A kind of preparation method of grouting material

A grouting material and a technology for grouting, which are applied in the field of grouting material preparation, can solve the problems of water resistance, difficulty in accurate control, and injectability of grout leakage in large-pore formations, so as to improve high temperature resistance, have little negative impact on strength, and The effect of controllable coagulation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

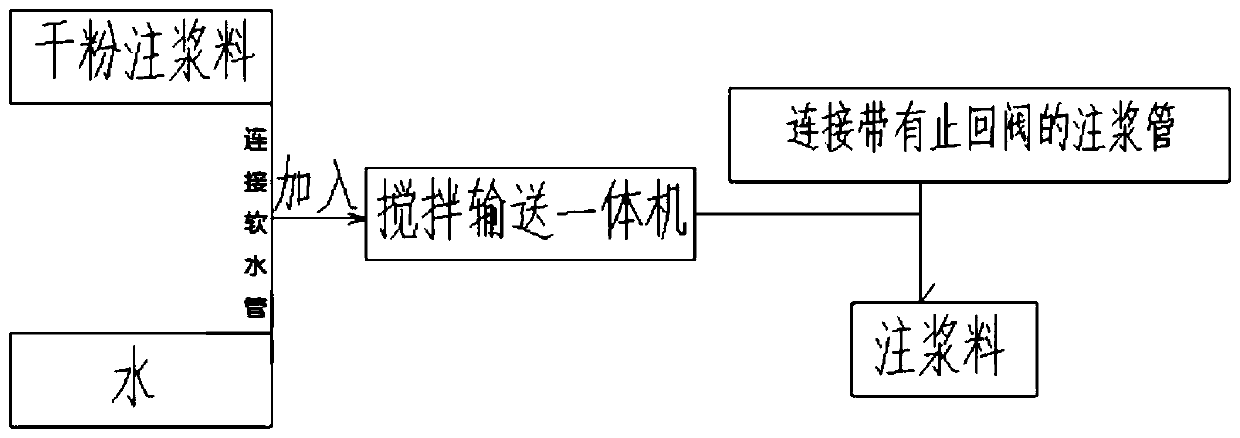

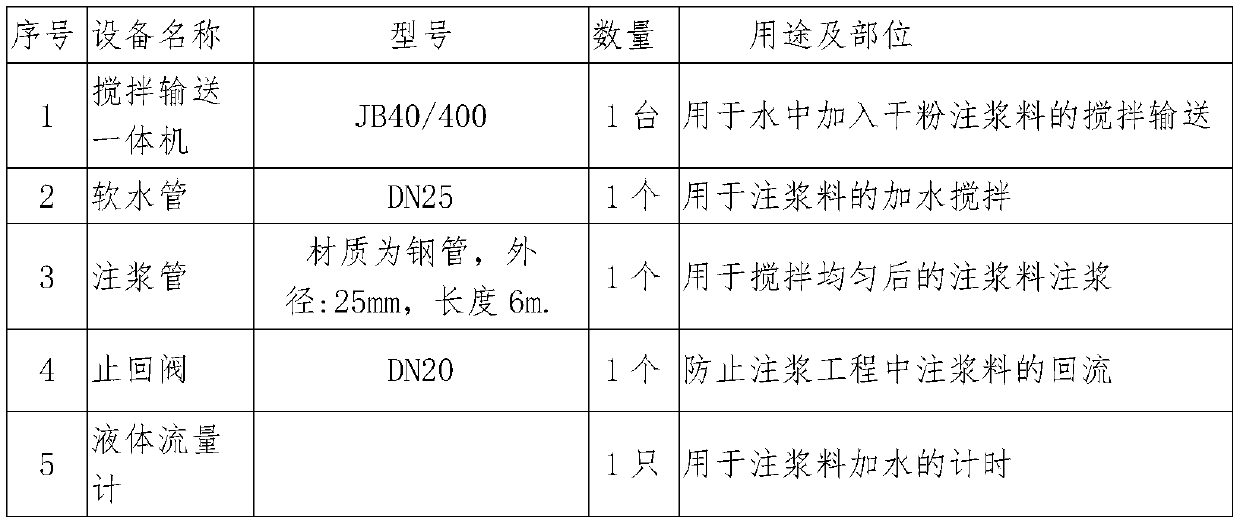

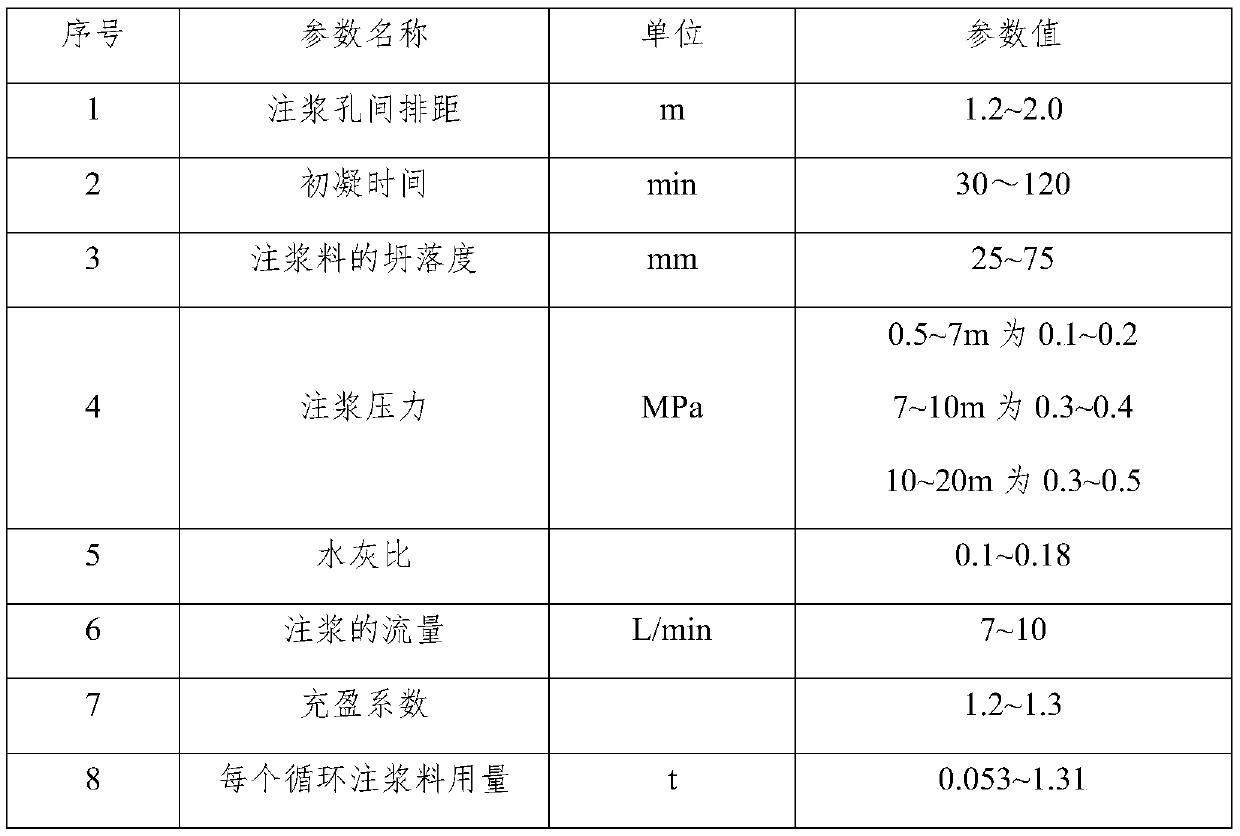

[0030] (1) Take magnesium phosphate cement, admixtures, admixtures and aggregates, pour the raw materials into the silo according to the mixing ratio, stir evenly, and put the obtained dry mixture into 50kg of inner film plastic through an automatic packaging machine Then put the dry mixture into the mixing hopper of the mixing and conveying machine, connect the soft water pipe to the water injection port of the mixing and conveying machine, and connect the other end to the water source connector of the construction site, and follow the instructions in the manual Water demand requirements, add the required water through the liquid flow meter;

[0031] (2) After adding the required amount of water to the dry mix in the mixing and grouting integrated machine, stir continuously for 2.5 minutes to obtain a uniform slurry-like grouting material.

[0032] The mixed material is calculated in parts by weight: 80 kg of magnesium phosphate cement, 4 kg of admixture, 10 kg of admixture, ...

Embodiment 2

[0039] (1) Take magnesium phosphate cement, admixtures, admixtures and aggregates, pour the raw materials into the silo according to the mixing ratio, stir evenly, and put the obtained dry mixture into 50kg of inner film plastic through an automatic packaging machine Then put the dry mixture into the mixing hopper of the mixing and conveying machine, connect the soft water pipe to the water injection port of the mixing and conveying machine, and connect the other end to the water source connector of the construction site, and follow the instructions in the manual Water demand requirements, add the required water through the liquid flow meter;

[0040] (2) After adding the required amount of water to the dry mix in the mixing and grouting integrated machine, stir continuously for 2 minutes to obtain a uniform slurry-like grouting material.

[0041] The mixture is calculated in parts by weight: 120kg of magnesium phosphate cement, 15kg of admixture, 15kg of admixture, and 100kg of...

Embodiment 3

[0048] (1) Take magnesium phosphate cement, additives, admixtures and aggregates, pour the raw materials into the silo according to the mixing ratio, stir evenly, and put the obtained dry mixture into 50kg of inner film plastic through an automatic packaging machine Then put the dry mixture into the mixing hopper of the mixing and conveying machine, connect the soft water pipe to the water injection port of the mixing and conveying machine, and connect the other end to the water source connector of the construction site, and follow the instructions in the manual Water demand requirements, add the required water through the liquid flow meter;

[0049] (2) After adding the required amount of water to the dry mixture in the mixing and grouting integrated machine, stir continuously for 3 minutes to obtain a uniform slurry-like grouting material.

[0050] The mixture is calculated in parts by weight: magnesium phosphate cement 110kg, admixture 8kg, admixture 13kg, aggregate 70kg. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com