Rice washer

A machine and rotating spindle technology, applied in the field of rice washing machines, can solve the problem of not being able to fully play the role of rice grains in washing rice, and achieve the effects of improving the performance of rice washing, simple structure and overall cost realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

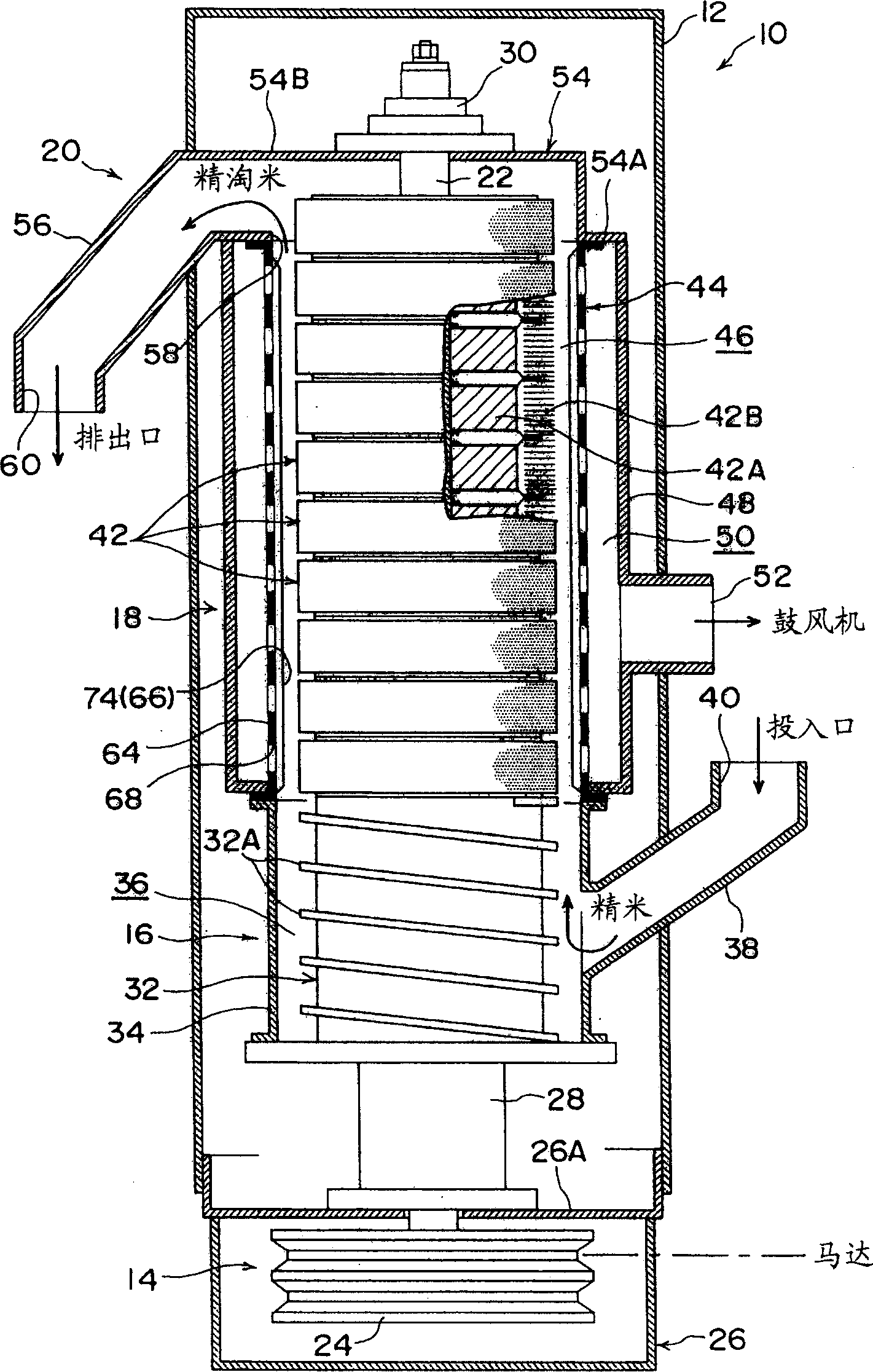

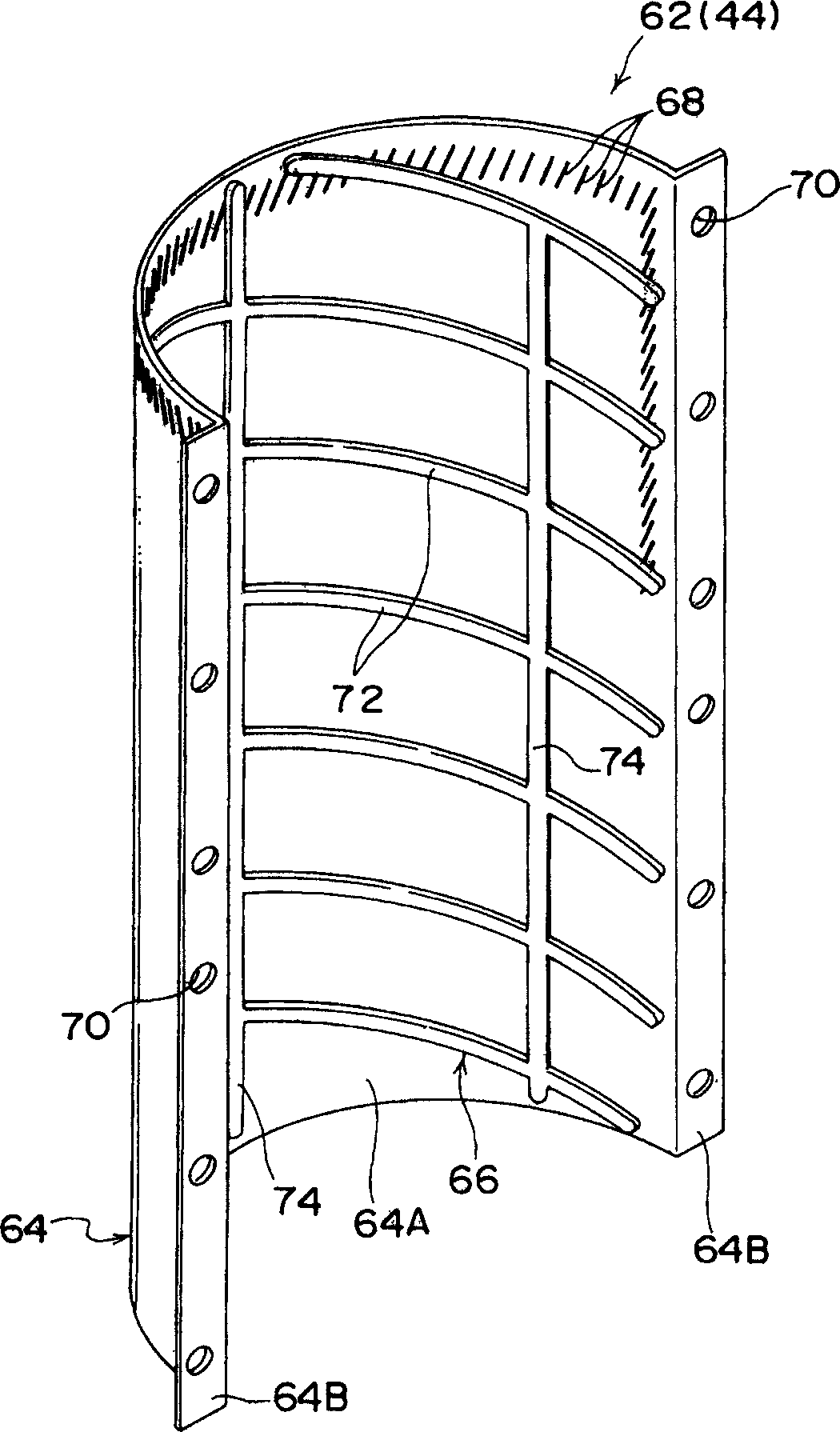

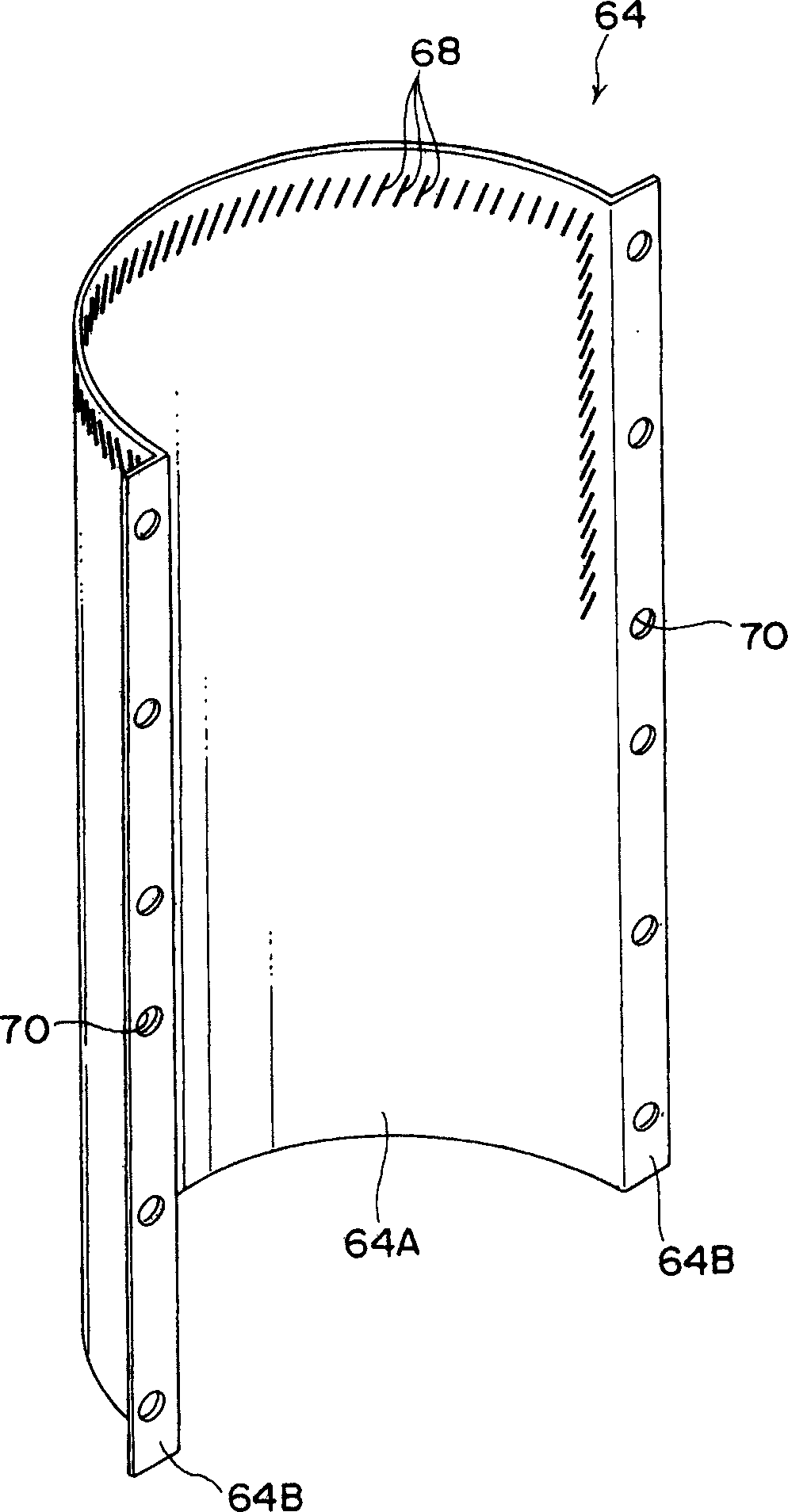

[0030] use below Figure 1 to Figure 5 The vertical dry rice washing machine 10 of the first embodiment of the present invention will be described.

[0031] figure 1 A longitudinal sectional view showing the overall structure of the dry-type rice washing machine 10 of the first embodiment is shown. As shown in the figure, the dry rice washing machine 10 has a box-shaped housing 12 that is long in the height direction. The drive mechanism part 14 and the grain feeding processing part 16 are provided in the lower part of this housing|casing 12, and the rice washing processing part 18 and the discharge part 20 are provided in the upper part of the housing 12. The outline of each component will be described in order below.

[0032] The driving mechanism part 14 is made up of following main parts: take the height direction of the dry-type rice washing machine 10 as the axial direction, the rotating main shaft 22 that is arranged on the approximate central part of the housing 12;...

no. 2 example

[0065] Figure 12 A vertical cross-sectional view showing the overall structure of the dry-type rice washing machine 10 according to the second embodiment of the present invention is shown in a state seen from the front side. Figure 11 The vertical cross-sectional view which shows the whole structure of this dry-type rice cleaning machine 10 in the state seen from the right side is shown.

[0066] As shown in the figure, the dry rice washing machine 10 has a housing 12 . The casing 12 has a front side wall 12A, a rear side wall 12B, a left side wall 12C, a right side wall 12D, and an upper wall 12E, and is formed in a box shape long in the height direction. The inside of the housing 12 is provided with a rice cleaning mechanism 13 . The rice cleaning mechanism 13 has the drive mechanism part 14 and the grain sending processing part 16 that is located at the housing 12 bottom, the rice cleaning processing part 18 and the discharge part 20 that are located at the housing 12 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com