Heat-insulating noise-proof foam tent material and production method thereof

A technology of thermal insulation and foaming materials, which is applied in the field of tent materials, can solve the problems of reducing loss, failure to reach, and small gradient changes, and achieve the effects of reducing loss, low density, and small gradient changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Preparation of thermal insulation and noise-proof foaming material for tent

[0043] 1) Prepare the adhesive layer coating solution: Weigh the raw materials according to the weight ratio of each component of the adhesive layer coating solution, then put them into the mixer, stir and mix for 20-30 minutes, and obtain the adhesive layer coating solution with a viscosity of 10000-15000 centimeters Park;

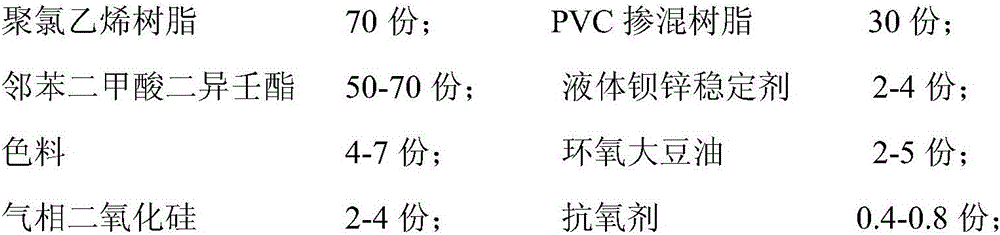

[0044] The subbing layer coating liquid comprises the following components by weight:

[0045]

[0046] 2) Preparation of foam layer coating solution: Weigh the raw materials according to the weight ratio of each component of the foam layer, then put them into a mixer, stir and mix for 15-30 minutes, and obtain a foam layer coating solution with a viscosity of 20000-30000 centimeters Poor; among them, the AC foaming agent needs to be ground before use, and the fineness is less than 20 μm.

[0047] The foam layer coating solution comprises the following comp...

Embodiment 2

[0056] Example 2 Preparation of thermal insulation and noise-proof foaming material for tent

[0057] 1) Prepare the adhesive layer coating solution: Weigh the raw materials according to the weight ratio of each component of the adhesive layer coating solution, then put them into the mixer, stir and mix for 20-30 minutes, and obtain the adhesive layer coating solution with a viscosity of 10000-15000 centimeters Park;

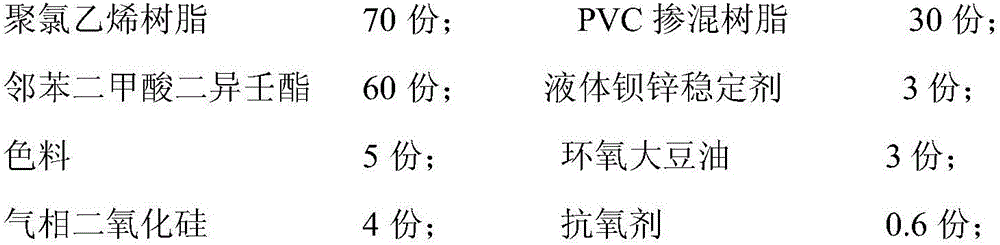

[0058] The subbing layer coating liquid comprises the following components by weight:

[0059]

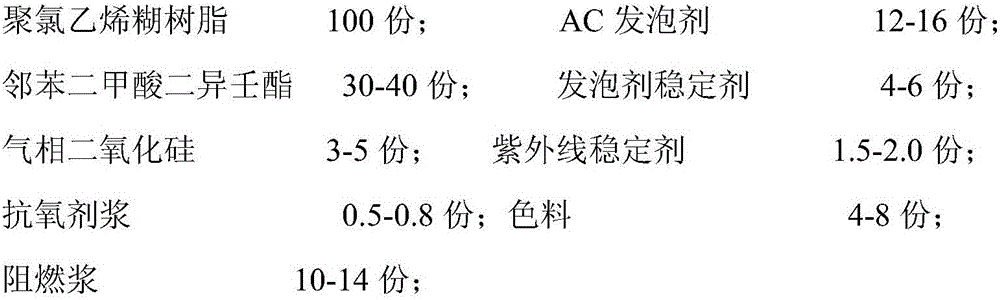

[0060] 2) Preparation of foam layer coating solution: Weigh the raw materials according to the weight ratio of each component of the foam layer, then put them into a mixer, stir and mix for 15-30 minutes, and obtain a foam layer coating solution with a viscosity of 20000-30000 centimeters Poor; among them, the AC foaming agent needs to be ground before use, and the fineness is less than 20 μm.

[0061]

[0062] 3) Prepare the coating solution for the treatmen...

Embodiment 3

[0068] Example 3 Preparation of thermal insulation and noise-proof foaming material for tent

[0069] 1) Prepare the adhesive layer coating solution: Weigh the raw materials according to the weight ratio of each component of the adhesive layer coating solution, then put them into the mixer, stir and mix for 20-30 minutes, and obtain the adhesive layer coating solution with a viscosity of 10000-15000 centimeters Park;

[0070] The subbing layer coating liquid comprises the following components by weight:

[0071]

[0072] 2) Preparation of foam layer coating solution: Weigh the raw materials according to the weight ratio of each component of the foam layer, then put them into a mixer, stir and mix for 15-30 minutes, and obtain a foam layer coating solution with a viscosity of 20000-30000 centimeters Poor; among them, the AC foaming agent needs to be ground before use, and the fineness is less than 20 μm.

[0073]

[0074] 3) Prepare the coating solution for the treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com