Cam mechanism and rotating ring forced resetting device for fingerprint lock

A technology of cam mechanism and reset device, which is applied in the field of anti-theft locks, and can solve the problems of large radial size, narrow space, separation of double clutches, and the reliability of closed locks, which affect the safety of locks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

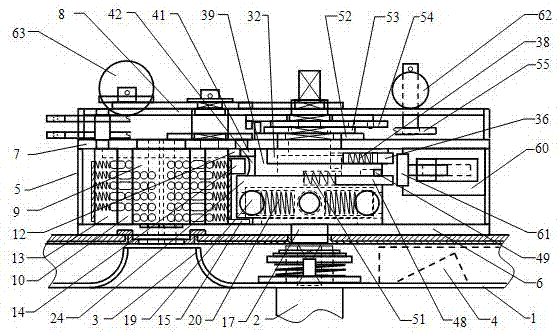

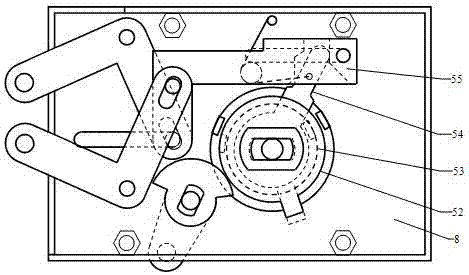

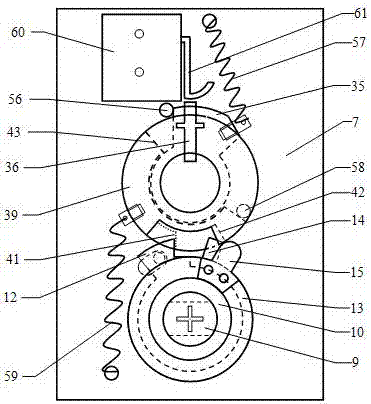

[0056] Combine below Figure 1 to Figure 27 The present invention is further described.

[0057] Such as figure 1 As shown, in the lock body 5 of the anti-theft lock matched with the device of the present invention, the lock cylinder group and the cam mechanism are all installed between the tamper-resistant plate 6 and the back plate 7, and the lock cylinder 9, the cam mechanism and the fingerprint collector 4 ( Can also include the password input window) are all arranged on the same vertical line, that is, the lock core 9 and the key insertion channel 3 are all located directly below the handle shaft of the handle 2. Such as figure 2 As shown, the transmission parts of the lock set matched with the device of the present invention are located between the back plate 7 and the buckle cover 8, and the corresponding lock cylinder 9 and cam mechanism are arranged in a horizontal direction. image 3 It is a schematic diagram of the assembly of the lock cylinder group in the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com