Imitation marble brick prepared by construction waste and preparation method thereof

A technology of imitating marble and construction waste, applied in the direction of construction, building components, building structure, etc., can solve the problems of high production cost and poor quality of imitation marble tiles, and achieve the effect of reducing the amount of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

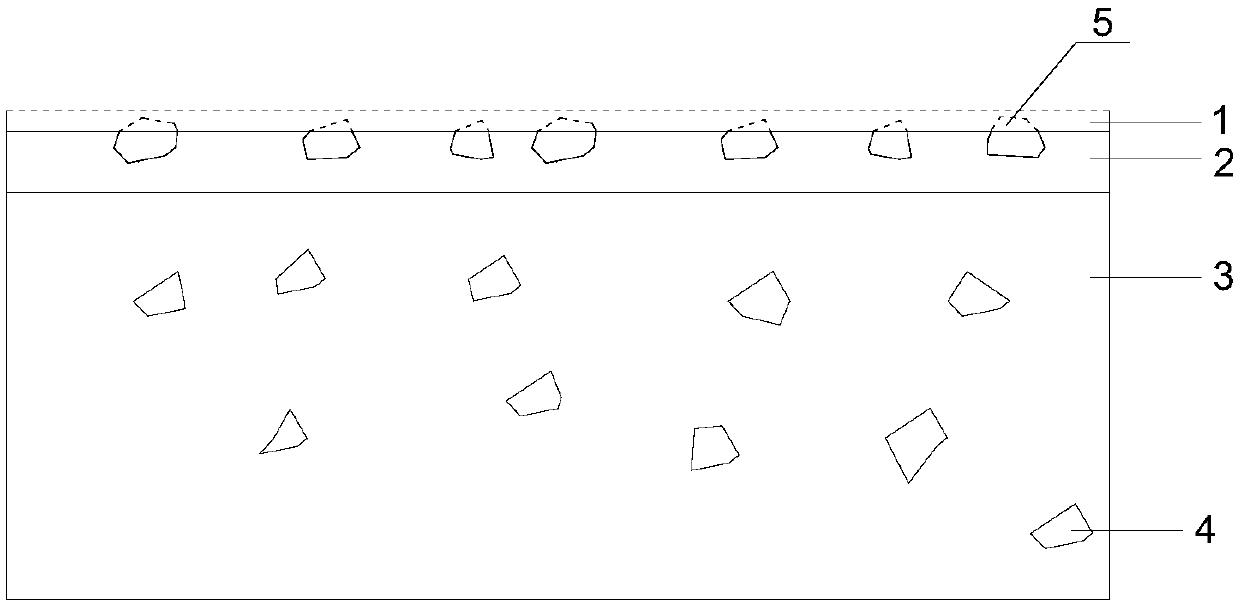

[0021] The preparation method of the imitation marble brick prepared by the construction waste, the specific method steps are:

[0022] (1) The construction waste with high concrete content is processed into general quality recycled coarse aggregate and general quality recycled fine aggregate through primary crushing and secondary crushing, and then processed into high quality recycled coarse aggregate and recycled powder through particle shaping material, and then heat, mill and activate the obtained regenerated powder to obtain highly active regenerated micropowder;

[0023] (2) According to the weight parts of raw materials, it is composed of: cement: 150-210 parts, general quality recycled coarse aggregate and general quality fine aggregate: 400-800 parts, high activity recycled micropowder: 10-60 parts, water: 60-60 parts 120 parts are weighed and mixed, paved into a bottom layer, and the bottom layer is compacted by vibratory compaction, wherein general quality recycled ...

Embodiment 1

[0028] The selected bottom material has a strength grade of C20 and a thickness of 40mm. It is prepared according to the following components by weight: 150 parts of cement, 400 parts of normal quality recycled coarse aggregate and normal quality recycled fine aggregate, 10 parts of high activity recycled micropowder, and 60 parts of water. The selected surface material has a strength grade of C30 and a thickness of 8mm. It is made according to the following components by weight: 150 parts of cement, 400 parts of high-quality recycled coarse aggregate, 10 parts of high-activity recycled fine powder, and 60 parts of water. When the imitation marble brick is prepared according to the above component ratios, the flexural strength of the imitation marble brick can reach 6.5MPa.

Embodiment 2

[0030] The selected bottom material has a strength grade of C20 and a thickness of 40mm. It is prepared according to the following components by weight: 180 parts of cement, 600 parts of normal quality recycled coarse aggregate and normal quality recycled fine aggregate, 40 parts of high activity recycled fine powder, and 90 parts of water. The selected surface material has a strength grade of C30 and a thickness of 8mm. It is made according to the following components by weight: 180 parts of cement, 500 parts of high-quality recycled coarse aggregate, 300 parts of high-activity recycled fine powder, and 80 parts of water. When the imitation marble brick is prepared according to the above component ratios, the flexural strength of the imitation marble brick can reach 4.4MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com