Structure of SiC or Si substrate GaN-based crystal and method for growing same

A growth method and substrate technology, applied in the field of optoelectronics, can solve problems such as complex implementation and no implementation method given, and achieve the effects of easy implementation, novel method, and improved crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

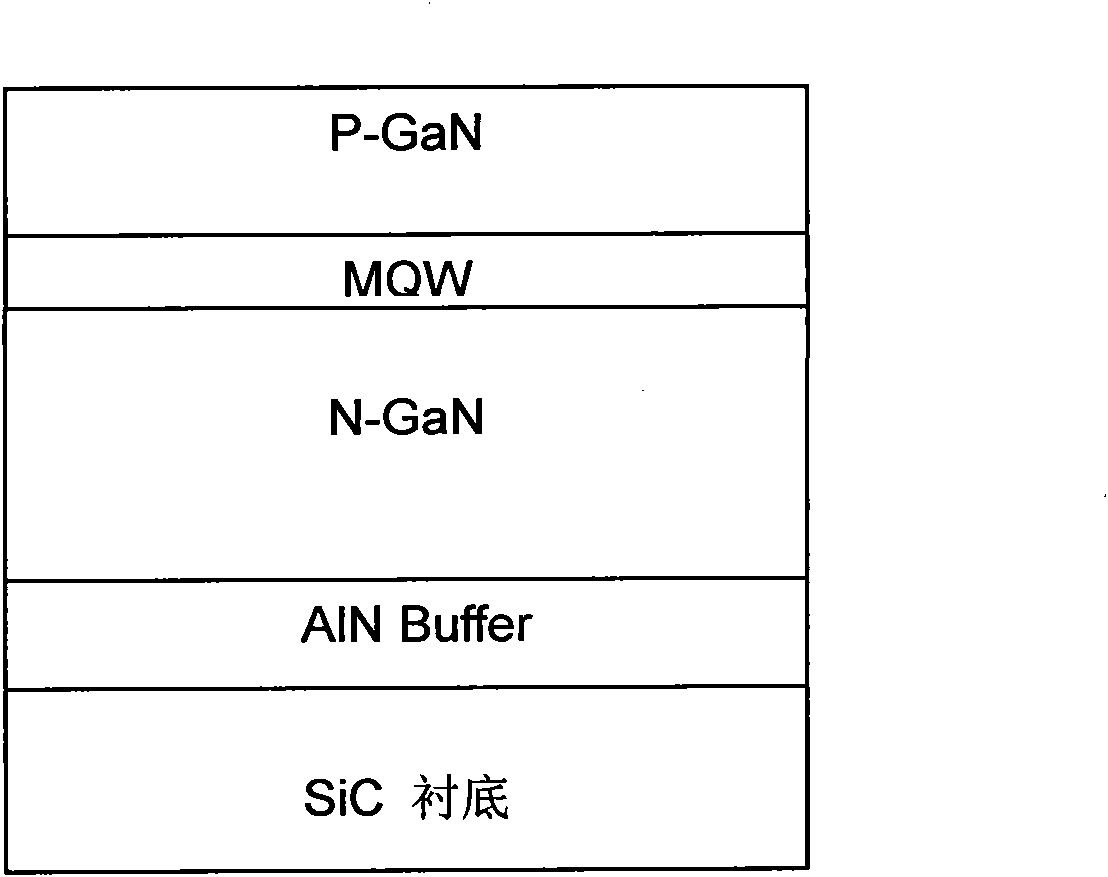

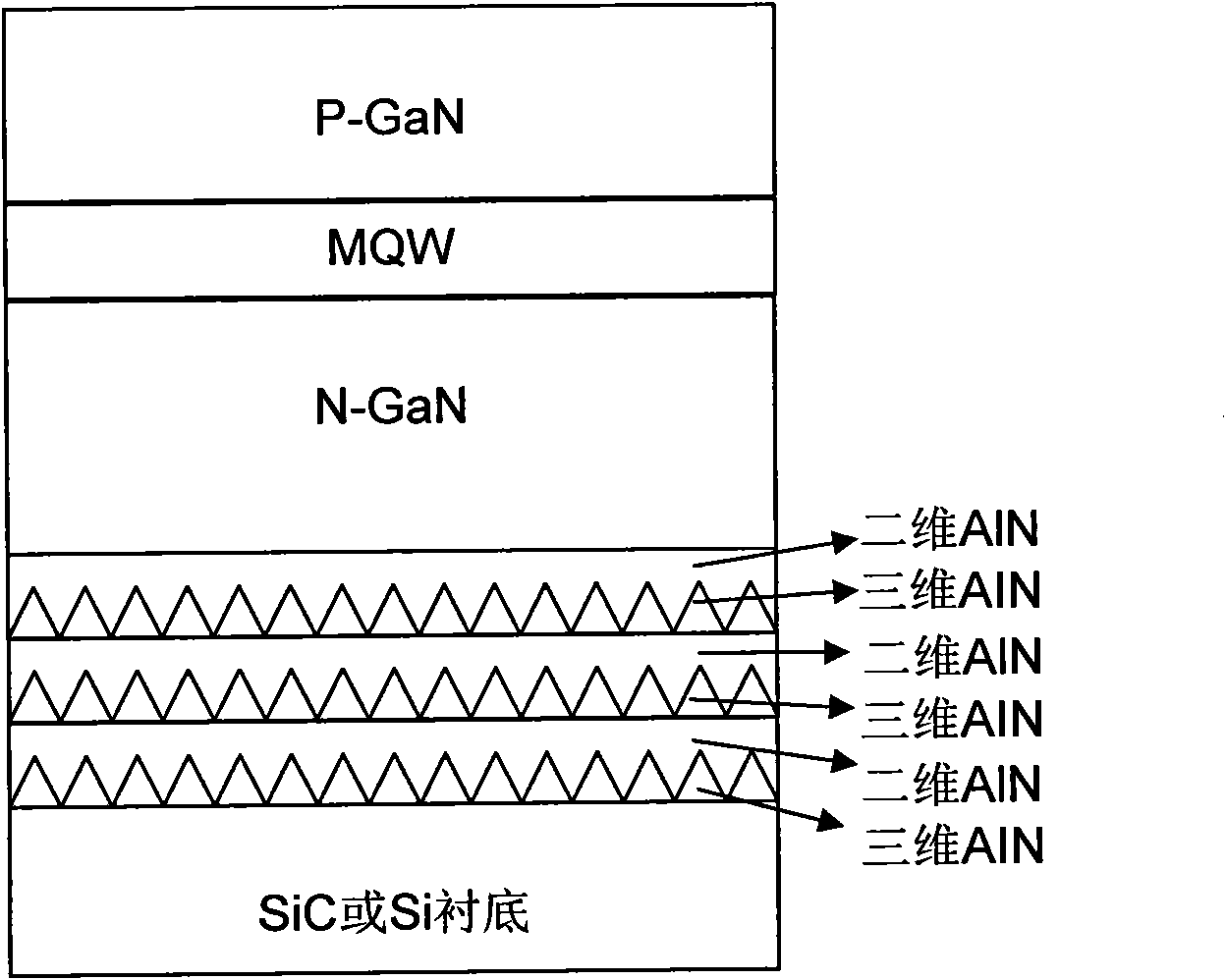

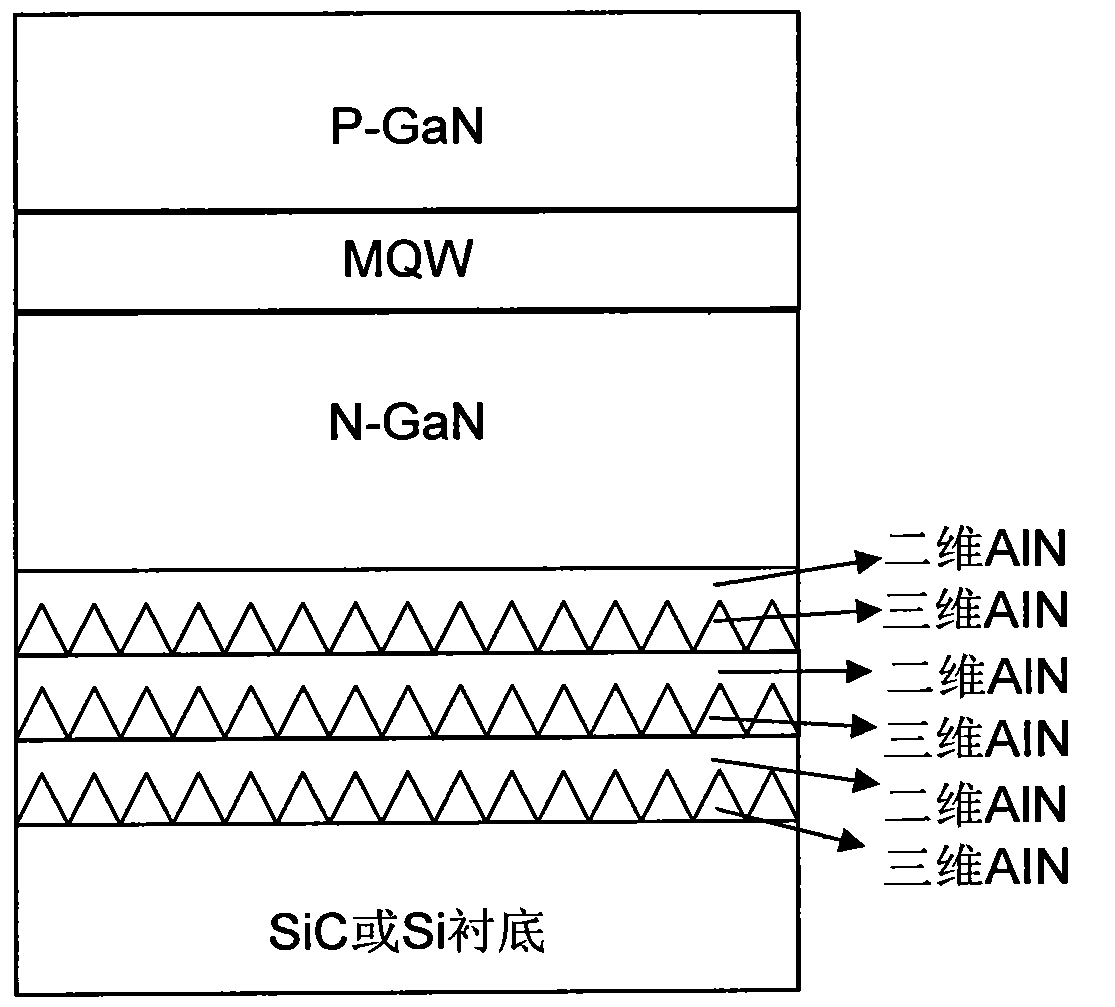

[0023] Such as figure 2 As shown, the present invention also includes SiC or Si substrate, AlN buffer layer, N-type GaN layer, MQW (Multiple Quantum Well) layer and P-type GaN by the structure of the SiC or Si substrate GaN-based crystal grown by resonance in the present invention from bottom to top layer. The AlN buffer layer has 3-5 cycles of three-dimensional and two-dimensional structures. The thickness of three-dimensional AlN is 50nm-100nm, and the thickness of two-dimensional AlN is 30nm-60nm. It is grown by MOCVD (metal organic chemical vapor deposition) method. AlN buffer layer It is obtained by the resonance growth method of three-dimensional and two-dimensional cyclic growth. The specific growth process is:

[0024] (1) First, deposit a layer of high-temperature AlN buffer layer on the SiC or Si substrate at 900°C-1100°C in the MOCVD equipment. The specific process is: first at 900°C-1000°C, NH 3 The three-dimensional growth of AlN (vertical growth rate is great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com