Raman coding microspheres and preparation method thereof

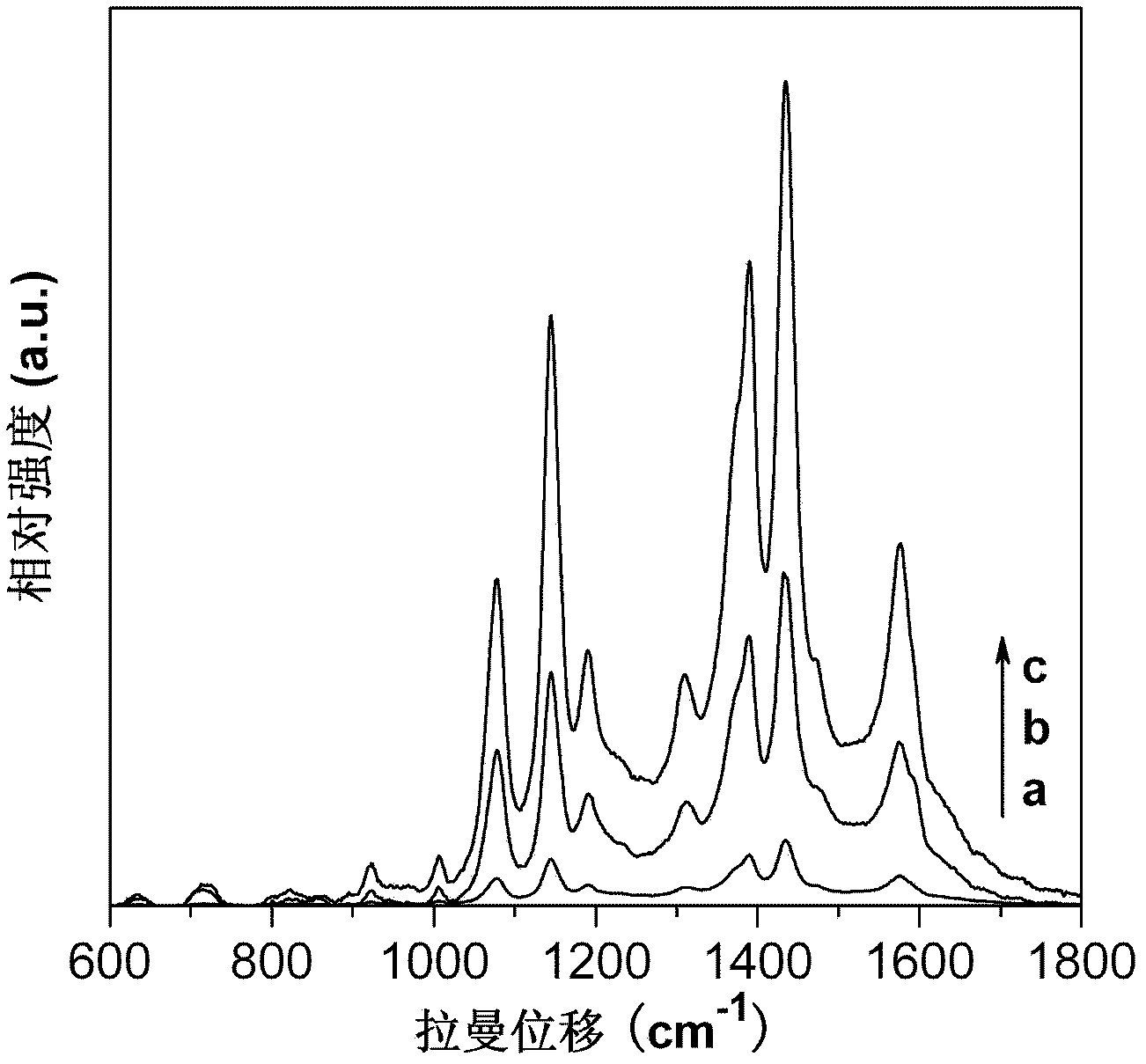

A coded microsphere and Raman coded technology, applied in the field of Raman coded microspheres and their preparation, to achieve the effect of strong Raman signal, simple preparation method and raw materials, and good repeatability of Raman signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

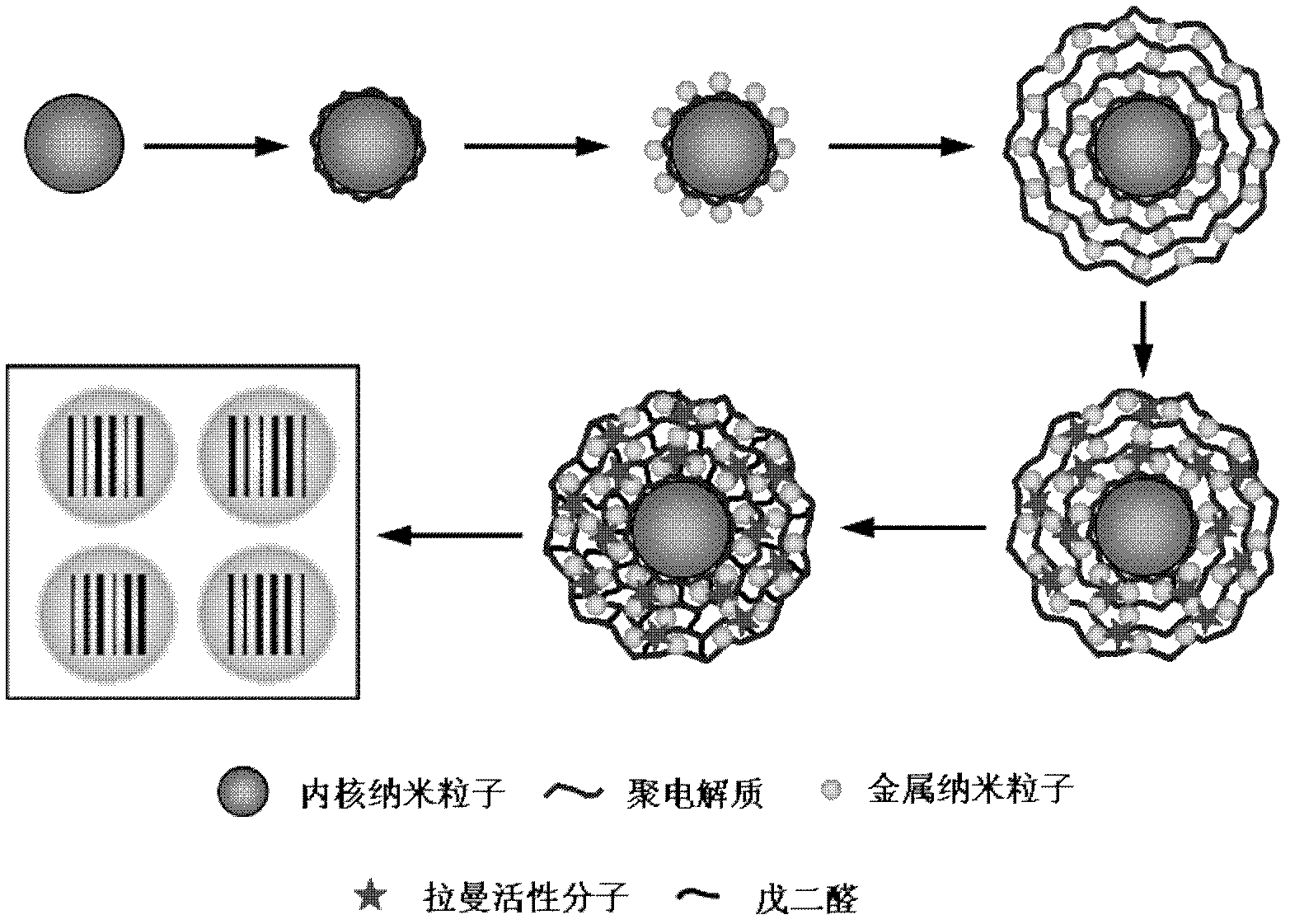

Method used

Image

Examples

Embodiment 1

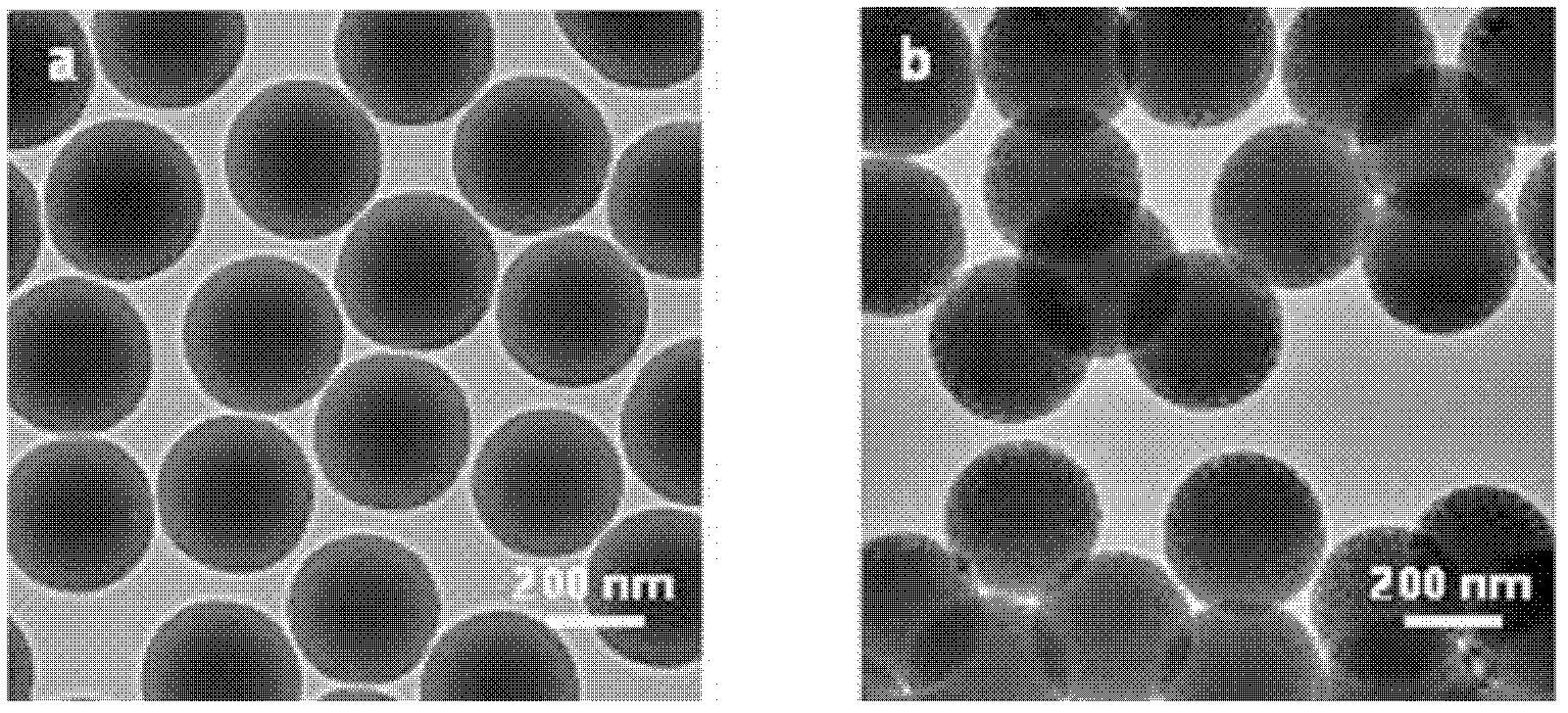

[0028] a. Preparation of Core Nanoparticles - Silica Nanoparticles

[0029] Mix 3.6mL tetraethyl orthosilicate and 88.1mL ethanol solution, add it to a 250mL round bottom flask, stir with a magnetic stirrer at a speed of 500rpm for 3 minutes, mix well, and then quickly add 11.9mL ammonia water to the above In the reaction solution, react at room temperature for 15-18 hours to obtain silicon dioxide nanoparticles.

[0030] b. Preparation of metal nanoparticle sol-silver nanoparticle sol

[0031] Take 95mL of ultrapure water, add 1mL of 30mM sodium citrate solution and 2mL of 5mM silver nitrate solution in turn, then quickly inject 1mL of 50mM sodium borohydride solution, stir at room temperature for 30 seconds, add 1mL of 5mg / mL polyvinylpyrrolidone, the solution gradually changes It is dark yellow, and the silver nanoparticle sol with a particle diameter of 5-15nm is obtained.

[0032] c. Preparation of core-shell nanospheres

[0033] Get 25mL (0.2g) of silica nanoparticles...

Embodiment 2

[0040] a. Preparation of Core Nanoparticles - Silica Nanoparticles

[0041] The preparation method of silica nanoparticles in this example is the same as that in Example 1.

[0042] b. Preparation of metal nanoparticle sol—silver nanoparticle sol

[0043] The preparation method of the silver nanoparticle sol in this embodiment is the same as that in Embodiment 1.

[0044] c. Preparation of core-shell nanospheres

[0045]Get 25mL (0.2g) of silica nanoparticles prepared in step a, centrifuge and disperse in 50mL 2mg / mL polyethyleneimine solution, NaCl is added in the polyethyleneimine solution, the concentration of NaCl is 0.5M, room temperature Stir for 30 minutes, then centrifuge, wash, disperse in the silver nanoparticle sol prepared in step b, stir at room temperature for 30 minutes to obtain the silica nanospheres coated with single-layer silver nanoparticles, and obtain the single-layer silver nanoparticle The particle-coated silica nanospheres were repeatedly added to ...

Embodiment 3

[0051] a. Preparation of Core Nanoparticles—Polystyrene Nanoparticles

[0052] Add 10 mL of purified styrene, 1 mL of acrylic acid and 50 mg of ammonium persulfate into 90 mL of deionized water, and pass nitrogen gas for 0.5 hours under stirring conditions to remove O in the system. 2 , and then the temperature was raised to 70° C., and the reaction was carried out for 15 hours. After the temperature of the system dropped to room temperature, the obtained product was washed three times with ethanol and water respectively to obtain carboxyl-functionalized polystyrene beads, which were dispersed in water for use.

[0053] b. Preparation of metal nanoparticle sol—gold nanoparticle sol

[0054] Add 0.425g of chloroauric acid and 250mL of ultrapure water into a 500mL round bottom flask, stir vigorously with a magnetic stirrer, then add 25mL of 12.5mM sodium borohydride solution dropwise, stir at room temperature for 30 seconds, then add 2mL of 5mg / mL polyvinylpyrrolidone, the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com