A horizontal machine tool for processing drill chuck jaw threads

A technology for processing drills and clamping jaws, which is used in metal processing mechanical parts, metal processing equipment, clamping and other directions, and can solve the problem of many unstable factors of three-hole milling tires, large fluctuation difference of three inclined holes, and thread rise angle. Instability and other problems, to achieve the effect of dimensional stability, long service life and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

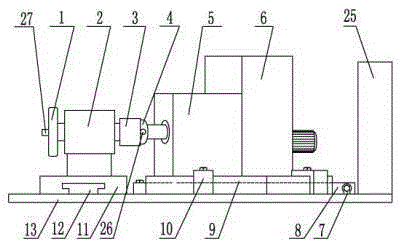

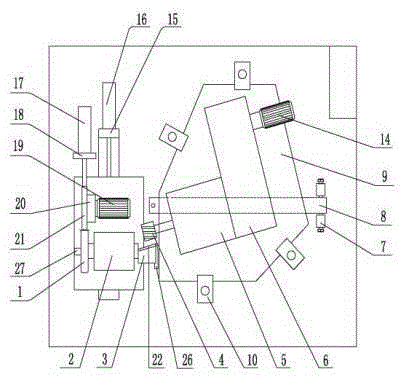

[0019] From figure 1 , figure 2 It can be seen that a horizontal machine tool for processing the threads of the clamping jaws of a drill chuck includes a base 13, a milling tire rotary feed device and a tool rotary feed device mounted on the base 13.

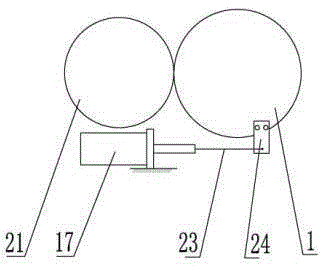

[0020] The thread milling tire rotary feed device is installed at one end of the machine tool base 13. The base 13 is equipped with a guide rail 12 and a longitudinal sliding table 11. The longitudinal sliding table 11 is driven by a hydraulic cylinder 16 to move smoothly on the guide rail 12, and a hydraulic cylinder fixing block 15 It is fixed on the base 13 and the hydraulic cylinder 16 is fixed. The longitudinal sliding table 11 is equipped with a milled tire axle seat 2 and a motor 19 with a clutch 20, as well as a driving gear 21 and a driven gear 1. One side of the milled tire axle seat 2 is installed with a milled tire axle. For the wire milling tire 3, the driven gear 1 drives the wire milling tire 3 to rotate through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com