Method and Device to Compact Biomass

a technology of biomass and compacting device, applied in the direction of presses, manufacturing tools, presses, etc., can solve the problems of inability to compact such biomass materials in one stage, high cost of pressing, and slow action, so as to prevent short-circuiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

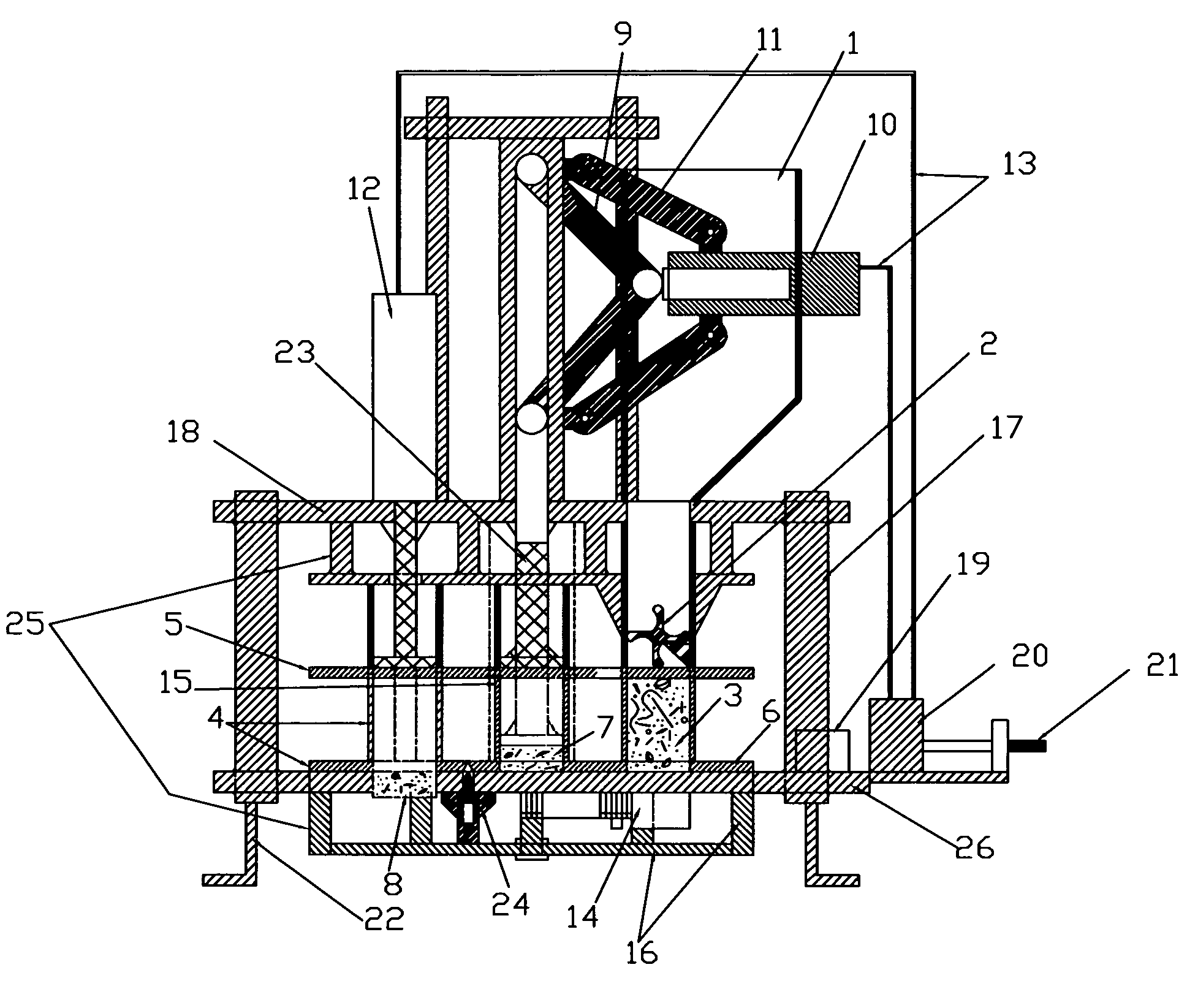

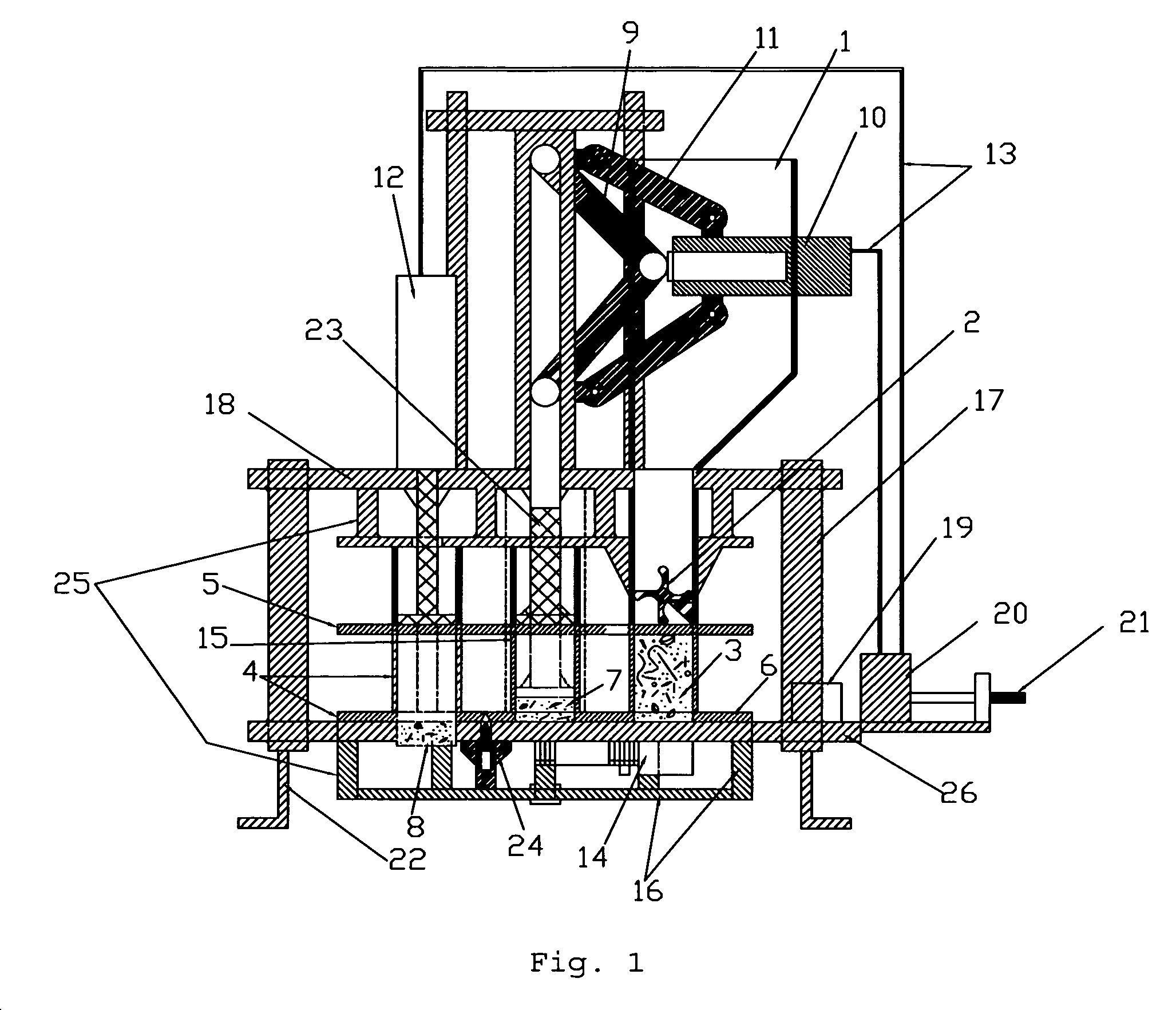

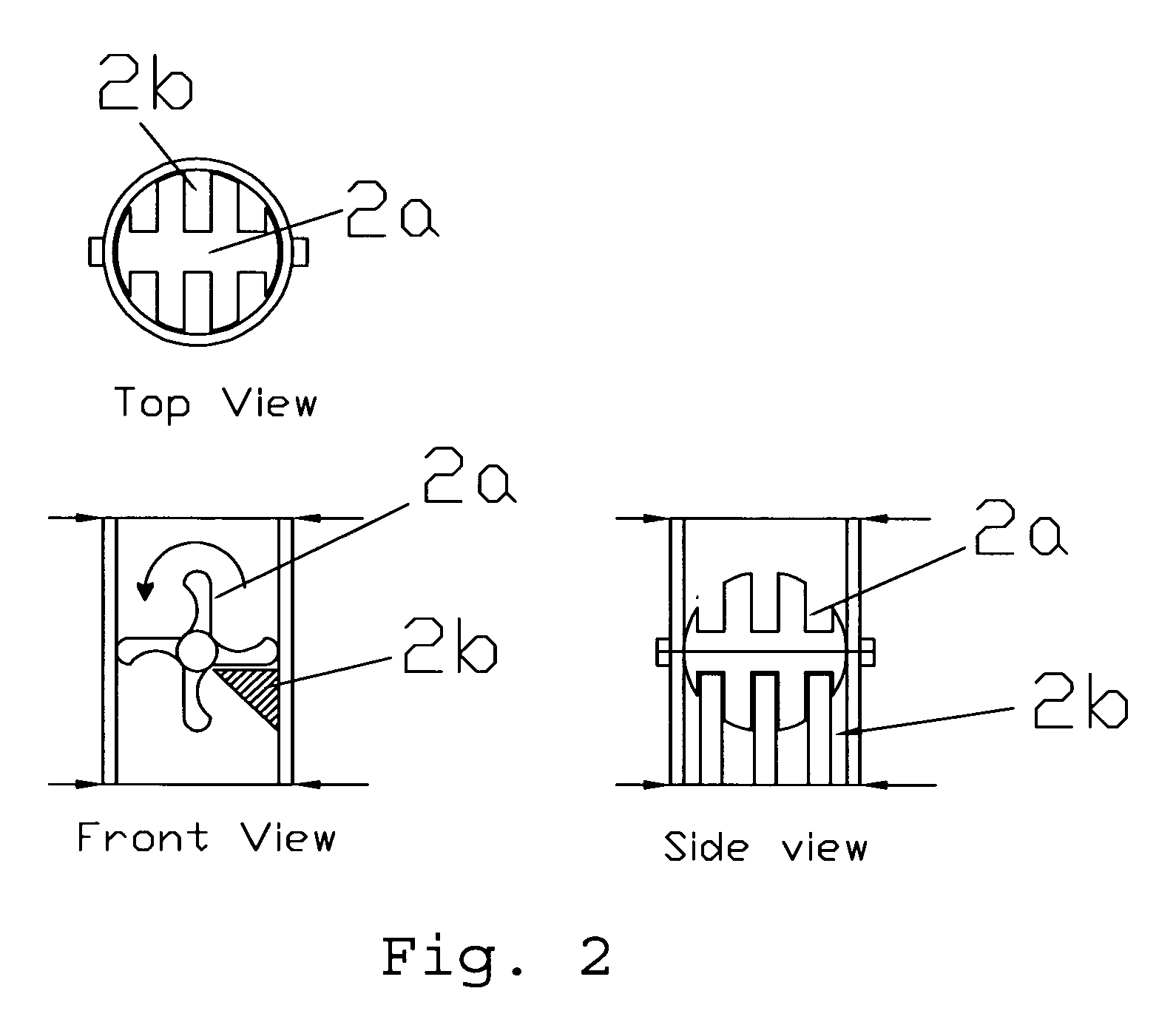

[0054]The current invention uses a two-stage compaction process to produce biomass logs from fluffy (loose) biomass materials such as leaves, grass, corn stovers, bushes, etc. In stage 1, the fluffy biomass material is fed into a mold (vertical cylinder) on the top of which is mounted a rotary feeder that continuously pushes the biomass into the mold, causing pre-compaction. The feeder will pre-compact the material to a density 20% to 60% of the final density of the log. After this initial stage of compaction, the biomass material in the mold is now ready for final compaction which can be done more easily due to the much shorter biomass column in the mold caused by pre-compaction. To further aid in rapid and efficient final compaction, a toggle mechanism, such as that used for holding and opening injection molds, is used here. The toggle mechanism is most suited for this type of compaction because it matches the load-versus-displacement curve for the compaction of fluffy biomass mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peak pressure | aaaaa | aaaaa |

| peak pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com