Thread trimming mechanism for two-needle sewing machine

A thread cutting mechanism and sewing machine technology, which is applied to the thread cutting mechanism, sewing machine components, sewing equipment, etc. in the sewing machine, which can solve the inconvenience of installation and debugging, low production efficiency of garment factories, and the inability to see the cooperation between fixed knives and moving knives and other issues to achieve the effect of improving work efficiency and reducing the intensity of adjustment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

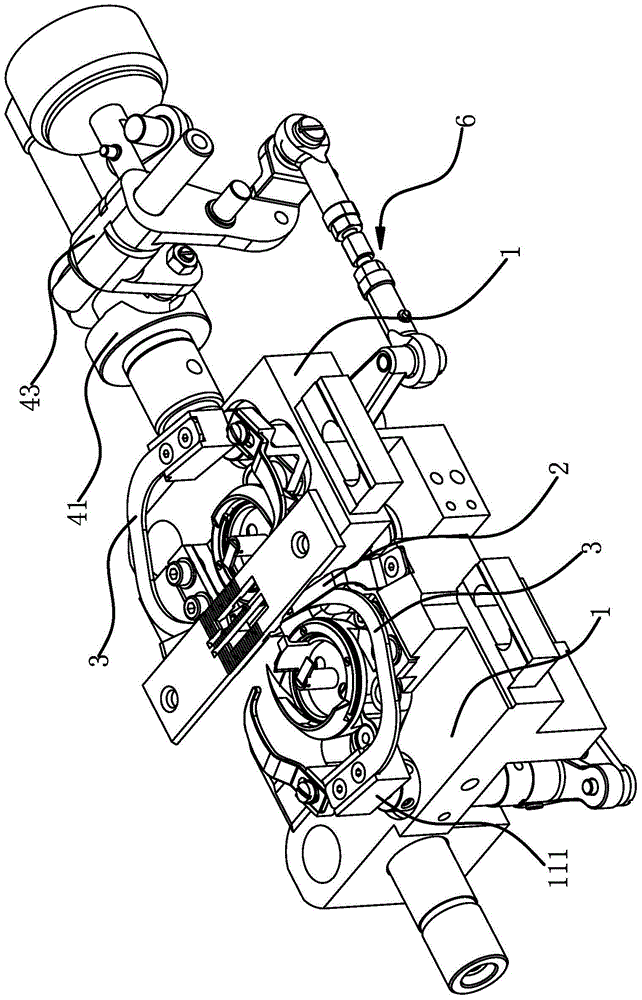

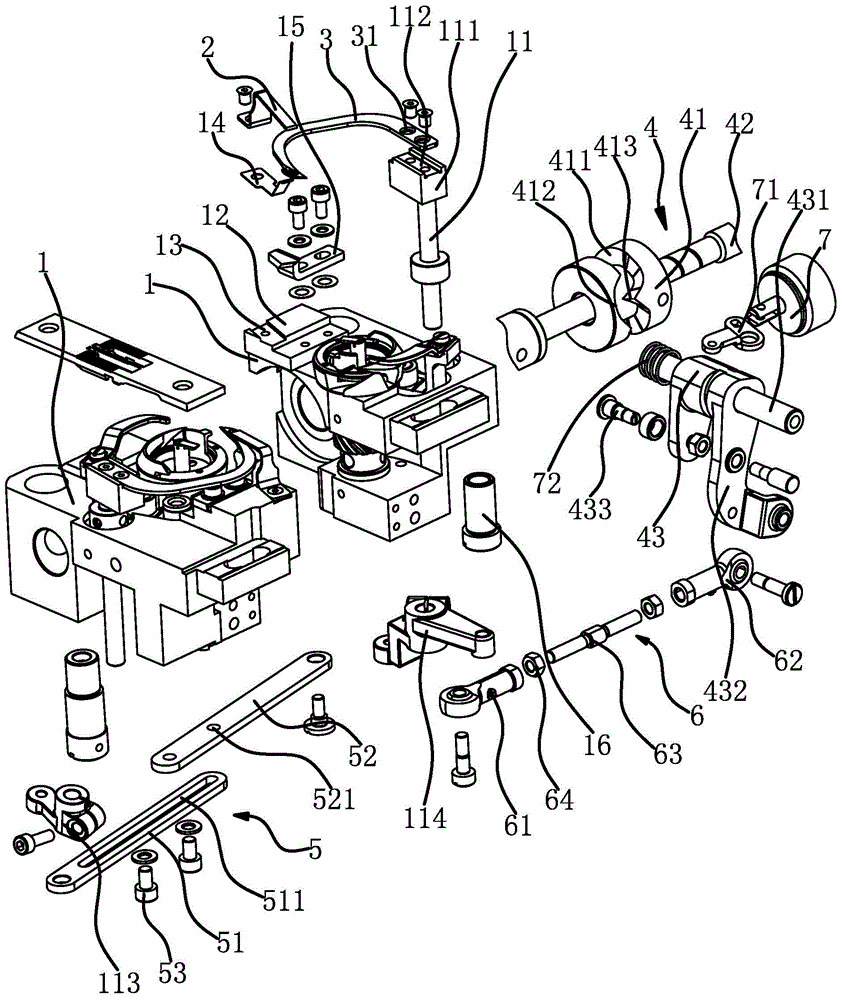

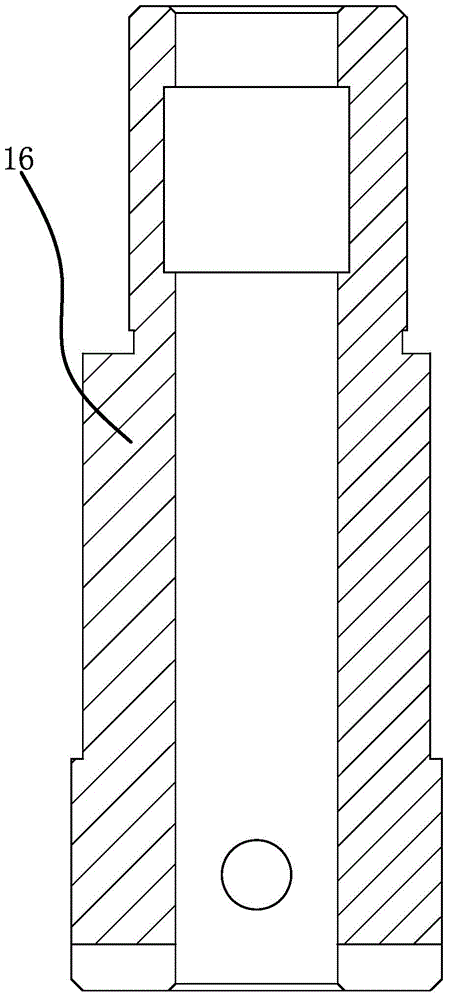

[0025] Such as figure 1 , figure 2 As shown, a thread trimming mechanism of a double-needle sewing machine, the sewing machine includes a casing, the thread trimming mechanism includes two rotary hook tables 1, a fixed knife 2 and a moving knife 3, the two rotary hook tables 1 are fixed in the casing, and Located below the needle plate, the two rotary hook tables 1 correspond to two needle positions respectively, the fixed knife 2 is fixedly connected to the rotary shuttle table 1, and the movable knife shaft 11 is connected to the rotary shuttle table 1 in rotation, and the movable knife 3 is fixed Connected to the upper end of the moving knife shaft 11, the knife face of the moving knife 3 fits against the knife face o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com