Patents

Literature

1569results about How to "Maintain color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antibacterial enamel and preparation method thereof

The invention discloses an antibiotic enamel, wherein the glaze-making base formulation includes SiO2 30-50%, Al2O3 5-10%, B2O3 5-20%, Na2O 2-20%, K2O 2-10%, CaO 0-5%, MgO 0-5%, TiO2 0-20%, Zr02 0-10%, ZnO 0-5%, BaO 0-5%, F 1-10%, NiO 0-2%, MnO 20-4%, Fe2O3 0-4%, CuO 0-2%, the added antibacterial agents being Cu, Ag, Sn, Zr, rare earth, Ca, Zn, B, Ba, Ti and their compounds, salts or oxide compounds, the total content being 1-5%.

Owner:丁文战

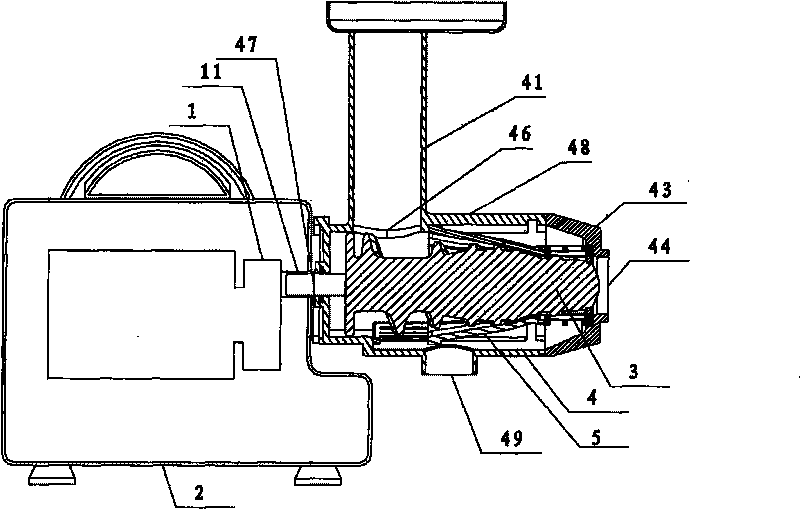

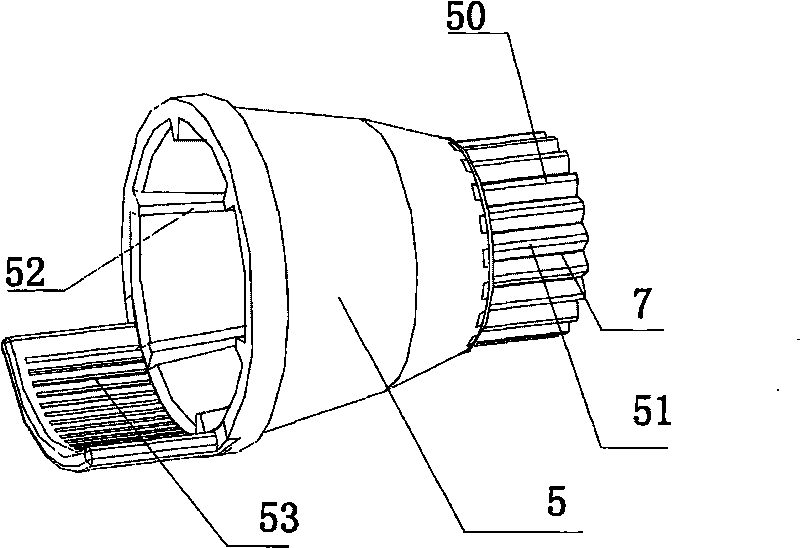

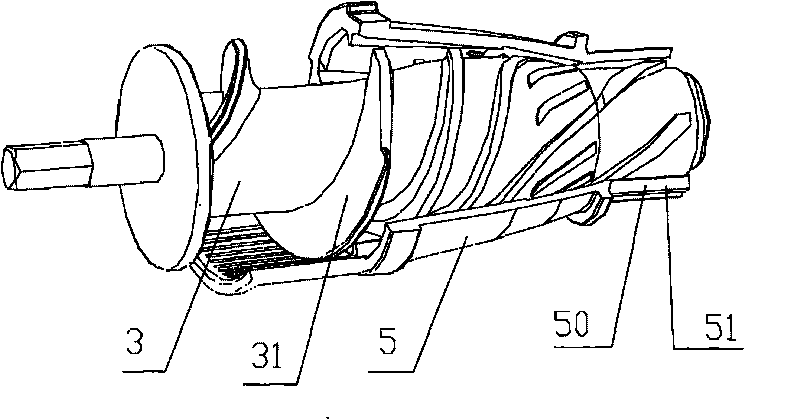

Easy cleaning extrusion type juicer

ActiveCN101697857AOutflow smoothlyImprove Juicing EfficiencyStrainersAgricultural engineeringFruits and vegetables

The invention discloses an easy cleaning extrusion type juicer which comprises an engine base, a motor, a juice collecting chamber, an extruding and crushing part and a filtering part, wherein the extruding and crushing part comprises a push-in screw and an extrusion cylinder matched with the push-in screw. The extrusion cylinder is arranged in the juice collecting chamber, and the filtering part is arranged on the lower part of the extrusion cylinder. The filtering part is characterized in comprising grids, and scum juice filtering gaps are arranged between the grids. The easy cleaning extrusion type juicer of the invention has the advantages that the size of the scum juice filtering gaps can change according to the size of the material under the action of the push-in screw to the material, the juice extrusion rate is high, so that the juicer is especially suitable for lone-term material feed; the juicer is easy to clean after being used, the extruded fruit and vegetable juice has less foam, and the inherent colour and taste of the fruit and vegetable juice can be kept to the maximum extend.

Owner:JOYOUNG CO LTD

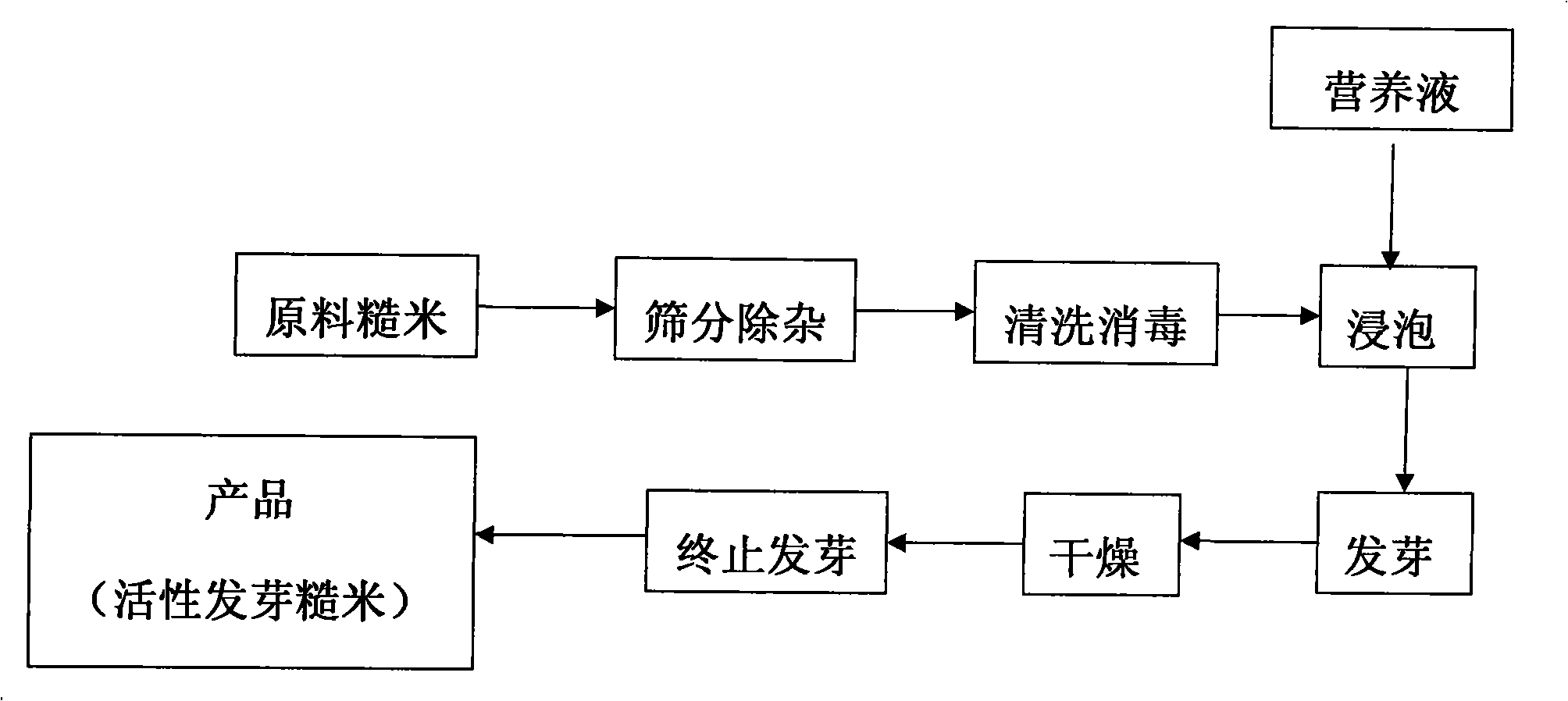

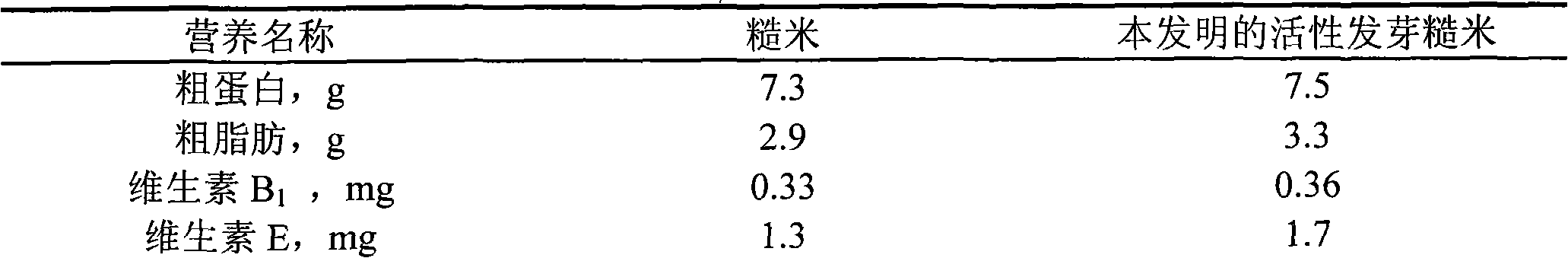

Production method of active germinated unpolished rice and its products

InactiveCN101283754APromote digestion and absorptionRich varietyFood preparationFertilizer mixturesNutritive valuesVitamin C

The invention belongs to the technology field of grain processing, specifically a method for producing active germinated brown rice and products thereof. The method comprises the following steps: screening brown rice raw material to remove impurity, washing, sterilizing, soaking in a nutrient fluid supplemented with calcium lactate, gibberellin, phytase, cellulase and vitamin C for 10-36 hours at 10-40 DEG C, draining, incubating for 10-36 hours at 10-40 DEG C under relative humidity of 50-90% to allow germination, drying with hot air of 40-55 DEG C for 0.5-3 hours until the sprout grows about 0.5-1.2 mm in height, drying with 2-10 w / g microwave for 2-10 minutes until the water content of germinated brown rice is below 15%. Compared with the prior art, the germinated brown rice is nutritious, retains almost all nutrients of brown rice and has high nutritional value.

Owner:HUAZHONG AGRI UNIV

Method for producing atmosphere heat drying and vacuum oil frying combined dewatered fruit and vegetable crisp chip

InactiveCN1554274AAvoid severe deformationKeep shapeFood preservationFood preparationFood materialEdible mushroom

The present invention belongs to the field of fruit and vegetable food producing technology. The production process of crisp fruit and vegetable chip includes the steps of: selecting fruit, vegetable material, edible mushroom and other food material; pre-treatment including washing, peeling, slicing, scalding to kill enzyme, etc; heating to dry at normal pressure; oil frying to dewater, centrifuging to eliminate oil, seasoning and packing. Owing to the combined dewatering process of normal pressure hot drying and vacuum frying, the present invention has low oil content in crisp fruit and vegetable chip, short frying time and well maintained food shape.

Owner:JIANGNAN UNIV +1

Method for producing instant pleurotus eryngii chips

The invention relates to a method for producing instant pleurotus eryngii chips, and belongs to the technical field of the deep processing of agricultural products. The main pleurotus eryngii chip production process comprises: performing pretreatment such as conventional selection, washing, precise segmenting, blanching, enzyme killing, cooling and the like on pleurotus eryngii, and performing ultrasonic auxiliary dipping, hot-air drying, vacuum frying and dewatering, centrifugal deoiling, seasoning and packaging. In the method, due to the adoption of a new process of combining the ultrasonic auxiliary dipping, the hot-air drying, the vacuum frying and dewatering, the dipping efficiency is improved, the moisture content of pleurotus eryngii pieces is reduced due to hot-air predrying, and the vacuum frying time is shortened greatly; and products of the pleurotus eryngii chips have the characteristics of high puffing rate, low oil content, excellent sensory quality and the like. In the method, the pleurotus eryngii is not processed by conventional freezing, so the production period of the finished products is shortened greatly, the production cost is saved, and a feasible new path is provided for the deep processing of the pleurotus eryngii.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

Former hot blast and latter vacuum microwave combining drying process of producing crisp fruit and vegetable grains

InactiveCN1672531AReduce drying loadReduced moisture removal requirementsFruits/vegetable preservation by dehydrationWater contentFood processing

The present invention is former hot blast and latter vacuum microwave combining drying process of producing fruit and vegetable grains, and belongs to the field of fruit and vegetable food processing technology. The drying process includes the steps of: washing fruit and vegetable material, dicing, scalding to killing enzyme, cooling in flow water, draining, optional fast freezing and defrosting, soaking with seasoning, draining, pre-dewatering with hot blast to obtain semi-finished product with water content of 40-60 %, and final vacuum microwave drying to obtain product with water content of 2-5 %. The said process has the nutritious components and color well maintained, crisp product, short production period, low cost, high product quality and other features.

Owner:JIANGNAN UNIV

Preparation method for aesthetic resin for improving affinity of aluminum powder pigment

ActiveCN102372904AGood dispersionIncrease speedPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsDispersityOrganic solvent

The present invention relates to a preparation method for an aesthetic resin for improving affinity of an aluminum powder pigment. According to the method, an organic solvent and an aluminum powder pigment are stirred at a middle-low speed in a stirring machine, and are added with a coupling agent; the resulting mixture is transferred to a high-speed mixer to carry out a treatment; the pretreatedaluminum powder pigment, a compatibilizer, and a plastic substrate are uniformly mixed in the high-speed mixer, and are extruded and pelletized to obtain the aluminum powder pigment master batch; finally, according to the requirement of the metal effect, the aluminum powder pigment master batch is added to various corresponding plastic substrates according to a certain ratio; after high-speed mixing, a double screw extrusion process is adopted to prepare the spray-free aesthetic resin with the special metal effect. The phenomenon of aluminum powder pigment shedding from the plastic substrate is easily generated after the aluminum powder pigment is added to the plastic substrate, and is extruded and pelletized. With the present invention, the shedding phenomenon of the aluminum powder pigment can be effectively improved, such that the dispersity of the aluminum powder pigment during the injection molding is improved, the cases of easy agglomeration and accumulation of the aluminum powder pigment are avoided, a technical support is provided for replace of the traditional paint spraying scheme by the green and environmental protection aesthetic resin.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Quick roasting method of fresh grosvenor momordica

ActiveCN102100394AGuaranteed circulationExtend the baking timeFood preservationPharmaceutical product form changeTime rangeMicrowave oven

The invention discloses a quick roasting method of a fresh grosvenor momordica, which comprises the following steps: (1) classifying the ripe grosvenor momordica according to large, middle and small specifications and respectively placing into a special roasting tray used for a microwave oven; (2) placing the roasting tray filled with the grosvenor momordica into an intelligent microwave vacuum drying oven; and (3) determining the roasting time according to the weight of the grosvenor momordica and the power of the microwave oven and roasting, wherein the roasting temperature range is 20-40 DEG C, and the roasting time range is 30-150 minutes under the condition of vacuum degree less than -0.08MPa. In the method, the microwave technology for roasting is utilized, the roasting process is carried out at low temperature and constant temperature, the time consumption is short, the cost is low, and the fresh grosvenor momordica well keeps the bright yellow color and nutrition constituents and has good taste.

Owner:桂林普兰德生物科技有限公司

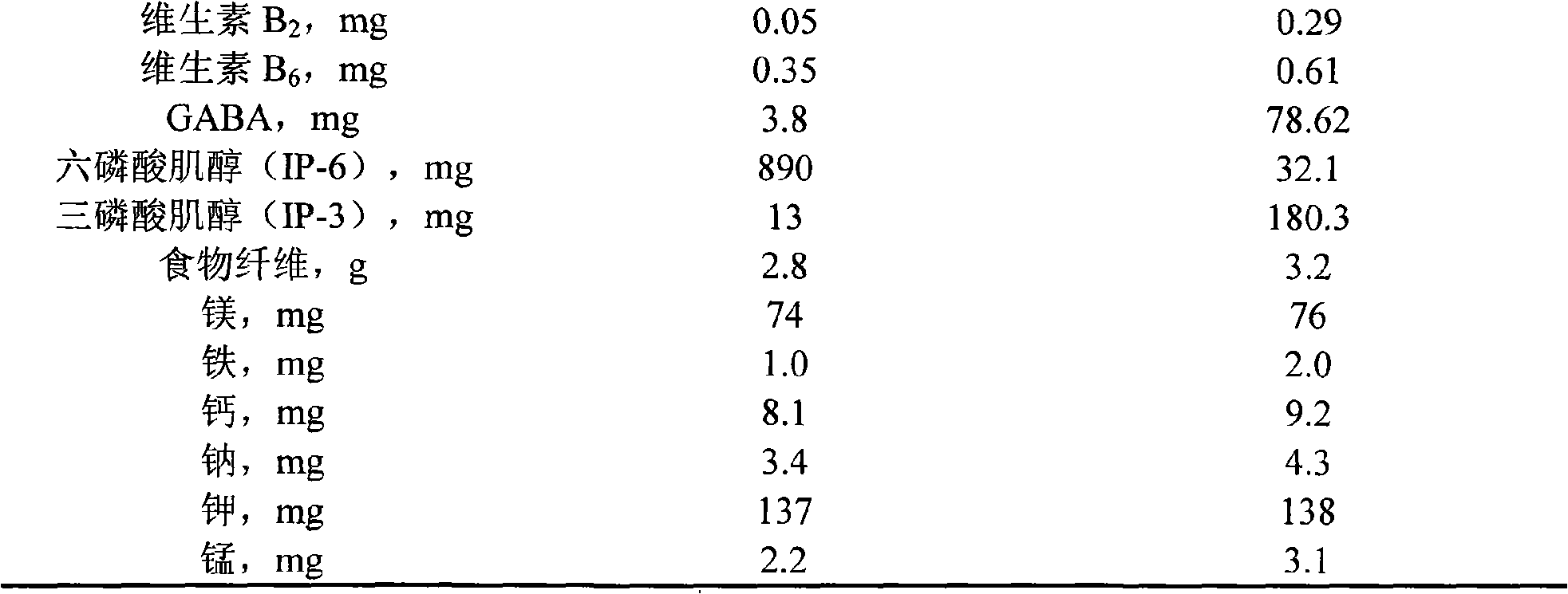

Cyclopropene preservative, and preparation and packaging methods thereof

ActiveCN102119719AExtended storage timeImprove qualityDead plant preservationFruit and vegetables preservationChemistryCyclopropene

The invention provides a cyclopropene preservative, which is characterized by containing 0.1 to 99 mass percent of cyclopropene coating material powder, 0.1 to 98 mass percent of compound, composition or material releasing water molecules, and 0 to 98 mass percent of one or more assistants. The invention also provides the preparation method and packaging method of the cyclopropene preservative. The preservative is convenient for use and has a remarkable preservation effect.

Owner:山东营养源食品科技有限公司

Food fruit material and its production method

ActiveCN101310614AGood for physical and mental healthWith weight loss effectFood preparationSucroseFood material

The invention relates to a food fruit material, wherein, 100 portions by weight of which is prepared from the raw materials as follows: 45 potions to 80 portions of fruit, 1 portion to 3 portions of modified starch, 0.01 portion to 0.06 portion of sodium citrate, 0.01 portion to 0.03 portion of Acesulfame-K and 0.01 portion to 0.1 portion of aspartame and the rest is water to make up 100 portions. The invention also provides a method for producing the food fruit material and a food added with the food fruit material which is produced by the method. The food fruit material provided by the invention has low content of cane sugar, contains various fruits and is good both in nutrition and taste. Furthermore, the manufacturing method provided by the invention can produce fruit-contained food with different flavors; selection and sterilization of the fruit are strict, and both the degree of hardness and softness and degree of tartness and sweetness of the fruit material can be set, thus being suitable for being selected and taken by the consumers for a long time.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Freeze-dried fermented glutinous rice and preparation method thereof

ActiveCN102304446ARetain nutrientsFull of nutritionAlcoholic beverage preparationAdditive ingredientFreeze-drying

The invention relates to a preparation technique of freeze-dried fermented glutinous rice, which comprises the following steps: elutriating glutinous rice to remove impurities, and soaking; boiling, and cooling to 28-30 DEG C; dispersing, evenly spreading, adding sterilized water, adding distillery yeast, evenly mixing, and fermenting; after finishing fermentation, carrying out solid-liquid separation, pre-freezing the solid part, and carrying out vacuum freeze-drying and vacuum packaging; and carrying out microwave sterilization and vacuum packaging on the liquid part. In the invention, the solid part is subjected to vacuum freeze-drying, so that the original quality of the material is maximally maintained, and the storage time of the freeze-dried fermented glutinous rice is longer. The sweet wine is subjected to microwave sterilization, so that the growth and development of microbes in the sweet wine are postponed, and the microbes can even die, thereby effectively protecting the massive effective constituents in the sweet wine from damage, and maintaining the original shape, color, flavor and nutritional ingredients of the product; and the freeze-dried fermented glutinous rice has the characteristics of energy saving, consumption reduction, no harm to human health, and favorable rehydration property. The technique provided by the invention is simple and convenient to operate; the prepared fermented glutinous rice is free of preservative, has the advantages of no loss of nutritional ingredients, good flavor and long storage time, and is convenient and quick to eat; and the invention is applicable to industrial production.

Owner:HUNAN AGRICULTURAL UNIV

Preparation method of instant flavor-conditioning fish dried bean curd stored at room temperature

The invention provides a preparation method of instant flavor-conditioning fish dried bean curd stored at room temperature, which belongs to the technical field of instant fish products. The instant fish dried bean curd is prepared from the following raw materials in percentage by weight: 30%-40% of frozen fish meat paste, 8%-10% of starch, 8%-9% of soybean protein isolate, 6%-7% of soybean oil, 0.5%-1.0% of egg white powder, 1%-3% of table salt, 0.2%-0.3% of glucose, 0.1%-0.3% of TG enzyme and the balance of pure water. The preparation method comprises the following steps of: adding the table salt into the frozen fish meat paste which is in a half-thawed state, and kneading for 10-20 minutes; then, adding the soybean protein isolate, the soybean oil and the egg white powder, and stirring uniformly; further, adding the TG enzyme, the glucose, the starch and the water, and chopping and stirring until the mixture is in a uniform exquisite pastry shape; and performing molding, streaming, vacuum frying, marinating, vacuum packaging and sterilizing on the materials, and cooling so as to obtain the instant flavor-conditioning fish dried bean curd. The fish dried bean curd can be eaten instantly after being unpacked, the shelf life of the fish dried bean curd stored at room temperature reaches 9 months, and as a healthy instant conditioning food, the fish dried bean curd is good in elasticity and toughness, fresh in taste, rich in nutrition and suitable for the young and the old.

Owner:温州市强能食品有限公司 +1

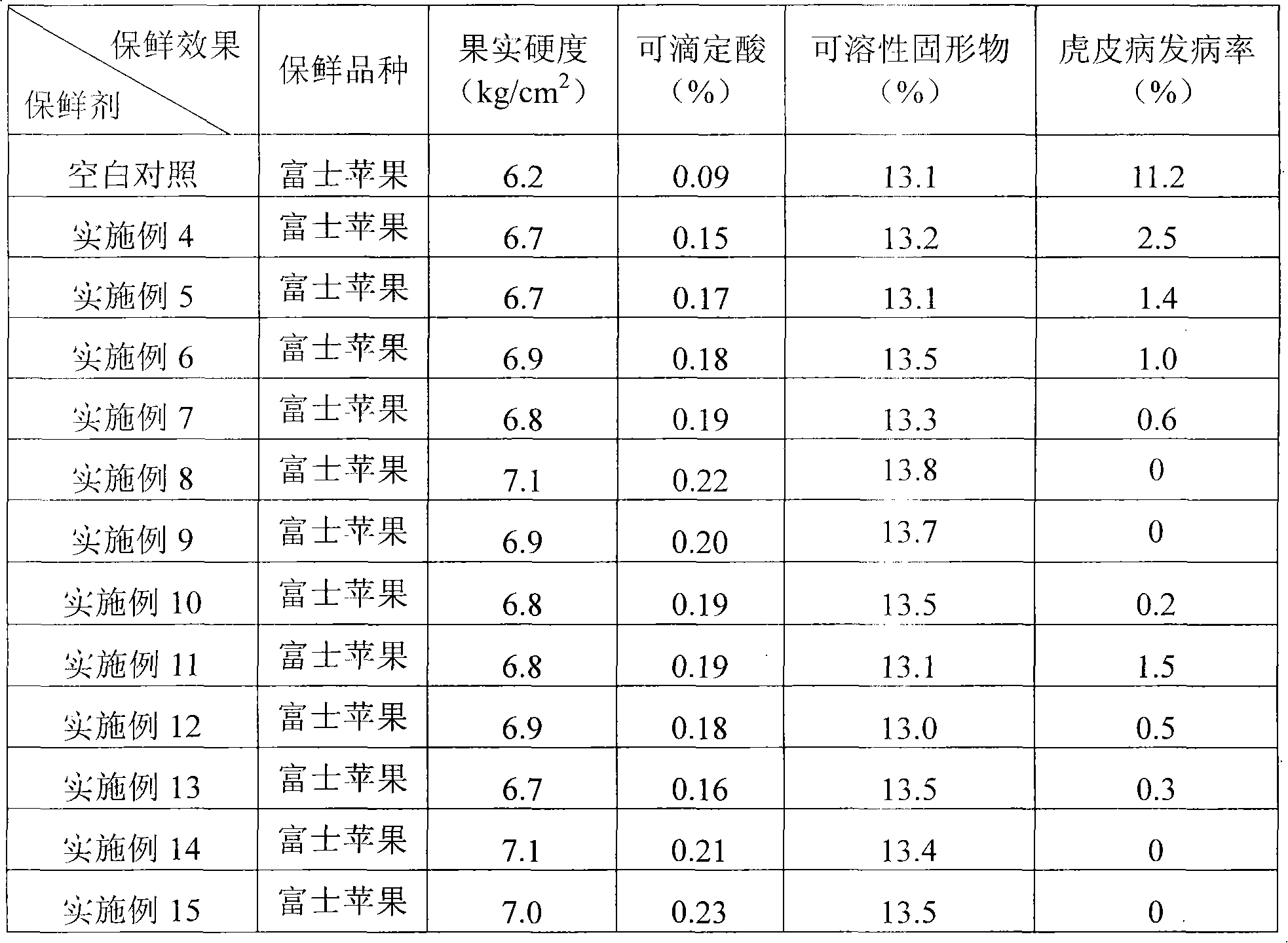

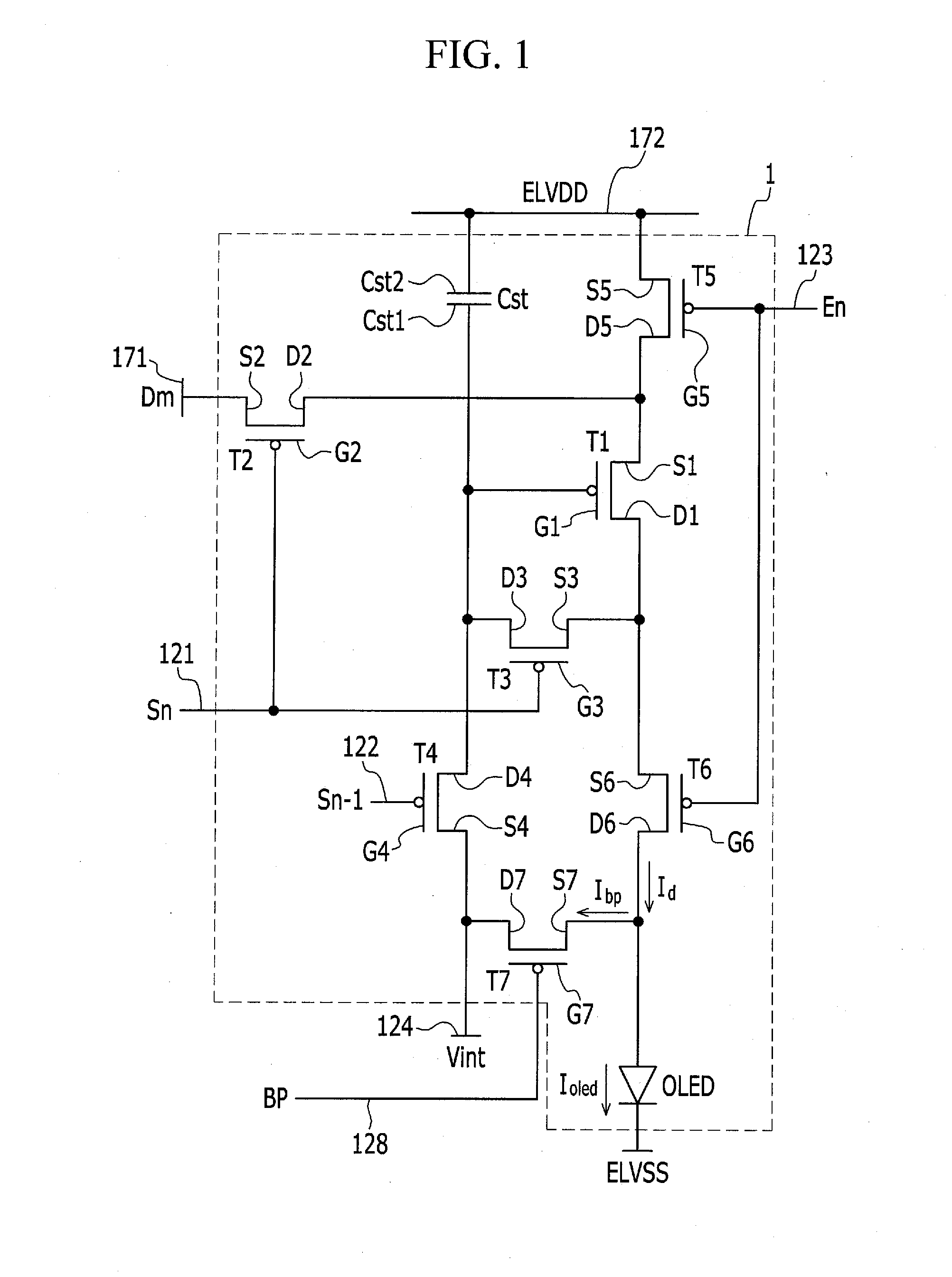

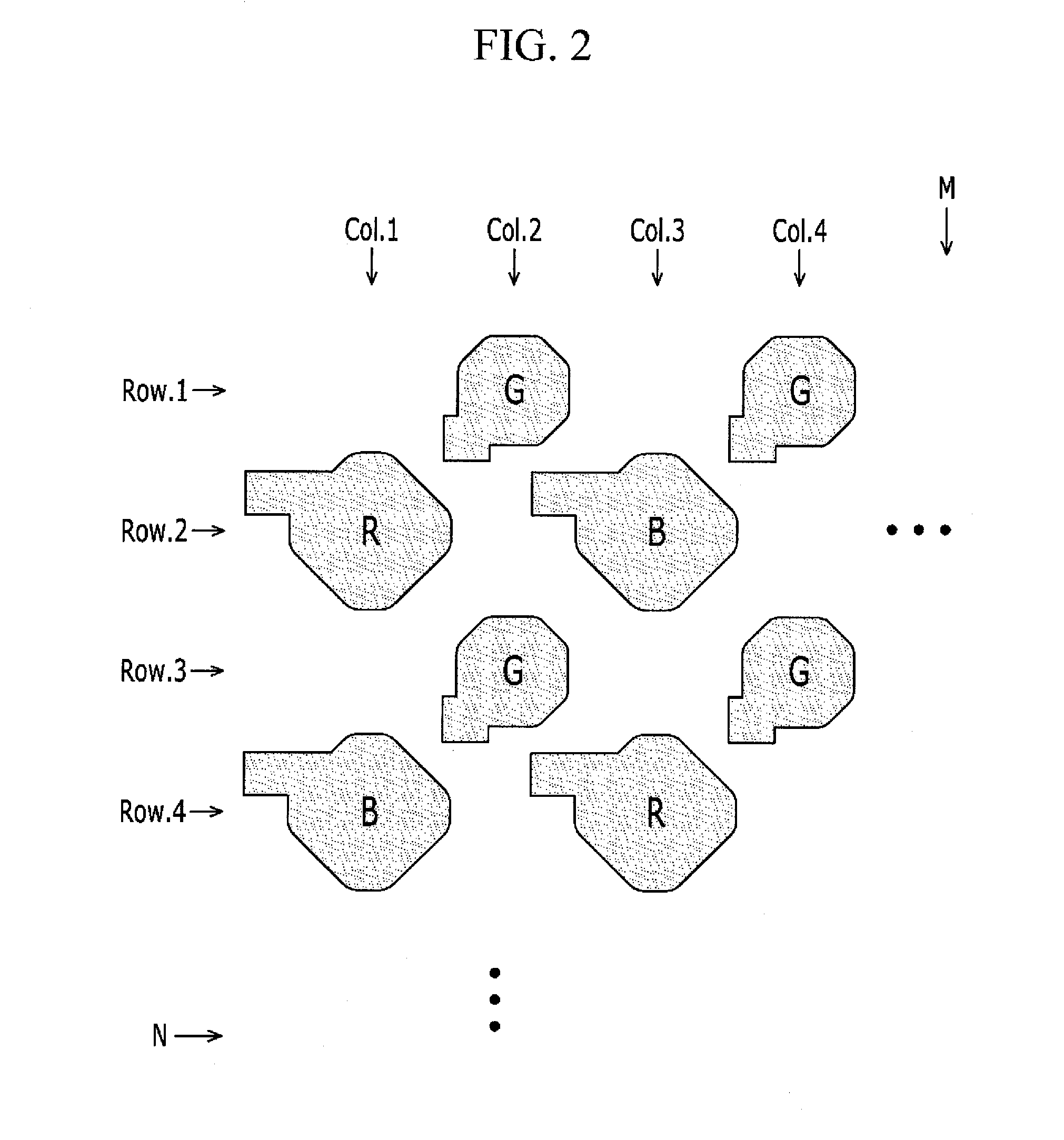

Organic light emitting diode display

ActiveUS20150170563A1Uniformly maintain luminanceUniform colorTransistorStatic indicating devicesScan lineDisplay device

An organic light emitting diode display includes a substrate, a scan line and a previous scan line formed on the substrate, a data line and a driving voltage line crossing the scan line and the previous scan line, a switching transistor coupled to the scan line and the data line, a driving transistor coupled to the switching transistor, a compensation transistor coupled to one end of the driving transistor and configured to compensate a threshold voltage of the driving transistor, a connecting member configured to couple a compensation semiconductor layer of the compensation transistor to a driving gate electrode of the driving transistor, a first electrode coupled to another end of the driving transistor, an organic emission layer on the first electrode, and a second electrode on the organic emission layer. The connecting member and the first electrode are spaced from each other on a planar surface of the substrate.

Owner:SAMSUNG DISPLAY CO LTD

Preparation method of freeze-dried fructus momordicae

ActiveCN102224838AKeep the colorMaintain colorFruit and vegetables preservationFlavorAdditive ingredient

The invention discloses a preparation method of freeze-dried fructus momordicae. The method comprises the following steps: selecting ripe fresh fructus momordicae with deep green surface; deactivating enzymes, cooling with clean water, perforating, pre-freezing and freezing; and drying with the vacuum freeze-drying technology and then discharging to obtain the entire freeze-dried fructus momordicae. Through the method disclosed by the invention, the freeze-dried fructus momordicae maintains the color, flavor, mouthfeel, shape and nutrient components of the fresh fructus momordicae.

Owner:安徽本纪控股有限公司

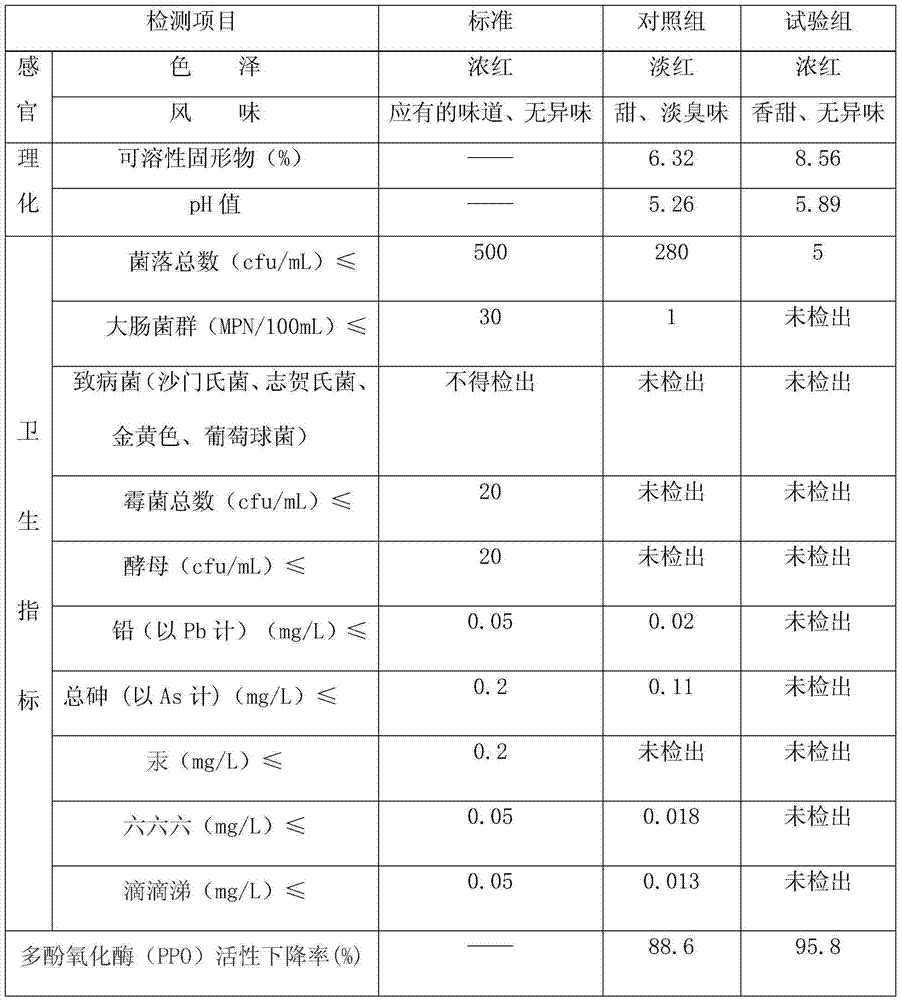

Watermelon juice probiotic fermented beverage and preparation method thereof

InactiveCN104770816AEnhanced abiotic and biotic stabilityReduce the introductionFood preparationHigh pressure pulseChemistry

The present invention discloses a watermelon juice probiotic fermented beverage and a preparation method thereof. The beverage preparation method uses watermelons as raw materials, scientifically blends prebiotic factors, does not add any essences and coloring matters, mainly uses low-temperature processing technology such as ultrasonic wave cleaning, high-pressure pulsed electric field treatment, biological enzymolysis, vacuum degassing, etc. in the whole process, replaces the existing heat sterilization and enzyme blunting technology, maintains the color and luster, flavor and mouth feel of the natural watermelon juice to a maximum degree, enhances the non-biological stability and biological stability of the watermelon juice, reduces the addition of chemical additives, increases the juice squeezing rate and food safety of the watermelon juice, and has a probiotic live bacteria content of 7 multiplied by 10^11 to 8 multiplied by 10^11 cfu / ml. The watermelon juice probiotic fermented beverage is environmentally friendly, can be processed into probiotic solid beverage and quantitatively packaged beverage which have natural taste, are nutritious and health-care, are convenient to drink, and have longer shelf lives, opens up a new way for watermelon deep processing and industrial development, and can achieve better economic and social benefits.

Owner:NINGXIA HENGRUI BIOLOGICAL FOOD TECH CO LTD

Mixed frozen food of fresh fruit and vegetable and concentrated fruit and vegetable juice and processing method thereof

InactiveCN101803671AMake full use of functional complementarityNutritional diversityFrozen sweetsQuick FreezeFruit juice

The invention relates to mixed frozen food of fresh fruits and vegetables and concentrated fruit and vegetable juice and a processing method thereof, belonging to the field of the quick-frozen fresh fruit and vegetable beverage product and the production method thereof. The method comprises the following steps: directly selecting fresh fruits and eatable vegetables collected from pollution-free planting bases as main raw materials, obtaining clean solid materials after cleaning, peeling, seed removal and slitting pretreatment, mixing with such components as concentrated fruit juice and / or concentrated vegetable juice, white granulated sugar, honey, pectin, drinking water and the like according to a proportion, vacuum packaging to form a semi-finished product, and quickly freezing, thereby obtaining the finished quick-frozen fresh fruit and vegetable mixed food which can be stored, transported and sold under low-temperature conditions. The raw materials comprise the following components by weight percentage: 55-77 percent of solid clean materials of fresh fruit or / and eatable vegetables, 7-16 percent of concentrated fruit juice or / and concentrated vegetable juice, 0.2-1 percent of pectin, 2.5-5 percent of white granulated sugar, 0.3-3 percent of honey and 20-30 percent of drinking water. Therefore, the processed product is a novel frozen fruit and vegetable mixed food product with a high solid content.

Owner:WUHAN EAST YONGTAI BEVERAGE

Method for preparing fermentation wine by super-high pressure technology

ActiveCN101182444AGuaranteed nutritional valueMaintain colorAlcoholic beverage preparationFruit juiceHigh pressure

The invention relates to a preparation method of fermenting fruit wine with no addition of sulphur dioxide; the method uses a super high pressure technology. The raw materials of fruit and vegetable are pulped, decomposed by enzyme and filtered to prepare fruit and vegetable juice; according to a conversion relationship of preparing alcohol of 1 degree with 1.7g of sugar, white sugar or honey or condensed fruit and vegetable juice of high sugar content is used for adjusting the sugar concentration of the fruit and vegetable juice; citric acid or malic acid is used for adjusting the pH value to be below 4. After being treated by super high pressure of 100MPa to 1000MPa and for 1 minute to 60 minutes, 0.2g / L to 0.5g / L of excellent dried yeast of fruit wine is added; the main fermentation is done at a temperature between 20 DEG C and 25 DEG C for about 7 days; then the secondary fermentation is done at a temperature between 10 DEG C and 20 DEG C; the alcohol content can achieve the set requirement; residual sugar is less than 1g / L; raw fruit wine can be prepared after fermentation. After being treated under the pressure of 200MPa to 500MPa and for 20 minutes to 60 minutes, the raw fruit wine can achieve the effects of sterilizing and speeding up the natural aging. Compared with the traditional process, the invention shortens the time, improves the efficiency, and reduces the production cost. The production process is simple; the production cost is low; and the produced fruit wine has high safety and nutrition for eating.

Owner:山东康来农业科技发展有限公司

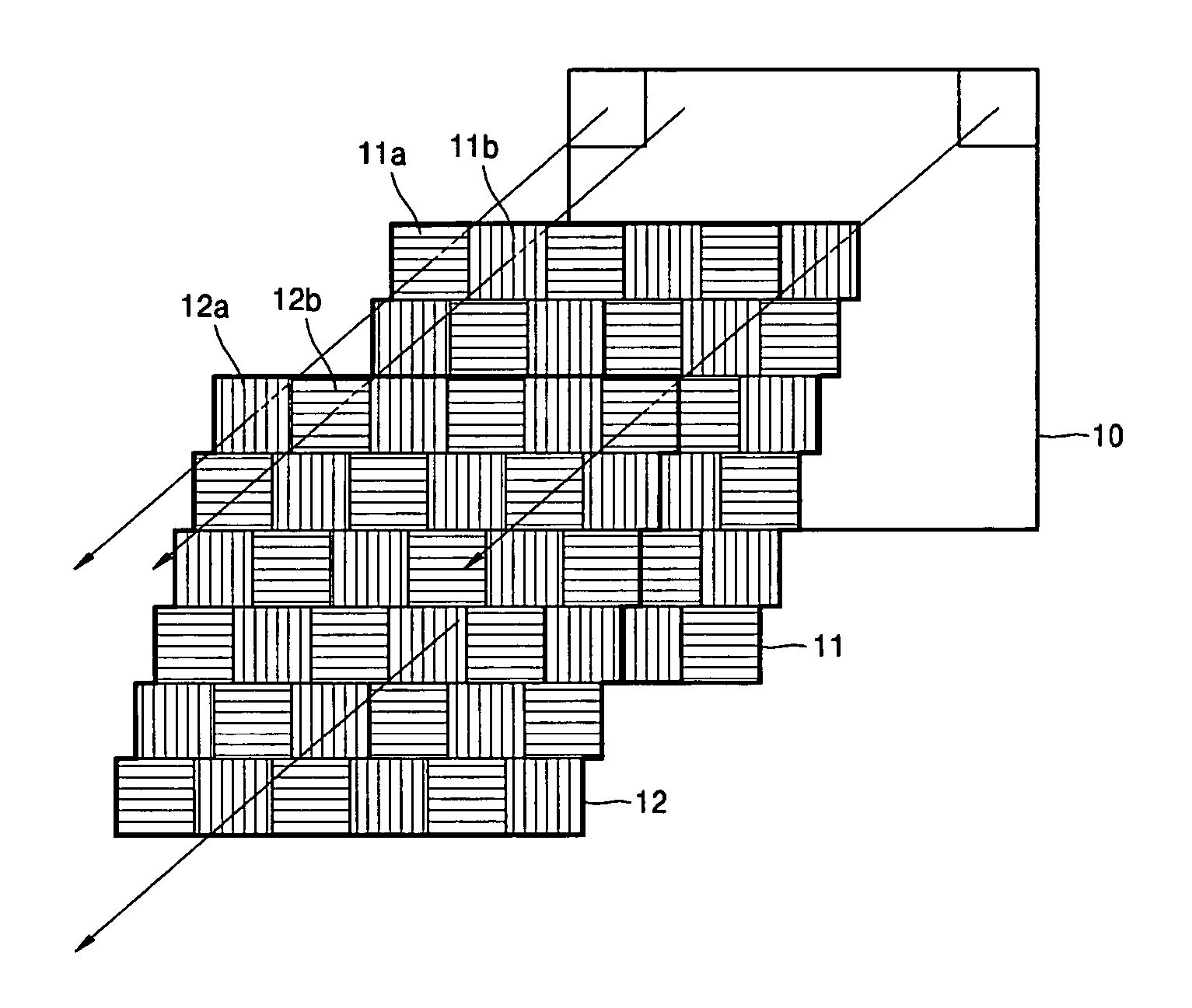

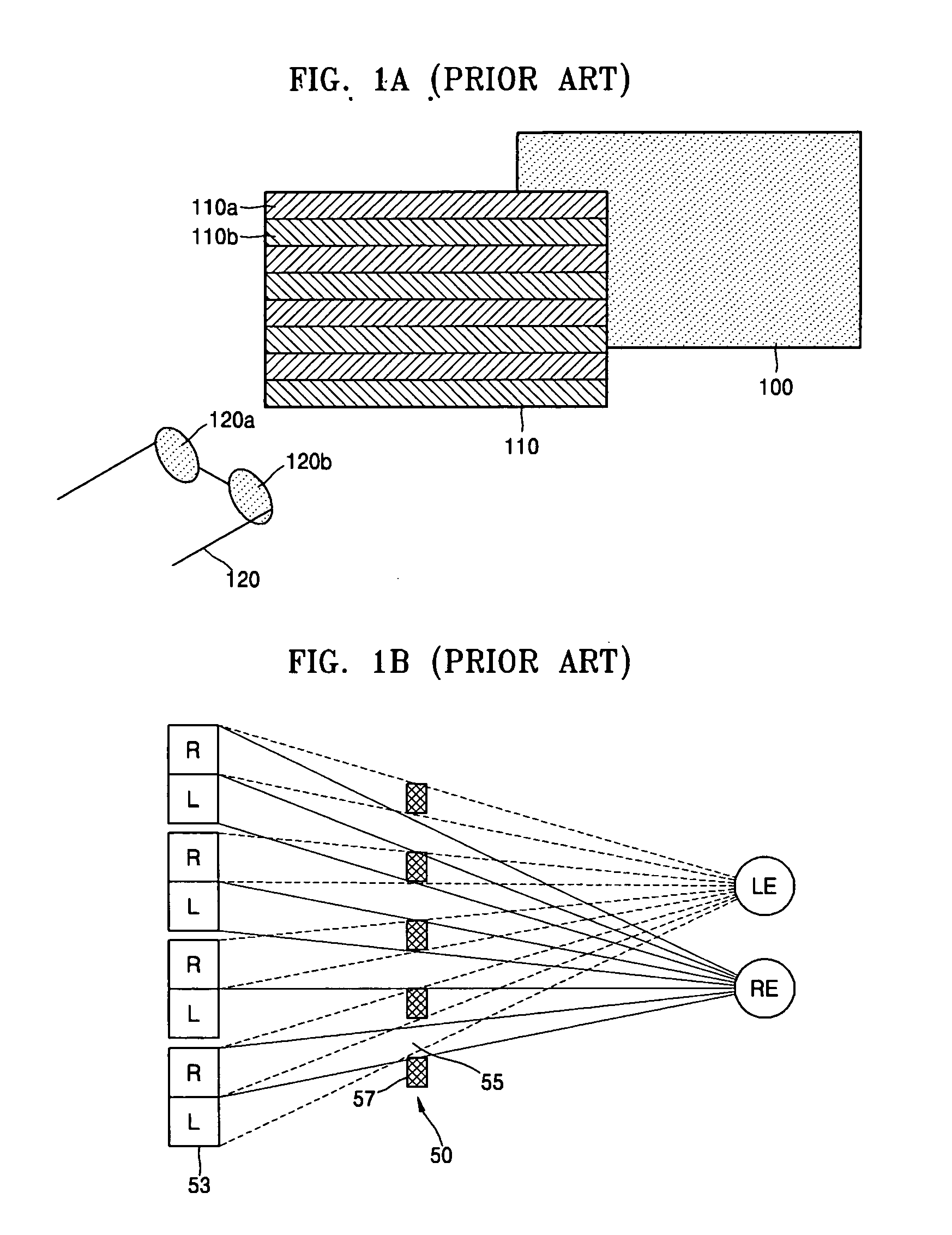

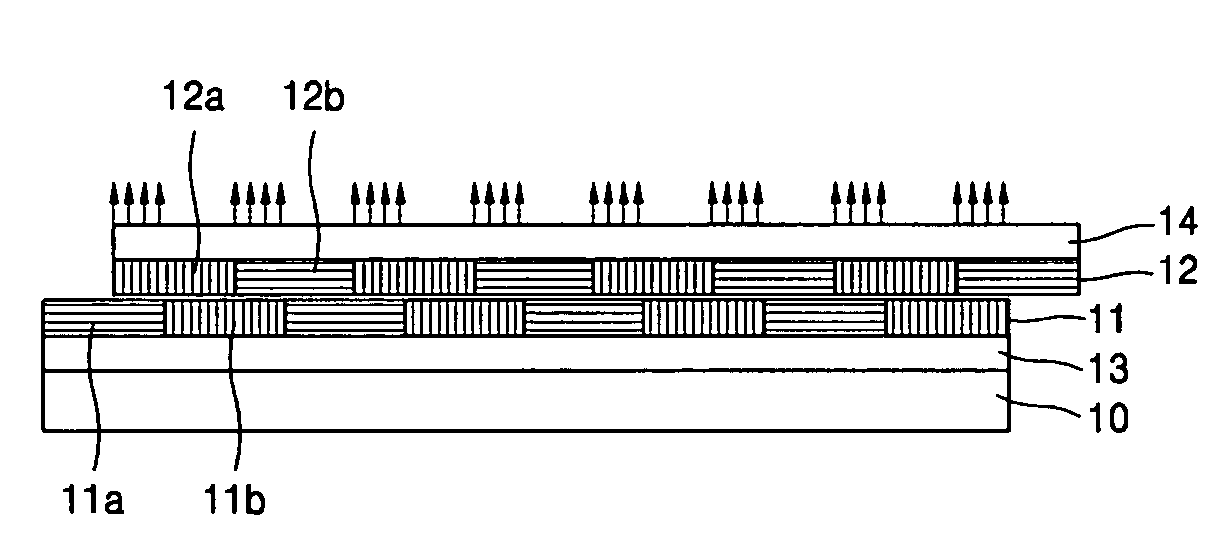

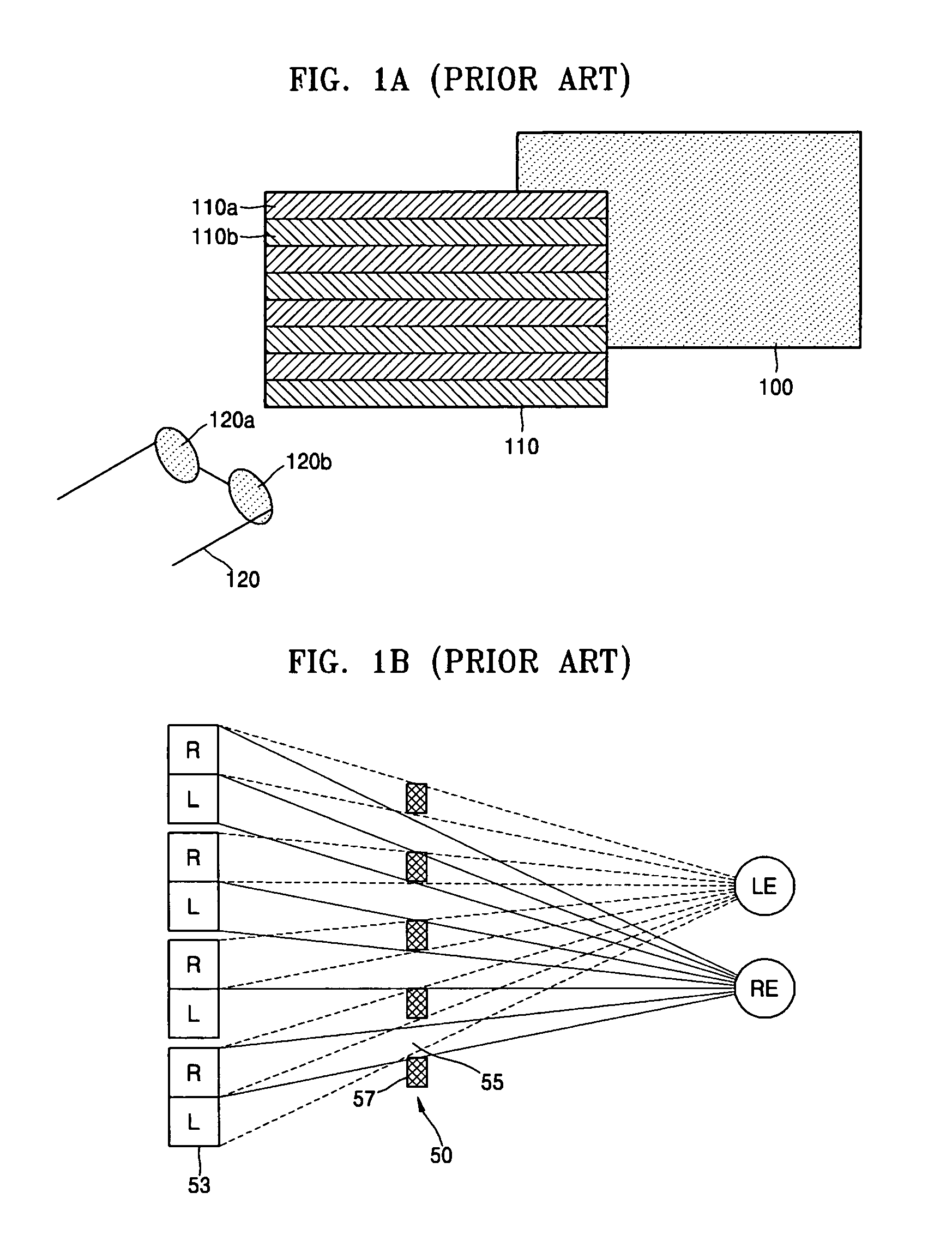

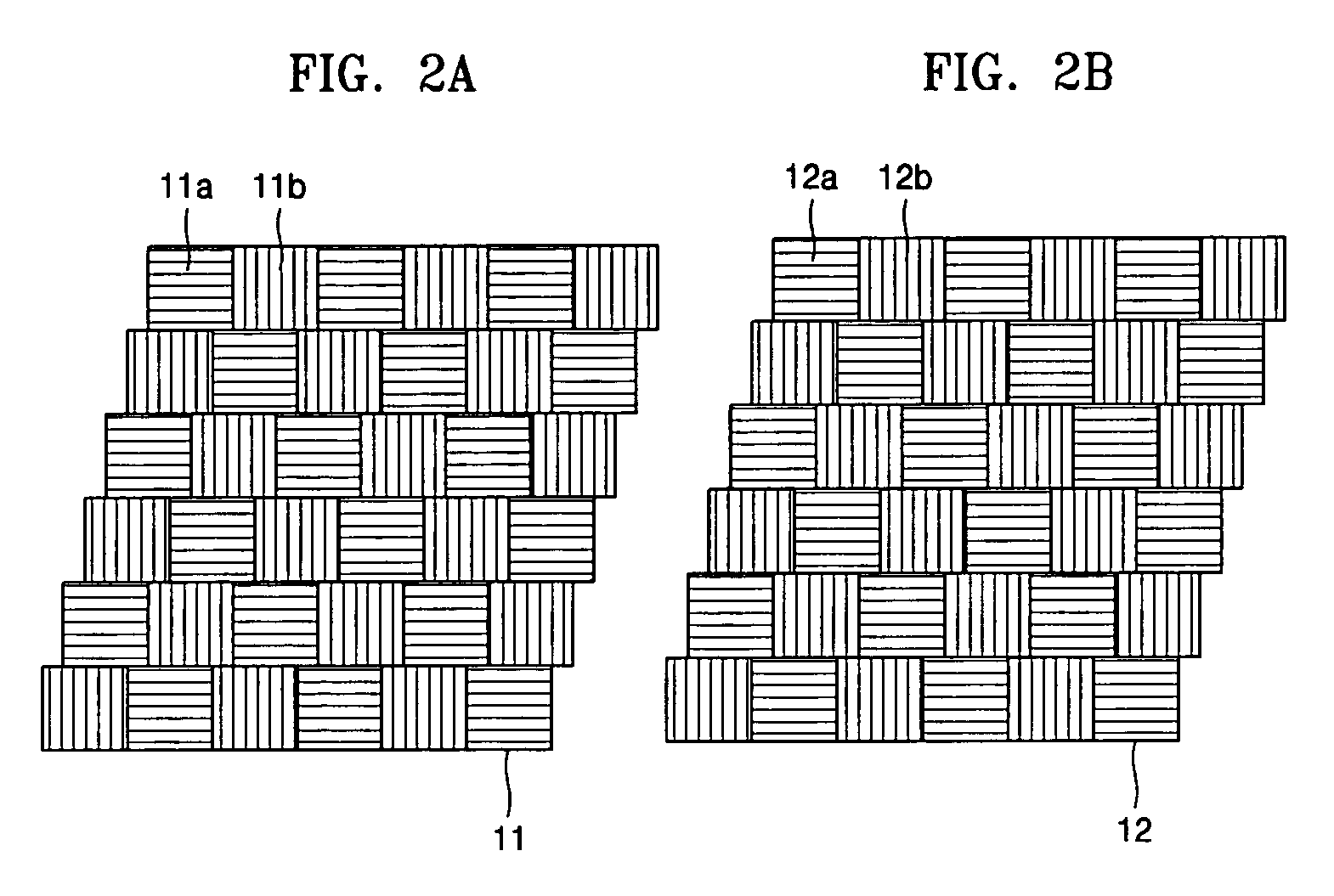

Stereoscopic display switching between 2D/3D images using polarization grating screen

InactiveUS20060227420A1High resolutionMaintain colorColor television detailsSteroscopic systems3d imageComputer science

A stereoscopic display for switching between two-dimensional (2D) and three-dimensional (3D) images. The stereoscopic display includes a display device providing an image and a parallax barrier unit that transmits all incident light in a 2D mode and forms barriers to separate an image for a left eye from an image for a right eye in a 3D mode by moving two facing polarization grating screens relative to each other. The polarization grating screens have a grating pattern such that two kinds of birefringence elements changing the directions of polarization of incident light into different directions are alternately disposed horizontally and vertically, and each row of the birefringence elements is shifted with respect to a previous row by a predetermined horizontal distance.

Owner:SAMSUNG ELECTRONICS CO LTD

Low-temperature airflow puffing process of producing crisp fruit and vegetable slice and its product

The present invention discloses low temperature pneumatic puffing process to produce fruit and vegetable crisps, it includes raw material selection, sorting, cleaning, slicing, colour protecting, predrying, resoftening, low temperature puffing, solidifying and packaging. The invented product is microporous in structure and is rich in vitamin, cellulose and minerals.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Method for processing peony pistil tea

The invention belongs to the field of flower tea processing, and particularly relates to a method for processing peony pistil tea. The method is characterized by comprising the following steps of: selecting, airing and drying raw materials, separating large impurities and pollen, and screening, molding and sterilizing the flower tea. The method takes the fresh peony pistil as a raw material, and reserves 60%-80% of pollen attached to the pistil compared with common peony flower tea taking peony flowers as a raw material, and thus the nutrition and health care values of peony flowers are maintained to a great extent; furthermore, the shapes and the color of the peony pistil are maintained, and the special fragrance and the original physiologically active ingredients of the peony pistil are reserved, so that the product is stable in performance; and the peony pistil tea with a health care effect for a human body is prepared by processing the peony pistil and auxiliary materials together, thus not only being fragrant and thick in taste, but also having the health care effect and being very good for human health.

Owner:HEZE YAO & SHUN PEONY BIOTECH

Thermosetting epoxy resin composition and semiconductor device

InactiveUS20080255283A1Minimal yellowingSatisfactory strengthSemiconductor/solid-state device detailsSynthetic resin layered productsDevice materialTriazine

A thermosetting epoxy resin composition is provided comprising (A) a reaction product obtained through reaction of a triazine derived epoxy resin with an acid anhydride, (C) a reflective agent, (D) an inorganic filler, and (E) a curing catalyst. In one embodiment, (B) an internal parting agent having a melting point of 50-90° C. is included. In another embodiment, (I) inorganic whisker fibers having an average fineness of 0.05-50 μm and an average length of 1.0-1,000 μm are included.

Owner:SHIN ETSU CHEM IND CO LTD

Stereoscopic display switching between 2D/3D images using polarization grating screen

InactiveUS7697203B2High resolutionMaintain colorColor television detailsSteroscopic systems3d imageGrating pattern

A stereoscopic display for switching between two-dimensional (2D) and three-dimensional (3D) images. The stereoscopic display includes a display device providing an image and a parallax barrier unit that transmits all incident light in a 2D mode and forms barriers to separate an image for a left eye from an image for a right eye in a 3D mode by moving two facing polarization grating screens relative to each other. The polarization grating screens have a grating pattern such that two kinds of birefringence elements changing the directions of polarization of incident light into different directions are alternately disposed horizontally and vertically, and each row of the birefringence elements is shifted with respect to a previous row by a predetermined horizontal distance.

Owner:SAMSUNG ELECTRONICS CO LTD

Edible insect full-powder and the production process and application thereof

InactiveCN101116472ARich varietyIncrease the number ofAnimal proteins working-upAdditive ingredientInternational market

The present invention relates to a method to fabricate a full edible insect powder, with the main raw material as the edible insects with the represent of the flour weevil, the cicada, the cryptympana atrata, the locust and the silkworm pupa. The exploited products in both domestic and international markets at present include the specific animal feeds and the dishes of edible insects, as well as the animal feed made from a certain amount of raw materials of insects. The present invention aims to exploit a full edible insect powder as well as the fabrication method and application thereof to accomplish the industrialized production with a large scale. The technical proposal is that the insects which undergoes both elimination of foreign bodies, toxins and cleaning up in the latter phase of cultivation are killed, dehydrated, roasted, (or dried through refrigeration) dried and refrigerated in vacuum, and then smashed and filtrateed to be the final product. The effect of the present invention is that the full insect powder contains all nutritious elements thereof, including proteins, lipids, vitamins and various trace elements. The present invention has unique characteristic, safety without toxins, wide application fields, feasibility to be the nutrition of serious snacks, and feasibility to be the stuffing of food of various cakes and candies.

Owner:西安市轻工业研究所

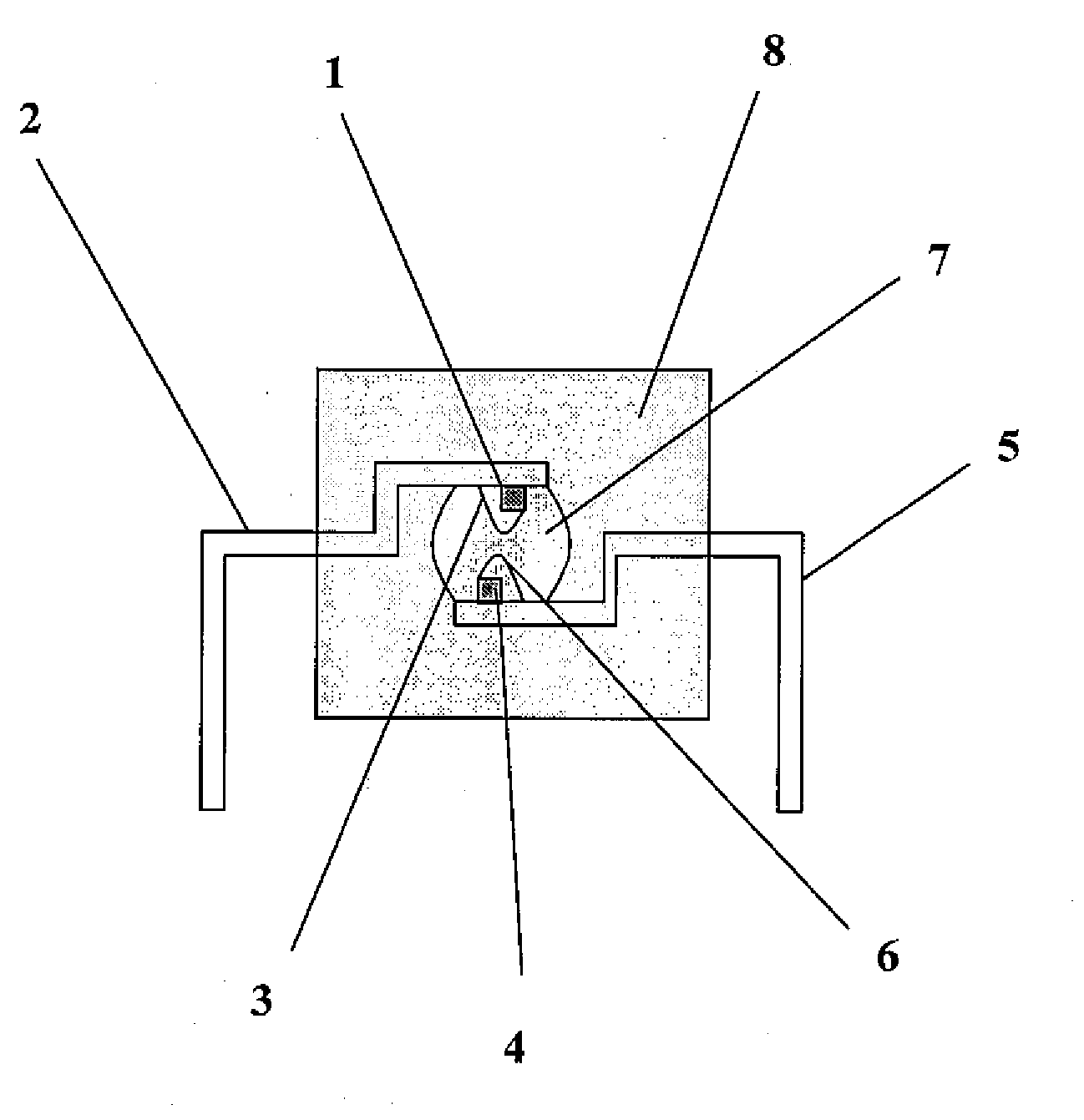

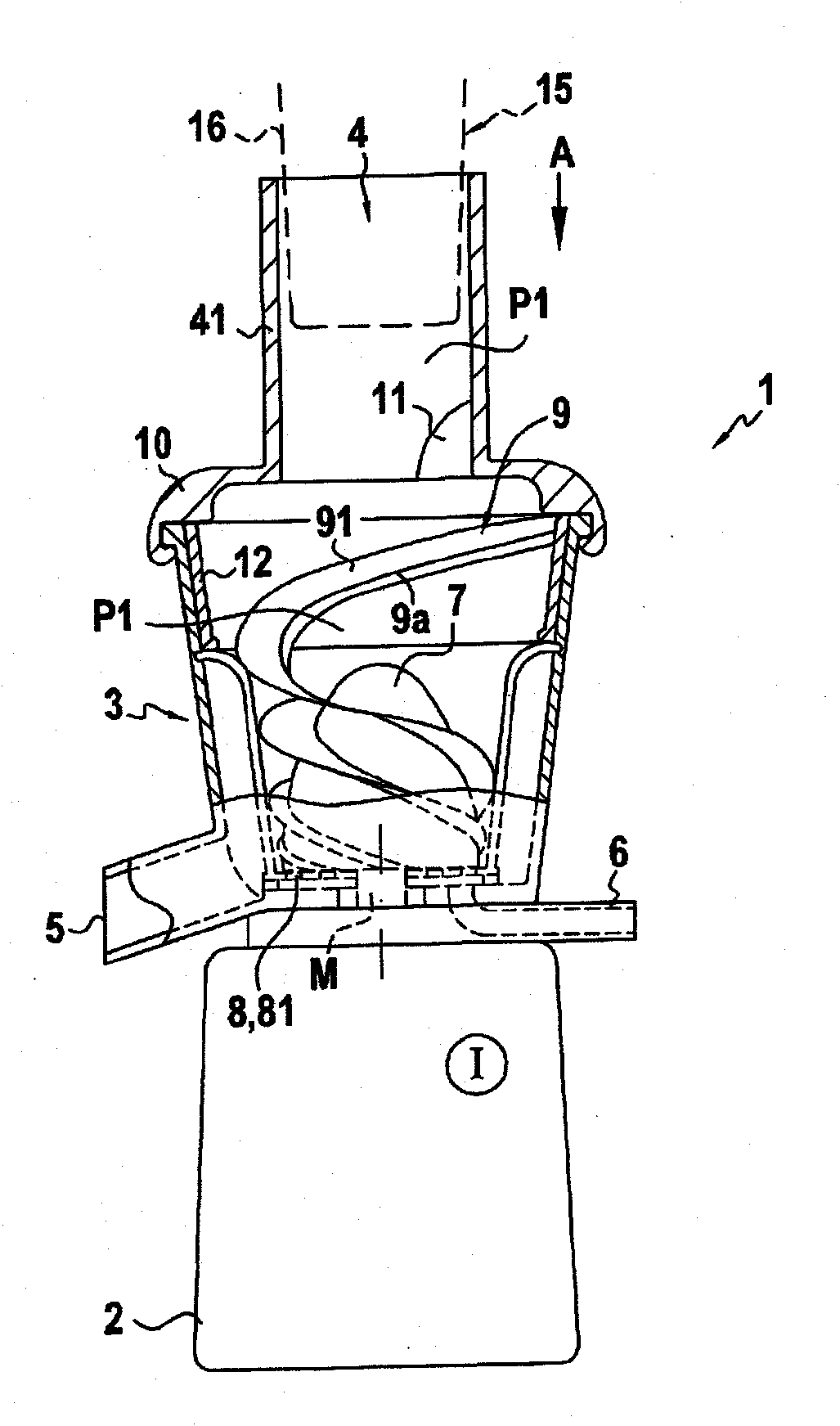

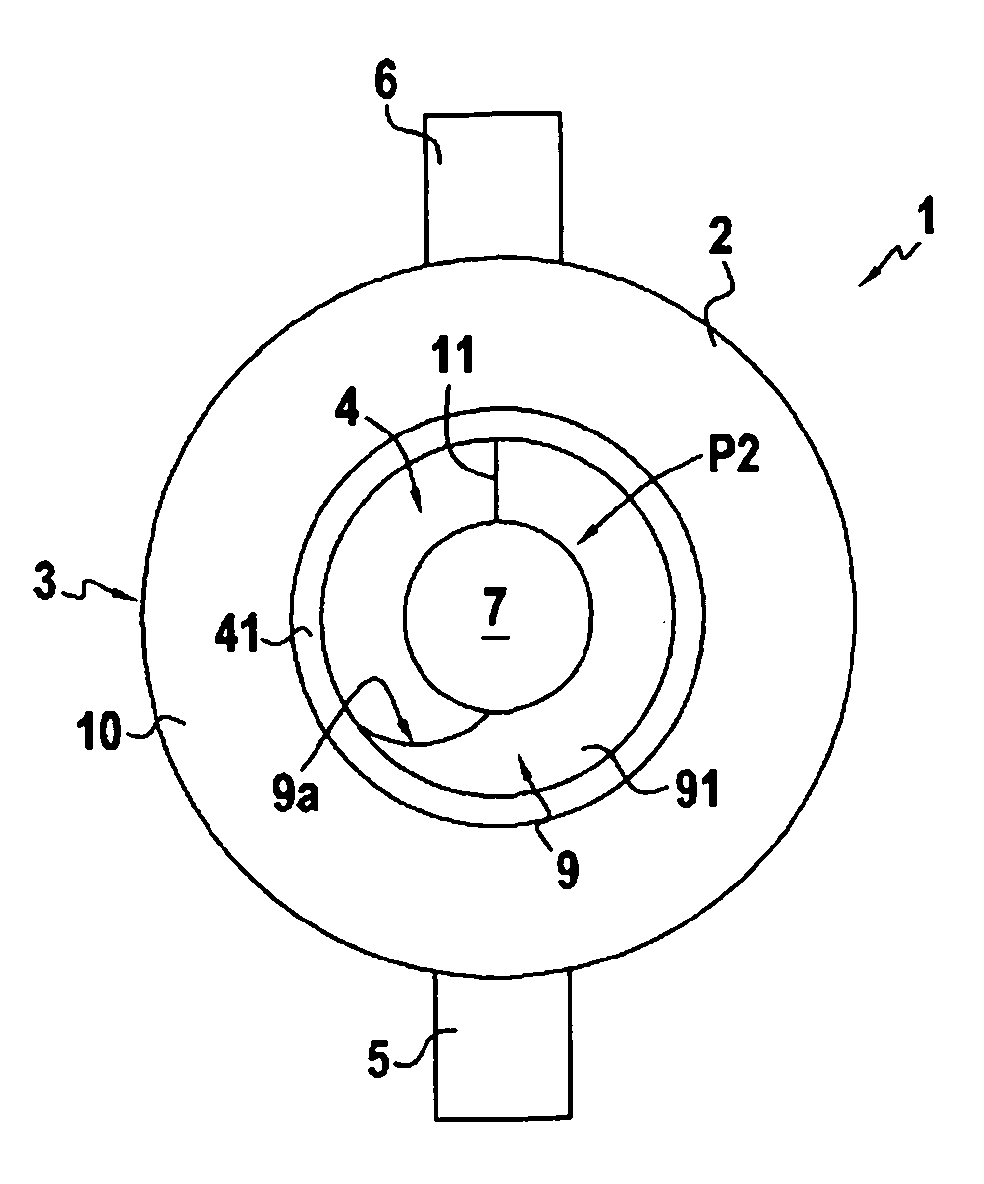

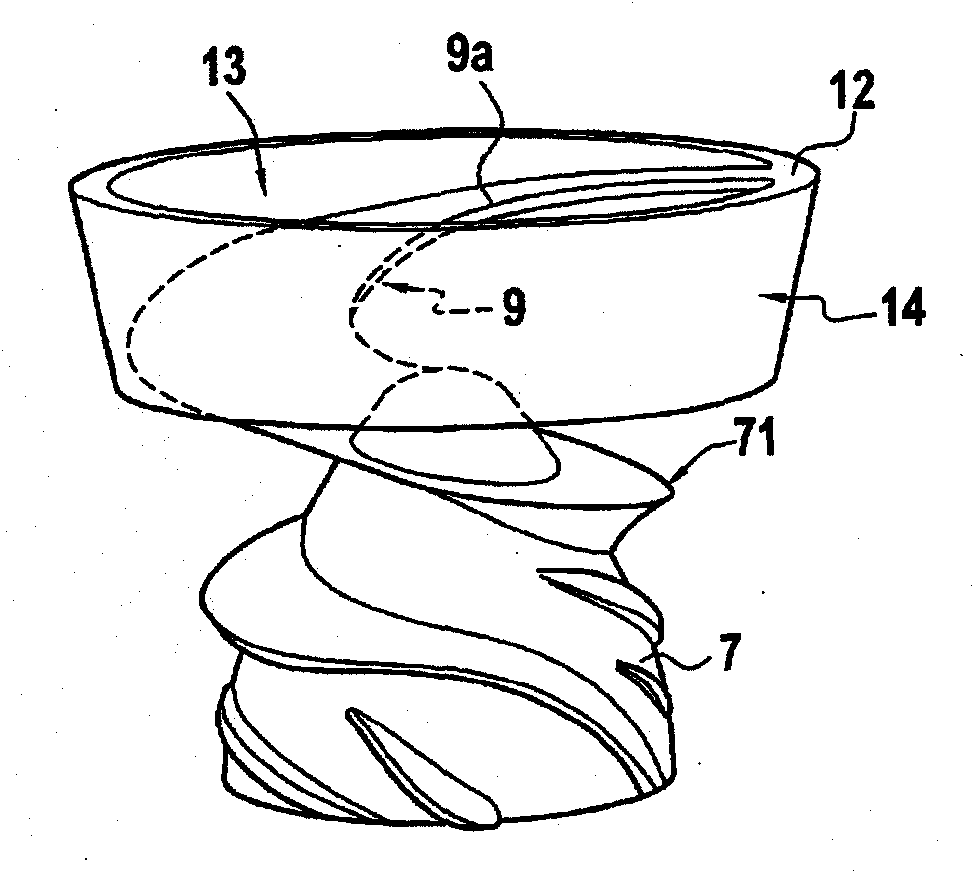

Electrical household appliance for preparing juice

The present invention relates to an electrical household appliance (1) for preparing juice by pressing foods, in particular of plant origin, such as fruits or vegetables, comprising: a housing (2) containing an electric drive motor; a work chamber (3) having a food inlet opening (4) and a first outlet (5) for the juice and a second outlet (6) for the pressing residues; a pressing screw (7) mounted inside the work chamber (3) and coupled mechanically to a drive shaft (M) of the electric motor; and a filtration means (8) mounted coaxially with the pressing screw (7) inside the work chamber (3) to separate the juice from the pressing residues. This appliance is characterized by the presence of a member (9) for cutting the foods located between the inlet opening (4) and the pressing screw (7).

Owner:SEB SA

Cherry jam and preparation method thereof

The invention relates to a method for preparing jam, in particular to cherry jam and a preparation method thereof, and belongs to the technical field of food processing. The invention has the advantages that: cherry flesh is taken as a main raw material and is added with jelly powder, so that the jam has high water binding capacity; and a method of performing dipping treatment on the cherry flesh raw material by using a low temperature sugar solution is adopted, and the flavor and color of the flesh can be better maintained. The cherry jam processing technology has a positive effect and social benefit for promoting the re-innovation of a jam processing technology.

Owner:DALIAN ZHAOYANG SOFTWARE TECH

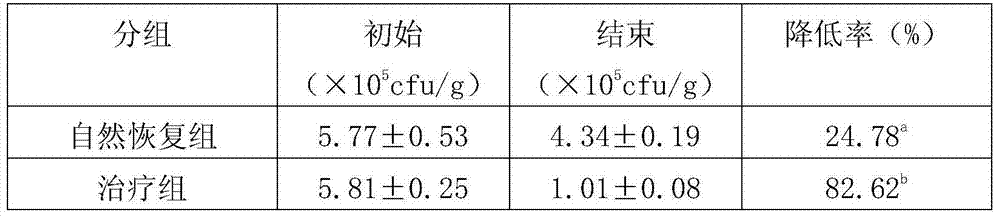

Preparation method of Muslim low-temperature mutton ham

ActiveCN105581273AReduce dosageImprove durabilitySugar food ingredientsFood ingredient as flavour affecting agentFlavorRoom temperature

The invention discloses a preparation method of Muslim low-temperature mutton ham and belongs to the field of meat product processing. The preparation method of the Muslim low-temperature mutton ham comprises the steps that mutton is subjected to pretreatment, microwave-assisted vacuum rolling and kneading with specially-made curing liquid and ultrasonic wave composite variable pressure curing, then the mutton is filled and formed, and finally, after being sterilized in a composite mode at low temperature, the mutton is cooled to room temperature and stored at the temperature of 0 DEG C-4 DEG C. Hind quarters of sheep are used as raw materials of the prepared Muslim low-temperature mutton ham, and processed at low temperature, so that the loss of nutrient substances of mutton is reduced; moreover, original flavor of the mutton can be retained well, by means of ultrahigh pressure curing, tenderness of the mutton is improved, the color of the mutton is kept better, curing efficiency is improved, the processing period is shortened, novel products with high quality, high safety and long shelf life are produced, and a new thought is provided for deep processing in the mutton industry.

Owner:NINGXIA UNIVERSITY

Processing method of instant lightly baked spicy squid

The invention relates to a processing method of instant lightly baked spicy squid, and the method comprises the following steps that fresh squid, or fresh frozen and thawed squid is selected as a raw material and cleaned; the head and the internal organs are removed; then the squid is cut and sliced, cooked, uniformly mixed with seasoning and cured, dried and baked until the water content is 40 percent + / -0.8 percent; and the slices are packaged, sealed and sterilized to obtain an instant lightly baked spicy squid finished product. The processing method has reasonable procedures and is simple in preparation. The seasoning for curing is mixed scientifically, so that the dainty flavor and palatability of the squid food are improved. The lightly baked spicy squid food which is prepared through the method has soft texture, maintains the nutrition of the squid as well as the original color and the appearance of the fresh squid to the largest extent, has long storage life, can be eaten conveniently only after a package is opened, the taste is dainty in hardness, saline taste and sweetness and delicious, and has the special aroma of seafood.

Owner:RONGCHENG HONGWEI FOOD

Cyclopropene preservative and preparation method thereof

ActiveCN102119718AExtended storage timeImprove qualityDead plant preservationFruit and vegetables preservationPreservativeCyclopropene

The invention provides a cyclopropene preservative, which is characterized by containing 0.1 to 99 mass percent of cyclopropene coating material powder, 0.1 to 98 mass percent of compound, composition or material releasing water molecules, and 0 to 98 mass percent of one or more assistants. The invention also provides the preparation method and using method of the cyclopropene preservative. The preservative is convenient for use and has a remarkable preservation effect.

Owner:山东营养源食品科技有限公司

Long shelf life fermented pickled vegetable and preparation method thereof

InactiveCN101518320AReasonable technologyThe process is simple and scientific and hygienicClimate change adaptationFruits/vegetable preservation using acidsSaline waterVegetable processing

The invention relates to long shelf life fermented pickled vegetable and a preparation method thereof, which belong to the technical field of picked fermented foods. The preparation method comprises the following steps: using tuber mustard as the raw material; slicing, picking, softening and then packaging the tuber mustard in a picked vegetable jar; filling ferment agent prepared by mixing 3-5 percent of Lact.Plantarum and Lact.Casei according to the proportion of 1:1 and salt water with 4-6 percent of salt content; fermenting for 48h under the temperature of 20-30 DEG C; ending the fermentation until the acidity of the fermented solution reaches 0.45-0.55 percent; dehydrating, seasoning and embrittlementing; packaging by using laminated film bags and sterilizing for 15min under the temperature of 70 DEG C. The preparation method basically keeps the fermented picked vegetable pure, tender and crisp, salubrious and tasty, the fermented picked vegetable has the basic characteristics of separating fat and stimulating the appetite, promoting the digestion, and the like, and can be kept for more than six months under the normal temperature. The invention can be popularized and applied to the vegetable processing industry.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES +1

Intermediate wave infrared and radio frequency combined drying method suitable for dehydration of large-scale seasoning edible mushrooms

ActiveCN102986838AHeating up fastLittle impact on qualityFruits/vegetable preservation by dehydrationNutritionDrying time

The invention relates to an intermediate wave infrared and radio frequency combined drying method suitable for dehydration of large-scale seasoning edible mushrooms, and belongs to the field of edible mushroom foodstuff processing technology. The method comprises the steps of pre-treating the edible mushrooms (carefully chosen, cleaning, sorting and sharding, blanching for enzyme deactivation at a temperature of 90-100 DEG C), cooling in a seasoning liquid, immersing and draining, pre-dehydrating with the intermediate wave infrared at a temperature of 60-70 DEG C with a wind speed of 1-3 m / s and a radiation distance of 10-18 cm to make moisture content reduced to 30%-60%; then performing radio frequency drying to make the moisture content of the edible mushroom reduced to 8%, wherein plate distance is 20.5 cm; frequency is 27 MHz; power is 6 KW; a material temperature is 50-60 DEG C; and material plates can be arranged in three layers. Problems of difficulty for removing the moisture in a later stage of the intermediate wave infrared drying by employing the intermediate wave infrared and radio frequency combined drying method, because the radio frequency has strong penetrability. The materials during the radio frequency drying process can be placed in a plurality of layers, so that nutrition and shapes of the product can be retained to a large extent; at the same time, drying time is shortened significantly; drying energy consumption is lowered; and cost is reduced.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com