Patents

Literature

154results about How to "No manual push required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

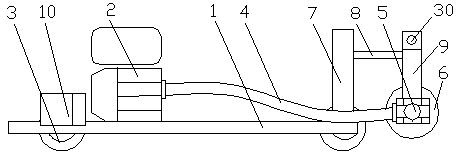

Efficient mixing machine convenient to move rapidly

InactiveCN105536614ASafe and reliable workReduce noiseRotary stirring mixersTransportation and packagingEngineeringLow noise

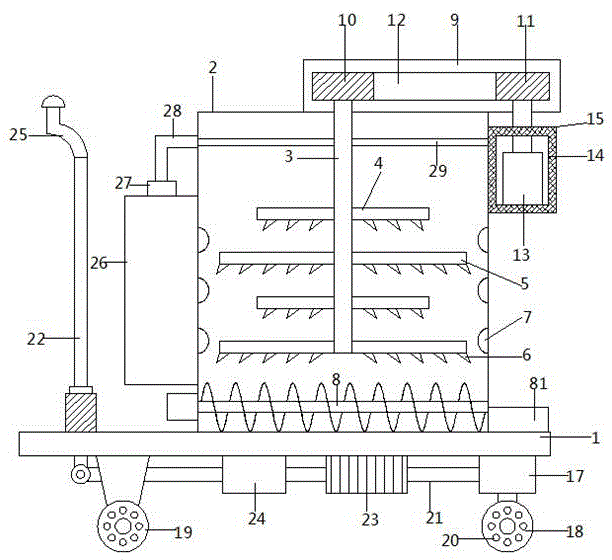

The invention discloses an efficient mixing machine convenient to move rapidly. The efficient mixing machine comprises a base, wherein a machine body is arranged in the center of the upper side of the base, a stirring rotating shaft is vertically arranged in the machine body, a connecting box casing is arranged on the upper right side of the machine body, a first belt pulley and a second belt pulley are arranged on the left and right inside the connecting box casing and connected through a drive belt, the first belt pulley is connected with the top end of the stirring rotating shaft, and a motor case is fixed on the outer wall of the right side of the machine body. The efficient mixing machine convenient to move rapidly adopts the belt pulleys for driving, is safe, reliable and stable in work, has low noise during work and can regulate the running speed; a drive device is arranged on the upper side of the machine body, sealing is not needed to be considered, the production and use costs are reduced, the stirring effect is good, the working efficiency is high, automatic cleaning and automatic discharging can be realized, time and labor are saved, and the working efficiency is further increased; besides, the efficient mixing machine can be moved rapidly and is high in convenience.

Owner:覃艺诗

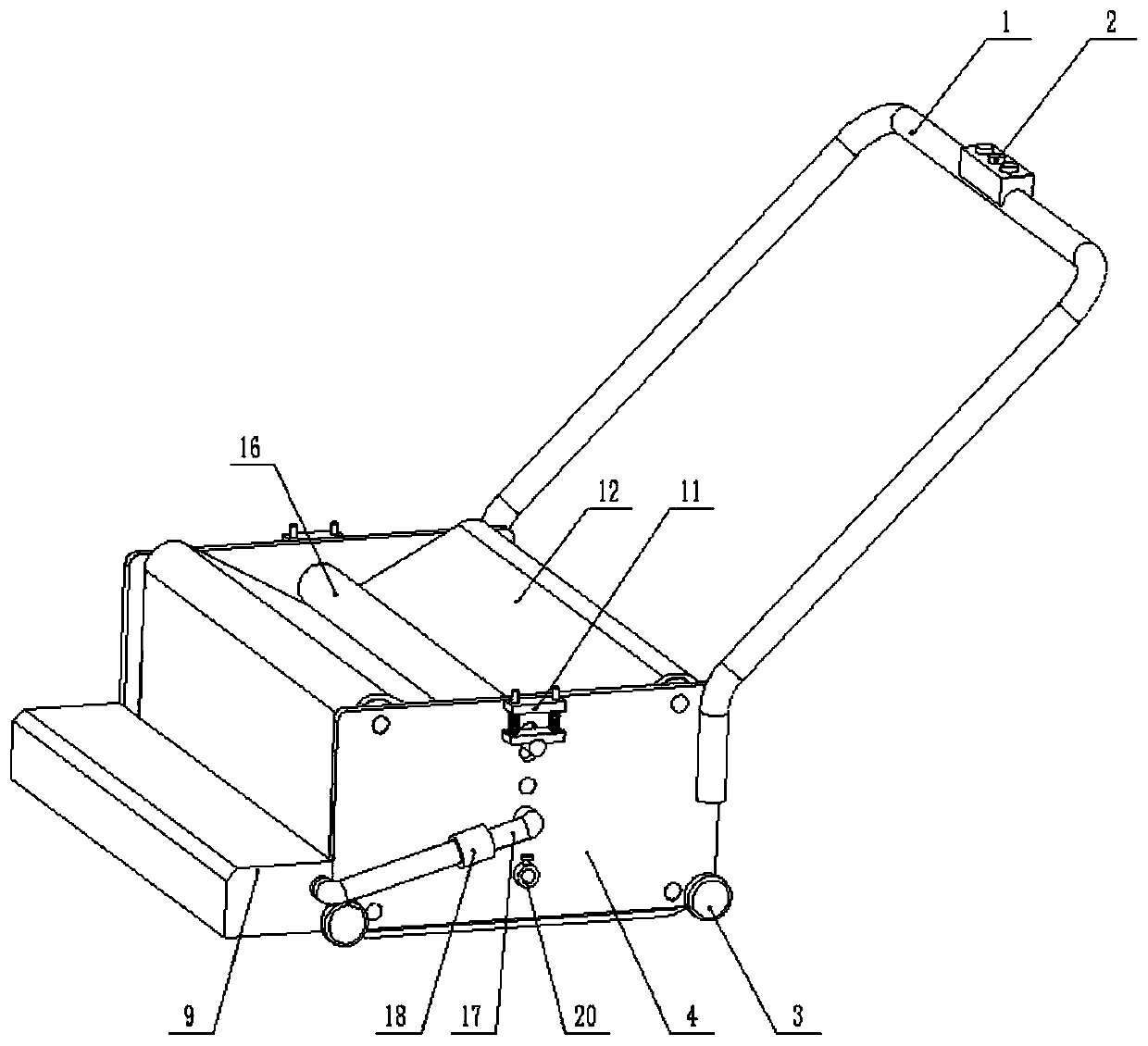

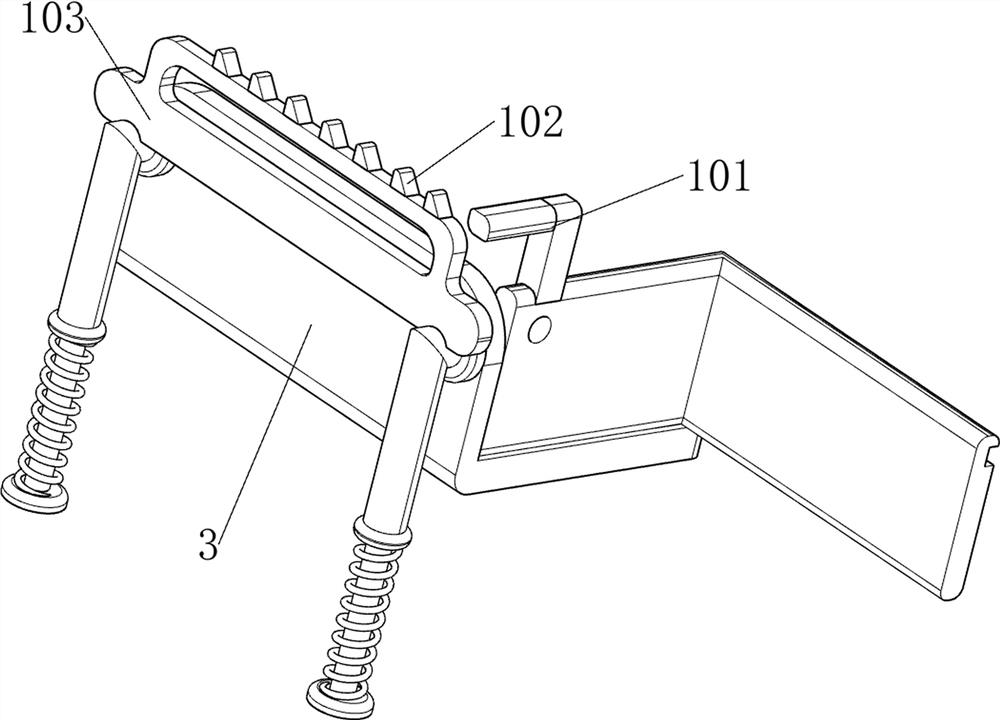

Hedgerow trimmer

ActiveCN103404378AReduce labor intensityAvoid fatigueHedge trimming apparatusVertical planeEngineering

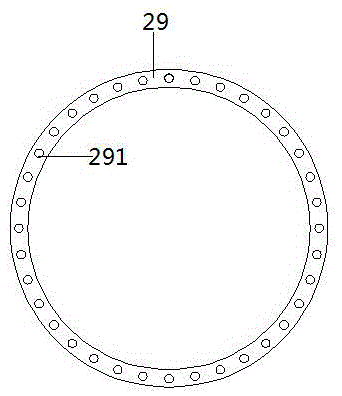

The invention discloses a hedgerow trimmer and belongs to the technical field of trimmers. The hedgerow trimmer comprises a machine body which is provided with a walking mechanism. A rotary column positioned in a vertical plane is rotatably arranged on the machine body, a regulation seat for regulating the height position is installed on the rotary column through fasteners, an oscillating rod is fixedly arranged on the regulation seat, the axial direction of the oscillating rod is perpendicular to the axial direction of the rotary column, and a top surface trimming cutter driven by a first power device and used for trimming the top surface of a hedgerow is fixedly arranged at one end of the oscillating rod. A fixed seat is arranged at the top of the machine body, a connection sleeve positioned in a vertical plane is arranged on the fixed seat, a connection rod is fixedly arranged in the connection sleeve, and a lateral surface trimming cutter driven by a second power device and used for trimming lateral surfaces of the hedgerow is arranged at the end portion of the connection rod. By means of the hedgerow trimmer, the trimmed hedgerow top surface is flat, attractive and uniform, work efficiency is improved, and labor intensity of workers is reduced.

Owner:山东绿美生态环境工程集团有限公司

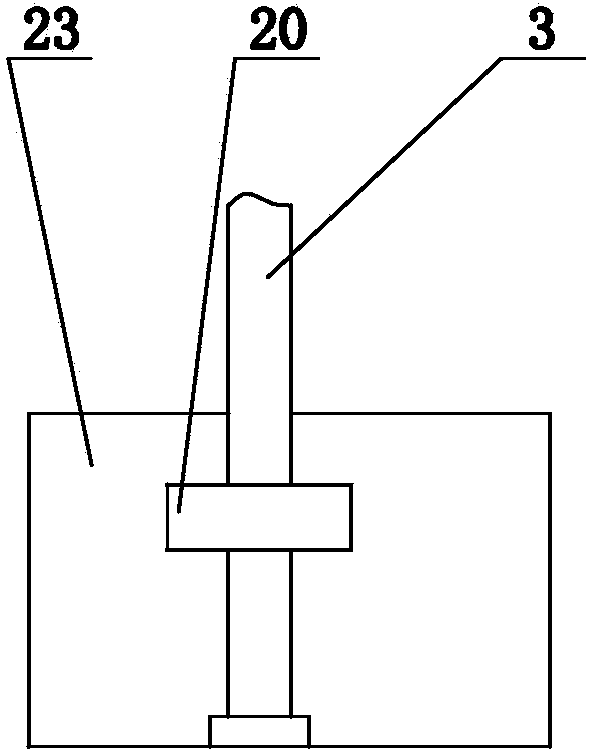

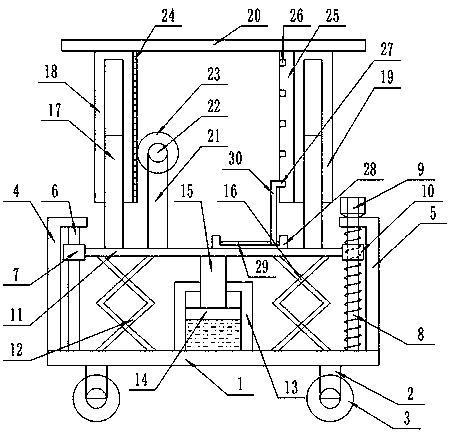

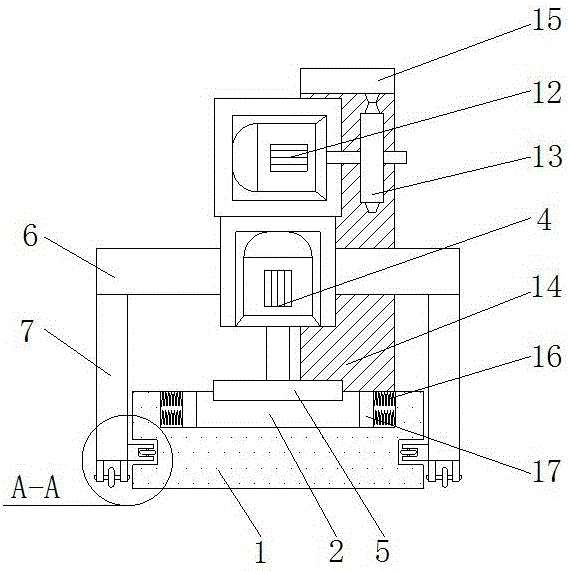

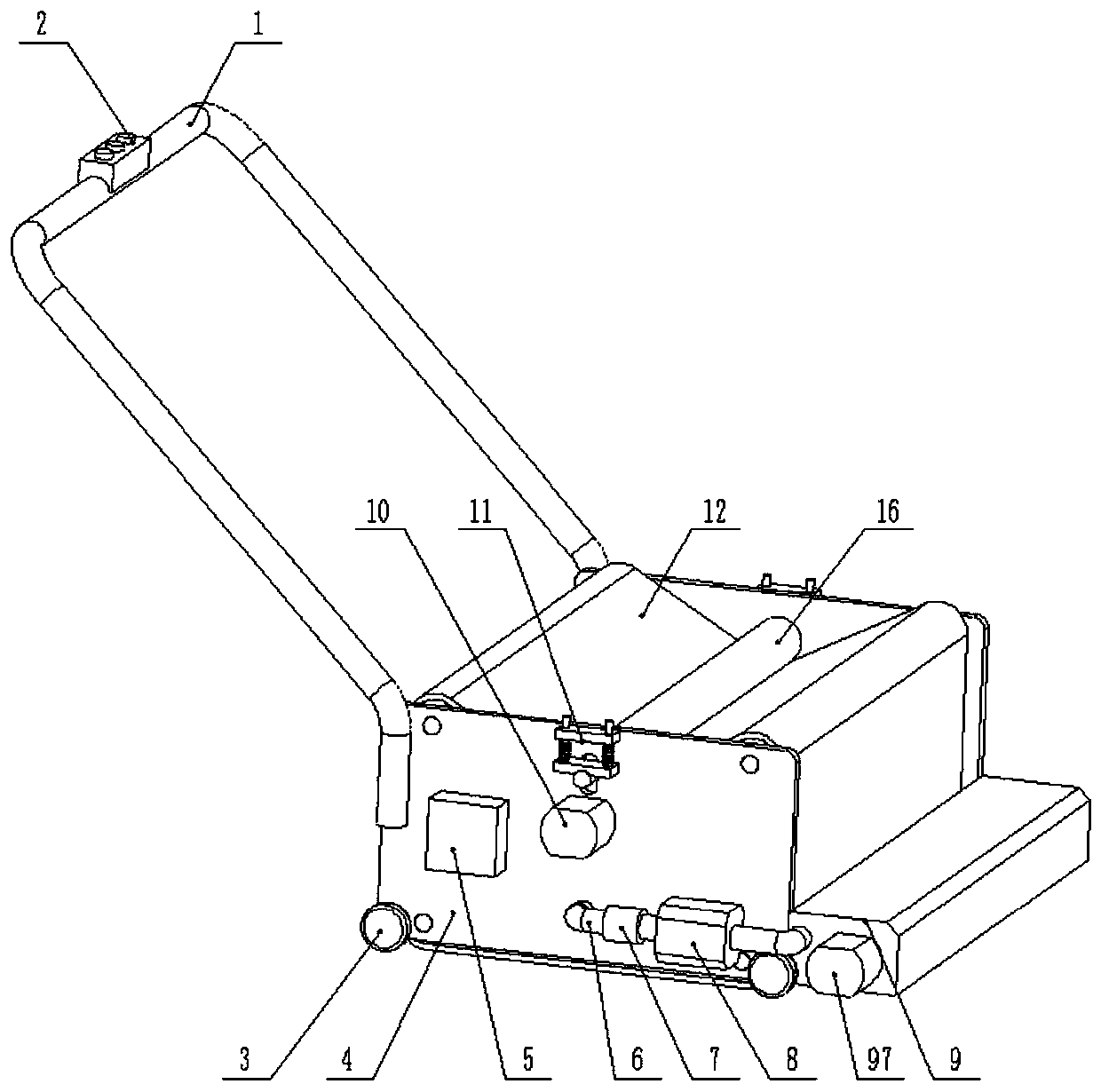

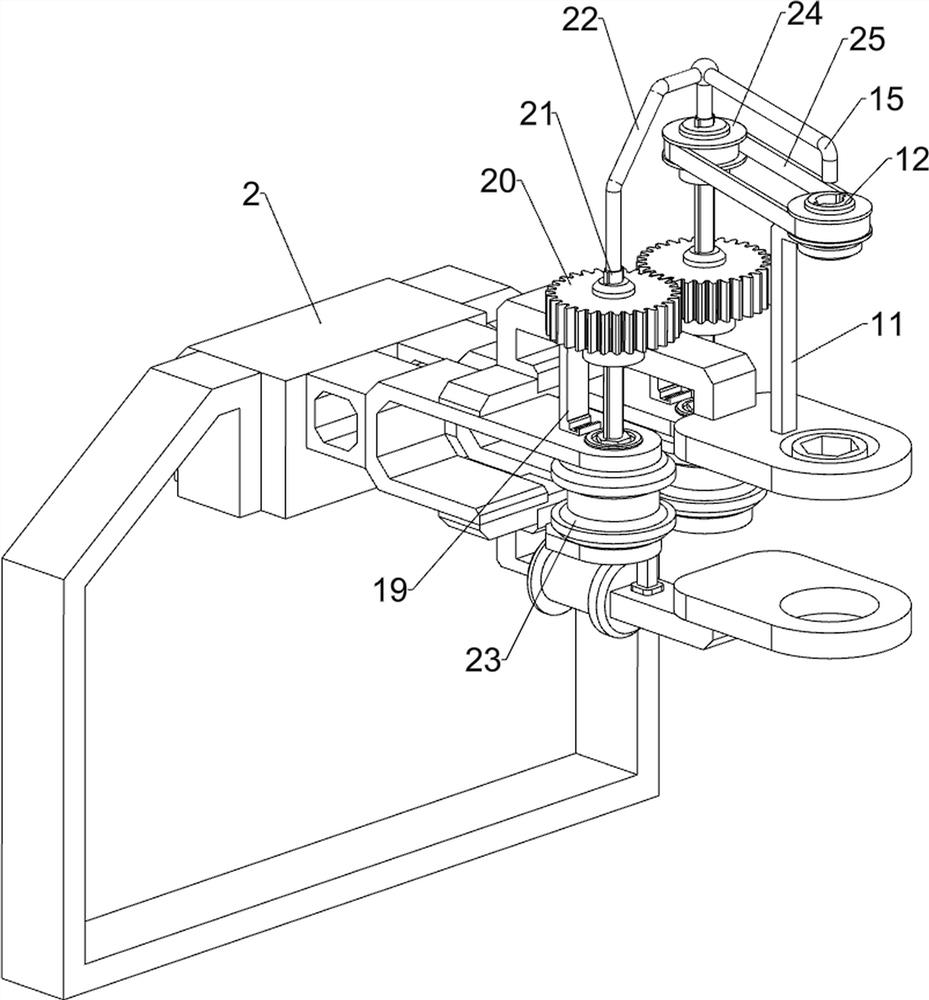

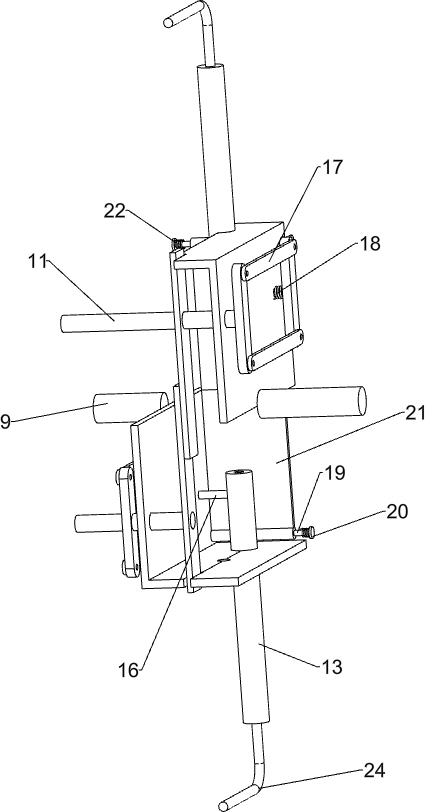

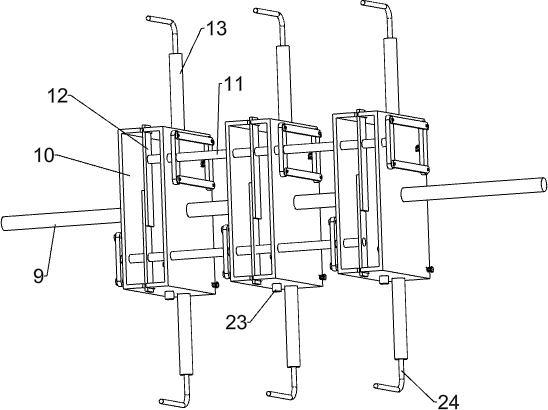

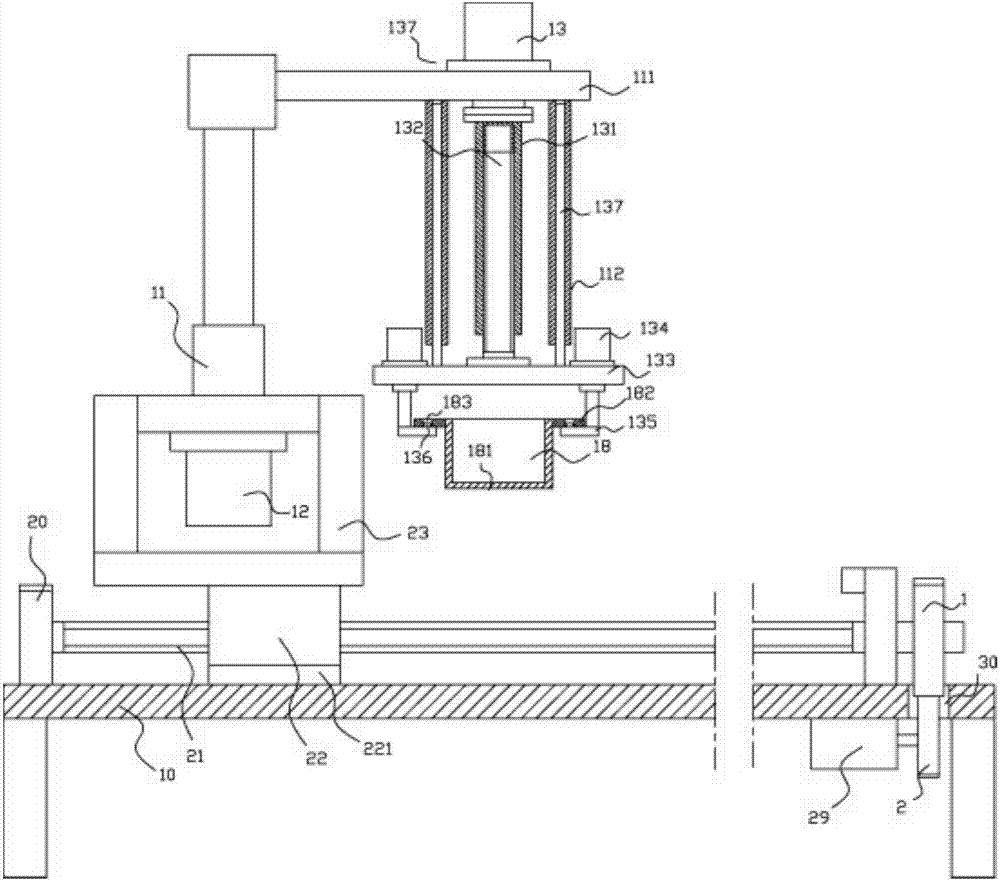

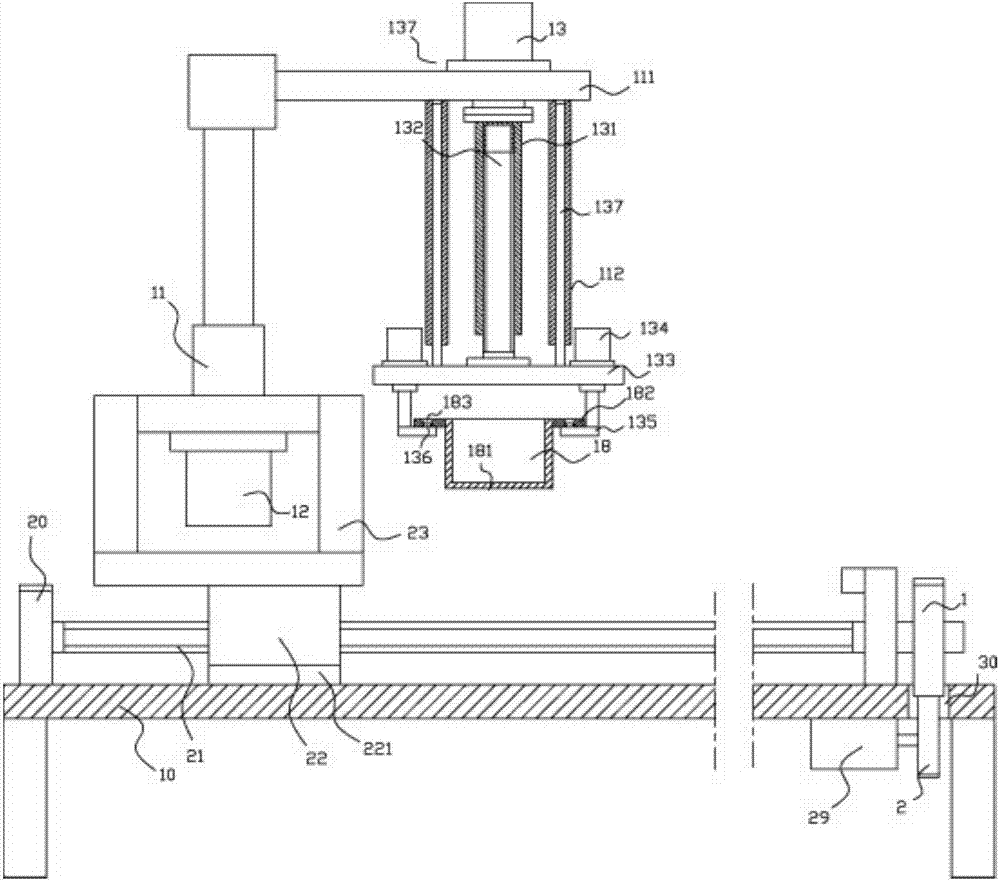

Lifting machine for automobile repair

InactiveCN109353960ASimple structureReduce manufacturing costVehicle fittings for liftingLifting framesHydraulic cylinderIndustrial engineering

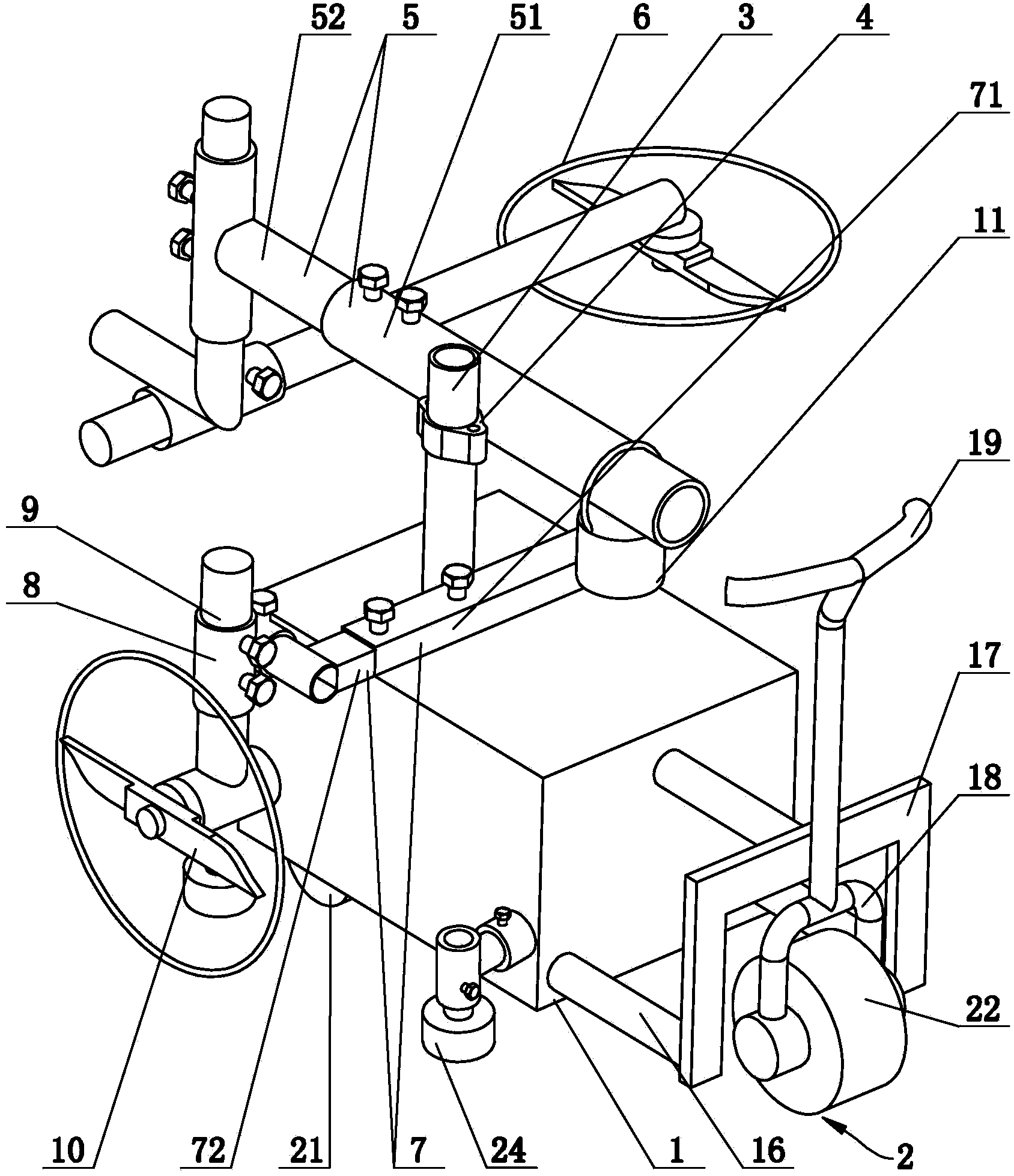

The invention discloses a lifting machine for automobile repair. The lifting machine comprises a base, sliding wheel installation rods, sliding wheels, a left L-shaped frame, a right L-shaped frame, astand column, a shaft sleeve, a lead screw, a first motor, a thread sleeve, a lifting platform, a left folding frame, a hydraulic cylinder, a sliding disc, a supporting column, a right folding frame,an inner pipe, a first outer pipe, a second outer pipe, a lifting platform, a motor installation rod, a second motor, a first gear, a rack and the like. The lifting machine has the advantages that the structure is reasonable and simple, the production cost is low, installation is convenient, lifting is carried out in a subsection mode through a multi-stage transmission device, transmission precision is high, and use is convenient; the sliding wheels are driven by the motors, movement is convenient, manual push is not needed, and great convenience is brought to use; and in order to prevent sliding, locking is carried out through a clamping block, and sliding is effectively prevented.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

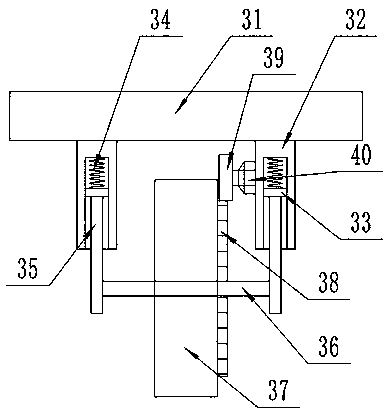

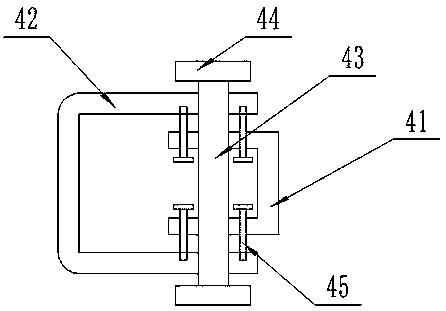

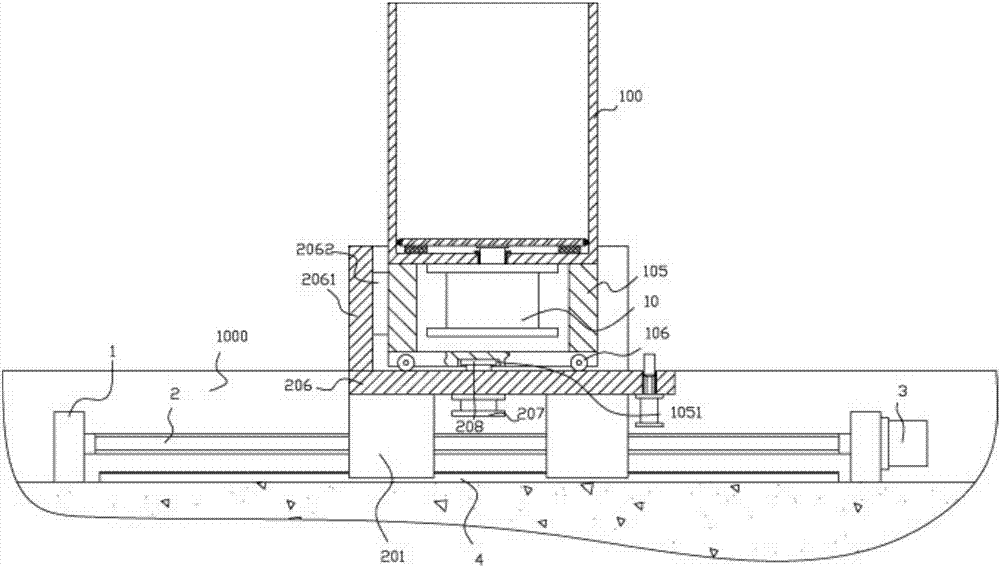

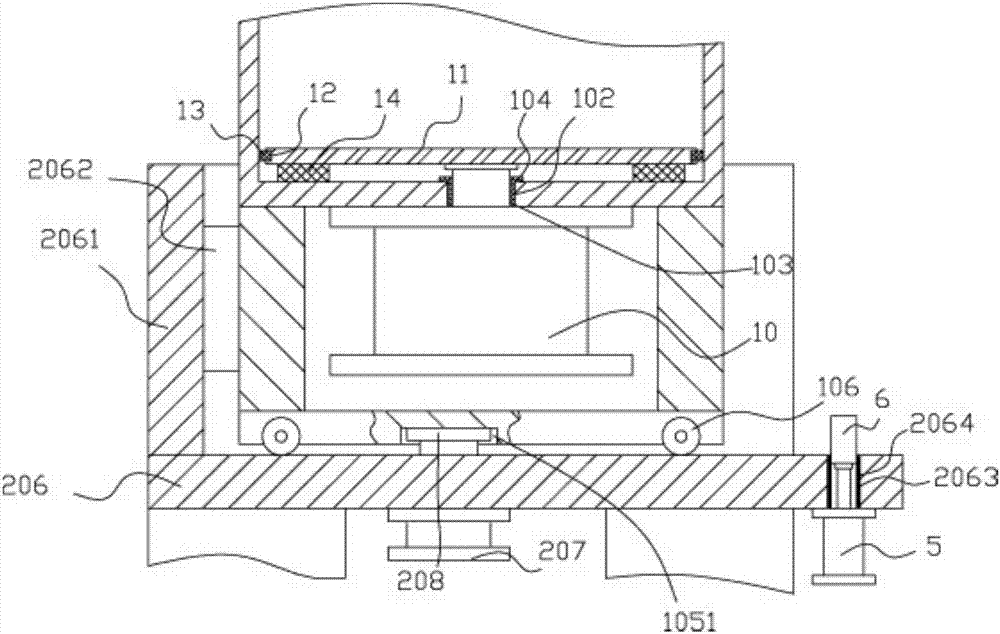

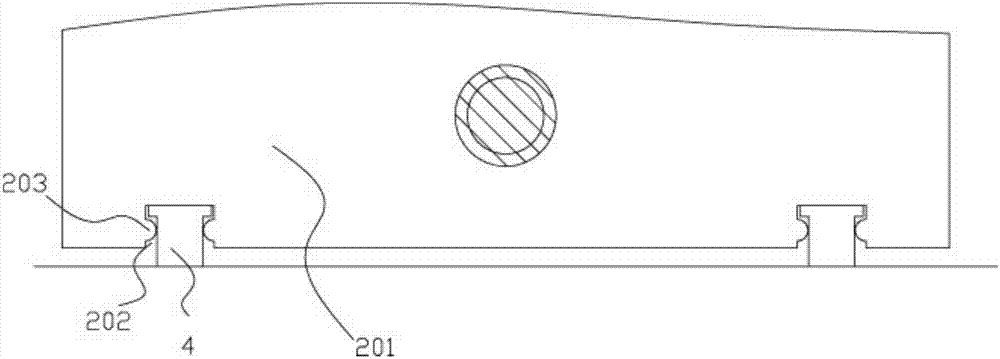

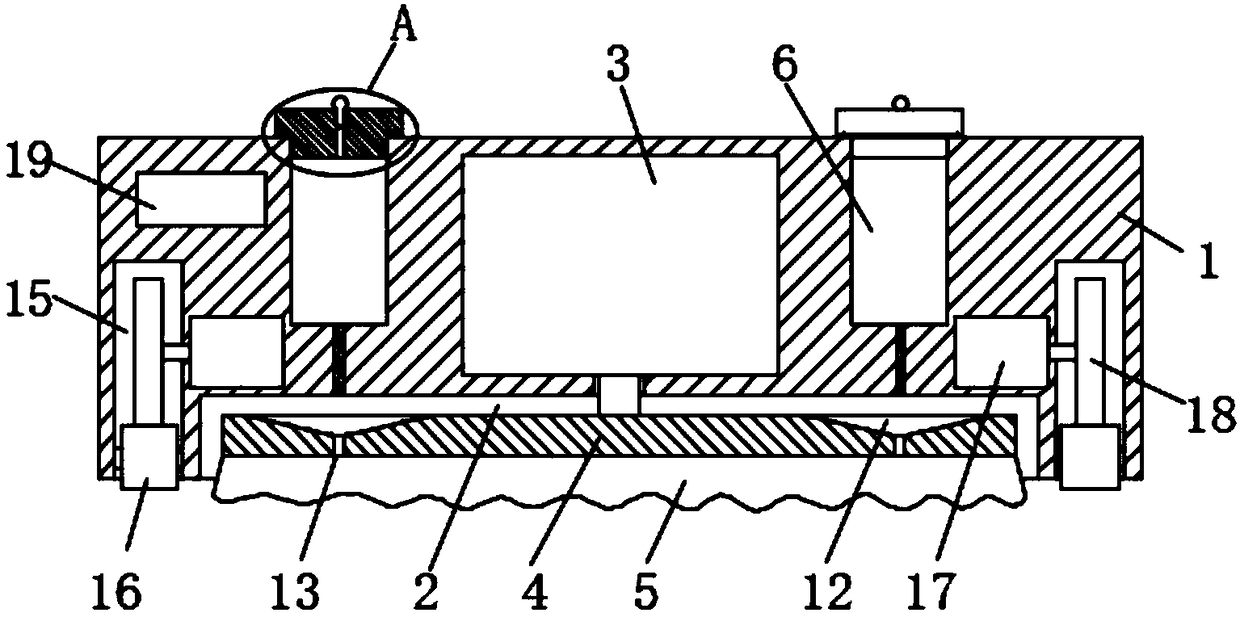

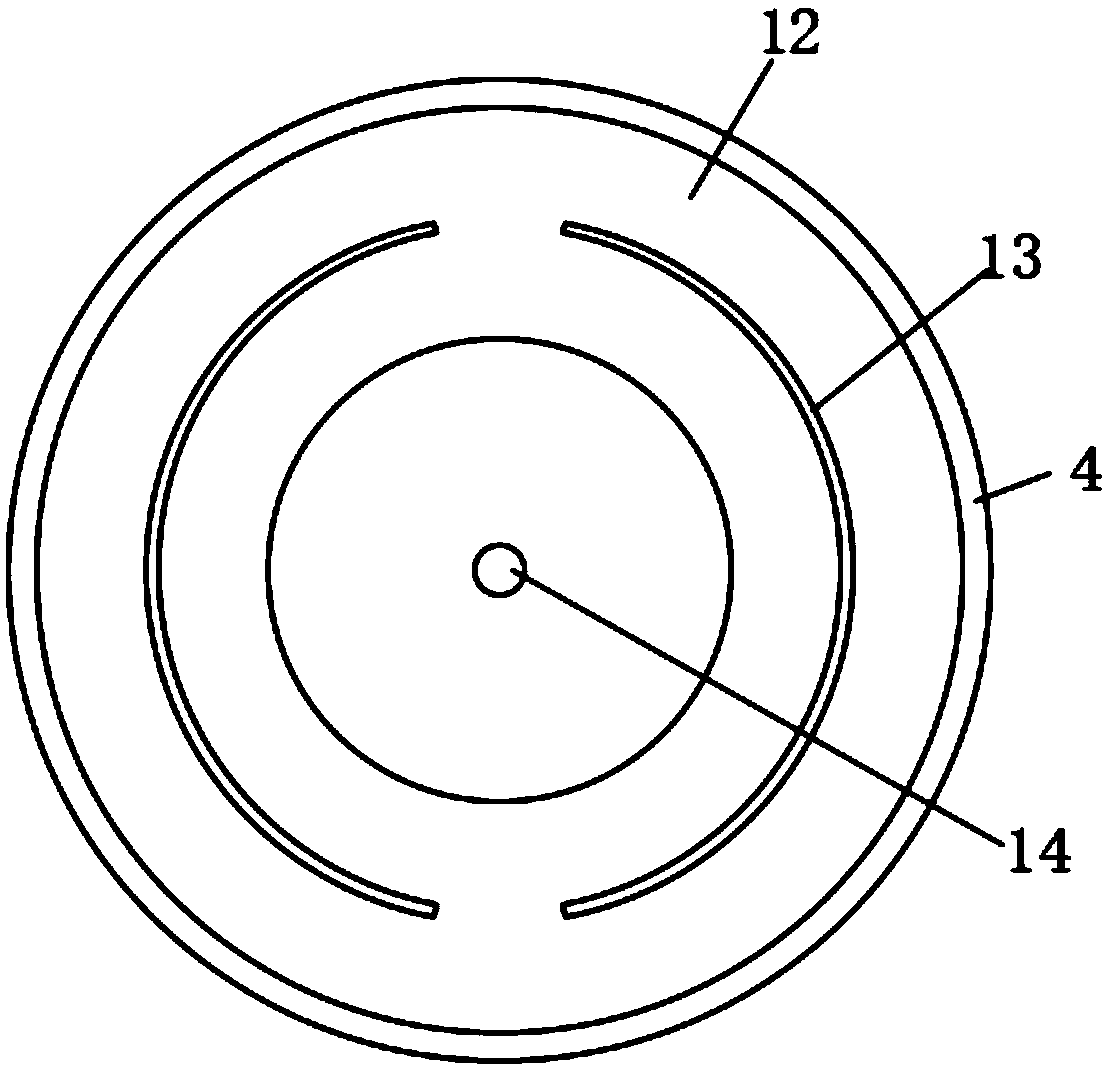

Automatic beverage filling equipment

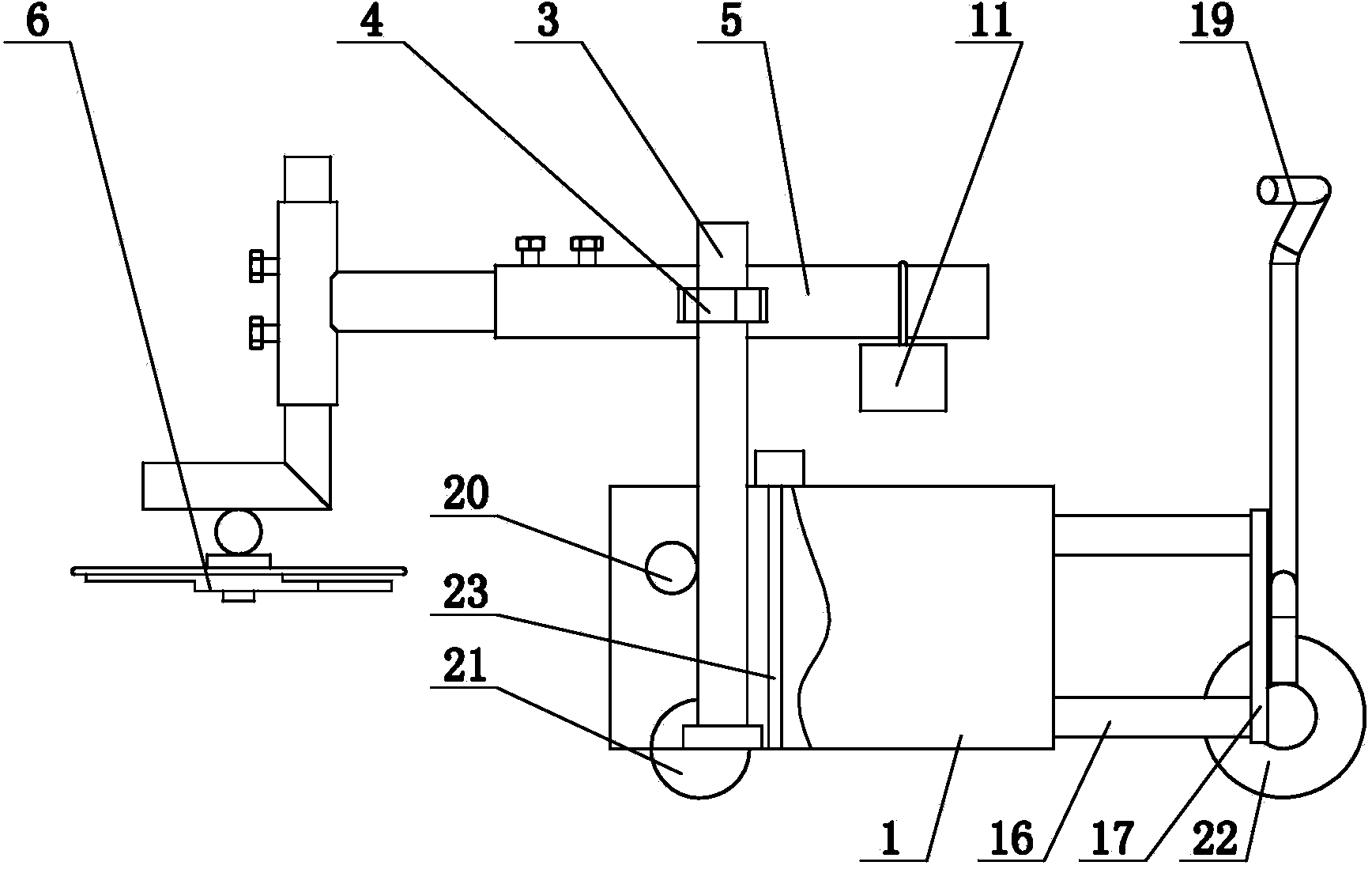

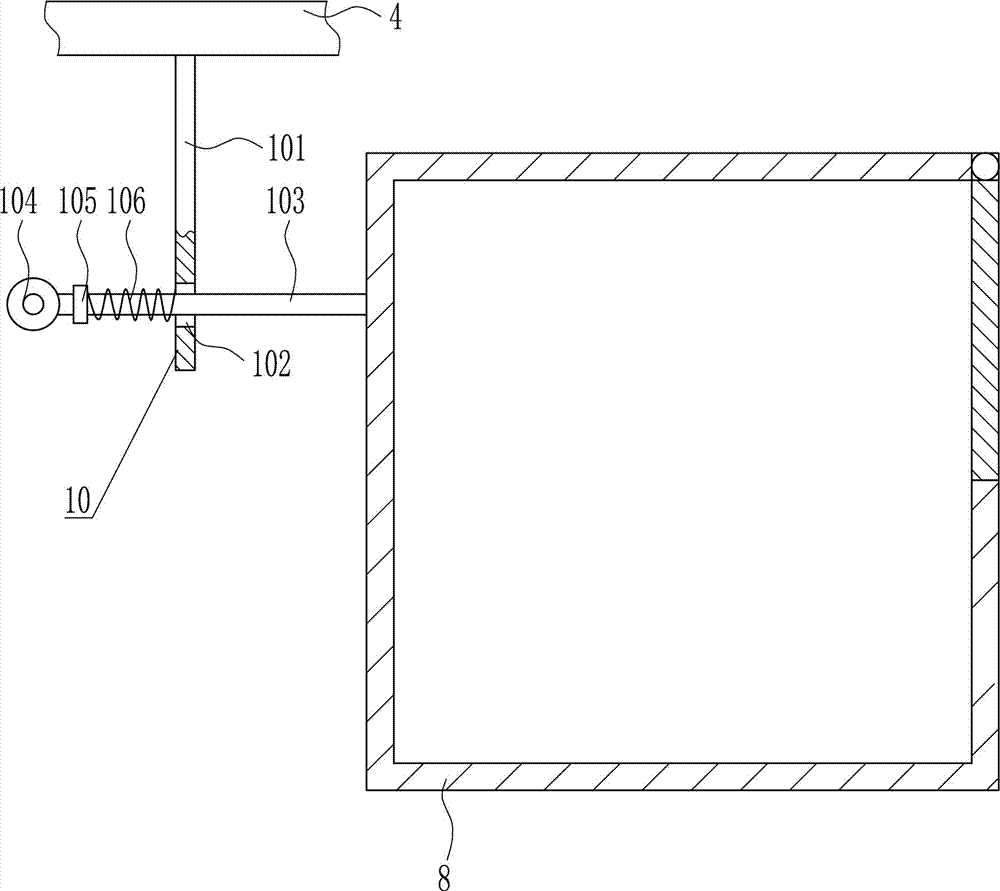

The invention relates to filling equipment, particularly relates to automatic beverage filling equipment and provides automatic beverage filling equipment capable of enabling bottles to be not prone to displacement and automatically filling beverages. The automatic beverage filling equipment comprises a base, a feeding device, a filling box, an opening and closing device and a lifting device, wherein a workbench is arranged at the top of the base; the feeding device is arranged at the top of the base; the filling box is arranged at the top of the base; a square groove is formed in the fillingbox; the opening and closing device is arranged at the top of the base; and the lifting device is arranged on the workbench. According to the automatic beverage filling equipment, the feeding device is capable of achieving intermittent leftward movement of the bottles; then the opening and closing device and the lifting device cooperate to intermittently fill the beverages into the bottles; a second connecting rod can drive a discharging pipe to move up and down; the lower part of the discharging pipe moves into bottles, so that the beverages can be better filled into the bottles; meanwhile, the automatic beverage filling equipment is also capable of preventing the beverages from flowing out of the bottles during infusion, so that the waste is avoided.

Owner:山东美果来食品有限公司

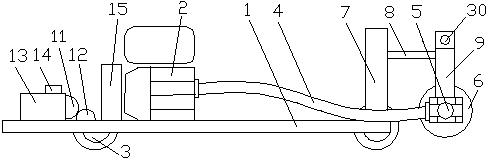

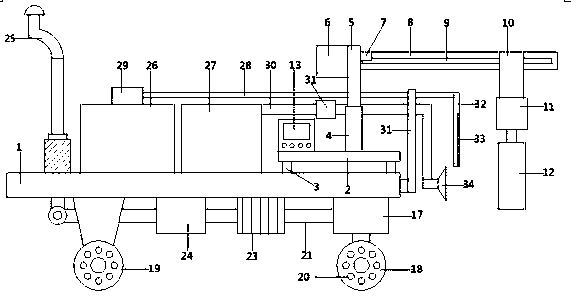

Automatic steel rail duplex rust removing machine

ActiveCN104631234AHard and wear-resistant working surfaceEasy to attachTrack superstructureRailway track constructionCouplingEngineering

The invention discloses an automatic steel rail duplex rust removing machine. The automatic steel rail duplex rust removing machine comprises a rack, engines and wheels connected to the lower portion of the rack, and is characterized in that the two engines are adopted and distributed on steel rails on the two sides respectively, the automatic steel rail duplex rust removing machine further comprises two soft shafts and two steering gears, one ends of the soft shafts are connected with rotating shafts of the engines through couplers, the other ends of the soft shafts are connected with input shafts of the steering gears, output shafts of the steering gears are connected with blade grinding wheels, the rack is fixedly connected with two connecting pieces, vertical adjusting pieces are arranged above the steering gears and elastically connected with the steering gears, connecting rods of the connecting pieces are connected with the vertical adjusting pieces, a transverse spring pull rod is connected between the vertical adjusting pieces of the steel rails on the two sides, and the rack is connected with a drive component. The kinetic energy of the engines is directly transmitted to the blade grinding wheels through the soft shafts, a duplex structure is adopted, synchronous automatic constant-speed rust removing can be carried out on pedal faces of the two steel rails at the same time, and the rust removing quality and efficiency are greatly improved.

Owner:德阳路安恒轨道技术开发有限公司

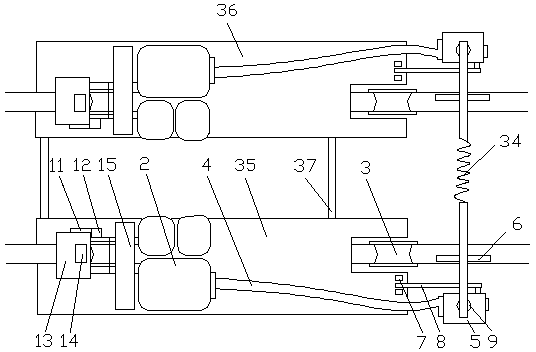

Automatic board grinding machine

InactiveCN105834847ARealize the effect of automatic grindingAvoid shaking from side to sideGrinding drivesGrinding work supportsEngineeringGrinding wheel

The invention discloses an automatic board grinding machine which comprises a base. A grinding groove is formed in the top of the base, limiting grooves are formed in the two sides of the base, a grinding motor is arranged above the grinding groove, and the bottom of the grinding motor is fixedly connected with the top of a grinding wheel through a rotary shaft. The left side and the right side of the grinding motor are both fixedly connected with a fixing beam. One side of the bottom of each fixing beam is fixedly connected with a fixing column, a support is arranged at the bottom of each fixing column, the lower portions of the supports are connected with auxiliary moving wheels in a sleeving mode through rotating shafts, and the lower portions of the fixing columns are provided with limiting blocks corresponding to the limiting grooves in position. The side, far away from the corresponding fixing column, of each limiting block is provided with a guide wheel. The top of the grinding motor is fixedly connected with a movable motor, and a rotary shaft of the movable motor is sleeved with a gear. The automatic board polishing machine achieves the automatic board grinding effect, manual pushing is not needed, time and labor are saved, and accidents caused by negligence of operators are avoided.

Owner:于法周

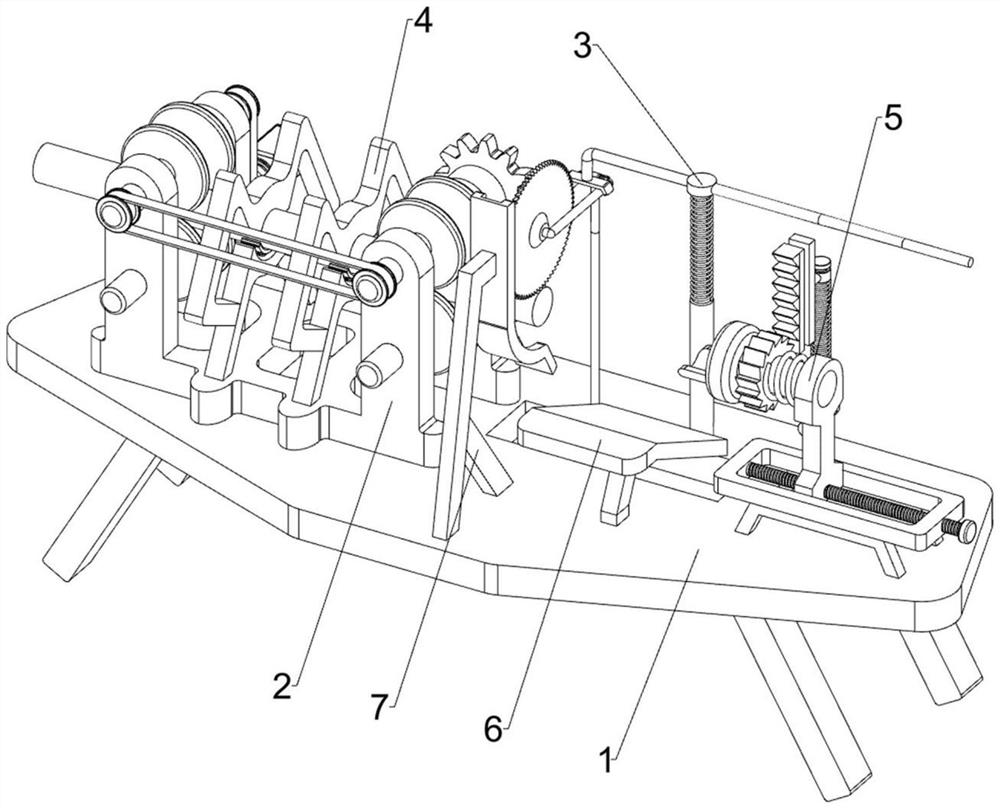

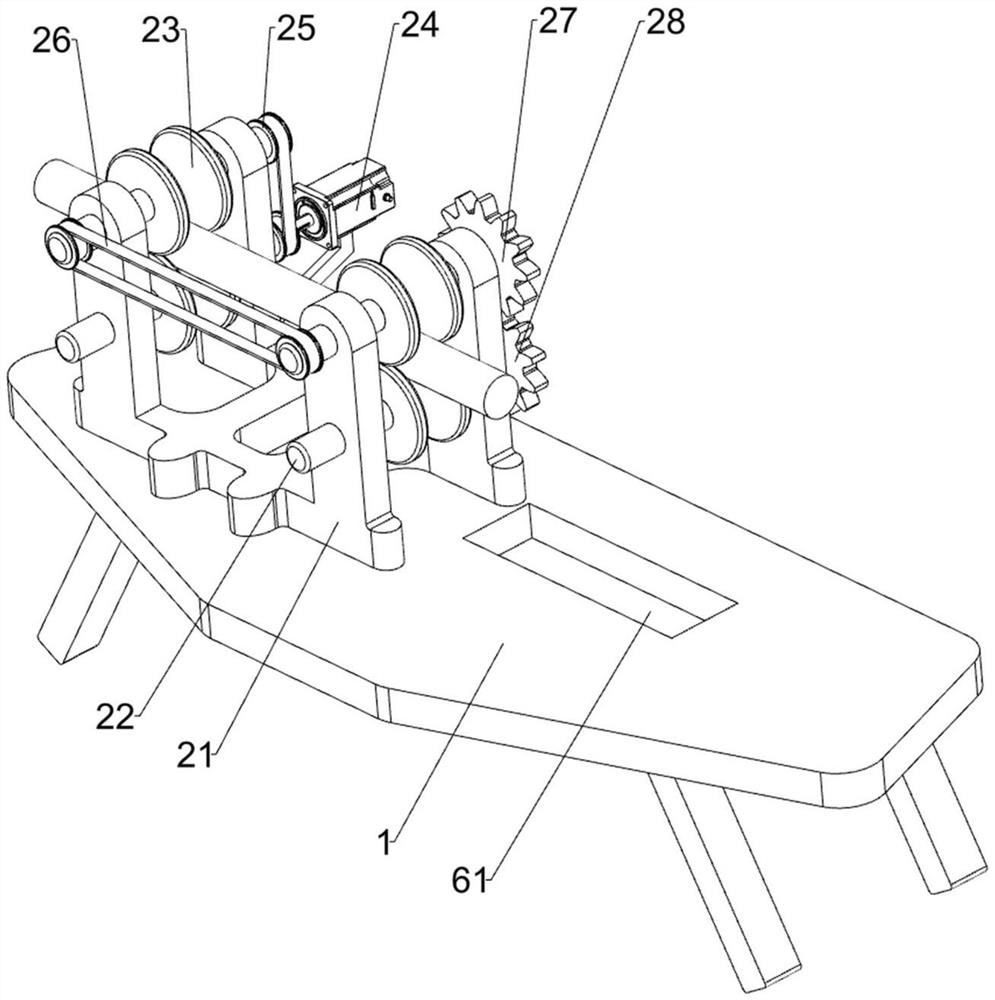

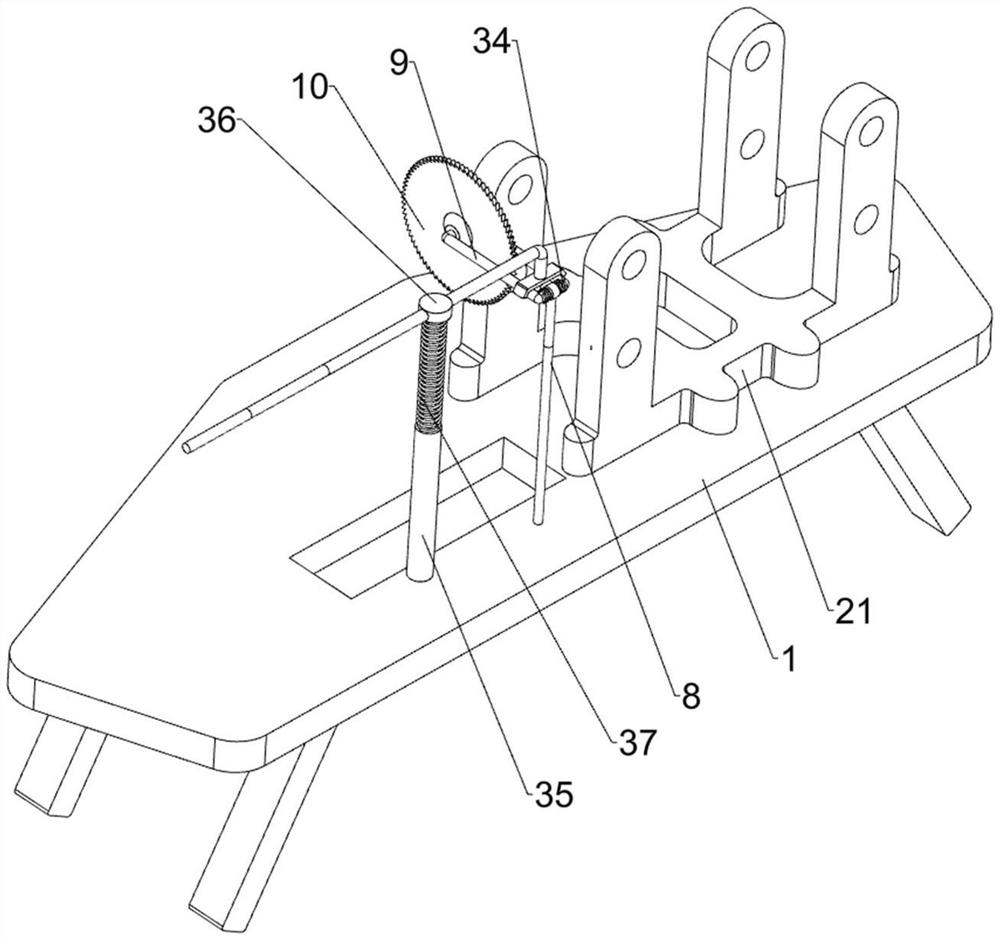

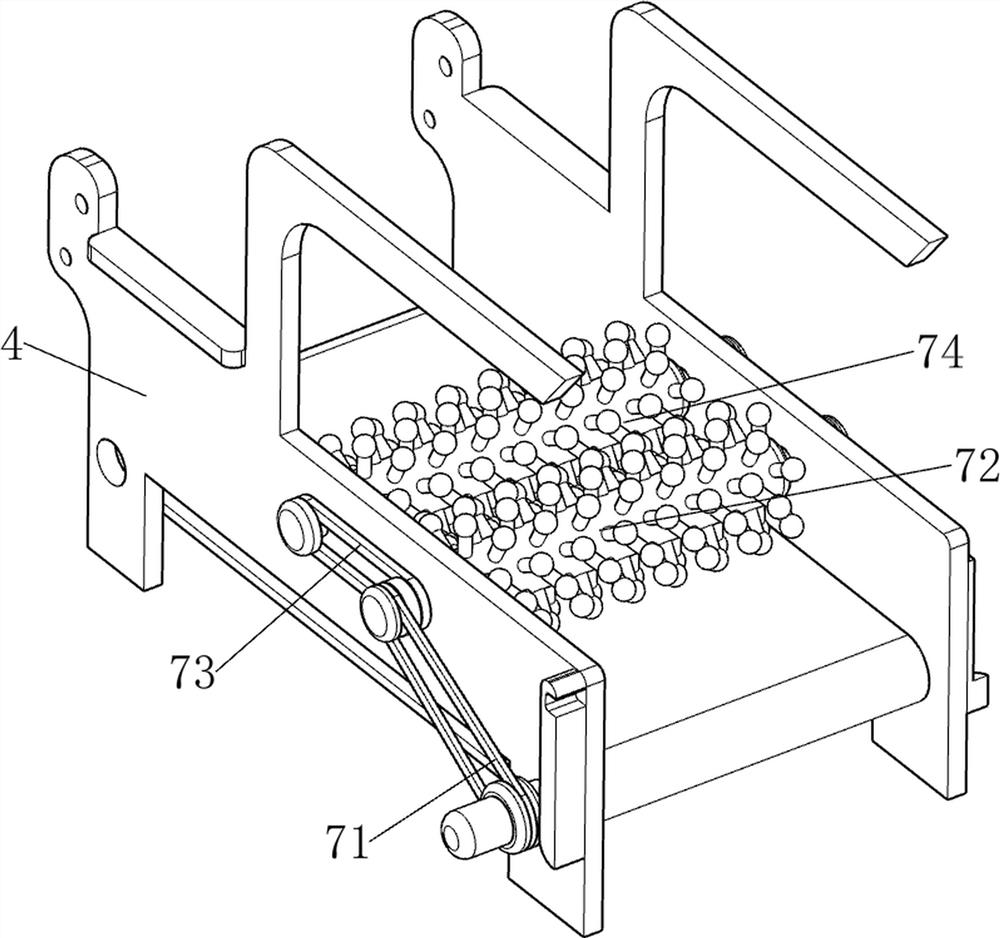

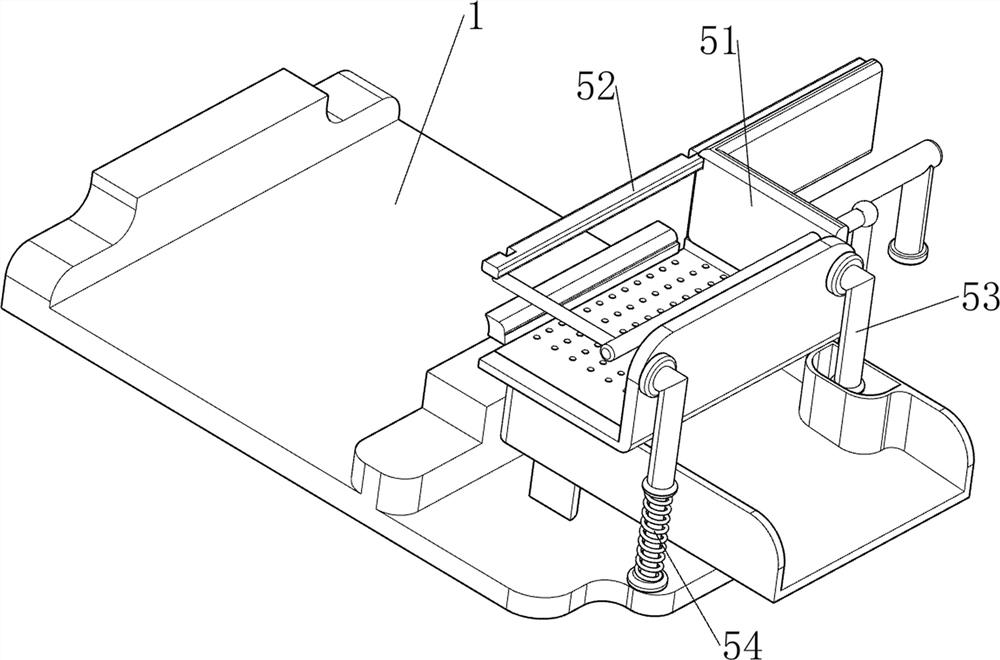

Rapid radish dicing and sorting equipment

ActiveCN111546408ANo manual push requiredSpeed up screeningSievingScreeningEngineeringMechanical engineering

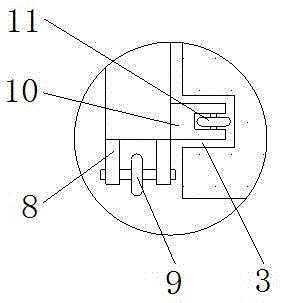

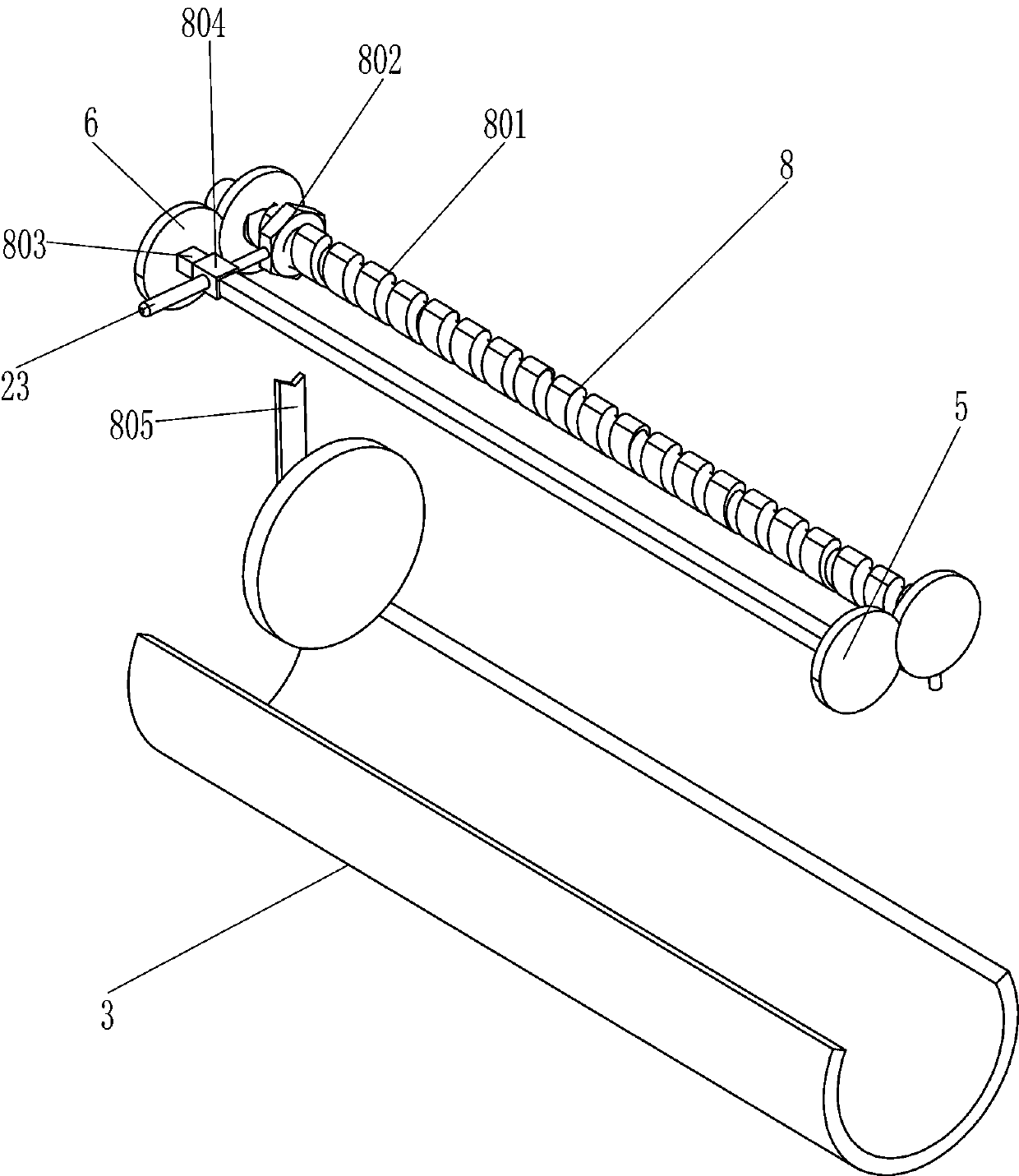

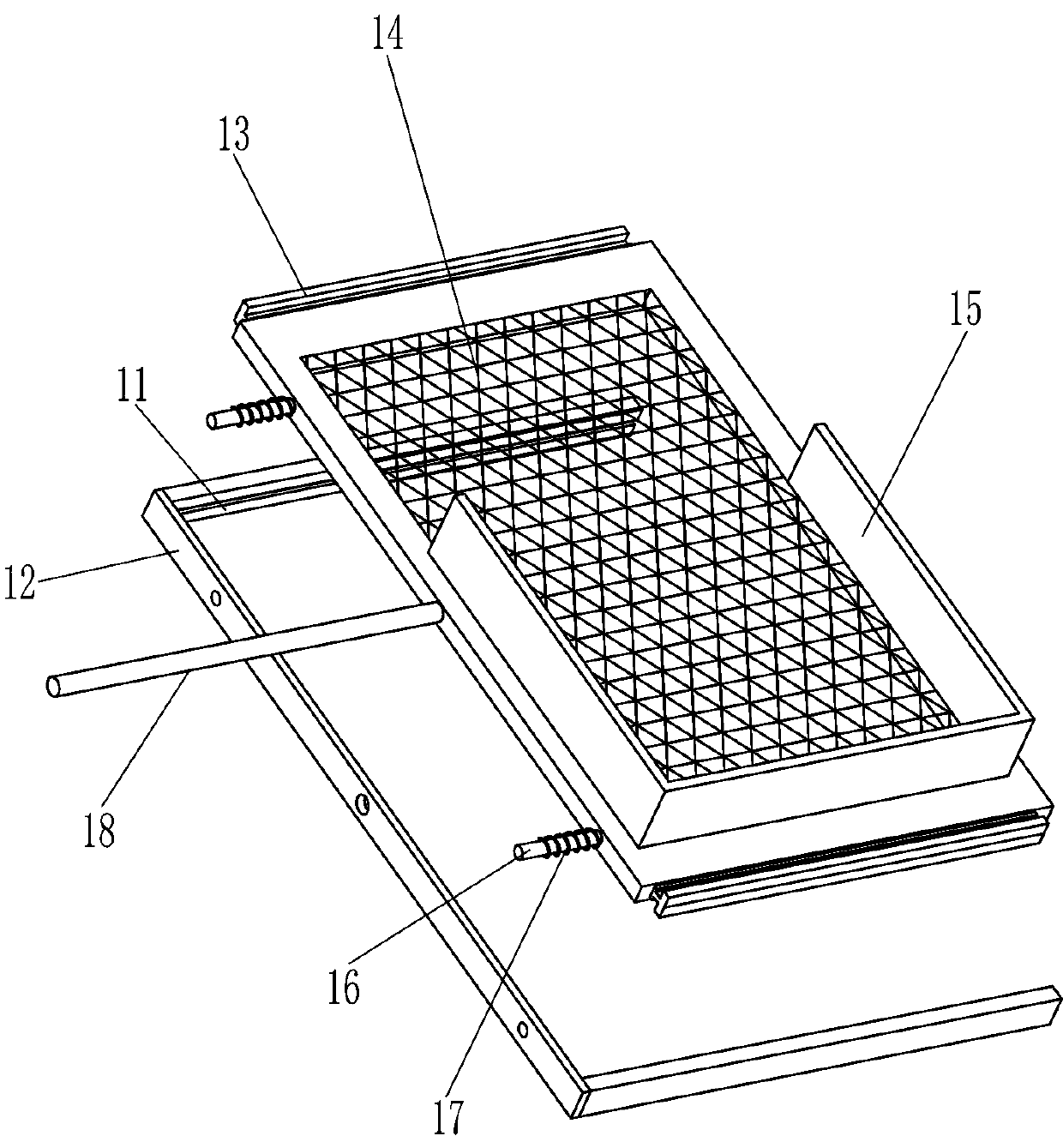

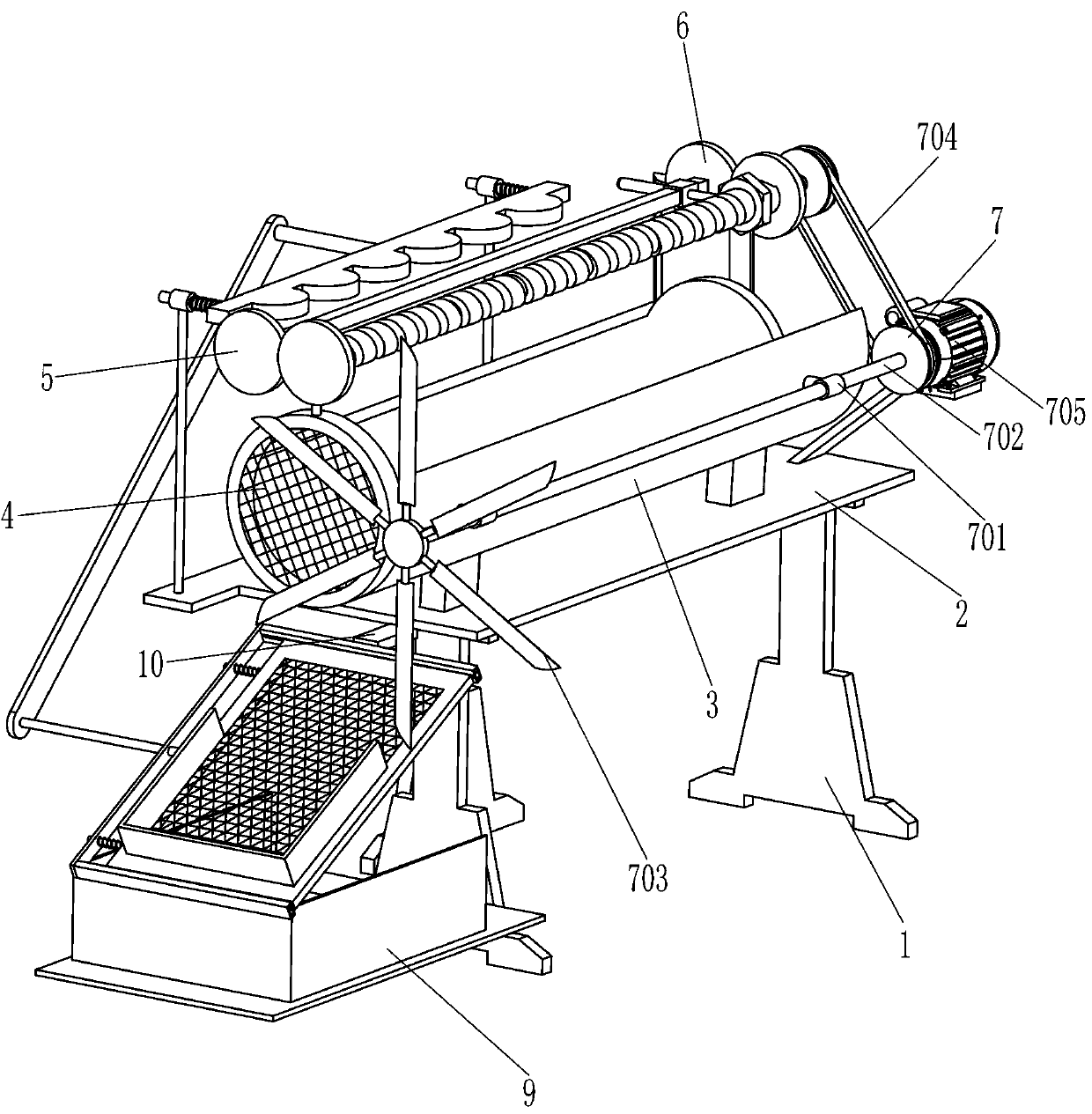

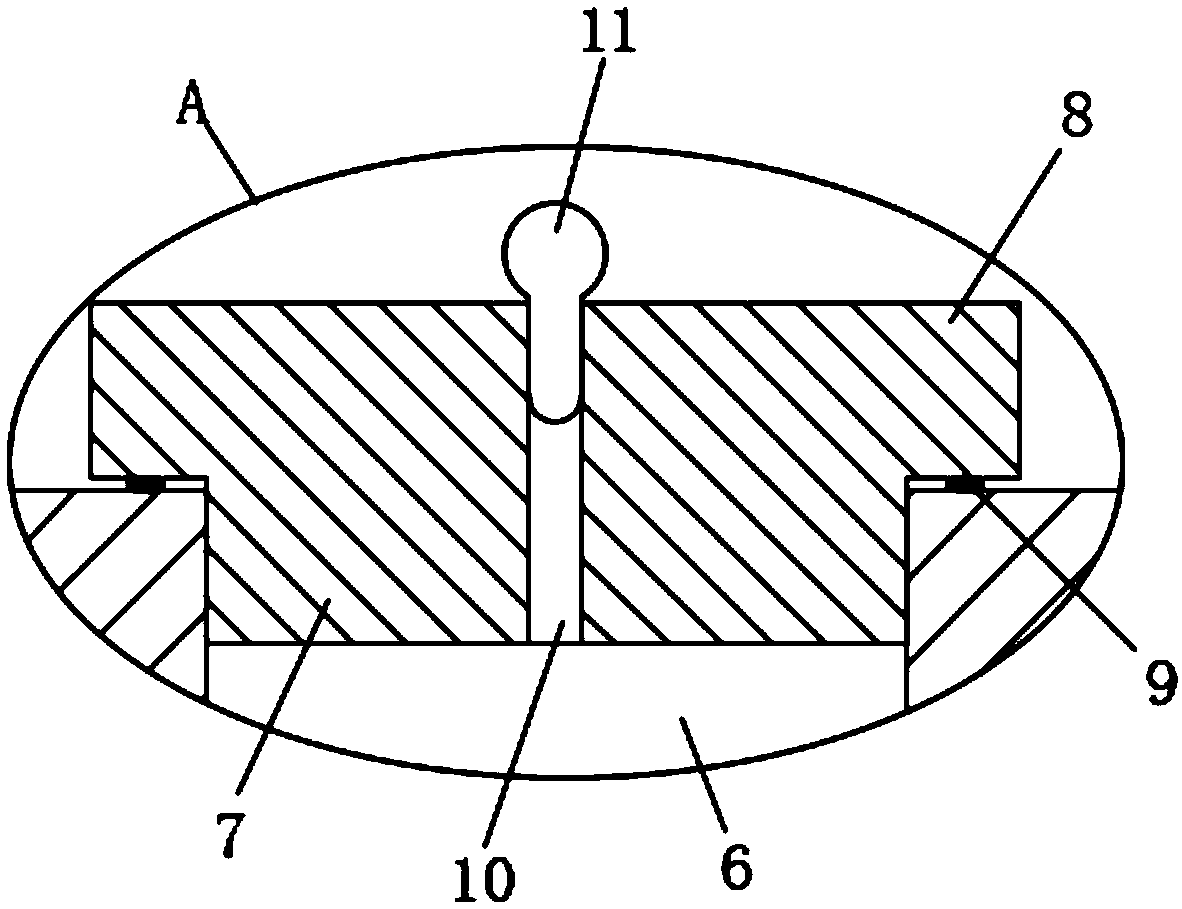

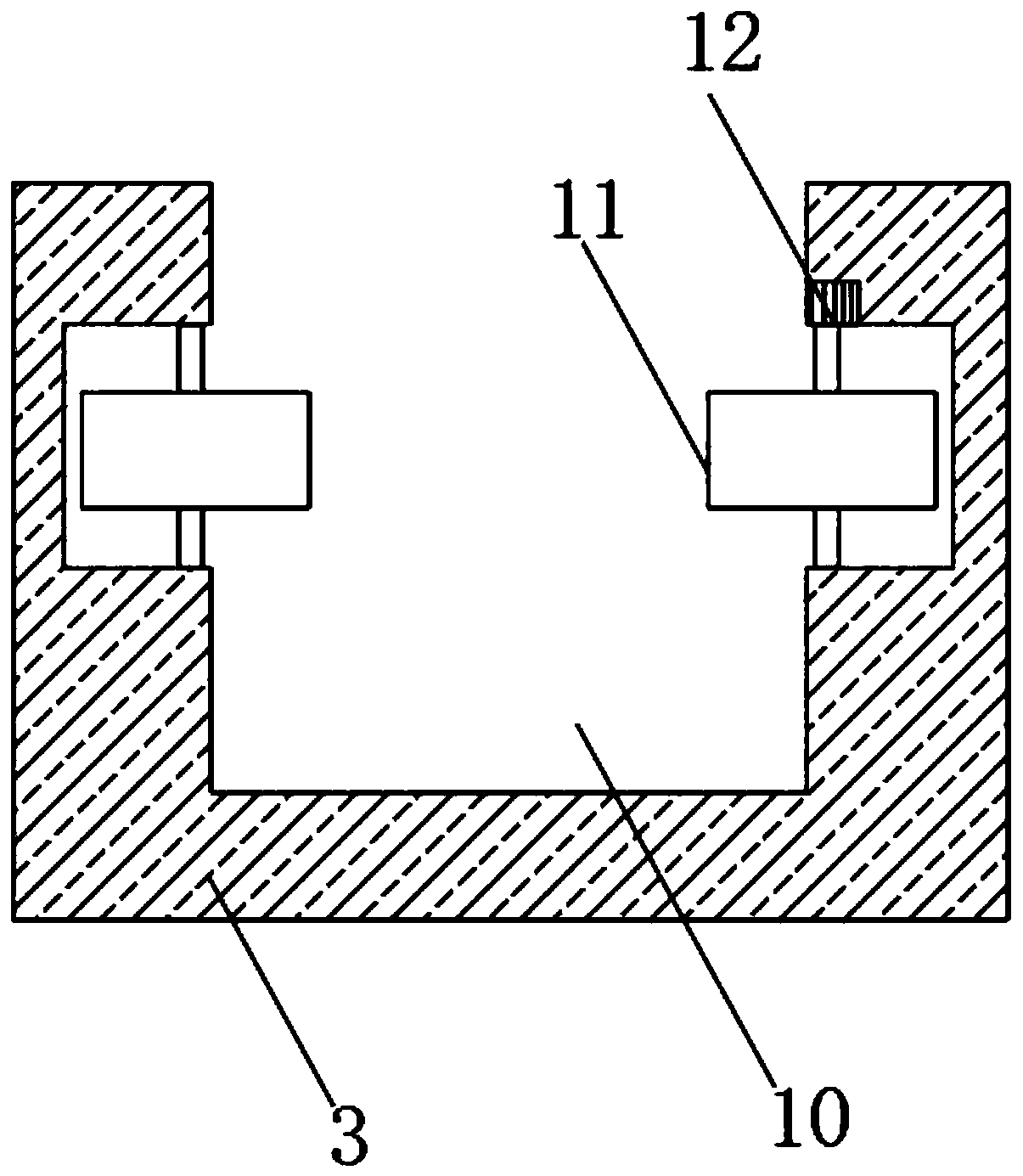

The invention relates to cutting and sorting equipment, in particular to rapid radish dicing and sorting equipment. The rapid radish dicing and sorting equipment is provided for replacing existing machines and manual work and achieving the rapid and easy radish dicing effect. According to the technical scheme, the rapid radish dicing and sorting equipment comprises a base, an arc-shaped plate, a circular screen frame and a second mounting plate, wherein a first mounting plate is mounted on the top of the base; the arc-shaped plate is arranged on one side of the top of the first mounting plate;the length direction of the arc-shaped plate is parallel to the length direction of the first mounting plate; the circular screen frame is arranged at the end of the arc-shaped plate; and the secondmounting plate is fixedly connected to the position, far away from the top of the first mounting plate, of the sidewall of the circular screen frame. Through cooperation of a cutting device and a pushing device, the rapid radish dicing and sorting equipment can cut radish into long strips and then cut the long radish strips into radish strips through the pushing device. The cutting device can conduct dicing on the radish strips without manually pushing radishes, and the effects of quickness, high efficiency and convenience are achieved.

Owner:临沂临港国有资产运营集团有限公司

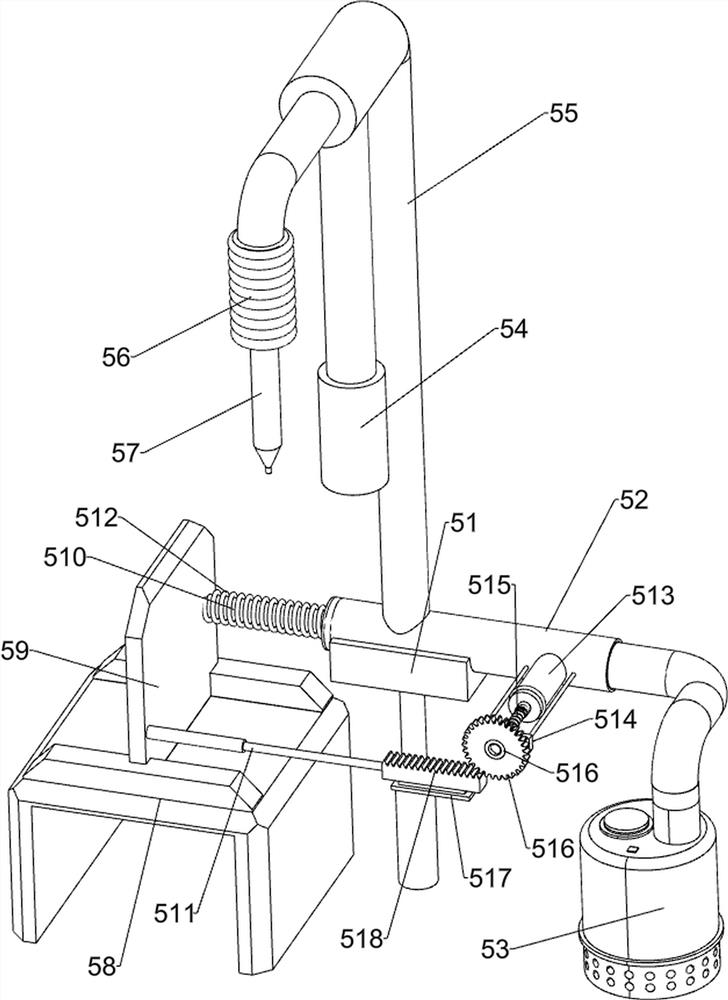

Drilling machine for highway construction

InactiveCN107724956ANo pollution in the processAvoid pollutionConstructionsDerricks/mastsArchitectural engineeringWater spray

The invention discloses a drilling machine for road construction, which comprises a base, a drilling machine base is arranged at the right end of the upper side of the base, fixing columns are arranged at the four corners of the lower side of the drilling machine base, and the bottom ends of the fixing columns are fixed on the base , there is an electric telescopic rod on the upper side of the base of the drilling machine, the movable end of the upper side of the electric telescopic rod is connected with a support rod, one side of the support rod is provided with a weighing block, the other side is connected with a cross bar, and the cross bar is set With a sliding mechanism, the drilling machine for highway construction of the present invention has a reasonable structural design, can realize precise drilling, has high drilling efficiency, can perform dust suction and water spraying operations, improves the environment, avoids pollution, and prolongs the working life of the drill bit. The service life ensures long-term continuous work. The entire working process is controlled by the control box, which has a high degree of automation and saves time and effort. In addition, it is convenient for quick transfer of drilling machinery, which improves work efficiency and has small vibration during movement.

Owner:陕西天策智汇建筑科技有限公司

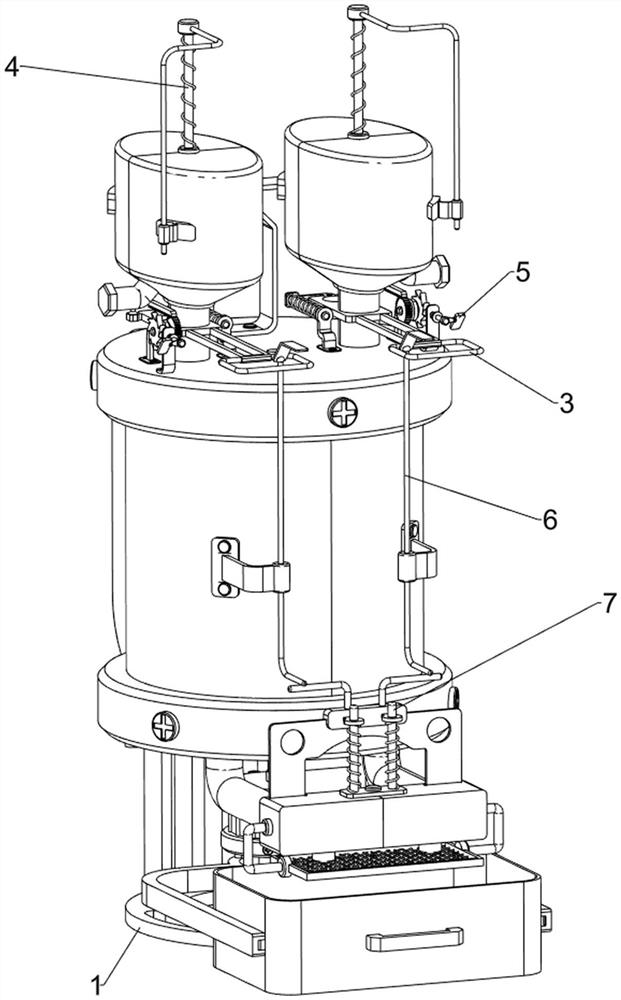

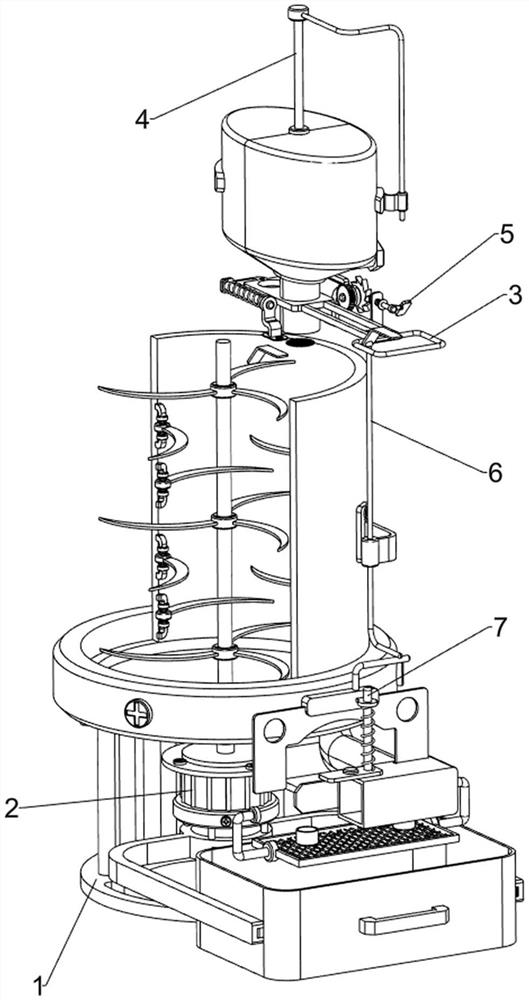

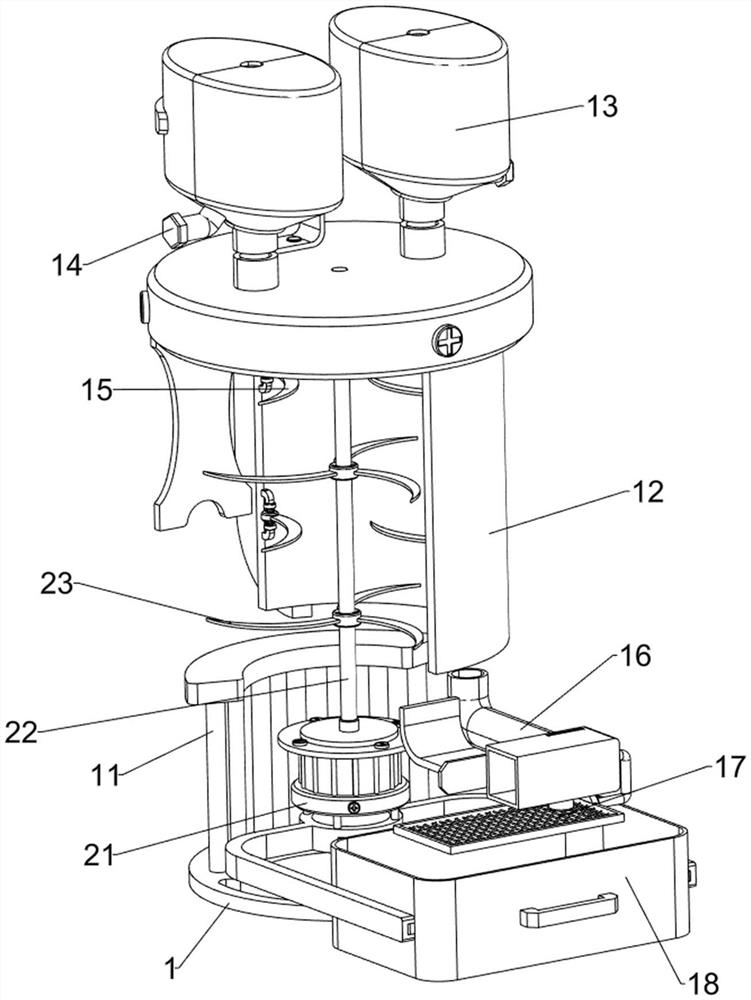

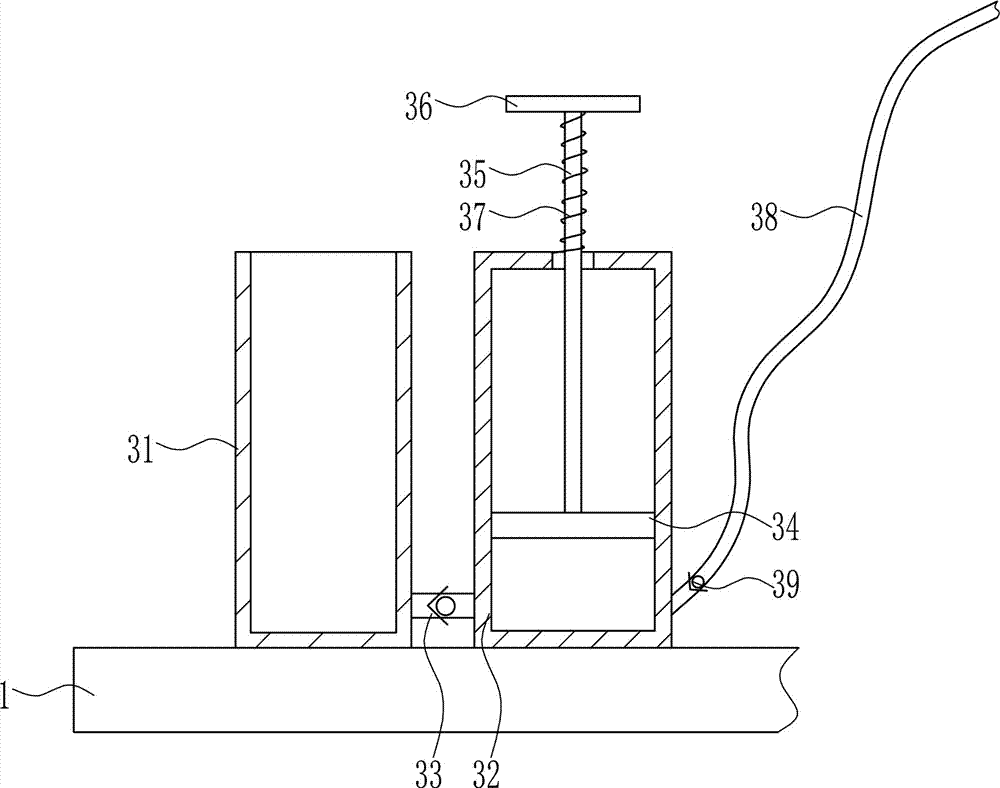

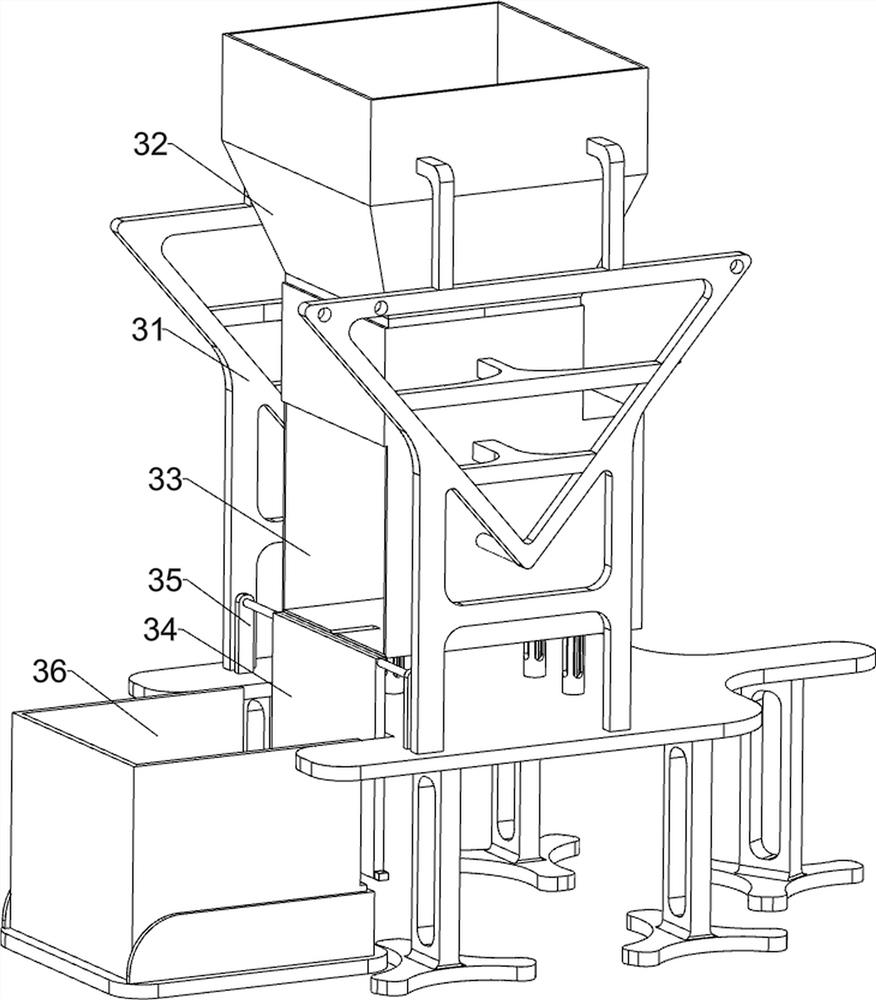

Automatic mixing device for colored glaze production

ActiveCN112844193AWell mixedAchieve broken effectTransportation and packagingRotary stirring mixersGlazeEngineering

The invention relates to a mixing device, and particularly relates to an automatic mixing device for colored glaze production. The automatic mixing device for colored glaze production is good in mixing effect, capable of reducing the labor intensity of workers and easy and understandable to operate. The automatic mixing device for colored glaze production comprises a base, a fixed supporting column, a mixing box body, a discharging box, feeding openings, static crushing cutters, a discharging channel and a filter screen, wherein the fixed supporting column is arranged on the base; the mixing box body is arranged at the top of the fixed supporting column; the discharging box is arranged at the top of the mixing box body; the feeding openings are formed in the two sides of the lower part of the discharging box; three static crushing cutters are rotationally arranged on each of the upper side and the lower side in the mixing box body; the discharging channel is arranged at the bottom of the mixing box body; and the filter screen is arranged between the two sides of the discharging channel. By arranging the crushing mechanism, the colored glaze in the mixing box body is more uniformly mixed through the operation of the crushing mechanism, and the crushing effect is achieved.

Owner:高安常莹新型材料有限公司

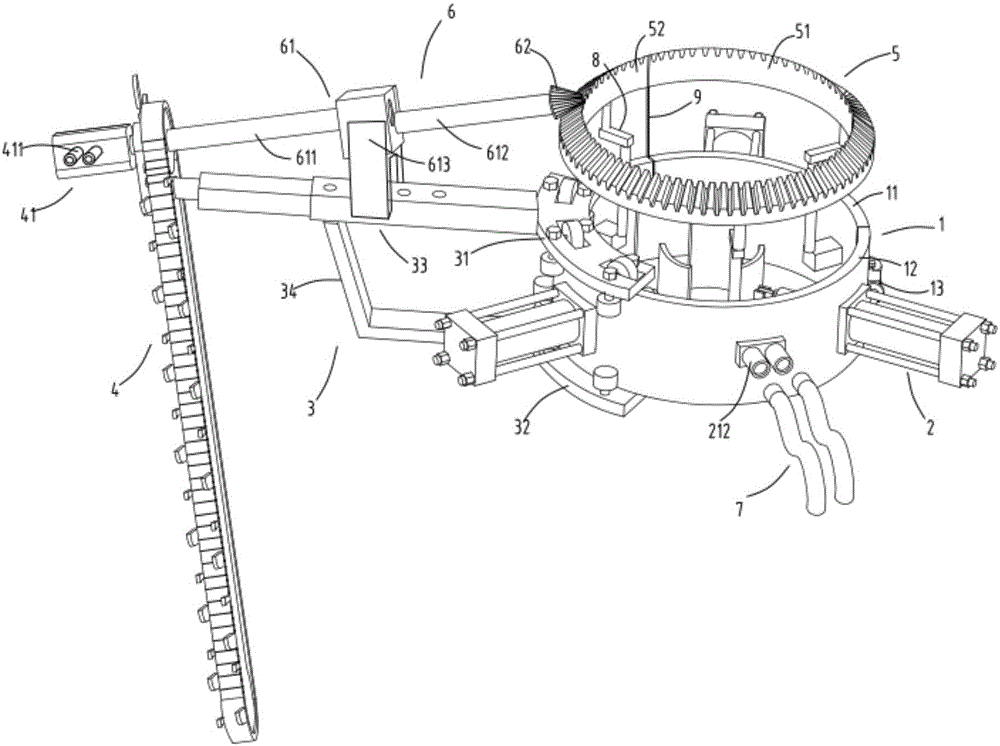

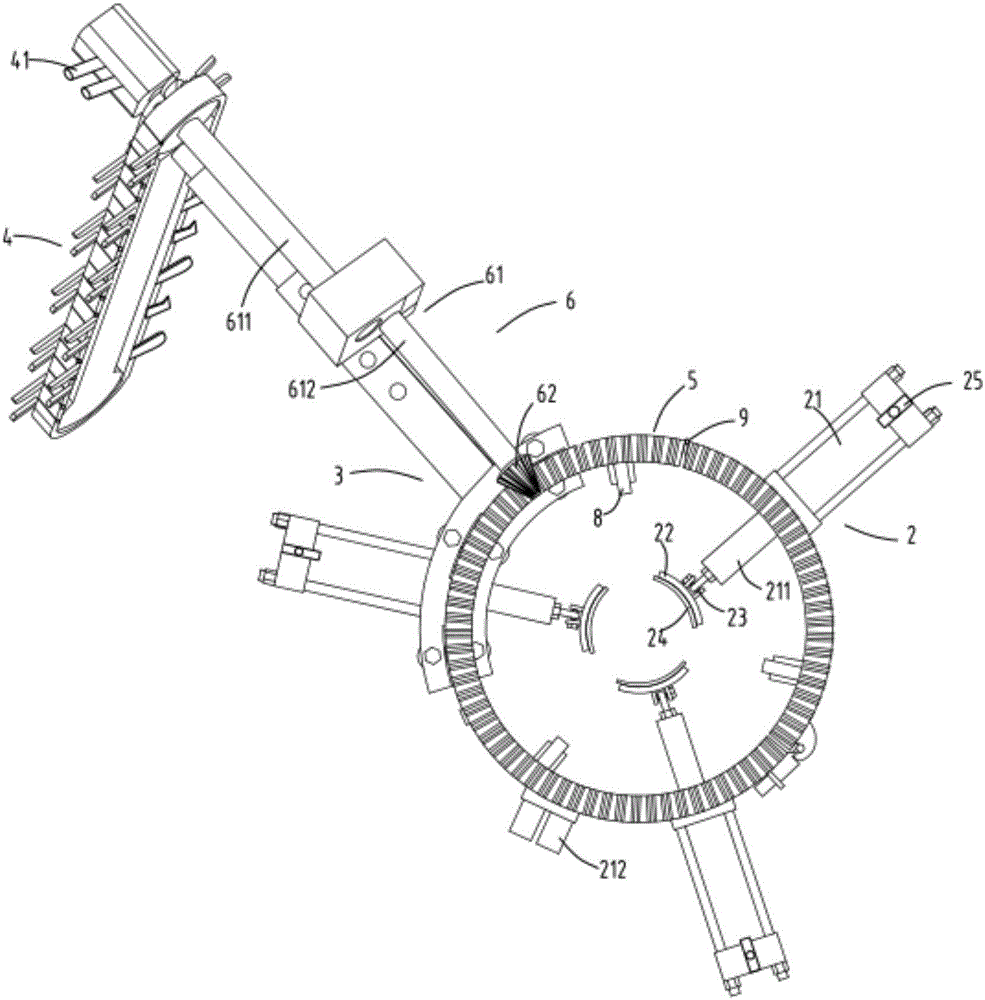

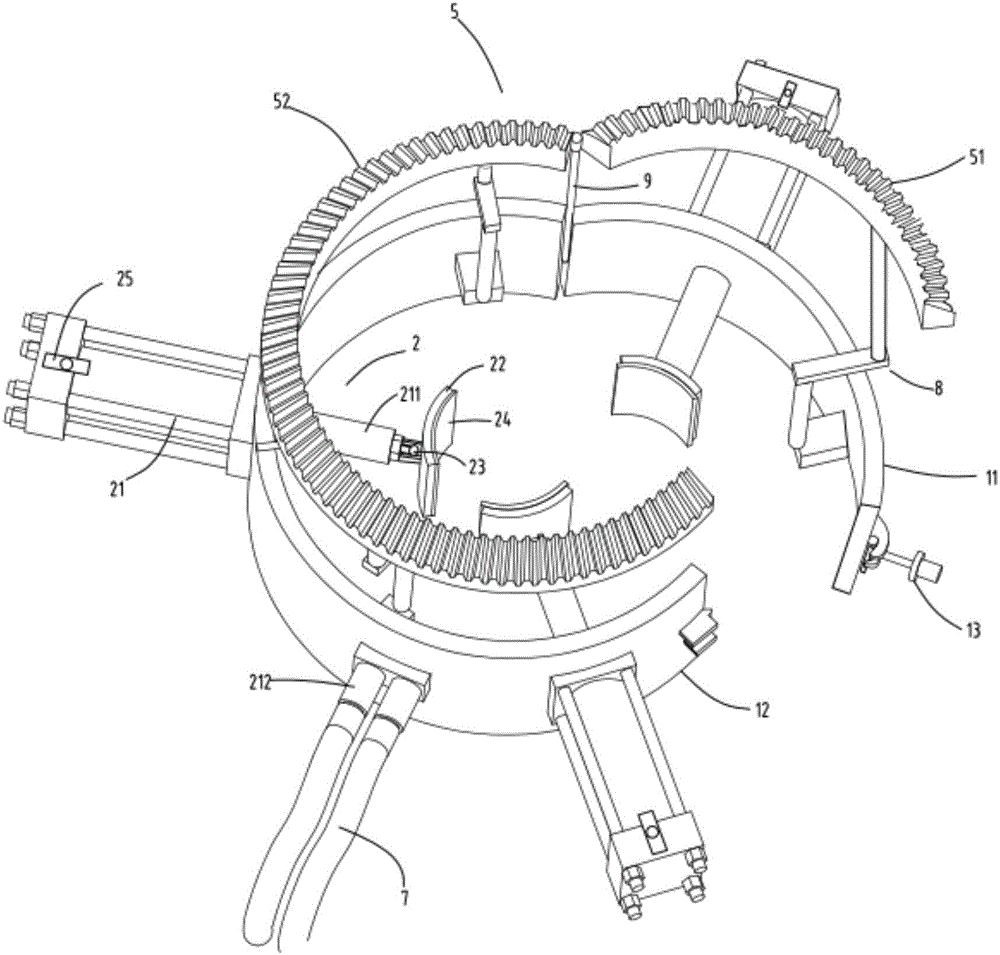

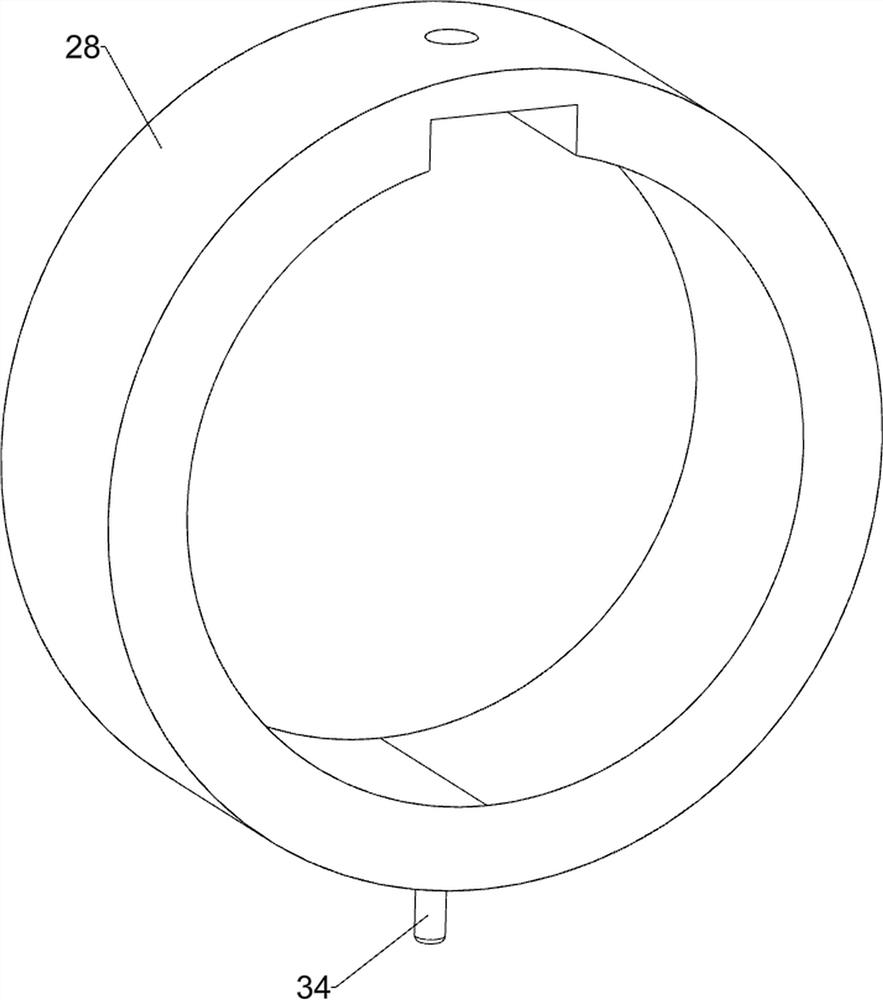

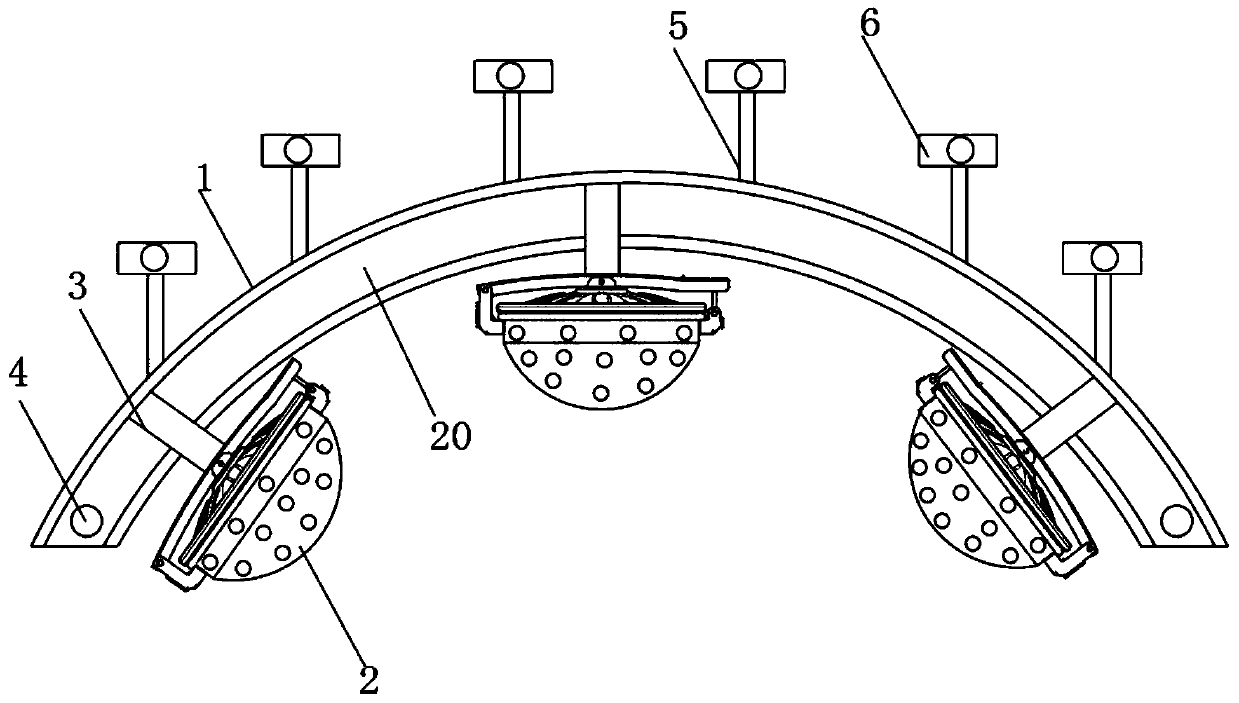

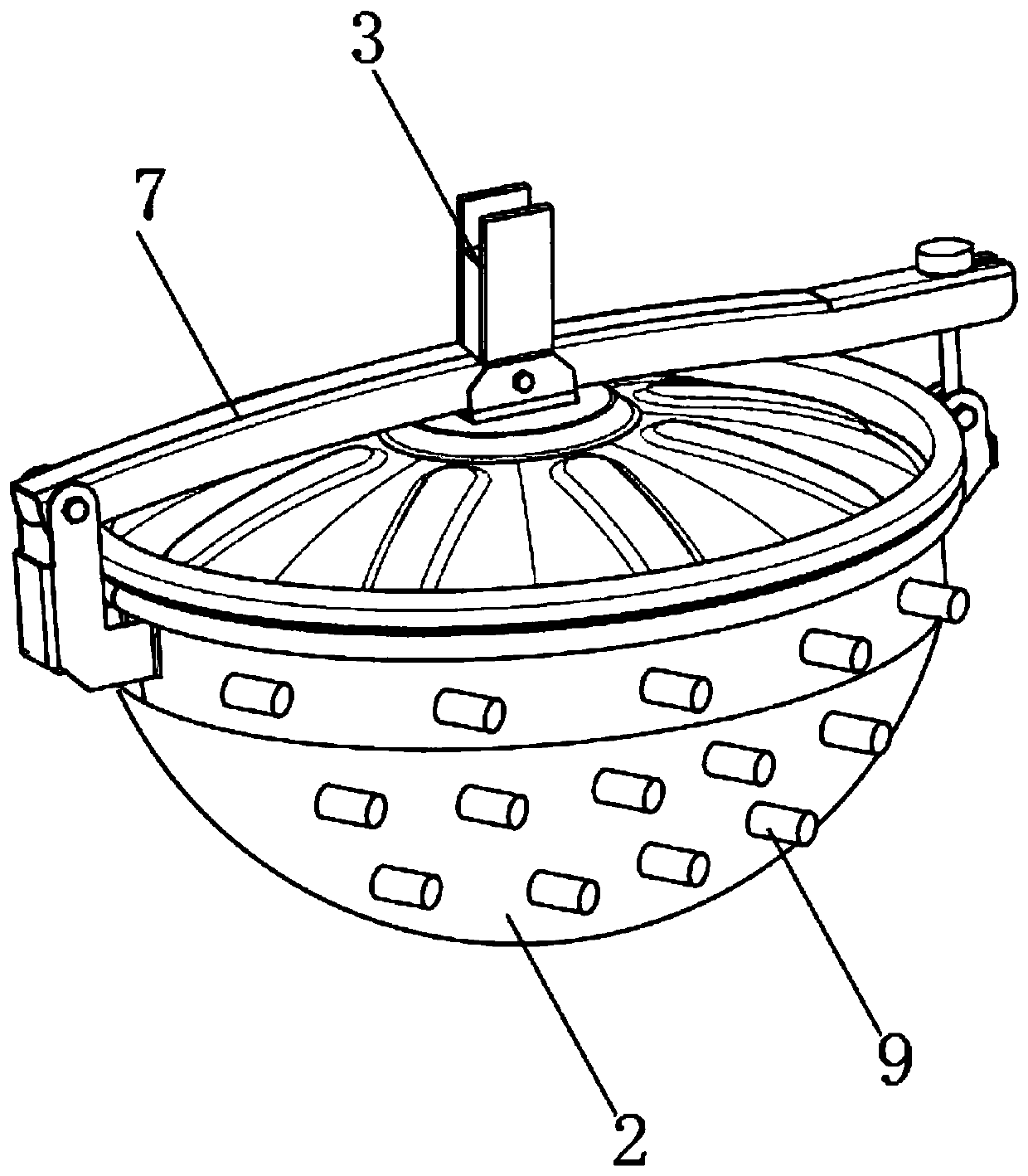

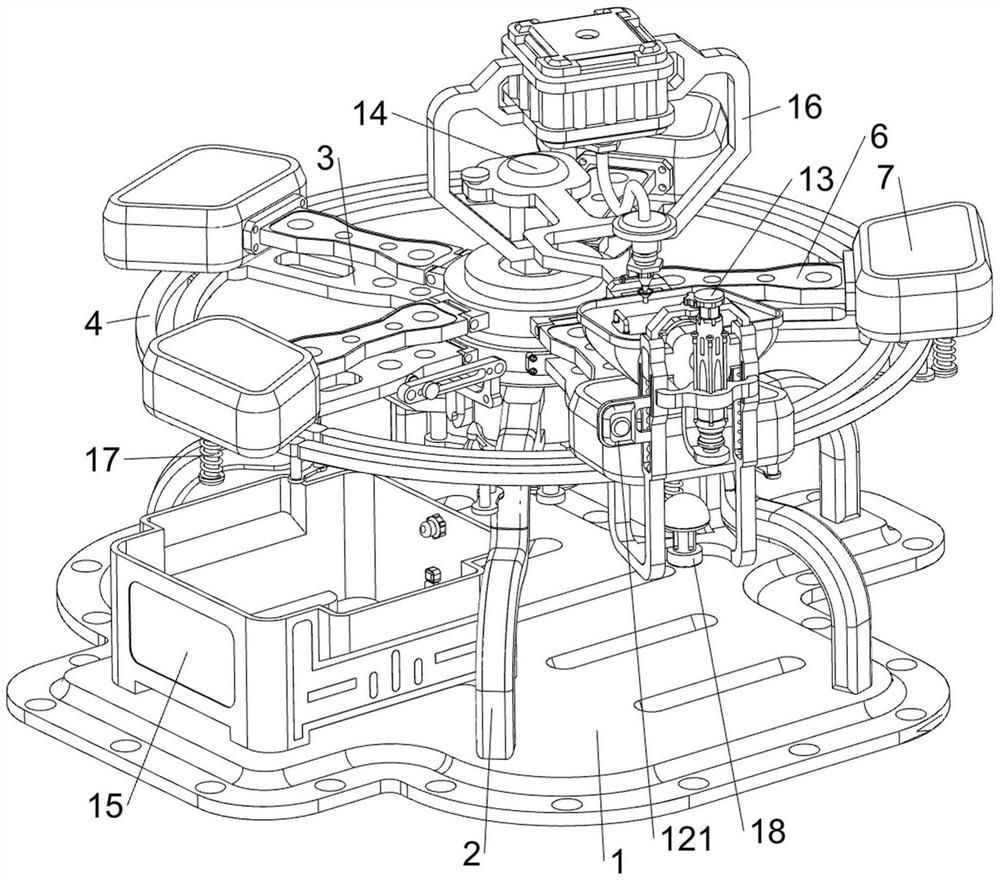

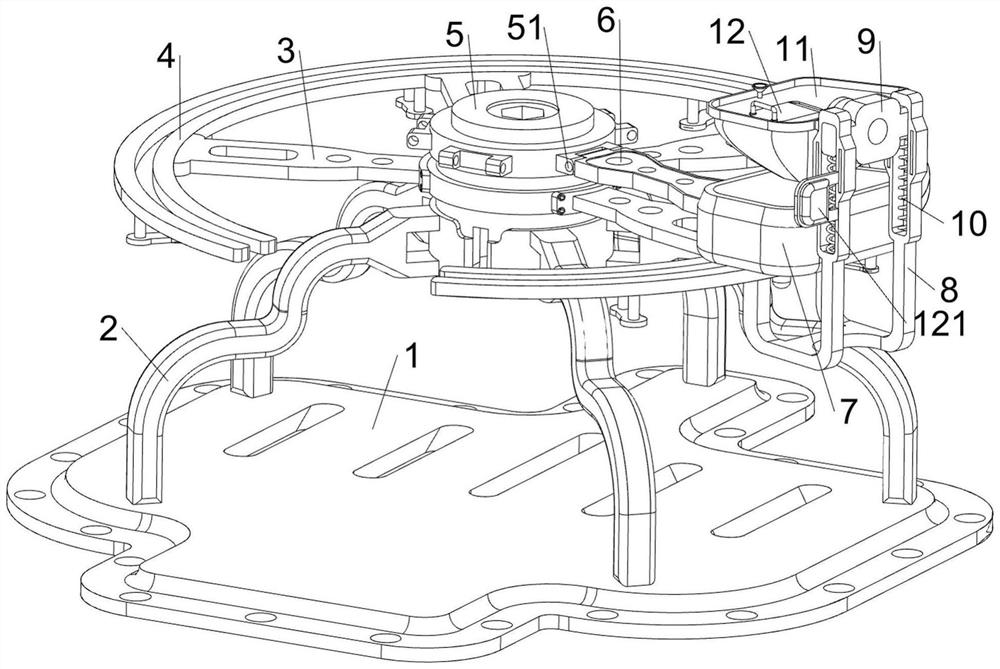

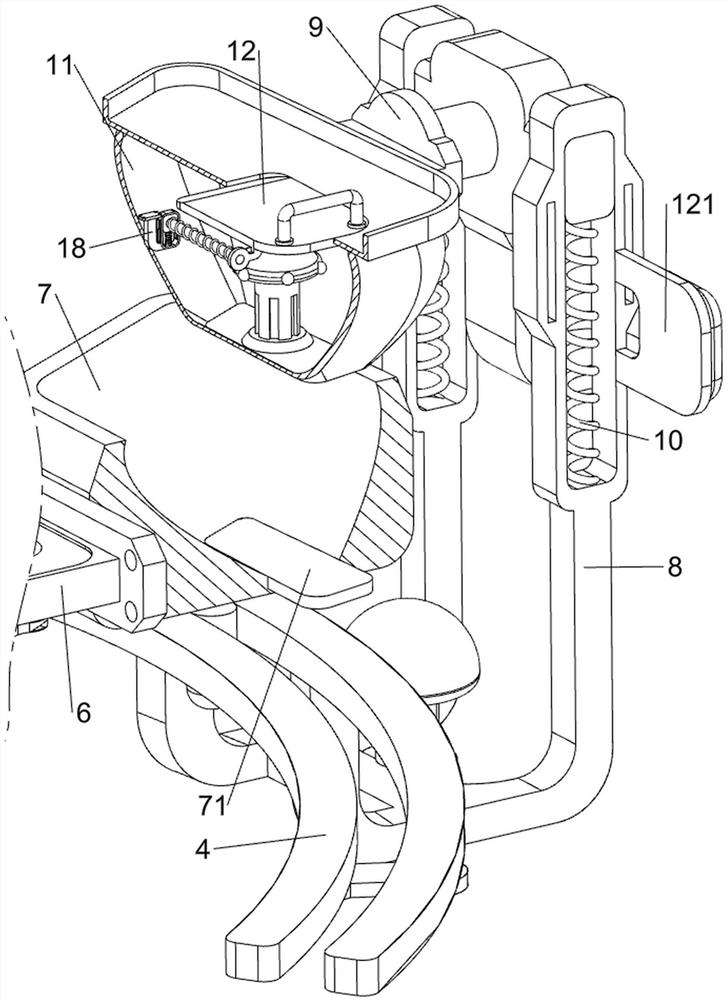

Portable automatic tree digging equipment

The invention relates to portable automatic tree digging equipment. The equipment comprises an annular frame, multiple clamping devices fixed to the annular frame, a rotating tool holder which is fixed to the annular frame and rotates in the circumferential direction of the annular frame, a tree digging knife fixed to the rotating tool holder, a conical gear disc arranged over the annular frame, a transmission device connecting the conical gear disc with the tree digging knife and a hydraulic power delivery pipe; the conical gear disc is fixed to a fixed frame; the conical gear disc comprises a gear disc part a and a gear disc part b; one end of the gear disc part a is rotatably connected with one end of the gear disc part b through a rotating shaft; the annular frame comprises an arc-shaped block a and an arc-shaped block b, one side of the arc-shaped block a and one side of the arc-shaped block b are connected through a buckle device, the other side of the arc-shaped block a and the other side of the arc-shaped block b are rotatably connected with the gear disc part a and the gear disc part b; the defects that tree digging equipment is large in size, use is limited, tree digging positioning is not accurate, and potential safety hazard exits due to the fact that personnel support is needed in the tree digging process are overcome.

Owner:伊美特(安徽)环保科技有限公司

Ground sewage treatment for material warehouse and use method thereof

ActiveCN109820457ANo manual push requiredImprove water absorptionGeneral water supply conservationMachine detailsRubber materialWater storage

The invention relates to a ground sewage treatment device for a material warehouse and a use method thereof. The ground sewage treatment device for the material warehouse comprises two parallel side plates, a cleaning box is arranged at front ends of the side plates, guide rollers, an extrusion roller and a driving roller are arranged between the side plates in parallel; a water absorption band use for absorbing sewage winds around the guide rollers, the extrusion roller and the driving roller, an extrusion device is installed on the side plates, and can press the extrusion roller on the driving roller, and a water storage box is arranged between the side plates and located below the driving roller; the cleaning box comprises a water collecting chamber and a water spraying chamber; an opening is formed in the lower end of the water collecting chamber, a flexible sheet made from a rubber material is installed on the rear side of the opening, a water wheel is installed in the water collecting chamber, and can push the sewage on the ground into the water collecting cavity; a water spraying hole is formed in the lower end of the water spraying chamber. Accordingly, time and labor are saved, the water absorption efficiency is high, and the effect is good. The invention further discloses the use method of the device.

Owner:JINING POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

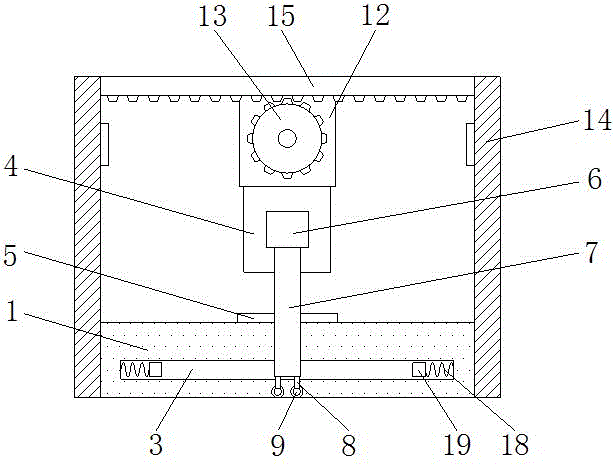

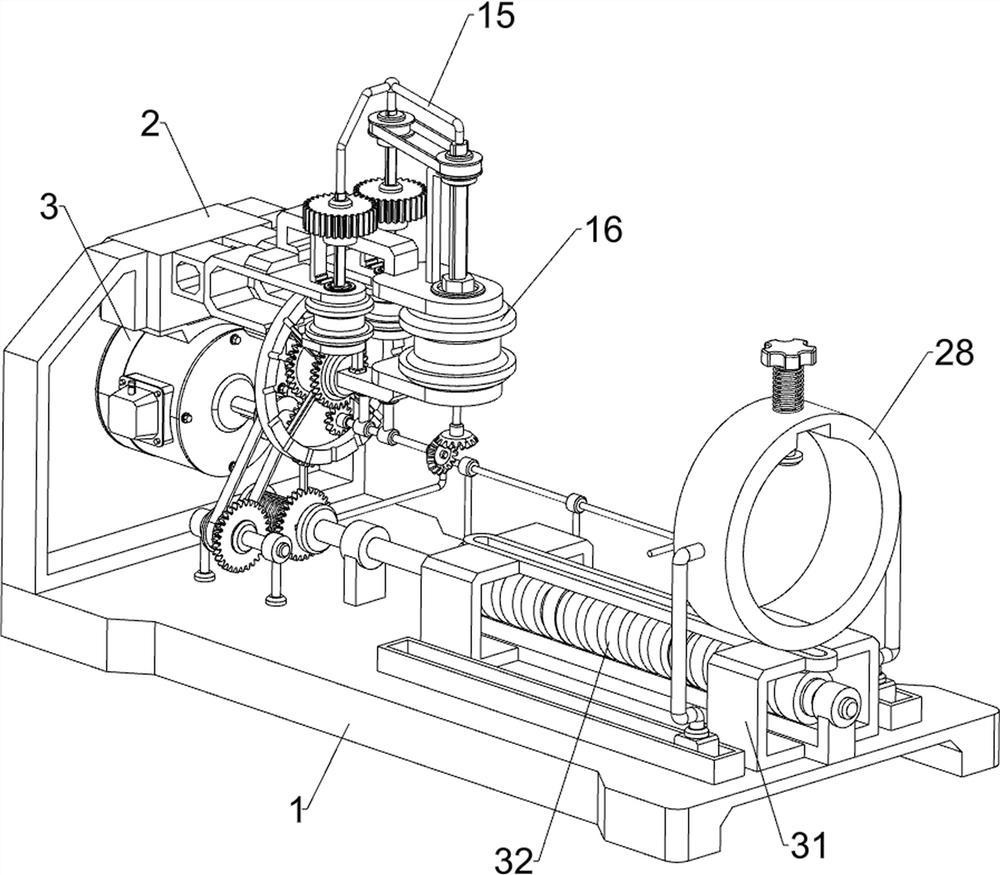

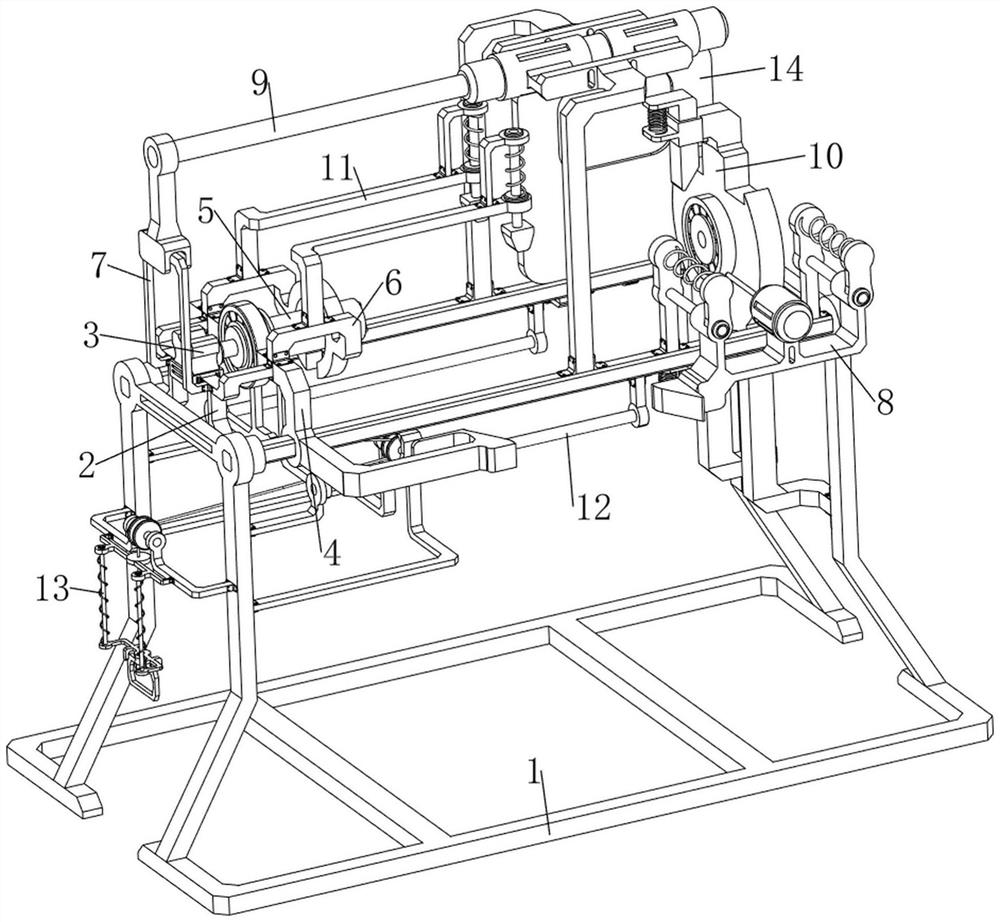

Automatic polishing machine for vertical bamboo flute wall

ActiveCN111843769AEasy to operateUniform sandingEdge grinding machinesGrinding carriagesFlutePolishing

The invention relates to a polishing machine, in particular to an automatic polishing machine for a vertical bamboo flute wall. The invention provides the automatic polishing machine for the verticalbamboo flute wall, and is characterized in that the automatic polishing machine is simple to operate and a polishing degree of each position of the vertical bamboo flute wall is even. The automatic polishing machine for the vertical bamboo flute wall comprises a base, an installation frame, a power component, a vertical bamboo flute wall polishing component and a corner polishing component, wherein the installation frame is installed on the base; the power component is installed on the installation frame; the vertical bamboo flute wall polishing component is installed on the installation frame; and the corner polishing component is installed between the installation frame and the vertical bamboo flute wall polishing component. According to the automatic polishing machine disclosed by the invention, the power component can drive the vertical bamboo flute wall polishing component and the corner polishing component to work to polish the vertical bamboo flute wall, the vertical bamboo flute wall does not need to be manually polished, and operation is simple. The automatic polishing machine can automatically drive a clamped vertical bamboo flute to move, the polishing degree of each position of the vertical bamboo flute wall is even, a polished part can be replaced, and a replacement operation is simple.

Owner:梁杰

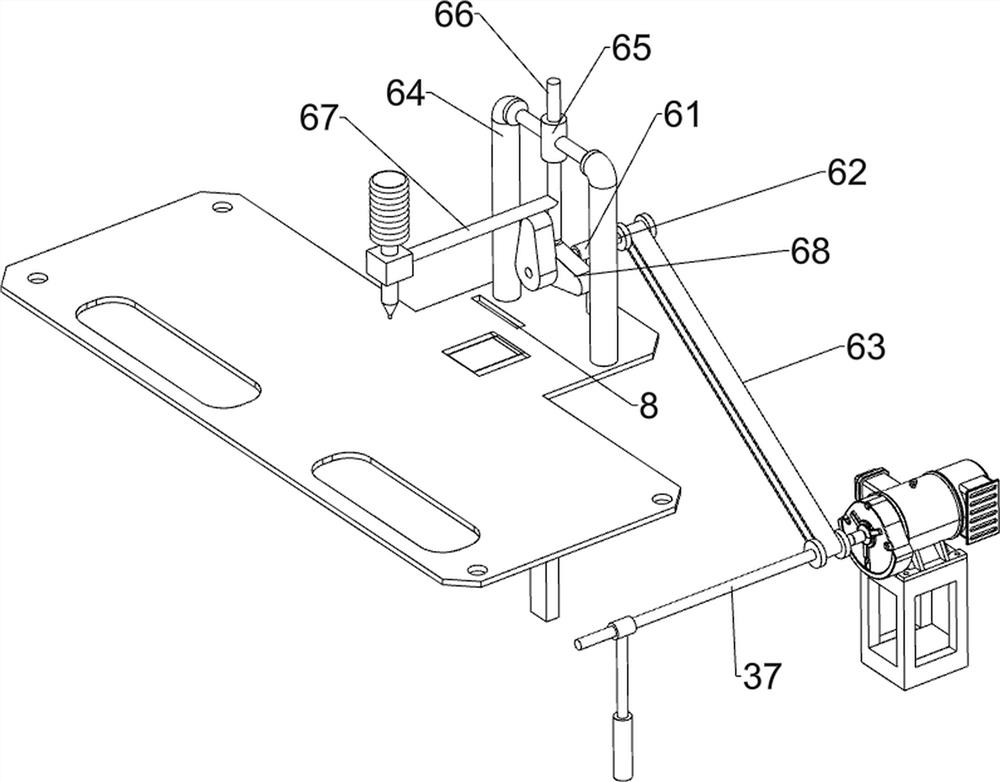

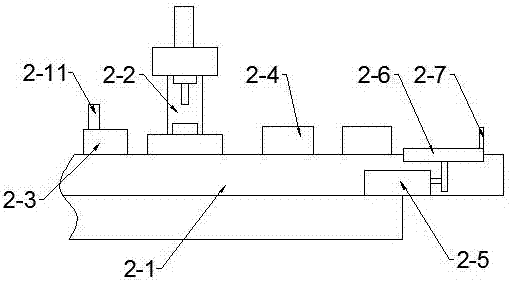

High-precision steel plate drilling equipment for orthopedics department

ActiveCN113600859AAvoid spillingImplement basic functionsFeeding apparatusPositioning apparatusOrthopedic departmentEngineering

The invention relates to drilling equipment, in particular to high-precision steel plate drilling equipment for the orthopedics department. The high-precision steel plate drilling equipment for the orthopedics department is convenient to adjust, easy to operate and accurate in drilling. The high-precision steel plate drilling equipment for the orthopedics department comprises a base, a first fixing frame, a second fixing frame, a heat dissipation plate, a sliding glass door, a rodless air cylinder and an electric drill, the first fixing frame is arranged on one side of the top of the base, the heat dissipation plate is arranged on the top of the first fixing frame, and the sliding glass door is arranged on one side of the first fixing frame in a sliding mode; and the rodless air cylinder is arranged on the inner wall of the upper portion of the first fixing frame, the electric drill is arranged on a telescopic rod of the rodless air cylinder, and the second fixing frame is arranged on the other side of the top of the base. By arranging a supporting mechanism and a moving mechanism, a steel plate is clamped and limited, then the steel plate is driven to move, the electric drill moves up and down to drill the steel plate, and the basic function of the high-precision steel plate drilling equipment is achieved.

Owner:南京市淑先科技有限公司

High-efficiency disinfection equipment for sport equipment

PendingCN107569702AFully contactedNo manual push requiredLavatory sanitoryChemicalsDisinfectantSports equipment

Owner:叶明

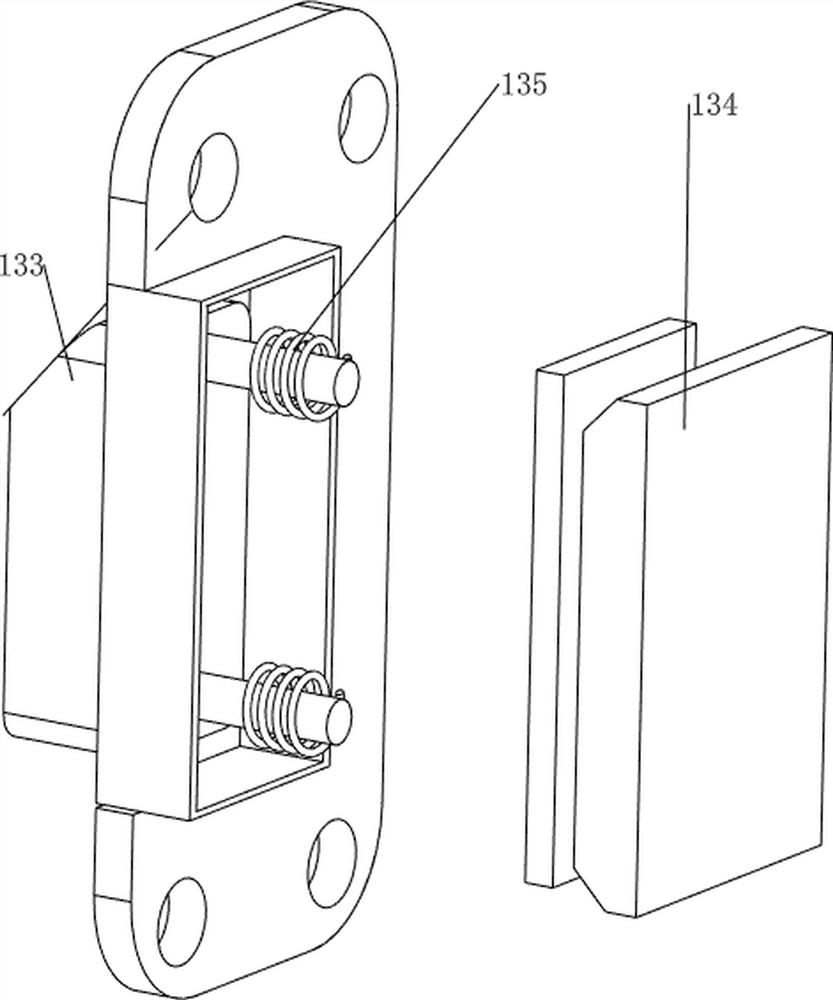

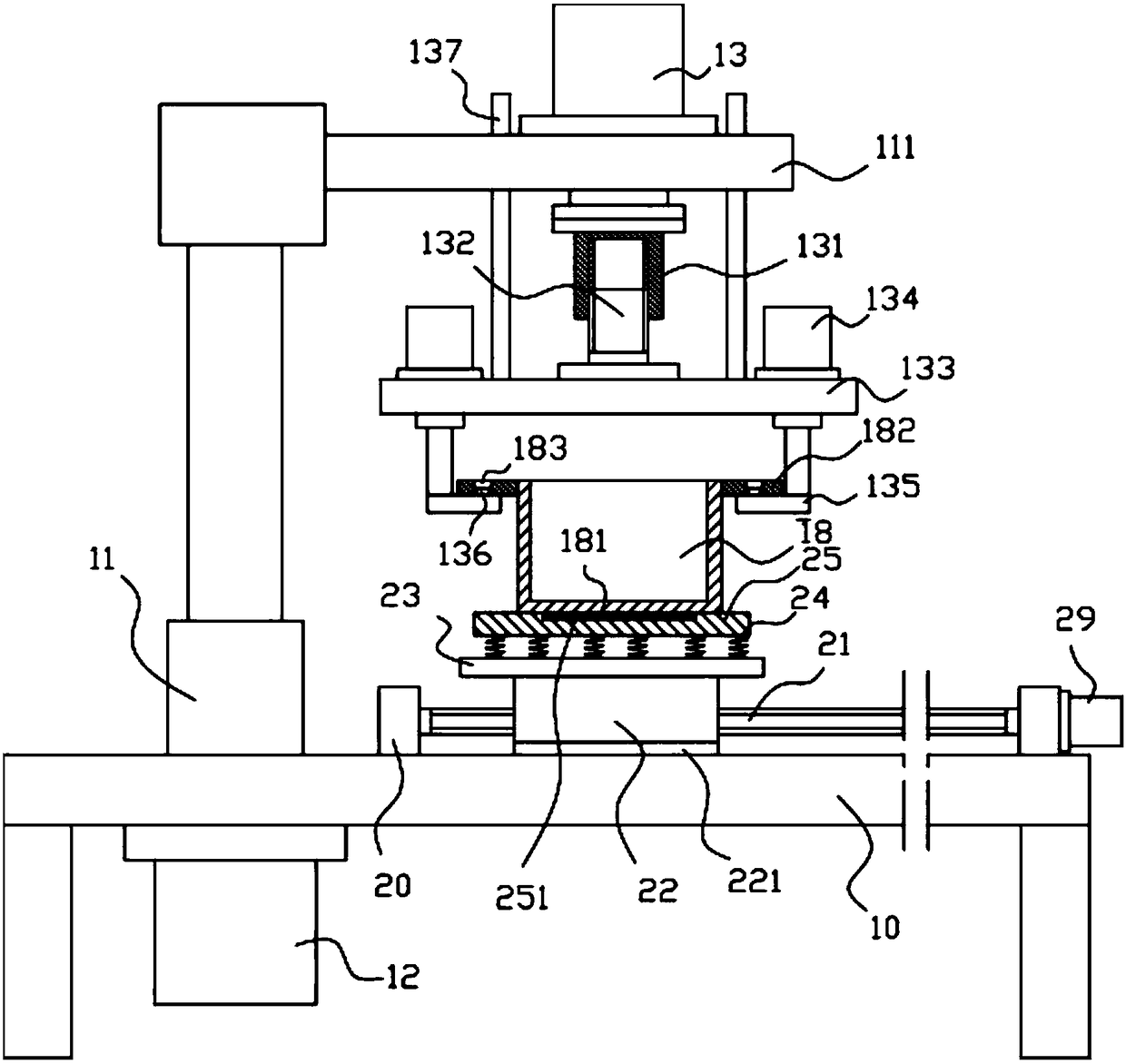

Batch flattening and recycling device for zip-top cans

PendingCN112810221APrevent affecting work processImplement basic functionsPressesMechanical engineeringIndustrial engineering

The invention relates to a flattening and recycling device, in particular to a batch flattening and recycling device for zip-top cans. The invention mainly aims to provide a batch flattening and recycling device for zip-top cans, which provides a closed extrusion environment, carries out automatic blanking, pushing and extrusion through a machine, reduces the operation amount and ensures the safety. The batch flattening and recycling device for the zip-top cans comprises a base, a zip-top can flow direction mechanism and a flattening mechanism, wherein the base and a bottom plate are arranged; the zip-top can flow direction mechanism is connected between the base and the top of the bottom plate; and the flattening mechanism is arranged at one side of the top of the base. Through the arrangement of the zip-top can flow direction mechanism and a baffle locking mechanism, when a baffle is clamped with a working cavity, a buckle is driven to clamp the baffle, so that the situation that the baffle is pushed away by too large force of a flattening plate, and the working process is affected is prevented; and through the arrangement of the flattening mechanism, the flattening plate is driven to move leftwards to flatten the zip-top cans, so that the basic functions of the device are achieved.

Owner:刘学丽

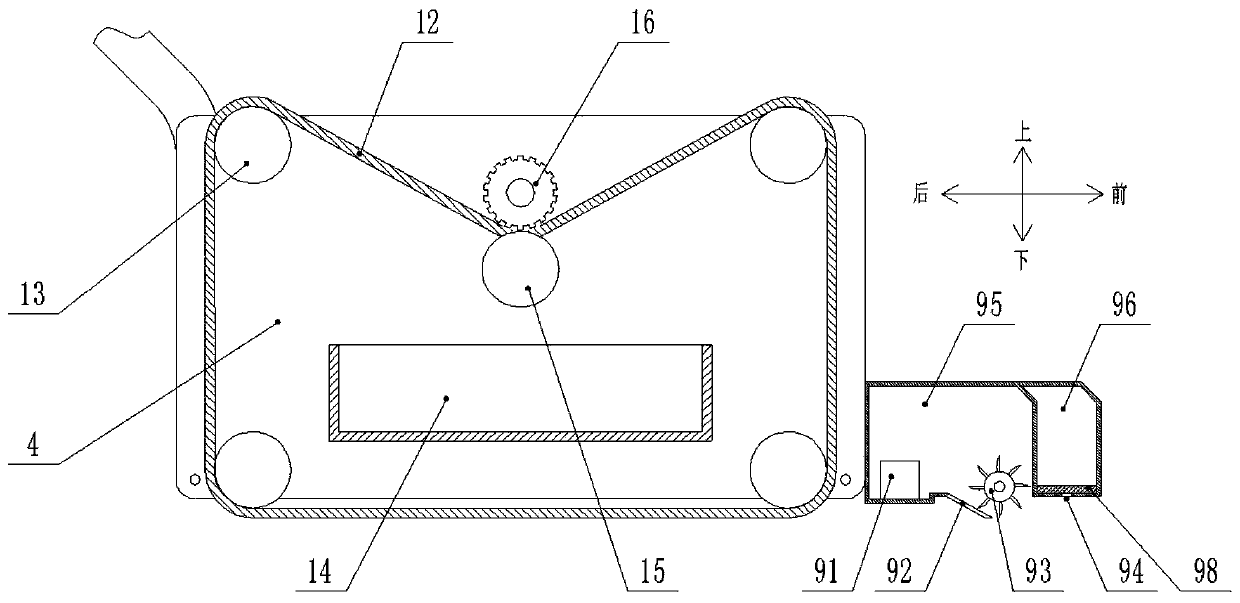

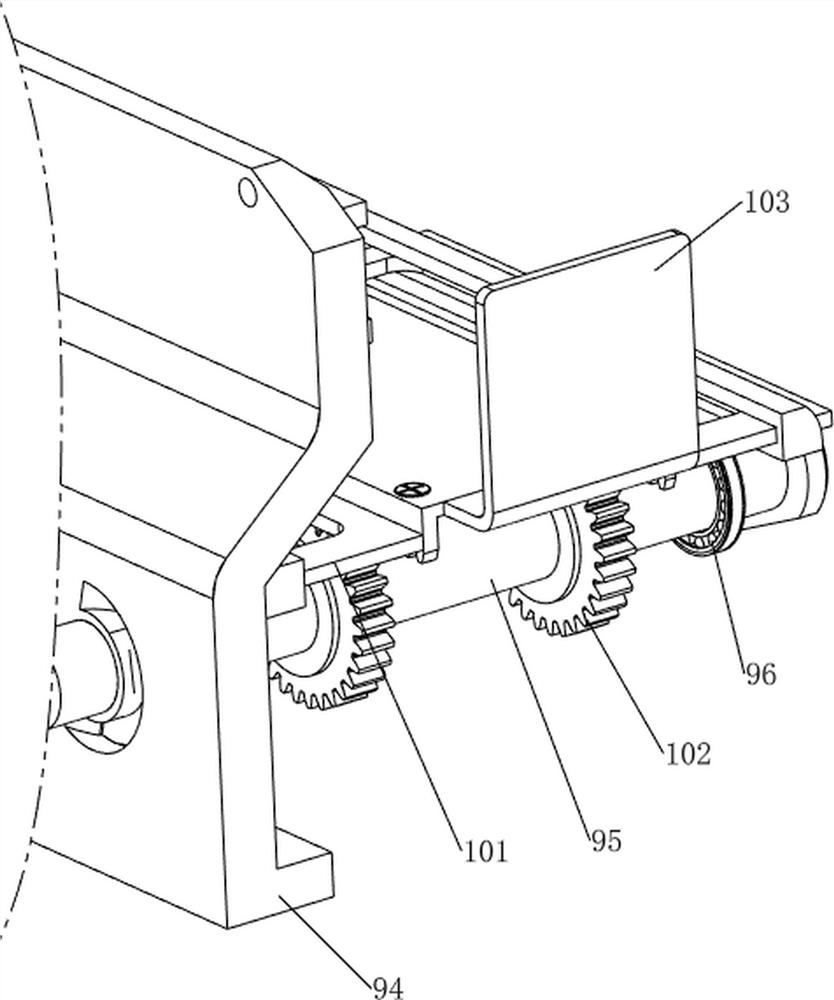

Sugarcane juicing device

ActiveCN111743168ARealize automatic movementNo manual push requiredJuice extractionFood treatmentBiotechnologyMechanical engineering

The invention relates to a juicing device, in particular to a sugarcane juicing device. According to the sugarcane juicing device, sugarcanes do not need to be washed clean manually, the sugarcanes donot need to be pushed manually, and multiple sugarcanes can be pressed at the same time. According to the technical scheme, the sugarcane juicing device comprises a base, a special-shaped base installed in the middle of the base, flow channel grooves evenly formed in one side of the special-shaped base, and a collecting frame for collecting sugarcane juice placed on the side, close to one side ofthe flow channel grooves, of the base; and a squeezing mechanism arranged between the front side and the rear side of the special-shaped seat. According to the sugarcane juicing device, the sugarcanecan be squeezed, sugarcane juice can be squeezed out and sugarcane juicing work can be completed through the squeezing mechanism, automatic movement of the sugarcane can be achieved through the feeding mechanism, the sugarcane does not need to be pushed manually, manual operation is reduced, meanwhile, due to the design of a feeding barrel and a roller, three sugarcanes can be juiced at the sametime, and the juicing efficiency is improved.

Owner:临沂市玉兴废旧物资回收有限公司

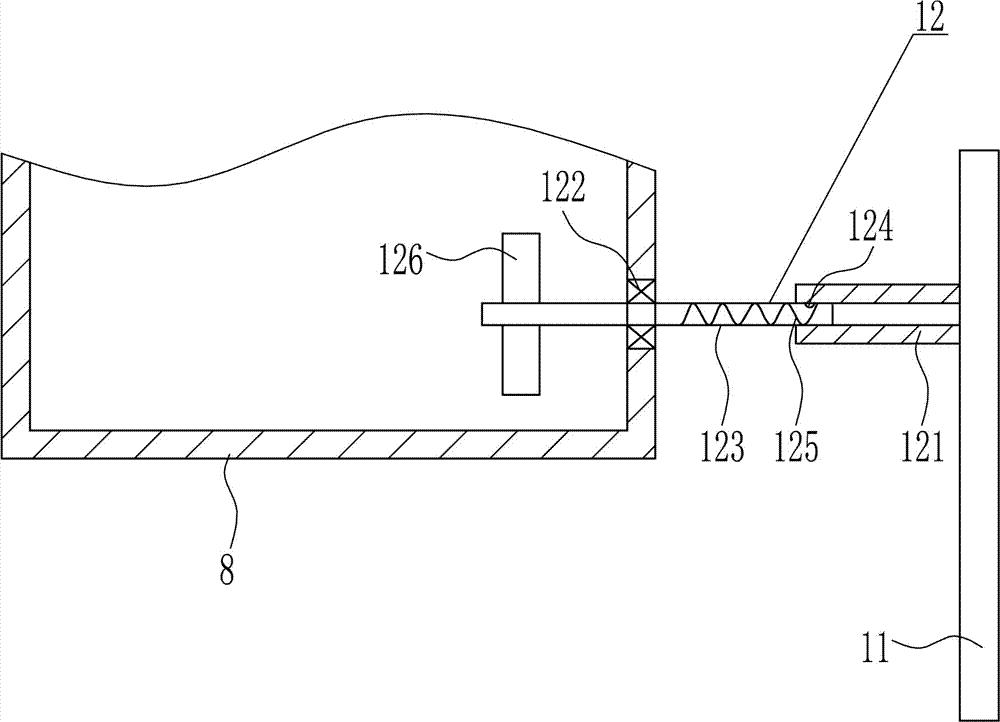

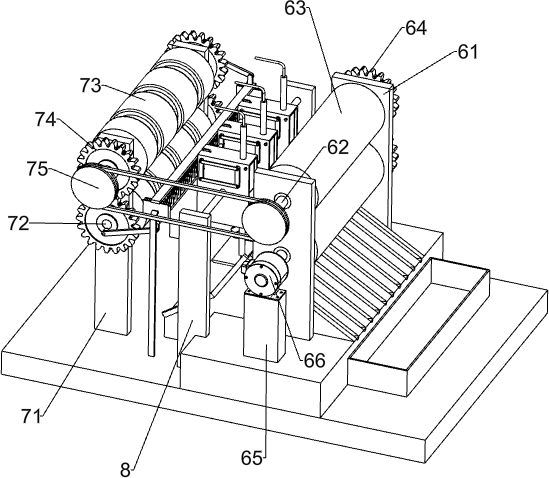

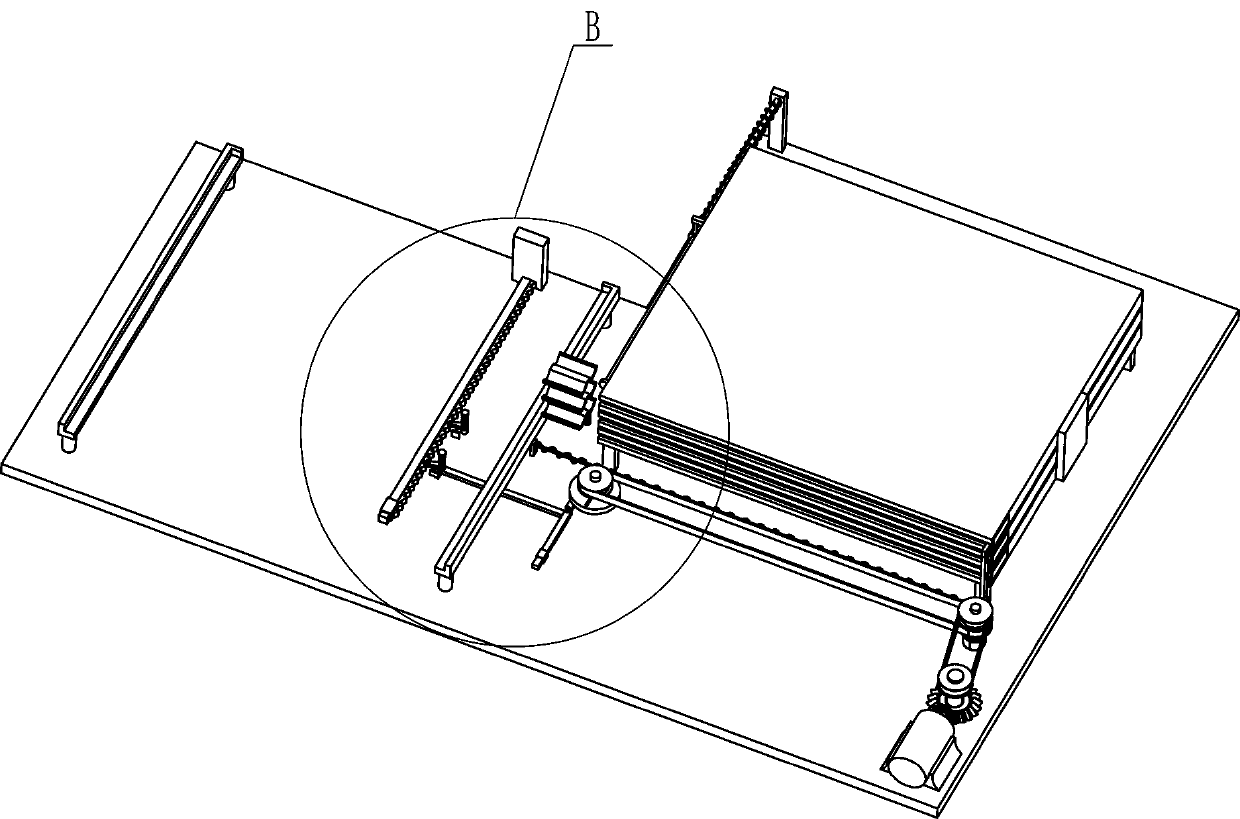

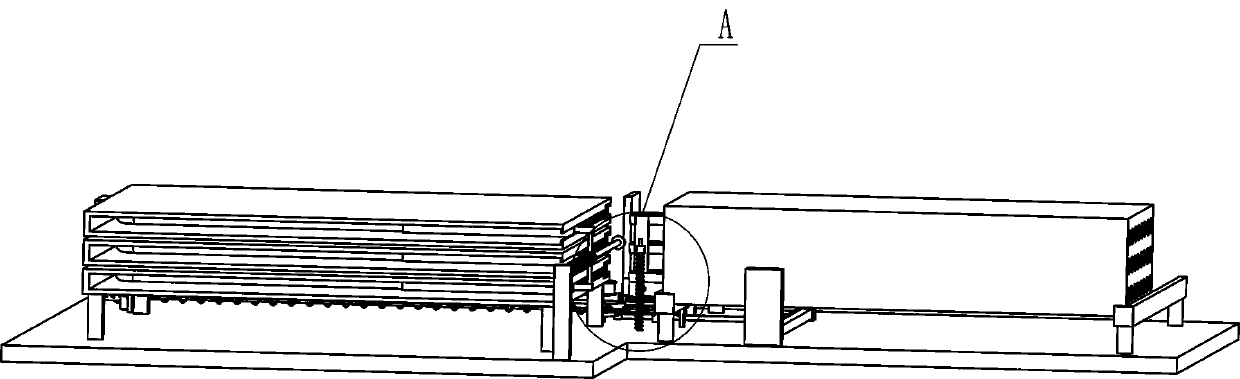

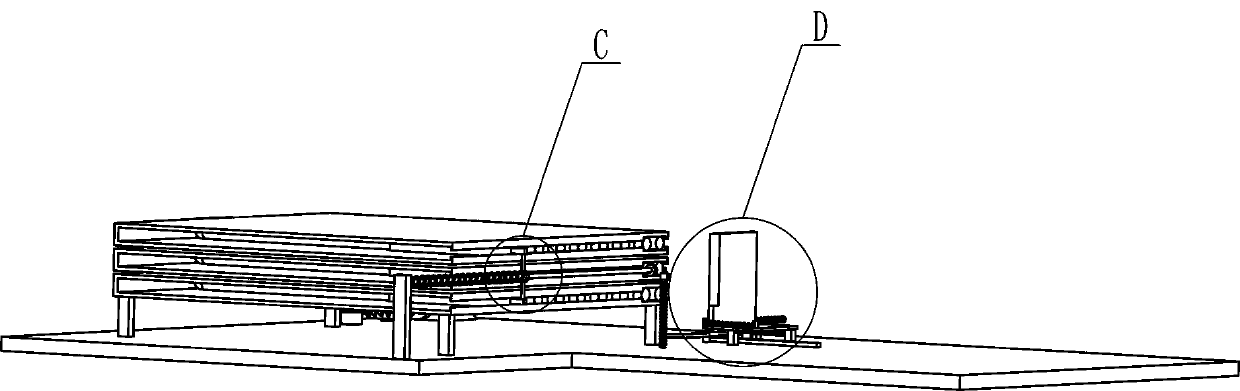

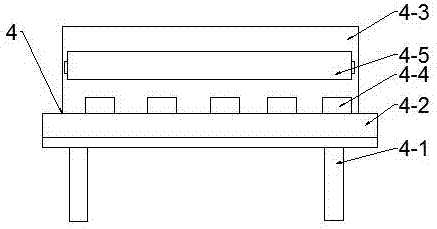

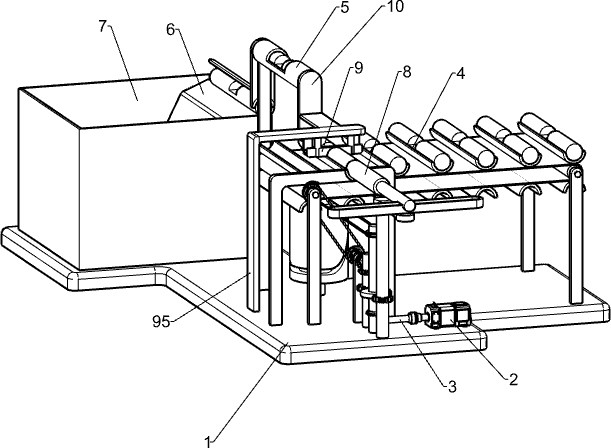

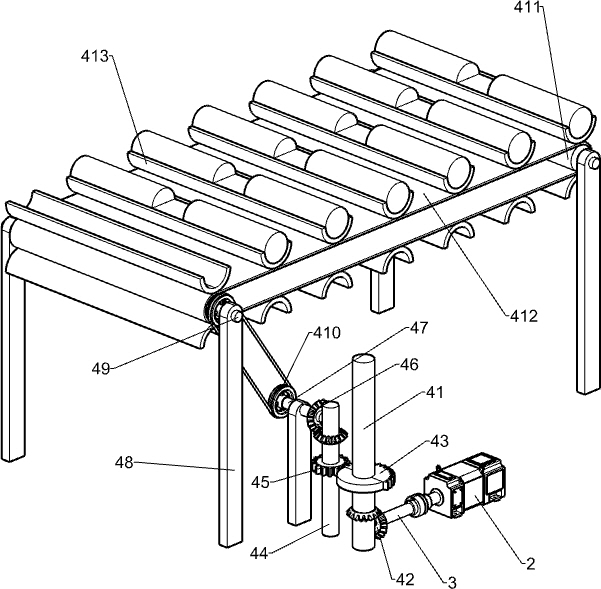

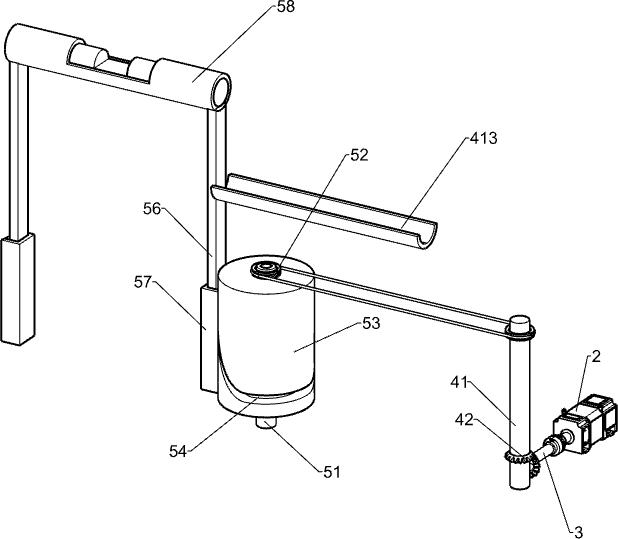

Automatic pipe inserting device for surface air cooler box

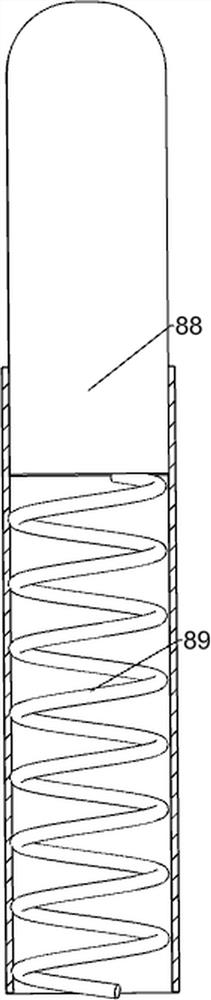

InactiveCN111571167ARealize automatic intermittent conveyingSimplify delivery operationsMetal working apparatusReciprocating motionElectric machinery

The invention relates to a pipe inserting device, and particularly relates to an automatic pipe inserting device for a surface air cooler box. The automatic pipe inserting device for the surface air cooler box aims at achieving the technical purposes that automatic conveying of U-shaped copper pipes can be achieved, manual inserting is not needed, and the work efficiency is greatly improved. The automatic pipe inserting device for the surface air cooler box comprises a bottom plate, a motor, feeding boxes and the like, wherein the motor is arranged on one side of the top of the bottom plate; and the at least three feeding boxes used for storing the U-shaped copper pipes are placed on the side, pointed by the end portion of an output shaft of the motor, of the bottom plate from bottom to top. According to the automatic pipe inserting device, through cooperation of a first push block capable of circularly moving, a first push frame and a second push frame, automatic intermittent conveying of the U-shaped copper pipes in the surface air cooler box can be achieved, when a drive pawl intermittently reciprocates left and right, the surface air cooler box can be driven to automatically replace the pipe inserting position, and through intermittent front-back reciprocating motion of a second push plate, the U-shaped copper pipes can be completely extruded into the surface air cooler box.

Owner:陈燕霞

Automobile waste collection box gripping device

The invention discloses a grabbing device for an automobile waste collection box, which includes a frame, and support plates are fixed on the left and right top surfaces of the top plate of the frame, and the two ends of the laterally moving screw rod are hinged on the two support plates Above, the main moving block is screwed into the horizontal moving screw, the top surface of the main moving block is fixed with a grabbing frame, one end of the lateral moving screw protrudes from the outer wall of one of the supporting plates and is fixed with a moving transmission gear, the top plate of the frame The bottom surface of the horizontal movement motor is fixed with a moving drive gear fixed on the output shaft of the transverse movement motor. The moving driving gear and the moving transmission gear are meshed. In the transmission slot; it can be set around the processing equipment, which can grab all the surrounding waste collection boxes and place them uniformly on the left side of the frame, which is convenient for subsequent equipment to process. It is very convenient and does not need to be manually pushed.

Owner:FOSHAN RUIPUDA OPTOELECTRONICS TECH CO LTD

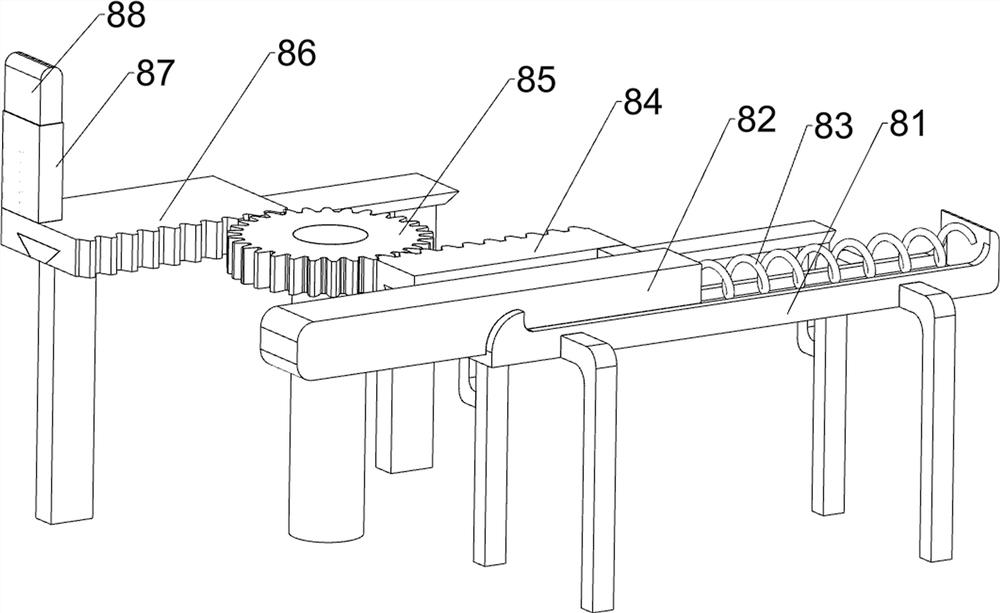

Cosmetic raw material barrel transverse conveying mechanism

InactiveCN106915612ANo manual push requiredFacilitate subsequent processingMechanical conveyorsInternal fittingsEngineeringMechanical engineering

The invention discloses a cosmetic raw material barrel transverse conveying mechanism, which comprises a ground installation groove, a main barrel body and a placement rack. Adjusting plates are fixed to the left end and the right end of the ground installation groove; two ends of a transverse adjustment screw rod are hinged onto the two adjusting plates; a transverse movement motor is fixed on one adjusting plate; an output shaft of the transverse movement motor is a spline shaft; the spline shaft is inserted and sleeved in a spline hole in one end of the transverse adjustment screw rod; a bottom plate of the placement rack is located in the ground installation groove; transverse movement blocks are fixed to the left side and the right side of the bottom surface of the bottom plate of the placement rack, and are screwed in the transverse adjustment screw rod; the main barrel body is located in the placement rack. The cosmetic raw material barrel transverse conveying mechanism can linearly and automatically convey the main barrel body without the need for manual pushing, and is time and labor saving, and convenient for subsequent processing; meanwhile, a lifting plate in the main barrel body can lift automatically to upwards push a material on the bottom part, so that liquid can be sucked conveniently through a sucker device without dumping the main barrel body.

Owner:蔡萍

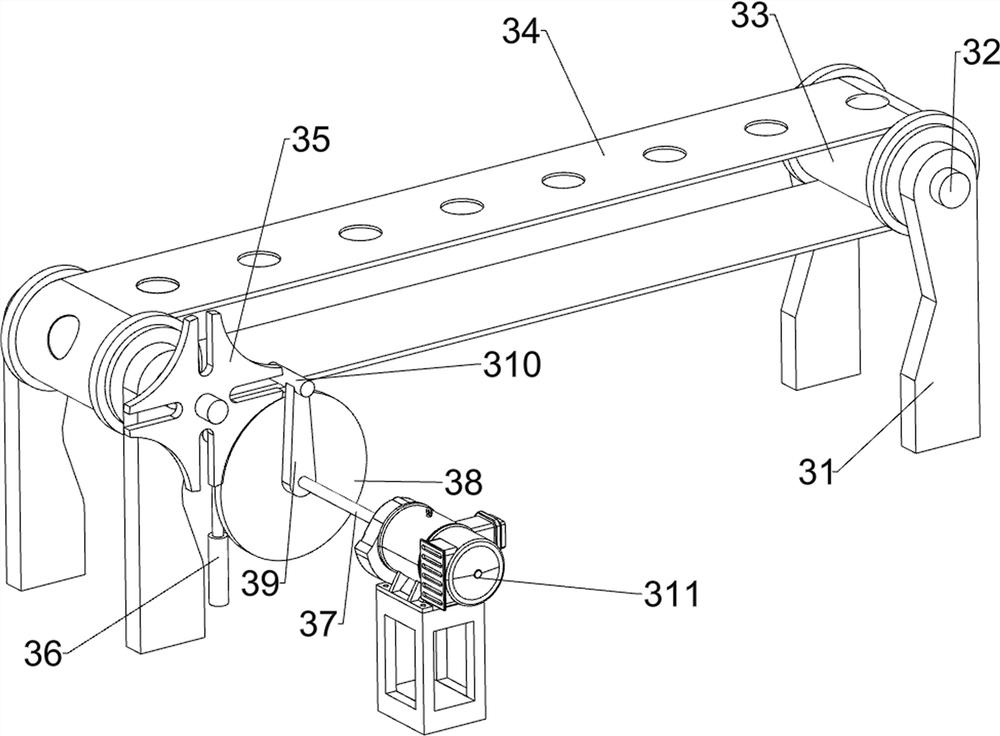

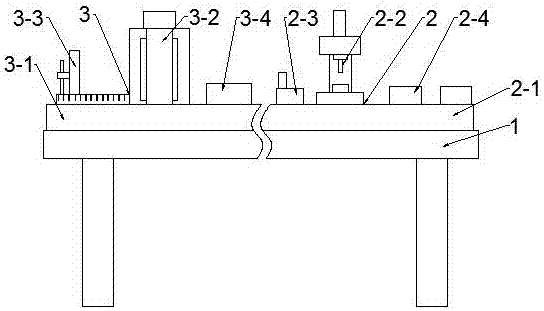

Grounded flat iron processing and manufacturing platform

ActiveCN107123914APrevent overshootPrevent problems such as slantingContact member manufacturingConnection contact member materialState of artEngineering

The invention discloses a grounded flat iron processing and manufacturing platform, which is used for solving the technical problems of low flat iron manufacturing mechanization degree, poor manufacturing quality, low work efficiency and the like in the prior art. The grounded flat iron processing and manufacturing platform comprises an operation platform and a spraying brushing mechanism, wherein a hole punching mechanism and a bending mechanism are arranged on the operation platform; the hole punching mechanism comprises a base, a hole punching machine, a support block and a positioning block are arranged at the upper part of the base; the support block is positioned at one side of the hole punching machine; the positioning block is positioned at the other side of the hole punching machine; the bending mechanism comprises a support seat; a bending machine, a positioning plate and a fixing plate are arranged on the support seat; the positioning plate is positioned at one side of the bending machine; the fixing plate is positioned at the other side of the bending machine; the spraying brushing mechanism comprises a spraying and brushing support frame; a fixing seat and a support plate are arranged on the spraying and brushing support frame; paint blocking plates are arranged on the fixing seat at intervals; a cover plate is arranged on the support plate. The fast and precise hole punching bending can be realized; the phase color mark can be formed in one step; the manufacturing time can be reduced from the original 50 minutes to 5 minutes; the work efficiency is improved by 10 times and the quality of the workpiece is ensured.

Owner:PUYANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER +2

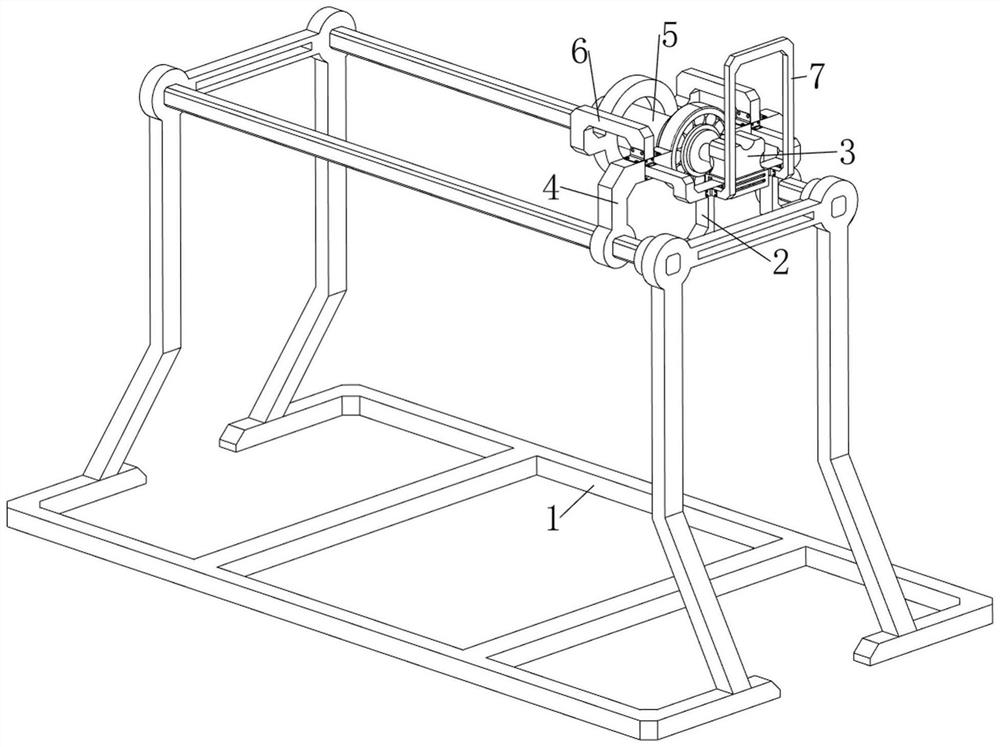

Steel bar specified-length cutting equipment for house building

ActiveCN112872243AAvoid warpingEasy to collectEngineering safety devicesConstruction engineeringHouse building

The invention relates to cutting equipment, in particular to steel bar specified-length cutting equipment for a house building. The technical problem to be solved is to provide the steel bar specified-length cutting equipment for the house building. The steel bar specified-length cutting equipment for the house building can automatically cut steel bars and can adjust the length of the cut steel bars. According to the technical scheme, the steel bar specified-length cutting equipment for the house building comprises a base, a conveying mechanism, a mounting column and a mounting rod. A downward pressing mechanism is arranged in the middle of the top of the base. The conveying mechanism is arranged on one side of the top of the base. The mounting column is arranged on one side of the top of the base. The mounting rod is rotationally arranged on the mounting column. The steel bars can be automatically moved through the arranged conveying mechanism, and manual pushing is not needed; and an electric cutting wheel can be conveniently moved and reset through the arranged downward pressing mechanism.

Owner:江西清江建设发展有限公司

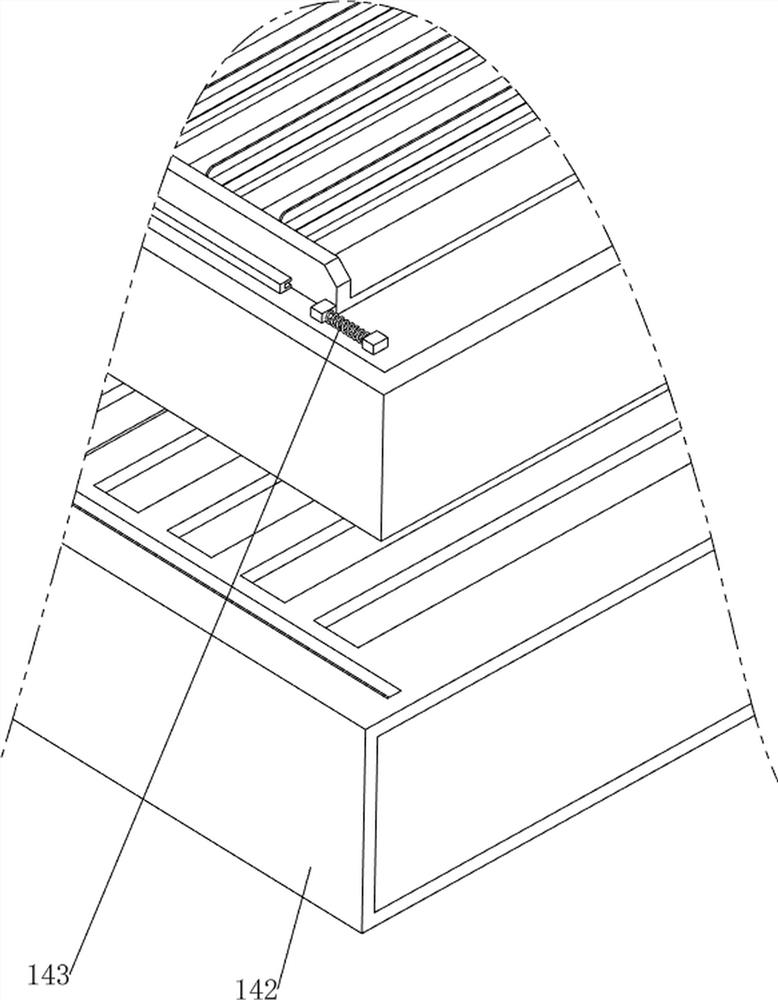

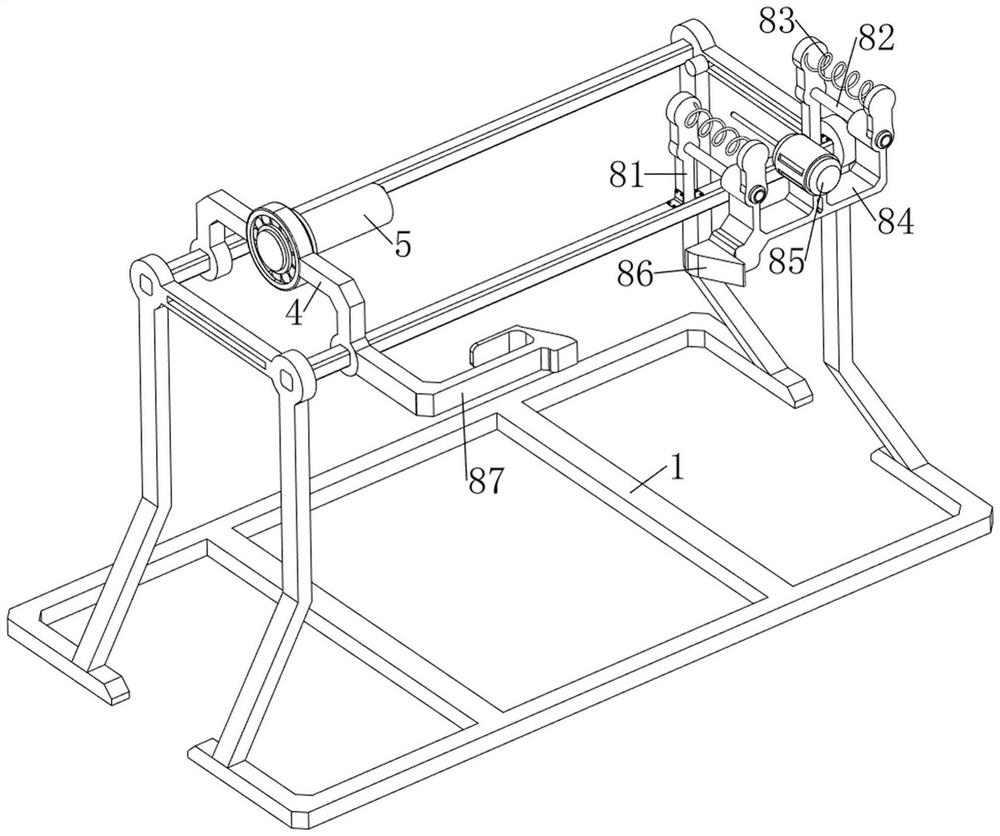

Screening device for rare earth raw material processing

InactiveCN113877817ARealize the push effectNo manual push requiredSievingGas current separationRaw materialSupport plane

The invention relates to a screening device, in particular to a screening device for rare earth raw material processing. The screening device for rare earth raw material processing is good in screening effect, capable of conducting secondary screening and low in cost. The screening device for rare earth raw material processing comprises a bottom frame, a first discharging frame, a first supporting frame, a first screening frame, a material pushing mechanism and a rotary reciprocating mechanism; the first discharging frame is arranged on the bottom frame; the first supporting frame is arranged on the bottom frame; the first screening frame is arranged on the first supporting frame in a sliding mode; the material pushing mechanism is arranged among the bottom frame, the first screening frame and the first supporting frame; and the rotary reciprocating mechanism is arranged among the bottom frame, the first supporting frame and the material pushing mechanism. According to the screening device, a material pushing frame is manually pushed to move backwards, rare earth is pushed together through the material pushing frame, screening is convenient, and the material pushing effect is achieved.

Owner:叶小刚

A household floor mopping and cleaning device

ActiveCN109199262AEasy to cleanReduce manpower expenditureCarpet cleanersFloor cleanersLow speedEngineering

A household floor mopping and cleaning device includes a device body and four rollers mounted on the bottom of the device body. A movable port is arranged on the bottom wall of the middle part of thedevice body. A low-speed motor is installed inside that device body, the motor shaft on the low-speed motor penetrates the device body and extends to the inside of the movable port, the bottom end ofthe motor shaft is provided with a mop mounting plate. The bottom wall of the mop mounting plate is fixedly connected with the mop, two water injection ports are symmetrically arranged on the top wallof the device body, the top ends of the two water injection ports are provided with sealing blocks, a knob is arranged on the top end of the sealing blocks, an air permeable hole is arranged on the top wall of the knob, and a rubber plug is inserted on the air permeable hole. The invention provides the portable and small device for cleaning the ground for modern families, which can easily complete the work that the floor-sweeping robot can not complete, is convenient to operate, can control the cleaning path through a remote controller, and has good use experience.

Owner:东阳市铭品日用品有限公司

Light-emitting diode for supplementing light in greenhouse

InactiveCN110859097AEasy to disassembleLow costSaving energy measuresHorticulture methodsPhysicsElectric machinery

The invention discloses a light-emitting diode for supplementing light in a greenhouse. The diode comprises a diode body, wherein the diode body is mounted on a lamp plate, the lamp plate is mounted inside a mounting cavity, a plurality of shock absorbing springs are connected between the bottom of the lamp plate and the inside of the mounting cavity, and a protective cover is mounted at the end part of the lamp plate outside the diode body. The mounting body moves slowly under a bearing plate through an upper sliding rail bracket, simulates different positions of sun irradiation at differenttimes, can irradiate crops from different directions at different times, has the same time of light supplement and actual sunlight irradiation, and can maximize the growth environment of crops. When the sliding rail bracket moves, a motor drives rotary wheels to roll in a sliding groove on the side surface of the bearing plate, so as to enable the diode body to move along with the mounting body atthe bottom of the bearing plate, and thus the position of the diode body can be freely changed. No manual pushing is needed, only electric control is needed, and thus the working efficiency is high.

Owner:马鞍山三投光电科技有限公司

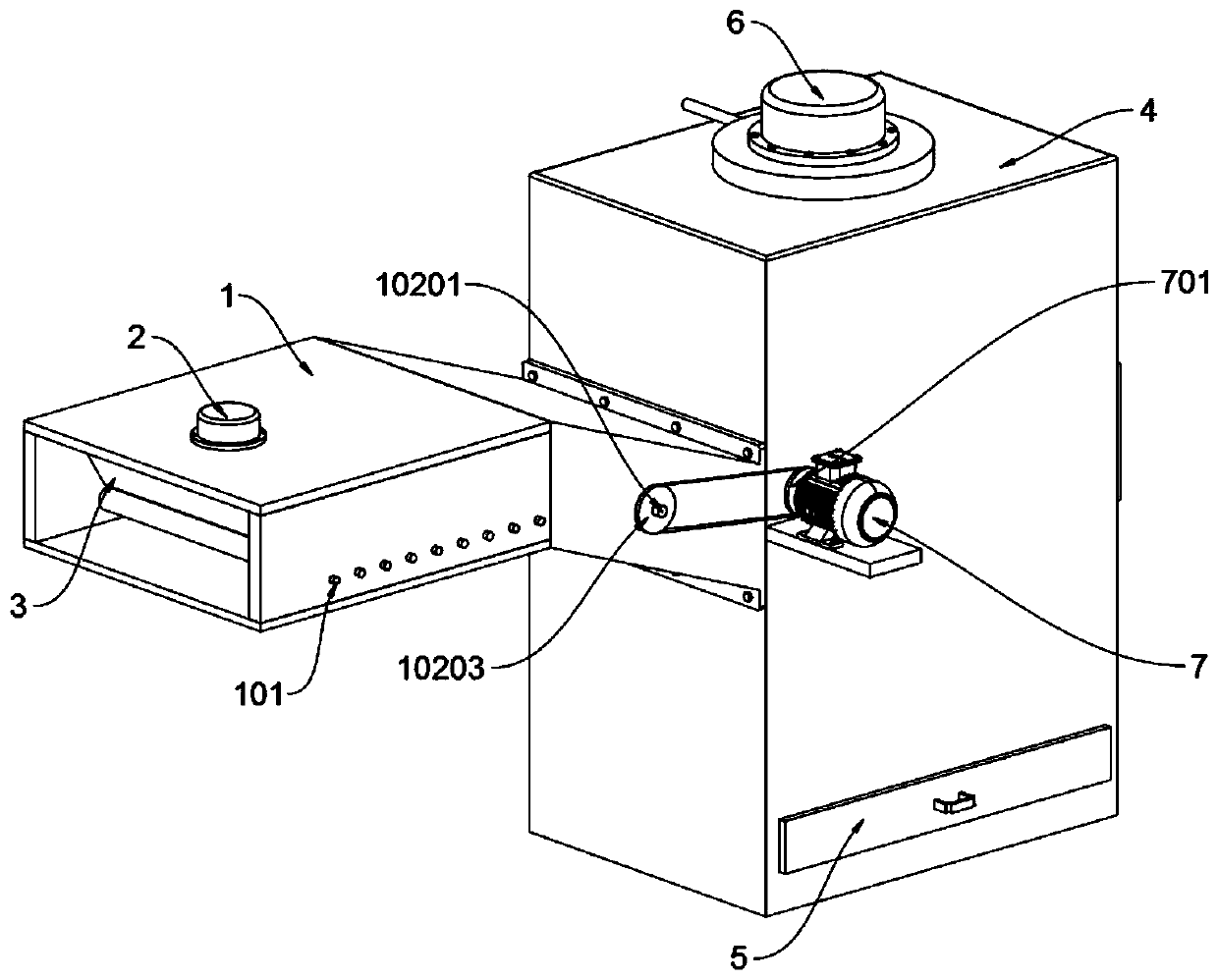

Iron piece automatic heat treatment device

ActiveCN111876565ANo manual push requiredRealize automatic feeding processQuenching devicesElectric machineEngineering

The invention relates to a heat treatment device, in particular to an iron piece automatic heat treatment device. According to the iron piece automatic heat treatment device, an iron piece can be automatically replaced, the heated iron piece is automatically thrown into water, and the operation safety is improved. According to the technical scheme, the iron piece automatic heat treatment device comprises a base and a cooling box; a motor is installed on the side of the base, an output rotating shaft is installed on an output shaft of the motor, and an intermittent feeding mechanism is arrangedon the side, close to the motor, of the base; and the cooling box is arranged on the side, away from the motor, of the base, and an intermittent lifting mechanism is arranged between the side of thecooling box and the side of the base. According to the iron piece automatic heat treatment device, by means of the intermittent lifting mechanism, the to-be-heated iron piece automatically moves upwards to make contact with a quenching device to be subjected to iron piece heat treatment, automatic feeding is achieved through an intermittent push-out mechanism, the heated iron piece automatically slides into the cooling box, and the iron piece does not need to be pushed manually.

Owner:郴州弘德尚铸造有限公司

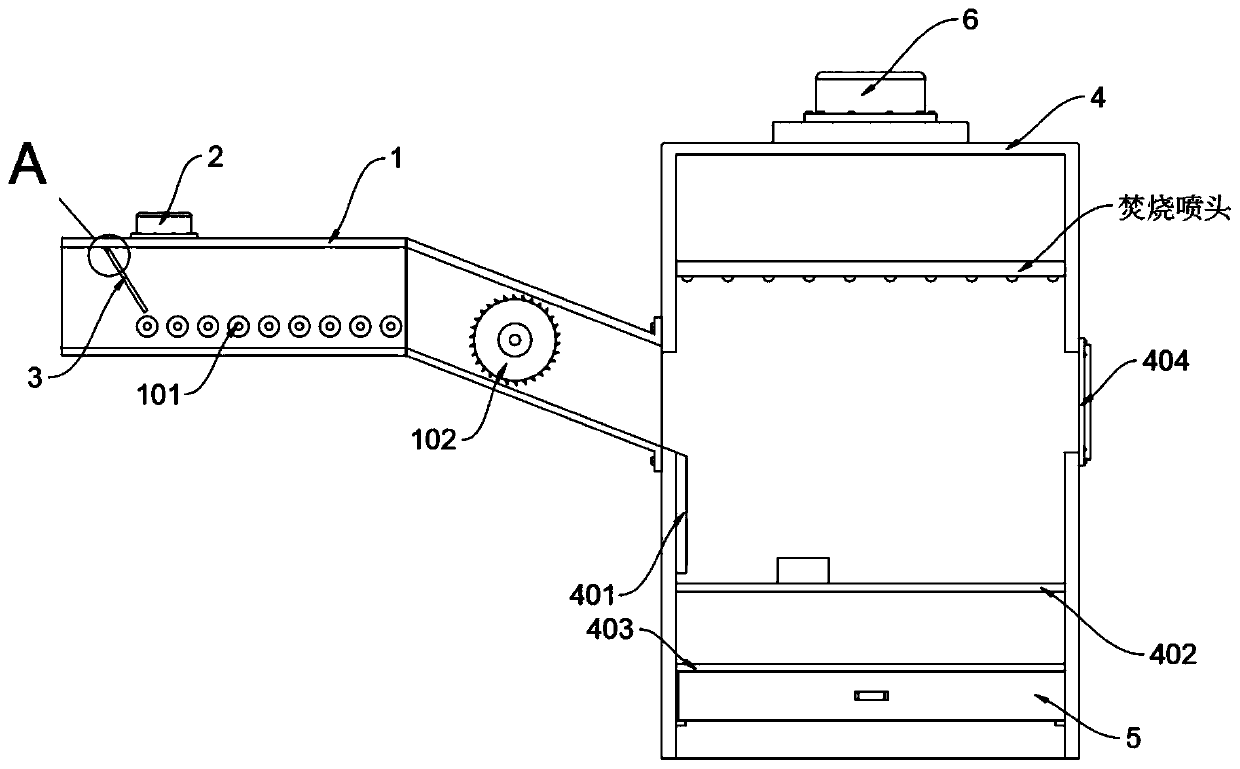

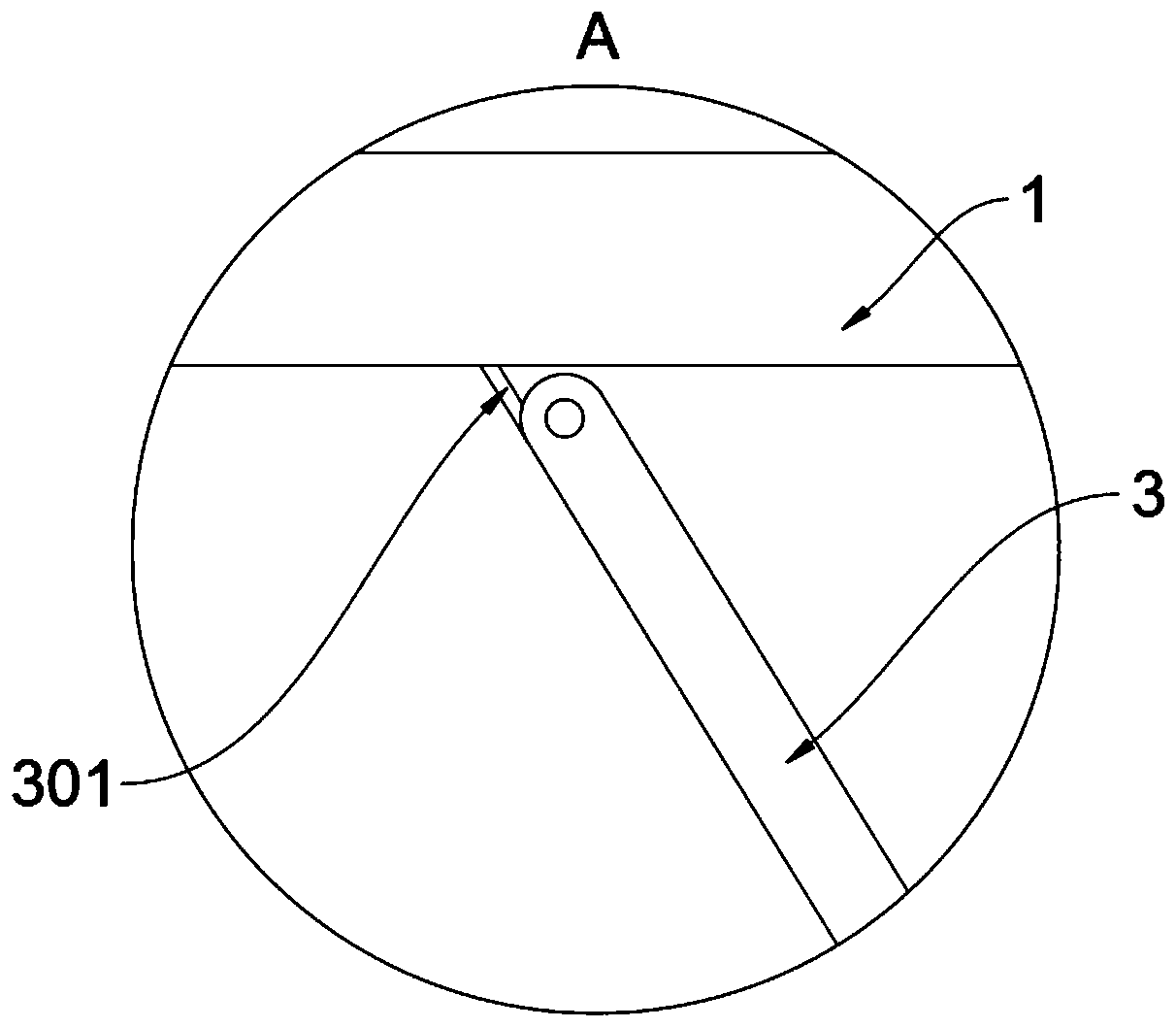

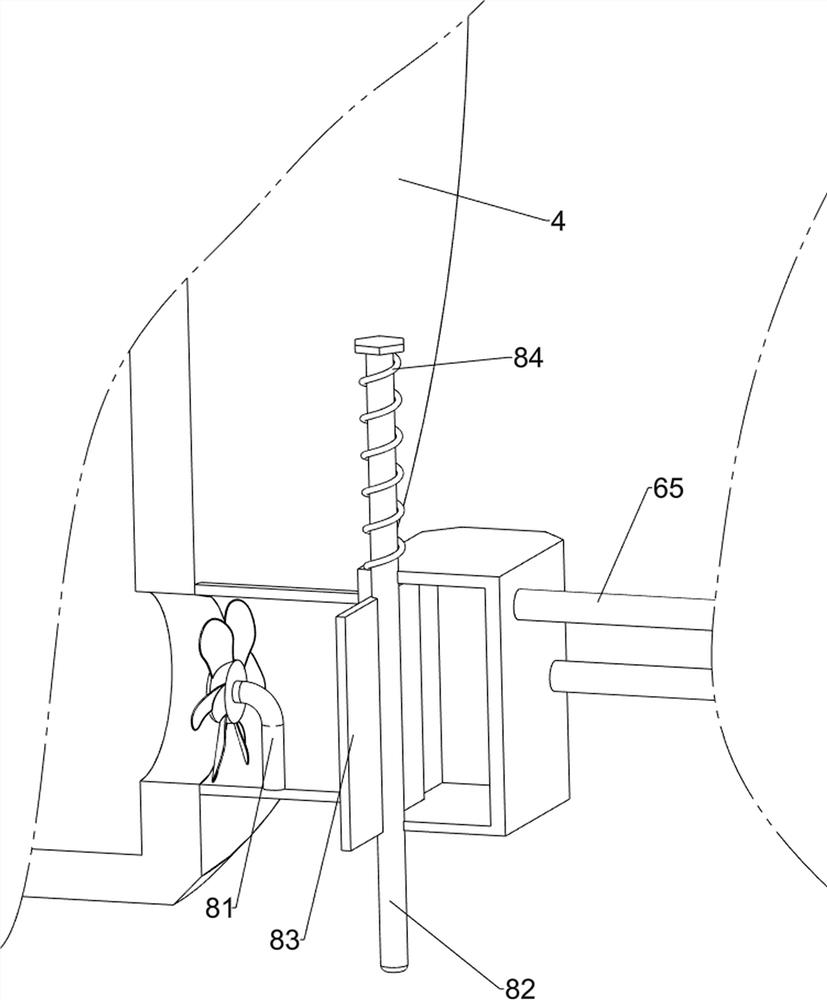

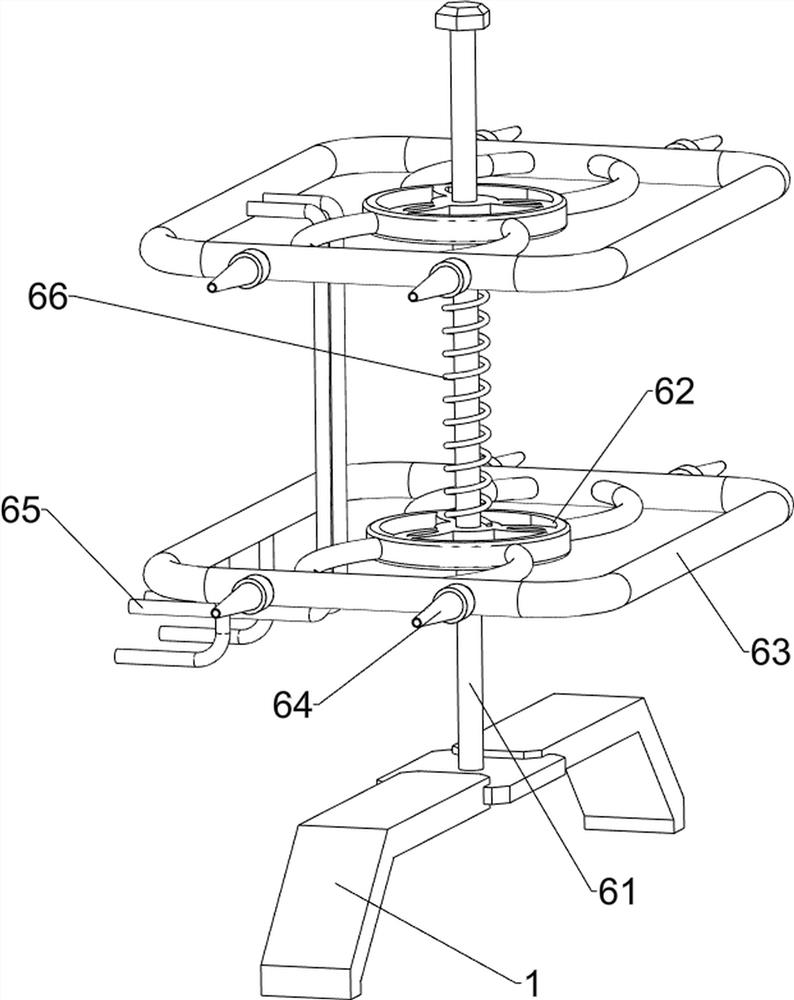

Intelligent energy-saving and environment-friendly dead pig incineration line system

ActiveCN111473332ASimple structureImprove convenienceCremation furnacesEnvironmental engineeringMechanical engineering

The invention provides an intelligent energy-saving and environment-friendly dead pig incineration line system, and relates to the field of dead pig incineration devices. The main problems that liquidgenerated by cutting cannot be collected, consequently, liquid and incineration residues are mixed, residues are hard to clear away, and when dead pigs are thrown in and residues are cleared away atfeeding openings, incineration gas is prone to being discharged through the feeding openings and clearing openings to cause environment pollution and even personnel infections are solved. The intelligent energy-saving and environment-friendly dead pig incineration line system comprises a feeding pipe; and the inner top end face of the feeding pipe is fixedly connected with a blowing fan through abolt. Due to the fact that the feeding pipe is of a bent pipe-shaped structure, and a cutting structure is rotationally connected to the lower bent part of the feeding pipe, a gravity self-push type cutting structure is formed by the feeding pipe and the cutting structure together, the resistance action generated during cutting can be eliminated through the gravity of dead pigs, and feeding convenience is improved; and compared with existing devices, the device structure is flexible, dead pigs can be automatically cut through self gravity, and manual pushing is not needed.

Owner:ZHEJIANG JI MEI BIOLOGICAL TECH CORP

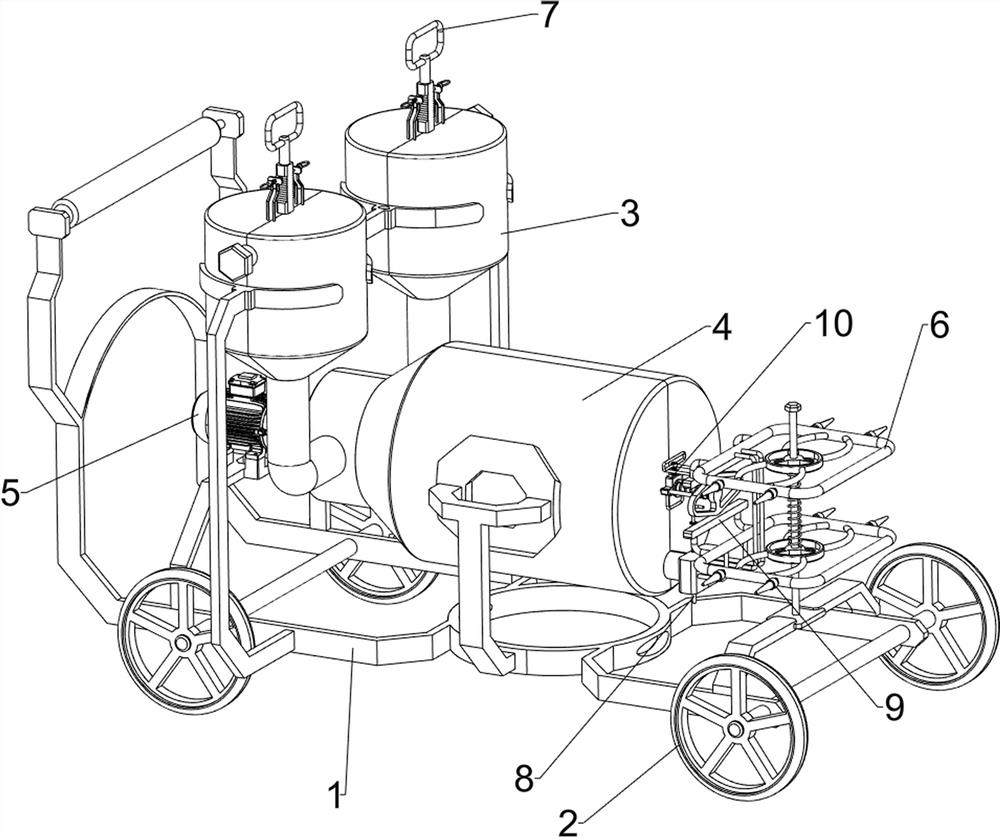

Automatic pesticide mixing and spraying device for gardens

ActiveCN113133439AAchieve stirring effectRealize the spray effectSpraying apparatusInsect catchers and killersAgricultural scienceAgricultural engineering

The invention relates to a mixing and spraying device, in particular to an automatic pesticide mixing and spraying device for gardens. The automatic pesticide mixing and spraying device for the gardens can automatically spray, reduce the labor intensity of workers and spray for a long time. The automatic pesticide mixing and spraying device for the gardens comprises a fixing piece, wheels, discharging boxes, a stirring box body, a stirring mechanism and a spraying mechanism, and the wheels are rotationally arranged on the two sides of the fixing piece; the two discharging boxes are arranged on the fixing piece; the stirring box body is arranged in the middle of the fixing piece, and the stirring box body is fixedly connected with the lower sides of the two discharging boxes; the stirring mechanism is arranged between the fixing piece and the stirring box body; and the spraying mechanism is arranged between the fixing piece and the stirring box body. By arranging the stirring mechanism, pesticide in the box body can be stirred through operation of the stirring mechanism, and the stirring effect is achieved.

Owner:昆山市常春藤环境工程有限公司

Automobile waste collection tank movable grabbing mechanism

InactiveCN108082928AEasy to handleNo manual push requiredConveyorsConveyor partsWaste collectionPulp and paper industry

The invention discloses an automobile waste collection tank movable grabbing mechanism. The automobile waste collection tank movable grabbing mechanism comprises a machine frame. Supporting plates arefixed to the top face of the left side and the top face of the right side of a top plate of the machine frame. The two ends of a transverse moving screw are hinged to the two supporting plates. A main movable block is in threaded connection with the interior of the transverse moving screw. A horizontal plate is fixed to the top face of the main movable block. A waste collection barrel is arrangedon the upper portion of the horizontal plate. A grabbing rotary column is hinged to the top face of the left side of the top plate of the machine frame. A rotary motor is fixed to the bottom face ofthe top plate of the machine frame. A spline shaft is used as an output shaft of the rotary motor and inserted into and sleeved with a spline hole formed in the bottom end of the grabbing rotary column. The automobile waste collection tank movable grabbing mechanism can be arranged around machining equipment, the waste collection barrel of the automobile waste collection tank movable grabbing mechanism can move left and right along the machine frame and thus moves to the position where waste needs to be received for waste receiving, and finally the waste collection barrel is automatically grabbed, rotated and moved to a waste collection barrel centralizing position outside the machine frame, so that processing of subsequent equipment is facilitated, convenience is achieved, and manual pushing is not needed.

Owner:FOSHAN RUIPUDA OPTOELECTRONICS TECH CO LTD

Automobile inner and outer mirror shell production mold

InactiveCN114228057ANo manual push requiredAutomation saves effortDomestic articlesEngineeringControl switch

The invention relates to a die, in particular to a die for producing inner and outer mirror shells of an automobile. According to the technical aims, the production mold for the inner and outer mirror shells of the automobile is high in working efficiency and capable of automatically cooling a formed mirror shell. According to the technical scheme, the automobile inner and outer mirror shell production mold comprises a bottom plate, a first supporting frame, first connecting rods, an annular block, a rotating shaft and the like, the first supporting frame is arranged at the top of the bottom plate, the four first connecting rods are annularly connected to the upper side of the first supporting frame in the circumferential direction, and the annular block is connected between the outer sides of the four first connecting rods; a rotating shaft is rotationally arranged in the middle of the top of the first supporting frame. An operator presses the control switch, the electric push rod works to drive the compaction module to move downwards to make contact with the shaping mold, the operator can inject molten liquid into a gap between the compaction module and the shaping mold for forming, the compaction module does not need to be manually pushed through the operation, and the operation is more stable and accurate.

Owner:YINGTAN KSD ELECTRONICS PLASTIC

Intelligent welding equipment for metal furniture stand column

PendingCN113857622AReduce manual operationsReduce troubleWelding protection meansElectric machineryRoller bearing

The invention relates to welding equipment, and particularly relates to intelligent welding equipment for a metal furniture stand column. The invention provides the intelligent welding equipment for the metal furniture stand column, and the intelligent welding equipment for the metal furniture stand column is safe to operate and does not need to be manually held by hand for welding. The intelligent welding equipment for the metal furniture stand column comprises a first supporting frame, a first fixing frame, a motor, a second fixing frame, a rotating rod, a second supporting frame and the like, the first fixing frame is arranged on the left side of the upper portion of the first supporting frame in a sliding mode, the motor is arranged on the first fixing frame, the second fixing frame is slidably arranged on the position, located on the right side of the first fixing frame, of the left side of the upper portion of the first supporting frame, the second fixing frame is connected with the first fixing frame and connected with the rotating rod through a roller bearing, and the second supporting frame is arranged on the top of the second fixing frame. An electric push rod works to push the stand column to move rightwards for welding work, manual pushing of the stand column is not needed, and more labor is saved and convenience is achieved.

Owner:JIANGXI EQUIP INDAL GROUP GREAT INSURANCENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com