Shrink film sealing and cutting packaging machine

A packaging machine and shrink film technology, applied in the directions of packaging, wrapping paper, wrapping paper shrinkage, etc., can solve the problems of time-consuming, labor-intensive cost, cumbersome operation, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

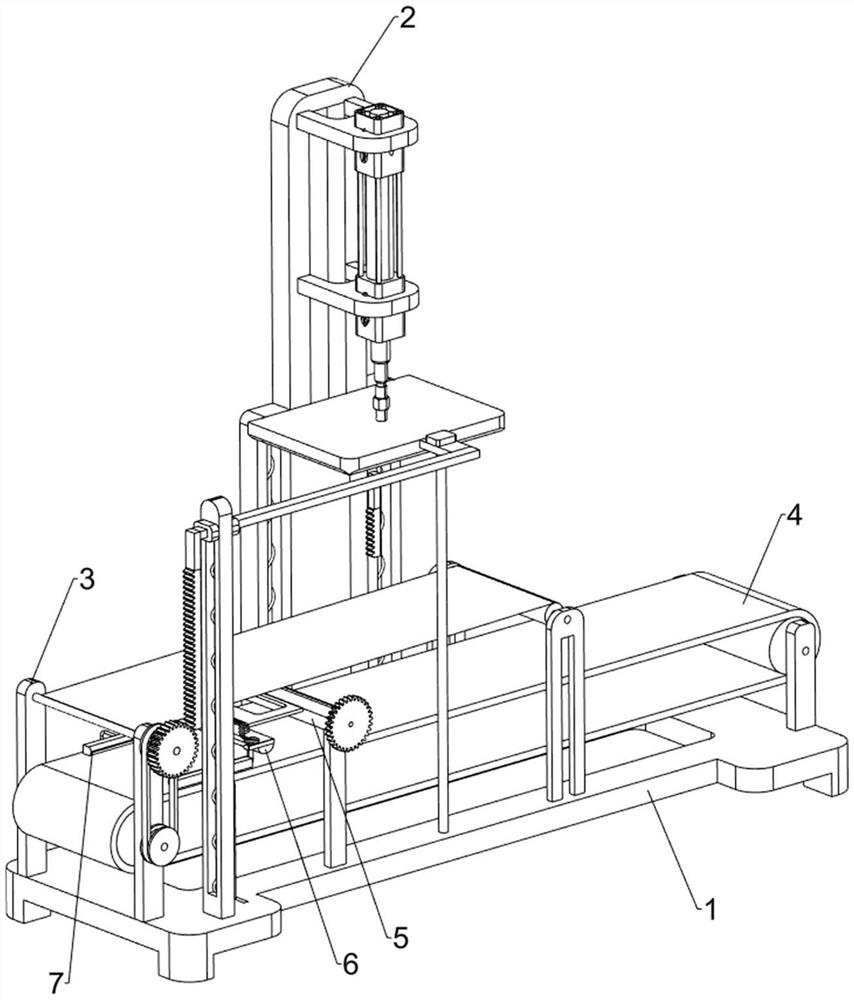

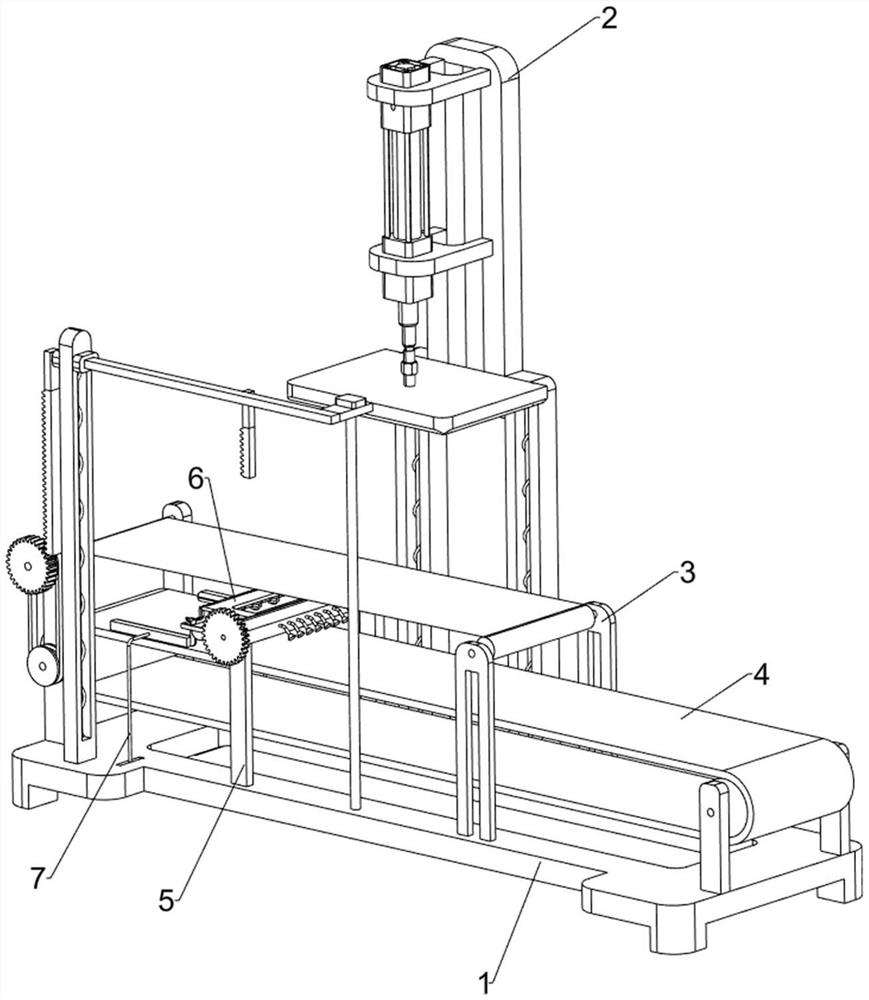

[0073] A shrink film sealing and cutting packaging machine, such as Figure 1-Figure 2 Shown, include base plate 1, sealing and cutting mechanism 2 and conveying film mechanism 3, bottom plate 1 upper rear portion is provided with sealing and cutting mechanism 2, and base plate 1 is provided with conveying film mechanism 3, and sealing and cutting mechanism 2 is connected with conveying film mechanism 3.

[0074] Ordinary sealing and cutting devices are cumbersome to operate, time-consuming and labor-intensive, and costly. This equipment can automatically seal and cut the shrink film, which is simple to operate, saves time and effort, and can reduce costs. The unsealed oil painting board is fixed at the position above the middle of the bottom plate 1, and the oil painting board is located below the shrink film in the film transport mechanism 3, and then the sealing and cutting mechanism 2 is operated, and the sealing and cutting mechanism 2 first cuts off the shrink film in the...

Embodiment 2

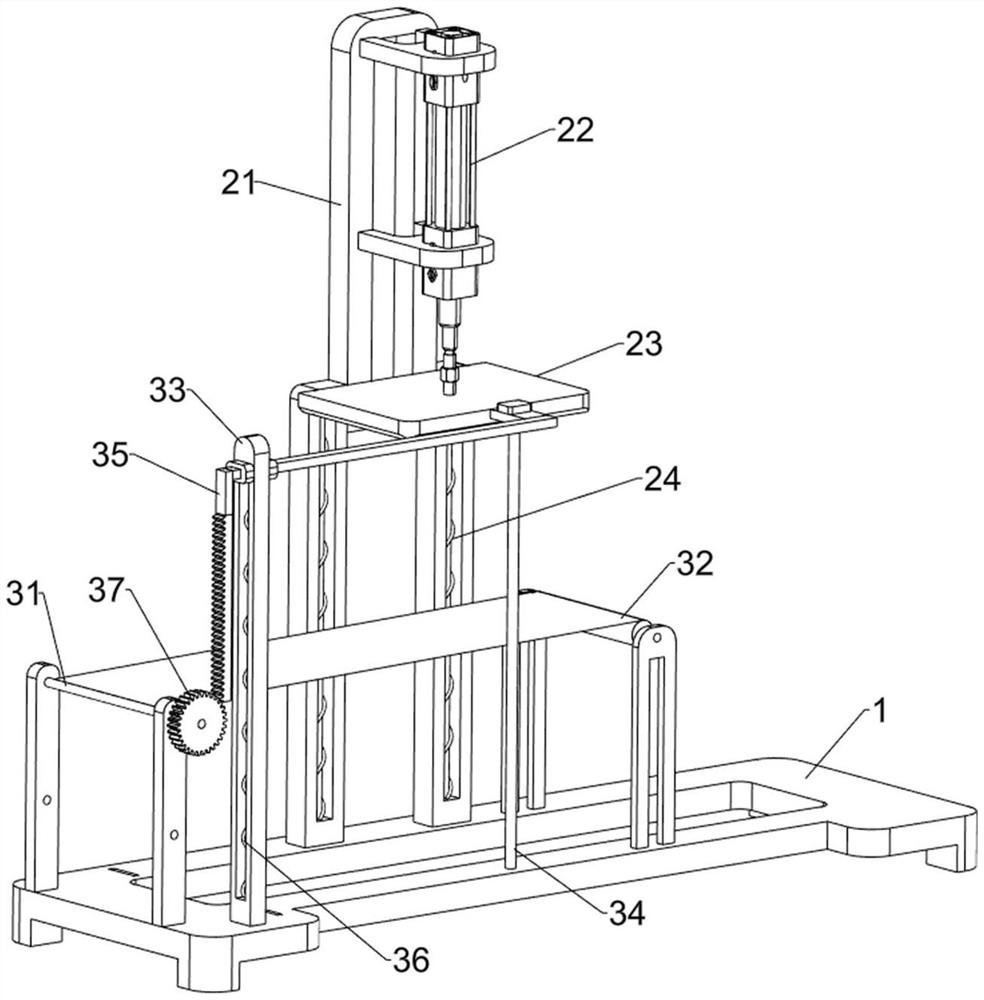

[0076] On the basis of Example 1, such as Figure 3-Figure 4 As shown, the sealing and cutting mechanism 2 includes a first guide frame 21, a cylinder 22, a sealing and cutting frame 23 and a first telescopic assembly 24, the bottom plate 1 is provided with a first guide frame 21 in the middle of the upper rear side, and the inner side of the upper part of the first guide frame 21 is provided with a The cylinder 22 is provided with a sealing frame 23 at the bottom of the cylinder 22, and the sealing frame 23 is slidably connected with the first guide frame 21, and two first telescopic components 24 are connected between the sealing frame 23 and the inner bottom of the first guide frame 21.

[0077] After people fix the oil painting board, open the cylinder 22, the operation of the cylinder 22 makes the sealing and cutting frame 23 repeatedly slide up and down in the first guide frame 21, when the sealing and cutting frame 23 moves downward, the first telescopic assembly 24 chan...

Embodiment 3

[0081] On the basis of Example 2, such as figure 1 and Figure 4-Figure 8 As shown, a transmission mechanism 4 is also included. The bottom plate 1 is provided with a transmission mechanism 4. The transmission mechanism 4 is connected to the first rotating shaft 31. The transmission mechanism 4 includes a second rotating shaft 41, a third rotating shaft 42, a transmission assembly 43 and a transmission assembly. 44. The upper left part of the bottom plate 1 is rotatably connected to the front and rear sides of the second rotating shaft 41. The second rotating shaft 41 is located below the first rotating shaft 31. The upper right part of the bottom plate 1 is rotatably connected to the front and rear sides of the third rotating shaft 42. The second rotating shaft A transmission assembly 43 is connected between the third rotating shaft 41 and the third rotating shaft 42 , and a transmission assembly 44 is connected between the front of the second rotating shaft 41 and the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com