Patents

Literature

64results about How to "Improve early compressive strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel liquid silicon anti-channeling cement slurry used in well cementation

InactiveCN105038745AApplicable temperature rangeHigh densityDrilling compositionPorosityWell cementing

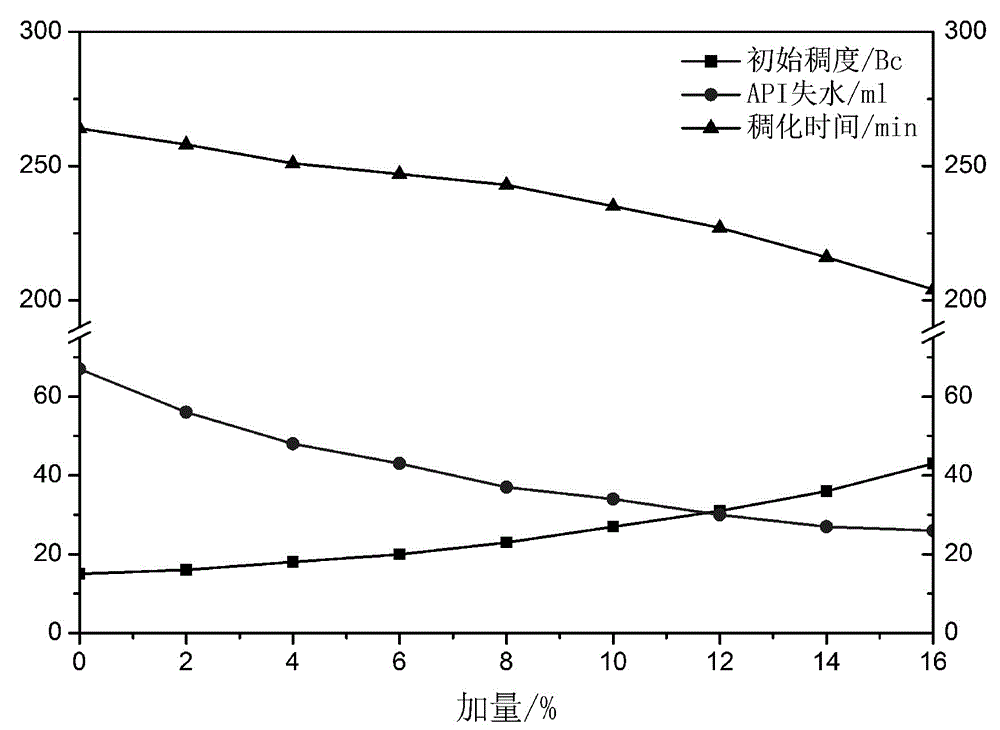

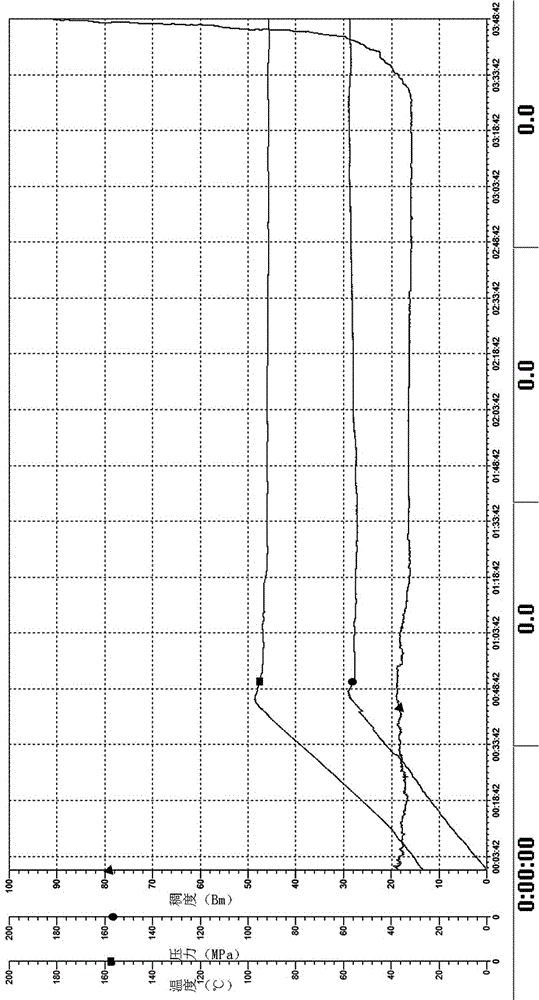

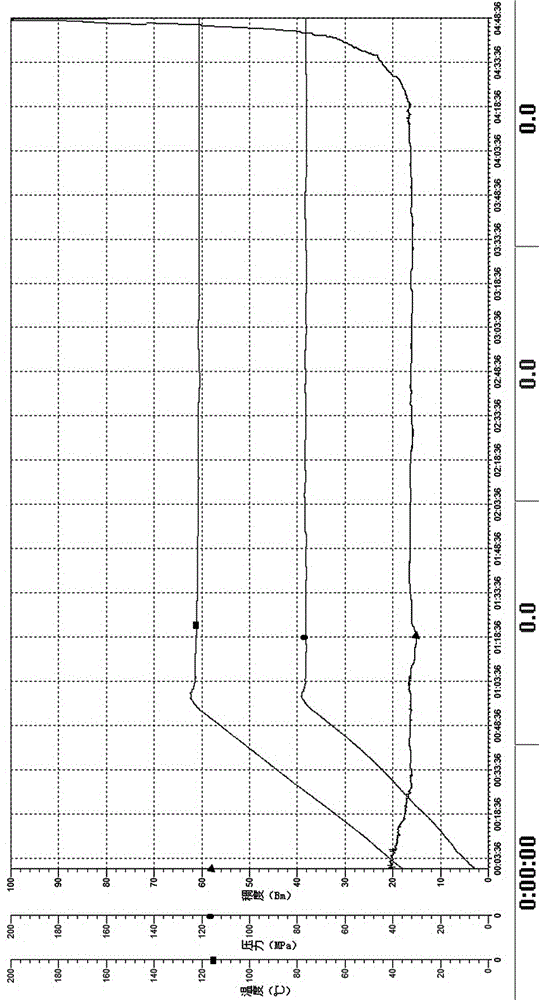

The invention discloses a novel liquid silicon anti-channeling cement slurry used in well cementation, which includes following raw materials, by weight, 95-105 parts of G-grade cement, 10-35 parts of a strength stabilizer, 0.5-4 parts of a retarder, 0.1-0.2 parts of a defoaming agent, 5-15 parts of a filling agent, 0.5-2 parts of a dispersing agent, 100 parts of water, 5-15 parts of an anti-gas channeling agent, 5-10 parts of a fluid loss agent and also a density adjusting agent. The raw materials are mixed and stirred uniformly to prepare the novel liquid silicon anti-channeling cement slurry. The anti-channeling cement slurry is low in water loss, is good in stability, is short in static gelatinization transition time, is strong in anti-gas channeling performance, is quick in early strength development at a low temperature and resists corrosion of acidic mediums. Set cement slurry is slight in expansion, is less in porosity, is high in compactness and low in permeability, and can satisfy requirements in various well cementation situations.

Owner:成都欧美克石油科技股份有限公司

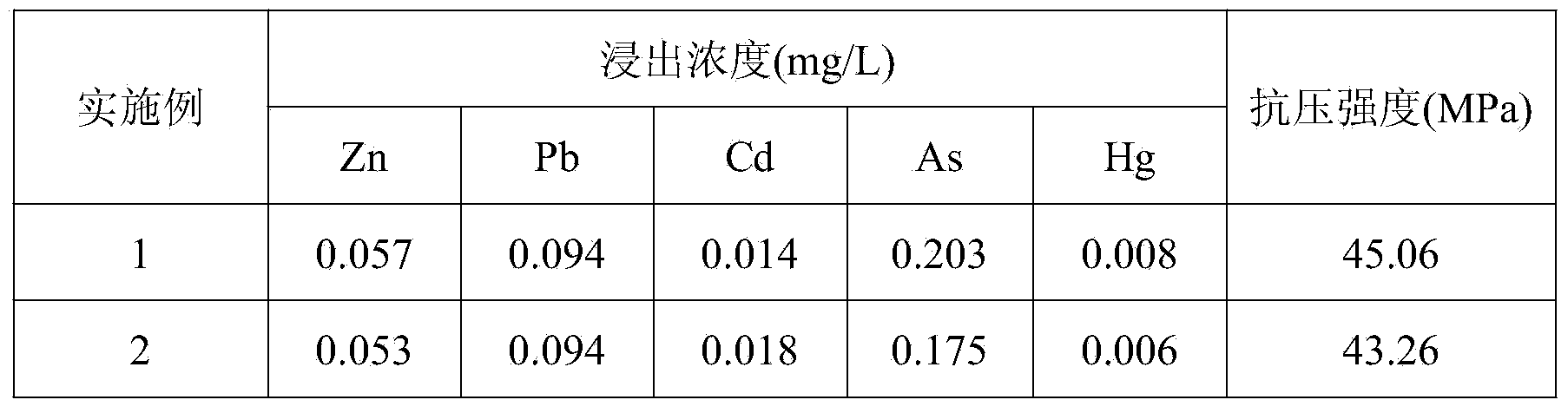

Method for preparing geopolymer gelled material from heavy metal gypsum

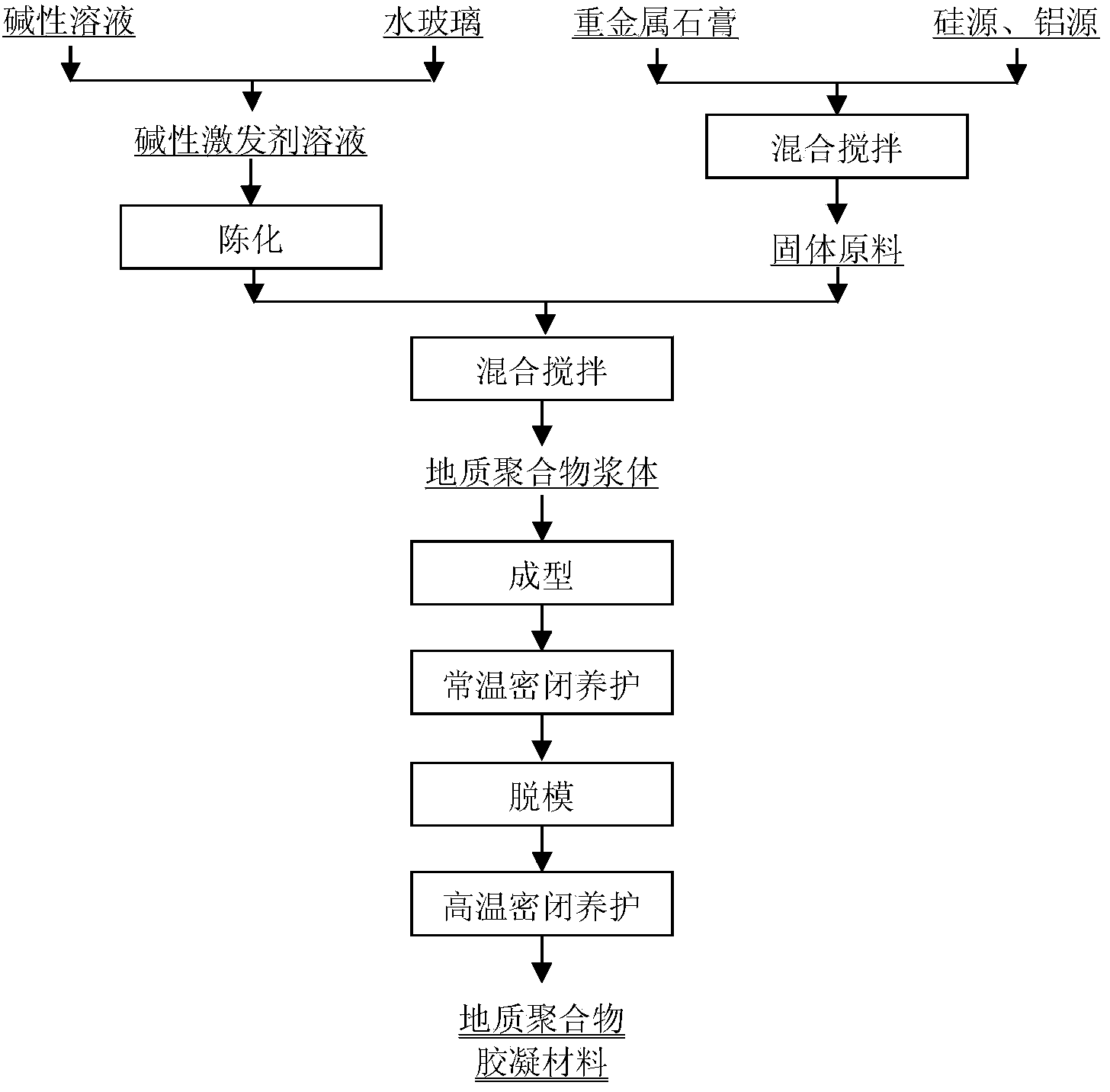

The invention relates to a method for preparing a geopolymer gelled material from heavy metal gypsum, belonging to the field of environmental protection and material engineering. According to the method, heavy metal gypsum is adopted as a main calcium source, silicon sources and aluminum sources including fly ash, coal gangues, mineral waste residues, steel slag and the like are added to prepare geopolymer slurry under the action of an alkaline excitant solution, and then the geopolymer gelled material is prepared through the processes of molding, normal temperature sealed maintenance, high-temperature sealed maintenance and the like. The 28d compression strength of the geopolymer gelled material prepared by the method disclosed by the invention can reach 48MPa, and the heavy metal leaching concentration limiting value of a finished product is lower than a national standard. The geopolymer gelled material can be used as a building material, such as replacing a natural aggregate in concrete or serving as a roadbed aggregate. The method achieves treatment of wastes with processes of wastes against one another and is simple in process and low in cost, so that the problems of recycling of calcium sulfate and heavy metal pollution are solved, and the stockpiling problem of industrial residues including the fly ash, coal gangues, mineral waste residues, steel slag and the like is solved at the same time.

Owner:UNIV OF SCI & TECH BEIJING

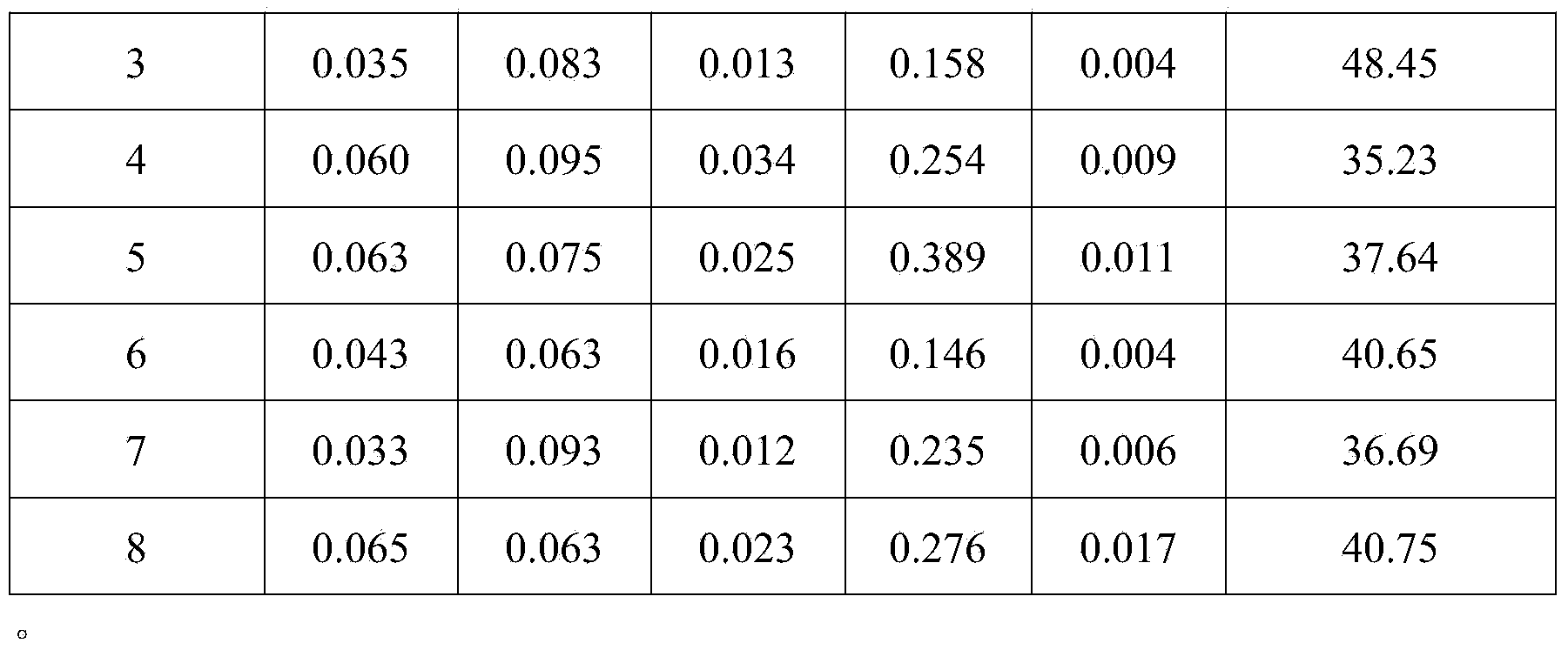

Green alkali-free liquid concrete setting accelerator and preparation method thereof

The invention relates to a green alkali-free liquid concrete setting accelerator and a preparation method thereof, and belongs to the technical field of concrete processing. According to the method, aluminum sulphate, calcium hydroxide, organic acid and deionized water are taken and are charged into a three-opening flask; stirring is performed under the condition of constant-temperature water bath; setting accelerator mother liquid is obtained; sodium fluoroaluminate is taken and is added into the deionized water; heating and stirring are performed; then, organic alcohol amine is added; continuous stirring is performed; then, the setting accelerator mother liquid is dripped; after the dripping is completed, ethylene diamine tetraacetic acid is added; heat insulation stirring is performed;after the materials are cooled to the room temperature, stabilizing agents are added; stirring is performed; the green alkali-free liquid concrete setting accelerator is obtained. The setting accelerator provided by the invention has the advantages of no alkali, non-toxicity, no smell and no corrosion; the environment is protected in the construction process; almost no harm is caused on the body health of construction personnel and ecological environment in the spraying process; the production process is simple; the preparation is easy; the storage is easy; the stability in the storage processis high.

Owner:常州琨瑶纺织品有限公司

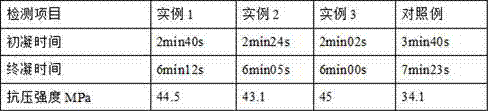

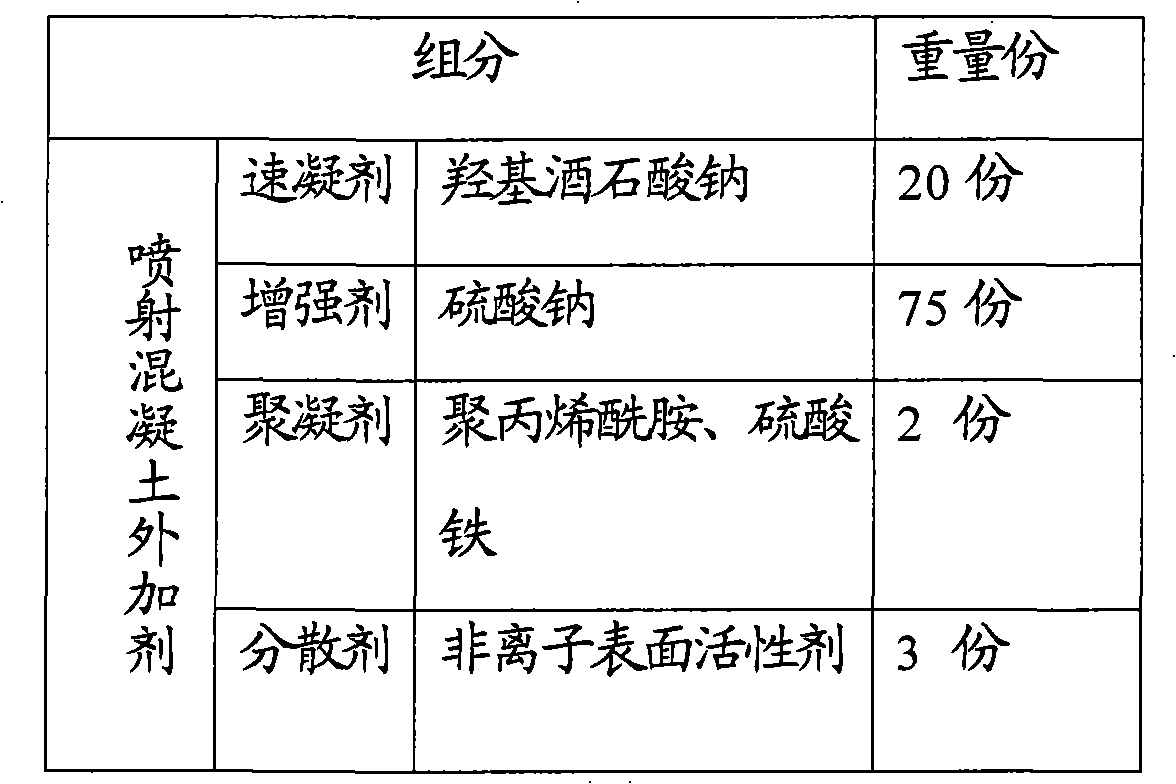

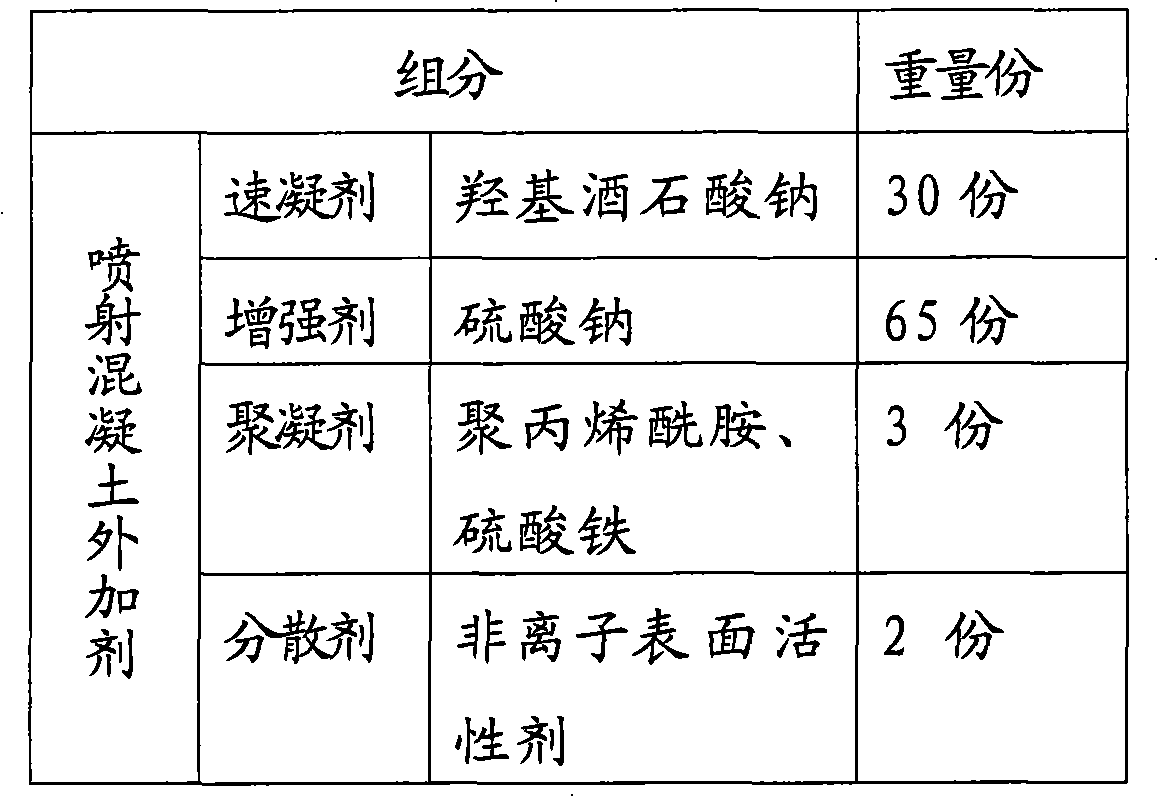

Shotcrete additive and spraying technology of shotcrete

InactiveCN102464466ALong-term performance is not compromisedLong-term performance impairmentShotcreteCoal

The invention provides a shotcrete additive and a spraying technology of shotcrete. The shotcrete additive comprises: 15-25 parts of a setting accelerator, 50-80 parts of a reinforcing agent, 1-5 parts of a dispersant, and 0.1-6 parts of a flocculating agent. The invention also provides a spraying technology of shotcrete. The technology employs the above shotcrete additive and utilizes an existing dry shotcreting machine under a coal mine for wet shotcreting operation. Therefore, the problems that existing dry shotcreting additives cannot satisfy the technological requirements of wet shotcreting as well as dry shotcreting technologies have a high dust concentration can be solved.

Owner:HUAINAN MINING IND GRP +1

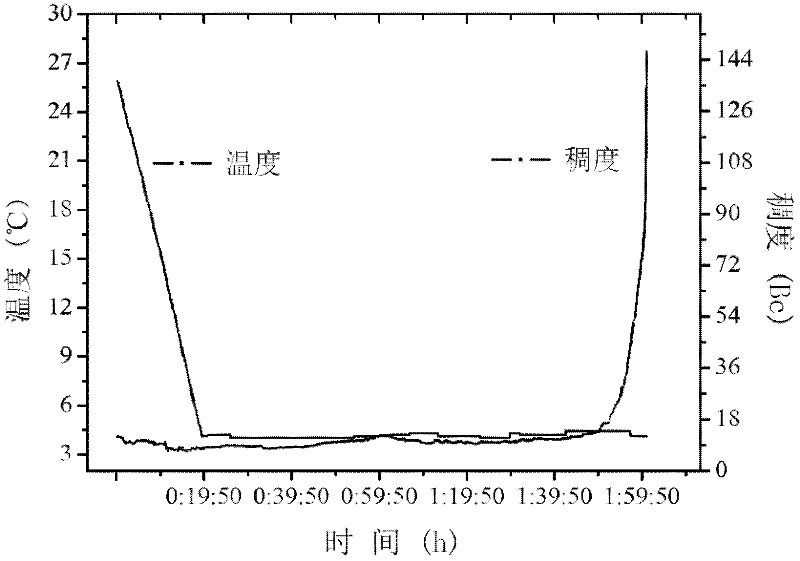

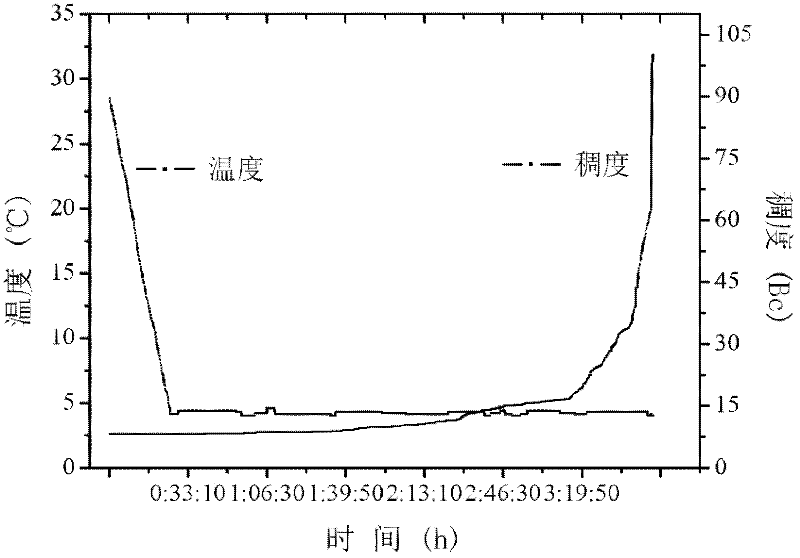

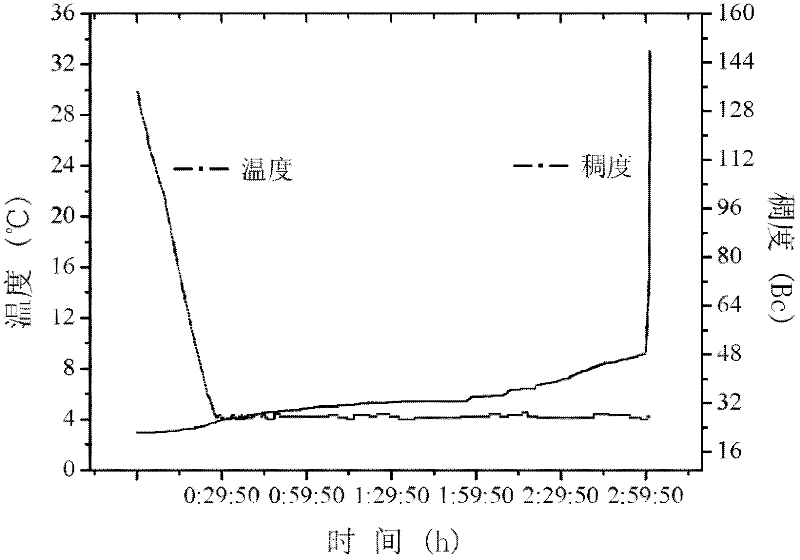

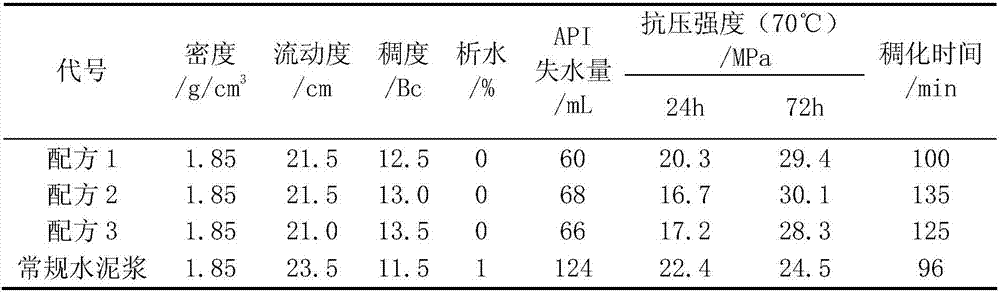

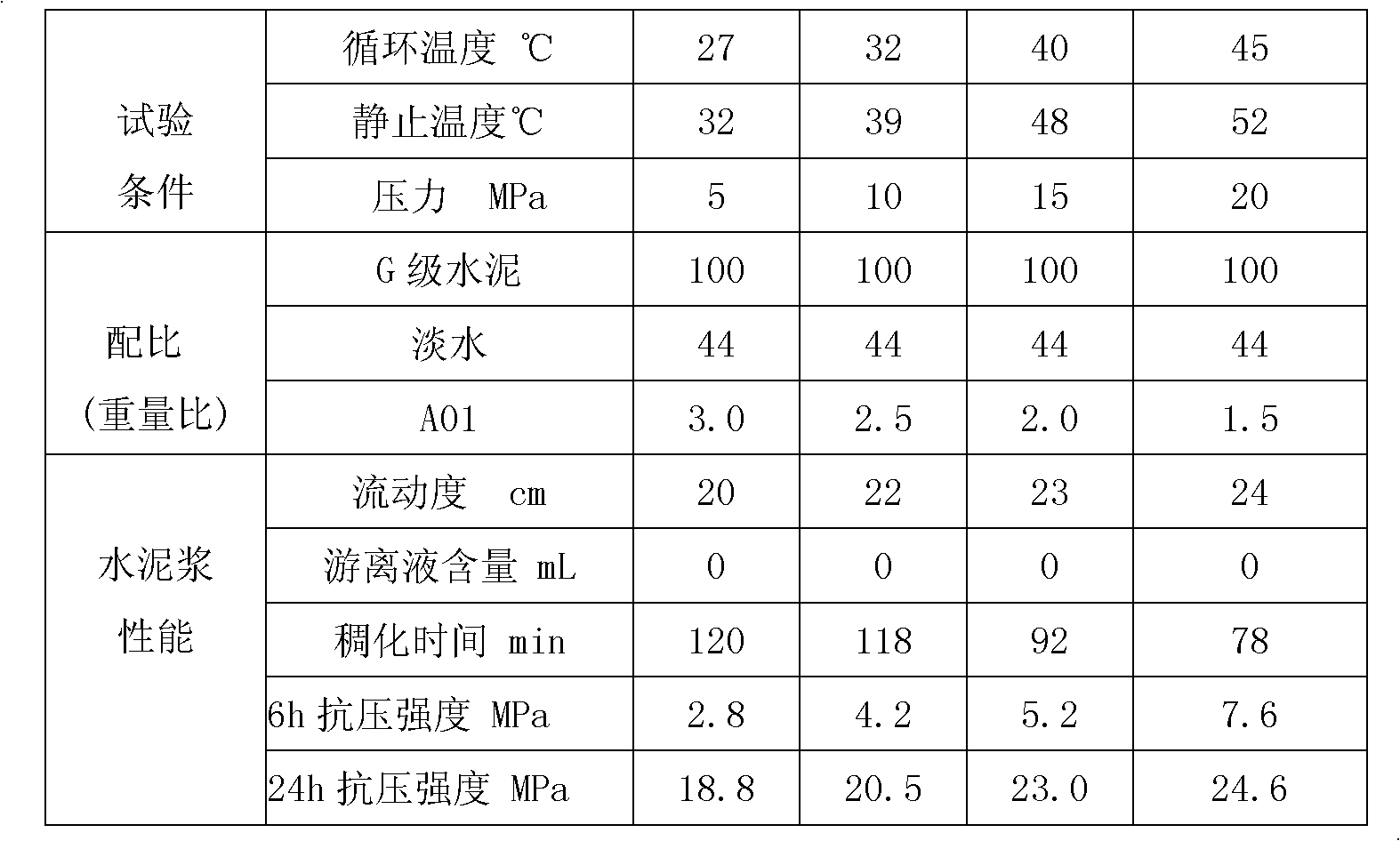

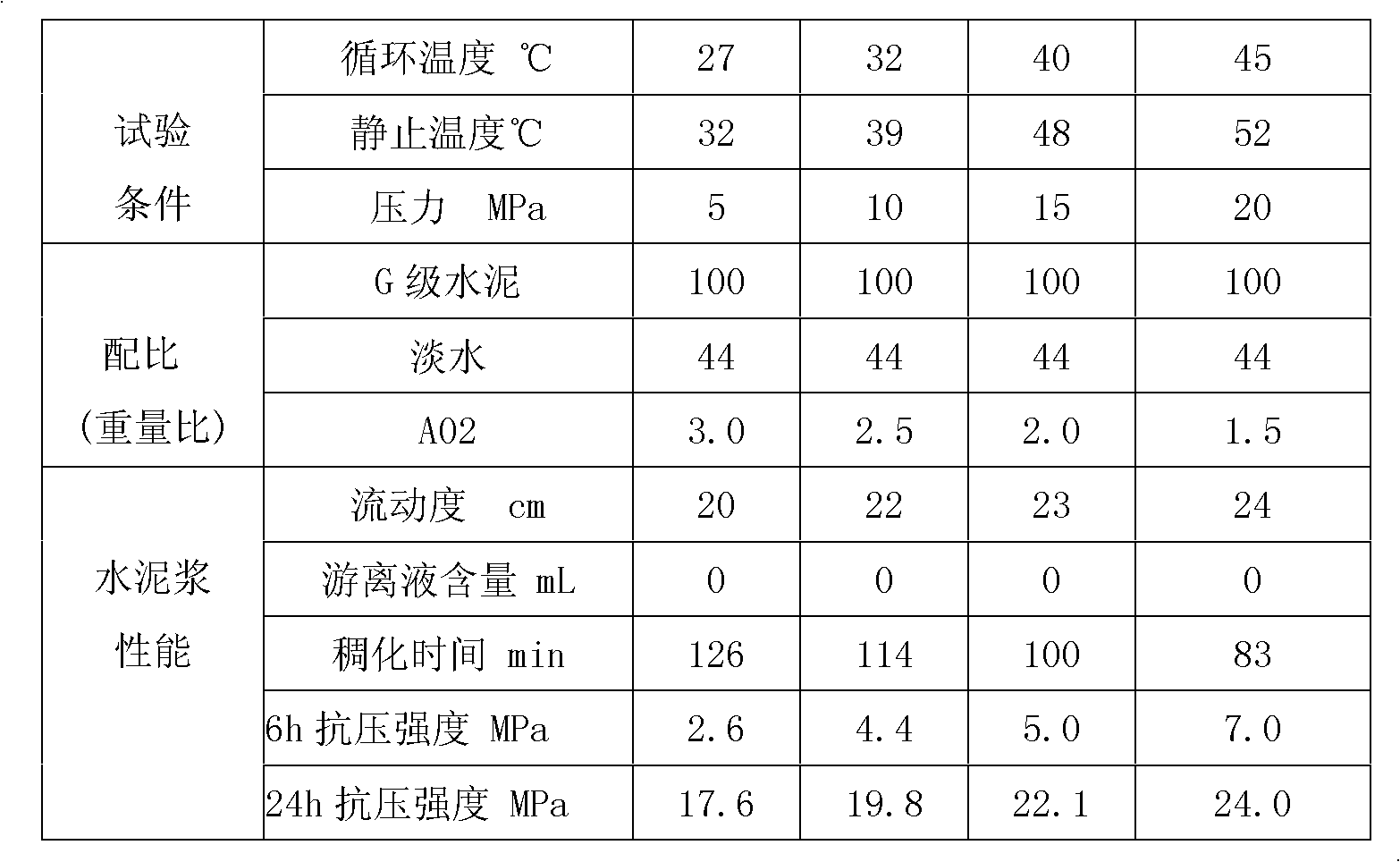

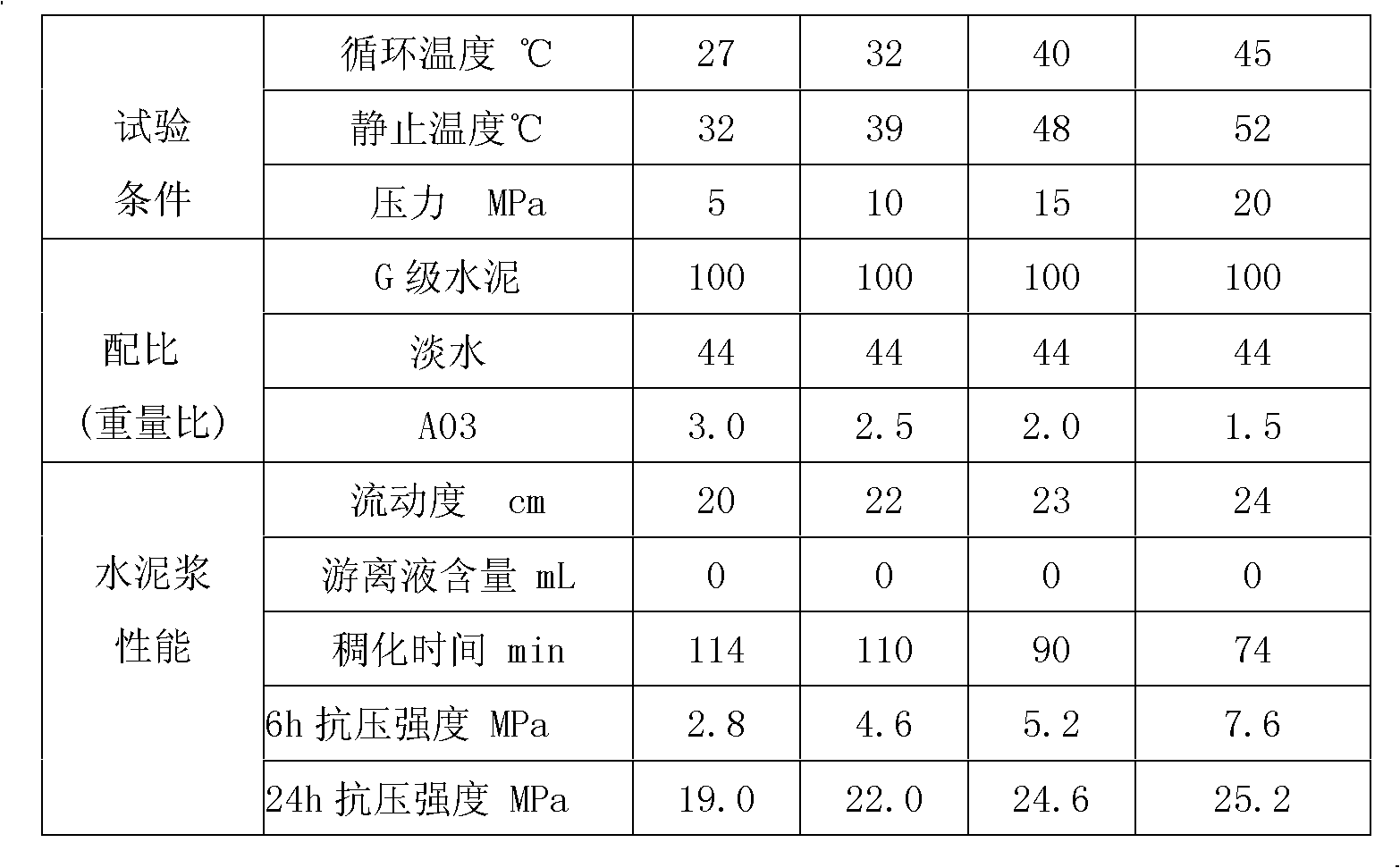

Low-temperature early-strength corrosion-resistant cement paste system for deepwater cementing

ActiveCN102329601AThickening time adjustableImprove liquidityDrilling compositionCement pasteCorrosion resistant

The invention relates to a low-temperature early-strength corrosion-resistant cement paste system for deepwater cementing. The system consists of the following components in part by weight: 100 parts of cement, 20 to 100 parts of density regulator, 0.3 to 0.6 part of retarder, 0.1 to 5 parts of fluid loss agent, 0.1 to 3 parts of early strength agent, 0 to 0.6 part of dispersant, 5 to 30 parts of heat regulator and 60 to 120 parts of water. 100 weight parts of cement contains the following components in part by weight: 20 to 70 parts of CaO, 20 to 60 parts of Al2O3, 5 to 20 parts of SiO2, 10 to 35 parts of P2O5, 0.5 to 5 parts of Fe2O3 and 1 to 4 parts of MgO. The cement paste system has excellent low-temperature early-strength, corrosion-resistant, thickening time-adjustable and 'right angle thickening' properties, and is expected to solve the main problems of low temperature, set cement corrosion, shallow water-gas channeling and the like that the deepwater cementing faces. The system is reliable in technology and low in cost, is convenient to construct on site, and is particularly suitable for low-temperature, corrosion and shallow water-gas channeling cementing operations under deepwater conditions.

Owner:SOUTHWEST PETROLEUM UNIV

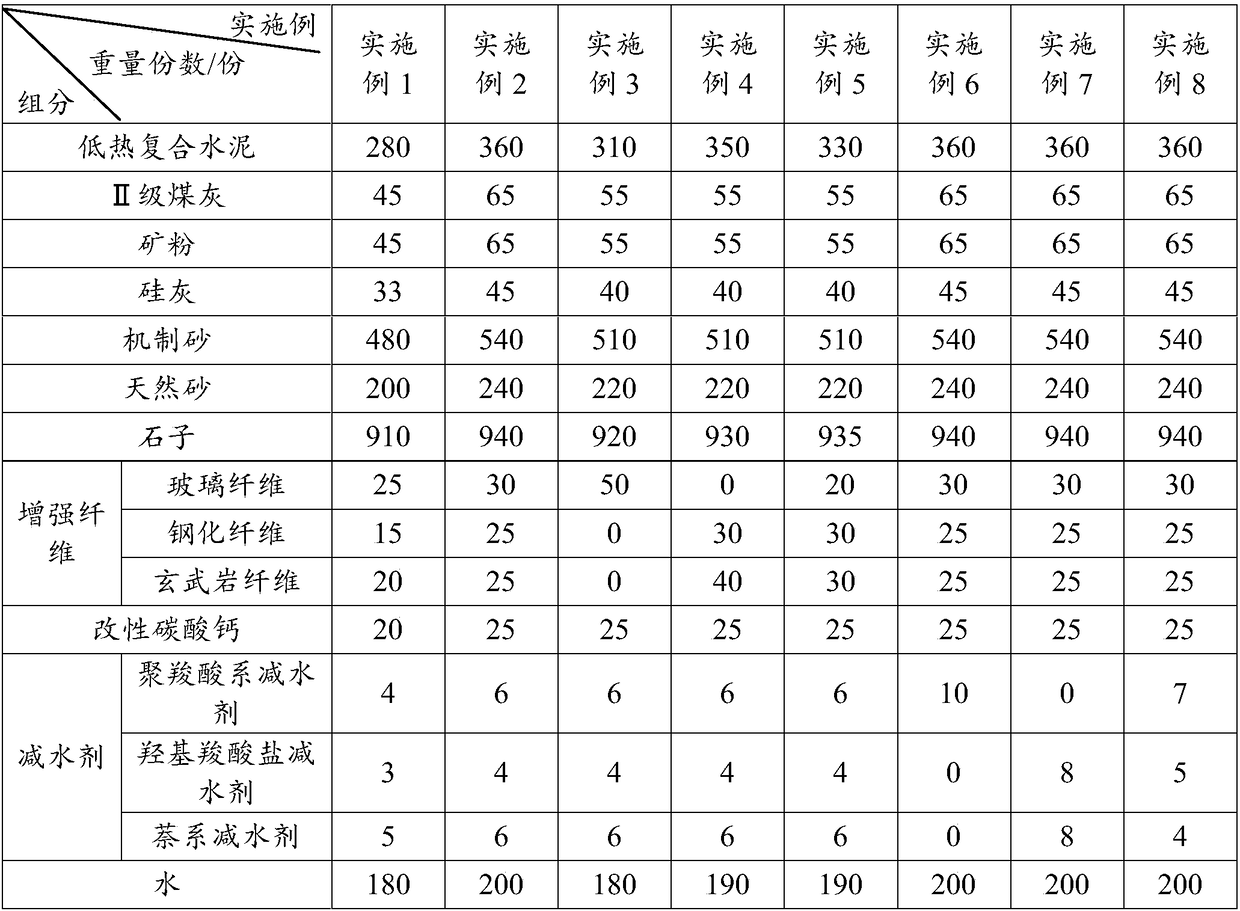

Concrete and preparation method thereof

The invention discloses concrete and a preparation method thereof, and belongs to the field of building materials. The concrete comprises the following raw materials in parts by weight: 280-360 partsof low-heat composite cement, 45-65 parts of II-level coal ash, 45-65 parts of mineral powder, 33-45 parts of silica fume, 480-540 parts of machine-made sand, 200-240 parts of natural sand, 910-940 parts of stones, 60-80 parts of reinforced fibers, 20-25 parts of modified calcium carbonate, 12-16 parts of a water reducing agent, and 180-200 parts of water. The reinforced fibers comprise at least one of glass fibers, tempered fibers and basalt fibers. The water reducing agent comprises at least one of a polycarboxylic acid water reducing agent, a hydroxycarboxylate water reducing agent, and a naphthalene water reducing agent. The provided concrete has the advantages of effectively reducing hydration heat of the concrete, and improving compressive strength of the concrete.

Owner:杭州金鼎实业有限公司

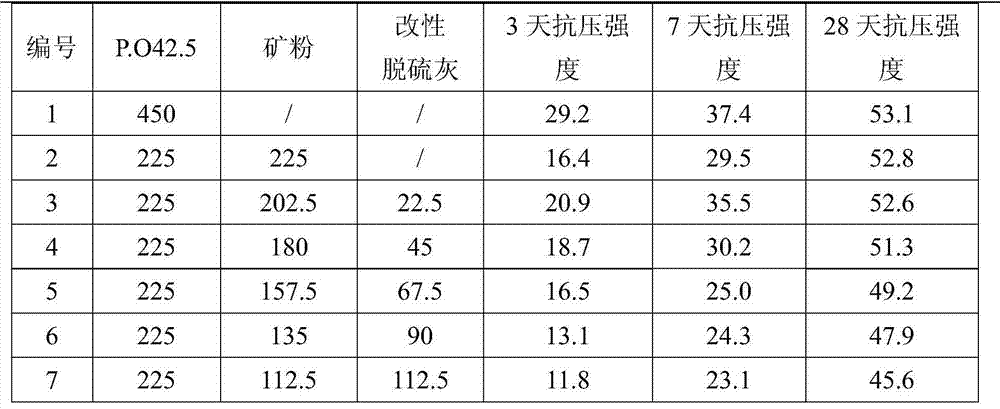

Modified desulfurization ash for cement and concrete and preparation method thereof

InactiveCN103803828AImprove early compressive strengthNo reduction in compressive strengthAcetic acidCompressive strength

The invention discloses modified desulfurization ash for cement and concrete and a preparation method of the modified desulfurization ash. The modified desulfurization ash for cement and concrete is prepared from desulfurization ash and an oxidizing agent through mixing at normal temperature, wherein the oxidizing agent comprises the following components by weight percentage: 70-80% of manganese dioxide, 5-10% of acetic acid and 10-25% of desulfuration residue, the conversion rate of CaSO4.2H2O in the modified desulfurization ash is 95-98%, the mixing amount of the modified desulfurization ash in cement and concrete is 5-25% (by weight percentage). The modified desulfurization ash has early compressive strength improved remarkably when being added into the cement and the concrete, has the compressive strength hardly reduced after being solidified completely, and has little swelling stress.

Owner:武汉武新新型建材股份有限公司

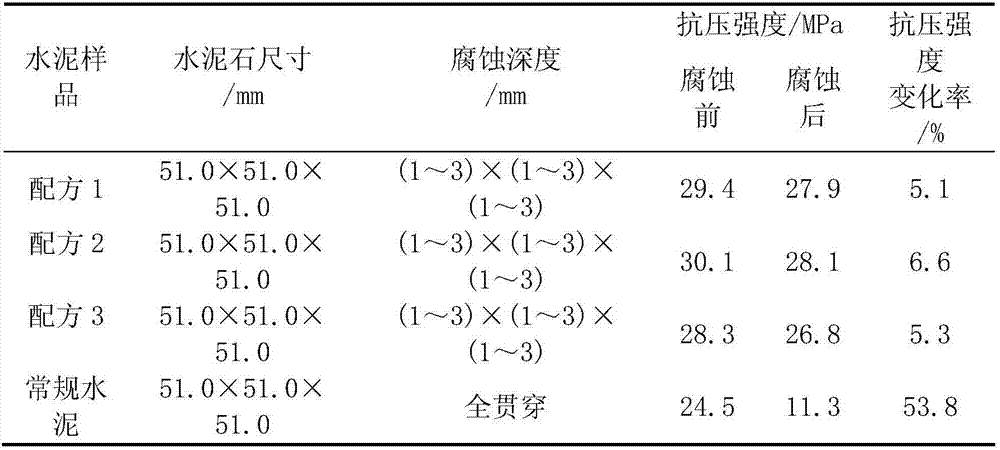

Well cementing slurry capable of preventing CO2 and H2S corrosion

ActiveCN106966648AImprove compactnessReduce permeabilityDrilling compositionBorehole/well accessoriesDefoaming AgentsWater soluble

The invention relates to well cementing slurry capable of preventing CO2 and H2S corrosion. The well cementing slurry comprises water and cement, wherein the mass ratio of the water to the cement is (0.40-0.50):1, and the cement comprises G-grade high-sulfate-resistance oil well cement, micro-cement, a dispersing agent, a fluid loss agent, micro-silicon, fly ash, an expanding agent, latex, water-soluble resin, an early strength agent, retarder and a defoaming agent. The well cementing slurry is excellent in CO2 and H2S corrosion resistance, capable of effectively resisting the corrosion of CO2 and H2S, capable of protecting underground tools such as sleeves to the maximum degree, and especially applicable to the well cementing of a high-CO2 and high-H2S acid oil-gas field.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

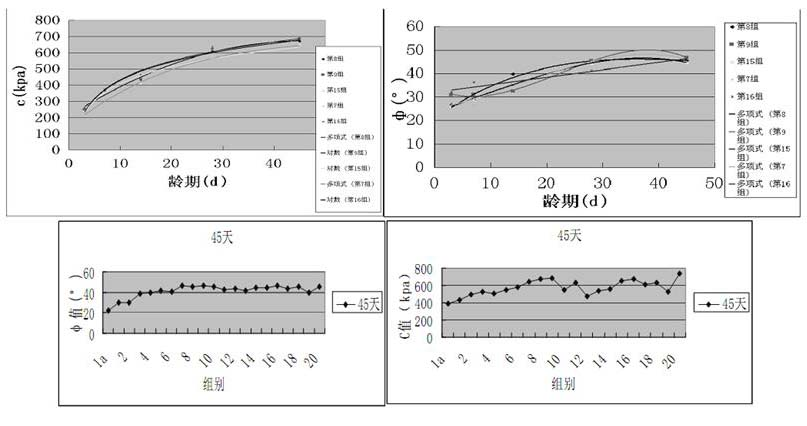

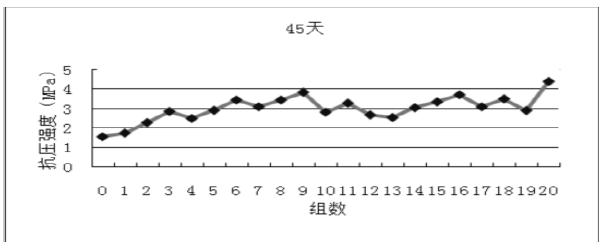

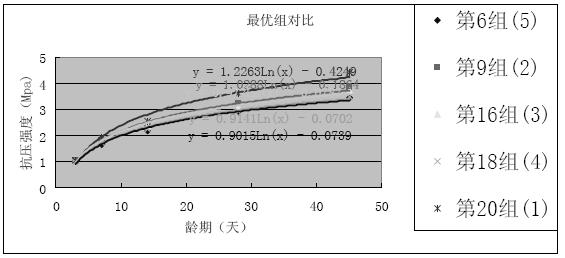

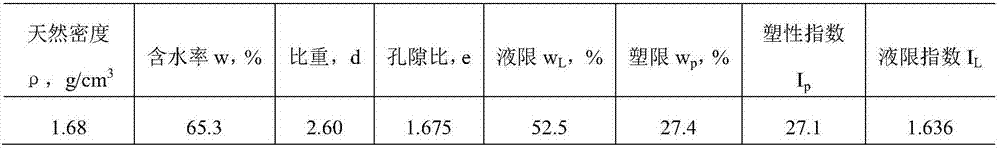

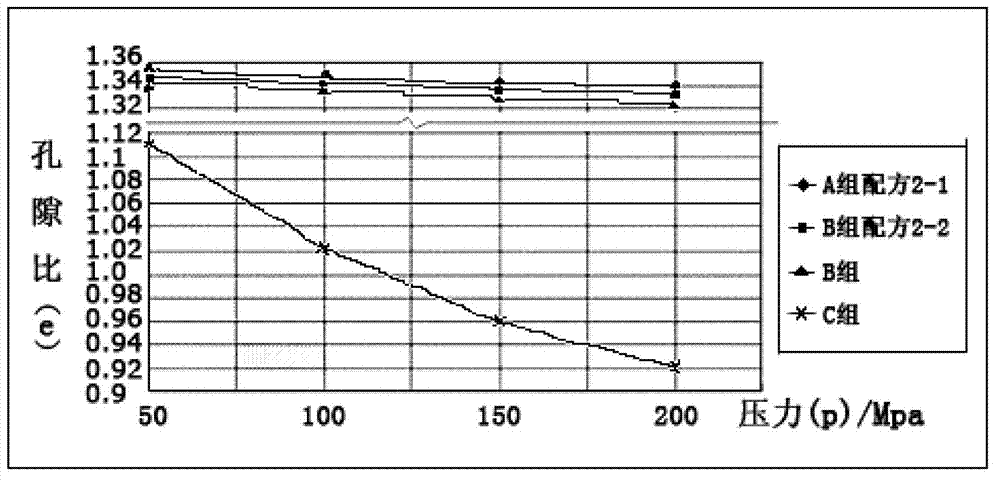

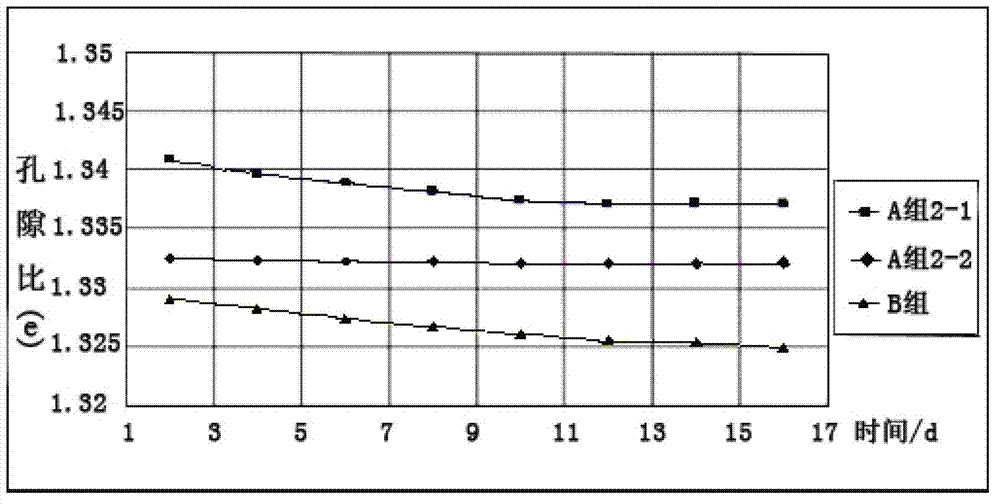

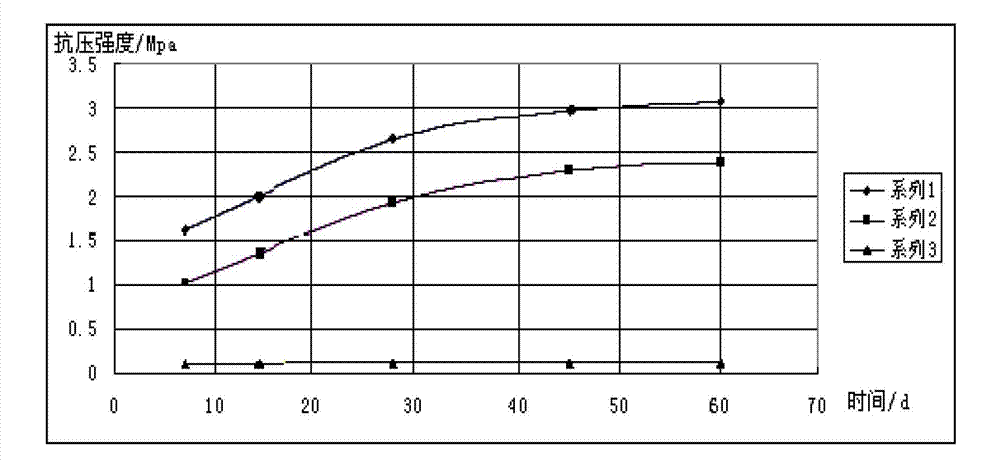

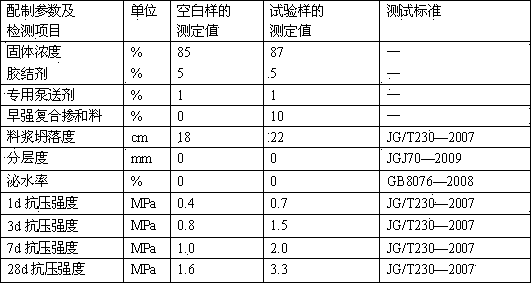

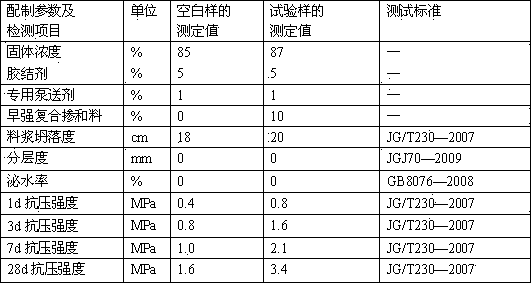

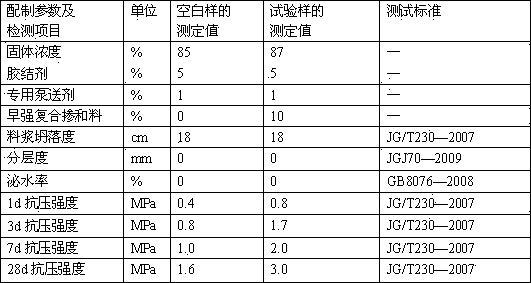

Muddy soil cement grout applied to vertical shaft part of pedestrian underpass in saturated soft clay region

The invention discloses a muddy soil cement grout and a composite additive applied to a vertical shaft part of a pedestrian underpass in a saturated soft clay region. A large number of indoor orthogonal tests show that the compression resistance and the shear resistance of muddy cement soil can be greatly improved by adding a plurality of composite admixtures and composite additives into Wenzhou soft cement soil of which the main component is muddy soil. The finding has great significance for constructing the vertical shaft part of the pedestrian underpass in an urban water-rich soft soil region. On the basis of the large number of indoor orthogonal tests, a new economical soft soil reinforcing formula of the vertical shaft part in the water-rich soft soil region, which is constructed by a shallow tunneling method, is found. By the pre-grouting method using the new formula, the geological conditions of the water-rich soft soil shallow-buried soil layer can be effectively improved and the smooth completion of constructing the pedestrian underpass by the shallow tunneling method is reliably guaranteed.

Owner:博地建设集团有限公司

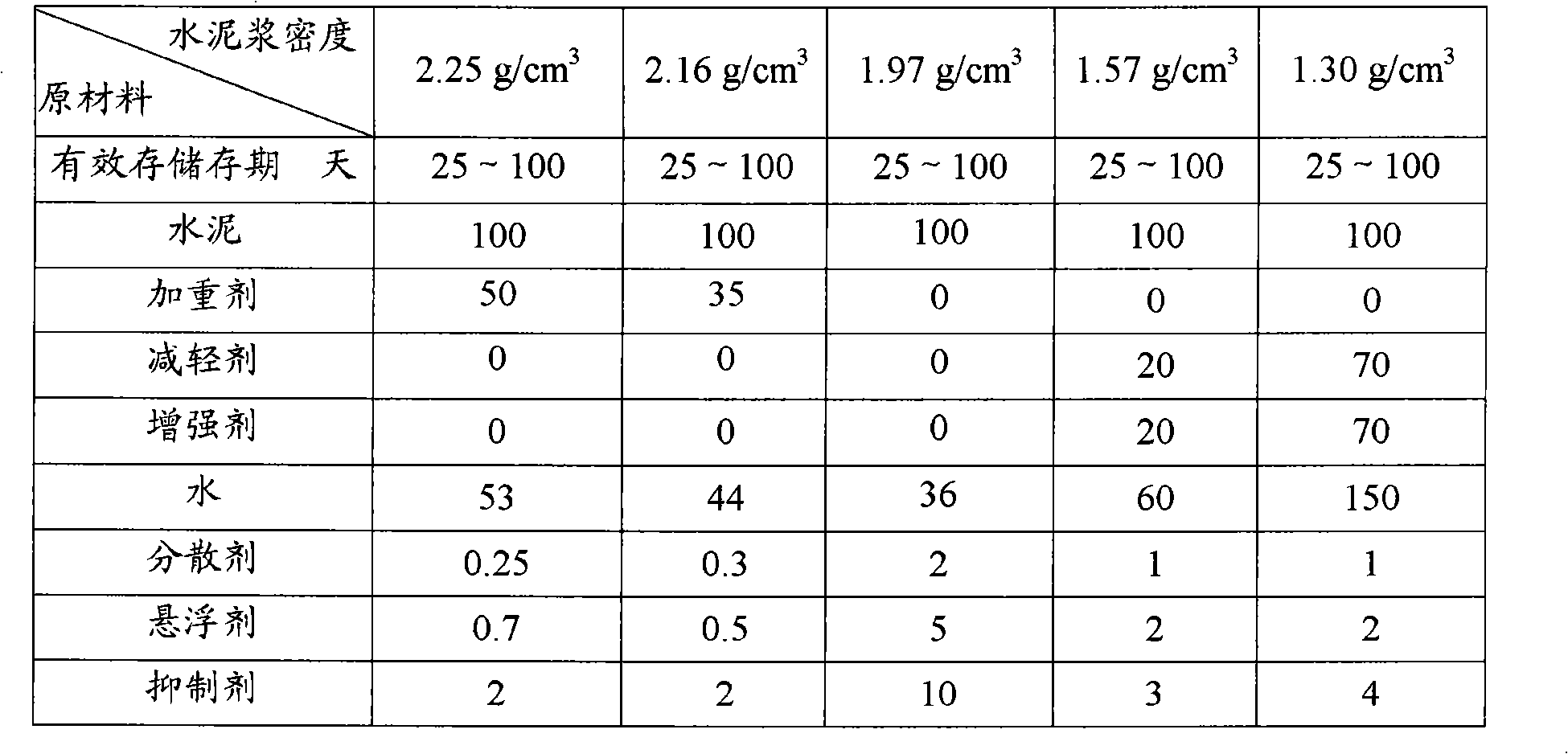

Liquid cement mortar capable of being stored

ActiveCN101337796AHigh compressive strengthEasy to transportSolid waste managementIntensifierCement mortar

The invention discloses liquified cement paste which can be stored. The liquified cement paste comprises 100 parts of cement, 0 to 70 parts of a light-weight additive, 0 to 50 parts of a weighting agent, 0 to 70 parts of an intensifier, 30 to 150 parts of water, 0.5 to 5 parts of a suspension stabilizer, 2 to 10 parts of a hydrate inhibitor and 0.3 to 2 parts of a dispersant. The storage period of the liquified cement paste which can be stored is 3 months; the density of the cement paste can be controlled between 1.30g / cm<3> to 2.10g / cm<3>; the cement paste is applicable for various well temperatures. By using a stimulator and an average retarder, the thickening time can be controlled between 1 and 72 hours; the early compressive strength of the cement paste is high with the 24 hour-strength of more than 14MPa; the cement paste is stable and reliable; the properties of the cement paste are basically kept unchanged before and after the cement paste is stored; other properties of the cement paste such as the fluid loss property, the rheological property and so on can be adjusted to meet the requirement of application by using well cementation additives.

Owner:CHINA NAT OFFSHORE OIL CORP +1

High-temperature silt stabilizing agent and preparation method thereof

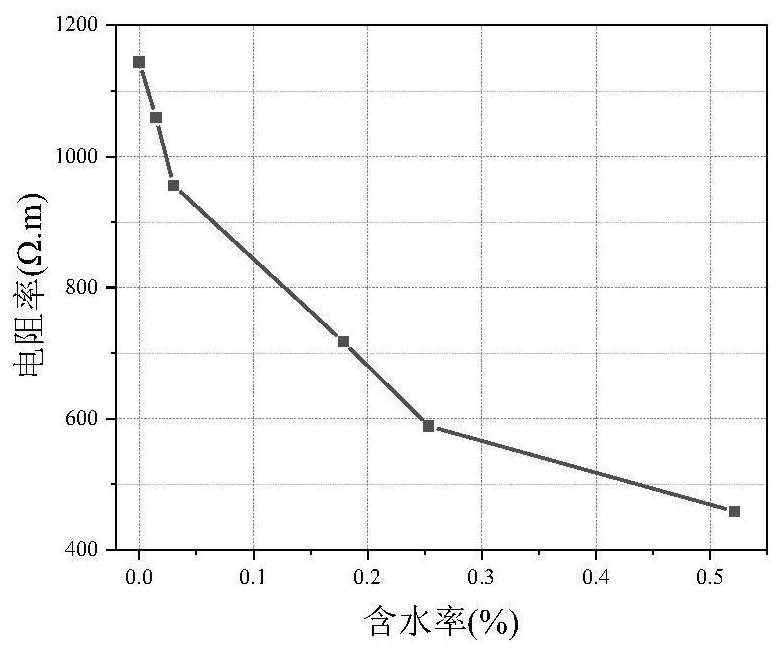

InactiveCN107445547AReduce moisture contentImprove stabilitySludge treatment by de-watering/drying/thickeningSlagMoisture

The invention discloses a high-temperature silt stabilizing agent which comprises the following components in percentage by mass: 30-60% of blast-furnace slag powder, 15-35% of fly ash, 10-20% of quick lime, 6-10% of a gelatinizing agent, 5-10% of phosphorus gypsum, 1-8% of a flocculating agent, 1-8% of an excitant and 1-5% of an enhancer. The high-temperature silt stabilizing agent is capable of effectively reducing the moisture content of silt, high in stability and short in curing time. The invention further discloses a preparation method of the high-temperature silt stabilizing agent.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD +1

Oil well cement chlorine-free coagulation accelerating early strength agent

ActiveCN102321459AObvious procoagulant effectReduce contentDrilling compositionCalcium formateCritical time

The invention relates to an oil well cement chlorine-free coagulation accelerating early strength agent, which consists of the following components in parts by weight: 1.0-2.0 parts of sulfate, 0.05-0.10 part of triethanolamine, 0.05-0.10 part of formamide, 1.0-2.5 parts of calcium formate, 0.5-2.0 parts of urea and 0.5-1.0 part of naphthalene sulfonate, wherein the suitable temperature of the coagulation accelerating early strength agent is 20-45 DEG C; the coagulation accelerating early strength agent can be applied to cement slurry systems of various densities, has high compatibility with various additive systems and does not have influence on cement slurry performance; a product designed by the invention does not contain any chloride; the cement slurry thickening time can be shortened; the cement slurry stability is improved; the cement stone early strength is improved; the critical time is shortened; thus, water channeling after well cementation is effectively prevented; and the early strength agent can be matched with corresponding additive and admixture for use and can be widely applied to low-temperature shallow wells and adjustment well cementation construction.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Novel formula for reclamation shoal soft soil suitable for ultra soft soil hydraulic reclamation method

InactiveCN102786281AHigh compressive strengthImprove early compressive strengthOrganic fertilisersSoil conditioning compositionsSludgeMaterials science

The invention provides a novel formula for reclamation shoal soft soil suitable for ultra soft soil hydraulic reclamation method. The formula comprises the following components, by mass part: 10 parts of dry soil powder, 2.40 parts of cement, 0.72 part of water glass, 0.576 parts of fly ash, 0.132 part of silicone powder, 0.12 part of gypsum powder, 6.08 parts of water, and 0.072 part of py4 composite admixture. According to a large number of indoor orthogonal experiments by the invention, reinforcement soft soil for hydraulic reclamation and water drainage method in Wenzhou coast, which mainly includes sludge reclamation, is mixed with cement and a plurality of admixtures and compound additives, and pressure resistance, shear resistance and compression performance of the soil can be greatly changed; and compared with s conventional cement formula, the novel formula consumes less supplies, but can greatly improve pressure resistance, shear resistance and compression performance of cement shoal soft soil, especially improve early compressive strength and significantly reduce settlement after construction. Therefore, the formula has important meaning for large area utilization and construction of ultra soft soil hydraulic reclamation coastal reclamation land in coastal southeastern industrial belt.

Owner:WENZHOU UNIVERSITY

High-performance superfine-cement-based grouting material

The invention relates to a high-performance superfine-cement-based grouting material. The high-performance superfine-cement-based grouting material is prepared by, by weight, 2640-2760 parts of superfine cement, 60-110 parts of modified nanoscale calcium powder, 19-25 parts of polycarboxylate superplasticizer, 65-105 parts of superfine expanding agent, 70-120 parts of superfine low-calcium fly ash, 10-28 parts of superfine desulfurization gypsum and 0.5-1.3 parts of sodium aliphatic alcohol sulfate. The high-performance superfine-cement-based grouting material is reasonable in formula, low in production cost, good in working performance, easy to process, environmentally friendly, energy-saving, free of pollution and wide in application range.

Owner:GANSU ZHITONG TECH ENG DETECTION CONSULTING CO LTD

Early strength compound admixture for full mill tailing pasty fluid cemented filling material

The invention belongs to the technical field of mine filling, and specifically relates to an early strength compound admixture for a full mill tailing pasty fluid cemented filling material. The early strength compound admixture is prepared by mixing the following components in parts by weight: gypsum, lime and superfine limestone flour in a ratio of (10-20):(5-10):(85-70). The effect is the best when the addition amount is 7.5-12.5% by weight of total solid in the full mill tailing pasty fluid cemented filling material. The early strength compound admixture provided by the invention is wide in raw material source and simple in production process. By adding the early strength compound admixture provided by the invention, the mobility and stability of the full mill tailing pasty fluid cemented filling material are improved, the early compressive strength is remarkably improved, and the early strength compound admixture has better environmental and economic benefits.

Owner:ZHENGZHOU UNIV

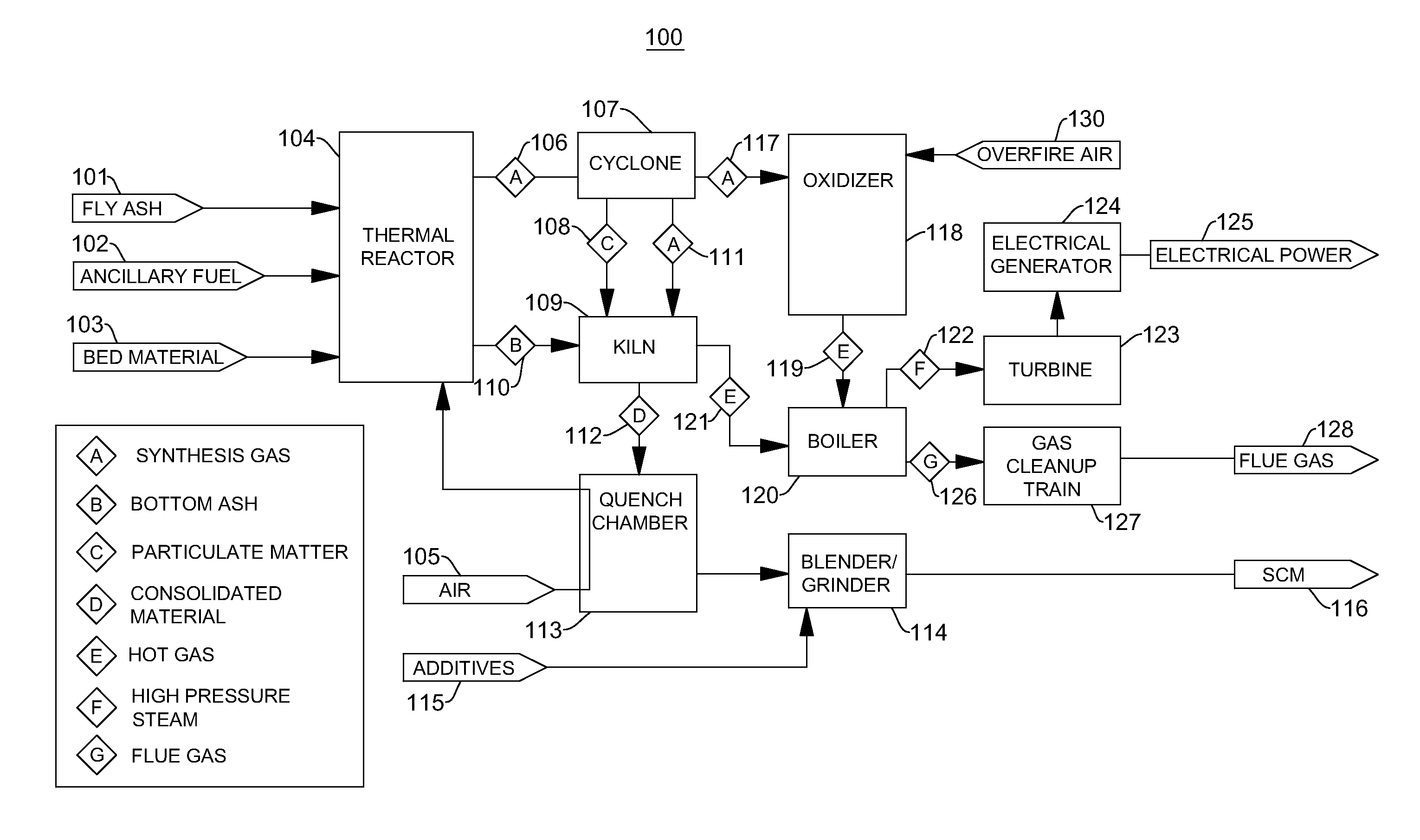

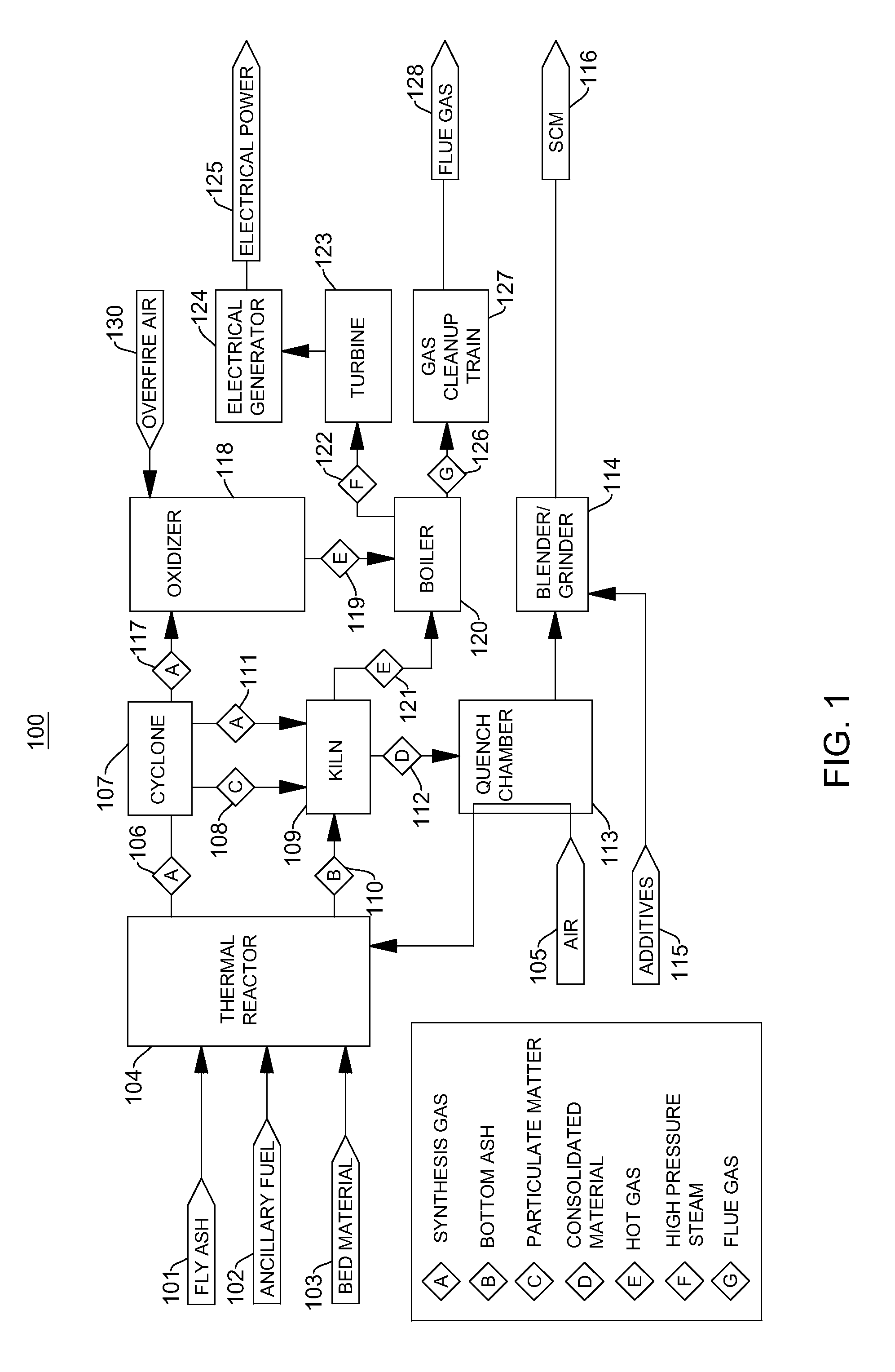

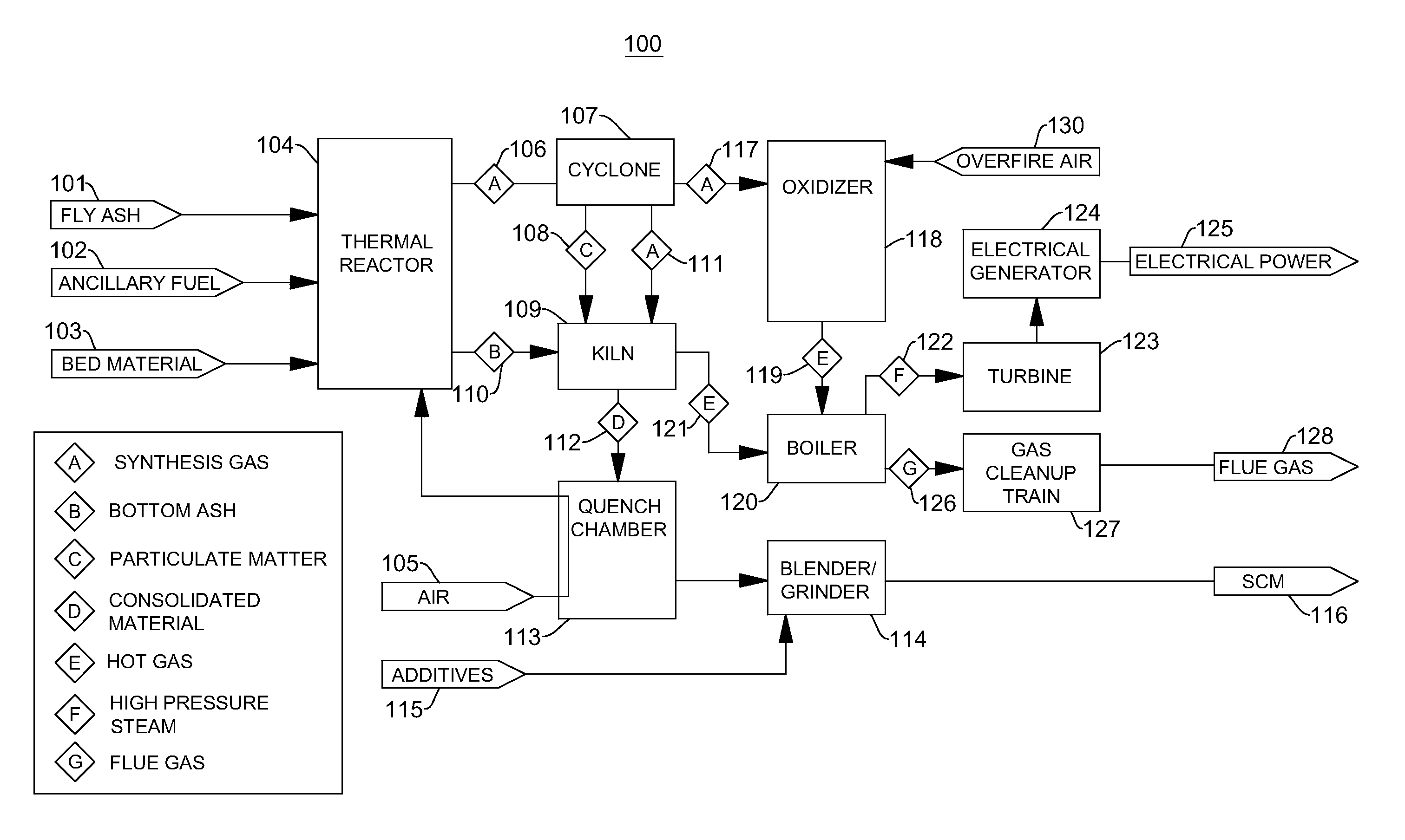

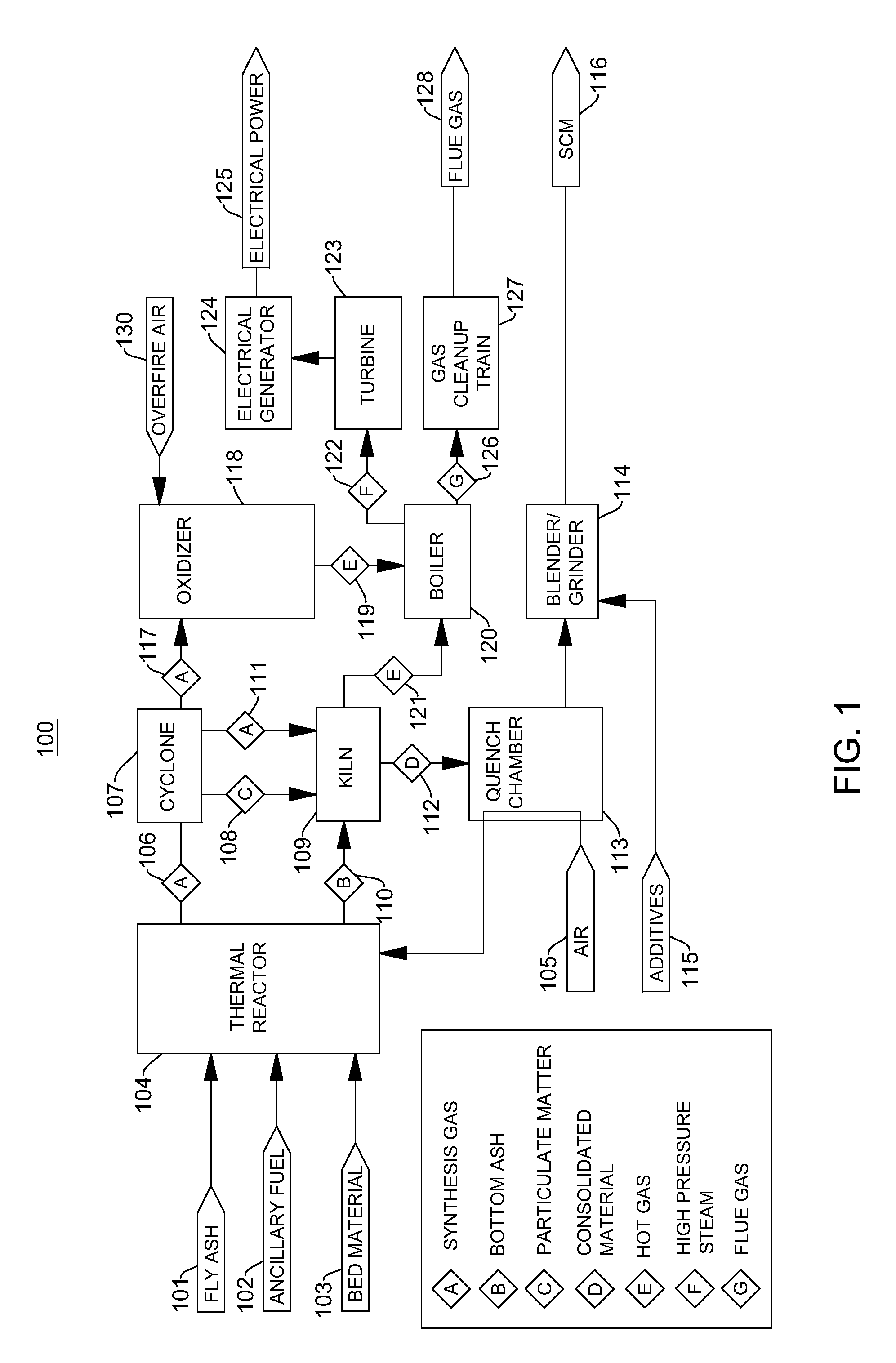

Method and system for reprocessing high carbon coal fly ash to produce cementitious materials

ActiveUS20130032061A1Improve early compressive strengthHigh strengthGasification processes detailsCombustible gas purificationHigh carbonVolcano

The invention provides a system and method of thermally processing high carbon coal fly ash to produce hydraulically reactive or pozzolanic supplemental cementitious material (SCM) and synthesis gas. In this “ash to energy and cement” (ATEC) process, coal fly ash and ancillary fuels are fed into a thermal reactor along with oxide materials, such as limestone. Carbon in the ancillary fuel and in the coal fly ash is converted to synthesis gas that is combusted to generate steam or electricity. The remaining low-carbon ash and bed material exits the thermal reactor chamber and is further processed at high temperature in a kiln or slagging unit to produce partially fused nodules or clinker. The nodules or clinker are cooled and ground to a desired fineness for use as a cementitious materials. The ATEC process effectively converts high carbon coal fly ash waste to energy and value added SCM.

Owner:MOBIL TENSOR HLDG LLC

Multifunctional compound grouting material

ActiveCN107337402AZero wasteFlexible adjustment of compatibilityMicrofine cementAluminum magnesium silicate

The invention relates to a multifunctional compound grouting material. The grouting material is prepared from, by weight, 2640-2760 parts of superfine cement, 50-80 parts of modified nanoscale calcium powder, 17-25 part of polycarboxylate superplasticizer, 60-120 parts of superfine steel slag fine powder, 75-120 parts of superfine high-calcium fly ash, 10-20 parts of superfine fluorine gypsum powder, 0.1-0.3 part of secondary nanoscale polymer and 1-3 parts of aluminum magnesium silicate, and the raw materials are evenly stirred to obtain the material. The multifunctional compound grouting material is reasonable in composition, low in production cost, good in working performance, easy to process, environmentally friendly, energy-saving, pollution-free, and wide in application range.

Owner:GANSU ZHITONG TECH ENG DETECTION CONSULTING CO LTD

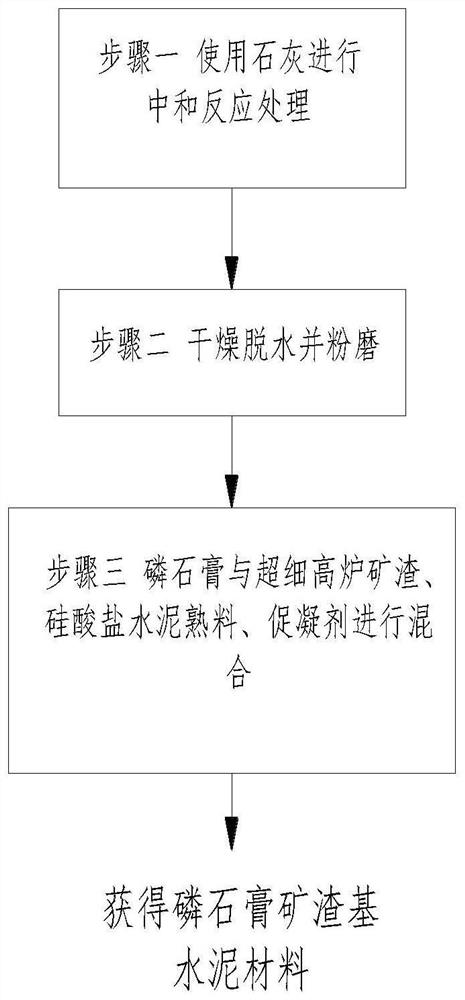

Preparation method of phosphogypsum slag-based cement

PendingCN112110661AHigh activityPromote disintegrationCement productionProcess engineeringEnvironmentally friendly

The invention discloses a preparation method of phosphogypsum slag-based cement. The method comprises the following steps: 1, carrying out neutralization reaction treatment on phosphogypsum by using lime; step 2, drying, dehydrating and grinding the prepared phosphogypsum; and 3, uniformly mixing the prepared phosphogypsum with ultrafine blast furnace slag, a Portland cement clinker and a coagulant according to a mass ratio of (15-20%):(75-85%):(1-5%):(1-2%) to obtain the phosphogypsum slag-based cement material. Compared with the prior art, the method has the advantages of turning waste intowealth, being economical and environmentally friendly and the like, and is simple in preparation process, easy to operate and low in cost. The prepared phosphogypsum slag-based cement is high in compressive strength, short in setting time, low in cost, energy-saving and environment-friendly, and has a wide application prospect.

Owner:四川绵筑新材料有限公司

Method for preparing geopolymer from stone coal vanadium extraction acid-leaching residues

The invention discloses a method for preparing a geopolymer from stone coal vanadium extraction acid-leaching residues. The method comprises steps as follows: grinding balls and the stone coal vanadium extraction acid-leaching residues are added to a stirring mill, water is used as an ore grinding medium, ore pulp is taken out after stirring activation is performed for 0.5-4 h, and activated residues are prepared after filtration and drying; the activated residues are evenly mixed with an activating agent, metakaolin and filler, and a mixture is obtained; an liquid alkali activator is added to the mixture with the mass ratio of the liquid alkali activator to the mixture being 0.7-1.4 and evenly mixed, and mixed mortar is prepared; the mixed mortar is poured into a mold, and a sample is obtained after vibration molding; the sample is sealed for maintenance at 30-80 DEG C for 3-12 h, demolded and left to stand at the room temperature for 1-4 d, and the geopolymer is obtained. The stone coal vanadium extraction acid-leaching residue activation process is simple, low in alkali consumption, low in cost and environment-friendly, the activity of tailings is high, and the prepared geopolymer is high in early compressive strength, high in sulfate corrosion resistance and high in thermal stability.

Owner:WUHAN UNIV OF TECH

Cement slurry with toughness and preparation method and application thereof

ActiveCN110386777AImprove adhesionReduce microcrack sizeDrilling compositionSuspending AgentsMaterials science

The invention discloses cement slurry with toughness and a preparation method and application thereof. The cement slurry with toughness is prepared from the components in parts by mass: 100 parts of oil well cement, 33-40 parts of a strength stabilizer, 0.3-0.5 part of a dispersing agent, 0.3-0.5 part of a suspending agent, 0.2-3 parts of a thickening time control agent, 2-5 parts of a fluid lossagent, 0.1-0.3 part of an antifoaming agent, 30-60 parts of water, and 1-3 parts of thermosetting phenolic resin; the strength stabilizer is prepared from silica fume and quartz sand, and the mass ratio of the silica fume to the quartz sand is (3 to 7) to (30 to 33); and the thermosetting phenolic resin is A-stage liquid phenolic resin with the molecular weight of 300-1,000 or B-stage partial cured phenolic resin with the molecular weight of 2,000-5,000. Set cement formed by the thickening of the cement slurry has high strength, low elastic modulus and low permeability, can meet the requirements of the performance of the cement slurry in gas storage well and gas injection drive oil well cementing construction, and ensures the safety of the cementing construction.

Owner:PETROCHINA CO LTD

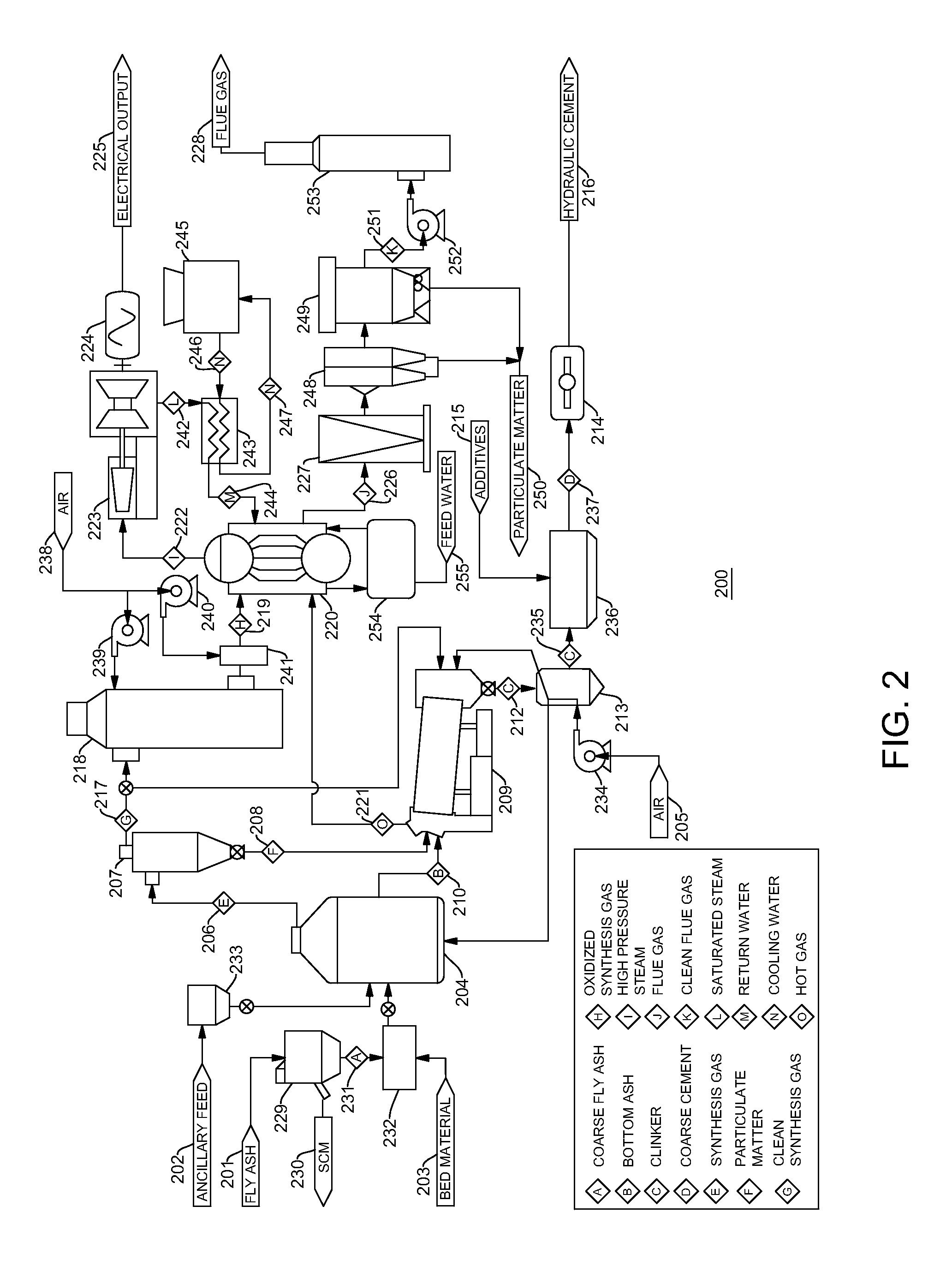

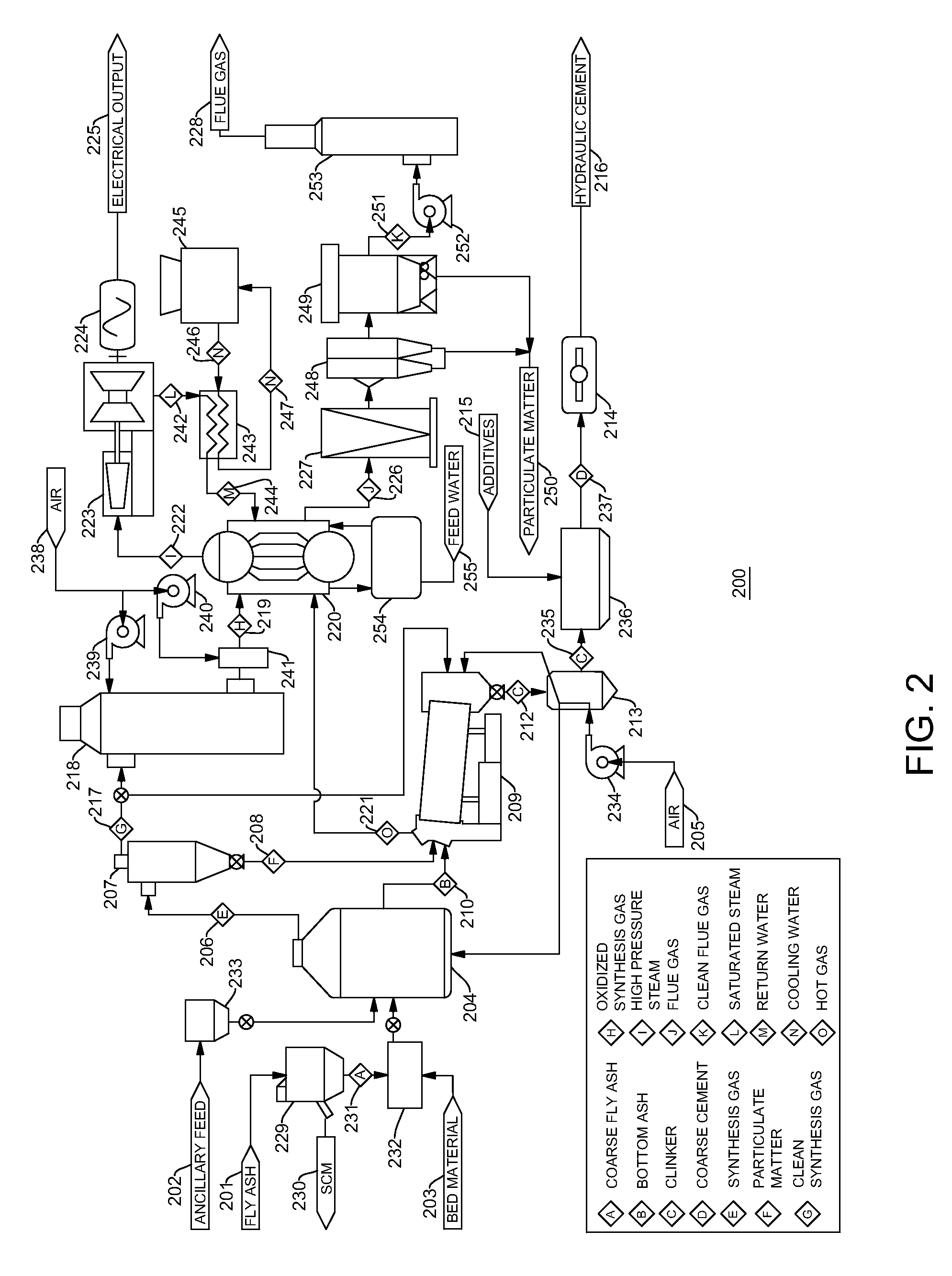

Method and system for reprocessing high carbon coal fly ash to produce cementitious materials

ActiveUS9284219B2Improve early compressive strengthHigh strengthGasification processes detailsCombustible gas purificationElectricityHigh carbon

A method is provided of thermally processing carbonaceous ash and ancillary carbonaceous material to produce a carbon-free inert, pozzolanic, or cementitious material and synthesis gas. The carbonaceous ash and ancillary fuels are fed into a thermal reactor along with oxides provided in the ash or in additives including limestone or glass. Carbon in the ancillary fuel and coal fly ash is converted to synthesis gas that is combusted to generate process steam and electricity. Remaining ash exits the thermal reactor chamber for processing at high temperature in a kiln gasifier to react the remaining fixed carbon and produce carbon-free partially-fused nodules or clinker that are cooled and ground to a desired fineness for cementitious or aggregate material in concrete. Carbonaceous ash, especially high carbon coal fly ash and other carbonaceous waste, are converted to energy and non-toxic, carbon-free aggregate or cementitious material used as architectural fill or in concrete mixes.

Owner:MOBIL TENSOR HLDG LLC

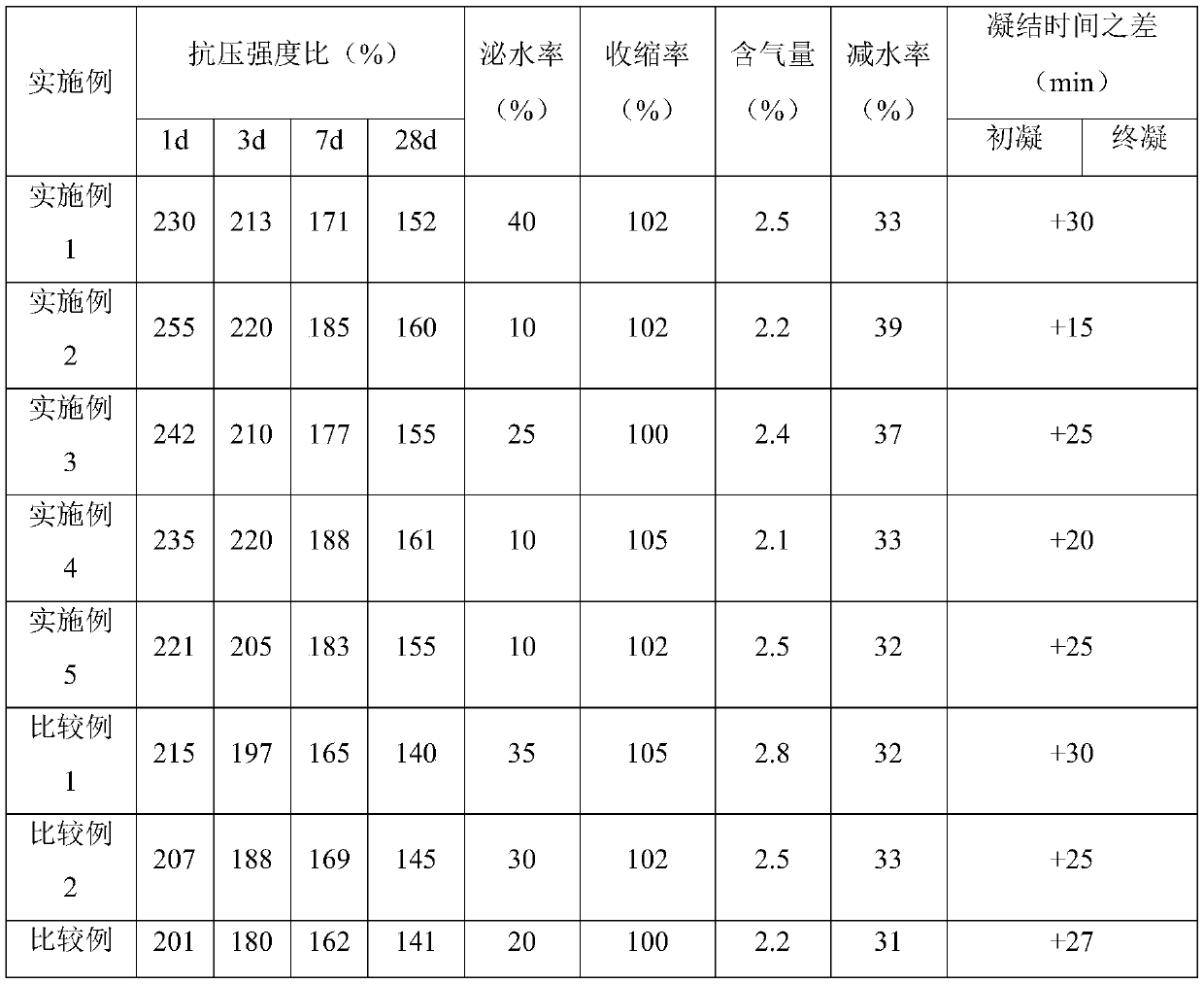

Early-strength-type polycarboxylate water reducer and preparation method thereof

InactiveCN110128601AImprove early compressive strengthImprove workabilityEthylenediamineMonoisopropanolamine

The invention provides an early strength type polycarboxylate superplasticizer and a preparation method thereof. The polycarboxylate superplasticizer is mainly prepared from the following raw materials, by weight, 420 to 440 parts of unsaturated polyoxyalkylene ether monomer with weight-average molecular weight of more than 5000, 2.7 to 3 parts of oxidant, 0.3 to 0.7 part of a reducing agent, 3 to5 parts of unsaturated anhydride monomer, 1.5 to 2 parts of a chain transfer agent, 500 to 540 parts of water, 70 to 100 parts of alcohol amine organic material, and unsaturated monocarboxylic acid and derivative monomer thereof. The alcohol amine organic material is at least one of triethanolamine, triisopropanolamine, diethanol monoisopropanolamine and ethylenediamine. Based on the oxidant-reductant initiation system in the formula, strong alkali does not need to be added into the whole system for neutralization instead of the alcohol amine organic material; after specific combination of polymer monomers with large molecular weight, unsaturated acid anhydride monomers and other substances is adopted, the early strength of the concrete is remarkably improved.

Owner:上饶市天佳新型材料有限公司

Method for preparing concrete enhancer by utilizing nickel slag

The invention belongs to the technical field of building materials and in particular relates to a method for preparing a concrete enhancer by utilizing nickel slag. The method is characterized by uniformly adding the nickel slag to 5-45wt% of formic acid solution and reacting at 20-80 DEG C for 1-24 hours, thus preparing the enhancer, wherein the mass ratio of the nickel slag to formic acid is (0.5-4.0):1. The method has the obvious advantages that after the enhancer is mixed in concrete according to 1.0-5.0% of the mass of cement or cementing materials, the early compressive strength of the concrete can be obviously improved, and the later compressive strength is also greatly improved; the enhancer can be widely applied to Portland cement-based materials such as slurry, mortar and concrete; the method is simple in formula and production process and is easy to popularize and apply.

Owner:福建源鑫环保科技有限公司

Eco-friendly pavior brick and preparation method thereof

InactiveCN107056199ASolve the problem that waste cannot be reusedSolve the insulation performanceSingle unit pavingsCeramicwareBrickSurface layer

The invention provides an eco-friendly pavior brick and a preparation method thereof, and relates to the technical field of pavior brick production. The pavior brick comprises a surface layer and a base layer, wherein the surface layer is prepared from, by weight, 15-27 parts of cement, 15-30 parts of grit, 5-7 parts of macadam, 30-40 parts of industrial waste cinder granules, 12-16 parts of waste ceramic particles, 3-6 parts of silica fume, 5-10 parts of coal ash, 3-10 parts of lime, 2-4 parts of air-entraining agents, 1.5-2.5 parts of waterproof agents, 0.3-0.5 part of antifreezing agents, 0.4-0.6 part of water reducing agent, 0.3-0.5 part of pigment powder and 1-3 parts of water; the base layer is prepared from, by weight, 16-18 parts of cement, 18-22 parts of grit, 17-25 parts of macadam and 2-3 parts of water; the preparation method includes the steps of (1) the preparation of surface layer ingredients, (2) preparation of base layer dosing, (3) molding, demoulding, stacking and maintaining; the eco-friendly pavior brick and the preparation method thereof solve the problems of unavailable recycling of wastes, poor heat insulation property, low water permeability and freezing resistance, a bad effect of reducing water and low compressive strength in the prior art.

Owner:合肥慧林建材有限公司

Cementing material with low-temperature resistance and preparation method thereof

PendingCN110981398AImprove mechanical propertiesGuaranteed early compressive strengthHydration reactionAluminite

The invention provides a cementing material with low-temperature resistance and a preparation method. The cementing material is prepared from sulphoaluminate cement clinker, anhydrite, monomineral anhydrous calcium sulphoaluminate, dihydrate gypsum and other additives. The cementing material disclosed by the invention adopts a sulphoaluminate clinker-anhydrite-anhydrous calcium sulphoaluminate-dihydrate gypsum quaternary system, so that the development of the strength of the cementing material at negative temperature is facilitated. The cementing material disclosed by the invention is subjected to hydration reaction at negative temperature to generate an ettringite crystal phase, so that the cementing material has excellent early compressive strength, and the cementing material is suitablefor construction in a low-temperature environment in winter. According to the formula of the cementing material, the problem of poor hydration performance in a negative temperature environment is effectively solved, and the cementing material has excellent negative temperature strength performance. The cementing material is safe, environment-friendly, non-toxic, pollution-free and convenient to operate and has remarkable application value and economic benefit.

Owner:BEIJING UNIV OF TECH

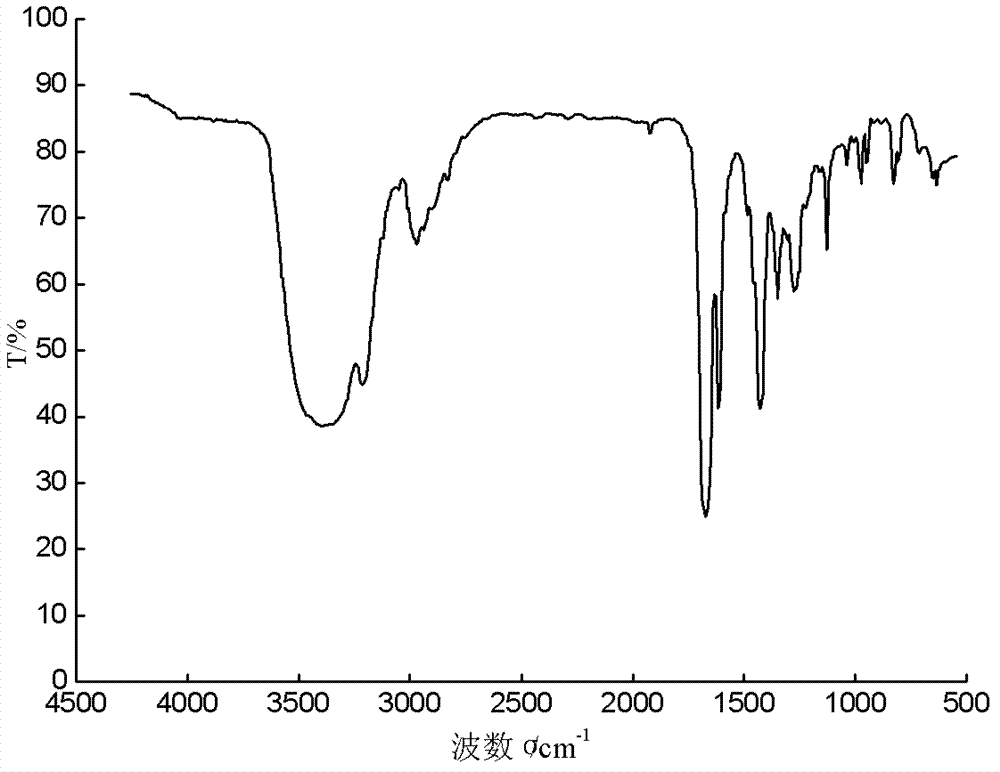

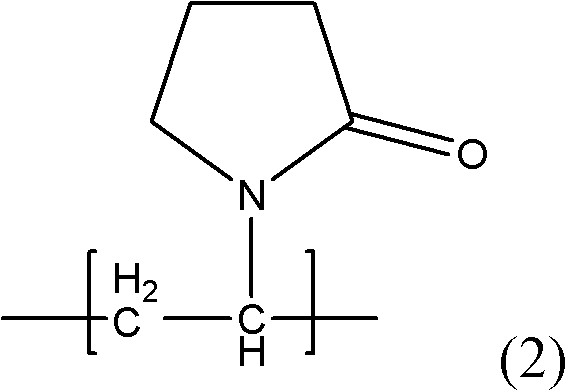

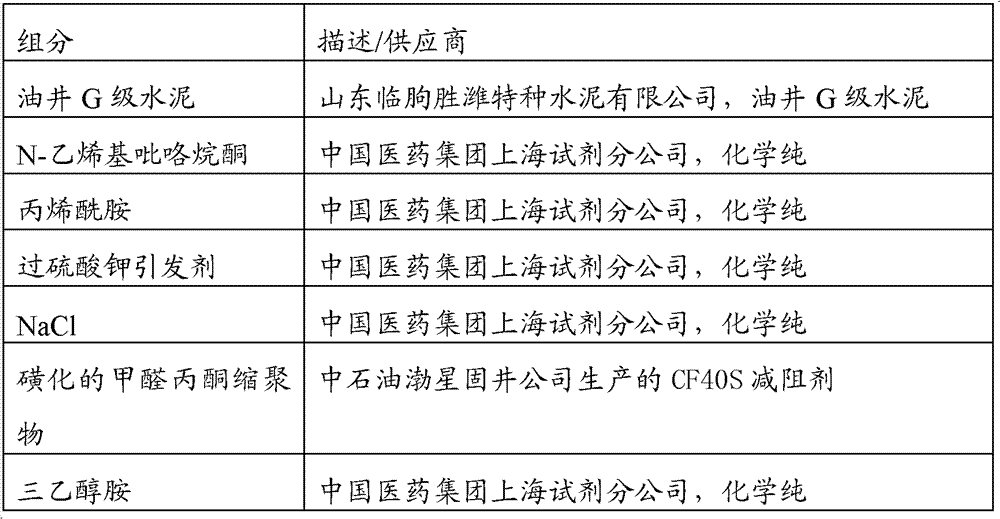

Water loss reducing composition, cement composition containing water loss reducing composition, and preparation method and use of water loss reducing composition

ActiveCN102786918AReduce water lossStrong salt resistanceDrilling compositionSealing/packingMaterials sciencePolymerization

The invention relates to a water loss reducing composition, a cement composition containing the water loss reducing composition, and a preparation method and a use of the water loss reducing composition. The water loss reducing composition comprises 55-75 parts by weight of an N-vinyl pyrrolidone-acrylamide copolymer, 28-45 parts by weight of a sulfonated formaldehyde-acetone polycondensate, and 0.7-2.0 parts by weight of an organic amine early strength agent, wherein the N-vinyl pyrrolidone-acrylamide copolymer is prepared through a polymerization reaction of N-vinyl pyrrolidone and acrylamide with the weight ratio of the N-vinyl pyrrolidone to the acrylamide of 1:0.12-1:0.4, and preferably 1:0.2-1:0.3.

Owner:CHINA UNITED COALBED METHANE +1

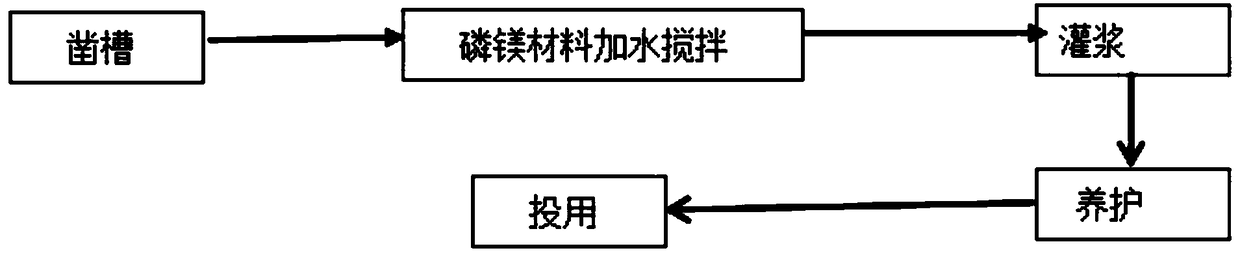

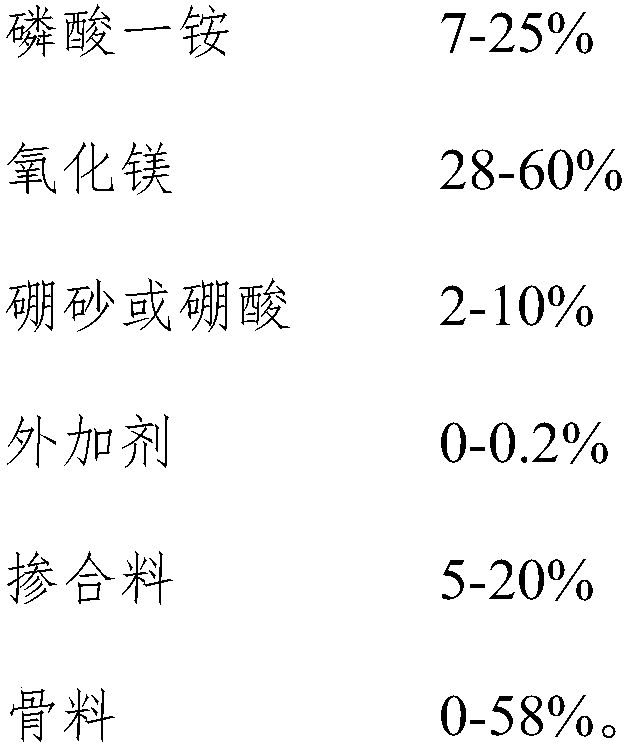

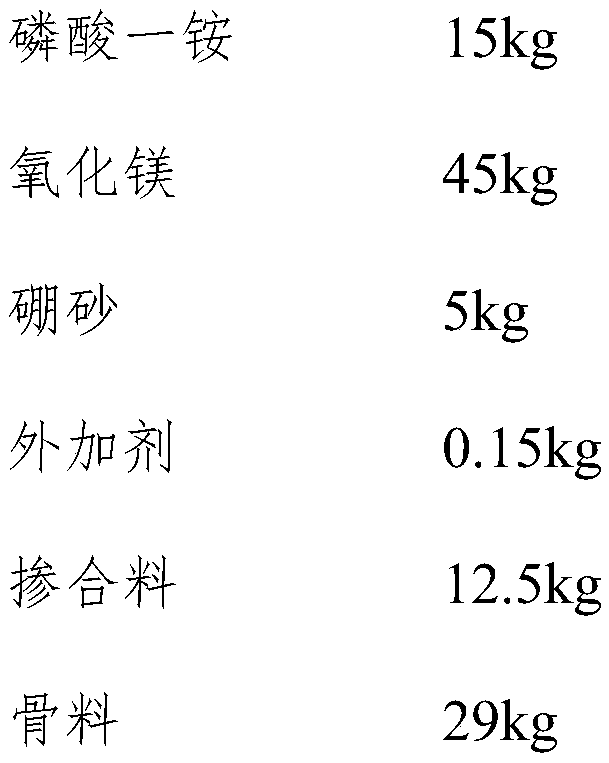

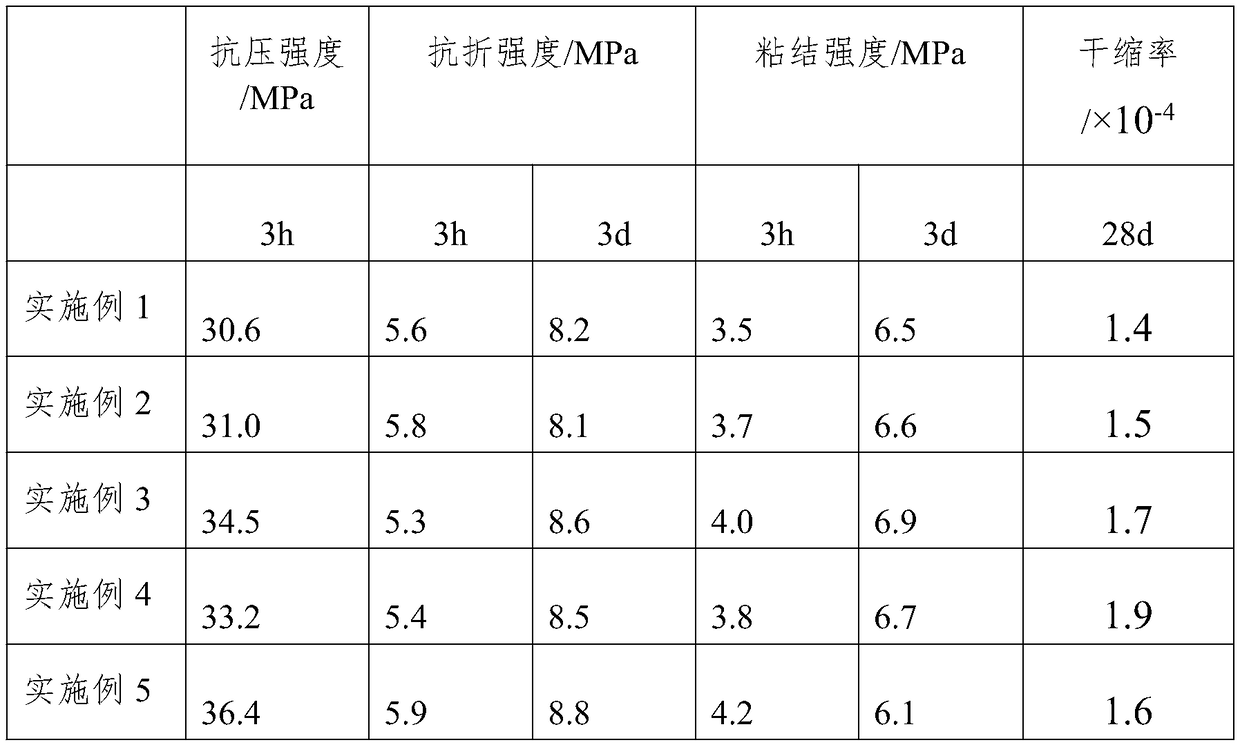

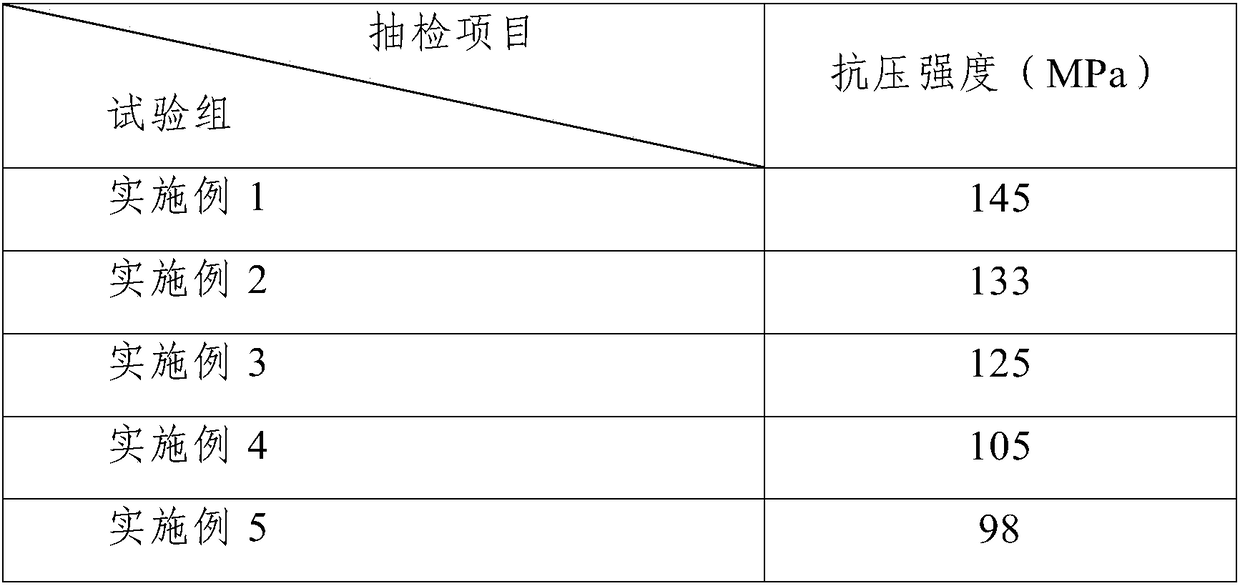

Concrete crack repairing material based on phosphorus magnesium material and construction technology thereof

The invention relates to the technical field of the concrete repair and in particular to a concrete crack repairing material based on a phosphorus magnesium material and a construction technology thereof. The concrete crack repairing material based on the phosphorus magnesium material is obtained by mixing monoammonium phosphate, magnesium oxide, borax or boric acid, an additive, an admixture andaggregate according to a specific proportion, and in a repairing process of a concrete crack, interface treatment does not need to be performed. The prepared concrete crack repairing material based onthe phosphorus magnesium material has the characteristics of short coagulation time, high compressive strength in early stage, high breaking strength, high bonding strength, low dry shrinkage rate, good durability, high abrasive resistance and the like, and is capable of solving problems in the prior art that cost is high, ageing is easy and service life is short, the material is harmful to a human body in a construction process, the construction technology is complicated, the bonding strength of a bonding surface of old and new materials is low, integrality of a repairing structure is weak,longer maintenance time is needed and the like.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

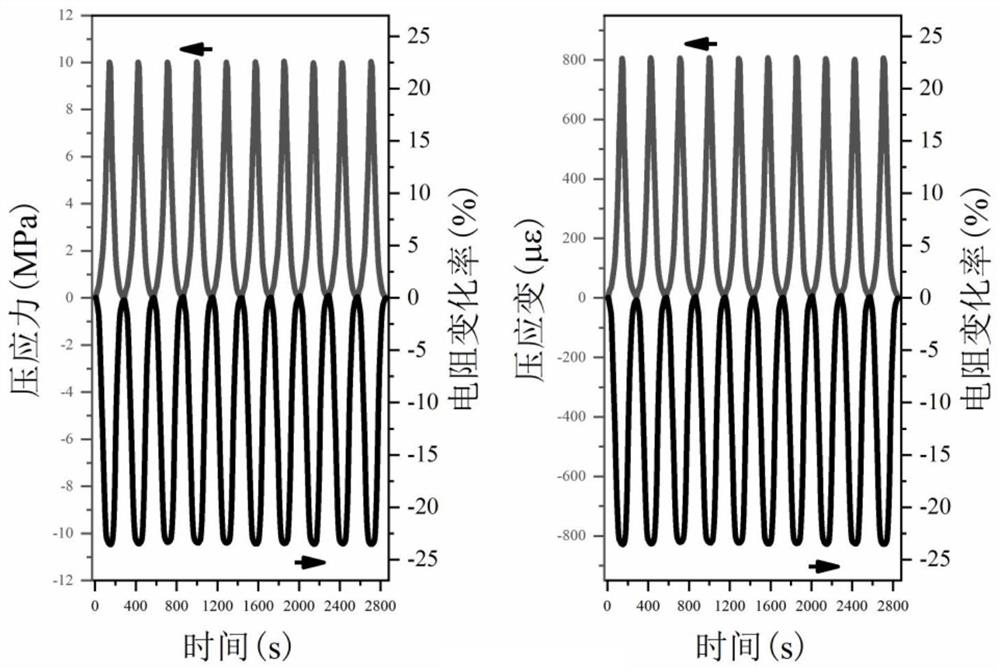

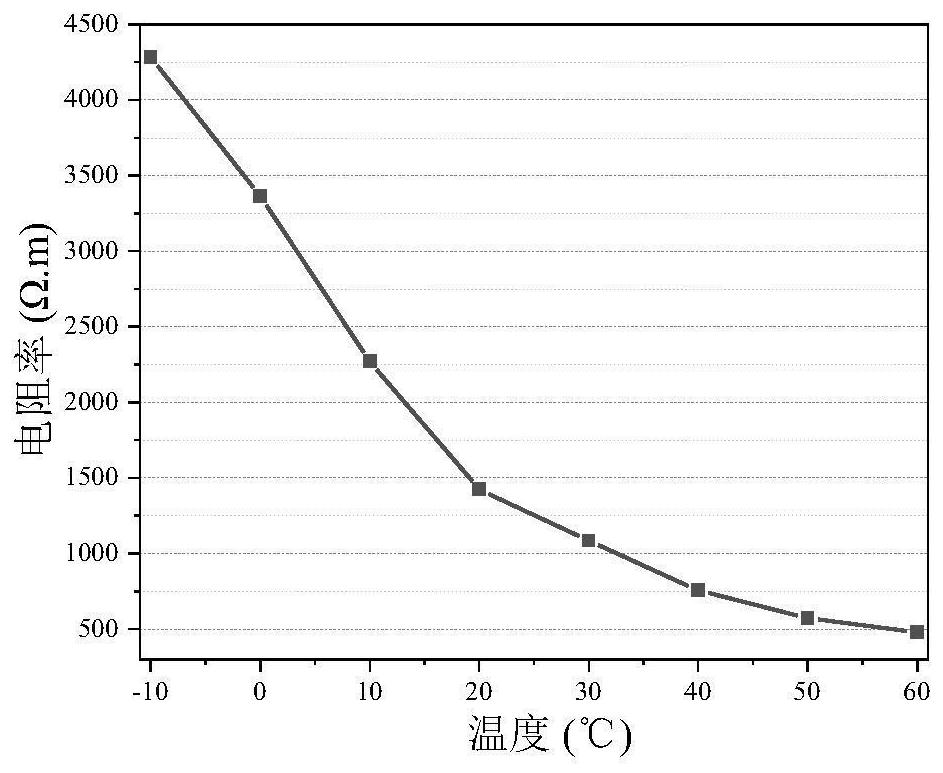

Concrete sensor with multi-intelligence characteristic and preparation method thereof

ActiveCN112268933AEnhanced Perceptual CharacteristicsSensitive characteristics are stable and highly sensitiveMaterial resistanceMoisture capacityStructural engineering

A concrete sensor with a multi-intelligence characteristic comprises the following components in percentage by weight: cement to nano silicon dioxide to slag to sand to water reducing agent to defoaming agent to three-dimensional carbon nano material aqueous dispersion liquid =1:(0.05-0.12):(0.1-0.2):(0.8-1.2):(0.02-0.03):(0.001-0.004):(0.240-0.284), the volume content of steel fibers is 1.0-2.0%,and the volume content is 0.5-1.5%. The invention further provides a preparation method of the concrete sensor with the multi-intelligence characteristic. The problems that intelligent concrete onlyserves as a single performance sensor, and the sensing performance is reduced after the load exceeds the elastic range of the intelligent concrete or the intelligent concrete cracks are solved, and meanwhile the temperature, humidity and load state change of the structure can be stably monitored.

Owner:ZHEJIANG UNIV OF TECH

Processing method of concrete holes or exposed bars

The invention relates to the technical field of concrete, and particularly relates to a processing method of concrete holes or exposed bars. The method comprises the following steps: chipping away unqualified concrete; cleaning a surface; erecting a template; stirring; pouring; performing conservation; dismantling the template; and putting into use. The method disclosed by the invention has the characteristics of convenience in operation, low cost, short construction working periods and good construction effect. Processing is carried out by adopting the method, so that the concrete applied toa restoration part has the characteristics that (1) a dry shrinkage ratio is low, even the concrete is expanded a little, and the phenomena of shrinkage and cracking are avoided, so that the durability of a concrete structure is ensured; (2) the condensation time is short, the early compressive strength is high, and the concrete structure is in a service state in time; and (3) the folding strengthand the bonding strength are high, and the adaptability of an environment of concrete components is improved.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

Ultra-high-performance fiber concrete and production method thereof

ActiveCN108409235ASlightly highImprove compactnessSolid waste managementSuperplasticizerWell cementing

The invention discloses ultra-high-performance fiber concrete, comprising cement, silica fume, sand, steel fiber, polypropylene fiber, a polycarboxylate superplasticizer, an organosilicon defoaming agent and water. The silica fume in the fiber concrete improves compactness and homogeneity for the concrete; the sand has filling and framework functions; stress can be effectively transmitted, and load can be effectively supported; contraction and cracking of the concrete are inhibited; the steel fiber inhibits and restrains the occurrence and development of microcracks in the concrete, so that the concrete has improved toughness and ductility. The invention also discloses a preparation method of the concrete, comprising: stirring well cement, silica fume, polypropylene fiber and sand, addingthe polycarboxylate superplasticizer, organosilicon defoaming agent and 90% by total mass of water, adding steel fiber, stirring well, adding the rest 10% of water, and stirring well. The production method has reasonable process and good simplicity as well as high efficiency.

Owner:陕西建研结构工程股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com