Seven-layer co-extruded film used for hot melting combination and preparation method

A co-extruded film and hot-melt technology, applied in chemical instruments and methods, synthetic resin layered products, applications, etc., can solve the problems of high unwinding noise level, difficult unwinding, etc., and achieve high strength and excellent heat sealing performance , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

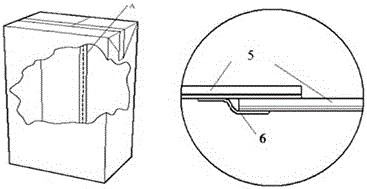

Image

Examples

Embodiment 1

[0033] The mass parts array of raw materials is 70 parts of PE, 15 parts of PA, 15 parts of EVOH, and 15 parts of TIE (resin binder);

[0034] Select the corresponding raw material components according to the formula, and extrude from the respective extruder heads after melting respectively, and then enter the different processing channels of the blow molding machine; the air is passed into the blow molding machine to blow the mold blank into a film foam, and lift upwards, cool naturally during the lifting process, after lifting, it is transformed into a seven-layer co-extrusion film through the closing mechanism set above; then it is pulled by the traction roller group, and finally winds up to obtain the finished product; the performance test of the obtained finished product is carried out. The test results are shown in Table 1.

Embodiment 2

[0039] The mass parts of raw materials are 70 parts of PE, 20 parts of PA, 15 parts of EVOH, and 15 parts of TIE (resin binder);

[0040] Select the corresponding raw material components according to the formula, and extrude from the respective extruder heads after melting respectively, and then enter the different processing channels of the blow molding machine; the air is passed into the blow molding machine to blow the mold blank into a film foam, and lift upwards, cool naturally during the lifting process, after lifting, it is transformed into a seven-layer co-extrusion film through the closing mechanism set above; then it is pulled by the traction roller group, and finally winds up to obtain the finished product; the performance test of the obtained finished product is carried out. The test results are shown in Table 1.

Embodiment 3

[0045] The mass parts of raw materials are 80 parts of PE, 15 parts of PA, 15 parts of EVOH, and 15 parts of TIE (resin binder);

[0046] Select the corresponding raw material components according to the formula, and extrude from the respective extruder heads after melting respectively, and then enter the different processing channels of the blow molding machine; the air is passed into the blow molding machine to blow the mold blank into a film foam, and lift upwards, cool naturally during the lifting process, after lifting, it is transformed into a seven-layer co-extrusion film through the closing mechanism set above; then it is pulled by the traction roller group, and finally winds up to obtain the finished product; the performance test of the obtained finished product is carried out. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com