Multi-hinge-line lifting-up spherical surface reticulated shell structure and construction method thereof

A reticulated shell and hinged wire technology, applied in the dome roof structure, arched structure, building components, etc., can solve the problems of not fully reflecting the superiority of the folded structure, the impact of structural safety, poor lateral stiffness, etc., and achieve savings. Scaffolding, good lateral stability and small overall damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

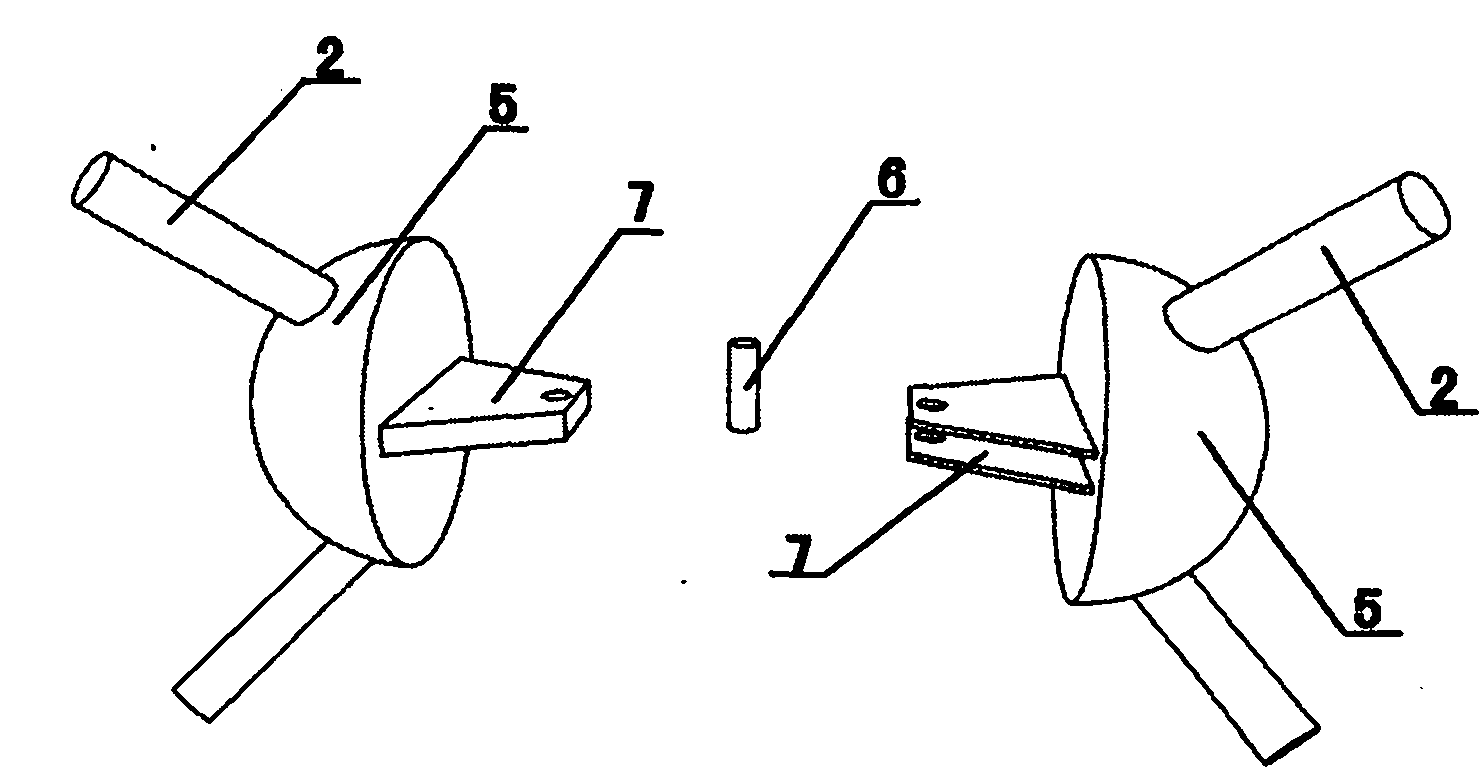

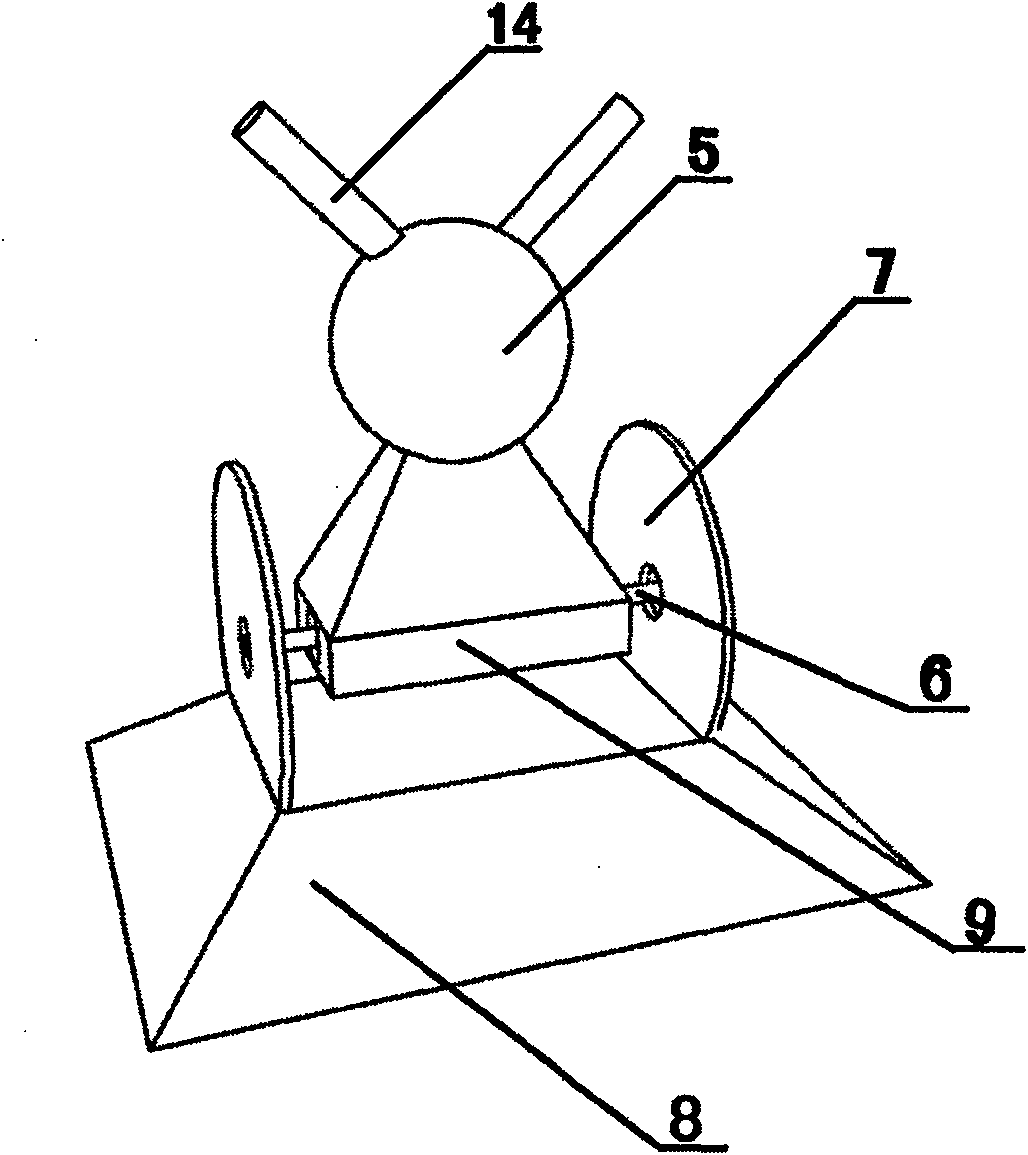

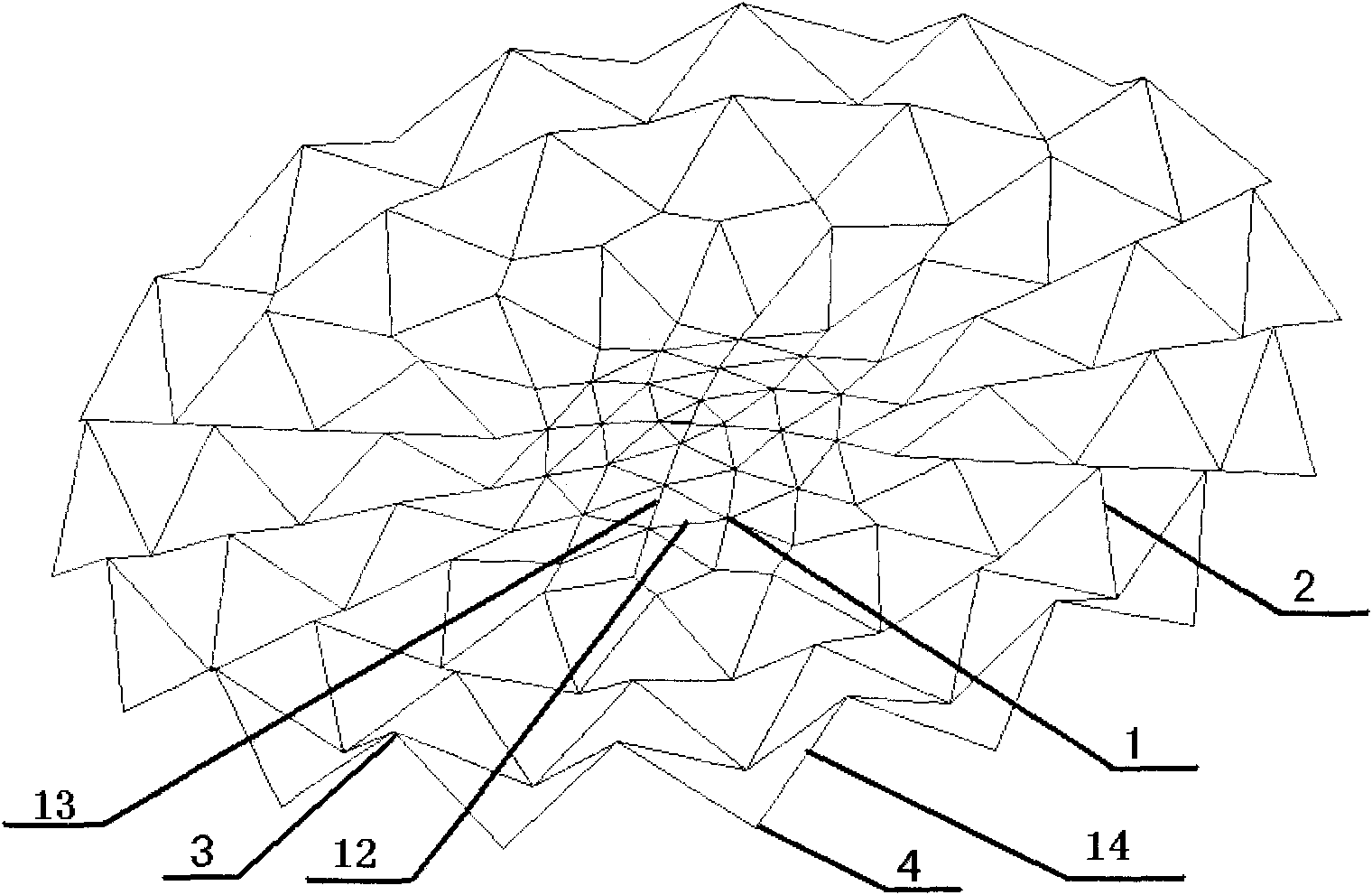

[0022] Such as figure 1 As shown, a multi-hinge lifting spherical reticulated shell structure includes rigid node 1, radial steel pipe a2, one-way hinge node 3, one-way rotating hinge support node 4, through-core steel ball 5, pin shaft 6, single Hole ear plate 7, cast steel support 8, single hole steel block 9, hinge line 10, circumferential steel pipe a11, circumferential steel pipe b12, radial steel pipe b13, and radial steel pipe c14.

[0023] First, assemble the inner ring small reticulated shell and the mechanism respectively: weld or bolt the circumferential steel pipe b12 and the radial steel pipe b13 to the through-hole steel ball 5 to form the connection form of the rigid node 1, as shown in Figure 8 shown.

[0024] Secondly, connect the small reticulated shell of the inner ring with the mechanism: weld or bolt the circumferential steel pipe a11 and the radial steel pipe a2 to the steel ball 5, and the upper end of the single-hole ear plate 7 is welded to the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com