Patents

Literature

37results about How to "Achieve oil resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and preparation method thereof

ActiveCN101597410AGood oil resistanceReach high temperaturePlastic/resin/waxes insulatorsClimate change adaptationPolymer scienceUltra fine

The invention relates to an anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and a preparation method thereof. The sheath material uses chlorinated polyethylene rubber as main raw material and adds chlorosulfonated polyethylene rubber, triallyl isocyanurate, 1,3-bis (tert-butyl peroxide isopropyl) benzene, trioctyl trimellitate, carbon black, antioxidant 1010, ultra-fine talc powder, antimony trioxide, and high-activity magnesium oxide R-150 according to ratios; the preparation method is as follows: at first, mixing part of the auxiliary agents, then mediating, internal mixing, open mixing, granulating and extruding are carried out on the mixture to form cables, thus the cables are obtained. In the formula, high temperature resistant plasticizer is utilized, various auxiliary agents with appropriate proportions are added into the formula, so that chlorinated polyethylene rubber cable material can reach a high temperature of 105 DEG C, and can be used at the lowest temperature of minus 50 DEG C. The sheath material has the advantages of good anti-aging property, excellent electrical insulation and mechanical property, environmental protection and high flame resistance, thereby being suitable for cold and oil-contaminated severe environment and transmission and distribution circuits of which the current-carrying capacities are large and the rated voltages are at or below 450 / 750V. Meanwhile, compared with traditional chloroprene rubber cable material, the sheath material has the characteristics of low cost, fast extruding speed and high output benefit.

Owner:NINGBO WELL ELECTRIC APPLANCE CO LTD

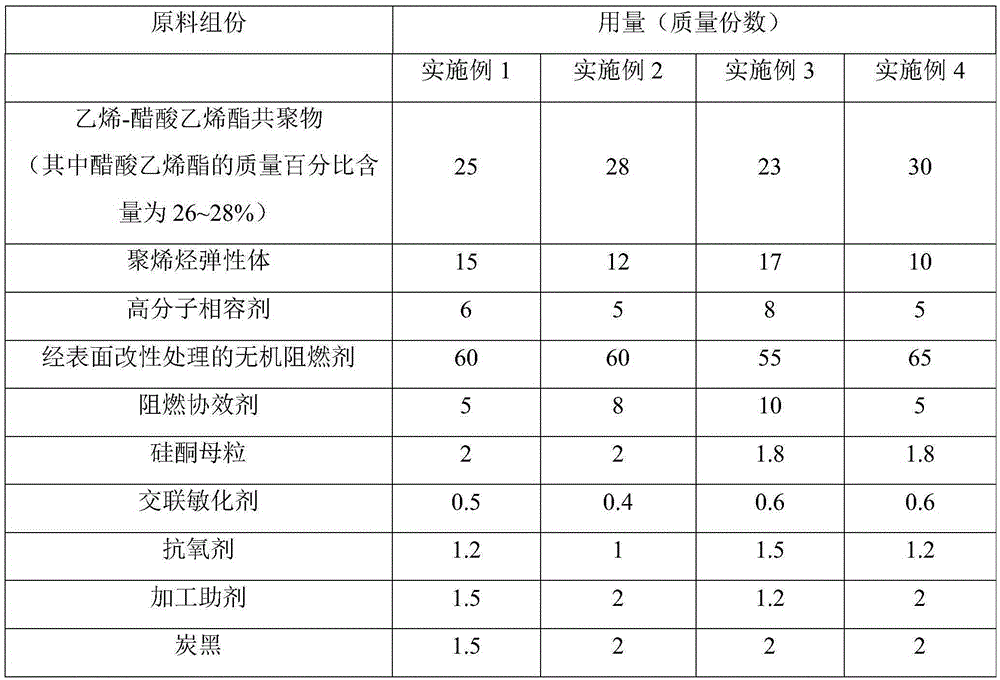

Irradiation crosslinking halogen-free flame retardant polyolefin material for locomotive wires and preparation method of irradiation crosslinking halogen-free flame retardant polyolefin material

InactiveCN105315541AAchieve oil resistanceAchieve high temperature resistancePlastic/resin/waxes insulatorsElastomerPolymer science

The invention belongs to the field of low-smoke halogen-free flame retardant materials, and particularly relates to an irradiation crosslinking halogen-free flame retardant polyolefin material for locomotive wires and a preparation method of the irradiation crosslinking halogen-free flame retardant polyolefin material. The polyolefin material comprises the following components in parts by mass: 20-30 parts of ethylene-vinyl acetate copolymer, 10-20 parts of polyolefin elastomer, 5-10 parts of a macromolecular compatilizer, 45-65 parts of an inorganic flame retardant subjected to surface modification treatment, 5-10 parts of a flame retardant synergist, 0.8-1.5 parts of an antioxidant, 1.5-2.5 parts of silicone masterbatches, 0.3-0.6 part of a crosslinking sensitizer, 1.5-2 parts of carbon black and 1-2 parts of a processing aid. The preparation method comprises the technological steps of surface treatment of the inorganic flame retardant, proportioning, mixing, melting, extrusion for pelletization, and the like. Compared with the prior art, the polyolefin material has the characteristics of excellent flame retardation (capable of passing the D type group burning test), oil resistance (mineral oil and fuel oil resistant), high temperature resistance (the grade is 150 DEG C), ultraviolet resistance, scratch resistance, low corrosion, low toxicity, environment friendliness, excellent processing performance, extrusion speed capable of reaching 100-150 m / min, and bright surface.

Owner:SHANDONG UNIV OF TECH +1

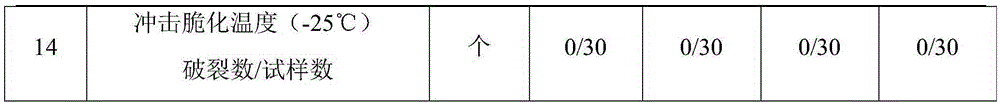

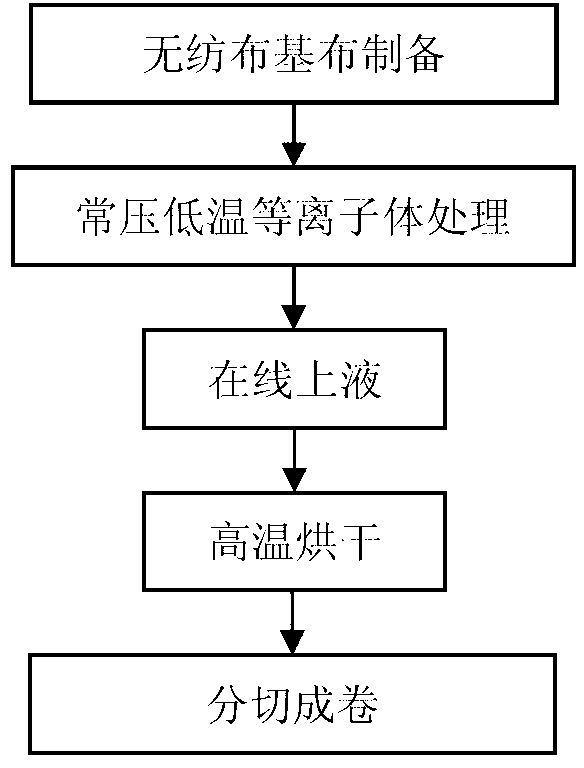

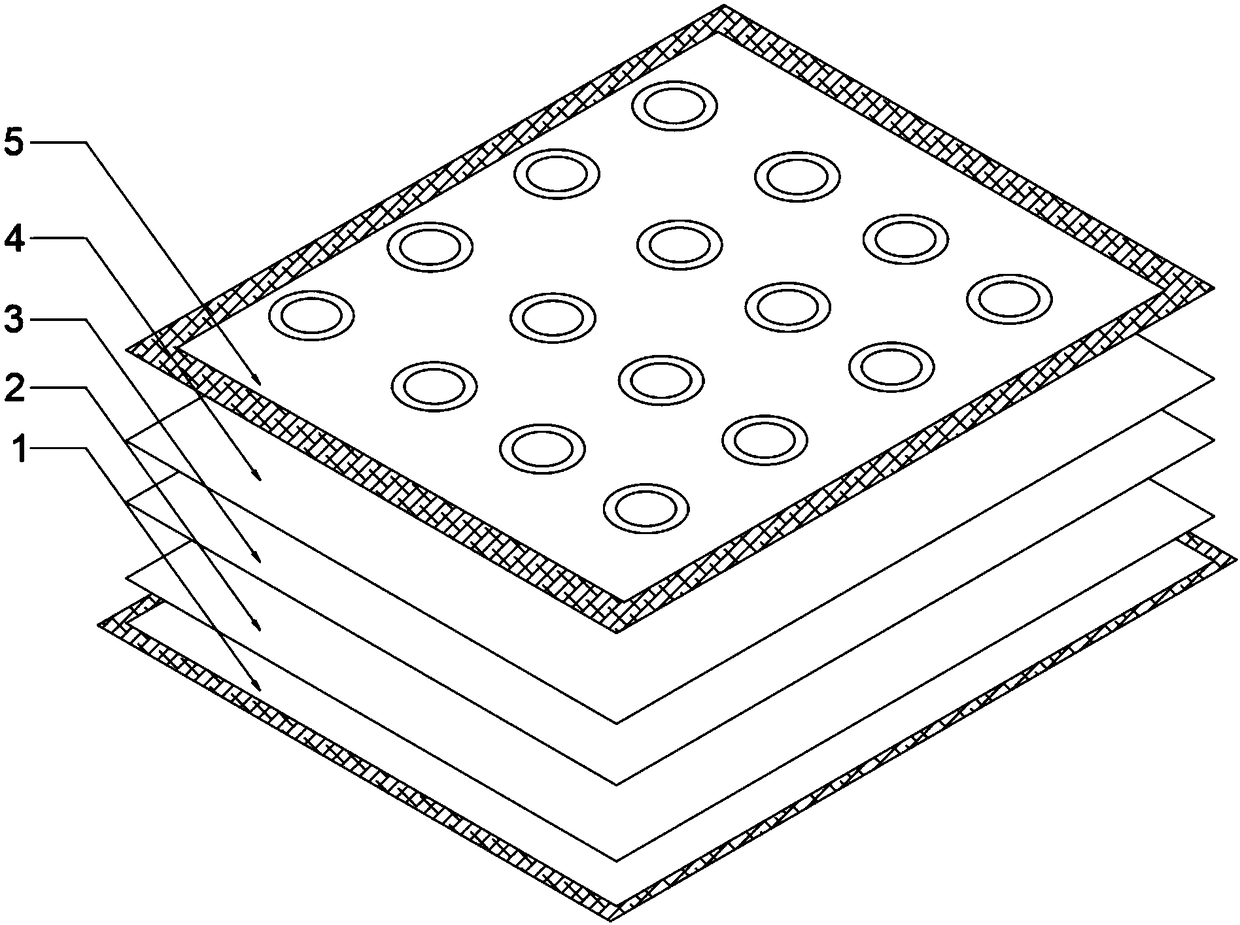

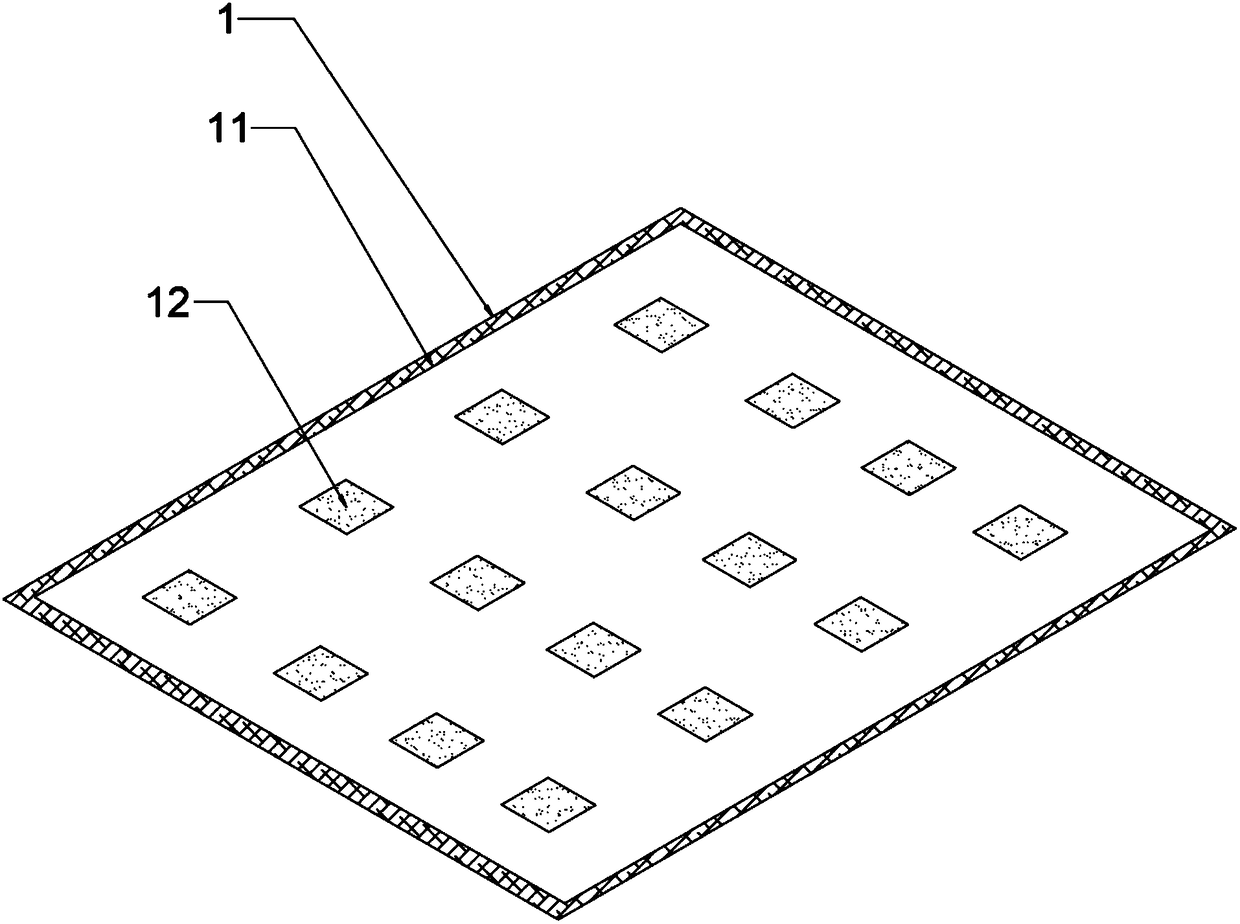

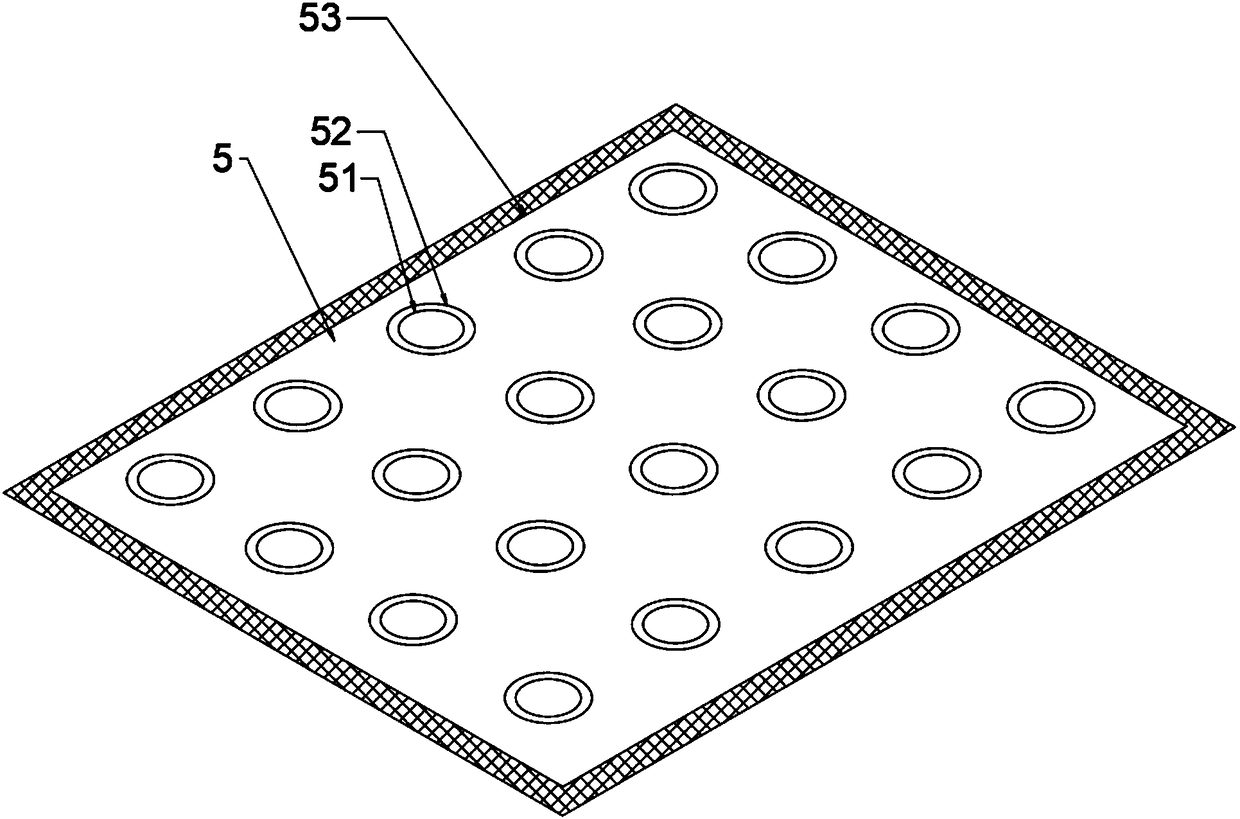

Finishing method for non-woven fabrics with high isolation performance and materials of non-woven fabrics with high isolation performance

ActiveCN102995400ALittle impact on air permeabilityReduce consumptionFibre treatmentAlcoholEngineering

The invention relates to a finishing method for non-woven fabrics with high isolation performance and materials of the non-woven fabrics with the high isolation performance. The finishing method combines on-line liquid feeding and normal-pressure low-temperature plasma processing, carries out normal-pressure low-temperature plasma processing before or after on-line liquid feeding, and forms a fluorine-containing polymer layer on the surface of the non-woven fabrics, so as to realize high isolation performance. The invention provides the finishing method for the non-woven fabrics which is novel, simple in process and good in finishing effect. Compared with the traditional saturated steeping, the finishing method has small influences on the non-woven fabrics, is high in production efficiency and has low energy consumption; compared with the existing plasma processing method, vacuum conditions are not needed, on-line liquid feeding is directly carried out, and low-temperature plasma processing is directly carried out under normal pressure, and other additional equipment conditions are not needed; and the contact angle between the prepared non-woven fabrics with high isolation performance and water can reach 120-160 degrees, and the prepared non-woven fabrics with high isolation performance has good air permeability and soft and comfortable feel, can reach requirements for resisting alcohol, oil and blood of each industry, and can well meet the large-scale industrial production.

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

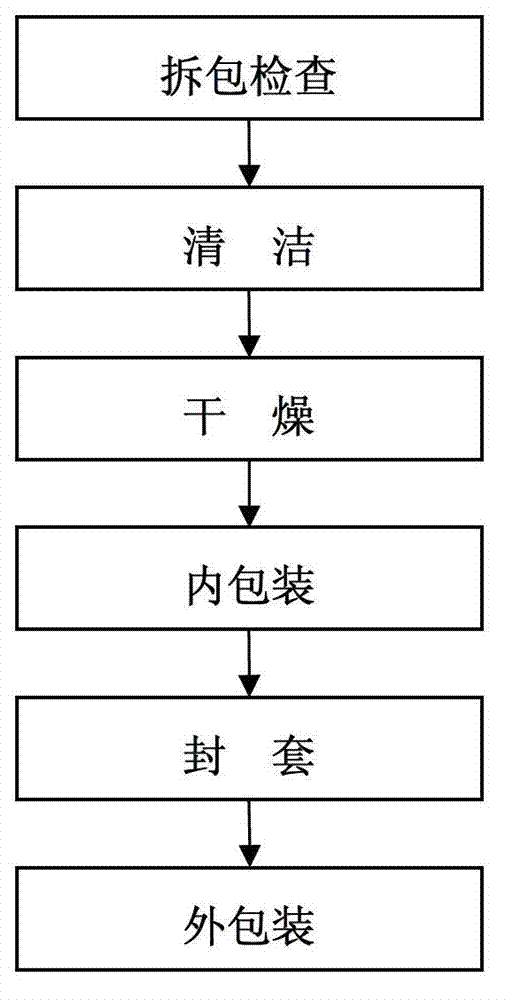

High-reliability hermetical packaging method for precise instruments

InactiveCN102815462AChange the internal environment of the packageFor long-term storageShock-sensitive articlesLiquid dispensingEngineeringAntistatic Materials

The invention discloses a high-reliability hermetical packaging method for precise instruments, and belongs to the technical field of packaging. The method includes: unpacking and checking a to-be-packaged instrument, replacing overdue oil in the to-be-packaged instrument, cleaning oil stains and dirt outside the to-be-packaged instrument, and drying; and performing interior packaging, envelope sealing treatment and exterior packaging and boxing. By controlling the interior packaging environment, taking protective measures such as envelope sealing, damping and buffering, and adopting novel packaging materials such as high-penetration-resistance materials, reinforced pierce preventing materials and antistatic materials, sealing reliability can be improved, various packaging protective effects can be achieved, and the requirements on sealing protection of various types of precise instruments can be met. The high-reliability hermetical packaging method for precise instruments has the advantages that the interior packaging environment of the precise instruments is changed, protective functions such as water proofing, damp proofing, shock proofing and oil proofing are realized, and stored articles can be protected from being damaged by severe environments to realize long-term storage.

Owner:中国人民解放军空军勤务学院

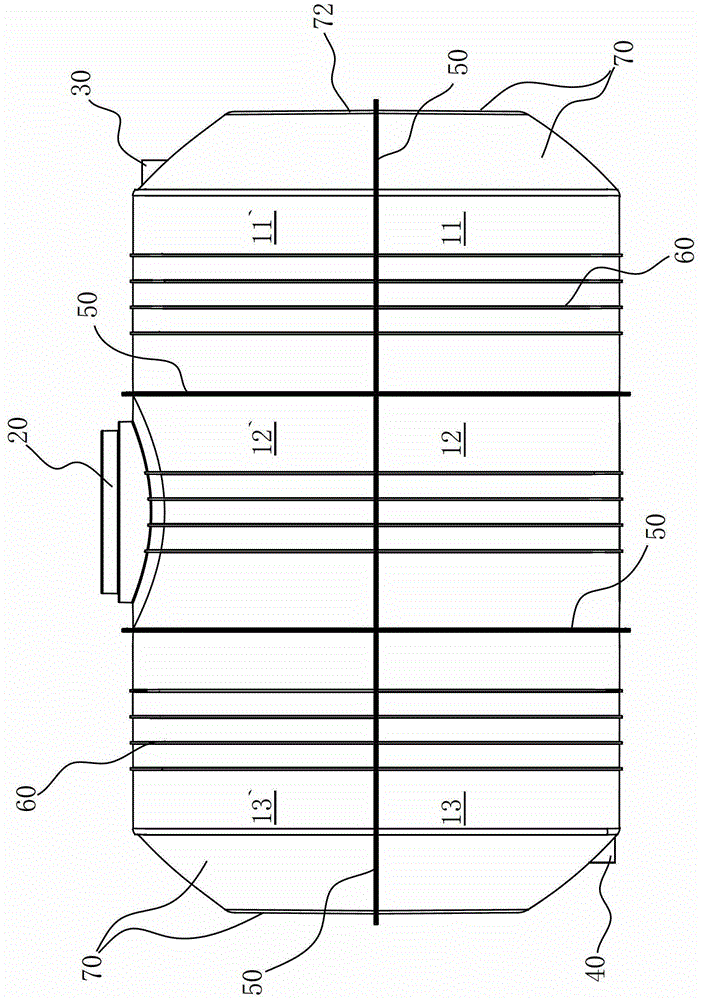

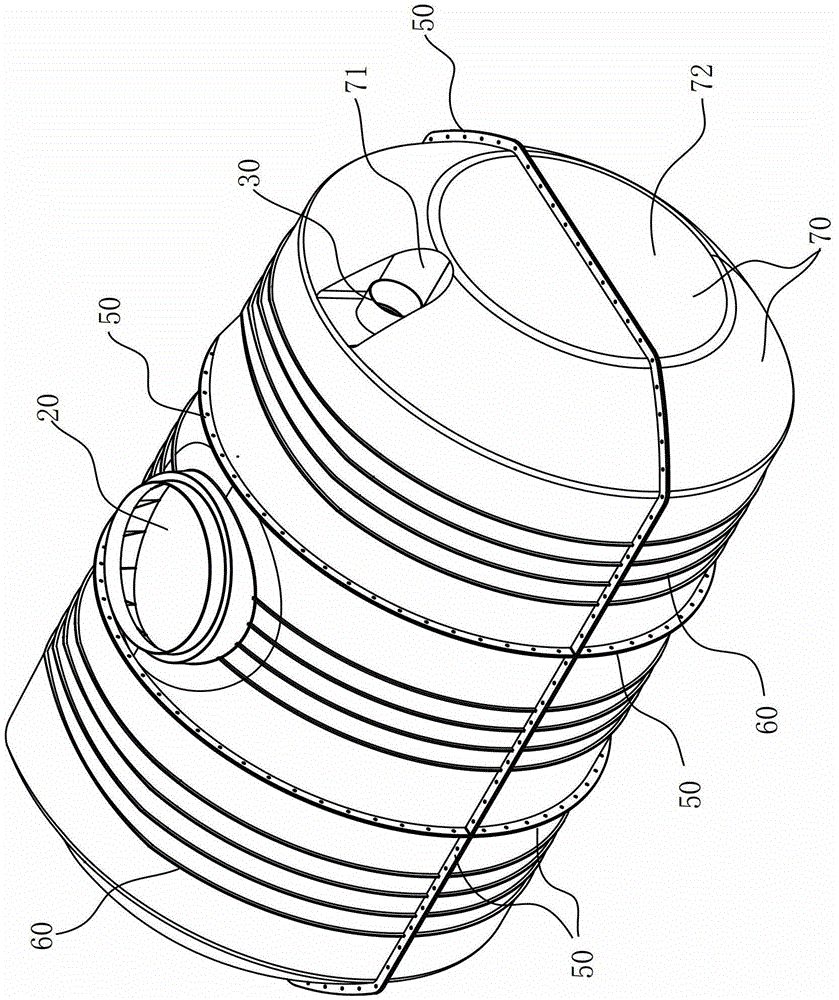

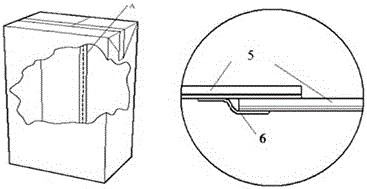

Anti-corrosion, oil-resistant and flame-retardant plastic oil tank

ActiveCN103214806AImprove impact resistancePhysical properties unchangedLarge containersPolyesterFiber

The invention relates to a reinforced plastic and an oil tank, and aims to provide an anti-corrosion, oil-resistant and flame-retardant oil tank which has reliable physical property and is made of reinforced plastic. The technical point is as below: the bulk molding compound comprises the following components in parts by weight: 34-47 parts of unsaturated polyester, 0.3-0.4 part of cobalt naphthenate, 0.3-0.35 part of methyl ethyl ketone peroxide, 45-47 parts of calcium carbonate, 0.1-0.3 part of antistatic agent, 0.1-0.15 parts of antioxygen, 0.1-0.15 part of pentabromo phenol, 0.1-0.3 part of microencapsulation tri-(2,3-dibromopropyl) isocyanuric acid ester, 0.1-0.2 part of melamine, 0.08-0.1 part of nano silica, a proper amount of silane coupling agent and 28-31 parts of reinforced fiber. The plastic can endure the temperature of 360 DEG C and 64 DEG C below zero, has constant physical property and has the advantages of high toughness and strength. The impact resistance of the unsaturated polyester fiber-reinforced bulk molding compounds is effectively improved. The reinforced plastic is anti-corrosion, anti-aging, oil resistant and flame retardant, and is suitable for manufacturing oil tanks.

Owner:KUNMING PURETOWN ENVIRONMENTAL TECH

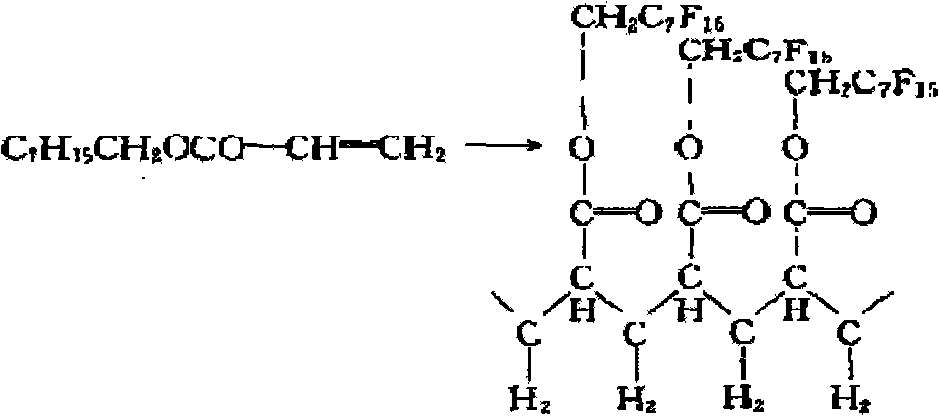

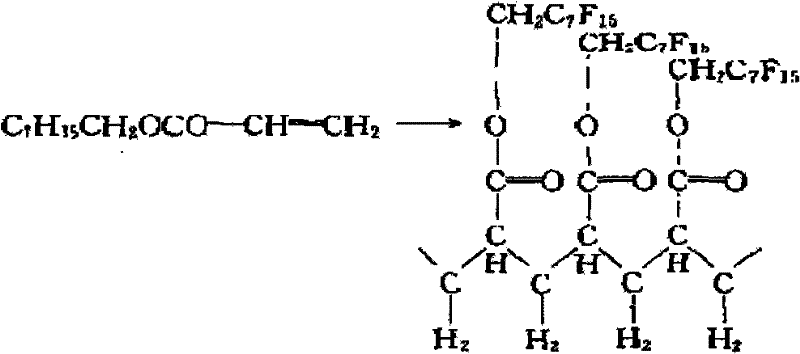

Oil repellent finish of fabric

ActiveCN101634107APrevents wetting and binding stainsImprove product gradeFibre treatmentMicrofiberWater soluble

The invention relates to an oil repellent finish of a domestic textile. Each liter of the oil-resisting finishing agent of a fabric contains the following components by weight: 30-50g of acrylic acid fluorocarbon ester resin, 1-3g of thickening agent, 3-5g of water soluble organic silicon, 0.9-2.5g of triethylamine and the balance of water. The invention is mainly used for the post-treatment of superfine fibre, resin containing fluorine forms a layer of protective film on the surface of the superfine fibre or a xuenierquanli carpet after a superfine fibre product is treated by the functional processing of the invention, and dirt can not infiltrate into the inside of the fibre but is coated by the surface of the fibre; thus, an oil repellent function is achieved. The invention has the superior functions of oil resistance and easy decontamination, and a processed product has flexible hand feel.

Owner:JINHUA JIELING HOUSE WARES CO LTD

Anti-corrosion flame-retardant wind power cable sheath, insulating material and preparation method of sheath and insulating material

InactiveCN106280024AGuarantee the safety of useExtended service lifeRubber insulatorsInsulated cablesPolyvinyl chlorideEngineering

The invention belongs to the field of power cables and particularly relates to an anti-corrosion flame-retardant wind power cable sheath, an insulating material and a preparation method of the sheath and the insulating material. The inner layer insulating material is prepared from, by weight, 40-60 parts of EPDM, 10-25 parts of polyvinyl chloride, 5-10 parts of paraffin oil, 5-15 parts of calcium carbonate, 30-60 parts of kaoline, 1-3 parts of anti-ageing agent, 1-3 parts of assistant crosslinker, 0.5-2 parts of vulcanizing agent and 1.5-3.5 parts of flame-retardant agent. The outer layer sheath material is prepared from, by weight, 40-60 parts of ethylene propylene terpolymer A, 35-60 parts of ethylene propylene terpolymer B, 3-8 parts of activating agent, 2-4 parts of stabilizer, 2-4 parts of antioxidant, 2-4 parts of cold-resistant plasticizer, 1-3 parts of silane coupling agent, 5-10 parts of compound vulcanizing agent, 3-8 parts of flame-retardant agent and 30-50 parts of filling agent. Process improvement is conducted on the inner layer insulting material and the outer layer sheath material of a wind power cable, the cable can be used in the environment of -40-100 DEG C for a long time, the cable has good softness, oil resistance, cold resistance, abrasion resistance, acid and alkali resistance, flame retardancy and the like, and the requirement that a draught fan safely and normally runs in the changeable and severe weather environment is met.

Owner:JIANGSU LONG E CABLE

Imitation marble brick prepared by construction waste and preparation method thereof

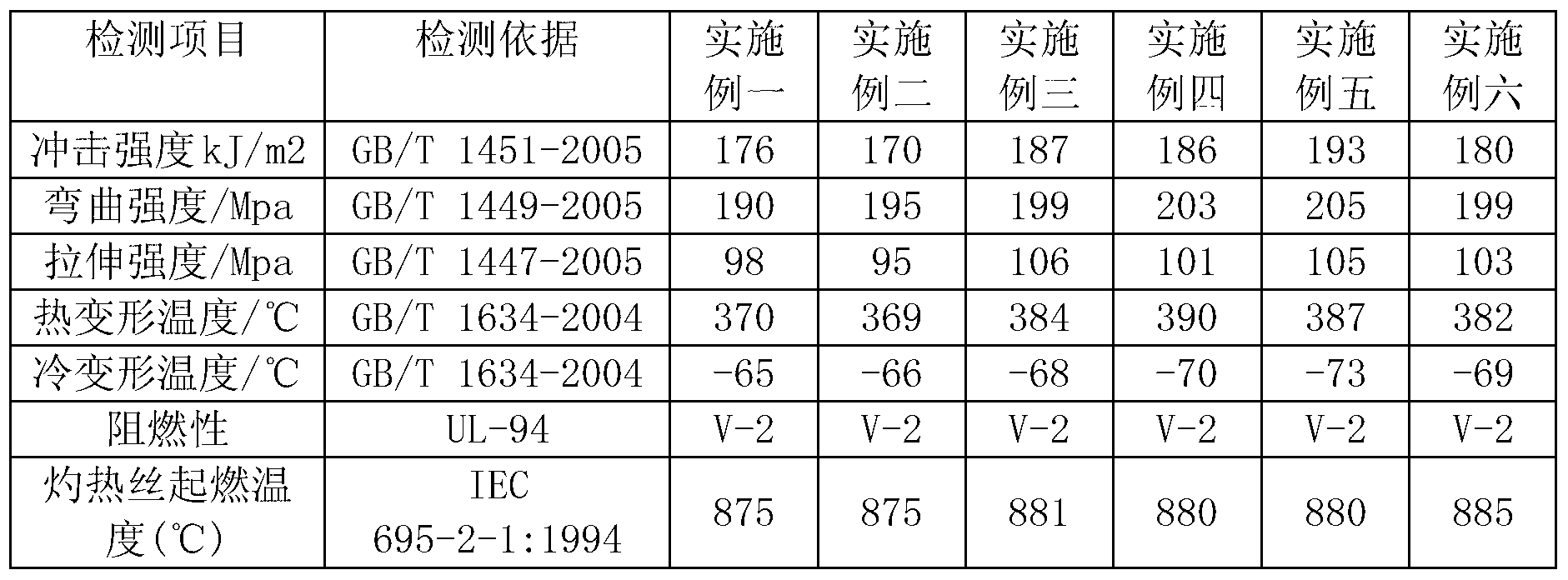

InactiveCN109650792AReduce cement consumptionReduce dosageSolid waste managementCeramic shaping apparatusFlexural strengthSurface layer

The invention provides an imitation marble brick prepared by the construction waste. The brick comprises a three-layer structure, which is successively a superficial layer, a surface layer material and a bottom layer material. The superficial layer is obtained by polishing after the surface layer material is coated with a curing agent; the surface layer material comprises high-quality recycled coarse aggregate; and the bottom layer material comprises general-quality recycled coarse aggregate and general-quality recycled fine aggregate. Meanwhile, the invention provides a manufacture method ofthe imitation marble brick. The recycled material produced by the construction waste accounts for more than 80% of the total materials. The flexural strength of the prepared imitation marble brick is4-6.5 MPa, and the surface marble pattern is durable in use.

Owner:深圳市绿发鹏程环保科技有限公司

Paint for coating chromatic bobbin printed sheet and preparation method thereof

InactiveCN101161929AAchieve oil resistanceAchieve antistaticCoatings with pigmentsCoatingsCardboardBobbin

The invention discloses a coating for painting colored yarn-tube face paper, which is made of the following materials: carboxylated styrene-butadiene rubber latex, oxidized starch, acid or direct dye, zirconium salt water-resistance agent and water. The production method of the coating of the invention made by the above materials is that: the oxidized starch is added into the water in proportion, mixed and heated to over 80 degree centigrade to make the oxidized starch fully gelatinized, and then the acid or the direct dye is added after being cooled lower than 60 degree centigrade for dissolution, carboxylated styrene-butadiene rubber latex is added at 10-40 degree centigrade before use, and proper zirconium salt water-resistance agent is added and stirred uniformly. The coat can be painted on paper, base paper used can be paper or cardboard of white, natural and colored with certain strength, crossed and solidified under catalyst or heating, thereby achieving certain performance of oil resistance, water resistance and operating requirements of non-decolorization, antistatic, etc. The invention is also a novel environmental protection product.

Owner:黄寒 +1

Long-acting acid and alkali resistant, solvent-free anticorrosion coating and its preparation method and application

ActiveCN103666201BStrong long-term anti-corrosion performanceGood long-term anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent free

The invention relates to a long-acting acid-base resistant solvent-free anticorrosive paint which comprises a host crystal and a curing agent, wherein the weight part ratio of the host crystal to the curing agent is (100:20)-(100:60). According to the invention, the solvent-free anticorrosive paint is prepared in the following way: low-viscosity epoxy resin and modified phenolic resin are compounded with pigments, a rust-proof material, padding, a dispersing agent, an antifoaming agent, a flatting agent, an anti-sagging agent and the like, and then are matched up with cashew nut shell phenol modified amine, modified fatty amine, a catalyst and the like. The long-acting acid-base resistant solvent-free anticorrosive paint can be painted on the surfaces of various steel materials under the condition of air drying or low-temperature baking, and the film thickness of one-time anticorrosive paint coating is 800-1200 microns; the anticorrosive pain dries quickly, does not sag, is level in paint film, has excellent physical and chemical properties and the best long-acting protective function on steel material products, and is widely applied to painting of oil pipelines, ports, oil tanks, gas pipelines, steel material products needing heavy corrosion protection and the like.

Owner:TIANJIN COLOROAD COATING & CHEM

Paint formula for water -proof and oil-proof colorful papers

InactiveCN101245568AAchieve oil resistanceAchieve antistaticCoatings with pigmentsCoatingsFirming agentPigment

The invention relates to a coating formula of colorful paper with water-proof and oil-proof properties. The coating is prepared by the following materials: Lauxite, oxidized starch, organic pigment, firming agent, water and other addition agents. The manufacture method for making each component into the coating of the invention is that; adding the organic pigment and a dispersant into the water according to a certain proportion, selecting proper grinding and dispersing equipment to lead the pigment to be evenly dispersed; then adding the oxidized starch into another part of water to be stirred and heated to more than 80 DEG C to be completely pasted and then cooled to below 60 DEG C, adding the dispersed organic pigment solution, adding the firming agent after complete cooling and mixing the coating into the Lauxite before being used. The invention also provides a method for producing the coating formula. The coating of the invention painted on the page can reach the using requirements of good oil-proof and water-proof properties and no decoloring after cross bonding and solidification under a certain condition. The coating is also a novel environment protective product.

Owner:GUANGDONG PAPER IND RES INST +1

Oil resistant rubber ring material composition and preparation method of oil resistant rubber ring

The invention discloses an oil resistant rubber ring material composition and a preparation method of an oil resistant rubber ring, wherein the composition is prepared from nitrile rubber, fluorinated silicone rubber, acrylate rubber, potassium permanganate, calcium nitrate, sulphur, zinc chloride and magnesium chloride; relative to 100 parts by weight of the nitrile rubber, the content of the fluorinated silicone rubber is 10 to 30 parts by weight, the content of the acrylate rubber is 20 to 50 parts by weight, the content of the potassium permanganate is 3 to 15 parts by weight, the content of the calcium nitrate is 5 to 20 parts by weight, the content of the sulphur is 1 to 5 parts by weight, the content of the zinc chloride is 3 to 10 parts by weight, and the content of the magnesium chloride is 3 to 10 parts by weight. Through the design, the effects of realizing effective oil resistance and greatly improving the usability under the environment with high grease are achieved.

Owner:WUHU HENGKUN AUTO PARTS

Light emitting road surface and preparation method thereof

ActiveCN110395952ATo achieve the artistic effect of appreciationBeautiful art deco effectSurface layerBrick

A light emitting road surface material comprises a surface layer material and a base layer material from top to bottom in turn, wherein that base layer material comprises the following components in parts by weight: cement 120-240; regenerated micro-powder of construction wastes 10-70; recycled coarse aggregate of construction wastes 500-900; construction waste recycled fine aggregate 200-600; water 60-140; water reducer <=6. The surface layer material comprises the following components in parts by weight: white cement 120-240; colored powder <=80; construction waste recycled fine aggregate 200-600; water 60-140; water reducer <=6. The invention further provides a light emitting road surface. The invention provides a light emitting road surface and a preparation method thereof, wherein thelight emitting art road is made of construction waste, the luminous aggregate and the brick aggregate can be inlaid according to a certain pattern, and the luminous aggregate and the brick aggregatehave an artistic effect after polishing, and the evening appreciation effect is better.

Owner:TONGJI UNIV

Anti-corrosion, oil-resistant and flame-retardant plastic oil tank

ActiveCN103214806BImprove impact resistancePhysical properties unchangedLarge containersPolyesterFiber

The invention relates to a reinforced plastic and an oil tank, and aims to provide an anti-corrosion, oil-resistant and flame-retardant oil tank which has reliable physical property and is made of reinforced plastic. The technical point is as below: the bulk molding compound comprises the following components in parts by weight: 34-47 parts of unsaturated polyester, 0.3-0.4 part of cobalt naphthenate, 0.3-0.35 part of methyl ethyl ketone peroxide, 45-47 parts of calcium carbonate, 0.1-0.3 part of antistatic agent, 0.1-0.15 parts of antioxygen, 0.1-0.15 part of pentabromo phenol, 0.1-0.3 part of microencapsulation tri-(2,3-dibromopropyl) isocyanuric acid ester, 0.1-0.2 part of melamine, 0.08-0.1 part of nano silica, a proper amount of silane coupling agent and 28-31 parts of reinforced fiber. The plastic can endure the temperature of 360 DEG C and 64 DEG C below zero, has constant physical property and has the advantages of high toughness and strength. The impact resistance of the unsaturated polyester fiber-reinforced bulk molding compounds is effectively improved. The reinforced plastic is anti-corrosion, anti-aging, oil resistant and flame retardant, and is suitable for manufacturing oil tanks.

Owner:KUNMING PURETOWN ENVIRONMENTAL TECH

Seven-layer co-extruded film used for hot melting combination and preparation method

InactiveCN106739033AFunctionalRealize functionSynthetic resin layered productsFlat articlesFree coolingHot melt

The invention discloses a production process of a seven-layer co-extruded film used for hot melting combination, and belongs to the technical field of co-extruded films. The film blowing process is adopted, raw materials are subjected to melt extrusion to form die blanks through seven extruder heads and are subjected to huffing and molding, and the seven-layer co-extruded film is prepared by conducting winding after natural cooling. The thin film of a seven-layer structure can be produced through the seven hot melting extruder heads, ratio optimization is conducted according to characteristics of each layer of the film, meanwhile, a blocking layer, a supporting layer and a bonding layer are reasonably distributed, and therefore the final product can have the beneficial effects of being good in barrier property, environment-friendly, free of pollution, low in cost and the like and is suitable for industrialized production. The one important application filed of the seven-layer co-extruded film is the field of filling and sealing of paper-plastic-aluminum composite packages used for liquid, the defect that an existing thin film is likely to overturn is overcome, higher interlaminar peeling strength is achieved, a large number of seven-layer co-extruded films can be applied to packages of liquid milk, juice beverages, alcohol products and drinking water, and market prospects are good.

Owner:SHANGHAI MAIGAO NEW MATERIAL TECH

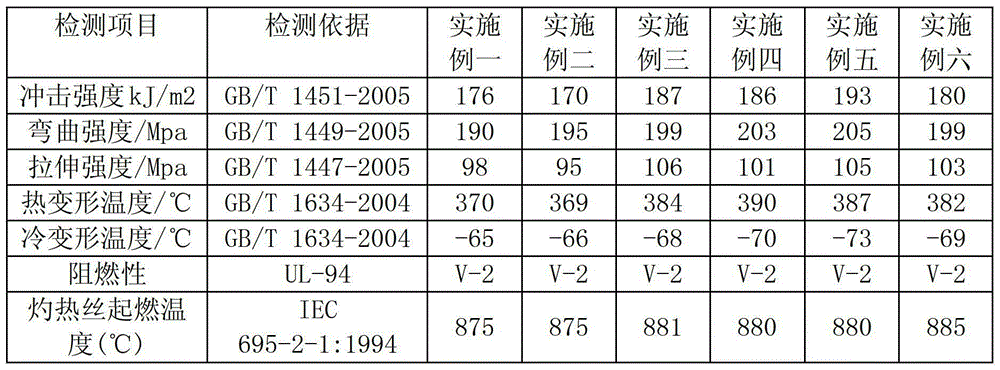

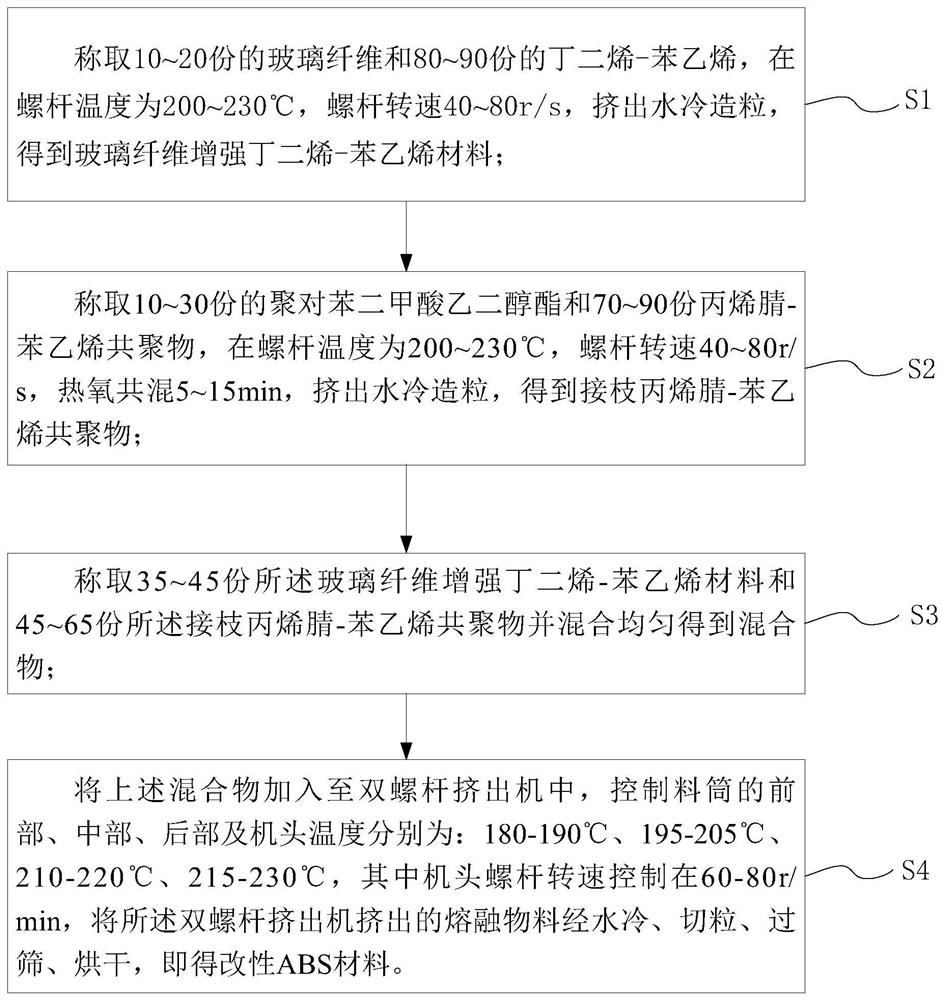

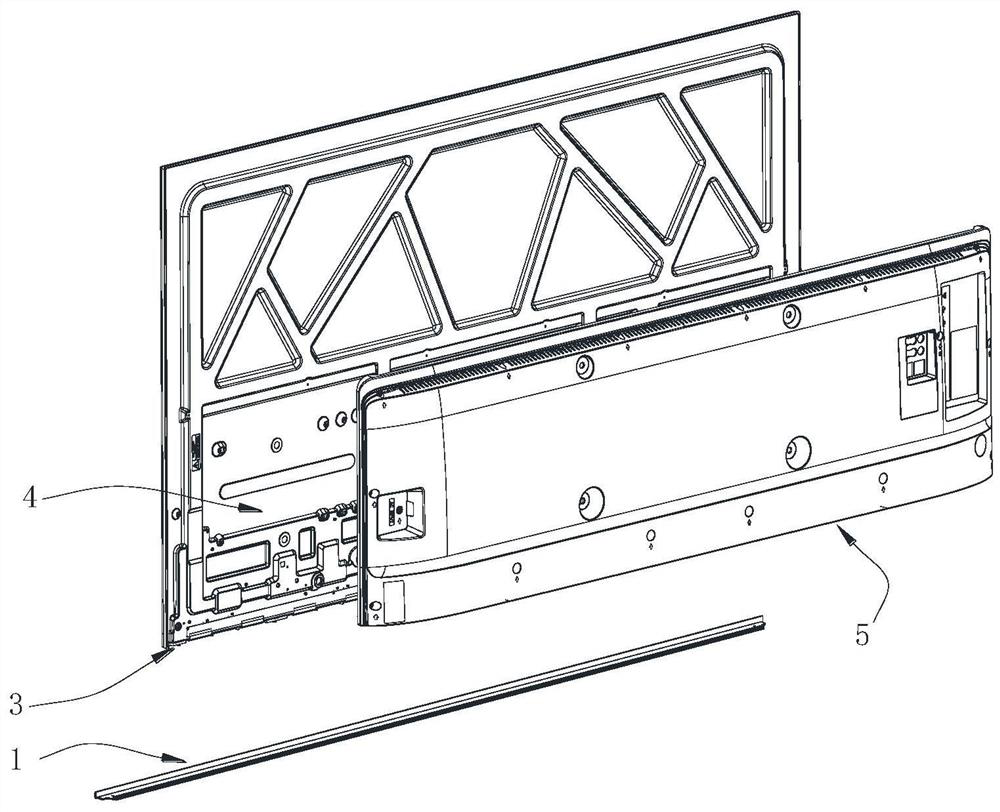

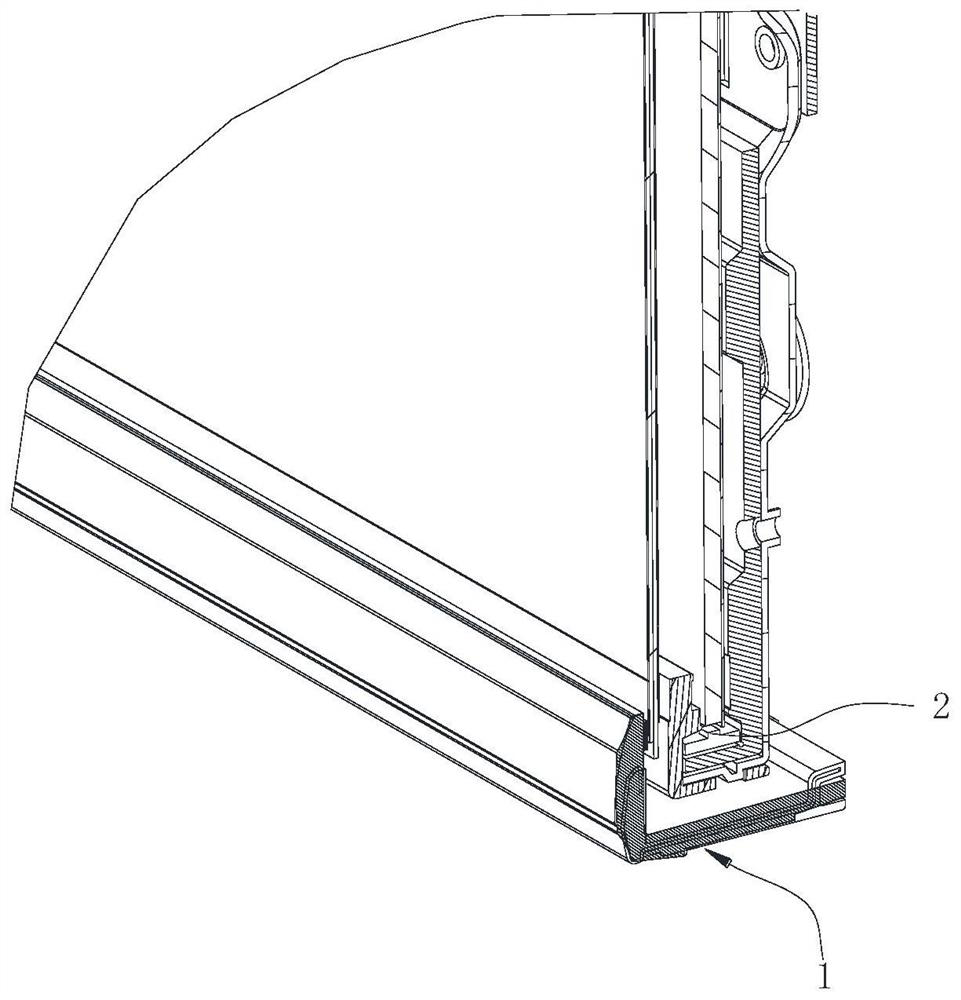

Display equipment, modified ABS material and preparation method of modified ABS material

ActiveCN113214594AAchieve oil resistanceInhibition of swellingPolytetramethylene terephthalatePolymer science

The invention provides a display device, a modified ABS material and a preparation method of the modified ABS material . The modified ABS material comprises the following components in parts by weight: 35-45 parts of a glass fiber reinforced butadiene-styrene material and 45-65 parts of a grafted acrylonitrile-styrene copolymer, wherein the glass fiber reinforced butadiene-styrene material comprises 10 to 20 parts of glass fibers and 80 to 90 parts of butadiene-styrene; and the grafted acrylonitrile-styrene copolymer comprises 10 to 30 parts of polyethylene glycol terephthalate and 70 to 90 parts of an acrylonitrile-styrene copolymer. According to the modified ABS material, an ordered microphase is generated through polybutylene terephthalate, and the swelling effect of grease on a plastic body is inhibited, so the oil resistance of the acrylonitrile-styrene copolymer is realized, and the oil resistance of the modified ABS material is further realized.

Owner:HISENSE VISUAL TECH CO LTD

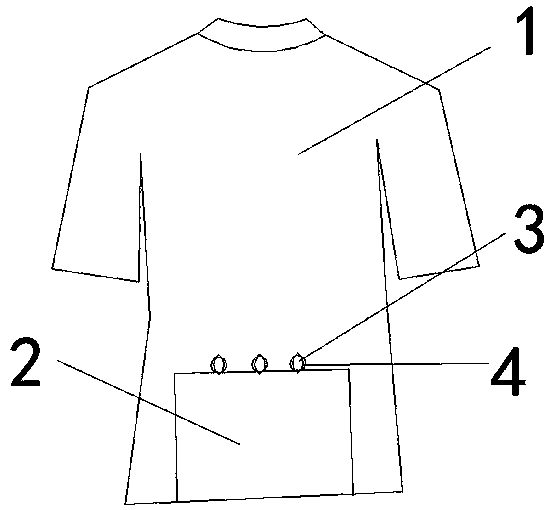

Antifouling clothing with cooling mat

The invention relates to antifouling clothing with cooling mat. The antifouling clothing with cooling mat comprises a clothing main body (1), a cooling mat (2) is formed at the rear lower hem of the clothing main body (1), the cooling mat (2) is made of the ice silk, a button (3) is formed being corresponding to the sewing part between the cooling mat (2) and the clothing main body (1), the buckle (4) is formed at the back waist of the clothing main body, the clothing main body (1) is made of the shell fabric, the shell fabric comprises the shell fabric main body and the shell fabric main body is knitted by the warp and weft, the antifouling coating is respectively formed at the upper surface and the lower surface of the shell fabric main body, the warp is 16S polyester yarn, the antifouling coating is polytetrafluoroethylene coating. The cooling mat is taken off to be used for hip when sitting down for avoiding direct contact between the hip and the chair, the button on the cooling mat is locked to the buckle at the back waist for carrying conveniently while the mat is not used. The antifouling clothing with cooling mat has antifouling function.

Owner:JIANGYIN HENGLI EDUCATION ARTICLES

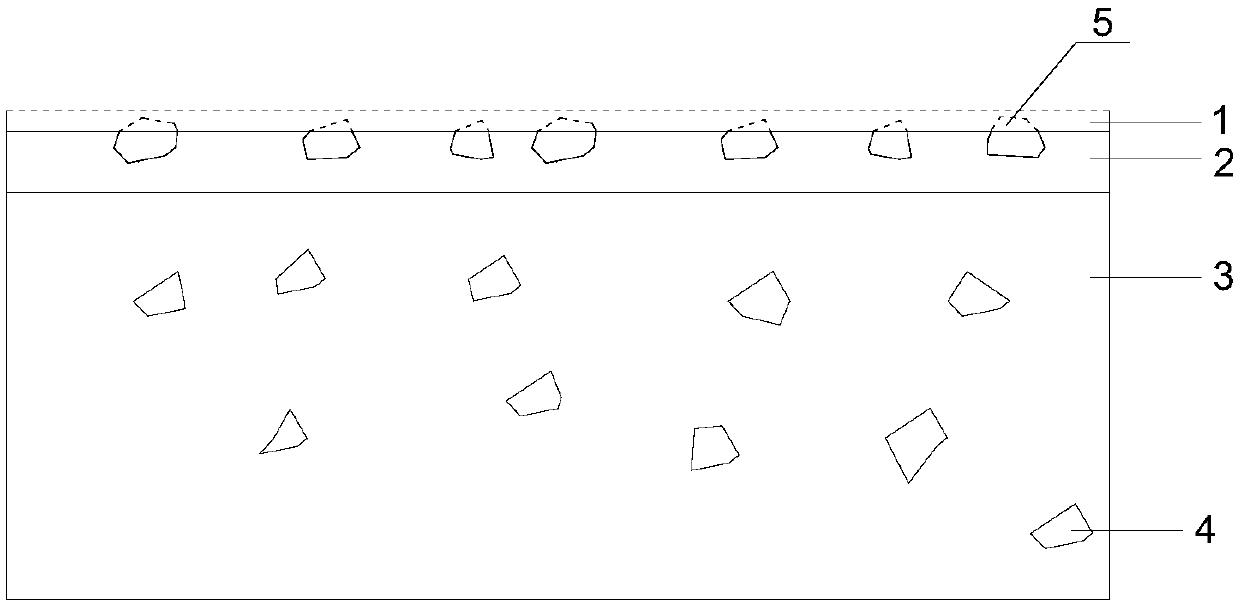

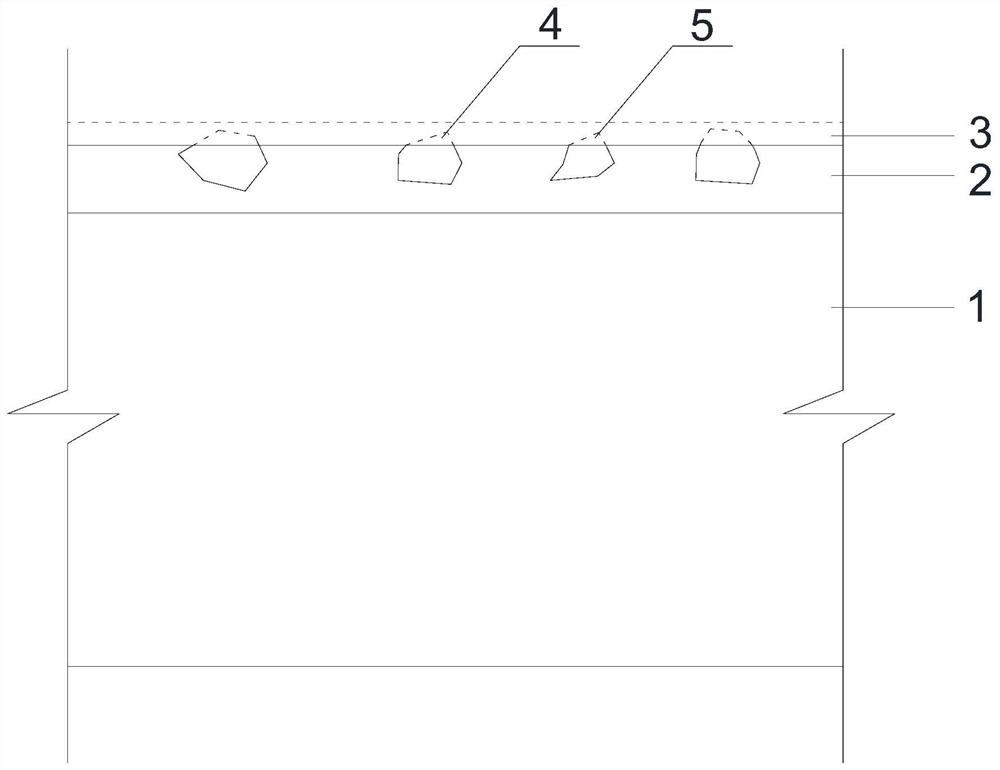

Waterproof, reflection and antifouling artificial leather

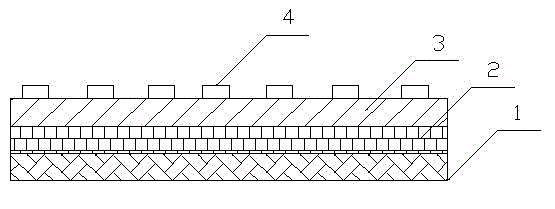

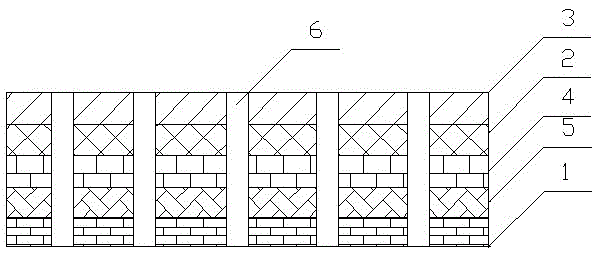

InactiveCN104420322AExtended service lifeImprove wear resistanceFibre typesSynthetic resin layered productsSurface layerLight reflection

The invention relates to waterproof , reflection and antifouling artificial leather, the artificial leather comprises a base layer (1) and a surface layer (2) which are mutually bonded, a plastic film layer (3) is arranged on surface of the surface layer (2), several reflective stripes (4) are arranged on the plastic film layer (3), the base is made by fabrics, the fabrics comprise fabrics body, the fabrics body can be made by interlacing warp yarn and weft yarn, antifouling layers are respectively arranged on the upper surface and lower surface of the fabrics body, the warp yarn is 16S terylene yarn, and the antifouling coating is a polytetrafluoroethylene coating. The artificial leather has light reflection function, simultaneously, other material layers of the artificial leather can be separated from outside by the plastic film layer, water can not immerse into the material layers of the artificial leather, so that usage life of the product can be prolonged. The artificial leather has antifouling function.

Owner:JIANGYIN FANRONG YARN DYE FABRIC

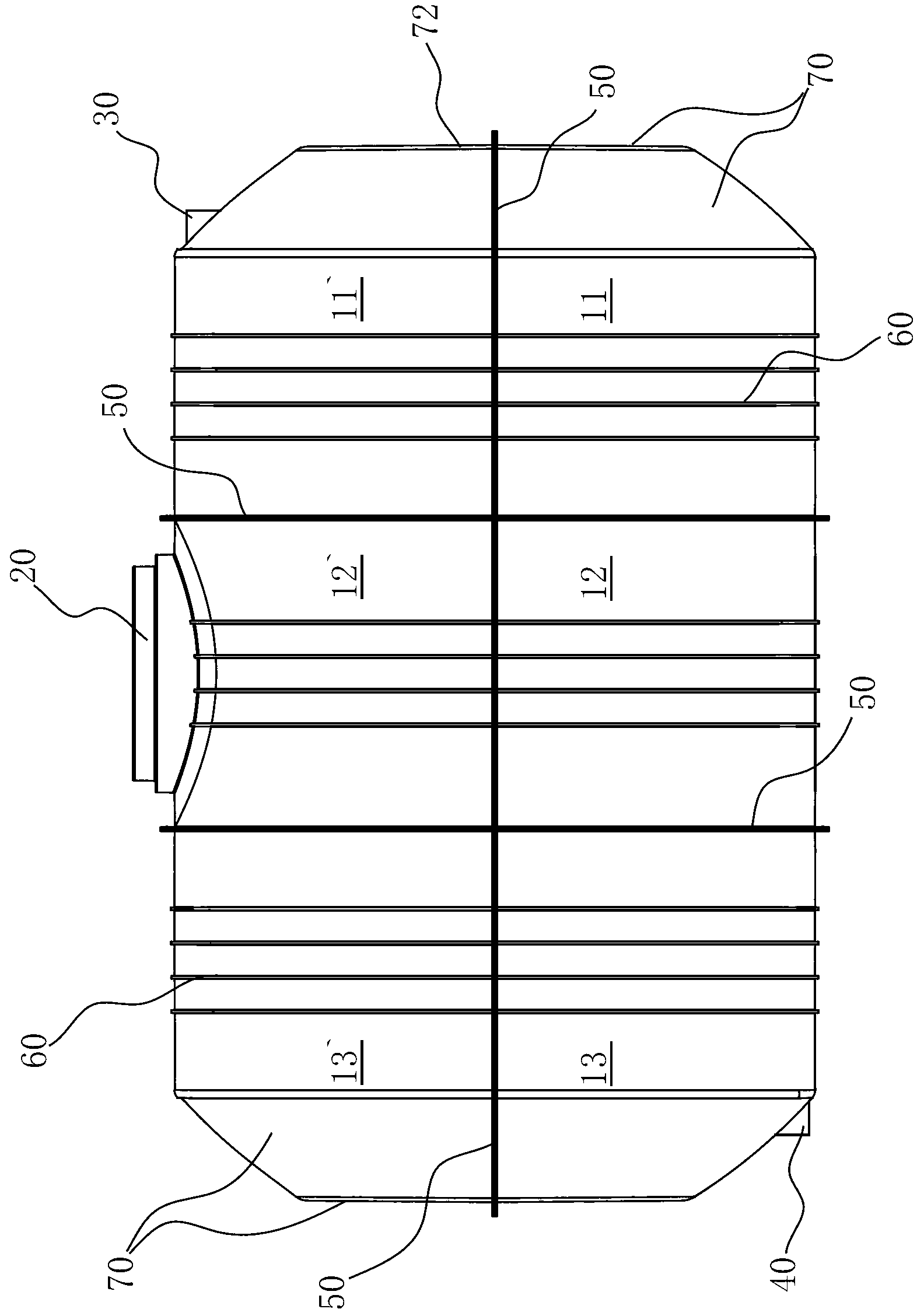

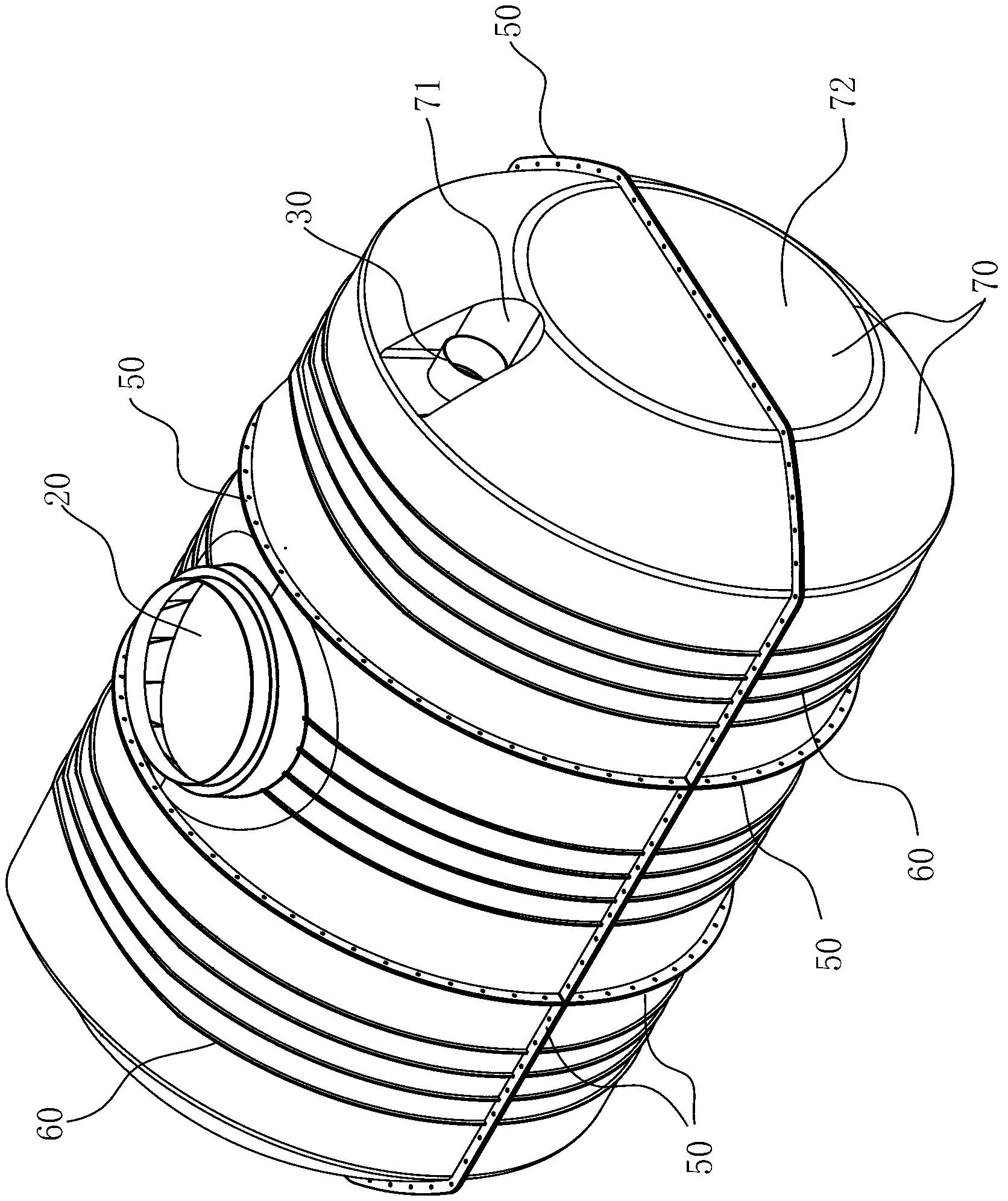

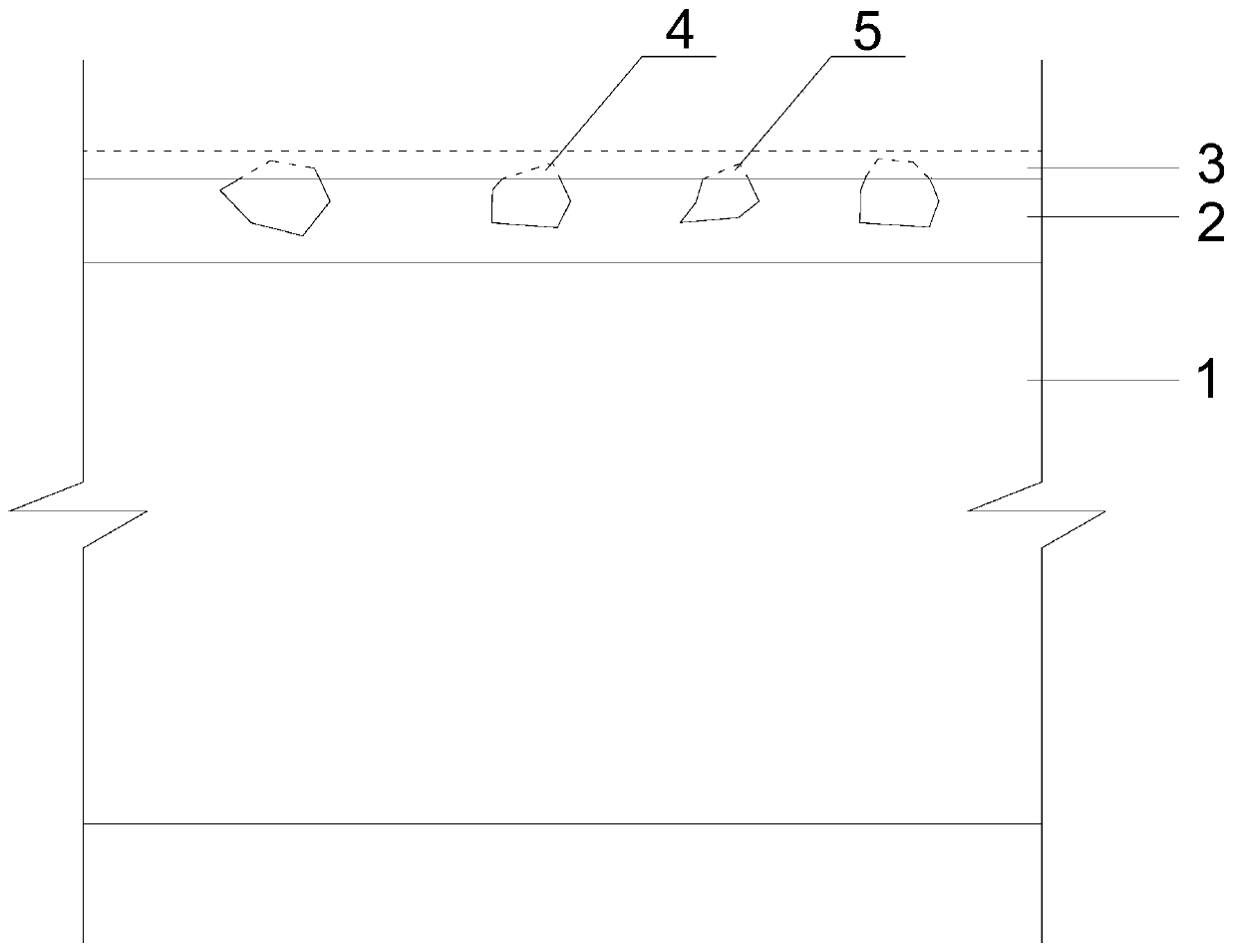

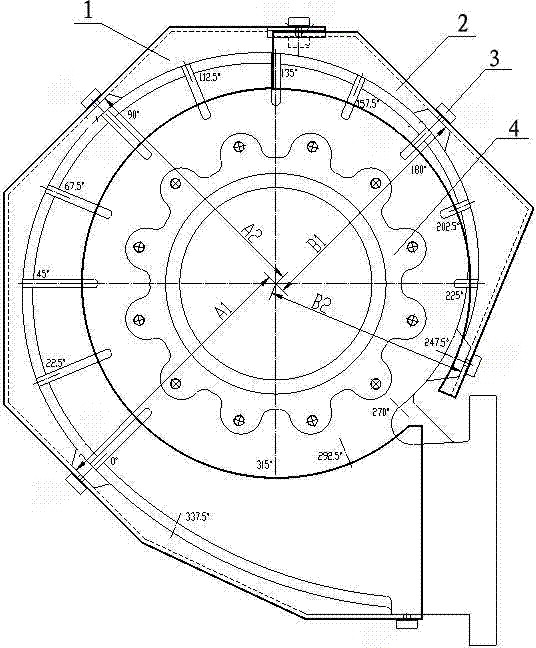

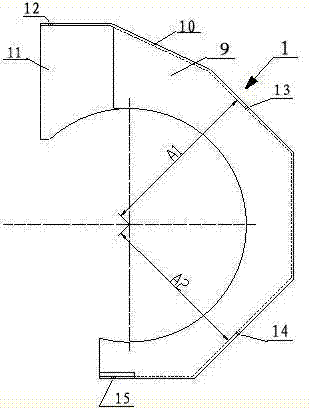

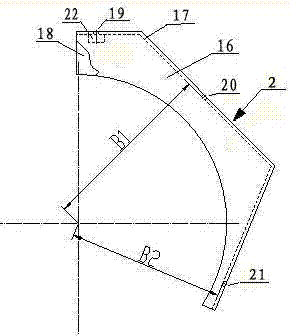

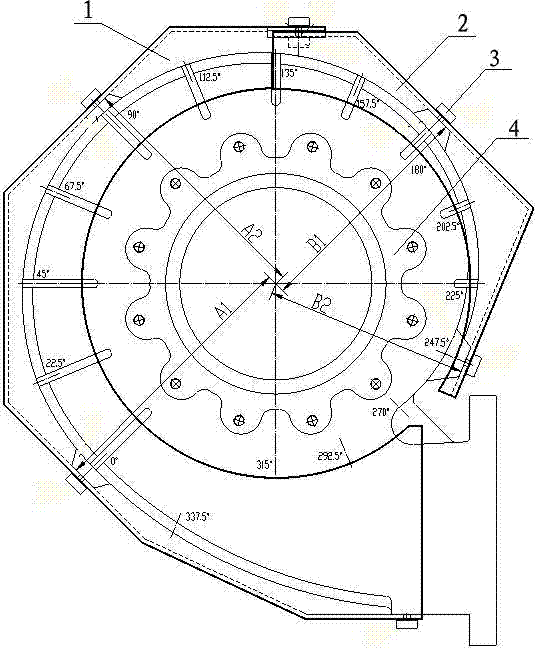

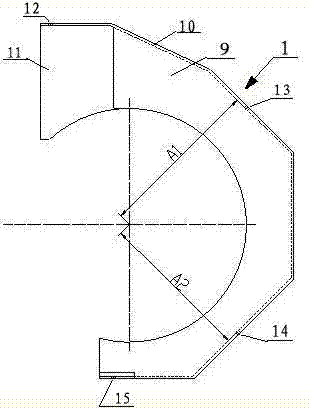

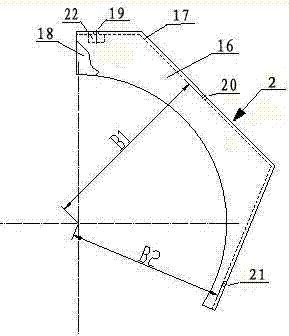

Anti-bursting device for worm gear box of turbosupercharger

ActiveCN103925017AEasy to assemble and disassembleEasy to replace and maintainMachines/enginesEngine componentsRear quarterTurbocharger

The invention relates to an anti-bursting device for a worm gear box of a turbosupercharger. The anti-bursting device comprises an upper protective cover (1), a lower protective cover (2), heatproof stop screws (3) and the worm gear box (4) to be protected. The worm gear box (4) is provided with a first positioning platform (5), a second positioning platform (6), a third positioning platform (7) and a fourth positioning platform (8), which are adjustable in height and convenient for positioning connection. The upper protective cover (1) and the lower protective cover (2) are fixed on the four positioning platforms on the worm gear box (4) through the heatproof stop screws (3). The upper protective cover (1) is composed of a first upper side plate (9), a first top plate (10) and a first lower side plate (11). The lower protective cover (2) is composed of a second upper side plate (16), a second top plate (17) and a second lower side plate (18). The protective covers are in split structure, thereby being convenient to demount, replace and maintain.

Owner:大同北方天力增压技术有限公司

Artificial leather with air permeability, impact resistance and stain repellent effects

InactiveCN104372650AStrong impact resistanceEasy to moveLayered productsFibre treatmentPolyesterPolymer science

The invention relates to artificial leather with air permeability, impact resistance and stain repellent effects. The artificial leather comprises a base (1), a first foaming layer (2) and a surface compact layer (3). The first foaming layer (2) is fixedly pasted to the inner surface of the surface compact layer (3). The base (1) is located at one side of the first foaming layer (2) back to the surface compact layer (3), and a second foaming layer (4) and an impact resistant layer (5) are arranged between the base (1) and the first foaming layer (2). The main body of the artificial leather is provided with through holes (6). The base is prepared from a fabric, the fabric comprises a fabric main body, the fabric main body is prepared by interweaving of warp yarn and weft yarn, the upper and lower surfaces of the fabric main body are provided with stain repellent coatings, the warp yarn comprises 16S polyester yarn, and the stain repellent coatings are Teflon coatings. The artificial leather is not damaged easily under the action of long-term impact and has gas permeability and stain repellent functions.

Owner:江苏红柳床单有限公司

Oil repellent finish of fabric

ActiveCN101634107BAchieve oil resistanceExcellent oil resistance and easy decontamination functionFibre treatmentFiberWater soluble

Owner:JINHUA JIELING HOUSE WARES CO LTD

Low-expansion automobile spot welding sealant

PendingCN108102575AStable spot welding effectGood spot welding effectFilm/foil adhesivesBiochemical engineeringHeat resistance

The invention relates to the technical field of automobile spot welding and especially provides a low-expansion automobile spot welding sealant. The spot welding sealant includes a seal film. An acid-resistant layer is arranged on the upper side of the seal film. An anti-oil layer is arranged on the surface of one side, which is far away from the seal film, of the acid-resistant layer. An anti-corrosion layer is arranged on the surface of one side, which is far away from the acid-resistant layer, of the anti-oil layer. A heat-resistant film is arranged on the surface of one side, which is faraway from the anti-oil layer, of the anti-corrosion layer. The spot welding sealant has simple structure and is convenient to use, by means of the seal film, the sealing performance of the sealant isguaranteed during an adhesive application process, so that automobile spot welding has more stable effects; by means of the acid-resistant layer, anti-oil layer and anti-corrosion layer, the sealant has performances of acid resistance, oil resistance and heat resistance, so that spot welding effect of the sealant in automobile spot welding is greatly enhanced. The spot welding sealant has great practicability and is convenient to promote.

Owner:浙江普利斐特汽车科技有限公司

Luminous road surface and preparation method thereof

ActiveCN110395952BTo achieve the artistic effect of appreciationBeautiful art deco effectBrickArchitectural engineering

The present invention provides a luminous pavement material, which includes a surface material and a base material in sequence from top to bottom, wherein the base material includes the following components in parts by weight: 120-240 parts of cement; 10 parts of recycled micropowder from construction waste ‑70 parts; 500‑900 parts of recycled coarse aggregate from construction waste; 200‑600 parts in recycled fine aggregate from construction waste; 60‑140 parts in water; The following components: 120-240 parts of white cement; ≤80 parts of coloring powder; 200-600 parts of recycled fine aggregate from construction waste; 60-140 parts of water; ≤6 parts of water reducing agent. The present invention further provides a luminescent road surface. The invention provides a luminous pavement and a preparation method thereof. Construction waste is used to make a luminous art road. Luminous aggregates and brick aggregates can be inlaid according to a certain pattern. After being polished, it has an artistic effect, and the appreciation effect is better at night.

Owner:TONGJI UNIV

Anti-bursting device for worm gear box of turbosupercharger

ActiveCN103925017BEasy to assemble and disassembleEasy to replace and maintainMachines/enginesEngine componentsRear quarterTurbocharger

The invention relates to an anti-bursting device for a worm gear box of a turbosupercharger. The anti-bursting device comprises an upper protective cover (1), a lower protective cover (2), heatproof stop screws (3) and the worm gear box (4) to be protected. The worm gear box (4) is provided with a first positioning platform (5), a second positioning platform (6), a third positioning platform (7) and a fourth positioning platform (8), which are adjustable in height and convenient for positioning connection. The upper protective cover (1) and the lower protective cover (2) are fixed on the four positioning platforms on the worm gear box (4) through the heatproof stop screws (3). The upper protective cover (1) is composed of a first upper side plate (9), a first top plate (10) and a first lower side plate (11). The lower protective cover (2) is composed of a second upper side plate (16), a second top plate (17) and a second lower side plate (18). The protective covers are in split structure, thereby being convenient to demount, replace and maintain.

Owner:大同北方天力增压技术有限公司

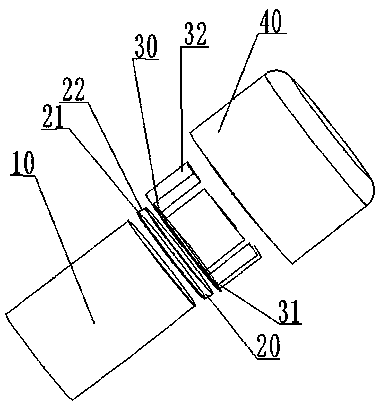

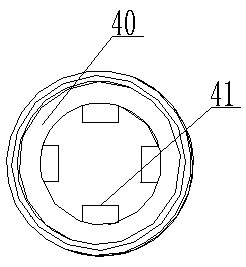

Dual waterproof breathable cap

PendingCN111457321AImprove securityPrecise positioningLighting and heating apparatusSignalling/lighting devicesHollow cylinderHeadlamp

The invention discloses a dual waterproof breathable cap, which comprises: a sealing piece, which is a hollow cylinder; a ventilation device, which is connected to the sealing piece and comprises a double-layer waterproof ventilation film and a connecting ring arranged in the middle of the waterproof ventilation film, with the connecting ring being connected to the waterproof ventilation film through hot melting; a cover body, which is arranged at the top end of the ventilation device, is equipped with a through hole, and is provided with first mounting check blocks around the cover body; a cap body, which covers the ventilation device, is internally equipped with a second mounting check block spaced from the top of the cap body, wherein the spacing is equal to the height of the first mounting check blocks, and the first mounting check blocks abut against the second mounting check block. By arranging the ventilation device, invasion of external water vapor, dust, greasy dirt and otherdirt is avoided, fog formation of headlamps in the driving process of an automobile is avoided, the headlamps the automobile can be guaranteed to not to form fog in the driving process, and safety isimproved; and the first mounting check blocks and the second mounting check block are arranged, so that the ventilation cap is precise in position positioning and ingenious in connection.

Owner:丹阳市科尔精密电子有限公司

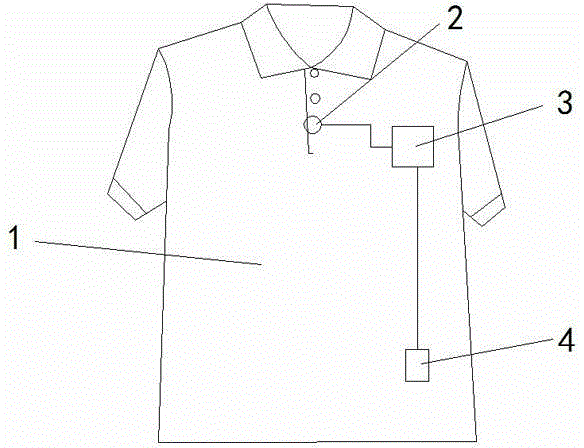

Anti-fouling coat with image pick-up function

InactiveCN104366760AImprove wear resistanceLow costGarment special featuresFibre treatmentYarnPolyester

The invention relates to an anti-fouling coat with an image pick-up function. The coat comprises a coat body (1). The front body of the coat body (1) is provided with a miniature camera (2). The upper pocket of the coat body (1) is provided with video equipment (3). The miniature camera (2) is connected with the video equipment (3) through a sensing wire. The lower pocket of the coat body (1) is provided with storage equipment (4). The coat body is made of fabric. The fabric comprises a fabric body. The fabric body is formed by interweaving warps and wefts. An anti-fouling coating is disposed on each of the upper and lower surfaces of the fabric body. The warps are 16S polyester yarn. Each anti-fouling coating is a teflon coating. When a crime or an illegal event occurs, the video equipment records people breaking the law and the illegal event, records are then copied out from the storage equipment, and the records can be used as evidence for protecting victims. The coat is anti-fouling.

Owner:JIANGYIN LICHEN IND

High-strength high-temperature-resistant oil-resistant cable material

InactiveCN111944315AImprove high strength and high temperature resistanceImprove high-strength, high-temperature and oil-resistant propertiesRubber insulatorsCoatingsDouble bondBisphenol A

The invention relates to a high-strength high-temperature-resistant oil-resistant cable material in the technical field of cable materials. The cable material is prepared from the following componentsin parts by weight: 30-40 parts of a modified ethylene-vinyl oxalate copolymer, 50-62 parts of silicone rubber, 15-20 parts of bisphenol A polyoxyethylene ether, 62-80 parts of a nano flame retardant, 2.8-3.2 parts of a sensitizer, 1-2 parts of a silane coupling agent, 0.8-1.2 parts of an antioxidant, 1.6-1.8 parts of a silicon lubricant, 0.8-1.8 parts of a colorant and 3.8-4.2 parts of molybdenum oxide. The main chain of the modified ethylene-vinyl oxalate copolymer is a saturated polar ester group, the side chain contains a large number of unsaturated double bonds, the unsaturated double bonds improve the stability of the material, the high strength and high temperature resistance of the cable material are improved; the repulsion phenomenon between the saturated polar ester group and oils occurs, so that the oil resistance of the cable material is realized; the silicon rubber and the bisphenol A polyoxyethylene ether are matched with each other, so that the high-strength, high-temperature-resistant and oil-resistant properties of the cable material are further improved.

Owner:安徽天虹电缆有限公司

Method and application of dye residue for preparing cement floor color paste and cement curing enhancer

The invention discloses a method and application for preparing cement floor color paste and cement solidification enhancer from dye residue. The method comprises the following steps: using dye residue to prepare mother liquor; mixing 70-85 parts by weight of mother liquor, polyether polyol 2~6 parts by weight, 2~8 parts by weight of triethanolamine, 6~10 parts by weight of lithium silicate, 3~10 parts by weight of urea and 3~10 parts by weight of diethylene glycol are mixed together and stirred evenly, and the stirring time is After 60 to 120 minutes, the cement floor color paste and cement curing enhancer are obtained, which are sealed and stored. If the specific gravity value of the dye residue is 1.15-1.17, it is used as mother liquor; if the specific gravity is lower than 1.15-1.17, the following steps are included: extracting polyacrylamide by 0.5-2% of the weight of the dye residue, adding an appropriate amount Dilution water dissolves polyacrylamide into a solution, the solution is added to the dye residue and stirred, then precipitated, and the upper part of the liquid close to water is removed, and when the specific gravity reaches 1.15~1.17, it is used as the mother liquor. The invention has the beneficial effects of simple method, convenient processing, effectively solving dye discharge and beautifying buildings.

Owner:HANGZHOU ZUONA IND CO LTD

Method for preparing cement floor color paste and cement curing enhancer from dye residual paste and application

The invention discloses a method for preparing cement floor color paste and a cement curing enhancer from dye residual paste and application. The method comprises the following steps: preparing mother liquor from the dye residual paste; mixing 70-85 parts by weight of mother liquor, 2-6 parts by weight of polyether polyol, 2-8 parts by weight of triethanolamine, 6-10 parts by weight of lithium silicate, 3-10 parts by weight of urea and 3-10 parts by weight of diethylene glycol, evenly stirring for 60-120 minutes to obtain the cement floor color paste and the cement curing enhancer, sealing, and storing. If the specific gravity value of the dye residual paste is 1.15-1.17, the dye residual paste is used as mother liquor; and if the specific gravity value is lower than 1.15-1.17, following steps are executed: extracting polyacrylamide according to 0.5-2% of the weight of the dye residual paste, adding a proper amount of dilution water to prepare polyacrylamide into a solution, adding the dye residual paste into the solution, stirring, precipitating, removing the upper part of the liquid similar with water, and taking the liquid as a mother liquor when the specific gravity value is 1.15-1.17. The method has the beneficial effects that the method is simple, processing is convenient, dye emission is effectively solved, and buildings are beautified.

Owner:HANGZHOU ZUONA IND CO LTD

A kind of thermally crosslinked thermoplastic polyurethane elastomer and its preparation method and application

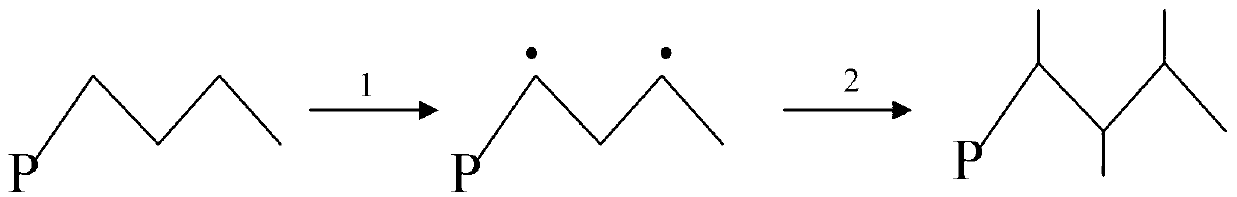

ActiveCN109535380BApplication temperature reductionAchieve oil resistancePolyurethane elastomerPolymer science

The invention belongs to the technical field of high polymer materials and discloses a thermo-crosslinking type thermoplastic polyurethane elastomer, a preparation method and an application thereof. The thermo-crosslinking type thermoplastic polyurethane elastomer comprises the following components by mole fraction: 1.0 part of hydroxy-terminated butadiene rubber, 2.2-8.8 parts of p-phenylenediisocyanate, 1.1-7.5 parts of terephthalyl alcohol and 0.003-0.025 part of diisopropyl ditert-butyl peroxide. The thermo-crosslinking type thermoplastic polyurethane elastomer provided by the invention isprepared according to the following steps: adopting a prepolymer method for preparing a prepolymer from reaction of hydroxy-terminated butadiene rubber and p-phenylenediisocyanate; adding vulcanizingagent diisopropyl ditert-butyl peroxide; mixing the prepolymer containing vulcanizing agent with terephthalyl alcohol, and then curing, thereby acquiring the thermo-crosslinking type thermoplastic polyurethane elastomer. The thermo-crosslinking type thermoplastic polyurethane elastomer provided by the invention has excellent low temperature resistance, high temperature resistance, mechanical properties and oil resistance, and can be used for preparing oil pipes and hydraulic and pneumatic sealing elements.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com