Fluidized bed granulator and filtering and reverse blowing control process

A fluidized granulator and fluidized bed technology, applied in the direction of dispersed particle filtration, dispersed particle separation, powder suspension method granulation, etc., can solve the problems of easy production failure, unreasonable design of filter device, poor shaking effect, etc. Achieve the effect of prolonging service life, eliminating production loss and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

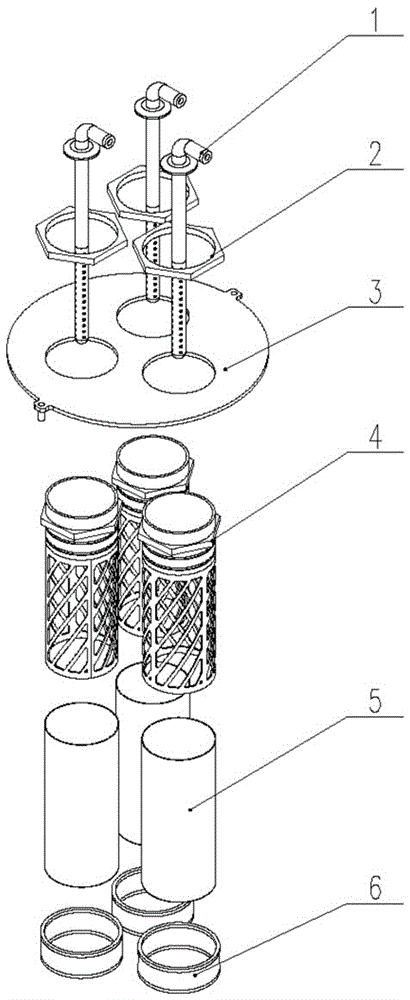

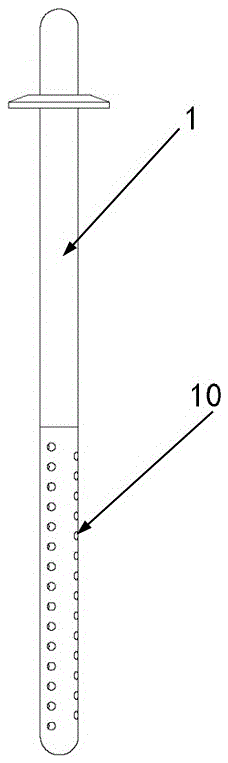

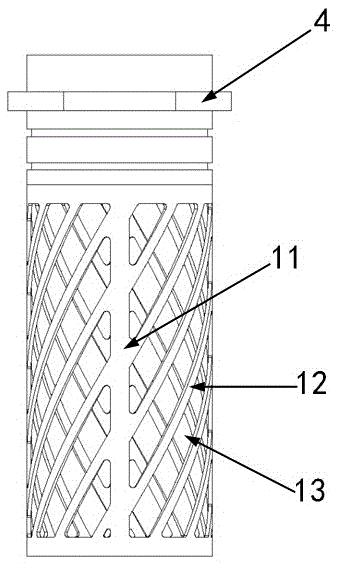

[0031] The fluidized drying granulator of the present invention is mainly composed of a fluidized bed host system, an air intake system, an exhaust system, a feeding system, and a filtration backflush system, wherein the intake system is connected to the fluidized bed 7 of the fluidized bed host system At the bottom, the exhaust system is installed on the top of the fluidized bed, specifically, the exhaust pipe 8 of the exhaust system (see figure 1 ) is installed on the top of the fluidized bed, which is a cylindrical exhaust pipe. The feeding system is mainly composed of a binder feeding mechanism and a material feeding mechanism. The intake system, exhaust system and feeding system are all existing conventional design structures.

[0032] Such as figure 1 As shown, the filter blowback system is installed between the interface of the fluidized bed 7 and the exhaust pipe 8, and it is mainly composed of a fixed plate 3, an air distribution part, a filter bag 5 and a blowback p...

Embodiment 2

[0034] Start the fluidized bed drying granulator with the structure shown in Example 1 to make the intake system and exhaust system work, and then put in the binder and materials respectively through the feeding system for granulation and drying. During the production process, the exhaust system exhausts from the upper part of the fluidized fluidized bed through the exhaust pipe, and when the exhaust gas enters the exhaust pipe from the fluidized fluidized bed, it passes through the filter blowback system.

[0035] When the exhaust gas passes through the filter blowback system, the control process of the filter blowback system is:

[0036] Blowback pressure control: start the air compressor, input compressed air into the blowback pipe, and adjust the pressure of the compressed air in the blowback pipe so that the pressure of the compressed air blown to the inner surface of the air distribution part is 0.8MPa;

[0037] Blowback mode control: the current blowback pipe is blown b...

experiment example 1

[0059] The control method in Example 2 was used to filter and backflush the devices in Example 1 and Comparative Examples 1 to 7. After the production was finished, the dust removal rate of the filter bag and the deformation of the filter bag were counted. The results are shown in Table 1:

[0060] Table 1:

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com