Patents

Literature

1920results about "Wrappers shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Triclosan-containing medical devices

InactiveUS6106505ALower levelAvoiding undesirably high releaseWrappers shrinkageShrinkage connectionsTriclosanAntiinfective agent

PCT No. PCT / US96 / 20932 Sec. 371 Date Jun. 30, 1998 Sec. 102(e) Date Jun. 30, 1998 PCT Filed Dec. 23, 1996 PCT Pub. No. WO97 / 25085 PCT Pub. Date Jul. 17, 1997The present invention relates to polymeric medical articles comprising the antiinfective agents chlorhexidine and triclosan. It is based, at least in part, on the discovery that the synergistic relationship between these compounds permits the use of relatively low levels of both agents, and on the discovery that effective antimicrobial activity may be achieved when these compounds are comprised in either hydrophilic or hydrophobic polymers. It is also based on the discovery that chlorhexidine free base and triclosan, used together, are incorporated into polymeric medical articles more efficiently. Medical articles prepared according to the invention offer the advantage of preventing or inhibiting infection while avoiding undesirably high release of antiinfective agent, for example into the bloodstream of a subject.

Owner:COLUMBIA UNIV OF THE CITY OF NEW YORK TRUSTEES OF THE

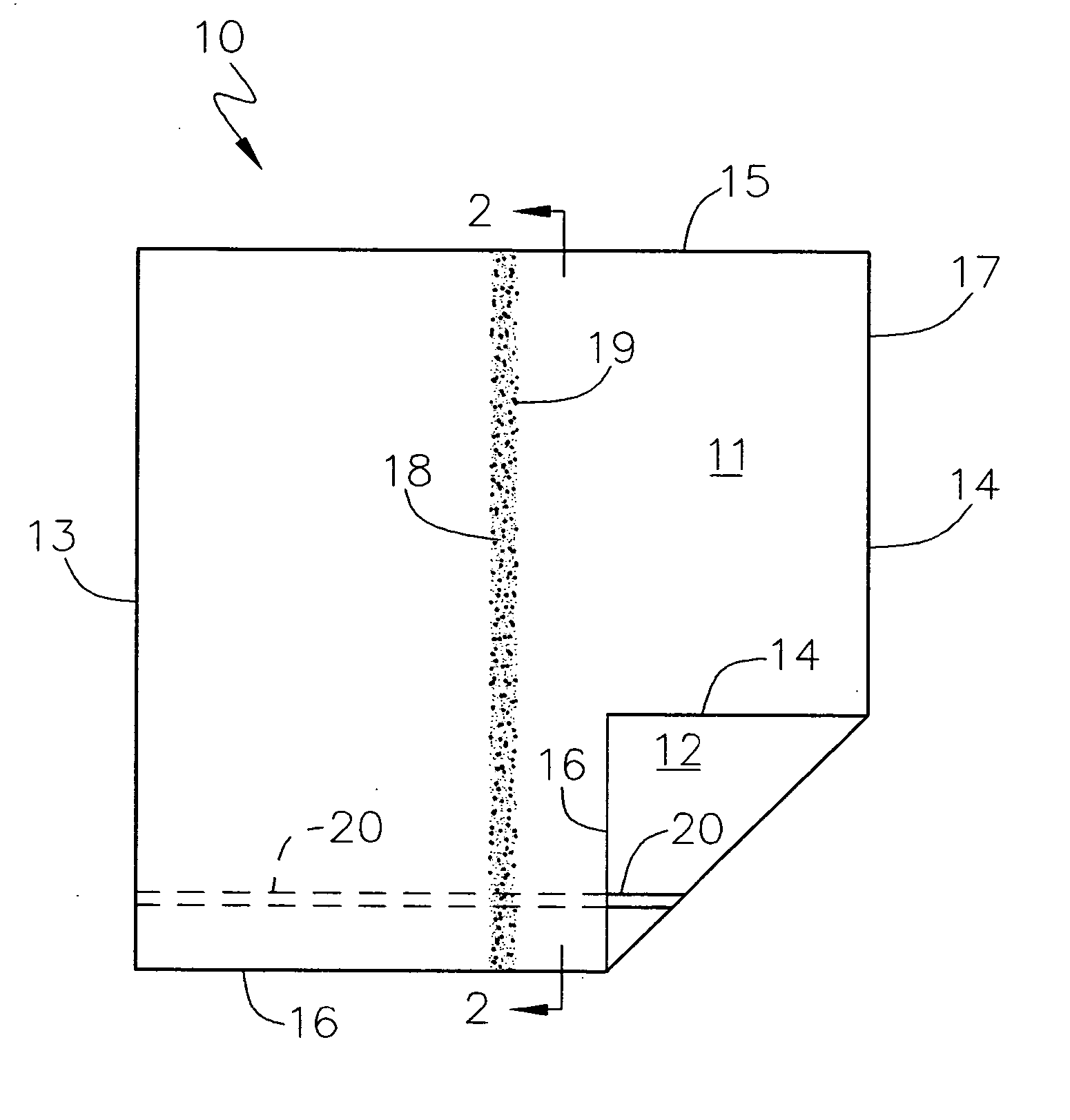

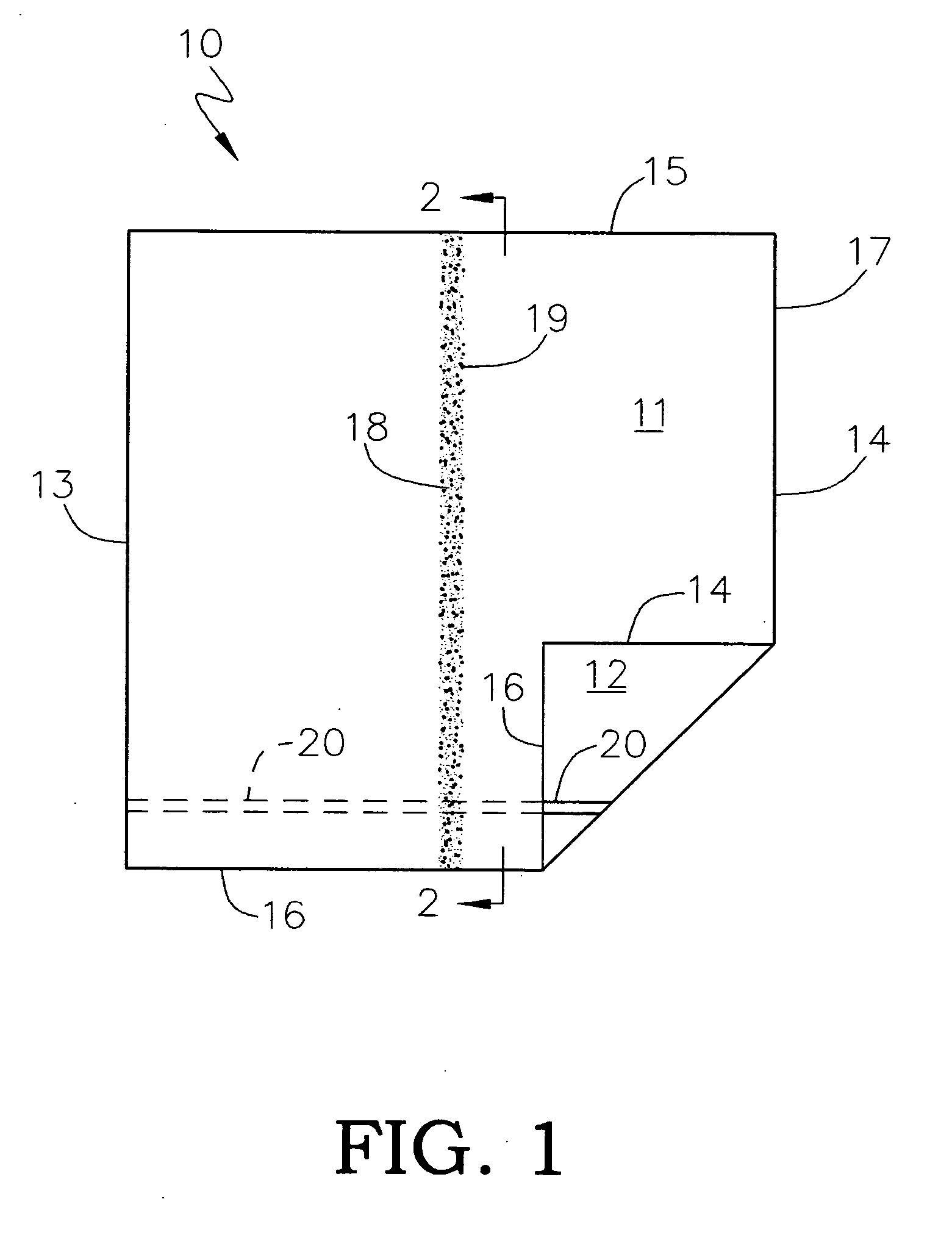

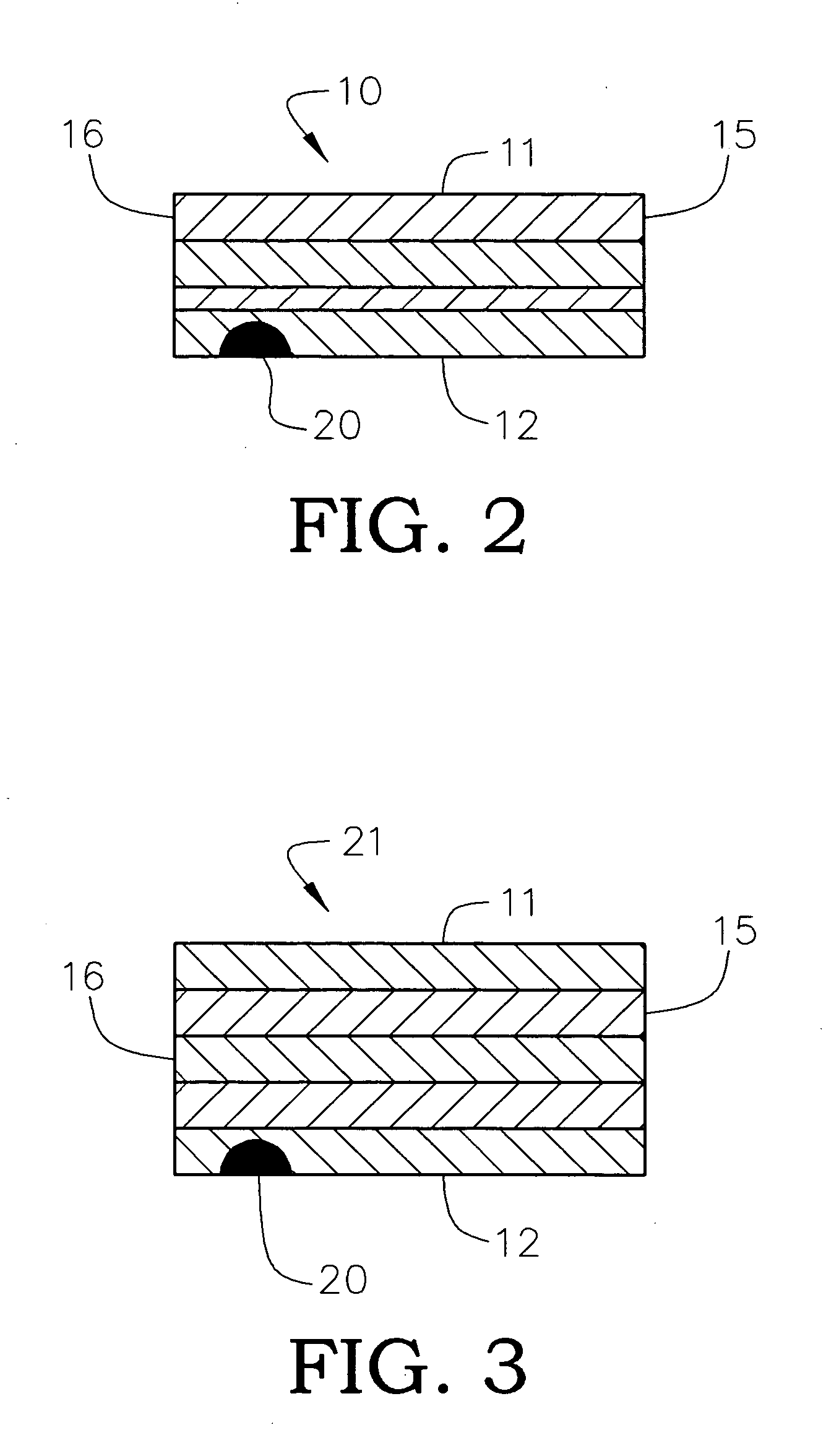

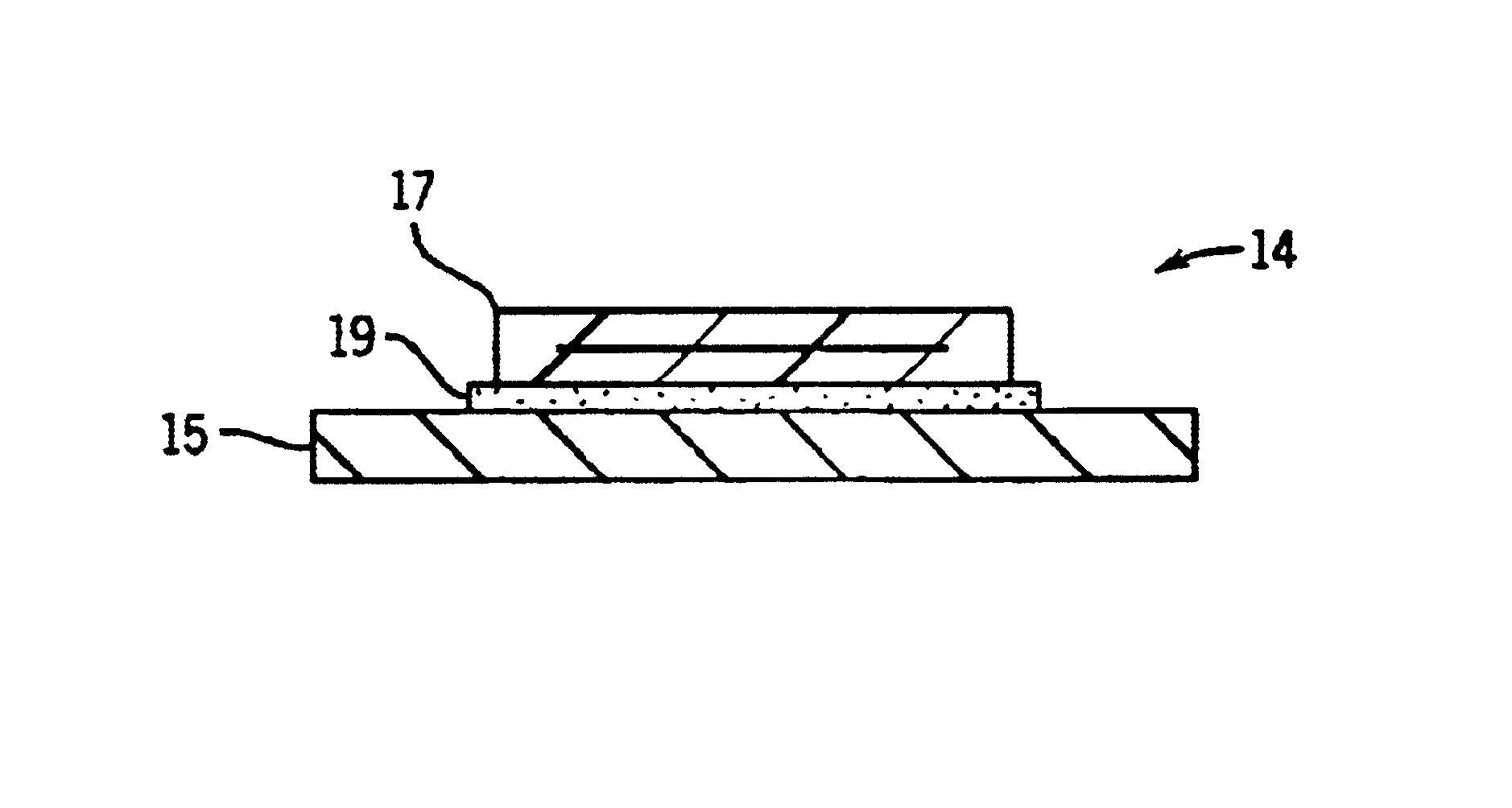

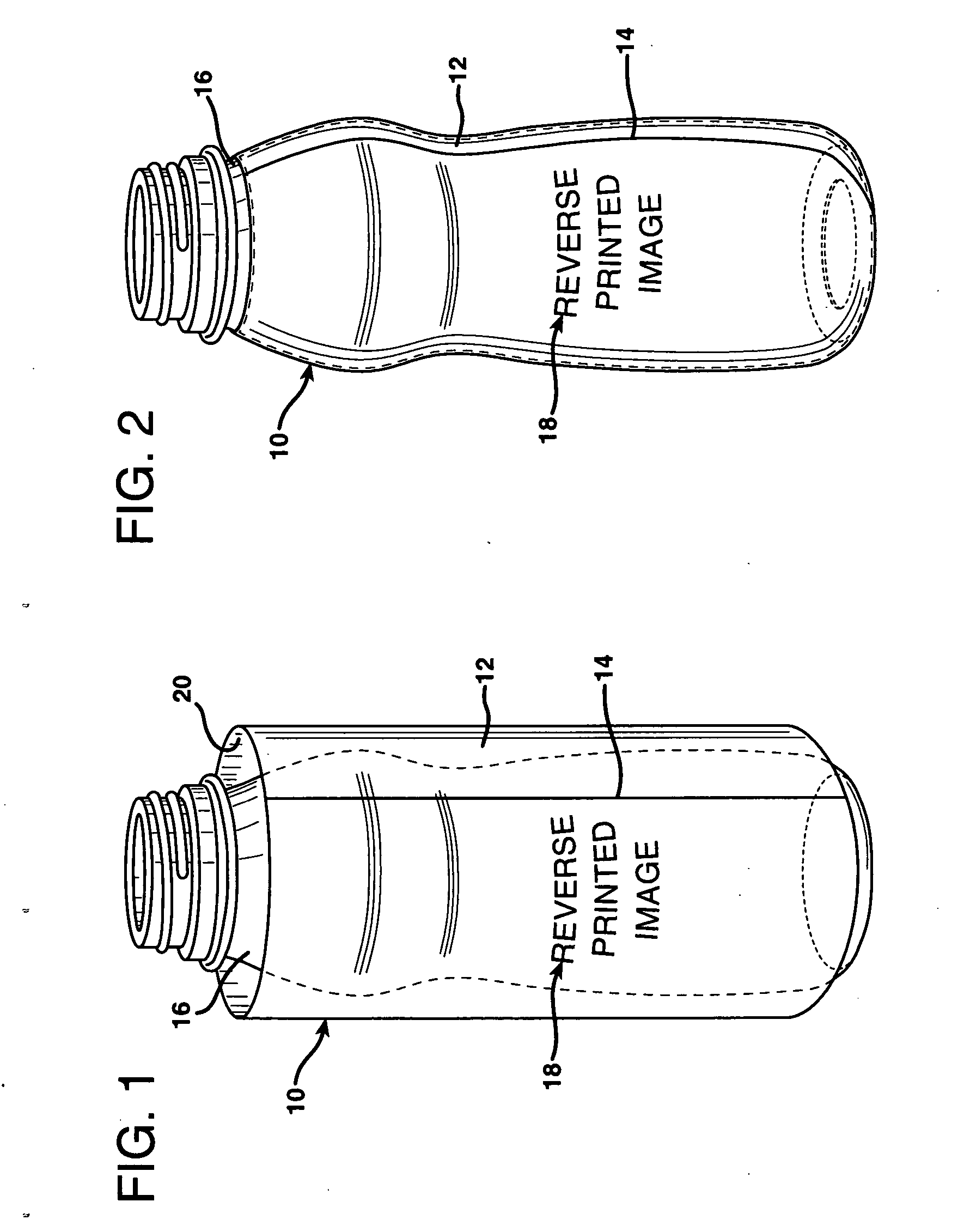

Insulated beverage or food container

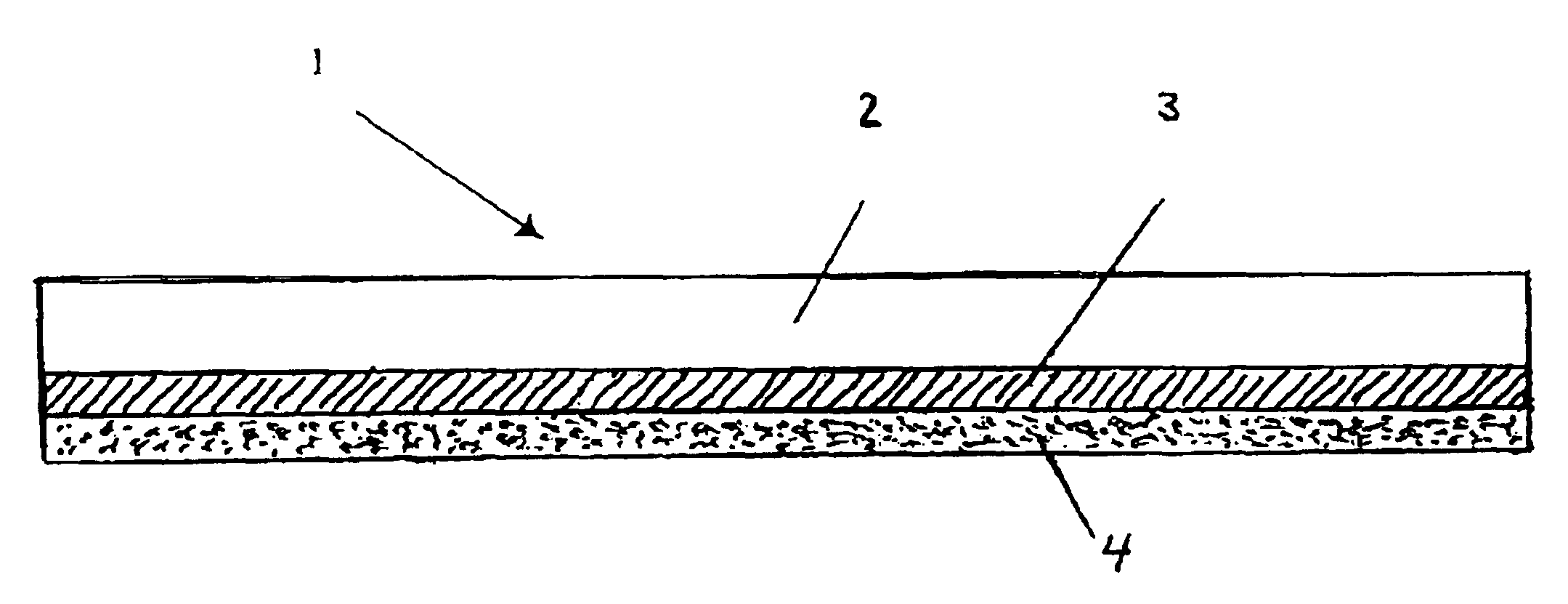

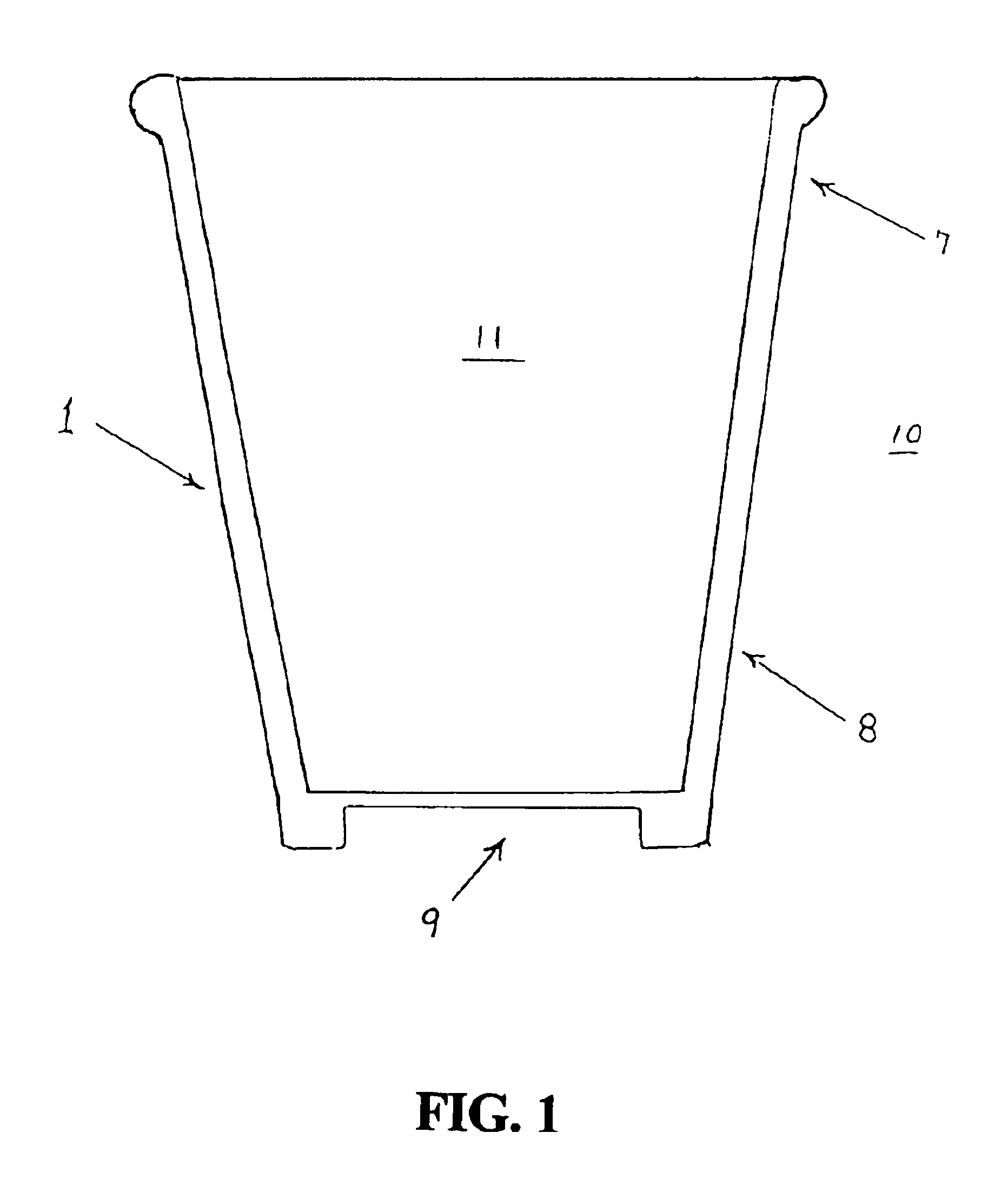

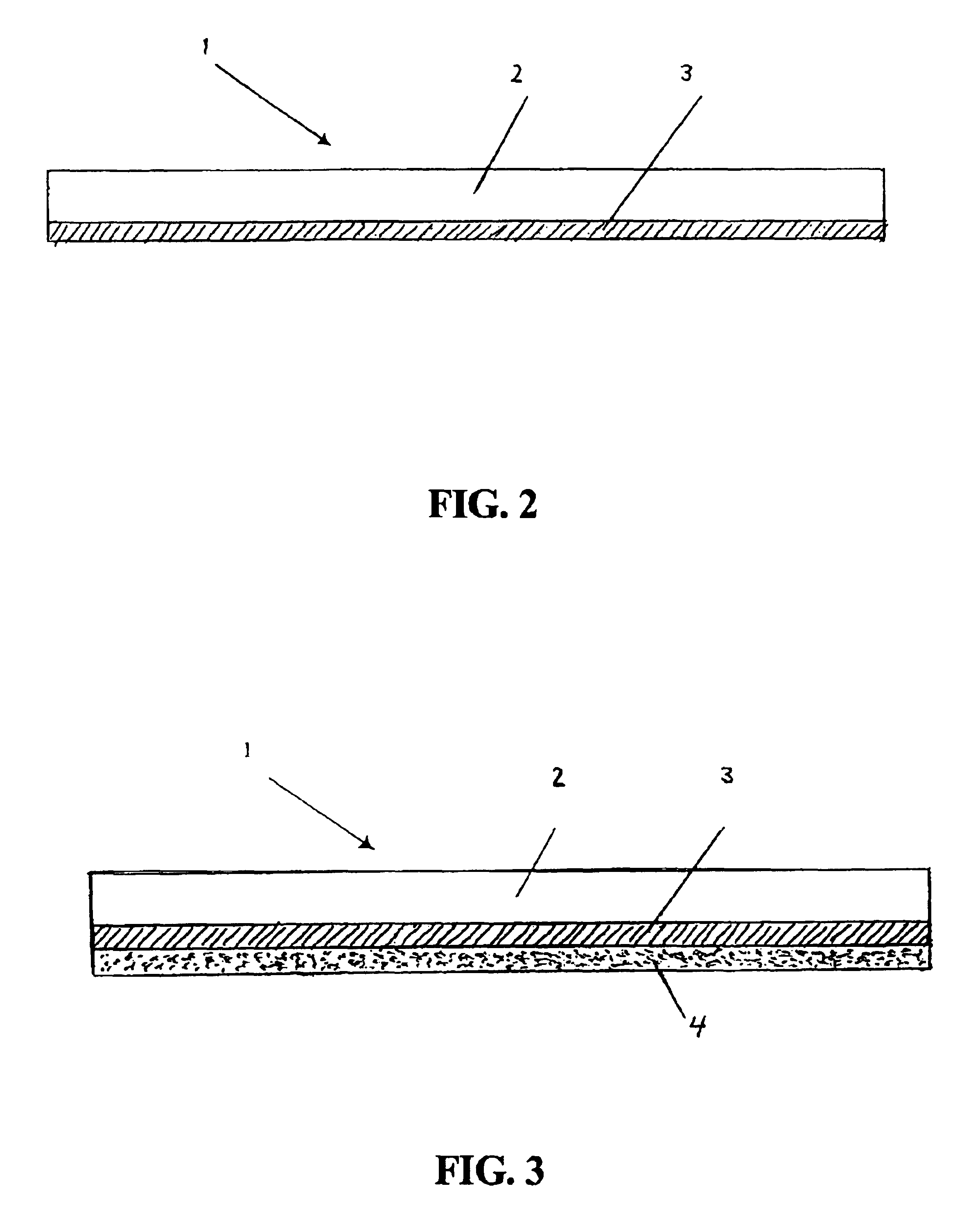

InactiveUS6852381B2Reduce energy transferImprove functionalityWrappers shrinkageRefuse receptaclesEnergy transferEngineering

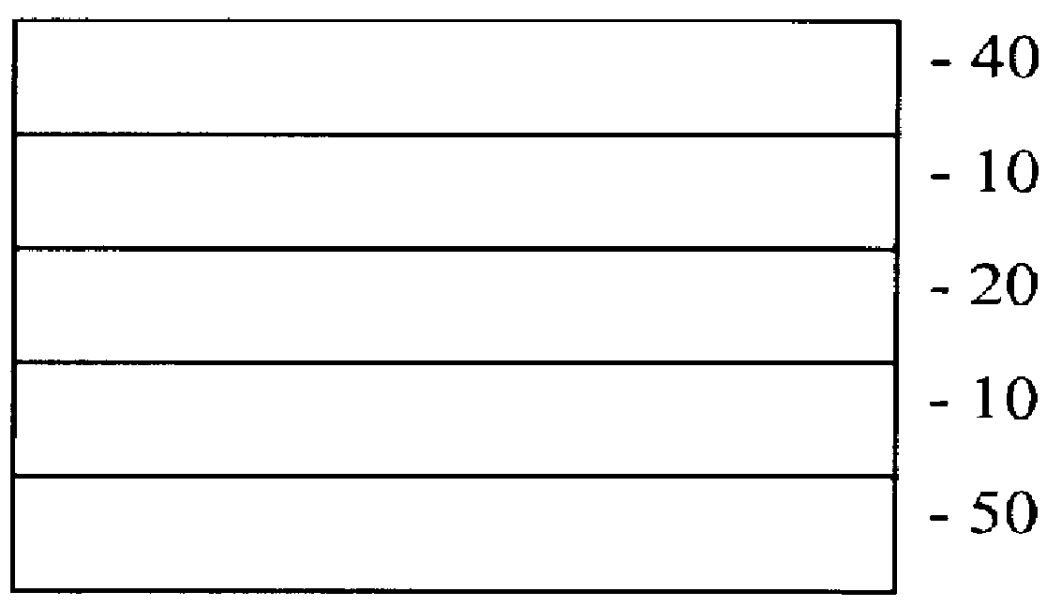

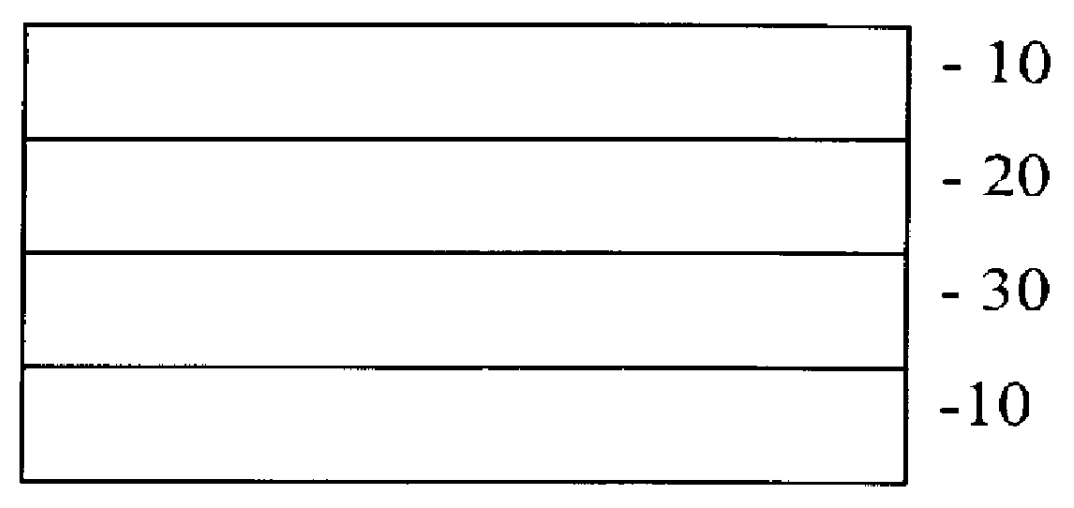

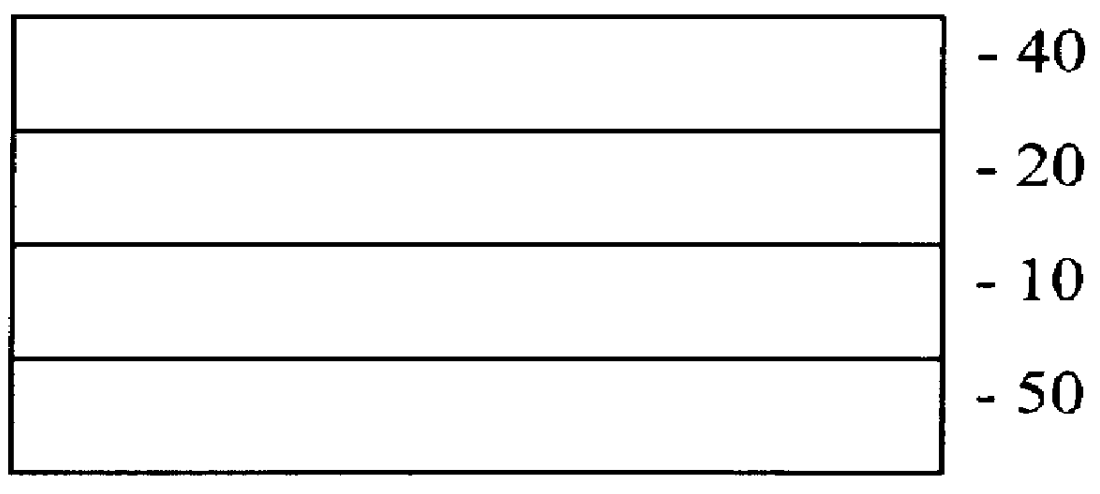

An insulating beverage or food container or sleeve is produced with a foam layer disposed on an inner surface of a paper stock. A polymer shrink film layer is arranged in a position along an inside surface of the beverage container. The foam layer is sandwiched between the polymer shrink film layer and the paper stock and decreases the energy transfer between the beverage and the user's hands allowing the user to hold onto the container for an extended period of time without causing user discomfort or pain. The polymer shrink film layer is produced from a shrink film polymer having a percent shrink in the range of 30% or less, and more particularly a percent shrink range of 5 to 10%.

Owner:APPVION LLC

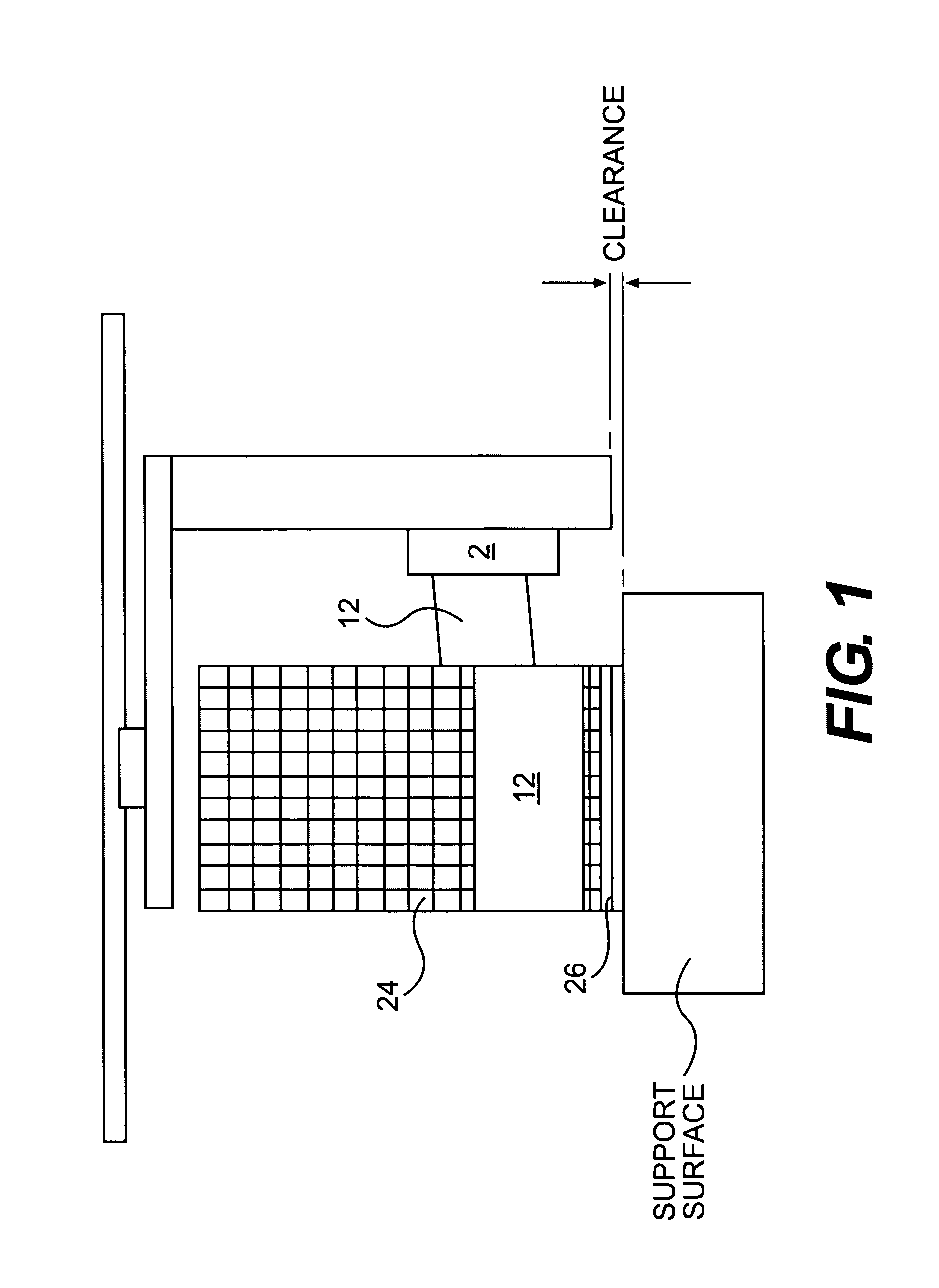

Filling and packaging machine

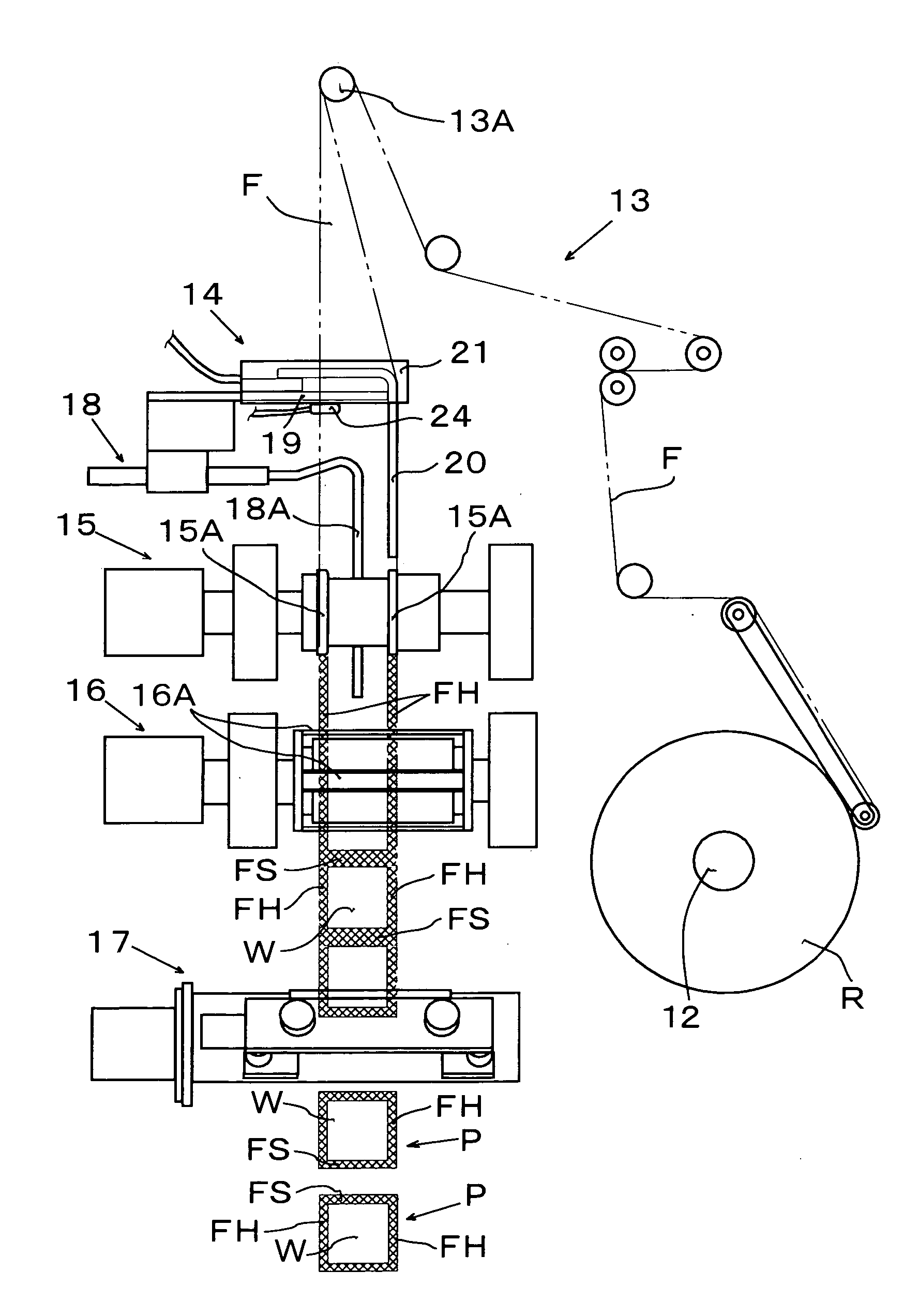

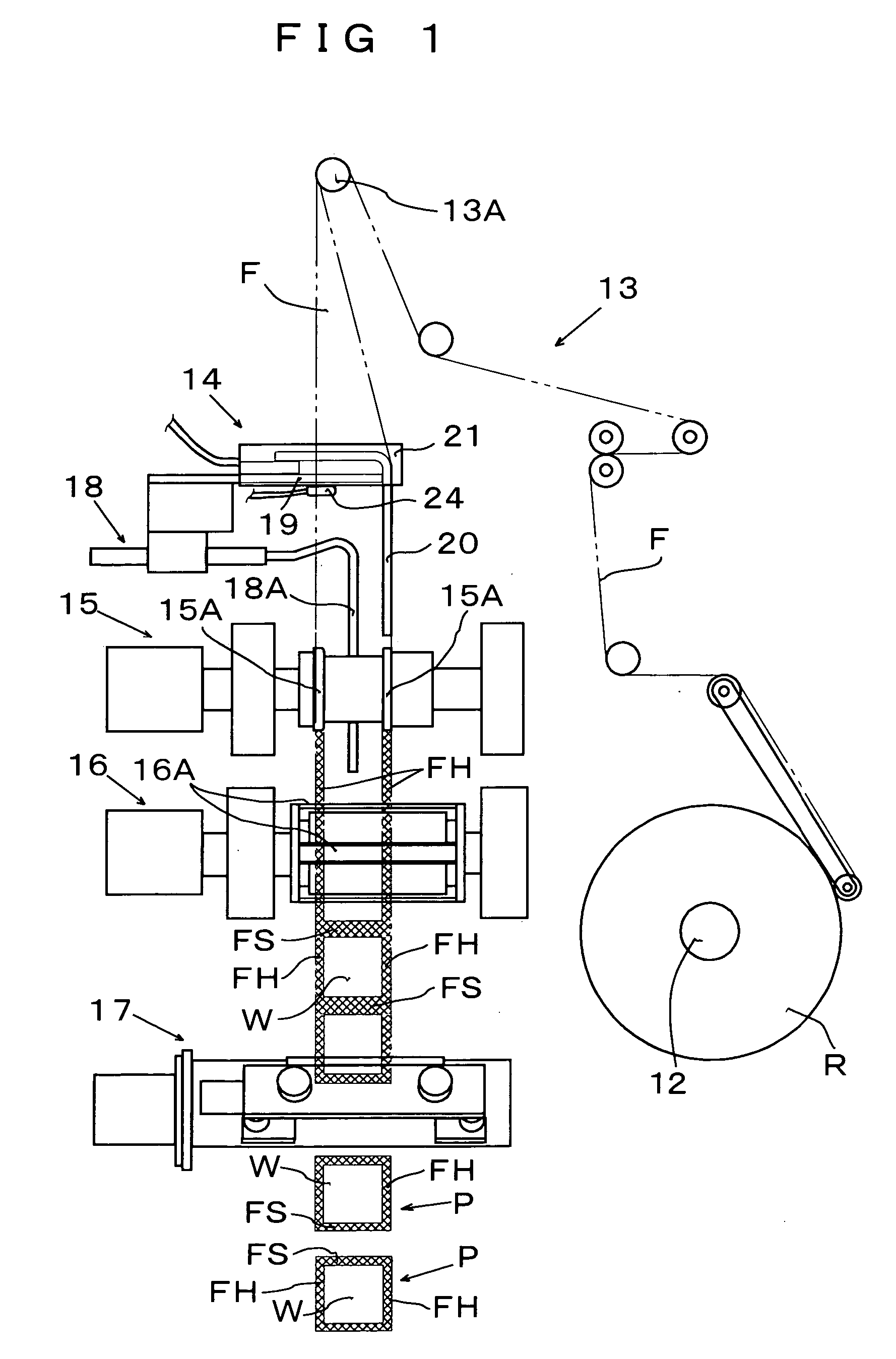

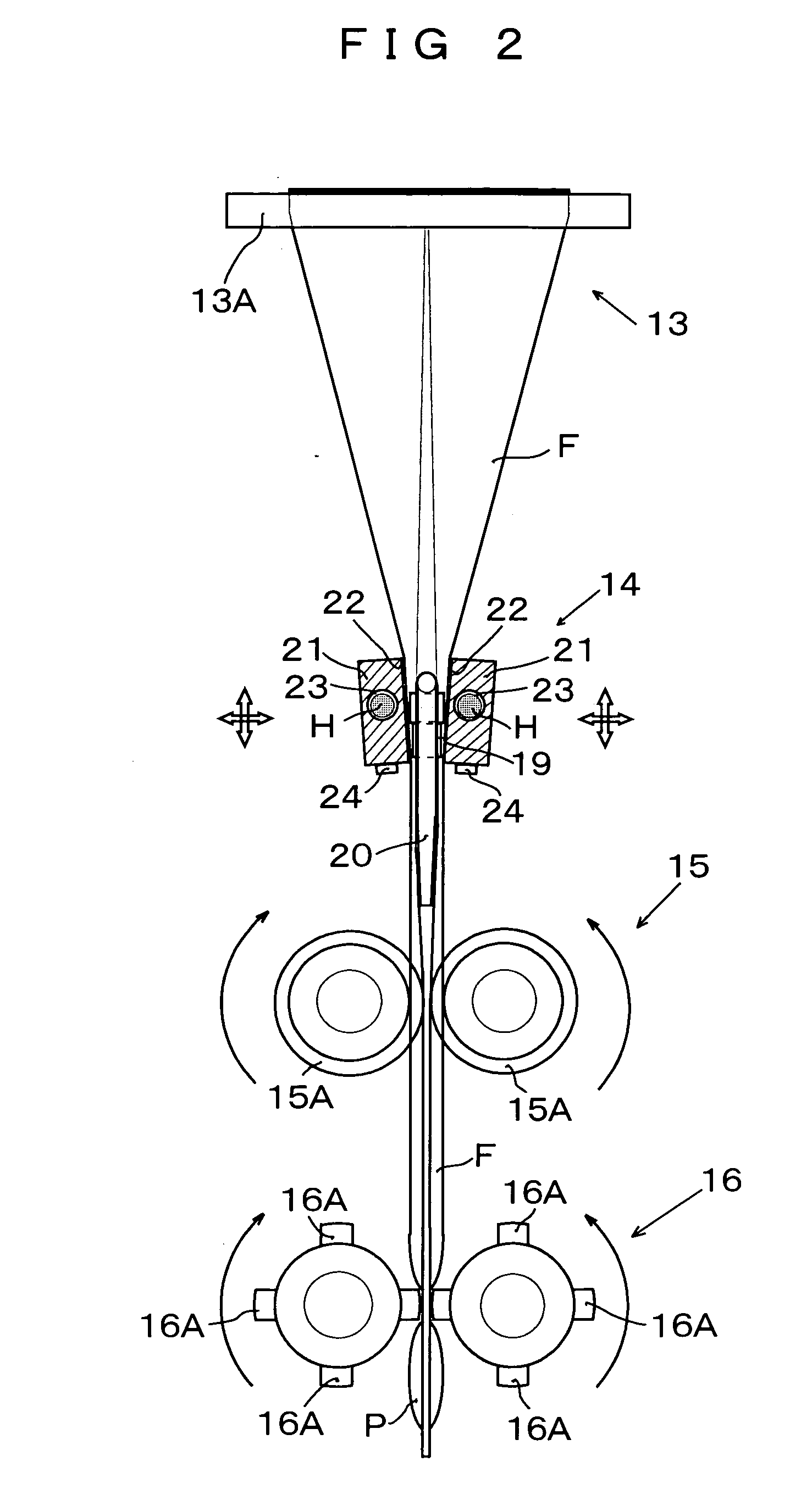

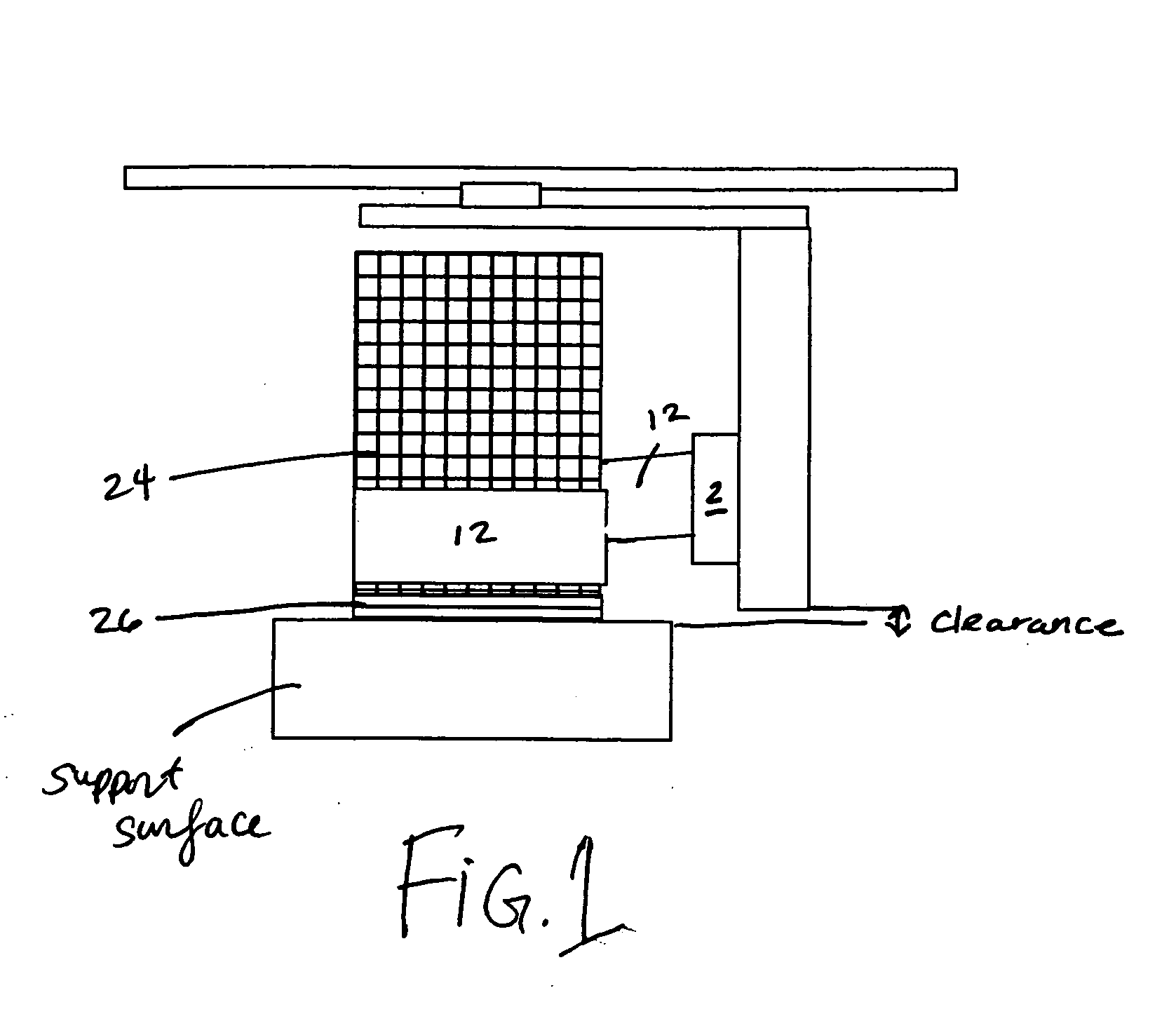

InactiveUS20060021300A1Melted excellentlyImperfect heat sealingWrappers shrinkagePaper-makingEngineeringSupport surface

A filling and packaging machine capable of supplementing the shortage of heat quality without lowering package speed when a film is heat-sealed while being pressurized by a vertical sealing mechanism, comprising a film folding mechanism having an inner surface guide member for guiding the film laterally, formed on the inner surface side of the film folded up into two parts, a pair of right and left pre-heating block members having tilted support surfaces or are support surfaces formed along the width-direction of the film on the outer surface side of the film through a specified interval from the inner surface guide member so that the interval on the upstream side of the film in feeding direction is larger than the interval on the downstream side, and heaters installed in the pre-heating block members.

Owner:NIPPON SEIKI CO LTD

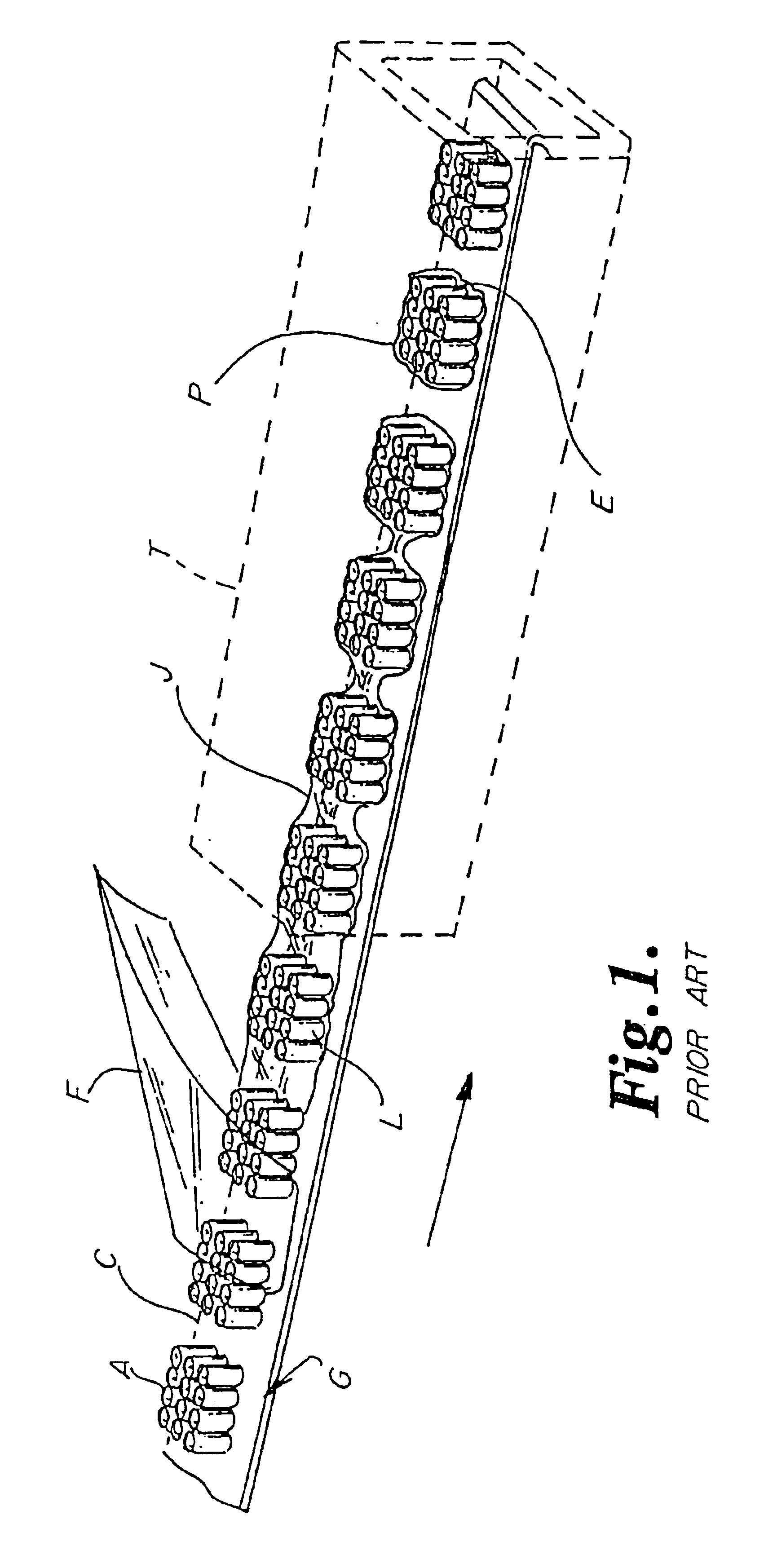

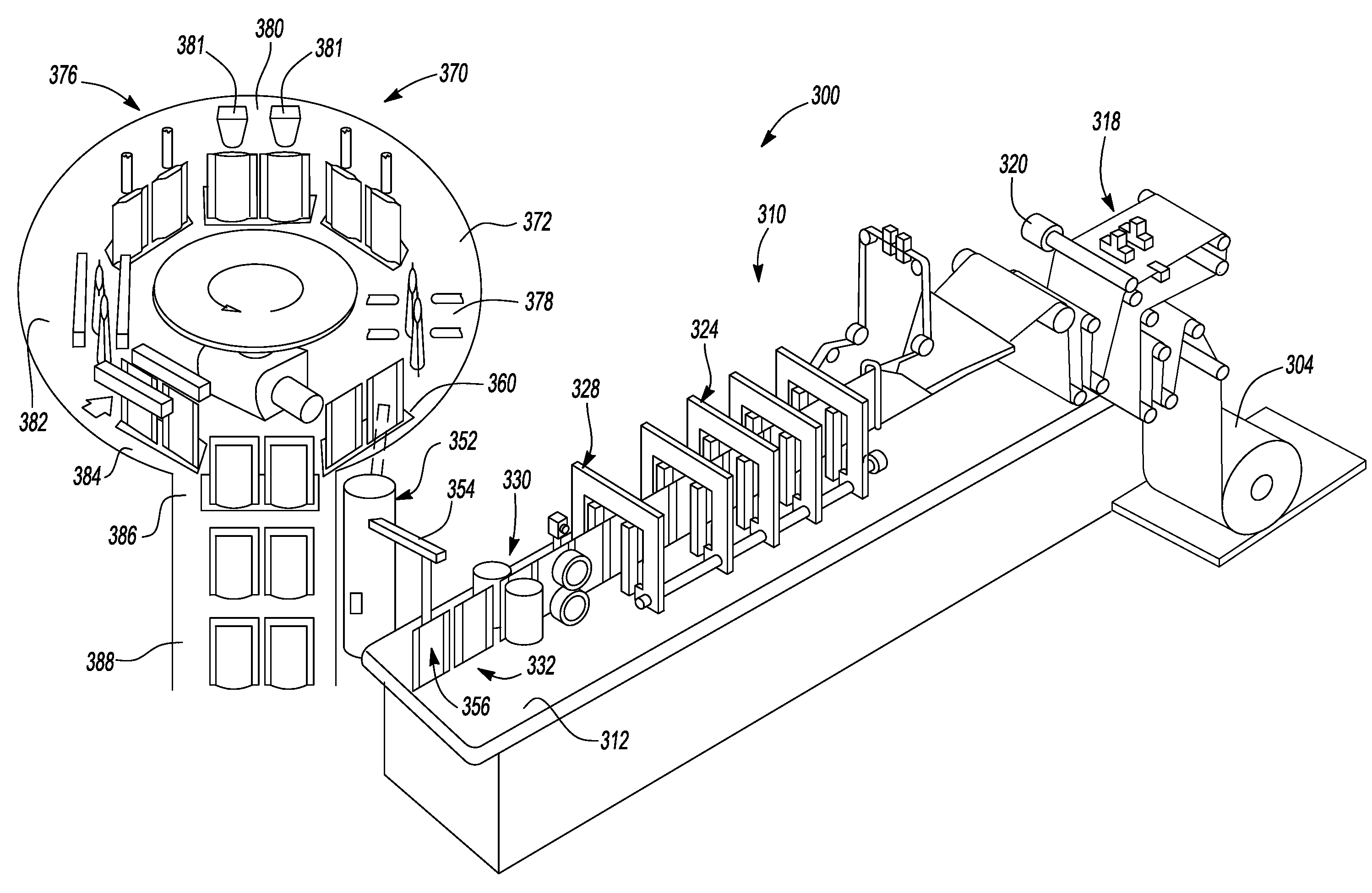

Method for dispensing a predetermined amount of film relative to load girth

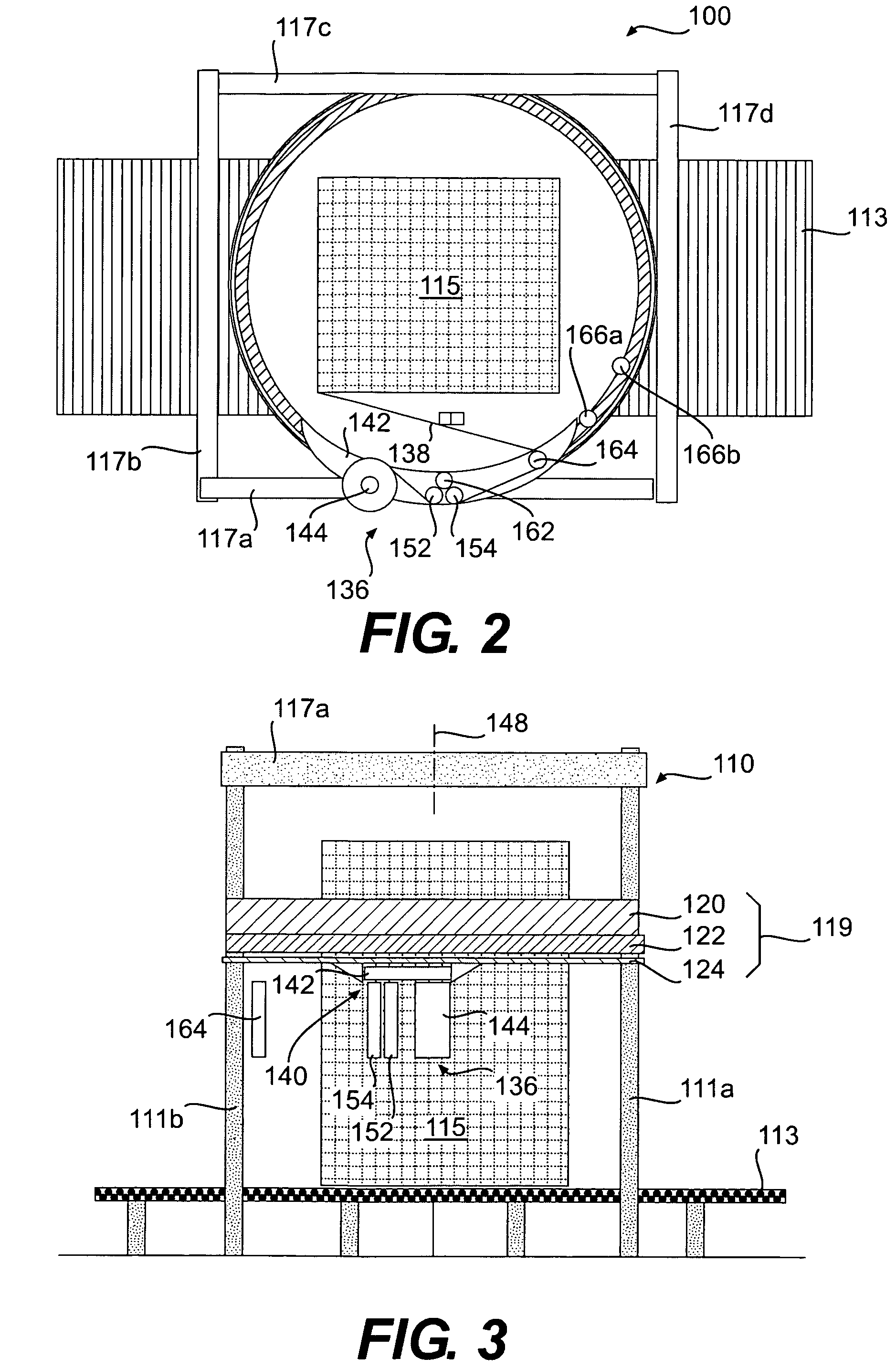

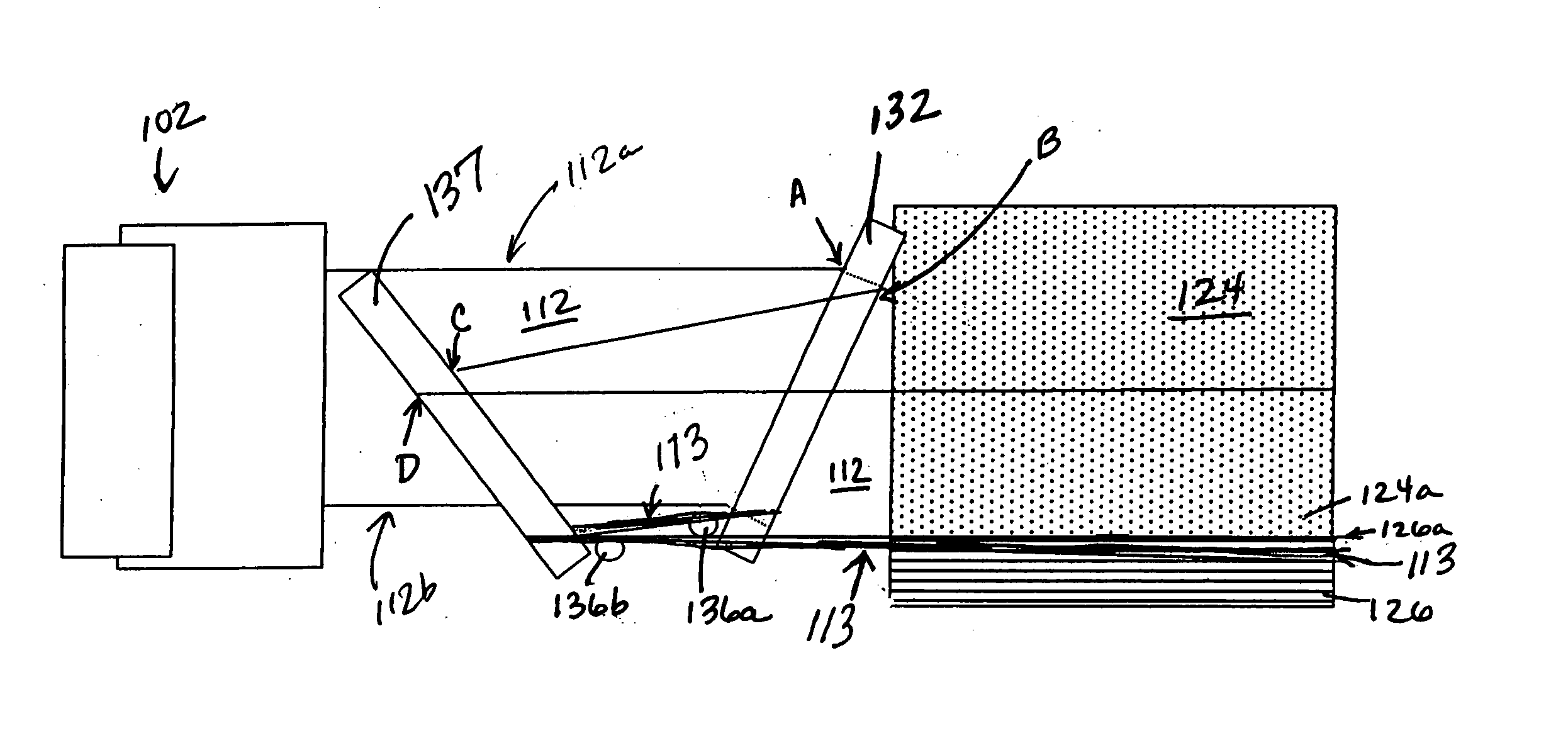

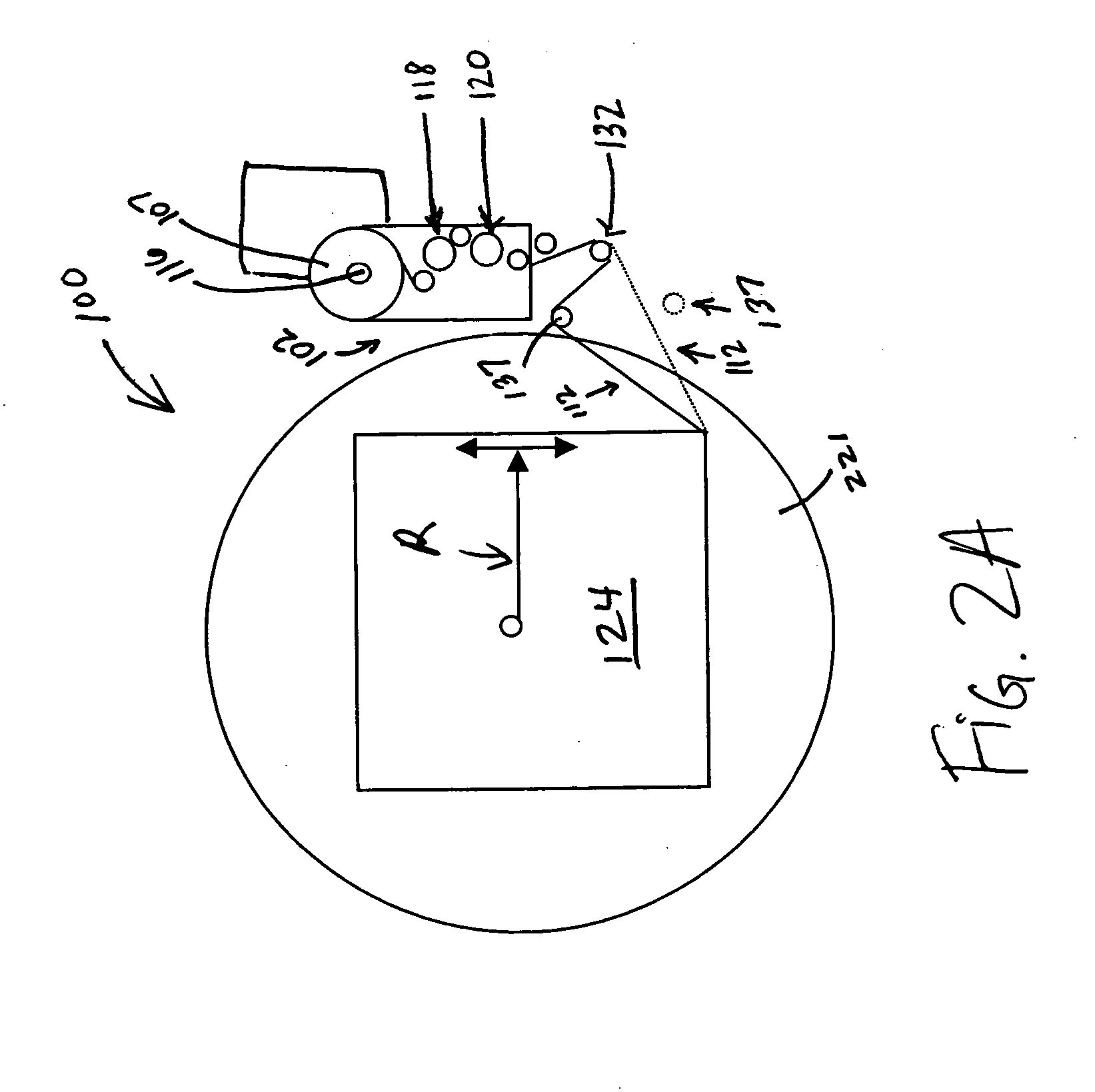

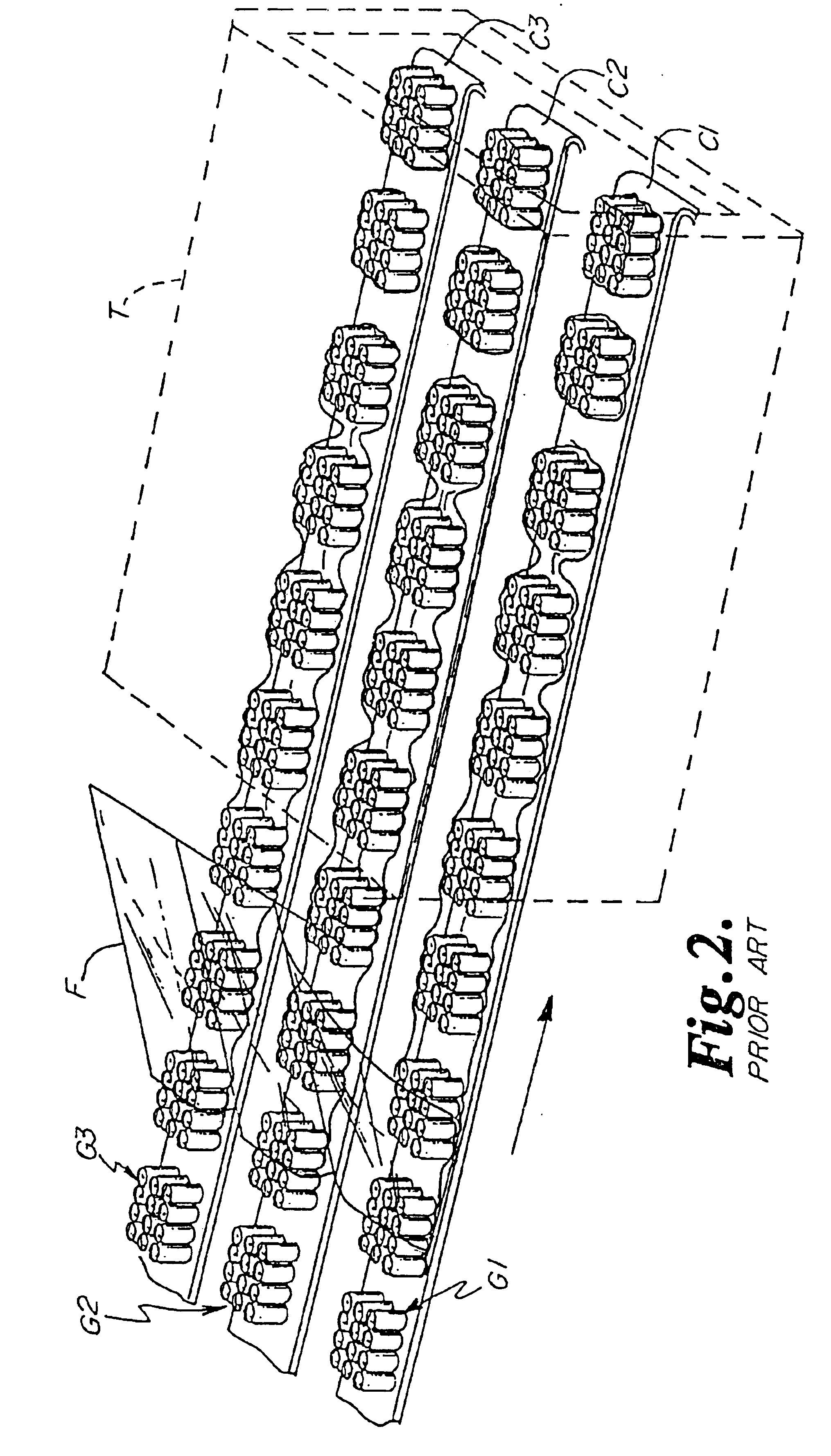

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched film based upon load girth. A non-rotating ring carries a belt. A film dispenser is mounted on a rotating ring, and the rotating ring includes a pulley that connects to the belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched film to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum film use is obtained by dispensing a length of pre-stretched film that is between approximately 100% and approximately 130% of load girth. Once the amount of film to be dispensed per revolution is determined, a mechanical ratio of ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / ring rotation) can be set. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of film is dispensed and wrapped around the load.

Owner:LANTECH COM

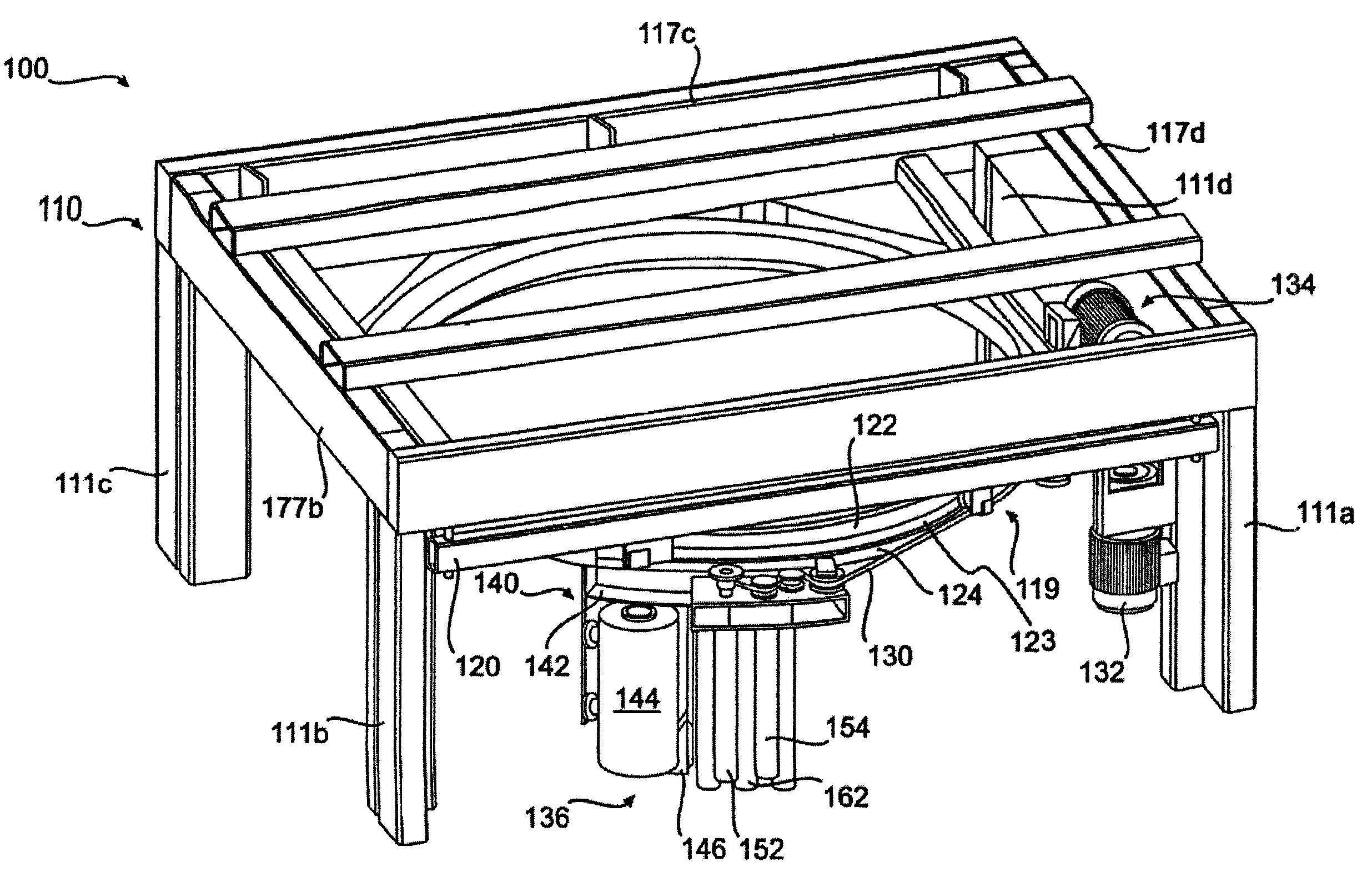

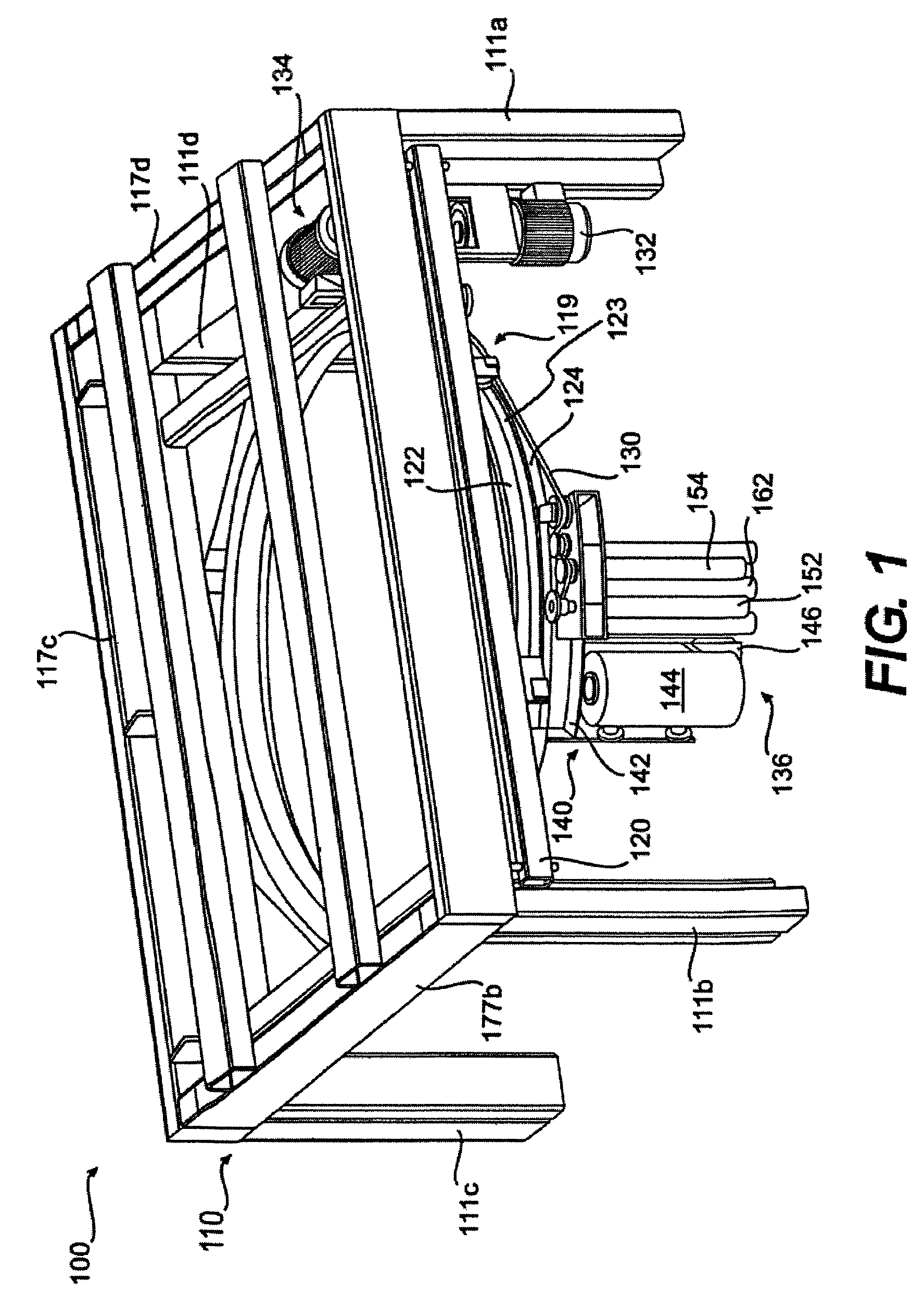

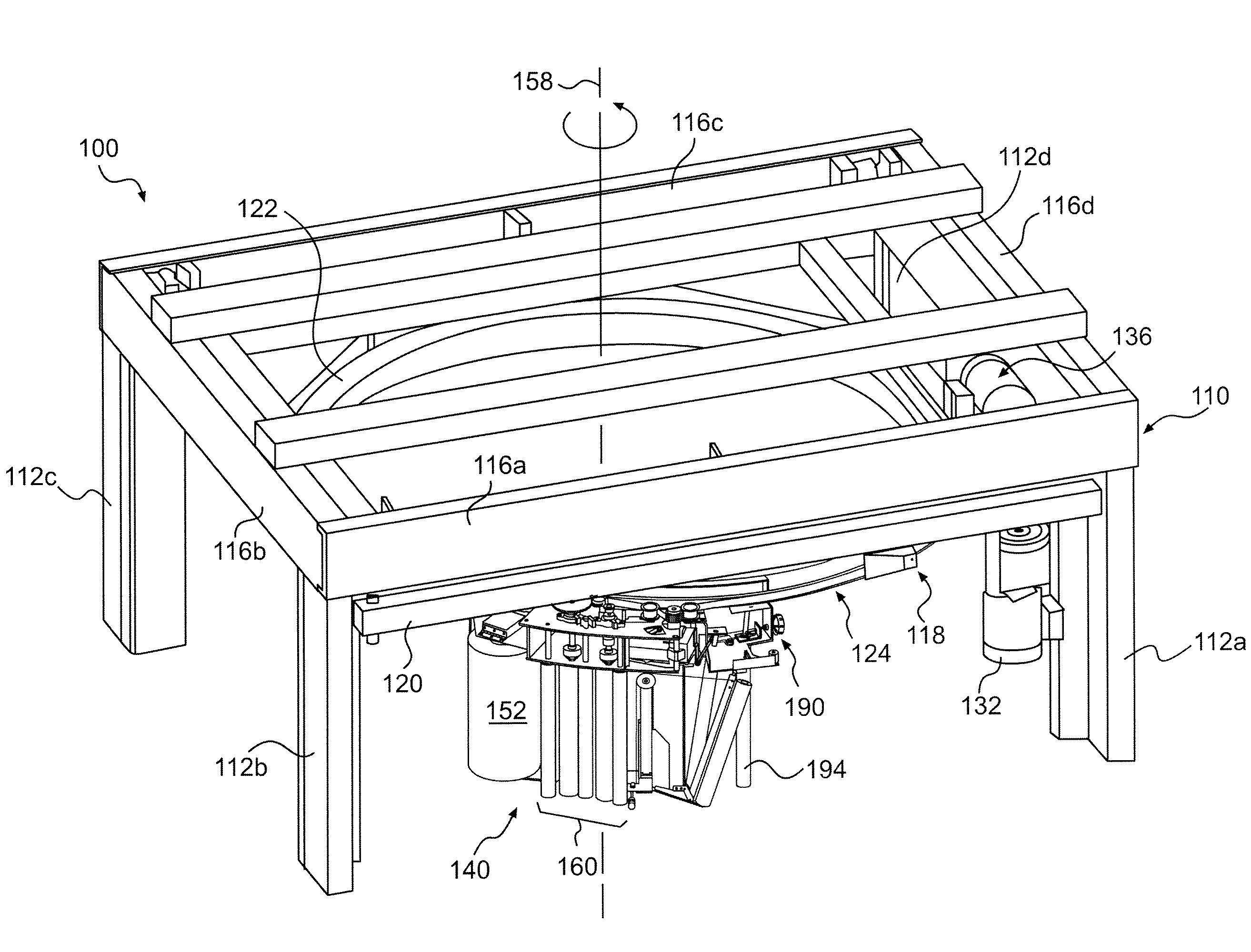

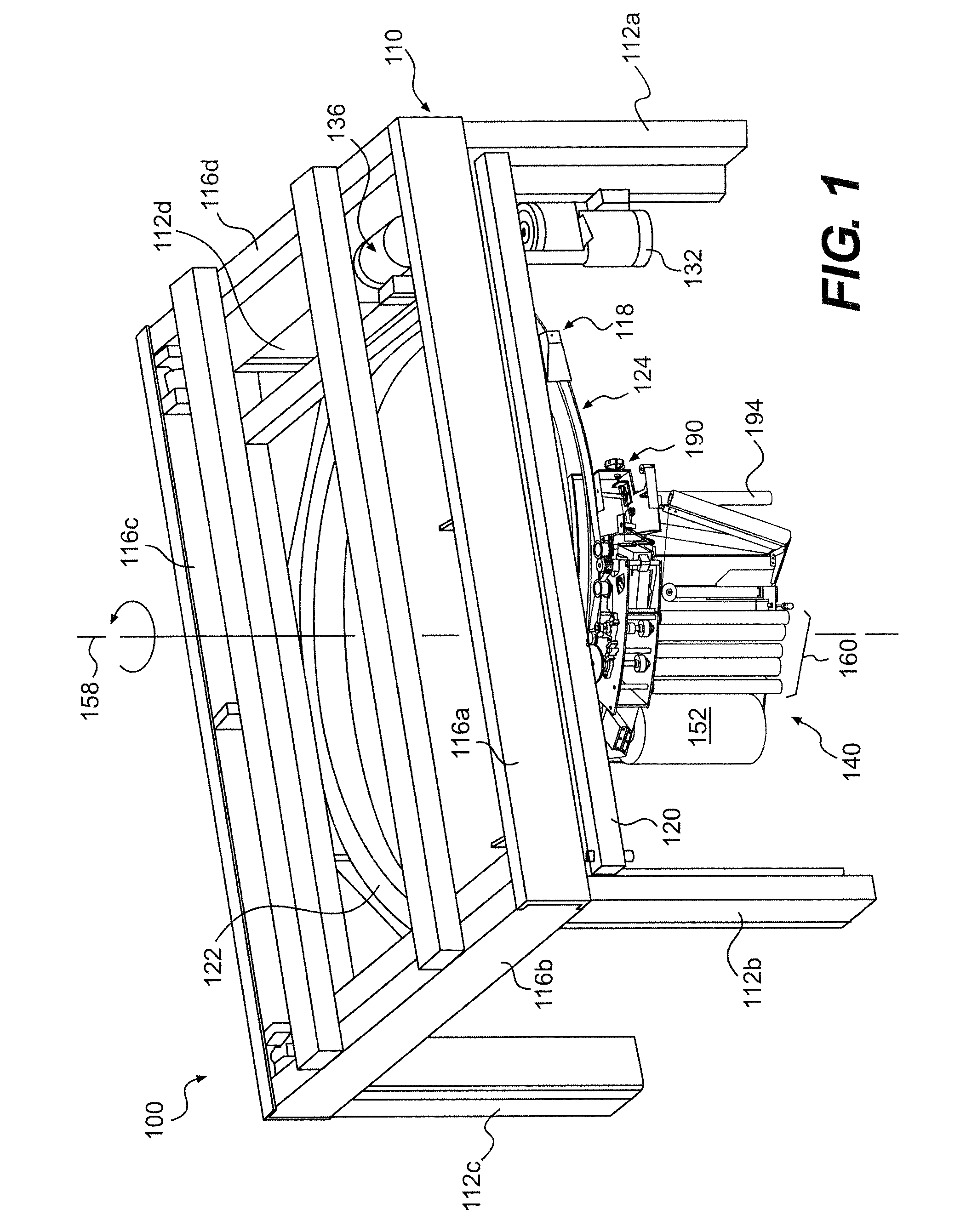

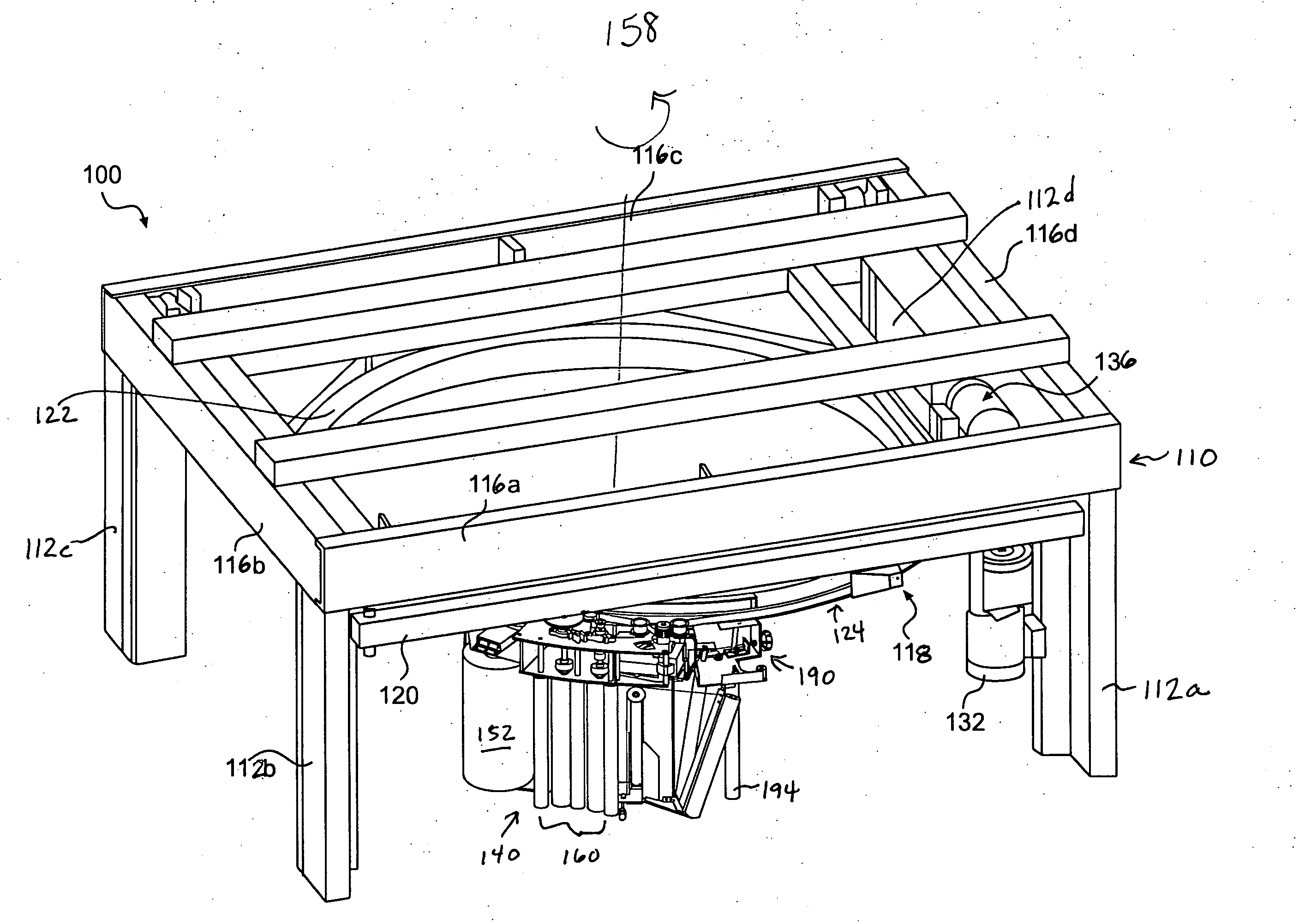

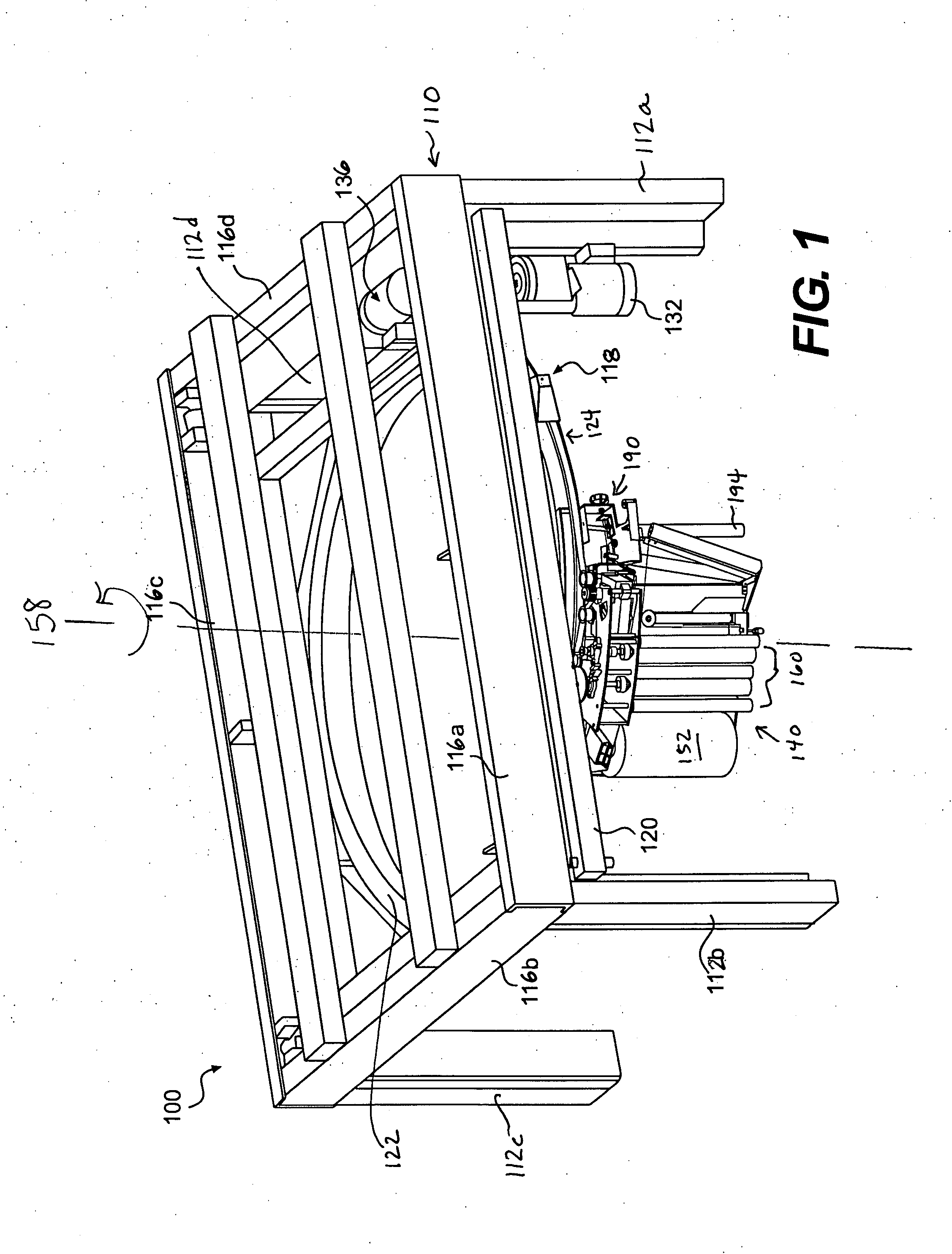

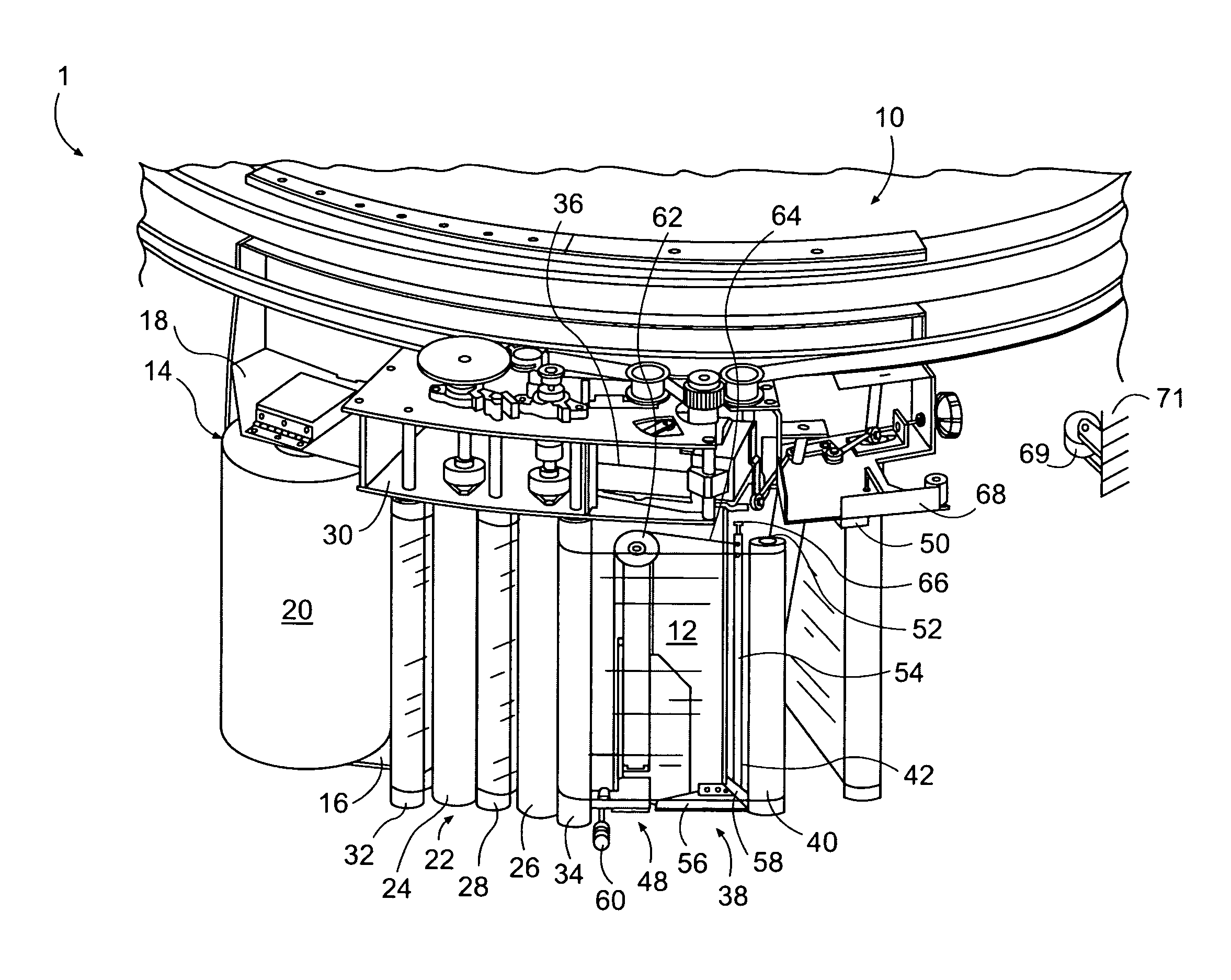

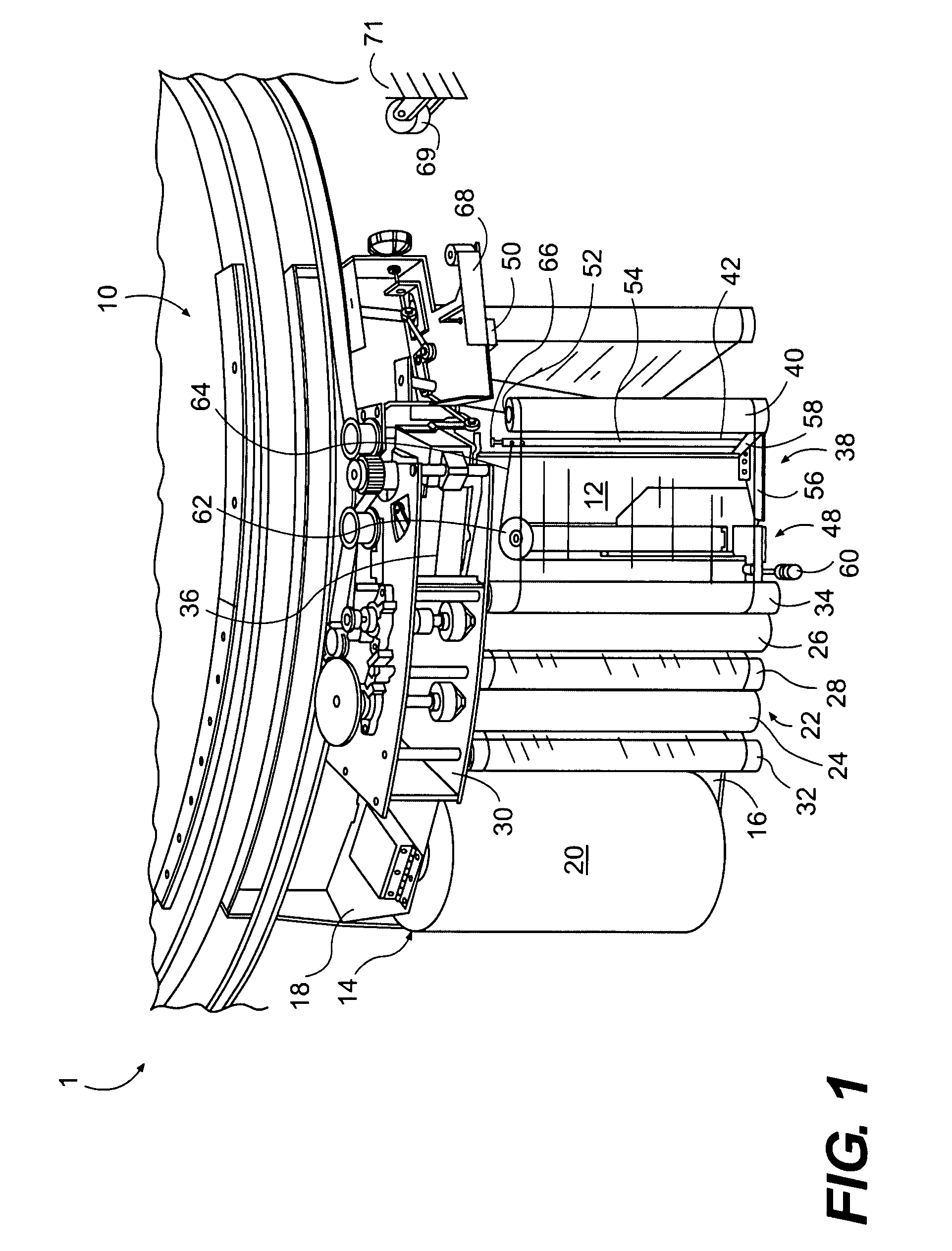

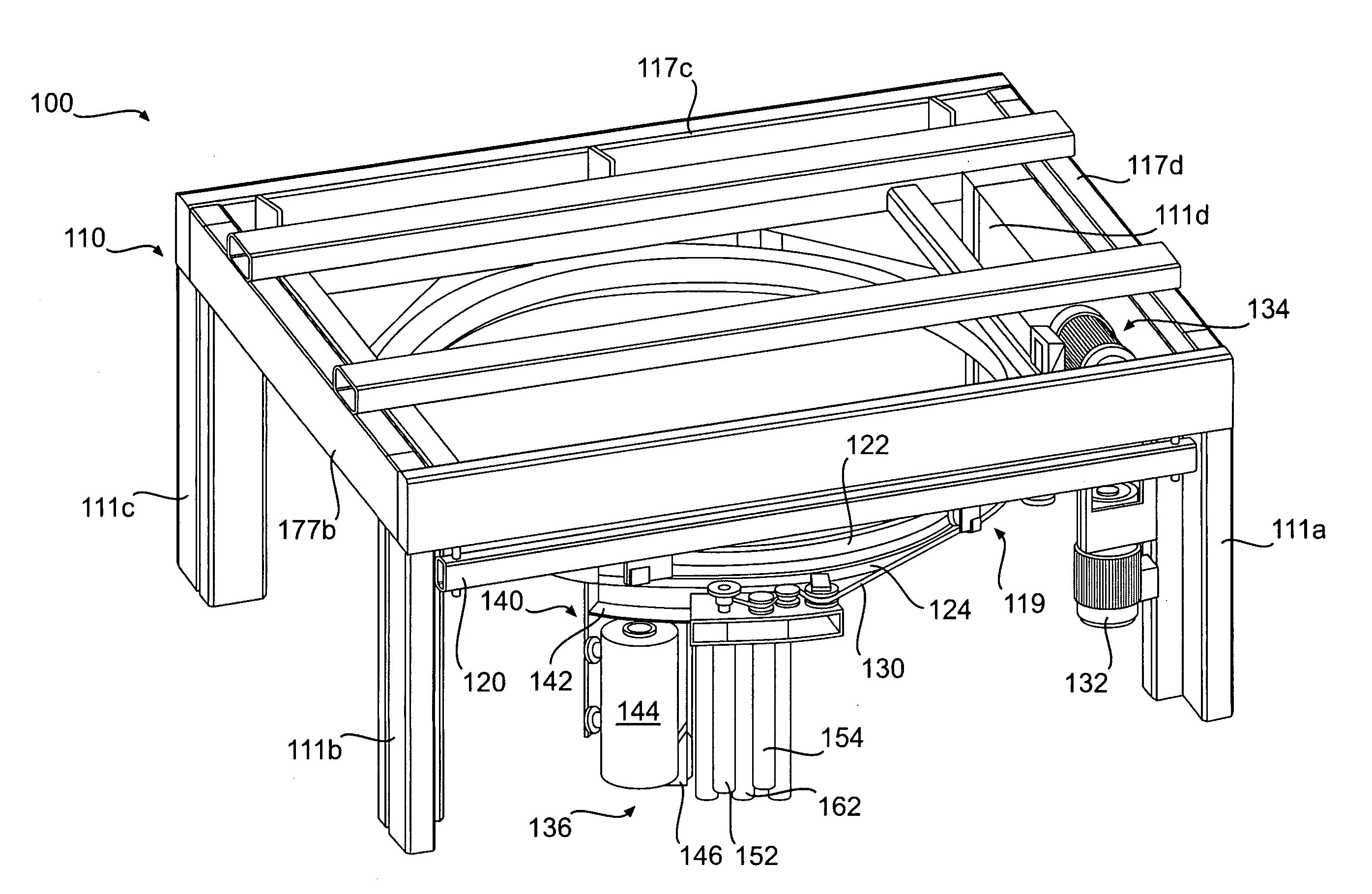

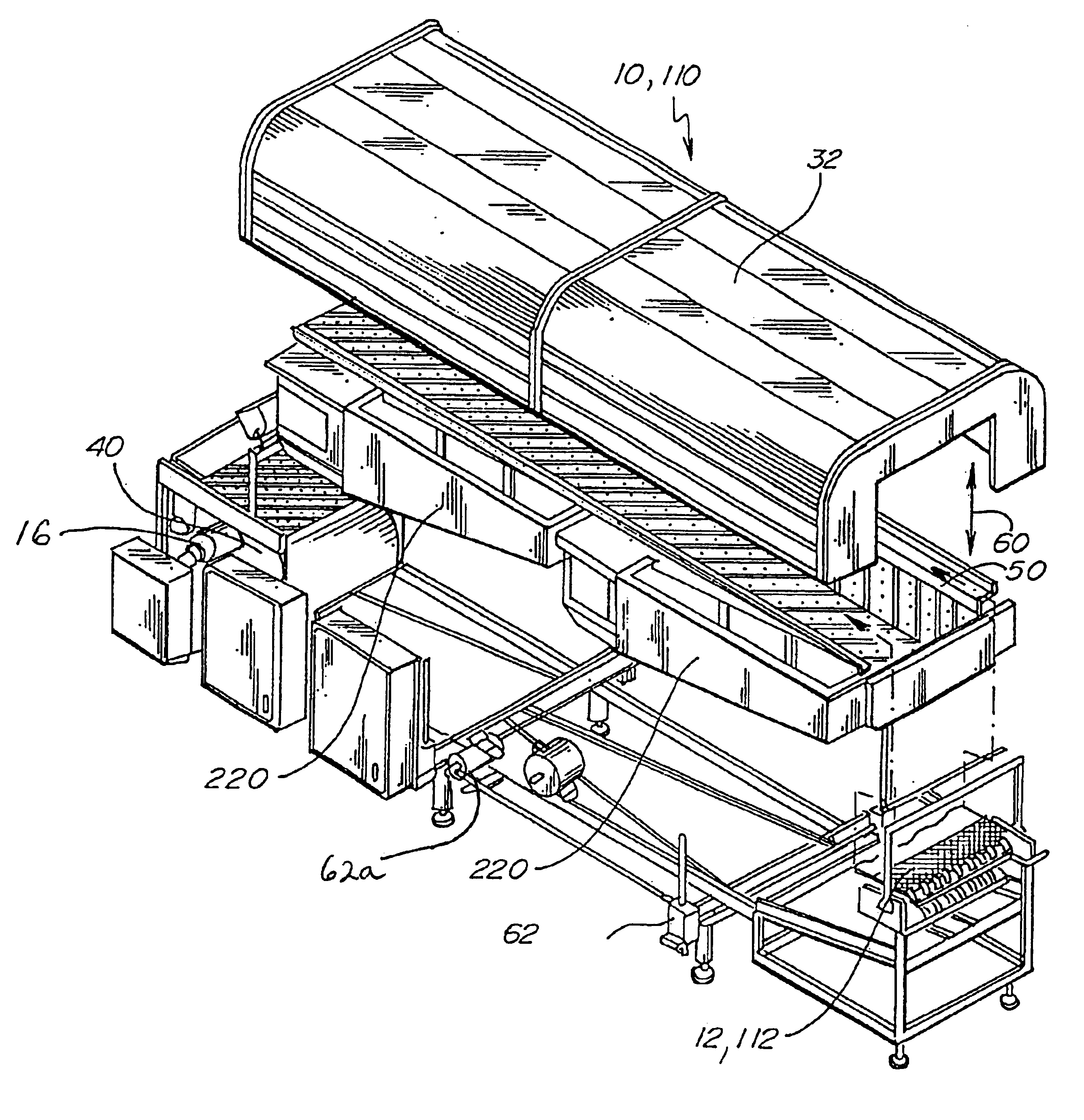

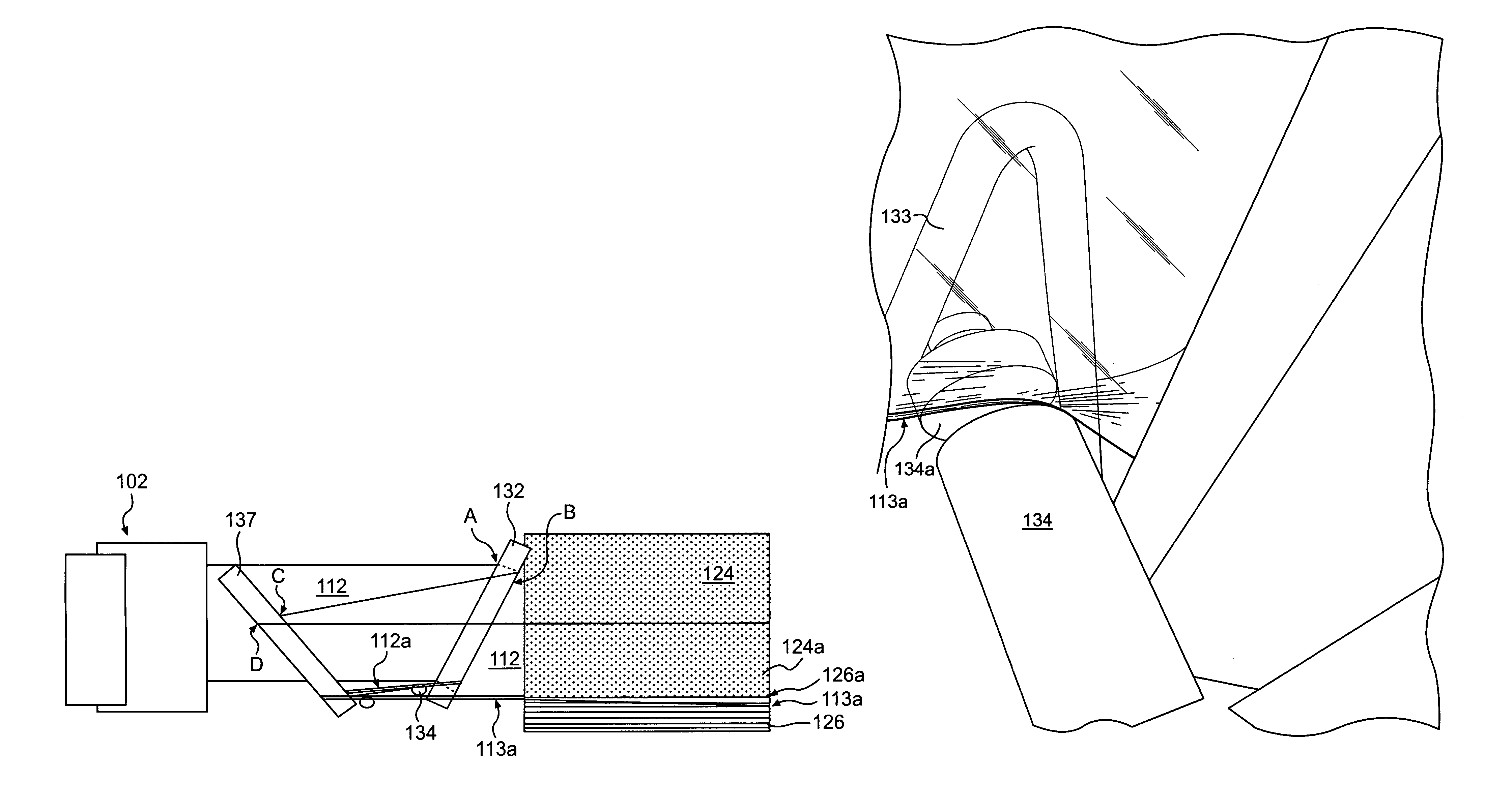

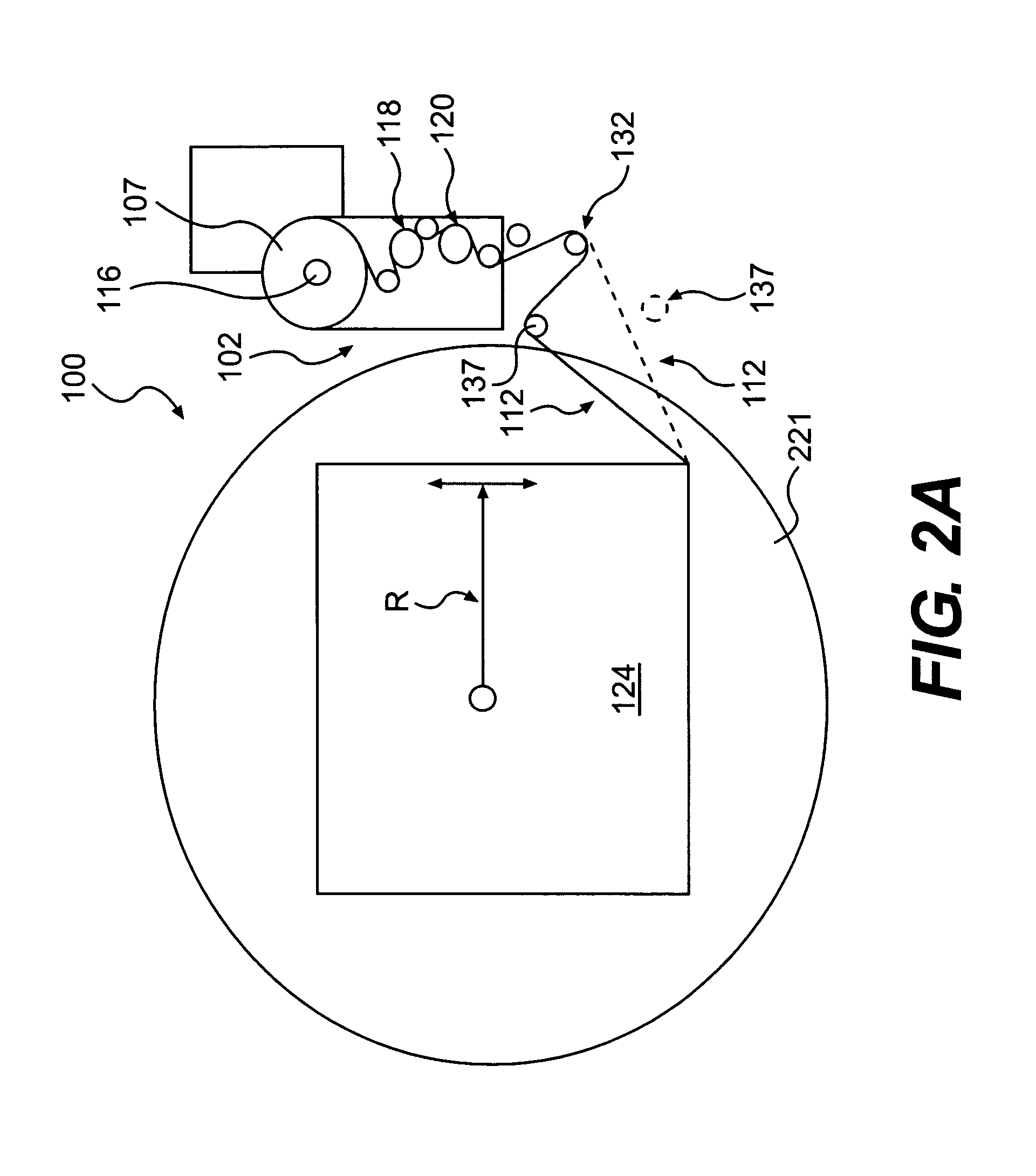

Wrapping apparatus including metered pre-stretch film delivery assembly and method of using

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched packaging material based upon load girth. A non-rotating ring carries a belt driven by a motor. A packaging material dispenser is mounted on a rotating ring, and the rotating ring may include a pulley that connects to the band, such that the rotating ring is driven by the drive belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched packaging material to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum packaging material use is obtained by dispensing a length of pre-stretched packaging material that is between approximately 90% and approximately 120% of load girth. Once the amount of packaging material to be dispensed per revolution is determined, a ratio of rotating ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / rotating ring rotation) can be set and mechanically controlled. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of packaging material is dispensed and wrapped around the load. In an alternative embodiment, the ratio is electronically controlled.

Owner:LANTECH COM

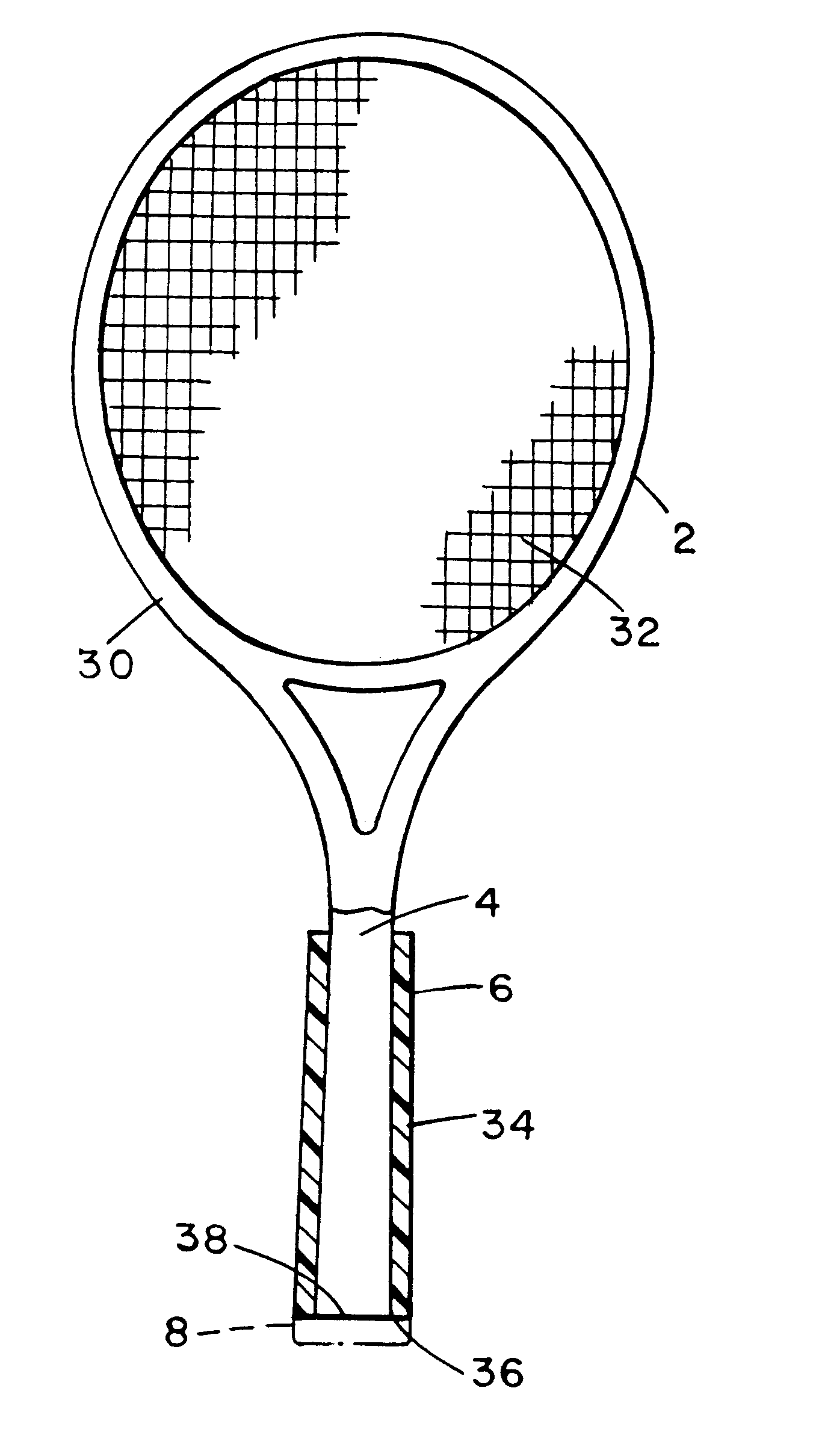

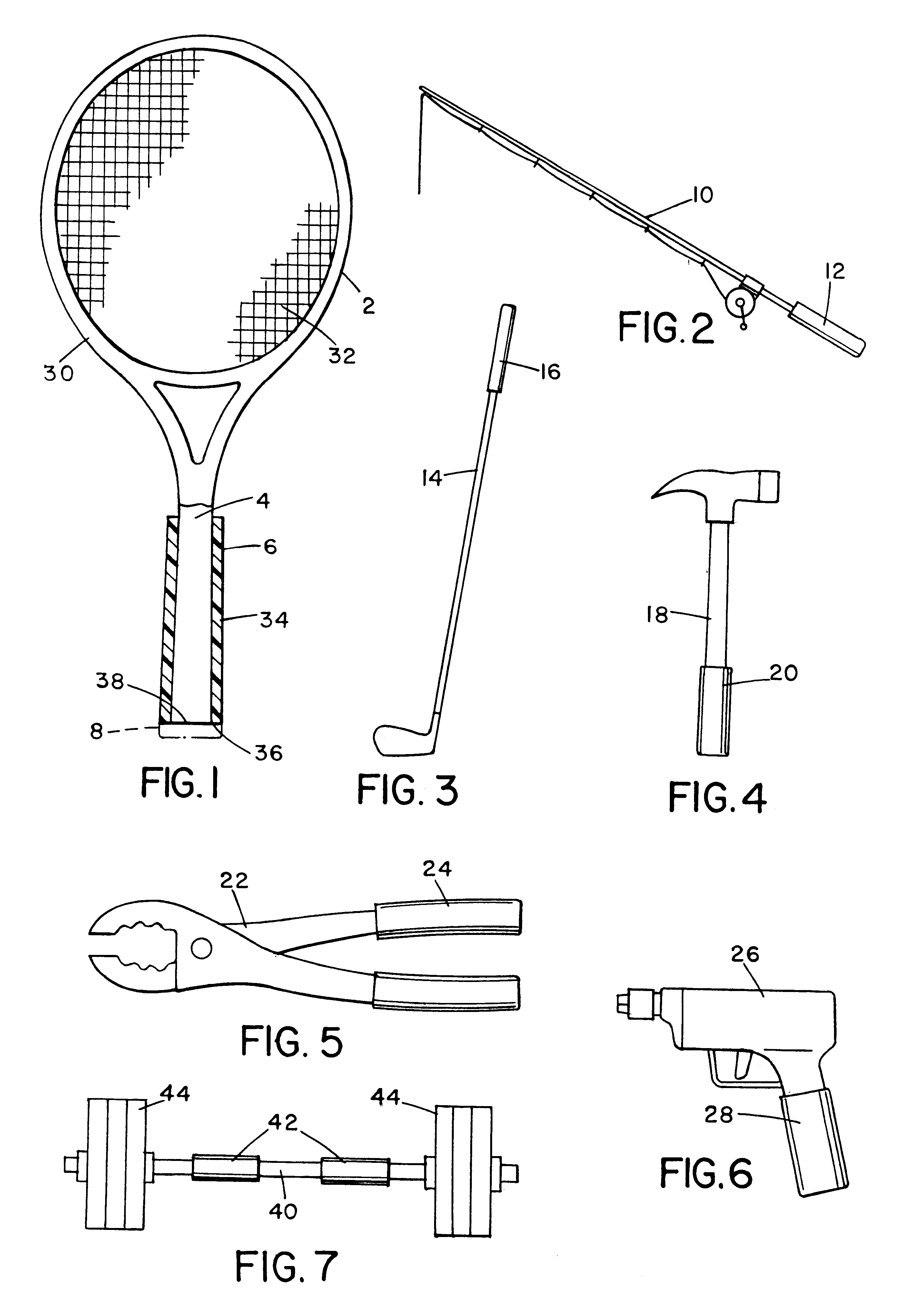

Low-odor single element equipment grip

A low odor grip is disclosed for a handle of a hand-held implement such as a sports implement or a manual or electric tool which is essentially free of disagreeable odors, which can be installed and quickly shrunk into a tight vapor resistant grip within a matter of a few minutes rather than requiring extended periods of time, and can be installed without the need for any application of heat or use of special tools, equipment or materials. The present device is therefore easy to install, merely sliding over the handle while in dilated state and then allowed to shrink and set by evaporation of the solvent, and thus can be satisfactorily installed in both fabrication facilities and in the field either as an original or replacement grip. The invention also includes an implement fitted with such grip. Representative implements include sports implements such as golf clubs, tennis racquets, weight bars and fishing poles, as well as tools such as hammers, drills, pliers, shovels, axes, and the like. The grip is preferable made of a swellable elastomeric material, preferably a natural or synthetic rubber. Suitable rubbers include EPDM rubber, neoprene or chlorosulfonate polyethylene (Hypalon(TM)) rubber, of which EPDM rubber is preferred.

Owner:JONES MICHAEL G

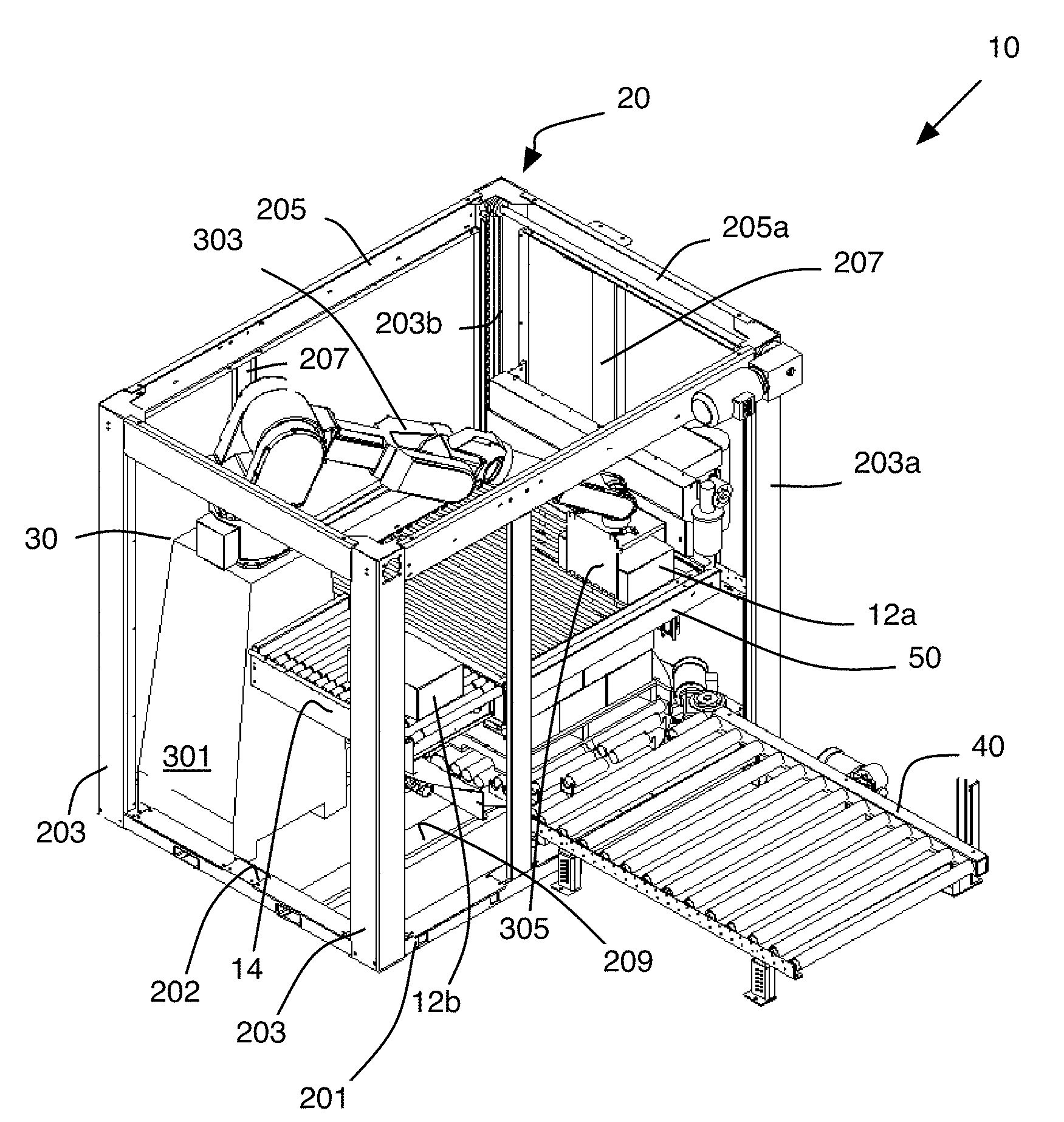

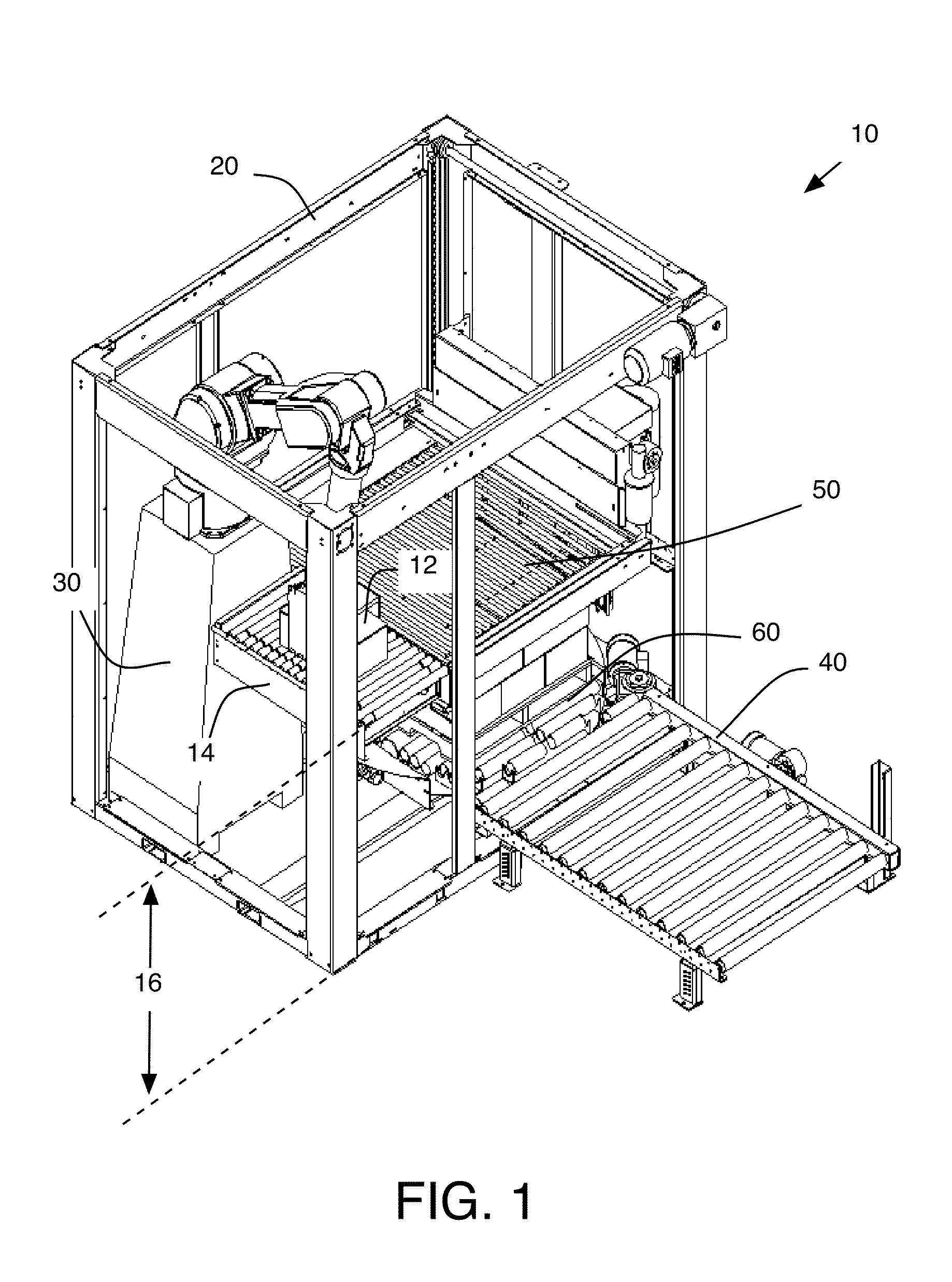

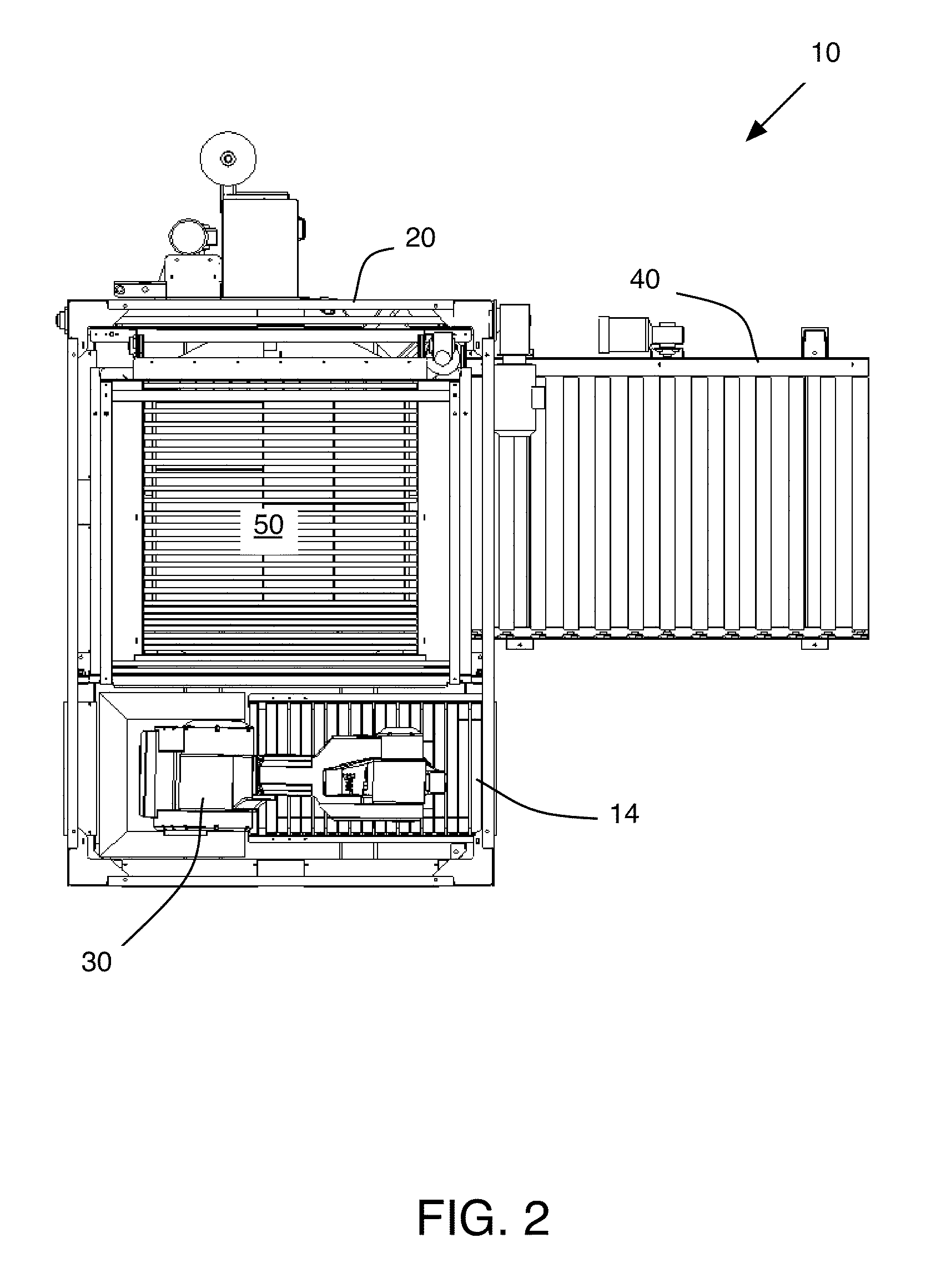

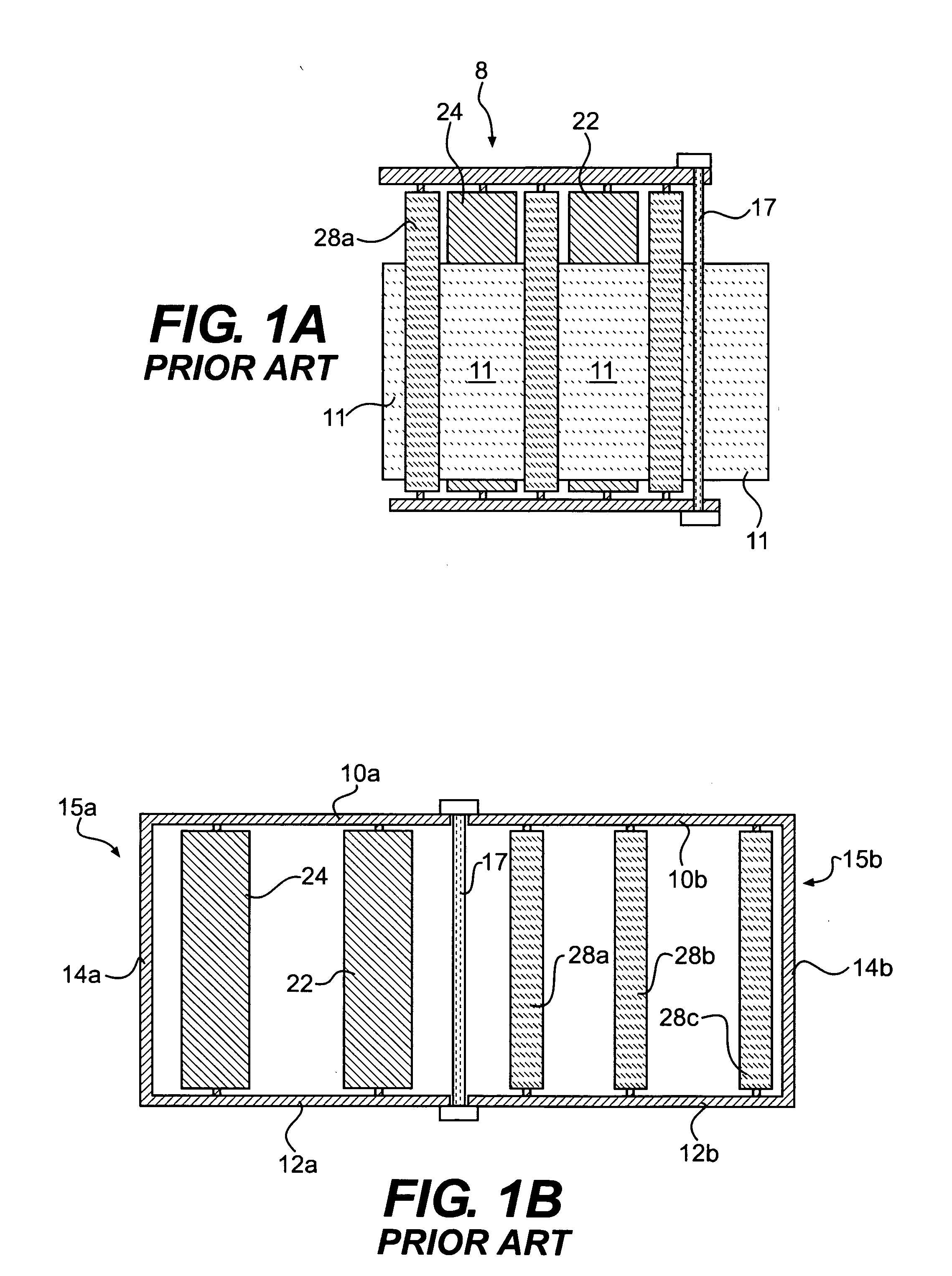

Hybrid palletizer

ActiveUS8074431B1Increase speedShorten the timeWrappers shrinkageSolid materialIndividual itemRobotic arm

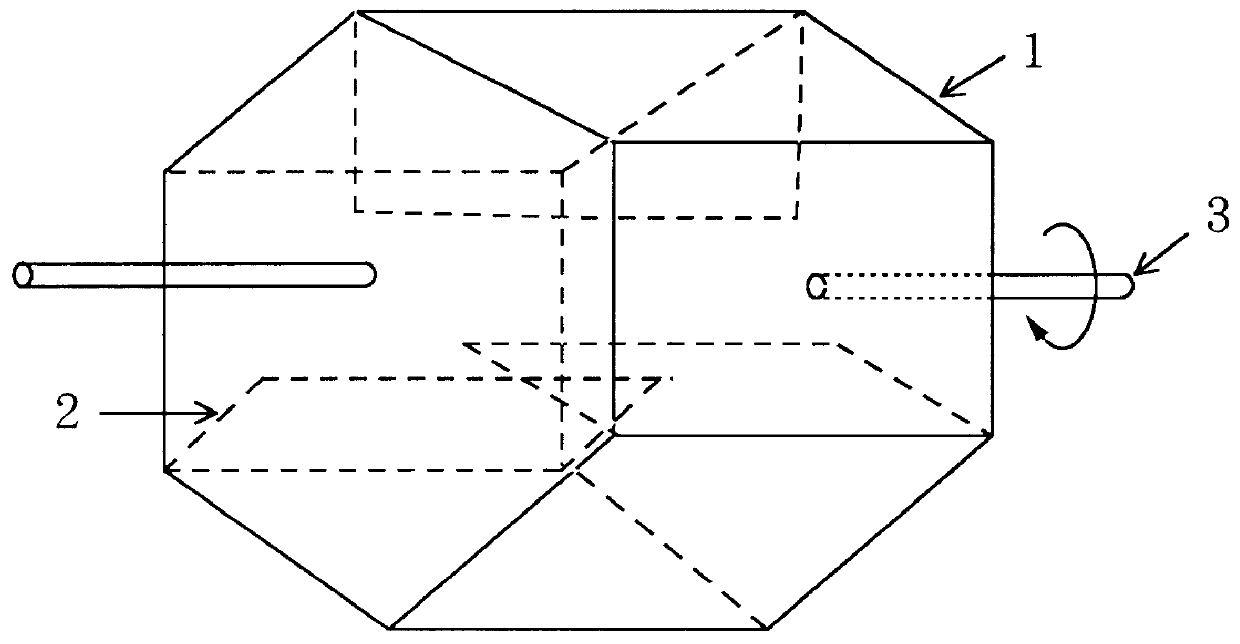

The present invention relates to compact palletizers that include a stretch-wrap operation as the pallet is built. Specifically, the present invention uses a robot to place items from a fixed infeed elevation either above or, alternatively, below the height of the finished load. A four-sided compression mechanism compresses the rough-built load to the final pallet size and then the entire layer is released to the pallet.Individual items or group of items are picked and placed onto a layer support device in a loose orientation. The loose orientation enables a much faster palletizing operation because the robotic arm that pick-and-places the item, the items, or the row of items, can travel much faster as it does not have to precisely locate the item, items, or row of items. During the time that a layer is being loosely constructed on the layer support device concurrent wrapping can occur.

Owner:TOP TIER

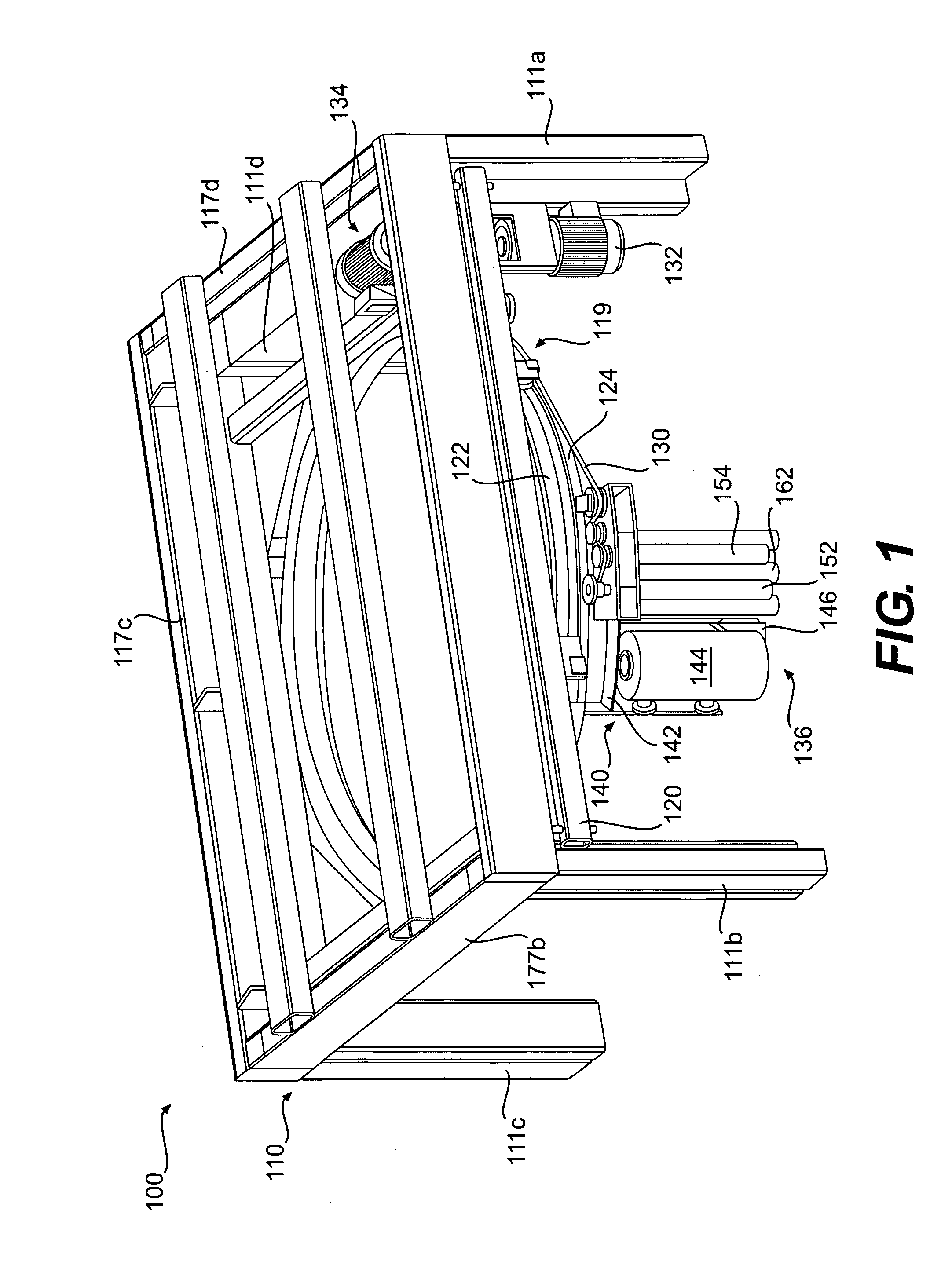

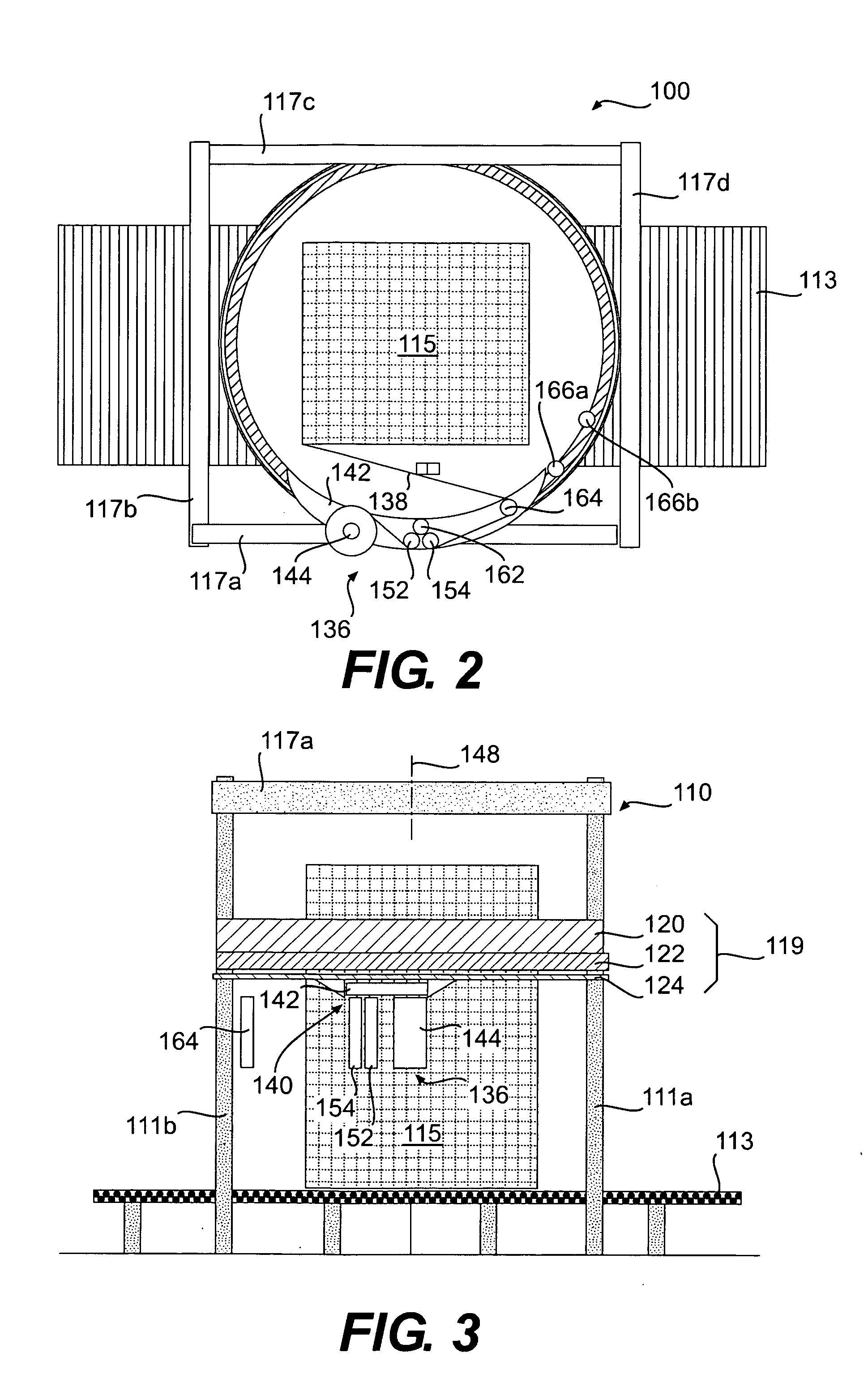

Ring wrapping apparatus including metered pre-stretch film delivery assembly

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched packaging material based upon load girth. A non-rotating ring carries a belt driven by a motor. A packaging material dispenser is mounted on a rotating ring, and the rotating ring may include a pulley that connects to the band, such that the rotating ring is driven by the drive belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched packaging material to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum packaging material use is obtained by dispensing a length of pre-stretched packaging material that is between approximately 90% and approximately 120% of load girth. Once the amount of packaging material to be dispensed per revolution is determined, a ratio of rotating ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / rotating ring rotation) can be set and mechanically controlled. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of packaging material is dispensed and wrapped around the load. In an alternative embodiment, the ratio is electronically controlled.

Owner:LANTECH COM

Stretch wrap films

InactiveUS6093480AImprove clingImproved maximum stretchWrappers shrinkageSynthetic resin layered productsStretch wrapGram

A multilayer, thermoplastic stretch wrap film containing at least three polymeric film layers and comprised of a first layer and a second layer. The first and second layers may comprise a polymer of two or more monomers, wherein a first monomer is ethylene, in a major amount by weight, and a second monomer is an alpha olefin of from about 3 to about 12 carbon atoms, in a minor amount by weight. If the first and second layers are outer layers, they have a cling force to each other of at least about 140 grams / inch. The stretch wrap film also has at least one inner polymeric layer, located between the first and second layers. The inner polymeric layer comprises a low polydispersity polymer having a polydispersity of from about 1 to about 4, a melt index (I.sub.2) of from about 0.5 to about 10 g / 10 min., and a melt flow ratio (I.sub.20 / I.sub.2) of from about 12 to about 22. The inner layer(s) comprise(s) from about 5 wt. % to about 40 wt. % of the stretch wrap film so as to produce a film having a maximum stretch of at least 340%, a F-50 dart drop value of at least about 130 g / mil, a machine directional tear resistance of at least about 125 g / mil and a transverse directional tear resistance of at least about 500 g / mil. It is contemplated that additional outer layers may be added such an outer high cling layer or an outer slip layer, as well as additional inner layers.

Owner:BERRY PLASTICS CORP

Heat-shrinkable multi-layer film

InactiveUS6146726AImprove sealingLow-temperature sealabilityWrappers shrinkageShrinkage connections1-OcteneCLARITY

The invention provides a heat-shrinkable multi-layer film comprising at least a thermoplastic resin layer as the outermost layer (A), a gas barrier resin layer as a core layer (B) and a sealing resin layer as the innermost layer (C), and optionally an adhesive layer between the individual layers, wherein (1) the sealing resin layer of the innermost layer (C) is a layer formed of a resin material (b) comprising a linear ethylene-1-octene copolymer (a) obtained by using a constrained geometry catalyst and having an 1-octene content not lower than 1 wt. % but lower than 20 wt. % and a density higher than 0.885 g / cm3 but not higher than 0.960 g / cm3, and (2) an intermediate layer (D1) formed of at least one resin (c) selected from the group consisting of polyamide resins, thermoplastic polyester resins and ethylene copolymer resins is provided between the outermost layer (A) and the core layer (B). The film has excellent sealing properties, clarity, mechanical strength, stretchability and bag-making property.

Owner:KUREHA KAGAKU KOGYO KK

Tear initiation and directional tear films and packages made therefrom

ActiveUS20050084636A1Control depthControl shapeEnvelopes/bags making machineryStampsPolyesterPolyolefin

The present invention provides a flexible multilayer packaging film and packages formed therefrom wherein the films include a first film layer comprising a first biaxially-oriented polymer selected from the group consisting of a polyester, a polyolefin, a polyamide, and a blend thereof and a surface-roughened portion, a second film layer comprising an adhesive, a third film layer comprising a barrier material, a fourth film layer comprising a second biaxially-oriented polymer selected from the group consisting of a polyester, a polyolefin, a polyamide, and a blend thereof and at least one score-line; wherein the packages comprise a tear-initiation area and a directional tear zone.

Owner:BEMIS COMPANY INC

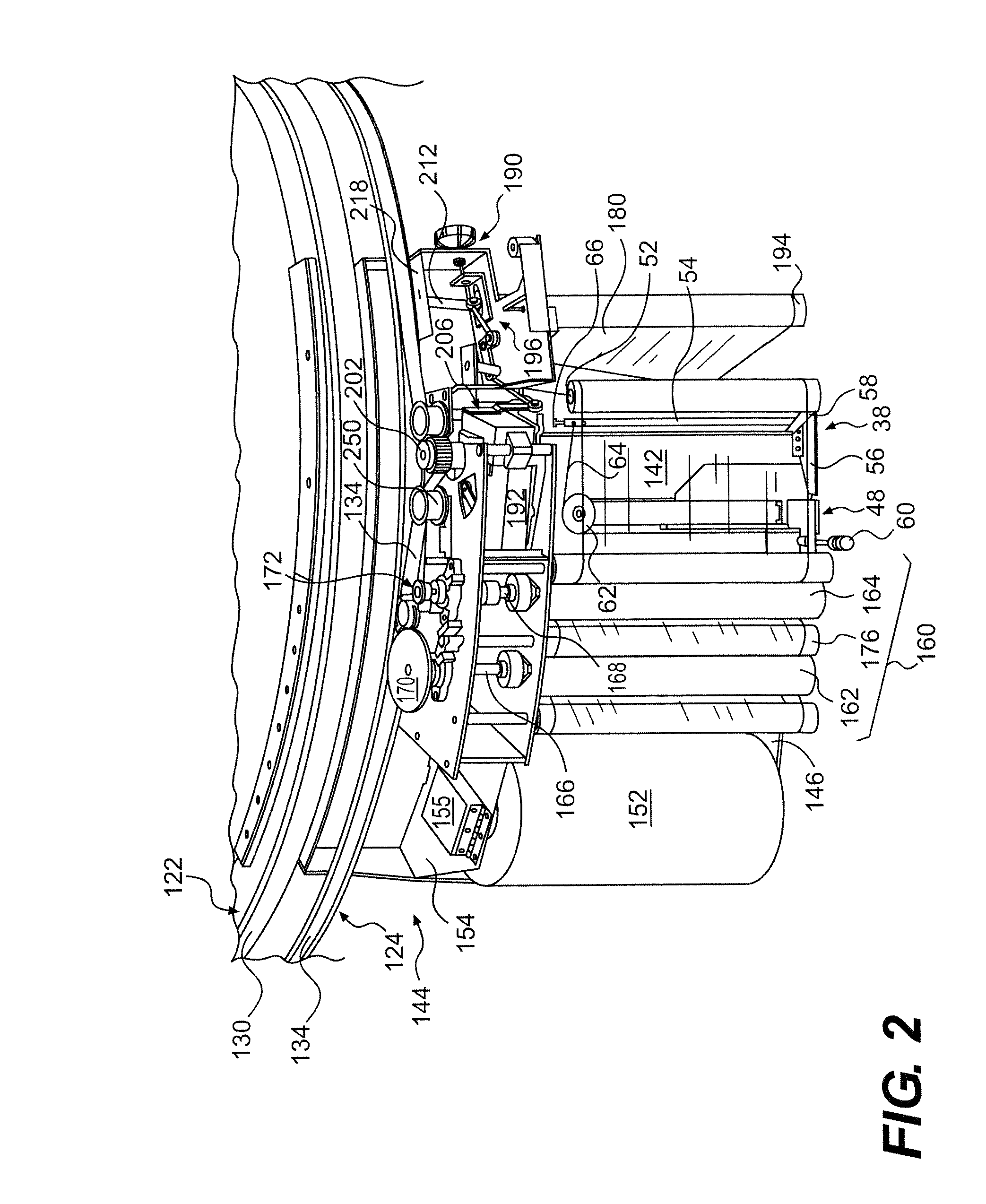

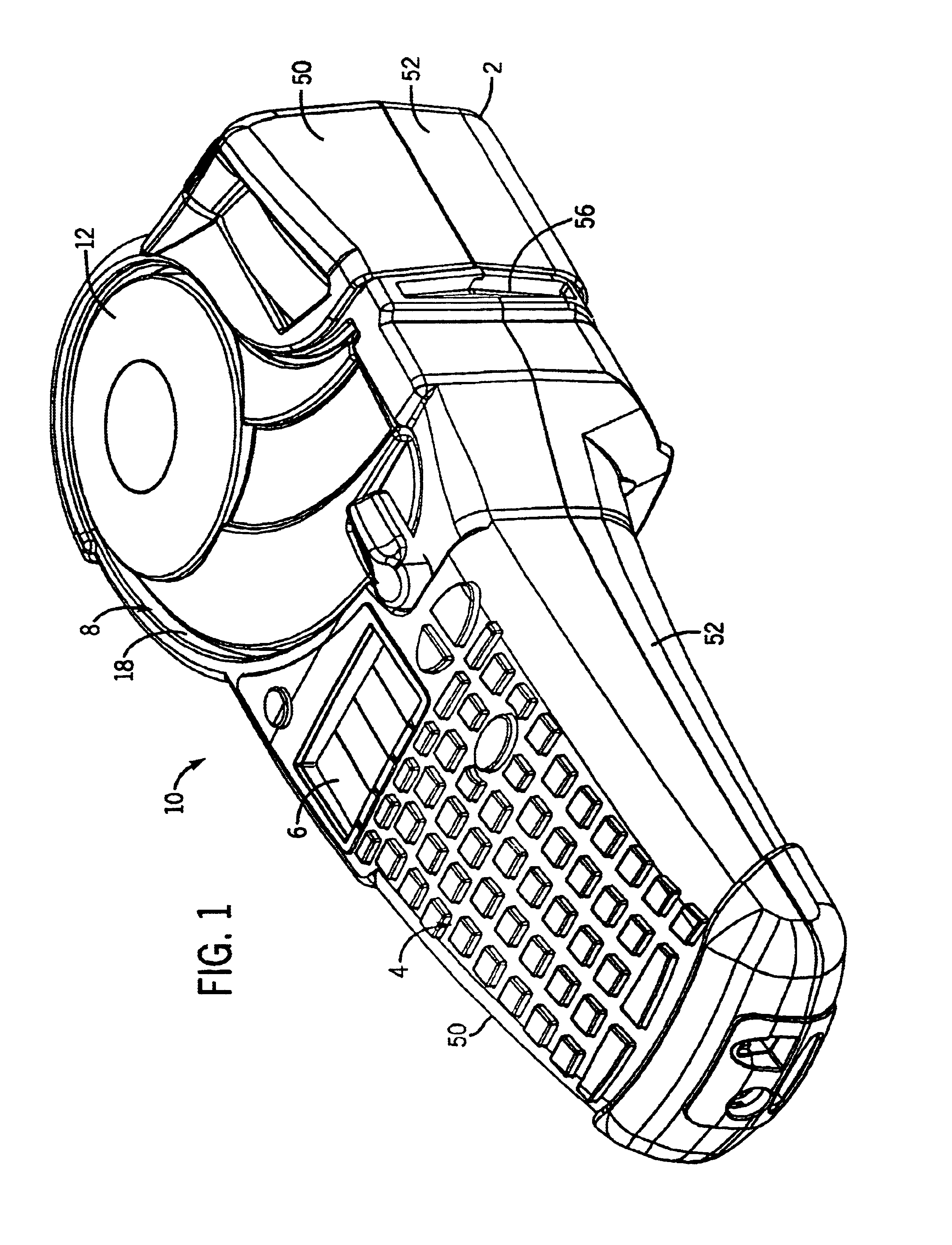

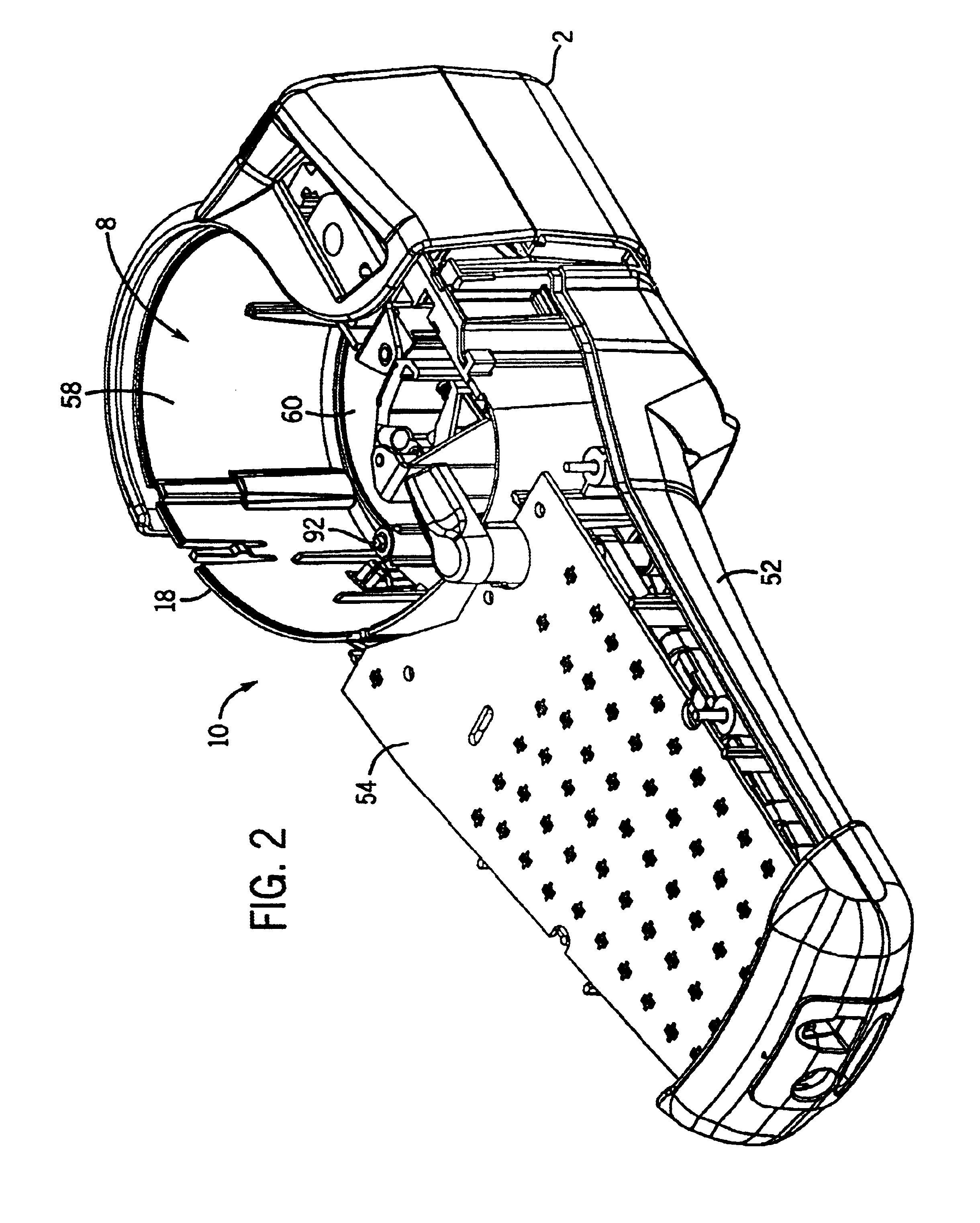

Method and apparatus for securing a load to a pallet with a roped film web

An apparatus and method for wrapping a palletized load are provided. The apparatus preferably includes a film dispenser for dispensing a film web, at least one drive down roller configured to engage the width of the film web, and at least one roping mechanism. The at least one roping mechanism may be a cable rolling element configured to roll a portion of the film web into a rolled cable of film. The apparatus may also include means for providing relative rotation between the load and the dispenser to wrap a roped portion of the film web around a base of the load / top portion of a pallet supporting the load.

Owner:LANTECH COM

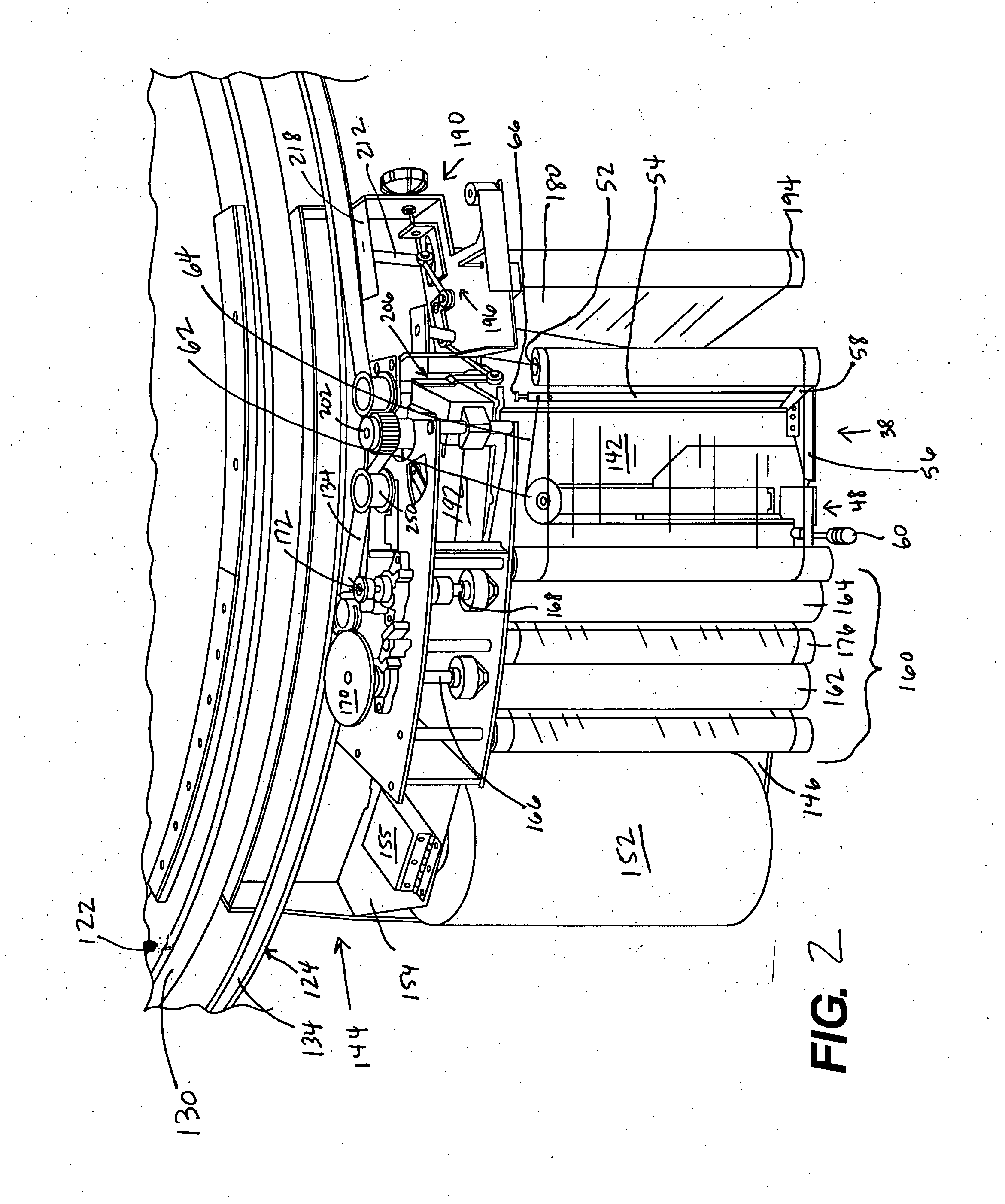

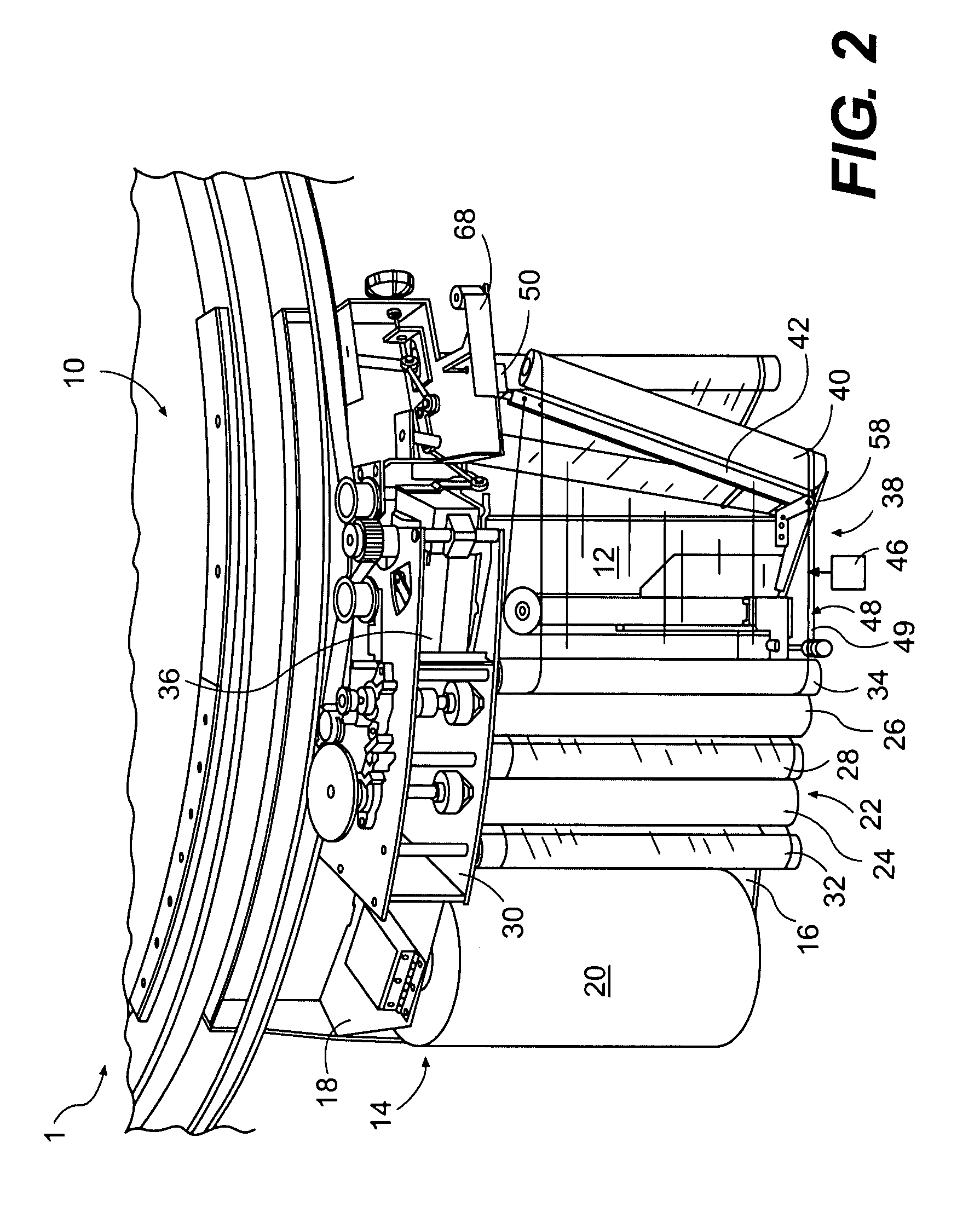

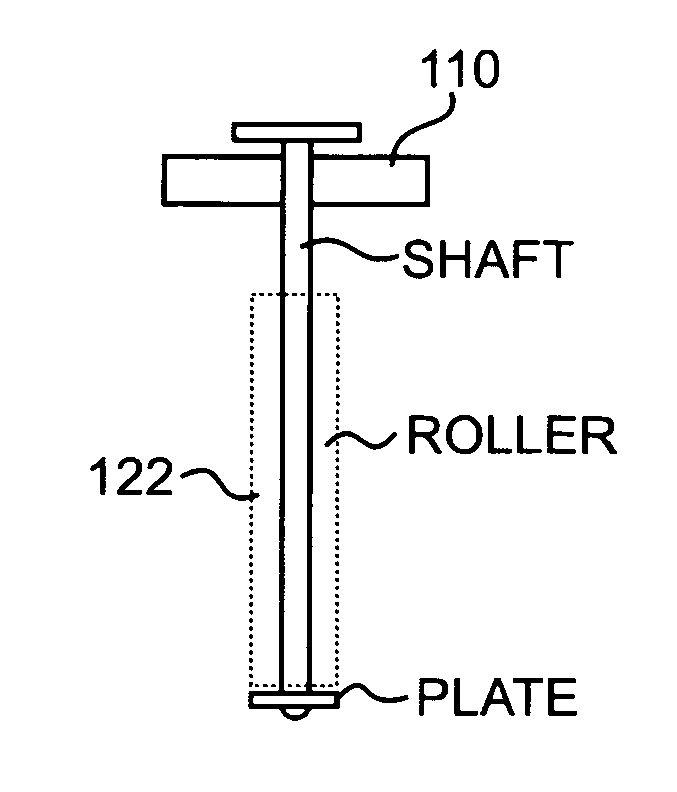

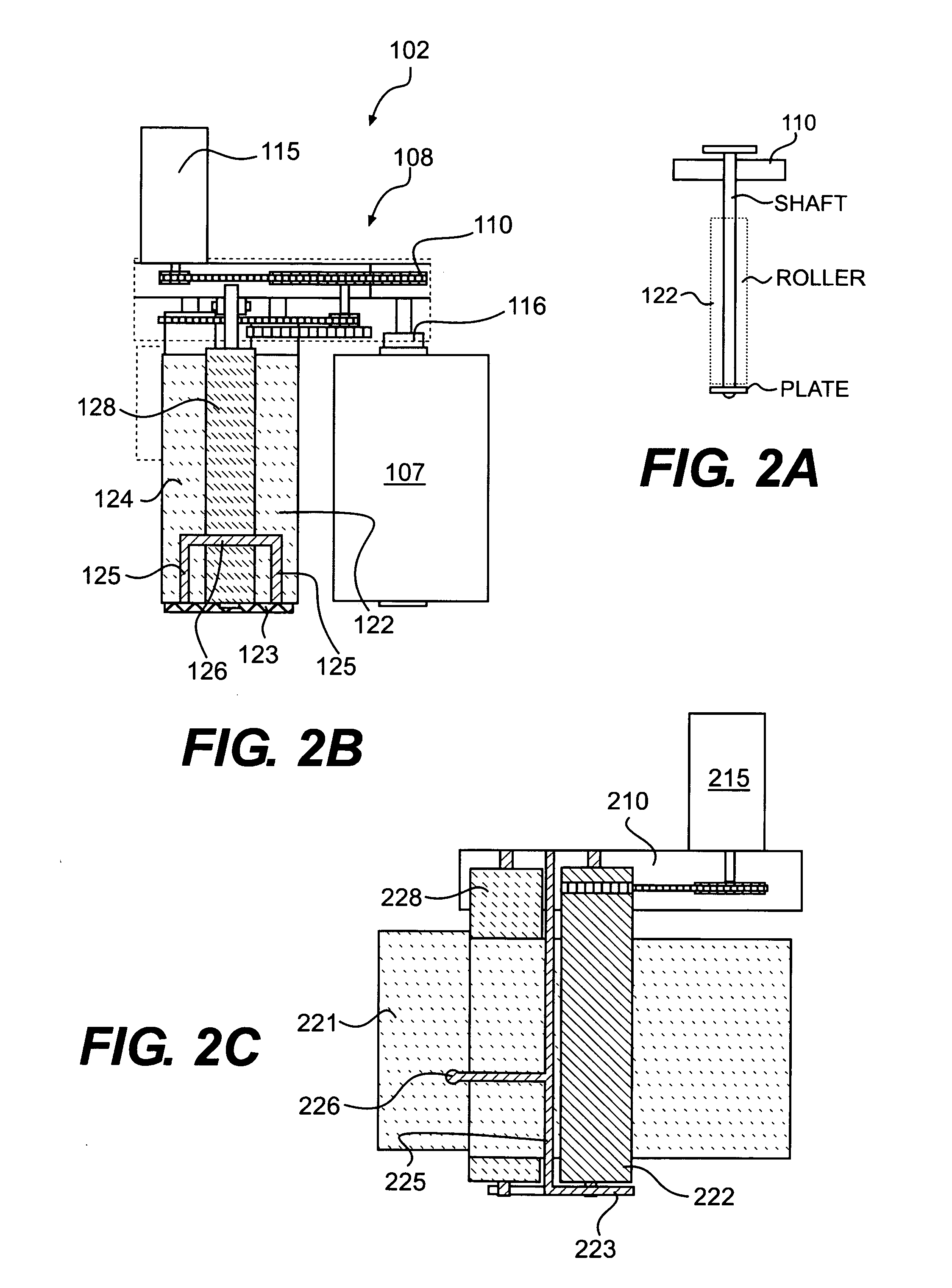

Stretch wrapping apparatus having film dispenser with pre-stretch assembly

A film dispenser for a stretch wrapping apparatus is provided. The film dispenser includes a pre-stretch assembly having a top portion mounted to and extending downwardly from a drive plate of a roll carriage frame. The pre-stretch assembly includes two pre-stretch rollers having first ends connected to the roll carriage frame and second ends connected to one another. The pre-stretch rollers may be coated. The pre-stretch assembly further includes a cantilevered idle roller mounted to the drive plate and positioned between the pre-stretch rollers. A film path is defined by the space between the pre-stretch rollers and the idle roller. The film path is easily accessible via the bottom end of the pre-stretch assembly.

Owner:LANTECH COM

Wire marker label media

InactiveUS6929415B2Accurate guideWrappers shrinkageLamination ancillary operationsEngineeringElectric wire

A label media for use in a label media printer forms dynamically sized label markers. The label media includes a continuous tube affixed to a length of a carrier web. Indicia is printed on the tube which is then cut to a desired length that accommodates the indicia printed thereon to dynamically form the wire marker.

Owner:BRADY WORLDWIDE INC

Adhesive polyethylene compositions and multi-layer laminated films using the same

InactiveUS6210765B1Improve adhesion strengthHigh heat sealing strength heatWrappers shrinkageShrinkage connectionsElastomerPolyamide

Disclosed is a specific adhesive polyethylene composition comprising [1] a modified ethylene / alpha-olefin copolymer resin or elastomer obtained by modifying a specific ethylene / alpha-olefin copolymer resin or elastomer, each of which comprises ethylene and an alpha-olefin of 3 to 20 carbon atoms, with an unsaturated carboxylic acid or anhydride, ester, amide, imide or metallic salt derivative of a unsaturated carboxylic acid thereof, [2] an unmodified ethylene / alpha-olefin copolymer resin and / or an unmodified ethylene / alpha-olefin copolymer elastomer and [3] a tackifier. Also disclosed is a multi-layer laminated film of 3 or more layers in which a layer of the above composition is interposed between an ethylene polymer layer and either a polyamide resin layer, an ethylene / vinyl alcohol copolymer layer or a layer of a mixture of polyamide resin and ethylene / vinyl alcohol copolymer. The adhesive polyethylene composition shows excellent adhesion strength to ethylene polymers, polyamide resins and ethylene / vinyl alcohol copolymers, high heat-sealing strength and heat resistance. The multi-layer laminated film shows excellent strength, heat resistance and gas barrier properties, and besides this film has heat shrinkability, so that the film is suitably used as a shrink film.

Owner:MITSUI CHEM INC

Method and apparatus for securing a load to a pallet with a roped film web

ActiveUS20050044812A1Narrow widthReduce widthWrappers shrinkageWrapping material feeding apparatusThin membranePallet

An apparatus and method for wrapping a palletized load are provided. The apparatus preferably includes a film dispenser for dispensing a film web, at least one guide rollers configured to engage the width of the film web, and at least one roping element. The at least one roping element may be a cable rolling roper configured to roll a portion of the film web into a rolled cable of film. The apparatus may also include means for providing relative rotation between the load and the dispenser to wrap a roped portion of the film web around a base of the load / top portion of a pallet supporting the load.

Owner:LANTECH COM

Method and apparatus for dispensing a predetermined fixed amount of pre-stretched film relative to load girth

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched film based upon load girth. A non-rotating ring carries a belt driven by a motor. A film dispenser is mounted on a rotating ring, and the rotating ring includes a pulley that connects to the belt, such that the rotating ring is driven by the belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched film to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum film use is obtained by dispensing a length of pre-stretched film that is between approximately 100% and approximately 130% of load girth. Once the amount of film to be dispensed per revolution is determined, a mechanical ratio of ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / ring rotation) can be set. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of film is dispensed and wrapped around the load.

Owner:LANTECH COM

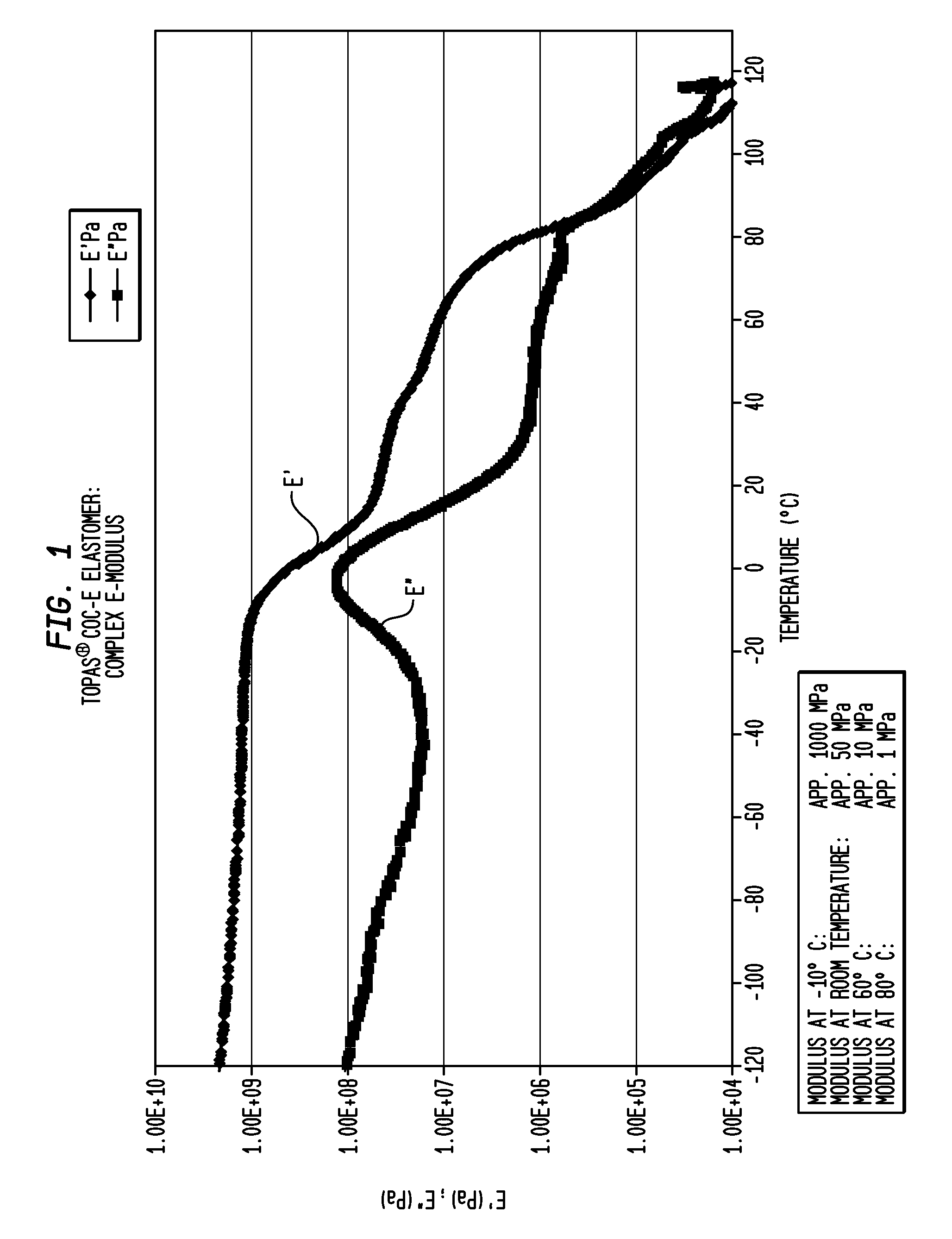

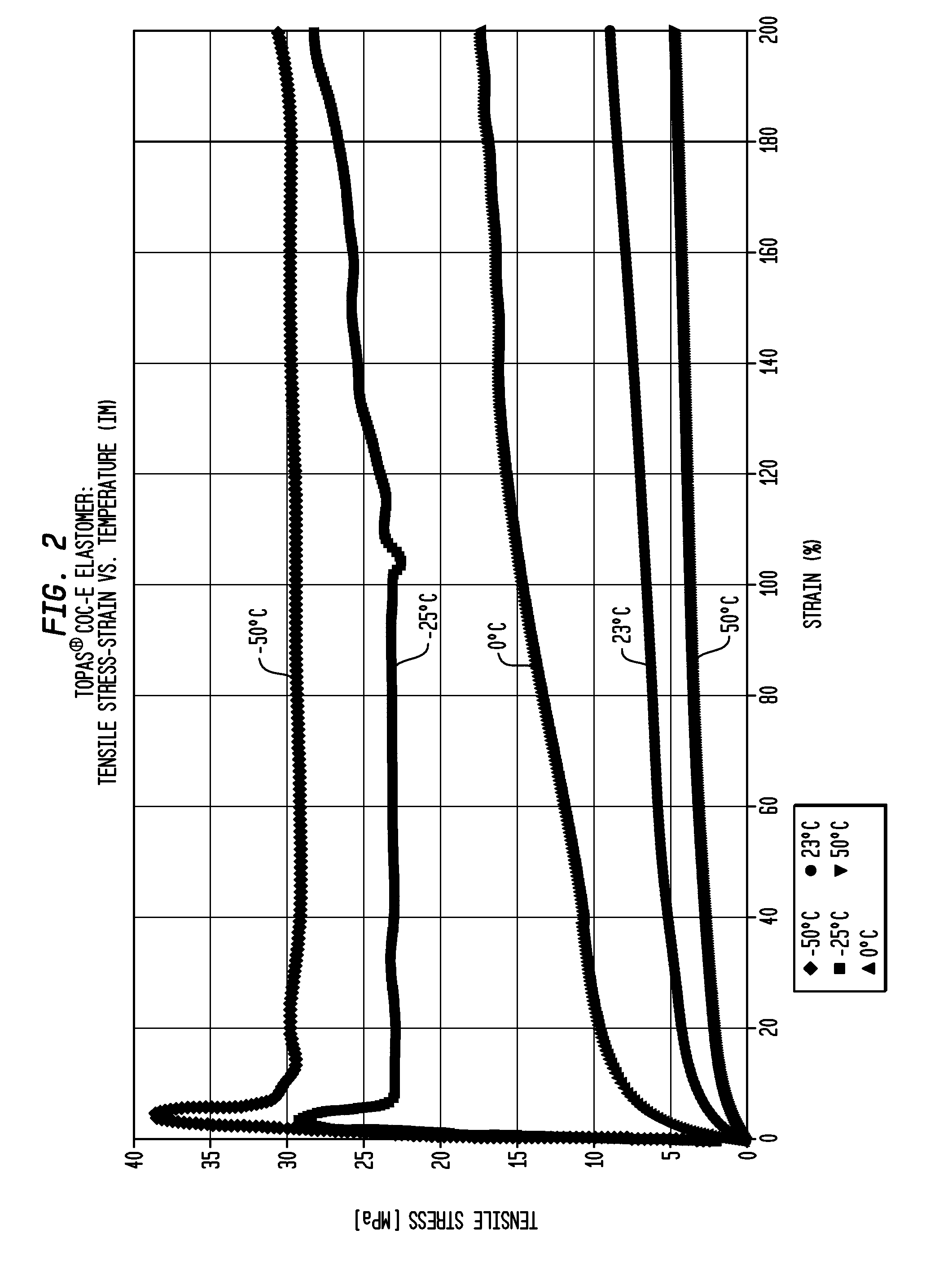

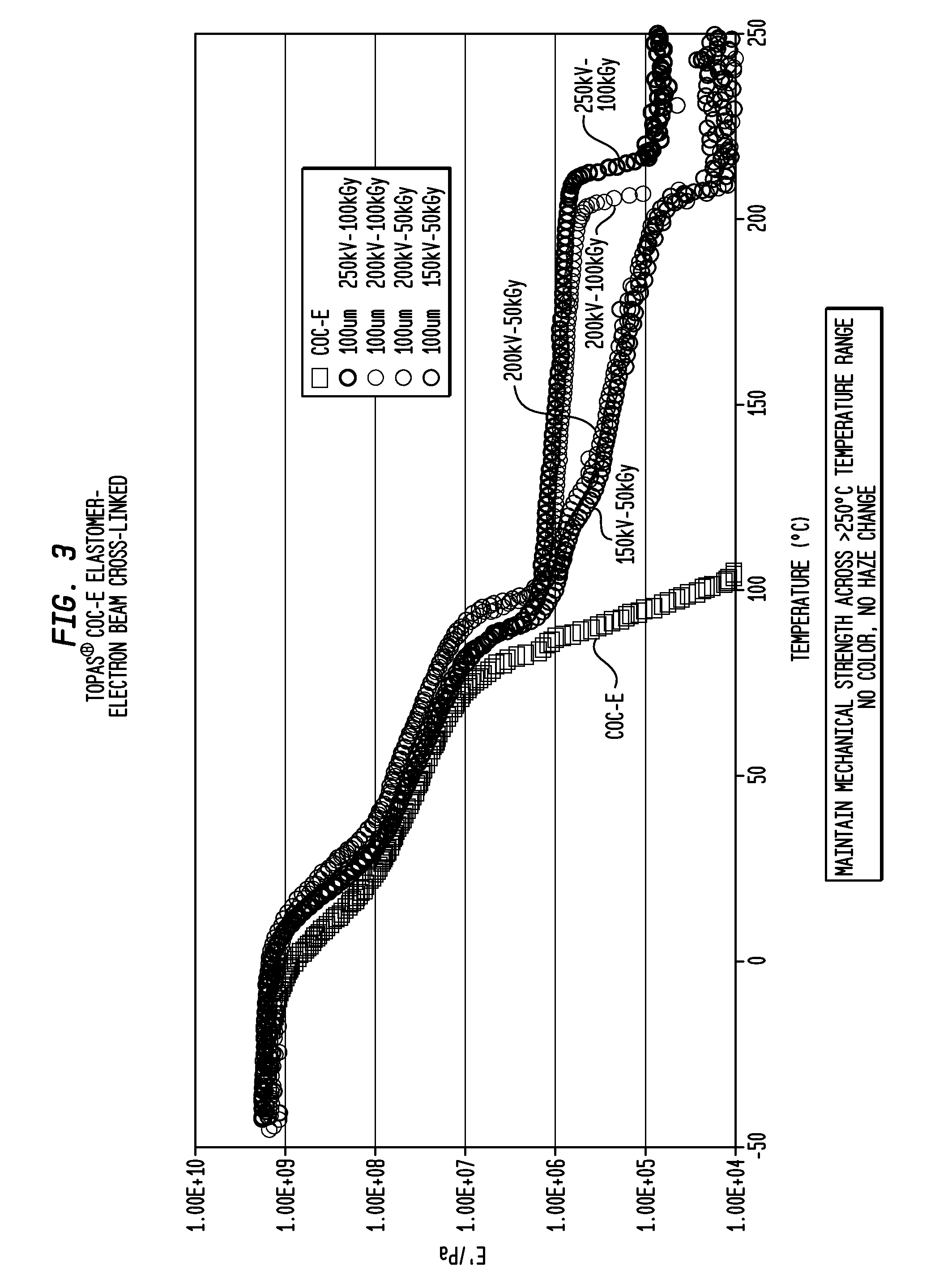

Transparent, Flexible Products Made With Partially Crystalline Cycloolefin Elastomer

InactiveUS20120021151A1Allocation is accurateImprove mechanical propertiesWrappers shrinkageClosuresElastomerNorbornene

Shaped articles made with a partially crystalline, cycloolefin elastomer of norbornene and ethylene typically having at least one glass transition temperature (Tg) in the range of from −10° C. to 15° C. and a crystalline melting temperature in the range of from 60° C. to 125° C. and a % crystallinity by weight in the range of from 5% to 40%. The shaped articles may be in the form of medical tubing; a contact lens mold or component thereof; a container such as a bottle, a squeeze bottle or a squeeze tube; an eyedropper or eyedropper component; an elastomeric closure, optionally a pierceable elastomeric closure or the shaped article is selected from shrink film and / or shrink tubing.

Owner:TOPAS ADVANCED POLYMERS

Heat-shrinkable film with improved inter-ply adhesion

A heat shrinkable film suitable for use in cook-in applications is provided which exhibits a transverse direction free shrink at 50° C. of less than about 2% and a transverse direction free shrink at 57° C. of at least about 3%. The film has at least two layers. The first layer includes an ethylene / vinyl alcohol copolymer and the film has a second layer directly adhered to the first layer, the second layer including at least one member selected from the group consisting of polyester, polyamide and polyurethane. Preferably, the desired shrink properties are attained by annealing the film under controlled conditions.

Owner:CRYOVAC INC

Heat tunnel for film shrinking

InactiveUS7155876B2Minimal distortionMinimum of wrinkles.Wrappers shrinkageFurnace componentsProcess engineeringShrink wrap

Owner:DOUGLAS MACHINE LIABILITY

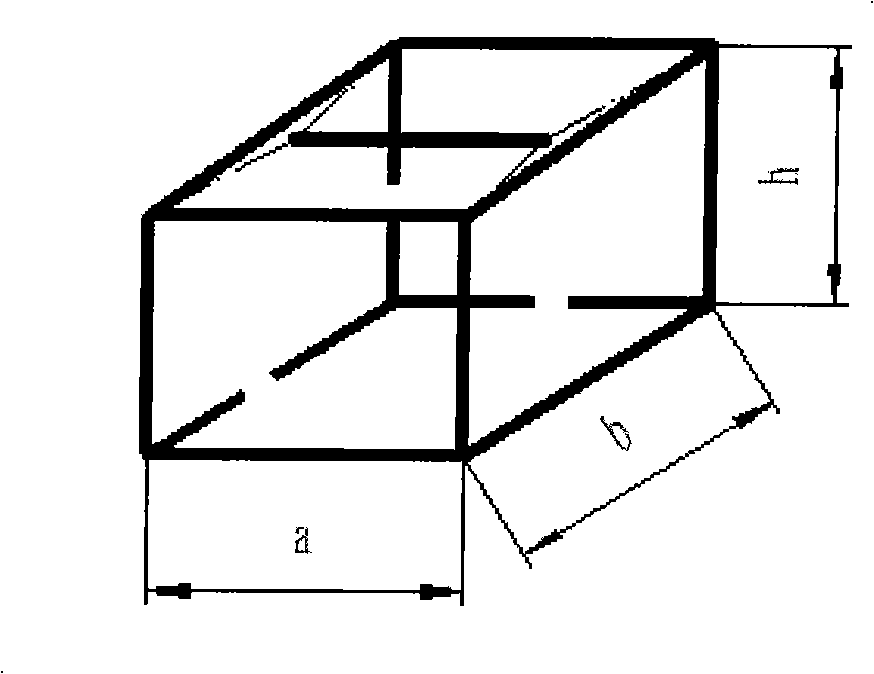

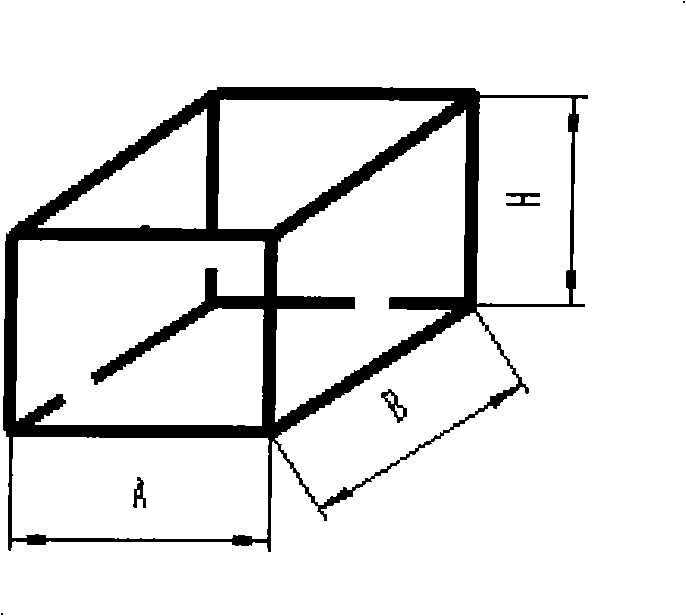

Trilaminar co-extrusion thermal contraction resin film, manufacturing method and application method thereof

InactiveCN101318392AReduce pollutionReduce packaging costsWrappers shrinkageSynthetic resin layered productsThermal contractionPuncturing

The invention discloses a three-layer coextrusion heat shrinkage resin film, a production method and an application method. The-three layer coextrusion heat shrinkage resin film is produced by taking PE(LDPE, HPPE, LLDPE, mPE), EVA, PP, PA and EVOH resins as the main materials which are matched with a functional master batch and adopting a production method of one-step huffing. The largest transverse and longitudinal shrinking rates of the product can reach 60 percent and 85 percent; the largest shrinking force of the product can reach 2.0N / cm. The shrinking rate and the shrinking force of the product can be controlled and adjusted by controlling various technical parameters to lead a package to be firm and endurable. The packaged objects are pertinently led to reach the anti-rust, anti static, illumination-resistance, anti-aging, anti-puncturing, anti-low-temperature, anti-isolation, anti-bacteria and anti-degradation effects and the like by adjusting the material composition and mixture ratio of each layer. The three-layer coextrusion heat shrinkage resin film is used for replacing the traditional paper box wrappage to reduce the packaging cost. The mechanical properties are good, the pertinence is strong, the materials are saved; when the three-layer coextrusion heat shrinkage resin film is used, the shrinking temperature is low, the power is saved and the packaging cost is saved, thus effectively reducing the production cost and having extremely high application value.

Owner:大连华诺塑胶科技有限公司

Method and apparatus for securing a load to a pallet with a roped film web

ActiveUS7568327B2Narrow widthReduce widthWrappers shrinkageWrapping material feeding apparatusThin membranePallet

An apparatus and method for wrapping a palletized load are provided. The apparatus preferably includes a film dispenser for dispensing a film web, at least one guide rollers configured to engage the width of the film web, and at least one roping element. The at least one roping element may be a cable rolling roper configured to roll a portion of the film web into a rolled cable of film. The apparatus may also include means for providing relative rotation between the load and the dispenser to wrap a roped portion of the film web around a base of the load / top portion of a pallet supporting the load.

Owner:LANTECH COM

Shrink sleeve label

A shrink film comprises a skin layer and a base layer. The skin layer may comprise polystyrene or modified polyester. The base layer may comprise alpha-olefin / cyclic-olefin copolymer or alpha-olefin / vinyl aromatic copolymer. The film has a free shrink at 100° C. of at least about 10%. The film is useful for shrink sleeve applications.

Owner:CRYOVAC INC

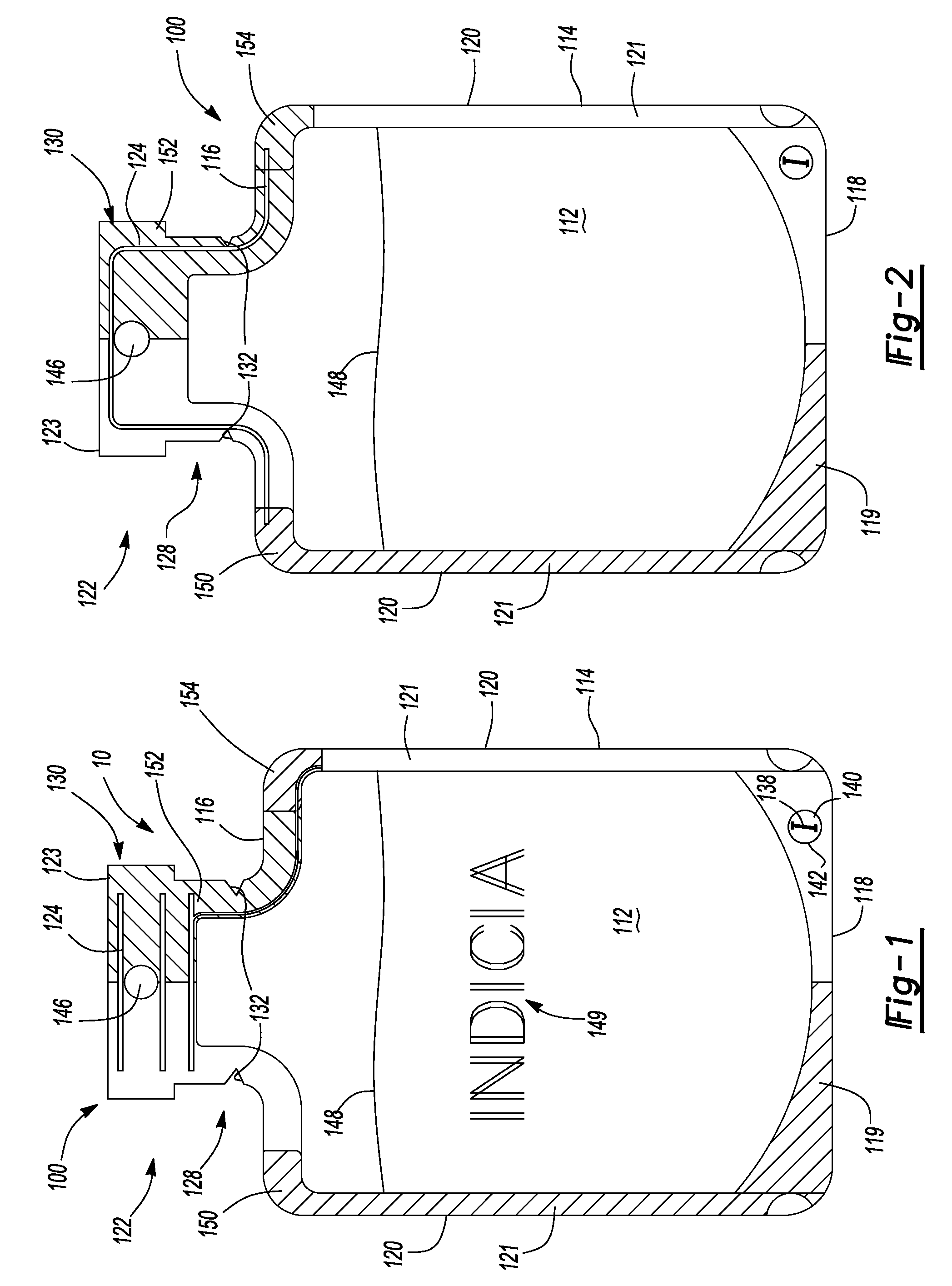

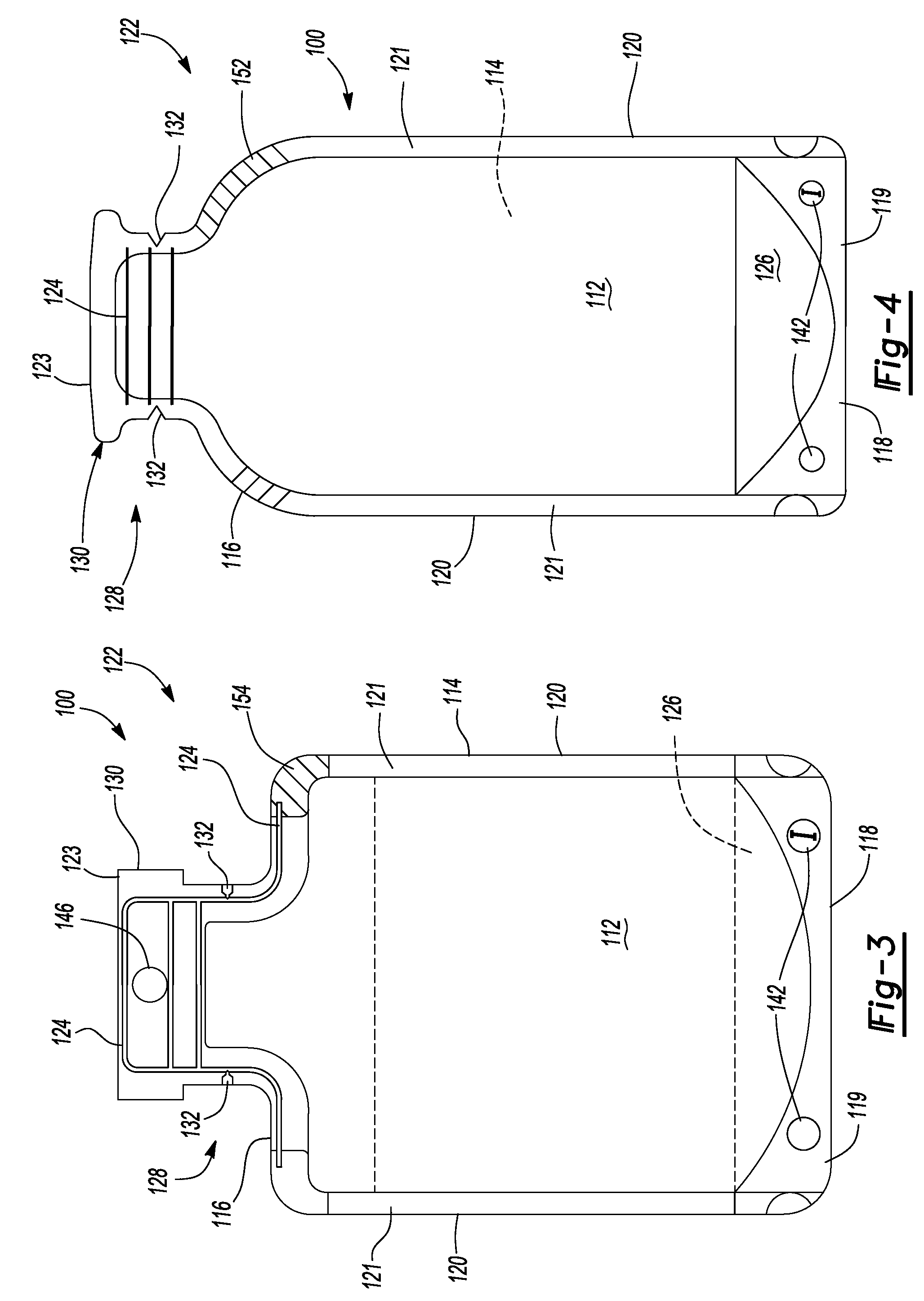

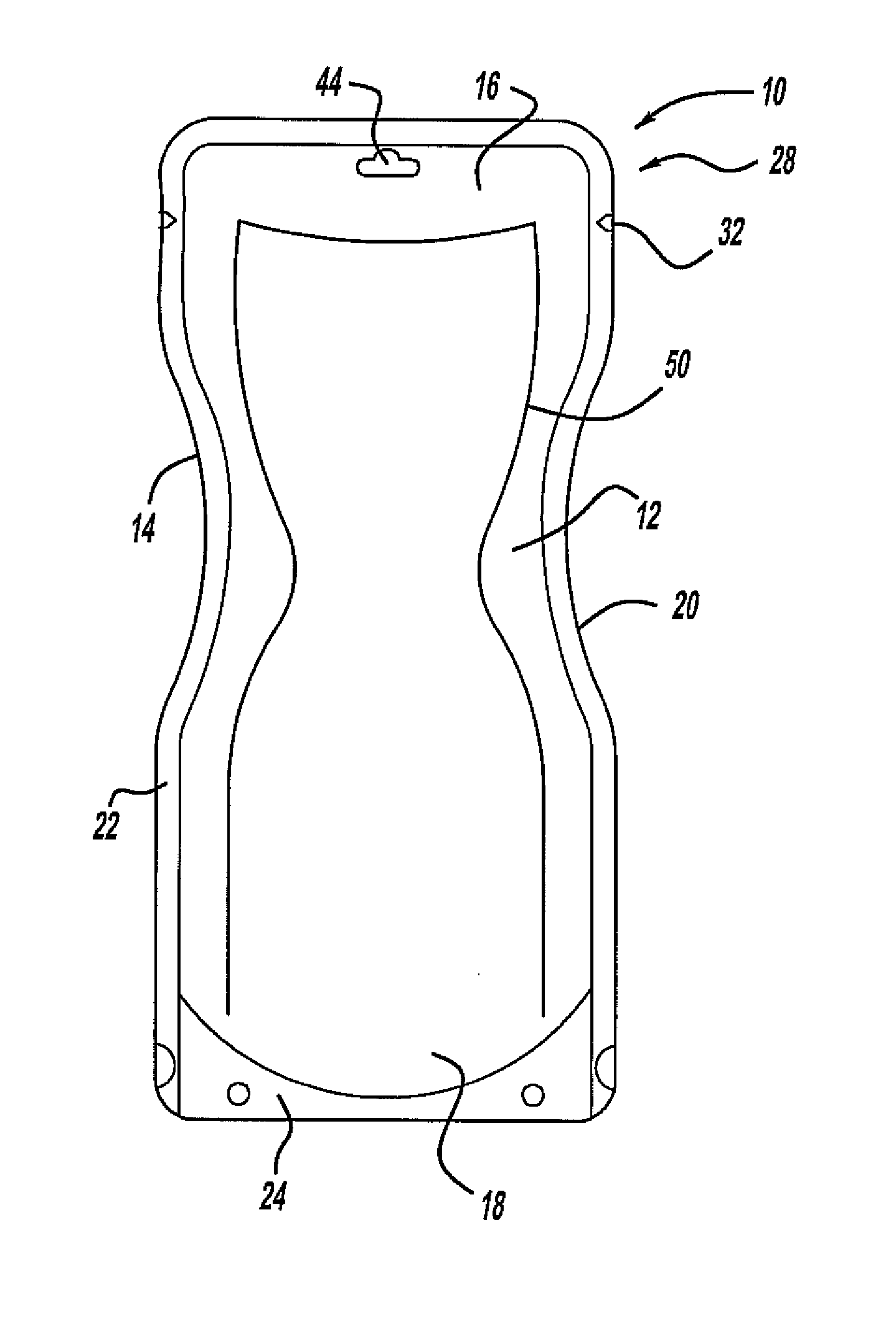

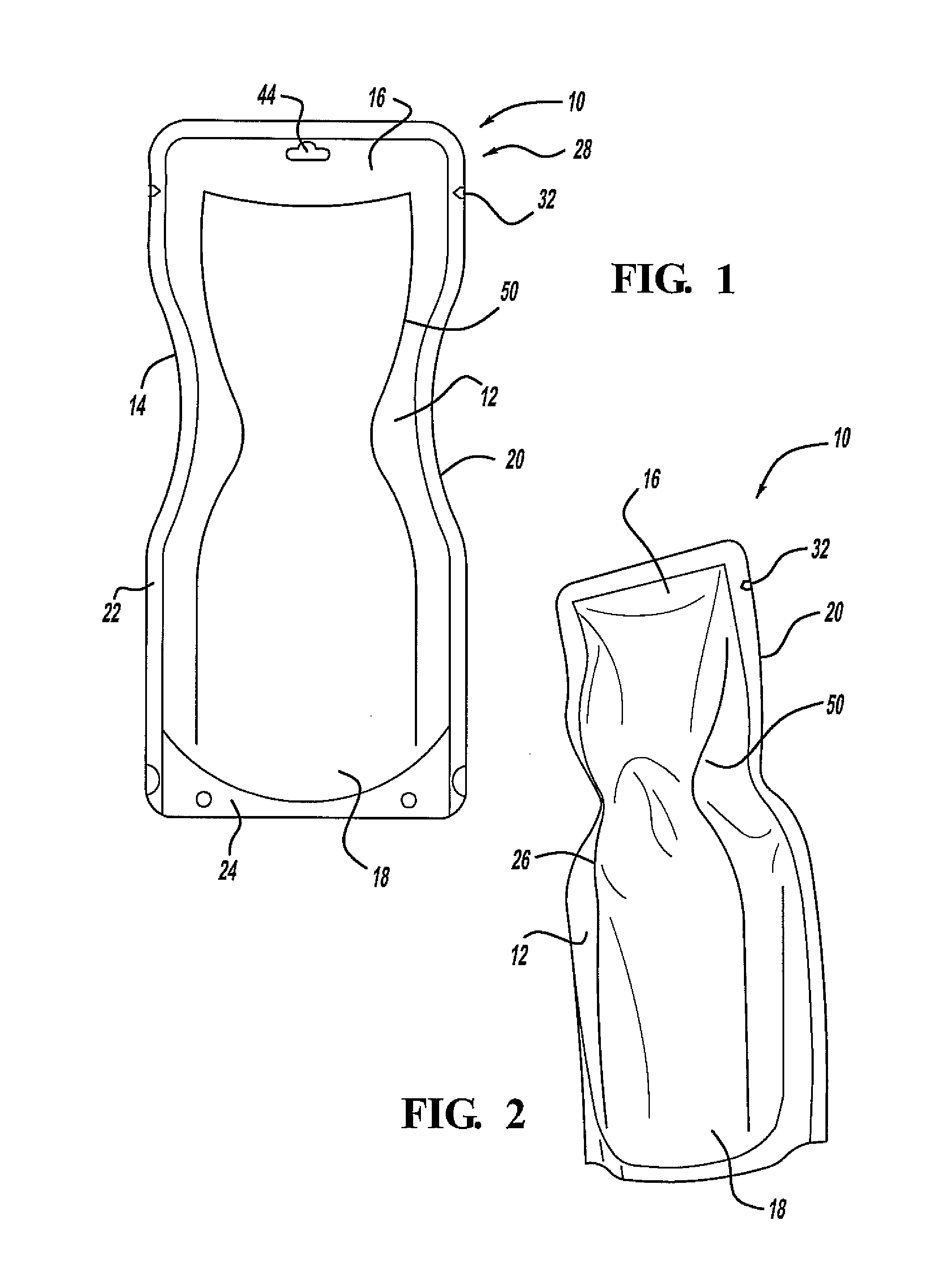

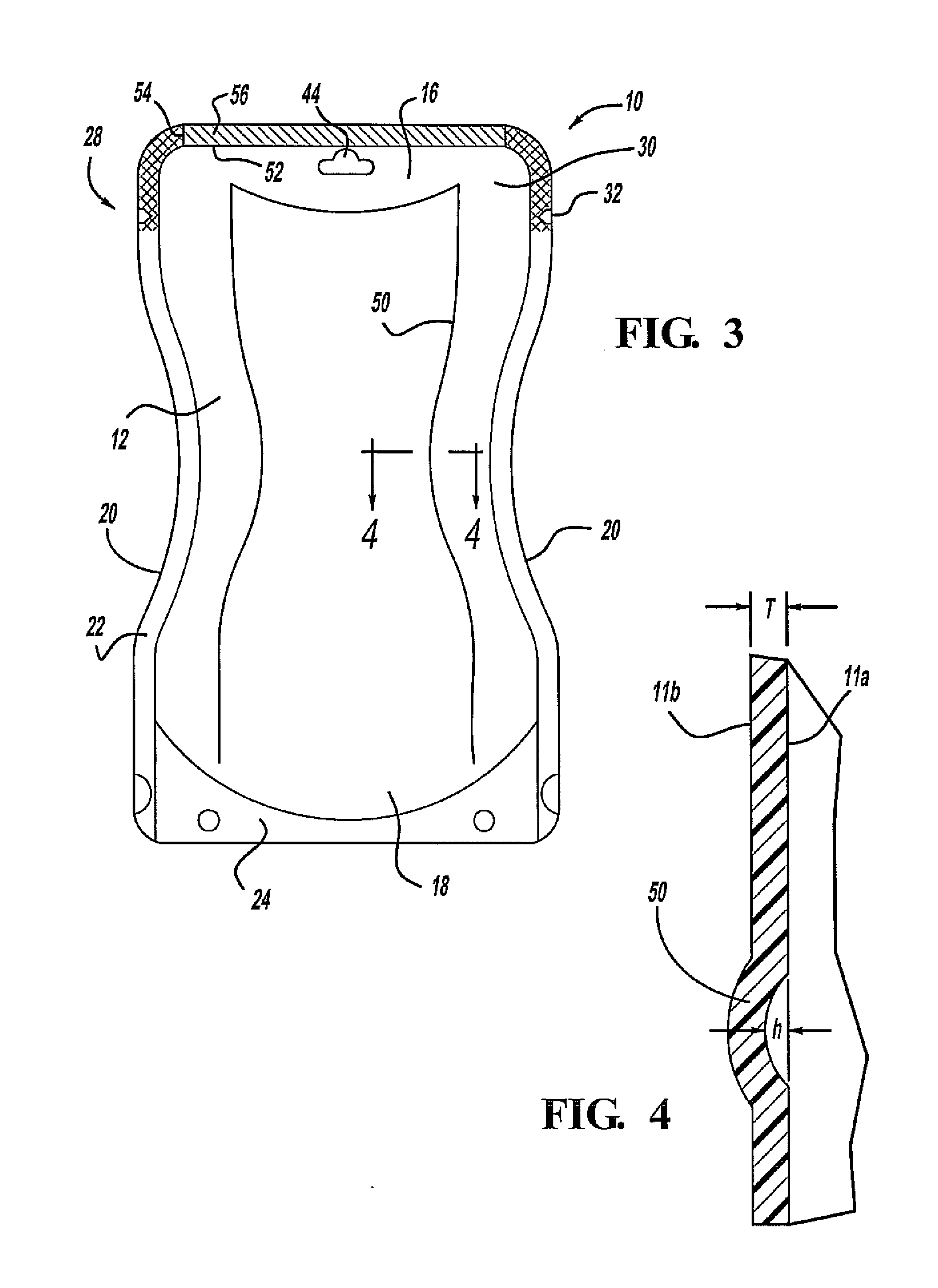

Shaped Flexible Pouch With Elongated Neck And Method Of Manufacture

Accordingly, the present invention is an improved flexible pouch for a product and an improved apparatus and method for manufacturing the pouch. The flexible pouch, apparatus and methodology for a pouch includes an upper edge and side edges extending therefrom. The upper edge includes an elongated spout portion extending therefrom. The elongated spout portion can have shape representative of a bottle cap attached to a top of bottle throat. In addition, the elongated spout portion can have an opening element that affords for tearing off the bottle cap shaped portion and allow access to the product.

Owner:POUCH PAC INNOVATIONS

Sulfonated aromatic copolyesters containing hydroxyalkanoic acid groups and shaped articles produced therefrom

InactiveUS7358325B2Optimized balanceOptimized of dimensionalWrappers shrinkagePaper coatingPolymer scienceCopolyester

Owner:EI DU PONT DE NEMOURS & CO

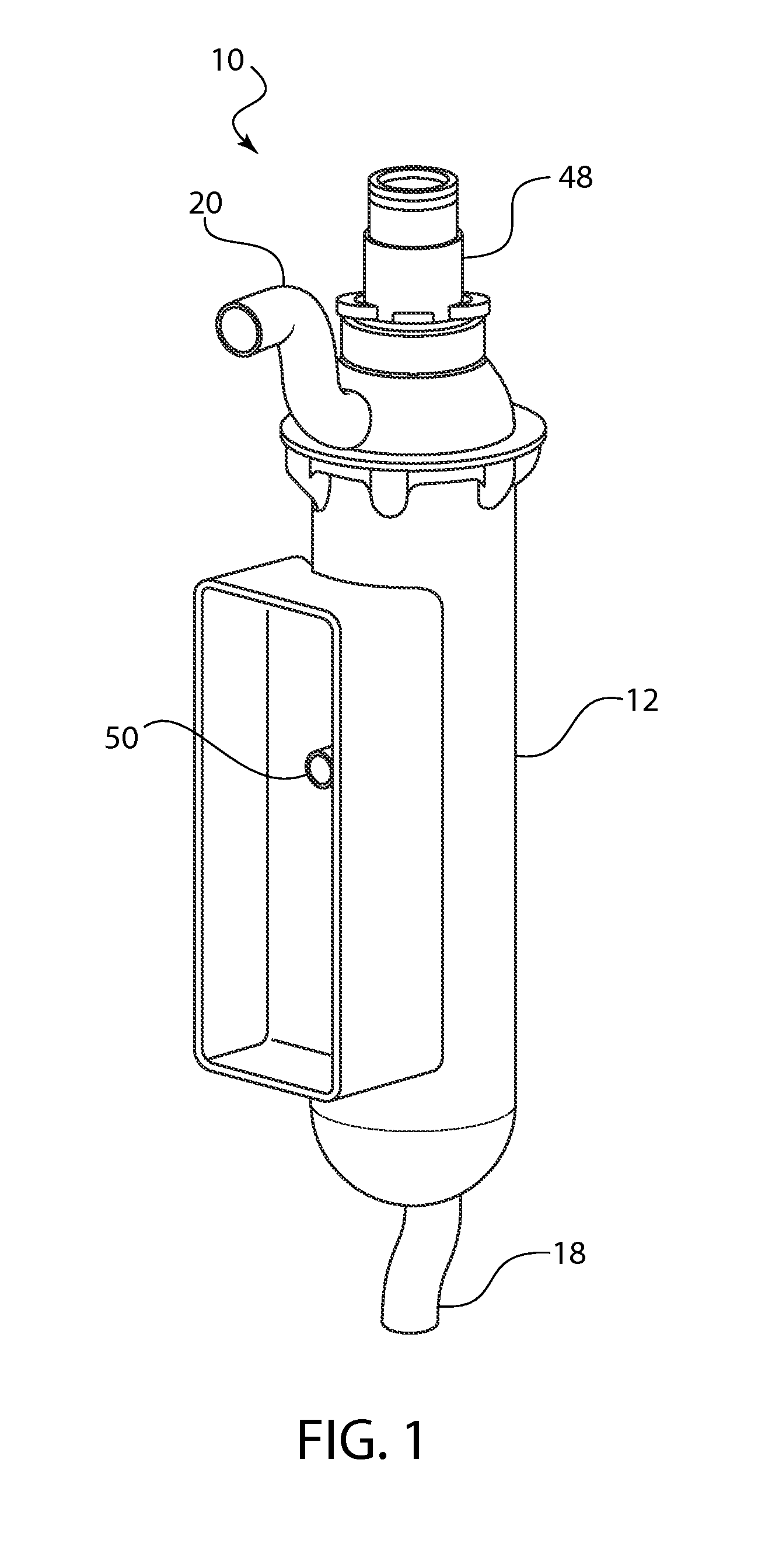

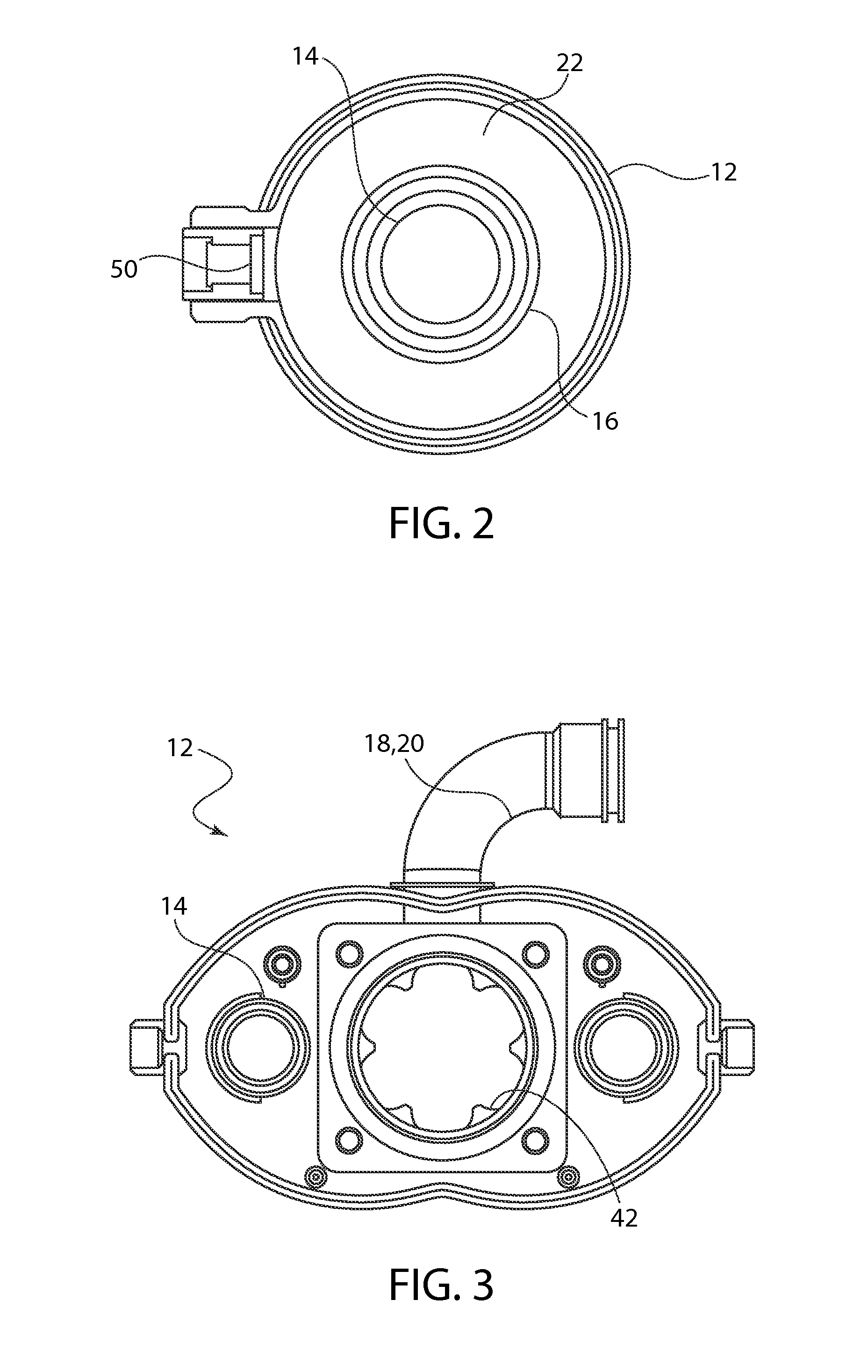

Systems and methods for disinfecting water

ActiveUS20120051977A1Reduce power consumptionLow costWrappers shrinkageScattering properties measurementsPotable waterOn board

Embodiments of the present invention provide systems and methods for point of use location treatment of potable water supplies on demand on board passenger vehicles, such as aircraft. The systems described generally provide increased safety features, alternate ultraviolet light sources, and reduced power consumption.

Owner:MAG AEROSPACE IND INC

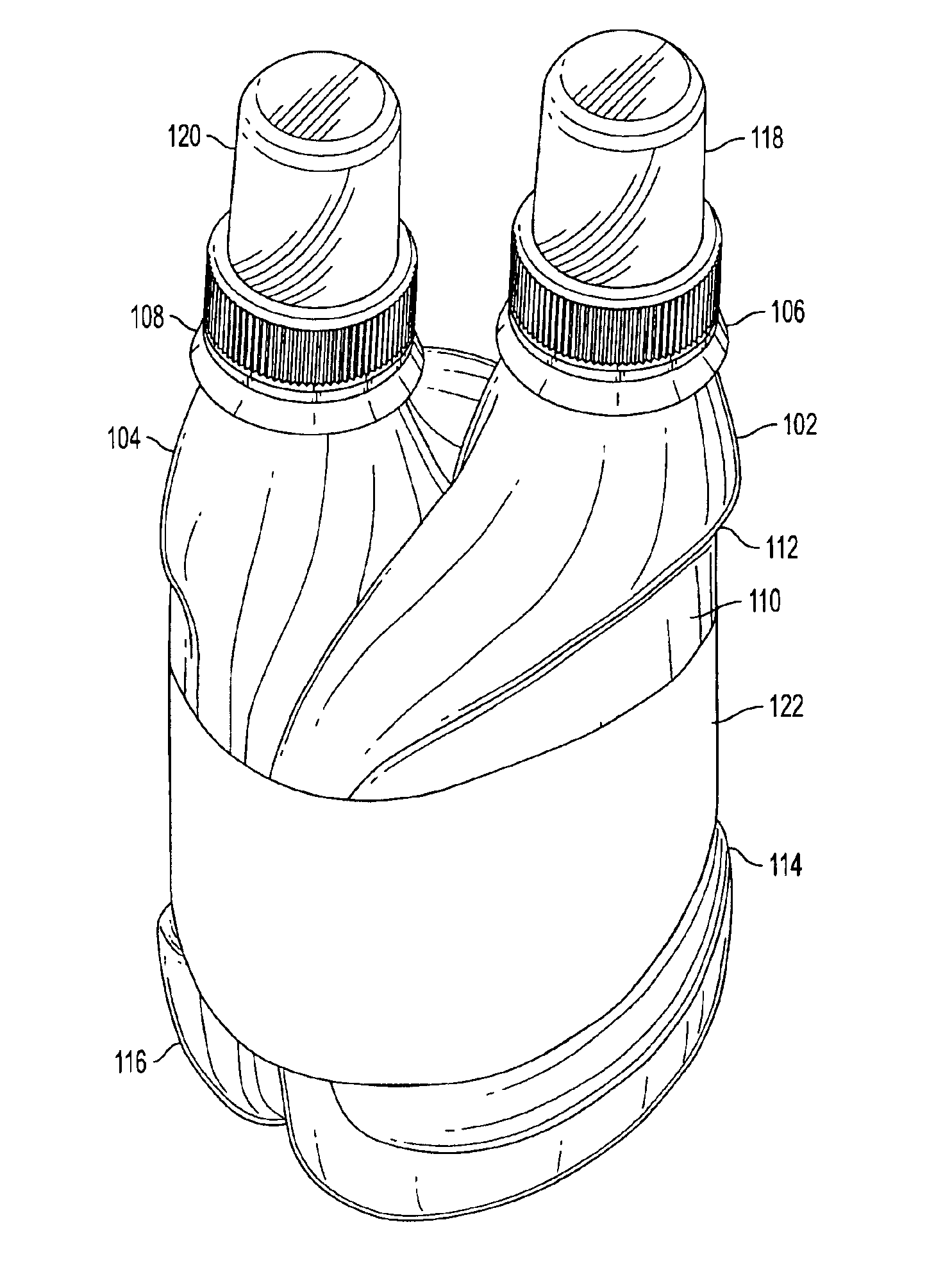

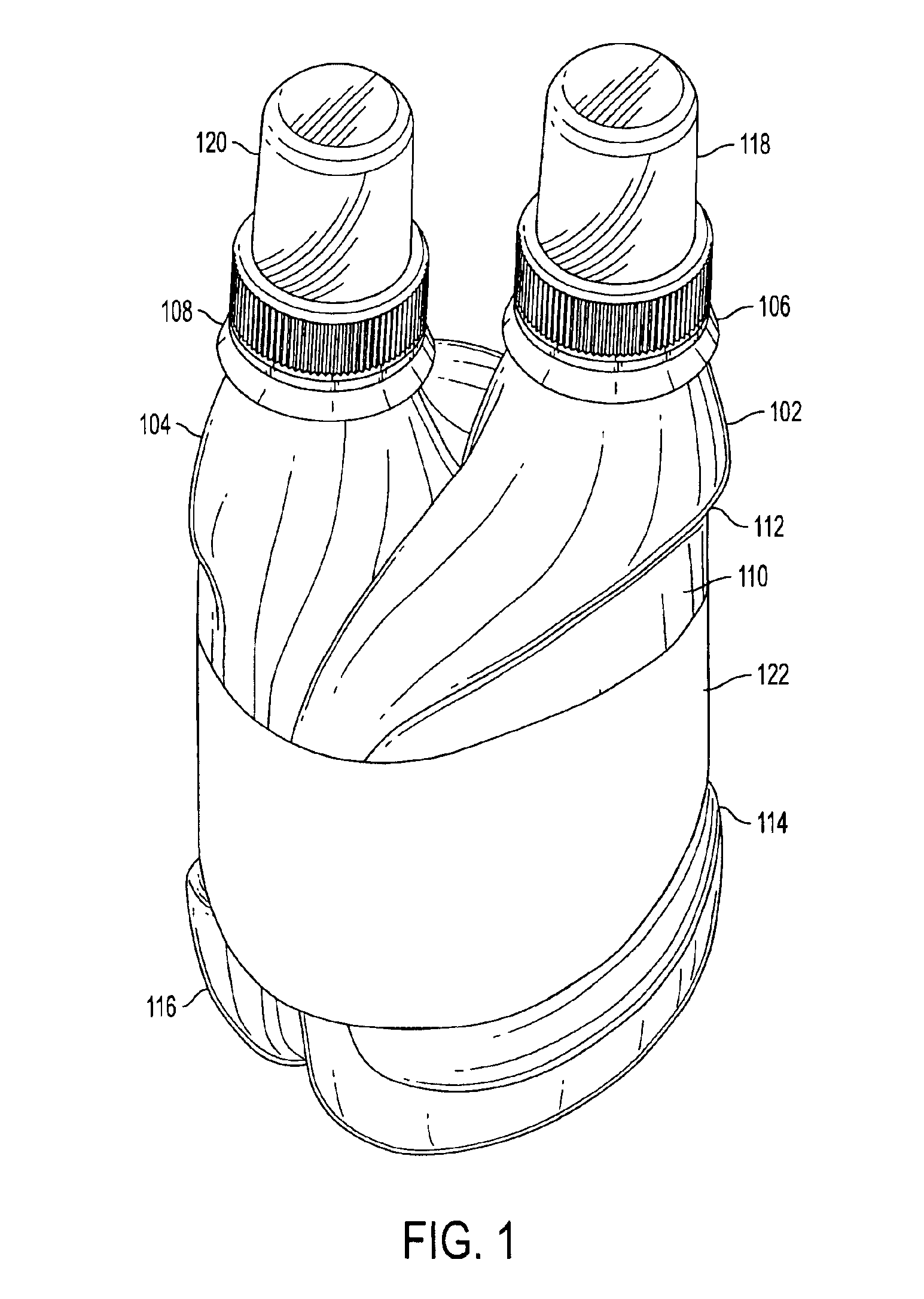

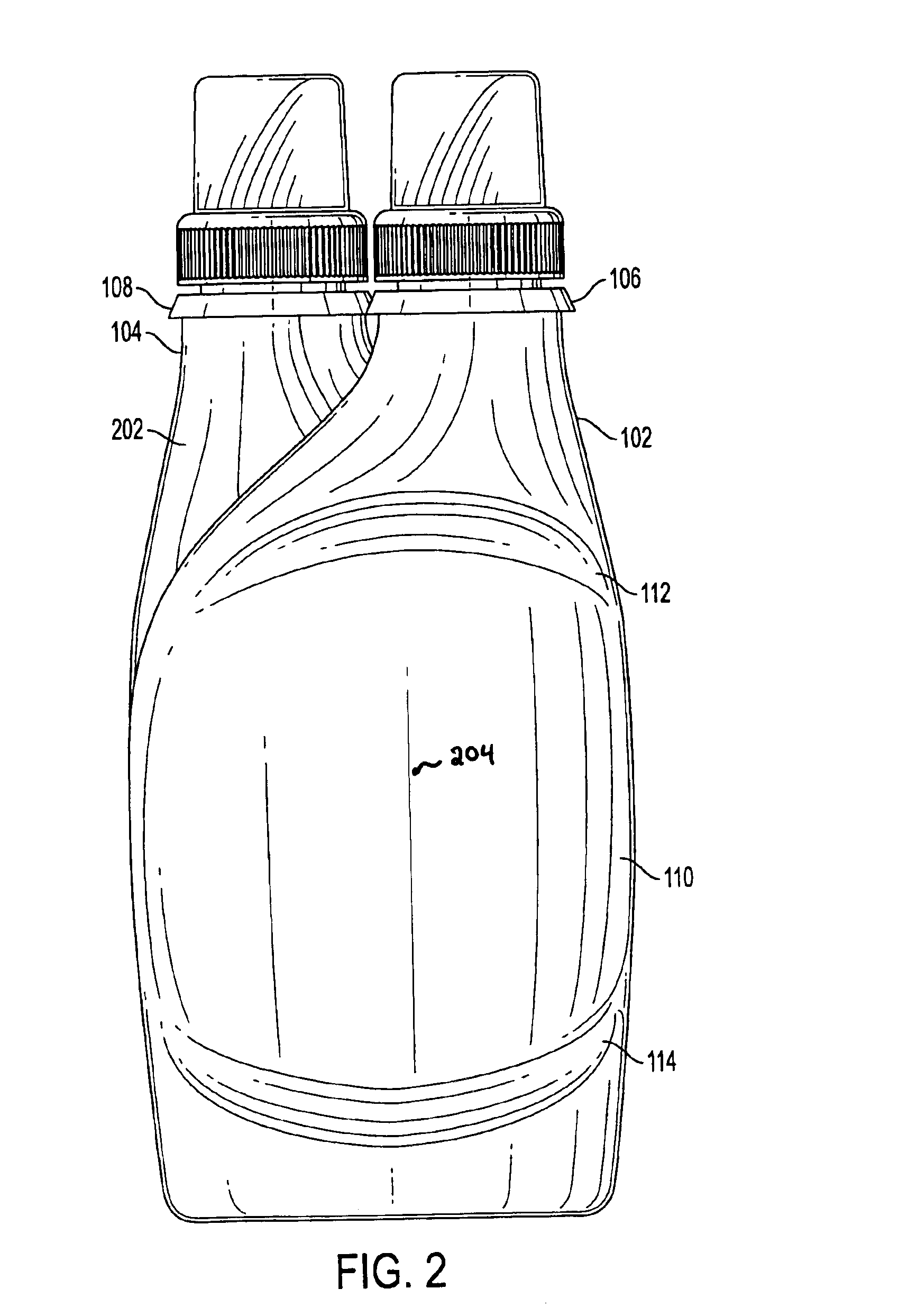

Package of interengaging containers for companion products

A package for companion products has two containers (102, 104), each comprising a mating formation (408, 502) protruding in a direction toward the other container and defining a mating surface facing at an angle to the direction of protrusion and engaging the mating surface of the other container. Each container has a generally flat bottom and a center of gravity in vertical alignment with the generally flat bottom, whereby each container can stand independently of the other container. The shape of each container is the same as the other, and the containers are attached to one another. The shape enables the mating surfaces to be brought into engagement with one another by movement in a plane parallel to the bottoms of the containers.

Owner:GRAHAM PACKAGING CO LP

Stand-up flexible pouch and method of forming

InactiveUS20120008884A1Provide rigidityEnvelopes/bags making machineryWrappers shrinkageEngineeringStructural rigidity

A stand-up flexible pouch for packaging a product and a method of forming and filling the pouch is provided. The pouch includes a panel forming a body of the pouch using a flexible material having an inner surface and an outer surface. A rib is integrally formed in the pouch body, and the rib is spaced a predetermined distance from an edge of the pouch body. The ribs provide structural rigidity to the pouch when filled, allowing the pouch to retain the filled shape and stand upright unassisted as the product is removed from the pouch.

Owner:POUCH PAK INNOVATIONS

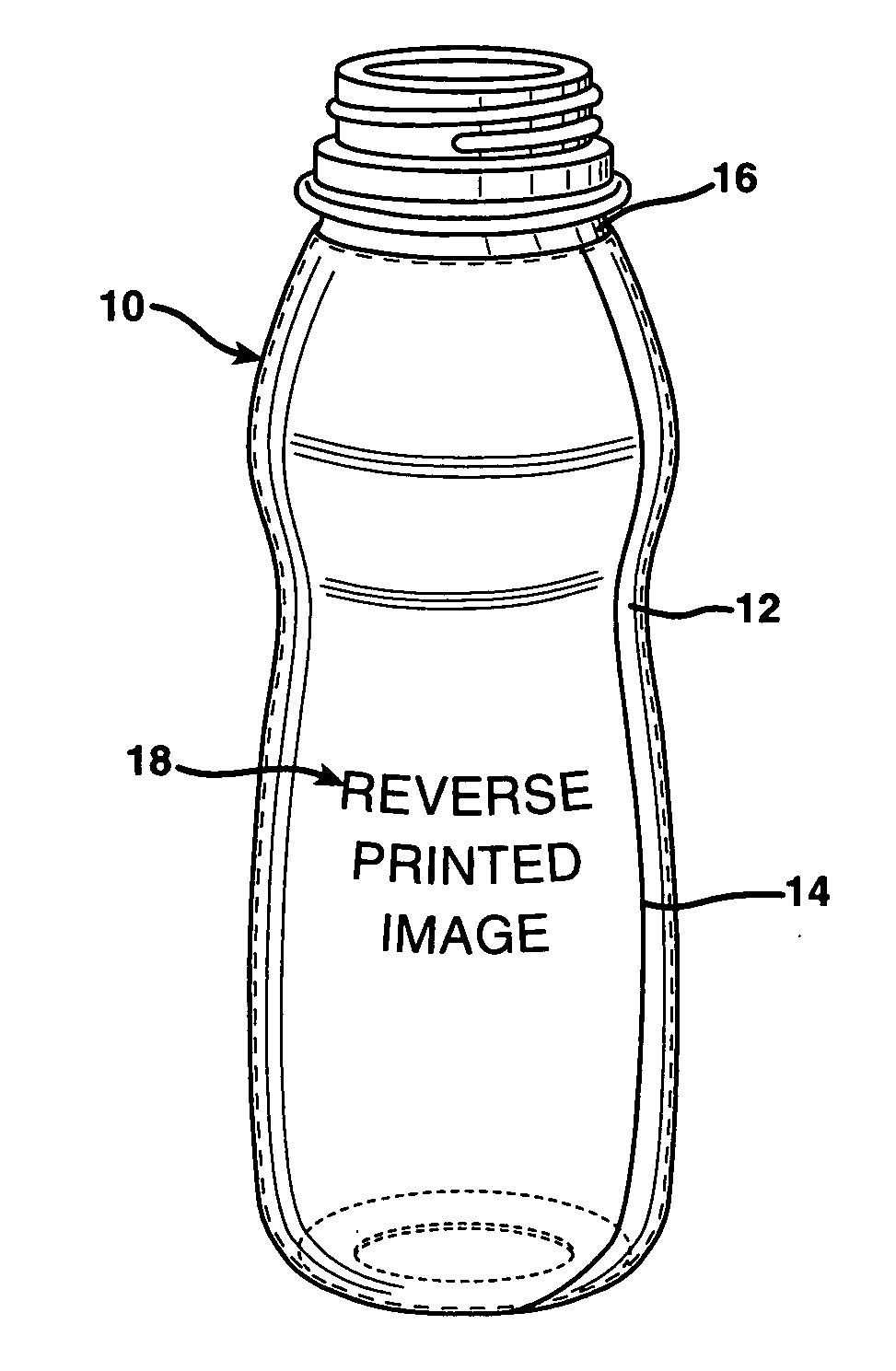

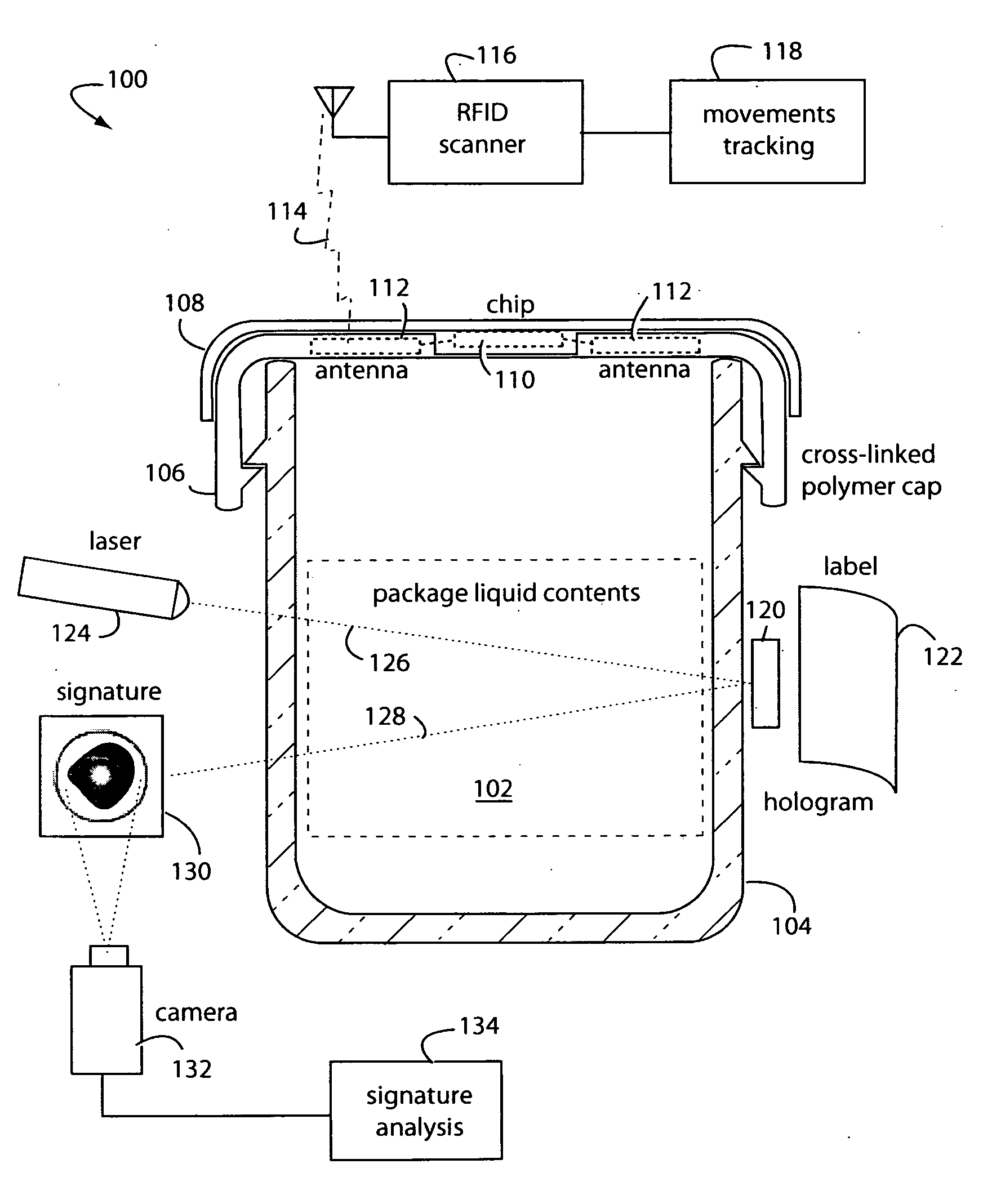

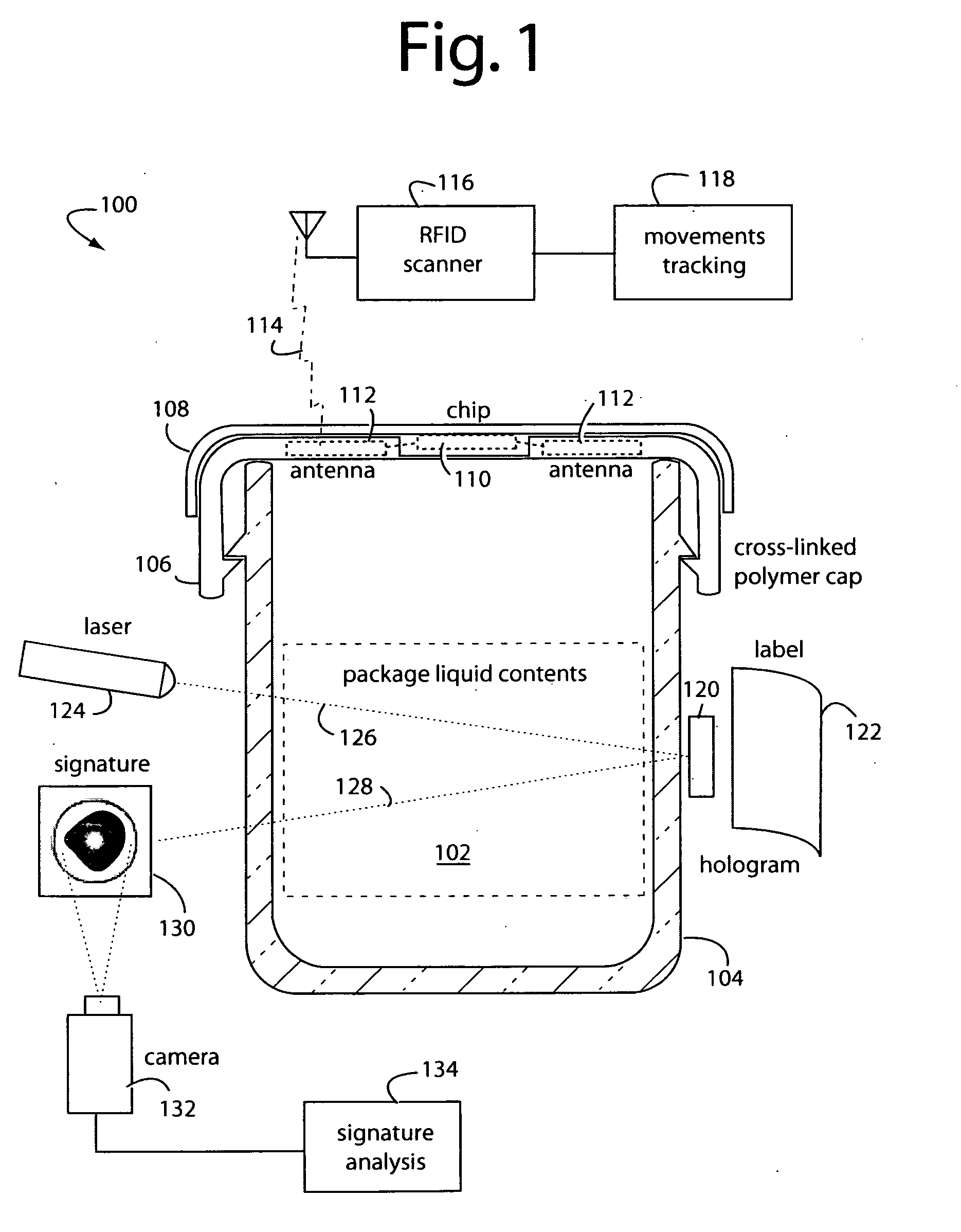

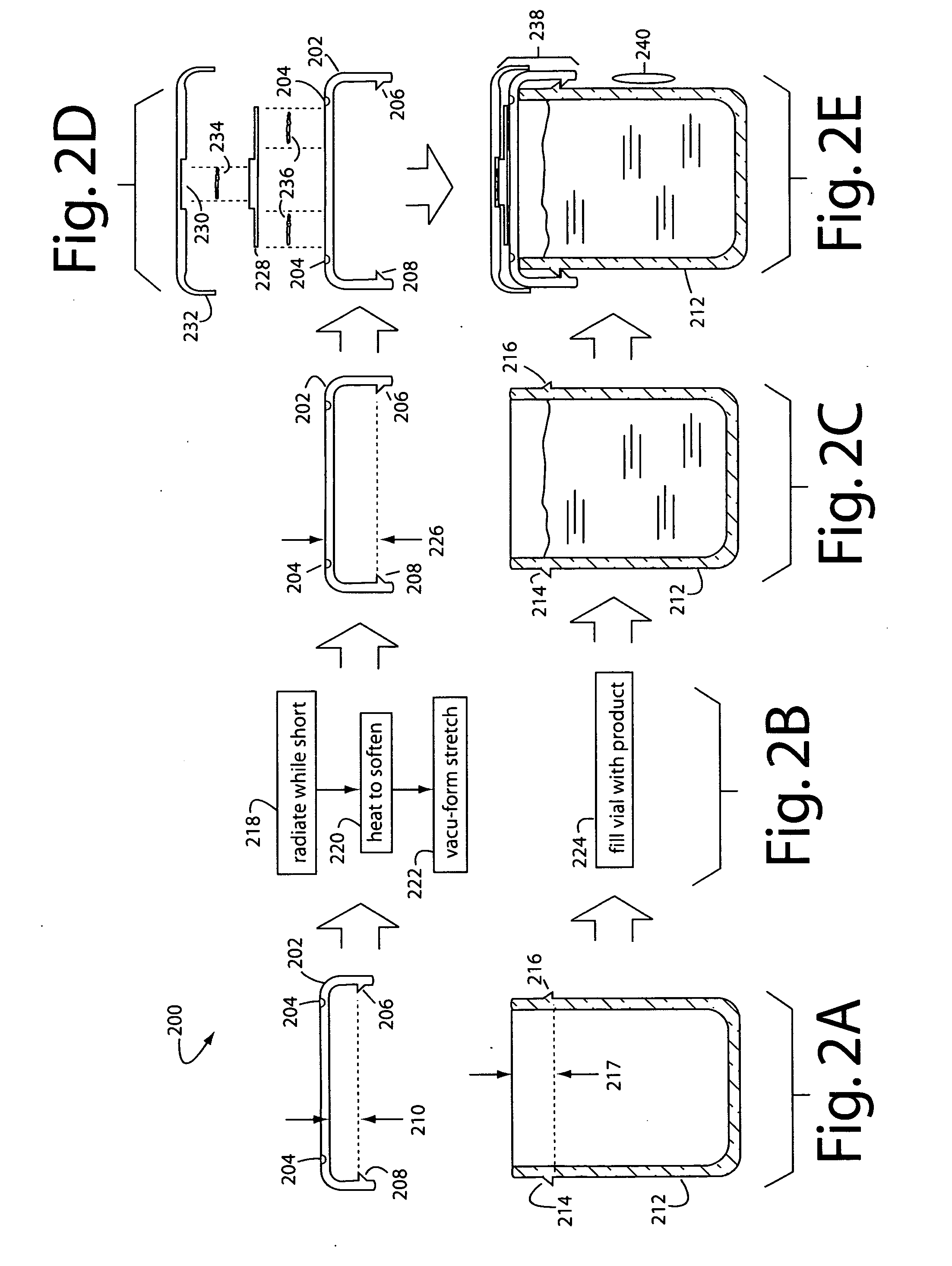

Secure product packaging

InactiveUS20080149584A1Readily ascertained non-invasivelyPrevent repackaging secure packaging productsWrappers shrinkageCharacter and pattern recognitionCross-linkEngineering

A product packaging comprises a cap on a transparent bottle to seal in a protected product. The cap includes an RFID chip and antenna that can report a serial number and product identification code to a nearby scanner. Reports from several such scanners in the distribution chain from manufacturer to retailers are logged and used to validate legitimate products by their movements. The caps are designed such that when opened the RFID antenna will break away from its associated RFID chip. The cap is molded of cross-linked polymers with a memory that makes it impossible to reseat it properly to the bottle once removed. A hologram target is placed backwards under a label on the side of the bottle so a laser beam can be directed through the backside of the bottle, through the contents, and to the hologram. The reflected laser light will have a signature that is very sensitive to the exact chemistry of the contents. Adulterations and fake products substituted for the genuine articles inside the bottle are detectable using non-invasive hologram reflected laser light and analysis.

Owner:MARTINELLI LAWRENCE G

Biaxially oriented film prepared from metallocene catalyzed polypropylene

Films prepared from metallocene polypropylene containing a low molecular weight hydrocarbon resin are shown to have certain improved properties as compared to such films prepared with such films prepared without said resin. In particular, these films have improved optical properties.

Owner:APPLIED EXTRUSION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com