Patents

Literature

334results about How to "Achieve stirring effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

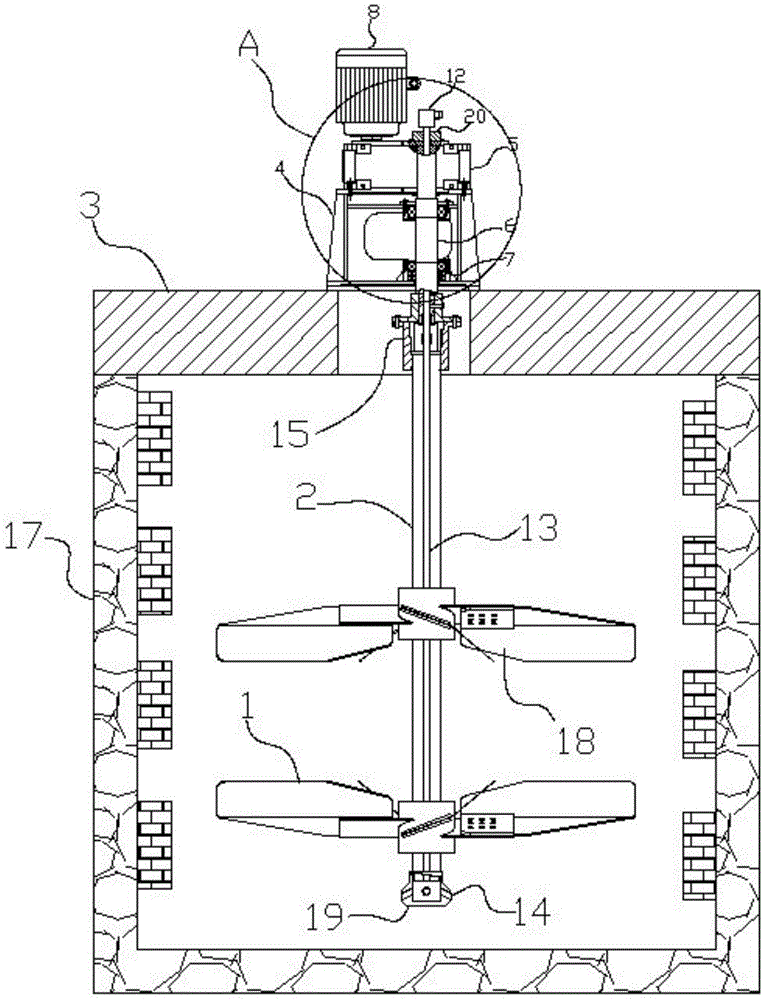

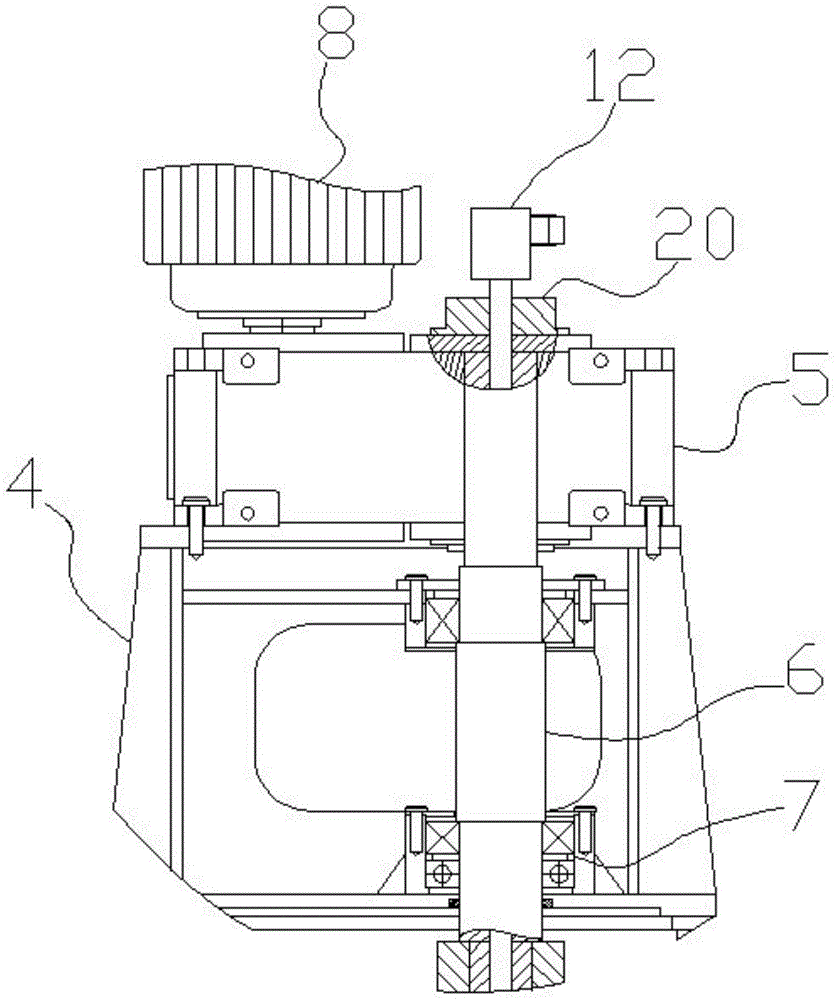

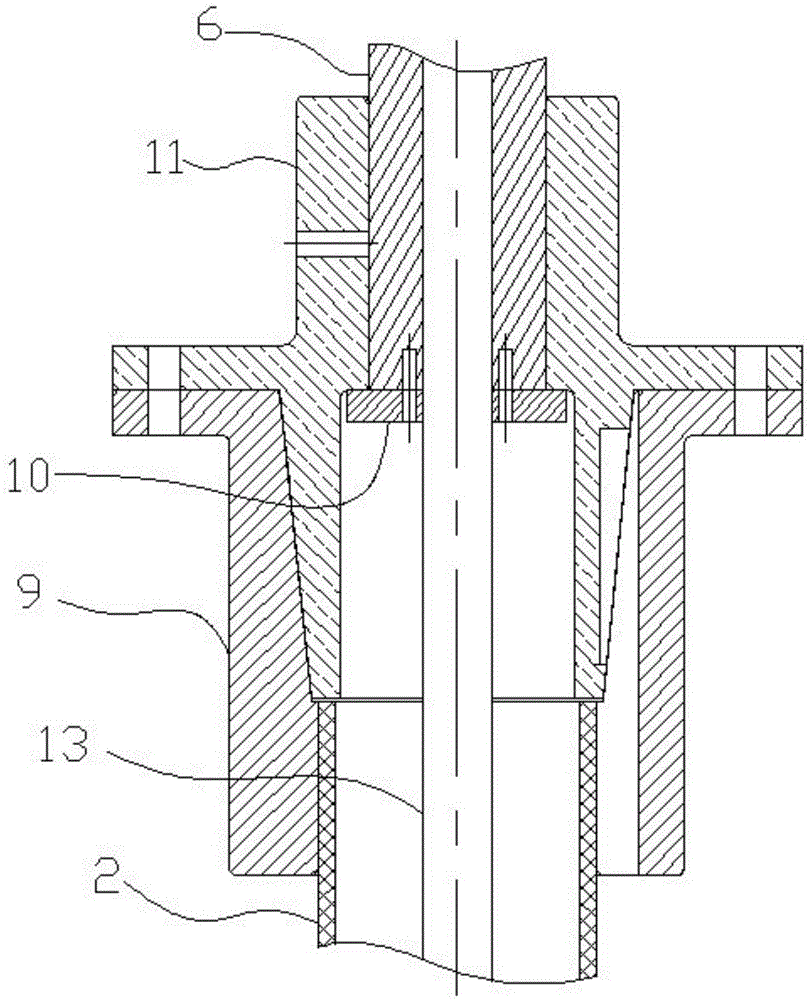

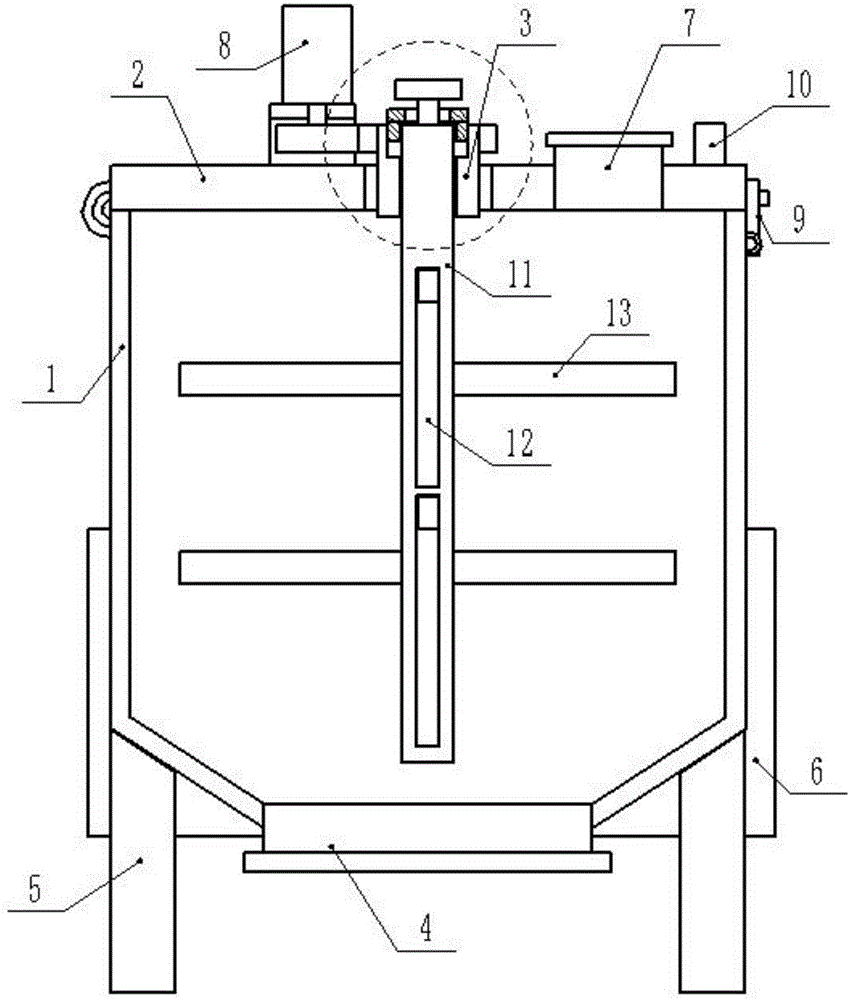

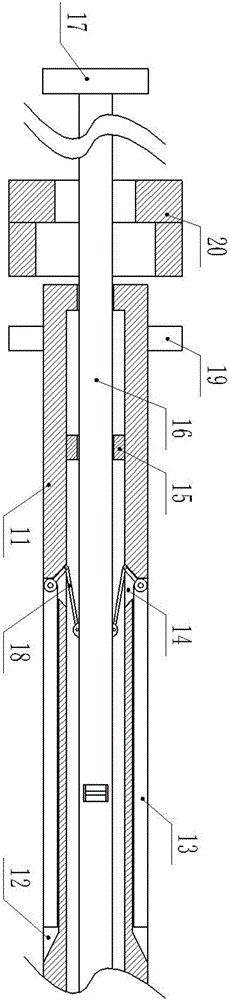

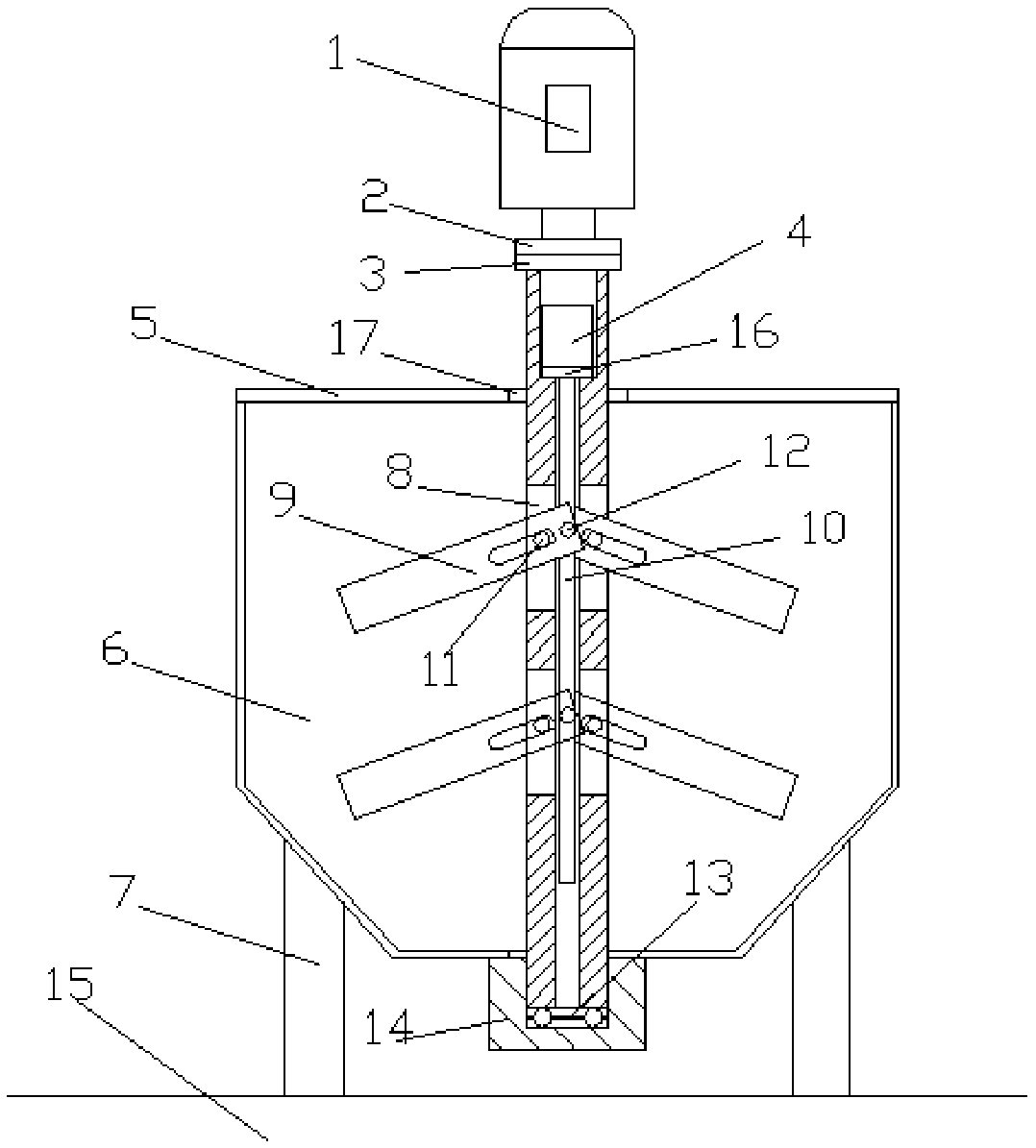

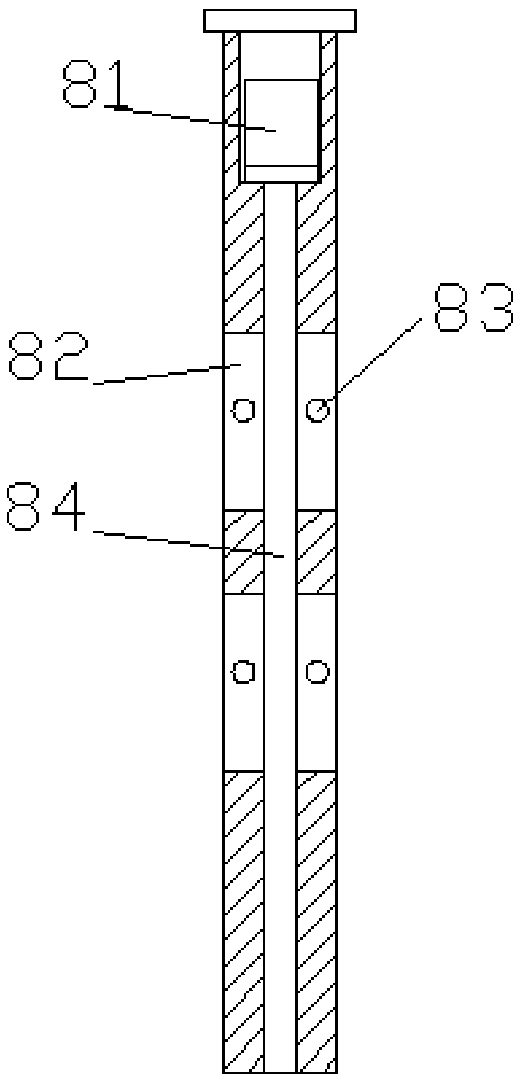

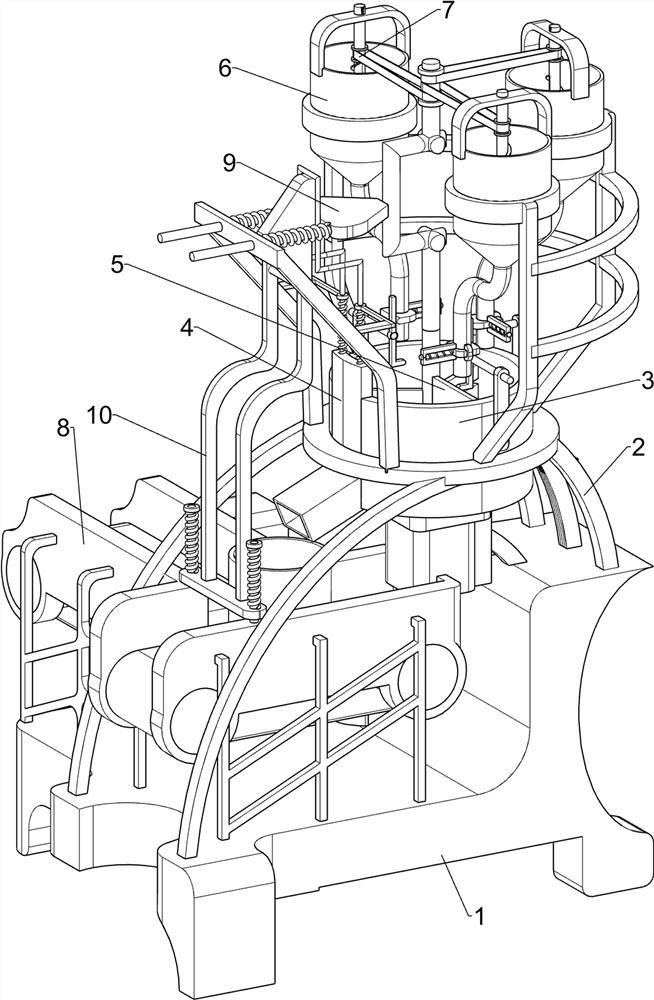

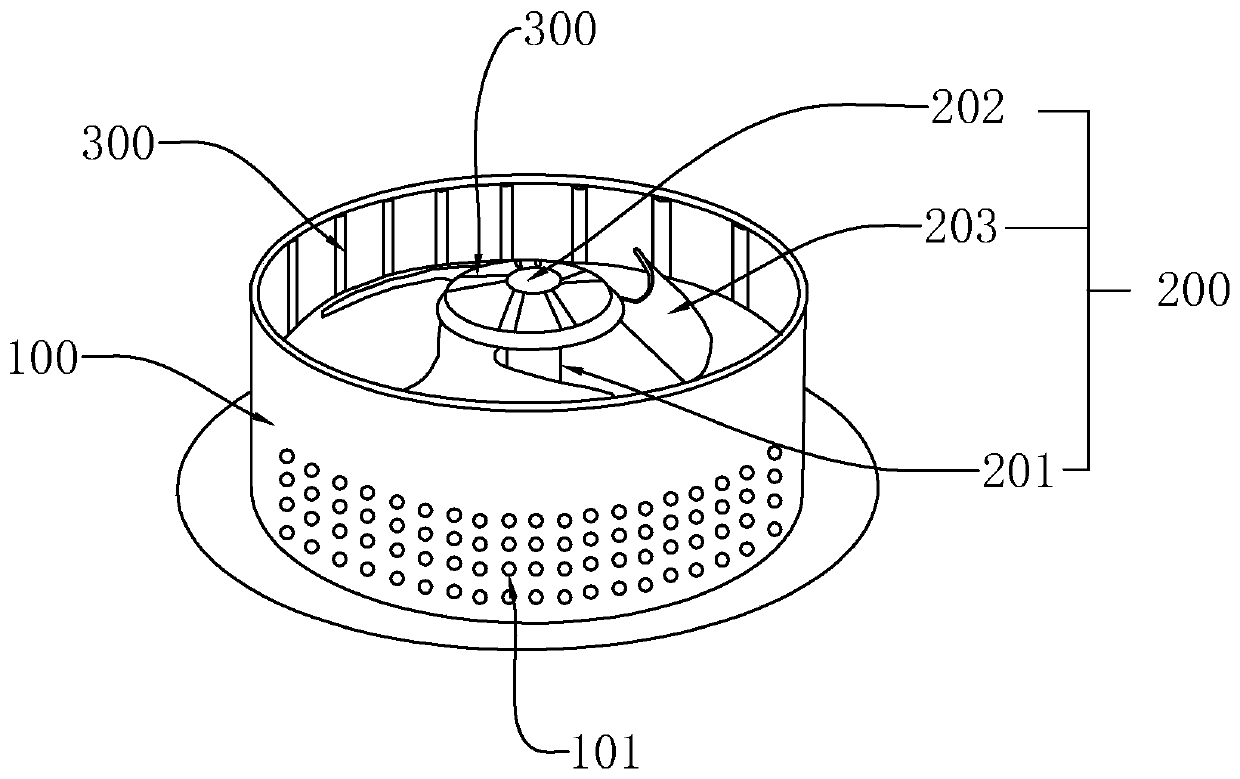

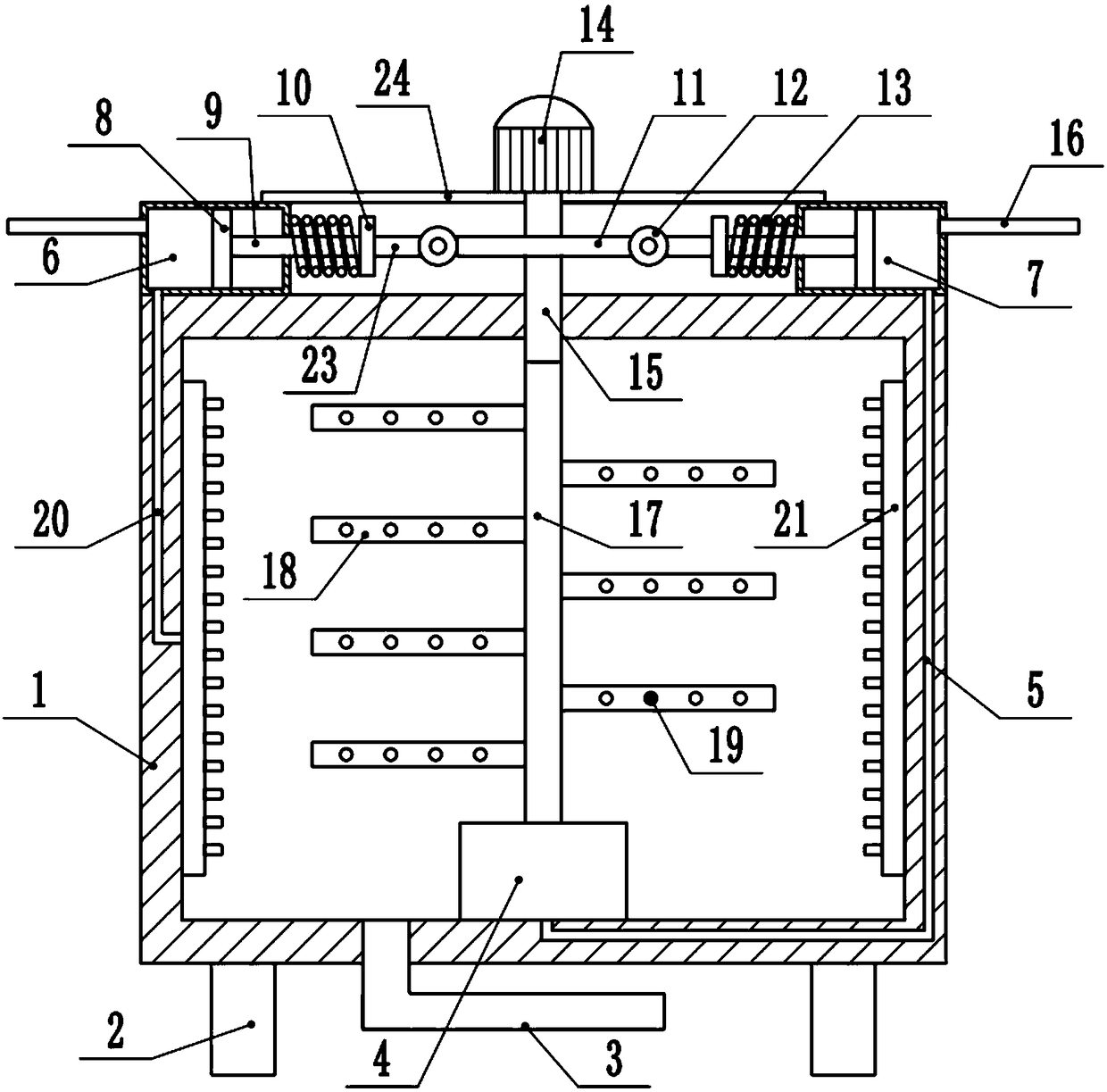

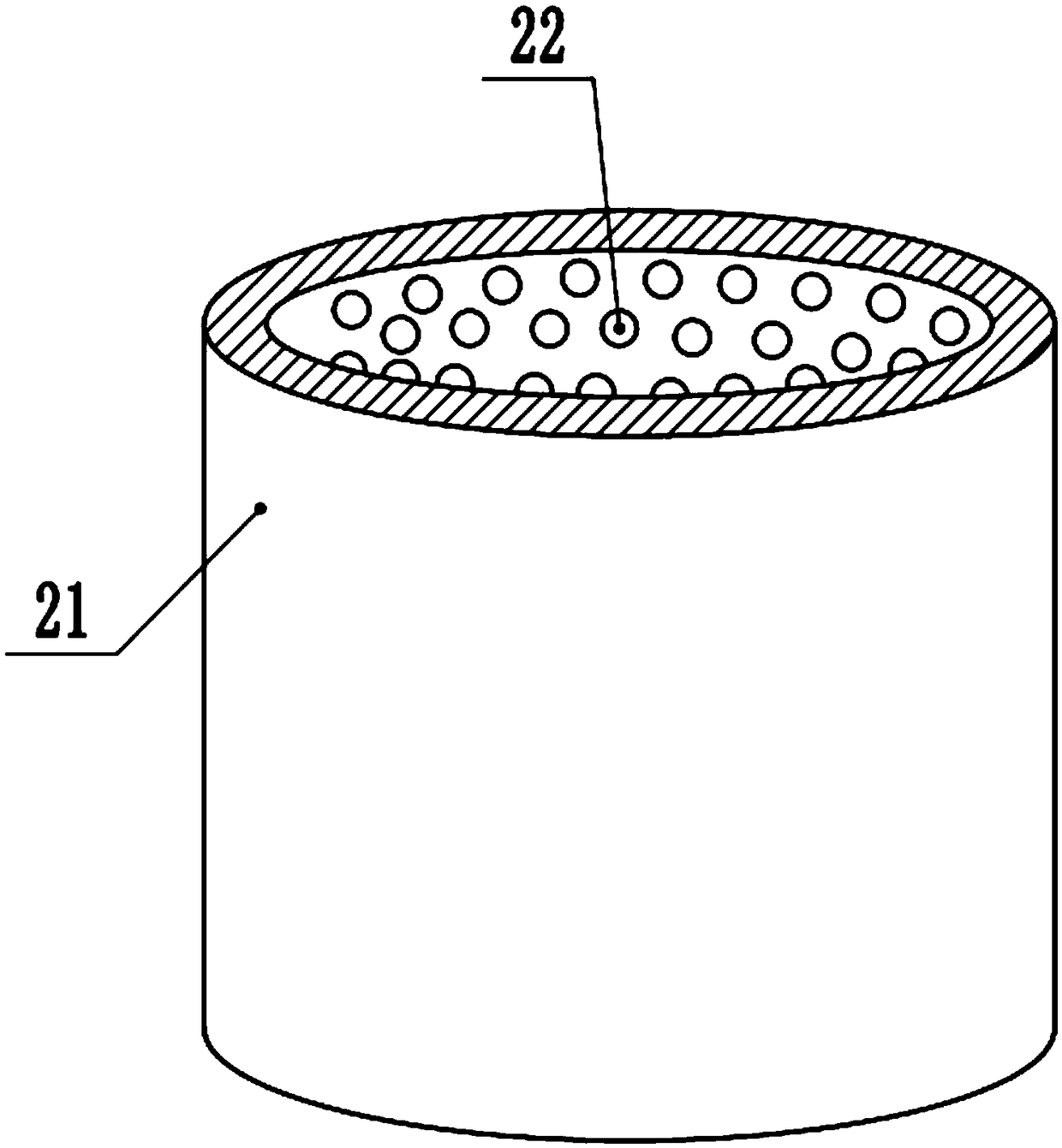

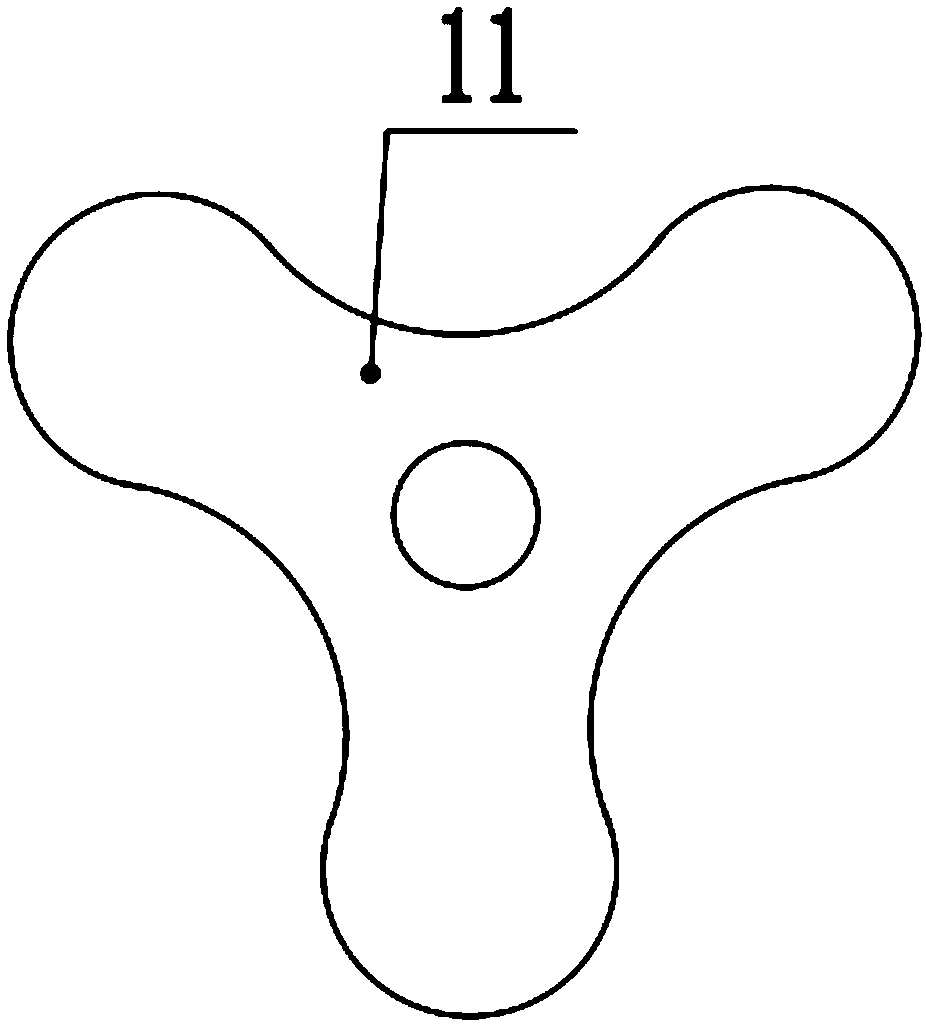

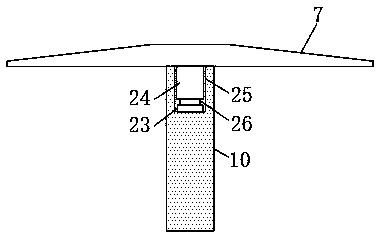

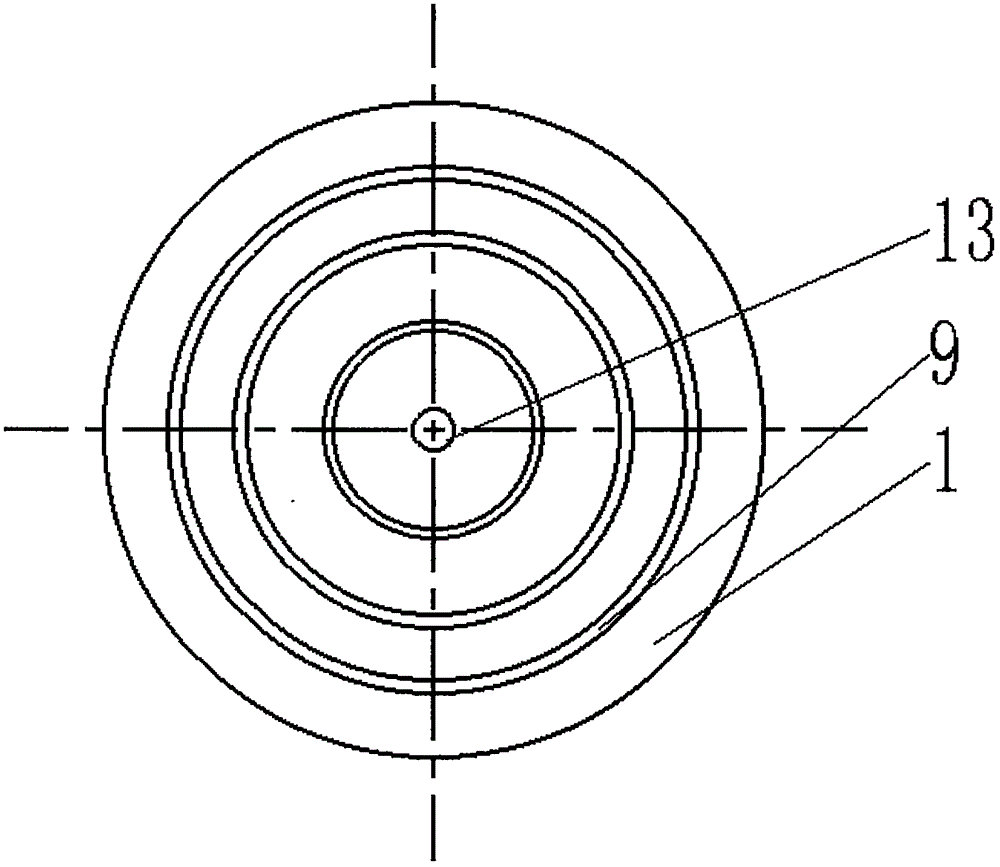

Axial ventilating type high-efficiency stirrer

ActiveCN105478047AEvenly distributedImprove the mixing effectMixing methodsTransportation and packagingImpellerEngineering

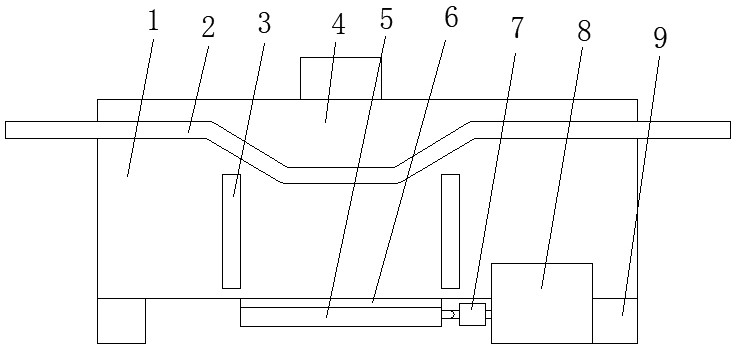

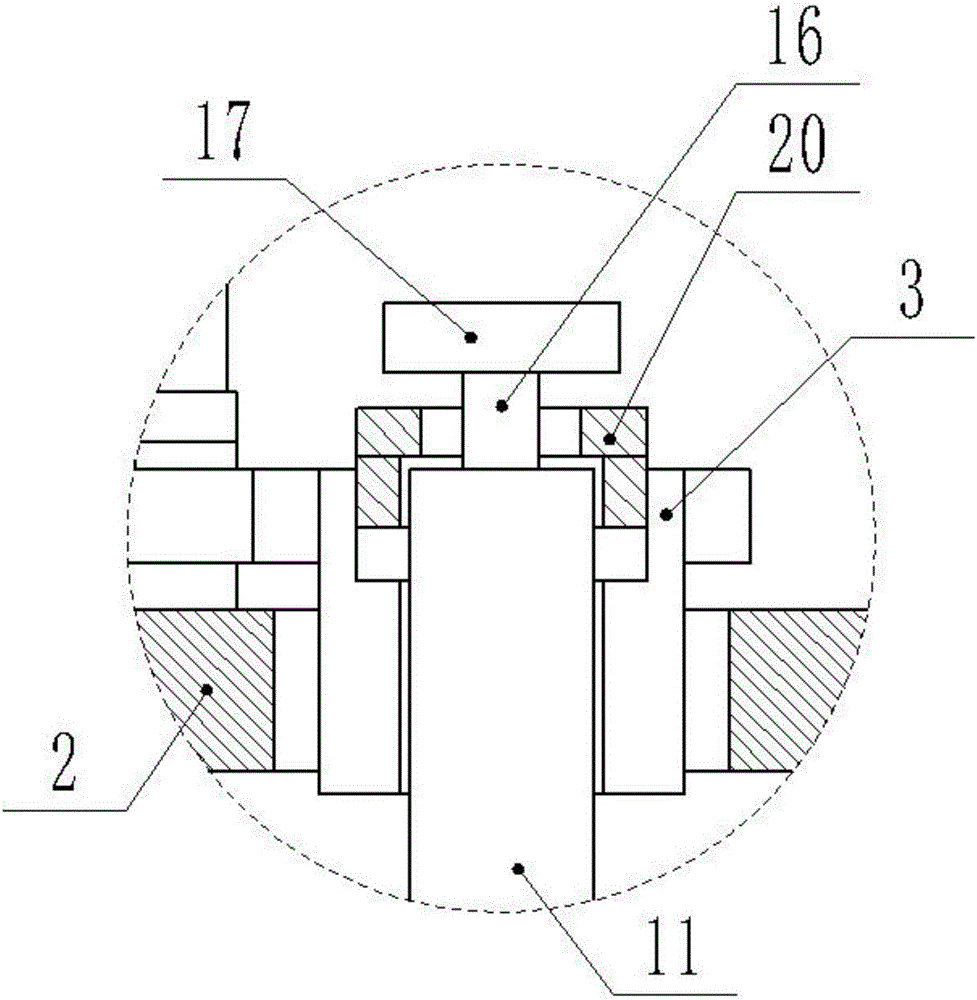

The invention discloses an axial ventilating type high-efficiency stirrer. The lower end of a machine base shaft is connected with a stirring rod through a conical centering and coupling device. An upper stirring impeller and a lower stirring impeller are arranged on the stirring rod. Stirring blades of the upper stirring impeller and stirring blades of the lower stirring impellers are symmetrically installed in the vertical direction. Each stirring blade comprises a base plate and a turning plate, wherein the base plate and the turning plate are connected to form an included angle of 100 degrees to 170 degrees, and a tilt angle of 10 degrees to 70 degrees is formed between the base plate and the horizontal plane. An air nozzle is fixed to the bottom end of the stirring rod which is a hollow pipe. An air guide pipe is arranged in the stirring rod. The upper end of the air guide pipe penetrates through a machine base cushion plate and is communicated with an air inlet connector. The lower end of the air guide pipe is communicated with the air nozzle. Air outlets are evenly formed in the air nozzle. A tilt angle of alpha degrees is formed between the air outlets in the circumference of the air nozzle and the diameter line, wherein alpha ranges from 5 degrees to 45 degrees. The traditional mode that air is only pressed in from the wall circumference of a container through a pipeline is changed, the defect of air shortage in the middle area of the container is overcome, the chemical combination effect is made better, and the quality and efficiency of wet metallurgy are greatly improved.

Owner:湖南中资混合搅拌机电科技有限公司

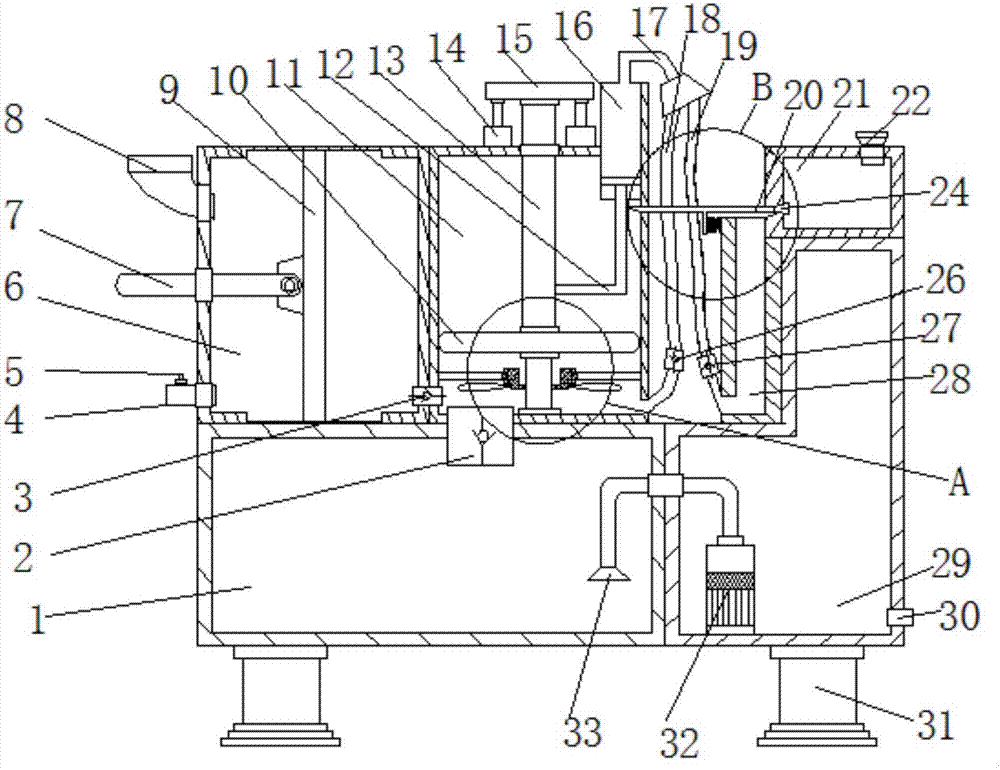

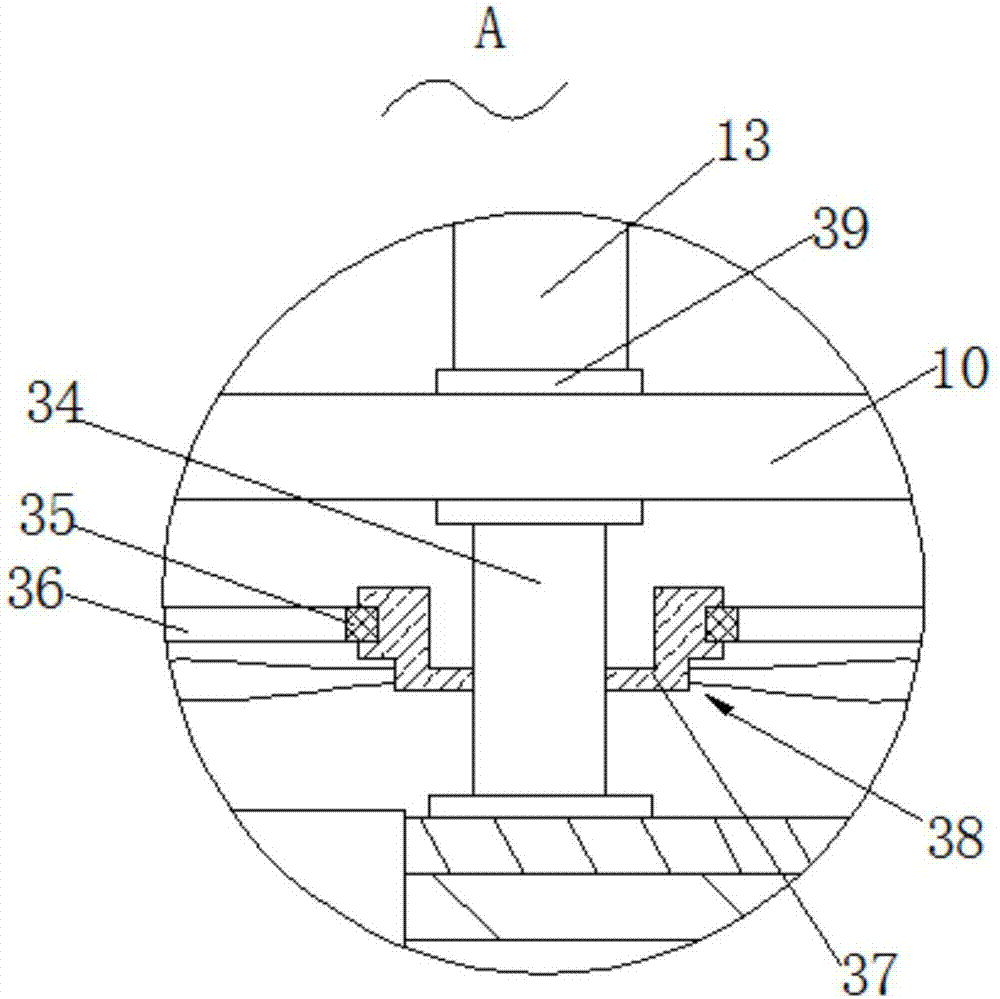

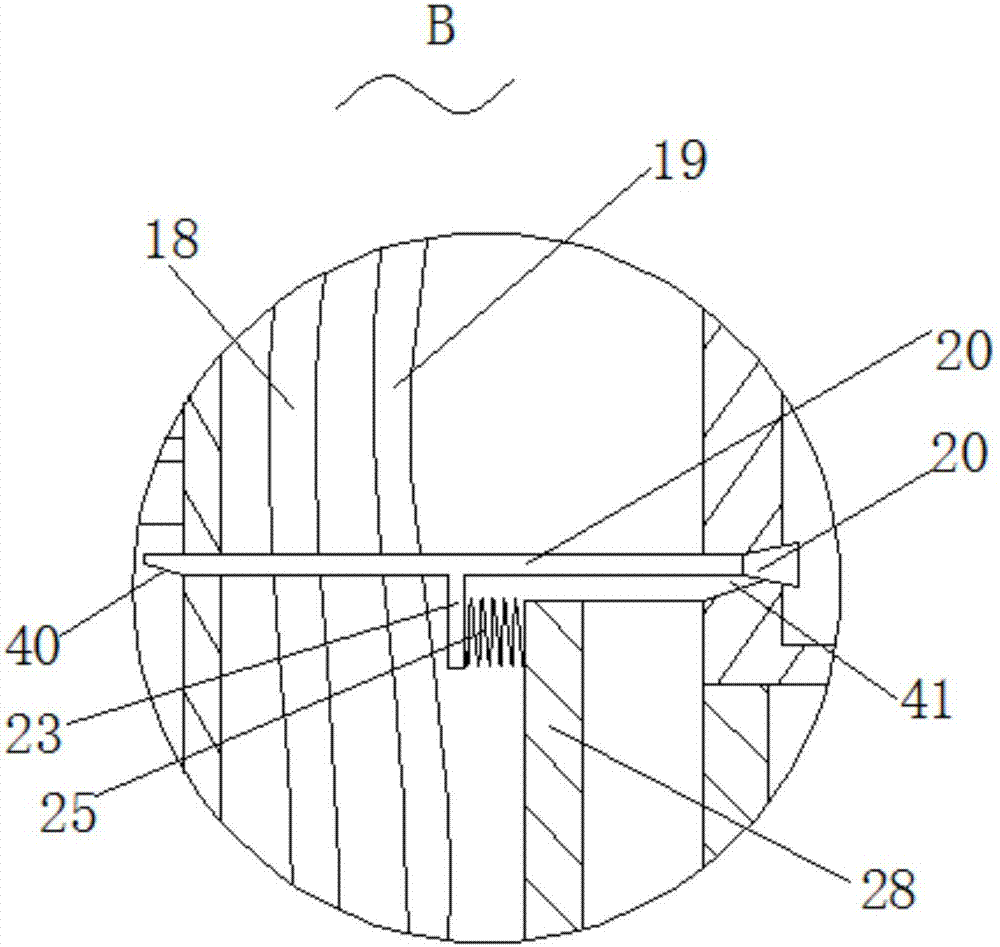

Sewage treatment device

ActiveCN106927605AEnhanced evaporationAchieve stirring effectGeneral water supply conservationMultistage water/sewage treatmentActivated carbonReclaimed water

The invention relates to a sewage treatment device comprising a flocculating mixing chamber, a flocculating settling chamber, water purifying tank, a composite activated carbon treatment chamber, an amorphous alloy treatment chamber and a reclaimed water storage chamber. By disposing and improving various parts, especially various parts of the flocculating settling chamber, the flocculating efficiency and the settling efficiency are improved, and a plurality of steps of flocculating, settling and condensing can be implemented simultaneously without increasing the treatment space; as a result, small and medium-sized efficient sewage treatment becomes reality.

Owner:灵山县风光污水处理有限公司

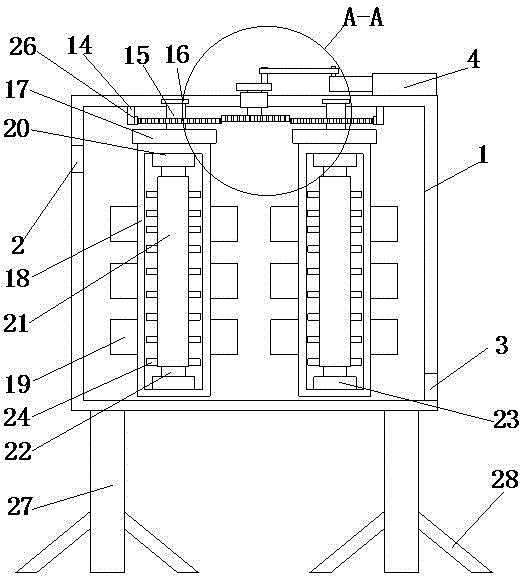

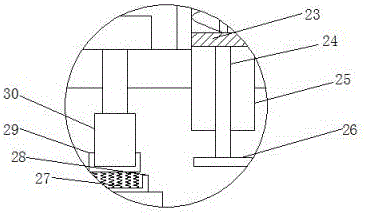

Processing stirring machine for plastic products

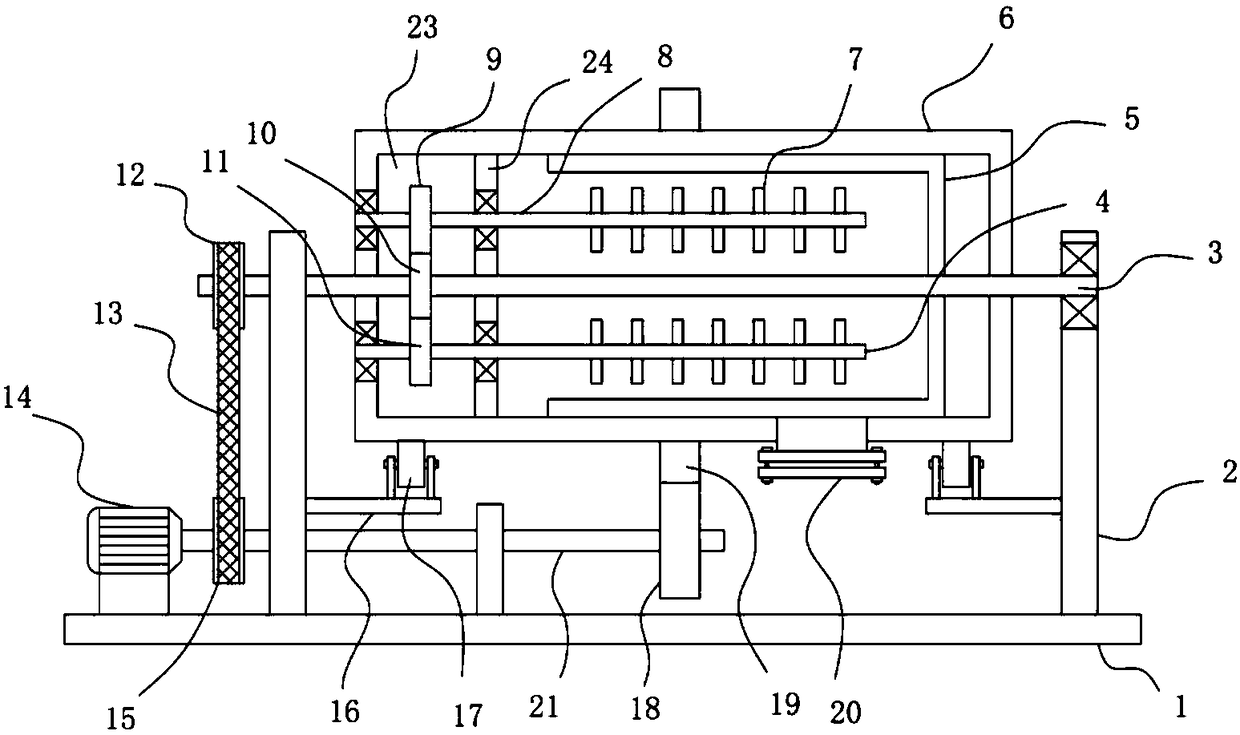

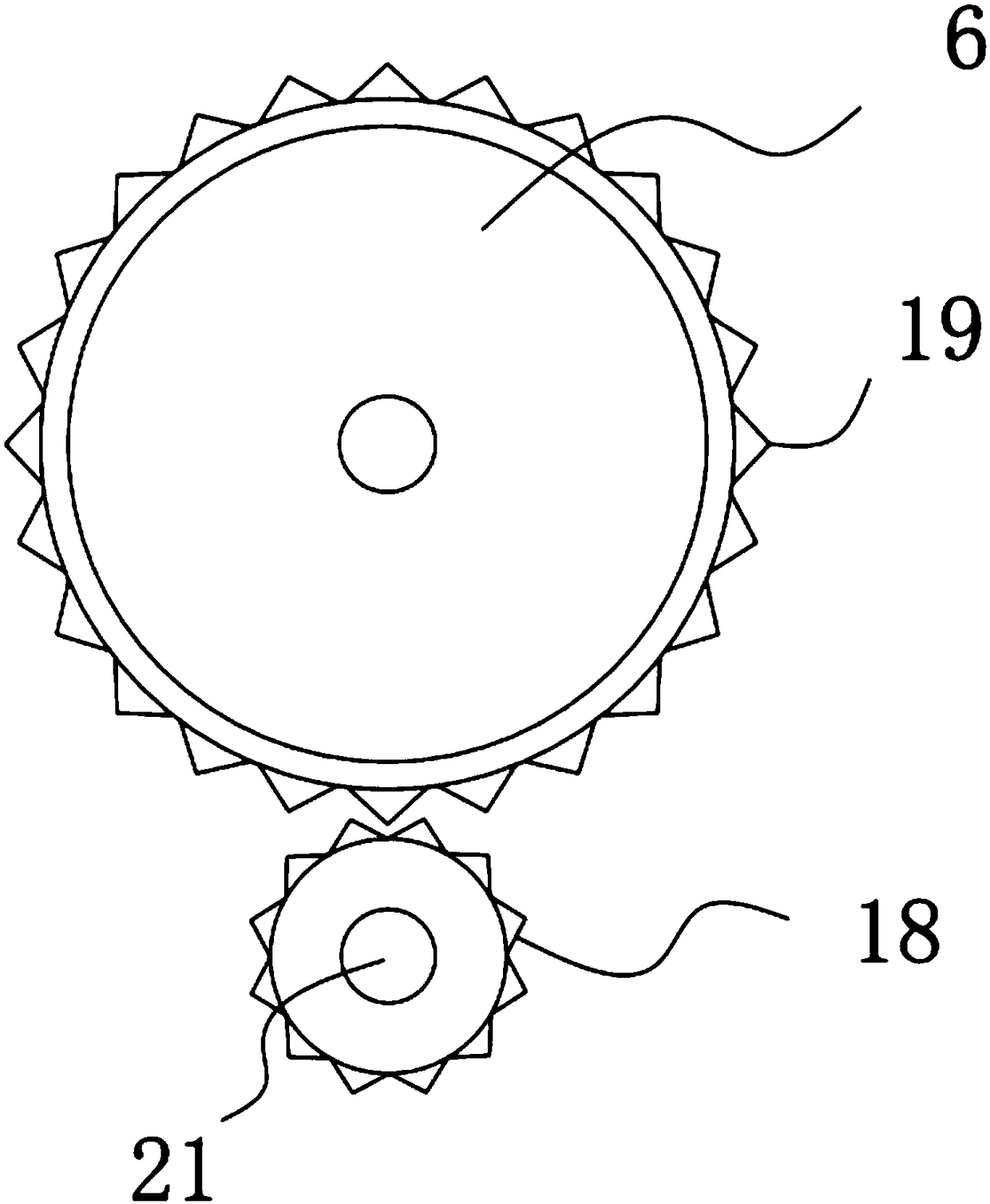

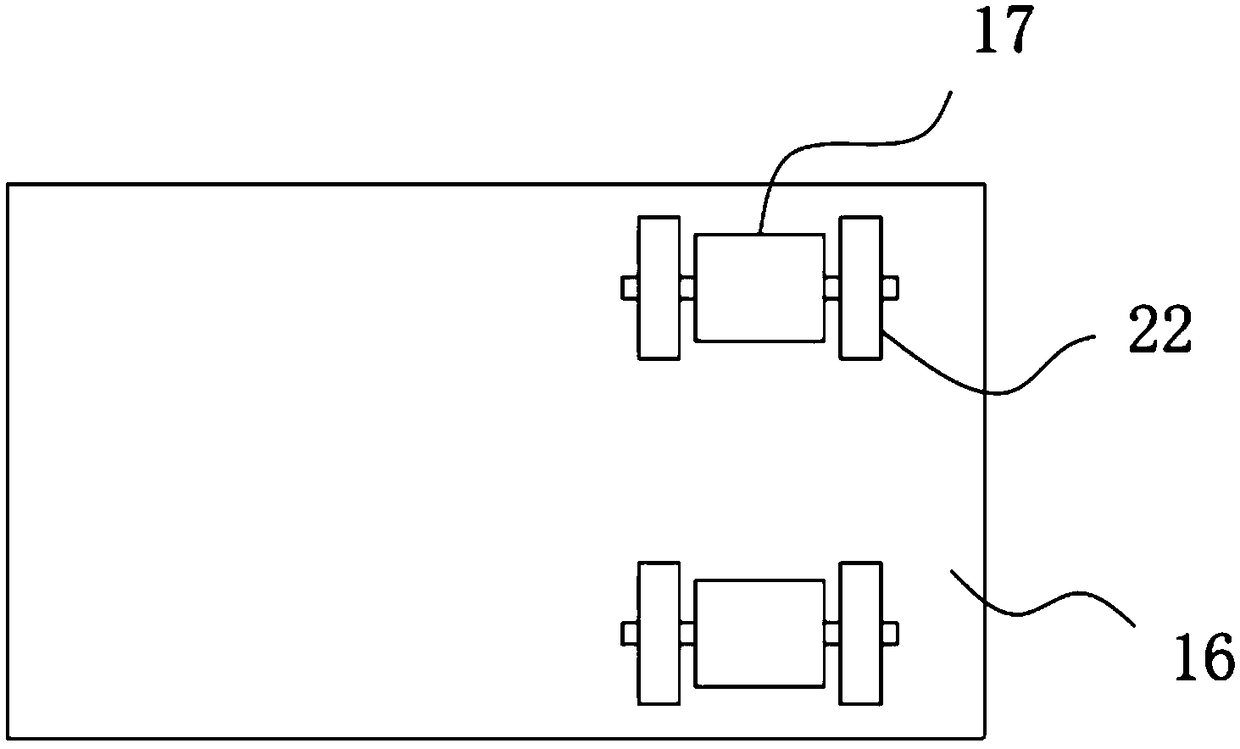

The invention discloses a processing stirring machine for plastic products. The processing stirring machine comprises a machine body, wherein a material inlet is arranged on the top of one side of the machine body; a material outlet is arranged on the bottom of the other side of the machine body; a cylinder is fixedly connected onto one end of the top of the machine body; the surface of the output end of the cylinder is fixedly connected with a first pin shaft; the surface of the first pin shaft is movably connected with a crank; the end, which is far away from the first pin shaft, of the crank is movably connected with the surface of a second pin shaft; the bottom of the second pin shaft is fixedly connected with a rotary disc; the bottom of the rotary disc is fixedly connected with a first rotary shaft; the top of the machine body is fixedly provided with a ferrule; and the end, which is far away from the rotary disc, of the first rotary shaft penetrates through the ferrule and extends into the machine body to be fixedly arranged on a first gear. By adopting the processing stirring machine for the plastic products, the effect that during stirring, stirring bodies circularly move in the machine body, so that raw materials are stirred is realized; and the problem of a current stirring machine that a stirring mode is single, so that the raw materials are easily caked due to nonuniform stirring, and waste materials are generated is solved.

Owner:无锡优萌模塑制造有限公司

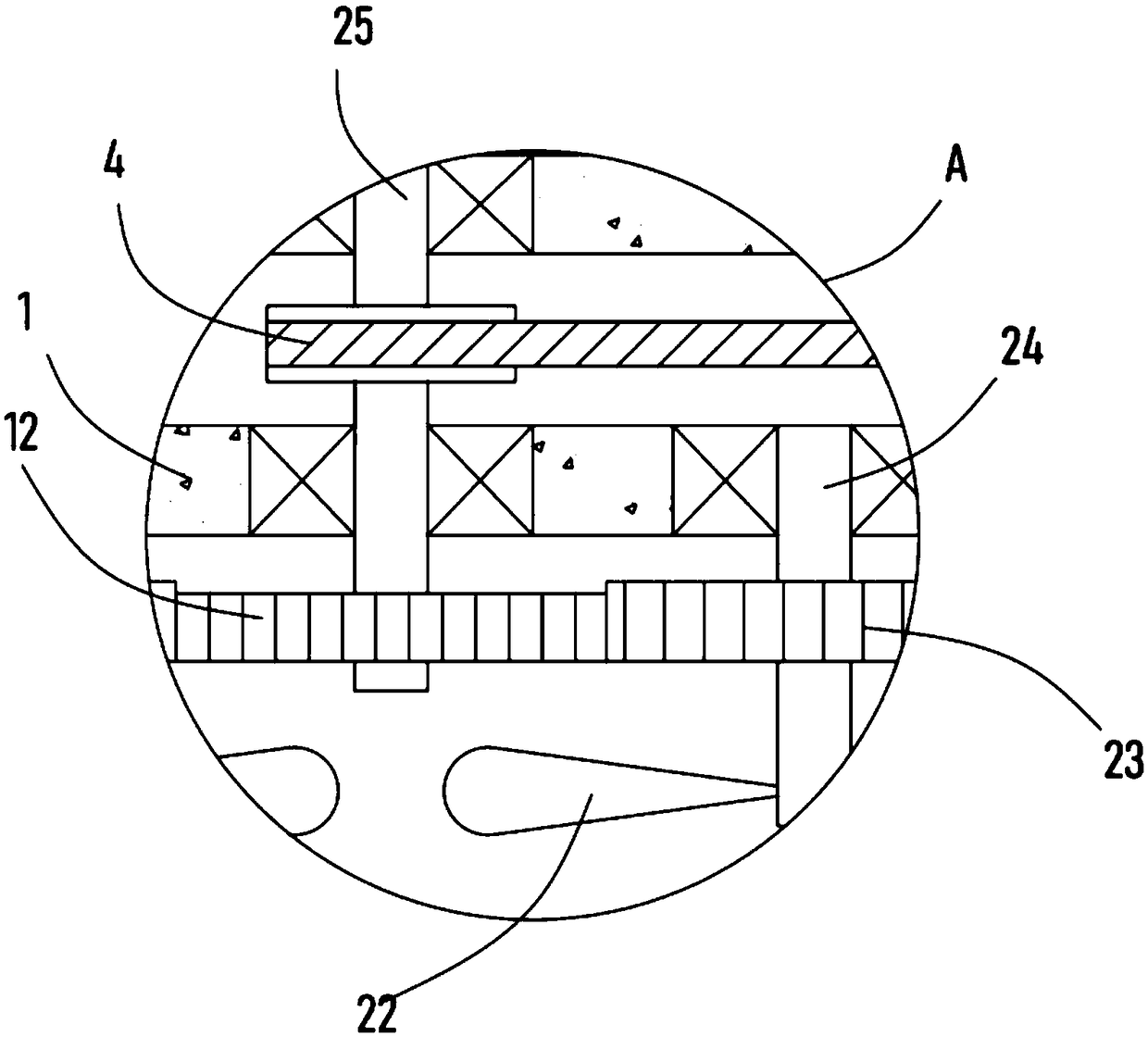

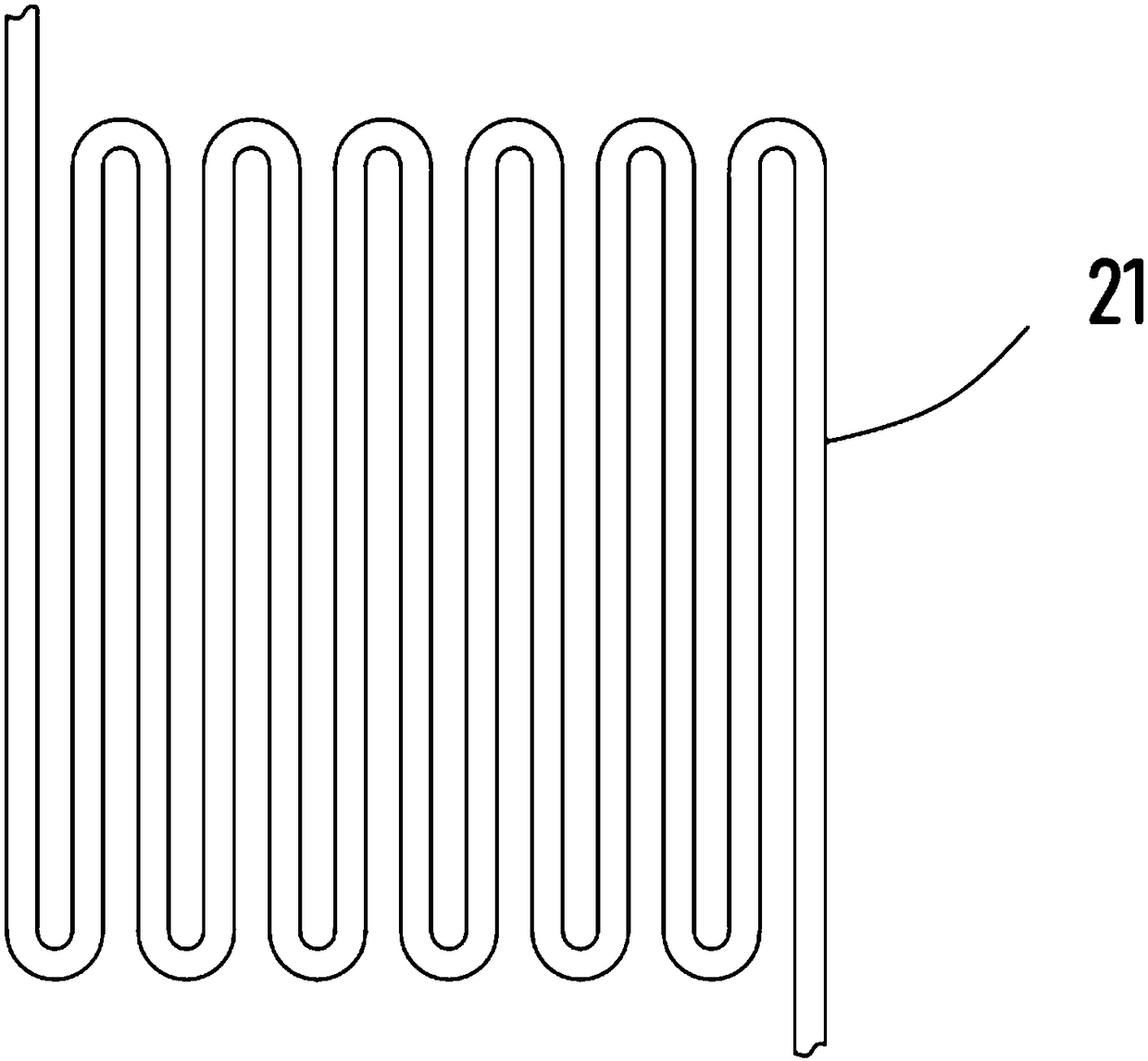

A desktop computer high-efficiency heat dissipation case

InactiveCN109240453AGood heat dissipation and exhaustImprove cooling effectDigital processing power distributionElectric machineryMetal mesh

A desktop computer high-efficiency heat dissipation case in accordance with that present invention, include a main body, the main body is fixedly installed with a double-shaft motor, A vertical mesh plate is vertically fixed in the main body, a driven shaft is horizontally arranged on the vertical mesh plate, fan blades are fixed on the surface of the driven shaft, driving bevel gears are fixed onthe driving shaft and meshed with the driven bevel gears, an air inlet mesh plate is fixedly installed on the right side wall of the main body, and an air outlet mesh plate is fixedly installed on the right side wall of the main body. The invention can realize that the driven shaft drives the fan blade to rotate and the rotating shaft I and the rotating shaft II drive the fan blade to rotate respectively, thereby realizing the stirring action to the air inside the main box, realizing the very good heat dissipation and exhaust action, and effectively improving the cooling effect; By circulating cold water in the serpentine tube, the cooling effect on the conductive metal mesh plate is realized, and then the heat absorption and cooling of the air inside the main box are realized.

Owner:南昌科悦企业管理咨询有限公司

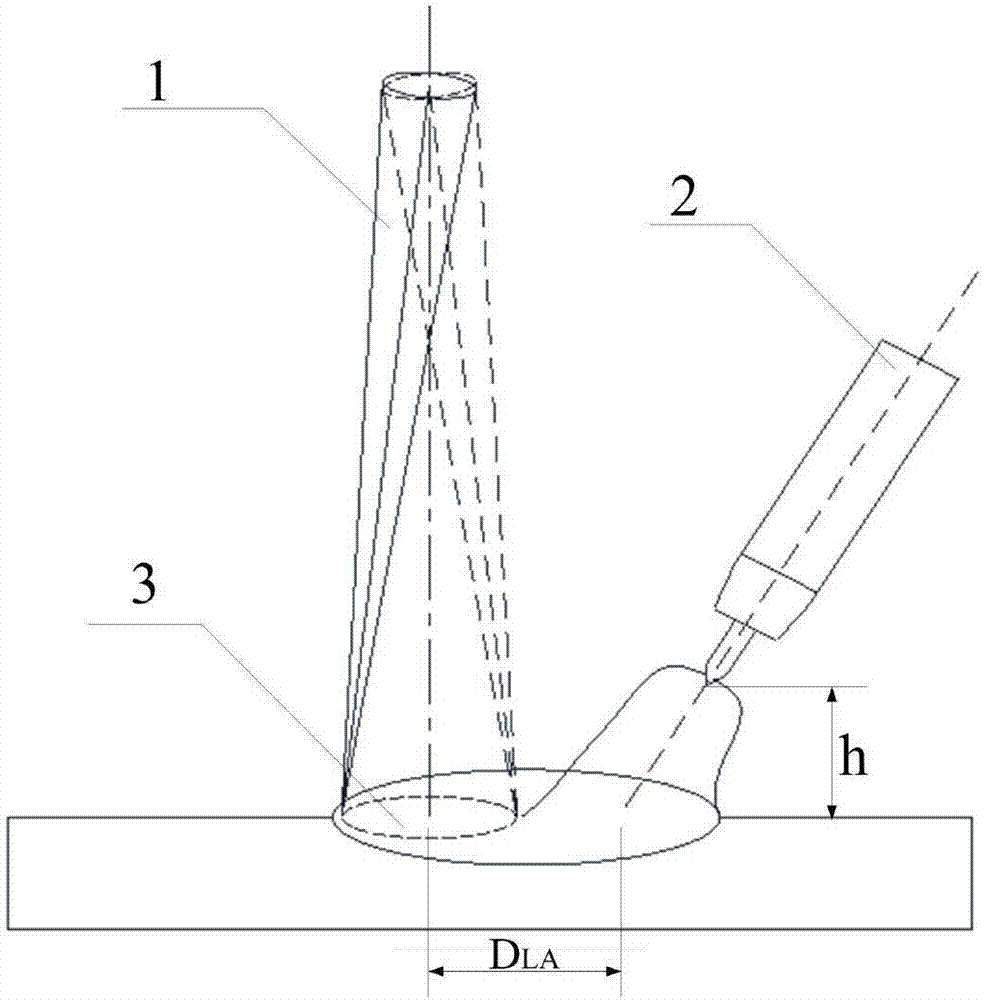

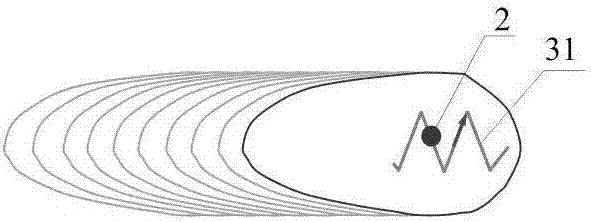

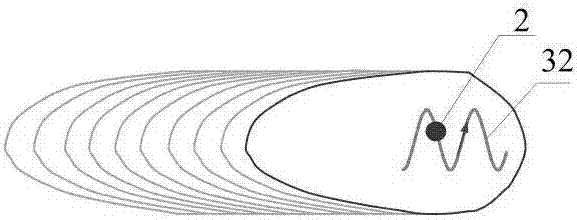

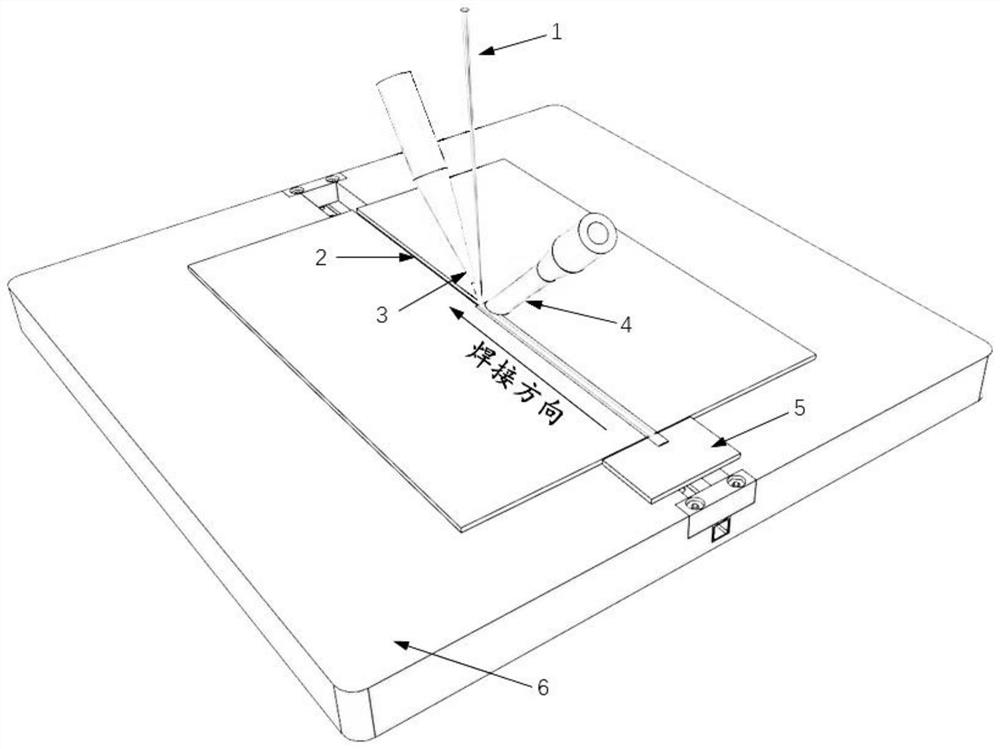

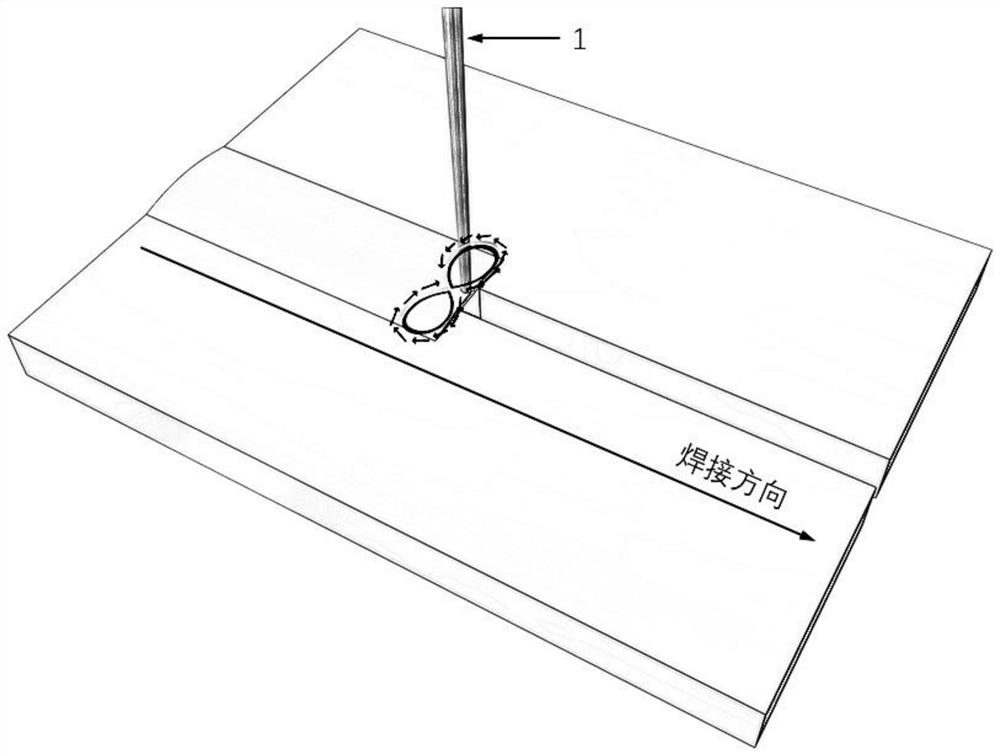

Vibrating welding method of laser scanning-TIG compound molten bath

InactiveCN107498182AAchieve stirring effectInhibition defectLaser beam welding apparatusLaser scanningMolten bath

The invention discloses a vibrating welding method of a laser scanning-TIG compound molten bath. The method is implemented by compounding laser scanning and TIG welding. According to the method, during welding, two compound welding modes of performing laser scanning of a groove first and performing welding by a TIG weld gun then or performing welding by the TIG weld gun first and performing laser scanning of the groove then are selected; as a result of different materials and welding demands, the track of the laser scanning molten bath has different modes. As the ranges on two sides of the laser scanning groove are same or different or only one side of the groove is scanned by laser, the scanning track can be round, sinusoidal and triangular or special regions are selectively scanned. By means of mutual enhancement and coupling action of laser and arc, the depth of fusion is increased and the efficiency is increased; the molten bath is stirred by scanning the welding molten bath by laser, so that the temperature gradient is reduced, the solidification and crystallization processes are improved, and the welding joint performance is improved.

Owner:SHANGHAI JIAO TONG UNIV

Cement mixing equipment

InactiveCN106738328AStir wellAchieve stirring effectCement mixing apparatusDischarge efficiencyAgricultural engineering

The invention discloses cement mixing equipment. The cement mixing equipment comprises a shell; a stirring shaft is arranged at the middle part of an inner cavity of the shell; stirring rods are connected to the outer side of the stirring shaft at equal intervals; an arc plate is arranged on one sides of stirring blades; the top of the stirring shaft is connected with a stirring motor through a motor frame; discharge holes are formed in inner cavities on two sides of a bracket at equal intervals; rotating shafts are respectively arranged on two sides of the inner cavity of the shell; the outer sides of the rotating shafts are connected with spiral stirring blades; a switch button and a reverse rotating button are respectively arranged on two sides of the surface of a controller; one side of the controller is connected with a discharge motor; feed pipes are respectively arranged on two sides of the top of the shell; discharge pipes are inserted and connected to two sides of the bottom of the shell; piston blocks are arranged in inner cavities of the discharge pipes; and the bottoms of the piston blocks are connected with pull rods. The cement mixing equipment has the advantages of uniform cement mixing and improvement of the discharge efficiency, and solves the problems of nonuniform cement mixing and slower discharge speed.

Owner:WUXI KONSTANT POWER TECH CO LTD

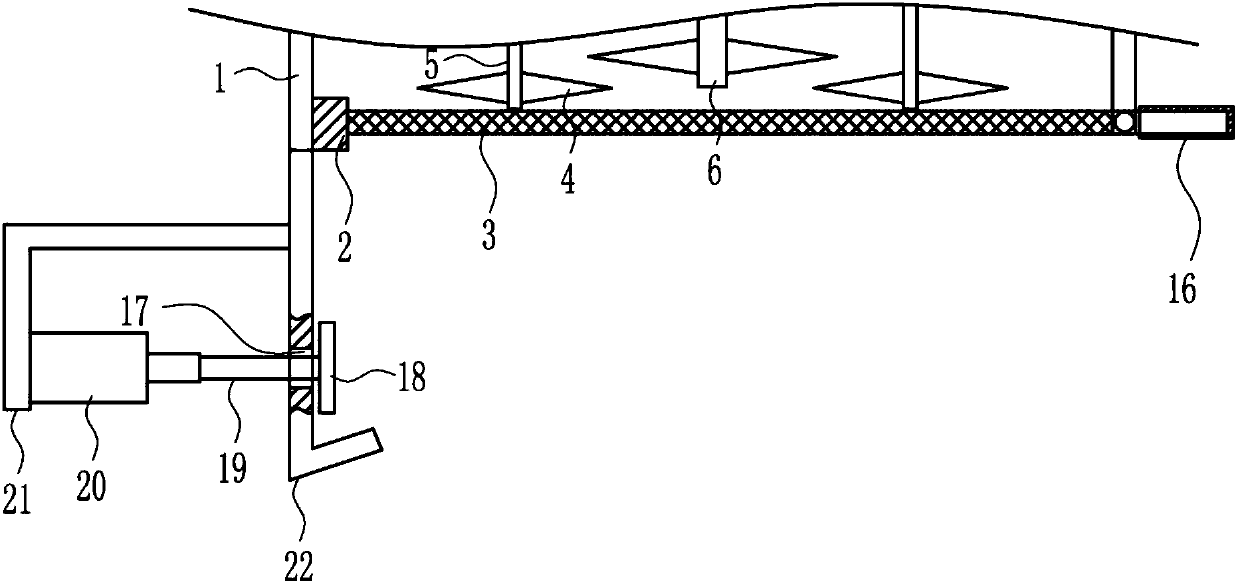

Linen fiber bleaching device for textile production

InactiveCN111826839AImprove bleaching efficiencyReduce lossTextile treatment machine arrangementsTextile treatment carriersFlax fibrePulp and paper industry

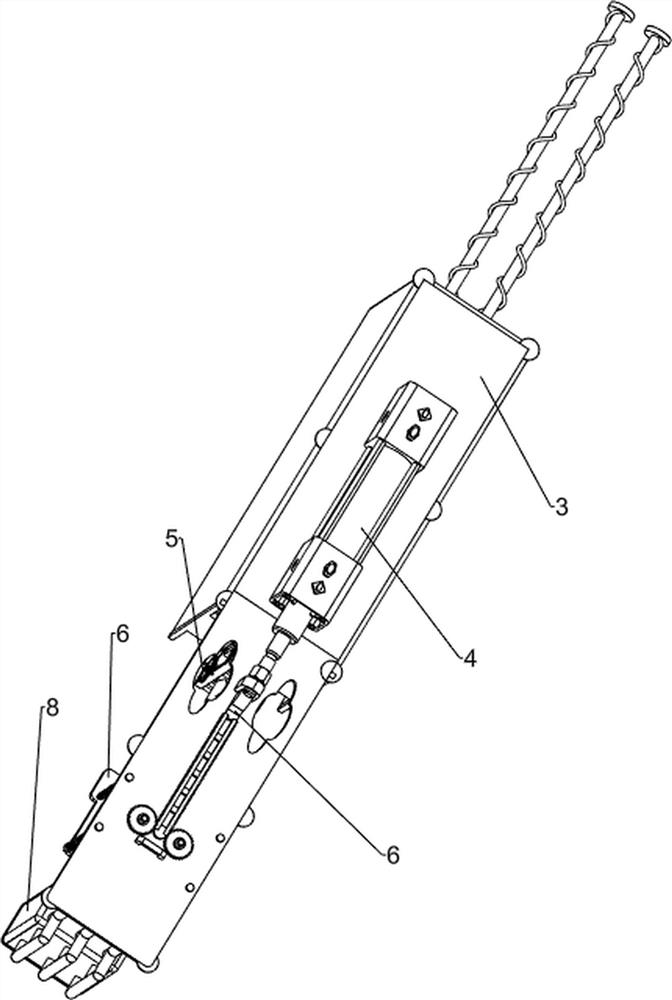

The invention discloses a linen fiber bleaching device for textile production and relates to the technical field of textile production. In order to solve the problem that the bleaching time is difficult to control and linen fibers are easy to damage when the linen fibers are soaked in a solution to be stirred, the linen fiber bleaching device specifically comprises a shell, a plurality of supporting frames are fixedly installed at the bottom of the shell, driving mechanisms are fixedly installed on the two sides of the top of the shell, a capping mechanism is fixedly installed between the topends of the two driving mechanisms, and bleaching sections extending downwards are arranged in the middle sections of the driving mechanisms. According to the linen fiber bleaching device for textileproduction, a bleaching solution is in contact with a heating mechanism when being sprayed out; the linen fibers are heated and cooked; the linen fiber bleaching efficiency is improved; the linen fibers are drained; a bleaching solution is recycled; the loss of the solution is reduced; the situation that the working environment is affected due to solution dripping is avoided; raw materials can becontinuously bleached due to the fact that the raw materials enter from one end and exit from the other end, and the linen fiber bleaching processing efficiency is improved.

Owner:宣城红妆美人床上用品有限公司

Medical cotton swab medicine applying equipment capable of achieving quick taking and using

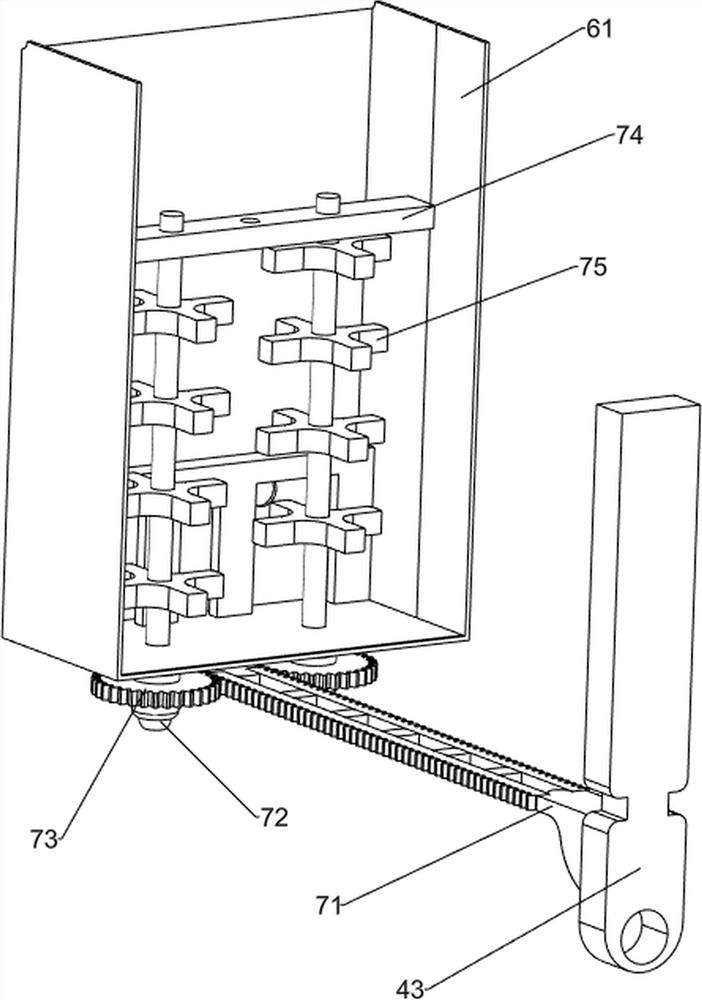

PendingCN112807558ARealize the feeding effectRealize the effect of pushing back and forthRotary stirring mixersTransportation and packagingBiotechnologyBiomedical engineering

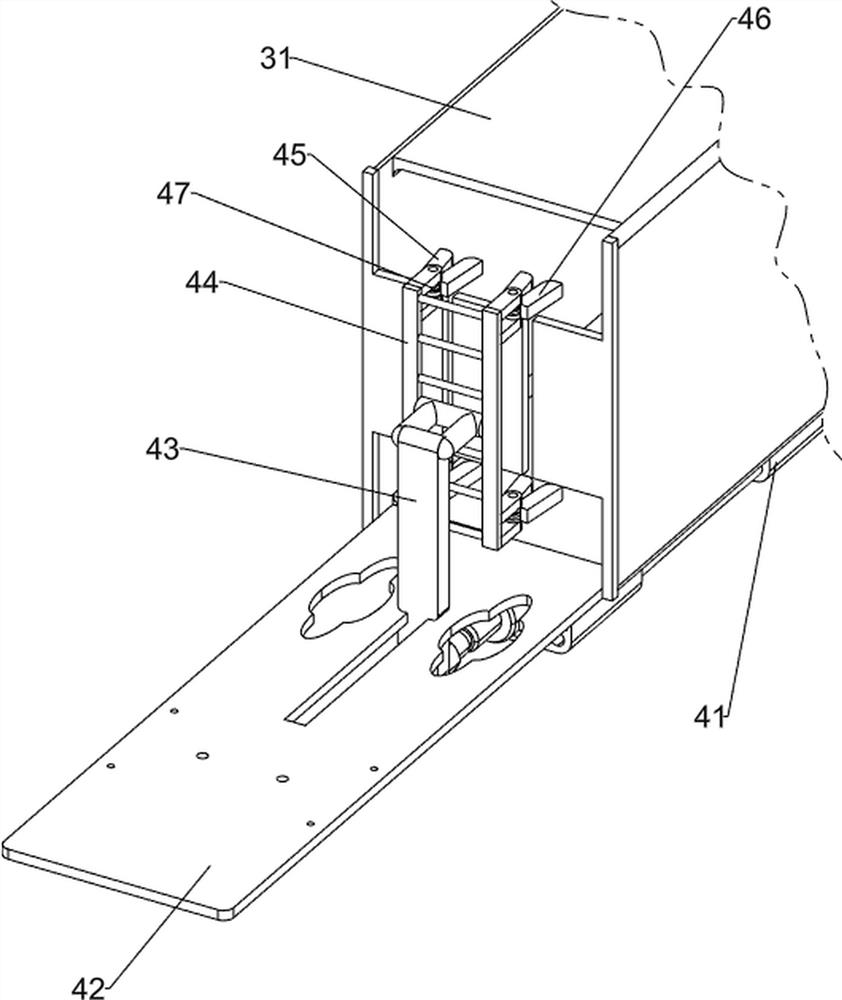

The invention relates to cotton swab medicine applying equipment, in particular to medical cotton swab medicine applying equipment capable of achieving rapid taking and using. The medical cotton swab medicine applying equipment capable of achieving rapid taking and using is capable of automatically applying medicine, convenient to operate and capable of automatically supplying liquid medicine. The medical cotton swab medicine applying equipment comprises a bottom plate, supporting columns, a feeding mechanism, a pushing mechanism, a rotating mechanism and a medicine applying mechanism, wherein the supporting columns are arranged at the top of the bottom plate; the feeding mechanism is arranged between the tops of the supporting columns on the rear side; the pushing mechanism is arranged between the top of the supporting column on the front side and the lower side of the feeding mechanism; and the rotating mechanism and the medicine applying mechanism are arranged on the pushing mechanism. After a first cotton swab is taken out through a rotating mechanism component, when another cotton swab needs to be taken out, a push rod is manually pulled to move forwards, a contraction spring is compressed, the rotating mechanism can take out the cotton swab again, and the feeding effect is achieved.

Owner:黄正豪

Environment-friendly sewage purifying device

InactiveCN107445353AAchieve rotationAchieve stirring effectTreatment involving filtrationMultistage water/sewage treatmentEngineeringSewage

The invention discloses an environment-friendly sewage purification device, which comprises a settling box, a filter box is installed on one side of the upper end of the settling box, a mixing box is installed on the other side of the upper end of the settling box, and a clean water tank is installed on the side of the settling box; the mixing box There is a decontamination agent box installed on the side, and the decontamination agent box is fixed on the clean water tank; the bottom of the filter box is equipped with a first one-way valve for the fluid to flow from the filter box to the mixing box, and the bottom of the mixing box is equipped with a fluid self-mixing The material tank flows to the second one-way valve of the sedimentation tank, and the decontamination tank is connected with the mixing tank; a water pump is installed at the bottom of the clean water tank, and a suction nozzle is installed on the upper part of the sedimentation tank, and the water pump is fixedly connected to the suction nozzle through a water pipe. The invention solves the problem that the decontamination agent can be quantitatively added without manual participation.

Owner:陈功鸿

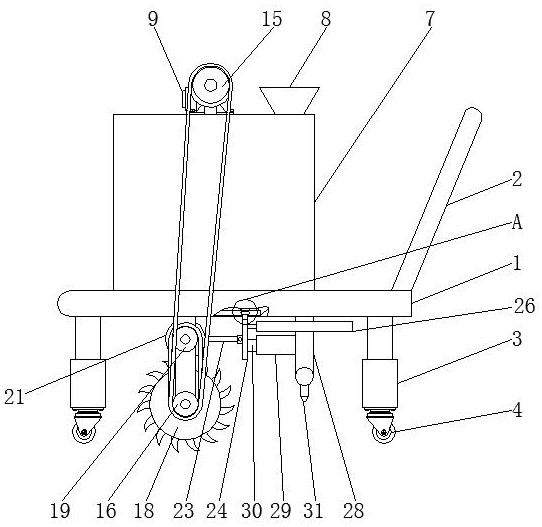

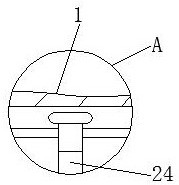

Plastic bag crushing and recovering device

ActiveCN107627494AExpand the range of crushingImprove crushing efficiencySievingScreeningEngineeringElectromagnet

The invention relates to a crushing and recovering device and in particular relates to a plastic bag crushing and recovering device. The invention provides the plastic bag crushing and recovering device. In order to solve the technical problem, the invention provides the plastic bag crushing and recovering device which comprises an iron crushing box, an electromagnet, a screen plate and a crushingcutter and the like. A "-"-shaped hole is formed in the top of the iron crushing box; the screen plate is rotatably connected to the bottom of the right side of the crushing box; the left end of thescreen plate is connected to the electromagnet; the right end of the screen plate is connected to a handle; a top plate is arranged above the iron crushing box; and a first slide rail and a linking device are arranged in the bottom of the top plate. The device provided by the invention achieves the effects of high plastic bag crushing efficiency, resource conservation and recycling and environmental protection, can limit the position of the screen plate to prevent the screen plate from swinging excessively to leak the crushed plastics, and further stir and mix the plastic bags in the crushingbox to more finely and uniformly crushing the plastic bags so as to prevent the plastic bags are left on the screen plate.

Owner:江苏通发环保科技有限公司

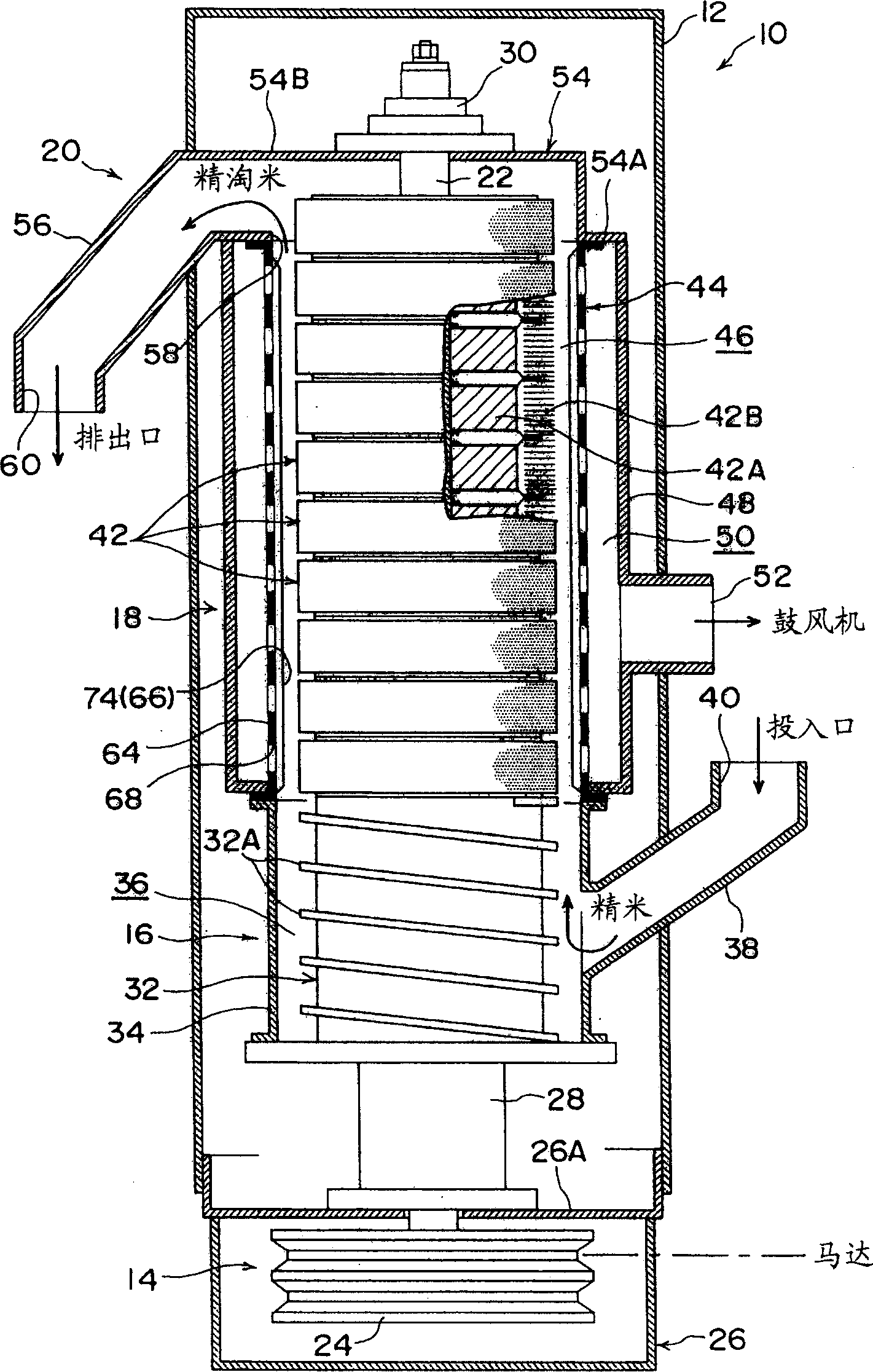

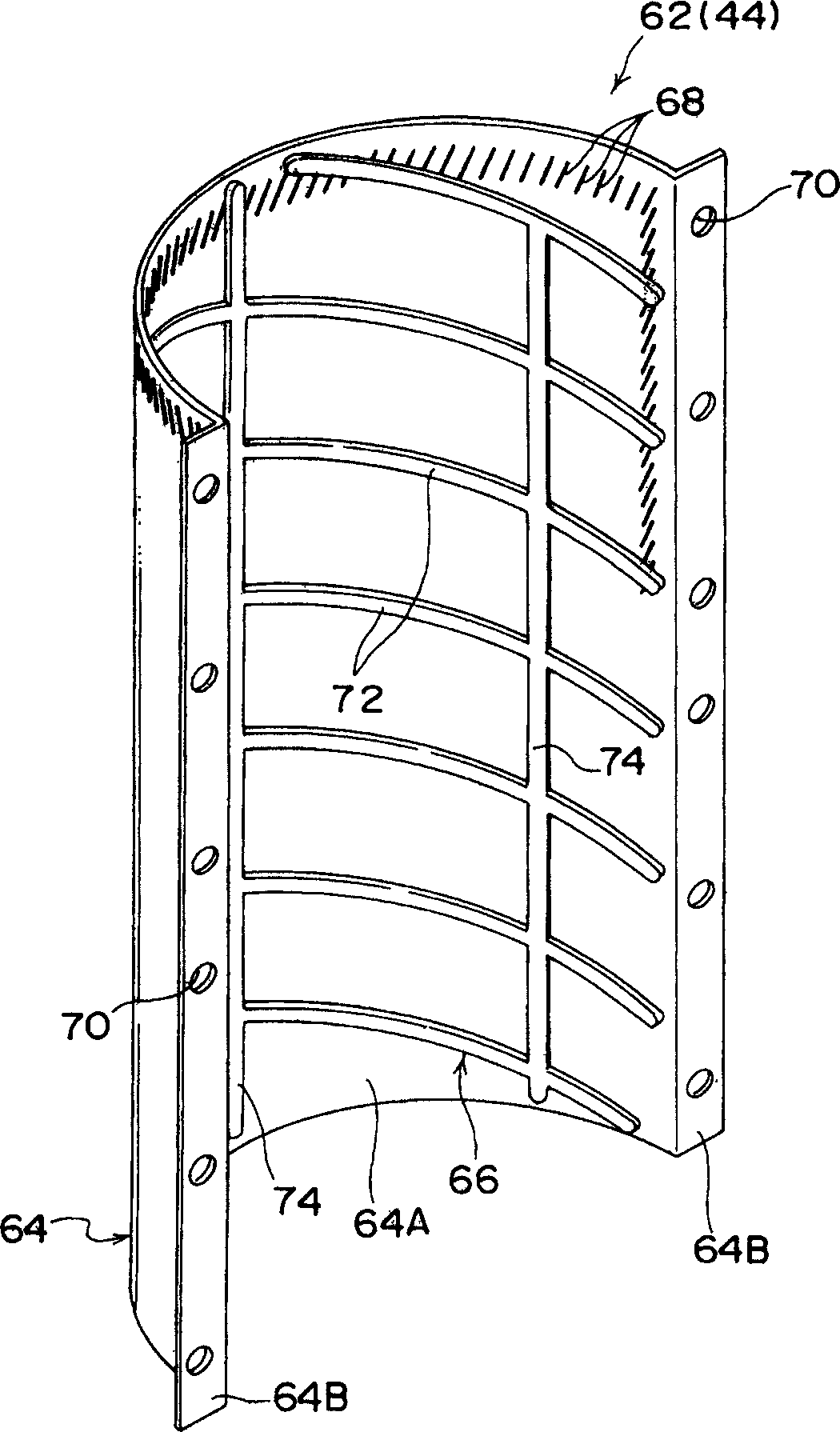

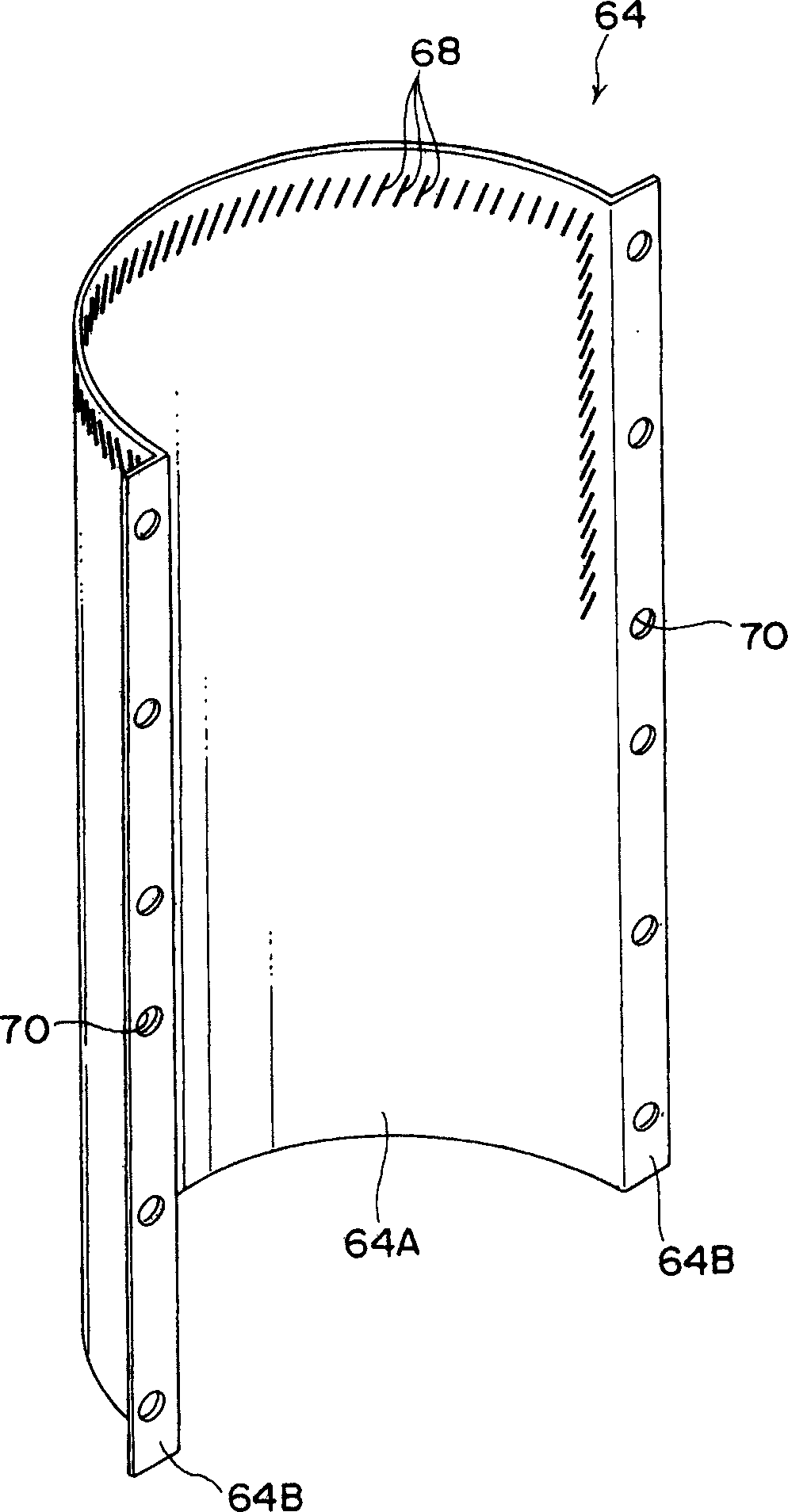

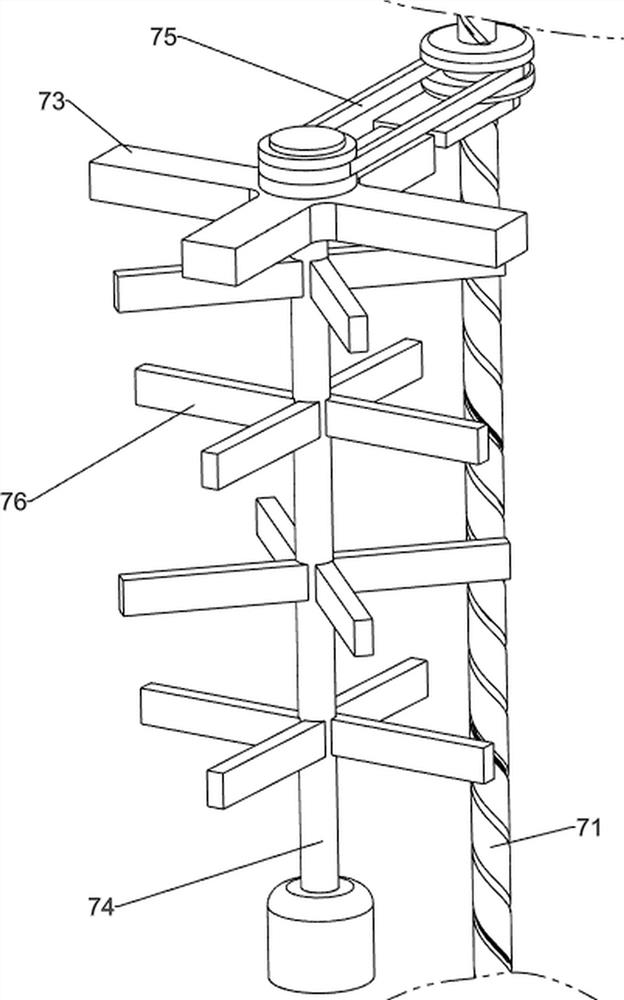

Rice washer

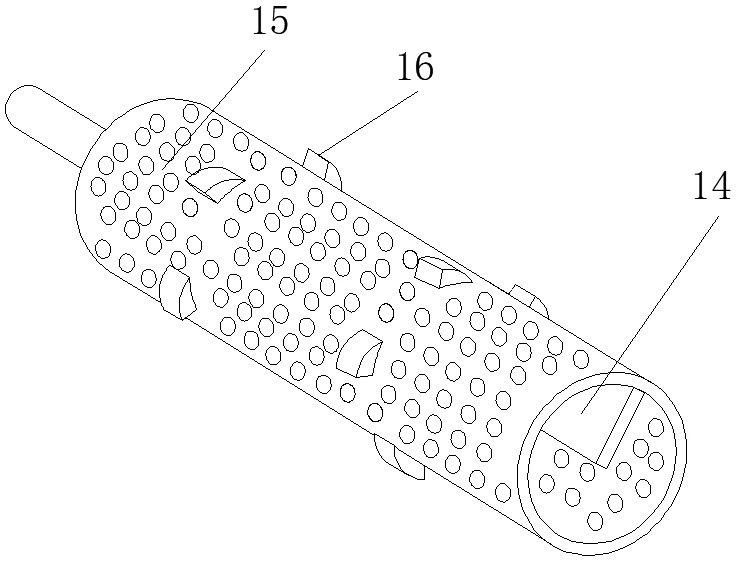

InactiveCN1727064ASimple compositionImprove rice washing performanceGrain huskingGrain polishingRice grainEngineering

The present invention provides a rice polisher with a simple structure and provided with an improved rice polishing capability. A rice bran removal cylinder 44 to be used in a dry type rice polisher is composed of a metal net 64 having rice bran removal holes 68 and projections 66 welded in its inner circumferential face. Each projection 66 comprises a plurality of slant projections 72 and a plurality of parallel projections 74 extended vertically. Accordingly, the rice polishing function is improved since a stirring function by the parallel projections 74 is obtained in addition to a transportation function of the slant projections 72 for rice grains.

Owner:YAMAMOTO CORPORATION

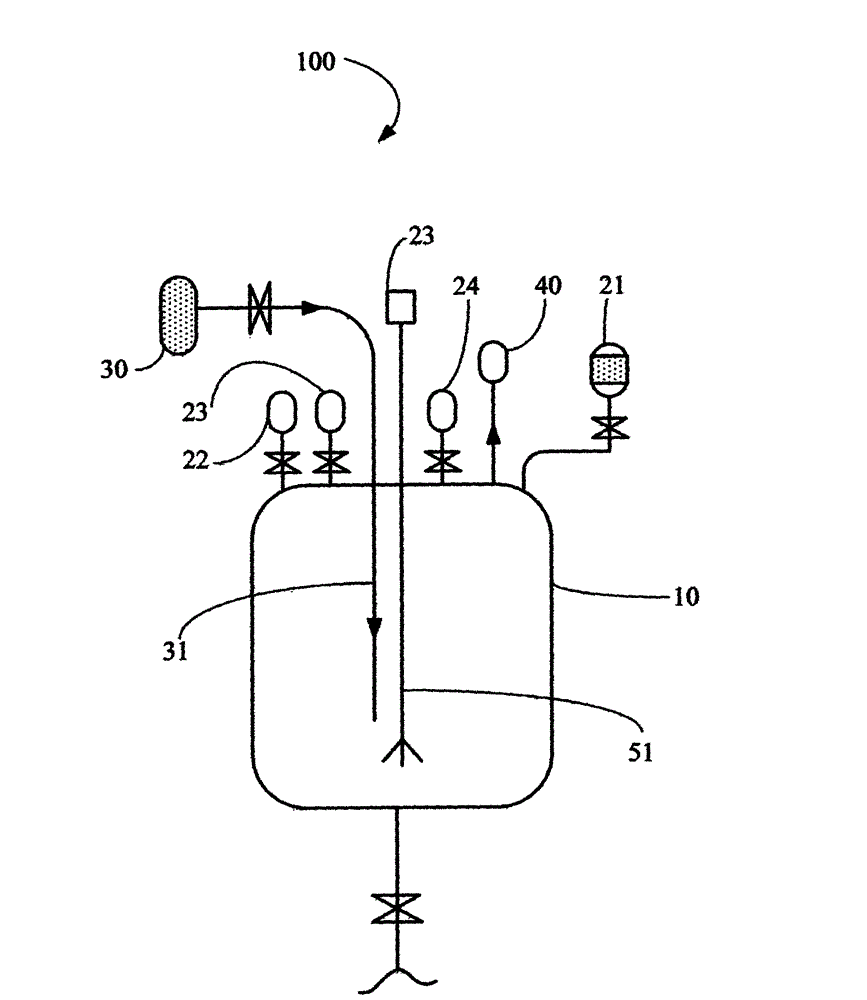

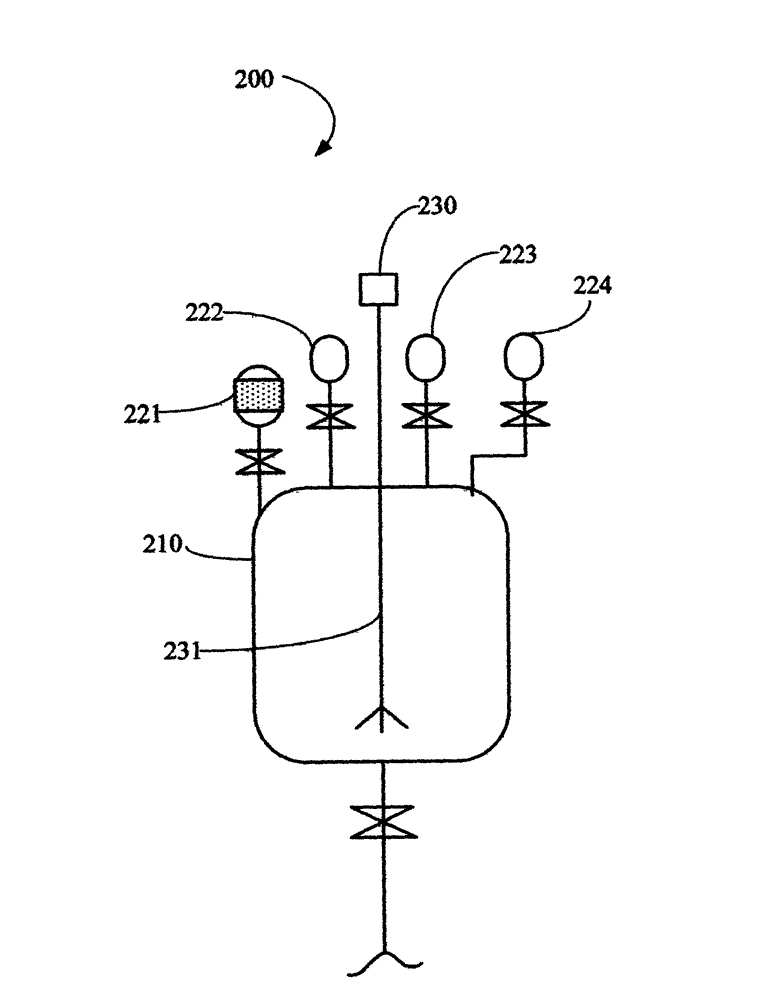

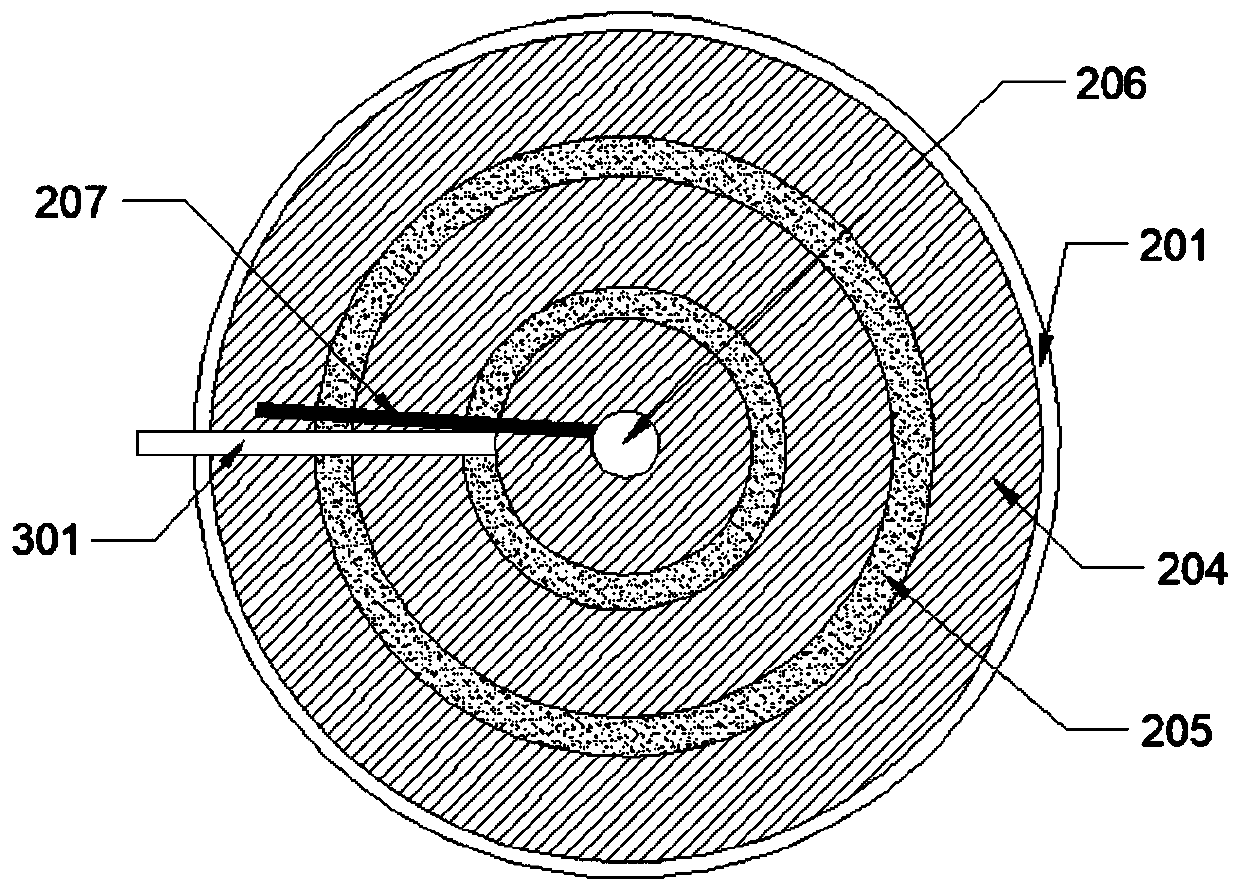

Convenient-to-maintain large-capacity quick-opening reaction kettle

ActiveCN106622084APromote prolapseAdjust the lengthTransportation and packagingRotary stirring mixersPush pullEngineering

Owner:ZHEJIANG DC CHEM

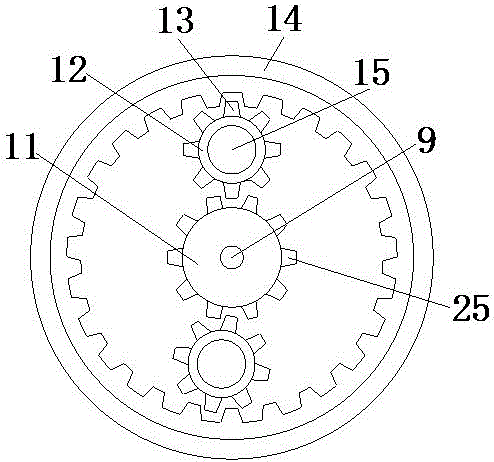

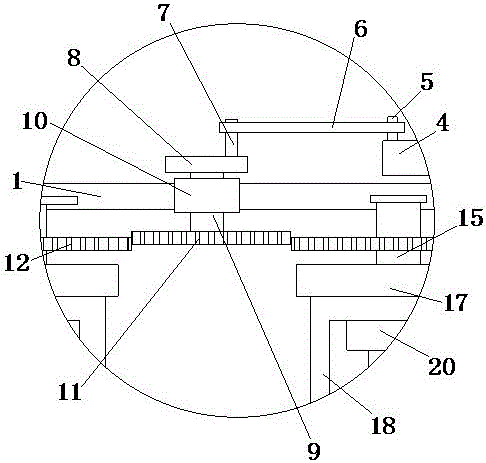

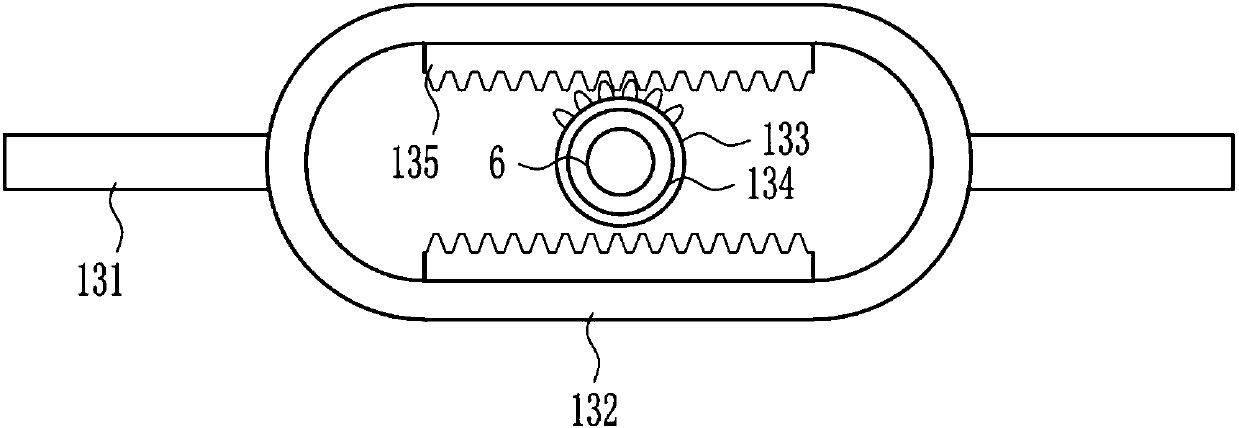

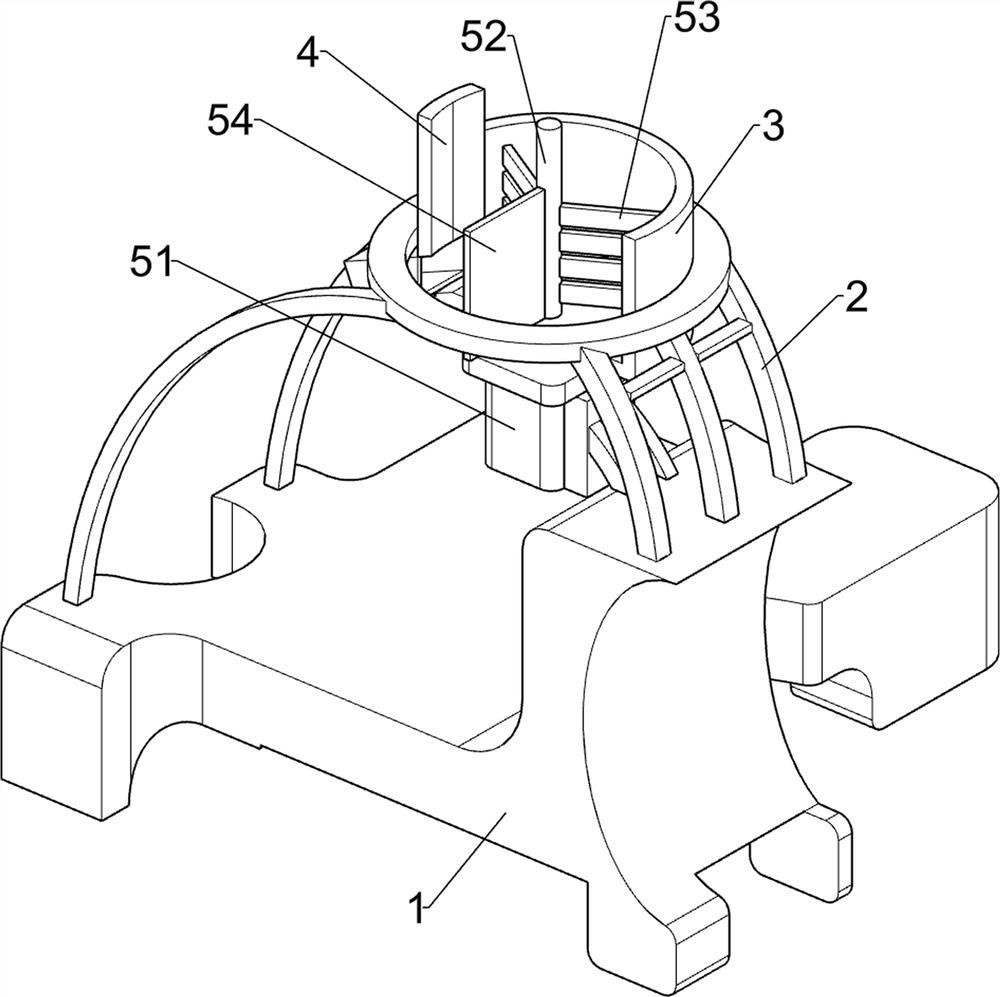

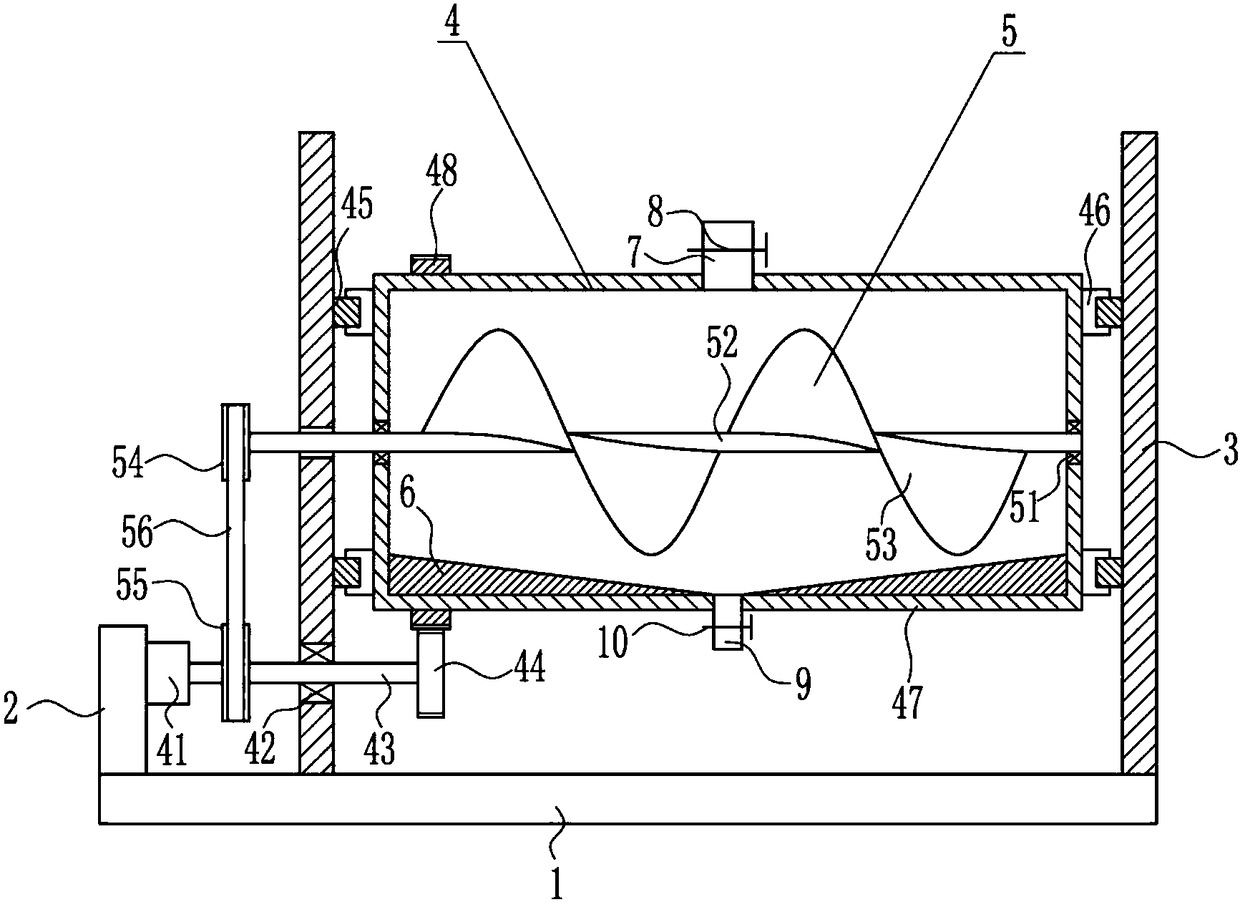

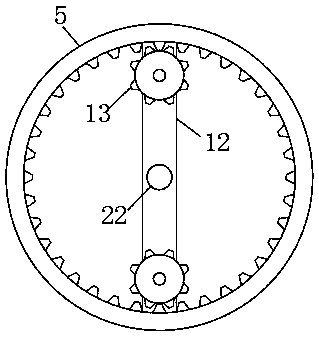

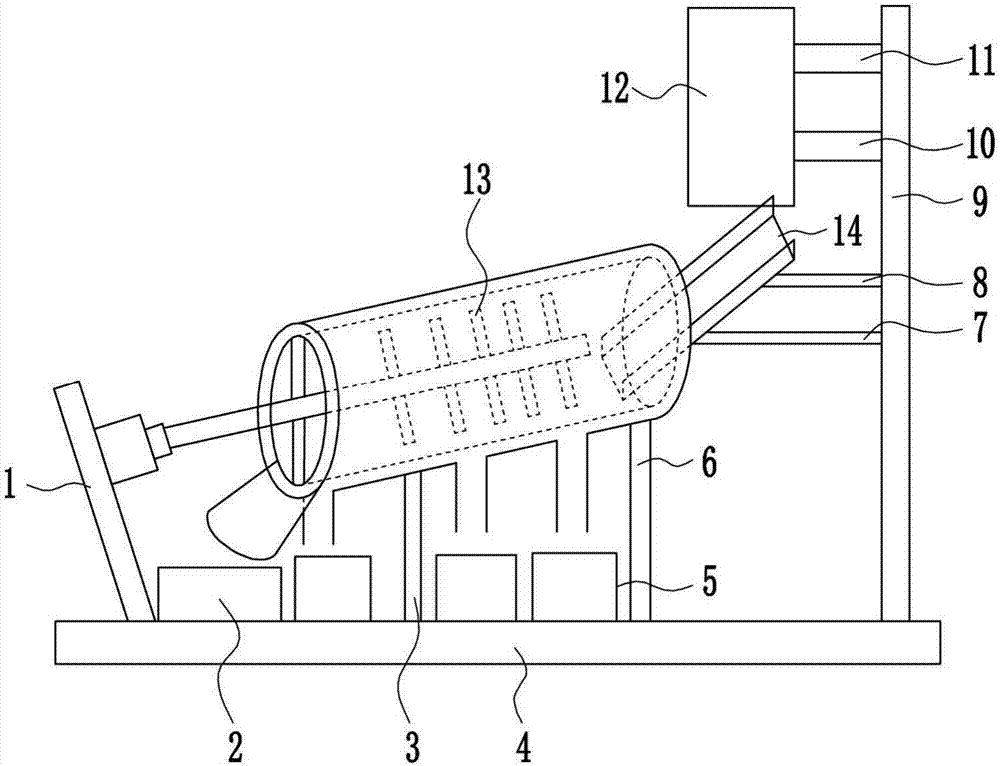

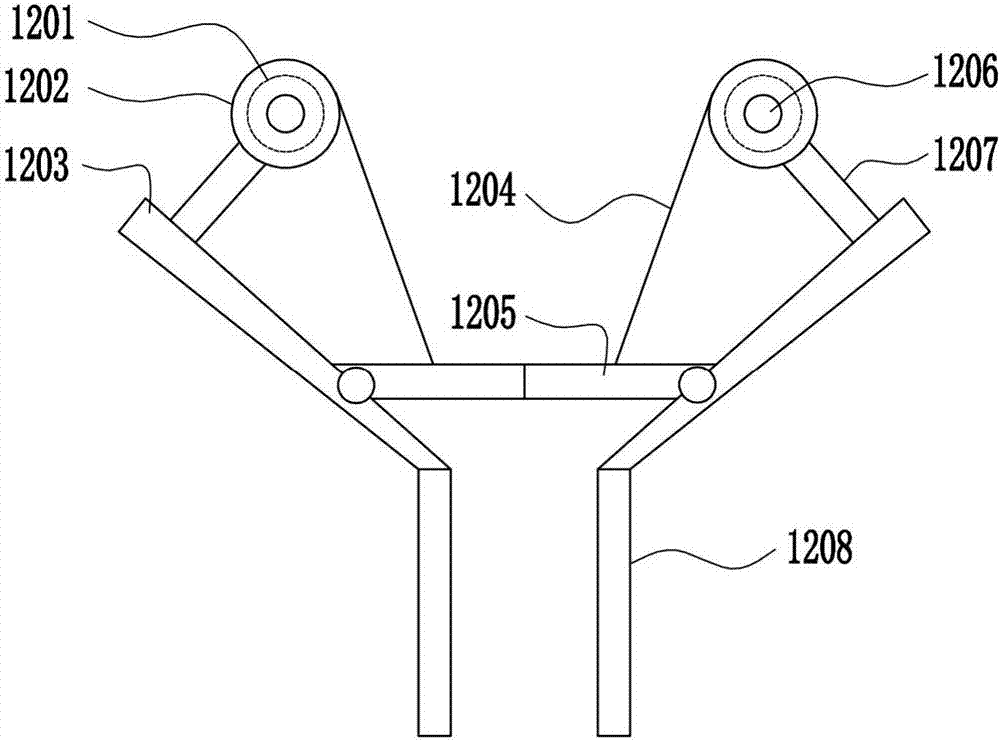

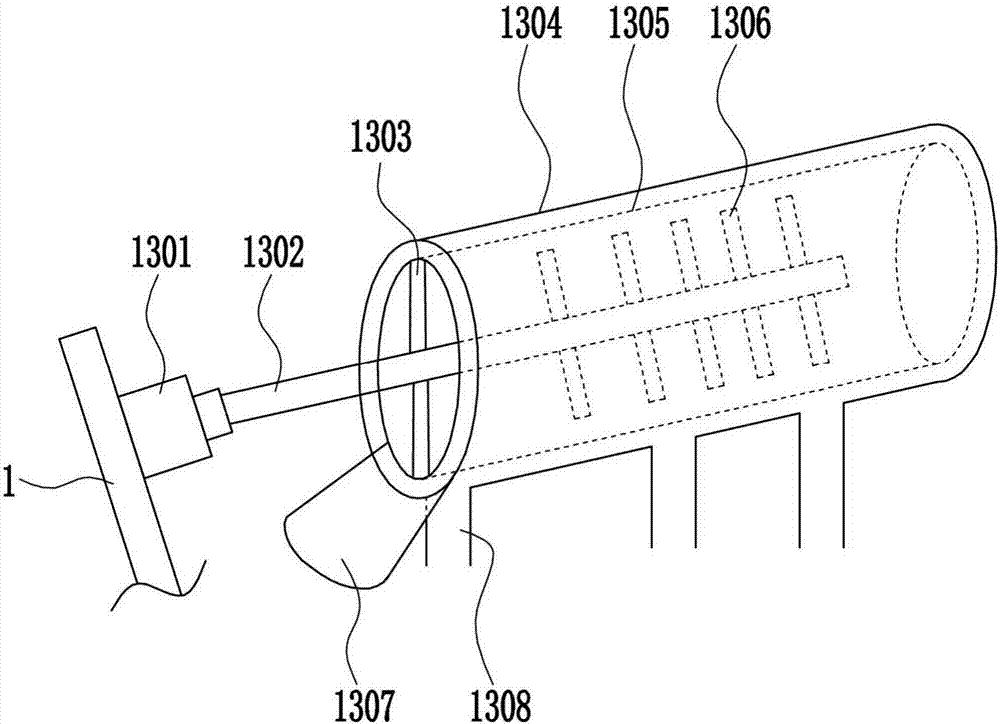

Building construction sand and stone mixing device

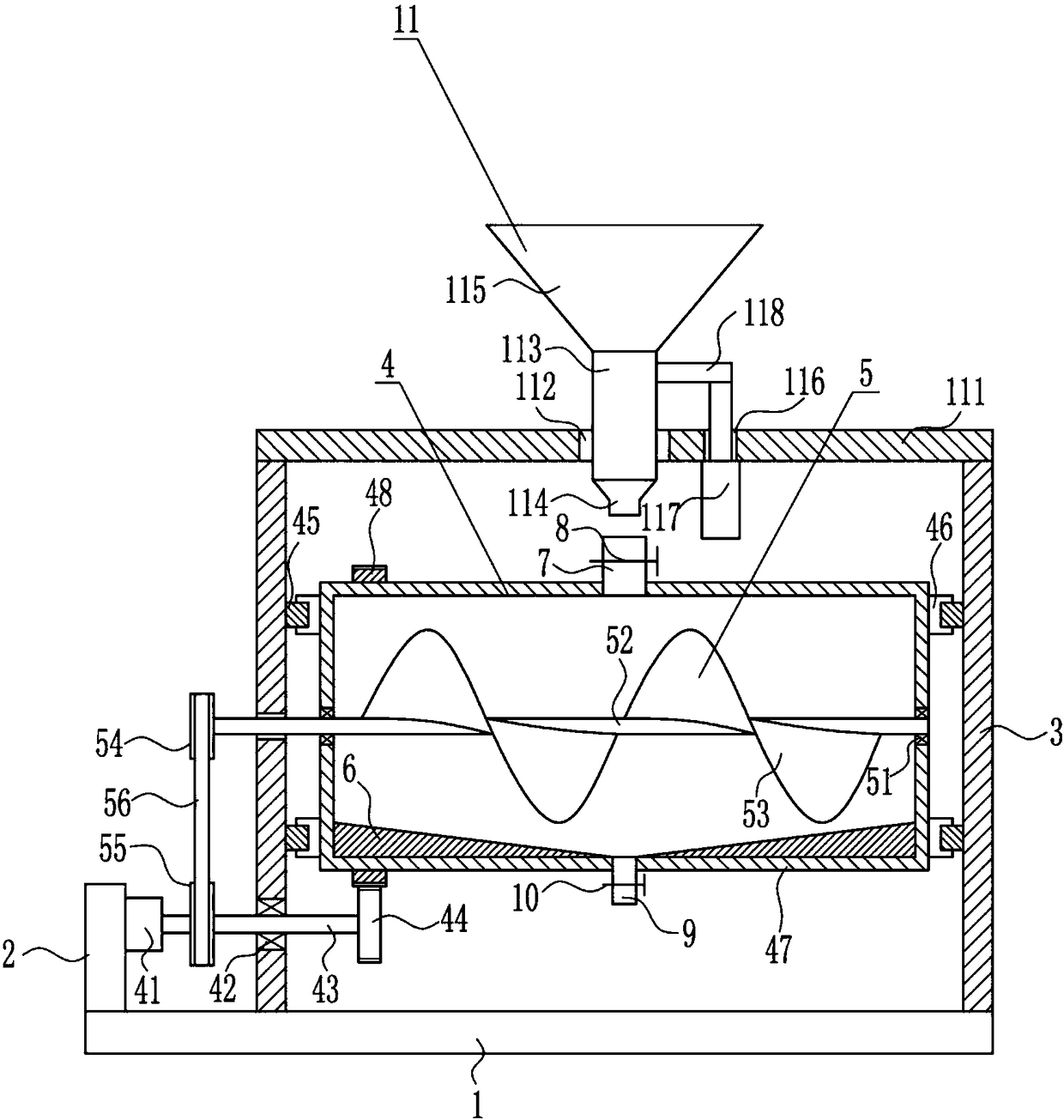

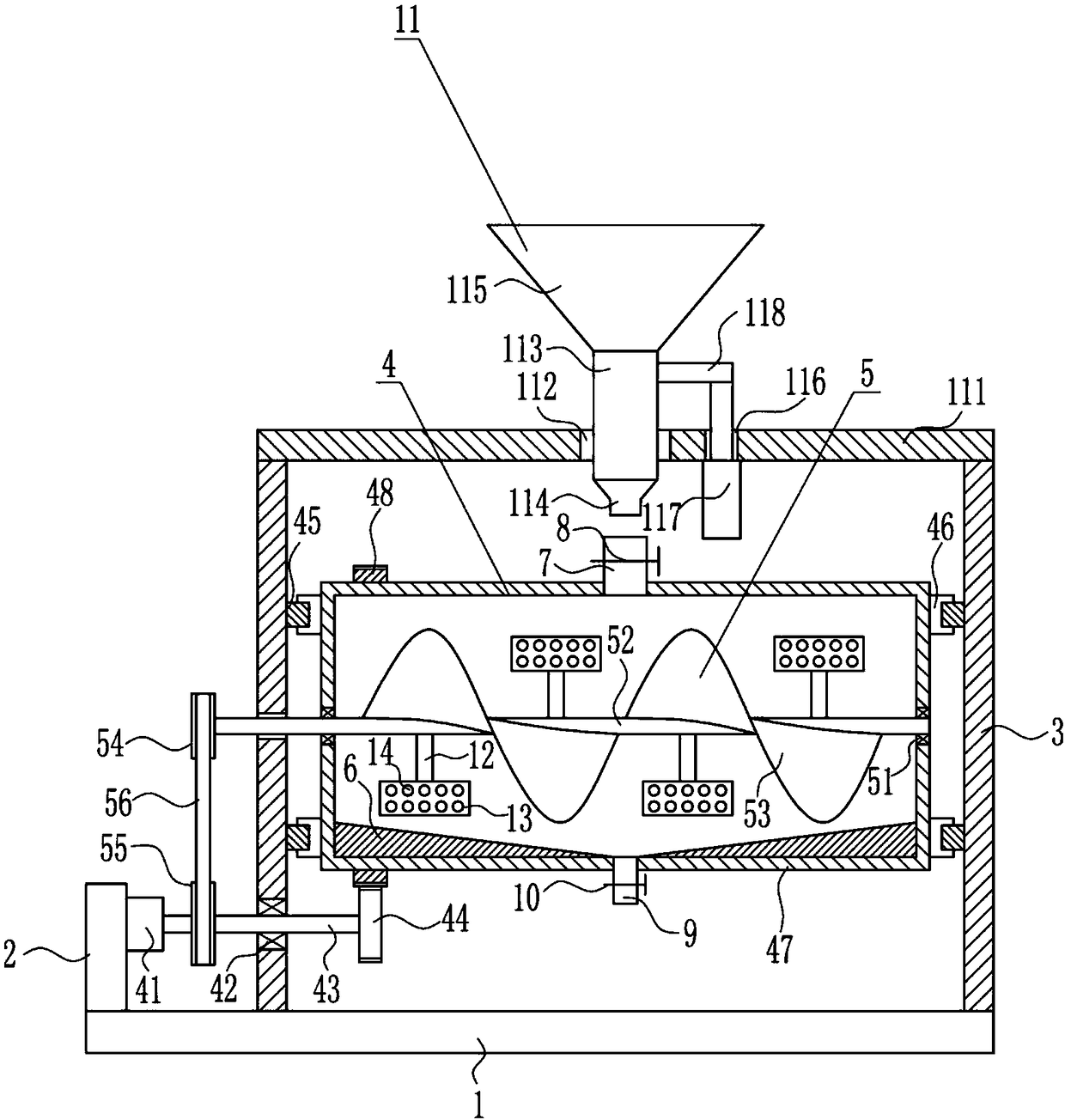

InactiveCN109129923AAchieve stirring effectStir to mix thoroughlyCement mixing apparatusDrive shaftArchitectural engineering

The invention discloses a building construction sand and stone mixing device which comprises a support bottom plate. Two support frames are vertically fixedly mounted on the support bottom plate, a stirring barrel is horizontally arranged between the support frames, a rotary shaft which is connected with the support frames by bearings is horizontally penetratingly arranged in the stirring barrel,L-shaped rotary frames are symmetrically fixedly mounted on the side walls of the rotary shaft, and the side walls of the rotary frames cling to the inner side wall of the stirring barrel. The building construction sand and stone mixing device has the advantages that the building construction sand and stone mixing device is ingenious in structure and reasonable in design; the rotary frames can rotate, accordingly, actions of stirring sand and stone in the stirring barrel can be implemented, the inner wall of the stirring barrel can be scraped, and the sand and the stone can be assuredly comprehensively stirred and mixed with each other; a driven shaft II and a driven shaft I can rotate, and accordingly sand and stone stirring effects of stirring blades can be greatly improved; a transmission gear and an outer tooth ring are connected with each other in a meshing manner, accordingly, the stirring barrel and the rotary frames can reversely rotate, mixing effects can be greatly enhanced,and quick sand and stone stirring and mixing effects can be realized by the building construction sand and stone mixing device.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

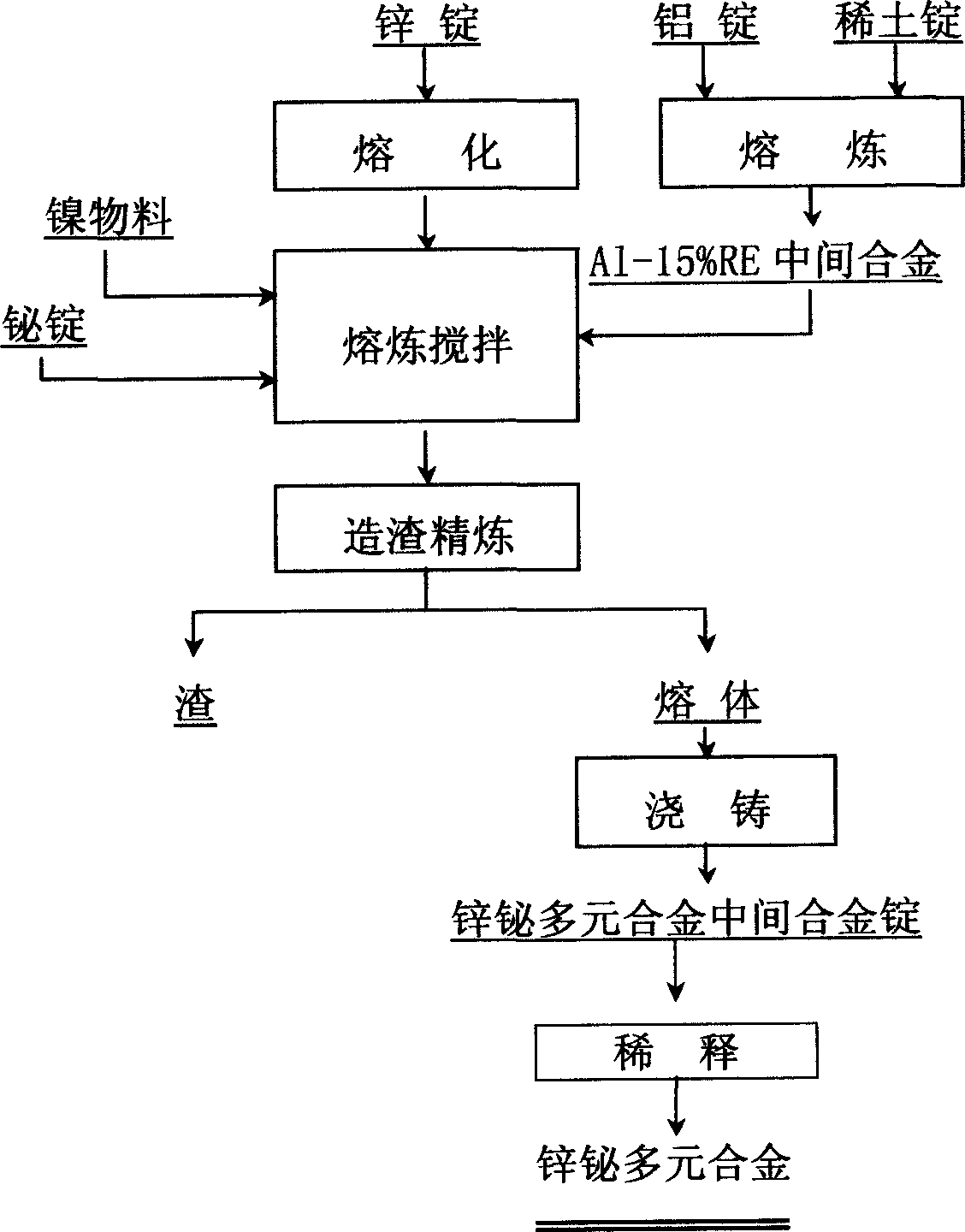

Method for producing zinc bismuth multicomponent alloy used for hot dip galvanizing of steel and iron members

The present invention relates to production of zinc alloy. The technological scheme of producing Zn-Bi alloy includes first compounding intermediate alloy with alloy ingot and RE ingot at the smelting temperature of 750-850 deg.c, subsequent smelting zinc ingot at 550-650 deg.c and adding nickel material and final adding bismuth ingot to form the polynary Zn-Bi alloy. The said process can avoid the burning loss of RE metal to avoid waste, may have certain amount of Al-RE intermediate alloy added to form different alloys, and has smelting and stirring time over 15 min to reach effect of homogeneous mixing. The present invention uses preferably inducing furnace as smelting apparatus and the product has stable and homogeneous alloy element components, high alloy element utilization and clean and environment friendly production process.

Owner:株洲冶炼集团有限责任公司

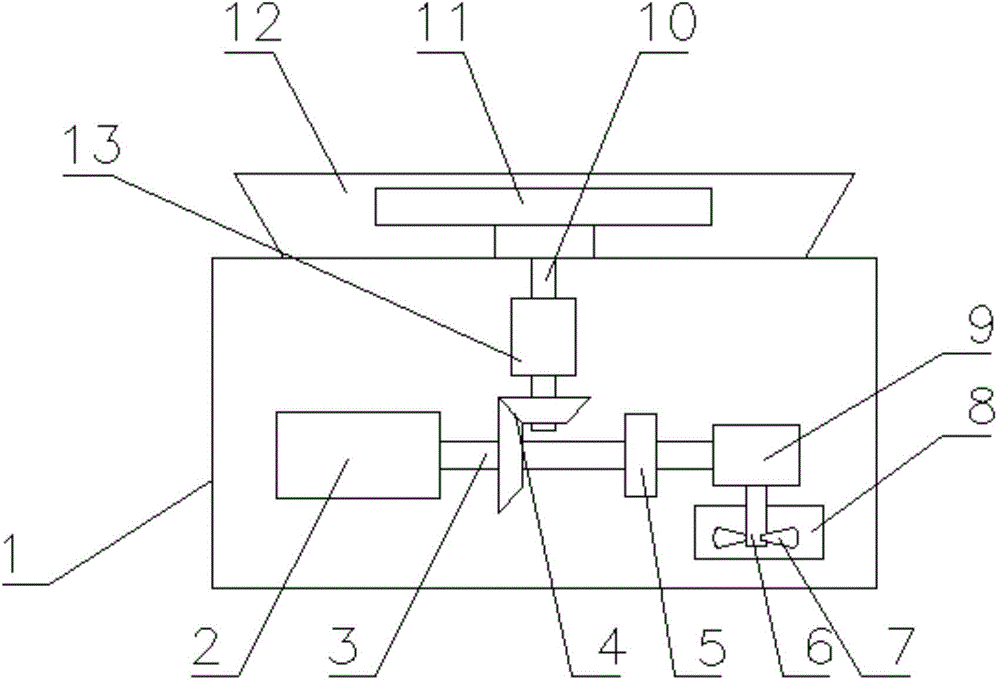

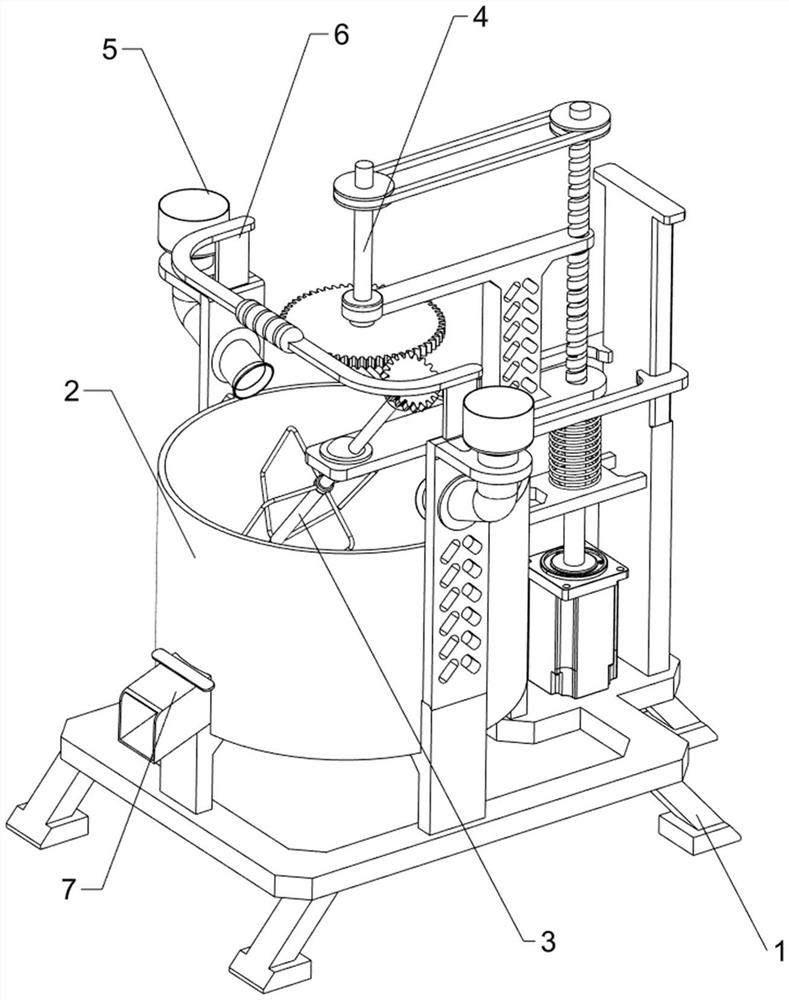

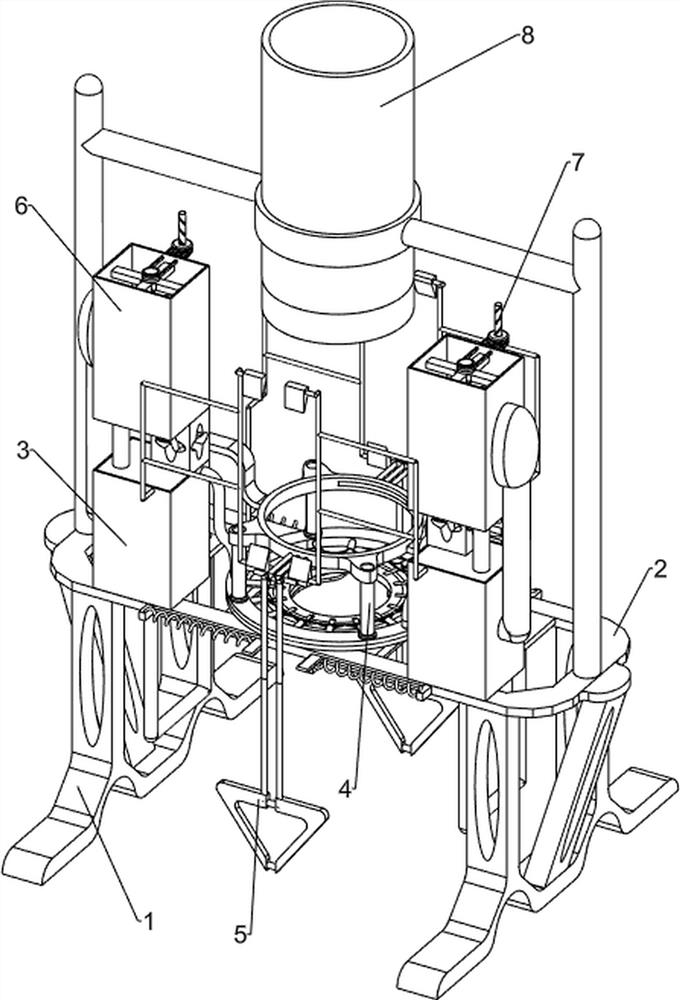

Throwing machine

InactiveCN104149159AAchieve stirring effectIncreased flexibility of useAuxillary shaping apparatusClay processing apparatusAgricultural engineeringClutch

The invention discloses a throwing machine. The throwing machine comprises a base, a motor, a spindle, a throwing shaft, bevel gears, a speed regulator, a throwing rotary plate, a retaining plate, a speed reducer, a clutch, a stirring shaft, blades and a stirring tank. The throwing rotary plate is positioned in the retaining plate which is arranged at the upper end of the base, the spindle is connected with the motor which is fixed in the base, the bottom end of the throwing shaft is connected with the spindle through the pair of bevel gears, the top end of the throwing shaft is connected with the throwing rotary plate, and the throwing shaft is provided with the speed regulator. The top end of the stirring shaft is connected with the spindle through the speed reducer, the clutch is arranged between the spindle and the speed reducer, and the blades are mounted at the bottom end of the stirring shaft and positioned in the stirring tank. The throwing rotary plate and the stirring shaft are driven to rotate simultaneously by one motor, stirring and throwing can be carried out at the same time, and the throwing machine is especially suitable for beginners.

Owner:ZHONGLI CERAMICS

Pharmaceutical stirrer

InactiveCN109012323AChange angleChange radiusRotary stirring mixersTransportation and packagingPulp and paper industryLiquid surfaces

The invention discloses a pharmaceutical stirrer. The stirrer comprises a stirring device and a cylinder, the stirring device comprises a motor, a stirring shaft and stirring blades, a shaft hole is arranged in the middle of the stirring shaft, limiting grooves are arranged in two sides of the stirring shaft, a first pinhole is arranged in every limiting groove, a telescopic shaft is arranged in the shaft hole in a clearance manner, the upper end of the telescopic shaft is connected with a telescopic cylinder, the telescopic cylinder is fixed in a cylinder mounting cavity, second pinholes arearranged in the telescopic shaft, and every stirring blade is provided with a U-shaped groove and a through hole. When the stirrer works, the telescopic cylinder drives the telescopic shaft to telescope, the stirring blades with the end parts hinged to the telescopic shaft are pulled together in the movement process of the telescopic shaft in order to realize the change of the angles and the radiuses of the stirring blades, and the rotating motion of the stirring blades is combined to realize the stirring of a plurality of liquid surfaces, so the stirring efficiency is greatly improved.

Owner:ZHENGZHOU ZHENGXIAN PHARMA CO LTD

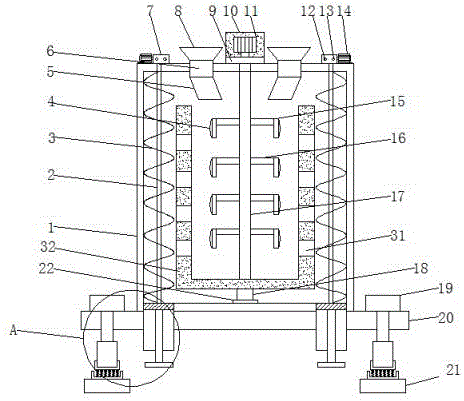

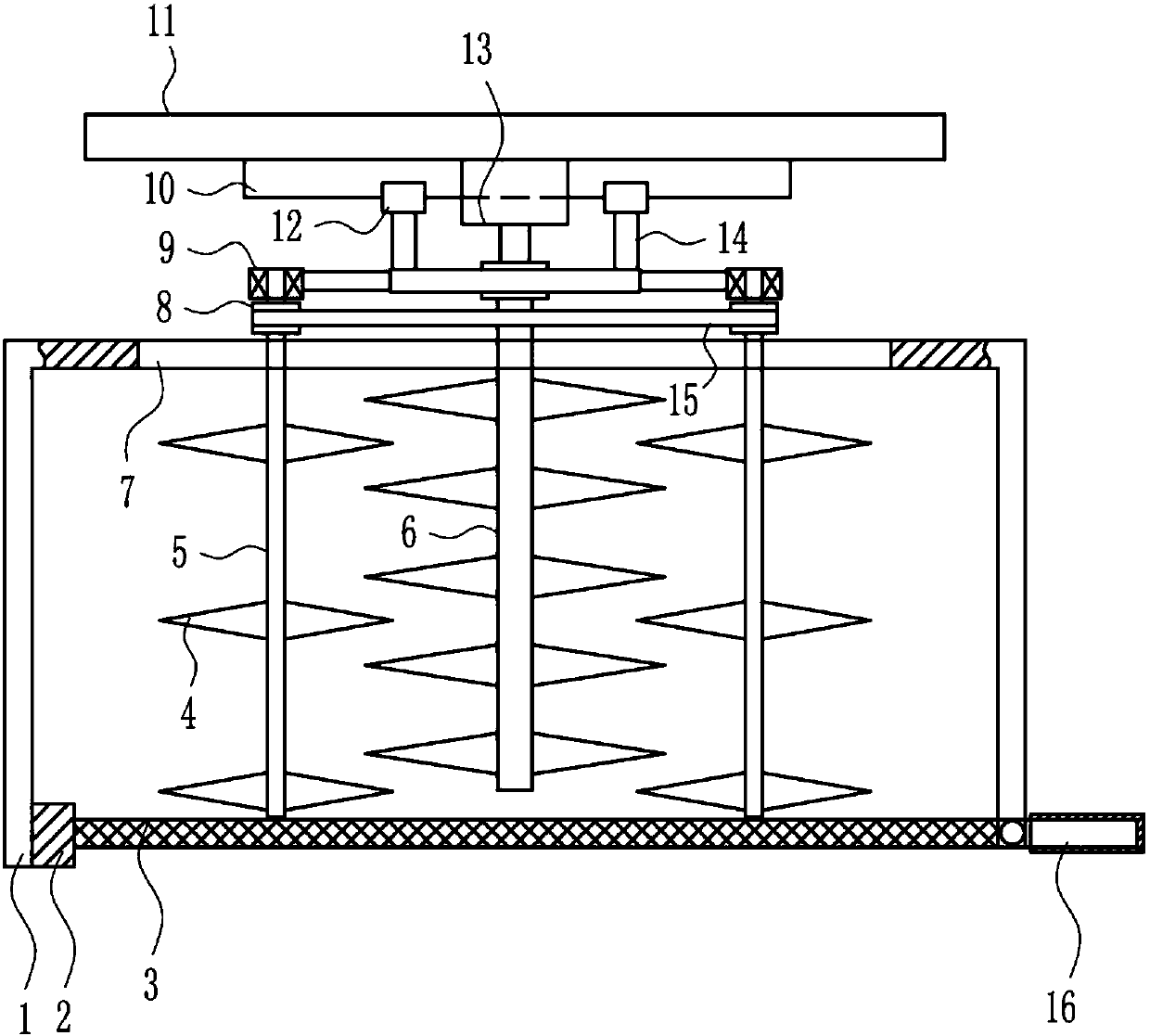

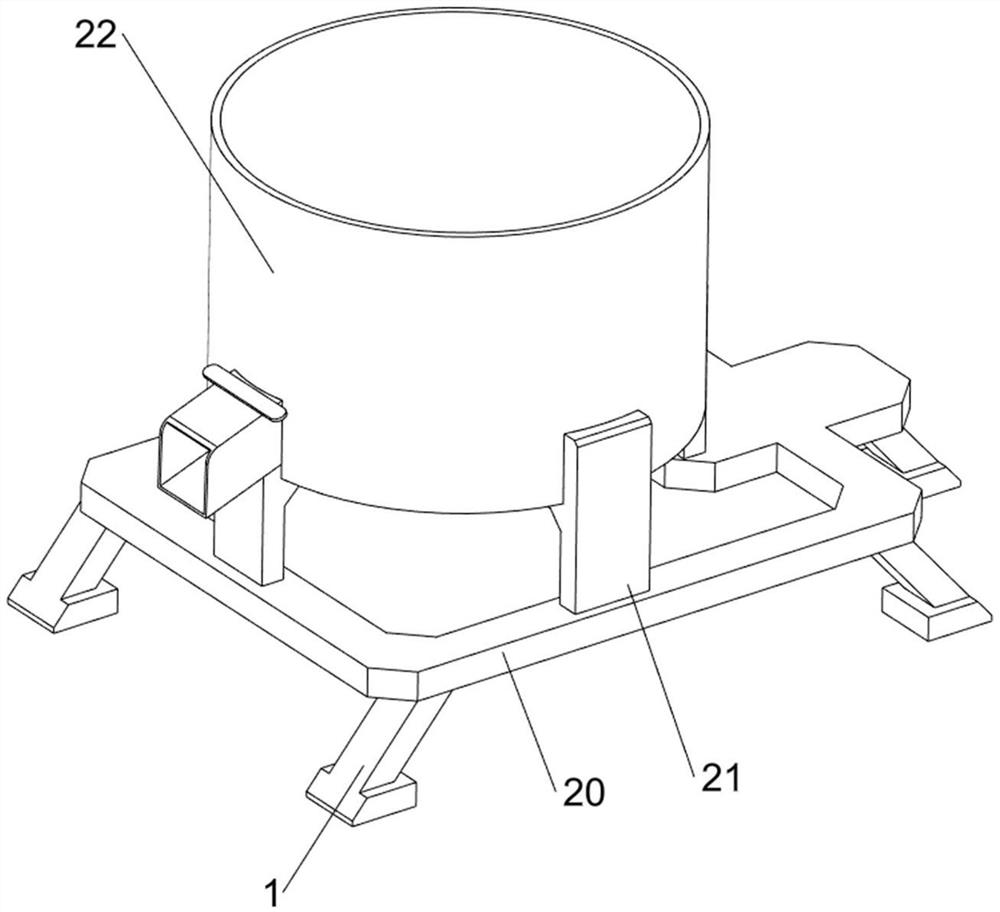

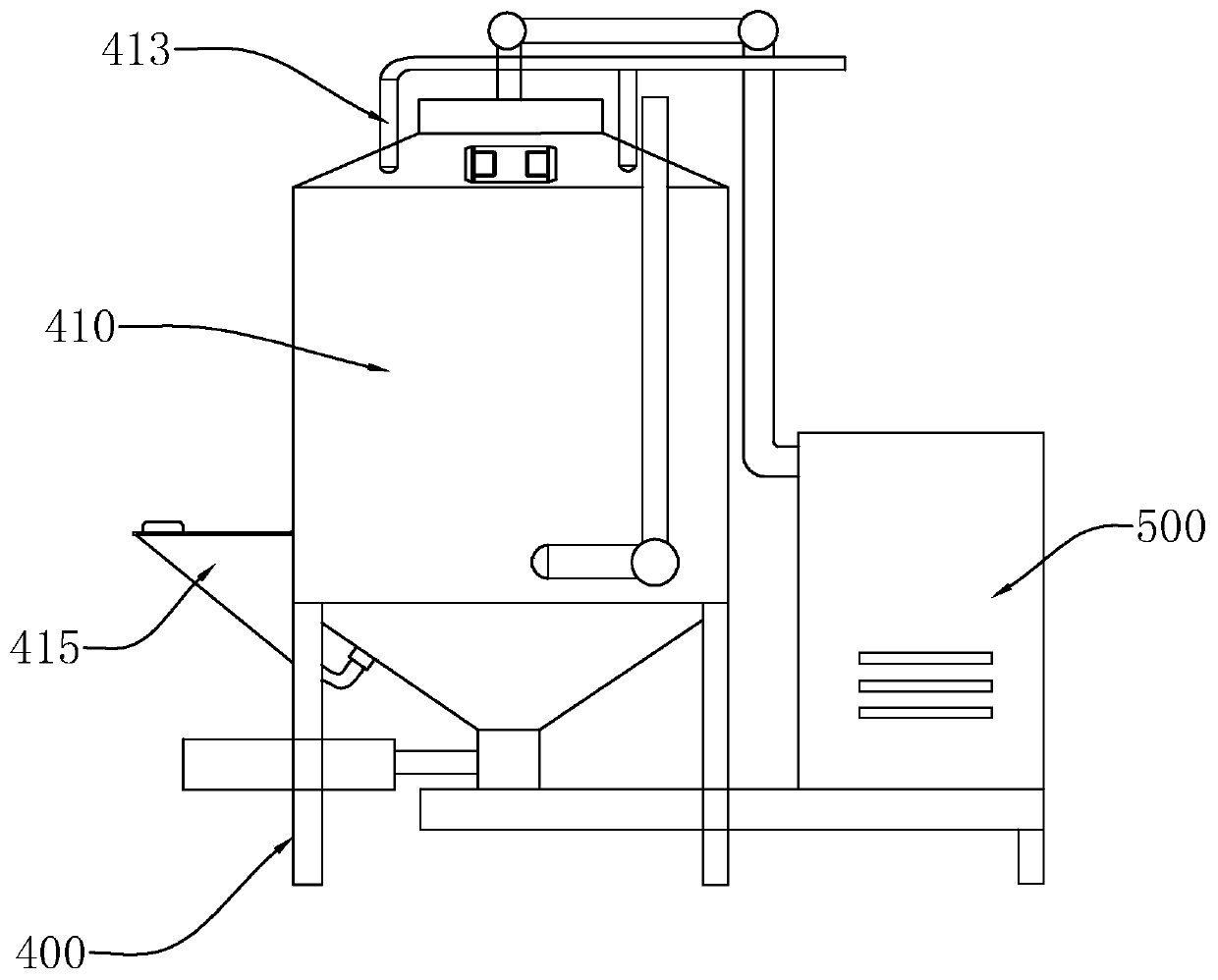

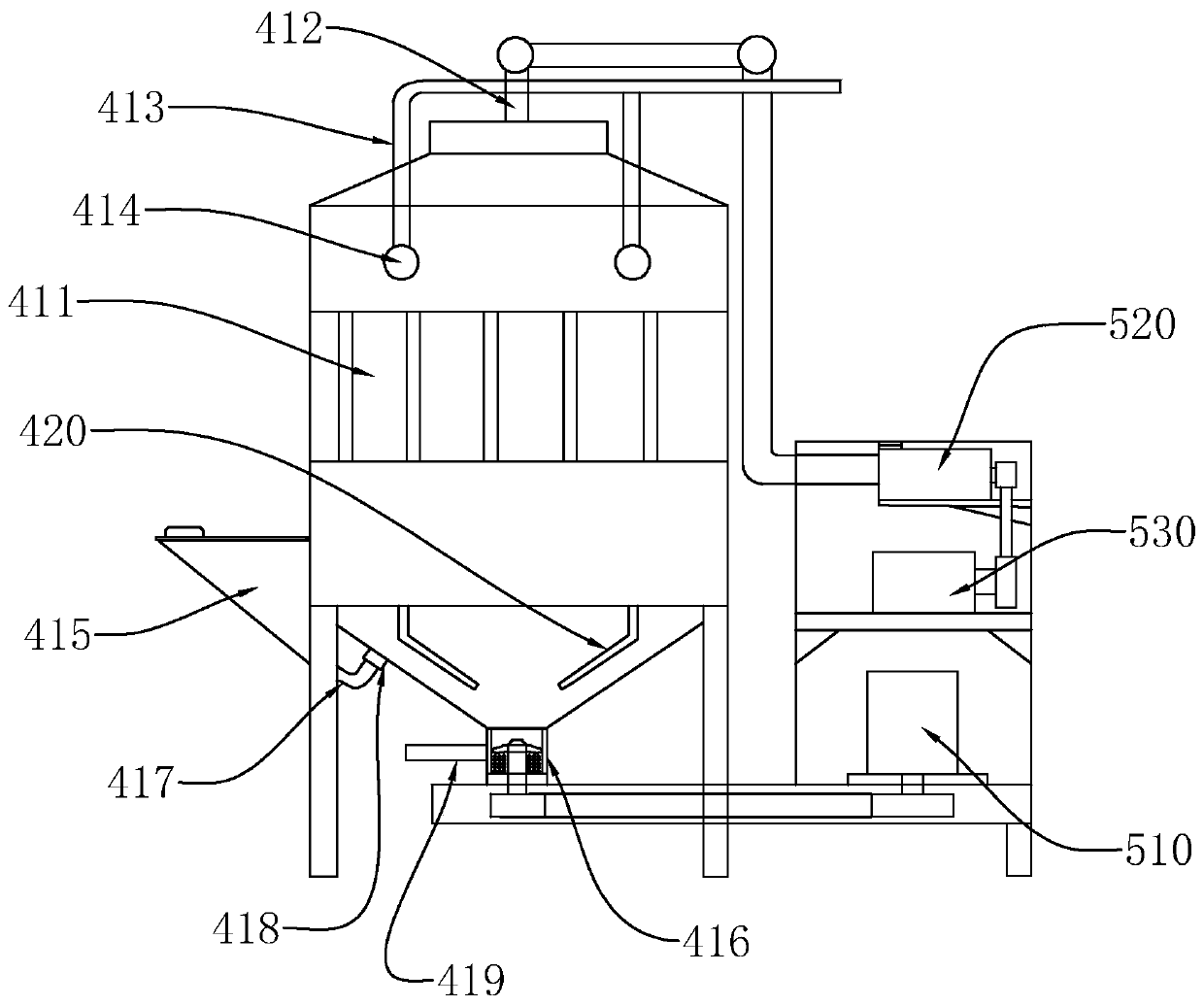

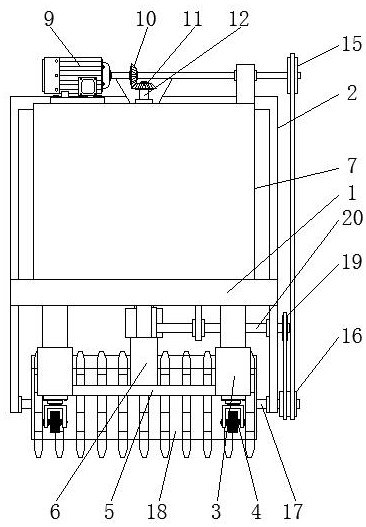

Multi-feed stirring equipment for animal husbandry

PendingCN113069955AAchieve stirring effectAchieve the effect of automatic feedingFeeding-stuffRotary stirring mixersAnimal scienceAgricultural science

The invention relates to stirring equipment, in particular to multi-feed stirring equipment for animal husbandry. The invention provides the multi-feed stirring equipment for animal husbandry, which has the advantages of automatic feeding and automatic stirring and is simple and convenient. The multi-feed stirring equipment for animal husbandry comprises a bottom plate, a support, a stirring barrel, a baffle, a stirring mechanism and an interval discharging mechanism; and the support is arranged on the bottom plate; the stirring barrel is arranged on the support; the baffle is arranged on the stirring barrel in a sliding manner; the stirring mechanism is arranged between the bottom plate and the stirring barrel; and the interval discharging mechanism is arranged between the support and the stirring barrel. A first servo motor is started, an output shaft of the first servo motor rotates to drive a first rotating shaft to rotate, so that a stirring plate and a scraping plate are driven to rotate, and when feed falls into a stirring barrel, the stirring effect is achieved.

Owner:张引

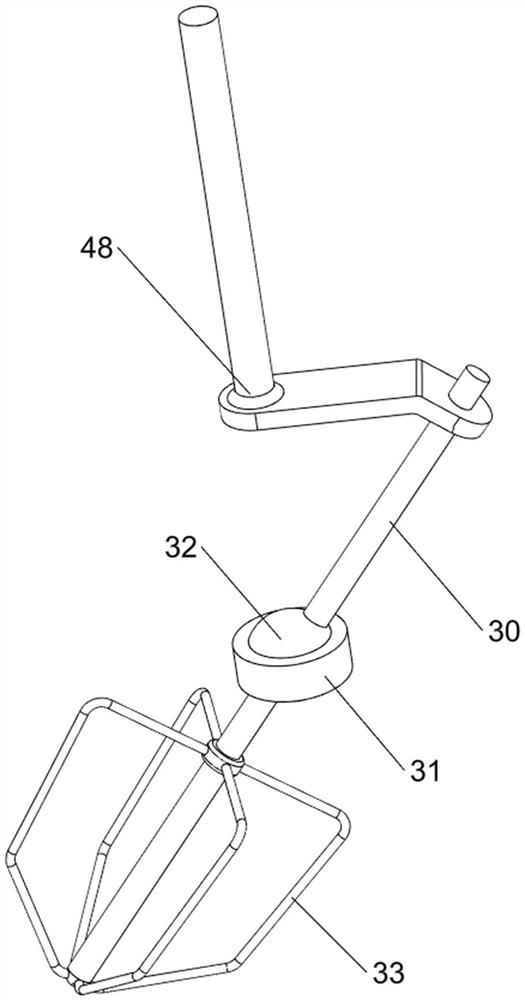

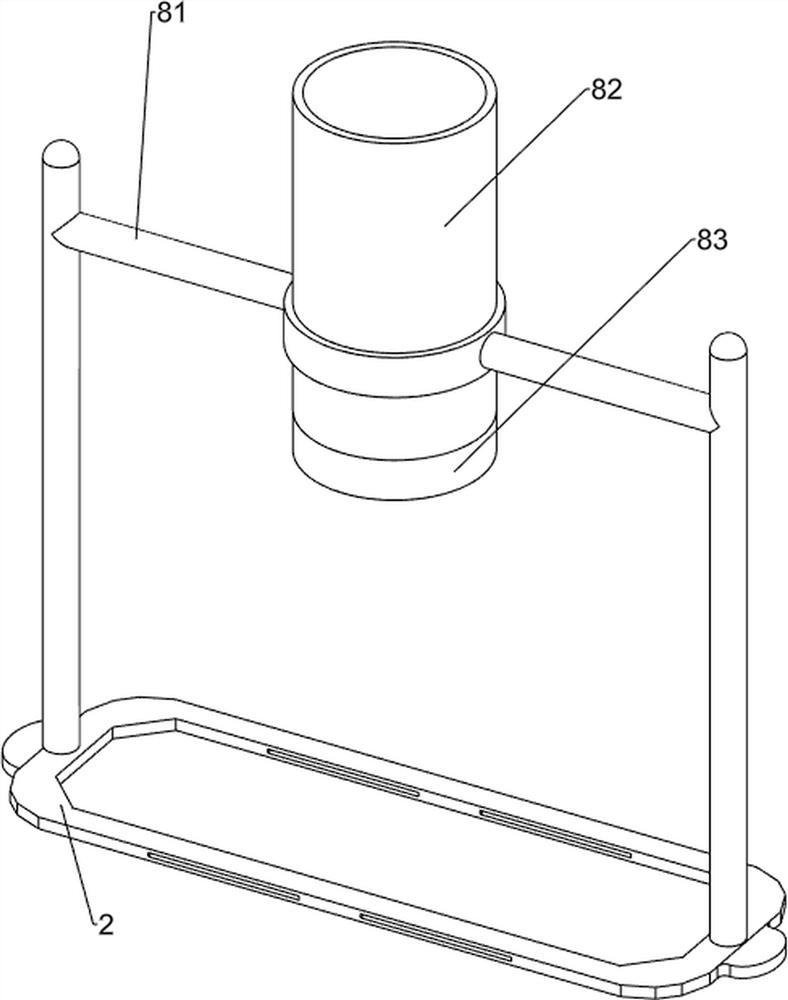

Calcium carbonate liquid stirring equipment for calcium carbonate production

The invention relates to stirring equipment, in particular to calcium carbonate liquid stirring equipment for calcium carbonate production. The calcium carbonate liquid stirring equipment for calciumcarbonate production can achieve automatic stirring, feeding is convenient, the ratio of calcium carbonate to water can be controlled, and collection is convenient. Calcium carbonate liquid stirring equipment for calcium carbonate production comprises supports among which a containing mechanism is arranged, and a stirring mechanism arranged in the containing mechanism. Through cooperation of the containing mechanism and the stirring mechanism, a universal ball is used for driving a stirring head to rotate, so that calcium carbonate liquid in the stirring barrel can be fully stirred, and the comprehensive stirring effect is achieved; a screw rod drives a rocker to rotate, so that the stirring head automatically stirs the calcium carbonate liquid, the screw rod drives a guide rod and a firstmounting base to move, up-and-down movement of the stirring head can be controlled, and the calcium carbonate liquid can be better poured out of the stirring barrel.

Owner:江西三和纳米钙有限公司

Raw-material stirring device used for cosmetics production

InactiveCN108465415AAchieve stirring effectAchieving stirringRotating receptacle mixersTransportation and packagingBiochemical engineeringSpiral blade

The invention relates to a stirring device, specifically to a raw-material stirring device used for cosmetic production. The invention is to solve the technical problem of providing the raw-material stirring device which is used for cosmetic production, can uniformly stir cosmetic production raw materials and is convenient for feeding and discharging of cosmetic raw materials. In order to solve the above-mentioned technical problem, the raw-material stirring device used for cosmetic production provided by the invention comprises a base plate, a mounting plate, supporting plates, a rotating device, a stirring device, oblique blocks, a blanking pipe, etc., wherein the left part of the upper side of the base plate is provided with the mounting plate; the left and right parts of the upper sideof the base plate are respectively provided with a supporting plate; a left-side supporting plate is located at the right side of the mounting plate; and the central parts of the inner sides of two supporting plates are provided with the rotating device which are located above the base plate. The raw-material stirring device provided by the invention achieves the beneficial effects of uniform stirring and convenient feeding and discharging for the cosmetic production raw materials; and a second rotating rod drives a spiral blade and stirring plates to rotate, so the cosmetic production raw materials in a roller can be uniformly stirred.

Owner:李超

Shearing mixing piece and vacuum mixer applying the same

InactiveCN111389246AAchieve stirring effectDissolve fastTransportation and packagingRotary stirring mixersThermodynamicsEngineering

The invention relates to the technical field of mixing equipment, and particularly discloses a shearing mixing piece and a vacuum mixer applying the same. The shearing mixing piece comprises a statorpart and a rotor part, the stator part sleeves the rotor part and the two parts are fixed to each other, a highest end of the rotor part is lower than a highest end of the stator part, the stator partand the rotor part are both provided with a turbulent flow part, and the vacuum mixer comprises the shearing mixing piece and a tank body. The invention has the beneficial effects that: the shearingmixing piece not only can realize a stirring effect, but also can shear added powder at a high speed, and rapid dissolution and sufficient mixing are achieved. According to the vacuum mixer, when liquid raw materials are added into a tank body, the vacuum equipment can be started, then feeding of powder is conducted through negative pressure in the tank body and intermittent opening of a materialsuction electromagnetic valve, the powder is directly sucked into the liquid to be mixed, and raw material waste caused by flying is avoided.

Owner:上海斯太堡实业有限公司

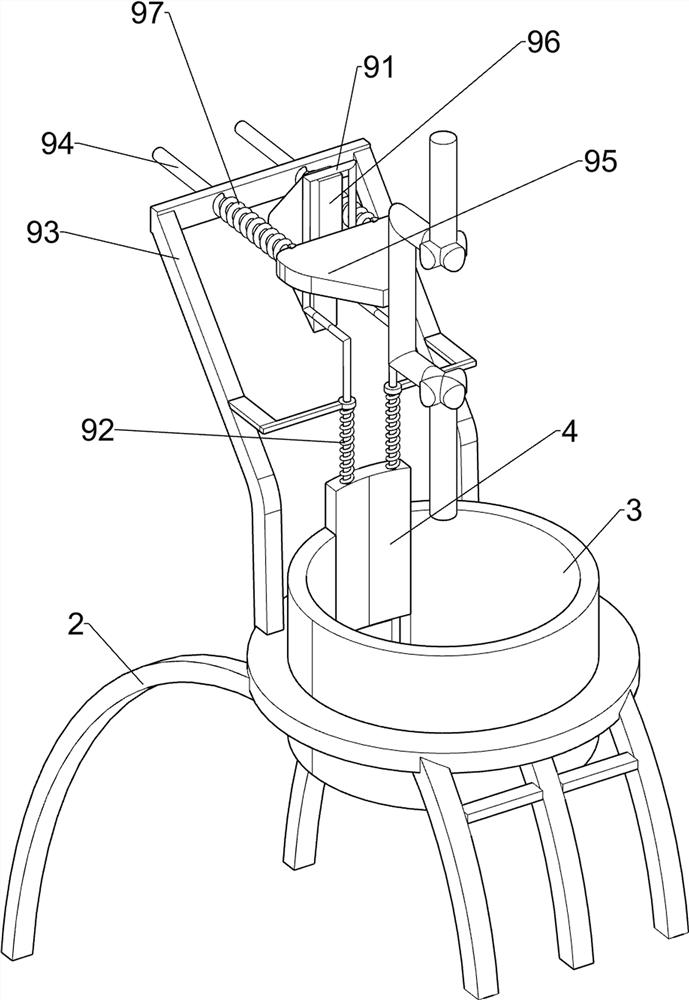

Cam type biological plant oil mixing and homogenizing device

InactiveCN109433063AReasonable structureInnovative designRotary stirring mixersTransportation and packagingFuel tankMixing effect

The invention discloses a cam type biological plant oil mixing and homogenizing device and belongs to the field of biotechnological equipment. The cam type biological plant oil mixing and homogenizingdevice comprises a homogenizing bucket, the left of the upper end of the homogenizing bucket is provided with a first oil inlet cylinder, the right of the upper end of the homogenizing bucket is provided with a second oil inlet cylinder, the insides of the first oil inlet cylinder and the second oil inlet cylinder are respectively provided with a piston, the outside of each piston is connected with a piston rod, the outside of the piston rod is connected with a limiting plate, the outside of the limiting plate is connected with a limiting rod, the outside of the limiting rod is connected witha limiting ball, a cam is mounted between the limiting balls, the middle of the cam is provided with a camshaft, the lower end of the camshaft penetrates through the middle of the upper end of the homogenizing bucket and is connected with a mixing shaft, the middle of mixing blades is uniformly provided with a mixing hole, the bottom end of the inside of the homogenizing bucket is provided withan oil inlet tank, and the inner wall of the homogenizing bucket is provided with an oil spray ring. The cam type biological plant oil mixing and homogenizing device ensures guide-in of oil of different varieties and meanwhile achieves stirring effects on mixed oil, and only through one power source, can meet the requirements on guide-in and mixing effects on plant oils of different varieties.

Owner:郑州韦尔特生物科技有限公司

Stirring device for production of chemical fiber nylon

InactiveCN108214966ASave extrusion mixing timeProtection against abnormal wearFiberPulp and paper industry

The invention provides a stirring device for production of chemical fiber nylon, and relates to the technical field of nylon production. The stirring device for production of the chemical fiber nyloncomprises two bases. A stirring tank is fixedly installed between the two bases. Two motor mounting brackets are fixedly installed on the two sides of the top of the stirring tank correspondingly. A stirring motor is fixedly installed between the two motor mounting brackets. According to the stirring device for production of the chemical fiber nylon, through cooperation of the stirring motor, a rotating rod, a bearing, a stirring rod, a stirring roller, a transverse cutting blade, a fixing ring and a longitudinal cutting blade, after the stirring motor is started, the rotating rod, the stirring rod and the stirring roller are driven to stir, and meanwhile, raw materials in the stirring tank can further be crushed through the transverse cutting blade and the longitudinal cutting blade; andin this way, the stirring effect is further improved, the extruding and stirring time of an extruding machine at a later stage is saved, meanwhile, the extruding machine is protected against abnormalabrasion, the service life of the extruding machine is prolonged, and the effects of crushing and stirring can be achieved.

Owner:胡和萍

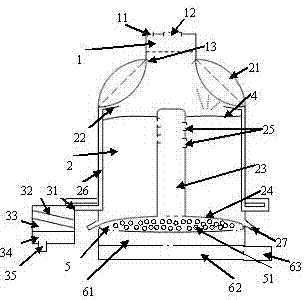

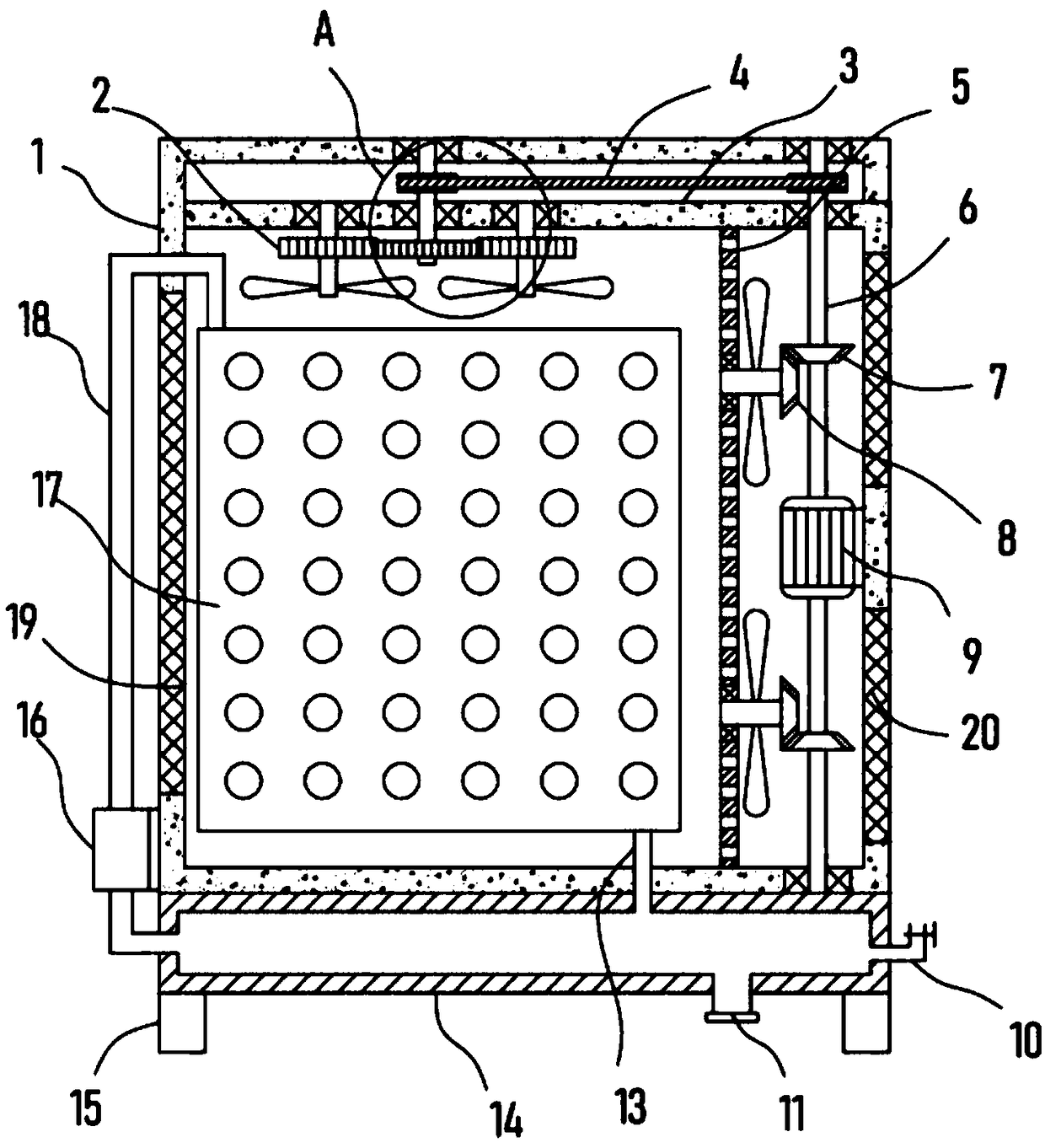

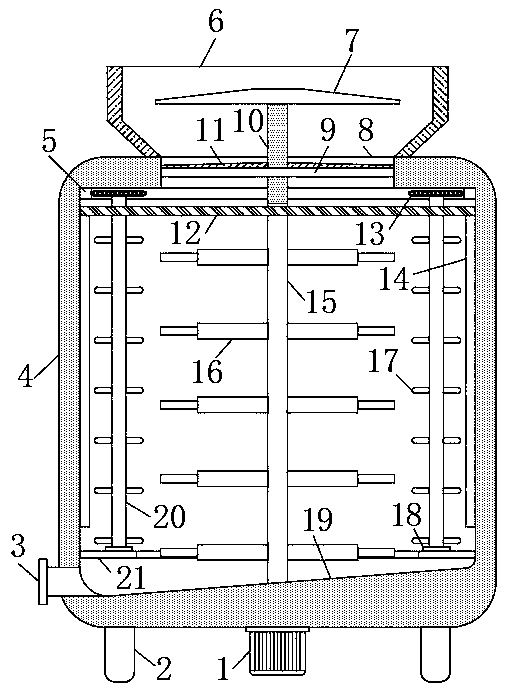

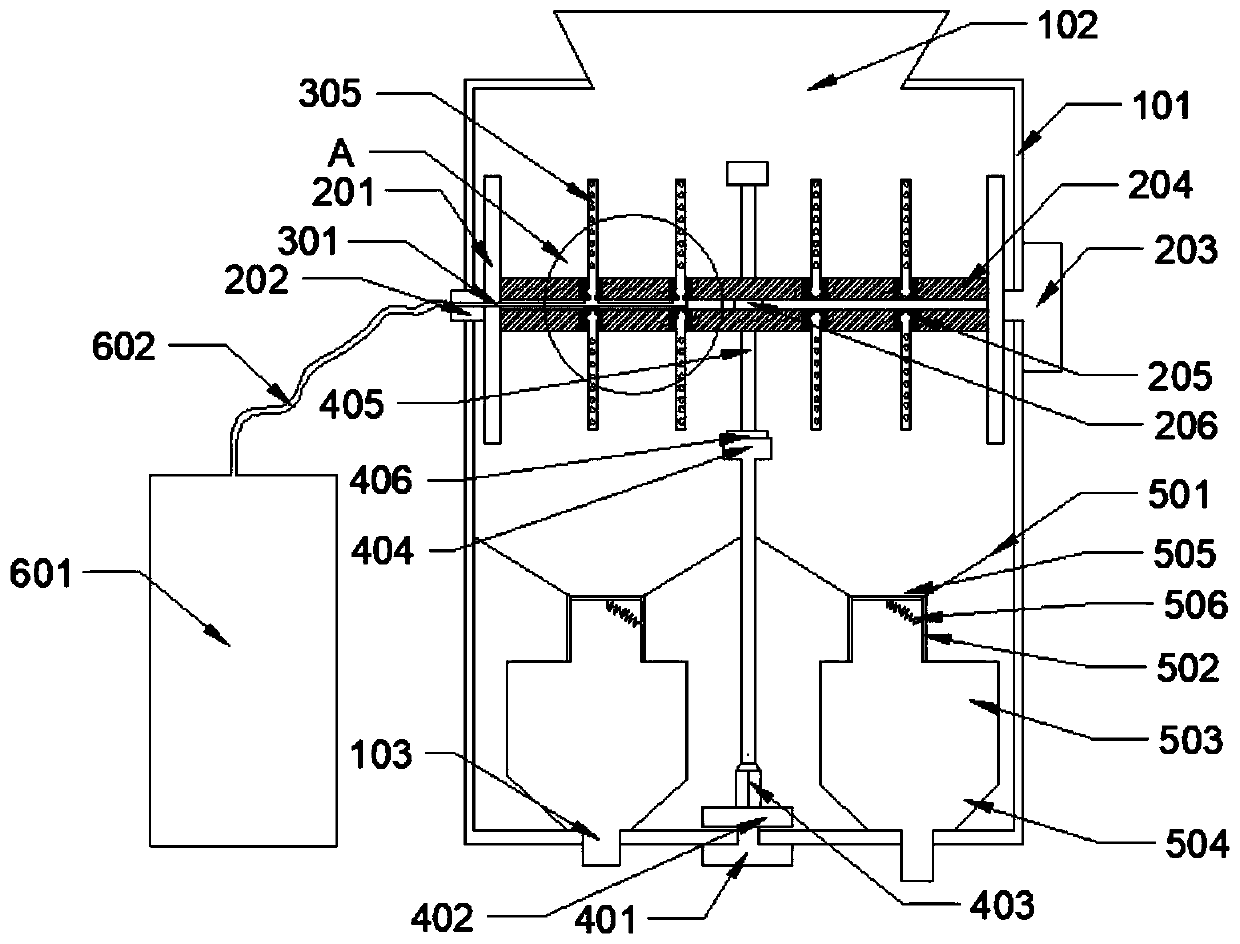

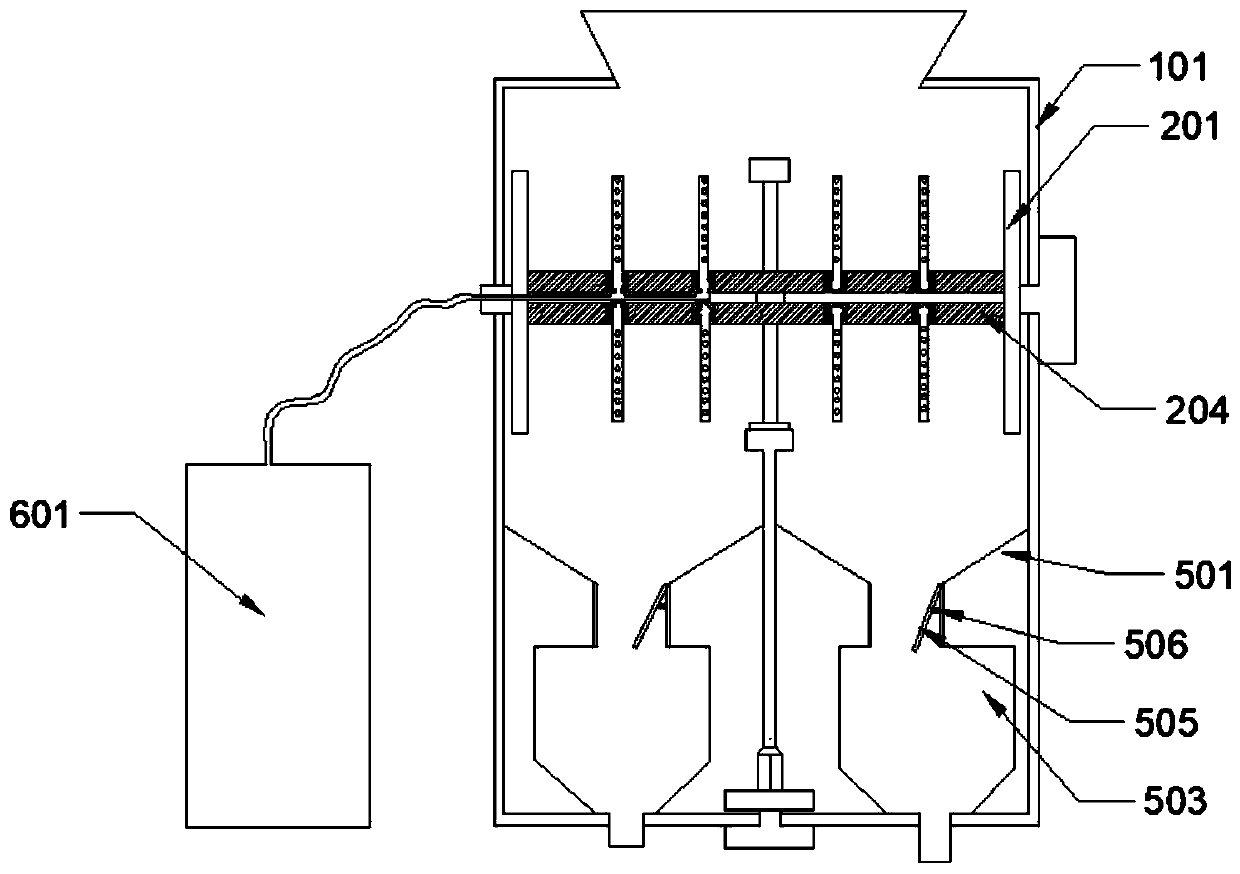

Energy-saving and environment-friendly pulping device for papermaking and printing

ActiveCN110552222AAffect the blending effectEasy to cleanRaw material divisionPapermakingElectric machinery

The invention discloses an energy-saving and environment-friendly pulping device for papermaking and printing. The pulping device comprises a box body, the lower end of the box body is fixedly connected with a plurality of supporting feet, a discharge port is arranged at the middle and lower position of the side wall of the box body, the middle part of the upper end of the box body is provided with a feed inlet, the upper end of the box body is fixedly connected with a feed hopper at a position corresponding to the feed port, the lower end of the box body is fixedly connected with a motor, theend of the output shaft of the motor penetrates through the lower end of the box body and is fixedly connected with a rotating rod, the output shaft of the motor is rotatably connected with the box body, a plurality of crushing knives are arranged at equal intervals along the axial direction on the outer side of the rotating rod, a rotating plate is sleeved on the rotating rod, and the two are fixedly connected. The invention has reasonable structural design, can disperse materials into the inside of the box body, is beneficial to improving the pulping effect, can fully mix the materials, andcan also prevent the materials from adhering to the inner wall of the box body.

Owner:温州市金龙纸业有限公司

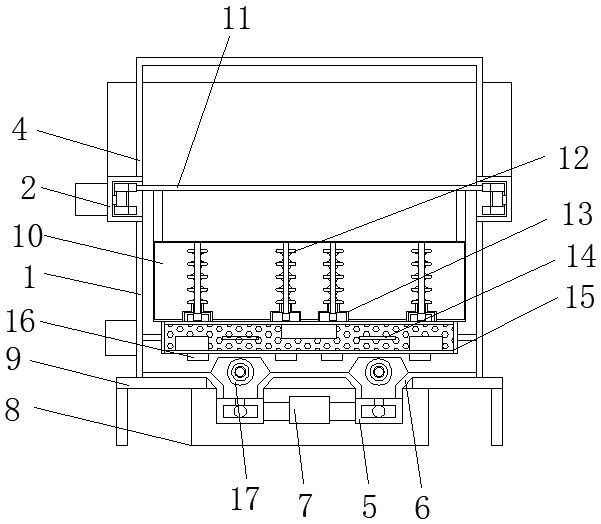

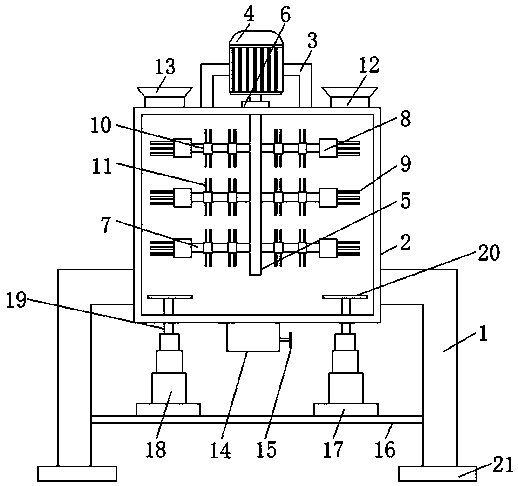

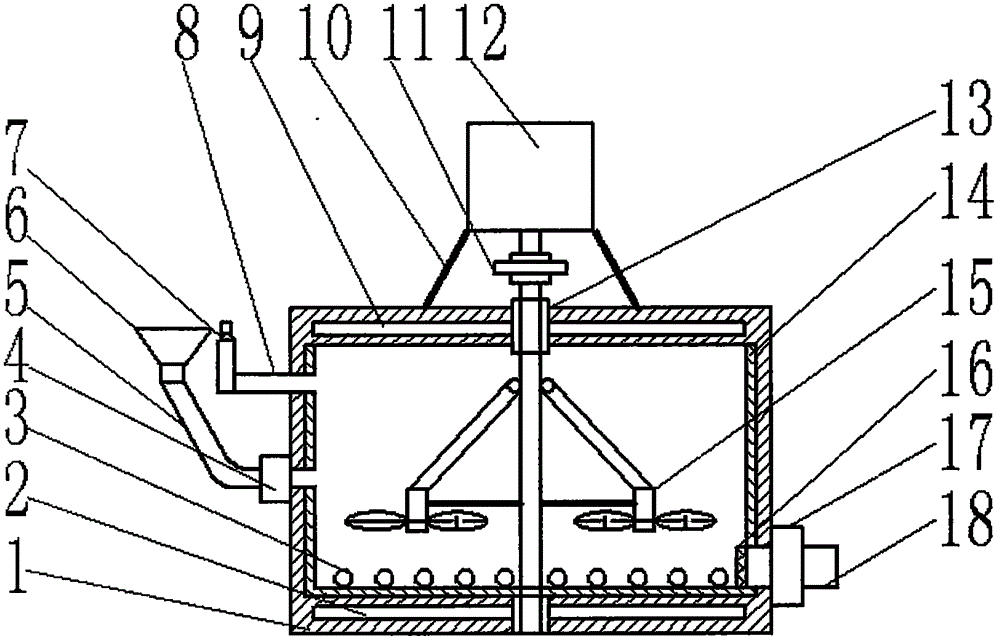

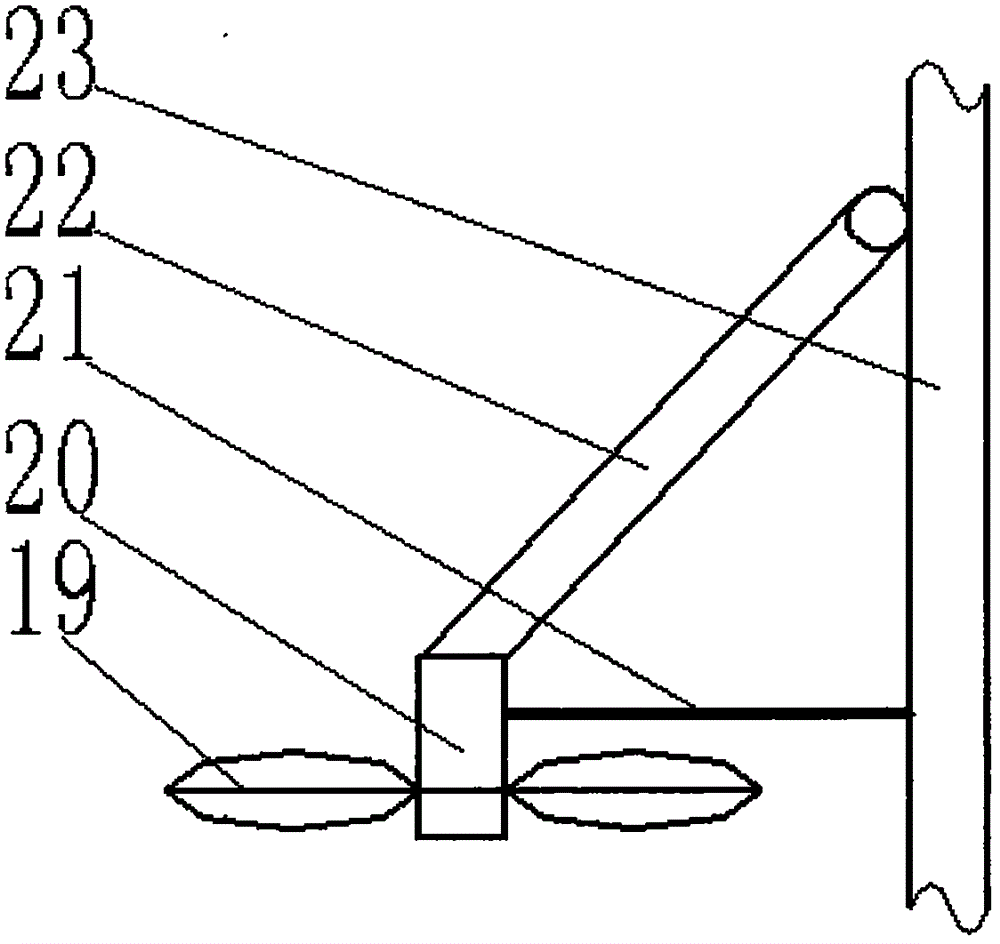

Stirring machine for plastic product production

The invention discloses a stirring machine for plastic product production. The stirring machine for plastic product production comprises a box body, stirring devices, a feeding device and a discharging device. A heating device is arranged on the lower end face of the box body. The feeding device is arranged on the left portion of the box body. The feeding device is composed of a conveying pipe, a first electromagnetic valve and a packing bin. A proportioning pipe is arranged on the portion, on the upper portion of the feeding device, of the box body. A blind plate valve piece is arranged on the proportioning pipe. The discharging device is arranged on the right portion of the box body. The discharging device is arranged on the lower side of the right portion of the box body and composed of a filter screen, a discharging pipe and a second electromagnetic valve. Electromagnets are arranged on the upper end face of the box body. The stirring devices are arranged in the middle of the box body. Each stirring device is composed of stirring blades, a connecting rod, an elastic rope, a movable rod and one shared stirring shaft. A stirring motor is connected to the upper portion of the stirring shaft through a coupling, and the stirring motor is arranged outside the box body and fixed to the upper portion of the box body through a motor support. The stirring machine for plastic product production is simple in structure and convenient to use, and the stirring effect is improved.

Owner:刘海明

Technology for producing azamethiphos in fully-sealed clean manner

InactiveCN103333207AReduce dwell timeAchieve stirring effectGroup 5/15 element organic compoundsPhosphoric Acid EstersParaformaldehyde

The invention provides a technology for producing azamethiphos in a fully-sealed clean manner. The technology comprises a step of providing a reaction device; a step of preparing a branched-chain chlorinated product, wherein chlorine gas is fed into a cyclone kettle, the cyclone kettle comprises a first body, a first reaction chamber with an inverted conic structure is disposed in the first body in a hollow manner, oxazolo [4,5-b]pyridine-2-(3H)-one, N,N-dimethyl formamide, paraformaldehyde, thionyl chloride and other raw materials are mixed, uniformly dispersed and pumped into the cyclone kettle by using a first powder-liquid mixing pump, and the raw materials are reacted in the first reaction chamber to obtain the branched-chain chlorinated product; a step of preparing thiophosphate ester in a second reaction unit; and a step of preparing the azamethiphos in a third reaction unit. According to the technology provided by the invention, the azamethiphos can be prepared in a fully-sealed environment and in a clean manner.

Owner:NINGBO YUANLI CHEM

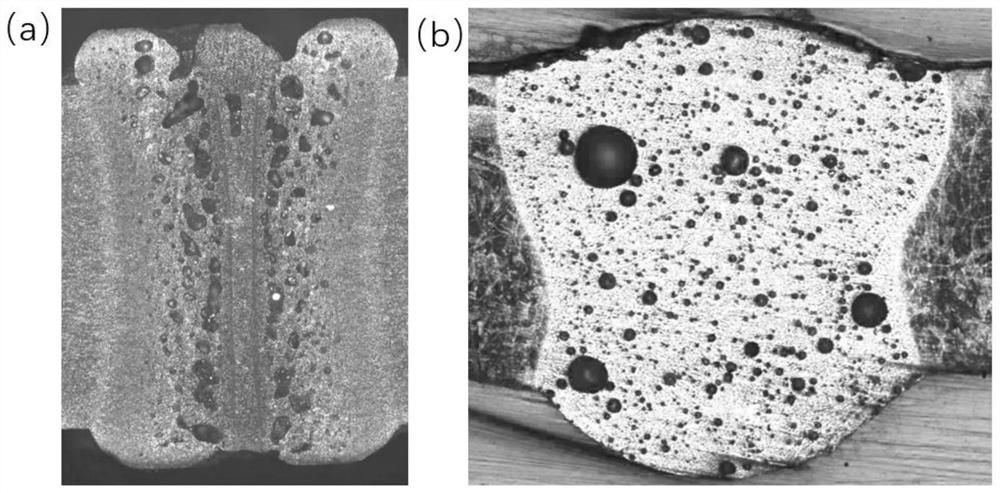

Swing laser filler wire welding method for large-gap butt joint of aluminum alloy sheets

ActiveCN112238298AReduce the amount of meltingLow dilution rateWelding/soldering/cutting articlesMetal working apparatusShielding gasLaser beams

The invention discloses a swing laser filler wire welding method for large-gap butt joint of aluminum alloy sheets. The method comprises the following steps that the two aluminum alloy sheets are prepared, and a gap is reserved between butt joint surfaces of the two aluminum alloy sheets; a laser head, a wire feeding nozzle and a shielding gas nozzle are arranged above the gap; a first guide plateis pre-arranged at the welding starting end of the gap, and after a molten pool is formed on the first guide plate through laser beams, the molten pool is introduced into the welding starting end ofthe gap; and then the wire feeding nozzle and the laser head correspond to the gap and advance in the same direction, the whole gap is filled with aluminum alloy welding wires after the aluminum alloywelding wires are heated and melted through the laser beams, and welding work of the two aluminum alloy sheets is completed. Due to the fact that the gap is reserved, the melting amount of the laserbeams to the aluminum alloy sheets can be reduced as much as possible in the whole welding process, then the dilution rate of a welding joint can be reduced, generation of metallurgical reaction brittle phases can be reduced, meanwhile, the porosity of the joint can be reduced, and welding of conventional aluminum alloy, aluminum-based composite materials and additive manufacturing aluminum alloysheets can be achieved.

Owner:北京金炬科技有限公司

Soil screening device for potted plant planting

The invention relates to a screening device, in particular to a soil screening device for potted planting. The technical problem to be solved by the present invention is to provide a soil screening device for potted planting. In order to solve the above technical problems, the present invention provides such a soil screening device for potted planting, which includes a first support rod, a coarse soil collection tank, a first support, a bottom plate, a fine soil collection tank, a second support, a second Support rod, third support rod, third support rod, fourth support rod, etc.; the first support rod is provided on the left side of the top of the bottom plate, the first support and the second support are provided on the top of the bottom plate, and the first support is located on the left side of the second support. On the side, the top of the first bracket and the second bracket are provided with a screening device, and the left side of the screening device is connected to the right side of the first pole. The invention achieves the effect of effectively screening the thickness of the soil, screening out the coarse soil or stones that are not conducive to plant growth in the soil, and facilitating the plant growth, and has good practicability and strong popularization.

Owner:何永萍

Heavy metal polluted soil improvement and remediation device for ecological remediation of mining areas

InactiveCN113068466APrevent crystallizationMeet needsSpadesTilling equipmentsManufacturing cost reductionDrive wheel

The invention discloses a heavy metal contaminated soil improvement and remediation device for ecological remediation of mining areas. The heavy metal contaminated soil improvement and remediation device comprises a bottom plate, a driving wheel, a first belt pulley and a nozzle. A push handle is fixed to the bottom plate, an automatic telescopic rod is fixed to the bottom plate, universal wheels are fixed at the lower end of the automatic telescopic rod, and a transverse plate is fixed to the automatic telescopic rod. A water pipe is connected with a cylinder, the water pipe is connected with a liquid mixing box, a piston is arranged in the cylinder, and the nozzle is connected with the water pipe. According to the heavy metal contaminated soil improvement and remediation device for ecological remediation of the mining areas, a liftable plowing device is adopted, the height of a plowing roller can be adjusted, then the plowing effect of different depths is achieved, and the actual requirement is met; the continuous stirring effect on mixing is achieved through a stirring mechanism, crystallization of mixed liquid is avoided, and the effects of quantitative discharging and automatic spraying are achieved by matching with a linkage rotating mechanism; and the heavy metal contaminated soil improvement and remediation device is compact in structure, multiple functions are achieved through a single power source, and therefore the manufacturing cost is reduced.

Owner:鄂尔多斯应用技术学院

Anti-rust paint spraying device for scale prevention of steel drum

ActiveCN112756133ARealize the spray paint effectRealize automatic paintingSpraying apparatusMetallurgySpray nozzle

The invention relates to a spraying device, in particular to an anti-rust paint spraying device for scale prevention of a steel drum. The invention provides the anti-rust paint spraying device for scale prevention of the steel drum, and through the anti-rust paint spraying device, the two hands of people are liberated, the productivity is improved, and spraying is uniform. The anti-rust paint spraying device for scale prevention of the steel drum comprises supporting legs, a long fixing plate, a paint spraying mechanism, a pull-down mechanism and a discharging mechanism; the long fixing plate is arranged between the upper portions of the two supporting legs; the paint spraying mechanism is arranged on the long fixing plate; the pull-down mechanism is arranged on the long fixing plate; and the discharging mechanism is arranged on the pull-down mechanism and the long fixing plate, and the discharging mechanism is matched with the pull-down mechanism. According to the anti-rust paint spraying device for scale prevention of the steel drum, a pressurizing barrel bottom cover is driven to slide upwards in a pressurizing barrel, and under the action of pressure, paint enters a hollow circular ring through a hose, so that paint is sprayed to the steel drum through a spraying nozzle.

Owner:济宁源盛包装容器有限公司

Degerming equipment for rhodiola rosea processing

ActiveCN111481683AAchieve stirring effectImprove sterilization effectLavatory sanitoryHeatRHODIOLA ROSEA ROOTStructural engineering

The invention discloses degerming equipment for rhodiola rosea processing. The degerming equipment comprises a bracket, a degerming tank, a material containing mechanism, a spraying mechanism, a driving mechanism and a steam generator, wherein the material containing mechanism comprises a material containing frame and two material containing assemblies, the material containing frame is arranged inthe degerming tank and rotationally connected with the sterilization tank, the two material containing assemblies are arranged in the material containing frame, and each material containing assemblycomprises a material containing disc rotationally connected with the inner side wall of the material containing frame; the spraying mechanism comprises a steam inlet pipe and an annular steam exhaustpipe, the end of the steam inlet pipe sequentially penetrates through a location hole and the material containing frame and is located between the two material containing discs, the annular steam exhaust pipe is arranged in the positioning block, and the end of the steam inlet pipe is communicated with a plurality of adjusting assemblies; the driving mechanism comprises a connecting shaft and a driving assembly which are coaxially arranged on the material containing disc; and one end, located outside the degerming tank, of the steam inlet pipe is communicated with the steam generator through asteam hose. By arranging the material containing mechanism and the spraying mechanism, steam can be sprayed to materials while the materials are stirred, and the degerming effect is effectively improved.

Owner:西藏天虹科技股份有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com