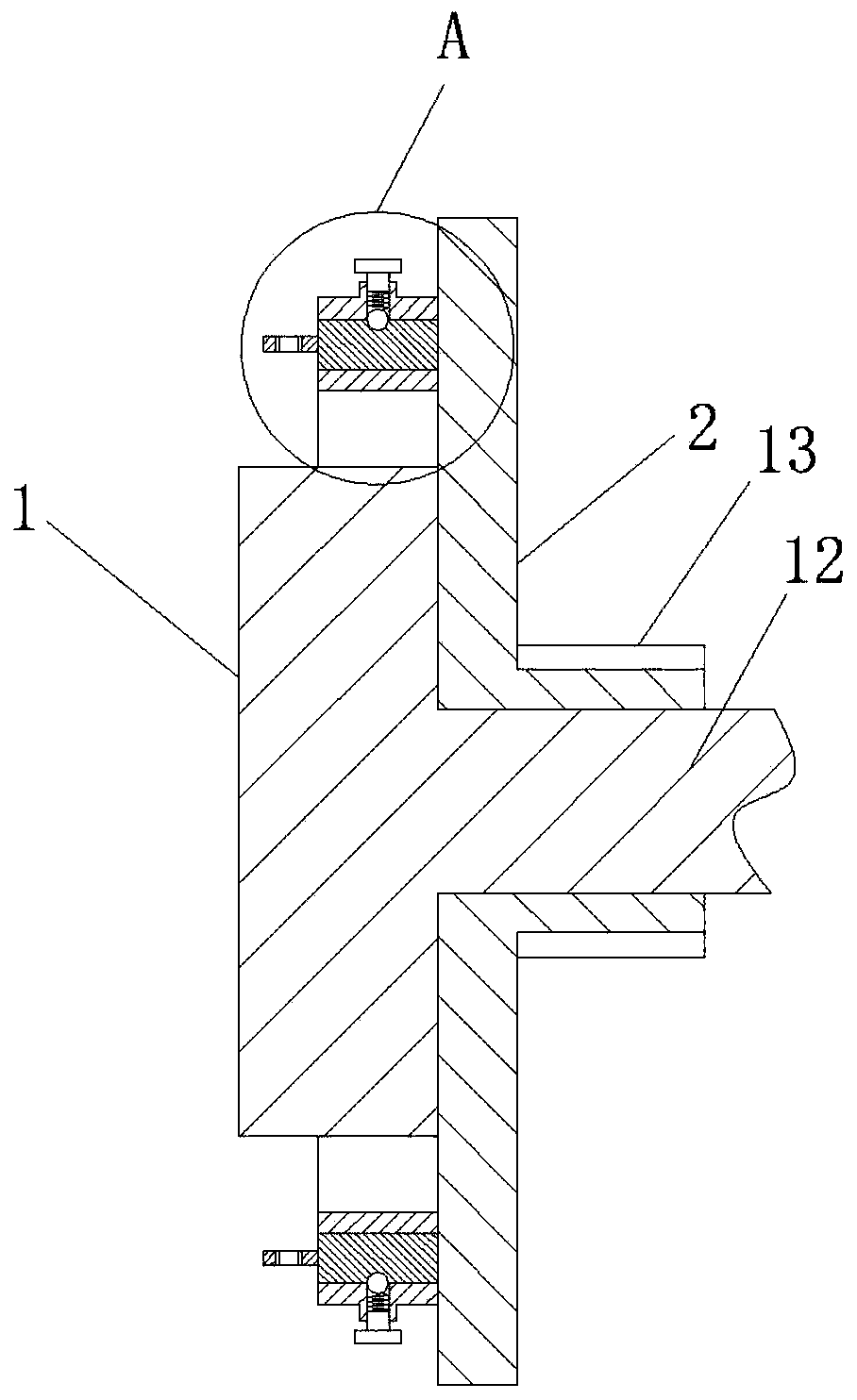

Electric pressure cooker

The invention provides an electric pressure cooker. The electric pressure cooker comprises an inner cover, a turntable with an annular side wall and a bottom wall, a cooker cover and a rotary handle assembly, wherein a mounting hole is formed in the middle of the inner cover; the turntable is mounted in the mounting hole, and can rotate around the axis of the mounting hole, and the lower end of the turntable is matched with the cooker cover so that the cooker cover rotates together with the turntable; the cooker cover is positioned below the inner cover, and is rotatably mounted on the inner cover; the rotary handle assembly is positioned above the inner cover, rotatably mounted on the inner cover, and positioned beside the mounting hole. The electric pressure cooker provided by the invention is simple in structure and convenient to assemble, and the production efficiency of the electric pressure cooker is well promoted; the rotary handle assembly is positioned in the middle of the cooker cover and arranged eccentrically, and a user can complete the operations of opening and closing the cooker cover by enabling the rotary handle assembly to rotate by a small angle, therefore, the operability is obvious, the drive dead angle does not exist, and the use performance is good.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

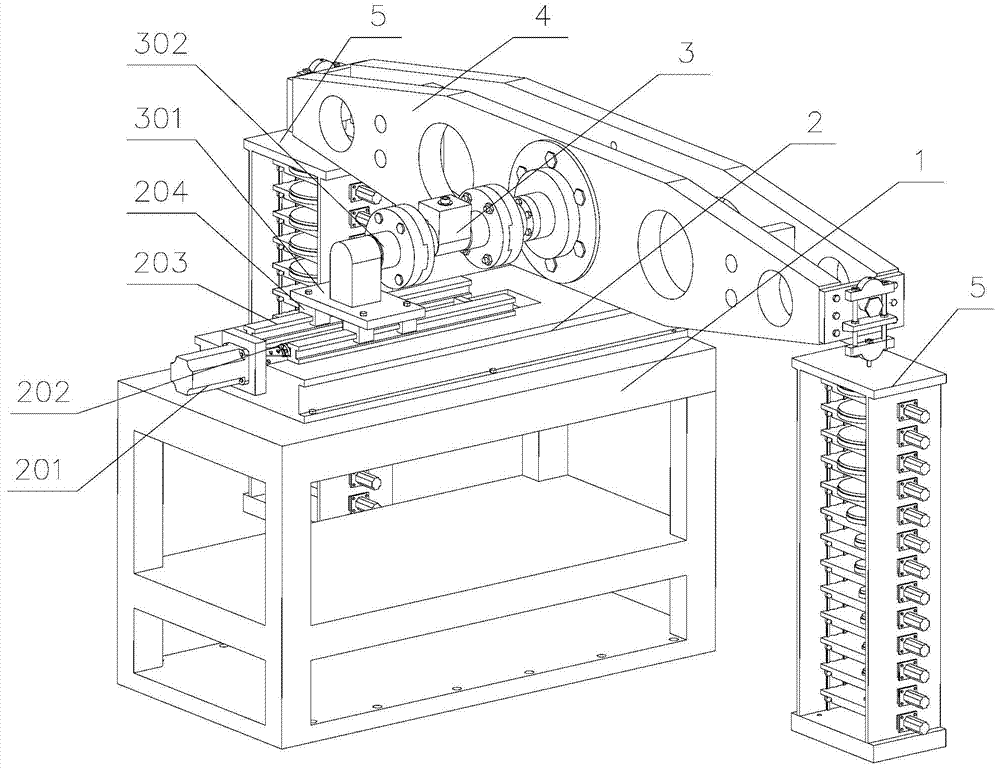

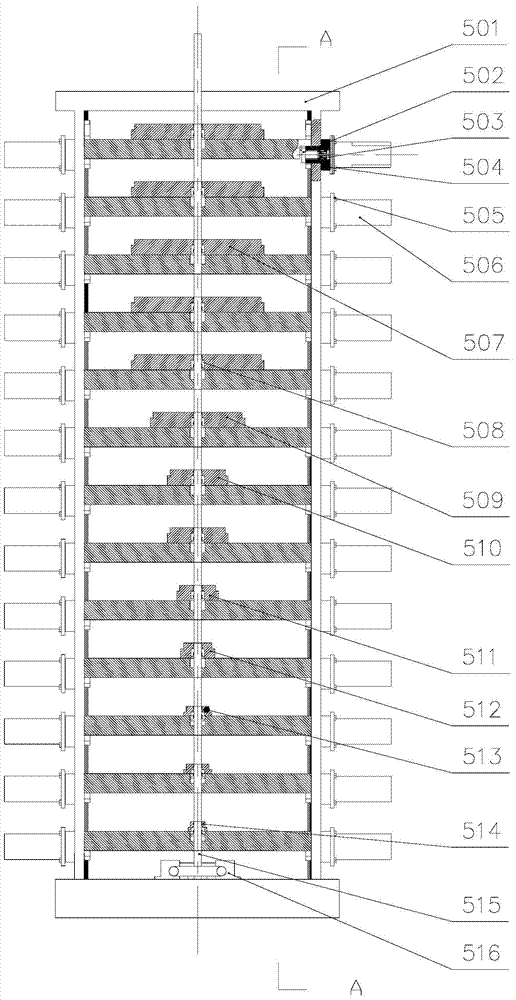

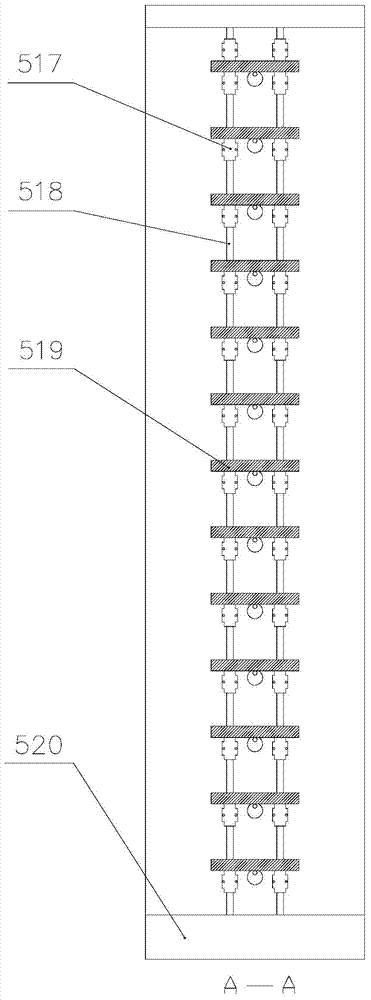

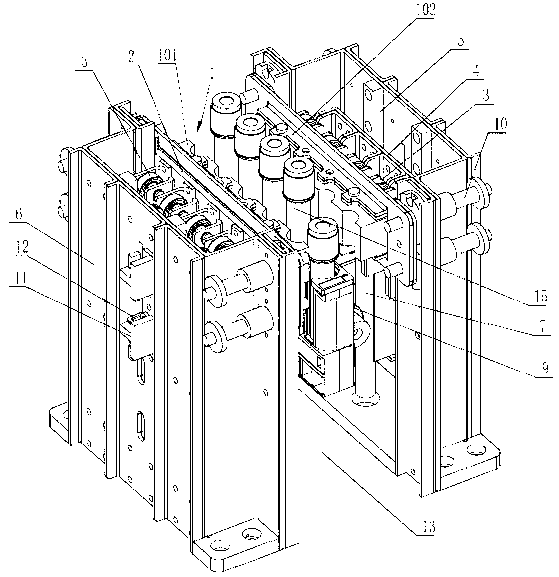

Independent weight loading-unloading dead-load type torque measurement device

InactiveCN103575463AImprove rigidityImprove stabilityForce/torque/work measurement apparatus calibration/testingMeasurement deviceMotor drive

The invention discloses an independent weight loading-unloading dead-load type torque measurement device, and belongs to the technical field of measuring testing. The independent weight loading-unloading dead-load type torque measurement device aims at solving the problems that in the prior art, the loading speed is low, a control device is complex, operation is difficult to achieve, and automation is difficult to achieve. The independent weight loading-unloading dead-load type torque measurement device comprises a supporting device, a loading device, a torque installation part, a leveling device and automatic loading devices, wherein the loading device is fixed on the upper surface of the supporting device, the torque installation part is connected with a guide rail sliding block and a nut supporting base of the loading device, the leveling device is connected with the other end of a long shaft of the torque installation part, and the automatic loading devices are fixed at the two ends of the leveling device. The automatic loading devices are characterized in that eccentric wheels are driven by stepping motors B to perform rotational motion, trays are driven by the eccentric wheels to perform linear lifting, and therefore automatic loading and automatic unloading of weights are achieved. According to the independent weight loading-unloading dead-load type torque measurement device, the eccentric wheels are driven by the stepping motors B to perform the rotational motion to achieve the automatic loading and the automatic unloading of the weights with any number, measurement on different torque values is accordingly achieved, and the motor driving structure is simple.

Owner:JILIN UNIV

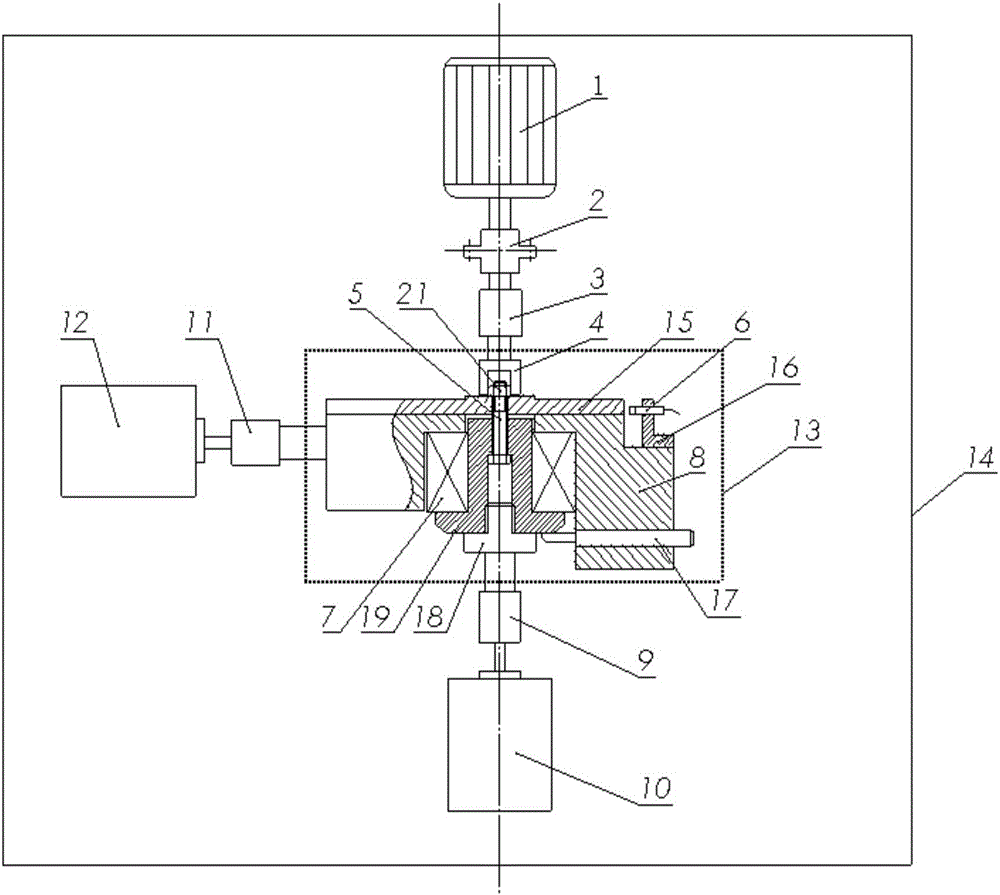

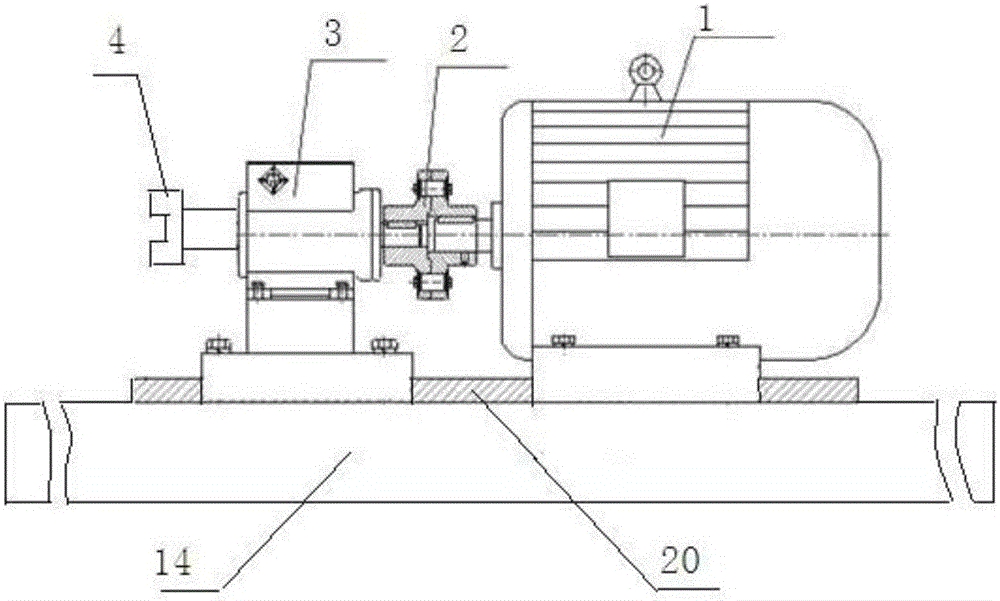

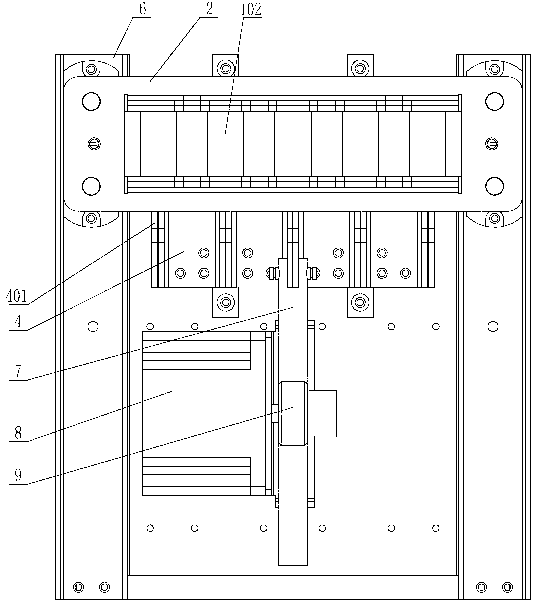

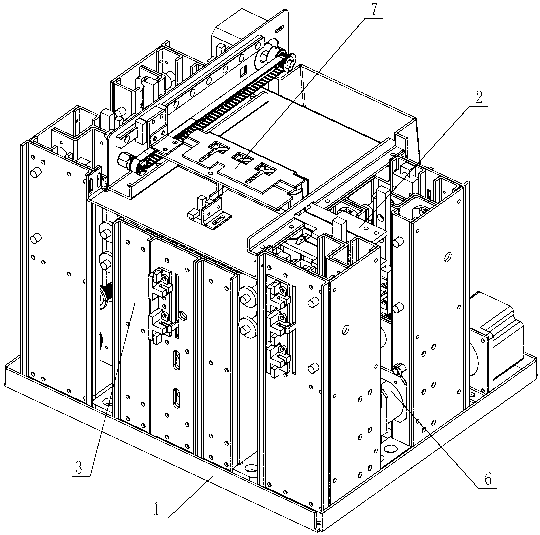

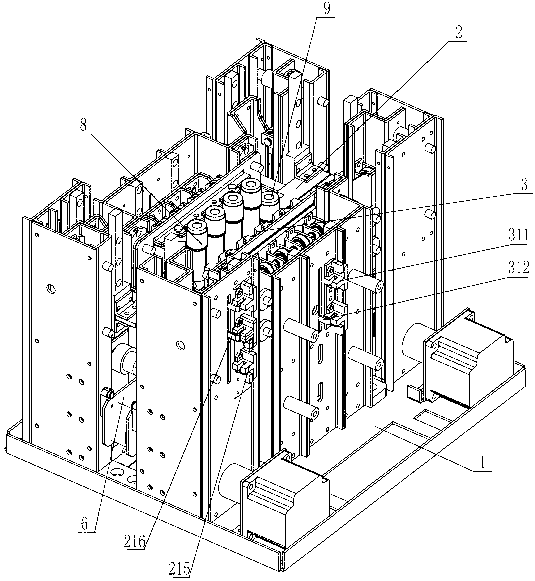

Multifunctional fastener testing machine

ActiveCN105784304AChange the ambient temperatureSimple drive structureVibration testingCouplingMultiple sensor

The invention provides a multifunctional fastener testing machine, belongs to the field of mechanical testing equipment, and relates to the multifunctional fastener testing machine. According to the testing machine, multiple sensors and vibration exciters are cooperatively adopted to test torque, force and displacement of a tested piece. A guide rail is installed on a base. The output shaft of a speed regulating motor installed on the guide rail is connected with a coupler. One end of a toque rotating speed sensor is connected with the coupler, and the other end is fixedly connected with a sleeve. The sleeve clamps the tested fastener. An intermediate connecting clamp plate is fixedly installed on the base. A transverse vibration exciter installed at the left part of the base is connected with an axial force sensor through threads. The other end of the axial force sensor is installed at the left end of the intermediate connecting clamp plate. The testing machine can perform pre-tightening loading and loading of vibration load on the same tested fastener without changing the state so that the measured data are enabled to be more accurate. The vibration exciters are adopted so that the structure is simplified, space is saved and test accuracy is enhanced.

Owner:DALIAN UNIV OF TECH

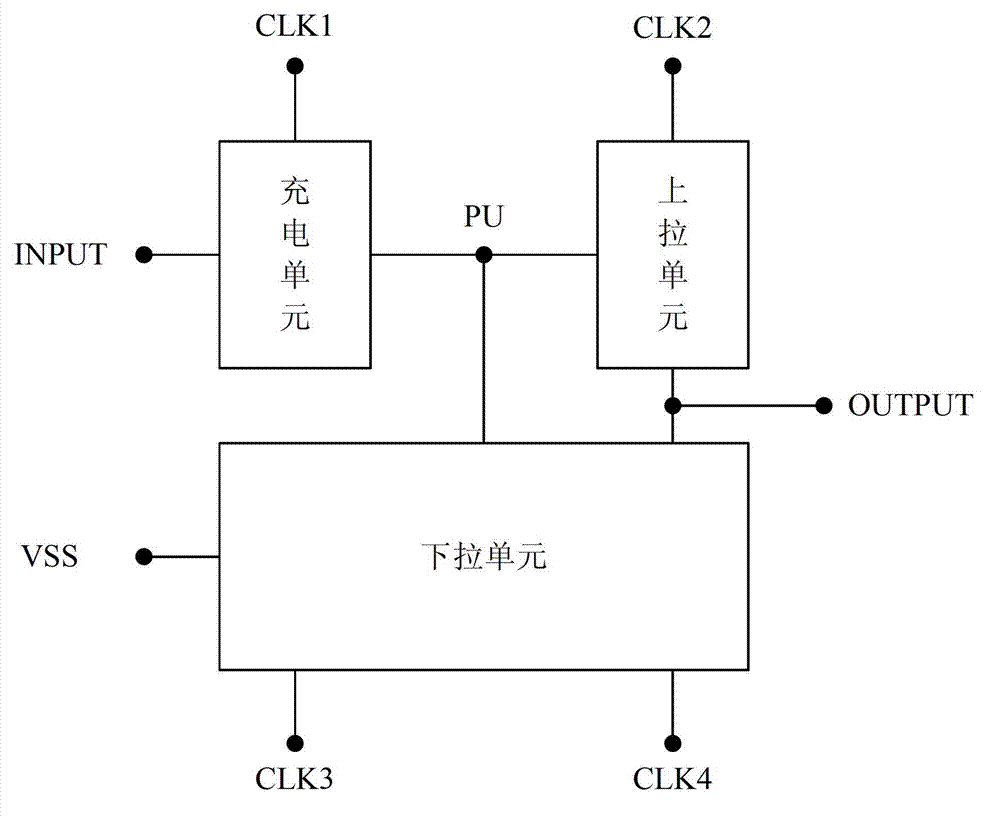

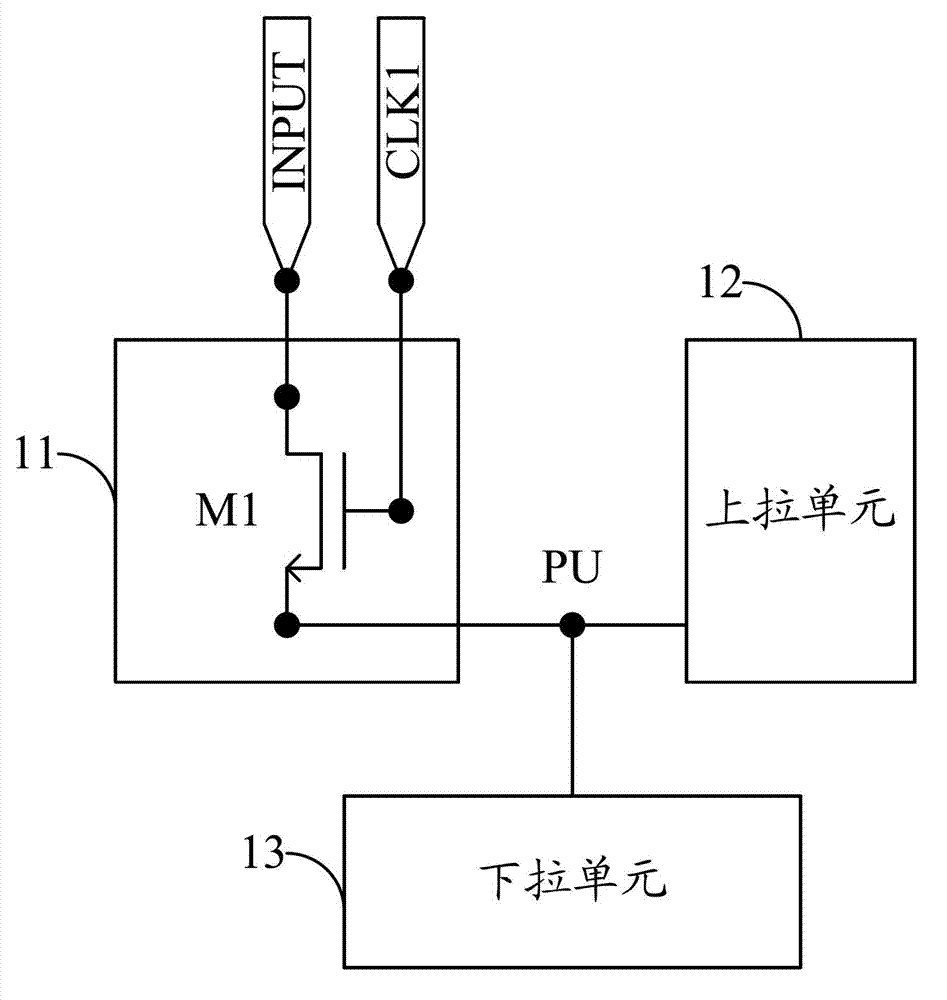

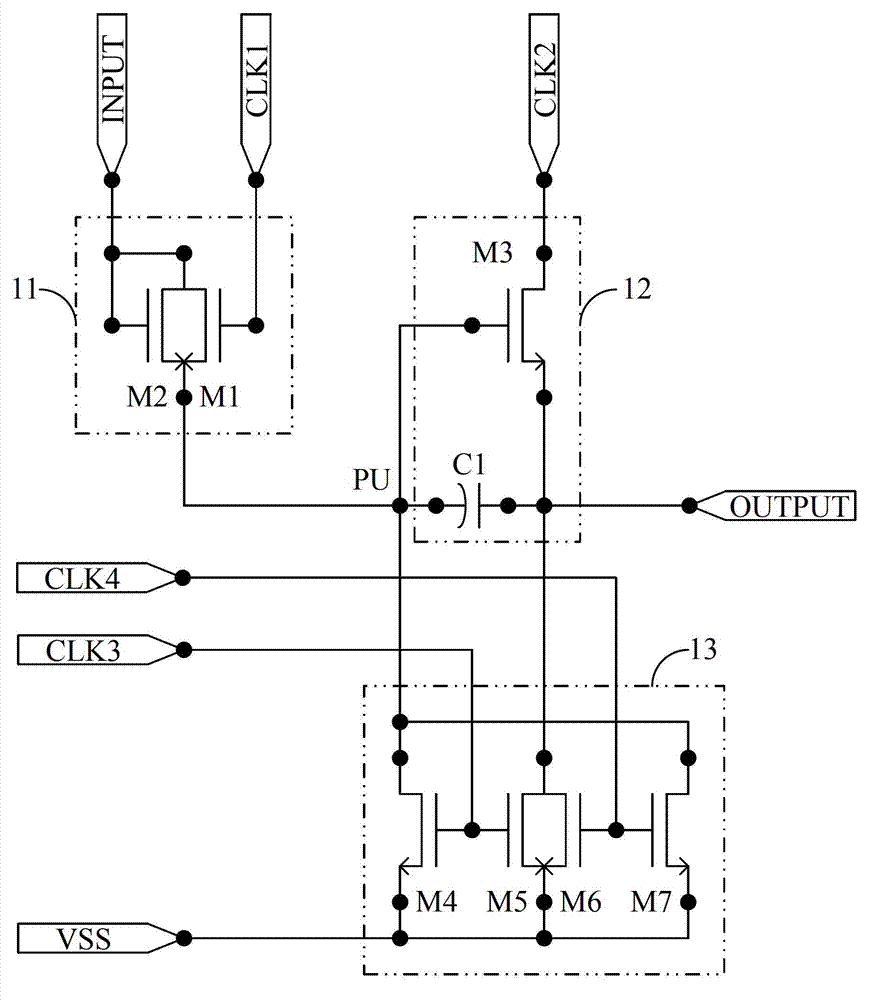

Shifting register as well as driving method thereof, grid electrode driving device and display device

InactiveCN102930814AReduce power consumptionSimple drive structureStatic indicating devicesDigital storageShift registerDisplay device

The invention provides a shifting register as well as a driving method thereof, a grid electrode driving device and a display device, wherein a charging unit, an upwards pulling unit, a downwards pulling unit, a grid electrode signal input end, a DC (direct current) low-level signal input end, a grid electrode signal output end and first, second, third and fourth clock signal input ends are arranged in the shifting register, so that the grid electrode driving structure is simplified and the power consumption for driving a grid electrode is reduced.

Owner:BOE TECH GRP CO LTD

Split type electric hot pot capable of being vertically driven and lifted

ActiveCN105902143ARealize split structureRealize the power connection workVessels with intergral heatingElectricityCoupling

The invention discloses a split type electric hot pot capable of being vertically driven and lifted. The split type electric hot pot capable of being vertically driven and lifted comprises a base, a hot pot body, a bottom plate, an electric heating device and a lifting tray, wherein a driving mechanism is arranged on the bottom plate, and a lower coupling conducting element is mounted on the base; an upper coupling conducting element which is electrically connected with the electric heating device is mounted at the bottom end of the bottom plate; the driving mechanism comprises a sliding barrel in which a driving screw is mounted; a lifting nut is mounted on the driving screw; a guide chute is formed in the sliding barrel; a lifting transmission barrel which is connected with the lifting tray is connected to the lifting nut; a power output mechanism is arranged in the base; the upper coupling conducting element and the lower coupling conducting element are provided with through holes which are intercommunicated in the vertical direction; the power output mechanism is in power connection with the driving screw through the corresponding through hole. According to the split type electric hot pot capable of being vertically driven and lifted, a split type connecting structure of the electric hot pot is achieved; the tray can be vertically lifted from the base, and a power supplying pivoting element cannot be avoided, so that the driving structure of the lifting tray can be simplified.

Owner:FOSHAN SHUNDE CHUANGUI APPLIANCE CO LTD

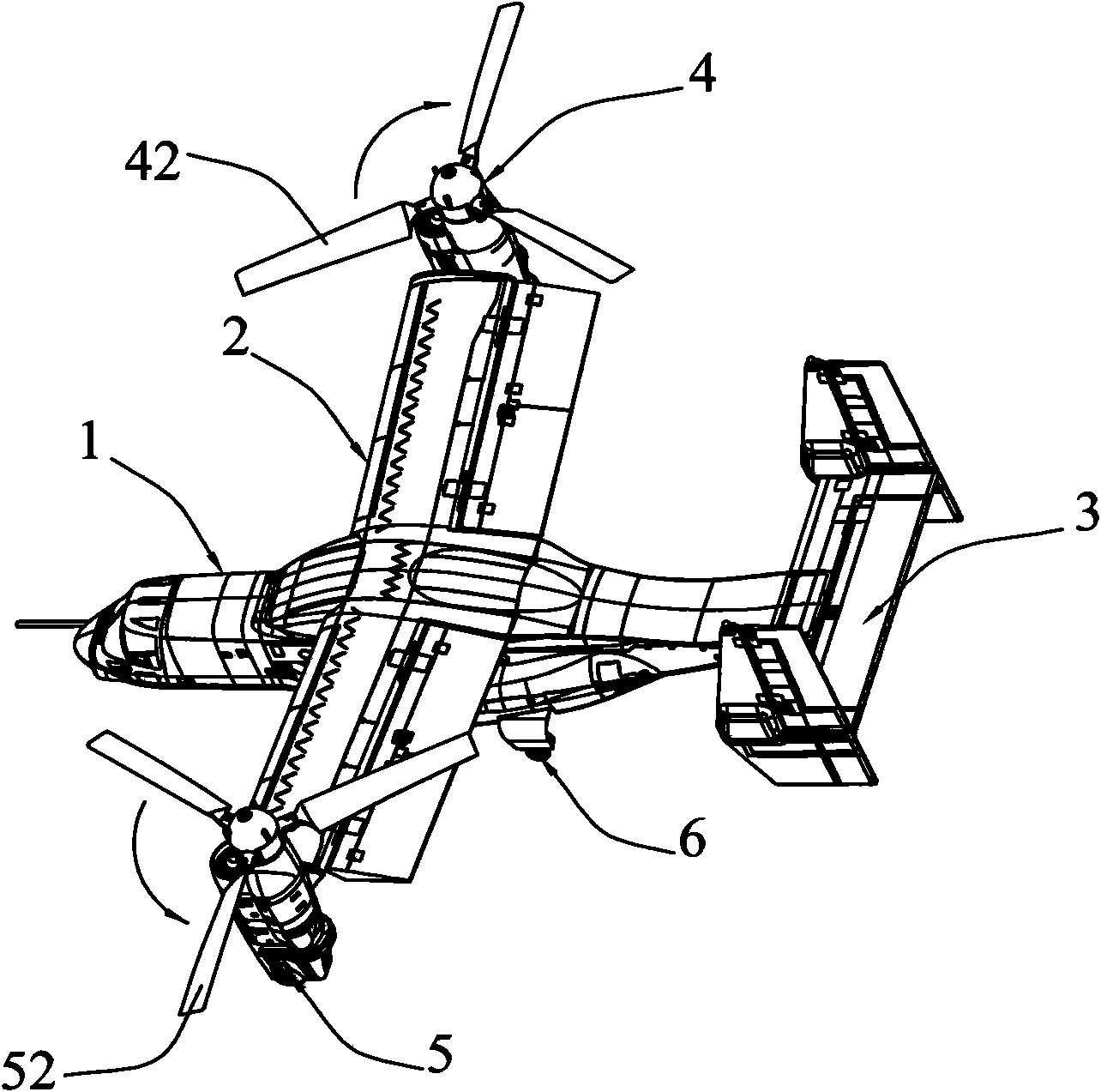

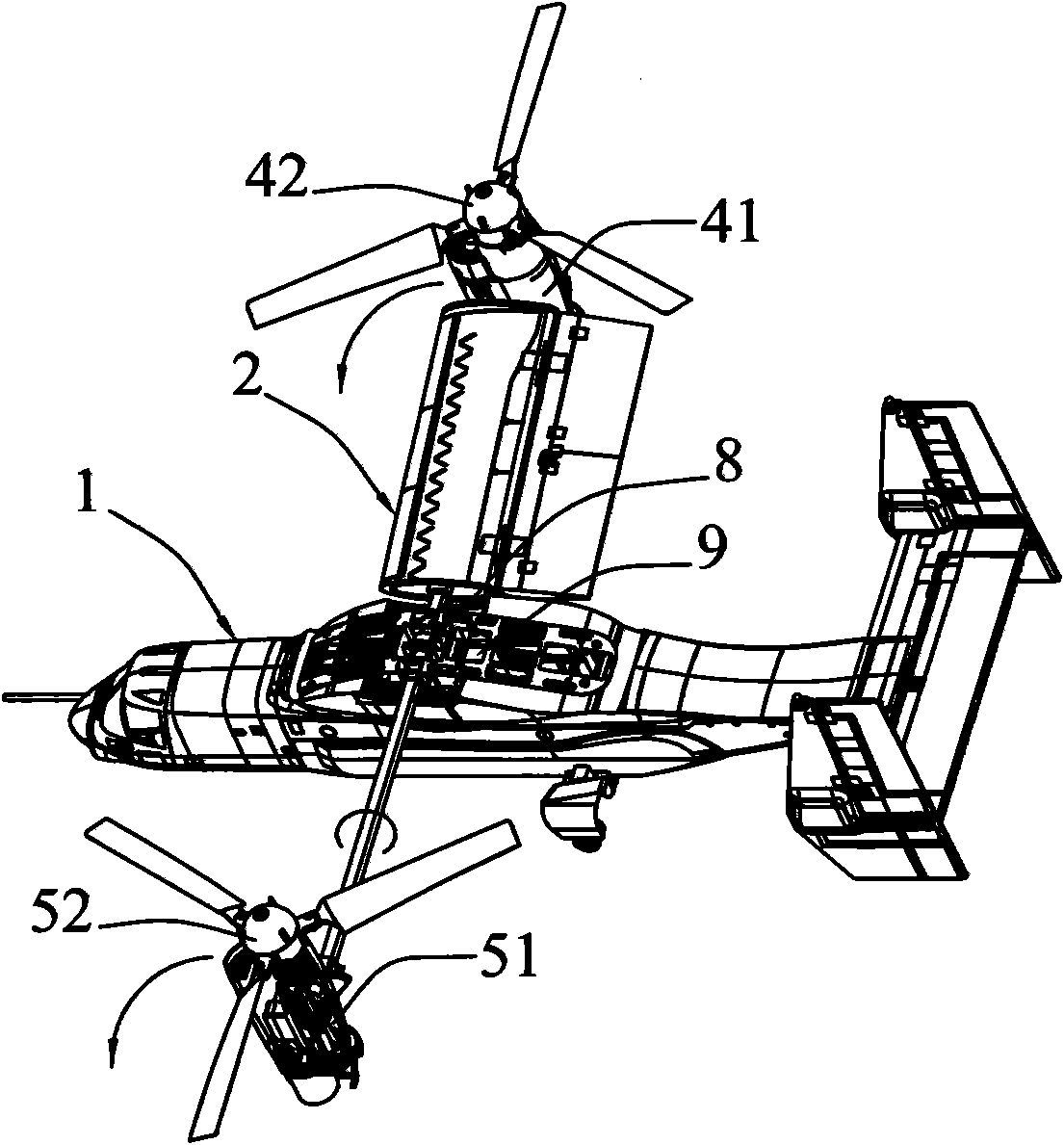

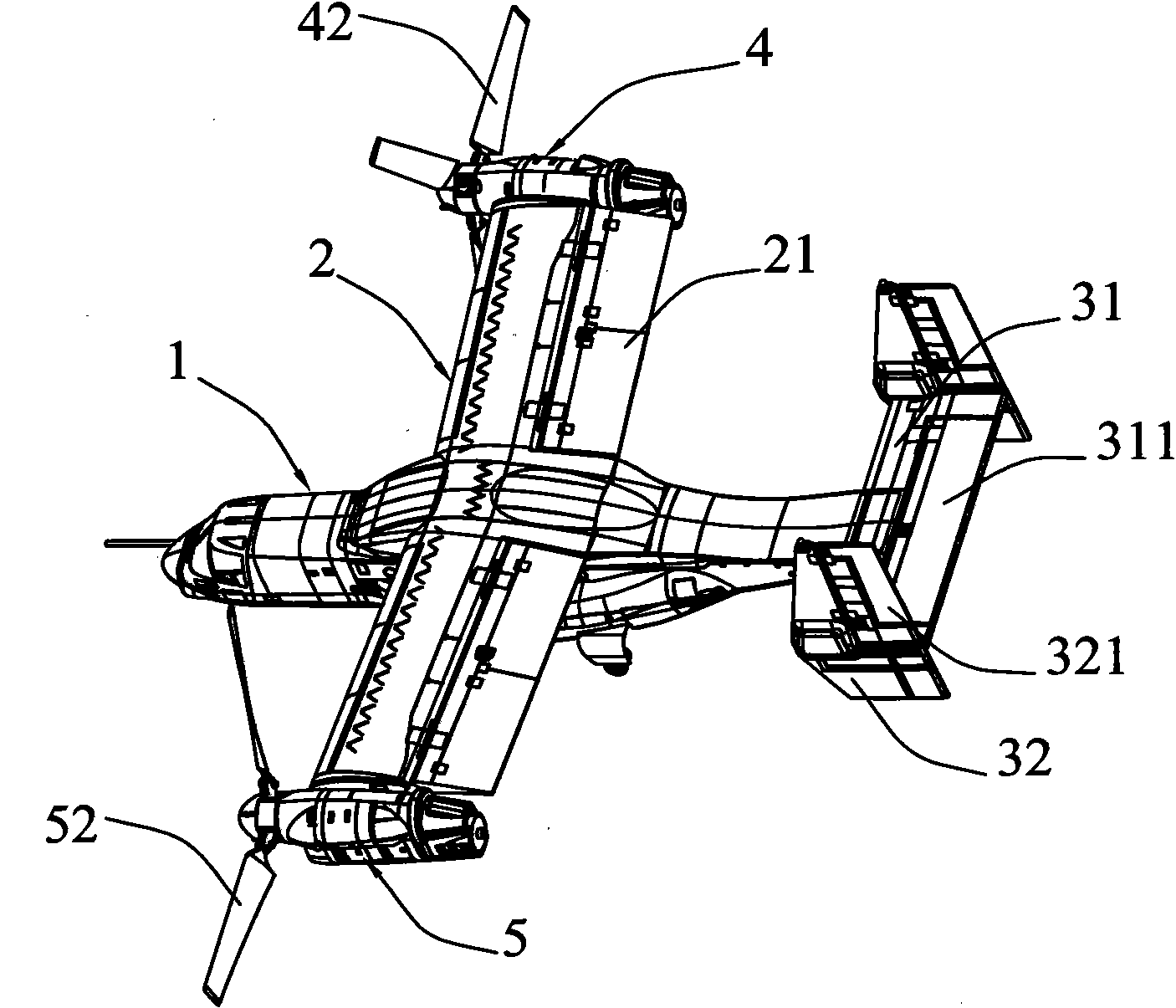

Model airplane with vertical takeoff and landing

ActiveCN101837195ARotate synchronouslyReduce weightToy aircraftsVertical landing/take-off aircraftsJet aeroplaneEngineering

The invention relates to the field of toy model airplanes and needs to solve the technical problems that a highly-simulated model airplane of a V-22 osprey is designed, can have the flight characteristics of the V-22 osprey and can be reduced to the specification size of a toy. A model airplane with vertical takeoff and landing, which is designed by the invention, comprises a fuselage, fixed wings and an empennage, wherein the fixed wings extend from both sides of the fuselage to the outside, the empennage is arranged at the tail part of the fuselage, the ends of the two wings are respectively provided with an airscrew engine, the rotation directions of the rotors of the two airscrew engines are opposite, the rotors of the two airscrew engines are connected into a whole by a rotating shaft mechanism distributed along the wings, the inside of the fuselage is provided with a rotating shaft driving mechanism, and the rotating shaft driving mechanism drives the rotating shaft mechanism to rotate so as to drive the airscrew engines at both ends of the rotating shaft mechanism to rotate synchronously between a vertical direction and a horizontal direction.

Owner:GUANGZHOU WALKERA TECH CO LTD

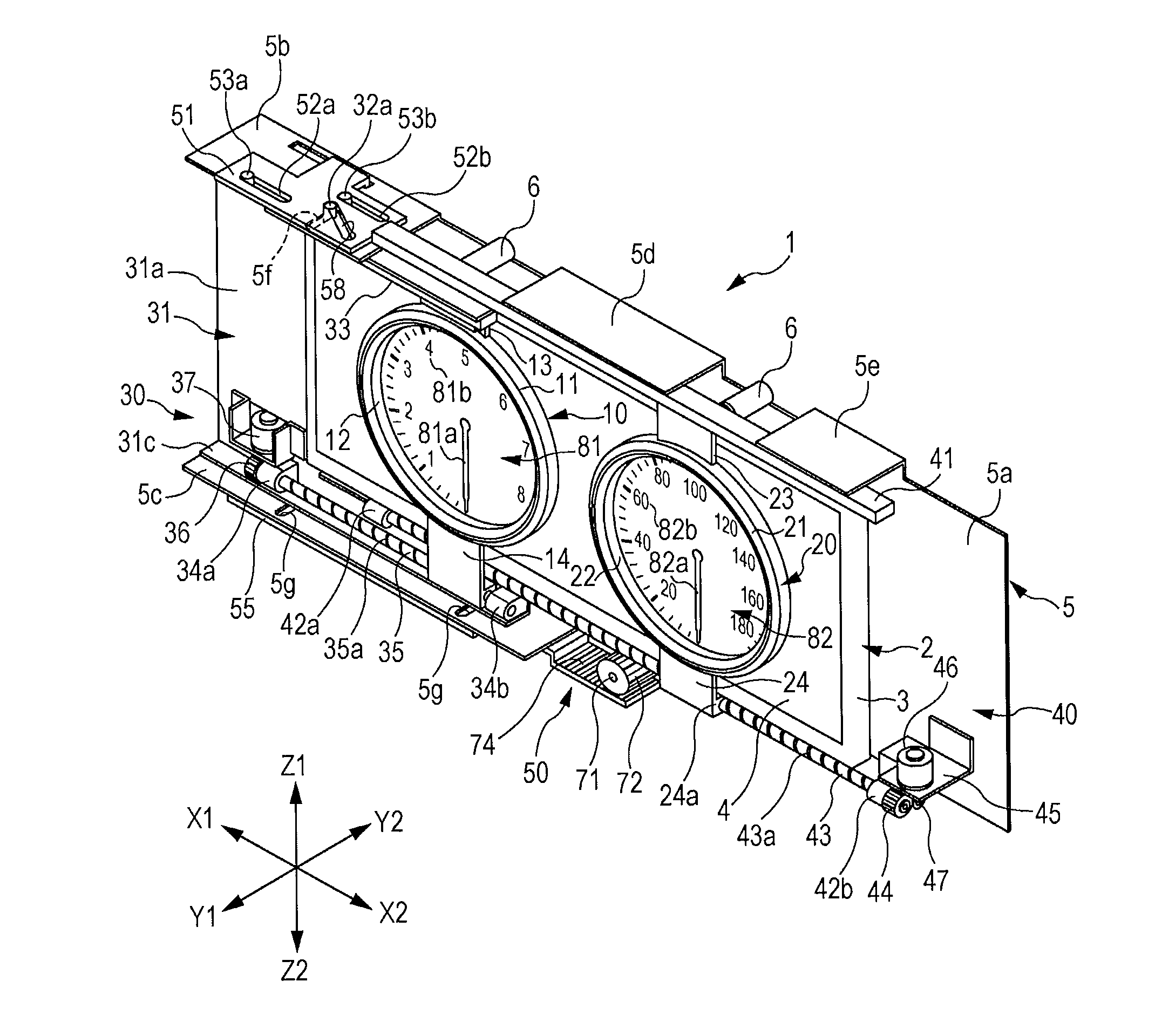

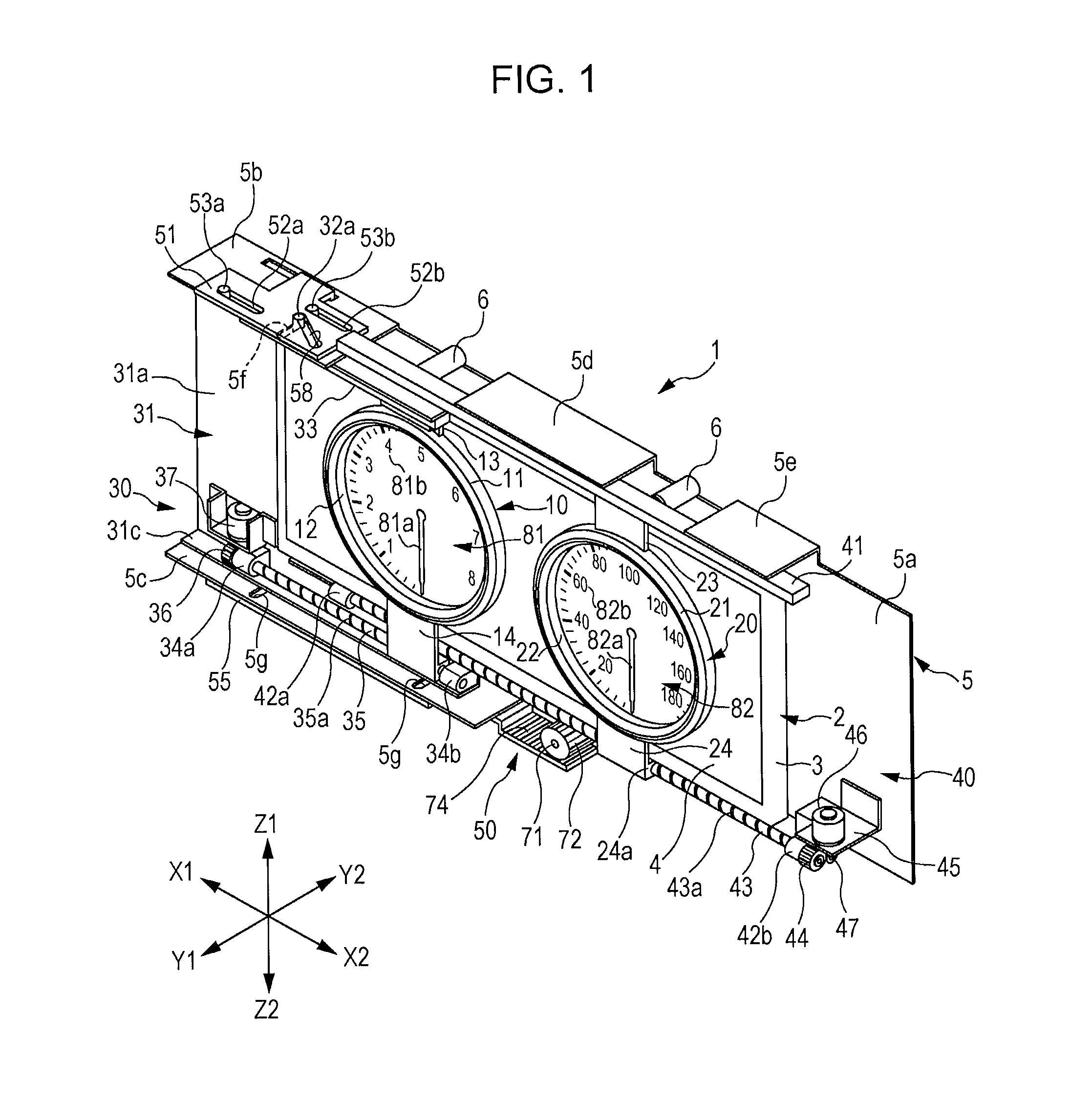

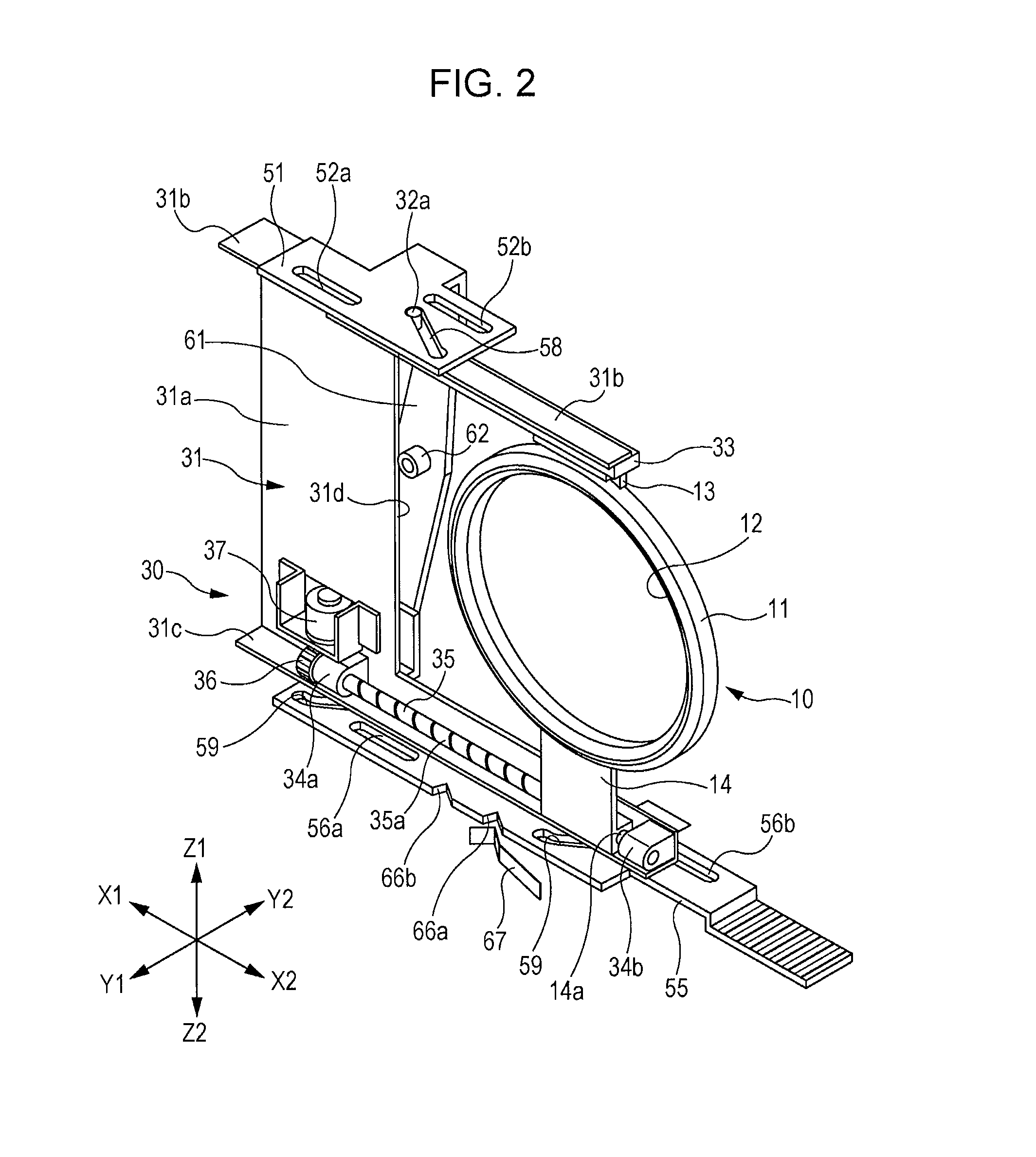

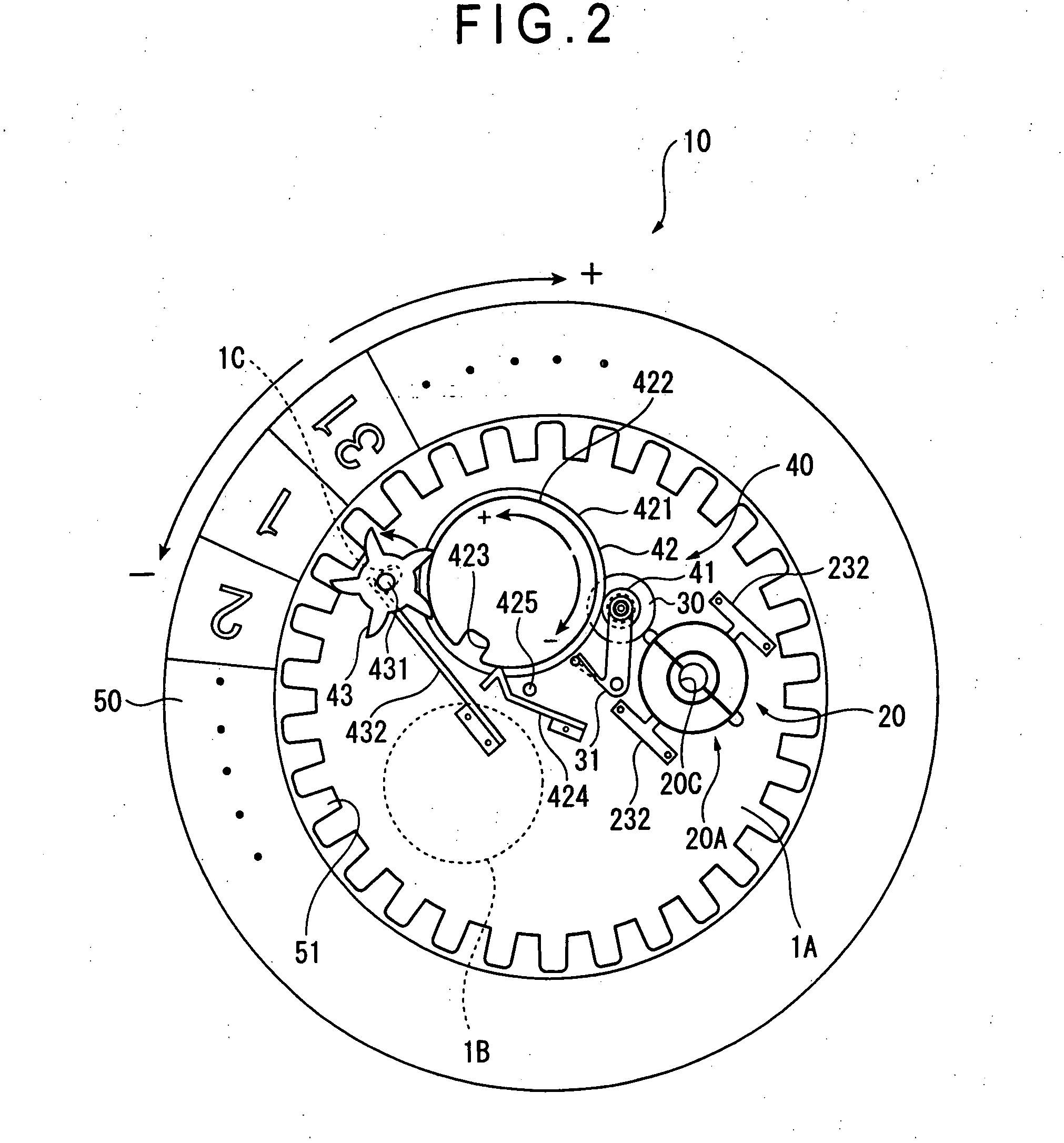

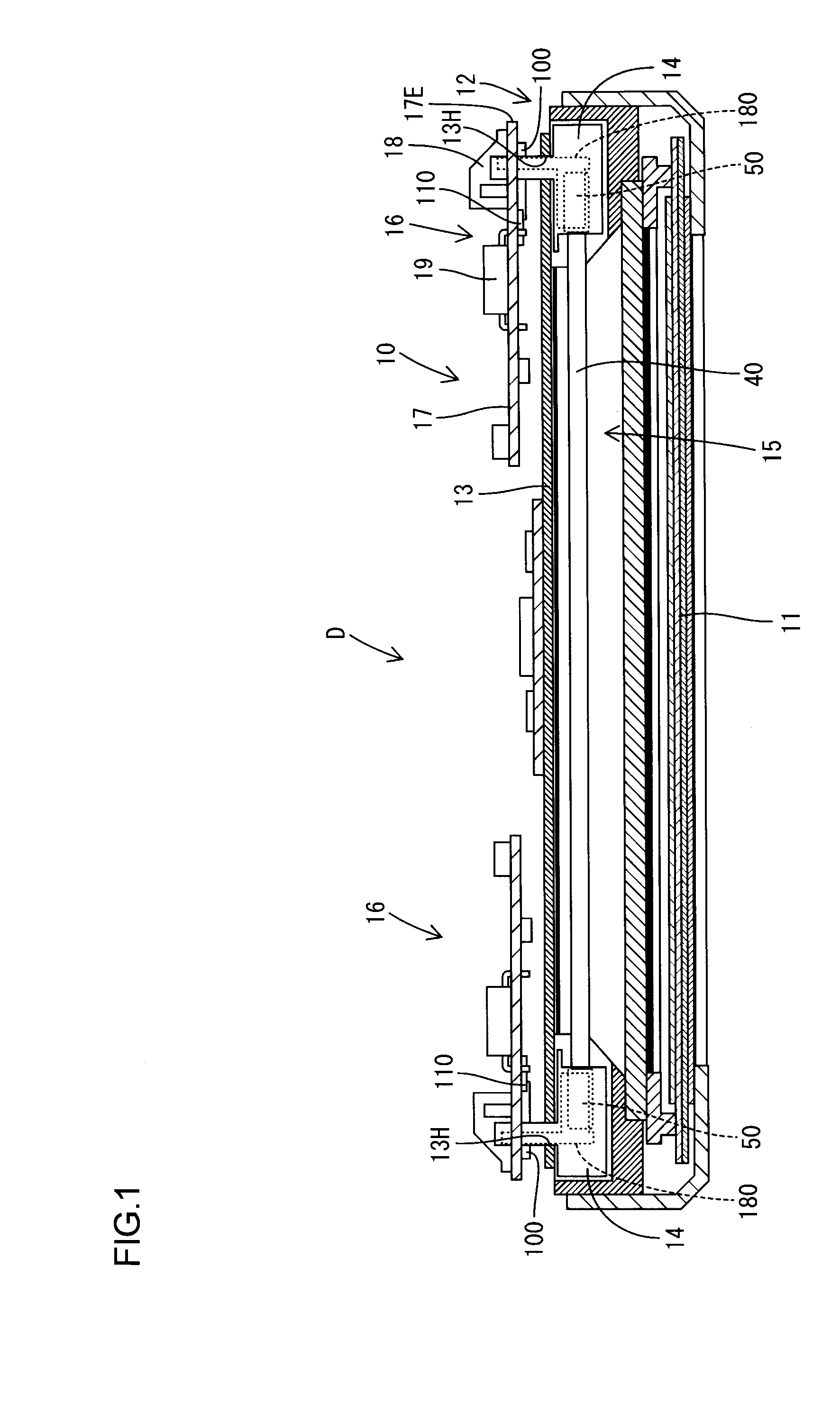

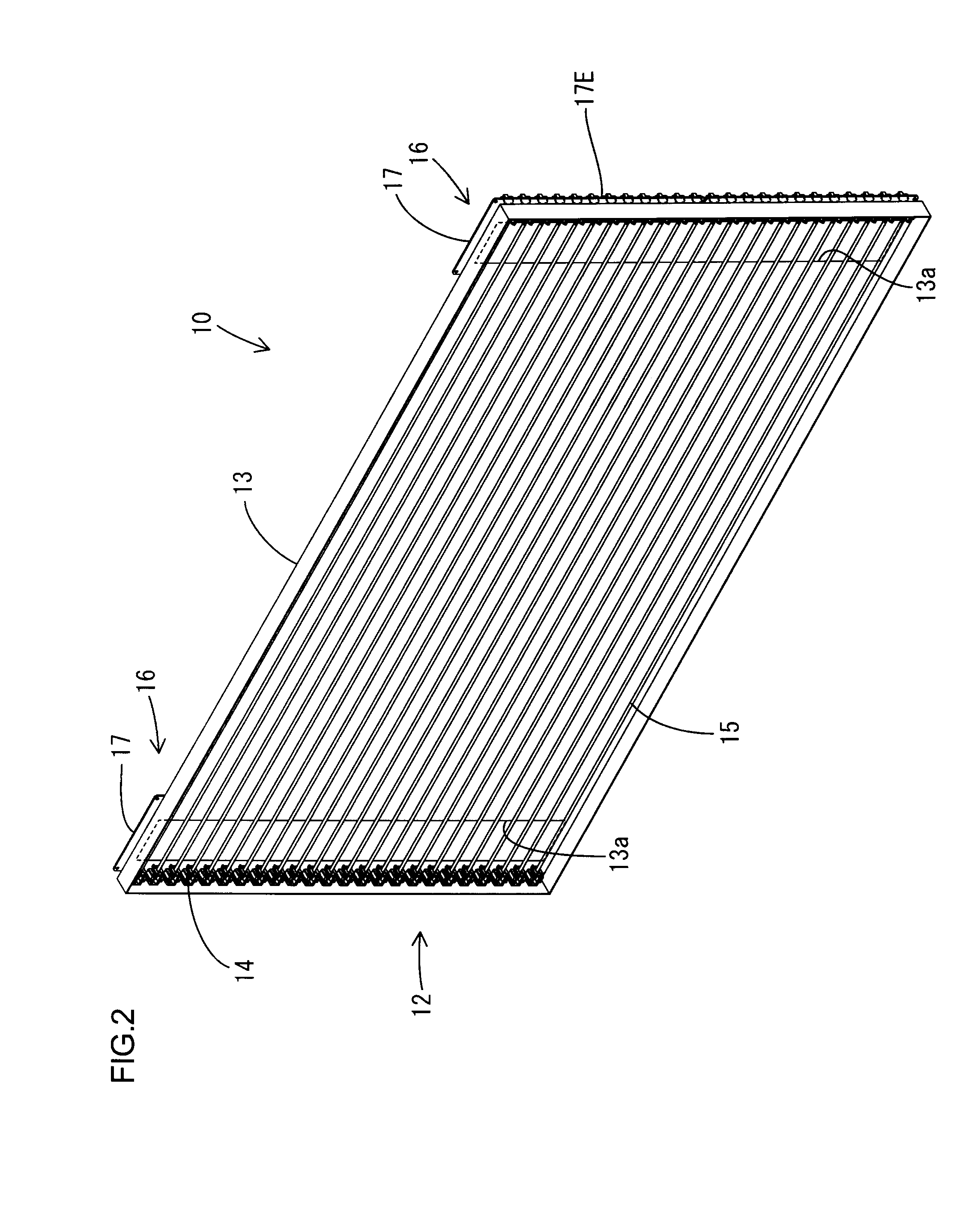

Vehicle display apparatus

InactiveUS20130186324A1Small depthSimple drive structureIndication apparatusInstrument arrangements/adaptationsElectrical and Electronics engineeringComputer hardware

Owner:ALPINE ELECTRONICS INC

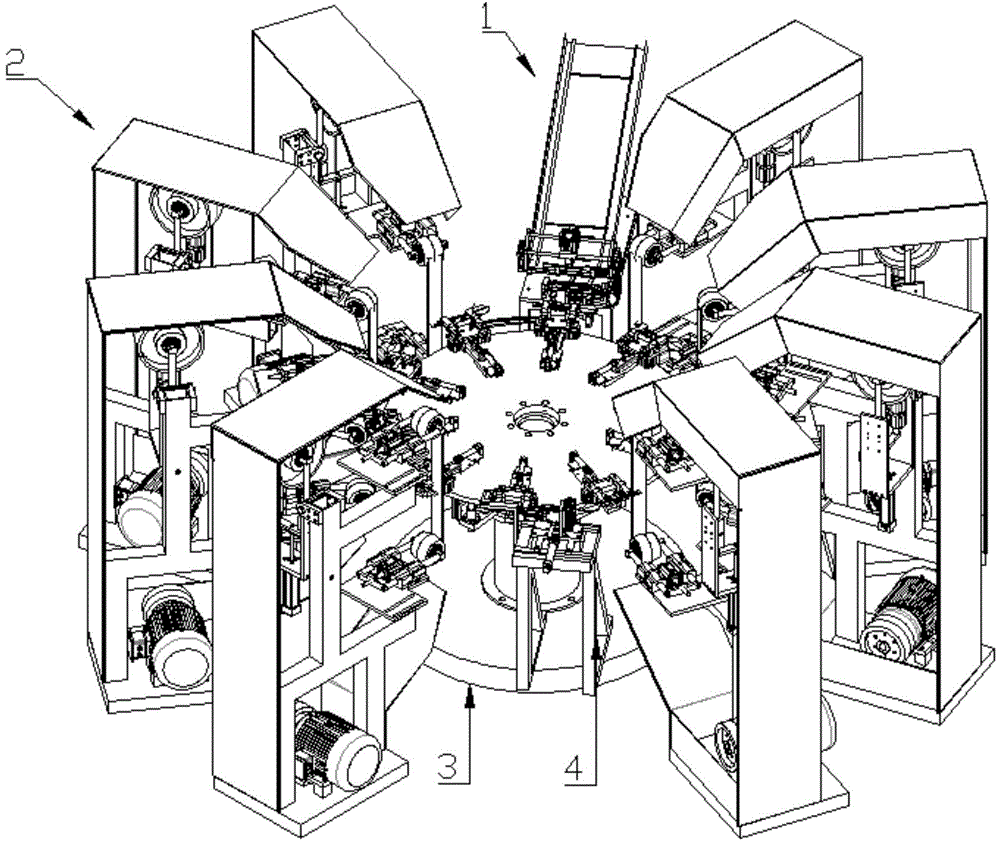

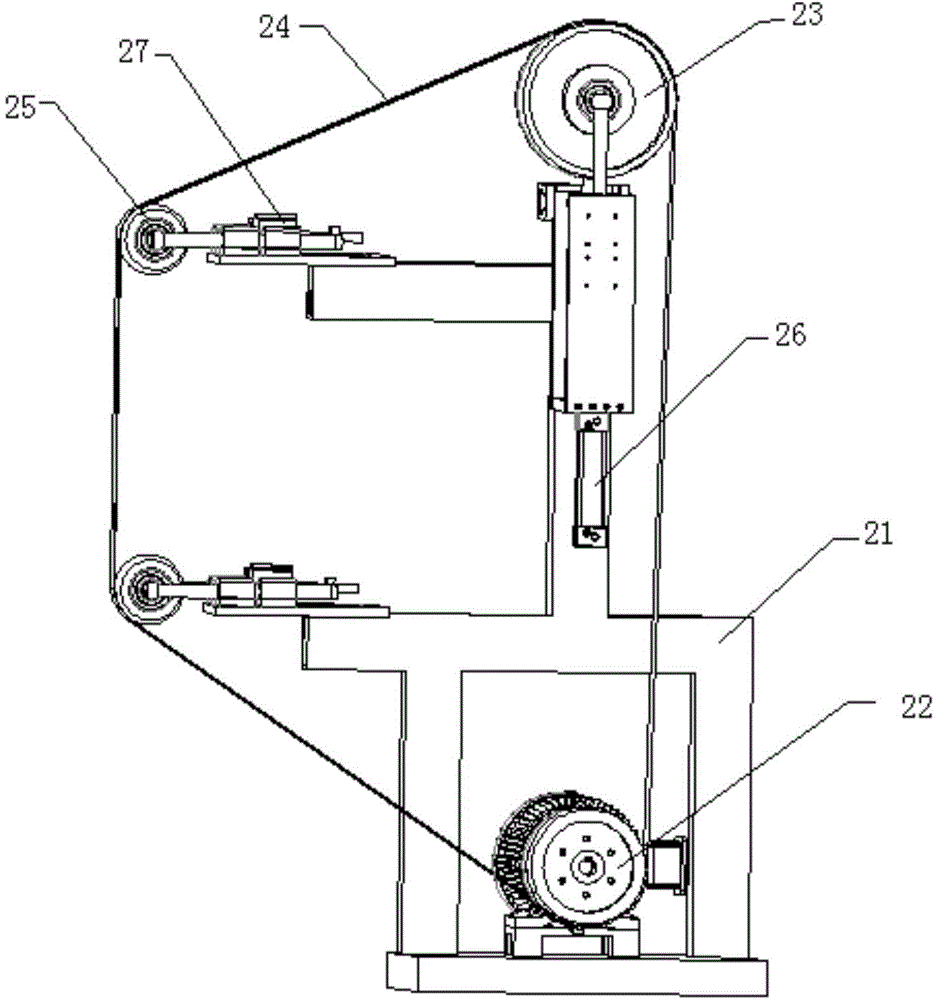

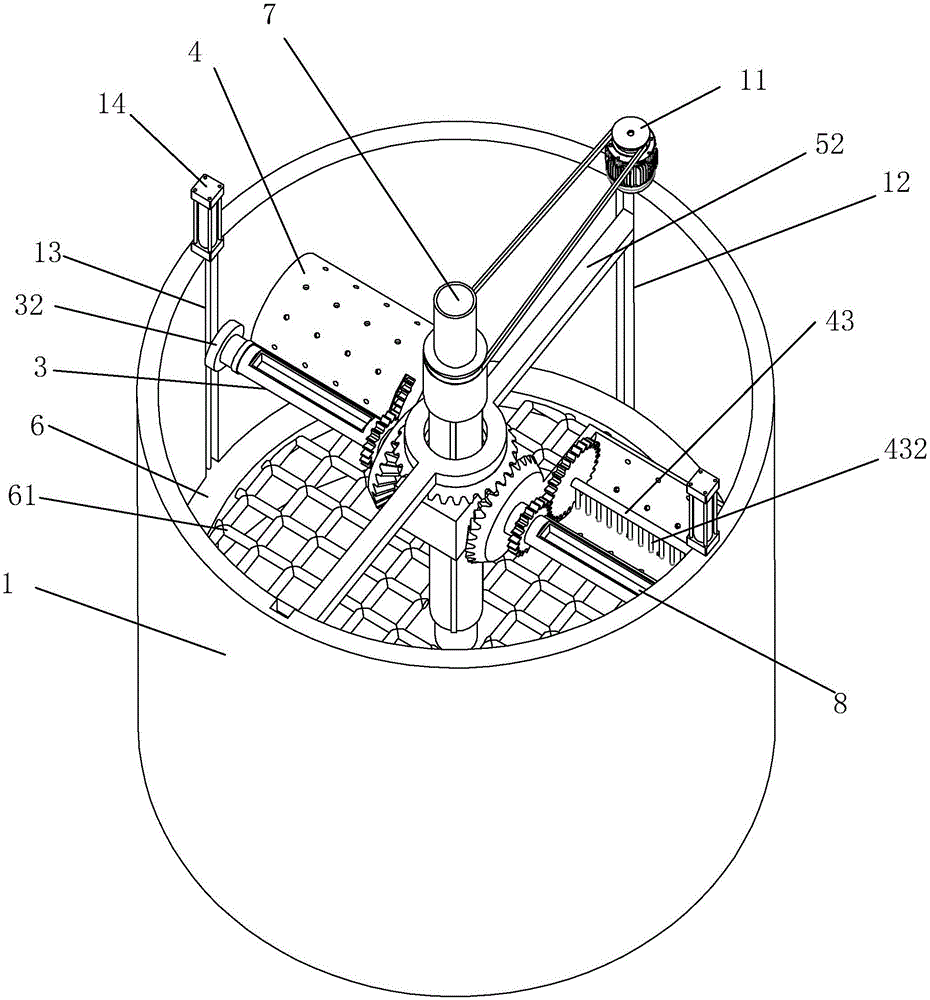

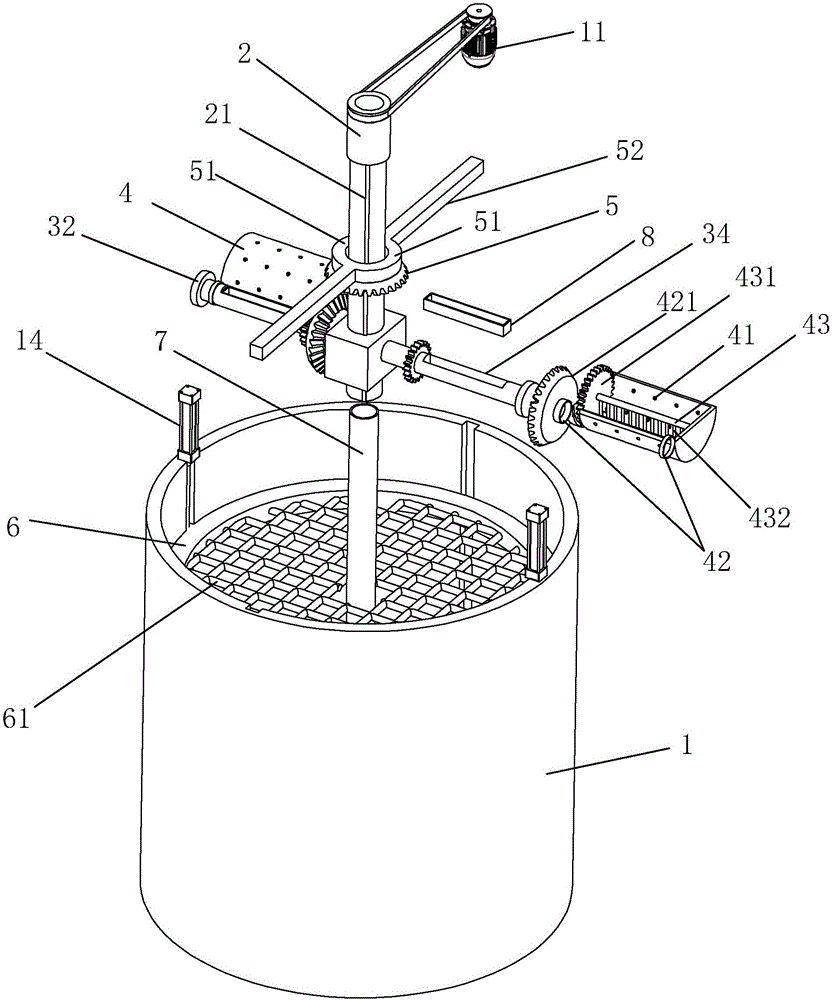

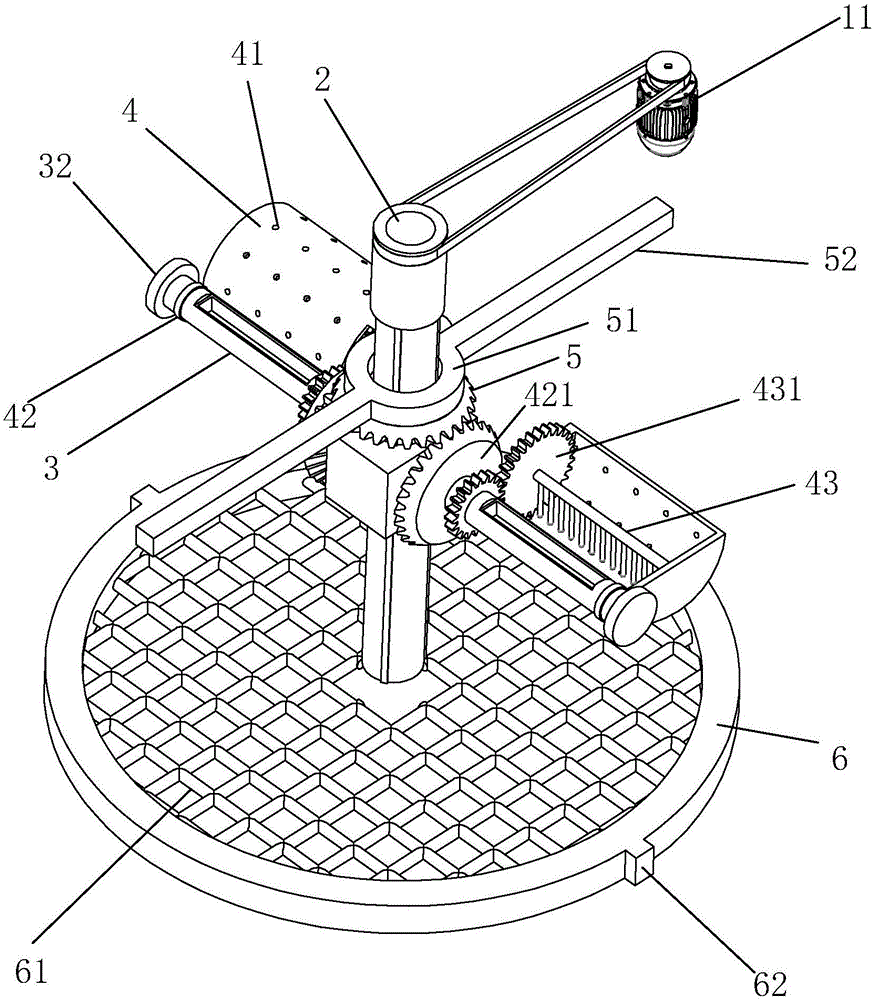

Edge grinding system for tableware processing

ActiveCN104097128AGuaranteed accuracyAvoid skewBelt grinding machinesGrinding feedersEngineeringReducer

An edge grinding system for tableware processing comprises a round rotatable transfer device. Feed stations are arranged outside the transfer device, and two grinding station sets are evenly arranged on two sides of each feed station, respectively. Each grinding station set is provided with a plurality of grinding devices. The round rotatable transfer device comprises a base. A support post is disposed at the center of the base. A servo motor and a reducer connected therewith are disposed inside the support post. The reducer is connected with a turnplate through a rotating bearing. Telescopic clamping devices arranged on the turnplate at positions corresponding to the grinding devices, the feed stations and extension lines of lines of the feed stations and the center of the turnplate. The edge grinding system for tableware processing is simple in structure, convenient to install and debug and low in energy consumption, requires small space of occupation, allows automatic production and is high in efficiency; the telescopic clamping devices are simple in structure and convenient to debug; feeding oblique slide plates provide large storage space, automatic sliding-down enables energy to be saved, and the use of the cylinders and suckers ensures feeding accuracy; the grinding devices are simple in structure, and abrasive belts are convenient to feed; the abrasive belts move forward, and grinding strength is improved; the use of overturn stations allows higher adaptability.

Owner:TIANJIN TTX GROUP

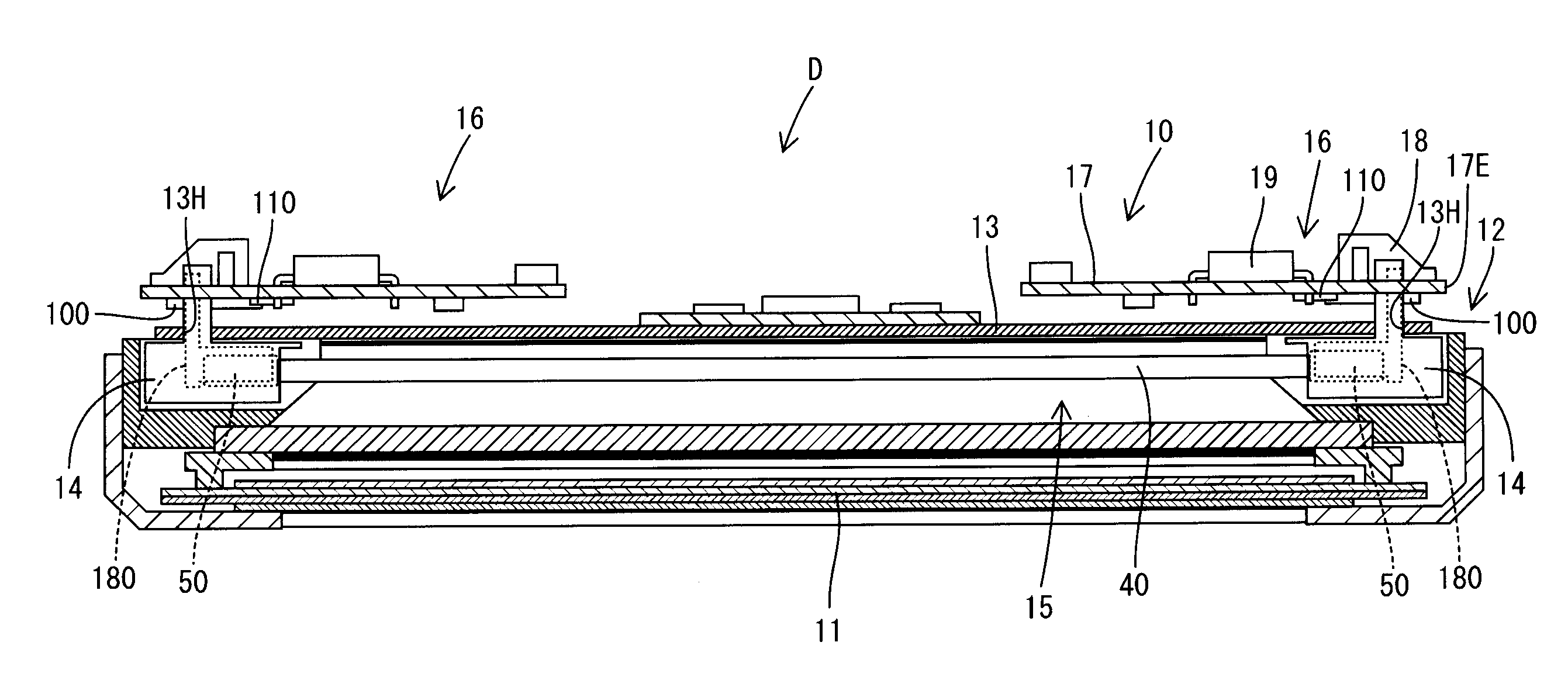

Liquid crystal display device and driving method thereof

InactiveCN104464678ASimple drive structureConducive to narrow bezel designStatic indicating devicesLiquid-crystal displayElectrical polarity

The invention discloses a liquid crystal display device. The liquid crystal display device comprises a gamma generator (50) and a liquid crystal display panel (40); the gamma generator (50) comprises a first storage unit (51) and a second storage unit (52); the first storage unit (51) stores a set of positive gamma voltage values or a set of negative gamma voltage values; the second storage unit (52) stores a set of negative gamma voltage values or the positive gamma voltage values; the gamma generator (50) periodically obtains the set of positive gamma voltage values or negative gamma voltage values from the first storage unit (51) or periodically obtains the set of negative gamma voltage values or positive gamma voltage values from the second storage unit (52) on the basis of control of polarity energizing signals; the liquid crystal display panel (40) carries out image display on the basis of one set of positive gamma voltage values and / or negative gamma voltage values. Compared with the prior art, the liquid crystal display device can effectively reduce the cost, meanwhile, the driving structure is simplified, the wiring area is reduced, and narrow-frame design is facilitated.

Owner:TCL CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

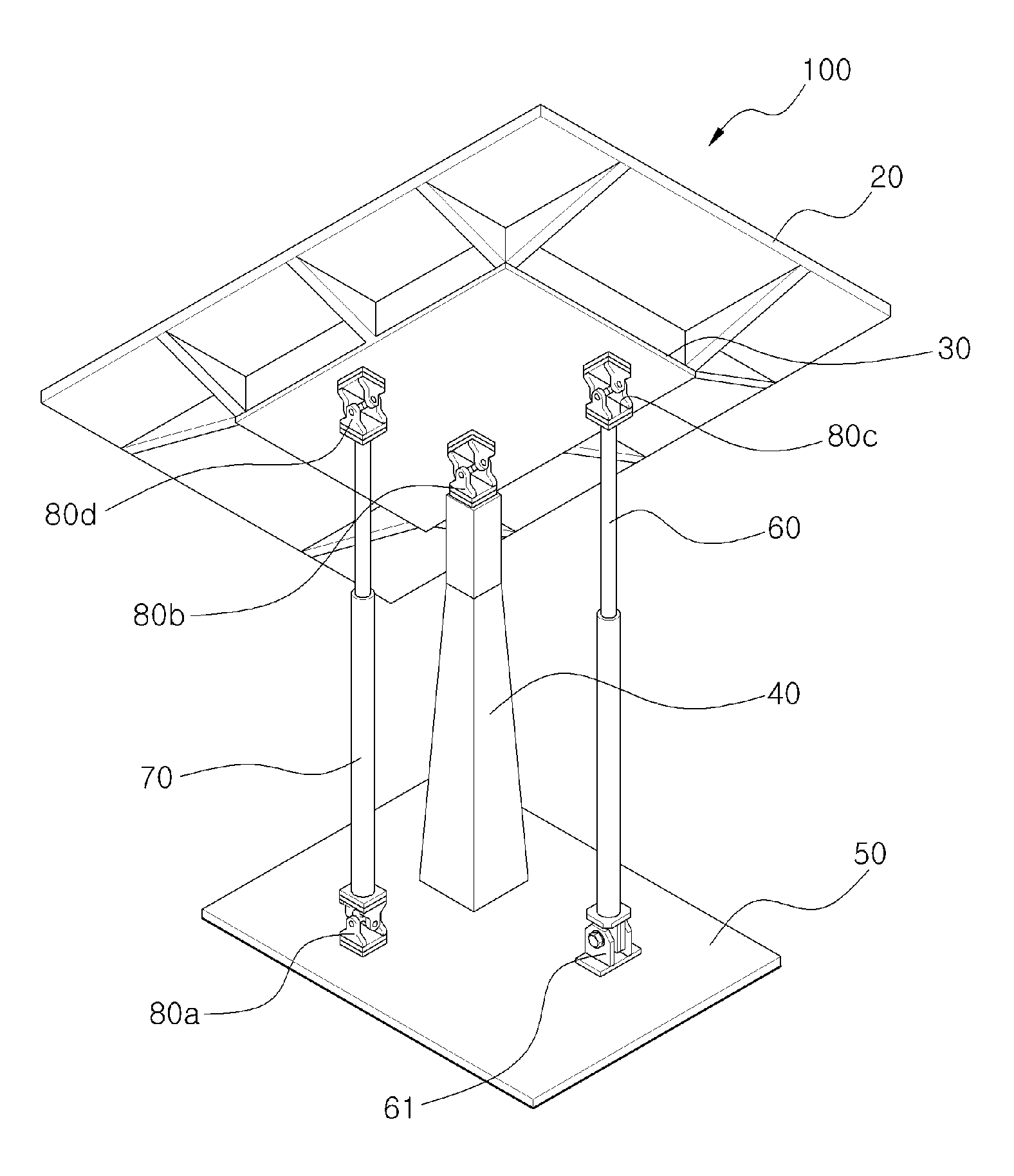

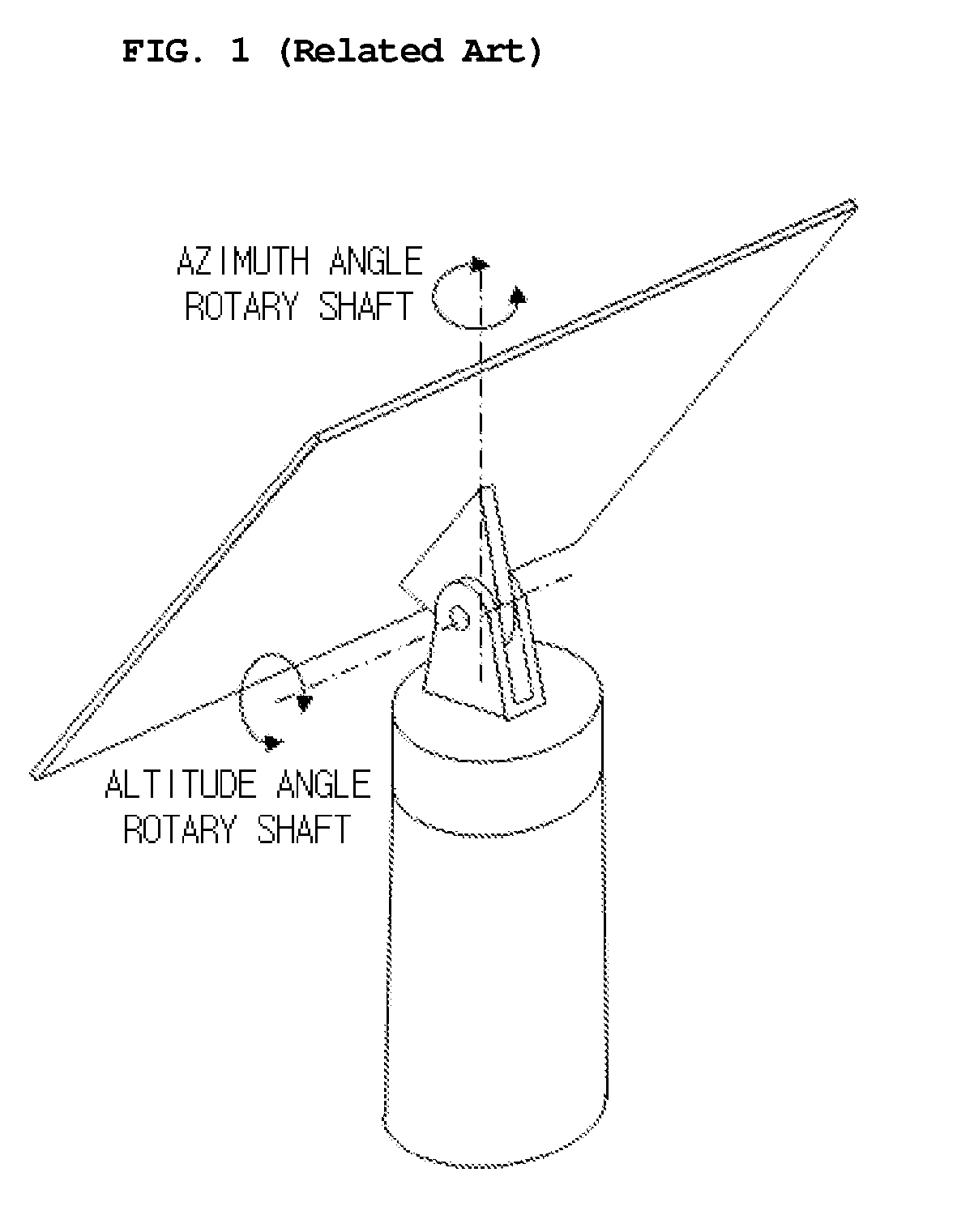

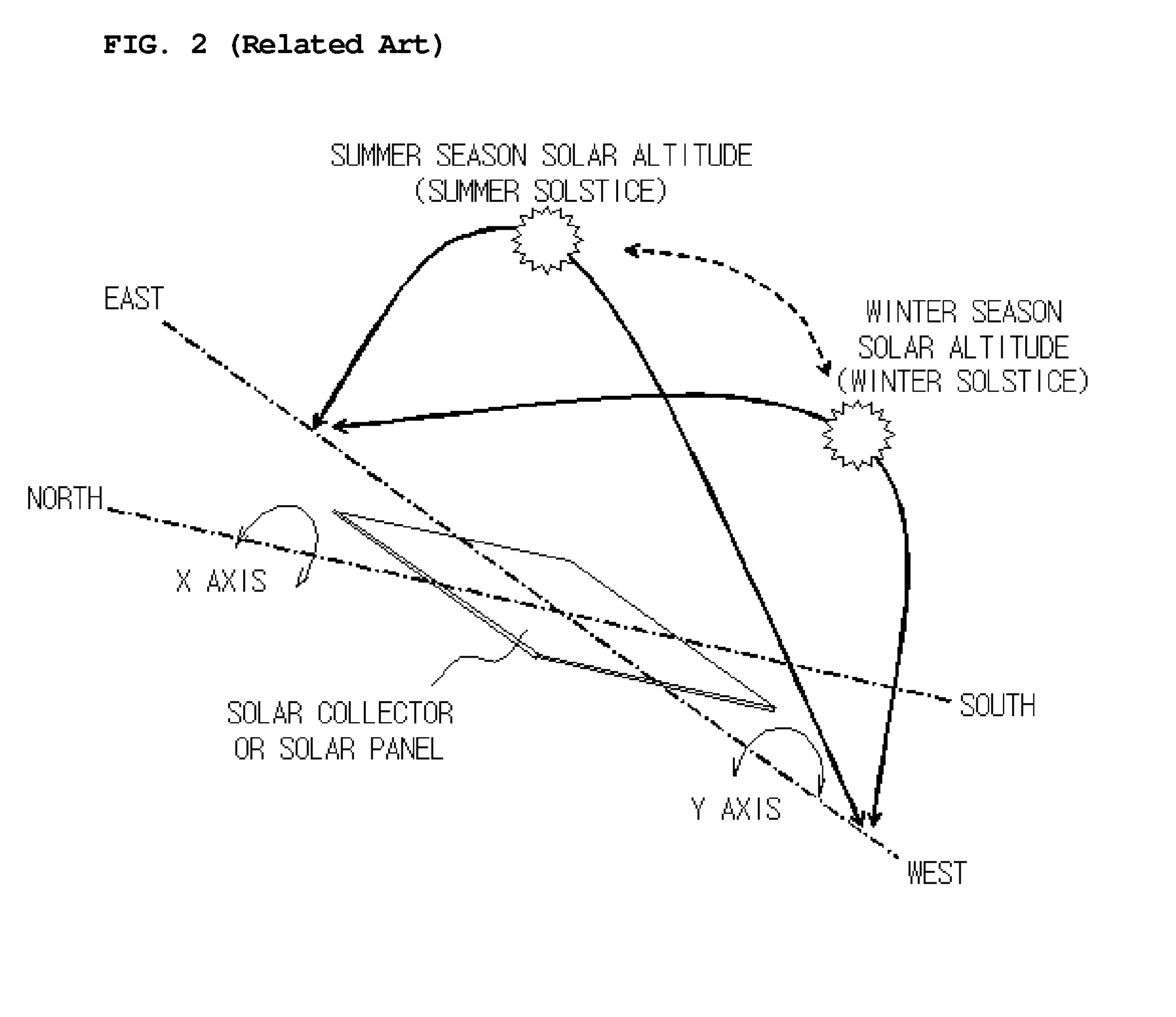

Solar tracker for photovoltaic power generation

InactiveUS20140069481A1Small diurnal changeConsumes driving powerPhotovoltaic supportsSolar heating energySolsticeSolar tracker

A solar tracker is provided to fix an altitude angle until the altitude of the sun secedes from a predetermined range after matching the altitude through once driving of one shaft that tracks the altitude angle and to drive only the other shaft that tracks an east-west azimuth angle in daily repetition in a state where the altitude angle of the sun, which is repeatedly changed according to seasons of the year in the range of the winter solstice having the lowest altitude angle and the summer solstice having the highest altitude angle, has an extremely small diurnal change, whereas the azimuth angle of the sun is repeatedly changed in one direction, that is, from sunup to sundown, in a day. Accordingly, consumption of firm power of a driving unit for tracking the sun can be minimized, and the operating and management costs of the device can be reduced.

Owner:HYPER

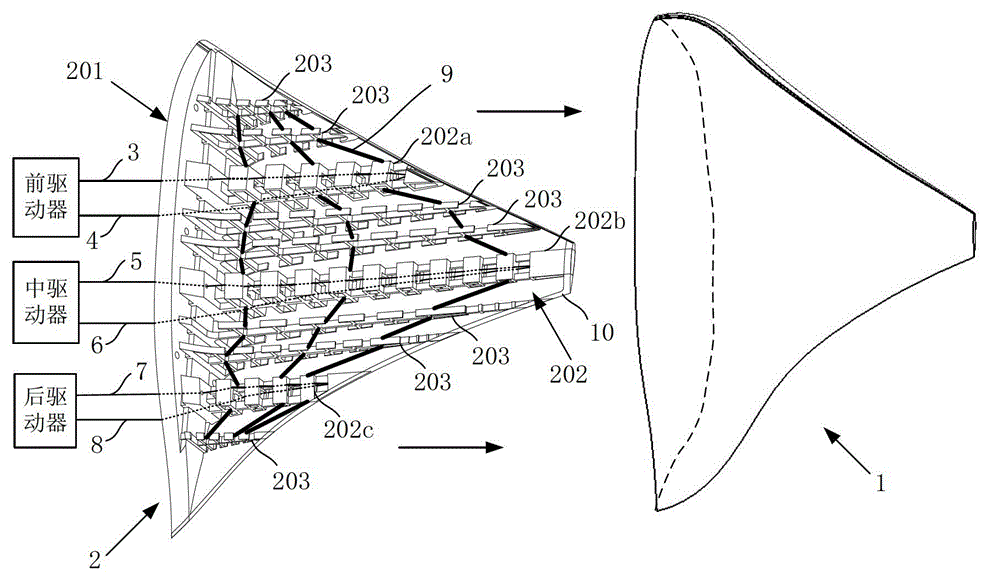

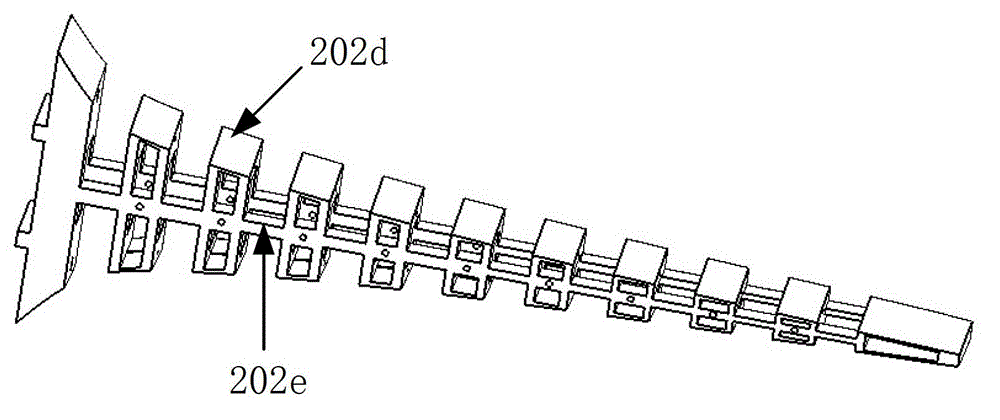

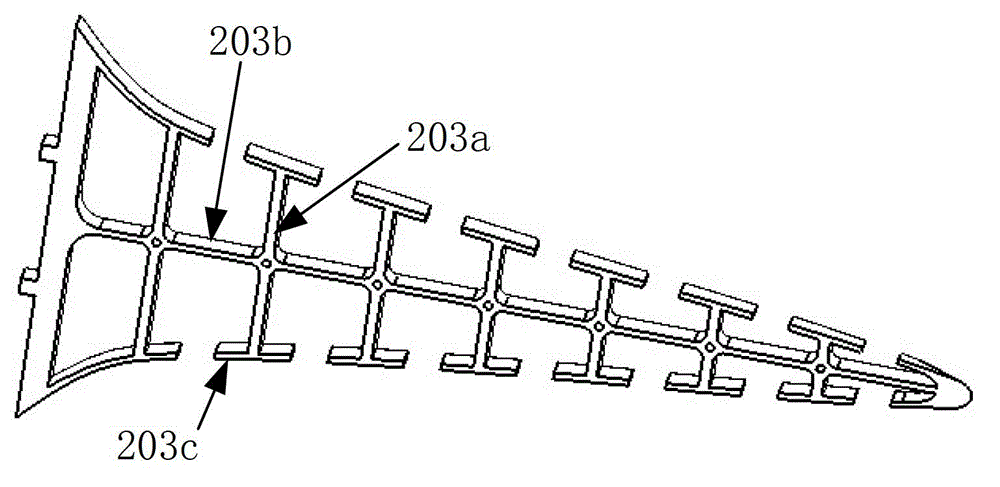

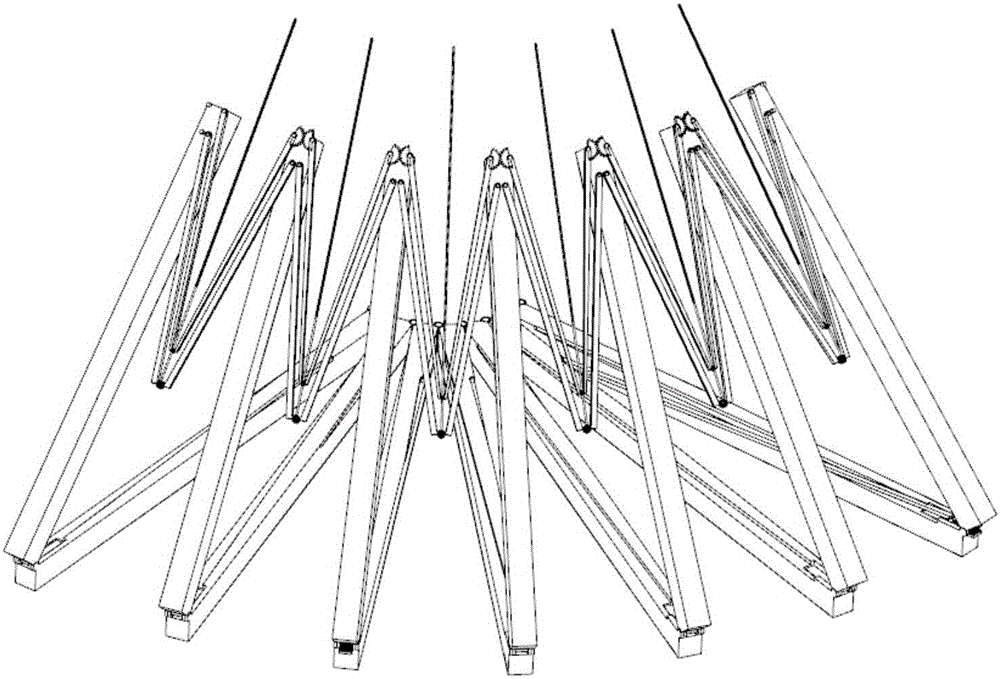

Bionic cow-nosed ray oscillating pectoral fin driven by wires of large-deformation flexible mechanism

InactiveCN103144755ARealize volatility transmissionRealize the flexible distribution in the span directionPropulsive elements of non-rotary typeFlexible MechanismsDrive by wire

The invention discloses a bionic cow-nosed ray oscillating pectoral fin driven by wires of a large-deformation flexible mechanism. The oscillating pectoral fin comprises a pectoral fin skin and a pectoral fin skeleton arranged in the pectoral fin skin, wherein the skeleton consists of a baseplate and fin rays; the baseplate is arranged in the chordwise direction of a bionic pectoral fin; fin rays with similar spanwise section shape to the original fin rays of the cow-nosed ray oscillating pectoral fin are mounted in the front part, in the middle and at the rear part of the baseplate in the pectoral fin spanwise direction; all fin rays are driven by wires to oscillate up and down; one or more soft limbs with similar chordwise section shape to the original fin ray of the cow-nosed ray oscillating pectoral fin is / are arranged on two sides of each fin ray; and all the soft limbs, as well as all the soft limbs and the adjacent fin rays, are connected through elastic thread ropes, so that the bionic cow-nosed ray oscillating pectoral fin achieves mild, smooth and continuous fluctuation transmission in the chordwise direction in the movement process, which more fits to the fluctuation of the natural original cow-nosed ray pectoral fin. The bionic cow-nosed ray oscillating pectoral fin has the advantages that spanwise flexible distribution and flexible deformation of the bionic fin rays are realized, and chordwise flexible distribution of the bionic pectoral fins and fluctuation transmission in the movement process are also realized.

Owner:BEIHANG UNIV

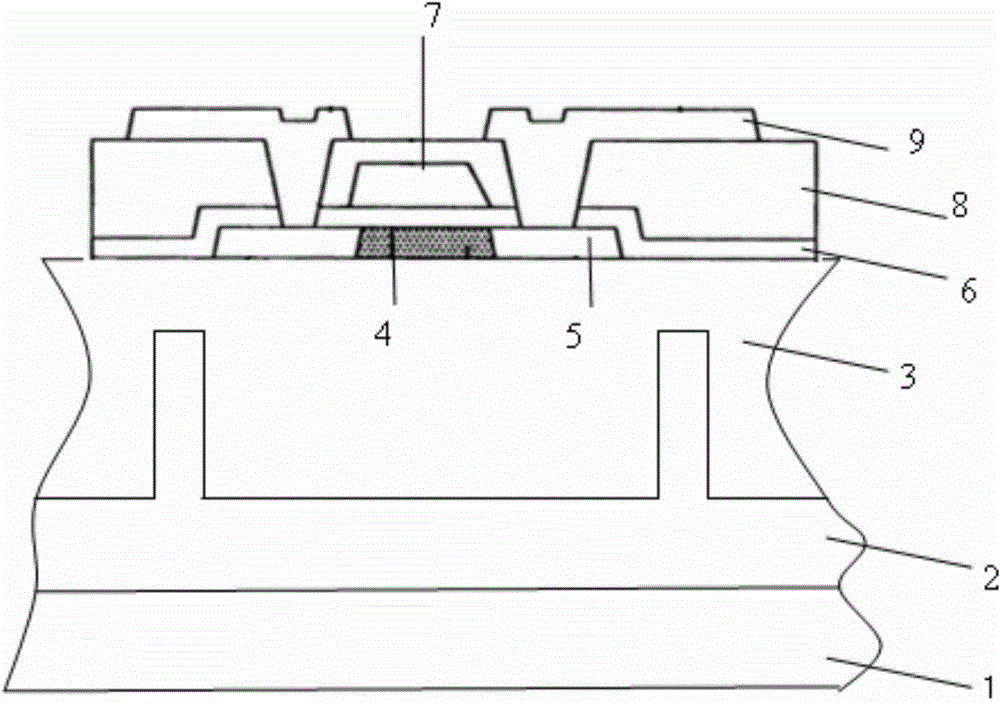

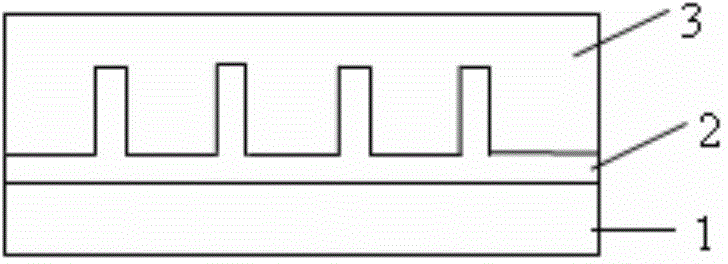

Low-temperature poly-silicon thin film transistor and preparation method thereof

ActiveCN104157700AIncrease subcoolingMobility effectTransistorSemiconductor/solid-state device detailsEngineeringSingle crystal

The invention provides a low-temperature poly-silicon thin film transistor and a preparation method of the low-temperature poly-silicon thin film transistor. The LTPS TFT sequentially comprises a substrate, a heat conducting layer provided with a plurality of strip-shaped protrusions, a planarization layer and an active layer with a plurality of active channels, wherein the active layer is formed by carrying out the yellow laser process on a low-temperature poly-silicon thin film, a gate insulator, a gate electrode, an interlayer insulator, a source electrode and a drain electrode are arranged on the active layer, each strip-shaped protrusion is located outside one side of the position where the corresponding active channel is located, each strip-shaped protrusion and the corresponding active channel are adjacent to each other in position, and the length of each strip-shaped protrusion is larger than the width of the corresponding active channel. According to the low-temperature poly-silicon thin film transistor and the preparation method of the low-temperature poly-silicon thin film transistor, because large poly-silicon crystal grains can be obtained and the active channels of the thin film transistor can be completely located inside one single crystal grain, adverse impact of a poly-silicon crystal grain boundary on carrier mobility is avoided, the leakage current phenomenon caused by the crystal grain boundary is eliminated, and a simplest pixel circuit driving structure can be implemented.

Owner:TRULY HUIZHOU SMART DISPLAY

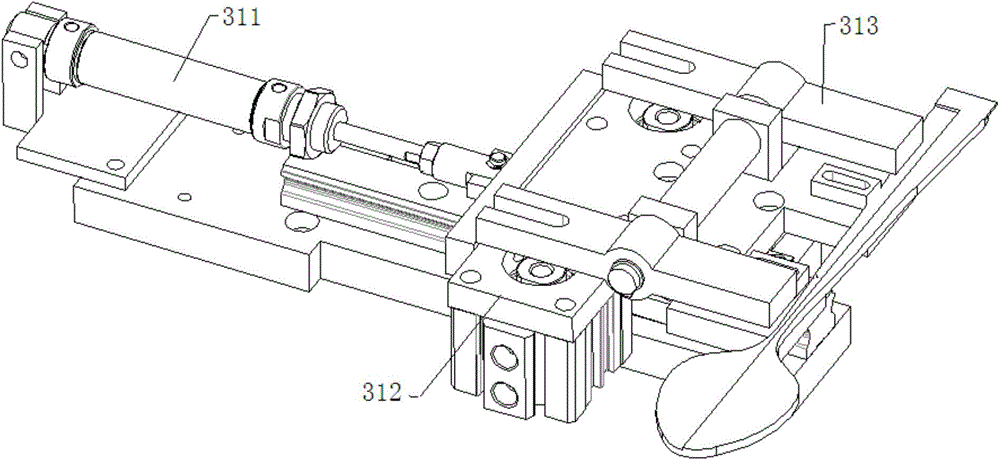

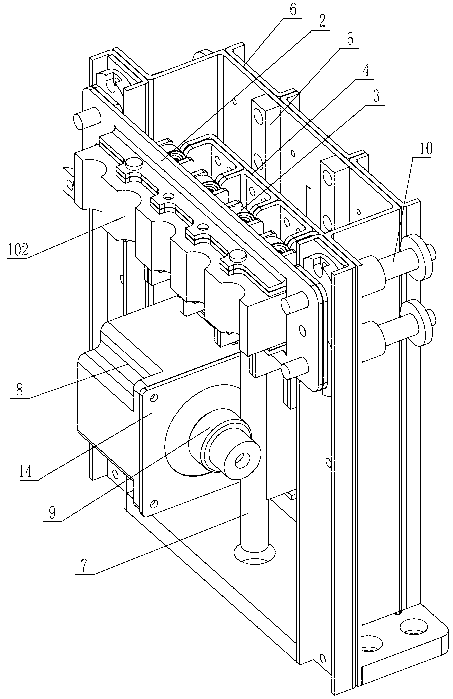

Test tube clamping mechanism in test tube cover removing device

InactiveCN103263953ASimple drive structureReliable clampingMaterial analysisTest tube stands/holdersTest tubeEngineering

The invention discloses a test tube clamping mechanism in a test tube cover removing device. The test tube clamping mechanism in the test tube cover removing device comprises test tube clamping devices arranged horizontally; the test tube clamping devices are fixedly connected to an installation seat; cams are fixedly connected to the other side of the installation seat; cam guide plates with guide oblique surfaces are arranged in front of the cams; the cams face to the guide oblique surfaces; the cam guide plates can be supported on a rack through linear guide rail pairs in a sliding mode, and are fixedly connected with toothed bars; a motor drives gears on the shaft end, the gears and the toothed bars are in meshed transmission so as to drive the cam guide plates to perform ascending and descending motions along linear guide rails in the linear guide rail pairs, and the guide oblique surfaces of the cam guide plates control the cams to move, so that the test tube clamping devices can be pushed to move longitudinally; the test tube clamping devices comprise a first test tube clamping device and a second test tube clamping device, and the first test tube clamping device and the second test tube clamping device are closed or loosened through the longitudinal moving of the first test tube clamping device and the second test tube clamping device. The test tube clamping mechanism in the test tube cover removing device provided by the invention can clamp a plurality of test tubes, is high in efficiency, and is reliable in running.

Owner:无锡特可思衡机贸易有限公司

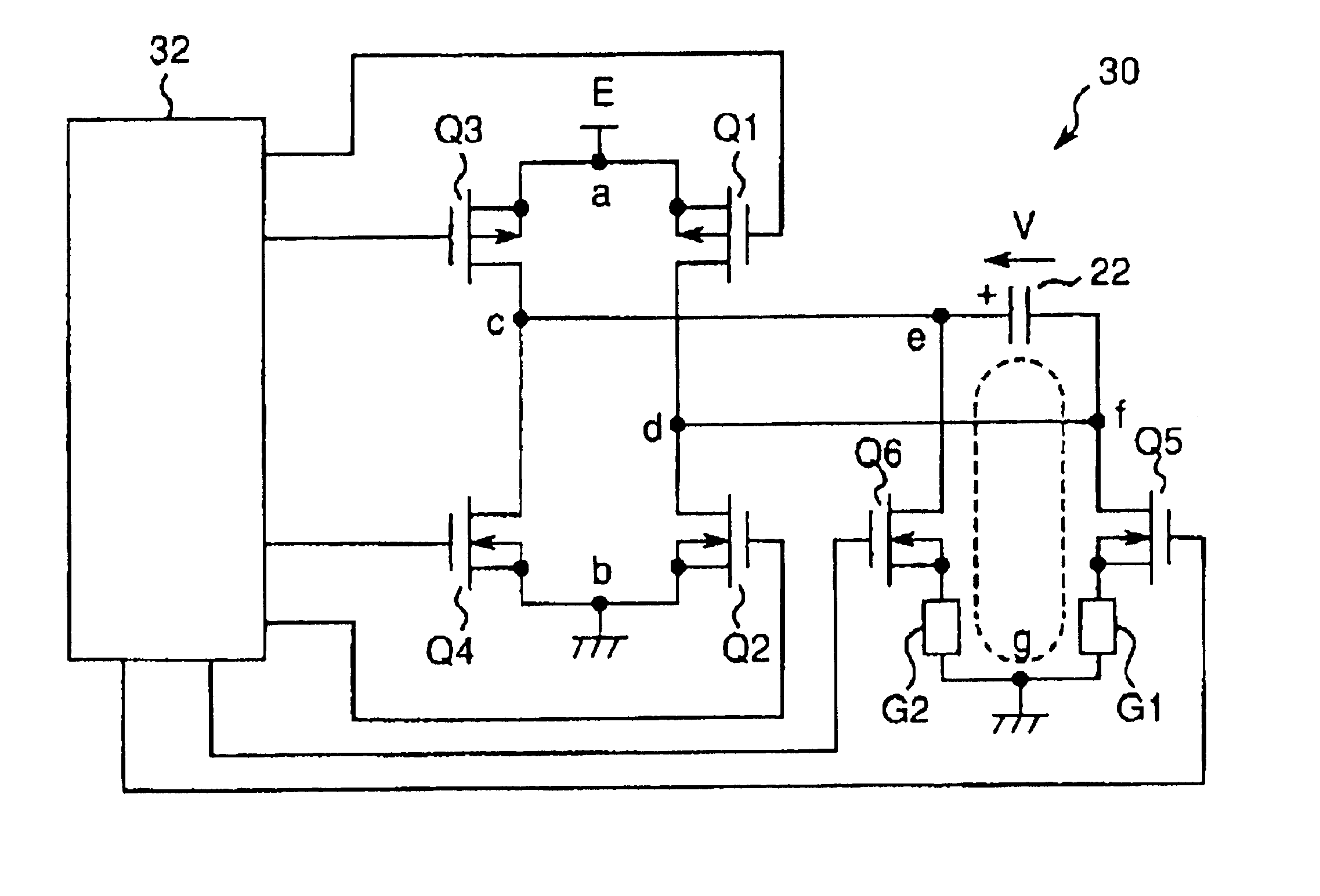

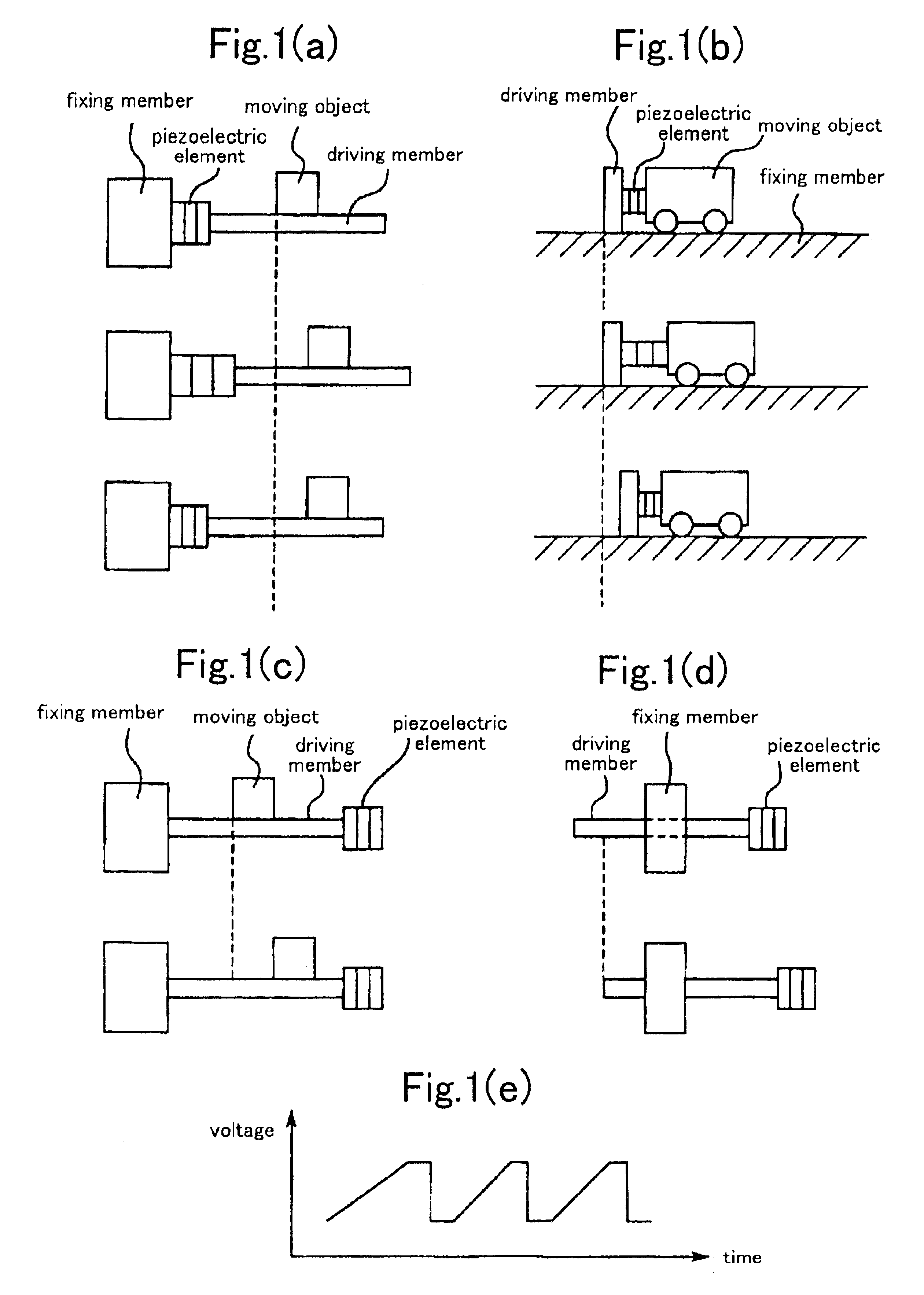

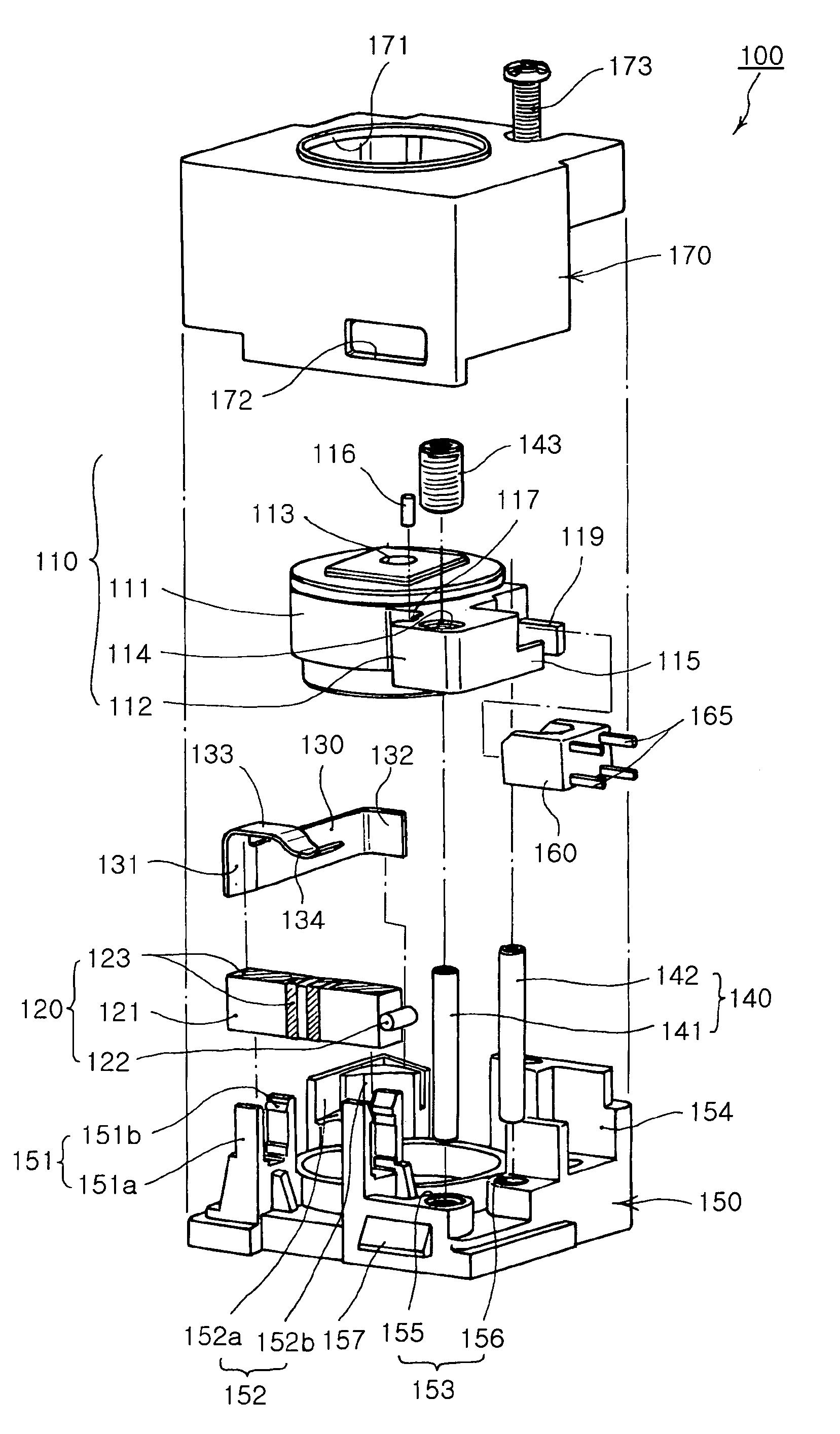

Drive apparatus

InactiveUS6844658B2Executed efficiently and easilyEasy and efficientPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device detailsEngineeringControl circuit

In order to provide a drive apparatus where a rush-current is small when a voltage is applied to a capacitive load so that the drive apparatus is driven, the drive apparatus has a capacitive load 22, first drive circuits Q1, Q4 for applying a power source voltage E to the capacitive load 22, second drive circuits Q2, Q3 for applying the power source voltage E to the capacitive load 22 to an opposite direction to the first drive circuits Q1 and Q4, and a control circuit 32 for operating the first and second drive circuits Q1, Q4; Q2, Q3 alternately. Discharging circuits Q5, G1, G2, Q6 which are connected with inductive element G1 and G2 are provided to both ends of the capacitive load 22. The control circuit 32 operates the first and second drive circuits Q1, Q4; Q2, Q3 with an interval, and operates the discharging circuits Q5, G1, G2, Q6 during the interval.

Owner:MINOLTA CO LTD

Test tube cover removal device

InactiveCN103288021AGuaranteed synchronicityImprove work efficiencyTight-fitting lid removalThreaded caps removalEngineeringTesting tubes

A test tube cover removal device comprises a transverse clamping, lifting and cover-opening mechanism. A transverse mounting space and a longitudinal mounting space are formed between the clamping, lifting and cover-opening mechanism and a base. A clamping mechanism is mounted in the longitudinal mounting space, and the transverse mounting space transversely passes through the clamping mechanism. The clamping, lifting and cover-opening mechanism is provided with a transverse cover clamp which can move longitudinally and up and down. A cam is controlled to move by a cam guide plate having a guide slant, so that the cover clamp longitudinally moves to close or open. The cover clamp is driven to ascend and descend by an upper longitudinal telescoping arm of the am guide plate, a test tube cover is clamped by the cover clamp moving longitudinally, and the test tube cover is removed by the cover clamp moving up. The clamping mechanism is provided with a transverse test tube clamp; the cam is controlled to move by the cam guide plate having the guide slant, so that the test tube clamp opens or closes for clamping a test tube. The test tube cover removal device is available for opening covers of test tubes in batches, and available for opening covers of test tubes equal in diameter and different in length.

Owner:无锡特可思衡机贸易有限公司

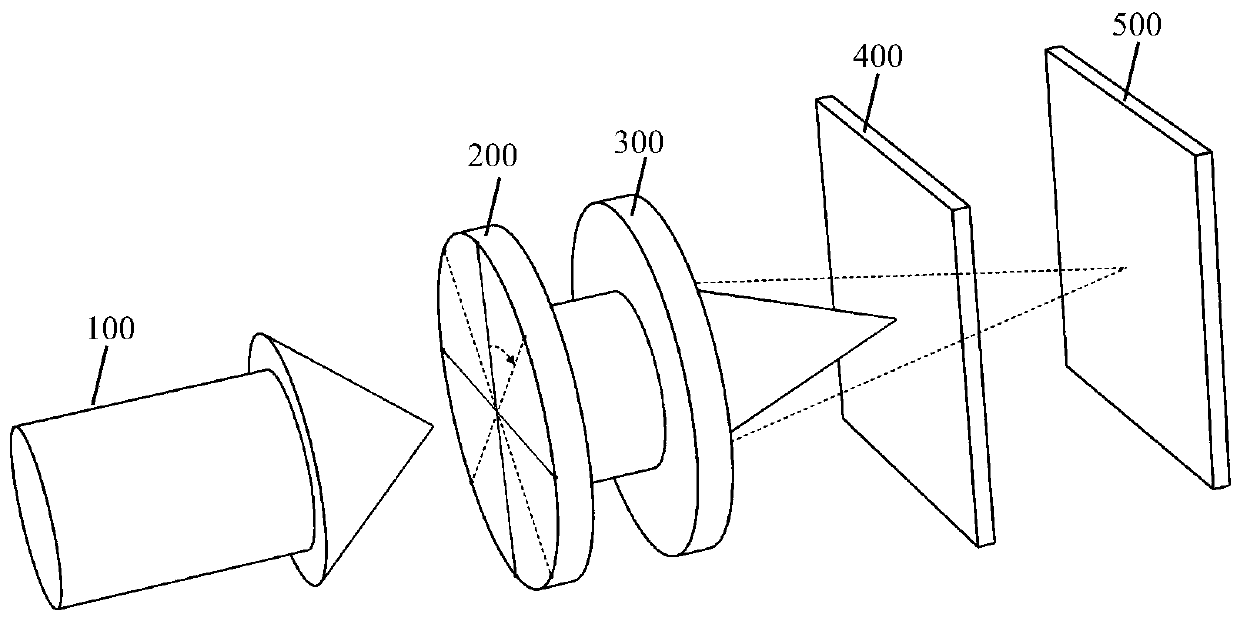

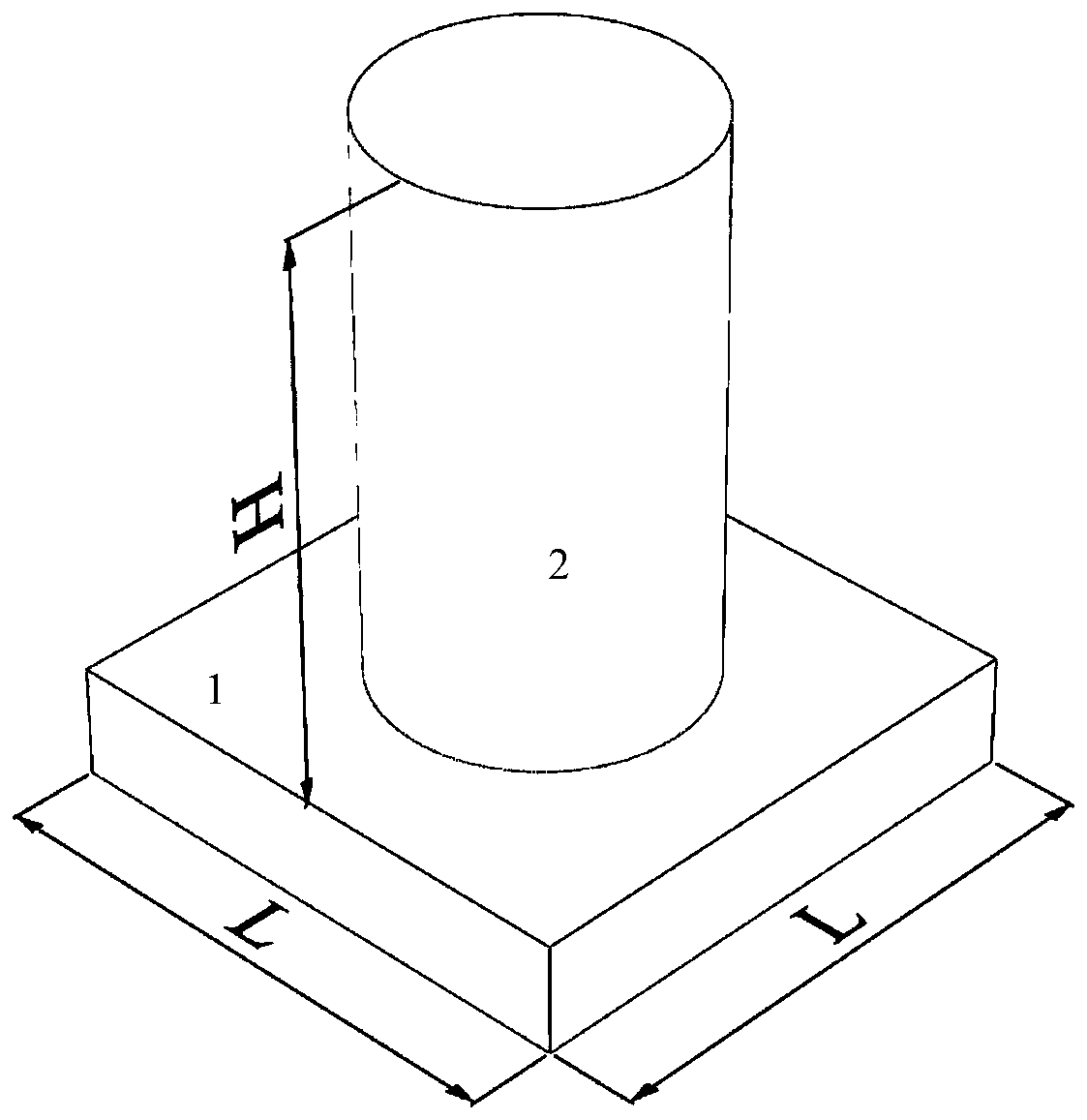

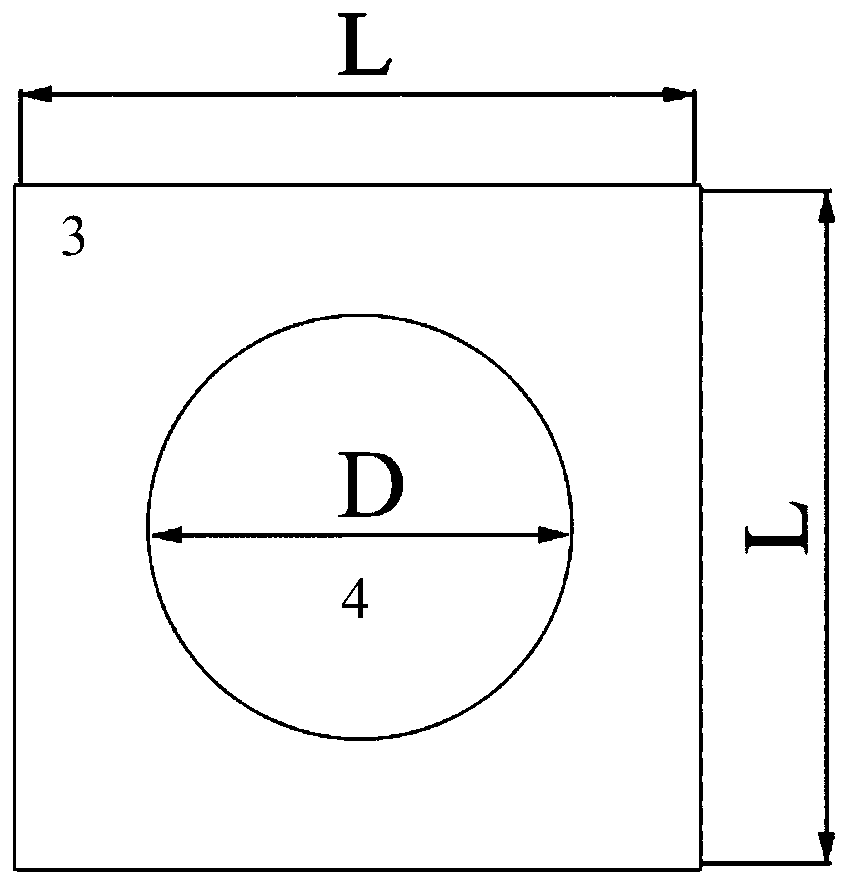

Double-layer dielectric metasurface-based optical zooming system

ActiveCN110161676AAchieve the purpose of zoomingAvoid the need for additional workspaceOptical elementsDielectricComputational physics

The invention discloses a double-layer dielectric metasurface-based optical zooming system. The system comprises a first layer of dielectric metasurface and a second layer of dielectric metasurface, wherein both the two layers of dielectric metasurface are formed by a plurality of basic units through splicing; each basic unit comprises a base plate and a cylindrical dielectric column arranged on the base plate; a mapping relationship exists among the diameters of the cylindrical dielectric columns of each layer of dielectric metasurface, the distances from the cylindrical dielectric columns tothe centers of the dielectric metasurface and the angles between the cylindrical dielectric columns and the dielectric metasurface; incident light is incident to pass through the two layers of dielectric metasurface in sequence; the two layers of dielectric metasurface carry out phase modulation on the incident light in sequence for two times, so as to realize a focusing effect for the incident light; and when the relative rotation angles of the first layer of dielectric metasurface and the second layer of dielectric metasurface change relative to an initial state, focusing focal lengths corresponding to the two layers of dielectric metasurface are changed, and the focusing effect of the two layers of dielectric metasurface for the incident light is changed. The zooming system provided bythe invention is capable of realizing zooming according to the sizes of the rotation angles and realizing large-scale zooming.

Owner:HUAZHONG UNIV OF SCI & TECH

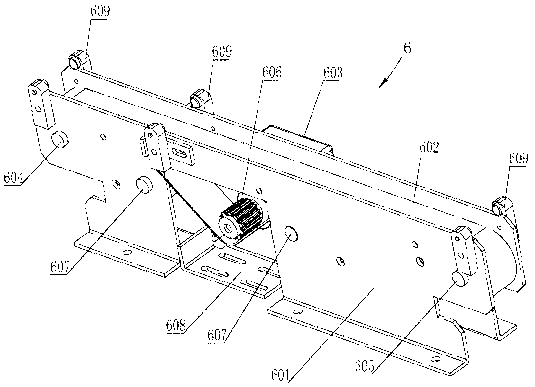

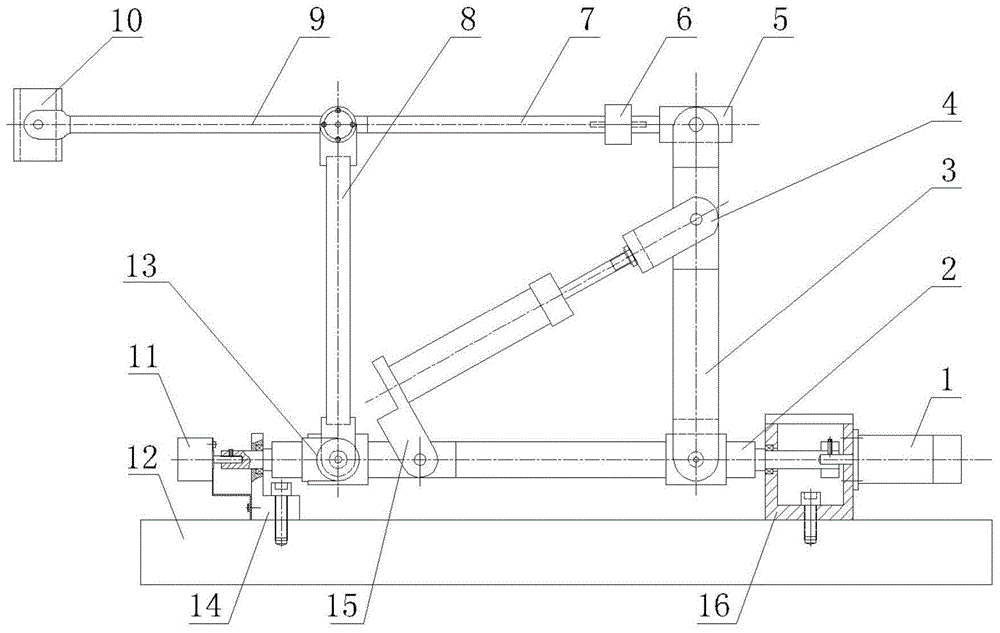

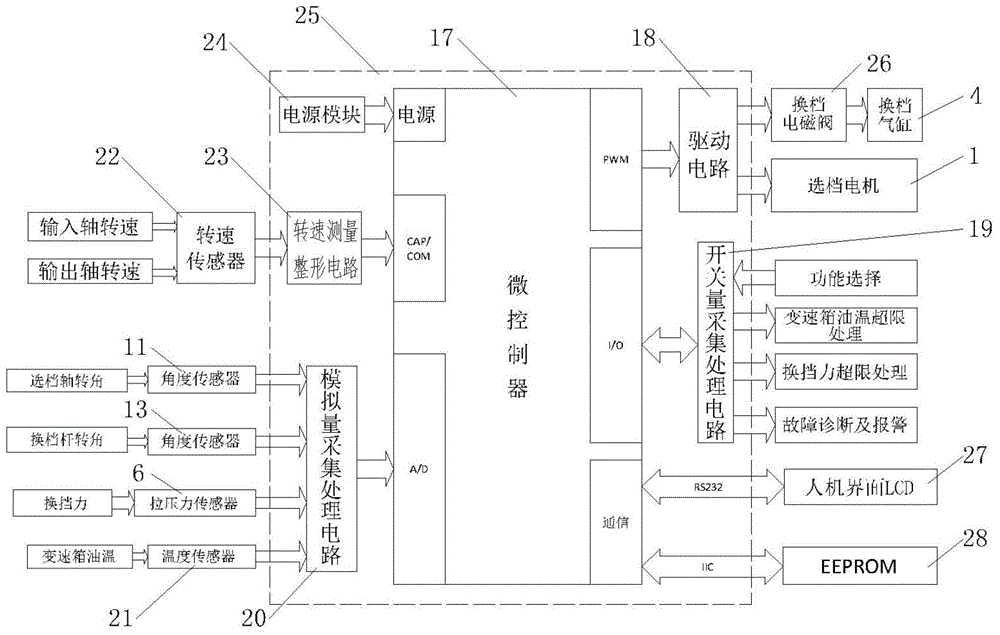

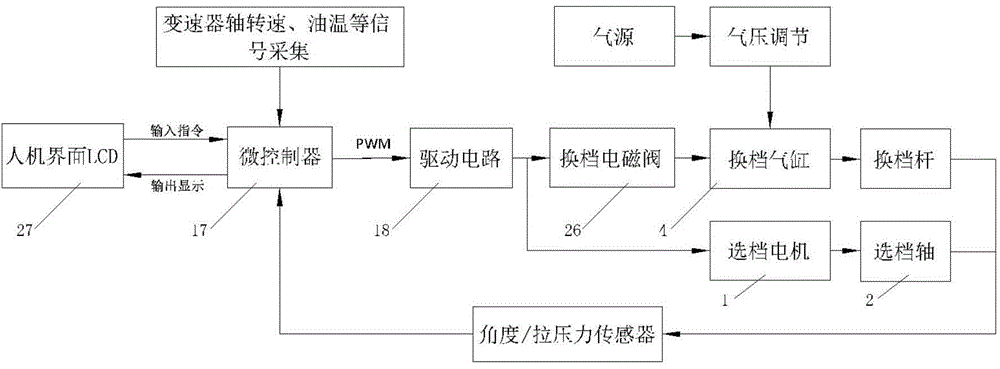

Gear shifting manipulator of automobile synchronizer testbed and control device of gear shifting manipulator

InactiveCN104792521AIncrease elasticityImprove buffering effectVehicle testingMachine gearing/transmission testingLiquid-crystal displayEngineering

The invention discloses a gear shifting manipulator of an automobile synchronizer testbed and a control device of the gear shifting manipulator. The gear shifting manipulator comprises a mounting bottom plate and a four-bar mechanism which is formed by hinge joint of a gear selecting shaft, a gear shifting rocker arm, a middle connecting bar and a gear shifting support bar, the gear selecting shaft is rotatably mounted on the mounting plate, an output shaft of a gear selecting motor is in transmission connection with the gear selecting shaft, a gear shifting air cylinder is hinged between the gear selecting shaft and the gear shifting rocker arm, a gear shifting connection bar is hinged to the upper end of the gear shifting support bar, and a tensile pressure sensor and angle sensors are arranged on the four-bar mechanism respectively. The control device comprises an MCU (micro control unit) and a human-computer interface LCD (liquid crystal display). The gear shifting manipulator is electrically connected with the MCU via the tensile pressure sensor and the angle sensors. The MCU is electrically connected with a gear shafting electromagnetic valve of the gear shifting air cylinder and the gear shifting motor. The human-computer interface LCD is in communication connection with the MCU. The gear shifting manipulator of the automobile synchronizer testbed and the control device of the gear shifting manipulator have the advantages of simplicity in operation, high positioning precision, precise controllability, stability in operation and capability of simulating a gear shifting effect of a human hand better.

Owner:JILIN UNIV

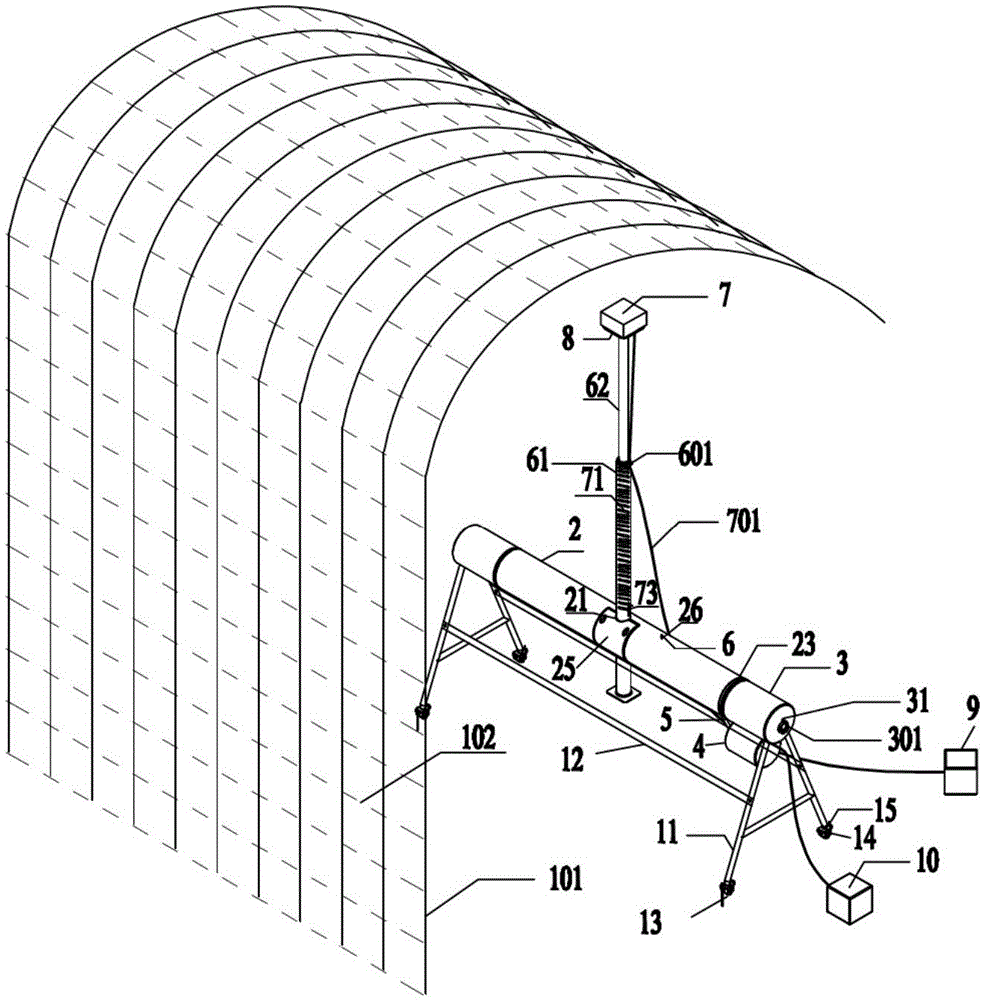

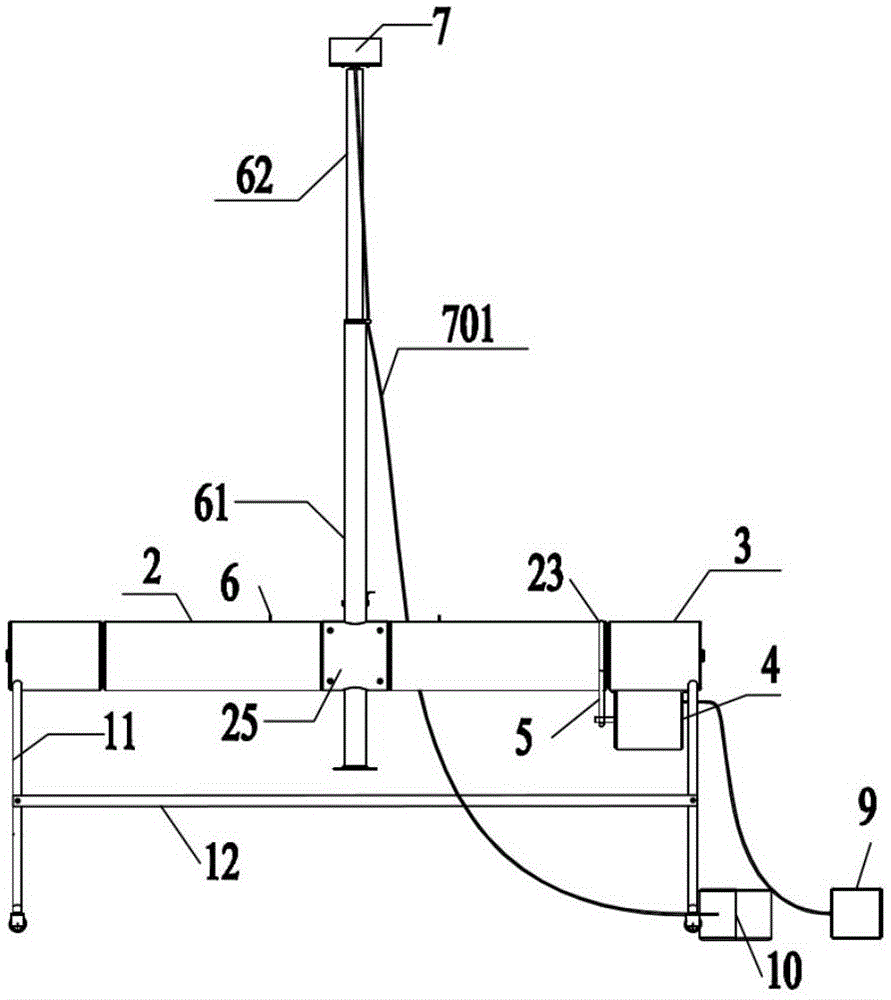

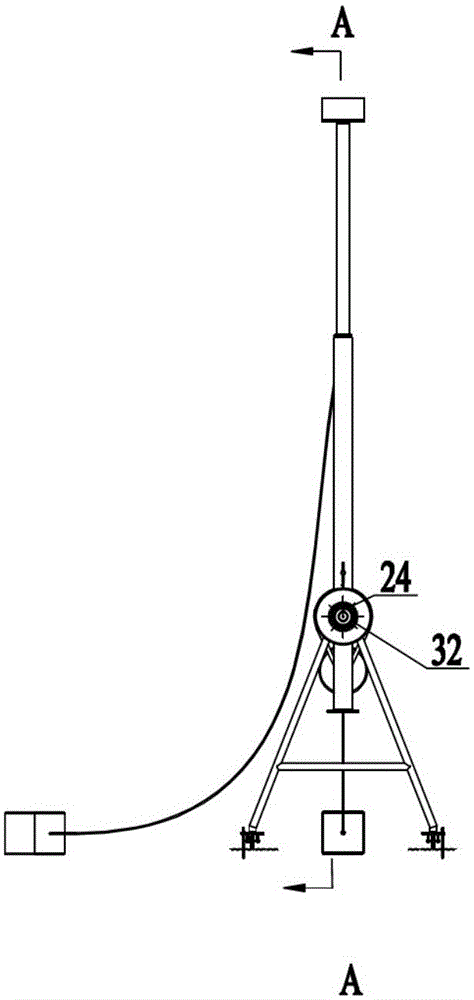

Exploration support, exploration device and exploration method used for detection geology of surrounding rocks of roadway

ActiveCN105137494AObserve rotation angleGuaranteed stabilityDetection using electromagnetic wavesLaser rangingEngineering

The invention discloses an exploration support, an exploration device and an exploration method used for detection geology of surrounding rocks of a roadway. The exploration device comprises a laser range finder, an LTD ground penetrating radar and an exploration support. The exploration support comprises a movable support, an axially rotating support, a radially rotating support and a driving device. The axially rotating support is arranged on and is in rotating fit with the movable support. The radially rotating support crosses the axially rotating support. The radially rotating support is telescopic along the axial direction itself. The driving device drives the axially rotating support and the radially rotating support to rotate. Compared with the prior art, the exploration support, the exploration device and the exploration method are advantageous in that continuous and precise exploration can be performed on the cross section of the roadway and detection results can be precisely positioned, thereby facilitating formation of a precise and effective three-dimensional geology variation diagram of the surrounding rocks of roadway in the region.

Owner:ANHUI UNIV OF SCI & TECH

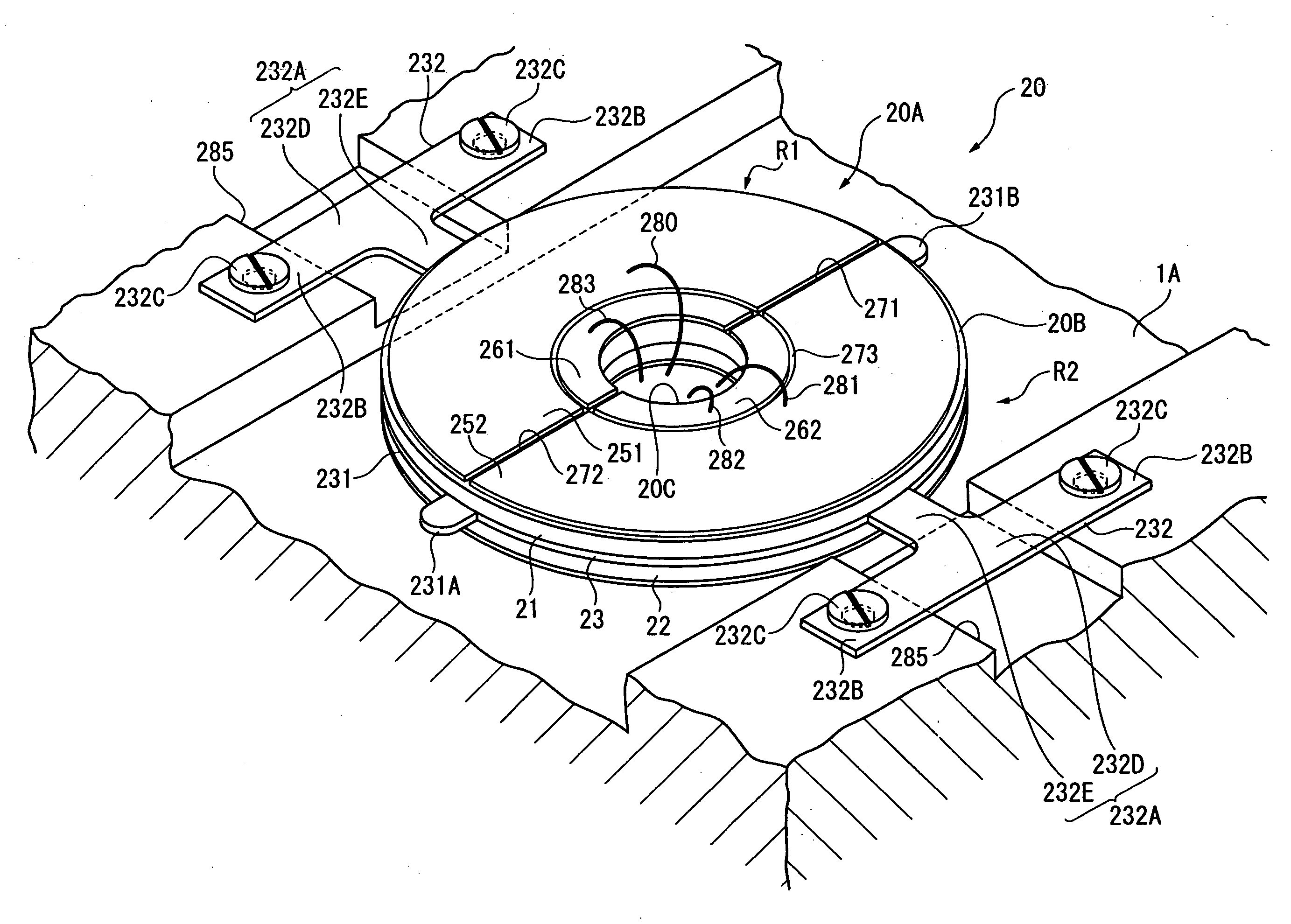

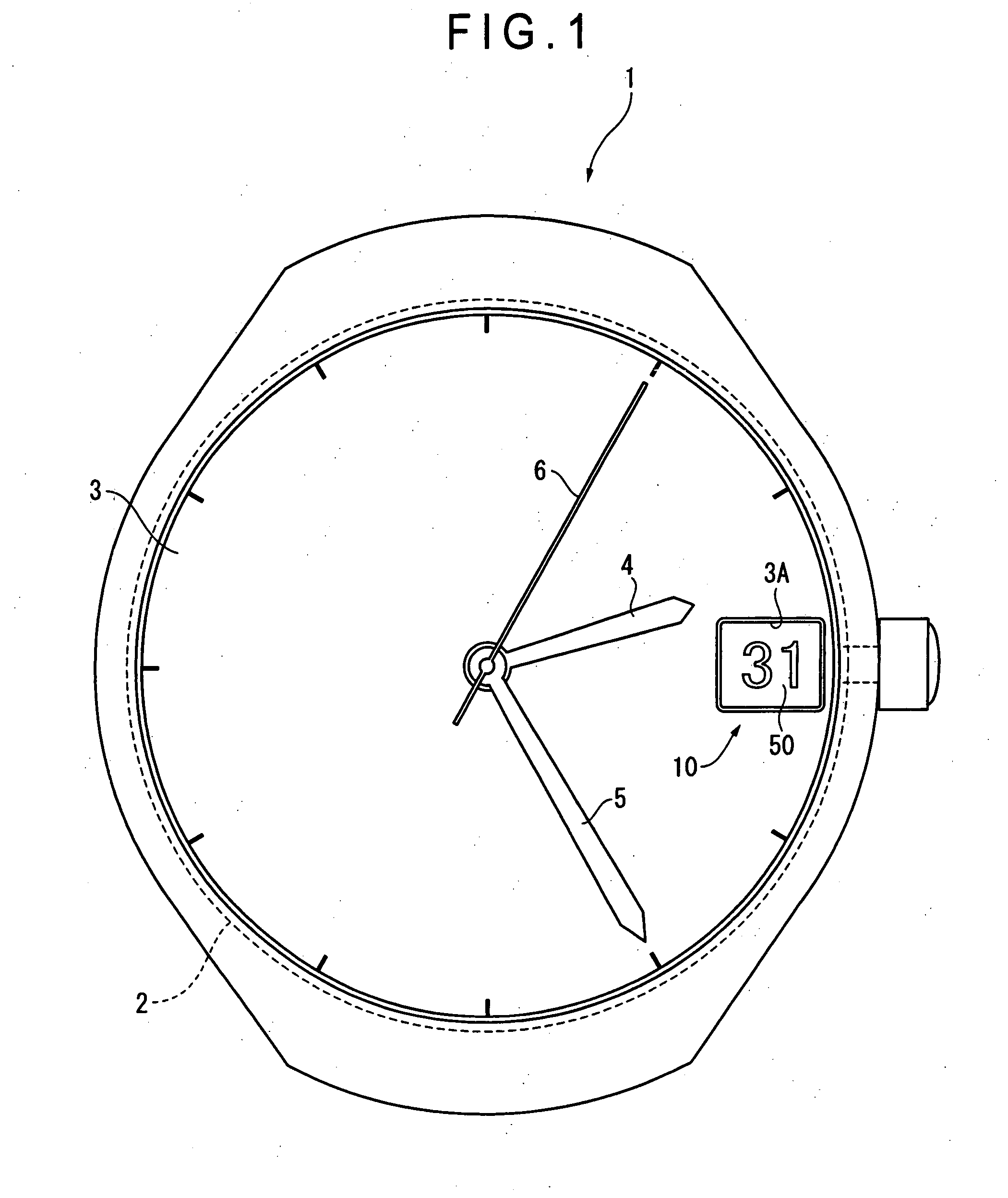

Piezoelectric actuator, drive control method of piezoelectric actuator, and electronic device

InactiveUS20070194660A1Easy to controlDrive stabilityElectric indicationPiezoelectric/electrostriction/magnetostriction machinesPhase differencePiezoelectric actuators

A piezoelectric actuator includes: a ring-shaped piezoelectric element, vibration of the piezoelectric element being transmitted to an object; a first vibration area and a second vibration area provided on both sides of a bisector bisecting the piezoelectric element along a diameter of the piezoelectric element, the first vibration area and the second vibration area being respectively provided with at least one drive electrode to which a drive signal is supplied, the drive electrode being arranged substantially axisymmetrically with respect to the bisector, the drive signal including a phase-advance drive signal and a phase-delay drive signal having a predetermined drive phase difference, the phase-advance drive signal that is phase-advanced relative to the phase-delay drive signal being supplied to one of the first vibration area and the second vibration area and the phase-delay drive signal that is phase-delayed relative to the phase-advance drive signal being supplied to the other of the first vibration area and the second vibration area; and a detection electrode that detects vibrating condition of the piezoelectric element to output a vibration signal, the detection electrode being provided on at least one of the first vibration area and the second vibration area to which the phase-delay drive signal is supplied, the drive of the piezoelectric actuator being controlled based on a detected phase difference between one of the phase-advance drive signal and the phase-delay drive signal and the vibration signal.

Owner:SEIKO EPSON CORP

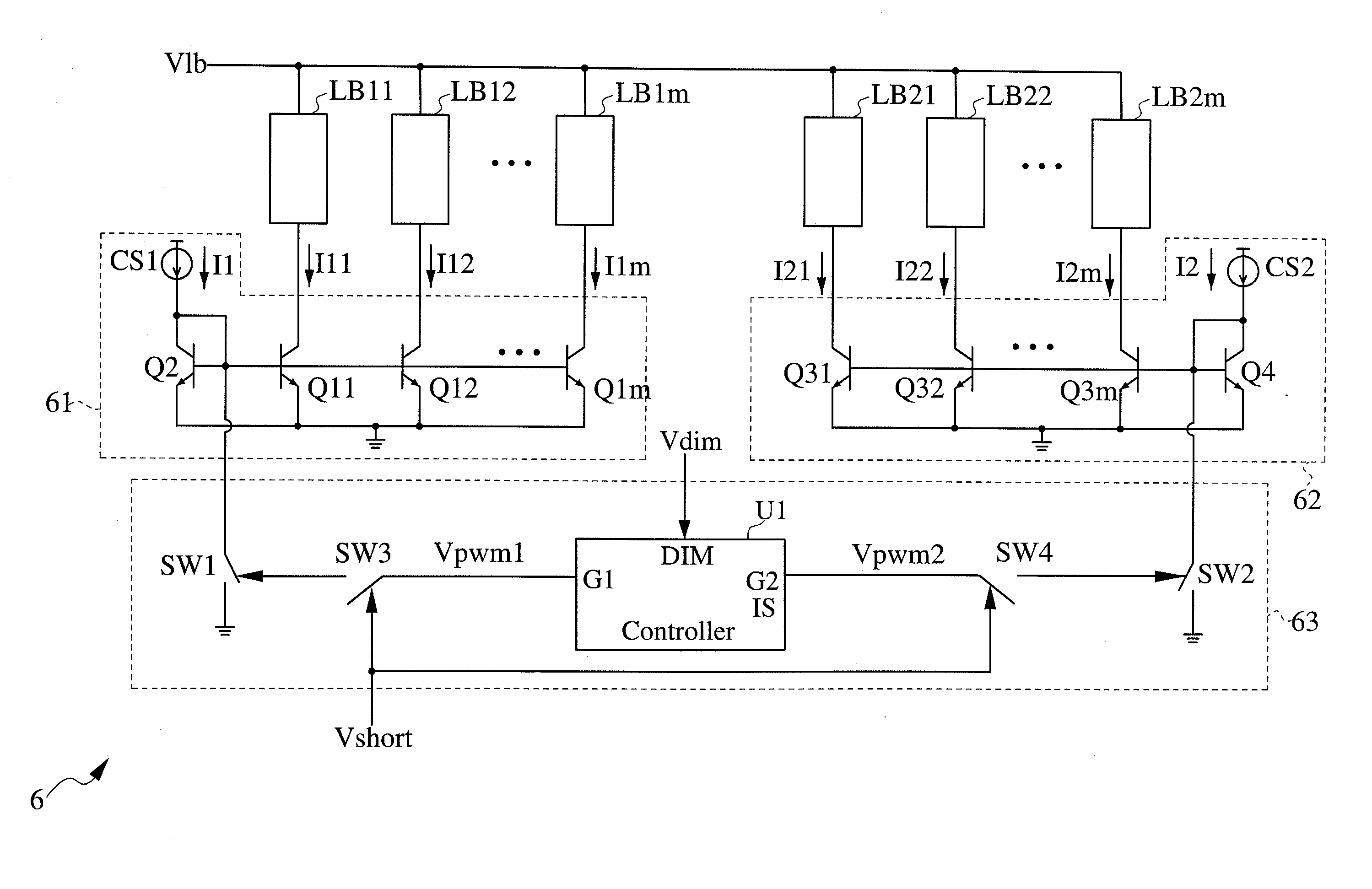

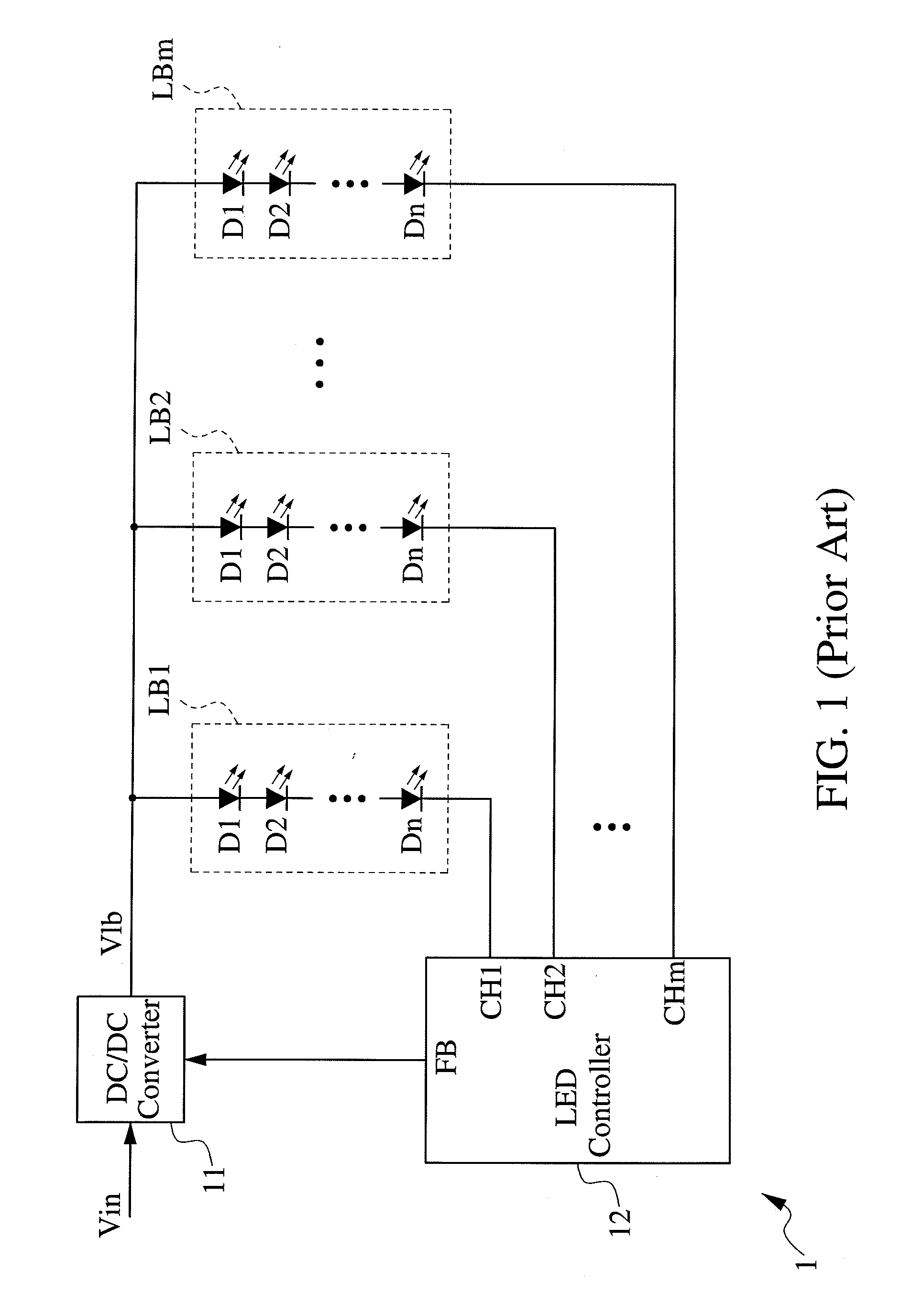

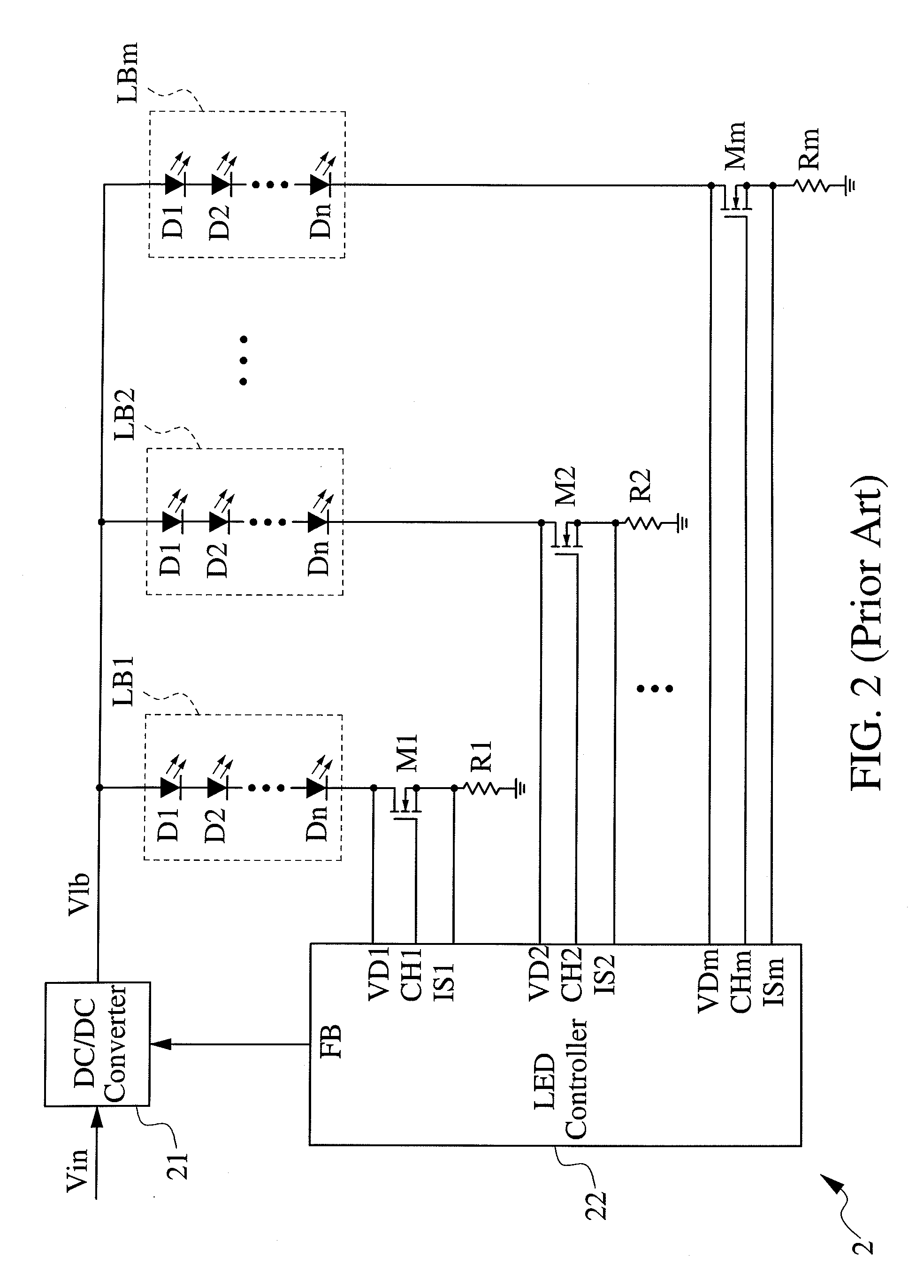

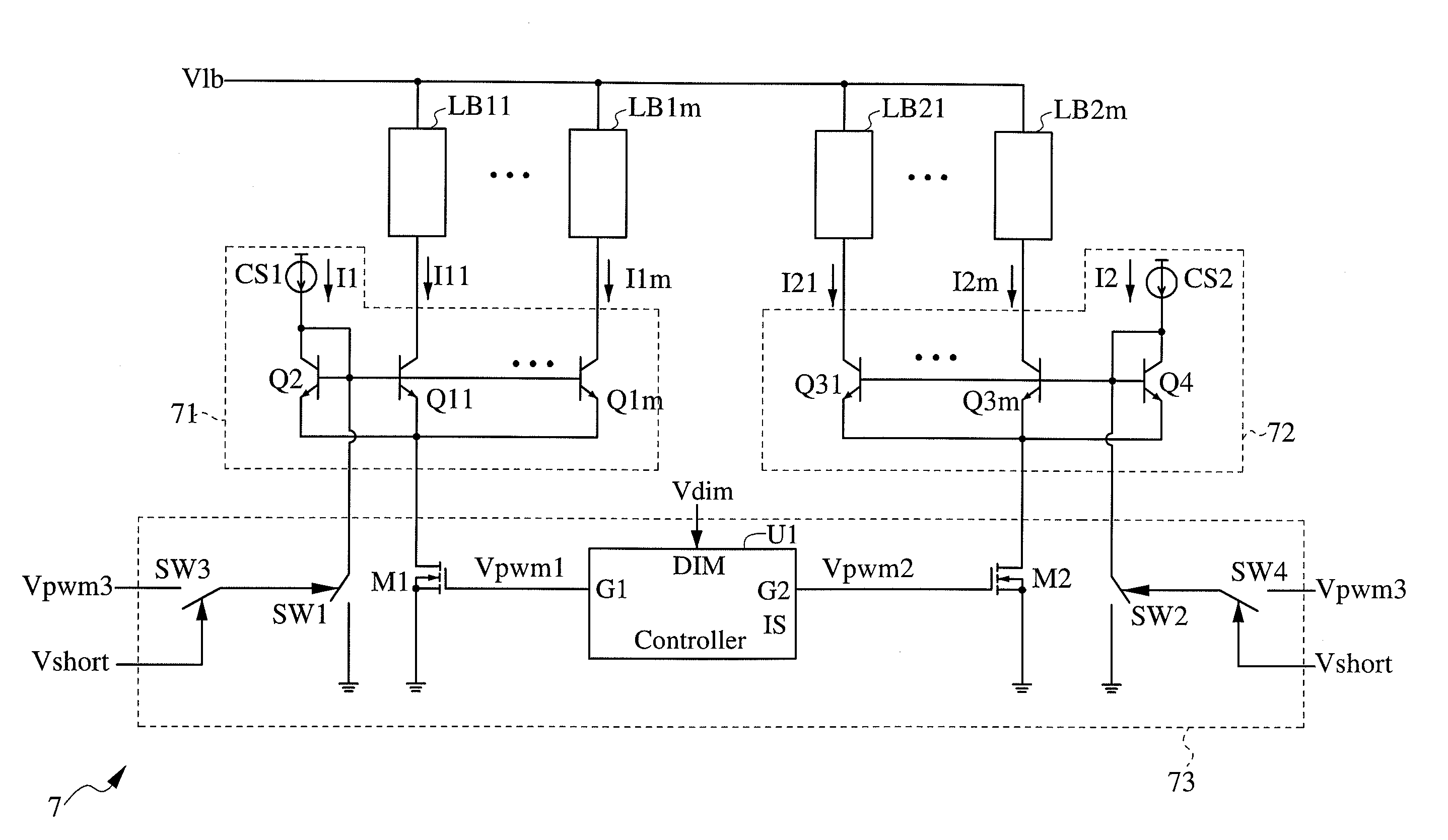

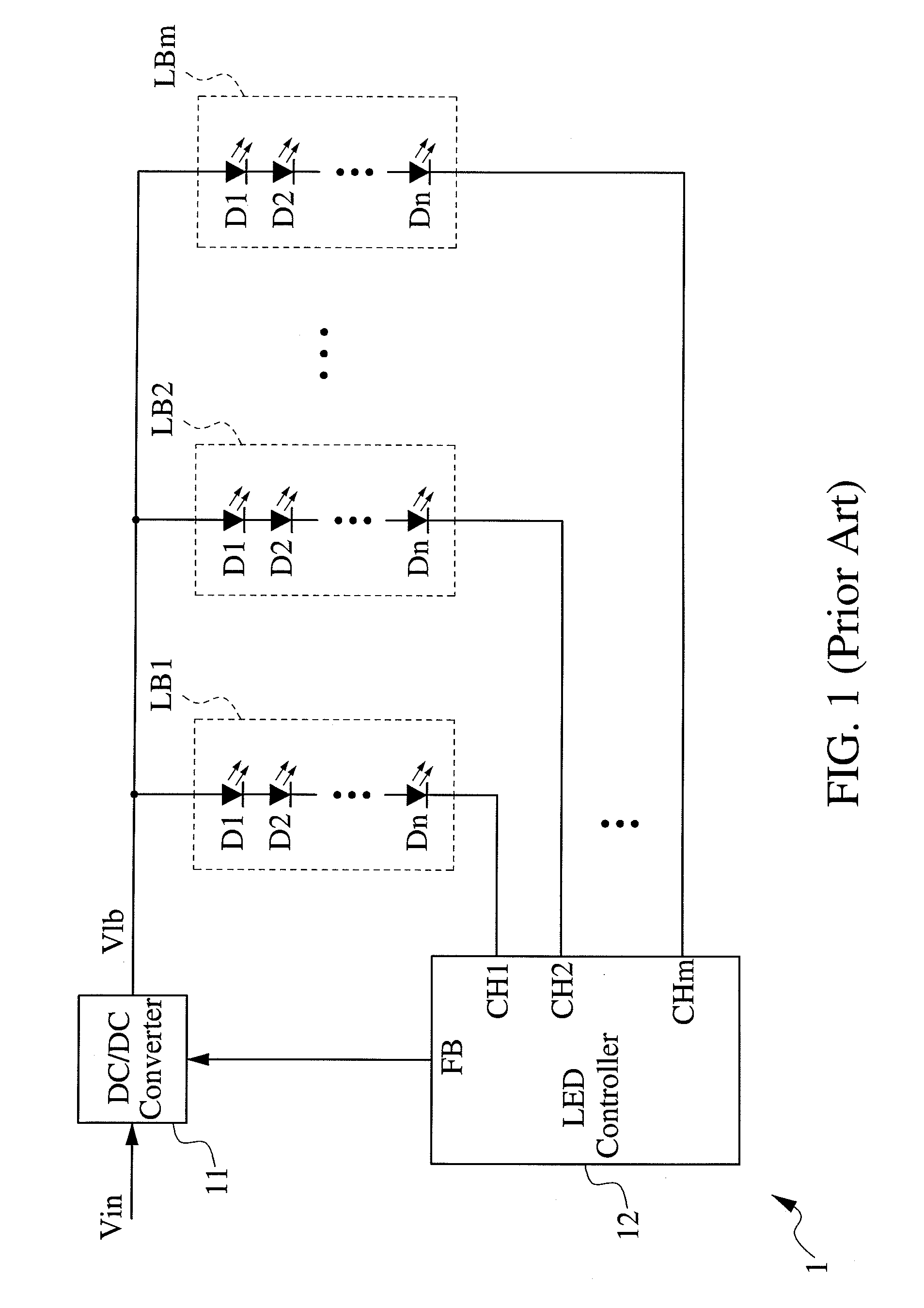

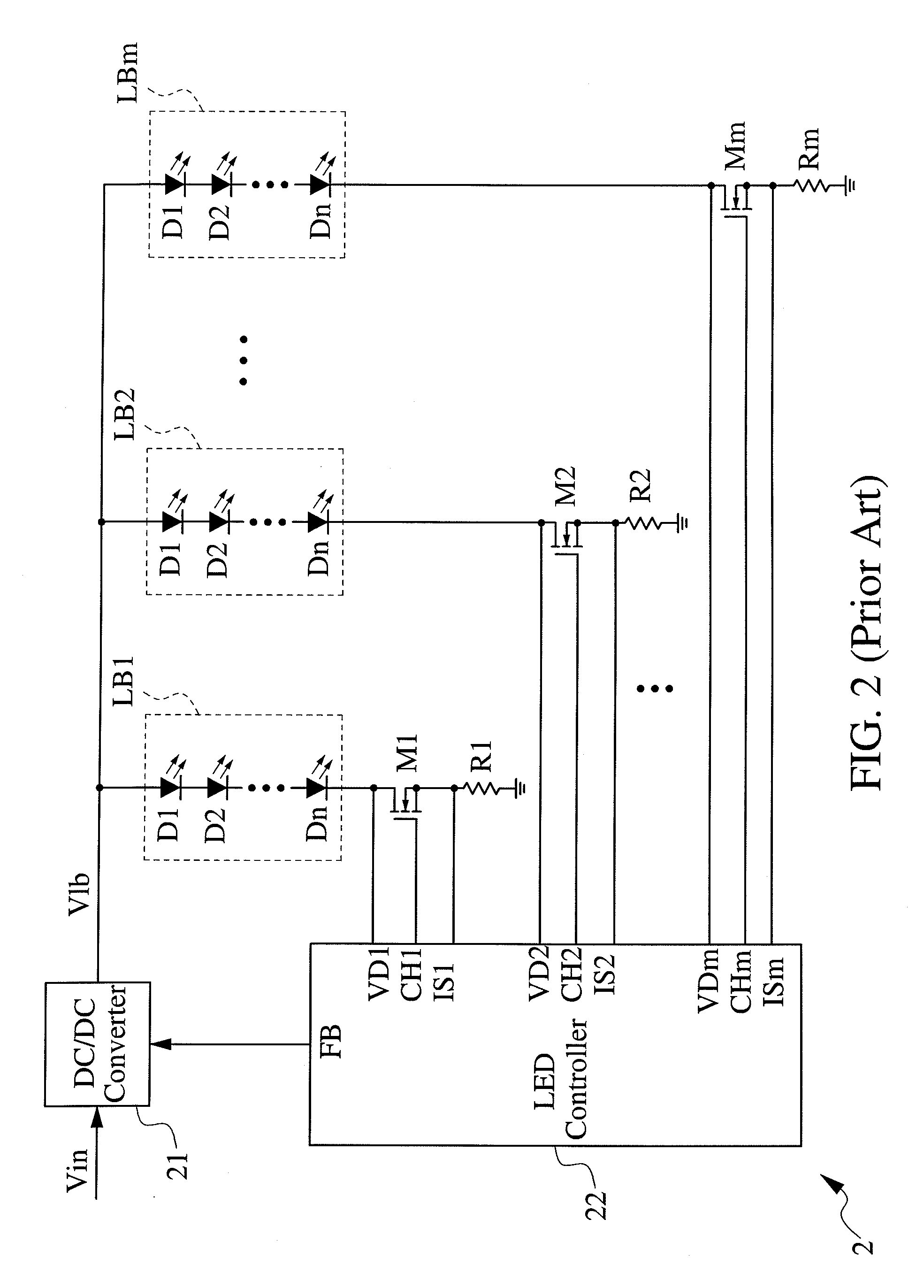

Light-emitting Diode (LED) Driving Circuit

ActiveUS20110096055A1Simple drive structureReduce componentsElectrical apparatusElectroluminescent light sourcesPower flowEngineering

A light-emitting diode (LED) driving circuit for driving a plurality of first lightbars and a plurality of second lightbars includes a first current mirror, a second current mirror and a control circuit. The first current mirror, if enabled, balances current among the first lightbars. The second current mirror, if enabled, balances current among the second lightbars. During a first period, the control circuit disables the second current mirror and adjusts the duration of enabling the first current mirror according to a dimming signal. During a second period, the control circuit disables the first current mirror and adjusts the duration of enabling the second current mirror according to the dimming signal. Therefore, only first or second lightbars are driven in each period.

Owner:TOP VICTORY INVESTMENTS

Light-emitting diode (LED) driving circuit

ActiveUS8525774B2Simple drive structureReduce componentsElectrical apparatusElectroluminescent light sourcesPower flowEngineering

Owner:TOP VICTORY INVESTMENTS

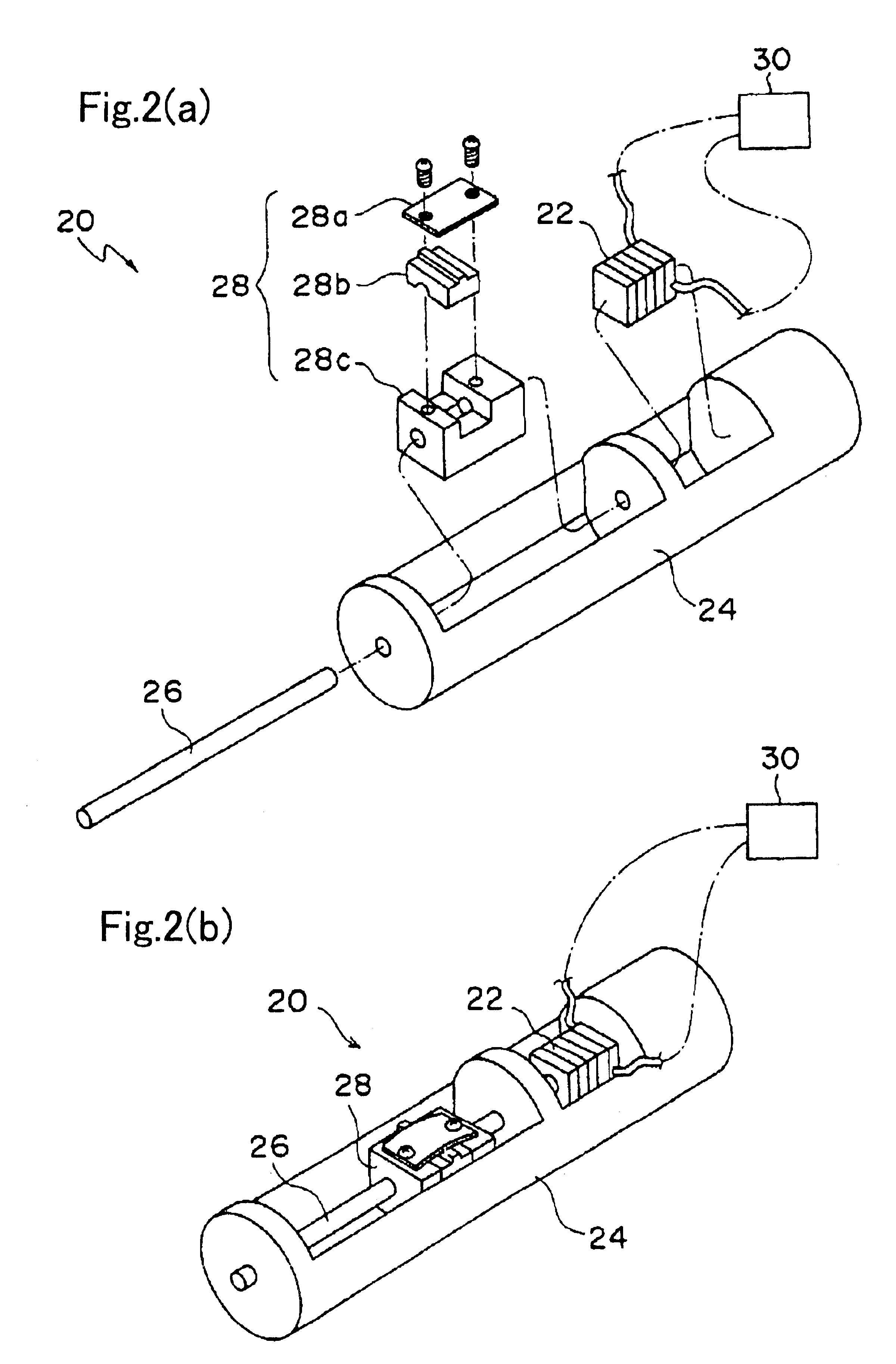

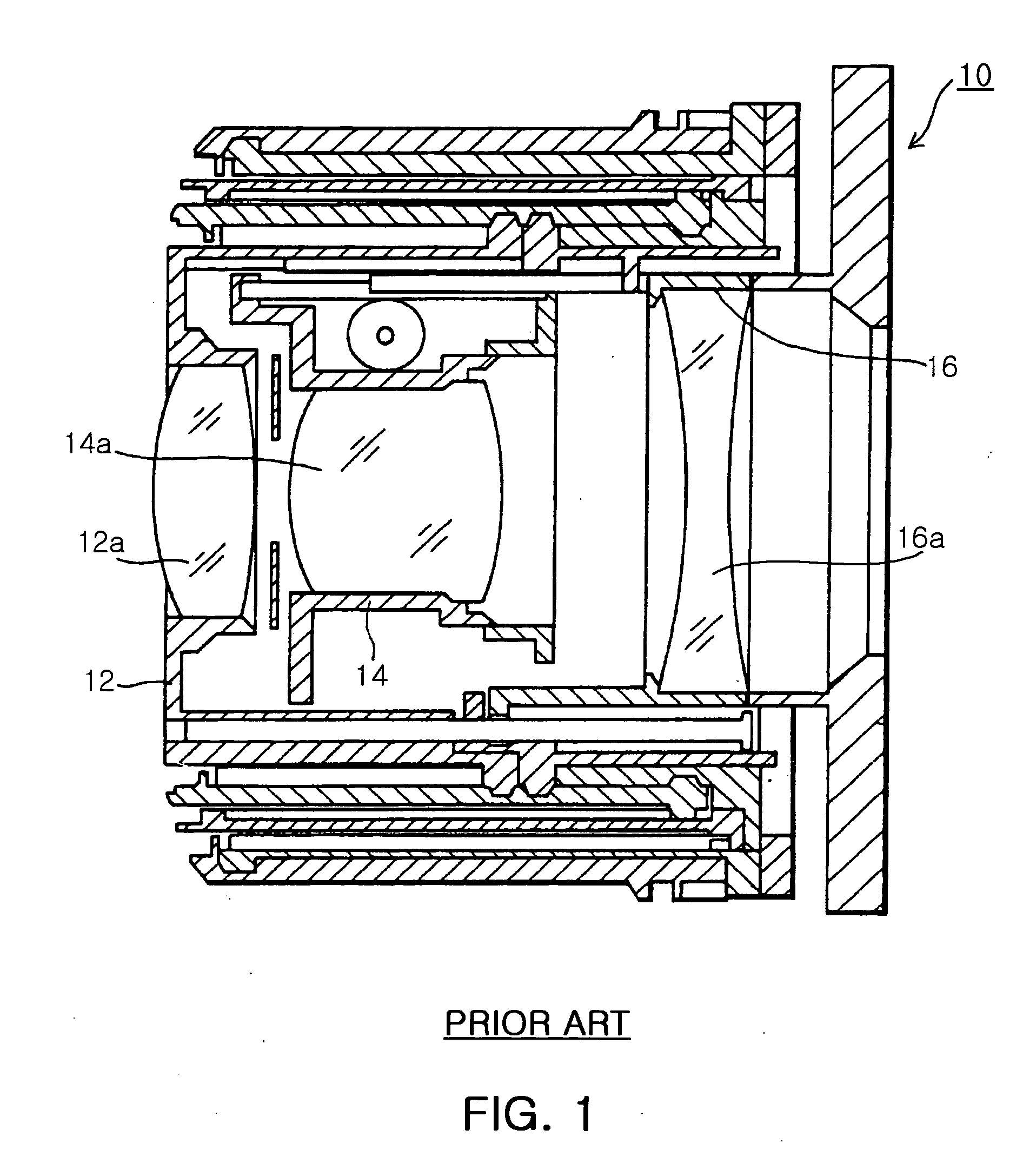

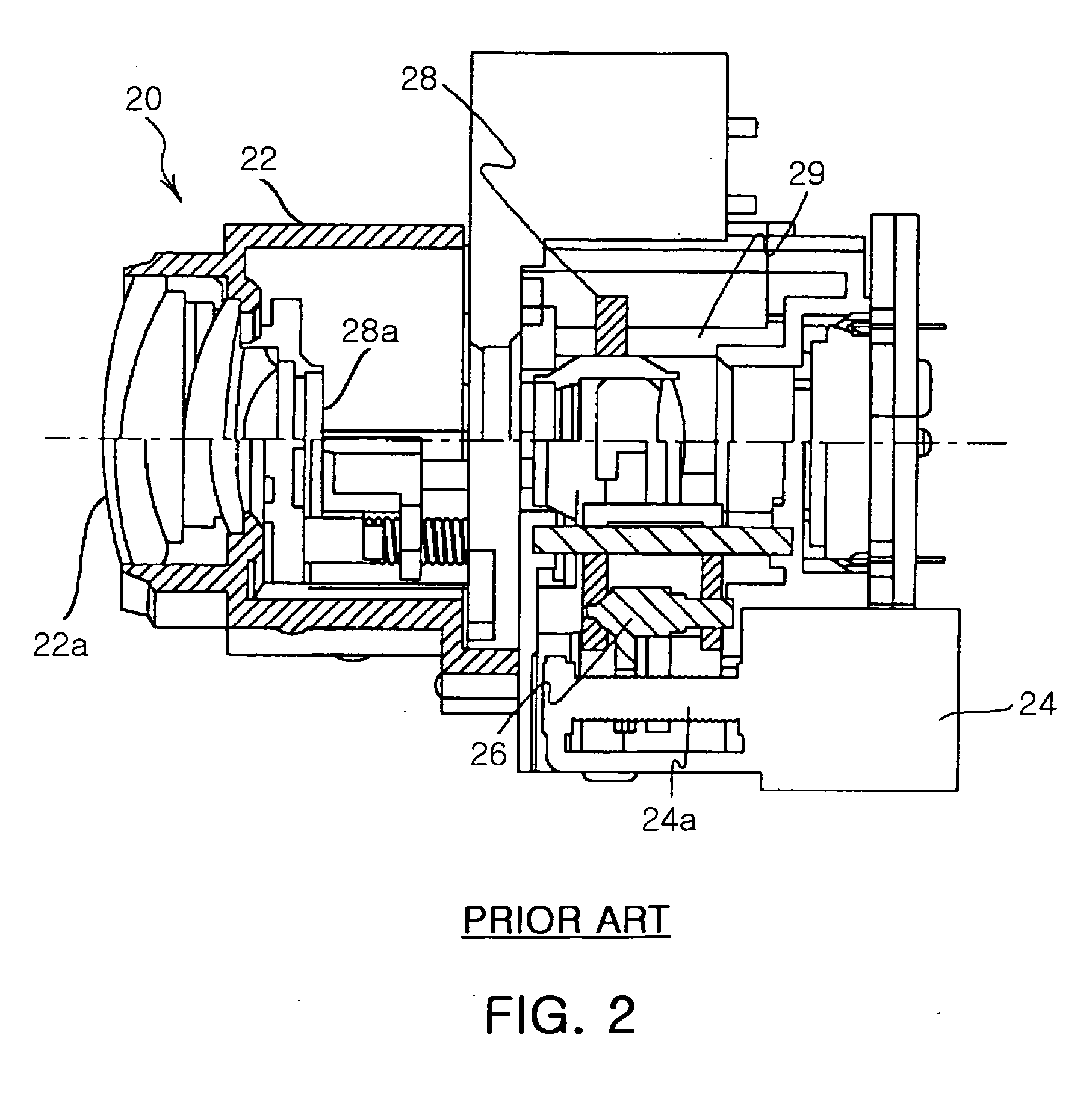

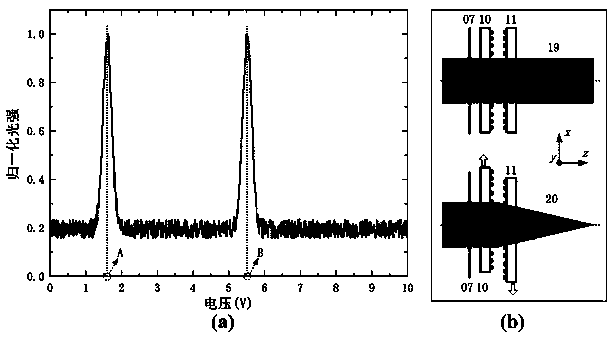

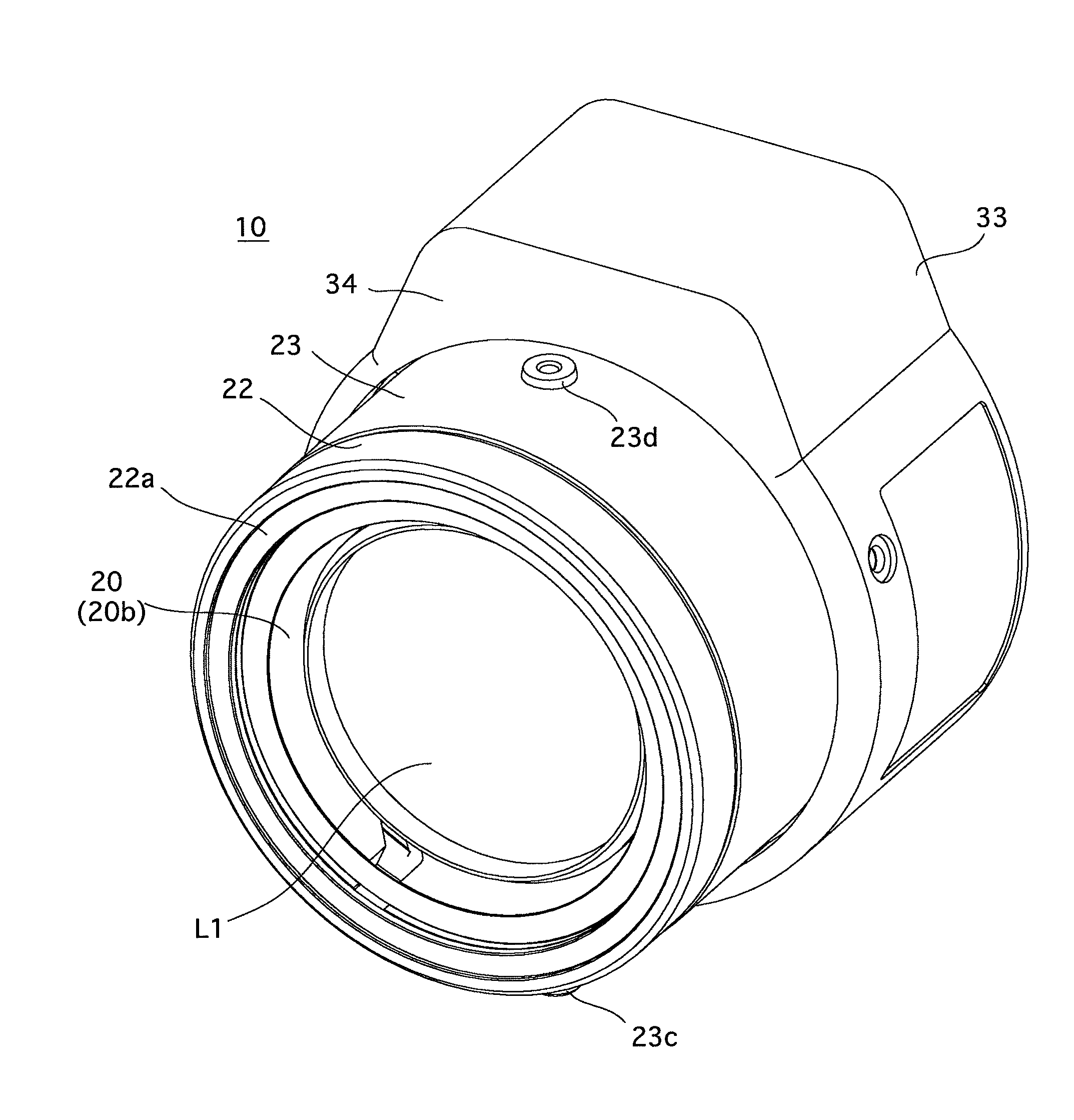

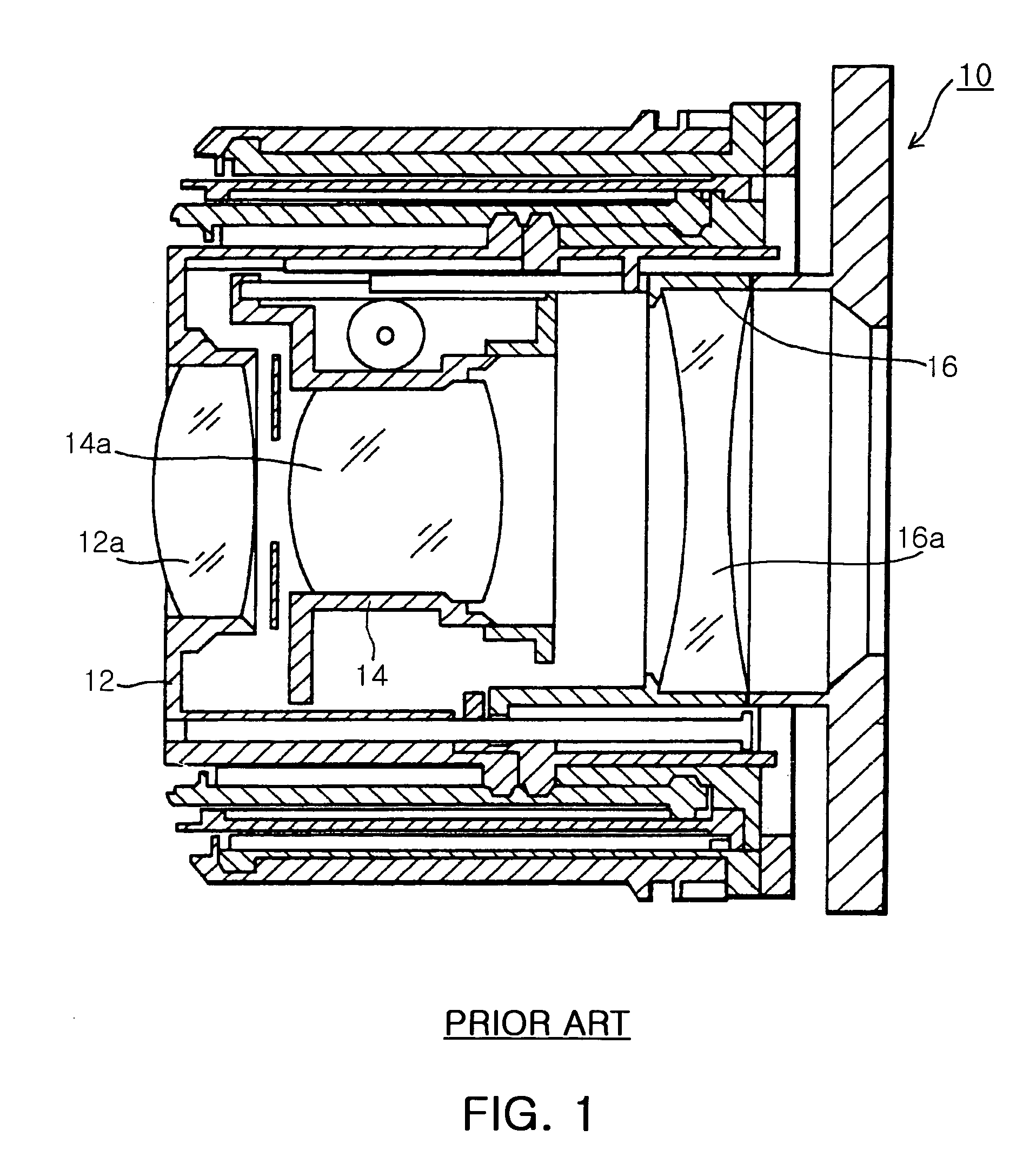

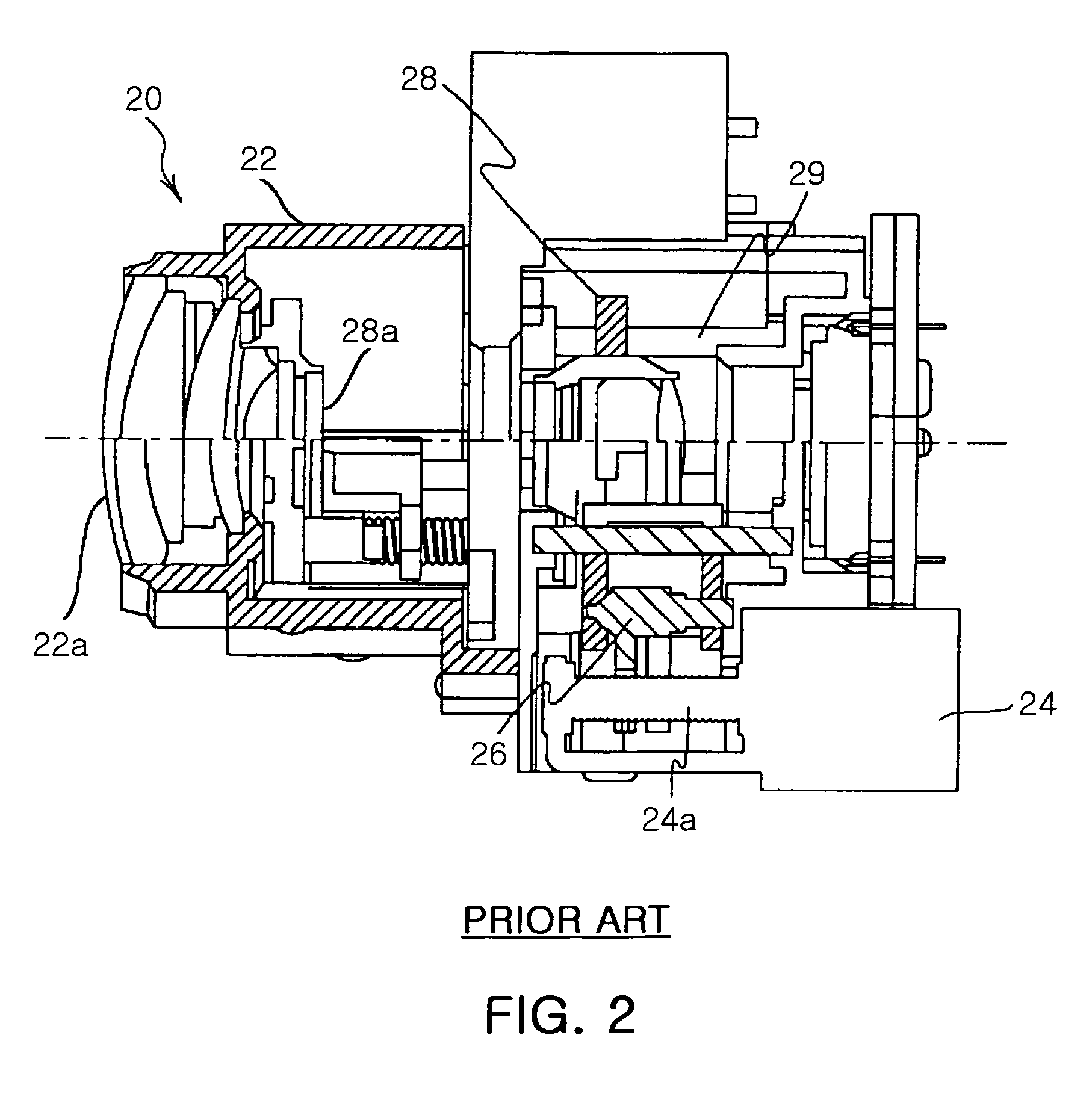

Lens transfer device

ActiveUS20070091463A1Simple drive structureMicro sizePiezoelectric/electrostriction/magnetostriction machinesProjector focusing arrangementInterior spaceVoltage

The invention provides a lens transfer device including at least one lens and a lens barrel. The lens barrel has a lens receiving part with the lens arranged in an inner space thereof and an extension extending radially from an outer surface of the lens receiving part. An actuator has a body and an output member at a leading end of the actuator to contact the extension, and is adapted to expand / contract and bend in response to an external supply voltage to provide a driving force necessary for transfer of the lens barrel through the output member. A pressing member has a free end contacting a rear end of the actuator to force the actuator against the extension, and a guide guides the transfer of the lens barrel along an optical axis.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

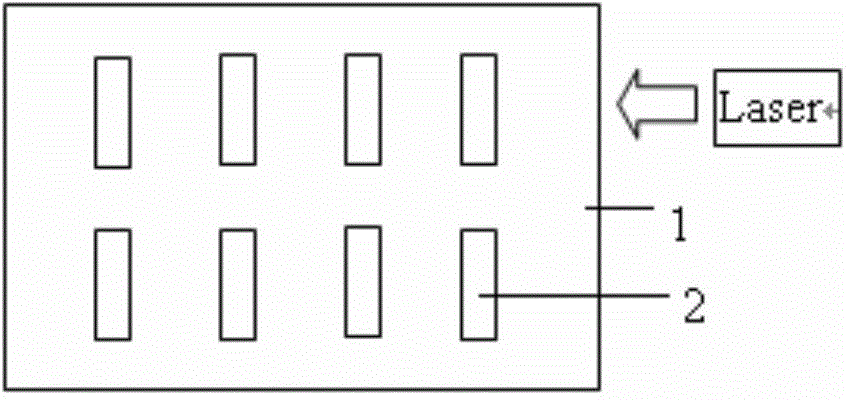

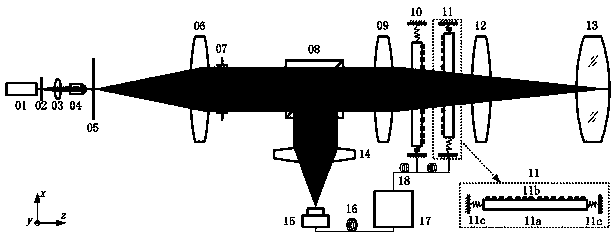

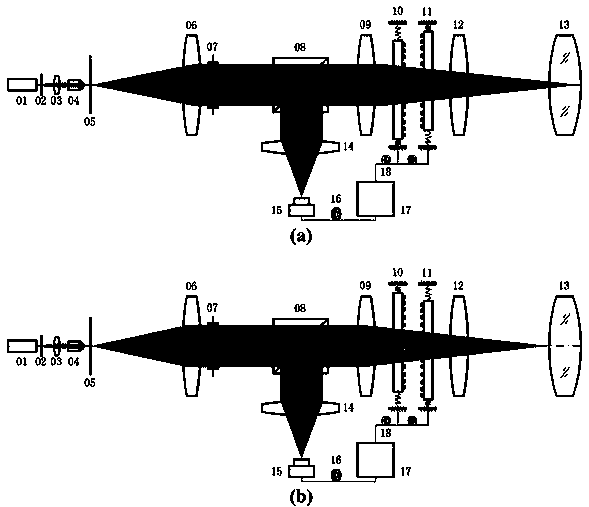

Solid-state zoom lens-based non-contact laser thickness measuring device and method

ActiveCN108827172AThe system is compactSimple and compactUsing optical meansData transmissionTransmission line

The invention belongs to the optical measurement field and relates to a solid-state zoom lens-based non-contact laser thickness measuring device and method. The device is composed of a laser, a lightintensity adjustable attenuator, a first collimating lens, a micro lens, a spatial filter, a second collimating lens, a diaphragm, a beam splitting prism, a first aberration correcting lens, a first solid-state zoom lens assembly, a second solid-state zoom lens assembly, a second aberration correcting lens, an object to be tested, a focusing lens, a photoelectric detector, a data transmission line, a signal control, data processing and display module, and a control signal transmission line. The solid-state zoom lens-based non-contact laser thickness measuring device of the invention is simplerand more compact than a conventional zoom lens group; and the solid-state zoom lens-based non-contact laser thickness measuring device of the invention is more stable, has superior performance, and is close to a diffraction limit compared with a liquid lens. According to the solid-state zoom lens-based non-contact laser thickness measuring device and method, the focal length of the solid-state zoom lens can be adjusted through a full-electronically controlled closed-loop, so that the focusing position of an outgoing beam on the object to be tested is changed; the position of the maximum valueof reflected light intensity is recorded through using a laser self-collimation effect; and therefore, the thickness measurement of the object to be measured can be realized, and the object to be measured is not required to be accurately moved or adjusted during a measurement process.

Owner:NAT UNIV OF DEFENSE TECH

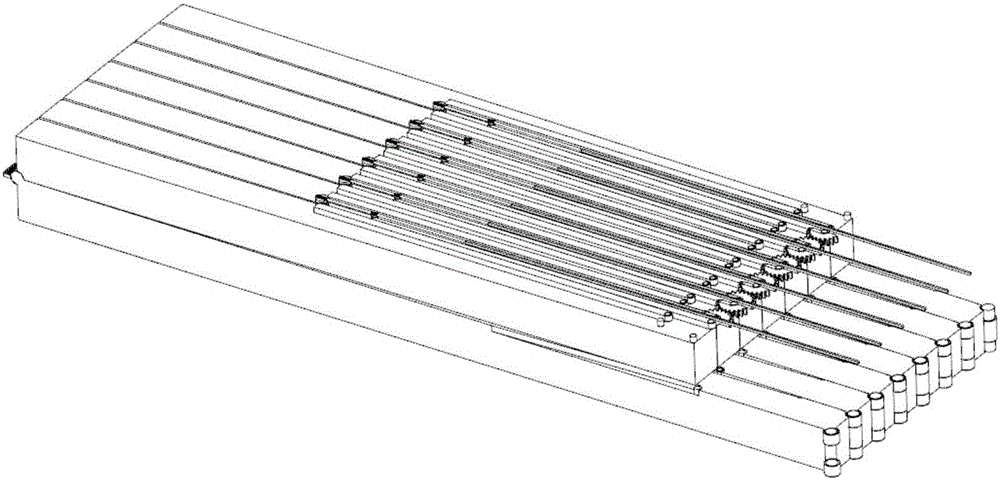

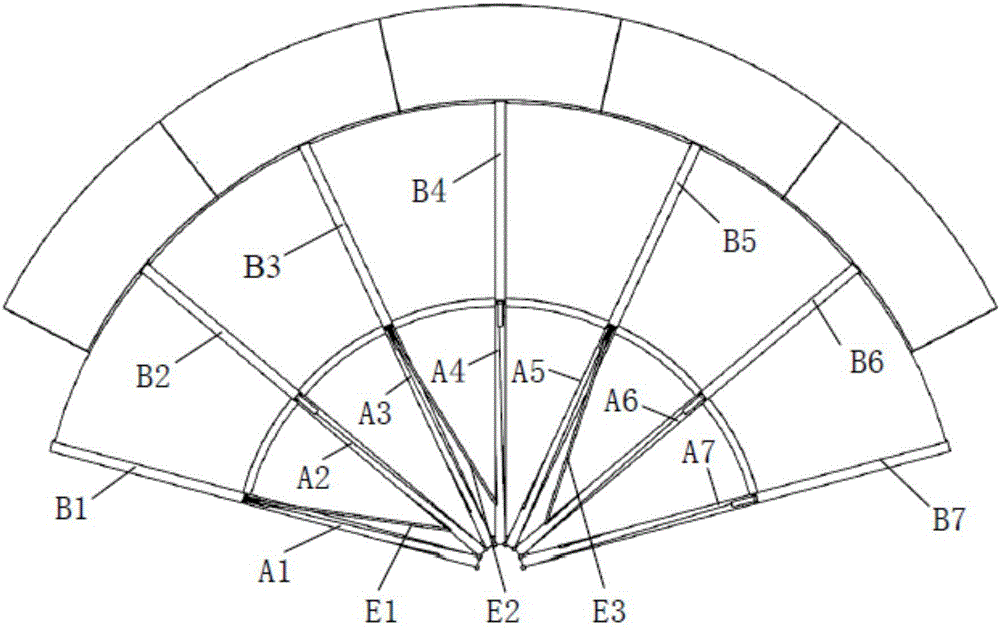

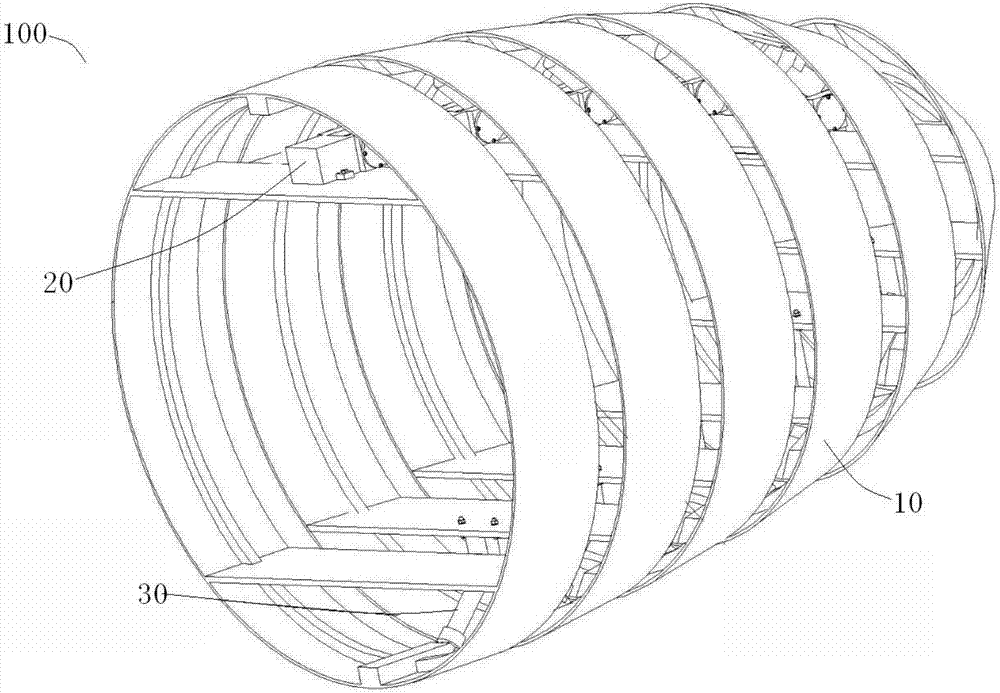

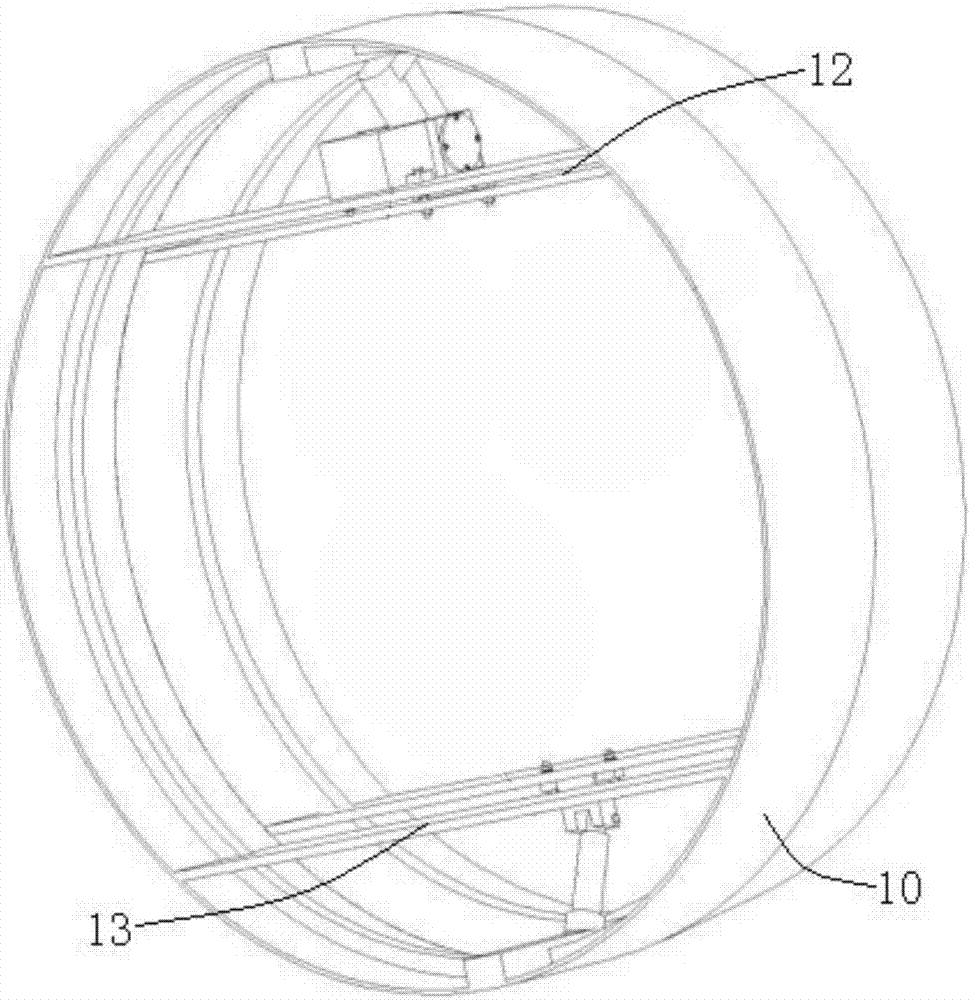

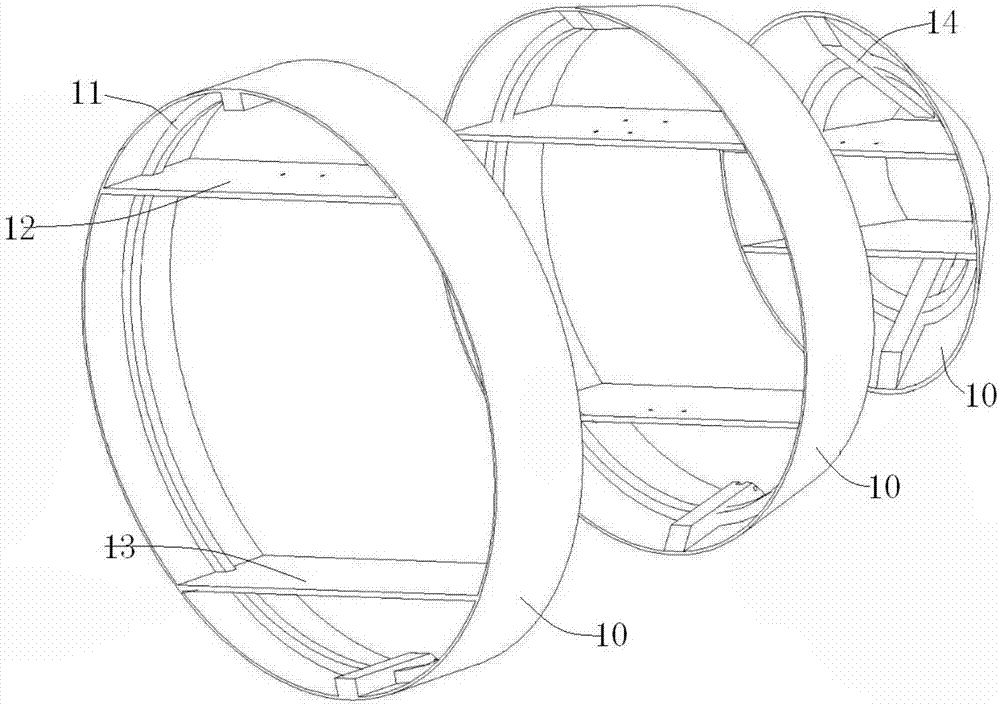

Space deployable mechanism designed on basis of posterior wing deployable mechanism of dermaptera insect earwigs

ActiveCN106364700AReduce weightImprove controllabilityCosmonautic vehiclesCosmonautic partsFiberPolyester

The invention discloses a space deployable mechanism designed on the basis of a posterior wing deployable mechanism of dermaptera insect earwigs. The space deployable mechanism is applied to a reflector of a satellite antenna and structurally comprises a first-grade rod set, a second-grade rod set, a third-grade rod set, a supporting rod set, a push-pull rod set, a combined hinge mechanism and a polyester film. End portions of rods in the first-grade rod set are sequentially connected through hinges. The second-grade rod set comprises rods and gears, and the gears are connected with the second-grade rods and then connected with the first-grade rods. Rods in the third-grade rod set are connected with the rods in the second-grade rod set through supporting rods. The rods in the first-grade rod set are driven so that the whole mechanism can be deployed. By the adoption of the space deployable mechanism, controllable folding and deployment of the satellite antenna of a spacecraft can be achieved, and the space deployable mechanism has the beneficial effects that the containing ratio is relatively large, and meanwhile a carbon fiber material is selected and used, so that the whole space deployable mechanism is small in weight, high in strength, good in stability and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Robot clamping tool

InactiveCN110340916AWide applicabilitySimple drive structureGripping headsEngineeringLocking mechanism

The invention discloses a robot clamping tool. The robot clamping tool comprises a base disc, a drive disc cooperating with the base disc in a rotation mode, a plurality of clamping arms arranged on the base disc and an unloading ring arranged on the drive disc, wherein the unloading ring drives clamp arms to swing and form an opening or clamping state, a dynamic locking mechanism is arranged on the drive disc and applies locking force to the unloading ring, the unloading ring and the drive disc cooperate in a transmission mode when relative torque of the unloading ring to the drive disc is smaller than locking torque of the dynamic locking mechanism, and the unloading ring overcomes the locking force and rotates relatively to the drive disc when the relative torque of the unloading ring to the drive disc is larger than the locking torque of the dynamic locking mechanism. The robot clamping tool has a clamping force unloading function, can automatically unload clamping force, and prevents the problem that the clamping force is large and damages a workpiece. The robot clamping tool drives the plurality of the clamp arms to synchronously rotate through rotation of the drive disc, anddue to the simple drive structure, the structure of the robot clamping tool is greatly simplified, and then the clamping arms are unified in motion, and synchronously clamp the workpiece, and therefore stress on the outer circle of the workpiece is uniform.

Owner:CHONGQING UNIV OF ARTS & SCI

Lighting device for display device, display device and television receiver

InactiveUS7615935B2Simple drive structureLow costPoint-like light sourceElectric discharge tubesTelevision receiversDisplay device

A lighting device for a display device includes a plurality of light sources, a power source arranged to provide drive power for the light sources, a common electrode arranged to supply the drive power to the plurality of light sources, a plurality of holder electrodes arranged to hold the respective light sources and supply the drive power from the common electrode individually to the respective light sources, and a dielectric portion provided between the common electrode and each of the holder electrodes.

Owner:SHARP KK

Aircraft deformation head cone device imitating bee abdomen

ActiveCN107539460ALarge amount of deformationSimple drive structureAircraft componentsMelenaVertical plane

The invention discloses an aircraft deformation head cone device imitating a bee abdomen. The aircraft deformation head cone device imitating the bee abdomen comprises multistage head cone outer shells, a deformation conversion device and a connecting mechanism, wherein the multistage head cone outer shells are arranged sequentially form back to front, and the outer diameters of the multistage head cone outer shells are gradually reduced from back to front; a deformation conversion device is arranged between the two adjacent head cone outer shells to drive the two adjacent head cone outer shells to be extended and curved; and the connecting mechanism is arranged between the two adjacent head cone outer shells to move when two adjacent head cone outer shells are extended and curved. According to the aircraft deformation head cone device imitating the bee abdomen, the extension in the axial direction and the bending motion in the vertical plane of the head cone device in the horizontal plane can be achieved, and the aircraft deformation head cone device has the advantages of being high in deformation, simple in driving structure, convenient to control, convenient to lock and smooth in appearance and the like.

Owner:TSINGHUA UNIV

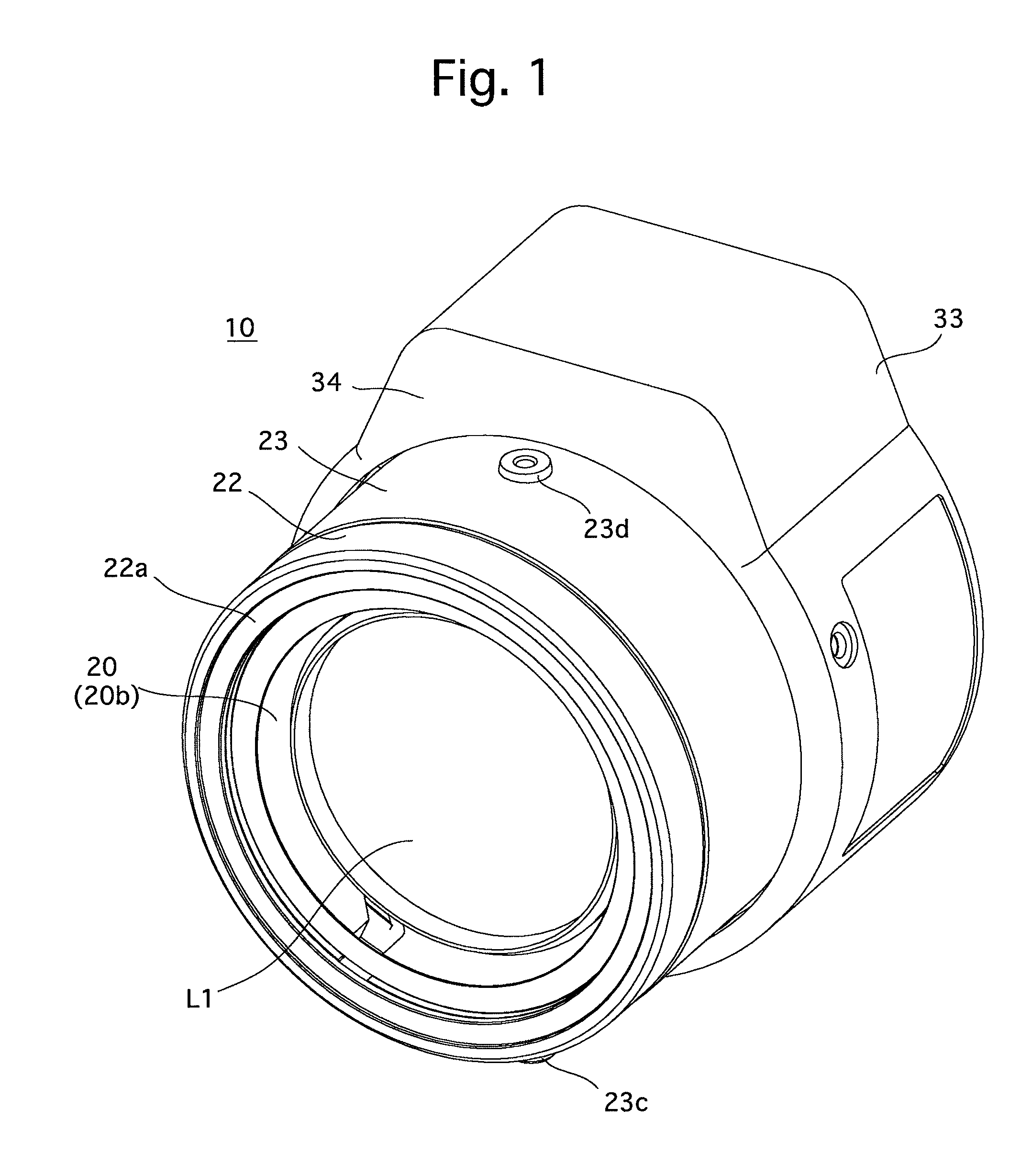

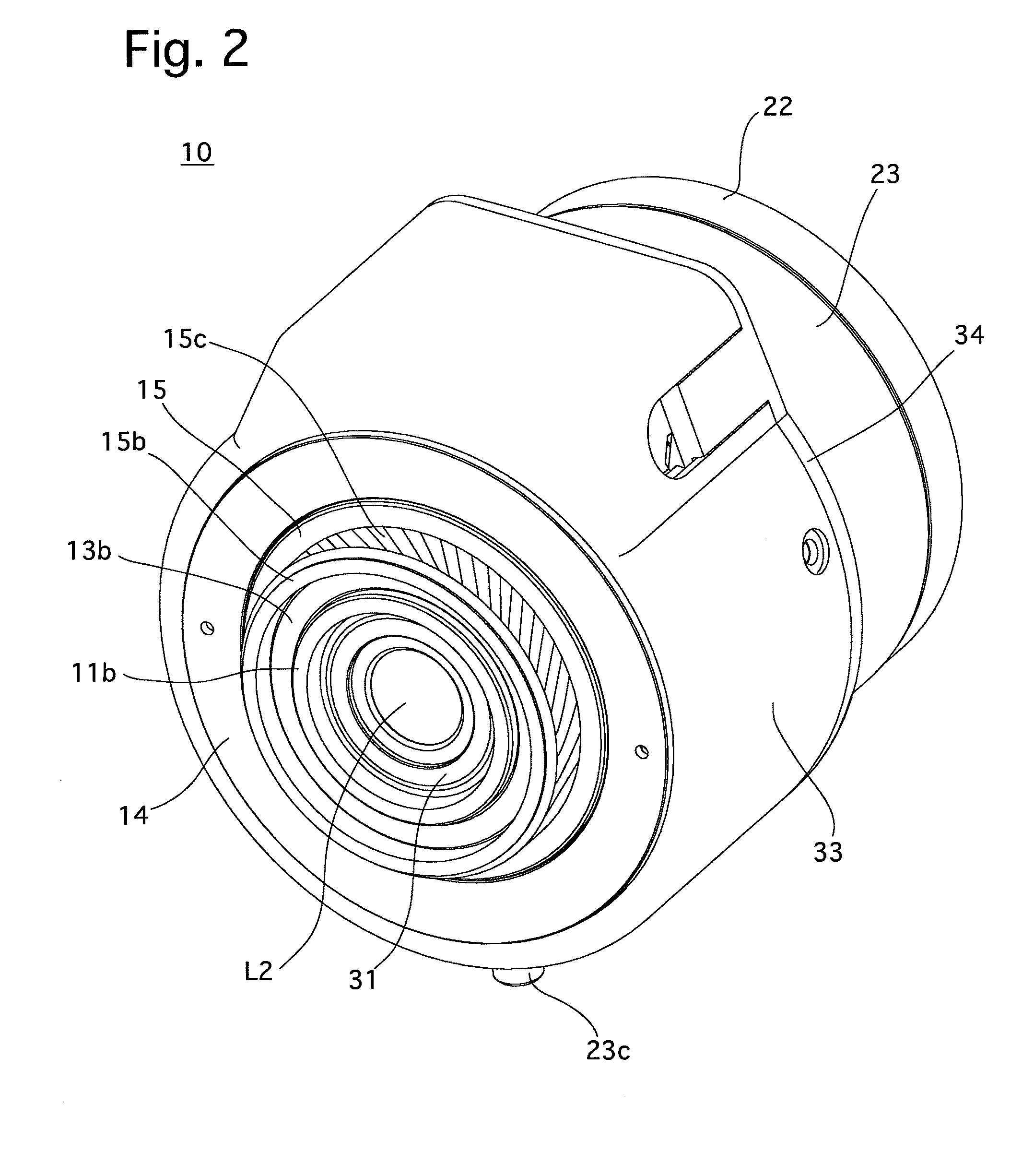

Variable power lens

A variable power lens, having first and second lens groups, includes first and second lens group support frames, a linear guide ring, first and second lens group drive rings which rotate to move the first and second lens group support rings in the optical axis direction relative to the linear guide ring, a drive ring coupler which couples the first and second lens group drive rings with each other to prevent relative rotation therebetween while allowing relative movement therebetween in the optical axis direction; and a drive-ring movement controller which integrally rotates the first and second lens group drive rings via the drive ring coupler without relatively moving in the optical axis direction when a power-variation operating member is operated, and moves one of the first and the second lens group drive rings in the optical axis direction without rotating when a focus operating member is operated.

Owner:RICOH IMAGING COMPANY

Drainage device used for collecting municipal sewage

InactiveCN106592747AImplementation driveAchieve cleanupFatty/oily/floating substances removal devicesSewerage structuresEngineeringMunicipal sewage

The invention discloses a drainage device used for collecting municipal sewage. The key points of the technical scheme are as follows: the drainage device comprises a water collecting tank, wherein a vacuum tube is arranged in the water collecting tank, a support rod is rotatably arranged on the outer wall of the vacuum tube, a cleaning hopper used for fishing up impurities on the surface of the sewage is rotatably arranged on the support rod in a form of surrounding the support rod, a collecting box used for receiving the impurities falling from the cleaning hopper is further arranged on the support rod, a first drive part used for driving the support rod to rotate is arranged on the vacuum tube, and a second drive part used for driving the cleaning hopper to rotate is further arranged on the support rod. When the impurities in the water collecting tank need to be treated, the cleaning hopper fishes up the impurities floating on the surface of the sewage, along with the rotation of the cleaning hopper, the impurities in the cleaning hopper fall into the collecting box under the effect of gravity to be collected, due to the adoption of the cleaning hopper, the first drive part and the second drive part, the impurities on the surface of the sewage are cleaned, the cleaning efficiency is high, the automatic cleaning is realized, and the cleaning cost is reduced.

Owner:温州晟瑞市政园林建设有限公司

Lens transfer device

ActiveUS7426081B2Simple drive structureMicro sizePiezoelectric/electrostriction/magnetostriction machinesProjector focusing arrangementInterior spaceCamera lens

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com