Patents

Literature

281 results about "Rotary feeder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rotary feeders, also known as rotary airlocks or rotary valves, are commonly used in industrial and agricultural applications as a component in a bulk or specialty material handling system. Rotary feeders are primarily used for discharge of bulk solid material from hoppers/bins, receivers, and cyclones into a pressure or vacuum-driven pneumatic conveying system. Components of a rotary feeder include a rotor shaft, housing, head plates, and packing seals and bearings. Rotors have large vanes cast or welded on and are typically driven by small internal combustion engines or electric motors.

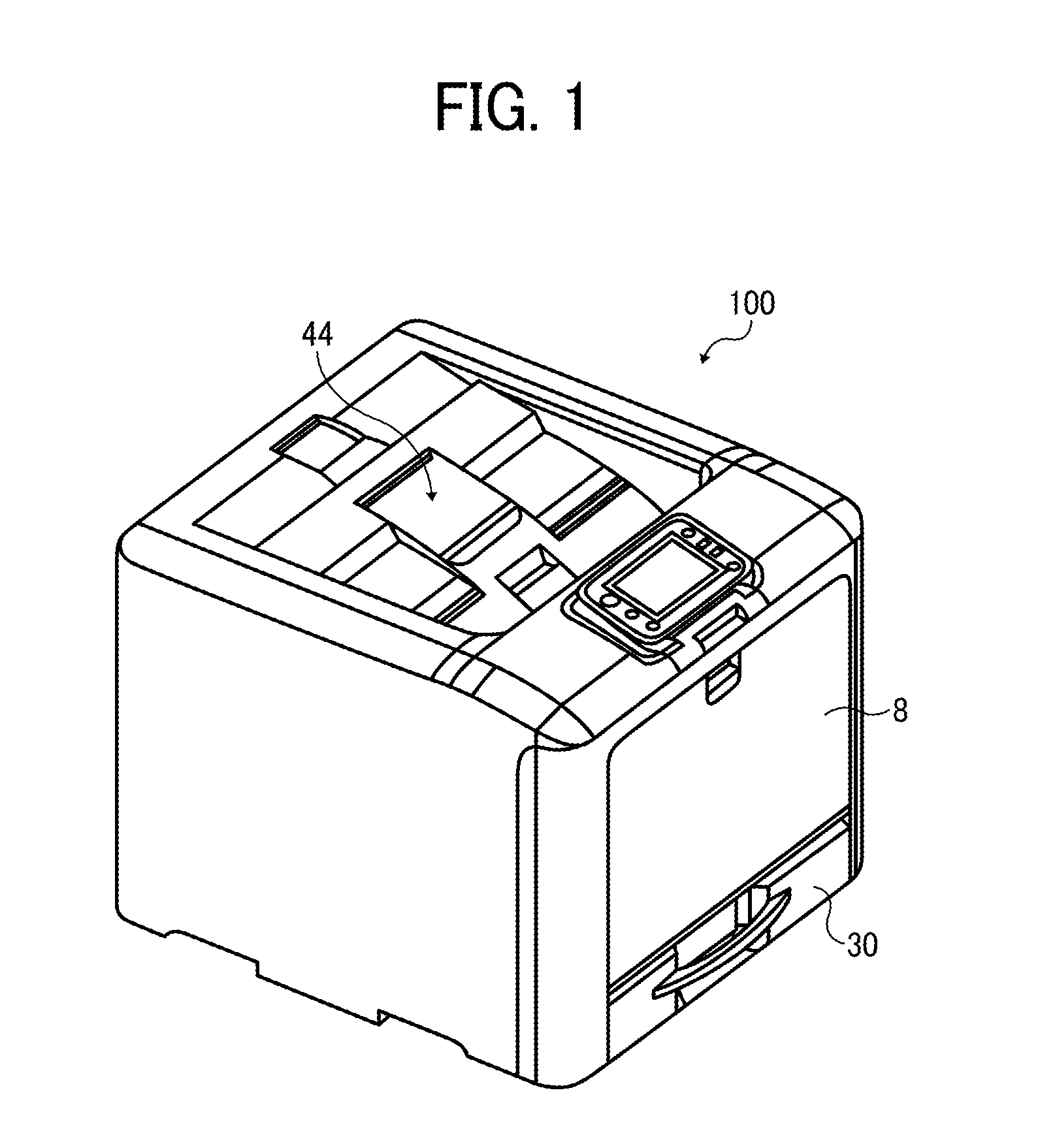

Rotary carton feeder

ActiveUS7695421B2Increase approach angleEasy maintenanceBox making operationsPaper-makingGear wheelGear system

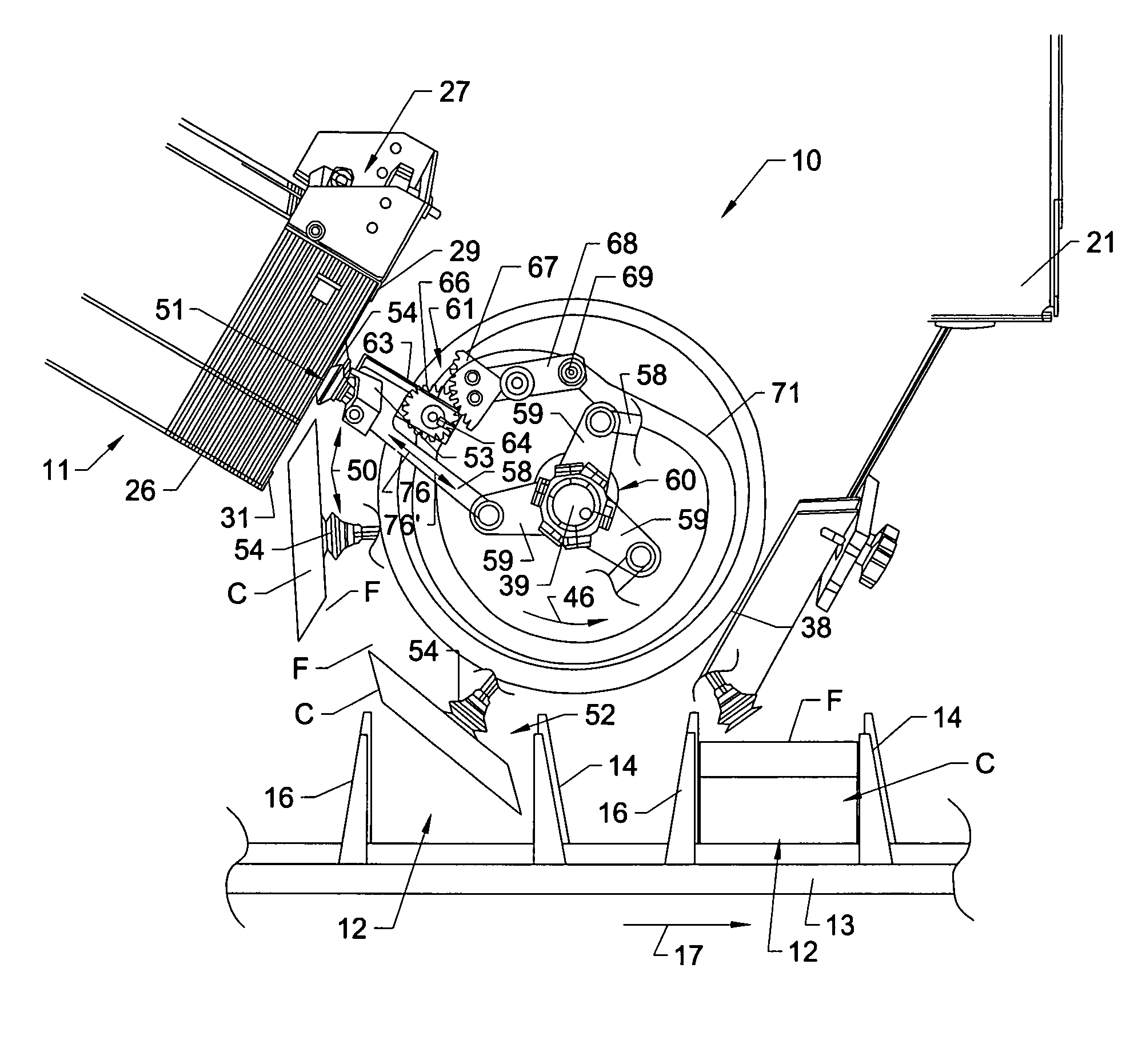

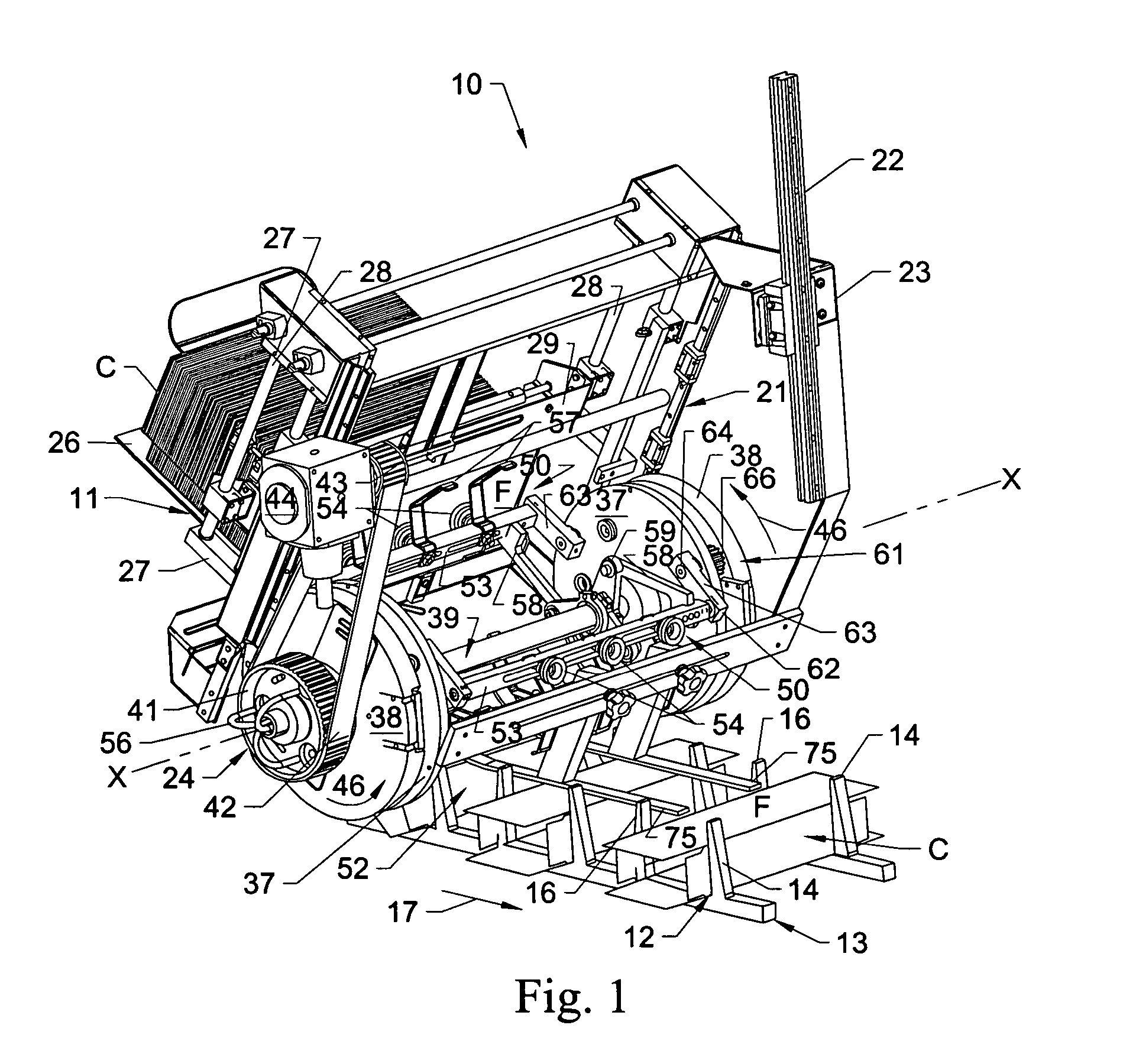

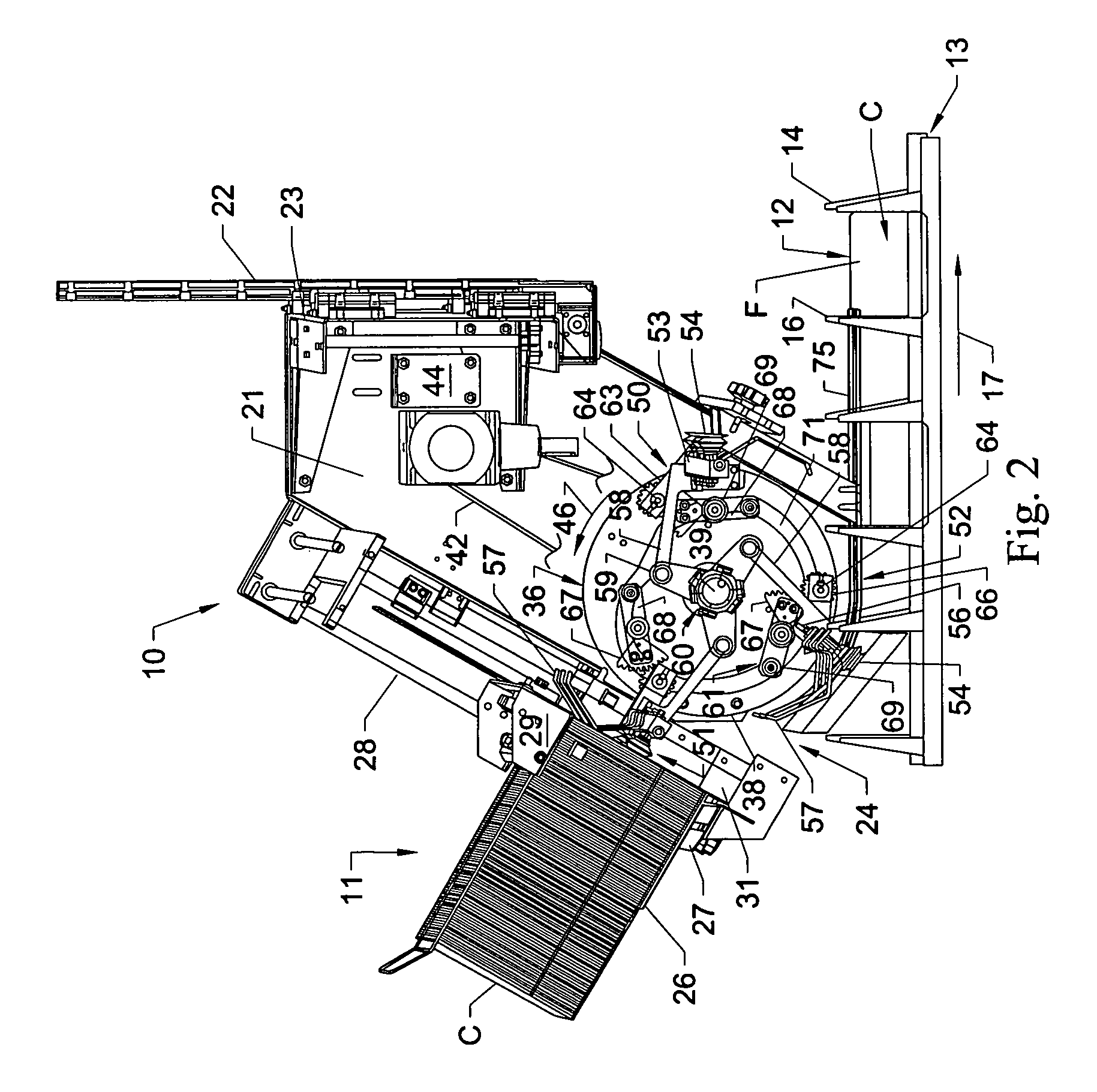

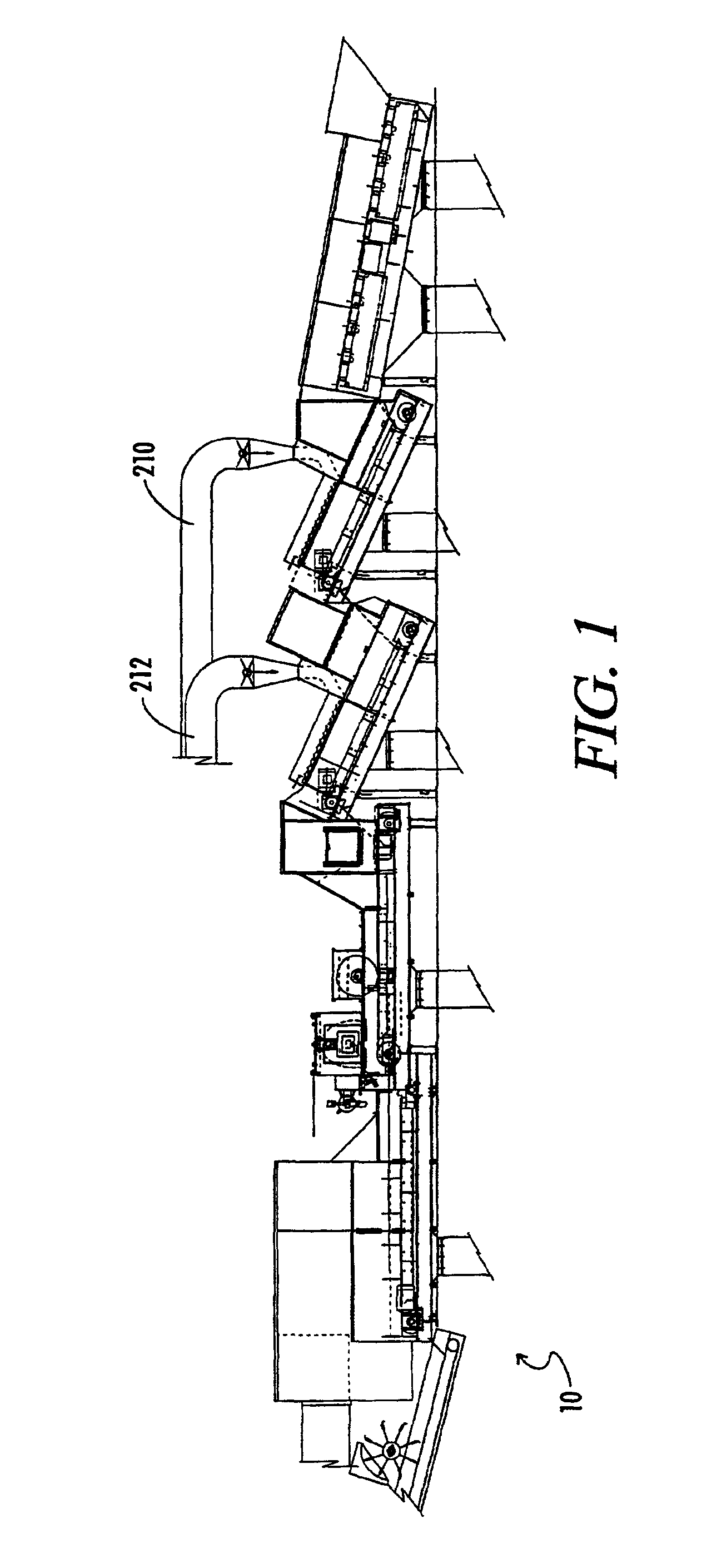

A carton feeding system for feeding a series of cartons into selected flights of a carton conveyor is disclosed. The carton feeding system generally includes a rotary feeder having a series of carton feeding assemblies rotated thereabout. The carton engaging assemblies are attached to a gearing system or mechanism that controls the operating angle of the carton engaging assemblies as they engage or pick the cartons from a magazine or supply. Thereafter, the cartons are erected within the flights of a carton conveyor moving beneath the rotary feeder as the carton engaging elements are carried about their path of travel.

Owner:GRAPHIC PACKAGING INT

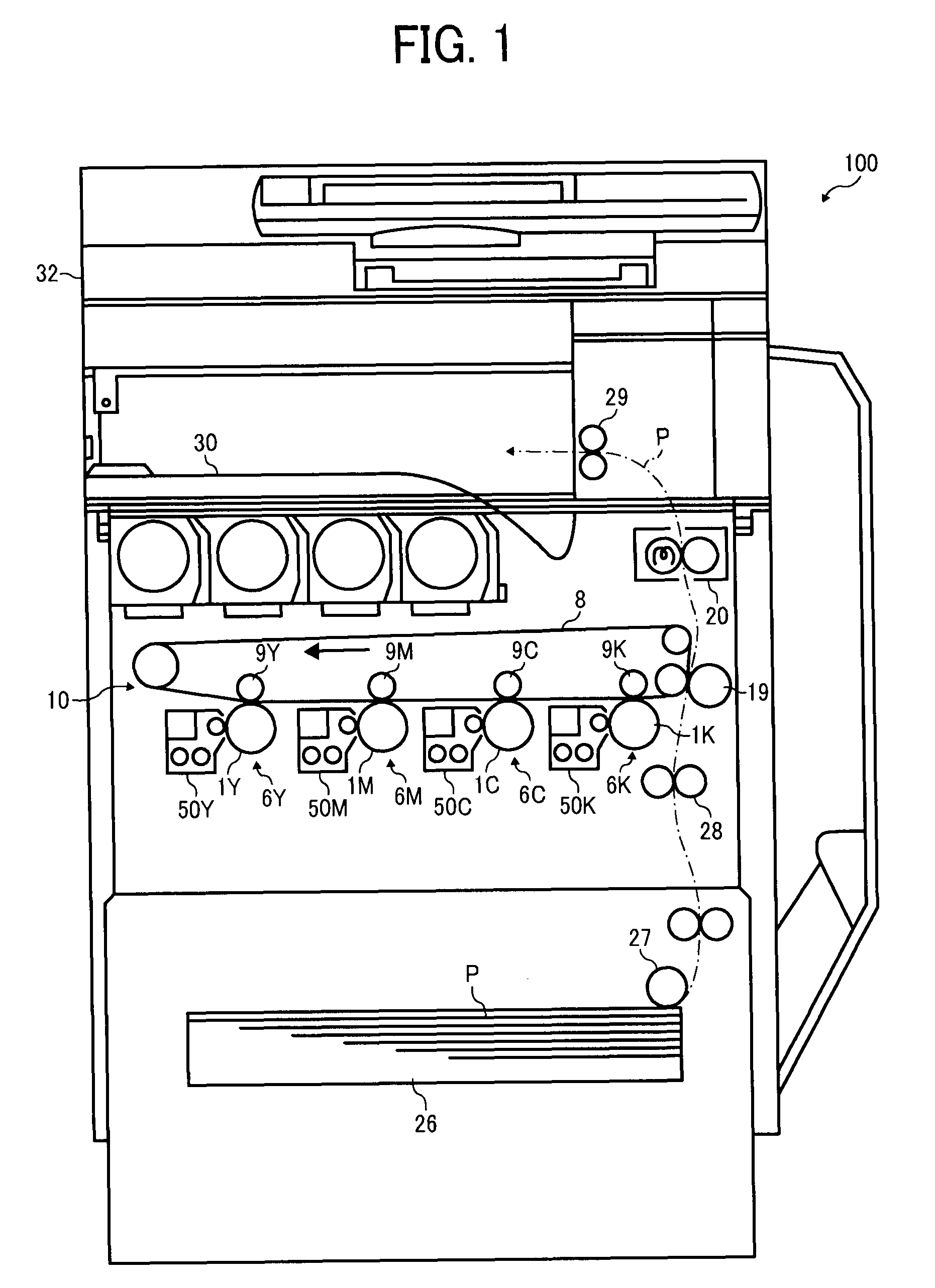

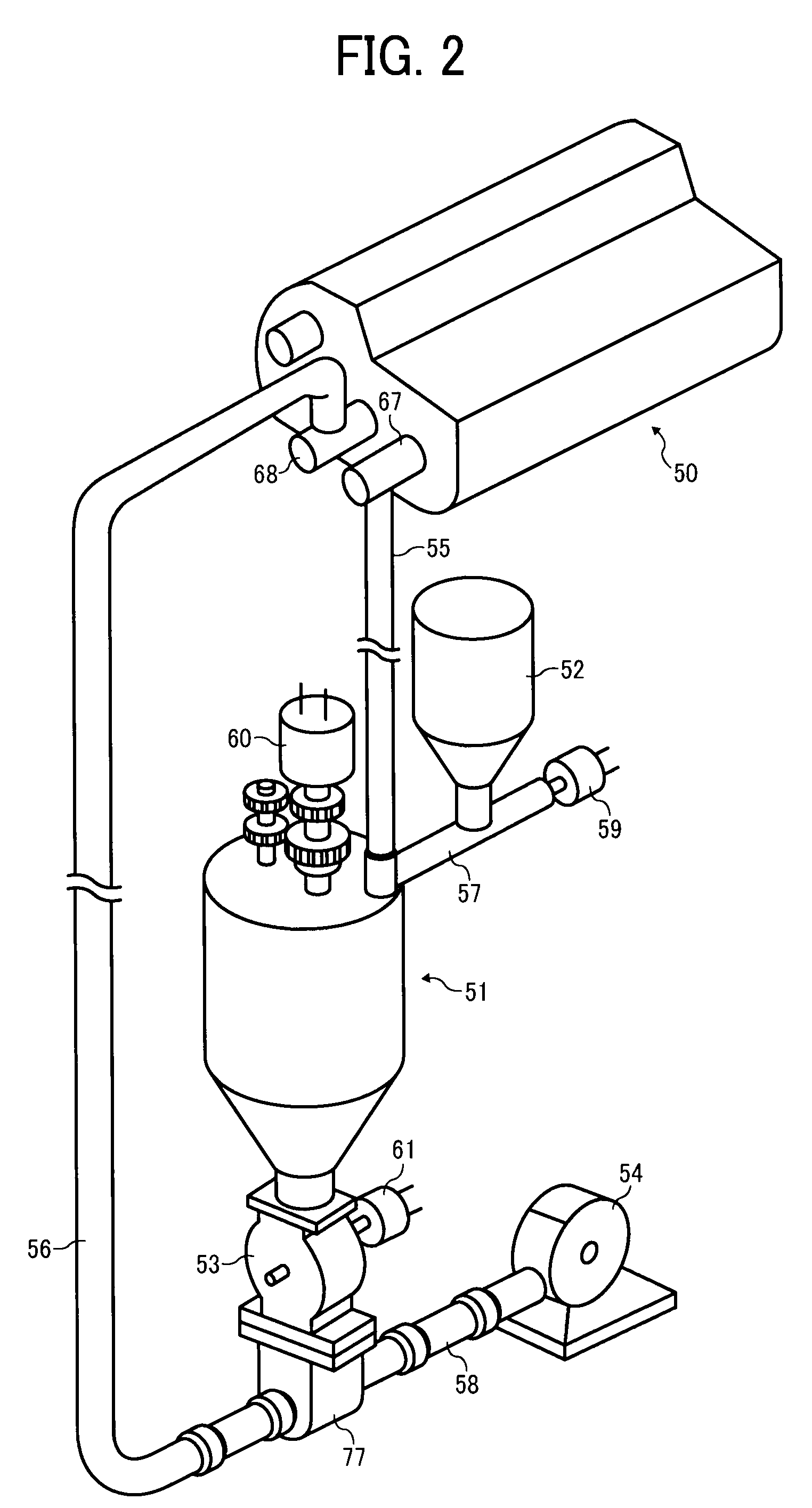

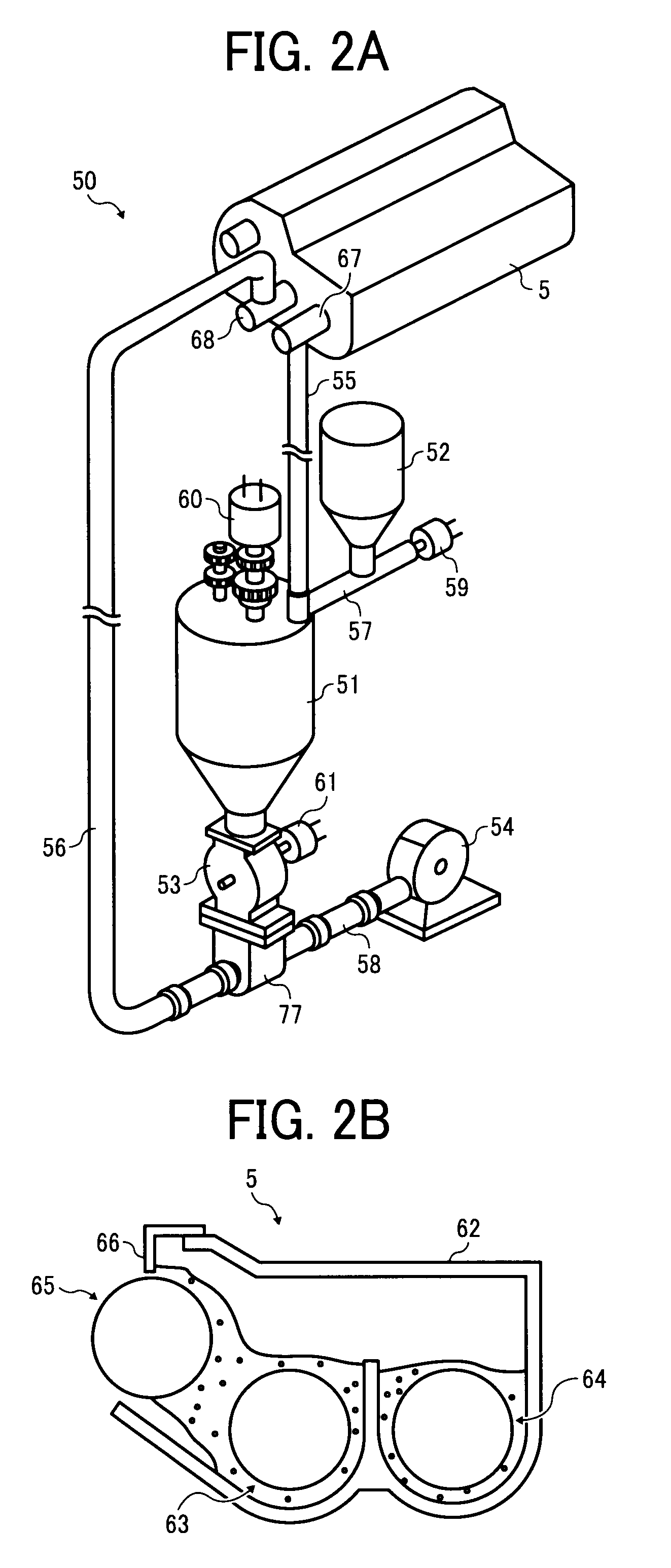

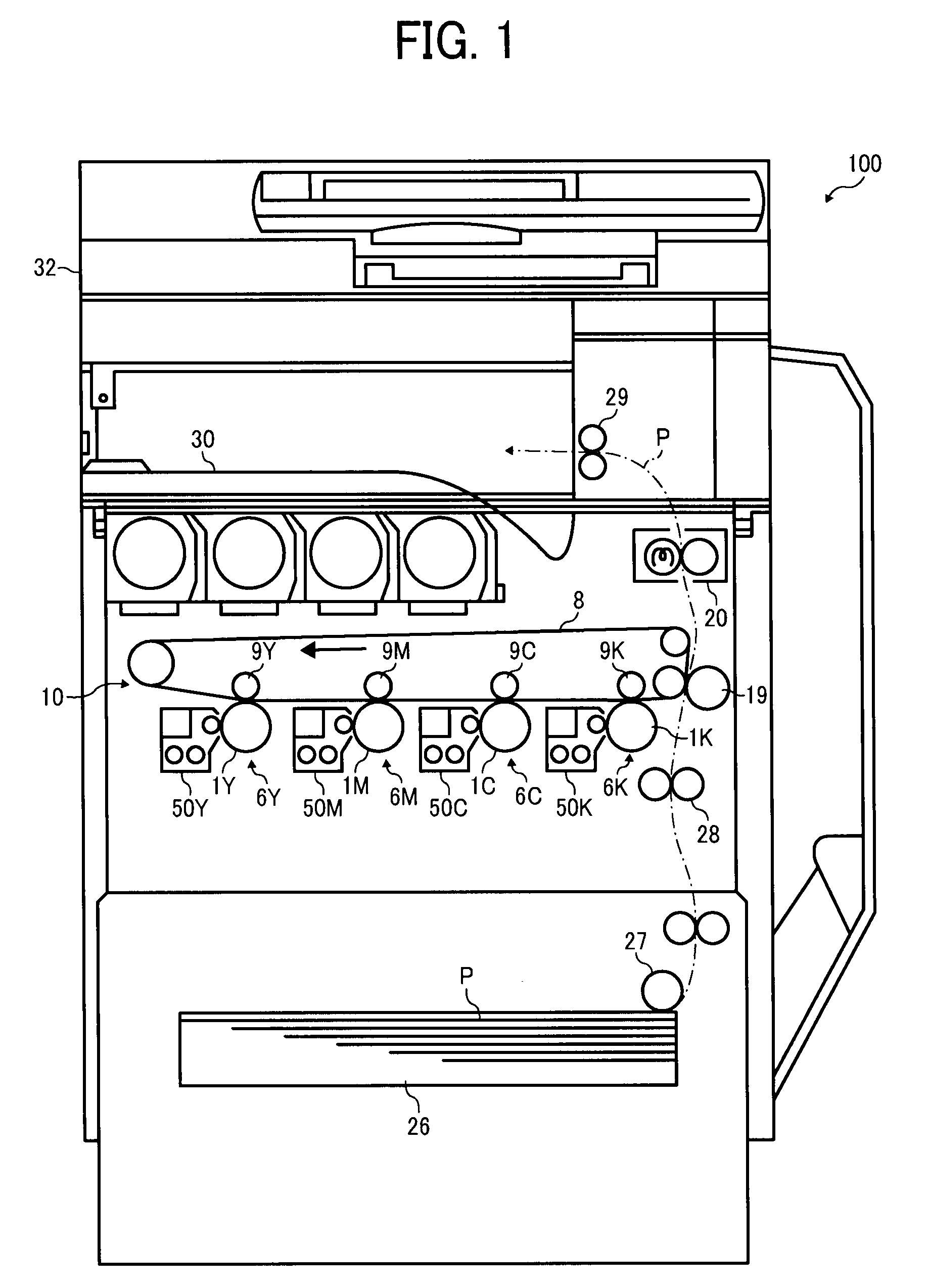

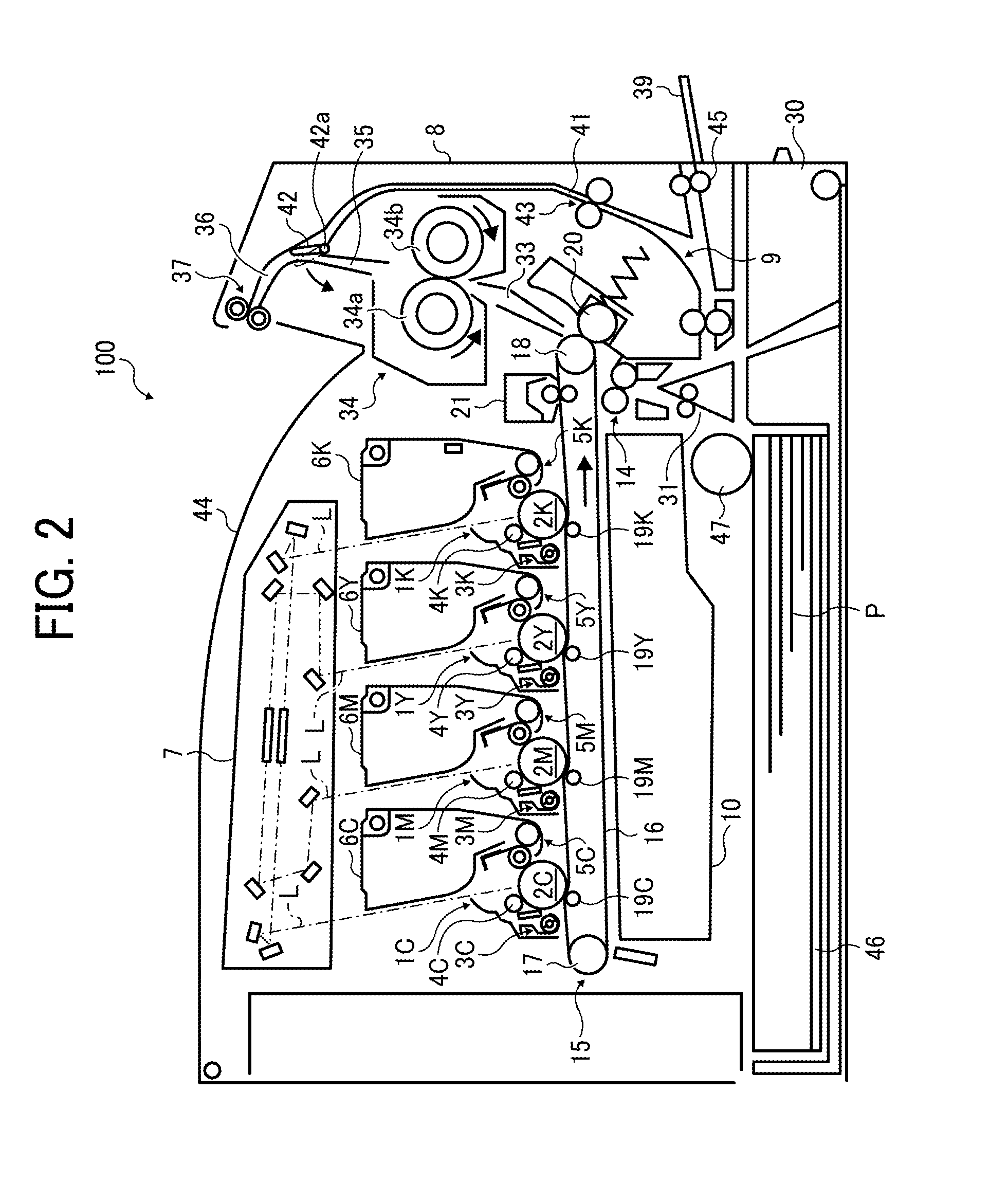

Developing agent circulation system and image forming apparatus using same

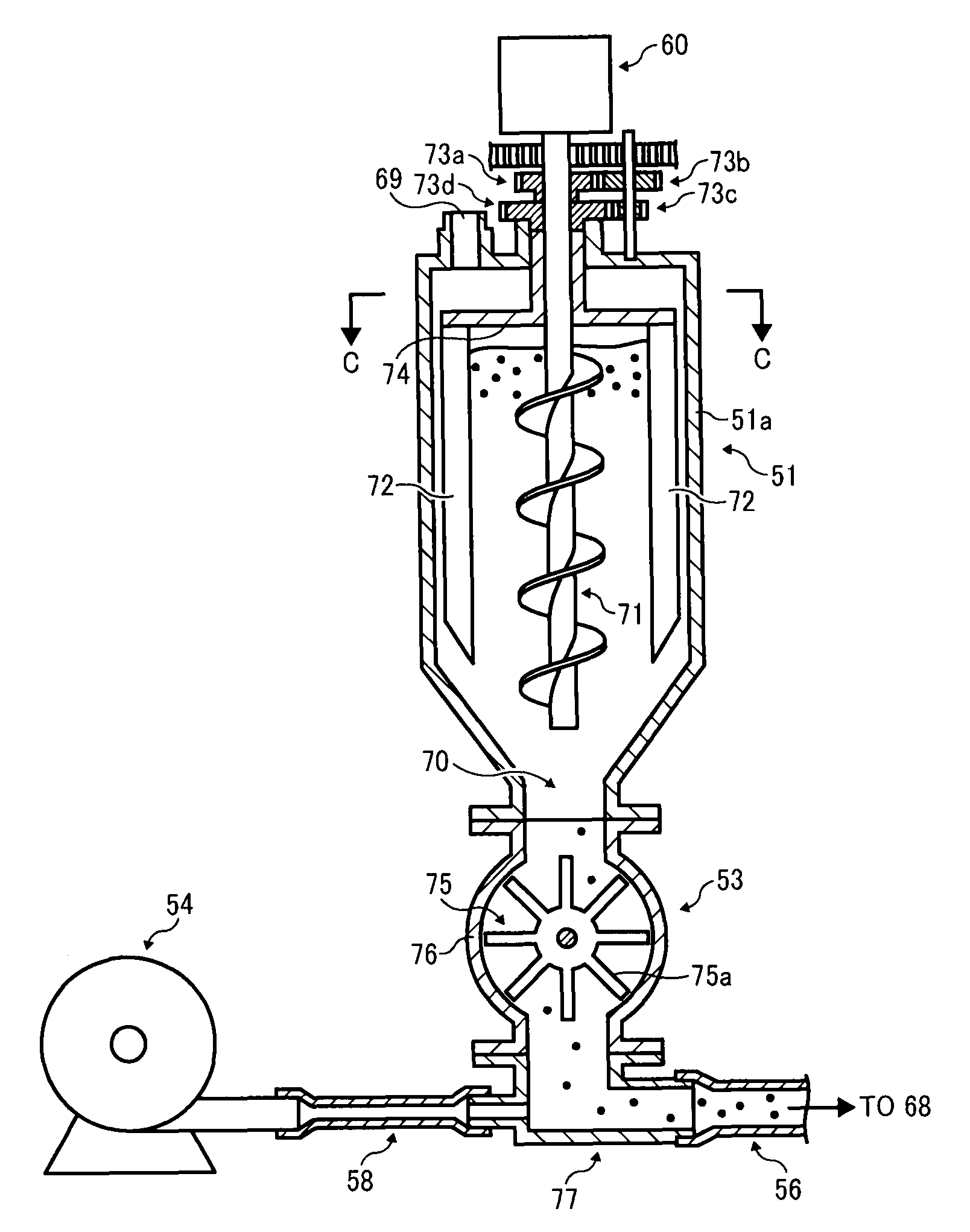

A development agent circulation unit includes a development unit, an agitation unit, and a rotary feeder. The development unit develops a latent image on an image carrier using a developing agent. The agitation unit agitates developing agent recovered from the development unit. The rotary feeder receives the developing agent from the agitation unit and discharges the developing agent in predetermined discrete amounts. The discharged developing agent is transported to the development unit using a gas stream. The rotary feeder includes a rotor and a stator having a clearance “t” between the rotor and the stator. The clearance “t” satisfies a relation “t<2D” where D denotes a developing agent particle diameter, and a toner particle diameter dt of a toner particle of the developing agent and a carrier particle diameter dc of a carrier particle of the developing agent satisfy a relation D=dc+2dt.

Owner:RICOH KK

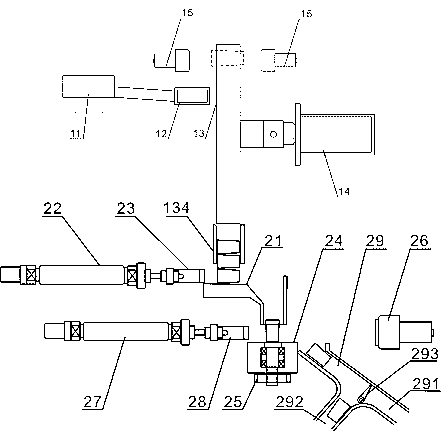

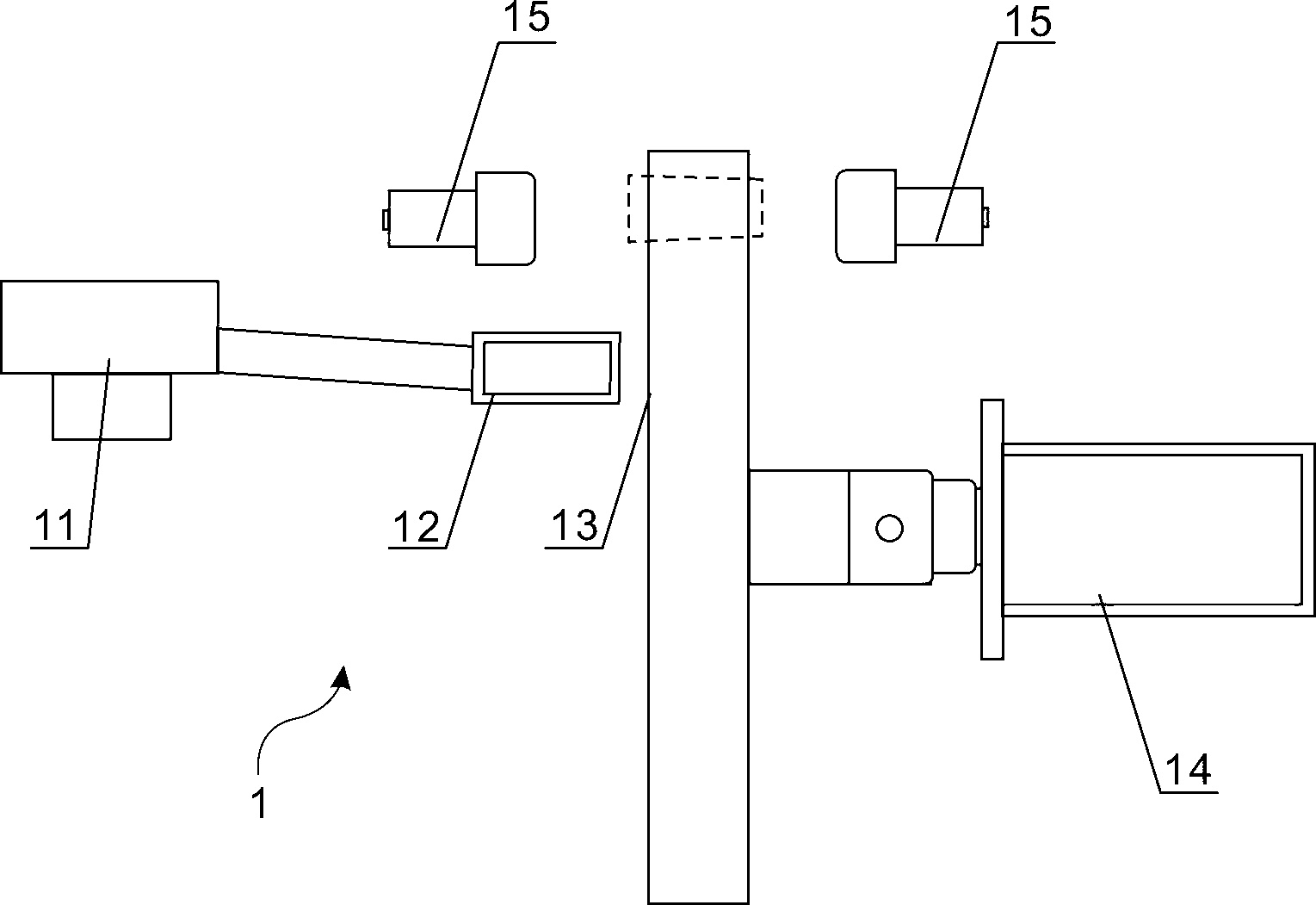

Tapered roller surface defect detection system

InactiveCN103264019AReduce wearEasy to sortOptically investigating flaws/contaminationSortingFace detectionEngineering

The invention discloses a tapered roller surface defect detection system. The tapered roller surface defect detection system comprises a tapered roller end-face detection mechanism and a tapered roller side-face detection mechanism. The tapered roller end-face detection mechanism comprises a feeder, a rotary feeder and an image acquisition device II. The tapered roller side-face detection mechanism comprises 1, a positioning clamp for vertical ordinal falling-off of tapered rollers, 2, a rotation table, 3, an image acquisition device I and 4, a sorting mechanism. The rotation table is located below an outlet of the positioning clamp and is driven by a stepping motor to rotate. One side of the rotation table is provided with the image acquisition device I and the other side of the rotation table is provided with a cylinder II. A push plate II in front of the cylinder II is corresponding to an automatic sorting table. The sorting mechanism receives qualified and unqualified tapered rollers sorted by a movable turnover panel. The tapered roller surface defect detection system effectively improves work efficiency and precision and realizes automatic production.

Owner:LUOYANG JIUDE BEARING MOLD TECH

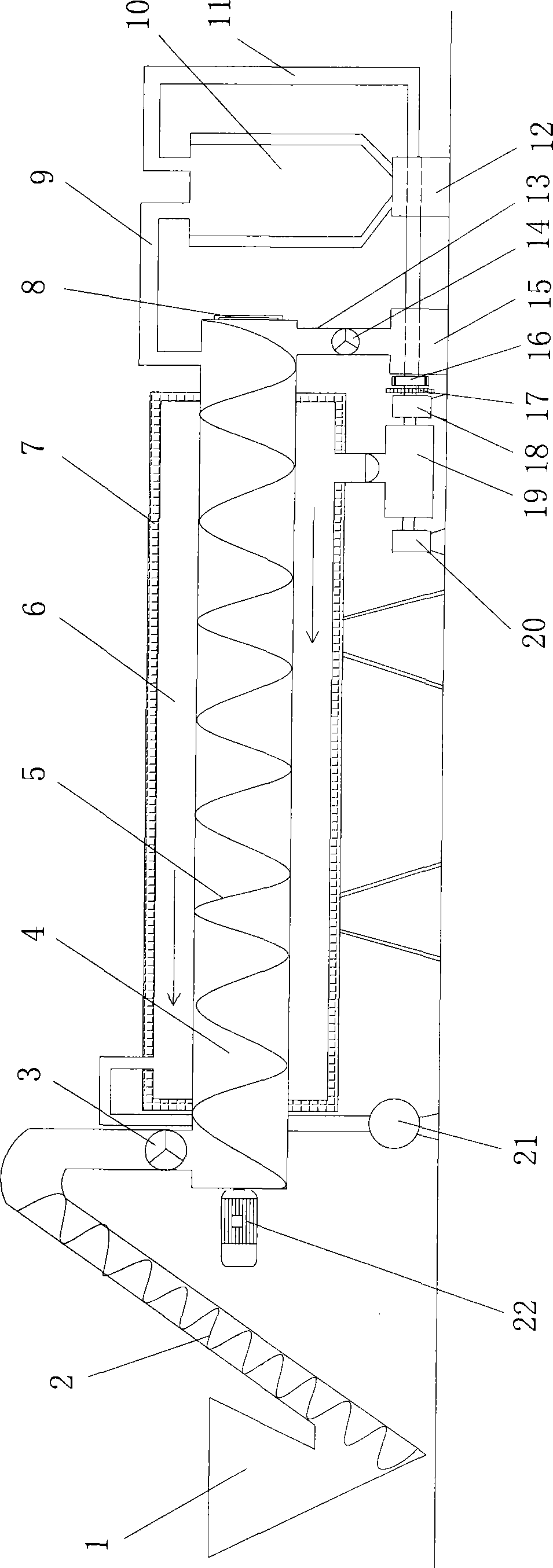

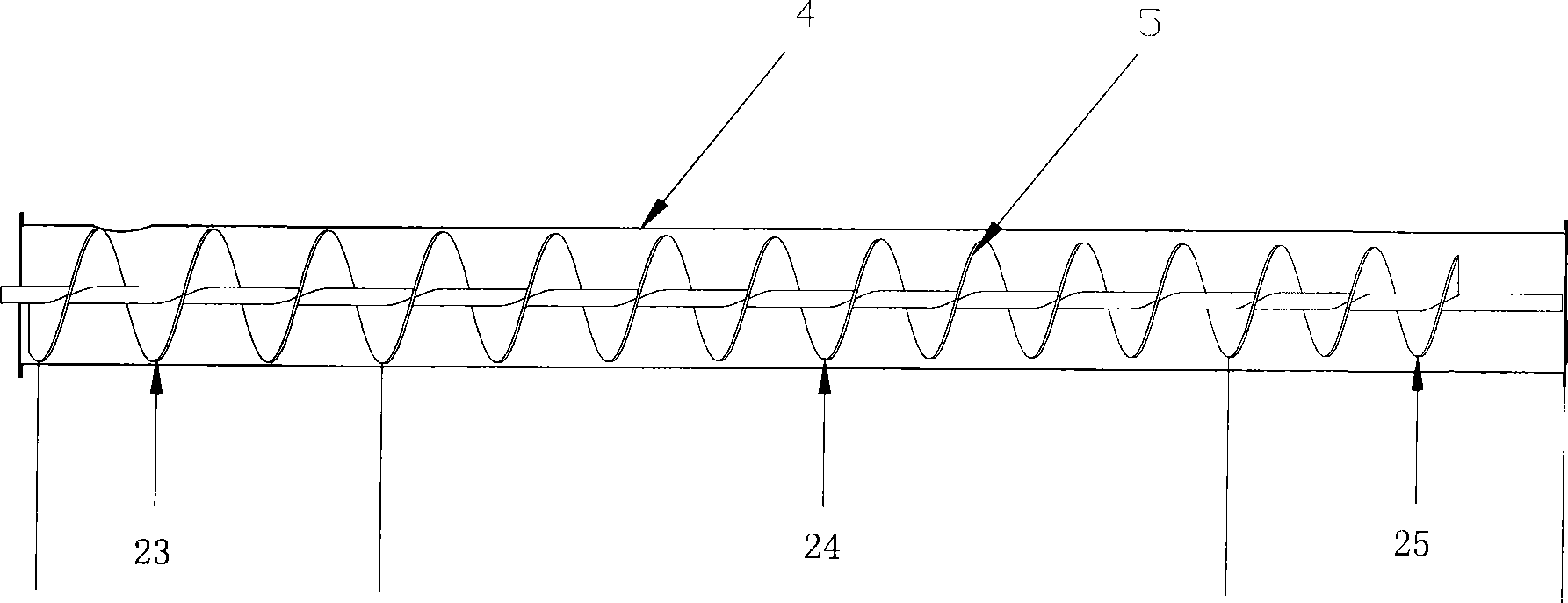

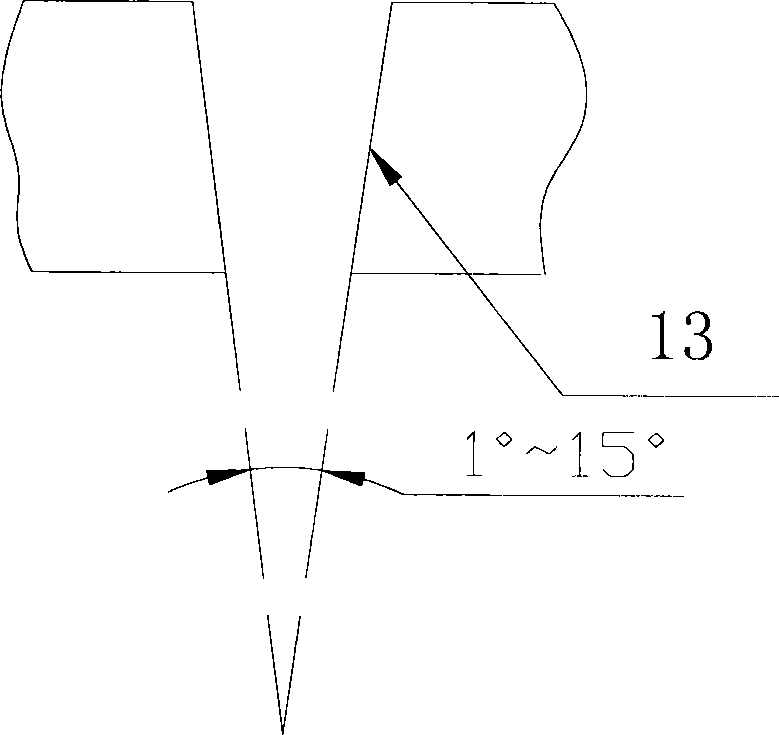

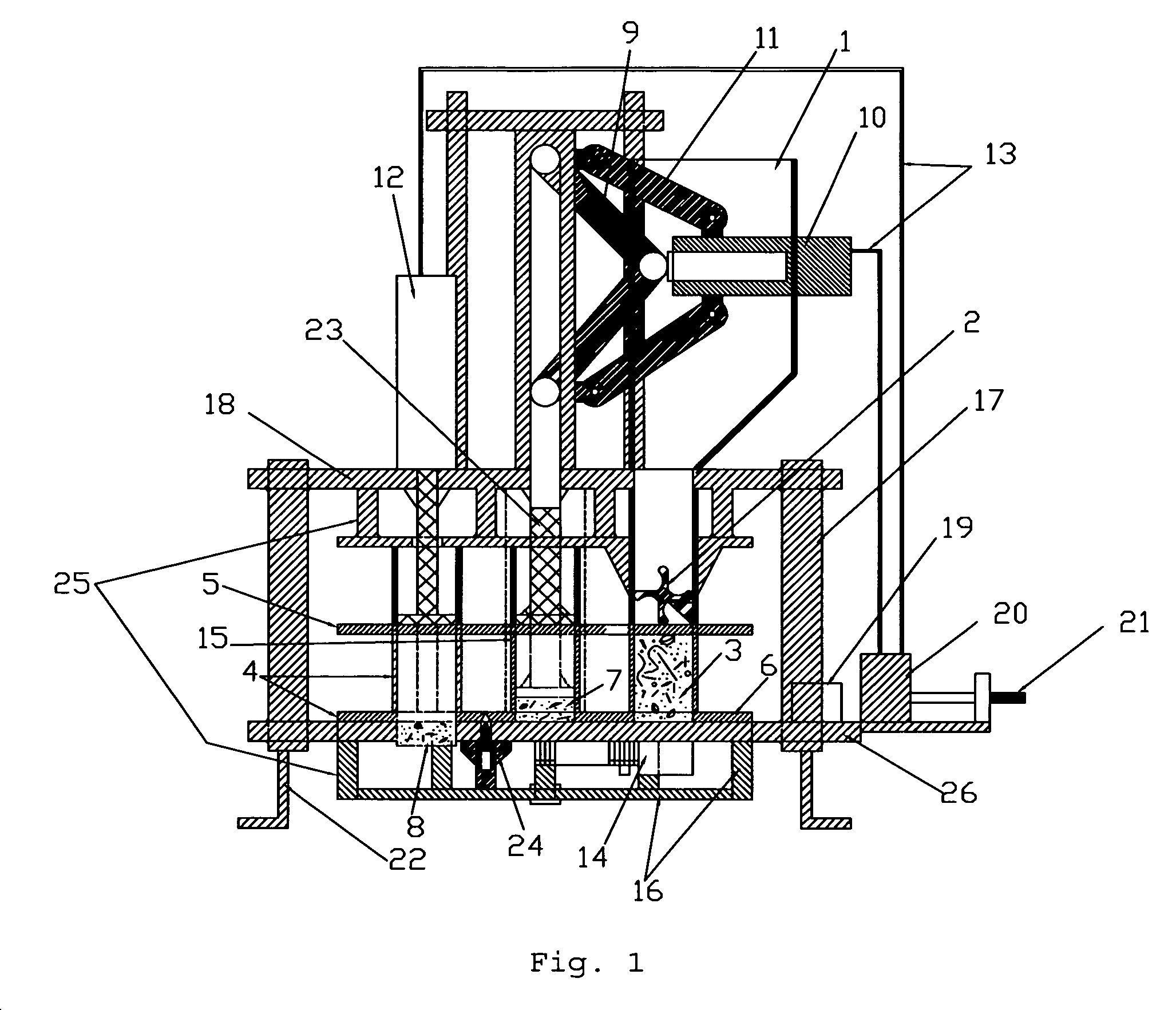

Horizontal-type continuous biochar carbonization device

InactiveCN103614151AGuaranteed sealing performanceAvoid enteringBiofuelsEnergy inputCombustion chamberCarbonization

The invention discloses a horizontal-type continuous biochar carbonization device, and belongs to the renewable energy technology field. The device comprises a feed hopper 1, a carbonization chamber 4, a high-temperature flue gas sleeve 6 and a gas combustor 18. The front end of the carbonization chamber 4 is connected with a feed spiral conveyer 2 through a feed inlet rotary feeder 3. The back end of the carbonization chamber 4 is connected with a char collecting box 15 through a char outlet pipe. The gas combustor 18 is connected with the high-temperature flue gas sleeve 6 through a combustion chamber. Raw materials are added into the carbonization chamber through the feed hopper; the diesel oil combustor is started; the temperature in the carbonization chamber rises; a pyrolysis reaction is generated; charred combustible gas is combusted, high-temperature flue gas is generated, and the carbonization chamber is heated for carbonization; the diesel oil combustor is shut down; the generated biochar is discharged through the char outlet pipe. The carbonization device solves the problems of difficult recycling of charred combustible gas and the like caused by discontinuous production during biomass char production processes, raises the quality and yield of biochar, and is suitable for different biomass raw materials. The carbonization device provides technical support for promotion of biochar industry development in our country.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

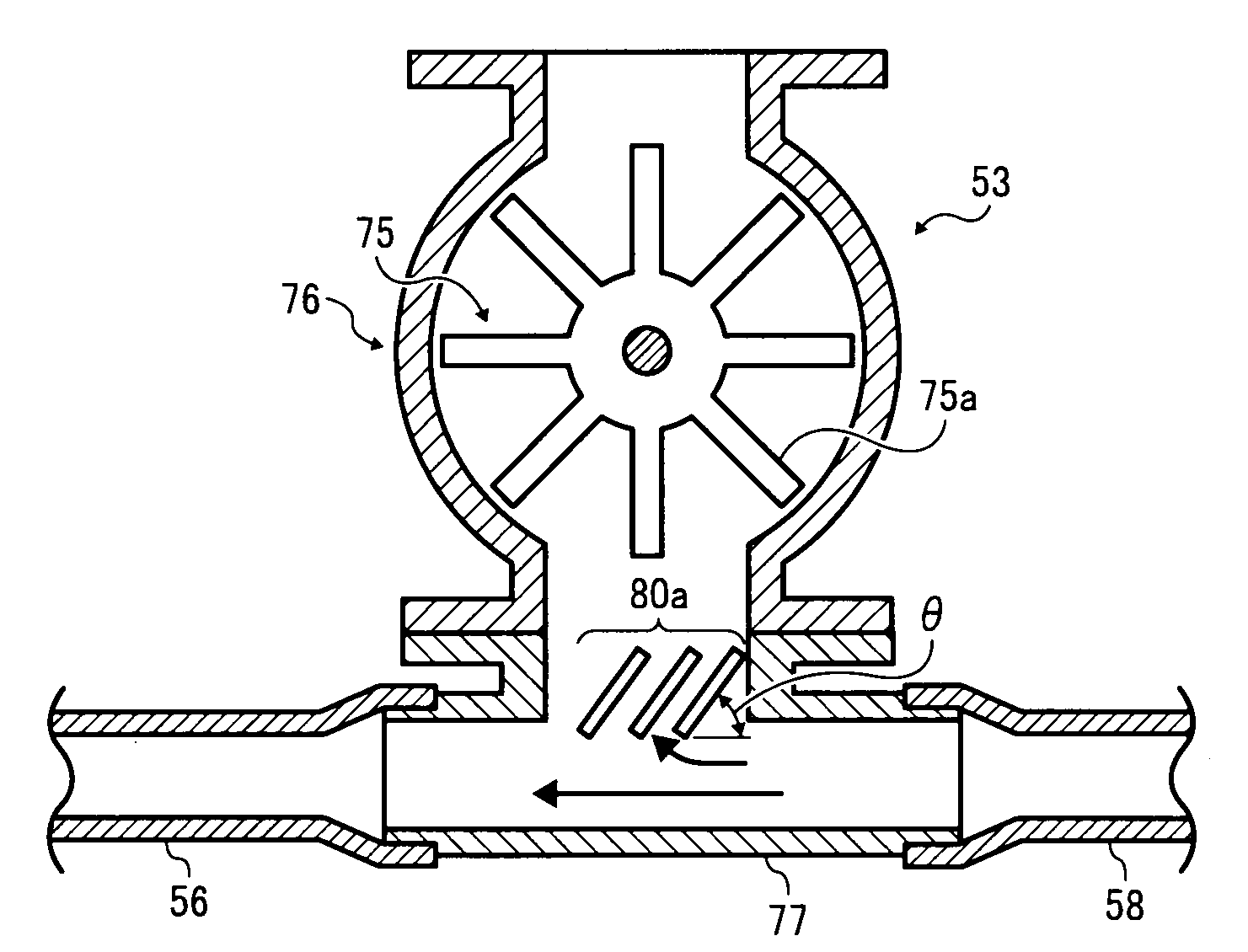

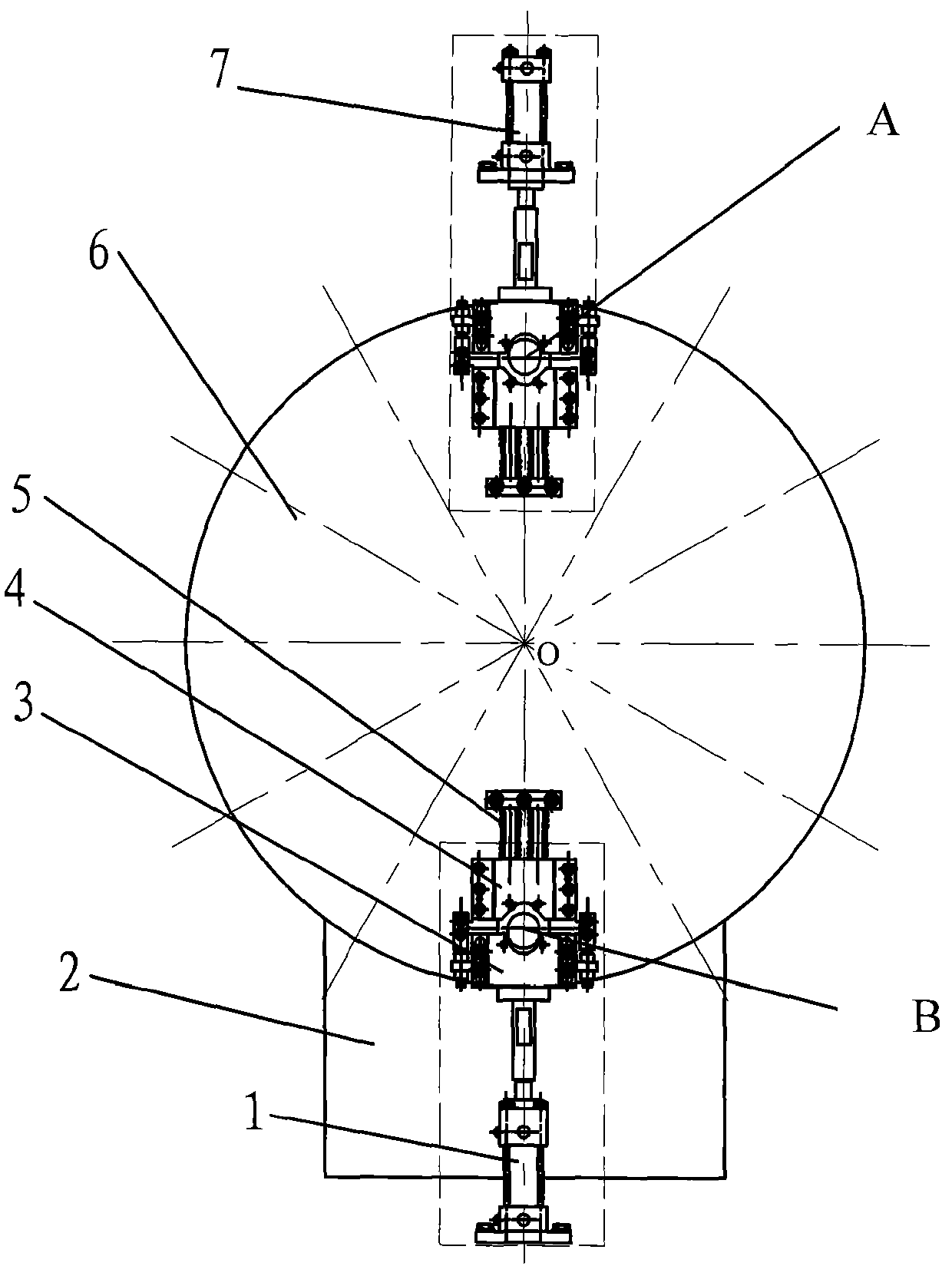

Separator rotary feeder and method of using the same

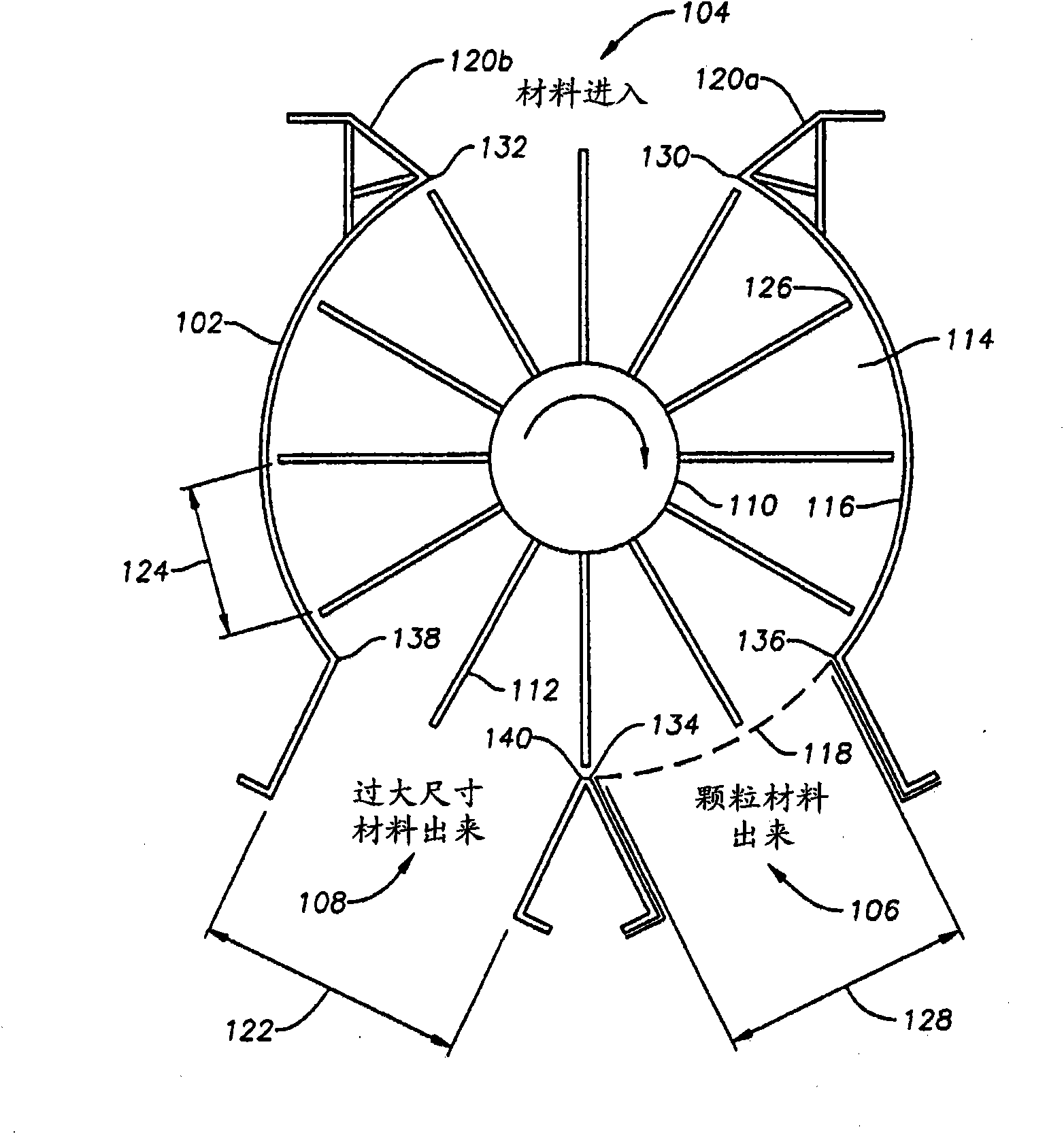

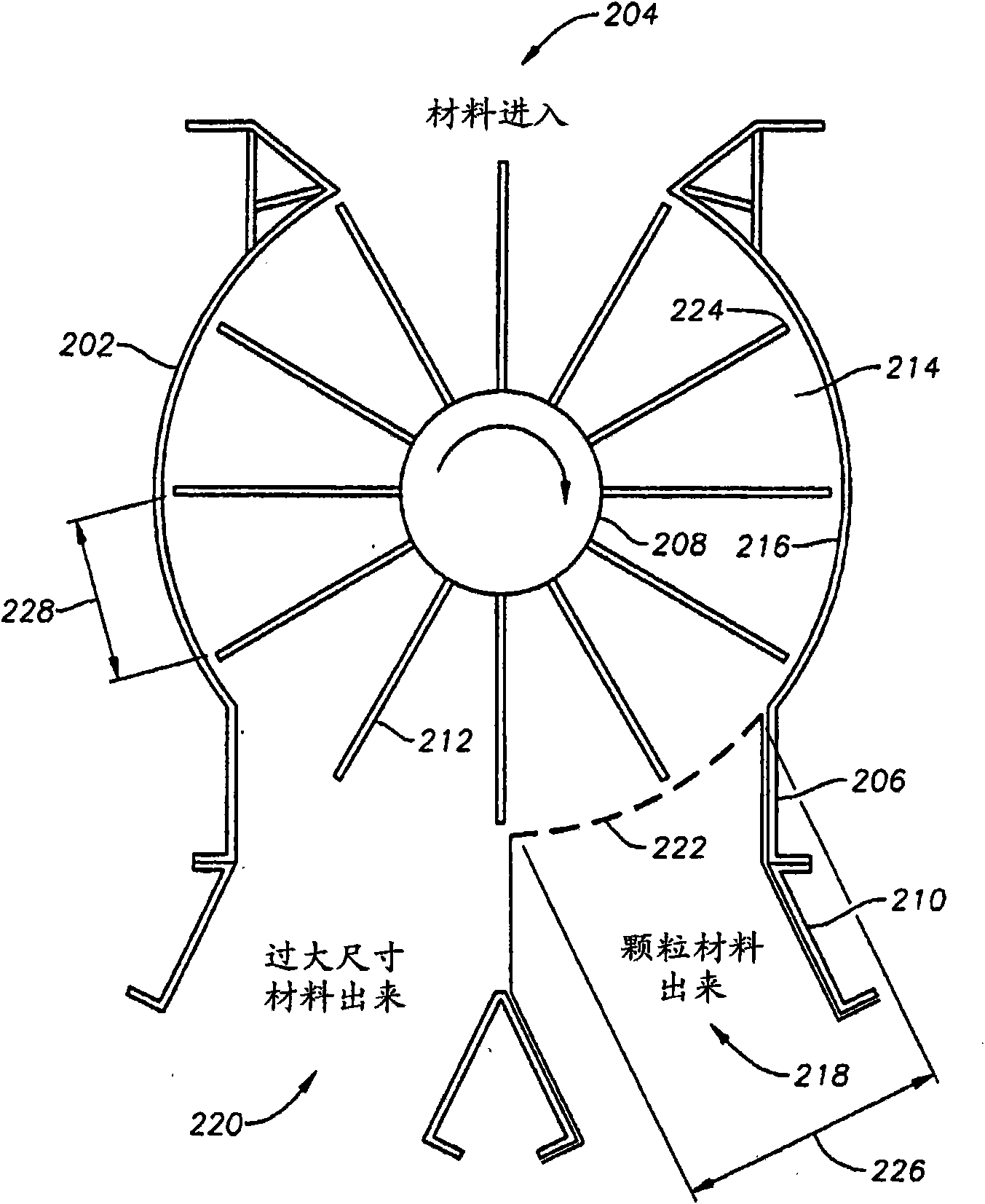

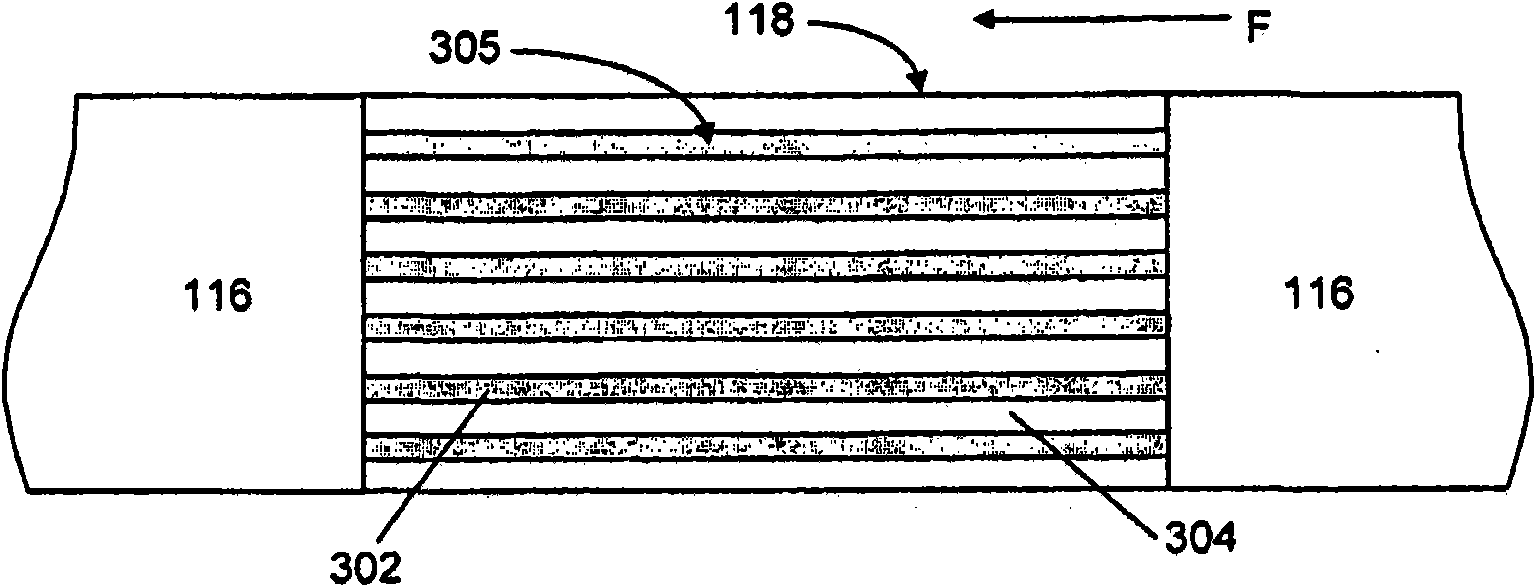

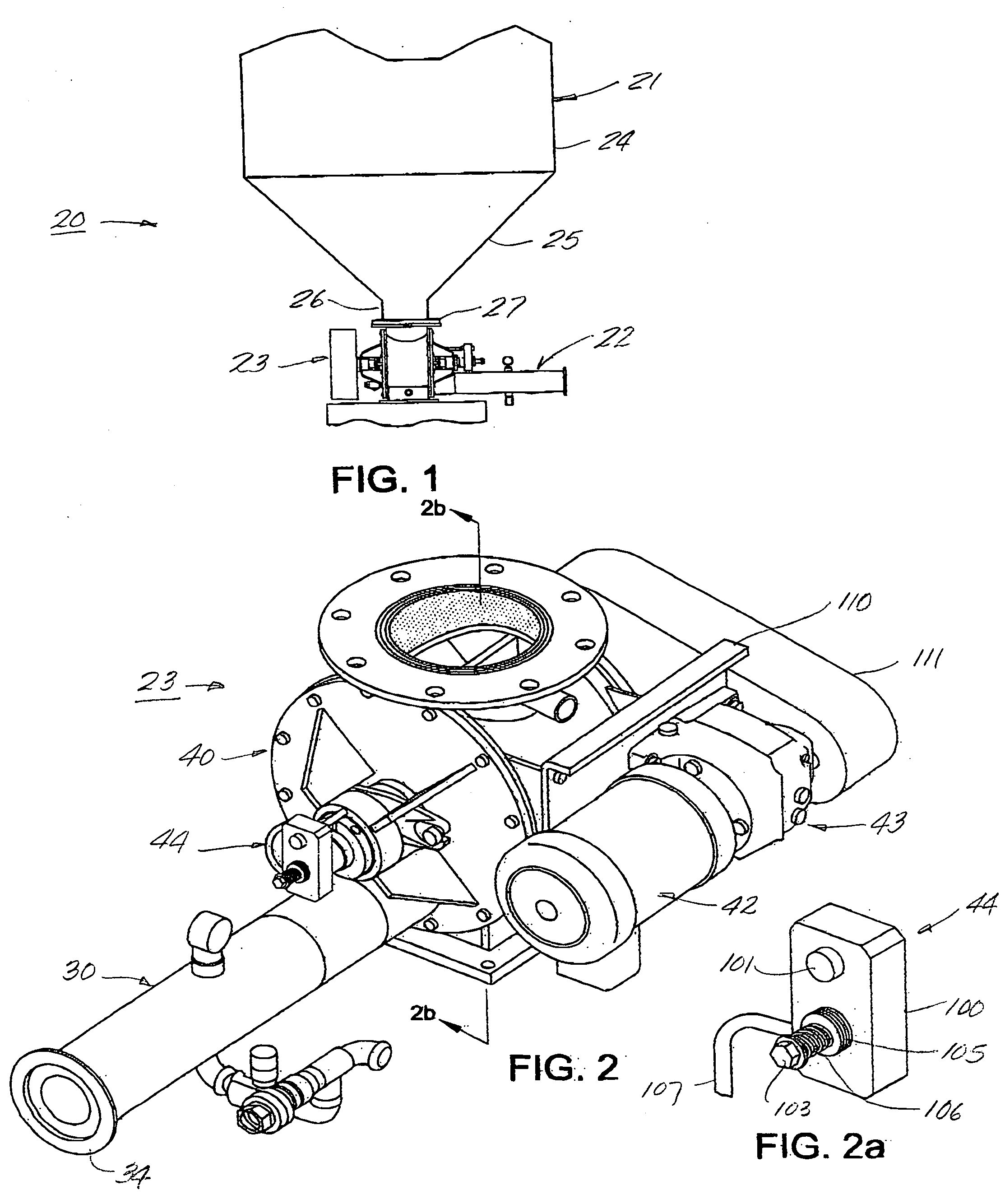

A rotary feeder for feeding a particulate material including: a cylindrical housing comprising a feeder inlet, a first feeder outlet, and a second feeder outlet; a rotor mounted in the cylindrical housing including a plurality of substantially impeller blades defining a plurality of circumferentially spaced pockets alignable with the feeder inlet, first feeder outlet, and second feeder outlet, and adapted to sweep a wall of the cylindrical housing as the rotor rotates in the cylindrical housing; a device for rotating the rotor; and a separating screen in the first feeder outlet to substantially prevent oversize material from exiting through the first feeder outlet, wherein each of the plurality of circumferentially spaced pockets will align with the feeder inlet to receive therein a particulate material and an oversize material through the feeder inlet, rotate in the cylindrical housing to align with the first feeder outlet and discharge the particulate material therefrom, and rotate in the cylindrical housing to align with the second feeder outlet after alignment with the first feeder outlet and discharge the oversized material therefrom is provided as well as a method of using the same.

Owner:UNIVATION TECH LLC

Method and Device to Compact Biomass

InactiveUS20090188160A1Prevent short-circuitingEconomical and practicalBiofuelsSolid fuelsCost effectivenessSolid fuel

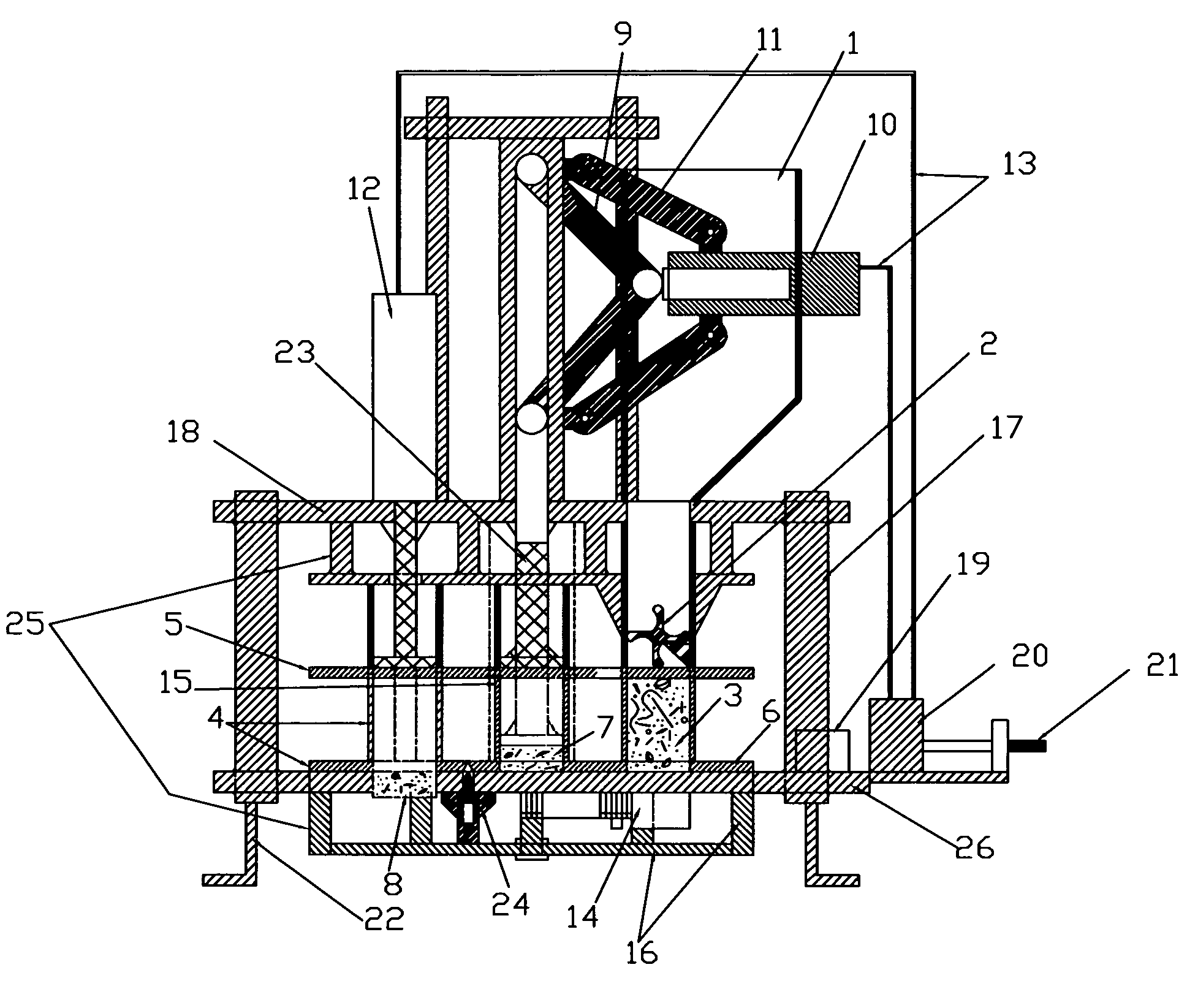

The biomass log fuel has not been commercialized due to difficulties in mass-producing the logs at low cost. The current invention solves this problem by introducing a three-step compaction process: pre-compaction, final compaction, and ejection. While a rotary feeder / compressor is used to perform pre-compaction, a ram driven by a toggle mechanism performs final compaction rapidly and efficiently. A press implementing the three-step compaction is designed and described. This invention should improve the cost-effectiveness of biomass solid fuel or feedstock.Biomass materials such as yard waste, corn stover and switchgrass are compacted at high pressure to form dense “biomass logs” without binder or heat. Biomass logs serve as a solid fuel for heating buildings, and as feedstock for bio-reactors for liquefaction or gasification. Densifying the uncompacted fluffy biomass reduces space needed for storage, decreases the number of vehicles needed to transport biomass, and increases the energy density of fuel.

Owner:LIU HENRY +3

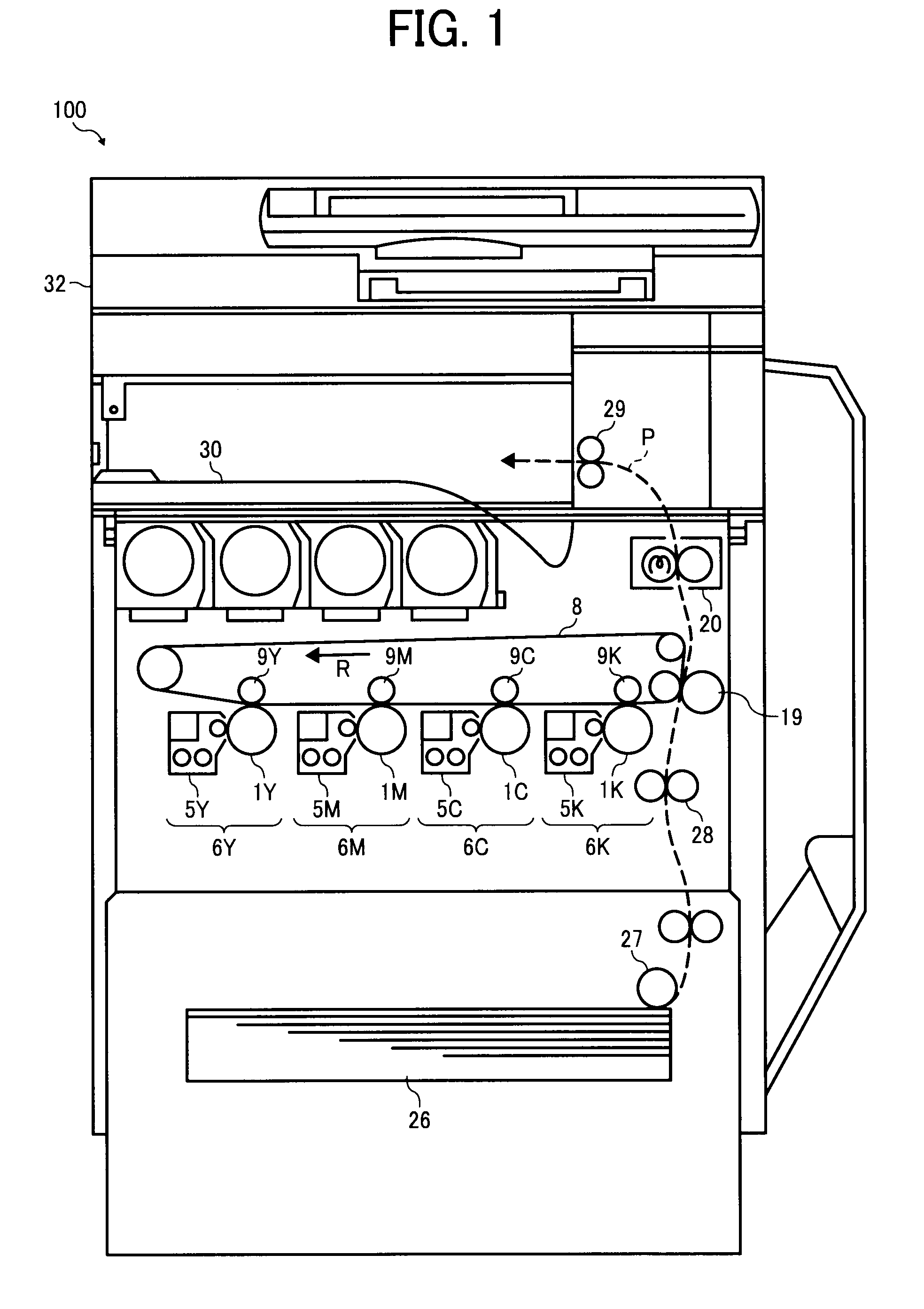

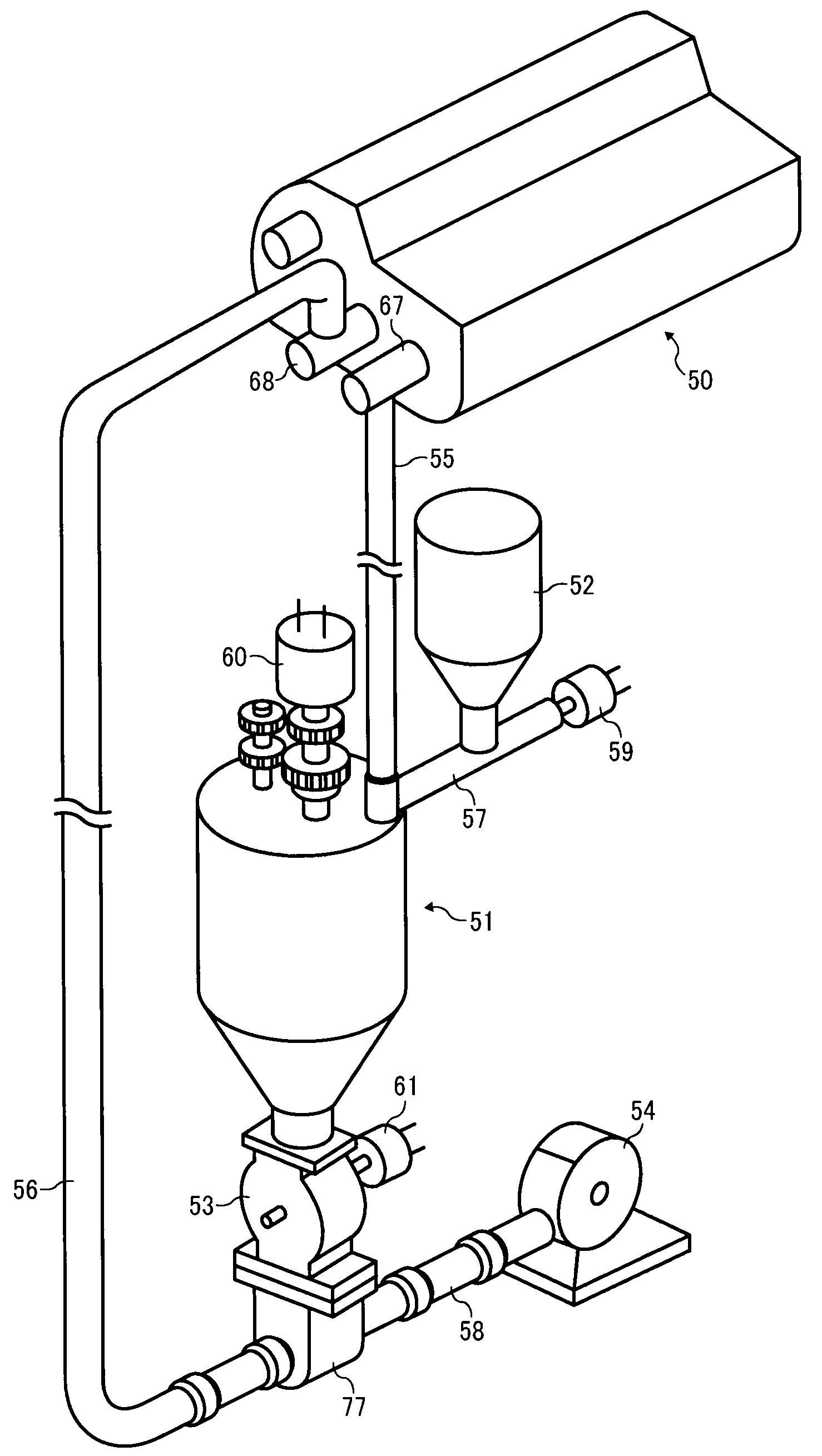

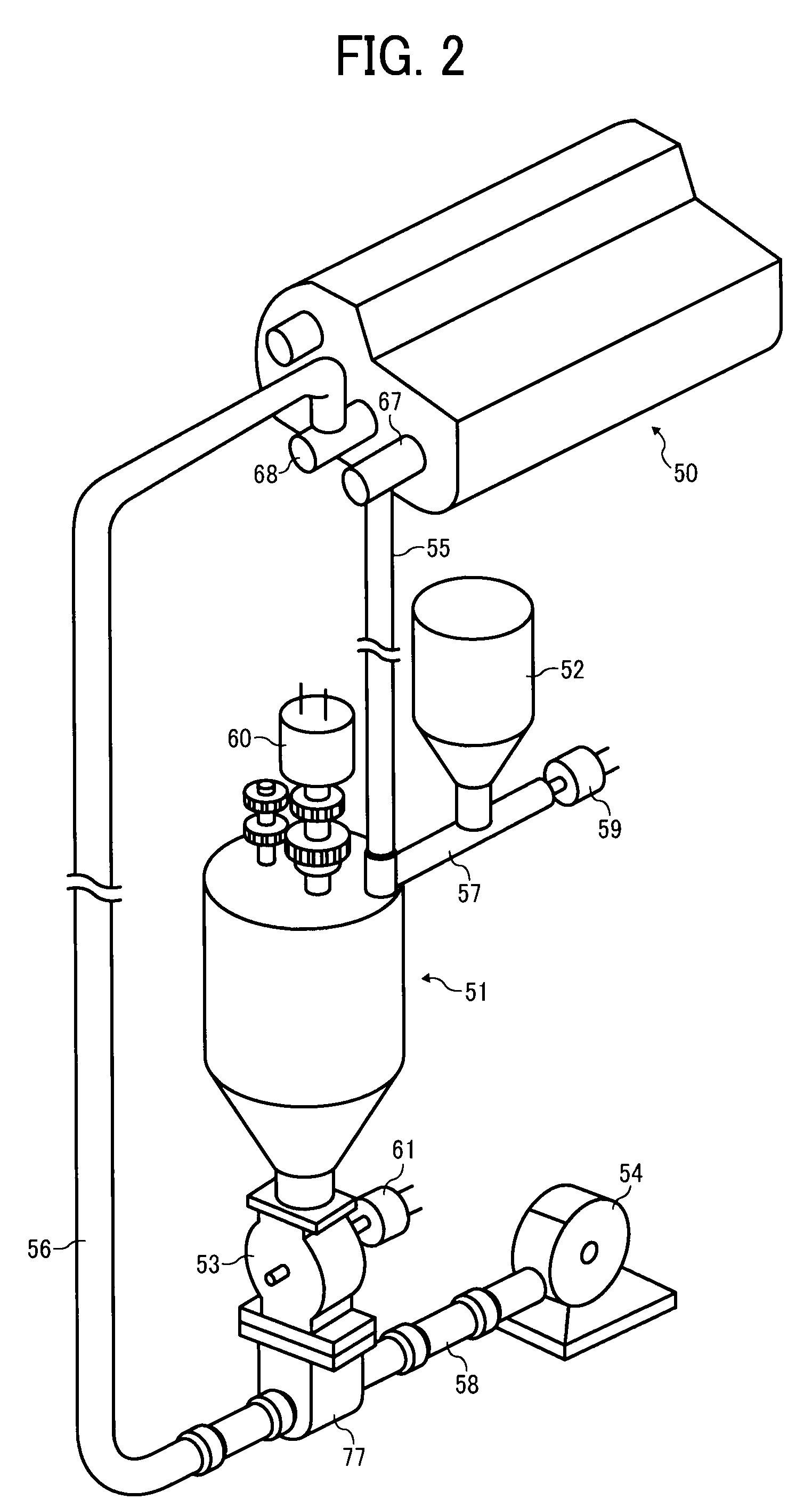

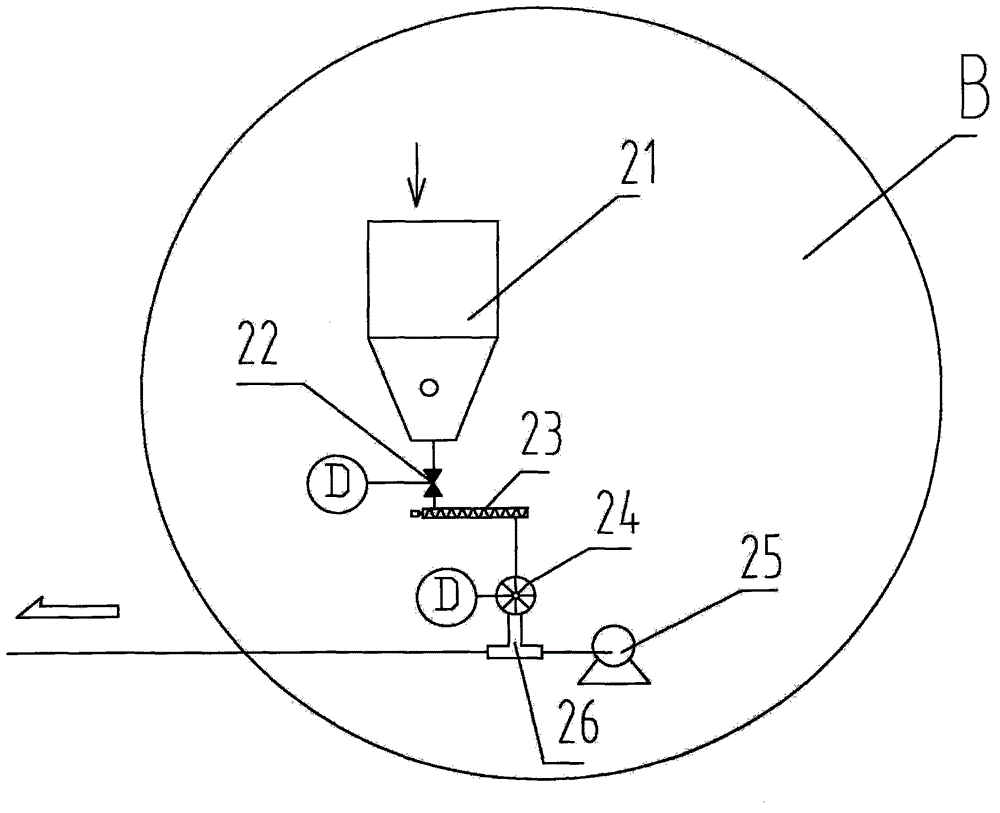

Developing system and image forming apparatus incorporating same

A developing system includes a developing unit, a mixing container, a rotary feeder, an air pump, and an airflow regulator. The developing unit is configured to convert a latent image into visible form using a developer. The mixing container is separated from the developing unit and is configured to hold and mix part of the developer after use. The rotary feeder is configured to dispense the developer from the mixing container to a delivery path. The air pump is configured to supply compressed air to deliver the dispensed developer to the developing unit through the delivery path. The airflow regulator is located where the rotary feeder connects to the delivery path, and is configured to prevent the compressed air from flowing toward the rotary feeder from the delivery path.

Owner:RICOH KK

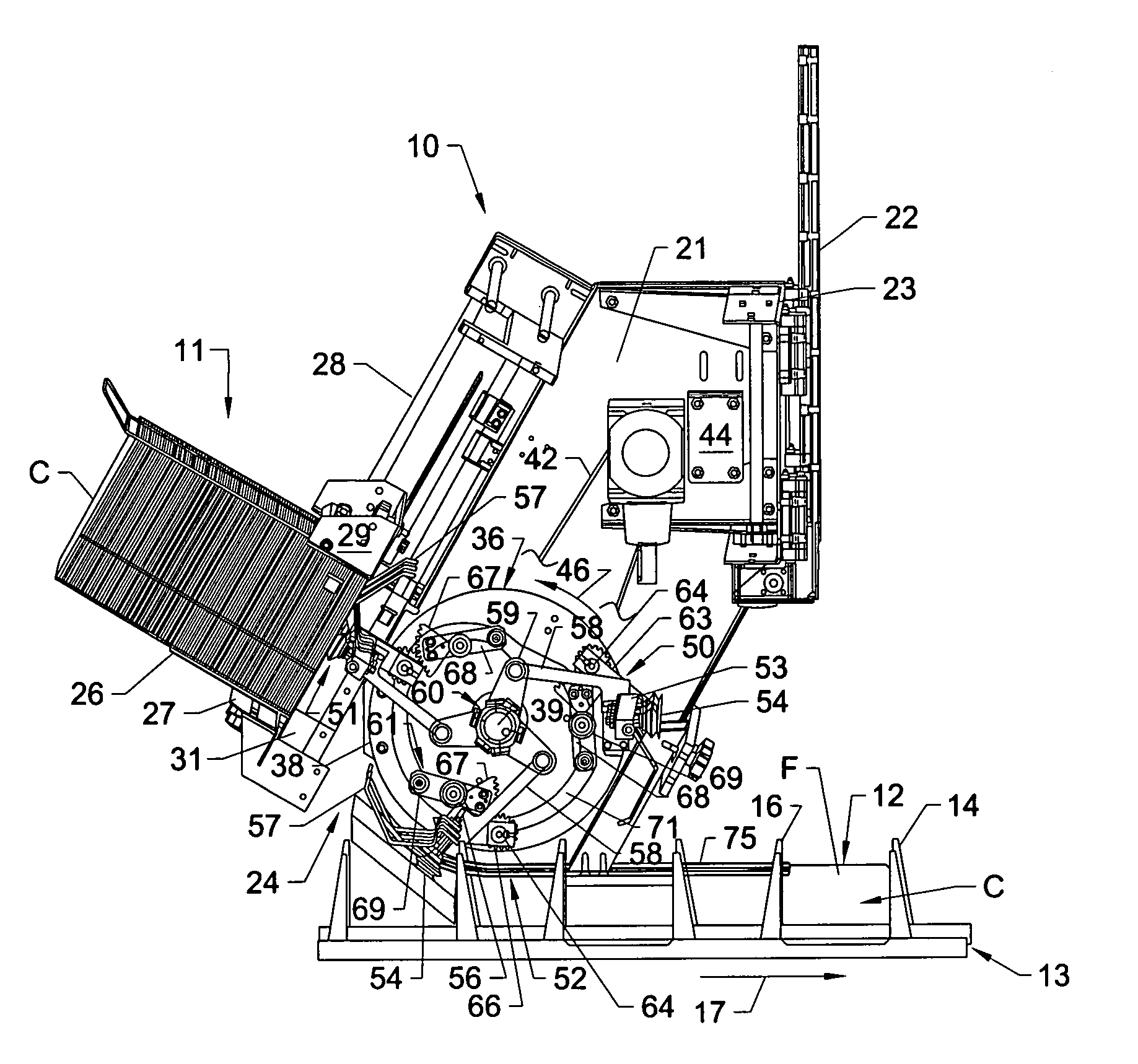

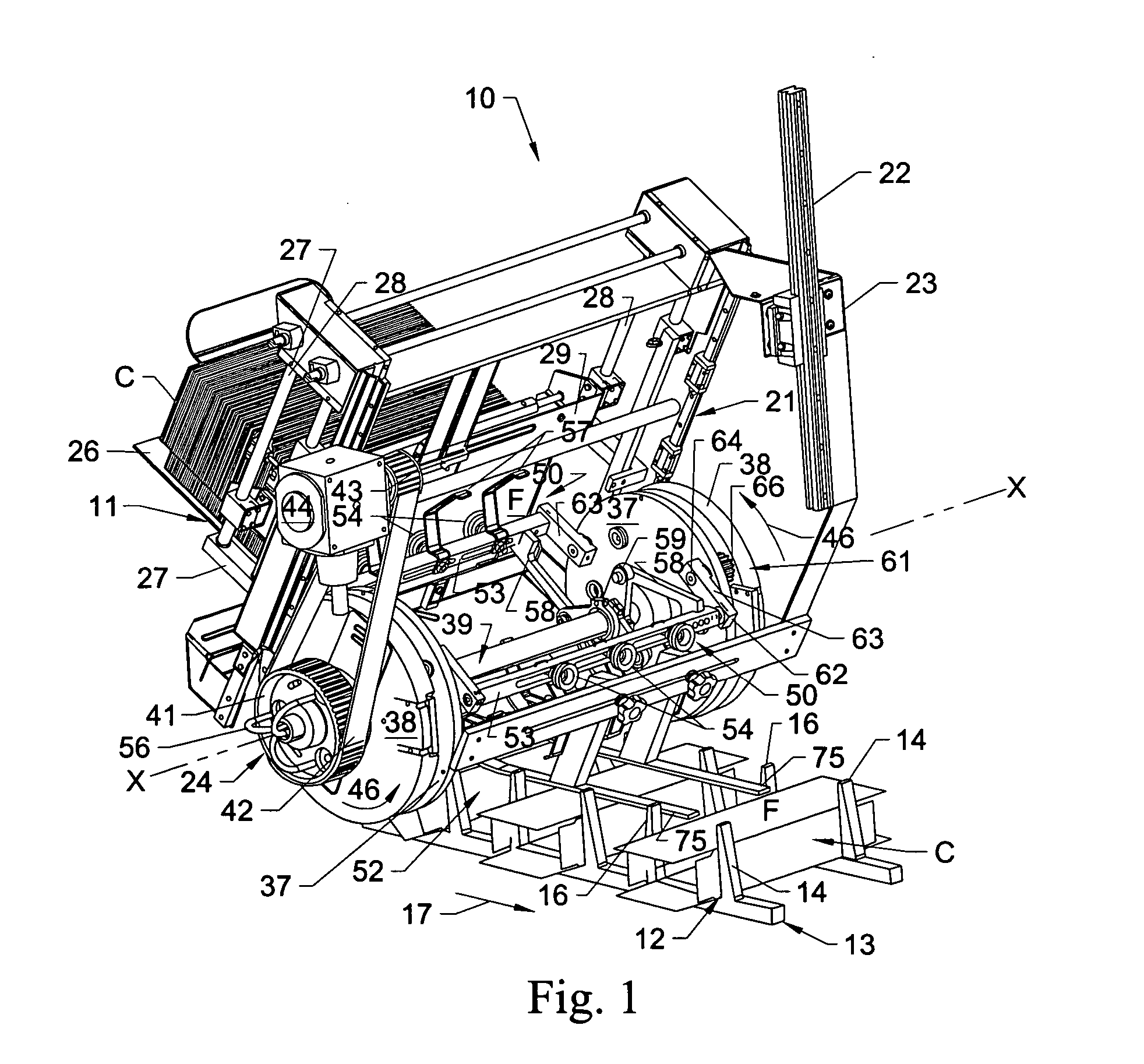

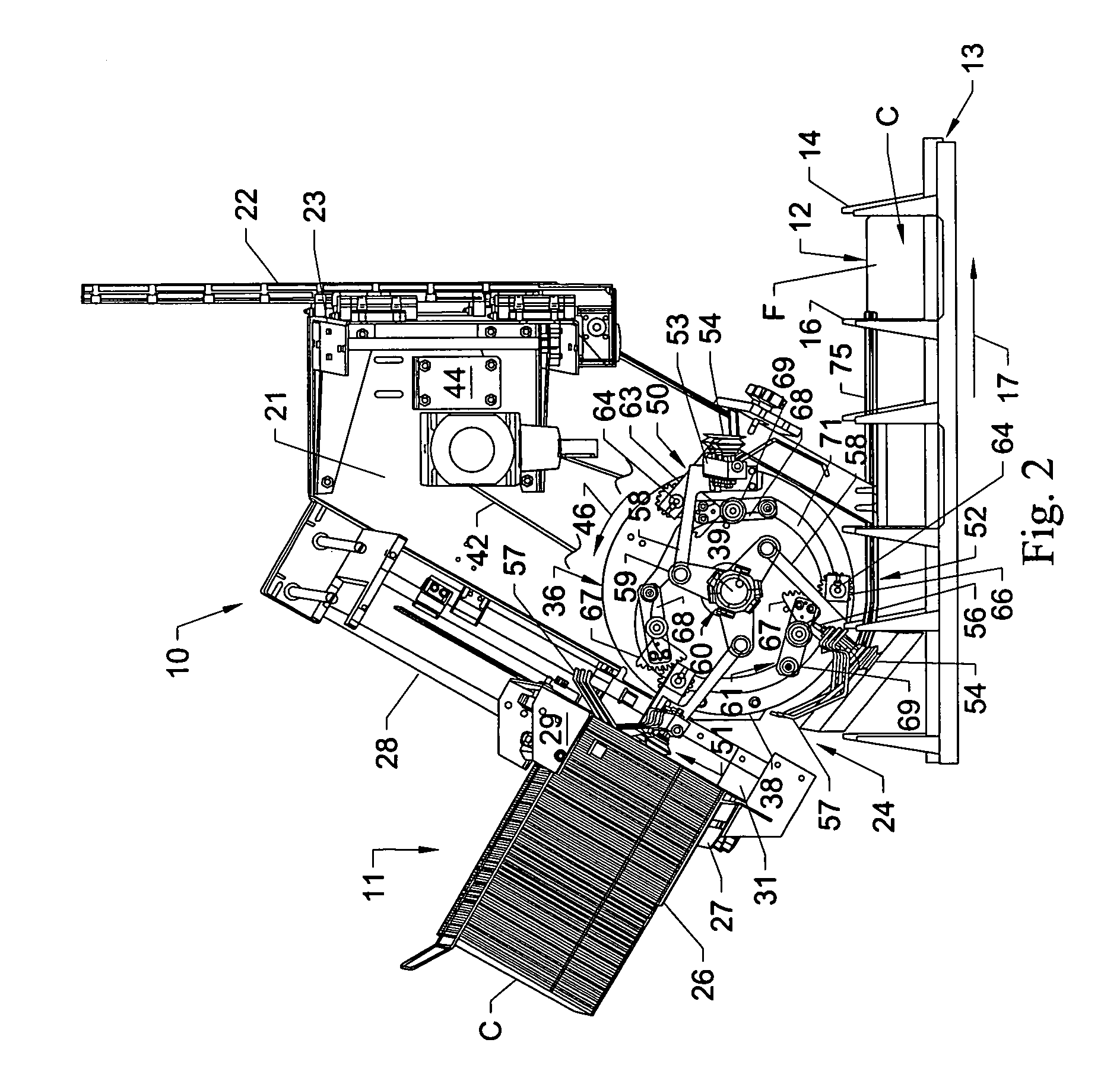

Rotary carton feeder

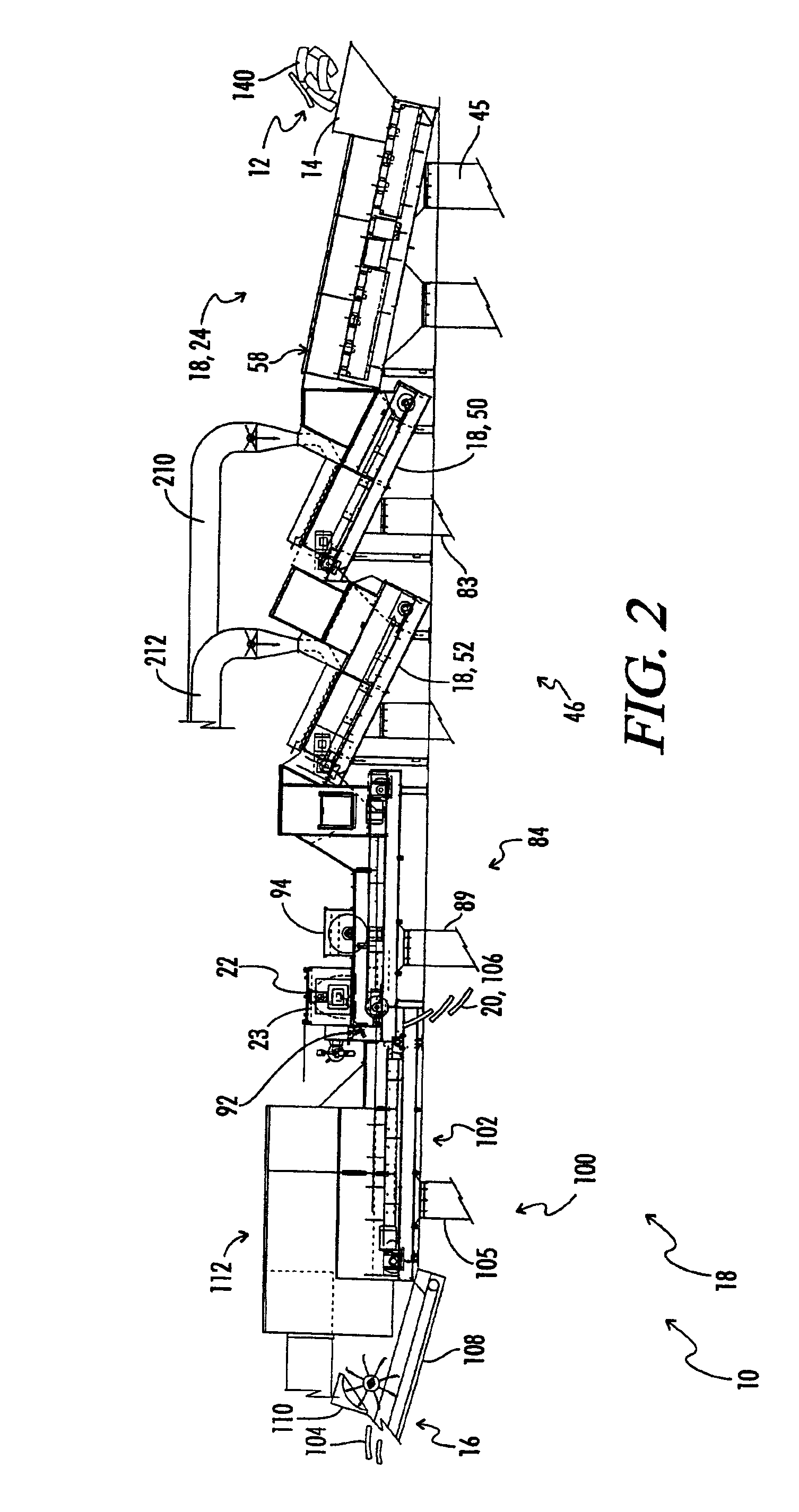

ActiveUS20070257416A1Increase approach angleEasy maintenanceBox making operationsPaper-makingCartonEngineering

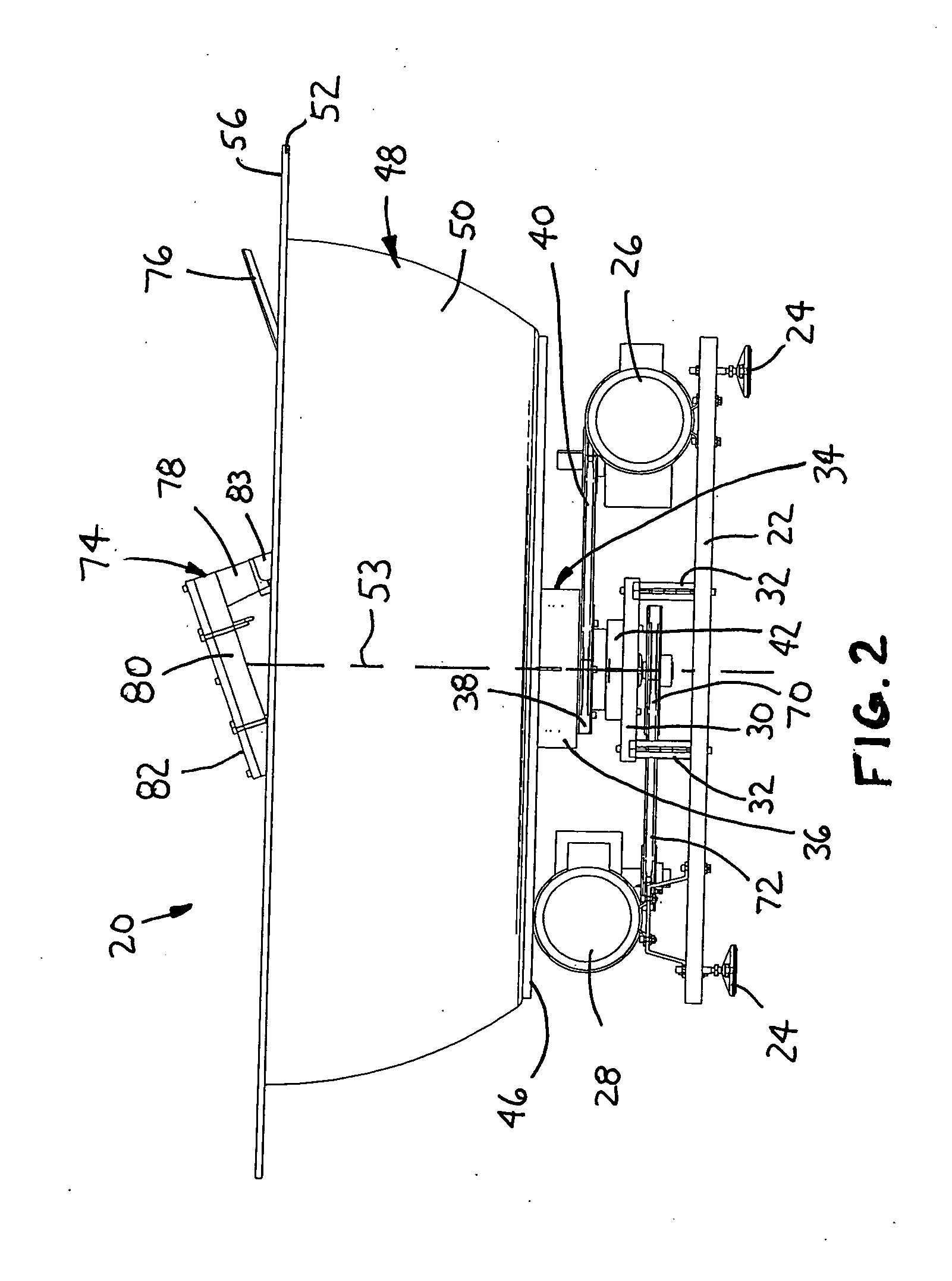

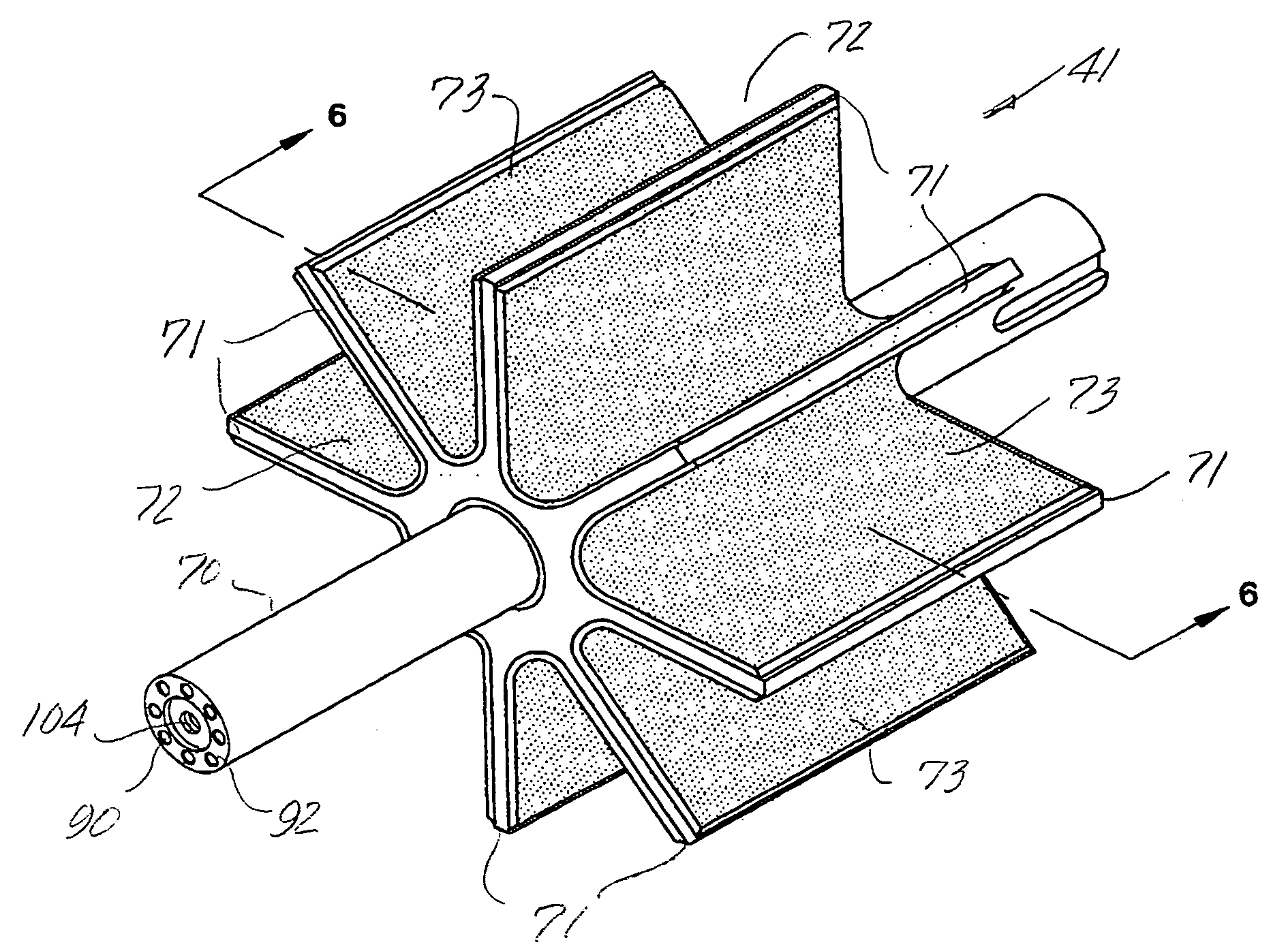

A carton feeding system for feeding a series of cartons into selected flights of a carton conveyor is disclosed. The carton feeding system generally includes a rotary feeder having a series of carton feeding assemblies rotated thereabout. The carton engaging assemblies are attached to a gearing system or mechanism that controls the operating angle of the carton engaging assemblies as they engage or pick the cartons from a magazine or supply. Thereafter, the cartons are erected within the flights of a carton conveyor moving beneath the rotary feeder as the carton engaging elements are carried about their path of travel.

Owner:GRAPHIC PACKAGING INT

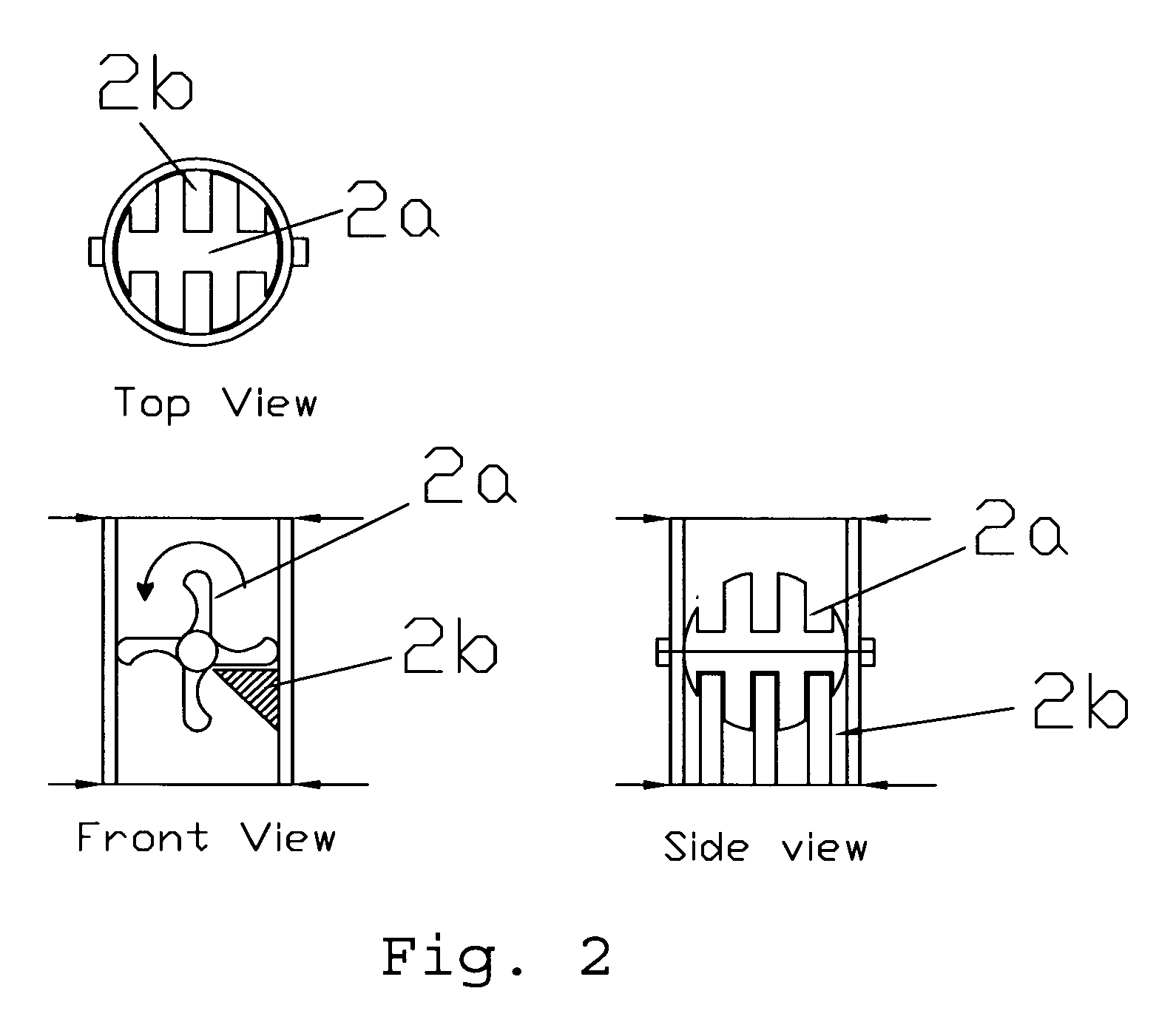

Developing agent circulation system and image forming apparatus using same

A development agent circulation unit includes a development unit, an agitation unit, and a rotary feeder. The development unit develops a latent image on an image carrier using a developing agent. The agitation unit agitates developing agent recovered from the development unit. The rotary feeder receives the developing agent from the agitation unit and discharges the developing agent in predetermined discrete amounts. The discharged developing agent is transported to the development unit using a gas stream. The rotary feeder includes a rotor and a stator having a clearance “t” between the rotor and the stator. The clearance “t” satisfies a relation “t<2D” where D denotes a developing agent particle diameter, and a toner particle diameter dt of a toner particle of the developing agent and a carrier particle diameter dc of a carrier particle of the developing agent satisfy a relation D=dc+2dt.

Owner:RICOH KK

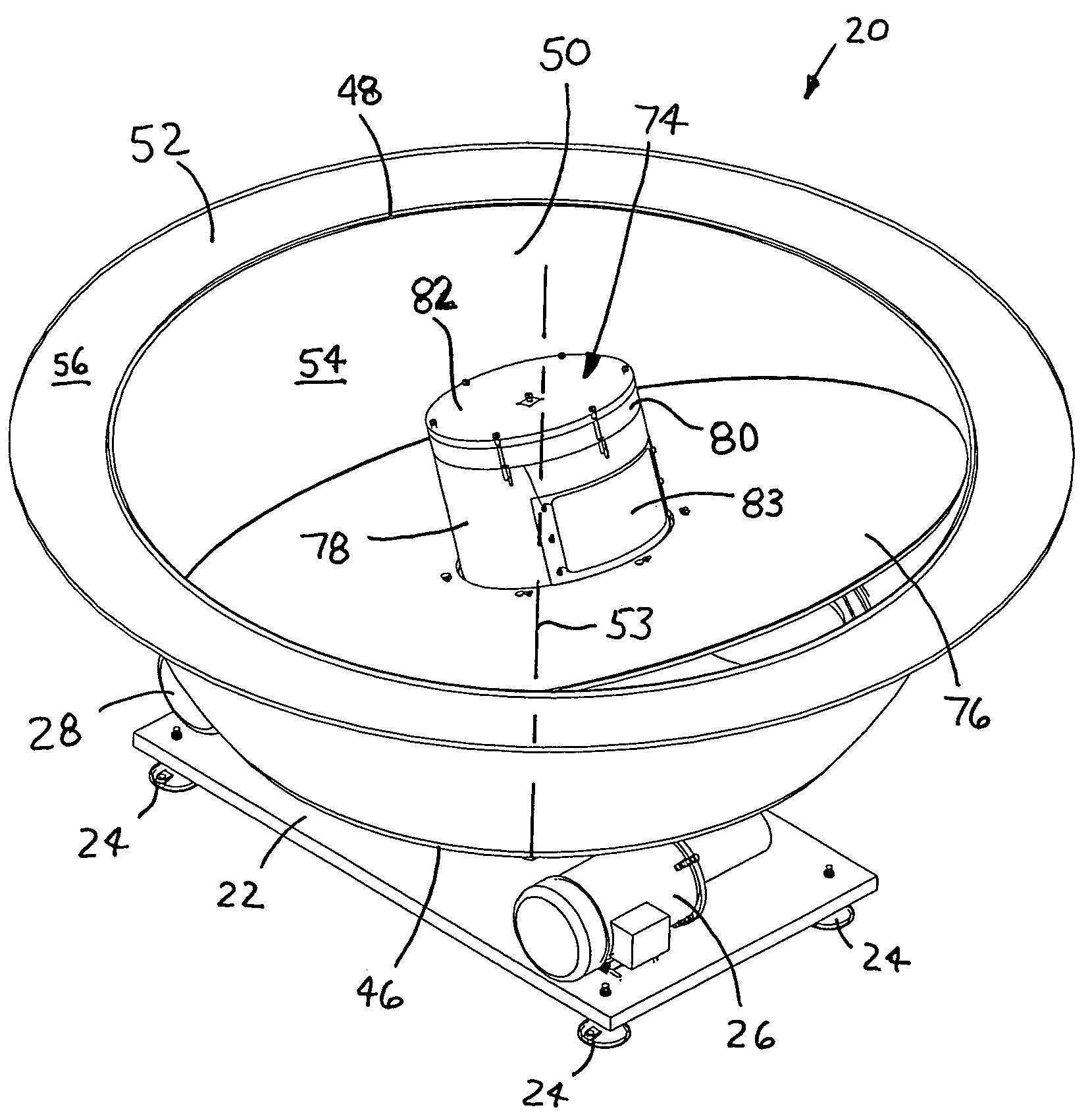

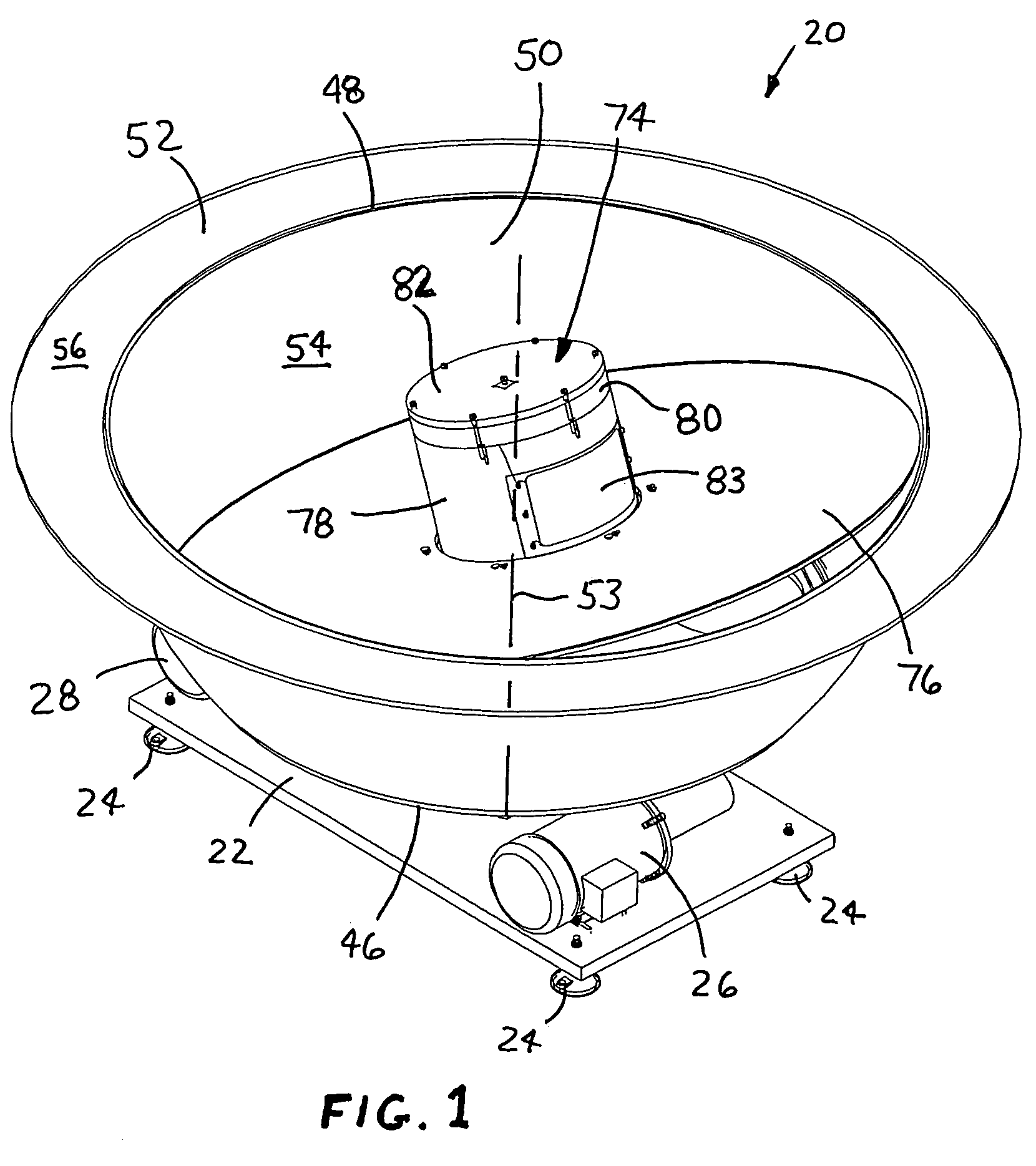

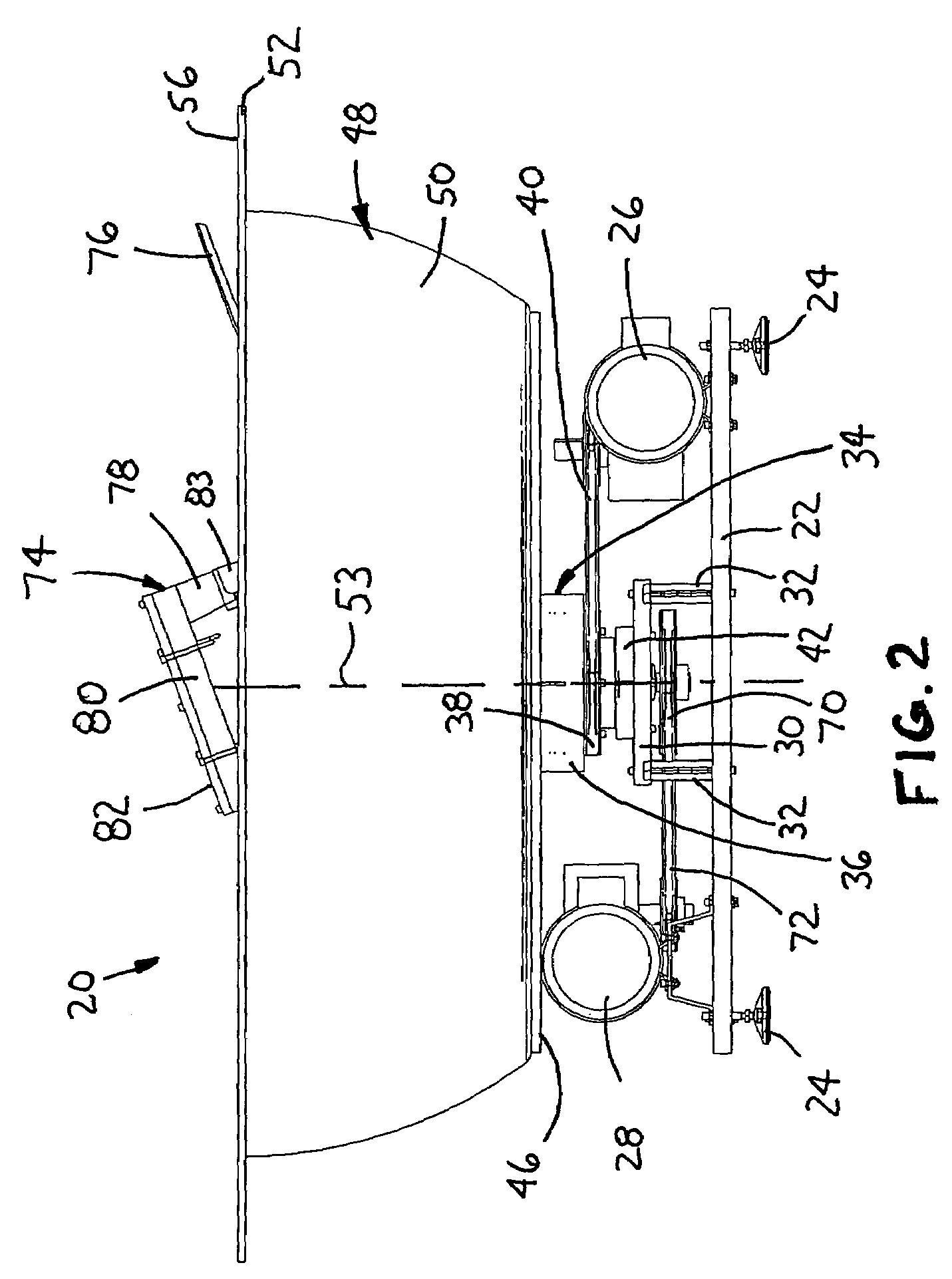

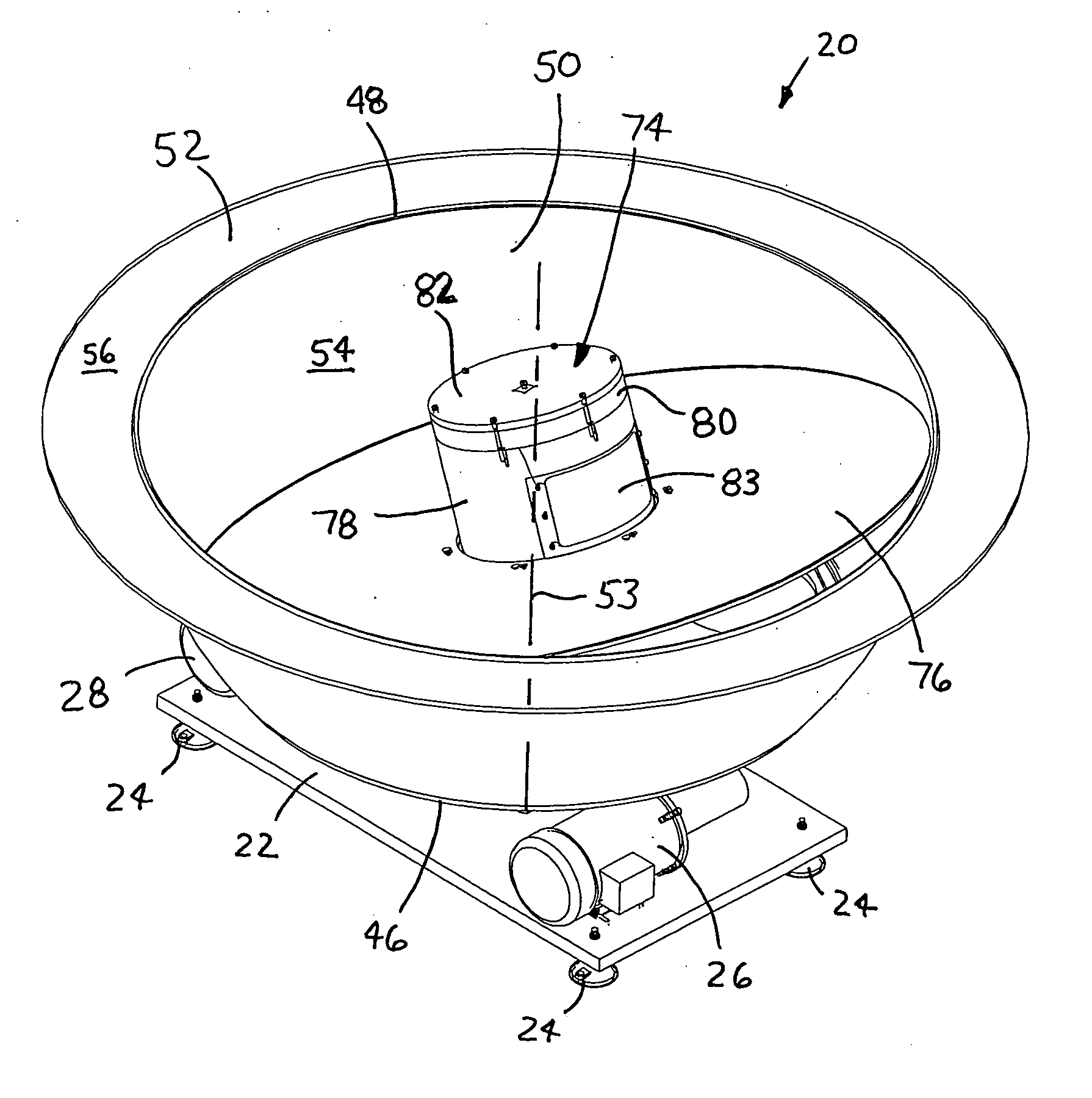

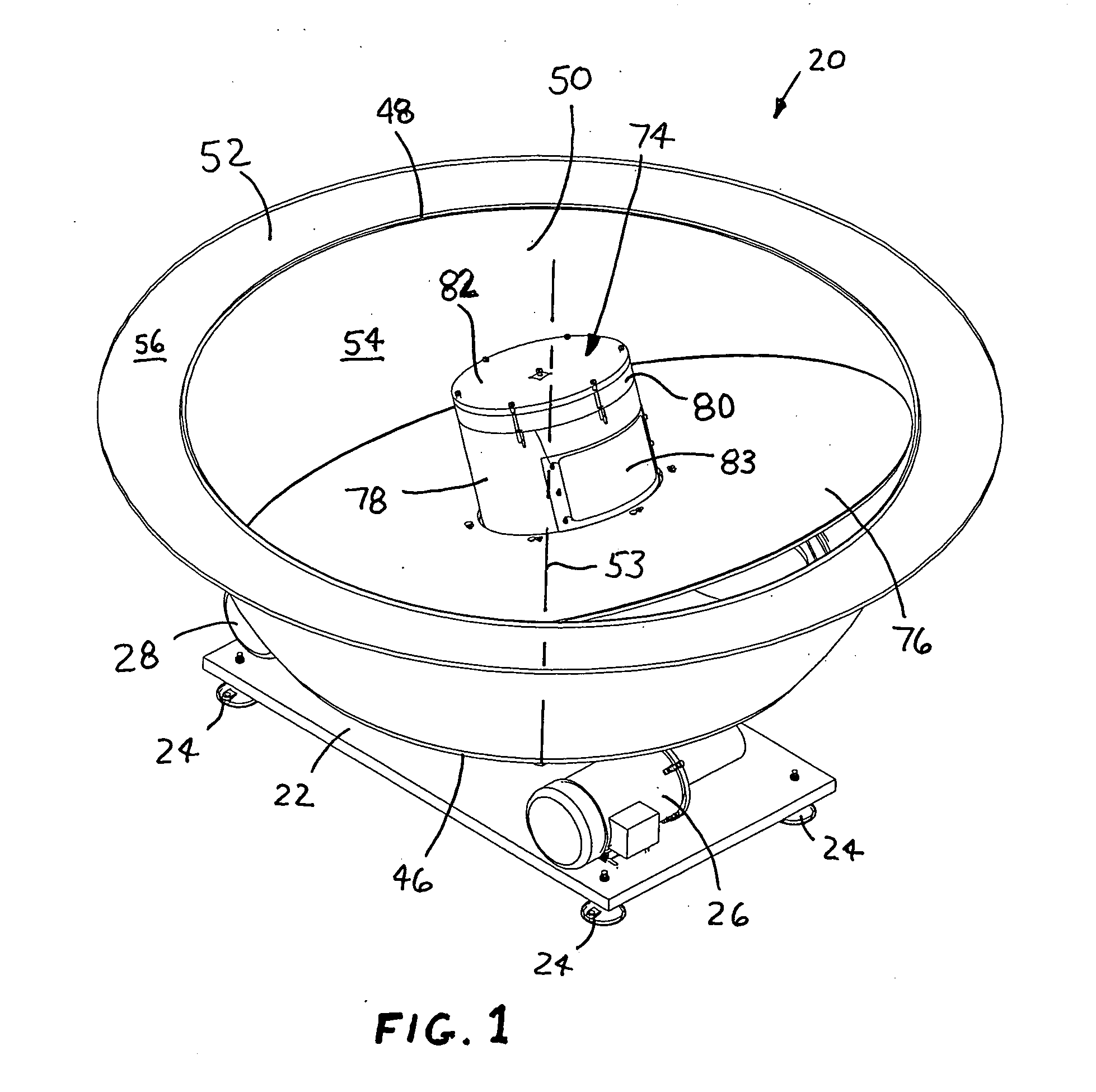

Rotary feeder

A rotary feeder for transferring articles includes a support frame, a rotatably driven bowl assembly mounted on the support frame and including a bowl mounted for rotation about a bowl axis, and a rotatably driven shaft mounted on the support frame for rotation about a shaft axis. A coupling is rotatably driven by the shaft and has a first end coupled to the shaft and a second end, the second end being pivotable with respect to the first end to define a tilt axis oriented at an angle with respect to the bowl axis. An adjustable guide assembly is mounted on the support frame and adapted to secure the coupling second end along a selected tilt axis. A disc is coupled to the coupling second end and rotates about the tilt axis, the disc including a lower portion and an upper portion, the upper portion defining an article transfer point.

Owner:HAUMILLER ENG

Rotary feeder

A rotary feeder for transferring articles includes a support frame, a rotatably driven bowl assembly mounted on the support frame and including a bowl mounted for rotation about a bowl axis, and a rotatably driven shaft mounted on the support frame for rotation about a shaft axis. A coupling is rotatably driven by the shaft and has a first end coupled to the shaft and a second end, the second end being pivotable with respect to the first end to define a tilt axis oriented at an angle with respect to the bowl axis. An adjustable guide assembly is mounted on the support frame and adapted to secure the coupling second end along a selected tilt axis. A disc is coupled to the coupling second end and rotates about the tilt axis, the disc including a lower portion and an upper portion, the upper portion defining an article transfer point.

Owner:HAUMILLER ENG

Rotary feeder valve for pneumatic conveying system

InactiveUS20050269369A1Improve liquidityEasy dischargeMovable measuring chambersBulk conveyorsRotary valveEngineering

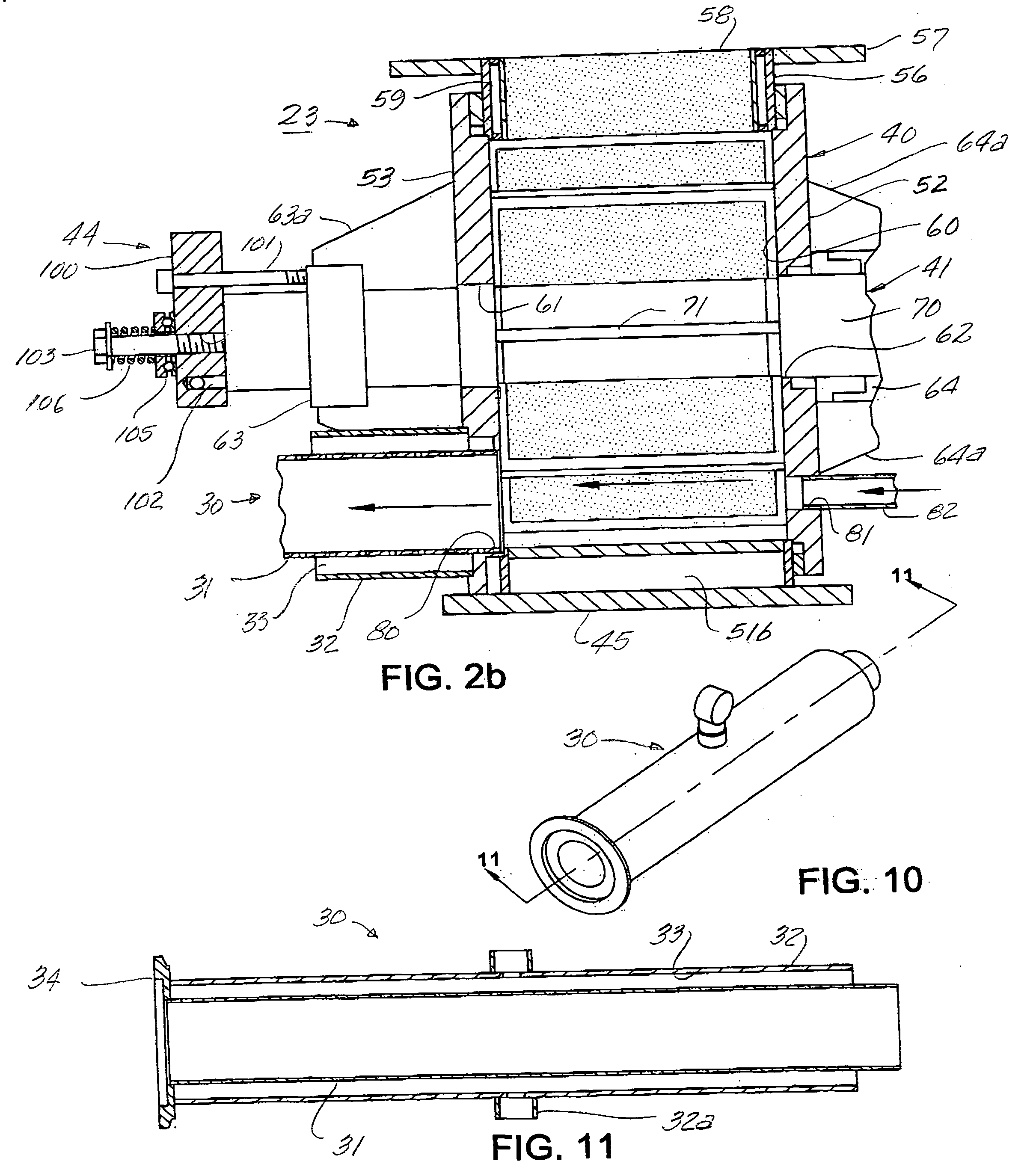

A rotary valve for metering bulk materials generally consisting of a housing defining a chamber having a material inlet, a material outlet and a fluid inlet connectable with a source of fluid under pressure, a chamber having a cylindrical wall, a portion of which is formed of a liner of permeable material, spaced from a portion of the housing to provide an annular chamber displaced radially relative to the axis of the cylindrical wall and having an inlet communicable with a source of fluid under pressure; and a rotor disposed in the chamber coaxially with the cylindrical wall thereof, having a shaft journaled in bearings supported on end walls of the housing and a set of vanes disposed radially relative to the axis of such cylindrical wall, defining a plurality of pockets each communicable successively with the material inlet and both of the material outlet and the first mentioned fluid inlet to cause material to be received through the material inlet and discharged through the material outlet as the rotor is rotated.

Owner:YOUNG INDS

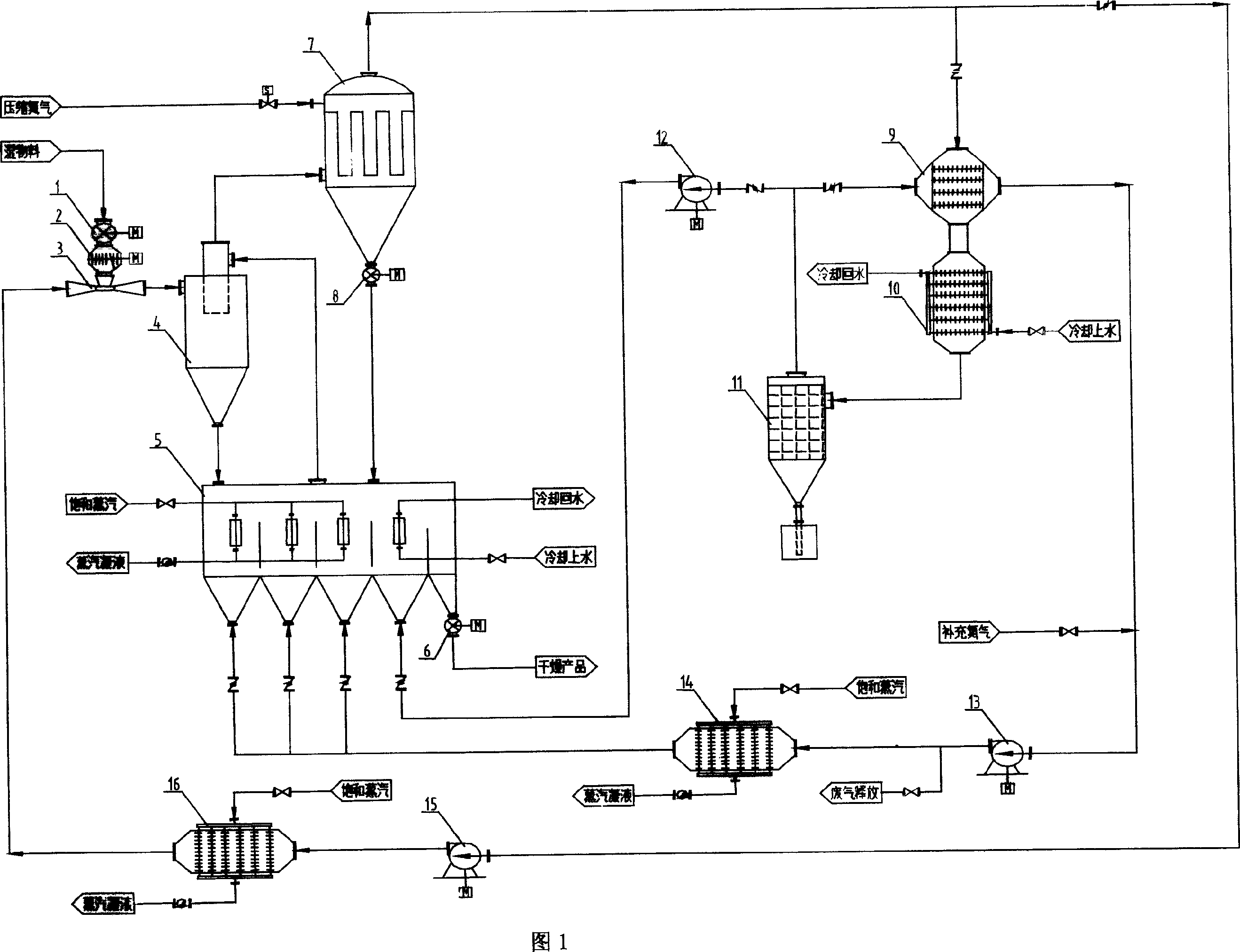

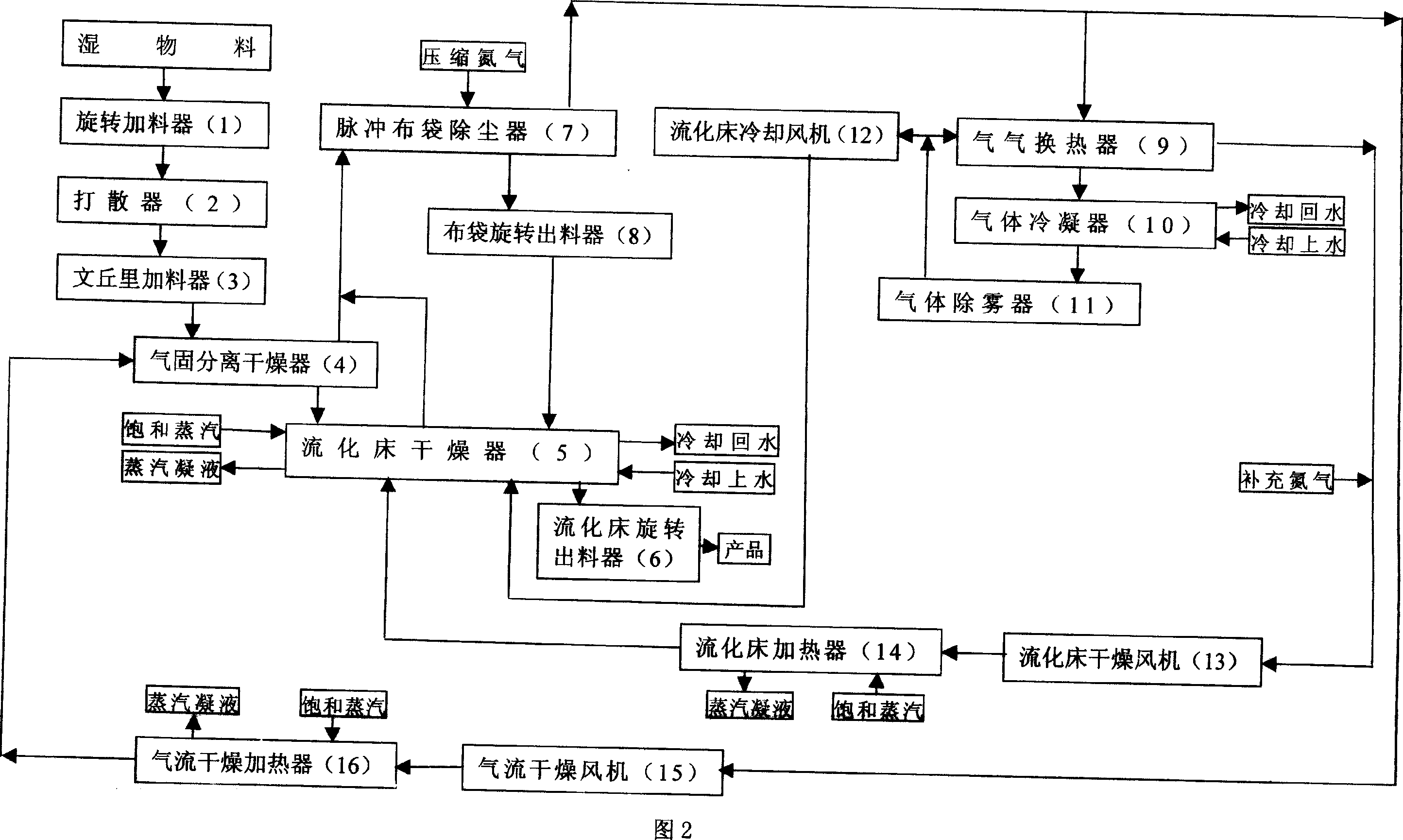

Two-stage gas flow-fluidized bed drying process and apparatus with nitogen circulated adipic acid and overheated steam

ActiveCN101088980AReduce heat lossHigh thermal efficiencyCarboxylic compound separation/purificationFluidized bed dryingNitrogen

The present invention is two-stage adipic acid drying process with circulating nitrogen and overheated steam. The technological process includes treating wet adipic acid material through a rotary feeder, a disperser and a solid-gas separating drier; drying in the fluidized bed of the drying section in a fluidized bed drier under the combined action of hot nitrogen and steam; and cooling in the cooling section of the fluidized bed drier under the combined action of cold nitrogen and cooling medium to obtain adipic acid product with temperature not higher than 25 deg.c and humidity not higher than 0.2 %. The process of the present invention is superior to traditional adipic acid drying process with hot air as the drying medium.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

Methods for preparing alkali cellulose and cellulose ether

ActiveUS20070144692A1Uniform alkali distributionEfficiently preparing alkali celluloseCellulosic pulp after-treatmentDigestersCellulosePolymer science

The invention is a method for efficiently preparing alkali cellulose having a uniform alkali distribution therein. More specifically, the invention is a method for preparing alkali cellulose comprising steps of bringing pulp into continuous contact with an alkali metal hydroxide solution in a rotary feeder type contactor to generate a contact mixture, and draining the contact mixture; and a method for preparing cellulose ether comprising use of the alkali cellulose thus prepared; an apparatus for preparing alkali cellulose, comprising a rotary feeder comprising a cyclic housing comprising an inlet port and an outlet port, a cyclic contact drum being circularly rotatable along the housing in the housing and comprising a plurality of filter cells arranged in a circumferential direction, and a filtrate-discharging tube being disposed in a diameter direction inside of the cyclic contact drum and collecting the filtrate which has passed the filter, and a drainer for draining a cake discharged from the contactor.

Owner:SHIN ETSU CHEM IND CO LTD

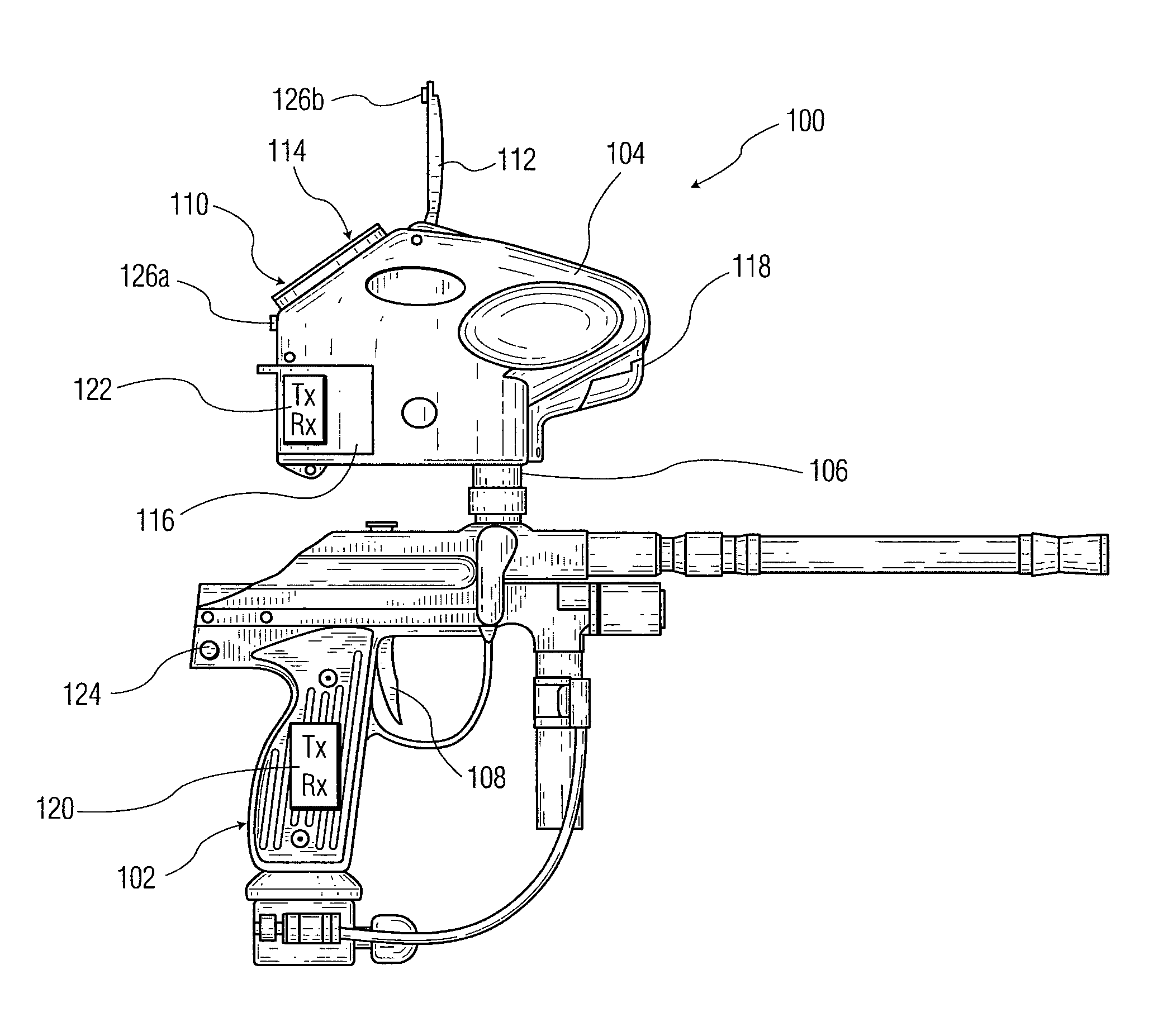

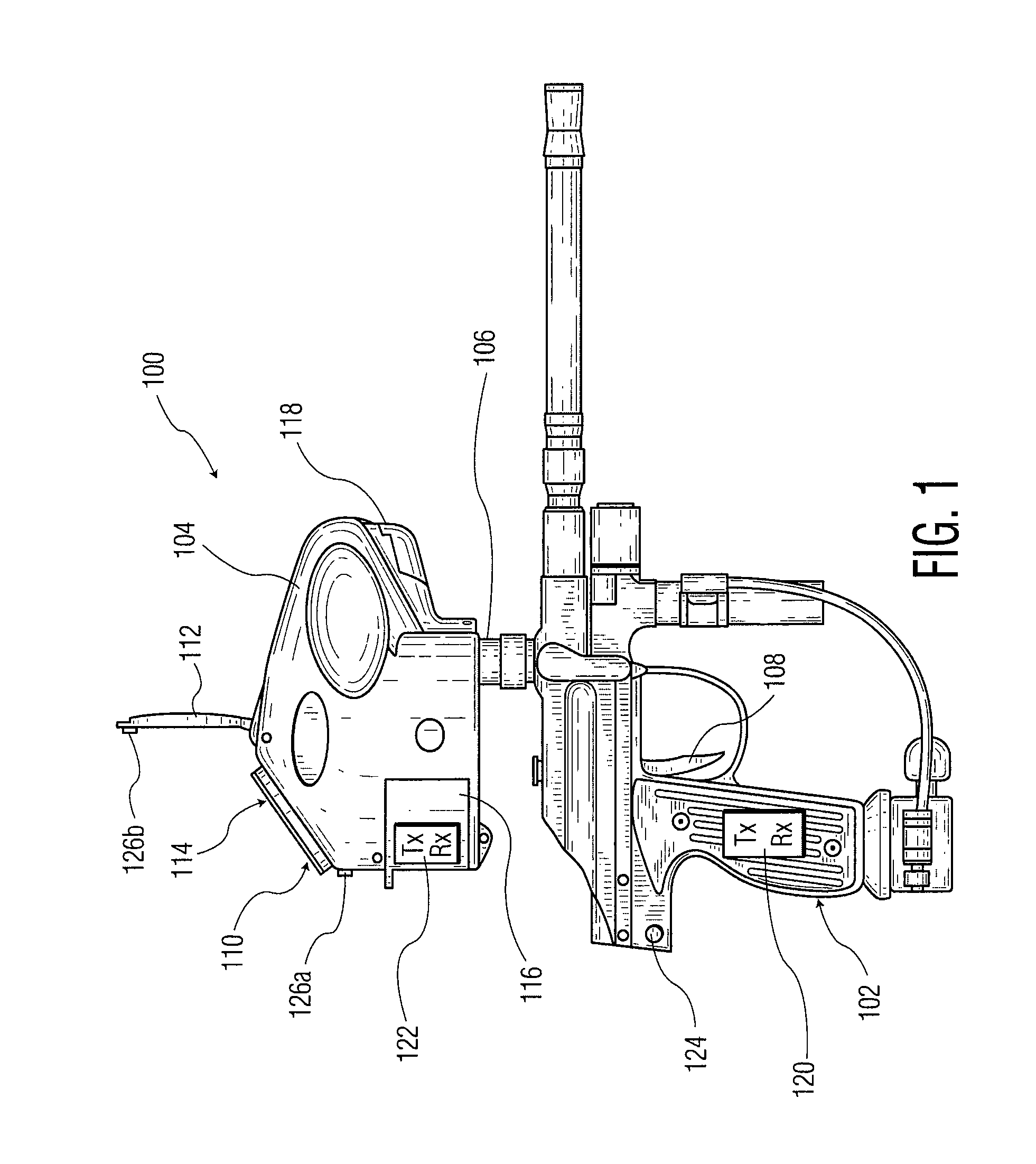

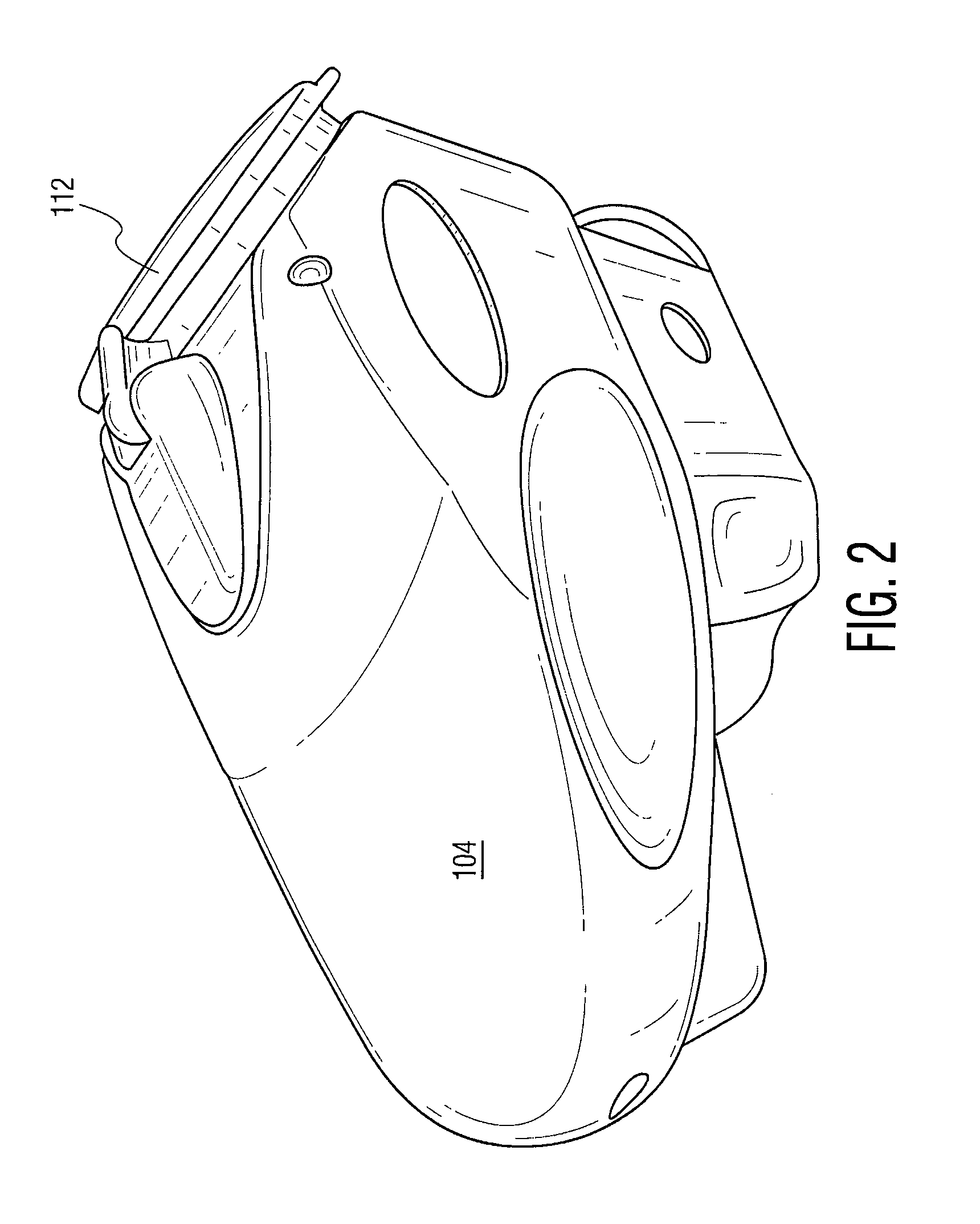

Paintball gun loading methods and apparatus

Owner:KORE OUTDOOR LTD

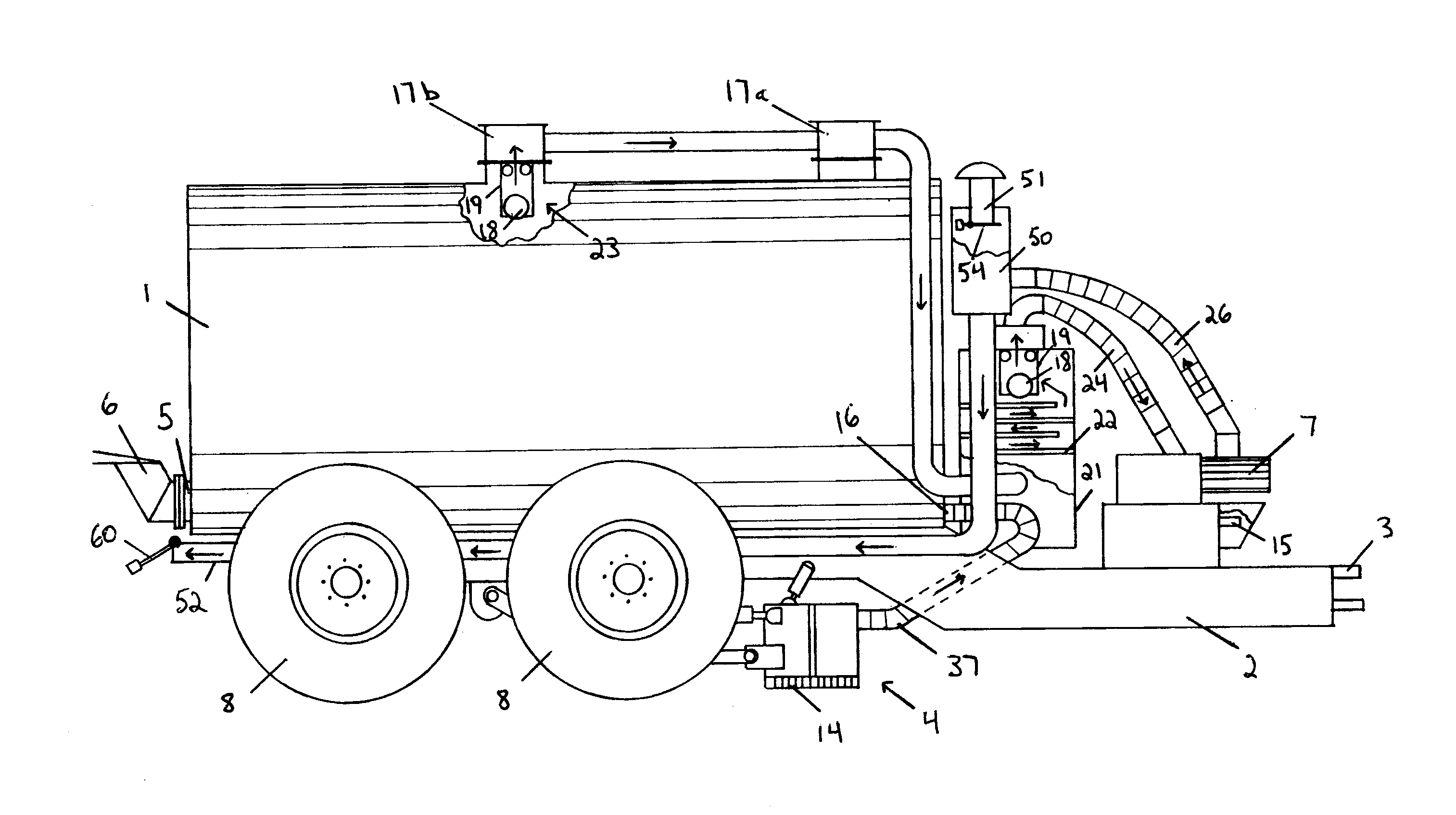

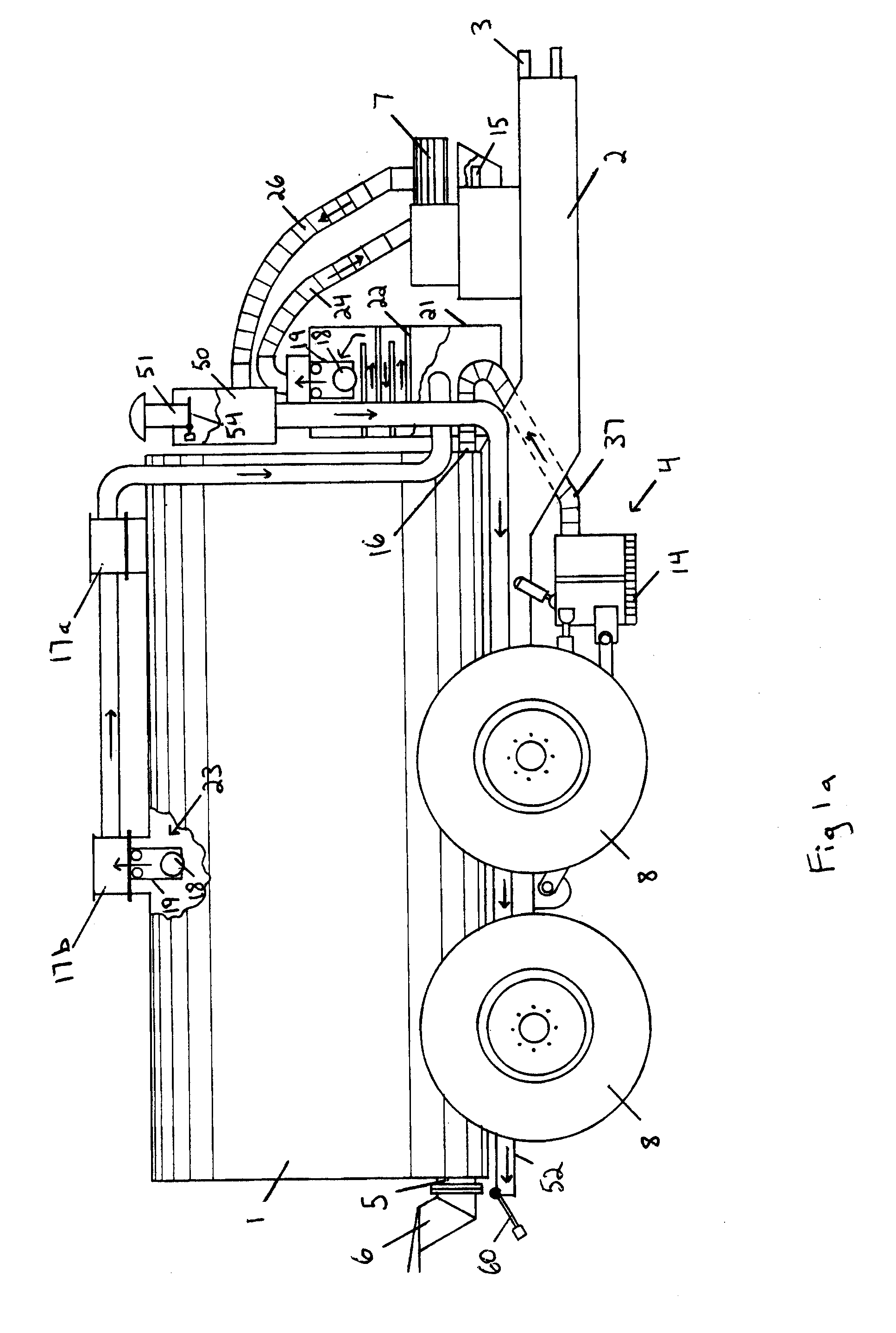

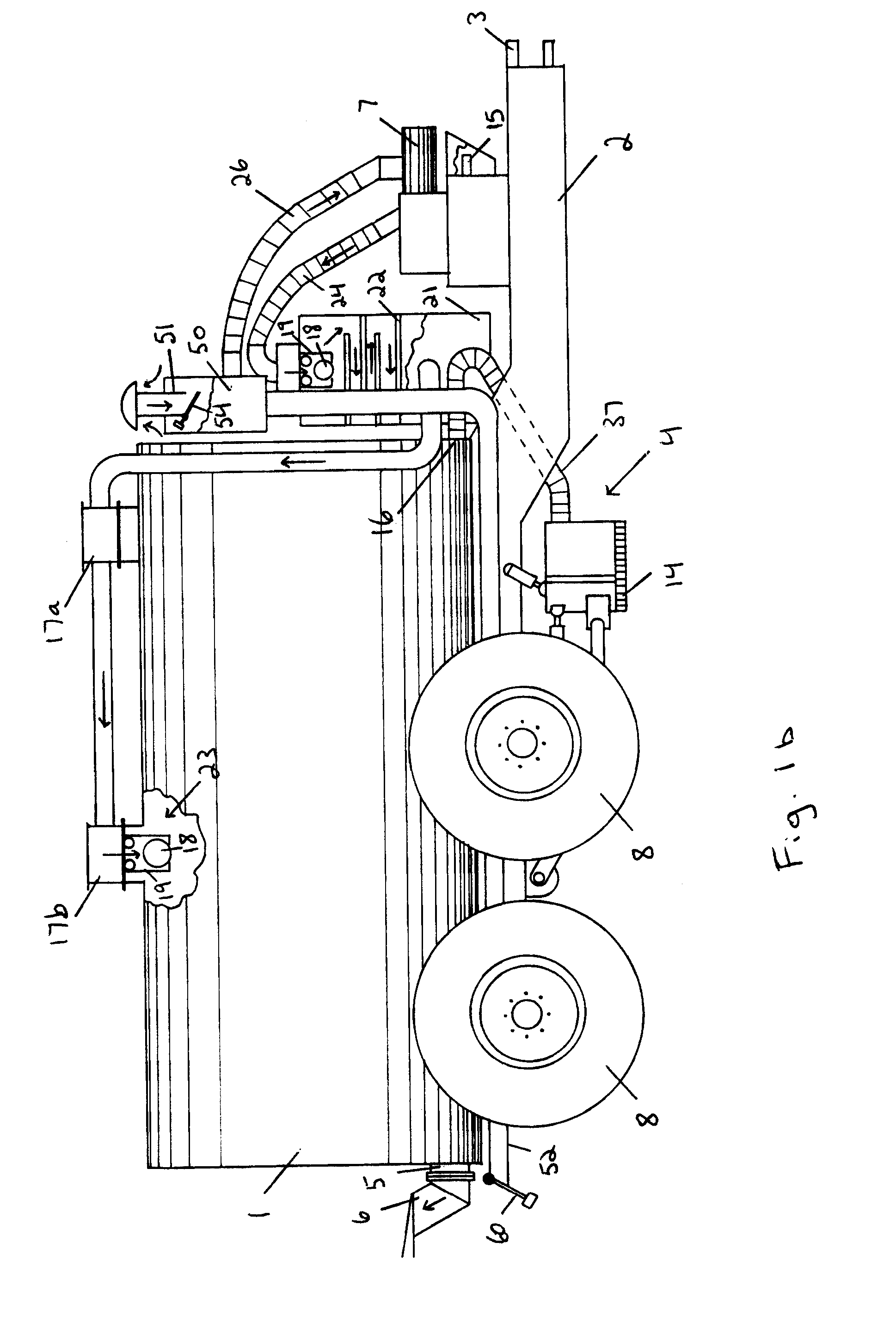

Collection means for a mobile vacuum apparatus for the collection of liquid or semi-liquid materials

ActiveUS20090293911A1Easy to adjustLess materialSuction nozzlesAnimal housingEngineeringRotary feeder

The apparatus comprises a front-mounted collection means for a vacuum tank for the collection of liquid or semi-liquid materials. The collection means comprises a substantially V-shaped housing with a scraper at the bottom thereof, a height adjustable suction inlet at the apex thereof, and a pair of laterally adjustable pivoting wings for varying its width to correspond to that of an alley or gutter. A plurality of rotary feeders, each having a vertical axis of rotation, are mounted to the housing adjacent the scraper to prevent accumulation of the materials on the scraper. The feeders do not contact either the surface upon which the scraper is operated, nor the scraper itself, but serve to mix thick consistency materials with thinner consistency materials and also to dislodge any accumulation that does occur.

Owner:NUHN INDS

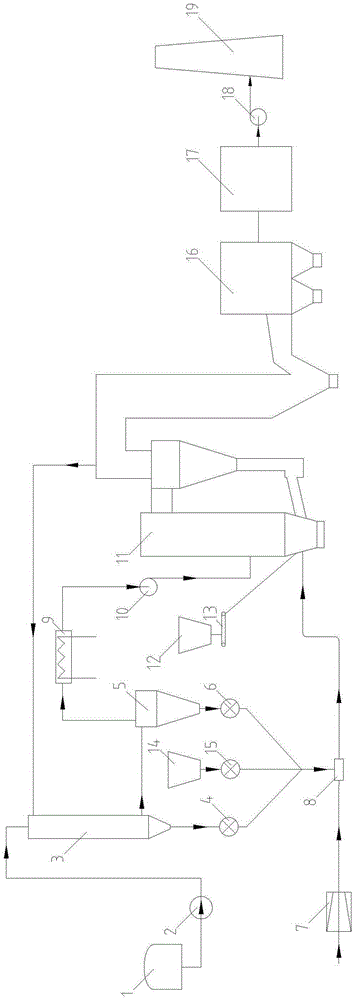

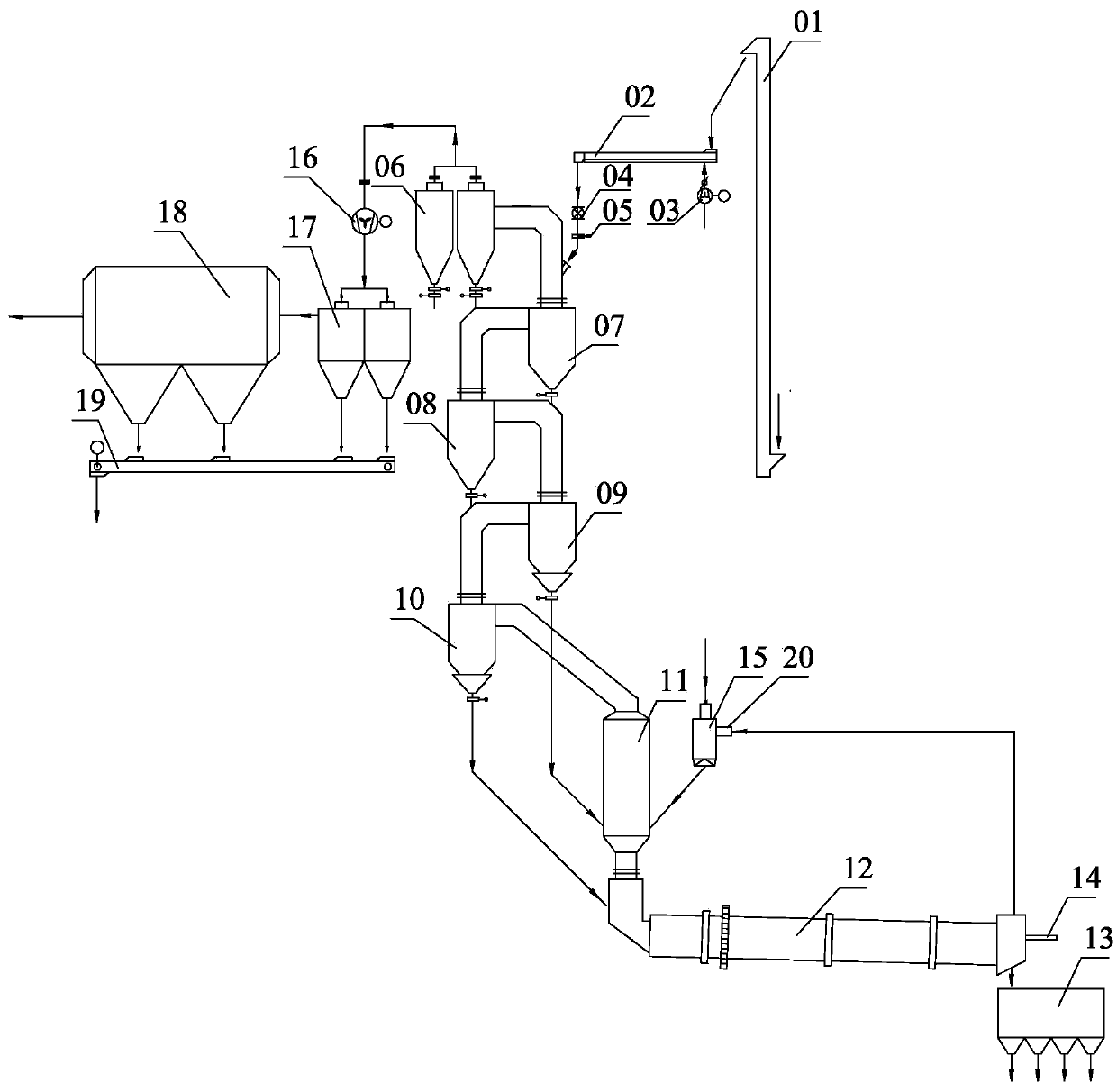

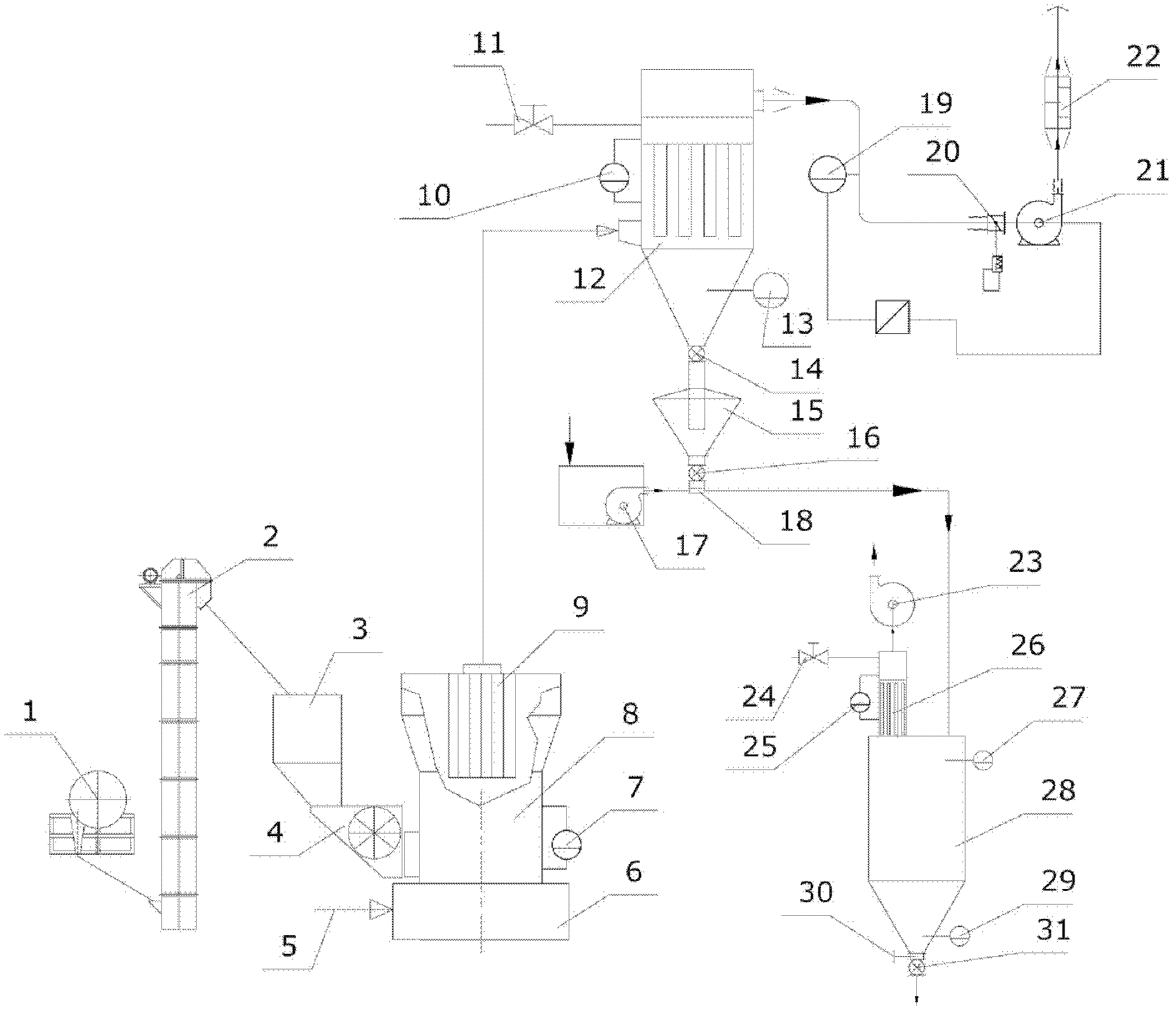

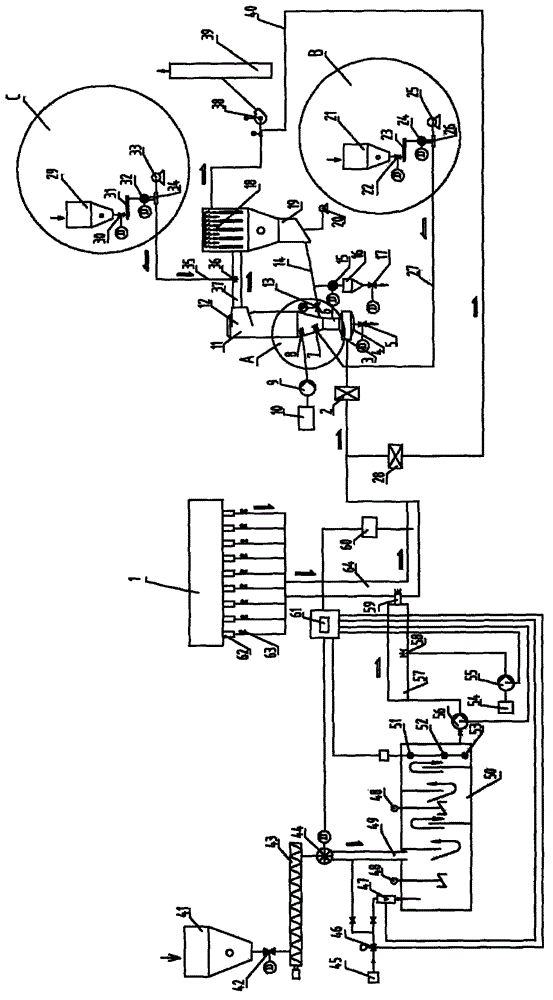

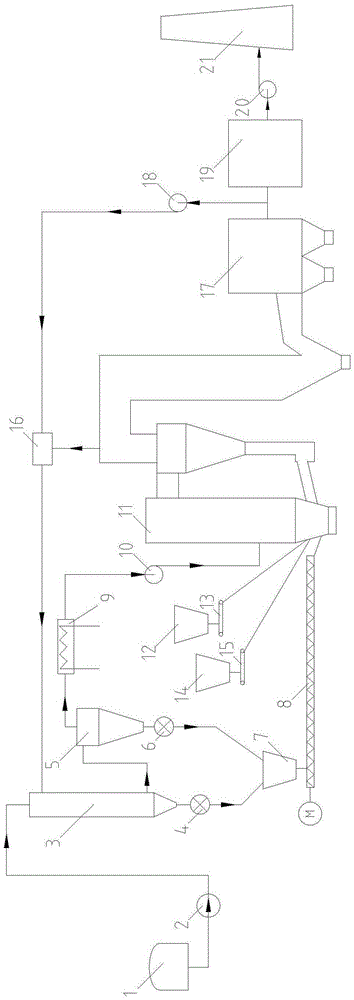

Coal-sludge co-combustion system based on high-temperature smoke drying and pneumatic conveying

ActiveCN105276603AIncrease speedEasy to handleSludge treatment by de-watering/drying/thickeningDispersed particle separationSludgeRotary feeder

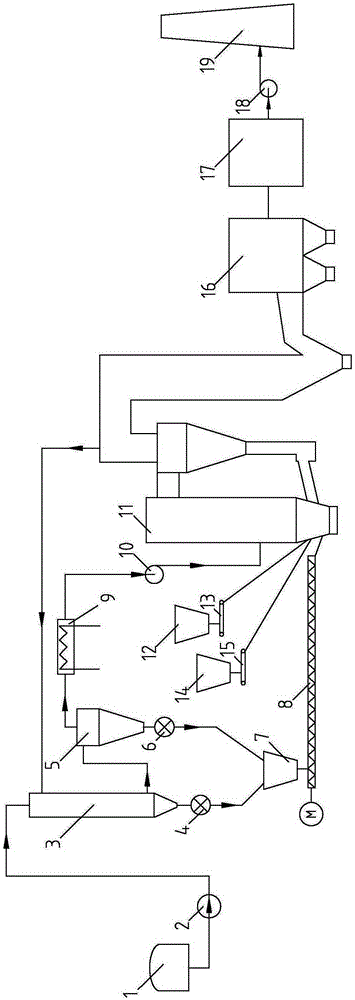

The invention relates to a coal-sludge co-combustion system based on high-temperature smoke drying and pneumatic conveying. A sludge storage bin is connected with a spray drying pipe through a screw pump. An air inlet of the spray drying pipe is connected with a cyclone separator outlet flue of a circulating fluidized bed boiler. A first outlet of the spray drying pipe is connected with a first rotary feeder, and a second outlet of the spray drying pipe is connected with a cyclone separator. An exhaust opening of the cyclone separator is connected with the circulating fluidized bed boiler through a cooling condenser and an exhaust gas fan, and a discharging opening of the cyclone separator is connected with a second rotary feeder. A limestone bin is connected with a third rotary feeder. An outlet of the first rotary feeder, an outlet of the second rotary feeder and an outlet of the third rotary feeder are connected with a feeding opening of a jet feeding device, an air inlet of the jet feeding device is connected with a Roots fan, and an outlet of the jet feeding device is connected with the circulating fluidized bed boiler. The functions of sludge drying and conveying, dry tail gas waste heat utilization, sludge and coal co-combustion, pollutant control and the like can be achieved, bad smell and dust diffusion can be avoided, and the coal-sludge co-combustion system has the beneficial effects of being simple, environment-friendly and efficient.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Microwave continuous graphite expansion apparatus

A microwave continuous graphite puffing device comprises a hopper; the lower part of the hopper is connected with a rotary feeder which is provided with a drive shaft and a rotary drum; a rotary vane is fixed on the rotary drum; the lower end of the rotary feeder is connected with a microwave feeding absorption chamber, the right end of which is connected with a microwave heating puffing chamber; a left microwave generator and a right microwave generator are arranged on the upper part of the microwave heating puffing chamber, the right end of which is connected with a microwave discharging absorption chamber; and the right end of the microwave discharging absorption chamber is provided with a rotary discharger. The conveyor belt of a belt conveyor respectively passes through the microwave feeding absorption chamber, the microwave heating puffing chamber, and the microwave discharging absorption chamber. The left end of the microwave heating puffing chamber is rotatablely connected with a feeding absorption chamber microwave baffle-board and the right end thereof is rotatablely connected with a discharging absorption chamber microwave baffle-board. The invention has the advantages of easy control, reliable operation, large material treatment quantity, can effectively prevent microwave leakage, and can realize continuous feeding and discharging as well as continuous microwave heating puffing graphite.

Owner:任崇桂

Vacuum flour mixer

InactiveCN101647478AContinuous productionSpeed up the flowMixing/kneading with vertically-mounted toolsEngineeringDrive motor

The invention provides a vacuum flour mixer and relates to a continuous vacuum flour mixer, which comprises a machine frame, a driving motor and a stirring container, wherein the stirring container isarranged on the machine frame and driven by the driving motor, and the inside of the stirring container is provided with a stirrer consisting of a stirring shaft and a stirring paddle. The vacuum flour mixer also comprises a flour feeding device, a water feeding device and a discharging device which are communicated with the stirring container. The vacuum flour mixer is provided with a control device controlling the flour feeding device and the water feeding device. The vacuum flour mixer also comprises a continuous vacuumizing device which is controlled by a circuit and connected with the stirring container, wherein the vacuumizing device comprises a vacuum connecting pipe and a vacuum pump. The vacuum flour mixer is characterized in that: a rotary feeder is arranged between the flour feeding device and the stirring container; the vacuum connecting pipe is provided with a dust filtering device; and the stirring paddle is connected to the stirring shaft through an angle adjusting device. The vacuum flour mixer has the function of insulating pressure to make the inside of the stirring container keep certain vacuum degree all the time so as to ensure the flour mixing quality.

Owner:JIANGSU YINGYANG INDAL

Method and device for preparing nickel iron roasted ore by utilizing lateritic nickel ore

ActiveCN103468930AFast heat and mass transferShorten decrystallization wateChemical reactionLaterite

The invention discloses a method and a device for preparing a nickel iron roasted ore by utilizing a lateritic nickel ore. The method comprises the following steps: firstly, grinding the lateritic nickel ore into an ore powder, then carrying out high-temperature roasting of the obtained ore powder, during the high-temperature roasting process, allowing the ore powder to be in a pre-reduction system and carry out a high-temperature preheating reduction reaction, followed by allowing the high-temperature roasted ore to go into a rotary kiln for high-temperature calcination, thus obtaining a roasted ore containing nickel pig iron after completing high-temperature calcination, and then after dipping the roasted ore into water for cooling, separating to obtain the nickel iron roasted ore. The device comprises a hopper-type elevator, an air chute, a chute draught fan, a rotary feeder, a sluice valve, a rotary kiln, a water-cooling stirring tank, a burner, a hot wind mixing chamber, a high-temperature draught fan, a cyclone dust remover, a bag-type dust remover, a chain-type conveyor, a burner and a pre-reduction system. The preparation method and the device allow the heat transfer area of the ore powder to be large, enable each particle to be uniformly and fully subjected to a chemical reaction, have short reaction time, and have high utilization rate of the lateritic nickel ore.

Owner:WUHAN BUILDING MATERIAL IND DESIGN & RES INST

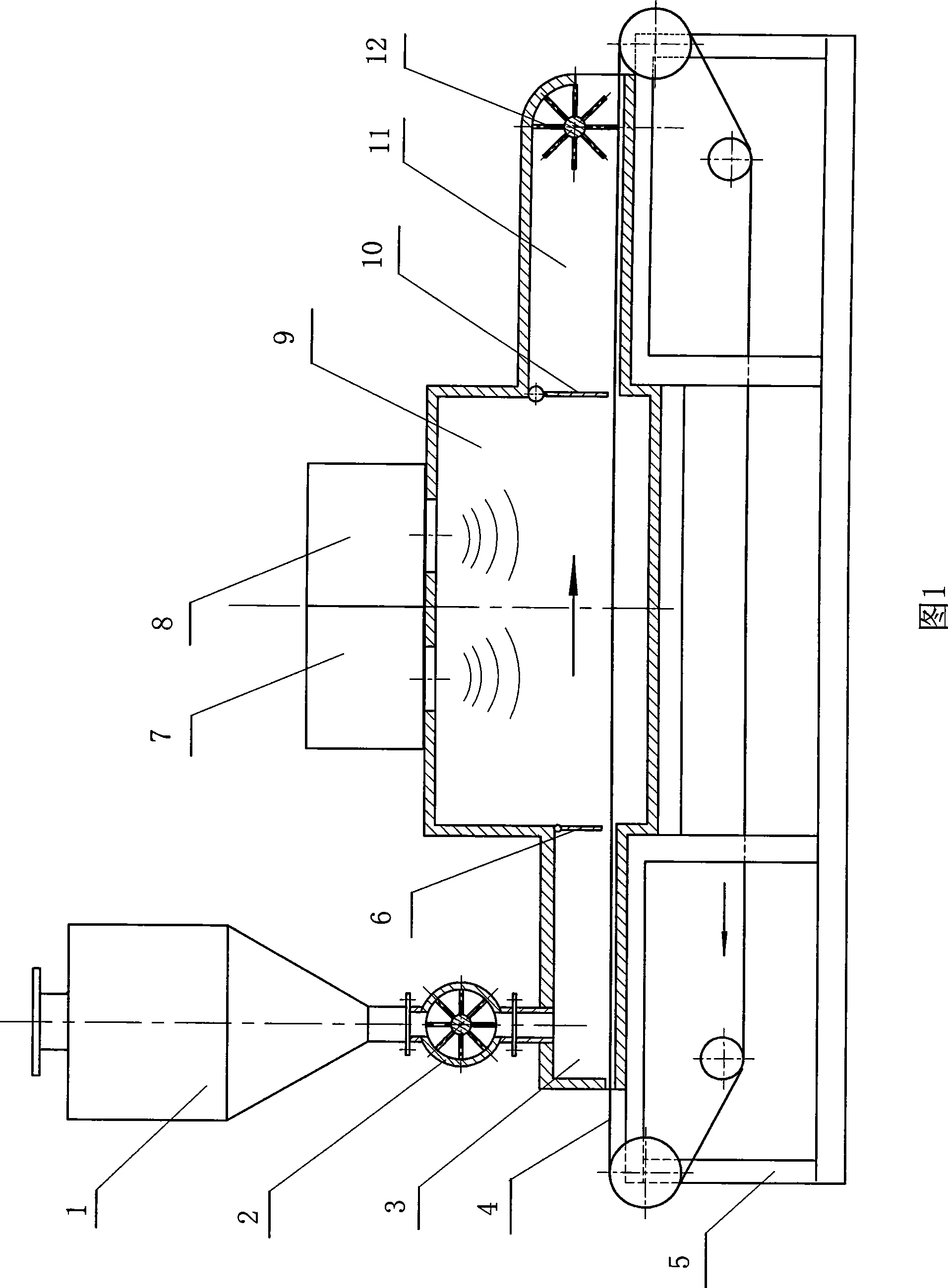

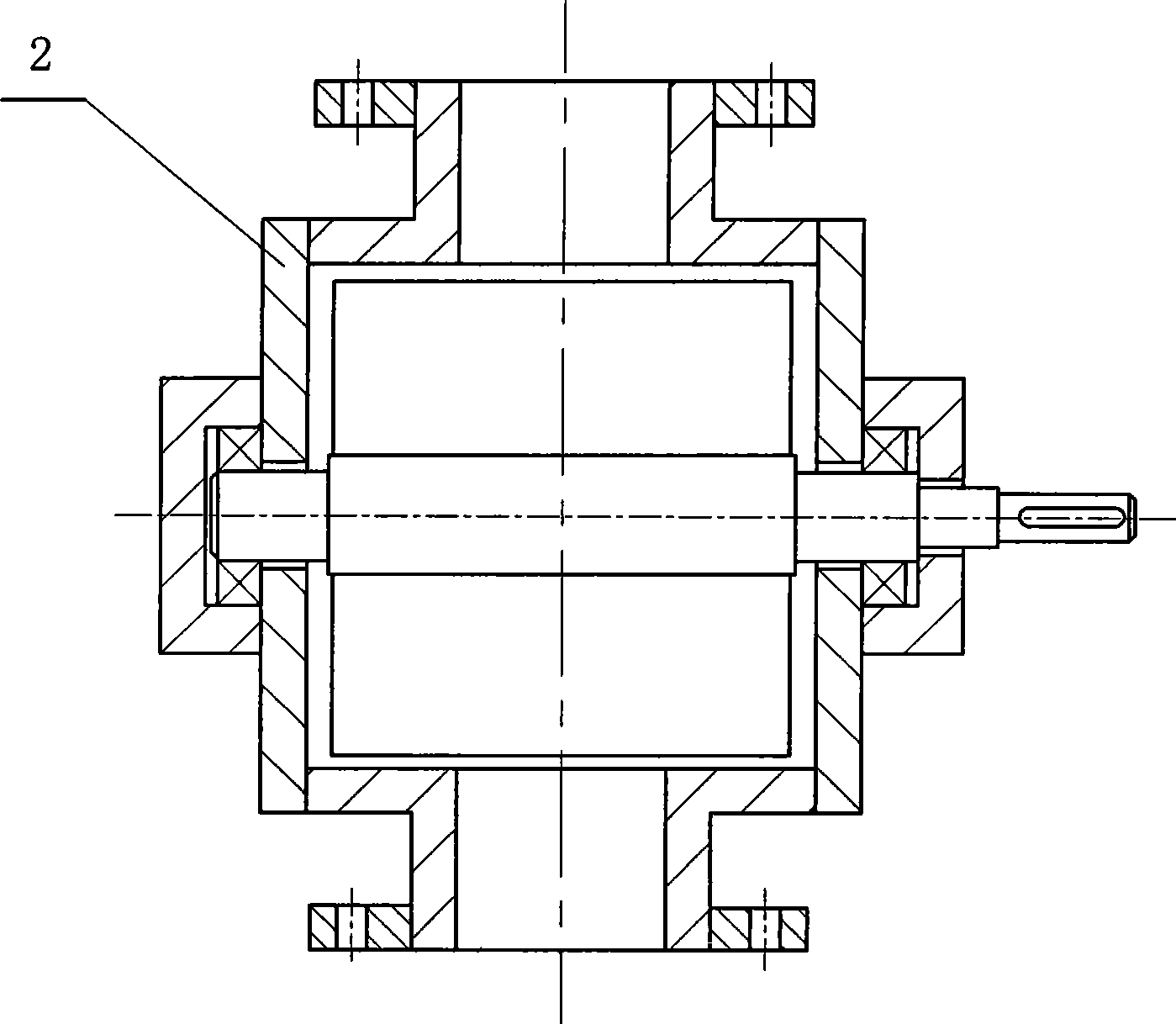

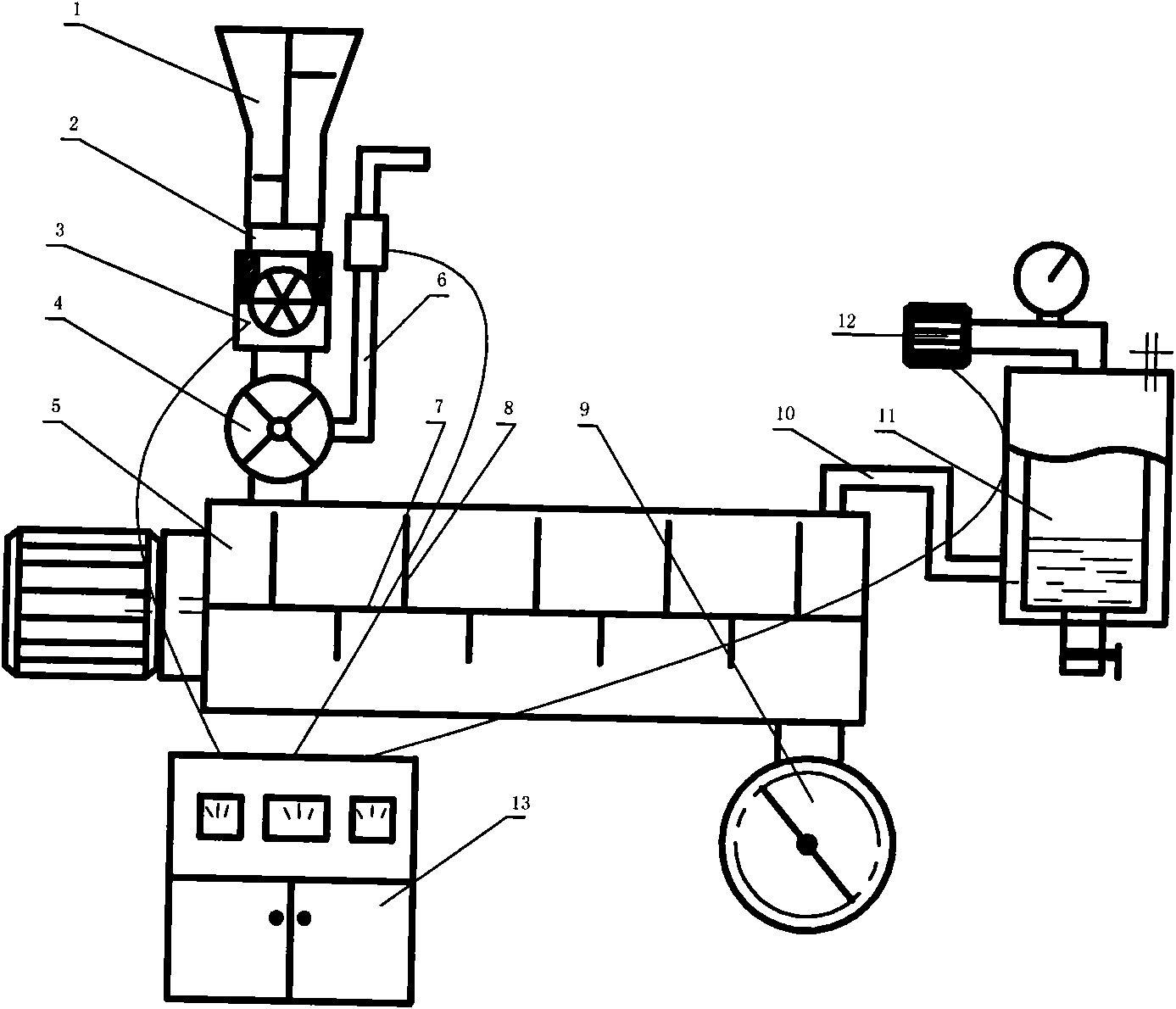

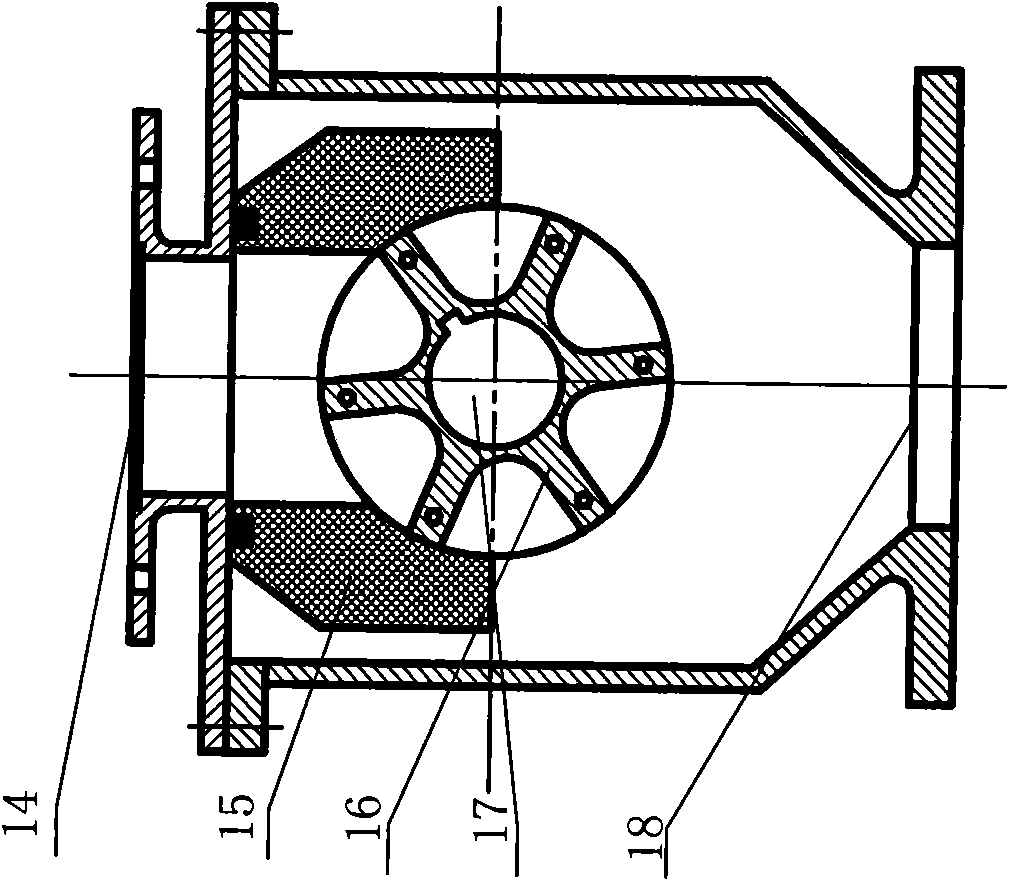

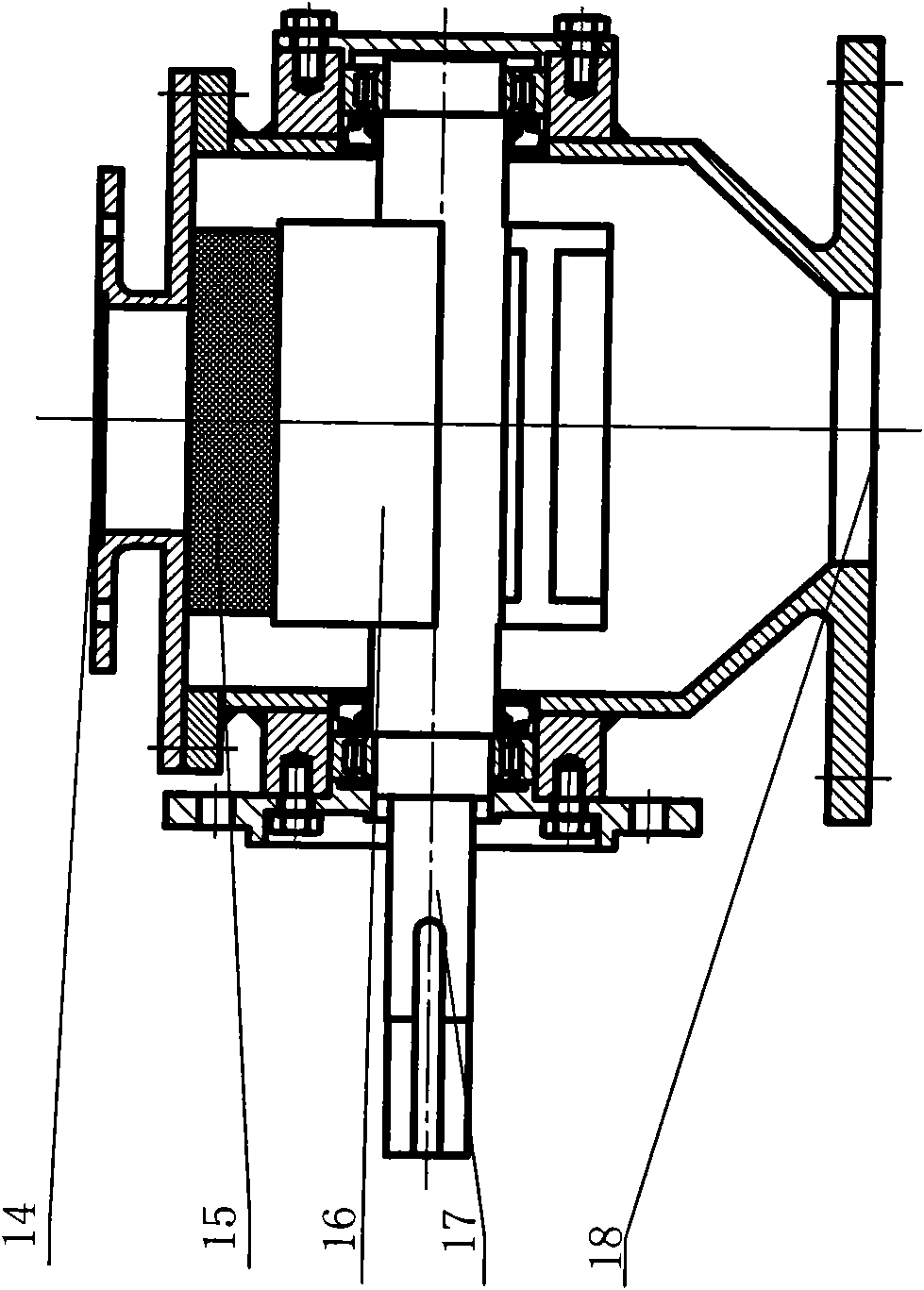

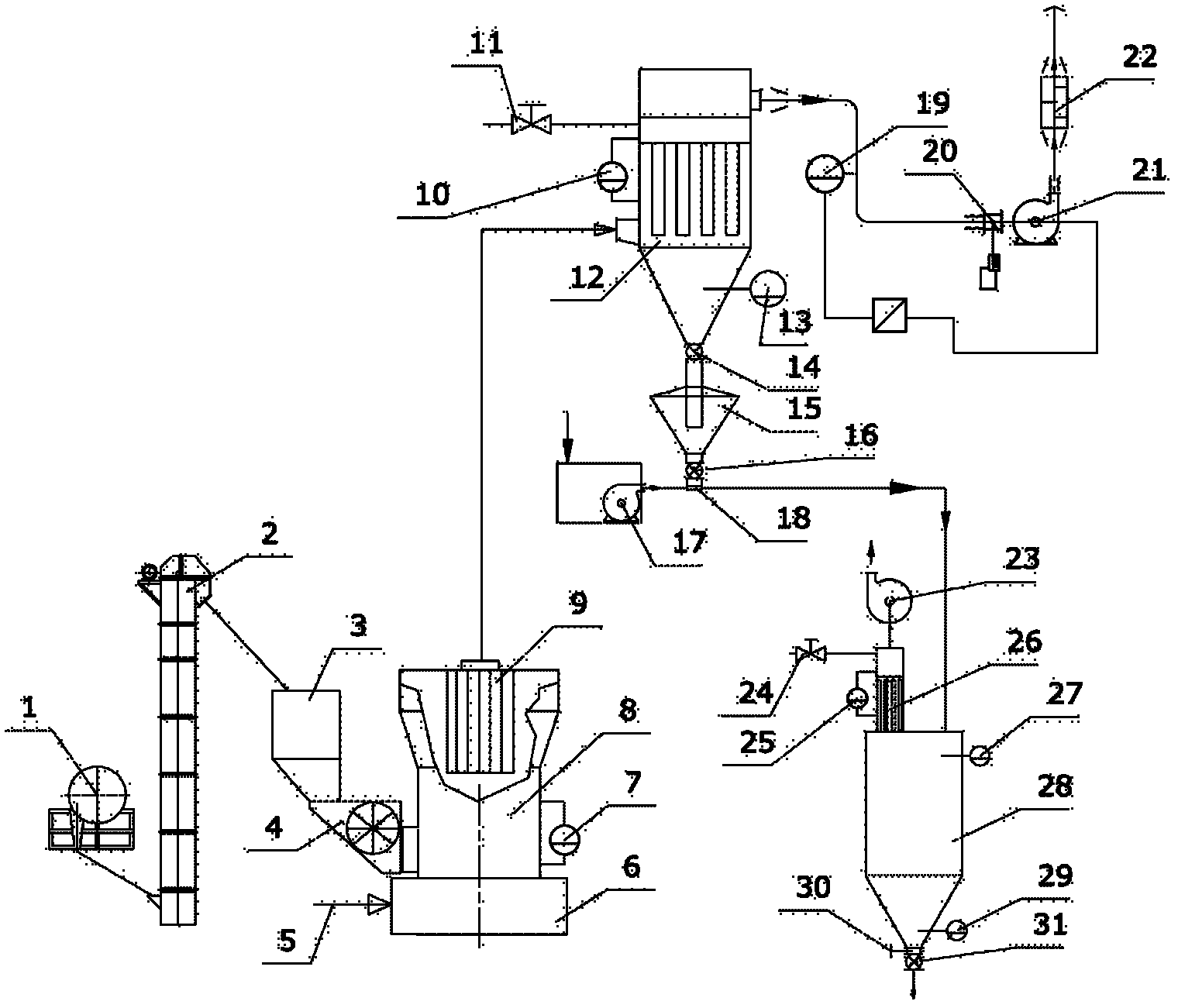

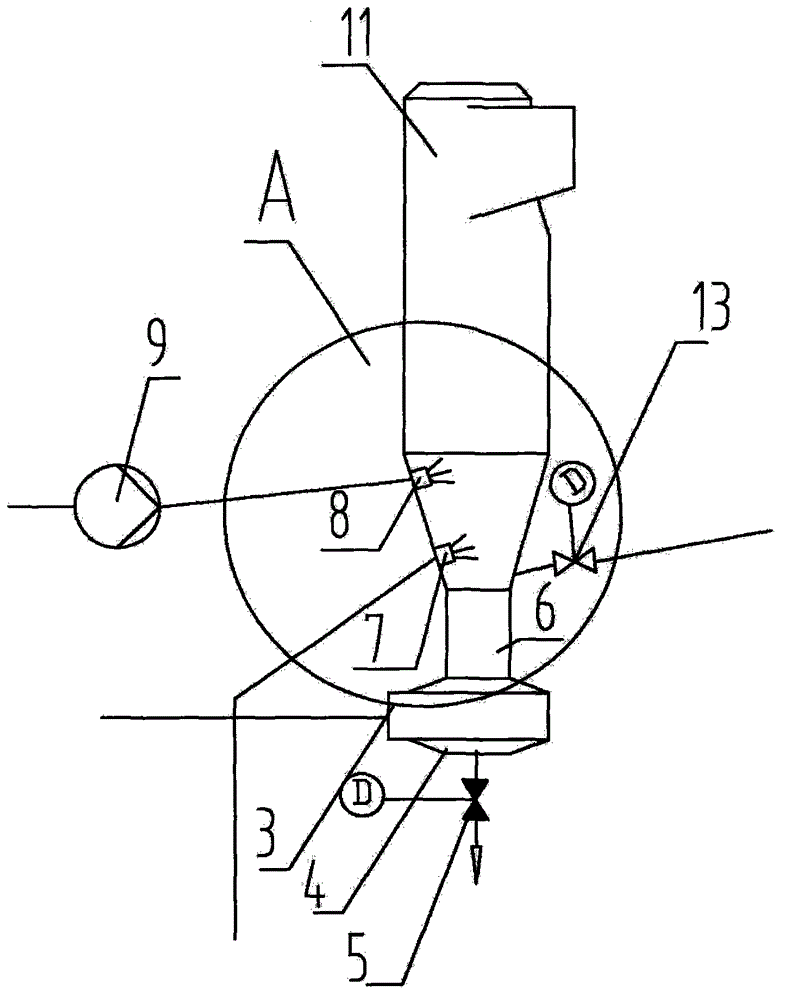

Boiler dust removal pneumatic transmission system

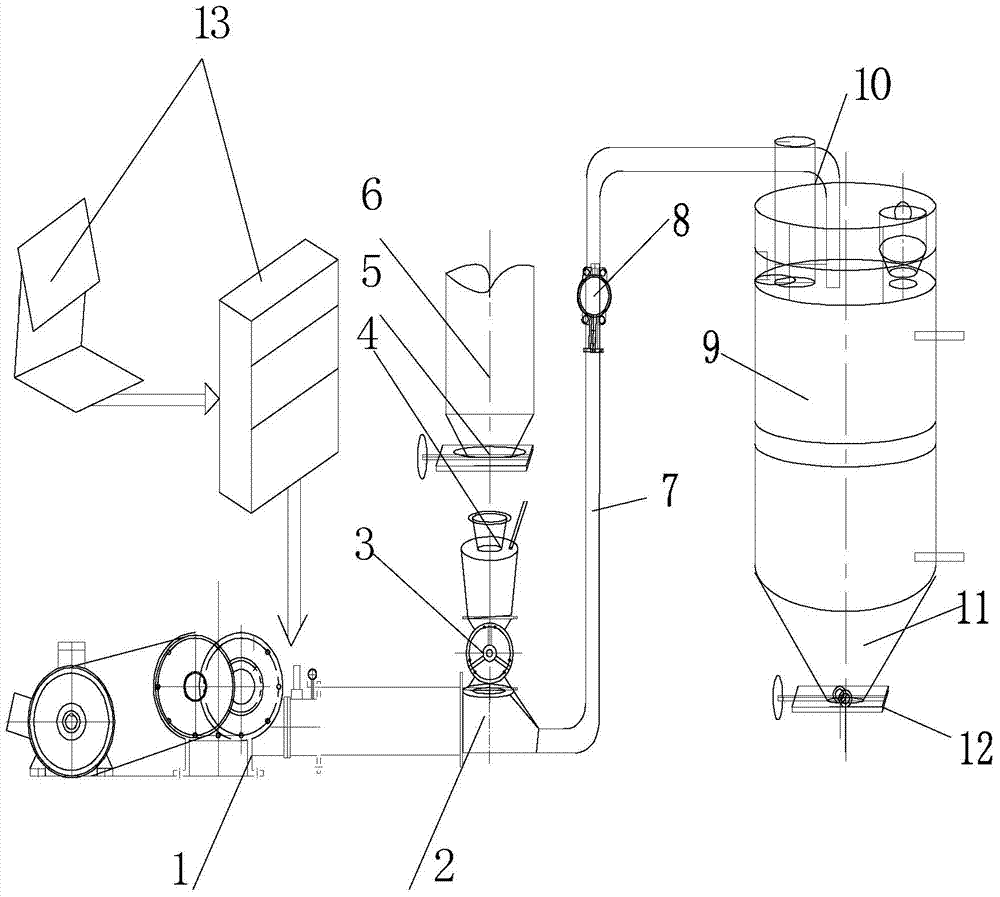

The invention relates to a boiler dust removal pneumatic transmission system, particularly to a boiler dust removal pneumatic transmission system applicable to the positive-pressure dilute phase of a rotary feeder. The boiler dust removal pneumatic transmission system comprises a Roots blower 1, a gas-solid mixing accelerating chamber 2, an electric rotary feeder 3, an suction chamber 4, a pneumatic gate valve 5, a material hopper 6, a material and compressed air transmission pipe 7, a pneumatic reversing valve 8, a storage bin 9, a pulse jet pocket type bin dust cleaner 10, a storage bin activating hopper 11, a storage bin pneumatic discharging valve 12 and an electric control system 13. The boiler dust removal pneumatic transmission system has the advantages of, through combination of the rotary feeder and the Roots blower, achieving uniform and continuous transmission and being simple and easy to maintain.

Owner:NINGXIA JIAXIANG AUTOMATIC CONTROL TECH

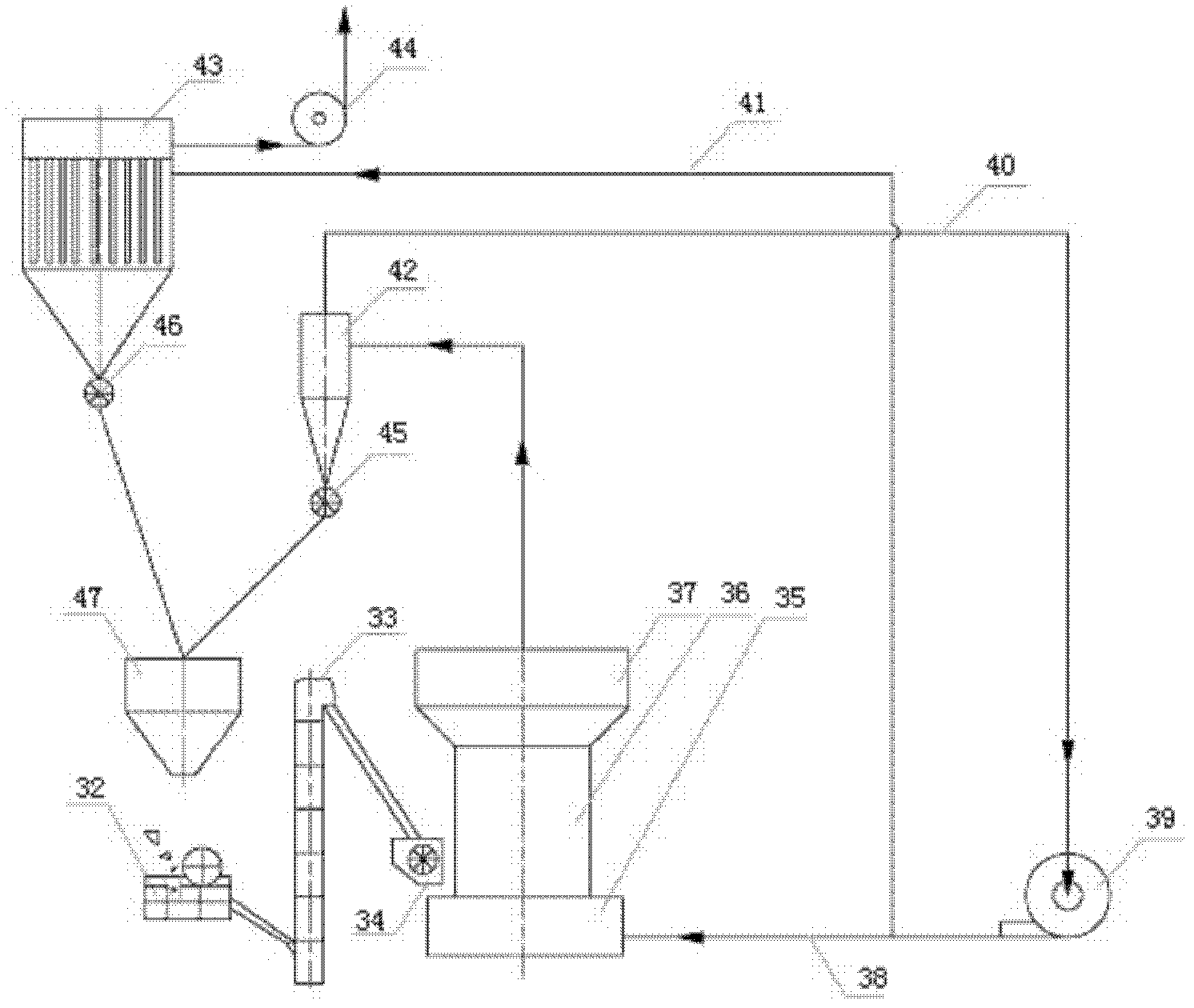

Coal-sludge co-combustion system based on high-temperature smoke drying and circulating fluidized bed boiler

The invention relates to a coal-sludge co-combustion system based on high-temperature smoke drying and a circulating fluidized bed boiler. A discharging outlet of a sludge storage bin is connected with a feeding inlet of a spray drying pipe through a screw pump. An air inlet of the spray drying pipe is connected with an outlet flue of a cyclone separator of the circulating fluidized bed boiler. An outlet I of the spray drying pipe is connected with a dry sludge bin through a rotary feeder I, and an outlet of the dry sludge bin is connected with the circulating fluidized bed boiler through a spiral conveyer so that dry sludge in the dry sludge bin can be fed into a dense-phase zone of the circulating fluidized bed boiler through the spiral conveyer to be combusted; an outlet II of the spray drying pipe is connected with the cyclone separator, an unloading opening of the cyclone separator is connected with the dry sludge bin through a rotary feeder II, and an exhaust opening of the cyclone separator is connected with the circulating fluidized bed boiler through a cooling condenser and a vent fan. The coal-sludge co-combustion system integrates the functions of sludge drying, combustion and pollutant control, and has the characteristics of being concise, environmentally friendly and efficient.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

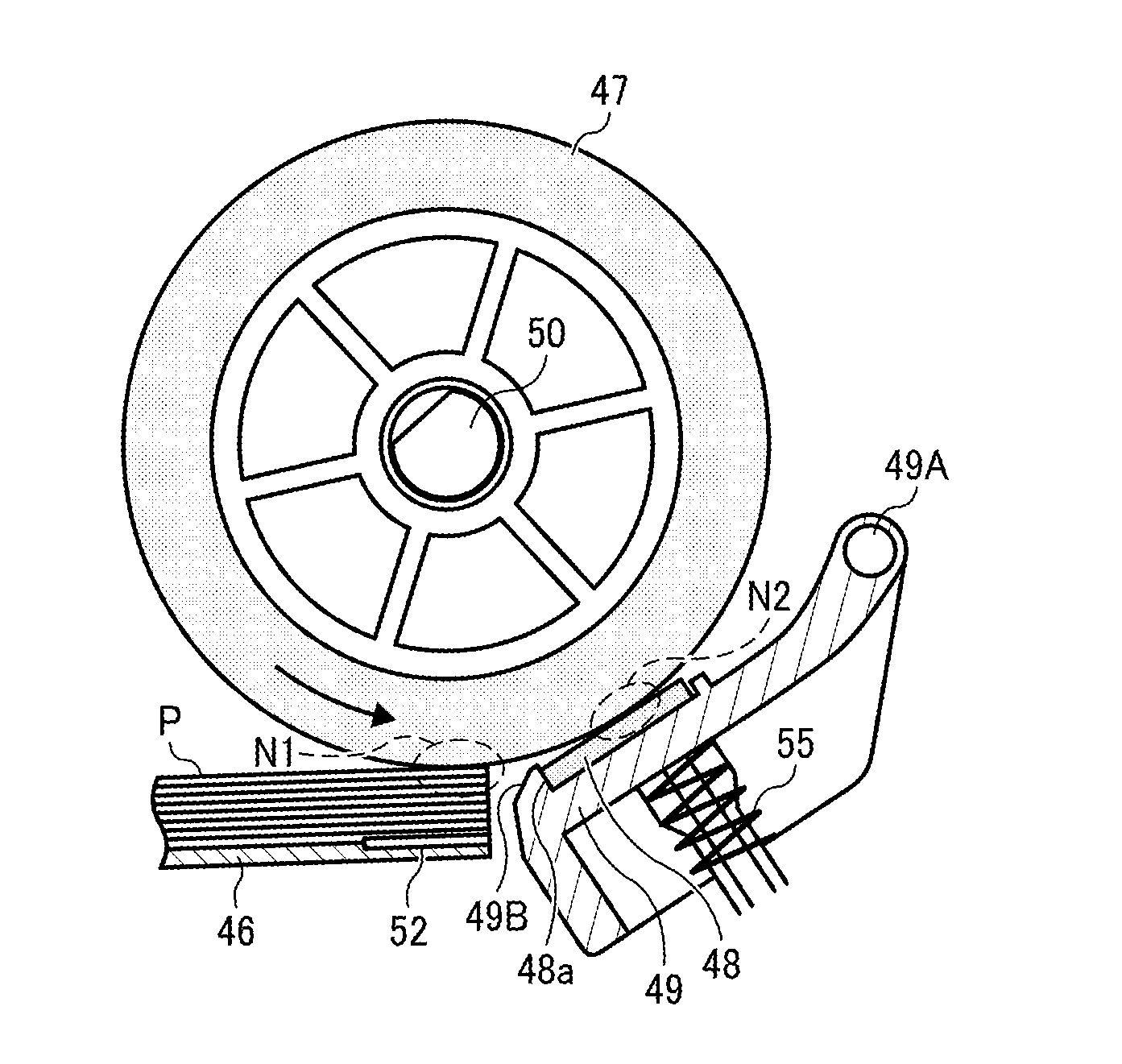

Acceleration conveyor

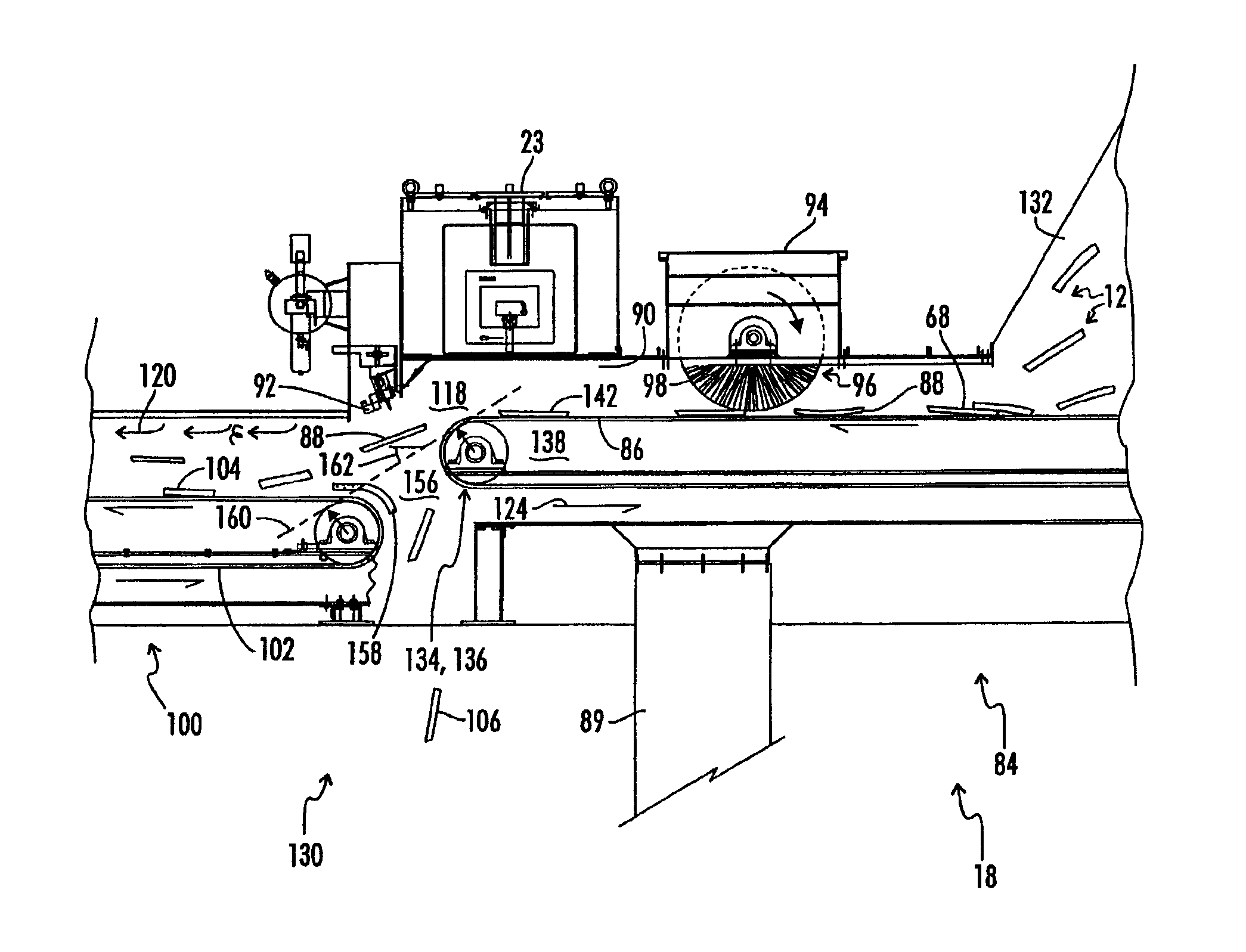

InactiveUS6891119B2Improve consistencyGood repeatabilityConveyorsGas current separationBristleEngineering

A paper handling system includes an acceleration conveyor having an acceleration belt operating at an acceleration speed. The system includes a pinning structure operably positioned to pin paper to the acceleration belt. The pinning structure is a rotary feeder which includes a plurality of flexible bristles extending radially from a roller into engagement with the acceleration belt. The speed of the acceleration belt is sufficiently high to create a suction phenomena such that when paper is pinned to the acceleration belt with the rotary feeder, the paper will be accelerated to a paper speed substantially equal to the acceleration speed. The system also includes a blower system operative to facilitate carrying the paper off of the acceleration belt across a transition gap between the acceleration belt and a product belt.

Owner:KABUSHIKI KAISHA MSS

Full-negative-pressure powder processing system

ActiveCN102319609ASolve leakage pollutionImprove working environmentGrain treatmentsEngineeringCrusher

The invention relates to a full-negative-pressure powder processing system, which is characterized by comprising a jaw crusher, an elevator, a pulverizing mill, a high-pressure box type pulse collector, a buffering air suction hopper, an accelerating pipe and a finished product storage bin, wherein the jaw crusher is in process connection with the elevator, the hopper, a rotary tangent feeder and a host machine of the pulverizing mill; the dust outlet of the high-pressure box type pulse collector is connected with the accelerating pipe through a rotary unloader I, the buffering air suction hopper and a rotary feeder in sequence; and the dust outlet of the finished product storage bin is provided with a manual valve and a rotary unloader II in sequence. Compared with the prior art, the invention has the advantages: (1) air current of the entire system fully runs under the negative pressure 15-25 mbar, so that the problem of dust pollution is solved, and the operating environment and the ambient environment are improved greatly; (2) the air current is uniform and smooth, so that the vibration of a unit is reduced, and the energy consumption is lowered; and (3) the yield of the pulverizing mill is increased from 4.5 t / h to 5.5 t / h, and the machine hour yield is increased by 23 percent.

Owner:辽宁艾海滑石有限公司

Dry desulfurization and urea solution direct injection denitrification device for flue gas of sintering machine

InactiveCN106139846AReduce emission concentrationReduce dosageHuman health protectionDispersed particle filtrationInlet valveRotary feeder

A dry desulfurization and urea solution direct injection denitrification device for flue gas of a sintering machine comprises the sintering machine, an air bellow, an online flue gas monitoring control device, an electric air inlet valve, a reaction tower, a bag-type dust collector, a fan and a chimney. The device is characterized in that the sintering machine is sequentially connected with the air bellow, the online flue gas monitoring control device, the electric air inlet valve, the reaction tower, the bag-type dust collector, the fan and the chimney, an electric flow regulating valve is connected between the air bellow and the online flue gas monitoring control device, the online flue gas monitoring control device is connected with a PLC (programmable logic controller) control box connected with a variable-frequency rotary feeder, the upper side of the variable-frequency rotary feeder is connected with an electronic screw scale connected with a discharger, the discharger is connected with a urea granule bin, and the lower side of the variable-frequency rotary feeder is connected with the upper side of a jet flow mixer. With the adoption of the device, harmful pollutants such as SO2, NOx, dioxin, heavy metals and the like in the flue gas of the sintering machine can be removed, up-to-standard emission of the flue gas is realized, and environmental pollution is avoided.

Owner:WUXI LUSHENG MACHINERY EQUIP

Sheet feeding device and image forming apparatus

A sheet feeding device includes a rotary feeder to contact a first side of a sheet to feed the sheet downstream along a feed passage; a friction pad disposed opposing the rotary feeder with the feed passage interposed between the rotary feeder and the friction pad to form a separation nip, the friction pad having a first side facing the separation nip and a second side opposite the first side of the friction pad; a holder disposed on the second side of the friction pad and having a first side holding the friction pad and a second side opposite the first side of the holder; a guide support disposed on the second side of the holder; and a pair of guides disposed on the guide support to contact a second side of the sheet facing the friction pad to raise the sheet from a surface of the friction pad.

Owner:RICOH KK

Coal-sludge composite firing system based on dual-medium flue gas drying and circulating fluidized bed boiler

Owner:UNIV OF SHANGHAI FOR SCI & TECH

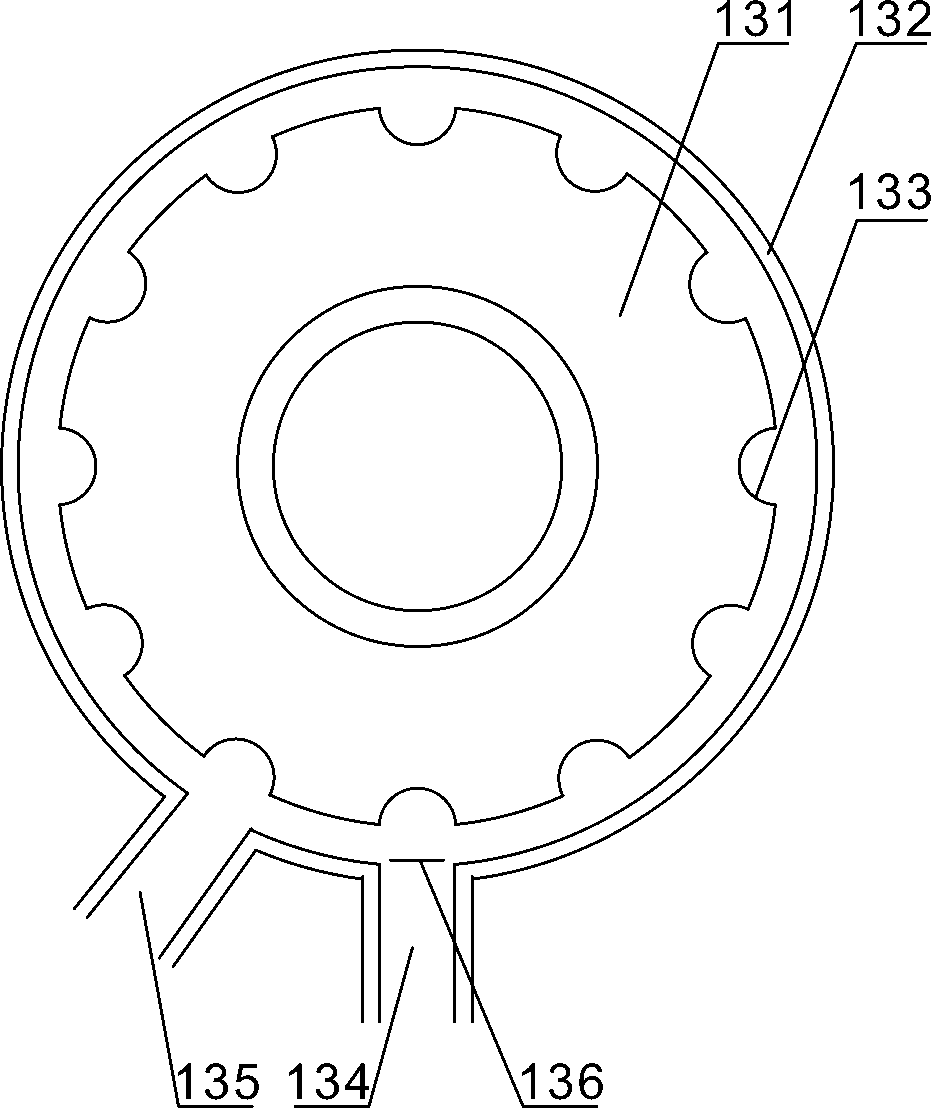

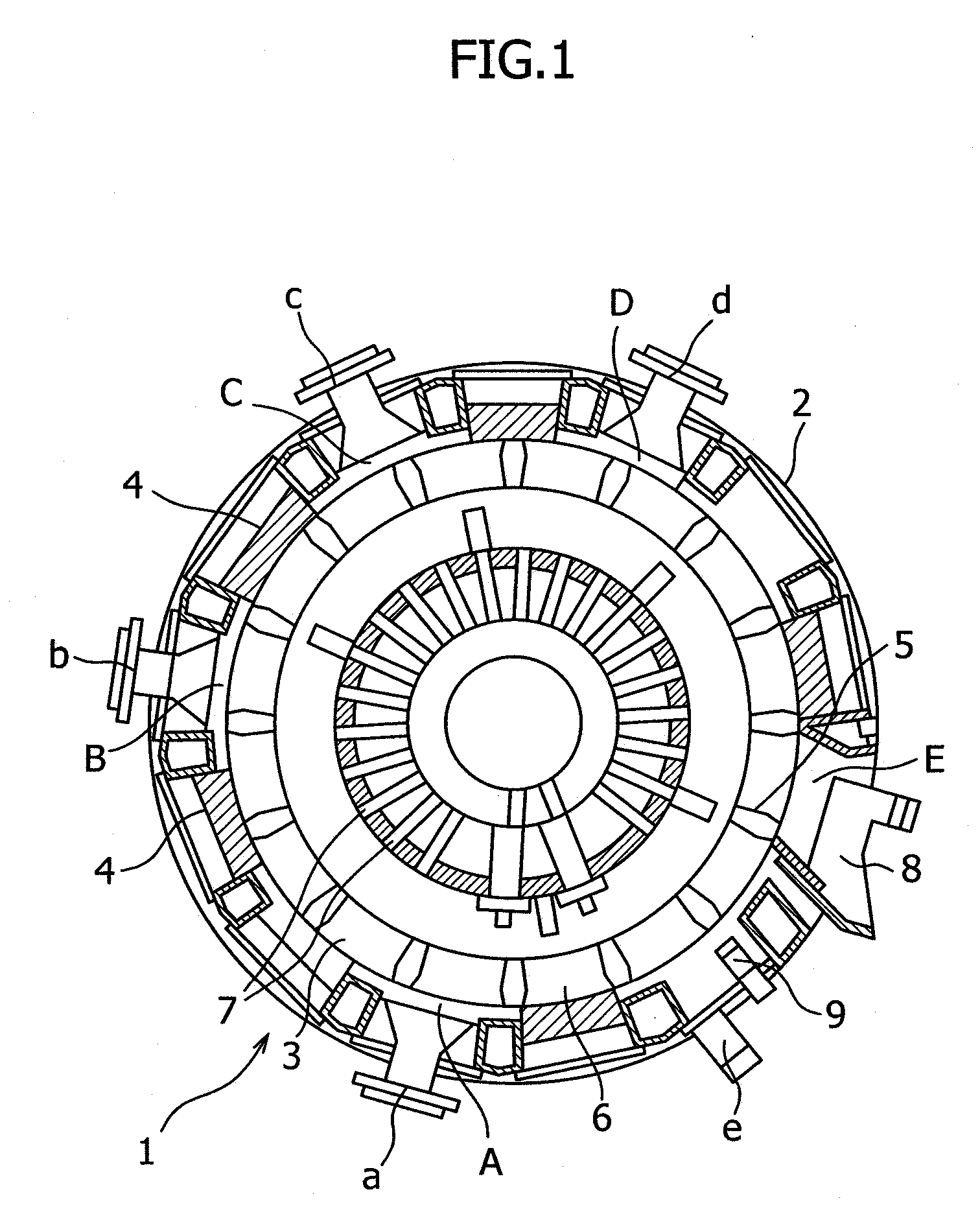

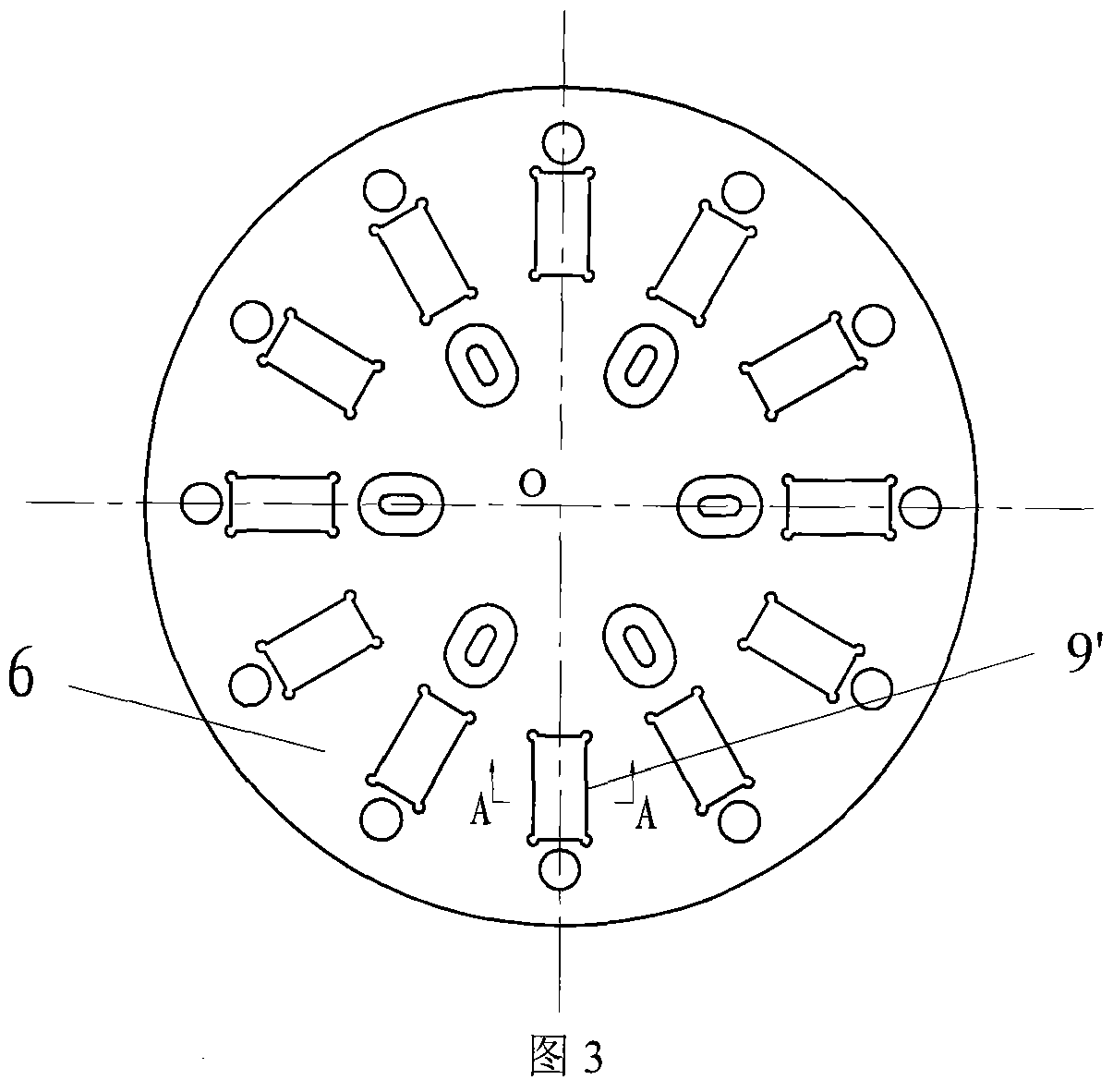

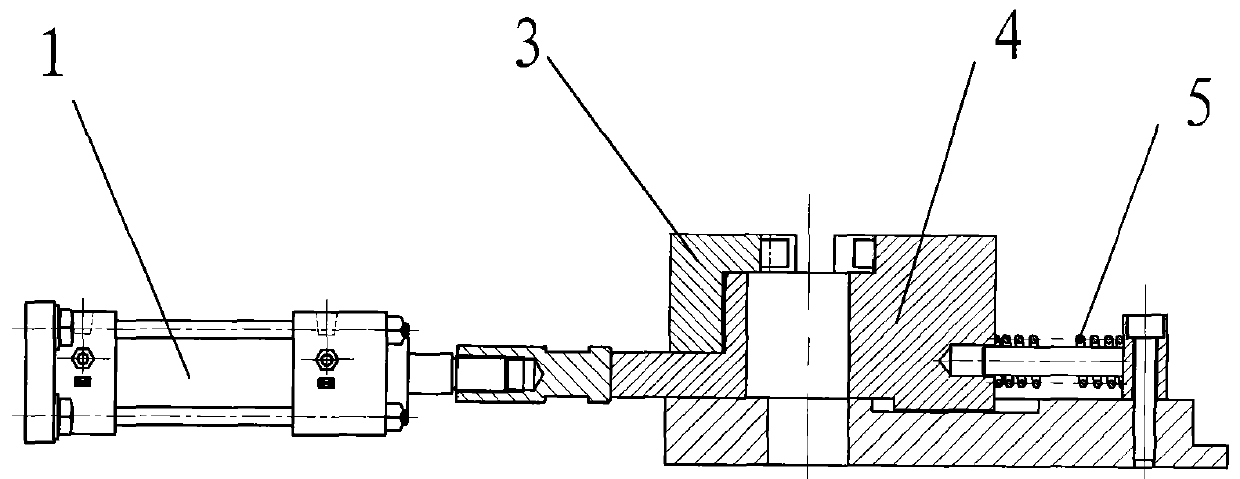

Cam rotary feeder of automatic assembler for milled assembled cam shaft

InactiveCN101028684AMeet precision assembly requirementsAchieve automationValve arrangementsAssembly machinesCamRotary feeder

A cam rotating-advancing unit for the automatic assembling machine of assembled knurled cam axle is composed of a numerally controlled rotary bench, a rotary disc on said rotary bench, and the movable block and static block for clamping workpiece. Said movable block is installed in the guide track fixed to said rotary disc and can slide in it. Its rear end is linked with a spring in its holder and its front end is in contact with cam loading or unloading cylinder.

Owner:JILIN UNIV

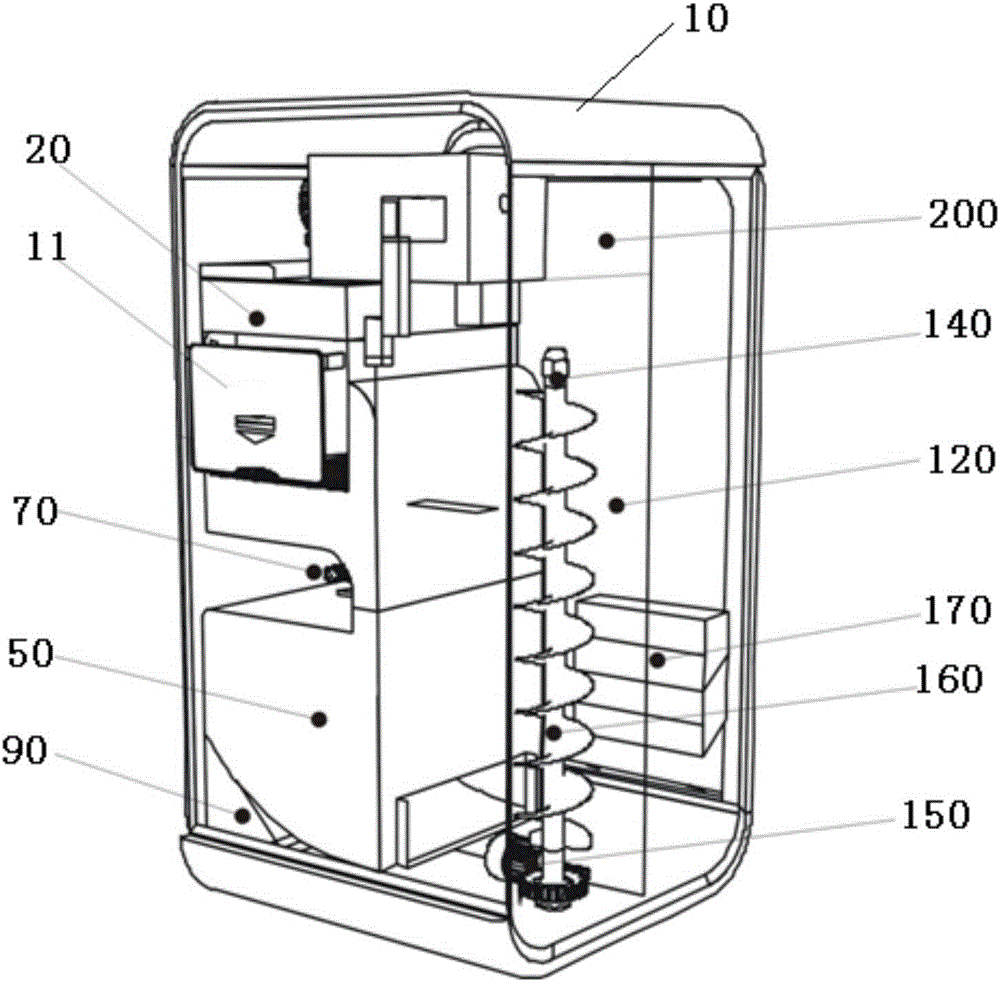

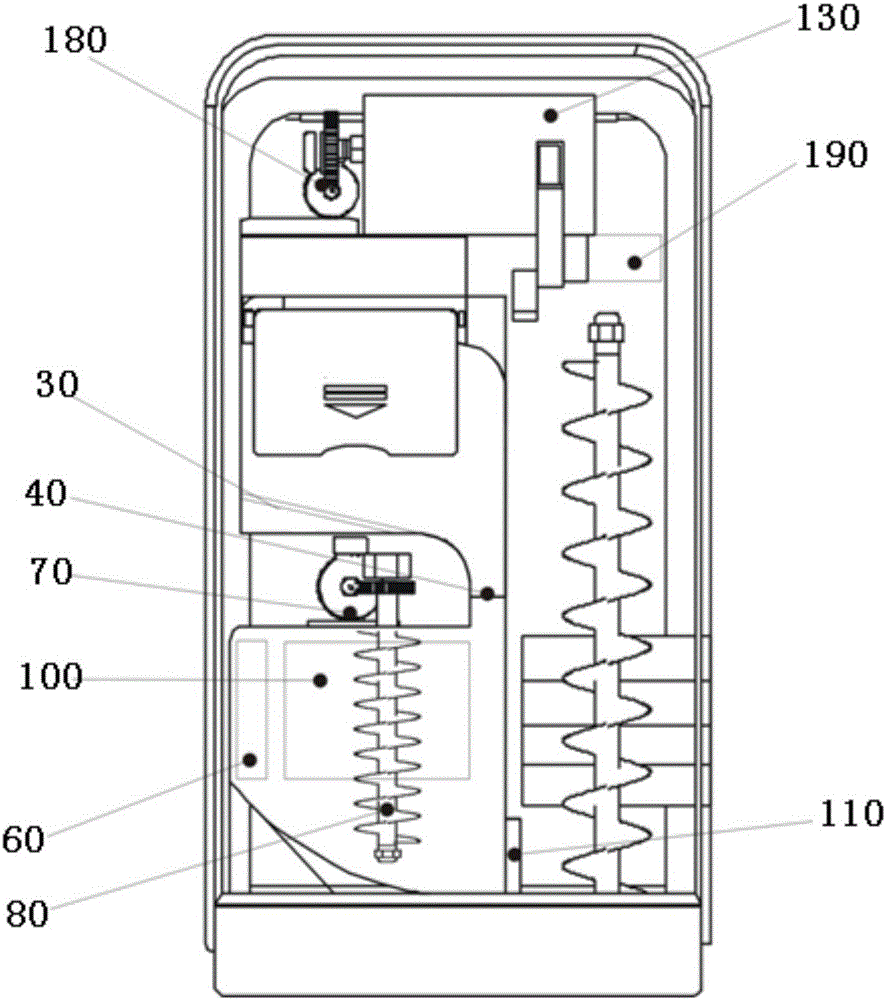

Fallen leaf collection type fertilizer production machine for communities

ActiveCN106431526ASimple structureEasy to useBio-organic fraction processingOrganic fertiliser preparationAgricultural engineeringDrinking straw

The invention discloses a fallen leaf collection type fertilizer production machine for communities. The fertilizer production machine comprises a shell with an opening, a screening device, a collection device, a fermentation chamber, an extruding device and a cooling device. The opening of the shell is provided with an openable push plate, the collection device is arranged below the screening device which is arranged in the shell, and the shell is internally provided with the fermentation chamber. The screening device comprises a fallen leaf chamber, a filter screen and a retaining plate; the collection device comprises a fallen leaf grinding chamber, a fan, a first motor, a rotary feeder, a deduster, a level detector and a suction pipe; the fermentation chamber is provided with a feeding port, a fermentation agent input port, a discharging port and a screw agitator, and the feeding port of the fermentation chamber is connected with the other end of the suction pipe; the extruding device comprises an extruding chamber, an extruding head, a second motor and a screw conveyor; the cooling device comprises a third motor and a cooling conveying belt, the cooling conveying belt is driven by the third motor, and one end of the cooling conveying belt is connected with the discharging port of the extruding chamber while the other end of the cooling conveying belt is connected with a collection tank. The fallen leaf collection type fertilizer production machine has advantages of simple structure, convenience in utilization, high operation efficiency, automation in fertilizer production and high environment friendliness.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

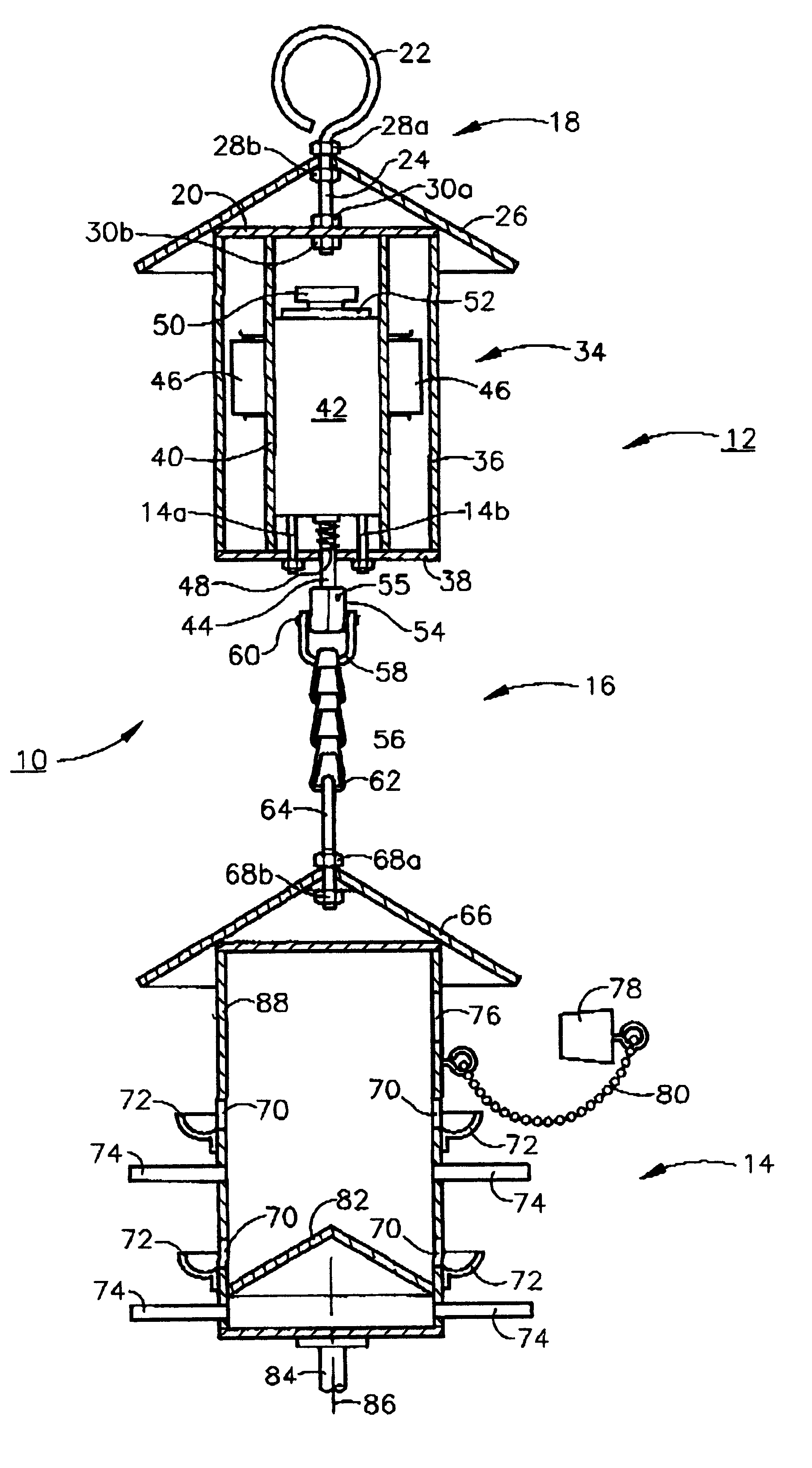

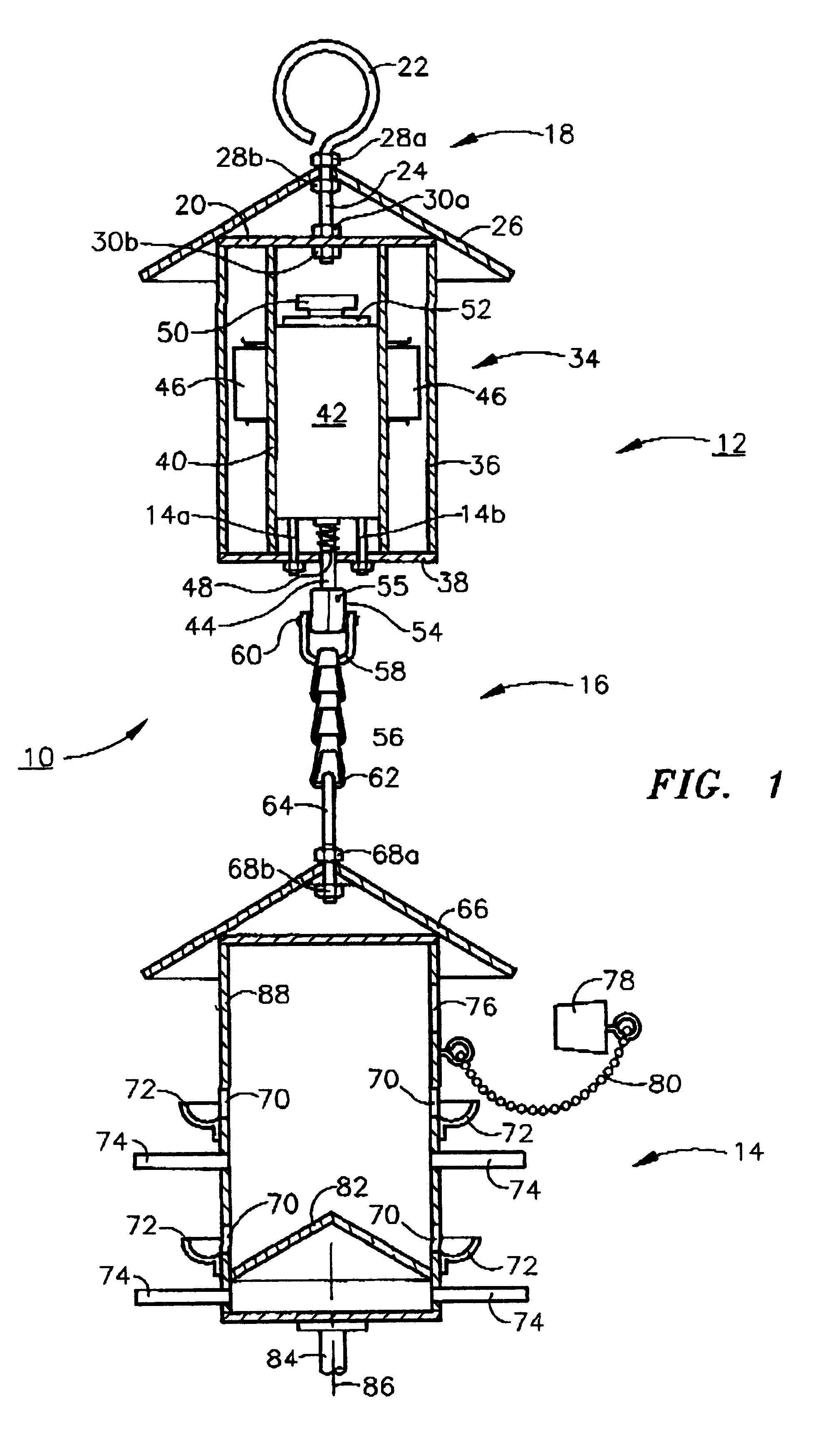

Squirrel repellent bird feeder

A bird feeder equipped with an electrically powered spinning mechanism that is triggered by the weight of a squirrel on the feeder is described. Upon detection of a squirrel on the feeder, the spinning mechanism rotates the feeder at a rate adequate to centrifugally remove the invading squirrel while resulting in a minimum loss of feed contained in the feeder.

Owner:ILS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com