Patents

Literature

176results about How to "Improve Juicing Efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

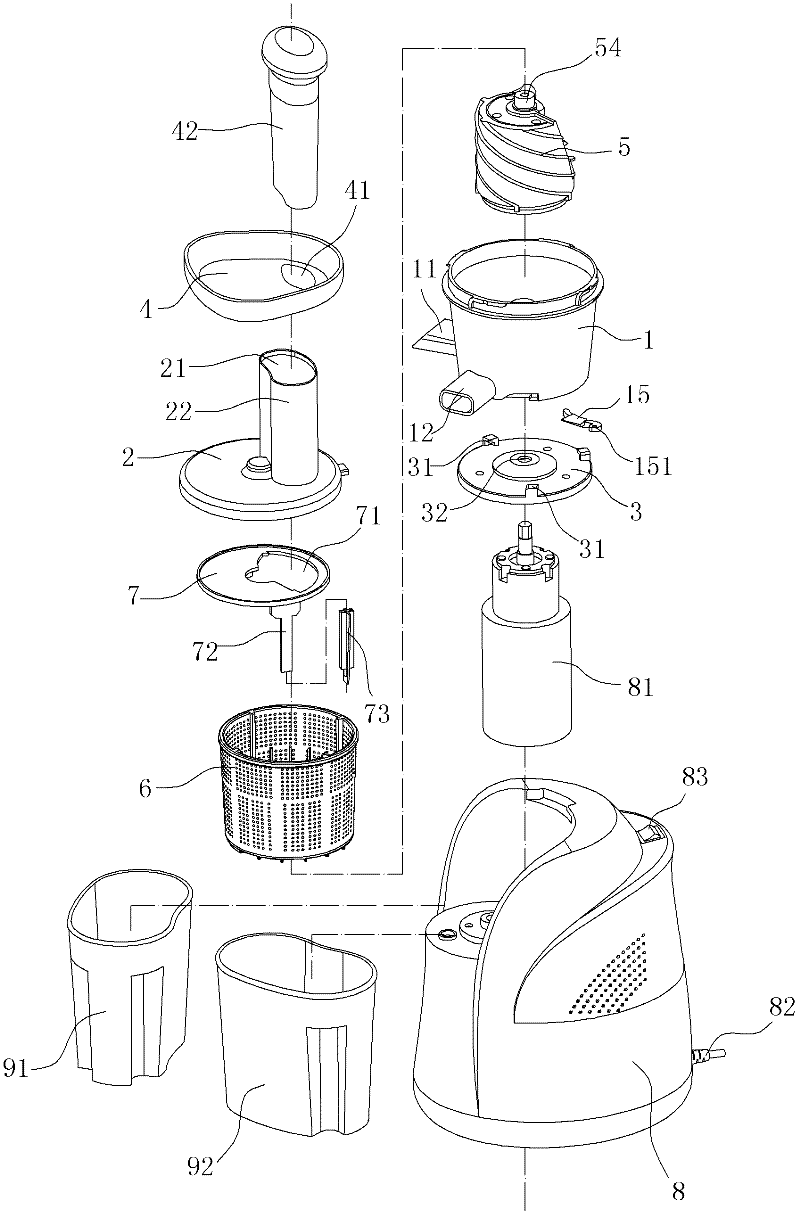

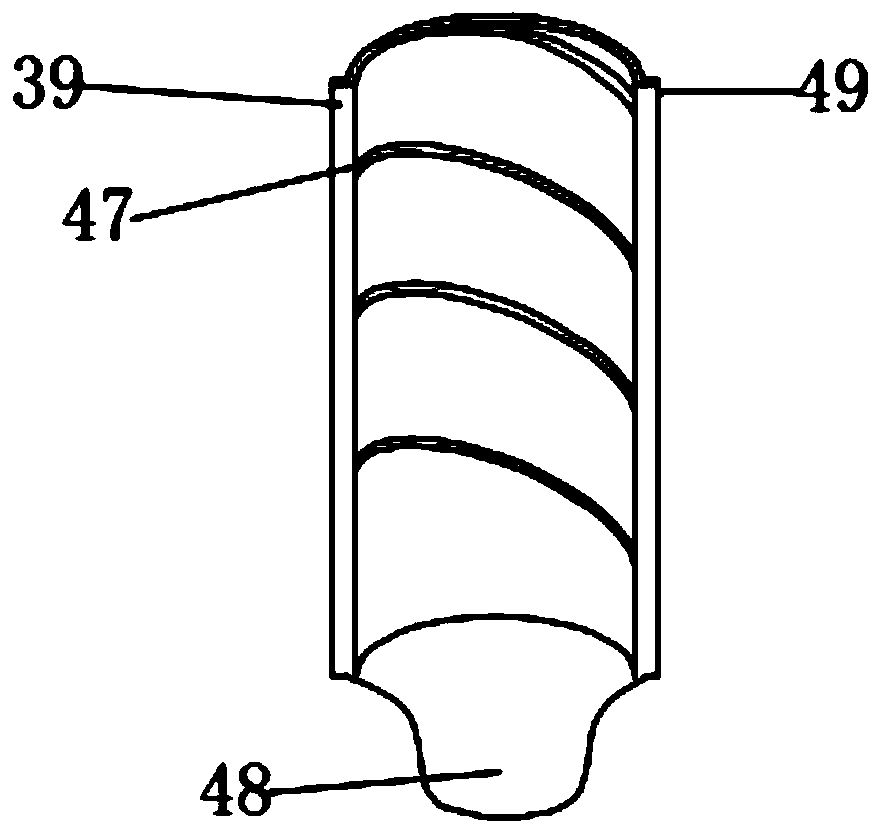

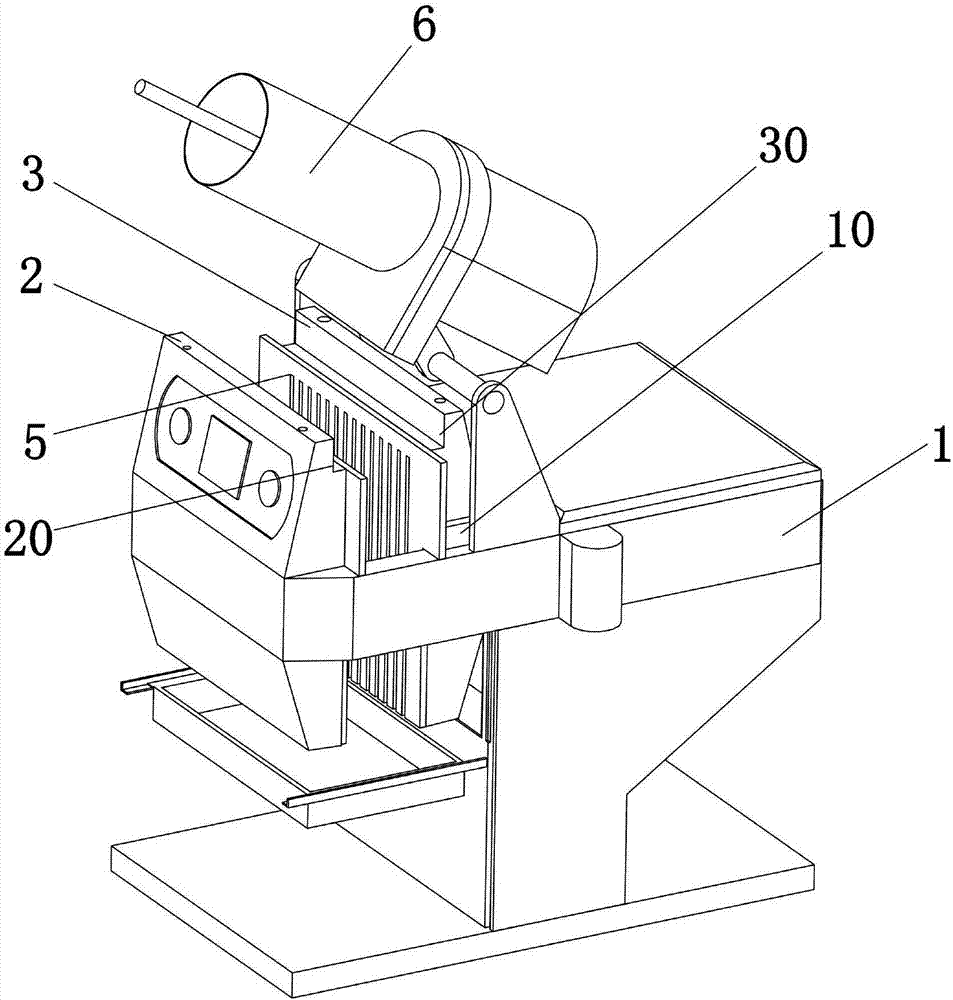

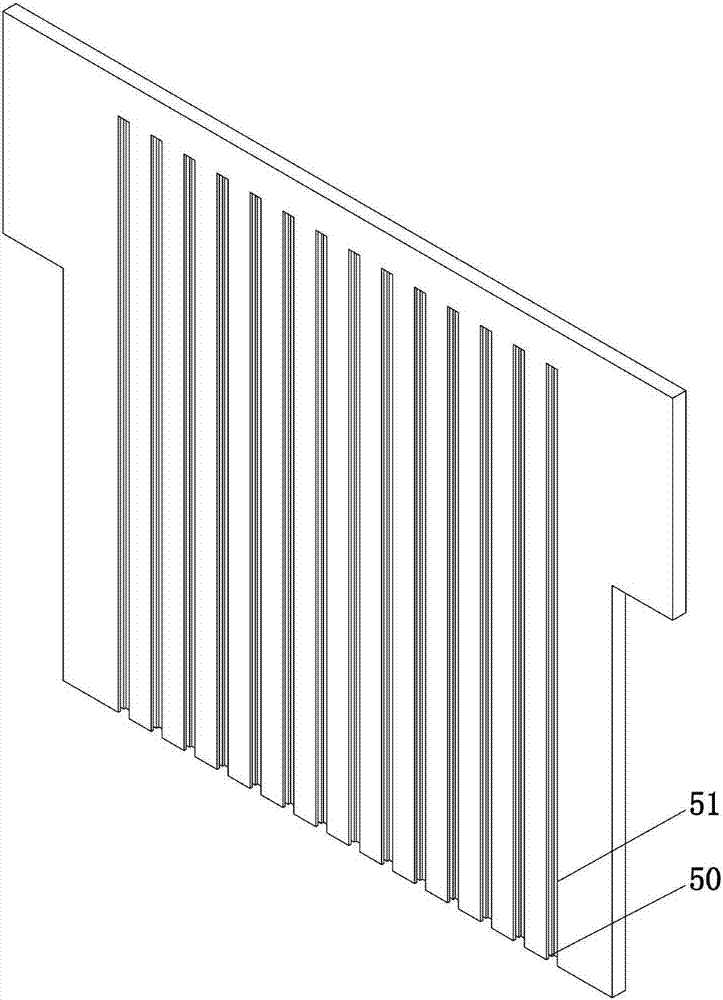

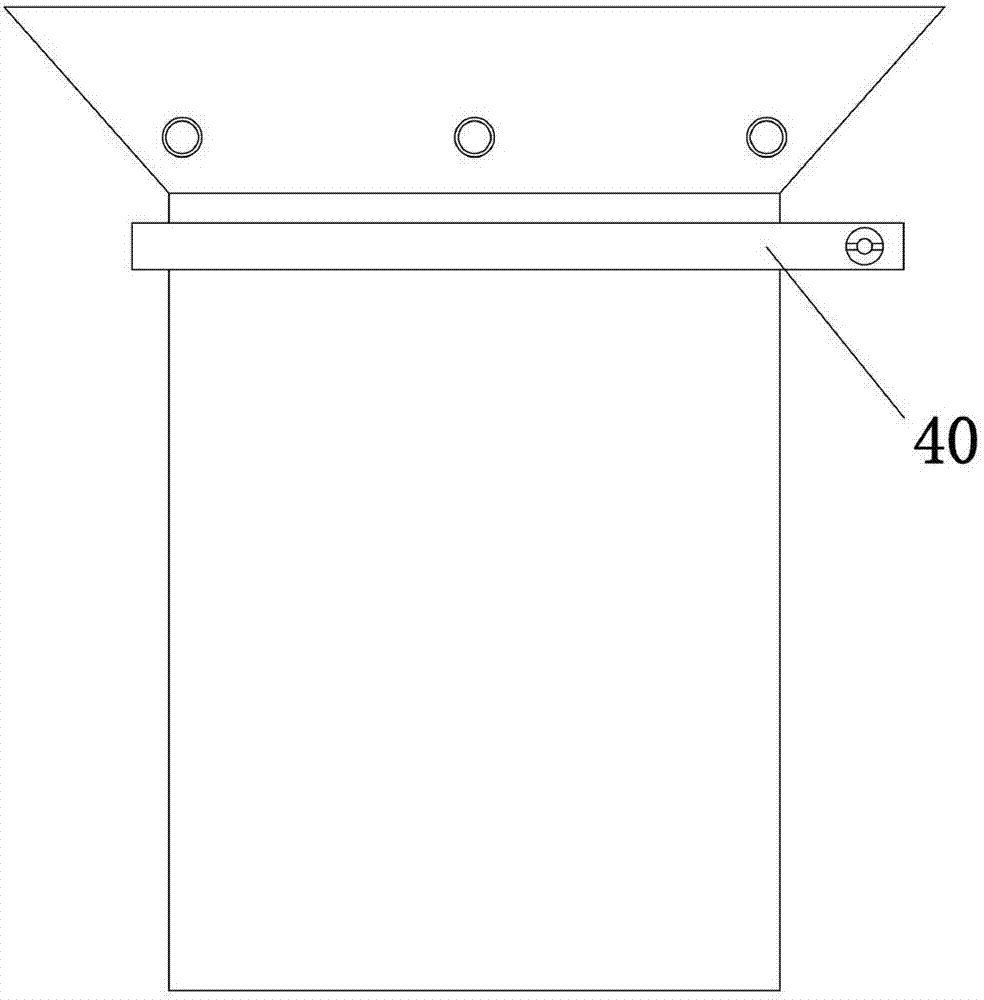

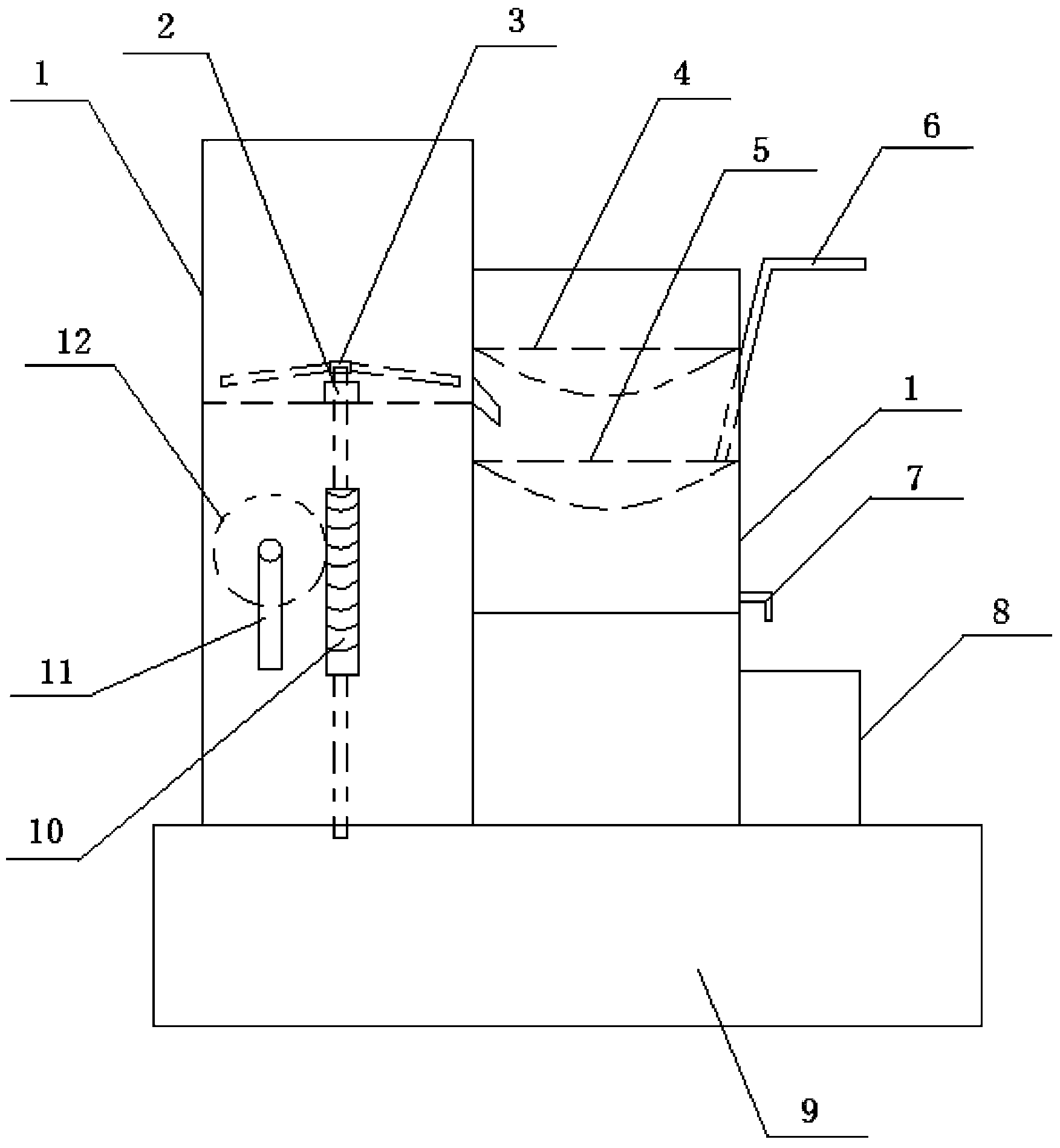

Easy cleaning extrusion type juicer

ActiveCN101697857AOutflow smoothlyImprove Juicing EfficiencyStrainersAgricultural engineeringFruits and vegetables

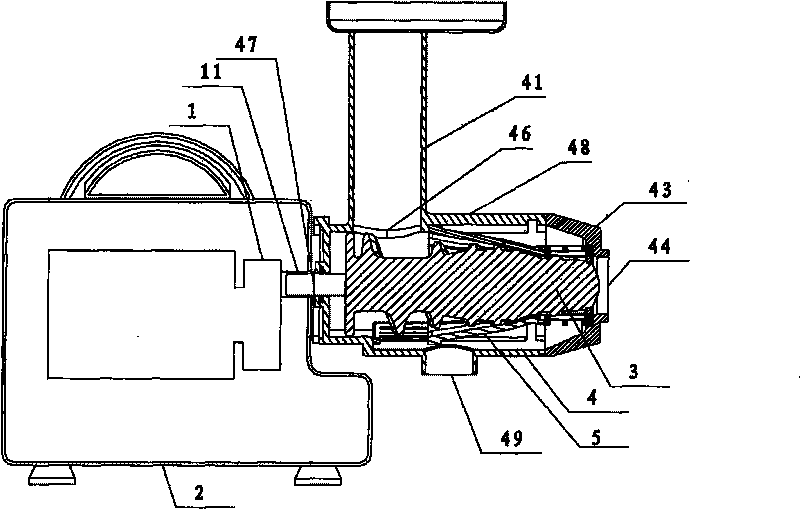

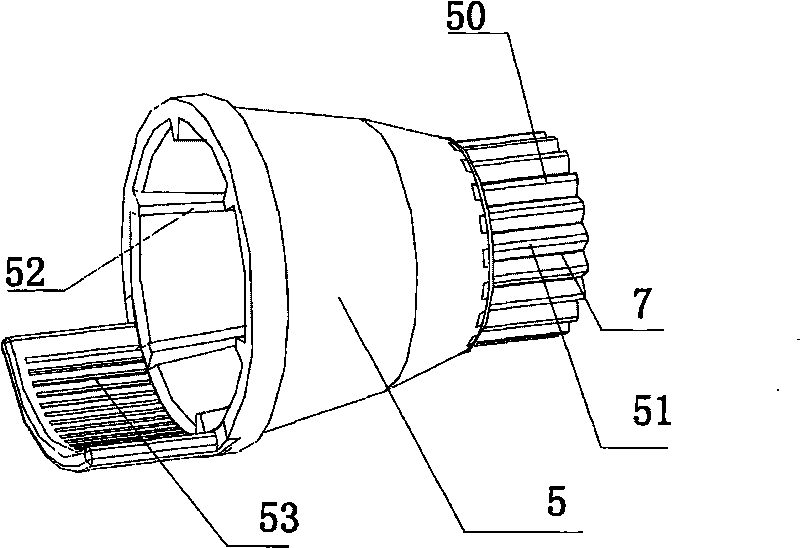

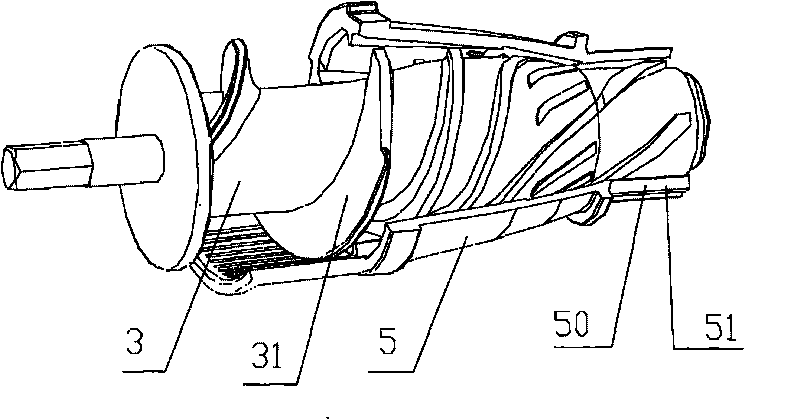

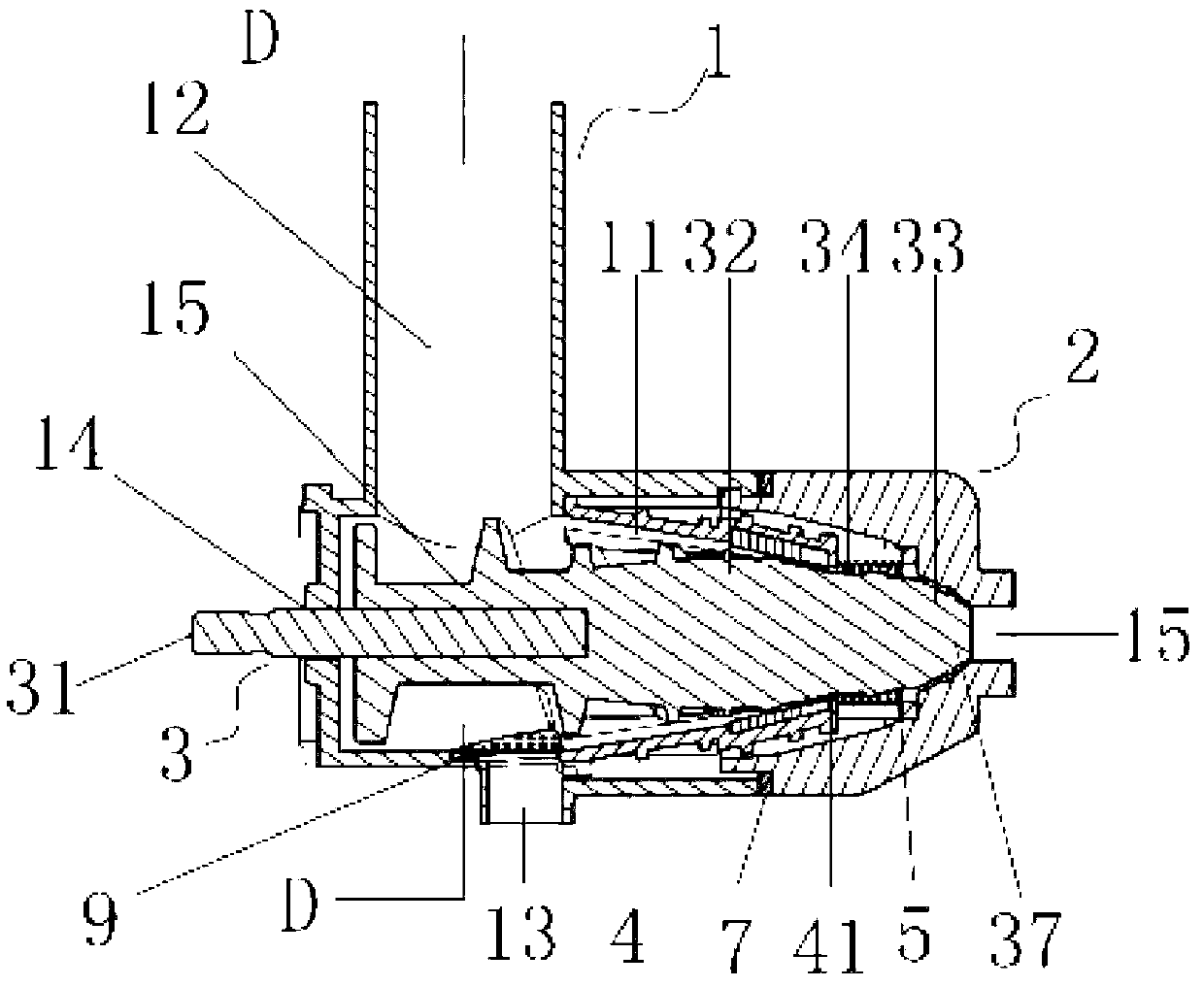

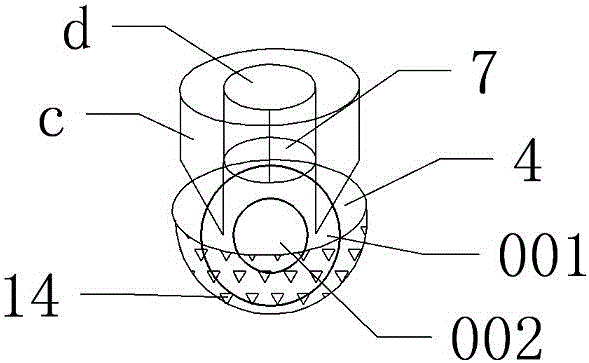

The invention discloses an easy cleaning extrusion type juicer which comprises an engine base, a motor, a juice collecting chamber, an extruding and crushing part and a filtering part, wherein the extruding and crushing part comprises a push-in screw and an extrusion cylinder matched with the push-in screw. The extrusion cylinder is arranged in the juice collecting chamber, and the filtering part is arranged on the lower part of the extrusion cylinder. The filtering part is characterized in comprising grids, and scum juice filtering gaps are arranged between the grids. The easy cleaning extrusion type juicer of the invention has the advantages that the size of the scum juice filtering gaps can change according to the size of the material under the action of the push-in screw to the material, the juice extrusion rate is high, so that the juicer is especially suitable for lone-term material feed; the juicer is easy to clean after being used, the extruded fruit and vegetable juice has less foam, and the inherent colour and taste of the fruit and vegetable juice can be kept to the maximum extend.

Owner:JOYOUNG CO LTD

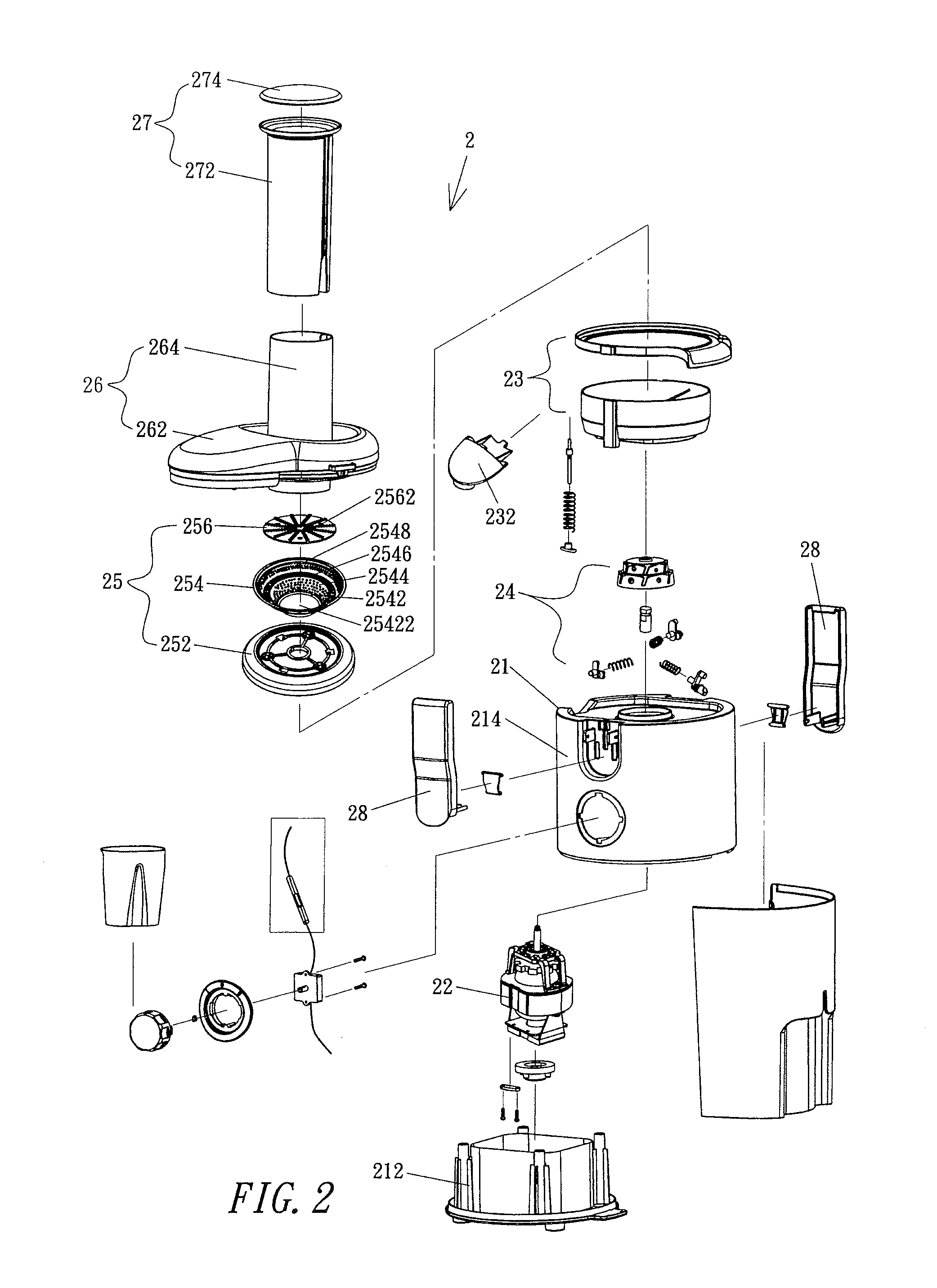

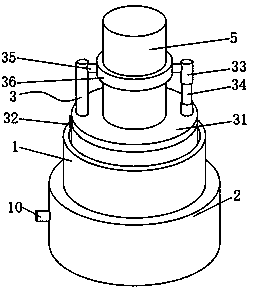

Juice extractor

The invention relates to a juice extractor. The juice extractor comprises a shell, a juice extracting component and a driving component, wherein a feed inlet, a juice outlet and a dreg outlet are formed in the shell; the juice extracting component is arranged in the shell; and the driving component is used for driving the juice extracting component to work and arranged below the shell. The juice extractor is characterized in that: the juice extracting component comprises a juice extracting body and a filtering screen; the juice extracting body is a columnar rotor which can be driven to rotate by the driving component; a notch which can be correspondingly communicated with the feed inlet of the shell is formed on the upper half part of the juice extracting body; spiral teeth are formed on the juice extracting body along an outer circumferential surface; the juice extracting body is arranged in the filtering screen in a rotatable way; and the filtering screen is fixedly arranged in the shell. The juice extractor has a more simple overall structure, a small number of parts, low production cost and high juice extracting efficiency and is safely used; automatic blanking can be realized in the rotating process of the juice extracting body; and the two ends of the juice extracting body are not required to be fixed, so that the juice extracting body can be directly connected with the driving component, and the juice extractor is more convenient to mount.

Owner:张建民

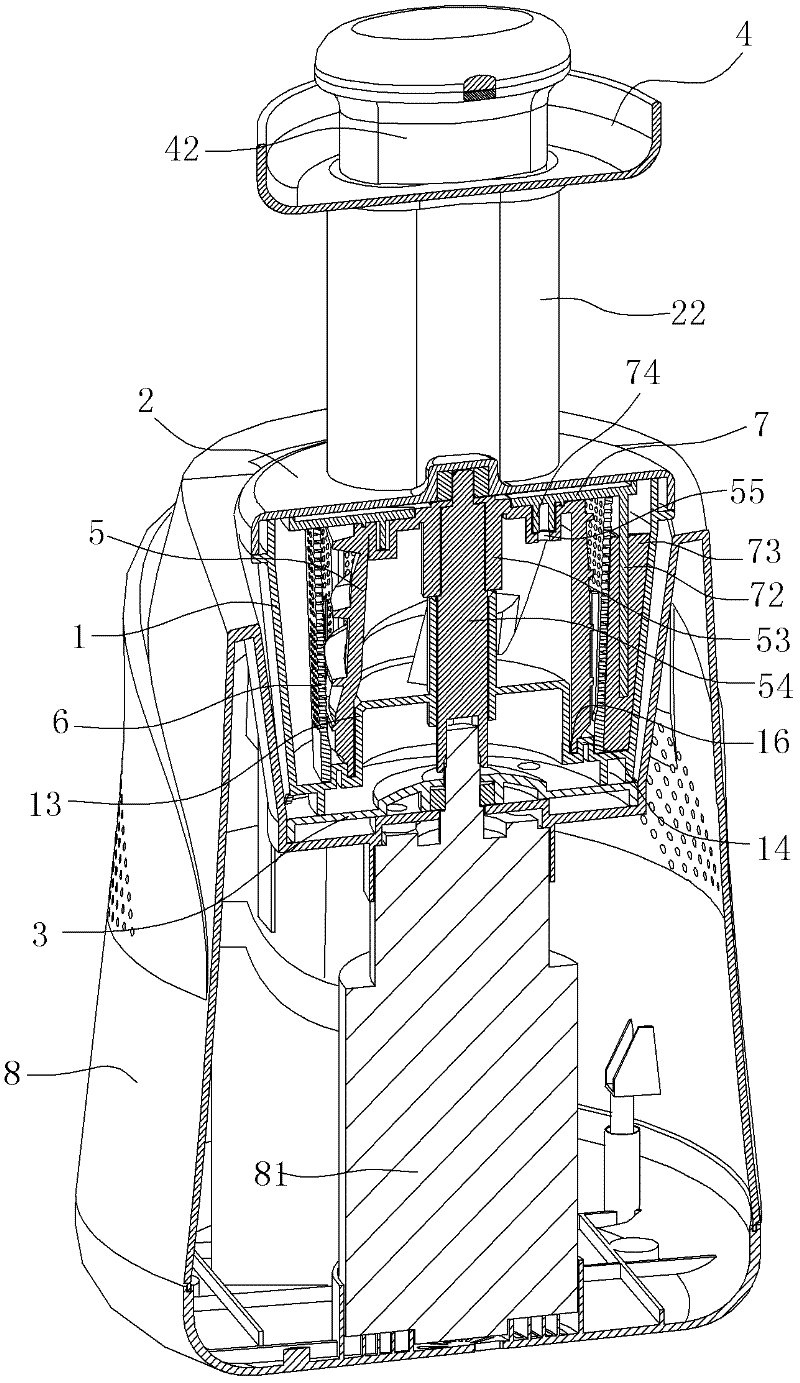

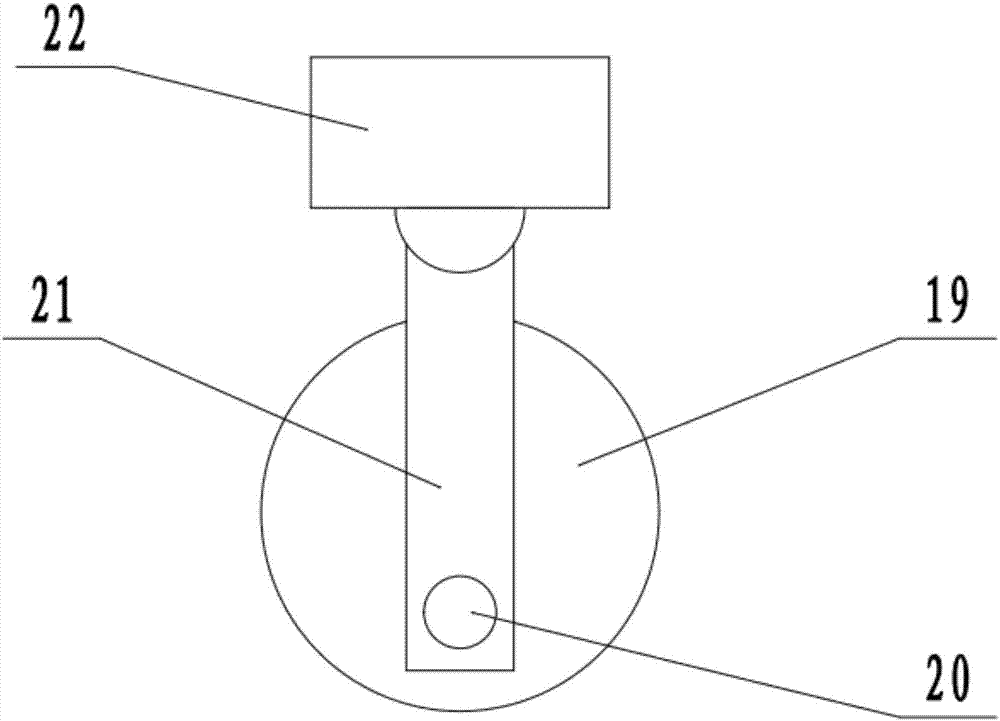

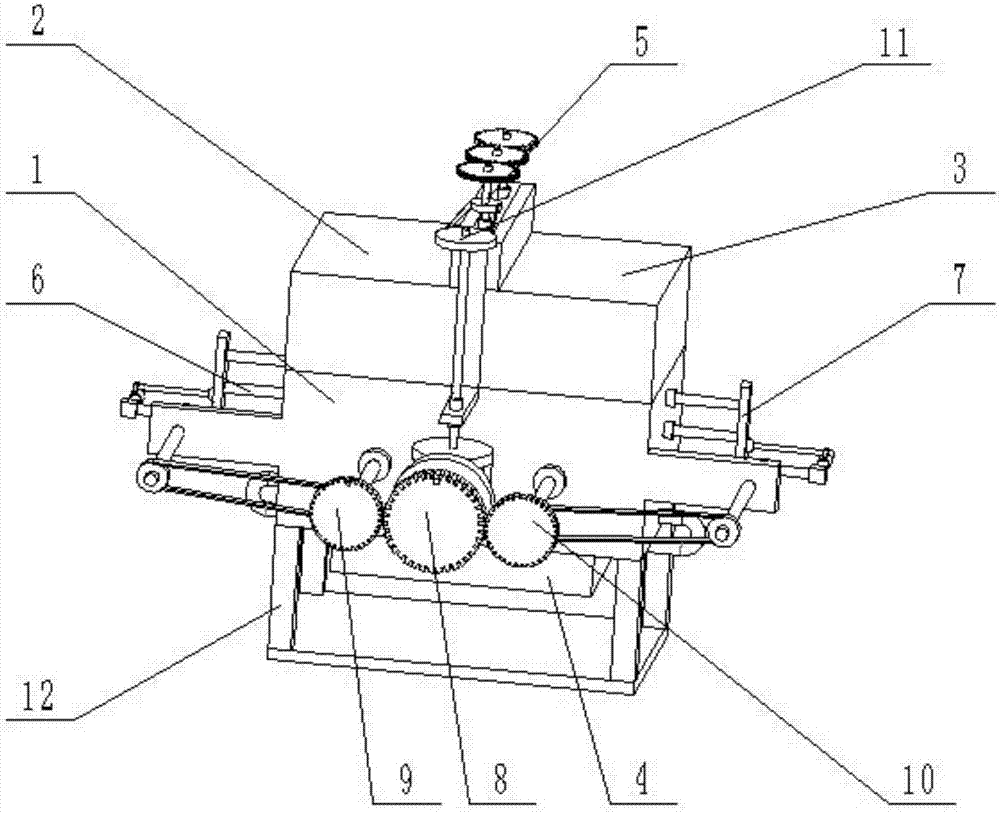

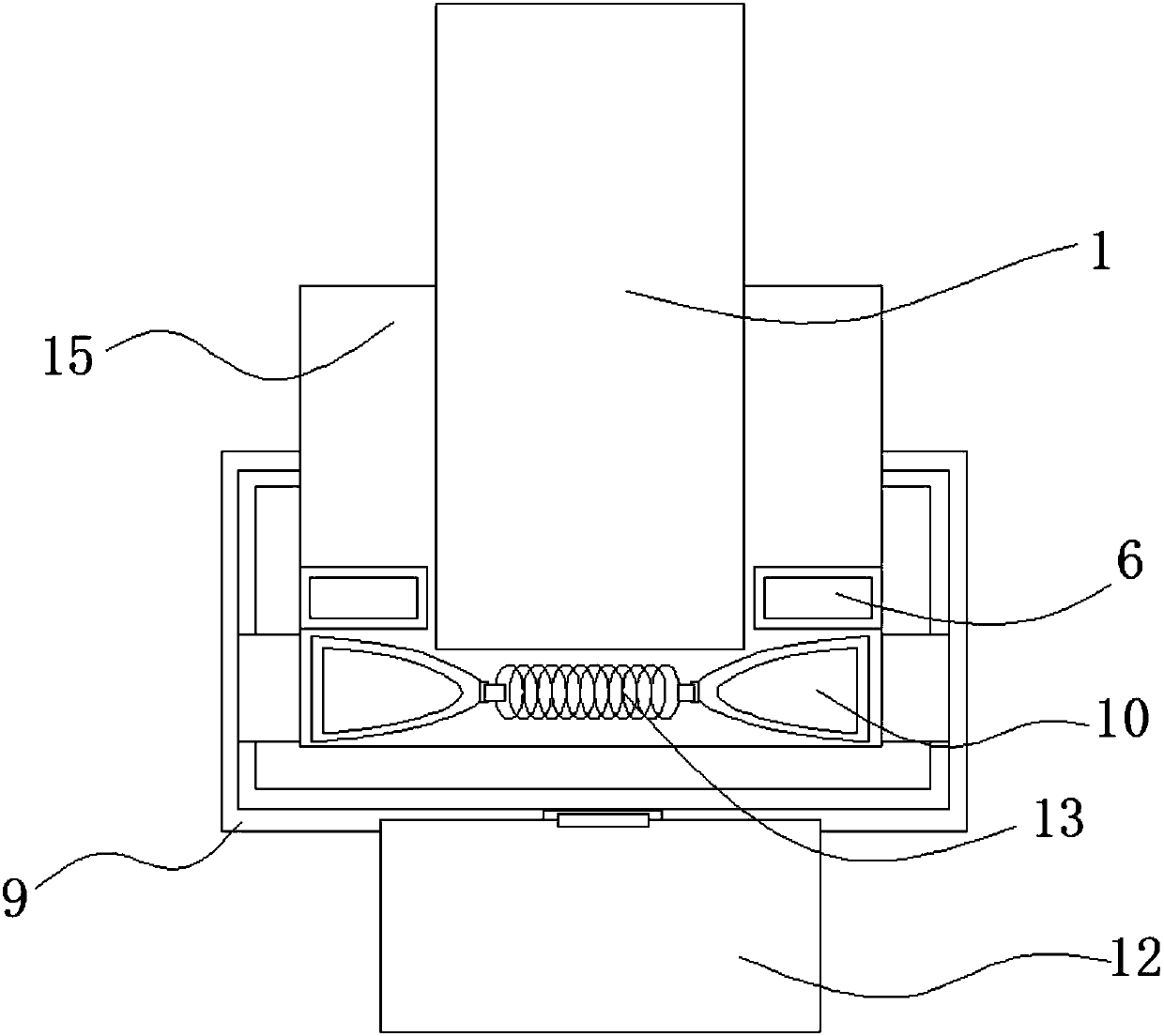

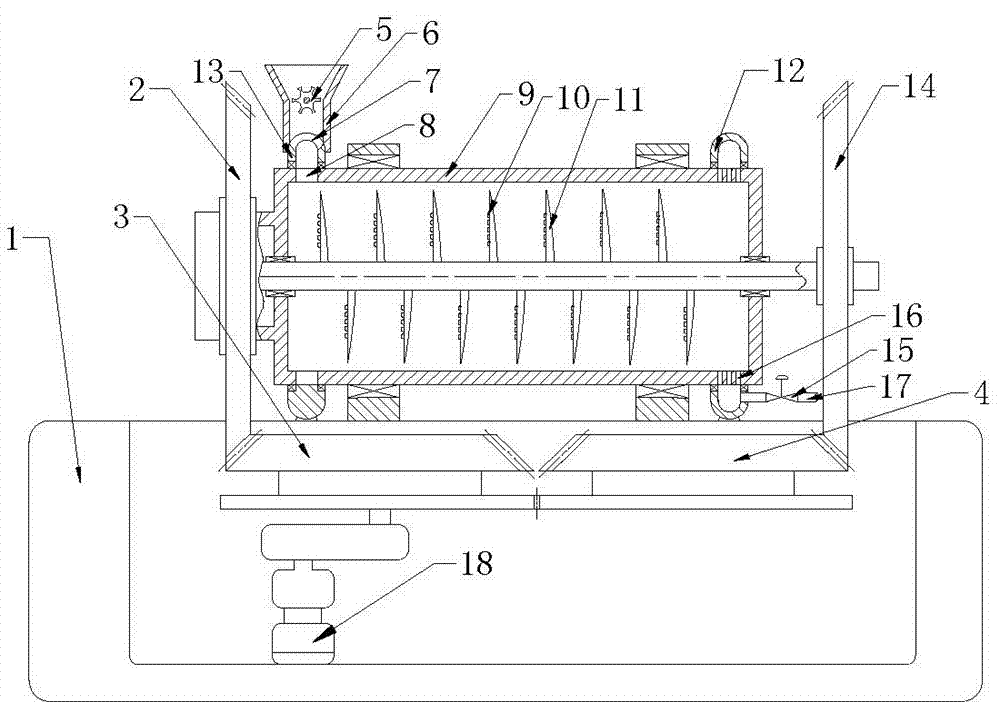

Split type juicer special for food detection

ActiveCN107876192AEven by forceConducive to squeeze outNon-rotating vibration suppressionGrain treatmentsDrive shaftEngineering

The invention discloses a split type juicer special for food detection. The split type juicer comprises a crushing bin, a feeding port, crushing rollers, a juicing bin and a damping base, wherein a driving shaft and a driven shaft are arranged inside the crushing bin in parallel. The crushing rollers sleeve the driving shaft and the driven shaft respectively, a crushing shaft is arranged below thecrushing rollers, a second motor is arranged on a scraping motor of the right side wall of the crushing bin, and crushing edges are distributed on the crushing shaft. The juicing bin is arranged below the crushing bin, a rotating frame is hinged to the inner wall of the right side of the juicing bin, a rotating shaft is arranged below the rotating frame, a fourth motor is fixedly connected to theouter wall of the right side of the juicing bin, a rotating disc is fixedly connected to the left end of the rotating shaft, and a connecting rod sleeves the fixing bar. The crushing blades are usedfor further crushing crushed food, so that the crushing is more thorough. The crushed food falls into the juicing bin, the crushed food is hammered by using a rammer, and the hammer can rotate while hammering, so that the squeezed juice is more thorough, the juicing efficiency is further improved, and the vibration can be reduced by a spring.

Owner:广东万田检测股份有限公司

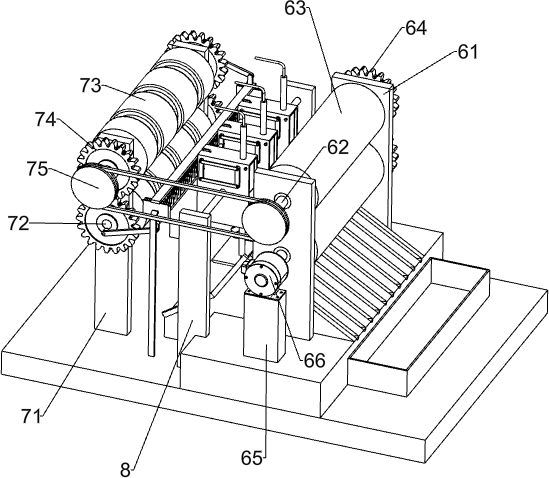

Efficient sugarcane juicing device for sucrose making

The invention relates to a juicer, in particular to a high-efficiency sugarcane juicer for sucrose production. The technical problem to be solved by the present invention is to provide a sugarcane high-efficiency juicer for making sucrose with high juice extraction efficiency. In order to solve the above technical problems, the present invention provides such a sugarcane high-efficiency juicer for sucrose production, which includes a bottom plate, a bracket, a collection tank, a filter screen, a crushing wheel, a crushing box, a first gear, a first rotating shaft, and a bearing seat , the second cylinder, the second iron baffle, etc.; the top bracket of the bottom plate is provided with a collection tank, and the left wall of the bracket is provided with a guide plate, a rolling box and a crushing box in sequence from top to bottom, and a guide hole is opened on the guide plate , the bottom of the left wall of the rolling box is hingedly connected with a first iron baffle. The invention achieves the effects of high sugarcane juice extraction efficiency, simple structure of the device, high utilization rate of sugarcane strips and simple operation of the device.

Owner:谢园园

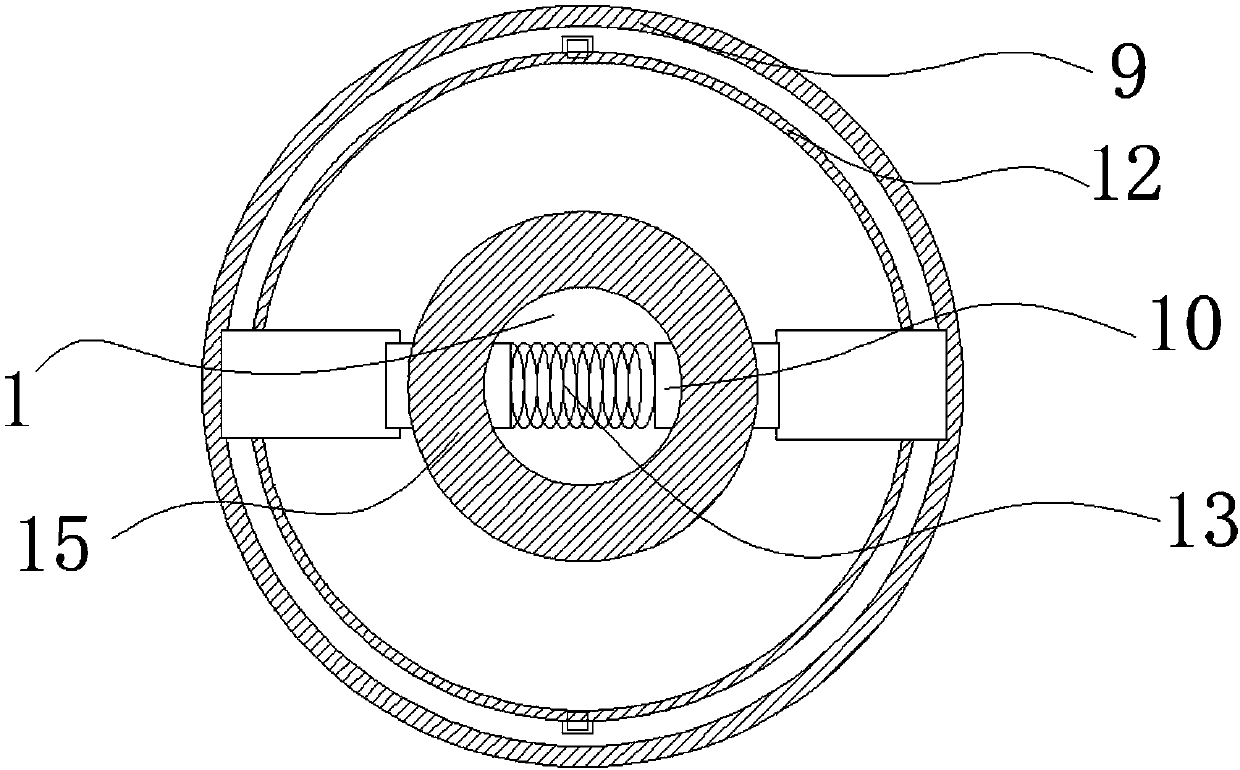

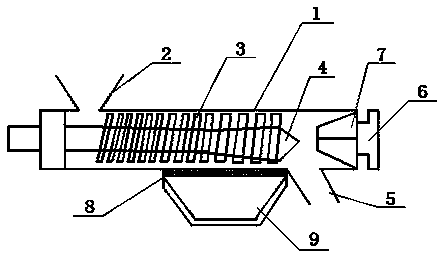

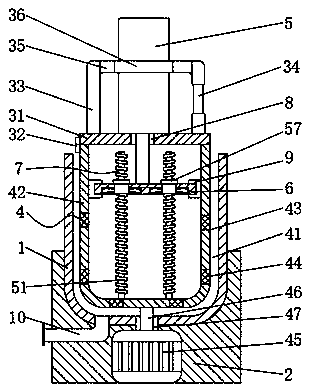

Squeeze type juice squeezing mechanism

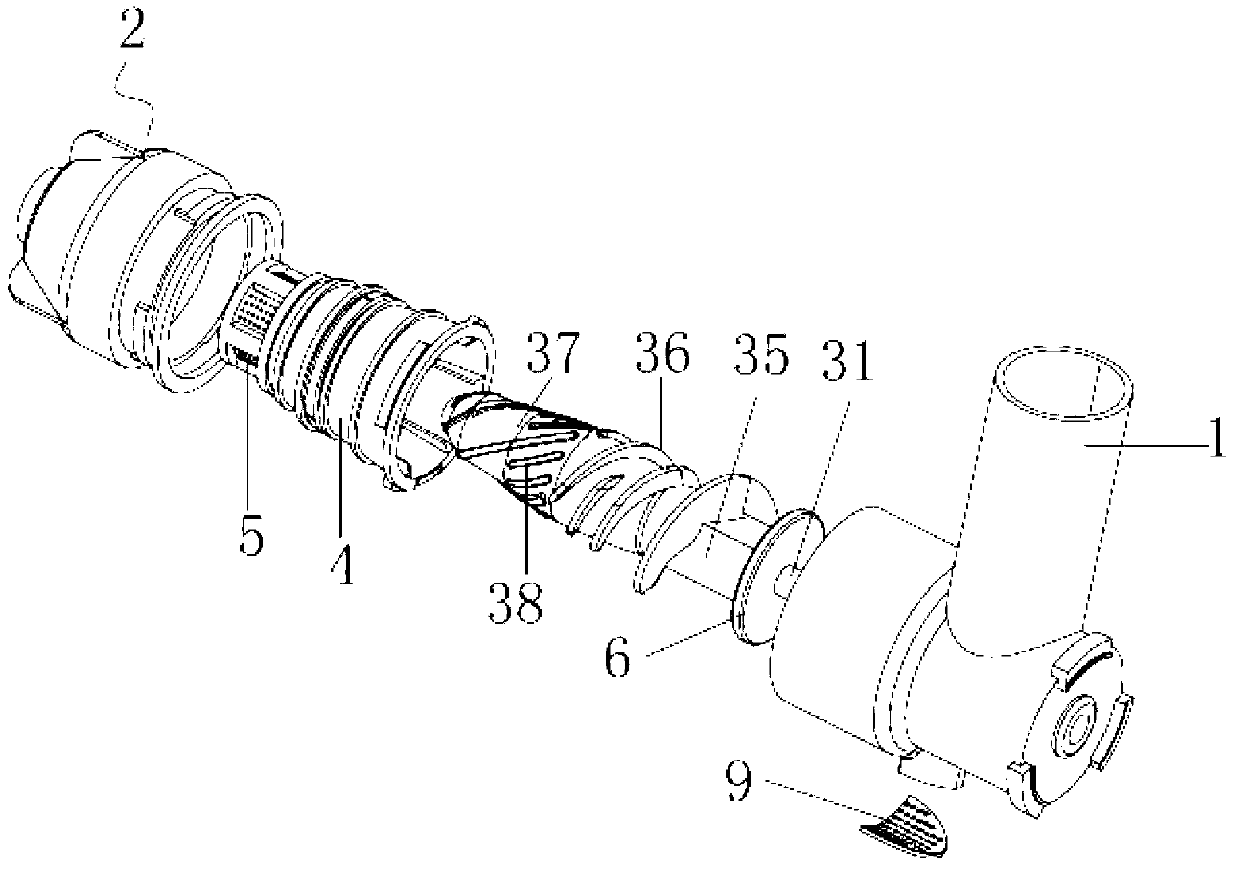

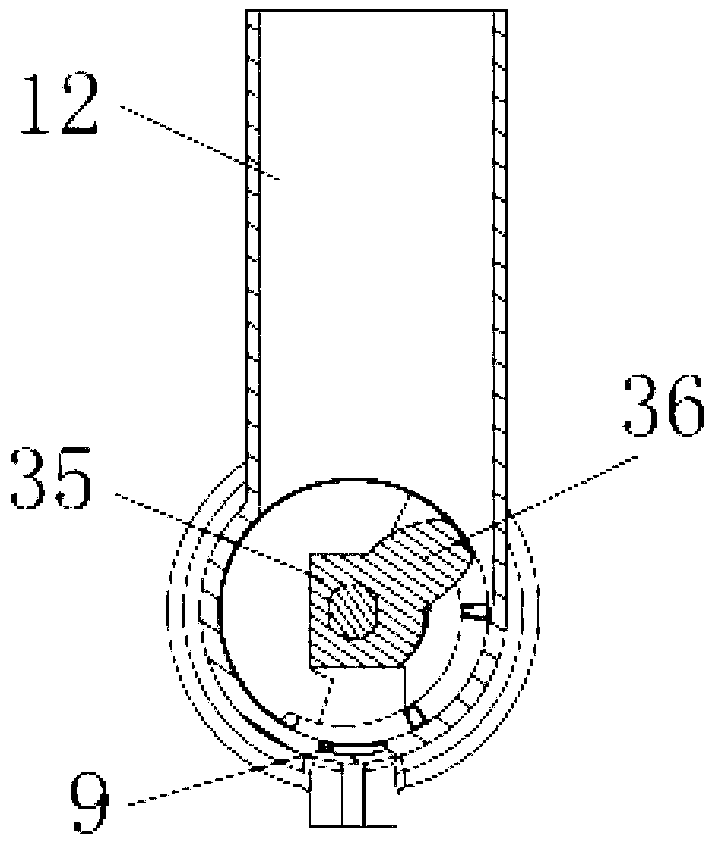

The invention relates to a squeeze type juice squeezing mechanism which comprises an outer shell body, a screw and a front cover movably connected with the outer shell body. The outer shell body is covered with the front cover to form a cylindrical inner cavity. The screw is placed in the cylindrical inner cavity and a gap used for squeezing juice squeezing materials is reserved between an inner wall of the front cover and the outer shell body. One end of the screw penetrates through an end face of the outer shell body and is capable of moving along the axial direction. A first limiting device and a second limiting device used for limiting the screw and preventing the screw from moving out of a set motion area when the screw moves along the axial direction are respectively arranged on the screw. According to the squeeze type juice squeezing mechanism, the screw has a certain degree of freedom when the screw moves along the axial direction so that the axial direction of the screw can be automatically adjusted according to the size of the juice squeezing materials and the juice squeezing mechanism is suitable for different kinds of juice squeezing materials. Meanwhile, a vane wheel main body portion is arranged to be a protruding prism and a feeding port is in tangency with the inner cavity of the outer shell body so that the materials can be cut effectively, feeding pressure of a juice squeezing machine is reduced and juice squeezing efficiency is improved.

Owner:GUANGDONG TONZE ELECTRIC CO LTD

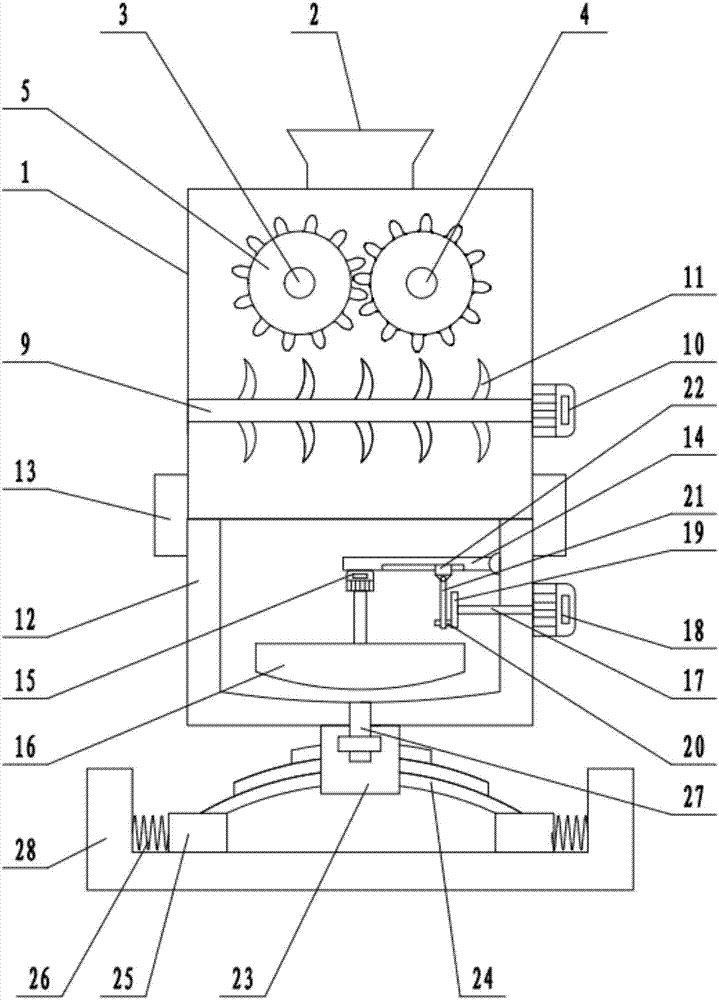

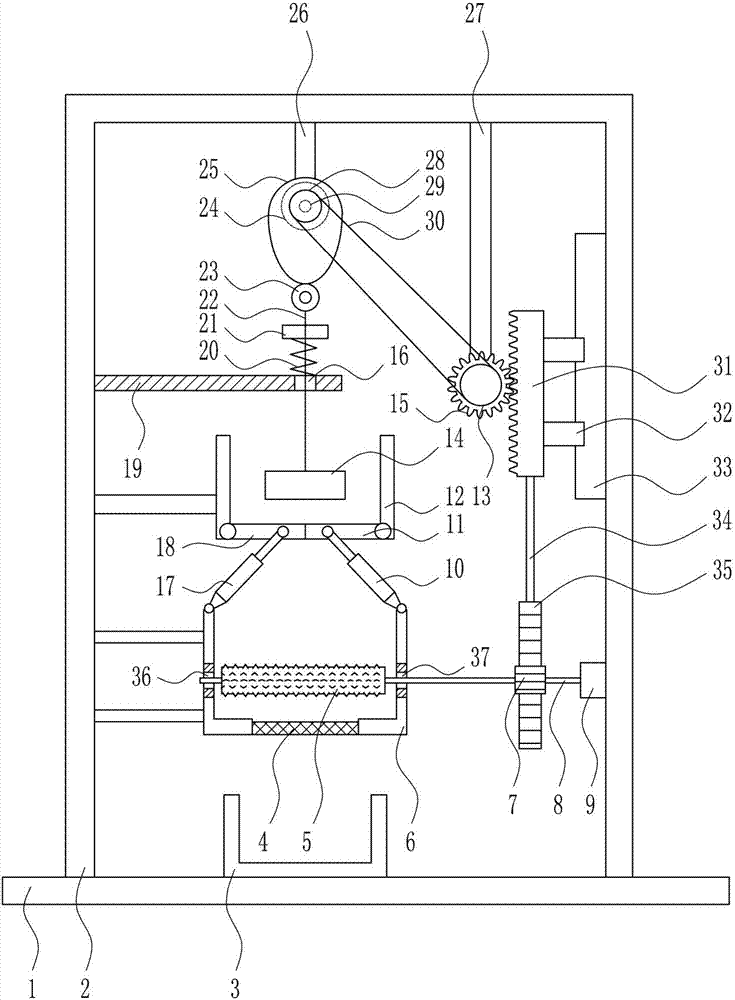

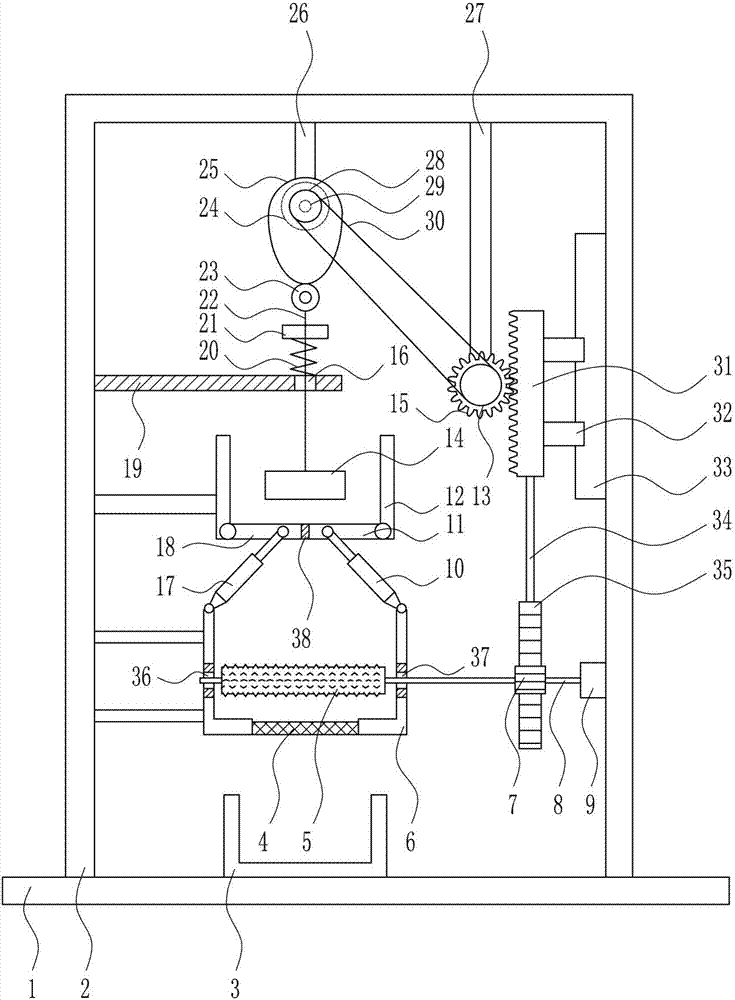

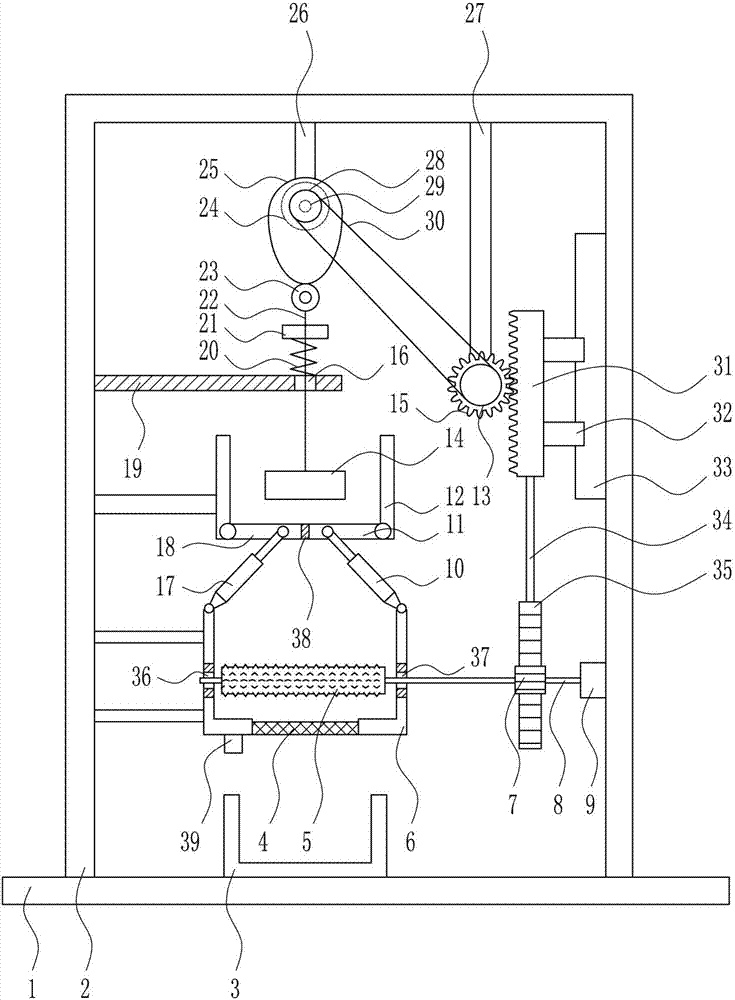

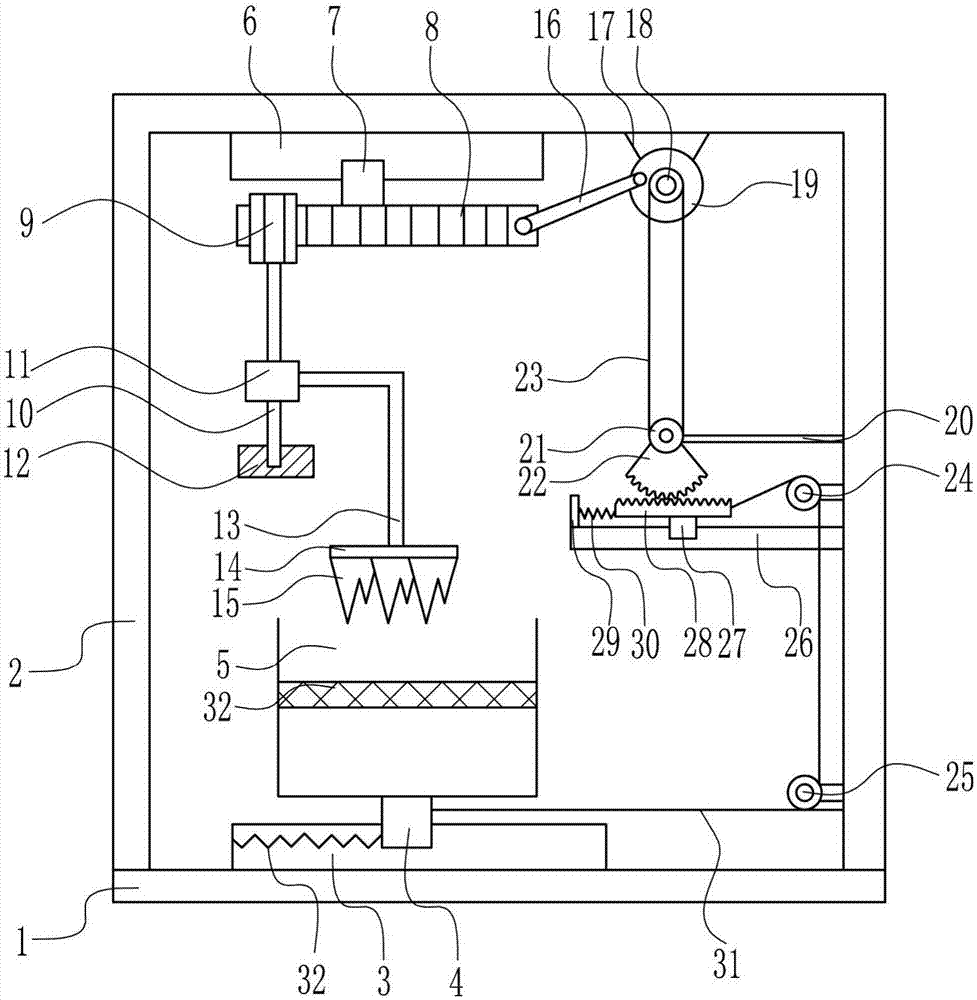

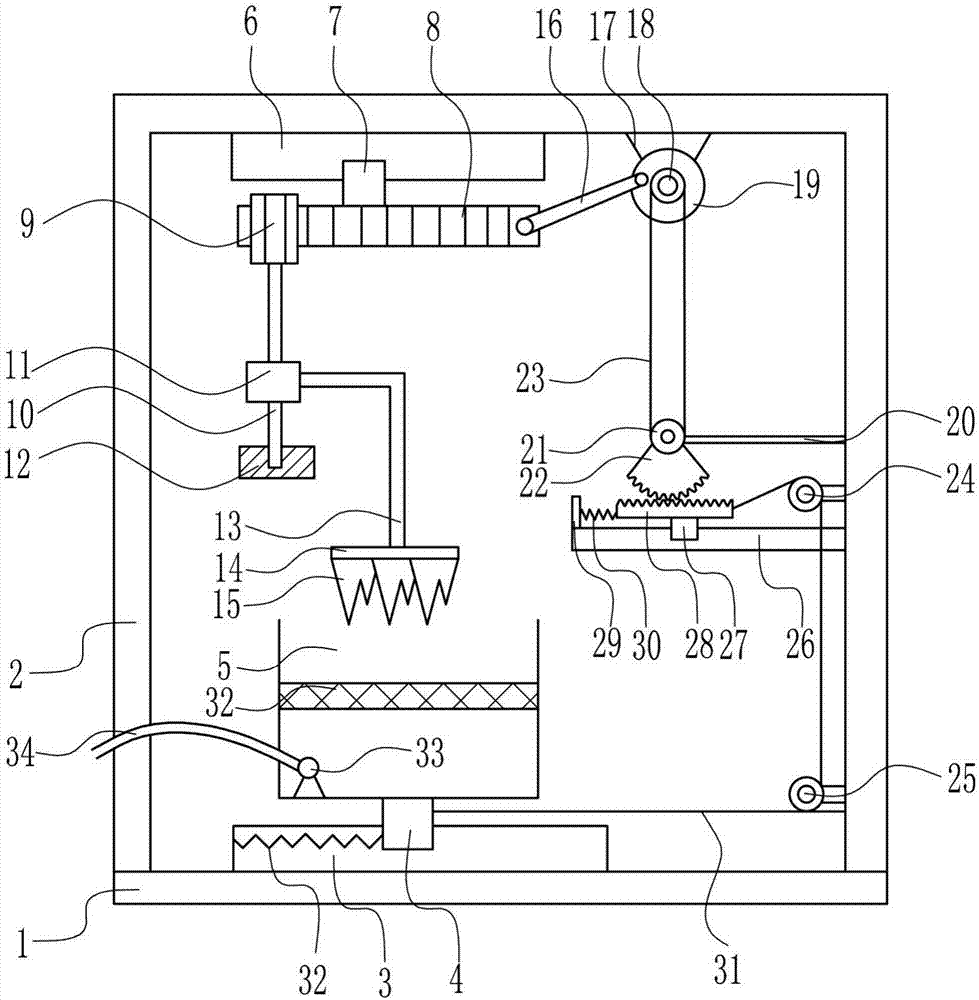

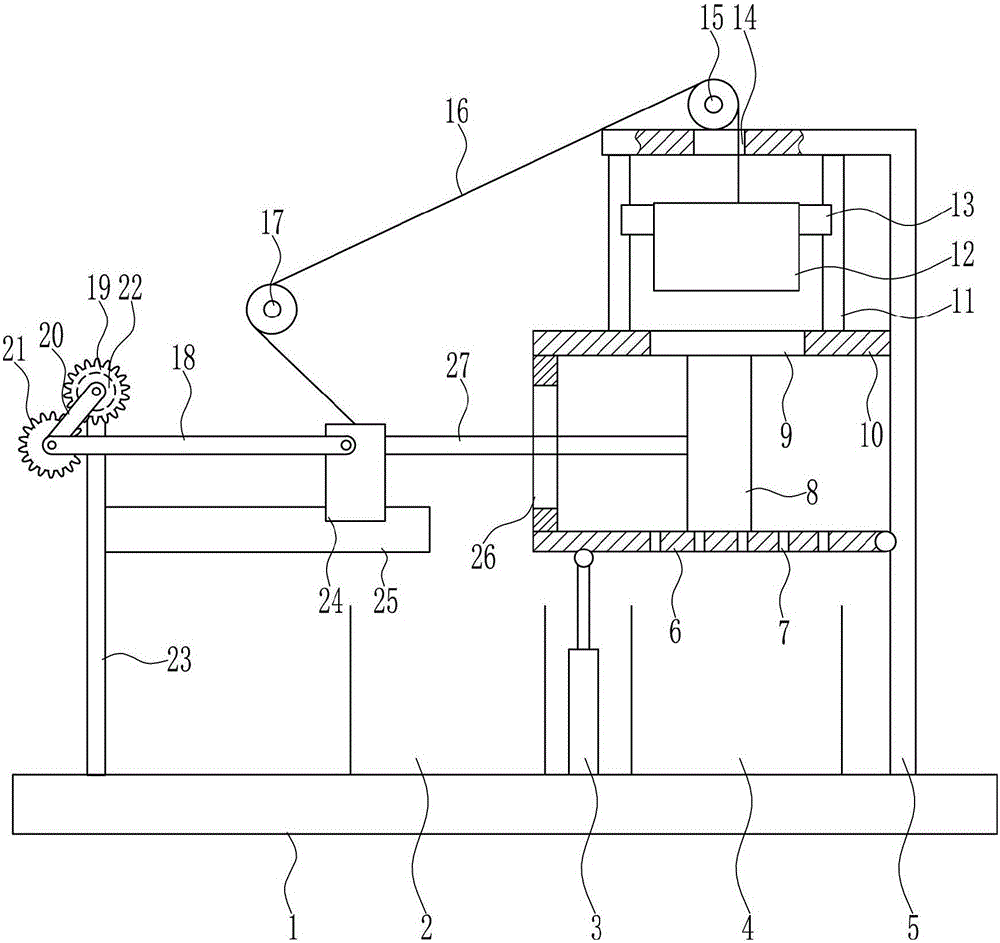

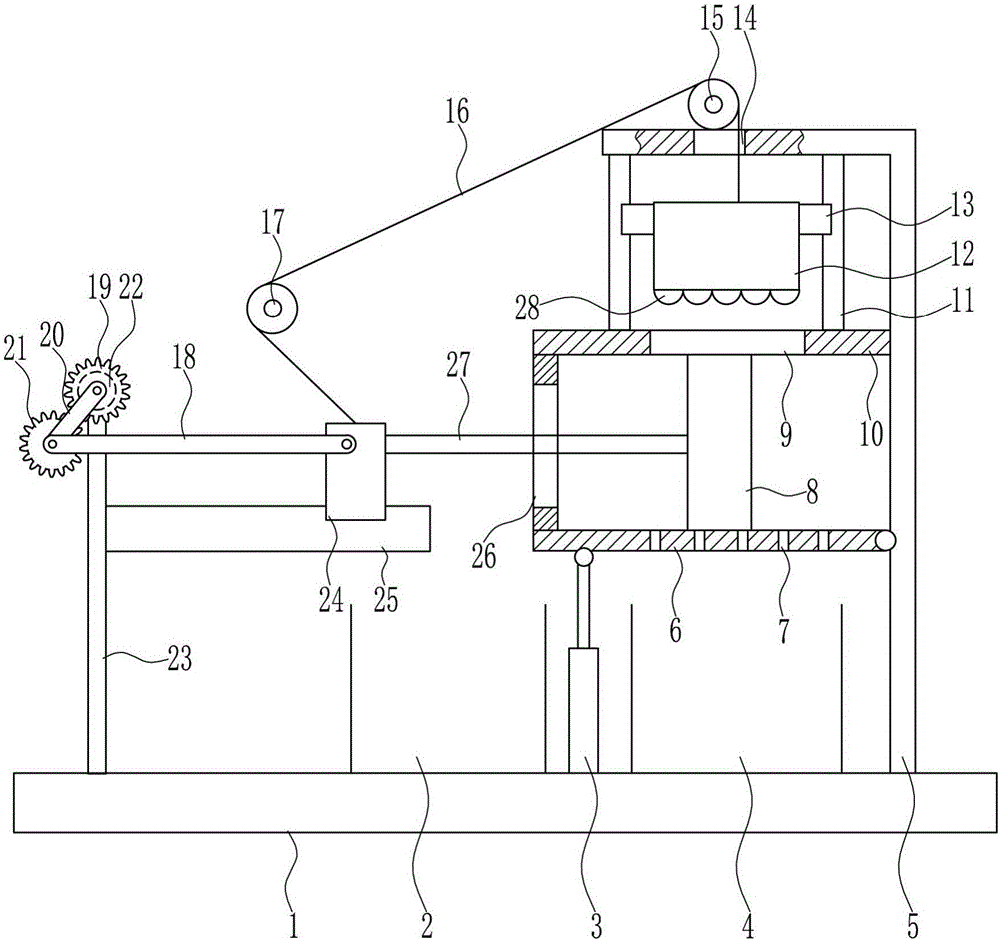

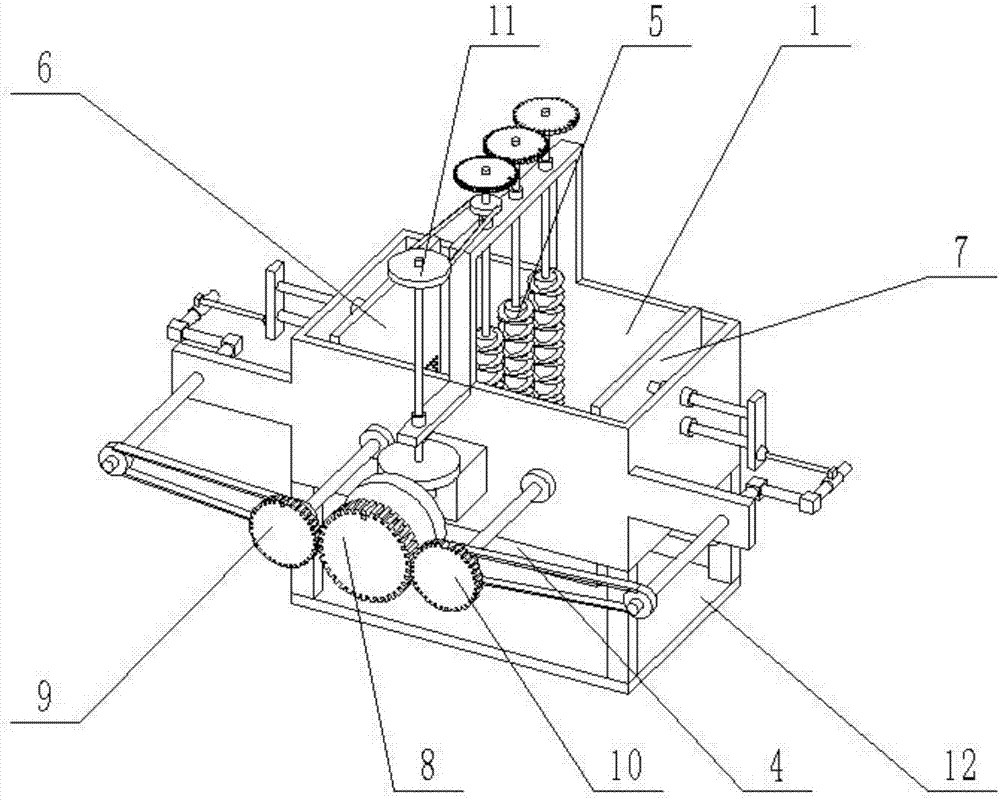

Efficient fruit juicing device for production

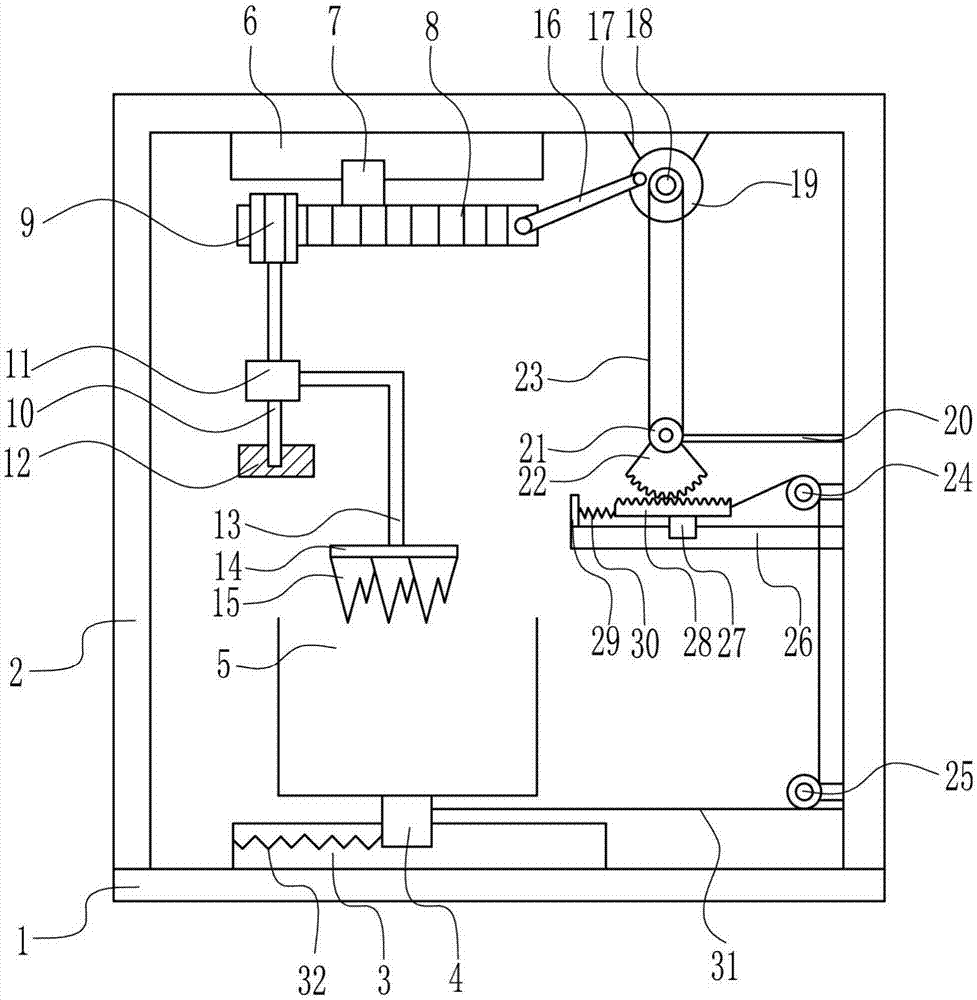

InactiveCN106974302ANo manual operation requiredImprove Juicing EfficiencyJuice extractionStrainersFruit juiceDrive wheel

The invention relates to a fruit juicing device, in particular to an efficient fruit juicing device for production. The technical purpose of providing an efficiency fruit juicing device which does not need manual operation and is high in juicing efficiency and easy to operate for production is achieved. In order to achieve the technical purpose, the efficient fruit juicing device comprises a base plate, an n-shaped frame, a first sliding rail, a first sliding block, a treatment box, a third sliding rail, a third sliding block, a second rack, a second gear, a screw, a nut, a bearing pedestal, a fixed rod, a fixed plate, rolling teeth, a connecting rod, an installation base, an electric wheel, a disc, a support rod, a driven wheel, a fan-shaped gear, a belt, a second pulley, a first pulley, a second sliding rail, a second sliding block, a first rack, a baffle, a second spring, a first spring and a stay wire, and the n-shaped frame is arranged on the base plate. Accordingly, the effects that manual operation is not needed, the juicing efficiency is high, and operation is easy are achieved.

Owner:朱铁凝

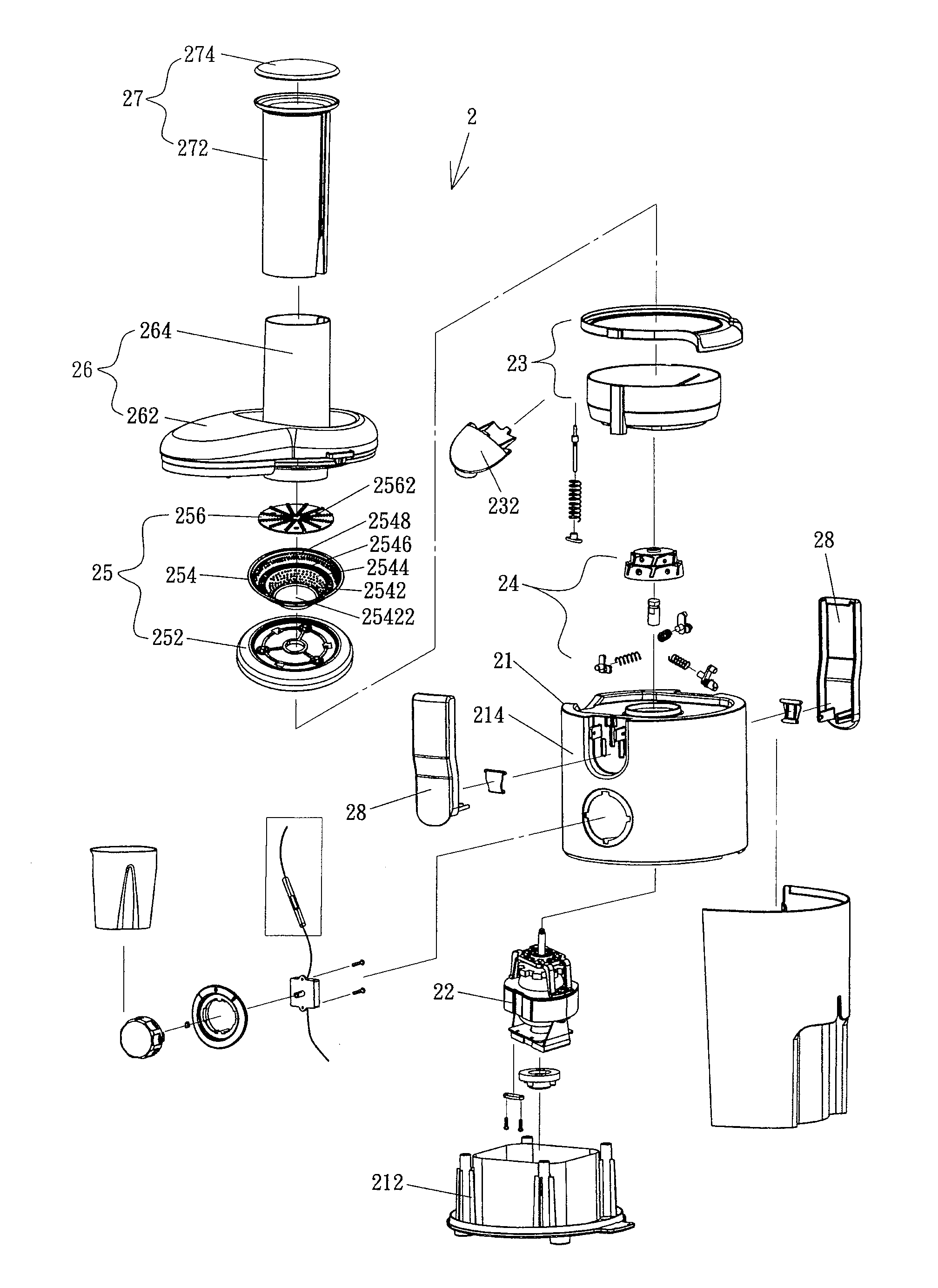

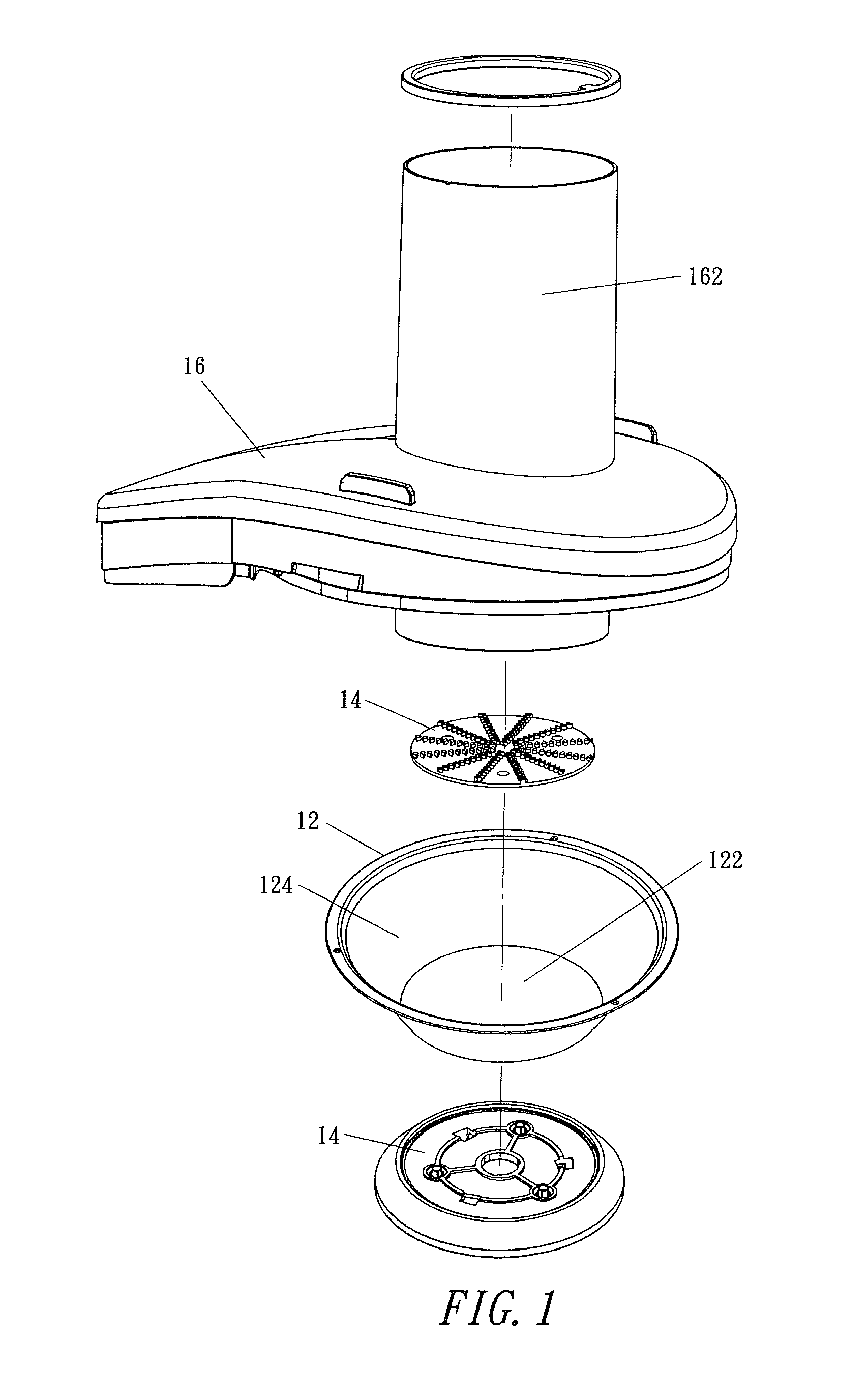

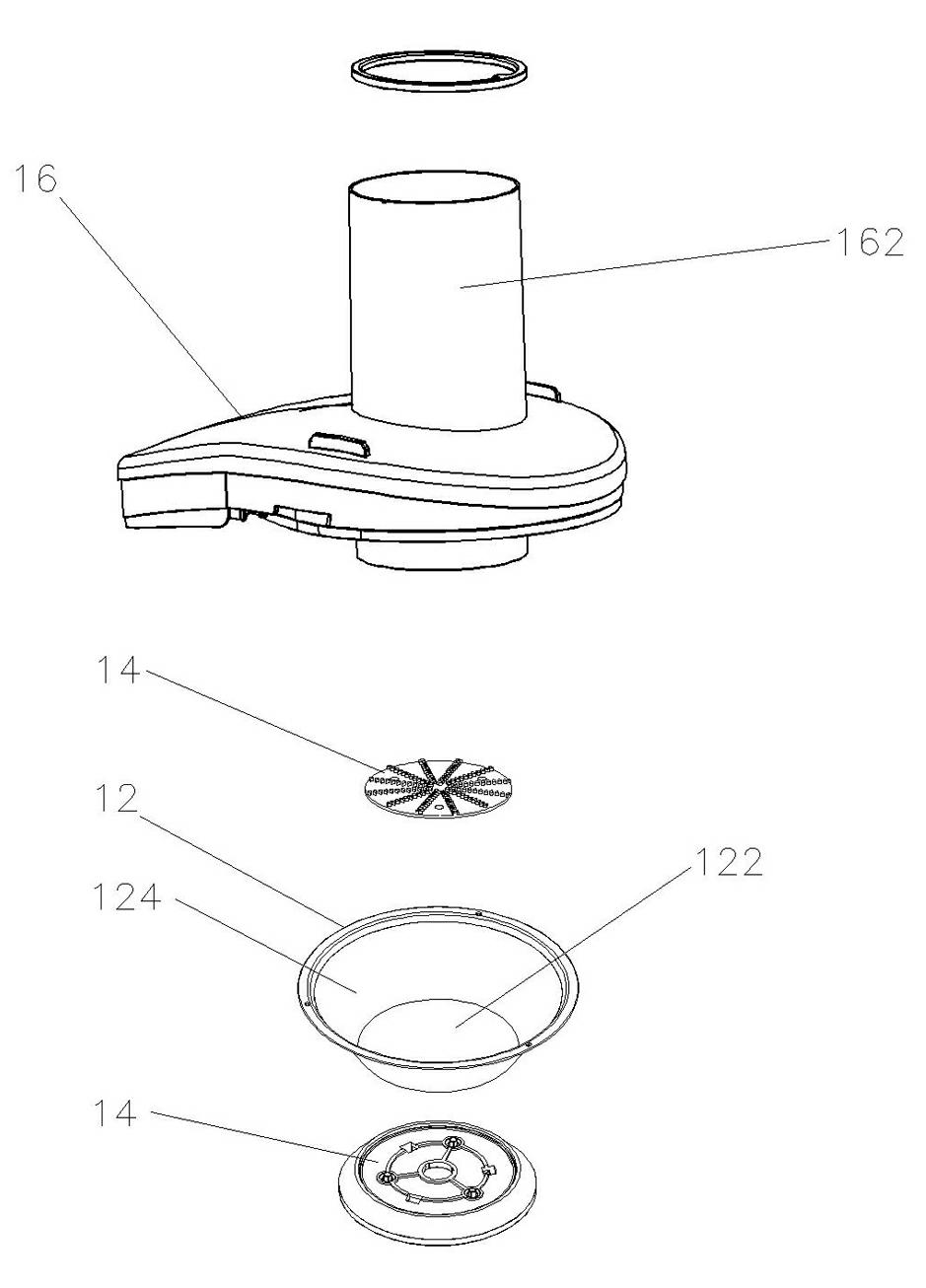

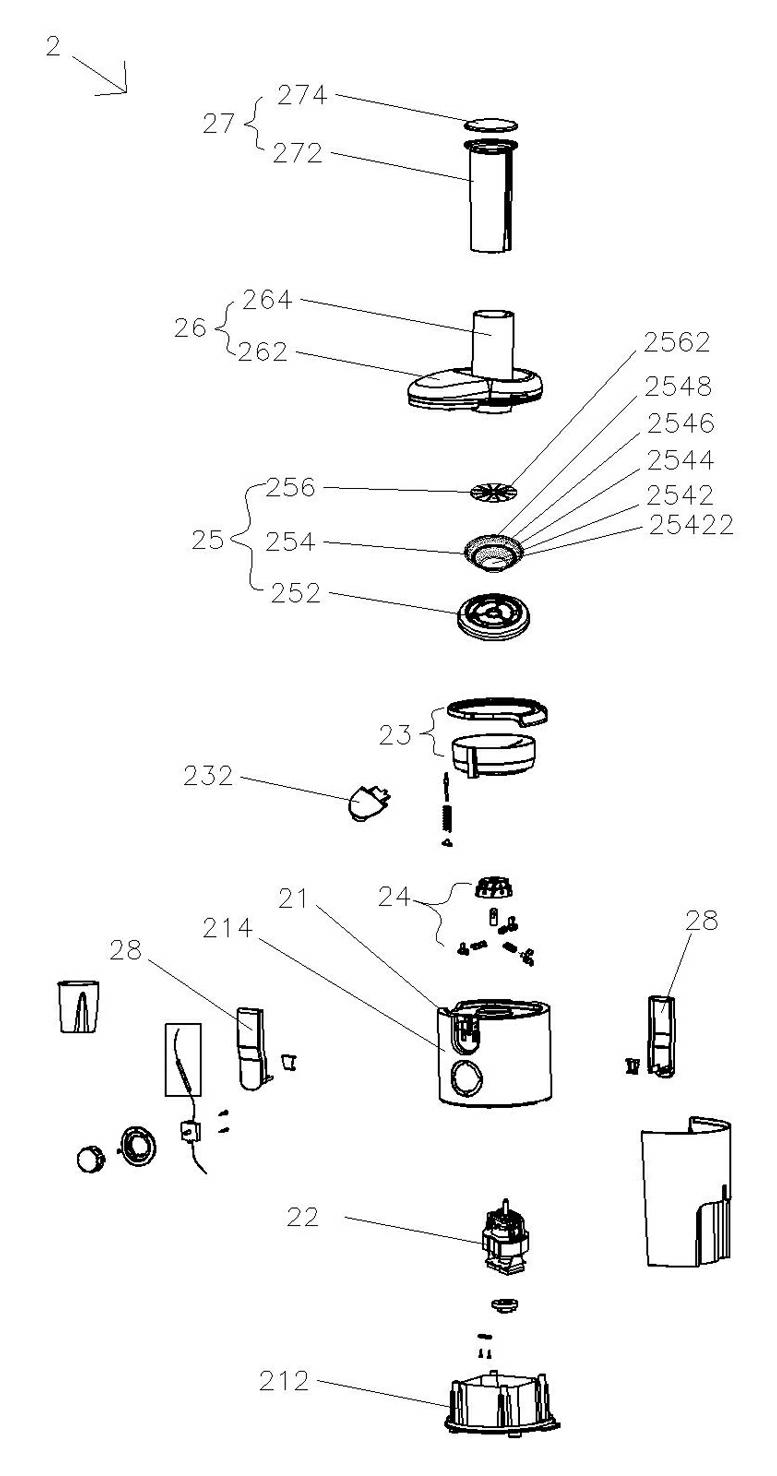

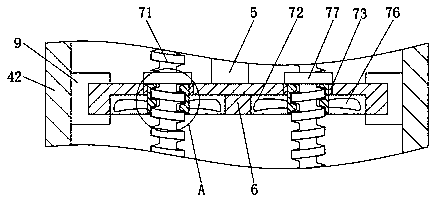

Juice Machine and Filter Thereof

InactiveUS20120192729A1Increase the juice yieldEnhance juice juice squeezing efficiencyJuice extractionCentrifugesEngineeringFlywheel

A juice machine includes a cutter module, and the cutter module includes a cutter turntable, a filter, and a cutter flywheel. The filter includes a bottom plate, a first side plate protruded and tilted upwardly from an external periphery of the bottom plate, a filter plate horizontally extended from the top of the first side plate, a tilted second side plate protruded upwardly from an edge of the filter plate, an opening formed at the center of the bottom plate, a plurality of first meshes formed on the first side plate, a plurality of second meshes formed on the filter plate, a plurality of third meshes formed on the second side plate. Therefore, the weight of the filter can be decreased to provide a stable filter and reduce vibrations and noises. The juice machine can enhance both juice squeezing efficiency and juice yield.

Owner:YA HORNG DONG GUAN ELECTRONICS +1

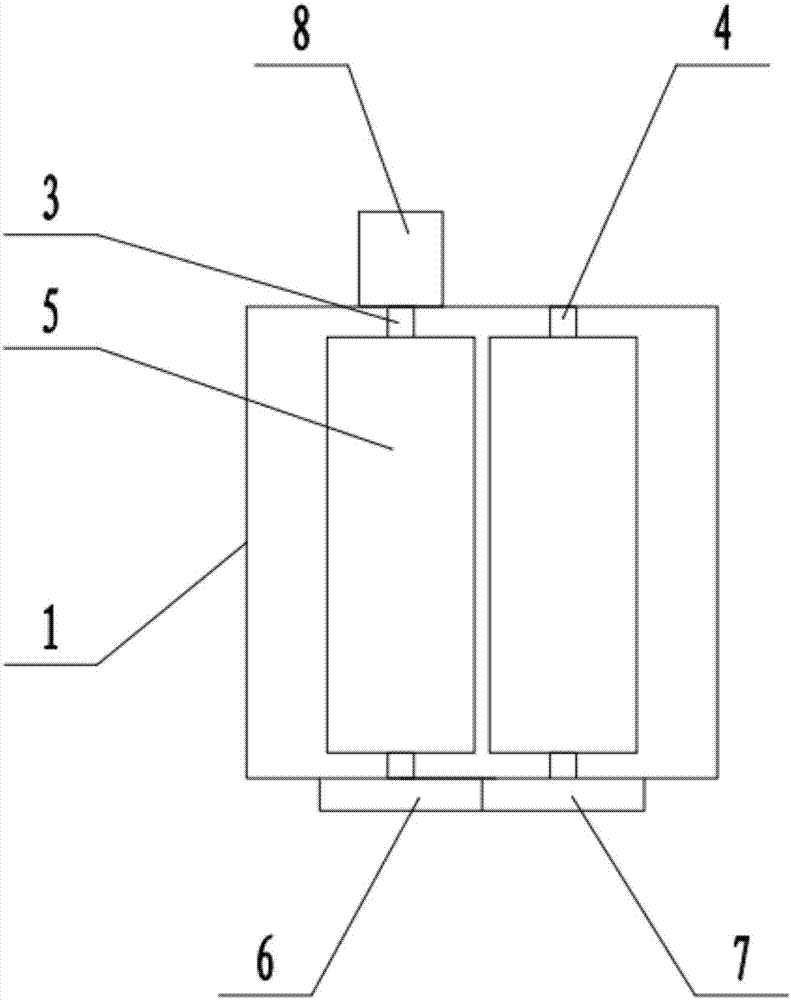

Sugar cane juicing device for sucrose production

ActiveCN106626485AImprove Juicing EfficiencyReduce volumePress ramJuice extraction from sugarcaneSucroseEngineering

The invention relates to a sugar cane juicing device, in particular to a sugar cane juicing device for sucrose production. A technical problem to be solved by the invention is to provide a sugar cane juicing device for sucrose production having advantages of high juicing efficiency, relatively small size and low manufacturing cost. In order to solve the above technical problem, the invention provides such a sugar cane juicing device for sucrose production that the sugar cane juicing device comprises a bottom plate, a first collecting frame, an air cylinder, a second collecting frame, a 7-shaped bracket, a baffle plate, a first extruding block, a cylinder body, a first slide rail, a second extruding block, a first slide block, a first pulley, a pull rope, a second pulley, a first connecting rod, a first gear, a second connecting rod, a second gear, a motor, a strut, a second slide block, a second slide rail and a third connecting rod; the strut, the first collecting frame, the air cylinder, the second collecting frame and the 7-shaped bracket are sequentially arranged on the bottom plate from left to right. The sugar cane juicing device provided by the invention achieves effects of high juicing efficiency, relatively small size and low manufacturing cost.

Owner:合山市祥星制糖有限责任公司

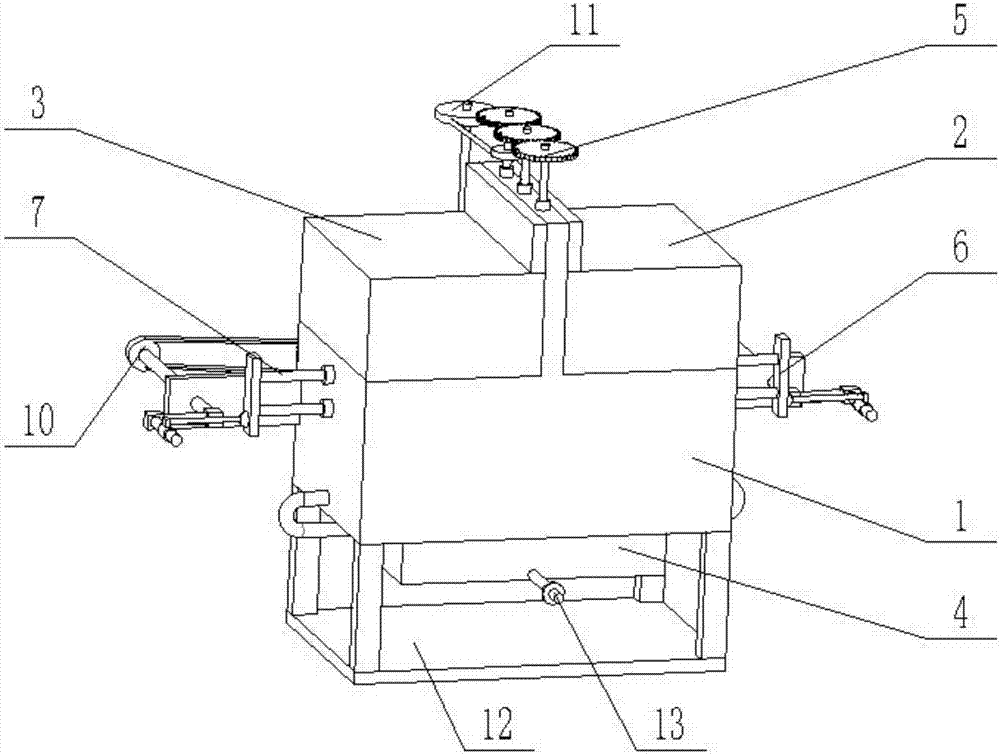

Juicing device for food processing

InactiveCN107116818AEasy to operateImprove Juicing EfficiencyJuice extractionGrain treatmentsEngineeringFruits and vegetables

The present invention relates to the field of food processing, in particular to a juice extracting device for food processing. Box cover; a rotary crushing device is installed at the middle end of the inside of the juicing box, and the rotary crushing device is connected to an upper transmission device arranged at the upper end of the front of the juicing box; The extruding device is connected to the left transmission device arranged at the left end of the juice extraction box; the right reciprocating extrusion device is arranged at the right end inside the juice extraction box, and the right reciprocating extrusion device is connected to the right transmission device arranged at the right end of the juice extraction box. The invention can effectively solve the problem that the structure of the juicing device in the prior art is single and cannot be reasonably applied to juicing different kinds of fruits and vegetables; it provides a food processing juicing device suitable for juicing different kinds of fruits and vegetables.

Owner:孙平波

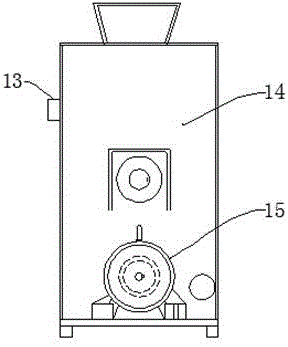

Automatic device of removing peel and seeds and squeezing juice for processing of grapes

InactiveCN106036942AImprove cleanlinessImprove Juicing EfficiencyJuice extractionFood treatmentGrape juicesWater pipe

The invention discloses an automatic peeling, seeding and juicing device for grape processing, which comprises a base, a casing, a juice extractor and a motor. A water output pipe, the motor is arranged above the base, a transmission shaft is arranged on the motor, a water inlet pipe is installed on one side of the casing, a cleaning pool is arranged above the inside of the casing, and the inside of the cleaning pool is An ultraviolet sterilizing lamp is installed on the top, the juice extractor is installed inside the casing, a solenoid valve is installed above the juice extractor, a rotating shaft is installed inside the juice extractor, and a compression blade is installed on the rotating shaft. An impurity output pipe is installed on one side of the juice extractor, a grape juice output pipe is installed below the juice extractor, and a feed hopper is arranged above the casing. The beneficial effect is that the invention can clean and sterilize the grapes, improve the cleanliness of the grapes, and improve the juice extraction efficiency of the grapes.

Owner:徐州源昌农业科技发展有限公司

Automatic juicer

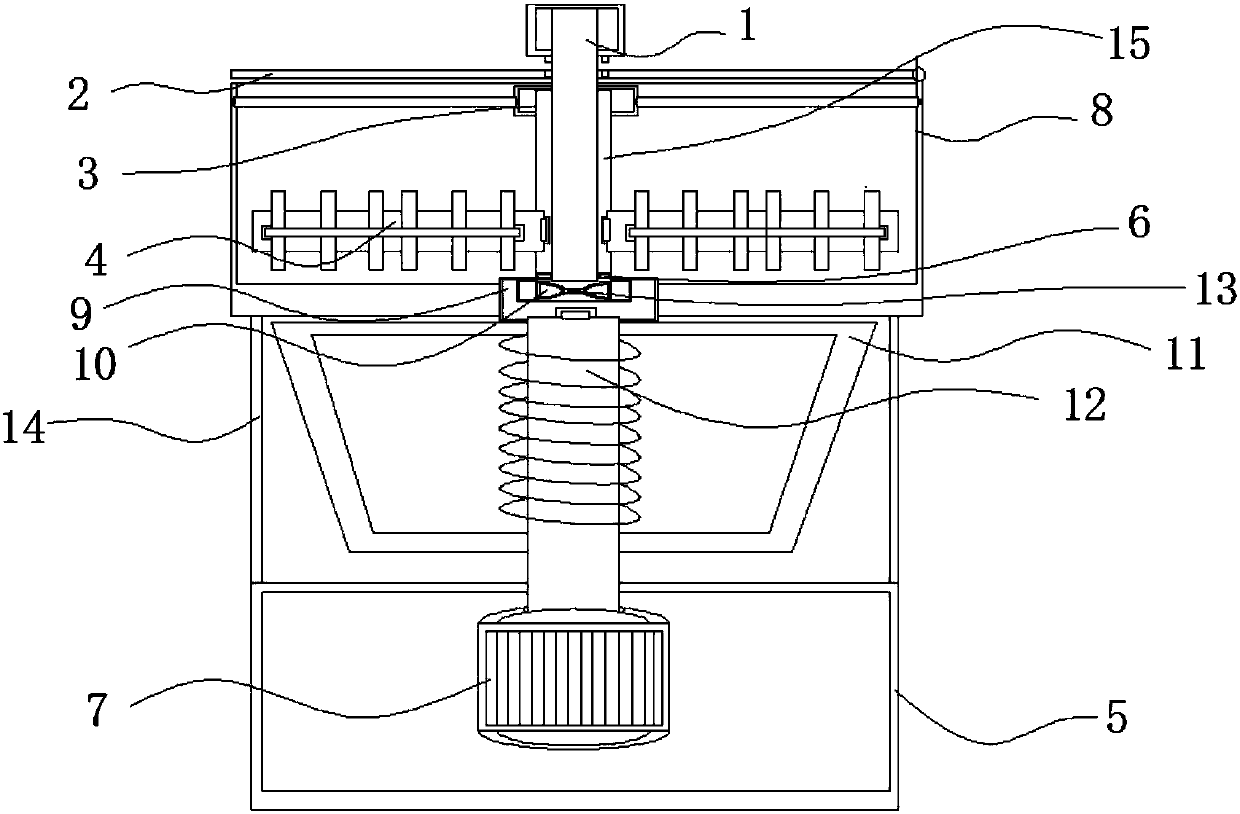

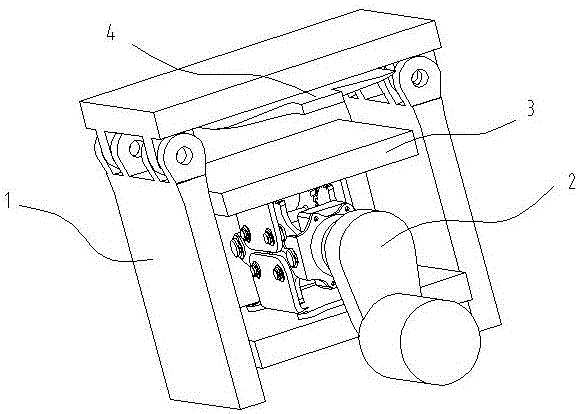

The invention relates to an automatic juicer which comprises a juicer head, a juice receiving cup, an upper juicing head and a lower juicing head. The juice receiving cup is arranged on the juicer head, the upper juicing head is arranged on the juice receiving cup, the lower juicing head is arranged in the juice receiving cup in a longitudinally-movable manner and positioned right below the upper juicing head, the juicer head comprises a casing, a speed reducing motor and a screw, the speed reducing motor is arranged in the casing, an output shaft of the speed reducing motor is in transmission connection with the screw, the screw is in threaded connection with the casing and extends into the juice receiving cup to be connected with the lower juicing head, the speed reducing motor comprises a driving motor and a speed reducing gearbox, a power input end of the speed reducing gearbox is connected with a rotating shaft of the driving motor while a power output end of the same is connected with an output shaft, and the rotating shaft, the power input end, the power output end, the output shaft and the screw are all arranged coaxially, namely being positioned on a same central line. The automatic juicer has the advantages of simple and reasonable structure, reliable and smooth running and low cost.

Owner:ZHONGSHAN CITY O BEKO ELECTRICAL APPLIANCES

Raspberry fruit vinegar carbonated beverage and making method thereof

The invention provides a raspberry fruit vinegar carbonated beverage and a making method thereof. The beverage comprises raspberry fruit concentrated liquid, raspberry fruit vinegar, xylitol, honey, potassium sorbate, sodium benzoate and beta-cyclodextrin. The beverage is natural and harmonious in color and moderate sour and sweet in taste, has refreshing taste and sweet fruity aroma, has the functions of arresting seminal emission, nourishing the kidney, tonifying yang, improving eyesight, dispelling the effects of alcohol, quenching thirst, removing phlegm and resolving toxin, and is an optimal beverage for people of all ages and both sexes.

Owner:XINING ZHIYE BIOTECH CONSULTING SERVICE

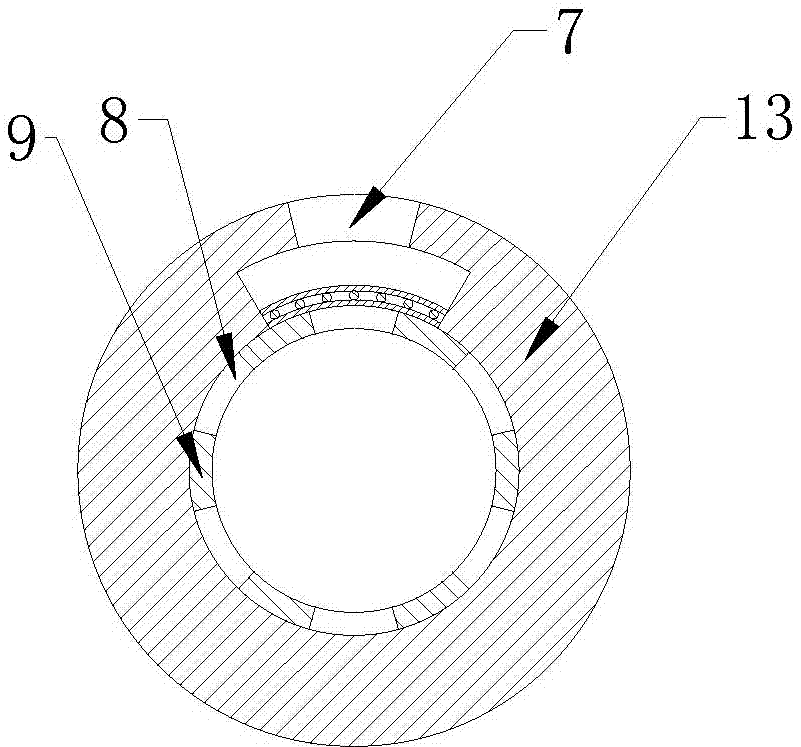

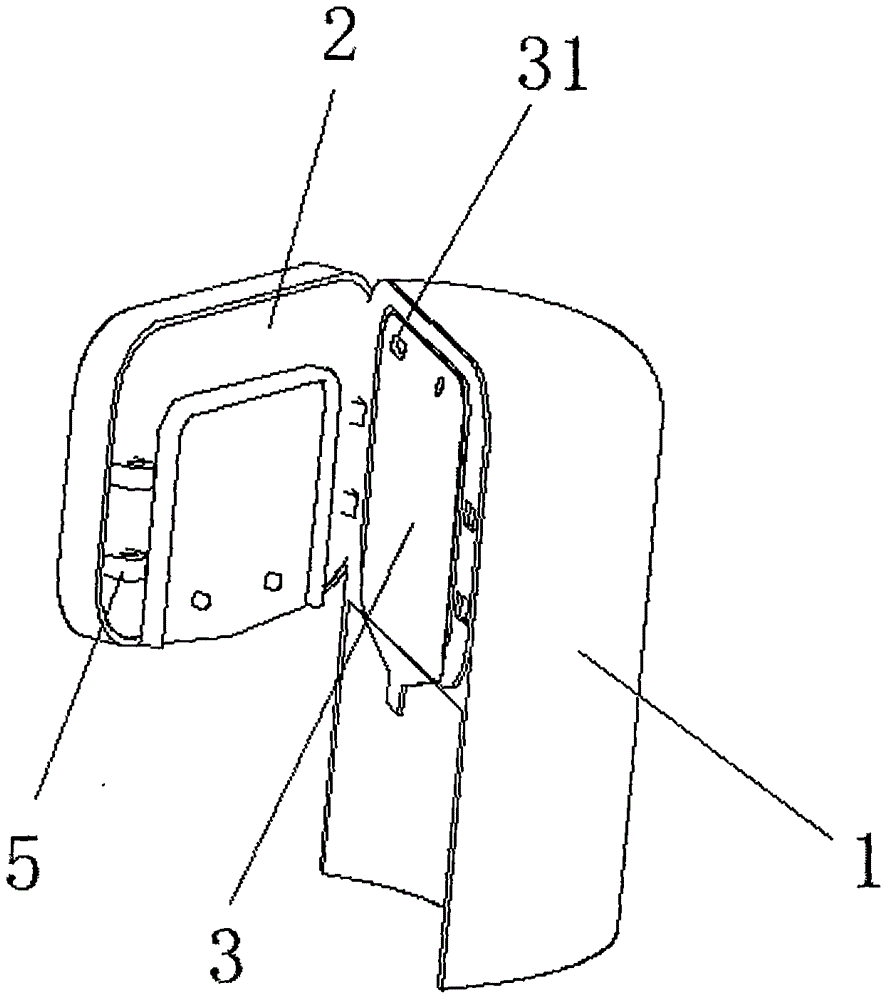

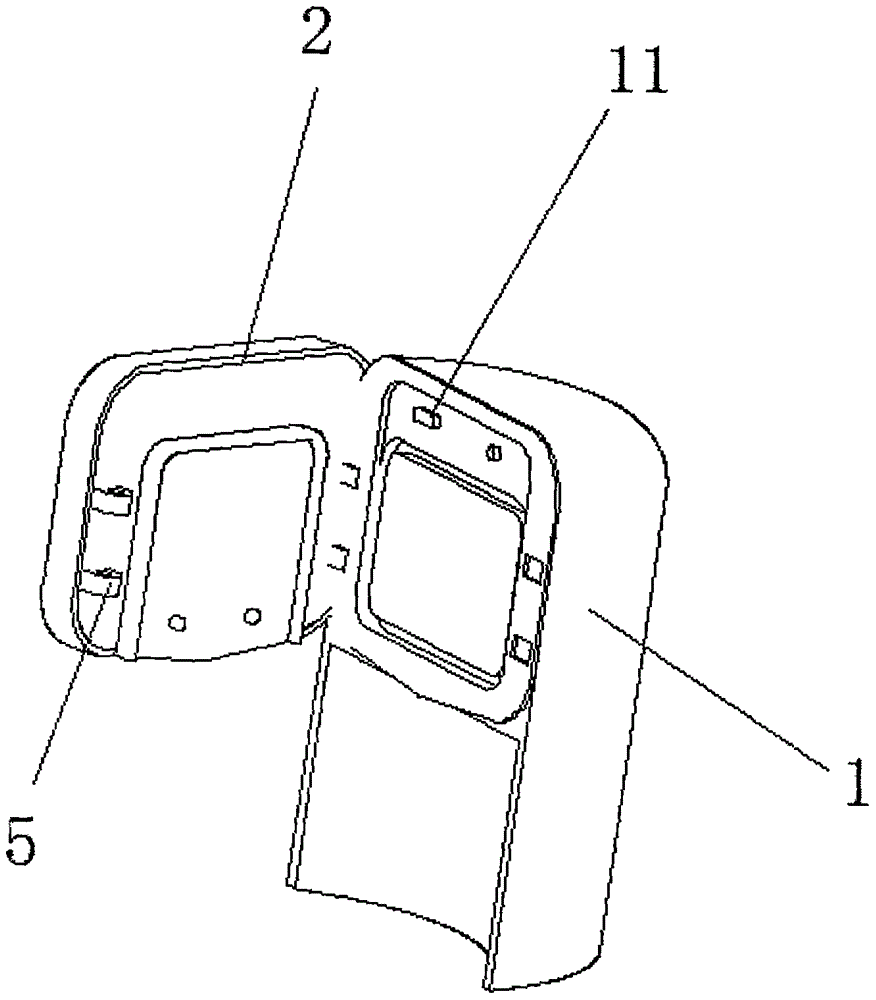

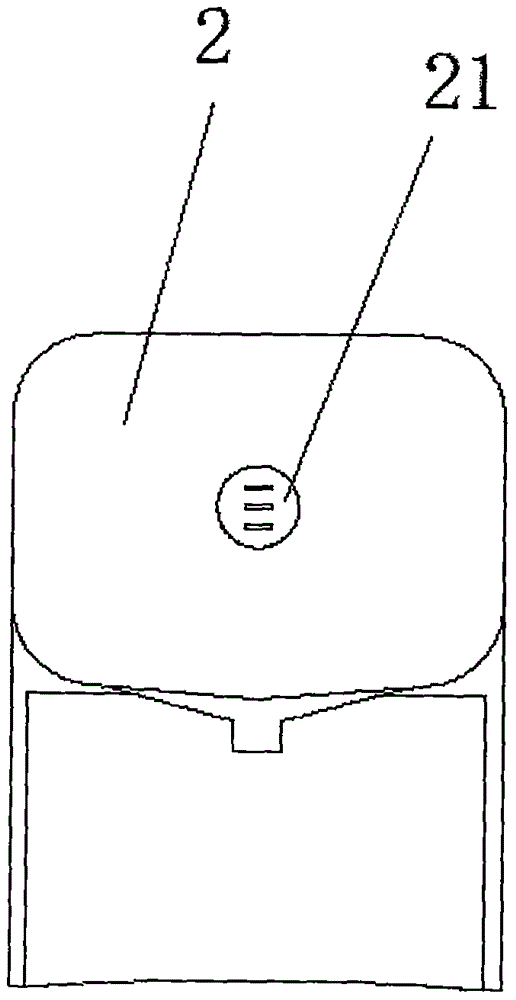

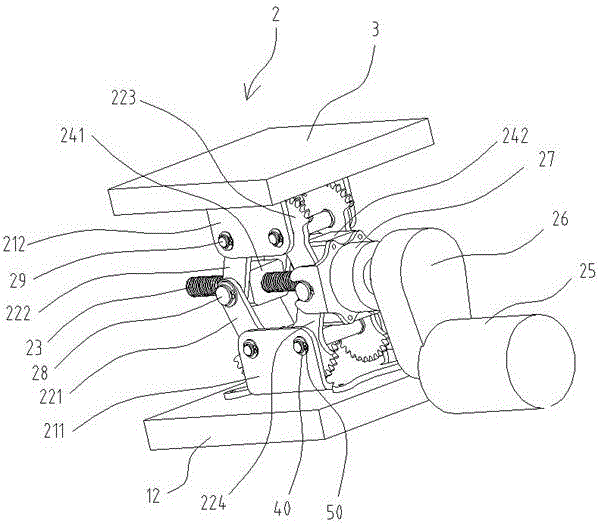

Squeezing juicer with selectively-synchronous cutting and juicing

The invention discloses a squeezing juicer with selectively-synchronous cutting and juicing. The squeezing juicer with selectively-synchronous cutting and juicing comprises a juicing part shell, a cutting part shell is fixedly connected with the upper portion of the juicing part shell, a driving part shell is fixedly connected with the lower portion of the juicing part shell, the juicing part shell is internally provided with a screw rod, a juicing net is arranged on the outer side of the screw rod, the driving part shell is internally provided with a motor, one end of the screw rod penetratesthe juicing net and is connected with the driving end of the motor, a rotating port is arranged on the bottom of the cutting part shell and internally provided with a first rotating ring, the other end of the screw rod is fixedly connected with the first rotating ring, the first rotating ring is internally provided with a rotation pipe, and clamping blocks are symmetrically arranged in the rotation pipe. By means of the squeezing juicer, there is no need to cut fruits and vegetables into cubes manually any more, and direct one-step completion can be chosen, so that convenience is brought to auser, and the efficiency of juicing the fruits and the vegetables is improved.

Owner:陈永

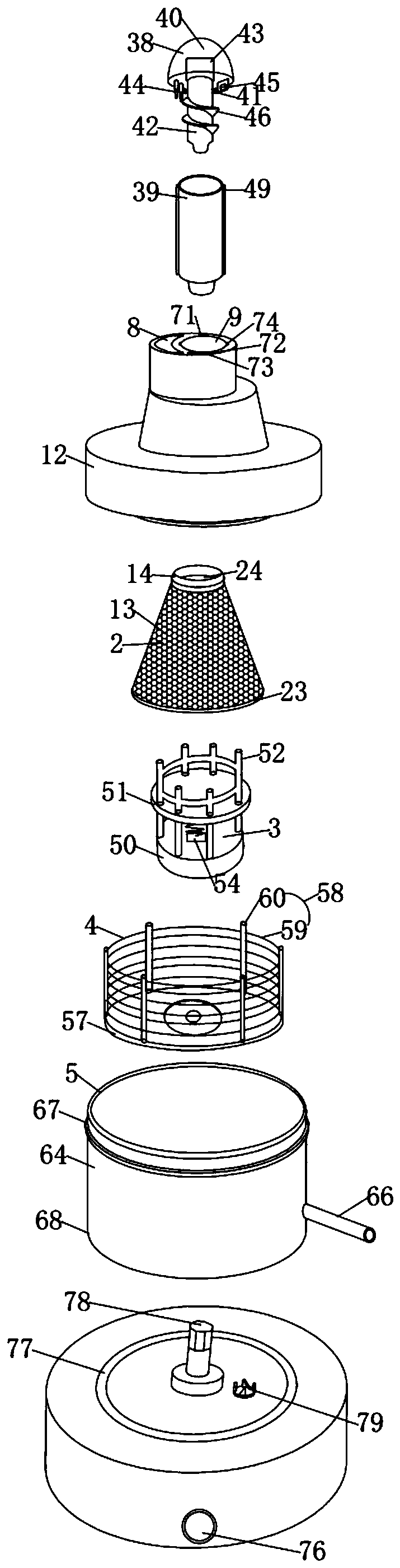

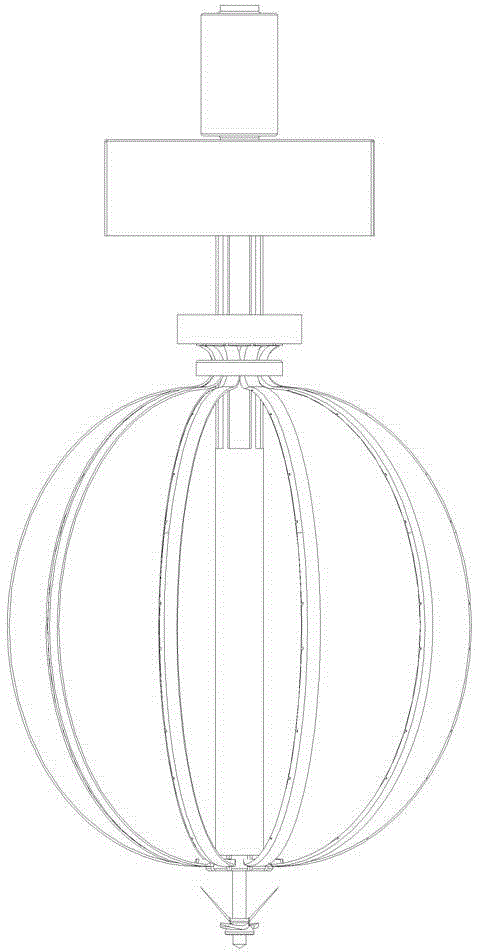

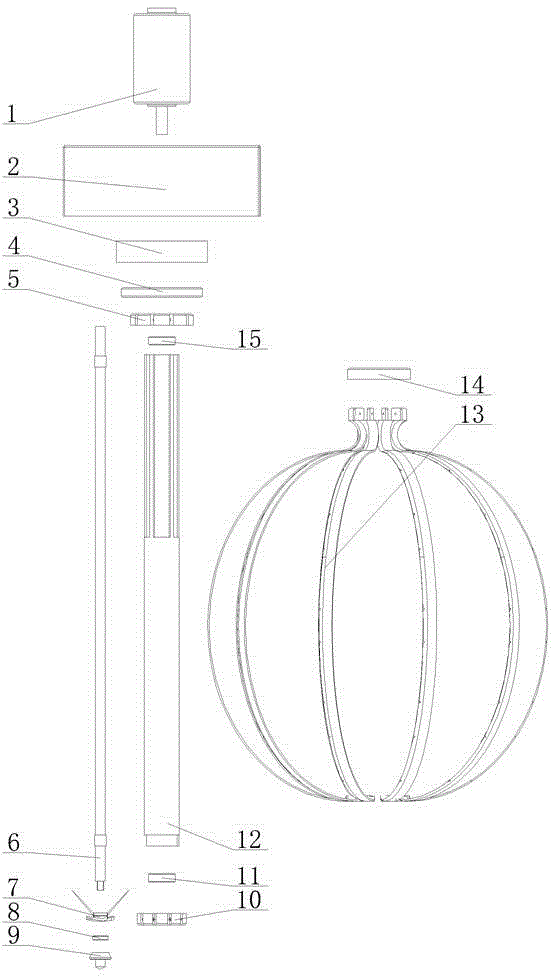

Coring-free complete core juicer

ActiveCN109730517AGuaranteed separation effectReduce contact timeStrainersEngineeringMechanical engineering

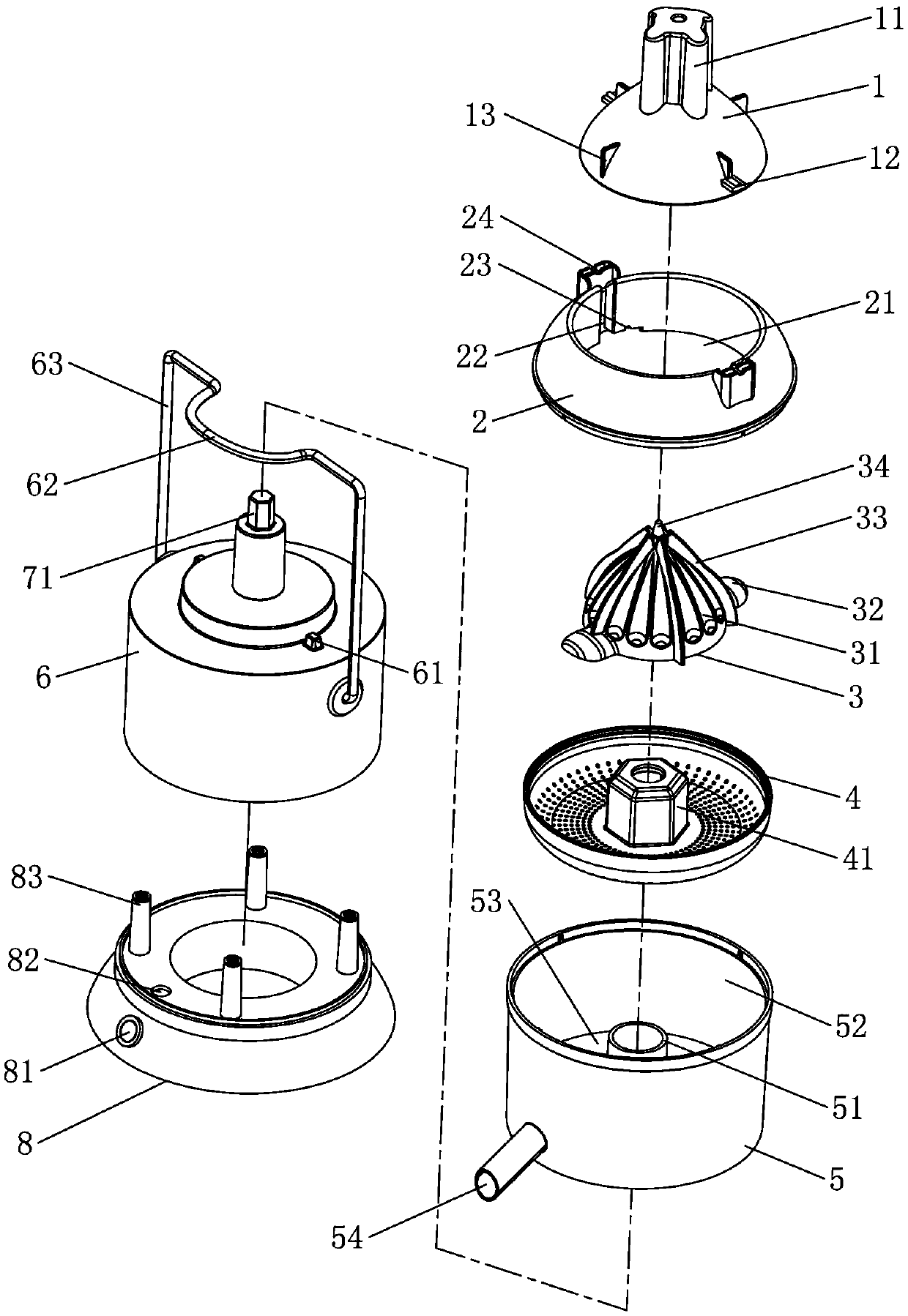

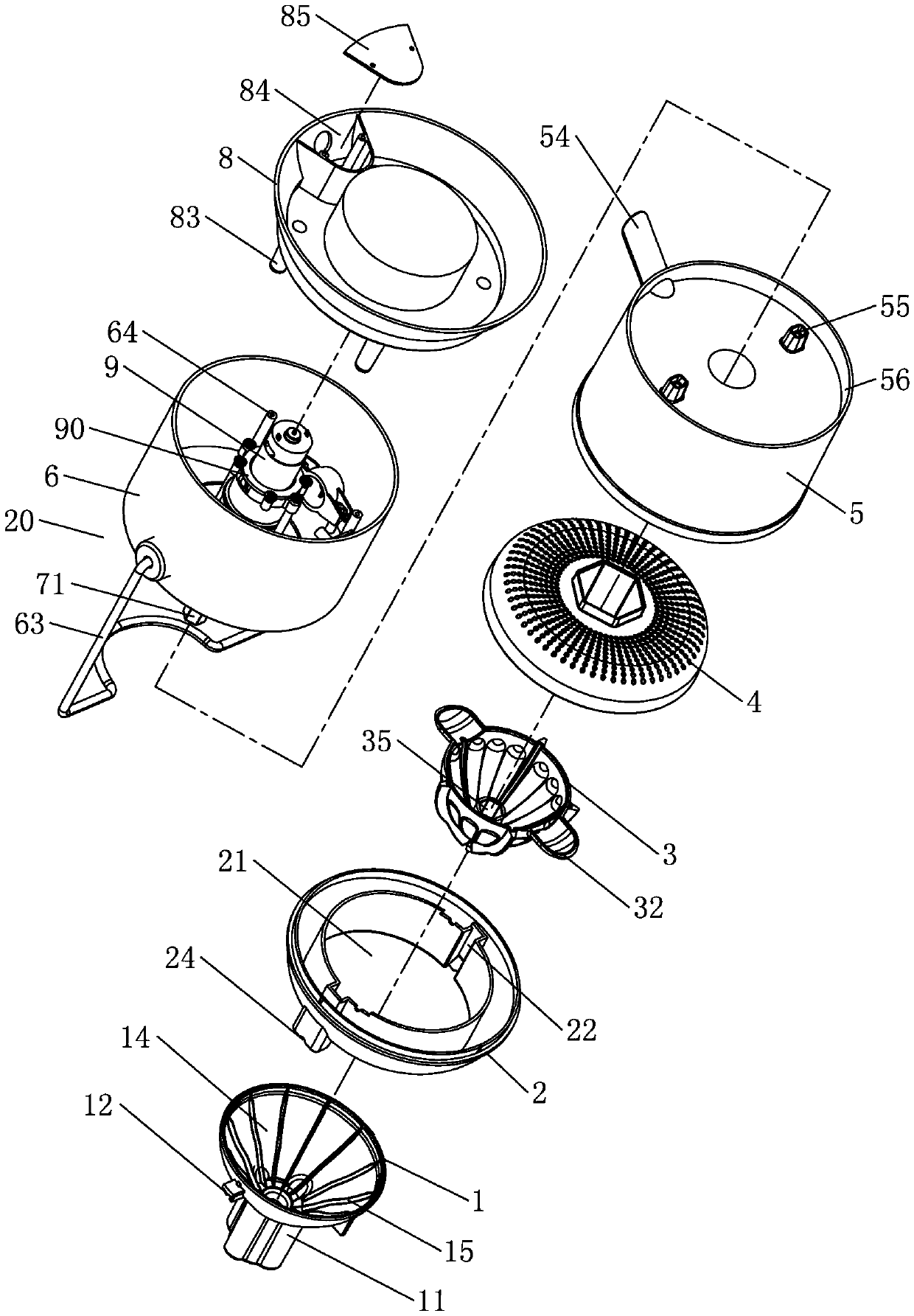

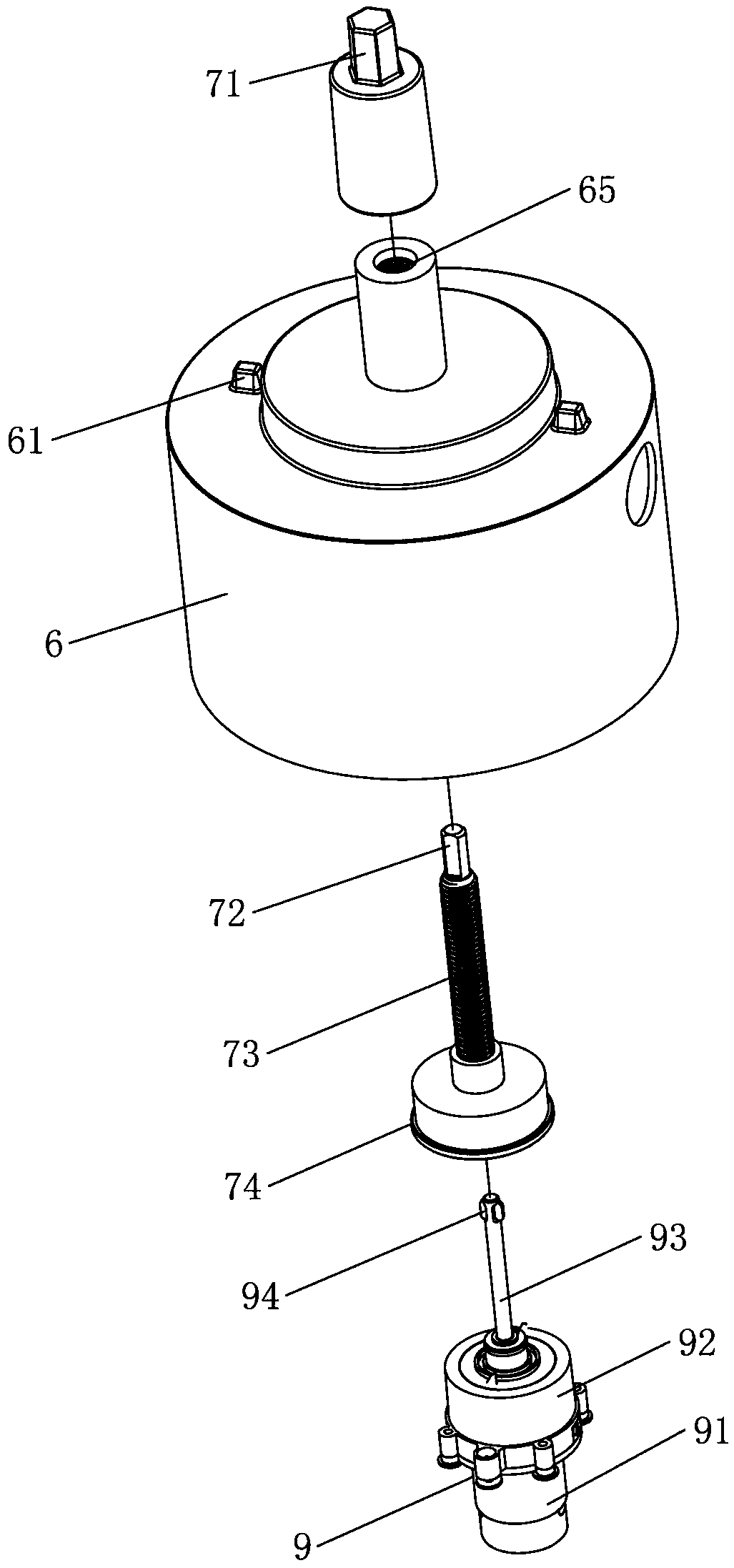

The invention discloses a coring-free complete core juicer which comprises a dual-channel top cover, a coring juicing head, a transmission limiting spring seat, a strainer basket, a juicer shell, a base and a full-automatic juicing pestle, wherein the dual-channel top cover is provided with a sponge knife food material channel, a spring knife food material channel, a guide hole, a sponge knife inner wall and a top cover outer wall; the coring juicing head is arranged inside the dual-channel top cover and comprises a sponge knife outer wall, a guide shaft and a spring knife juicing part; the full-automatic juicing pestle is arranged on the top of the dual-channel top cover; the juicer shell is arranged on the upper part of the base; the top of the juicer shell is clamped with the top coverouter wall; the strainer basket is arranged in the juicer shell and nested at the lower bottom of the coring juicing head; the transmission limiting spring seat is nested at the bottom of the strainerbasket; and the top of the transmission limiting spring seat is connected with the coring juicing head. The invention belongs to the field of food processing, the technical prejudice of the conventional juicer is overcome, and the technical effects of simultaneously performing operations of full-automatic complete separation between the pulp and the core, juicing and fruit and core separation canbe achieved.

Owner:XUZHOU YUNCHUANG PROPERTY SERVICE CO LTD

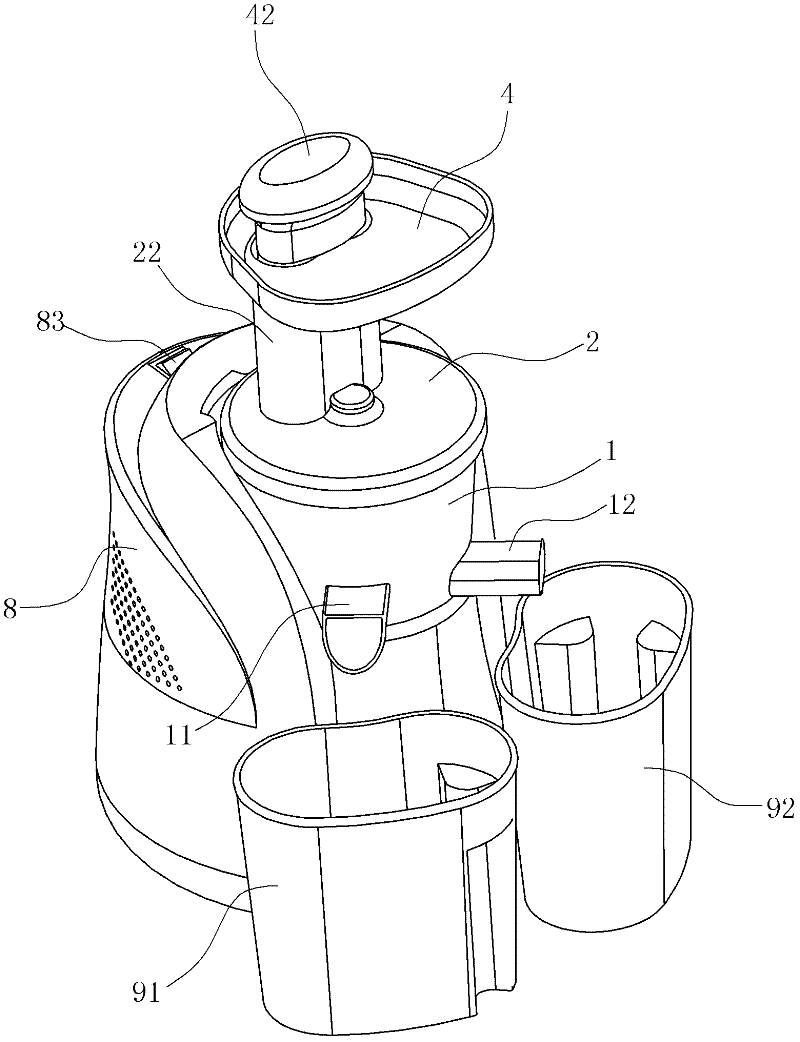

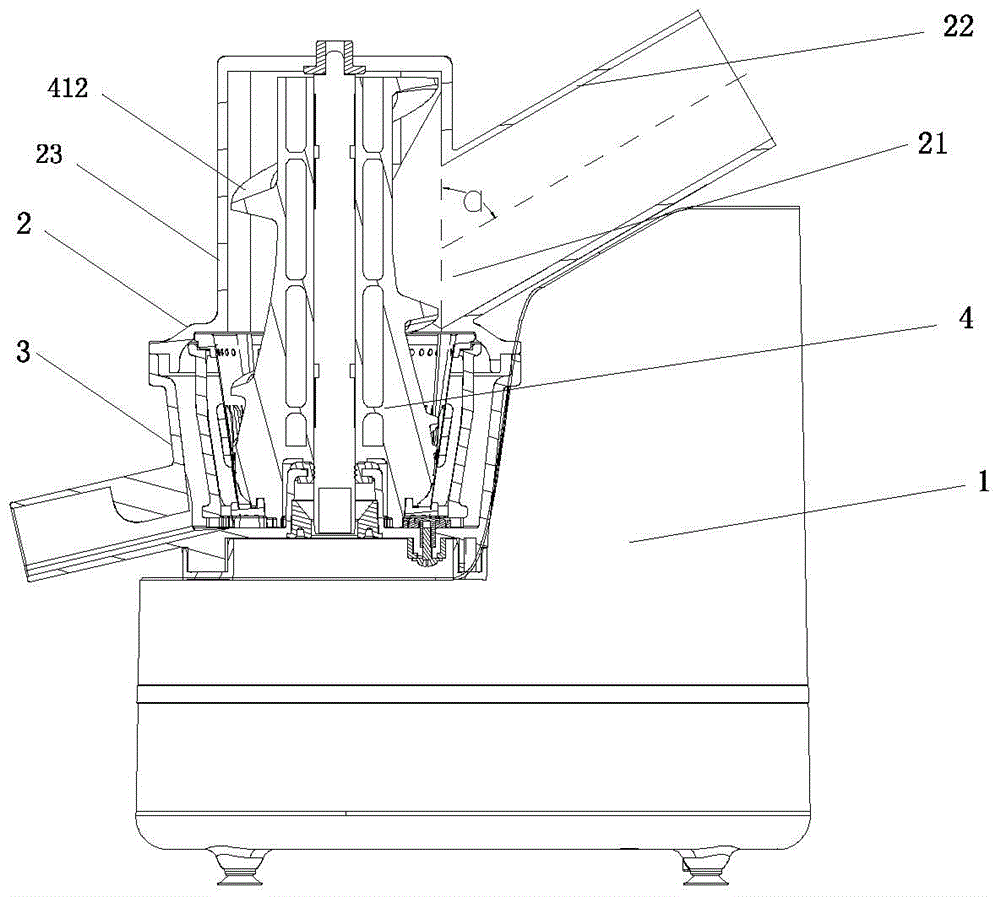

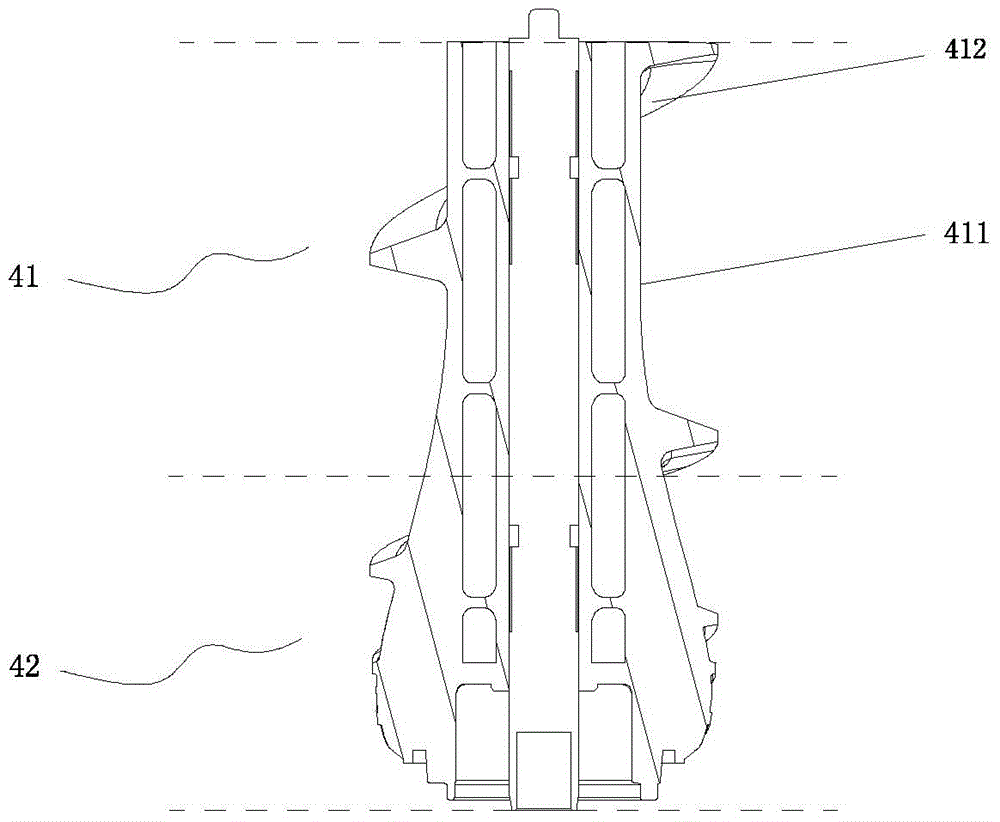

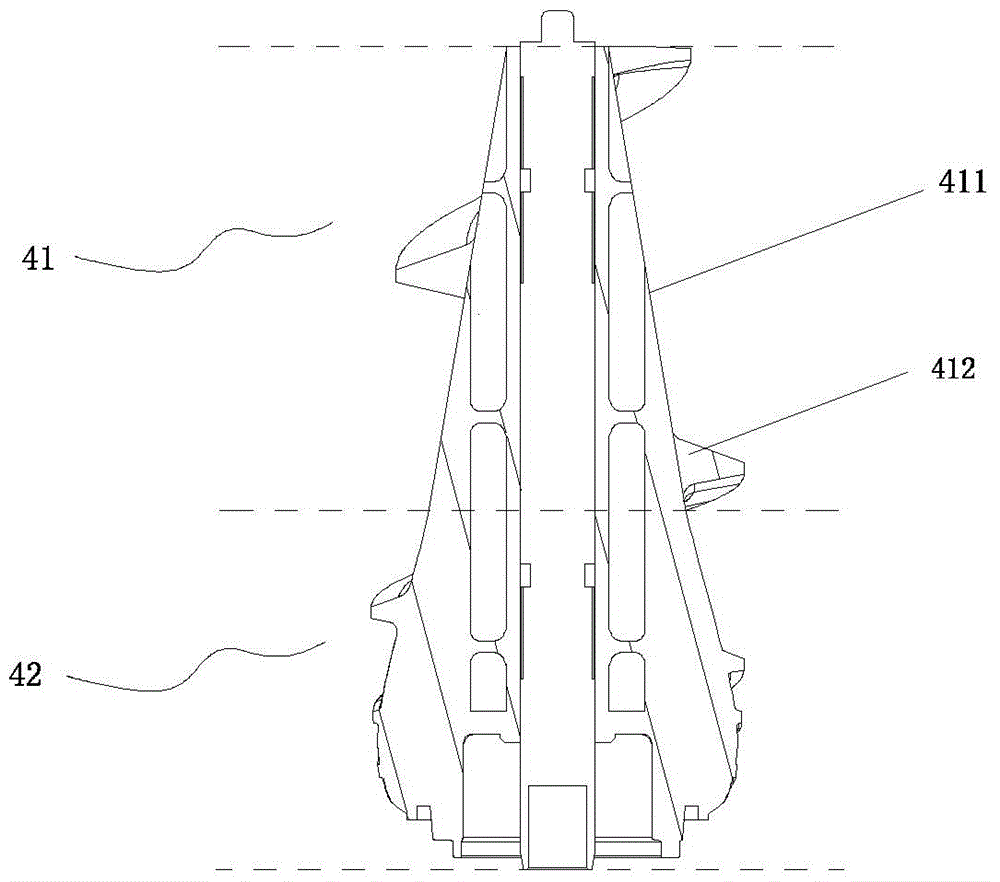

Vertical screw extruding juice extractor

The invention discloses a vertical screw extruding juice extractor, which comprises a machine base, a motor arranged in the machine base, an extrusion screw, a pressing chamber cooperating with the extrusion screw to extrude materials, and an upper cover installed above the pressing chamber , the pressing chamber is installed on the machine base, the extruding screw is installed in the pressing chamber, the upper cover is provided with an accommodating part protruding upwards and used to accommodate the upper part of the extruding screw, and the side wall of the accommodating part is set There is a feed port and a feed channel connected to the feed port, the angle between the geometric center of the two ports of the feed channel and the vertical plane is a, 30°≤a≤60°, so that the material depends on itself The gravity can quickly enter the accommodating part directly through the feeding channel, and is quickly brought into the extrusion grinding part of the extrusion screw and the pressing chamber formed by the downward guidance of the material propulsion part at the corresponding position of the feeding port. Squeeze in the juice gap, easy to realize fast automatic feeding.

Owner:JOYOUNG CO LTD

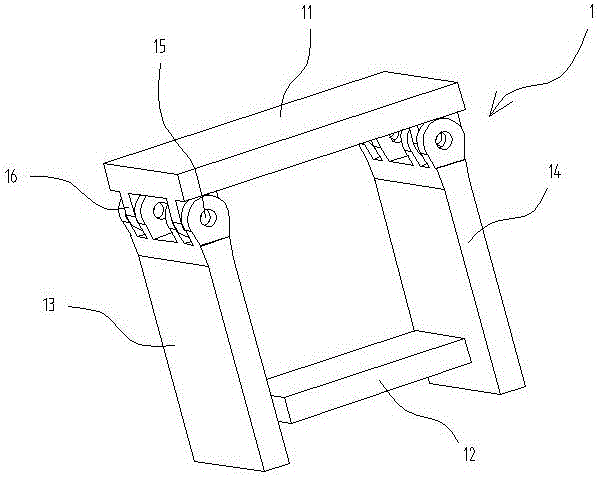

Pressing and filtering device for cold pressing juicer

The invention discloses a pressing and filtering device for a cold pressing juicer. The device comprises a rack, a fixed pressing plate, a movable pressing plate and a filtering bag, wherein the fixed pressing plate is arranged on the rack; the movable pressing plate is movably arranged on the rack, and can move forwards and backwards with respect to the fixed pressing plate; and the filter bag is connected between the fixed pressing plate and the movable pressing plate in a suspending manner. The device provided by the invention is simple in structure, can full squeeze fruits and vegetable, so that a juicing rate is improved, oxygenation efficiency is reduced, and meanwhile the problem that a hand of an operation staff is pressed during a cold pressing process is avoided.

Owner:厦门润饮生物科技有限公司

Hand juicer

The invention relates to a hand juicer, in particular to a hand juicer used for juicing vegetables and fruits. The hand juicer comprises a base, a rotating handle, crushing blades, a gear, a worm, an outer shell, an extruding mechanism, a juice outlet, a juice containing mug and an isolation plate, wherein the outer shell is installed on the base; the gear and the worm are both located inside the outer shell, and the gear is in transmission connection with the worm; the rotating handle is located outside the outer shell, penetrates through the outer shell and extends into the outer shell to be connected with the gear; one end of the worm is installed on the base, and the other end of the worm is connected with the crushing blades; the isolation plate is installed inside the outer shell and communicated with the extruding mechanism; the extruding mechanism is located inside the outer shell; the juice containing mug is installed on the base and located outside the outer shell; the juice outlet is formed in the outer shell and connected with the extruding mechanism. The hand juicer has the advantages of being simple in structure, convenient to operate and carry, easy to clean, long in service life, flexible in operation, high in universality and capable of juicing the vegetables and the fruits through manual crushing and extruding.

Owner:CHONGQING CITY DAZU DISTRICT YUNSEN AUTO PARTS

Automatic aseptic cold loading production technology

The invention discloses an automatic aseptic cold loading production technology. The technology comprises fresh fruit selection, cleaning and disinfection, filter strip-type aseptic beating, loading and storage, raw and accessory material disinfection, aseptic blending, homogenization, lamp detection, packaging and finished product examination. The automatic aseptic cold loading production technology is free of hot treatment, reduces a fruit paste nutrient loss, realizes a good fruit juice local flavor, saves energy and has good juicing effects by use of a filter strip-type juicer.

Owner:GUANGDONG SOLOMON GRP

Sugarcane juicing device

ActiveCN111743168ARealize automatic movementNo manual push requiredJuice extractionFood treatmentBiotechnologyMechanical engineering

The invention relates to a juicing device, in particular to a sugarcane juicing device. According to the sugarcane juicing device, sugarcanes do not need to be washed clean manually, the sugarcanes donot need to be pushed manually, and multiple sugarcanes can be pressed at the same time. According to the technical scheme, the sugarcane juicing device comprises a base, a special-shaped base installed in the middle of the base, flow channel grooves evenly formed in one side of the special-shaped base, and a collecting frame for collecting sugarcane juice placed on the side, close to one side ofthe flow channel grooves, of the base; and a squeezing mechanism arranged between the front side and the rear side of the special-shaped seat. According to the sugarcane juicing device, the sugarcanecan be squeezed, sugarcane juice can be squeezed out and sugarcane juicing work can be completed through the squeezing mechanism, automatic movement of the sugarcane can be achieved through the feeding mechanism, the sugarcane does not need to be pushed manually, manual operation is reduced, meanwhile, due to the design of a feeding barrel and a roller, three sugarcanes can be juiced at the sametime, and the juicing efficiency is improved.

Owner:临沂市玉兴废旧物资回收有限公司

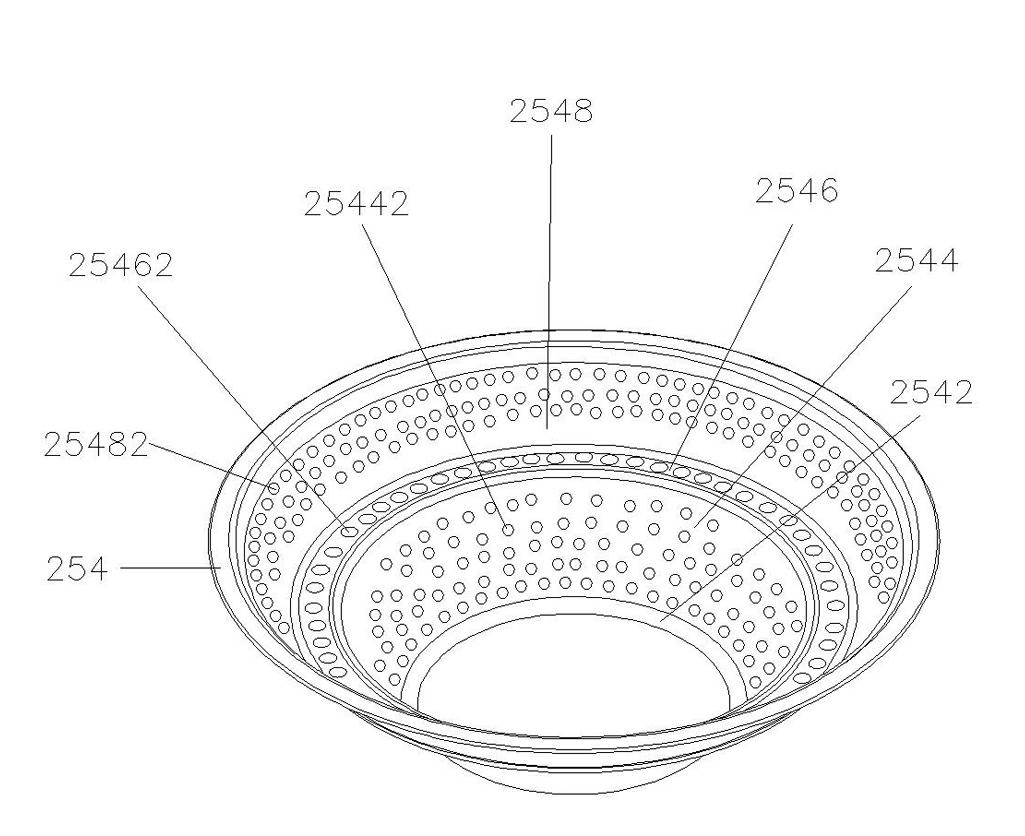

Juicer and filter screen applied by same

The invention discloses a juicer, comprising a cutter assembly. The cutter assembly comprises a cutter turntable, a filter screen and a cutter head; the filter screen comprises a bottom plate, a first inclined side plate protruding upwards from the outer edge of the bottom plate, a filter plate extending outwards from the top end of the first side plate, and a second inclined side plate protruding upwards from the outer edge of the filter plate, wherein the middle of the bottom plate is provided with an opening, the first side plate is provided with a plurality of first meshes, the filter plate is provided with a plurality of second meshes, and the second side plate is provided with a plurality of third meshes. Due to the adoption of the filter screen disclosed by the invention, , the weight of the filter screen can be reduced, the filter screen can be stabilized, and vibrations and noises can be decreased. The juicer disclosed by the invention has improved juicing efficiency and high juice output rate.

Owner:YA HORNG DONG GUAN ELECTRONICS +1

Lycium rethenicum Murr fruit-vinegar carbonated beverage and preparation method thereof

InactiveCN105211990AHarmonious colorLow viscosityVinegar preparationFood scienceIsomaltooligosaccharideSodium benzoate

The invention provides a Lycium rethenicum Murr fruit-vinegar carbonated beverage and a preparation method thereof. Raw materials comprise Lycium rethenicum Murr juice concentrate, Lycium rethenicum Murr fruit vinegar, white granulated sugar, honey, potassium sorbate, sodium benzoate, isomaltooligosaccharide and beta-cyclodextrin; the Lycium rethenicum Murr fruit-vinegar carbonated beverage is natural and harmonious in color, moderately sour and sweet in mouthfeel, fresh in mouthfeel and fragrant and sweet in fruity, has the functions of nourishing and strengthening the body, and is an optimal drink suitable for people of all ages and both sexes.

Owner:XINING ZHIYE BIOTECH CONSULTING SERVICE

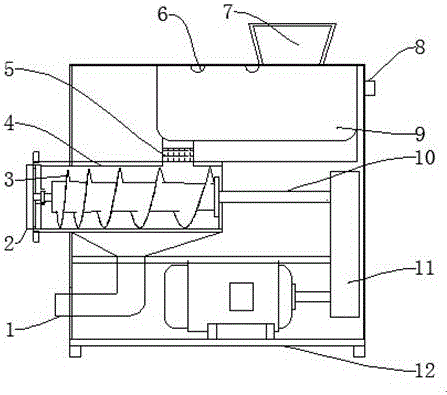

Improved device of spiral juicer

InactiveCN103462177AImprove Juicing EfficiencyRealize automatic separationJuice extractionEngineeringMotor shaft

The invention discloses an improved device of a spiral juicer. The improved device comprises a cylinder, a feeding hopper, a discharge hopper, a screw rod and a liquid collection disc, wherein the feeding hopper is positioned on the upper part of one end of the cylinder; the discharge hopper is positioned on the lower part of the other end of the cylinder; the screw rod is positioned in the cylinder, is connected with a motor shaft of the spiral juicer and is driven to rotate by the motor; the liquid collection disc is positioned at the bottom of the cylinder. The invention discloses the improved device of the spiral juicer. The improved device has the advantages of rational design, simple structure, safety and reliability, the juicing efficiency of the spiral juicer is greatly improved, automatic separation of juice and residues is realized better, the defect of browning of the juice is overcome, and the clarification of the juice is guaranteed.

Owner:KUNSHAN RONGAO WEIJIE TRADE

Squeezing device provided with filtering mechanism

The invention discloses a squeezing device provided with a filtering mechanism. The squeezing device comprises a main squeezer body, a base, a putting assembly, a filtering assembly, a hydraulic rod,an extruding disc, a crushing assembly, a telescopic hole, a first sealing ring and a discharging pipe, the filtering assembly is fixed to the inner wall of one side of the main squeezer body, the crushing assembly is fixed to the inner wall of the bottom of a filtering bucket, and the putting assembly is fixed to the outer wall of the top of the filtering bucket. The first sealing ring fixedly sleeves the outer wall of one side of the extruding disc, and the opposite sides of the first sealing ring fit the inner wall of one side of the filtering bucket. A squeezing box adopts a motor for rotating the filtering bucket, during squeezing, firstly, crushing treatment is conducted, so that raw materials get smaller, and squeezing is facilitated; then centrifugal force is provided to separate the raw materials from juice, and the efficiency of squeezing juice is higher; moreover, when raw material residues are cleaned away, since the filtering bucket can be taken out to pour the raw material residues out, and then next round of squeezing is conducted, the production efficiency is improved.

Owner:杨毅

Continuous-material-supplementation type juicer

The invention relates to a continuous-material-supplementation type juicer. The juicer comprises a feeding hopper, a feeding port is formed in the feeding hopper, a rotating shaft is connected inside the feeding hopper in a rotating mode, a rotating cutter is connected to the rotating shaft, a first bevel gear is fixedly connected to one side of the feeding hopper and meshed with a first dual gear, a second bevel gear is connected to one side of the rotating shaft and meshed with a second dual gear, the first dual gear is meshed with the second dual gear, the first dual gear is connected with a motor, sieving holes are further formed in the feeding hopper, a first supporting ring and second supporting rings are connected to the feeding hopper in a rotating mode, the feeding port is wrapped by the first supporting ring, an opening is formed in the first supporting ring, the sieving holes are wrapped by the second supporting rings, and juice outlets are formed in the second supporting rings. Compared with the prior art, through arranging the first supporting ring and the second supporting rings, fruit raw materials can be continuously added and fruit juice can be taken out without turning off the motor, the number of operation steps is decreased, and juicing efficiency is improved.

Owner:CHONGQING NONGZHENG AGRI DEV CO LTD

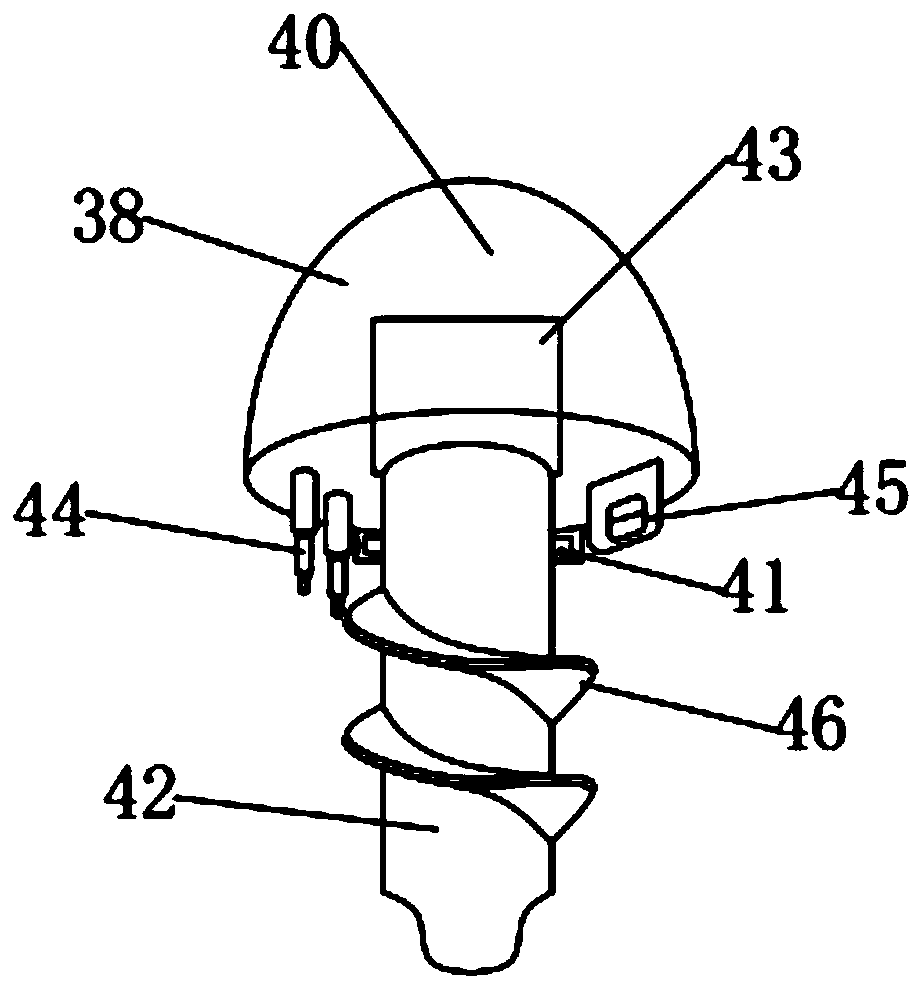

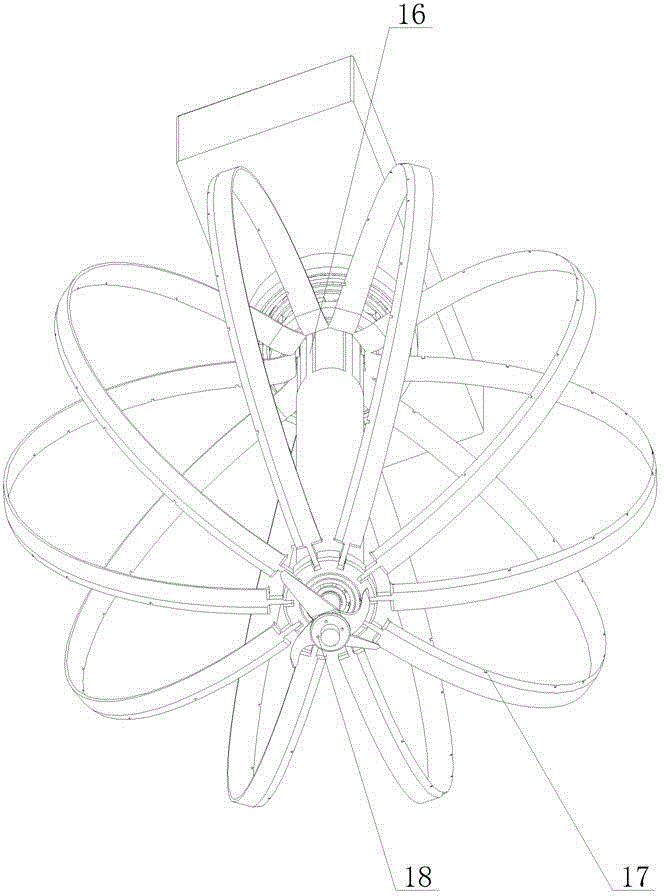

Cutting-free direct squeezing type melon juice squeezing machine

The invention provides a cutting-free direct squeezing type melon juice squeezing machine, which comprises a juice squeezing cutter, a high-speed motor and a regulator. The juice squeezing cutter consists of a flexible cutting blade set and a rigid juice squeezing cutter set, wherein a main shaft is a composite shaft, which is formed by enabling a hollow shaft to sleeve a solid shaft by virtue of a bearing, the solid shaft is connected with the rigid juice squeezing cutter set, and the hollow shaft is connected with the flexible cutting blade set; an annular press ring and a limit ring are arranged above a flexible cutter, and the high-speed motor respectively transmits power to the solid shaft and the hollow shaft by virtue of a speed reducer. The cutting-free direct squeezing type melon juice squeezing machine can finish perforating, cutting and juice squeezing operations on the premise of keeping a melon shell intact, so that the juice squeezing process is simplified, the structure is simple, the size is small, the juice squeezing efficiency is high, and the juice squeezing fun is improved.

Owner:NORTHWEST A & F UNIV

Bayberry wine preparation method

InactiveCN106085717AIncrease Juicing RateImprove Juicing EfficiencyAlcoholic beverage preparationMicroorganism based processesContinuous fermentationYeast

The invention discloses a bayberry wine preparation method. The preparation method comprises the following steps: S1, raw material treatment: selecting fresh and ripe bayberries and cleaning up and draining the bayberries; S2, crushing and juicing: mixing the drained bayberries with citric acid and sodium citrate, then putting the mixture in a crusher and a squeezer to be crushed and juiced in sequence and removing bayberry kernels, wherein the additive amount of the citric acid is 0.07-0.09% of the weight of the bayberries; the additive amount of sodium citrate is 3-5 times that of the citric acid; S3, primary fermentation: conveying bayberry juice into a fermentation tank and adding fruit wine yeast and white sugar to carry out fermentation for 6-8 days, wherein the temperature in the fermentation tank is 23-25 DEG C; 0.2-0.3kg of fruit wine yeast and 4-5kg of white sugar are added to every 50kg of bayberry juice; S4, secondary fermentation: adding white sugar again and carrying out continuous fermentation for 19-21 days, wherein 2.5-3.5kg of white sugar is added to every 50kg of bayberry juice; S5, distillation and extraction of brewing alcohol; S6, blending, sterilization and filling. In the bayberry wine preparation method, the juicing rate of the bayberries is high.

Owner:温州康隆杨梅专业合作社

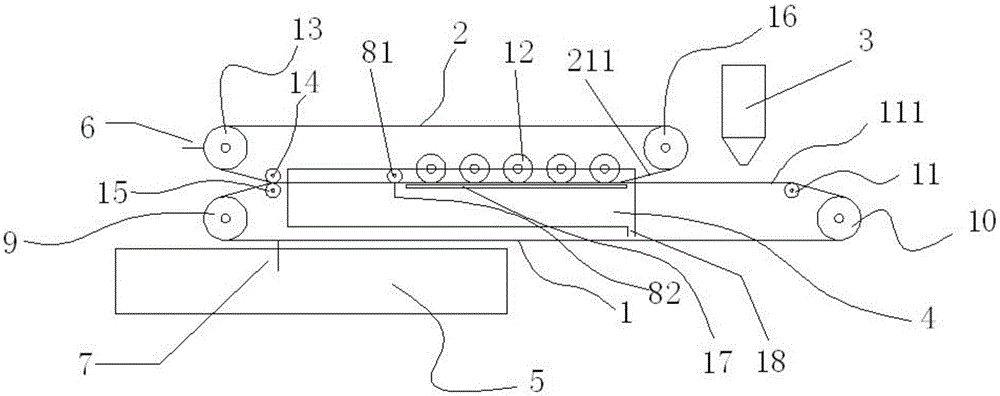

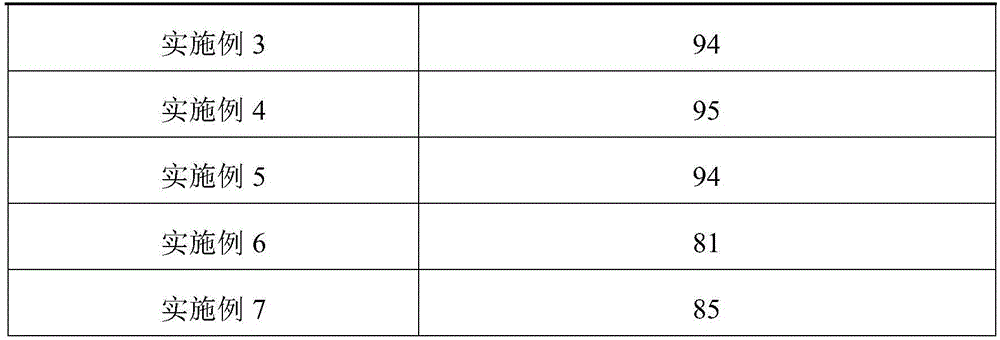

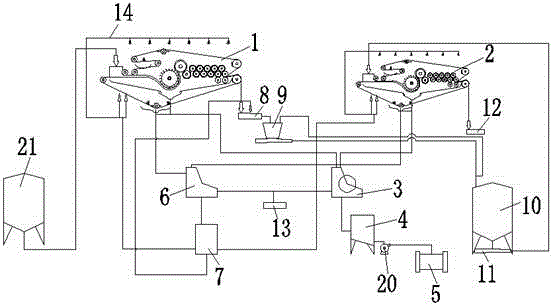

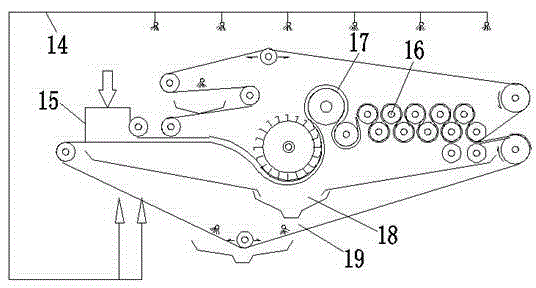

Waxberry juice extracting system in waxberry juice production

The invention relates to a waxberry juice extracting system in waxberry juice production. The waxberry juice extracting system comprises a band type juice extractor. A juice outlet of the band type juice extractor is connected with a spin vibration sieve, the spin vibration sieve is connected with a fruit juice buffer tank, the fruit juice buffer tank is connected with a duplex filter, a water outlet of the band type juice extractor is connected with a hydraulic sieve, the hydraulic sieve is connected with a cleaning water collecting tank, a residue outlet of a band type juice extractor I is connected with a deslagging device I, the deslagging device I is connected with a screw pump device, the screw pump device is connected with a secondary squeezing pulp tank, the secondary squeezing pulp tank is connected with an inlet of a band type juice extractor II through a screw pump, a residue outlet of a deslagging device II, and the band type juice extractor is provided with a CIP system. The waxberry juice extracting system is high in juicing pulp utilization rate and high in fruit juice quality, performs cleaning automatically, and runs stably.

Owner:YIXING HENGSHENG AGRI DEV CO LTD

Juice extractor

InactiveCN106377151AReduce noiseAvoid cleaningStrainersAgricultural engineeringFruits and vegetables

The invention relates to the fruit and vegetable processing machinery field, and specifically discloses a juice extractor comprising a machine casing, a machine cover, and a package bag used for containing fruit and vegetable and filtered fruit and vegetable juice after juicing; the machine cover is connected with the machine casing; an extrusion mechanism used for extruding the package bag to the machine cover is arranged in the machine casing; the package bag is arranged between the extrusion mechanism and the machine cover; the juice extractor is simple in structure, small in working noises, safe, reliable, and cleaning is not needed.

Owner:卜鹏飞

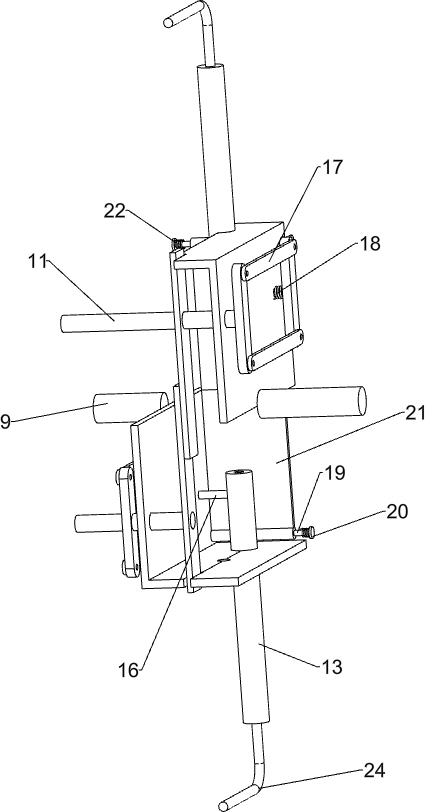

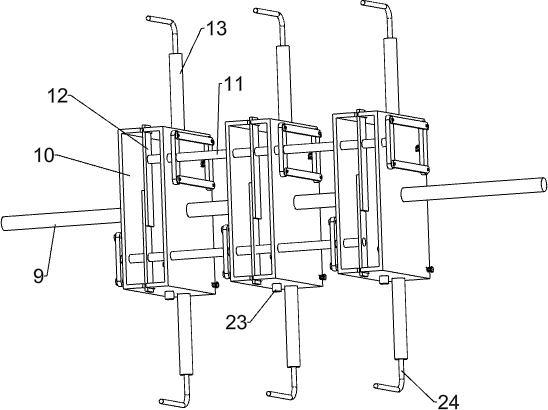

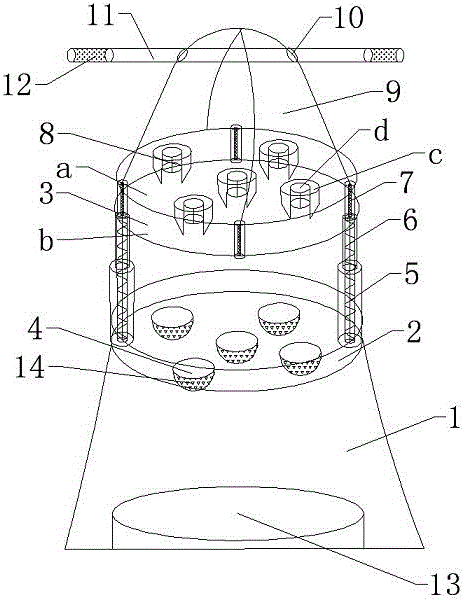

Manual waxberry juicing tool

The invention discloses a manual waxberry juicing tool. An outer frame of the manual waxberry juicing tool is a cylindrical table made of hard plastic; the manual waxberry juicing tool mainly consists of five parts of a base, a base top, a double-layer push plate, a thrust cap and flexible tubes; the base and the base top are connected as a whole; the thrust cap and the double-layer push plate are connected as a whole; the base top serves as the top of the base; the double-layer push plate serves as the bottom of the thrust cap; the flexible tubes are distributed between the base top and the double-layer push plate; each flexible tube comprises three flexible tube bodies of a main flexible tube body, an assistant flexible tube body and a branch flexible tube body. Through the exquisite design of the three-section flexible tubes, the double-layer push plate, waxberry filtration bowls and juicing heads, the parts mutually cooperate and are linked with one another; waxberry pulp is separated through extrusion, meanwhile waxberry pulp columns are punctured to be extruded for juicing, waxberry can be transformed into waxberry juice only through one process step in the whole juicing process, and the operation is simple; besides five waxberry filtration bowls are arranged to be coordinated with five juicing heads to conduct juicing at the same time, and the juicing efficiency is high.

Owner:来安县永阳知识产权运营有限公司

Juice squeezer

The invention provides a juice squeezer, and belongs to the technical field of juice squeezing. The juice squeezer comprises a frame body, an actuator and a capsule bag, wherein the actuator also comprises a fixed piece, a movable piece, a driving rod, an acting block and a driver; according to the juice squeezer, a mounting surface is arranged in the frame body, and a surface which is opposite to the mounting surface is arranged as a fixed surface; the actuator is arranged on the mounting surface; a propelling plate is arranged on one side, far away from the mounting surface, of the actuator; the actuator drives the propelling plate to perform reciprocating rectilinear movement along the mounting surface to the fixed surface, so as to extrude a food raw material which is stored between the propelling plate and the fixed surface; therefore, the work of squeezing juice is finished, and the noise is low; the juice squeezer is driven by a motor, and is provided with a speed changing device, so that the thrust of the actuator is greater, the squeezing is more thorough, and the efficiency is higher; by adopting the coordinated movement of a screw and the acting block, the reciprocating property is high, and the working time is effectively prolonged; the capsule bag is arranged between the actuator and the fixed surface, so that squeezed juice cannot be sputtered on components, and the purpose of avoiding cleaning is achieved.

Owner:SHANGHAI AIWEI ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com