Patents

Literature

540results about How to "Raw materials are simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxide catalyst composition

InactiveUS7012039B2High selectivityLow selectivityOrganic compound preparationCarboxylic acid esters preparationLanthanideMethacrolein

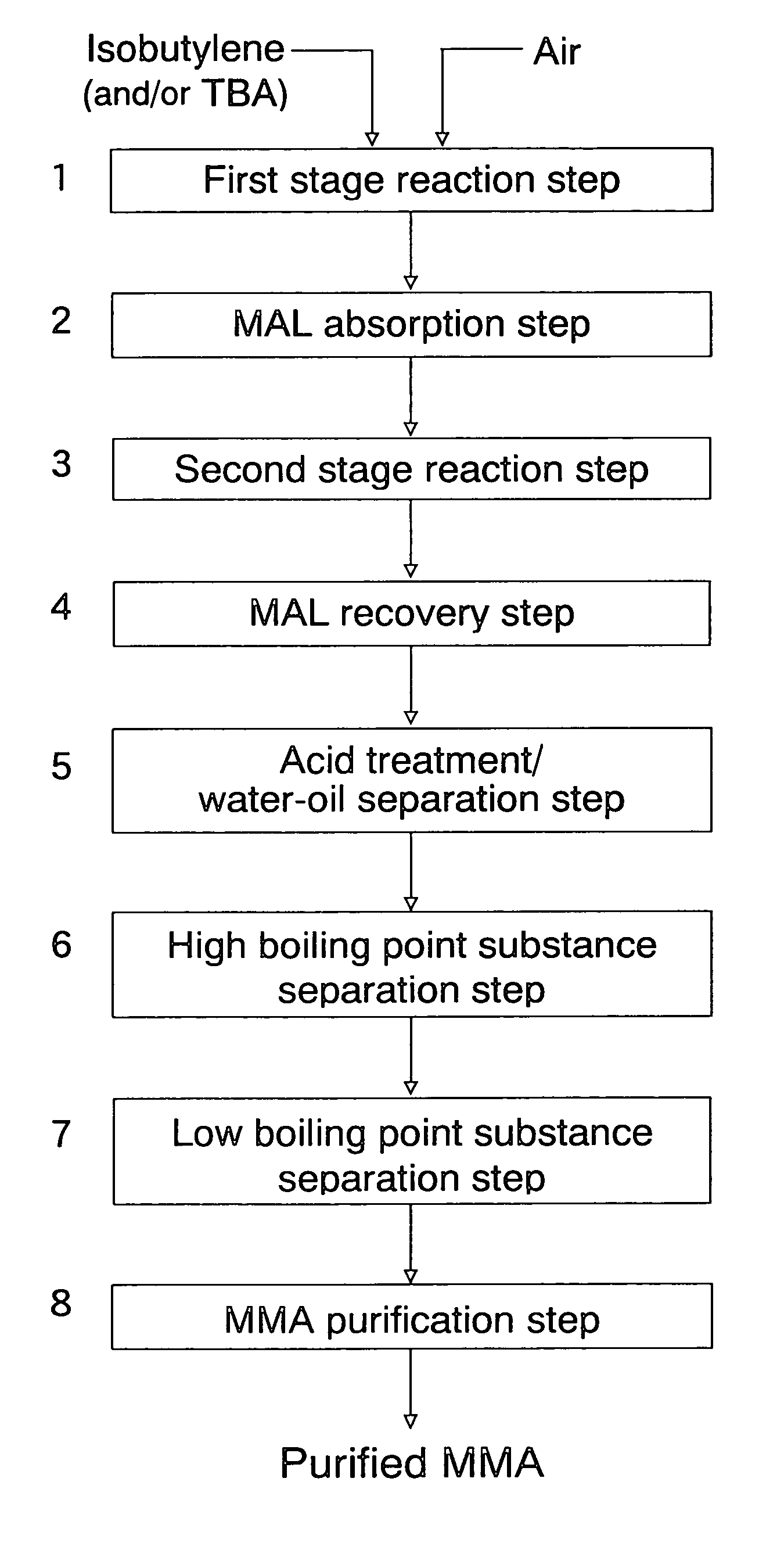

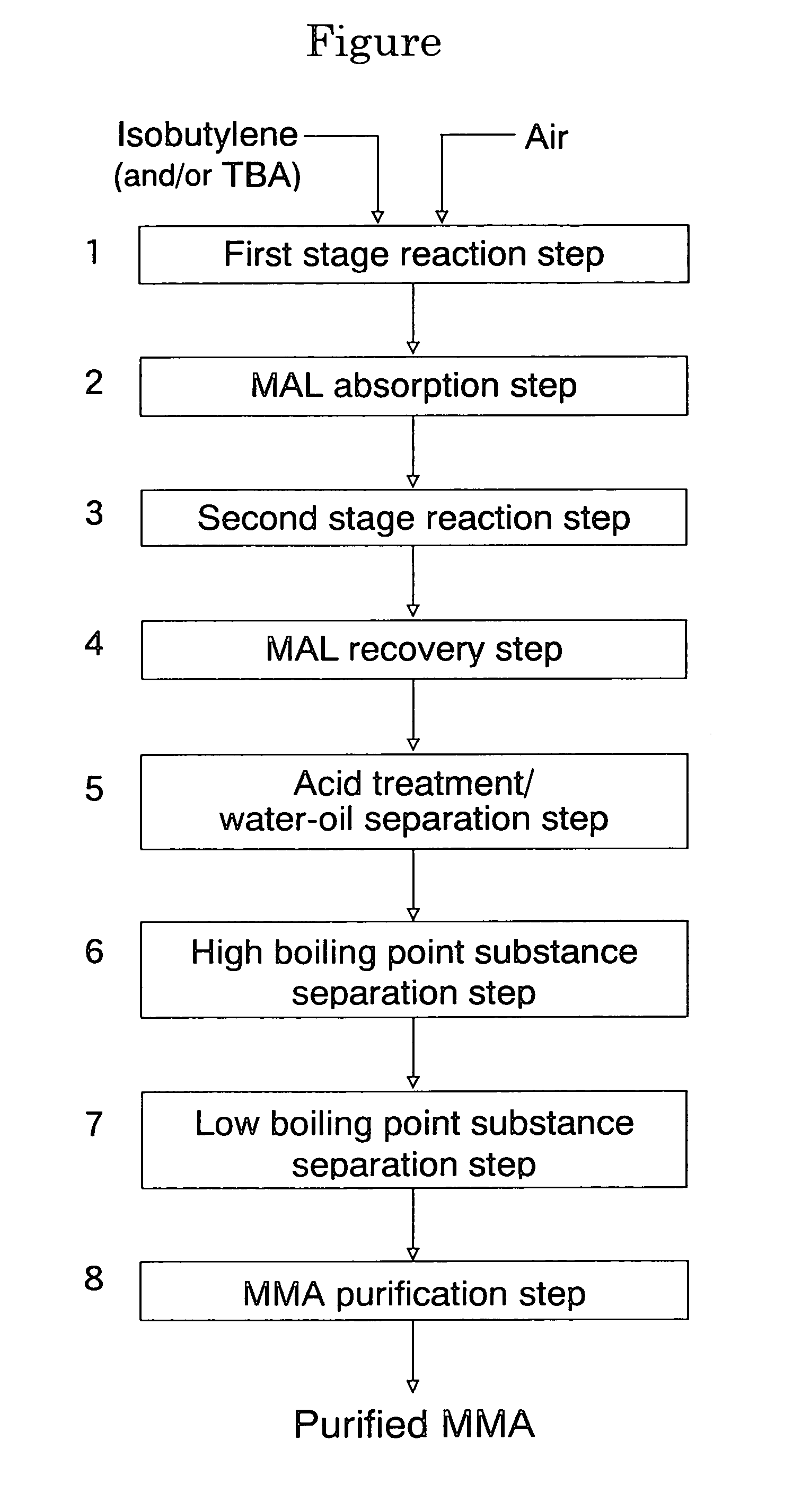

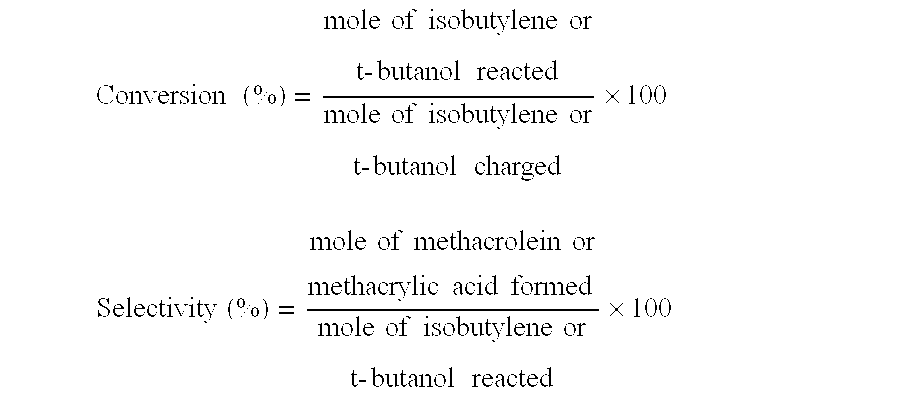

An oxide catalyst composition for use in producing methacrolein or a mixture of methacrolein and methacrylic acid, wherein the oxide catalyst composition is represented by the formula (Mo+W)l2BiaAbBcFedXeSbfOg, wherein: A is at least one member selected from the group consisting of Y and the elements of the lanthanoid series exclusive of Pm; B is at least one member selected from the group consisting of K, Rb and Cs; X is Co solely, or a mixture of Co and at least one member selected from the group consisting of Mg and Ni; and a, b, c, d, e, f and g are, respectively, the atomic ratios of Bi, A, B, Fe, X, Sb and O, relative to twelve atoms of the total of Mo and W, wherein the atomic ratios (a to f) of the elements and the relationship between the amounts of the elements are chosen so as to satisfy specific requirements.

Owner:ASAHI KASEI CHEM CORP

Cellulose Nonwoven Fabric

ActiveUS20070207692A1Raw materials are simpleSimple structureFats/resins/pitch/waxes removal in pulpPaper/cardboardPorosityCellulose fiber

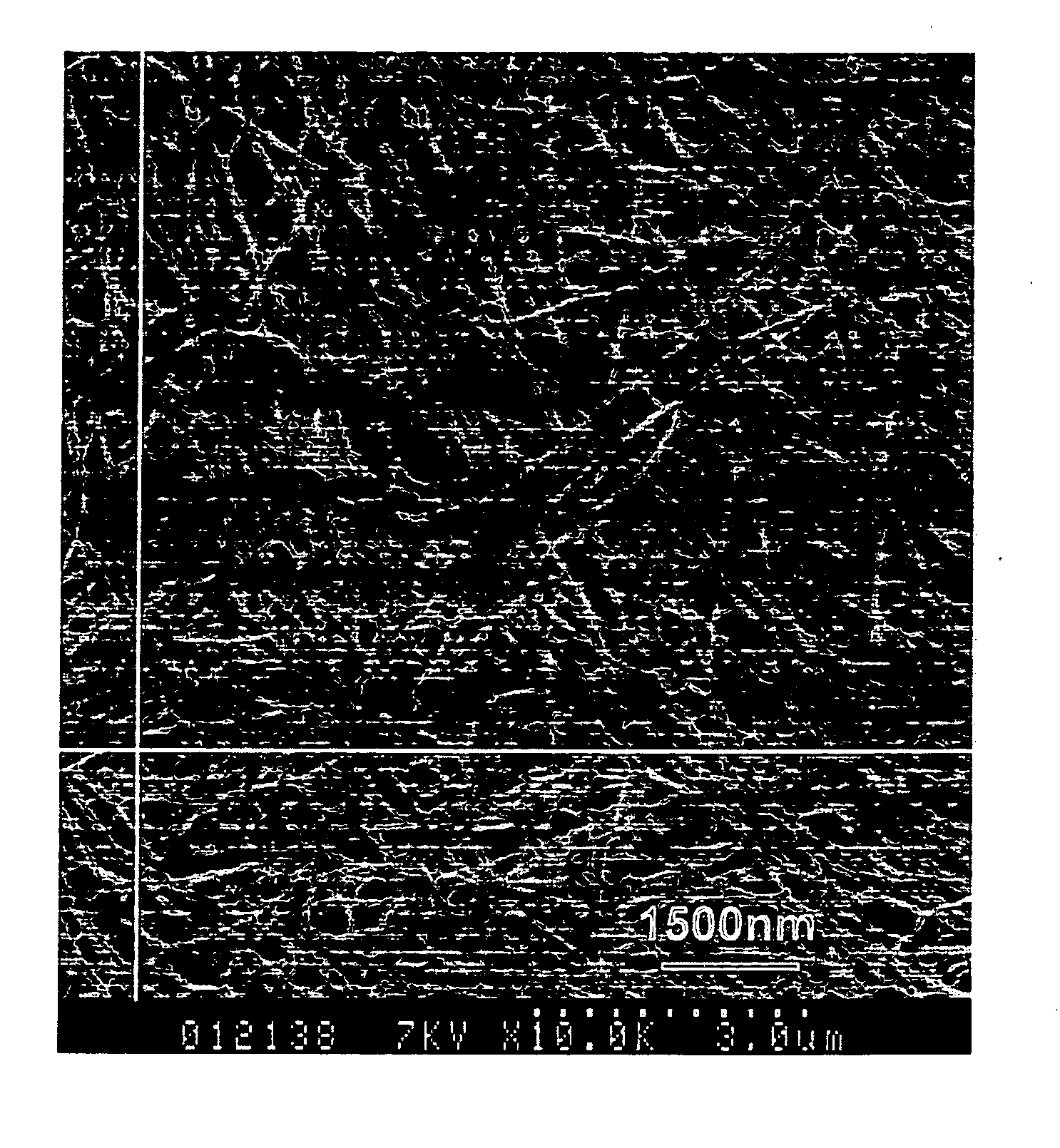

Disclosed is a cellulose nonwoven fabric containing cellulose fibers having a maximum fiber diameter of not more than 1500 nm and a crystallinity determined by solid state NMR techniques of not less than 60%. The porosity of the cellulose nonwoven fabric is not less than 40% and not more than 99%.

Owner:ASAHI KASEI KK

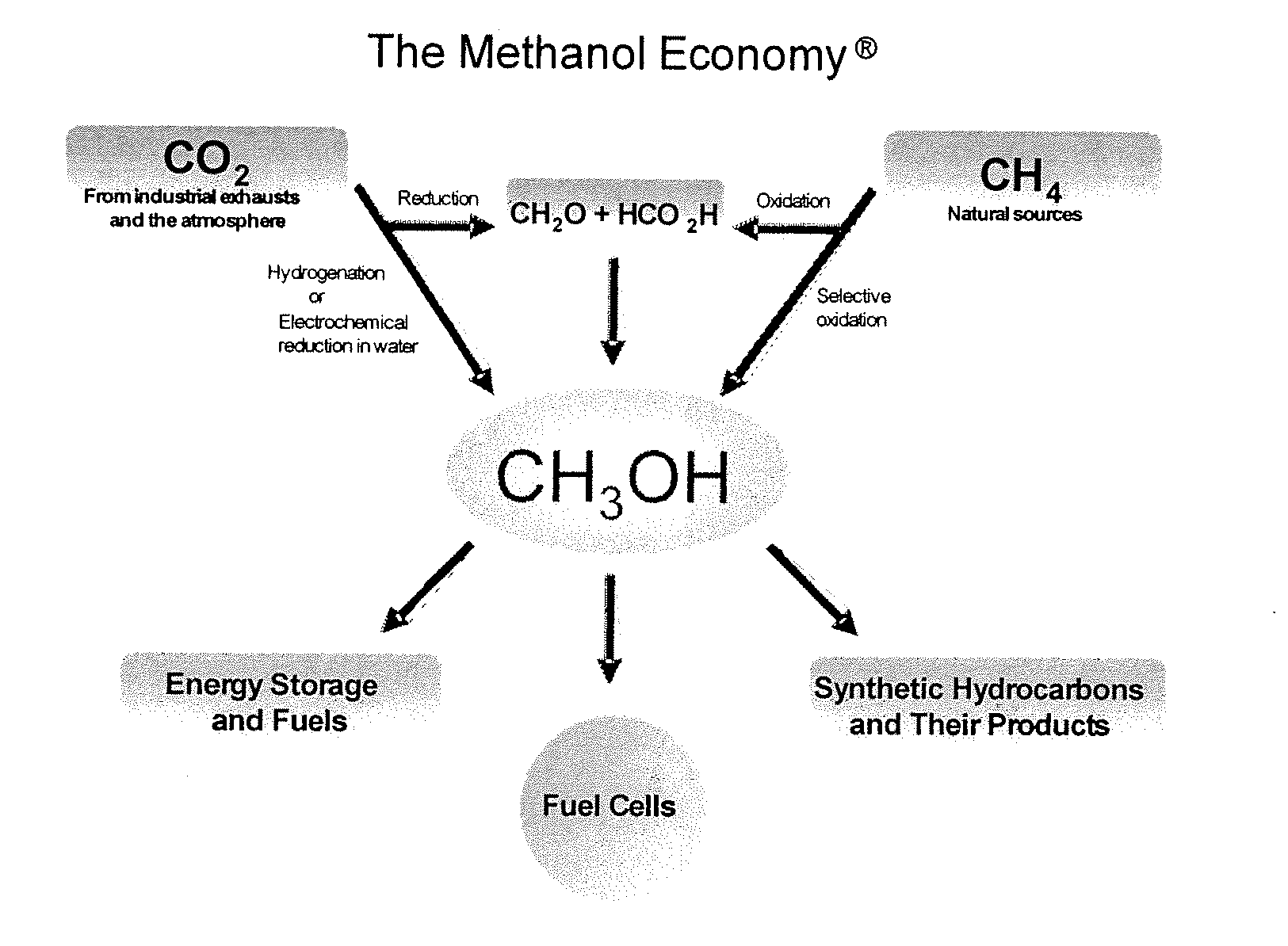

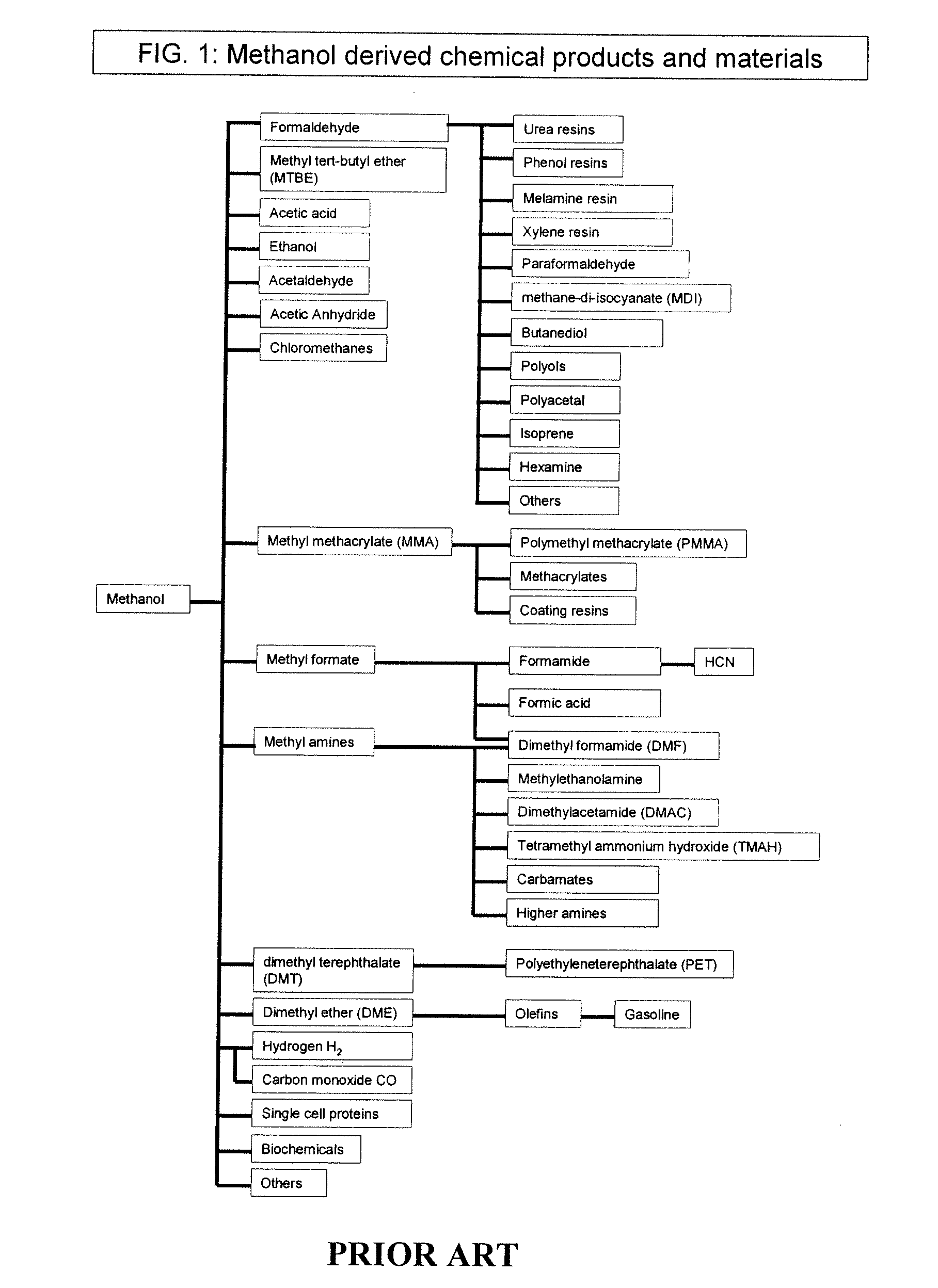

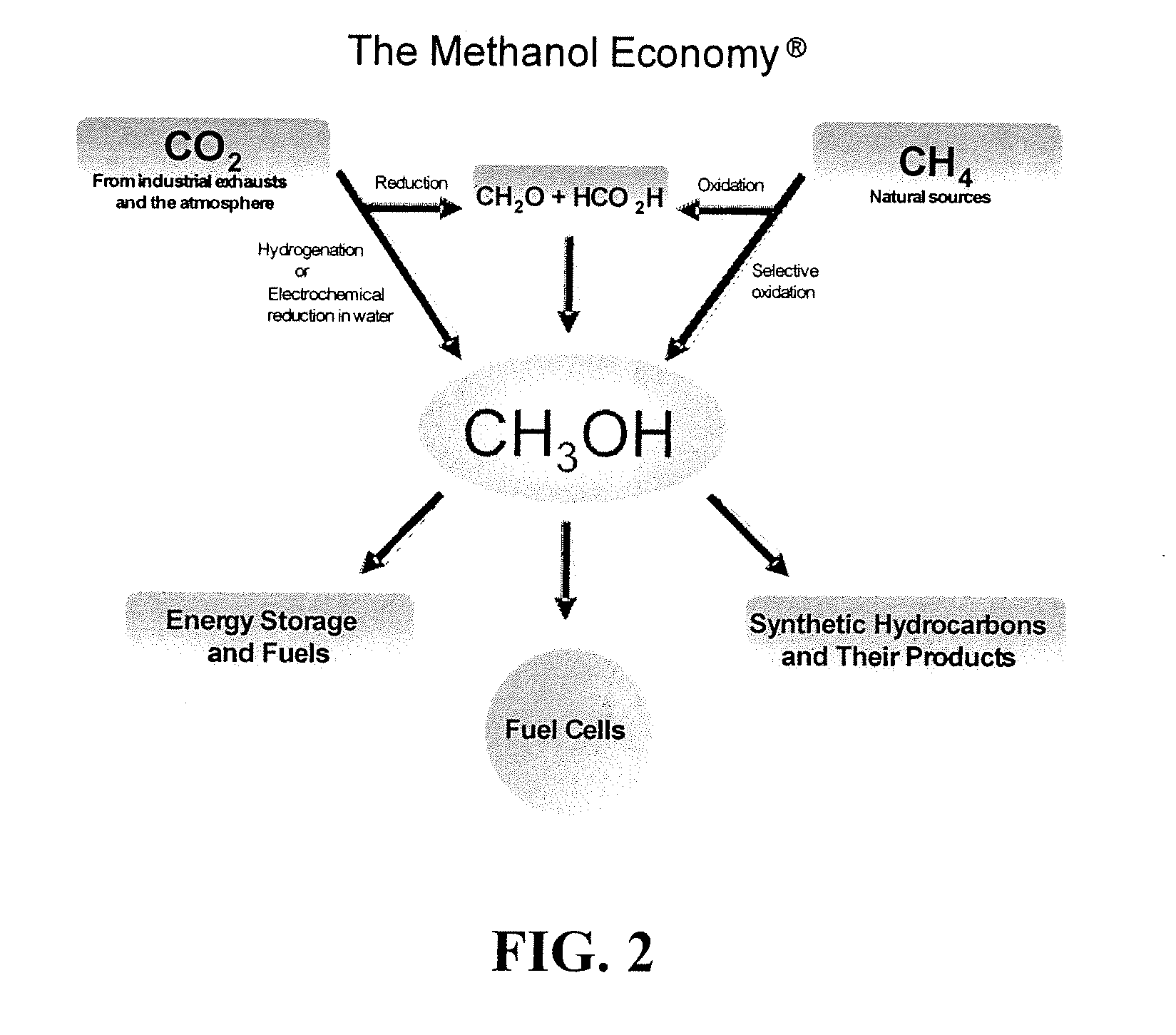

Conversion of carbon dioxide to methanol and/or dimethyl ether using bi-reforming of methane or natural gas

ActiveUS20080319093A1Raw materials are simplePromote recoveryPreparation by oxidation reactionsHydrogenCatalytic methodHydrogen

The invention discloses a method of converting carbon dioxide to methanol and / or dimethyl ether using any methane source or natural gas consisting of a combination of steam and dry reforming, in a specific ratio to produce a 2:1 molar ratio of hydrogen and carbon monoxide with subsequent conversion of the CO and H2 mixture exclusively to methanol and / or dimethyl ether. This method is termed the BI-REFORMING™ process. Dehydrating formed methanol allows producing dimethyl ether (DME) using any suitable catalytic method, including use of solid acid catalysts. When recycling formed water into the bi-reforming step the conversion of carbon dioxide with methane produces exclusively dimethyl ether without any by-product formation and complete utilization of hydrogen

Owner:UNIV OF SOUTHERN CALIFORNIA

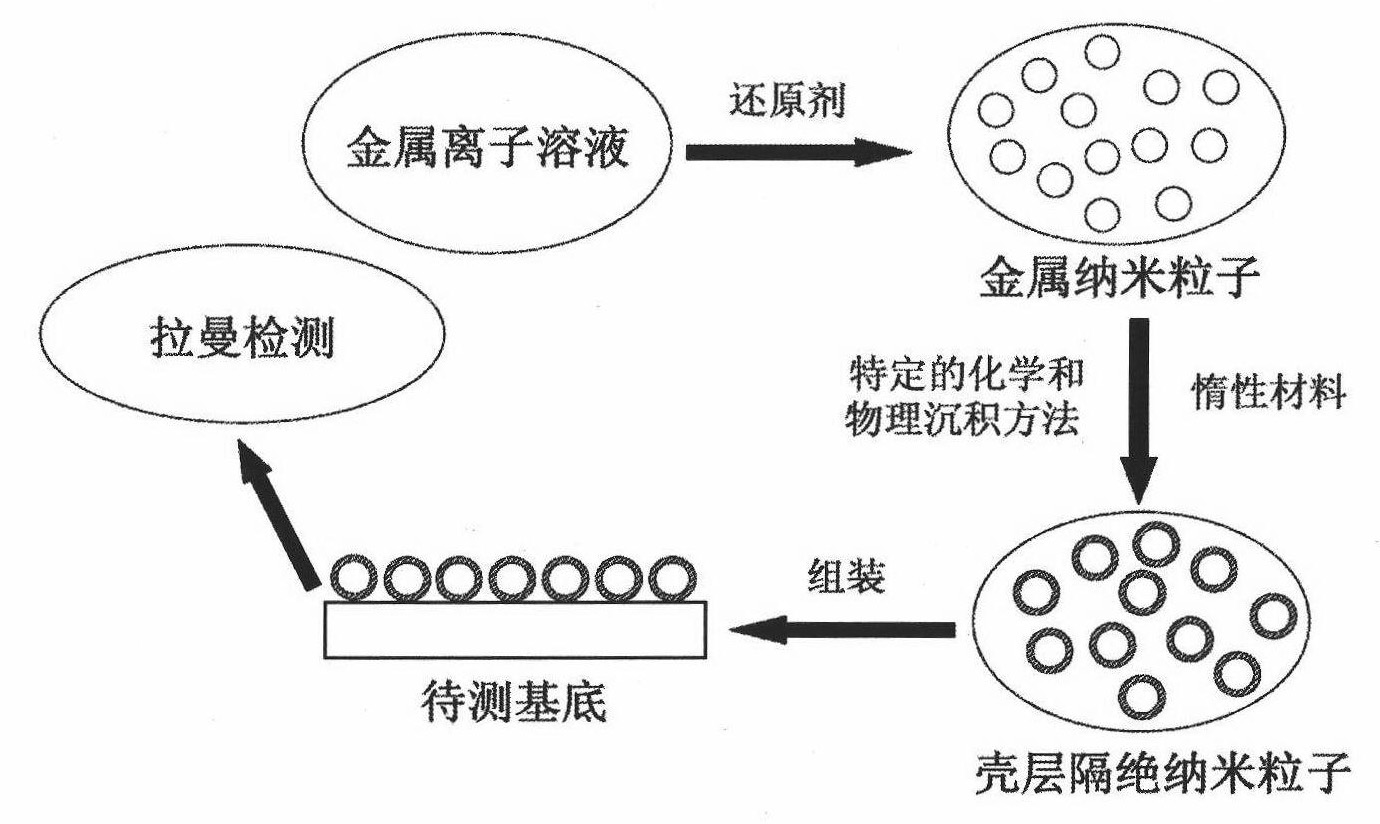

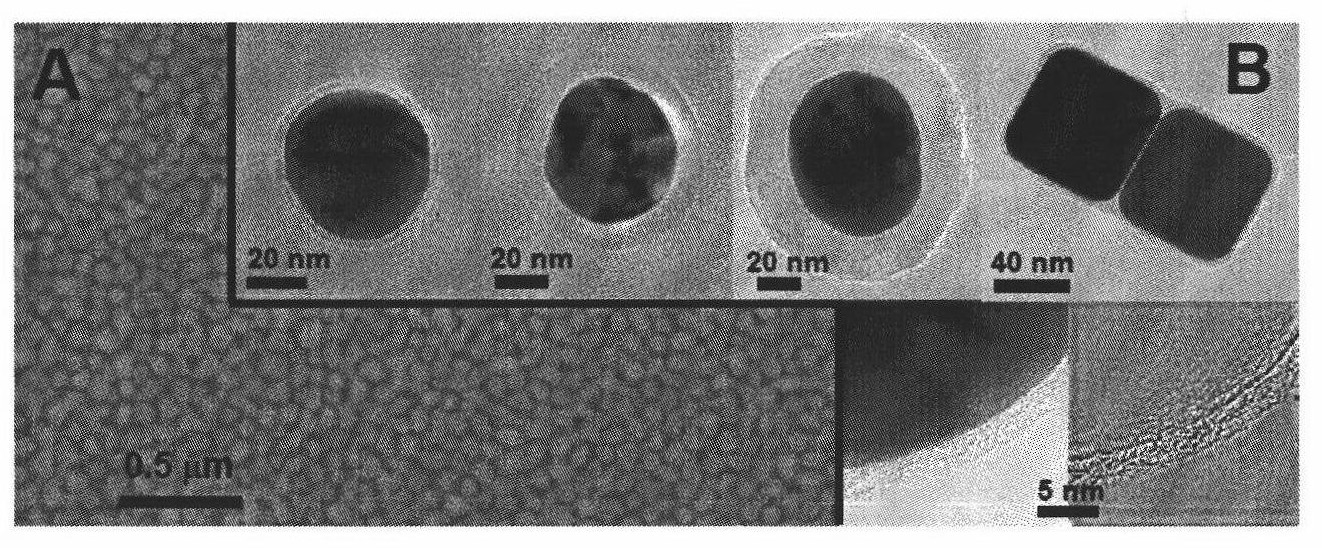

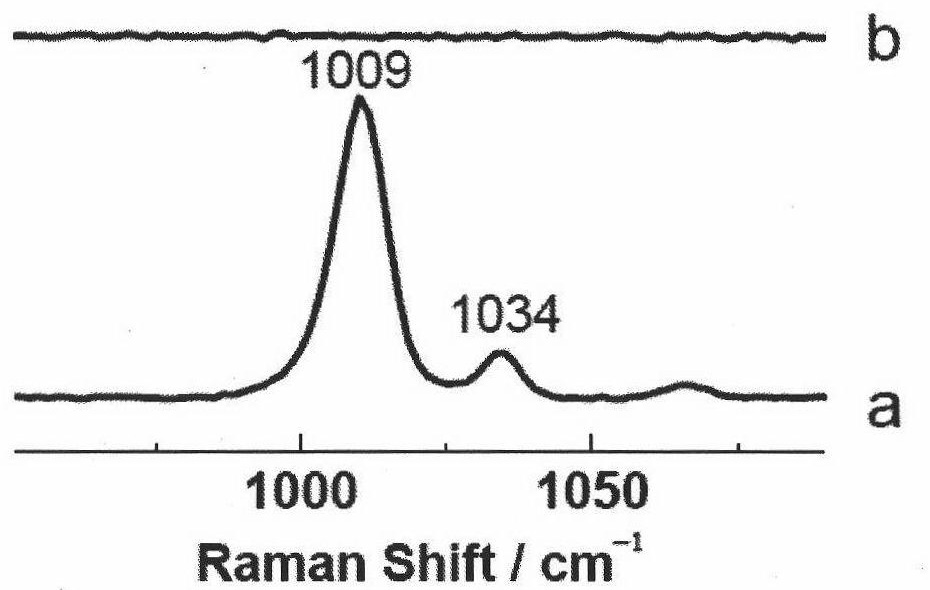

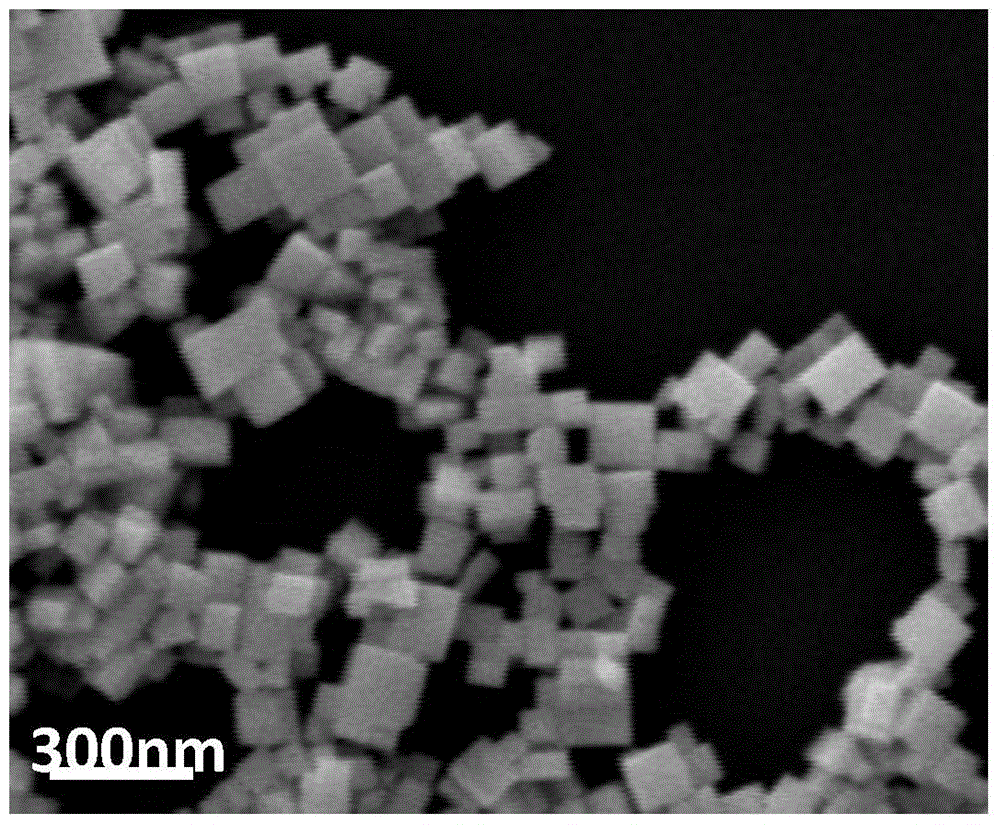

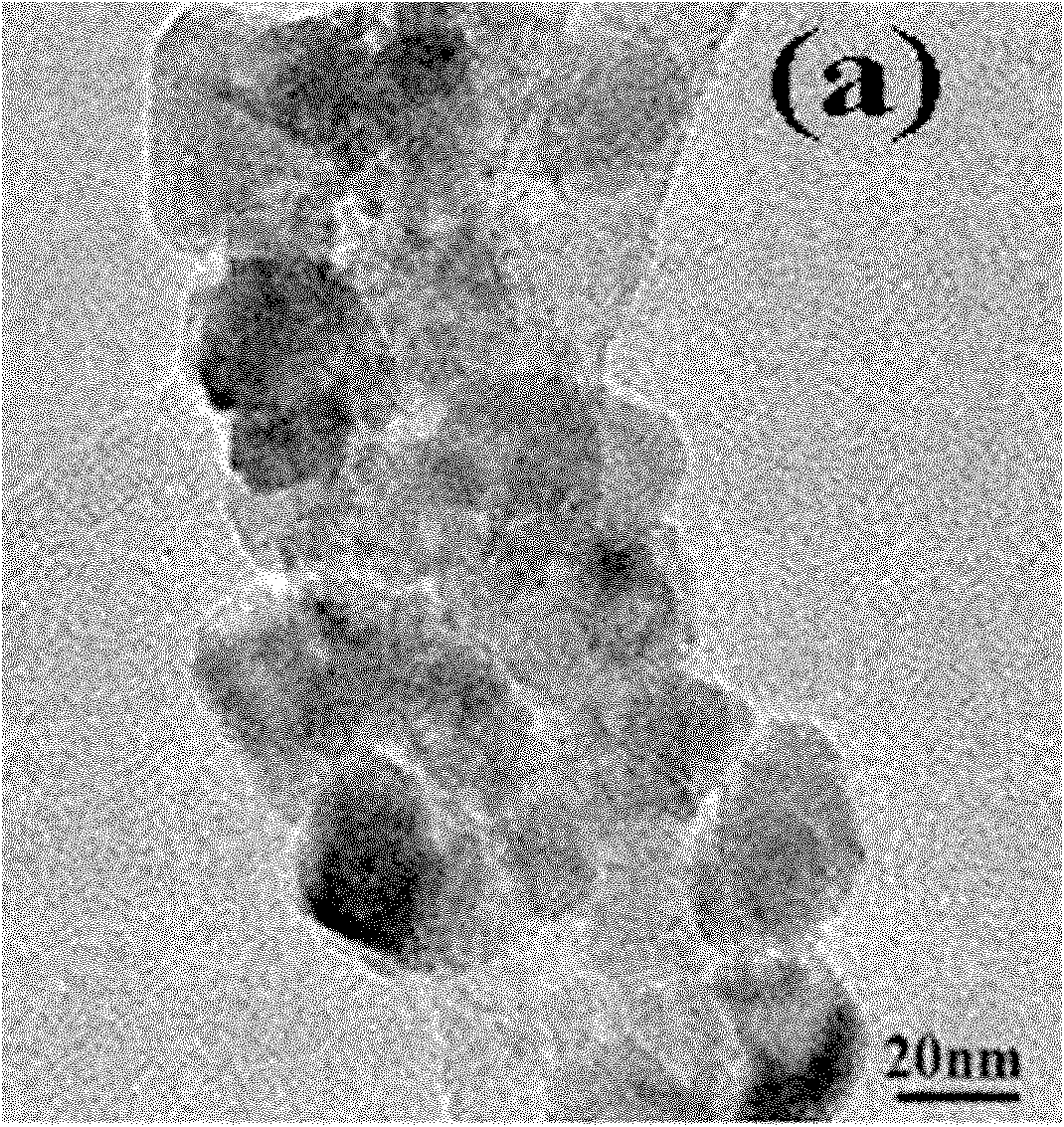

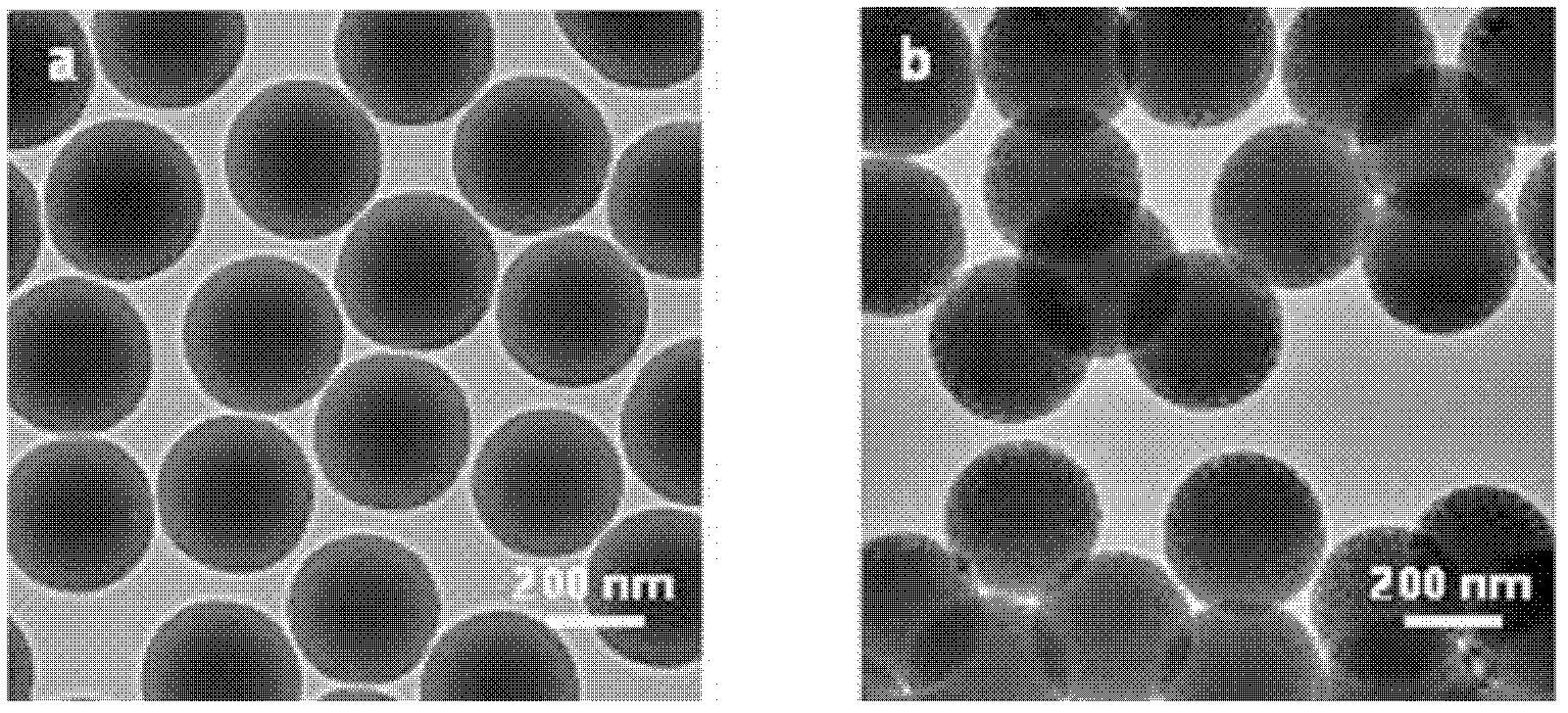

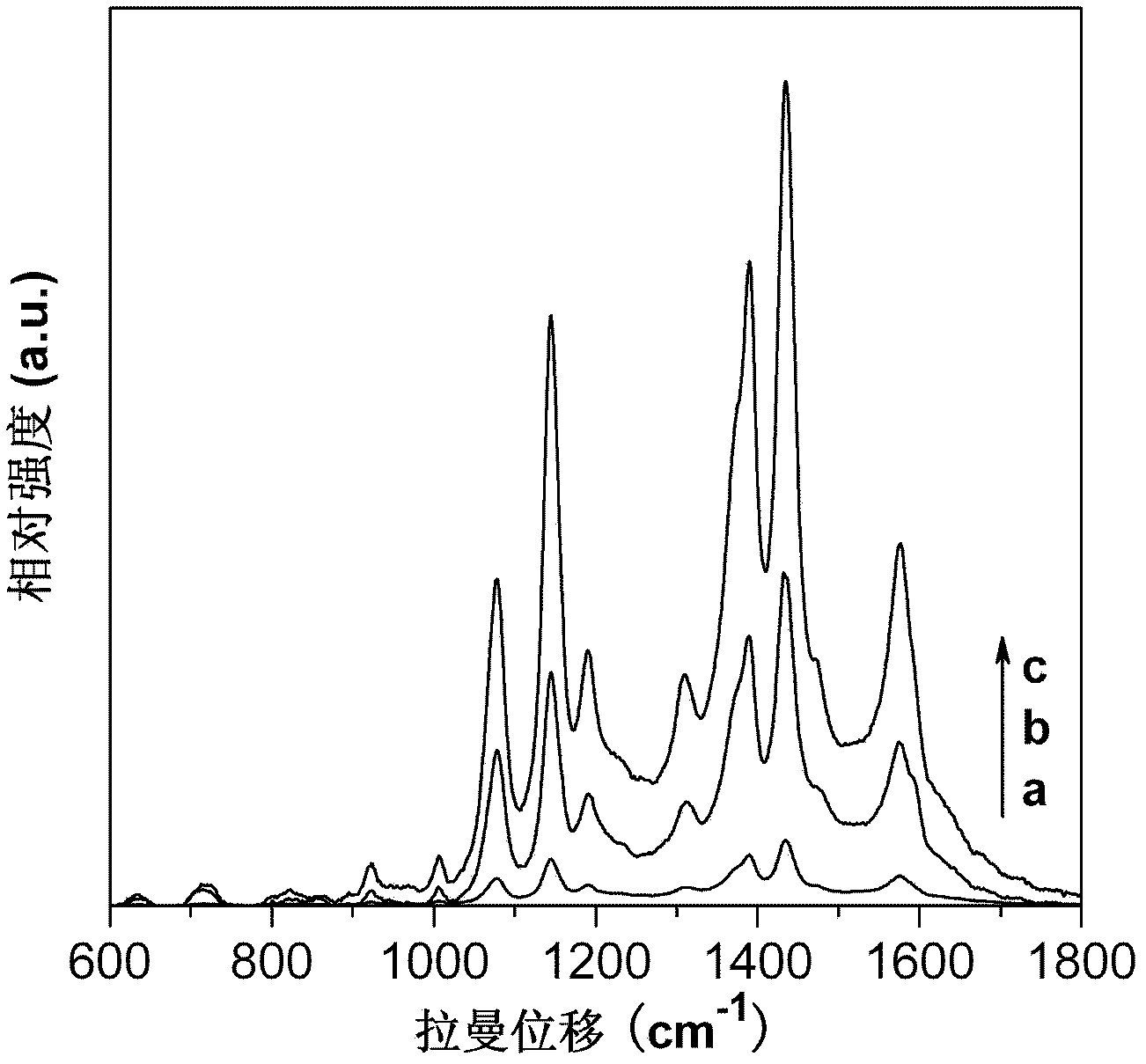

Method for enhancing Raman spectrum by using shell isolated nano particles

ActiveCN101832933AThe preparation method and raw materials are simpleHigh detection sensitivityRaman scatteringThin shellsL-shell

The invention relates to a method for enhancing a Raman spectrum by using shell isolated nano particles, relating to the field of detection of laser Raman spectrums. The invention provides the universal method which has easy and fast preparation, low cost, strong Raman signal, good repeatability and accurate result, and is used for enhancing the Raman spectrum by using the shell isolated nano particles. The method comprises the following steps of: preparing the shell isolated nano particles with nuclear shell structures taking metal nano particles as kernels and extremely-thin shell inert materials as outer shells; uniformly scattering the shell isolated nano particles on the surface of a sample to be measured; and directly detecting the surface enhanced Raman spectrum.

Owner:XIAMEN PUSHI NANO TECH CO LTD

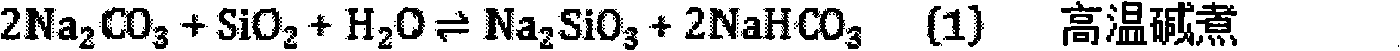

Method for producing porous nano silica and active carbon by utilizing rice hull ash

InactiveCN101920966AIncrease the reaction areaImprove reaction speedSilicaSolid waste disposalActive carbonChemistry

The invention discloses a method for producing porous nano silica and active carbon by utilizing rice hull ash, which comprises the following steps of: at lower temperature and normal pressure, performing secondary alkali dissolution on subcarbonate, and filtering to obtain alkali-dissolved filter liquor and filter residue; adding a certain amount of dispersing agent into the filter liquor, reducing temperature for ageing, filtering, washing, and removing the dispersing agent to obtain the porous nano silica; and adding an activating agent into the alkali-dissolved filter residue, activating, washing and drying to obtain the high specific surface area active carbon. The alkali and the active carbon can be recycled, and only a small amount of alkali and active carbon is lost. The method has the advantages of not seriously corroding equipment due to no high-temperature and high-pressure alkali boiling, sufficient raw materials, low price, no environmental pollution, and higher quality of the obtained active carbon and silica.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN +1

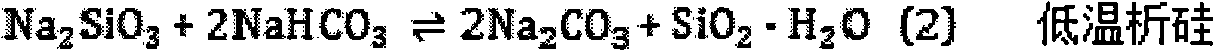

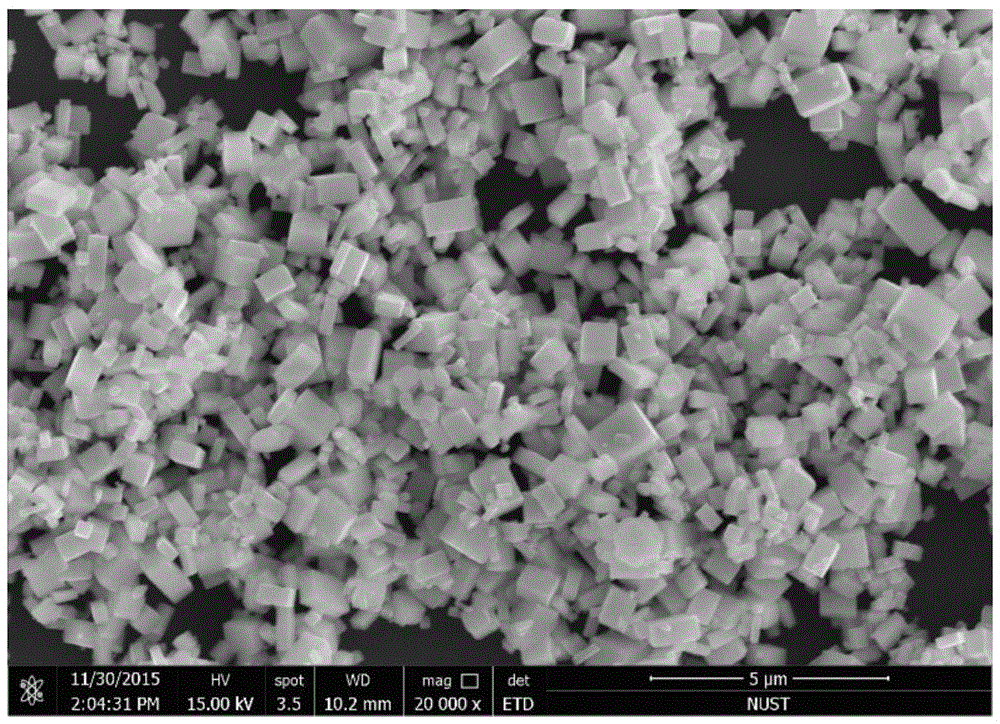

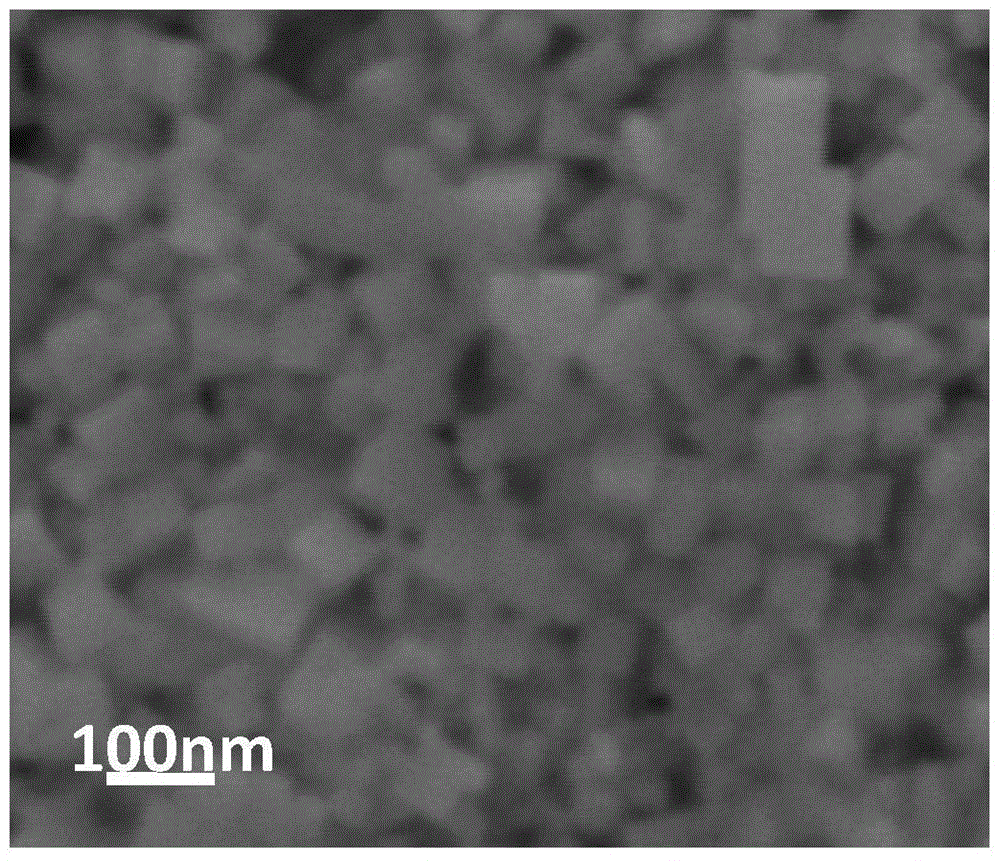

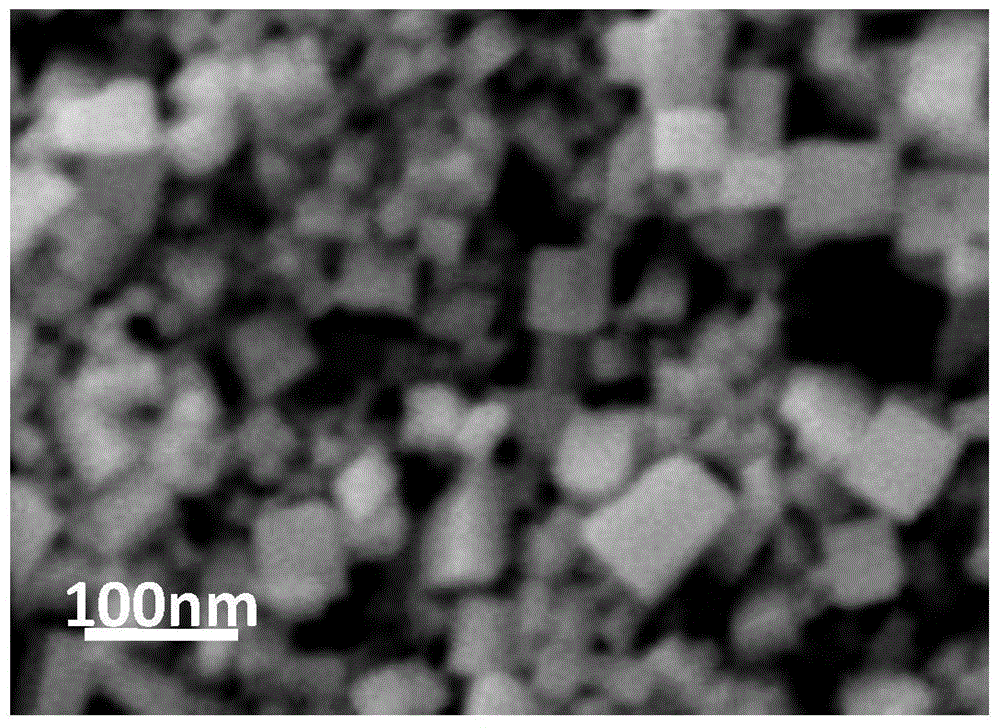

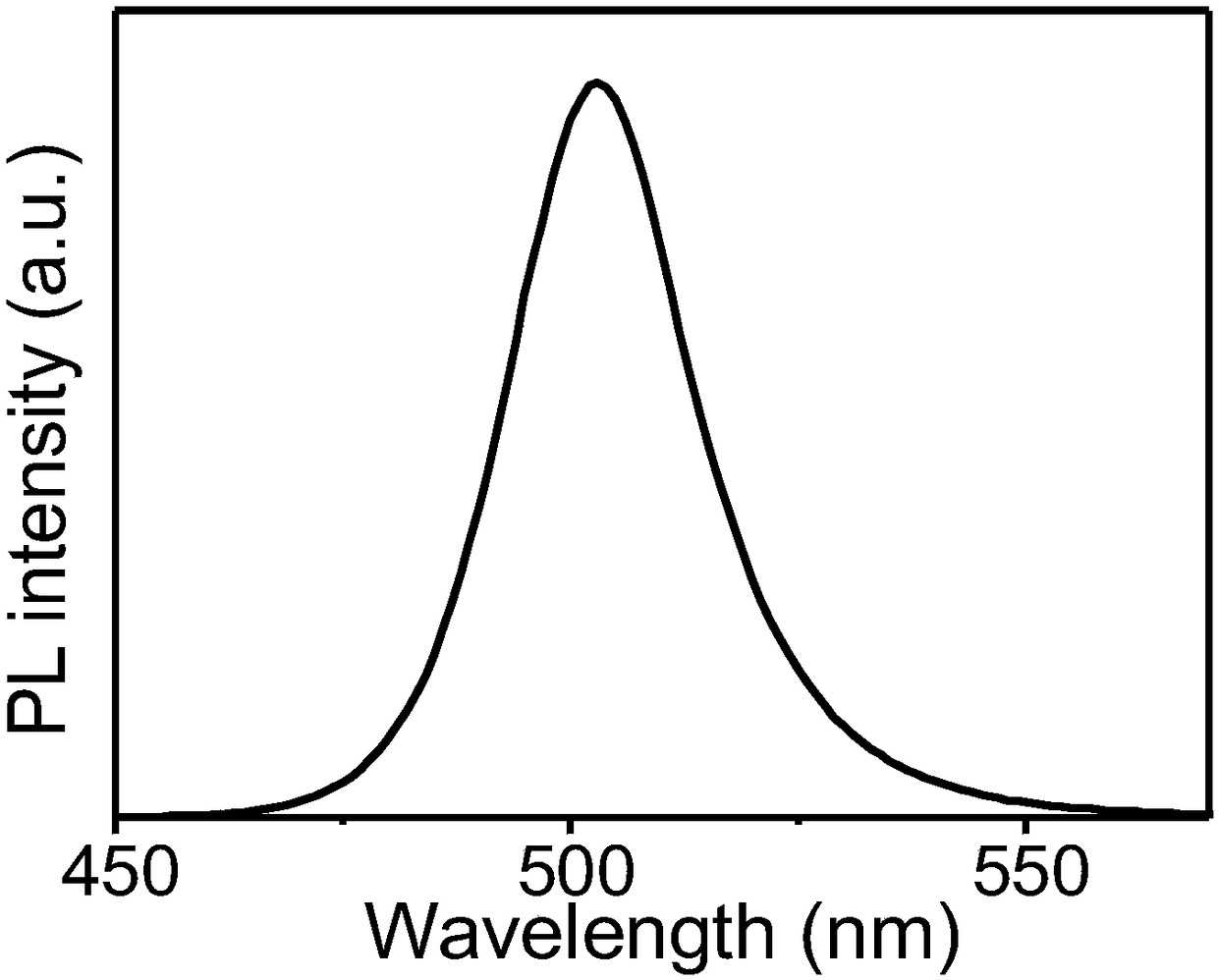

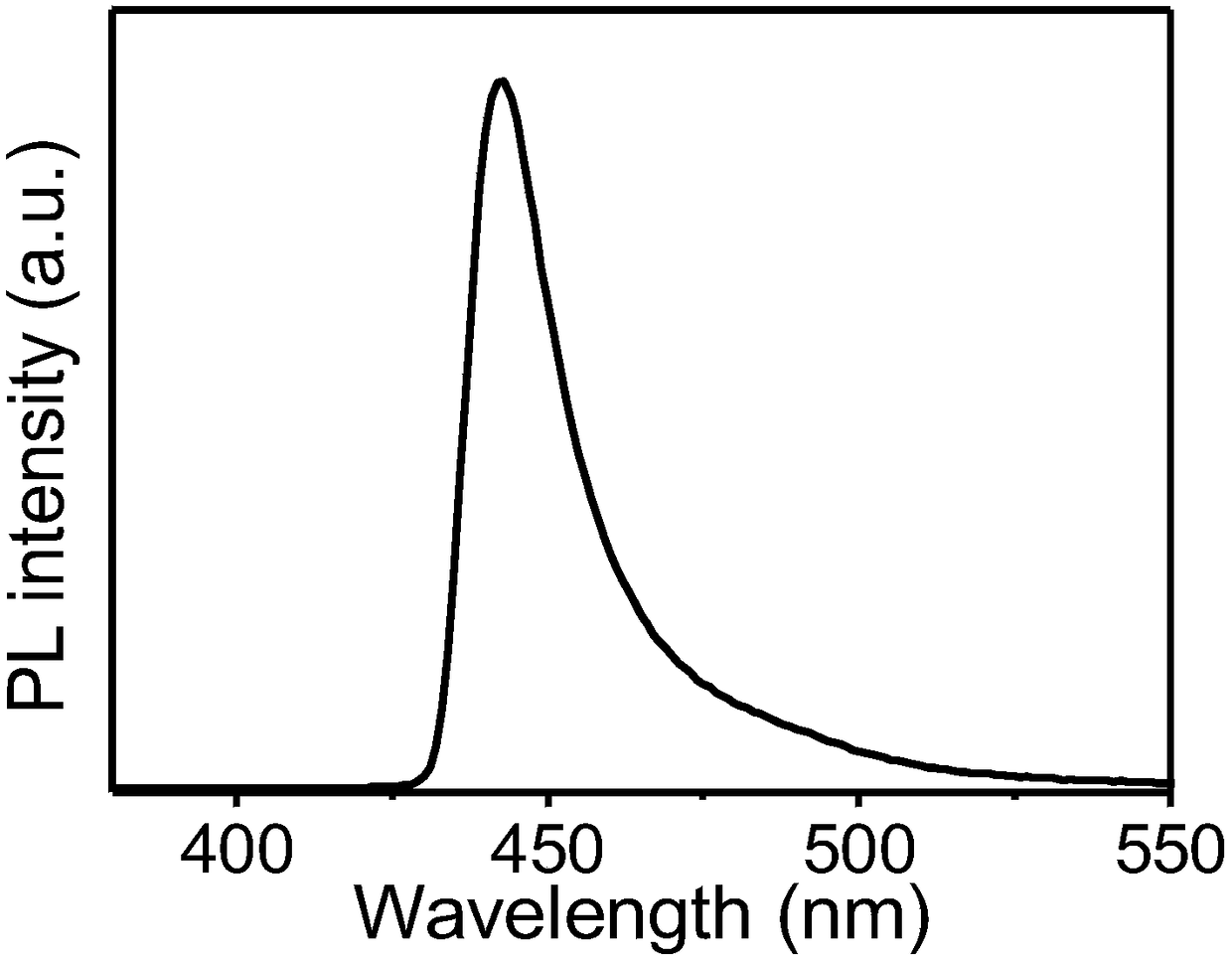

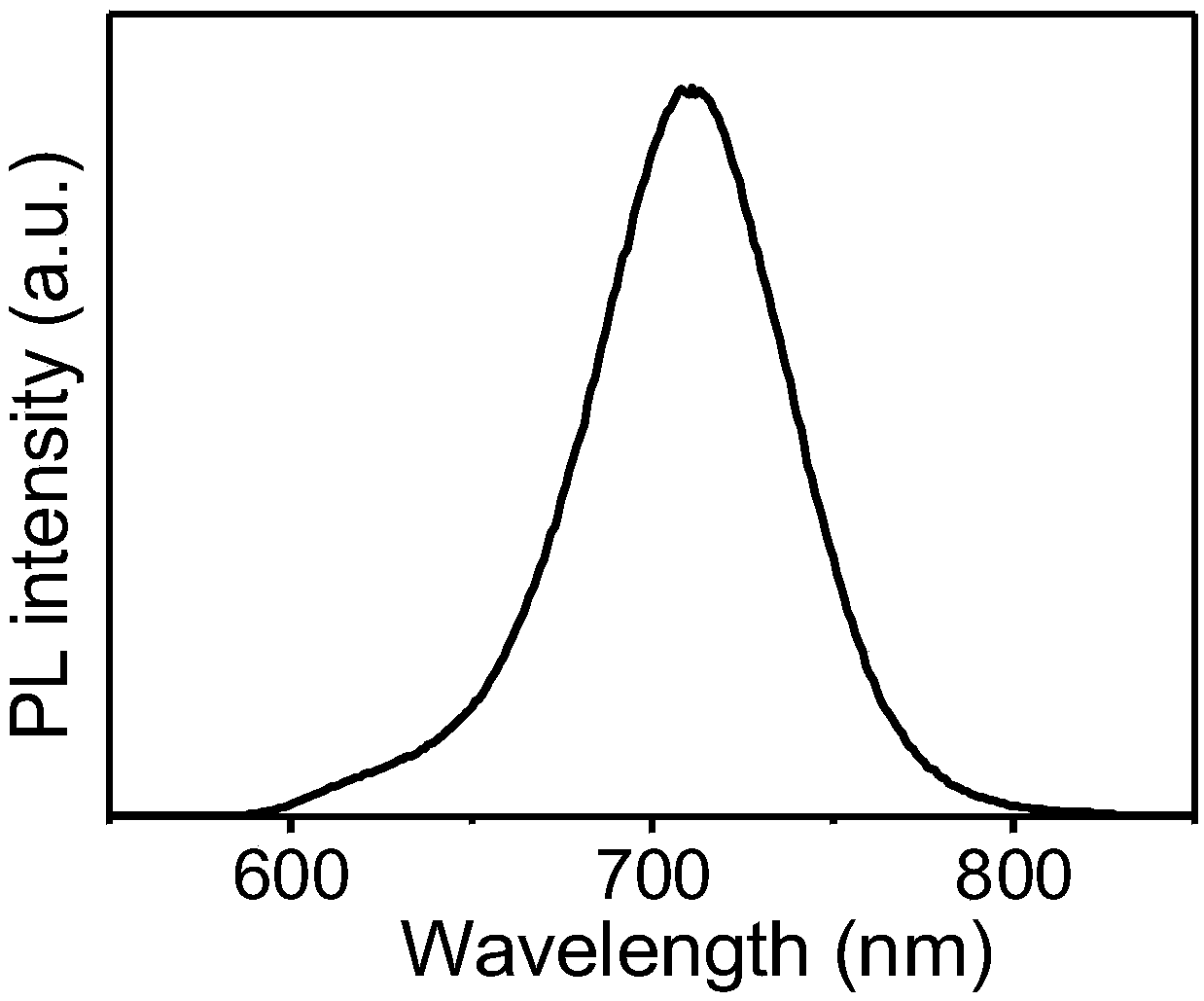

Preparation method of metal halide inorganic perovskite quantum dots

The invention discloses a preparation method of metal halide inorganic perovskite quantum dots. The method includes the steps of firstly, dissolving metal halide salt BX2 and AX in DMSO, and adding surface active agents; secondly, rapidly injecting the mixed liquid in reaction solvent; thirdly, making BX2 and AX rapidly react under the effect of the surface active agent to generate the ABX3 type metal halide inorganic perovskite quantum dots of different morphologies. According to the method, in the low-temperature solution method system, by using different surface active agents and reaction solvent for changing the morphologies of the metal halide inorganic perovskite quantum dots, the performance of the metal halide inorganic perovskite quantum dots is regulated and controlled, and the method has profound significance in constructing high-performance full-solution photoelectric devices.

Owner:NANJING UNIV OF SCI & TECH

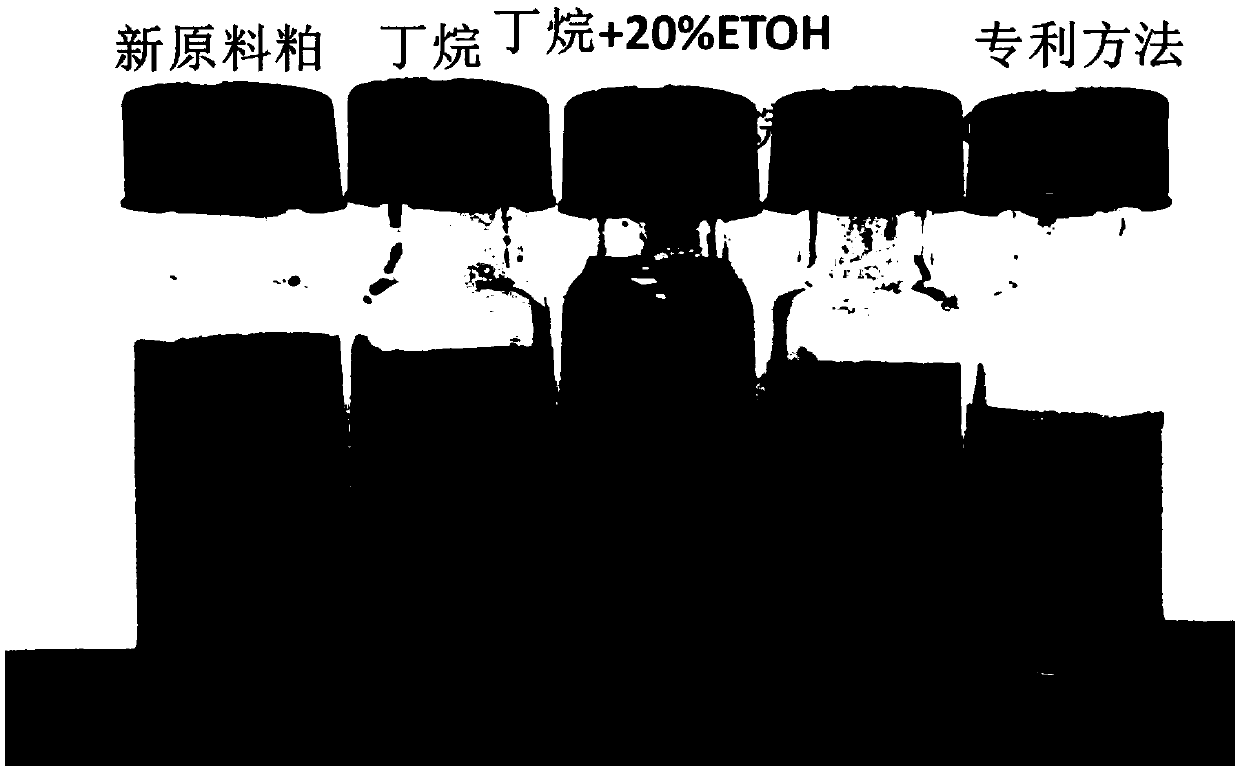

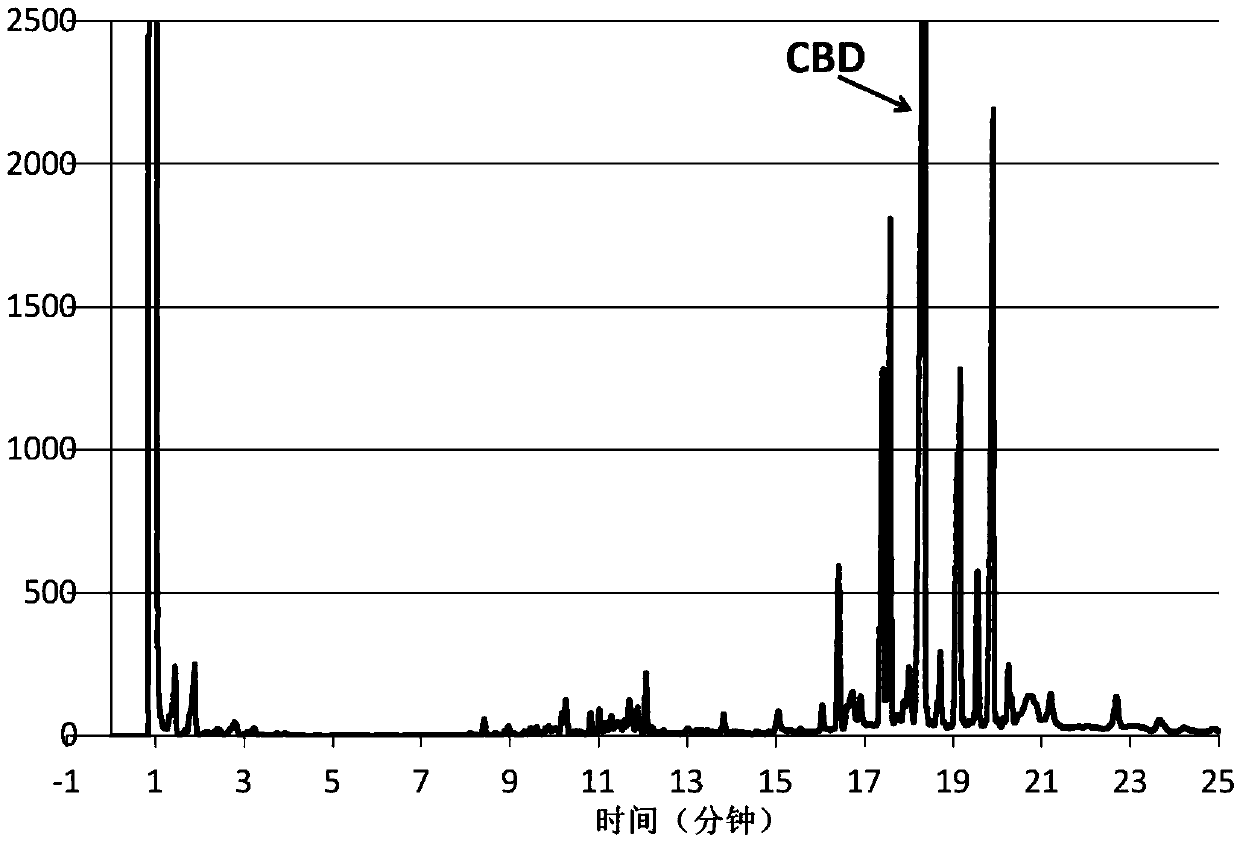

Cannabis sailve extract rich in cannabidiol and preparation method of cannabis sailve extract

ActiveCN105535111AImprove extraction efficiencyHigh in CBDPlant ingredientsActivated carbonChemistry

The invention discloses cannabis sailve extract which is extracted from flowers and leaves of industrial cannabis sailve and rich in cannabidiol (CBD) and a preparation method of the cannabis sailve extract. The preparation method includes the steps that firstly, heat dry treatment is conducted on the flowers and leaves of cannabis sailve, then a subcritical butane extraction technology is adopted, ethyl alcohol serves as entrainer, and crude extract which is rich in cannabidiol is obtained; the crude extract is dissolved in an ethanol solution of a certain proportion, and low-temperature odstearynowanie is conducted; centrifugation is conducted through a centrifugal machine, or filtering is conducted through a filtering machine to remove waxiness; activated carbon is added to liquid supernatant, and decolorization and filtration are conducted; finally, filtrate is subjected to rotary evaporation to remove ethyl alcohol, and the cannabis sailve extract rich in CBD can be obtained. The obtained cannabis sailve extract is high in CBD content and good in color and has a good physiological property. The method is simple in process, industrialized application is achieved easily, and development and utilization of high value-added products of Cannabis sailve are promoted.

Owner:山西汉麻生物科技有限公司

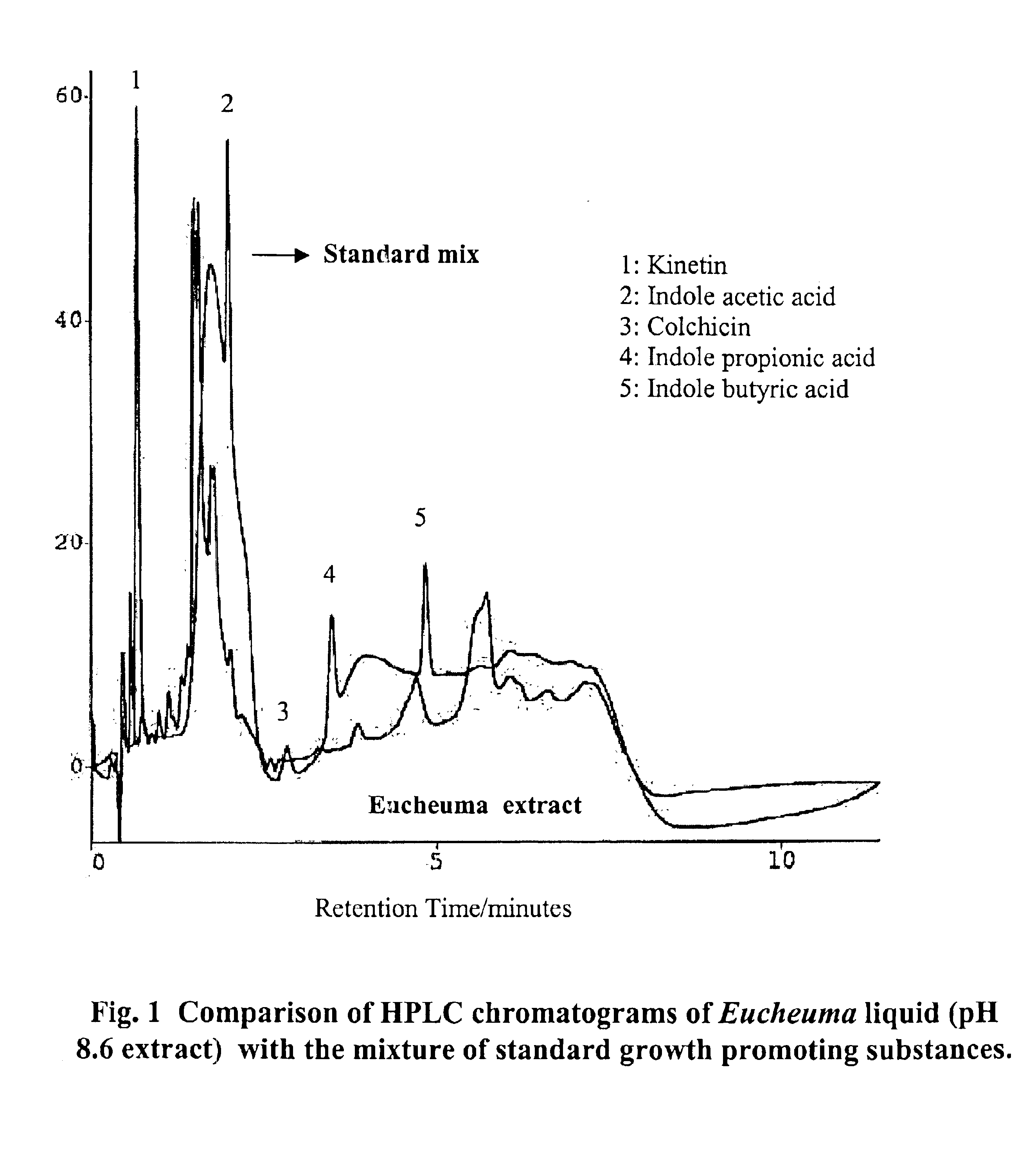

Integrated method for production of carrageenan and liquid fertilizer from fresh seaweeds

An integrated method is developed to utilize to a maximum extent the fresh biomass of seaweeds such as Kappaphycus alvarezii that can be crushed to release sap and where the sap is useful as a potent liquid fertilizer after suitable treatment with additives and dilution while the residue is a superior raw material for extraction of κ-carrageenan, thereby enhancing the value of the seaweed. Other advantages of the invention include a reduced drying time and drying area to obtain the raw material for κ-carrageenan production in dry and storable form, a reduced cost of transporting and storing this raw material because of its lesser bulk, easier handling due to its free flowing granular nature, and its direct use for gel preparation in certain applications.

Owner:COUNCIL OF SCI & IND RES

Method for preparing perovskite quantum dots by low-temperature solution process

The invention relates to a method for synthesizing high-luminescence-efficiency wide-color-range metal halide perovskite quantum dots by a low-temperature solution process. A solution injection process is utilized to synthesize the uniform-size high-dispersity metal halide perovskite quantum dots. The method comprises the following steps: keeping a reaction solvent at a certain temperature while stirring, quickly injecting a metal halide precursor salt into the reaction solvent, and finally, carrying out water cooling to room temperature, thereby obtaining the metal halide perovskite quantum dots with very high luminescence efficiency. The halogen doping ratio can be adjusted to obtain the color light with all wavelengths from infrared light to ultraviolet light, and thus, the perovskite quantum dots have wide luminescence range.

Owner:NANJING UNIV OF SCI & TECH

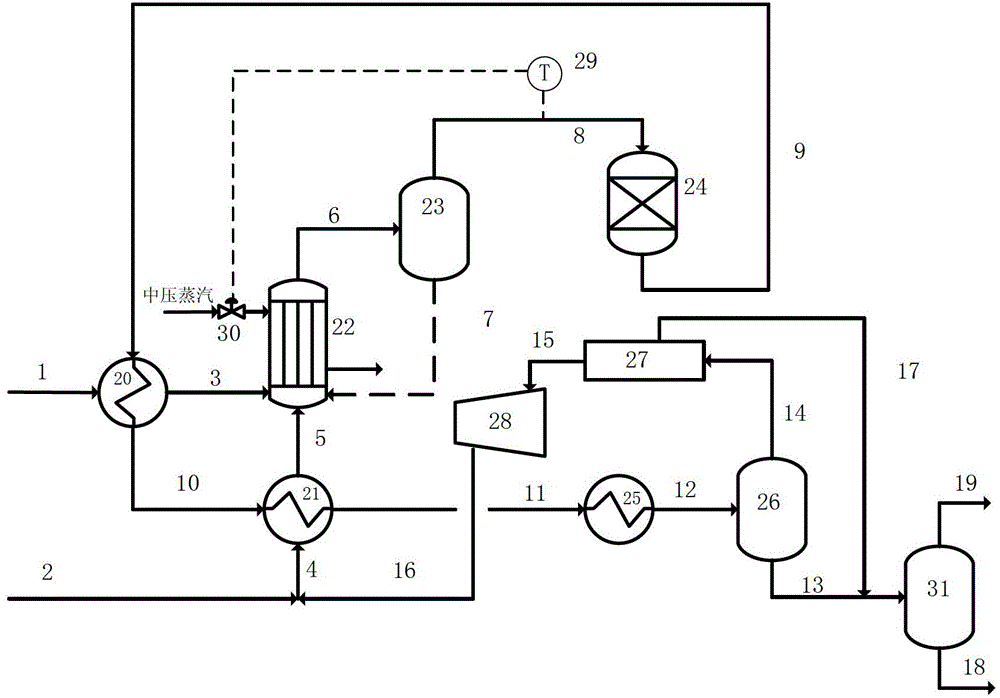

Method for preparing ethanol via hydrogenation of acetic ester based on recirculating of recovered hydrogen

ActiveCN102942446ALow costReduce heating effectOrganic compound preparationEnergy inputGas phaseProduct gas

The invention relates to a method for preparing ethanol via hydrogenation of acetic ester based on recirculating of recovered hydrogen. The method comprises the steps of: recycling hydrogen in the gas phase of a product by using a pressure swing adsorption (PSA) device and then increasing the pressure for recirculating; heating the mixed gas of acetic ester, circulated hydrogen and fresh hydrogen by using reaction heat; heating the preheated raw material gas by medium-pressure steam and then importing into a reactor so as to realize high acetic ester conversion rate and high ethanol selectivity in the presence of a catalyst; and carrying out gas-liquid separation on the product gas obtained via the reaction, and liquefying and separating the reaction principal product ethanol, a small amount of byproducts and unreacted acetic ester to obtain an initial product. According to the method, hydrogen is recycled and recirculated via PSA so that the use of the raw material hydrogen can be greatly reduced, the reaction raw materials are preheated by fully utilizing the reaction heat so that the energy consumption of the heating and the cooling is decreased, the flow is simple and the control is simple and convenient.

Owner:DATANG INT CHEM TECH RESINST

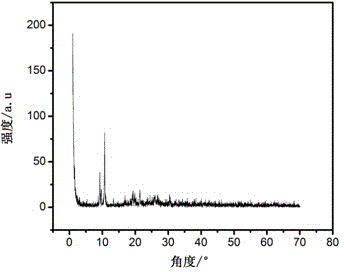

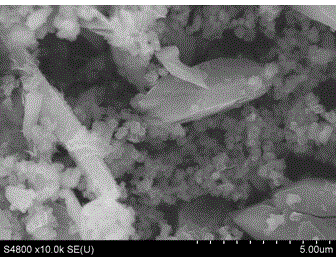

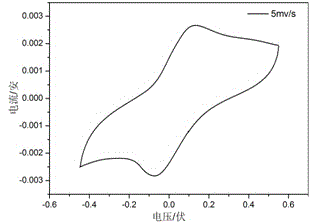

Graphene / Fe-MOFs composite material and preparation method thereof

InactiveCN104538200AImprove electrochemical performanceHigh specific capacitanceHybrid capacitor electrodesHybrid/EDL manufactureSupercapacitorTerephthalic acid

The invention discloses a graphene / Fe-MOFs composite material and a preparation method thereof. Adding oxidized graphene, FeCl3 and terephthalic acid into N, N-dimethyl formamide according to the corresponding ratio of 1-15 g : 100 g: 200 g : 150 ml, ultrasonically dissolving the mixture at a power of 600 W for 1 h, and then controlling the temperature to be at 150 degrees to conduct hydrothermal reduction reaction for 15 h; conducting suction filtration on the obtained reaction liquid, conducting repeated washing and suction filtration on the filter cake with N, N-dimethyl formamide till the filter does not contain incompletely reacted oxidized graphene, FeCl3 and terephthalic acid, controlling the temperature to be at 80 degrees to conduct drying, and then the graphene / Fe-MOFs composite material with good electro-chemical performance is obtained and can be used for super capacitor electrode materials. The graphene / Fe-MOFs composite material is simple and controllable in preparation technology, mild in conditions, low in production cost and suitable for industrial production.

Owner:SHANGHAI INST OF TECH

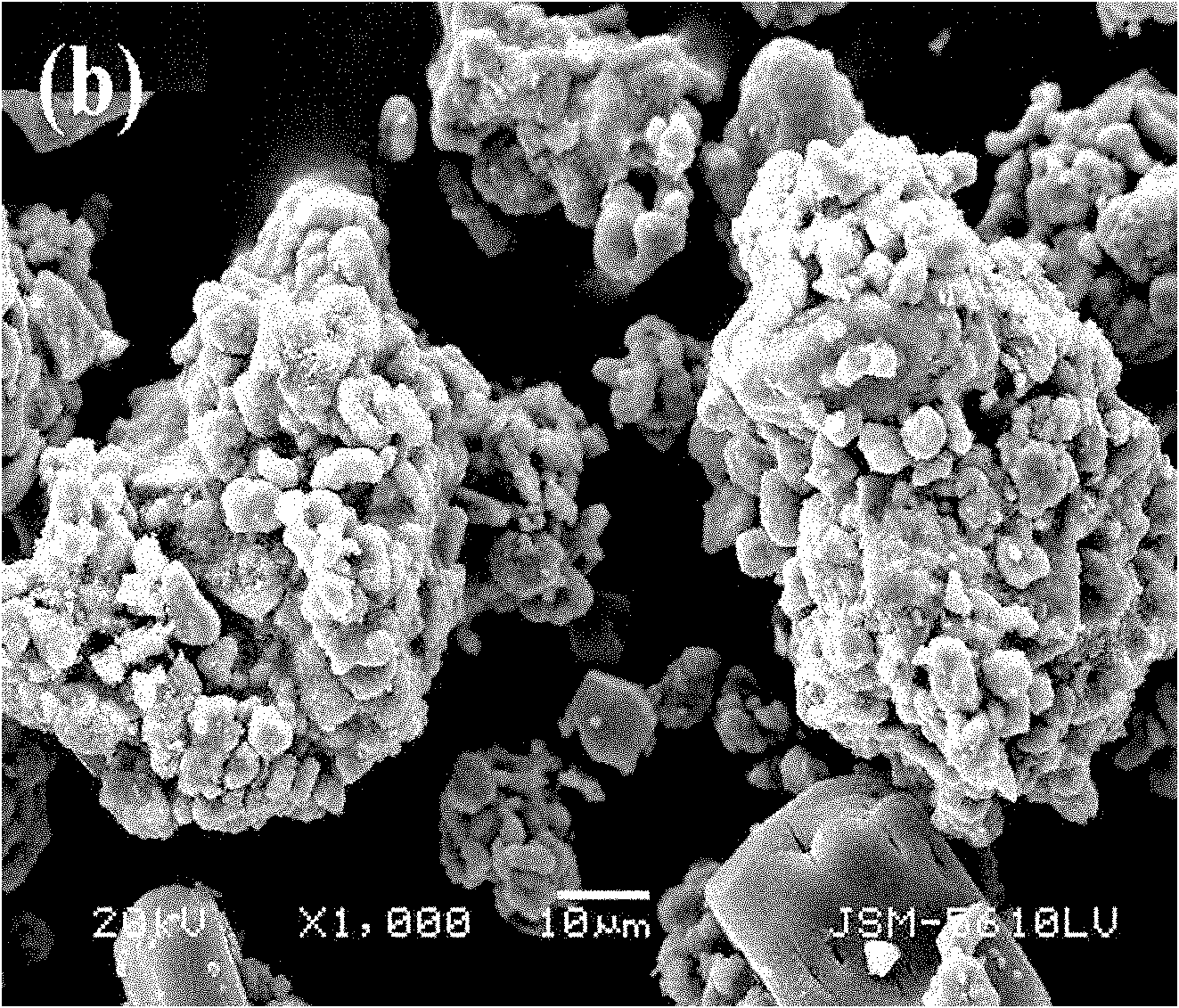

Ceramic material of porous spinel, and preparation method

InactiveCN1915903ASmall average pore sizeHigh purityCeramic shaping apparatusCeramicwarePericlasePore distribution

This invention relates to a method for preparing porous spinel ceramic material. The method comprises: (1) mixing magnesite powder 10-90 wt.%, Al(OH)3 powder 10-90 wt.%, water 2-10 wt.% and adhesive 0-3 wt.%; (2) molding; (3) drying the green bodies at 110 deg.C for 4-24 h; (4) sintering at 1600-1800 deg.C, and keeping the temperature for 1-8 h. The porous spinel ceramic material mainly contains MgO and Al2O3, and has main crystal phase of periclase-spinel, spinel or spinel-corundum. The porous spinel ceramic material can be directly contacted with flame retardant magmesium and spinel materials, and is a lightweight heat-insulating flame retardant with uniform pore distribution and high strength.

Owner:WUHAN UNIV OF SCI & TECH

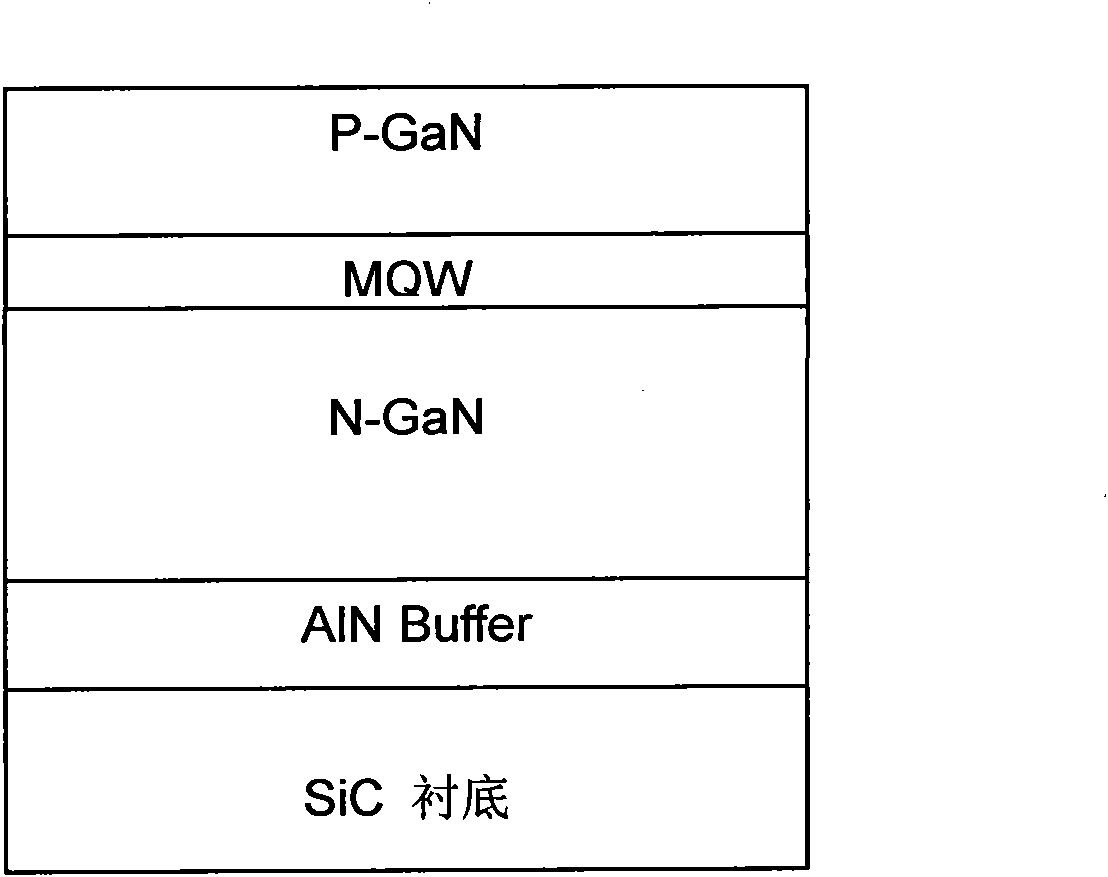

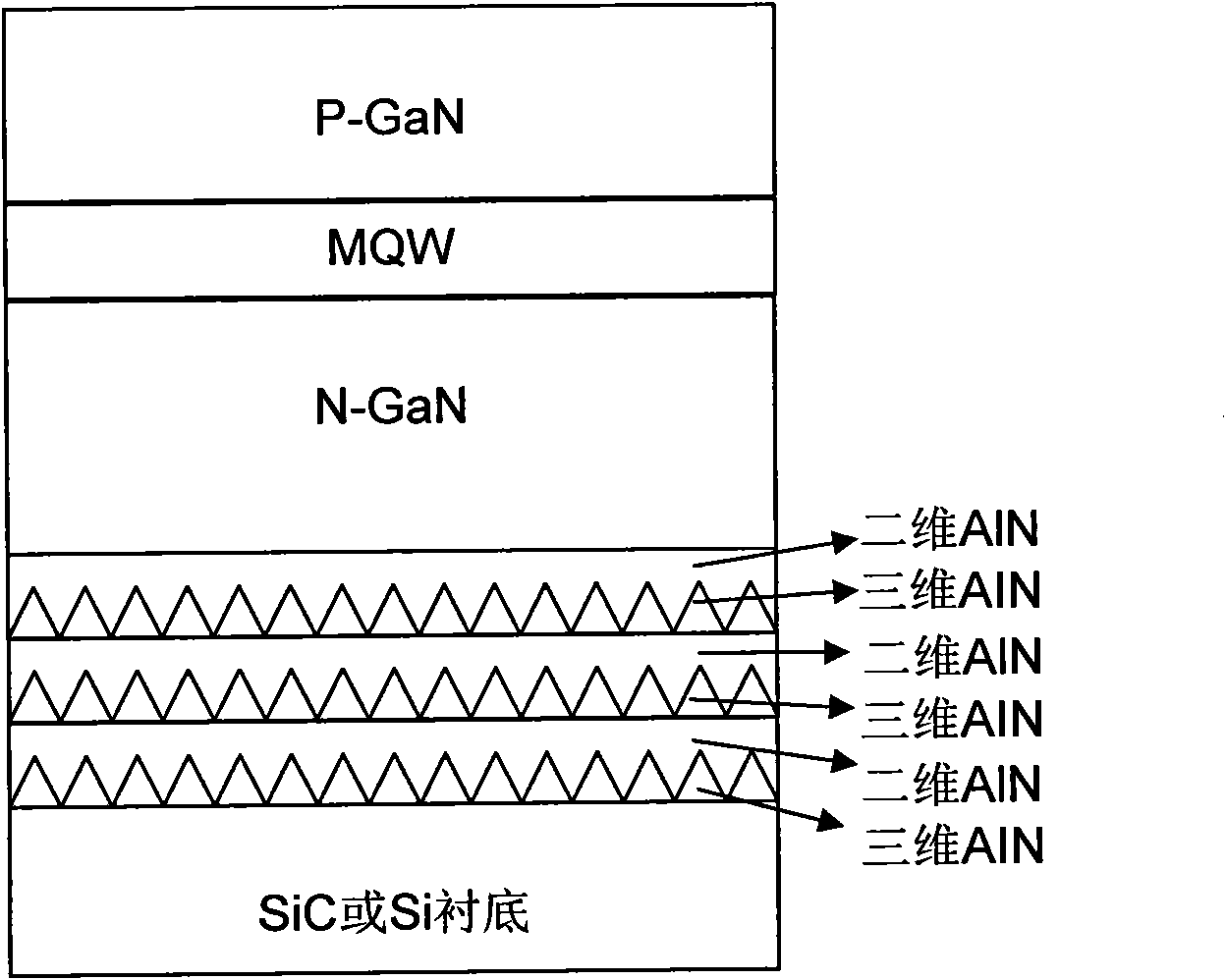

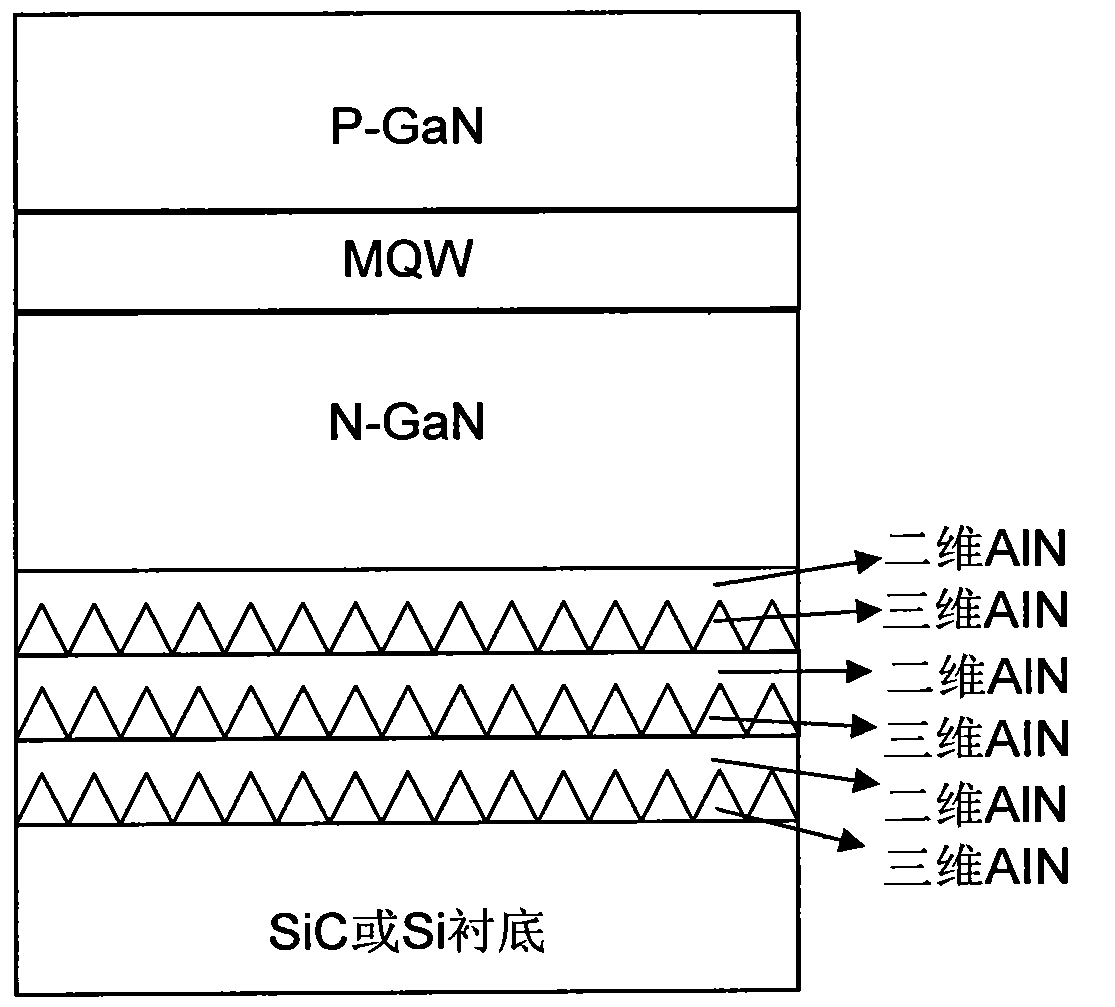

Structure of SiC or Si substrate GaN-based crystal and method for growing same

InactiveCN101771121ARaw materials are simpleEasy to implementFrom chemically reactive gasesSemiconductor devicesDislocationSi substrate

The invention provides a structure of SiC or Si substrate GaN-based crystal and a method for growing the same. The structure of the GaN-based crystal, from the bottom to the top, comprises an SiC or Si substrate, an A1N buffer layer, an N-type GaN layer, an MQW and a P-type GaN layer, wherein the A1N buffer layer comprises 3 to 5 three-dimensional and two-dimensional circulations, the thickness of the three-dimensional A1N is 50 to 100 nanometers, and the thickness of the two-dimensional A1N is 30 to 60 nanometers. The method for growing the structure comprises the following steps of: performing the three-dimensional growth of the A1N, wherein the growth thickness is 50 to 100 nanometers; performing two-dimensional growth of the A1N, wherein the growth thickness is 30 to 60 nanometers; circulating the steps for 3 to 5 times; and growing the N-type GaN layer, the MQW layer and the P-type GaN layer. In the method, the A1N is used as the buffer layer, and the three-dimensional and two-dimensional circulation resonant growth of the MOCVD is utilized, so that the dislocation density is effectively reduced, and the dislocation density of the grown film is very low; and because the crystal quality is improved and the stress is released, the thicker full-structure LEDs can be obtained by growth and no crack occurs.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

Pyrolysis oil and other combustible compositions from microbial biomass

InactiveUS20120266530A1Raw materials are simpleBiofuelsWaste based fuelMicrobiologyComponents of crude oil

Owner:CORBION BIOTECH INC

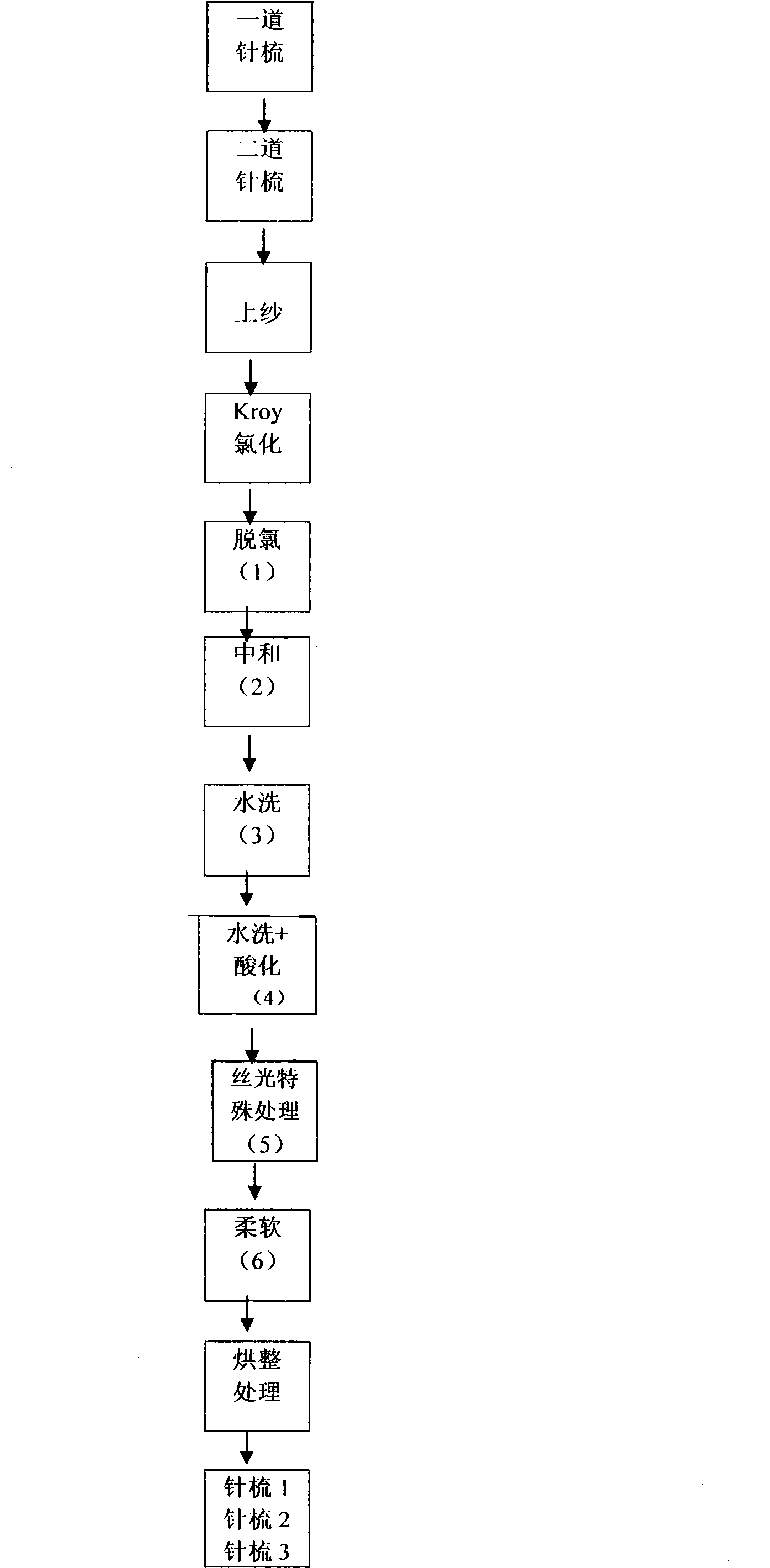

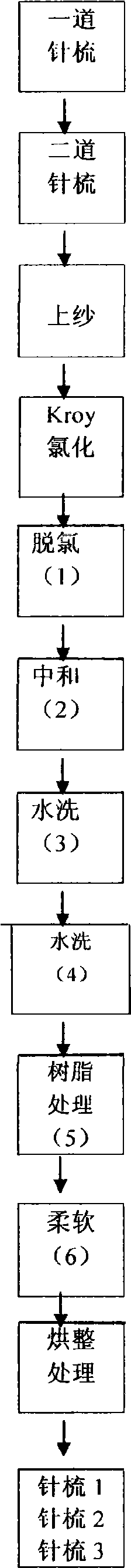

Wool shrinkproof mercerization method

ActiveCN101519838AGorgeous ingredientsRaw materials are simpleMercerising of sliversBiochemical fibre treatmentChlorinated solutionsEngineering

The invention provides a wool shrinkproof mercerization method which comprises the following steps: wools are combed by a needle, combed and opened again through secondary needle combing before chloriThe invention provides a wool shrinkproof mercerization method which comprises the following steps: wools are combed by a needle, combed and opened again through secondary needle combing before chloridization, and wetting agent is added during the needle combing for the chemical preliminary treatment; the secondary needle combing further ensures the opening and the fully and evenly wetting of thedization, and wetting agent is added during the needle combing for the chemical preliminary treatment; the secondary needle combing further ensures the opening and the fully and evenly wetting of thewools; chlorination scale stripping of chlorination solution is performed for the wools after the spraying of the wetting agent and the combing opening are performed, and the wools uniformly and sequewools; chlorination scale stripping of chlorination solution is performed for the wools after the spraying of the wetting agent and the combing opening are performed, and the wools uniformly and sequentially pass through a chlorination solution spraying device under the conditions of no tension and no twist number of each wool and are sprayed twice by adopting the chlorination solution. Compared wntially pass through a chlorination solution spraying device under the conditions of no tension and no twist number of each wool and are sprayed twice by adopting the chlorination solution. Compared with the technical level held by China, international fellow traders and international wool office at present, the product of the wools obtained by the wool shrinkproof mercerization method has the advith the technical level held by China, international fellow traders and international wool office at present, the product of the wools obtained by the wool shrinkproof mercerization method has the advantages of shrinkproof size stability, soft hand feeling, attractive cloth cover, stable coloring and other excellent properties, improves the coloring stability, expands the function of the wool prodantages of shrinkproof size stability, soft hand feeling, attractive cloth cover, stable coloring and other excellent properties, improves the coloring stability, expands the function of the wool product and prolongs the service life of the wool product for wearing.uct and prolongs the service life of the wool product for wearing.

Owner:浙江新中和羊毛有限公司

Preparation method of aluminium hydroxide micro powder

ActiveCN1927719APerfect crystal developmentFine granularityAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium sulfateAluminium hydroxide

The present invention relates to technological process of producing fine aluminum hydroxide powder as fire retardant stuffing, and is especially technological process of producing fine aluminum hydroxide powder with high crystallization degree. The gel seed prepared with sodium aluminate solution through CO2 introducing carbon process and with sodium aluminate solution through aluminum sulfate neutralization process is converted via a special process into fine pure alpha-aluminum hydroxide powder without beta-aluminum hydroxide. The fine pure alpha-aluminum hydroxide powder is coated, modified and stoved to obtain submicron level pure alpha-aluminum hydroxide powder. Or, the completely converted fine powder slurry is added into sodium aluminate solution directly or after being concentrated and further decomposed to obtain fine aluminum hydroxide powder with excellent fire retarding performance.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

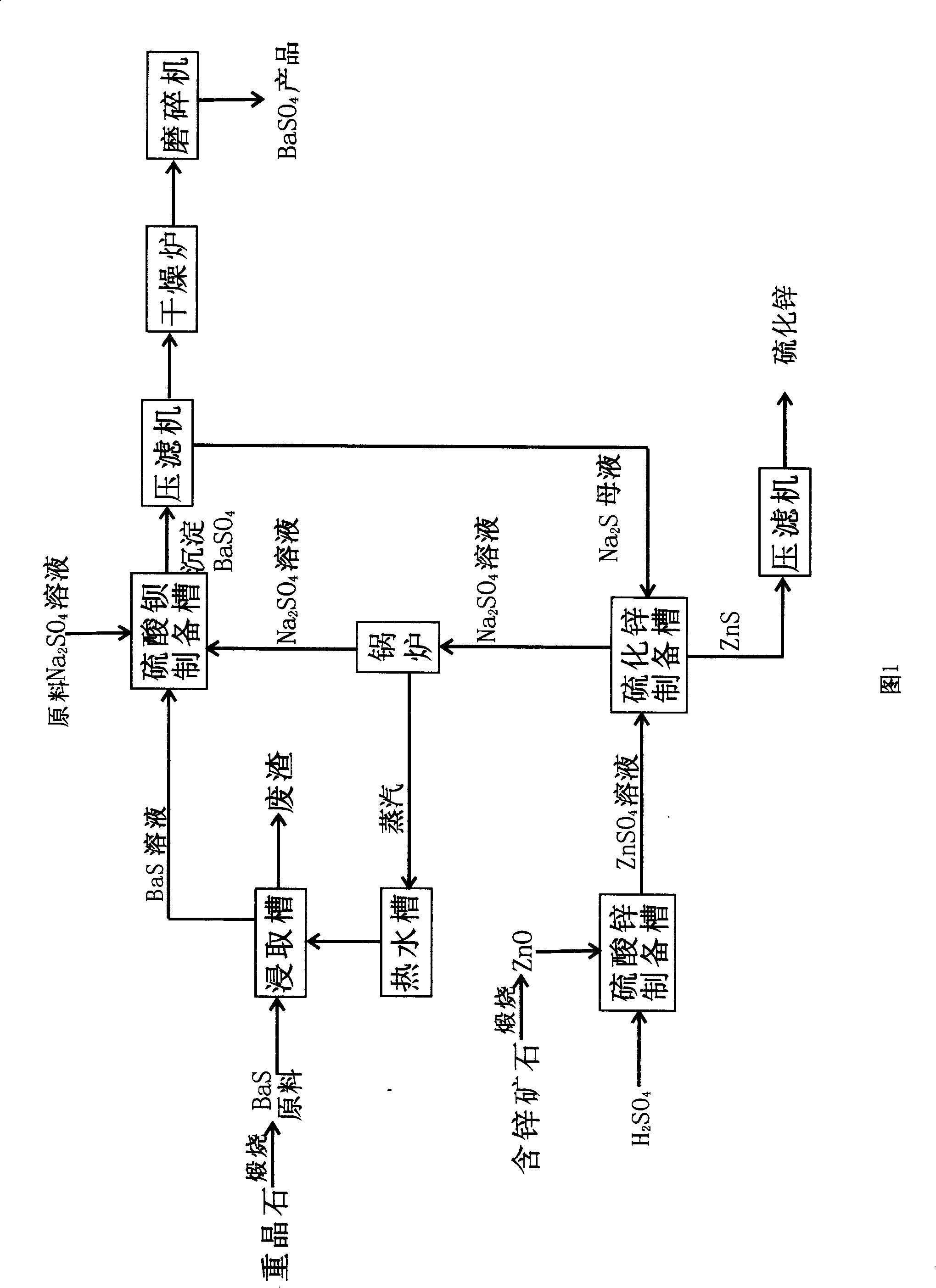

Method for preparing barium sulfate and zinc sulfide

InactiveCN101205077AIncrease profitImprove protectionCalcium/strontium/barium sulfatesZinc sulfidesSulfateMirabilite

The invention discloses a method for preparing barium sulfate and zinc sulphide, which takes barites and zinc containing ore as principal material and includes the following steps: firstly, black ash raw material which contains more than 50% of barium sulphide prepared by the mixed calcinations of barites and coal is leached to get pellucid barium sulphide solution; secondly, the barium sulphide solution reacts with mirabilite to get barium sulfate products after filter pressing separation, drying and grinding; thirdly, zinc oxide obtained by the calcinations of the zinc containing ore reacts with sulphuric acid, and zinc sulfate solution is prepared by the purification of reacting solution; fourthly, depurative zinc sulfate solution reacts with vulcanized alkali containing mother liquor which is prepared after the separation of the barium sulfate from the reacting resultant obtained from step two to get zinc sulphide after filter pressing separation; the sodium sulfate containing mother liquor which is separated from zinc sulphide is put into a boiler for concentration; the steam formed heats the leach barium sulfide water; the concentrated sodium sulfate containing solution reacts with barium sulfide to prepare precipitated barium sulfate.Due to the adoption of closed cycle, the invention has the advantages of simple operation, high yield, energy conservation and environmental protection.

Owner:LUOYANG HONGYUAN BARIUM SALT CHEM IND INST

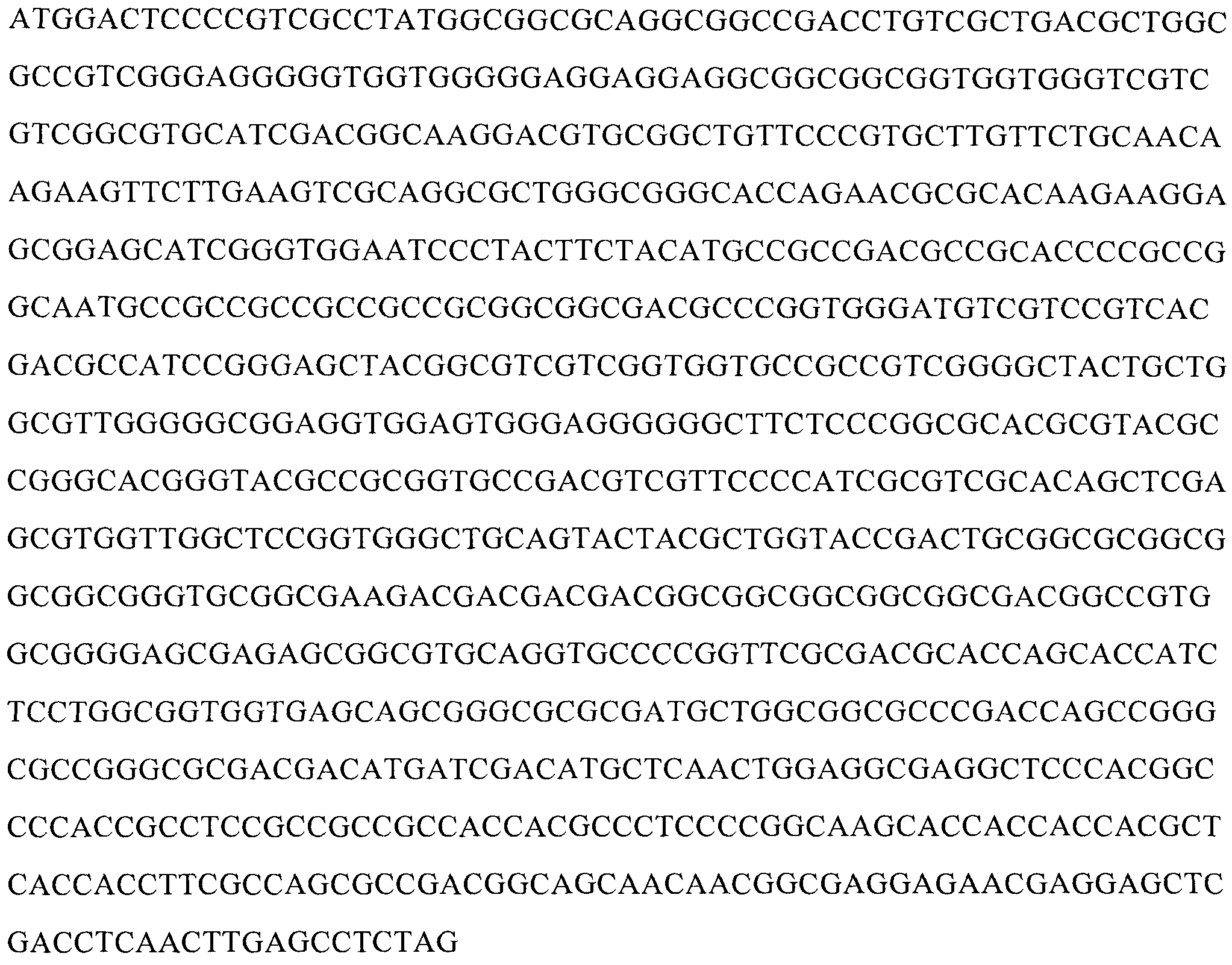

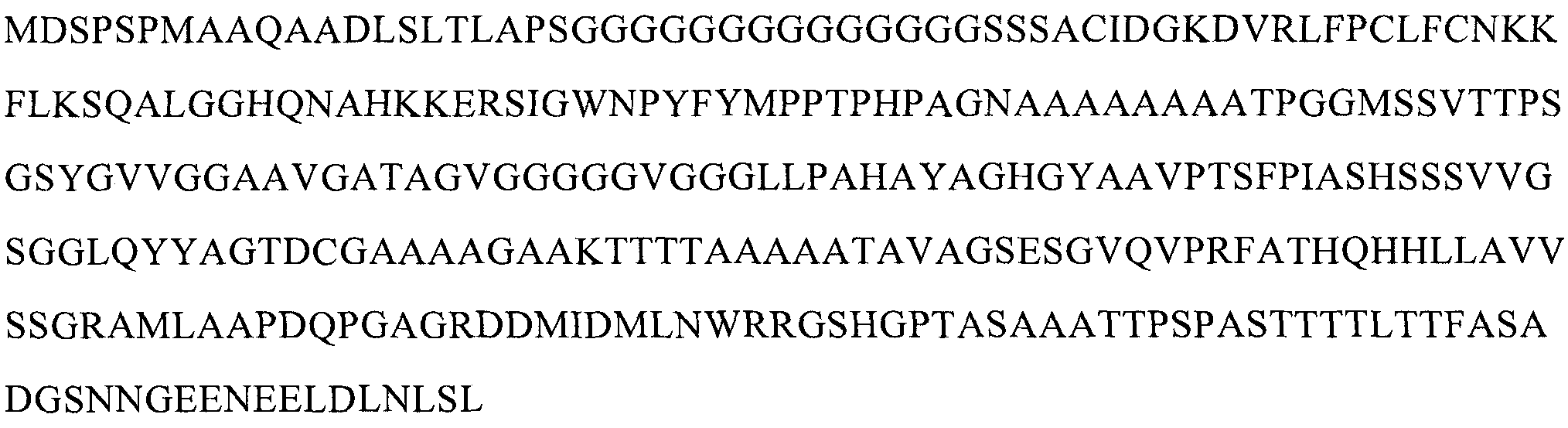

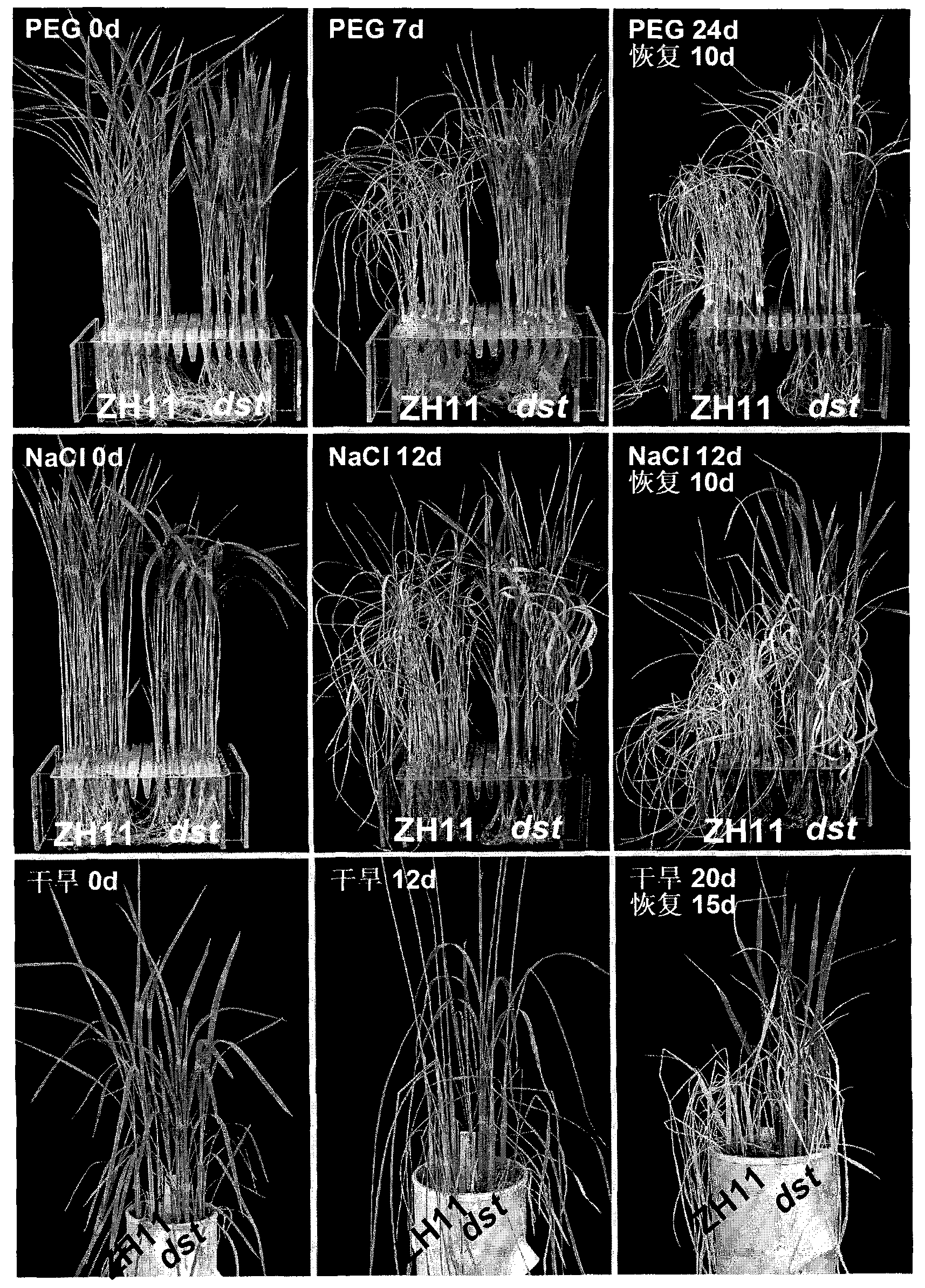

New gene for rice zinc-finger protein transcription factor and application thereof to drought resistance and salt tolerance

ActiveCN101875689AImproved resistance to salt or drought stressRaw materials are simpleFungiBacteriaAgricultural scienceCis-regulatory element

The invention relates to a new gene for the rice zinc-finger protein transcription factor and the application thereof to drought resistance and salt tolerance, in particular to the rice zinc-finger protein transcription factor, a coding sequence thereof, a carrier or host, a cis-acting element and antagonist of the rice zinc-finger protein transcription factor or the coding sequence. The rice zinc-finger protein transcription factor comprises polypeptide, and the polypeptide can be the polypeptide having the amino acid sequence of SEQ ID NO: 2, the conservative variant polypeptide or the homologous polypeptide separated from the same; the carrier or host includes the coding sequence; and the cis-acting element is combined with the rice zinc-finger protein transcription factor. The invention also relates to a method for improving the drought resistance and the salt tolerance of the rice and a method for sieving the rice with high drought resistance and salt tolerance. The novel method for improving and studying the drought resistance and the salt tolerance of the rice has wide application prospect.

Owner:CAS CENT FOR EXCELLENCE IN MOLECULAR PLANT SCI

Compound feed and preparing method thereof

InactiveCN103719598AImprove immunityGuaranteed immunityAnimal feeding stuffBiotechnologyPoultry disease

The invention discloses a compound feed and a preparing method thereof. The compound feed comprises a solid feed, wherein the solid feed comprises the following ingredients by weight: 0.56-3% of dried honeysuckle stem powder, 1.12-4% of living yellow mealworm or 0.28-1% of dried yellow mealworm, 5.6-20% of yellow mealworm excrement, 0.28-1% of malt powder, 1.12-3% of dried hawthorn powder, 0.56-1% of dried eucommia leaf and eucommia bark mixed powder, 0.672-1.2% of dried fructus forsythiae stem and leaf powder, 0.28-0.5% of ginko fruit and the balance of maize and bean pulp, wherein the sum of the quantities of all the ingredients is equal to 100%. The use of the compound feed for feeding laying hens can prevent chicken flocks from having poultry diseases and improve poultry immunity, and can obviously improve the nutrient ingredients of laid eggs. The cost investment is low.

Owner:TAIZHOU ZHONGJIA AGRI DEV

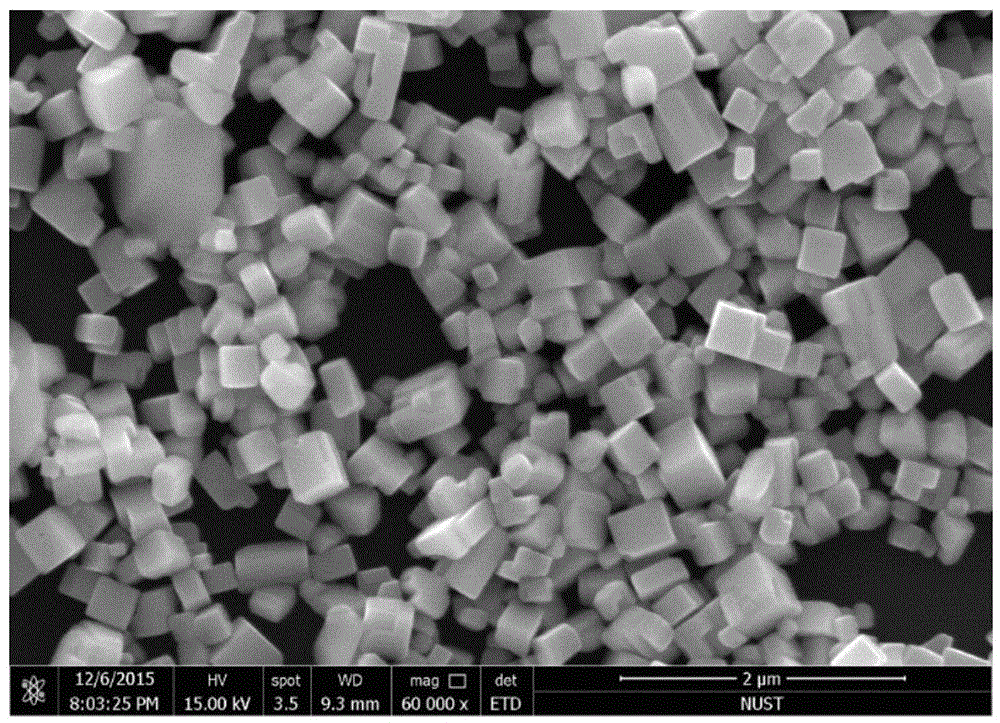

Method for preparing perovskite quantum dot at room temperature

InactiveCN108219786ASimple particle sizeUniform particle sizeLead halidesNanoopticsFluorescenceShielding gas

The invention discloses a method for preparing a perovskite quantum dot at a room temperature. The luminescent quantum dot is MPbX3; in the formula, M is methyl amine (MA) or Cs, and X is any one of Cl, Br and I. According to the method disclosed by the invention, MX and PbX2 are dissolved in an organic solvent, and a certain amount of surfactant is added to form a precursor solution; an appropriate amount of the precursor solution is added into a poor solvent to form the perovskite quantum dot. By changing the quantity of the surfactant, the luminescence wavelength of the quantum dot can be adjusted, so that luminescence of fully-visible wave bands is realized. The method disclosed by the invention can be carried out at the normal temperature, protective gas is not needed, equipment is simple, and scale production is realized. According to the perovskite quantum dot prepared by the method, the fluorescent full width at half maximum is 20 to 43nm; the fluorescent quantum efficiency isnearly 90 percent, and the perovskite quantum dot can be applied to the fields of solar batteries, laser, photo-detectors, light-emitting diodes and the like.

Owner:ZHEJIANG SCI-TECH UNIV

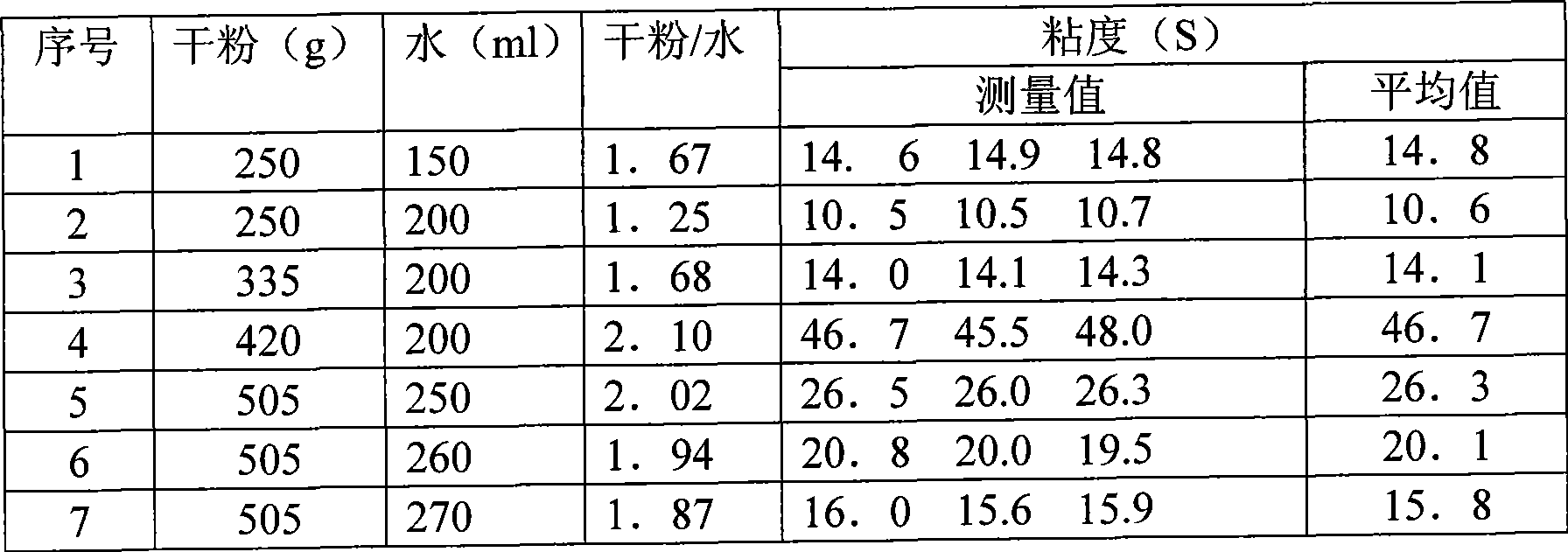

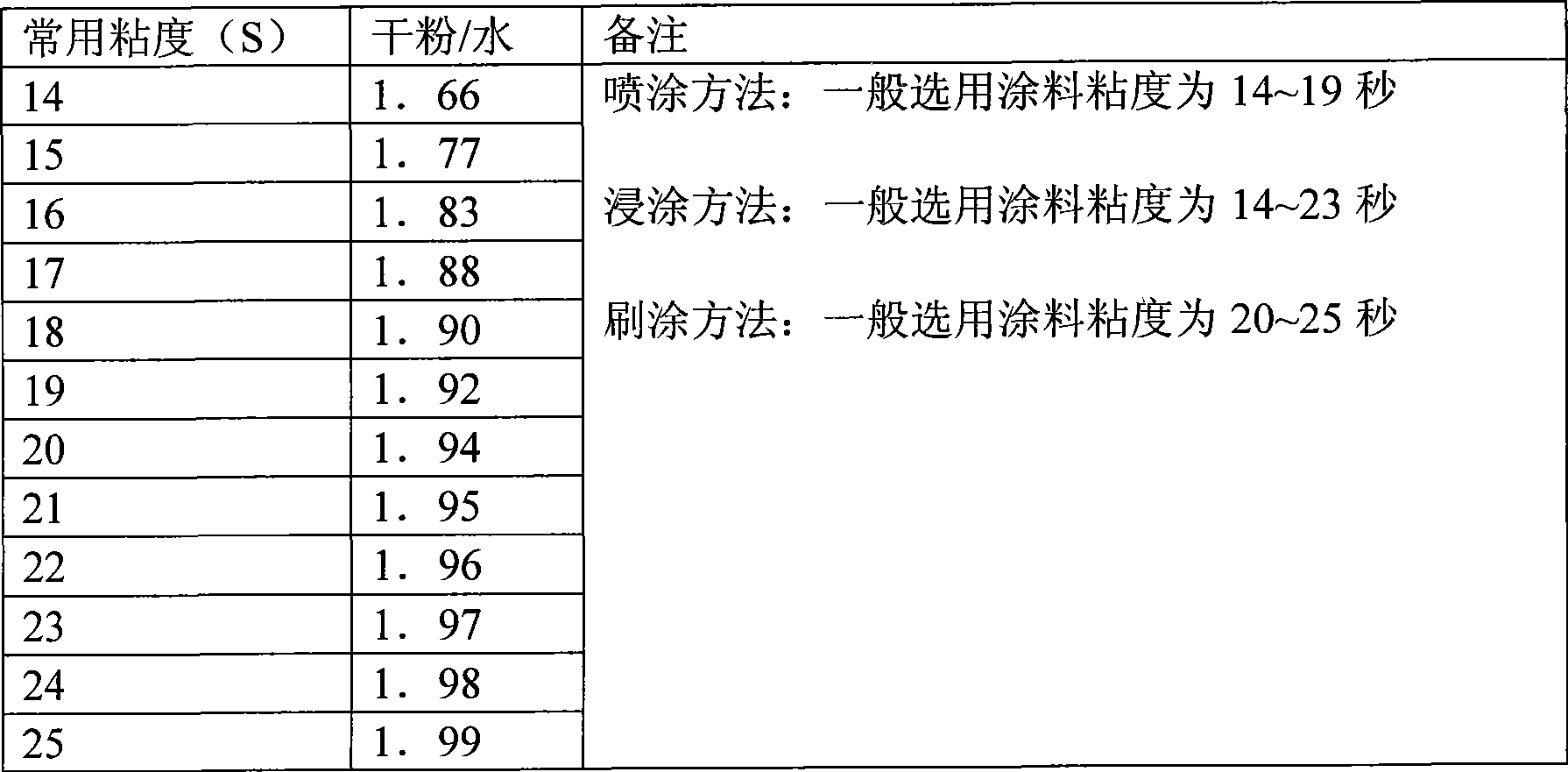

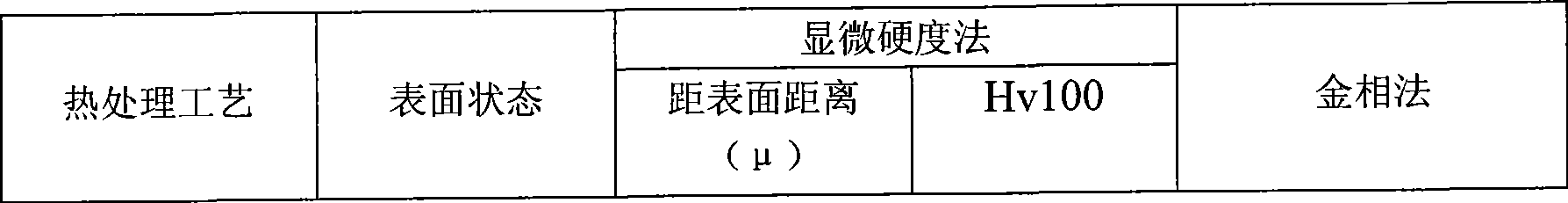

High temperature anti-oxidation dry powder coating

A high temperature anti-oxidation coating is a protective coating used for inhibiting oxidation at high temperature and aims at solving the defects of comprehensive properties of present high temperature protective coatings used for stainless steel and refractory steel. A high temperature anti-oxidation dry powder coating consists of the following raw materials according to weight percentage: 45-50% of frit, 40-45% of clay and 5-10% of talcum powder. The coating has the advantages of good protection effect when being used in high heat treatment of stainless steel and refractory steel, prevention of oxidation and decarbonization at high temperature between 900-1200 DEG C; no increase of hydrogen in the process of inhibiting oxidation, no harmful effect on parts; automatic fall-off in cooling, reduction of subsequent processing procedures; and convenient coating brush application, as well as readily available raw materials.

Owner:SHENYANG AIRCRAFT CORP +1

Method for extracting cannabidiol-containing hemp extract

InactiveCN107898826AImprove extraction efficiencyHigh in CBDPlant ingredientsFood scienceActivated carbonCentrifugation

The invention discloses a method for preparing cannabidiol-containing hemp extract. The method comprises the following steps: taking mature industrial hemp seeds, drying the hemp seeds, removing impurities, and crushing the hemp seeds for later use; carrying out extraction on the crushed hemp seeds with ethanol with the concentration being 95-100% (V / V) according to a solid-liquid ratio of 1:5 to1:20; filtering the obtained extract, and carrying out reduced pressure concentration to obtain industrial hemp seed extract; dissolving the obtained hemp seed extract in ethanol, and carrying out low-temperature winterization; centrifuging the obtained winterized suspension by using a centrifuge or a filtration technique; decolorizing a supernatant obtained after the centrifugation by using activated carbon, and filtering the supernatant; and carrying out rotary evaporation on a filtrate obtained after the filtration to obtain the cannabidiol-containing hemp extract. The product obtained in the invention has the advantages of high CBD content, good color and good physiological characteristics. The method has the advantages of simple process, easiness in industrial application, and promotion of the development and utilization of high added value products of hemp.

Owner:云南谷益美农业开发有限公司

Copper-plated carbon nanotube reinforced pantograph pan material and preparation method thereof

InactiveCN102031439ACompact structureImprove performancePower current collectorsCopper platingHydrogen

The invention provides a copper-plated carbon nanotube reinforced pantograph pan material and a preparation method thereof. The material comprises the following raw materials: Cu, CNTs, Ti3SiC2 and TiB2 in a volume ratio of (65-90):(1-20):(2-30):(1-20). The preparation method comprises the following steps of: uniformly mixing the four raw materials and glycerol, baking the mixture, loading the mixture into a steel mould, cold molding, placing the mixture in a high-temperature furnace under the protection of hydrogen, raising the temperature to 700 to 900 DEG C, preserving heat for 5 to 30 minutes, taking out the sample, cold molding again, sintering the sample at the temperature of between 800 and 900 DEG C for the second time and preserving heat for 30 to 60 minutes. The method has a simple process; the performance of the pantograph pan material can be greatly improved by the traditional equipment; and the prepared pantograph pan material has the advantage of relatively low cost.

Owner:WUHAN UNIV OF TECH

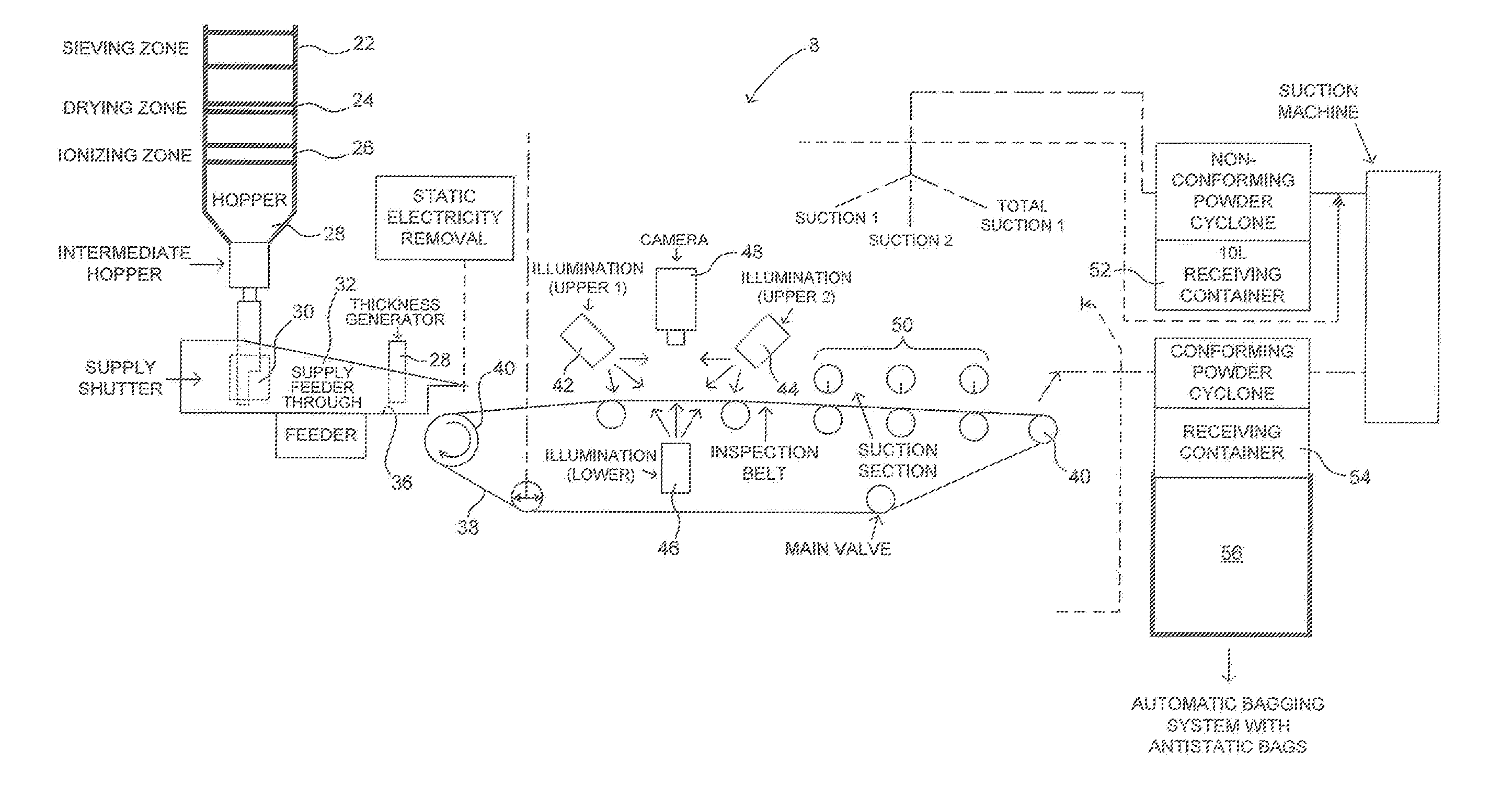

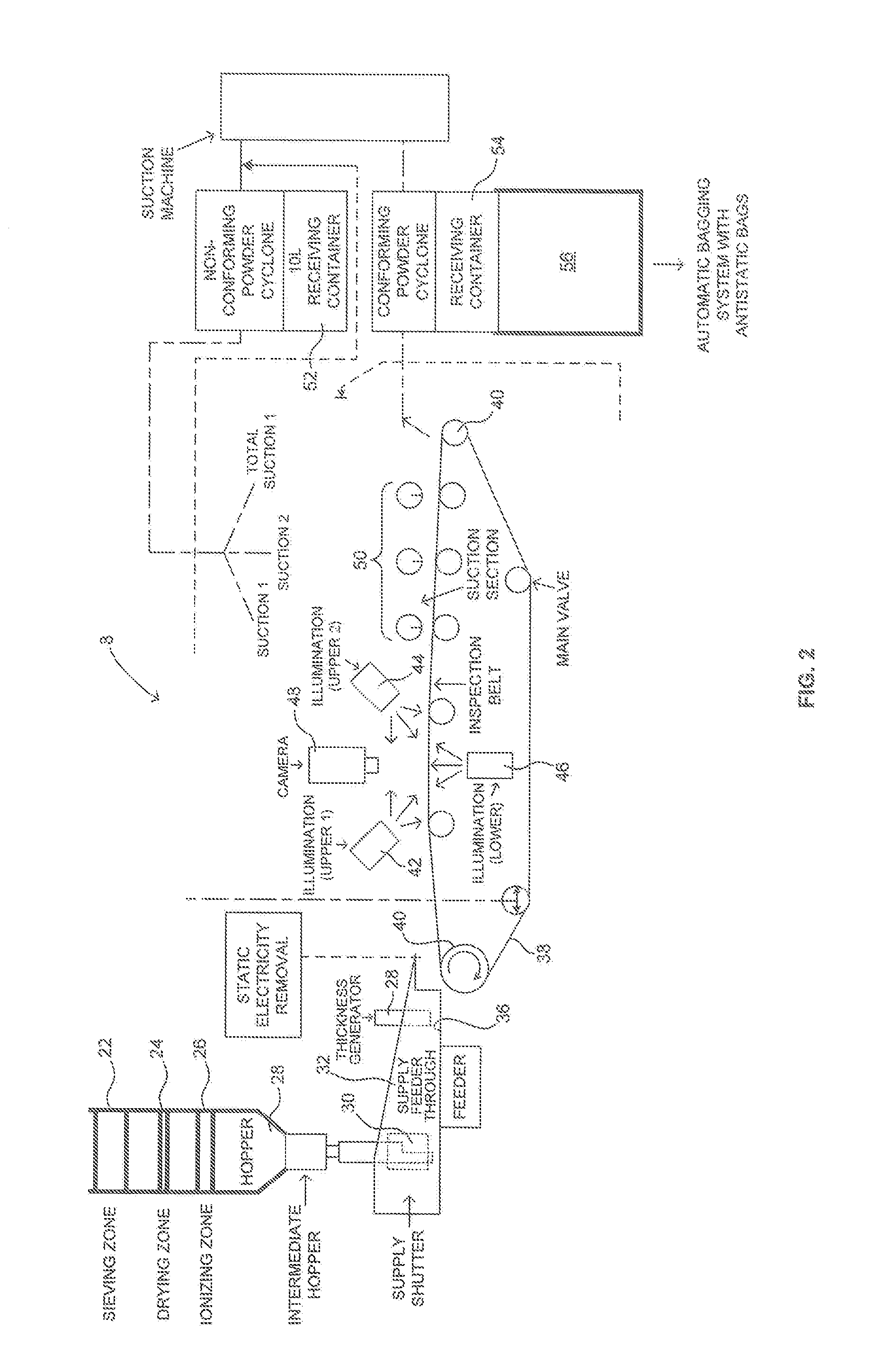

Process for removing contaminants from polymeric powders

InactiveUS20140250835A1Improve detection accuracyImprove throughputSolid materialPackaging under special atmospheric conditionsPolymer resinCcd camera

A method for detecting and removing foreign particles in polymeric resin powder comprising drying the resin powder; removing static energy from the resin powder; producing a layer of resin powder 0.2 to 0.8 mm in height in a feeding tray which feeds a conveyor; conveying the layer of resin powder with a transparent conveyor belt at a speed of between 12.2 and 36.64 meters / minute into a foreign particle detection zone; illuminating the polymeric resin powder in the detection zone from above and below with a light; continuously imaging the resin powder from above with a high speed digital CCD camera; continuously analyzing the images with a control device to detect particles having nonwhite colors; and actuating a suction system with the controller to suction off any detected particles to produce a polymeric resin powder having a reduced number of foreign particles.

Owner:HOWMEDICA OSTEONICS CORP

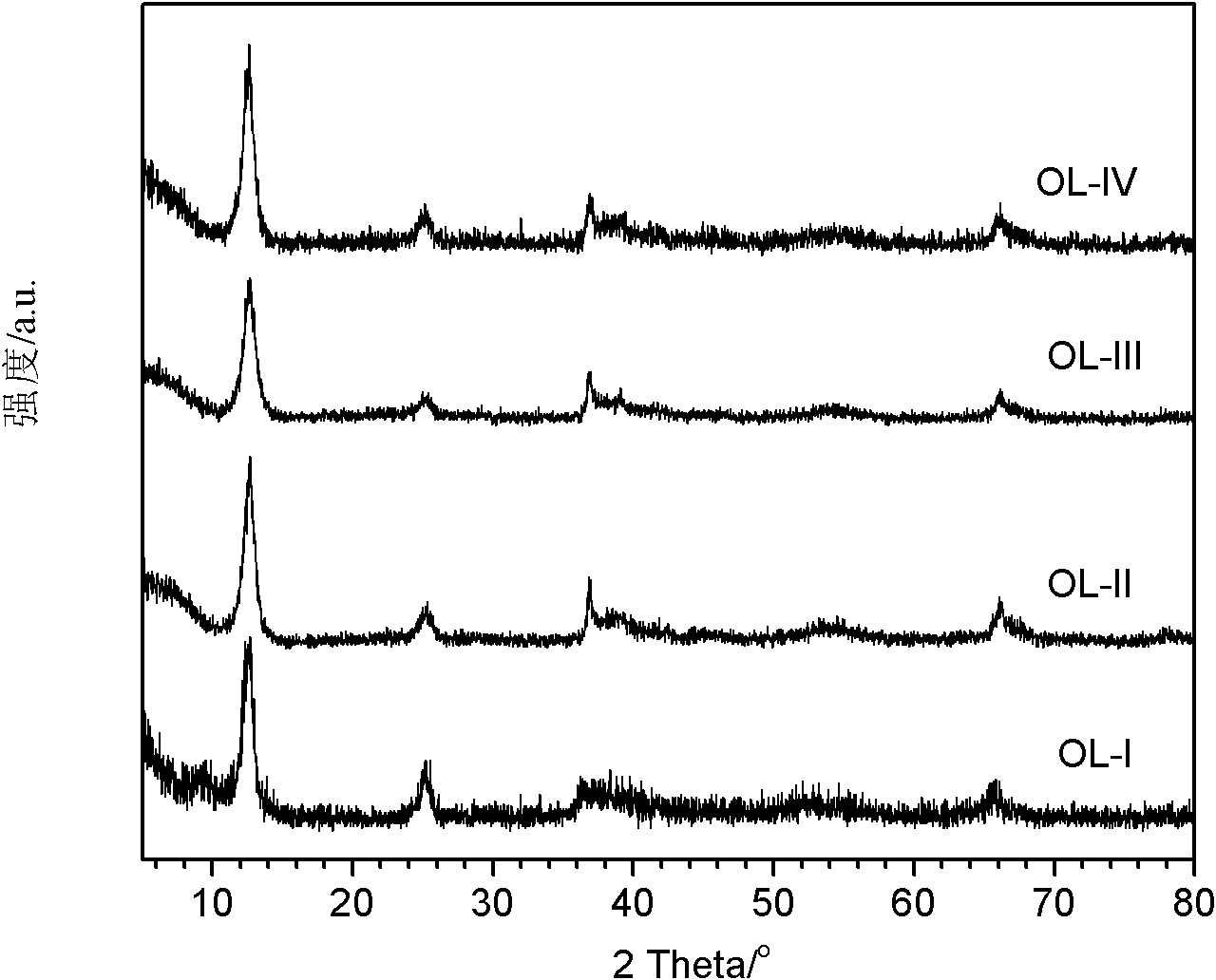

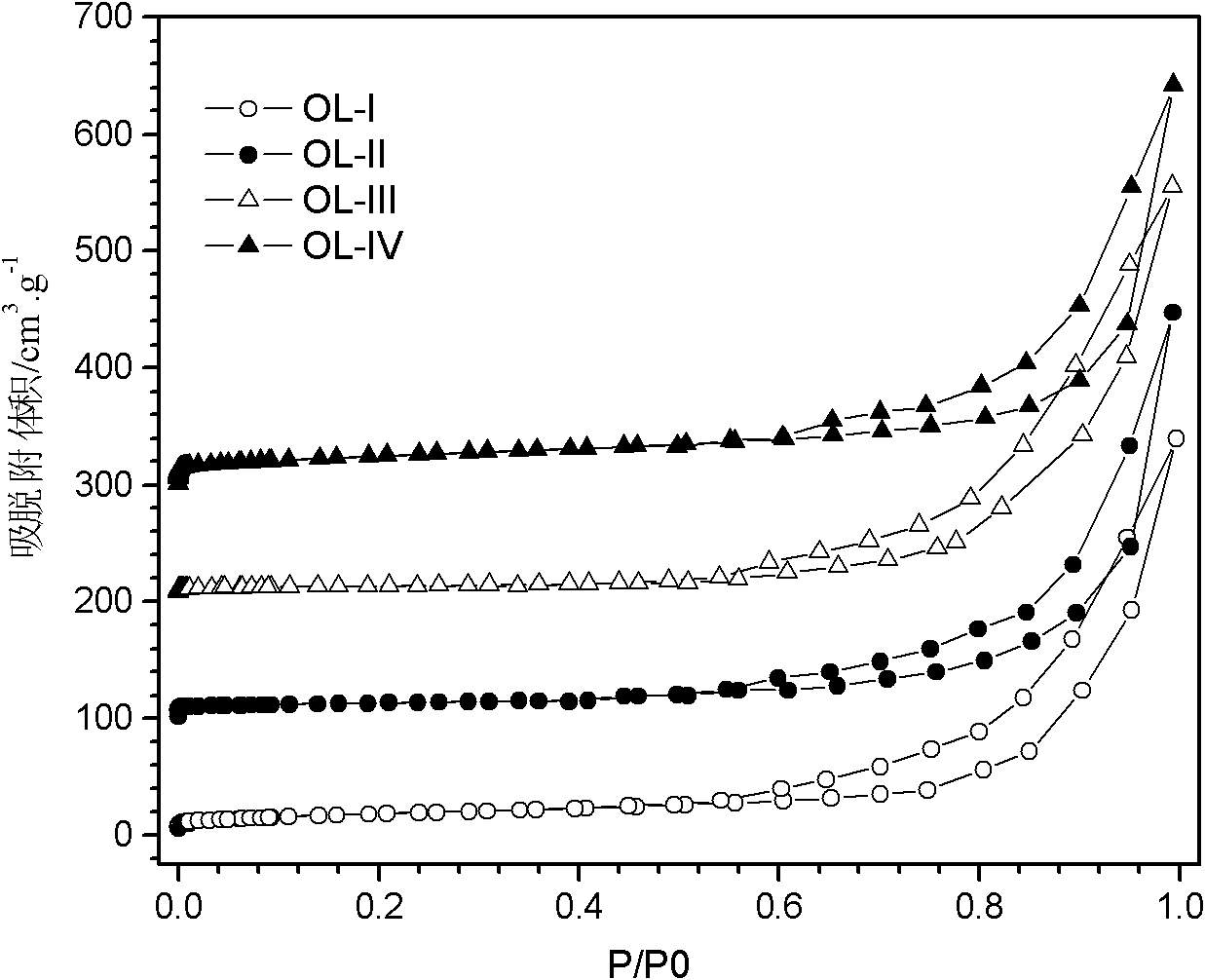

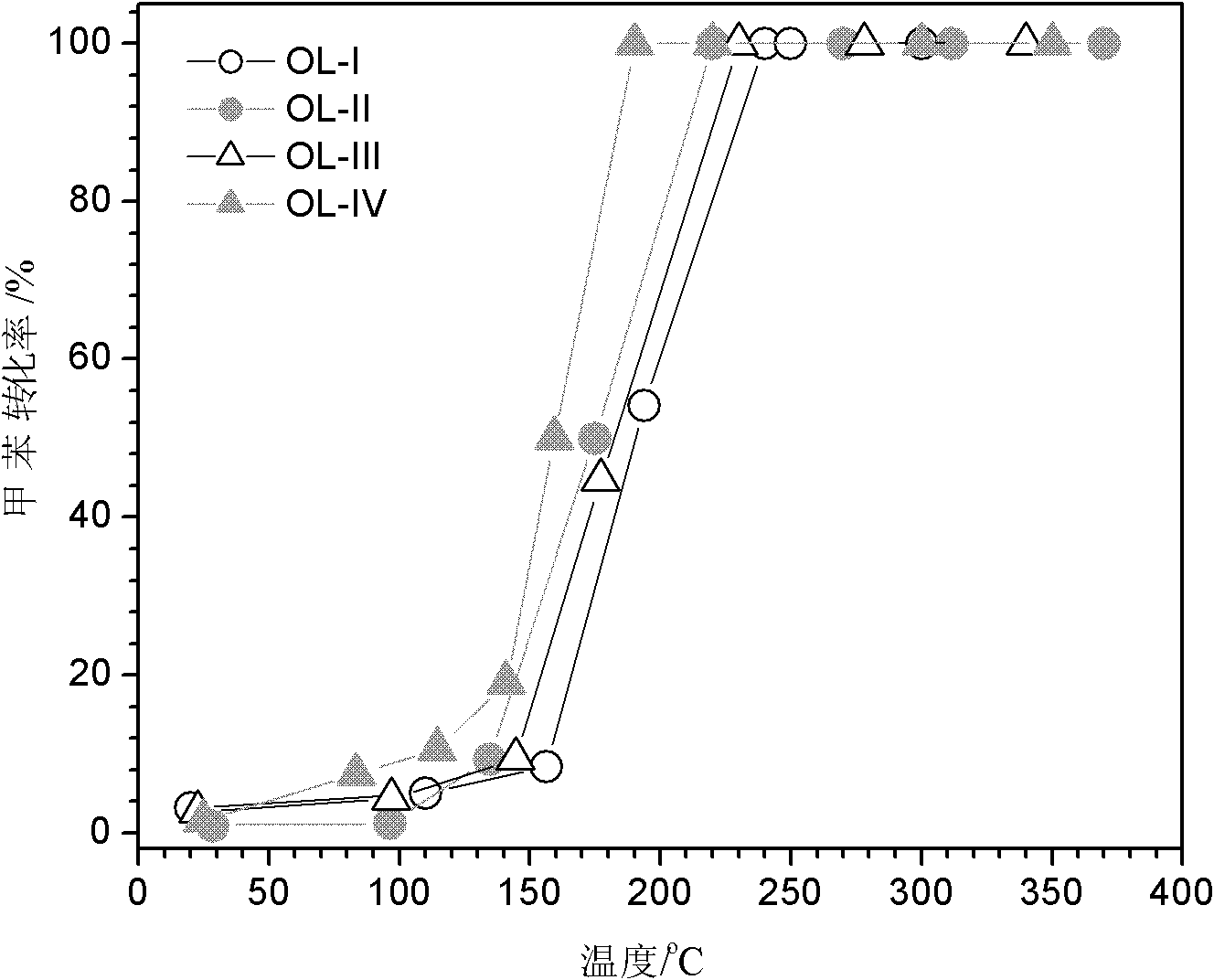

Preparation method and application of lamellar manganese oxide catalyst used for eliminating VOCs (volatile organic compounds) gases at low temperature

InactiveCN102172524AEasy to makeReduce energy consumptionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMolecular sievePtru catalyst

The invention discloses a preparation method and application of lamellar manganese oxide catalyst used for eliminating VOCs (volatile organic compounds) gases at low temperature. The low-cost potassium permanganate and alcohol are adopted as raw materials for the catalyst, and alkaline solution and dispersing agent are used for adjustment, thus a lamellar manganese oxide structure type molecular sieve (OL, open loop) with high specific surface area (97m<2> / g) and high thermal stability (more than 500 DEG C) is prepared. The catalyst prepared by the invention has higher eliminating efficiency on high-airspeed (60000-100000 / h) and low-concentration (500-1000ppm) VOCs gases. When the temperature is 190 DEG C, methylbenzene can be completely converted into non-poisonous materials CO2 and H2O, and elimination factor of methylbenzene can be maintained to be more than 90% within 100 hours; and when the temperature is 90 DEG C, formaldehyde can be completely converted into non-poisonous materials CO2 and H2O, and the elimination factor of formaldehyde can be maintained to be more than 90% within 100 hours. The catalyst prepared by the invention has the advantages of available raw materials, simple preparation process, strong practicability, low temperature high efficiency and no secondary pollution, VOCs gases can be completely eliminated.

Owner:BEIJING UNIV OF TECH

Nucleic acid detecting method

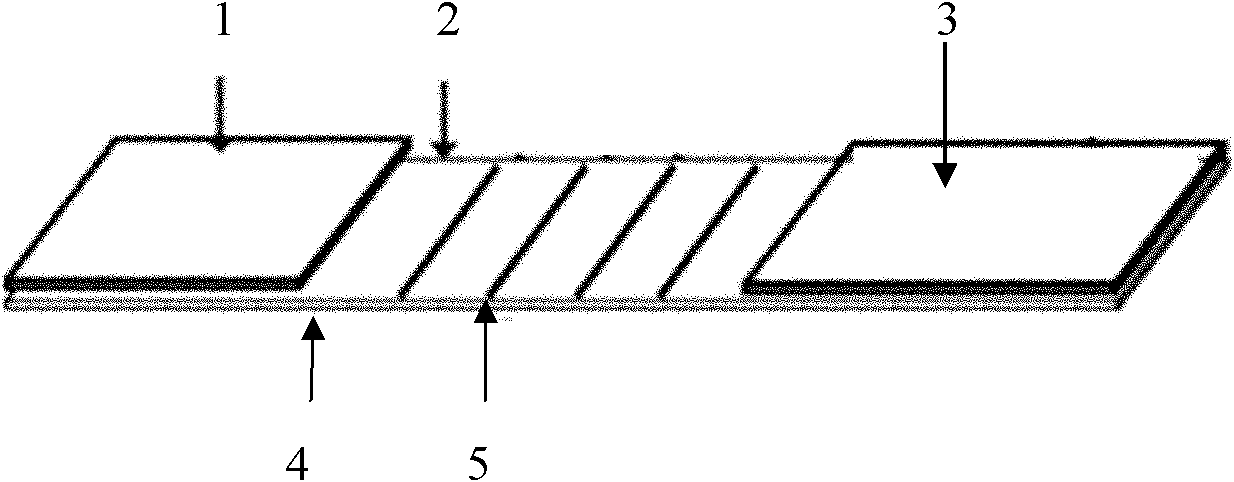

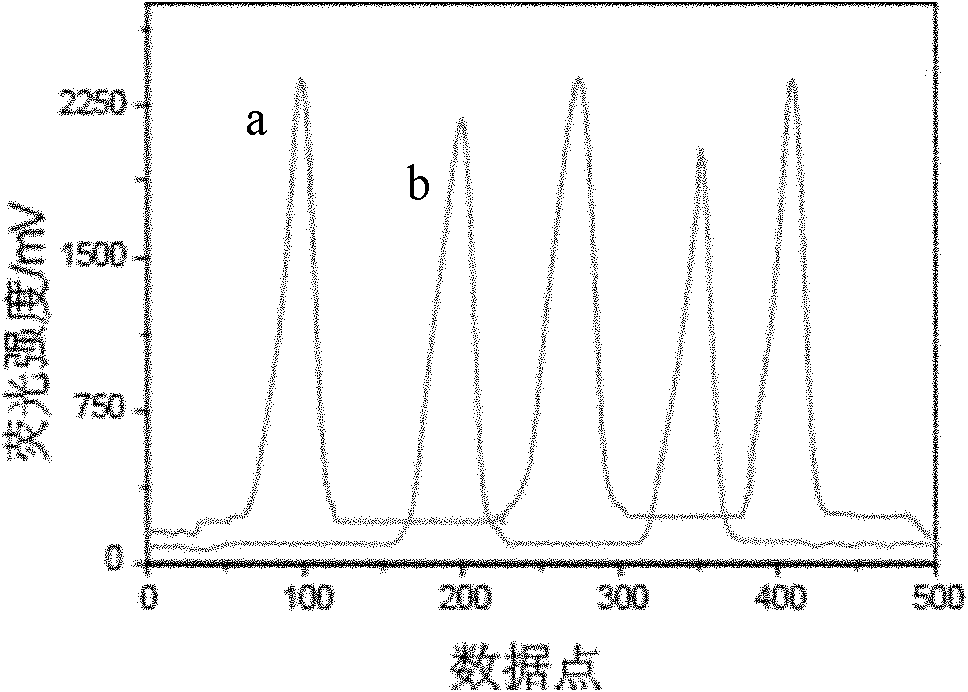

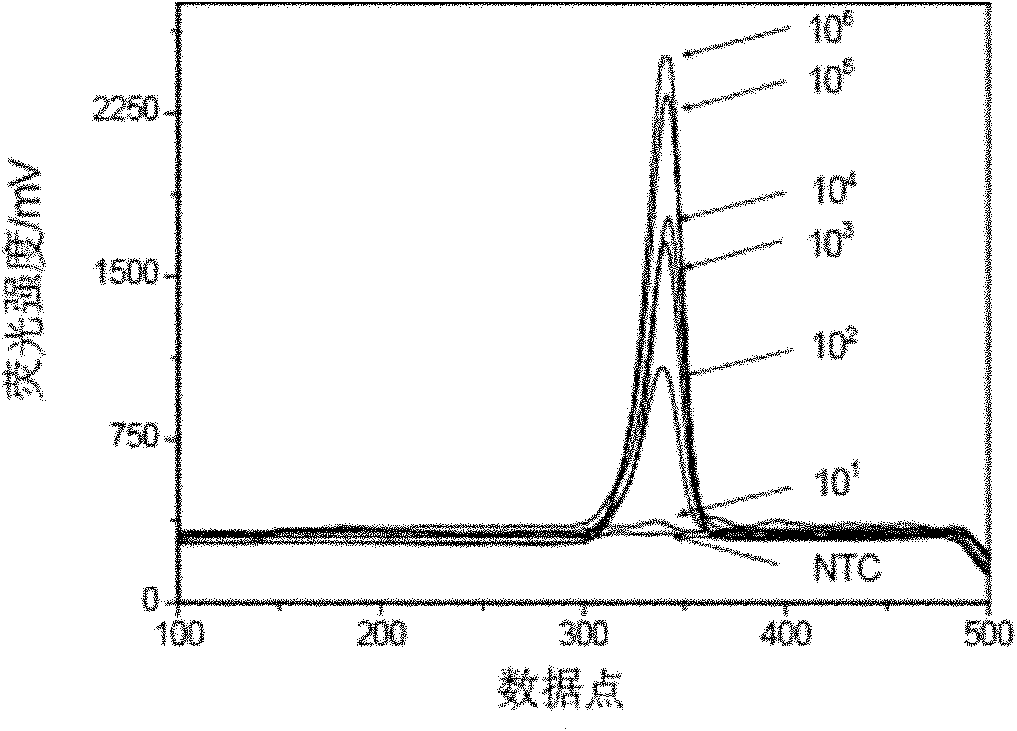

ActiveCN102154498AHigh throughputRealize typing detectionMicrobiological testing/measurementMicroorganism based processesFluorescenceBiology

The invention relates to a technology for detecting nucleic acid and provides a nucleic acid detecting method having the advantages of high sensitivity, high accuracy, low cost, simple operation and quickness, and a nucleic acid film chromatographic hybrid strip thereof. The nucleic acid film chromatographic hybrid strip comprises a sampling pad, target nucleic acid sequence capturing probes, a chromatographic film, a water absorbent pad and a back lining, wherein the chromatographic film is bonded to the middle of the back lining; the sampling pad and the water absorbent pad are bonded to both ends of the chromatographic film respectively; and the target nucleic acid sequence capturing probes are fixed on the chromatographic film between the sampling pad and the water absorbent pad in a straight line. In the method, the colored fluorescence marking probes and the film chromatography technology are combined, the type of a template of a sample can be differentiated by two parameters, namely fluorescence and a physical position, so that the quick genotyping detection of nucleic acid is realized. The nucleic acid detecting method is high in sensitivity, and the detection sensitivity reaches 101 copies / reaction. The nucleic acid detecting method is high in specificity, the high specificity are jointly guaranteed by the primers, detection probes and capturing probes, so that the detection result is more stable and accurate.

Owner:XIAMEN UNIV

Bamboo shoot sulfur-free drying process

InactiveCN101869135AGood color and flavorMaintain colorFruits/vegetable preservation by dehydrationSulfurImpurity

The invention relates to a bamboo shoot sulfur-free drying process, which is characterized by comprising the following steps: (1) raw material preparation, during which fresh phyllostachys praecox shoots with a base part of which the diameter is greater than 3 centimeters, washing the fresh phyllostachys praecox shoots to remove impurities, removing sheaths, cutting off aged parts, and cutting the shoots along longitudinal axes to obtain bamboo shoot blocks; (2) soaking the bamboo shoot blocks in color protecting solution for 20 to 90 minutes, wherein the ratio of the bamboo shoot blocks to the color protecting solution is 1g:3-4ml; (3) blanching color protection treatment, during which blanching the bamboo shoot blocks, which are soaked in the color protecting solution, in the color protecting solution at 80 to 100 DEG C for 2 to 10 minutes, and immediately washing the bamboo shoot blocks with water after the blanching; (4) permo-treatment, during which the bamboo shoot blocks, which are blanched for color protection, are soaked in osmotic solution for 20 to 40 minutes, and the ratio of the bamboo shoot blocks to the osmotic solution is 1g:3-4ml; (5) drying; and (6) packaging to obtain dry bamboo shoot products. The dry shoots prepared by the invention is short in rehydration time, convenient, sanitary and long in storage life and provides good raw material guarantee for the subsequent bamboo shoot deep processing.

Owner:JIANGNAN UNIV

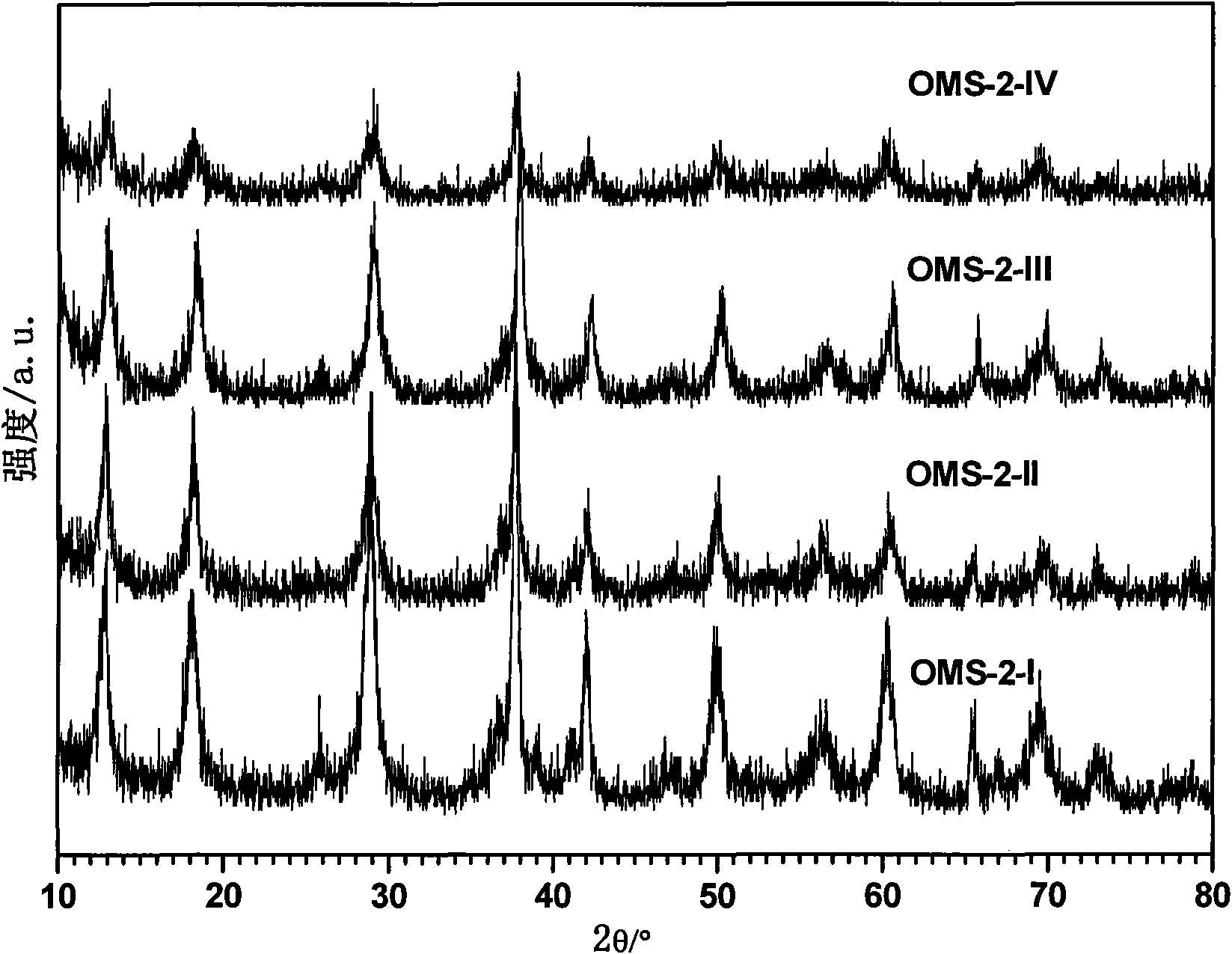

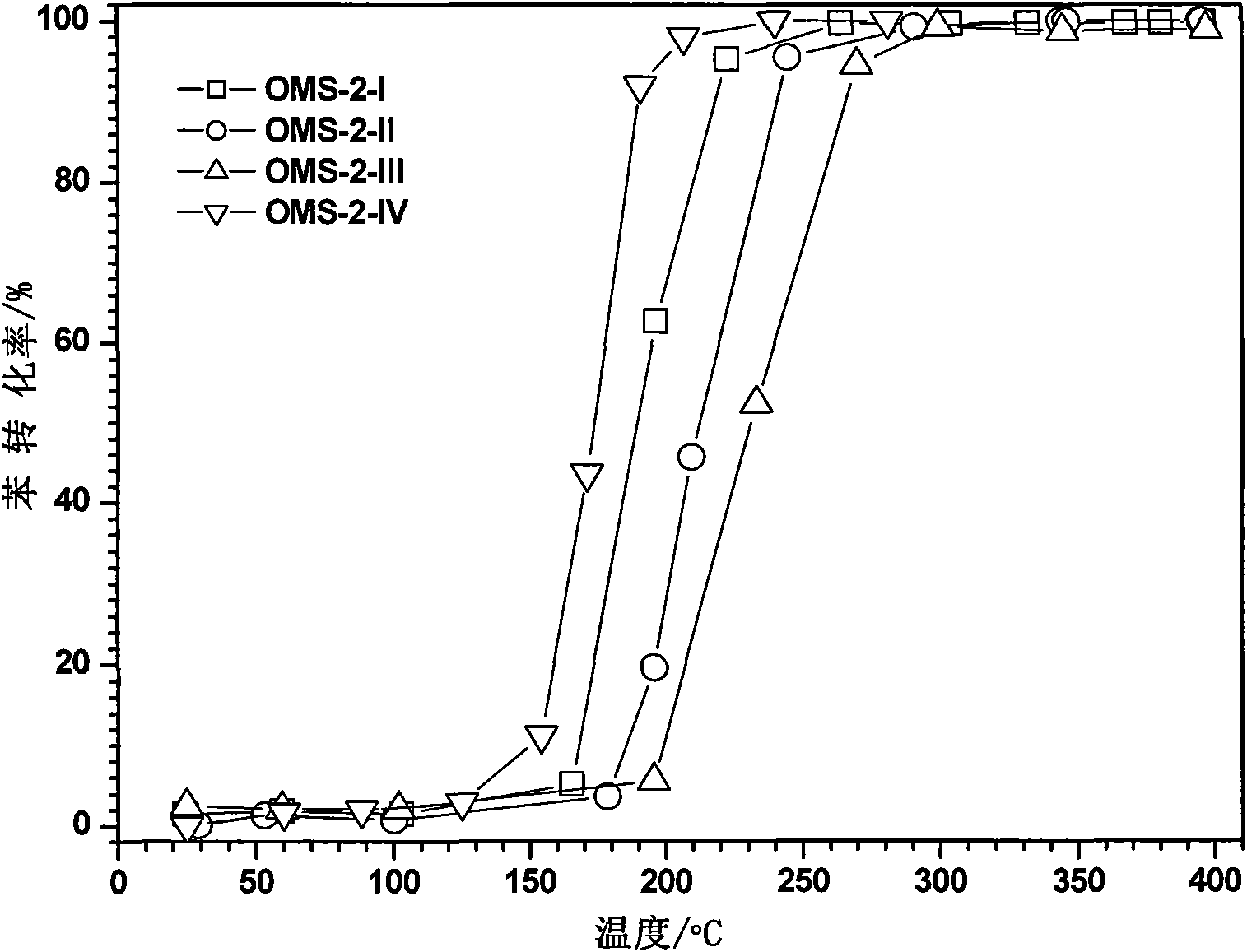

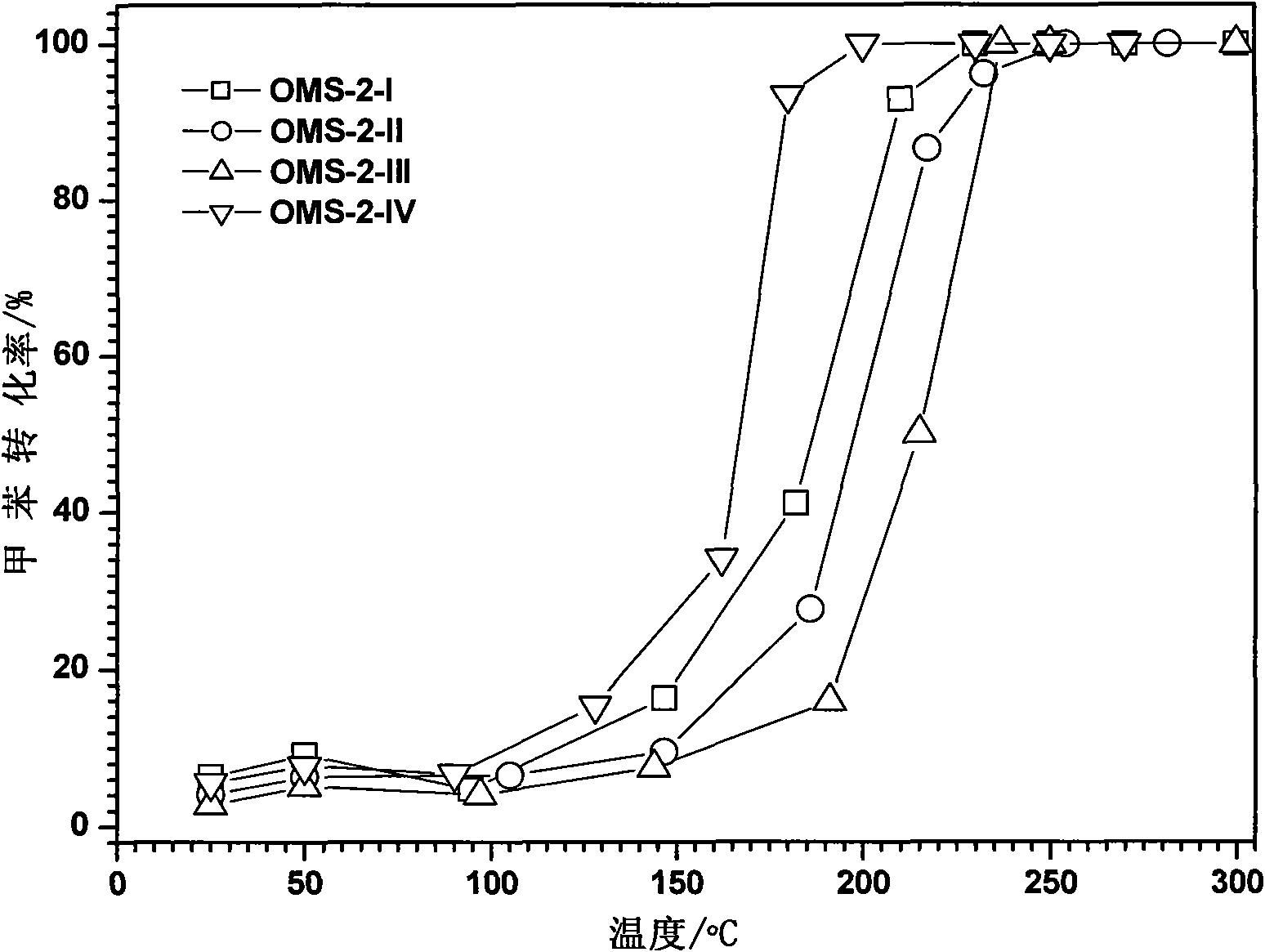

OMS-2 catalyst used in elimination of benzene series at low temperature and preparation and application

InactiveCN101927179AEasy to makeHigh and low temperature catalytic combustion to eliminate activityMolecular sieve catalystsDispersed particle separationMANGANESE ACETATEMolecular sieve

The invention discloses an OMS-2catalyst used in the elimination of benzene series at the low temperature, preparation and application. The catalyst is a manganese oxide octahedral molecular sieve and has a molecular formula of KMn8O16.nH2O. The material is prepared by using a reflux method which comprises the following steps of: preparing buffer solution of KAc-HAc with a pH value of 3.7 to 5.6; adding the buffer solution into PVP-containing Mn(Ac)2 solution; adding solution of KMnO4; stirring; refluxing; aging by sealing; filtering; washing with water; drying; baking; and performing other processing. The catalyst of the invention has the advantages of higher specific area and heat stability, high activity and high stability when the catalyst is applied to the elimination of the benzene series through low-temperature catalytic combustion, capacity of keeping the elimination ratio of the benzene series over 90 percent and not changed within 100 hours, cheap used raw material, namely manganese acetate, simple preparation process, no load of other metals or noble metals,.

Owner:BEIJING UNIV OF TECH

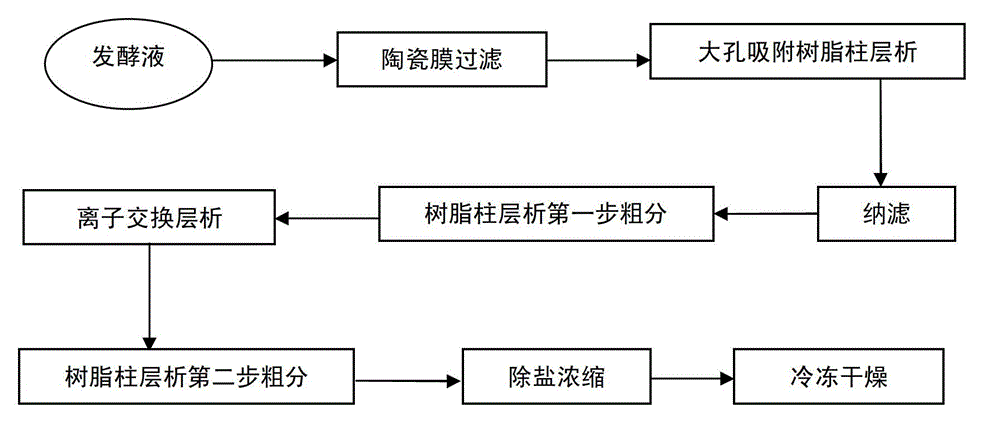

Method for separating and purifying daptomycin

ActiveCN102718839ALittle side effectsRaw materials are simplePeptide preparation methodsChemistryDaptomycin

The invention provides a method for separating and purifying daptomycin. The method overcomes the defects of the exiting extraction technology of the daptomycin, the purity of the daptomycin is improved, and the final purity of the daptomycin reaches higher than 99.2, so a method capable of industrially purifying the daptomycin is provided.

Owner:鲁南新时代生物技术有限公司

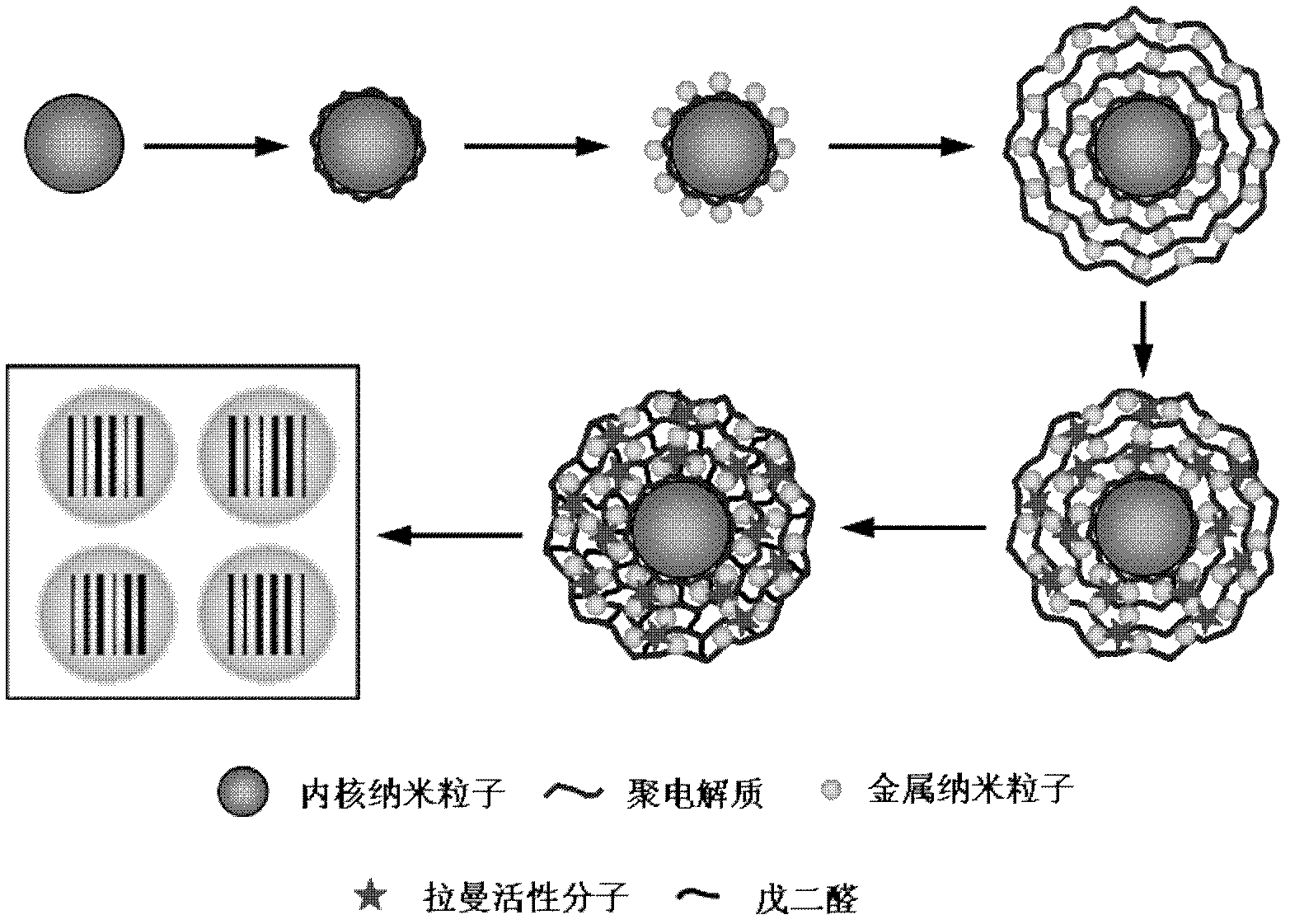

Raman coding microspheres and preparation method thereof

ActiveCN102423670AEasy to prepareRaw materials are simpleRaman scatteringMicroballoon preparationLayer by layer self assemblyMicrosphere

The invention discloses Raman coding microspheres and a preparation method thereof, wherein the Raman coding microspheres are obtained by coating multi-layer metal nanoparticles on the surfaces of inner core nanoparticles through a layer-by-layer self-assembly method and marking with a Raman active substance. The preparation method and raw materials of the Raman coding microspheres are simple, and the strength of Raman signals of a marker can be regulated and controlled through the number of assembly layers of the metal nanoparticles; compared with the existing Raman making technology, the Raman coding microspheres according to the invention are strong in the Raman signals, uniform in aggregation state of the particles and good in repeatability of the Raman signals.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com