Patents

Literature

1110 results about "Joint (building)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A building joint is a junction where building elements meet without applying a static load from one element to another. When one or more of these vertical or horizontal elements that meet are required by the local building code to have a fire-resistance rating, the resulting opening that makes up the joint must be firestopped in order to restore the required compartmentalisation.

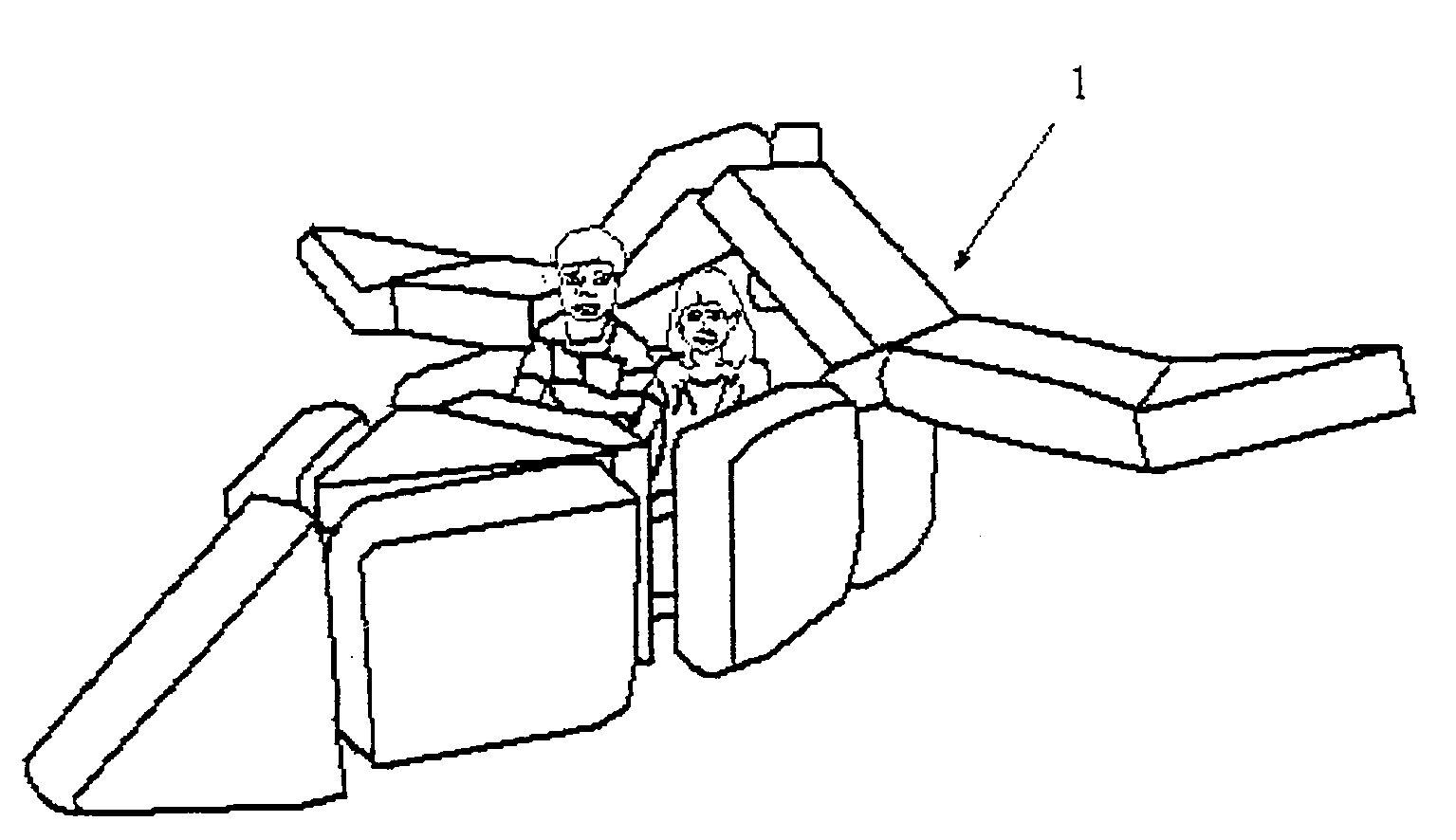

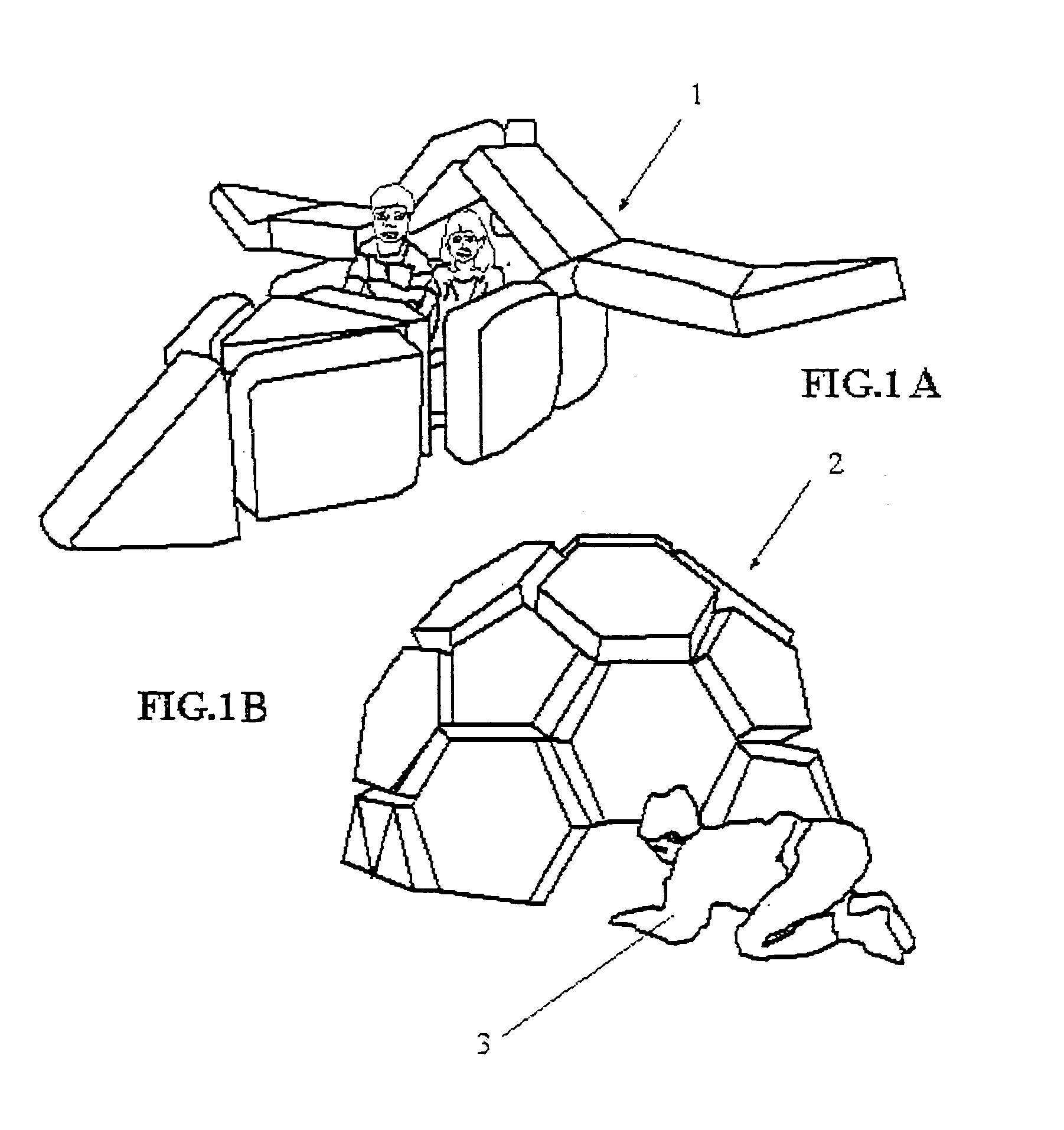

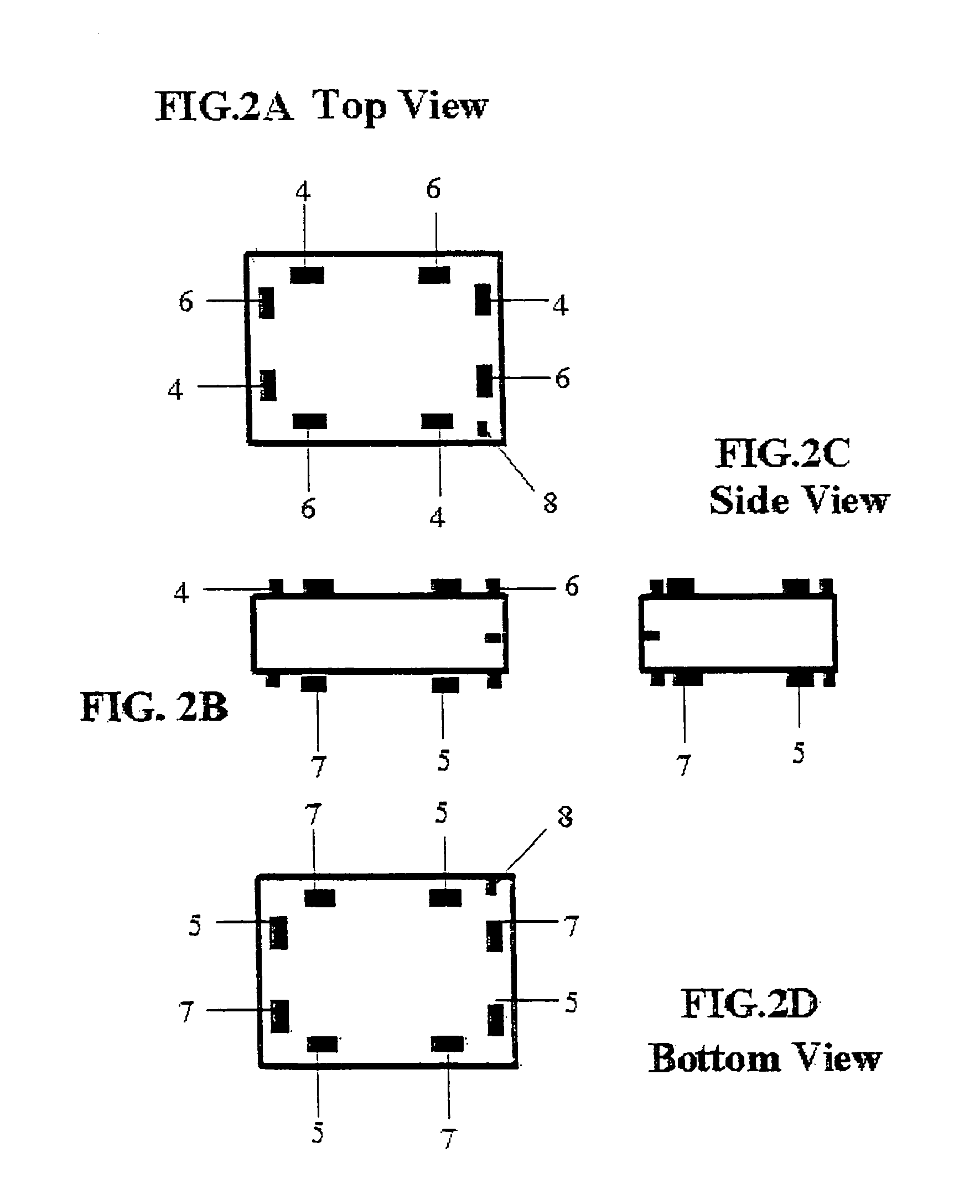

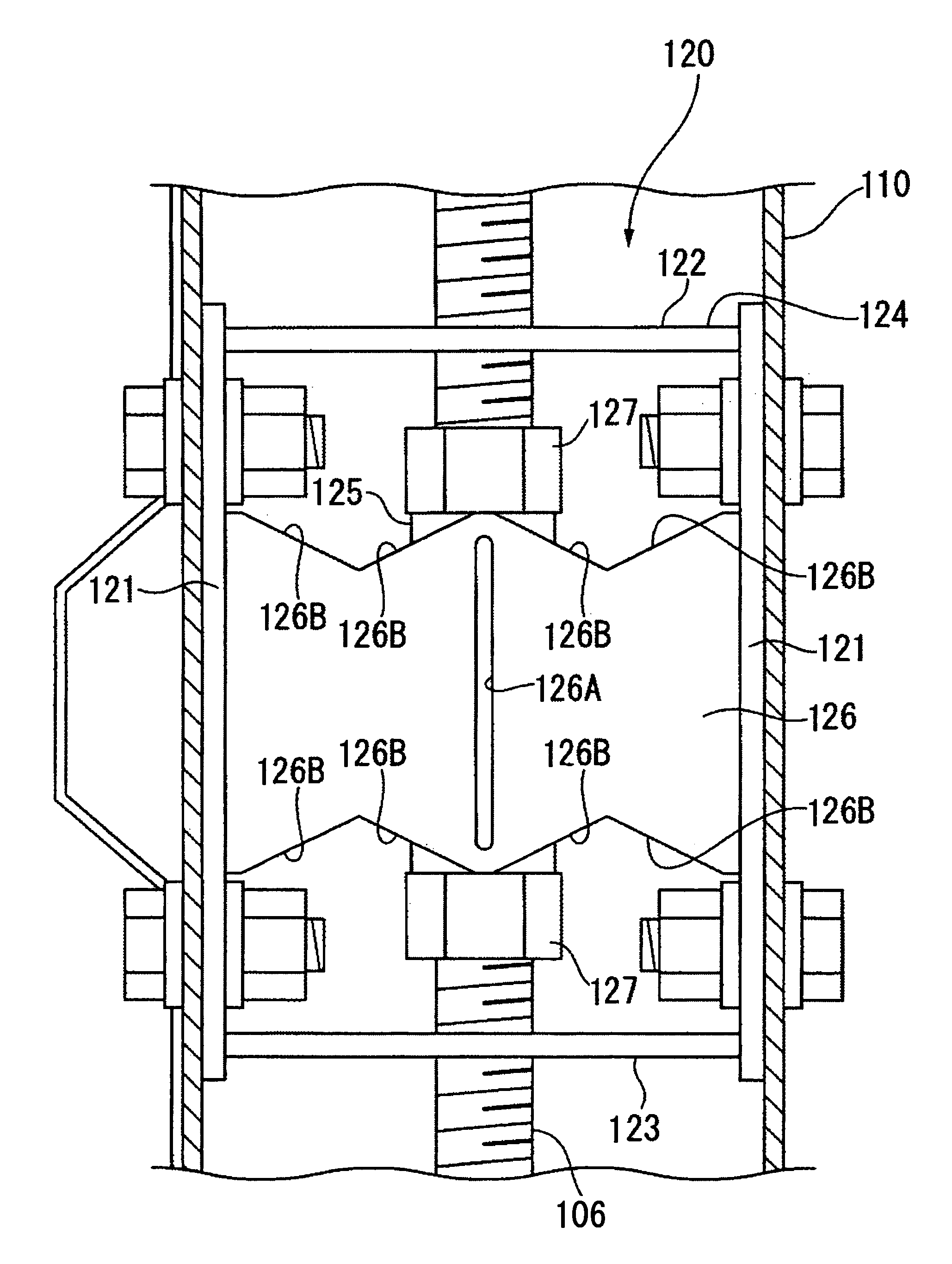

Blocks and building system for the construction of lifesize inflatable play structures

A system for the construction of life size play structures includes a multiplicity of inflatable building blocks, each being a member of a finite set of different multi-sided block types. Each such type is a cylinder having the cross section of a regular polyhedron, and the length of each side of each polyhedron is identical. The blocks are attached to each other by means of a rotating joint which aligns each contiguous side of each block with the contiguous side of the adjoining block, but which does not allow each such to translate relative to the adjoining block. The joints are constructed at fixed locations along the sides according to specific dimensional ratios. Stiffening means are used to maintain the dimensional integrity of each block, and to maintain the uniformity of the system from block to block.

Owner:LIOU DICK

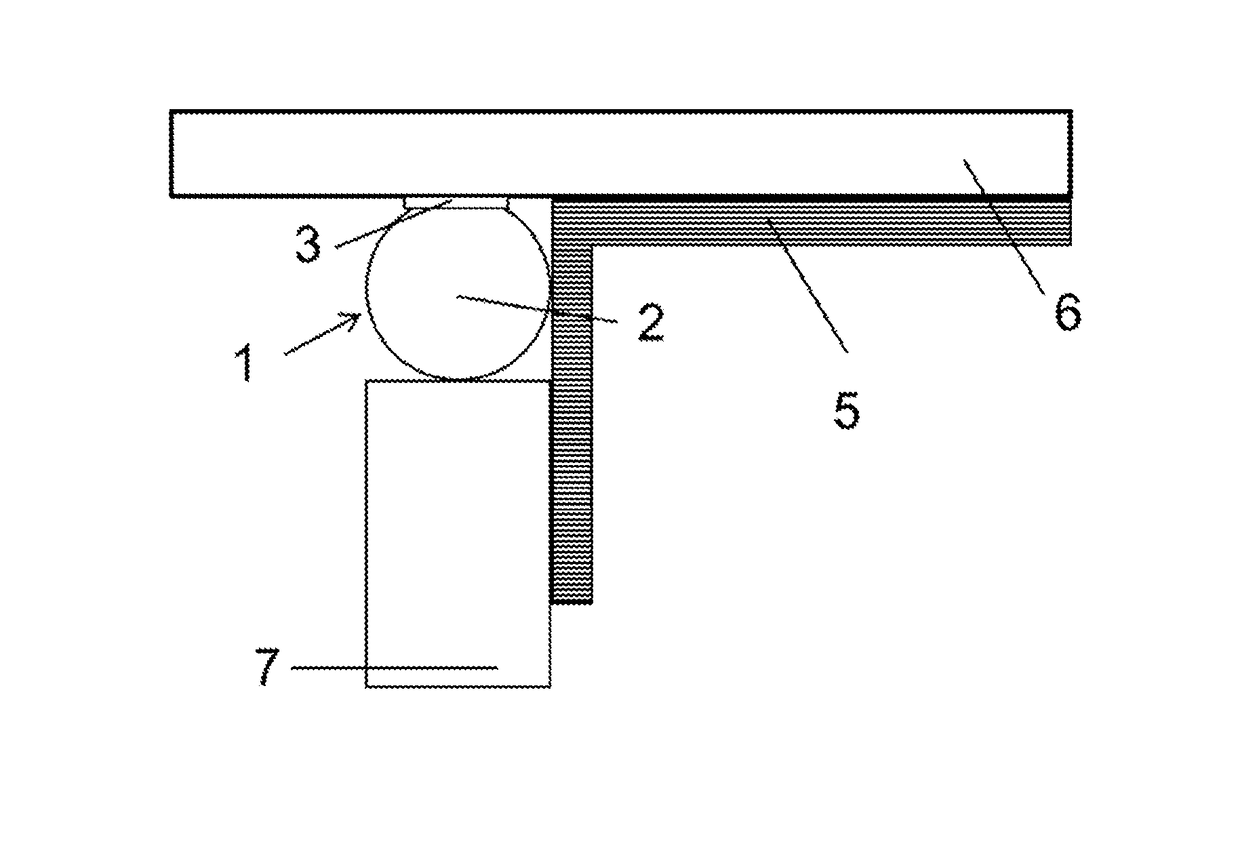

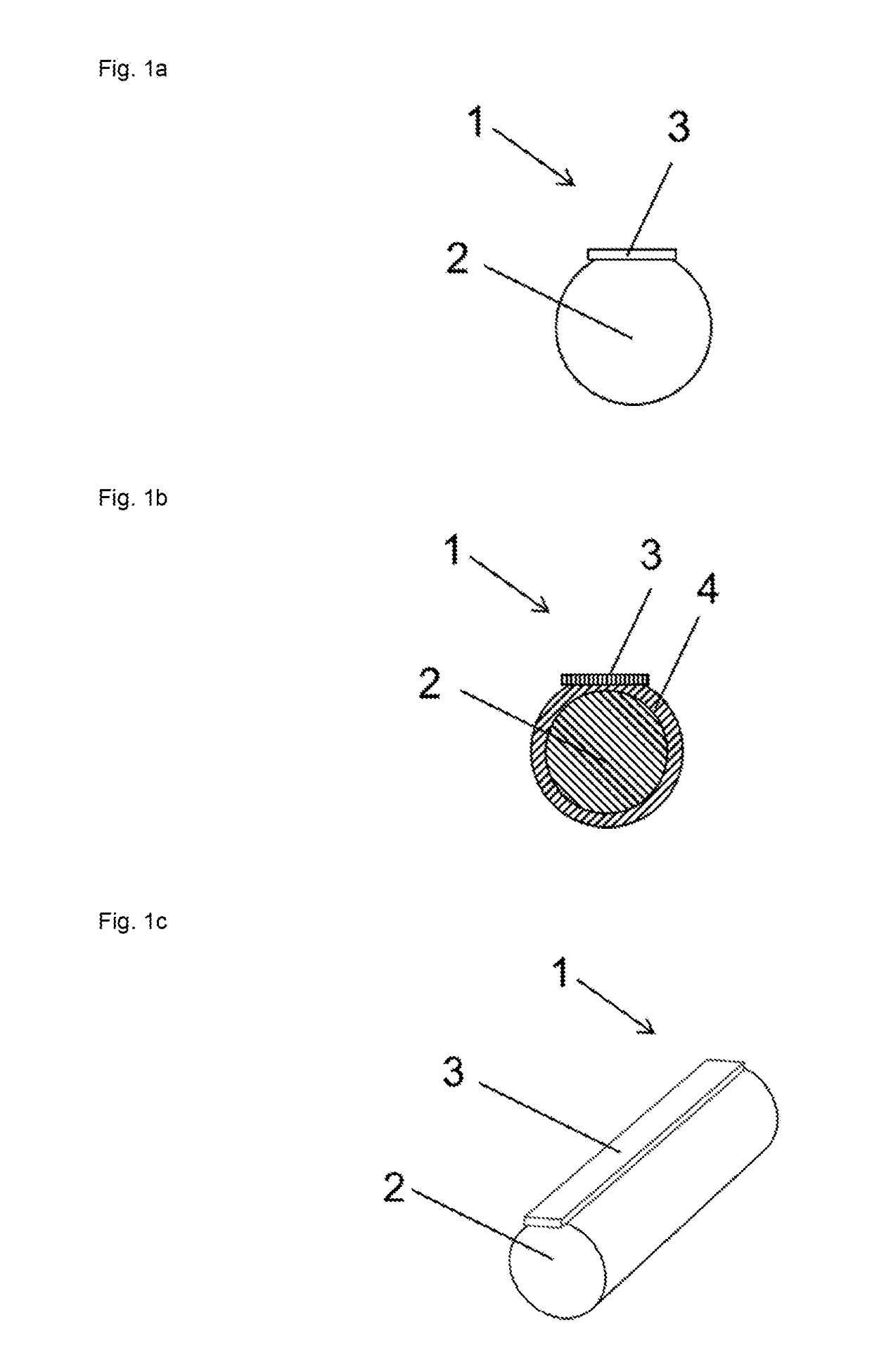

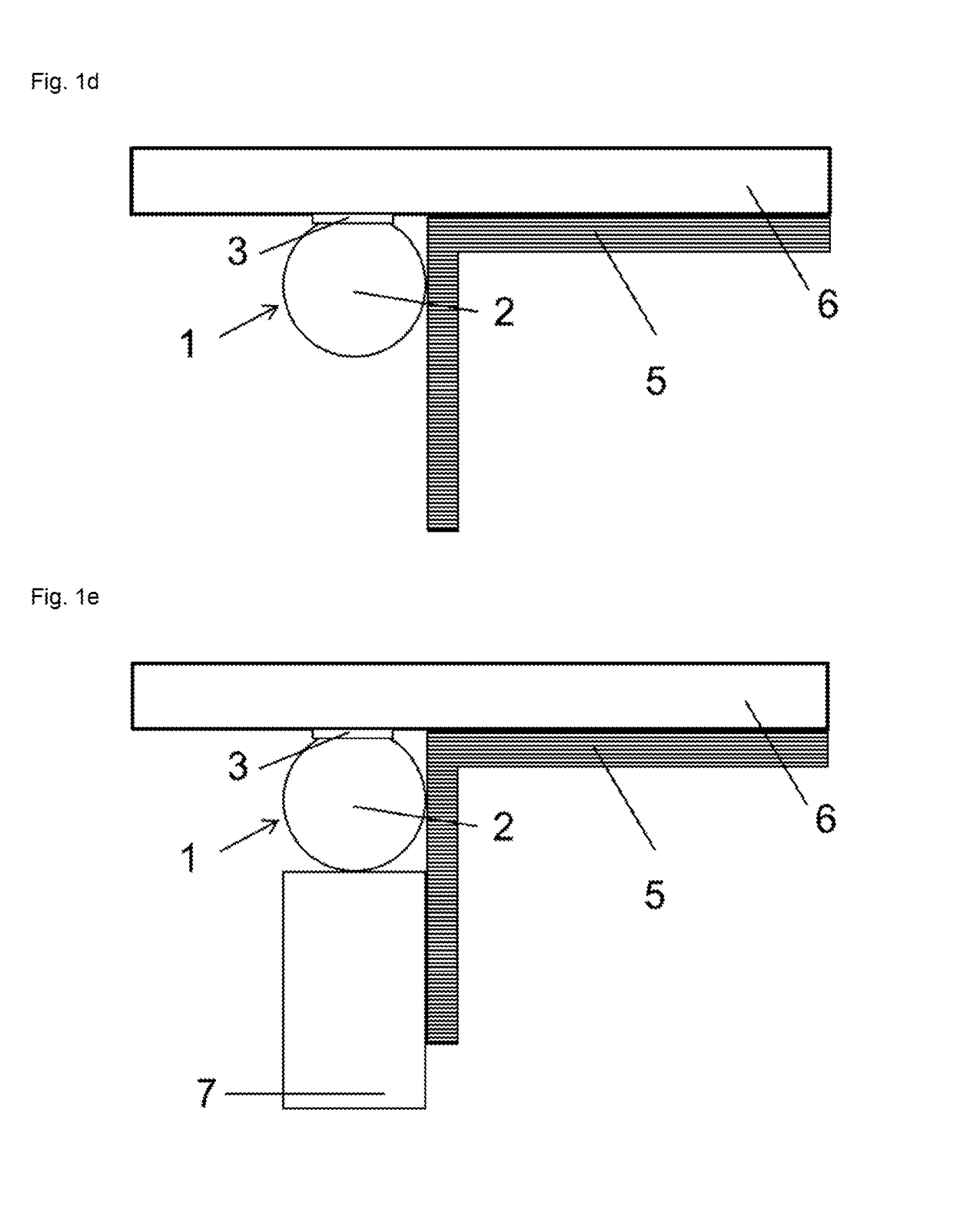

Joint-sealing tape with predetermined geometry and sealing arrangement with such joint sealing tape

A joint-sealing tape is useful for sealing building-structure joints, especially for sealing against sound and / or smoke and if necessary against fire. In particular, the joint-sealing tape is suitable for sealing a joint between a first building part and a second building part, with a sealing element and an adhesive layer, which sealing element has a predetermined geometry. Furthermore, a sealing arrangement contains such a sealing tape and is suitable for sealing of building structure joints, especially for sealing against sound and / or smoke and if applicable against fire.

Owner:HILTI AG

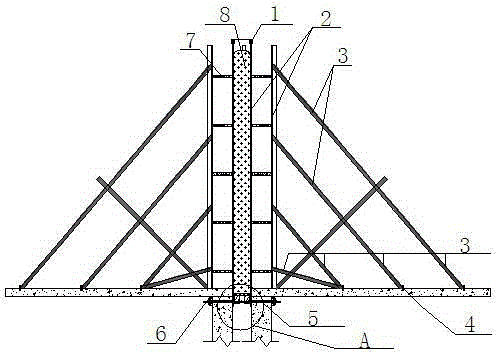

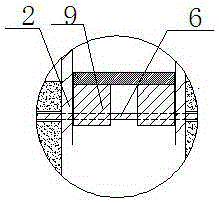

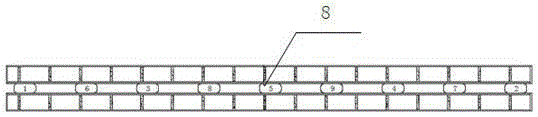

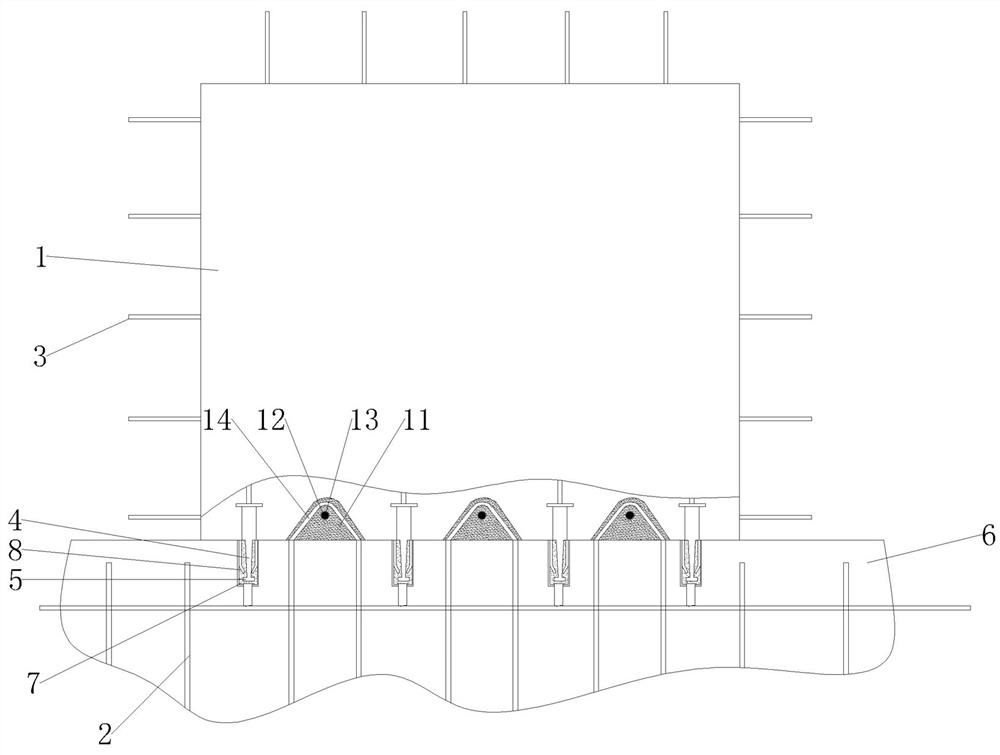

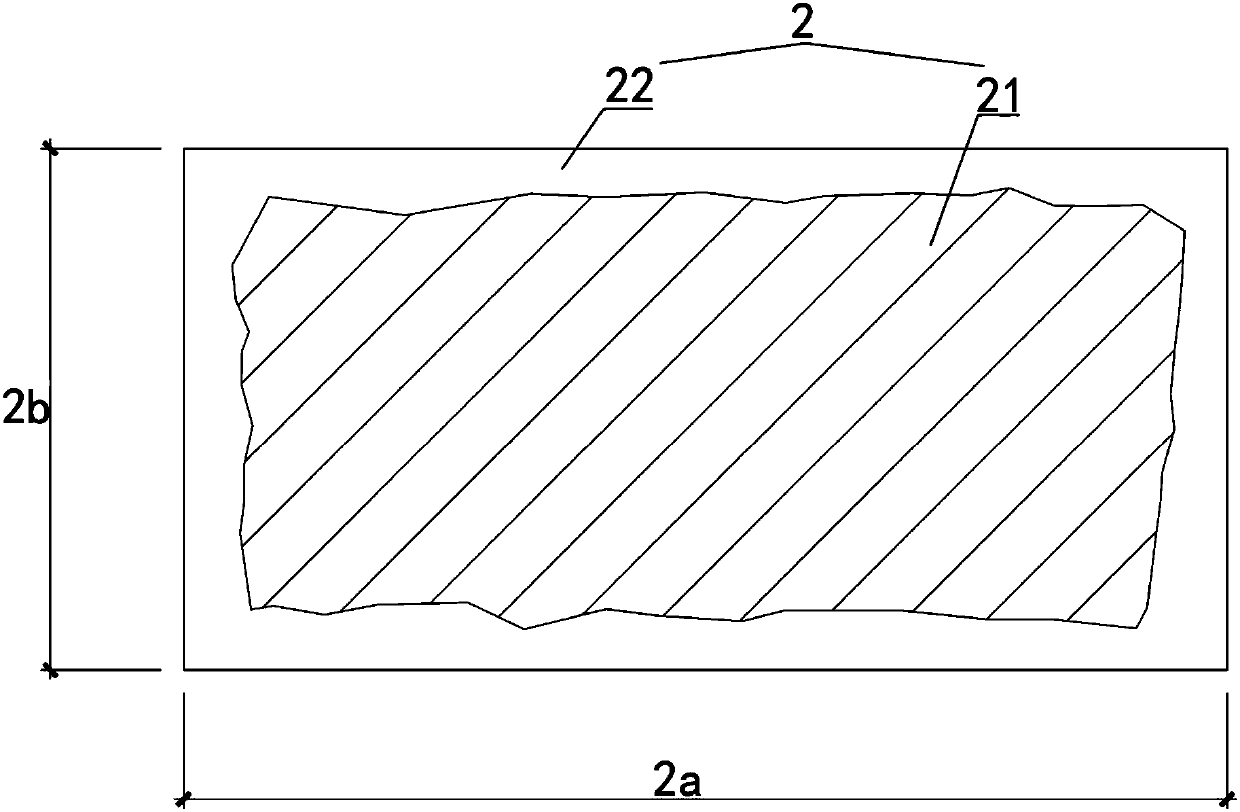

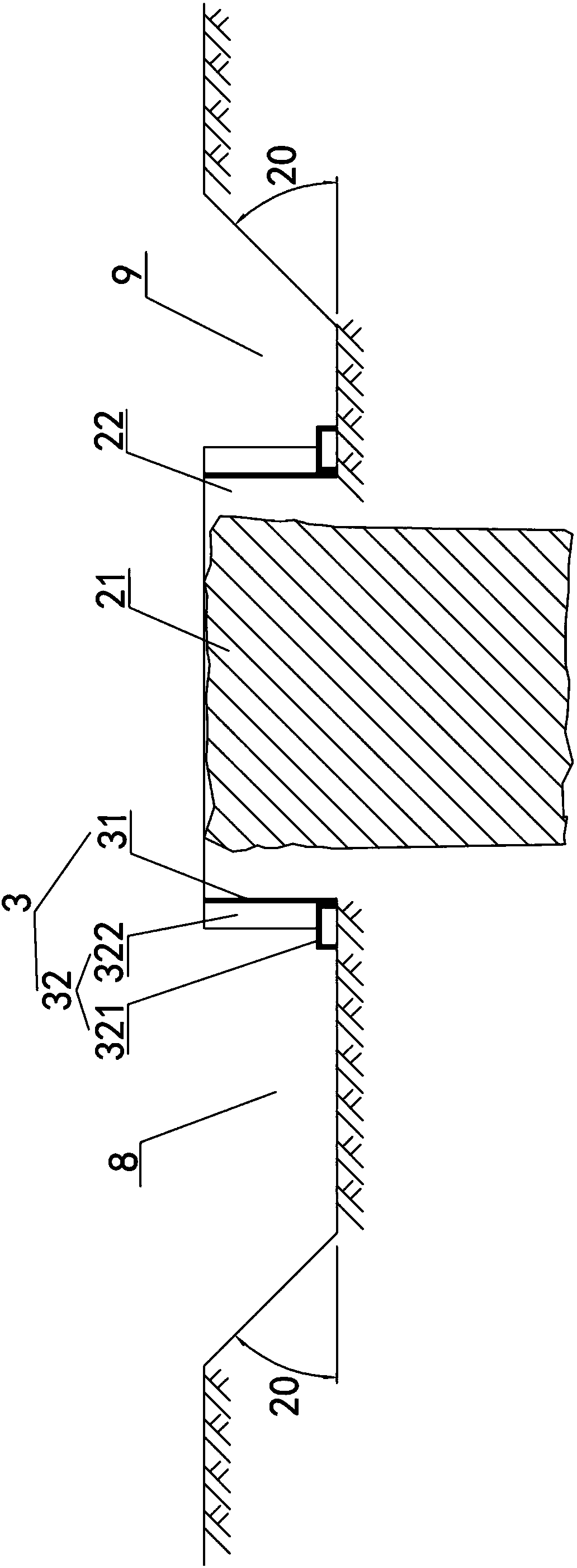

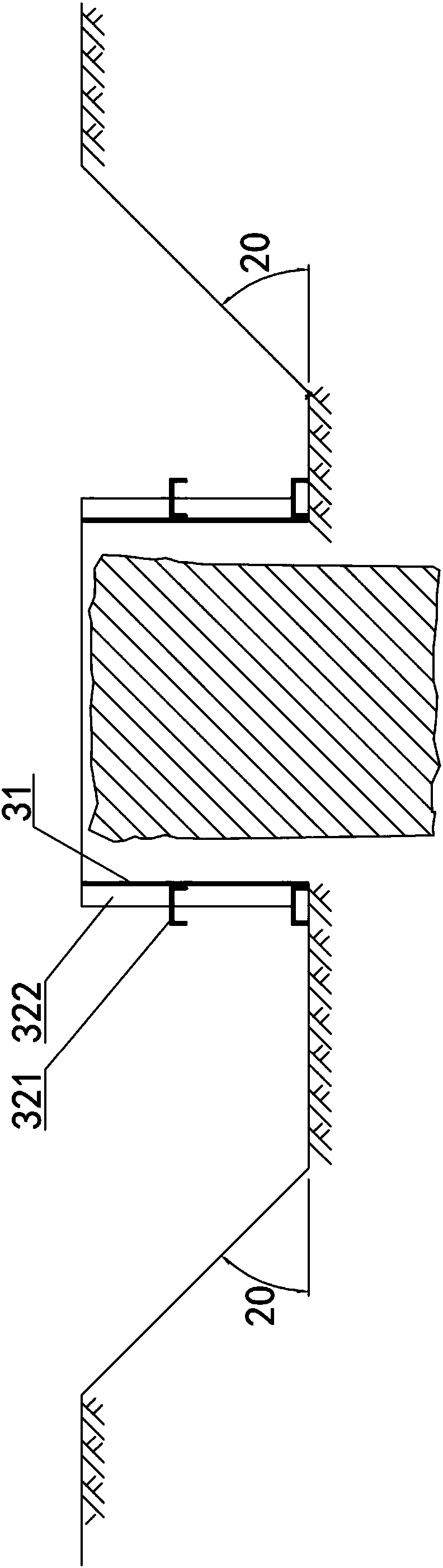

Construction method of double-shear wall template formwork at deformation joint

ActiveCN105201106AEasy construction and operationShorten the construction periodWallsForms/shuttering/falseworksSupporting systemAirbag

The invention belongs to the technical field of construction of building deformation joints and particularly relates to a construction method of a double-shear wall template formwork at a deformation joint. Shear wall template support systems at two sides of the deformation joint are deeply researched and analyzed, a high-pressure hollow airbag is used as shear wall template supports at the two sides in the deformation joint, and the airbag can be inflated to form a pressure-proof rigid body to be combined with shear wall templates at the two sides and steel tube supports at the outer side of the deformation joint to form a steady two-side shear wall template support system, thereby realizing simultaneous support of the shear wall templates at the two sides of the deformation joint; and after the shear wall templates are dismantled, the high pressure airbag can be deflated to reduce the pressure so as to be smoothly removed, and then the templates at the inner side of the deformation joint can be conveniently lifted out sequentially, so that residual wastes of building construction do not exist in the deformation joint and the materials can be recycled many times.

Owner:SHANDONG HUABANG CONSTR GRP

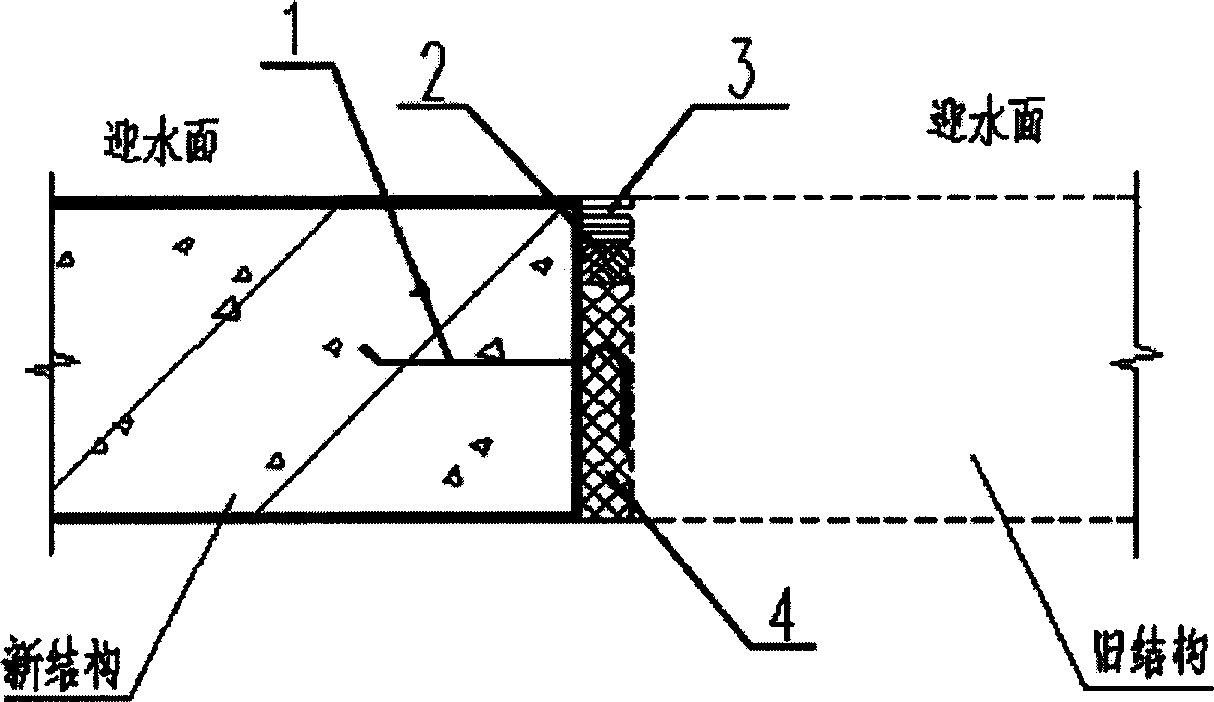

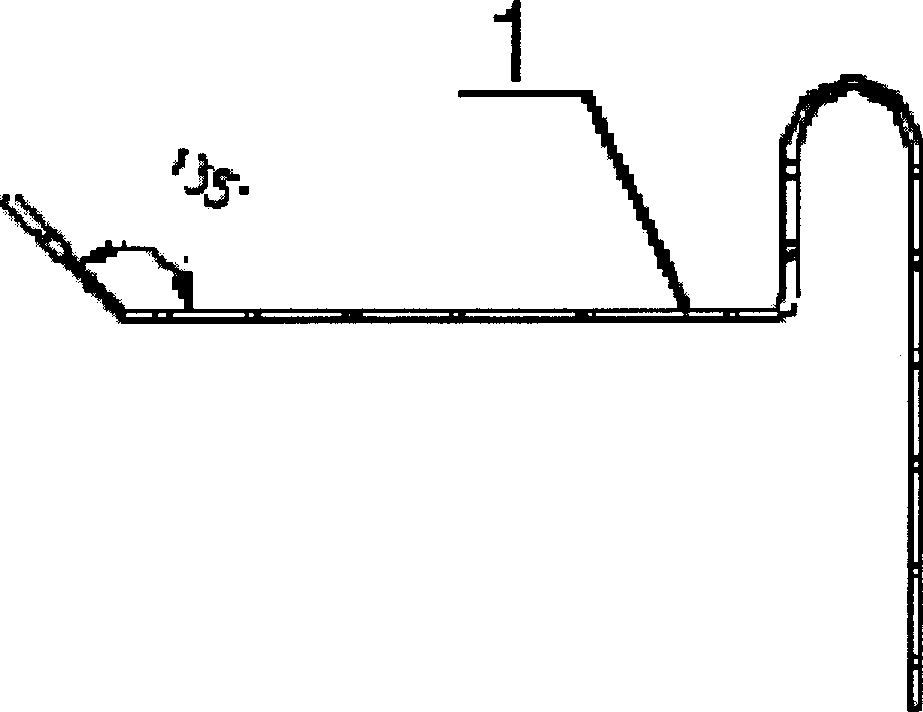

Method for constructing water-proof telescopic seam between new and old concrete building joints and structure thereof

InactiveCN1837528AOvercome positionOvercome immobilityBuilding insulationsArchitectural engineeringEngineering

Owner:GUIYANG AL-MG DESIGN & RES INST

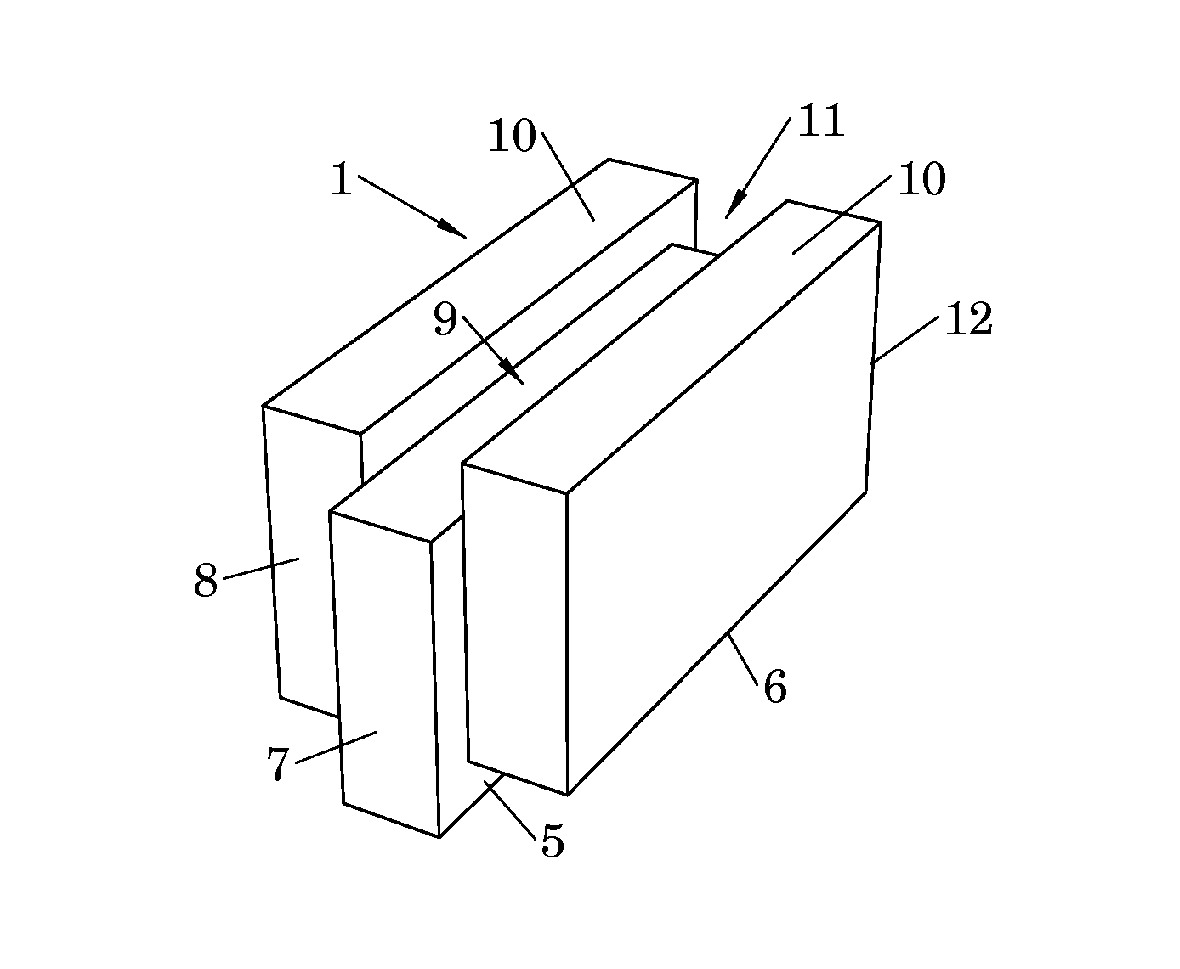

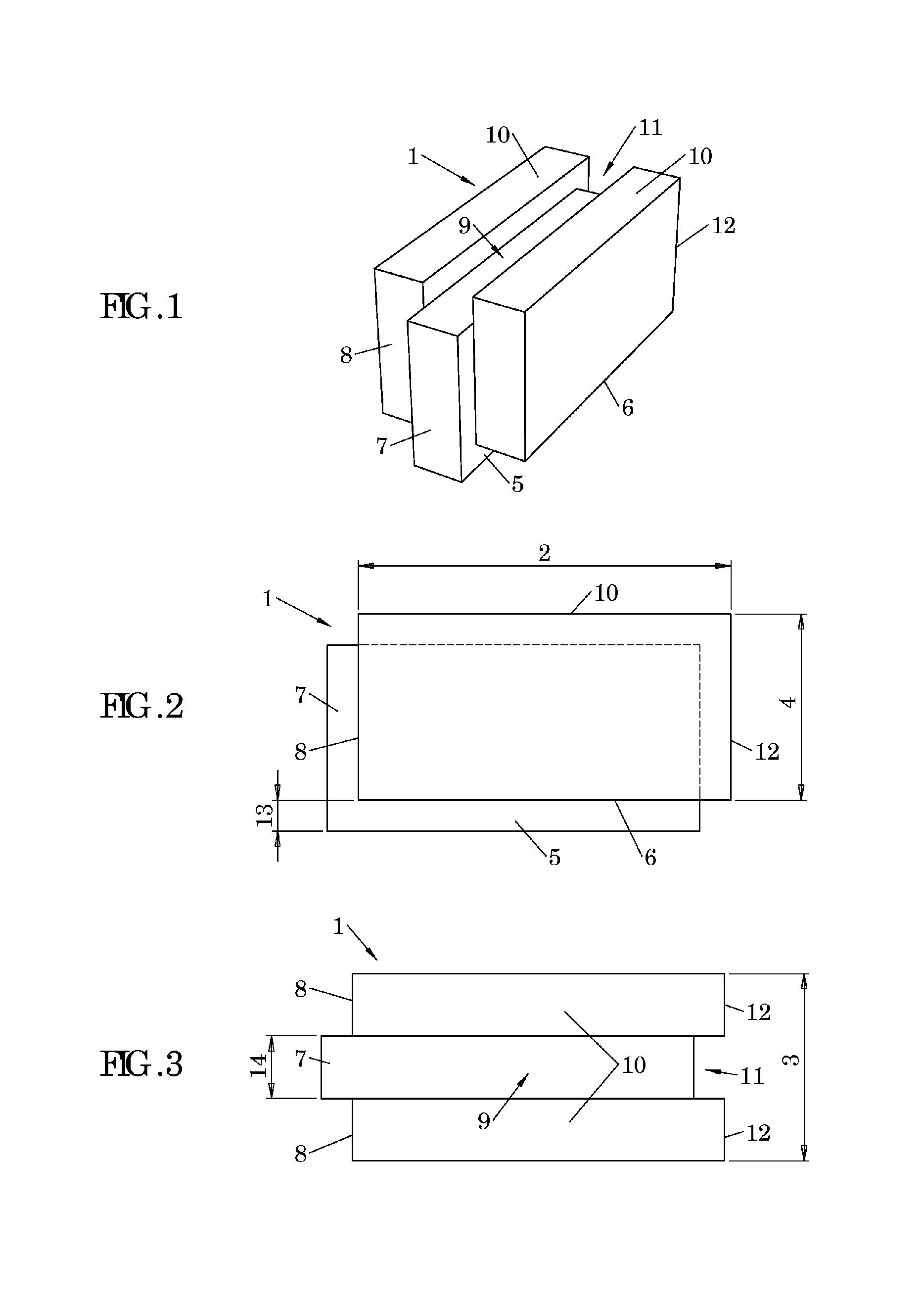

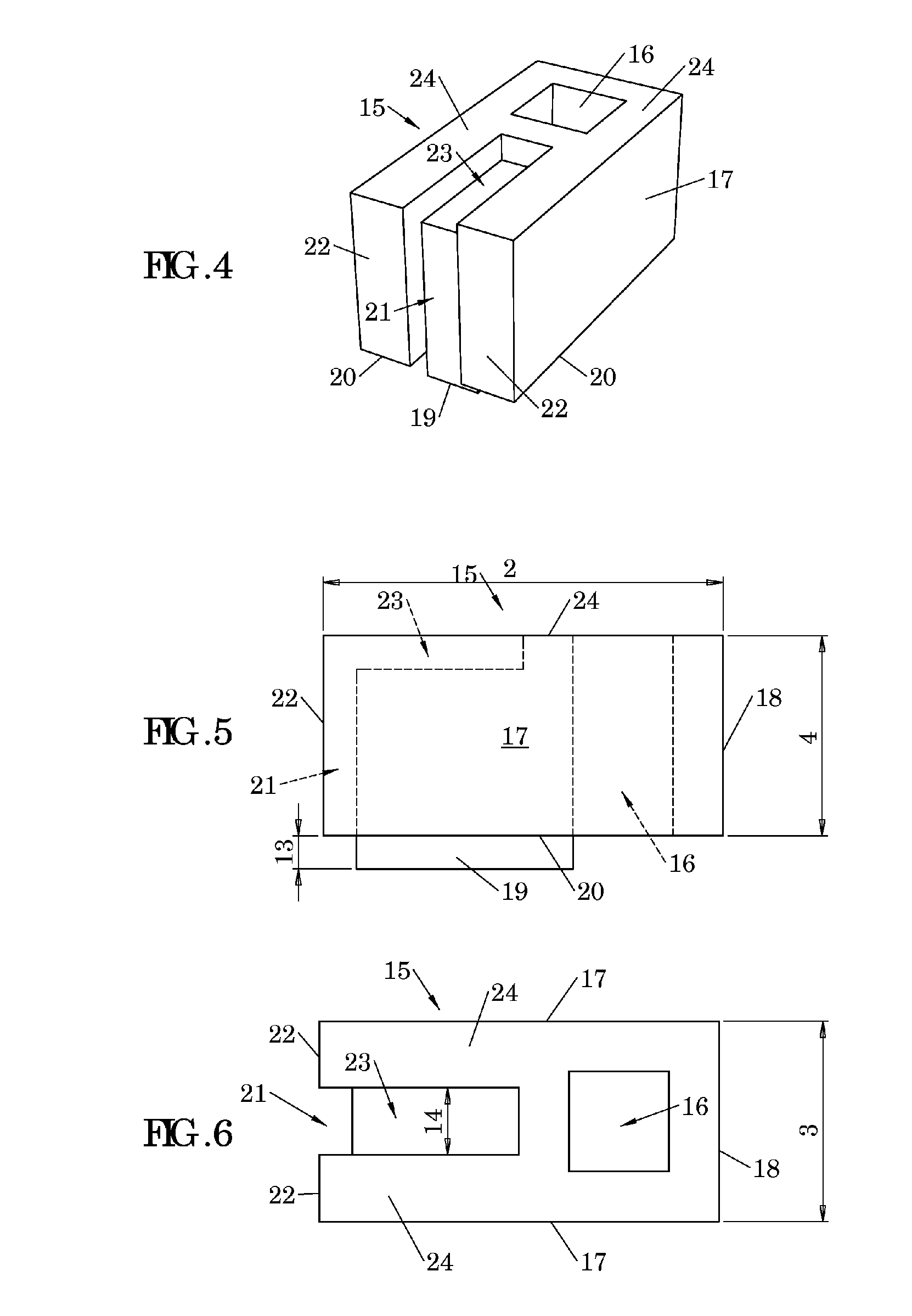

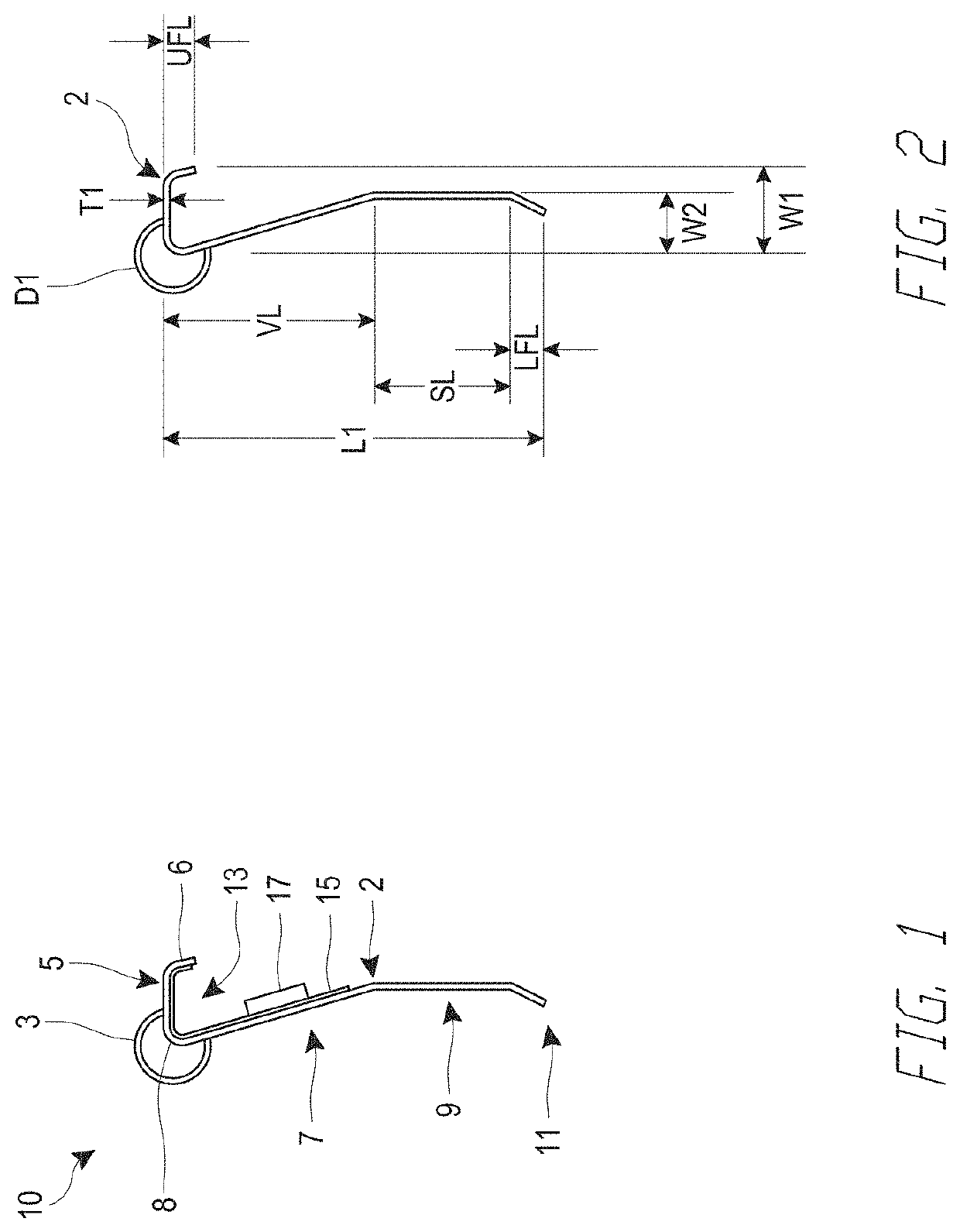

Method for constructing a building using bricks connected using dry joints

The invention relates to a brick (1) made from a material comprising vegetable fibres agglomerated using a binder (such as hemp concrete), said brick being provided with a groove (9, 11) and a tongue (5, 7) allowing the dry-joint connection of bricks. The invention also relates to a method for constructing a building using such bricks.

Owner:VICAT

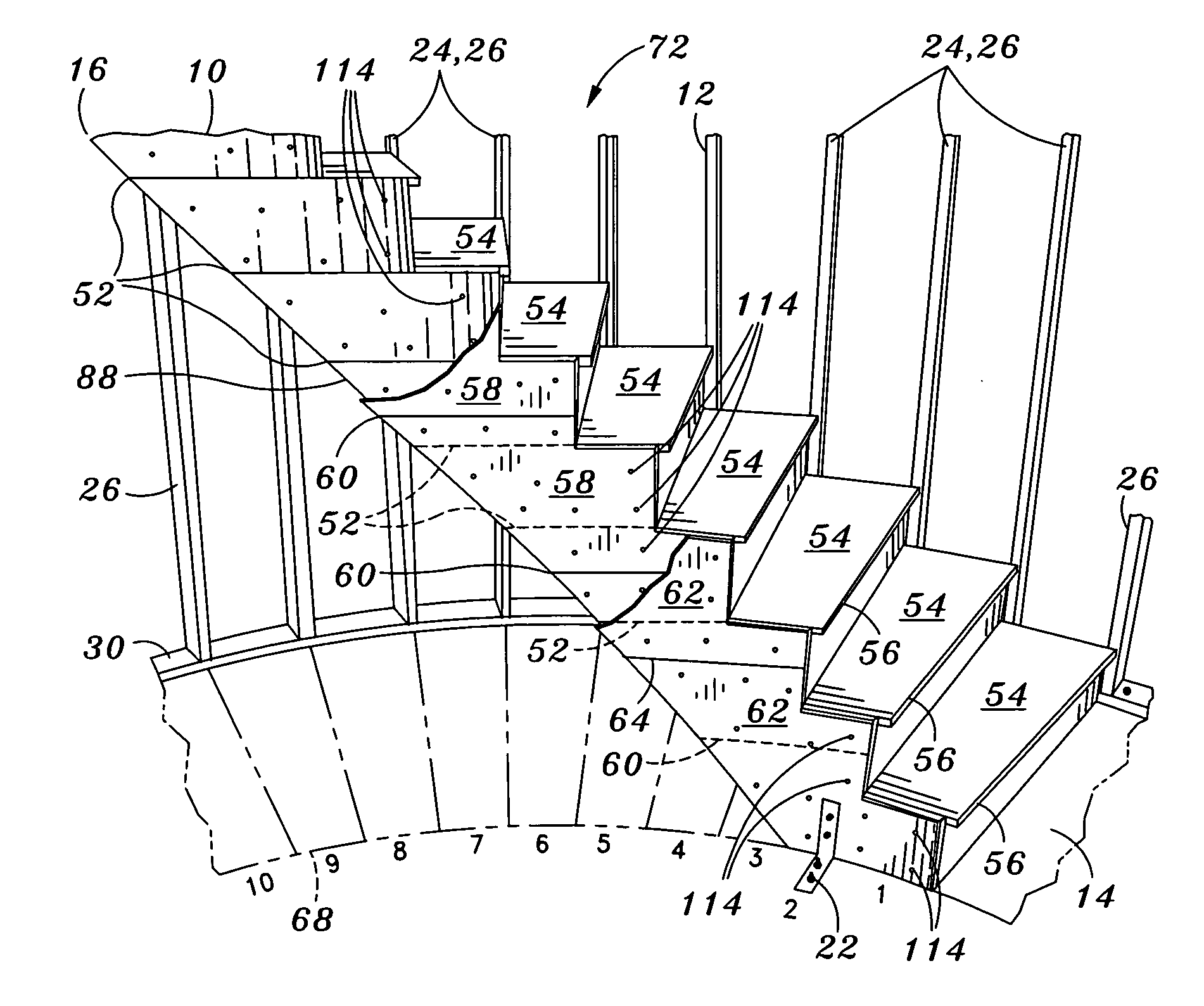

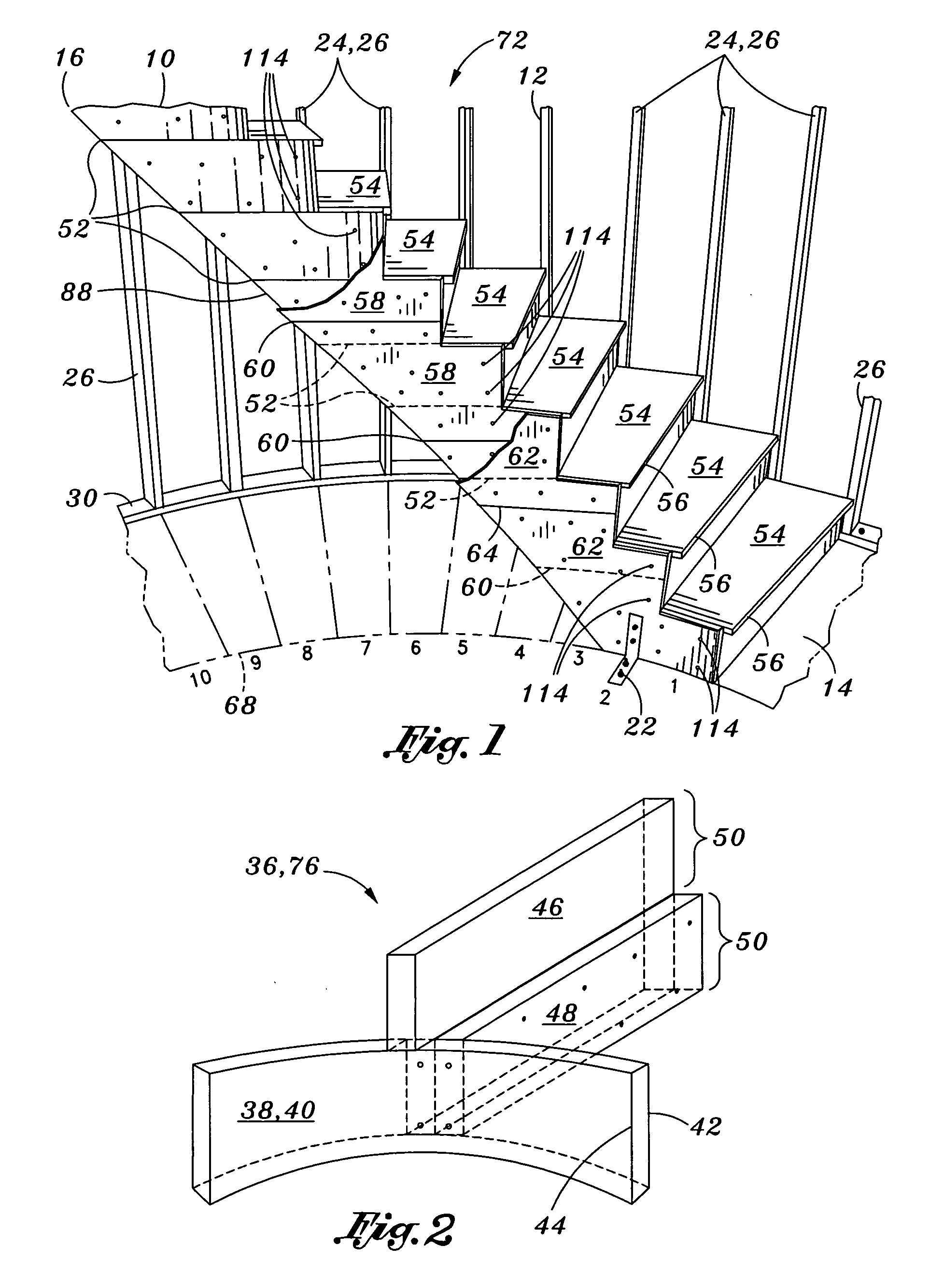

Modular staircase kit

InactiveUS20070144084A1Shorten assembly timeReduce construction costsTreadsWood working apparatusClassical mechanicsJoint (building)

A staircase kit comprises a plurality of side panels and a plurality of inner and outer reinforcing panels disposed in layered arrangement over the side panels. The side panels and inner and outer reinforcing panels have preformed holes extending axially therethrough. The side panels are disposed in stacked relation to one another to form a plurality of module joints there between. Likewise, the inner reinforcing panels are disposable in overlapping relationship to the module joints. The inner reinforcing panels form a plurality of inner panel joints that are preferably disposed in staggered relationship to the module joints. The outer reinforcing panels are disposed in overlapping relationship to the inner panel joints to form a plurality of outer panel joints that are disposed in staggered relationship to the inner panel joints. The preformed holes of the side panels are axially alignable with the preformed holes of the inner and outer reinforcing panels such that mechanical fasteners may be installed at the job site in order to assemble the staircase kit for interconnection to a building structure.

Owner:ARCH RITE

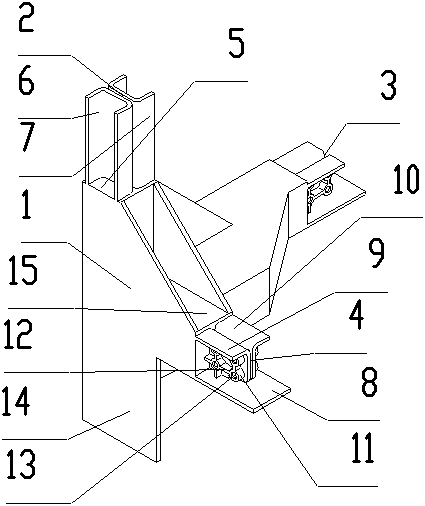

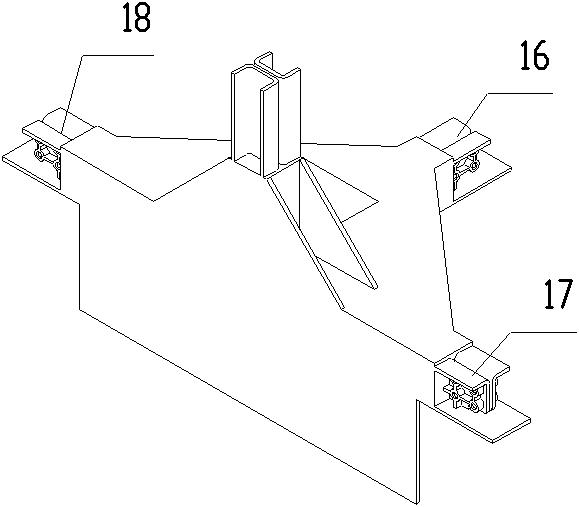

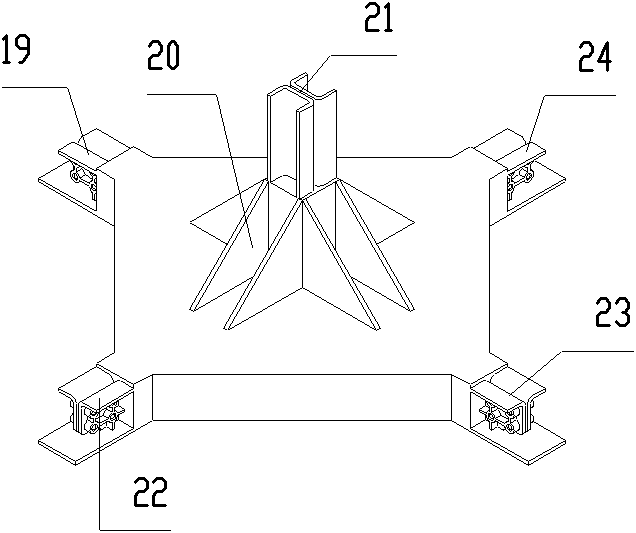

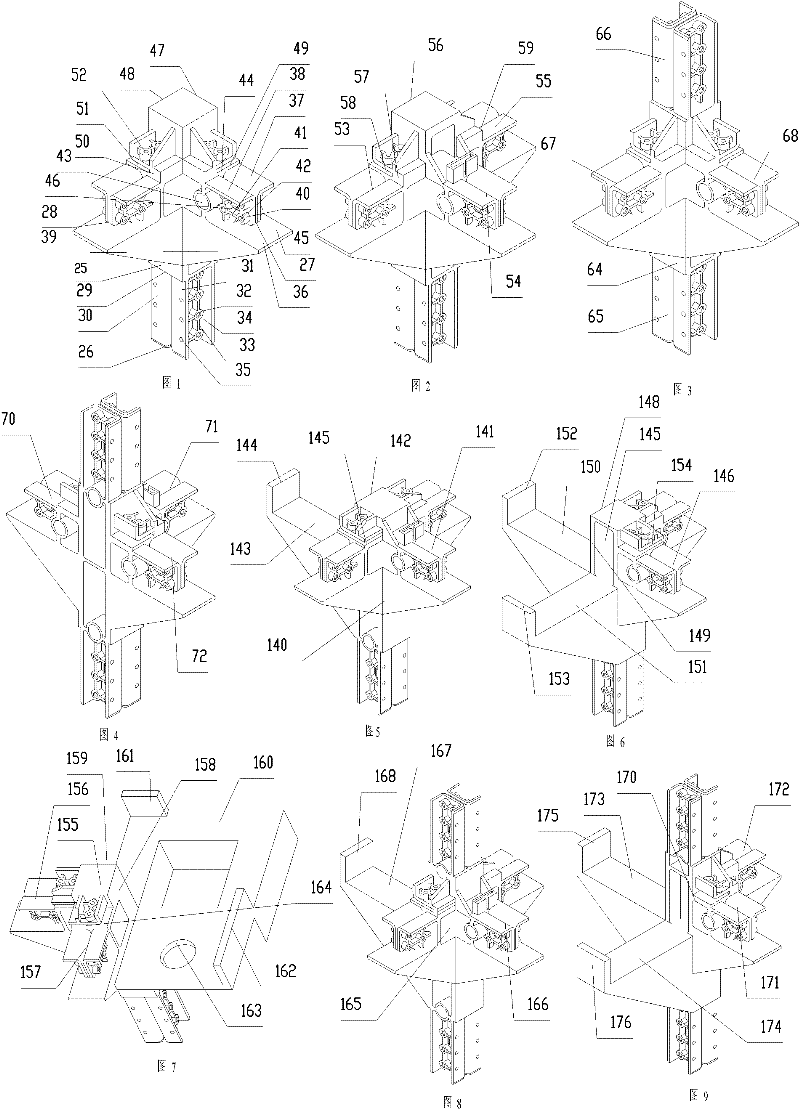

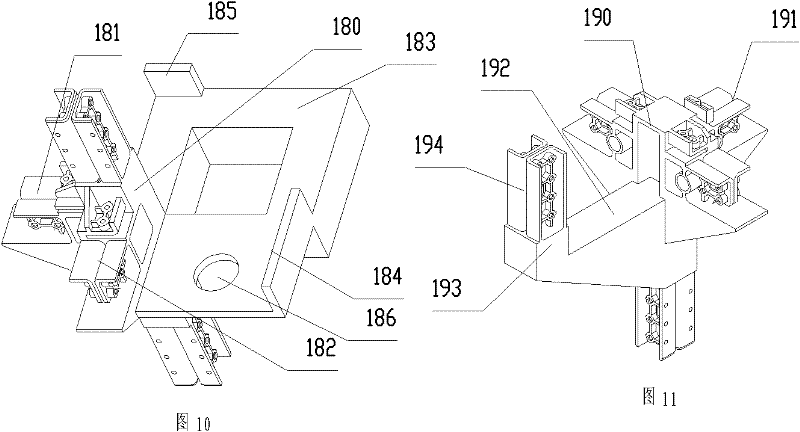

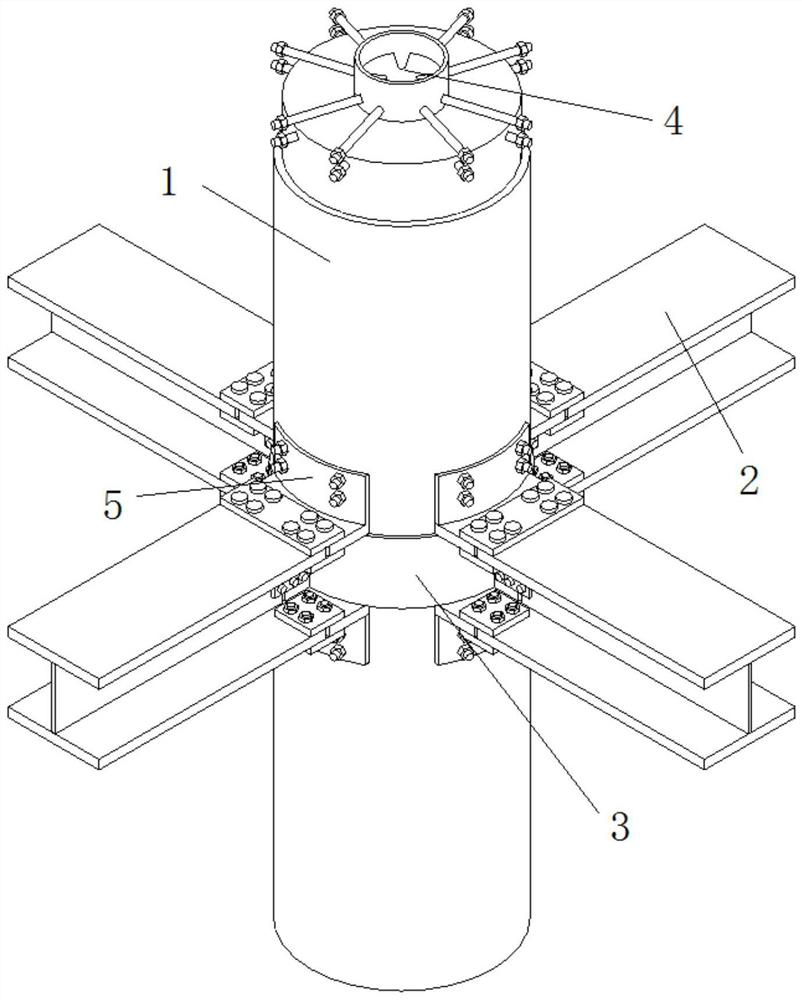

Beam-column connector and forming method, building frame structure and installation method

InactiveCN102277904AImprove installation efficiencyReduce force differenceBuilding material handlingEngineeringSeismic resistance

The invention discloses a beam and column connecting member which comprises an integrally-formed beam and column connecting member body, upright splicing heads and a horizontal support joint, wherein the beam and column connecting member is formed through casting; and a building frame structure comprises the beam and column connecting member, an upright spliced and fixed with the upright splicinghead, and a beam supported and fixed with the horizontal support joint. An installing method comprises the steps of: installing the upright spliced and fixed with the lower upright splicing head, installing the beam and column connecting member, and installing the beam. The invention has the advantages of greatly reducing connecting links of fastening connection or welding of bolts and the like, greatly reducing defects of poor stress and weak connection of connecting positions, caused when stress is excessively concentrated on beams and column or connecting positions among the beams, therebygreatly increasing installing efficiency and seismic resistance function, service life and use safety of a building frame structure. The beam and column connecting member can be massively pre-produced in a standardized manner.

Owner:杨东佐

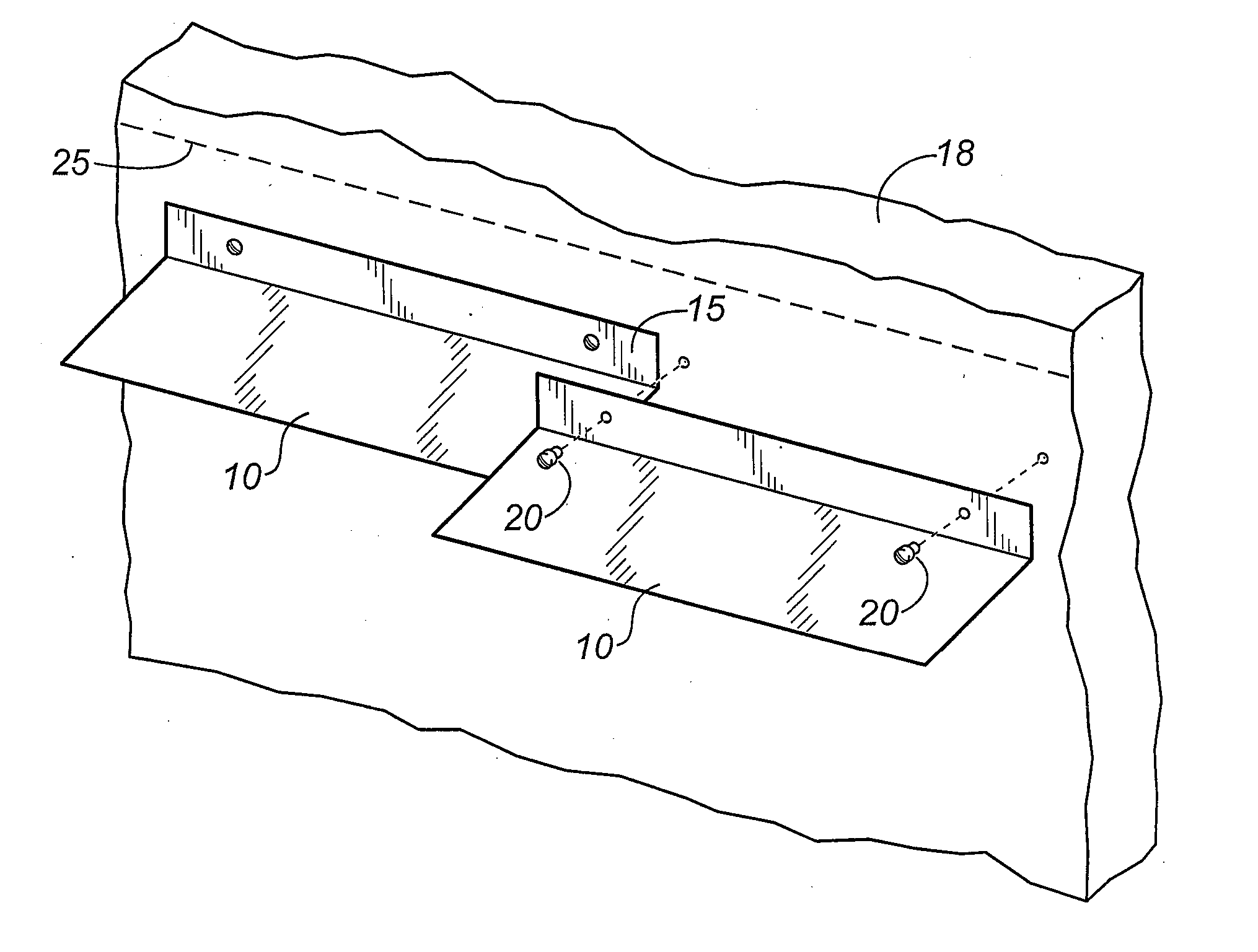

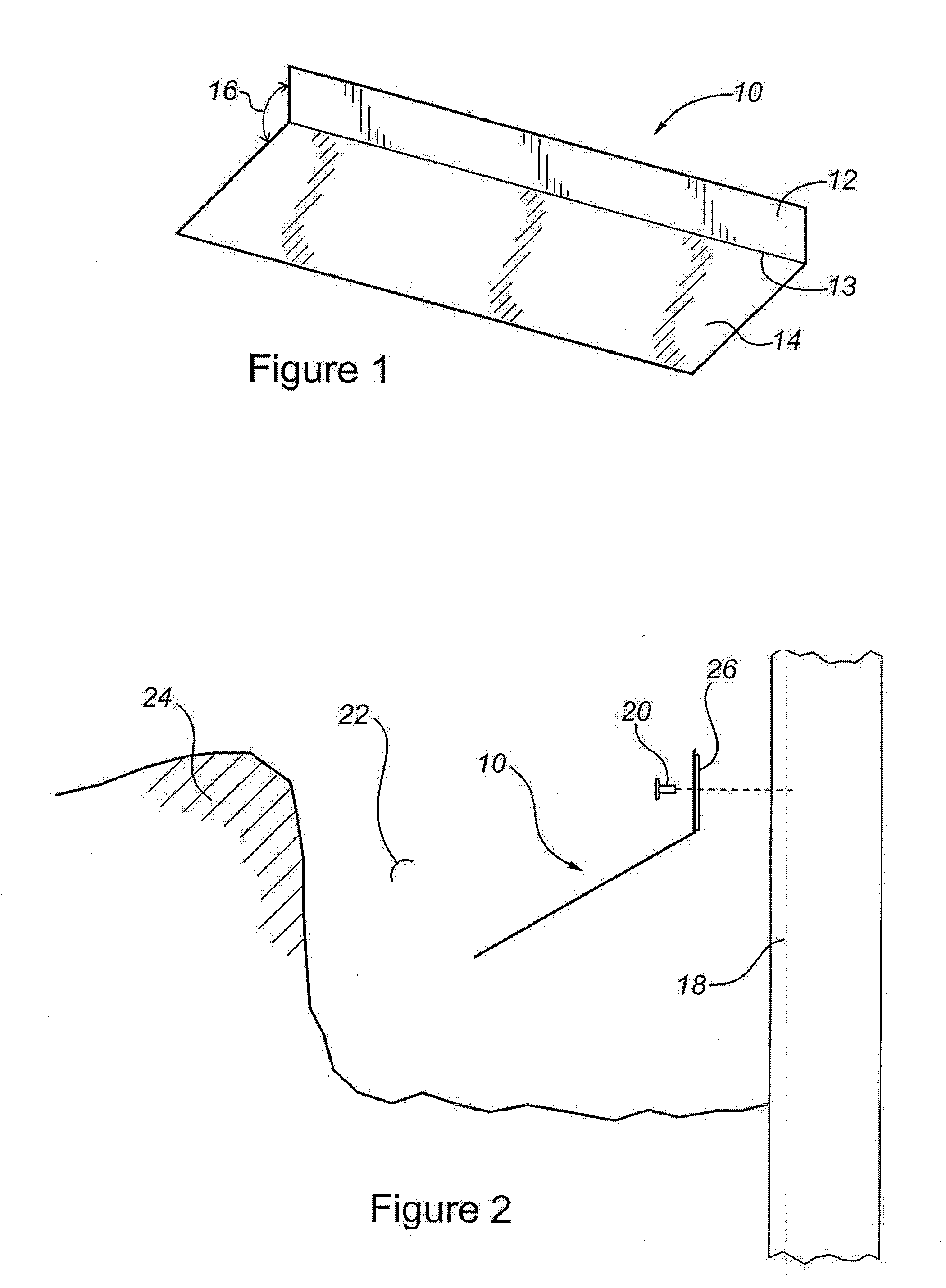

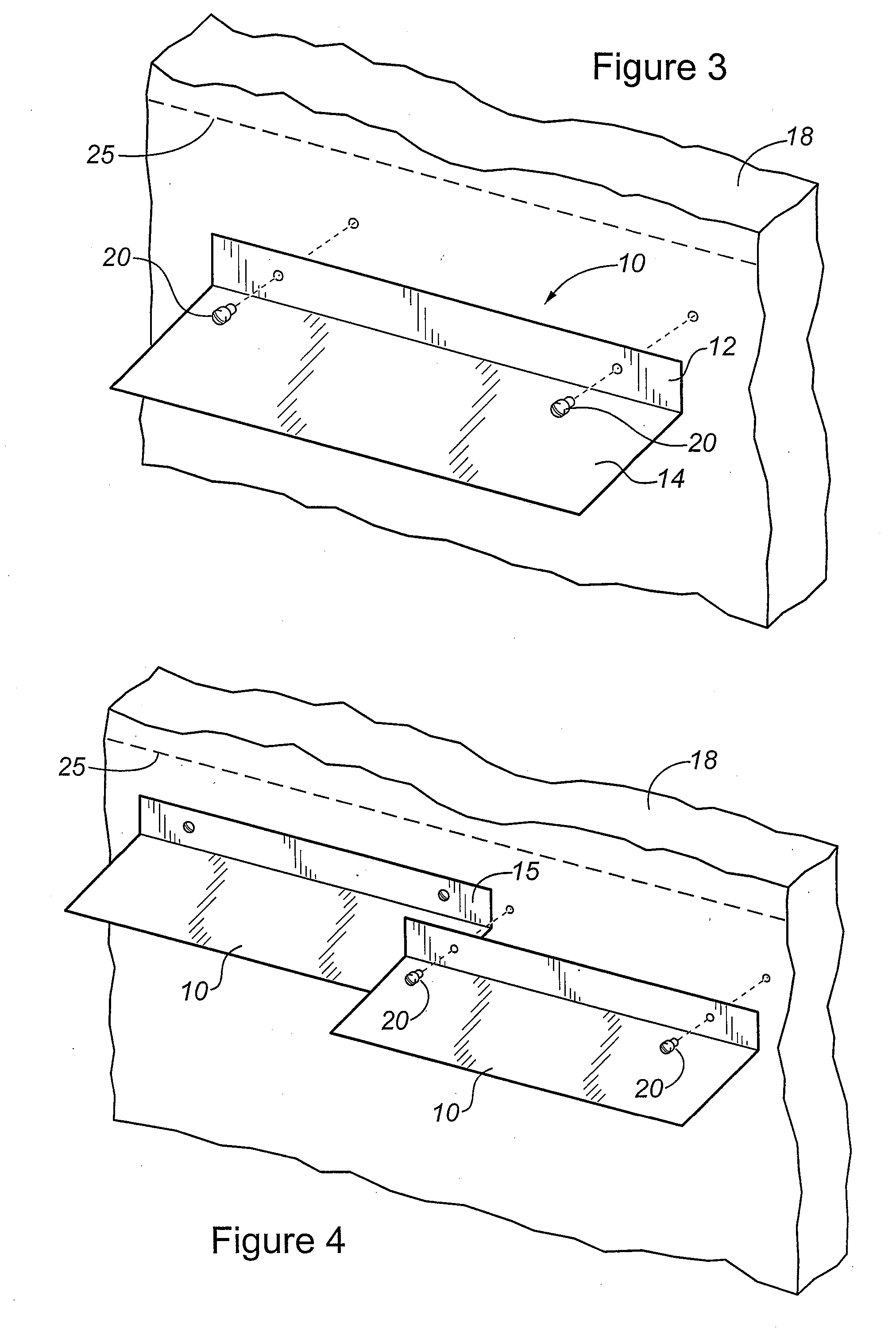

Method and apparatus for deflecting liquid from a foundation wall

InactiveUS20070175113A1Easy to moveAddressing Insufficient CoverageProtective foundationBuilding constructionsStructural engineeringBasement floor

Rain water is deflected from the foundation wall of a building structure by a flashing of non-ferrous metal that is fastened to the foundation below the grade level of the soil. Soil is trenched and exposed about the foundation. Multiple sections of foundation flashing are installed in the trench around the perimeter of the foundation wall. Adjacent flashing sections overlap in a continuous manner. After installation, the trench is backfilled with soil thereby covering the flashing and restoring grade. During heavy rains or floods, water seeping into the soil is deflected away from the foundation by the flashing. This prevents water from pooling at the bottom of the foundation and seeping up into the structure through the joint where the foundation meets the basement floor.

Owner:ALL TERM FINANCING

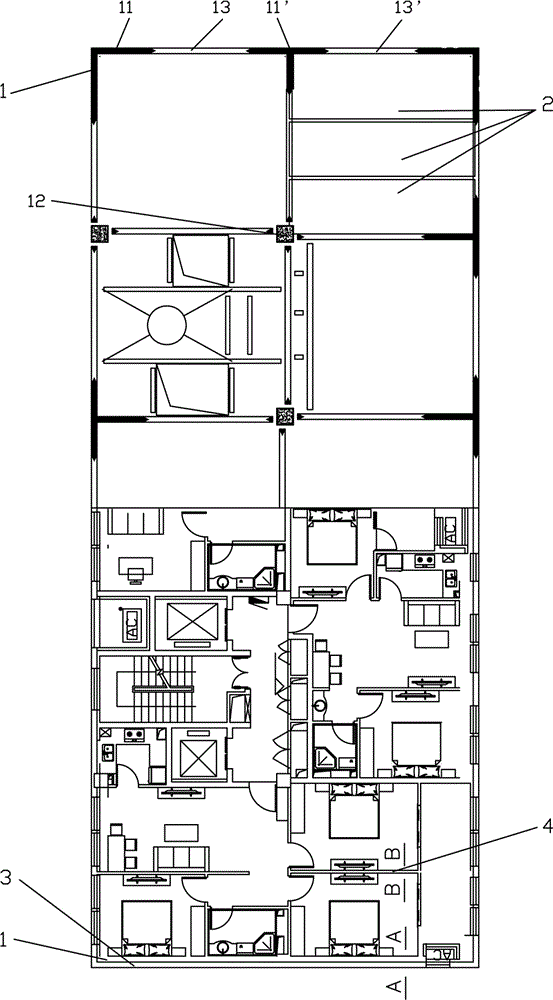

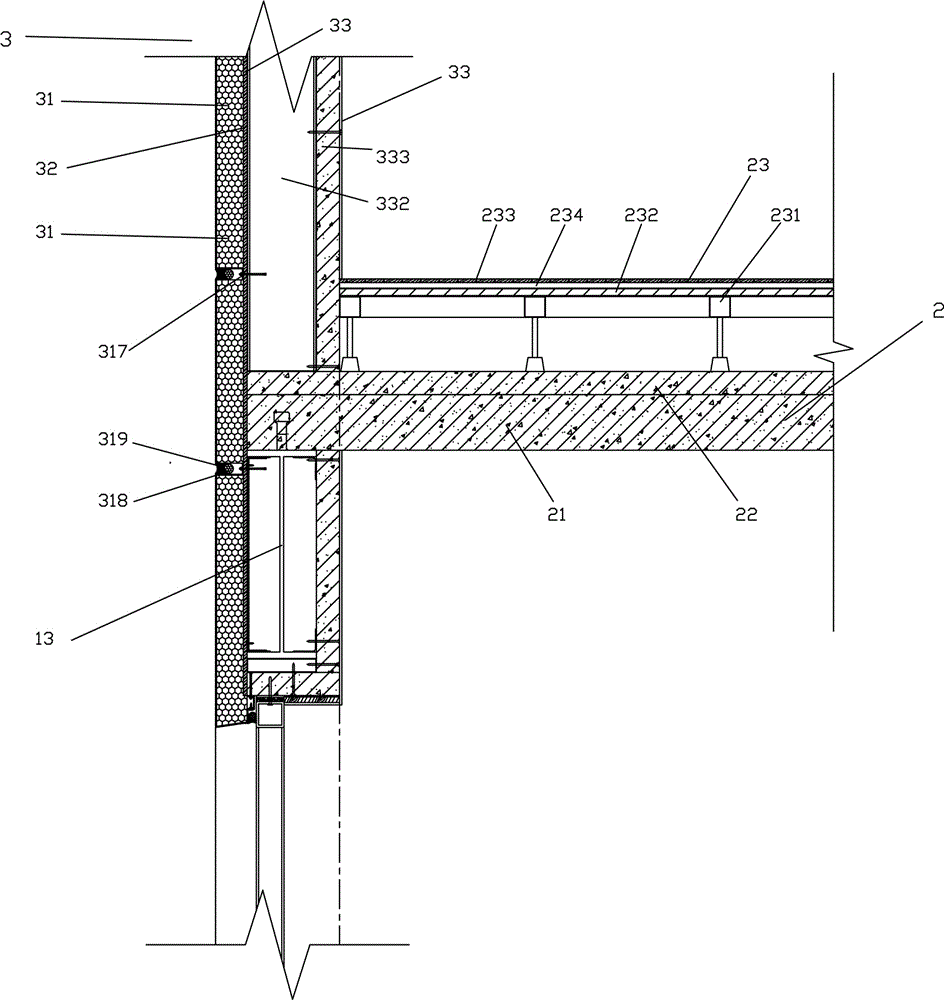

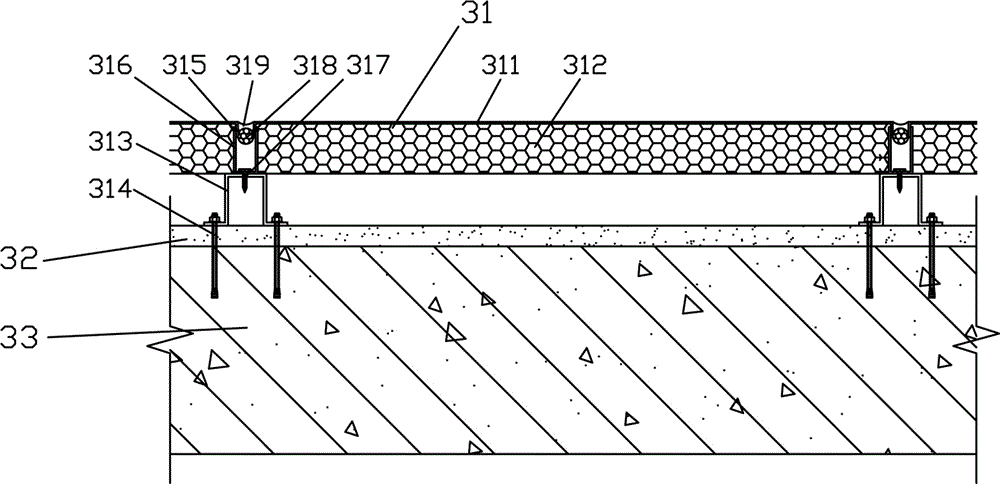

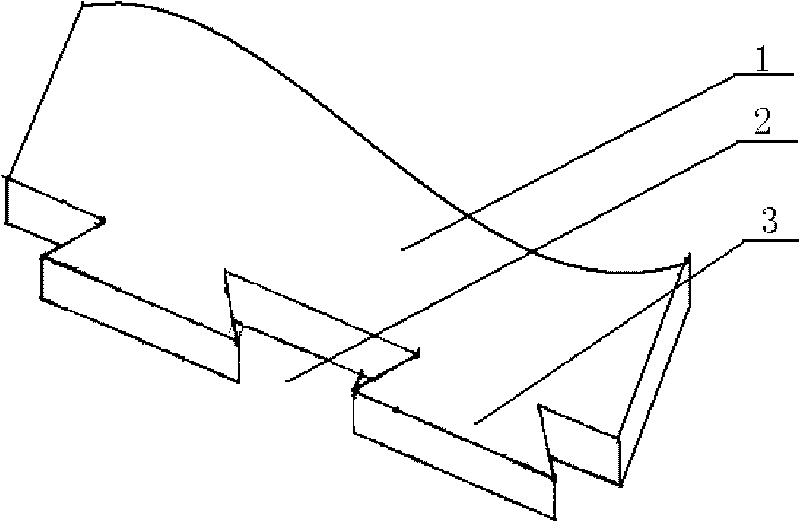

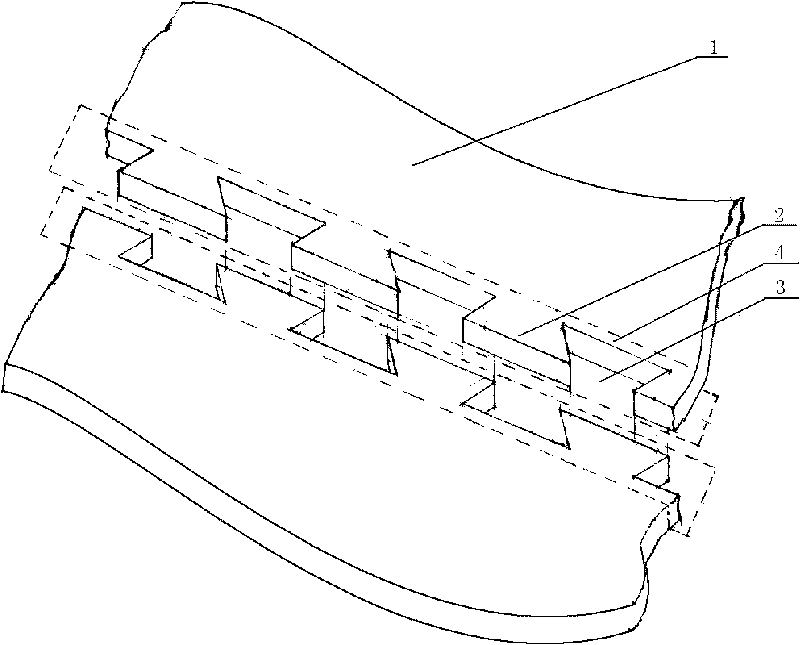

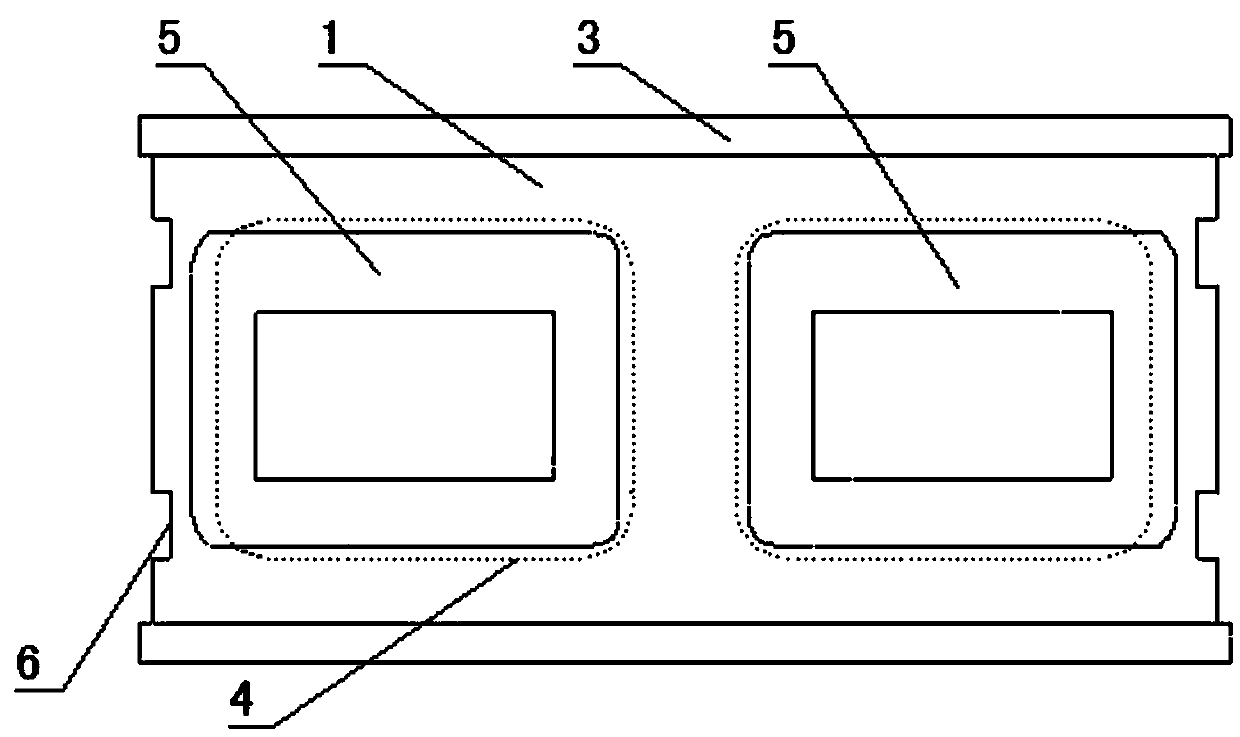

Assembled steel structure building system and construction method thereof

The invention provides an assembled steel structure building system and a construction method thereof. The assembled steel structure building system comprises a steel structure framework system, an assembled and integrated floor system, an assembled outer wall system and an assembled inner wall system; the steel structure framework system comprises double layers of steel plate concrete combined shear wall, steel tube concrete pillars, H-shaped steel beams and connection joints. The steel beams in the steel framework system serves as supports of the assembled and integrated floor system, and the assembled and integrated floor system comprises a precast concrete bottom plate, a cast-in-situ concrete super-position layer and an overhead floor layer located on the cast-in-situ concrete layer. The assembled outer wall system comprises a heat preservation and decoration integrated plate system, a waterproof interface layer and a base wall. According to the assembled steel structure building system, the design concept of separating a supporting body from a filling body is adopted, a large-span space capable of being divided flexibly can be provided, and the assembled steel structure building system and the construction method thereof have the advantages of being high in construction speed, reliable in quality and good in anti-seismic property.

Owner:SHANGHAI IRON & STEEL TECHN INST

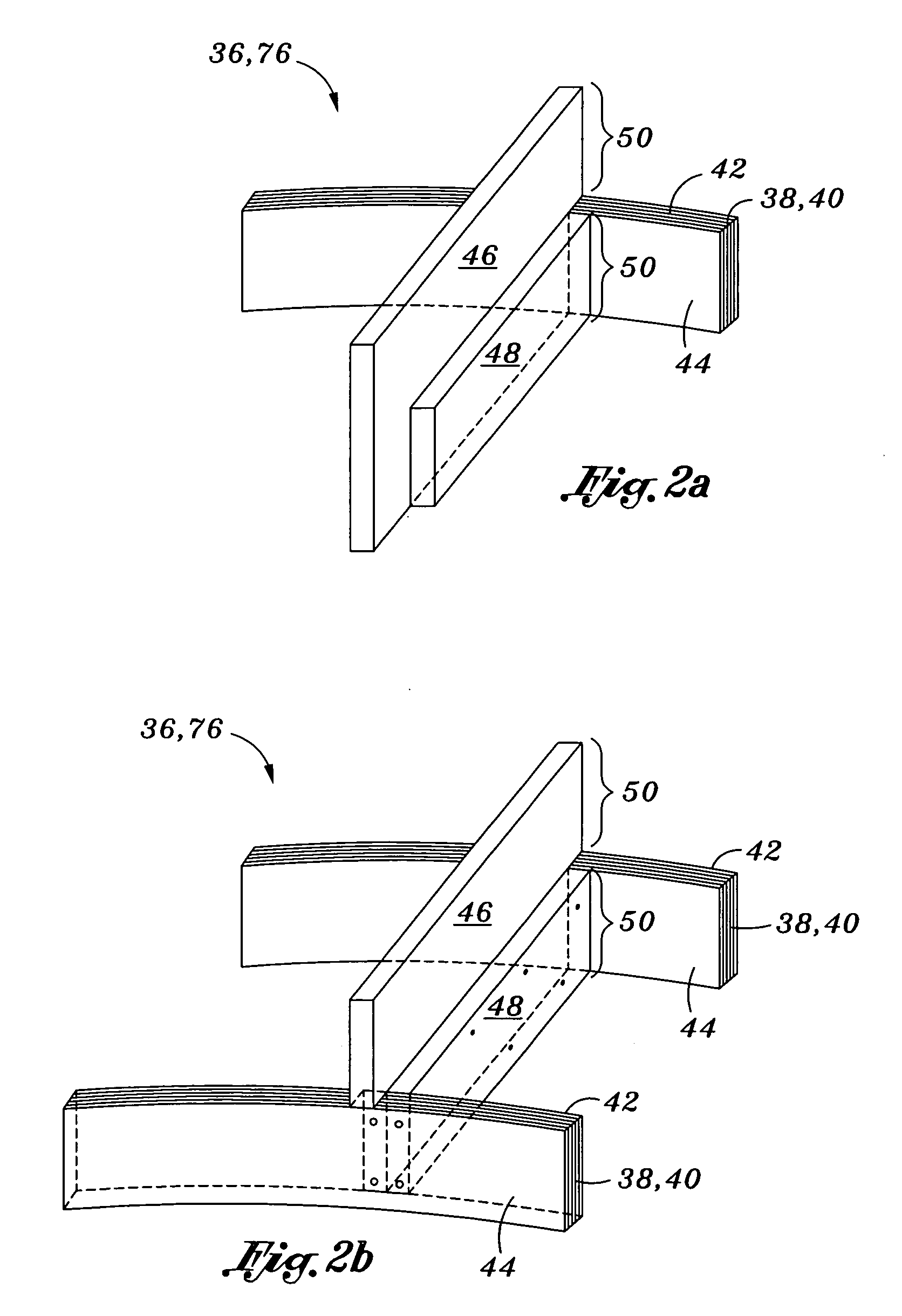

Dovetail mortise-tenon connection method between assembly parts in building project

ActiveCN101761140AImprove seismic performanceQuality improvementBuilding constructionsEngineeringRigid structure

The invention relates to a building project, in particular to a dovetail mortise-tenon connection method between assembly parts in the building project, which is characterized in that dovetail tenons are arranged at the joints of the assembly parts in the building project at intervals, a dovetail slot-shaped mortise is formed between the adjacent two tenons, the tenon of one assembly part is clamped in the mortise of another assembly part for forming the dovetail mortise-tenon connection, if a gap is formed after the connection of one tenon and the corresponding mortise, then the gap is filled through a filler; and two or more assembly parts are connected together for forming a whole structure through the dovetail mortise-tenon connection. The dovetail mortise-tenon connection method can lead a building to become a structural whole which can bear the force as the whole, but be not a rigid structure, thereby leading the whole building to have good seismic performance and good quality.

Owner:刘长生

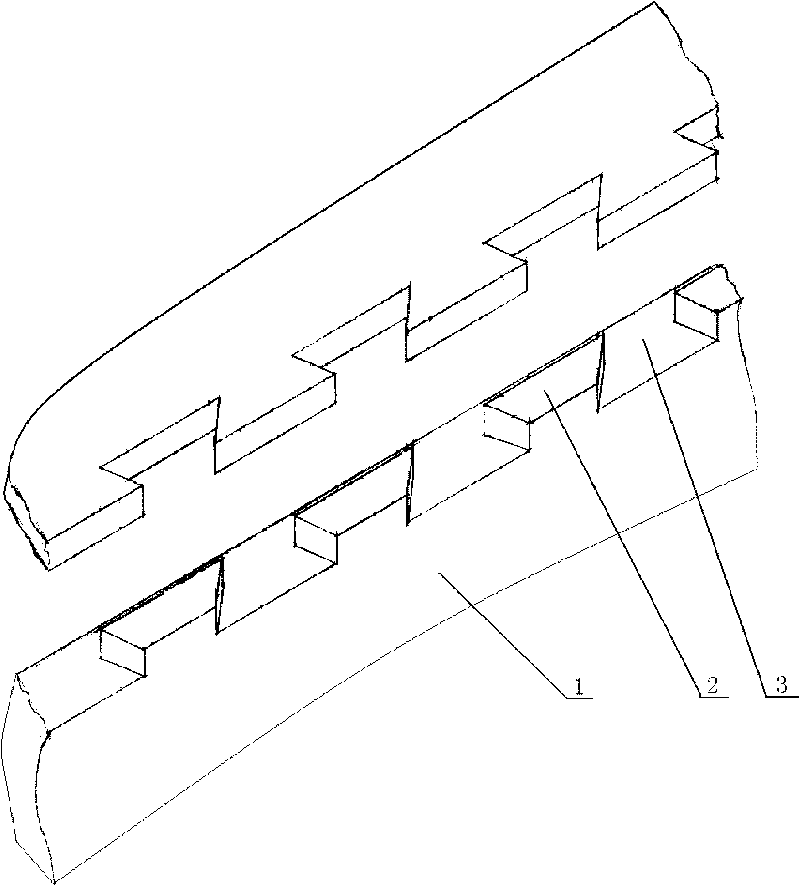

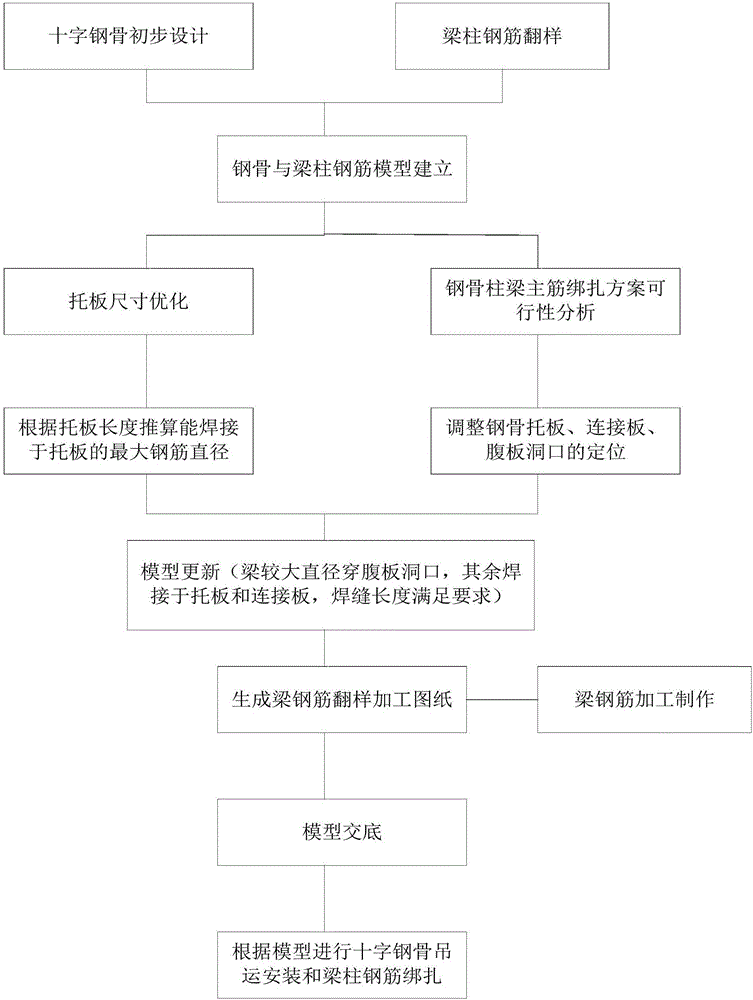

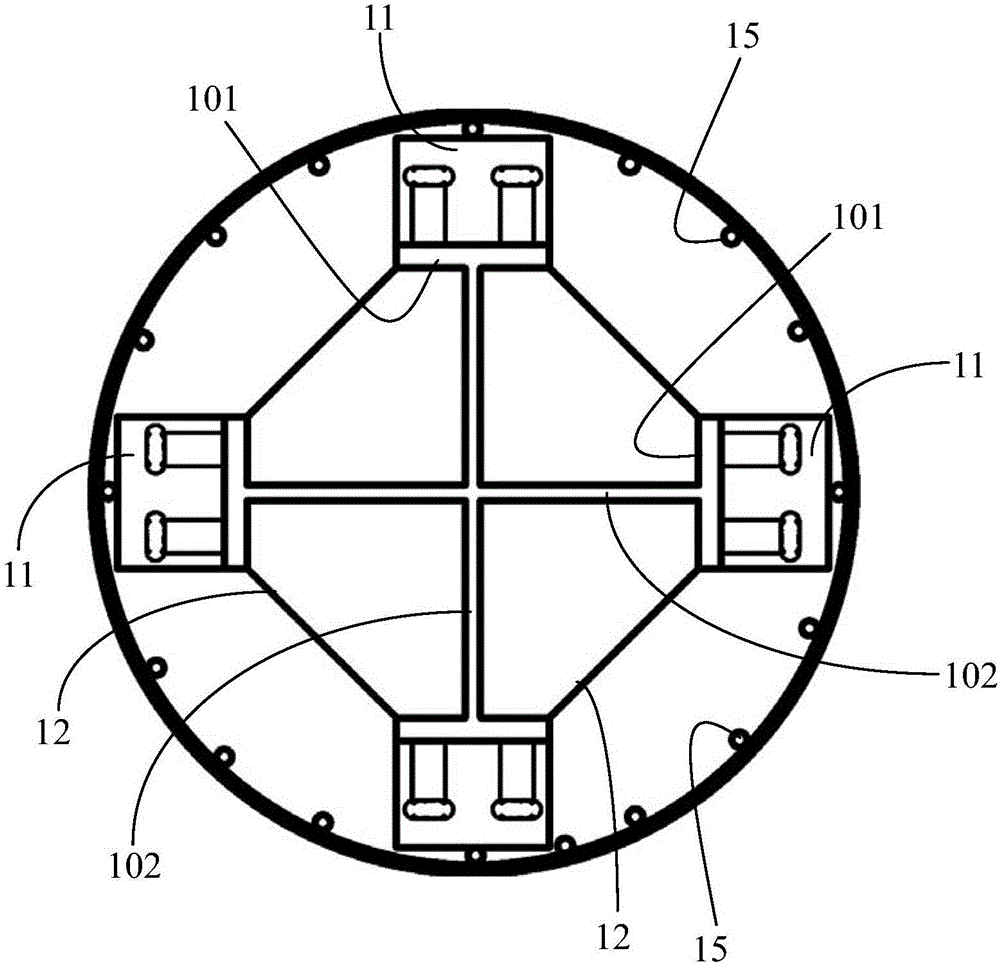

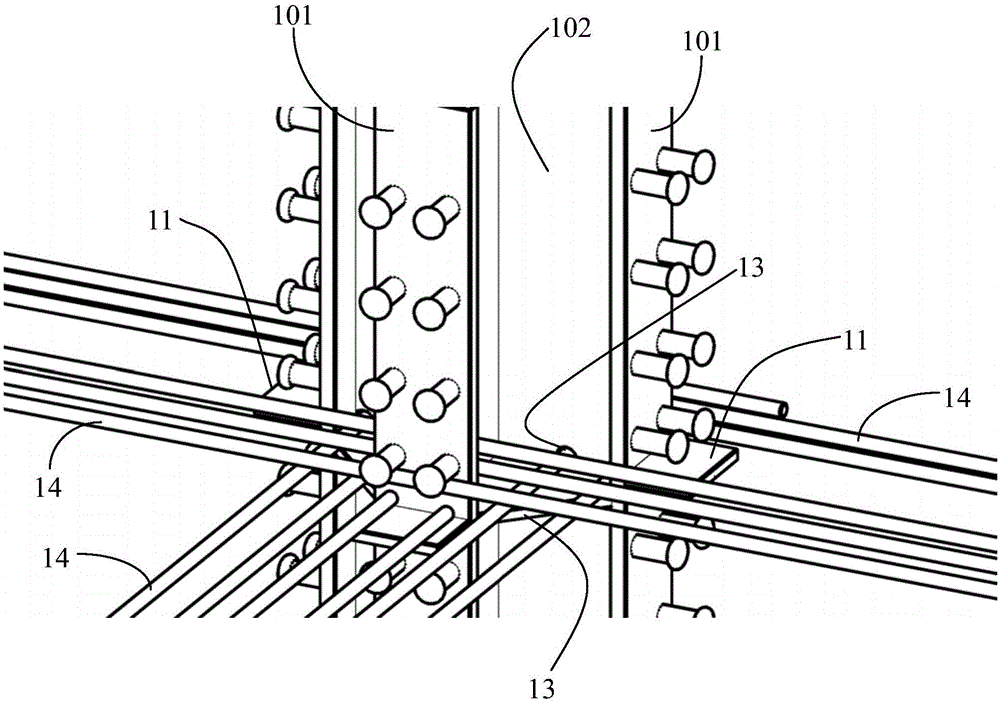

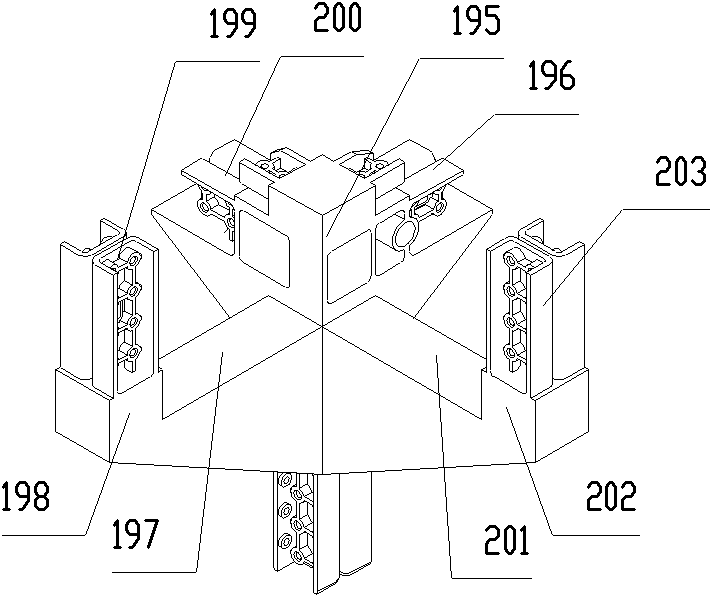

Method for treating reinforcing steel bars at cross-shaped steel reinforced column and beam joints on basis of BIM (building information modeling)

ActiveCN106682266AAvoid the situation where the main reinforcement hits the palletReduce wasteGeometric CADSpecial data processing applicationsRebarJoint (building)

The invention discloses a method for treating reinforcing steel bars at cross-shaped steel reinforced column and beam joints on the basis of BIM (building information modeling). The method has the advantages that parameterized BIM models are built, the lengths of supporting plates of cross-shaped steel reinforced columns are constrained by the BIM in advance, accordingly, the supporting plates can be accurately positioned, and a condition that main reinforcing steel bars are collided with the supporting plates can be prevented; the setting-out of longitudinal beam reinforcing steel bars at column and beam intersections is simulated by the aid of the BIM, processes for treating each beam reinforcing steel bar are determined, beams with the weld lengths meeting requirements are welded on the supporting plates and connecting plates, the reinforcing steel bars with large diameters penetrate holes of web plates, and the beam reinforcing steel bars can be directly set out by site staffs according to the models; the beams, the columns and steel ribs can be simulated by the aid of the BIM in advance, disclosure can be carried out on teams and groups, the reinforcing steel bars can be directly placed and welded according to the models during site construction, accordingly, the work efficiency can be improved, wastage of the reinforcing steel bars can be reduced, the construction progress can be accelerated in sites, and the quality of the steel reinforced columns can be improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Metal joint and building comprising the same

ActiveUS8511025B2Effective energy absorptionImprove seismic performanceNon-rotating vibration suppressionFoundation engineeringRelative displacementUltimate tensile strength

Owner:NIPPON STEEL CORP

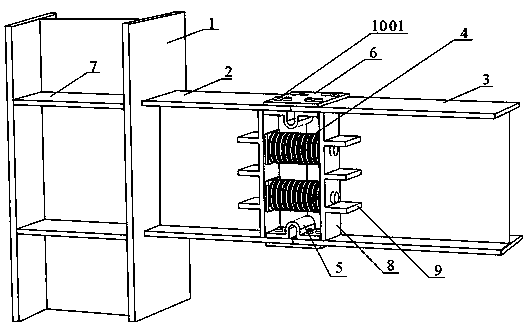

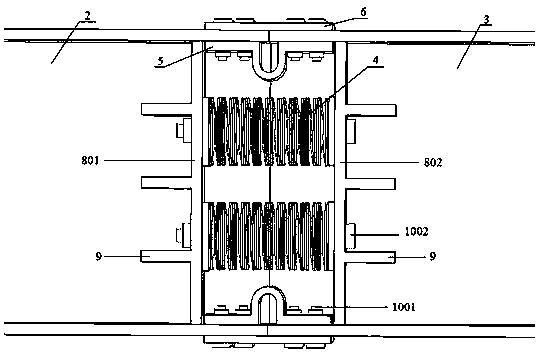

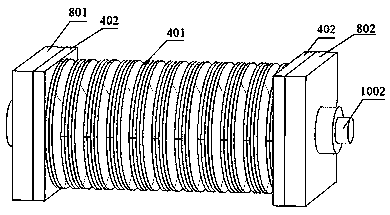

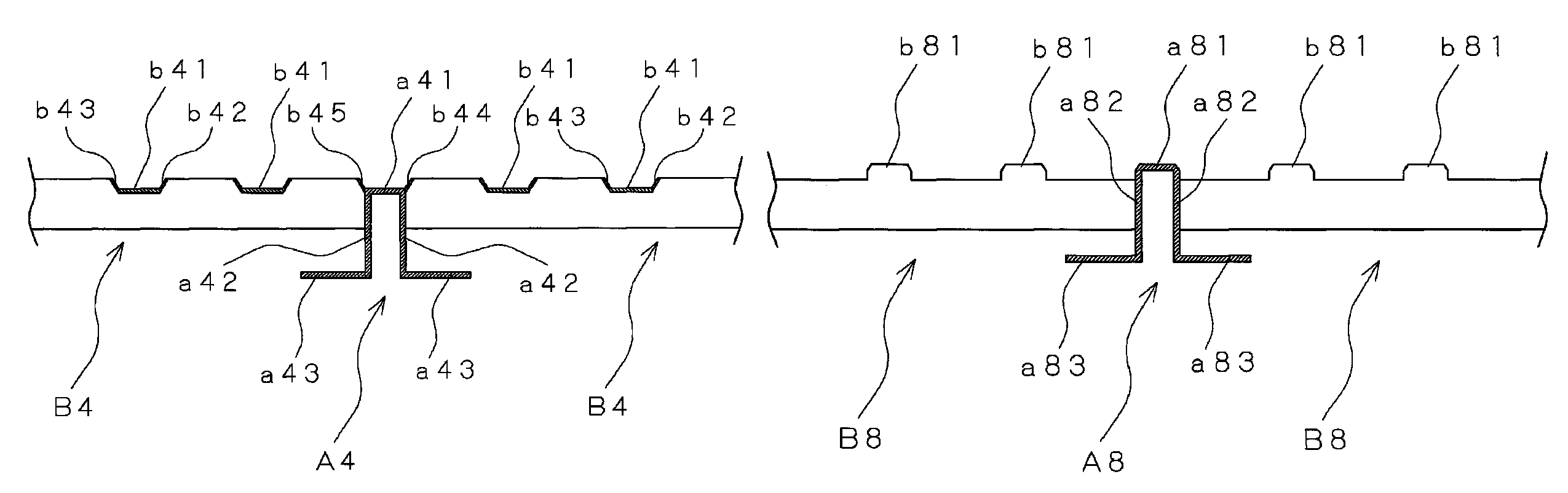

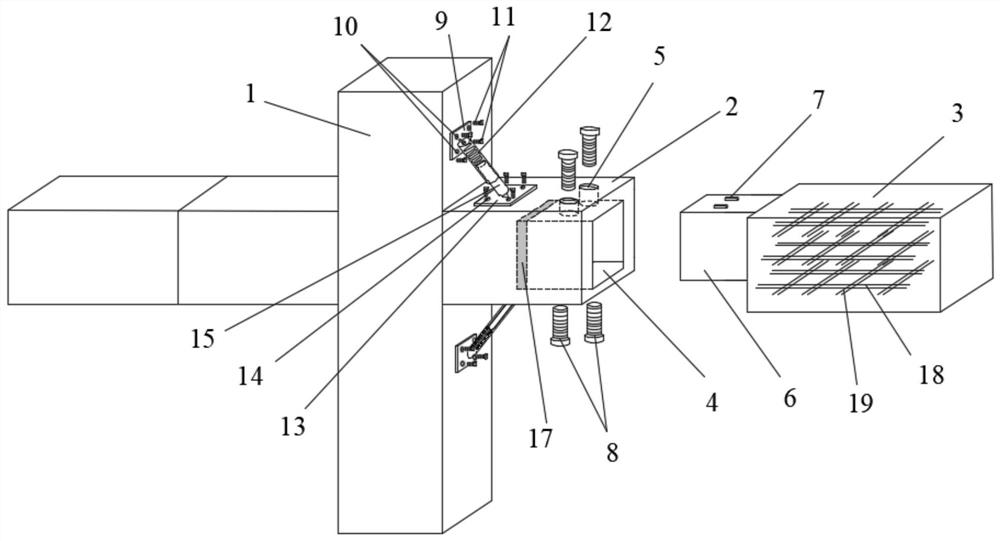

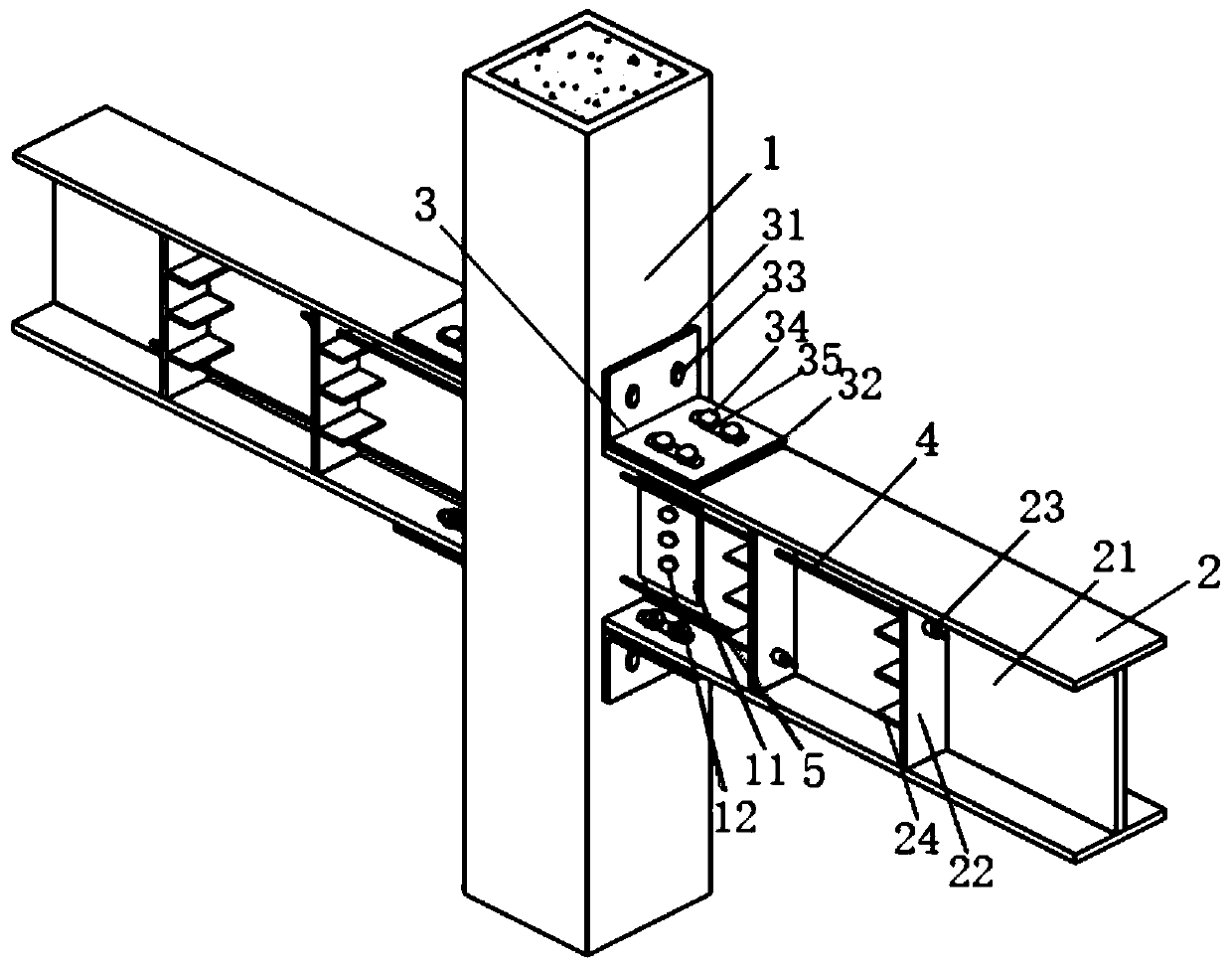

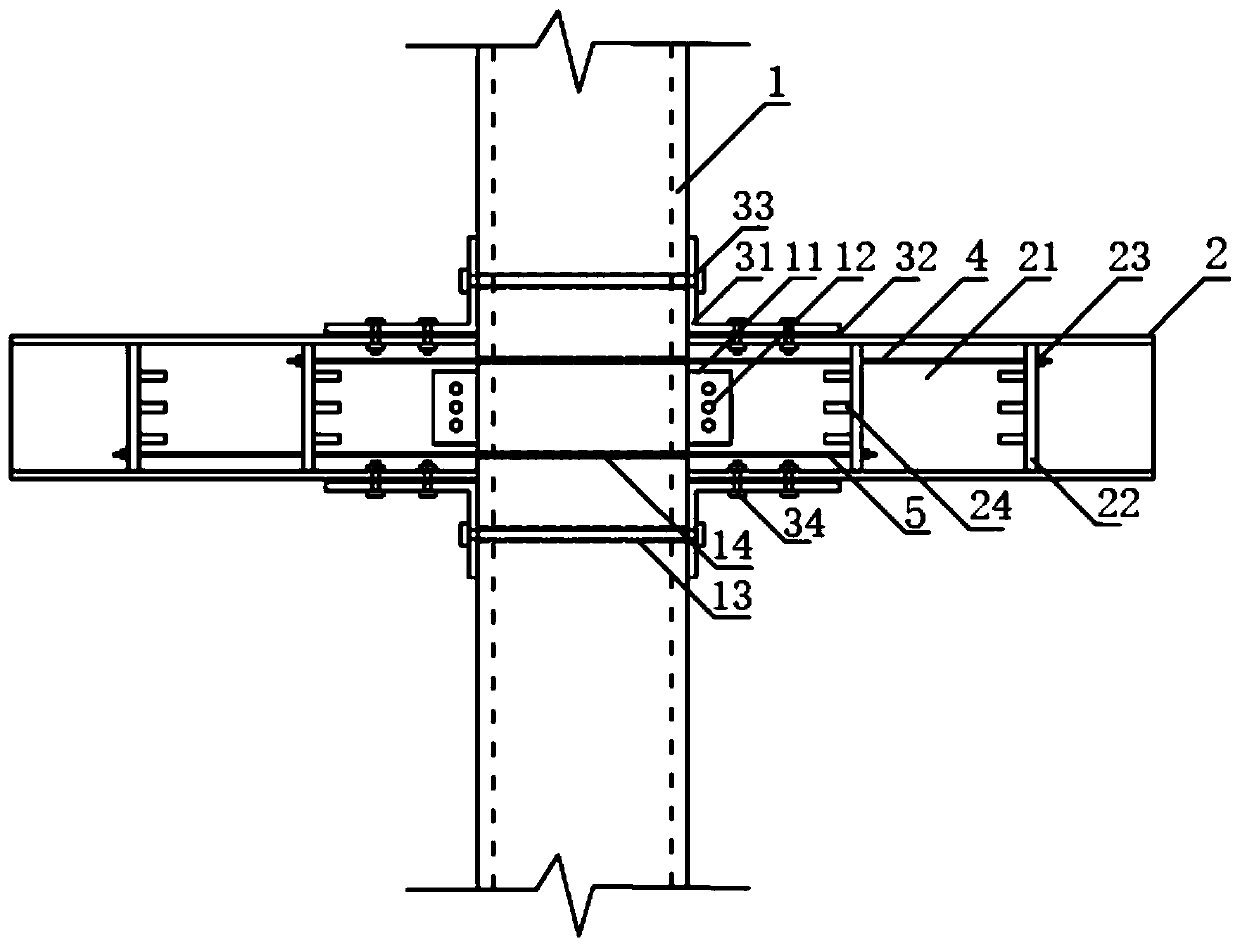

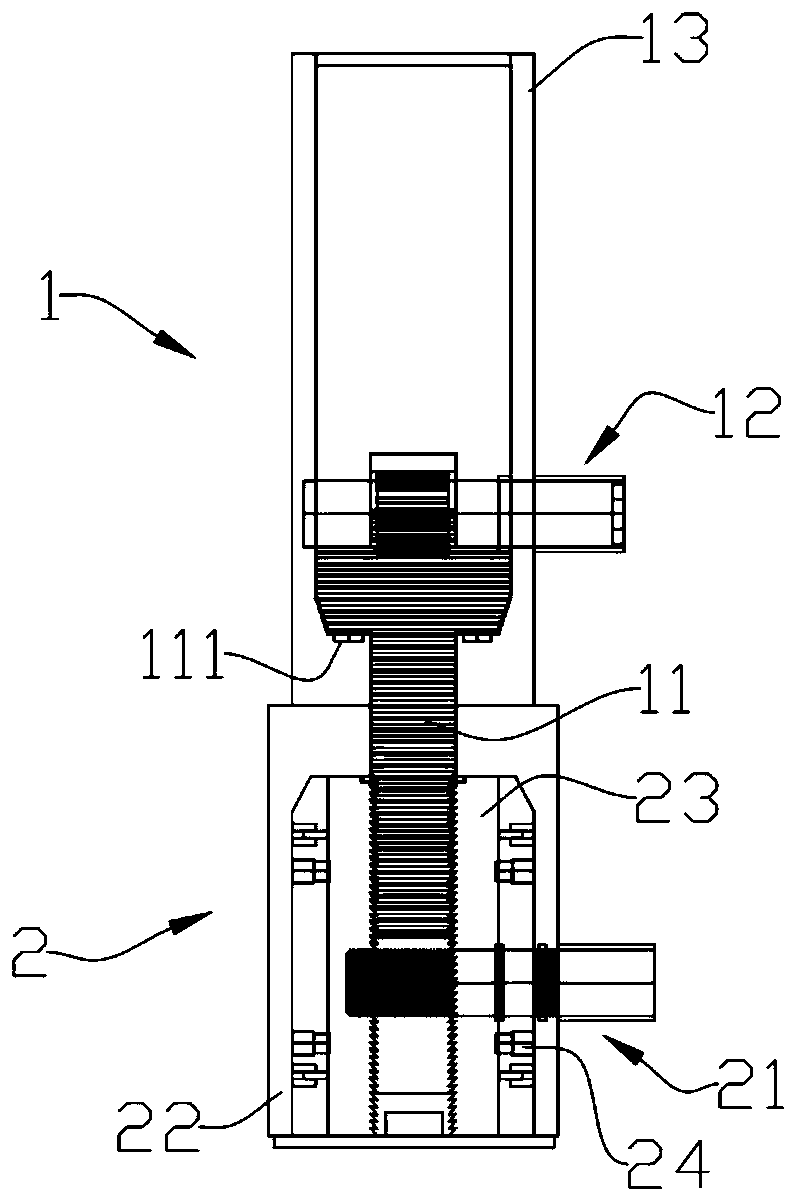

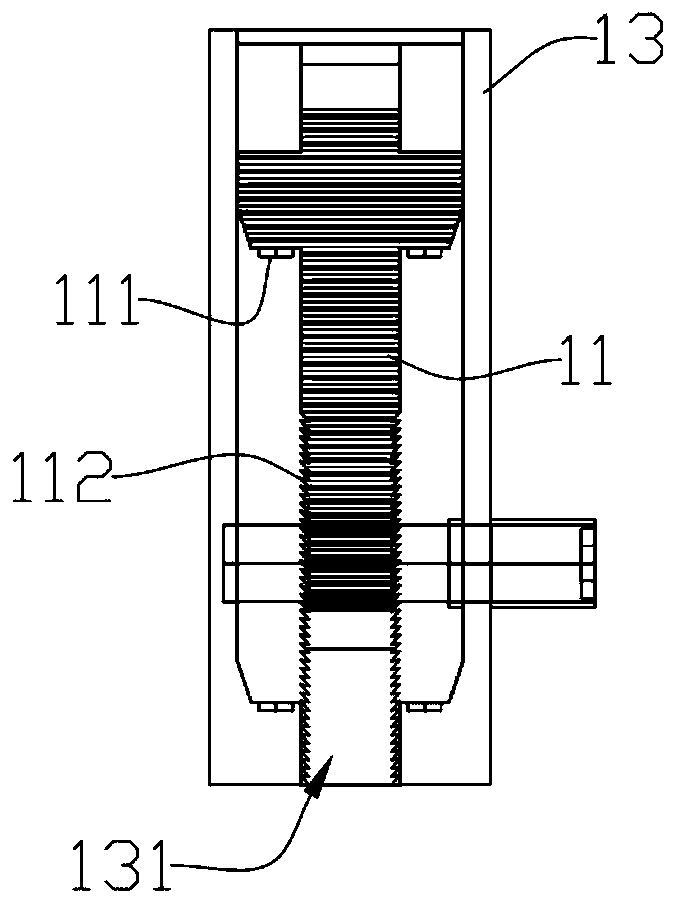

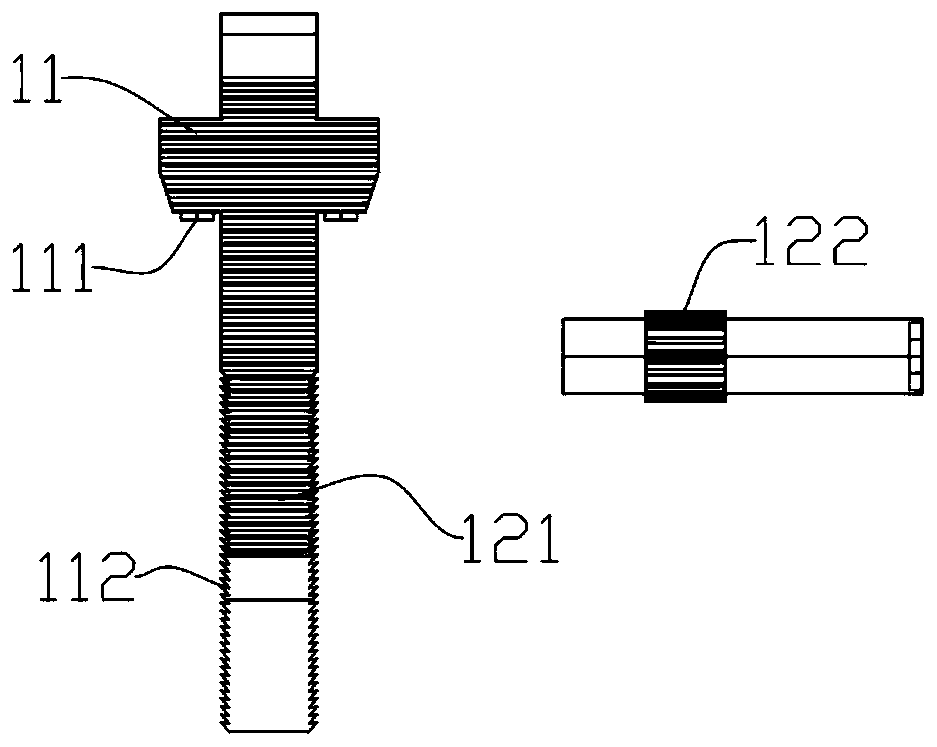

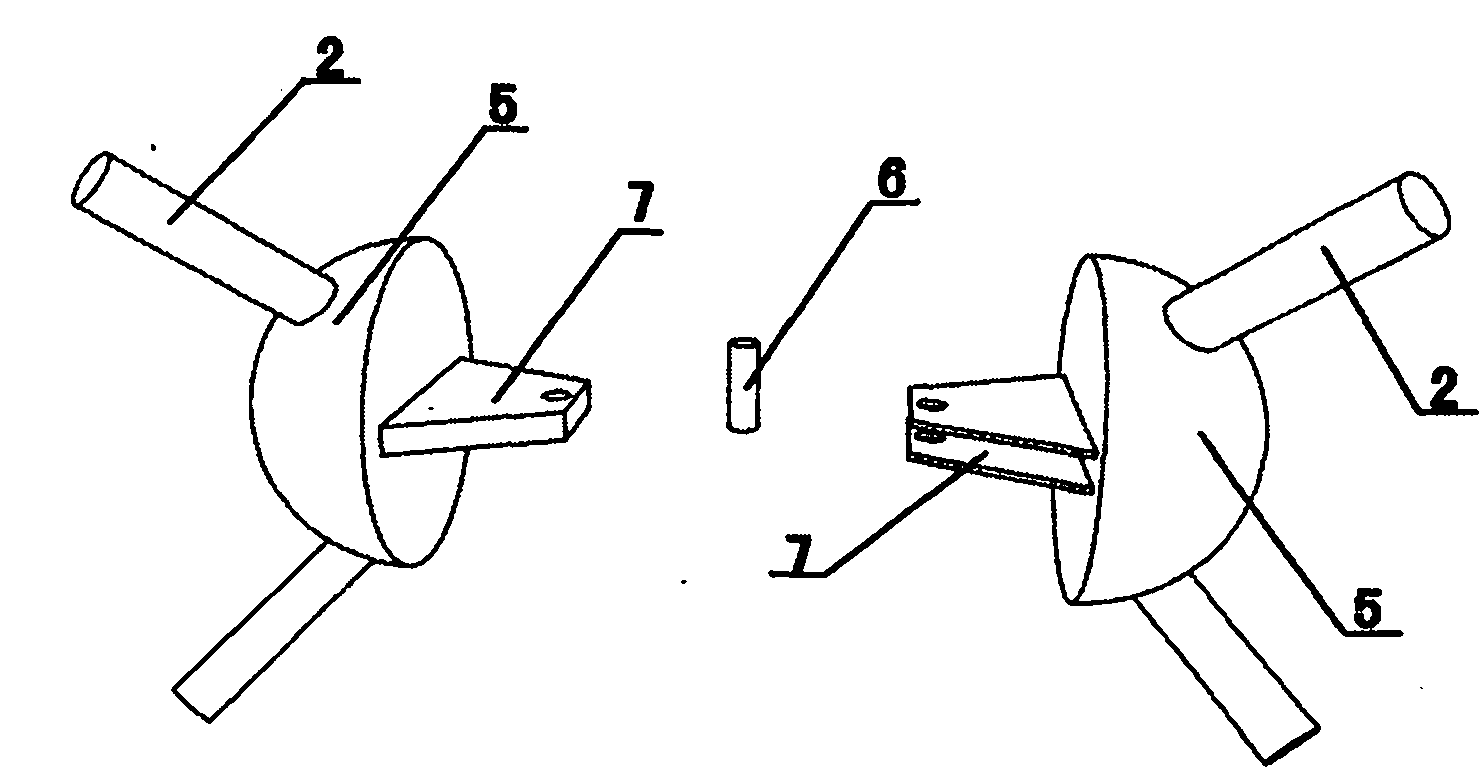

Disc spring self-resetting joint connecting device

ActiveCN111188425AReduce bending momentAvoid brittle failureProtective buildings/sheltersShock proofingEngineeringSteel columns

The invention discloses a disc spring self-resetting joint connecting device, and belongs to the technical field of building structure engineering. The disc spring self-resetting joint connecting device is composed of a steel column, a cantilever short beam, a middle beam, a disc spring resetting device, a U-shaped damper, a connecting steel plate, a column stiffening rib, an anchoring plate, a beam stiffening rib and a high-strength bolt. The steel column and the cantilever short beam are welded, the cantilever short beam is in bolted connection with the middle beam through the connecting steel plate, and the disc spring resetting device and the U-shaped damper are arranged between upper and lower flanges of the steel beam. Under an earthquake action, joints bear bending moment and shearing force through the U-shaped damper and the connecting steel plate, energy input from the outside is consumed, after the earthquake action disappears, self-resetting of the joints is achieved throughthe disc spring resetting device, and a structure is not damaged or slightly damaged after an earthquake. A disc spring self-resetting joint connecting method is simple and convenient, the structureis simple, bolt connection is mostly adopted, assembling can be achieved, and if a component is damaged after the earthquake, the component can be replaced in time. The disc spring self-resetting joint connecting device can be widely applied to the technical field of shock absorption and energy dissipation of building structures.

Owner:YANSHAN UNIV

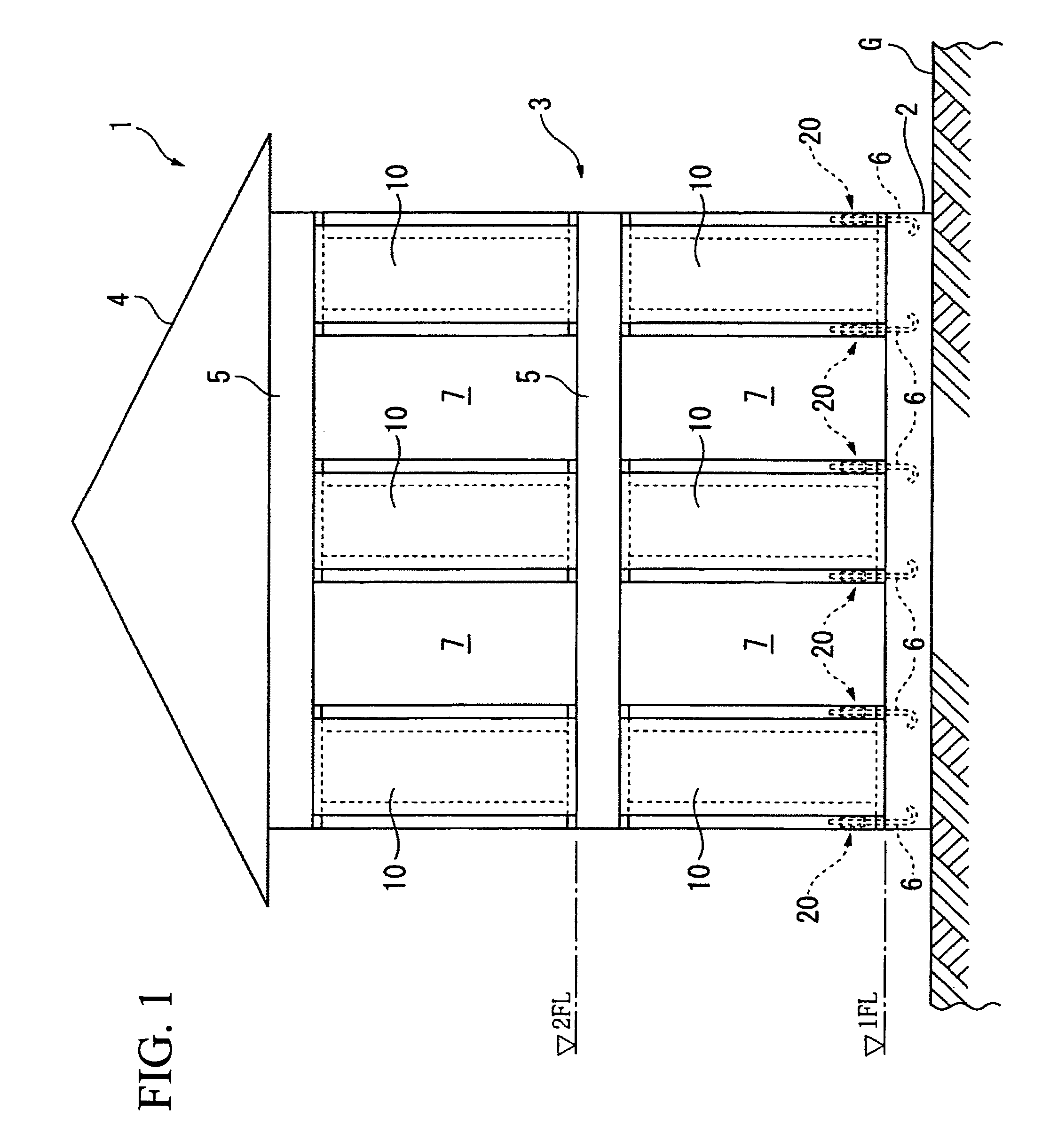

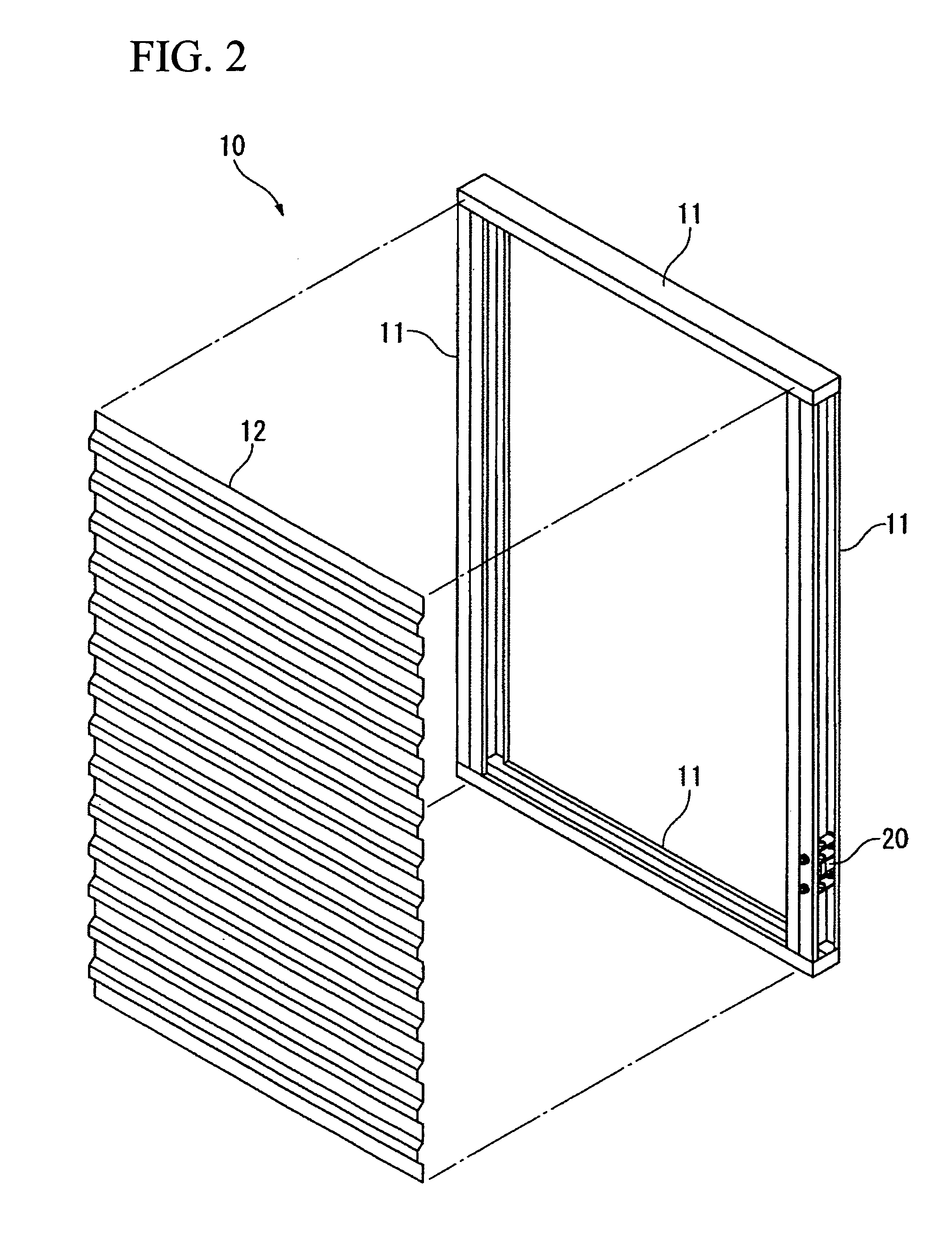

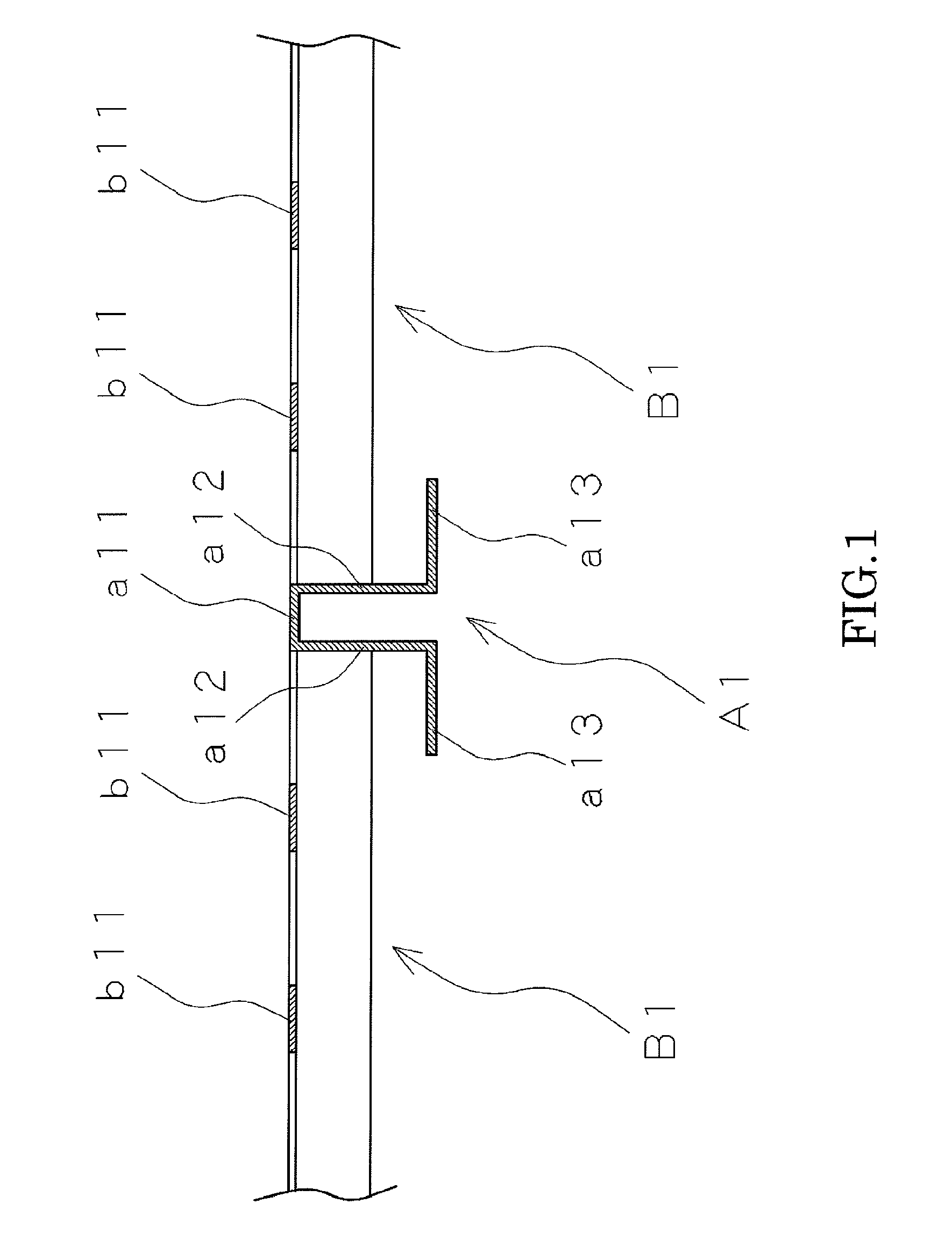

Construction structure of wall surface

A construction structure of wall surface includes: a hat joiner; and a building board. The hat joiner has a fixing plate portion and a design portion, and the building board has a design portion extending linearly on a surface. A joint at which the design portion of the hat joiner constitutes a design surface, and a design pattern at which the design portion of the building board constitutes a design surface, are formed in a same direction, by arranging the building board in plurality to left and right, or above and below, of the design portion of the hat joiner. A width of the joint at the design portion of the hat joiner is the same as a width of each of the design portions on the surface of each of the building boards.

Owner:NICHIHA CORP

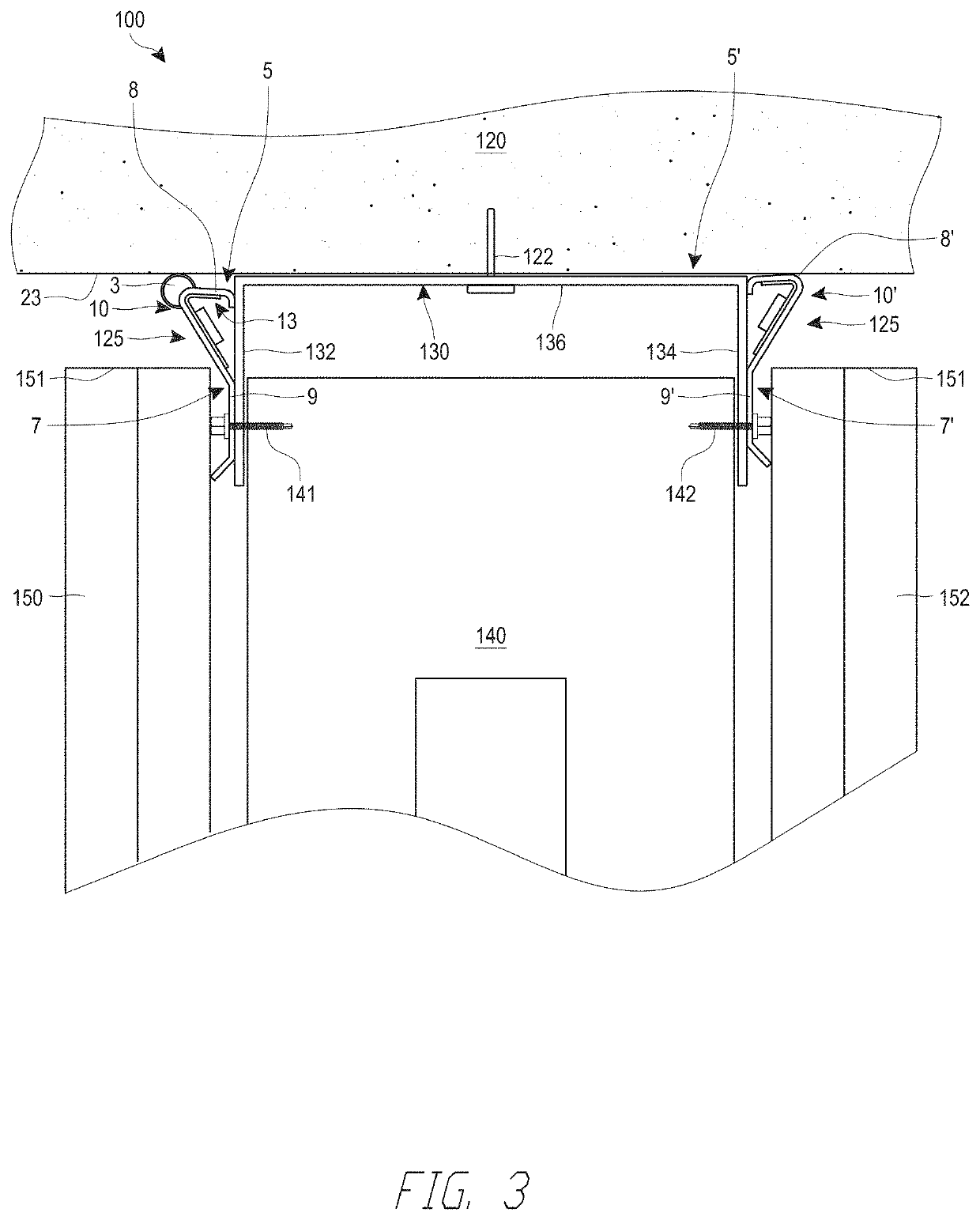

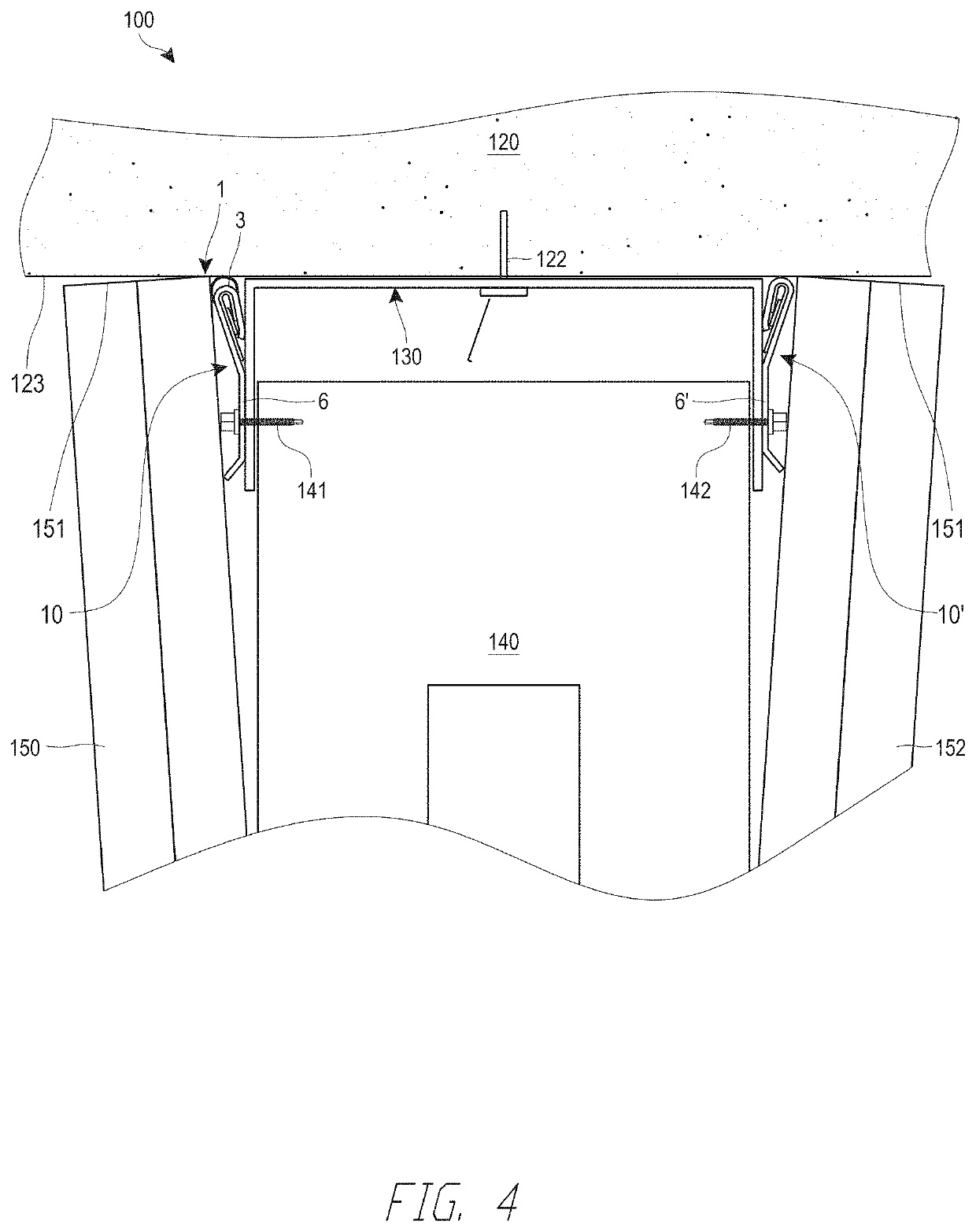

Multi-layer fire-rated joint component

ActiveUS10689842B2Open the deflection gapExcessive noiseWallsSynthetic resin layered productsSmoke EmissionJoint (building)

An improved fire-blocking gasket profile for a fire-rated joint, such as a head-of-wall assembly. Fire-rated joints are aimed at inhibiting or preventing fire, heat, or smoke from leaving one portion of a building and entering another portion of a building. Fire-rated joints can also accommodate movement between adjacent building structures, such as between a ceiling and the top of a wall. The improved fire-blocking gasket profile includes a first layer formed of an intumescent material, a second layer formed of a foil lining and a third layer formed of the vinyl profile. The vinyl profile includes an air gap with the intumescent material positioned therein. A vertical portion of the vinyl profile is positioned between a header track and a wallboard in the fire-rated joint. A horizontal portion of the vinyl profile is positioned at least partially within a deflection gap and sealingly engages with the ceiling.

Owner:CEMCO LLC

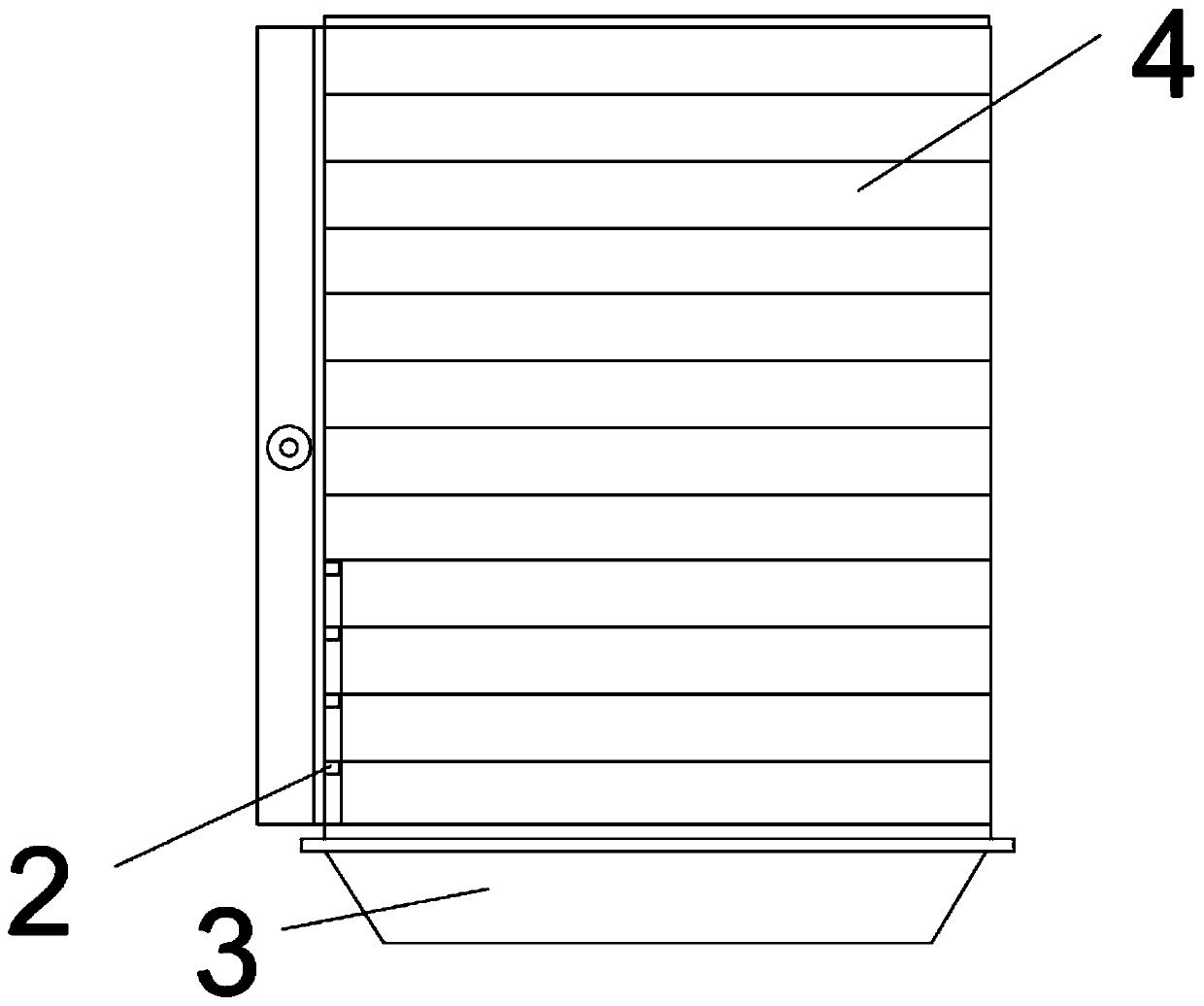

Fabricated building sealing waterproof construction system

InactiveCN111877573ANot easy to produceDifficult to enterWallsBuilding insulationsWater vaporExternal cladding

The invention relates to a fabricated building sealing waterproof construction system which comprises a plurality of prefabricated outer wall units which are connected with one another. A joint of every two adjacent prefabricated outer wall units comprises a main embedding part and an auxiliary embedding part which are embedded with each other, and a waterproof structure is fixed between each mainembedding part and the corresponding auxiliary embedding part. Each waterproof structure comprises a waterproof layer and an elastic mechanism fixedly connected with the waterproof layer. According to the fabricated building sealing waterproof construction system, gaps are not prone to being generated between the waterproof layers and the prefabricated outer wall units, water vapor does not easily enter a building through splicing seams, and the sealing and waterproof effects are good.

Owner:广东珠江建筑工程设计有限公司

Interlocking building system using one-piece skin-and-frame panels, vacuum-insulation, vertical slide-locks, multi-story slides, and snap-locks

ActiveUS20190024360A1Prevent backward movementHuman health protectionConstruction materialEngineeringTetrahedron

A system of structural interlocking panels for forming disaster-resistant buildings, comprising: a hollow, internally-braced, vacuum-insulated panel shell having at least two interlocking sides, the first side having a convex-inward single-curvature, the second side having a straight surface, the third side having a straight surface with at least one integral tongue with at least one head extending vertically-upward for receiving a complementary groove of a first side of an adjacent panel. Panels are thus vertically slide-locked along panel sides and faces, thereby triggering automatic snap joints that prevent backward movement of the panel. The system can assemble spheres, cylinders, toroids, tetrahedrons, flat shapes, and irregular shapes.

Owner:HABERMAN KURT EVAN

Beam-to-column connectors for construction

InactiveCN102261129AReduce wasteRealize high-volume standardized productionShock proofingFloor slabManufactured material

The invention discloses a beam column connecting piece used for building. The beam column connecting piece comprises a beam column connecting piece body, an upright post connection-peg and a horizontal supporting joint, wherein the beam column connecting piece body is formed integrally; the beam column connecting piece body is arranged on the upright post connection-peg convexly along the vertical direction, and the beam column connecting piece body is arranged on the horizontal supporting joint convexly along the horizontal direction; the beam column connecting piece comprises an outside surface and a horizontal side baffle plate positioning groove, wherein the outside surface is not provided with the horizontal supporting joint; the horizontal side baffle plate positioning groove is communicated with the outside surface and a beam end surface resisting surface; circular platforms are arranged on the top surface of the side baffle plate positioning groove; reinforcing ribs are connected among the circular platforms; and threaded through holes are reserved in the circular platforms. The beam column connecting piece used for building has the advantages that: L-shaped side baffle plates are convenient to install; the L-shaped side baffle plates and the beam column connecting pieces form a baffle wall of which the periphery is in end-to-end connection; the L-shaped side baffle plates, floor slab supporting templates and the like form accommodation space for casting cement floor slabs, so that cement concrete is convenient to cast to form the floor slabs parallel to a horizontal plane; a conventional template does not need to be used for supporting any longer when the cement floor slabs are cast; and the waste of raw materials is greatly reduced.

Owner:杨东佐

Construction process of flexible shockproof joint for deposited pipe tunnel

InactiveCN1399044AGuarantee normal constructionFlexible, waterproof and shockproofArtificial islandsProtective foundationPre stressArchitectural engineering

The present invention belongs to the field of building engineering and features the longitudinal position limitation ofmuff jointed prestressed steel cable mainly. Pipe section joint rigidity is first determined based on foundation conditions; pipe section anti-seismic performance is analyzed based on the joint rigidity, and the joint form and the construction process are further determined. It has the features of simple structure for in-situ installation, flexible steel rope, no joint leakage, anticorrosive steel rope; and waterproof and anti-seismic performance, maintained even in fire.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

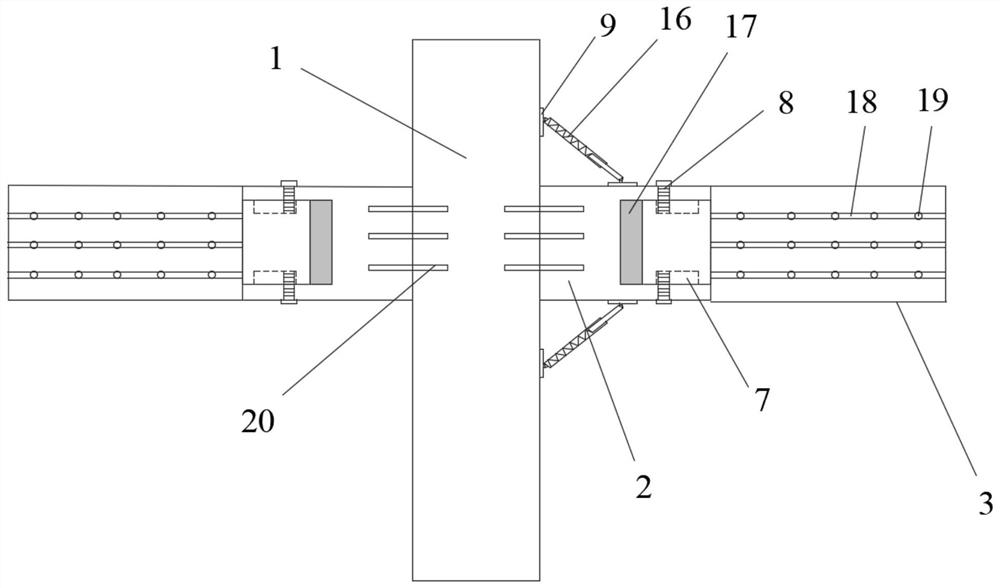

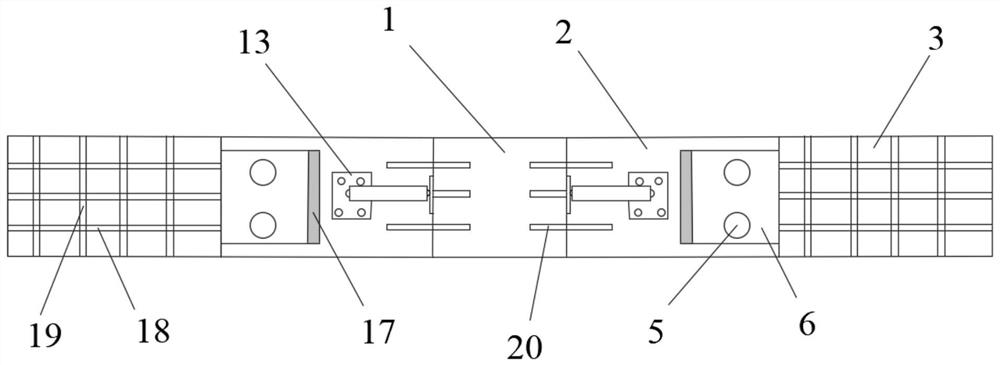

Anti-seismic prefabricated beam-column joint of fabricated building and construction method of anti-seismic prefabricated beam-column joint

InactiveCN112376687AReduce lateral impactImprove seismic performanceProtective buildings/sheltersShock proofingEarthquake resistanceJoint (building)

Owner:安徽一品小院建筑科技有限公司

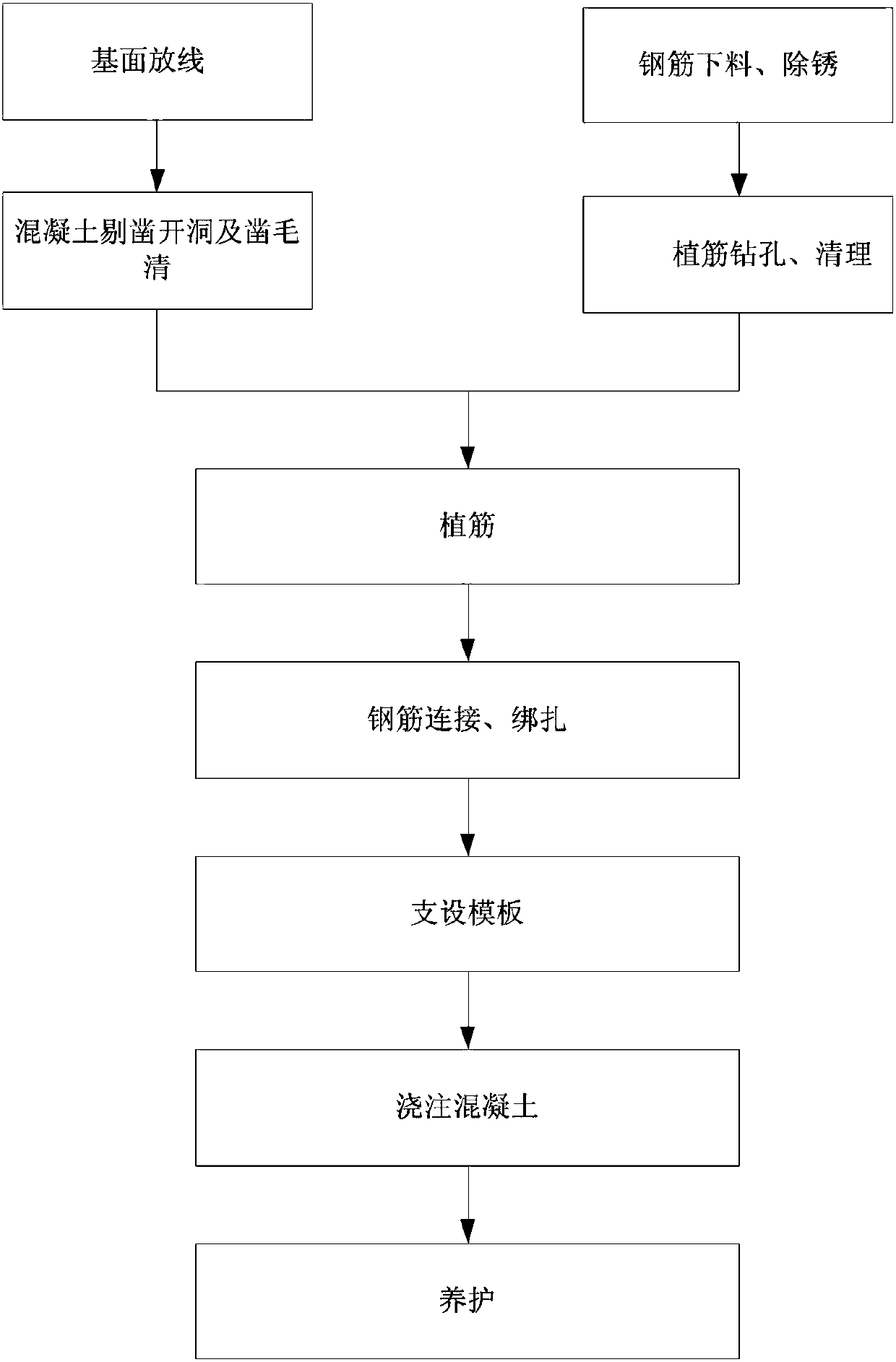

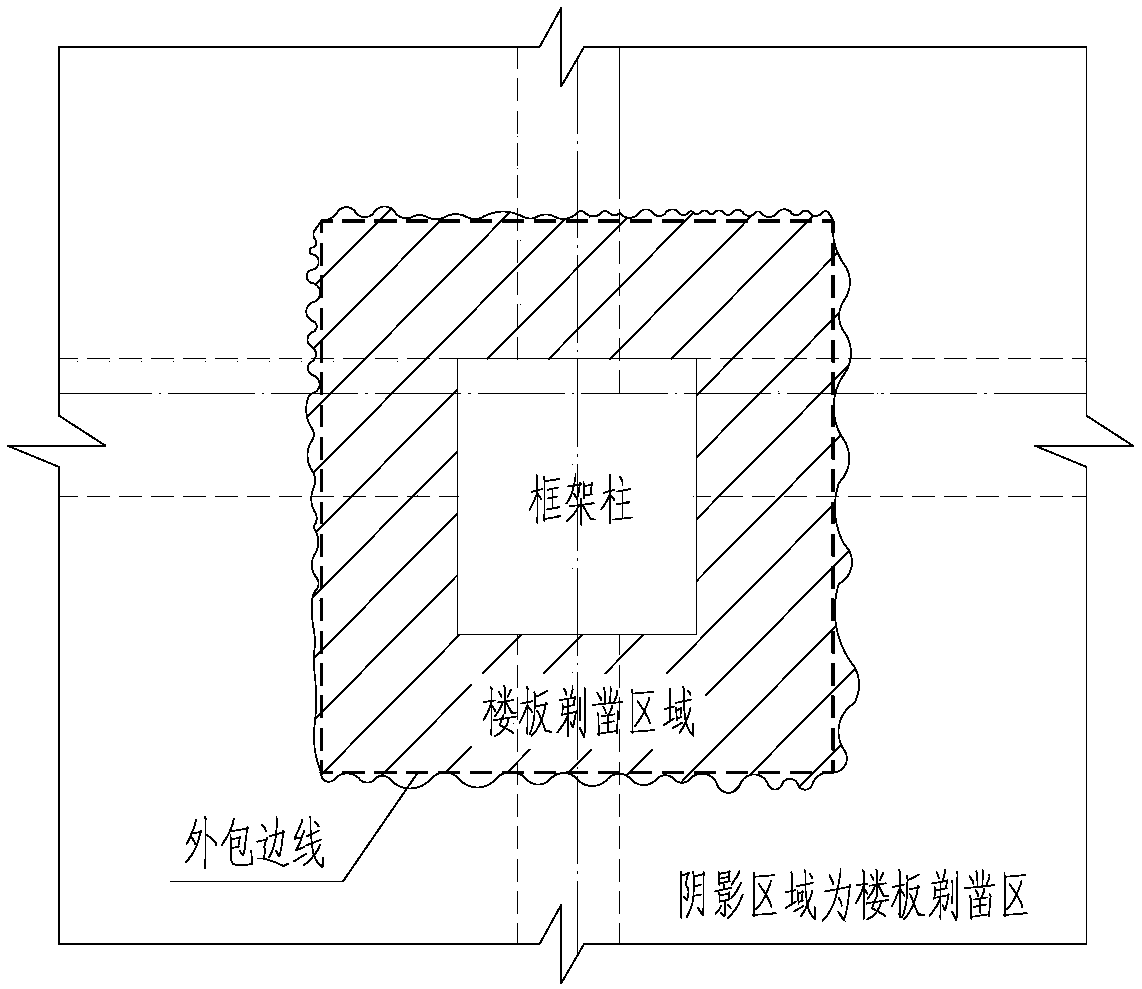

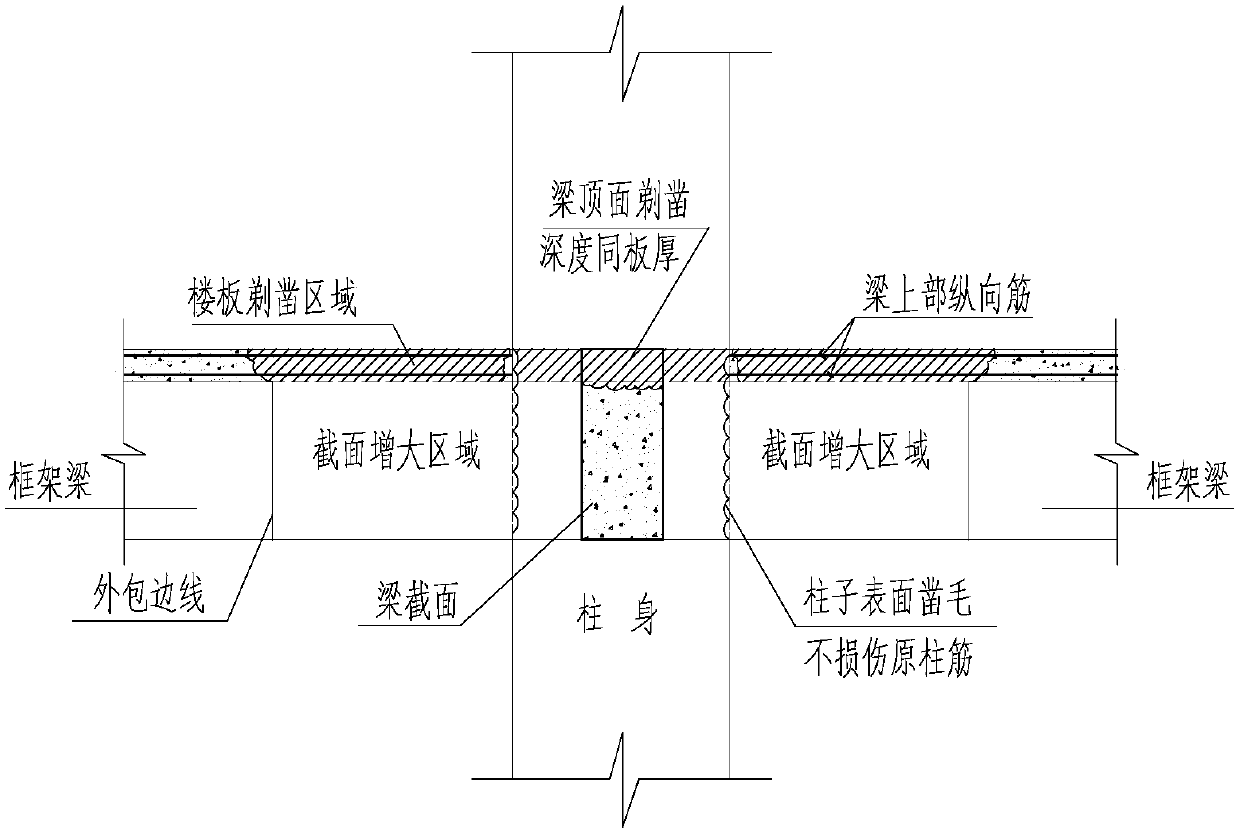

Reinforcing treatment construction method for concrete beam-column joints with different strength grades of high-rise buildings

The invention discloses a reinforcing treatment construction method for concrete beam-column joints with different strength grades of high-rise buildings. The reinforcing treatment construction methodcomprises the following steps that setting out is conducted on a measuring base plane; 2, steel bar surface treatment is conducted, specifically, steel bars needed to be used as embedded steel bars are subjected to polishing and rust removing treatment, and then the surfaces of the steel bars are wiped cleanly; 3, chiseling and hole forming are conducted on concrete, and dabbing is conducted on the concrete; 4, drilling and clearing are conducted on the embedded steel bars; 5, the steel bars are embedded; 6; the steel bars are connected and bound; 7, formworks are erected; and 8, the concretepouring and curing are conducted. Compared with traditional treatment measures and technologies of the beam-column joints, the concrete strength at the core joints is guaranteed, the shrinkage crackat the concrete joints is reduced to some extent, the problem handling efficiency is improved, and the problem of the concrete strength at the joints is better solved; and the reinforcing treatment construction method has a certain practicality, scientificity and applicability, and can be widely used in beam-column joint core areas of complex high-rise buildings.

Owner:中铁建设集团南方工程有限公司 +1

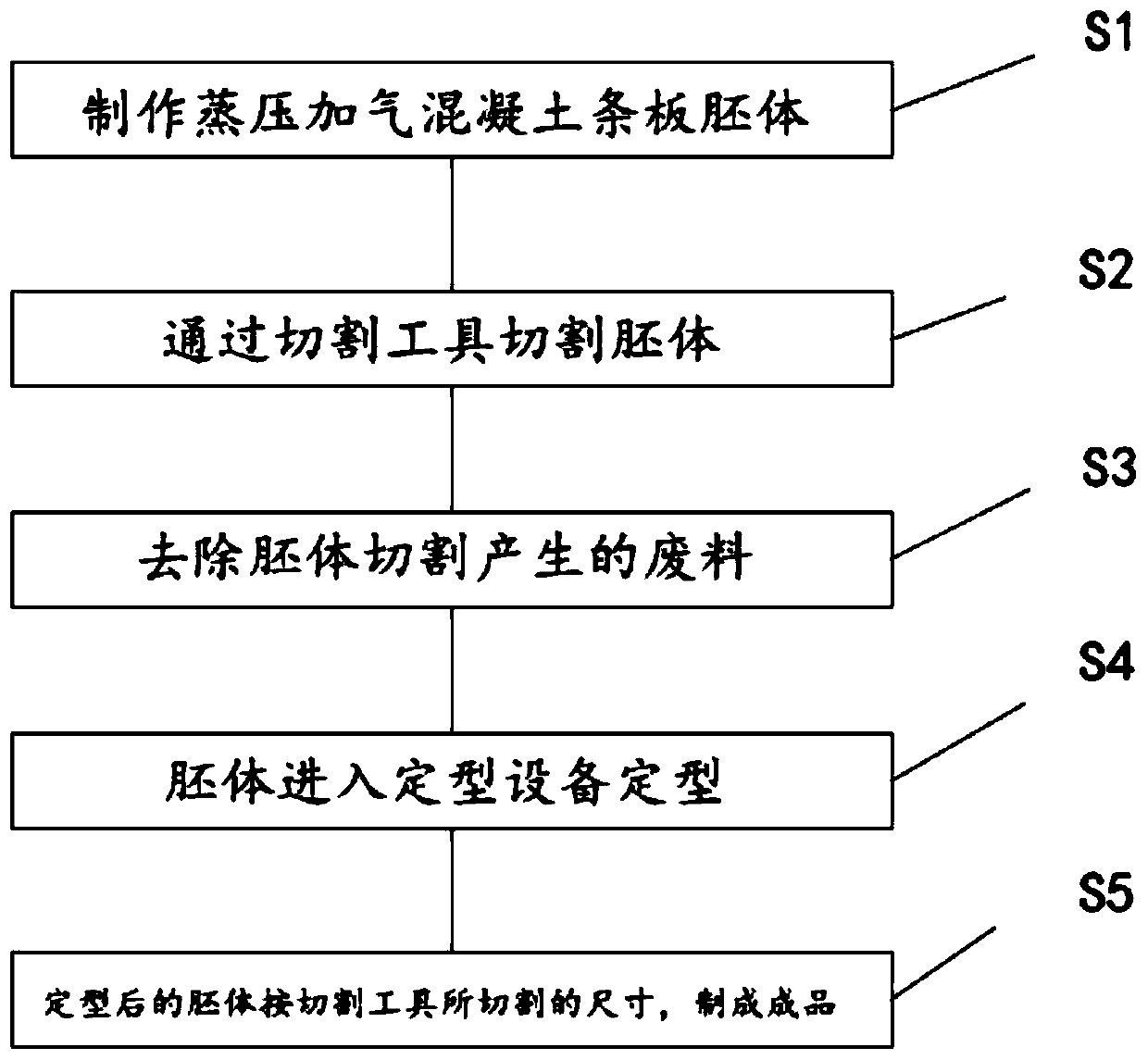

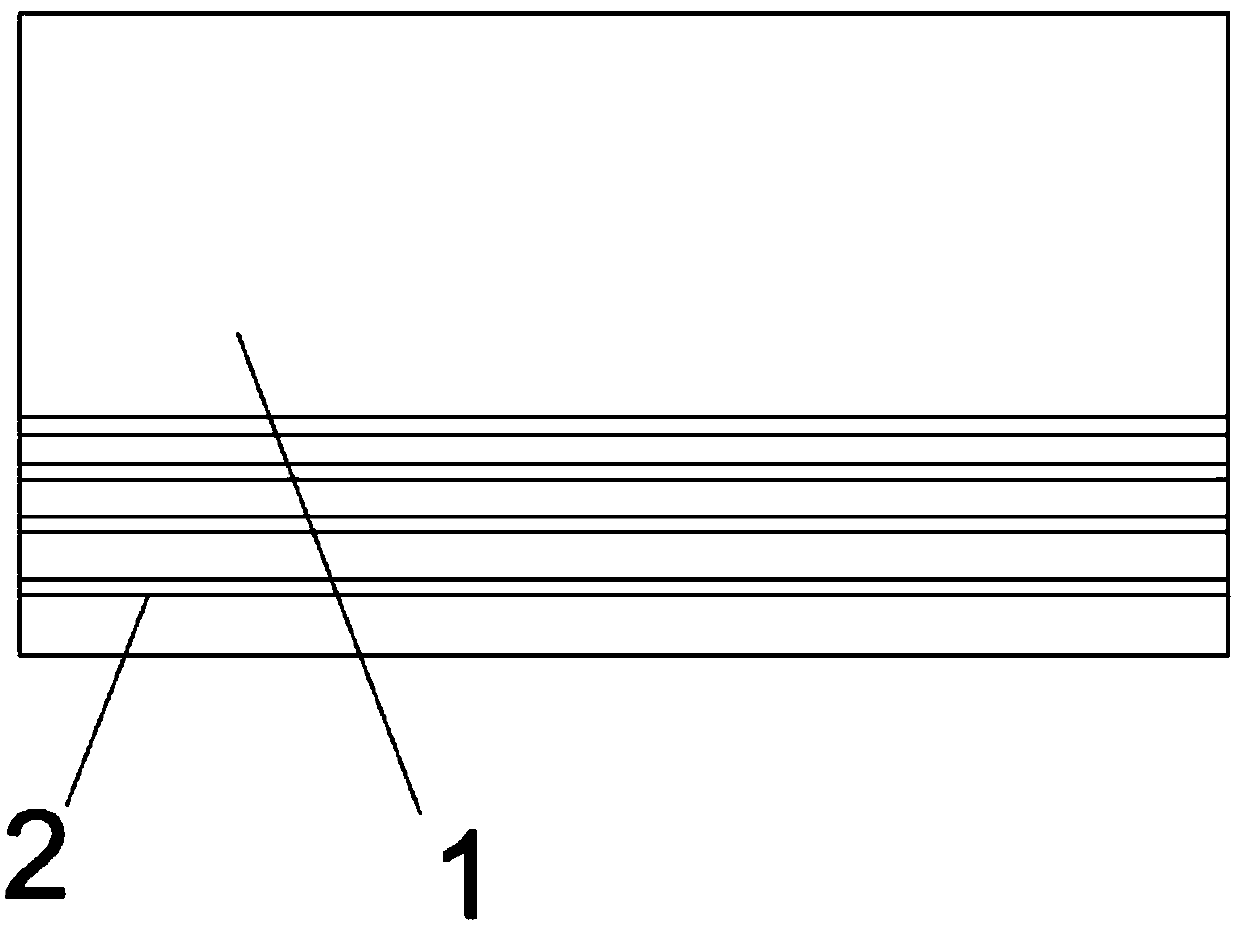

Process and device for preventing bonding of autoclaved aerated concrete battens

ActiveCN111516116AReduce manufacturing costImprove yieldCeramic shaping apparatusCeramicwareConstruction engineeringBatten

The invention provides a process and device for preventing bonding of autoclaved aerated concrete battens and relates to the technical field of buildings. According to the process and device for preventing bonding of the autoclaved aerated concrete battens, after a blank is horizontally cut, during bottom and top skin waste removal through turnover, flat iron is additionally mounted on a backboardof a turnover machine; and when the blank is overturned to be flat placed, due to the action of the flat iron, a cut joint of a board on the lowermost portion of the blank is slightly expanded due tothe action of gravity, air enters the cut joint, and the physical environment in the cut joint changes. Although after the blank is overturned back, the cut joint is closed again, the crystallizationstrength generated by steaming in the cut joint is greatly reduced; when a board severing machine carries out separation, the boards can be separated from the cut joint, and bonding damage is avoided. According to the process and device for preventing bonding of the autoclaved aerated concrete battens, by means of the production process of the autoclaved aerated concrete battens and machining equipment adopted needed in the production process, the rate of finished products is effectively increased and reaches 95% or above, and the production cost is reduced for enterprises.

Owner:孙秀杰

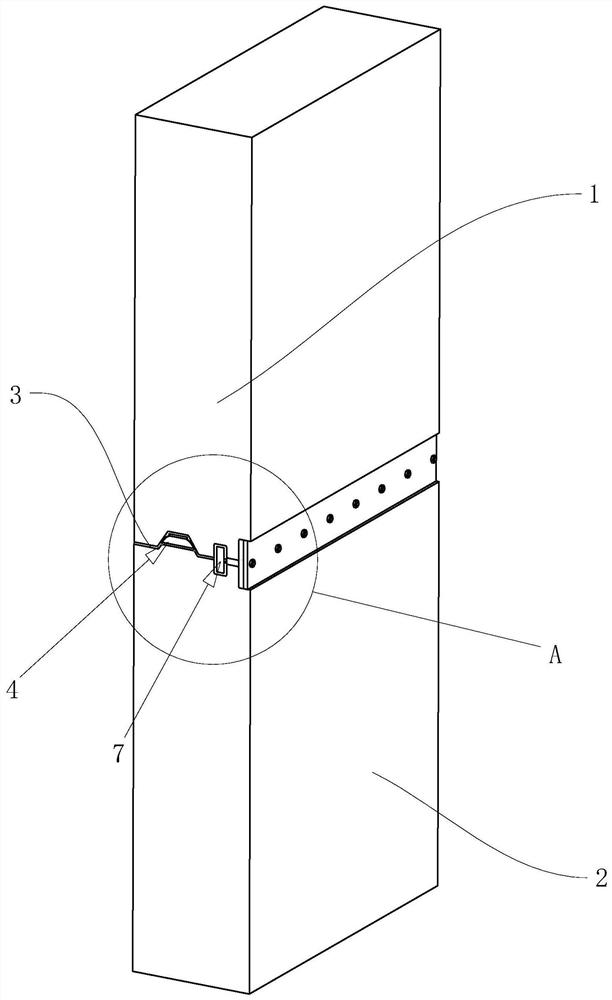

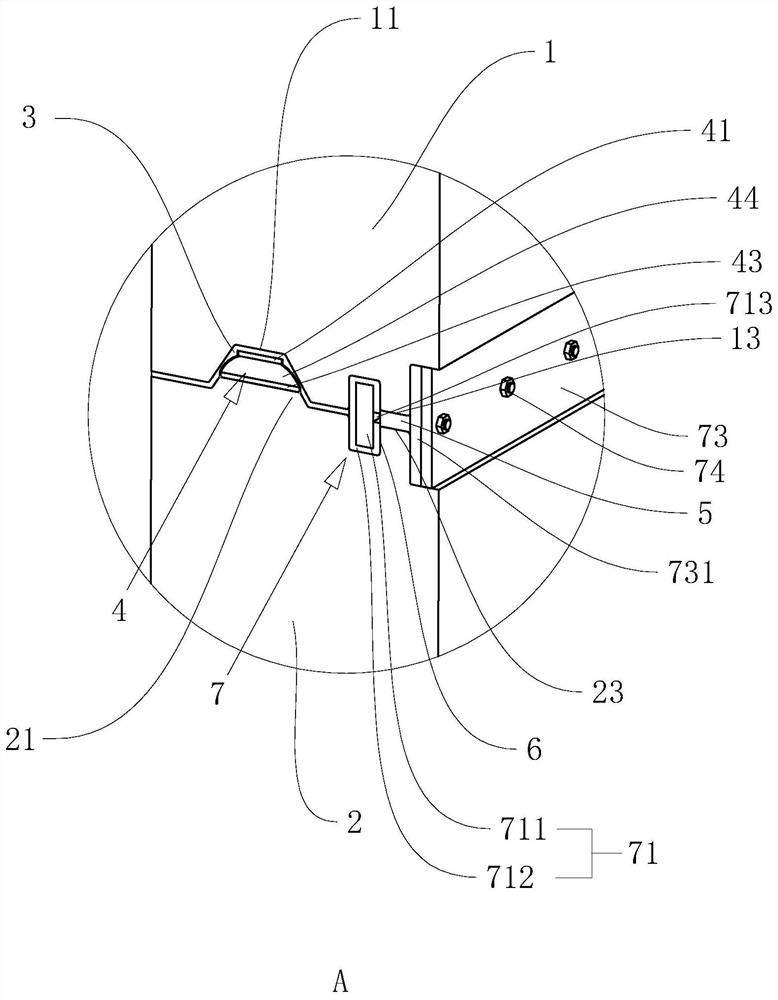

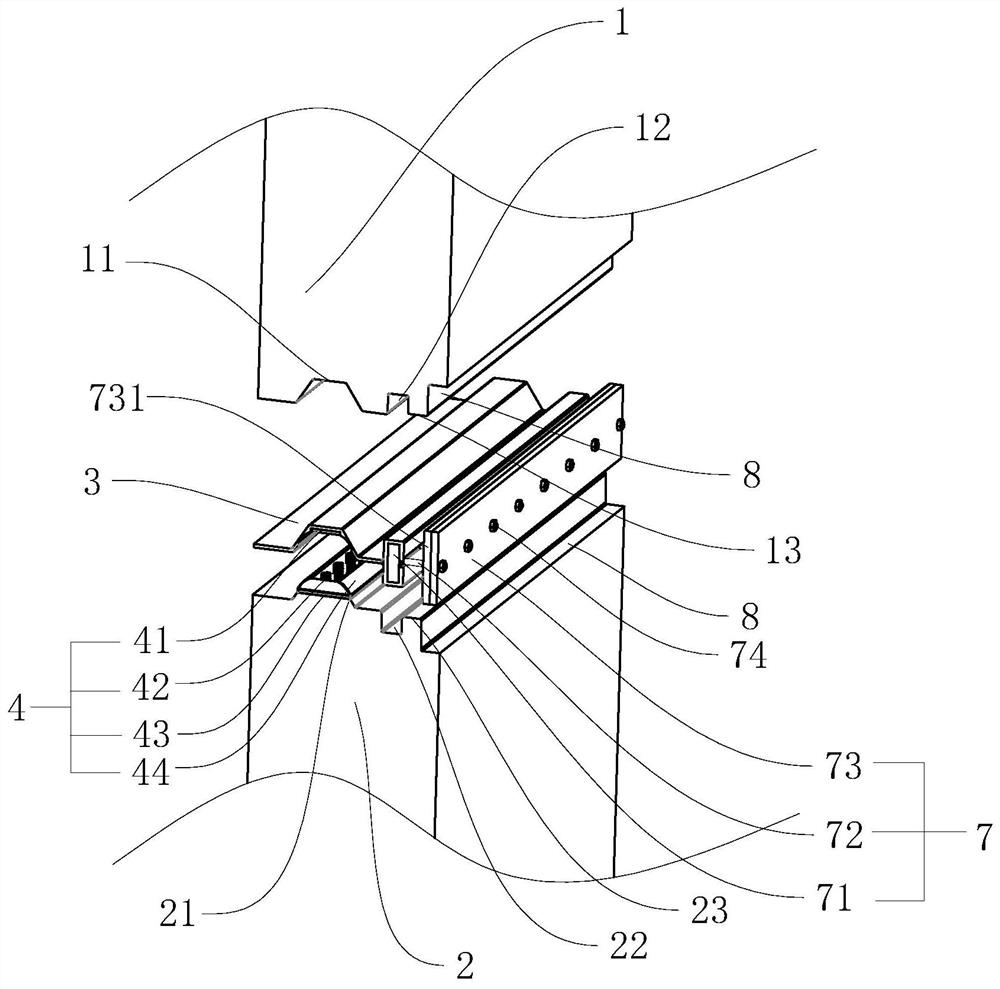

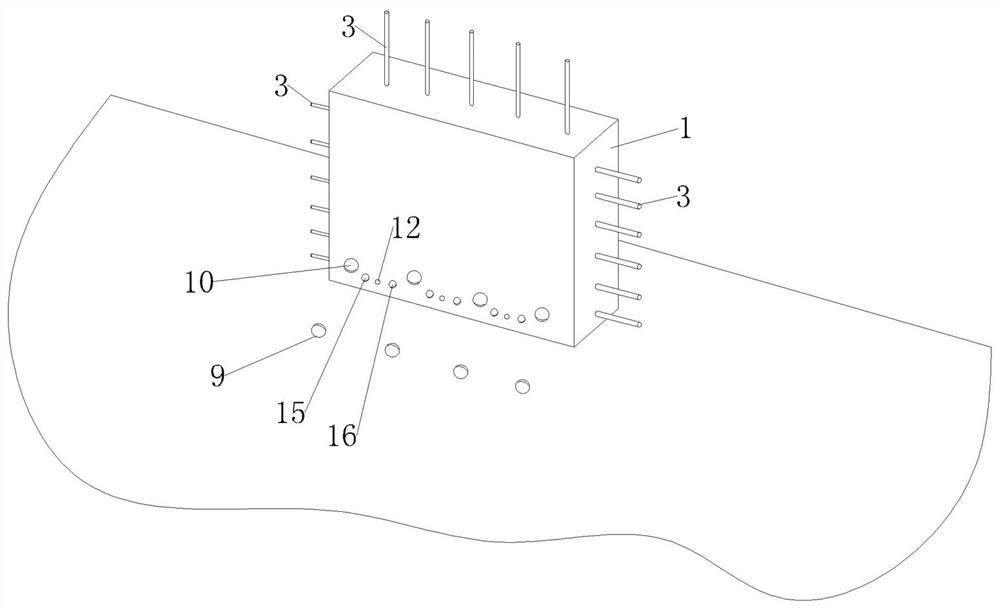

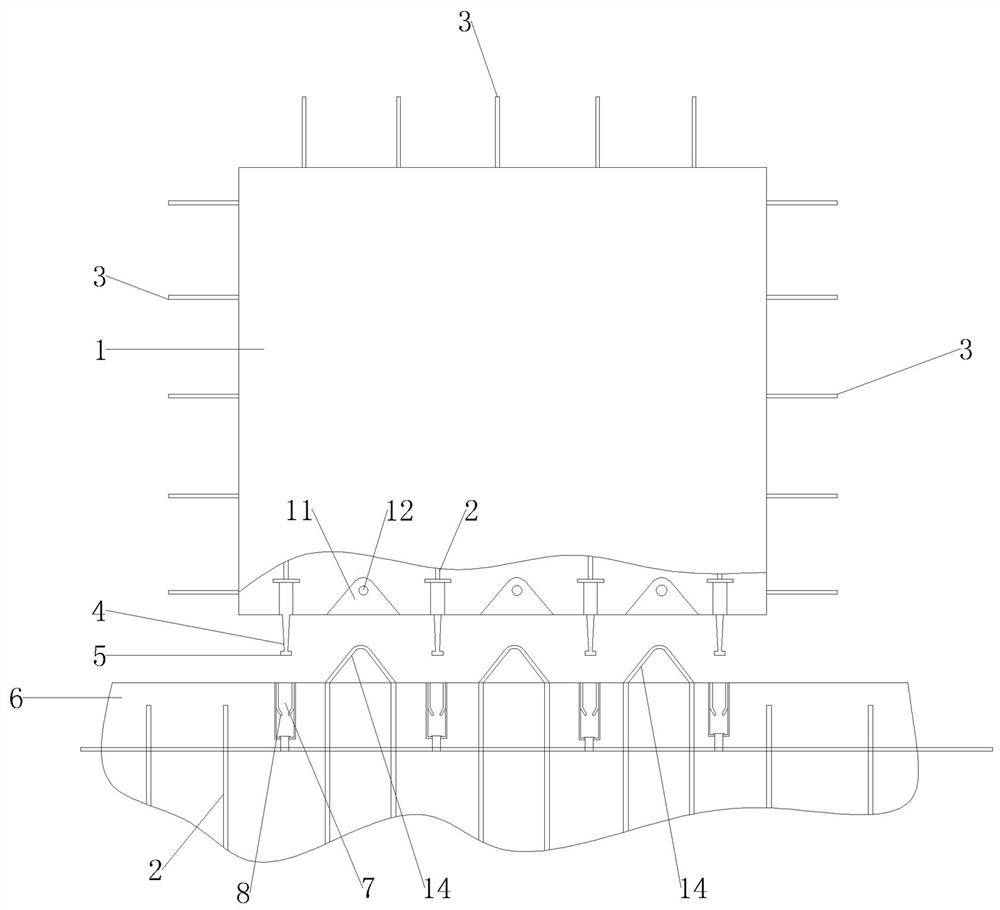

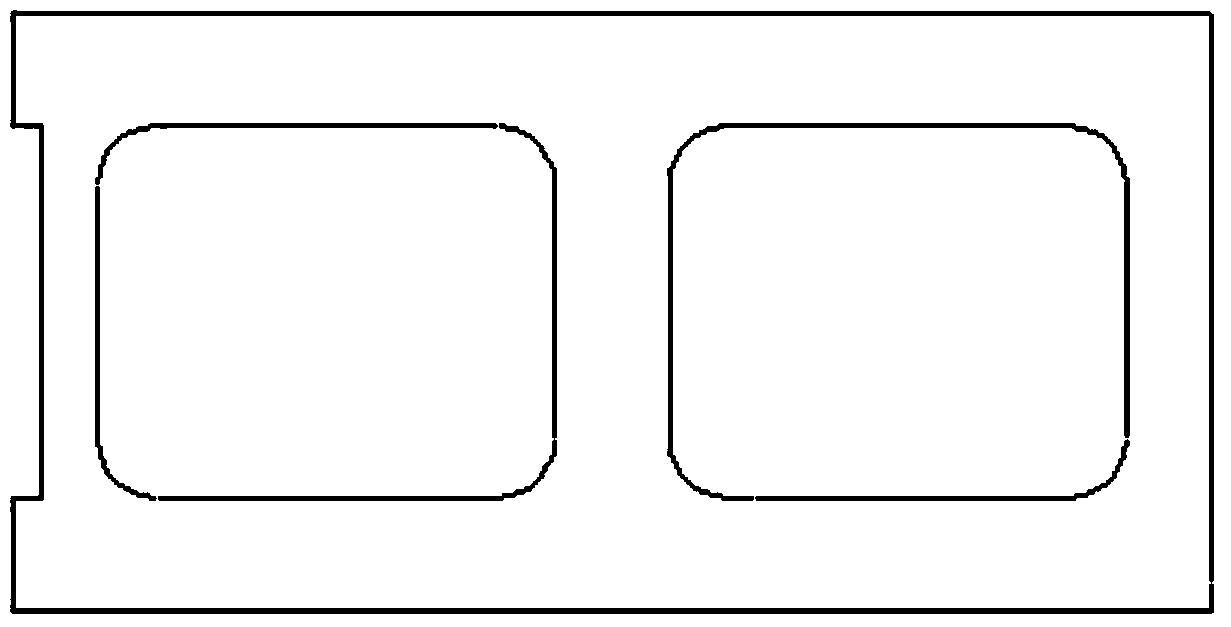

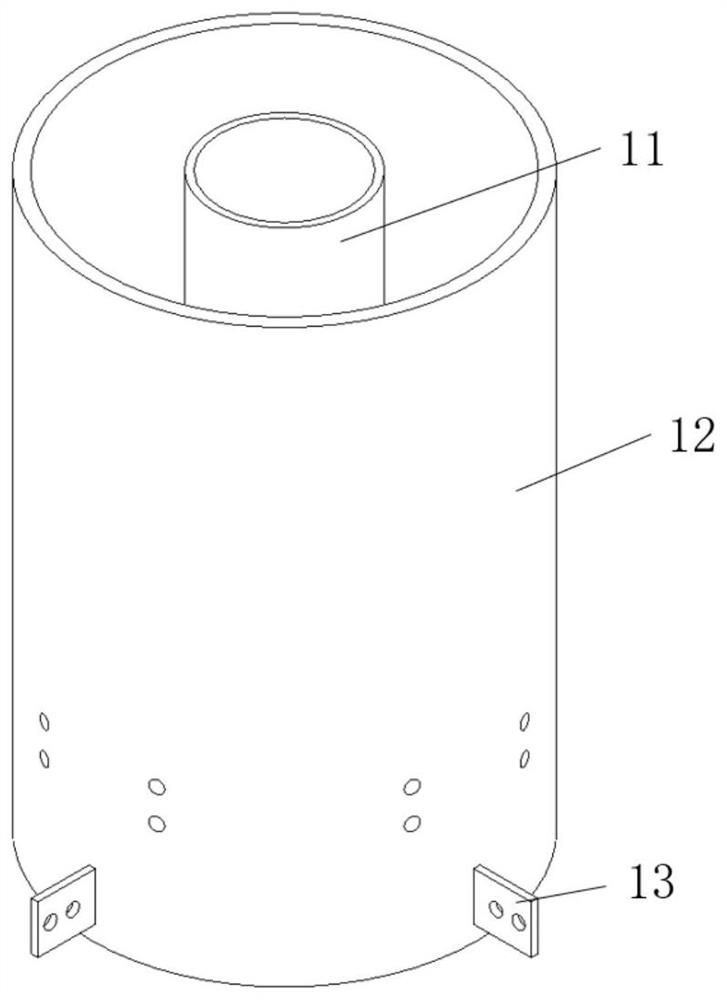

High-strength fabrication type shear wall structure

The invention discloses a high-strength fabrication type shear wall structure. The high-strength fabrication type shear wall structure comprises a high-strength prefabrication wall plate, a steel reinforcement cage is arranged in the prefabrication wall plate, local steel reinforcing bars of the steel reinforcement cage of the prefabrication wall plate extend towards the upper side end, the left side end and the right side end to form steel reinforcing bar ends, metal inserting ends are inserted into inserting holes, elastic clamping parts are clamped on the rear sides of clamping ends, the inserting holes communicate with first grouting holes in building floors, first grout vent holes are formed in the side wall of the prefabrication wall plate, seal plugs are configured on the grout ventholes, high-strength non-shrinkage cement grouting materials are poured into the first grouting holes, the matching positions of the inserting holes and the metal inserting ends are full of the high-strength non-shrinkage cement grouting materials, the joints of the prefabrication wall plate and the building floors are full of the high-strength non-shrinkage cement grouting materials, the invention further relates to a construction method of the high-strength fabrication type shear wall structure, according to the shear wall structure and the construction method thereof, a fabrication type prefabrication shear wall and the building ground can be rapidly connected, alignment is more easy, and combination of the prefabrication wall plate and the building ground is firmer.

Owner:WENZHOU GUANGCHENG CONSTR ENG CO LTD

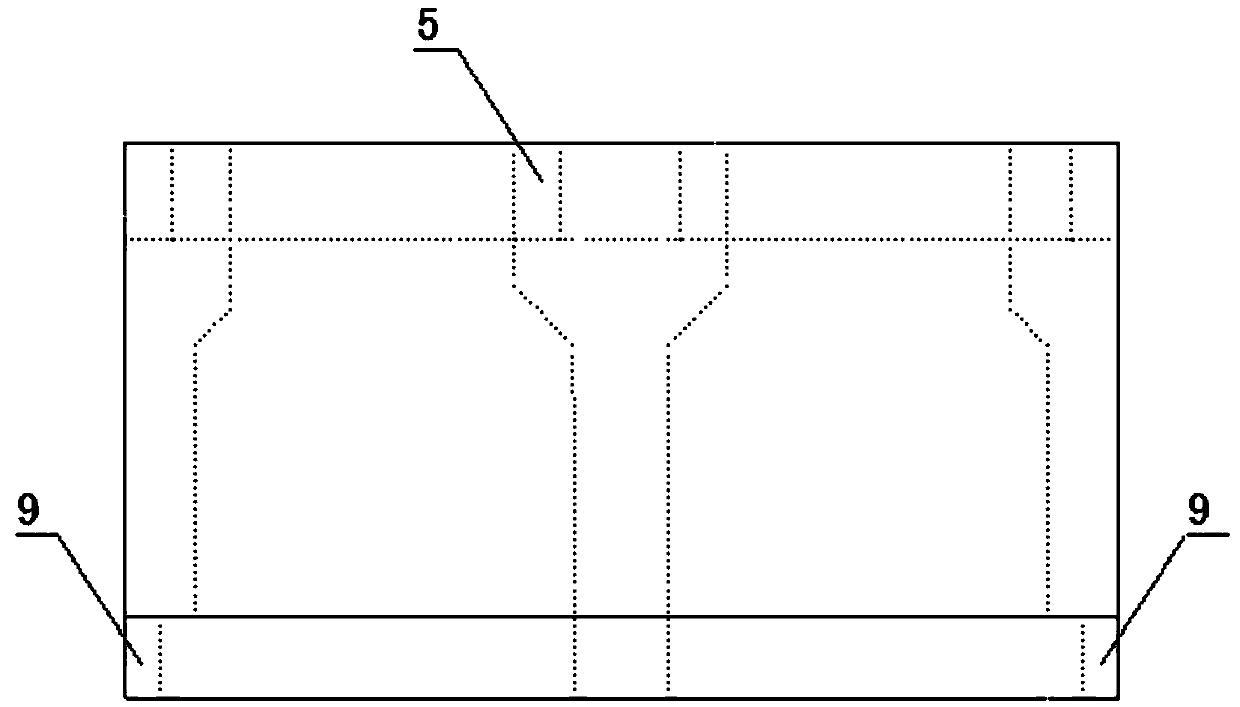

Hollow brick for quickly building walls

The invention discloses a hollow brick for quickly building walls. The hollow brick is characterized in that building joint surfaces are added to an upper plane of the hollow brick and are formed in such a manner that a hollow brick body extends into through holes of the hollow brick; continuous upward bulges are arranged on the inner sides of the added building joint surfaces on the upper plane; continuous upward bulges are arranged on the outer edges of the upper plane; closed grooves are formed between the bulges on the added building joint surfaces on the upper plane and the bulges on the outer sides of the upper plane; bulges matched with the grooves formed in the upper plane are arranged on a lower plane of the hollow brick; quick diversion trenches are formed on the left and right sides of the hollow brick. By utilizing the hollow brick, the labor intensity of workers can be greatly reduced, the work efficiency can be improved, the obtained walls have small joints and even the walls are unnecessary to be whitewashed.

Owner:吴刚

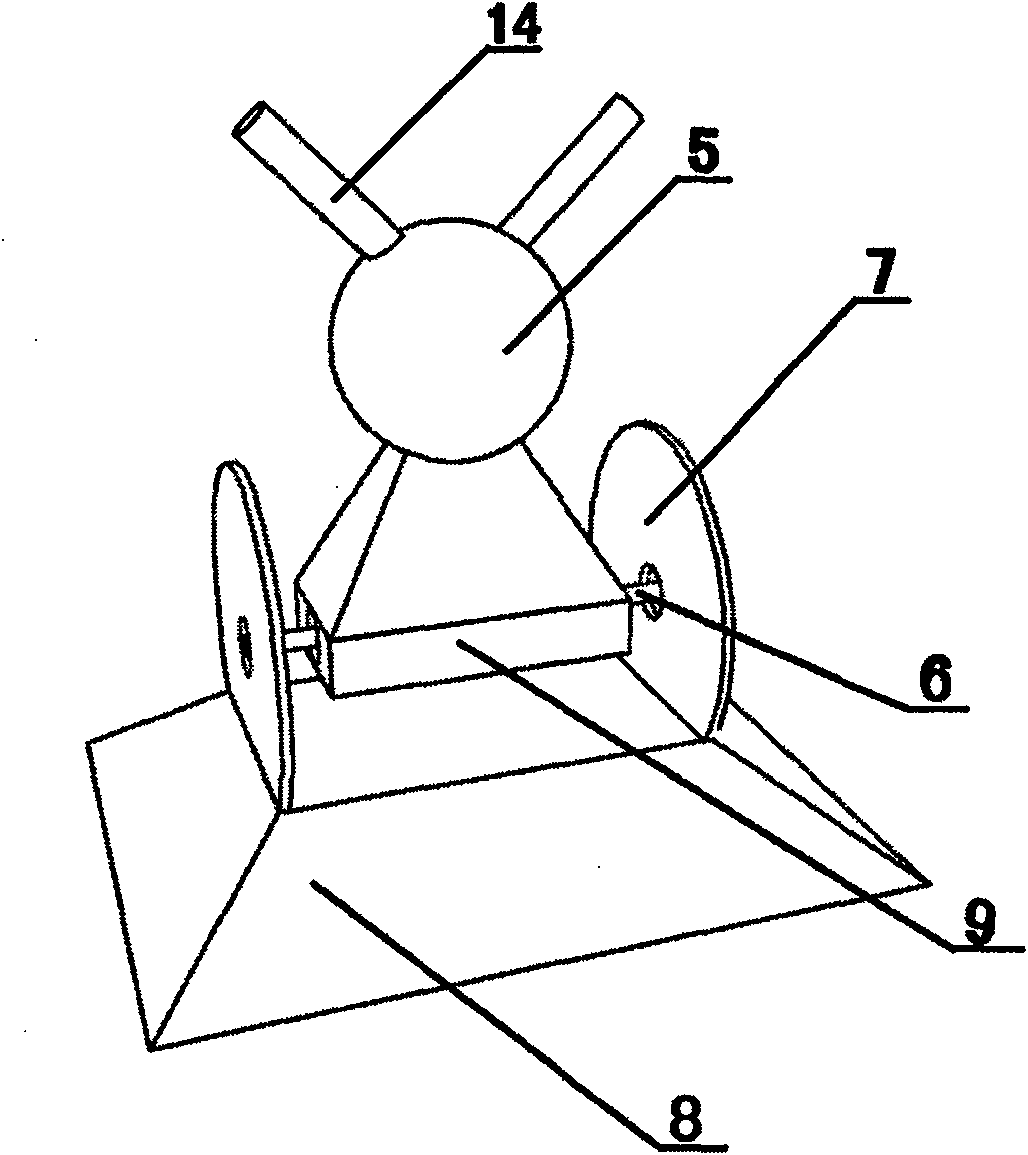

Self-reset concrete-filled steel tube column-steel beam node connecting device

ActiveCN110924539AIn line with future development trendsEasy constructionProtective buildings/sheltersShock proofingPre stressRebar

Owner:YANSHAN UNIV

Locking mechanism of assembled building

The invention relates to the field of assembled construction of structural engineering, in particular to a locking mechanism of an assembled building. The locking mechanism comprises a plug-in part and a locking part. The plug-in part comprises a lockpin, wherein a first locking structure is arranged on the outer side wall of the lockpin. The locking part comprises a second driving device, a second shell and a locking assembly arranged in a second shell, a lock hole, the inner part of which communicates to outside, is formed in the second shell, a second locking structure is arranged on the locking assembly, and the first locking structure is matched with the second locking structure in shape. When adjacent two building bodies are in abut joint, the lockpin is arranged in the lock hole ina penetrating manner, so that the first locking structure and the second locking structure are arranged oppositely. The second driving device drives the locking assembly to be connected to or separated from the lock pin, so that the first locking structure is connected to or separated from the second locking structure, and therefore, the plug-in part and the locking part are fixedly connected quickly.

Owner:GUANGZHOU METRO DESIGN & RES INST

Self-resetting displacement magnification type shape memory alloy damper

ActiveCN107217899AImprove energy consumptionTo achieve the purpose of energy consumption effectProtective buildings/sheltersShock proofingShape-memory alloyJoint (building)

The invention belongs to the technical field of civil engineering and provides a self-resetting displacement magnification type shape memory alloy damper. By the self-resetting displacement magnification type shape memory alloy damper, small displacement generated at a beam-column joint or between structural layers of a building structure under the action of an external load can be magnified according to requirements, and the magnified displacement is limited in order to give full play to energy dissipation capacity of a shape memory alloy material in the damper, so that favorable energy dissipation effects can be achieved; namely, when the small displacement is generated at the beam-column joint or between the structural layers of the building structure, the displacement is magnified through a lever mechanism and then transferred to shape memory alloy wires, and the ultra-elastic shape memory alloy material dissipates energy by tensile deformation. The displacement magnification can be adjusted according to practical conditions of building structures of building components, simplicity in mounting is realized, and the shape memory alloy damper is a flexible and efficient energy dissipation element.

Owner:DALIAN UNIV OF TECH

Jacking pipe cutting protective structure for building remains and construction method thereof

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +2

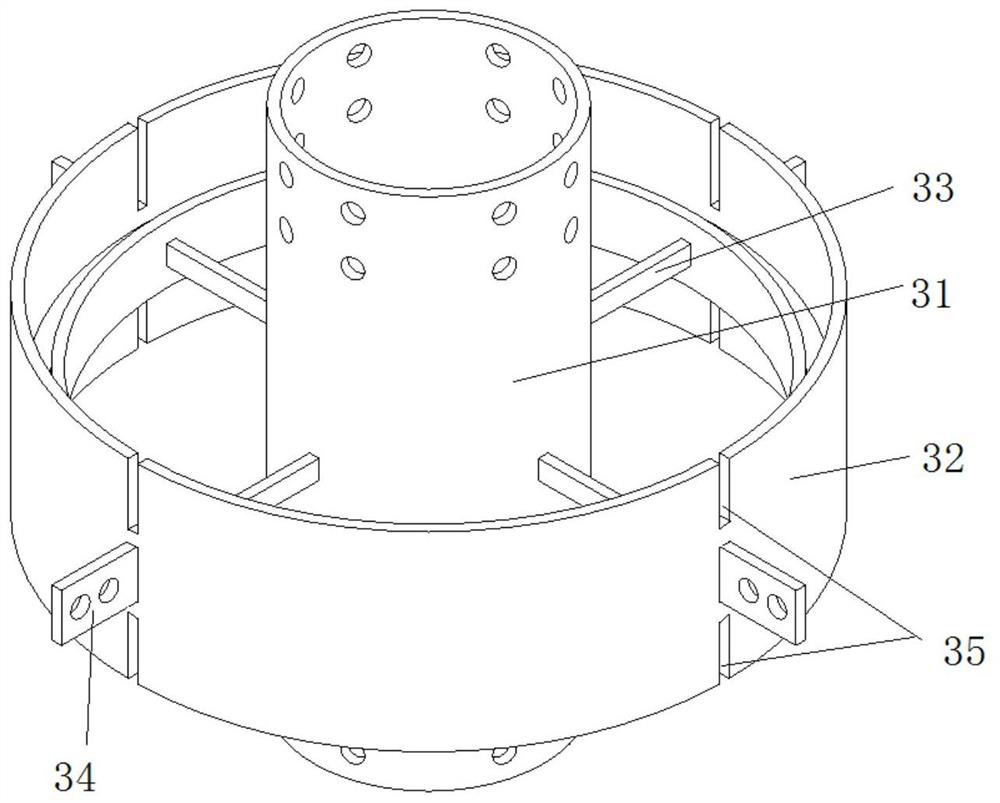

Double-steel-pipe concrete beam-column joint with built-in FRP rib connecting device and mounting method

ActiveCN111733986APrevent bucklingHigh strengthStrutsBuilding reinforcementsShaped beamConcrete beams

The invention relates to the field of building structures, in particular to a double-steel-pipe concrete beam-column joint with a built-in FRP rib connecting device. The double-steel-pipe concrete beam-column joint comprises double steel pipe columns, an I-shaped beam, a joint connecting piece, an inner supporting piece and an outer ring plate. The double steel pipe columns comprise inner steel pipes and outer steel pipes. The joint connecting piece comprises a connecting inner pipe and a connecting outer sleeve disc, and the connecting inner pipe and the connecting outer sleeve disc are bothround steel pipes. The inner supporting piece is of a columnar structure, and bolt holes are evenly distributed in the two ends of the inner supporting piece along the circumference. The outer ring plate comprises a horizontal part and an annular part which are perpendicular to each other. The upper-layer steel pipe column and the lower-layer steel pipe column are connected through the joint connecting piece and the inner supporting piece, the two ends of the inner supporting piece are inserted into the upper inner steel pipe and the lower inner steel pipe correspondingly, and FRP ribs sequentially penetrate through the annular part, the outer steel pipes, the connecting inner pipe and the inner steel pipes and then are fixed into the bolt holes of the inner supporting piece. According tothe double-steel-pipe concrete beam-column joint, the excellent tensile property and fatigue load resistance of the FRP ribs are utilized, the anti-seismic energy dissipation capacity of the joint iseffectively improved, and the safety and bearing capacity of the structure are enhanced.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

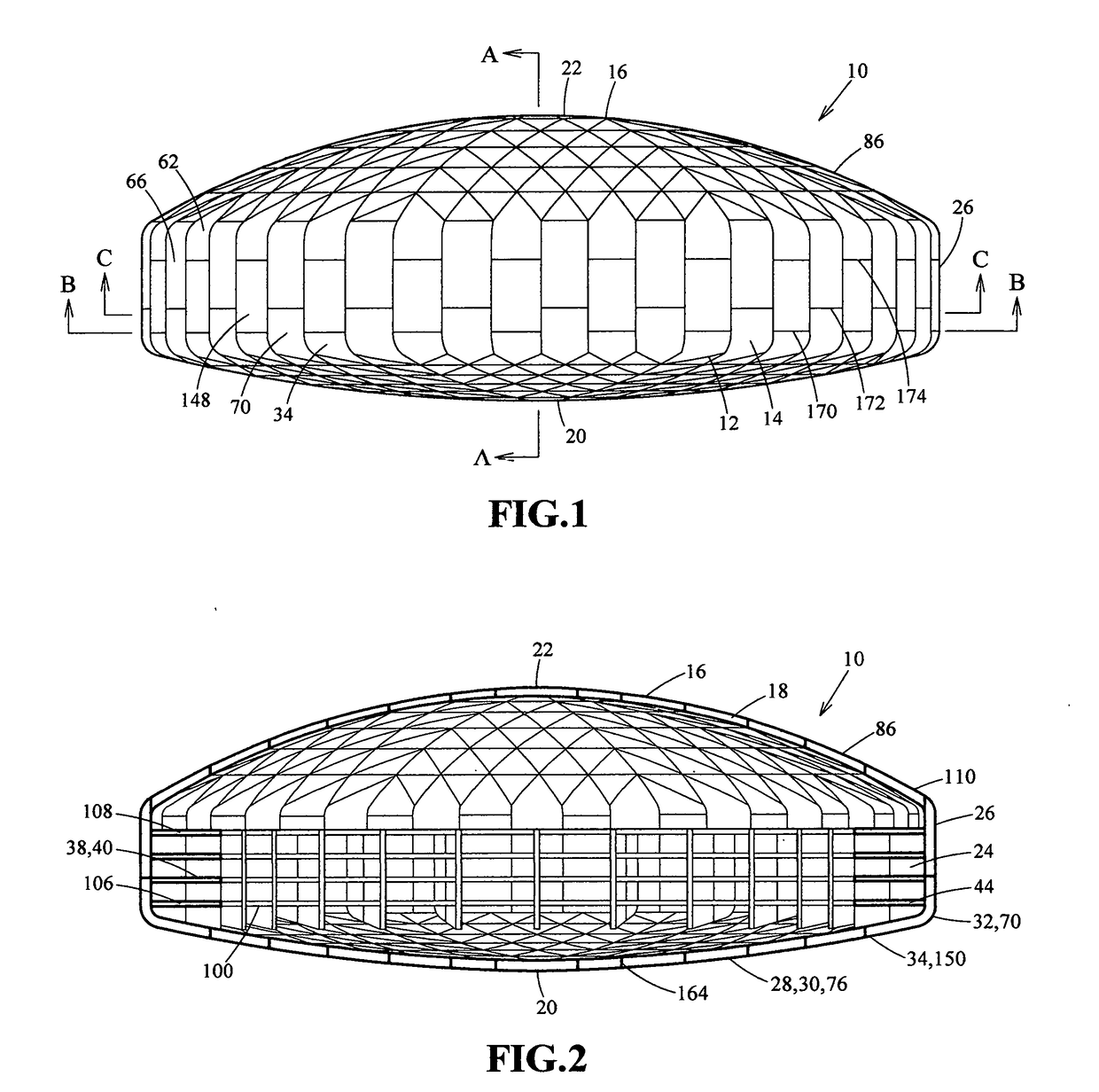

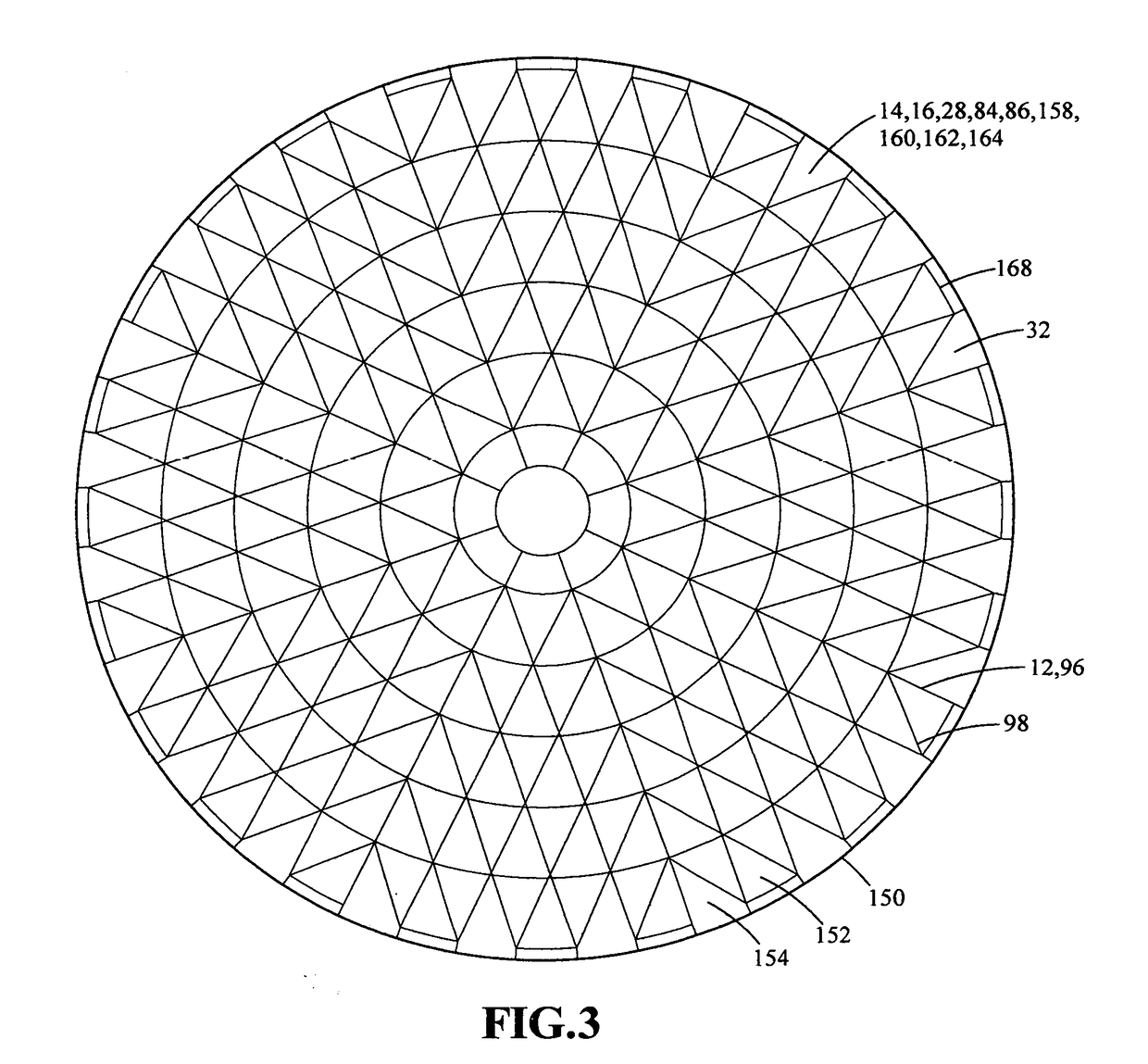

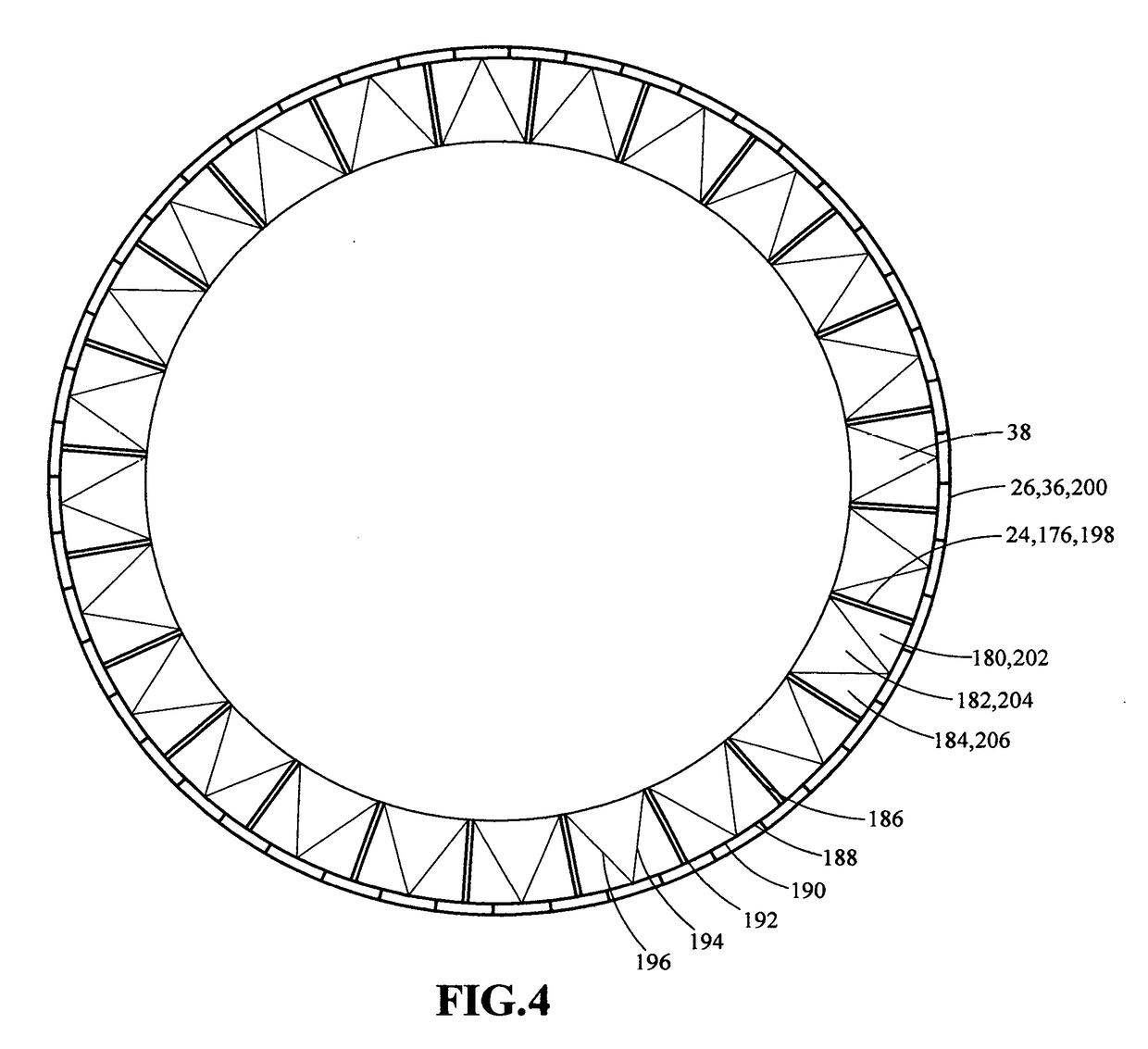

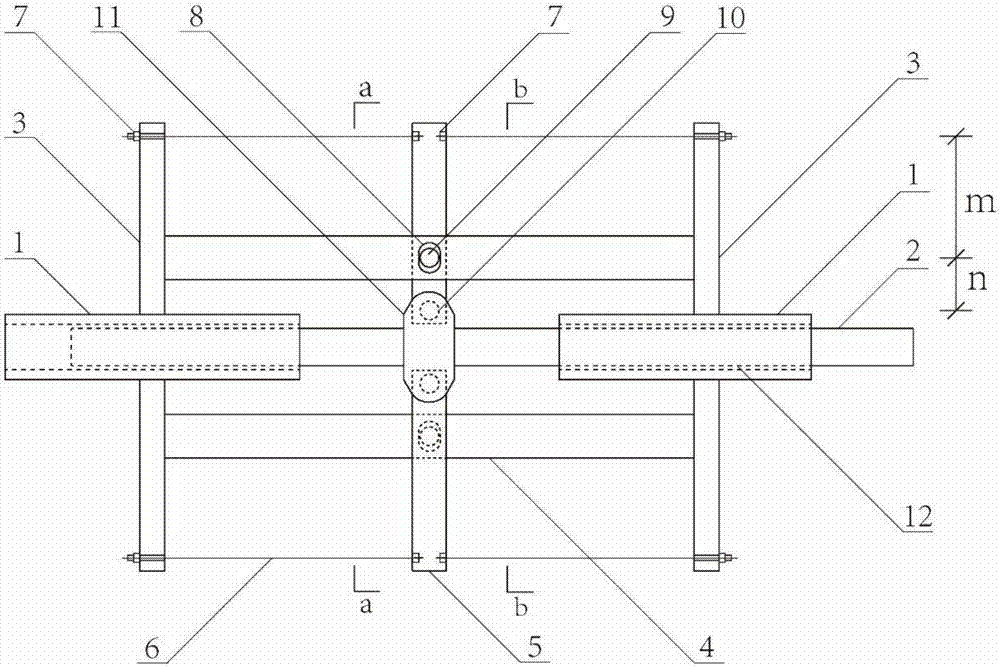

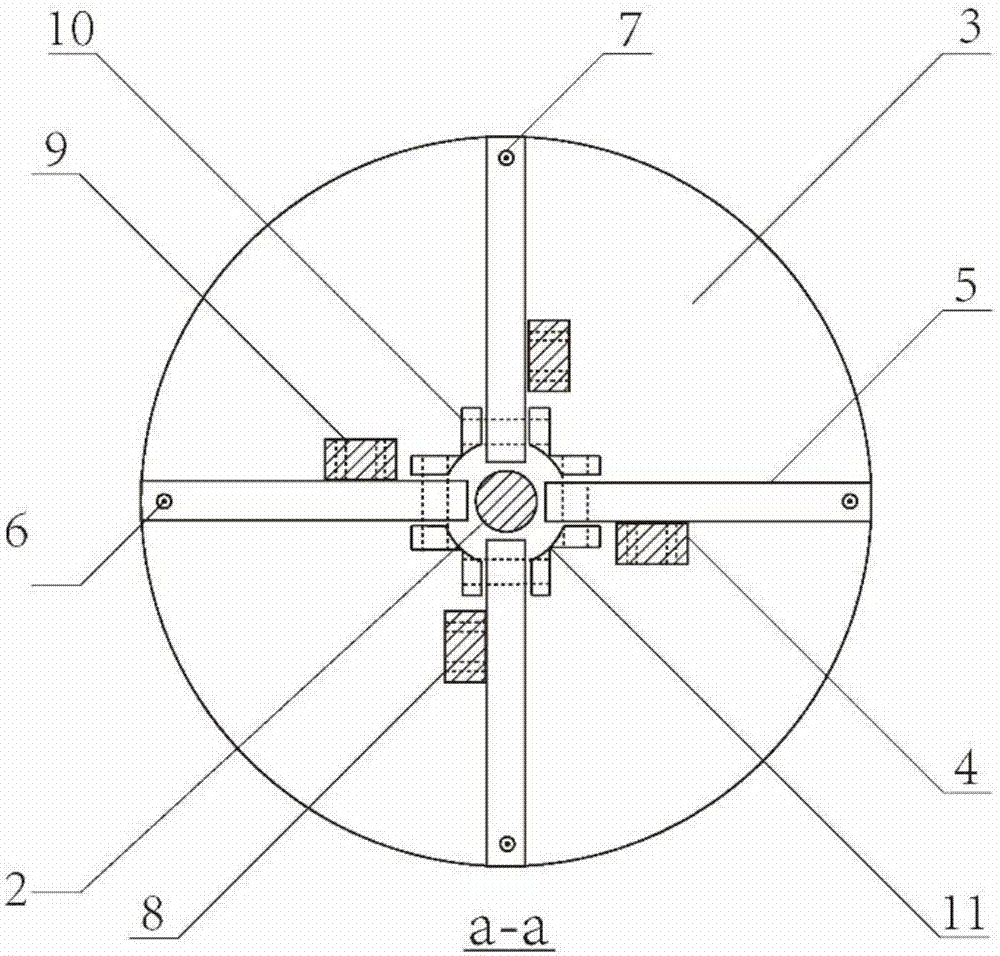

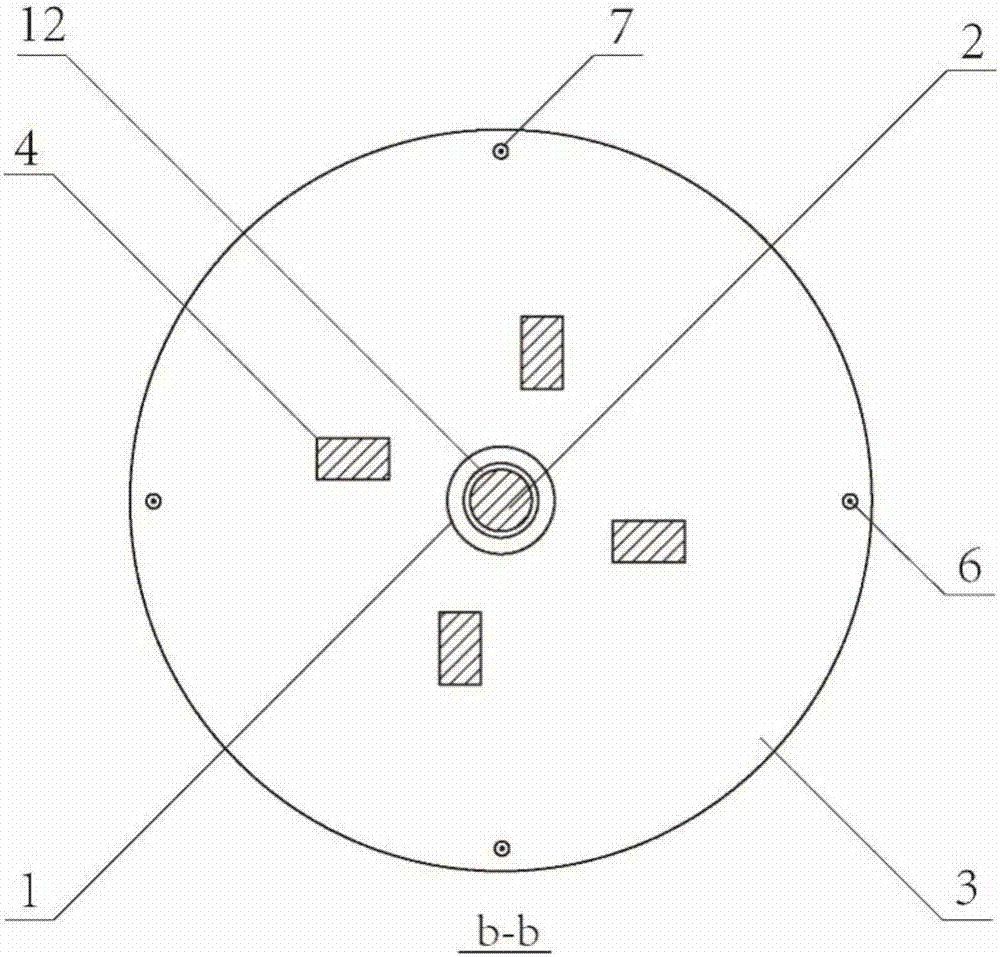

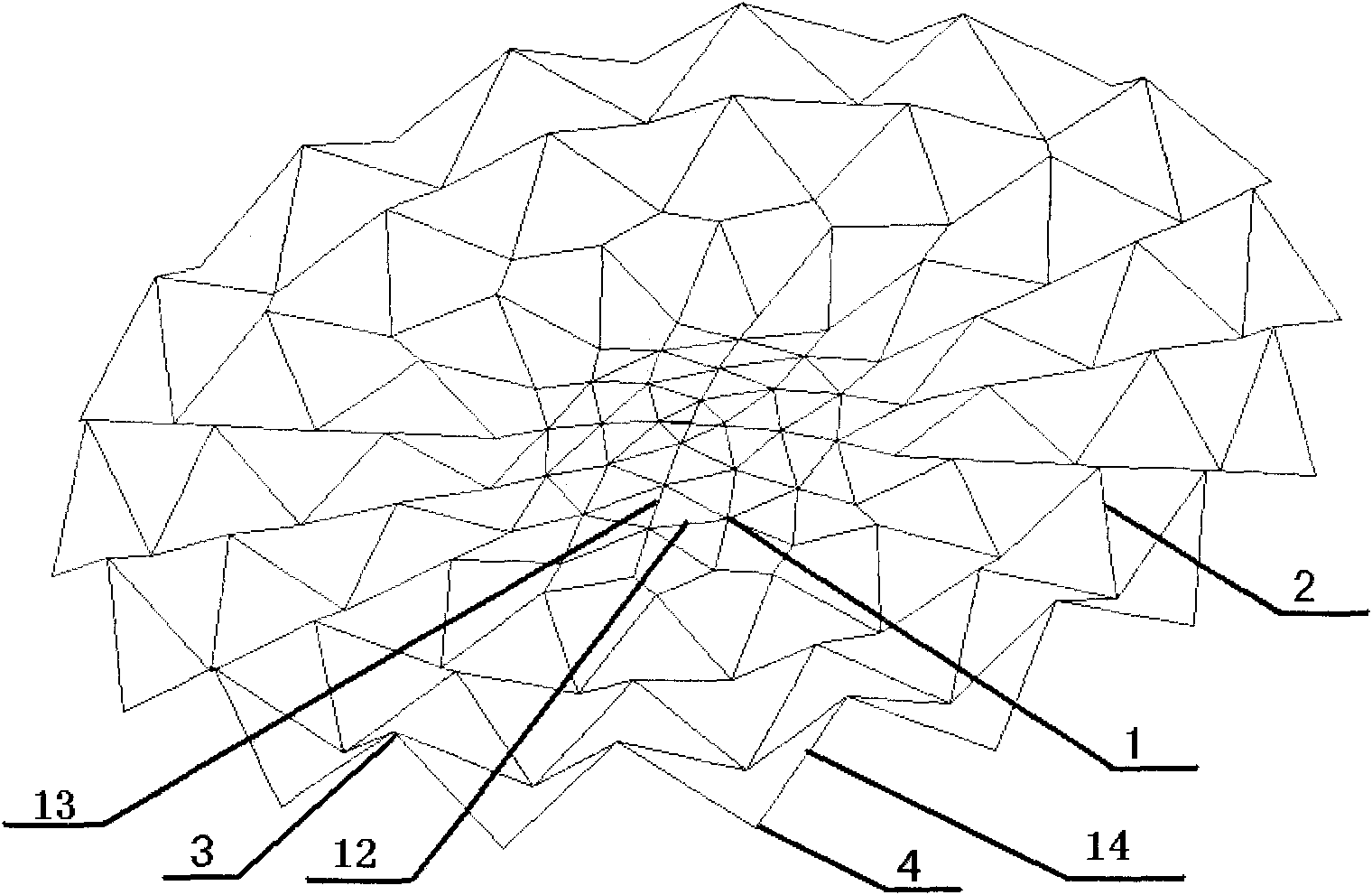

Multi-hinge-line lifting-up spherical surface reticulated shell structure and construction method thereof

InactiveCN101956426AAvoid damageUniform distribution of internal forceArched structuresVaulted structuresHinge lineSteel ball

The invention relates to a multi-hinge-line lifting-up spherical surface reticulated shell structure and a construction method thereof. The multi-hinge-line lifting-up spherical surface reticulated shell structure comprises a toroidal steel tube a, a toroidal steel tube b, a radial steel tube a, a radial steel tube b, a radial steel tube c, a perforated steel ball, a pin shaft, a single-hole bloom, a single-hole ear plate, a cast steel support, rigid nodes, a unidirectional hinged joint and a unidirectional rotary hinge support node, which are connected through the rigid nodes to assemble into an inner ring small-sized reticulated shell and a mechanism, the inner ring small-sized reticulated shell and the mechanism are connected through the unidirectional hinged joint to form a hinge line, and the hinge line is connected with the support through the unidirectional rotary hinge support node so that the inner ring small-sized reticulated shell is lifted up to drive the adjacent mechanism to rise. When three hinge lines rises to a designed height, two hinge lines are cancelled, the lifted part becomes a structure, and the process is repeated until a whole structure is formed. The invention has the advantages of convenient construction, short construction period and clear and reasonable force flow and is suitable for common industrial and civil buildings, in particular large-span space structures such as exhibition centers, gymnasiums, airport terminals and the like.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com