Patents

Literature

204results about How to "Achieve the effect of automatic feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

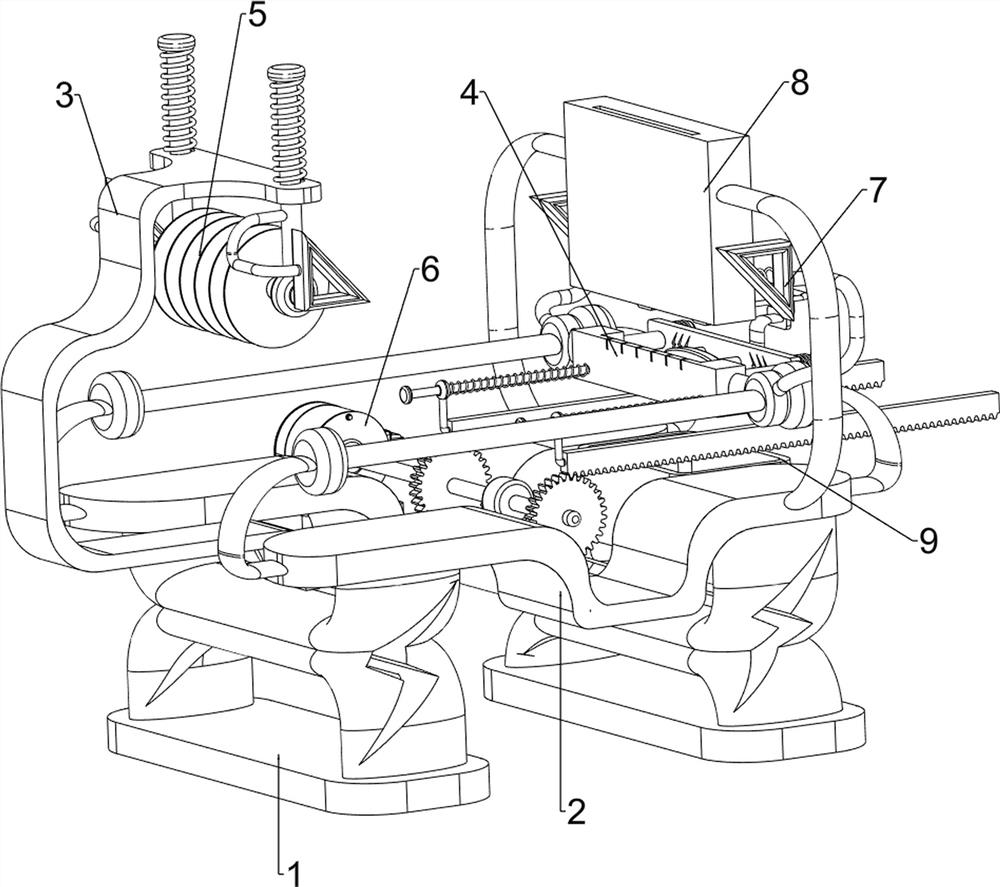

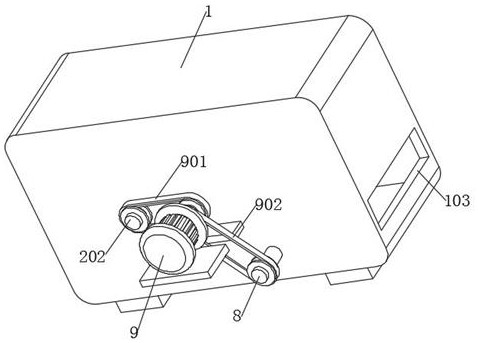

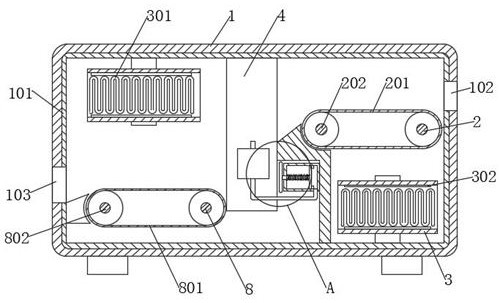

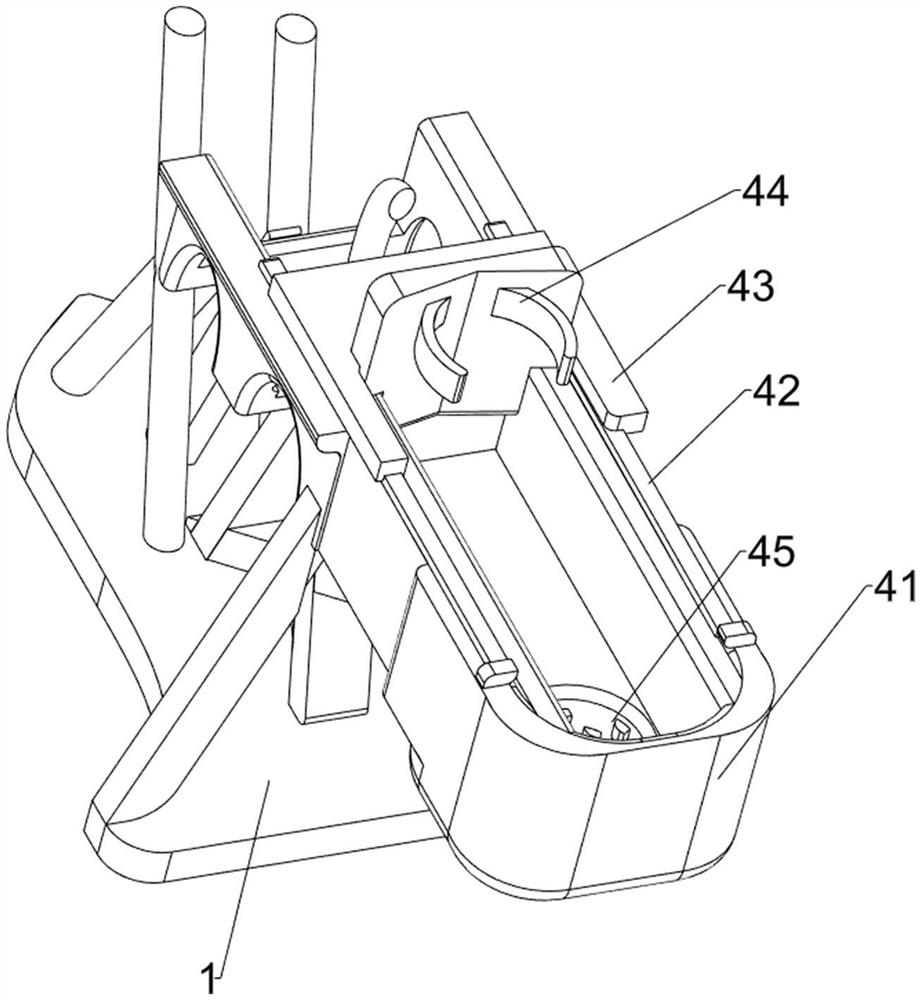

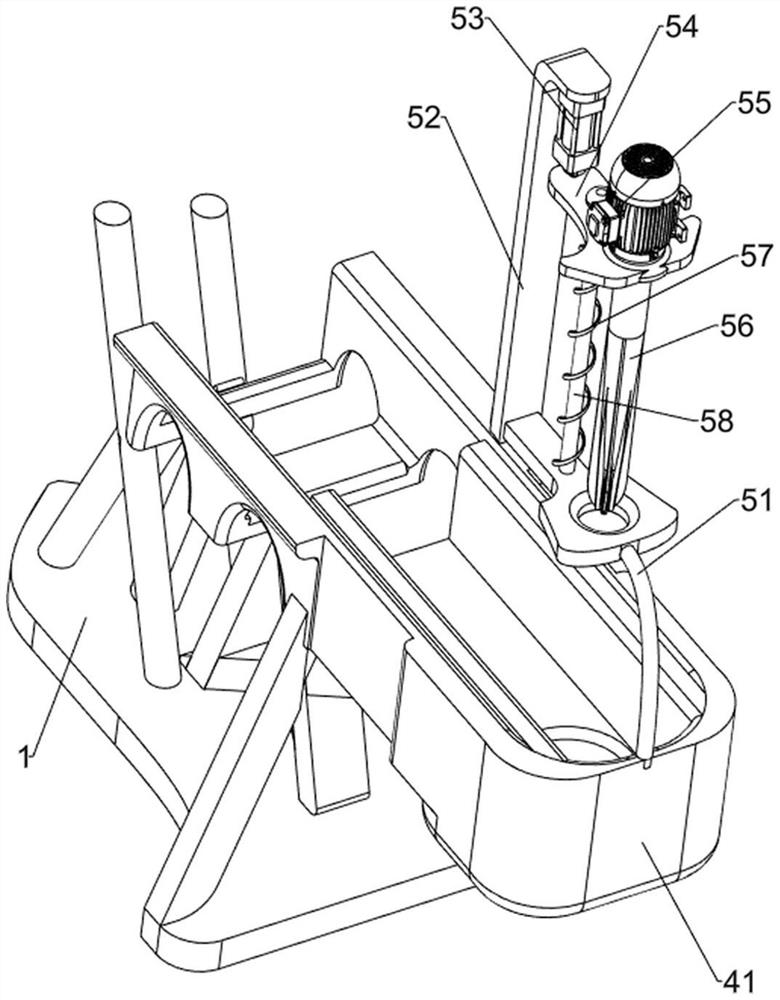

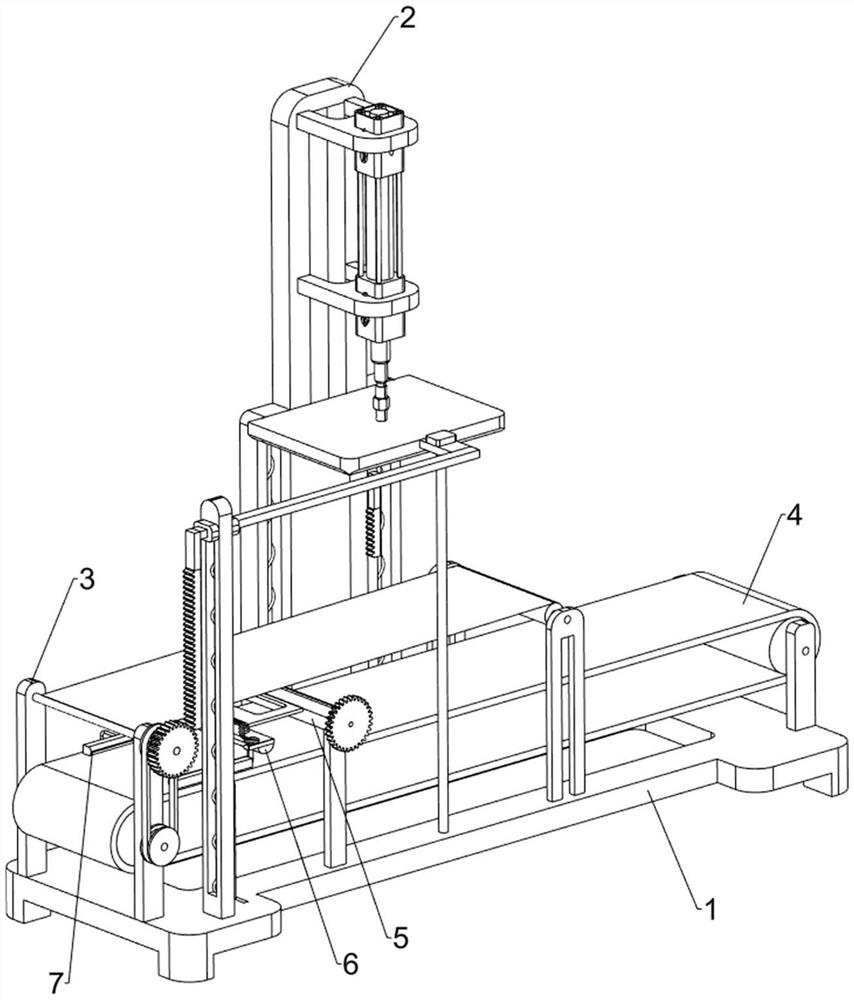

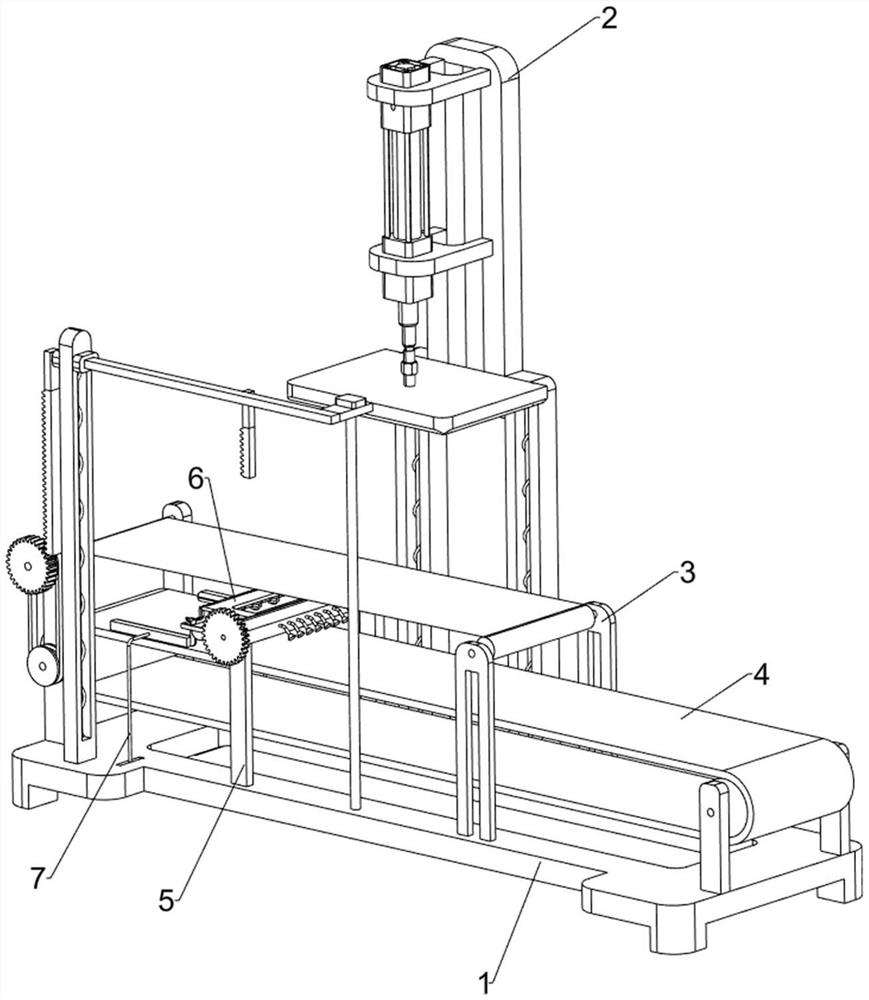

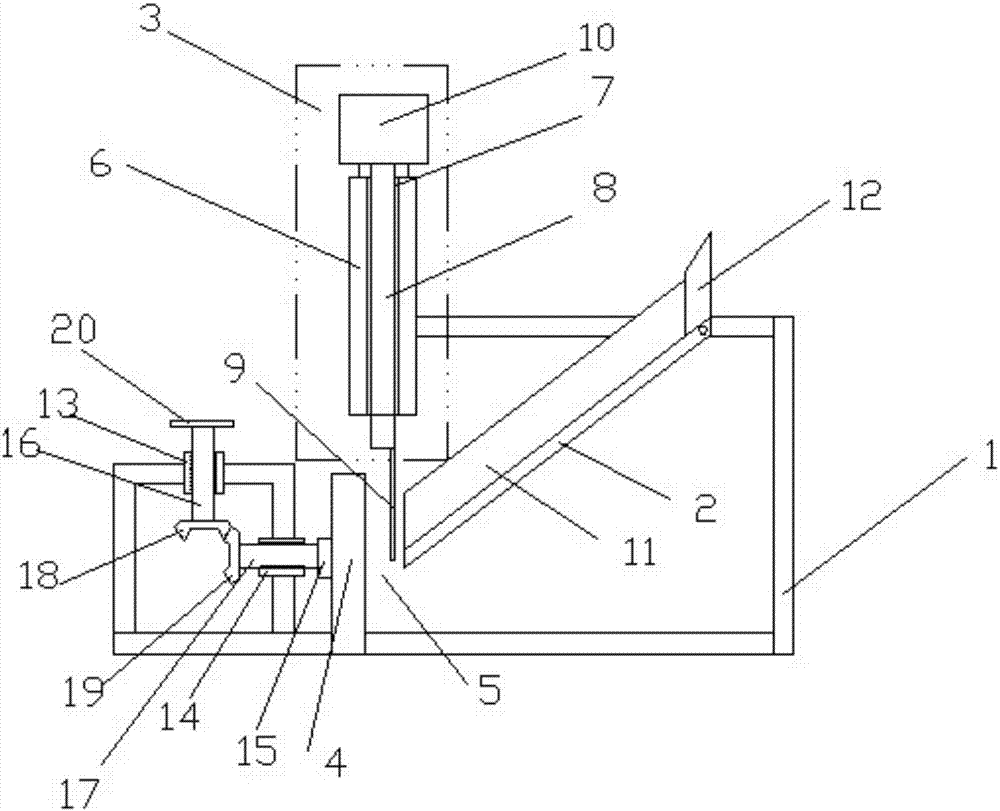

Notched steel plate punching equipment for buildings

InactiveCN112246939AAchieve the effect of automatic feedingRealize intermittent feedingMetal-working feeding devicesPositioning devicesPunchingArchitectural engineering

The invention relates to punching equipment, in particular to notched steel plate punching equipment for buildings. The notched steel plate punching equipment can push out a steel plate clamped on a punching block, can automatically feed the steel plate, and comprises a bottom plate, an air cylinder and the punching block, wherein the middle of the bottom plate is fixedly connected with an L-shaped rod; the air cylinder is installed on the L-shaped rod; and the punching block is connected to a piston rod of the air cylinder. According to the notched steel plate punching equipment, the effect that the steel plate clamped on the punching block can be pushed out and can be automatically fed is achieved, when the punching block moves downwards, a first rack and a feeding propelling plate can be driven to move leftwards through a series of transmissions, the lowermost steel plate can be pushed to the position below the punching block through leftward movement of the feeding propelling plate, then the feeding propelling plate is reset, and in this way, intermittent discharging is achieved.

Owner:李冰娜

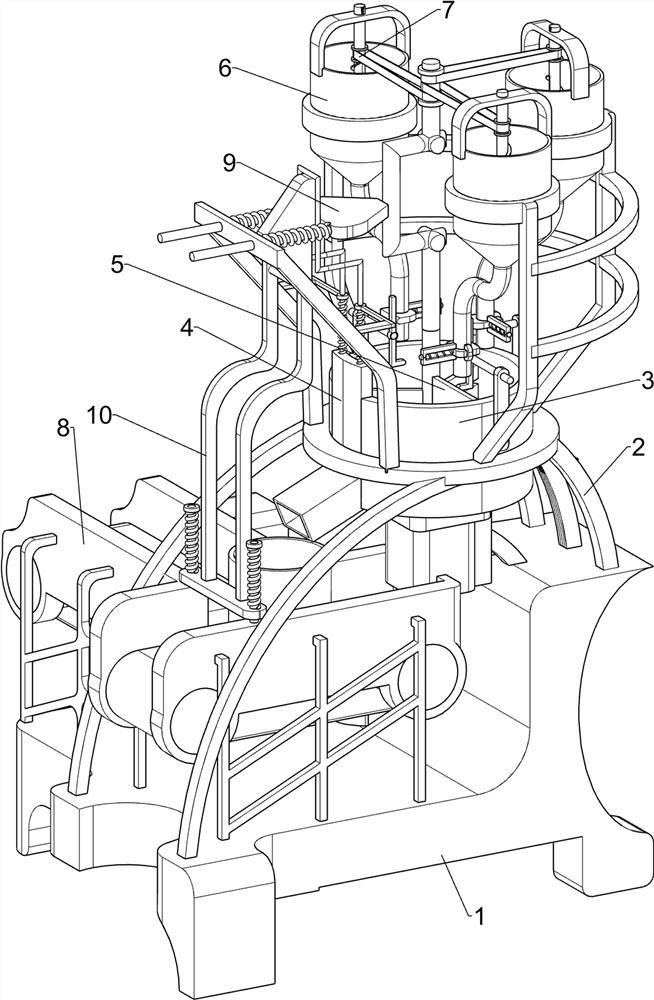

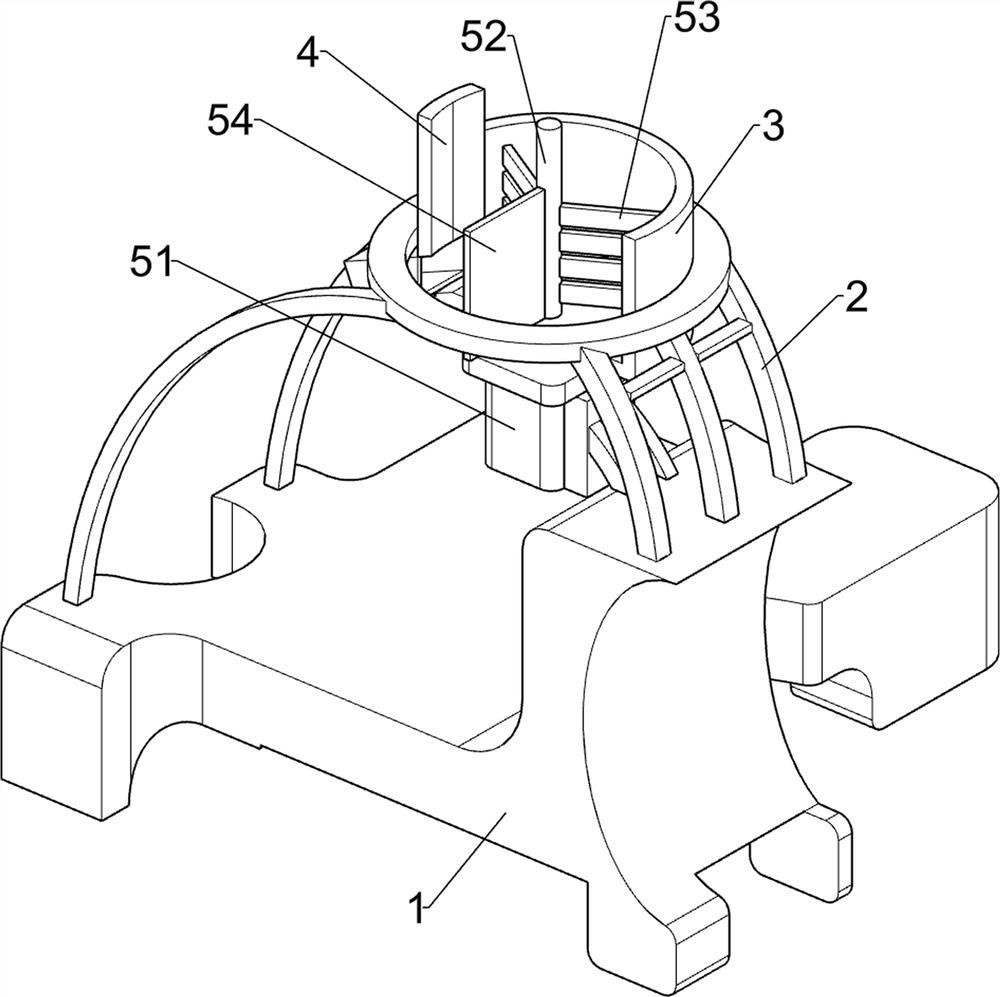

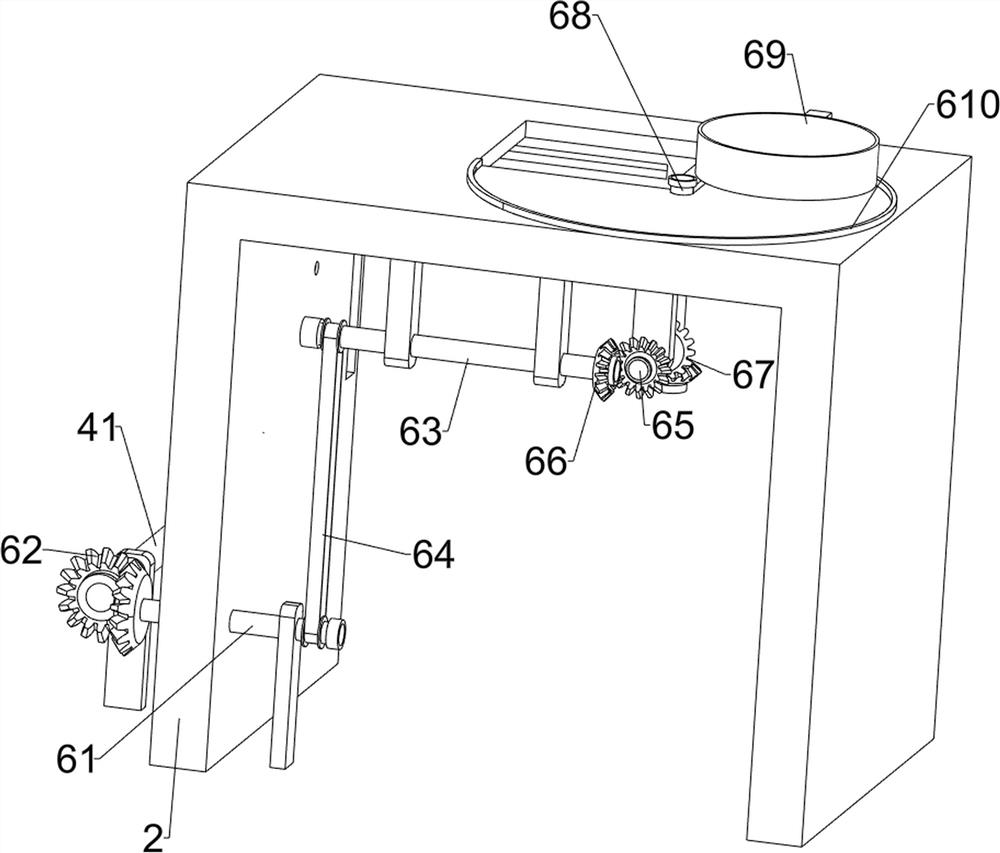

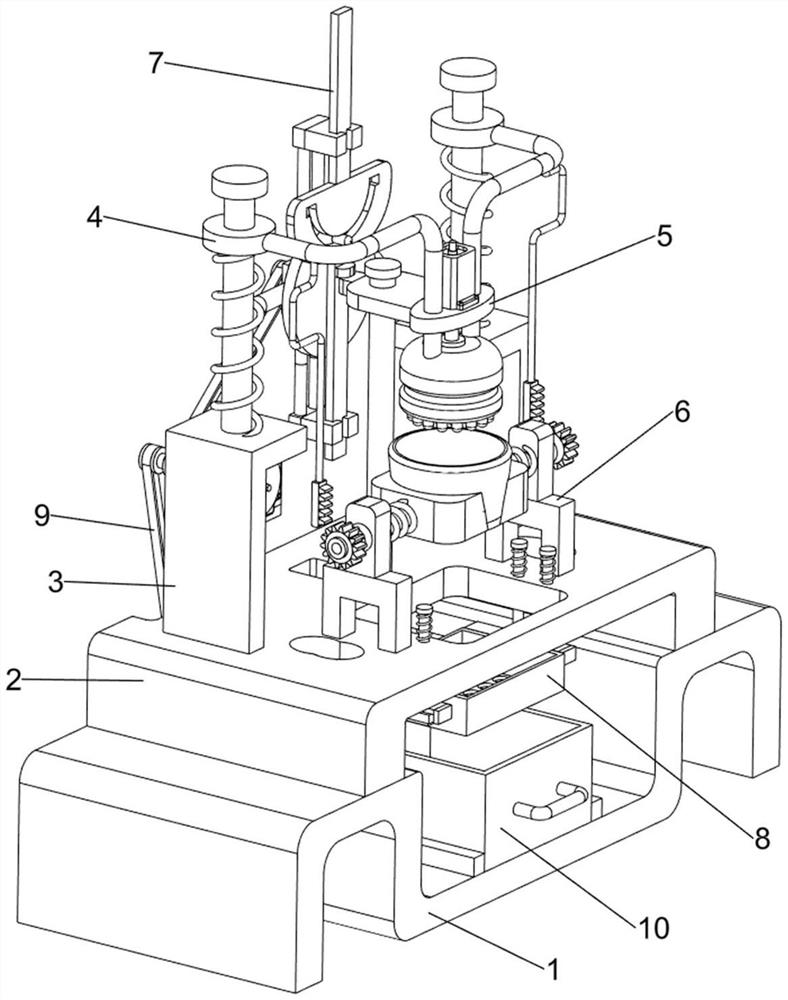

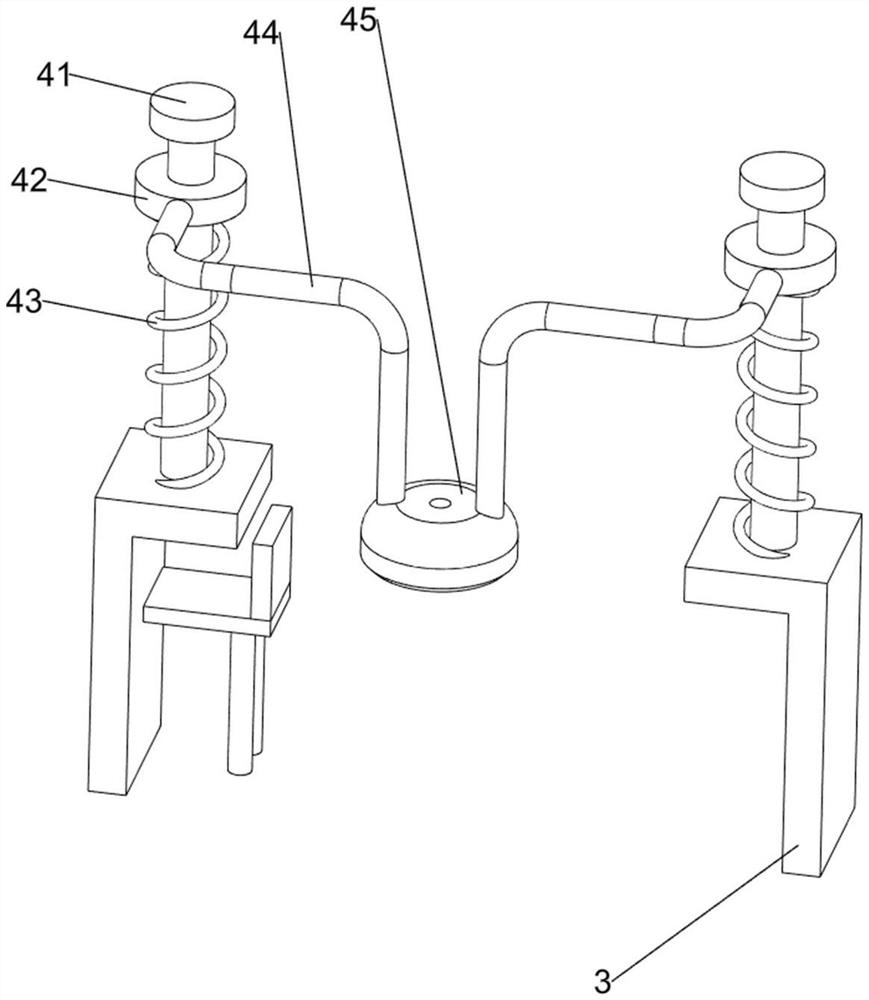

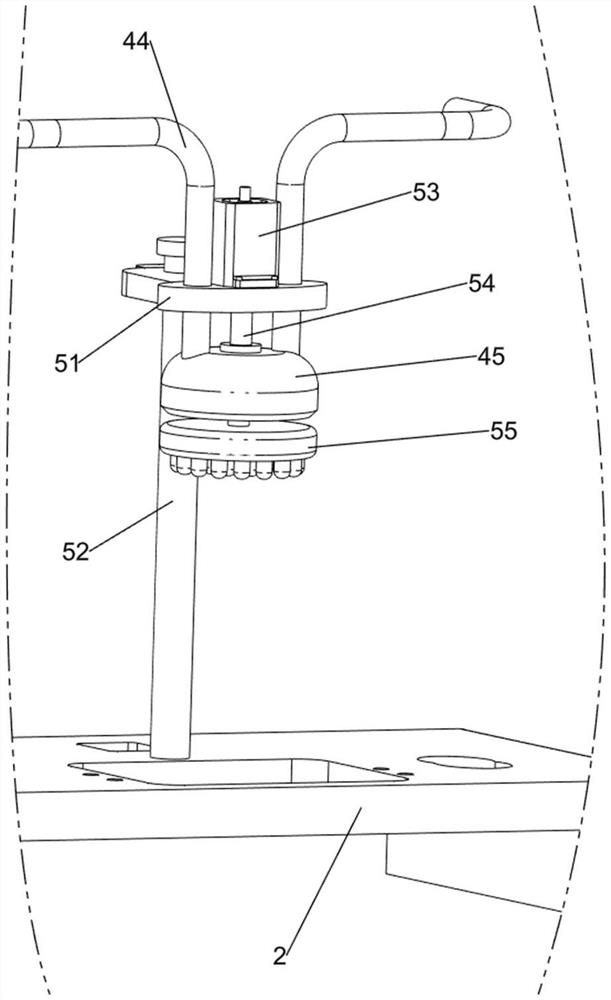

Copper-containing wastewater treatment device for industrial production

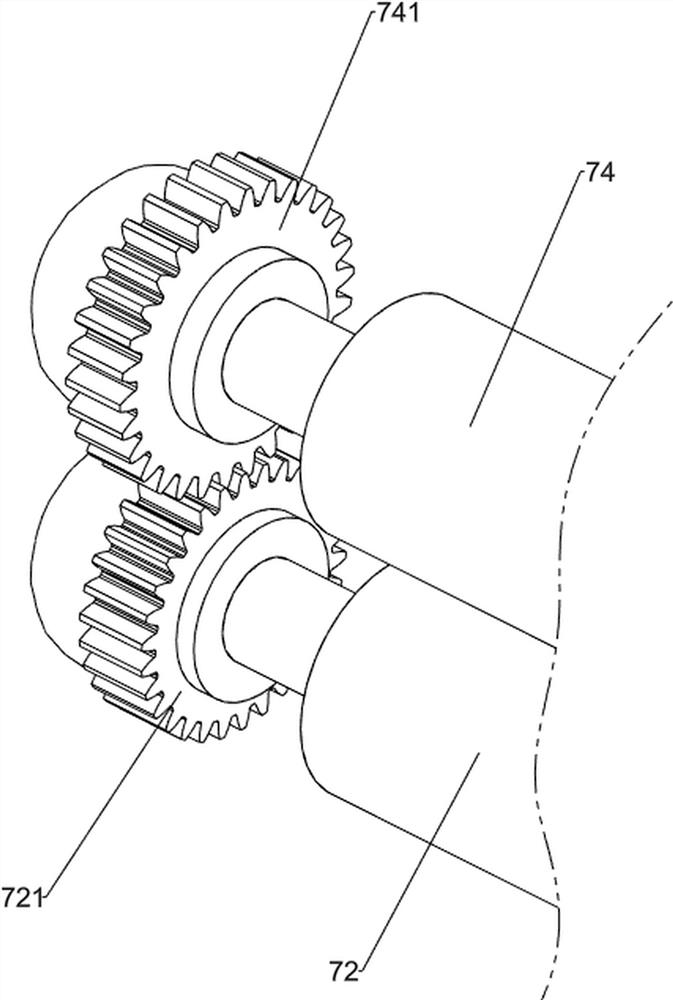

ActiveCN112607900AAchieve the effect of automatic stirringEasy to removeRotary stirring mixersTransportation and packagingGear wheelElectric machinery

The invention relates to a treatment device, in particular to a copper-containing wastewater treatment device for industrial production. The invention provides a copper-containing wastewater treatment device for industrial production. The copper-containing wastewater treatment device can realize automatic blanking, automatic cleaning and automatic collection. The copper-containing wastewater treatment device for industrial production comprises a bottom plate, a first supporting frame arranged on the bottom plate, a motor mounted at the top of the first supporting frame, a rotating mechanism arranged on the bottom plate and connected with the first supporting frame and an output shaft of the motor, and a discharging mechanism is arranged on the rotating mechanism. A space cam is matched with a third rotating shaft, the space cam rotates to enable a third rotating shaft to move left and right repeatedly, then a roller moves left and right repeatedly, a second gear enables the roller to move and rotate at the same time, the roller moves and cleans garbage in a filtering frame, and therefore the automatic cleaning effect is achieved.

Owner:广东凯链环保科技有限公司

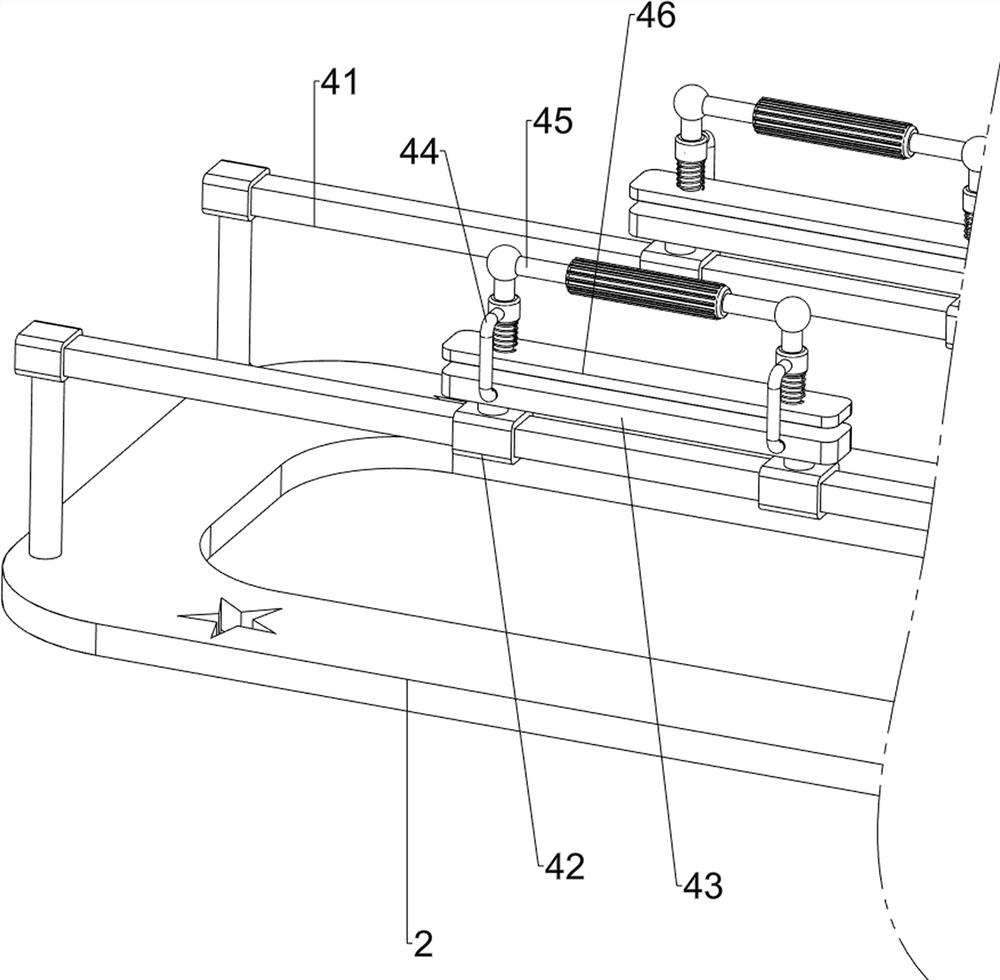

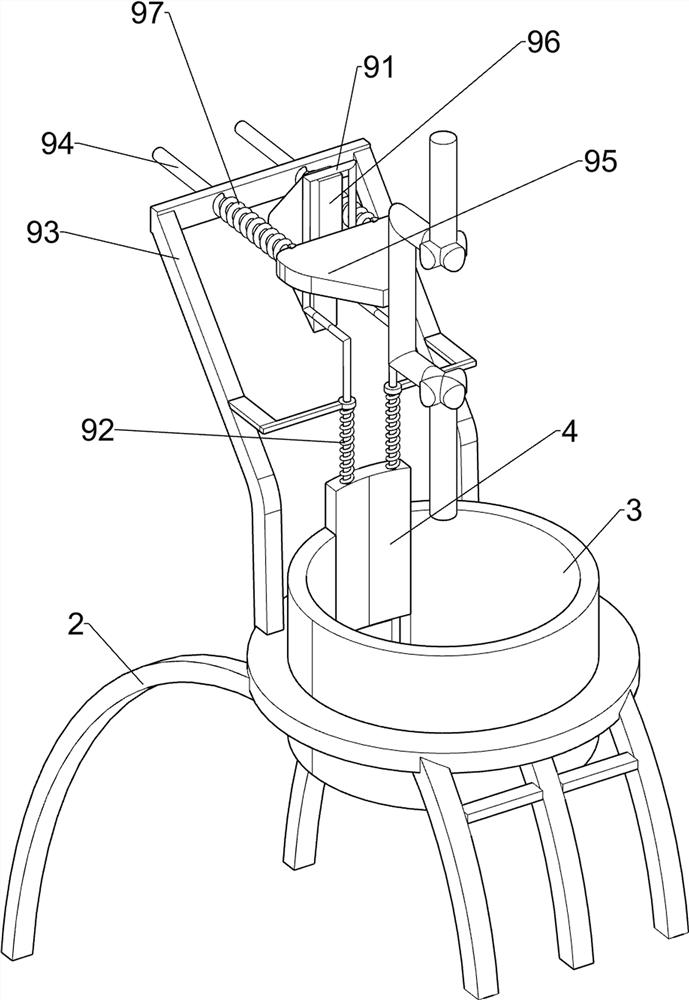

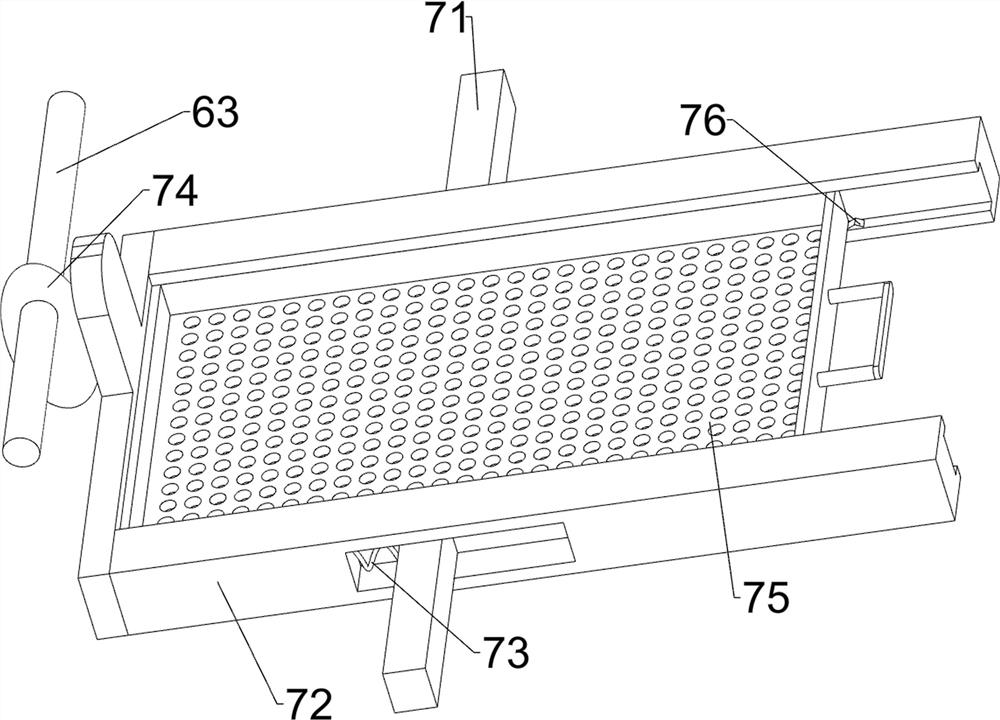

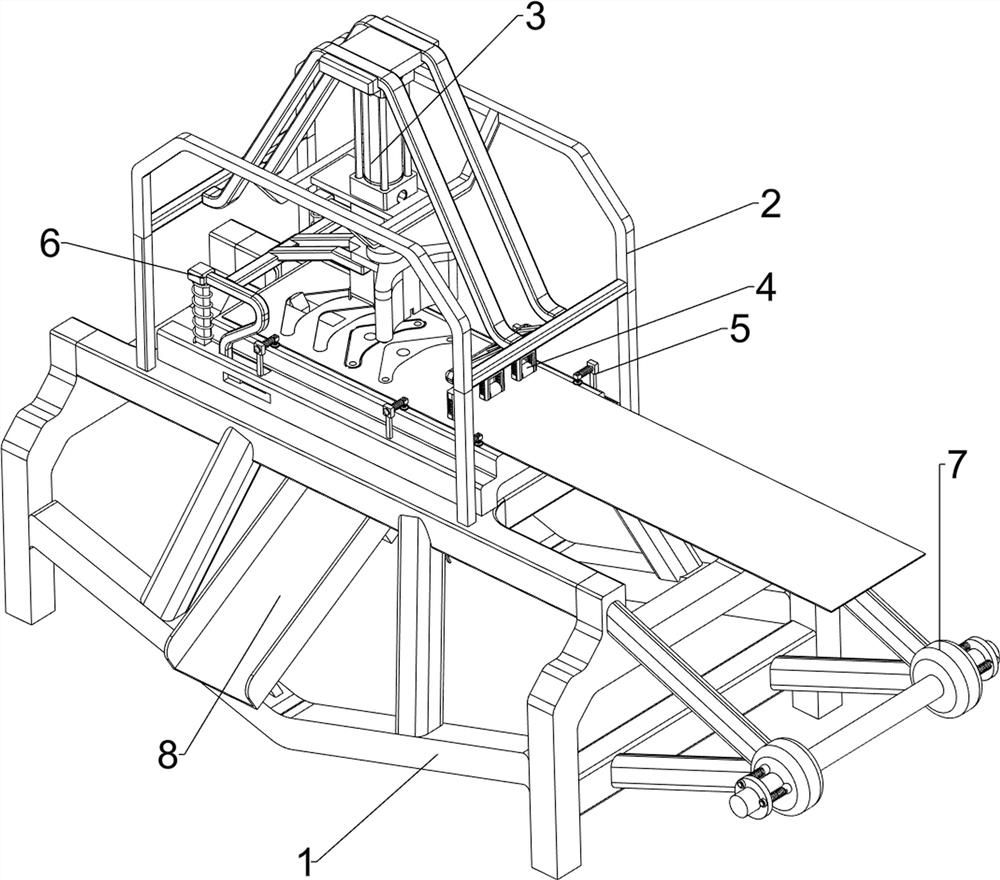

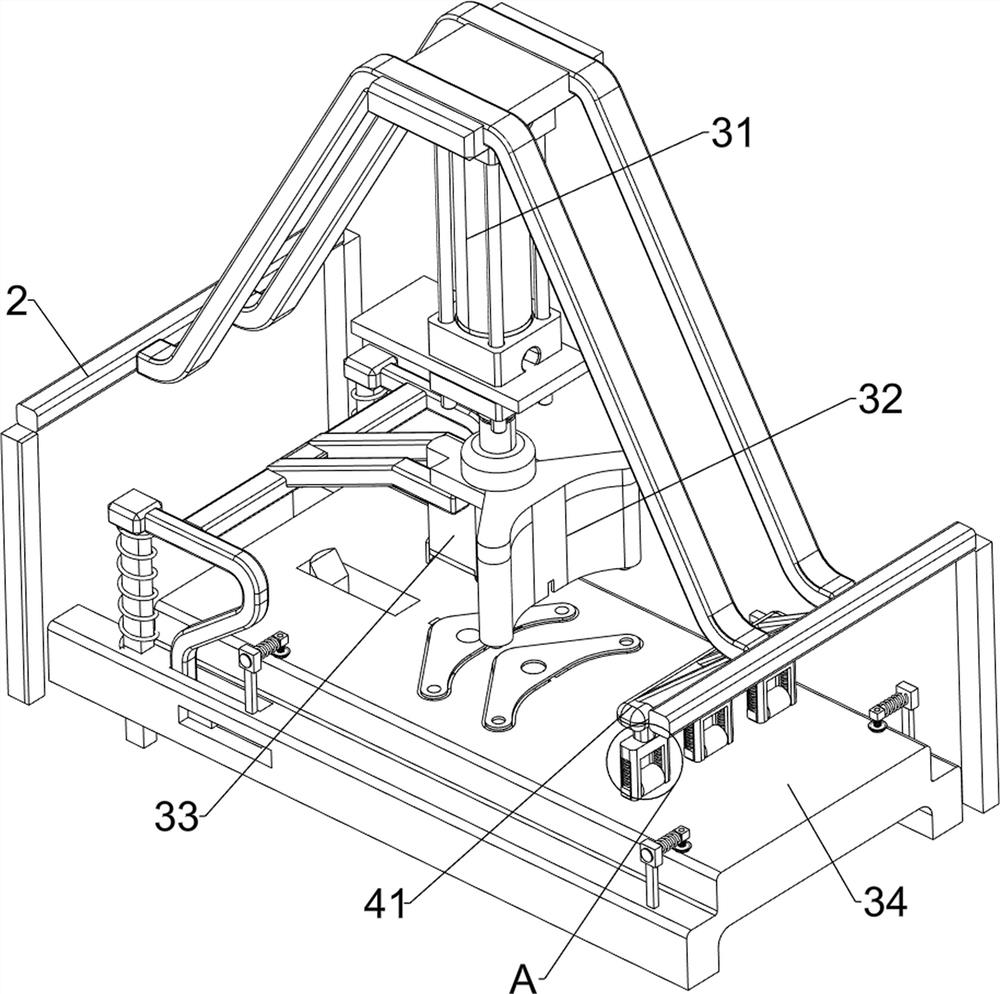

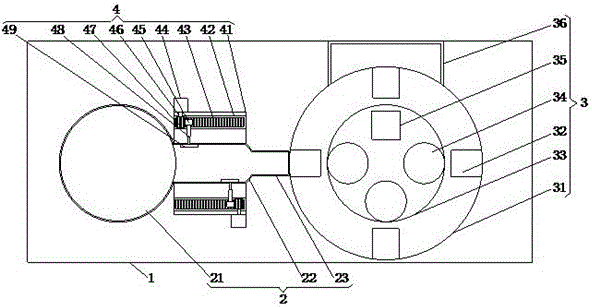

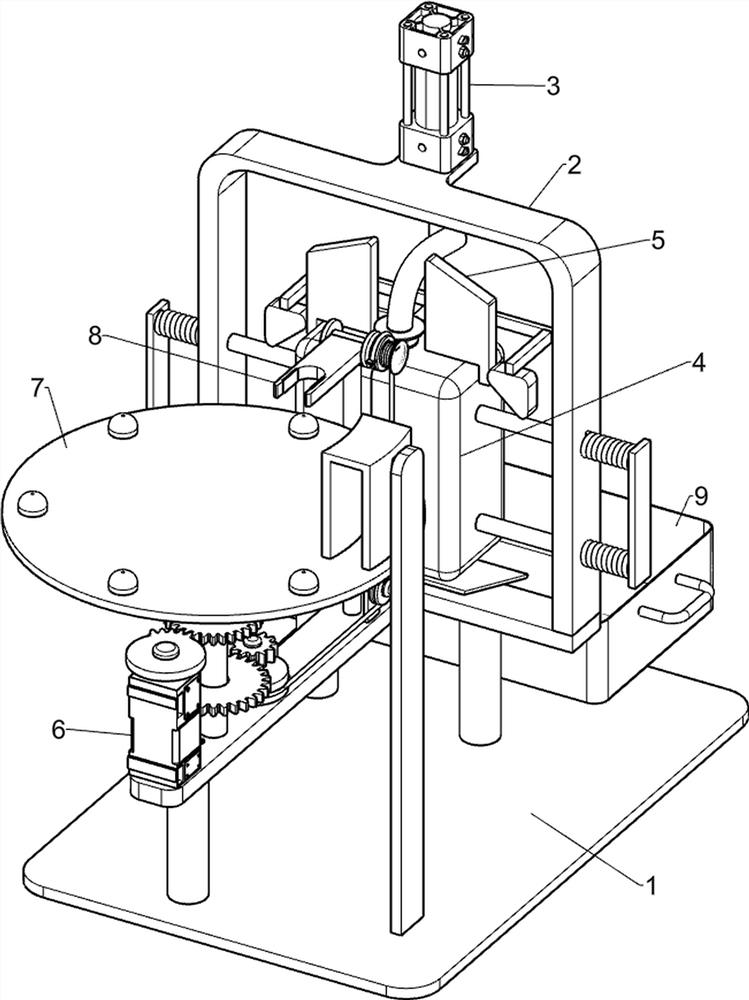

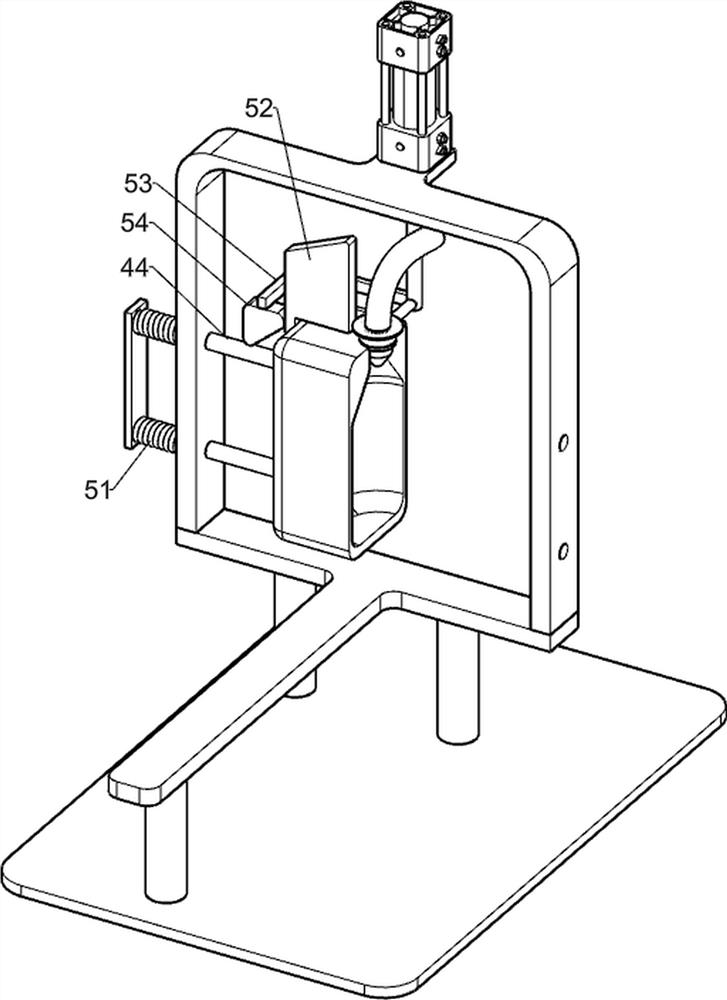

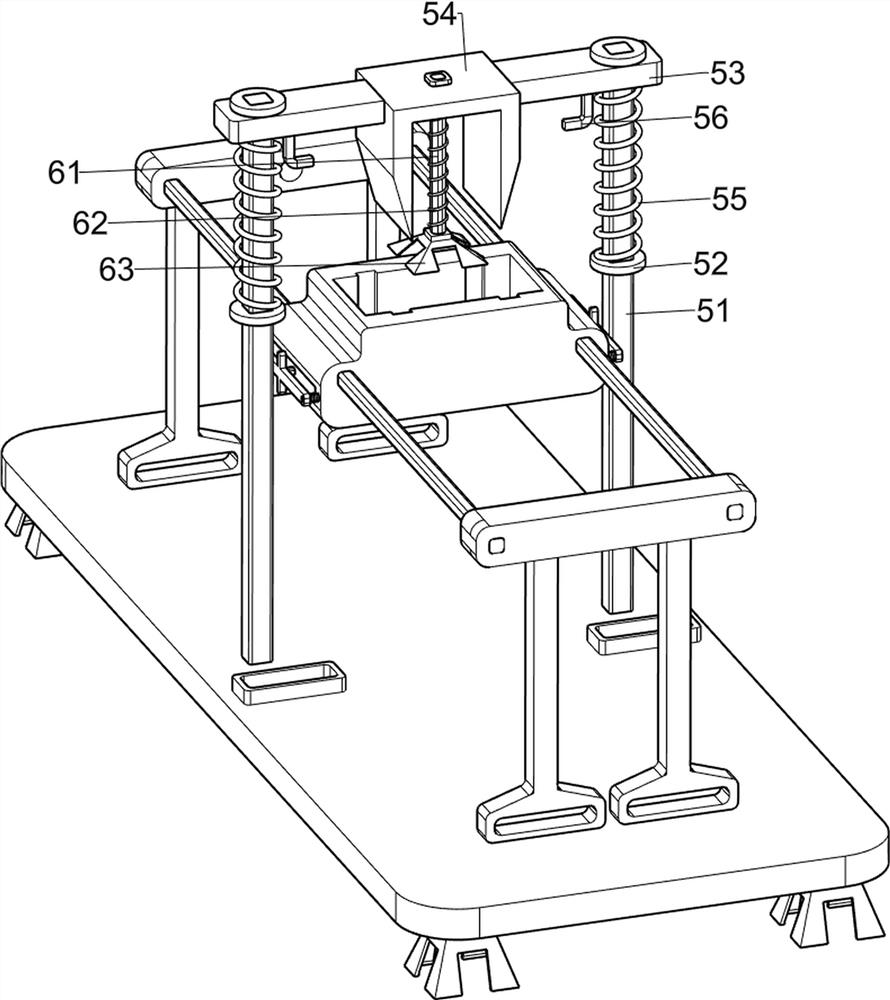

PCB bending resistance measuring device for LED production

PendingCN112504867AEasy and fast testingBending resistance is simple and convenientMaterial strength using steady bending forcesMechanical engineeringElectrical and Electronics engineering

The invention relates to a measuring device, and particularly relates to a PCB bending resistance measuring device for LED production. The invention provides a PCB bending resistance measuring devicefor LED production, and the PCB bending resistance measuring device has a relatively complete automatic test flow. The PCB bending resistance measuring device for LED production comprises supporting legs, a bottom plate and a collecting frame, wherein the bottom plate is arranged at the top of the supporting legs, the collecting frame is arranged at the bottom of the bottom plate, and a clamping mechanism and a pressing mechanism are arranged on the bottom plate. According to the invention, the clamping mechanism and the pressing mechanism are arranged, the clamping mechanism can fix the PCB,the pressing mechanism can test the bending resistance of the PCB, and the effect of simply and conveniently testing the PCB is achieved; and the device is provided with a rotating mechanism, the rotating mechanism is matched with the pressing mechanism, the rotating mechanism can drive the clamping mechanism to move to the position below the pressing mechanism, and the automatic feeding effect isachieved.

Owner:张吉锋

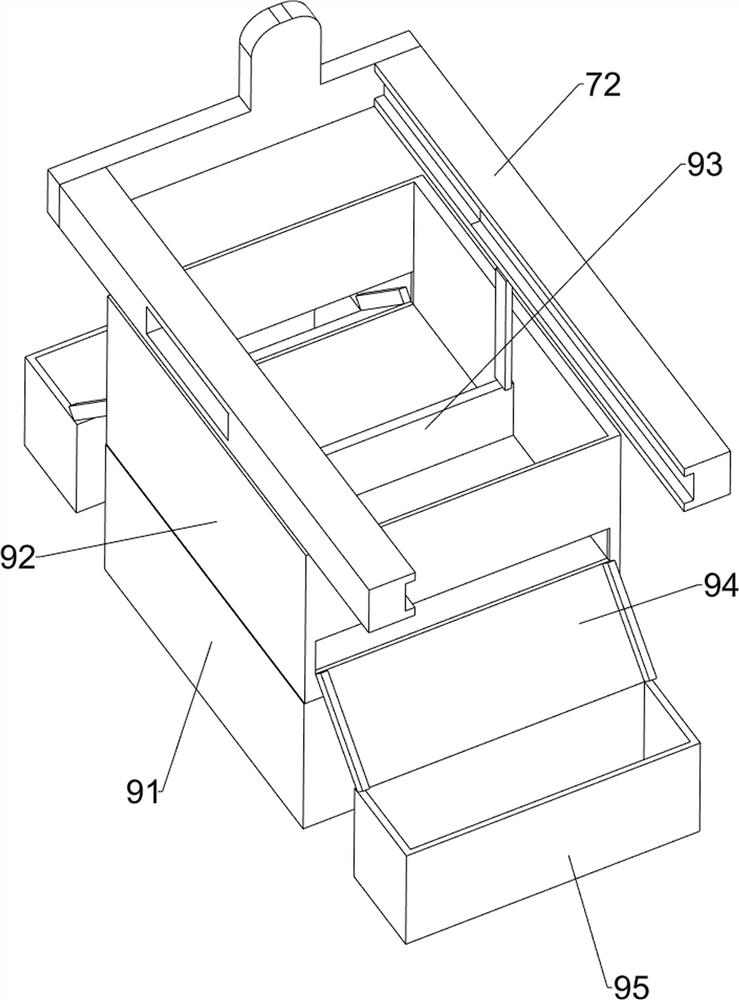

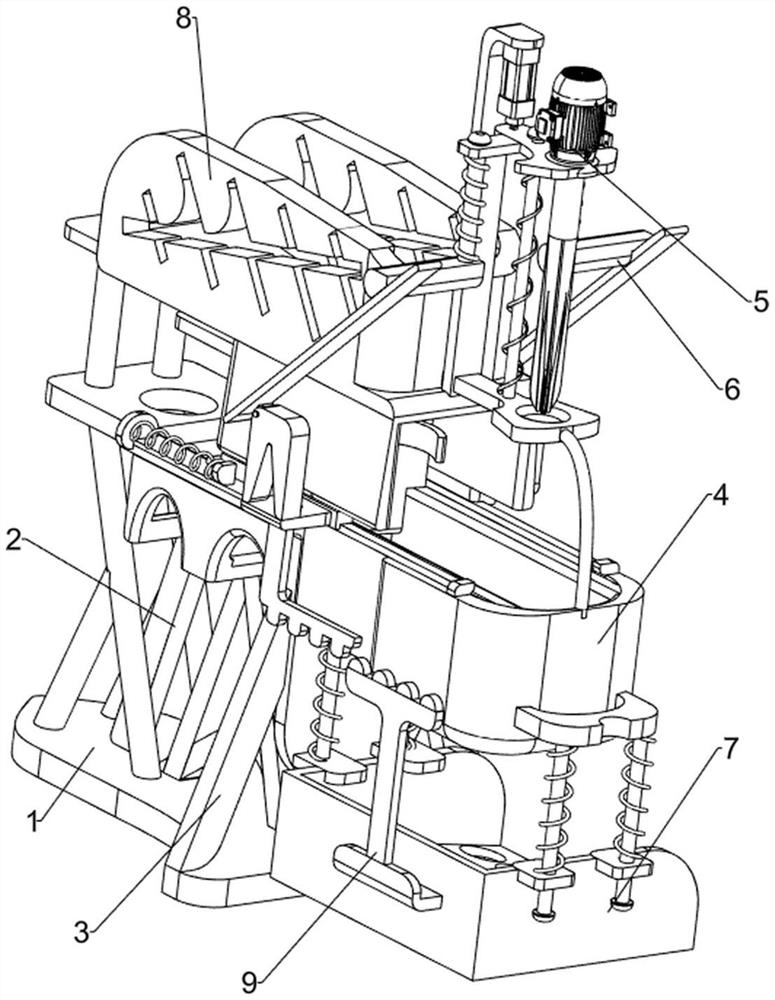

Overdue pill crushing and recycling device for pediatric department

ActiveCN113042158AAchieve the effect of automatic scrapingAchieve the effect of automatic cleaningPlastic recyclingGrain treatmentsElectric machineryEngineering

The invention relates to a crushing and recycling device, in particular to an overdue pill crushing and recycling device for the pediatric department. The overdue pill crushing and recycling device for the pediatric department can achieve automatic discharging, automatic scraping and automatic filtering. The overdue pill crushing and recycling device for the pediatric department comprises supporting legs, a material containing frame, a motor, a rotating shaft, a first fixing block, a grinding column, a scraping mechanism and a discharging mechanism. The material containing frame is arranged on the inner sides of the upper portions of the supporting legs, the motor is installed in the middle of the top side of the interior of the material containing frame, and the rotating shaft is rotationally arranged on the inner side of the lower portion of the material containing frame and connected with an output shaft of the motor. And the first fixing block is arranged on the upper portion of the rotating shaft, the grinding column is rotationally arranged on the first fixing block, the grinding column is slidably connected with the material containing frame, and the scraping mechanism is arranged on the first fixing block. According to the overdue pill crushing and recycling device for the pediatric department, the scraping mechanism is arranged, and the first fixing block rotates to drive the scraping mechanism to operate, so that crushed pills in the material containing frame are scraped off, and the effect of automatic scraping is achieved.

Owner:南京中隐客归网络科技有限公司

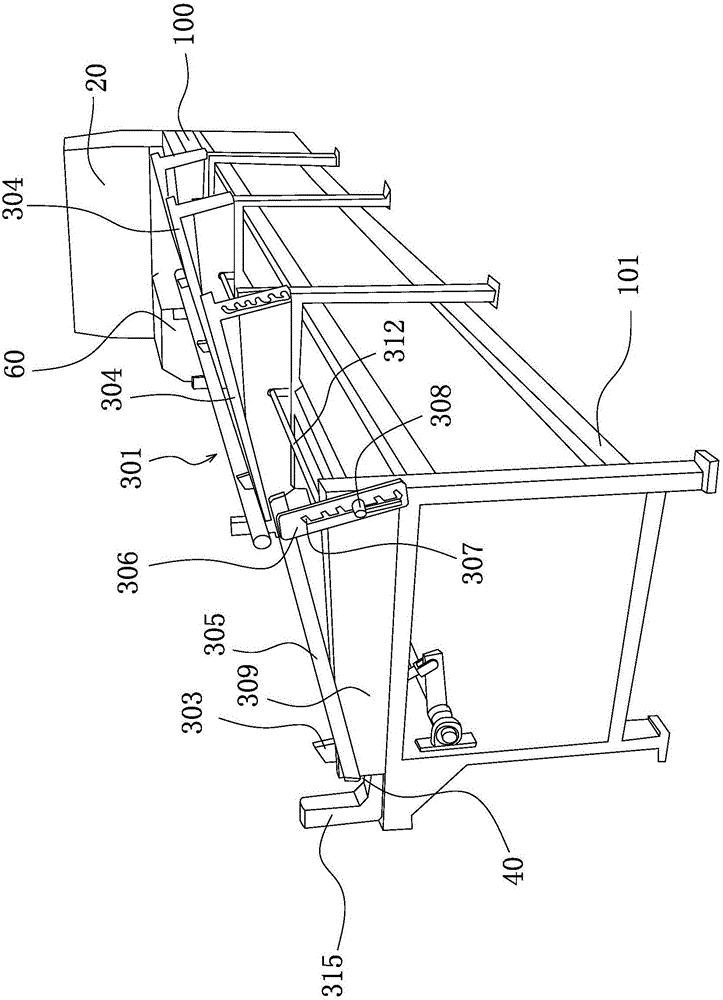

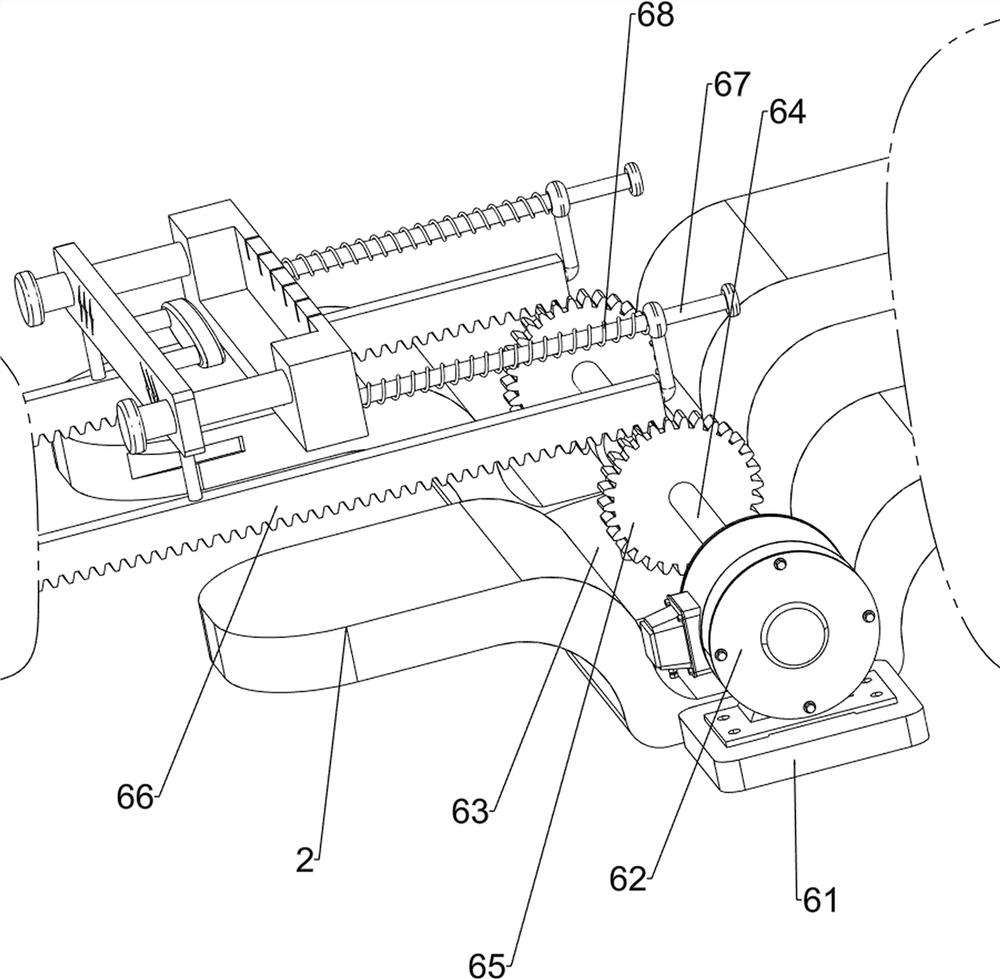

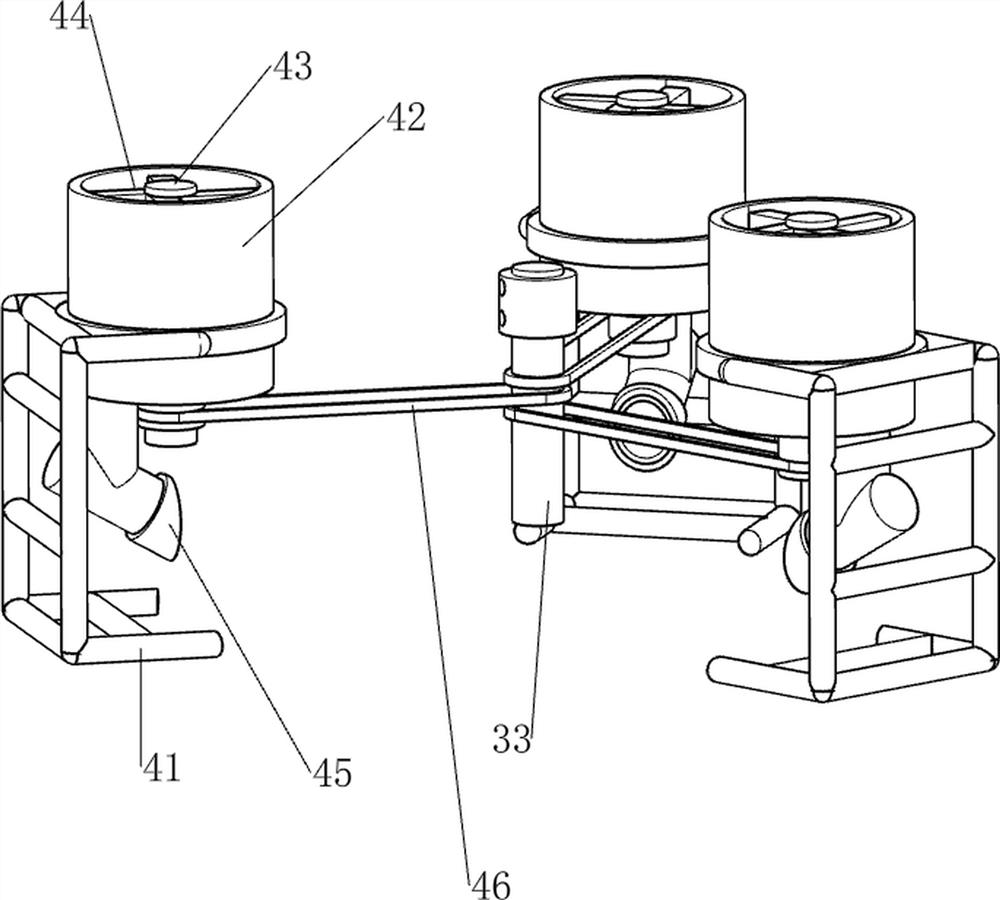

High-speed metal cutting circular saw

ActiveCN106001757AFast cutting speedImprove automation and work efficiencyMetal sawing devicesReciprocating motionMetal cutting

The present invention belongs to the technical field of metal cutting, and relates to a high-speed metal cutting circular saw. The high-speed metal cutting circular saw comprises a machine base, a cutting mechanism is disposed on the machine base, the machine base is connected with a feed mechanism, the cutting mechanism comprises a cutting disc and a cutting disc driver in drive connection with the cutting disc, a cutting base driver with an output end capable of reciprocating motion in an axial direction is disposed on the machine base, the cutting disc is disposed inside a cutting base and is flexibly connected with the cutting base, and the bottom of the cutting base is hinged to the machine base while the top of the cutting base is hinged to an output end of the cutting base driver. The circular saw provided by the invention is high in speed, efficiency and precision.

Owner:ZHEJIANG LONGLI MACHINERY

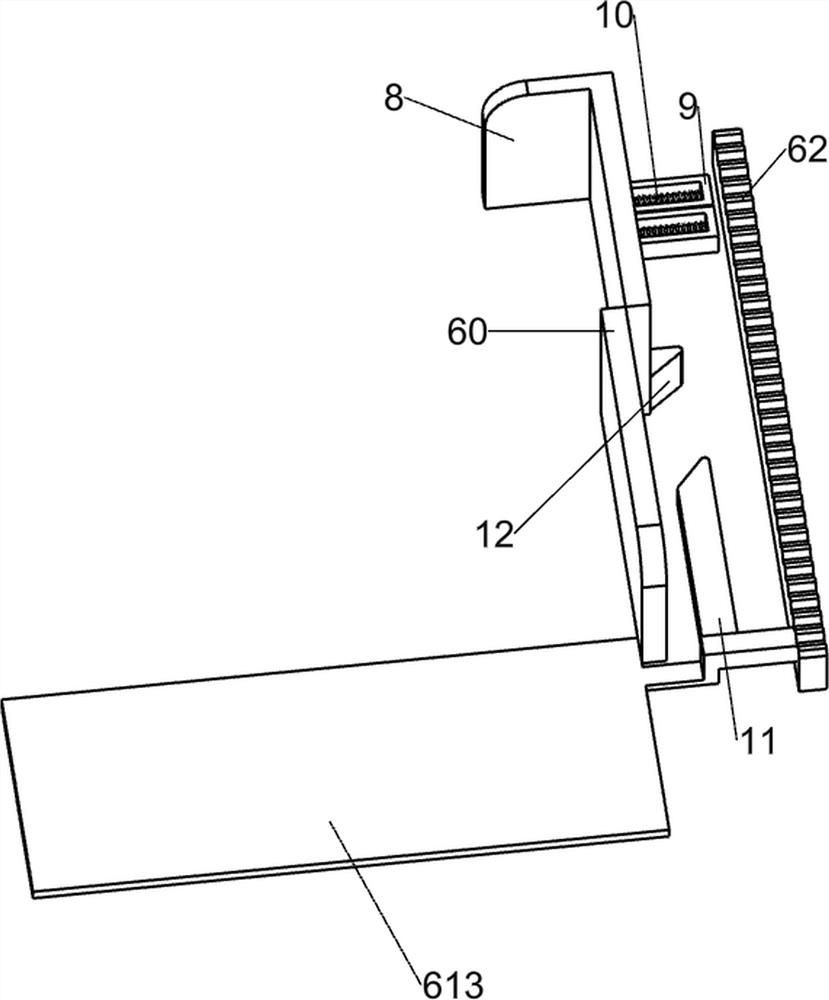

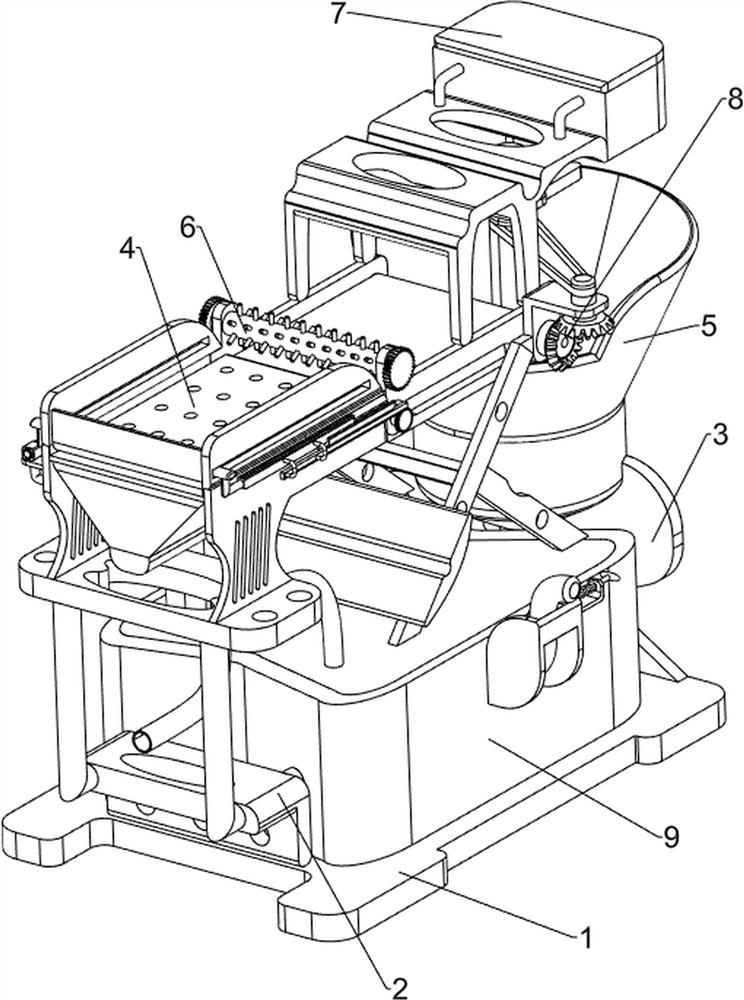

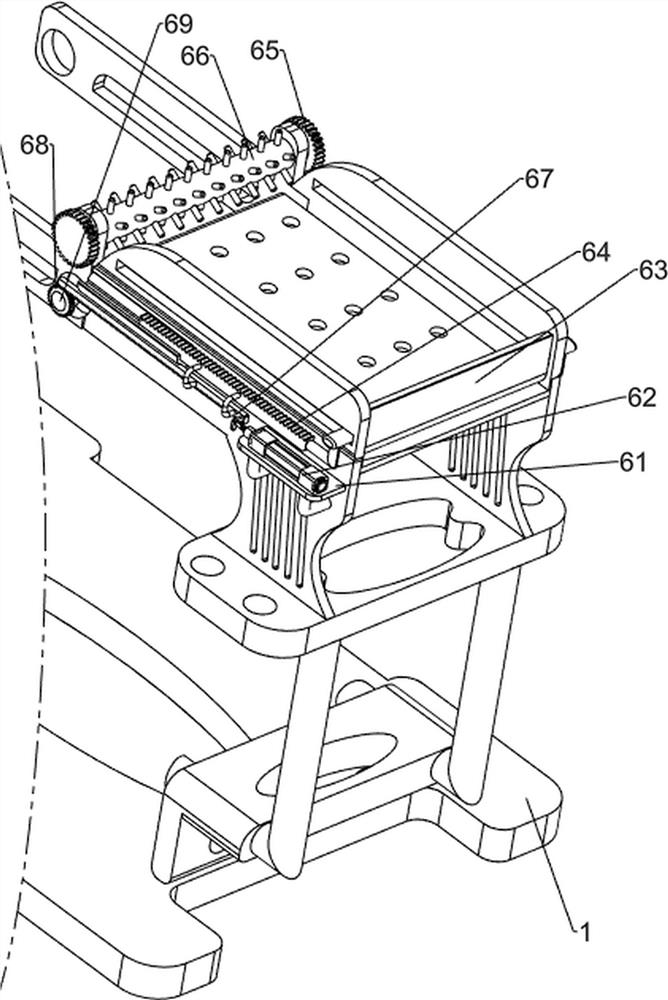

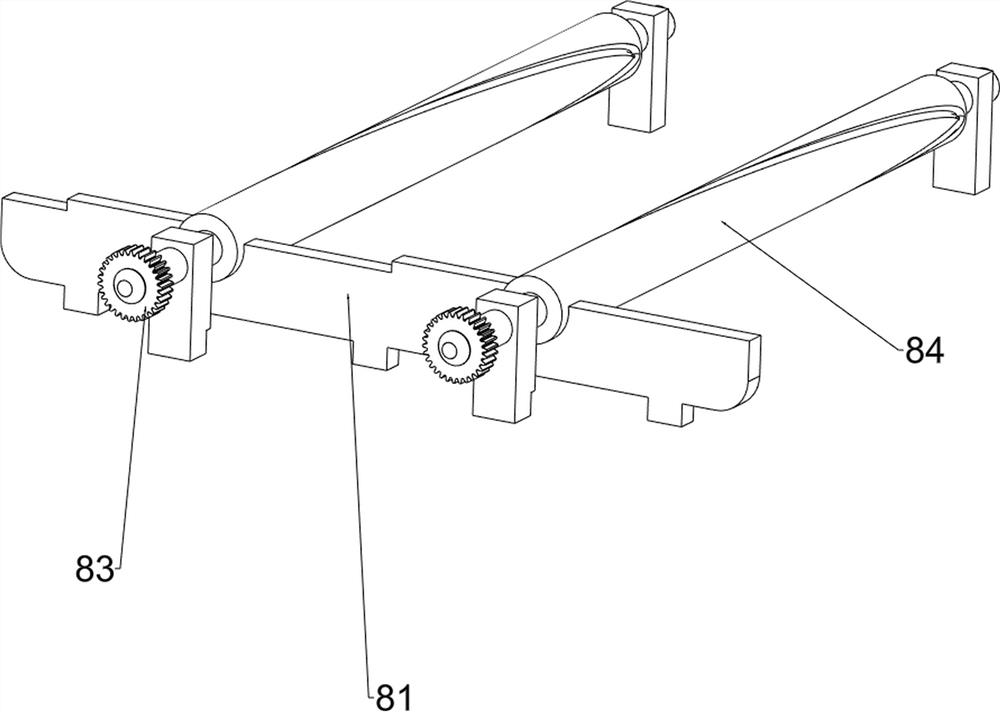

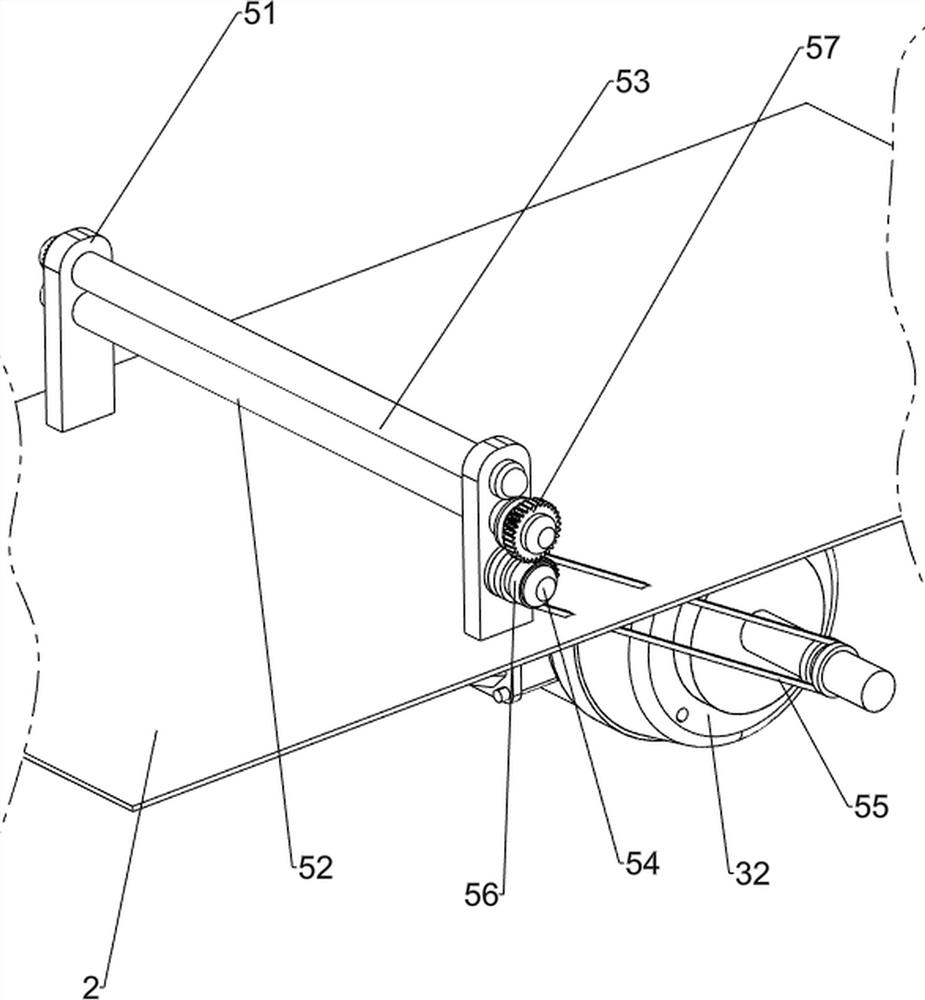

Slotting device for manufacturing wood tooth comb

ActiveCN112589931AAchieve the effect of automatic feedingAchieve the effect of automatic clampingWood mortising machinesWood slotting machinesWood plankWorkbench

The invention relates to a slotting device, in particular to a slotting device for manufacturing a wood tooth comb. The invention provides the slotting device for manufacturing the wood tooth comb with the advantages of high tooth forming precision, time and labor saving and low cost. The slotting device for manufacturing the wood tooth comb comprises supporting legs, workbenches, a first supporting frame, a fixing mechanism and a cutting mechanism, wherein two workbenches are connected onto the two supporting legs; the first supporting frame is arranged on one supporting leg; the fixing mechanism is arranged on the workbenches; the cutting mechanism is arranged at the upper part of the first supporting frame; and the cutting mechanism cooperates with the fixing mechanism. The slotting device for manufacturing the wood tooth comb has the advantages that through cooperation of first wedge blocks and second wedge blocks, the second wedge blocks apply pressure to the first wedge blocks, so that the first wedge blocks moves downwards, and first connecting rods moves downwards, and finally a cutting device moves downwards; the cutting device cuts a wood plate, and an automatic cutting effect is achieved; and the tooth forming precision is high, and time and labor are saved.

Owner:谢凤香

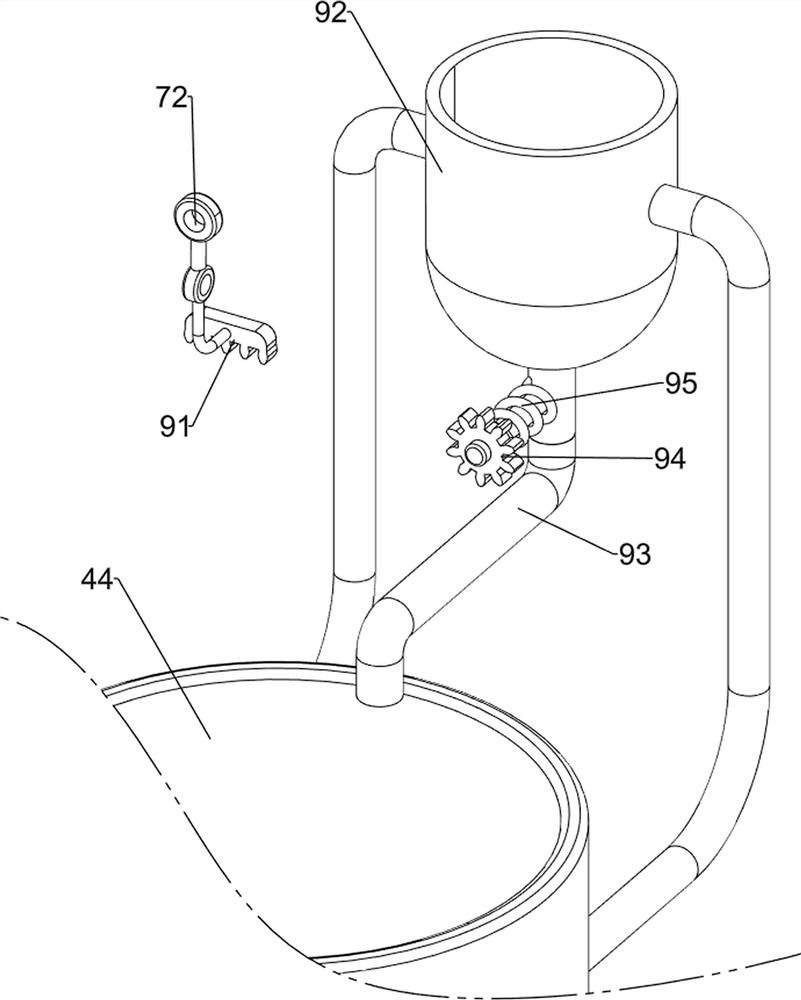

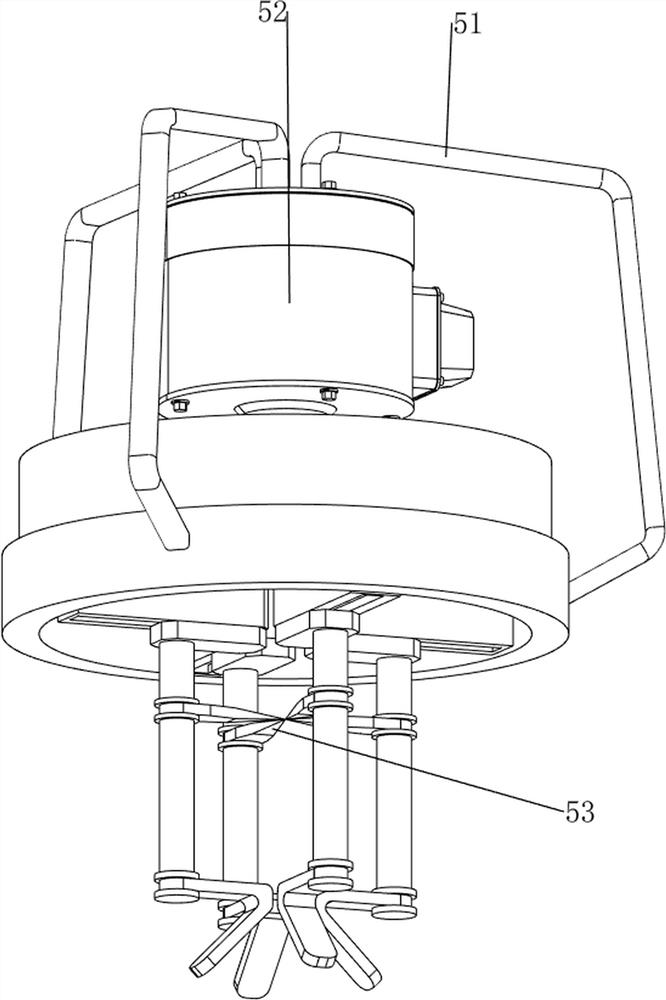

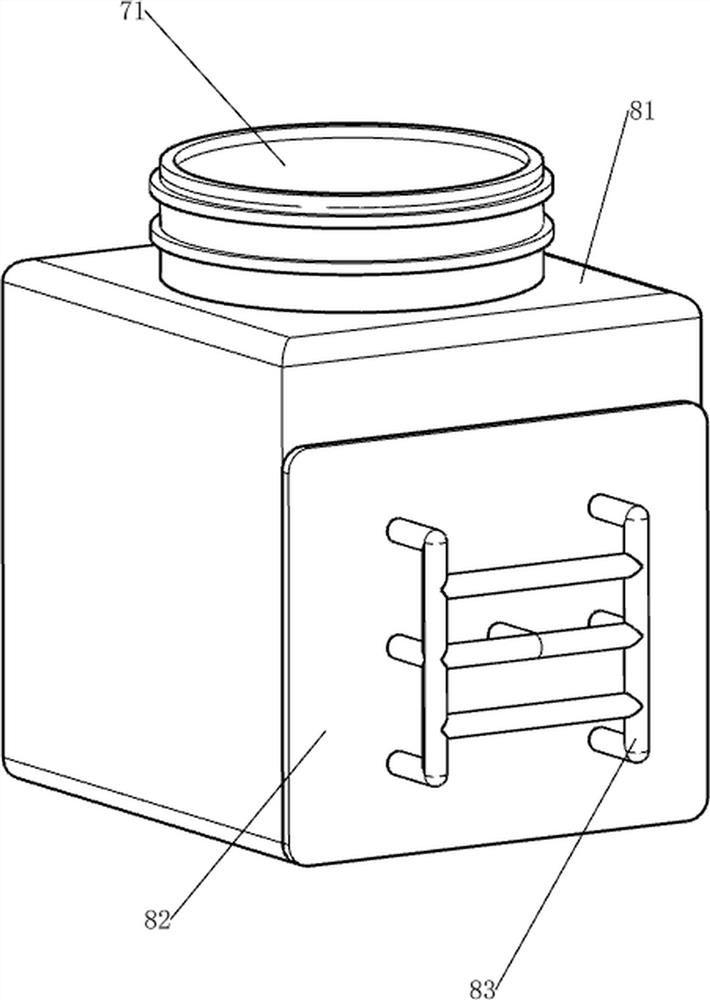

Multi-feed stirring equipment for animal husbandry

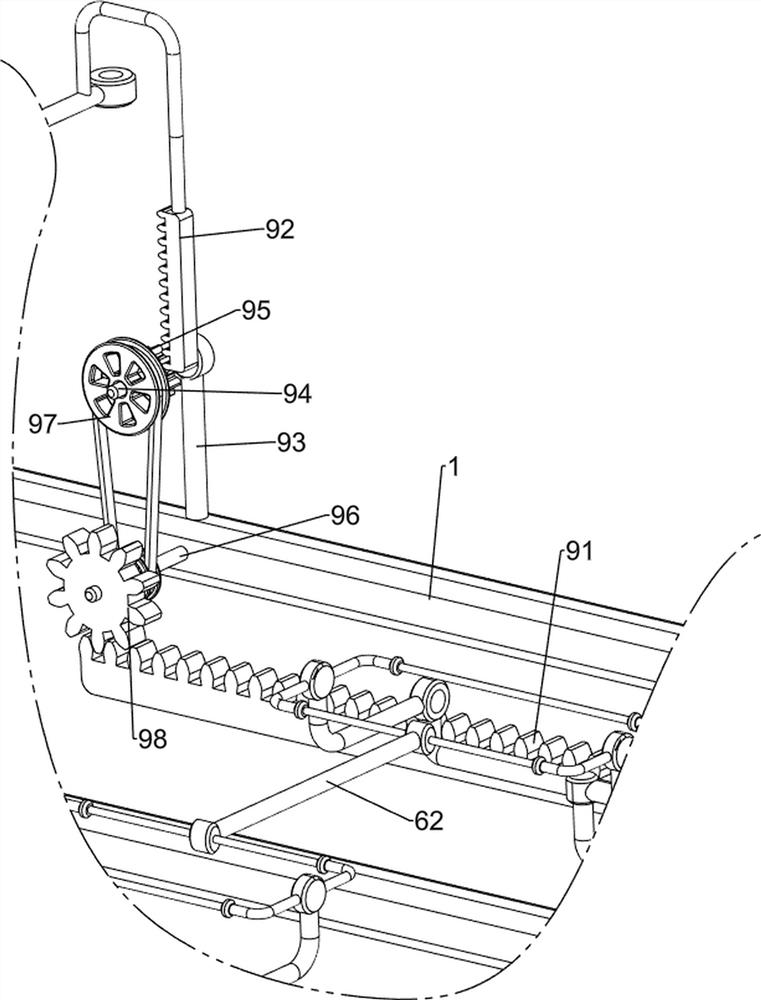

PendingCN113069955AAchieve stirring effectAchieve the effect of automatic feedingFeeding-stuffRotary stirring mixersAnimal scienceAgricultural science

The invention relates to stirring equipment, in particular to multi-feed stirring equipment for animal husbandry. The invention provides the multi-feed stirring equipment for animal husbandry, which has the advantages of automatic feeding and automatic stirring and is simple and convenient. The multi-feed stirring equipment for animal husbandry comprises a bottom plate, a support, a stirring barrel, a baffle, a stirring mechanism and an interval discharging mechanism; and the support is arranged on the bottom plate; the stirring barrel is arranged on the support; the baffle is arranged on the stirring barrel in a sliding manner; the stirring mechanism is arranged between the bottom plate and the stirring barrel; and the interval discharging mechanism is arranged between the support and the stirring barrel. A first servo motor is started, an output shaft of the first servo motor rotates to drive a first rotating shaft to rotate, so that a stirring plate and a scraping plate are driven to rotate, and when feed falls into a stirring barrel, the stirring effect is achieved.

Owner:张引

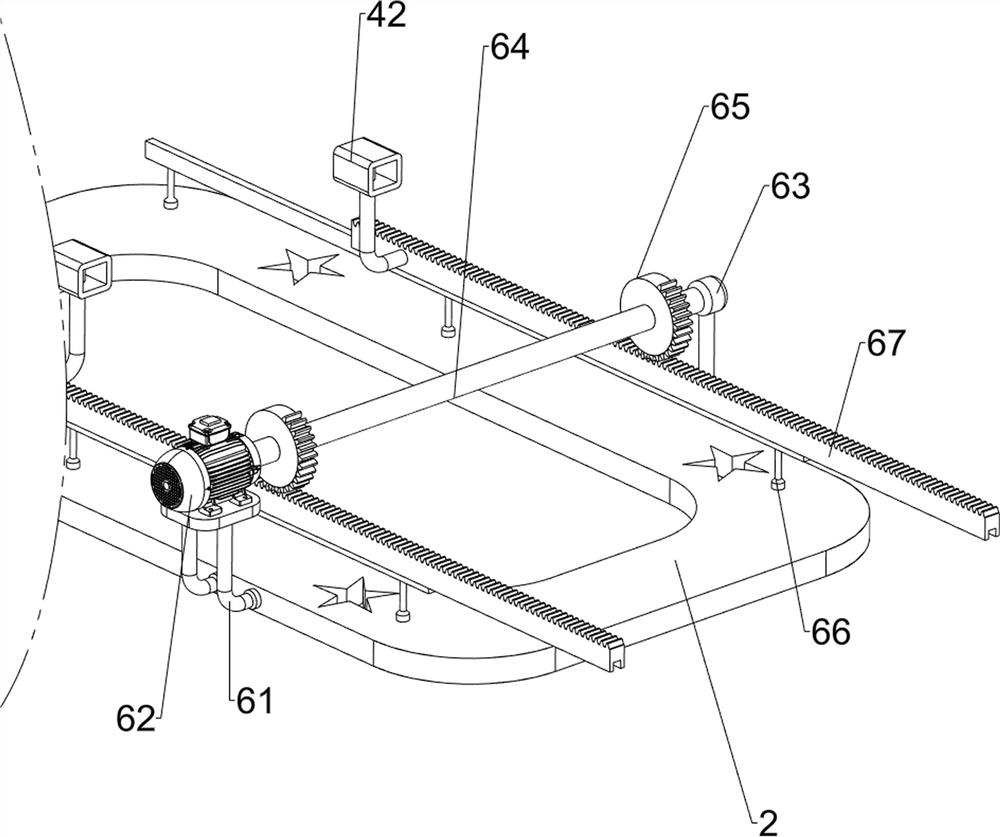

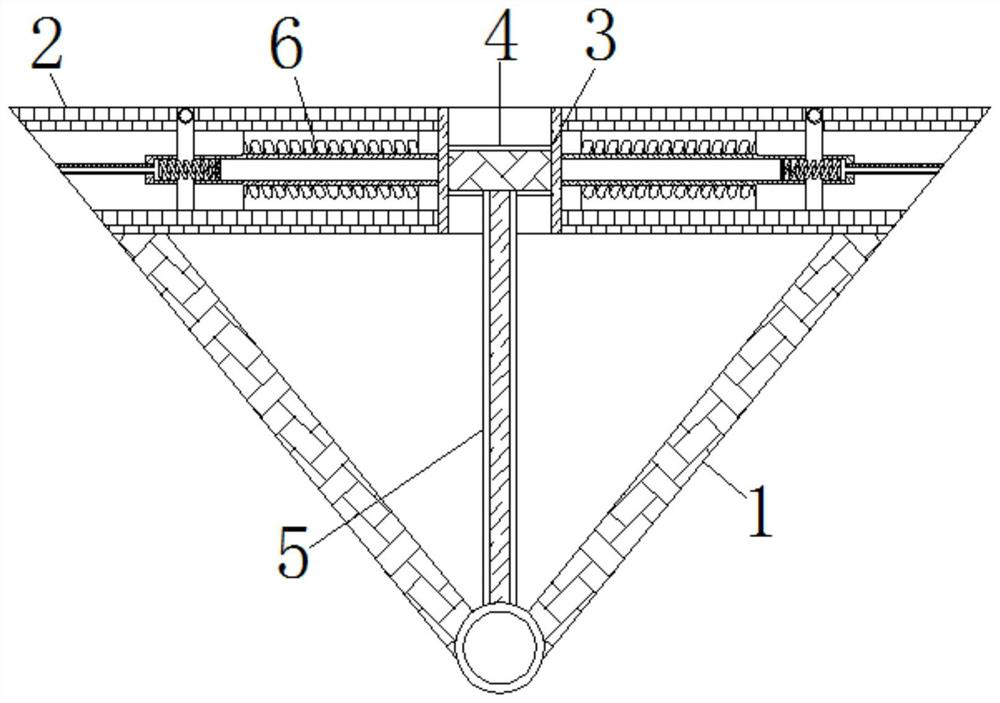

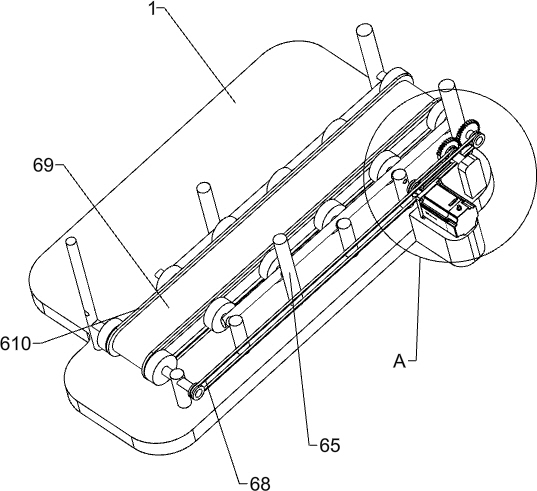

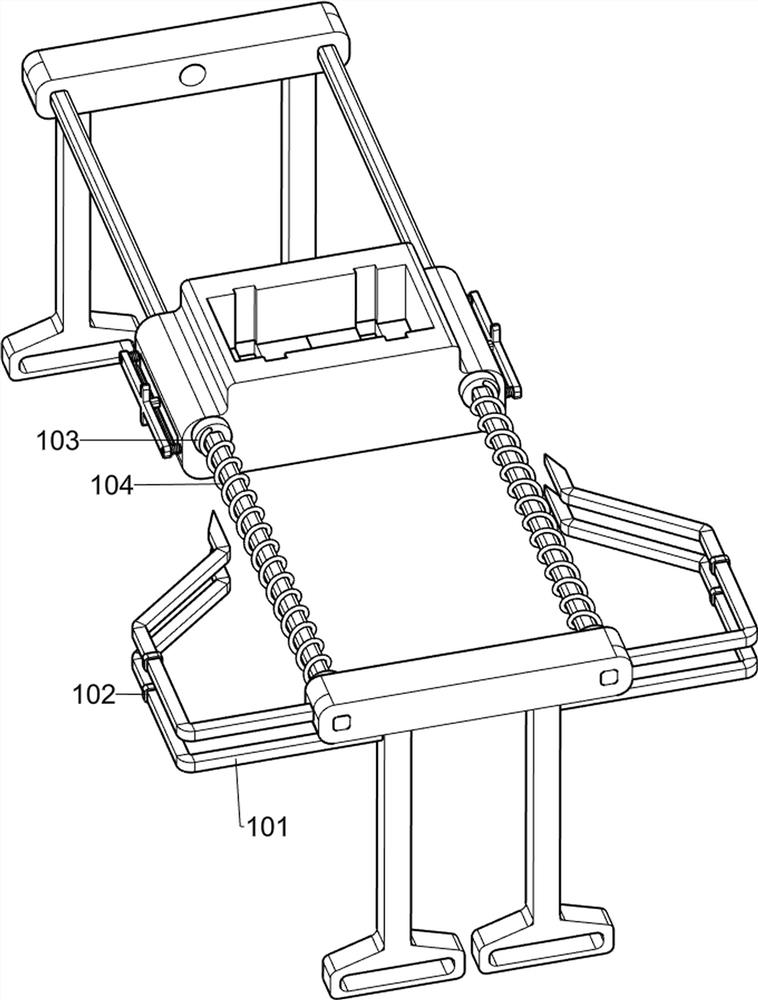

Equidistant segmented cutting device for building logs

ActiveCN113305947AAchieve the effect of automatic feedingTo achieve the purpose of automatic pressingProfiling/shaping machinesWood working safety devicesArchitectural engineeringStructural engineering

The invention relates to a cutting device, in particular to an equidistant segmented cutting device for building logs. The equidistant segmented cutting device can protect a cutting tool, automatically limit materials and is safe. The equidistant segmented cutting device for building logs comprises a bottom plate, two supports, cutters, a moving mechanism and a pressing mechanism, the two supports are arranged on the bottom plate, the moving mechanism is connected between the two supports, the pressing mechanism is arranged on the moving mechanism, the cutters are arranged on the pressing mechanism, and the cutters are matched with the moving mechanism. According to the equidistant segmented cutting device, the pressing mechanism is arranged, the pressing mechanism operates to press a round log, so that the purpose of automatic pressing is achieved, then the round log can be prevented from moving at will when being cut, safety is achieved, a protection mechanism is arranged, the protection mechanism operates to enable the surface of a cutter to be evenly smeared with lubricating oil, and therefore the effect of protecting a cutting tool is achieved.

Owner:新晟建设集团有限公司

Nut shelling equipment for food processing

ActiveCN112189854AAchieve automatic flappingAchieve the effect of automatic feedingSievingGas current separationProcess engineeringWaste material

The invention relates to a shelling equipment, in particular to a nut shelling equipment for food processing. The invention provides a nut shelling equipment for food processing, which has high shelling efficiency and capable of collecting waste materials in time. The nut shelling equipment for food processing comprises a base and a workbench, the workbench is arranged on the top of the base, a servo motor which is mounted on the base, a beating mechanism which is arranged on an output shaft of the servo motor and the workbench, and a discharging mechanism which is arranged on the the base, the beating mechanism and the workbench. Through ingenious cooperation of the beating mechanism and the discharging mechanism, the effects of automatic beating and automatic discharging are achieved, and the purpose of automatic shelling is realized; and through cooperation of a poking mechanism, the beating mechanism and the discharging mechanism, the nuts are intermittently poked to the baffle forbeating and shelling.

Owner:阿克苏浙疆果业有限公司

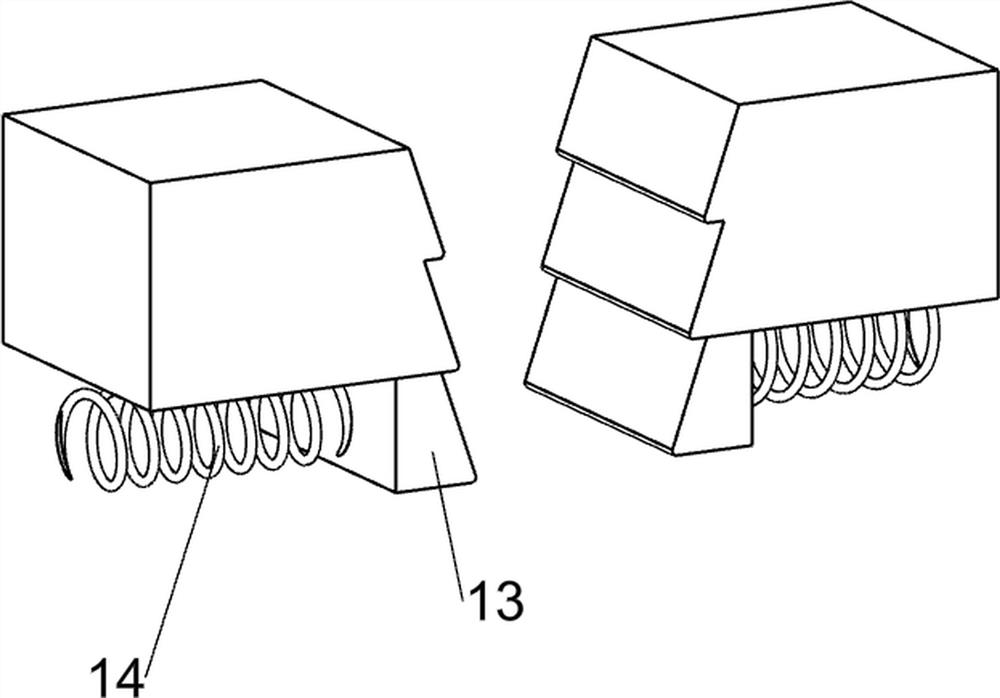

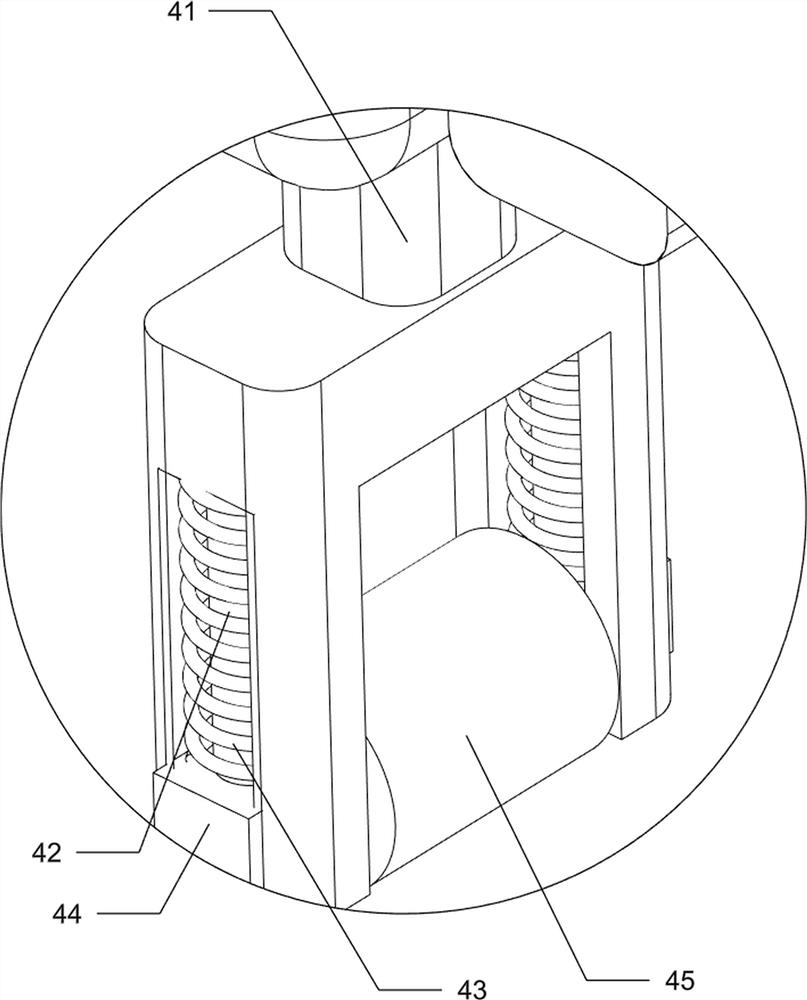

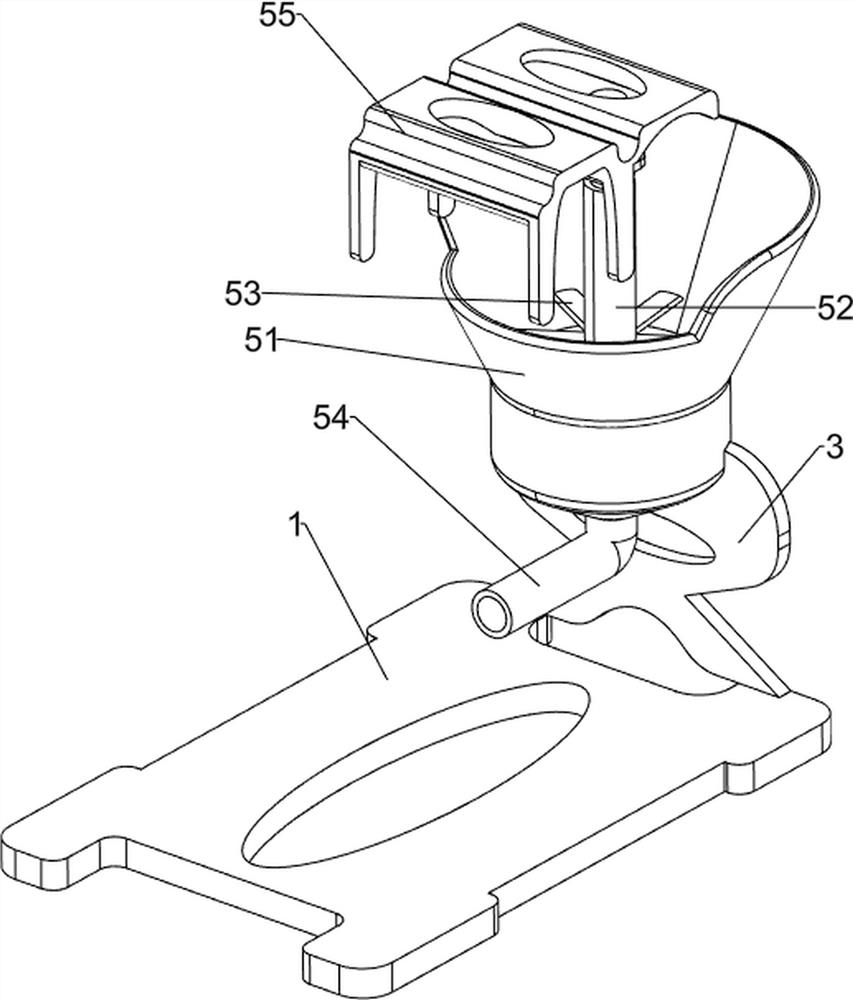

Button locating mounting equipment for knitwear

InactiveCN111691075AAchieve the effect of automatic feedingAvoid the phenomenon of fallingWork-feeding meansTextile shapingGear wheelEngineering

The invention relates to the technical field, and discloses button locating mounting equipment for knitwear. The equipment includes a supporting plate, expansion rods are connected with two side wallsof the inner part of the supporting plate separately in a moving mode, sliding grooves are formed in the expansion rods, ejection blocks are connected with the surface of the sliding grooves in a sliding mode, ejection rods are fixedly connected with the bottom of the ejection blocks, and spring rods are connected with one ends of the sliding grooves far away from the ejection blocks in a movingmode. A connecting rod is connected with the top of the supporting plate in a moving mode, a compression spring is connected with the surface of the connecting rod in a moving mode, an ironing mask isconnected with one end of the compression spring far away from the connecting rod in a moving mode, a bevel gear is connected with the connecting rod far away from the supporting plate in a moving mode, a gear is connected with the surface of the bevel gear in a moving mode, an extension rod is connected with the bottom of the gear in a moving mode, and a mounting plate is connected with the extension rod in a moving mode. Symmetric pulling force is exerted into the surface of clothing, then the mounting plate is pushed to move to the direction close to the ejection blocks, a contact rod is subjected to upward pushing force, and the effects that a button is located by the machinery and suitable dragging force is provided are achieved.

Owner:HAINING AILI KNITTING CO LTD

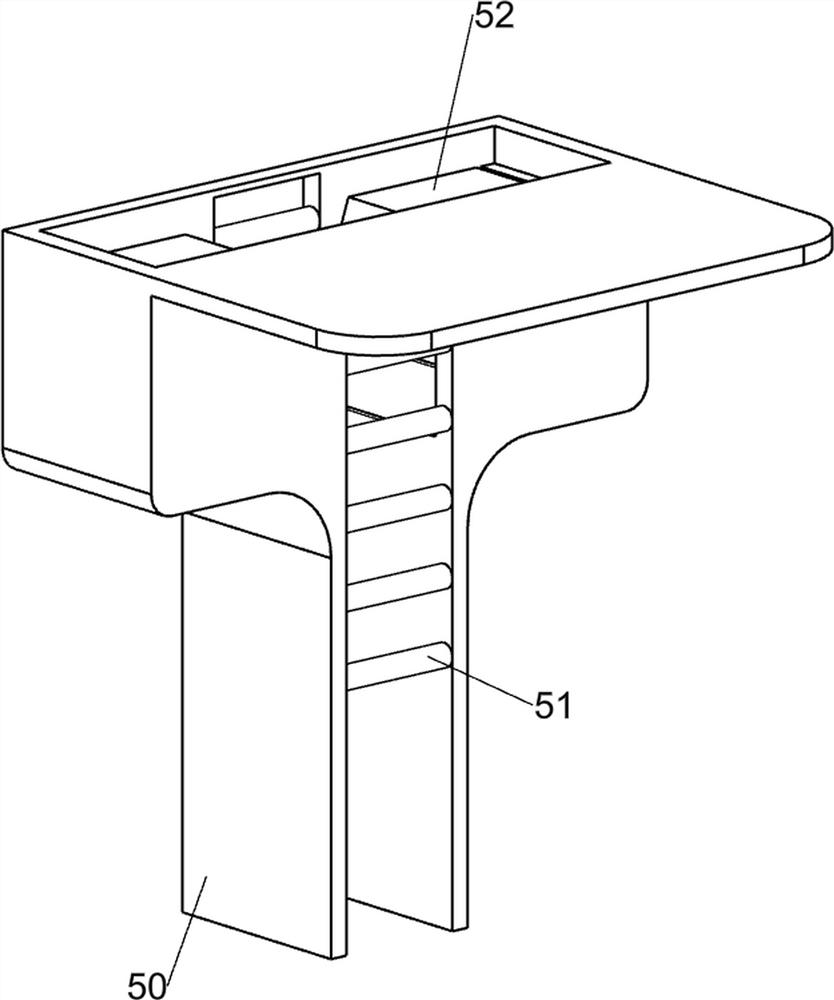

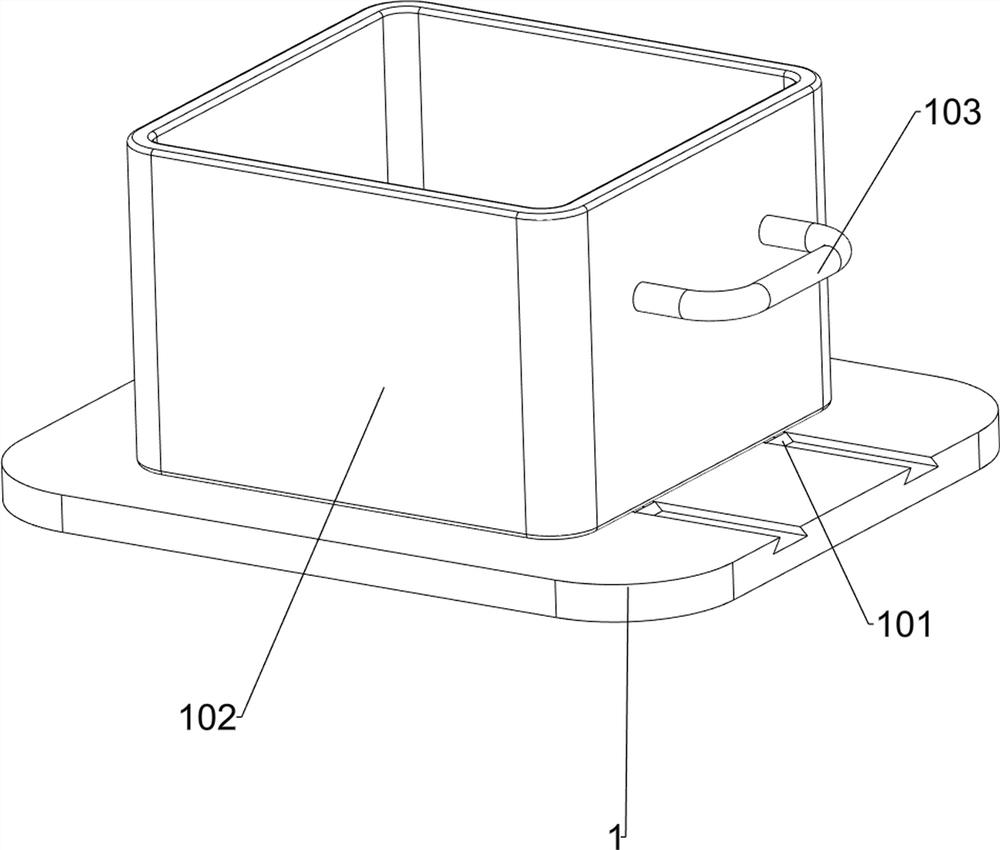

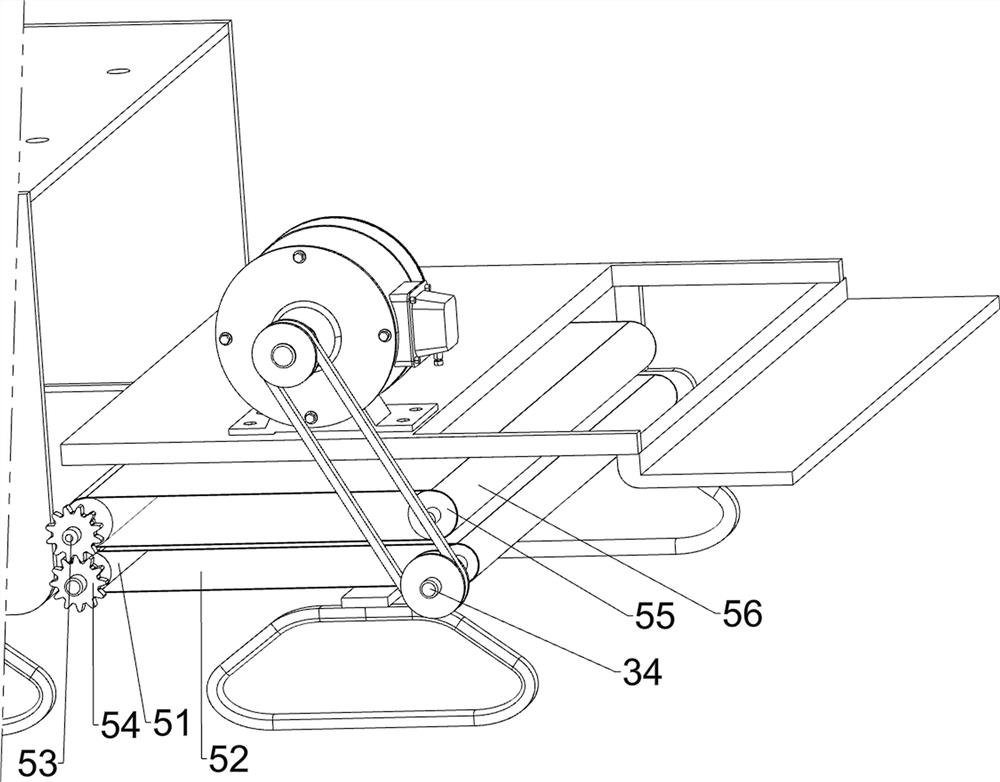

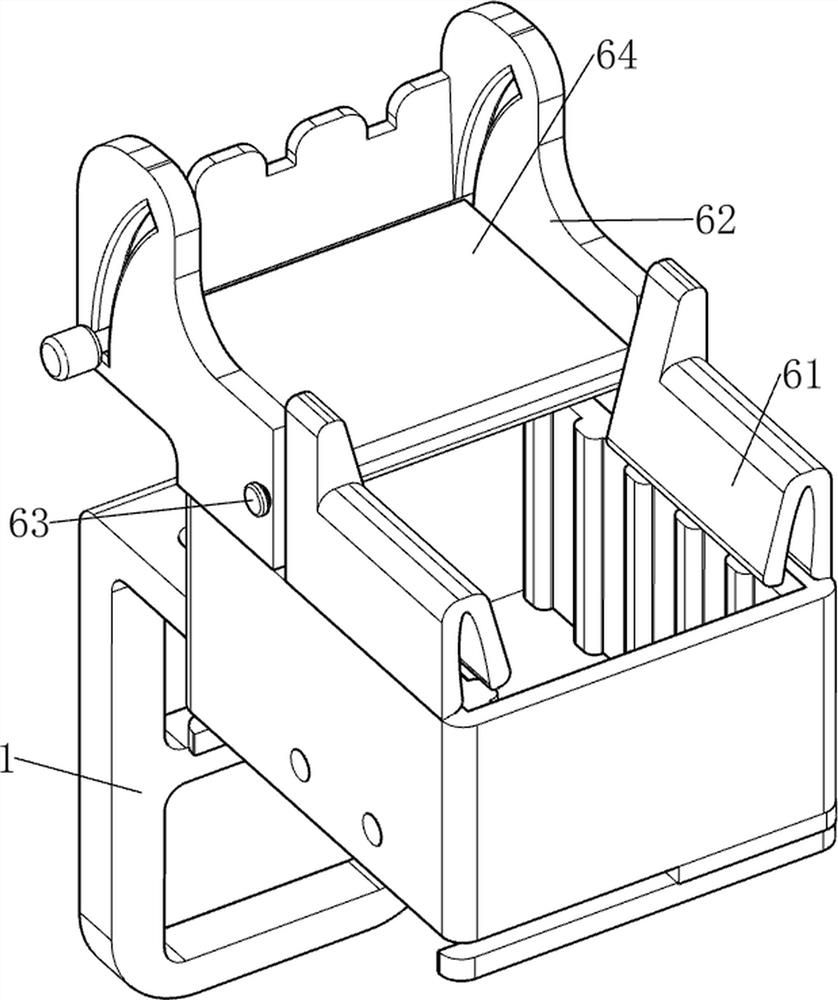

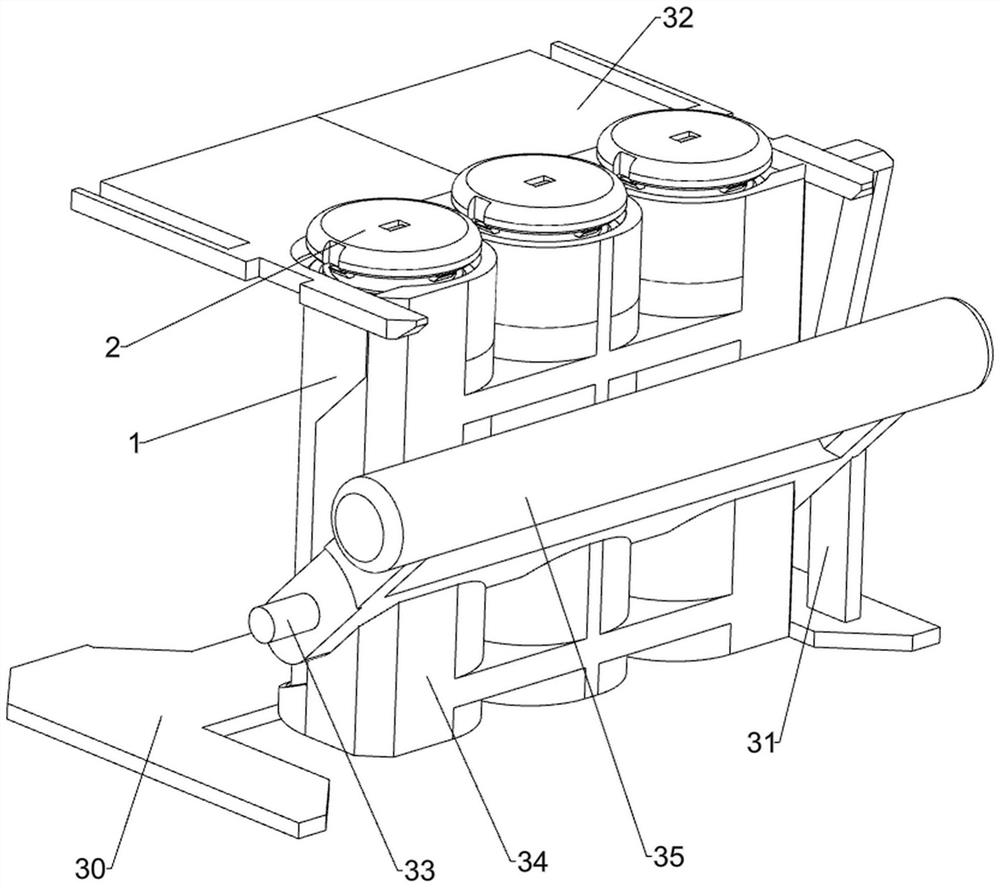

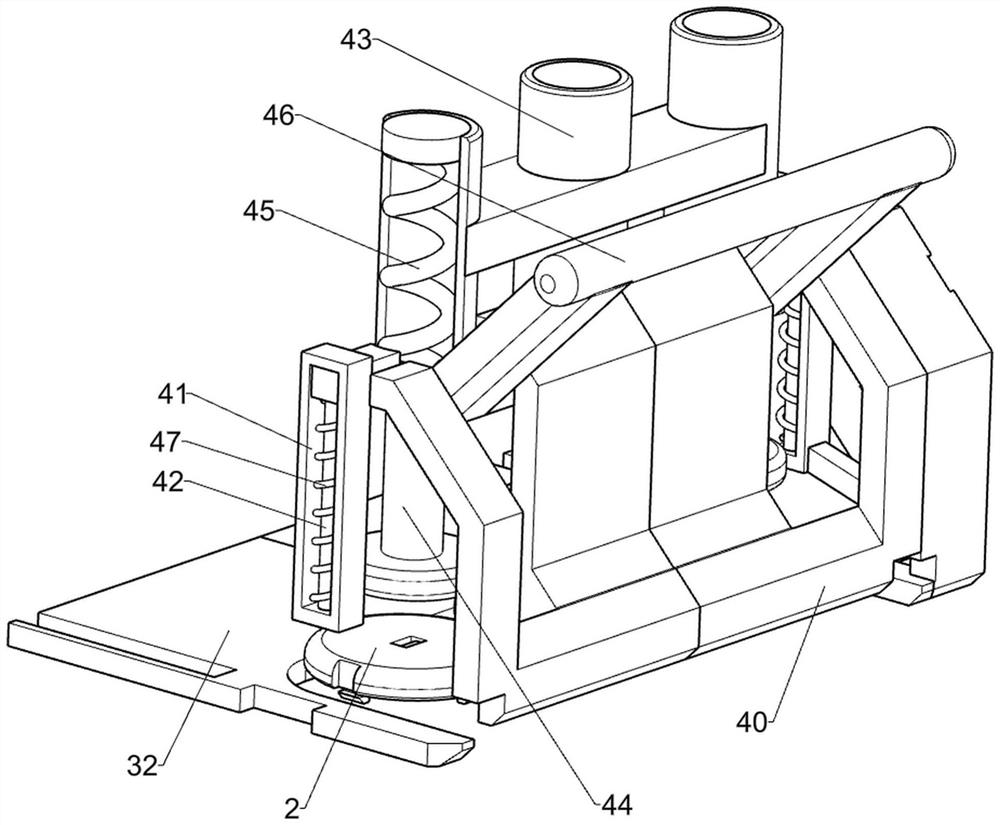

Manufacturing device for hollow bricks

PendingCN111958774AControlled fallAchieve the effect of automatic feedingFeeding arrangmentsShaping conveyorsBuilding materialManufacturing engineering

The invention relates to building material manufacturing equipment, in particular to a manufacturing device for hollow bricks. The manufacturing device for the hollow bricks can control falling of brick materials, automatically convey the brick materials, press the brick materials into the hollow bricks and automatically discharge the hollow bricks. The manufacturing device for the hollow bricks comprises a base and a servo motor, wherein the servo motor is arranged on the right front side of the top of the base. The manufacturing device for the hollow bricks also comprises a conveying mechanism, third supporting posts, a fixing frame, a discharging basket, a sliding plate and a pressing mechanism, wherein the conveying mechanism is arranged on the front side of the top of the base; the third supporting posts are evenly arranged on the side, close to the servo motor, of the top of the base; the fixing frame is connected among the tops of the third supporting posts; the discharging basket is placed in the middle of the fixing frame; the sliding plate is arranged on the side, away from the conveying mechanism, of the top of the base; and the pressing mechanism is arranged on the side, close to the servo motor, of the top of the base. According to the manufacturing device for the hollow bricks, the effects of controlling the falling of the brick materials, automatically conveyingthe brick materials, pressing the brick materials into the hollow bricks and automatically discharging the hollow bricks can be realized, and thus the working efficiency of hollow brick manufacturingis improved.

Owner:王金智

Caking treatment device for modified starch production

ActiveCN112619782ATo achieve the effect of automatic processingAchieve the effect of automatic feedingSievingScreeningProcess engineeringStarch production

The invention relates to a treatment device, in particular to a caking treatment device for modified starch production. The invention provides the caking treatment device for modified starch production, which is time-saving, labor-saving, relatively low in cost and high in crushing rate. The caking treatment device for modified starch production comprises a bottom plate, a workbench, mounting frames, pressing mechanisms, a rotating mechanism and a discharging mechanism; the workbench is arranged on the bottom plate; two mounting frames are arranged at the top of the workbench; the pressing mechanisms are arranged at the tops of the mounting frames; the rotating mechanism is arranged at the top of the workbench, and the rotating mechanism is connected to the pressing mechanism; and the discharging mechanism is arranged at the top of the workbench, the discharging mechanism is matched with the rotating mechanism, and the discharging mechanism is connected to the pressing mechanism. According to the invention, a third transmission shaft drives a belt assembly II to rotate, so that a cam rotates; the cam rotates to enable screened materials to move left and right repeatedly, and therefore the smashed raw materials are screened, the automatic screening effect is achieved, and time and labor are saved.

Owner:DONGXIANG HEDA IND CO LTD

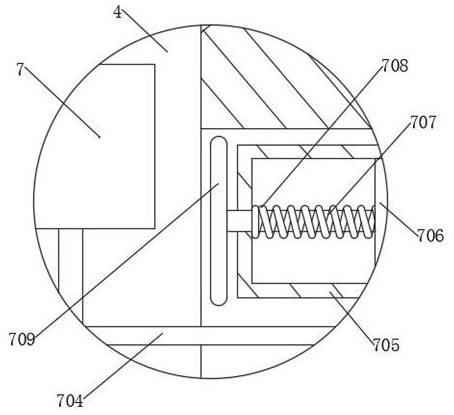

Resistance characteristic electrical variable measuring device of electronic component

ActiveCN113252983AMeasure impactAvoid compromising accuracyResistance/reactance/impedenceElectrical testingElectrical resistance and conductanceStructural engineering

The invention discloses a resistance characteristic electrical variable measuring device of an electronic component, and belongs to the technical field of measuring equipment. The resistance characteristic electrical variable measuring device of the electronic component comprises a box body and an electronic component body, and further comprises a feeding hole and a discharging hole which are respectively formed in two sides of the box body; a frame, which is fixedly connected to the inner wall of the box body; a self-locking assembly which is arranged on the frame; a conducting ring which is arranged on the self-locking assembly and is connected with the electronic component body in an inserting manner; and a signal source which is matched with the conducting ring to transmit an electric signal to the electronic component body. According to the invention, when an electronic component body is measured, a limiting effect can be achieved, the situation that displacement occurs during measurement and measurement of the electronic component body is affected is avoided, dust attached to the conductive column can be cleaned while limiting is conducted, and the situation that the measurement accuracy is affected due to the fact that a large amount of dust is attached is avoided; after measurement, automatic blanking is performed and workers do not need to manually take the electronic component bodies, so that the measurement efficiency is prevented from being affected.

Owner:江苏振宁半导体研究院有限公司

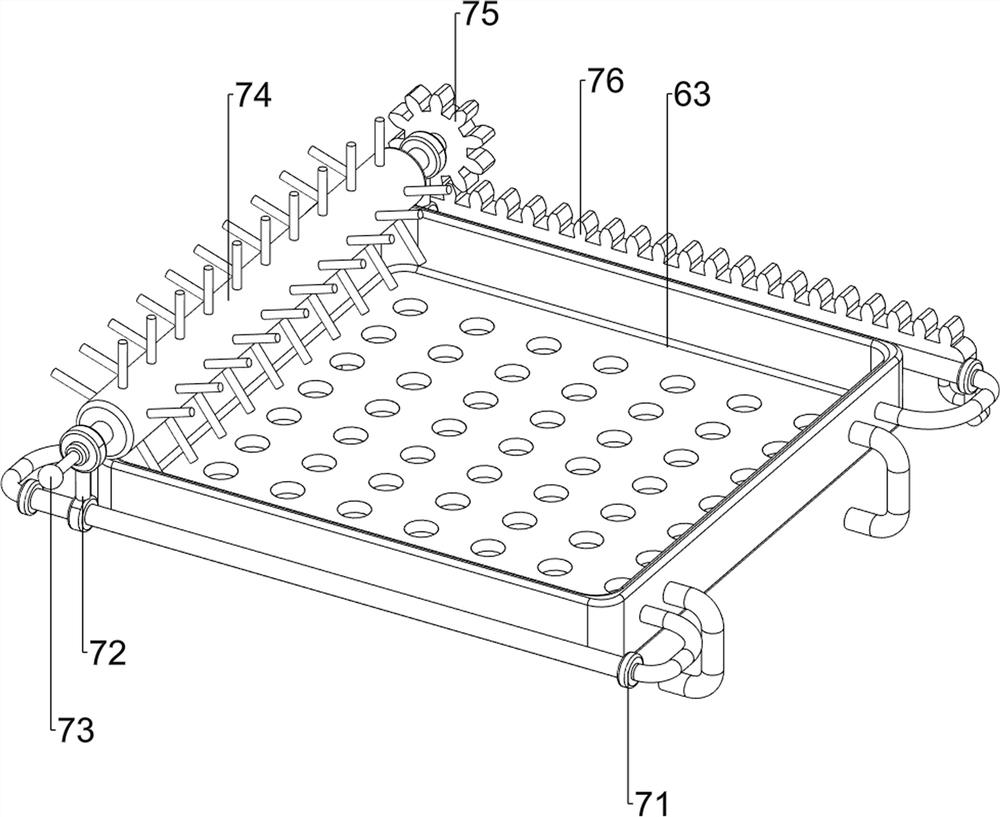

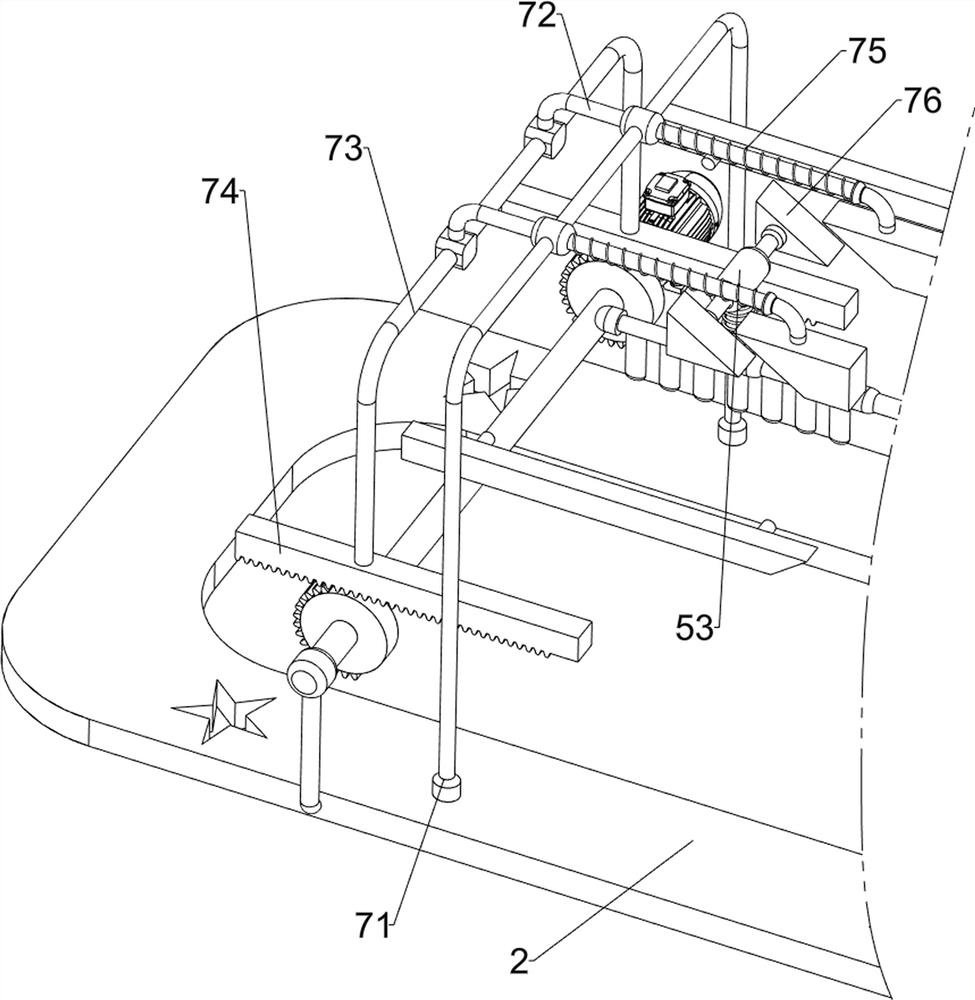

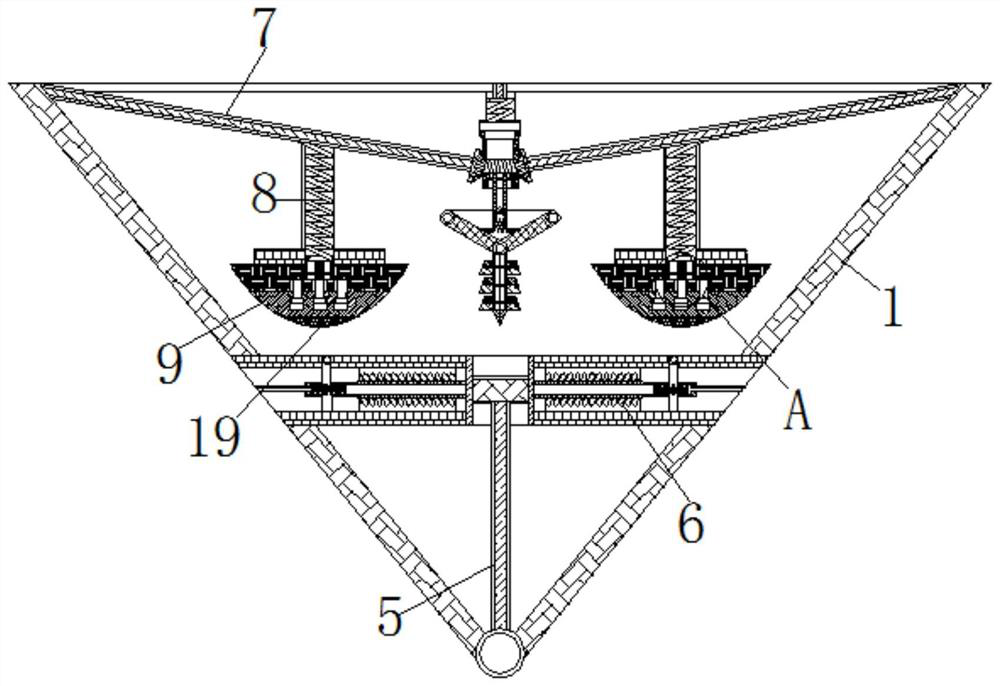

Corn thresher for agricultural product processing

InactiveCN112314188AAchieve the effect of automatic threshingAchieve the effect of automatic extrusionThreshersAgricultural scienceAgricultural engineering

The invention relates to a thresher, in particular to a corn thresher for agricultural product processing. The corn thresher for agricultural product processing can conduct automatic and even discharging, automatic feeding and automatic screening. The corn thresher for agricultural product processing comprises a base, a supporting block, first fixing frames, pushing mechanisms and extrusion mechanisms; the supporting block is arranged on the base; the two first fixing frames are arranged on the base; the pushing mechanisms are connected between the top of the supporting block and the tops of the first fixing frames; and the extrusion mechanisms are arranged on the pushing mechanisms. According to the corn thresher, corn is threshed through cooperation of the extrusion mechanisms and the pushing mechanisms, so that the automatic threshing effect is achieved; and through cooperation of rolling wheels and inclined rods, the rolling wheels are made to move forwards, the rolling wheels moveand push connecting blocks to move forwards, then a first sliding frame is made to move forwards, and the corn is made to move forwards, so that the effect of automatic feeding is achieved.

Owner:FUZHOU JINXI AGRI DEV CO LTD

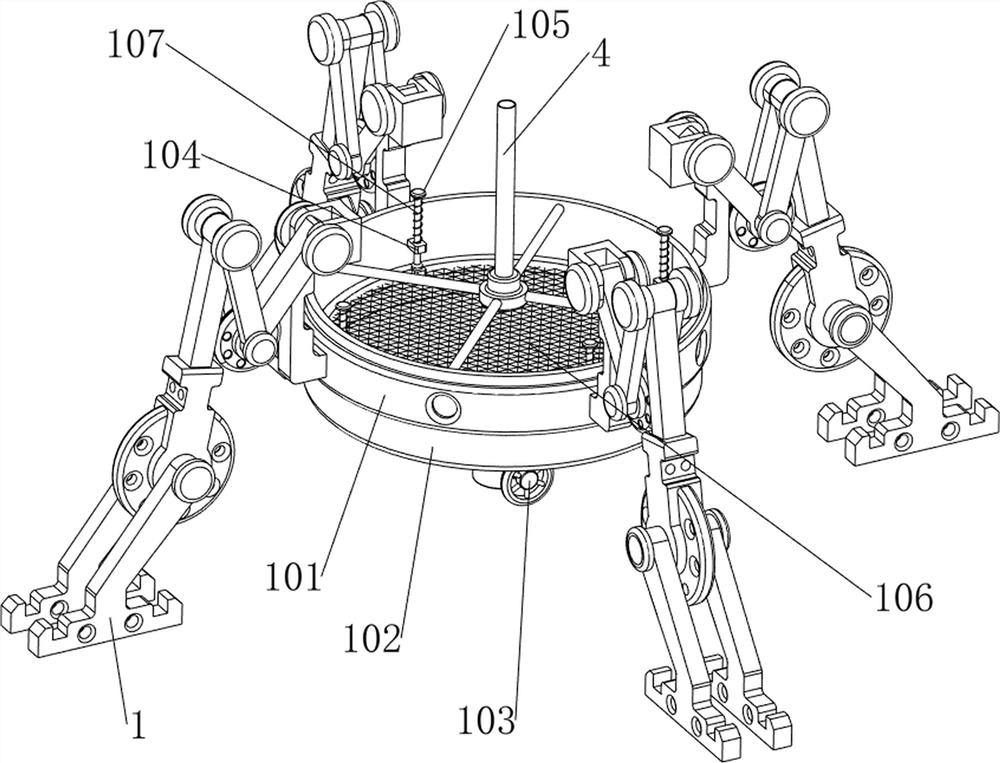

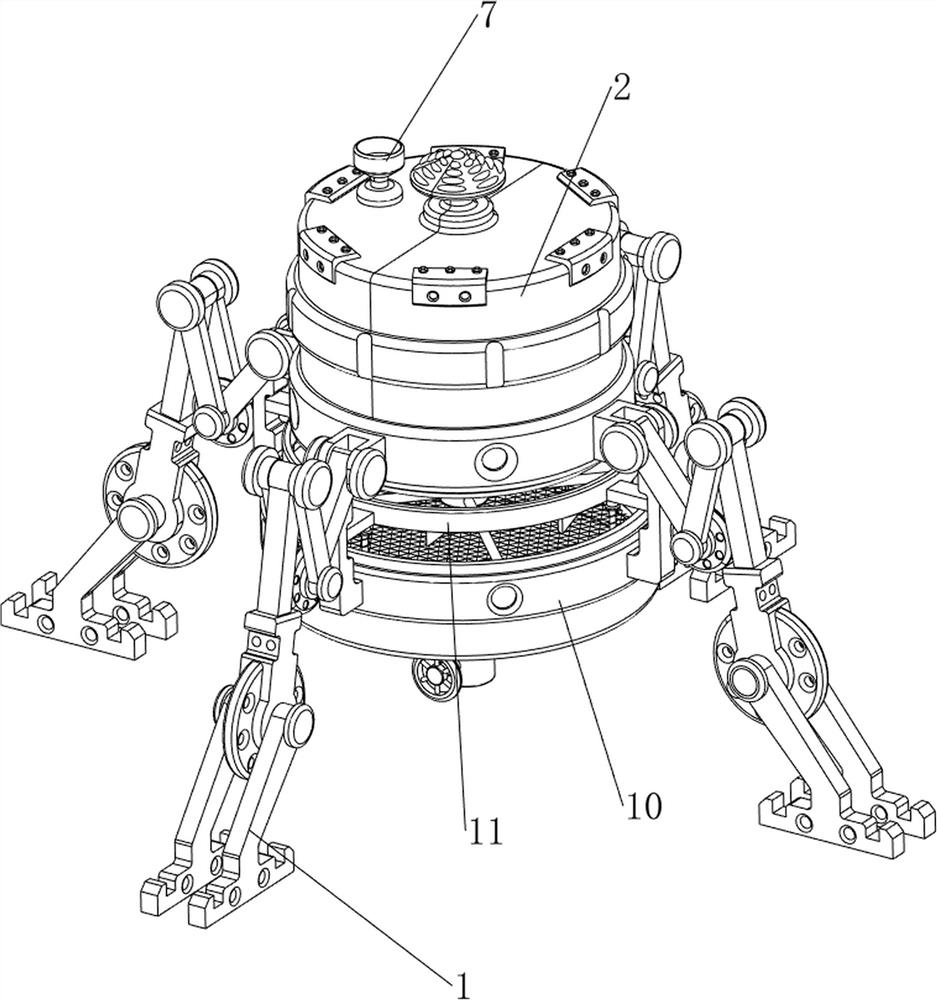

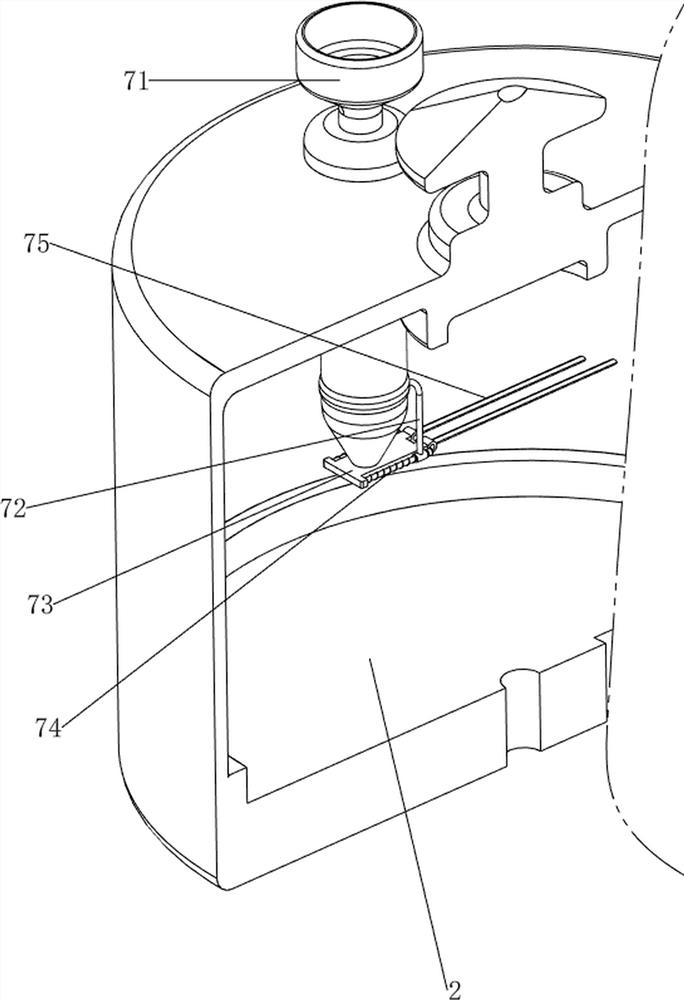

Disassembling device for waste battery recycling

PendingCN113363608APrevent fallingReduce stepsReclaiming serviceable partsWaste accumulators reclaimingBattery recyclingBattery cell

The invention relates to a disassembling device, in particular to a disassembling device for waste battery recycling. The disassembling device for waste battery recycling is provided with an automatic partitioning mechanism, an automatic feeding mechanism and an automatic cutting mechanism. The disassembling device for waste battery recycling comprises a bottom plate, three supporting frames, a connecting chassis, a discharging mechanism, a rotary cutting mechanism and a feeding mechanism, wherein the three supporting frames are evenly arranged on the bottom plate; the connecting chassis is connected among the top parts of the three supporting frames; the discharging mechanism is arranged on the connecting chassis; the rotary cutting mechanism is arranged on the discharging mechanism; and the feeding mechanism is arranged between the connecting chassis and the bottom plate. According to the invention, a first sliding connecting rod and a sliding placing plate are driven by first springs to move towards the inner side, so that a battery is clamped, and the battery is prevented from falling off in the disassembling process.

Owner:刘昕

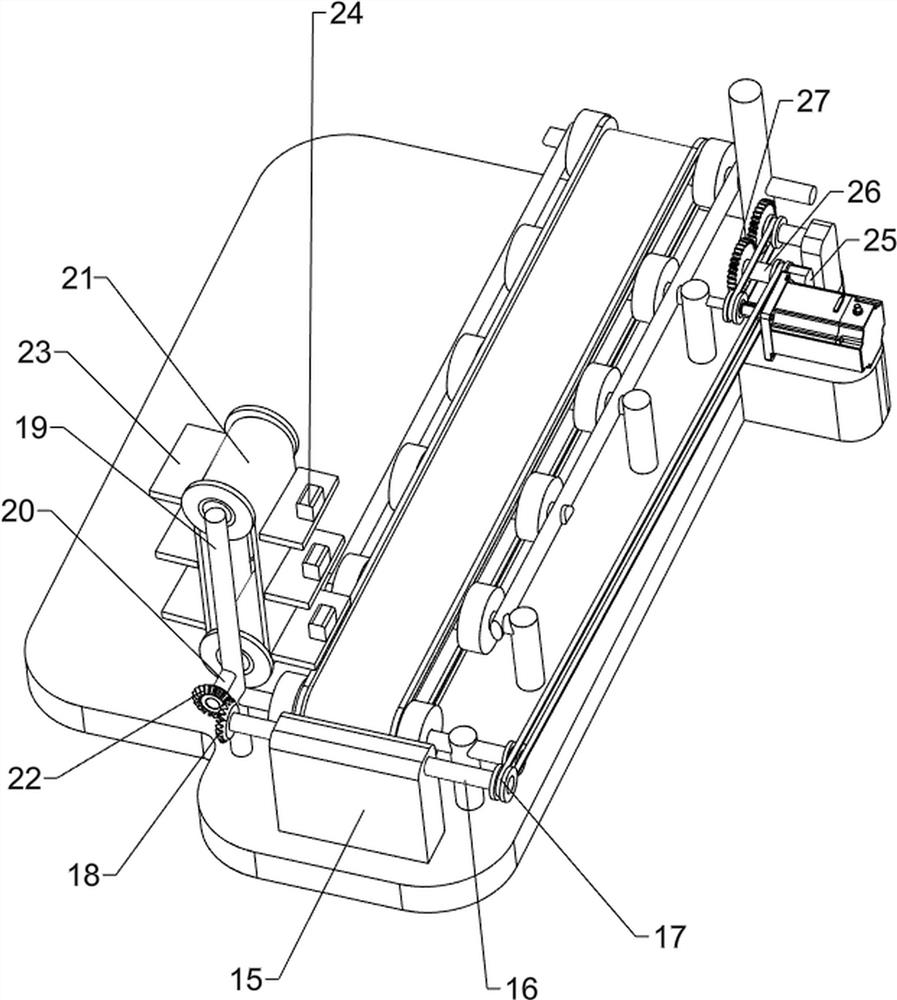

Printing device of printing equipment for intelligent manufacturing

InactiveCN112278928AAchieve the effect of automatic printingEasy to operateRotary pressesArticle feedersElectric machineryEngineering

The invention relates to a printing device, in particular to a printing device of printing equipment for intelligent manufacturing. The printing device of the printing equipment for intelligent manufacturing saves time and labor, and is high in efficiency and convenient to operate. The printing device of the printing equipment for intelligent manufacturing comprises a lathe body, a gear motor, a transmission assembly and a coining assembly. The gear motor is installed on the lathe bed. The transmission assembly is arranged on the lathe bed, and the transmission assembly is connected with an output shaft of the gear motor. And the coining assembly is arranged on the lathe bed, and the coining assembly is connected with the transmission assembly. According to the printing device of the printing equipment for intelligent manufacturing, a cam is matched with a pressing plate, when the protruding part of the cam makes contact with the pressing plate, and the cam applies pressure to the pressing plate, so that the pressing plate moves downwards, then a guide rod moves downwards, the pressing plate moves to enable an upper mold plate to slide downwards in the lathe bed, the upper mold plate is matched with a lower mold plate, products can be printed, and the effect of automatic printing is achieved. Time and labor are saved and operation is simple and convenient.

Owner:广州市丰兆电子科技有限公司

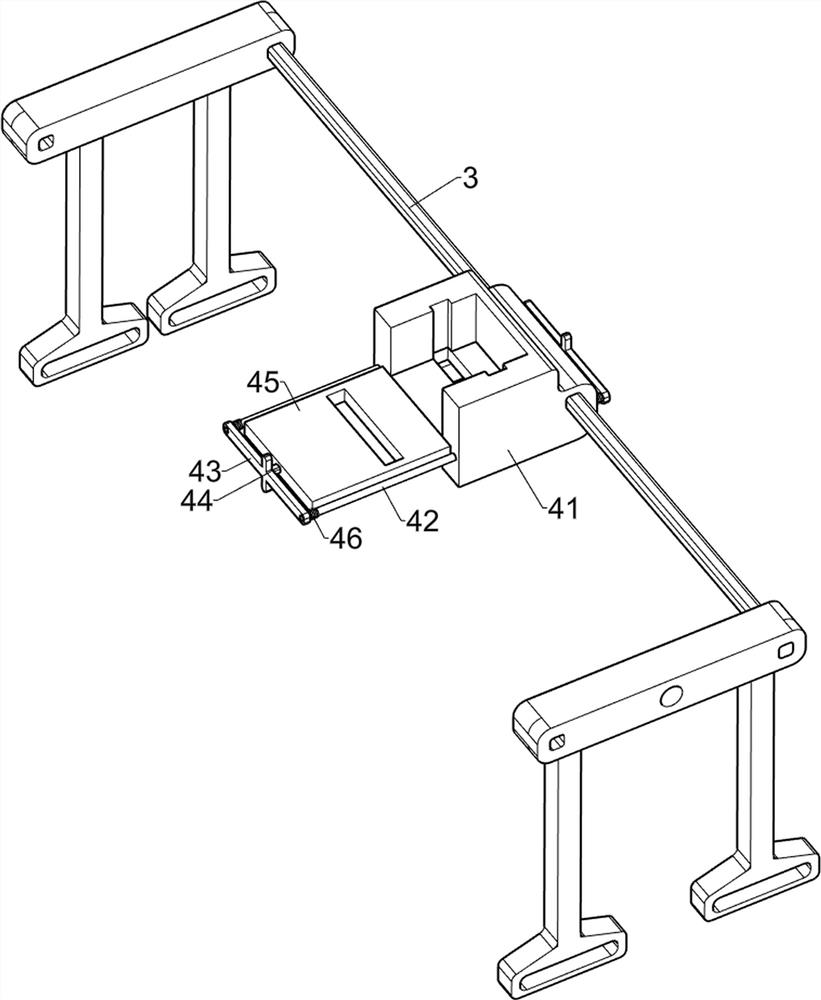

Rapid batch cutting equipment for perforated special-shaped metal pieces

PendingCN112719029AEasy Batch CuttingCutting effectMetal-working feeding devicesPositioning devicesMetal sheetFriction force

The invention relates to cutting equipment, in particular to rapid batch cutting equipment for perforated special-shaped metal sheets. According to the rapid batch cutting equipment for the perforated special-shaped metal sheets, iron sheets are easily fixed and limited from moving, the iron sheets are automatically conveyed, and metal sheets and waste materials are conveniently and uniformly collected. According to the technical scheme, the rapid batch cutting equipment for the perforated special-shaped metal pieces comprises a base, a cutting mechanism and a clamping mechanism; a top supporting frame is connected to the upper portion of the base; the cutting mechanism is arranged between the lower side of the middle of the top supporting frame and the upper portion of the base; and the clamping mechanism is arranged in the middle of one side of the top supporting frame. A spherical connecting rod is clamped into a dial, rotation of a rotating shaft is limited through friction force between the spherical connecting rod and the dial, the effect of limiting conveying of raw material iron sheets is achieved, the situation that the iron sheets cannot move to the accurate position due to inertia and other reasons is prevented, and accurate cutting of the metal pieces is guaranteed.

Owner:李昊儒

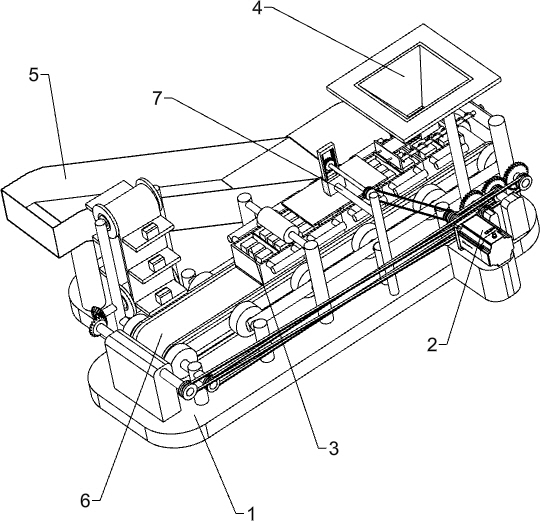

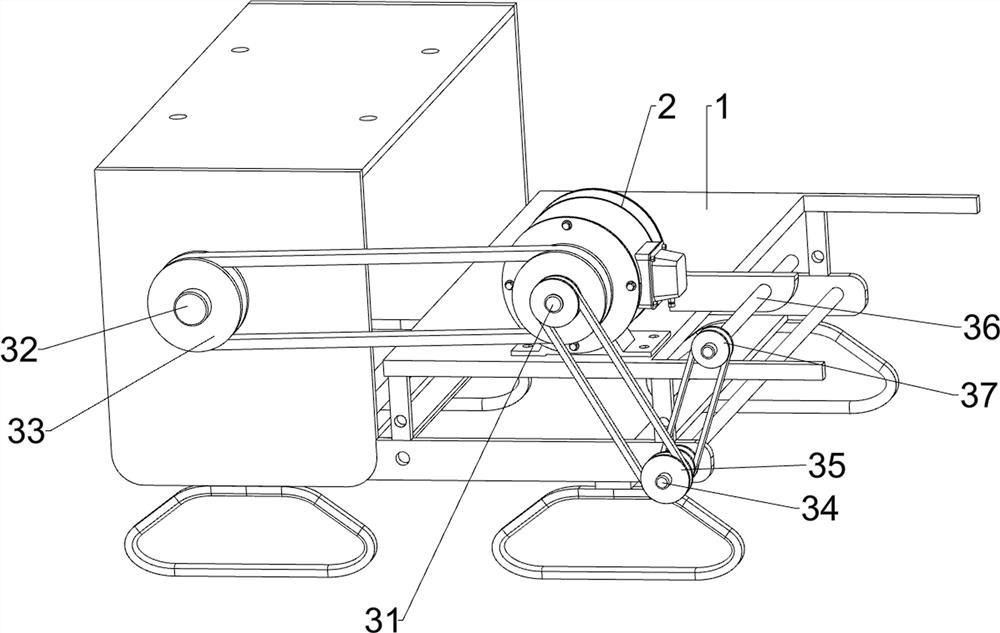

Shrink film sealing and cutting packaging machine

ActiveCN112644807AAchieve the effect of automatic sealing and cuttingLow costWrappers shrinkageEngineeringFriction force

The invention relates to a sealing and cutting packaging machine, in particular to a shrink film sealing and cutting packaging machine. The shrink film sealing and cutting packaging machine is easy to operate, saves time and labor and can reduce cost. The shrink film sealing and cutting packaging machine comprises a bottom plate, a sealing and cutting mechanism and a film conveying mechanism, wherein the sealing and cutting mechanism is arranged on the bottom plate, the film conveying mechanism is arranged on the bottom plate, and the sealing and cutting mechanism is connected with the film conveying mechanism. A sealing and cutting frame repeatedly slides up and down in a first guide frame through operation of an air cylinder, when the sealing and cutting frame moves downwards to make contact with a shrink film in the film conveying mechanism, the sealing and cutting frame seals and cuts the shrink film, and the automatic sealing and cutting effect is achieved; and a first rotating shaft rotates to drive a transmission assembly to rotate, then a second rotating shaft rotates, then a conveying assembly rotates, meanwhile, the conveying assembly makes contact with an oil painting plate and generates friction, and the friction force enables the oil painting plate to move leftwards, so that the automatic feeding effect is achieved, manual operation is replaced, time and labor are saved, and cost is reduced.

Owner:江西怡中堂生物科技有限公司

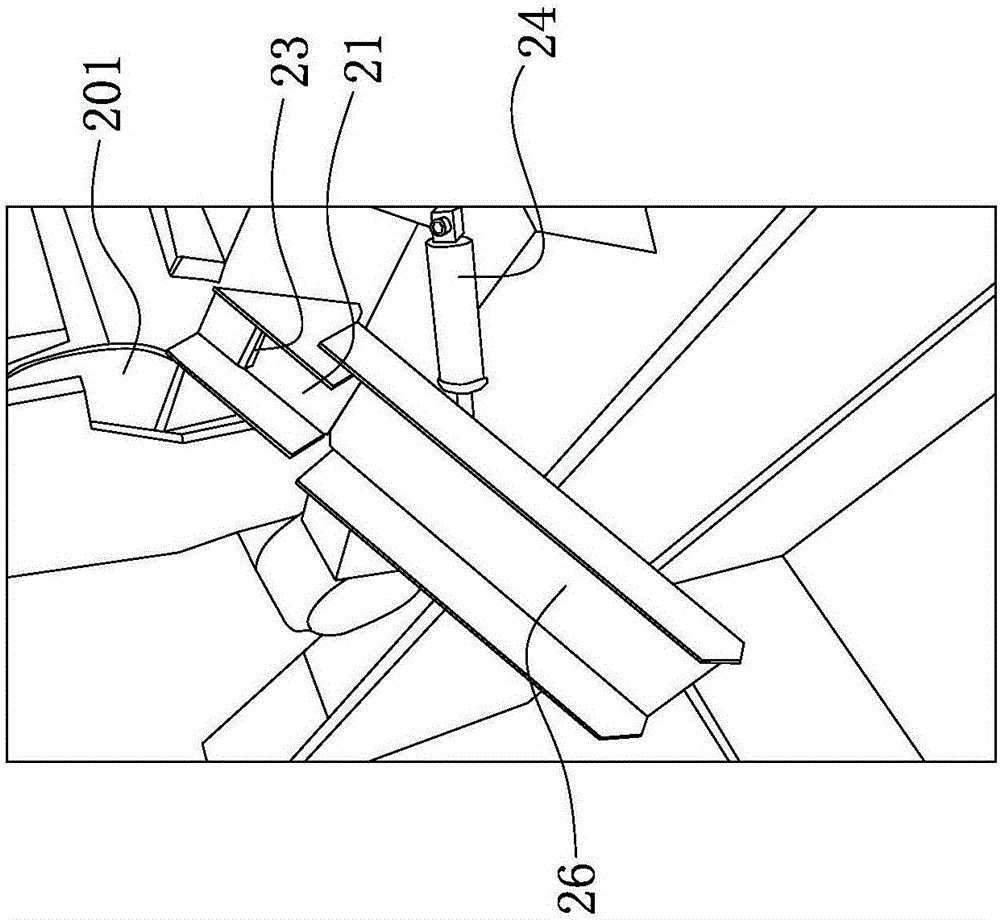

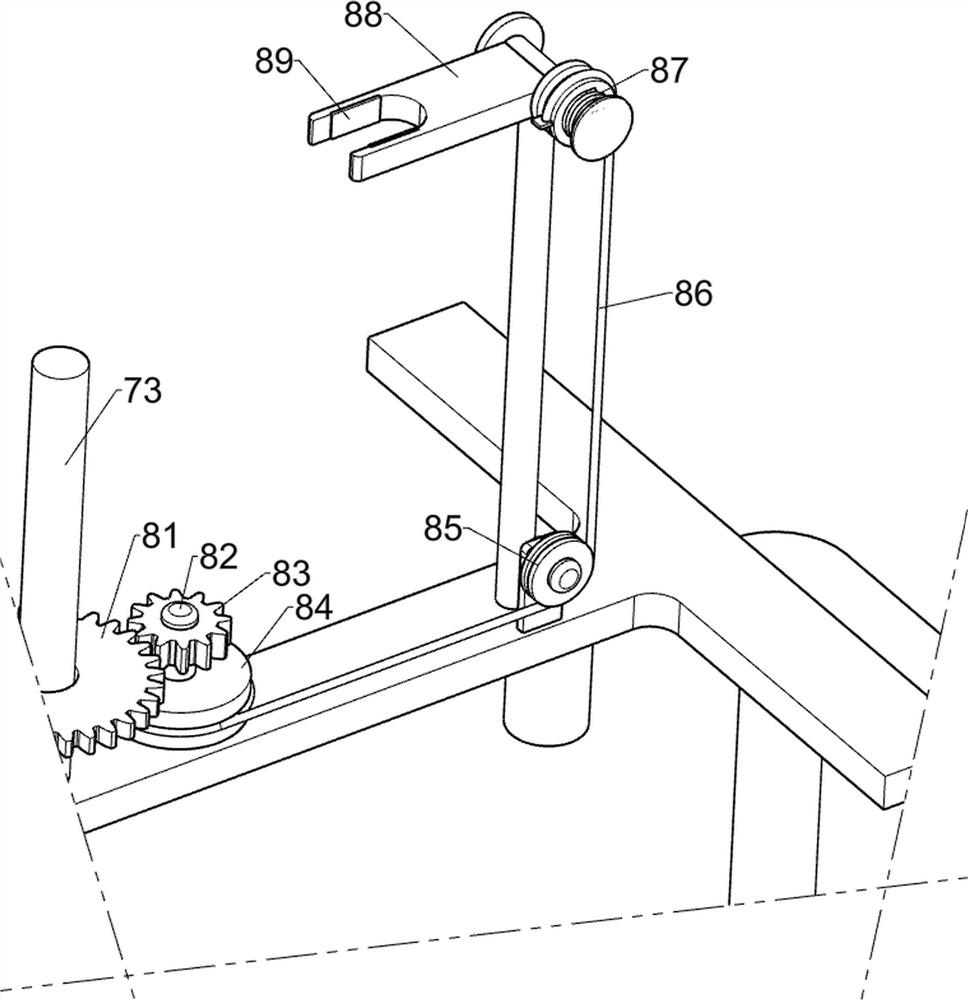

Hinge perforating machine with automatic feeding and correcting functions

InactiveCN105921601AEffect achievedAchieve the effect of automatic feedingMetal-working feeding devicesPositioning devicesGear wheelEngineering

The invention discloses a hinge perforating machine with automatic feeding and correcting functions. The hinge perforating machine comprises an operating floor. An automatic feeding mechanism and a perforating device are sequentially arranged at the top of the operating floor from left to right. The automatic feeding mechanism comprises a vibrating disk. A discharge outlet of the vibrating disk is connected with a first sliding groove, and the other end of the first sliding groove is connected with a second sliding groove. Two sets of correcting devices are arranged at the top of the operating floor. The two sets of correcting devices are located on the front side and the rear side of the first sliding groove respectively. Each correcting device comprises a storage box, and a storage cavity is formed in each storage box. Two turning wheels arranged in each storage cavity are connected through a soft toothed rail, and each soft toothed rail is provided with a toothed gear and a connecting block. A motor is arranged on the side face, deviating from the first sliding groove, of each storage box. The output end of each motor is connected with the corresponding toothed gear through a rotating shaft. By the adoption of the hinge perforating machine, working efficiency is improved, defective goods caused by inaccuracy of the perforating positions are prevented, and therefore economic losses are avoided.

Owner:WUXI HUISHAN HELI HEAT TRANSFER EQUIP FACTORY

Energy-saving and environment-friendly kitchen waste treatment device

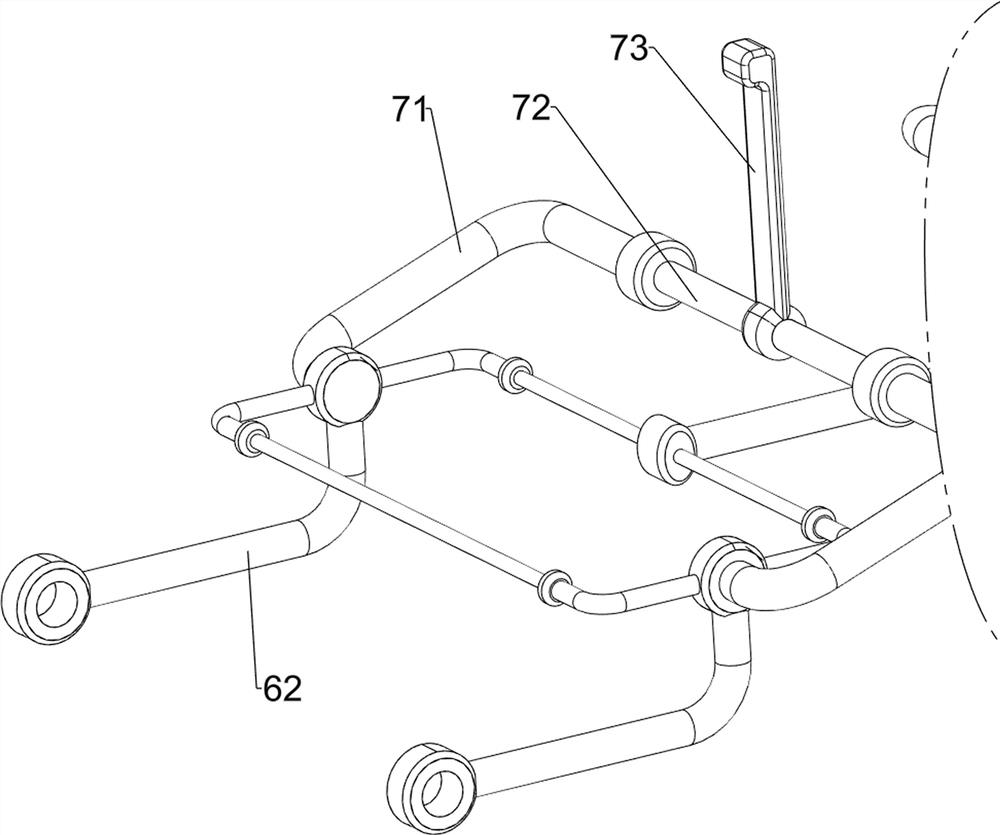

PendingCN112625872ATo achieve the purpose of solid-liquid separationAchieve the effect of automatic feedingBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringWaste treatment

The invention relates to a treatment device, in particular to an energy-saving and environment-friendly kitchen waste treatment device. The energy-saving and environment-friendly kitchen waste treatment device is capable of realizing automatic stirring, automatic and intermittent discharging and automatic feeding. The energy-saving and environment-friendly kitchen waste treatment device comprises a base, a supporting block arranged on the base, a first fixed frame arranged on the base, a filtering mechanism arranged on the supporting block, and a stirring mechanism arranged at the top of the first fixed frame and connected with the filtering mechanism. According to the invention, a roller on the rear side drives a bevel gear set to rotate, the bevel gear set rotates to drive a fourth rotating shaft to rotate, then a first transmission assembly rotates, a first rotating shaft rotates to enable a stirring block to move, the stirring block stirs waste and a catalyst to be fully mixed, and therefore the purpose of automatic stirring is achieved.

Owner:邱小芳

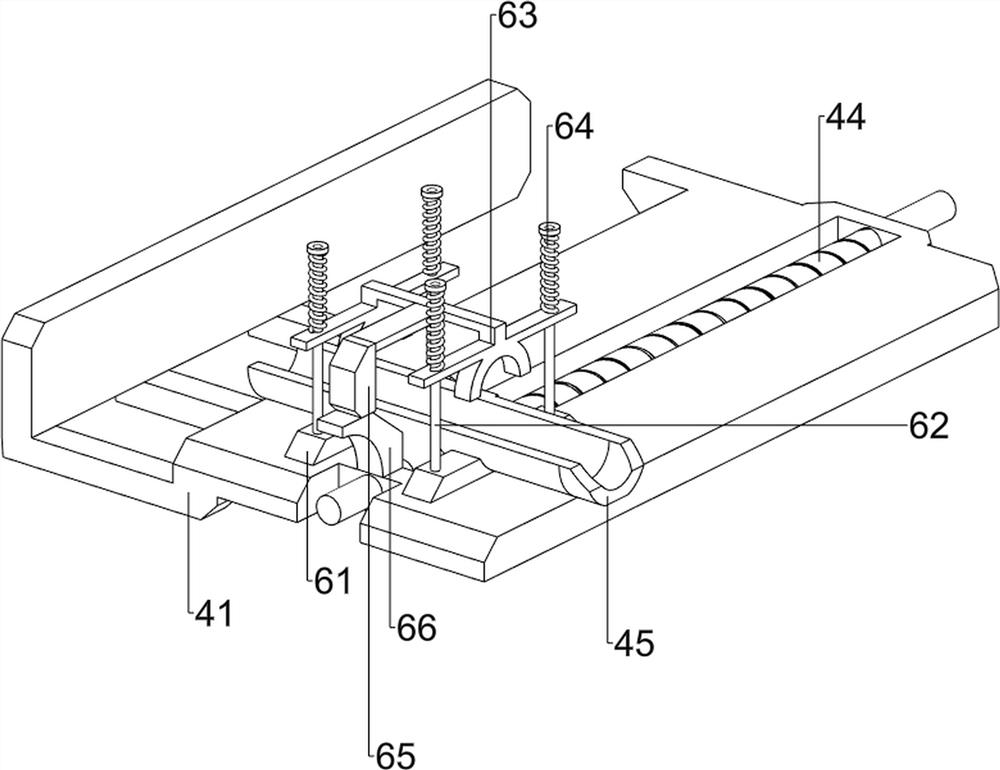

Automatic stamping equipment for chain safety production

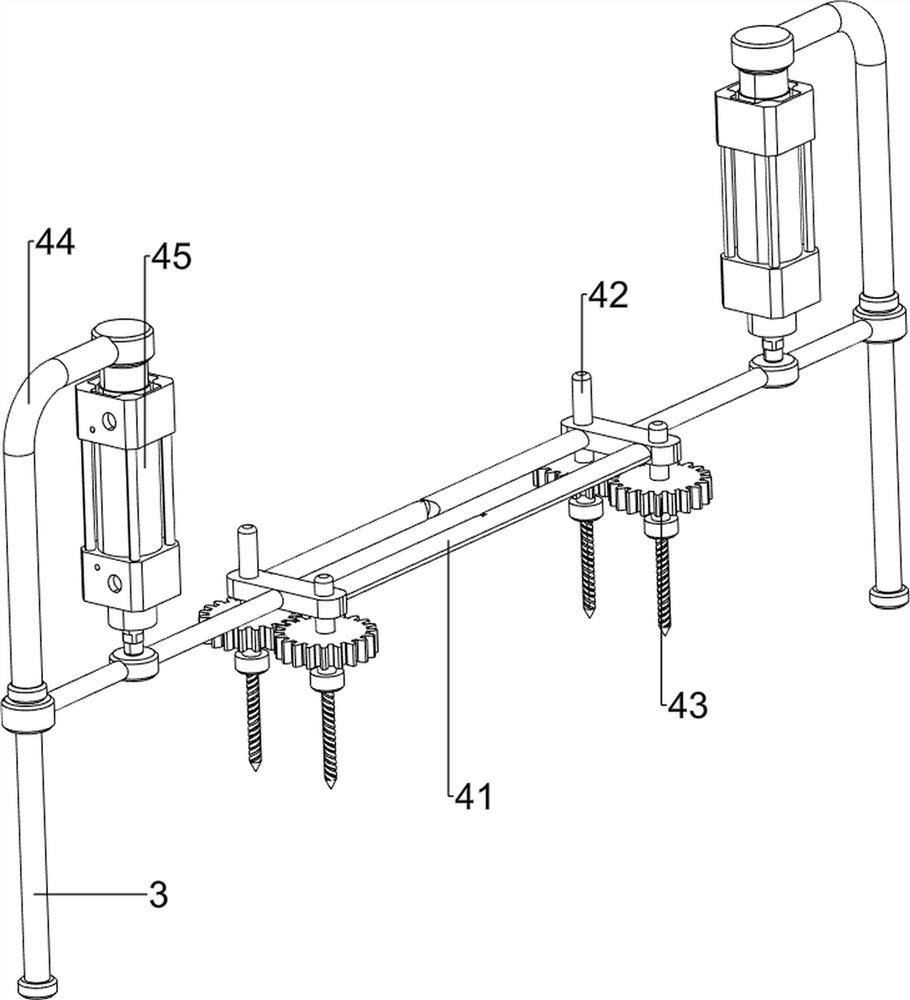

PendingCN112404240AQuick punchShorten the timePerforating toolsMetal-working feeding devicesStampingChain link

The invention relates to automatic stamping equipment, in particular to automatic stamping equipment for chain safety production. The automatic punching equipment for chain safety production is high in steel plate punching efficiency and capable of achieving automatic feeding; The automatic stamping equipment for chain safety production comprises a bottom frame, a working plate, a punching mechanism and a discharging mechanism, wherein the working plate is arranged on the bottom frame; the punching mechanism is arranged on the working plate; and the discharging mechanism is arranged on the working plate. According to the automatic punching equipment, the effect of quickly punching a steel plate is achieved, the pressed and punched steel plate is punched through cooperation of the punchingmechanism and a pressing mechanism, a roll of steel plate is quickly punched, the manual punching time is shortened, and the working efficiency is improved; and meanwhile, automatic feeding of the steel plate is completed through cooperation of the discharging mechanism, a main pulling mechanism and an auxiliary pulling mechanism, the steel plate is output from the discharging mechanism, and leftward movement of the steel plate is achieved through cooperation of the main pulling mechanism and the auxiliary pulling mechanism.

Owner:谢胜

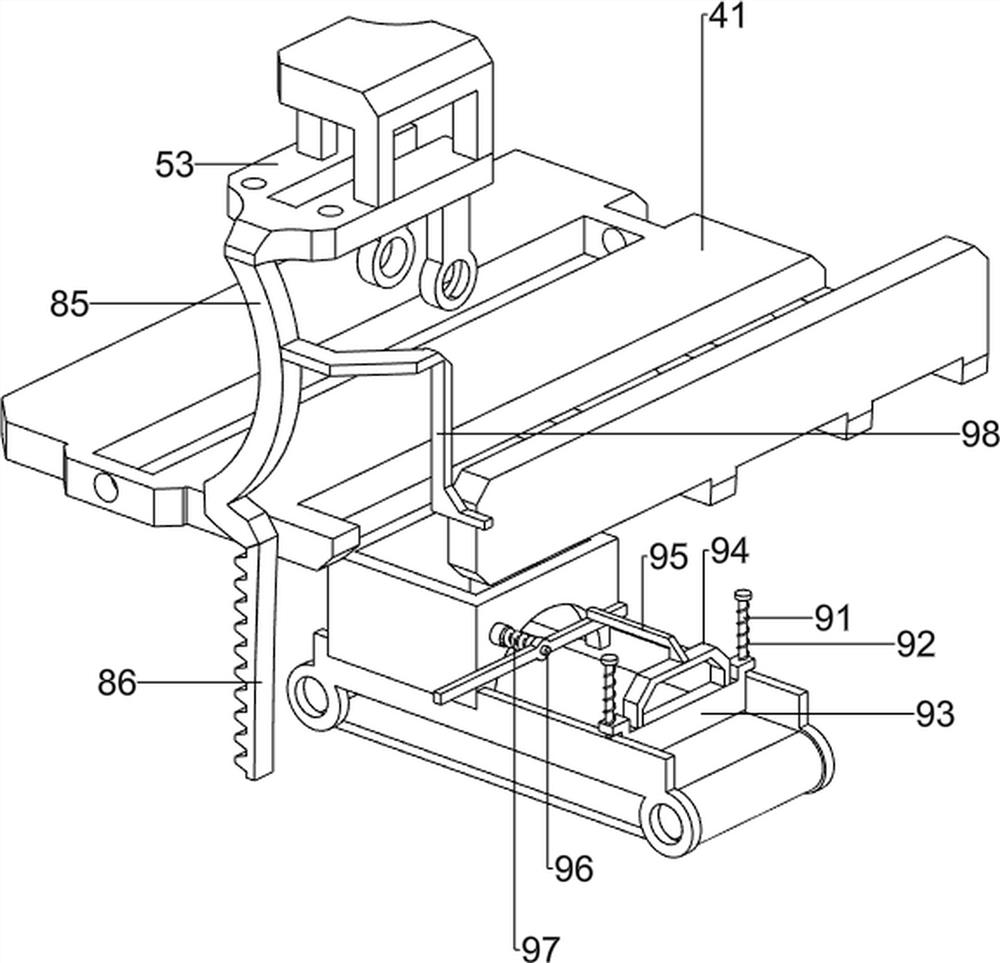

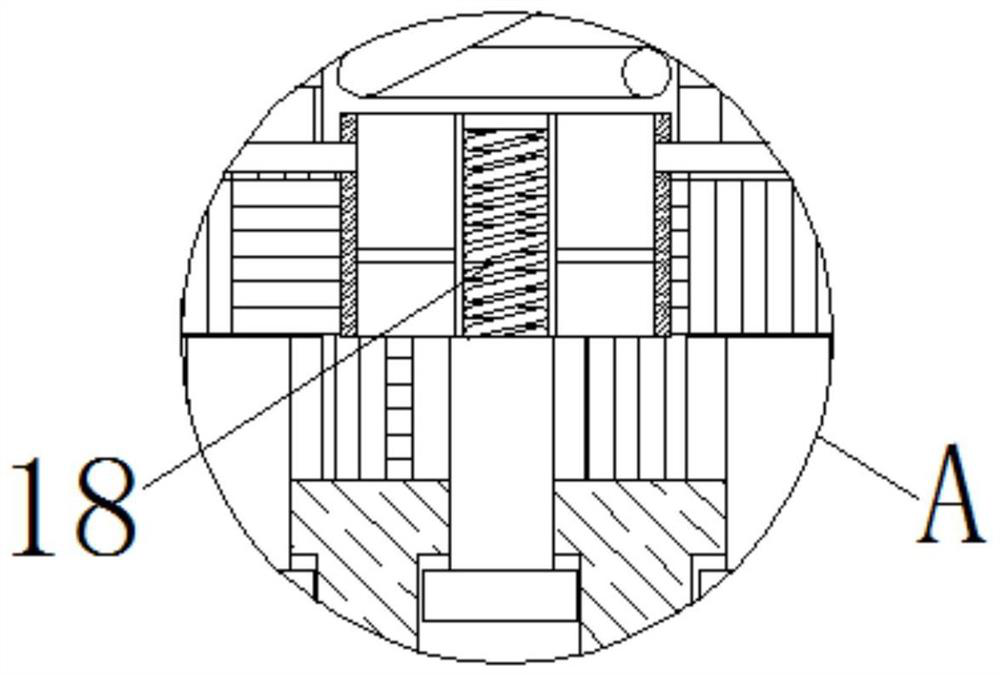

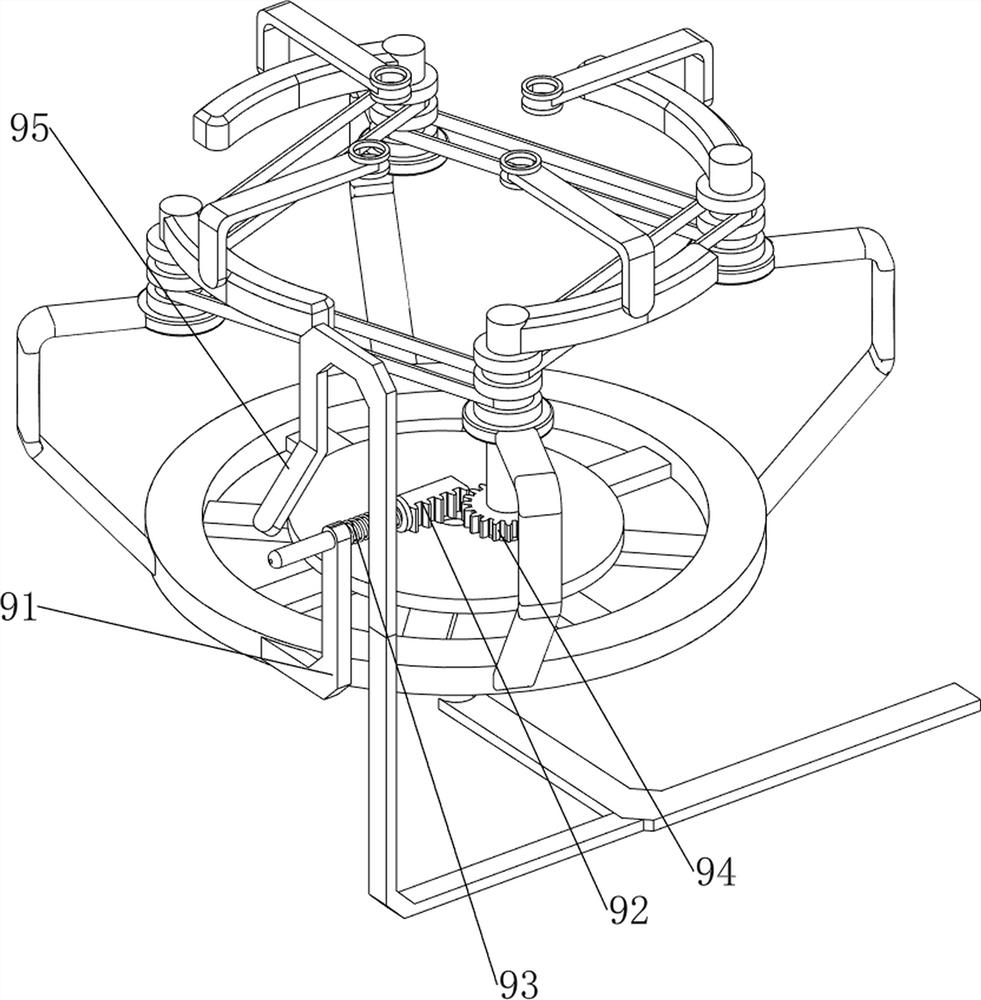

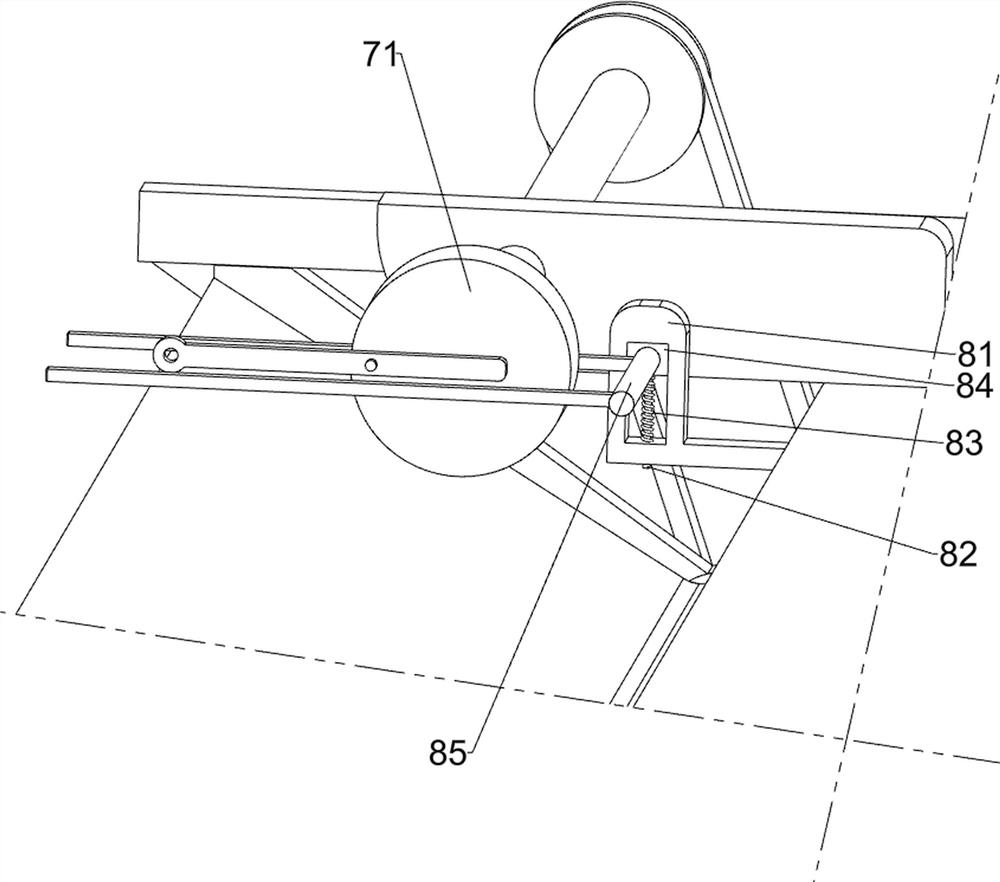

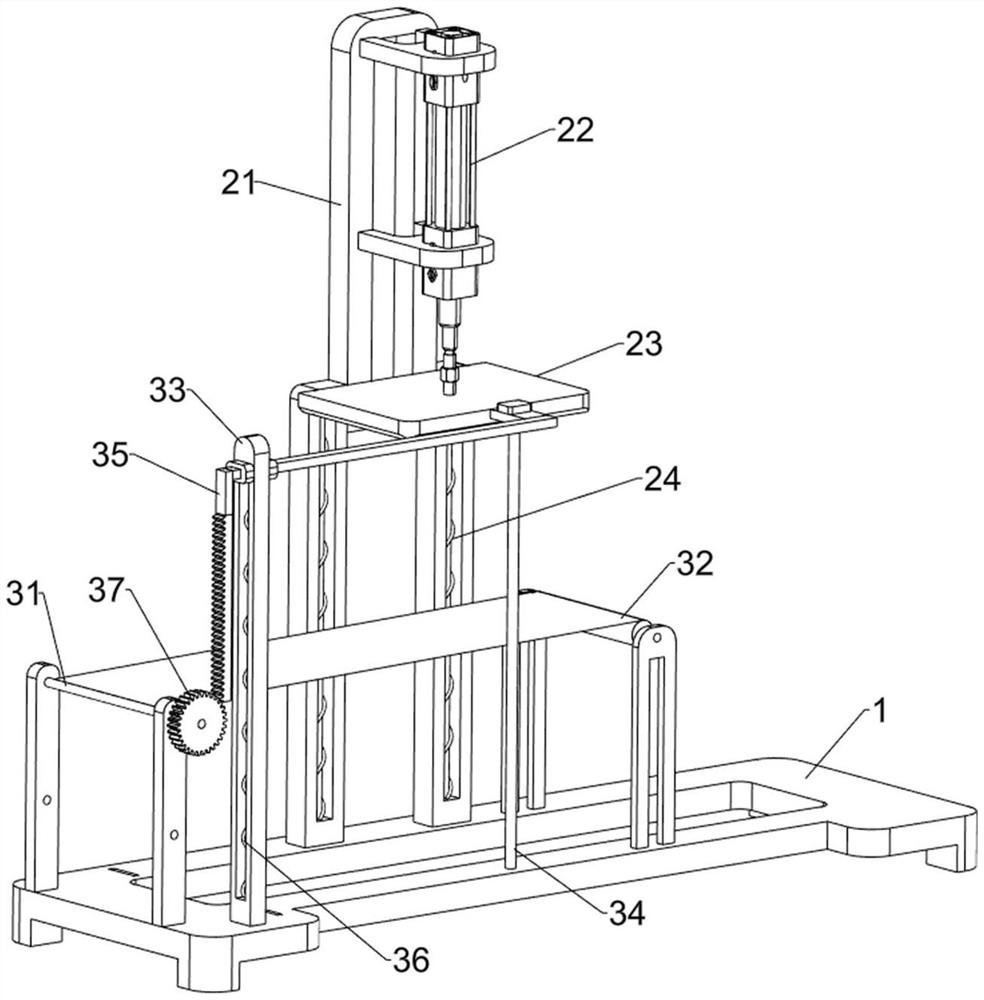

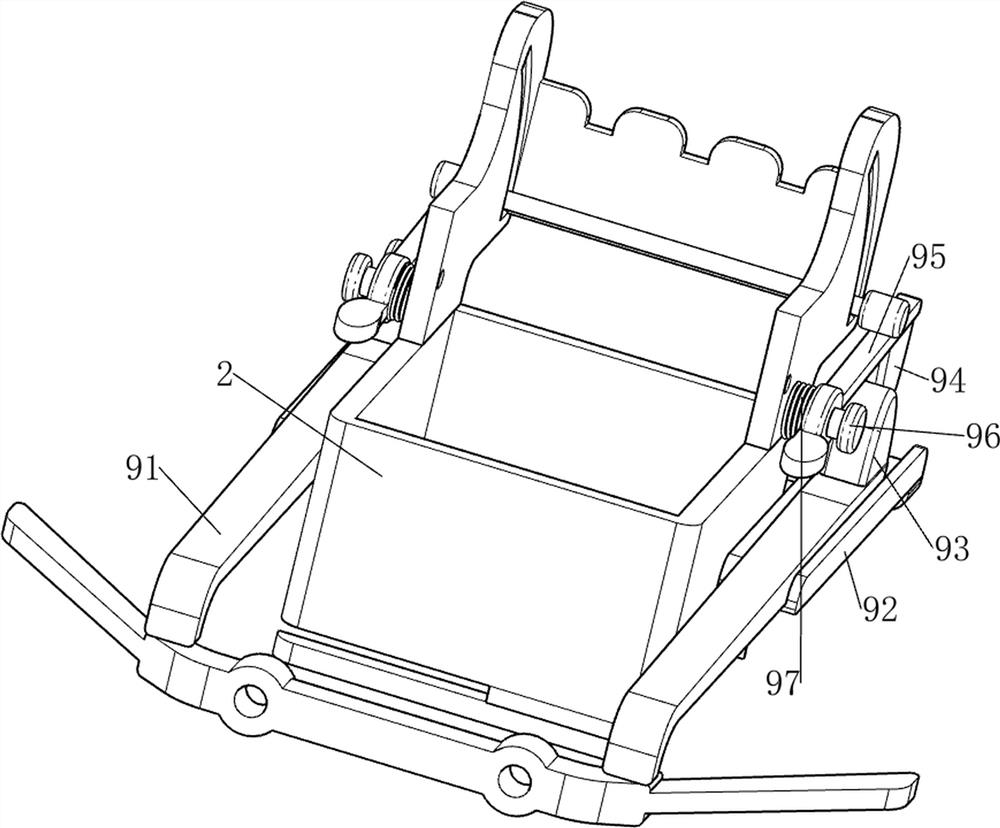

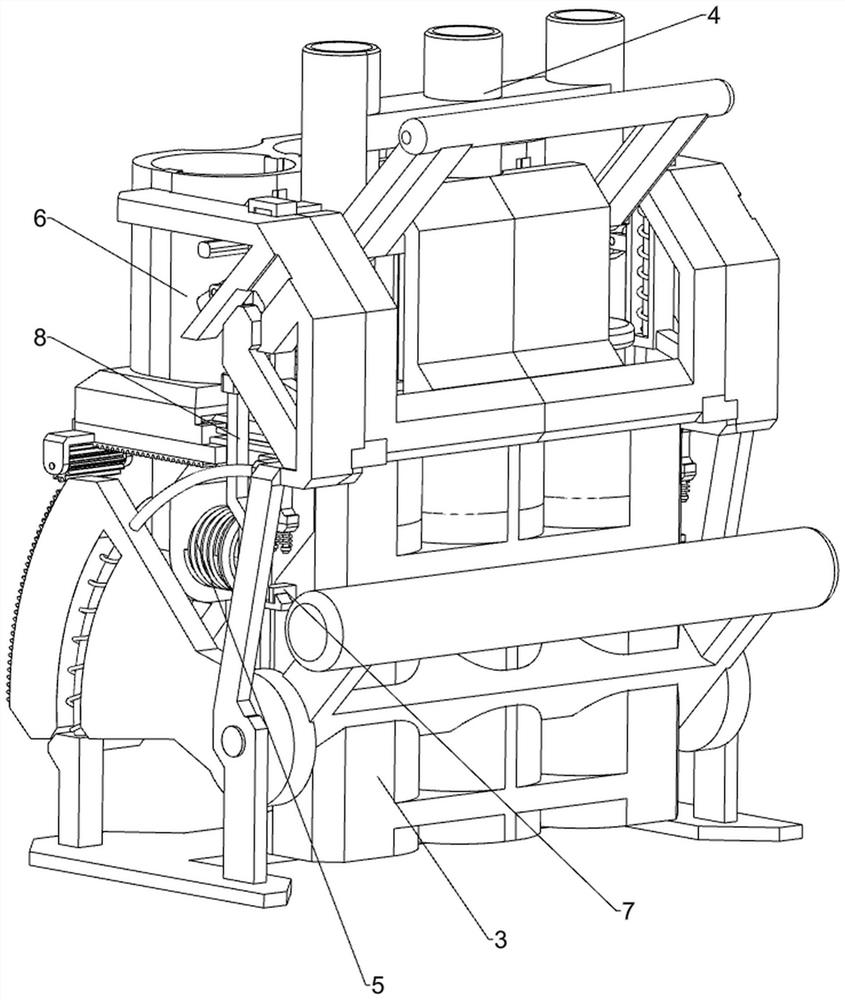

Metal plate riveting and punching device for industrial production

ActiveCN113351905AAchieve the effect of automatic punchingEasy to punchPositioning apparatusMetal working apparatusPunchingEngineering

The invention relates to a punching device, in particular to a metal plate riveting and punching device for industrial production. According to the metal plate riveting and punching device for industrial production provided in the invention, automatic feeding and automatic punching can be achieved, and the punching precision can be improved. A metal plate riveting and punching device for industrial production comprises a base, first supporting frames and first sliding rails, wherein the two first supporting frames are arranged on the base, the first sliding rails are arranged at the tops of the two first supporting frames, a drilling mechanism is connected between the two first sliding rails, and a rotating mechanism is arranged on the drilling mechanism. By arranging the drilling mechanism and the rotating mechanism, people enable the drilling mechanism to partially operate and enable the rotating mechanism to operate, and the rotating mechanism operates to enable the drilling mechanism to completely operate, so that a metal plate is drilled and the automatic drilling effect is achieved; and by arranging a pressing mechanism, people enable the pressing mechanism to operate, so that the metal plate is pressed; and in this way, the punching precision can be improved.

Owner:明光市瑞佳机械科技有限公司

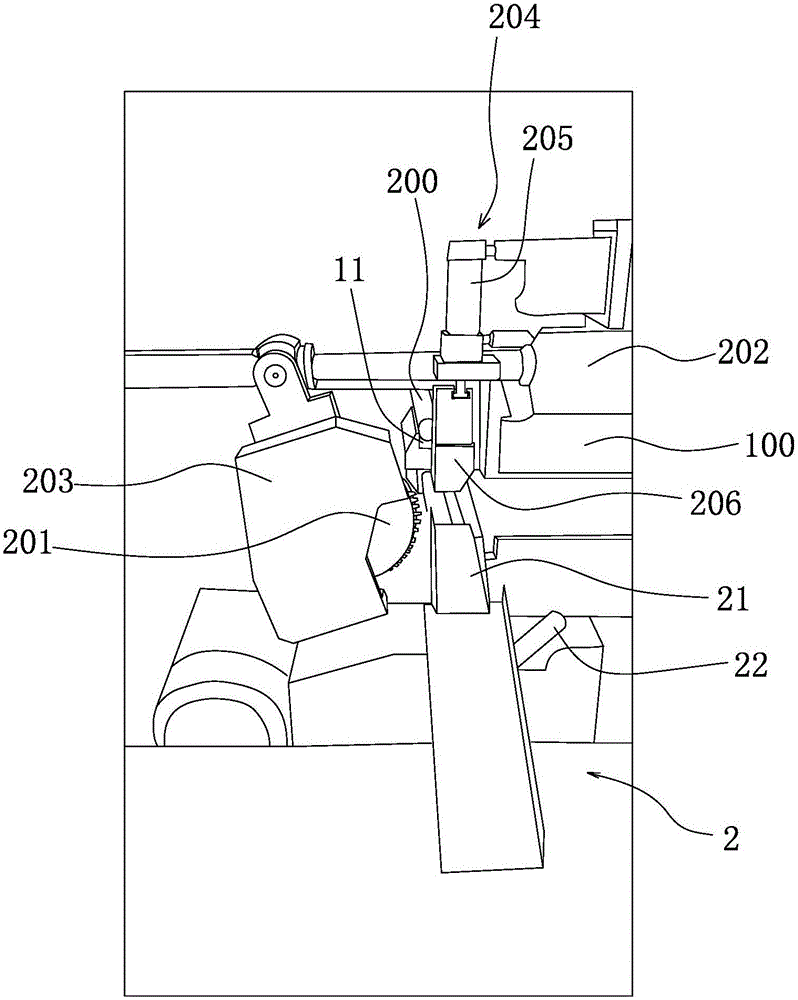

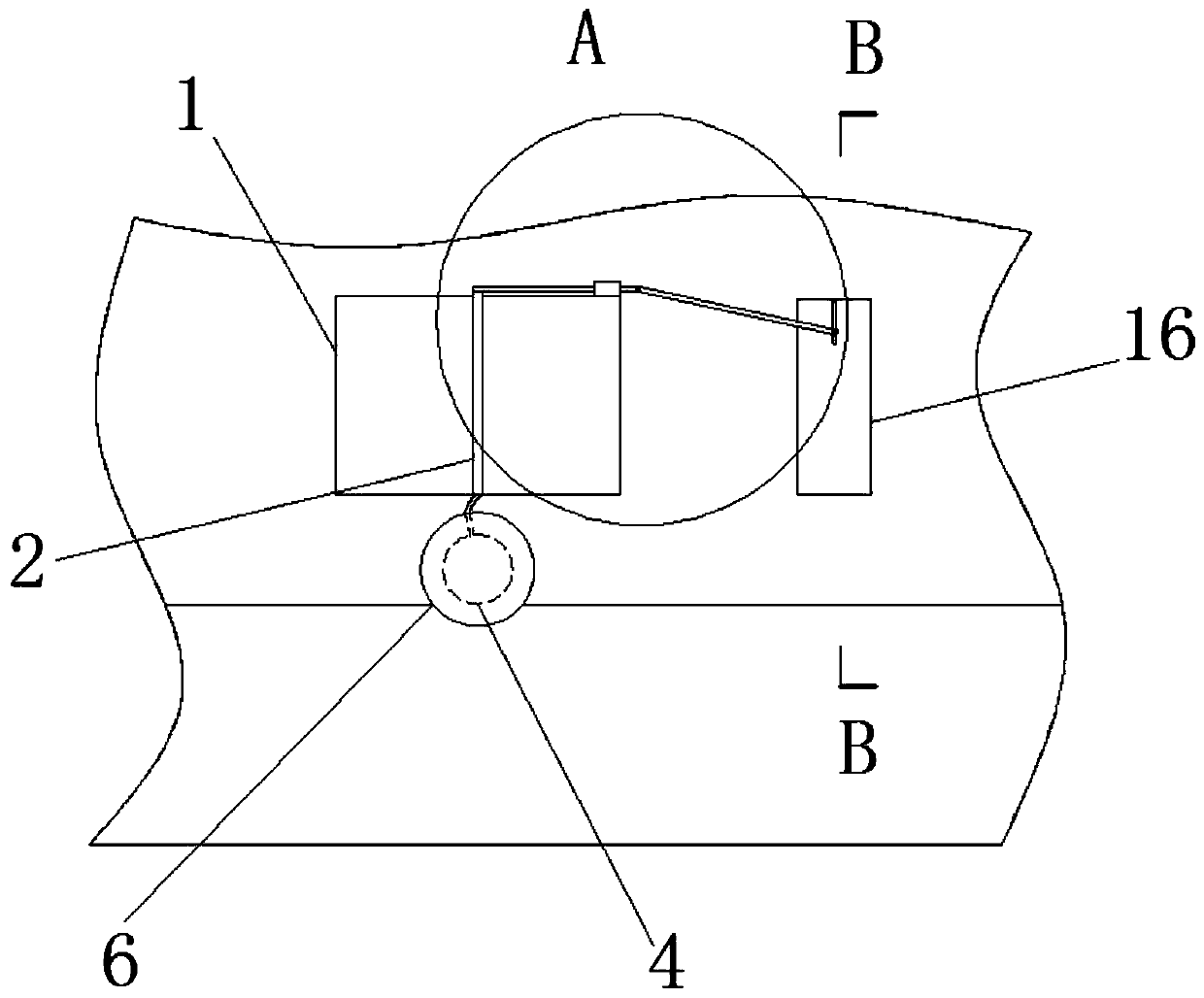

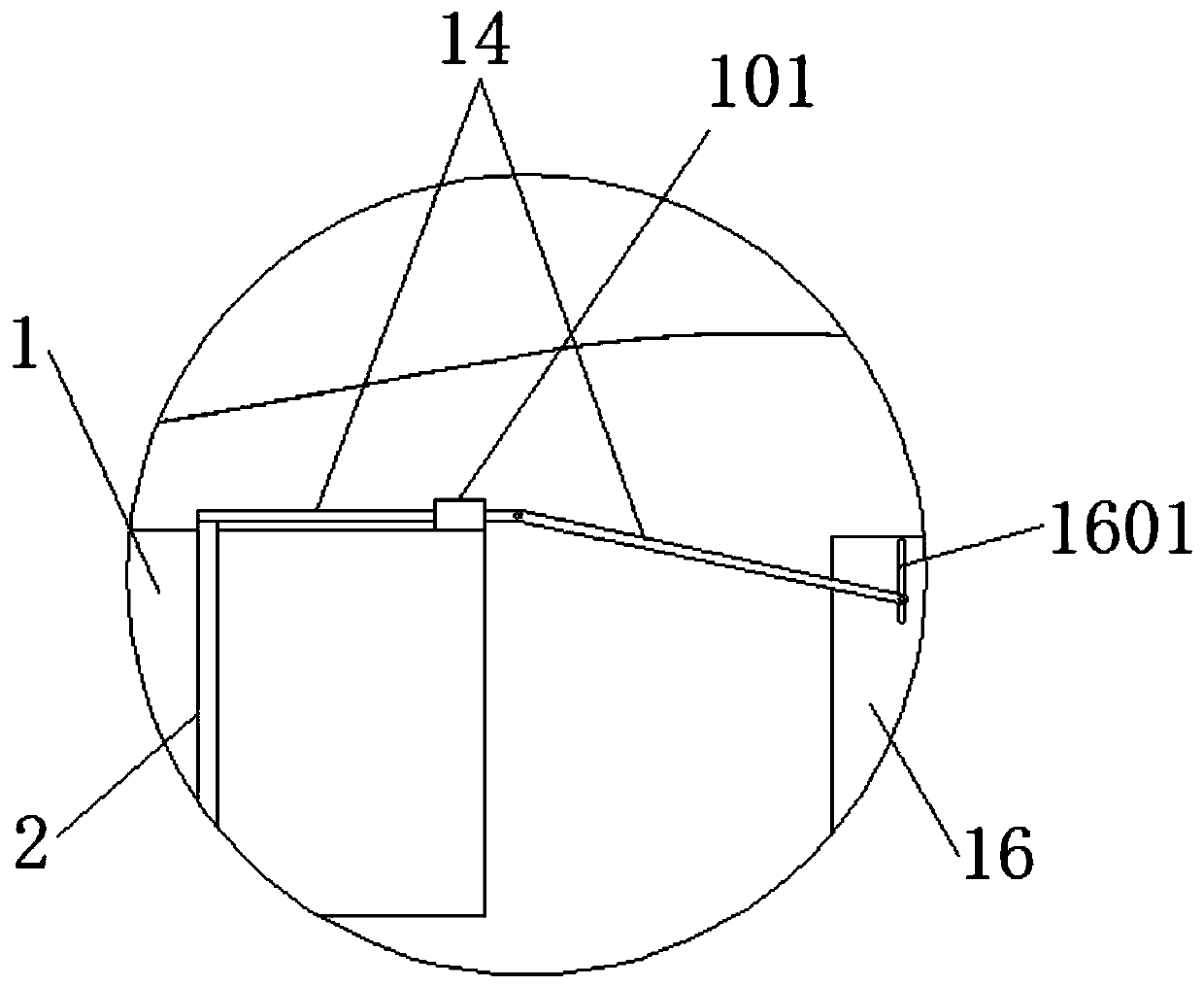

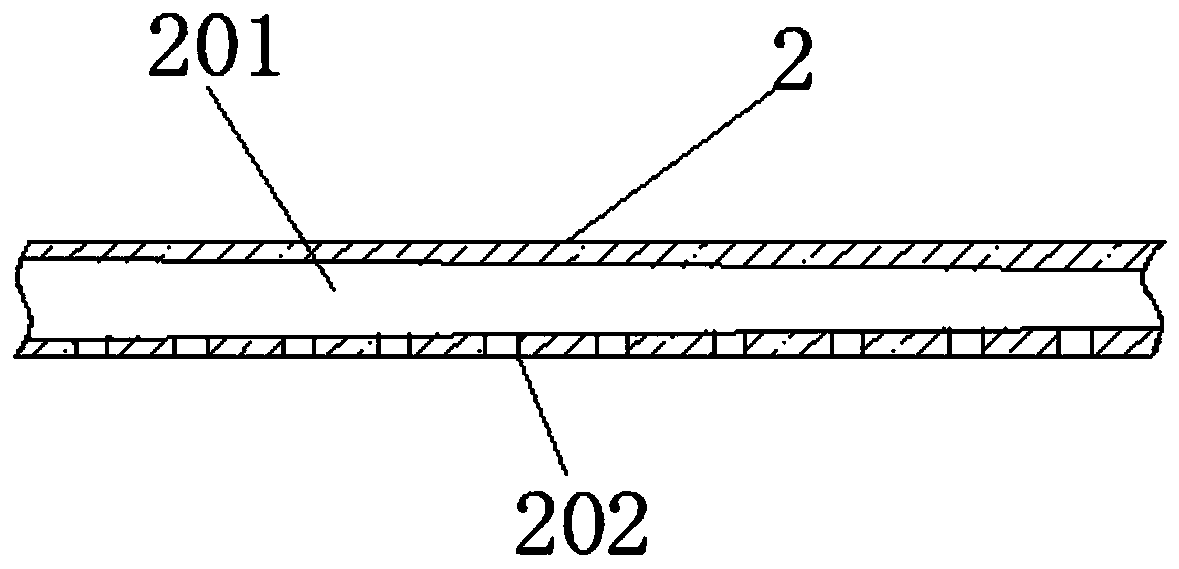

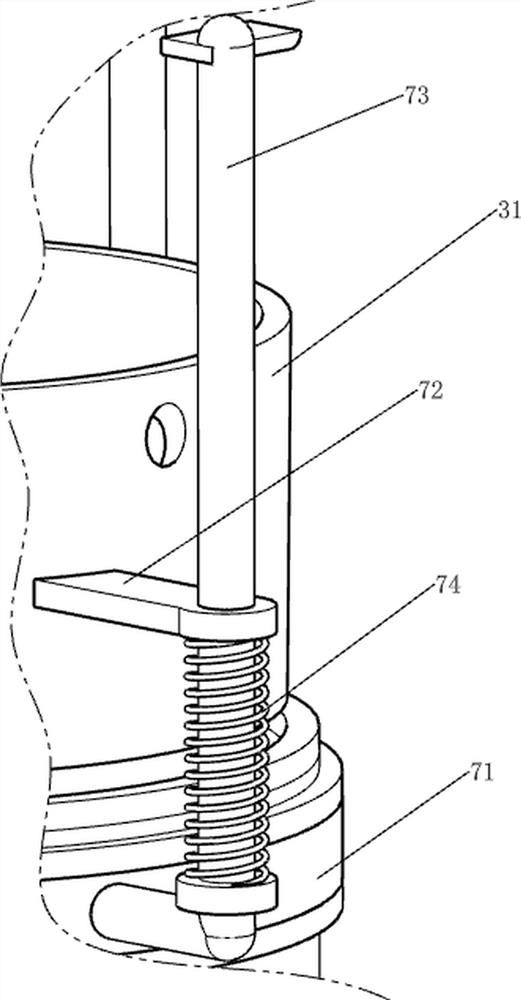

Adjustable Chinese yam slicing device

InactiveCN107160446AEnsure safetyAchieve the effect of automatic feedingMetal working apparatusSlice thicknessMechanical engineering

The invention relates to the technical field of food processing equipment, in particular to an adjustable Chinese yam slicing device comprising a rack (1). The rack (1) is provided with a feeding channel (2) and a cutter mechanism (3). The feeding channel (2) is arranged obliquely. A material retaining plate (4) is arranged at the oblique tail end of the feeding channel (2). The cutter mechanism (3) is located between the feeding channel (2) and the material retaining plate (4). The material retaining plate (4) is connected with a thickness adjusting mechanism mounted on the rack (1) so as to adjust the distance between the material retaining plate (4) and the cutter mechanism (3). A gap is reserved between the material retaining plate (4) and the feeding channel (2) to form a material falling opening (5). According to the adjustable Chinese yam slicing device, the shape characteristic of a Chinese yam is utilized, automatic feeding and slicing are achieved, the labor cost is saved, the slicing thickness can be further adjusted, and the adjustable Chinese yam slicing device has large popularization prospects.

Owner:桂平市金田镇旷福淮山种植专业合作社

Distributed energy system based on blockchain technology

InactiveCN111066708ASolve the waste of electricityAvoid electricity supplyClimate change adaptationAgricultural fishingNew energyMarine engineering

The invention relates to the technical field of new energy breeding equipment, and discloses a distributed energy system based on a blockchain technology. The distributed energy system comprises a breeding frame, wherein a fan blade plate is arranged at the outer side of the central part of a second rotating shaft; a sliding plate is connected with and arranged at the rear end of the second rotating shaft; a sliding block is respectively arranged at the upper and lower ends of the sliding plate; a rotating column is arranged at the upper part of the sliding block located at an upper end position; a spring is respectively arranged at the rear end of the sliding plate and the rear end of a water power generation box; and second fixed frames are arranged at the lower end of the water power generation box and located underwater. According to the invention, the fan blade plate drives the second rotating shaft to rotate, and centrifugal forces generated by the fan blade plate driven by different water flow speeds are different, so the fan blade plate pushes a sliding plate to be at different positions on the water power generation box; and connecting rods are driven to move through sliding blocks and a rotating column on the sliding plate, and a guide sleeve guarantees that the connecting rod located at a left end position moves for a large distance, so the movement track of a fish feed in water is guaranteed to fall into a fishing net as much as possible, and waste of the fish feed is further avoided.

Owner:南京优米亚信息科技有限公司

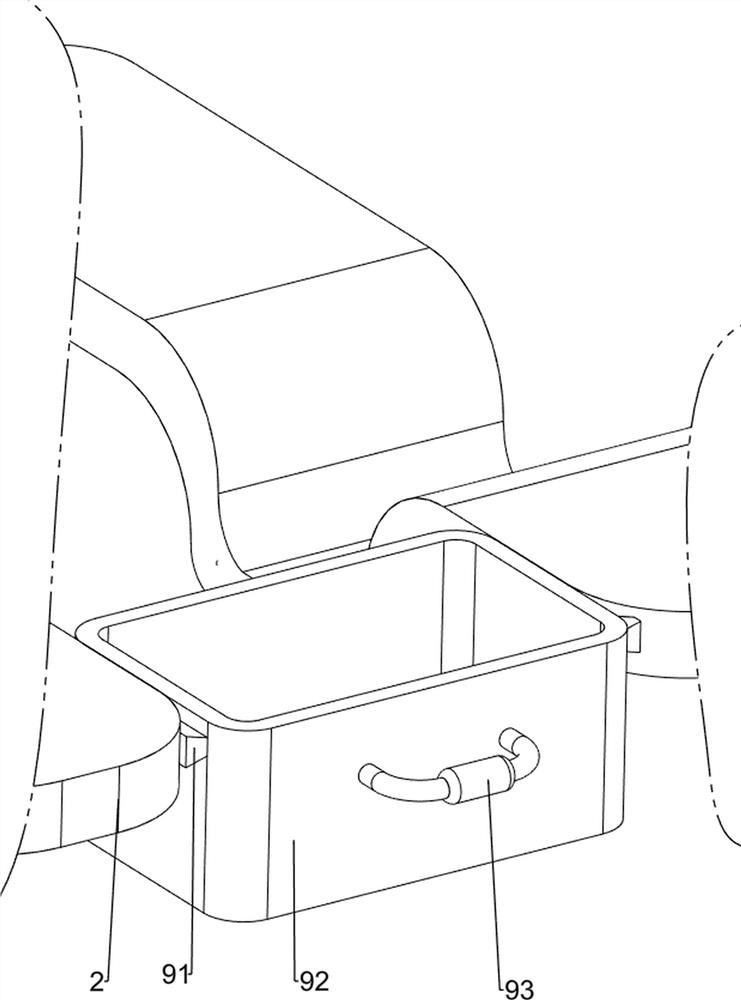

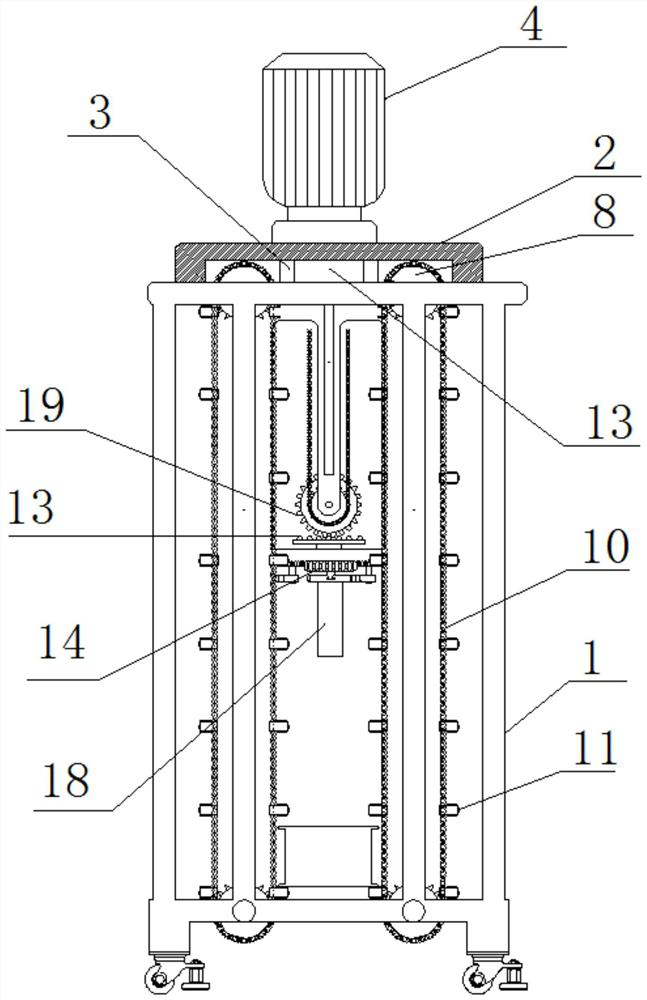

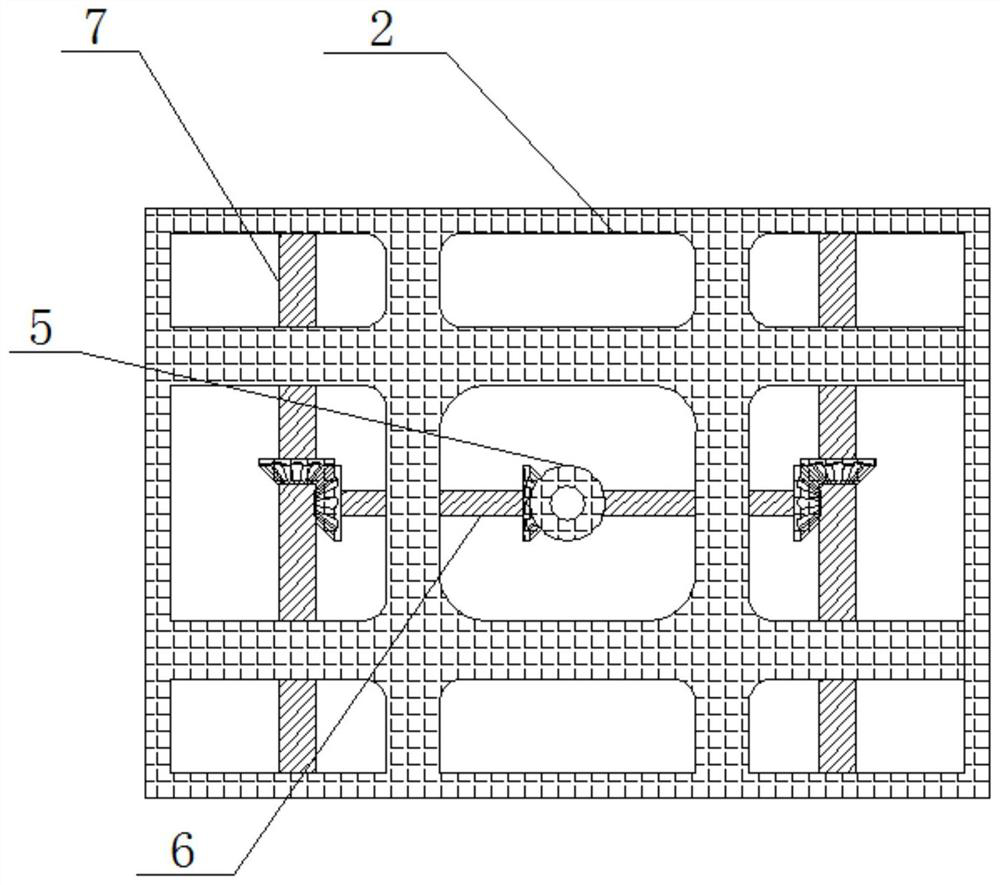

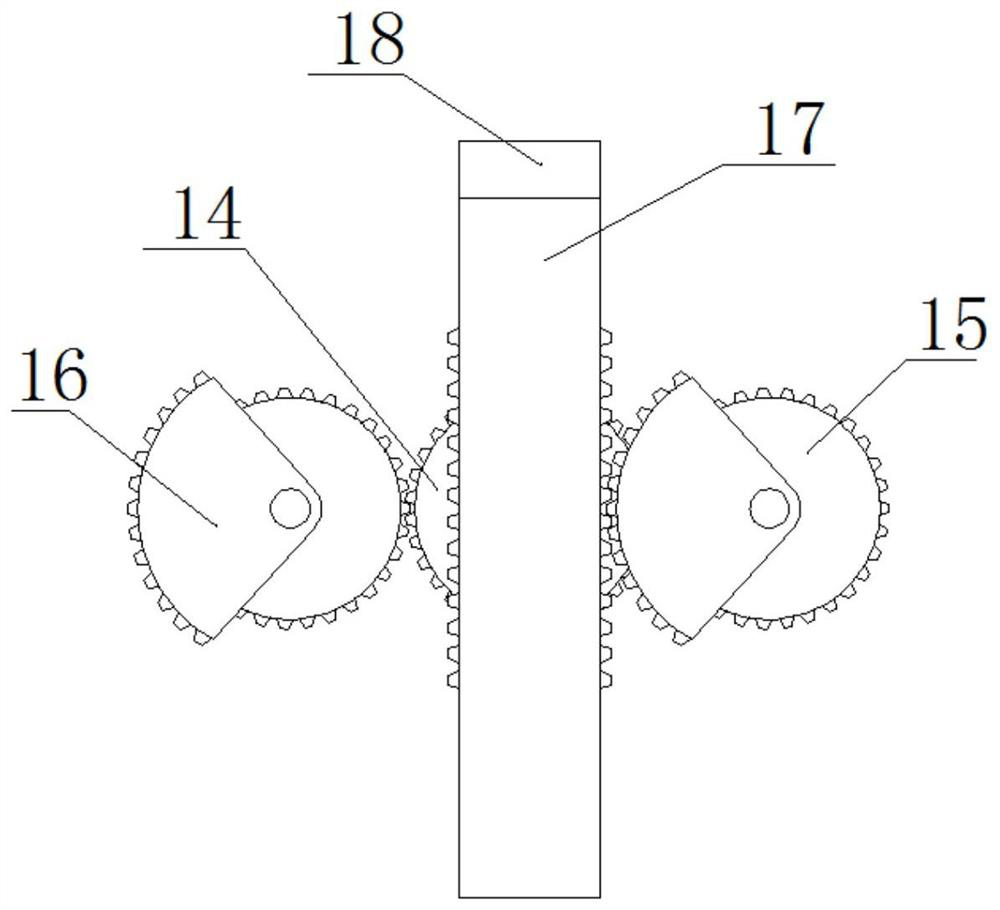

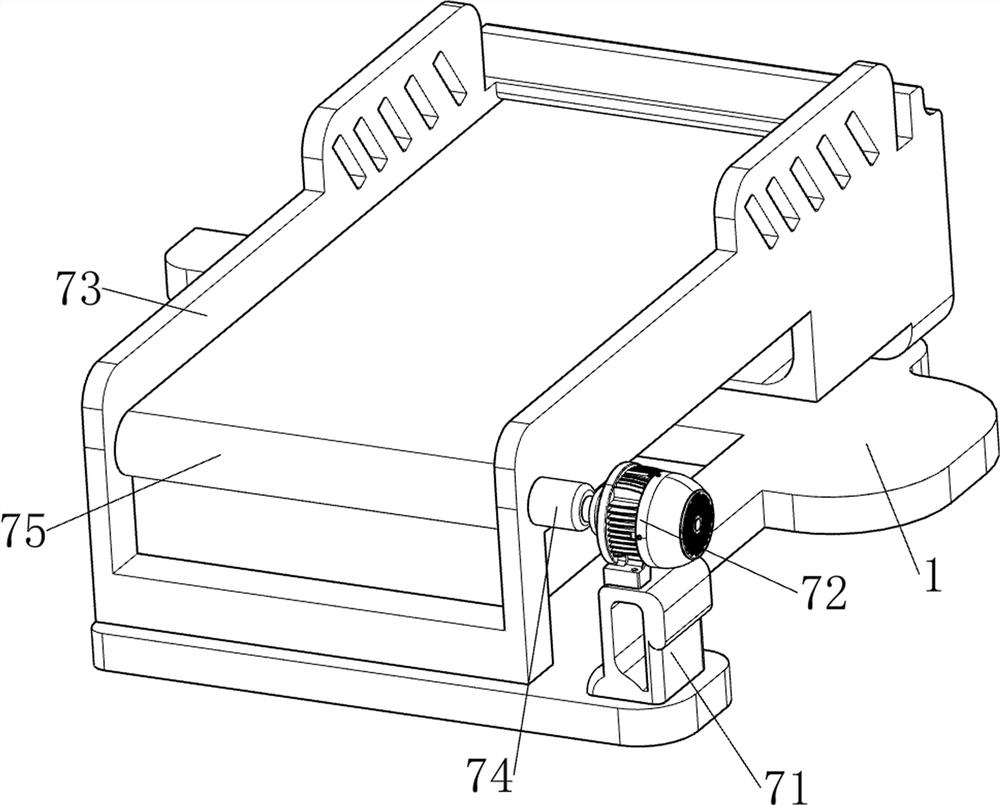

Fruit turnover box vehicle-ground transferring mechanism

ActiveCN111806965ASmooth liftAchieve the effect of automatic feedingConveyorsDrive wheelElectric machinery

The invention relates to the technical field of transportation and discloses a fruit turnover box vehicle-ground transferring mechanism which comprises a rack; a motor bracket is fixedly connected with the top of the rack; a feeding bracket is fixedly connected with the bottom of the motor bracket; a lifting motor is fixedly connected with the top of the motor bracket; a driving wheel is rotatablyconnected with the bottom of the lifting motor; a transmission wheel is rotatably connected with the bottom of the motor bracket; a driven wheel is rotatably connected into the rack; and a left chainwheel and a right chain wheel are fixedly connected with the outer side of the driven wheel. According to the fruit turnover box vehicle-ground transferring mechanism, the lifting motor drives the driving wheel to rotate, the driving wheel drives the transmission wheel to rotate, the transmission wheel drives the driven wheel to rotate, the driven wheel drives the left chain wheel and the right chain wheel to rotate, the left chain wheel and the right chain wheel drives a transmission chain to rotate, the transmission chain drives an idler wheel plate to move, and through cooperative application of a movable idler wheel and other mechanisms, a stable lifting effect is realized.

Owner:南京丰浩华食品供应链管理有限公司

Municipal domestic kitchen garbage treatment device

PendingCN113334822ATo achieve the squeeze effectTo achieve the feeding effectPressesClimate change adaptationProcess engineeringRefuse Disposals

The invention relates to a treatment device, in particular to a municipal domestic kitchen garbage treatment device. The municipal domestic kitchen garbage treatment device can realize automatic compression, automatic discharging and automatic conveying. The municipal domestic kitchen garbage treatment device comprises a bottom frame, an extrusion frame, a material baffle, first extrusion plates, compression mechanisms and an overturning mechanism. The extrusion frame is arranged on the bottom frame. The material baffle is arranged on the extrusion frame in a sliding manner. The first extrusion plates are arranged on the two sides in the extrusion frame in a sliding manner. The compression mechanisms are arranged between the extrusion frame and the first extrusion plates. The overturning mechanism is arranged at the upper part of the extrusion frame. According to the municipal domestic kitchen garbage treatment device, first sliding rods and the first extrusion plates move towards the inner side, first springs are compressed, then the two first extrusion plates move oppositely to extrude garbage, and the extrusion effect is achieved.

Owner:张庆忠

Plastic bottle production device for food processing

PendingCN112497715AIncrease productivityTo achieve the purpose of automatic opening and closingDomestic articlesHollow articlesProcess engineeringHeating effect

The invention relates to a production device, and particularly relates to a plastic bottle production device for food processing. The plastic bottle production device for food processing saves time and labor, and is high in efficiency and stable in bottle blowing. The plastic bottle production device for food processing comprises a bottom plate, a first supporting frame, an air cylinder and a blowmolding assembly, wherein the first supporting frame is arranged on the bottom plate; the air cylinder is arranged on the first supporting frame; and the blow molding assembly is arranged on the first supporting frame, and the blow molding assembly is connected with the air cylinder. According to the plastic bottle production device for food processing, an air nozzle moves downwards, the air nozzle is matched with a mold, so that air is sprayed to raw materials, the raw materials are subjected to blow molding, the automatic blow molding effect is achieved, a teeth-uncomplated gear is meshed with a first gear, the teeth-uncomplated gear rotates to drive the first gear to rotate, a rotary disc rotates, and then the raw materials move, when the raw materials pass through a heating device, the heating device heats the raw materials, the automatic heating effect is achieved, and time and labor are saved.

Owner:林超辉

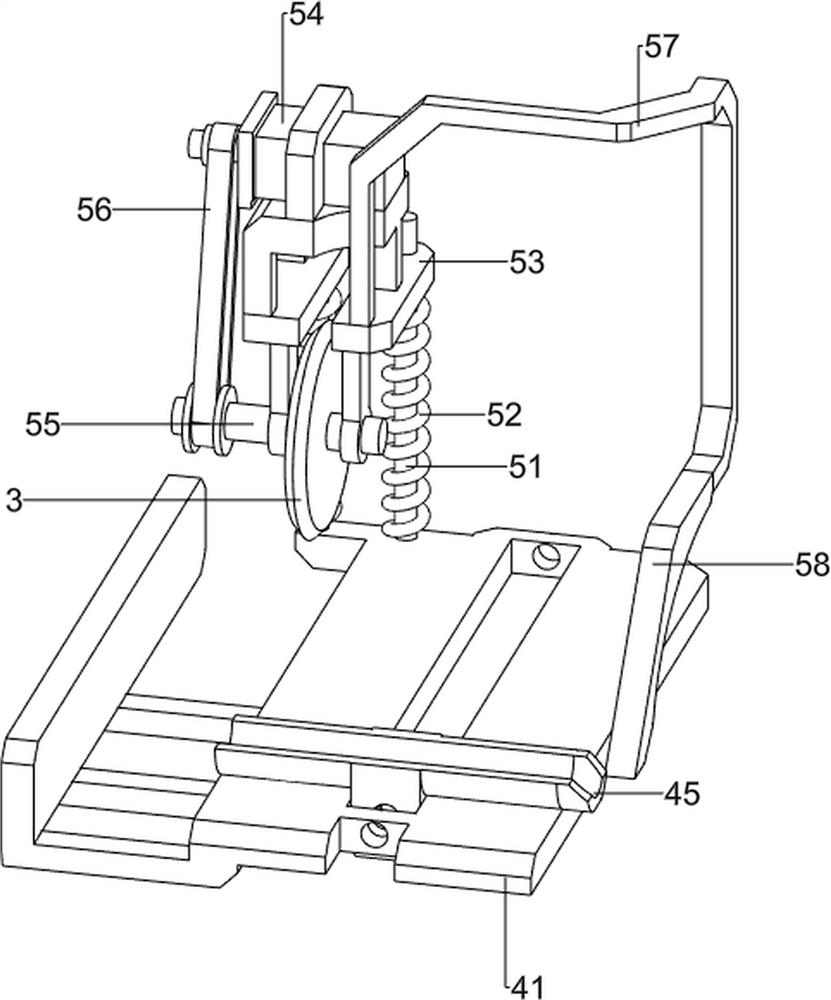

Bottom cover pressing equipment based on electronic cigarette battery production

InactiveCN113017145AStable gland workImprove capping efficiencyTobacco pipesGear driveElectrical battery

The invention relates to bottom cover pressing equipment, in particular to bottom cover pressing equipment based on electronic cigarette battery production. According to the technical aims, the bottom cover pressing equipment based on electronic cigarette battery production has an automatic feeding function and is good in clamping effect. The bottom cover pressing equipment based on electronic cigarette battery production comprises three electronic cigarette boxes; covers, which are arranged at the tops of the electronic cigarette boxes in a sliding manner; placing mechanisms, which are arranged between the electronic cigarette boxes; and capping mechanisms, which are arranged on the placing mechanisms. When a first rotating rod rotates anticlockwise, a sector gear is driven to rotate to be meshed with a first gear, a fourth spring is compressed, the first gear rotates clockwise, the first gear drives a rack and a sliding plate to move rightwards, the sliding plate conveys a bottom cover to a cover pressing rod, and the automatic feeding effect is achieved.

Owner:SHENZHEN AIRUISI ELECTRONICS CO LTD

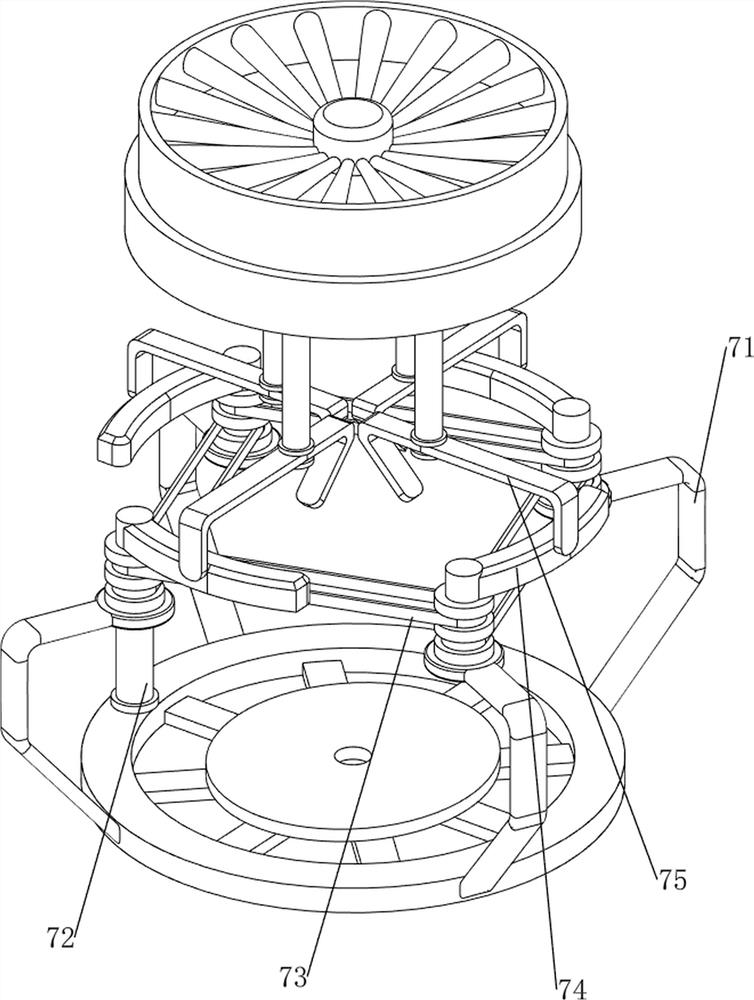

Pharmacy department granular medicine crushing and mixing equipment

ActiveCN113102053AImprove production efficiencyReduce work timesTransportation and packagingMixersPharmacy medicineMechanical engineering

The invention relates to crushing and mixing equipment, particularly relates to pharmacy department granular medicine crushing and mixing equipment, and provides the pharmacy department granular medicine crushing and mixing equipment which is high in mixed medicine powder manufacturing efficiency and capable of achieving automatic feeding and discharging. The pharmacy department granular medicine crushing and mixing equipment comprises a fixing plate, fixing frames, a stirring mechanism and a crushing mechanism, wherein the fixing plate is provided with the three fixing frames, the stirring mechanism is arranged on the three fixing frames, and the crushing mechanism is arranged on the stirring mechanism. According to the equipment, the effect of improving the mixed medicine powder manufacturing efficiency is achieved, through cooperation of the stirring mechanism and the crushing mechanism, mixed medicine powder can be obtained only by placing tablets in the crushing mechanism, working time consumed for manually grinding the tablets and mixing the medicine powder is shortened, through cooperation of a primary feeding mechanism and an intermittent feeding mechanism, the tablets can be indirectly supplemented into the crushing mechanism, and the frequency of adding the tablets into the equipment by people is reduced.

Owner:濮阳市汇元药业有限公司

Square wet tissue edge cutting equipment for wet tissue production

PendingCN112431010AEasy to operateConsistent shapeLiquid/gas/vapor article treatmentSevering textilesStructural engineeringMechanical engineering

The invention relates to edge cutting equipment, in particular to square wet tissue edge cutting equipment for wet tissue production. The square wet tissue edge cutting equipment for wet tissue production is safe, capable of saving time and labor and tidy in edge cutting. The square wet tissue edge cutting equipment for wet tissue production comprises a base, two brackets arranged on the base, twosliding rods connected between the two brackets, a discharging mechanism connected to the two sliding rods in a sliding manner and a manual cutting mechanism arranged in the middle of the upper portion of the base and matched with the discharging mechanism. According to the invention, a limiting plate is matched with an L-shaped limiting rod, the limiting plate exerts pressure on the L-shaped limiting rod, the L-shaped limiting rod moves downwards, then a second connecting block moves downwards, and a cutter moves downwards through movement of the second connecting block, so that edge cuttingis conducted on tissue, the automatic cutting effect is achieved, and time and labor are saved.

Owner:赵才友

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com