Patents

Literature

87results about How to "Reduce edges and corners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

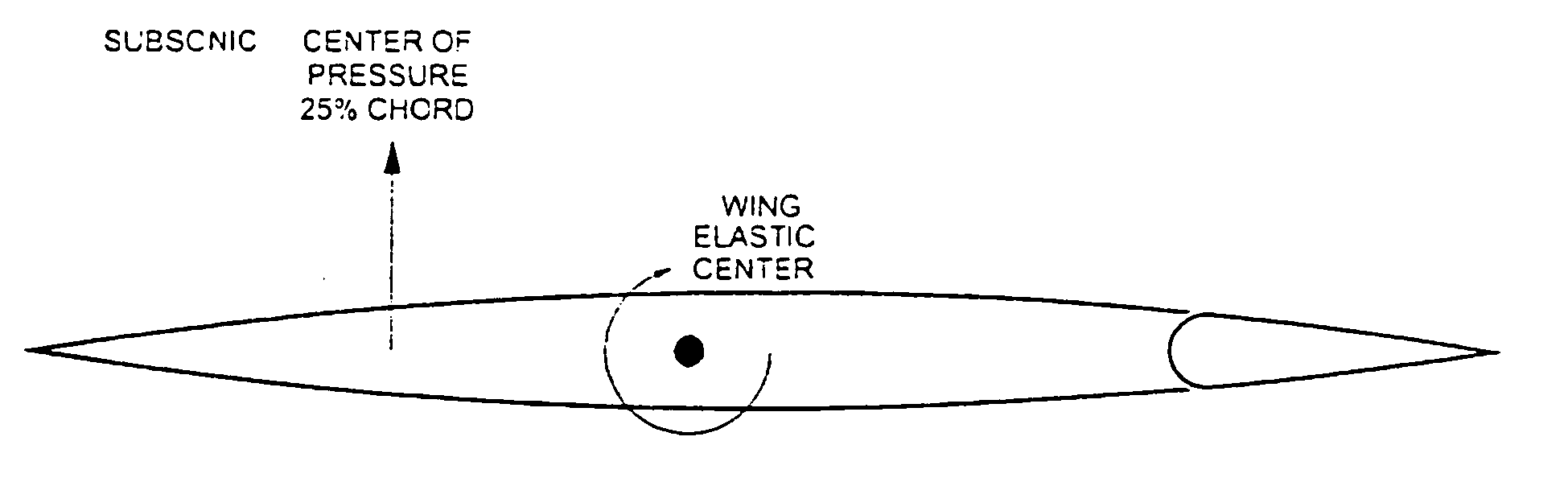

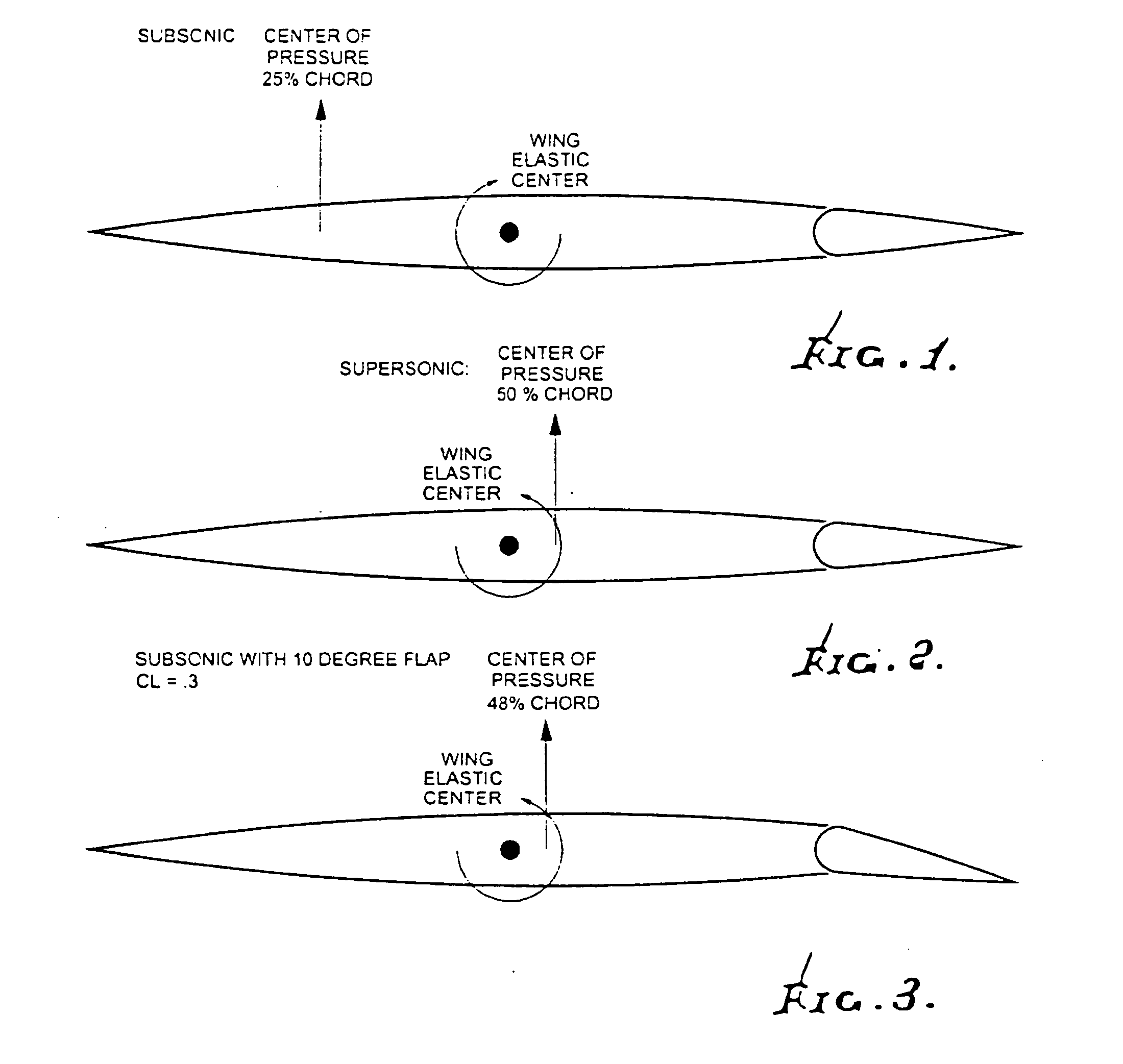

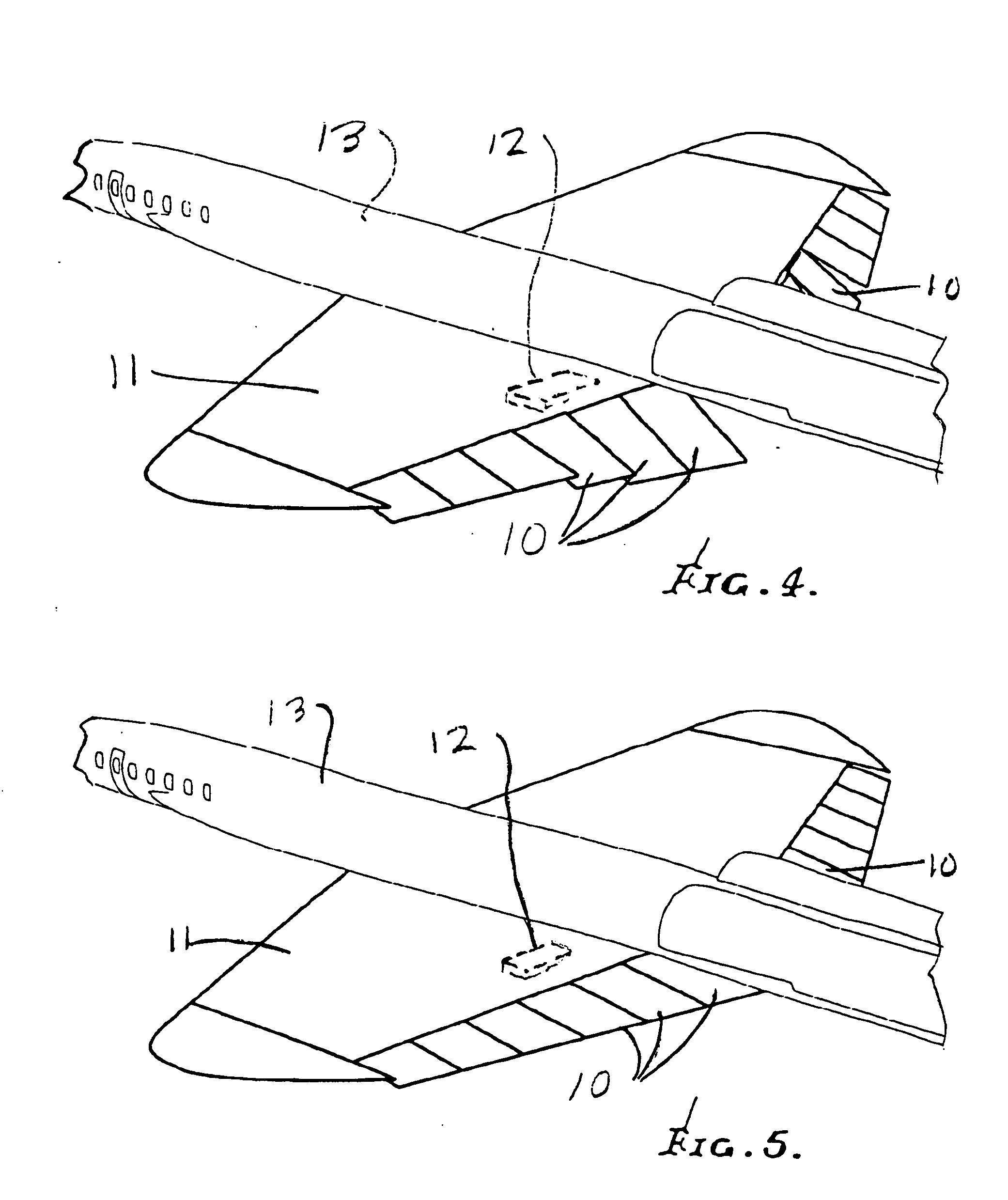

Lift and twist control using trailing edge control surfaces on supersonic laminar flow wings

ActiveUS20050151029A1Reduce subsonic wing leading edge vortex dragImprove compression performanceAircraft controlWing lift eficiencyFlight vehicleClassical mechanics

An aircraft comprising a fuselage, thin supersonic wings on the fuselage, there being trailing edge flaps carried by the wings, the flaps configured to provide flap deflection to simultaneously control wing twist and to reduce drag, when the aircraft is operated at subsonic flight conditions.

Owner:AERION INTPROP MANAGEMENT CORP

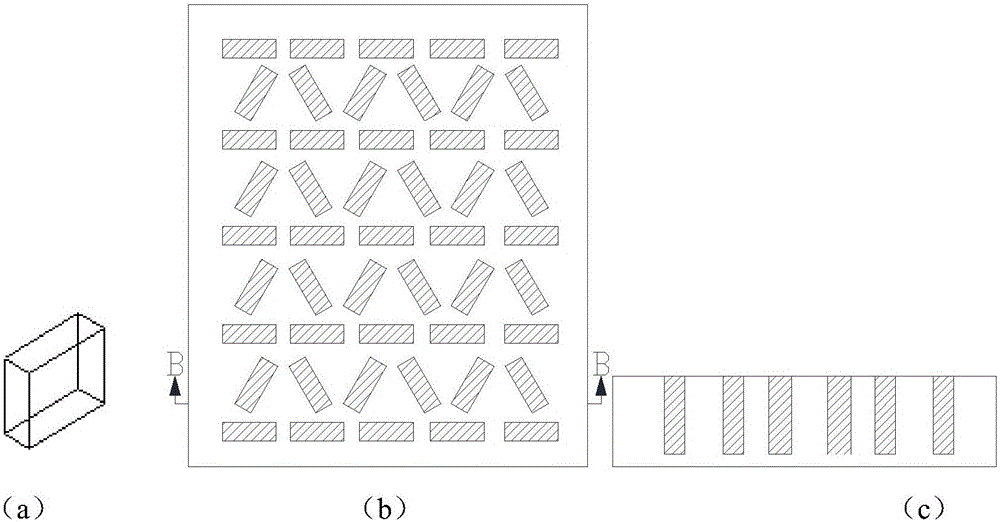

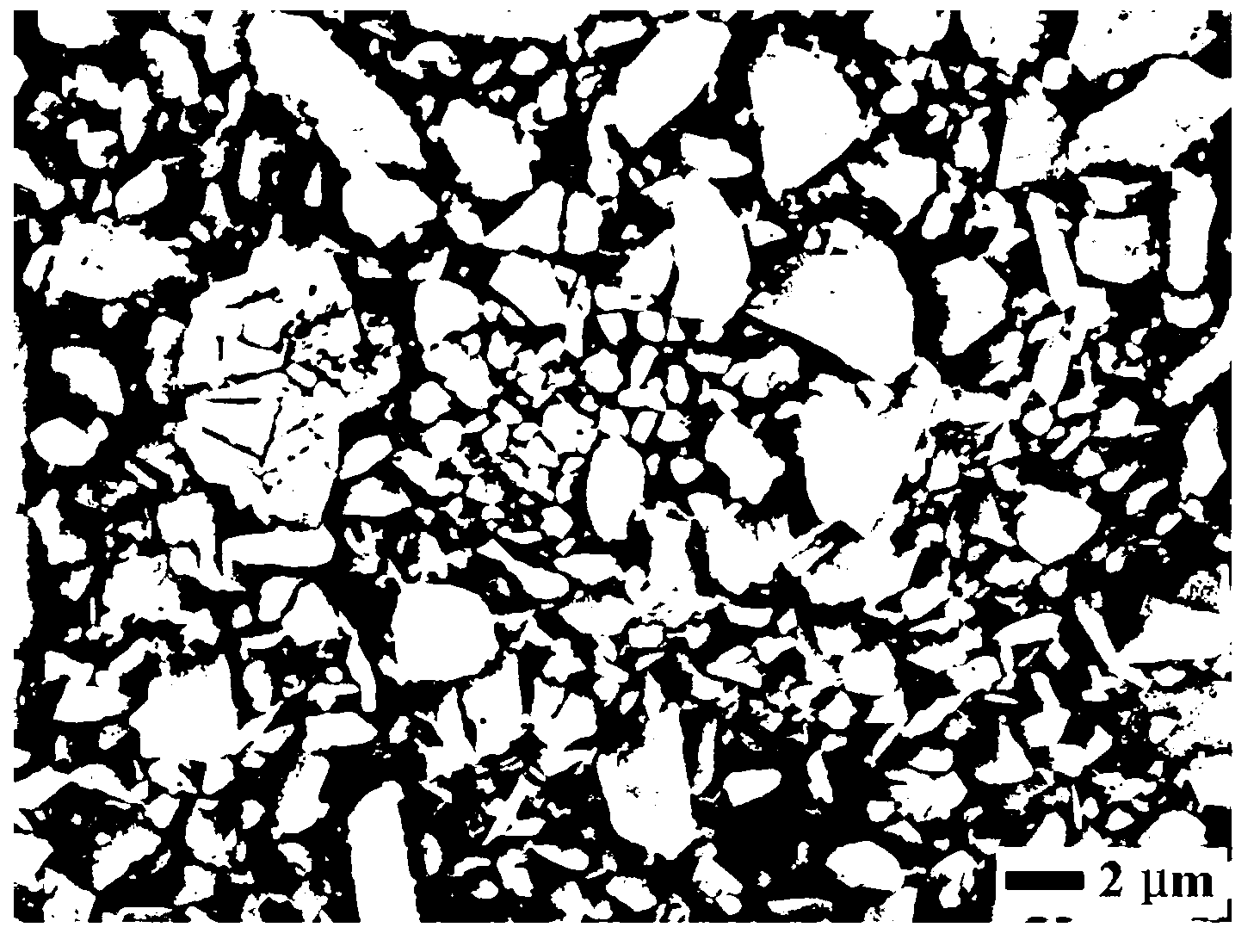

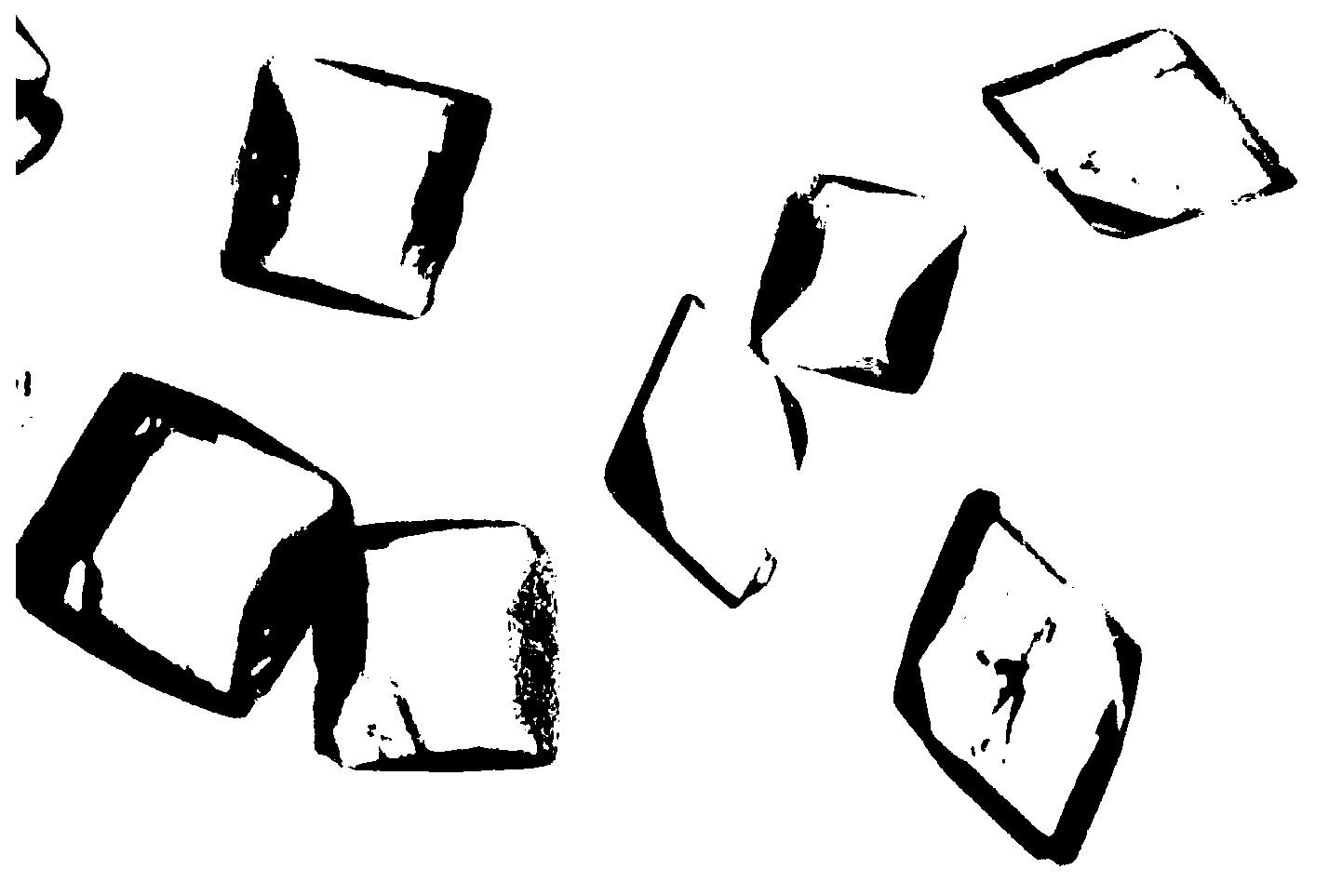

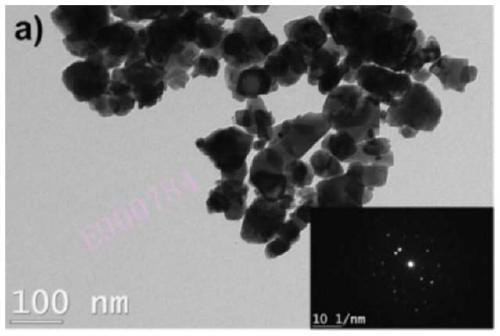

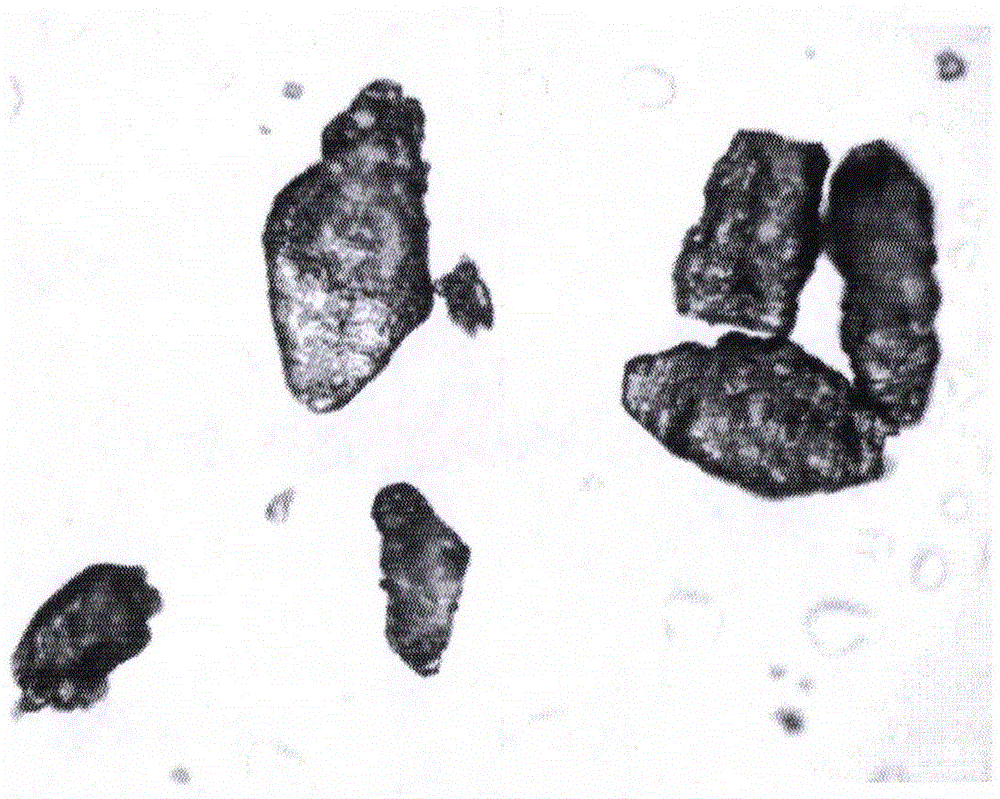

Preparation method of hexaazaisowurtzitane crystal

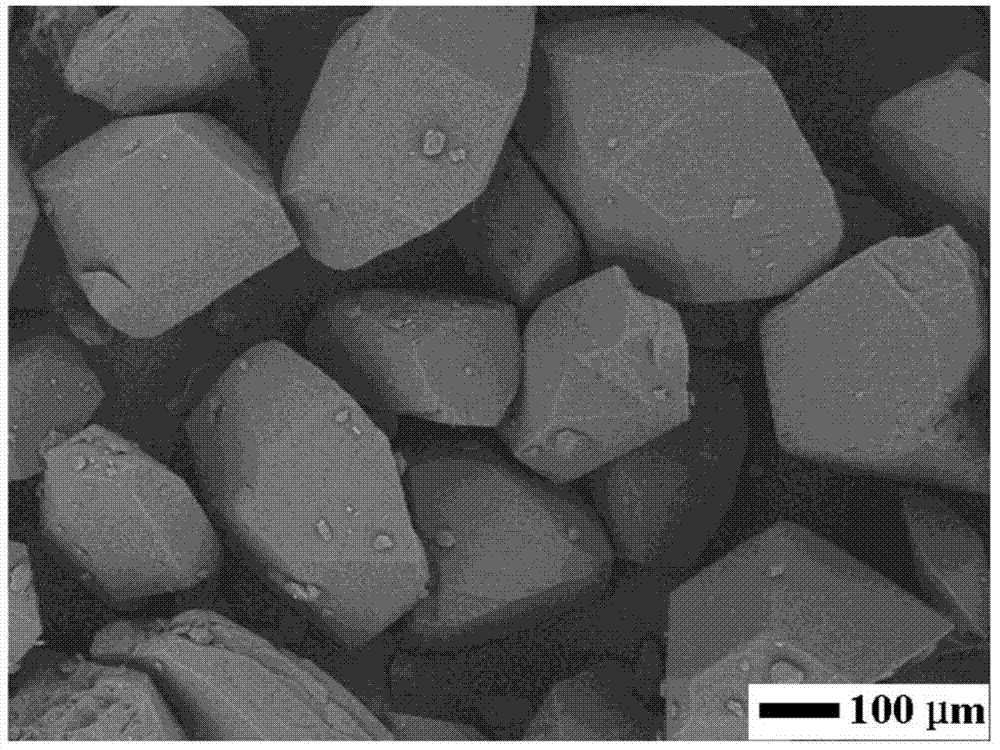

ActiveCN103214325ARegular particle shapeUniform particlesExplosive working-up apparatusSingle substance explosivesMechanical crushingTwo step

The invention discloses a preparation method of a hexaazaisowurtzitane crystal. The preparation method of the hexaazaisowurtzitane crystal comprises the following steps of: carrying out wet-crushing onto explosives until the particle dimension is 0.1 micron to 5 microns, centrifuging, washing, freezing and drying the crushed materials; placing the material in the step I to a solvent for carrying out ultrasonic treatment, heating, re-filtering, washing and drying under the standing condition or the stirring condition to obtain a hexaazaisowurtzitane explosive crystal. According to the preparation method of the hexaazaisowurtzitane crystal, the high-quality explosive crystal product, which is prepared by a preparation technology adopting a two-step process including mechanical crushing and solvent thermal-induction growing, is regular in particle shape, jewel-shaped, uniform in particle dimension, smooth in surface, less in internal defects of the crystal, and lower in mechanical sensitivity. Besides, the preparation method of the hexaazaisowurtzitane crystal is simple in process, gentle in reaction conditions, good in reproducibility, high in yield and suitable for large-scale industrial production.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

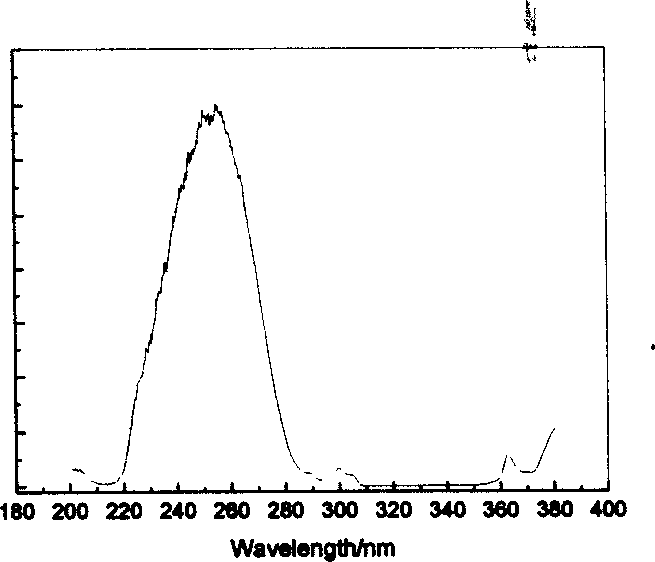

Prepn of red phosphor

InactiveCN1637115AChange coordination environmentSmall particle sizeLuminescent compositionsAlkaline earth metalPhosphate

The preparation process of red phosphor includes: mixing Eu2O3, Y2O3 and MgO, Al(NO3)3 or Sb2O3 to form mixture, adding HNO3 solution and citric acid and heating at 60-100 deg.c to prepare red phosphor mother liquid; compounding oxalic acid solution with oxalic acid and deionized water, adding ethanol and heating to 80 deg.c; mixing red phosphor mother liquid with H2O2 at 25-30 deg.c and heating to 80 deg.c, adding the oxalic acid solution to produce precipitate, filtering, washing the precipitate with deionized water and stoving at 90 deg.c in stove for 2 hr; initial roasting of the precipitate in high temperature furnace and cooling; adding to the roasted product with one or two kinds of fluoride, chloride, phosphate or carbonate of alkali metal and alkali earth metal, secondary roasting in high temperature furnace, cooling, washing with dilute nitric acid, washing with deionized water and stoving to obtain the red phosphor.

Owner:SHAANXI NORMAL UNIV

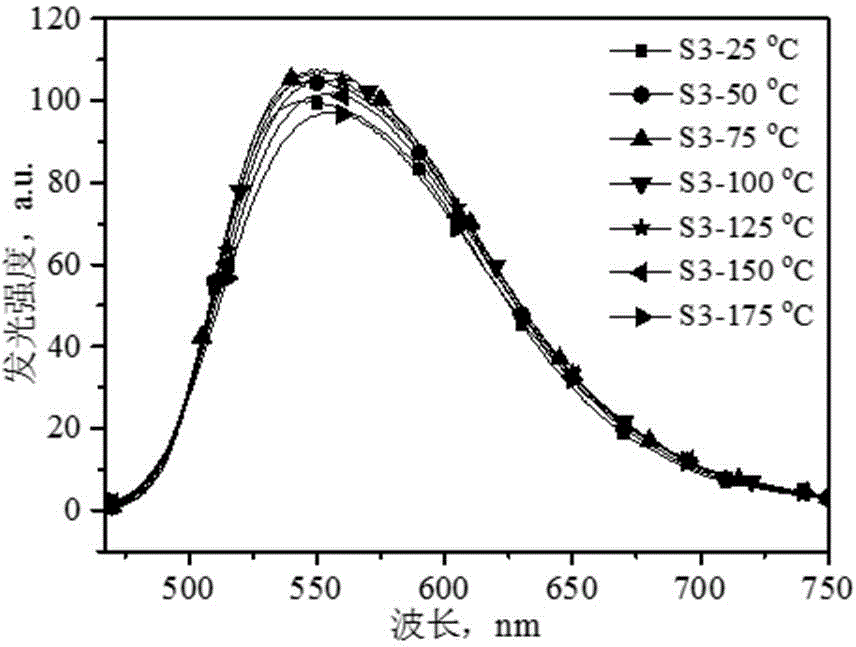

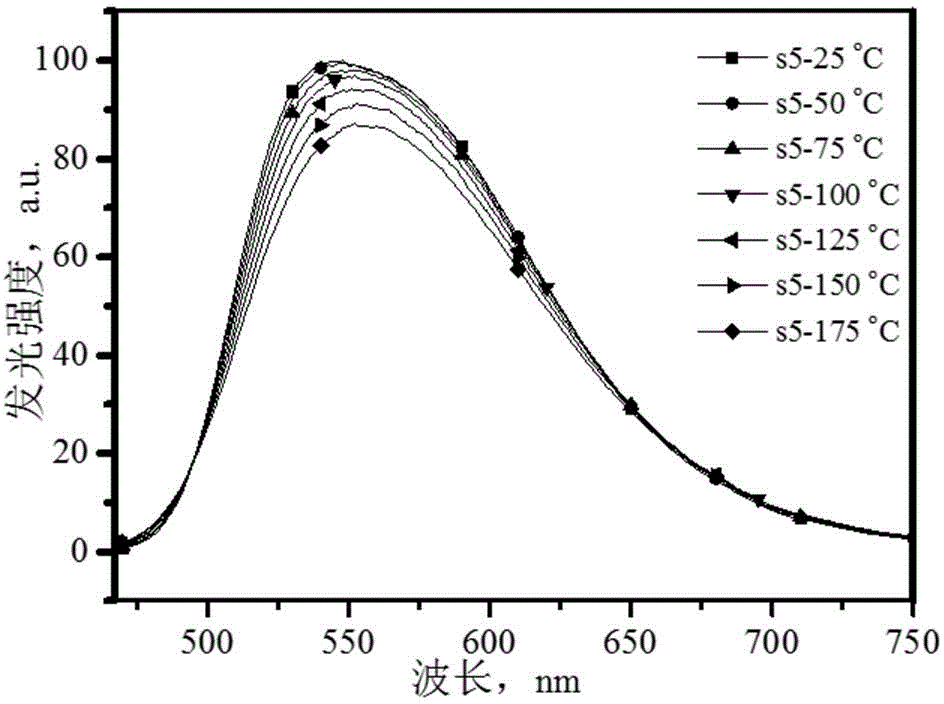

Rare earth luminescent material preparation method containing crystal defect repair technology and product thereof

ActiveCN104818023ADecreased luminosityDecreased Internal Quantum EfficiencyLuminescent compositionsDefect repairRare earth

The invention provides a rare earth luminescent material preparation method containing crystal defect repair technology and a product thereof to overcome disadvantages in synthesis of garnet activated rare earth aluminate fluorescent materials in the prior art. The preparation method comprises the following four steps: preparation of clinker; preparation of clinker blended with a raw material; preparation of a fluorescent powder material having undergone secondary annealing; and preparation of the finished fluorescent material. The finished fluorescent material prepared by using the method has external quantum efficiency of 0.706 to 0.745 and internal quantum efficiency of 0.953 to 0.992 in a temperature range of room temperature to 150 DEG C. The invention has the following beneficial technical effects: the raw material is used to replace an activator during secondary reduction; and in virtue of cooperative action of surface modification and secondary reduction thermodynamics, crystal defects are eliminated, and internal quantum efficiency and photo-thermal stability of the Ce<3+> activated garnet structure rare earth aluminate luminescent material are improved.

Owner:HEFEI UNIV OF TECH

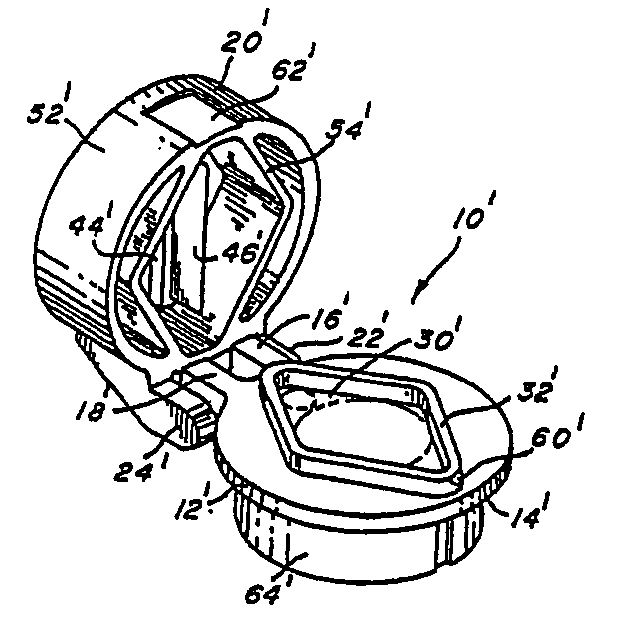

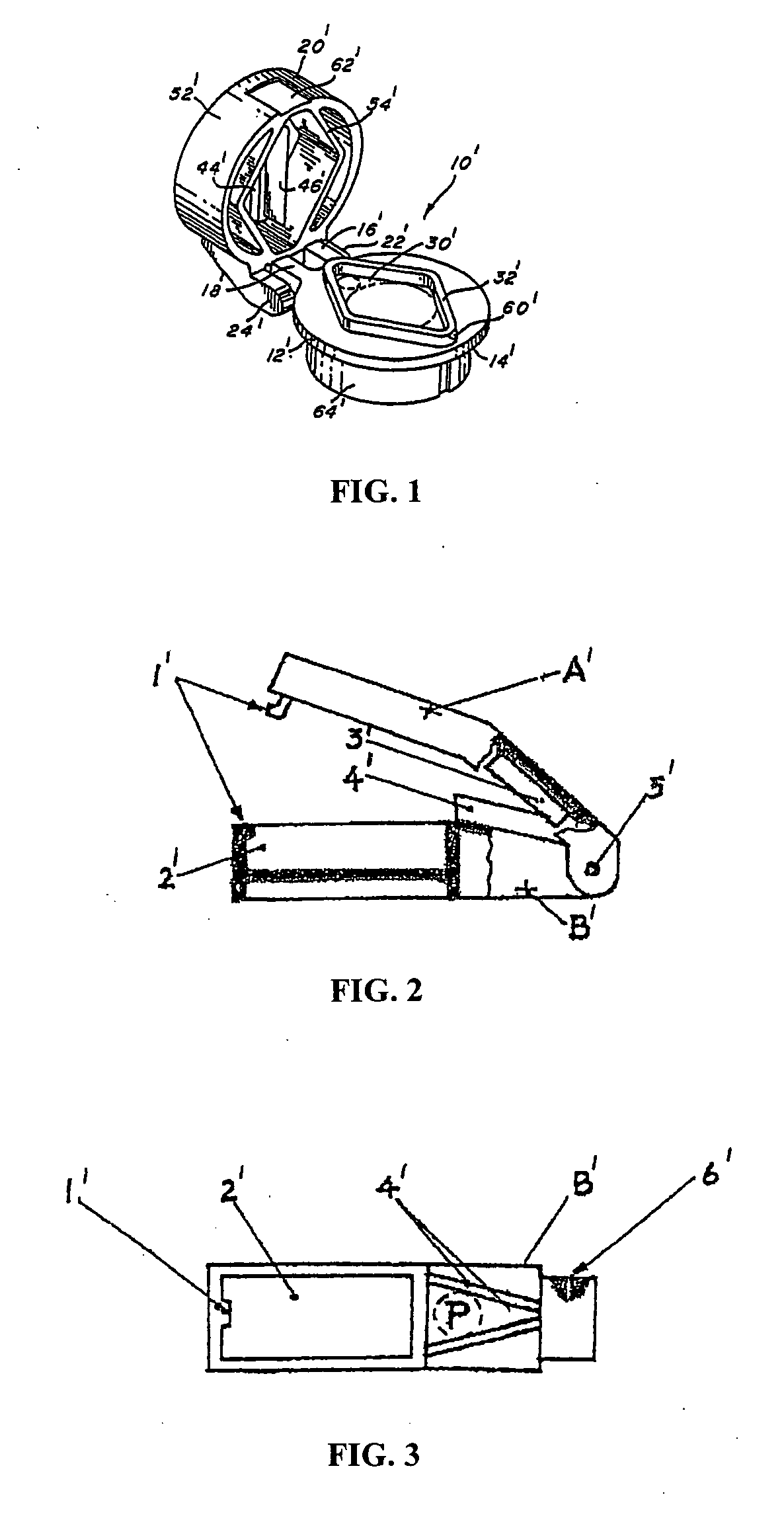

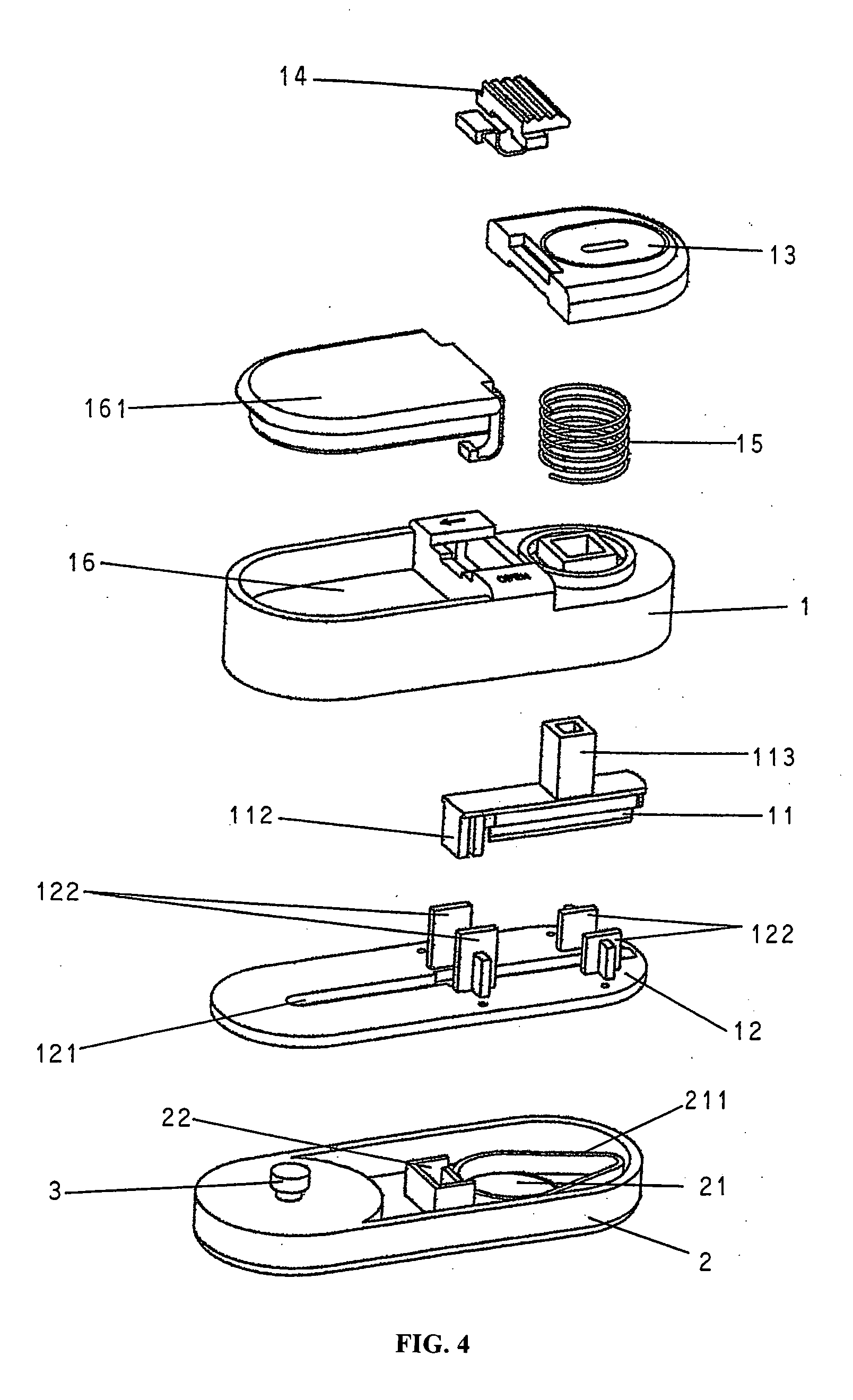

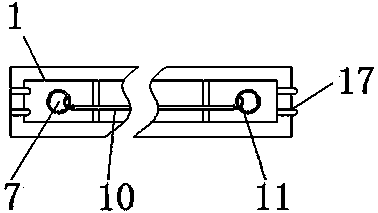

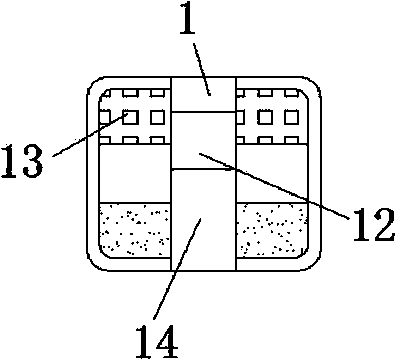

Pill box

InactiveUS20050051587A1Reduce edges and cornersIncrease spaceOral administration devicePortable power-driven toolsEngineeringMechanical engineering

The present invention relates to a pill box for splitting pills into halves. The pill box comprises a cover and a base which are connected pivotally by a staff. The cover has a blade holder inside, which has a plug pin at the bottom. At the bottom of the cover, there is a partition with an opening. The base has a pill receptacle and a slot. When the blade holder moves down, the blade and the plug pin pass through the opening. The blade cuts at the position of the pill receptacle and the plug pin plugs into the slot. The cover and the base are locked together. When the blade holder moves up and the plug pin completely moves out from the slot, the cover or the base can rotate out with the staff as a pivot. The present invention is safe, reliable, small and portable.

Owner:BENISON INDAL

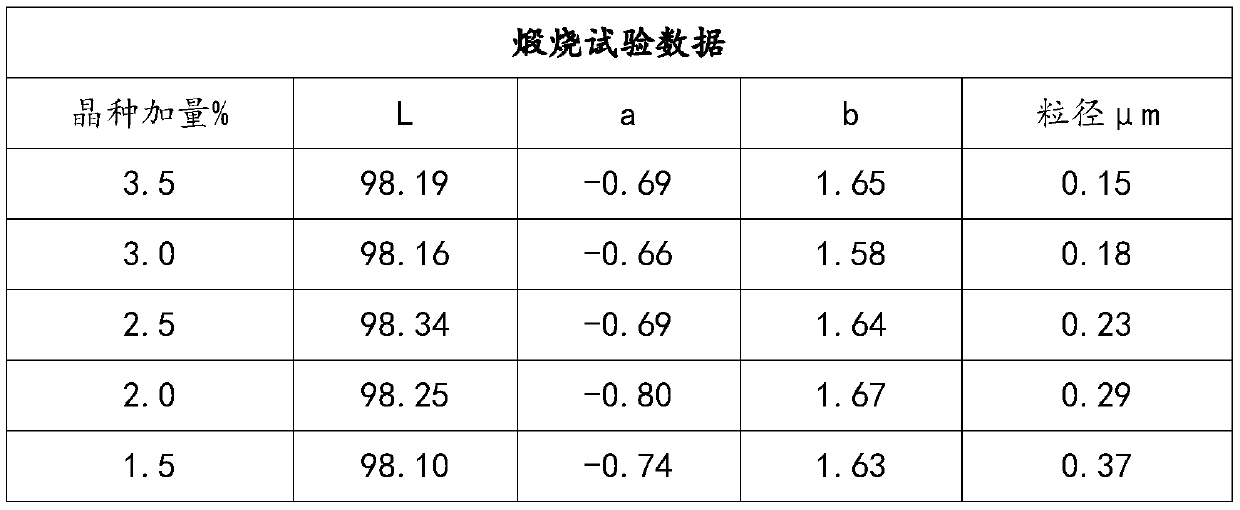

Method for improving whiteness of titanium dioxide by adjusting granularity

The invention belongs to the technical field of titanium dioxide production, and particularly relates to a method for improving whiteness of titanium dioxide by adjusting granularity. In the prior art, the particle size of titanium dioxide particles is not well controlled in a titanium dioxide production process, so that the whiteness of the titanium dioxide product is not high. Based on the problem in the prior art, the method of the invention comprises: crushing, acidolysis, sedimentation, hot filtration, crystallization, ferrous separation, hydrolysis, primary water washing, bleaching, secondary water washing, salt treatment, pre-kiln filter pressing, calcination, intermediate crushing, coating, tertiary water washing, drying and jet milling, wherein in the bleaching step, a calcined seed crystal with a fraction content of 1.5-2.5% into a slurry based on the Ti content calculated as TiO2 in the slurry. The method the invention is used for producing high-whiteness titanium dioxide.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD

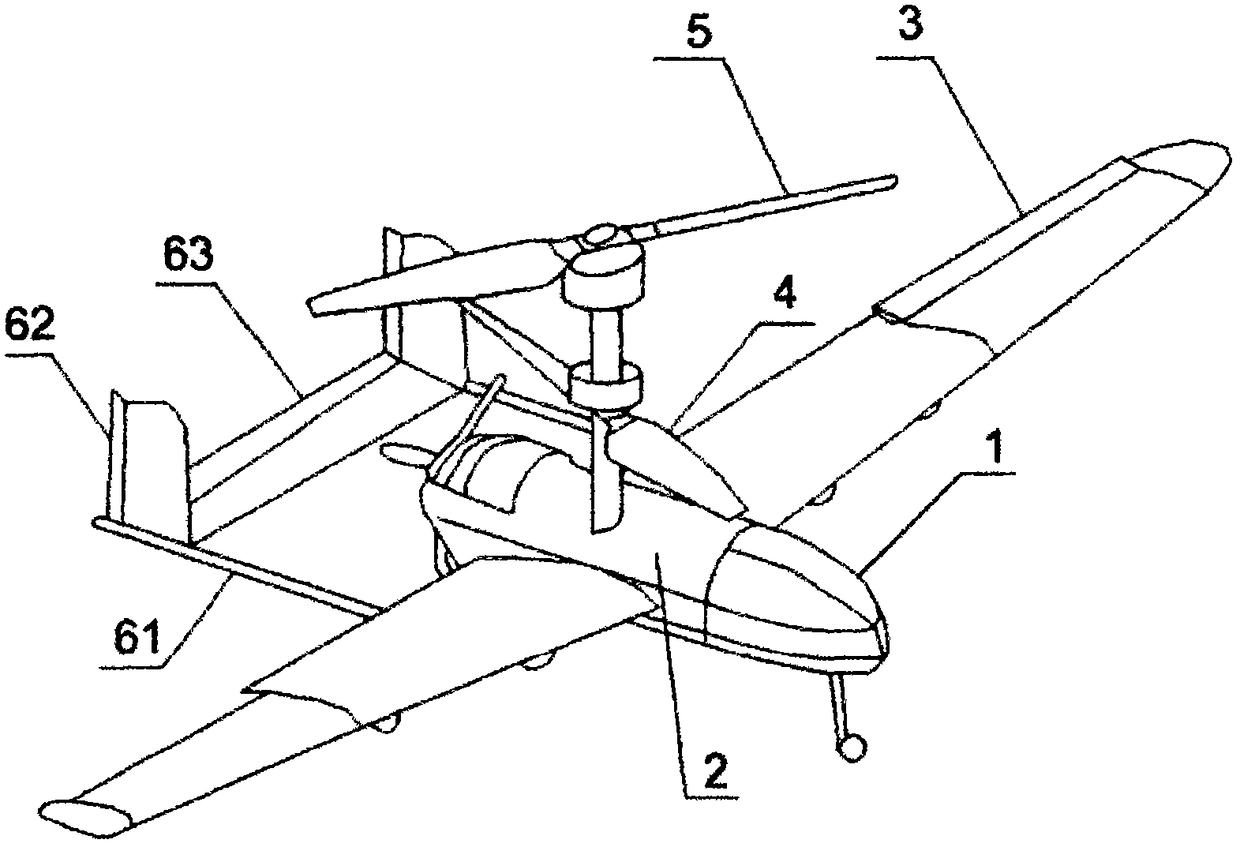

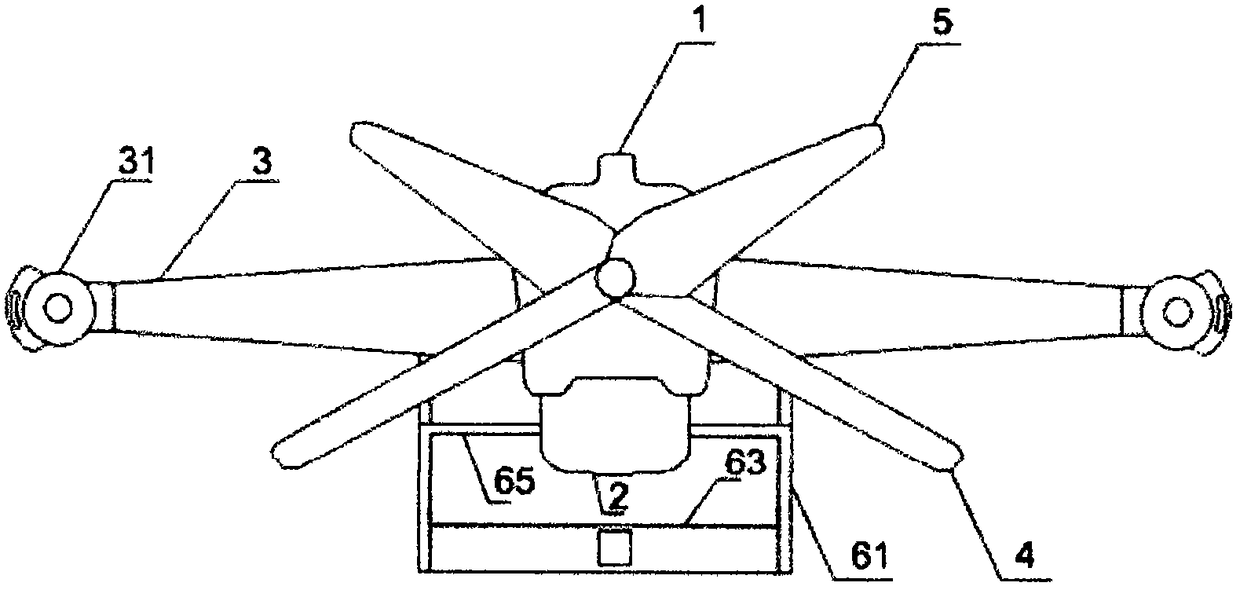

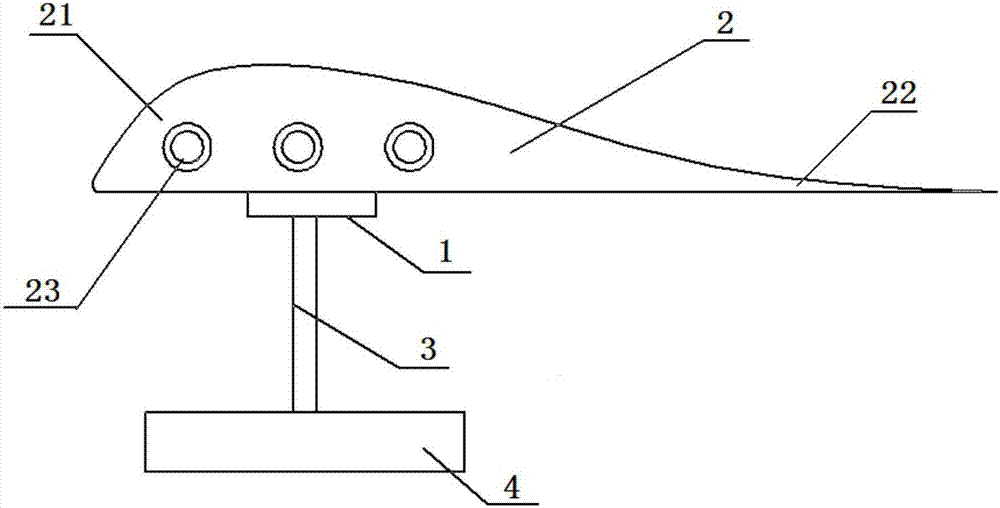

Unmanned aerial vehicle for air route survey of air traffic

InactiveCN108639330AImprove balanceImprove structural strengthCharging stationsAircraft stabilisationElectricityRadar

The invention discloses an unmanned aerial vehicle for air route survey of air traffic. The unmanned aerial vehicle comprises an unmanned aerial vehicle head, an unmanned aerial vehicle body, a pair of side wings, a first balance wing, a second balance wing and a balance tailstock, wherein a radar height sensor, a Beidou positioning sensor, an ultrasonic detector and an infrared detector are arranged in the unmanned aerial vehicle head; a storage battery and a signal match are arranged in the unmanned aerial vehicle body, and an electric quantity detector is arranged below the unmanned aerialvehicle body; an information processor is arranged next to the electric quantity detector, and a command locker is arranged next to the information processor; a signal receiver is arranged below the command locker, and a wireless charging receiver is arranged below the signal receiver; and a positioning camera is arranged next to the wireless charging receiver, and a positioning supporting foot isarranged at the lower end of the unmanned aerial vehicle body. The unmanned aerial vehicle can maintain good stability and balance performance when encountering obstacles, severe weather and other special environments, self-charging can be realized, a locking mechanism is provided, instructions cannot be input from the outside during locking, and the situation of falling caused by the power consumption of the unmanned aerial vehicle when the unmanned aerial vehicle is instructed by the outside can be avoided.

Owner:智飞智能装备科技东台有限公司

A composite additive for coal-fired sulfur-fixing catalytic combustion and its preparation method

A composite additive for coal-burning sulfur-fixing catalytic combustion, which is composed of a main sulfur-fixing agent and an auxiliary additive. The main sulfur-fixing agent is composed of dolomite powder and slaked lime, and the auxiliary additive is one of alumina, cerium oxide, iron oxide and quartz sand. or a combination of two or more in arbitrary proportions; its preparation method is: firstly crush dolomite powder and slaked lime to 80-300 mesh respectively and mix them according to the mass percentage, and then mix the selected auxiliary additives uniformly according to the mass percentage to prepare compound additives. The invention has the advantages of: excellent sulfur fixation effect, catalytic combustion performance and coal-saving performance; the product generated by catalytic combustion contains CaO-Al2O3-SiO2 system substances, which can wrap glassy quartz fragments in fly ash, making the original sharp The edges and corners are reduced, which reduces the wear of the fly ash on the pipeline; the preparation method is simple and easy to implement, and can be widely used in coal-fired fields such as industry, civil boilers, casting, and metallurgical power generation.

Owner:力博(天津)节能环保科技有限公司

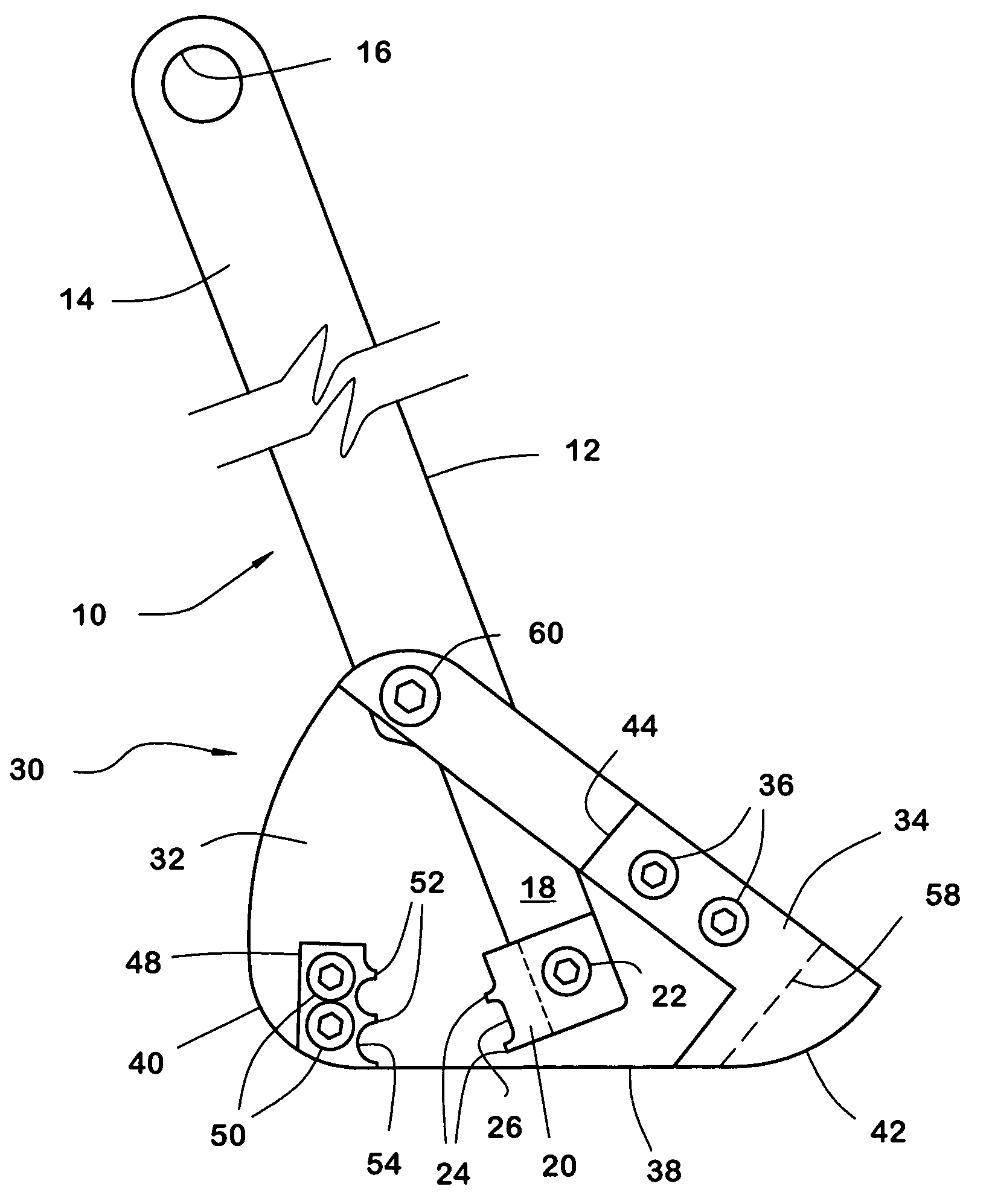

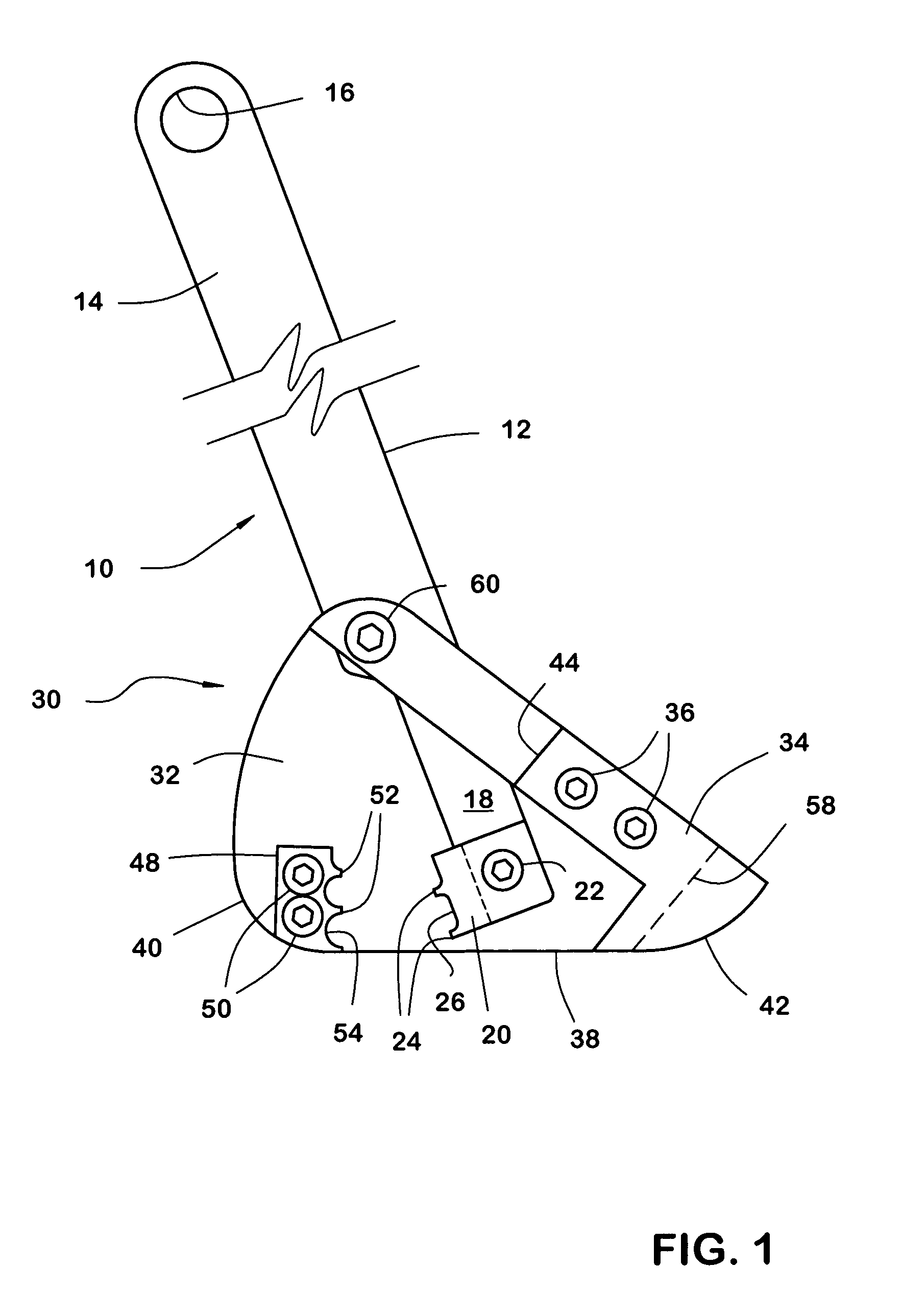

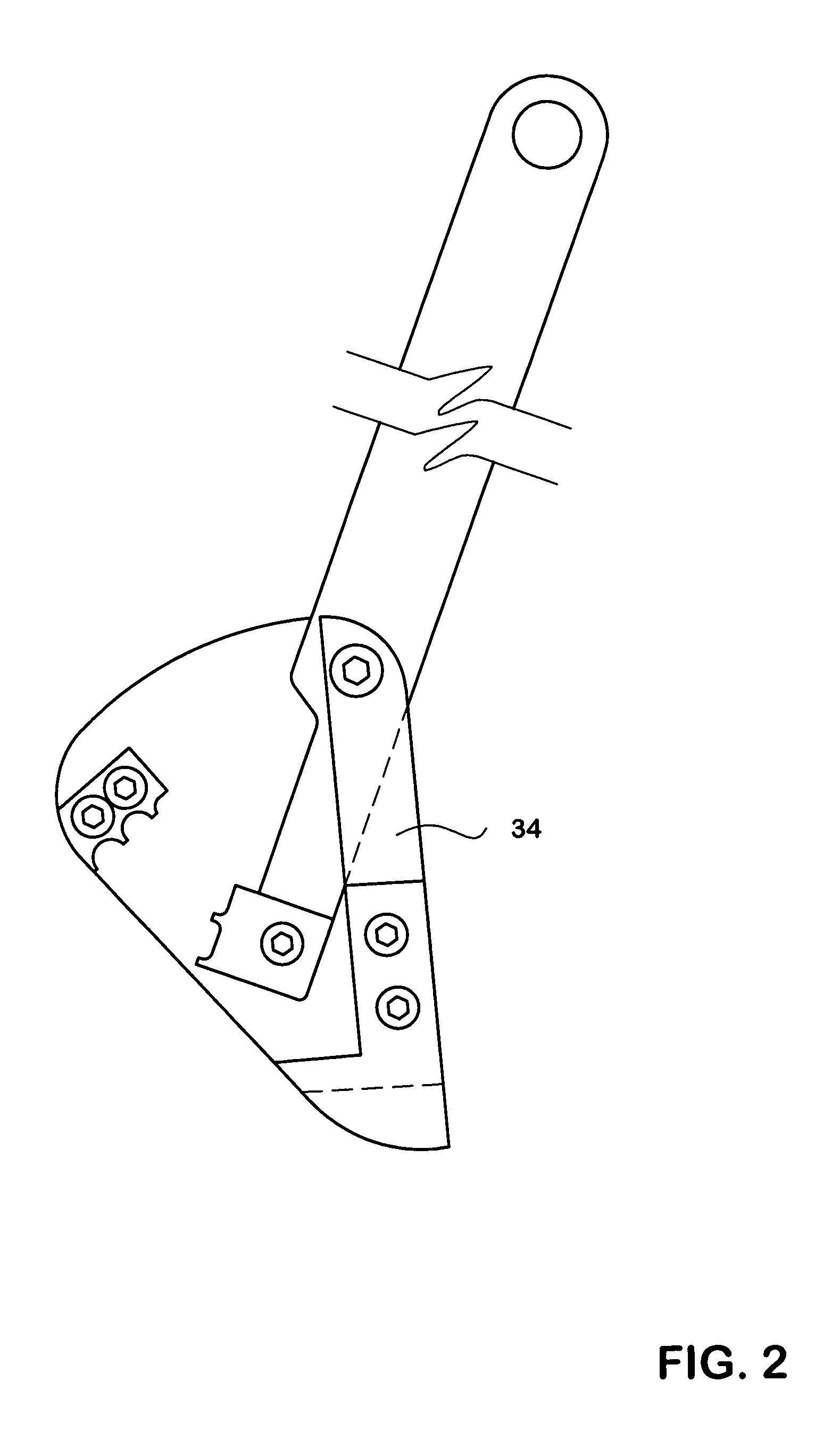

Nail puller

Owner:FORRESTER JOSEPH

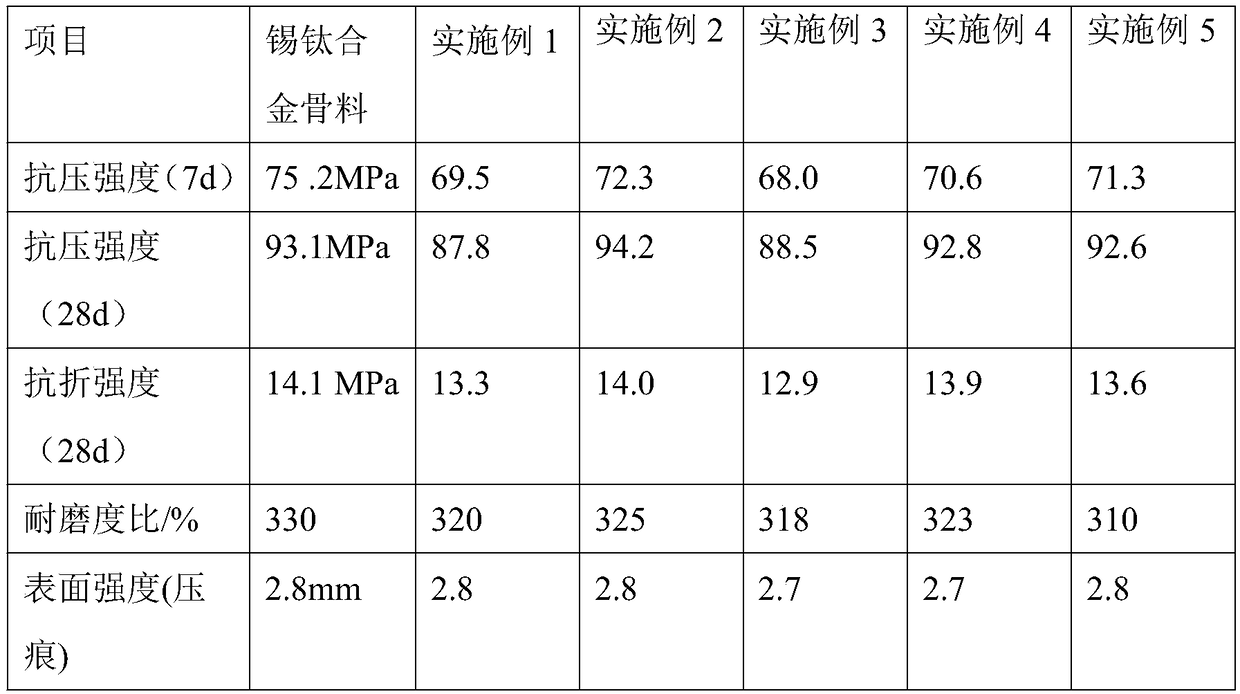

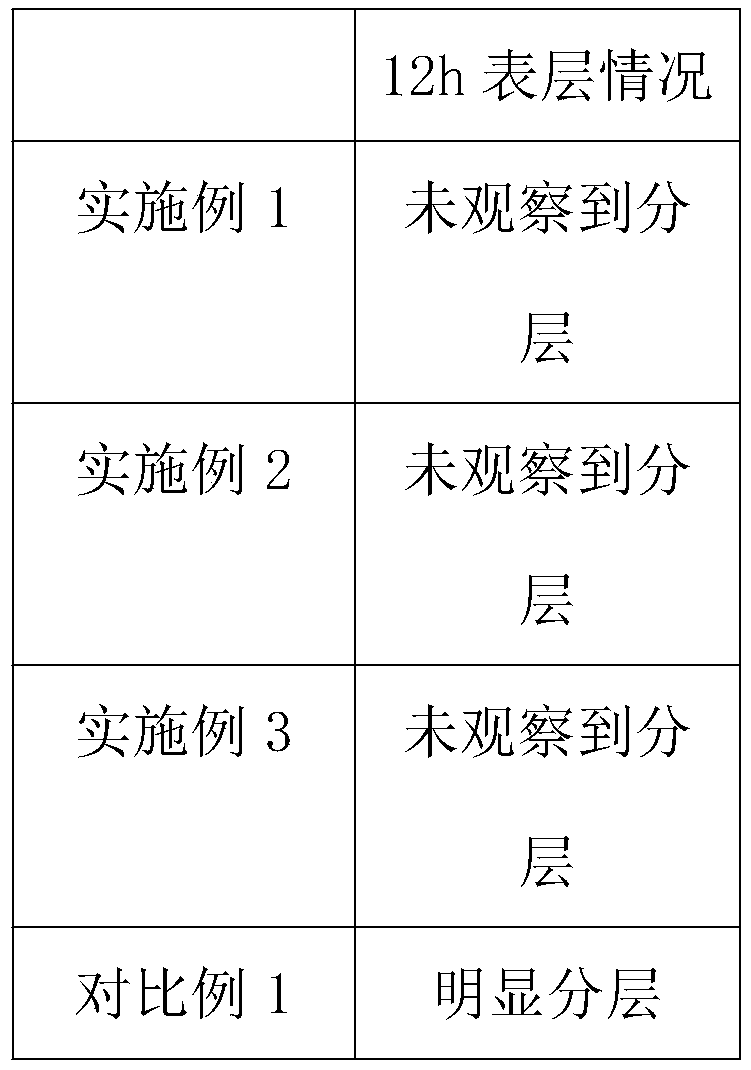

Dry-scattering ground hardening agent and using method thereof

InactiveCN108975809AImprove mechanical propertiesImprove wear resistanceRoads maintainenceAlloyUltimate tensile strength

The invention belongs to the field of concrete ground hardening agents, and particularly discloses a dry-scattering ground hardening agent and an using method thereof. The dry-scattering ground hardening agent is prepared by uniformly mixing the following raw materials in parts by weight: 320 to 350 parts of cement, 15 to 20 parts of silica fume, 750 to 800 parts of copper slag and 4 to 6 parts ofa water reducing agent. The dry-scattering ground hardening agent is prepared by taking copper slag undergoing treatment and grading optimization as aggregate, so that the wear resistance, surface strength, impact resistance and oil resistance of the ground are improved greatly. Meanwhile, the problem of high aggregate cost in the conventional alloy aggregate and metal aggregate dry-scattering ground hardening agents is solved, and a novel way is provided for the efficient recycling utilization of the copper slag.

Owner:成都宏基建材股份有限公司

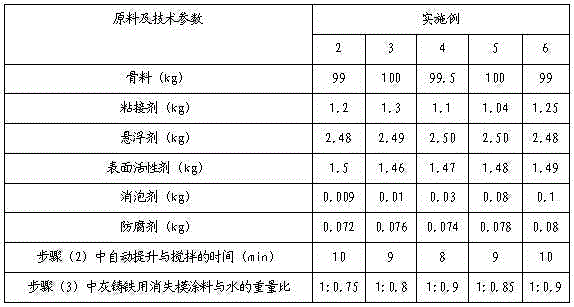

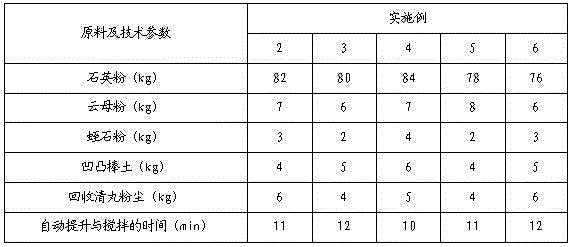

Lost foam casting coating for gray cast iron and preparation method of lost foam casting coating

InactiveCN104624922AVolume phase transition is stableReduce dosageFoundry mouldsFoundry coresDefoaming AgentsActive agent

The invention discloses a lost foam casting coating for gray cast iron and a preparation method of the lost foam casting coating. The lost foam casting coating comprises an aggregate, a binder, a suspending agent, a surfactant, a defoaming agent, water and a preservative, wherein recovered pill-cleaning dust is adopted as one part of the aggregate; the finally prepared coating is good in air permeability; a high-temperature gas can be rapidly and almost invariantly discharged out of a coat when a thick-walled casting is poured; carbon black and blowhole defects are reduced to the minimal extent; in addition, absence of an adhesive sand defect is also ensured; the lost foam casting coating can be mixed evenly by the preparation method disclosed by the invention; and later use is facilitated. The lost foam casting coating is suitable for preparation of the lost foam casting coating.

Owner:SHIJIAZHUANG MANDINGFU CASTING CO LTD

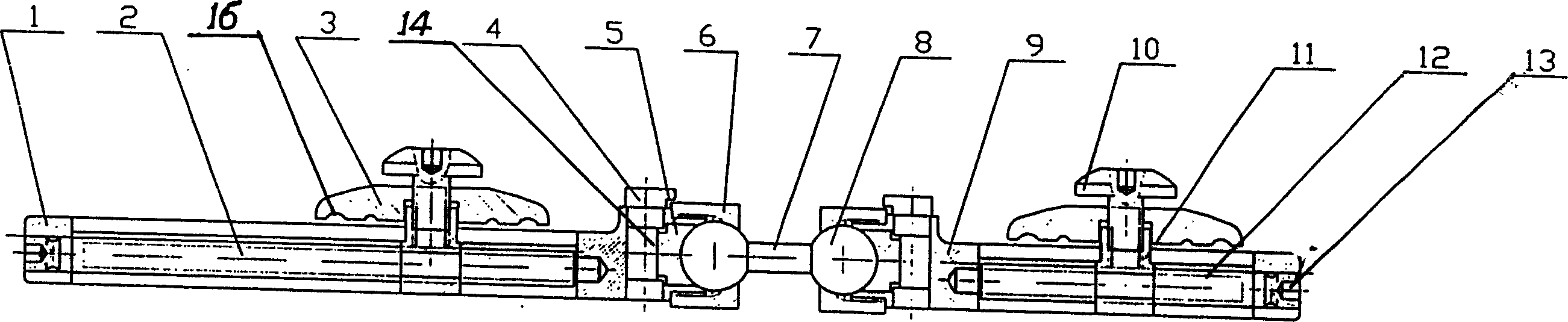

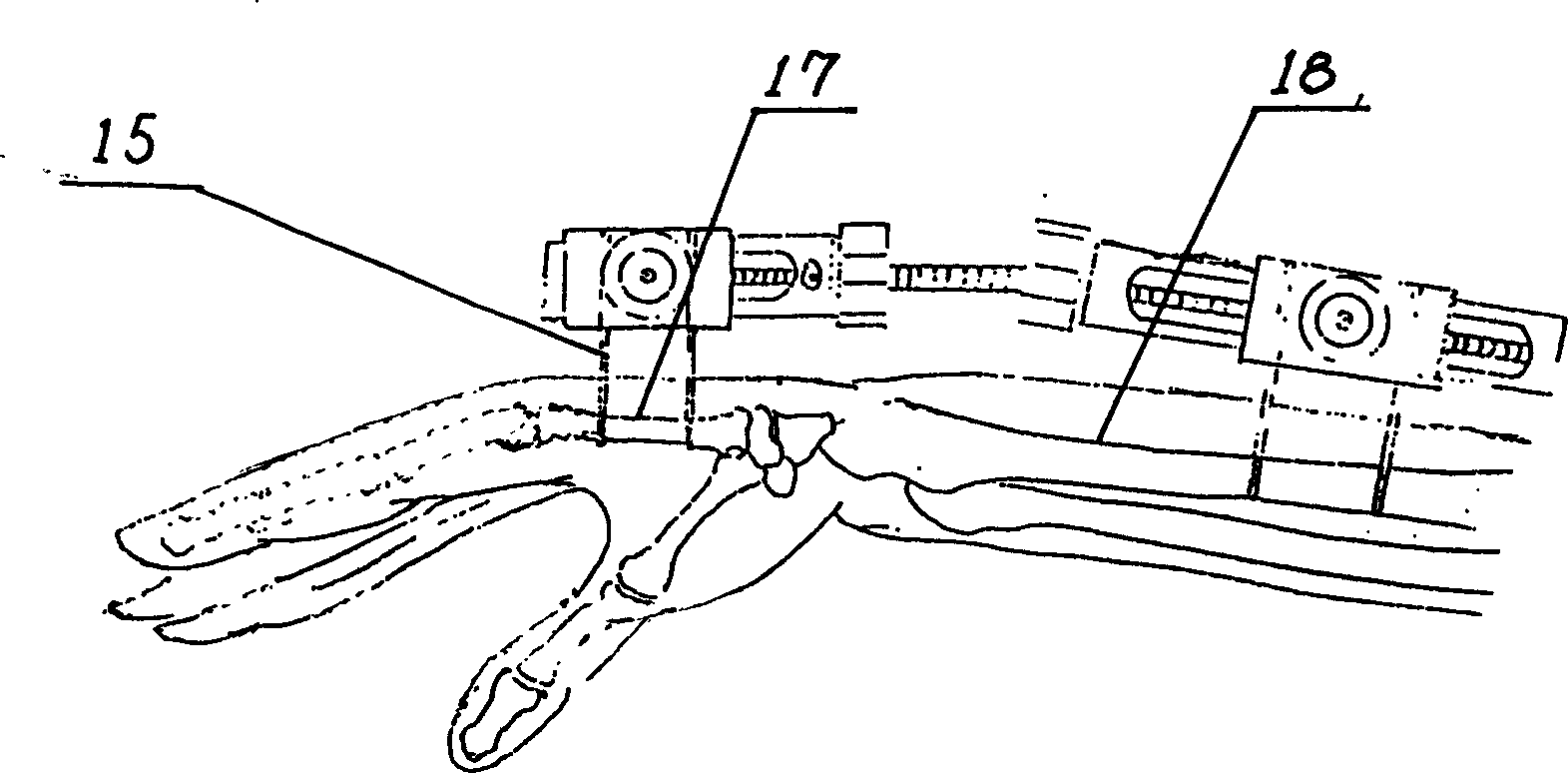

External fixer for radius distal fracture

The invention relates an external fixator for treating radius far-end bone fracture, wherein ball-shaped cushions are arranged on the bulb structure connected with the long and short fixed bar, eccentric pins are arranged on the long and short fixed bar, thus forming the locking arrangement for the bulb structure, a long screw bolt and a short screw bolt are arranged in the hollow space of the long and short fixed bars, the slide blocks thereon are connected with the fixed blocks on the long and short fixed bars, the surface on the fixed blocks contacting the long and short fixed bars are provided with screw-threaded securing slot, thus accomplishing the action of treating radius far-end bone fracture.

Owner:NANJING DRUM TOWER HOSPITAL

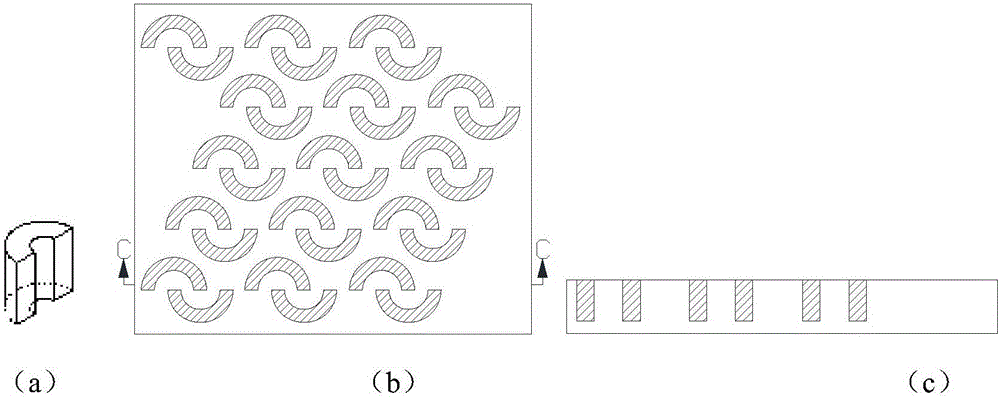

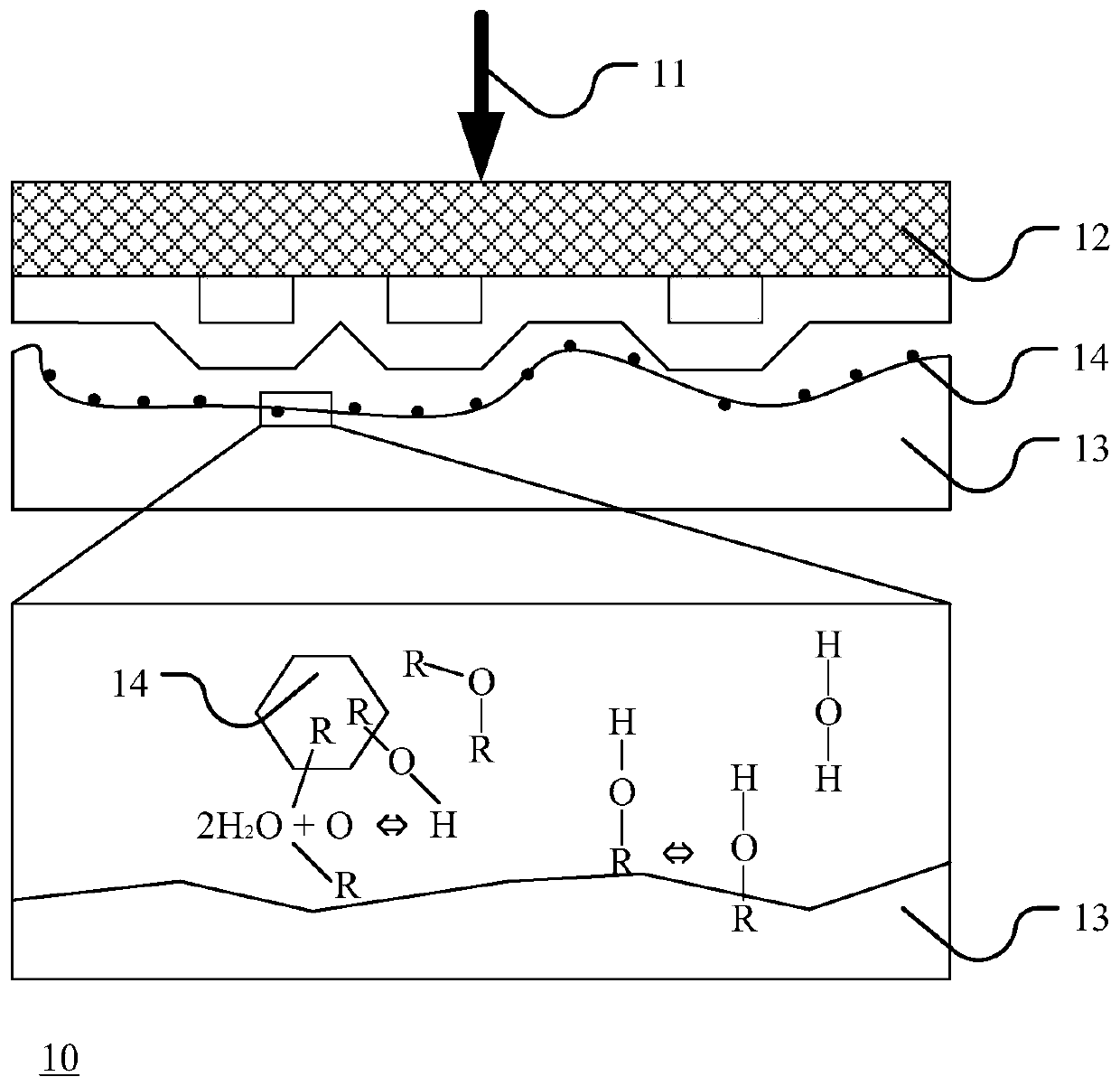

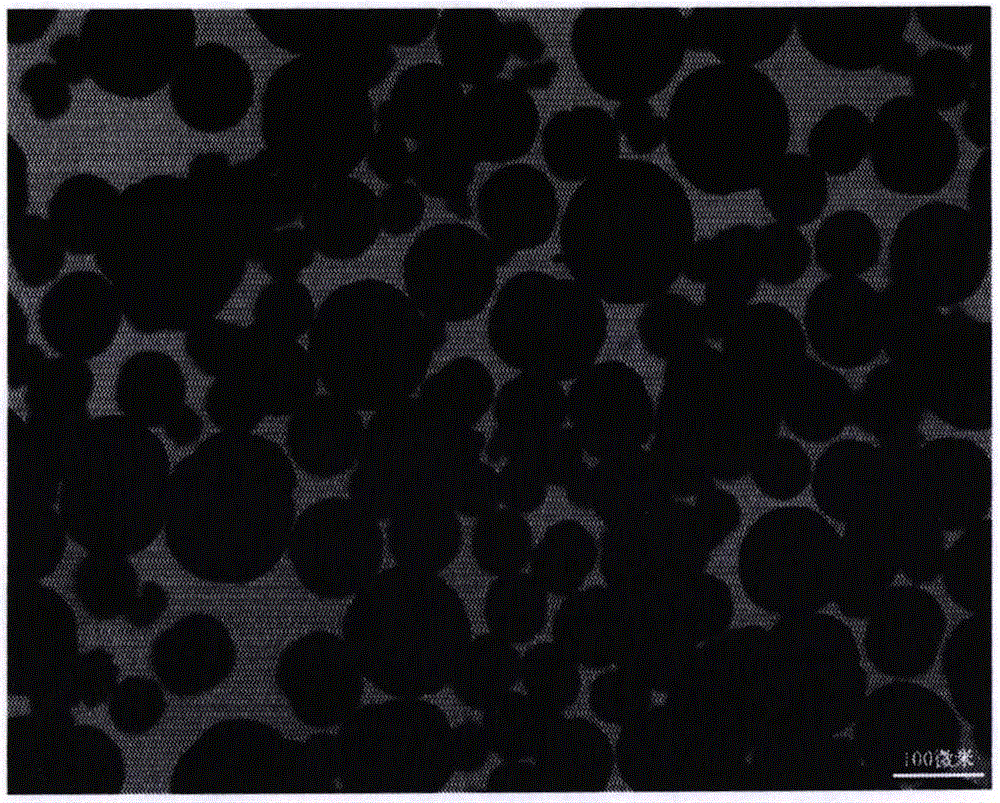

Polishing particle and method for manufacturing same, and polishing agent

PendingCN111500258AReduce edges and cornersReduce scratchesOther chemical processesPorous carbonMicrosphere

The present invention relates to a polishing particle and a method for manufacturing the same. The polishing particle comprises: a core, which is an elastic core having a spherical structure and elastically deforms under pressure; and a first core shell, which wraps the core, is a grinding layer and is used for grinding a target material, wherein the first core shell has a mesoporous structure. The grinding particle provided by invention is of a microsphere structure composed of the porous carbon core and the cerium oxide first core shell, and the porous carbon core can be elastically deformedunder pressure, so the risk of scratching the surface of a semiconductor due to irregular surface of the polishing particle can be reduced; and in addition, the first core shell is of the mesoporousstructure, so the toughness of the polishing particle can be improved, and the breakage rate of the polishing particle in use can be reduced.

Owner:YANGTZE MEMORY TECH CO LTD

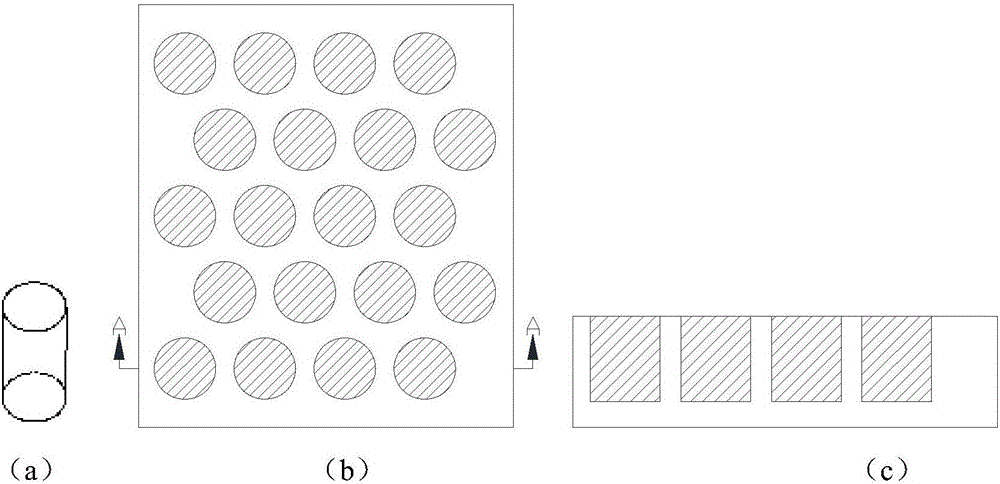

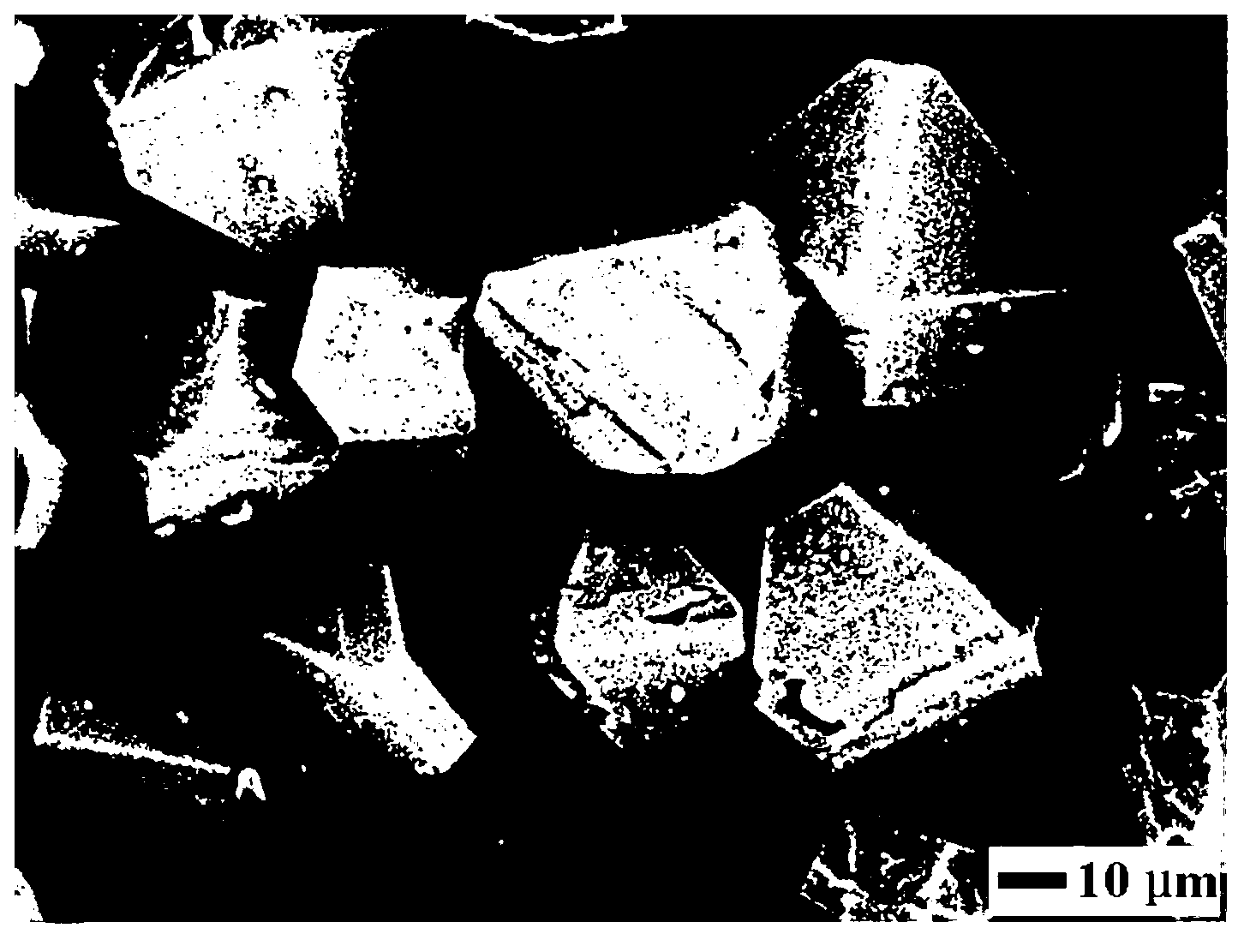

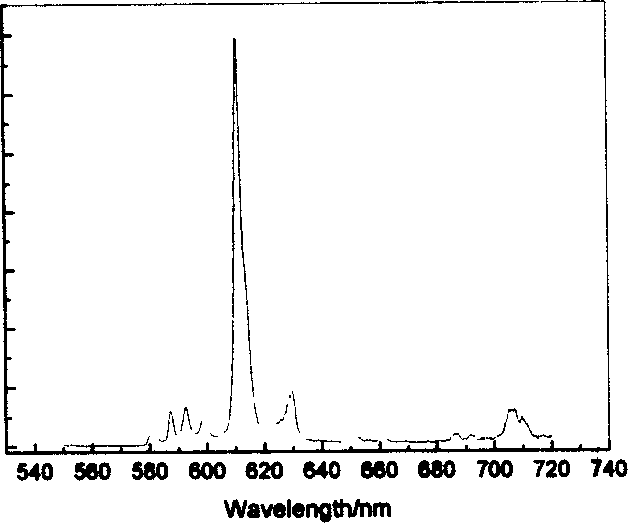

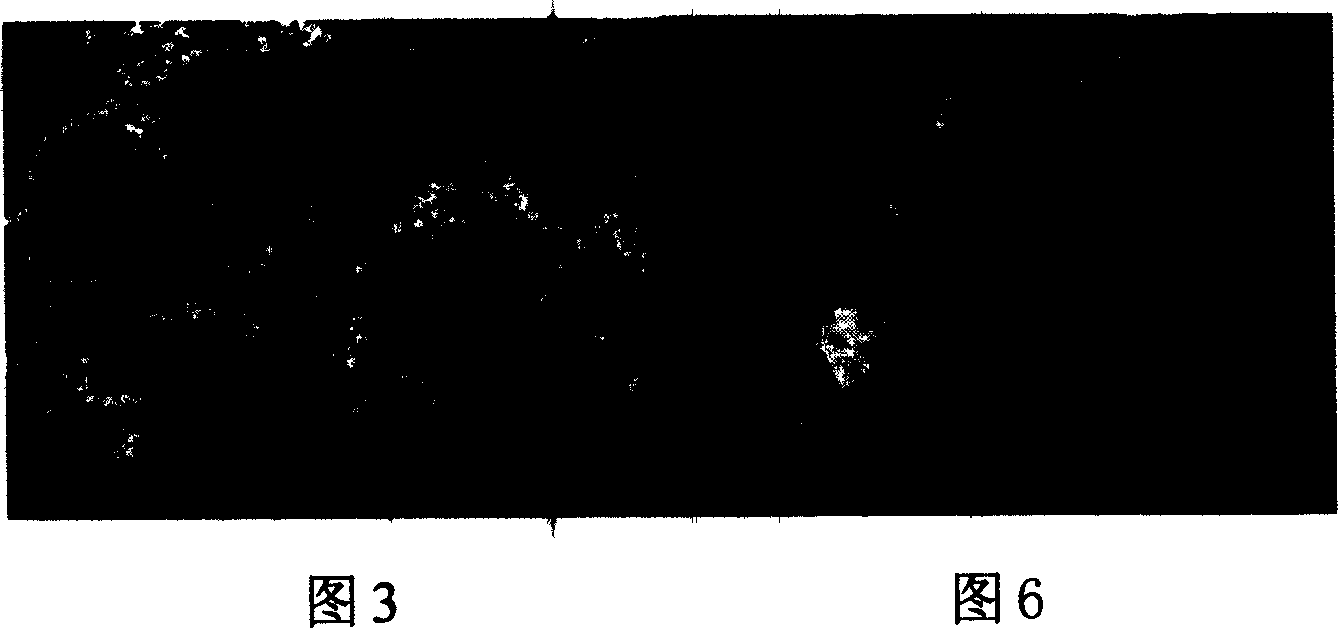

Method for spheroidizing hexanitrohexaazaisowurtzitane (HNIW) explosive

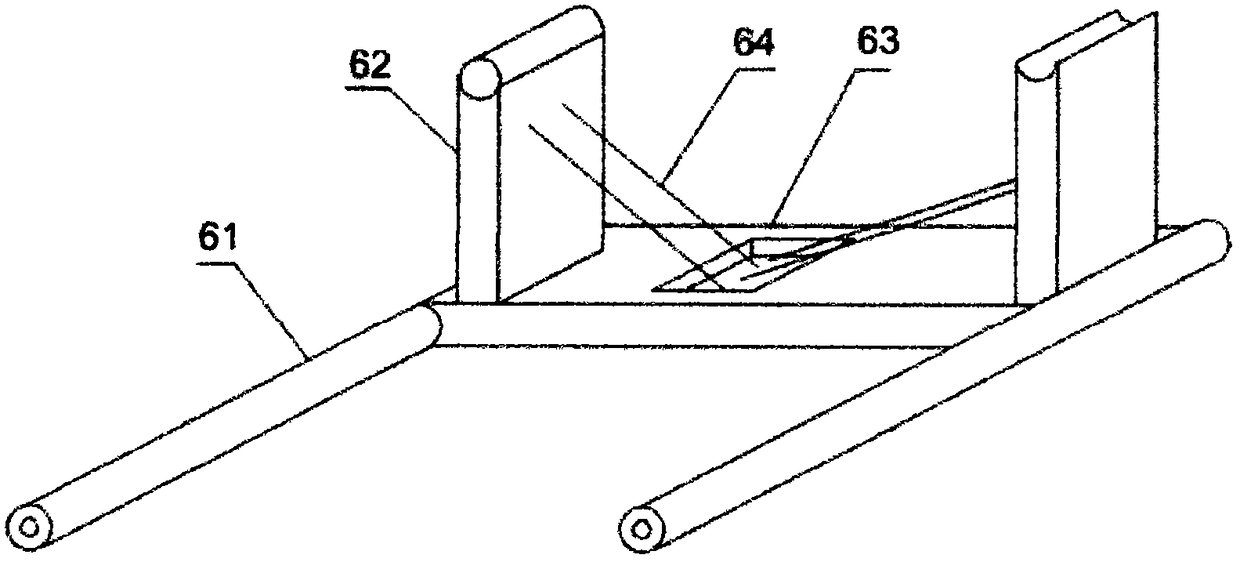

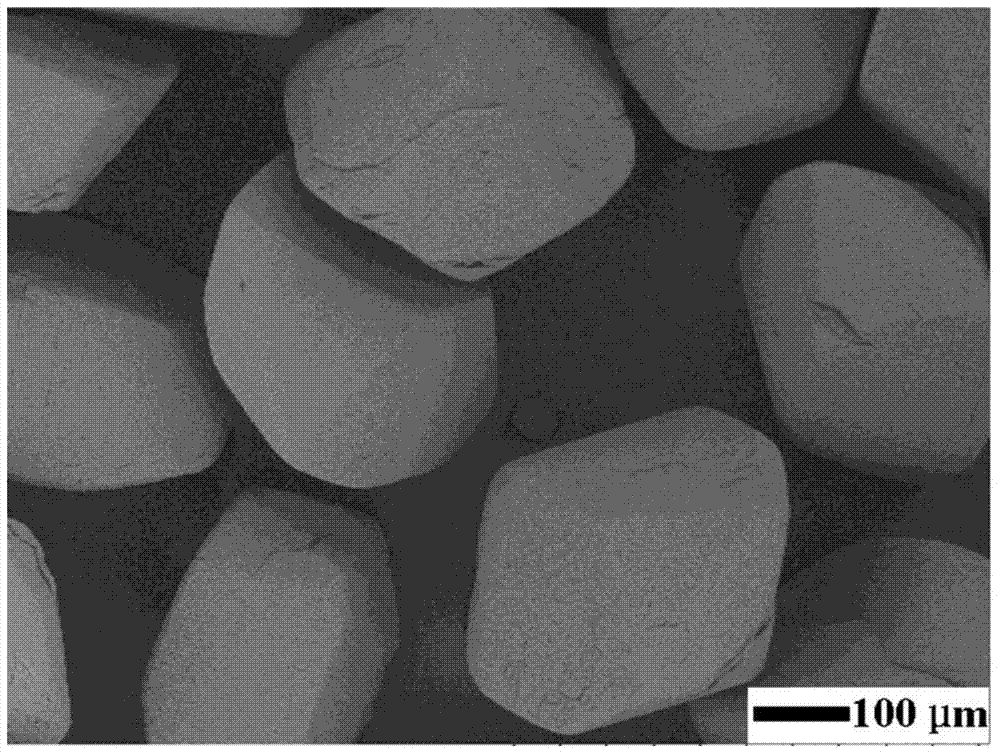

ActiveCN103497070AHigh degree of spherificationSuitable for industrial mass productionExplosive working-up apparatusPrillVolumetric Mass Density

The invention discloses a method for spheroidizing a hexanitrohexaazaisowurtzitane (HNIW) explosive. The method comprises the following steps: I. adding explosive crystals into an etching liquid, heating to a certain temperature, mechanically agitating for certain time, and then filtering and washing the explosive; II. adding the explosive in the step I. into a surface polishing solvent, mechanically agitating at normal temperature, then filtering and washing materials, and drying to obtain the spherodized explosive crystals. The method is applicable to spheroidization of CL-20 crystals with various particle size and various crystal forms, is simple in technological flow, mild in reaction conditions, good in reproductivity, high in yield, and applicable to industrial batch production; the prepared spheroidized CL-20 explosive crystal product is approximately spherical, has less edges and smooth surfaces; the internal defects of the particle crystals are fewer, the open-setting stacking density is high, and the mechanical sensitivity is obviously reduced.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

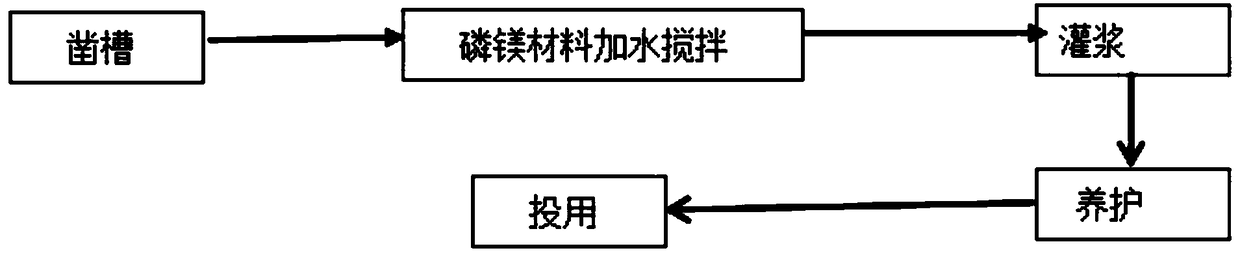

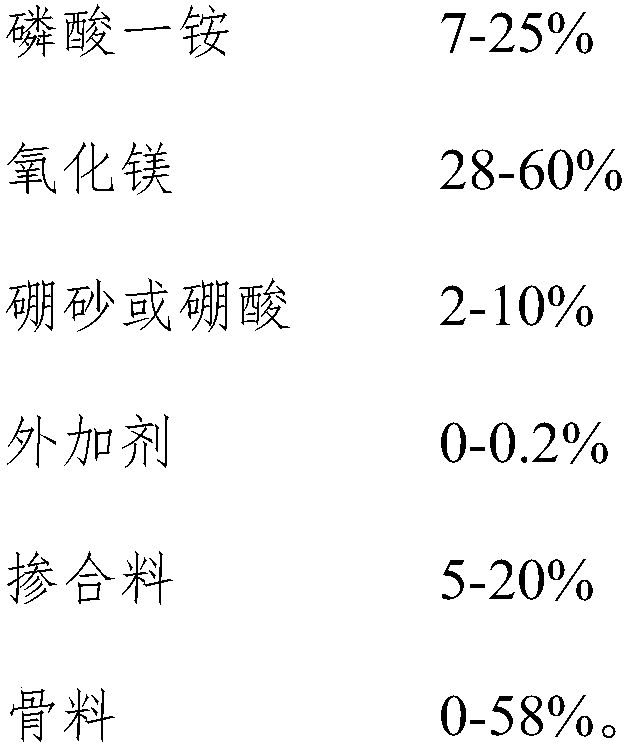

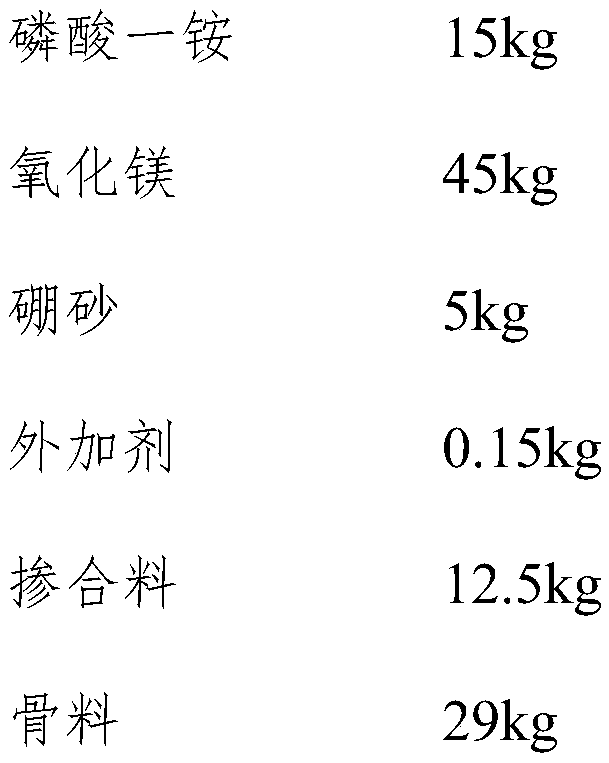

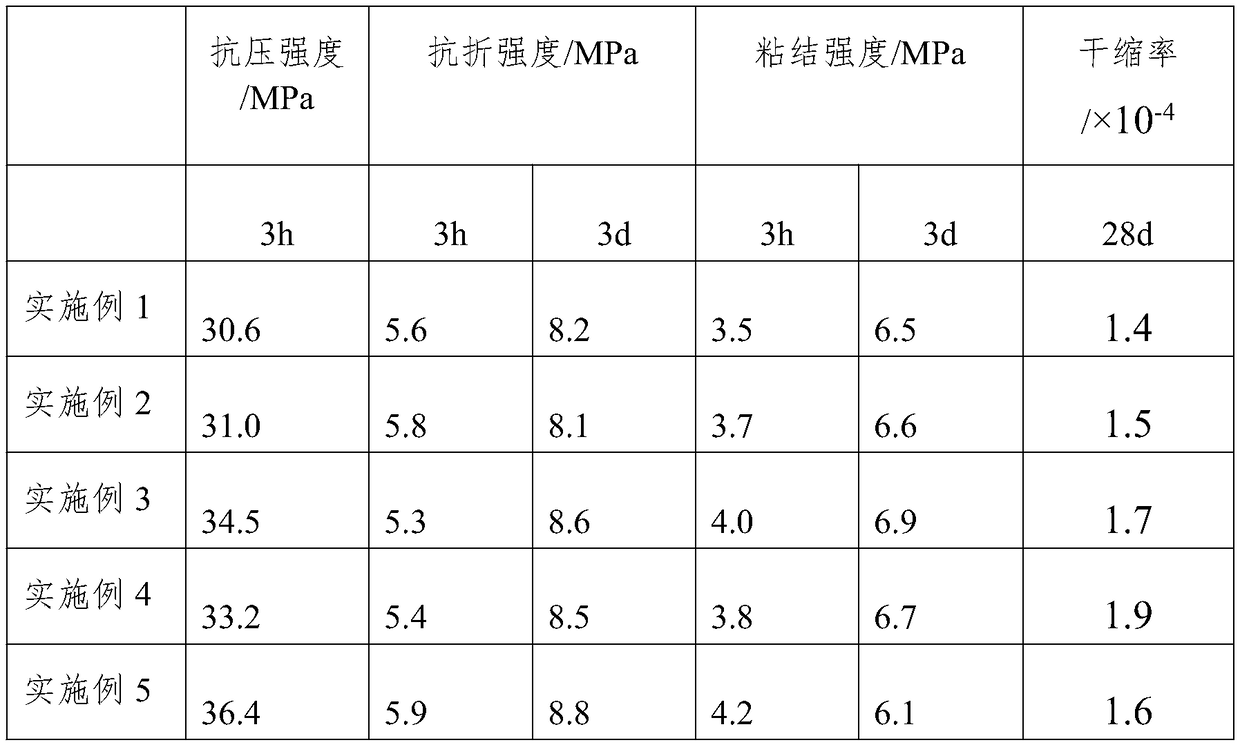

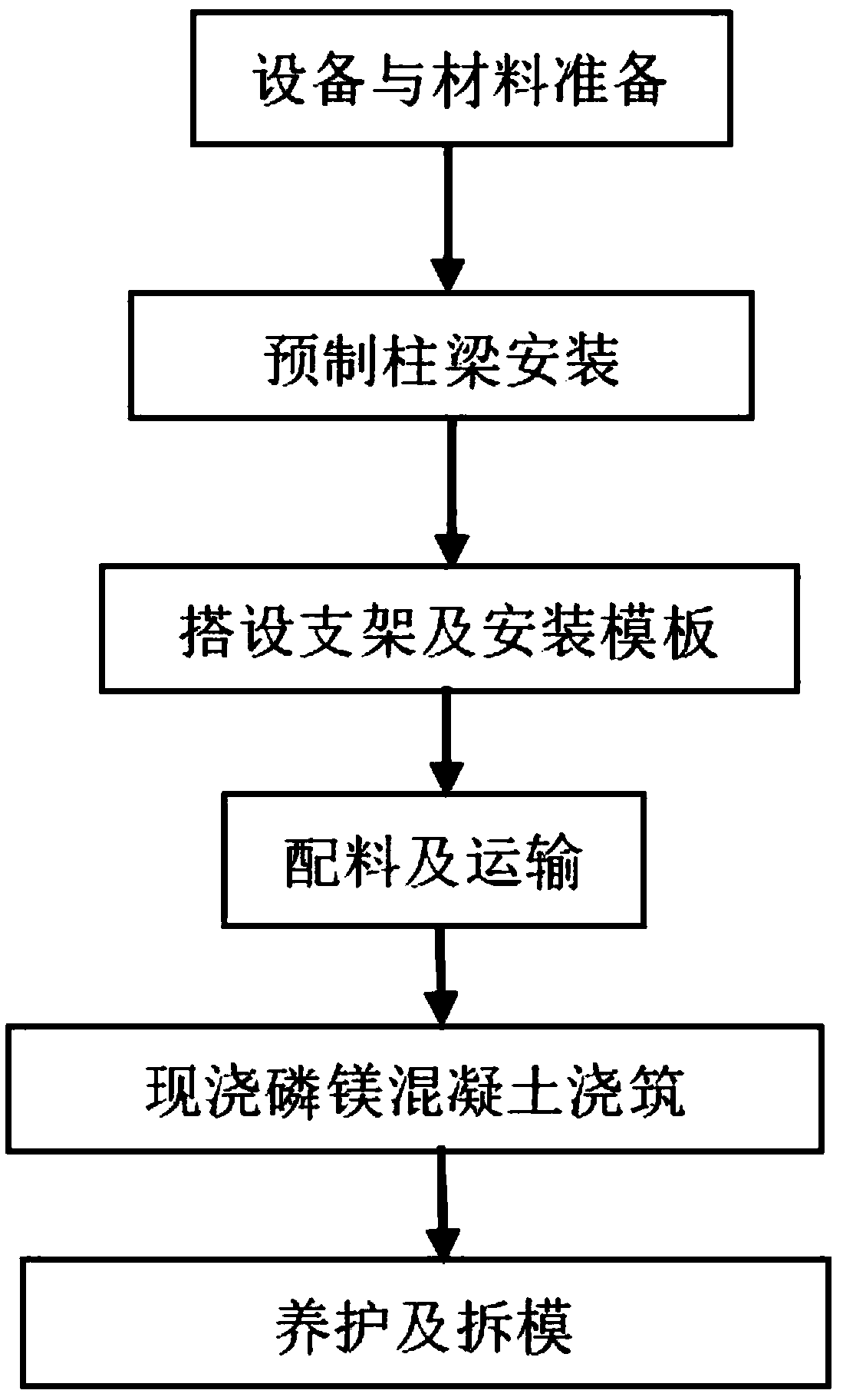

Concrete crack repairing material based on phosphorus magnesium material and construction technology thereof

The invention relates to the technical field of the concrete repair and in particular to a concrete crack repairing material based on a phosphorus magnesium material and a construction technology thereof. The concrete crack repairing material based on the phosphorus magnesium material is obtained by mixing monoammonium phosphate, magnesium oxide, borax or boric acid, an additive, an admixture andaggregate according to a specific proportion, and in a repairing process of a concrete crack, interface treatment does not need to be performed. The prepared concrete crack repairing material based onthe phosphorus magnesium material has the characteristics of short coagulation time, high compressive strength in early stage, high breaking strength, high bonding strength, low dry shrinkage rate, good durability, high abrasive resistance and the like, and is capable of solving problems in the prior art that cost is high, ageing is easy and service life is short, the material is harmful to a human body in a construction process, the construction technology is complicated, the bonding strength of a bonding surface of old and new materials is low, integrality of a repairing structure is weak,longer maintenance time is needed and the like.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

Processing method of concrete holes or exposed bars

The invention relates to the technical field of concrete, and particularly relates to a processing method of concrete holes or exposed bars. The method comprises the following steps: chipping away unqualified concrete; cleaning a surface; erecting a template; stirring; pouring; performing conservation; dismantling the template; and putting into use. The method disclosed by the invention has the characteristics of convenience in operation, low cost, short construction working periods and good construction effect. Processing is carried out by adopting the method, so that the concrete applied toa restoration part has the characteristics that (1) a dry shrinkage ratio is low, even the concrete is expanded a little, and the phenomena of shrinkage and cracking are avoided, so that the durability of a concrete structure is ensured; (2) the condensation time is short, the early compressive strength is high, and the concrete structure is in a service state in time; and (3) the folding strengthand the bonding strength are high, and the adaptability of an environment of concrete components is improved.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

Multistage type mechanical arm protection case

InactiveCN107671895AExtended service lifeStable working environmentManipulatorFiltrationAgricultural engineering

The invention discloses a multistage type mechanical arm protection case, which comprises a case body, hanging rings, a filter layer and a fixing block. A protection sleeve is arranged on the bottom part of the case body; a bolt is fixedly connected above the protection sleeve; a waterproof layer is connected into a shock absorption cavity; rubber strips are fixedly arranged above the waterproof layer; the case body is fixedly connected above the hanging rings; the upper parts of the hanging rings are connected with pothooks through pull ropes; a mechanical arm placing hole is formed in the middle of the rubber strips; the case body is arranged above damping springs; through holes are fixed to the upper side and the lower side of the filter layer; protection layers are arranged on the leftside and the right side of the filter layer; a protection sleeve is arranged under the fixing block; and a bolt is connected above the fixing block. The multistage type mechanical arm protection caseis provided with the shock absorption cavity, so that a machine can not be affected by an external factor during a working process, meanwhile, a mechanical arm can be well protected, and the servicelife of the whole mechanical arm is prolonged.

Owner:刘和勇

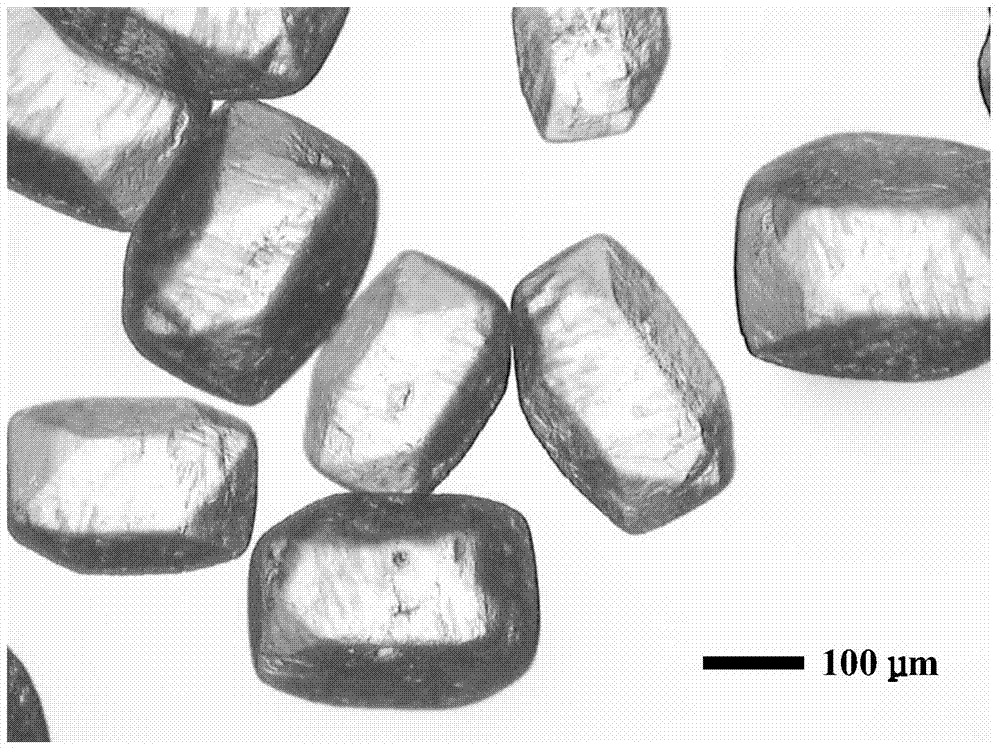

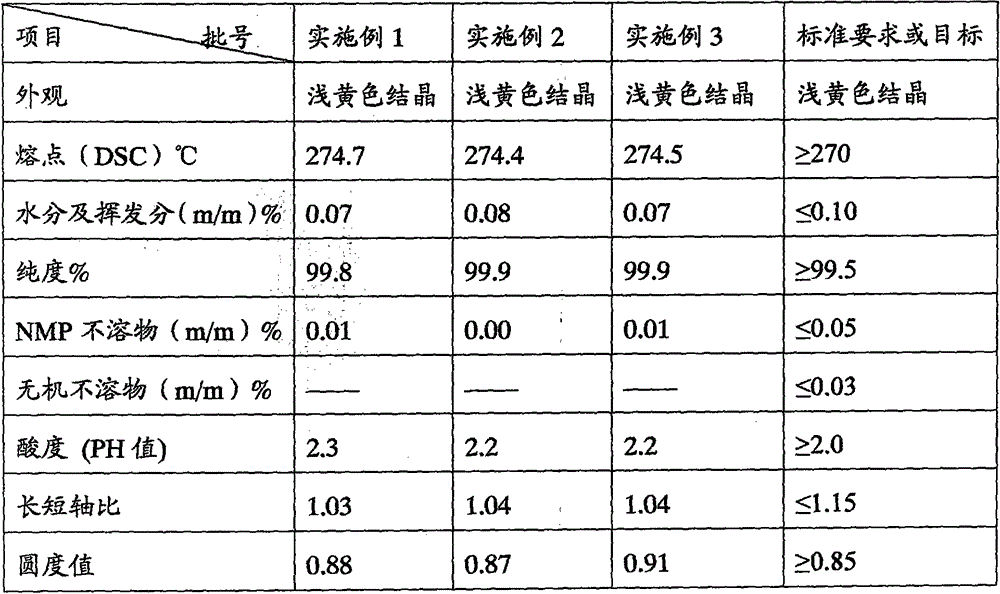

Method for preparing special 3-nitro-1,2,4-triazole-5-ketone

The invention discloses a method for preparing special 3-nitro-1,2,4-triazole-5-ketone. The method comprises the following steps: providing a 3-nitro-1,2,4-triazole-5-ketone solution; and cooling the 3-nitro-1,2,4-triazole-5-ketone solution with a cooling medium and crystallizing to obtain the special 3-nitro-1,2,4-triazole-5-ketone. According to the provided method, a recrystallization technology is employed for increasing crystal density of a single-compound explosive, reducing internal defect of the crystal, and eliminating surface defects, so that the surface is smooth and dense, crystal shape and granularity can be controlled, quality of the single-compound explosive is enhanced, and moulding performance can be satisfied.

Owner:SHANXI BEIHUA GUANLYU CHEM IND

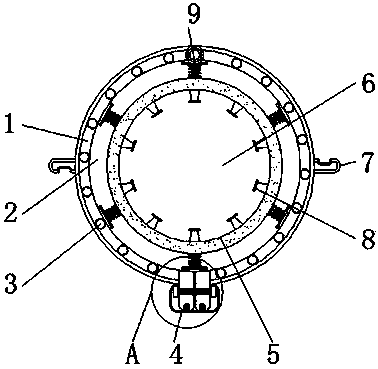

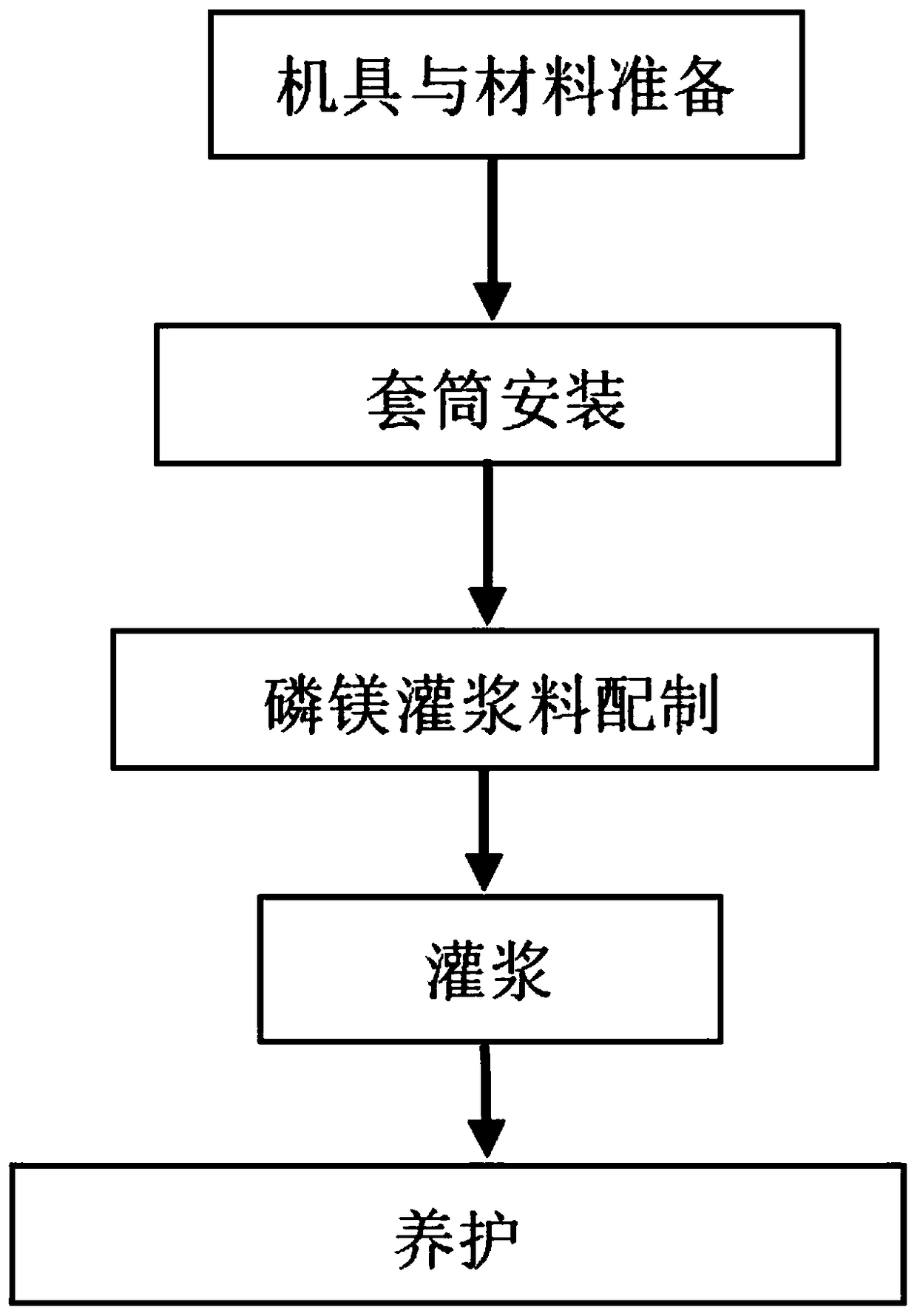

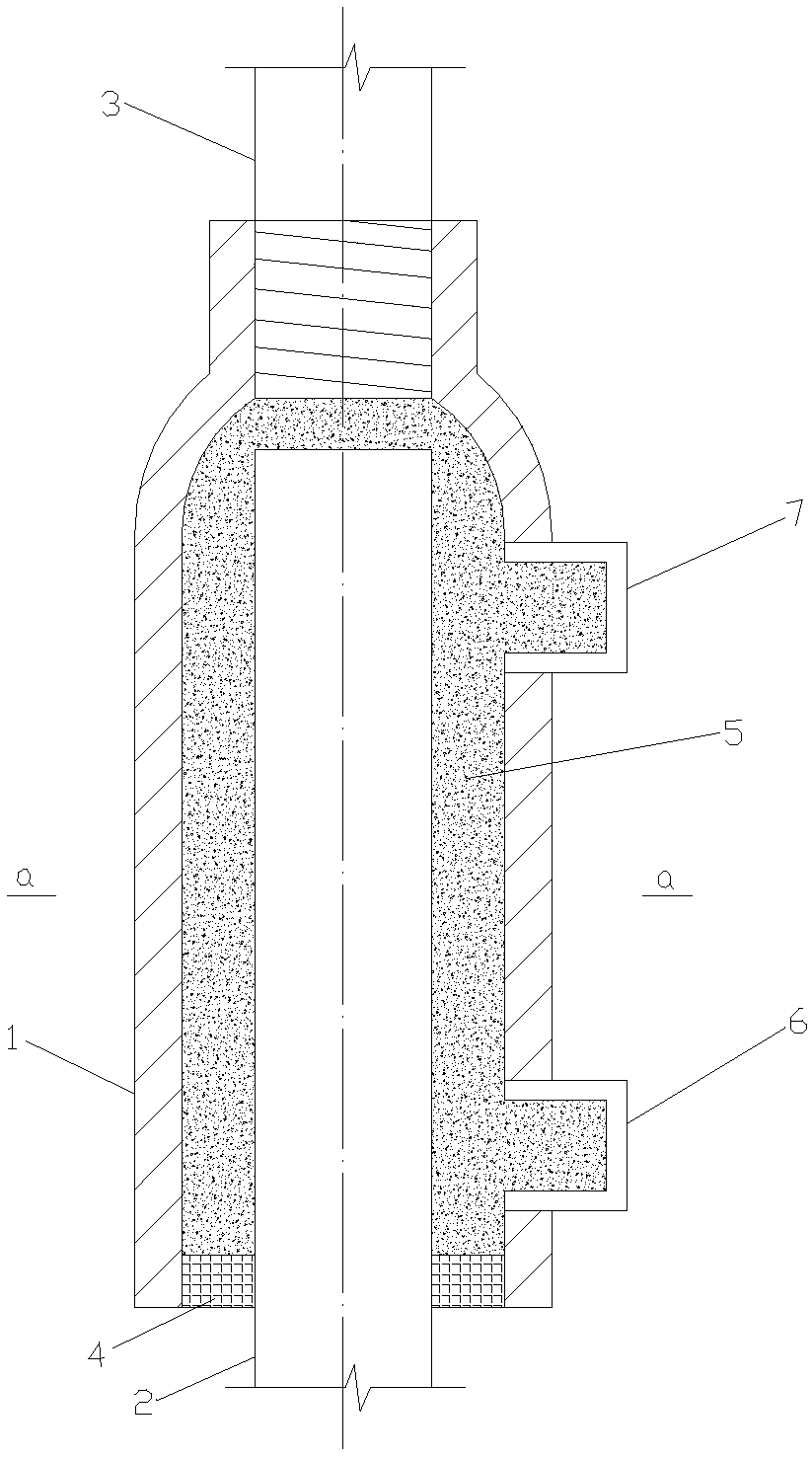

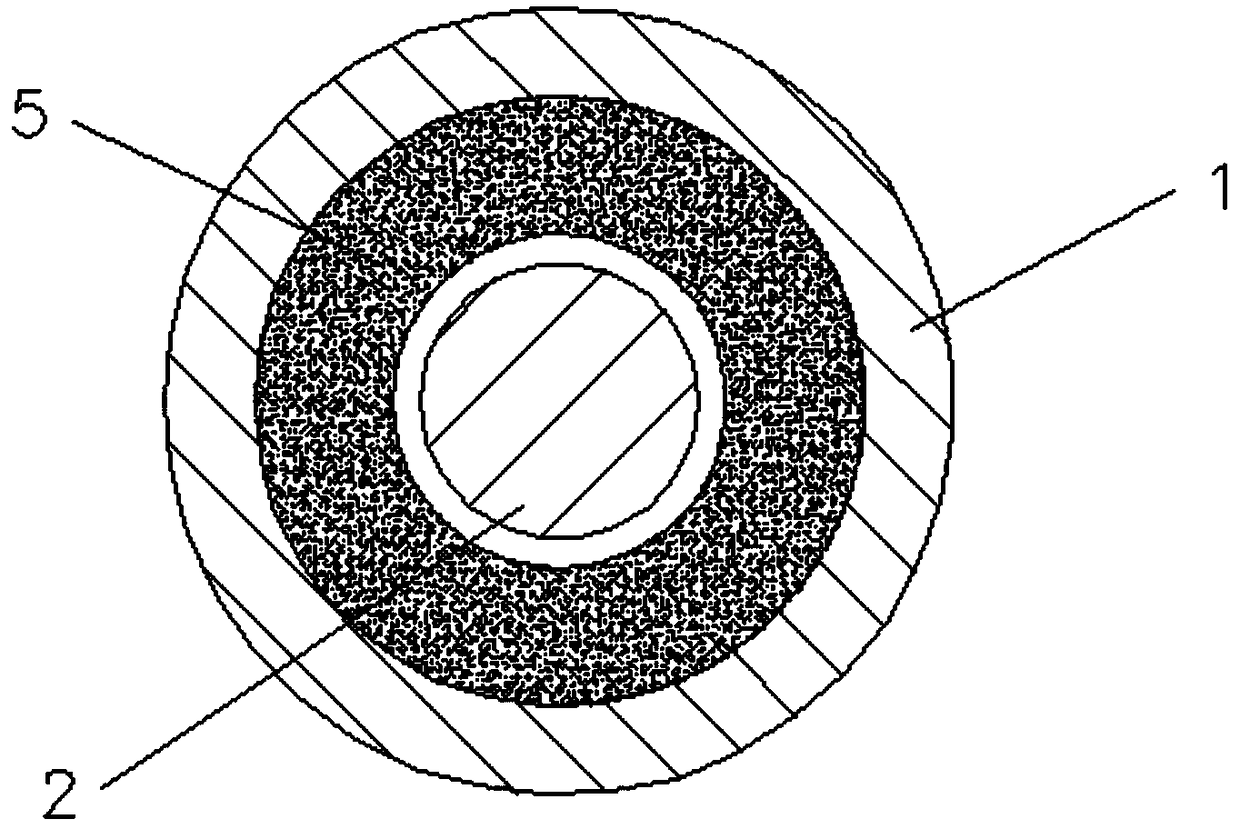

Fabricated building sleeve connecting grouting material based on phosphorus and magnesium materials and construction method of grouting material

InactiveCN108947463AHigh strengthControllable solidification timeBuilding reinforcementsFreeze thawingMagnesium phosphate

The invention discloses a fabricated building sleeve connecting grouting material based on phosphorus and magnesium materials and a construction method of the grouting material. The grouting materialis prepared from the following raw materials in parts by weight: 80-120 parts of magnesium phosphate cement, 3-16 parts of an additive, 10-25 parts of an admixture and 0-130 parts of aggregates. The phosphorus-magnesium grouting material has good corrosion resistance and freeze thawing resistance, good durability and fluidity, low contractibility, good steel adhesion, strong self-compaction property and environment temperature adaptability, is easy for pouring and can be used for construction at any time; an oxide film can be formed on the surface of the grouting material, has very good associativity and high bonding strength and has good attachment property with sleeves and steel bars; the grouting material can be mixed on site and convenient to construct, the construction procedure is simplified, the grouting material can be condensed and hardened after 10-30 minutes of the grouting, the compressive strength of the phosphorus-magnesium grouting material can reach over 40MPa after 1.5hours of the grouting, and the phosphorus-magnesium grouting material basically does not need to be maintained, so that the construction efficiency is improved, the construction period is greatly shortened, and the cost is saved.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

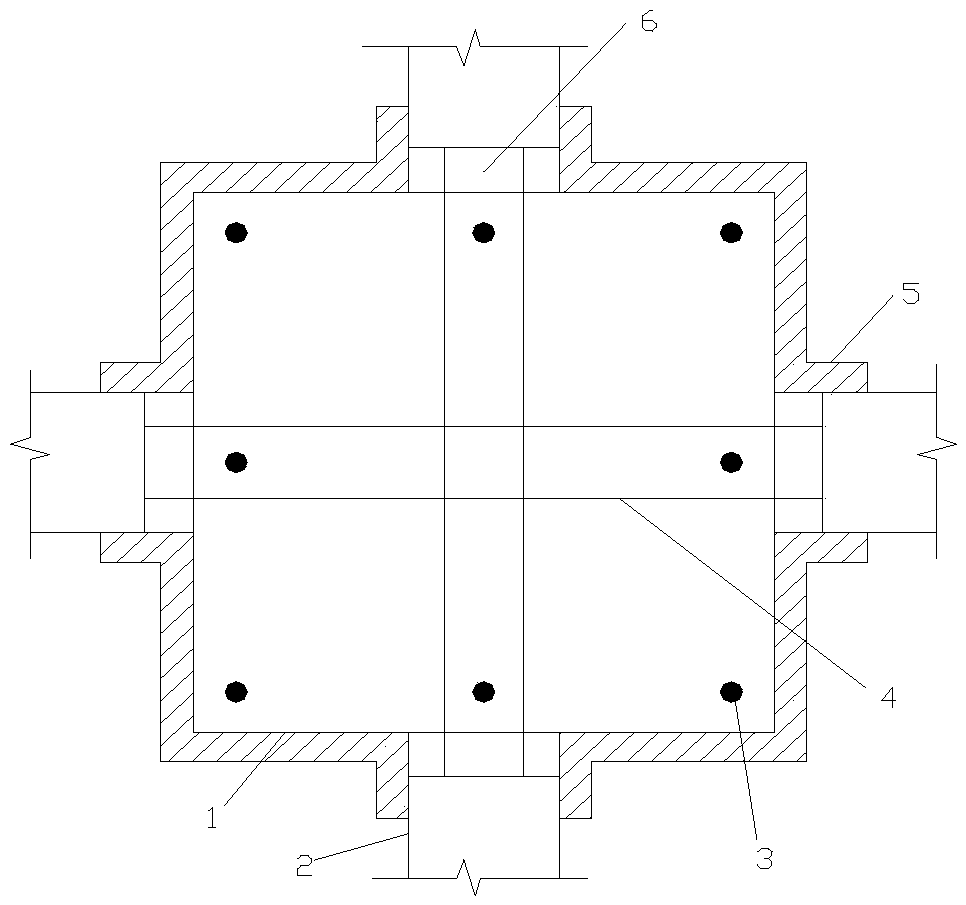

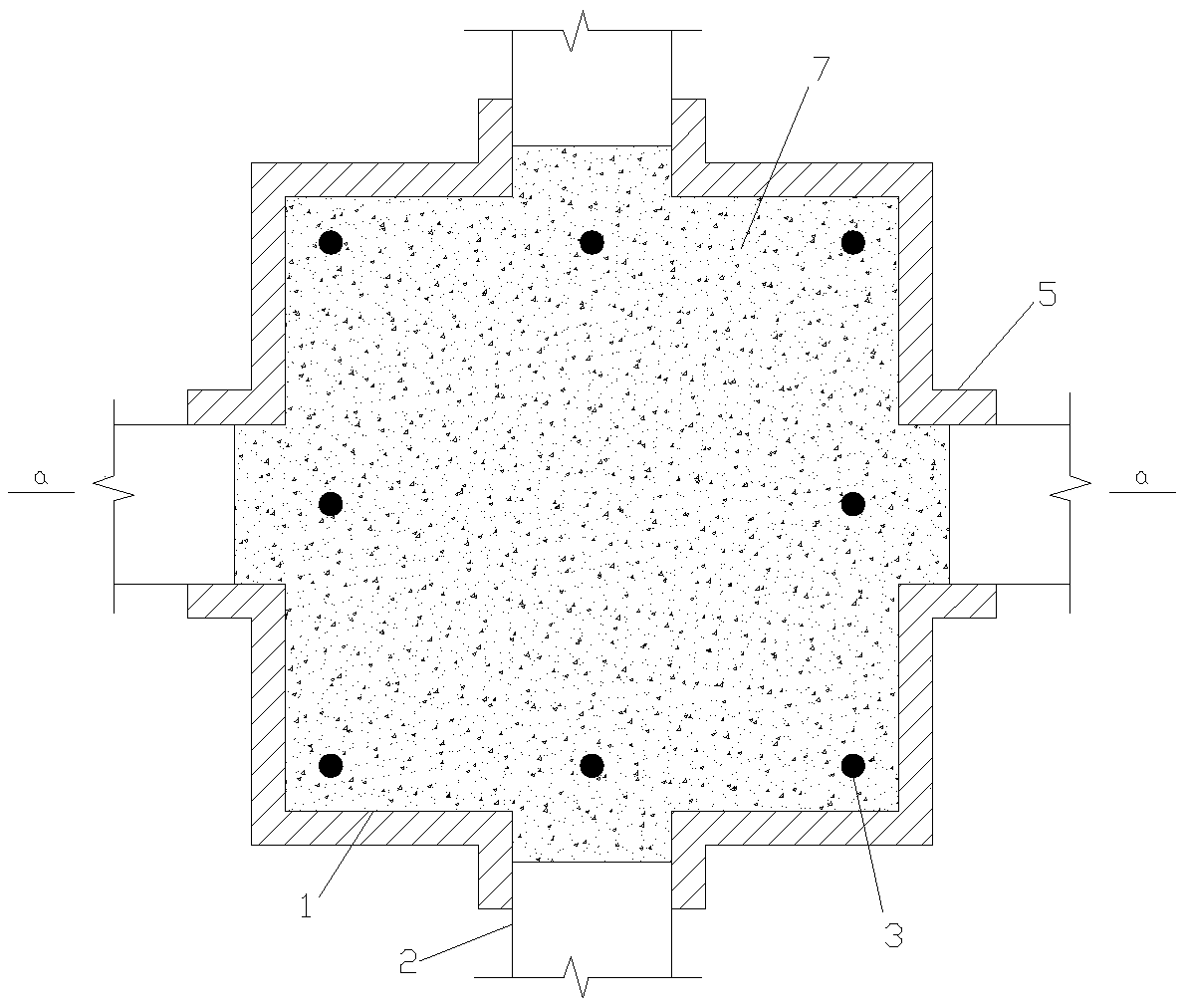

Phosphorus and magnesium material based cast-in-place phosphorus magnesium concrete of precast pillar joint and construction method

InactiveCN108751926AHigh strengthControllable solidification timeBuilding constructionsMagnesium phosphateMagnesium orthophosphate

The invention discloses a phosphorus and magnesium material based cast-in-place phosphorus magnesium concrete of a precast pillar joint. The phosphorus and magnesium material based cast-in-place phosphorus magnesium concrete of the precast pillar joint is prepared through the following raw materials in parts by weight: 80-120 parts of magnesium phosphate cement, 3-18 parts of an additive, 10-40 parts of admixture, and 100-400 parts of aggregate. The invention also discloses a construction method of the phosphorus and magnesium material based cast-in-place phosphorus magnesium concrete of the precast pillar joint. The cast-in-place phosphorus magnesium concrete is resistant to corrosion, high in frost thawing resistance, high in durability, high in mobility, easy to pour, low in shrinkage,hard to crack, high in compactness, and high in adaptability to the environmental temperature, and can be constructed at anytime; an oxide film is formed on the surface of the concrete; the attachmentperformance relative to the precast pillar joint is high, and the adhering intensity is high; the concrete is short in setting time, high in early strength, and short in maintenance time; the concrete can be coagulated and hardened after being poured for 20-40min; the compressive strength is more than 40MPa after 1.5-3h after pouring; the concrete can be put into use once being poured; the construction efficiency is improved; and the cost is reduced.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

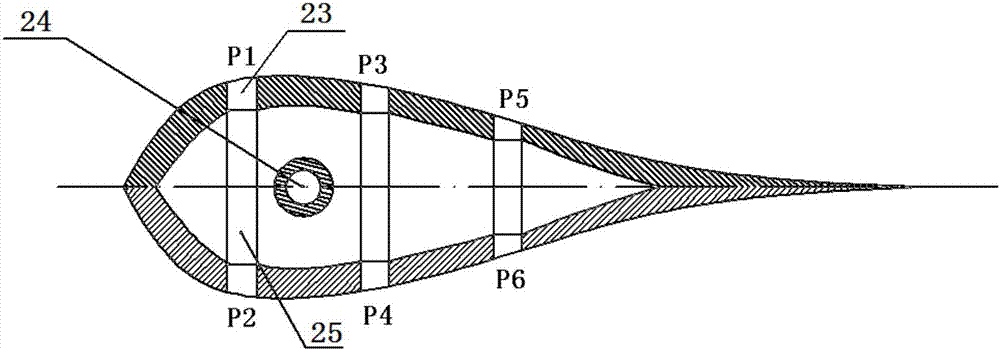

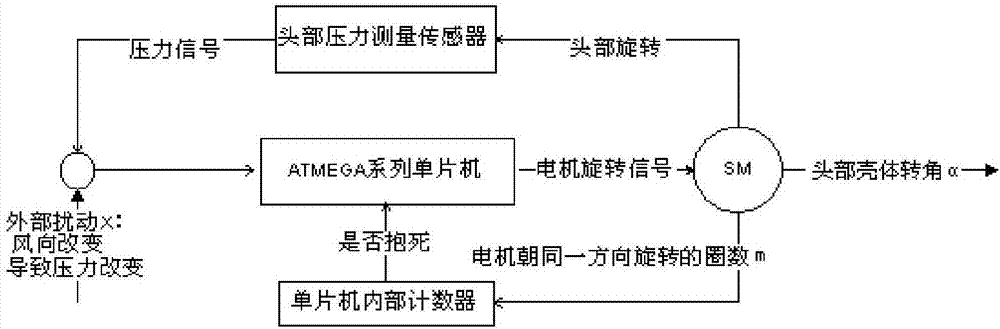

Wind direction tester and testing method

ActiveCN107255733AReduce edges and cornersLight in massIndication/recording movementControl signalElectric machine

The invention discloses a wind direction tester, and the tester comprises a measurement system, a control system, and a rotating motion system. The measurement system comprises a substrate, a head housing installed on the substrate, and at least three groups of pressure sensors which are installed at two sides of the interior of the head housing in a manner of axial symmetry. The head housing comprises a front end and a tail end, and the pressure sensors are sequentially arranged from the front end to the tail end. The rotating motion system comprises a rotating shaft, a pedestal and a servo motor. One end of a rotating shaft is connected with a substrate of the measurement system, and the other end of the rotating shaft is connected with the output shaft of the servo motor. The servo motor is disposed in the pedestal. A microprocessor of the control system receives a wind pressure signal measured by each pressure sensor, carries out the processing of each group of wind pressure signals, outputs a control signal to the servo motor, controls the forwarding and reverse rotation of the servo motor, and further controls the left and right rotation of the head housing, so as to enable the front end of the head housing to point the direction of incoming wind. The tester is good in anti-interference performance, is high in measurement precision, and is good in convenience.

Owner:SOUTHEAST UNIV

Preparation method of natural graphite slurry

The invention provides a preparation method of natural graphite slurry. The preparation method comprises the following steps of separating the natural graphite powder according to a particle size range; carrying out different treatment processes according to different particle size ranges, and pulping and mixing the treated natural graphite according to different modes, so that the dispersity of the natural graphite slurry, the stability of the slurry and the performance of an electrode obtained by coating can be improved.

Owner:泰州纳新新能源科技有限公司

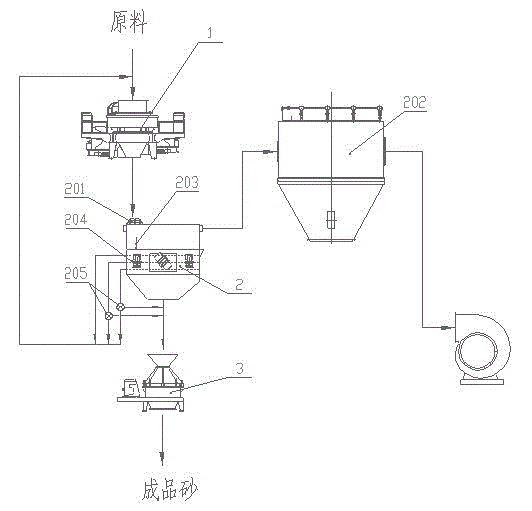

Production system and production method of high-quality machine-made sand

The invention discloses a production system and a production method of high-quality machine-made sand. By adopting the production system and the production method, the problem that conventional machine-made sand is unreasonable in grading and poor in particle shape can be fundamentally solved. The production method comprises the following steps: crushing broken stones by virtue of a crushing machine, conveying the broken stones to a grading controller by virtue of conveying equipment, classifying machine-made sand and finely controlling the grading of the machine-made sand, returning unqualified materials to the crushing machine to be crushed again, adding a particle shape optimizing machine behind the grading controller, and optimizing the particle shape of the machine-made sand. According to the machine-made sand produced by using the method disclosed by the invention, the fineness modulus and stone powder content can be accurately adjusted, the machine-made sand is mellow and full in particle shape and less in edge and corner, the improvement of concrete performance can be facilitated, the consumption of water and cement can be saved, and huge economic benefits can be provided.

Owner:SHANGHAI ZENITH MINING & CONSTR MACHINERYCO

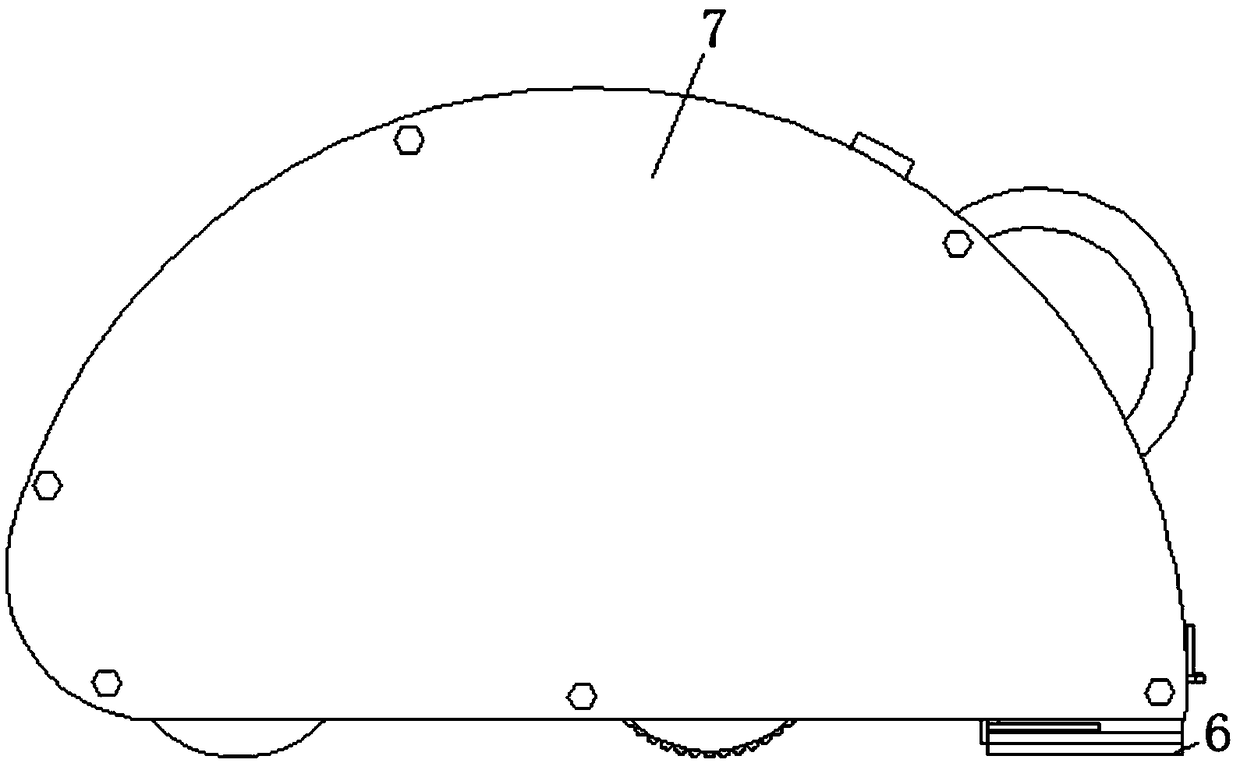

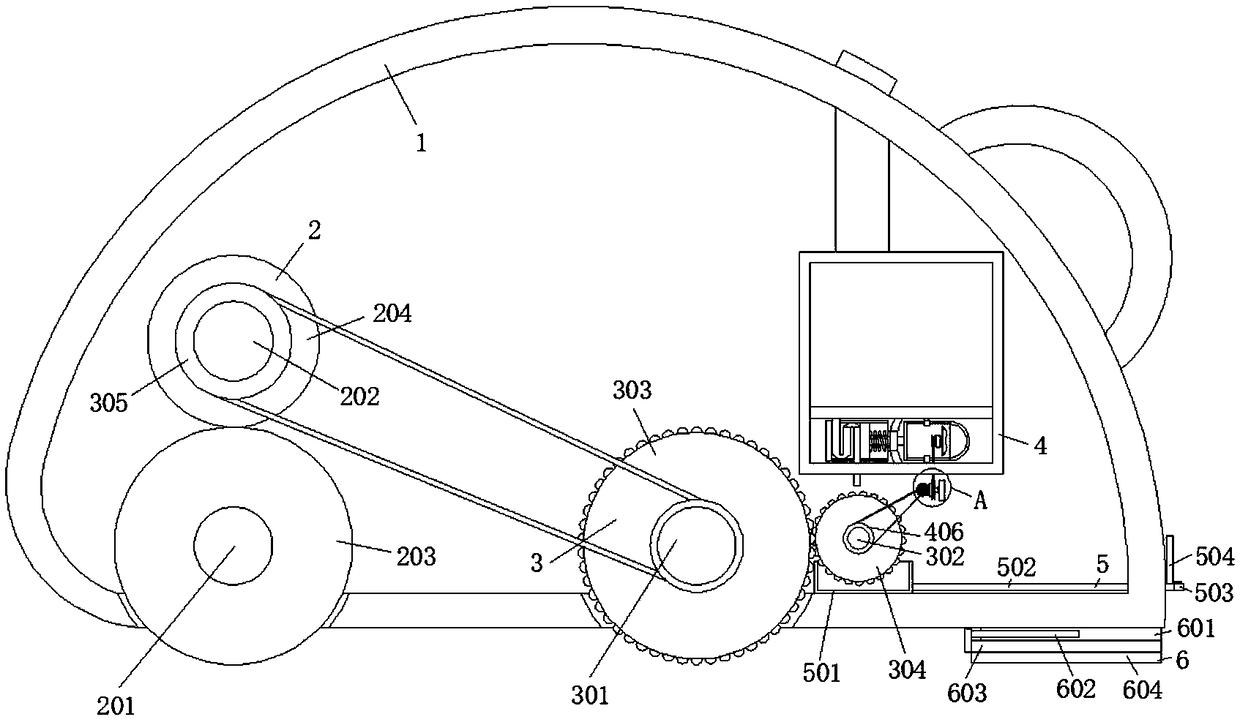

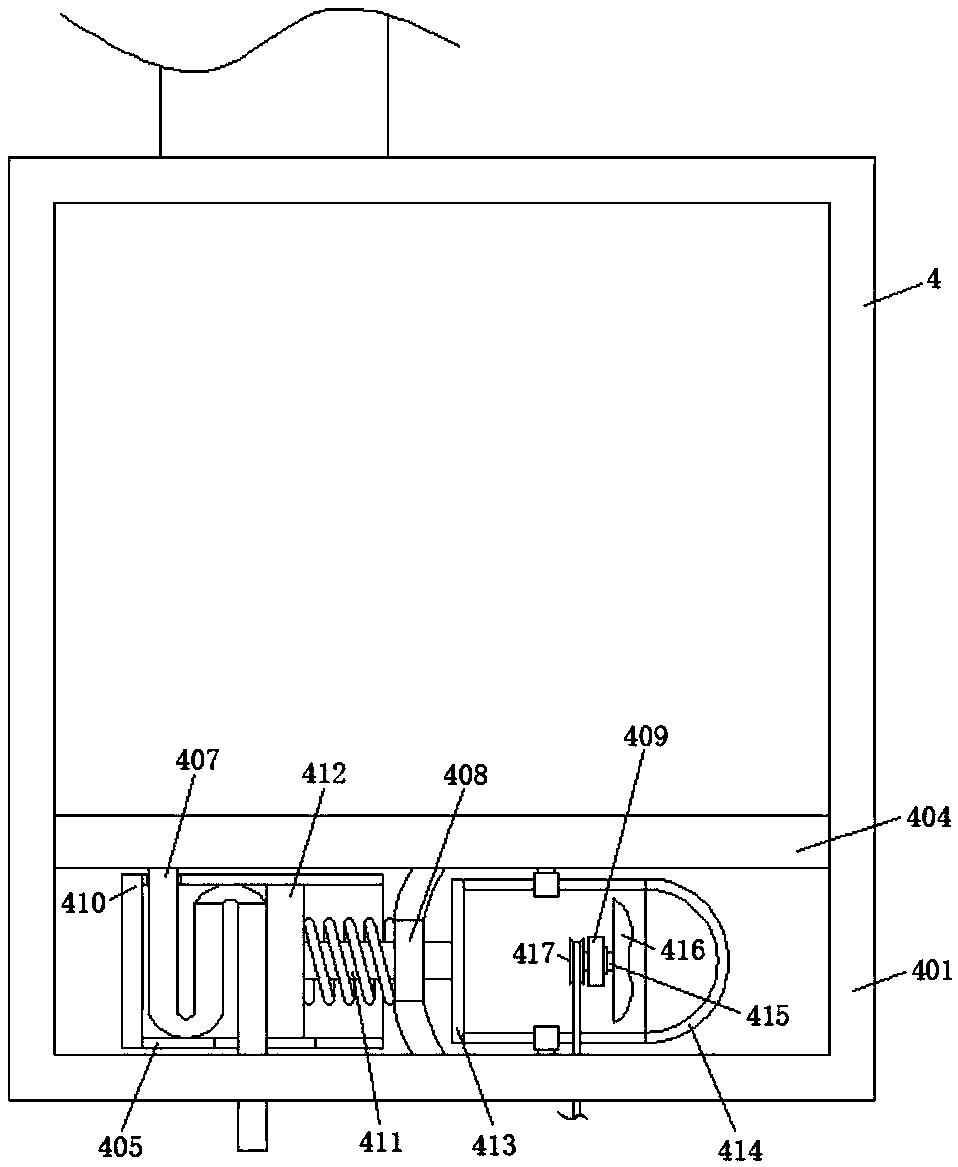

Summer sleeping mat wiping device suitable for family

The invention relates to the technical field of daily products, in particular to a summer sleeping mat wiping device suitable for a family. The summer sleeping mat wiping device suitable for the family needs to solve the technical problem that lots of time and physical power are wasted when a sleeping mat is wiped. In order to solve the technical problem, the summer sleeping mat wiping device suitable for the family is provided and comprises a shell in which a kinetic energy transmitting device, a friction cleaning device, a water outflow device and a water receiving device are arranged; and awiping unit is arranged at the bottom of the shell. According to the summer sleeping mat wiping device suitable for the family, in the reverse rotating process of a large rotating wheel, a summer sleeping mat can be wiped many times, one time wiping performed on the summer sleeping mat is equivalent to many-time wiping performed on the summer sleeping mat, and the efficiency of wiping the summersleeping mat is improved; and it is guaranteed that in the wiping process, a sponge ball cannot be dry, the wiping effect of the sponge ball on the summer sleeping mat is netter; and after wiping, a sponge mat is used for absorbing water, it can be avoided that too much water exists on the summer sleeping mat, and the service life of the summer sleeping mat is prolonged.

Owner:临沭县济才人力资源服务有限公司

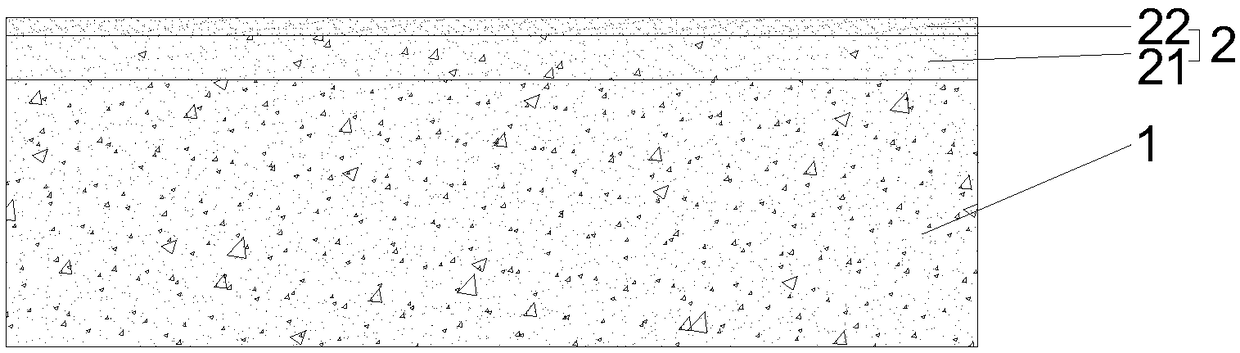

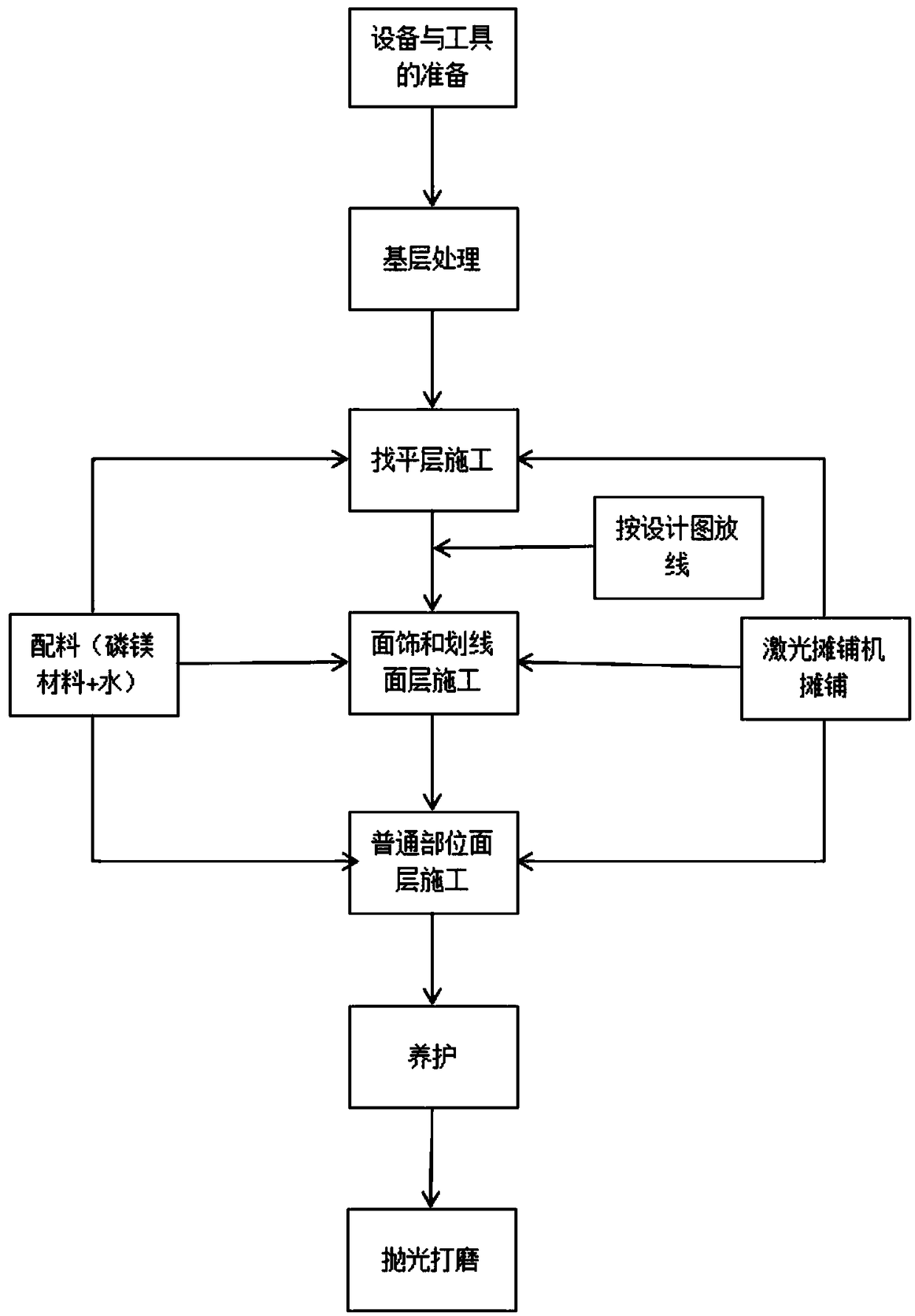

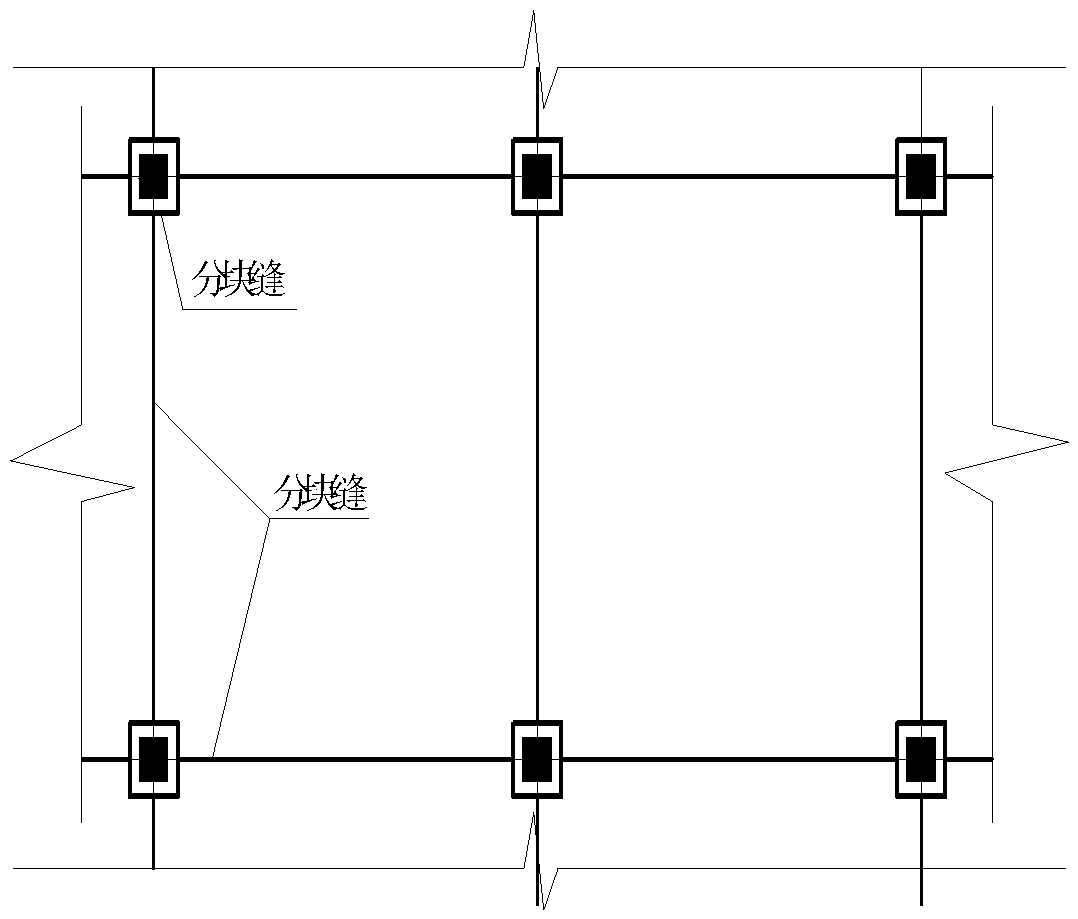

Ground surface course based on phosphorus and magnesium material and construction process thereof

ActiveCN108947464AShort construction periodQuality improvementFlooringMagnesium phosphateWear resistant

The invention relates to the technical field of terraces, in particular to a ground surface course based on a phosphorus and magnesium material and a construction process thereof. The ground surface course based on the phosphorus and magnesium material is formed by combining magnesium phosphate cement, an additive, an admixture, a pigment and an aggregate in a specific proportion. The ground surface course based on the phosphorus and magnesium material has high strength, wear resistance and bonding property and can be constructed anytime without construction joints. The content of volatile organic compounds (VOCs) is zero, and the ground surface course has very good fire resistance. The ground surface course is high in early strength, short in setting time, short in maintenance time, highin mechanical strength, unlike to crack, high in fracture resistance, wear-resistant and short in construction period and can be put into use immediately. By means of a paving process using a laser paver, a level ground is paved by the precision laser paver, the ground smoothness and levelness can be improved by over 3 times, and the compactness and strength can be improved by over 20%, and meanwhile, the work efficiency can be also improved and the labor is saved. The whole paved matrix is homogenous and compact.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

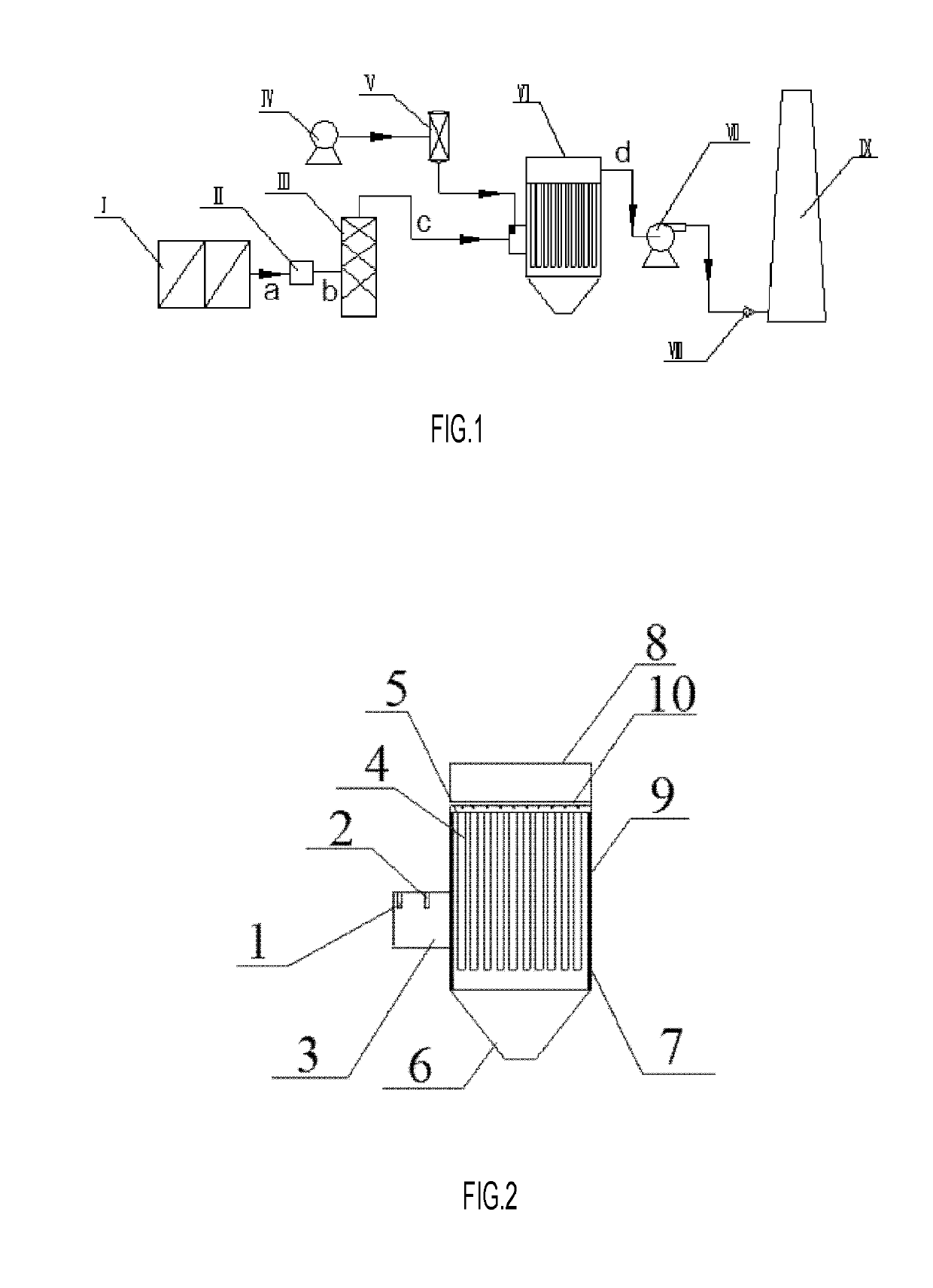

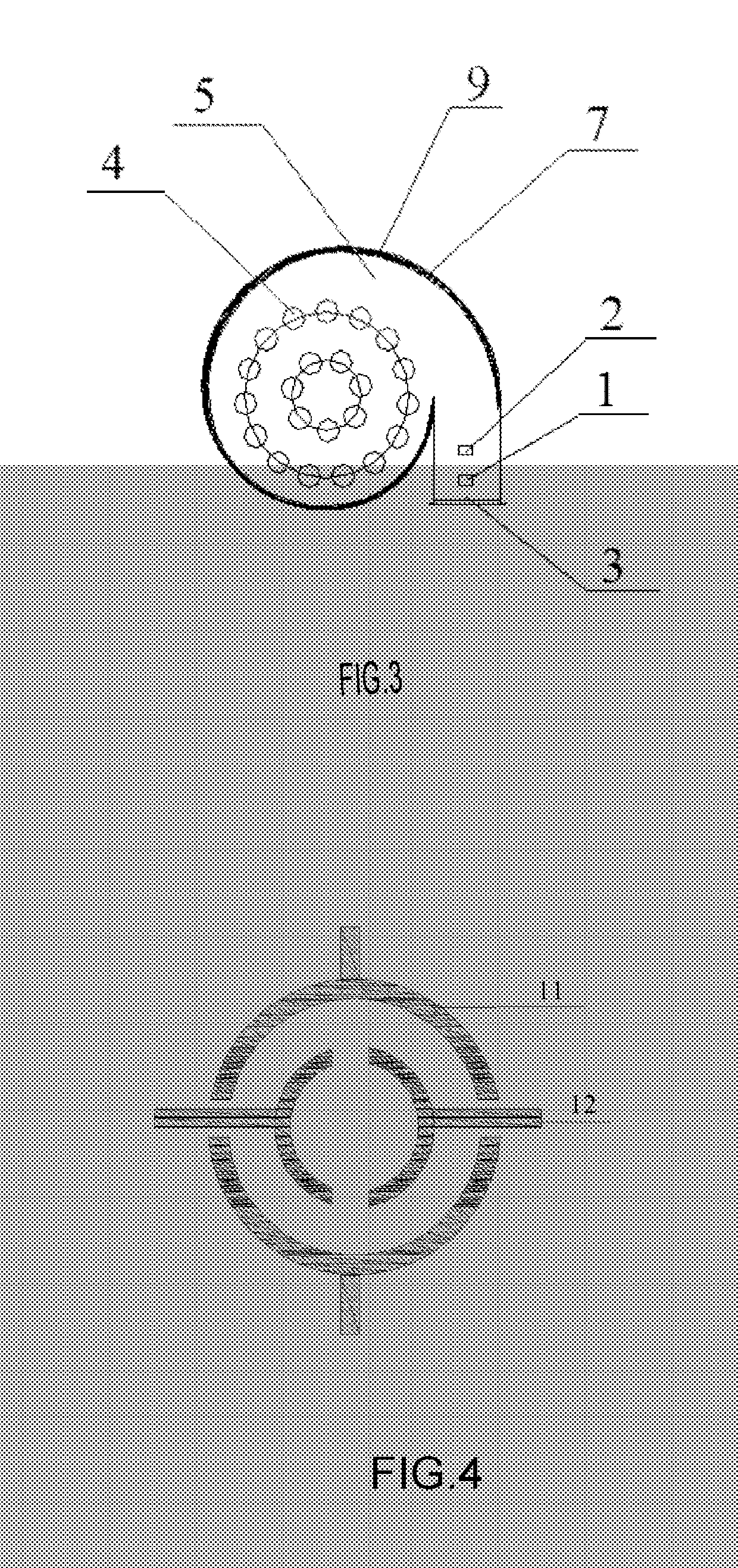

Membrane method processing system and process for high-concentration salt-containing organic waste liquid incineration exhaust gas

ActiveUS20190201830A1Increase running resistanceReduced service lifeGas treatmentDispersed particle filtrationHigh concentrationInorganic salts

A membrane method processing system and process for a high-concentration salt-containing organic waste liquid incineration exhaust gas is described. The system consists essentially of a waste liquid incinerator (I), a gas-solid separator (II), a heat exchanger (III), an air blower (IV), an anti-caking agent storage tank (V), a membrane method dust cleaner (VI), an induced draft fan (VII), a check valve (VIII), and a desulfurization tower (IX). The present invention introduces the dust collecting membrane into the tail gas treatment system and utilizes the small pore size and high porosity of the dust collecting membrane to prevent inorganic salt particles from entering the internal of the filter material and agglomerating there. When the humidity of the gas entering the dust collector increases during the dust removing process, the anti-caking agent is also introduced into the tail gas treatment system to change the surface structure of the inorganic salt crystal to prevent the crystal from agglomeration.

Owner:JIANGSU JIULANG HIGH TECH CO LTD

Machining technology for optical lens rounding

The invention discloses a machining technology for optical lens rounding to mainly solve the problems of corner angles, chamfers and radians existing in the existing optical lens machining process. A centerless grinding machine main shaft grinding wheel is utilized for carrying out optical lens peripheral grinding, and the bottom of an optical lens is ground to be round; then, the rotating speed of a main grinding wheel and the rotating speed of a main shaft wheel are adjusted so that fine grinding can be directly carried out; finally, cleanout fluid is used for cleaning the optical lens under the action of ultrasonic waves, and the purpose that technology meets the requirement for 360-degree radians of the final optical lens is achieved. According to the technology, the machining procedure of the machining technology of the optical lens is effectively simplified; fast forming is achieved; the production cost is effectively saved; the finished product pass percent is greatly increased.

Owner:CHANGZHOU OPTICAL MATERIAL

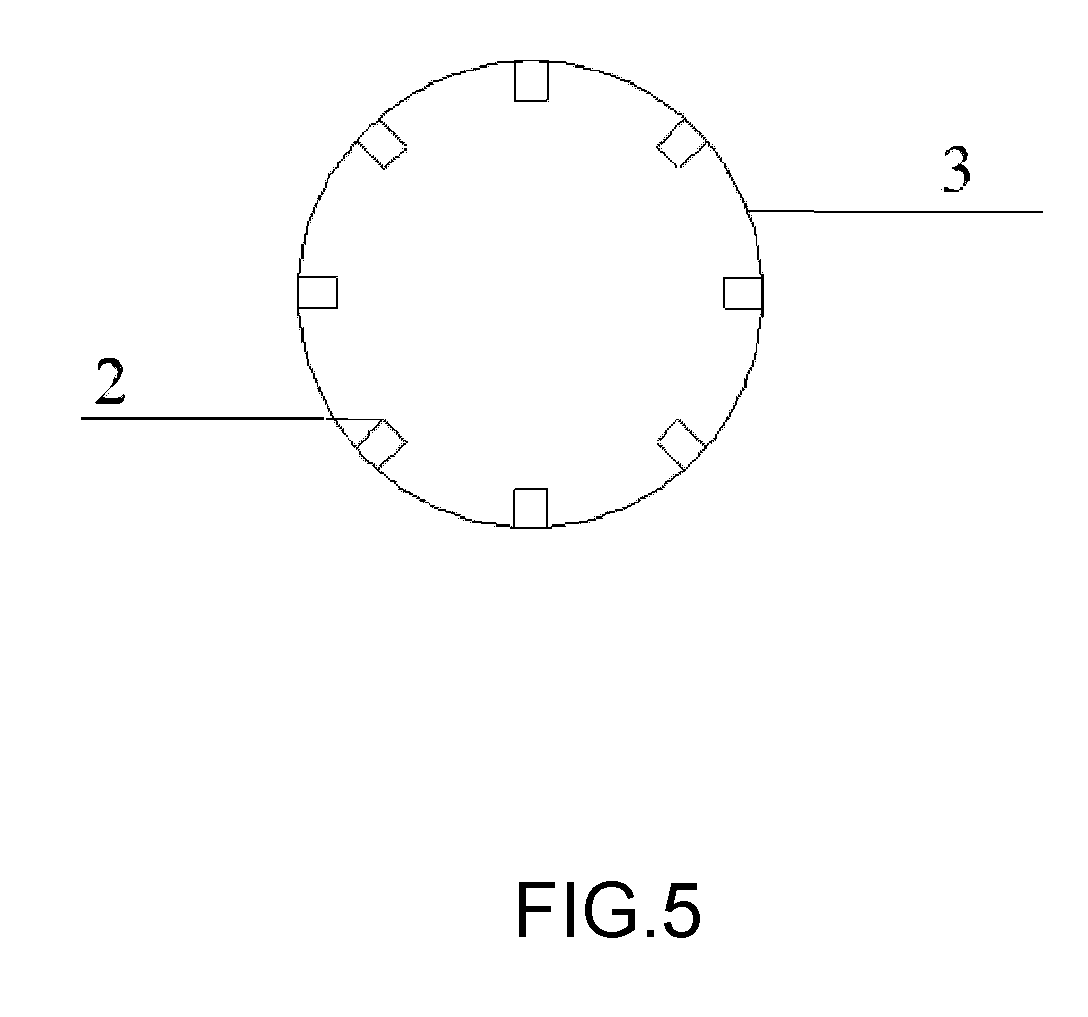

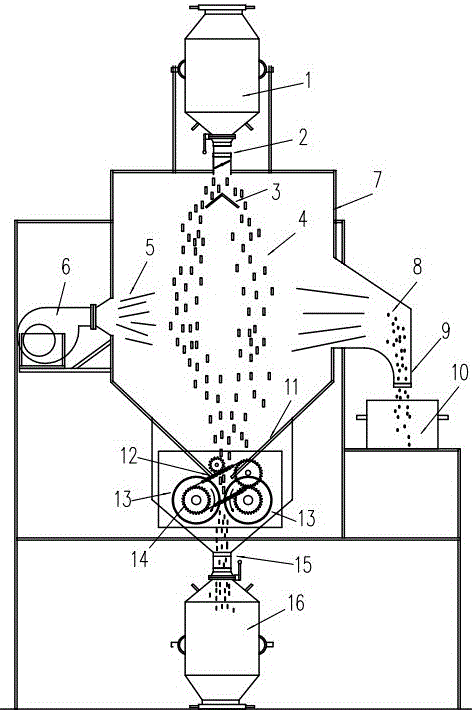

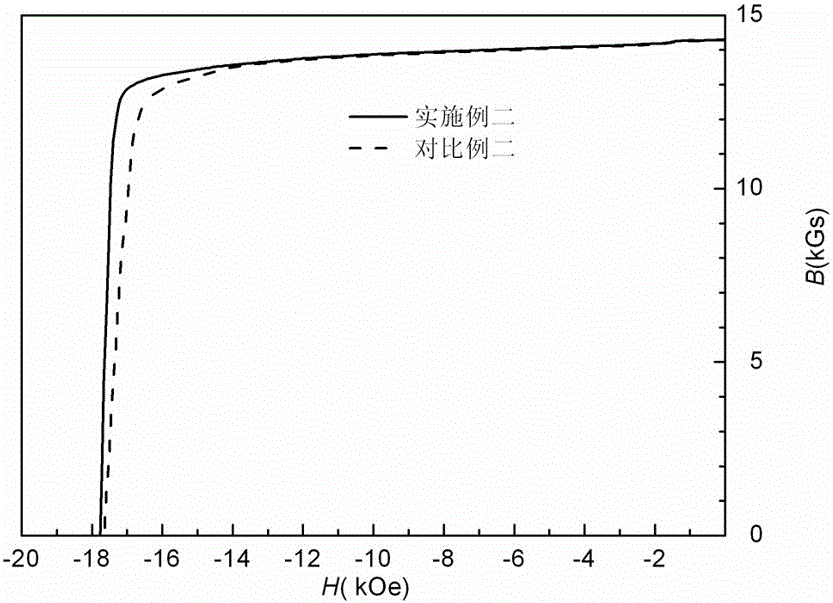

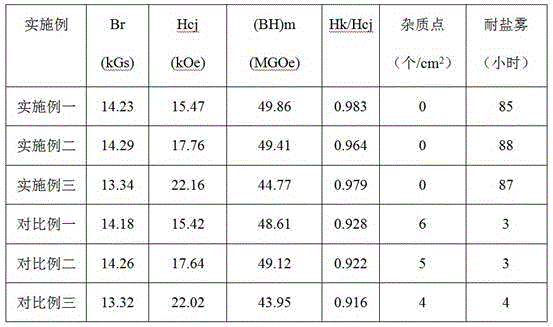

Method and apparatus for improving square degree and corrosion resistance of demagnetizing curve of sintered neodymium iron boron

The invention discloses a method and an apparatus for improving square degree and corrosion resistance of a demagnetizing curve of sintered neodymium iron boron. The apparatus comprises an air blowing apparatus and a quick coagulating sheet coarse crushing apparatus; according to the method, after a quick coagulating sheet is obtained and before a hydrogen decrepitation process is performed, a quick coagulating sheet cleaning and coarse crushing process is added, wherein the cleaning of the quick coagulating sheet is performed by enabling the quick coagulating sheet to pass through an air blowing wind belt so as to clean dust and needle-shaped amorphous neodymium iron boron alloy and other impurities, attached to the surface of the quick coagulating sheet, through wind power; the cleaned quick coagulating sheet is rolled and crushed by a reversely rotating roller with a rough surface; and next, subsequent processing of hydrogen decrepitation, airflow milling and the like is performed. By virtue of air-blowing wind power, foreign matters on the surface of the quick coagulating sheet can be effectively removed; and meanwhile, foreign matters are not introduced again, so that the component and structural uniformity of the base magnet are finally improved, and black spots on the surface after acid washing or electroplating are reduced, thereby improving the square degree and corrosion resistance of the demagnetizing curve of the magnet.

Owner:NINGBO KETIAN MAGNET

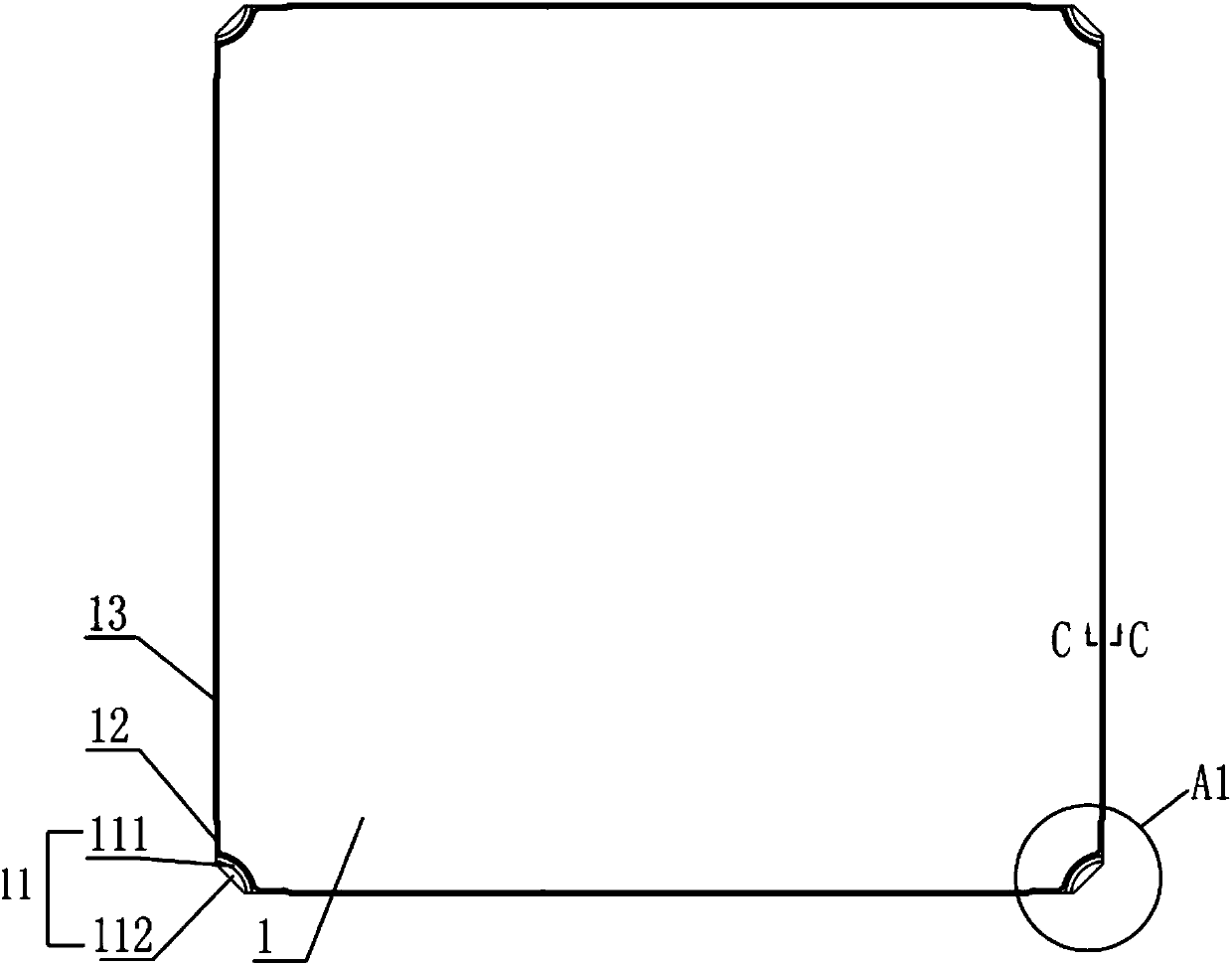

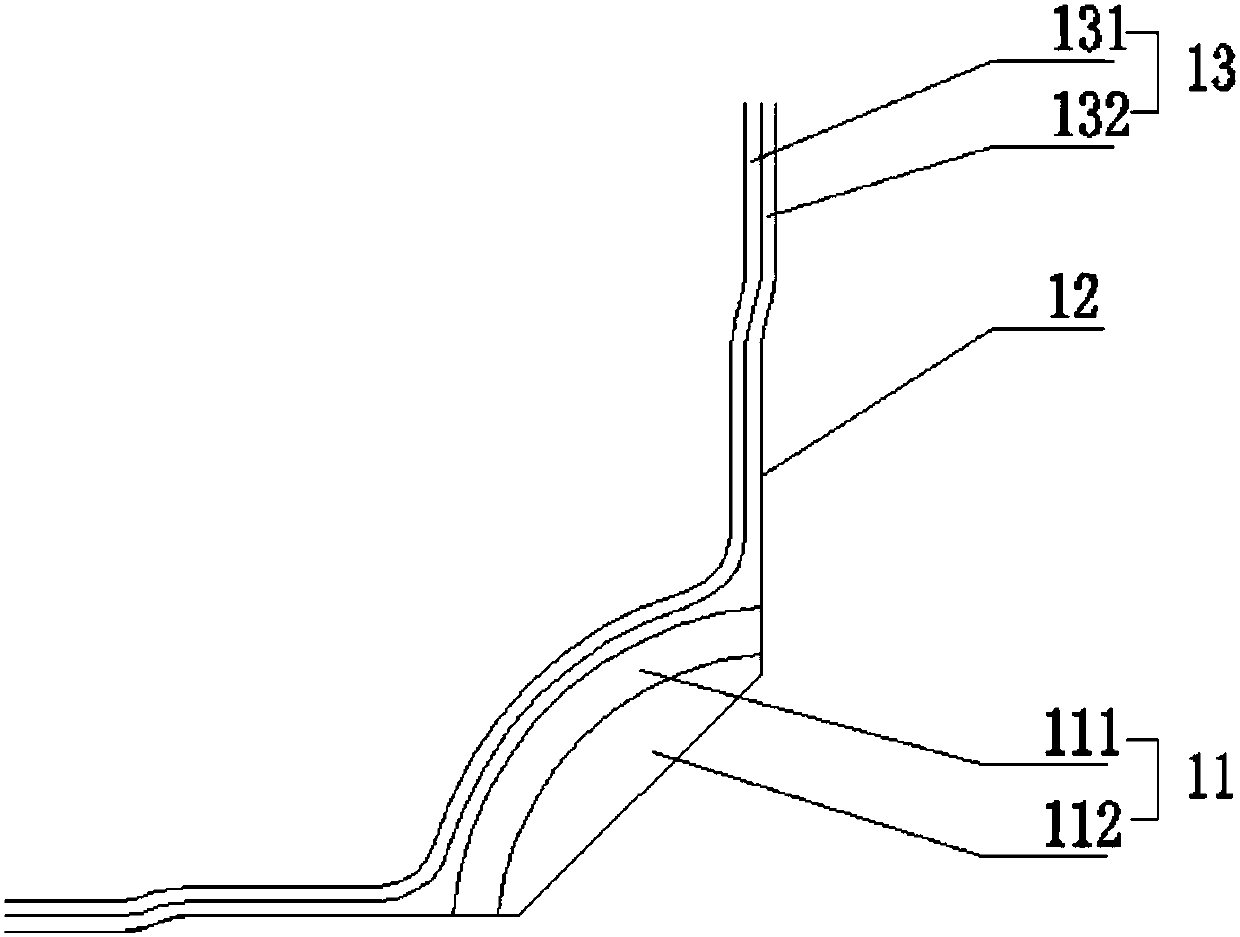

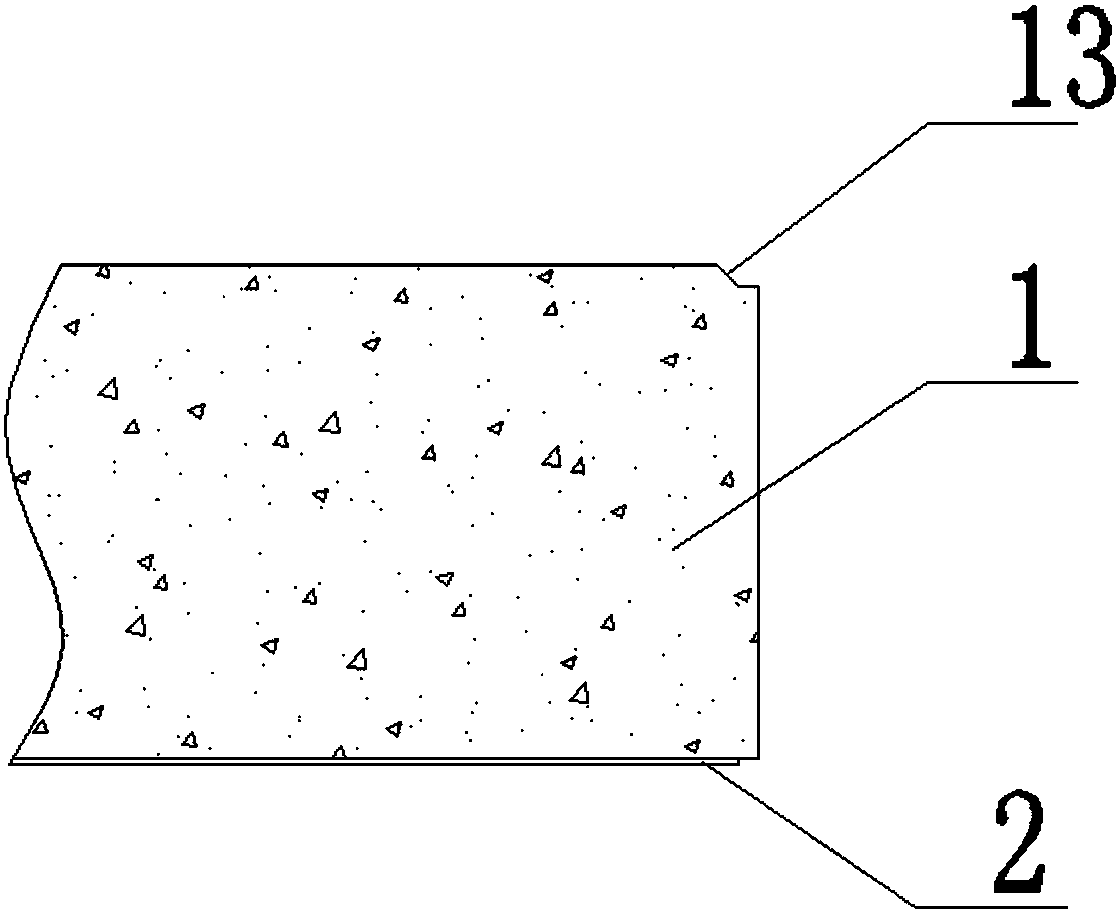

Calcium sulfate composite raised flooring

PendingCN107762103AEliminate multiple processing stepsReduce usageFalse floorsEngineeringMechanical engineering

Owner:江苏华集新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com