Patents

Literature

226results about "Firelighters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

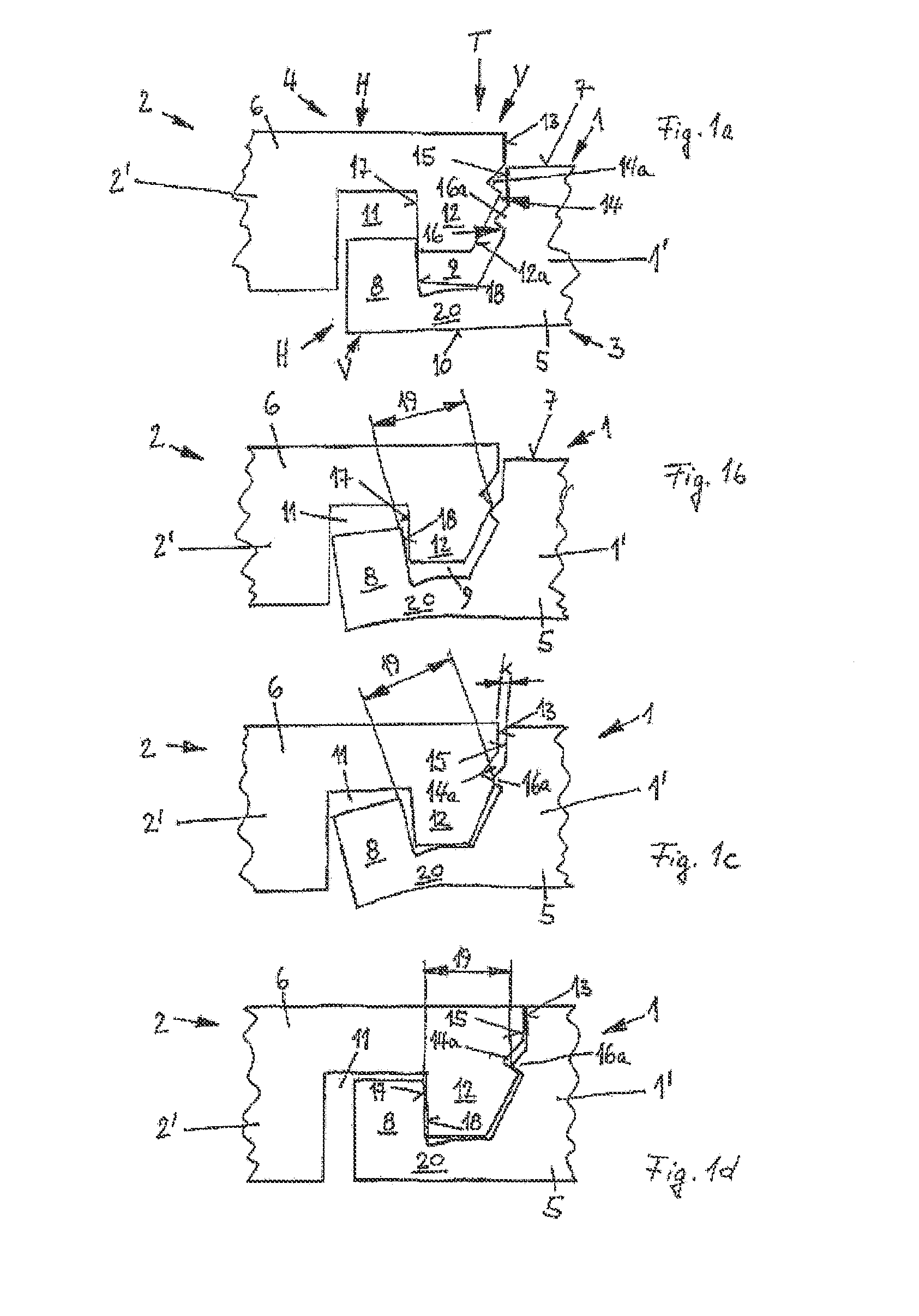

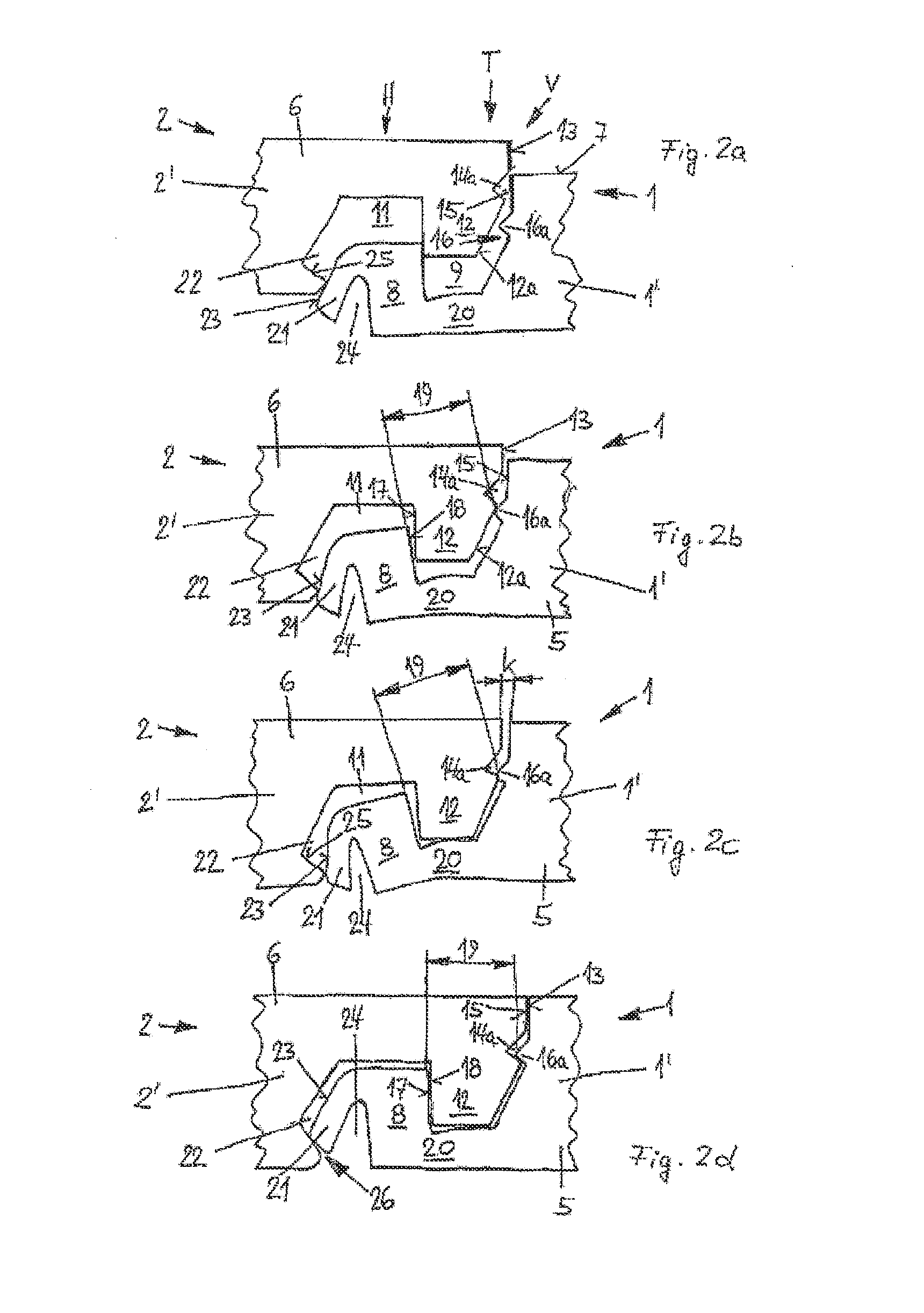

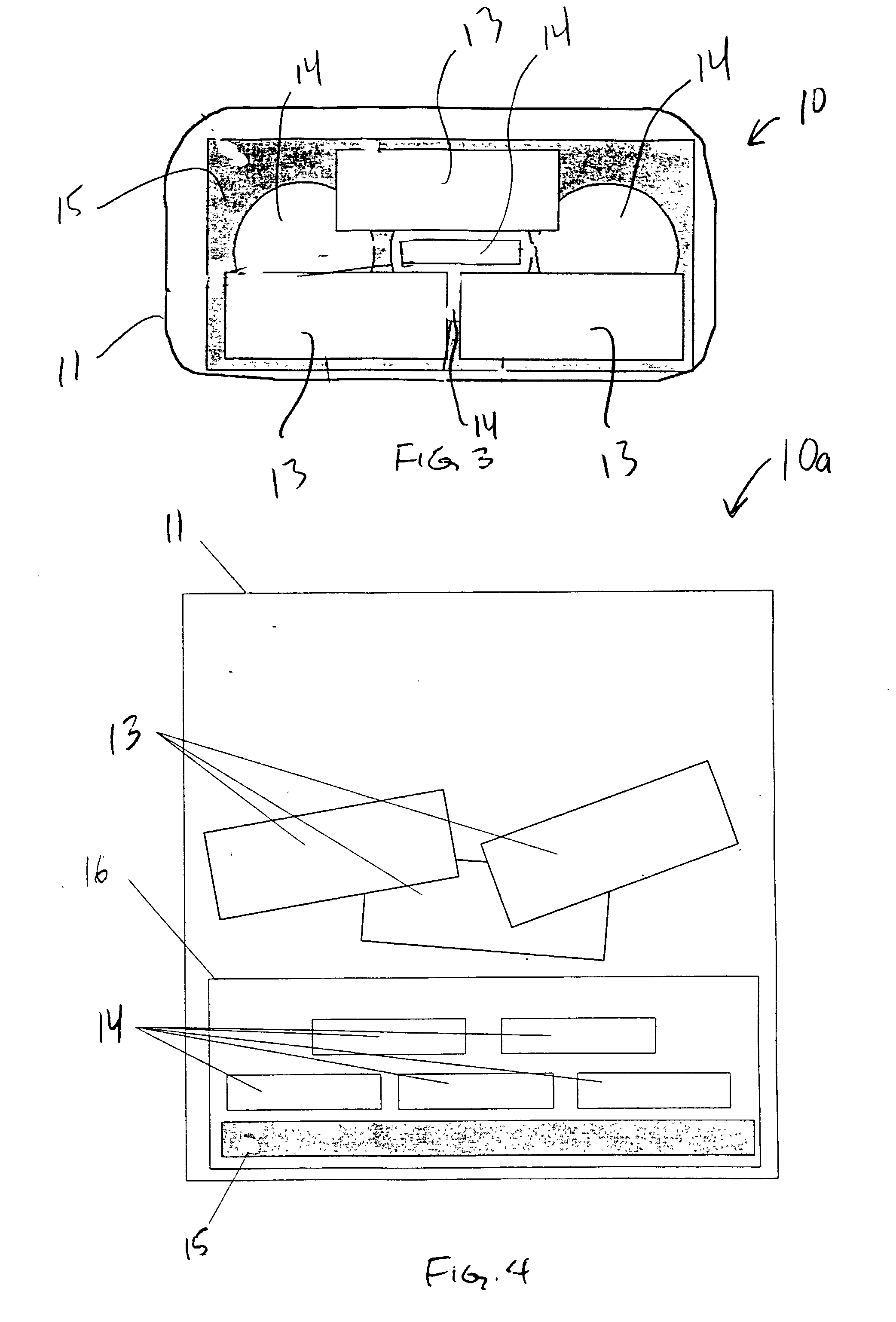

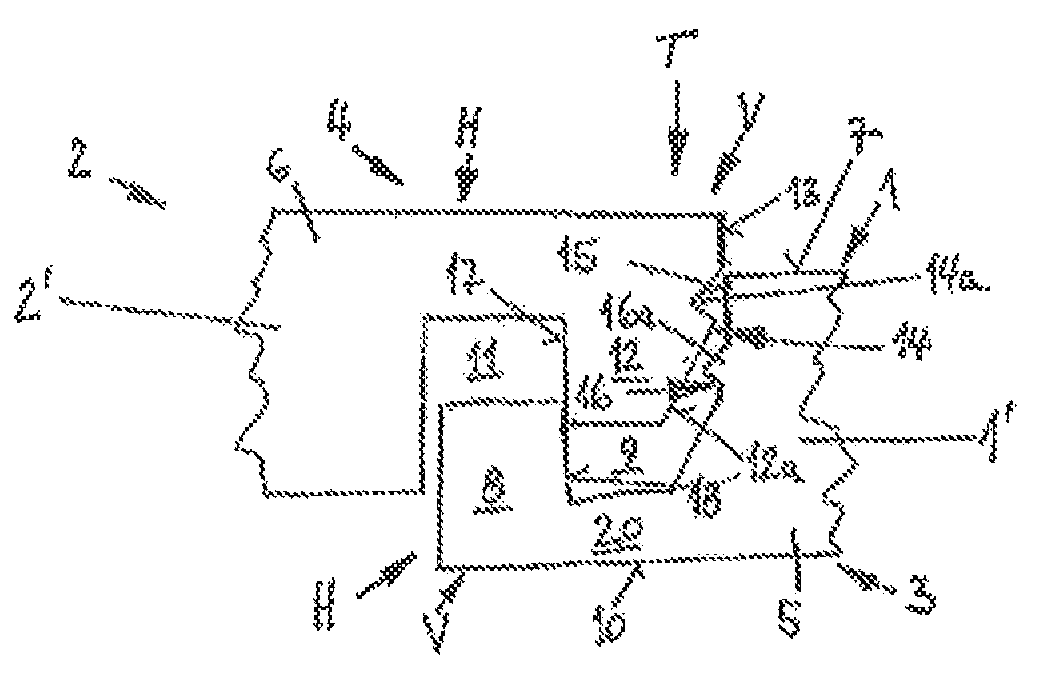

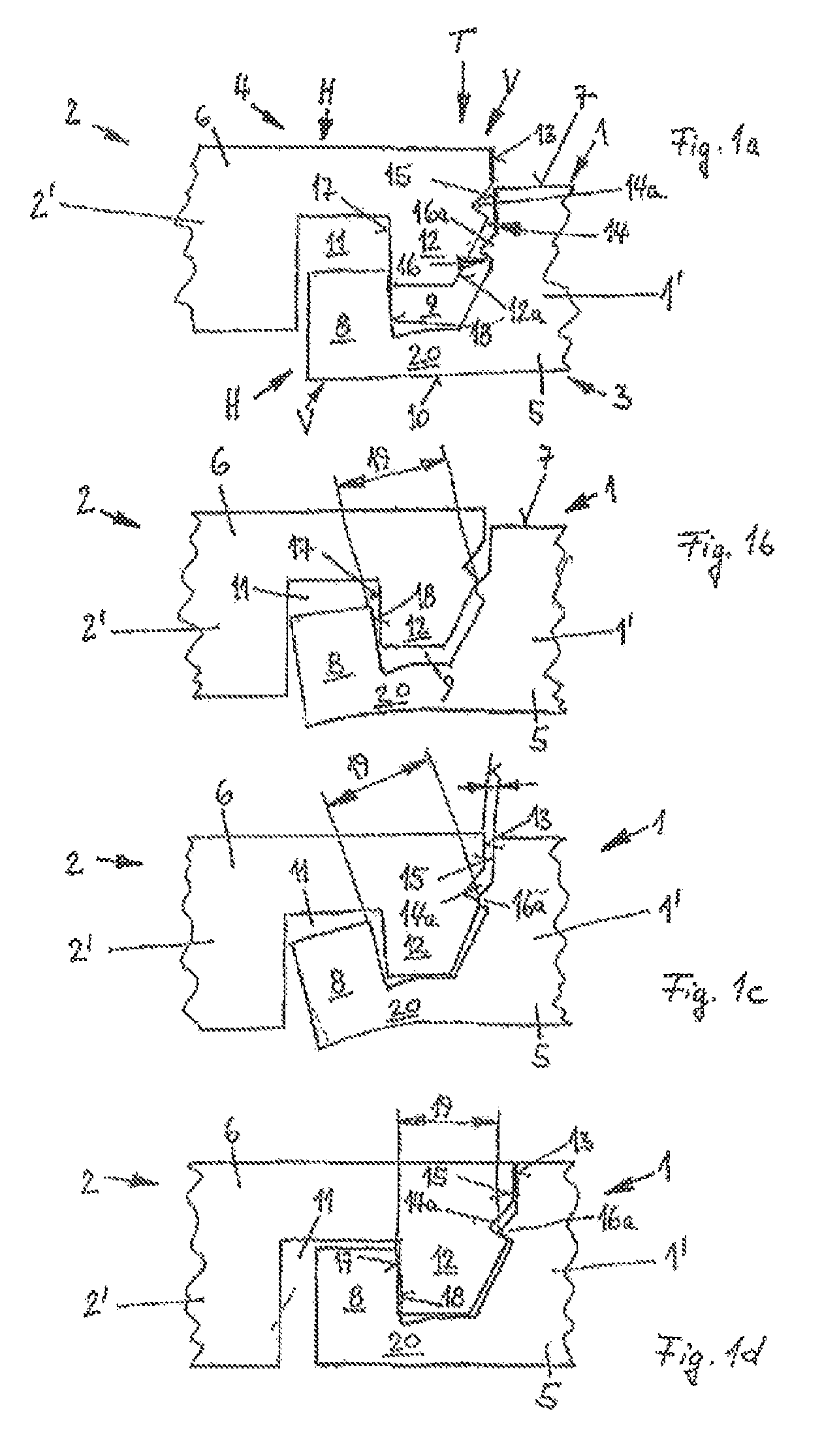

Panel

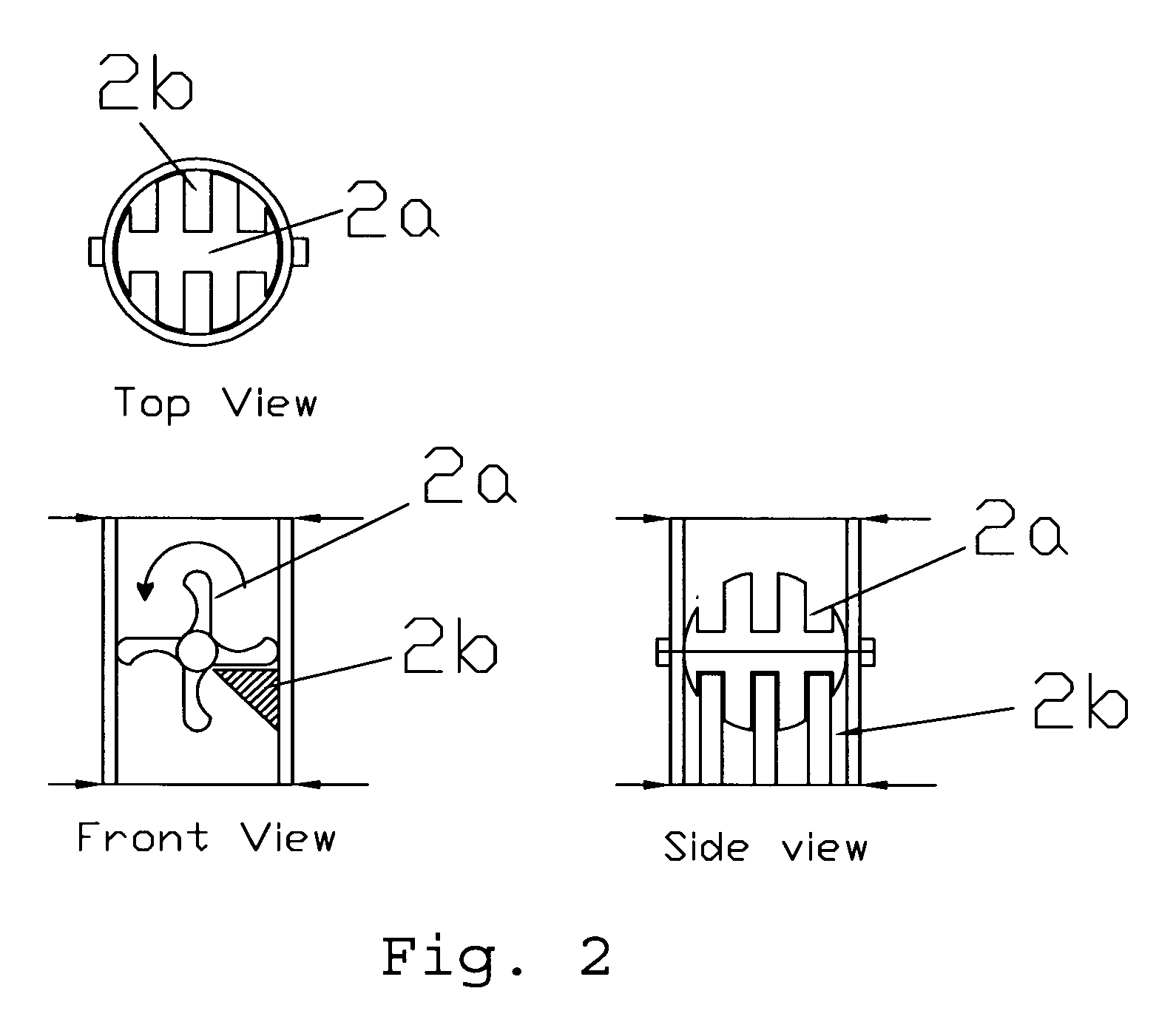

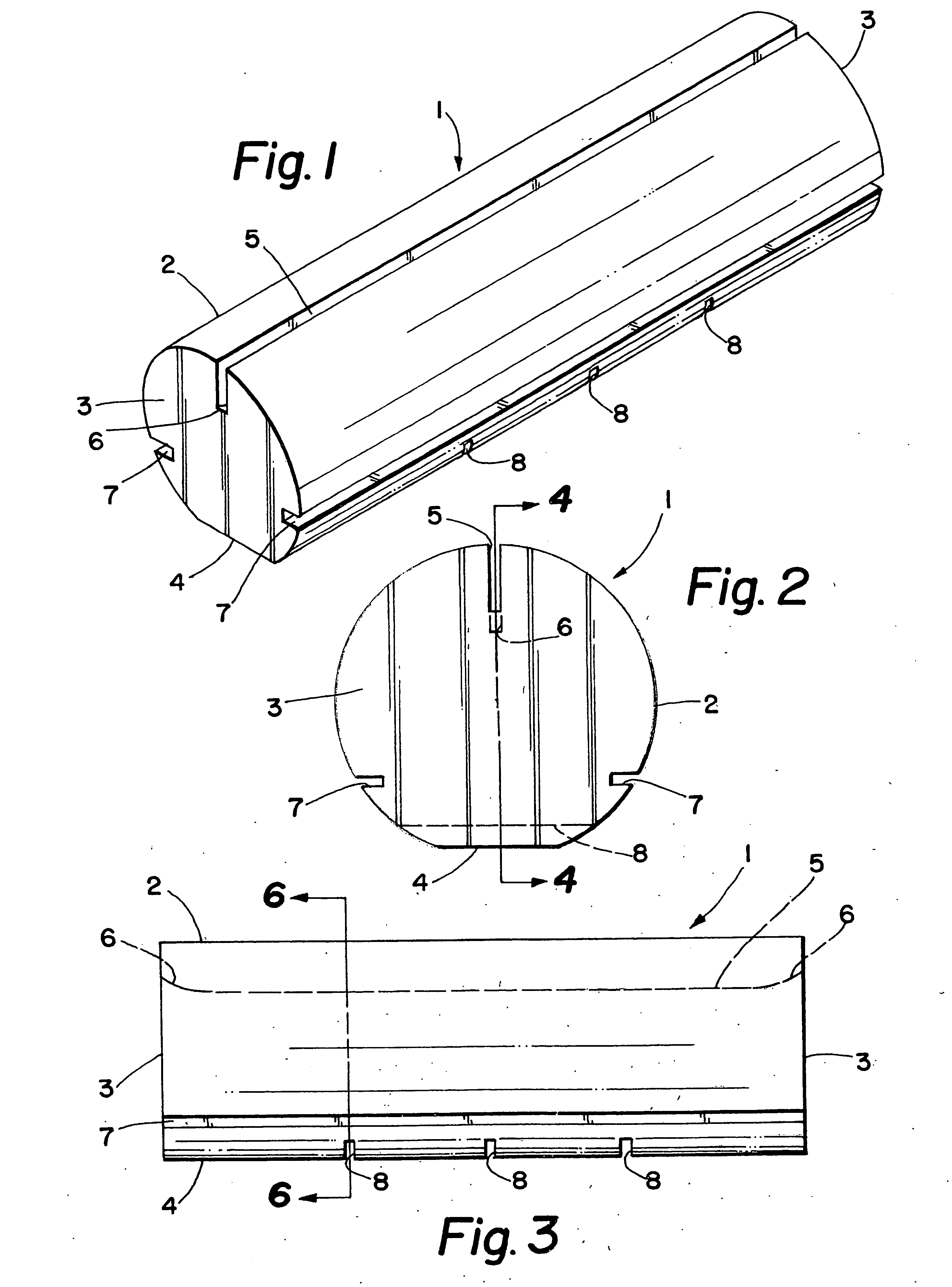

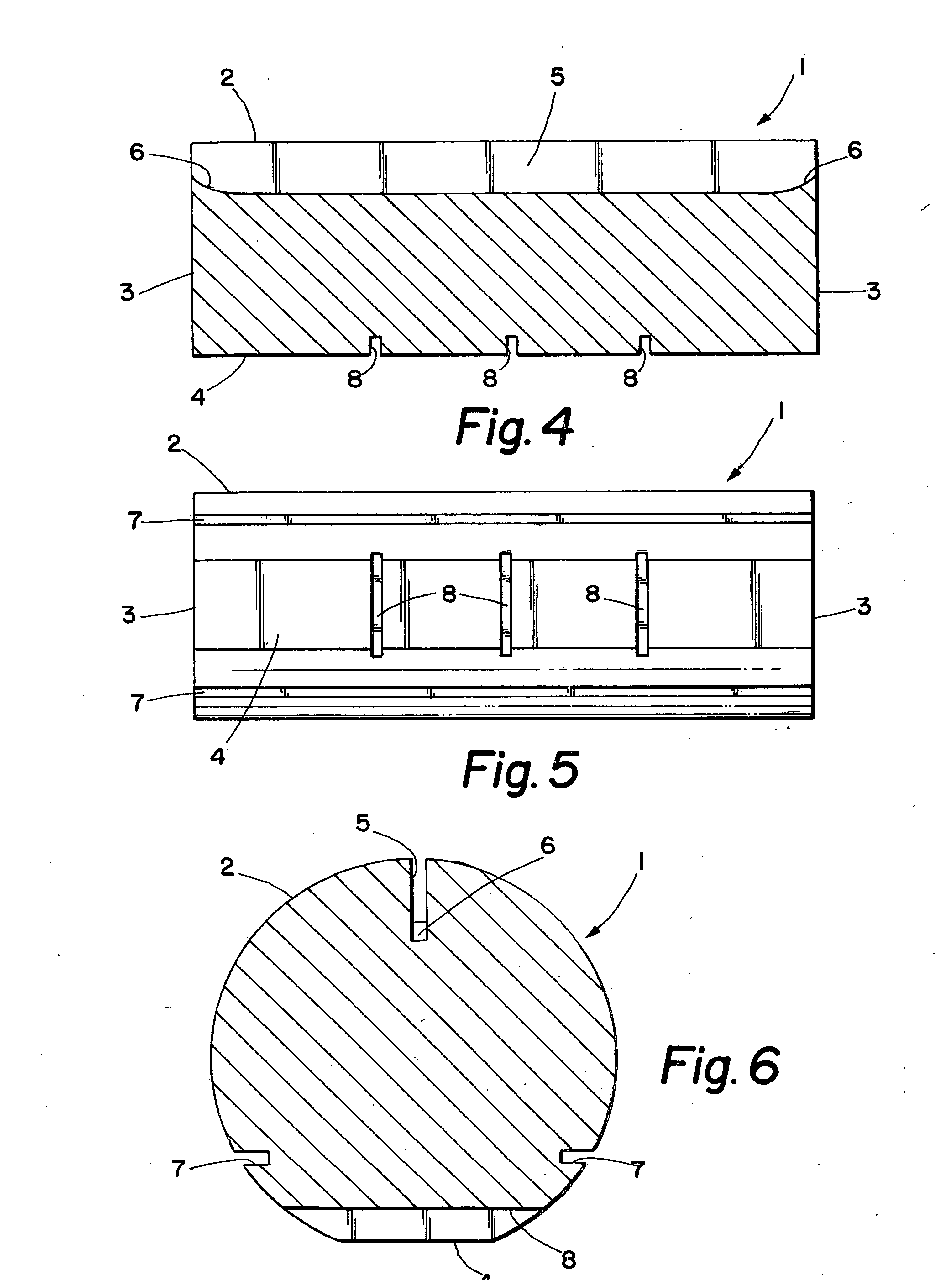

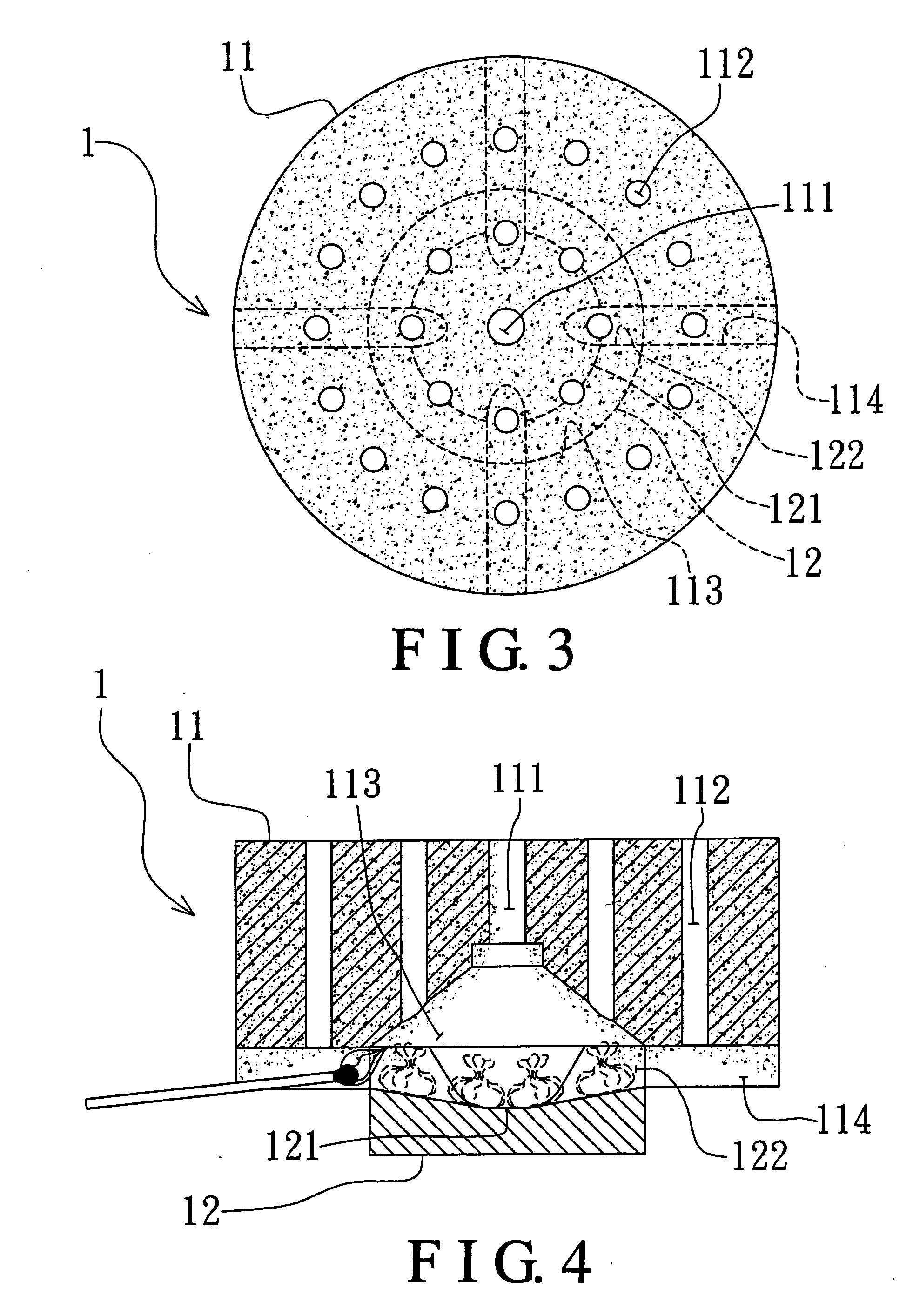

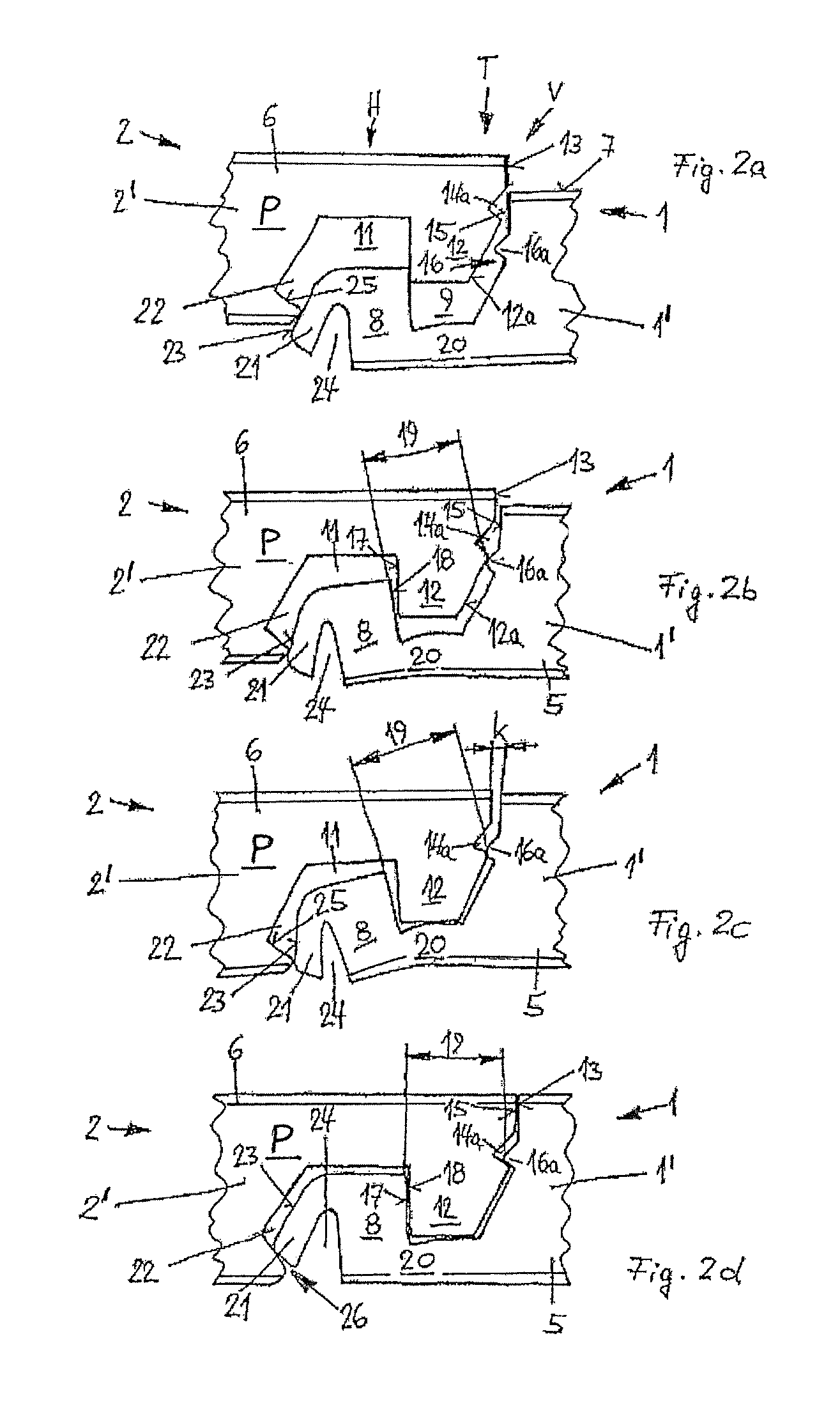

The invention relates to a panel with complementary locking means provided in pairs on opposite panel edges. One of the locking means is hook profiles with a receiving hook and a locking hook. The fee step end of the locking hook is designed narrower than the width of the receiving opening of the receiving hook. The locking contour of the locking hook protrudes at least partially past the plane of the joint surface of the receiving hook so that the free step end fits into the receiving opening far enough at first that a part of the horizontal locking surface of the locking hook makes contact with the horizontal locking surface of the receiving hook during a joining motion without elastic deformation of the hook profiles, and that the receiving hook bends so that the width of the receiving opening con be expanded so that the locking step can be inserted entirely I to the receiving recess and the locking contour of the locking hook is further inserted into a form-fit contour of the receiving hook.

Owner:AKZENTA PANEELE PROFILE GMBH

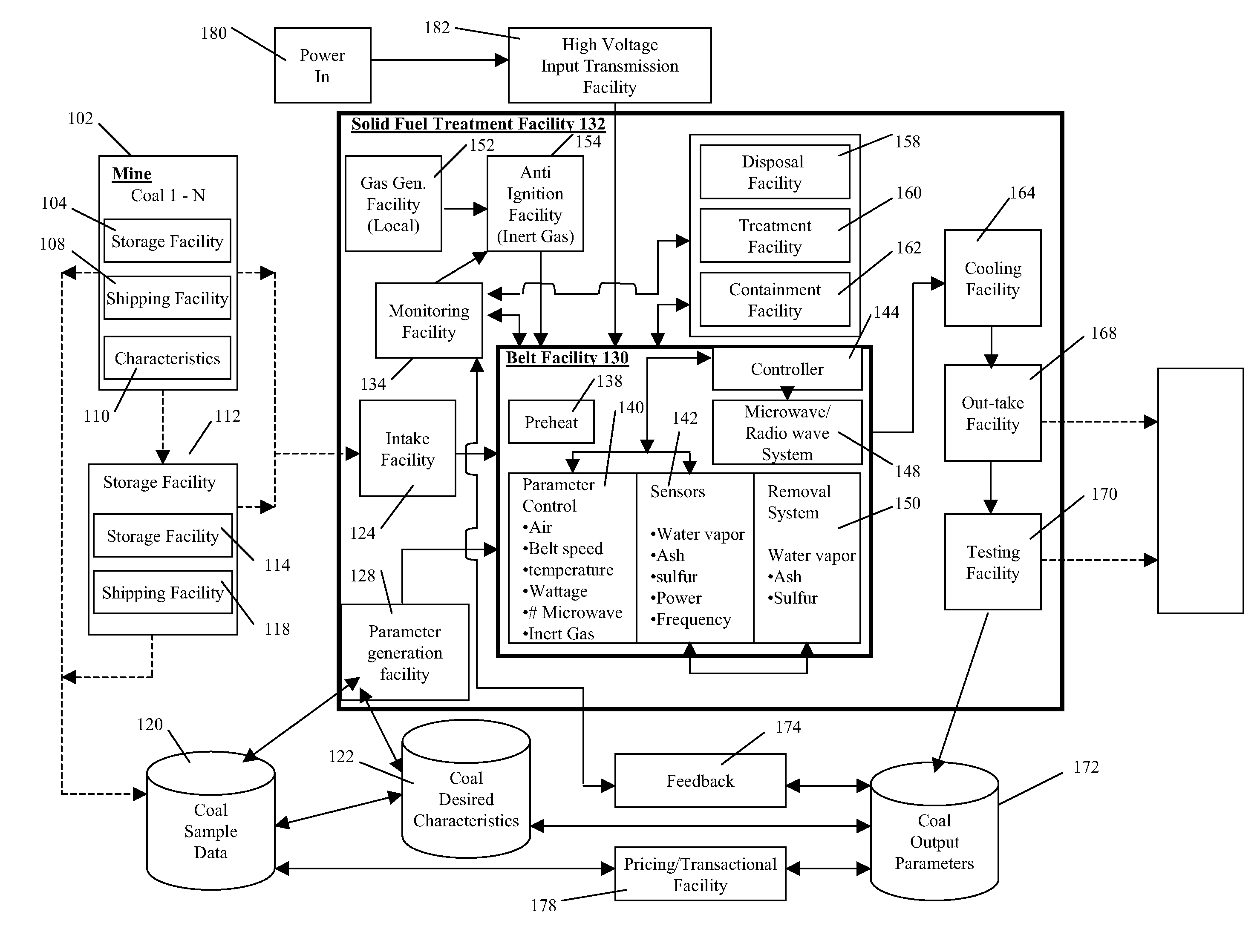

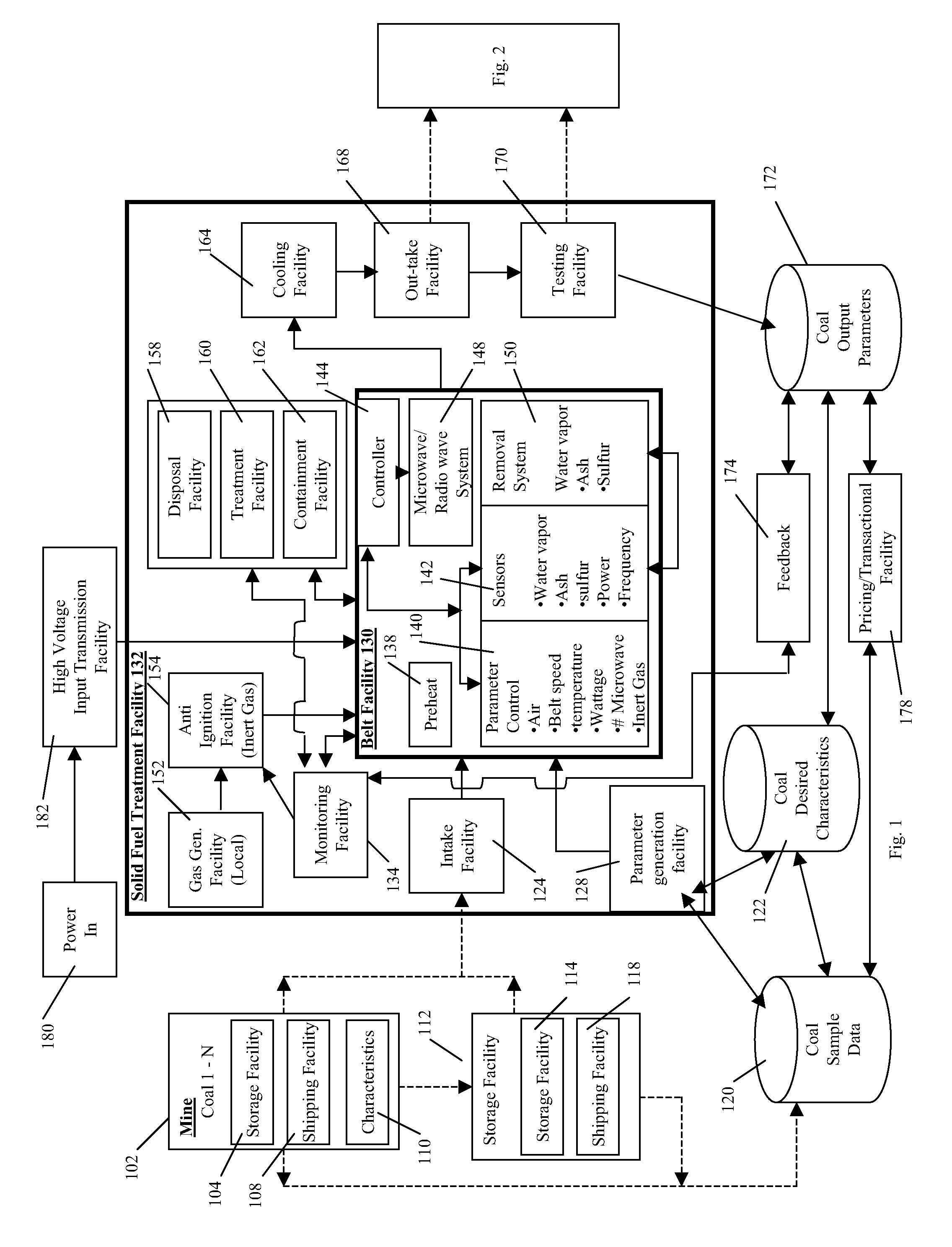

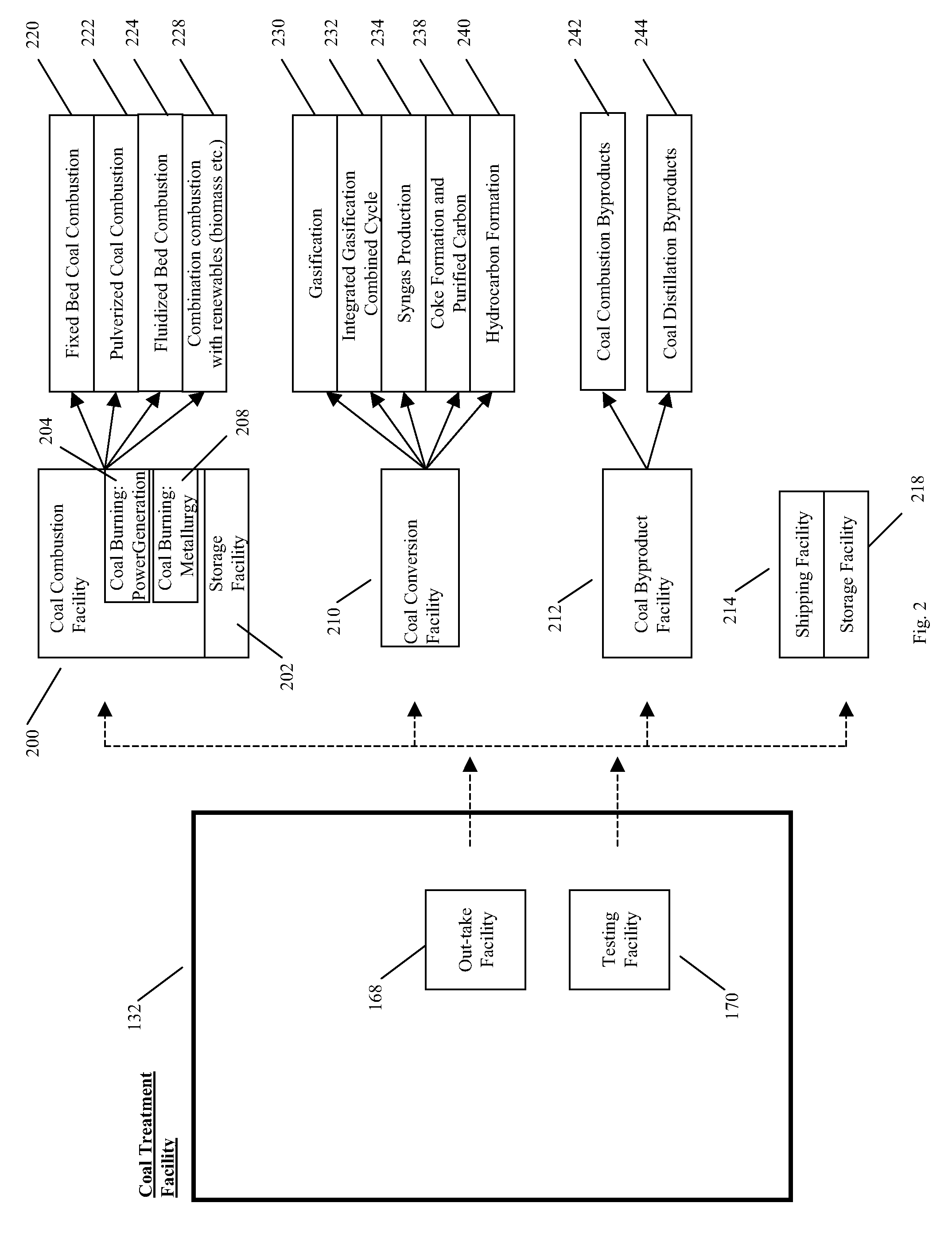

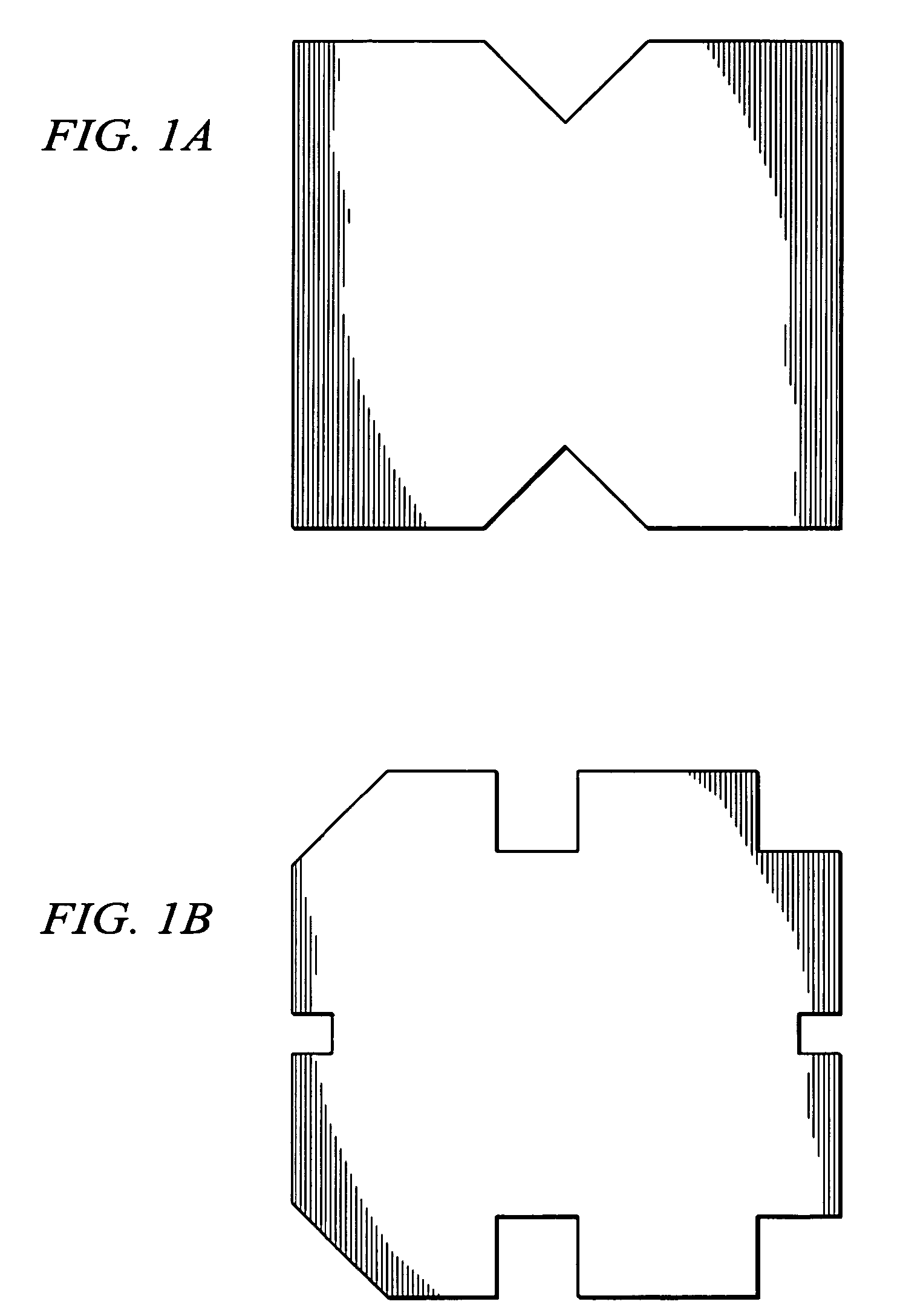

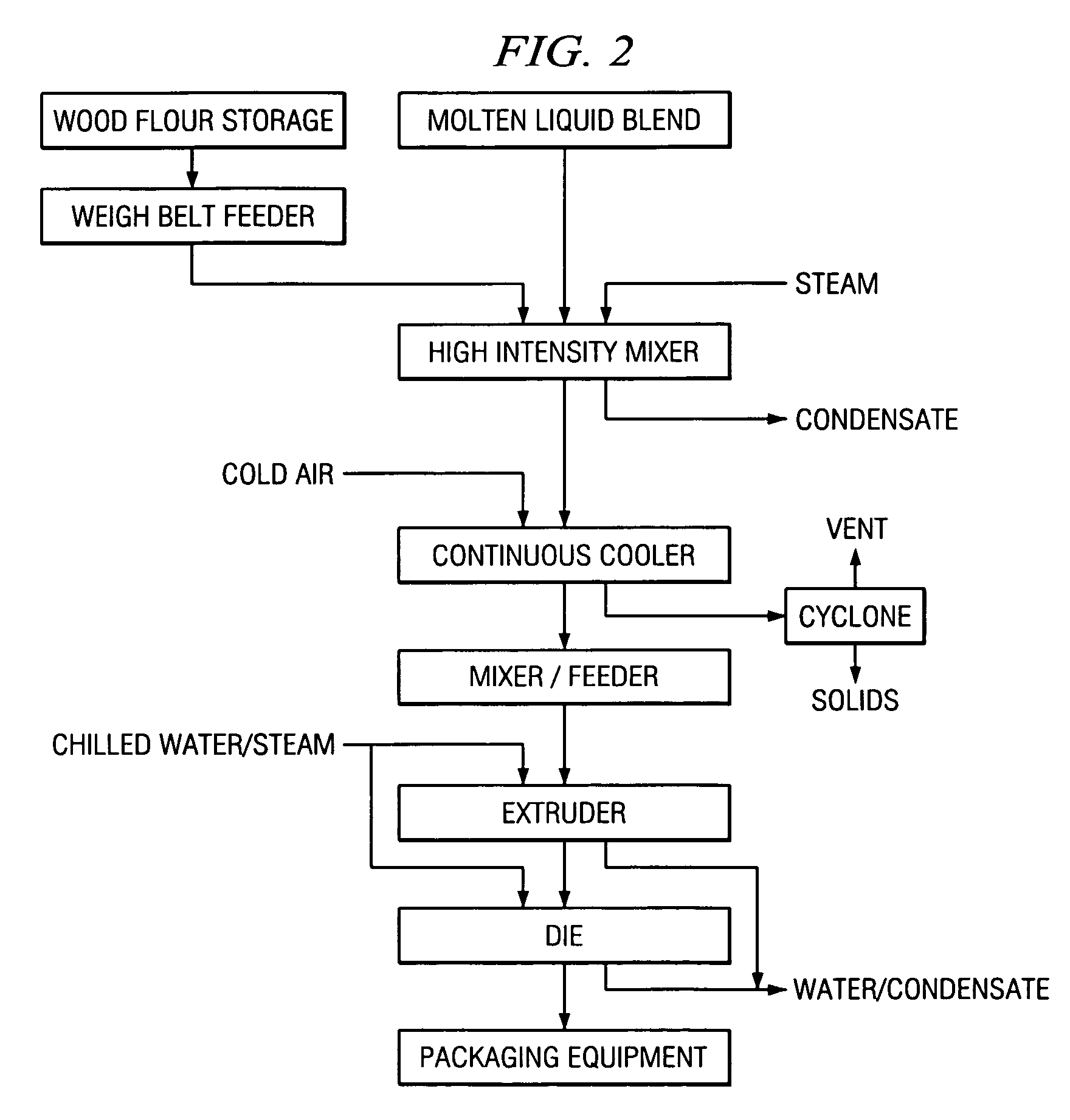

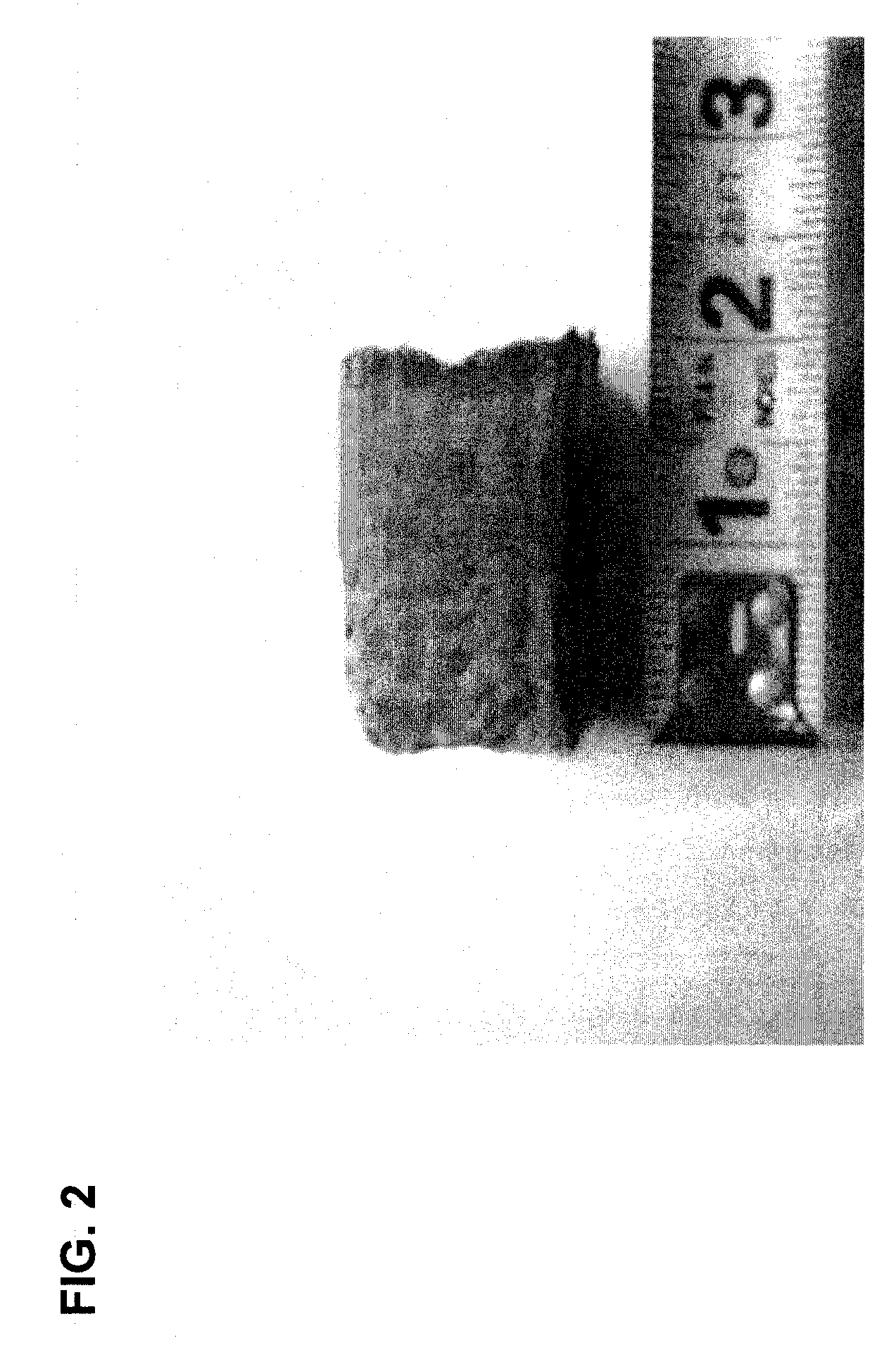

Methods and systems for briquetting solid fuel

InactiveUS20090119981A1Low microwave lossIncrease resistanceSolid fuel pretreatmentSolid fuelsAfter treatmentSolid fuel

In embodiments of the present invention improved capabilities are described for a system and method for briquetting solid fuel before or after treatment with electromagnetic energy. In the system and method, solid fuel is transported through a continuous feed solid fuel treatment facility, treated using electromagnetic energy, and briquetted after treatment.

Owner:COALTEK INC

Processed solid burnable fuel composition

A solid burnable fuel composition which contains a major proportion of spent dried coffee grounds is described. The fuel composition includes at least 50% dried spent coffee grounds and a combustible wax which are mixed together and compressed into a suitable shape for combustion. The fuel composition may further include a small amount, 10% or less, of a coking agent useful to control burn rate and to prevent cracking of compressed fuel during combustion. Small amounts of cellulosic material may also be incorporated to improve the structural properties of the composition. Due to its superior heat and flame production, dried spent coffee grounds are an excellent fuel source for processed fuel products such as fire-logs and fuel pellets. The advantage is a hotter, cleaner burn which produces less soot and smoke, releases fewer harmful pollutants and provides a brighter flame over a longer period of time.

Owner:ROYAL OAK ENTERPRISES

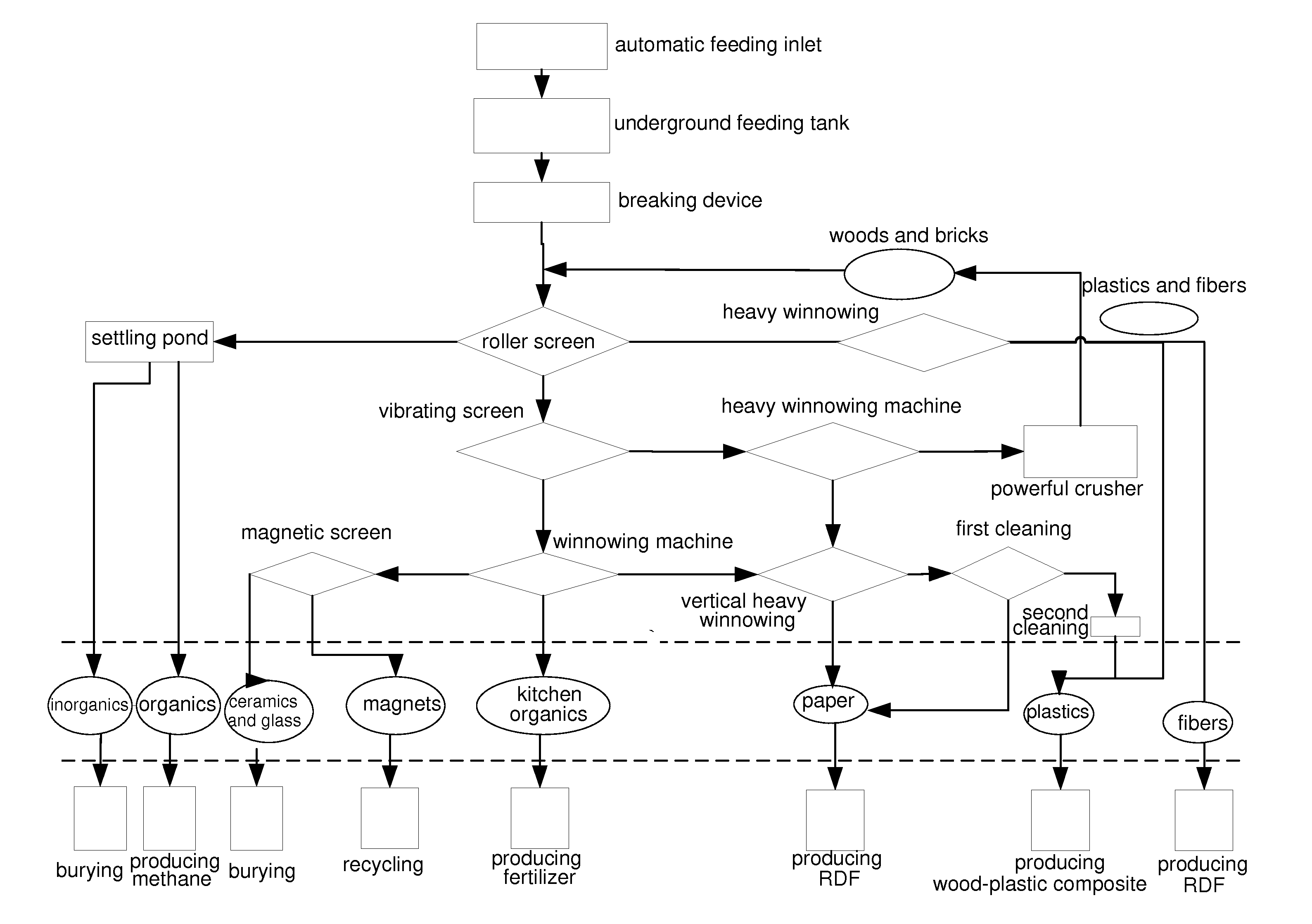

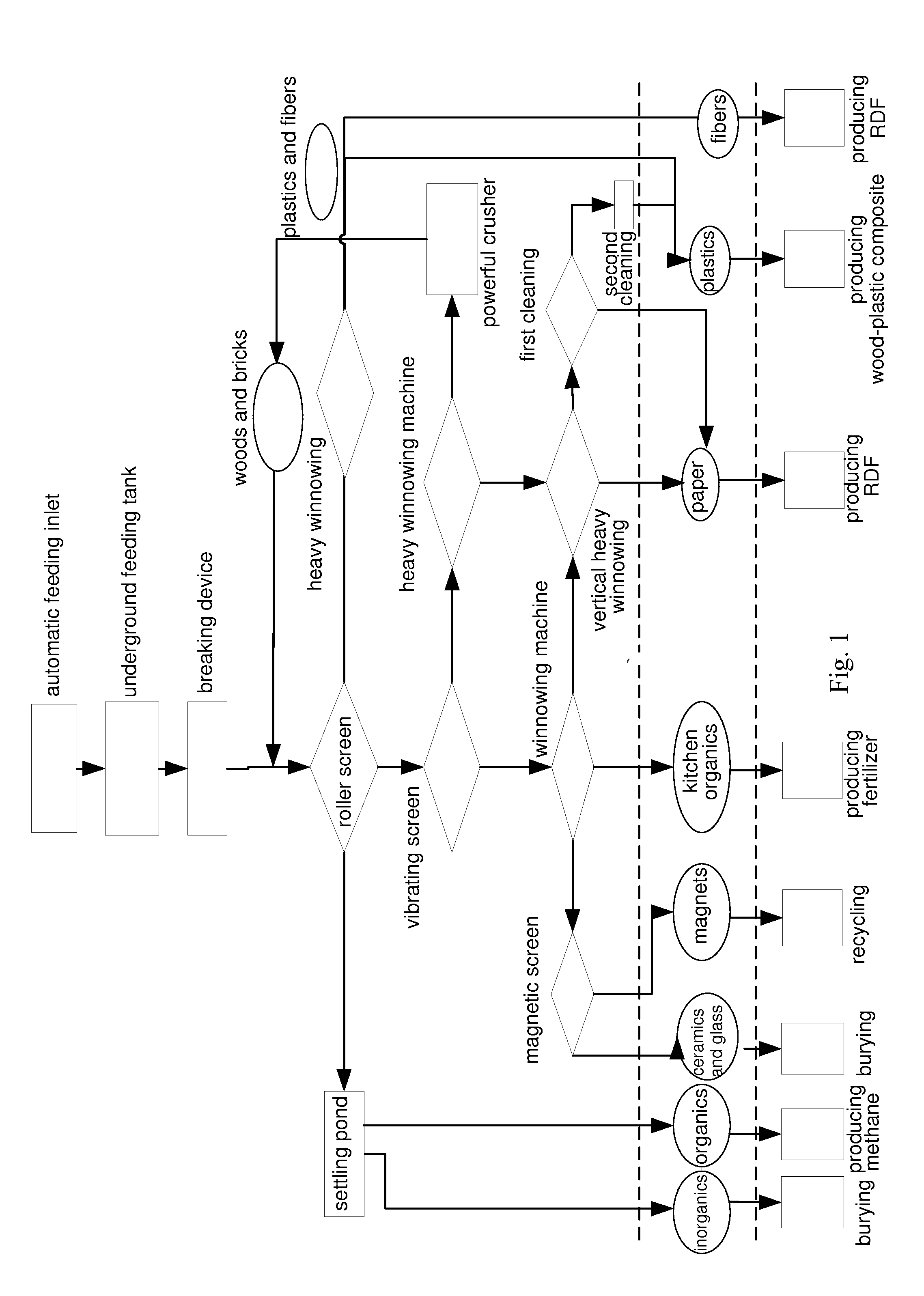

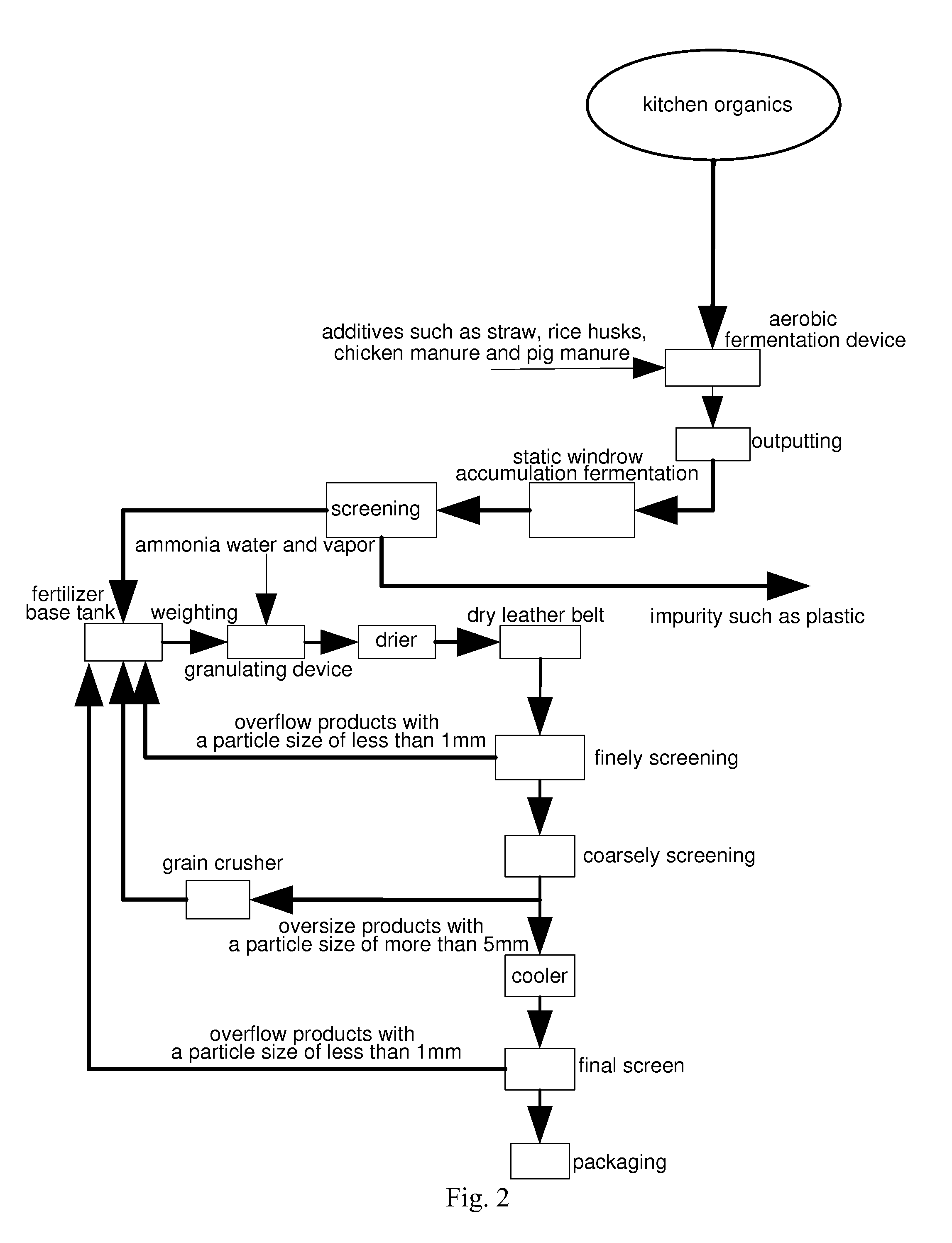

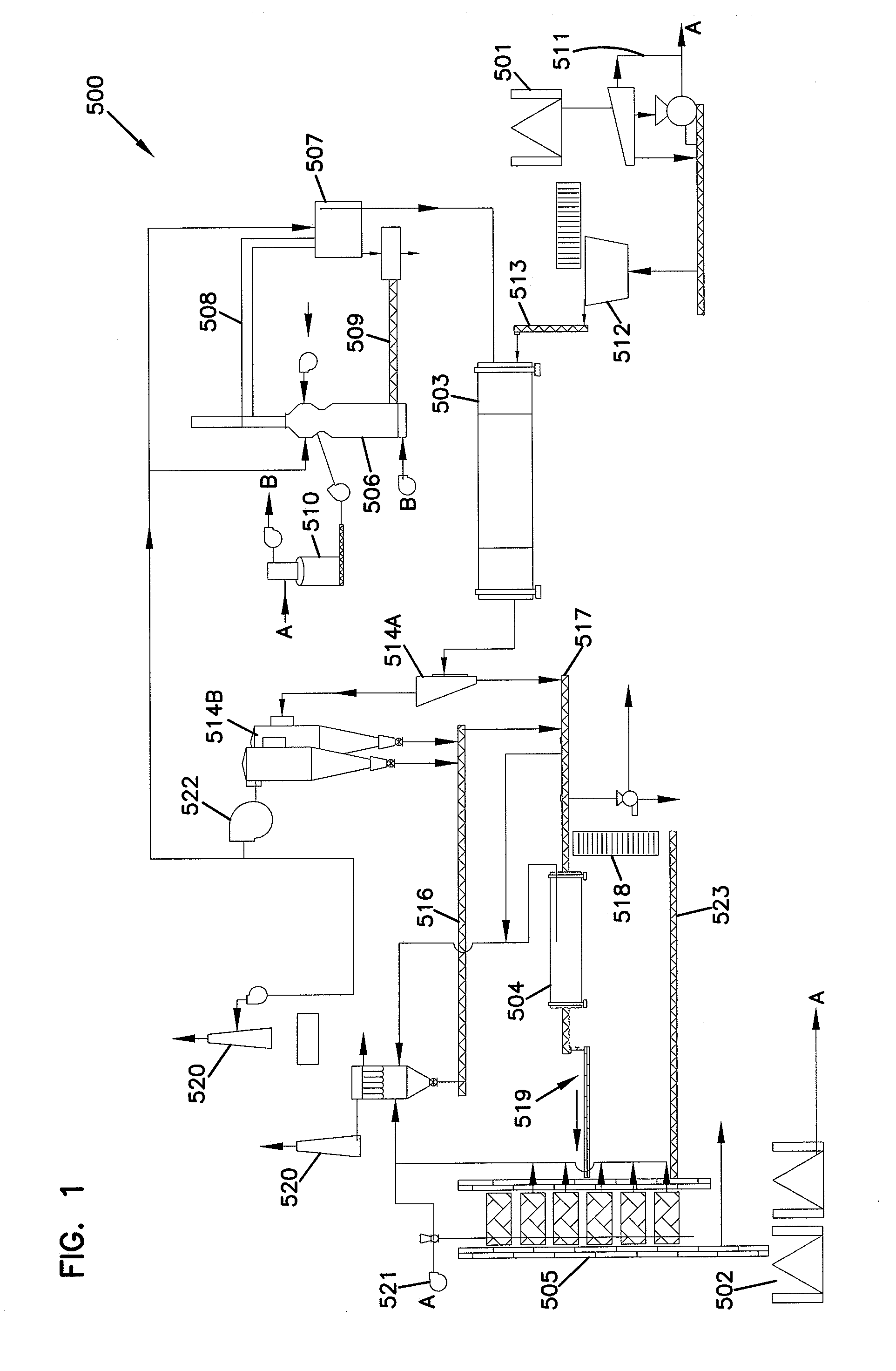

Method for sorting and comprehensively utilizing municipal solid waste

InactiveUS20150135785A1Maximize resource utilizationEfficient combinationBio-organic fraction processingSolid waste disposalRefuse-derived fuelFiber

A method for sorting and comprehensively utilizing municipal solid waste includes steps of: 1) feeding the municipal solid waste into a feeding tank through a feeding inlet, then outputting into a breaking device; 2) breaking refuse bags and large blocks by the breaking device; 3) transporting broken refuse into a two-stage roller screen for screening out dusts with a particle size of less than 3 mm, and hanging strips; and 4) transporting mixed refuse screened by the two-stage screen into a vibrating screen; screening oversize products by a heavy winnowing machine for separating inorganic blocks, large plastics and paper; transporting underflow products into a two-room multi-functional winnowing machine for dividing into heavy materials, light materials and medium materials. By effectively combining sorting devices, effective sorting and reutilization of mixed refuse are achieved. Thereafter, paper, fibers, plastics and kitchen organic refuse are respectively for producing refuse derived fuel, wood-plastic composite and fertilizer.

Owner:XI AN JIAOTONG UNIV

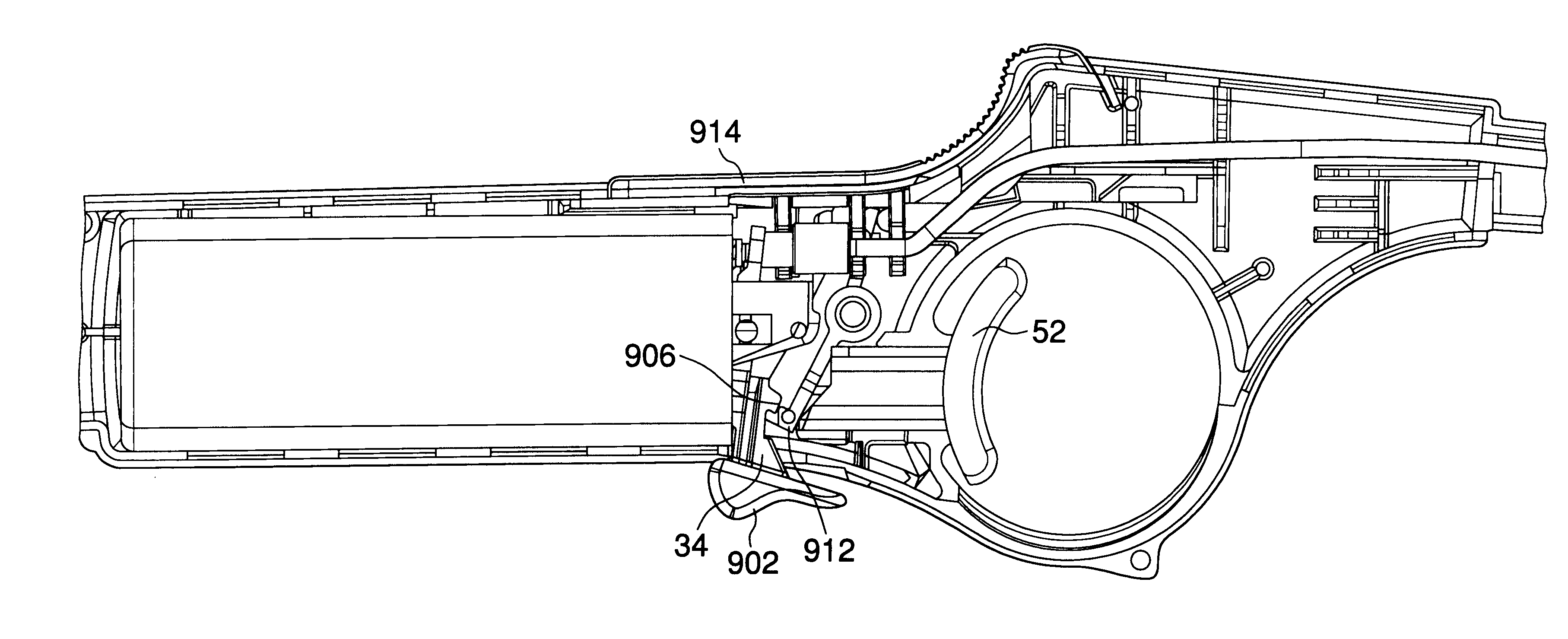

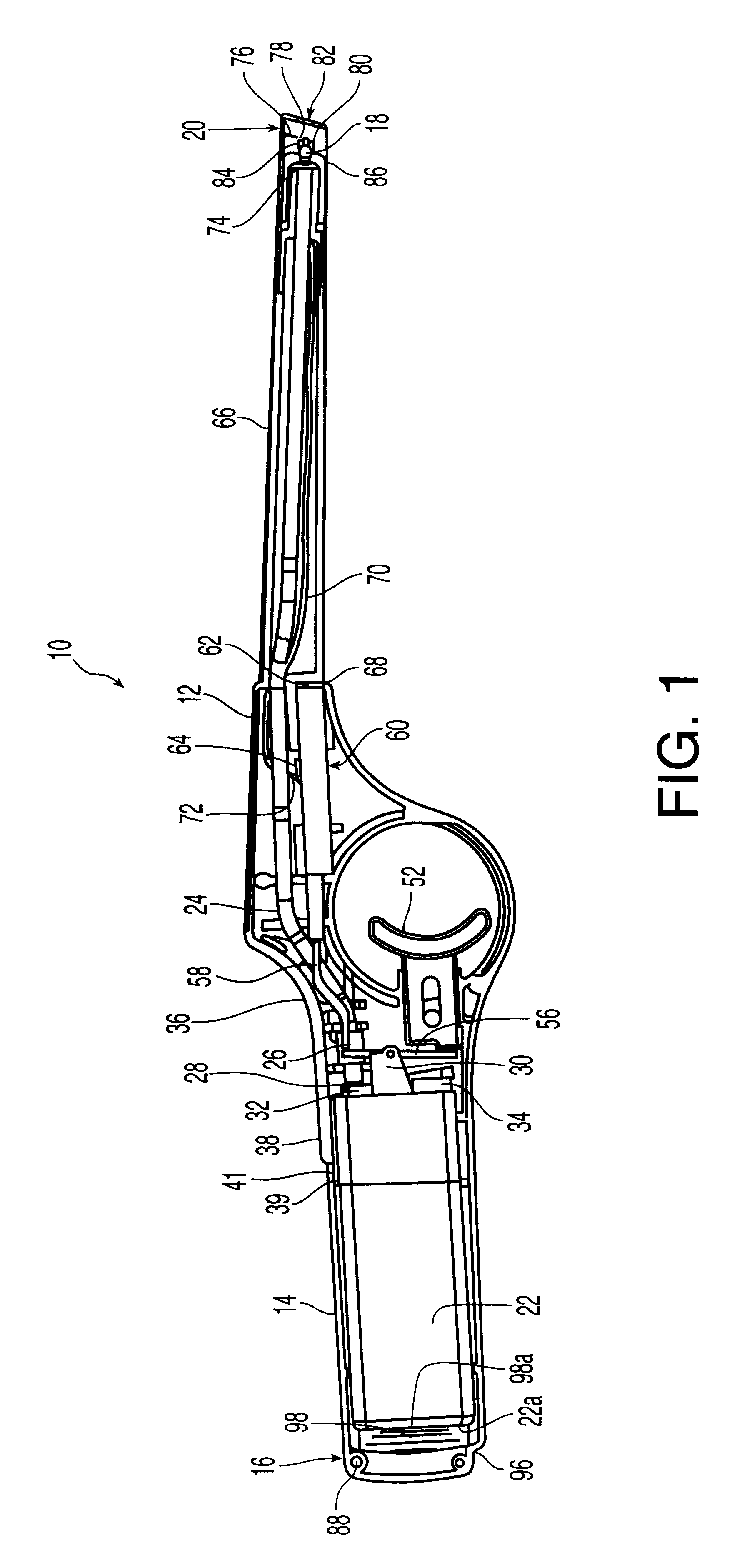

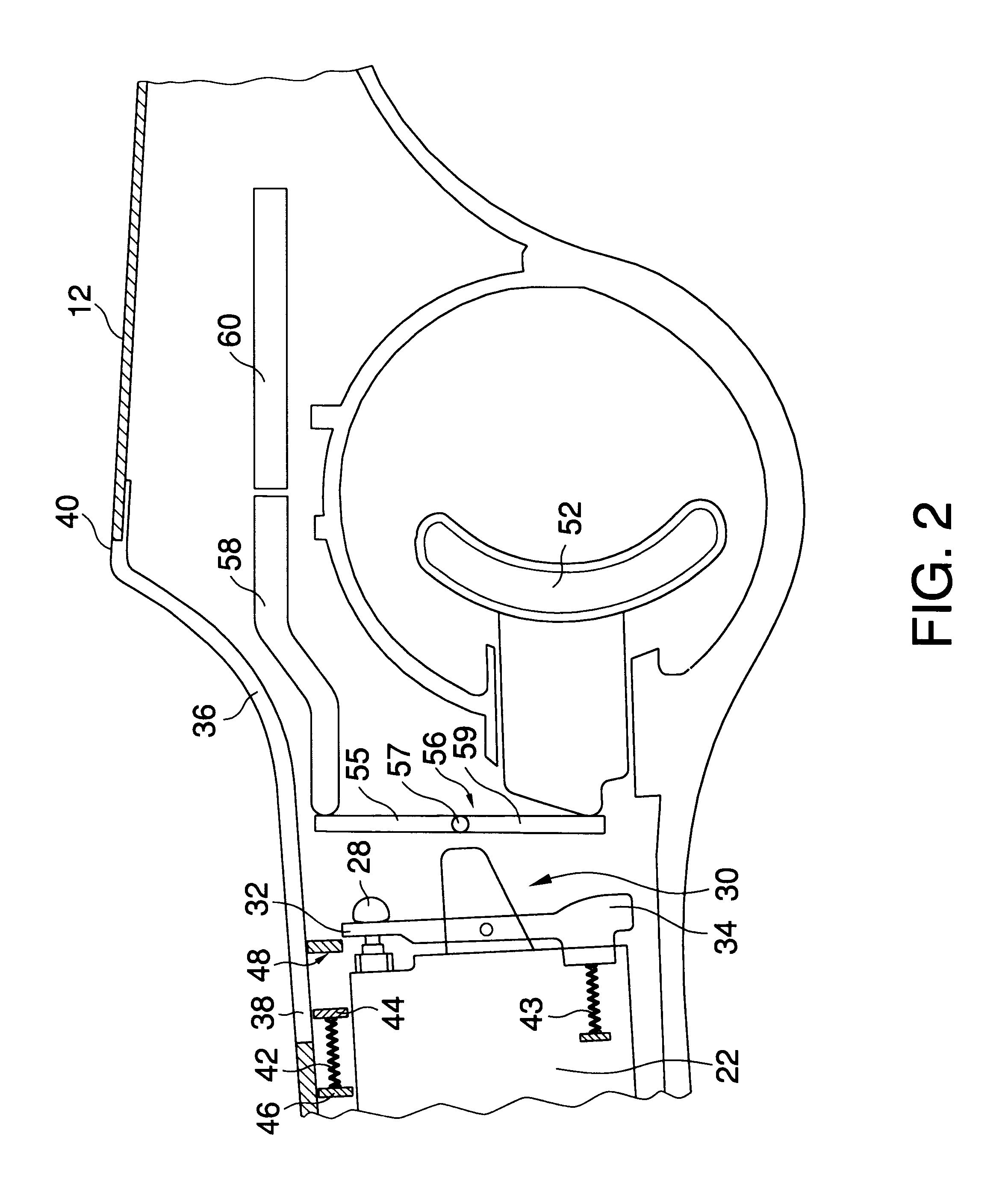

Utility lighter

The present invention relates to a lighter including a housing having a handle at one end and a nozzle at another end and including a fuel supply connected for selective fluid communication with the nozzle. A release member is cooperatively connected to the housing to initiate the flow of fuel from the fuel supply to the nozzle. An ignitor, such as a piezoelectric mechanism, is provided for generating a spark proximate the nozzle. A trigger spaced from the release member is operatively connected to the housing for actuating the ignitor for the generation of a spark igniting the fuel present at the nozzle.

Owner:SOC DITE SOC BIC

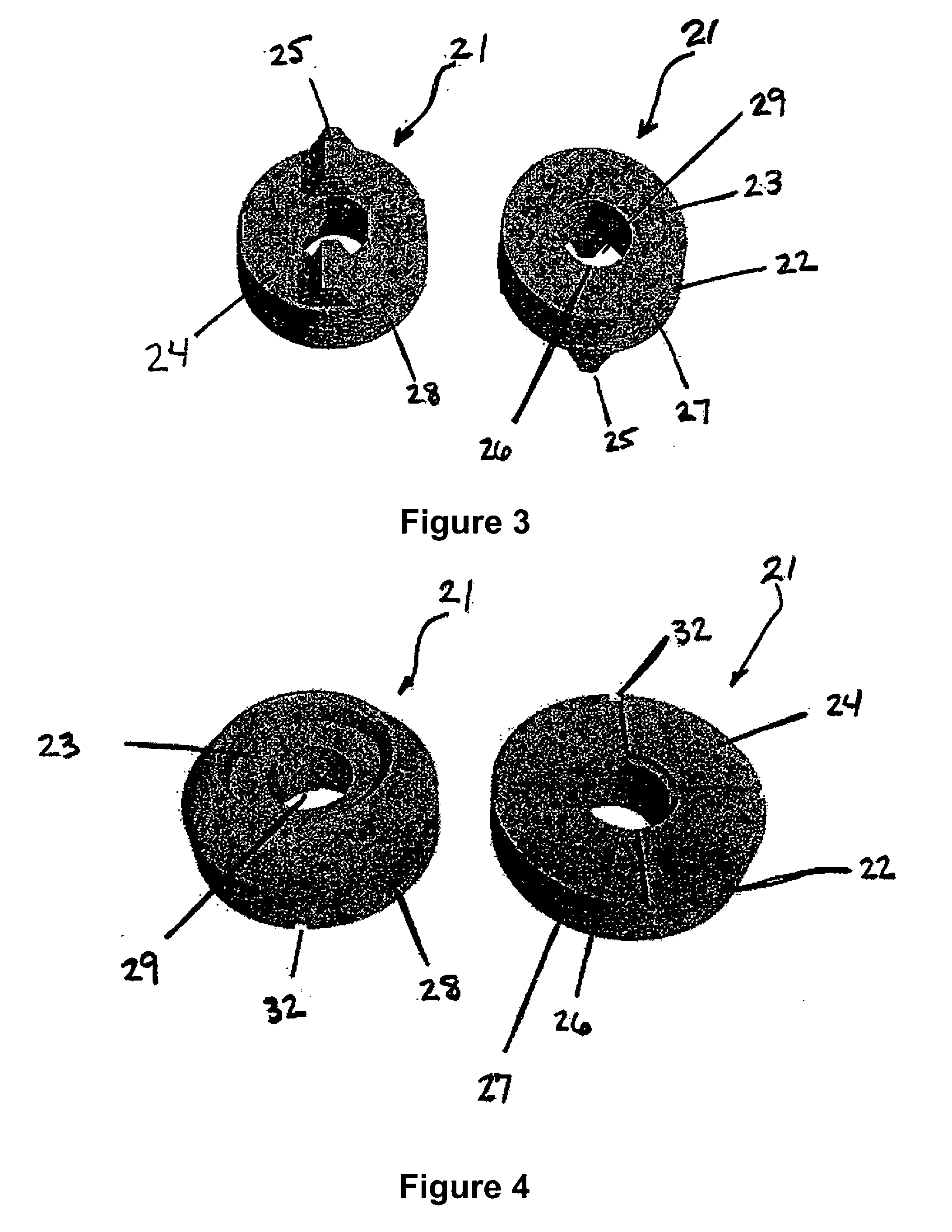

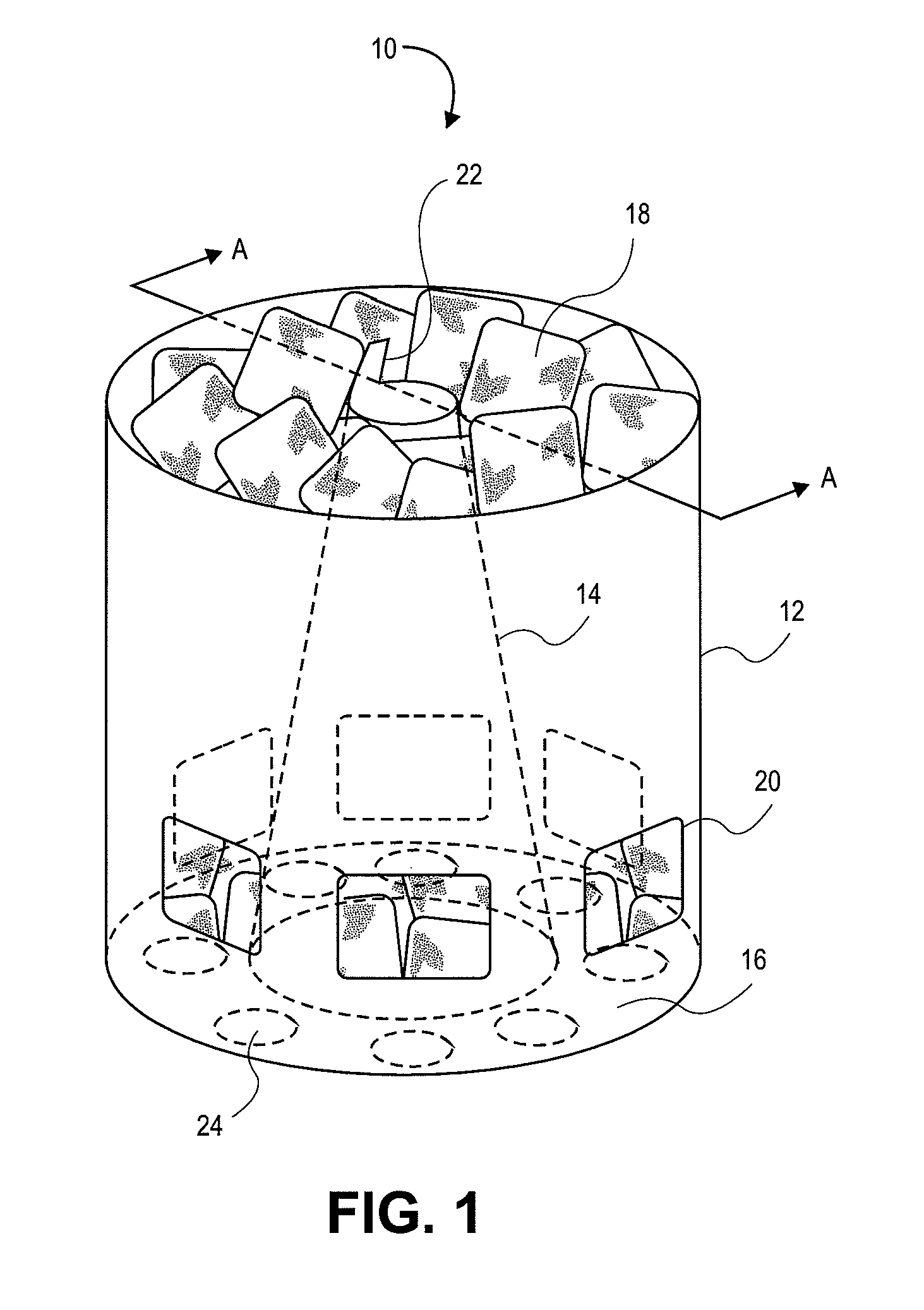

Combustible package for charcoal briquettes and a fire starter

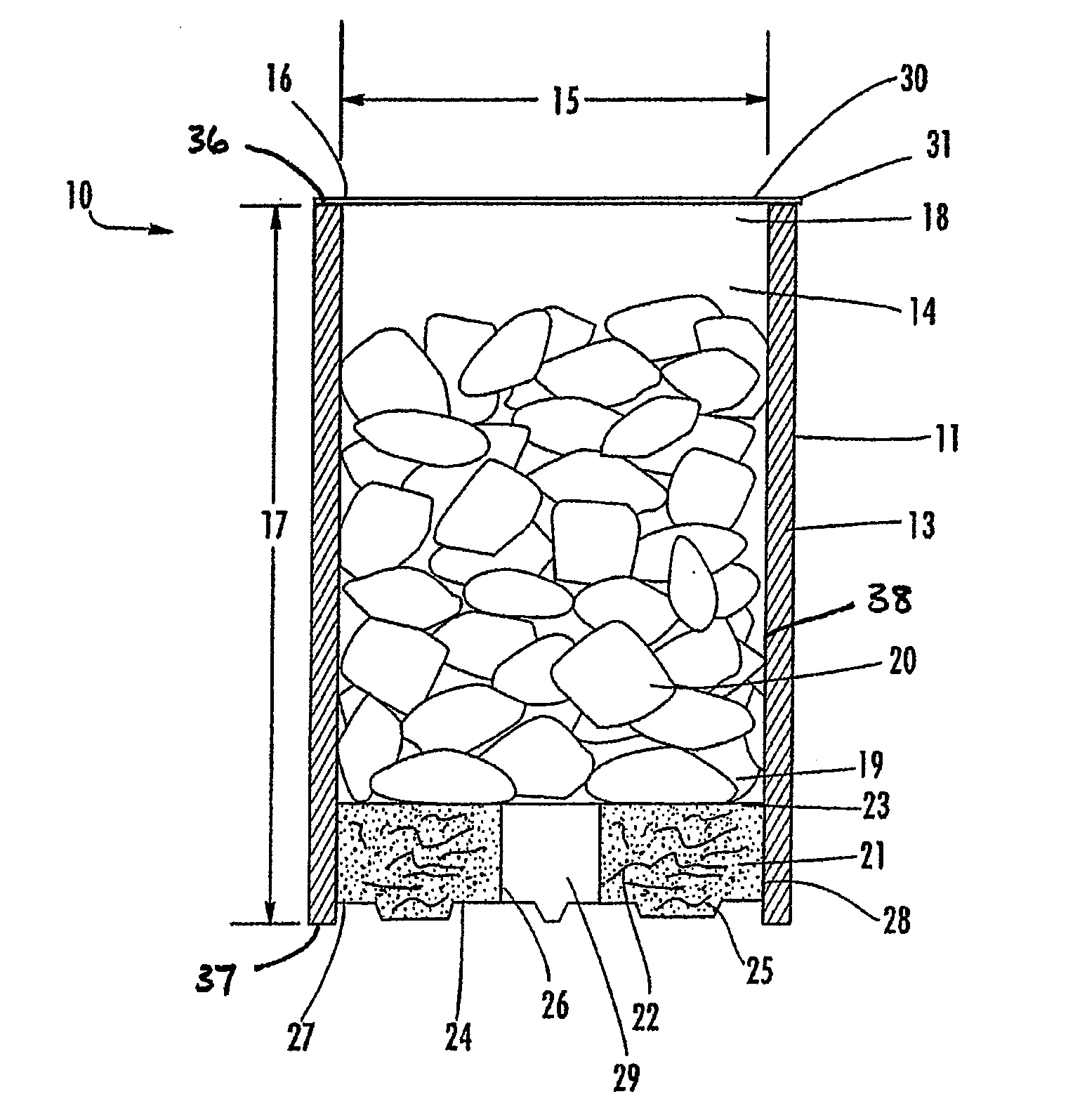

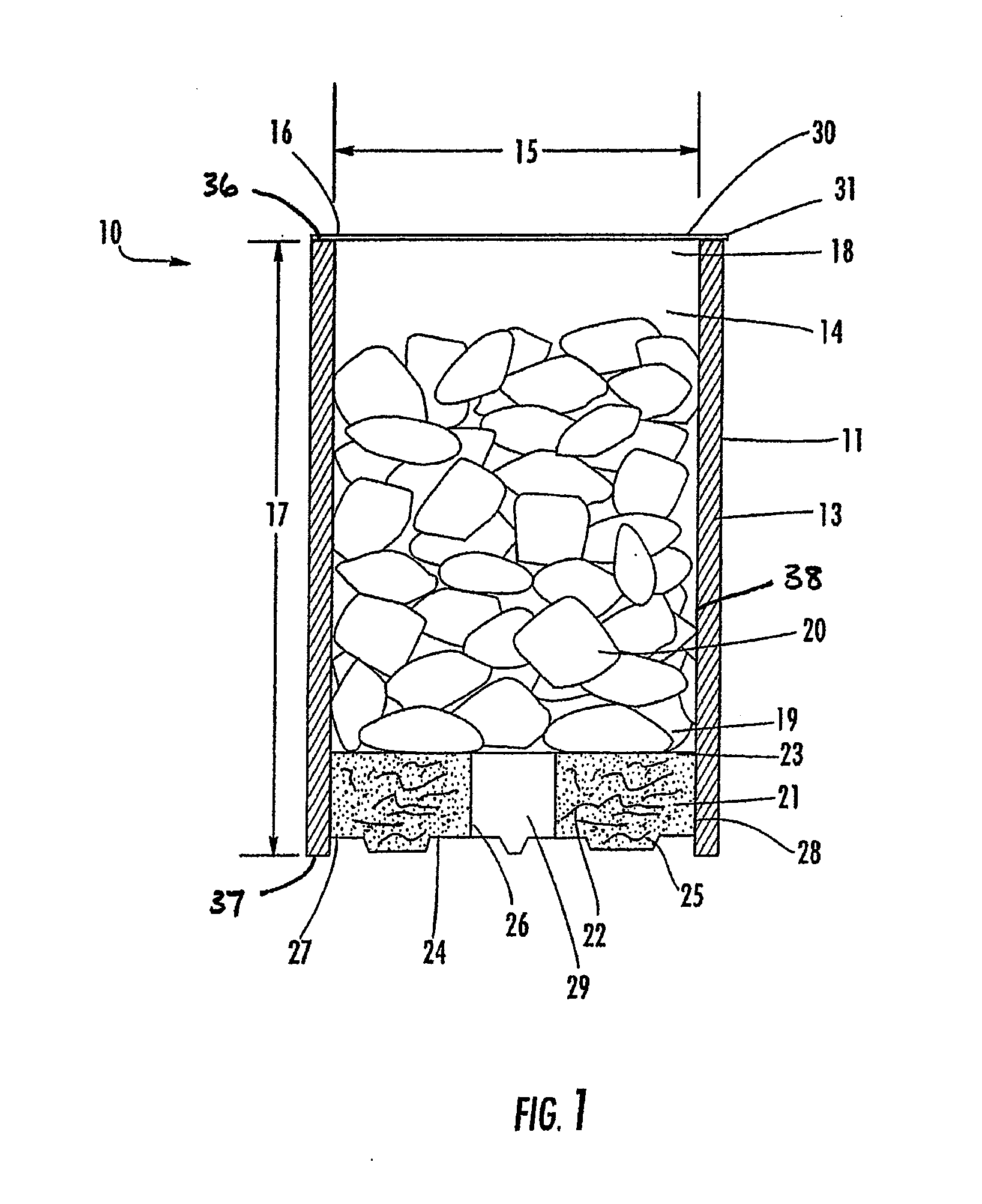

InactiveUS20060156621A1Low production costSimple processSolid fuelsFirelightersInterior spaceEngineering

A package made from all combustible materials for containing a fuel source, such as charcoal briquettes, and a fire starter. The package includes a wound paper tube with an interior space where the charcoal briquettes are stored along with the fire starter. The top of the interior space is closed off by a top lid made from combustible material. The fire starter is located underneath the charcoal briquettes at the lower end of the interior space. The fire starter may also function as bottom lid or a separate bottom lid may be employed.

Owner:SONOCO DEV INC

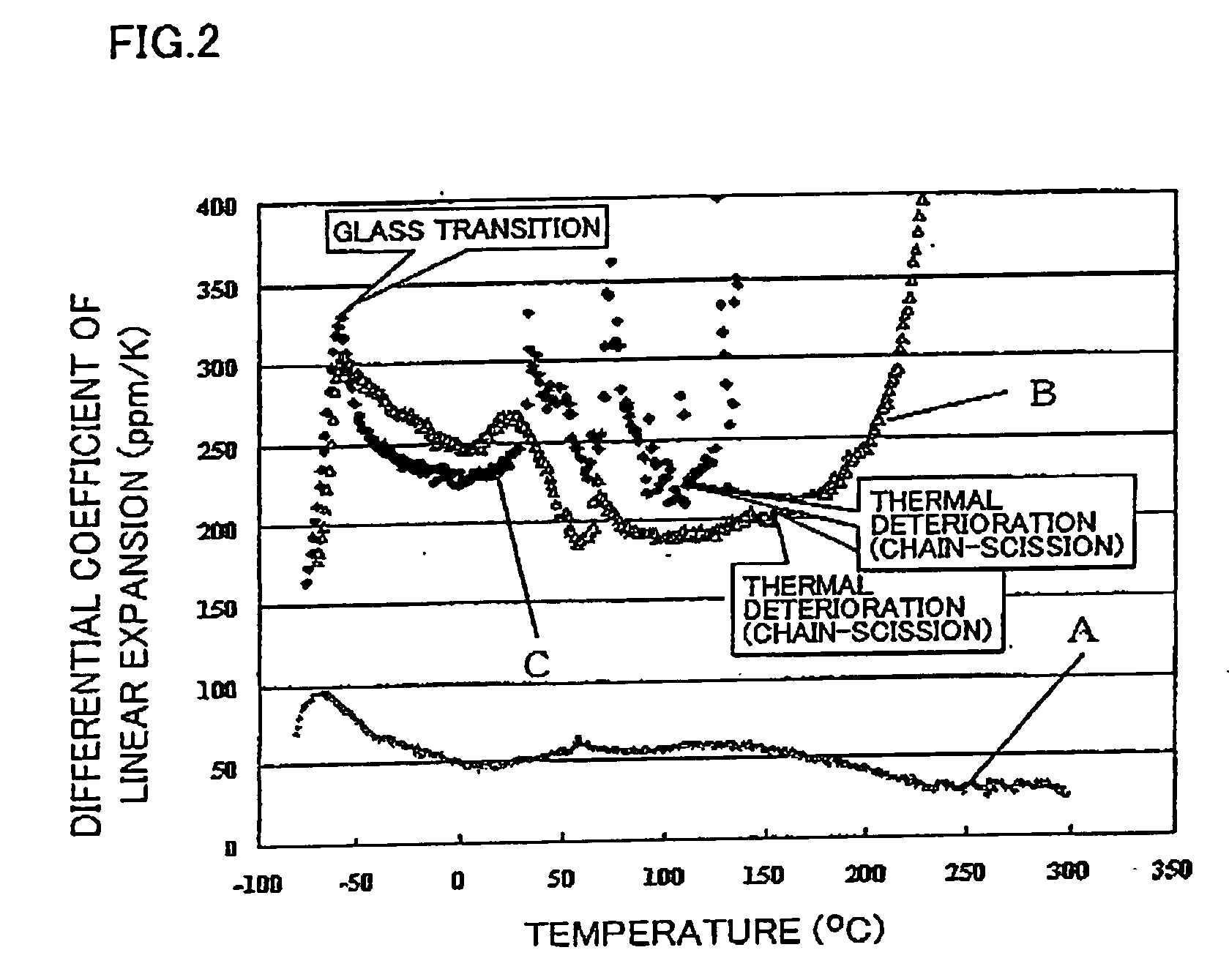

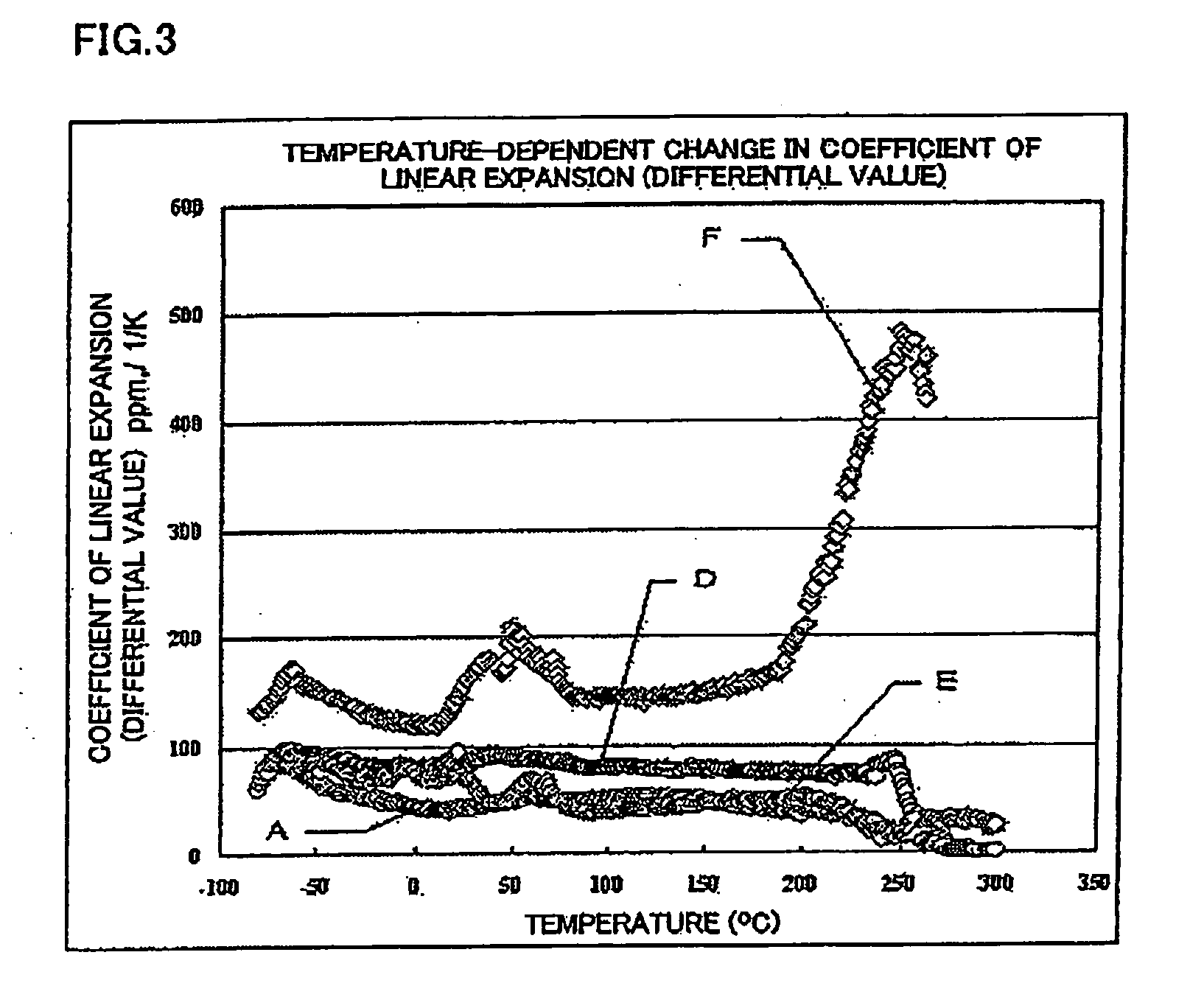

Carbon fiber composite material

Owner:NISSIN KOGYO CO LTD

Agricultural fibre fuel pellets

A method of preparing fuel pellets includes the steps of providing a feedstock in the form of agricultural hull fibres having a moisture content of about 10 to about 16%; and compressing and extruding the agricultural fibre feedstock through a die to obtain fuel pellets in the form of small cylinders having a diameter of about ⅜ inch to ¾ inch or more, said pellets having an ash content of about 1.1% to about 20% by weight and a calorific value of about 7,000 BTUs per pound of fuel on a dry basis. The agricultural hull fibres may be derived from all whole grains and seeds. For example, are comprised of at least one of corn bran fibre, rye bran fibre; oat bran fibre, rice bran fibre, soy bran fibre, canola bran fibre and wheat bran fibre. The method may include the step of pre-treating the agricultural whole grain and seed hull fibre feedstock with high temperature steam before being formed into pellets at a sufficient temperature and sufficient time to activate hemicellulose within the fibre as a binding agent. The method may include the step of mixing the agricultural whole grain and seed hull fibre feedstock with a sequestering agent before being formed into pellets for sequestering alkali metal vapors and raising the fusion point of the inorganic elements during combustion of the pellets. The sequestering agent may be calcium carbonate added in amounts up to about 0.5% by weight. The pellets contain additives comprised of ammonium nitrate, calcium, manganese, magnesium, aluminum, barium, iron, potassium and amorphous silicate, which sequester potassium and chlorides and alter the fusion point of the inorganic elements present in the fuel.

Owner:EVERGREEN BIOFUELS

Pyrolysis oil and other combustible compositions from microbial biomass

InactiveUS20120266530A1Raw materials are simpleBiofuelsWaste based fuelMicrobiologyComponents of crude oil

Owner:CORBION BIOTECH INC

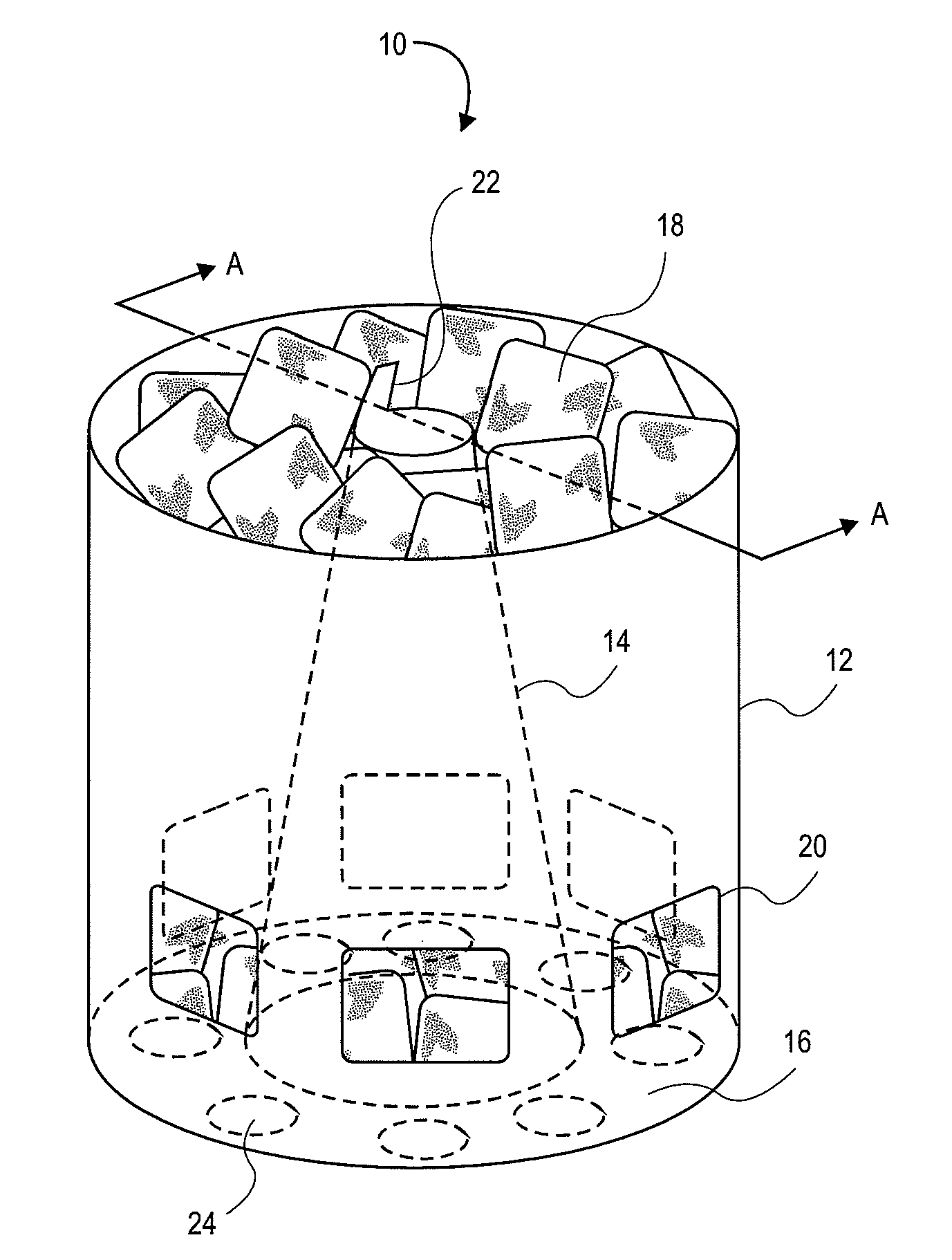

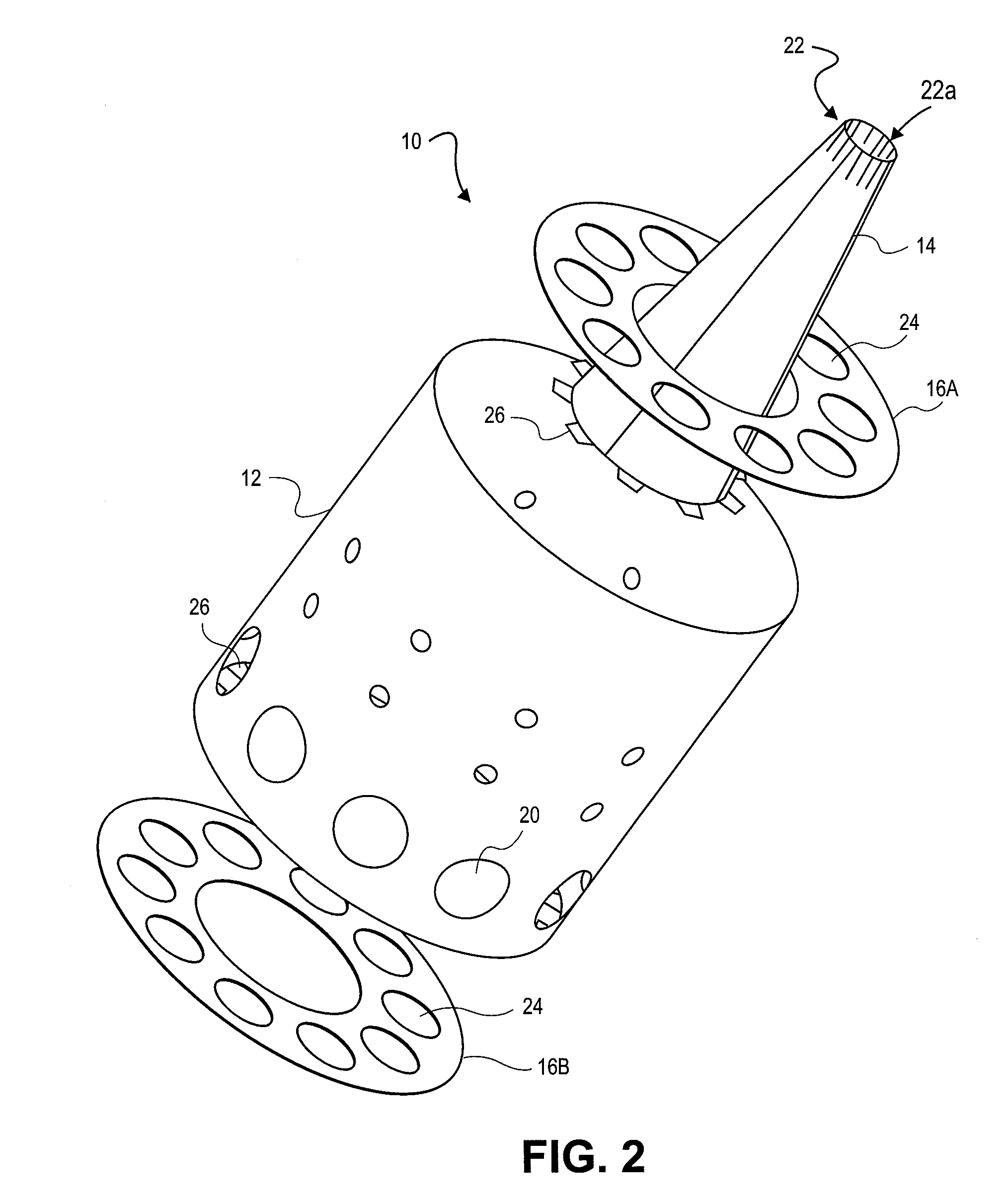

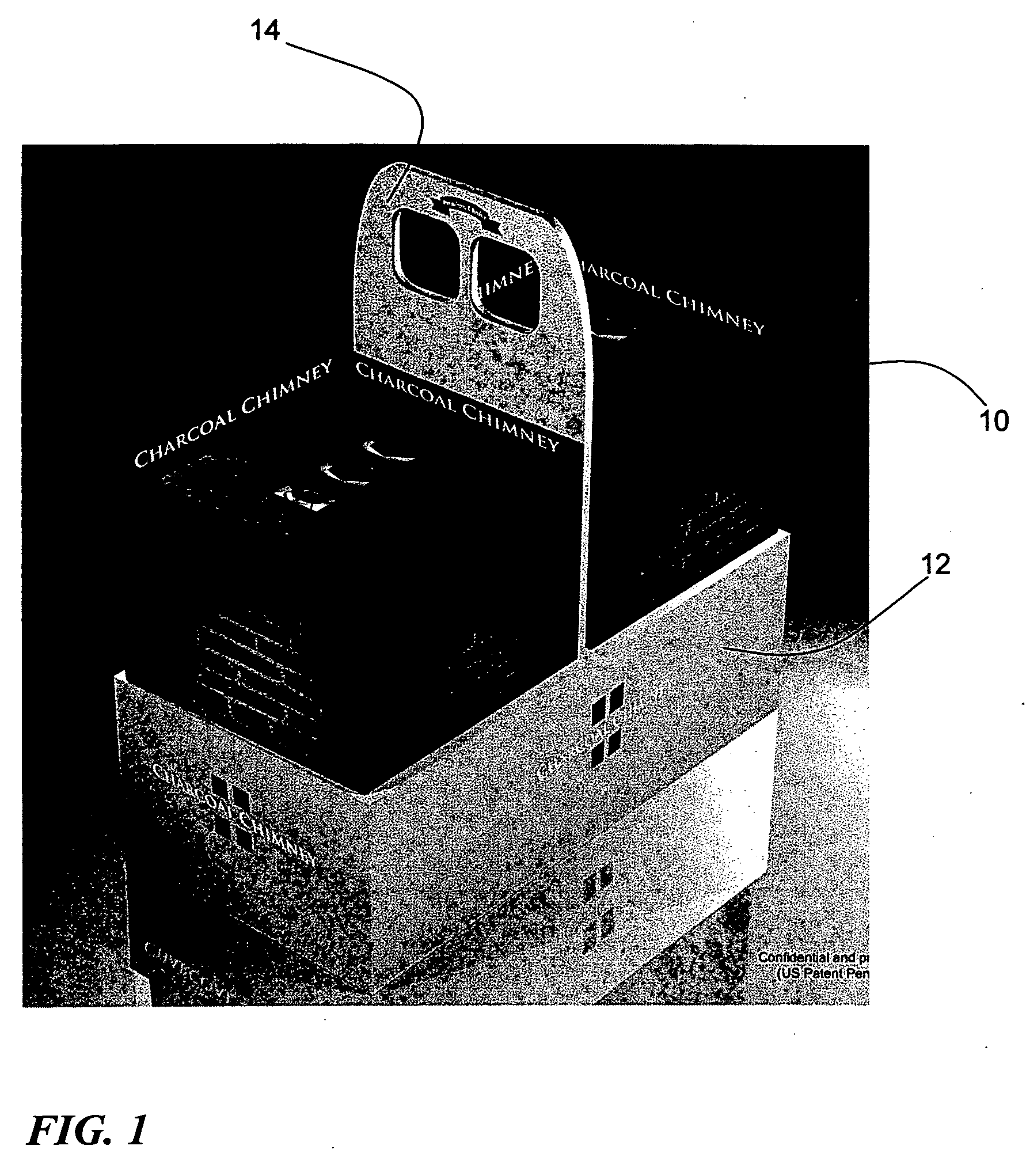

Charcoal Starting Device and Method

InactiveUS20090277438A1Easy to optimizeDomestic stoves or rangesLighting and heating apparatusEngineeringCharcoal

A charcoal igniting device includes an envelope, a chimney, and a base. The envelope has an envelope height and an envelope width, the envelope height is greater than the envelope width. The envelope sidewall defines a series of holes. The envelope has an upper envelope rim and a lower envelope rim. The chimney is disposed co-axially within the envelope. The chimney has a sidewall impregnated with wax, an upper chimney rim, an ignition element disposed upon the upper chimney rim, and a lower chimney rim. The base defines a series of holes disposed through the base. The base has an outer base perimeter mated to the lower envelope rim and an inner base perimeter mated to the lower chimney rim.

Owner:GREIF PACKAGING

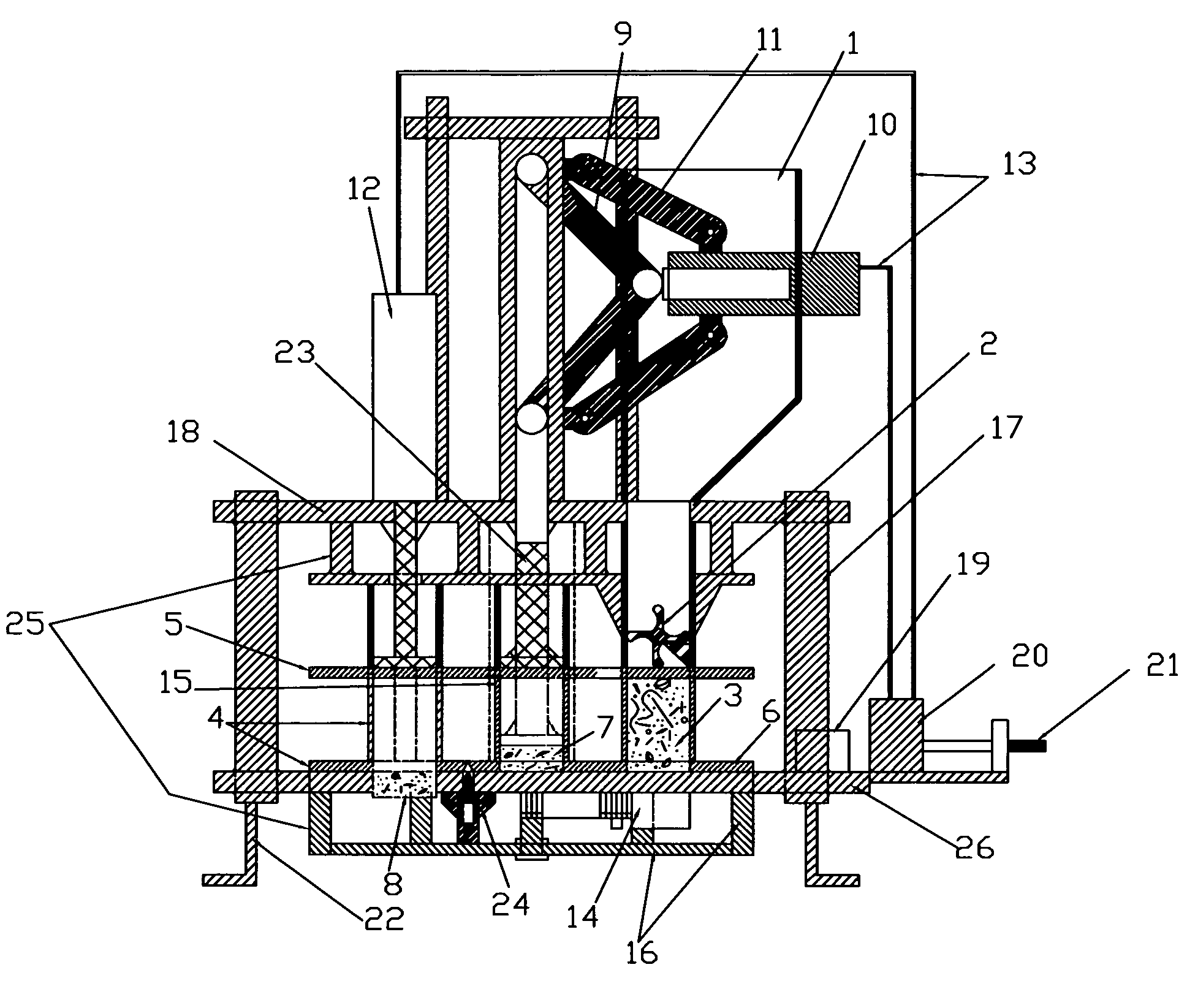

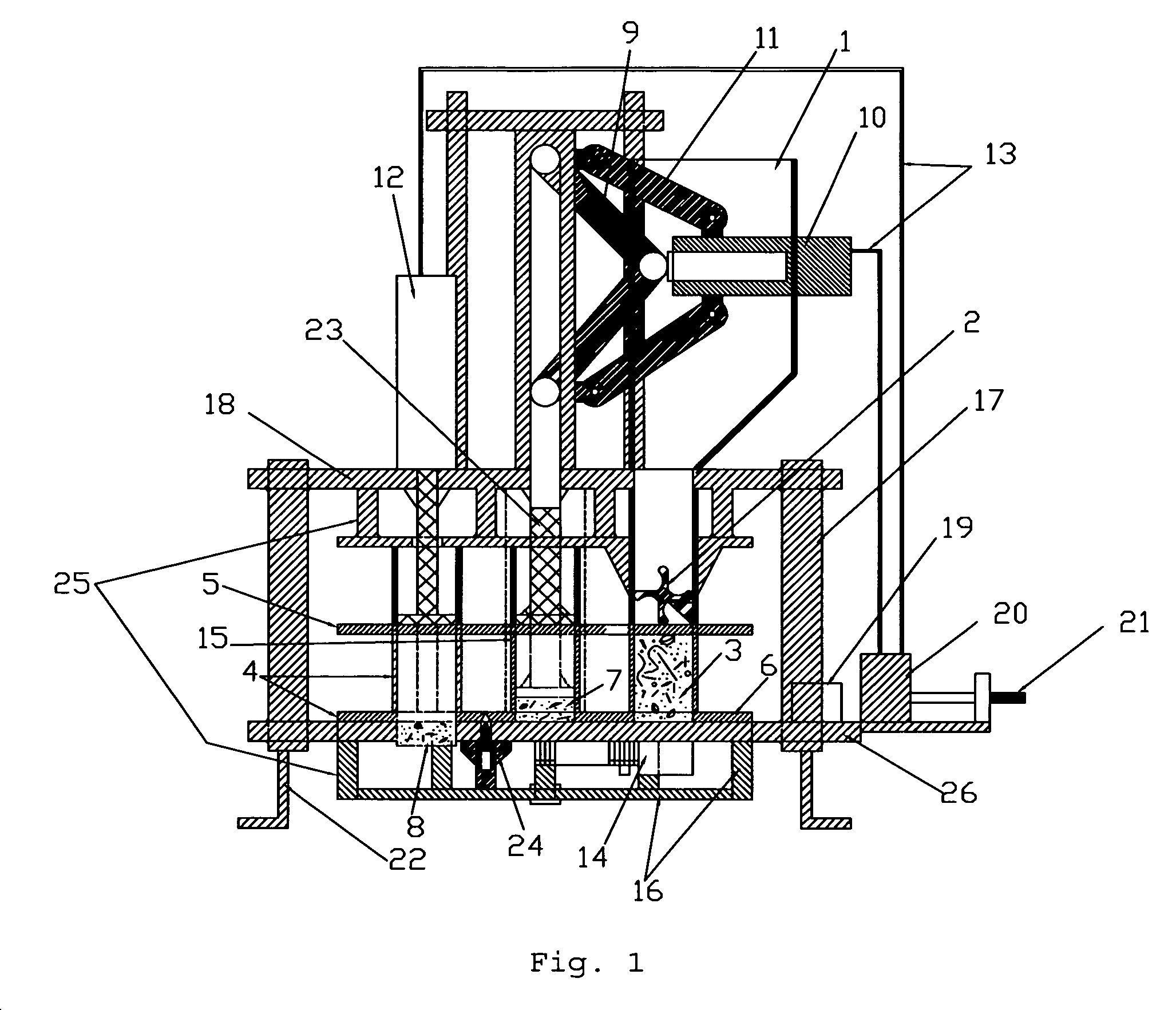

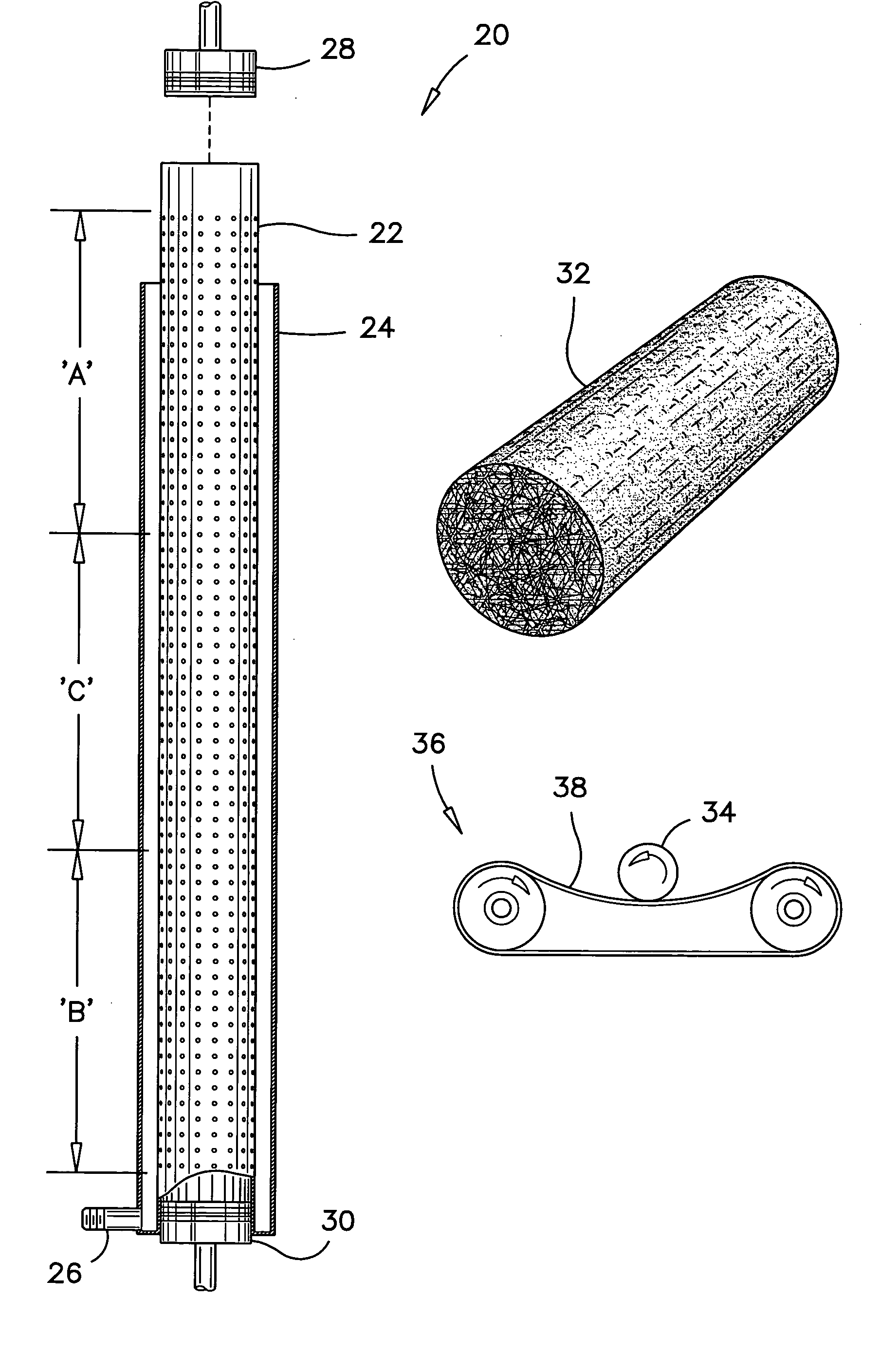

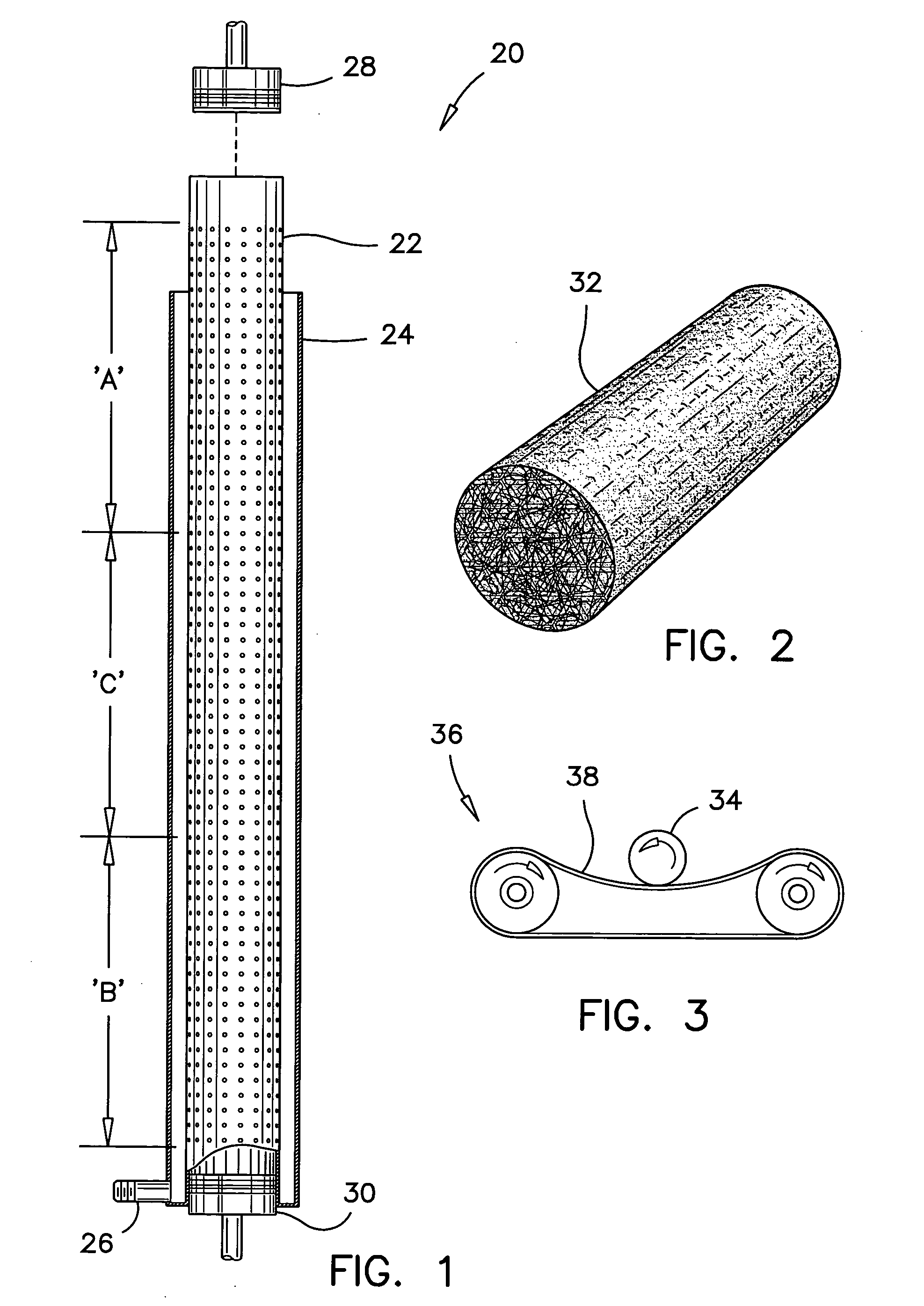

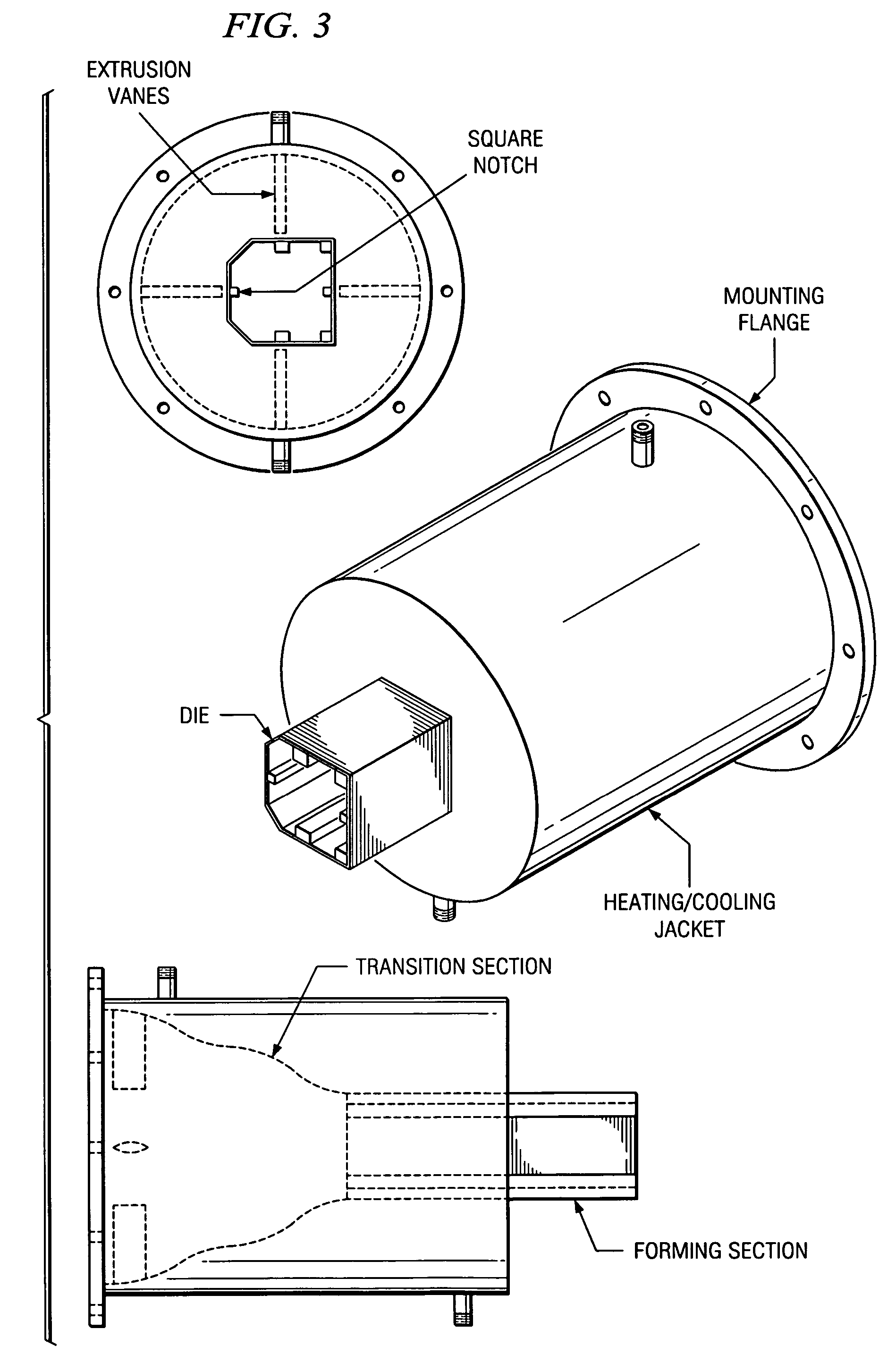

Method and Device to Compact Biomass

InactiveUS20090188160A1Prevent short-circuitingEconomical and practicalBiofuelsSolid fuelsCost effectivenessSolid fuel

The biomass log fuel has not been commercialized due to difficulties in mass-producing the logs at low cost. The current invention solves this problem by introducing a three-step compaction process: pre-compaction, final compaction, and ejection. While a rotary feeder / compressor is used to perform pre-compaction, a ram driven by a toggle mechanism performs final compaction rapidly and efficiently. A press implementing the three-step compaction is designed and described. This invention should improve the cost-effectiveness of biomass solid fuel or feedstock.Biomass materials such as yard waste, corn stover and switchgrass are compacted at high pressure to form dense “biomass logs” without binder or heat. Biomass logs serve as a solid fuel for heating buildings, and as feedstock for bio-reactors for liquefaction or gasification. Densifying the uncompacted fluffy biomass reduces space needed for storage, decreases the number of vehicles needed to transport biomass, and increases the energy density of fuel.

Owner:LIU HENRY +3

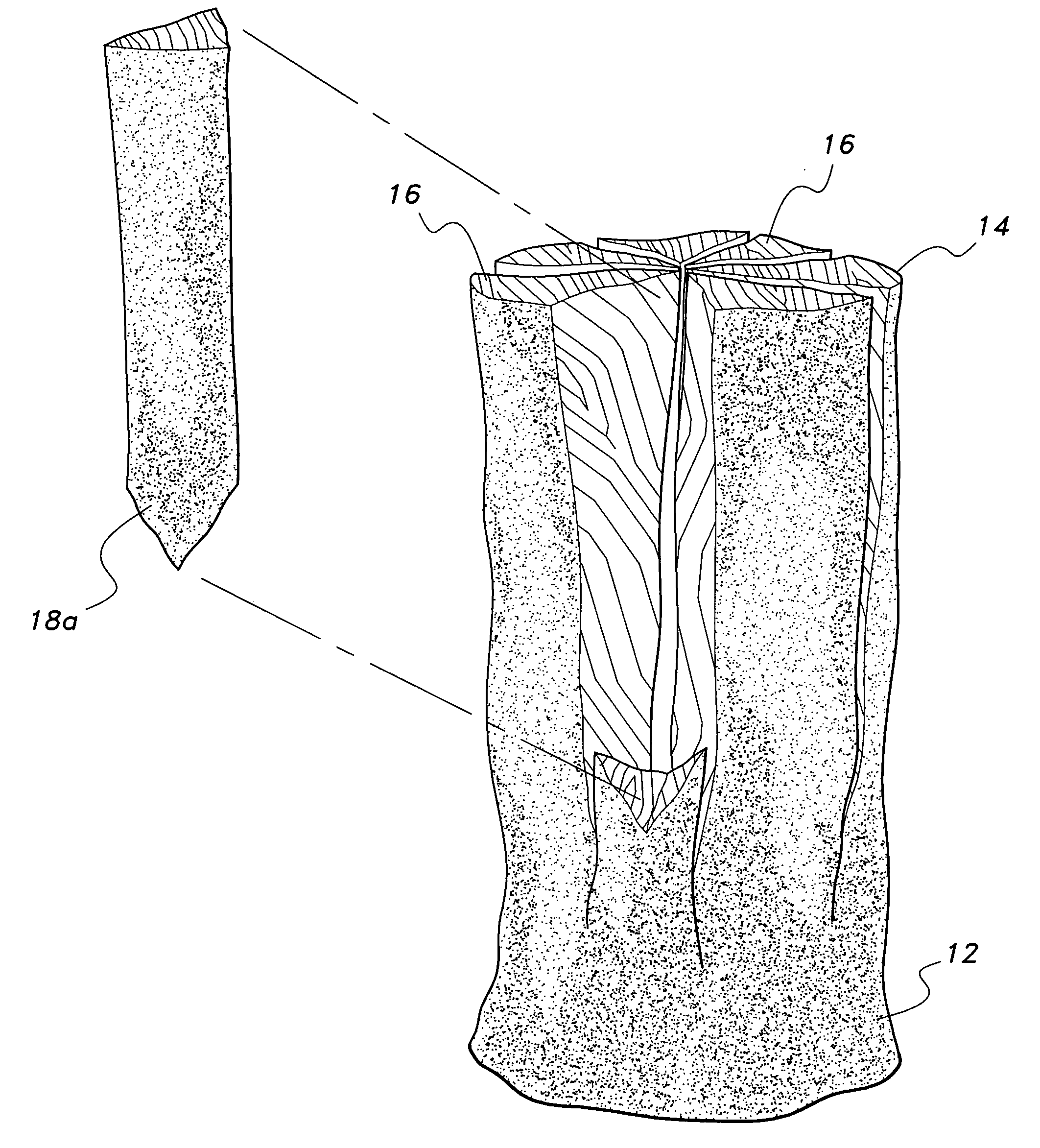

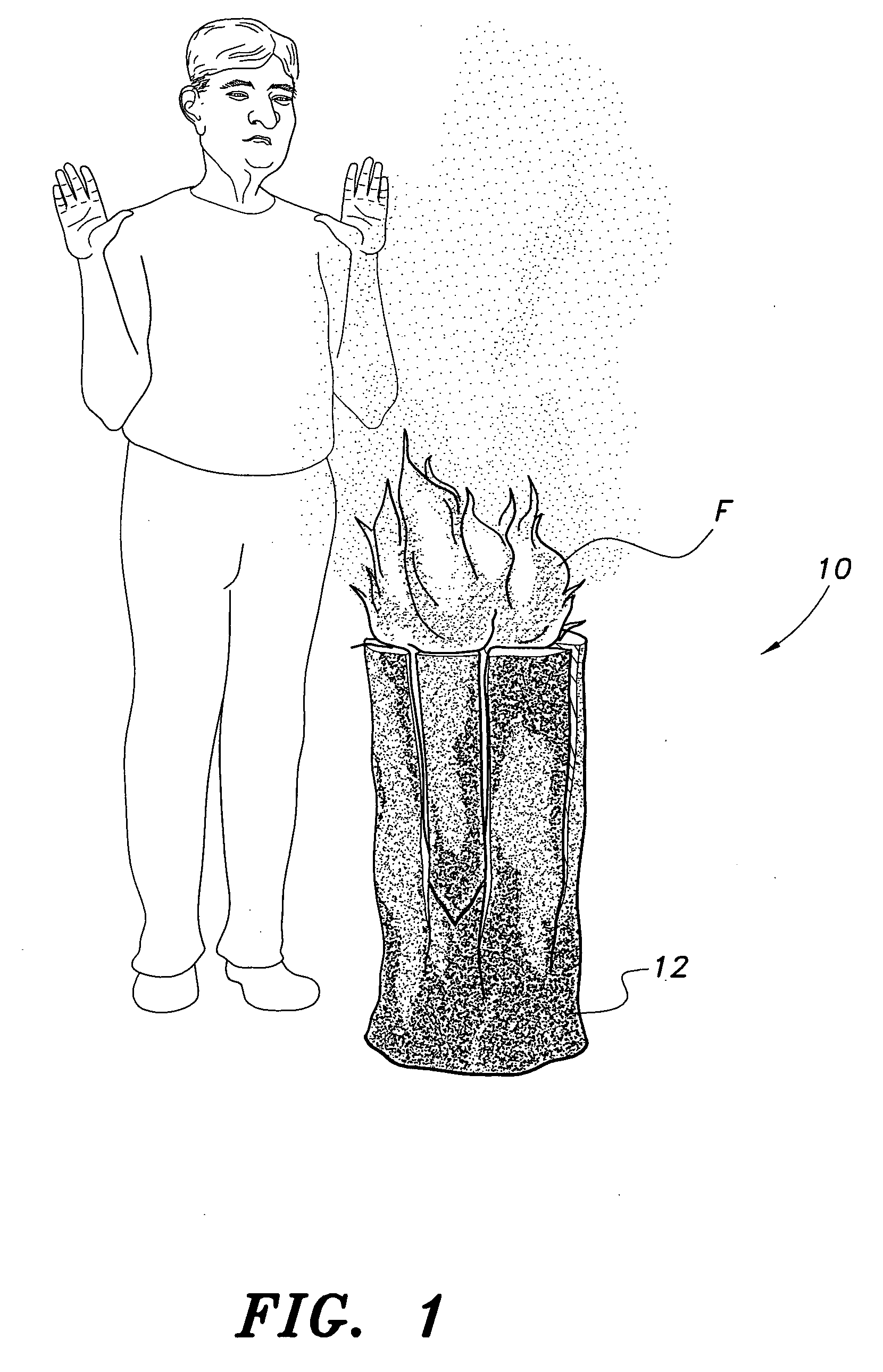

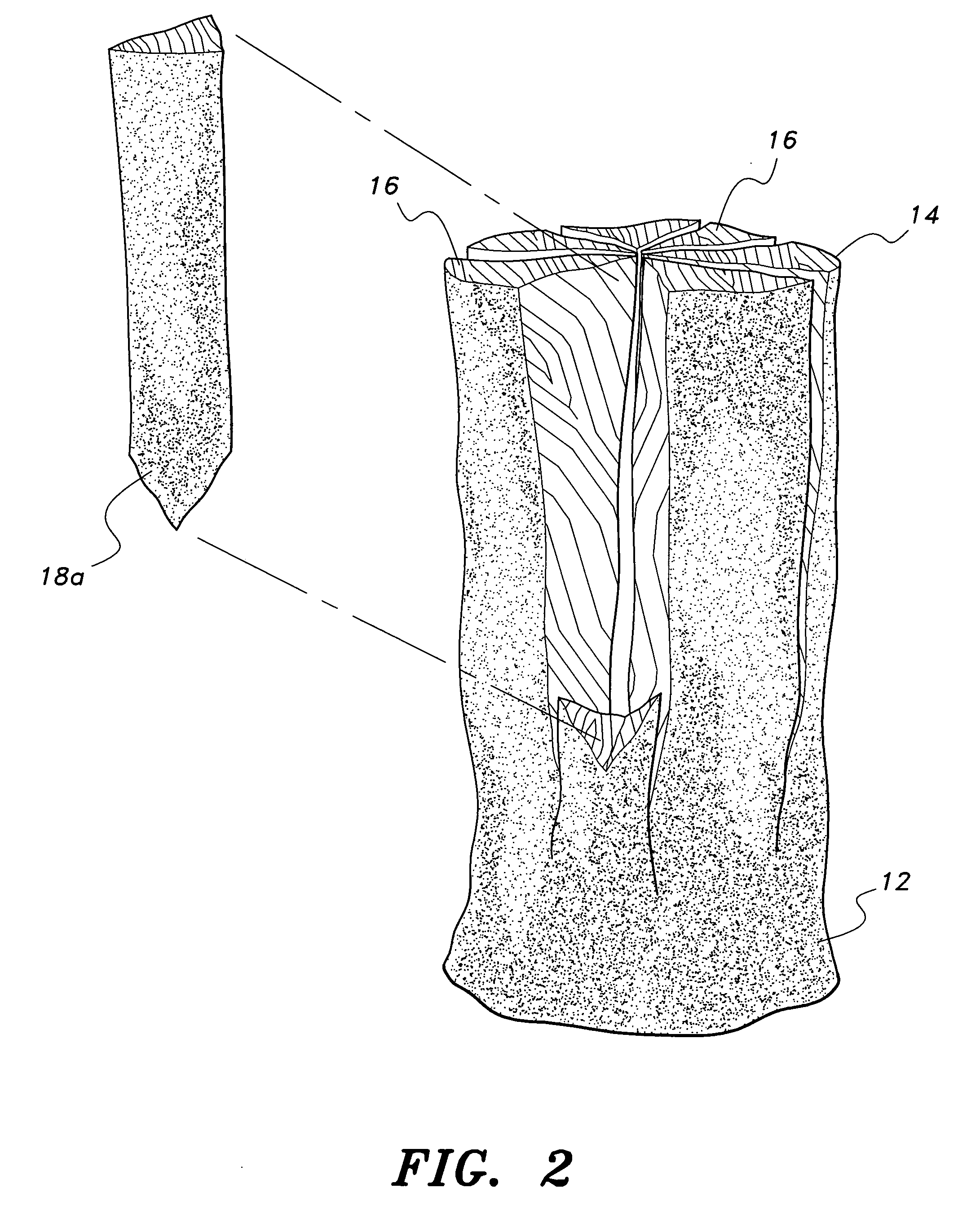

Whole timber firelog impregnated with combustible material

InactiveUS20060230673A1Process safetyProcess environmental protectionBiofuelsSolid fuelsEngineeringCombustion process

Disclosed is a new and improved firelog comprising whole timber to which highly combustible fuel is injected. The log further comprises a plurality of slits to enhance the combustion process. Various combustible fluids or combinations thereby may be used as fuel. Applicants further disclose a method of impregnating said combustible fuel into said firelog.

Owner:BARFORD ERIC DENNIS +1

Environmentally safe charcoal-based heat source

An environmentally-safe, disposable, and combustible charcoal-based heat source includes a first chimney structure and a second wall structure surrounding the chimney structure. An inner chimney flue receives air for igniting and burning the charcoal-based heat source and an outer chimney flue exhausts combustion fumes from the charcoal-based heat source. A bottom wall member secures to the inner chimney flue and the outer chimney flue and forms of a combustible material to be consumed during the ignition and burning of the charcoal-based fuel. A top wall member secures to the inner chimney flue and the outer chimney flue to be consumed during the ignition of the charcoal-based fuel. A plurality of exhaust apertures are arranged within the top wall for exhausting the combustion fumes from the outer chimney flue. An ignition ring establishes a sustained ignition of sufficient duration to ignite uniformly the charcoal-based fuel. A plurality of flaps provide an initial ignition of the ignition ring. The inner chimney flue, the outer chimney flue, the plurality of exhaust apertures, the flaps and the ignition lattice cooperating to provide uniform and rapid burning of the charcoal-based fuel.

Owner:THE KINGSFORD PRODS

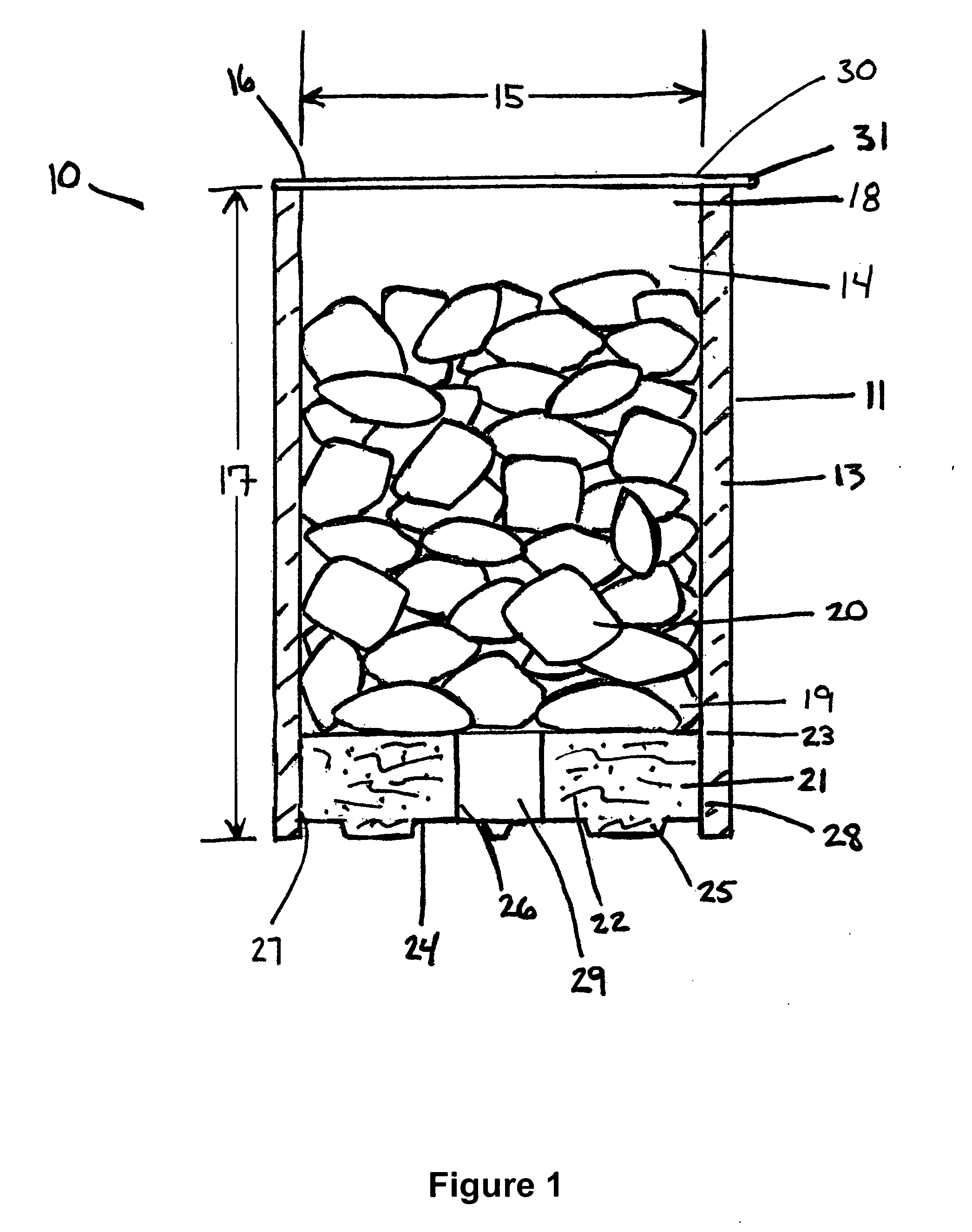

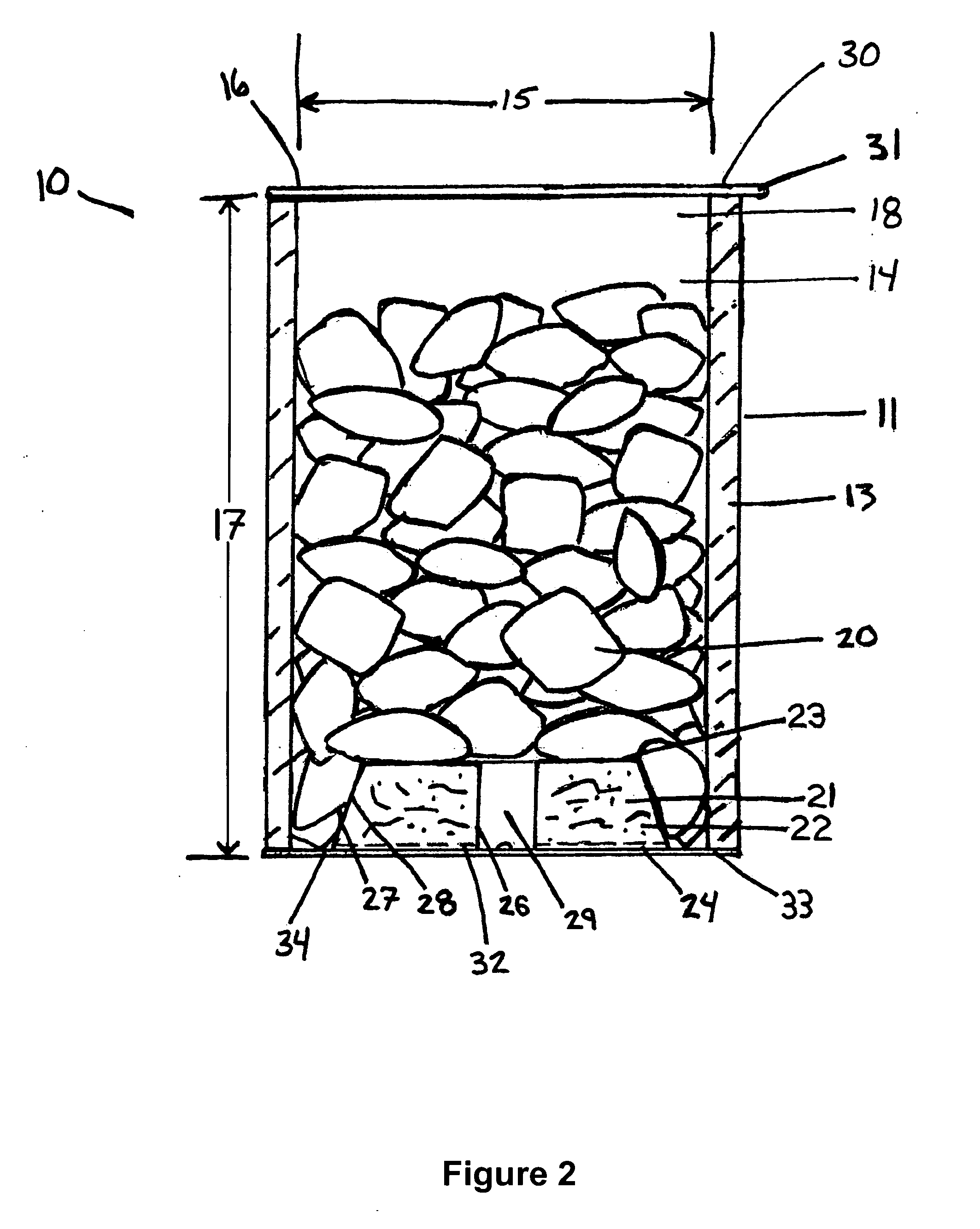

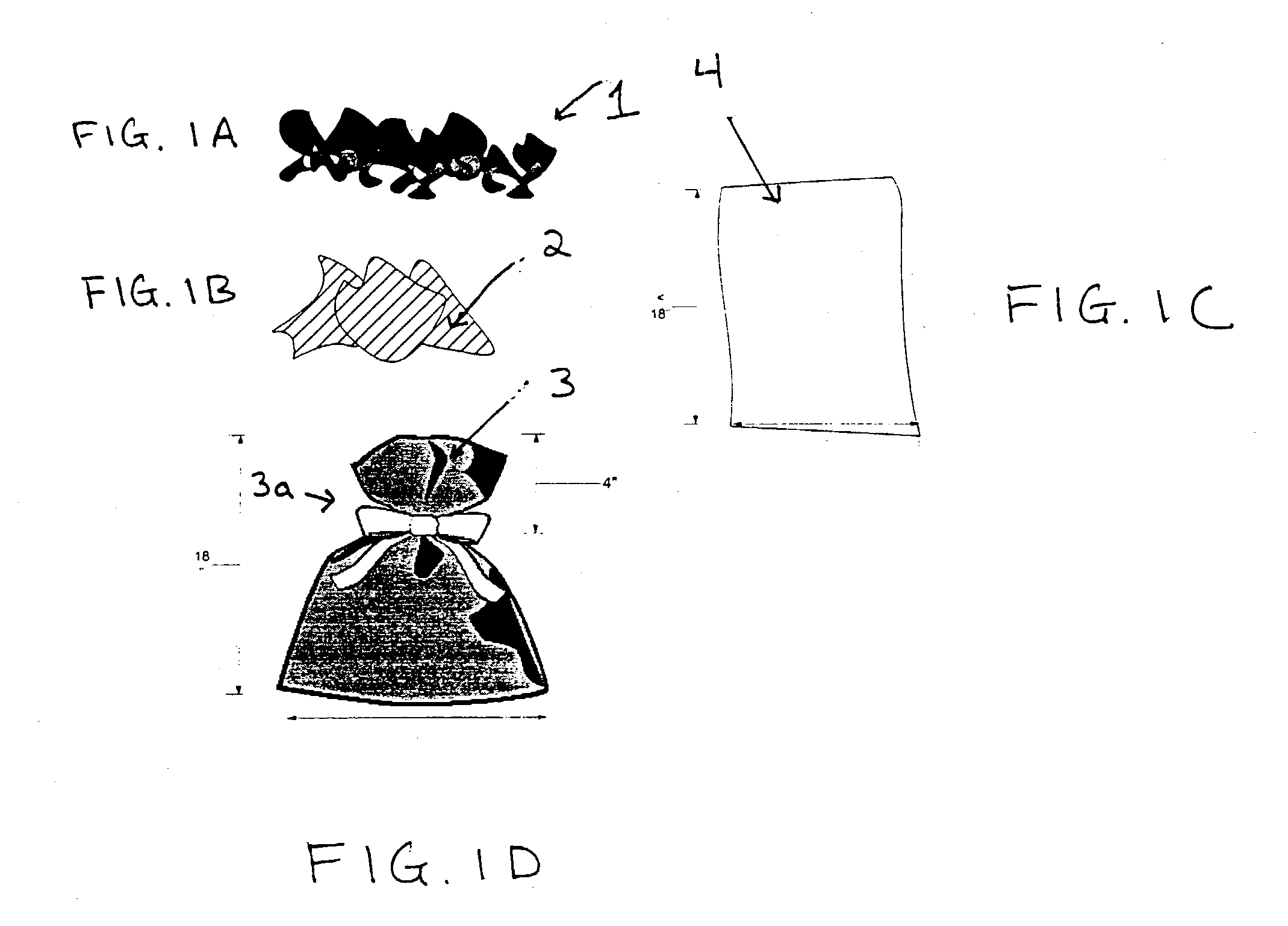

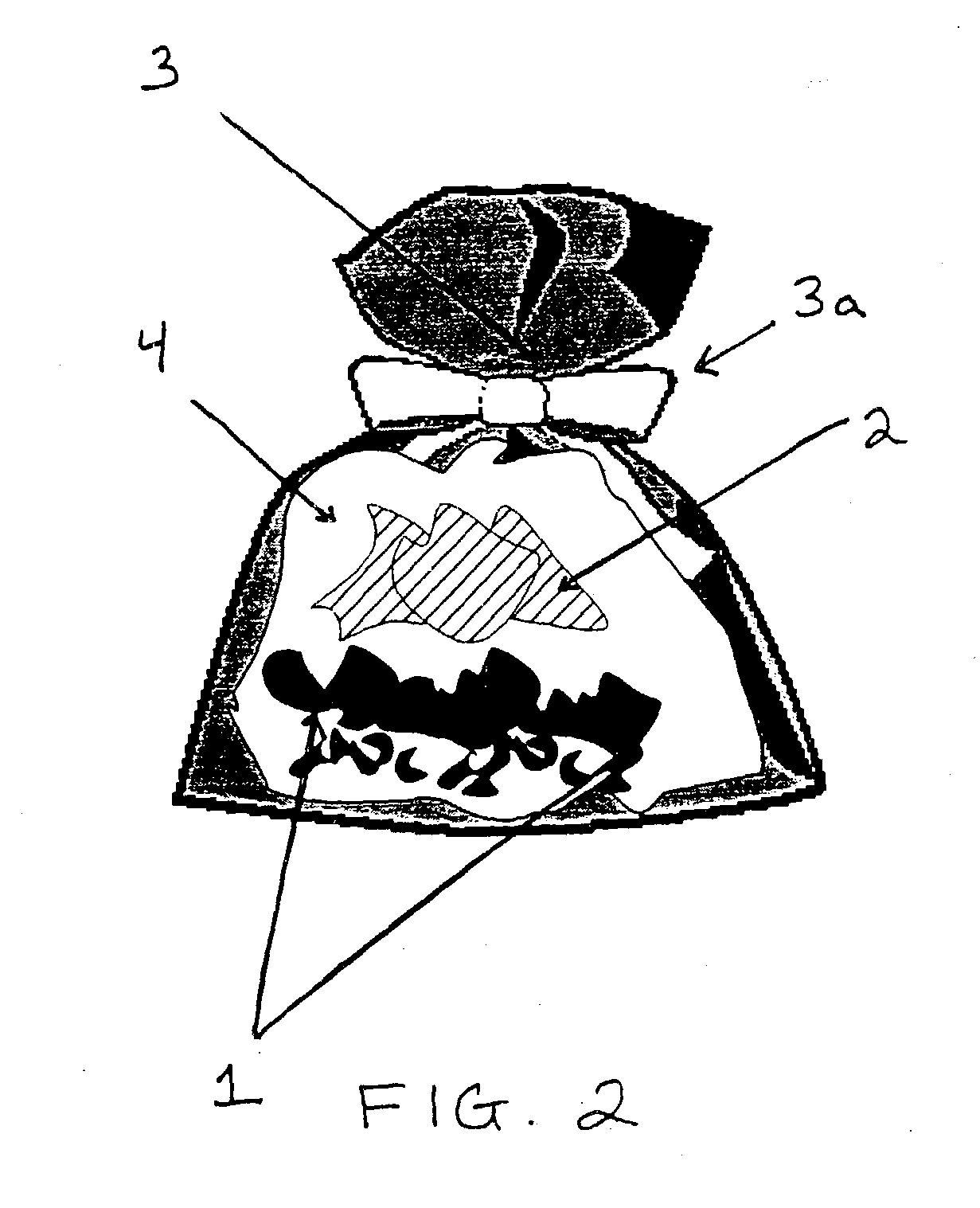

Combustible wood-based fuel package and method of manufacture thereof

InactiveUS20030079400A1Improved combustible fuel packagePrevent leakageBiofuelsSolid fuelsWaxPulp and paper industry

A combustible wood-based package is disclosed which includes an outer wrapper, preferably formed from burlap or other similar woven material that encloses large pieces of wood material, medium pieces of wood material and smaller pieces of wood material coated or otherwise soaked in a vegetable wax to form an aggregate. The aggregate is disposed at or near the bottom of the burlap wrapper, with the medium-size pieces of wood material disposed thereon with the larger pieces of wood material disposed on top of the medium-sized pieces of wood material. Preferably, all wood materials are fabricated from all-natural wood logs fabricated from compressed wood particles without the use of odor causing binders.

Owner:SUMMIT VIEWS

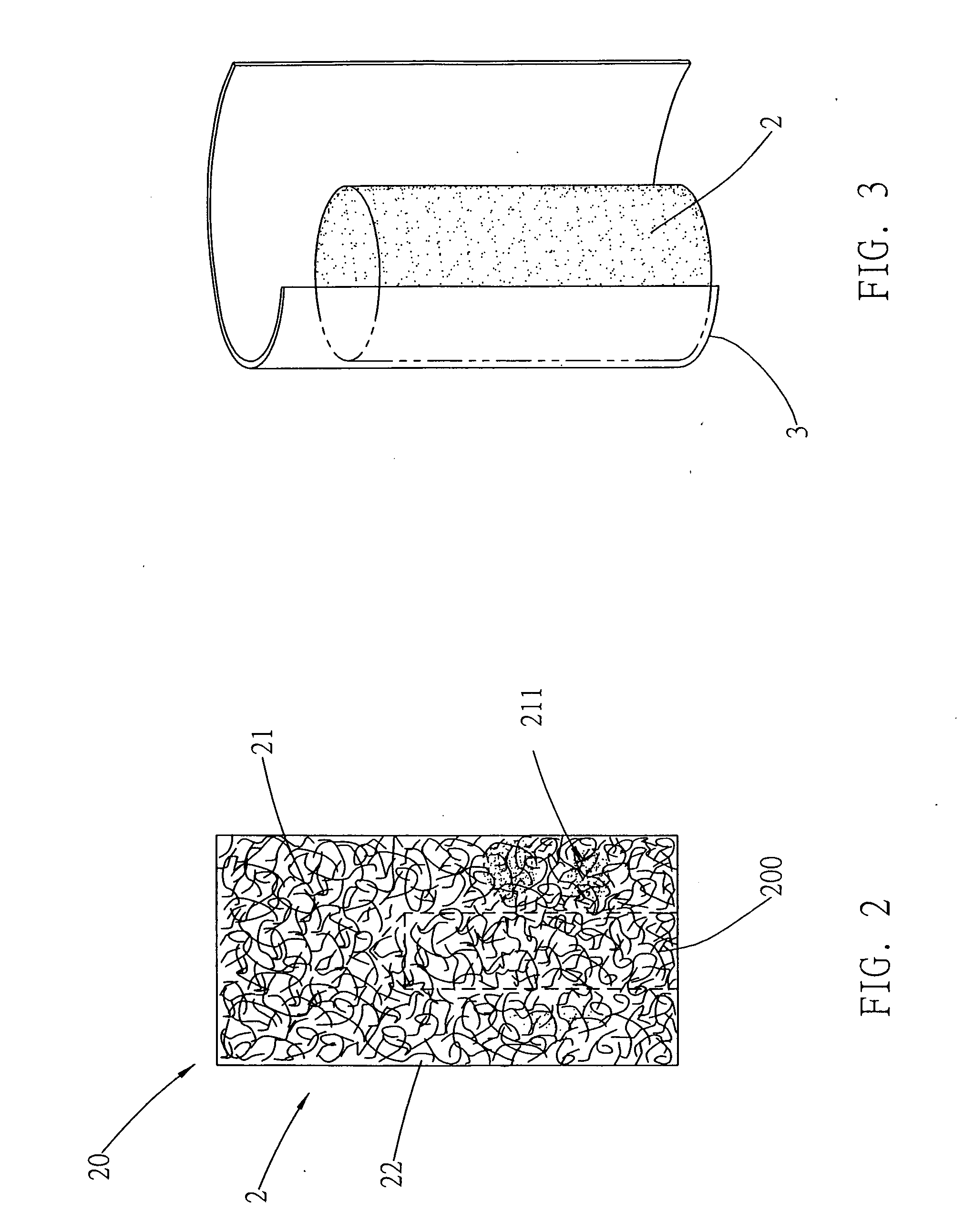

Fire log made of recycled materials and a method and an apparatus for manufacturing the same

The fire log comprises an organic fibre base that is over-saturated with vegetable cooking oil. The vegetable oil is contained and sealed therein by a casing made of the vegetable wax. More specifically, the fire log is over saturated with 65%-75% by weight of vegetable oil. The vegetable oil is used vegetable cooking oil. The organic fibre base represents about between 20%-30% by weight and consists of compressed paper-based products such as cardboard, newsprint and recyclable paper. The vegetable wax casing represents about between 1-5% of its weight. In another aspect of the present invention, the organic fibre base is made of broken fibres and interstices, and the vegetable oil is infused therein while these fibres are dilated from their natural states. In yet another aspect, the organic fibre base is formed in a perforated cylinder whereby a bark-like appearance is imprinted on its surface.

Owner:BONNELL RICKARD CARLA +1

Lighter fluid composition

InactiveUS6843812B2Clean burningLow VOC emissionSolid fuelsLiquid carbonaceous fuelsCross-linkMethanol

A lighter fluid composition usable for starting barbecues and the like that comprises naturally occurring combustible materials, which is clean burning and results in low volatile organic compound (VOC) emission during combustion, which is biodegradable and easily disposable, and which burns with a pleasant aroma and does not impart any unpleasant hydrocarbon odor or flavor to food cooked on a barbecue. The composition preferably comprises between approximately 0.5 weight percent and approximately 90 weight percent of a terpene or terpenoid oil, and between approximately 0.5 weight percent and approximately 98.5 weight percent of short chain alcohol, between approximately 0.5 weight percent and approximately 60 weight percent of water, between approximately 0.1 weight percent and approximately 10 weight percent of surfactant, and between approximately 0.5 weight percent and approximately 10 weight percent of thickening agent. The preferred terpene preferably comprises d-limonene or a citrus derived oil containing d-limonene such as cold-pressed orange oil. The preferred alcohols are methanol and ethanol. The preferred surfactant is a non-ionic detergent or detergents, and the preferred thickener is a pH controllable slightly cross-linked polyacrylic acid material.

Owner:STEPHANOS PRODROMOS PERICLES

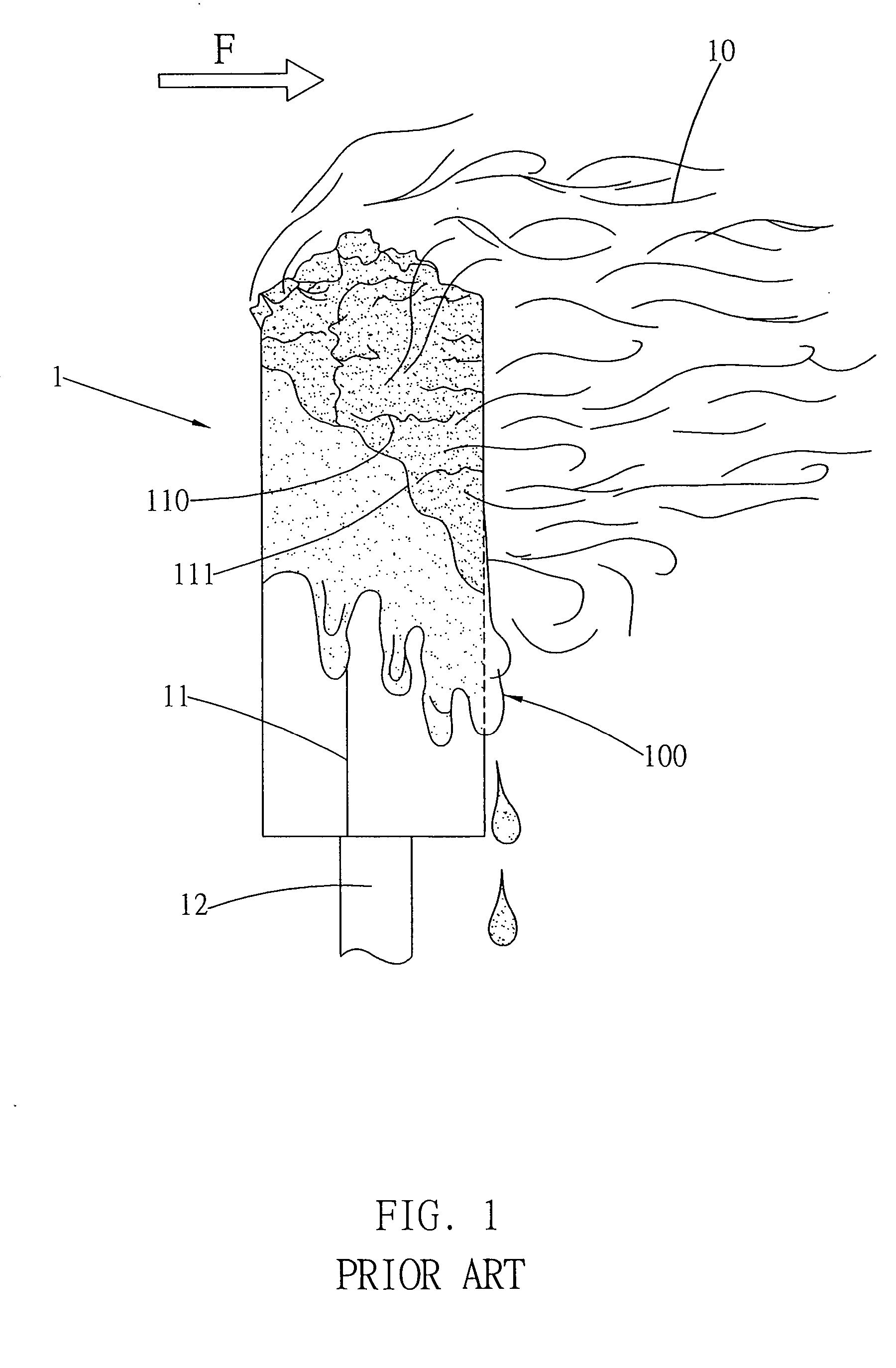

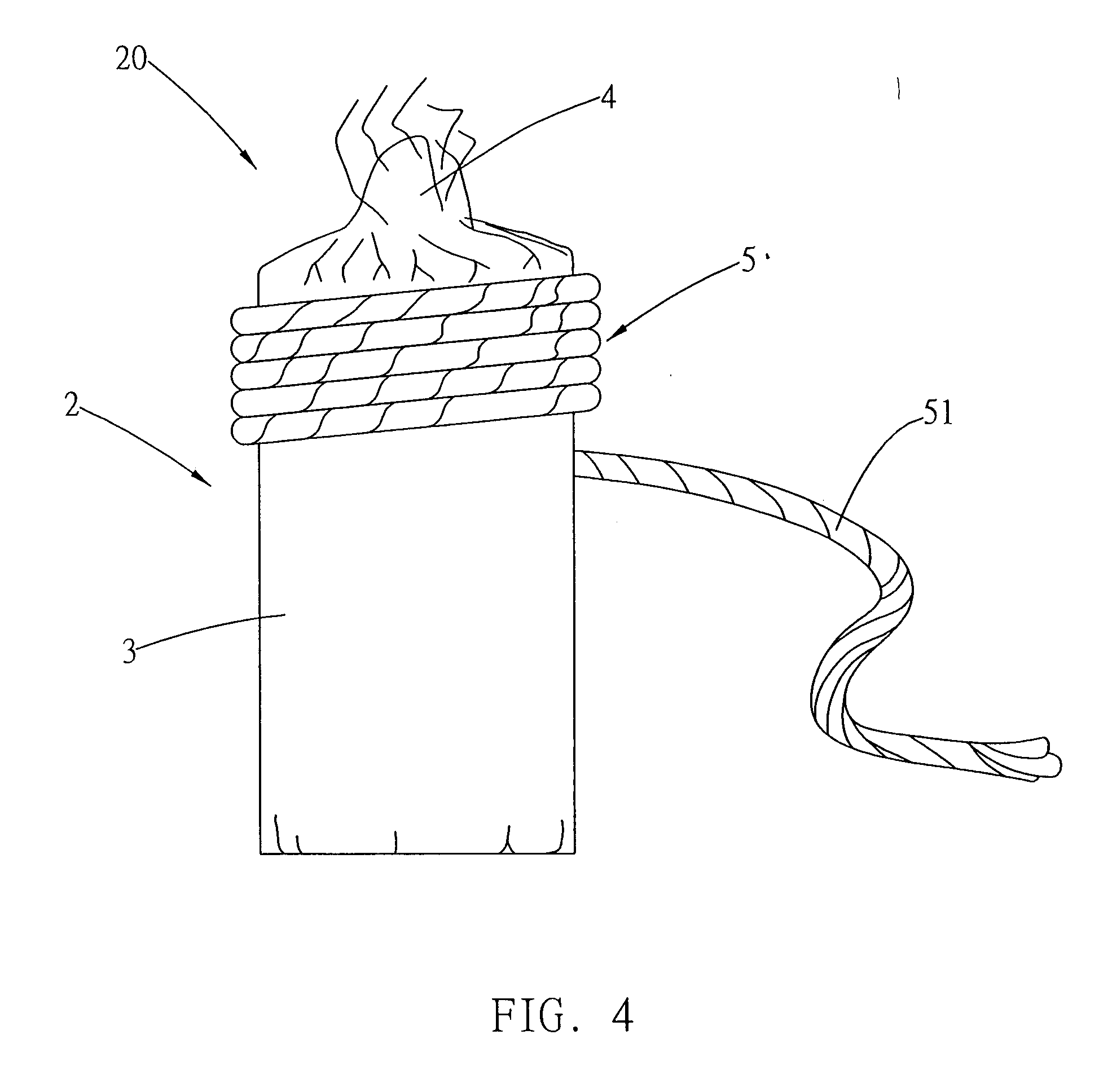

Torch

A torch, especially a wind-proof torch which can be installed in an upright position or be carried for lightening in outdoor camping, is composed of a torch body which is primarily made by mixing fiber yarns with fuel which is in a solid state in a room temperature, and is made into a three-dimensional body after being fixed. An outer surface of torch body is enclosed with a combustible confining material in a strap shape to achieve a transient heat resistance. A burning end of torch is not affected by air flow to maintain a transversally descending thermal interaction due to an adsorption and restriction of hot molten fuel liquid by the fiber yarns. A bottom of the torch is connected to a modular elastic handling bar, to achieve a multipurpose function.

Owner:CHANG CHIOU FU

Combustible smoke-free briquette

A briquette includes an upper briquette part, and a lower briquette part under the upper briquette part; both of the upper and the lower briquette parts are made of completely carbonized cinders of burnt shells of grains and small pieces of grass and wood, and are formed by compressing and drying a mixture of the cinders and incombustible adhesives such that the briquette won't fall apart easily after it is burnt; when the upper briquette part is positioned on top of the lower briquette part, a room will be formed between the upper and the lower parts, in which kindling materials will be held and burn, and the upper briquette part propped up off a ground by the lower briquette part; several air passages extend through the briquette from lateral sides of the briquette to the room for the kindling materials.

Owner:HSIAO JEN TE

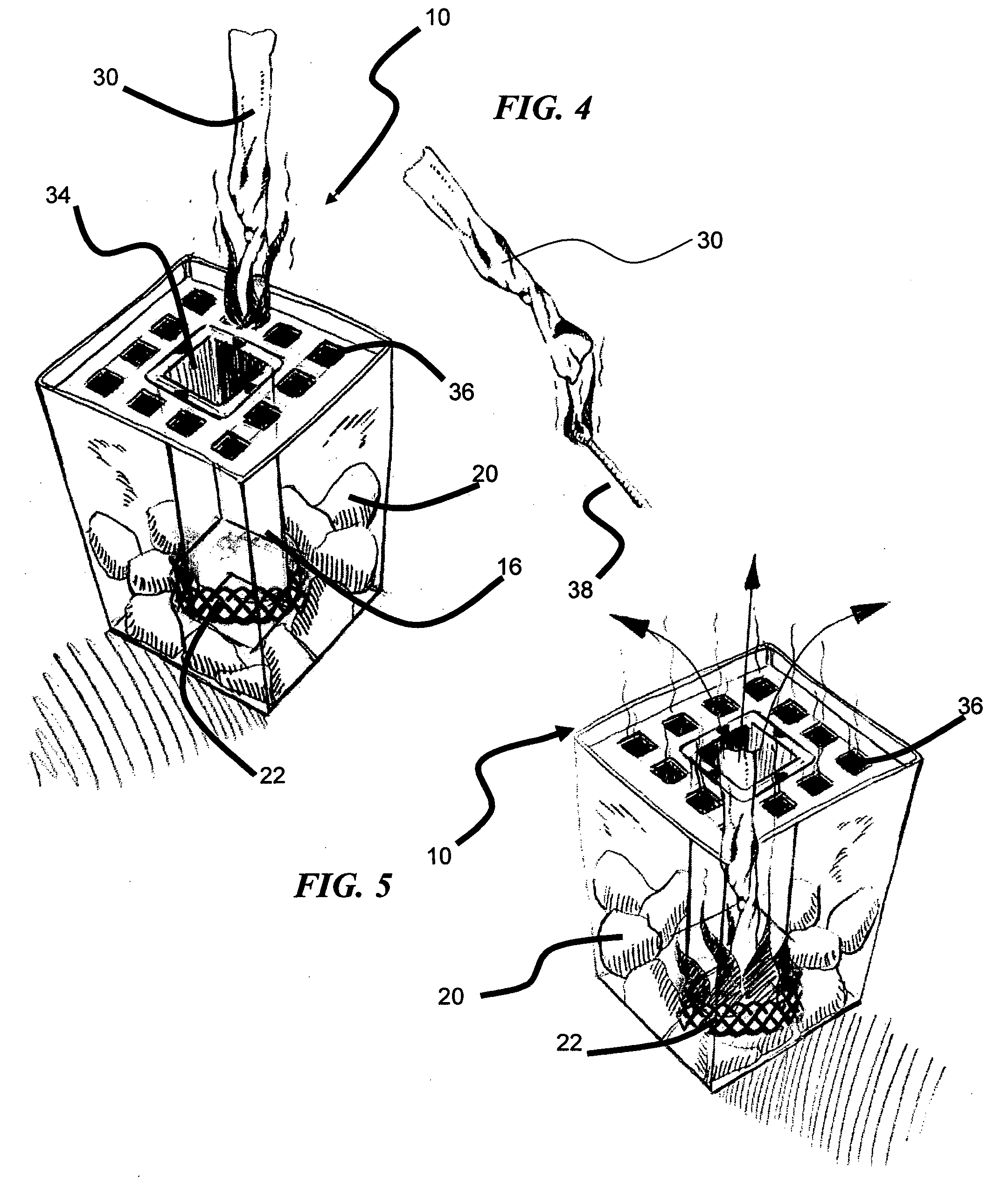

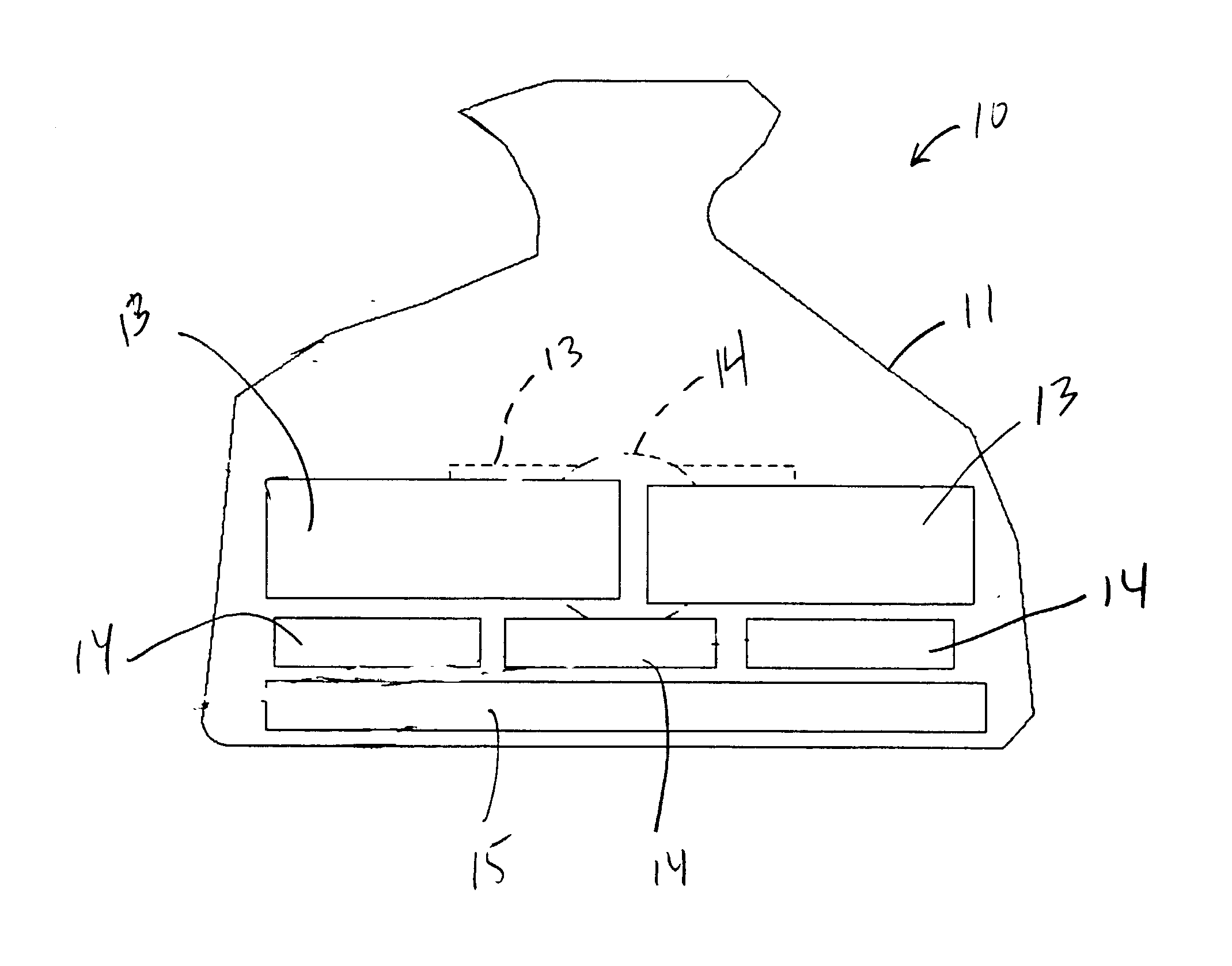

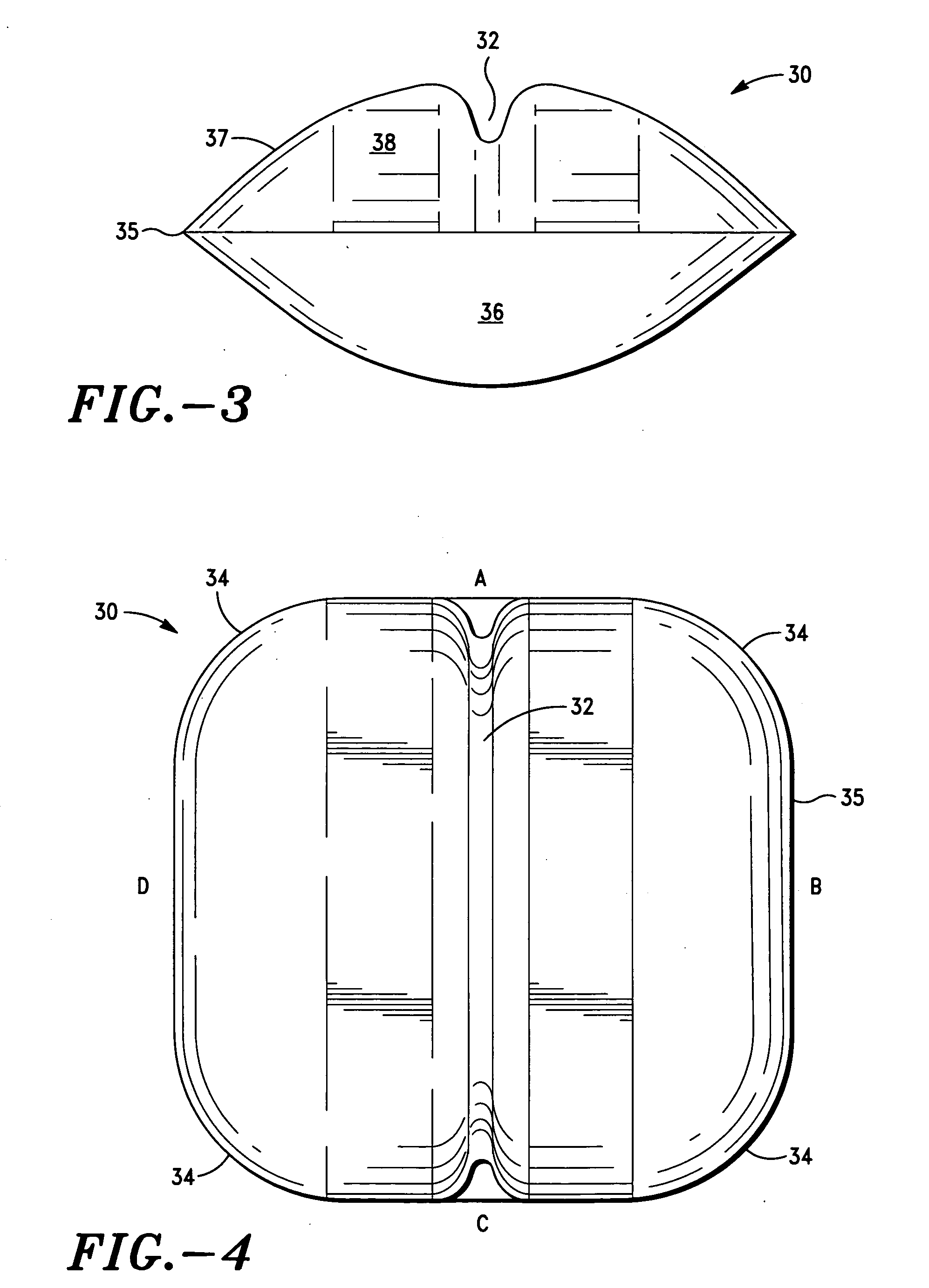

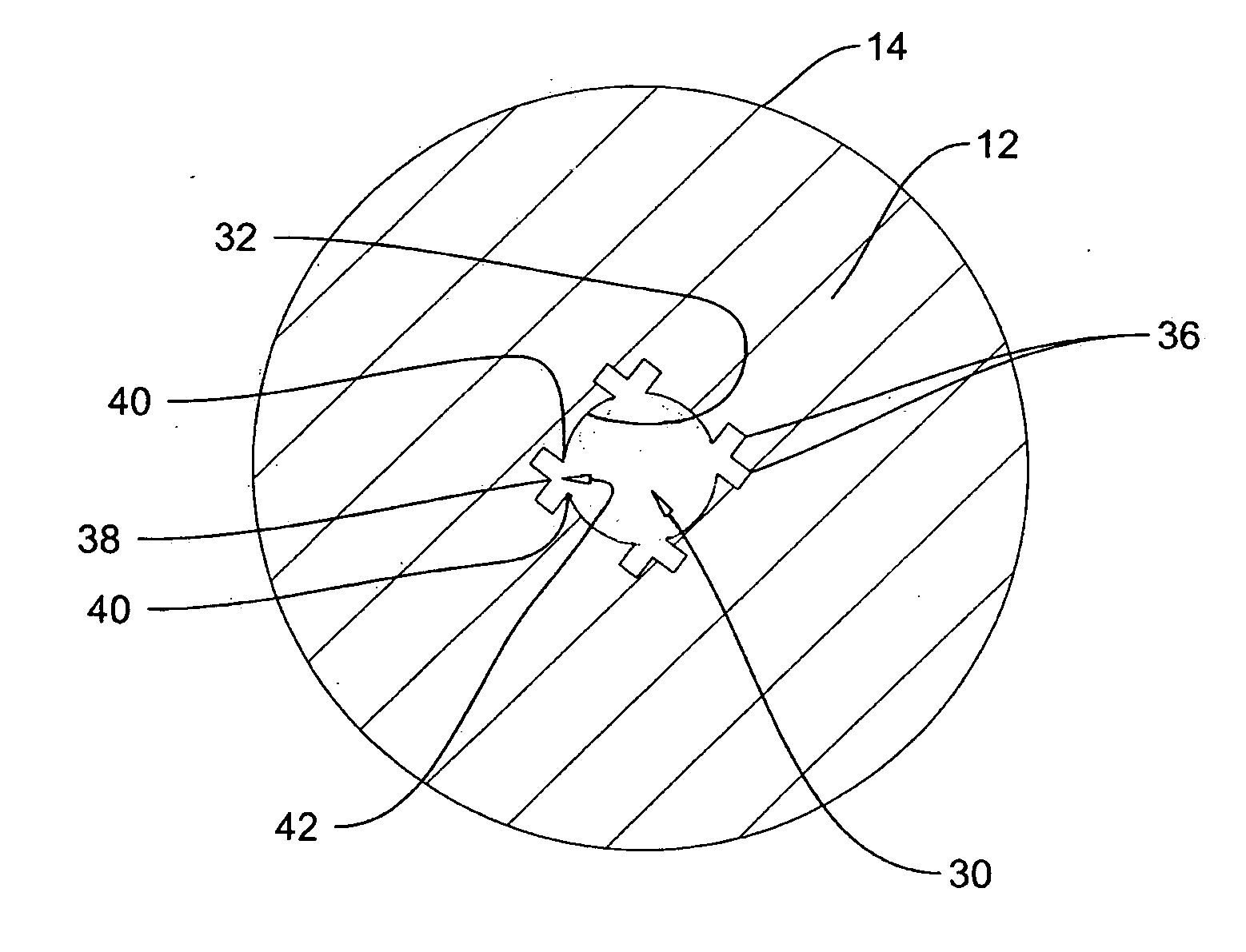

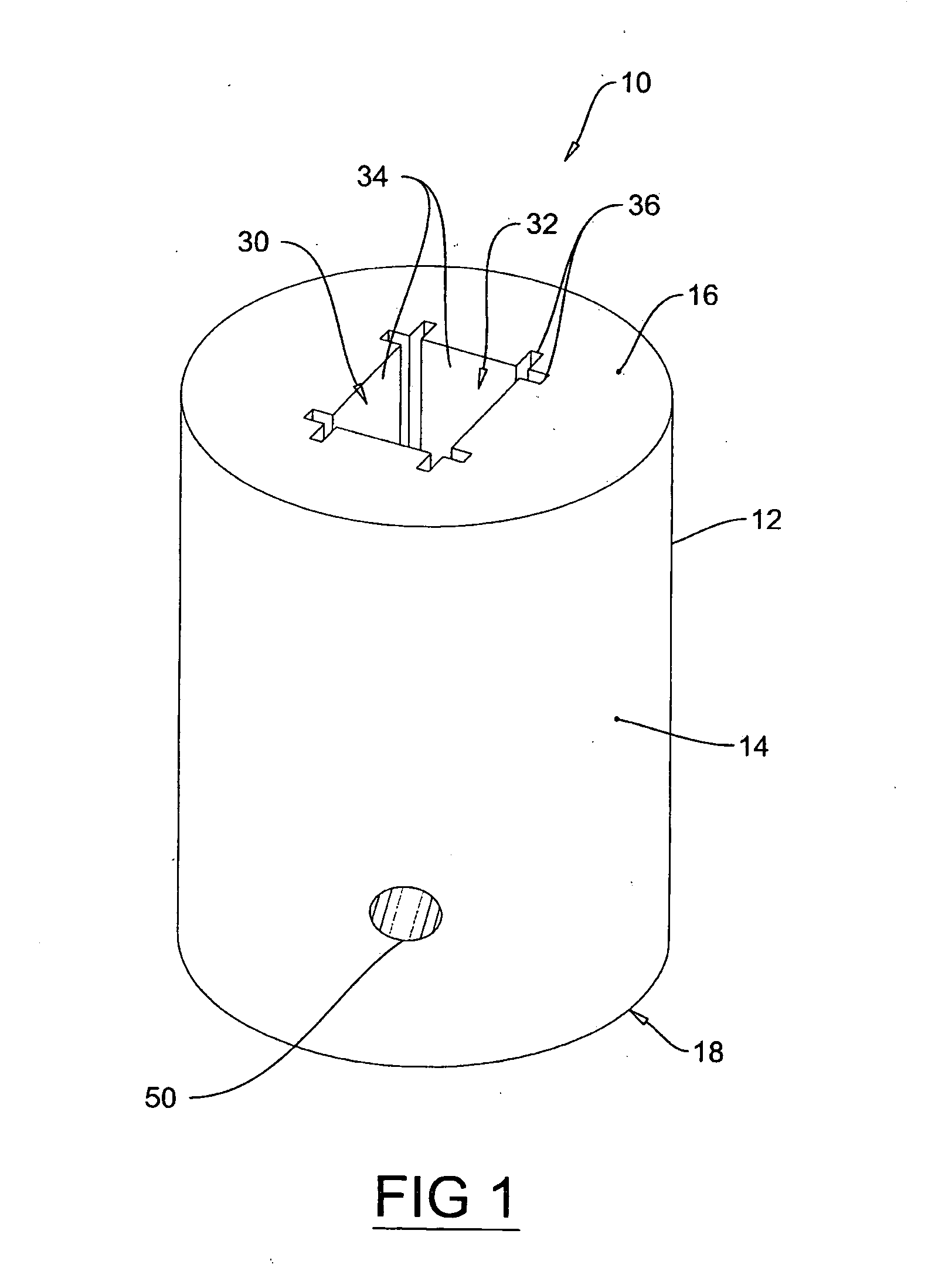

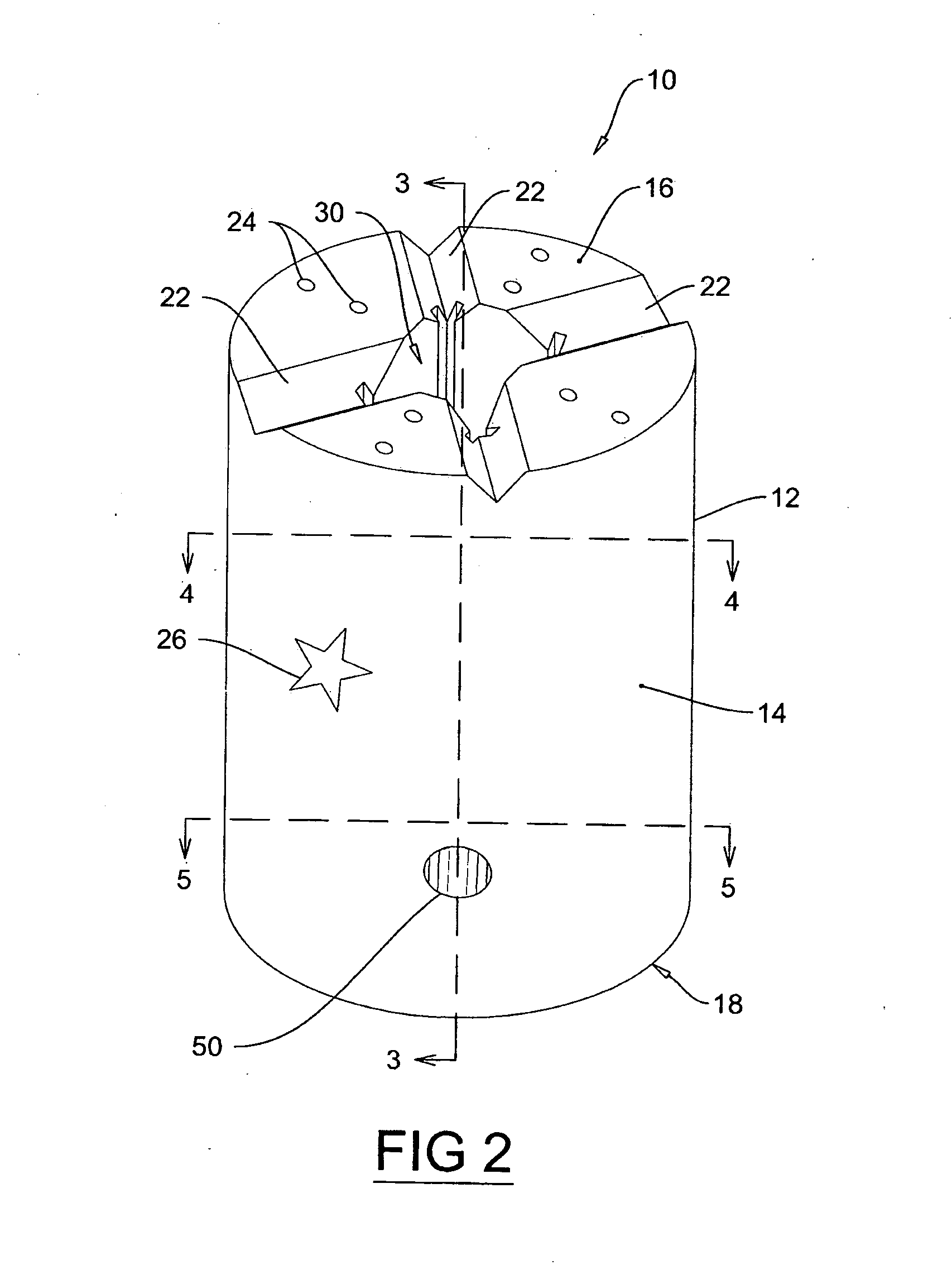

Combustible Packages for Containing a Fuel Source and a Fire Starter

Combustible packages for containing a fuel source and a fire started are provided. A combustible package may include a cardboard outer wall and top and bottom lids for substantially closing top and bottom openings defined by the outer wall. Each lid may define a central panel for extending across an opening and a plurality of tabs for facilitating a press fit between the lids and the outer wall. Each lid may also define a central opening for receiving an end of a fire starter. The fire starter may be wound paper tube impregnated with an accelerant. The fuel source may be a plurality of charcoal briquettes contained between the outer wall, the top and bottom lids and the fire starter. The outer wall may define one or more ventilation openings between the bottom edge and the bottom lid. Or the bottom edge may be scalloped to provide ventilation openings.

Owner:SONOCO DEV INC

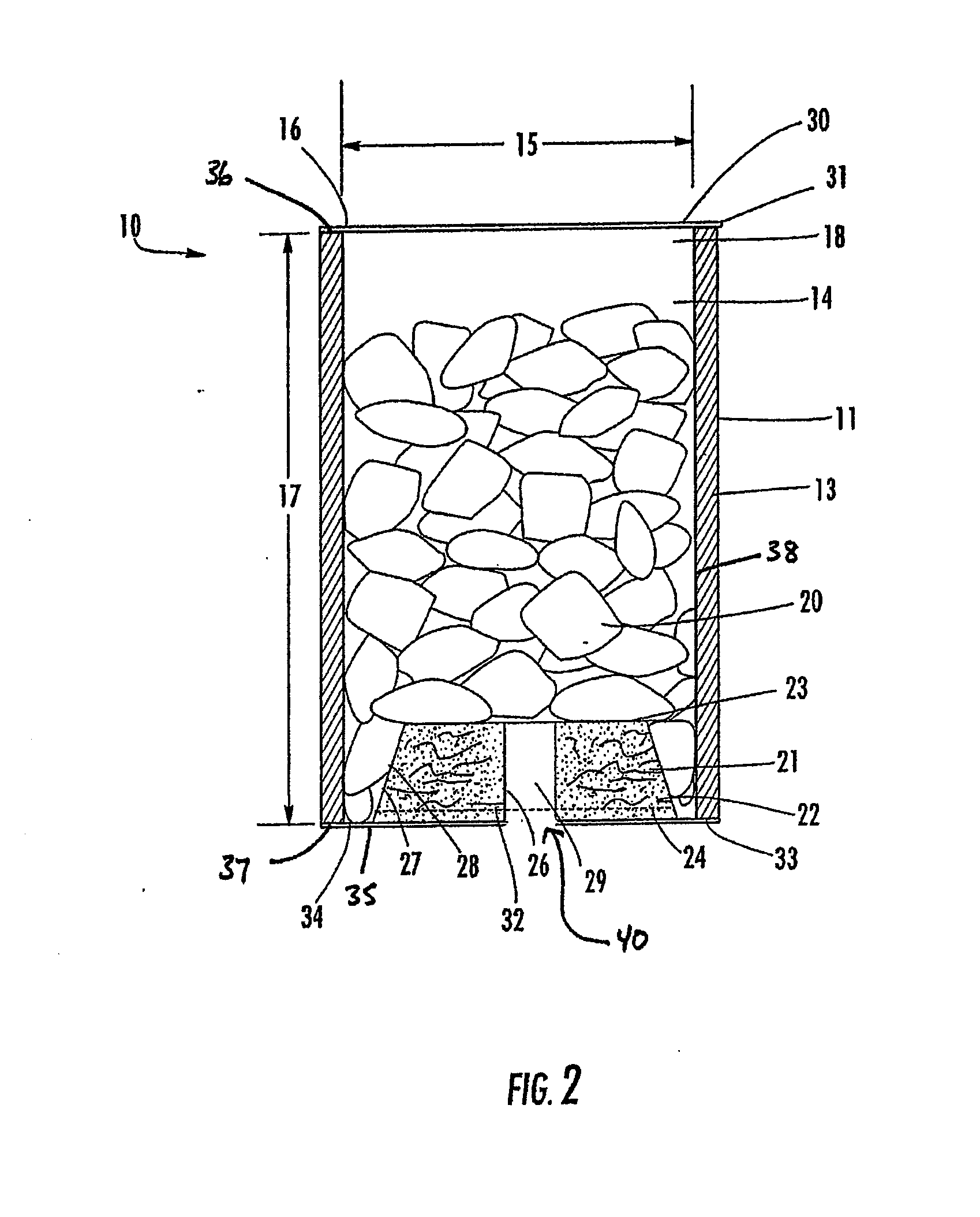

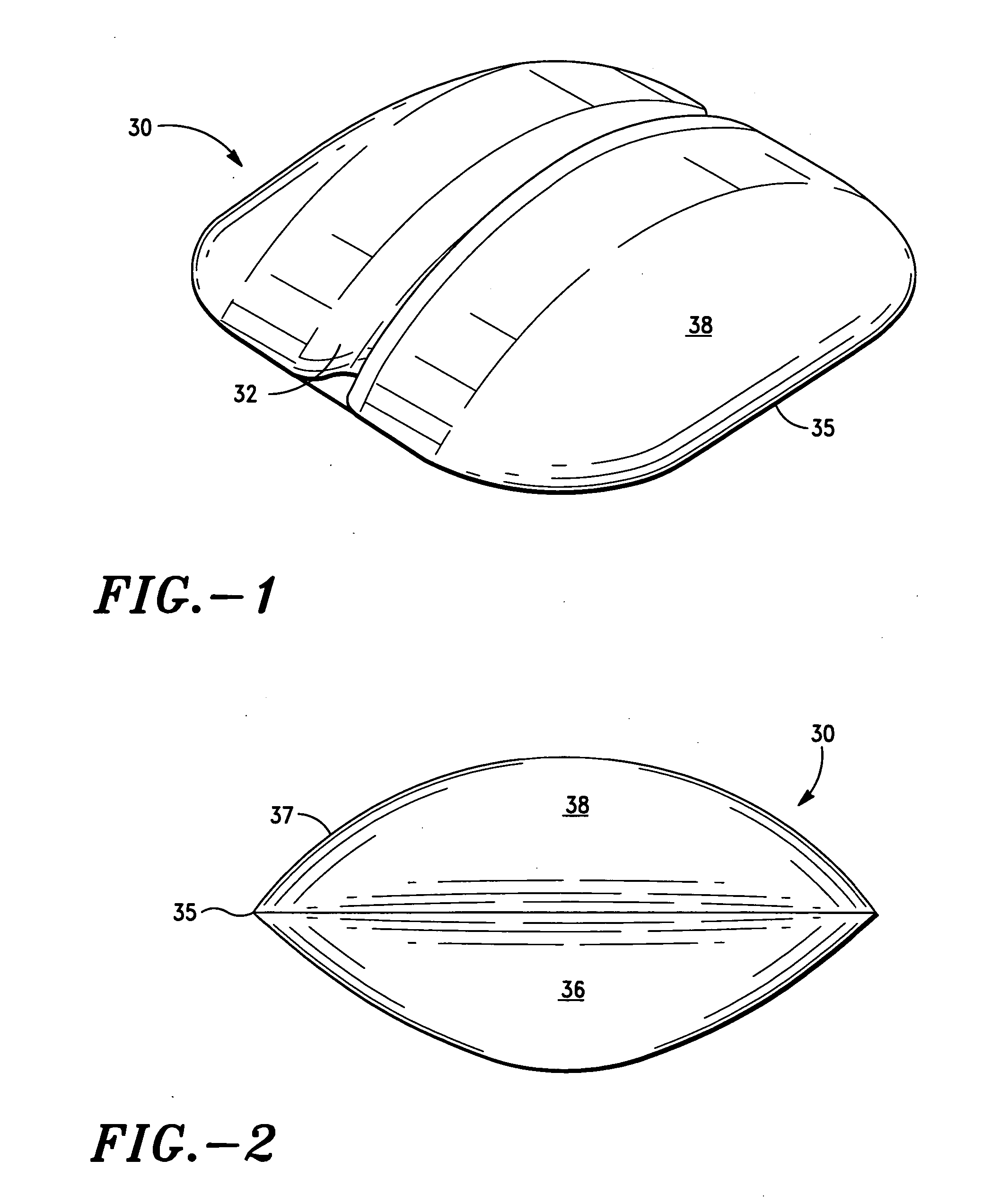

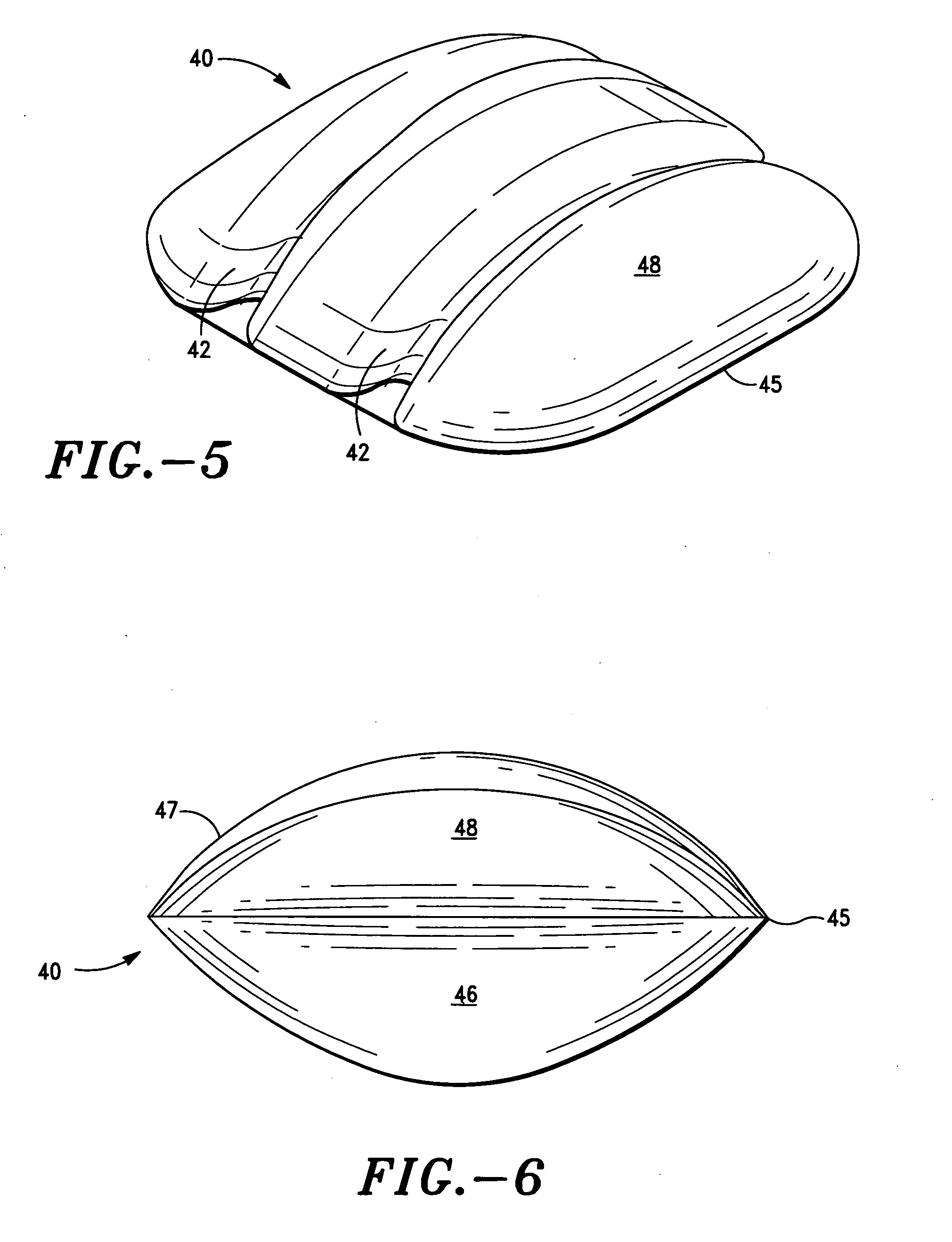

Charcoal briquet having a grooved surface

InactiveUS20060064926A1Improve surface featuresImprove stacking effectBiofuelsSolid fuelsEngineeringCharcoal

A generally pillow-shaped charcoal briquet having a convex upper surface and a convex lower surface, wherein at least one of these surfaces contain an enhanced surface feature comprising one or more grooves. When two or more grooves are located on one or both convex surfaces, the grooves are generally parallel to each other and to two opposing sides of the briquet, and generally perpendicular to two opposing sides of the briquet. The briquets have improved ignition characteristics and enhanced burn phase properties.

Owner:MELIN SCOTT +5

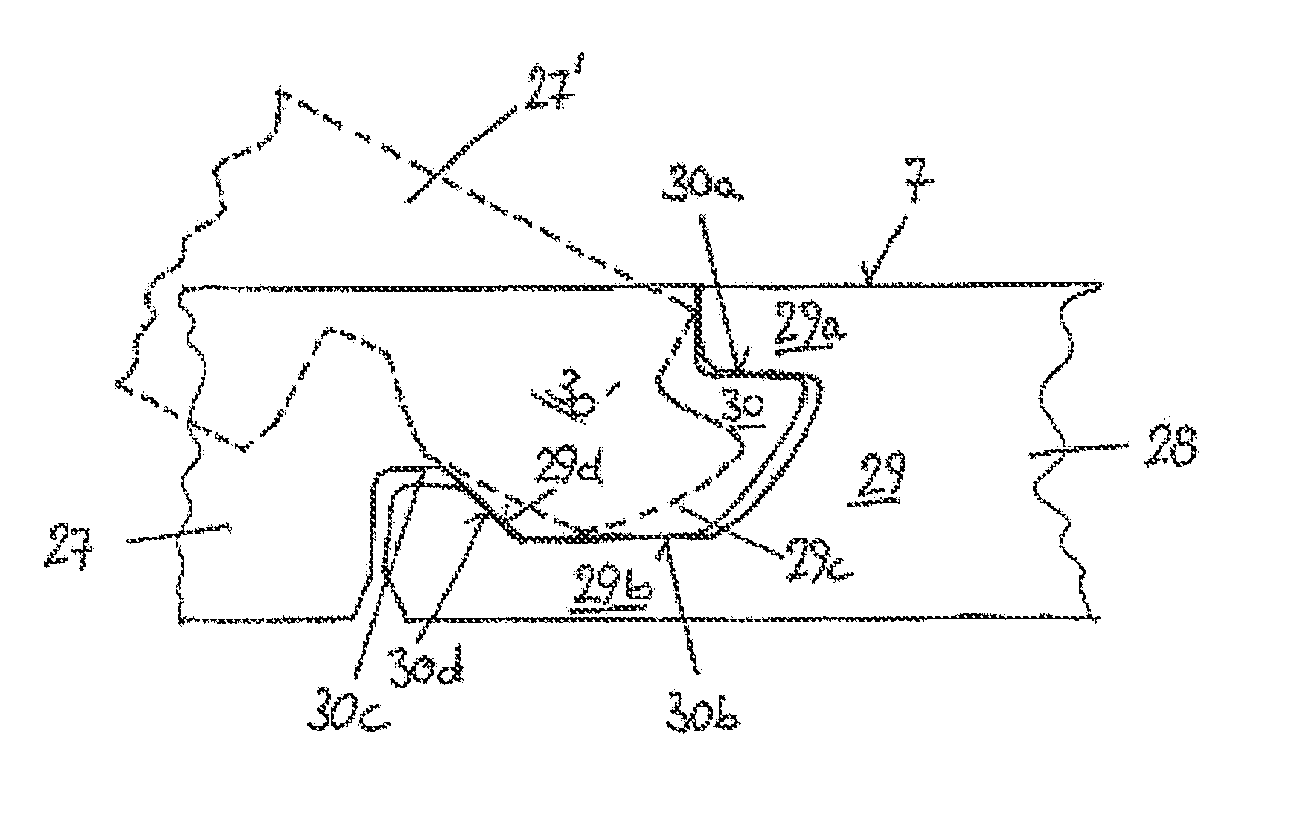

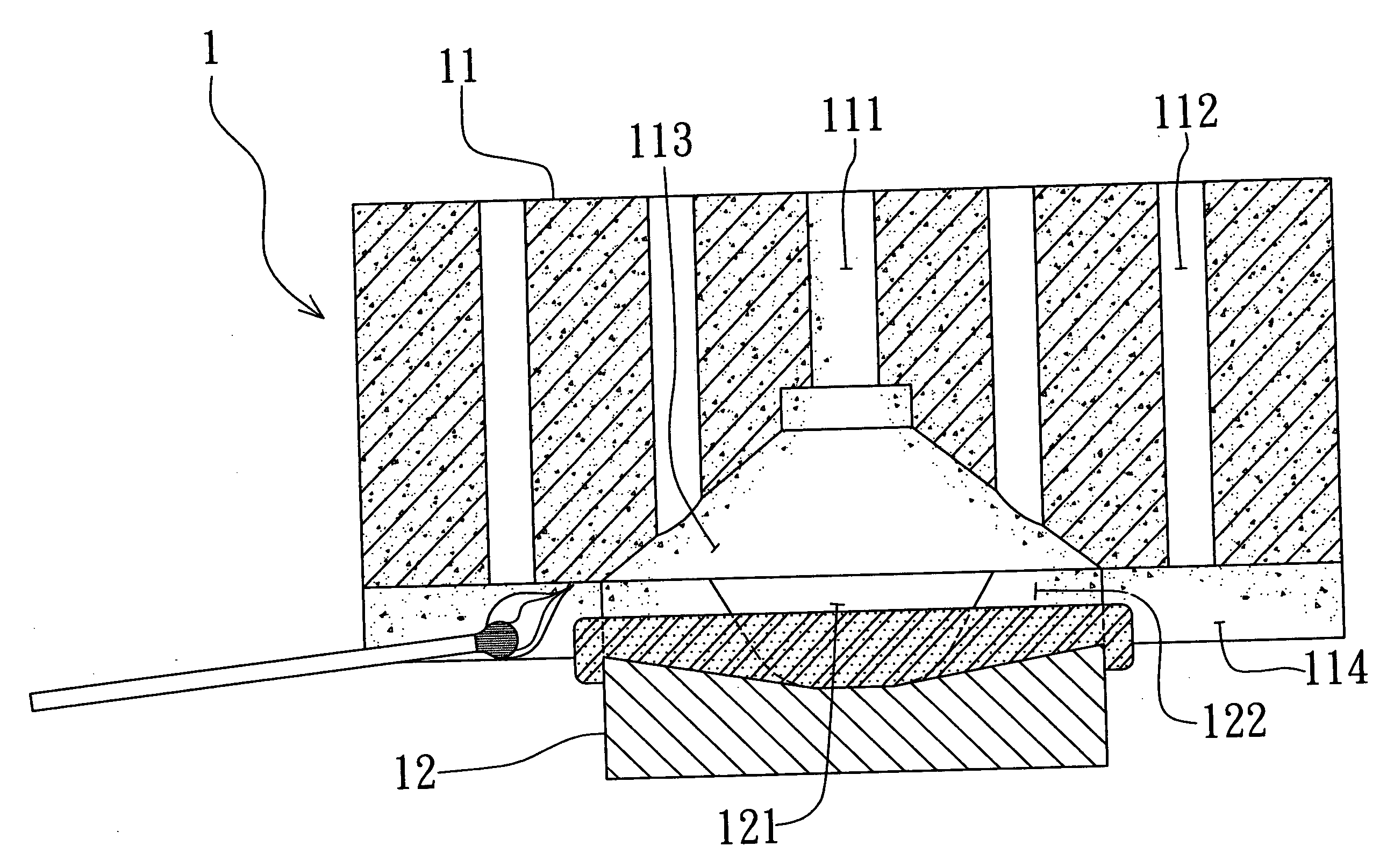

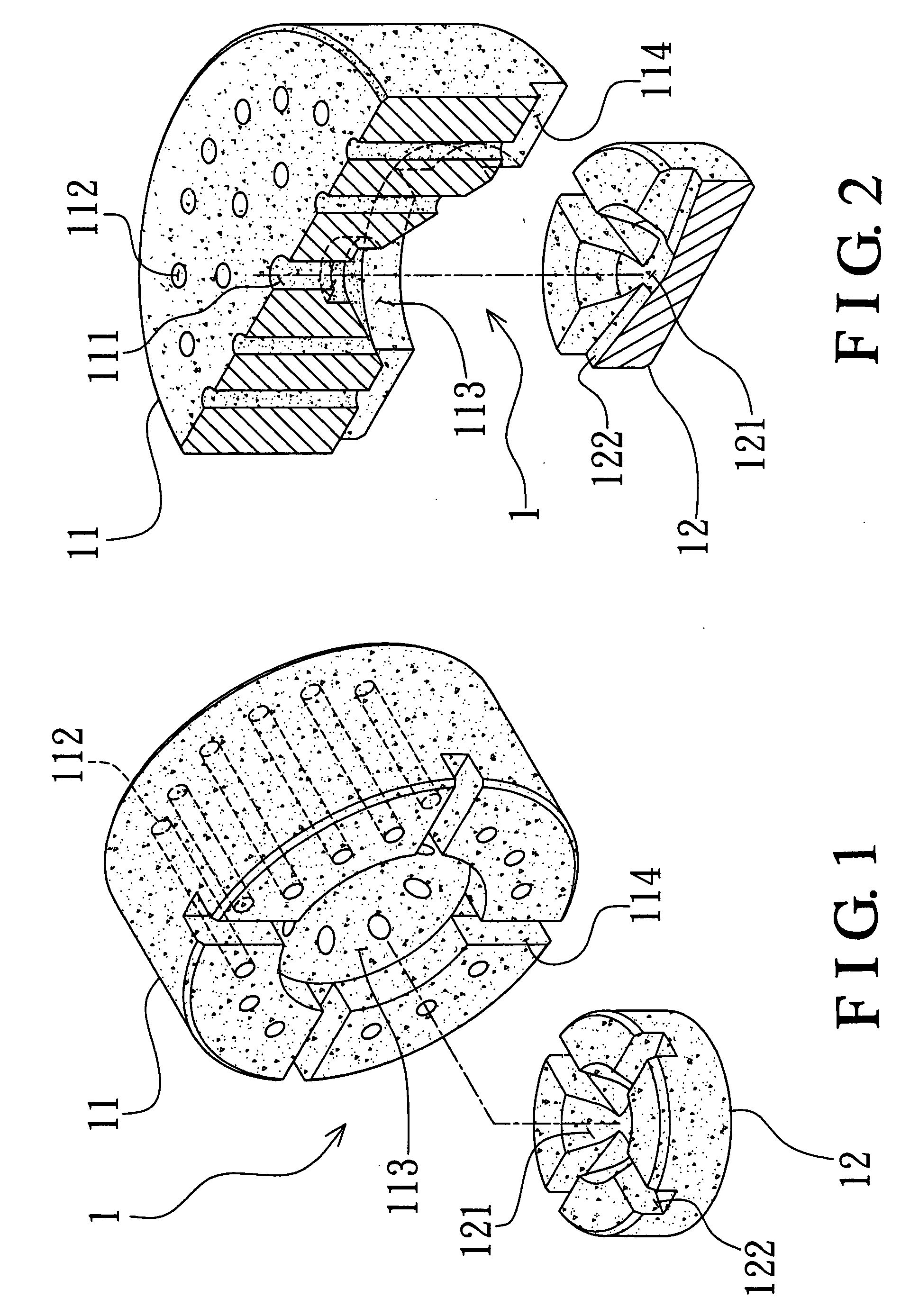

Panel

The invention relates to a panel with complementary locking means provided in pairs on opposite panel edges. One of the locking means is hook profiles with a receiving hook and a locking hook. The free step end of the locking hook is designed narrower than the width of the receiving opening of the receiving hook. The locking contour of the locking hook protrudes at least partially past the plane of the joint surface of the receiving hook so that the free step end fits into the receiving opening far enough at first that a part of the horizontal locking surface of the locking hook makes contact with the horizontal locking surface of the receiving hook during a joining motion without elastic deformation of the hook profiles, and that the receiving hook bends so that the width of the receiving opening can be expanded so that the locking step can be inserted entirely into the receiving recess and the locking contour of the locking hook is further inserted into a form-fit contour of the receiving hook.

Owner:AKZENTA PANEELE PROFILE GMBH

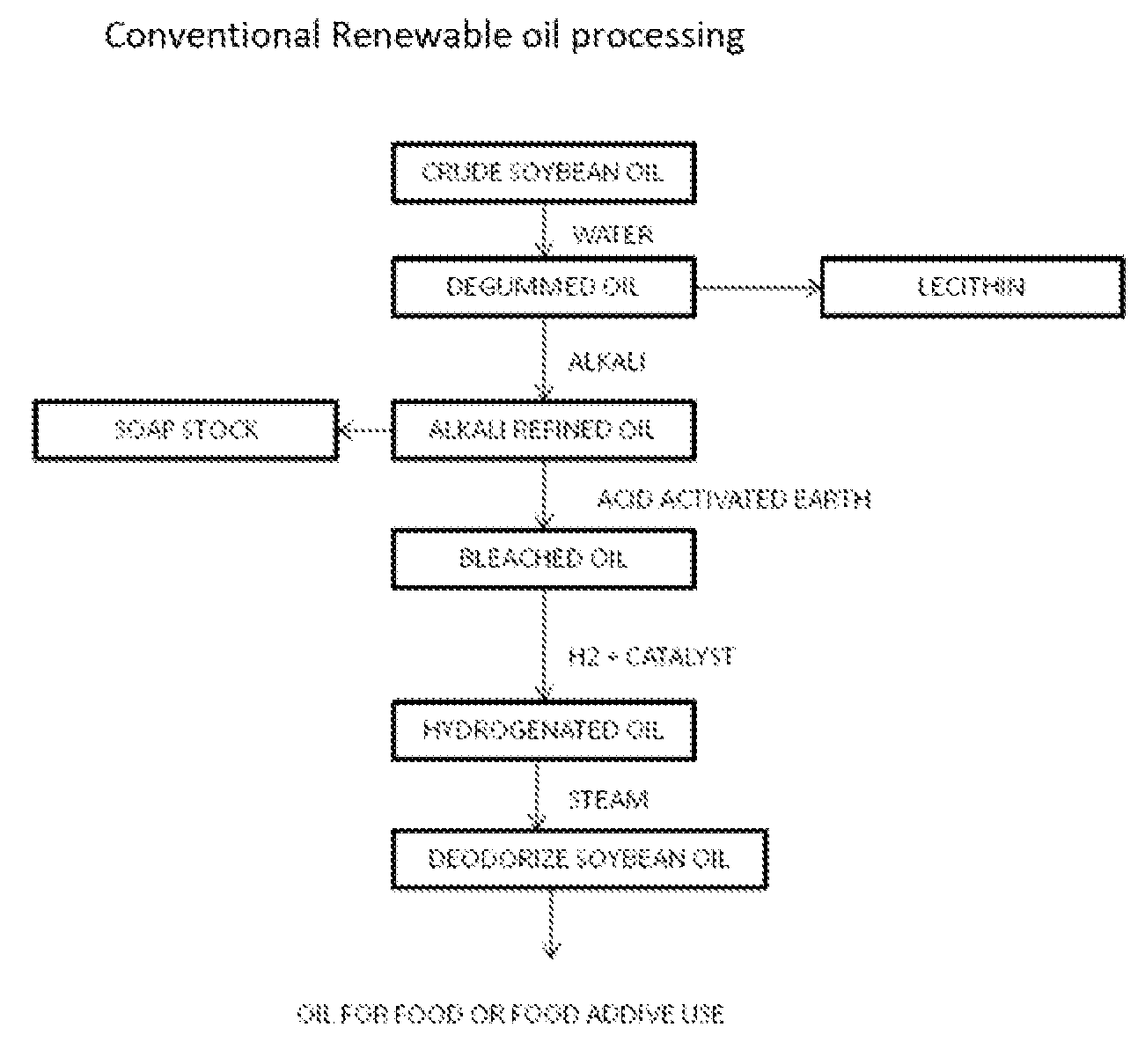

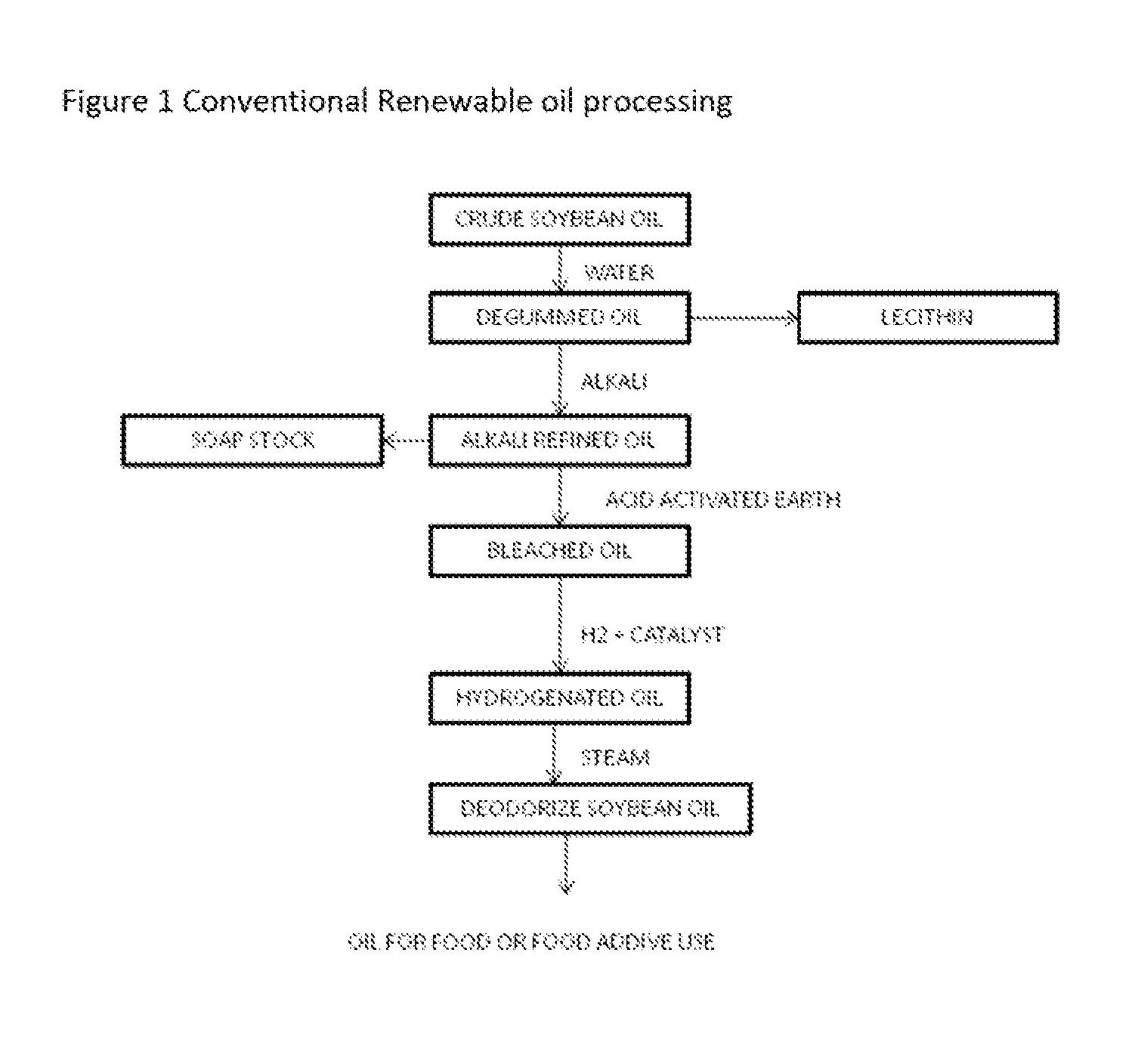

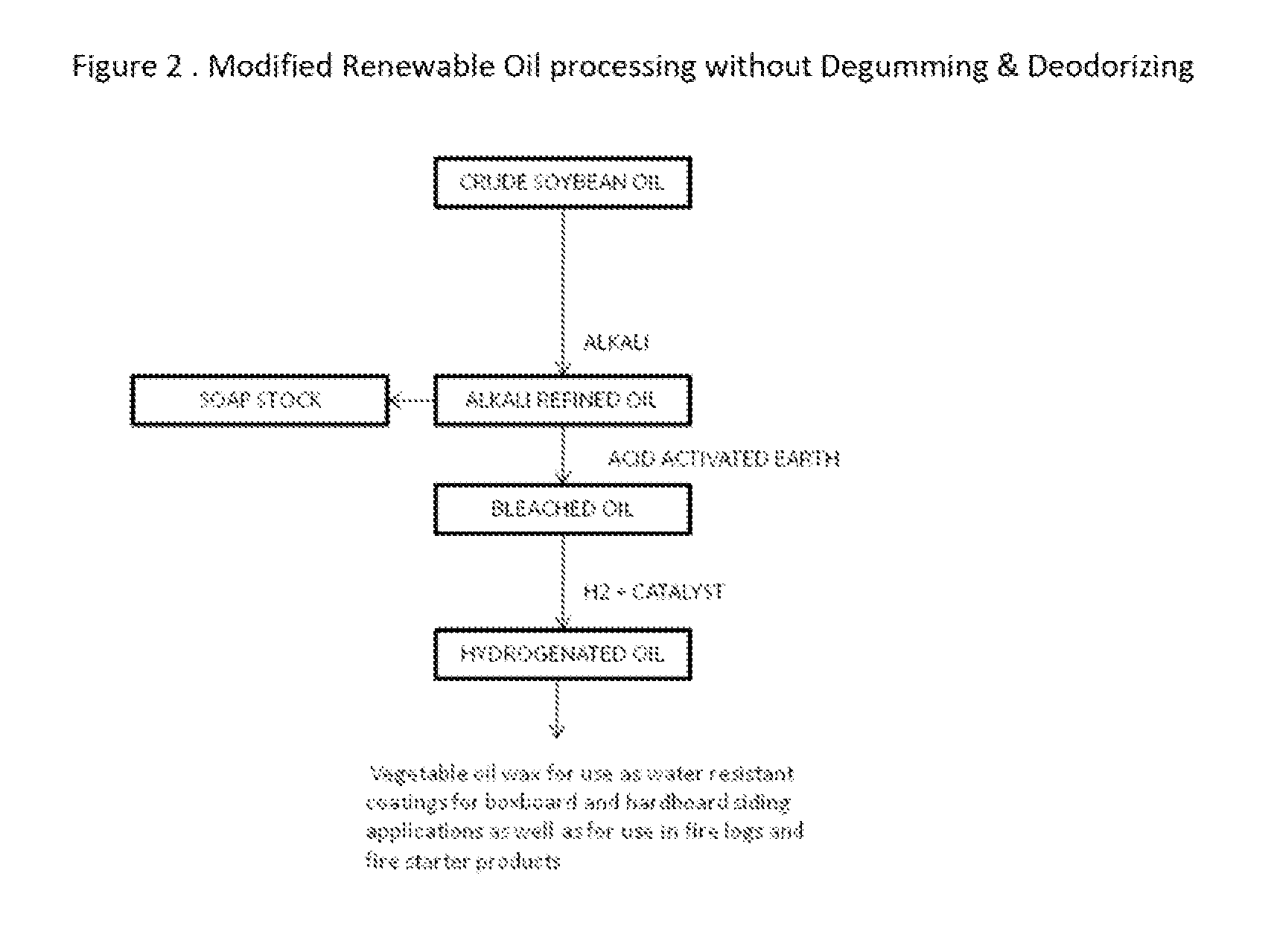

Process for upgrading low value renewable oils

InactiveUS20110287159A1Monocarboxylic acid ester polymer adhesivesFatty oils/acids recovery from wasteCelluloseWater resistant

Steps in the processing of oils derived from plants or vegetables include the degumming, deodorizing and bleaching of the oil before it can be used for further applications. By eliminating one or more of these steps from the processing of the oil, followed by hydrogenating the oil to a specified degree of hydrogenation, the resulting upgraded oils can be incorporated into products having commercial applications. The process uses a high shear mixing device and a hydrogenation catalyst. The process can utilize a single or multiple high shear devices, and utilize renewable oils instead of increasingly scarce petroleum based products. The resulting hydrogenated products may then be utilized in a variety of other commercial applications, such as to render cellulosic products water resistant, provide a coating for numerous cellulosic products, adhesive compositions, ink compositions, firelog compositions, drilling muds or asphalt modifiers.

Owner:HRD CORP

Switch grass fuel objects with high heat output and reduced air emissions designed for large-scale power generation

InactiveUS20100139155A1Reduce exhaust emissionsHigh calorific valueBiofuelsSolid fuelsFiberNuclear engineering

Owner:RENEWAFUEL

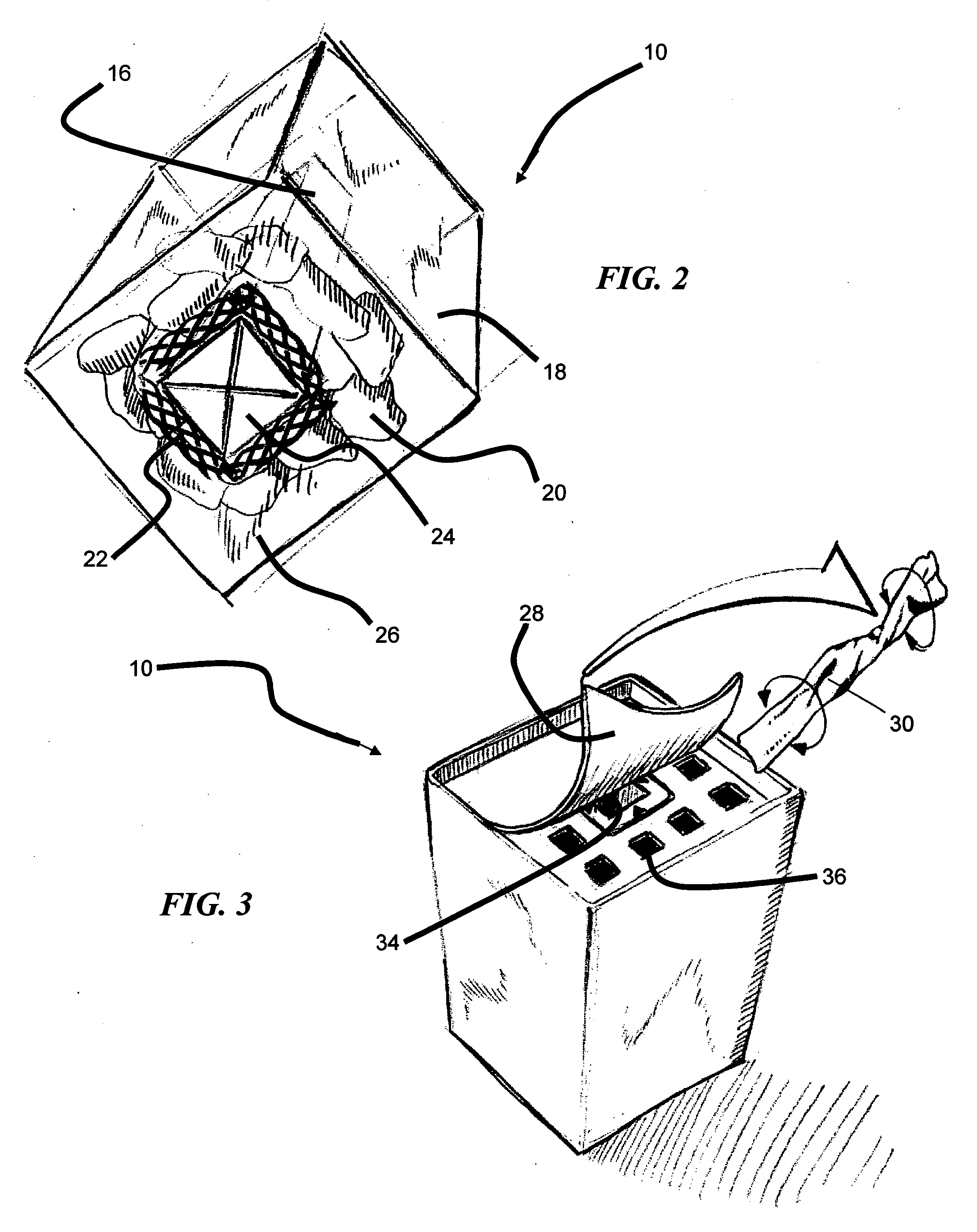

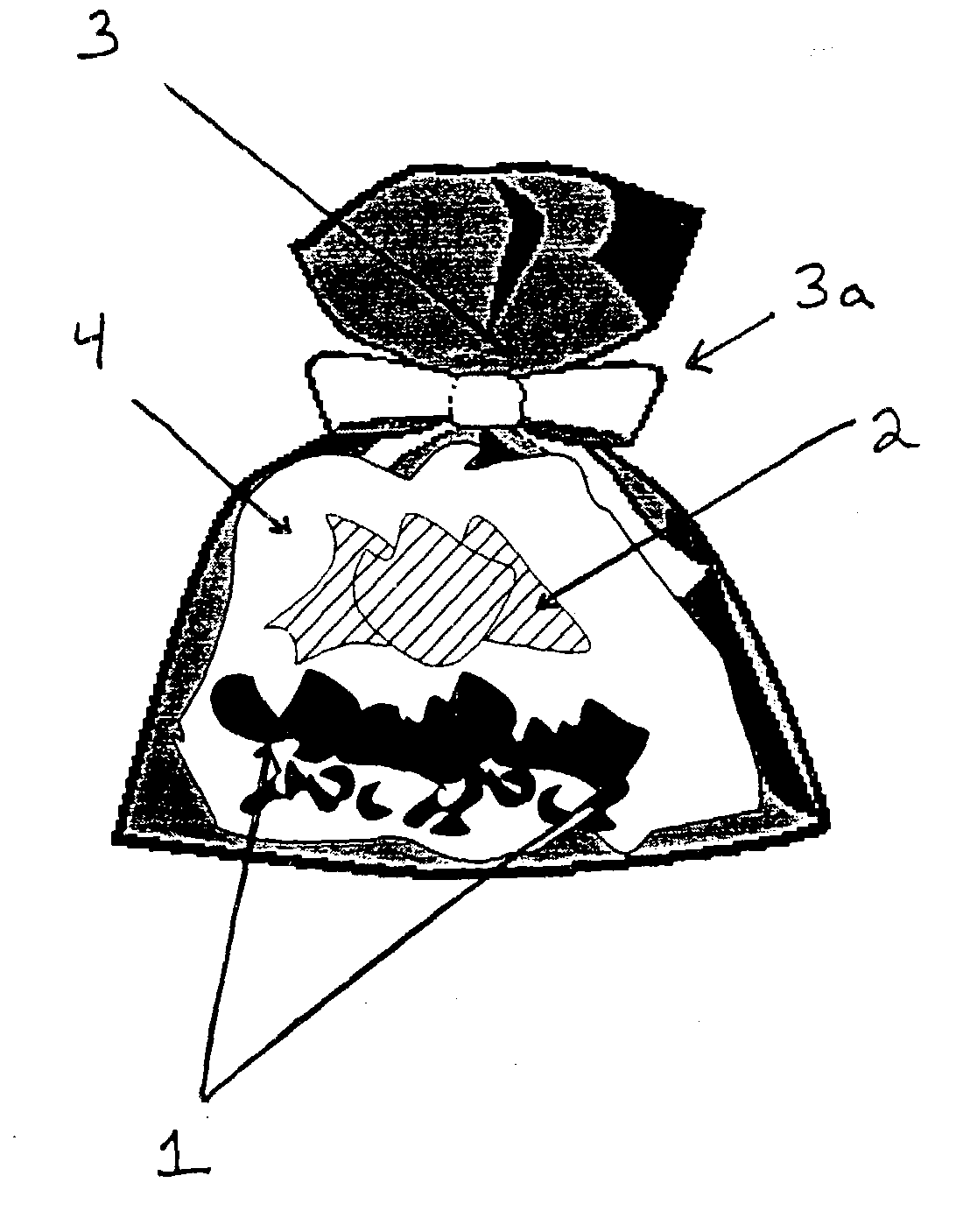

Method and apparatus for packaging charcoal fuel and other fuels for easy lighting

A combustible charcoal fuel package is disclosed which includes an outer wrapper, preferably formed from burlap or other similar woven material that encloses large pieces of charcoal material, medium pieces of charcoal material and smaller pieces of charcoal material coated or otherwise soaked in a vegetable wax to form an aggregate. The aggregate is disposed at or near the bottom of the burlap wrapper, with the medium-size pieces of charcoal material disposed thereon with the larger pieces of charcoal material disposed on top of the medium-sized pieces of charcoal material. Preferably, all charcoal materials are fabricated from all-natural charcoal logs fabricated from compressed charcoal particles without the use of odor causing binders.

Owner:SUMMIT VIEWS

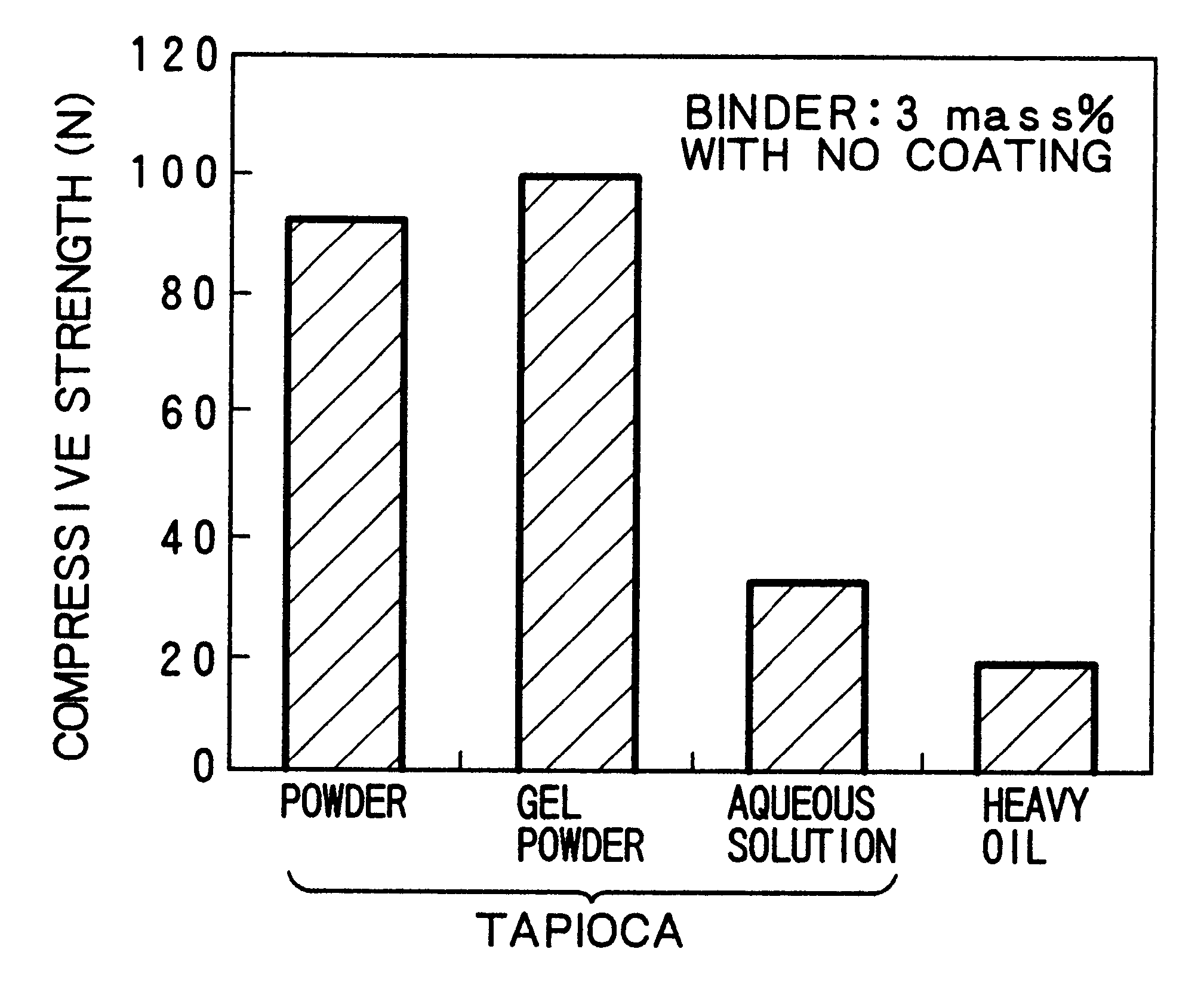

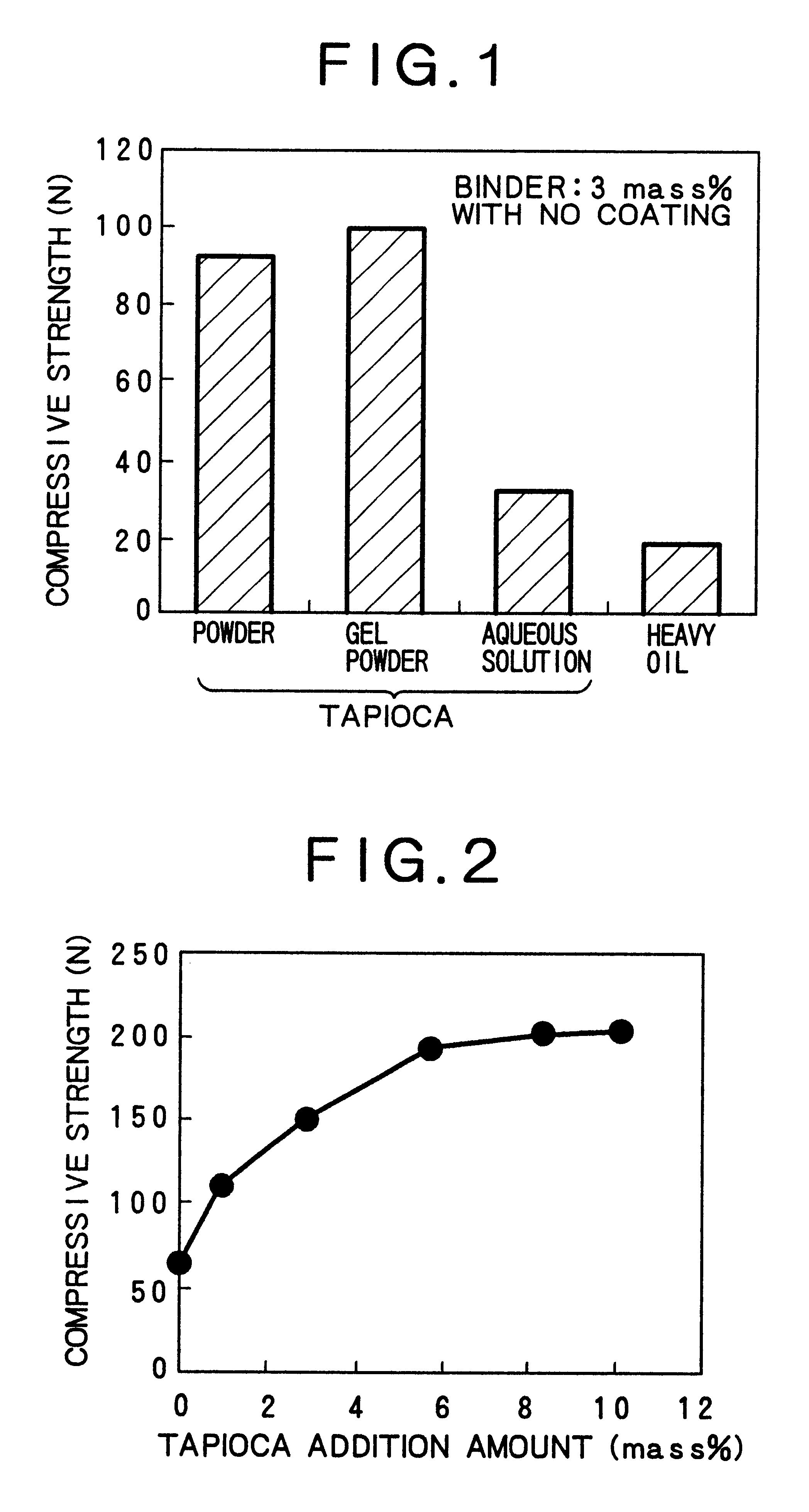

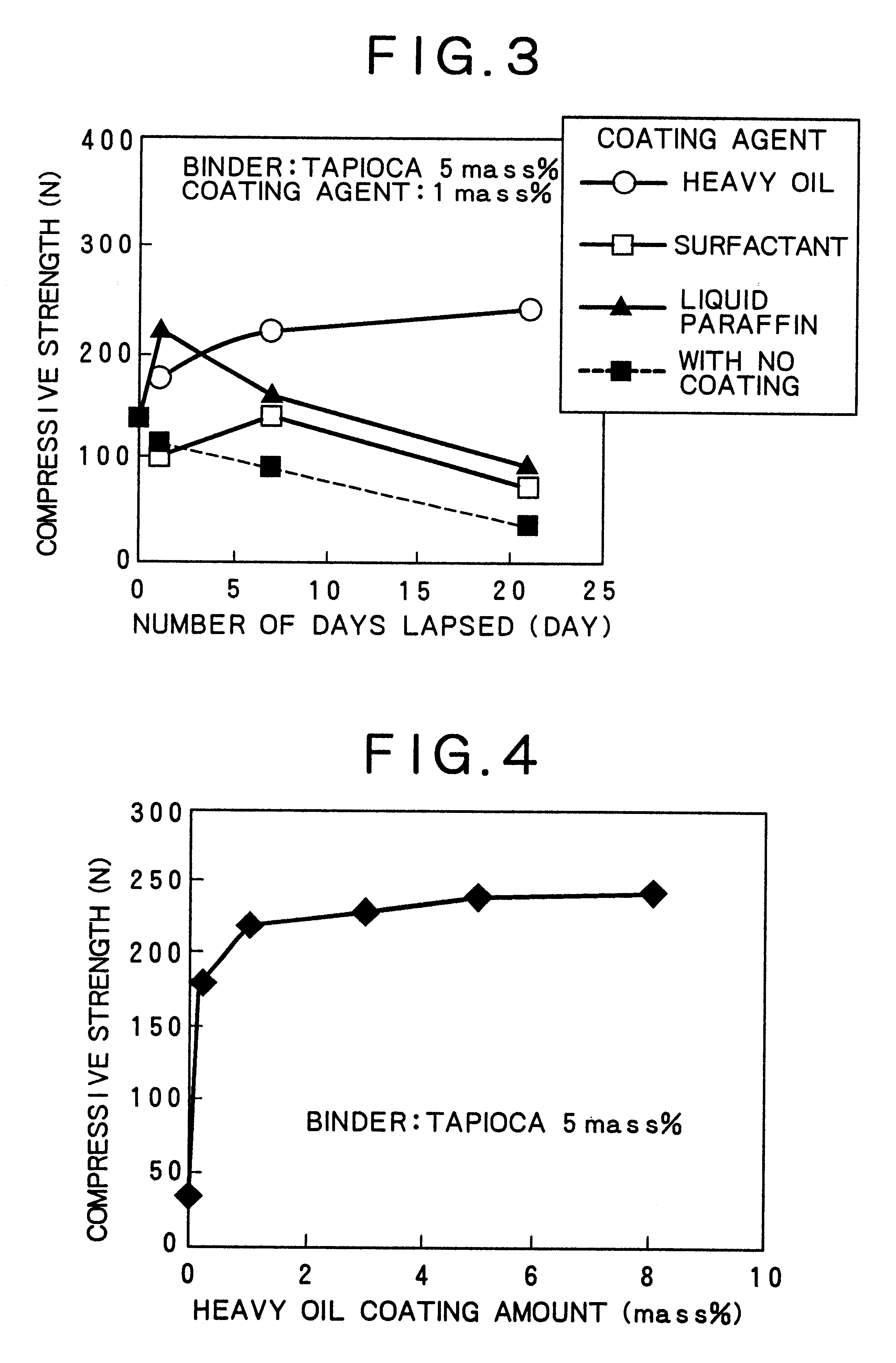

Coal briquette and production thereof

A method of producing coal briquette at a low energy cost by saving heating step or drying step for fine coal, which comprises adding and mixing from 1 to 10 mass parts of powdery starch to a coal having 15 mass % or more of water content and comprising 50 mass % or more of particles with grain size of 5 mm or less to form 100 mass parts of a mixture, and coating the surface of the briquette product with 0.1 to 5 mass parts of a heavy oil component simultaneously with or after pressure briquetting the mixture by a double roll briquetting machine in which concaves are formed on the roll surface, as well as coal briquette which is inexpensive and has high strength and high waterproof.

Owner:KOBE STEEL LTD

Agricultural fibre fuel pellets

A method of preparing fuel pellets includes the steps of providing a feedstock in the form of agricultural hull fibres. The agricultural hull fibres may be derived from all whole grains and seeds. For example, are comprised of at least one of corn bran, rye bran; oat bran, rice bran, soy bran, canola bran and wheat bran. The method may include the step of mixing the feedstock with a sequestering agent before being formed into pellets for sequestering alkali metal vapors and raising the fusion point of the inorganic elements during combustion of the pellets. The sequestering agent may be calcium carbonate added in amounts up to about 0.5% by weight. The pellets contain additives comprised of ammonium nitrate, calcium, manganese, magnesium, aluminum, barium, iron, potassium and amorphous silicate, which sequester potassium and chlorides.

Owner:EVERGREEN BIOFUELS

Fire log

InactiveUS20090307968A1Easy to igniteIncrease or decrease intensitySawing apparatusBiofuelsMostly TrueEngineering

A fire log includes a single fire log cut in a specific design to enable easy ignition and sustenance of a self-contained campfire. The single log is designed to stand vertically and may range from twenty-four to seventy-two inches in height depending on diameter. In most instances, four vertical, diametrical cuts are made in the log forming eight pie-slice segments. The cuts extend from the top surface of the log downward toward the base of the log. The vertical cuts stop short of the entire length of the log leaving approximately 25% of the length uncut. The uncut portion forms the base of the log. One of the segments is cut horizontally at its lower end adjacent the top of the base so that the segment can be removed from the log for air flow control.

Owner:PARKER WALTER Z

Combustible article

Owner:BLACKMORE RICHARD GUY

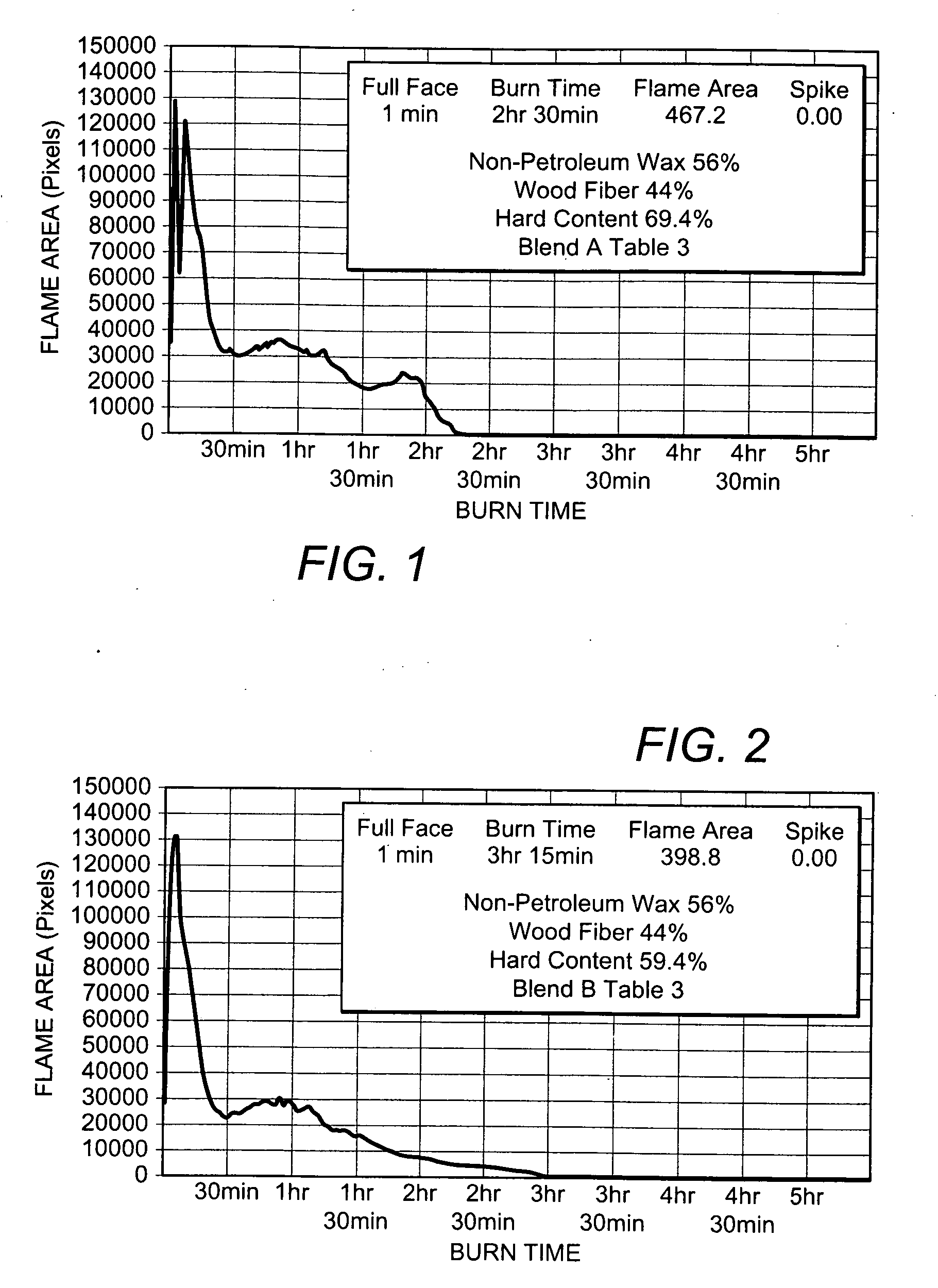

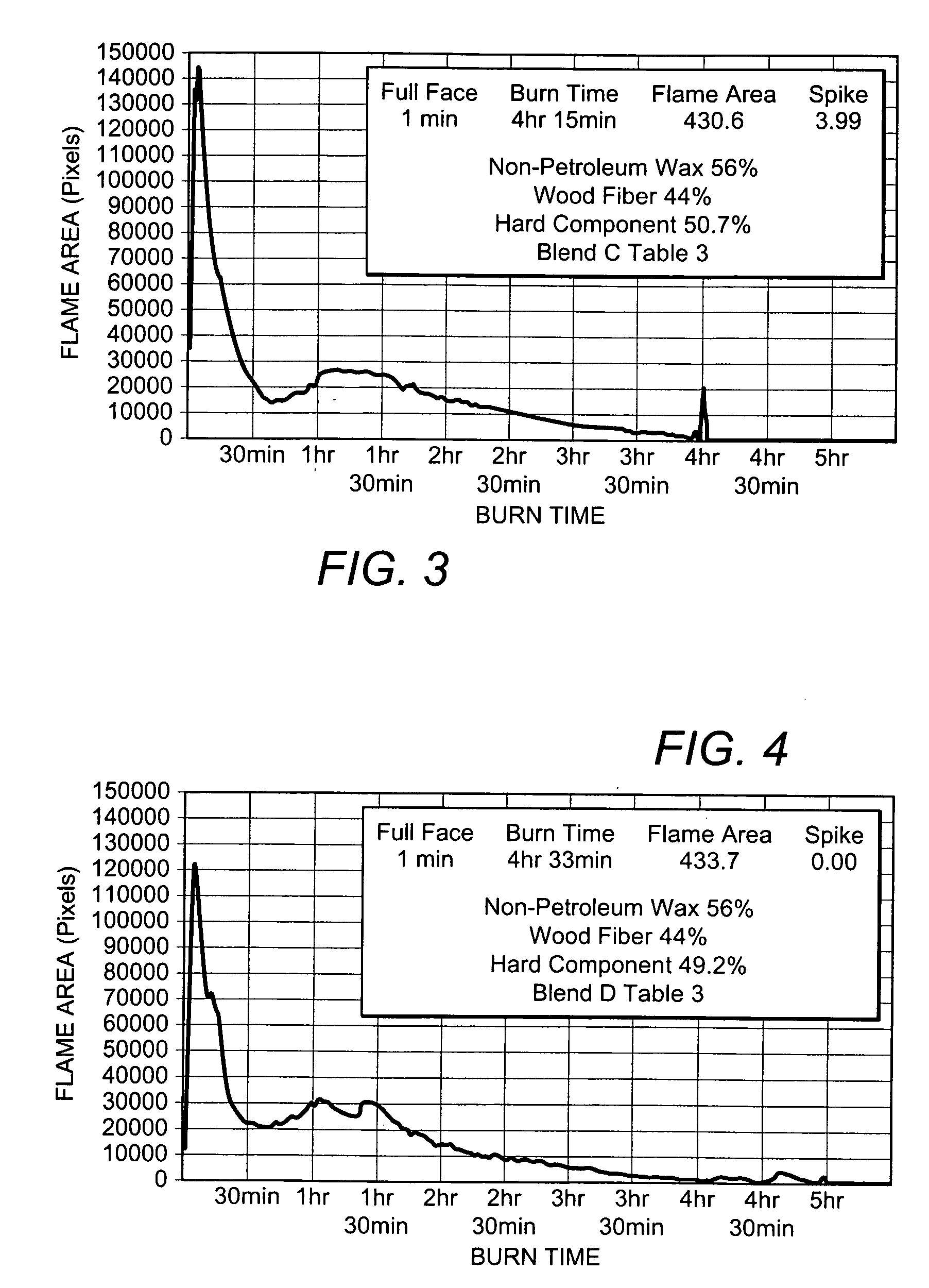

Artificial firelog using non-petroleum waxes

InactiveUS20080196301A1Lower cost end product without an appreciable loss in heat energy contentEnhanced environmental sustainability characteristicBiofuelsSolid fuelsWaxRelative scale

An artificial firelog of the invention includes as constituents (a) a combustible cellulosic material and (b) a combustible non-petroleum wax, wherein the relative proportions of the constituents are, by weight, from about 30% to about 70% of (a) and from about 30% to about 70% of (b) for 100 parts of (a) and (b). In one form of the invention, the combustible non-petroleum wax constituent may include one or more combustible materials derived from plant oils, vegetable oils, animal oils, fats, rosin, pitch, waxy materials and combinations thereof. In another form of the invention, the combustible non-petroleum wax constituent may include a formulated blend of individual non-petroleum wax components. In yet another form of the invention a combustible binding agent can be added to the blend of materials resulting in reduction of the portion of the more costly combustible wax component. A firelog according to the invention can provide a number of benefits, including lower cost, better lighting and flaming performance, and more environmentally sustainable in comparison to firelogs using petroleum waxes.

Owner:DURAFLAME

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com