Patents

Literature

50results about How to "Achieve antistatic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trilaminar co-extrusion thermal contraction resin film, manufacturing method and application method thereof

InactiveCN101318392AReduce pollutionReduce packaging costsWrappers shrinkageSynthetic resin layered productsThermal contractionPuncturing

The invention discloses a three-layer coextrusion heat shrinkage resin film, a production method and an application method. The-three layer coextrusion heat shrinkage resin film is produced by taking PE(LDPE, HPPE, LLDPE, mPE), EVA, PP, PA and EVOH resins as the main materials which are matched with a functional master batch and adopting a production method of one-step huffing. The largest transverse and longitudinal shrinking rates of the product can reach 60 percent and 85 percent; the largest shrinking force of the product can reach 2.0N / cm. The shrinking rate and the shrinking force of the product can be controlled and adjusted by controlling various technical parameters to lead a package to be firm and endurable. The packaged objects are pertinently led to reach the anti-rust, anti static, illumination-resistance, anti-aging, anti-puncturing, anti-low-temperature, anti-isolation, anti-bacteria and anti-degradation effects and the like by adjusting the material composition and mixture ratio of each layer. The three-layer coextrusion heat shrinkage resin film is used for replacing the traditional paper box wrappage to reduce the packaging cost. The mechanical properties are good, the pertinence is strong, the materials are saved; when the three-layer coextrusion heat shrinkage resin film is used, the shrinking temperature is low, the power is saved and the packaging cost is saved, thus effectively reducing the production cost and having extremely high application value.

Owner:大连华诺塑胶科技有限公司

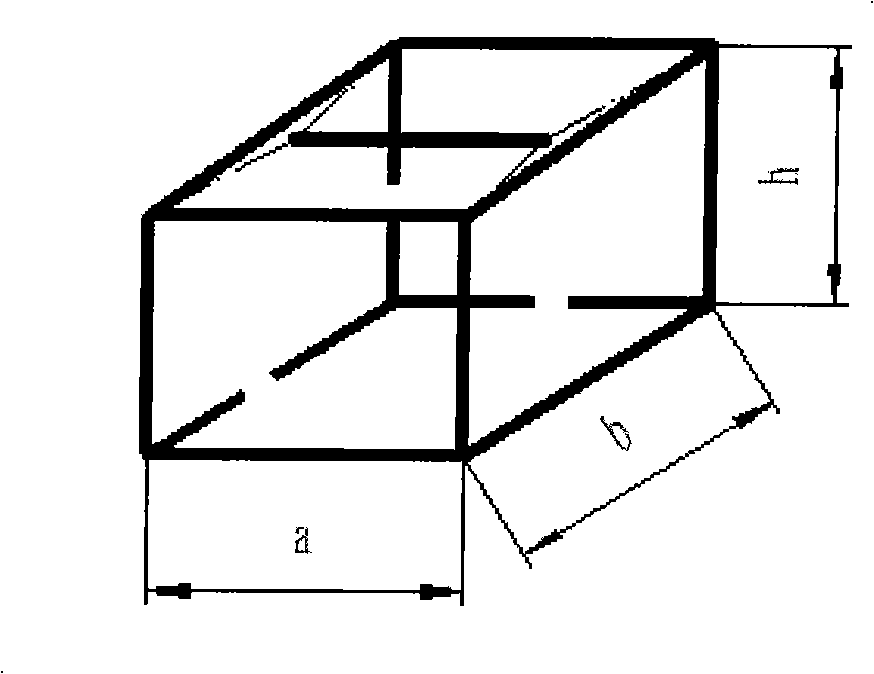

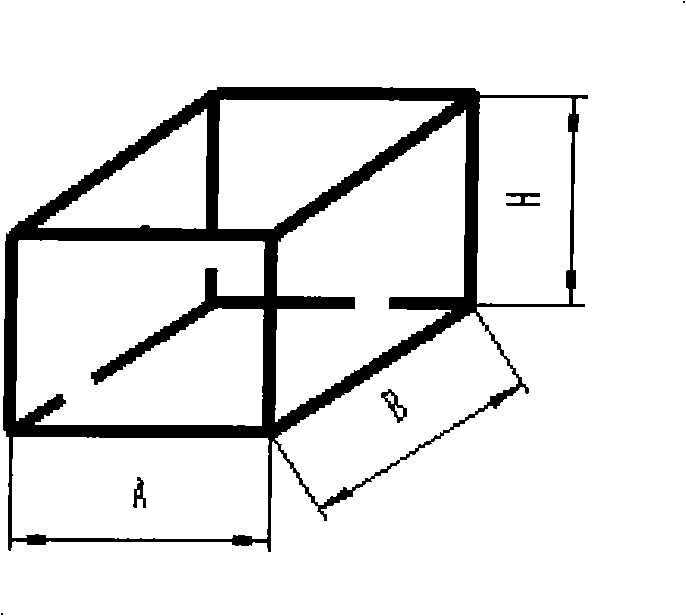

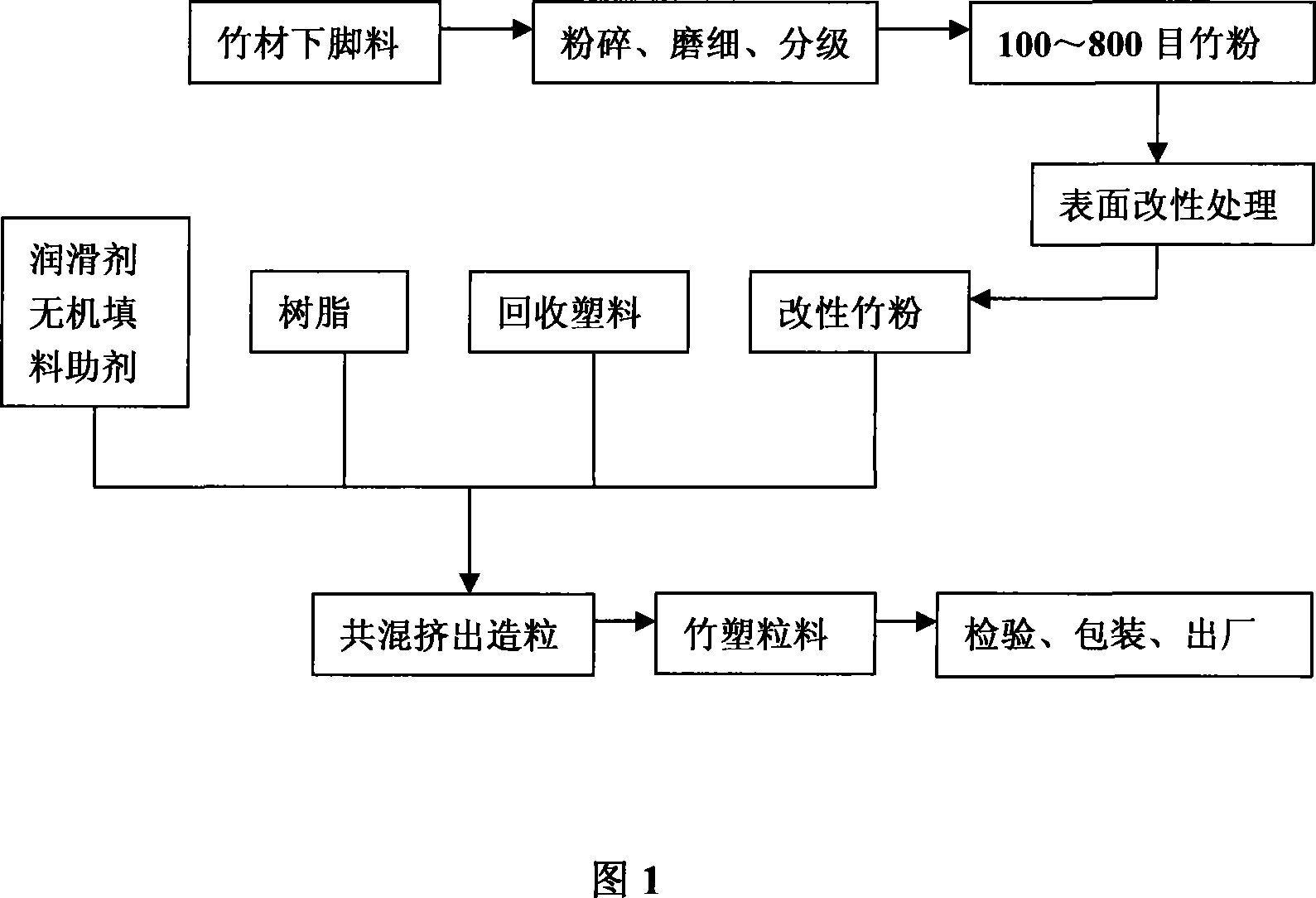

Bamboo-plastic composite material

The invention provides a bamboo-plastic composite material which is obtained by that raw materials such as plastic, recycled waste plastics, bamboo powder, modifier, chemical agent, lubricant, etc. are mixed in different proportions and extruded out to get series bamboo-plastic granule; the invention can be used for manufacturing different products such as bamboo-plastic boards, wood-plastic composite profiles and wood-plastic tubular products, etc. through extruding. The series bamboo-plastic granule can be produced in a continuous large volume and is characterized in that the production efficiency is high, the cost is low and the performance-price ratio is high, etc. The series bamboo-plastic granule can be used for replacing wood, and the cost thereof is lower than wood-plastic materials while the mechanical strength thereof is higher than wood-plastic materials, therefore the series bamboo-plastic granule can be widely popularized for use. The series bamboo-plastic granule is a novel cyclically reutilized material resource after wood-plastic material.

Owner:戴福寿 +1

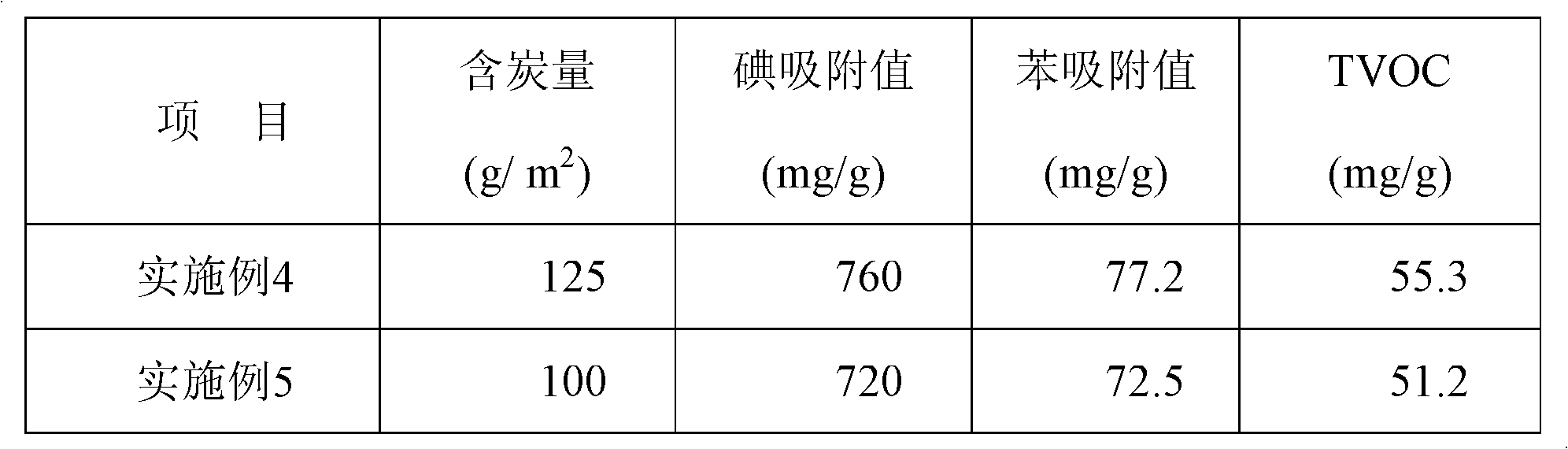

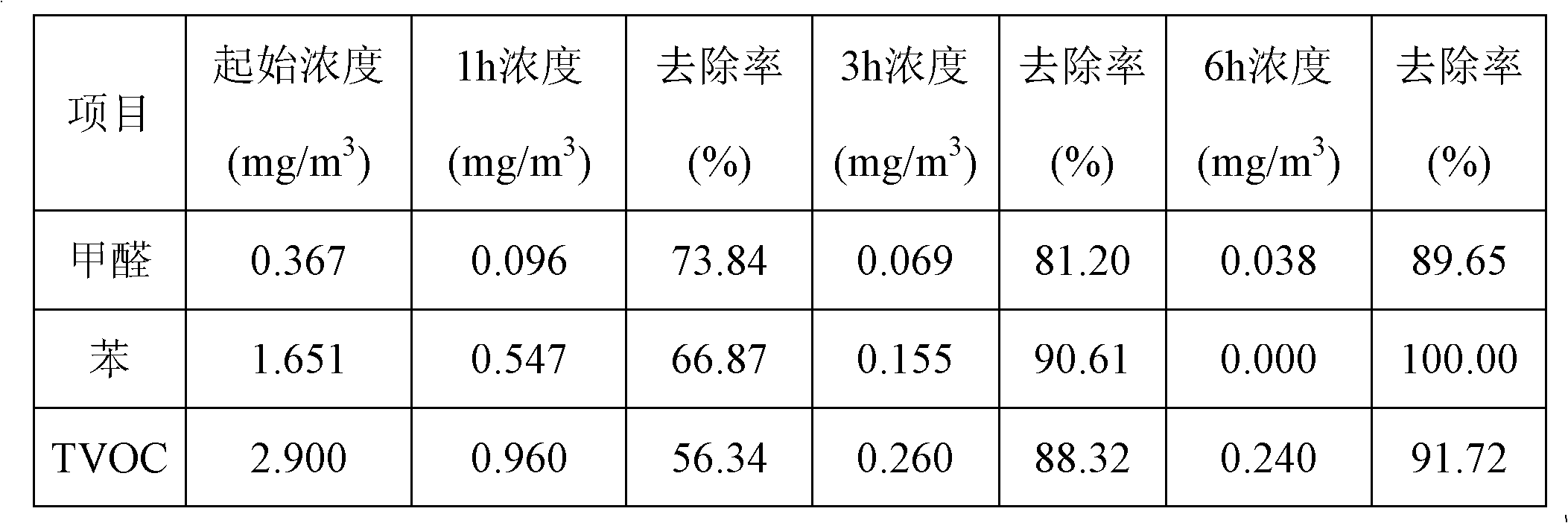

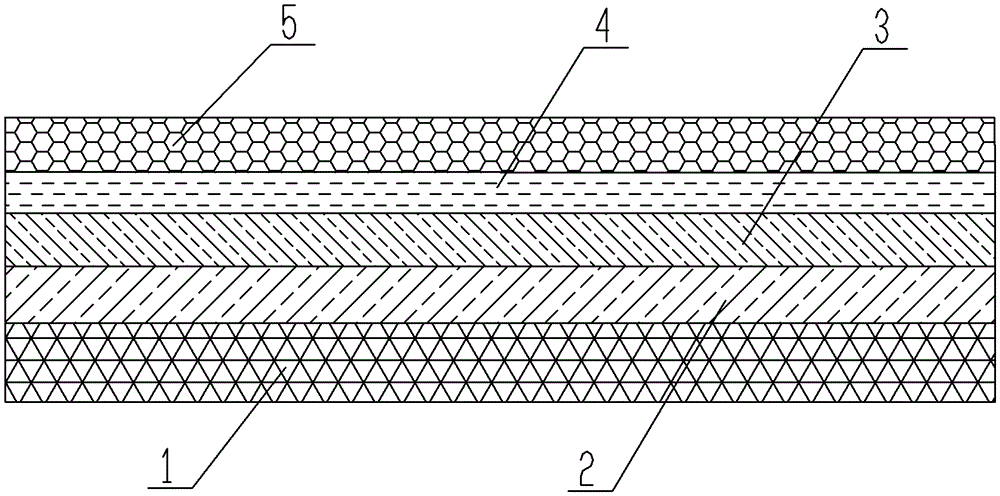

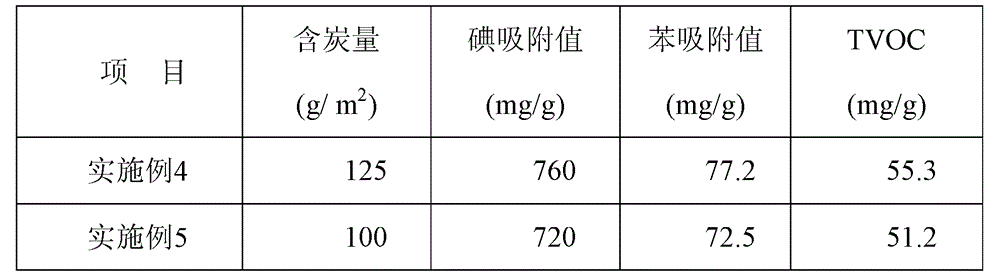

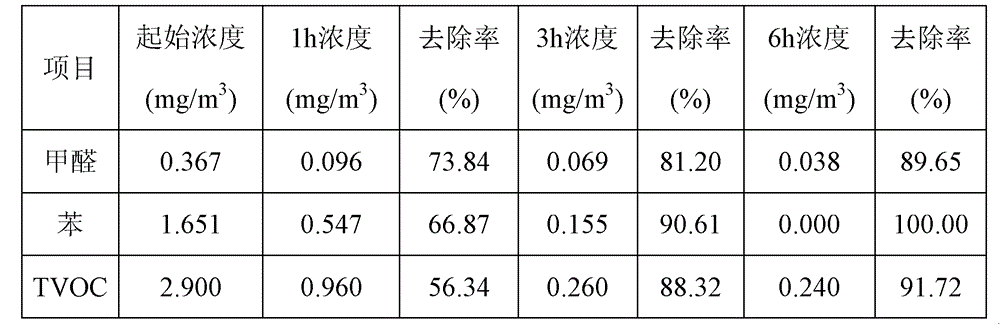

Flame-retardant activated carbon fabric and preparation method thereof

ActiveCN102529254ASimple processGood flame retardant performanceSynthetic resin layered productsActivated carbonChemistry

The invention relates to a flame-retardant activated carbon fabric and a preparation method thereof. The flame-retardant activated carbon fabric is characterized in that an activated carbon layer, a water-based adhesive film layer and a hot-melt adhesive powder particle layer are sequentially covered on a base material which is subjected to flame-retardant treatment. The preparation method comprises the following steps of: spraying or padding the base material with an environment-friendly water-based flame retardant and drying; serially coating a prepared activated carbon paste and a water-based flame-retardant hot-melt adhesive powder particle paste on the base material, and drying to obtain the final product of flame-retardant activated carbon fabric. During the drying process, the water-based adhesive film layer is formed between the carbon layer and the hot-melt adhesive powder particle layer. The preparation method of the flame-retardant activated carbon fabric is simple and environment-friendly, and the product has good flame retardant property. Owing to the good adsorption property of activated carbon, the fabric can remove formaldehyde, benzene, TVOC and other harmful gases in the air. When the fabric is used, the fabric can be cut freely and laminated thermally. The flame-retardant activated carbon fabric is easy and convenient to use and has a wide application range.

Owner:WUXI DINGHAO NEW MATERIAL SCI RES

Flame-retardant and antistatic nylon composite material and preparation method thereof

InactiveCN103881221AImprove antistaticImprove flame retardancy and antistatic propertiesFlame resistanceAntioxidant

The invention relates to a flame-retardant and antistatic nylon composite material and a preparation method thereof and belongs to the field of nylon modification. The nylon composite material is prepared from the following components in parts by mass: 4%-12% of conductive filler, 6%-12% of halogen-free flame retardant, 0.2%-1% of antioxidant, 0-4% of inorganic silicate and the balance of nylon resin and ethylene-vinyl acetate copolymer. According to the flame-retardant and antistatic nylon composite material, the flame retardance and the antistatic property of a nylon material are greatly improved, the mechanical property is not influenced, high physical property balance is achieved, meanwhile, the operation process is simple, the preparation cost is low, and the flame-retardant and antistatic nylon composite material is suitable for industrial production.

Owner:ZHEJIANG AOQIANG ENVIRONMENT PROTECTION TECH

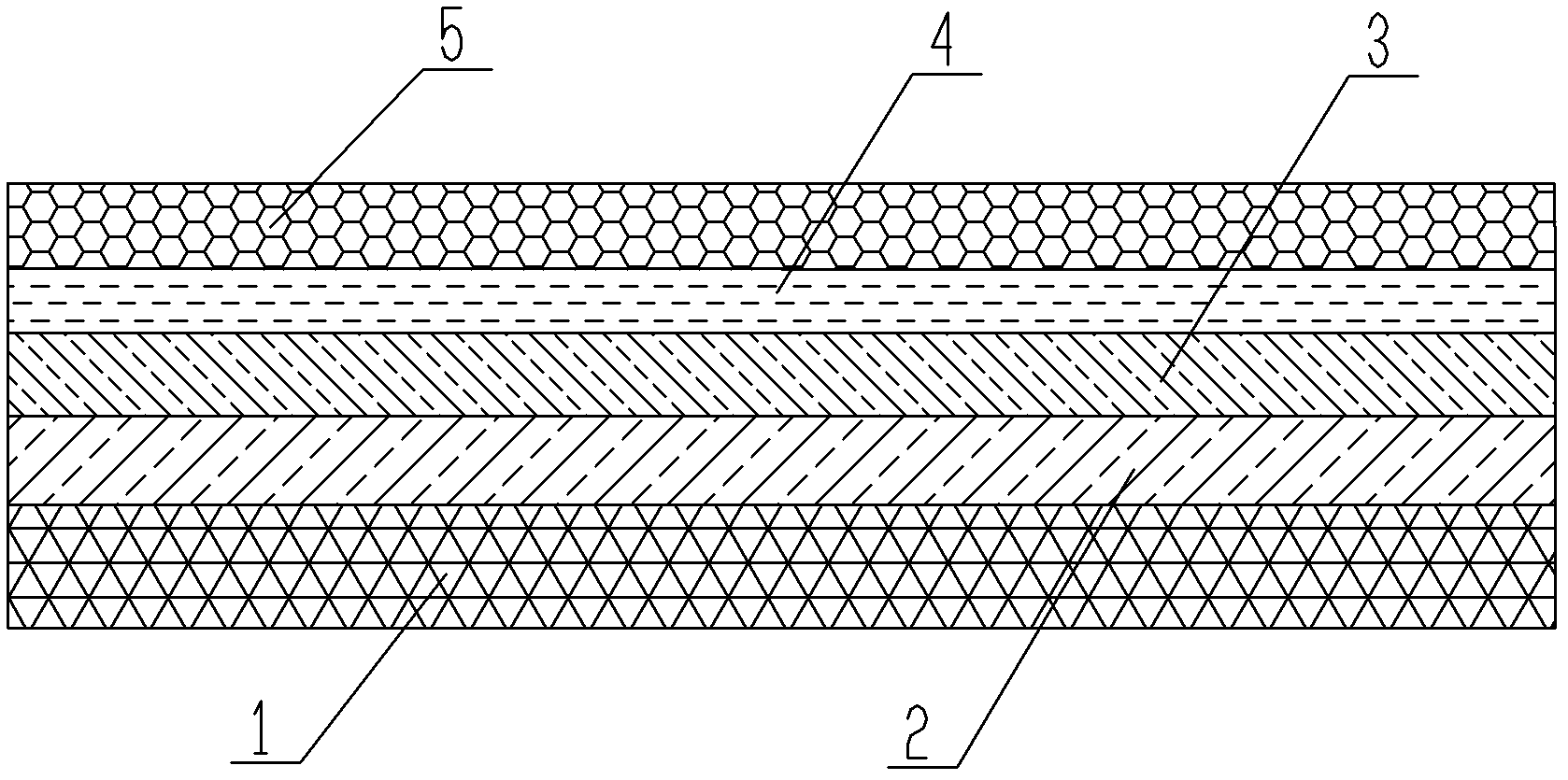

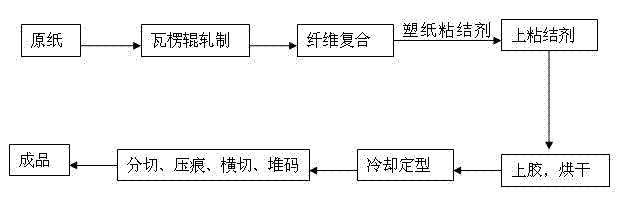

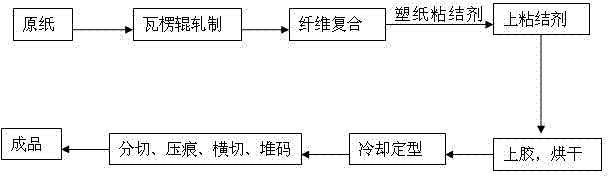

Processing method of fiber strengthening composite corrugated board

ActiveCN103114490AImprove carrying capacityReduced carrying capacityPaper-making machinesCardboardFiber

The invention relates to a processing method of a fiber strengthening composite corrugated board and belongs to the technology field of corrugated board processing. The processing method includes the steps of suppressing fiber on a face board paper in a wire rod or gridding mode, applying paper plastic adhesive on the fiber, and then compositing the fiber with a corrugated paper, conducting drying and cooling to finalize the design, slitting, creasing, transversely cutting and stacking. The paper plastic adhesive is mixture of additive, borax, caustic soda liquid, corn starch and water. The processing method of the fiber strengthening composite corrugated board has the advantages of being simple in procedure, convenient to implement, high in intensity of obtained paperboards, good in mechanical property of the obtained paperboards, relatively low in cost, capable of being applied to the fields such as corrugated paperboard processing and the like.

Owner:浙江希望包装有限公司

Anti-impact flexible protective composite material based on shear thickening adhesive and preparation method thereof

InactiveCN110091562AImprove isotropic performanceImprove mechanical propertiesNon-macromolecular adhesive additivesProtective equipmentAdhesiveDiluent

The invention discloses an anti-impact flexible protective composite material based on a shear thickening adhesive, and a preparation method of the composite material comprises the following steps of:(1) preparing the shear thickening adhesive; (2) preparing a shear thickening adhesive diluent and a fixed shape shear thickening adhesive; (3) preparing a shear thickening adhesive composite flexible protective fabric; and (4) placing the fixed shape shear thickening adhesive obtained in the step (2) into an interlayer of two layers of the shear thickening adhesive composite flexible protectivefabric obtained in the step (3) or interlayers of multiple layers of the shear thickening adhesive composite flexible protective fabric obtained in the step (3), and sewing and fixing the periphery ofthe interlayers to obtain the flexible protective composite material. The anti-impact flexible protective composite material not only maintains good flexibility but also has excellent antistatic property and impact resistance.

Owner:JIANGNAN UNIV

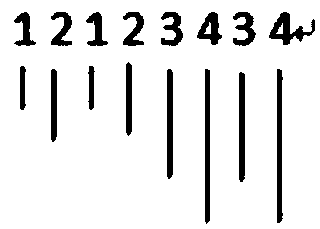

Polyester spandex super-quick-drying knitted fabric and processing method thereof

ActiveCN109056171AAchieve the effect of moisture absorption and quick dryingSoftSolvent-treatmentWeft knittingFiberPolyester

The invention discloses a polyester spandex super-quick-drying knitted fabric and a processing method thereof. The fabric is woven through a special weaving method with complete-extinction super-fine-denier polyester fibers with the filament number of 1.1-1.7 D and spandex fibers as the raw materials, and the close-fitting surface of the fabric is provided with dotted jacquard protrusions capableof guiding moisture in one direction. The processing method includes the steps of conducting weaving through a four-track single-side knitting machine, wherein four needles 1, 2, 3 and 4 are adopted;forming one loop through fourteen paths; conducting post-processing through polyester keratase. By means of the special weaving structure, the close-fitting surface has a small protrusion jacquard effect, the contact area of the close-fitting surface and a human body is reduced, and the movable friction coefficient is reduced; the dotted protrusion jacquard part making contact with skin has a one-way moisture guide function, and the water expanding capacity is improved. The complete-extinction super-fine-denier polyester fibers are selected as the raw material, the surface area of the fibers is increased, subsequent fibers have a certain anti-UV effect, and the knitted fabric has the advantages of being soft in color and luster, good in deep dyeing performance, high in textile drapability,strong in shielding performance and the like.

Owner:SHANGHAI JIALE

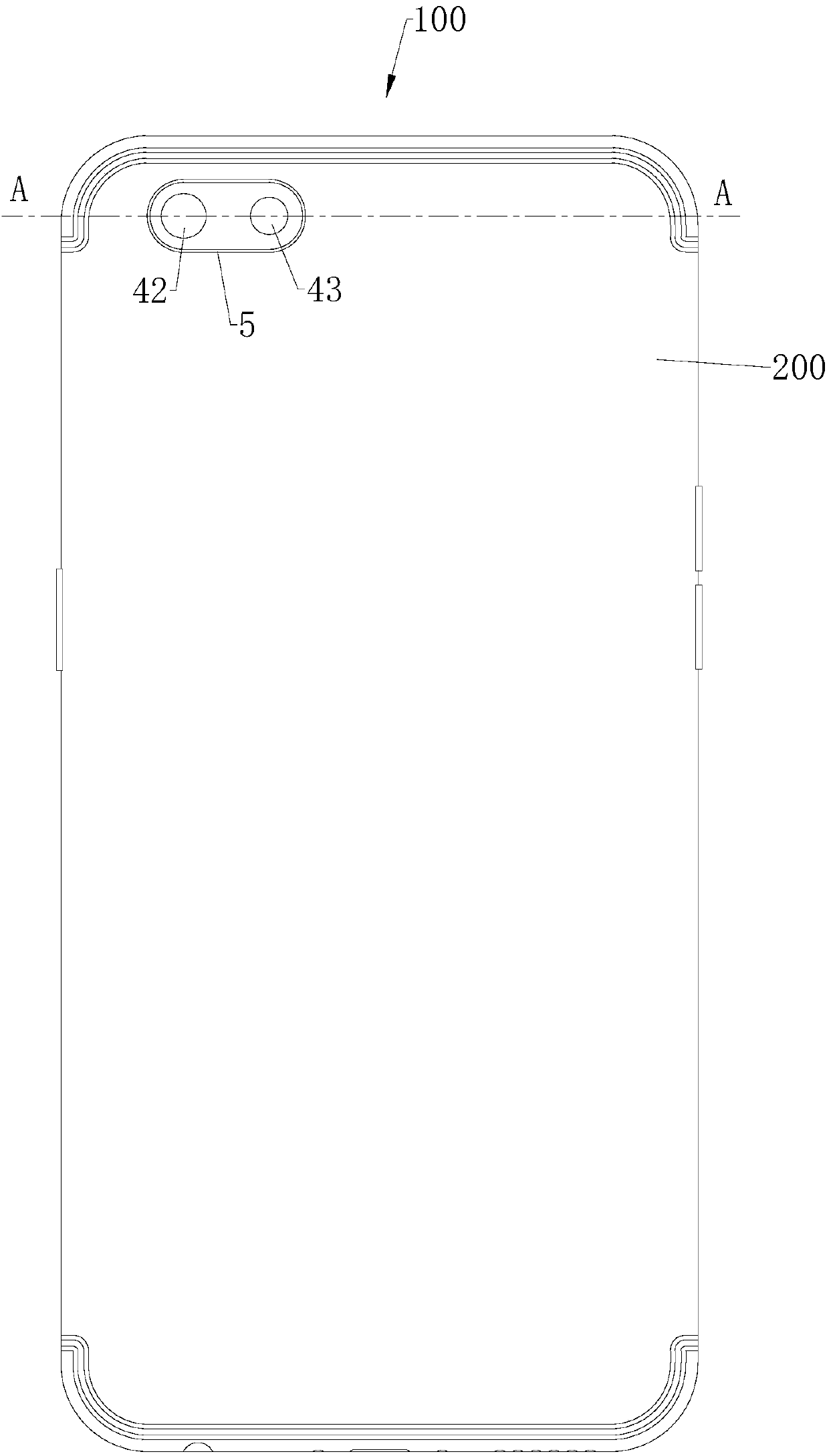

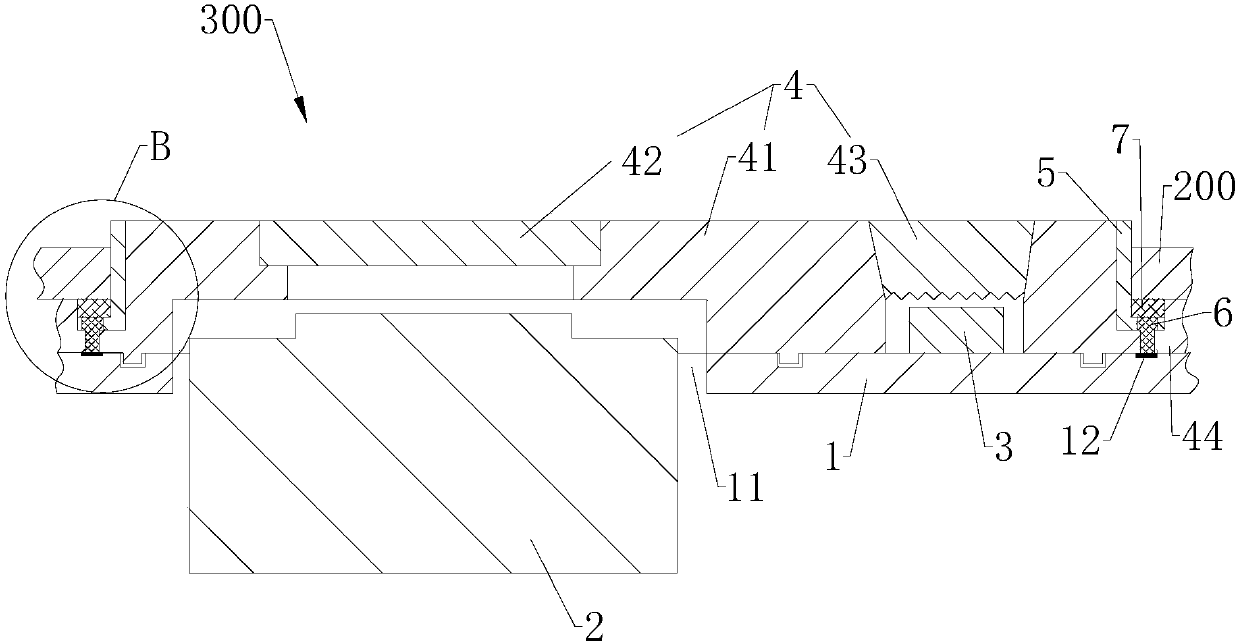

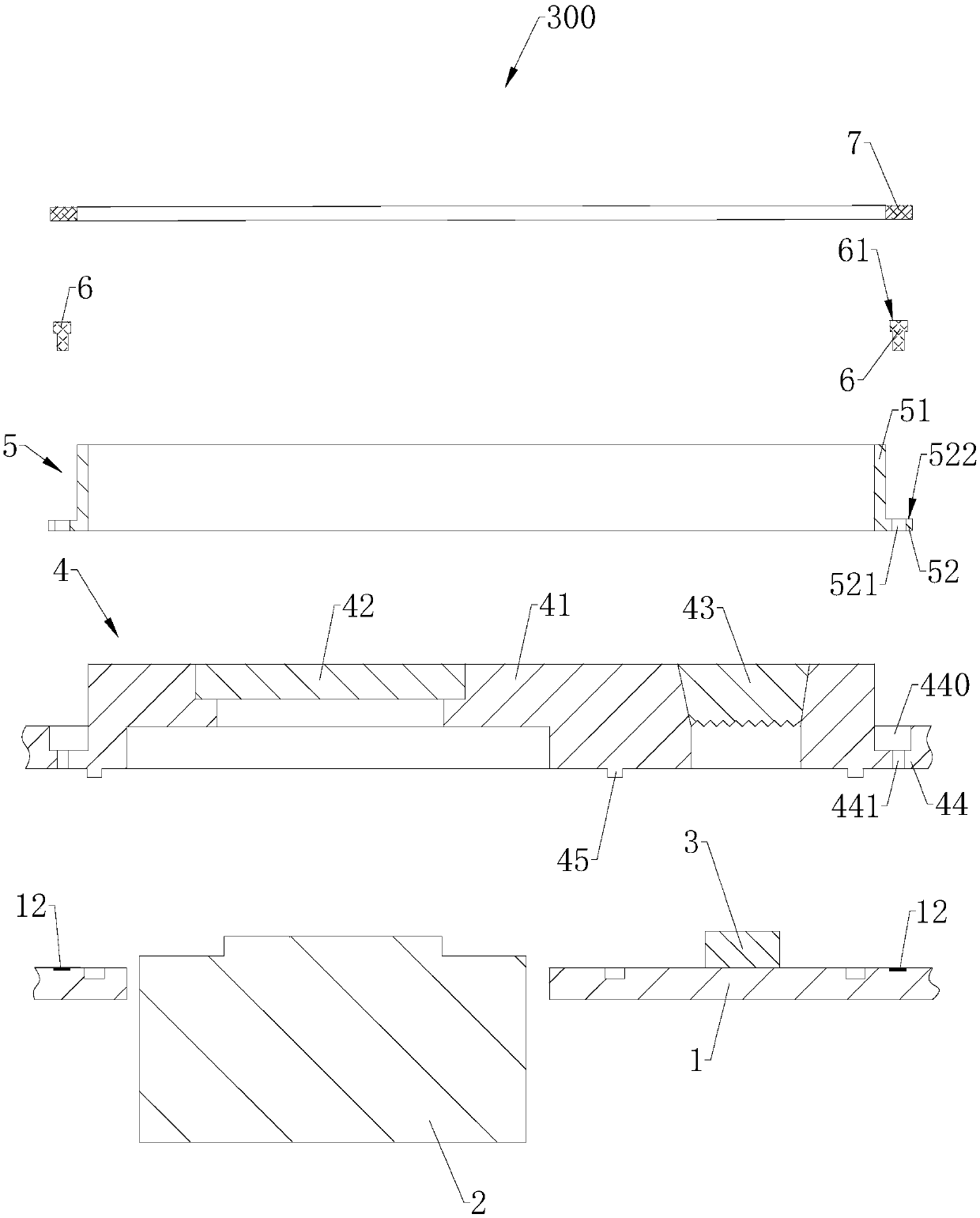

Camera assembly and mobile terminal

InactiveCN107707794AAntistaticAchieve antistaticTelevision system detailsColor television detailsComputer terminalEngineering

The invention provides a camera assembly, comprising a circuit board, a camera module, a flash lamp, a cover plate and a decoration ring. The circuit board is equipped with a hollowed avoiding area. The camera module is set in the avoiding area. The flash lamp is fixed on the circuit board. The cover plate covers the camera module and the flash lamp. The cover plate comprises a bearing part, and afirst light transmission part and a second light transmission part set on the bearing part at an interval. The bearing part is fixed on the circuit board, so the first light transmission part alignswith the camera module to transmit light entering the camera module. The second light transmission part aligns with the flash lamp to transmit the light of the flash lamp. The decoration ring is sleeved at the outer side of the bearing part and is electrically connected with a grounding terminal of the circuit board. The camera assembly has anti-static property. The invention also discloses a mobile terminal.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

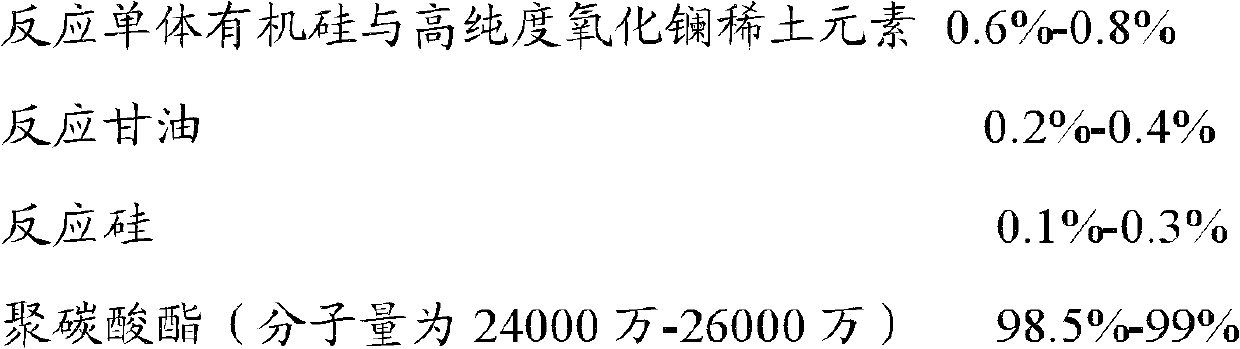

Optical high-transparency polycarbonate material and preparation method thereof

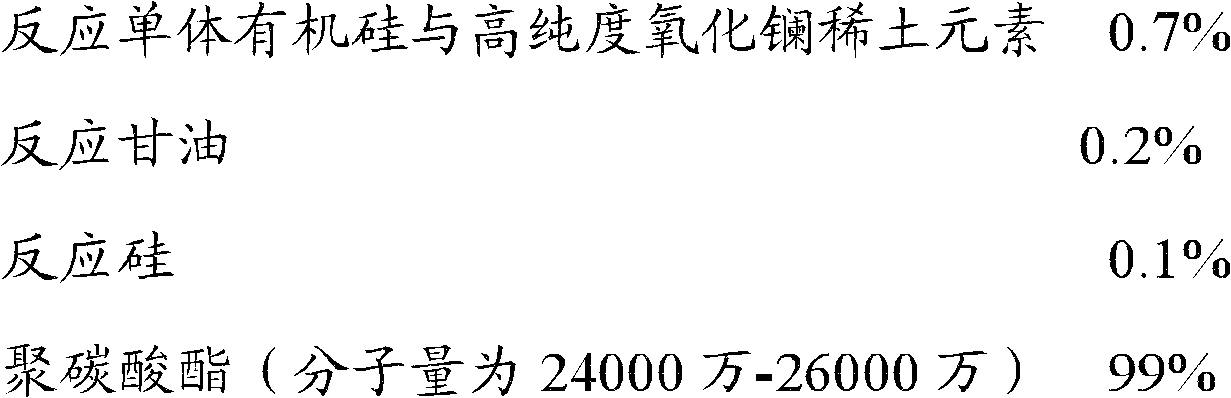

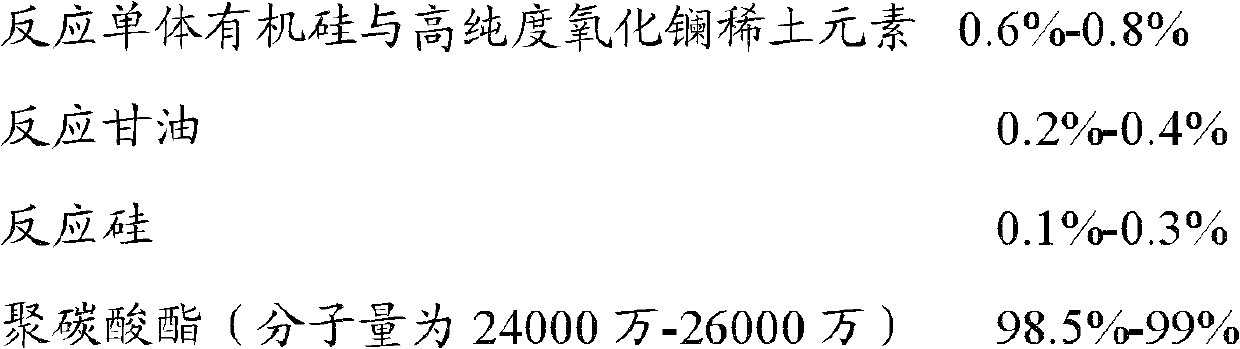

The invention provides an optical high-transparency polycarbonate material which comprises the following components in percentage by mass: 0.6-0.8% of reaction monomer organosilicon and high-purity lanthanum oxide rare-earth element, 0.2-0.4% of glycerol, 0.1-0.3% of reaction silicon and 98.5-99% of polycarbonate (the molecular weight is 240-260 million). The preparation method comprises the following steps: adding macromolecular monomer organosilicon and high-purity lanthanum oxide rare-earth element in a ratio of 9:1 into a reaction kettle, and reacting to synthesize a liquid activating agent, thereby implementing organic element sufficient branching and uniform distribution of nano bond and silicon bond, and obtaining an optical atom linear distribution structure; after mixing the glycerol and reaction silicon in the mass ratio, adding the liquid activating agent to carry out secondary low-temperature reaction, thereby obtaining the monomer high-transparency liquid substance; adopting universal polycarbonate (the molecular weight is 240-260 million) according to the mass ratio, adding 1-1.2% of the monomer high-transparency liquid substance, and drying and mixing in a high-speed mixer; and compounding by using a high-performance double screw extruder, and optimizing and extruding the polymer and polycarbonate, thereby obtaining the high-performance optical polycarbonate resin.

Owner:珠海市远康企业有限公司

Fire retardant antistatic plastic false top net for coal mine well

InactiveCN1724846ACorrosion resistantHas acid and alkali resistanceProtective coversAntistatic agentFire retardant

The invention relates fire retardant antistatic plastic false top wire for coal mine, characterized in that it uses plastics as raw material, adds certain amount of fire retardant chemical, antistatic agent and conductive charcoal black according to the proportion as follows: plastics raw material 85-90%, fire retardant chemical 5-7%, antistatic agent 1-2%, and conductive charcoal black 4-6%, mixes them to extrude and mold once. The advantages of the products include fire-retardant, antistatic corrosion resistance, acid base resistance, high mechanical strength, primary product molding, etc.

Owner:张贵福

Paint for coating chromatic bobbin printed sheet and preparation method thereof

InactiveCN101161929AAchieve oil resistanceAchieve antistaticCoatings with pigmentsCoatingsCardboardBobbin

The invention discloses a coating for painting colored yarn-tube face paper, which is made of the following materials: carboxylated styrene-butadiene rubber latex, oxidized starch, acid or direct dye, zirconium salt water-resistance agent and water. The production method of the coating of the invention made by the above materials is that: the oxidized starch is added into the water in proportion, mixed and heated to over 80 degree centigrade to make the oxidized starch fully gelatinized, and then the acid or the direct dye is added after being cooled lower than 60 degree centigrade for dissolution, carboxylated styrene-butadiene rubber latex is added at 10-40 degree centigrade before use, and proper zirconium salt water-resistance agent is added and stirred uniformly. The coat can be painted on paper, base paper used can be paper or cardboard of white, natural and colored with certain strength, crossed and solidified under catalyst or heating, thereby achieving certain performance of oil resistance, water resistance and operating requirements of non-decolorization, antistatic, etc. The invention is also a novel environmental protection product.

Owner:黄寒 +1

A kind of flame-retardant activated carbon cloth and preparation method thereof

ActiveCN102529254BSimple processProcess environmental protectionSynthetic resin layered productsWater basedEnvironmental resistance

The invention relates to a flame-retardant activated carbon fabric and a preparation method thereof. The flame-retardant activated carbon fabric is characterized in that an activated carbon layer, a water-based adhesive film layer and a hot-melt adhesive powder particle layer are sequentially covered on a base material which is subjected to flame-retardant treatment. The preparation method comprises the following steps of: spraying or padding the base material with an environment-friendly water-based flame retardant and drying; serially coating a prepared activated carbon paste and a water-based flame-retardant hot-melt adhesive powder particle paste on the base material, and drying to obtain the final product of flame-retardant activated carbon fabric. During the drying process, the water-based adhesive film layer is formed between the carbon layer and the hot-melt adhesive powder particle layer. The preparation method of the flame-retardant activated carbon fabric is simple and environment-friendly, and the product has good flame retardant property. Owing to the good adsorption property of activated carbon, the fabric can remove formaldehyde, benzene, TVOC and other harmful gases in the air. When the fabric is used, the fabric can be cut freely and laminated thermally. The flame-retardant activated carbon fabric is easy and convenient to use and has a wide application range.

Owner:WUXI DINGHAO NEW MATERIAL SCI RES

Technological formula of mulberry silk and wool fiber blended moistening emulsion

The invention discloses a technological formula of a mulberry silk and wool fiber blended moistening emulsion. When mulberry silk and wool fiber blending is conducted by means of a semi-worsted spinning system, moistening pretreatment is conducted on mulberry silk and wool fiber respectively, wherein a pretreatment emulsion of the wool fiber is prepared from, by weight of the wool fiber, 0.3%-0.5% of wool lubricant, 1.0%-1.6% of softening agent, 0.8%-1.2% of electrostatic agent, 0.5%-0.8% of penetrant, 0.3%-0.6% of emulsion and 15%-20% of water, and a pretreatment emulsion of the mulberry silk is prepared from, by weight of the mulberry silk, 0.5%-0.8% of softening agent, 1.5%-1.8% of electrostatic agent, 0.5%-0.8% of penetrant and 18%-22% of water. Treatment is conducted on the two fibers through the two emulsions respectively, the two emulsions can permeate into the interiors of the fibers, the effects of resisting static electricity, softening and increasing cohesive force are achieved, and the spinnability is improved; meanwhile, the technological requirements of spinning can be met, and the phenomena that a carding machine cylinder is wound, and wool is rolled on a drawing frame can be relieved; the technological formula is convenient to operate, low in operation cost and very prone to industrial application.

Owner:TONGXIANG YIDE TEXTILE

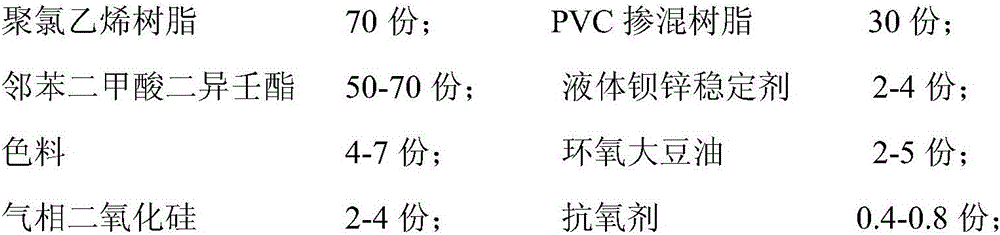

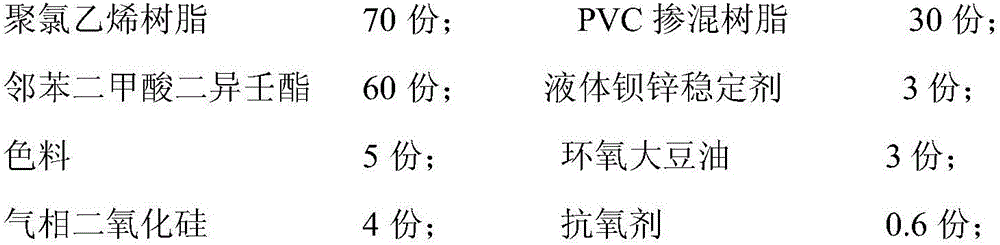

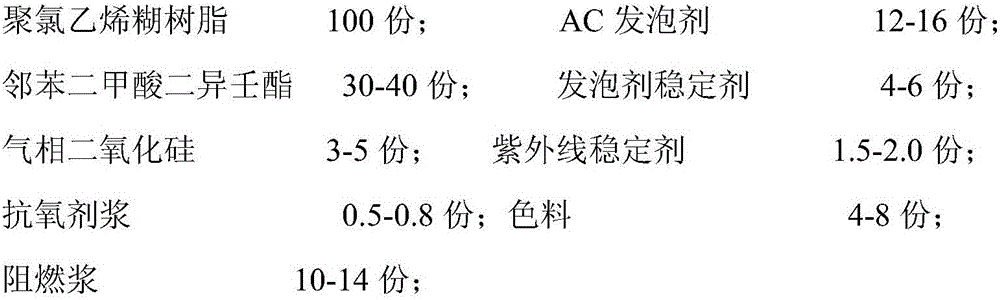

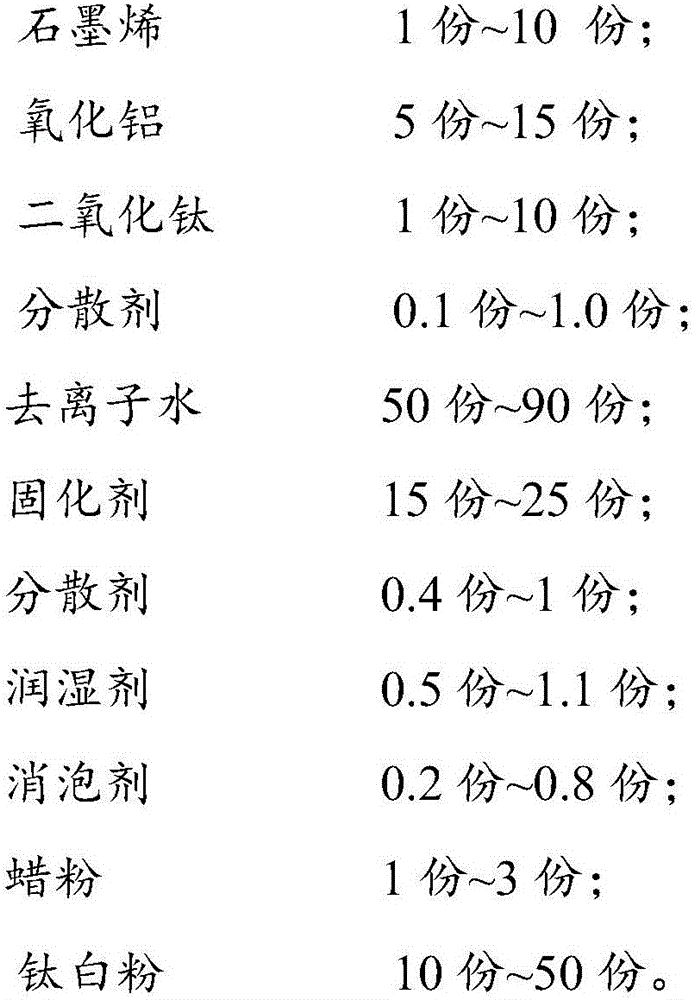

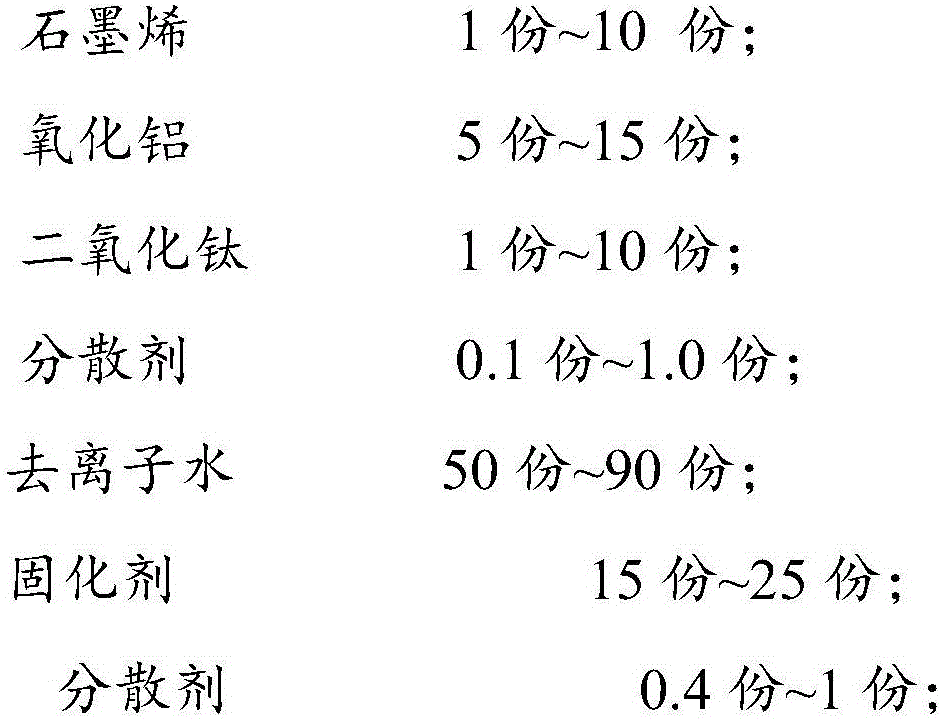

Heat-insulating noise-proof foam tent material and production method thereof

ActiveCN105780506AImprove stabilityEasy to processBiochemical fibre treatmentFibre typesPolyesterFiber

The invention discloses a heat-insulating noise-proof foam tent material. The heat-insulating noise-proof foam tent material comprises a polyester fiber mesh fabric layer, rubber layers, a foam layer and a treatment layer, wherein the rubber layers are formed by respectively coating rubber layer coating liquid onto a top surface and a bottom surface of the polyester fiber mesh fabric layer and then performing drying, plasticization and cooling; the foam layer is formed by coating foam layer coating liquid onto the rubber layer on the top surface of the polyester fiber mesh fabric layer and then performing drying, plasticization and cooling; the treatment layer is formed by coating treatment layer coating liquid onto the rubber layer on the bottom surface of the polyester fiber mesh fabric layer and then performing drying, plasticization and cooling, such that the heat-insulating noise-proof foam tent material is produced. The foam material produced by adopting the production method is low in heat conductivity coefficient, small in density, high in flexibility and good in stability, has good heat-insulating and noise-proof effects, is simple to produce, facilitates erection and recovery and is applicable to outdoor tents.

Owner:思嘉环保材料科技(上海)有限公司

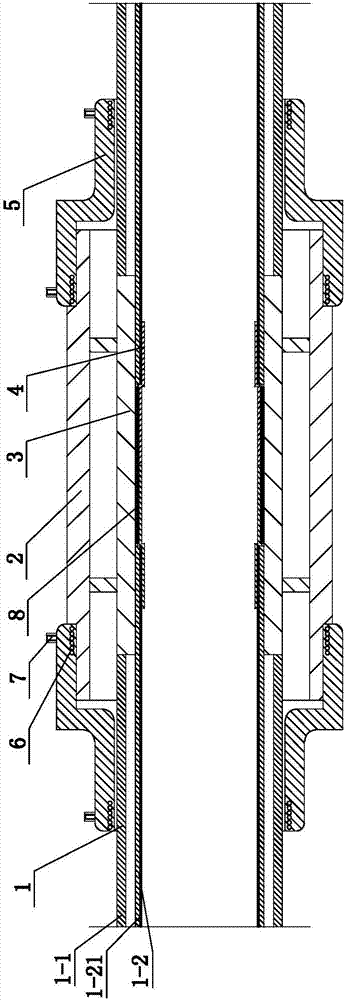

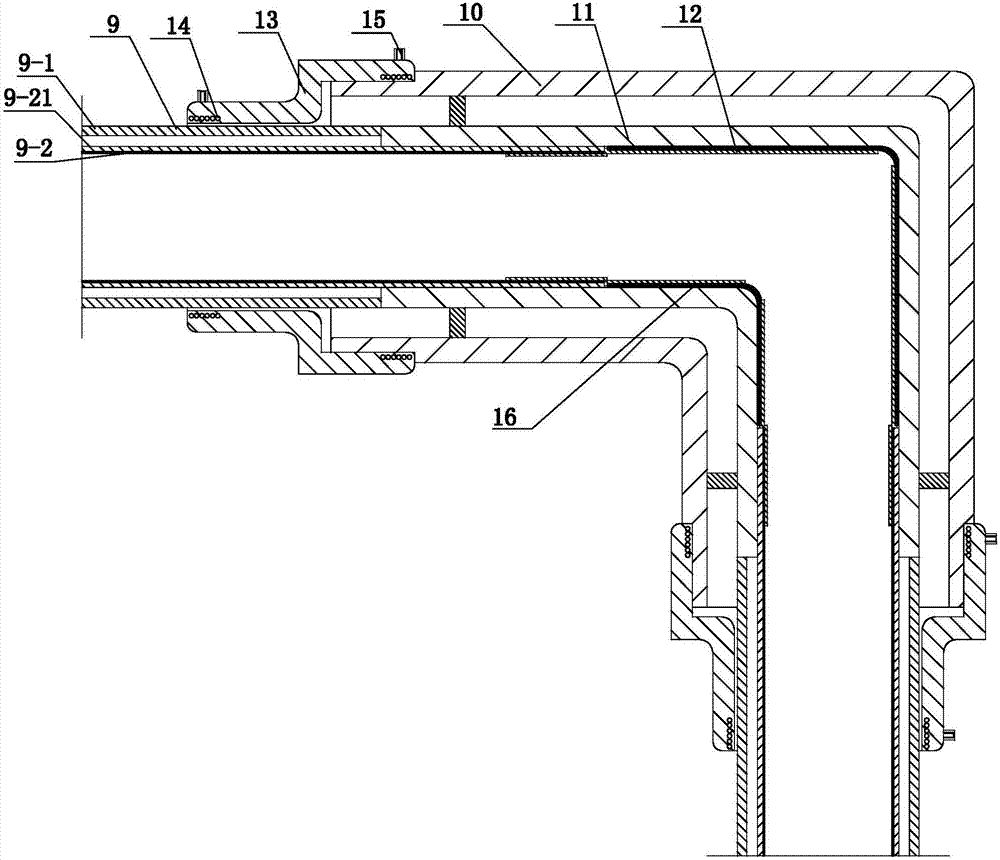

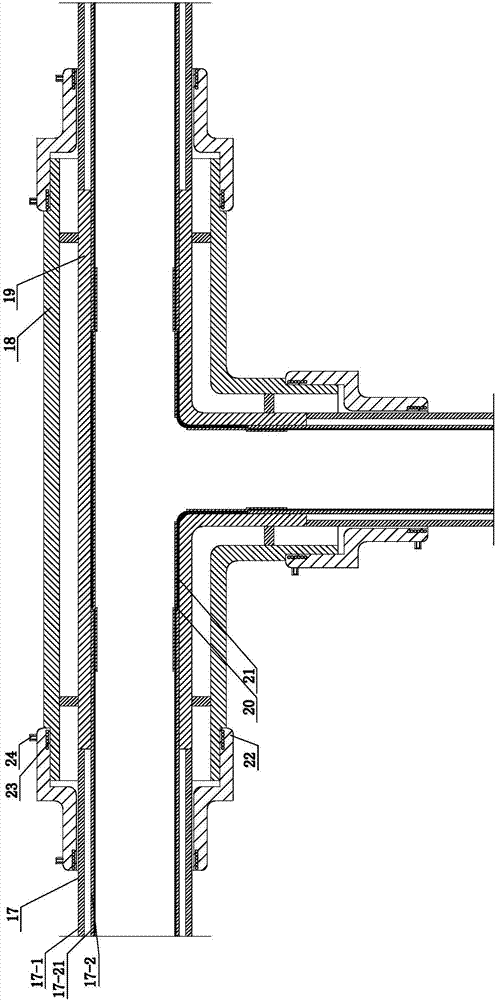

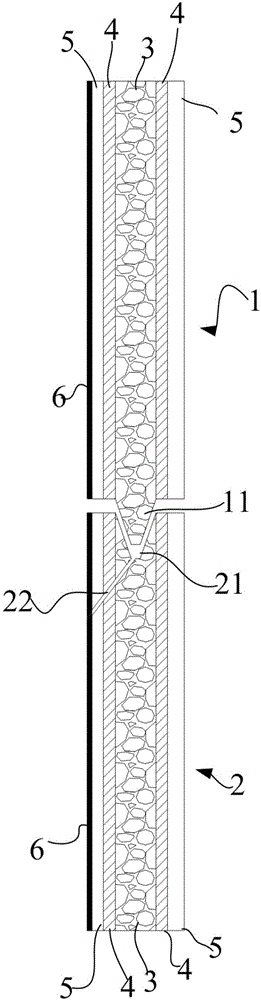

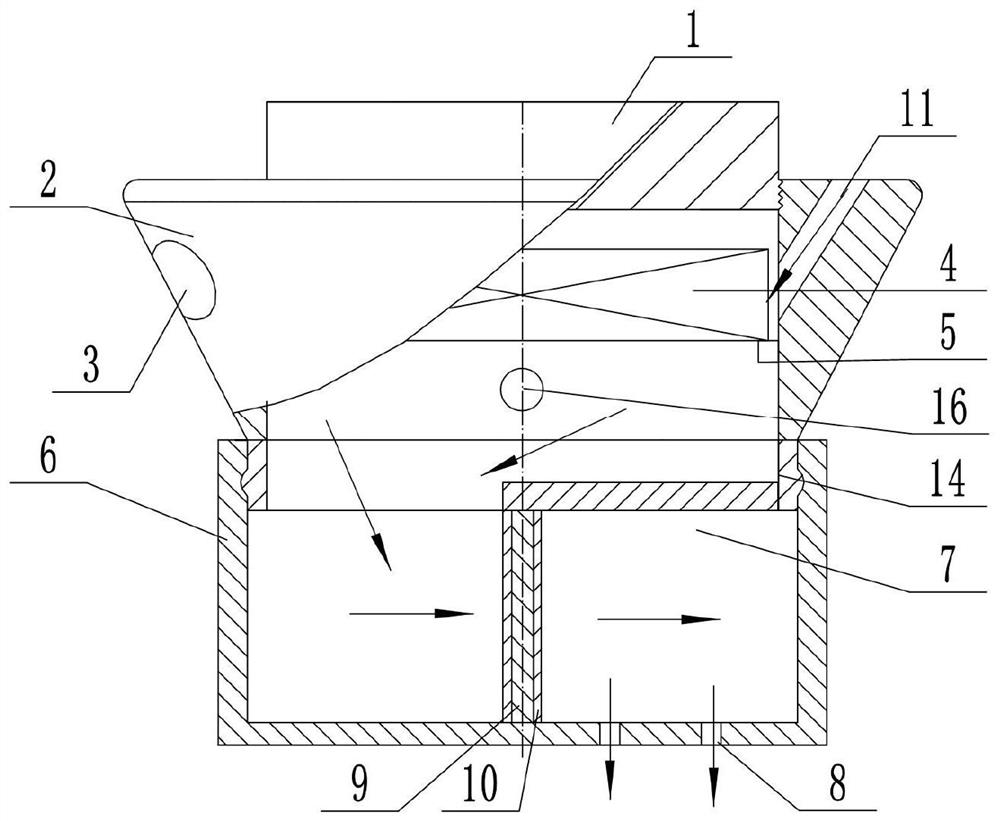

Static-conducting connecting structure of coupling for double-layered pipes

InactiveCN107191728AFirmly connectedImprove sealingBranching pipesPipe-jointsElectrical conductorCoupling

The invention discloses a static-conducting connecting structure of a coupling for double-layered pipes, and relates to the technical field of pipe connection. The structure comprises an outer connecting pipe and an inner connecting pipe which are both straight pipes. The two end ports of the inner connecting pipe are internally provided with tubular inserts correspondingly. One ends of the inserts are sleeved with the inner connecting pipe in a sealed mode, and the other ends of the insert are sleeved with inner oil conveying pipe bodies. The inner oil conveying pipe bodies are sleeved with outer oil conveying pipe bodies. The two ends of the outer connecting pipe are sleeved with connecting sleeves correspondingly. The connecting sleeves are used for enabling the outer connecting pipe and the outer oil conveying pipe bodies at the corresponding ends to be integrated in a sealed mode. The inner wall of the inner connecting pipe is coated with a second static conductor layer which is connected with the inserts in the two end ports of the inner connecting pipe at the same time. According to the static-conducting connecting structure, through the inserts arranged in the both end ports of the inner connecting pipe, and the second static conductor layer, first static-conducting layers of the inner oil conveying pipe bodies are connected, and it is guaranteed that good static-conducting performance is achieved between oil conveying pipes.

Owner:江苏法利沃环保科技有限公司

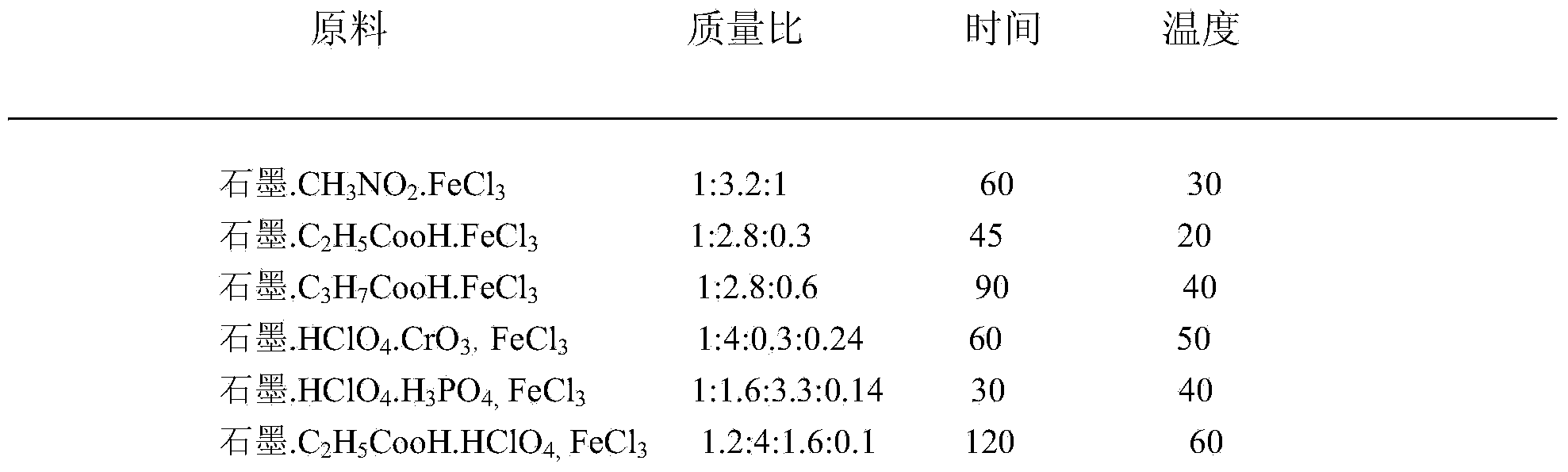

Multifunctional graphite interlayer compound as well as preparation method and application thereof

ActiveCN103881139AEfficient and stable processingEfficient and stable intercalation processing Convenient processingNon-macromolecular adhesive additivesCoatingsAlloyElectromagnetic radiation

The invention relates to a multifunctional graphite interlayer compound as well as a preparation method and application thereof. The multifunctional graphite interlayer compound comprises an Ni-Fe alloy as an intercalator, wherein the intercalator is suitable for shielding low-frequency electromagnetic radiation with the wavelength of 3-8 mm, the intercalator can be multiply combined with other intercalators in a multistep way, achieves a very good effect of shielding a wide-frequency electromagnetic wave, has multiple functions of electrostatic prevention, thermal resistance reduction and the like and can be used for realizing the breakthrough in the field. The invention also provides a preparation method with convenience for processing and low cost, further application of an expanded graphite product in preparing various terminal products and application in preparing a functional expandable particle especially.

Owner:GAOBEIDIAN SHUNXIN CHEM

Paint formula for water -proof and oil-proof colorful papers

InactiveCN101245568AAchieve oil resistanceAchieve antistaticCoatings with pigmentsCoatingsFirming agentPigment

The invention relates to a coating formula of colorful paper with water-proof and oil-proof properties. The coating is prepared by the following materials: Lauxite, oxidized starch, organic pigment, firming agent, water and other addition agents. The manufacture method for making each component into the coating of the invention is that; adding the organic pigment and a dispersant into the water according to a certain proportion, selecting proper grinding and dispersing equipment to lead the pigment to be evenly dispersed; then adding the oxidized starch into another part of water to be stirred and heated to more than 80 DEG C to be completely pasted and then cooled to below 60 DEG C, adding the dispersed organic pigment solution, adding the firming agent after complete cooling and mixing the coating into the Lauxite before being used. The invention also provides a method for producing the coating formula. The coating of the invention painted on the page can reach the using requirements of good oil-proof and water-proof properties and no decoloring after cross bonding and solidification under a certain condition. The coating is also a novel environment protective product.

Owner:GUANGDONG PAPER IND RES INST +1

External wallboard with waterproof structures for transformer substations

InactiveCN105952053AFor the purpose of waterproofingAchieve heat preservationAntifouling/underwater paintsPaints with biocidesTransformerElectric power equipment

The invention belongs to the field of electric power auxiliary equipment, and in particular relates to an exterior wall panel with a waterproof structure for a substation. It includes an upper prefabricated slab and a lower prefabricated slab that are set up and down with each other. The bottom of the upper prefabricated slab is provided with a protrusion for inserting into the lower prefabricated slab, and the lower prefabricated slab is provided with a groove for matching the protrusion. The protrusion is in the shape of a trapezoid The bottom of the groove is provided with a drain pipe, and the drain pipe is arranged downward from the inside to the outside. Both the upper and lower prefabricated panels include a base layer in the middle and reinforcement layers on both sides of the base layer. The side of the reinforcement layer is far away from the base layer. A waterproof mortar layer is provided, and the outer surface of the upper prefabricated board and the lower prefabricated board is also provided with an antistatic coating layer. The present invention provides an upper prefabricated board and a lower prefabricated board arranged in cooperation with each other, and utilizes its layered structure and The mutual cooperation structure can effectively achieve the purpose of waterproofing, and at the same time, achieve the purposes of heat preservation, sound insulation, fire prevention, earthquake resistance and antistatic.

Owner:GAOTANG COUNTRY POWER SUPPLY BUREAU OF STATE GRID SHANDONG ELECTRIC POWER CO

Preparation process of hyaluronic acid blanket

The invention discloses a preparation process of a hyaluronic acid blanket. The preparation process comprises the following steps of selecting raw materials, namely selecting pure cotton yarns with warp yarns of 47.6*2tex, selecting white cashmere with the length of 28-30mm and the fineness of 16.02 mu m as weft yarns, adopting 1 / 3 broken twill weft double as a fabric weave, and adopting special treatment liquid. The special treatment liquid comprises weak acid, a washable finishing agent, a hyaluronic acid finishing agent and clear water, the bath ratio of the washable finishing agent is 18-25g / L, and the bath ratio of the hyaluronic acid finishing agent is 36-75g / L; and the washable finishing agent and the hyaluronic acid finishing agent are added according to the mass ratio of 1: (2-3).According to the preparation process of the hyaluronic acid blanket, the hyaluronic acid finishing agent is ingeniously adopted for processing the household blanket, so that the water content of theskin can be effectively kept when a user uses the blanket, the skin is tender, glossy and elastic, the skin is prevented from being dry, and the effects of skin care, beauty maintaining, health and beauty maintaining are achieved; and meanwhile, the blanket also has antistatic and easy-to-clean functions and comfortable and soft hand feeling.

Owner:CHANGZHOU GOLDEN SPRING TEXTILE

Processing method of fiber strengthening composite corrugated board

ActiveCN103114490BImprove carrying capacityReduced carrying capacityPaper-making machinesCardboardFiber

The invention relates to a processing method of a fiber strengthening composite corrugated board and belongs to the technology field of corrugated board processing. The processing method includes the steps of suppressing fiber on a face board paper in a wire rod or gridding mode, applying paper plastic adhesive on the fiber, and then compositing the fiber with a corrugated paper, conducting drying and cooling to finalize the design, slitting, creasing, transversely cutting and stacking. The paper plastic adhesive is mixture of additive, borax, caustic soda liquid, corn starch and water. The processing method of the fiber strengthening composite corrugated board has the advantages of being simple in procedure, convenient to implement, high in intensity of obtained paperboards, good in mechanical property of the obtained paperboards, relatively low in cost, capable of being applied to the fields such as corrugated paperboard processing and the like.

Owner:浙江希望包装有限公司

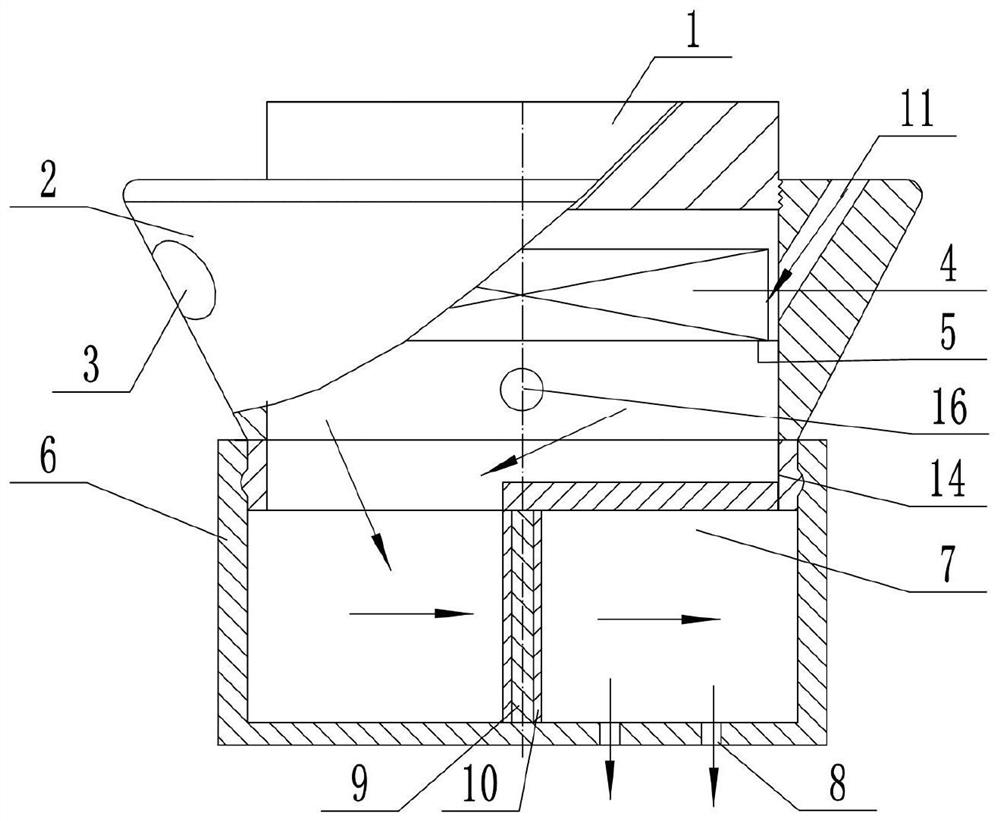

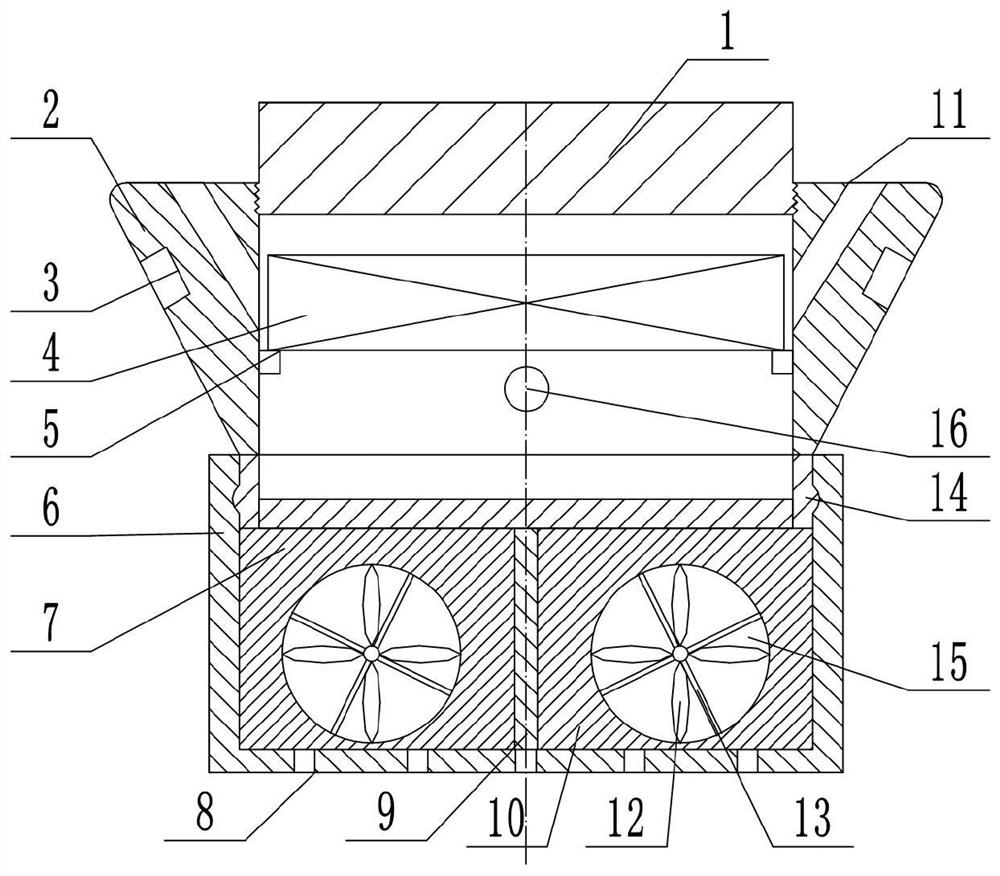

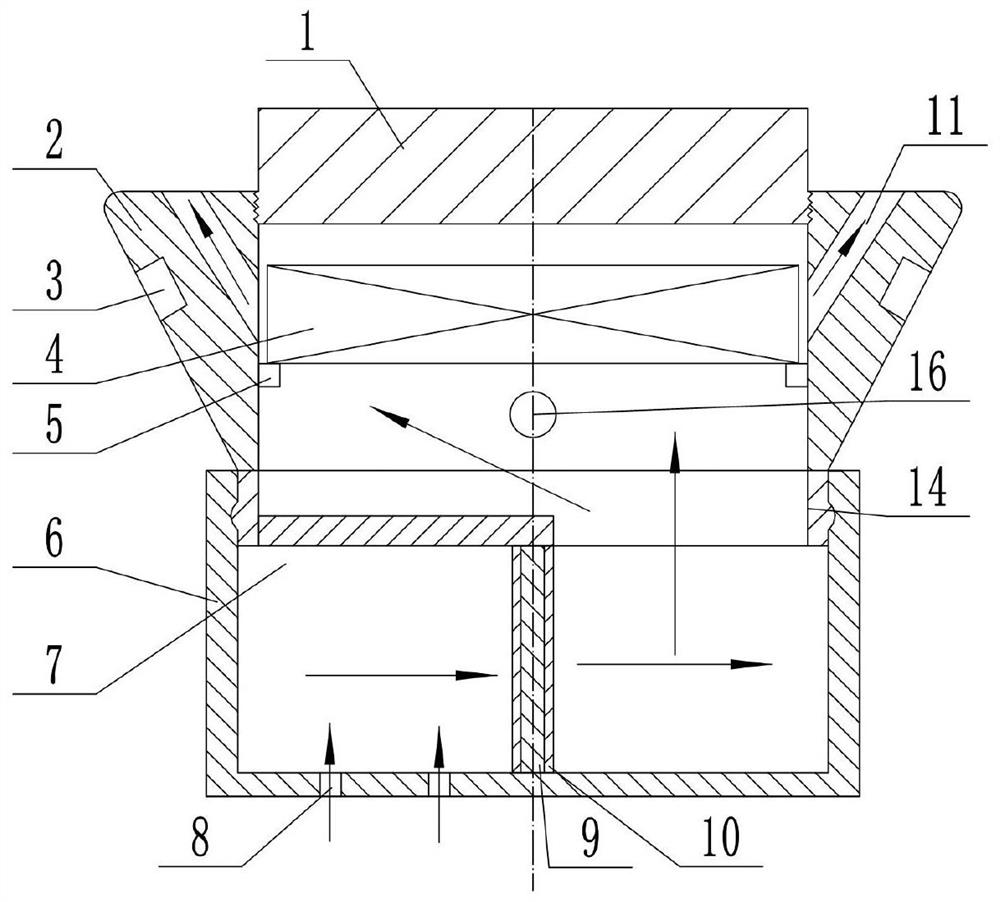

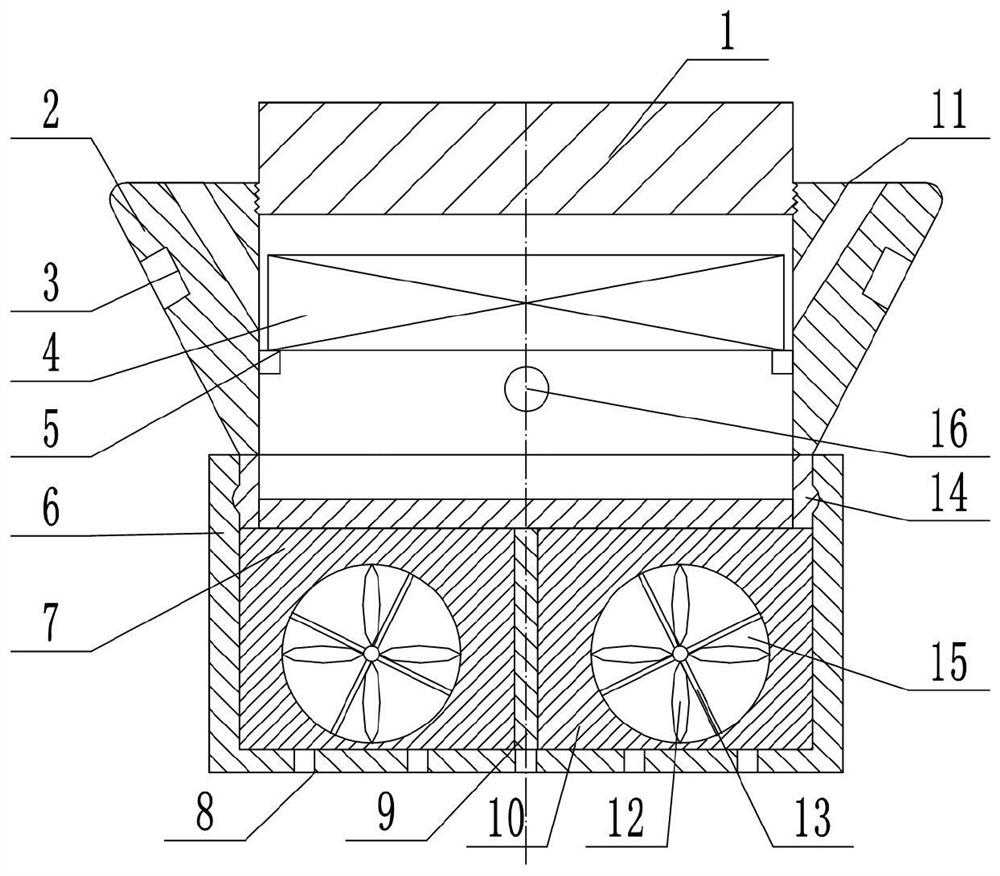

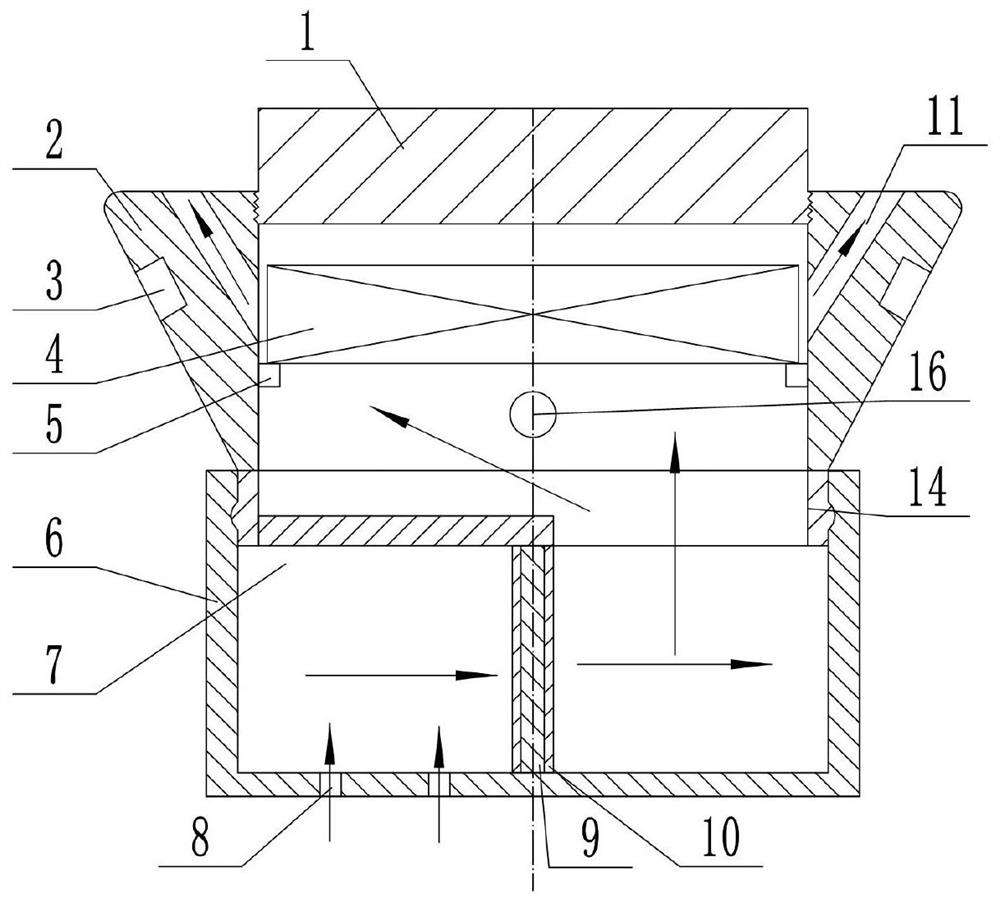

Electric appliance fire detector

ActiveCN112669559AShort lifeReduced detection sensitivityDispersed particle filtrationMagnetic/electric field screeningFire detectorStructural engineering

The invention discloses an electric appliance fire detector, which belongs to the technical field of monitoring detectors and comprises a mounting support block, a shell, an alarm device and a smoke sensor probe, the alarm device and the smoke sensor probe are arranged in the shell, an external thread is arranged on the outer side wall of the lower end of the mounting support block, a cylindrical cavity is coaxially arranged in the shell, the shell is a circular truncated cone, the large end of the shell is coaxially in threaded connection with the lower end of the installation supporting block through internal threads at the upper end of the cavity, the small end of the shell is coaxially and fixedly connected with a connecting cylinder, an alarm device is installed on the upper portion of the cavity, the smoke sensor probe is located on the lower portion of the cavity of the shell, an annular protrusion is arranged on the outer circumferential face of the connecting cylinder, a cylinder body with a closed lower end is coaxially arranged outside the connecting cylinder in a sleeving manner, the cylinder body is rotatably mounted on the connecting cylinder, and a fan assembly is fixedly arranged in the cylinder body. According to the electric appliance fire detector, the problems that a traditional electric appliance fire detector is prone to dust adsorption, and a fire cannot be monitored in time are solved.

Owner:HUNAN SMART QUICK SMART ELECTRONIC TECH CO LTD

Multifunctional thermal-insulation antibacterial elastic yarn and silk stockings

ActiveCN111118653AImprove tensile strengthIncrease elasticityElectroconductive/antistatic filament manufactureFlame-proof filament manufacturePrepolymerIsocyanate

The invention relates to a multifunctional thermal-insulation antibacterial elastic yarn and silk stockings. The elastic yarn is prepared by the steps of preparing silver nanowires by adopting a solvothermal method; in the process of preparing SiO2 aerogel, adding silver nanowires to prepare silver nanowire aerogel composite powder; and adding the silver nanowire aerogel composite powder, a silanecoupling agent and a micromolecular polyisocyanate prepolymer as additives into molten thermoplastic polyurethane, and spinning to obtain the multifunctional thermal-insulation antibacterial elasticyarn. Through the silane coupling agent in the invention, composite powder and polyurethane can be further firmly combined, so that the thermal insulation and antibacterial functions can be kept for along time; and the micromolecular polyisocyanate prepolymer is added into the thermoplastic polyurethane spinning process, so that the micromolecular polyisocyanate prepolymer reacts with a fracturesubstance, polyurethane with a linear structure is changed into a three-dimensional structure, and the elasticity is improved.

Owner:湖南岩拓新材料科技有限公司

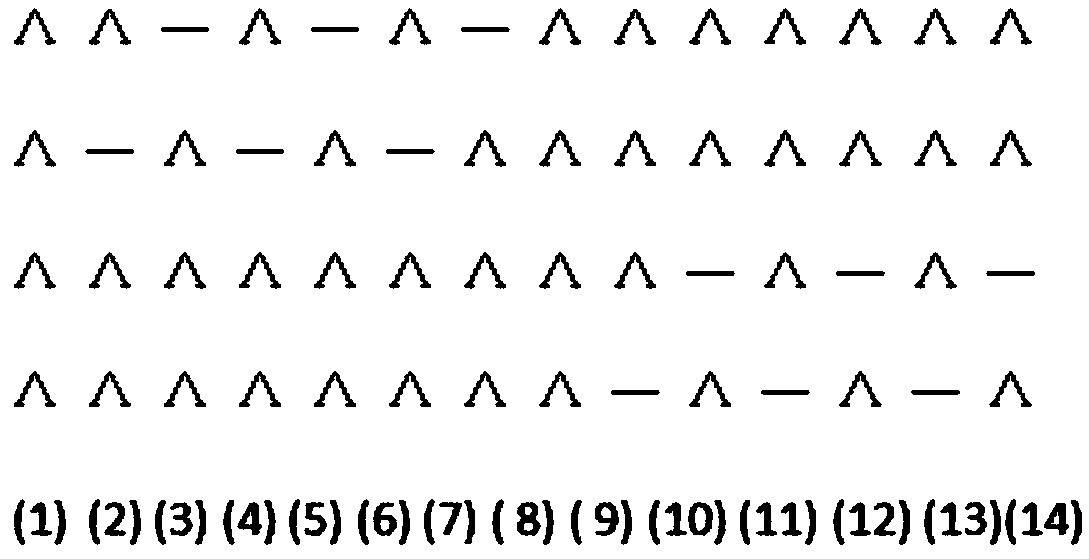

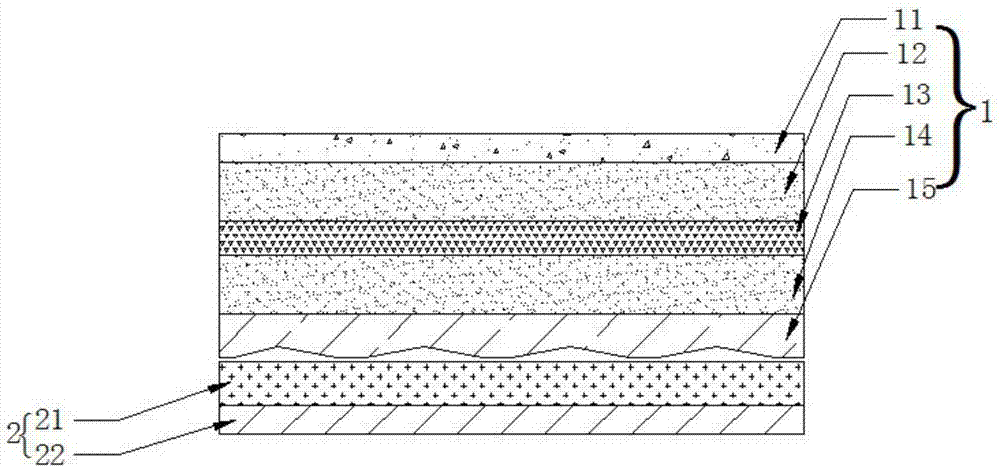

Multifunctional protective film

InactiveCN107418468AAchieve scratch resistanceAchieve antistaticFilm/foil adhesivesElectrically-conductive paintsPolyethylene terephthalateBlue light

The invention discloses a multifunctional protective film which comprises a use layer and a peeling layer. The use layer sequentially comprises a scratch-resistant layer, a first PET (polyethylene terephthalate) base film layer, a blue light preventive coating, a second PET base film layer and an antistatic pressure-sensitive adhesive layer; the peeling layer comprises a release film layer and an antistatic coating, and the release film layer clings to the antistatic pressure-sensitive adhesive layer and is arranged on the lower side of the antistatic pressure-sensitive adhesive layer. The multifunctional protective film has the advantages that scratch-resistant, antistatic and blue light preventive effects can be realized by means of composite modification; the multifunctional protective film with the netted pressure-sensitive adhesive layer is easy to stick and tear and free of adhesive residues.

Owner:FOSHAN NANHAI HAOSEN MACHINERY EQUIP CO LTD

Mulberry silk wool fiber blend wetting emulsion

InactiveCN110924154AAlleviate the phenomenon of hair curlingAchieve antistaticMechanical cleaningTextile treatment containersChemistryPolymer chemistry

The invention discloses a mulberry silk wool fiber blend wetting emulsion which comprises a wool fiber wetting pretreatment emulsion and a mulberry silk fiber wetting pretreatment emulsion. The wool fiber wetting pretreatment emulsion is prepared from the following raw materials in parts by weight: 0.3 to 0.5 part of wool lubricant, 1.0 to 1.6 parts of softening agent I, 0.8 to 1.2 parts of antistatic agent I, 0.5 to 0.8 part of penetrating agent I, 0.3 to 0.6 part of emulsifier, and 15 to 20 parts of water. According to the mulberry silk wool fiber blend wetting emulsion provided by the invention, after two blended fibers are emulsified through the two emulsions, the mulberry silk wool fiber blend wetting emulsion can fully permeate into the fibers so as to achieve the effects on resisting static, softening and increasing a cohesive force. The spinnability is improved, and meanwhile, not only can the process requirement on spinning be met, but also the phenomena of lapping and the like of a card cylinder and a drawing frame can be relieved.

Owner:TONGXIANG YIDE TEXTILE

Environment-friendly paper tank material

The invention discloses an environment-friendly paper tank material. The environment-friendly paper tank material contains the following components in parts by weight: 50-60 parts of paper pulp, 20-30parts of polylactic acid fibers, 15-20 parts of polyacrylamide, 10-20 parts of alpha-olefin sulfonate, 10-15 parts of aluminum polychlorid, 10-20 parts of polyglycolic acid, 20-25 parts of titanium dioxide, 25-30 parts of cationic polyacrylamide, 10-15 parts of oxyalkylamine polyoxyethylene ether, 20-30 parts of diisooctyl phthalate, 5-10 parts of methylcellulose, 5-10 parts of sodium polyacrylate, 3-5 parts of chitosan and 100 parts of deionized water. According to the environment-friendly paper tank material, the anti-pressure capacity of a paper tank can be improved, articles are not damaged during the transportation, and meanwhile, the paper tank is not damaged due to the pressing of the articles, so that the wasting of a paper board is avoided, and the environment is protected; and the prepared paper tank is high in drying speed and strength, the ridging, moisture adsorption and damping are not easily occur, the anti-microbial, mildew-proof, deodorization and moisture-adsorptioneffects can be achieved, and the anti-wrinkle, anti-static and strength-improving functions are realized; and prepared paper is soft, plump and comfortable in hand feel.

Owner:锦上包装江苏有限公司

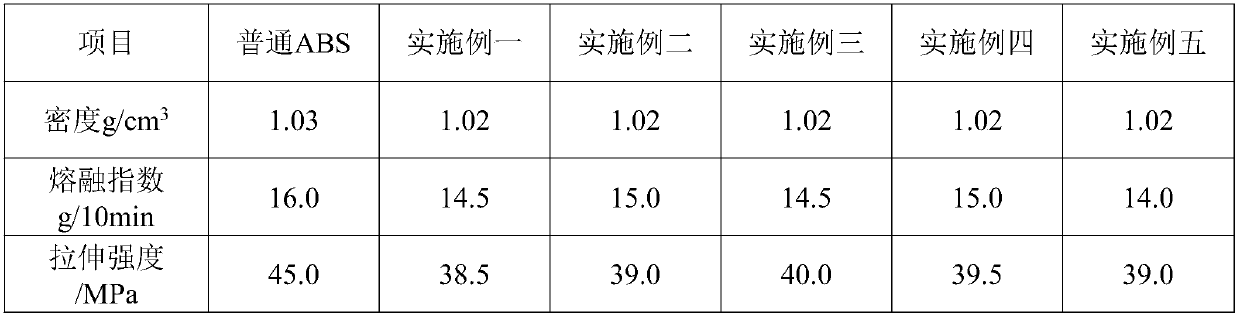

Low-filler antistatic and highly-tough ABS plastic and preparation method thereof

The invention relates to a low-filler antistatic and highly-tough ABS plastic and a preparation method thereof. The preparation method comprises the following steps: swelling natural rubber particlesin toluene; adding the swelled natural rubber particles to a carbon black suspension formed by dimethylformamide and deionized water to make the carbon black penetrate into the natural rubber particles, washing the natural rubber particles with deionized water, and drying the washed natural rubber components to a constant weight; blending 100 parts by weight of ordinary ABS plastic, 5-10 parts byweight of an ethylene-acrylic acid copolymer, 10-30 parts by weight of natural rubber penetrated with the carbon black particles, 0.1-3 parts by weight of a coupling agent and 0.1-0.4 part by weight of an antioxidant; and extruding the obtained mixture at 160-210 DEG C, and cooling the extruded mixture to obtain low-filler antistatic and highly-tough ABS plastic particles. The ABS plastic preparedin the invention has the advantages of low filler content, good antistatic property, easiness in processing, and good mechanical properties.

Owner:ANHUI JIHONG MATERIAL TECH

Multifunctional heat-insulating and antibacterial elastic silks and silk stockings

PendingCN111691004AImprove hydrophilicityIncrease contact areaElectroconductive/antistatic filament manufactureFlame-proof filament manufacturePolymer scienceSpinning

The invention relates to multifunctional heat-insulating and antibacterial elastic silks and silk stockings. A preparation method of the elastic silks comprises the following steps that silver nanowires are prepared by a solvothermal method; silver nanowires are added in the process of preparing SiO2 aerogel to prepare silver nanowire aerogel composite powder; the silver nanowire aerogel compositepowder, a silane coupling agent and a small molecule polyisocyanate prepolymer are added as additives to molten thermoplastic polyurethane, and the multifunctional heat-insulating and antibacterial elastic silks are obtained through spinning. The silane coupling agent can further firmly combing the composite powder and the polyurethane, heat-insulating and antibacterial function can be maintainedfor long time, the small molecular polyisocyanate prepolymer is added in the thermoplastic polyurethane spinning process, the small molecular polyisocyanate prepolymer reacts with the breaking substance, and the polyurethane of the linear structure becomes a three-dimensional structure, so that the elasticity is improved.

Owner:湖南岩拓新材料科技有限公司 +1

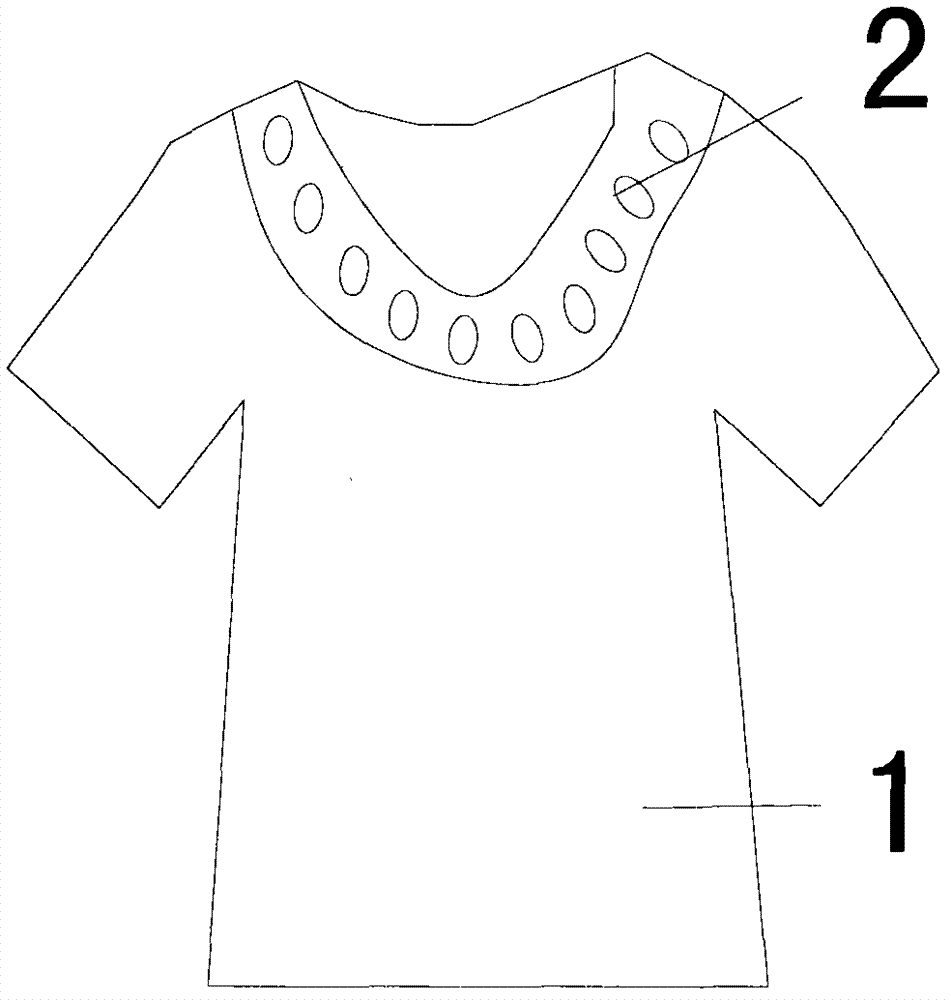

Antistatic antibiosis T-shirt with hook flower collar

InactiveCN103110209AEnhance layeringImprove aestheticsProtective garmentSpecial outerwear garmentsAntibiosisEngineering

The invention relates to an antistatic antibiosis T-shirt with a hook flower collar. The antistatic antibiosis T-shirt with the hook flower collar comprises a T-shirt body (1), and is characterized in that a collarband of the T-shirt body (1) is provided with the hook flower collar (2) which is made of diamond cotton, the T-shirt body (1) is made from fabric in a sewed mode, the surface of the fabric is coated with a teflon coating, and a fabric body is a nylon layer. The collarband of the T-shirt body is provided with the hook flower collar, so that the overall layering is strengthened and the beautifulness is improved. In addition, the antistatic antibiosis T-shirt with the hook flower collar has an antistatic and antibiosis function.

Owner:周忠平

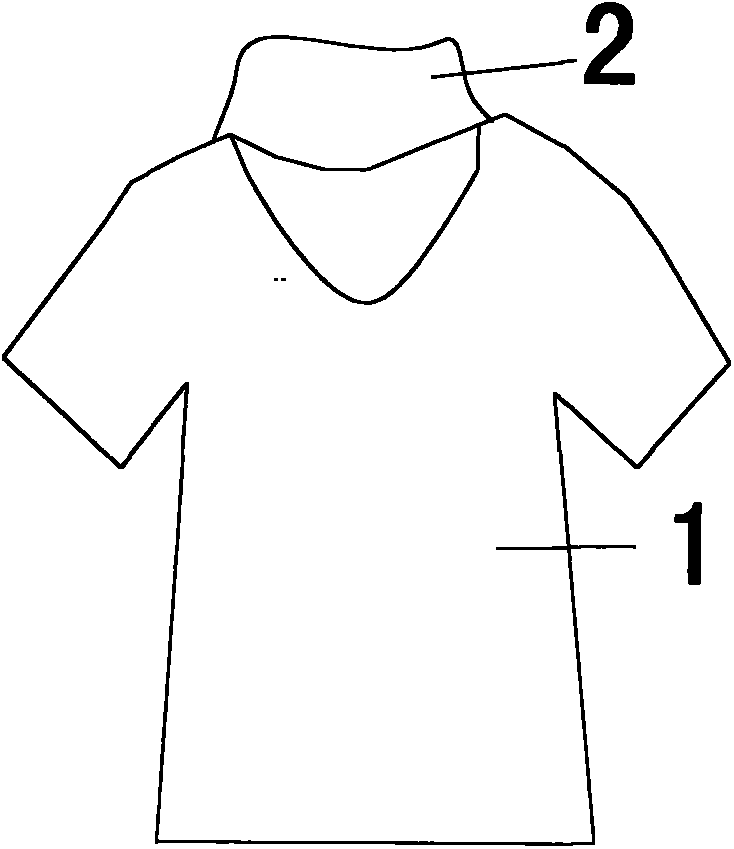

Anti-static anti-microbial short-sleeved shirt with detachable collar

InactiveCN103110211AAchieve structural variabilityAchieve antistaticProtective garmentSpecial outerwear garmentsPolyesterBiochemical engineering

The invention relates to an anti-static anti-microbial short-sleeved shirt with a detachable collar. The short-sleeved shirt comprises a short-sleeved shirt body (1), wherein the detachable collar (2) is arranged at a collar position of the short-sleeved shirt body (1), the collar (2) is connected with the short-sleeved shirt body (1) through buttons or a zipper, and the short-sleeved shirt body (1) is formed through sewing of a fabric. The fabric comprises a fabric body and a Teflon coating layer coated on the surface of the fabric body, wherein the fabric body is a nylon cloth layer, a polyester cloth layer or a cotton layer. Due to the fact that the collar of the short-sleeved shirt body is detachable, the short-sleeved shirt body is in different styles before and after the collar is detached, structural variability of the same short-sleeved shirt body is achieved, and the short-sleeved shirt body is fashionable and capable of achieving anti-static and anti-microbial functions.

Owner:陈国银

Electrical Fire Detector

ActiveCN112669559BShort lifeReduced detection sensitivityDispersed particle filtrationMagnetic/electric field screeningFire detectorEngineering

The invention discloses an electrical fire detector, which belongs to the technical field of monitoring detectors and comprises an installation support block, a casing, an alarm device and a smoke sensor probe all arranged in the casing, and the outer wall of the lower end of the installation support block is provided with an external thread , the inside of the housing is coaxially provided with a cylindrical cavity, the housing is a round platform, and its large end is coaxially threaded with the lower end of the installation support block through the internal thread at the upper end of the cavity, and its small end A connecting cylinder is fixedly connected coaxially, and an alarm device is installed on the upper part of the cavity. The outer coaxial sleeve of the connecting cylinder is provided with a cylinder with a closed lower end. The cylinder is rotatably mounted on the connecting cylinder, and a fan assembly is fixed inside the cylinder. The invention solves the problem that the traditional electrical fire detector is easy to absorb dust and The problem of untimely fire monitoring.

Owner:HUNAN SMART QUICK SMART ELECTRONIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com