Beam-to-column connectors for construction

A beam-column connection and construction technology, applied in the direction of building components, buildings, building structures, etc., can solve the problems of high labor intensity, large waste of construction raw materials, and increase the difficulty of installation, so as to solve the pollution of the surrounding environment and reduce construction waste , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

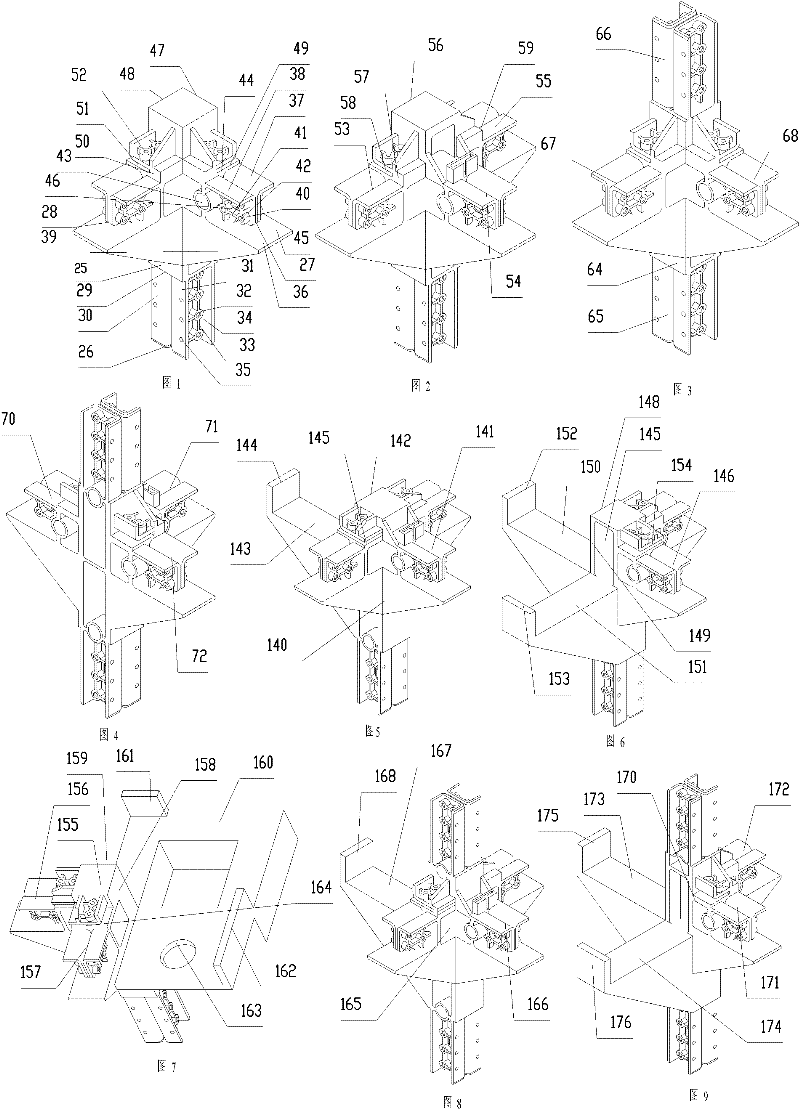

[0088] Such as figure 1 As shown, the beam-column connector, which is a top-level beam-column connector, includes an integral beam-column connector body 25, and a lower column plug connector 26 that needs to be inserted and fixed with the end of the column perpendicular to the horizontal plane. Two cross beams that are perpendicular to each other and directly support parallel to the horizontal plane, a horizontal support joint 27 and a horizontal support joint 28 fixedly connected to the ends of the cross beam.

[0089] Below the beam-column connector body 25 is provided a column-supported horizontal plane 29 directly supported by the column. The lower column plug connector 26 includes two symmetrical U-shaped blocks 30 and U-shaped blocks 31 that extend vertically downward from a horizontal plane 29 supported by the column, with openings facing both sides, and horizontally side by side. The bottom plane of the U-shaped groove of the U-shaped block 31 is provided with a round tab...

Embodiment 2

[0093] Such as figure 1 As shown, the difference from Embodiment 1 is that there are three horizontal support joints, namely horizontal support joint 53, horizontal support joint 54, horizontal support joint 55, horizontal support joint 53, horizontal support joint 54, and horizontal support joint 55 are mutually perpendicular , Into a T shape. The beam-column connector includes an outer side surface 56 without support joints, a horizontal side baffle positioning groove 58 communicating with the outer side surface 56 and the cross beam end face 57 of the horizontal support joint 53, and the outer side surface 56 and the horizontal support joint A horizontal side baffle positioning groove (not shown) connected with the end face of the beam 55 and the resisting surface 59 is connected.

Embodiment 3

[0095] Such as image 3 As shown, the beam-column connector includes an integral beam-column connector body 64, and a lower column protruding vertically downward from the bottom of the beam-column connector body 64 needs to be inserted and fixed to the end of the column in the vertical horizontal direction. The plug connector 65 and an upper column plug connector 66 projecting vertically upward from the top of the beam-column connector body 64, two perpendicular to each other, directly supporting the beam parallel to the horizontal plane, and a horizontal support connector 67 connected and fixed to the end of the beam , Horizontal support joint 68.

[0096] The structures of the lower column plug connector 65, the horizontal support connector 67, and the horizontal support connector 68 are the same as the first embodiment. The upper column plug connector 66 and the lower column plug connector 65 are horizontally symmetrical with respect to their central positions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com