Trilaminar co-extrusion thermal contraction resin film, manufacturing method and application method thereof

A three-layer co-extrusion, production method technology, applied in the field of packaging materials, can solve the problems of low fastness, low rigidity, shrinkage rate and shrinkage force of packaged items, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

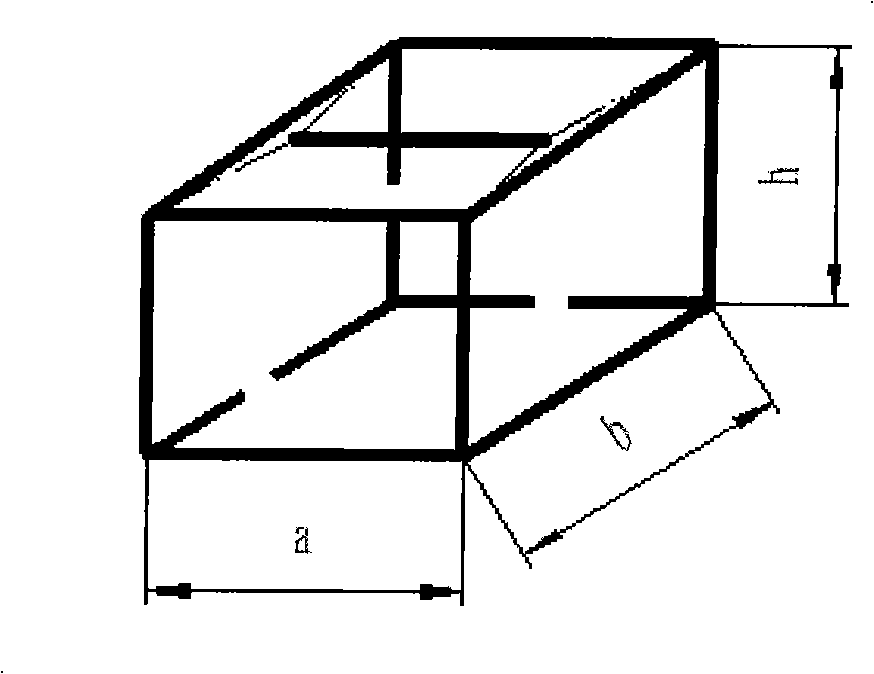

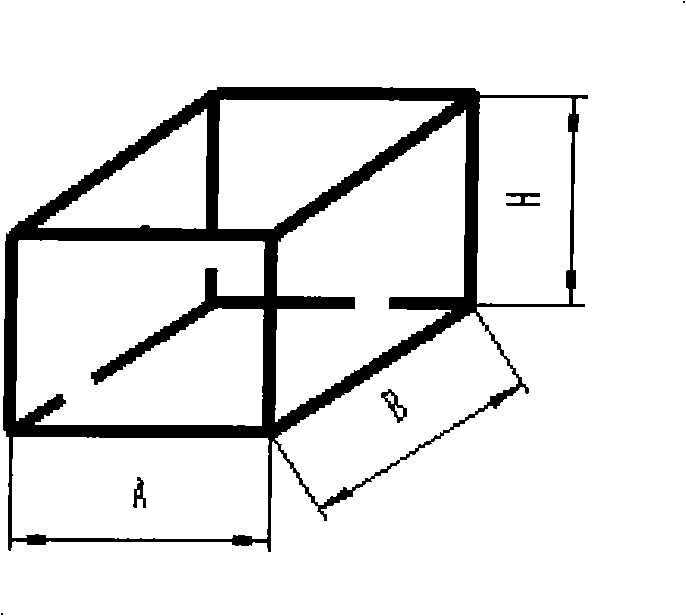

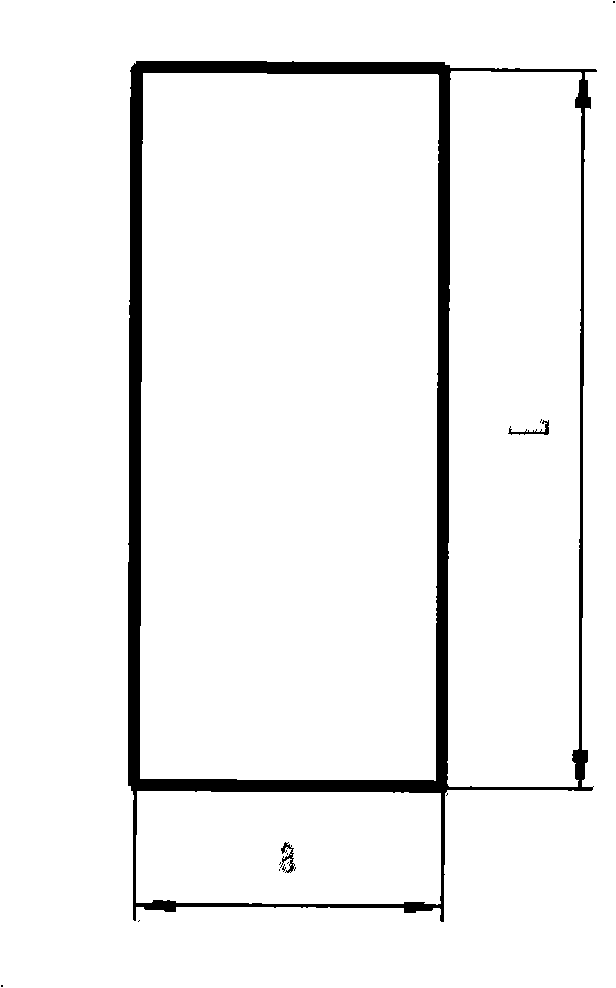

Image

Examples

Embodiment 1

[0174] Building materials (such as hollow bricks, floor tiles, refractory bricks, ceramic products, etc.), chemical raw materials and other bagged items packed in packaging trays, in order to prevent a large amount of dust from being adsorbed on the outer surface of the packaging and reduce the impact of sunlight on the performance of the packaging , add antistatic masterbatch and weather resistance antiaging masterbatch to the raw material of the outer layer extruder:

[0175] The composition that each layer contains and the percentage by weight between it are:

[0176] inner layer

[0177] LDPE 54.35%

[0178] LLDPE 43.48%

[0179] Antistatic agent 2.17%

[0180] Middle

[0181] HDPE 9.80%

[0182] LLDPE 39.22%

[0183] PP or EVOH recycled material 49.02%

[0184] Compatibilizer 1.96%

[0185] outer layer

[0186]LDPE 83.33%

[0187] Antistatic agent 13.89%

[0188] Anti-aging agent 2.78%

[0189] Its production process steps are:

[0190] (1) Extrusion: Mix the...

Embodiment 2

[0196] When packaging food-grade glass bottles and other utensils and food collective packaging, antibacterial masterbatch is added to the inner layer of extrusion, and anti-aging masterbatch is added to the outer layer to ensure hygienic quality;

[0197] The composition that each layer contains and the percentage by weight between it are:

[0198] inner layer

[0199] LDPE 54.35%

[0200] LLDPE 43.48%

[0201] Antibacterial Masterbatch 2.17%

[0202] Middle

[0203] LLDPE 44.44%

[0204] LDPE 44.44%

[0205] mPE 11.11%

[0206] outer layer

[0207] LDPE 32.61%

[0208] LLDPE 65.22%

[0209] Anti-aging agent 2.17%

[0210] Its production process steps are:

[0211] (1) Extrusion: Mix the raw materials of each layer in proportion and send them to the three extruders of the three-layer co-extrusion film blowing unit for extrusion;

[0212] (2) Blown film: made by one-time blowing of a three-layer co-extrusion blown film unit;

[0213] (3) cooling;

[0214] The thr...

Embodiment 3

[0217] Packaging machinery parts (such as flanges, iron castings, etc.) In order to prevent the items from being wet and rusted, which will affect the assembly and use, anti-rust masterbatch is added to the inner layer of the extruder, and anti-aging masterbatch is added to the outer layer of raw materials;

[0218] The composition that each layer contains and the percentage by weight between it are:

[0219] inner layer

[0220] LDPE 48.54%

[0221] LLDPE 48.54%

[0222] Rust inhibitor 2.91%

[0223] Middle

[0224] HDPE 9.80%

[0225] LLDPE 39.22%

[0226] PA or EVOH recycled material 49.02%

[0227] Compatibilizer 1.96%

[0228] outer layer

[0229] LLDPE 83.33%

[0230] mPE 13.89%

[0231] Anti-aging agent 2.78%

[0232] Its production process steps are:

[0233] (1) Extrusion: Mix the raw materials of each layer in proportion and send them to the three extruders of the three-layer co-extrusion film blowing unit for extrusion;

[0234] (2) Blown film: made by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com