Method for constructing a building using bricks connected using dry joints

a technology of dry joints and bricks, applied in the field of construction, can solve the problems of limited use of building professionals, high degree of technicality and difficult implementation, and marginal savings, and achieve the effect of improving the use of plant fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

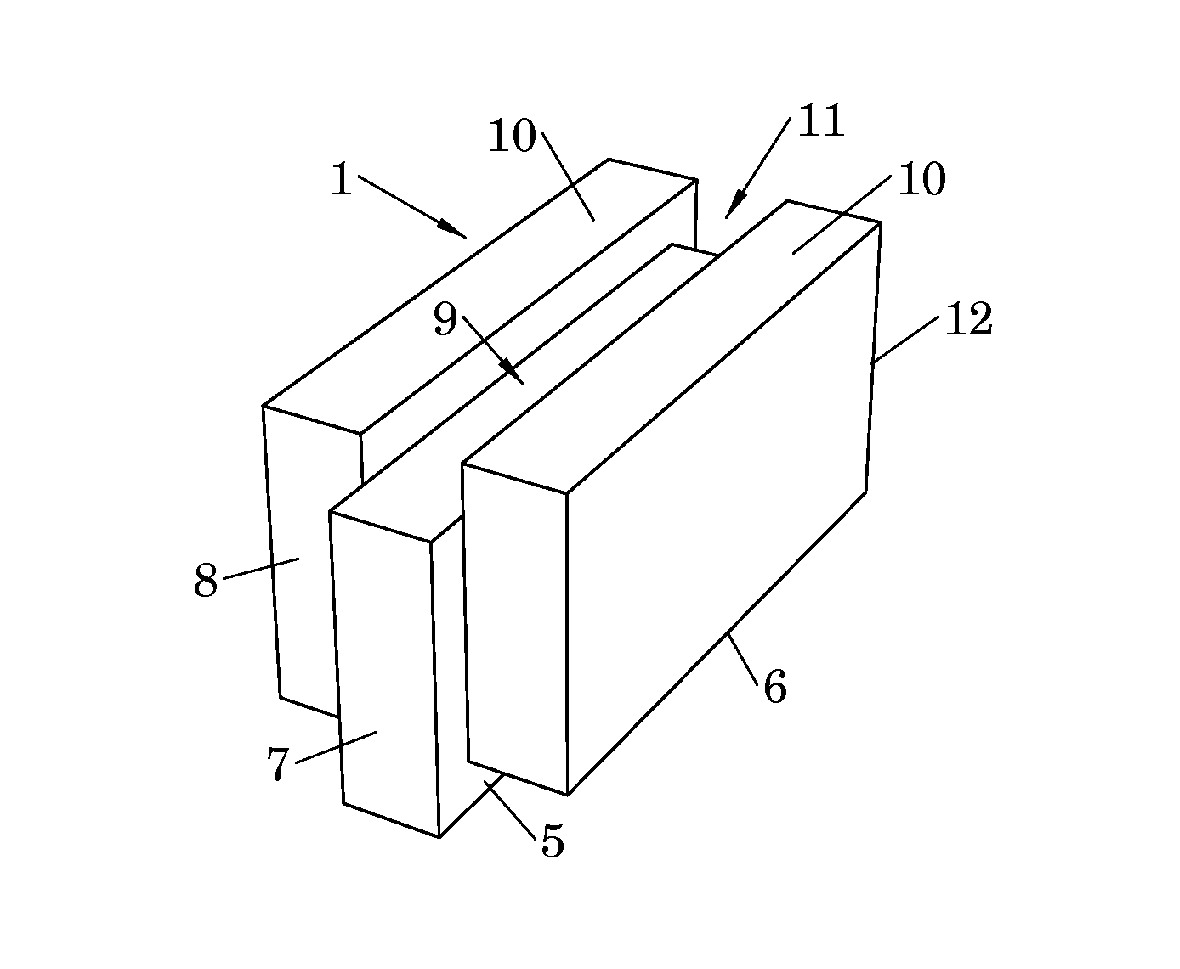

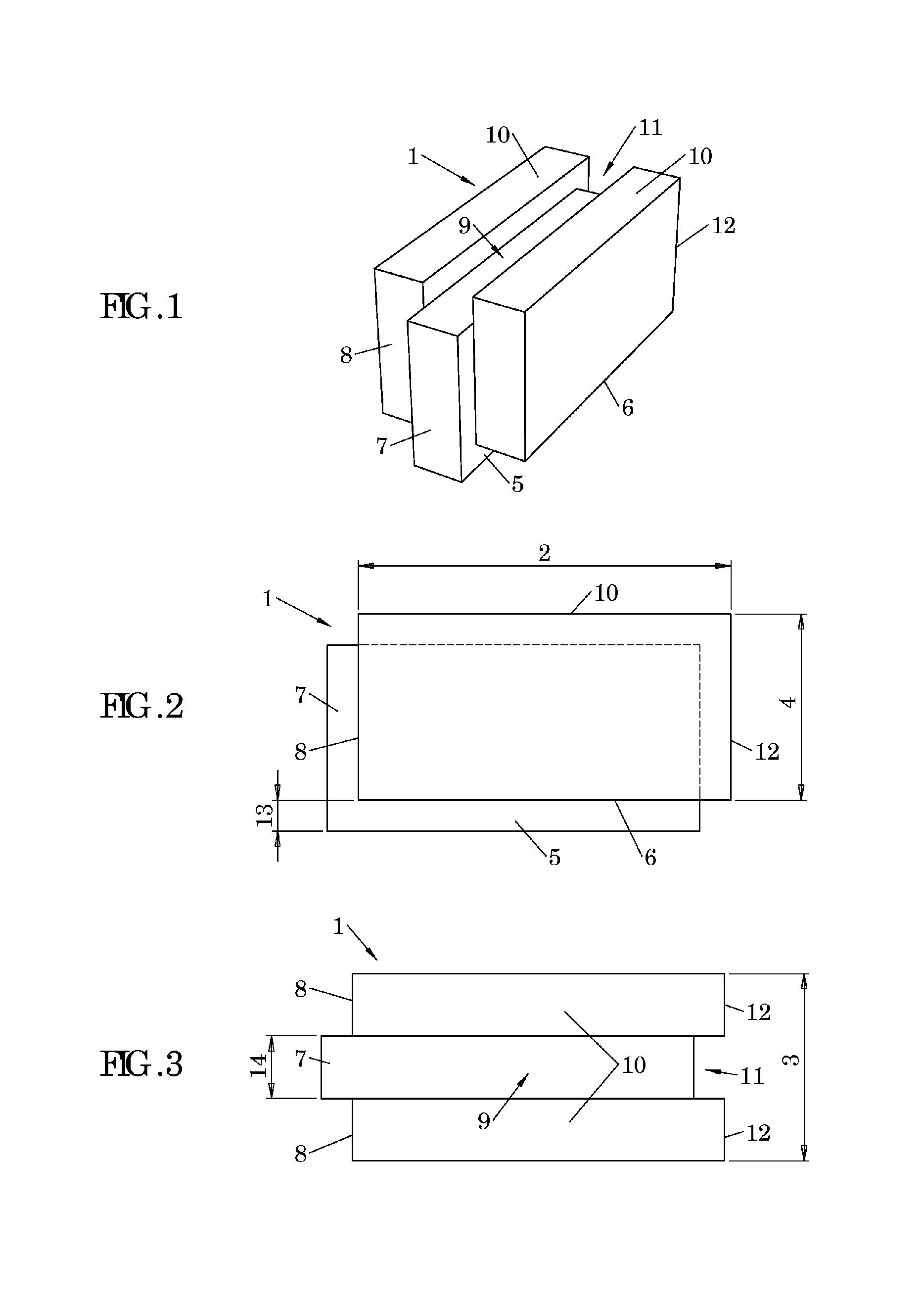

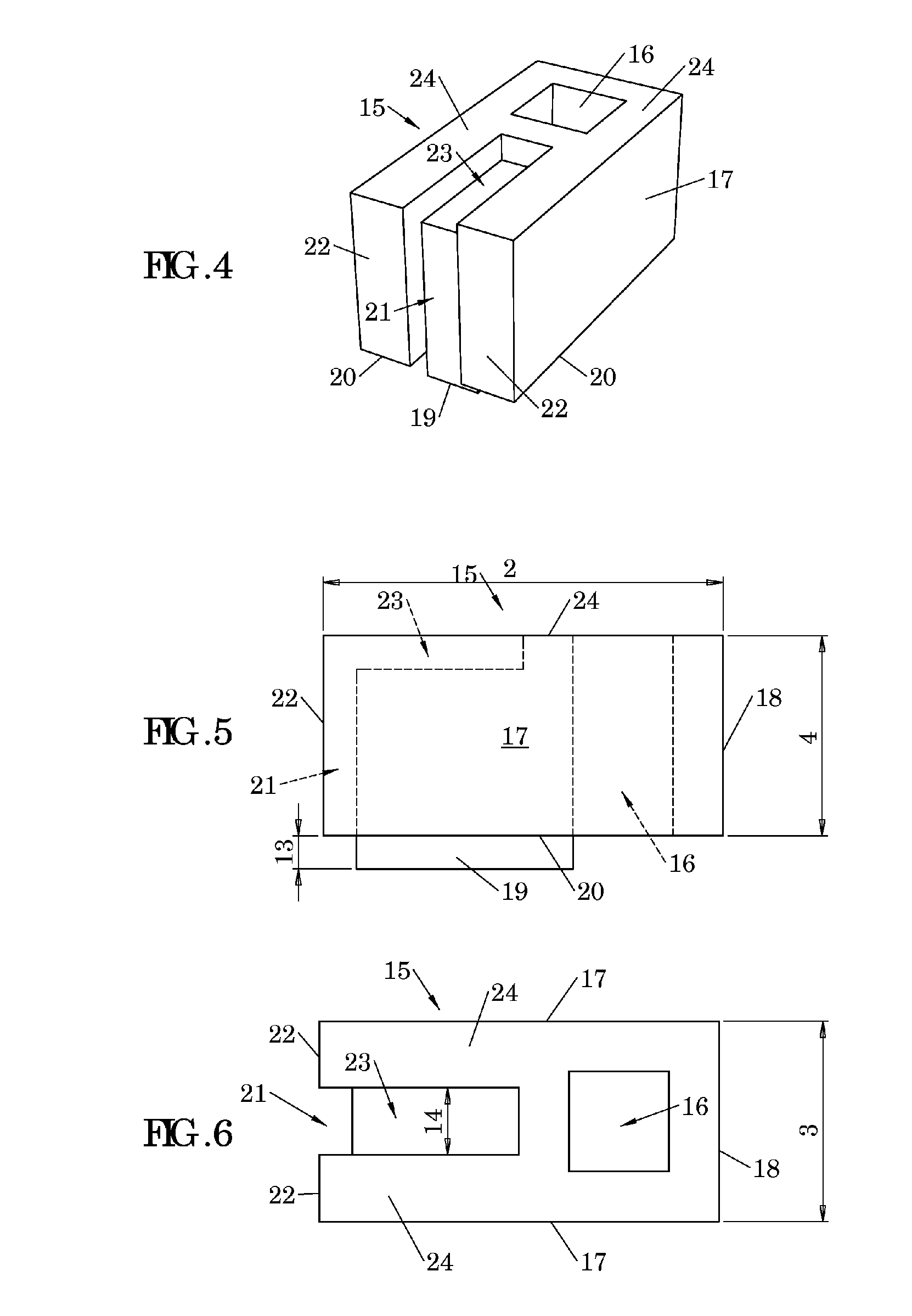

[0045]FIGS. 1 to 12 show four different types of prefabricated hemp concrete elementary bricks. The concrete is prepared from hemp or hemp chaff aggregate, which is the fragmented inner part of the hemp stalk. The hemp chaff used meets the recommendations of hemp producers for use in construction, cf. the aforementioned volume Construire en Chanvre. The density of the dry hemp chaff used is approximately 100 kg / m3 bulked (i.e. not tamped). The binder used may comprise non-hydraulic or hydraulic lime (standard NF EN 459-1 to 3), potentially with added pozzolana (standard NF P 18-308), but in the case at hand is preferable to use pure non-hydraulic lime. The composition also comprises quick-setting cement and mixing water (meeting the stipulations of standard NF EN 1008).

[0046]The proportions by volume of the preferred composition are as follows: hemp chaff 73%; non-hydraulic lime 8%; quick-setting cement 4%; water 15%, i.e., for 100 l (10 kg) of hemp chaff, approximately 11 l of non-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com