Ultra-high-performance fiber concrete and production method thereof

A fiber-reinforced concrete, ultra-high-performance technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of poor brittleness, poor compactness and poor homogeneity, and achieve increased toughness and ductility, good Fluidity, the effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

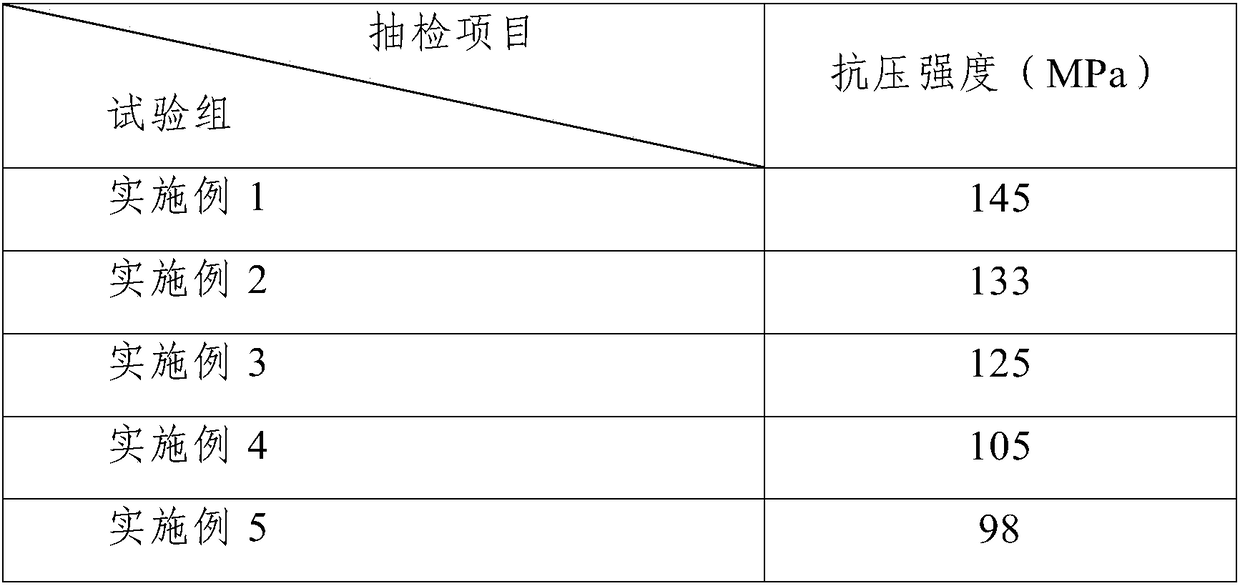

Examples

Embodiment 1

[0020] A kind of ultra-high-performance fiber concrete of this embodiment is composed of P.O.52.5R Portland cement, silica fume, sand, steel fiber, polypropylene fiber, early-strength polycarboxylate high-efficiency water reducer, silicone defoamer and Composition of water; the loss on ignition of the silica fume is 6%, and the specific surface area of the silica fume is 16000m 2 / kg, the mass content of silicon dioxide in the silica fume is 92%, the particle diameter of the sand is 0.85mm~2mm, and the mass ratio of the P.O.52.5R Portland cement, silica fume, sand and water is 1: 0.24:1.25:0.2, the water reducing rate of the early-strength polycarboxylate superplasticizer is 35%, and the dosage of the early-strength polycarboxylate superplasticizer is P.O.52.5R Portland cement and silica fume 2.38% of the total mass, the dosage of the organosilicon defoamer is 0.137% of the total mass of P.O.52.5R Portland cement and silica fume, the steel fiber is Shanghai Zhenqiang brand s...

Embodiment 2

[0023] A kind of ultra-high-performance fiber concrete of this embodiment is composed of P.O.52.5R Portland cement, silica fume, sand, steel fiber, polypropylene fiber, early-strength polycarboxylate high-efficiency water reducer, silicone defoamer and Composition of water; the loss on ignition of the silica fume is 5%, and the specific surface area of the silica fume is 19000m 2 / kg, the mass content of silicon dioxide in the silica fume is 95%, the particle diameter of the sand is 0.85mm~2mm, and the mass ratio of the P.O.52.5R Portland cement, silica fume, sand and water is 1: 0.21:1.26:0.22, the water reducing rate of the early-strength polycarboxylate superplasticizer is 40%, and the dosage of the early-strength polycarboxylate superplasticizer is P.O.52.5R Portland cement and silica fume 2.35% of the total mass, the dosage of the organosilicon defoamer is 0.12% of the total mass of P.O.52.5R portland cement and silica fume, the steel fiber is Sichuan Sanhe brand steel ...

Embodiment 3

[0026] A kind of ultra-high-performance fiber concrete of this embodiment is composed of P.O.52.5R Portland cement, silica fume, sand, steel fiber, polypropylene fiber, early-strength polycarboxylate high-efficiency water reducer, silicone defoamer and Composition of water; the loss on ignition of the silica fume is 7%, and the specific surface area of the silica fume is 19000m 2 / kg, the mass content of silica in silica fume is 94%, the particle diameter of described sand is 0.85mm~2mm, and the mass ratio of described P.O.52.5R Portland cement, silica fume, sand and water is 1: 0.22:1.27:0.24, the water reducing rate of the early-strength polycarboxylate superplasticizer is 33%, and the dosage of the early-strength polycarboxylate superplasticizer is P.O.52.5R portland cement and silica fume 2.35% of the total mass, the dosage of the organosilicon defoamer is 0.12% of the total mass of P.O.52.5R Portland cement and silica fume, and the steel fiber is the steel fiber produce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com