Patents

Literature

189results about How to "Rotate synchronously" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

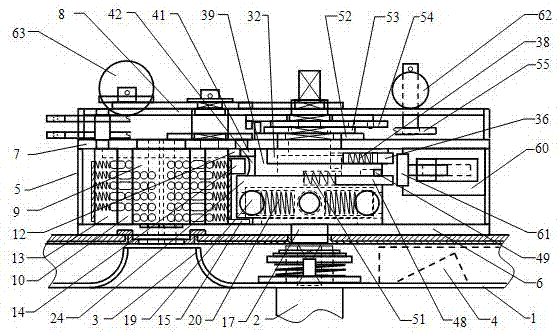

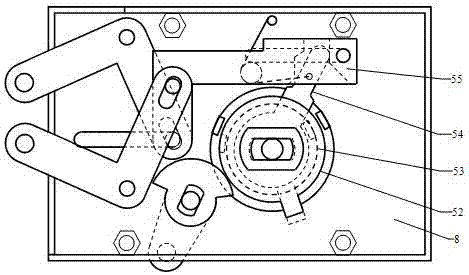

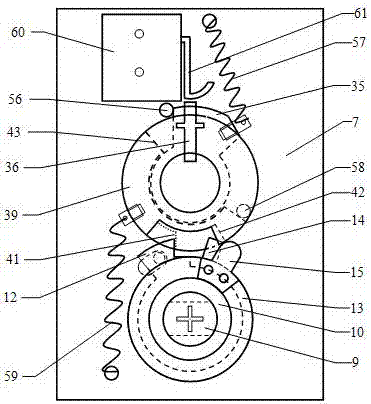

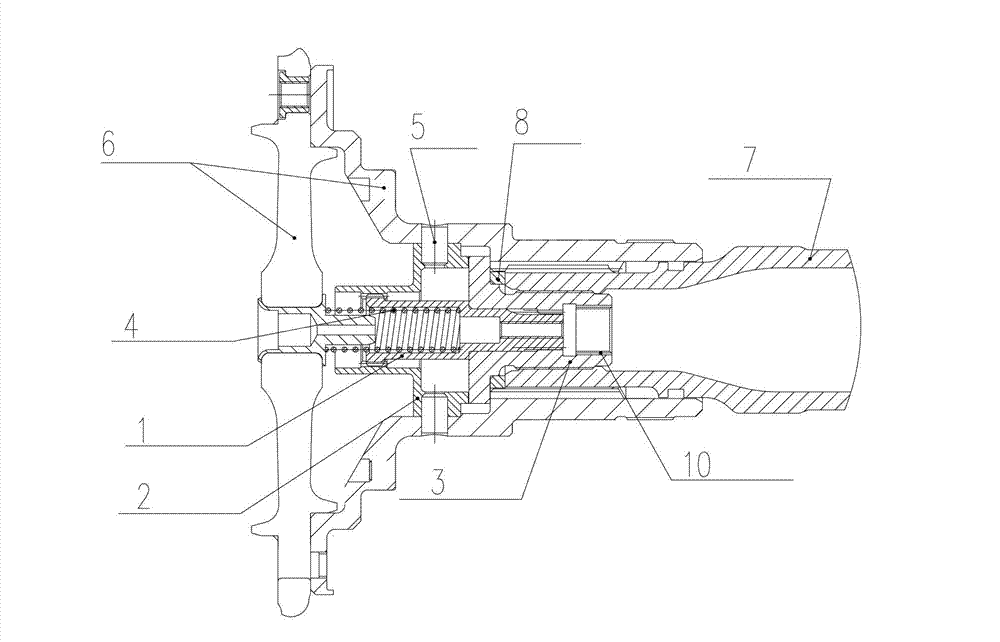

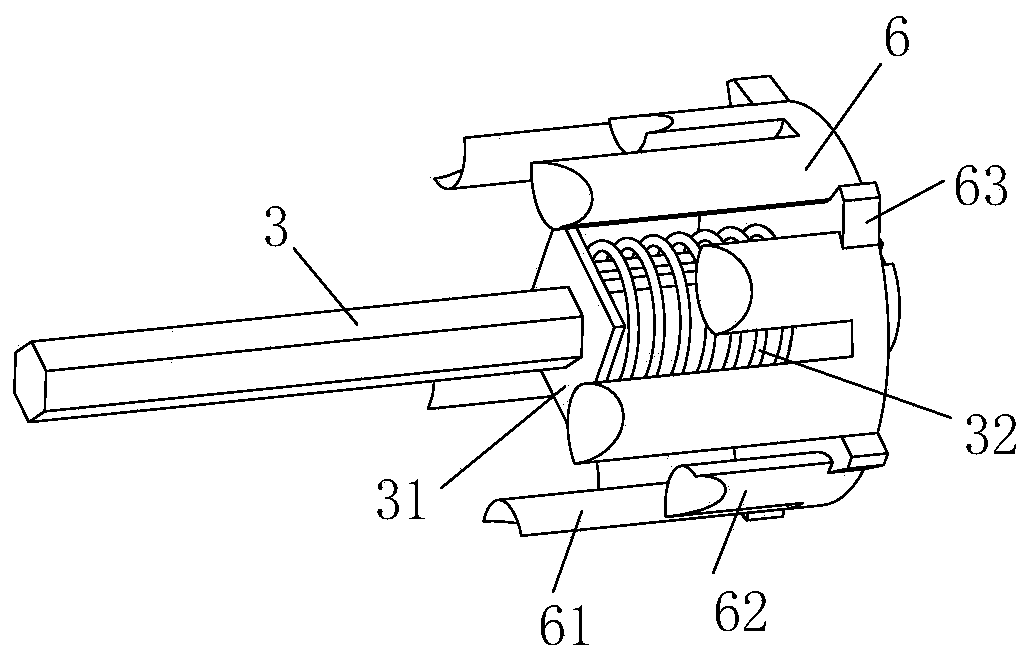

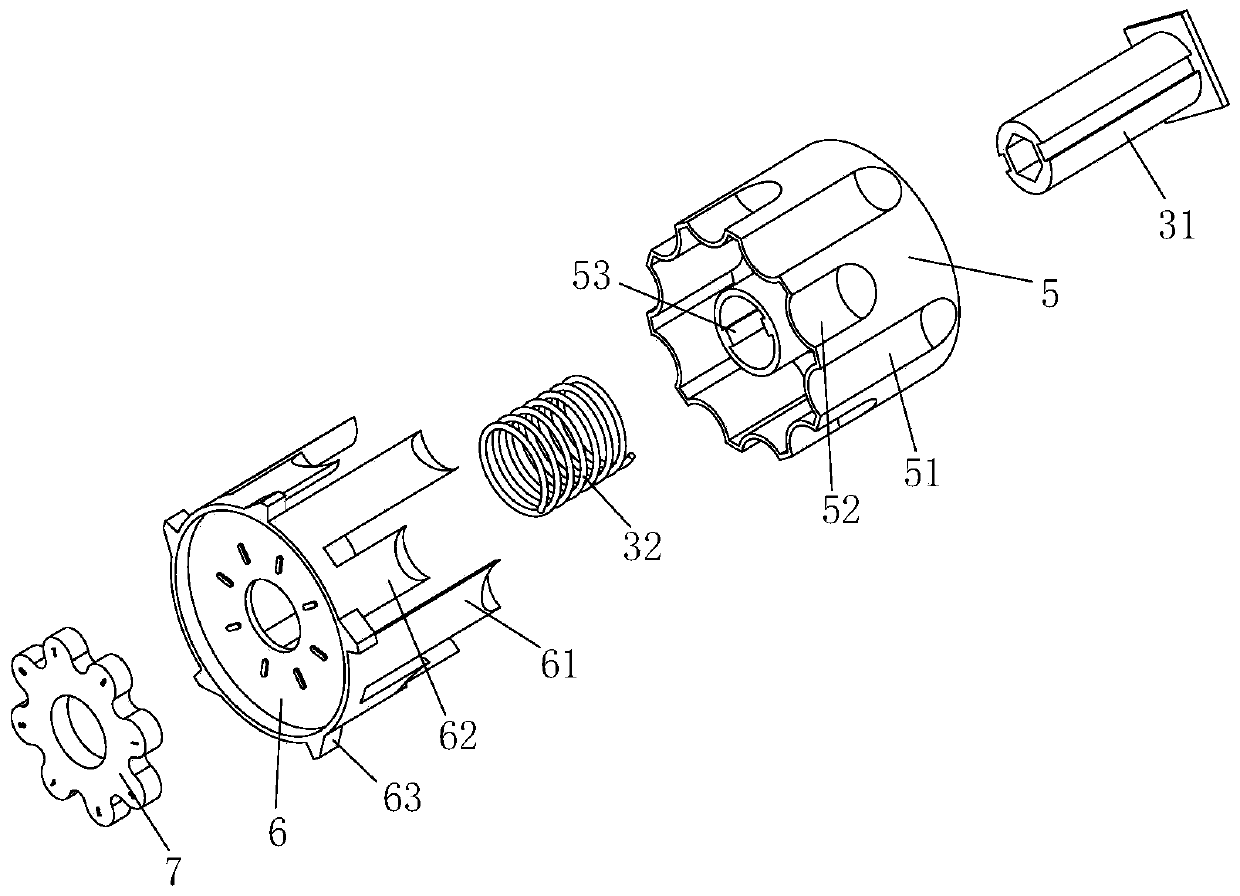

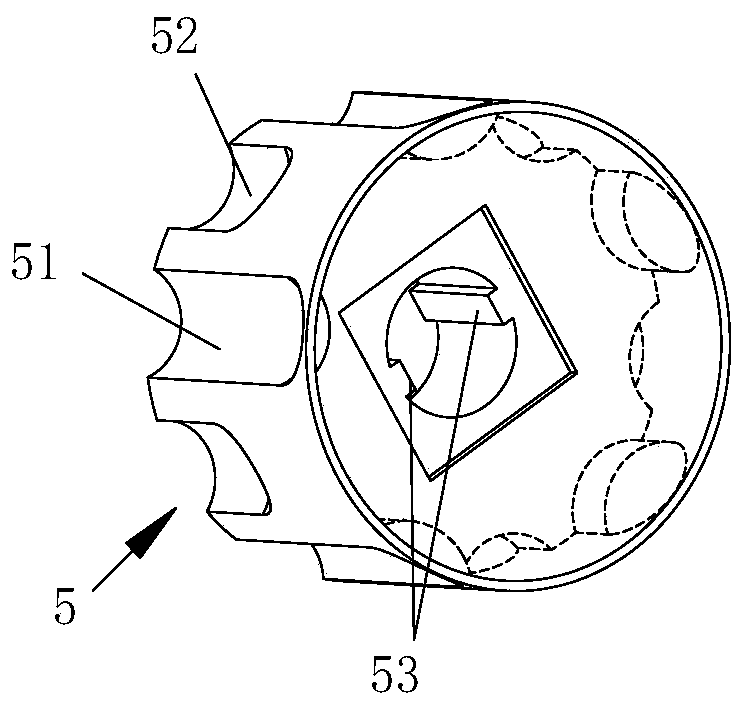

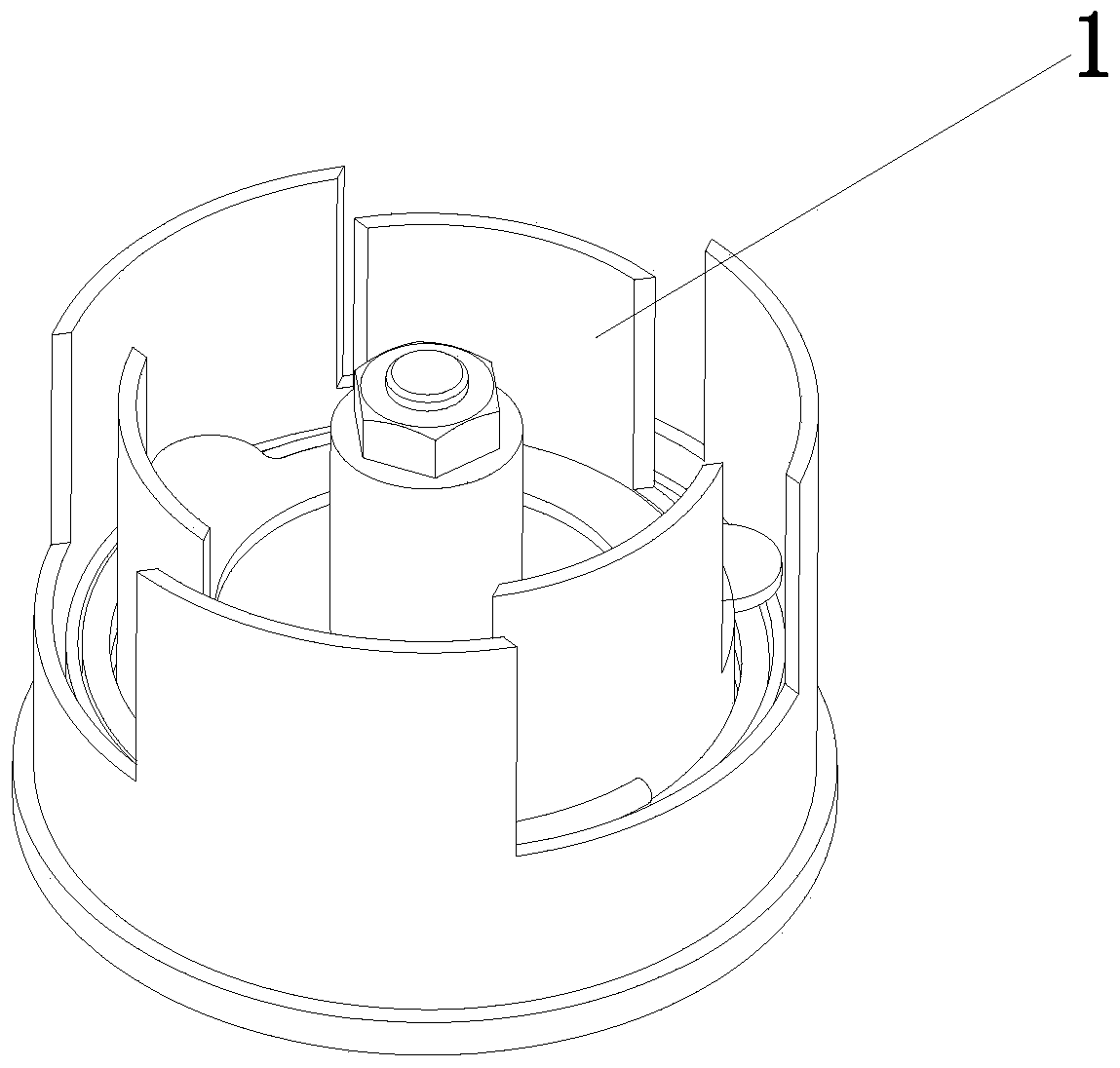

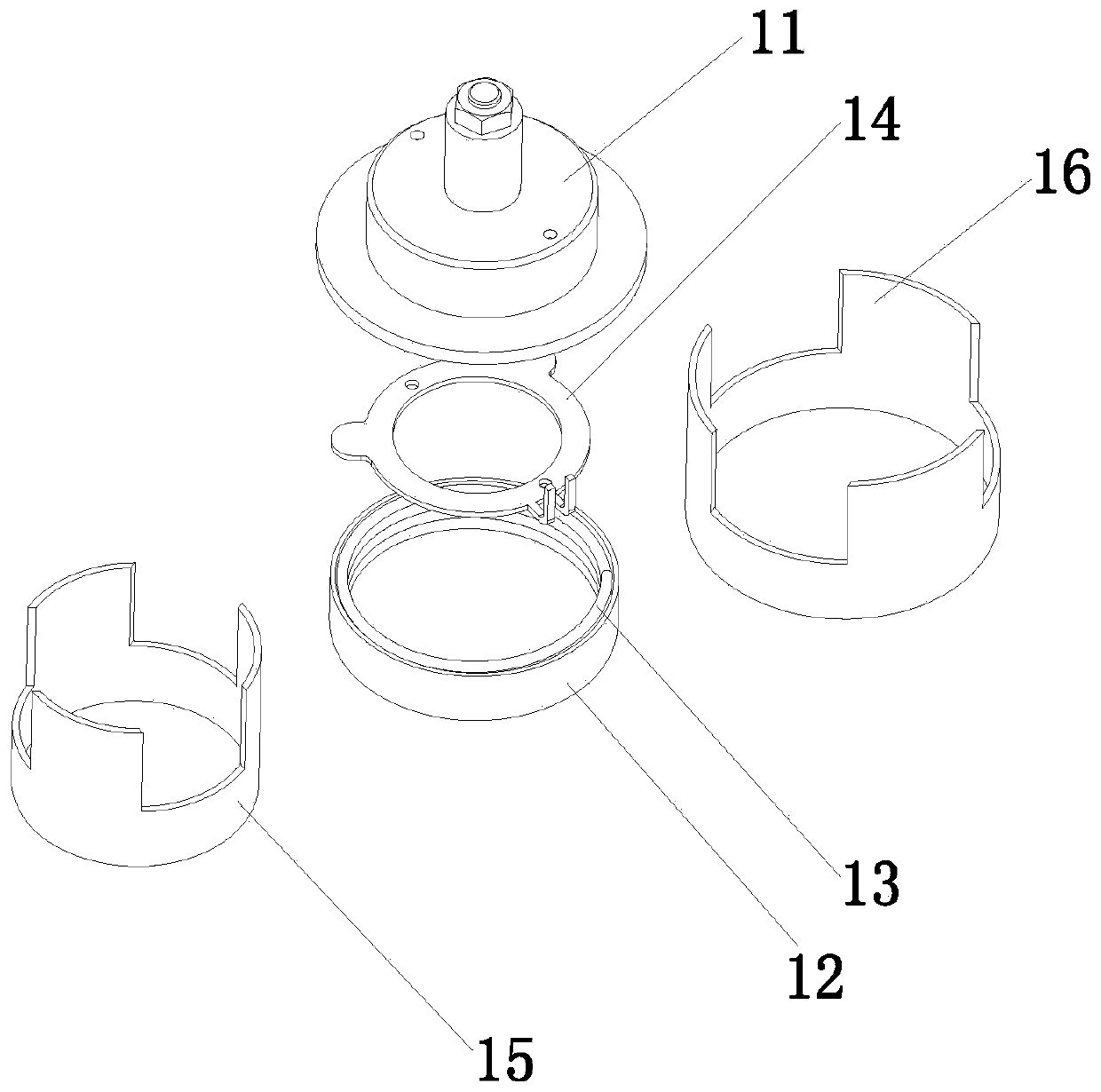

Cam mechanism and rotating ring forced resetting device for fingerprint lock

ActiveCN107035230ANo signs of wear and tearSimple structureNon-mechanical controlsElectric permutation locksEngineeringCam

The invention discloses a cam mechanism and rotating ring forced resetting device for a fingerprint lock and relates to the field of anti-theft locks. According to the cam mechanism and rotating ring forced resetting device for the fingerprint lock, the main improvement is that the specific structure and the assembling mode of an overload protection device of the cam mechanism are changed; a collision bead sliding way, a collision bead spring and the like are radially assembled onto a cam shaft which is amplified locally; meanwhile, a collision bead large in diameter is adopted, on one hand, it is guaranteed that the idle function of the cam mechanism is stable and reliable, and on the other hand, space can be saved; the rotating ring forced resetting device which is simple and easy to implement can be arranged conveniently so that potential dangers can be eliminated; in addition, the resetting device is free of wear in routine operation and low in production cost; and meanwhile, axial dimensions and radial dimensions of main components of a double clutch can be increased so that reliability of the double clutch and safety of the lock can be improved.

Owner:重庆桐雨石科技有限公司

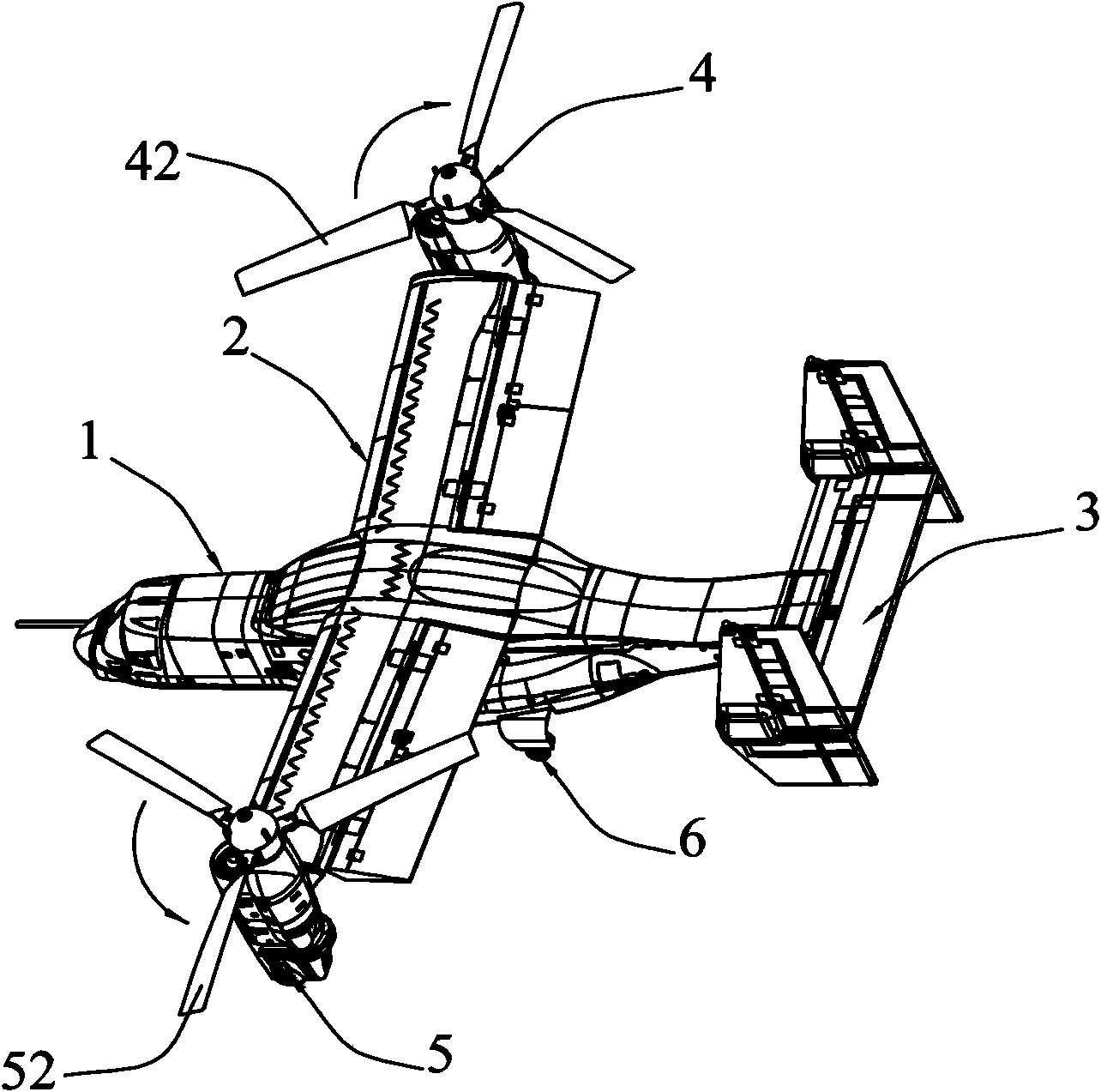

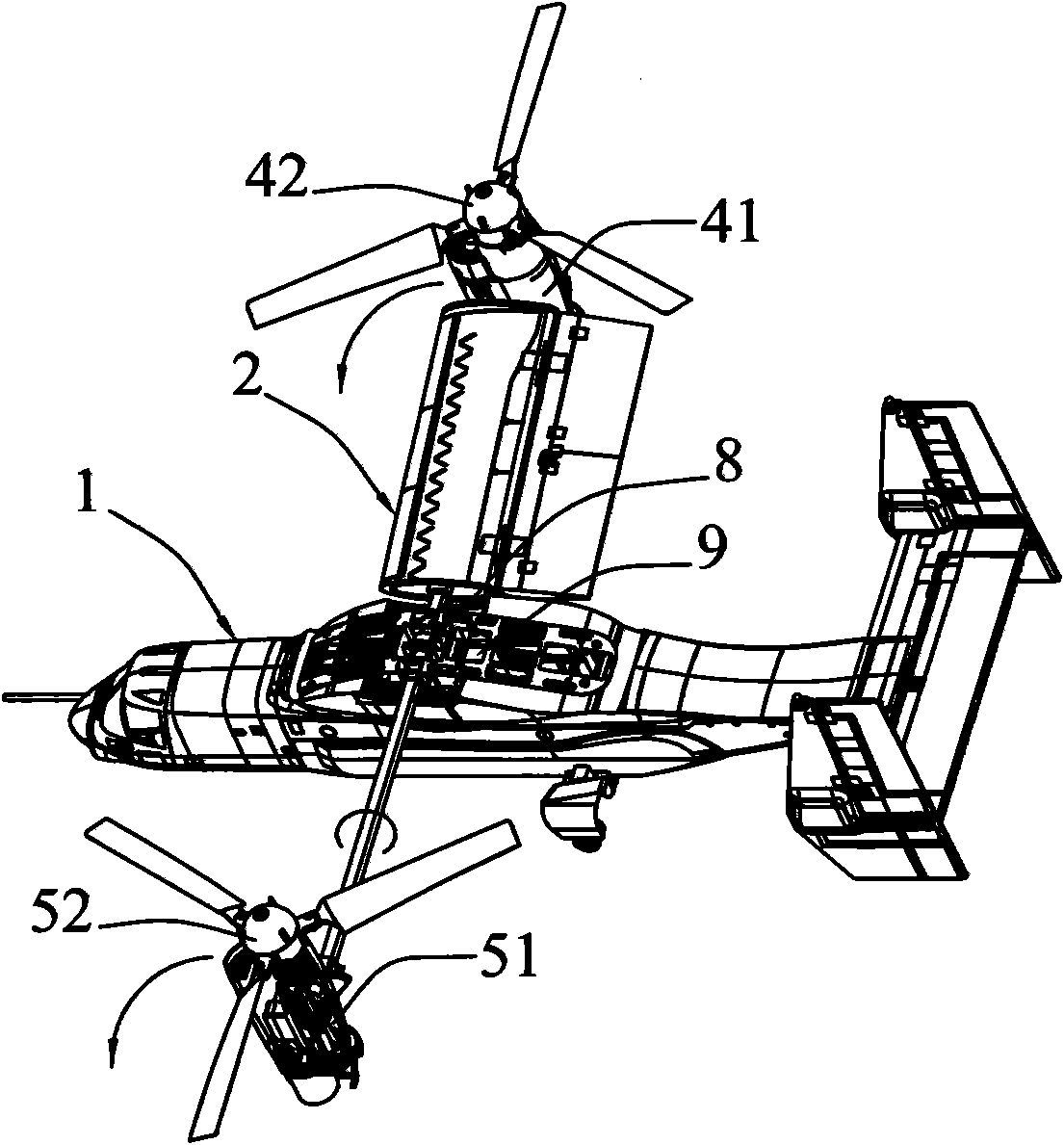

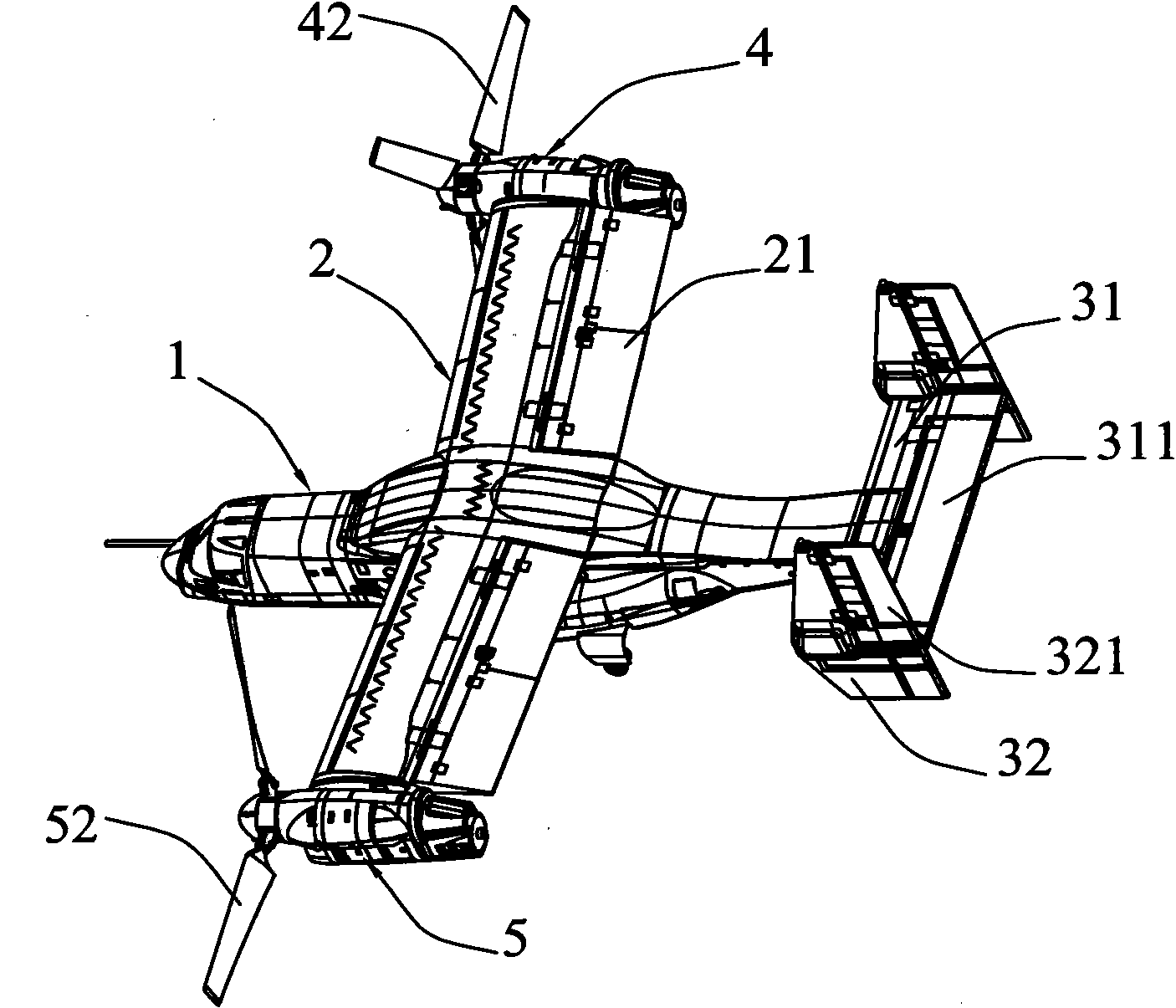

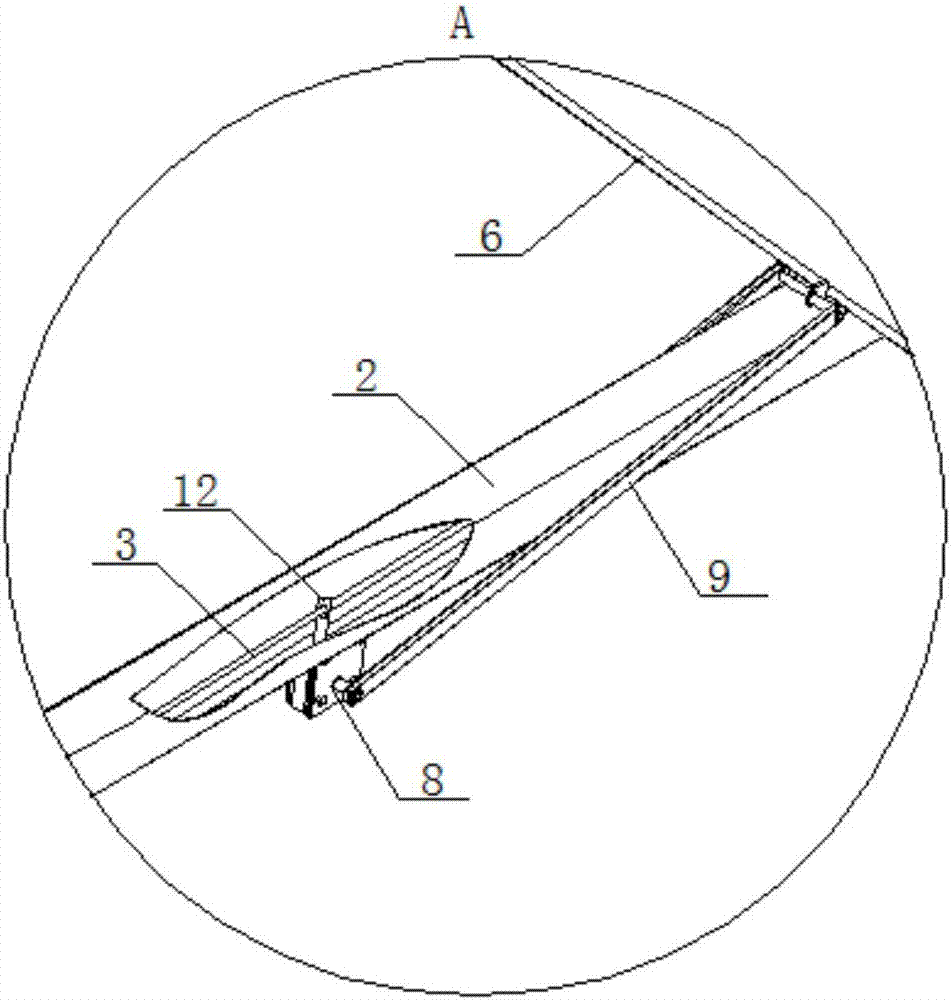

Model airplane with vertical takeoff and landing

ActiveCN101837195ARotate synchronouslyReduce weightToy aircraftsVertical landing/take-off aircraftsJet aeroplaneEngineering

The invention relates to the field of toy model airplanes and needs to solve the technical problems that a highly-simulated model airplane of a V-22 osprey is designed, can have the flight characteristics of the V-22 osprey and can be reduced to the specification size of a toy. A model airplane with vertical takeoff and landing, which is designed by the invention, comprises a fuselage, fixed wings and an empennage, wherein the fixed wings extend from both sides of the fuselage to the outside, the empennage is arranged at the tail part of the fuselage, the ends of the two wings are respectively provided with an airscrew engine, the rotation directions of the rotors of the two airscrew engines are opposite, the rotors of the two airscrew engines are connected into a whole by a rotating shaft mechanism distributed along the wings, the inside of the fuselage is provided with a rotating shaft driving mechanism, and the rotating shaft driving mechanism drives the rotating shaft mechanism to rotate so as to drive the airscrew engines at both ends of the rotating shaft mechanism to rotate synchronously between a vertical direction and a horizontal direction.

Owner:GUANGZHOU WALKERA TECH CO LTD

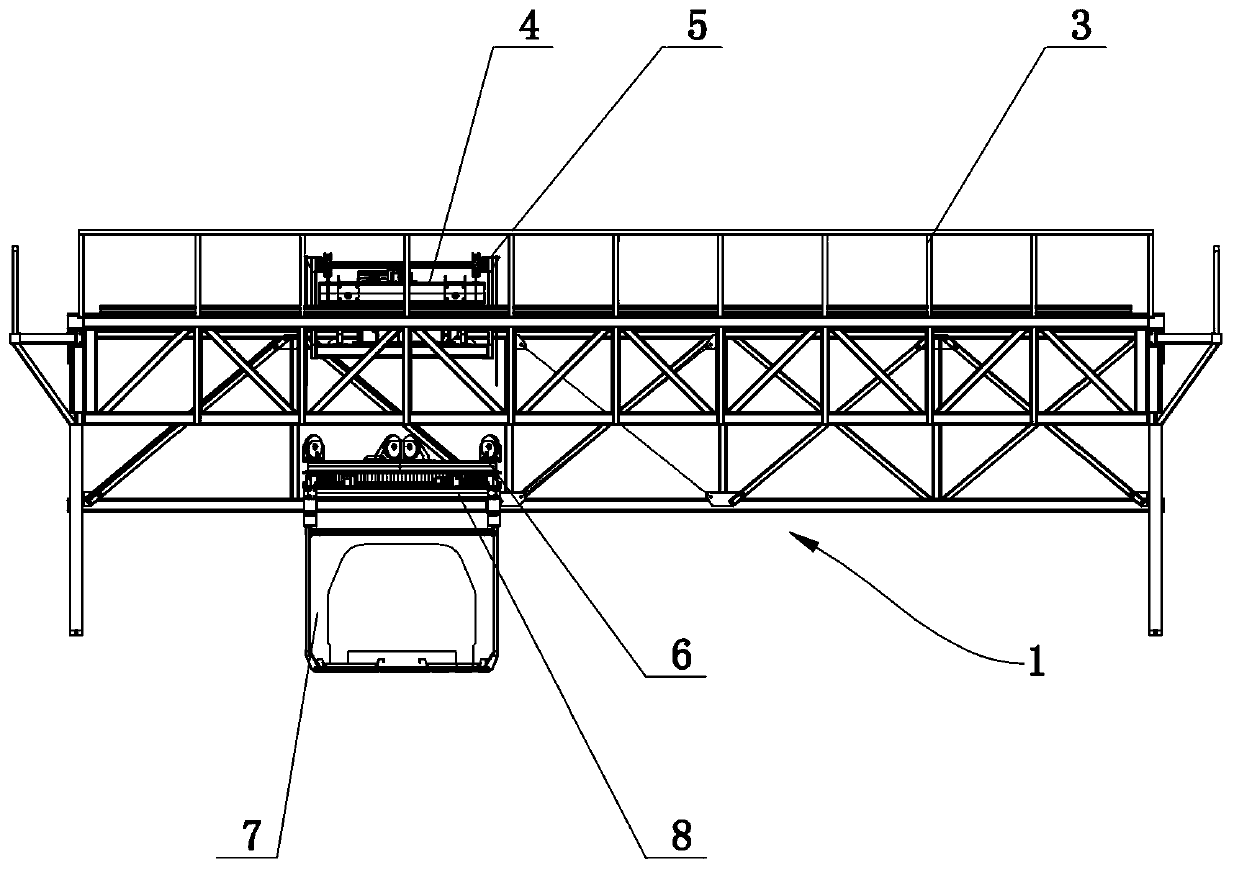

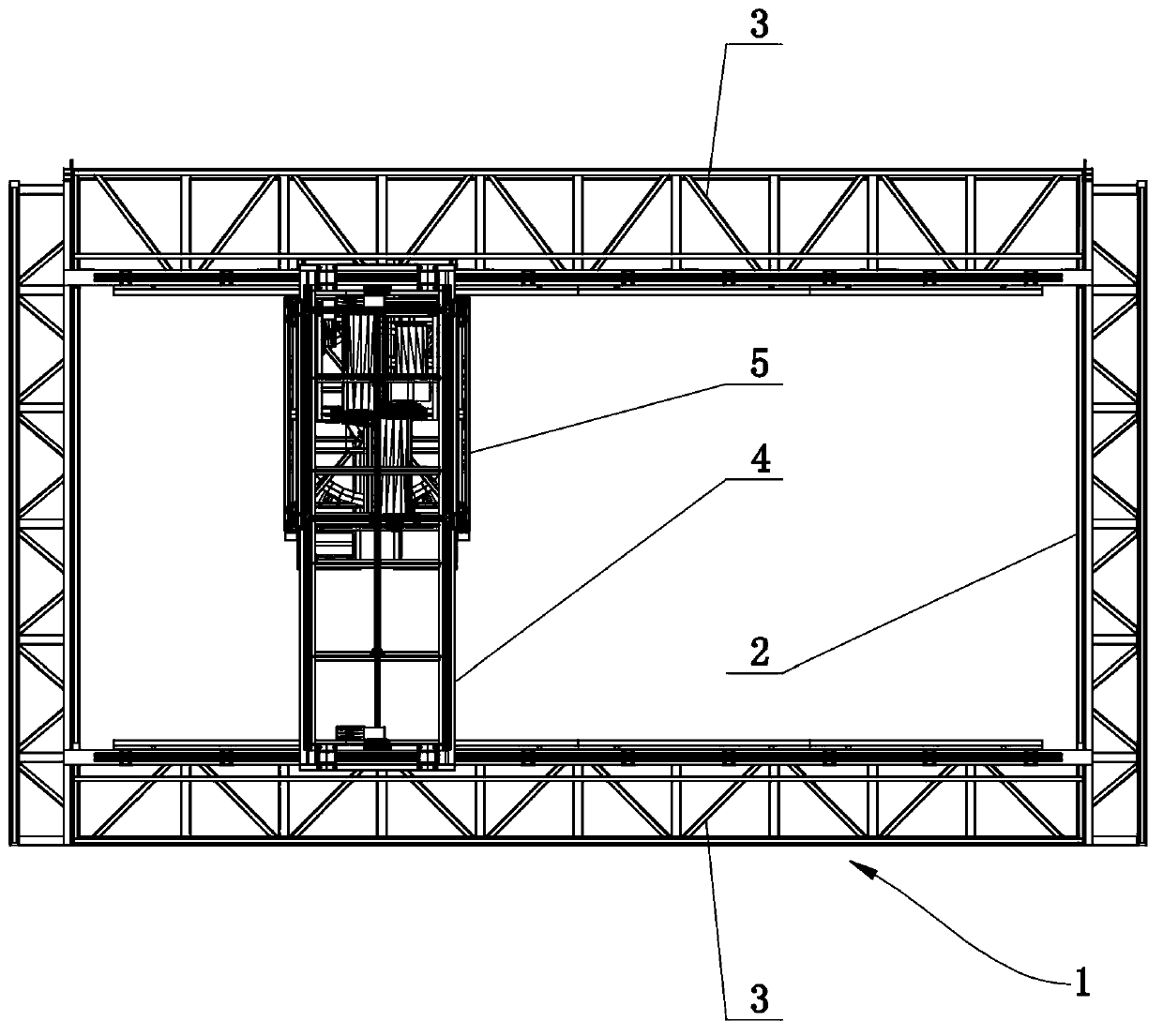

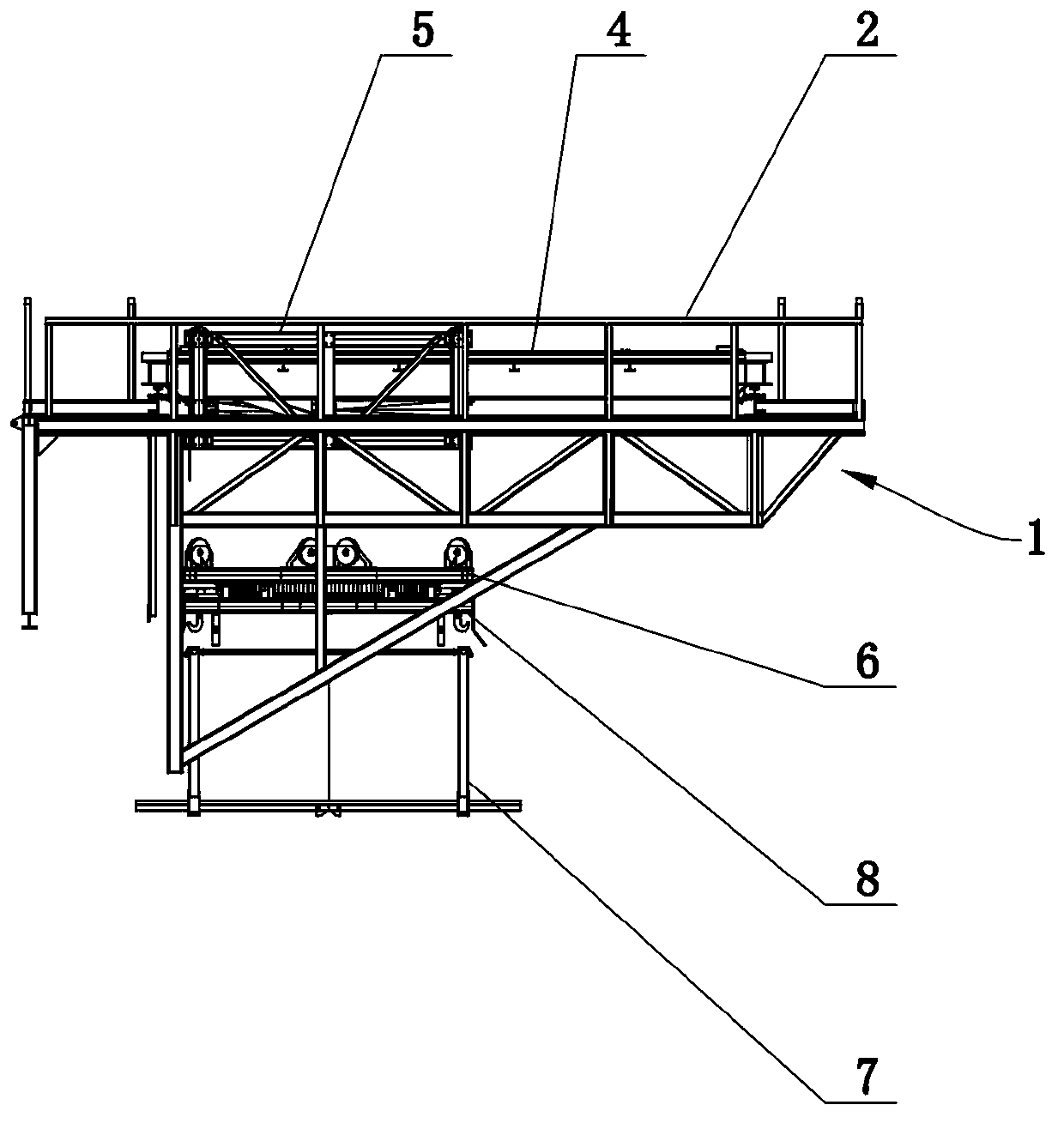

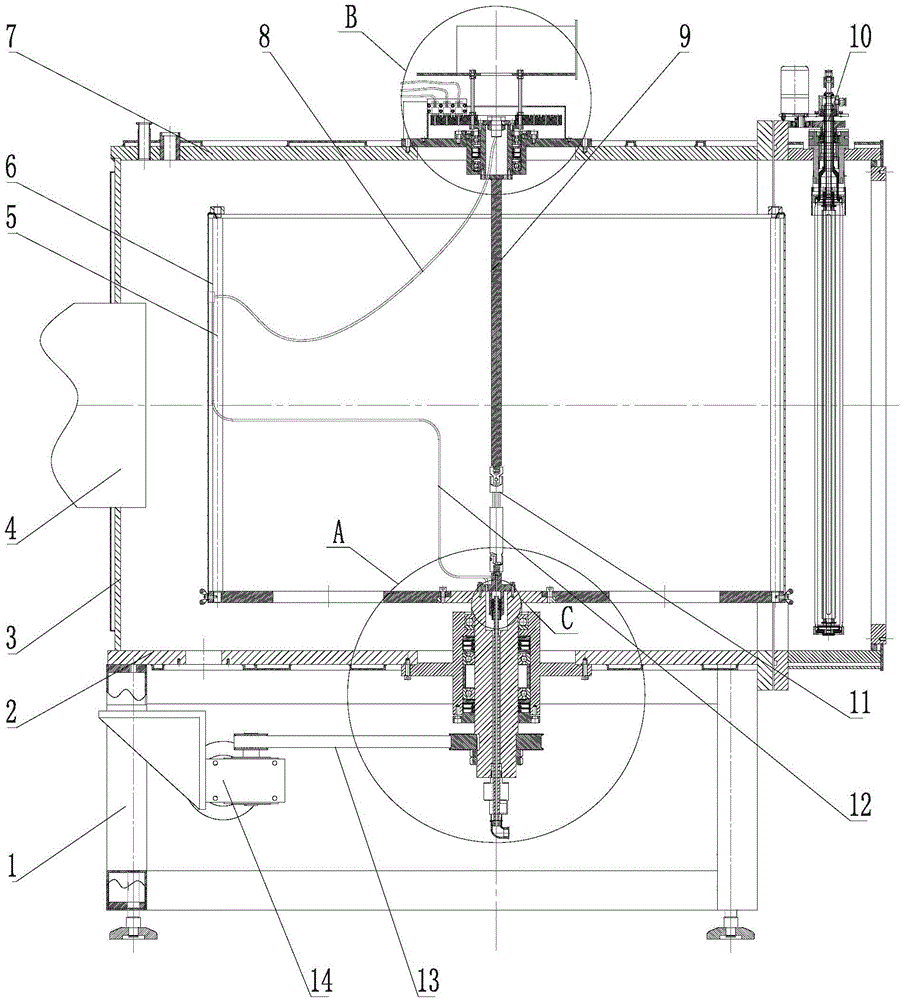

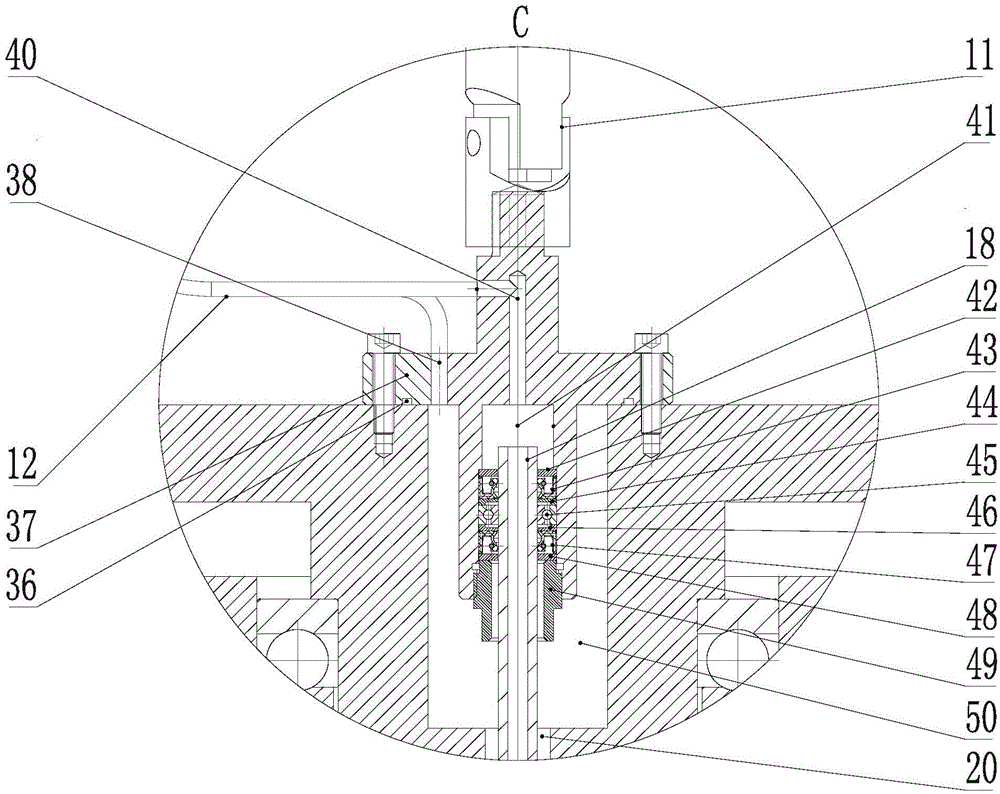

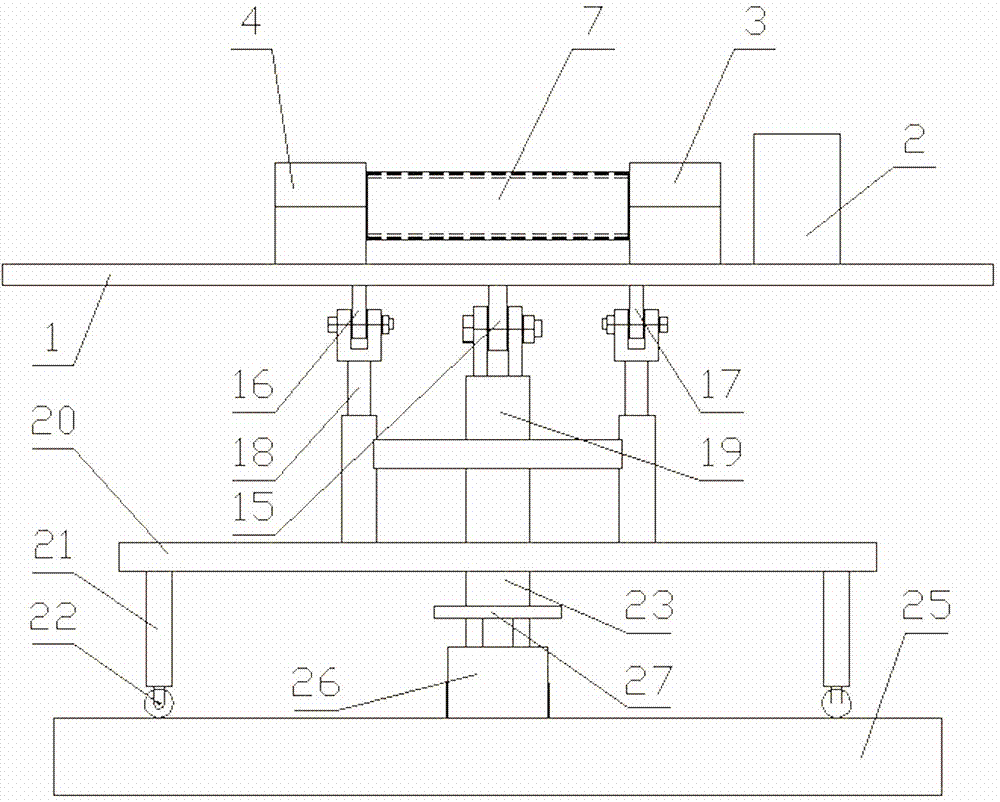

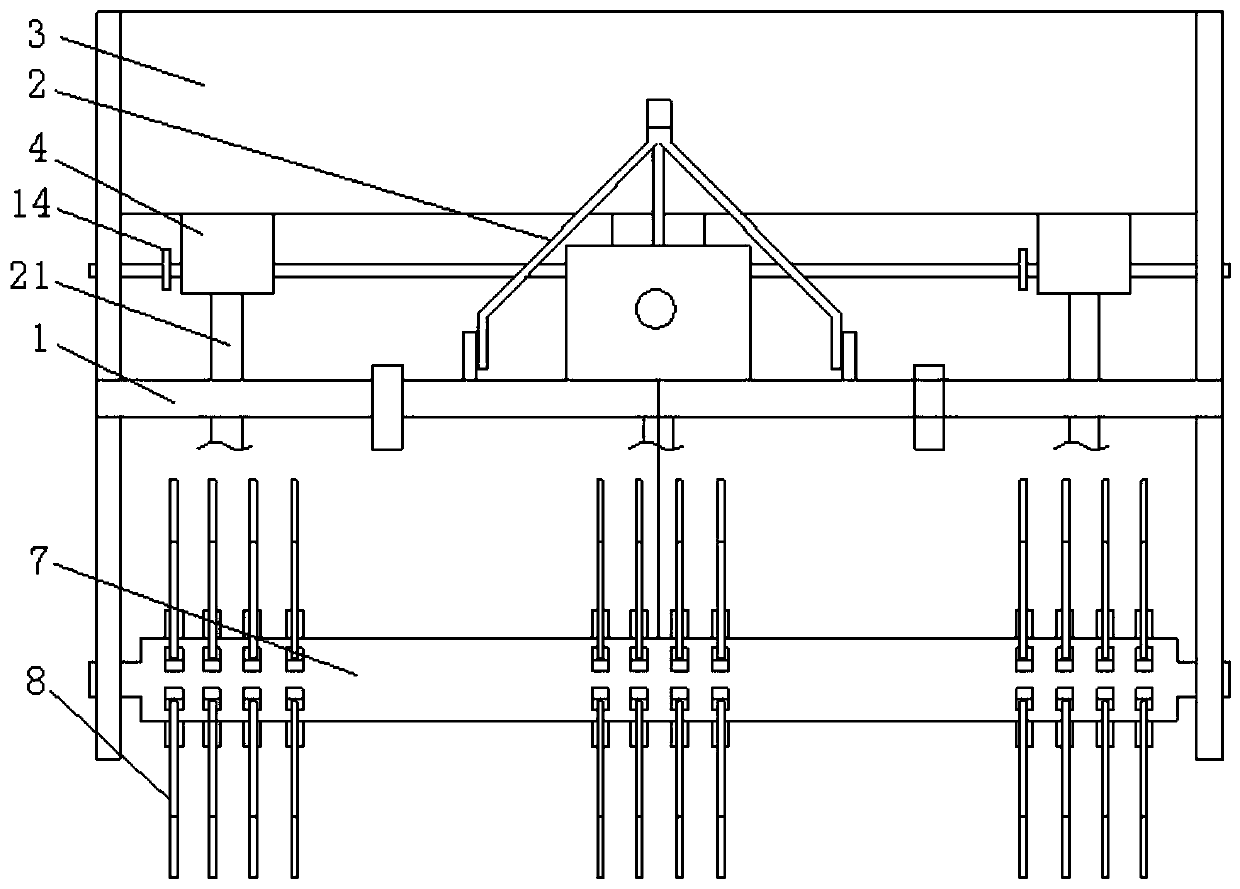

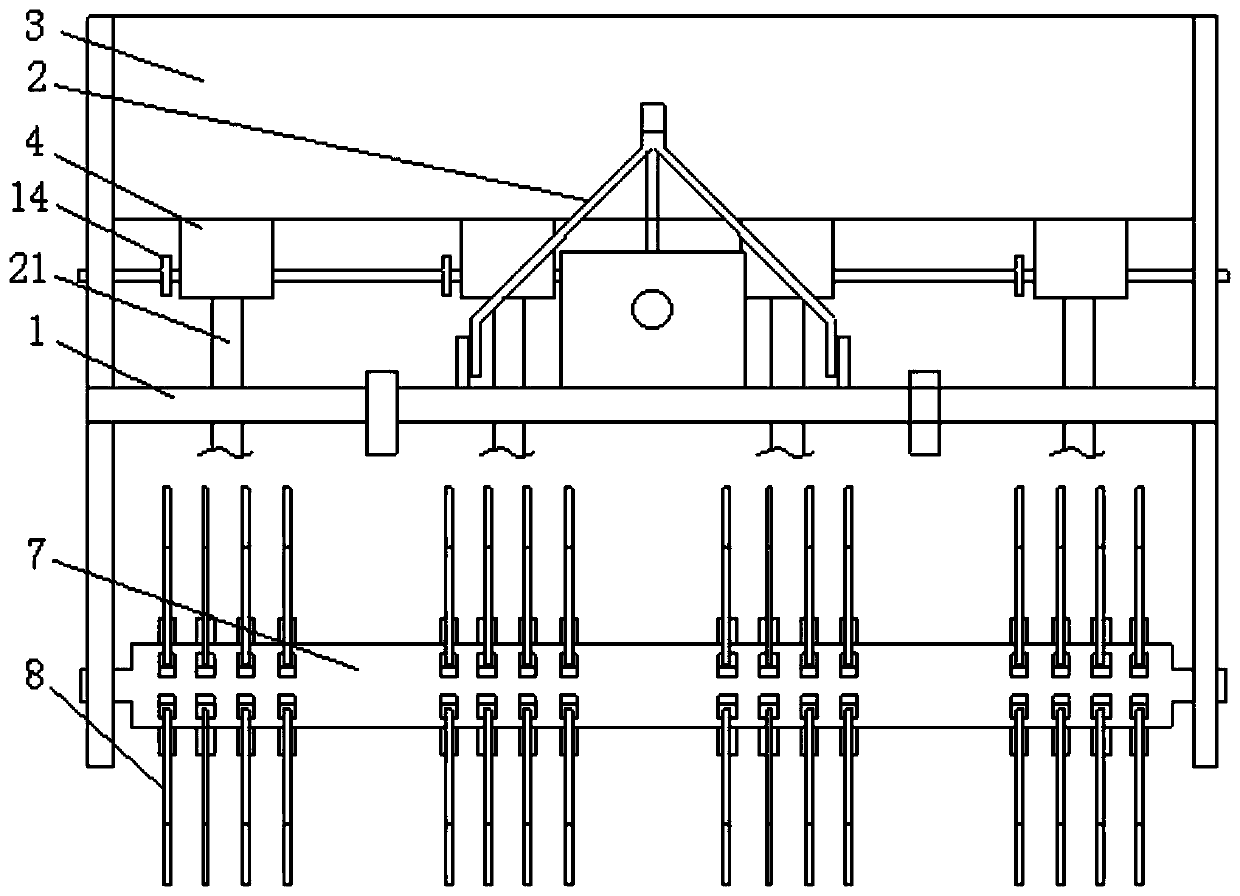

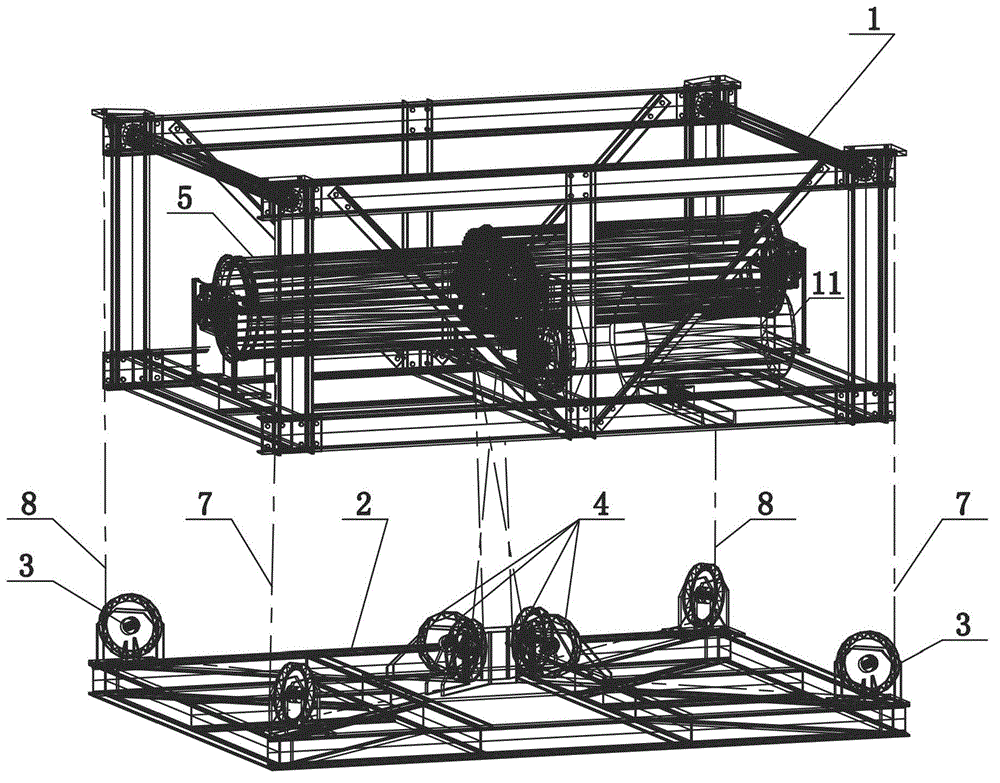

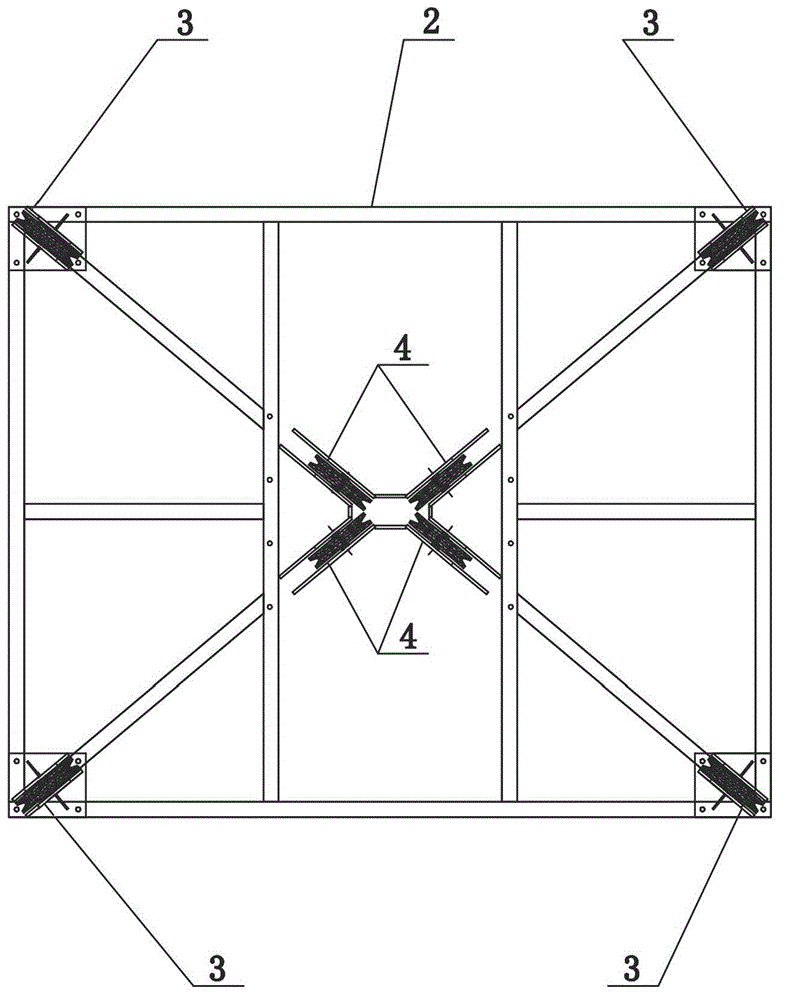

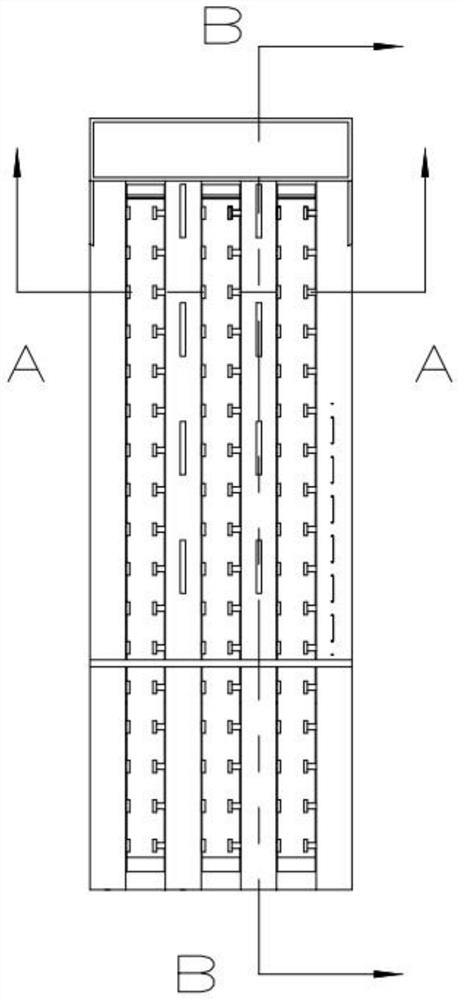

Four-freedom-degree vehicle carrier for three-dimensional parking equipment

The invention discloses a four-freedom-degree vehicle carrier for three-dimensional parking equipment and belongs to the technical filed of mechanical parking devices. The four-freedom-degree vehicle carrier comprises a cantilever support above a top-layer parking space, the cantilever support comprises two oppositely-arranged cantilever longitudinal beams and two oppositely-arranged cantilever cross beams, and the cantilever longitudinal beams and the cantilever cross beams are arranged in a rectangular mode. A transversely-moving mechanism driven by a first power plant is arranged on the cantilever support in a transversely-moving mode, and a longitudinally-moving mechanism driven by a second power plant is arranged on the transversely-moving mechanism in a longitudinally-moving mode. The longitudinally-moving mechanism is provided with a lifting transmission mechanism which is driven by a third power plant and capable of lifting in the vertical direction, and the lifting transmission mechanism is connected with a grabbing rotary mechanism which is driven by a fourth power plant and capable of rotating around a vertical axial line and used for grabbing lifting vehicle platforms. The four-freedom-degree vehicle carrier does not occupy ground space and enables arrangement of garage entrances and exits to be flexible; in the process of parking and taking vehicles, transverse moving, longitudinal moving, lifting and rotating of the vehicles and the lifting vehicle platforms can be finished at the same time, and working efficiency of parking and taking the vehicles is improved.

Owner:DAYANG PARKING CO LTD

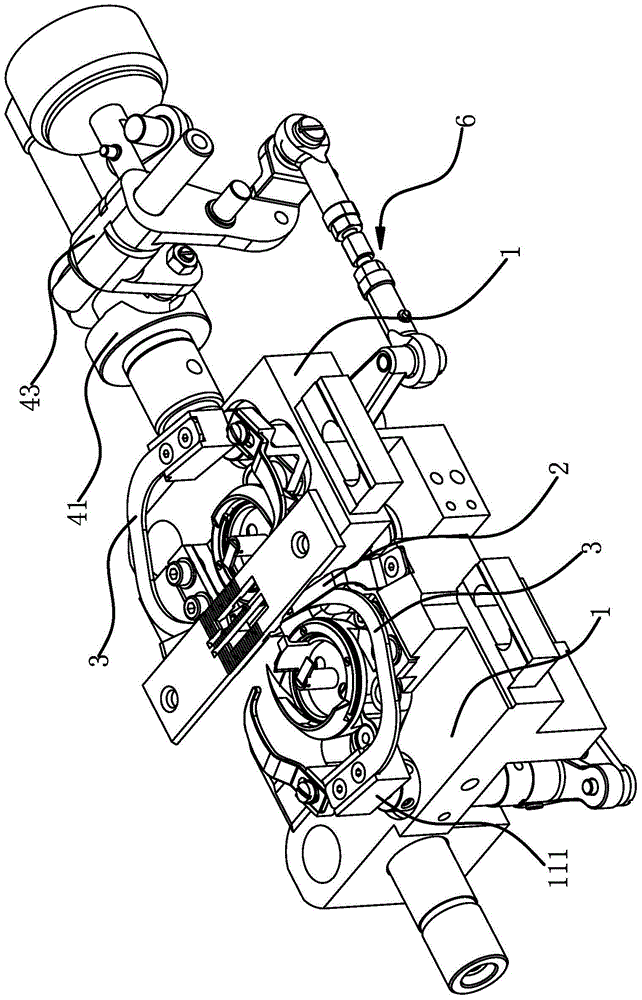

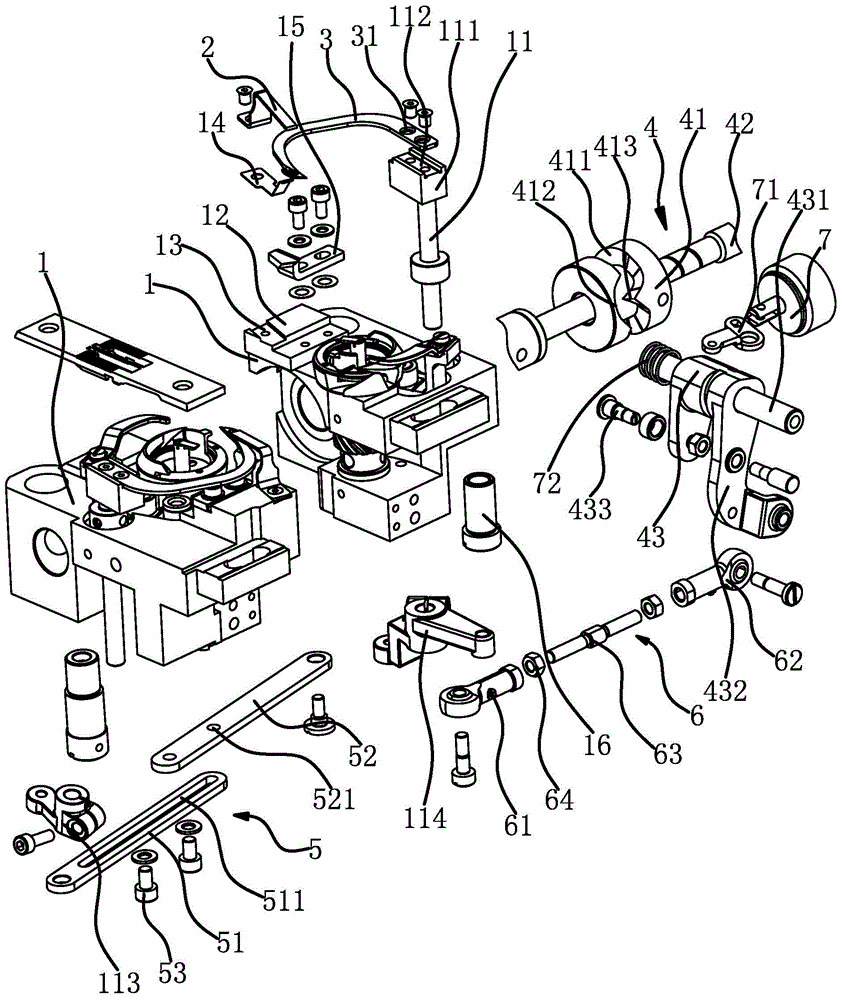

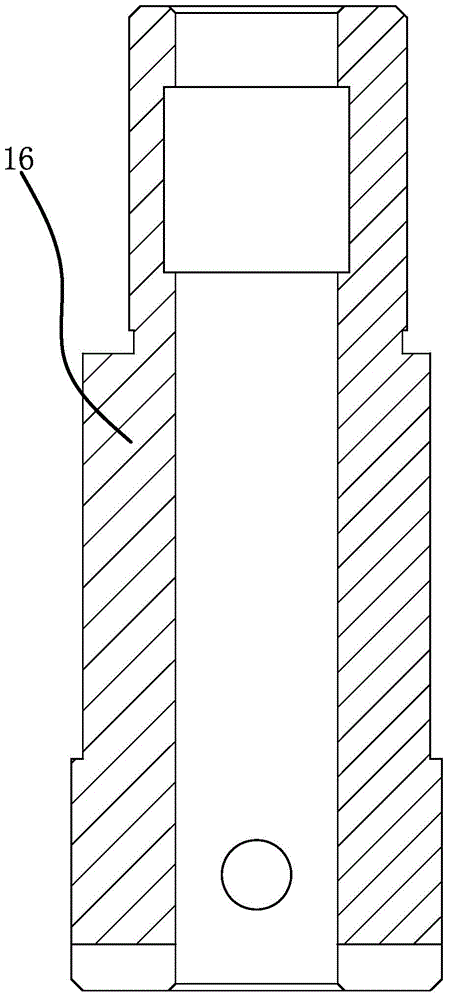

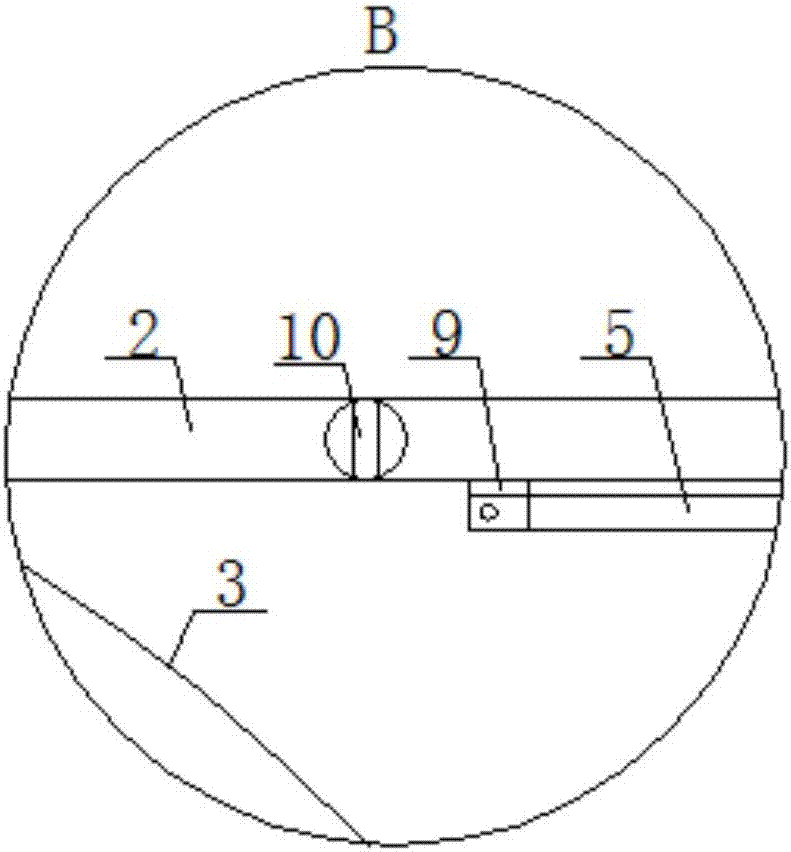

Thread trimming mechanism for two-needle sewing machine

InactiveCN104532491AImprove work efficiencyReduce adjustmentNeedle severing devicesEngineeringSewing machine

The invention provides a thread trimming mechanism for a two-needle sewing machine, and belongs to the technical field of sewing machine equipment. The problem that it is difficult for the current sewing machine to trim two stitches simultaneously is solved. The thread trimming mechanism for the two-needle sewing machine comprises two hook tables, the two hook tables are both fixedly connected with fixed blades, and are both rotatably connected with moving blade shafts, the upper end of each moving blade shaft is fixedly connected with a moving blade, the surfaces of the moving blades are attached to and abut against the surfaces of the fixed blades, a driver is arranged in a machine shell, and a connecting rod structure which can drive the two moving blade shafts to conduct reciprocating rotation along the opposite direction in a set angle is arranged between the driver and the two moving blade shafts. According to the thread trimming mechanism for the two-needle sewing machine, the installation and debugging are more convenient, the reliability of the thread trimming is high, a bottom thread and an upper thread can be hooked and trimmed simultaneously at one time, and two stitches can be trimmed simultaneously.

Owner:ZHEJIANG SHANGGONG GEM SEWING TECH CO LTD

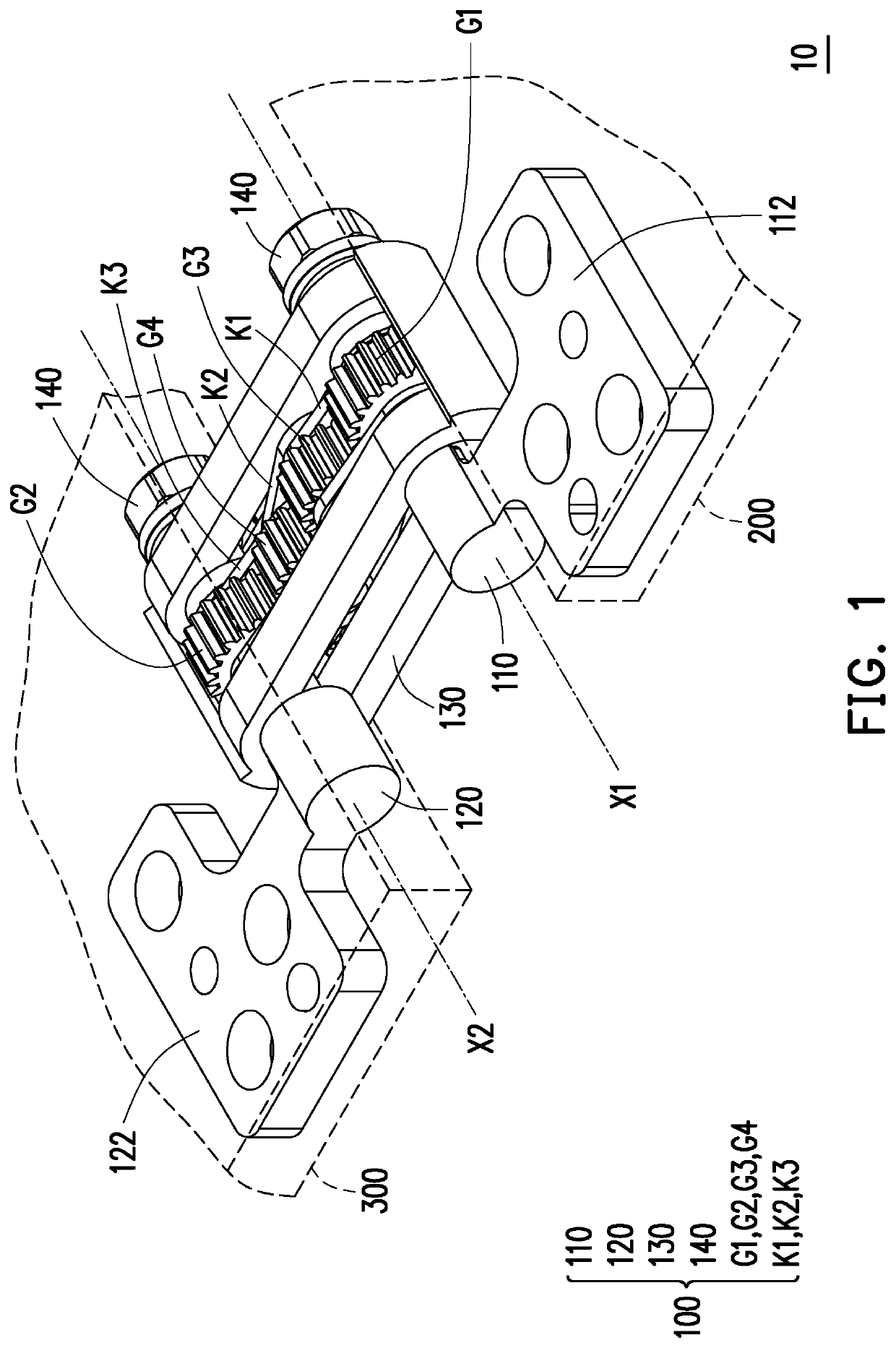

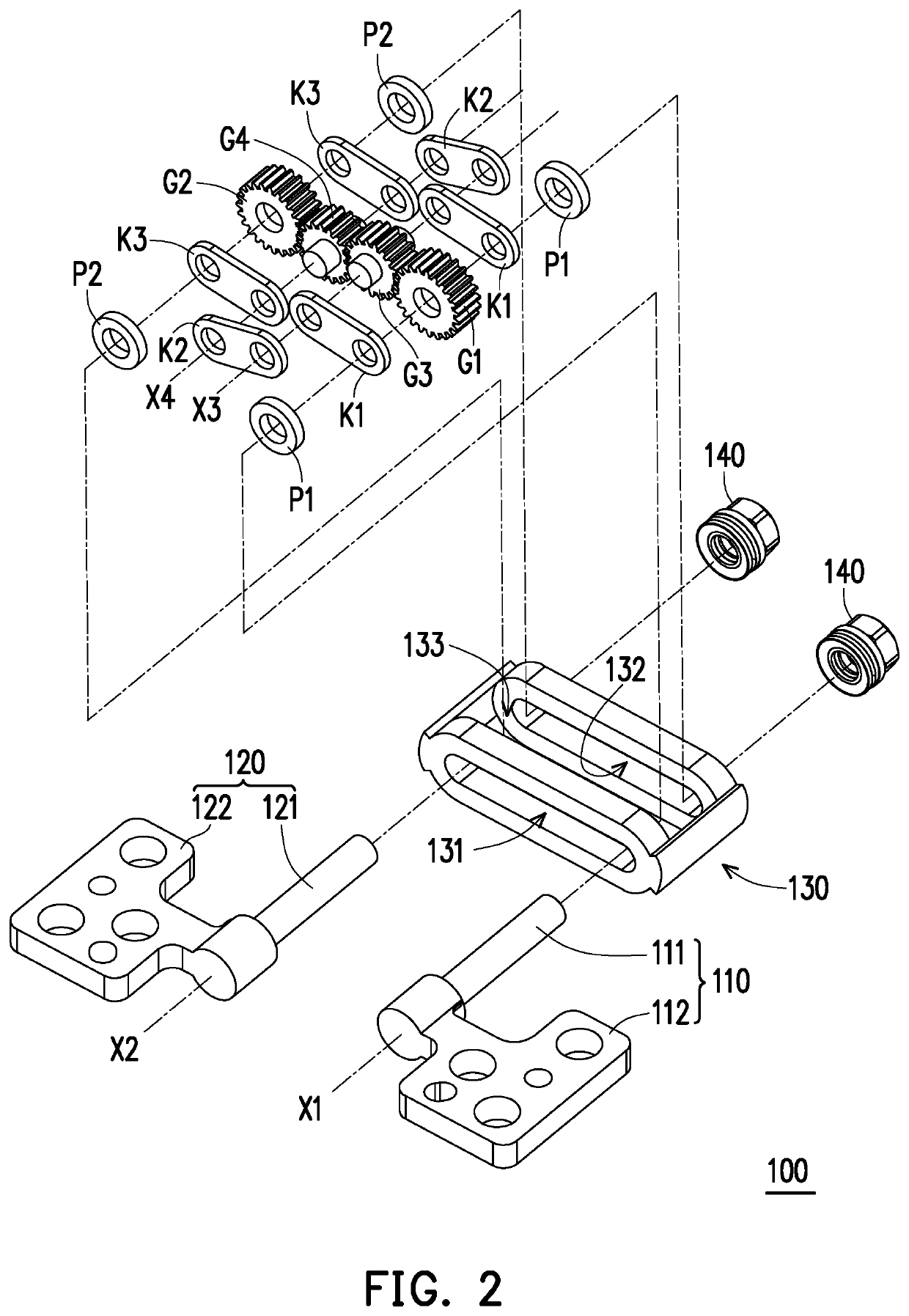

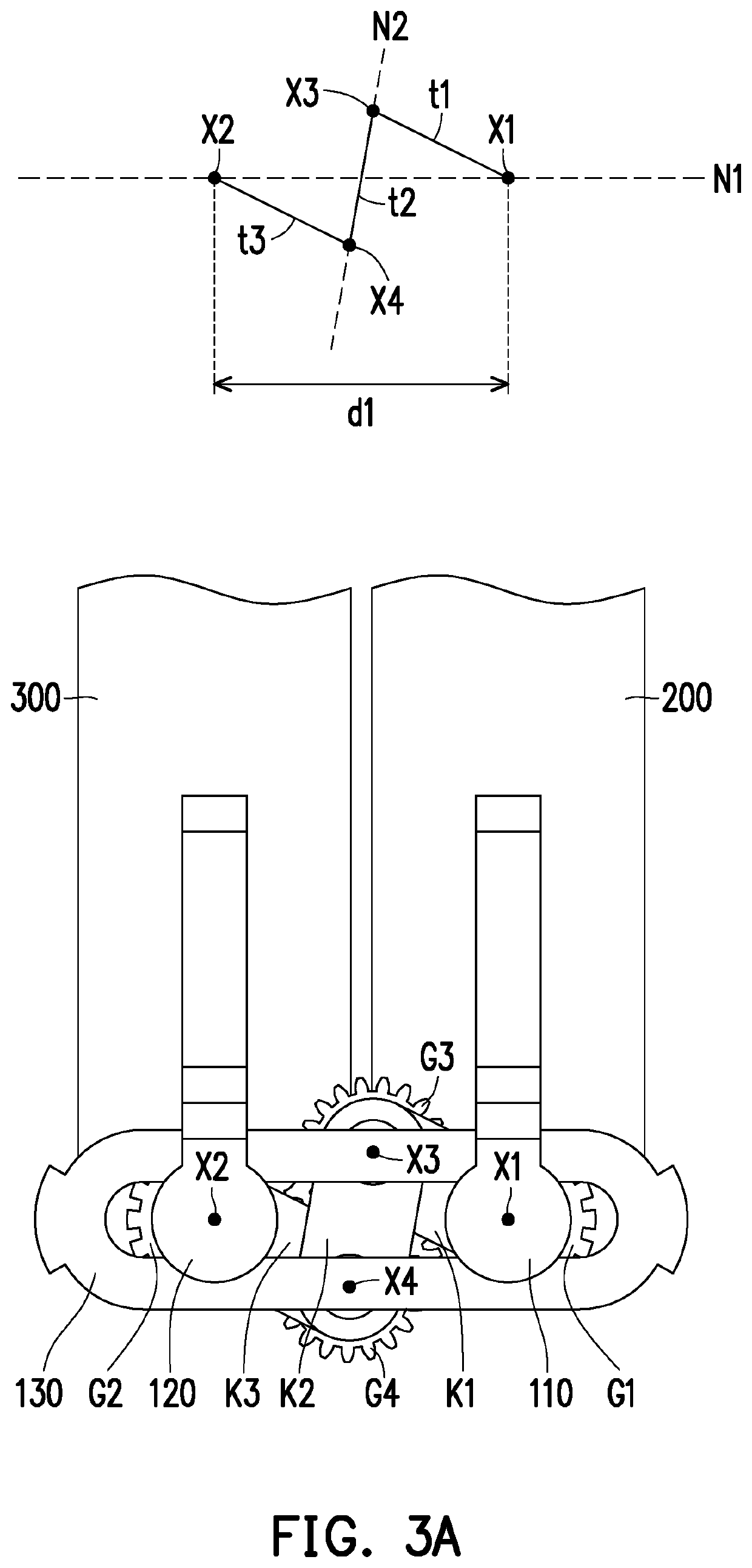

Dual-shaft hinge module and portable electronic device

ActiveUS20200291702A1Rotate synchronouslySynchronous rotationDigital data processing detailsWing accessoriesElectronic equipmentGear wheel

Owner:COMPAL ELECTRONICS INC

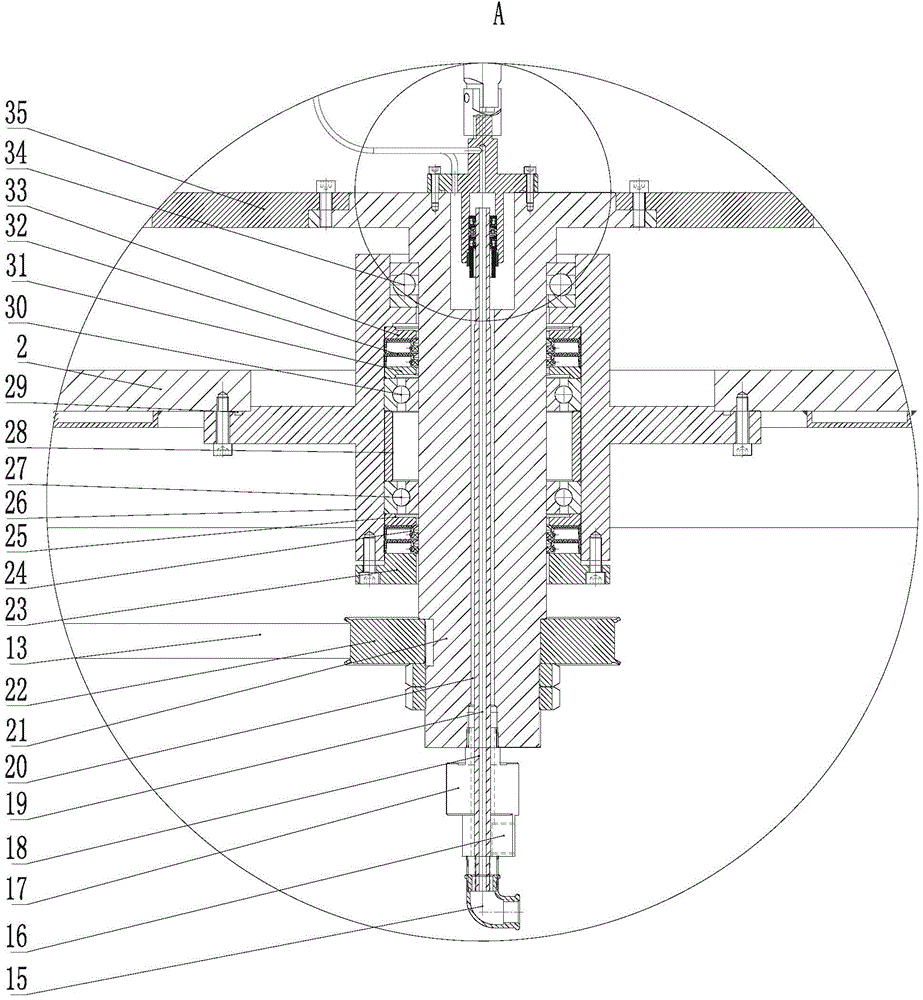

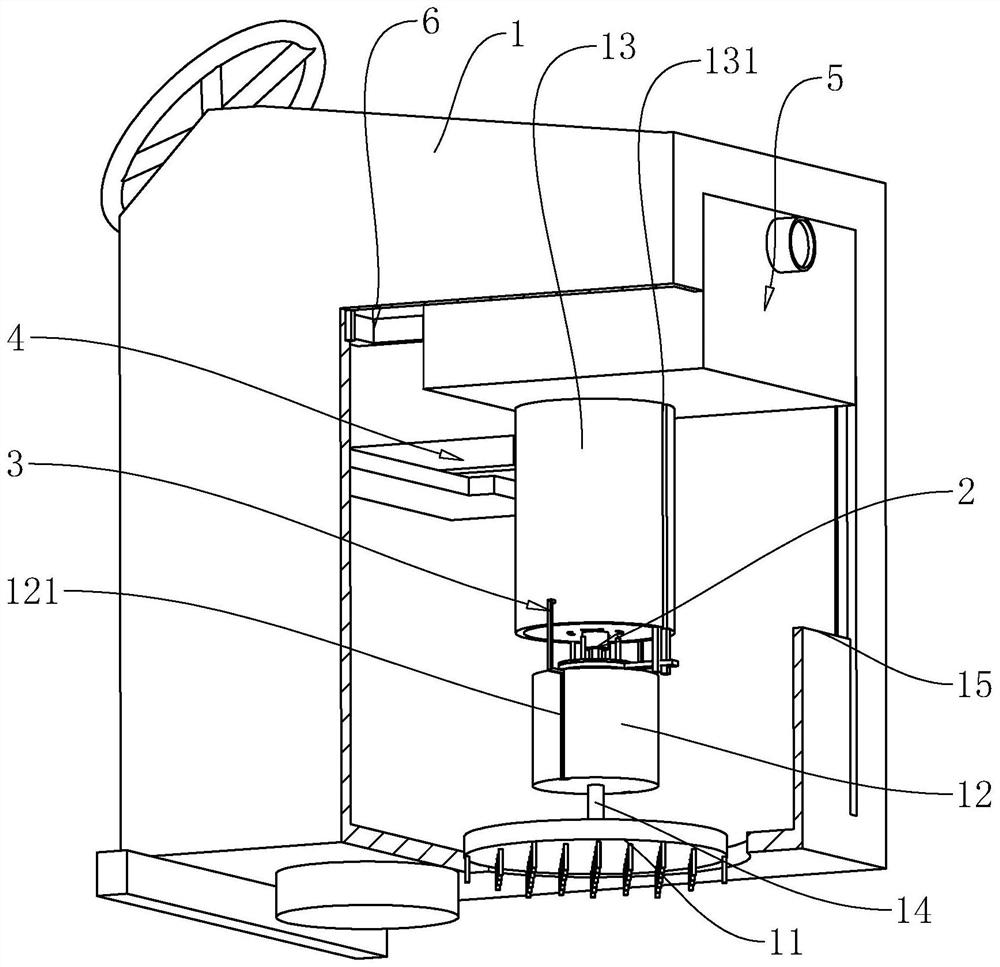

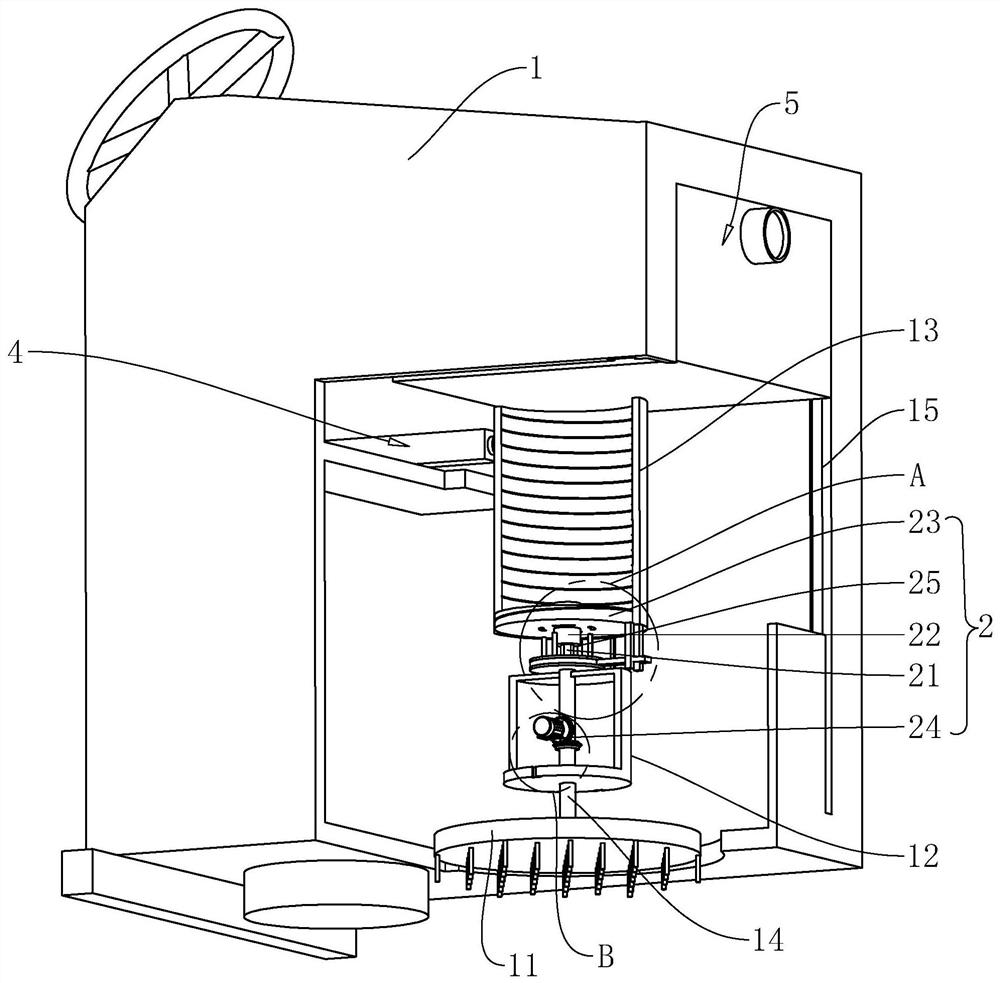

Vacuum optical coating machine capable of moving along with workpiece and in-place dynamically monitoring membrane thickness

ActiveCN104131261ASimple structureImprove reliabilityVacuum evaporation coatingSputtering coatingOptical coatingDynamic monitoring

The invention discloses a vacuum optical coating machine capable of moving along with workpiece and in-place dynamically monitoring the membrane thickness. The host of a membrane thickness controller is arranged on the upper end of a rotation shaft above the top plate of a furnace body, a crystal oscillation probe is arranged on a workpiece rotation rack, the conductive wire and signal wire of the crystal oscillation probe hermetically go through the furnace body from a hollow cavity in the upper part of the rotation shaft; a cooling water circuit hermetically goes through the furnace body from a hollow cavity in the lower part of the rotation shaft, and the separated delivery is achieved in the crystal oscillation probe. The cooling water circuit and the conductive wire and signal wire of a crystal oscillation probe are respectively transferred from the lower part and the upper part of a transmission shaft of a furnace body, the conventional transfer mode that the cooling water circuit, the conductive wire, and the signal wire are all transferred in the upper part of a transmission shaft, is changed, the water transfer and electric transfer are separated, the complicated structure of the transmission shaft is simplified, the reliability of equipment is improved, and the fault rate is reduced.

Owner:DONGGUAN HUICHENG VACUUM TECH

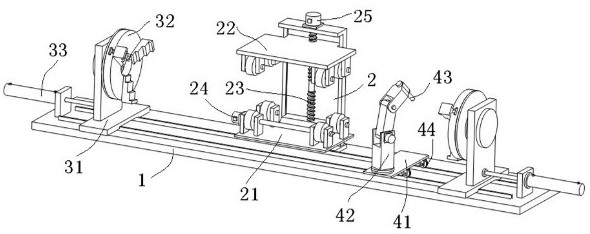

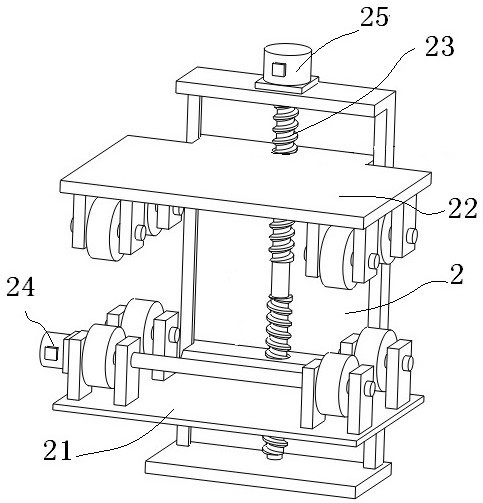

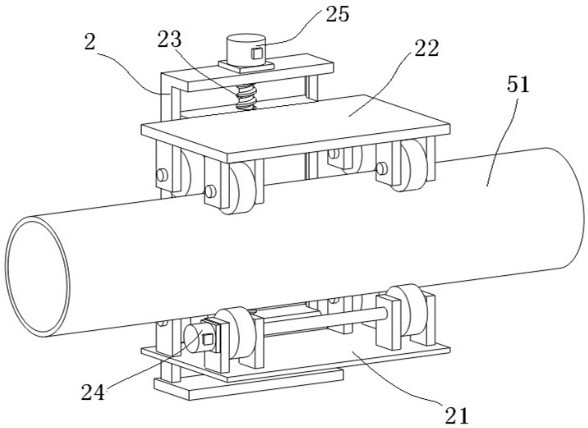

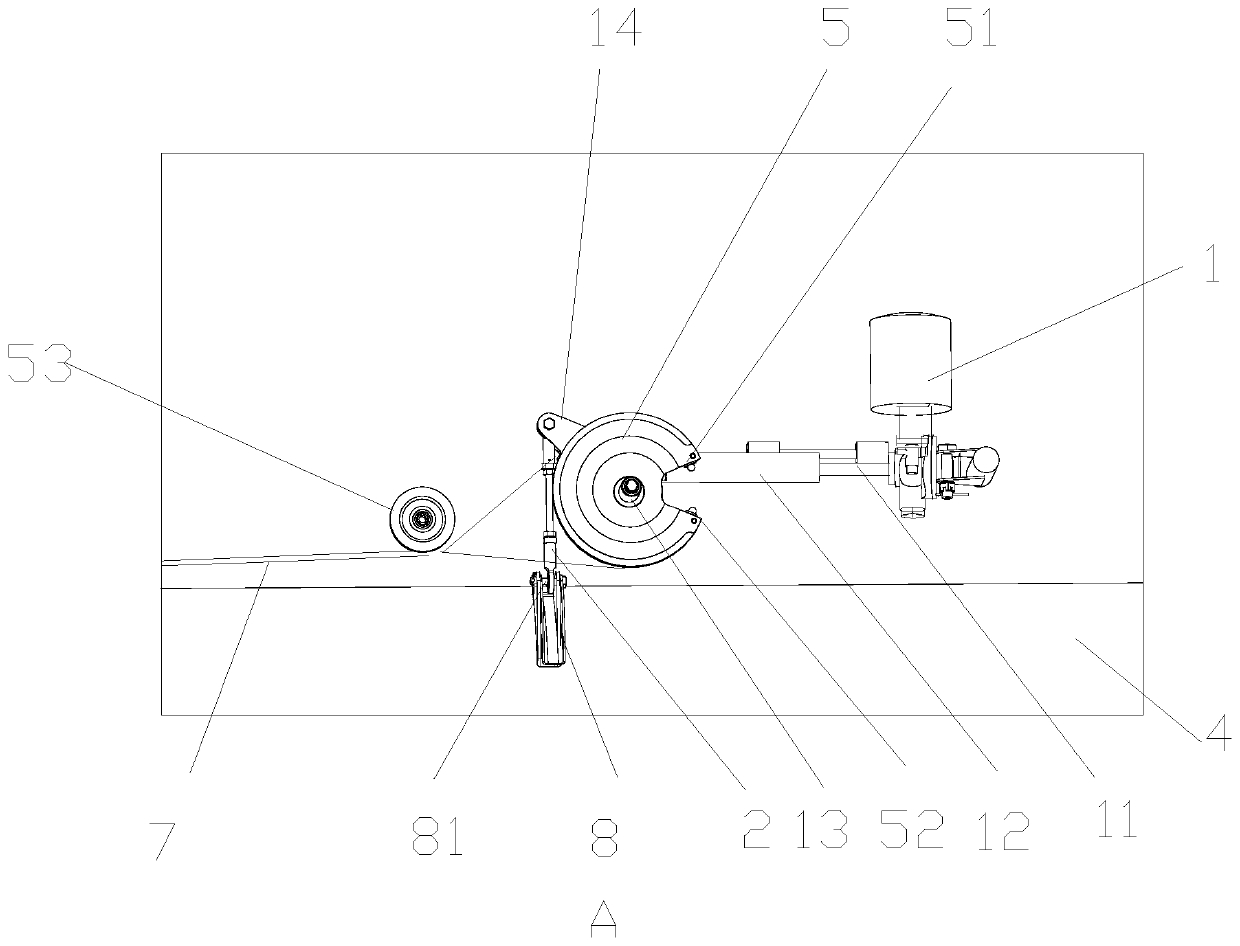

Automatic welding device for end flange of pipefitting

PendingCN112264737AQuick clampingEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesManufacturing engineeringFlange

The invention relates to the technical field of welding automation and provides an automatic welding device for an end flange of a pipefitting. The device comprises a pipefitting rotating unit, a flange supporting unit and a welding gun operating unit. The pipefitting rotating unit is arranged in the middle of a base for clamping and rotatably driving the pipefitting to be welded, and a rack is provided with a centering and clamping driving mechanism for driving a lower roller set and an upper roller set to move synchronously and reversely; the flange supporting unit is arranged at a longitudinal outer end of the base for clamping the flange to be welded and comprises a movable seat and a chuck, and the base is provided with a linear power part for driving the movable seat to move longitudinally; and the welding gun operating unit is arranged on the outer side of the base for moving the automatic welding gun. The automatic welding device for the end flange of the pipefitting can realize clamping, abutting and automatic welding operations of the pipefittings with different lengths and outer diameters to flanges, so that the device is easy to operate, high in degree of automation andsuitable for being applied to operational occasions of welding the pipefittings to the flanges.

Owner:东营胜滋自动化科技有限责任公司

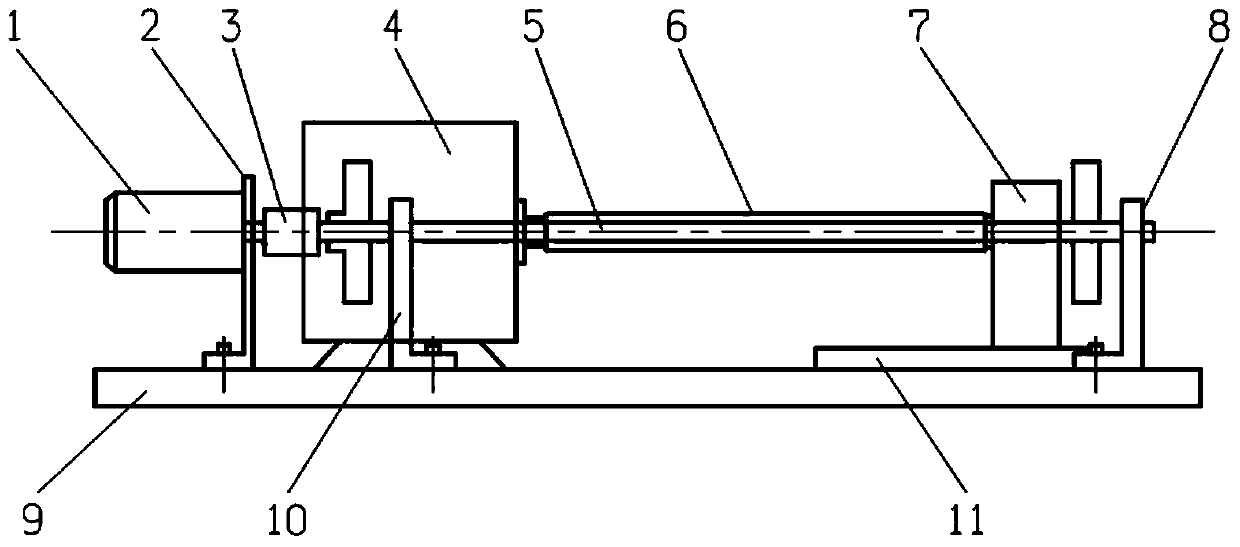

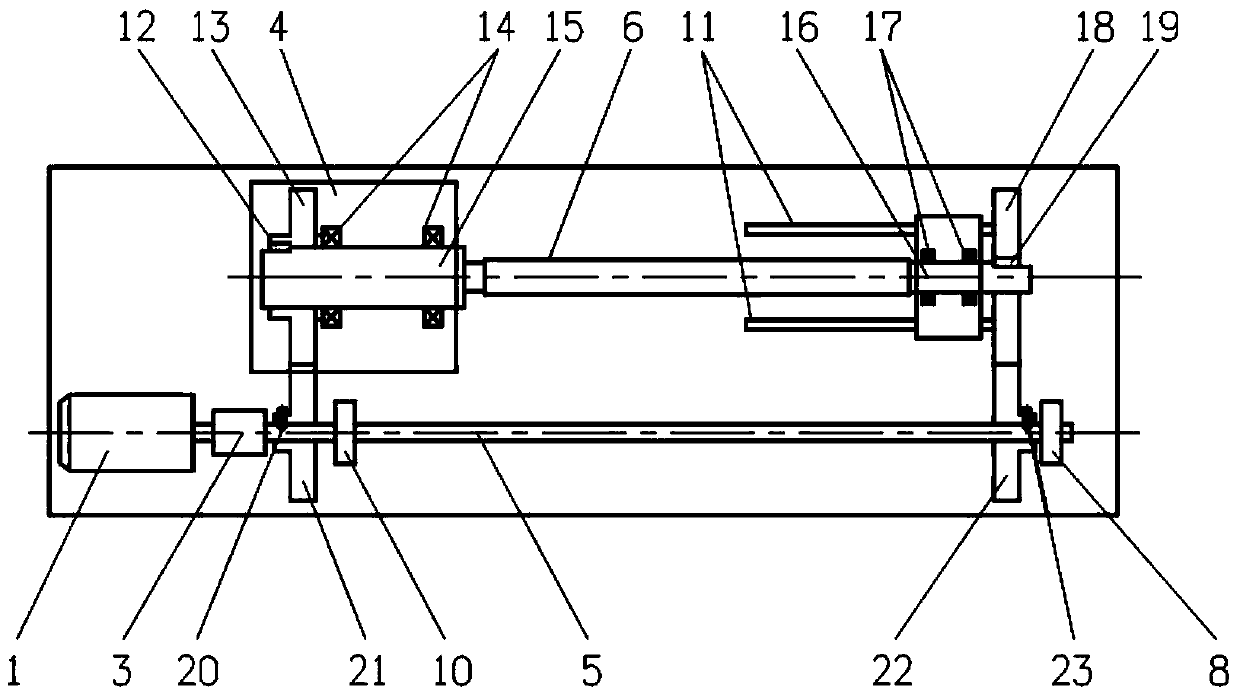

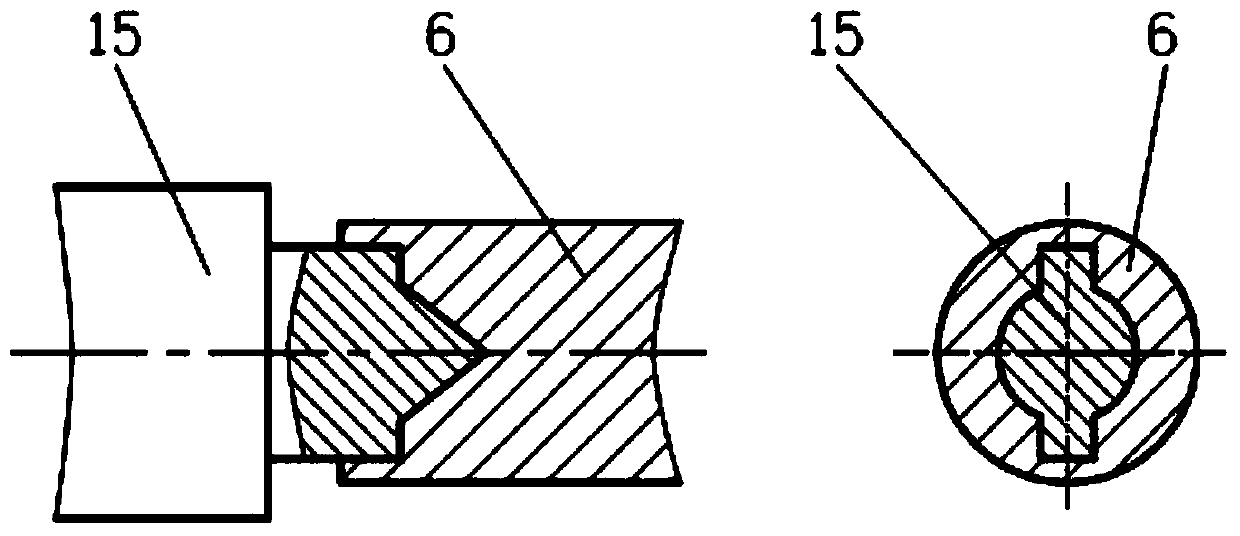

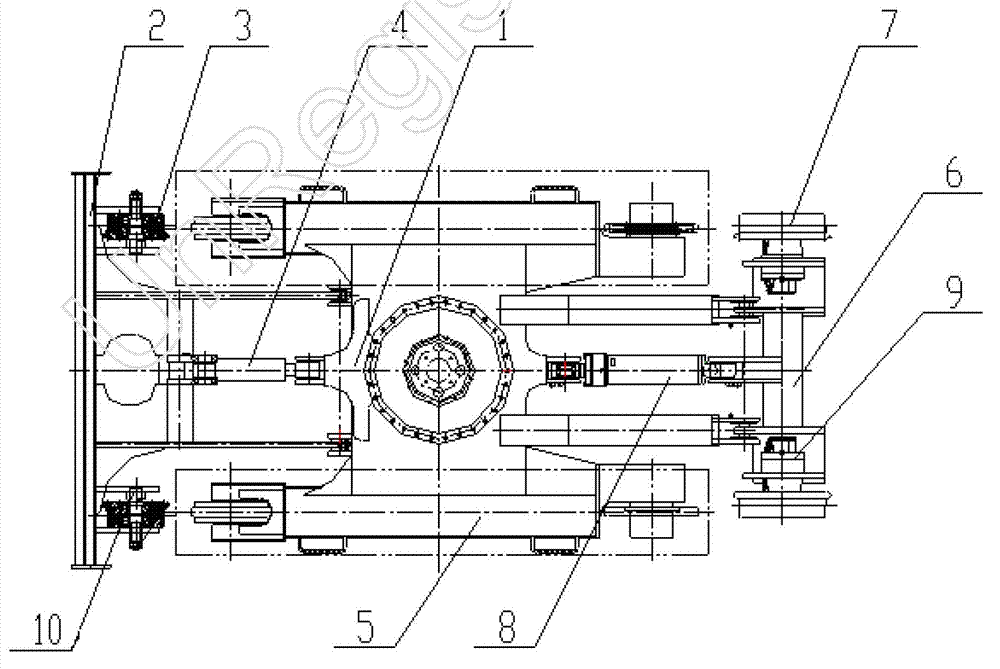

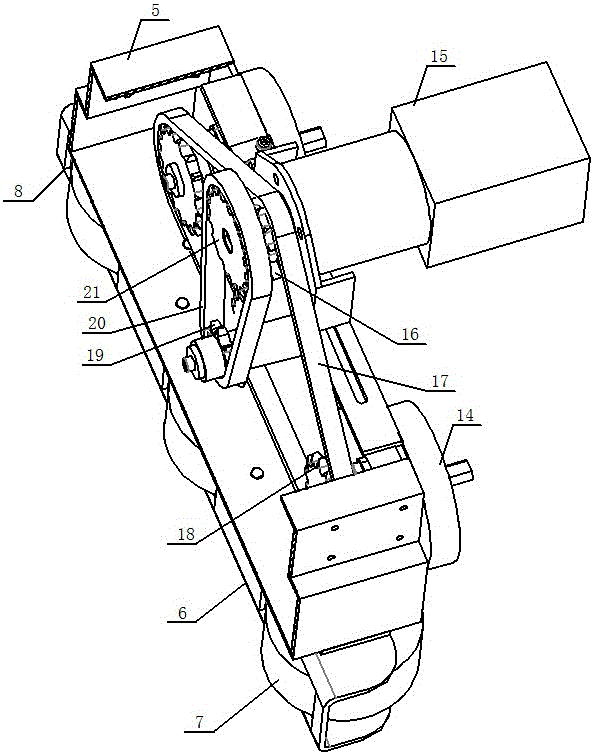

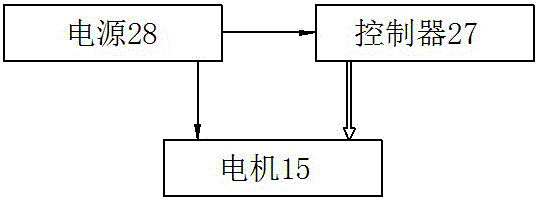

Workpiece clamping and driving device of numerical-control camshaft grinding machine

ActiveCN103737489ARotate synchronouslyNo torsional deformationGrinding drivesGrinding work supportsNumerical controlControl system

The invention relates to a workpiece clamping and driving device of a numerical-control camshaft grinding machine. The workpiece clamping and driving device comprises a workpiece clamping system, a workpiece driving system and an electric control system. The workpiece clamping and driving device has the advantages that the device can be mounted on the numerical-control camshaft grinding machine for clamping a workpiece and driving the workpiece to rotate; the workpiece clamping and driving device of the numerical-control camshaft grinding machine can guarantee that two ends of the workpiece synchronously rotate, torsional deformation can be prevented when the workpiece is machined, and accordingly the machining precision can be improved; a heart carrier for the workpiece clamping and driving device of the numerical-control camshaft grinding machine is omitted, accordingly, the workpiece loading and unloading time can be shortened, and the workpiece machining efficiency can be improved; an existing numerical-control camshaft grinding machine can be modified by the aid of the device, or the device can be used for clamping and driving workpieces of novel numerical-control camshaft grinding machines, and accordingly has an excellent application prospect.

Owner:内江金鸿曲轴有限公司

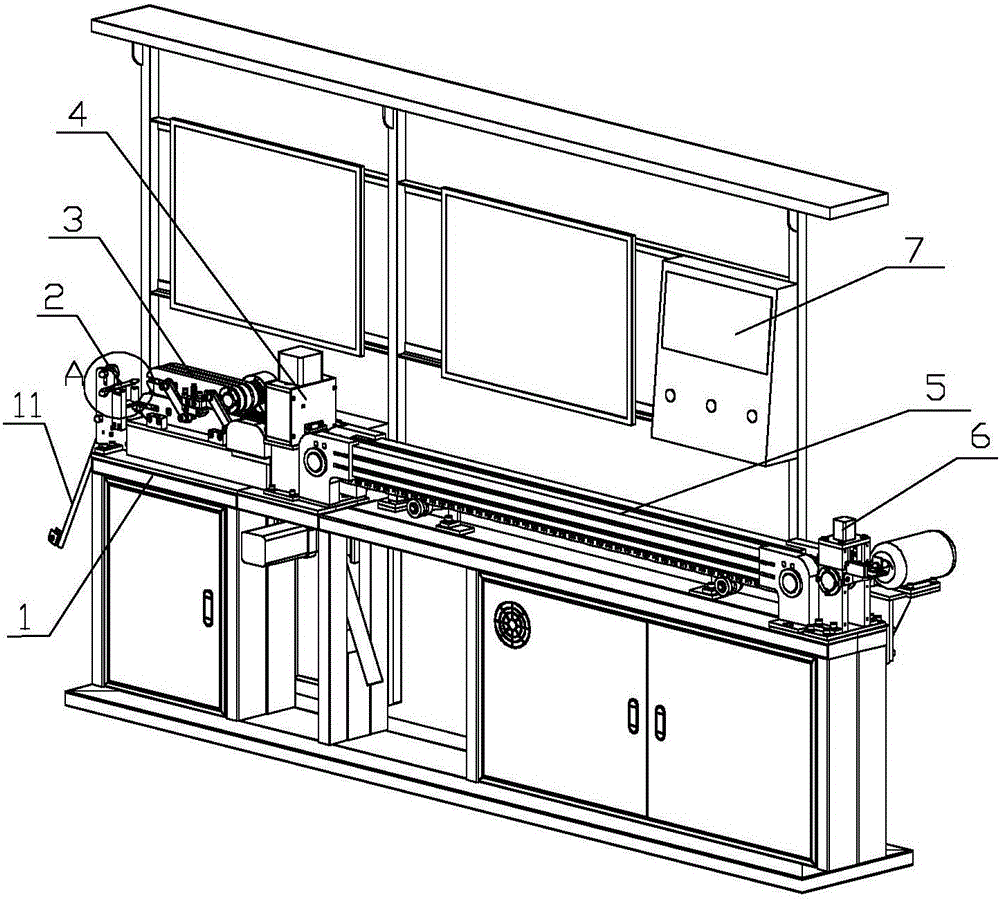

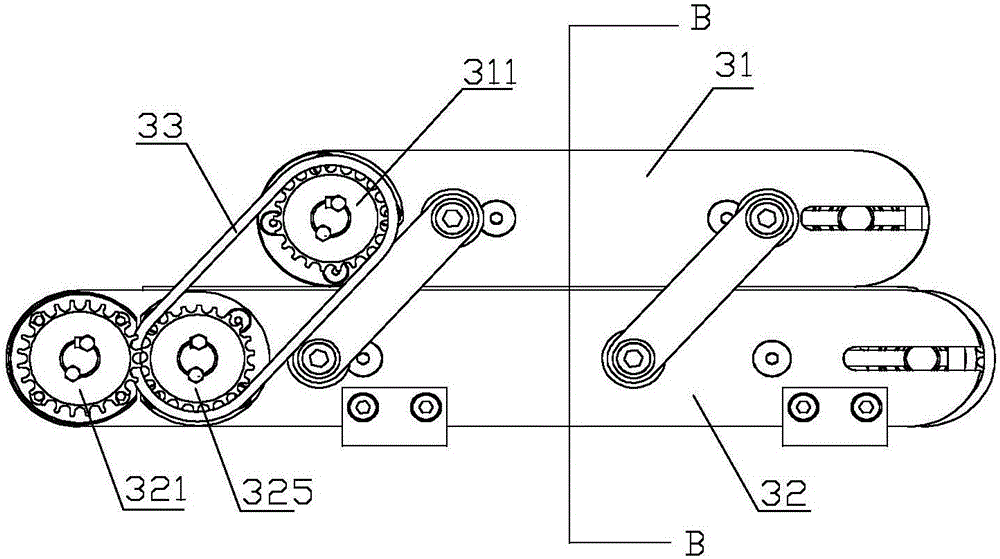

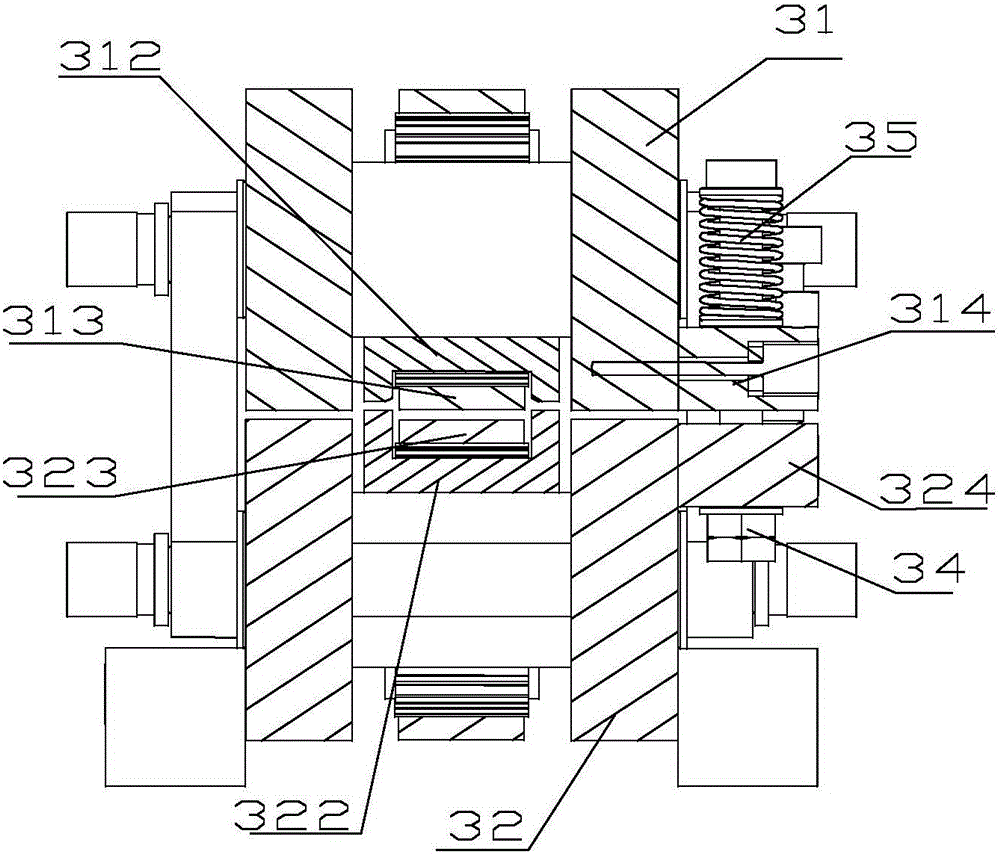

Automatic magnetic strip passing machine

The invention discloses an automatic magnetic strip passing machine. The automatic magnetic strip passing machine comprises a rack and a magnetic strip tractor, wherein the magnetic strip tractor is positioned on the rack, a magnetic strip passes through a guide rod, a pressing wheel and the magnetic strip tractor in sequence, the magnetic strip tractor comprises two conveying machines respectively including an upper conveying machine positioned on the top and a lower conveying machine positioned at the bottom, an upper guide groove is formed in one surface, which is opposite to the lower conveying machine, of the upper conveying machine, a lower guide groove which is opposite to the upper guide groove is formed in the lower conveying machine, a conveying belt of the upper conveying machine is arranged in the upper guide groove, a conveying belt of the lower conveying machine is arranged in the lower guide groove, the magnetic strip is positioned in a gap formed by the conveying belts of the upper conveying machine and the lower conveying machine and is clamped to move forward by the conveying belts of the upper conveying machine and the lower conveying machine, and the gap is positioned in the upper guide groove or the lower guide groove. According to the automatic magnetic strip passing machine, whether the magnetic force of the magnetic strip is qualified can be automatically detected, the traction of the magnetic strip does not slip, the cutting length of the magnetic strip is accurate, the qualified rate of products is increased, and the cost is reduced.

Owner:QINGDAO HENGJUN EQUIP MFG CO LTD

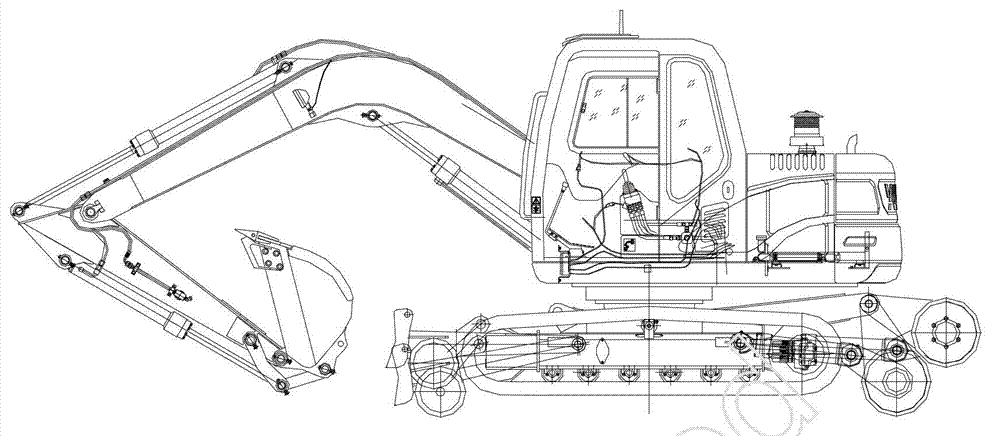

Dual-purpose excavator railway wheel system lifting and driving device for highways and railways

InactiveCN102963227ARotate synchronouslyMechanical machines/dredgersRail and road vehiclesVehicle frameDual purpose

The invention relates to a dual-purpose excavator railway wheel system lifting and driving device for highways and railways. The dual-purpose excavator railway wheel system lifting and driving device comprises a vehicle frame and a push shovel, wherein the front part of the vehicle frame is hinged with the push shovel, the back part of the push shovel is provided with a pair of driven wheels, a front hydraulic oil cylinder is hinged between the middle of the back part of the push shovel and the front end of the vehicle frame, the push shovel is driven through the hydraulic oil cylinder for lifting the driven wheels, the back part of the vehicle frame is hinged with a driving wheel support frame, a pair of driving wheels are arranged on the driving wheel support frame, in addition, a back hydraulic oil cylinder is hinged between the middle of the back part of the driving wheel support frame and the back end of the vehicle frame, the driving wheel support frame is driven through the hydraulic oil cylinder for lifting the driving wheels, and the driving wheels are driven through a hydraulic motor. A railway wheel system capable of realizing the driving lifting through a hydraulic system is hinged at the front and back parts of the existing crawler type excavator vehicle frame, so an ordinary crawler type excavator can operation along the railway, and the dual-purpose excavator railway wheel system lifting and driving device can be widely applied to operations such as railway line emergency repair, new line erection and cable construction at two sides of the railways.

Owner:中铁宝工有限责任公司

Intelligent walking rehabilitation nursing device

ActiveCN106924933ARotate synchronouslyHigh strengthMovement coordination devicesCardiovascular exercising devicesAccelerometerGyroscope

The invention discloses an intelligent walking rehabilitation nursing device, and belongs to the technical field of rehabilitation nursing. The intelligent walking rehabilitation nursing device comprises a rotating disc as well as an MEMS (Micro-electromechanical Systems) sensor module, wherein a walking training mechanism is arranged above the rotating disc; a steering mechanism is arranged below the rotating disc; a control module is arranged on the rotating disc and positioned beside the walking training mechanism; the MEMS sensor module is worn by a patient; the MEMS sensor module comprises an MEMS gyroscope, an MEMS accelerometer and a wireless signal emitter; the wireless signal emitter is in electric signal connection with the control module. By adopting the intelligent walking rehabilitation nursing device, not only are simulated rehabilitation training environments such as flat ground, upslope and downhill provided for patients, but also advancing directions of the intelligent walking rehabilitation nursing device can be changed according to turning action of the patients, then baldness and upset emotion caused by view limits in walking rehabilitation training can be eliminated for the patients, and thus rehabilitation of the patients can be facilitated.

Owner:NANYANG CITY CENT HOSPITAL

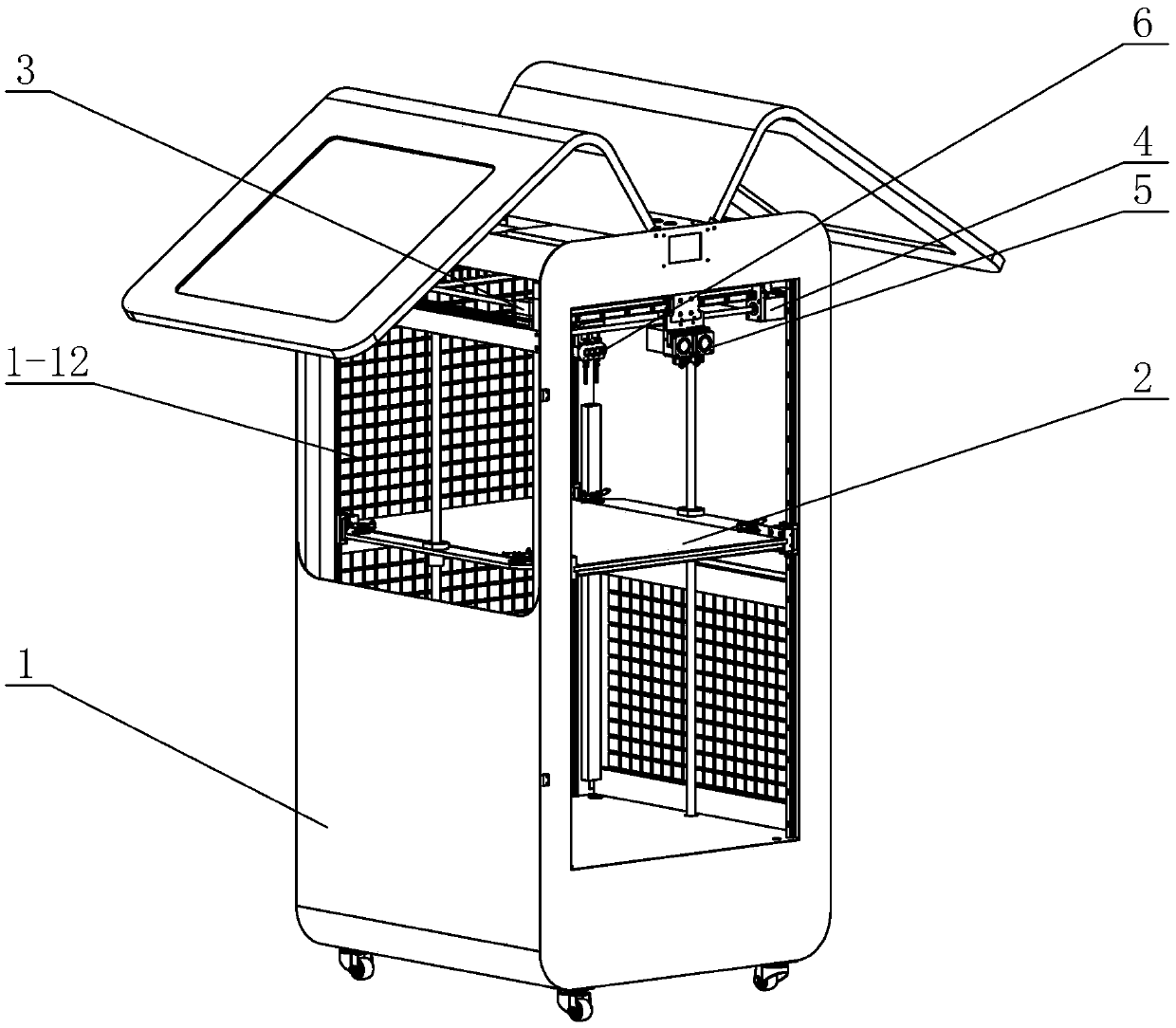

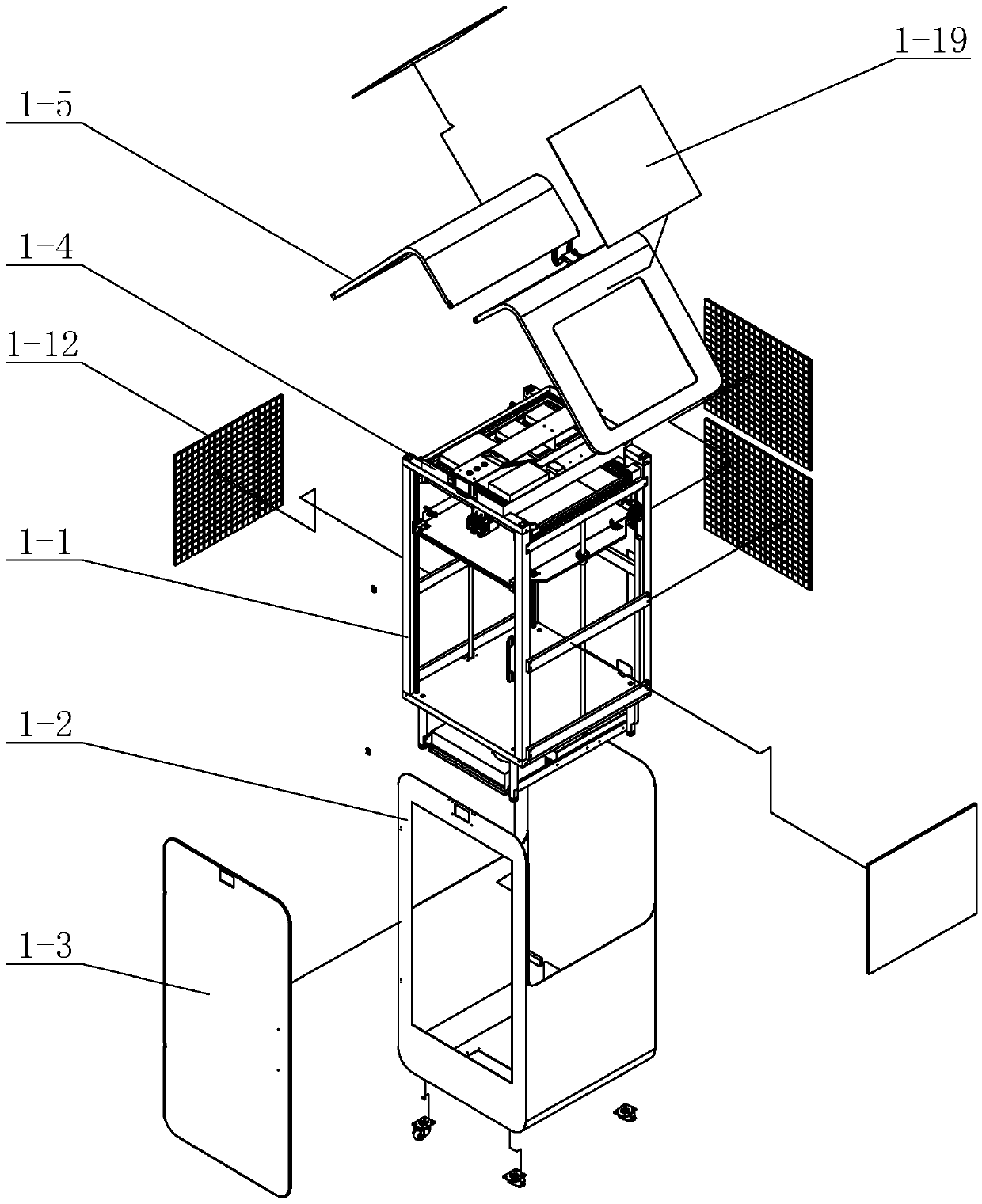

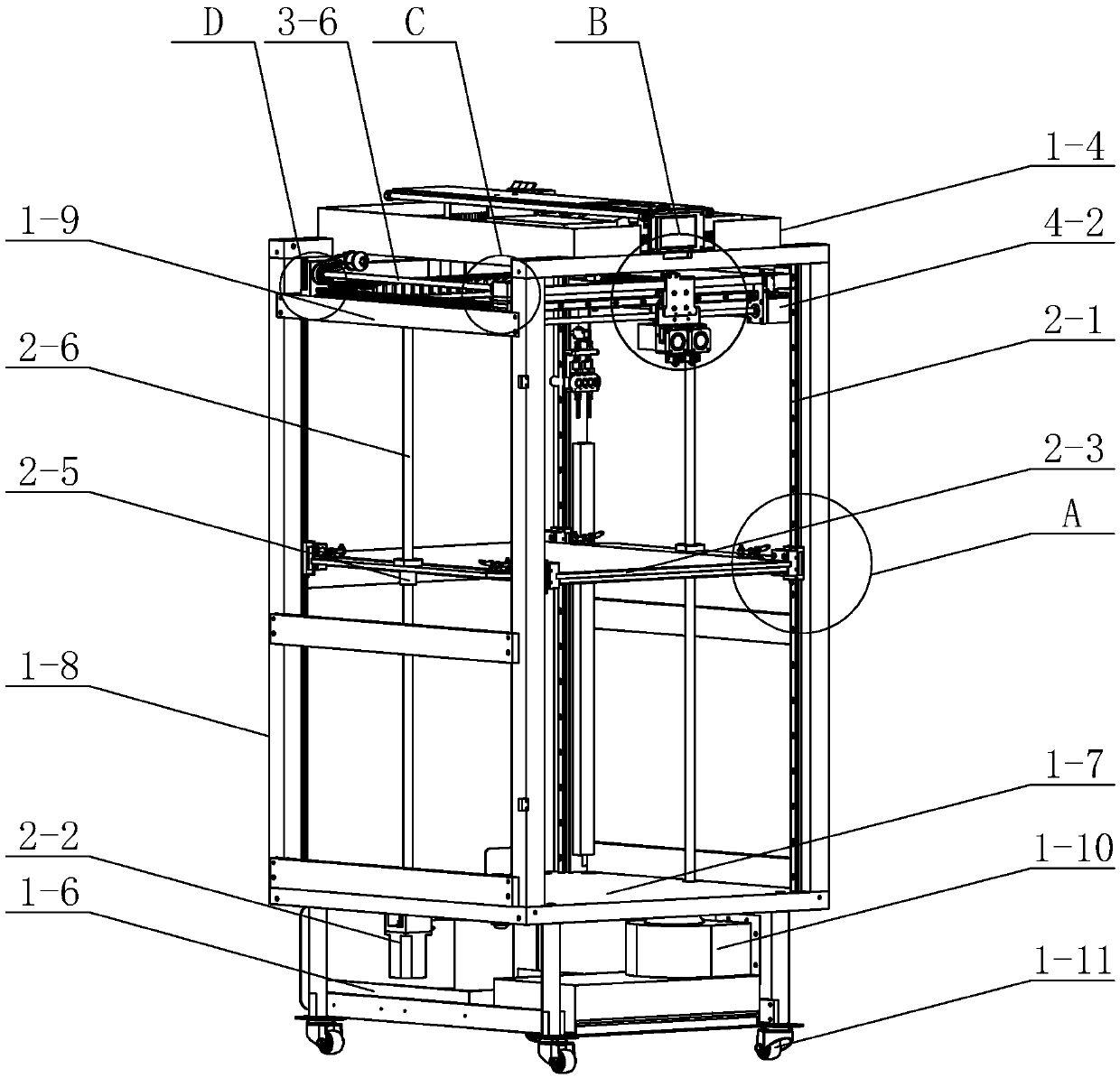

Intelligent high-speed high-precision 3D printer

ActiveCN105500718AImprove stabilityImprove printing accuracyAdditive manufacturing apparatusIntelligent lightingEngineering

The invention discloses an intelligent high-speed high-precision 3D printer and mainly relates to the technical field of 3D printing. The intelligent high-speed high-precision 3D printer comprises a machine shell, a Z-axis movement mechanism, a Y-axis movement mechanism, an X-axis movement mechanism and an extruding machine. The machine shell is of a sealed structure and comprises an internal frame and an external shell. The Z-axis movement mechanism comprises Z-axis guide rails, Z-axis lead screws, a Z-axis stepping motor, a Z-axis synchronous pulley and a benchmark platform. The Y-axis movement mechanism comprises Y-axis guide rails, Y-axis lead screws, a Y-axis stepping motor, a Y-axis synchronous and a supporting frame. The X-axis movement mechanism comprises X-axis guide rails, X-axis lead screws, a spray head frame and an X-axis stepping motor. The intelligent high-speed high-precision 3D printer has the advantages that high stability is achieved, high-precision printing can be achieved in the high-speed printing process, it is facilitated to take out a printing model, equipment operation noise can be lowered, and harm, caused by toxic polymeric particles generated in the printing process, to the human body can be avoided.

Owner:WUHU AISANDI ELECTRONICS TECH CO LTD

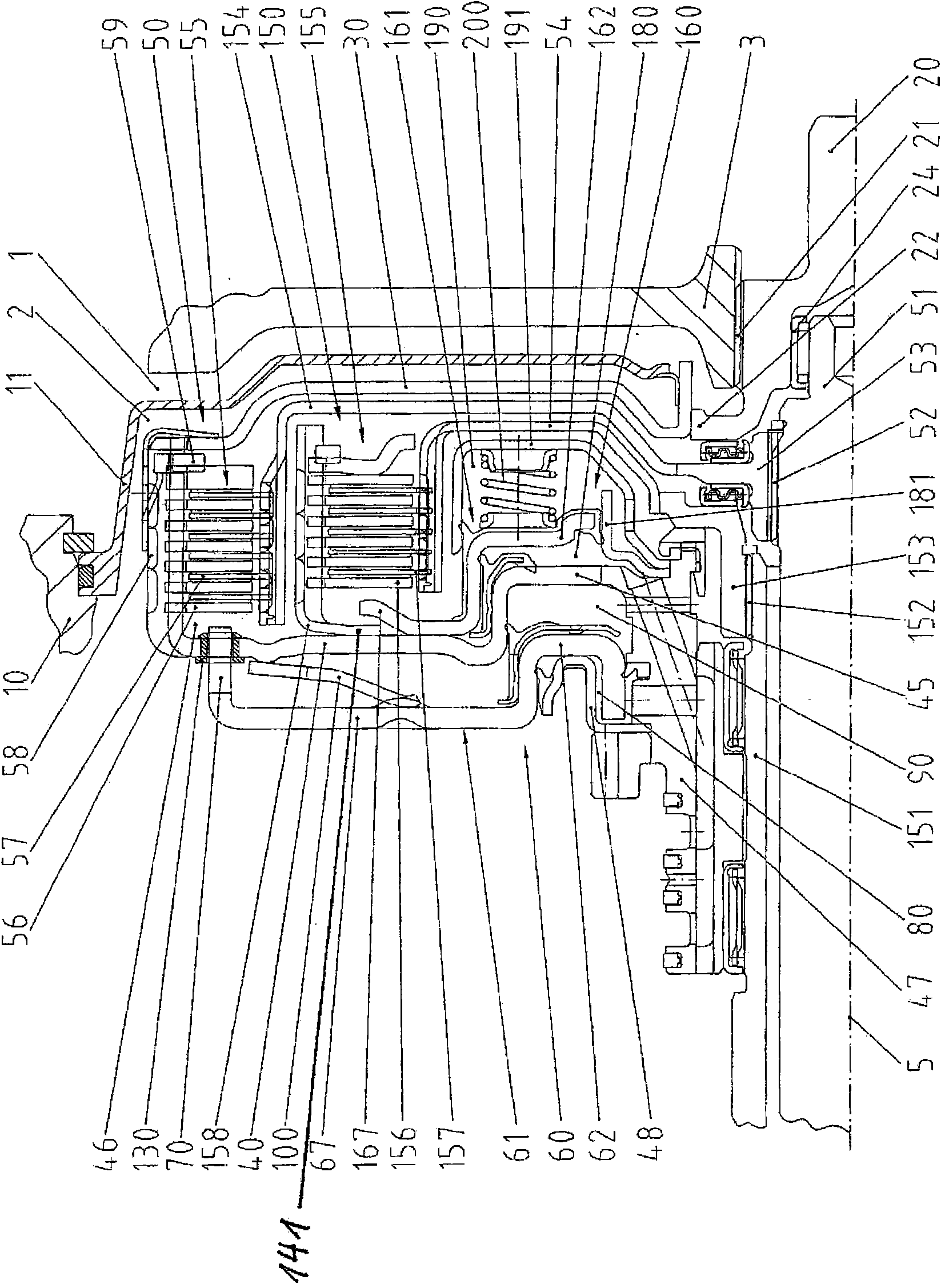

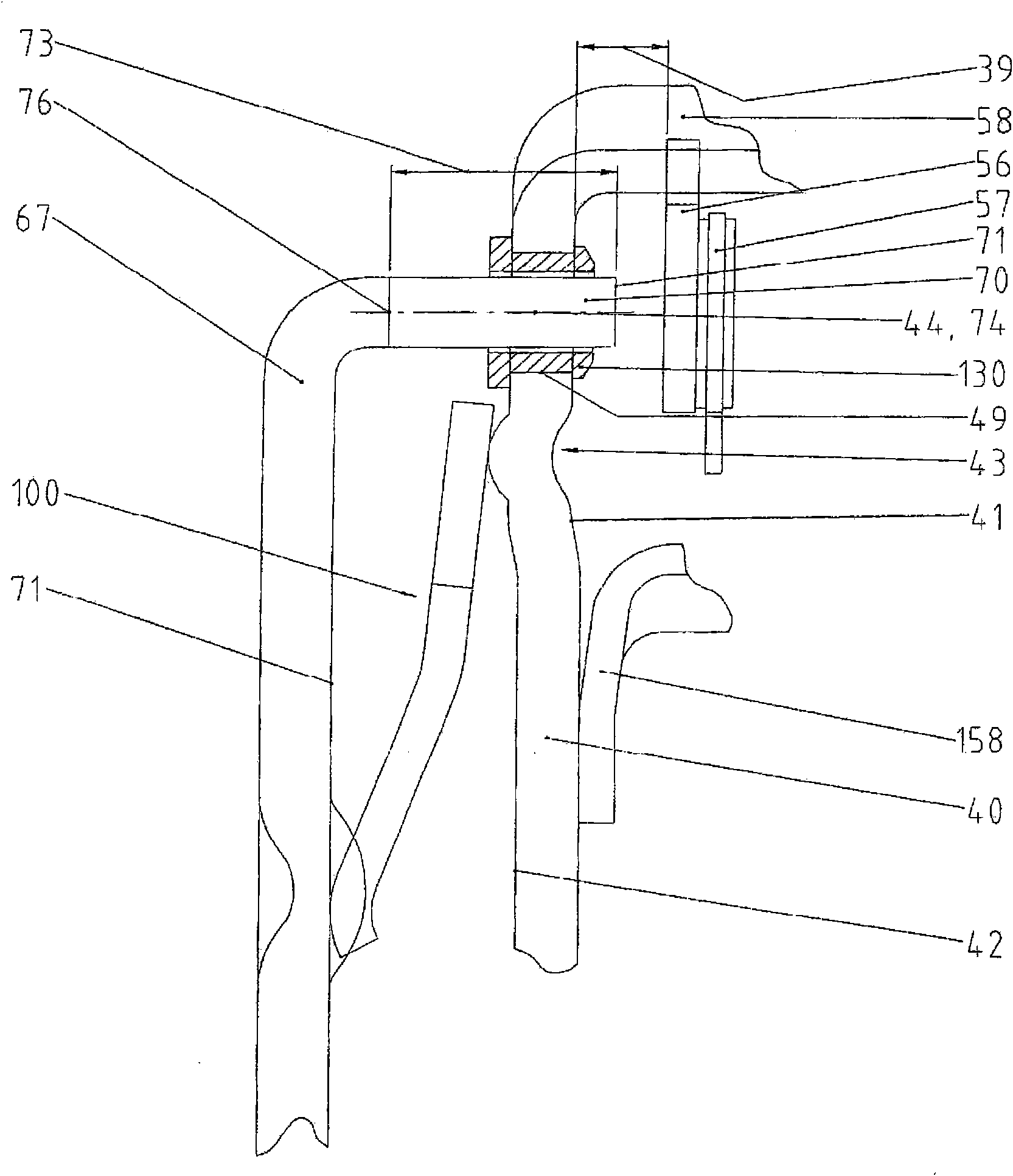

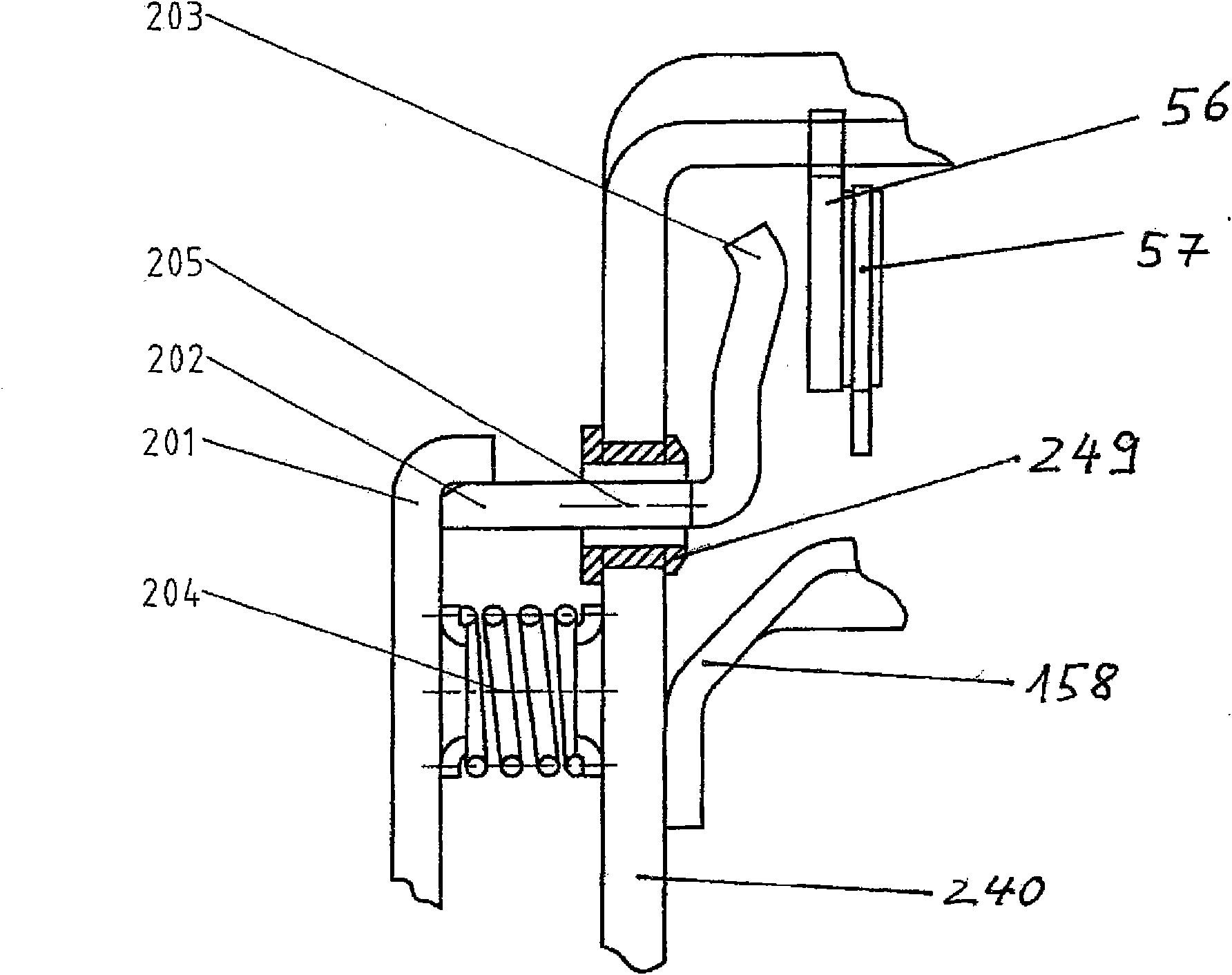

Dual clutch arrangement having a piston guide element

ActiveCN101675263ARotate synchronouslyMechanical actuated clutchesFluid actuated clutchesMobile vehiclePiston Guide

The invention relates to a clutch system for motor vehicle drives having a clutch input shaft (20) and at least one transmission input shaft (51,151), wherein the transmission input shaft is connectedto the clutch input shaft via a fluid-lubricated and cooled friction clutch (50, 150) equipped with slat packs (55, 155), which is positioned in the transmission space, and wherein at least one slatpack is pressed against a stop (59) for coupling via a force transmission element (62) that can be moved by an actuating member (60, 160). At least one coupling component of the friction clutch has aplurality of recesses (49) in the region of the corresponding slat pack. The force transmission section of the corresponding actuating member further comprises a plurality of fingers (70) that act upon the corresponding slat pack through the recesses. The present invention creates a clutch system comprising an exterior slat carrier having a short construction size in the axial direction with at least one clutch.

Owner:BORGWARNER INC

Coupler assembly

InactiveCN102927141AGuaranteed no axial movementMachining accuracy does not need to be too highGas turbine plantsCouplings for rigid shaftsCouplingGas compressor

Owner:HARBIN DONGAN ENGINE GRP

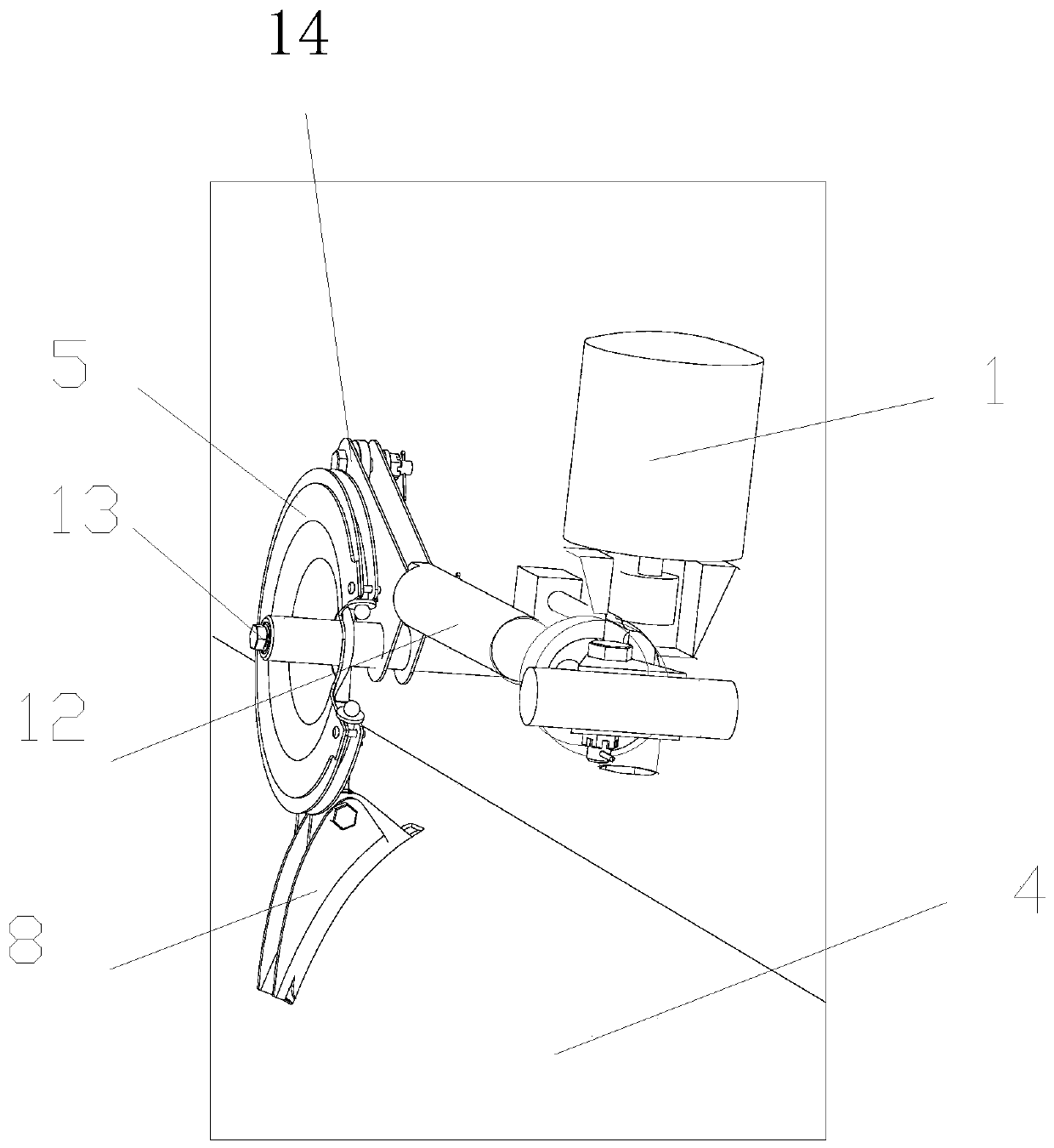

Seed sowing wheel component capable of adjusting sowing rate and seed sowing device

PendingCN110419304AImprove practicalityIncrease elasticitySeed depositing seeder partsMechanical engineeringSowing

The invention provides a seed sowing wheel component capable of adjusting sowing rate and a seed sowing device. The seed sowing wheel component capable of adjusting the sowing rate comprises a seed sowing wheel, an adjusting shaft, an adjusting nut and an elastic ejector part, the adjusting nut is connected on the adjusting shaft in a threaded manner, the elastic ejector part is arranged on the adjusting shaft in a sleeving manner and elastically abutted to a first wheel and a second wheel, the seed sowing wheel includes the first wheel and the second wheel which are coaxial, a plurality of cavities are alternately formed in the peripheral surface of the first wheel along a peripheral direction of the first wheel at intervals, the lengths of the cavities are different, each cavity extendsalong an axis direction of the first wheel, a plurality of projecting columns are alternately and correspondingly distributed on the peripheral surface of the second wheel at intervals, the lengths ofthe projecting columns are different, the projecting columns are placed into the corresponding cavity to form holes for containing seeds, and the sizes of the holes can be adjusted as the adjusting nut is screwed in or screwed out. According to the seed sowing wheel component capable of adjusting the sowing rate, the sowing rate can be adjusted, and the component has good practicability.

Owner:HEBEI AGRICULTURAL UNIV.

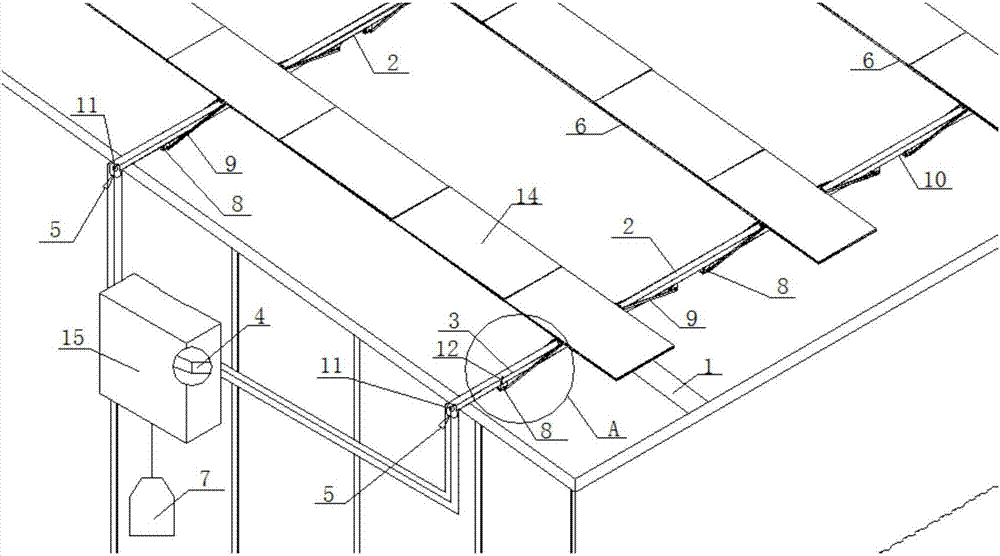

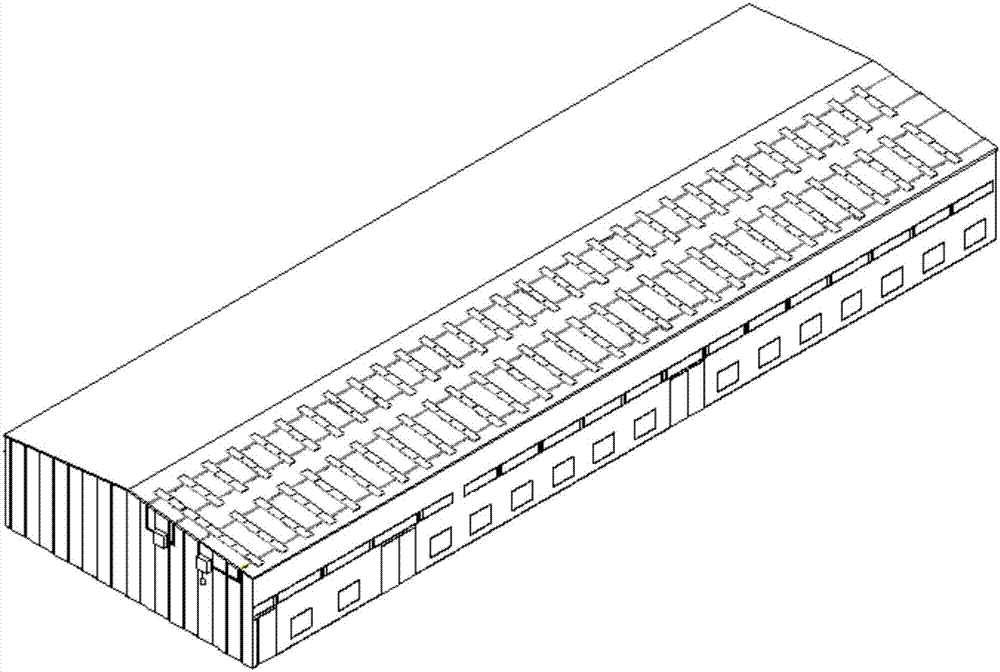

Rooftop linkage tracing photovoltaic stent and photovoltaic power generation system

InactiveCN107171628AEnsure safetyAvoid lostPhotovoltaic supportsSolar heat devicesLinkage conceptPhotovoltaic power generation

The invention discloses a rooftop linkage tracing photovoltaic stent and a photovoltaic power generation system, which belongs to the technical field of photovoltaic power generation equipment. The stent comprises a driving mechanism, guide rails and a component unit. The guide rails are laid on rooftop and are fixed. The component unit is arranged across two adjacent guide rails, and comprises a component frame, a sliding part and a connecting rod. The sliding part is arranged in the guide rails. One end of the connecting rod is hinged with the sliding part. The other end is hinged with the component frame. The driving mechanism is applied to the sliding part of the component unit. When the photovoltaic stent is used, the connecting rod is pushed to hold up or lay the component frame. The whole photovoltaic stent structure can be close to the rooftop plane, which effectively reduces wind resistance; the weight of the entire photovoltaic stent structure is light, which reduces the overall structural strength requirement; and the rooftop linkage tracing photovoltaic stent and the photovoltaic power generation system have the advantages of long service life, simple structure, reasonable design and easy manufacture.

Owner:安徽含羞草智能科技有限公司

Floor brushing machine with full-automatic brush cleaning function

ActiveCN112493937AEasy to cleanReduce labor intensityCarpet cleanersFloor cleanersRotational axisBrush

The invention relates to a floor brushing machine with a full-automatic brush cleaning function. The floor brushing machine comprises a floor brushing machine body, brushes arranged at the bottom of the floor brushing machine body, lifting cylinders arranged above the brushes at intervals, sleeves arranged above the lifting cylinders at intervals, rotating shafts arranged between the sleeves and the brushes, telescopic mechanisms arranged on one sides of the sleeves and used for driving the sleeves to move, guide mechanisms arranged between the sleeves and the lifting cylinders. a lifting mechanism arranged between the sleeve and the lifting cylinder, a cleaning box connected to the floor brushing machine body in a sliding mode, and a moving mechanism arranged between the cleaning box andthe floor brushing machine body. One end of the rotating shaft is detachably connected with the brush, the other end of the rotating shaft can slide in the sleeve, the rotating shaft penetrates through the lifting cylinder and is rotationally connected with the lifting cylinder, the inner diameter of the sleeve is larger than the diameter of the lifting cylinder, the lifting cylinder can slide inthe sleeve, and a cleaning outlet is formed in the floor brushing machine body, and a brush inlet is formed in the top of the cleaning box, and the brush of the floor brushing machine is convenient toclean.

Owner:深圳市启明城市环境产业服务有限公司

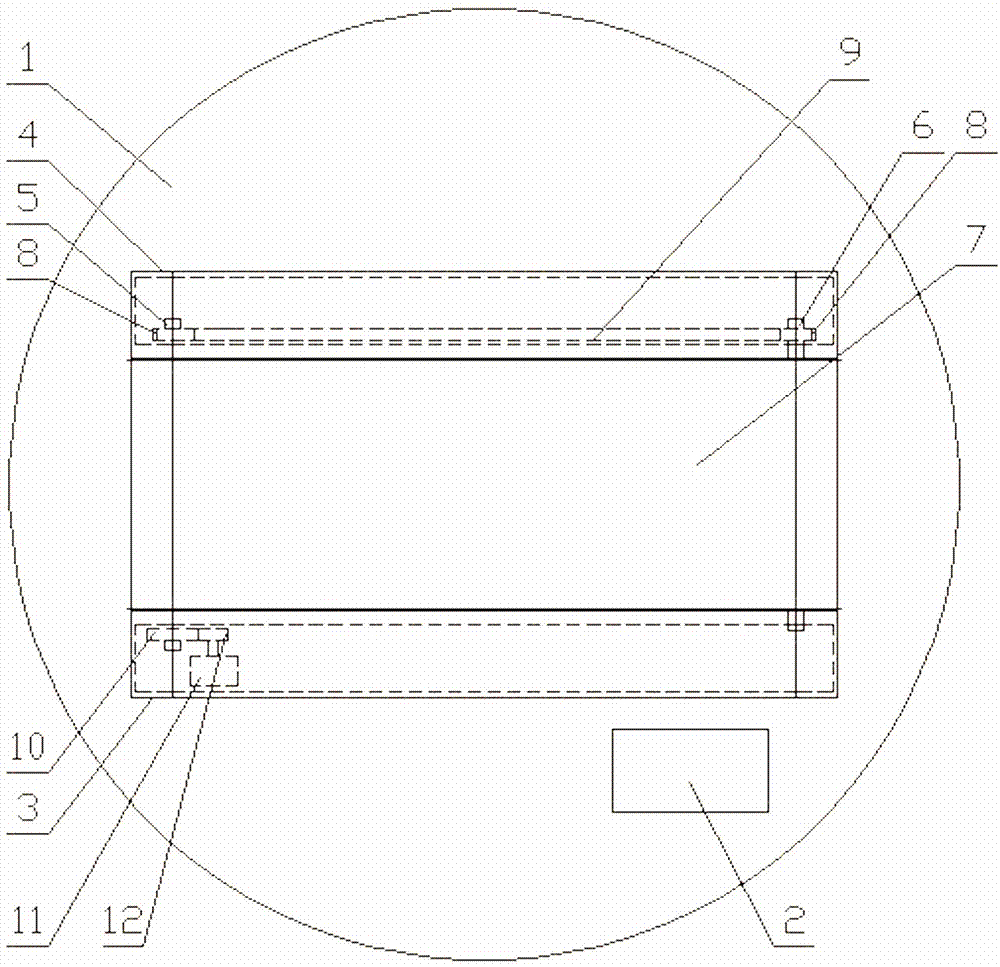

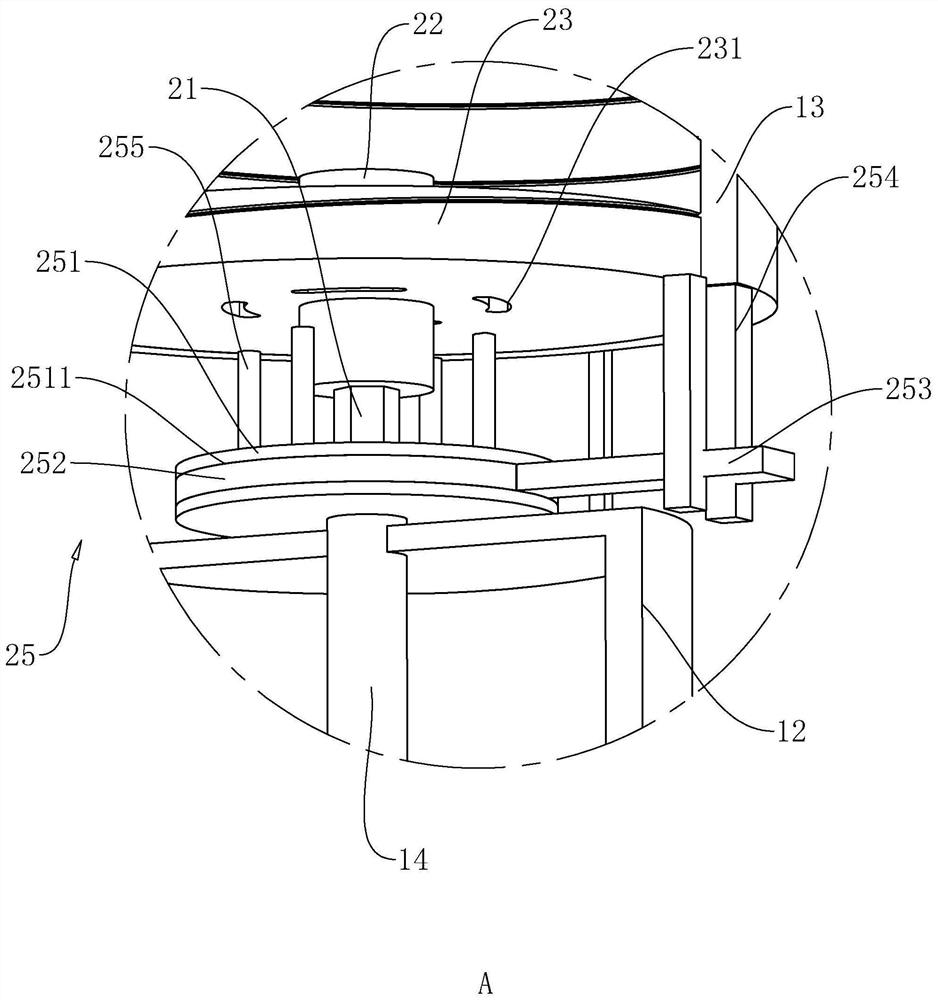

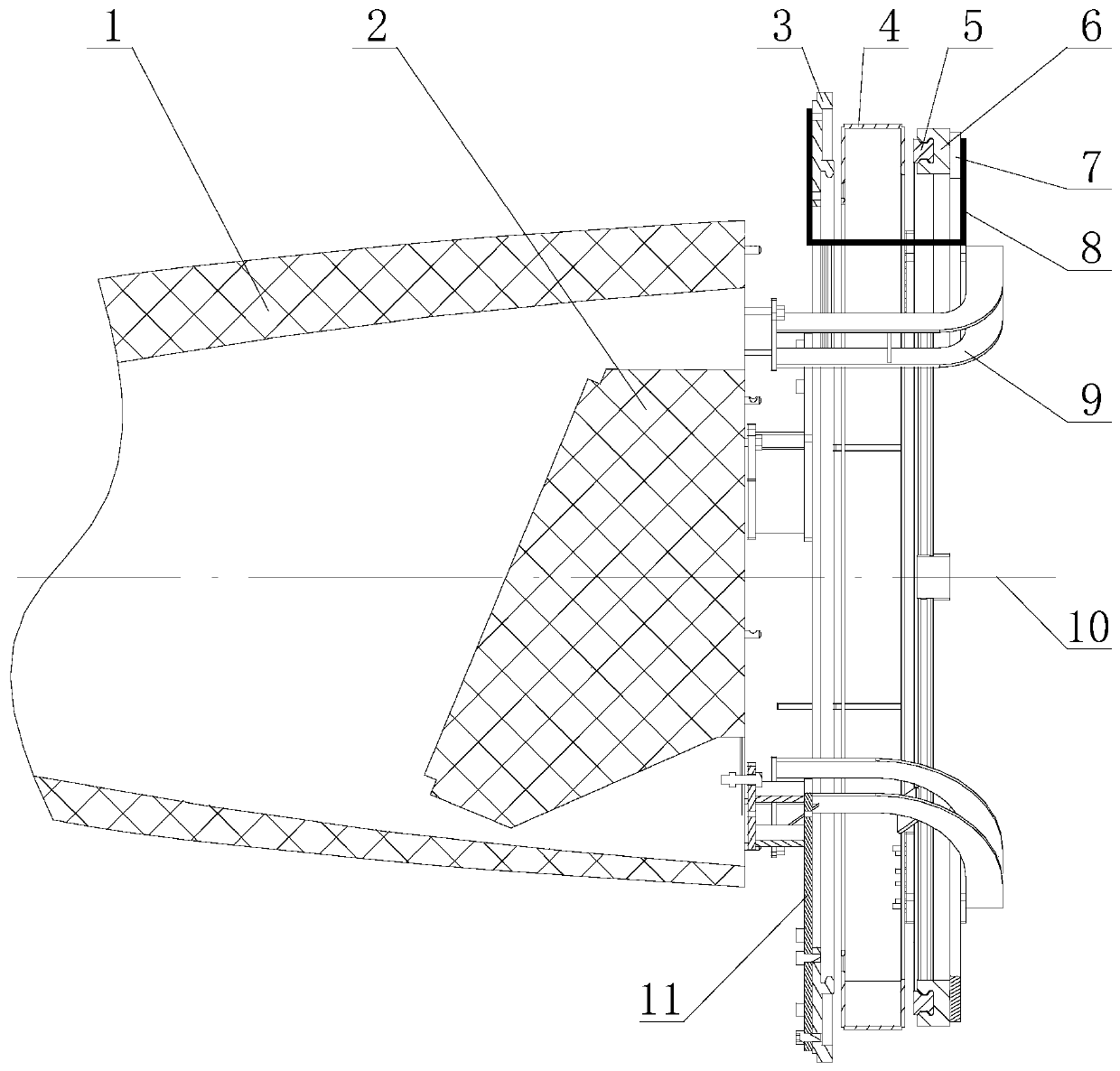

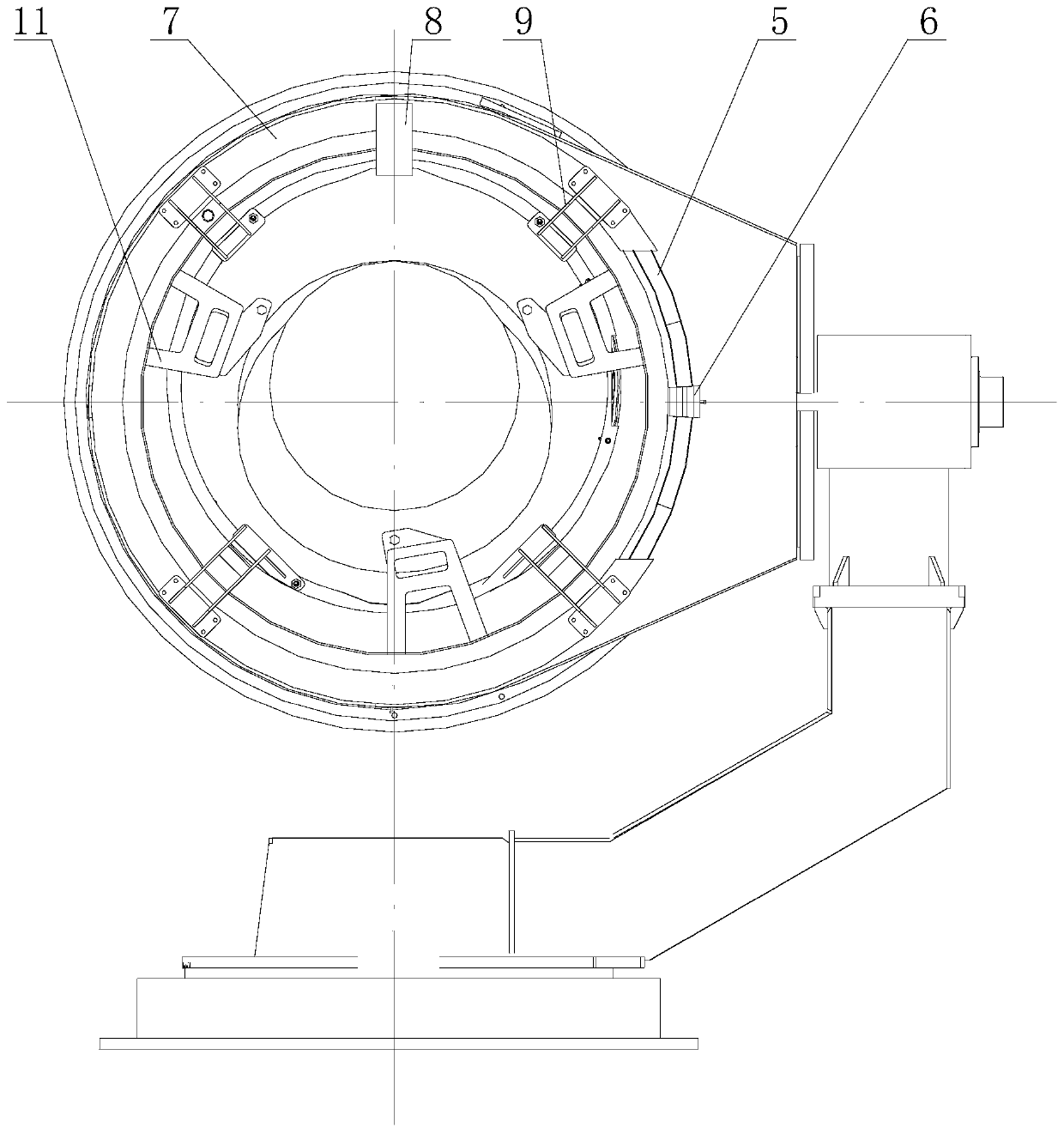

Multi-angle adjustment device for electric performance testing of large radome

InactiveCN110456187ARotate synchronouslyImprove test efficiencyElectrical testingMeasurement instrument housingTest efficiencyElectricity

The invention belongs to the technical field of radome tooling design and particularly relates to a multi-angle adjustment device for electric performance testing of a large radome. In the process ofthe electric performance testing of a phased array radome, the testing posture changes frequently and the time and energy are wasted. The multi-angle adjustment device comprises an annular turntable;a front end of the annular turntable is provided with a rotatable rolling ring; an antenna is mounted on the rolling ring; a circular sliding rail is further mounted on a rear end of the annular turntable; a mounting ring is rotatably mounted on the sliding rail through a slider; two ends of a U-shaped connecting plate are respectively connected with the rolling ring and the mounting ring; one endof a mounting claw is mounted on the mounting ring, and the other end of the mounting claw is connected with the radome after passing through a middle hole of the mounting ring, the circular turntable and the rolling ring. The working procedure that the radome and a clamp thereof need to be dismounted each time the posture is changed is omitted, and the rolling ring and the mounting ring can be controlled to roll synchronously through a computer, thus the manufacturing cost is low, the operation is convenient and the testing efficiency is improved.

Owner:THE RES INST FOR SPECIAL STRUCTURES OF AERONAUTICAL COMPOSITE AVIC

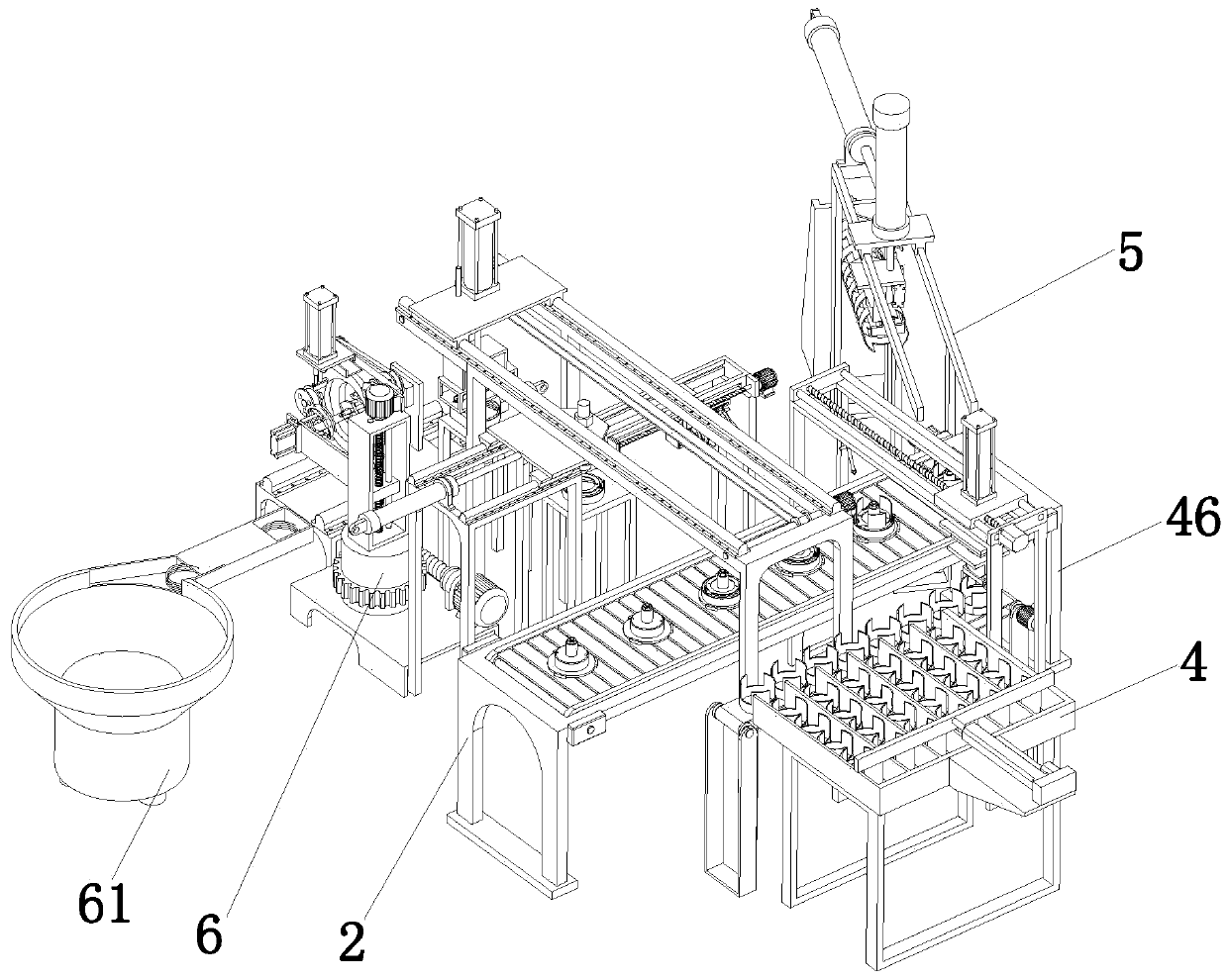

Core pipeline assembling mechanism of automatic production line of anesthesia evaporator core

InactiveCN110948220AEasy to installRotate synchronouslyLiquid surface applicatorsWelding/cutting auxillary devicesCotton clothEngineering

The invention provides a core pipeline assembling mechanism of an automatic production line of an anesthesia evaporator core. The core pipeline assembling mechanism comprises a vibrating disc, a cotton cloth wrapping assembly, a ridge framework feeding assembly, a fixing piece welding assembly and a fixing piece feeding assembly, wherein a workbench is arranged between the fixing piece welding assembly and the fixing piece feeding assembly; the cotton cloth wrapping assembly comprises a cotton cloth wrapping part, a gluing and cloth pressing part, a feeding table, a support, a feeding air cylinder and an automatic cutting part; a vertically-arranged supporting vertical plate is arranged on one side of the feeding table; and two guide rails are arranged at the top of the support. Accordingto the core pipeline assembling mechanism, a cotton cloth wheel can automatically wrap a ridge framework through the cotton cloth wrapping assembly, so that cotton cloth on the cotton cloth wheel wraps the ridge framework, storage and sequential feeding of fixing pieces can be realized through the fixing piece feeding assembly, and the ridge framework can be taken out through the ridge framework feeding assembly and can be wrapped in a horizontal state.

Owner:JILIN UNIV

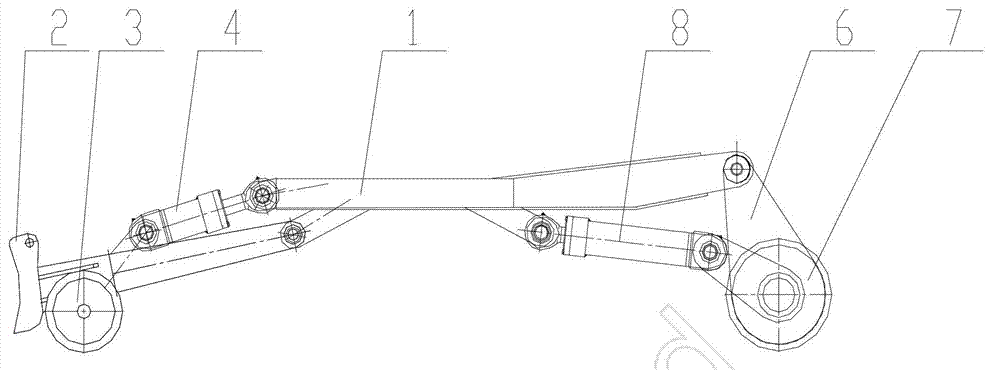

Light aircraft flap manipulation device

PendingCN109911180AReduce power loadEasy maintenanceWith power amplificationActuated personallyFailure rateEngineering

The invention discloses a light aircraft flap manipulation device, wherein a flap driving mechanism comprises a motor, the output shaft of the motor is fixedly connected with a worm, the outer side ofthe worm is screwed and coupled with a worm shaft barrel, and the end of the worm shaft barrel is hinged with a triangle, and one end of the triangle is fixedly connected with a first rotating shaft;a flap linkage mechanism comprises a first pull rod and a second pull rod, the first pull rod and the second pull rod are respectively hinged in two flap rotating positions, the upper end of the first pull rod is hinged with one end of the triangle, the first rotating shaft is fixedly installed with a first fan-shaped rocker, the upper end of the second pull rod is hinged with a connection block,the lower end of the connection block is fixedly installed on a second rotating shaft, the second rotating shaft is fixedly installed with a second fan-shaped rocker, and the first fan-shaped rockerand the second fan-shaped rocker are connected with two guide cables. The device may better reduce the aircraft power load, achieve the synchronous rotation of flaps, reduce the failure rate, and be convenient for maintenance.

Owner:重庆恩斯特龙通用航空技术研究院有限公司

Sweeping machine for photovoltaic panel

PendingCN106807669ALow costEasy to controlSolar heating energyPhotovoltaicsElectrical and Electronics engineeringDrive shaft

Owner:济南纽兰数控机械有限公司

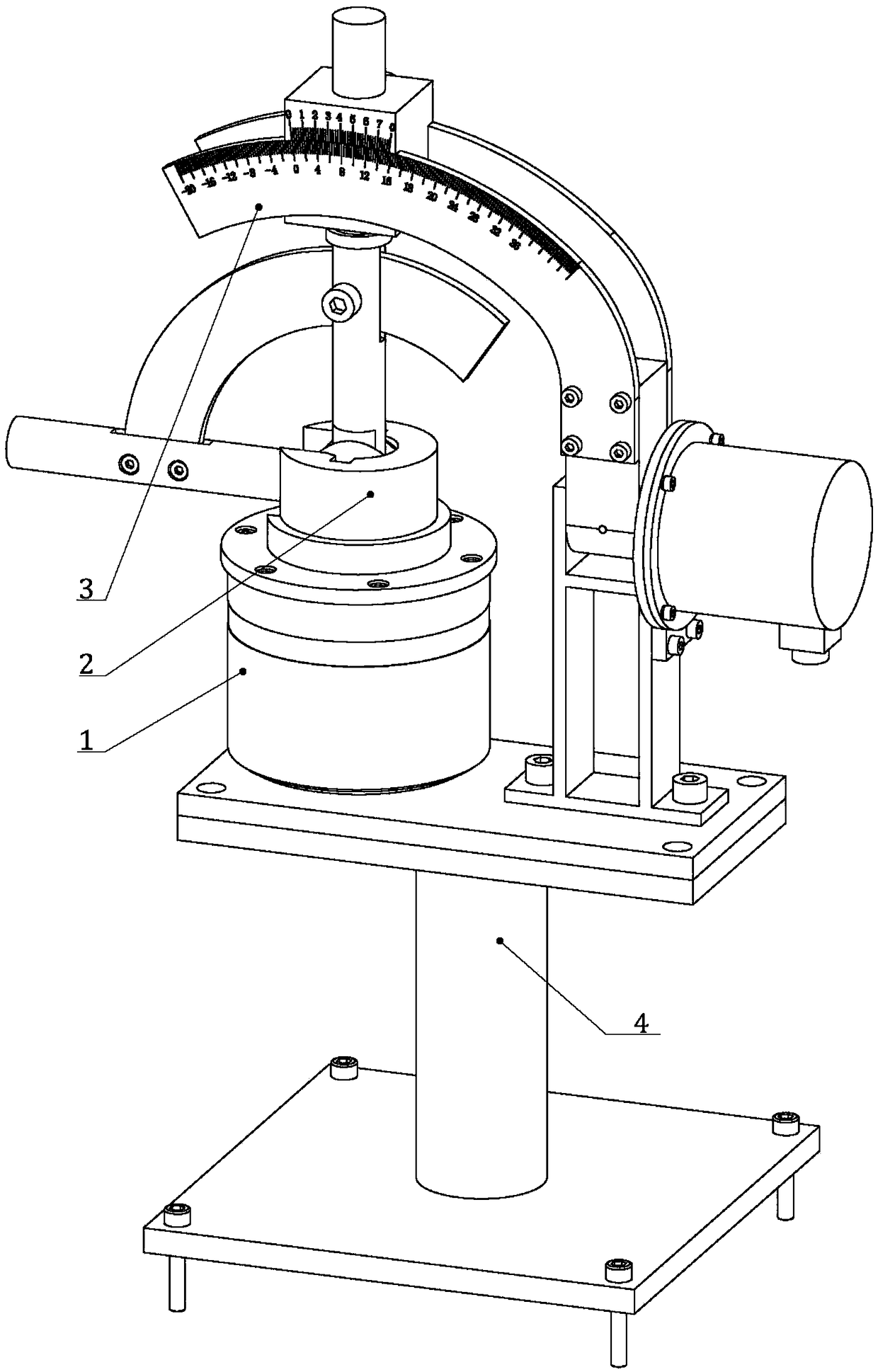

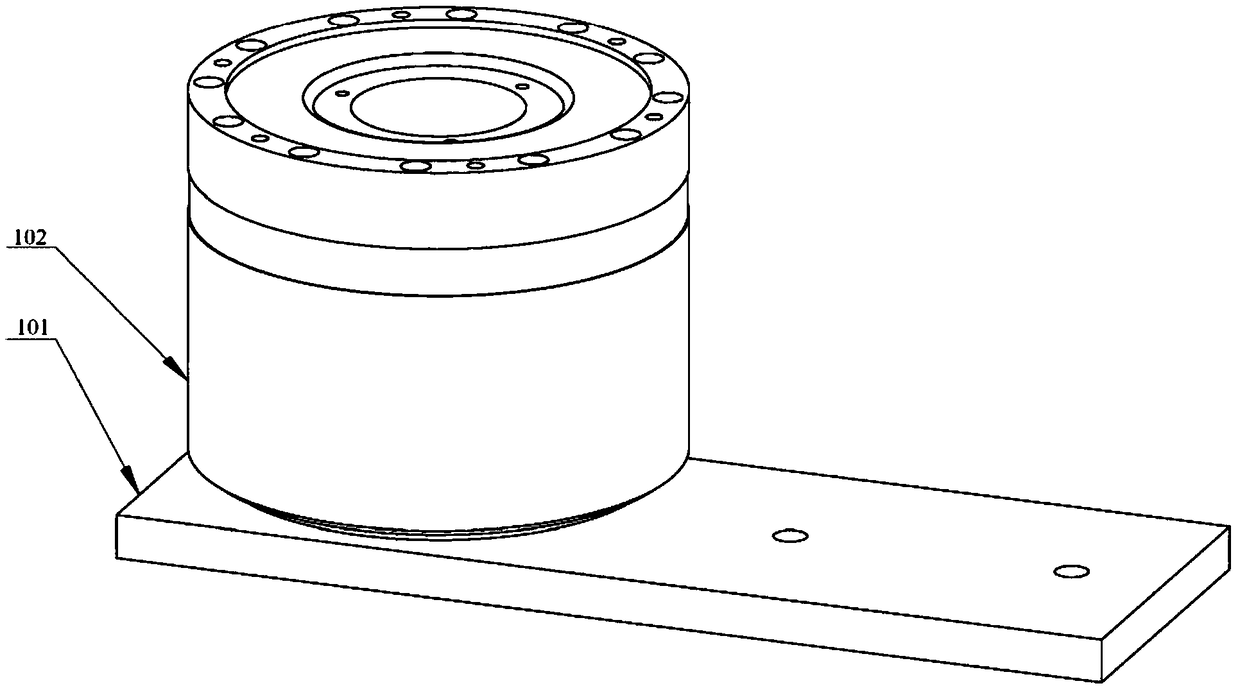

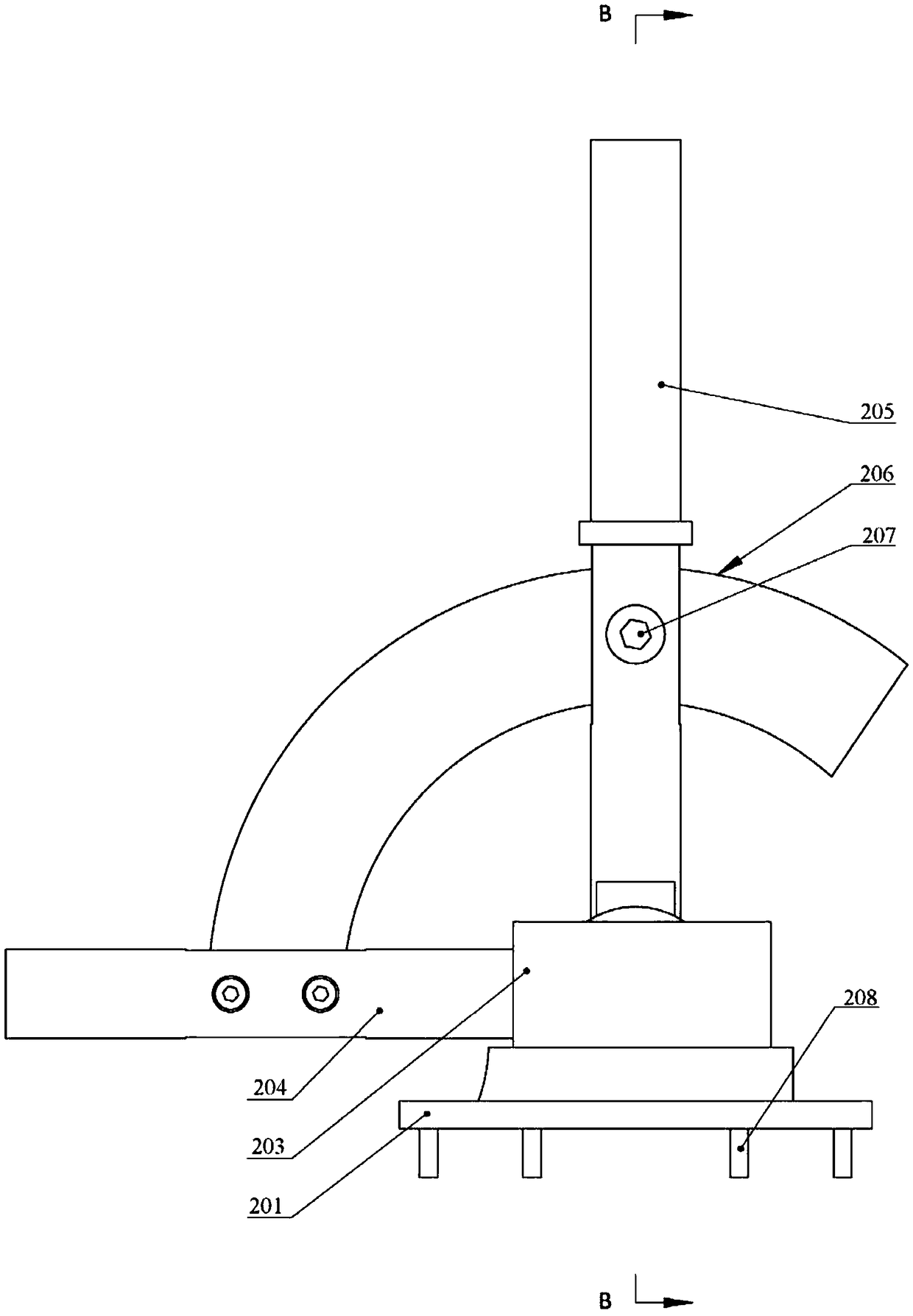

Verification device for slotted ball pin oriented curved arm single four-wheel aligner

The present invention relates to a verification device for a slotted ball pin oriented curved arm single four-wheel aligner, and belongs to the verification device for automobile warranty detection equipment. The horizontal corner driving measuring portion is fixedly connected with the upper plane of the bottom support in the bottom supporting portion by using bolts, and the lower plane of the inner spherical lower seat in the spherical universal portion is fixedly connected with the upper plane of the direct drive motor in the horizontal corner driving measuring portion; and the center hole of the master pin connection vernier in the curved arm swing arm driving measuring portion is glidingly matched and connected with the shaft portion of the analog master pin in the spherical universalportion without a gap, and the lower plane of the fixed seat of the swing arm in the curved arm swing arm driving measuring portion is fixedly connected with the horizontal corner driving measuring portion. Advantages of the verification device provided by the present invention are that, the structure is compact, the weight is relatively light, and the cost is low, the verification device can meetthe requirements of the relevant standards for the inspection devices, and the verification device can be used for the inspection of the factory products of the four-wheel aligner manufacturer and the calibration of the four-wheel aligner being applied on the market.

Owner:JILIN UNIV

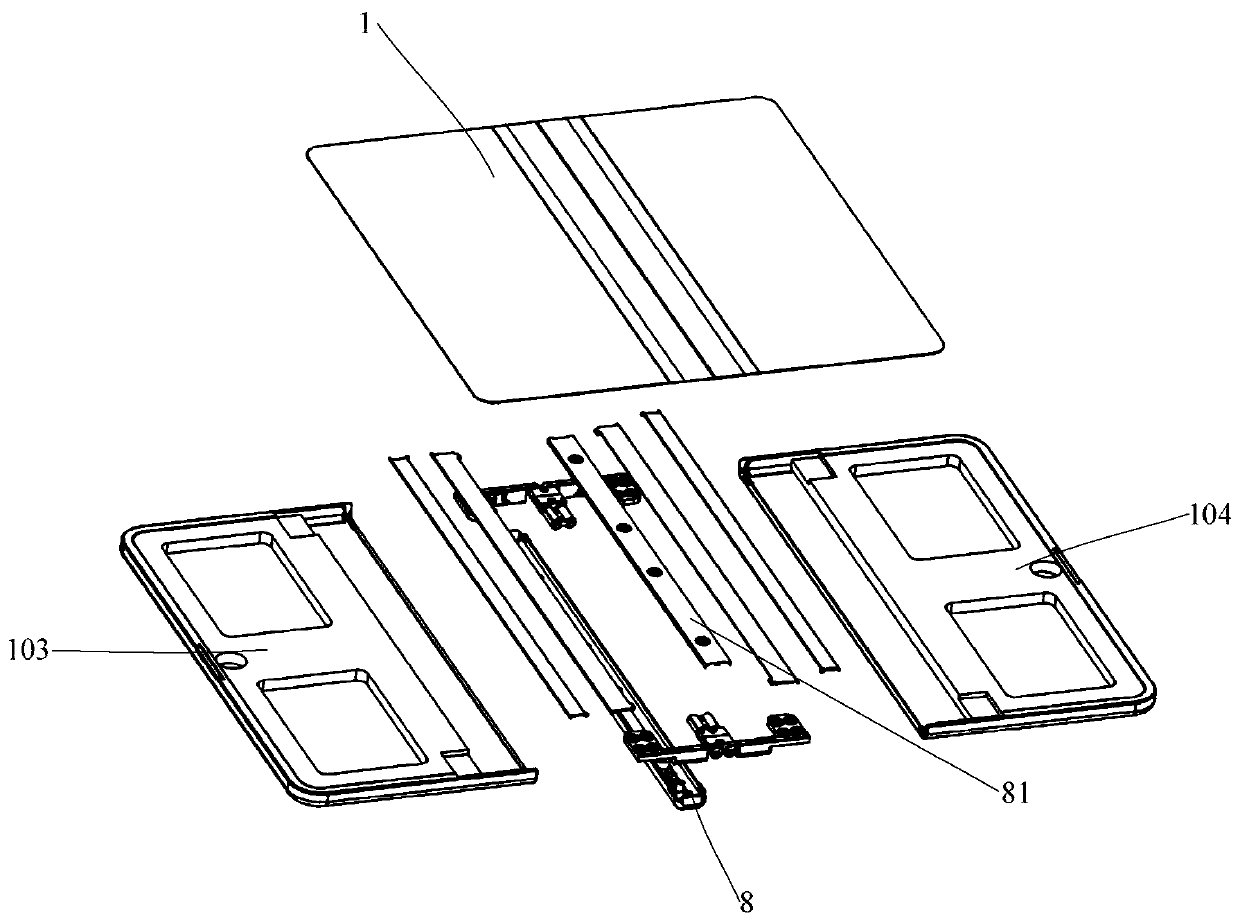

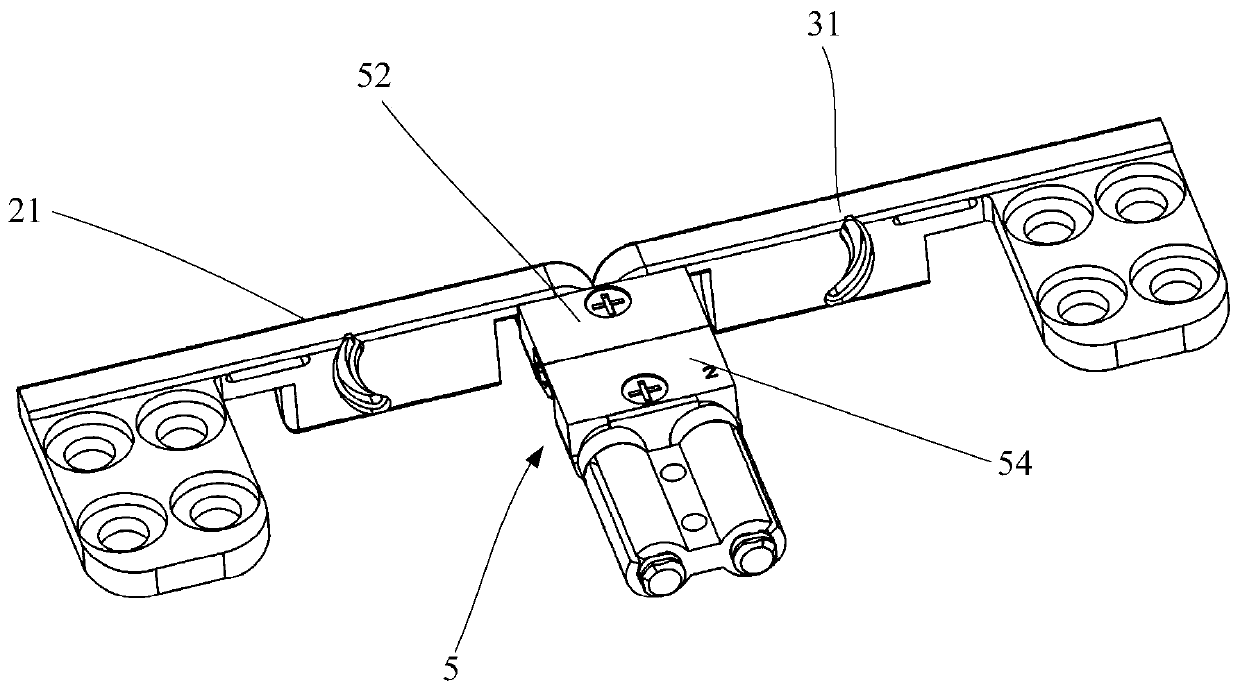

Rotating mechanism and flexible screen device

PendingCN110714978ARotate synchronouslyAchieve rotationPivotal connectionsIdentification meansScreens (device)Bevel gear

The invention discloses a rotating mechanism and a flexible screen device. The rotating mechanism and the flexible screen device are used for realizing synchronous rotation. The rotating mechanism comprises a first rotating shaft, a first movable frame, a first cone gear, a second rotating shaft, a second movable frame, a second cone gear, a middle bevel gear and a positioning portion. The first movable frame is fixedly connected with the first rotating shaft. The first rotating shaft penetrates through and is fixedly connected with the first bevel gear. The second movable frame and the secondrotating shaft are fixedly connected. The second rotating shaft penetrates through and is fixedly connected with the second cone gear. The two sides of the middle bevel gear are correspondingly provided with cone gears, and the cone gears on the two sides of the middle bevel gear are correspondingly engaged with the first cone gear and the second cone gear. The positioning part and the middle bevel gear can rotate relatively, and the positioning part is used for fixing the position of the middle bevel gear. Through the linkage of the middle bevel gear, the first cone gear and the second conegear can synchronously rotate. Therefore, the first movable frame and the second movable frame are driven to rotate synchronously, and synchronous rotation between rotating mechanism components is achieved.

Owner:DONGGUAN HONGLIAN ELECTRONICS

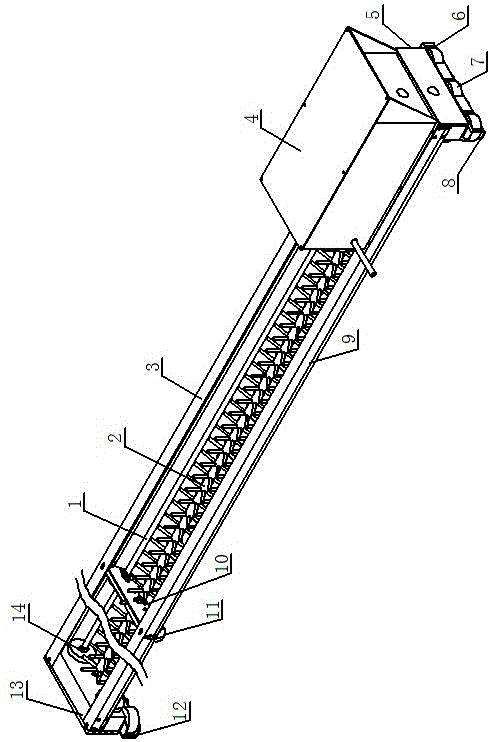

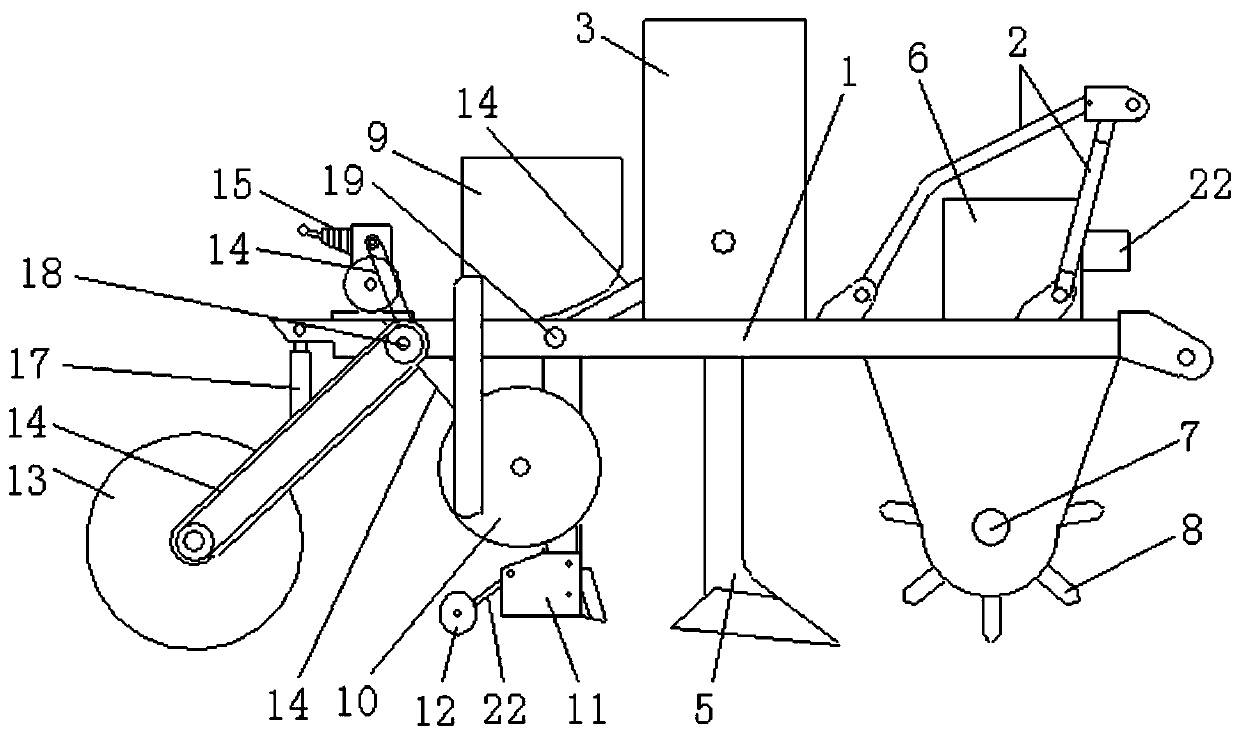

Novel corn zero-tillage fertilization application and sowing machine with function of triangular final seedling singling

PendingCN110506462AIncrease seeding densityAchieve dense plantingSpadesPlantingAgricultural engineeringSeedling

The invention discloses a novel corn zero-tillage fertilization application and sowing machine with the function of triangular final seedling singling. A hoeing and soil loosening shovel and a depth wheel on an existing corn sowing machine are removed, a seed belt processing device is installed at the position of the hoeing and soil loosening shovel, and multiple twining-prevention cutter blade sets capable of following a cutter shaft to rotate are arranged on the cutter shaft of the seed belt processing device, each twining-prevention cutter blade set corresponds to a sowing opener set at therear position, a land wheel rotates and drives seeding devices and fertilizing devices to rotate, and through the sowing opener sets and fertilizer application openers, fertilization application andsowing work is conducted in a processing area formed through rotation of the cutter shaft of the seed belt processing device. According to the novel corn zero-tillage fertilization application and sowing machine with the function of triangular final seedling singling, the seed belt processing device is adopted for replacing the hoeing and soil loosening shovel and the depth wheel on the existing corn sowing machine, then straw and soil are smashed, the spacing of the corresponding seeding devices is adjusted, positioned sowing on seeds is achieved, the triangular final seedling singling sowingfunction is achieved, and the sowing density of corn is increased on the condition that the sowing plant spacing and the basic row spacing are not changed.

Owner:漯河市农机推广服务中心

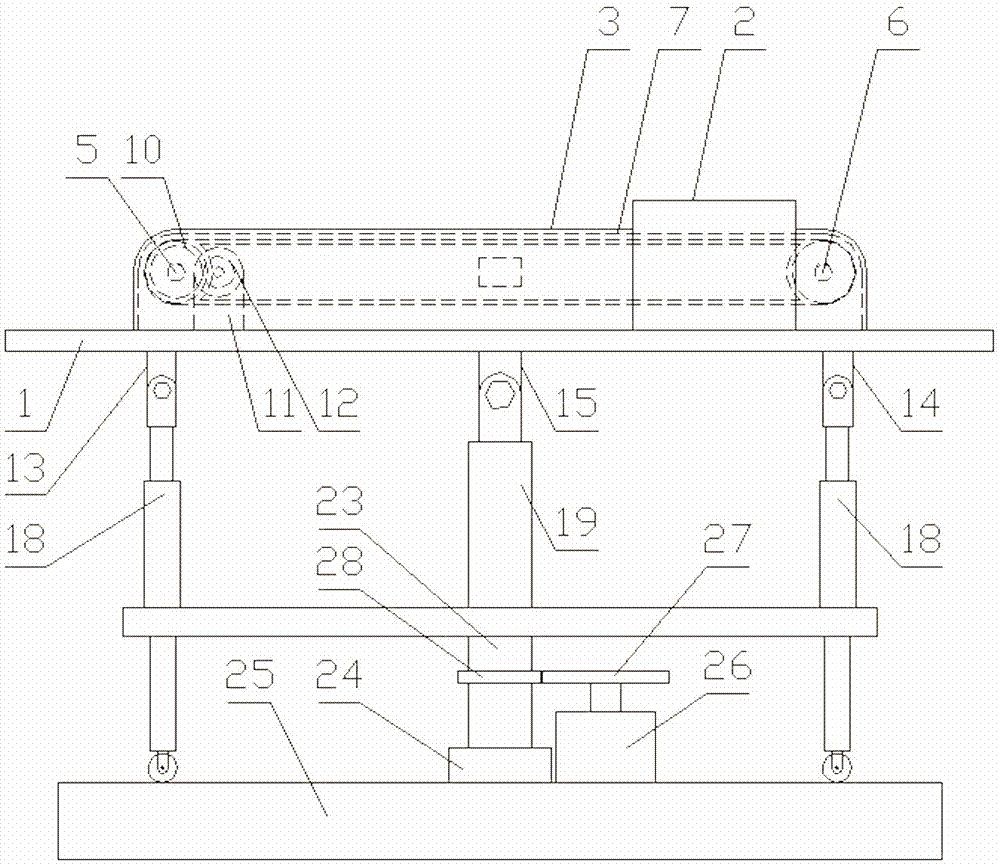

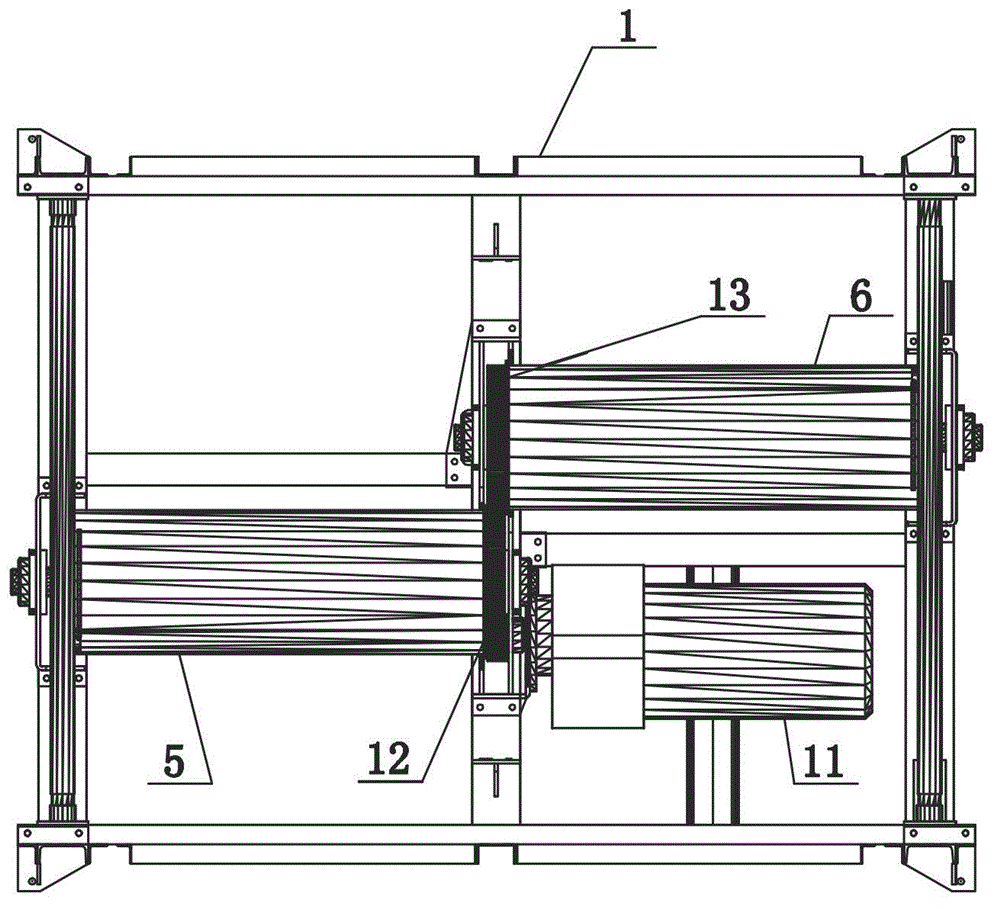

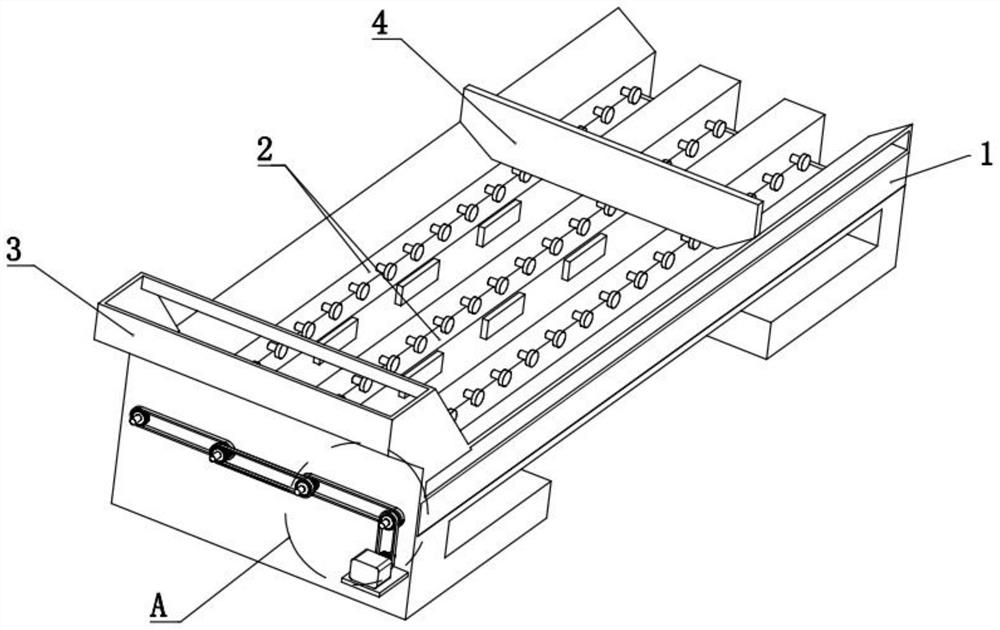

Lifting and transmission mechanism for stereoscopic parking equipment

The invention discloses a lifting and transmission mechanism for stereoscopic parking equipment, and belongs to the technical field of mechanical parking equipment. The lifting and transmission mechanism for the stereoscopic parking equipment comprises a supporting frame and a rectangular lifting frame. Four sets of movable pulleys are arranged on the top of the rectangular lifting frame, each set of the movable pulleys comprises a first movable pulley and a second movable pulley, the first movable pulley is located at one corner of the rectangular lifting frame, and the second movable pulley is close to the center part of rectangular lifting frame. A driving winding drum and a driven winding drum which are driven by a power device are arranged in the supporting frame, two first steel wire ropes which are mounted on the driving winding drum pass by the second movable pulleys, then the first movable pulleys of two adjacent sets of movable pulleys in a winding mode and finally are fixedly mounted on the supporting frame, and two second steel wire ropes which are mounted on the driven winding drum pass by the second movable pulleys, then the first movable pulleys of the other two adjacent sets of movable pulleys in a winding mode and finally are fixedly mounted on the supporting frame. The lifting and transmission mechanism for the stereoscopic parking equipment is compact in structure, the lifting process is stable, work is reliable, the force acted on the rectangular lifting frame is reasonable, and cost is low.

Owner:DAYANG PARKING CO LTD

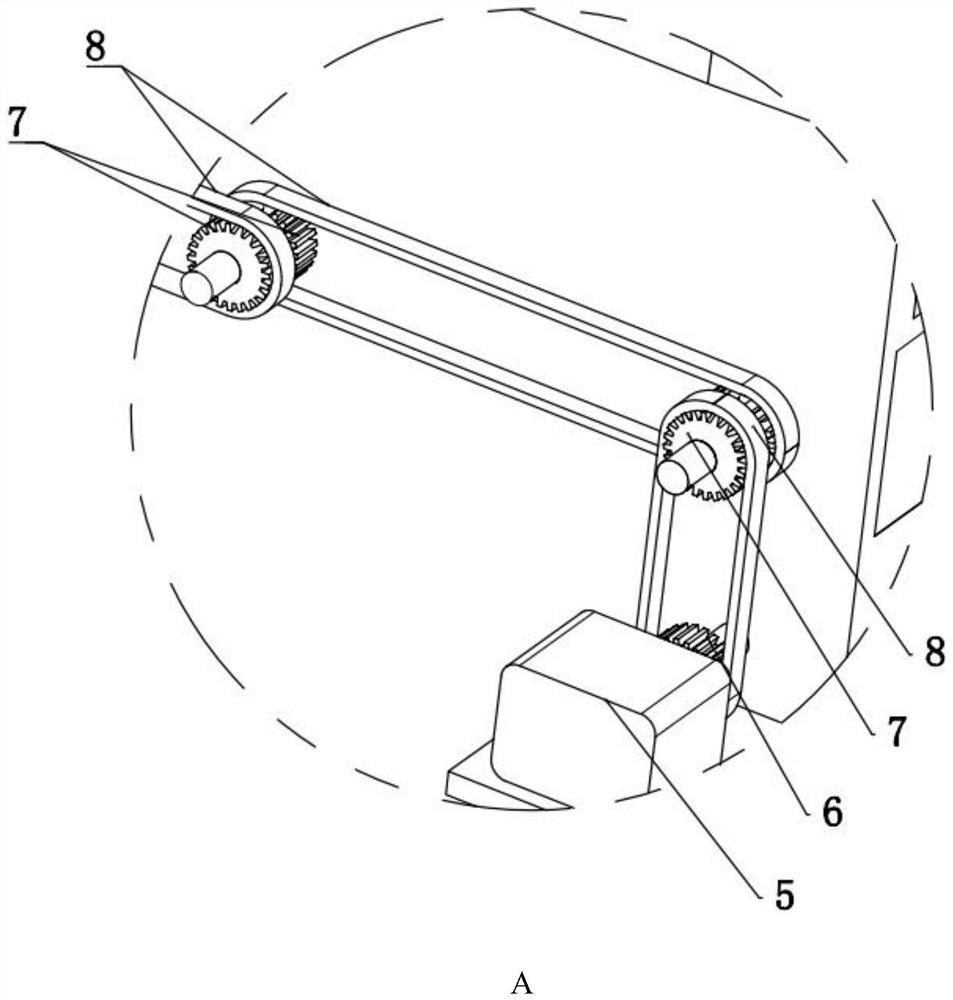

Soaking-centrifugalizing equipment

ActiveCN102962162ASimple structureEasy to operateLiquid surface applicatorsCoatingsControl systemEngineering

The invention discloses soaking-centrifugalizing equipment. The soaking-centrifugalizing equipment comprises a base, a soaking-centrifugalizing device and a slurry recovery device which is arranged at one side of the base and can move forwards and backwards in horizontal direction. The soaking-centrifugalizing device comprises a clamping tool which can continuously rotate and drive a foam filter tube precursor to synchronously rotate when rotating continuously, a soaking device which can move upwards and downwards, a rotary drive motor for driving the clamping tool to continuously rotate, and a control system for controlling and adjusting the rotation direction and the rotation speed of the rotary drive motor; the clamping tool is arranged above the base; a power output shaft of the rotary drive motor is connected with the clamping tool through a transmission mechanism; the clamping tool is arranged horizontally; and the foam filter tube precursor is horizontally arranged on the clamping tool. The soaking-centrifugalizing equipment is simple in structure, convenient to use and operate, safe and reliable in work and high in processing efficiency, realizes slurry recoverability and can be used for finishing the preparation process of various sizes of foam metal filter tubes conveniently and fast.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Automatic distributing and transporting mechanism

ActiveCN112456083AGood technical effectAvoid lateral sticky transfersConveyor partsEngineeringMechanical engineering

Owner:宁波高新区利威科技有限公司

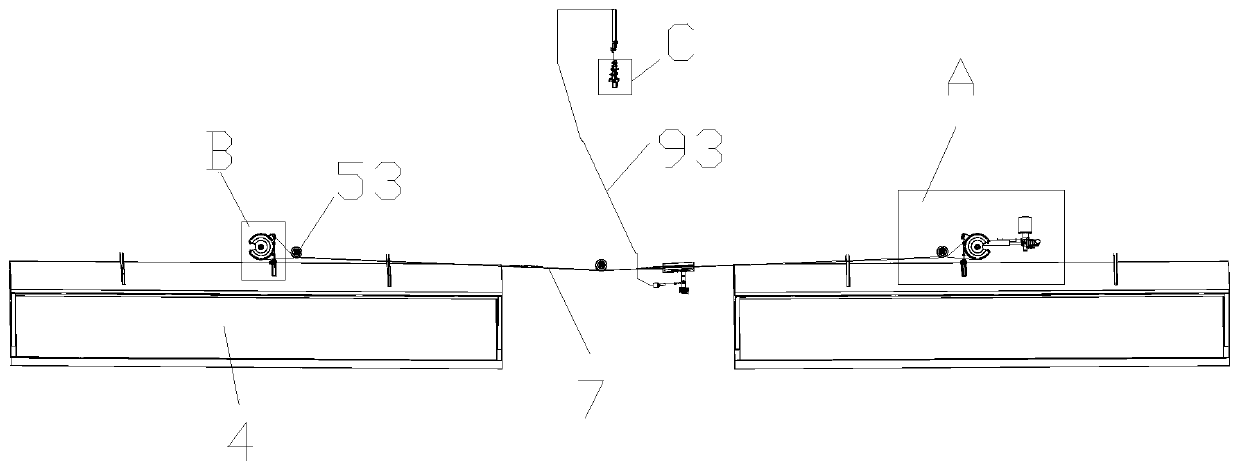

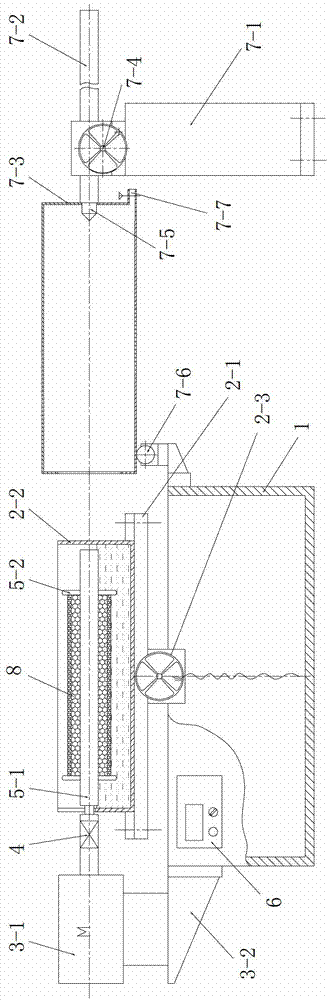

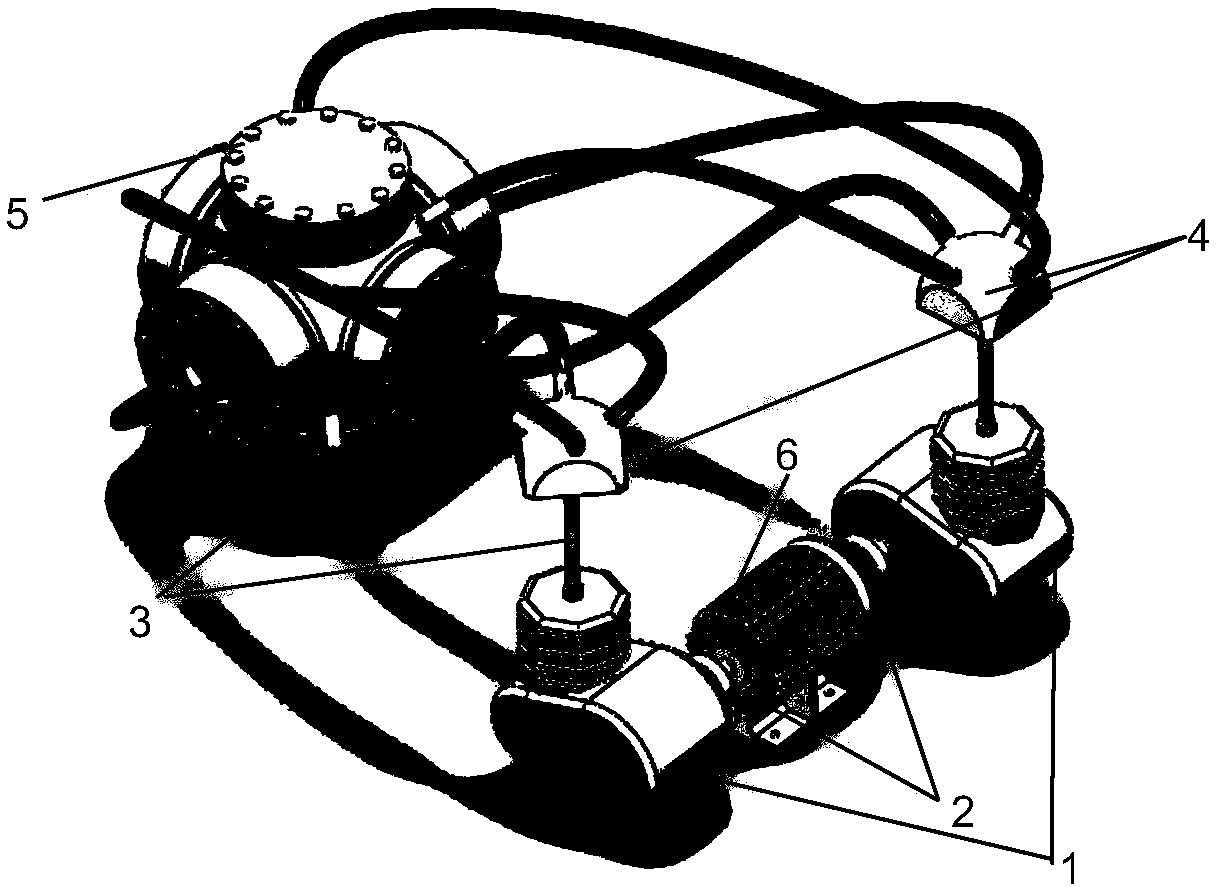

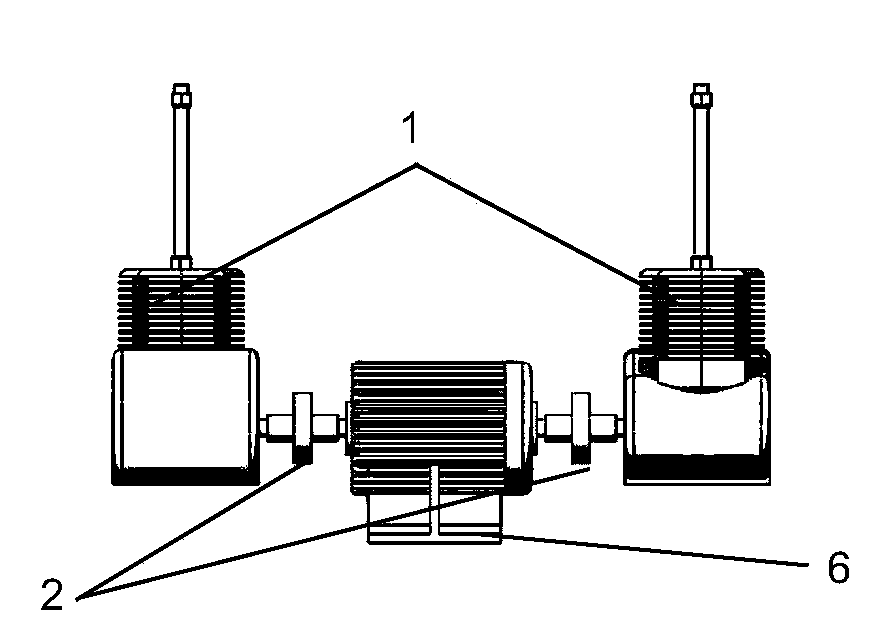

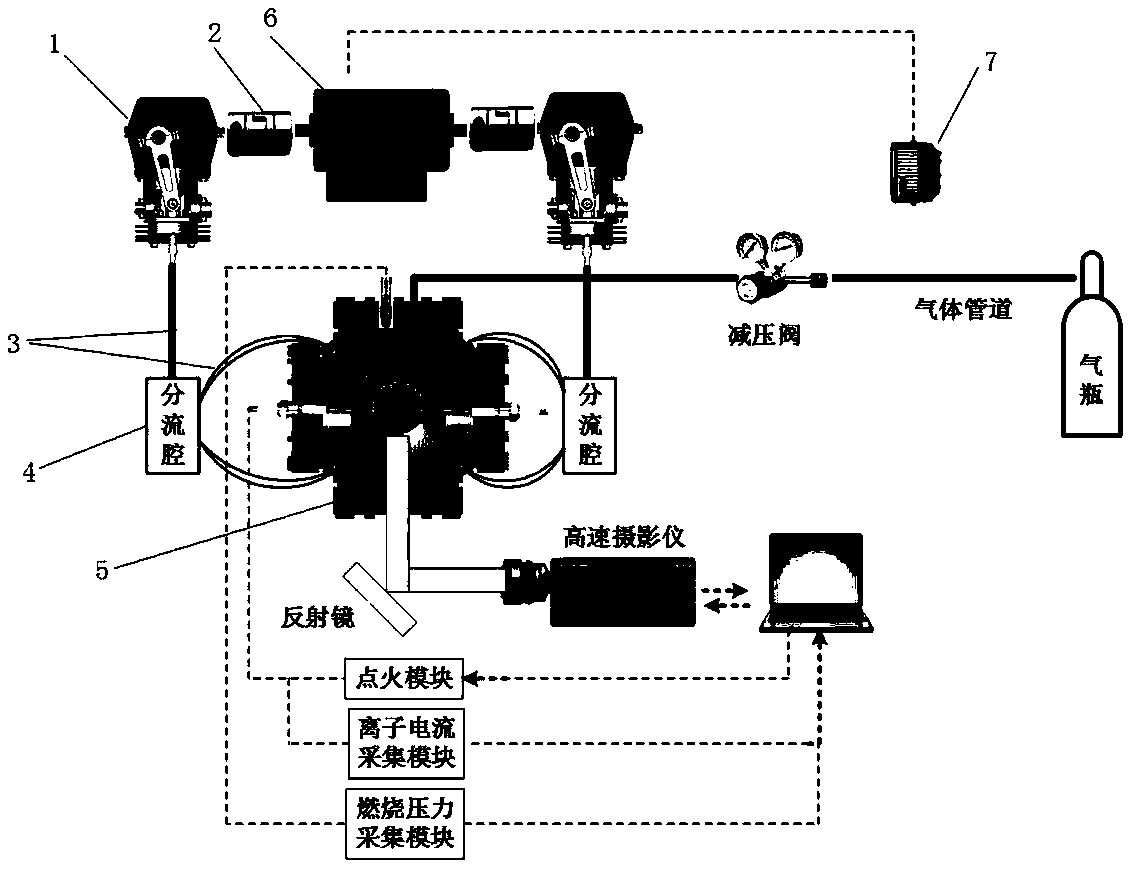

Turbulence generating device capable of controlling turbulence intensity

InactiveCN109580870ARotate synchronouslyWith buffer protectionChemical analysis using combustionMotor driveJet flow

The invention provides a turbulence generating device capable of adjusting the turbulence intensity. The device is applied to constant volume combustion bomb test equipment. The device is composed ofsingle-cylinder engines (1), flexible couplings (2), gas pipelines (3), flow distribution cavities (4), a constant volume combustion bomb (5), a double-output shaft motor (6) and a digital frequency modulator. The motor drives pistons of the single-cylinder engines to move in a reciprocating mode, and jet flow is generated through the gas pipelines to generate a collision in the center of the constant volume combustion bomb, so that an isotropic turbulence environment is formed in the center; and the rotating speed of the double-output shaft motor is controlled by adjusting the digital frequency modulator so as to control the turbulence intensity. Compared with a traditional turbulence generating device, the device can generate controllable and isotropic stable turbulence; the double-output shaft motor can enable the two single-cylinder engines to synchronously and stably move through the flexible couplings, so that the overall structure is compact; and the flow distribution cavities ensure that the speed and the flow are same when the gas flow in the reciprocating motion process of the pistons passes through connected gas holes of the constant volume combustion bomb, so that the accuracy of a simulation experiment is further improved.

Owner:BEIJING JIAOTONG UNIV

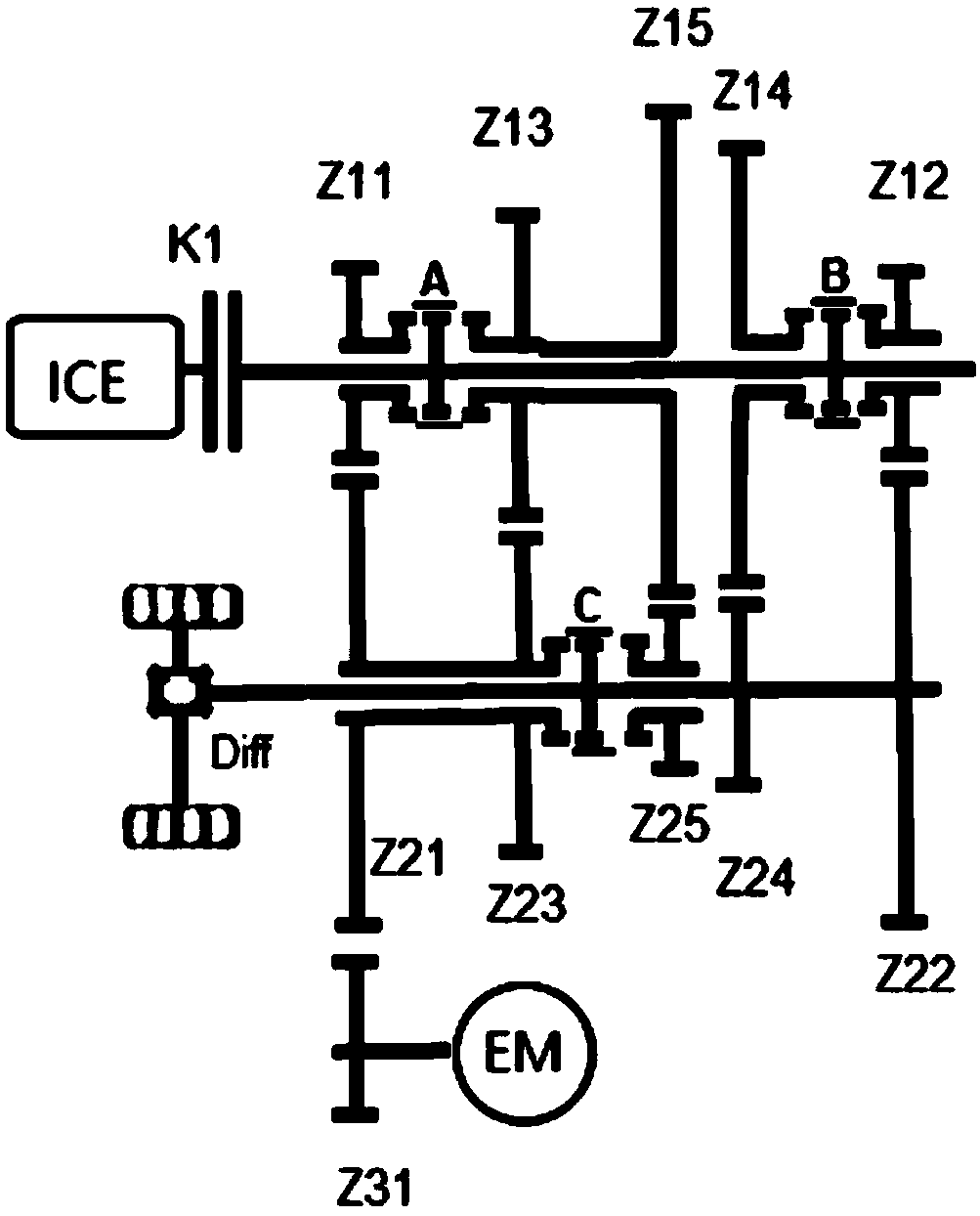

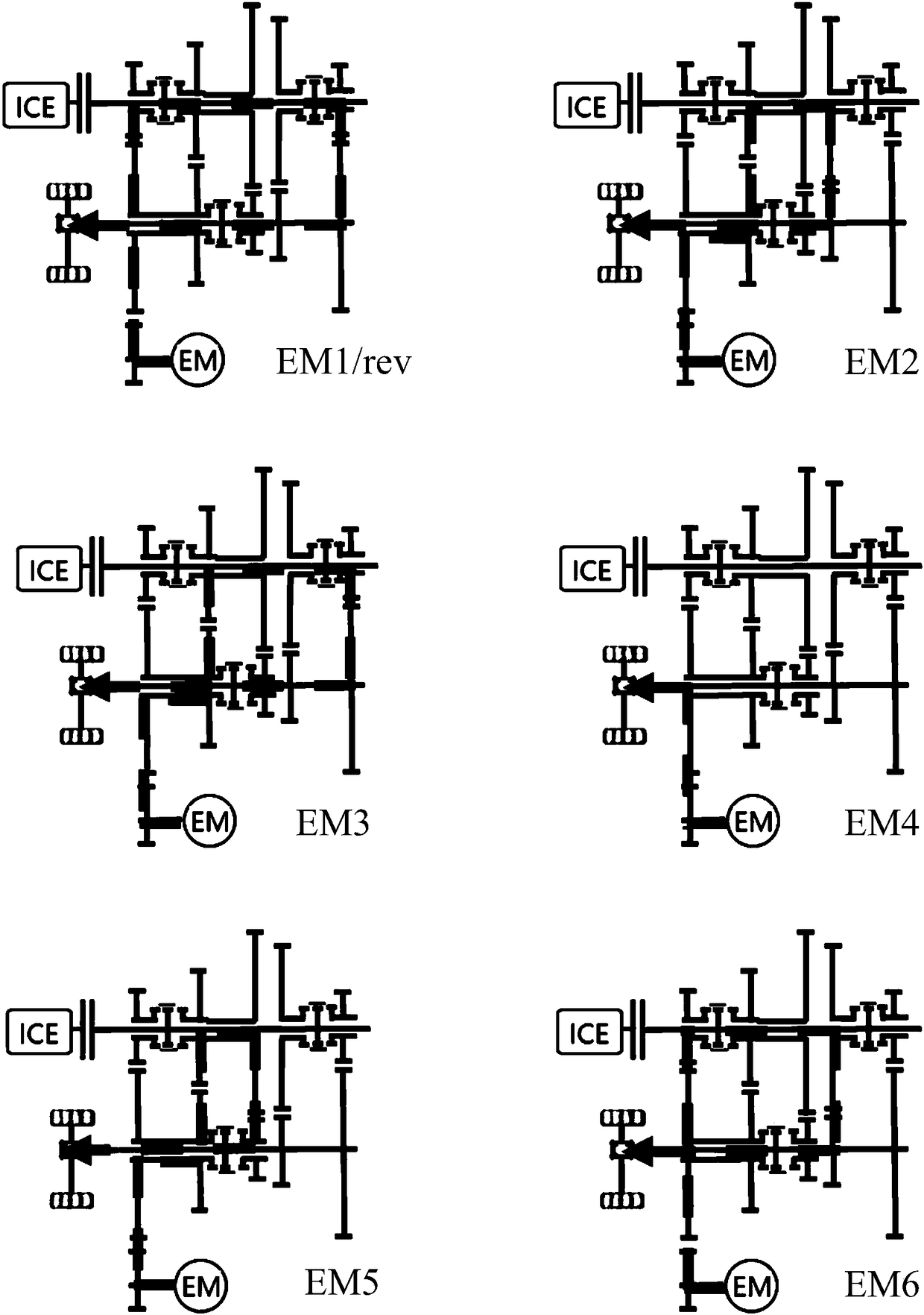

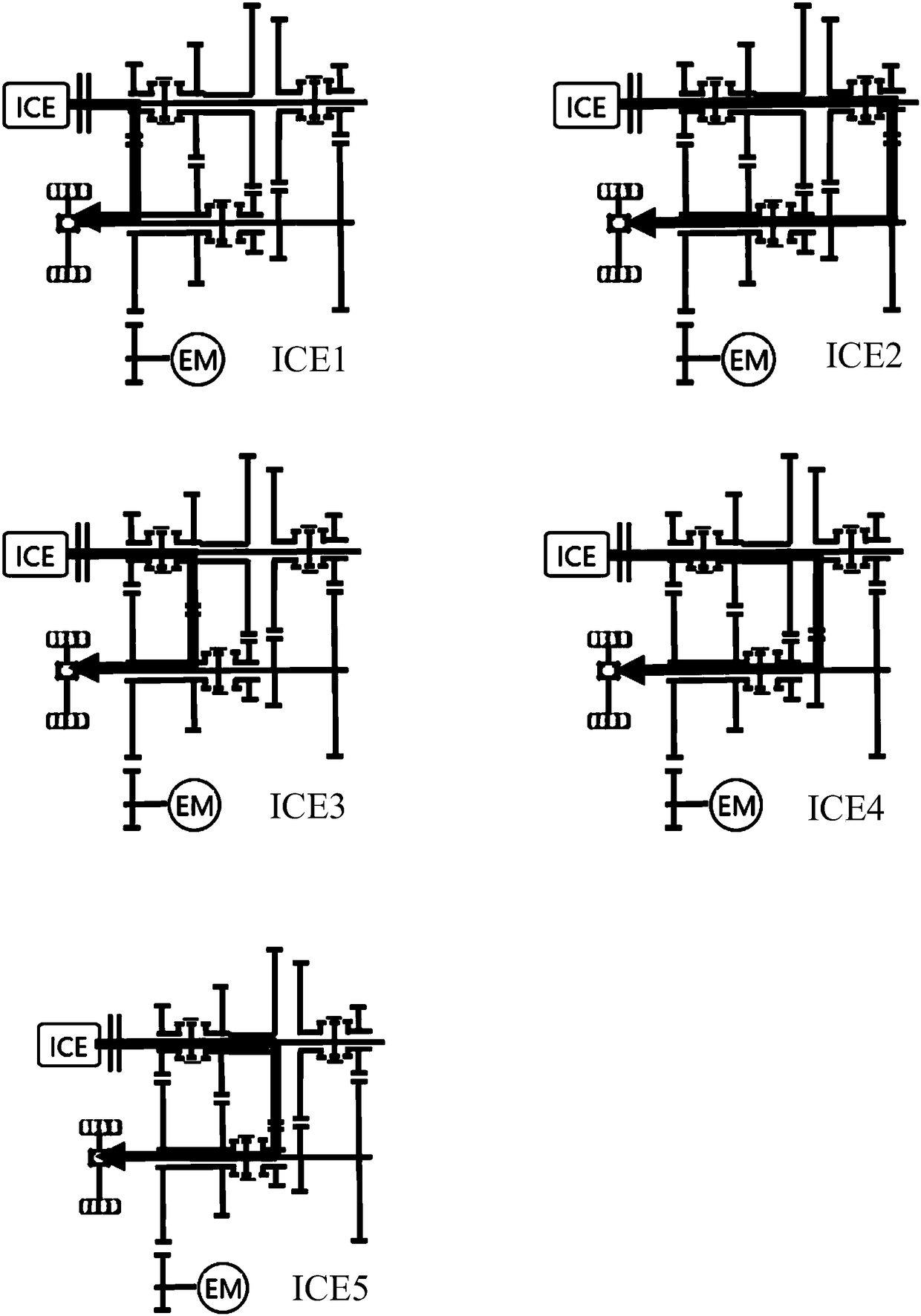

Hybrid power transmission and vehicle

InactiveCN108397521ARotate synchronouslyStrong torsion-resistant connectionHybrid vehiclesToothed gearingsCombustionGear wheel

The invention discloses a hybrid power transmission used for a hybrid power system and a vehicle. The hybrid power transmission comprises a transmission input shaft connected with an internal combustion machine through a clutch, a transmission output shaft, a first gear, a third gear, a fifth gear, a second gear, a fourth gear, a sixth gear, a first synchronizer arranged on the transmission inputshaft in a torsion resistance mode and a second synchronizer arranged on the transmission output shaft in a torsion resistance mode, wherein the first gear, the third gear and the fifth gear are arranged on the transmission input shaft in an empty sleeving mode, and the second gear, the fourth gear and the sixth gear are arranged on the transmission output shaft in an empty sleeving mode. The first gear and the second gear are engaged, the third gear and the fourth gear are engaged, and the fifth gear and the sixth gear are engaged. The first synchronizer can be connected with the first gear or the third gear in a torsion resistance mode, the second synchronizer can be connected with the fourth gear or the sixth gear in a torsion resistance mode, the third gear and the fifth gear are connected in a torsion resistance mode, and the fourth gear and the sixth gear are connected in a torsion resistance mode.

Owner:SCHAEFFLER TECH AG & CO KG

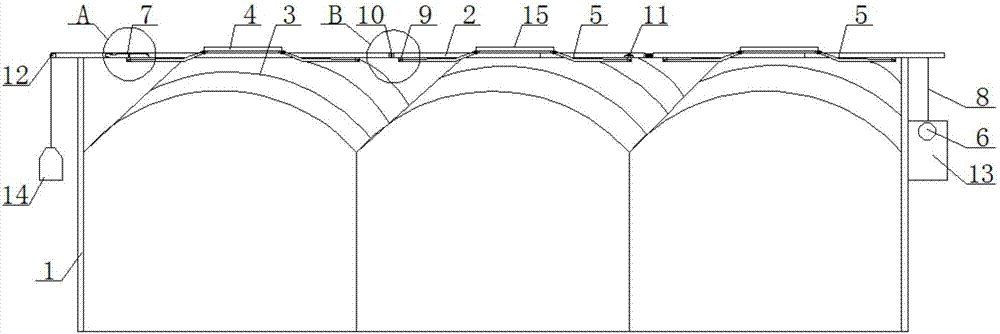

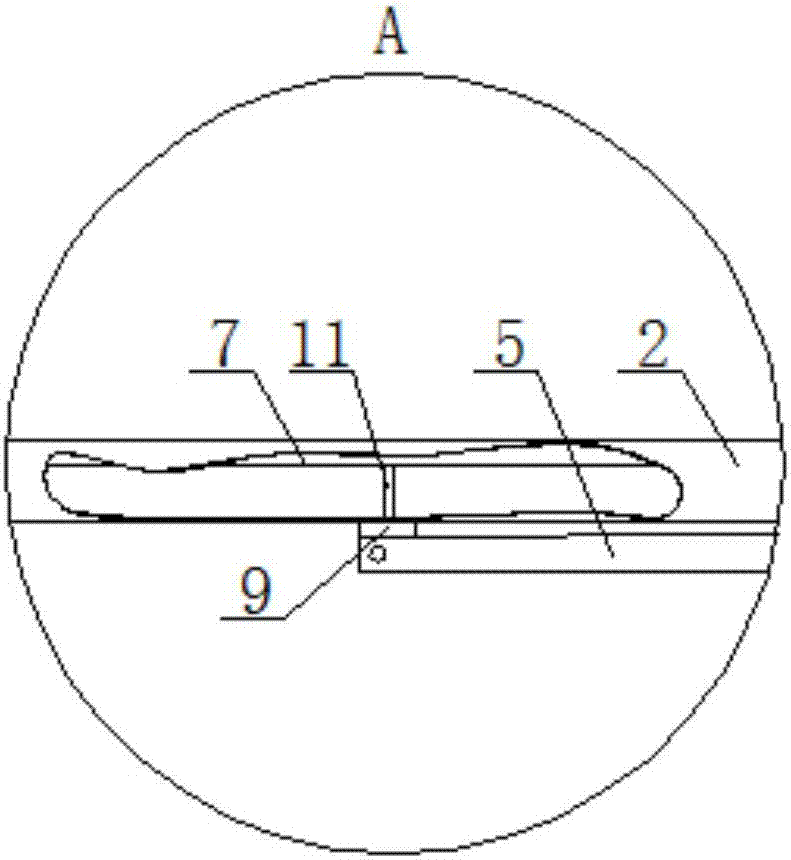

Agricultural greenhouses linkage tracking photovoltaic stent and photovoltaic power generation system

InactiveCN107171627AEnsure safetyArrange lighting time reasonablyPhotovoltaic supportsPhotovoltaic monitoringAgricultural engineeringPhotovoltaic power generation

The invention discloses an agricultural greenhouse linkage tracking photovoltaic stent and a photovoltaic power generation system, which belongs to the technical field of photovoltaic power generation equipment. The stent comprises a column stent, a driving mechanism, guide rails and a component unit. The column stent is arranged above an agricultural greenhouse. The height of the column stent is slightly higher than the height of the agricultural greenhouse. The guide rails are fixed on the column stent. The component unit is arranged across two adjacent guide rails, and comprises a component frame, a sliding part and a connecting rod. The sliding part is arranged in the guide rails. One end of the connecting rod is hinged with the sliding part. The other end is hinged with the component frame. The driving mechanism is applied to the sliding part of the component unit. When the photovoltaic stent is used, the connecting rod is pushed to hold up or lay the component frame. According to the invention, the design thought of wind hiding and the theory of bionics are used; in one minute, the component unit automatically lays down, so that the windward surface is small and the wind resistance is reduced to ensure the safety of the stent, the system and the agricultural greenhouse; loss caused by the disaster is avoided; and the stent and the system have the advantages of simple structure, reasonable design and easy manufacturing.

Owner:安徽含羞草智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com