Patents

Literature

395 results about "Vegetable fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dark-colored vegetables. In general, the darker the color of the vegetable, the higher the fiber content. Carrots, beets, and broccoli are fiber-rich. Collard greens and Swiss chard have 4 grams of fiber per cup.

Degradable nourishing flowerpot and sprout cultivation bowl

The degradable flower pot and the seedling growing pot are produced with the material including plant fiber, adhesive, assistant and organic fertilizer; and the assistant is paraffin, animal or vet oil, stearic acid, talcum powder, calcium carbonate, lime or their mixture. The degradable flower pot and the seedling growing pot are produced through the steps of cutting plant fiber, mixing with adhesive, assistant, organic fertilizer and water via stirring, hot pressing to cure and form, and demolding. Inside the pot, the roots of plant are attached to the inside wall for well air exchange. During the degradation of the pot, nutrients are released and provided to plant gradually. The pot is ventilate and hydrophobic and has certain humidity and fertilizer maintaining effect and no environmental pollution.

Owner:SHANGHAI SAFBON WATER SERVICE CO LTD

Full-biodegradable polylactic acid composite material and preparation method thereof

The invention discloses a full-biodegradable polylactic acid composite material and a preparation method thereof. The composite material comprises the following components in parts by weight: 40-93 parts of polylactic acid, 5-40 parts of flexibilizer, 1-10 parts of plasticizer, 1-30 parts of vegetable fibre, 0.1-2 parts of antioxygen and 0.1-1 part of silane coupling agent. In the invention, the vegetable fibre composite polylactic acid is modified, which can enhance the mechanical property and the heat resistance of the polylactic acid material, and moreover, the polylactic acid material can be fully degraded, and the raw materials of the polylactic acid material are renewable and abundant; a lateral feed mode is applied to the fiber, therefore, the damage of a screw to the fibre is smaller, the strengthening and toughening effects of the fibre are better. Polydiethylene glycol sebacate (PBS), grafted with a polylactic acid copolymer, serves as the flexibilizer, which not only greatly improves the compatibility of the PBS and the polylactic acid but also can improve the toughness and the heat resistance of the composite material.

Owner:CHERY AUTOMOBILE CO LTD

Leech bait

InactiveCN104543447AMeeting nutritional needsNo pollutionAnimal feeding stuffWater sourceMultivitamin

The invention relates to the field of feeds, and in particular relates to a leech bait. Saccharides, protein, plant fibers, microelements, multivitamins and the like are fused in various growth periods of leech; research on an artificial feed has achieved initial success; the artificial feed can meet the nutrient requirements of the leech at different growth stages, and is easy to absorb; standardized breeding is achieved; the feed is fed without residues; a water source is not polluted; and the storage is facilitated.

Owner:ANHUI GUANCHAN BIOTECH

Method for preparing jerusalem artichoke beverage

The preparation method of girasole beverage includes three technological process steps: 1. preparation of girasole hydrolyzate; 2. preparation of osmanthus flower extract; and 3. blending, packaging and sterilizing. The girasole hydrolyzate, osmanthus flower extract, phosphoric acid and citric acid are mixed according to the mixing ratio of 100:(10-12):3:(4-6), then water is added according to the ratio of the above-mentioned mixed material liquor and water of 1:(50-60), uniformly stirred, bottled, capped and sterilized so as to obtain the invented product with rice nutrients and several health-care functions of reproducing bifidobacteria in human body, inhibiting the growth of intestinal salmonella and spilage organism, raising immunity of human body and reducing blood-lipid, etc.

Owner:林杨

Fruit and vegetable colorful health care soybean curd and preparation thereof

A multi-colored health care tofu containing fruit and vegetable comprises the following raw materials with the weight portions of 8 to 10 portions of soybean, 4 to 10 portions of fruits, 8 to 10 portions of vegetables and 0.3 to 1 portions of ecological coagulant, wherein, the fruit and the vegetable are the fruits and the vegetables with the pH of less than 7. The ecological coagulant is the mixture of glucose and plaster which is in the ratio of 1 to 3:22 to 28. The production process comprises screening and sorting soybean, soaking and removing peels, grinding for separation, mixing and coloring by adding the extracted natural vegetable juice and fruit juice, cooking and coagulating, squeezing and forming and packing the finished products. In the invention, algin, mannite, plant fiber, protein, a plurality of amino acids, a plurality of vitamins, a plurality of trace elements including calcium, iron and selenium which are the essential matter inside the body are added, which can effectively prevent a plurality of diseases including high blood pressure, obesity, cardiovascular genomic, biliary calculus and other diseases.

Owner:晏亚清

Method of producing an animal food product with a core and shell

ActiveUS20070020355A1Simple wayNot produce unpleasantMilk preservationAnimal feeding stuffFiberCold formed

The present invention relates to a method of producing an animal food product with a core and a shell at least partially covering the core, in which the core starting material includes meat and / or meat-like components, water, oil and / or fat, vitamins, minerals, salts, antioxidising agents, dyes and / or preservatives, vegetable fibres, and other ingredients. The shell starting material includes vegetable and / or animal protein, cereal, starch and / or dextrin, blood plasma, water, cereal derivative and / or sugar or sugar derivative, and vitamins, minerals, salts, antioxidising agents, dyes and / or preservatives. The method includes the steps of: either producing core particles by mixing the core materials, baking the mixture thus obtained, conditioning, cutting into small pieces and conditioning again, or producing core particles by mixing the core materials, cold forming the mixture thus obtained and cutting it into small pieces, and then mixing the core particles with the components of the shell in a coating pan, baking or deep-frying and finally conditioning.

Owner:MARS INC

Matrix material and restoration method for ecological restoration of gangue dump of mining area

InactiveCN105993259AEnsure balanceReduce the cost of ecological reconstructionGrowth substratesCulture mediaFiberRestoration method

The invention provides a matrix material and restoration method for ecological restoration of a gangue dump of a mining area. The matrix material consists of two parts, i.e., a seed germination layer and a root inducing layer and is mainly prepared from loam, acidified coal gangue, inorganic nonmetallic minerals, plant fibers, a water retention agent, an agglomerating agent, a disinfectant, a compound fertilizer, a seed mixture and the like. The matrix material has the characteristics of water retention, fertilizer retention, good stability, erosion resistance, easiness in plant establishment and the like; and by using wastes such as the coal gangue as main matrix materials, the consumption of imported soil can be effectively lowered, the soil environment of abandoned mines is improved, the environmental pollution is reduced, and the ecological restoration cost is reduced.

Owner:SHANXI UNIV

Frozen aerated confection and method of production

InactiveUS8940352B2Minimize thermal denaturationSoften the frozen confectionFrozen sweetsConfectioneryFiberVegetable fibre

Frozen aerated packaged ice confection with very high softness at −18° C. which keeps this property without shrinkage or layering up to the final consumer over the product shelf life contains polyol and vegetable fiber.

Owner:NESTEC SA

Frozen Aerated Confection And Method Of Production

InactiveUS20070202231A1Good flexibilityImprove stabilityFrozen sweetsFood preparationFiberVegetable fibre

Frozen aerated packaged ice confection with very high softness at −18° C. which keeps this property without shrinkage or layering up to the final consumer over the product shelf life contains polyol and vegetable fibre.

Owner:NESTEC SA

Degradable paper plastic composite bag and preparation method thereof

The invention discloses a degradable paper plastic composite bag including a plastic layer and a paper layer, the plastic layer is arranged on the surface of the paper layer, the plastic layer includes starch, vegetable fibre, polyvinyl alcohol, poly Beta-hydroxybutyrate, polyethylene, polycarbonate, nanometer titanium dioxide, glycerin, a plasticizer, and a stabilizing agent. The degradable paper plastic composite bag has excellent photodegradation and biodegradation properties, and is mild in degradation conditions and short in degradation time. The nanometer titanium dioxide in the plastic layer further improves the ultraviolet resistance capability of the plastic layer on the basis of having excellent degradability. In addition, the preparation method of the degradable paper plastic composite bag is simple in step and the degradable paper plastic composite bag can be produced industrially in batch because the raw materials are easy to get.

Owner:TONGLING FOUNDER PLASTICS TECH

Plastic fiber cultivating soil and preparation method thereof

ActiveCN105367216AReduce weightGood construction curingOrganic fertilisersFertilizer mixturesPlastic fiberPlant soil

Plastic fiber cultivating soil is prepared from 15-35% of foundation soil, 5-35% of plant fiber powder, 10-50% of perlite, 5-15% of peat soil and 5-15% of dual-component hot-melt adhesion composite fibers. The composite fibers are formed by compositing two thermoplastic polymers through composite spinning according to a sheath-core type structural mode. The difference of melting points of the adopted two thermoplastic polymers is not lower than 30 DEG C. The composite fibers are composed of dual-component hot-melt adhesion composite fibers A with the particle size being 15-25 mm and dual-component hot-melt adhesion composite fibers B with the particle size being 3-8 mm. The composite fibers A and the composite fibers B can be made of same materials or different materials. The particle size of the plant fiber powder is 0.2-0.9 mm. The plastic fiber cultivating soil has the advantages that the cultivating soil can be cured and formed and is long in service life, not prone to weathering, low in weight, high in moisture-preserving performance and breathability, capable of being recycled after being discarded and the like. The plastic fiber cultivating soil has the main effects that the problems that in the vertical greening construction process, plants cannot be easily attached to walls, planting soil is large in gravity, and the soil is not easily shaped and is prone to dispersion are solved, and the problem that large-scale mechanical seedling inserting is difficult in upland soil planting. Due to the fact that most raw materials come from agricultural and forestry waste, a contribution can be made to agriculture and environmental protection, and the fiber soil can be recycled or directly used as combustion improver after being used.

Owner:湖南尚佳绿色环境有限公司

Vegetable gum based on modified starch, preparation method thereof and application of vegetable gum

The invention discloses vegetable gum based on modified starch. The vegetable gum is prepared from the following raw materials in parts by weight, 40-90 parts of modified starch, 3-30 parts of gelatinizing agents, 2-20 parts of plasticizers, 2-20 parts of polymer, 2-20 parts of plant fibers, 10-50 parts of deionized water and 1-15 parts of cross-linking agents. The raw materials are mixed and subjected to reaction at the temperature ranging from 20 DEG C to 120 DEG C for 10-200 minutes, and the vegetable gum is prepared by kneading, extruding and cutting procedures. The starch and the polymer or macro-molecules are compounded and mixed or grafted and copolymerized, the vegetable gum overcomes the shortcomings of poor plasticity, low tensile strength and frangibility of original starch and difficulty in degradation and non-renewable performance of the macro-molecules, the vegetable gum is degradable, renewable, low in cost, good in plasticity, stable on heat and resistant to aging, and a preparation method of the vegetable gum controls extrusion temperature, screw rotation speed, cutter rotation speed and granule cooling, so that granules cannot be adhered and are uniform in size and good in plasticity. The vegetable gum is applied to related products such as degradable plastics, capsules and food and drug packing materials.

Owner:安顺济世科技有限公司

Enzymatic preparation of plant fibers

InactiveUS8603802B2Efficient and effective extractionReduce harmMicrobiological testing/measurementVegetable materialFiberAqueous solution

Owner:NAT RES COUNCIL OF CANADA

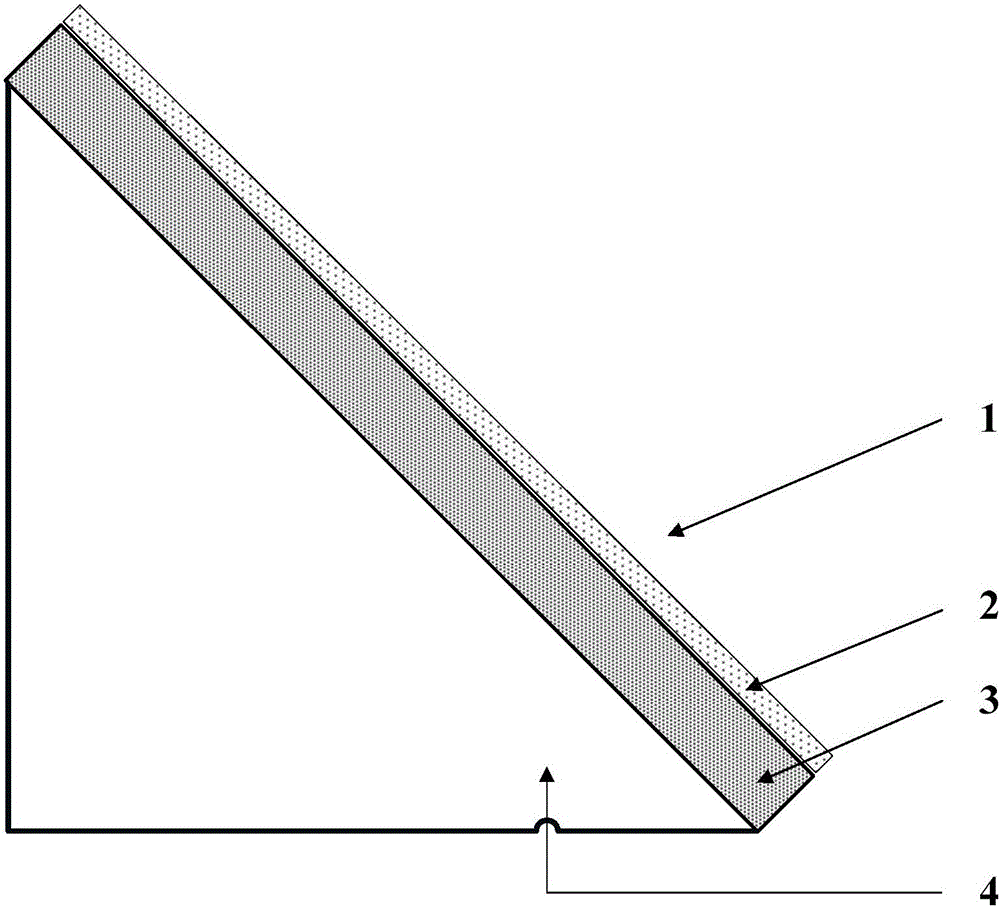

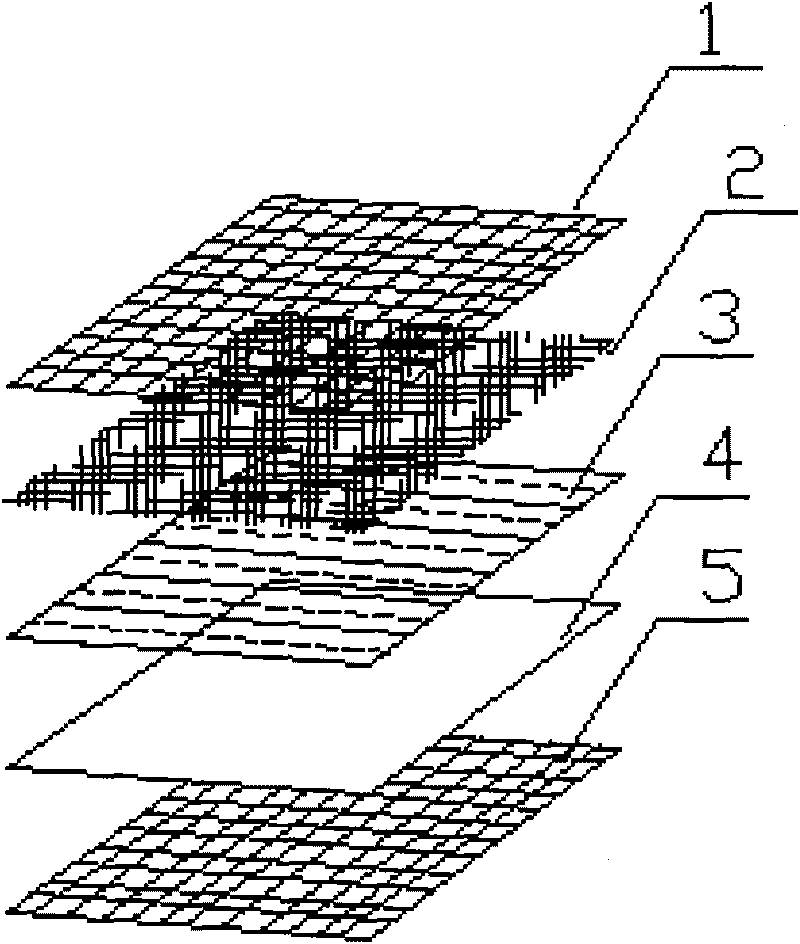

Grass blanket with soil

InactiveCN101692769AHigh strengthPlay a protective effectSeed arrangmentsHorticultureRevegetationOrganic layer

The invention provides a grass blanket with soil, which at least comprises an upper net, a fiber layer, an organic layer, a lining and a lower net, which are arranged in turn and are sewn together, wherein the organic layer is composed of nutrient soil, water-loss reducer and seeds. As the grass blanket is provided with the organic layer for providing an environment for seeds to grow and adopts straw, palm fibers and / or hemp which contain plant fibers as the fiber layer which is covered on the lining, the strength of the grass blanket is enhanced, the seeds and the nutrients are protected, and a plurality of nutrients for grown grasses can be provided after the composing materials of the fiber layer are degraded. The invention is applicable to the greening and vegetation recovery of deserts, mines and roadbeds, and has lower cost and stronger suitability.

Owner:康莱德国际环保植被(北京)有限公司

Method for preparing barley seedlings green juice powder and wheat green flour

InactiveCN101167571ABig color changeBright green colorDough treatmentFood preparationNutritive valuesFiber

The invention provides a process for preparing barley grass green powder, and comprises sorting, cleaning and sterilizing, cutting into sections, blanching, cooling, drying, and low-temperature airflow comminuting. The invention can fully utilize nutritional substances which exist in the barley grasses. The invention has extensive usages, which not only can be used as beverages, but also can be used as the natural pigment and plant fiber extender to be charged in the flour, and improves the nutritive value of flour and vitamin contents. The invention further provides the process for preparing barley green flour.

Owner:SICHUAN XIANGZHEN ENTERPRISE

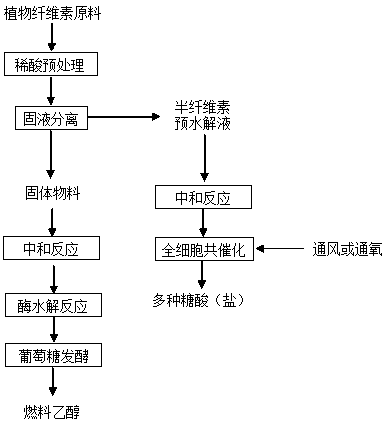

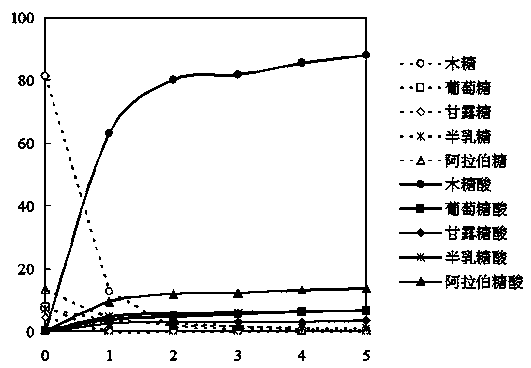

Method for co-producing plurality of saccharic acids from cellulose fuel ethanol

InactiveCN103627735ARelieve stressIncrease profitBiofuelsMicroorganism based processesSaccharic acidFiber

The invention discloses a method for co-producing a plurality of saccharic acids from cellulose fuel ethanol. The method comprises the following steps: performing dilute acid hydrolysis pretreatment or dilute acid steam explosion pretreatment on plant fiber raw materials to obtain a hemicellulose pre-hydrolysate and cellulose-enriched solid material through solid-liquid separation, wherein an enzyme hydrolysate is obtained by neutralizing and performing cellulose enzyme hydrolysis on the solid material, and fuel ethanol is produced by anaerobically fermenting the enzyme hydrolysate through saccharomyces cerevisiae or zymomonas mobilis; and a plurality of saccharic acids are produced by whole-cell co-catalyzing through gluconobacter oxydans or pseudomonas fragi under an aerobiotic condition after the hemicellulose pre-hydrolysate is concentrated and neutralized. The plurality of saccharic acids can be co-produced from fuel ethanol prepared from the plant fiber raw materials, the inhibiting effect of hemicellulose pre-hydrolysate sugar fermentation can be effectively overcome, the utilization efficiency of various carbohydrate substances in the plant fiber raw material can be obviously improved, the pollution load in industrial wastewater is effectively reduced, thereby improving the economic benefit of bio-refinery of the plant fiber raw materials. The utilization rate of total carbohydrate in the raw materials is over 80%, and the carbohydrate conversion rate is more than 90%.

Owner:NANJING FORESTRY UNIV

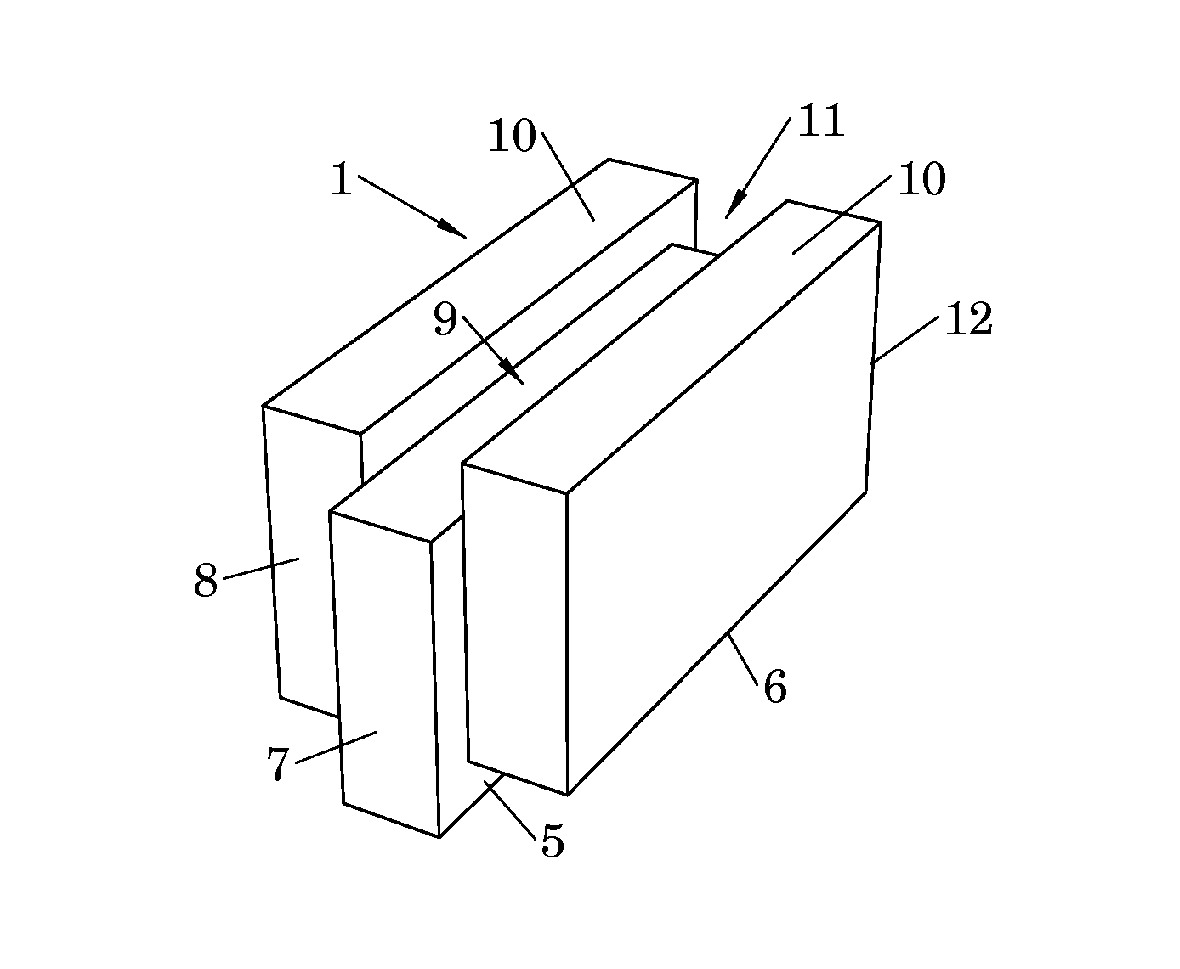

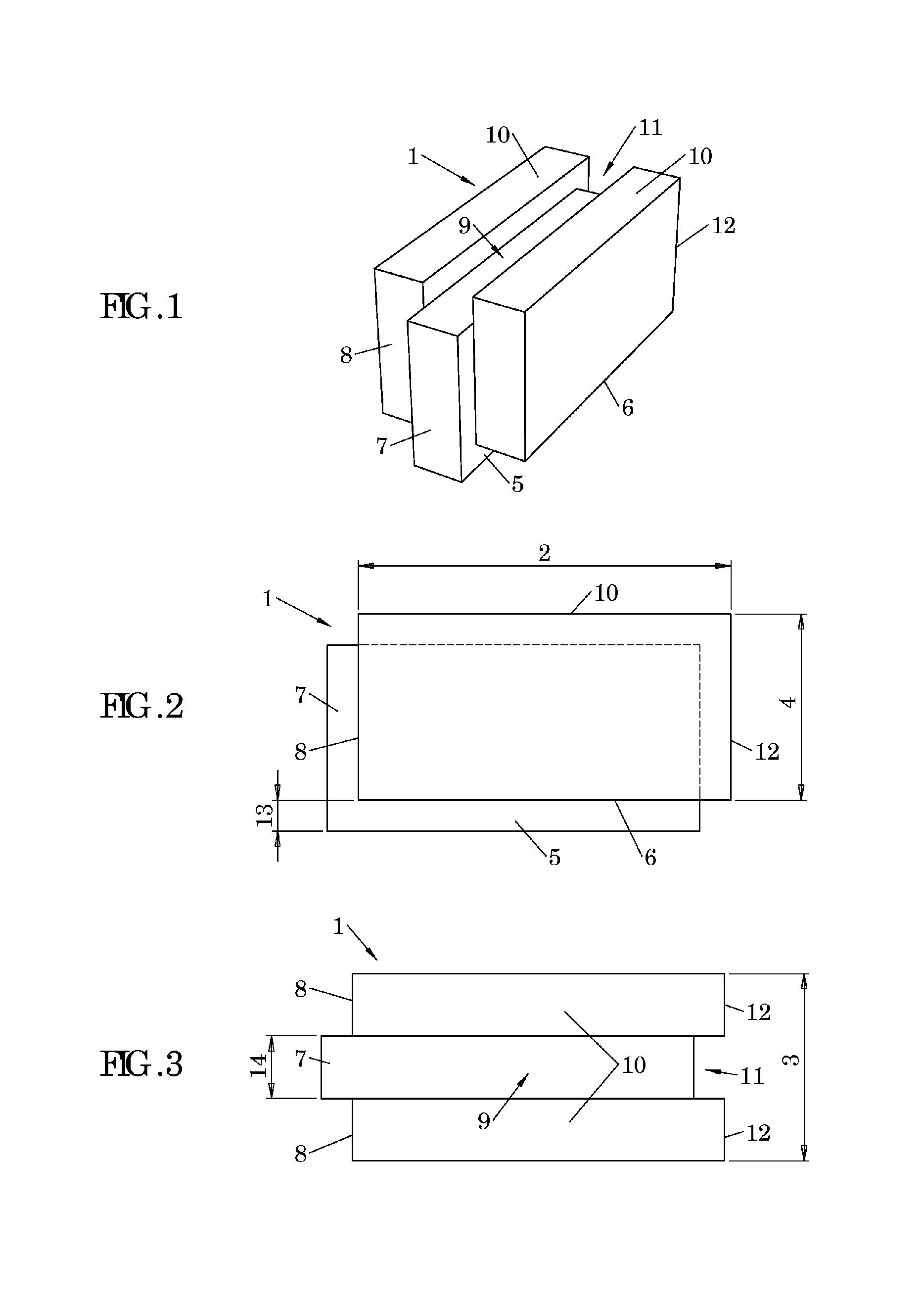

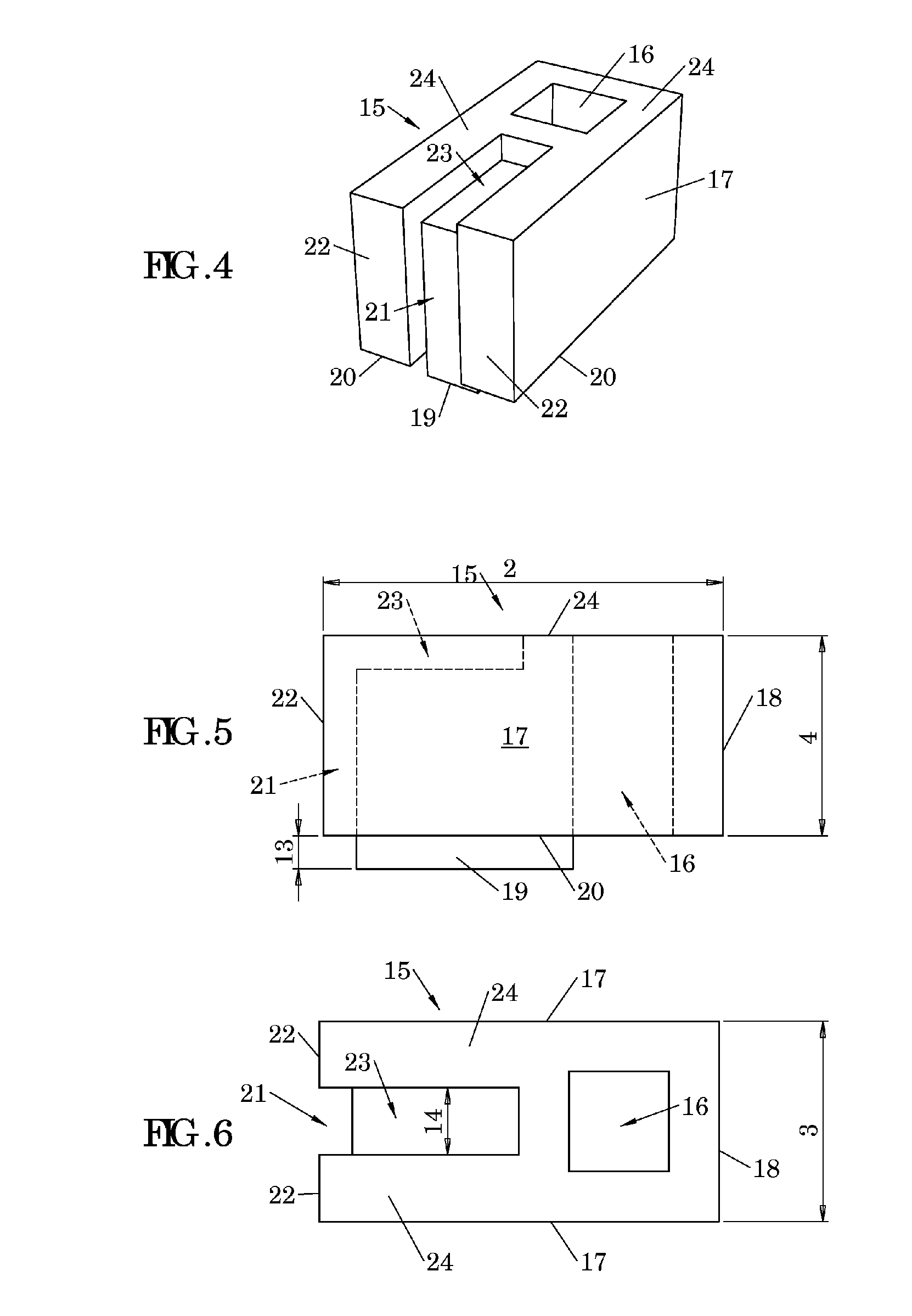

Method for constructing a building using bricks connected using dry joints

The invention relates to a brick (1) made from a material comprising vegetable fibres agglomerated using a binder (such as hemp concrete), said brick being provided with a groove (9, 11) and a tongue (5, 7) allowing the dry-joint connection of bricks. The invention also relates to a method for constructing a building using such bricks.

Owner:VICAT

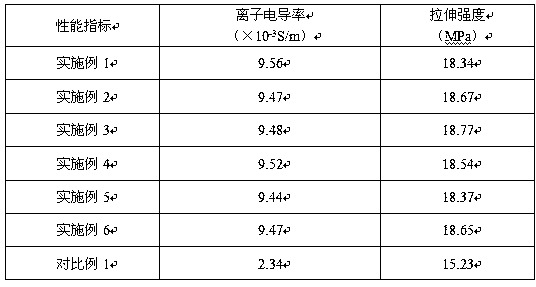

Method for cleaning type screw extrusion preparing of lithium battery polymer electrolyte membrane

The invention belongs to the technical field of lithium battery electrolyte membranes, and provides a method for cleaning type screw extrusion preparing of a lithium battery polymer electrolyte membrane. The method comprises the steps that after polyvinylidene fluoride, polyoxyethylene, lithium salt, a fast ion conductor, nano inorganic filler and plasticized plant fiber are mixed, strong airflowis used for impacts, a compound is prepared, and after the compound and elastomer are mixed, the mixture is conveyed into a double-screw extruder to be subjected to continuous shearing, mixing and scattering, die head sheet forming, roller calendering sheet forming, liquid nitrogen quenching and annealing treatment are continuously conducted, and the lithium battery composite polymer electrolyte membrane is prepared. Compared with a traditional method, the polymer composite electrolyte membrane prepared through the method has a large number of lithium ion transmission channels, conductivity isgood, meanwhile, good mechanical performance and heat resistance are achieved, meanwhile, the preparing process is clean and free of pollution, and cost is low.

Owner:湖北奇见新材料有限公司

Wood-plastic composite material and preparation method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof. The wood-plastic composite material comprises the following components in parts by weight: 100 parts of plastic resin, 300-350 parts of wood flour, a proper amount of plant fibers, 2-15 parts of a compatilizer, 2-6 parts of a lubricant and 10-20 parts of a filler, wherein the compatilizer is selected from one or more of ethylene-vinyl acetate copolymer, ethylene-acrylic acid copolymer, chlorinated polyethylene, dicumyl peroxide, aluminate, a titanate compound, a silane coupling agent and maleic anhydride modified polypropylene. The wood-plastic composite material prepared with the method is excellent in toughness and heat resistance.

Owner:WUHU INST OF TECH

Enzymatic preparation of plant fibers

InactiveUS20110312066A1Promote acidic hydrolysisLonger treatment timeMicrobiological testing/measurementVegetable materialFiberAqueous solution

A method of extracting fibers from decorticated plant bast skin involves pre-treating decorticated plant bast skin of a fiber plant with an aqueous solution containing trisodium citrate having a pH in a range of about 8-14 at a temperature of about 90° C. or less; and subsequently treating recovered fibers with a protease at alkaline pH.

Owner:NAT RES COUNCIL OF CANADA

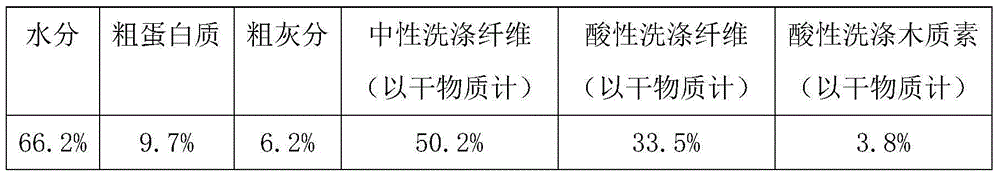

Preparation method of whole corn silage

The invention provides a preparation method of whole corn silage. The preparation method comprises the following steps: cleaning and disinfecting a silage silo, digging drains around the silage silo, paving plant fibers on the bottom of the silo and paving a separating membrane on the wall of the silo; harvesting corn plants and chopping the whole plants in the milk-ripe stage of corn; filling and compacting silage raw materials layer by layer until the height of the silage raw materials exceeds the silo depth, and after filling, sprinkling table salt on the top layer of the silage raw materials; and covering the silage raw materials with the part of the separating membrane outside the silage silo, sequentially paving a waterproof membrane and a light-shading membrane on the separating membrane, placing a balancing weight on the light-shading membrane, and fermenting the silage raw materials in the silage silo so as to obtain silage. The silage prepared by the method disclosed by the invention is free from the addition of any silage additive, therefore preparation cost is low; and the silage prepared by the method disclosed by the invention is good in palatability and high in nutritive value, and corrosion rate is less than 1%.

Owner:QICHUN HENGLI ANIMAL HUSBANDRY

Peach patch of fruits and vegetables, and method of processing the same

The invention discloses a fruit and vegetable peach piece and manufacturing method, which comprises the following steps: adopting glutinous rice, walnut kernel, plant oil, refined granulated sugar, vegetable or / and fruit as raw material; using color protective, sugar and dehydrating technical to dispose vegetable or / and fruit into preserved vegetables fruits with water content at 20-22%; blending the vegetables preserved fruits with glutinous rice flour and walnut kernel into the boiled sugar liquid; obtaining the product with rich vitamin and plant fiber. The invention overcomes long traditionally technical time and difficult control, which is controlled by set technical flow path and parameter.

Owner:CHENGDU UNIV

Plant fibre reinforced foam composite material with hard polyurethane structure and production thereof

Vegetable reinforced fibre foam composite material with hard polyurethane structure and its production are disclosed. The composite material consists of organic polyol resin 100 proportion, organic polyisocyanate 105í½160 proportion, catalyst 0.4í½0.8 proportion, promoter 0.1í½0.2 proportion, foam stabilizer 1í½3 proportion, foamer 5í½15 proportion and vegetable fibre 1í½5 proportion. The composite material is prepared by surface treating for raw linen etc. vegetable fibre, which comprises alkali process and acid wash, and mould pressure forming from one-step process, which comprises raw material preparing, adding chopped strand, pouring mould pressure forming and mould unloading. It achieves simple process, low cost and biological degradation.

Owner:WUHAN UNIV OF TECH

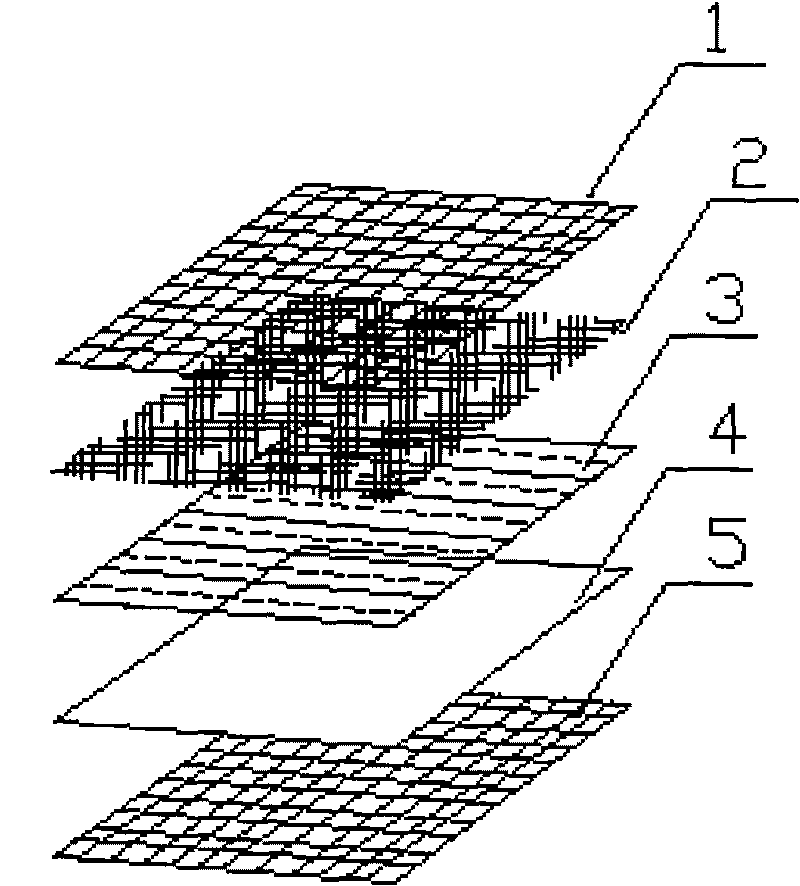

Graphene nanometer far-infrared anion composite fiber conductive heating film and preparation method thereof

InactiveCN106900089AAdjustable surface resistivityEfficient releasePaper/cardboardRosin additionSurface resistivityFar infrared

The invention relates to the field of improving an electric heating element, in particular to a graphene nanometer far-infrared anion composite fiber conductive heating film and a preparation method thereof. The conductive heating film is prepared by the plant fiber pulp, graphene powder glue, nanometer bamboo charcoal fiber powder or nanometer far-infrared anion powder through the grinding, mixing, stirring, stir-frying, drying, pressing and winding processes. During preparation, through the steps of grinding, mixing and stirring, the plant fiber is processed by a disc mill into a broom shape so as to be more easily combined with the graphene powder glue, the graphene powder glue is added to mix and stir, and then a fiber dispersant and the nanometer bamboo fiber powder or nanometer far-infrared anion powder are added to stir evenly. According to the invention, the conductive heating film has the characteristic of adjustable surface resistivity, can be used for an antistatic circuit, can effectively release the charge, and also has the functions of far-infrared emission and anion release to play roles both in purifying and disinfecting and in human health.

Owner:王敏

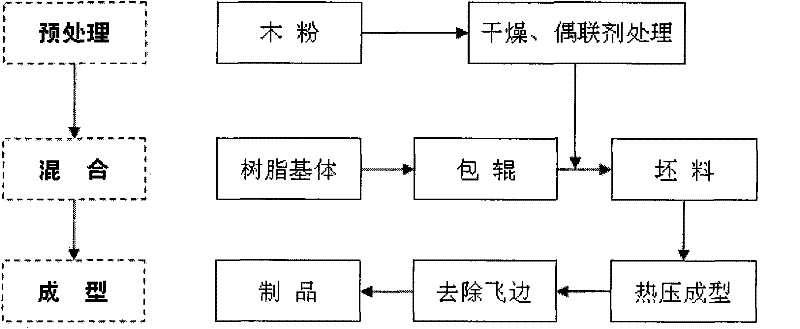

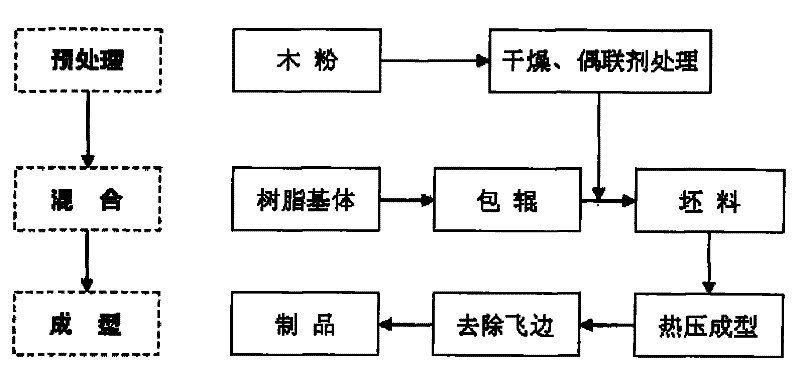

Preparation method of wood plastic material

The invention discloses a preparation method of wood plastic material, which comprises the following raw materials according to parts by weight: 100 parts of thermoplastic plastic, 20-50 parts of wood powder or vegetable fibre, 0.4-0.9 part of silane or aluminate coupling agent, 4-15 parts of ethylene-vinylacetate and 0.8-1.5 parts of paraffin. The above materials are mixed at a high speed and are milled on an open mill, a blank is prepared, and the prepared blank is shaped by hot pressing by a vulcanizer. The invention has simple operation, needs less equipment, correspondingly lowers operation difficulty and equipment investment, can lower cost, has strong competitive power, especially can substantially lower and put an ends to air bubbles in products, improves the quality of a product and improves the rank; the product has the advantages of high strength, light weight, worm damage prevention, low cost, no toxin, environment protection and reuse.

Owner:CHONGQING UNIV OF TECH

Method of processing vegetable fibre formed pipe and the preparing system

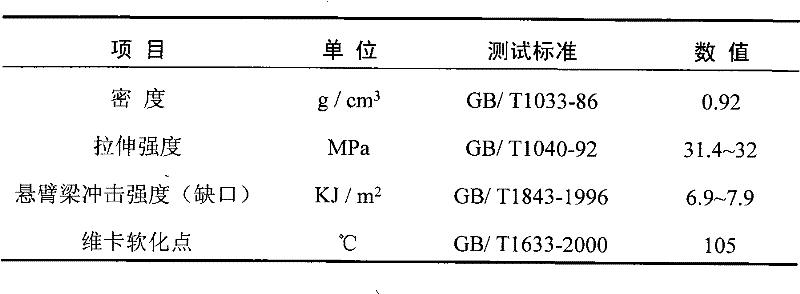

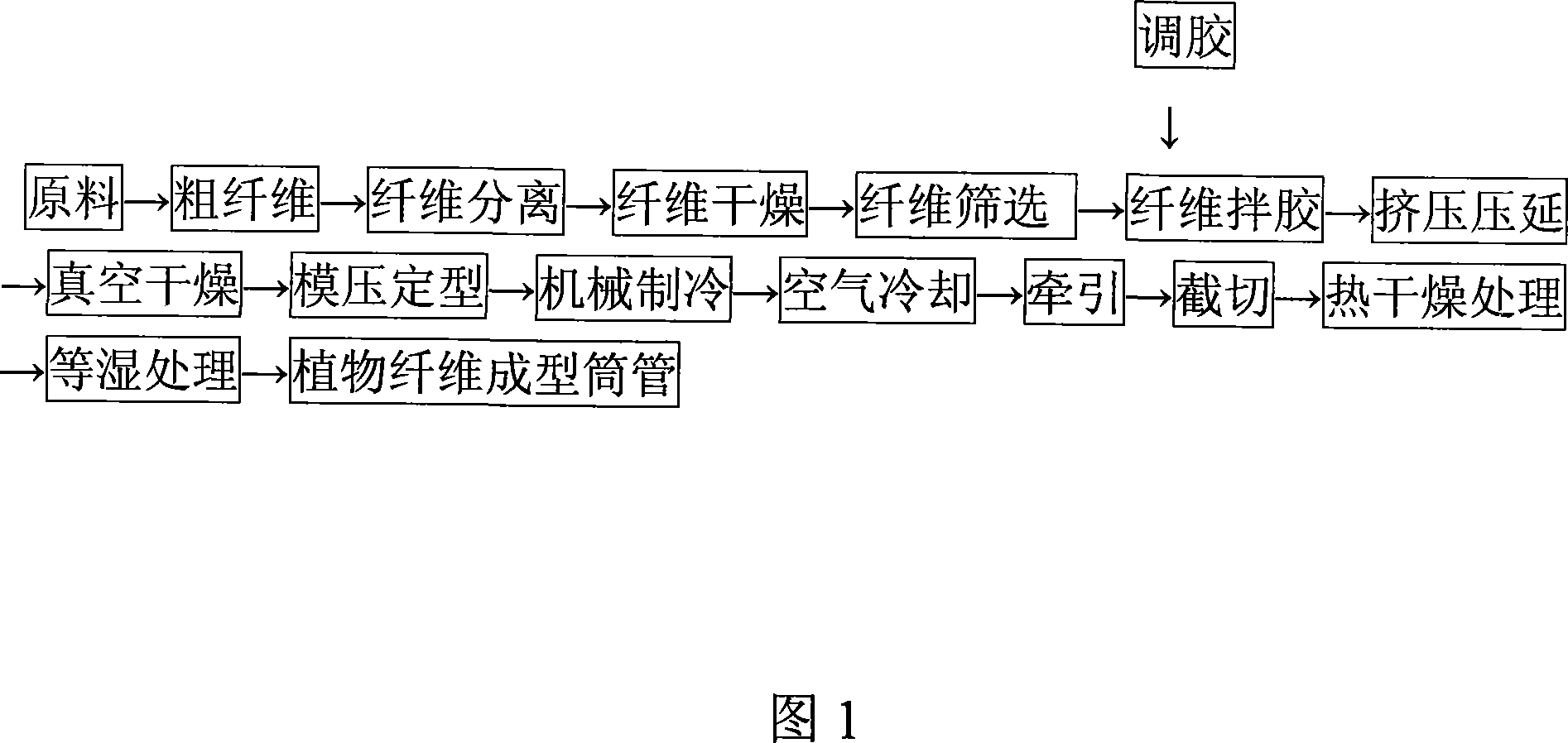

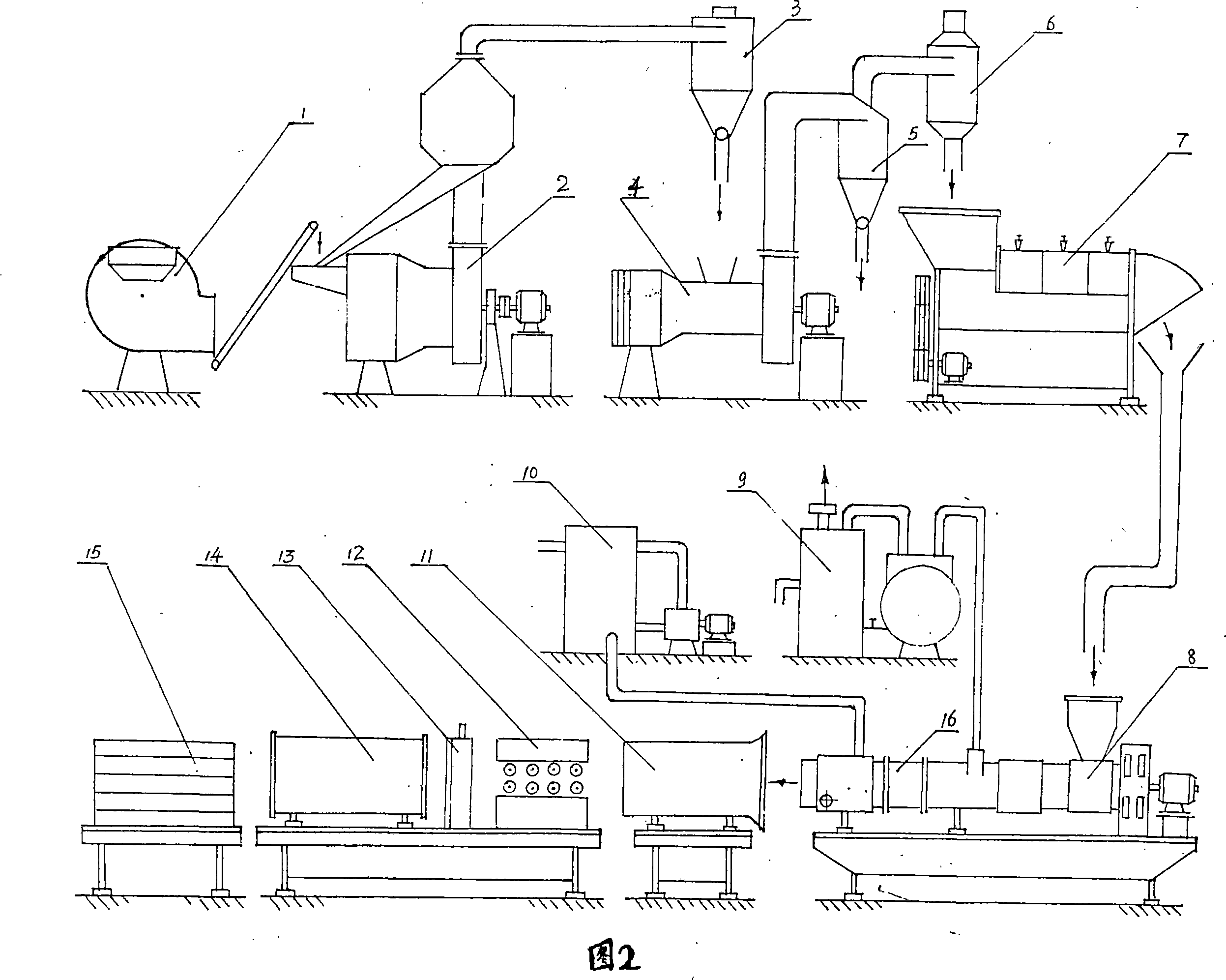

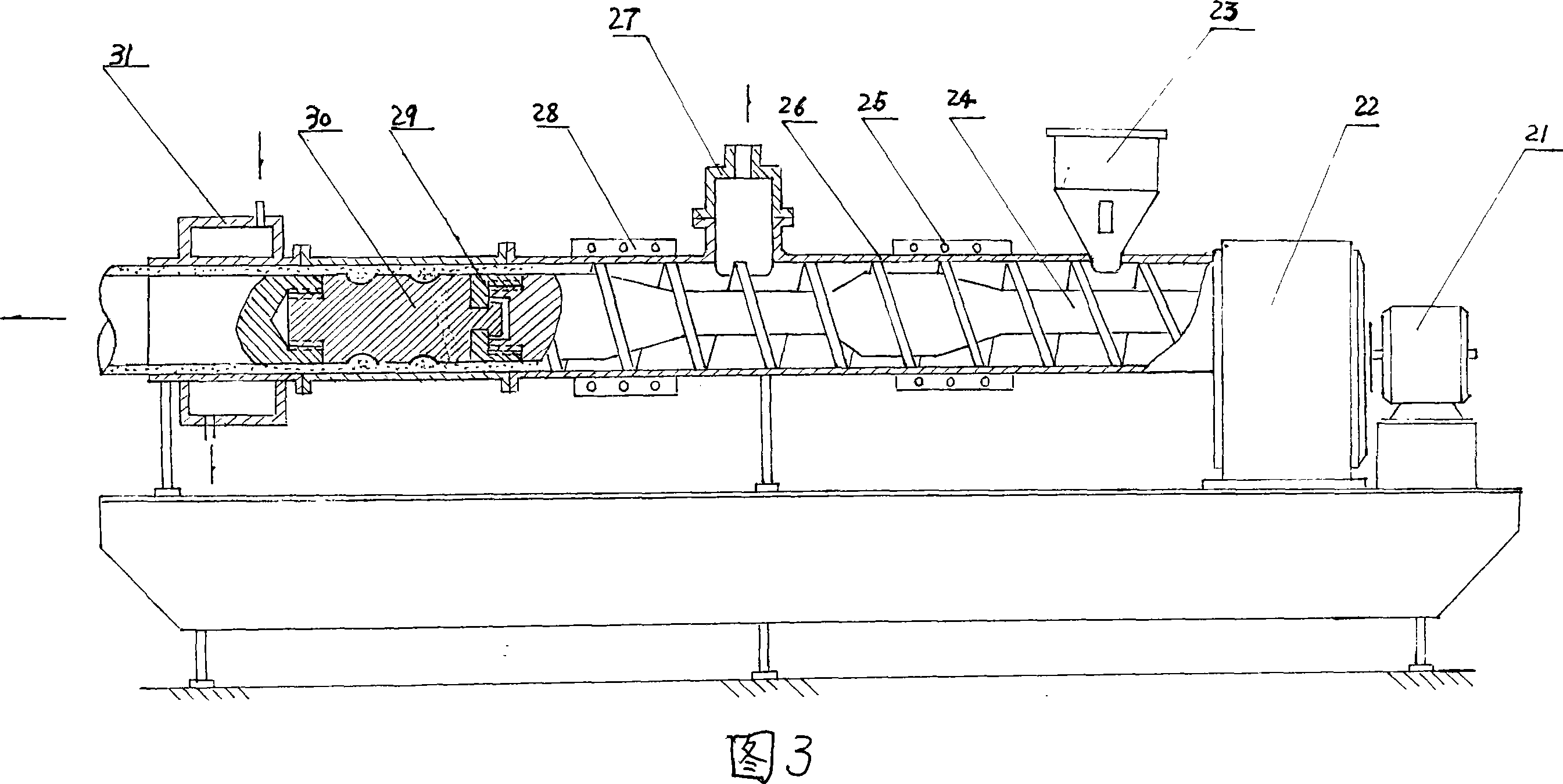

The process of forming bobbin with plant fiber includes the following steps: crushing material, separating, winnowing to further separate coarse fiber, drying the winnowed fiber, mixing fiber with glue to obtain mixture containing glue in 5-40 %, and treating the mixture through extrusion, heating, softening fiber and vacuum drying in an extruding and forming unit to form bobbin. The corresponding forming system includes a plant fiber processing unit, a glue mixing unit, and an extruding and forming unit connected together. The produced plant fiber bobbin is used to replace paper bobbin.

Owner:程兆民

Method for producing kaolin compressed nutritional soil

ActiveCN104119166AReduce manufacturing costReduce shipping costsFertilizer mixturesFiberEcological environment

The invention discloses a method for producing kaolin compressed nutritional soil. According to the technical scheme, the method comprises the following steps: firstly, acidizing kaolin and sludge, further stirring the ingredients of the kaolin compressed nutritional soil, compressing, and sterilizing with microwaves at a low temperature, and finally packaging, thus obtaining a finished product, wherein the kaolin compressed nutritional soil consists of materials such as acidified kaolin, acidified sludge, instant sodium silicate, polyving alcohol, ferrous sulfate, peat, flower ceramsite, hyper-viscous attapulgite clay, biogas slurry, biogas residue, crushed plant fiber, expanded vermiculite, expanded perlite and high-water-absorption resin. As the kaolin compressed nutritional soil contains a great deal of nitrogen, phosphorus, potassium, organic matters and multiple microelements, can provide nutritional elements essential for plant growth, can reduce damage of pathogenic bacteria and injurious insects to plants, is good for normal growth and development of plants and protects the ecological environment; and the method for producing the kaolin compressed nutritional soil is applicable to production of kaolin compressed nutritional soil according to different formulas.

Owner:度测(上海)科技服务中心

Method for producing construction waste compressed nutrient soil

ActiveCN104109038AImprove protectionAvoid secondary pollutionFertilizer mixturesEcological environmentPolyvinyl alcohol

The invention discloses a method for producing construction waste compressed nutrient soil. According to key points of the technical scheme, the method comprises the following steps: acidizing construction wastes and sludge; stirring, compressing and performing microwave low-temperature sterilization on construction waste compressed nutrient soil; packaging to obtain the finished product. The construction waste compressed nutrient soil consists of acidized construction wastes, acidized sludge, instant sodium silicate, polyvinyl alcohol, ferrous sulfate, peat, flower ceramsite, high-viscosity attapulgite clay, biogas slurry, biogas residues, crushed plant fibers, expanded vermiculite, expanded perlite, super absorbent resins and other materials. The construction waste compressed nutrient soil contains lots of nitrogen, phosphorus, potassium, organic matters and multiple trace elements, can provide nutrient elements essential for plant growth and has the effects of reducing hazard of pathogenic bacteria and injurious insects to plants, promoting normal growth and development of plants and protecting the ecological environment, and the method for producing the construction waste compressed nutrient soil is suitable for producing construction waste compressed nutrient soil of different formulas.

Owner:江苏世澳非金属应用科技有限公司

Production method of laminated paper

InactiveCN105109177AImprove bindingHigh bonding strengthLaminationLamination apparatusSlurryPulp and paper industry

The invention discloses a production method of laminated paper. The production method of the laminated paper comprises the following steps: carrying out wet process web forming on wood pulp, namely repulping plant fibers in a pulper for obtaining slurry with the concentration of 6-8%, and carrying out double cylinder moulding, so that wood pulp paper with humidity of 80-86% is obtained; compounding the wood pulp paper, namely implanting and entangling the wood pulp paper and quantitative 8-150g / m<2> non-woven fabric each other by adopting a spunlace process, so that wood pulp fabric is obtained, wherein 2-7 needles are adopted during spunlace, and pressure is 6-14MPa; dehydrating, namely removing moisture of the compounded wood pulp fabric by virtue of a vacuum water sucking box until humidity is 50-70%; spraying, namely spraying the surface of the dehydrated wool pulp fabric; and drying, namely drying with the sprayed wood pulp fabric by virtue of a drying oven provided with multiple drying cylinders, so that the laminated paper is obtained.

Owner:丽水保舒康无纺布有限公司 +1

Vegetable and fruit fiber nutrient powder product and production method as well as application thereof

The invention discloses a vegetable and fruit fiber nutrient powder product. A processing method of the vegetable and fruit powder comprises the following steps of: (1) pre-treating, i.e., cleaning fruit and vegetable raw materials, peeling off and pulping to obtain fruit and vegetable pulp; (2) drying, i.e., performing spray drying on concentrate to obtain the fruit and vegetable powder; (3) mixing, i.e., adding according to a proportion; and (4) packaging. The fruit and vegetable powder is prepared by the following raw materials in parts by weight: 20 parts of plant fiber, 15 parts of plant gum, 10 parts of probiotic factor, 5 parts of composite amino acid, 0.6 part of ribonucleic acid, 6 parts of whet malt flour, 3 parts of enzyme, 10 parts of malt extract, 1 part of unsaturated fatty acid, 1 part of guarana extract, 8 parts of albumen powder, 0.03 part of flavoring agent, 0.6 part of composite vitamin and mineral matter and 10 parts of vegetable and fruit powder. The vegetable and fruit powder has the advantages of good taste, low water content, easiness in storage, high nutrition, low heat quantity, excellent detoxifying and skin nourishing effects and effects of improving sleep quality and weakening anxiety emotion.

Owner:EASYPHA MAX GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com