Combustible smoke-free briquette

a smoke-free, briquette technology, applied in biofuels, waste-based fuels, fuels, etc., can solve the problems of incomplete carbonization of charcoal products, and inability to completely replace coal and charcoal products, etc., to achieve excellent cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

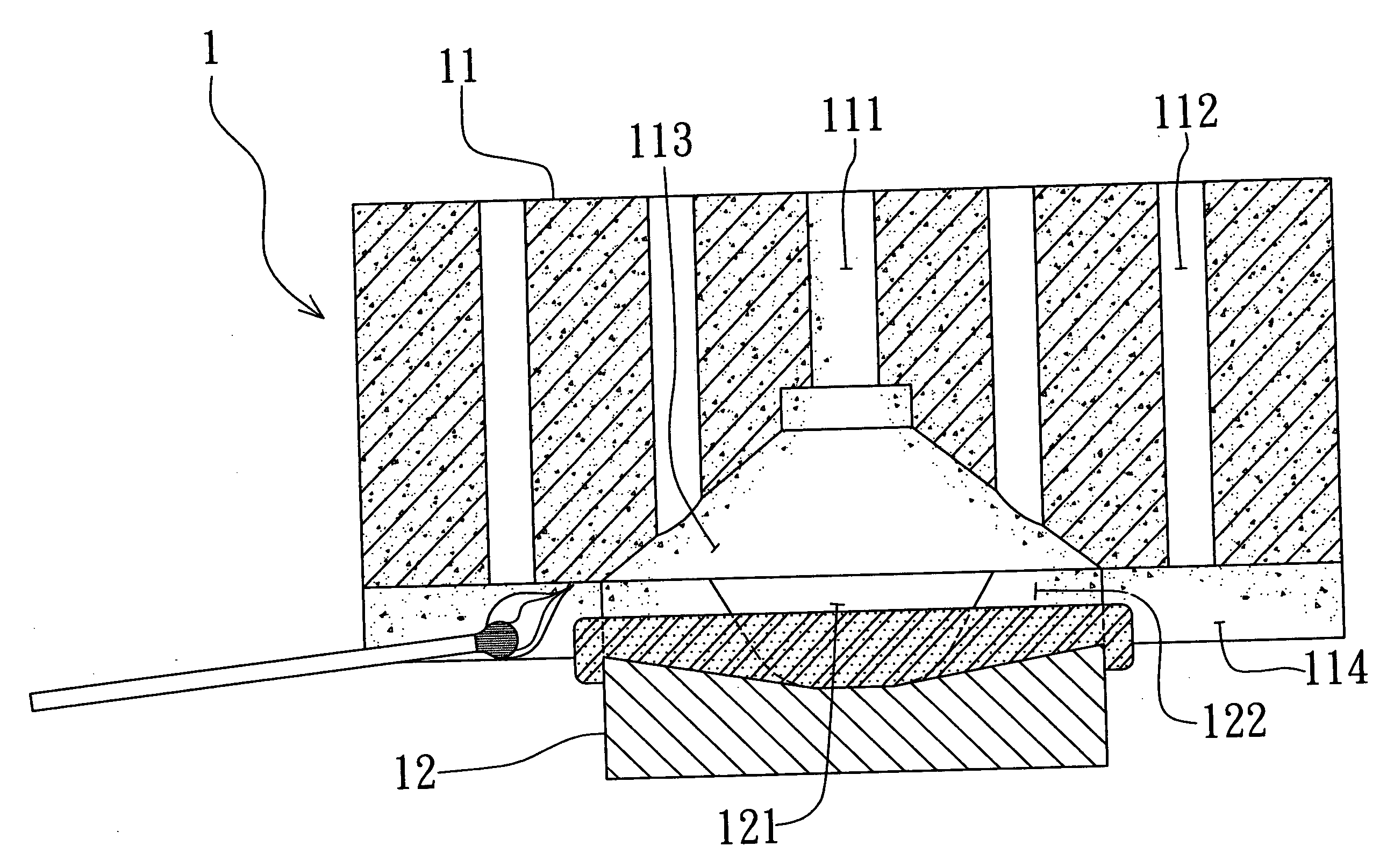

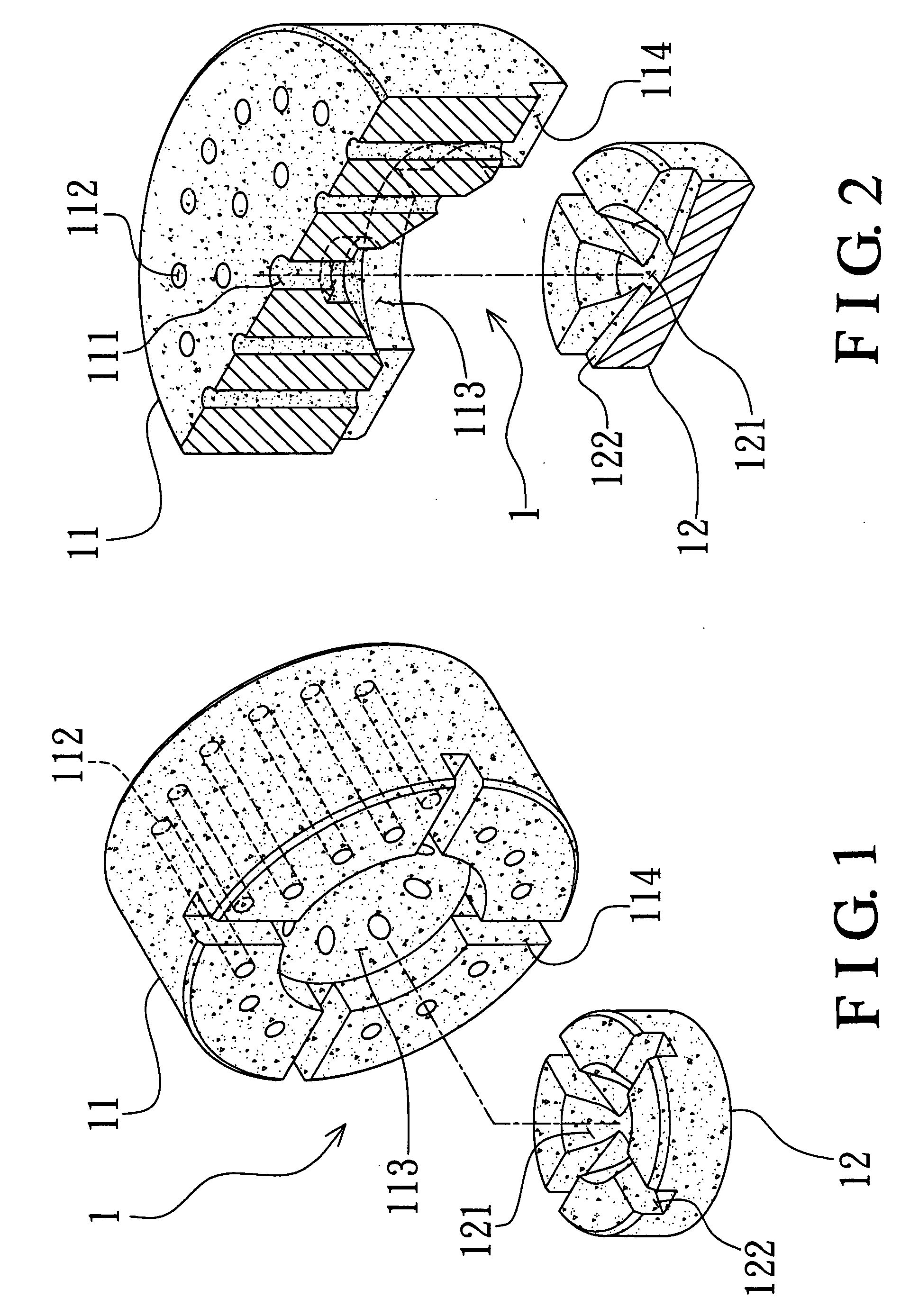

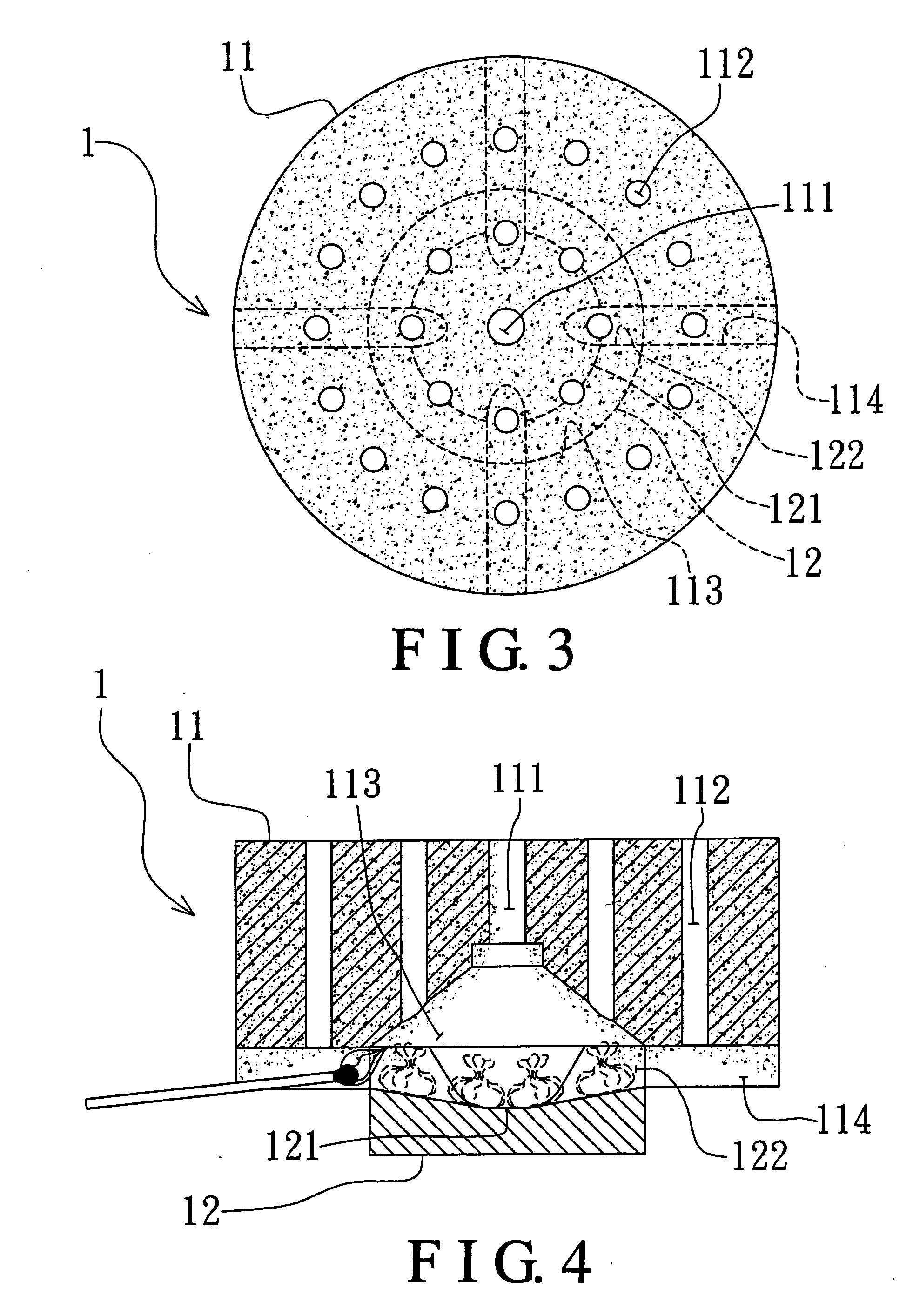

[0018] Referring to FIGS. 1 and 2, a preferred embodiment 1 of a combustible smoke-free briquette includes an upper briquette part 11, and a lower briquette part 12.

[0019] Both the upper and the lower briquette parts 11 and 12 are made of completely carbonized cinders of agricultural waste and natural waste such as burnt shells of grains and small pieces of grass and wood, which agricultural waste and natural waste are burnt in closed kilns at high temperature. And, the briquette parts 11 and 12 are formed by means of compressing and drying a mixture of the completely carbonized cinders and those kinds of incombustible adhesives that won't decompose when heated, e.g. water glass (sodium silicate solution), and clay.

[0020] The upper briquette part 11 has several through holes 111 and flame passages 112 extending from an upper side to a lower side thereof, a combustion room 113 for kindling materials on the lower side, and several air passages 114 on the lower side, which communicate...

second embodiment

[0030] 6. Pans, barbecue grilles and so on can be directly positioned on the briquette without use of an additional stove because the upper briquette part (the second embodiment) has the supporting portions on the upper side thereof.

[0031] 7. Because the briquette has the flame passages, little light will be present owing to the flames when the briquette is burning. Therefore, people a distance away won't notice the briquette when the briquette is burning, and the briquette can be used by militaries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com