Patents

Literature

89results about How to "Solve the yield problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

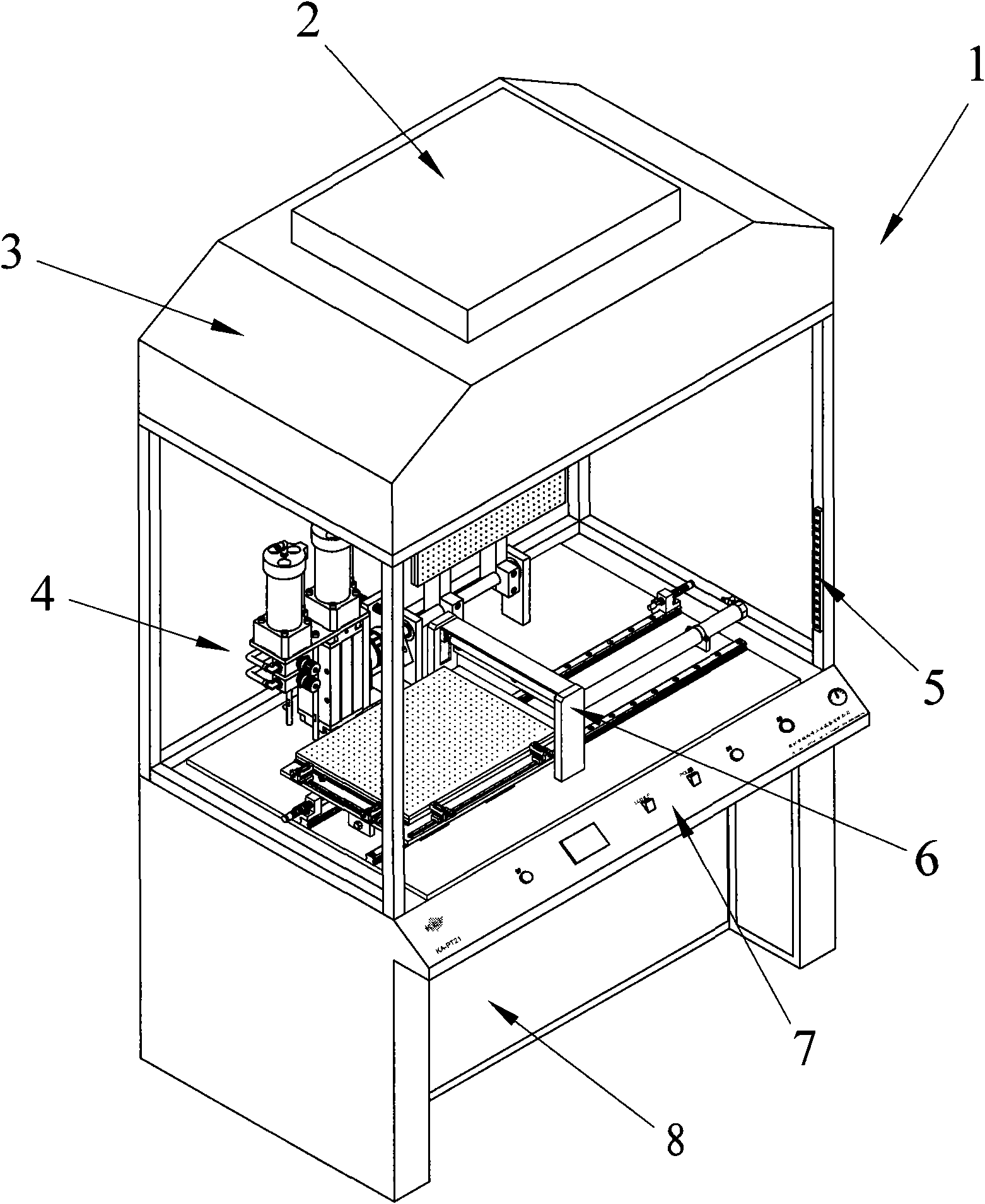

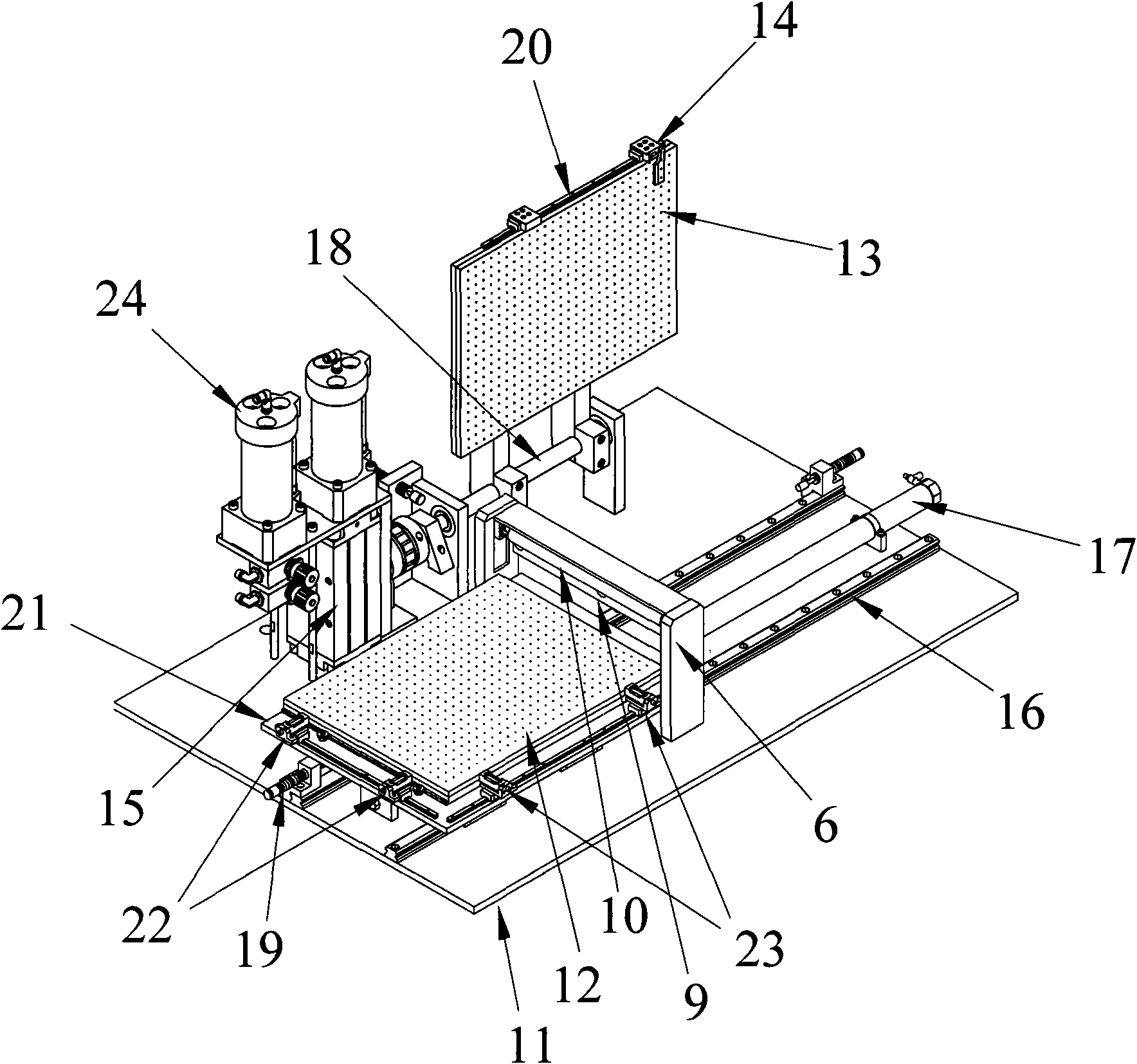

Semi-automatic laminating machine and laminating method thereof

InactiveCN101581850AGuaranteed cleanlinessEasy to operateLaminationLamination apparatusSemi automaticAtmospheric pressure

The invention discloses a semi-automatic laminating machine and a laminating method thereof. The semi-automatic laminating machine is provided with a stand, wherein an operating space for accommodating a laminating device is arranged in the middle part of the stand, an electric component box is placed in the stand and positioned below the laminating device, an air inlet opening is arranged at the top of the stand, an air purifier is placed at the top of the stand and an operating panel is installed on the stand and used for controlling the laminating machine. The material laminating is carried out by material placing, aligning, laminating by pressure roller, laminating completion and returning for standby. The semi-automatic laminating machine adopts various ways of vacuum adsorption, mechanical positioning and pneumatic motion to be provided with a precision fine adjustment device, a limitator, an oil-gas convertor, a linear slide rail and other precision components, thereby ensuring the laminating accuracy, reducing the dependence on the operators, overcoming the phenomenon of inaccurate positioning, low yield, air bubble, gauffer and defects existing in the laminating process of the diaphragm and the base material, reducing the running time due to the overlapped type motion and improving the production efficiency.

Owner:郑春晓

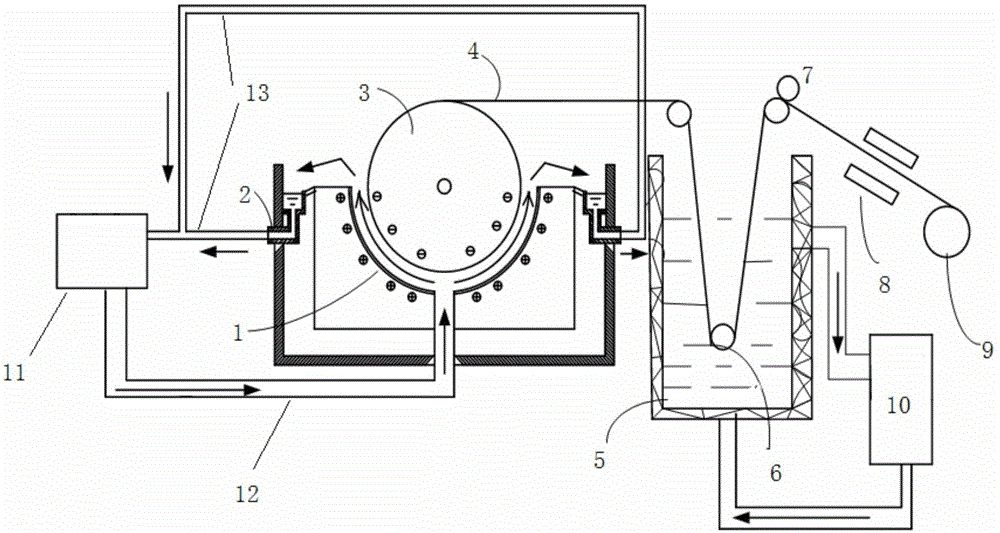

Oxidation prevention process used for lithium ion battery copper foil

InactiveCN105039947ASolve prone to wrinklesSolve the yield problemMetallic material coating processesCapacitancePotassium hydroxide

The invention provides an oxidation prevention process used for lithium ion battery copper foil. The method comprises the steps that a semi-finished copper foil product which is not oxidized is introduced into an anti-oxidation passivation solution to be soaked, then squeezed dry through a squeeze roll, dried through hot air of an oven and directly wound, and a copper foil product is obtained after the oxidation prevention process. The anti-oxidation passivation solution comprises, 100-200 g / m<3> of benzotriazole, 0-1000 g / m<3> of chromic anhydride, 0.1-2 g / m<3> of rare earth metals of phosphoric acid, 0.1-2 g / m<3> of organic silane coupling agents, 10-30 L / m<3> of ethyl alcohol, and the balance water. The pH value is adjusted to be 5.5-8.5 through alkali such as sodium hydroxide and potassium hydroxide. The process is free of pollution to the environment; an anti-oxidation film of the produced copper foil product is moderate, even and consistent in thickness; the copper foil product is high in electrical conductivity and wettability, and the properties of the capacitance, the number of times of charge and discharge and the service life of a lithium ion battery can be effectively improved.

Owner:ANHUI TONGGUAN COPPER FOIL

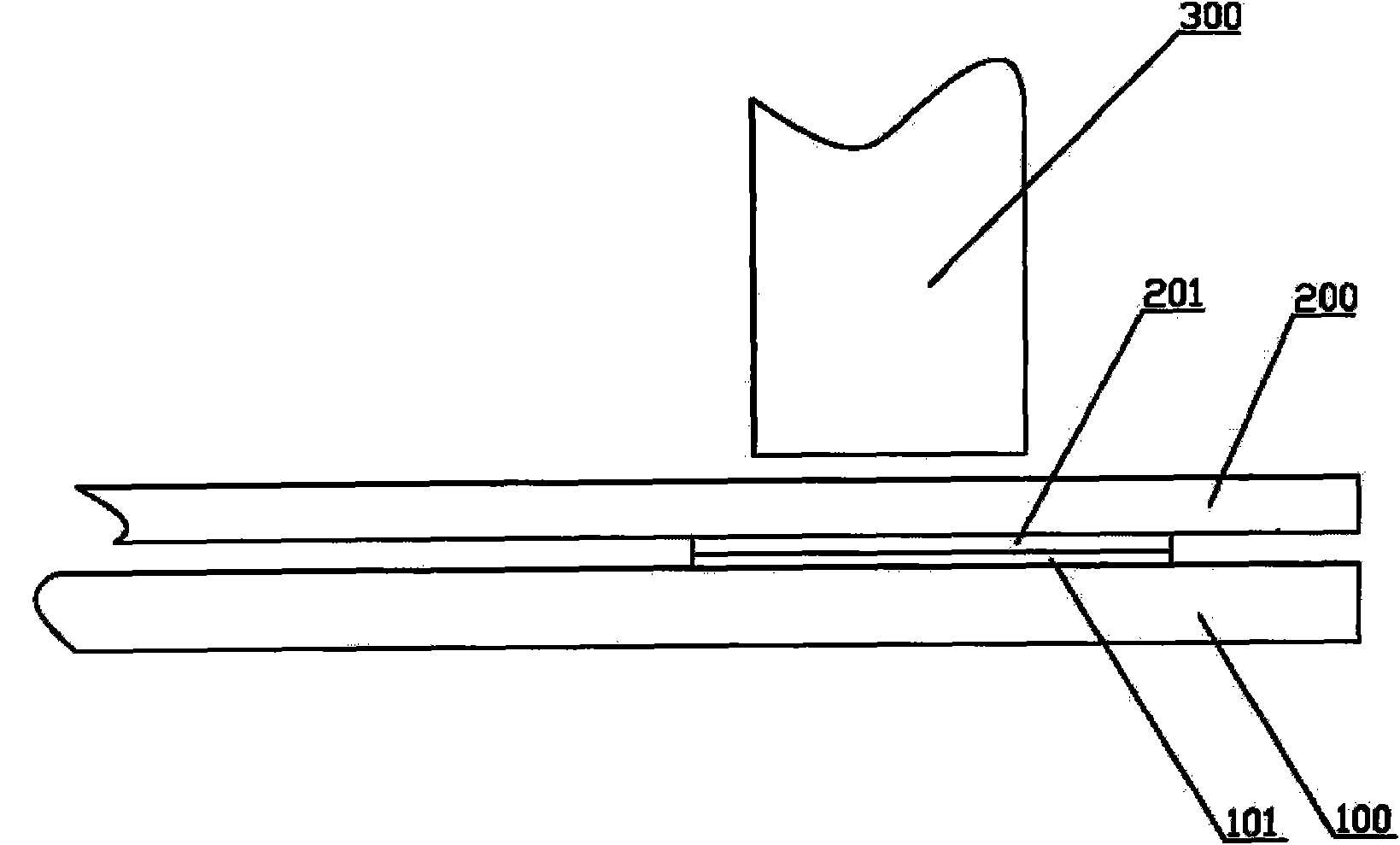

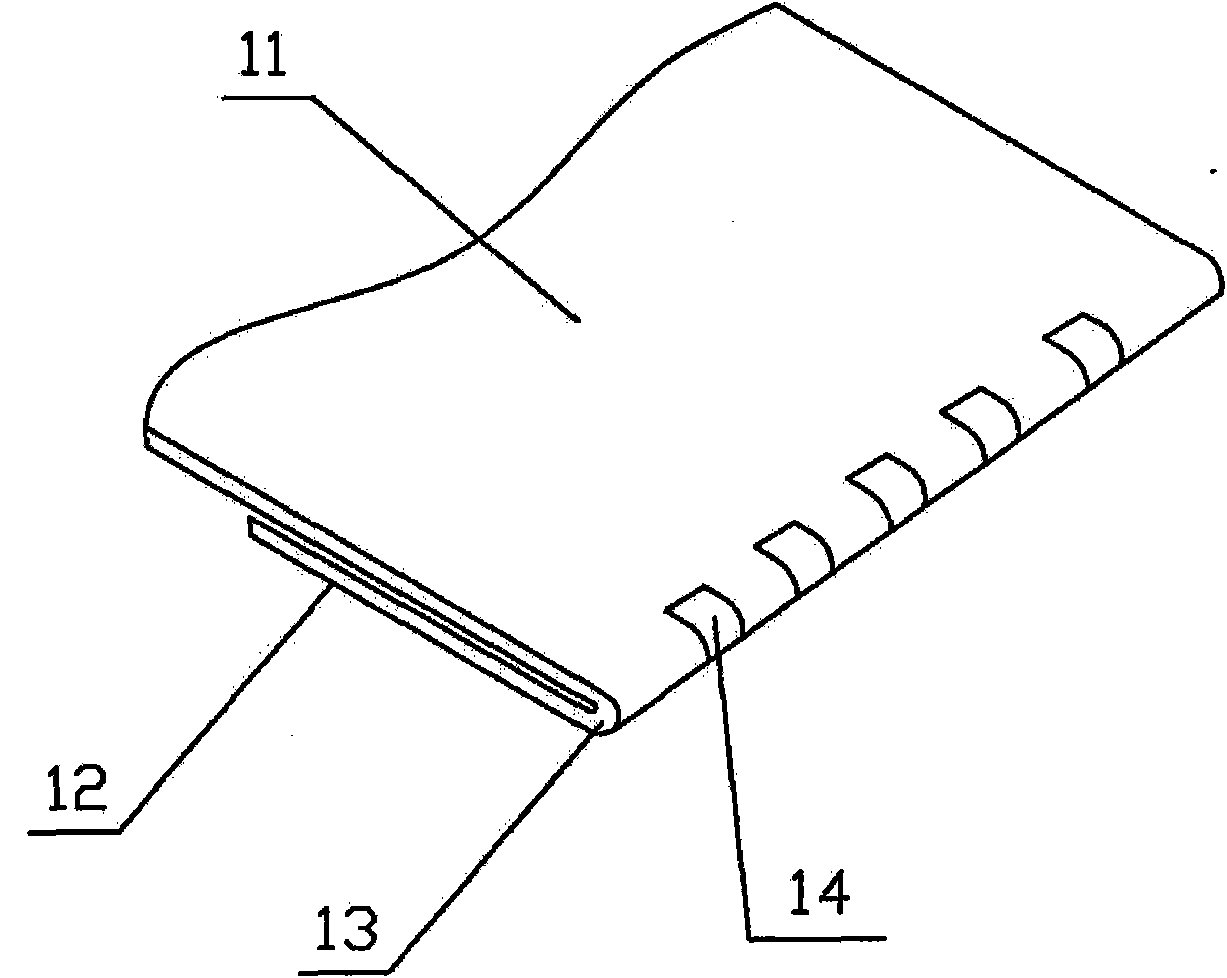

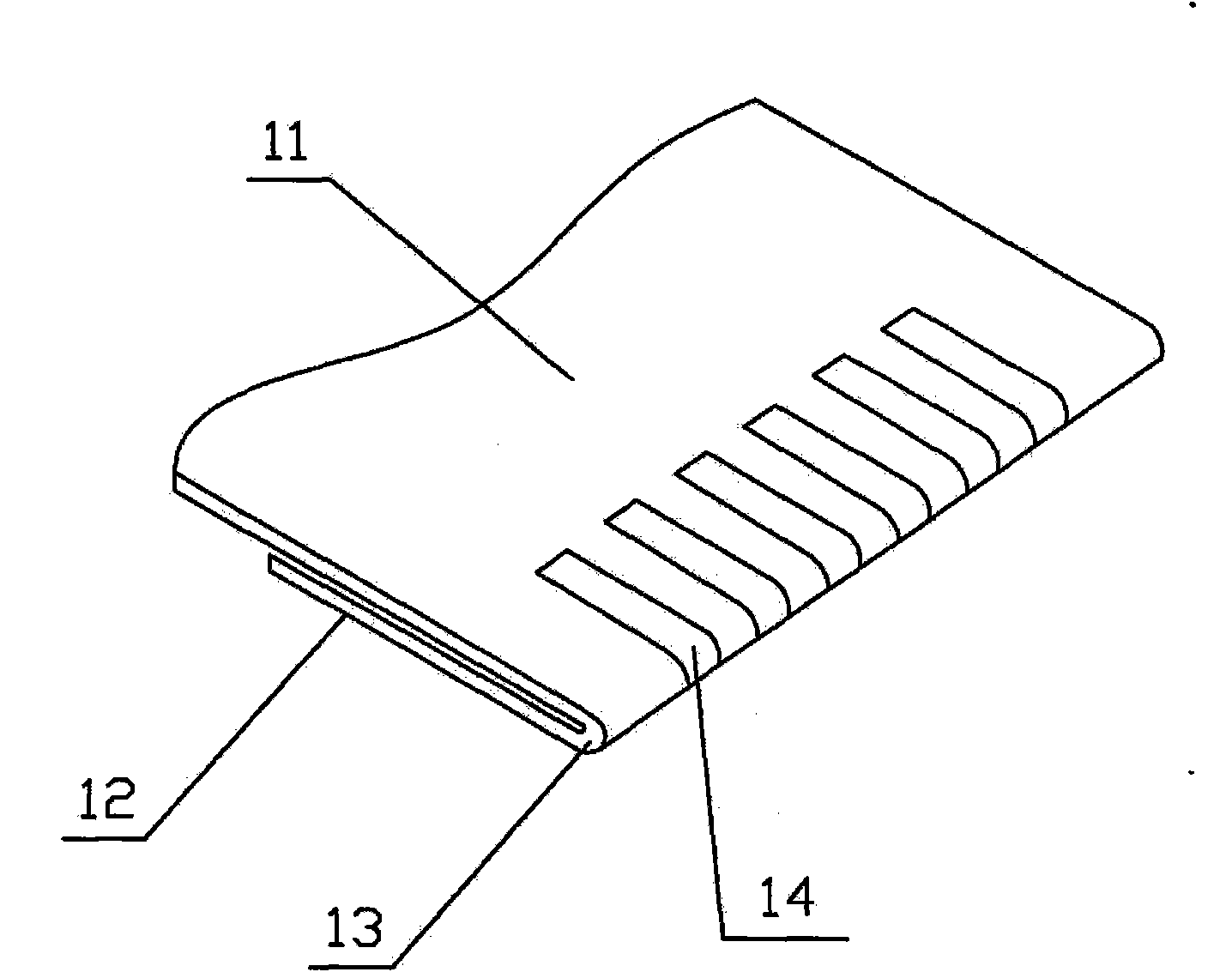

Flexible circuit board, and mechanism and method for connecting flexible circuit board and printed circuit board

InactiveCN101945538ASolve the yield problemAddress reliabilityPrinted circuit assemblingElectrical connection printed elementsFlexible circuitsWelding defect

The invention provides a flexible circuit board and a mechanism and a method for connecting the flexible circuit board and a printed circuit board, and belongs to the technical field of machinery. One end of the flexible circuit board is bent to form a U-shaped bending part, and a bonding pad is arranged on the surface of the U-shaped bending part. Therefore, the bending part is adhered to the printed circuit board, and the bonding pad on the surface of the U-shaped bending part and a bonding pad on the surface of the printed circuit board are opposite and welded. The invention can improve the connecting reliability, and can effectively solve the problems of low yield and low reliability for manually welding a low-cost single-sided FPC. Meanwhile, the welding spots of the connecting structure can be clearly seen, and the welding defect can be discovered through appearance inspection. Therefore, the mode has high reliability.

Owner:HUAWEI DEVICE CO LTD

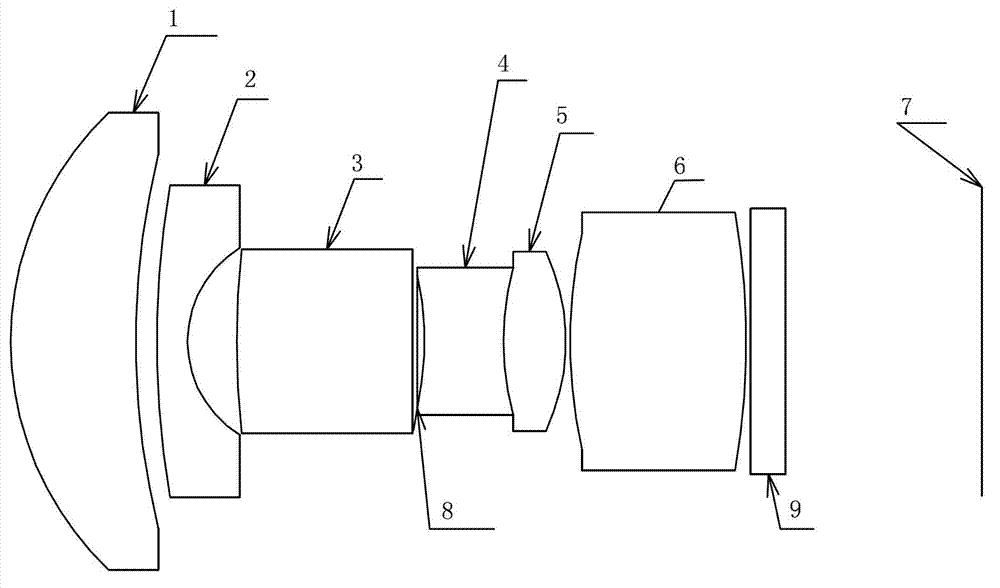

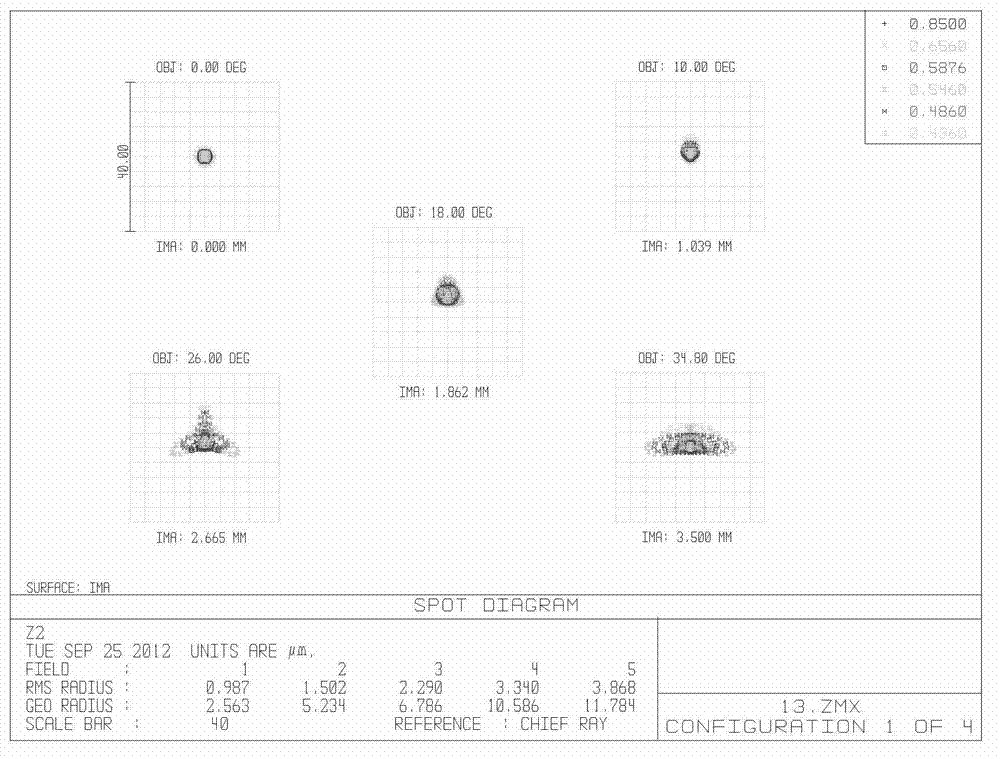

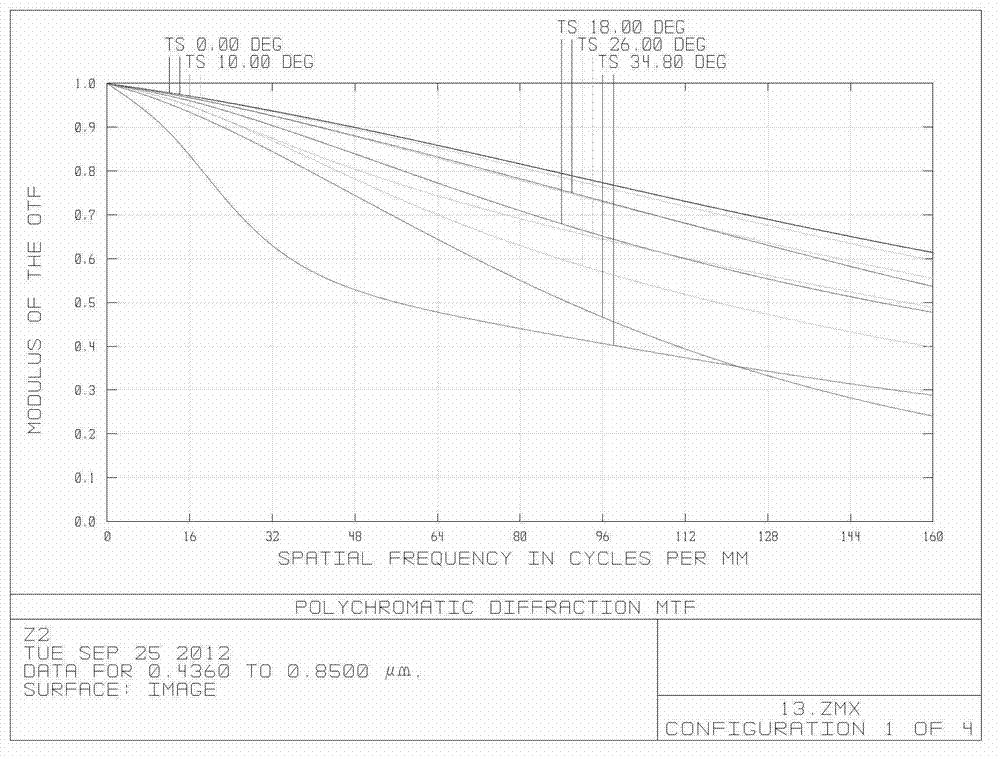

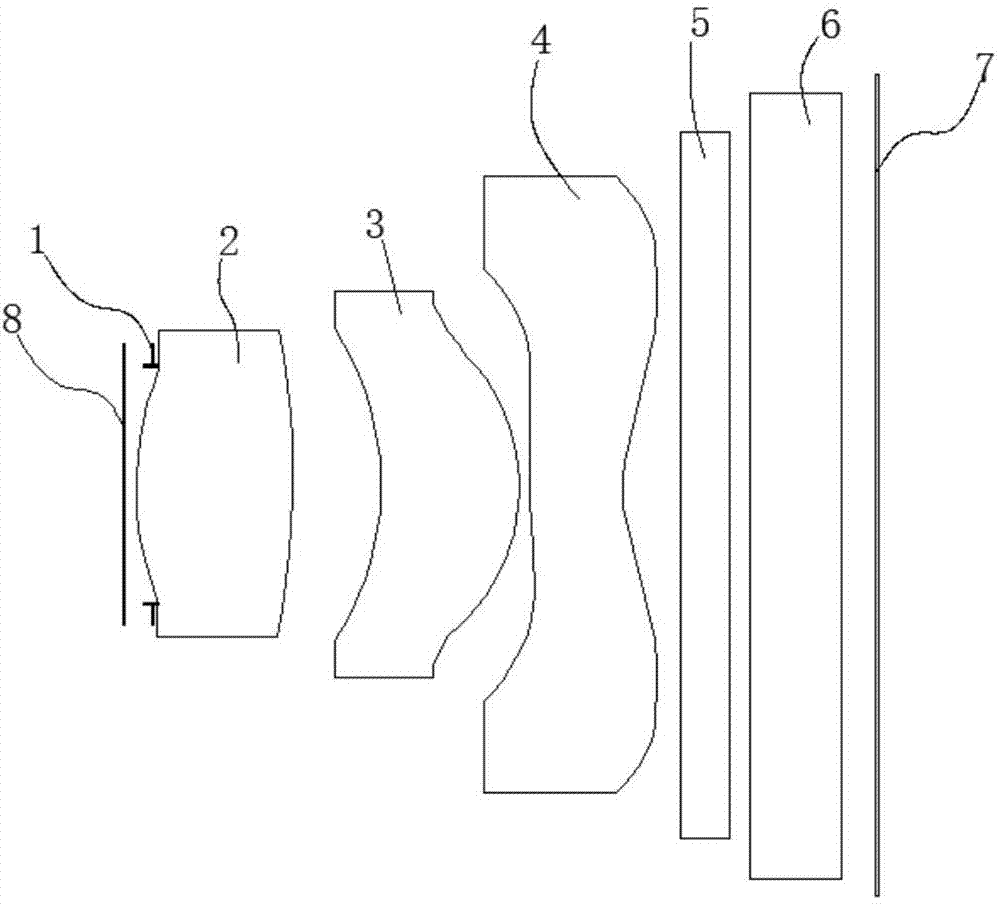

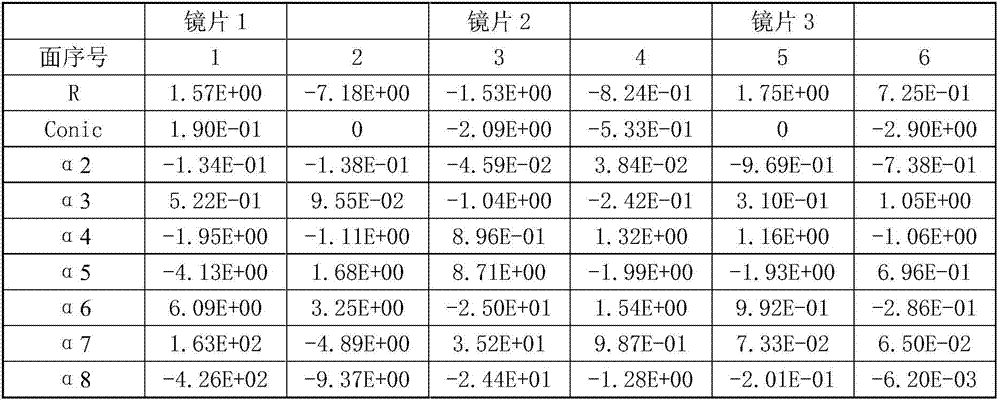

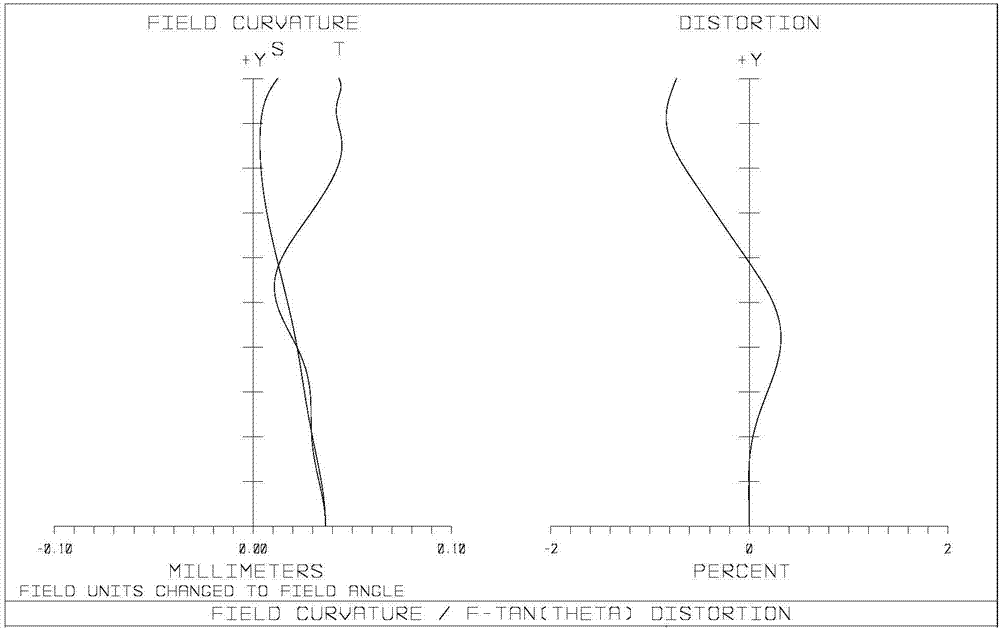

Optical system applied to monitoring, shooting and vehicles

The invention relates to an optical system applied to monitoring, shooting and vehicles. The optical system comprises a first lens, a second lens, a third lens, a fourth lens, a fifth lens, a sixth lens and an image surface which are sequentially arranged from an object space to an image space. The first lens, the second lens, the third lens, the fourth lens, the fifth lens and the sixth lens are all made of optical glass, and the surface types of the lenses are all spherical surface types. The optical system applied to monitoring, shooting and vehicles aims at overcoming the shortcoming in the prior art.

Owner:UNION OPTECH

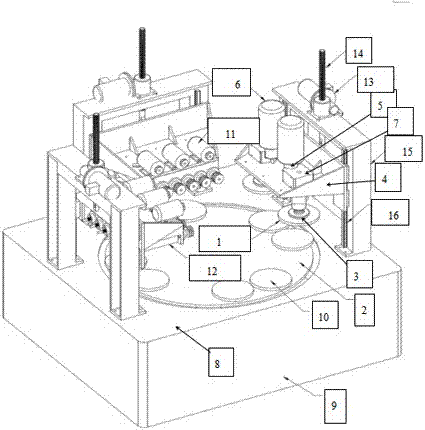

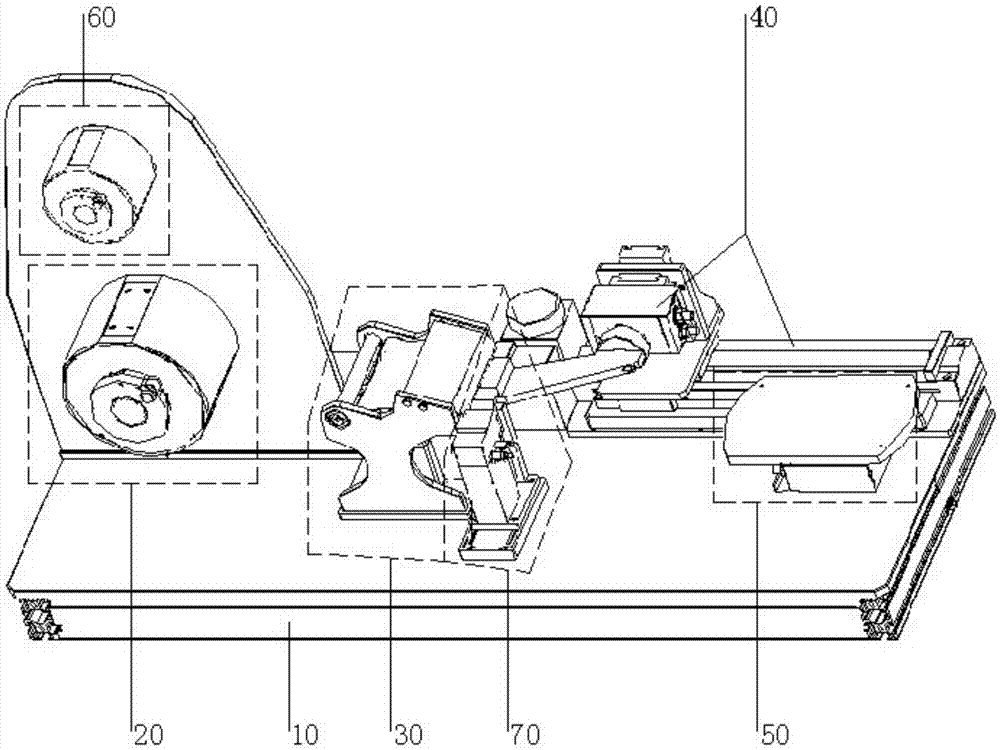

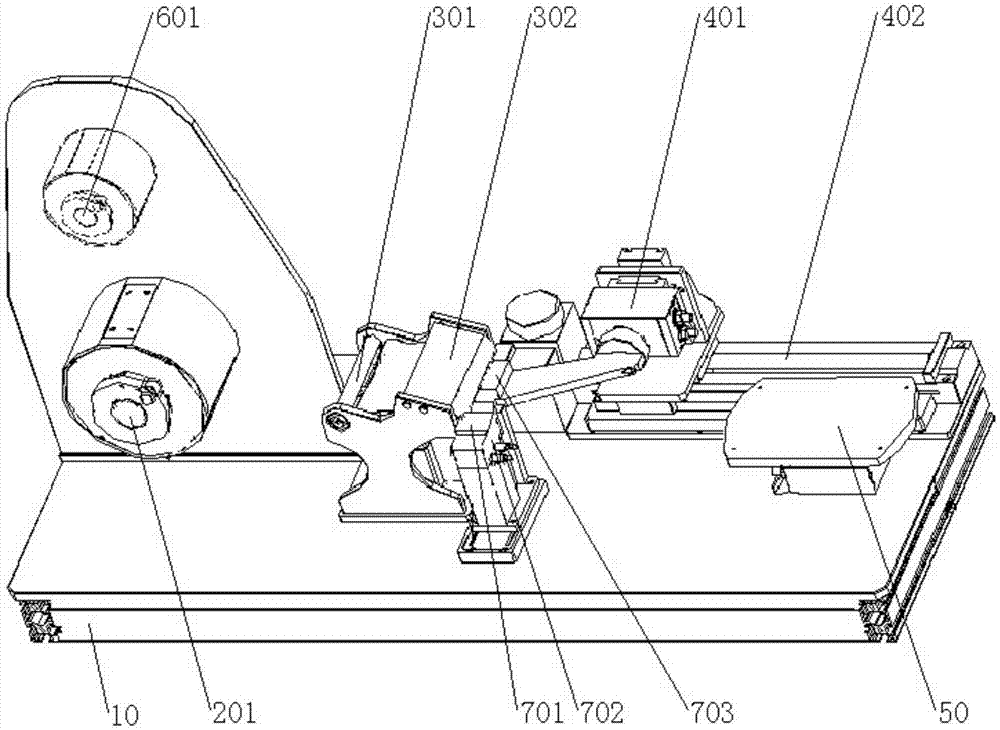

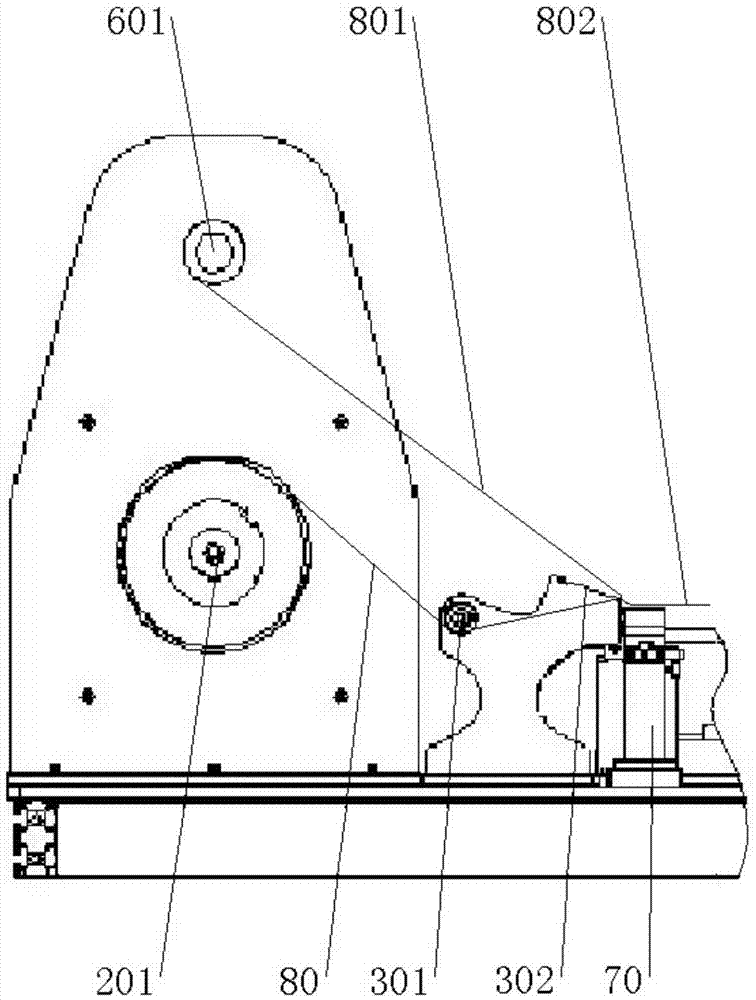

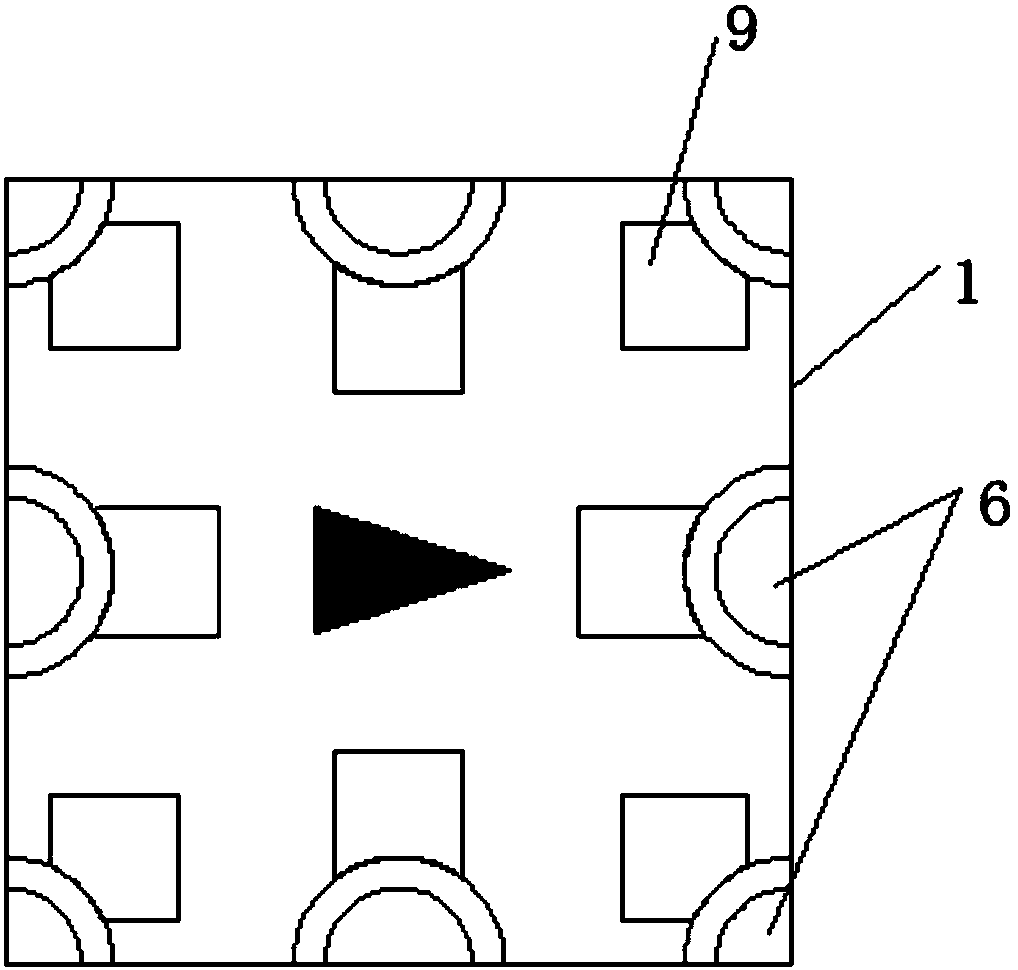

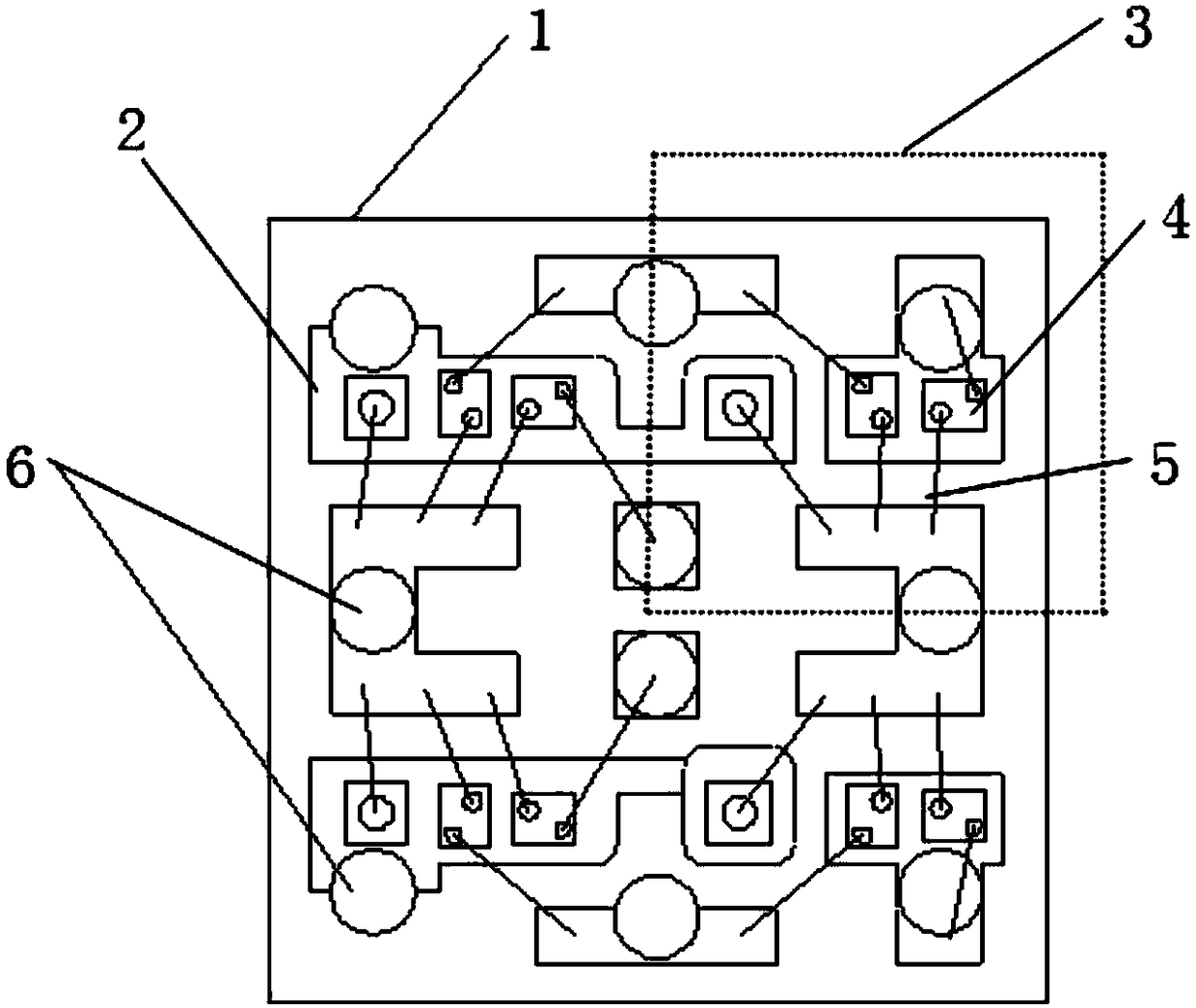

Novel precision sweeping machine equipment, method and application

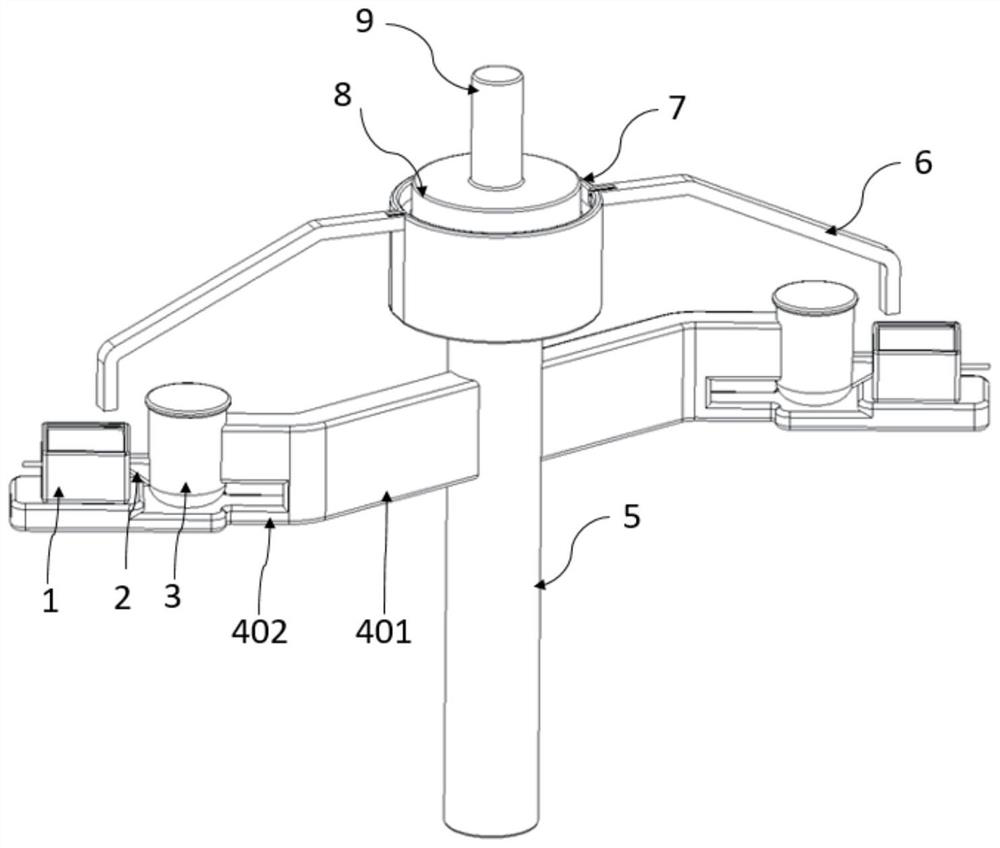

InactiveCN107052972ASolve the accuracy problemSolve efficiency problemsPolishing machinesGrinding drivesRotational axisGear wheel

The invention discloses novel precision sweeping machine equipment, a method and an application. The equipment comprises multiple working rotation disks (1), a revolution working platform (2), vacuum suction cups (3), shaft sleeves (4), rotating shafts (5), bearings (6), large and small gears (7), a rack base (8) and a gearbox (9). The lower disk of a machine body adopts the eight working disks which are divided into four groups, and each group contains two working disks. The rotation and revolution combined structure is realized. Combined rotating joints are adopted, and the vacuum absorption function is realized. The self-cleaning machine function is adopted, and high-pressure cleaning is realized through running water and high-pressure gas. The upper disk adopts a drum and flat sweeping combined structure, the stop type working manner is adopted, and the whole machine works continuously.

Owner:SHENZHEN XIKEO IND CO LTD

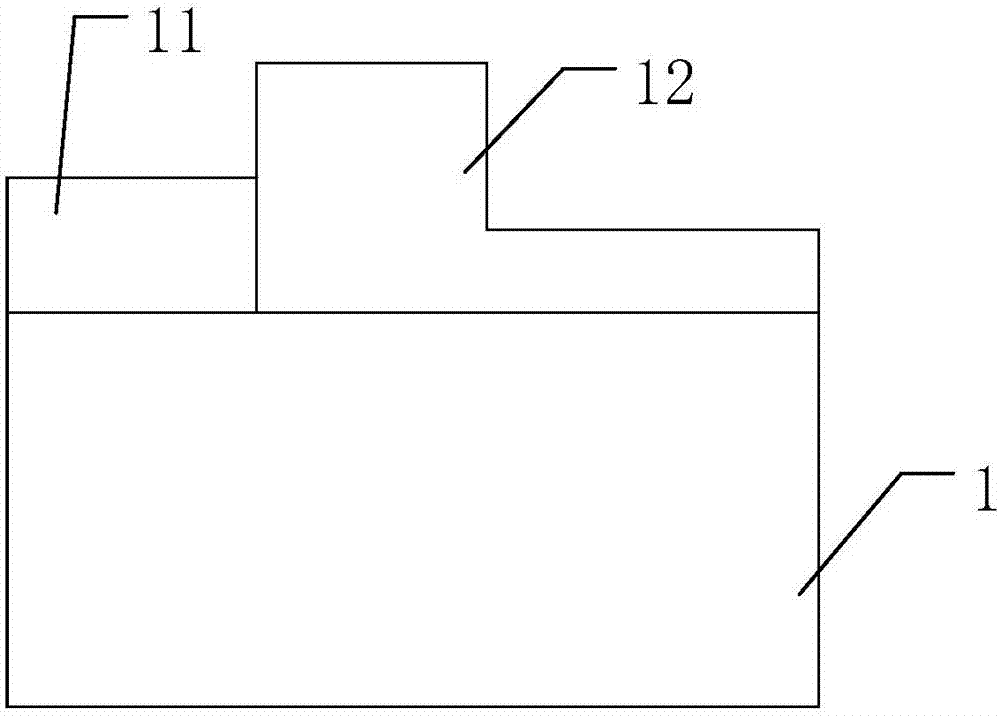

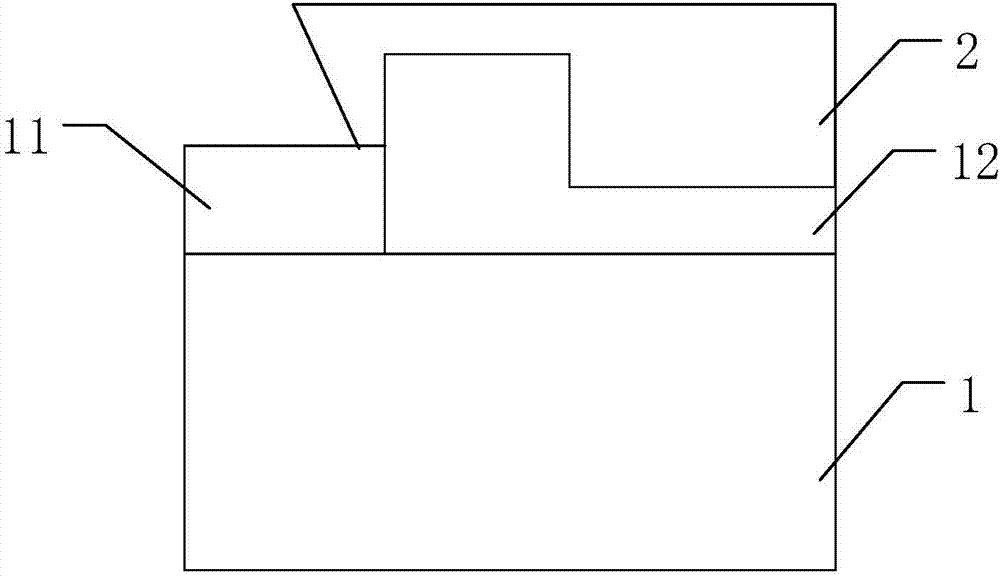

Graphite bearing disc for LED epitaxial process, and matching substrate thereof

InactiveCN103824796AImprove yieldReduce warpageSemiconductor/solid-state device manufacturingGraphiteEngineering

The invention provides a graphite bearing disc for an LED epitaxial wafer process, and a matching substrate thereof. The bearing disc comprises a bearing disc body. The body is uniformly provided with wafer grooves; the center of the body is provided with a shaft hole; the edge inner sides of the wafer grooves are provided with erection bench surfaces; there are distances between the erection bench surfaces and the edge top portions of the wafer grooves; and the erection bench surfaces are uniformly distributed at the edges of the wafer grooves. The substrate comprises a substrate body and wings erected on the erection bench surfaces. The advantages are mainly reflected as follows: the bearing disc provided by the invention overcomes the disadvantages of not high overall epitaxial wafer yield rate and unstable uniform distribution of epitaxial wafer wavelengths due to uneven heating by use of a conventional graphite bearing disc, the overall yield rate of grown LED epitaxial wafers is high, the wavelength uniformity is good, and the problems of the epitaxial wavelengths and standard deviation yield rate of the LED epitaxial wafers are well solved.

Owner:SUZHOU NANOJOIN PHOTONICS

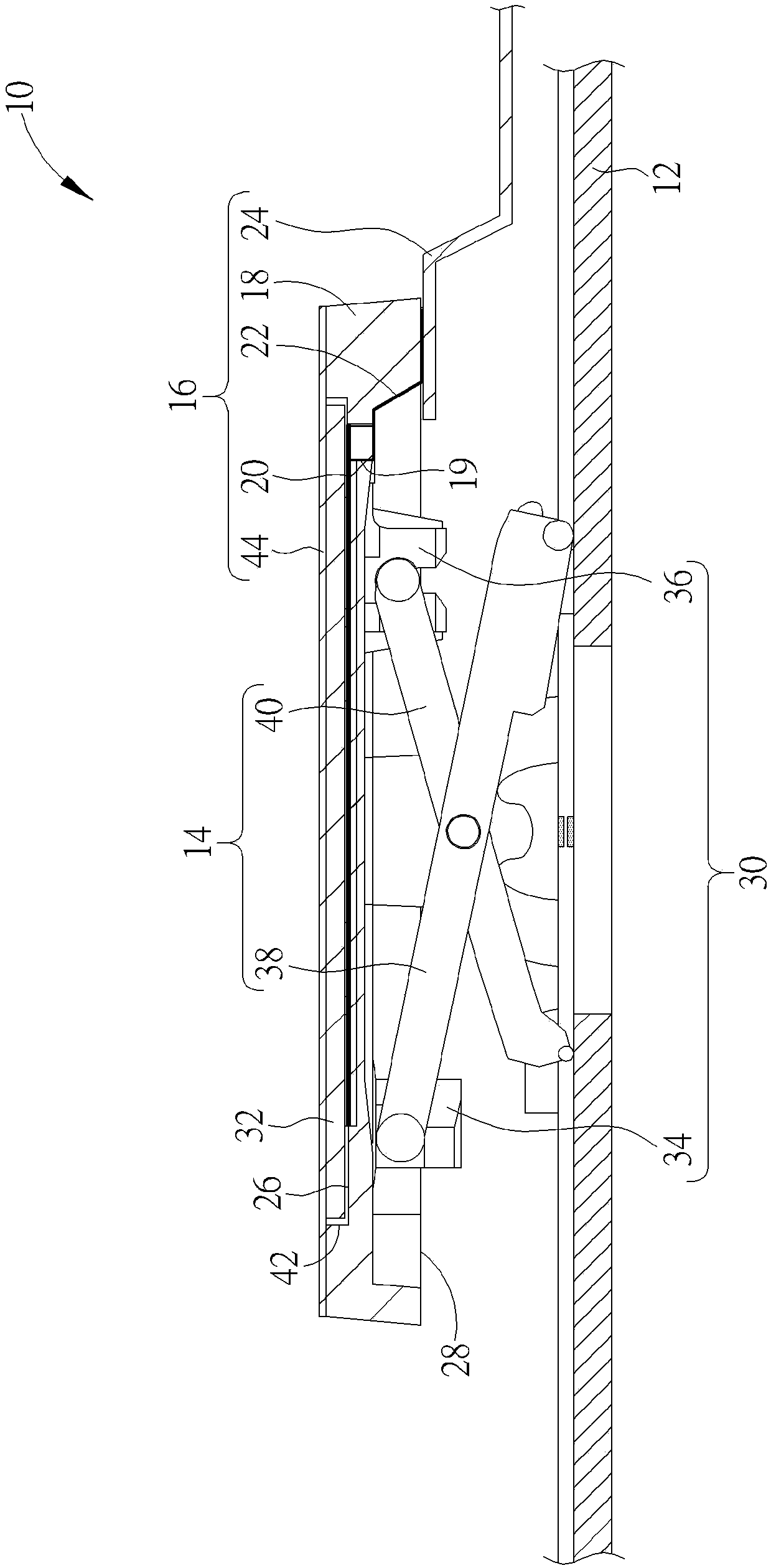

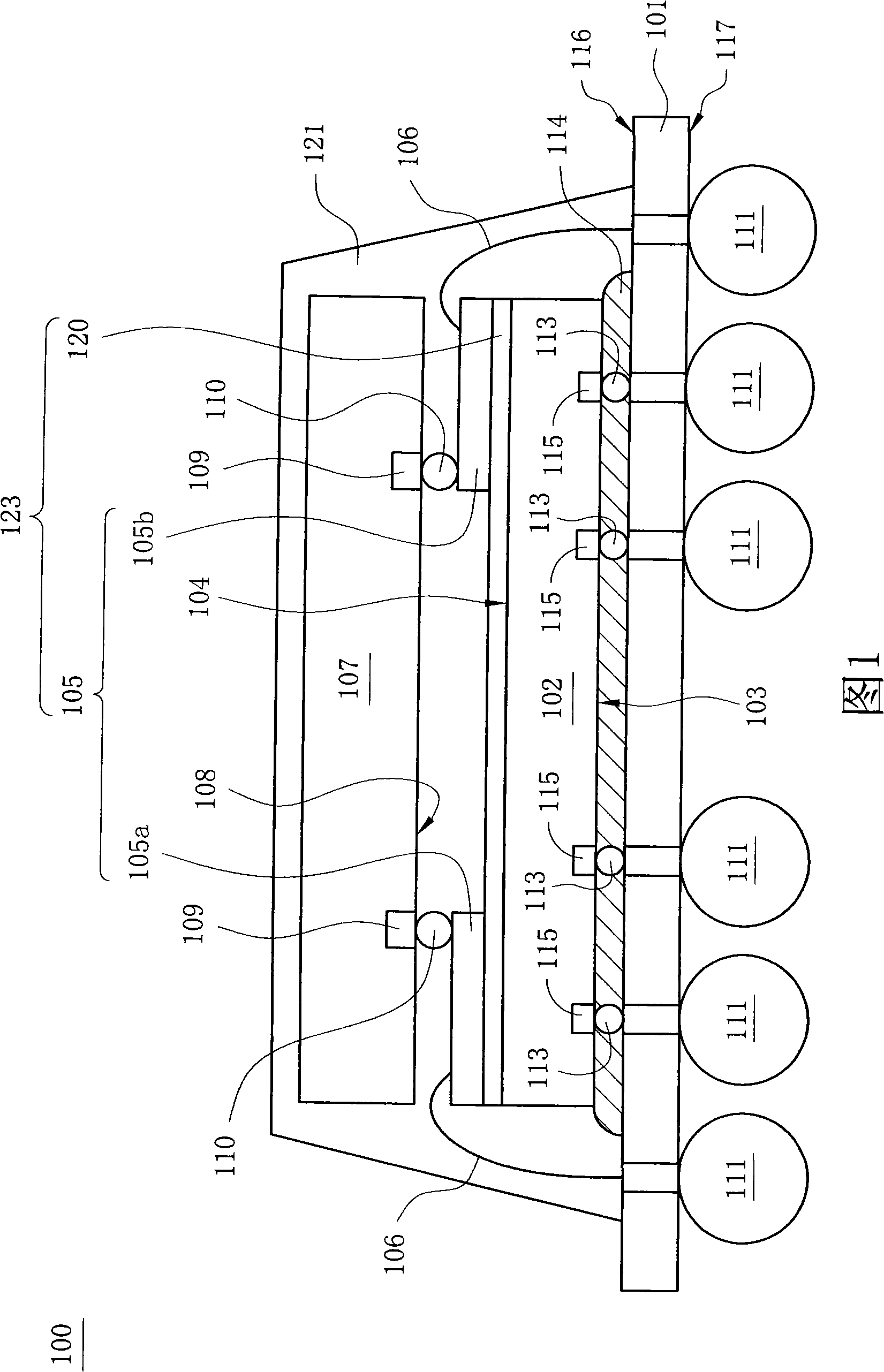

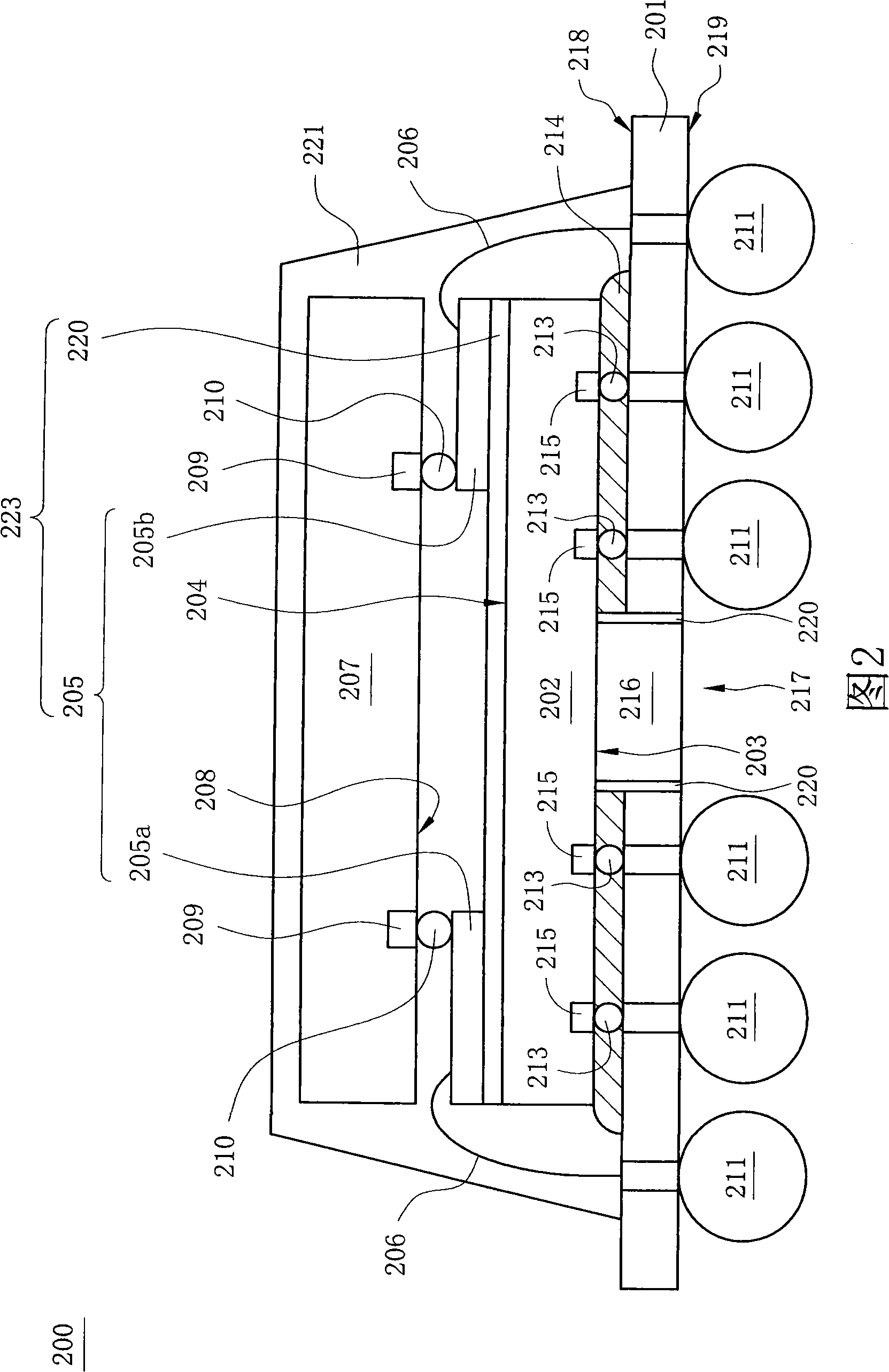

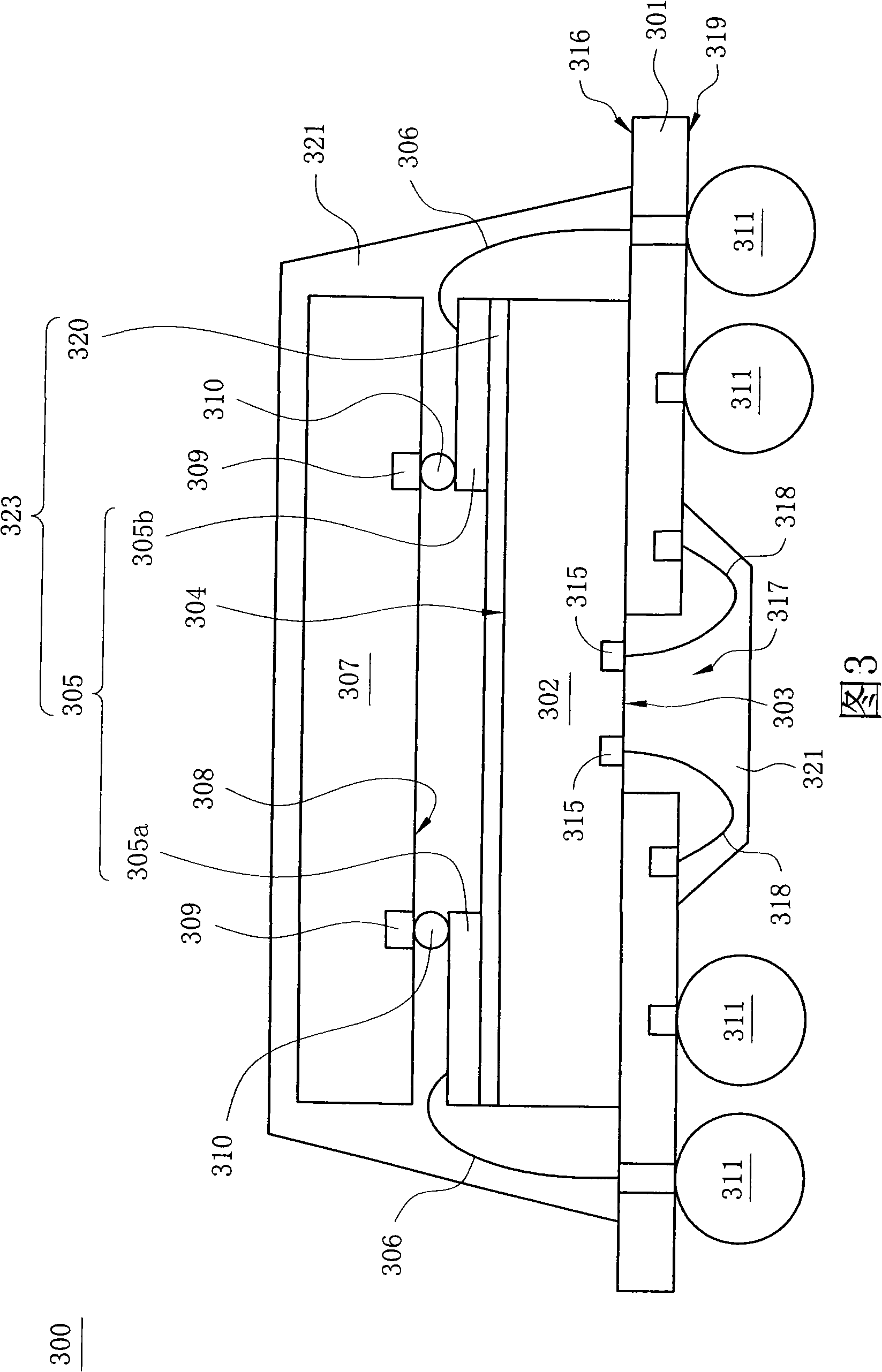

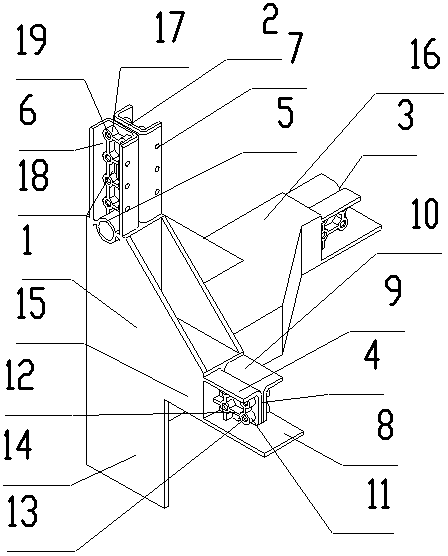

Tape discharging mechanism and tape attaching device

InactiveCN105437725AFix damageAvoid serious wasteLamination ancillary operationsLaminationTectorial membraneAdhesive belt

The invention provides a tape discharging mechanism and a tape attaching device, which belong to the technical field of displays, and can solve the problem that the efficiency is low and the cost is high due to the fact that the tape is manually cut and attached to assemble backlight products in the prior art. The tape discharging mechanism comprises a coil stock tape discharging unit and a protective film stripping unit, wherein the coil stock tape discharging unit comprises a discharge air swelling shaft used for rotationally transporting the coil stock tape; the protective film stripping unit is arranged at the rear opposite to the coil stock tape discharging unit, is used for stripping the protective film from the tape, and transporting the tape. The tape discharging mechanism realizes an automatic discharging and stripping process of the coil stock tape, and the problems of low operation efficiency and high cost due to manual operation are solved. The tape attaching device comprises a manipulator and the tape discharging mechanism, can further complete a process of automatic tape attaching, the efficiency and precision of attaching are further improved, and the cost is reduced.

Owner:BOE OPTICAL SCI & TECH +1

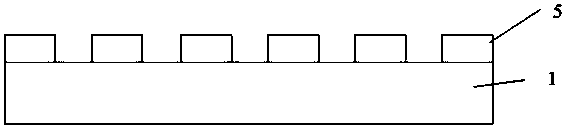

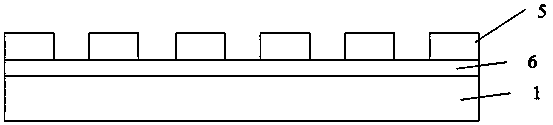

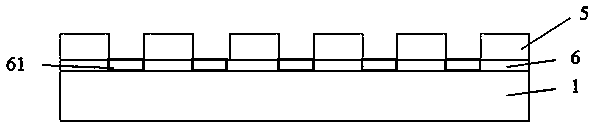

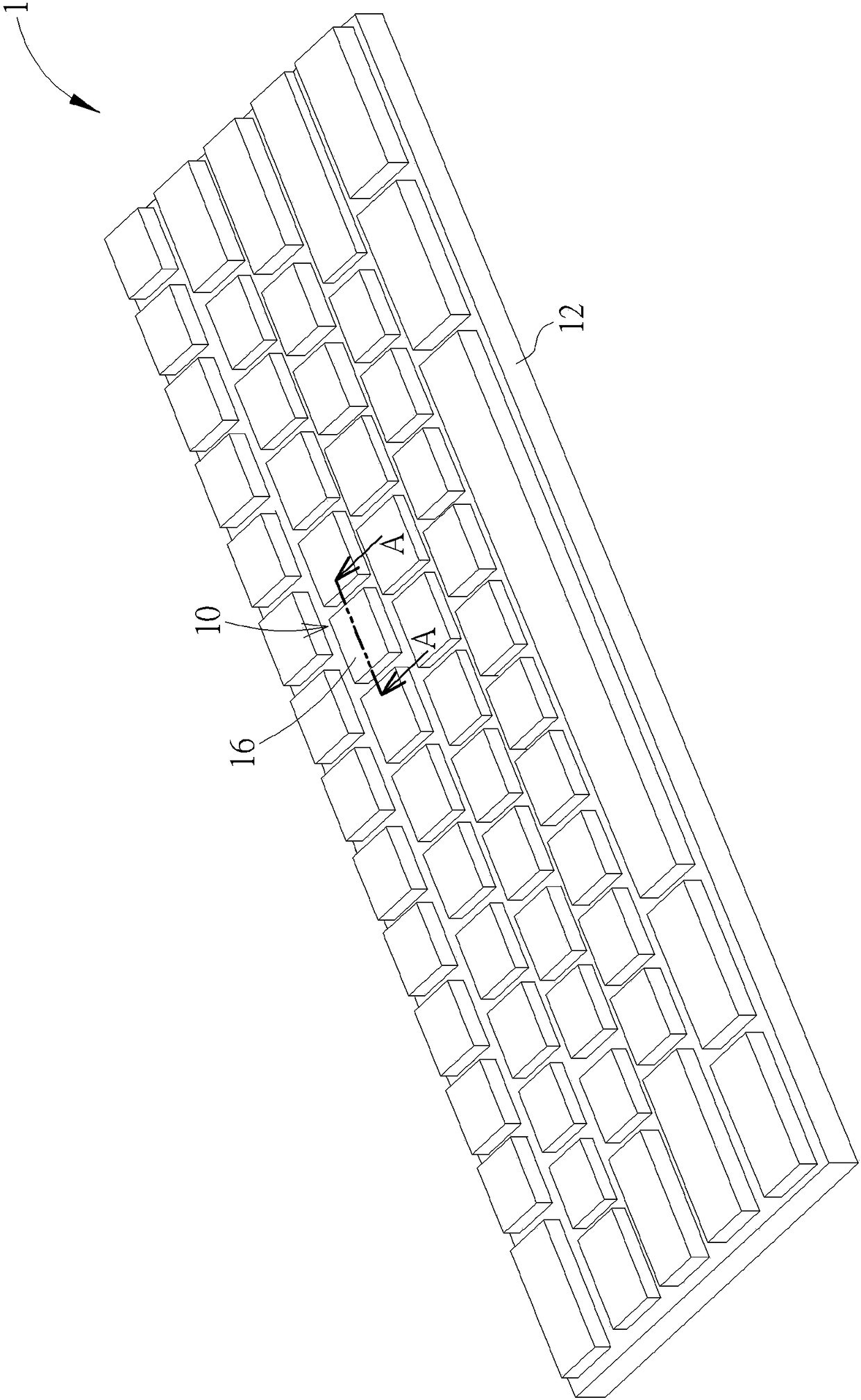

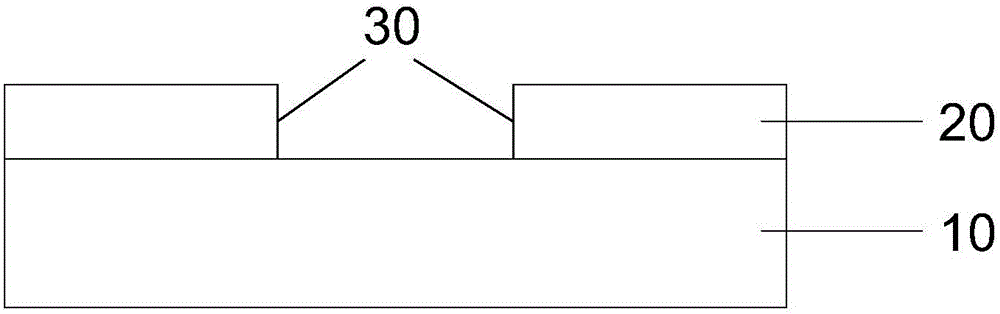

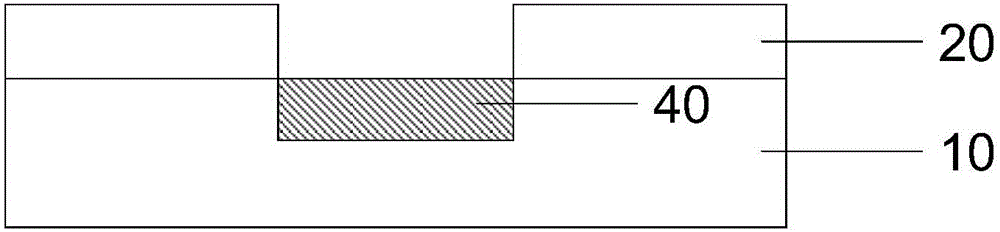

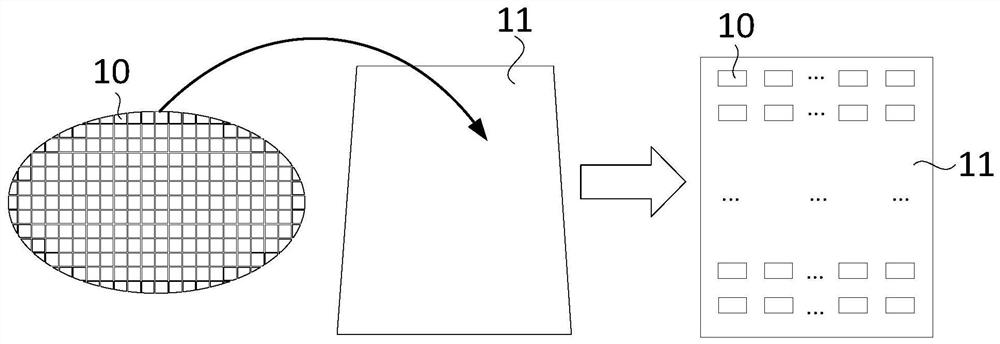

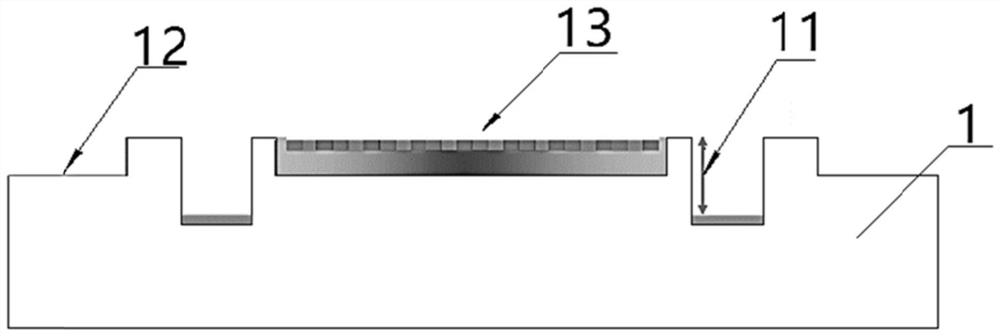

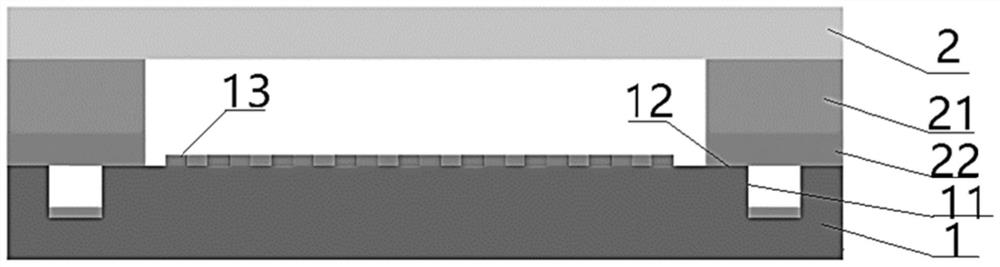

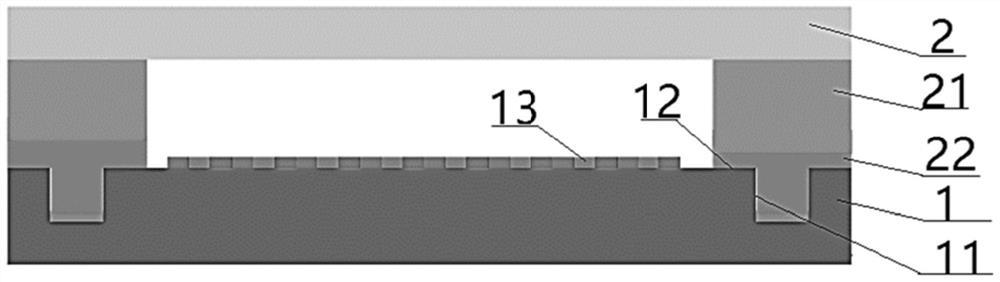

Electrostatic transfer head and manufacturing method thereof

ActiveCN109994417AHigh dielectric constantSolve the lack of suctionSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringDielectric layer

The invention provides an electrostatic transfer head and a manufacturing method thereof and belongs to the technical field of Micro LED massive transfer. The transfer head includes a substrate, a first patterned metal layer and a dielectric layer, wherein the substrate includes a concave portion and a convex portion, the dielectric layer includes a first concave hole corresponding to the concaveportion, and the first metal layer is embedded in the substrate. The transfer head is advantaged in that the metal is embedded in the substrate or a flat layer, problems of rim projection, poor glue distribution uniformity, insufficient absorption due to edge leakage and low process yield rate of a transfer head in the prior art are solved, and different micro elements can be transferred without obstruction while massive transfer is better completed.

Owner:NANJING CEC PANDA LCD TECH

Keycap structure and button

ActiveCN108470655AImprove sexual functionImprove practicalityLegendsElectric switchesFailure rateKey pressing

A keycap structure is combined with an elevating mechanism so as to move between a pressing position and a non-pressing position. The keycap structure comprises a keycap, a first lead circuit, a second lead circuit and a flexible circuit board. The keycap possesses a top surface, a bottom surface and a clamping structure. The top surface and the bottom surface are opposite to each other. The clamping structure is formed through protruding from the bottom surface so as to be clamped and connected to the elevating mechanism. The first lead circuit is arranged on the top surface so as to connectan induction device or display equipment attached to the top surface. The second lead circuit is arranged on the bottom surface, avoids the position of the clamping structure and passes through the keycap so as to connect the first lead circuit. The flexible circuit board is connected to the second lead circuit and carries out electric signal transmission of the induction device or the display equipment via the first lead circuit and the second lead circuit. The problems of the time consuming and labor consuming and the high assembling failure rate of a button assembling process can be effectively solved, the manufacturing yield of a keyboard is improved, and through the additional function of the induction device, the functionality and the practicality of a key are increased.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

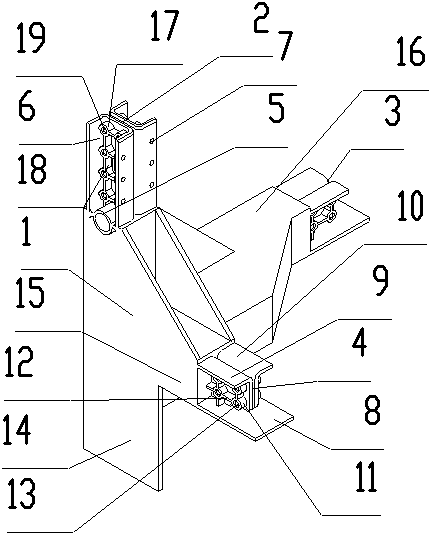

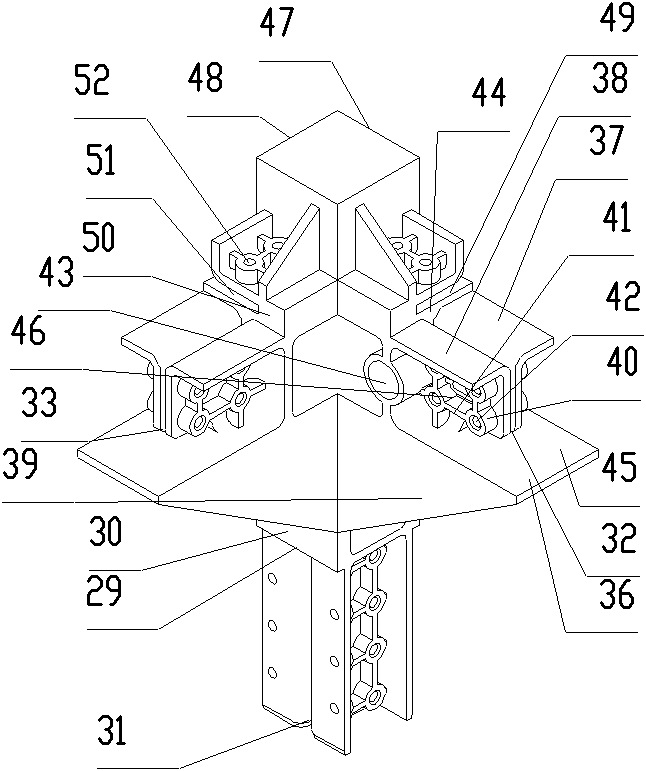

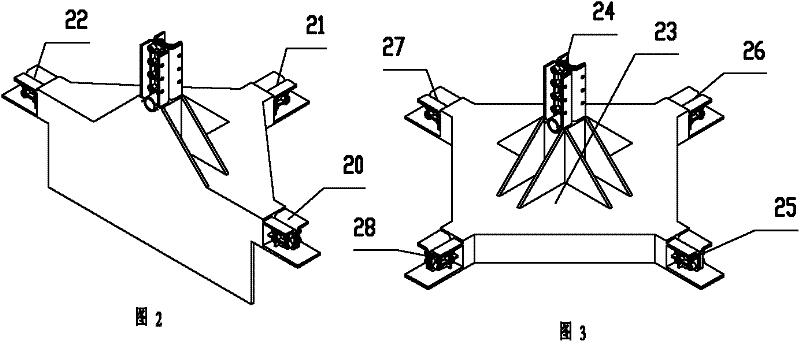

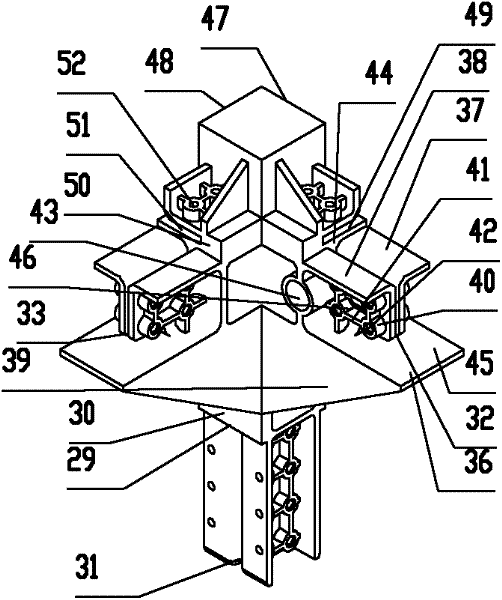

Beam-to-column connectors

InactiveCN102277903AReduce labor intensitySolve pollutionBuilding constructionsRound tableSeismic resistance

The invention discloses a beam and column connecting member which comprises an integrally-formed beam and column connecting member body, upright splicing heads convexly arranged on the beam and column connecting member body along a vertical direction, and a horizontal supporting joint convexly arranged on the beam and column connecting member body along the horizontal direction, wherein each upright splicing head comprises two symmetrical parallel U-shaped blocks vertically and convexly arranged on the beam and column connecting member body and provided with openings towards two sides, round tables are arranged on planes at the bottoms of U-shaped grooves of the U-shaped blocks, reinforcing ribs are connected between the round tables, and threaded through holes are arranged in each round table. The invention has the advantages of greatly reducing fastening connection or welding and the like, and greatly reducing the defects of poor stress and weak connection of connecting positions, caused when stress is excessively concentrated on beams and column or connecting positions among the beams, thereby greatly increasing installing efficiency and seismic resistance function, service life and use safety of a building frame structure. The beam and column connecting member can be massively pre-produced in a standardized manner.

Owner:杨东佐

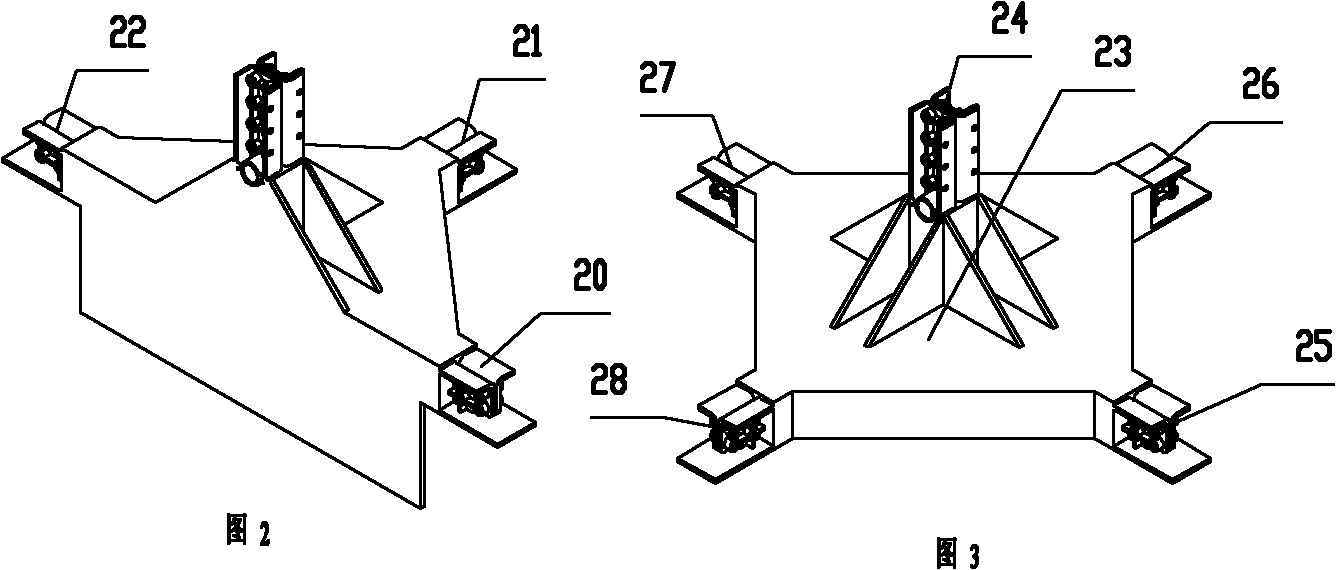

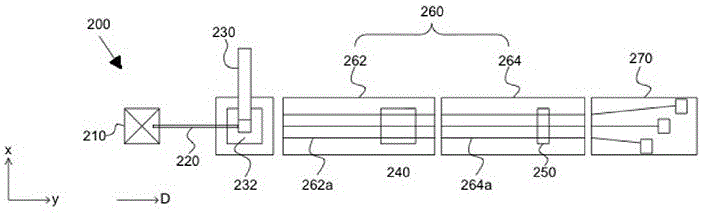

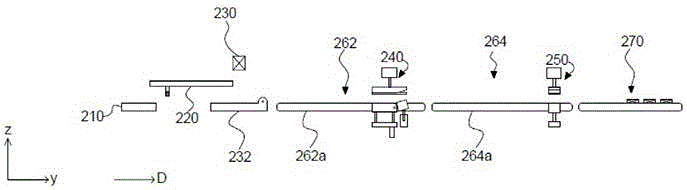

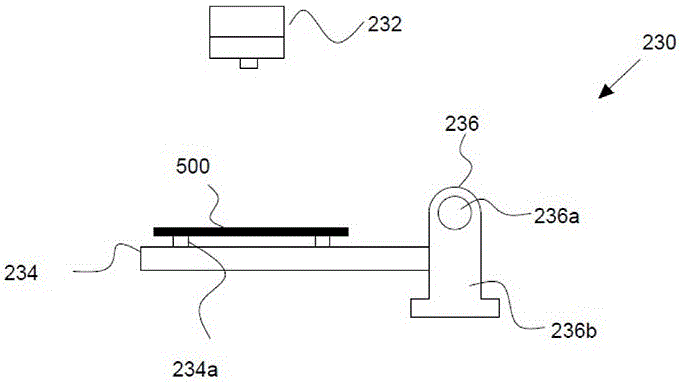

Automatic cutting and separating equipment for photovoltaic cells

ActiveCN106847993AStreamline manpowerReduce labor costsFinal product manufactureSemiconductor/solid-state device manufacturingLong axisEngineering

The invention provides automatic cutting and separating equipment for phtovoltaic cells. The equipment comprises a feeding device, a laser cutting device, a conveying device, a transverse disconnecting device, a longitudinal disconnecting device and a separating device. After the feeding device conveys stacked cells to the fixed position, laser beams generated by the laser cutting device are used for conducting transverse and longitudinal grooving on the cell surfaces. The cells obtained after grooving are conveyed to the transverse disconnecting device through the conveying device. The transverse oblique-folding part of the transverse disconnecting device is provided with a long shaft, selectively unfolded to form a plane and obliquely folded by an angle. The longitudinal disconnecting device comprises at least two longitudinal oblique-folding parts, a rotating shaft is arranged at the junction of the two adjacent longitudinal oblique-folding parts, the axial direction of the rotating shaft is parallel to the conveying direction, at least one longitudinal oblique-abutting part is selectively unfolded to form a plane and obliquely folded to be an angle by taking the rotating shaft as the axis. The separating device is located on the lower side of the longitudinal disconnecting device, the two adjacent conveying belts form an angle, and cell units are completely separated to different storing locations. The automatic cutting and separating equipment eliminates the phenomenon that a large amount of manual work is adopted in the process in the prior art, full automatic equipment is adopted, the labor cost is greatly lowered, and meanwhile the yield can be increased, and the production efficiency is improved.

Owner:OPES SOLUTIONS (CHANGZHOU) CO LTD FACTORY

Chip stack packaging structure and method of producing the same

InactiveCN101315920ASolve the yield problemSolve densitySemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

The invention provides a chip stack packaging structure and a manufacturing method thereof, the packaging structure comprises: a substrate, a first chip, a circuit substrate and a second chip, wherein, the substrate is provided with a first surface and an opposite second surface, the first chip is positioned at the first surface of the substrate, provided with a first driving surface and an opposite first wafer backside, and electrically connected with the substrate by the flip chip packaging bonding mode. The circuit substrate is formed on the first wafer backside, comprising a dielectric layer which is arranged on the first wafer backside and a patterned circuit layer which is formed on the dielectric layer, and the patterned circuit layer is electrically connected with the substrate by a wire bond. The second chip is positioned on the patterned circuit layer, comprising a second driving surface and at least one second welding pad which is arranged on the second driving surface, wherein, the welding pad is electrically connected with the patterned circuit layer and further electrically connected with the substrate by the wire bond.

Owner:CHIPMOS TECH INC

Connecting element for building framework structures

InactiveCN102330472AReduce labor intensitySolve pollutionBuilding constructionsStress concentrationEarthquake resistance

The invention relates to a connecting element for building framework structures, which comprises an integrally formed connecting element body and a plug head convexly arranged on the connecting element body, wherein the plug head comprises two symmetrical side-by-side U-shaped convex parts convexly arranged on the connecting element body, openings of the U-shaped convex parts are opposite, and the distance between corresponding surfaces of the two position limiting convex parts is matched with the vertical part of H-shaped steel or I-shaped steel with the end part being processed into a T shape. The connecting element for the building framework structures has the advantages that the fastening connection or the welding and the like are greatly reduced, and the defects of poor stress and weak connection of connecting positions caused by excessive stress concentration in the connecting positions between beams and columns or between beams are greatly reduced, so the installation efficiency, the earthquake resistance function and the use safety of the building framework structures are greatly improved, the service lives of the building framework structures are greatly prolonged, and beam and column connecting elements can be produced in a standardized mass production way in advance.

Owner:杨东佐

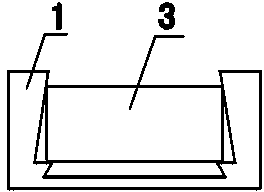

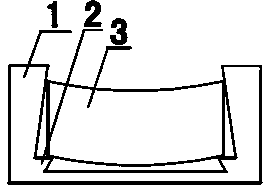

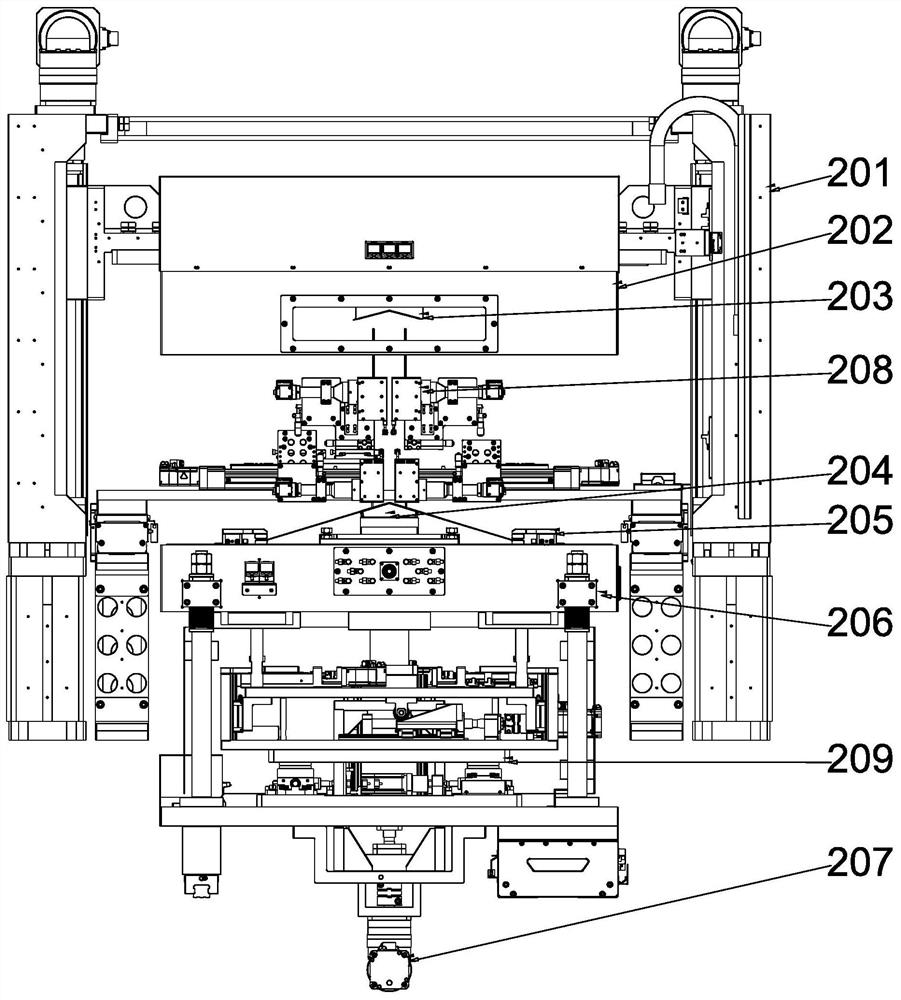

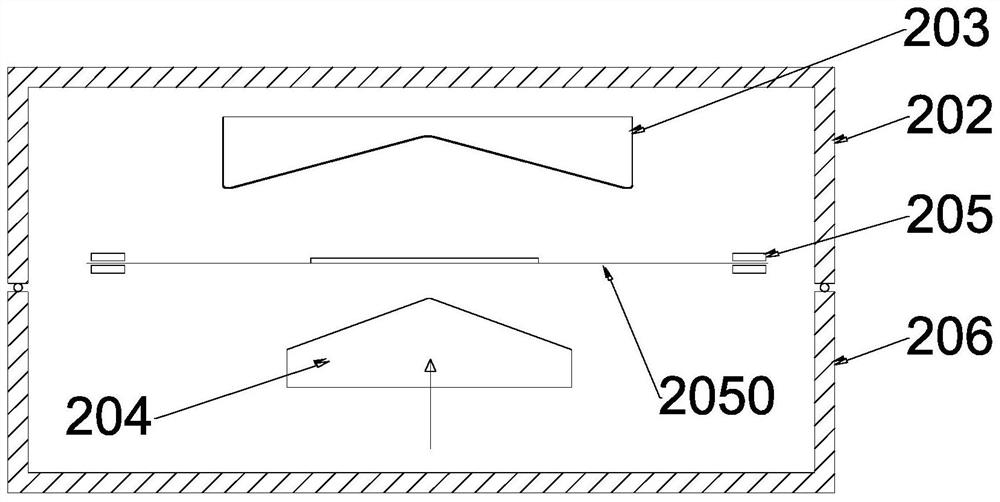

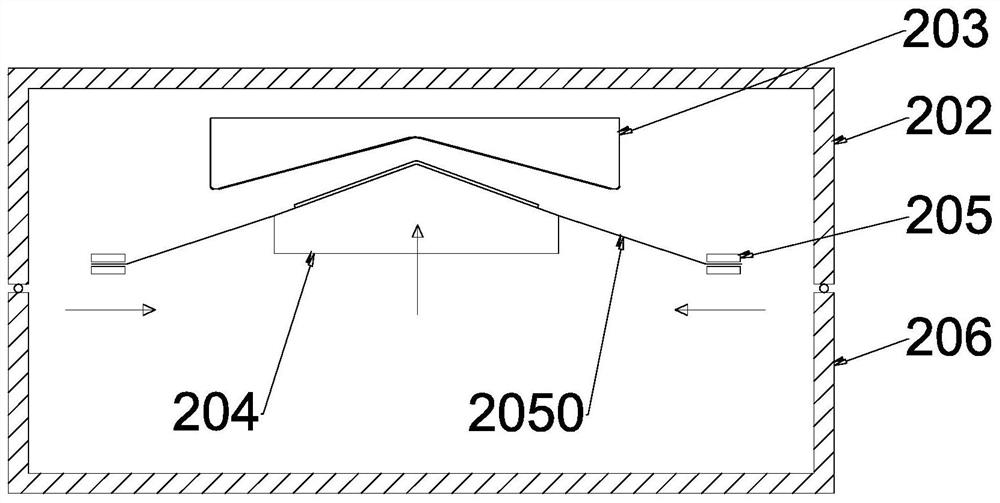

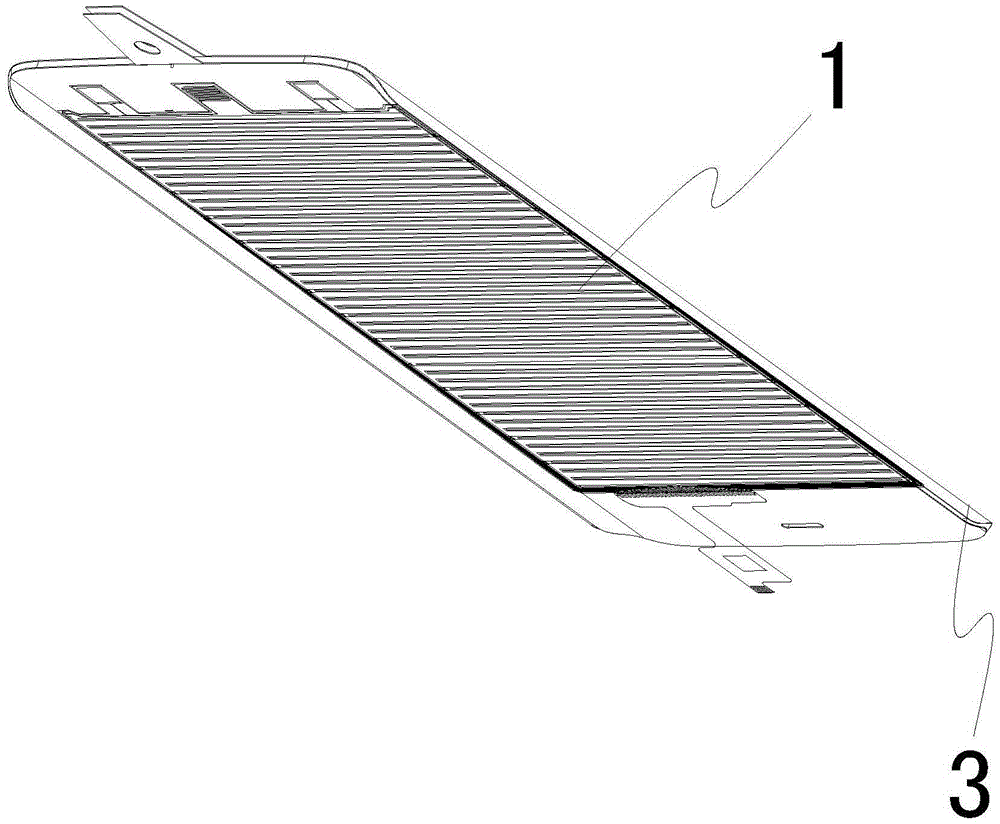

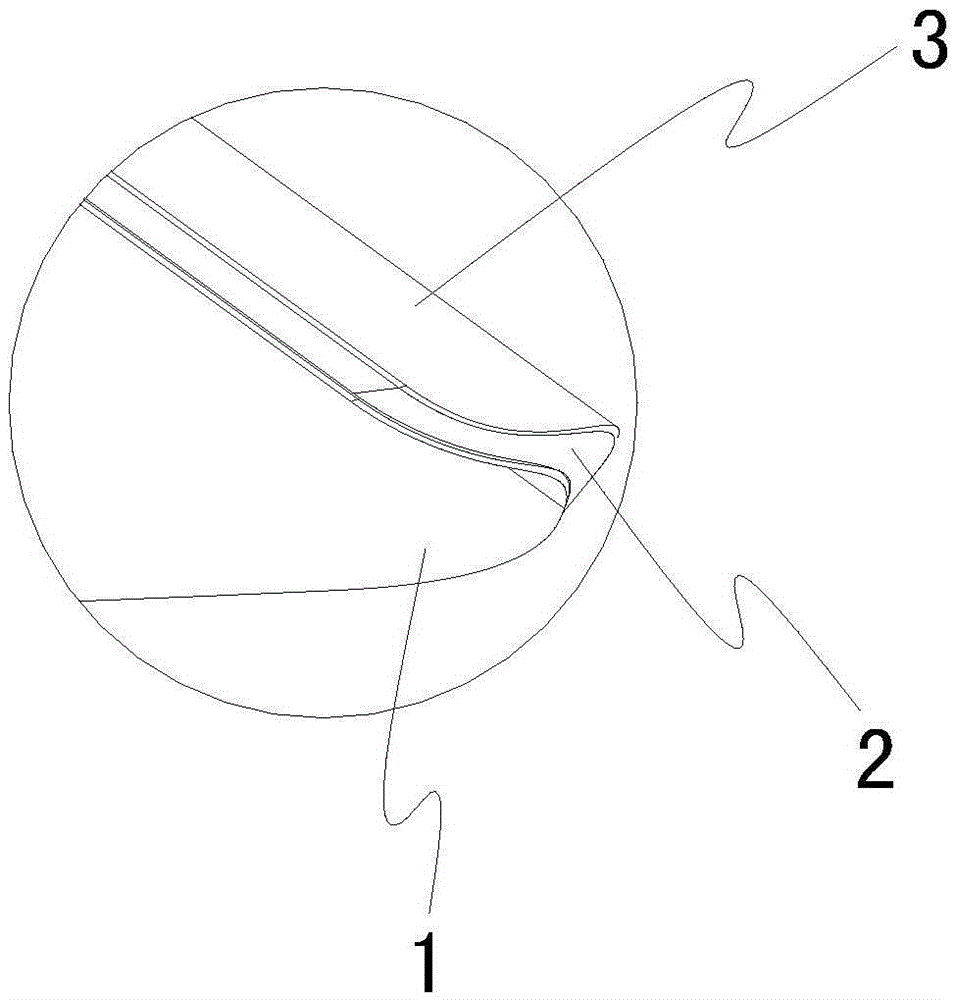

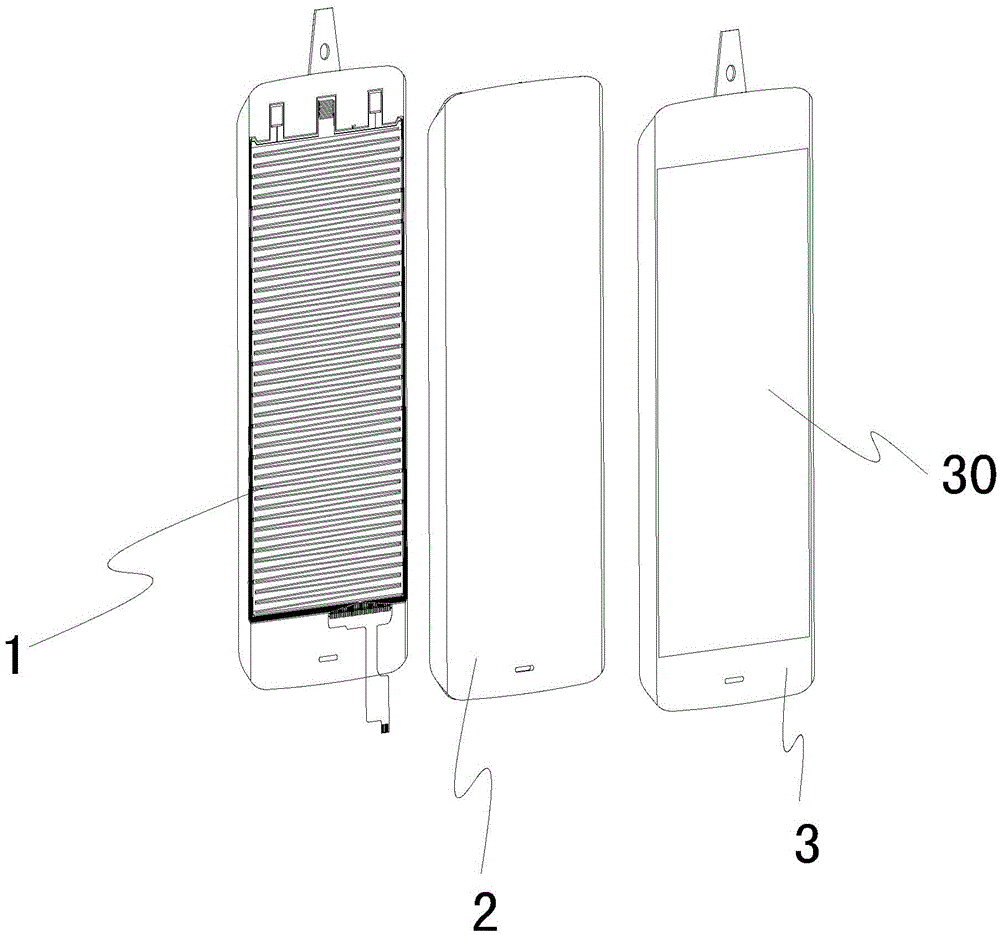

V-shaped vacuum laminating device

PendingCN112874118ASolve the yield problemSolve the problem of longevityLaminationLamination apparatusEngineeringMechanical engineering

The invention discloses a V-shaped vacuum laminating device. The device comprises an upper laminating mechanism comprising an upper cavity, an upper cavity lifting Z shaft for driving the upper cavity to lift, and a V-shaped electrostatic adsorption platform arranged in the upper cavity and used for adsorbing a material A, and a lower laminating mechanism comprising a lower cavity in butt joint with the lower portion of the upper cavity, a bearing film arranged in the lower cavity and used for adsorbing a material B, a bearing film clamping assembly clamping the two sides of the bearing film and straightening the bearing film, a profiling PAD arranged below the bearing film and in butt joint with the V-shaped electrostatic adsorption platform, and a PAD lifting Z shaft used for driving the profiling PAD to ascend and descend so as to jack up a material B on the bearing film to be close to a material A attached to the V-shaped electrostatic adsorption platform; and the centers of the V-shaped electrostatic adsorption platform, the profiling PAD, the material A and the material B are located on a same straight line. According to the invention, the folding screen is attached in a V-shaped folding state, so that the problems of product attachment yield, folding life and the like can be effectively solved.

Owner:深圳市九天中创自动化设备有限公司

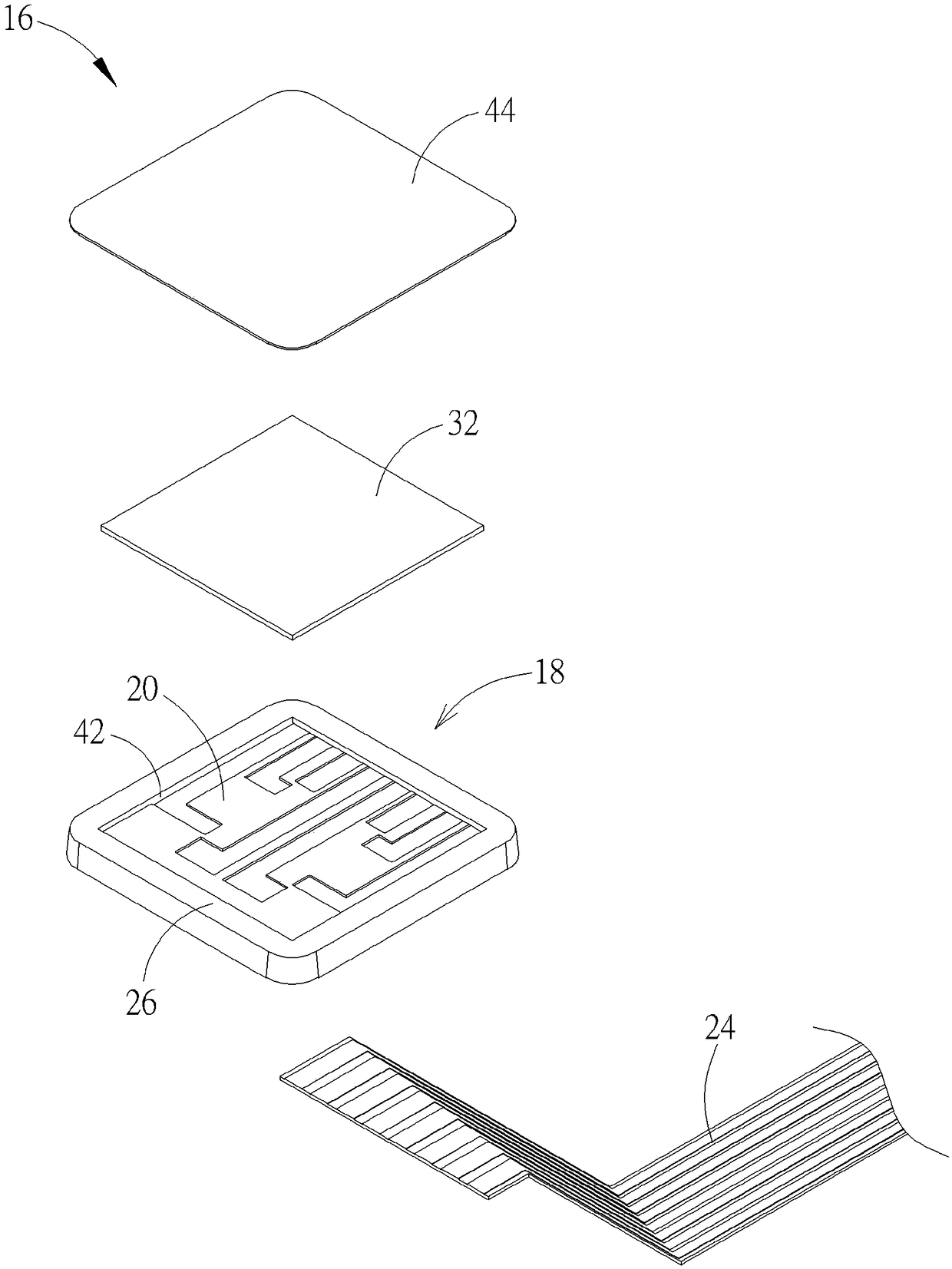

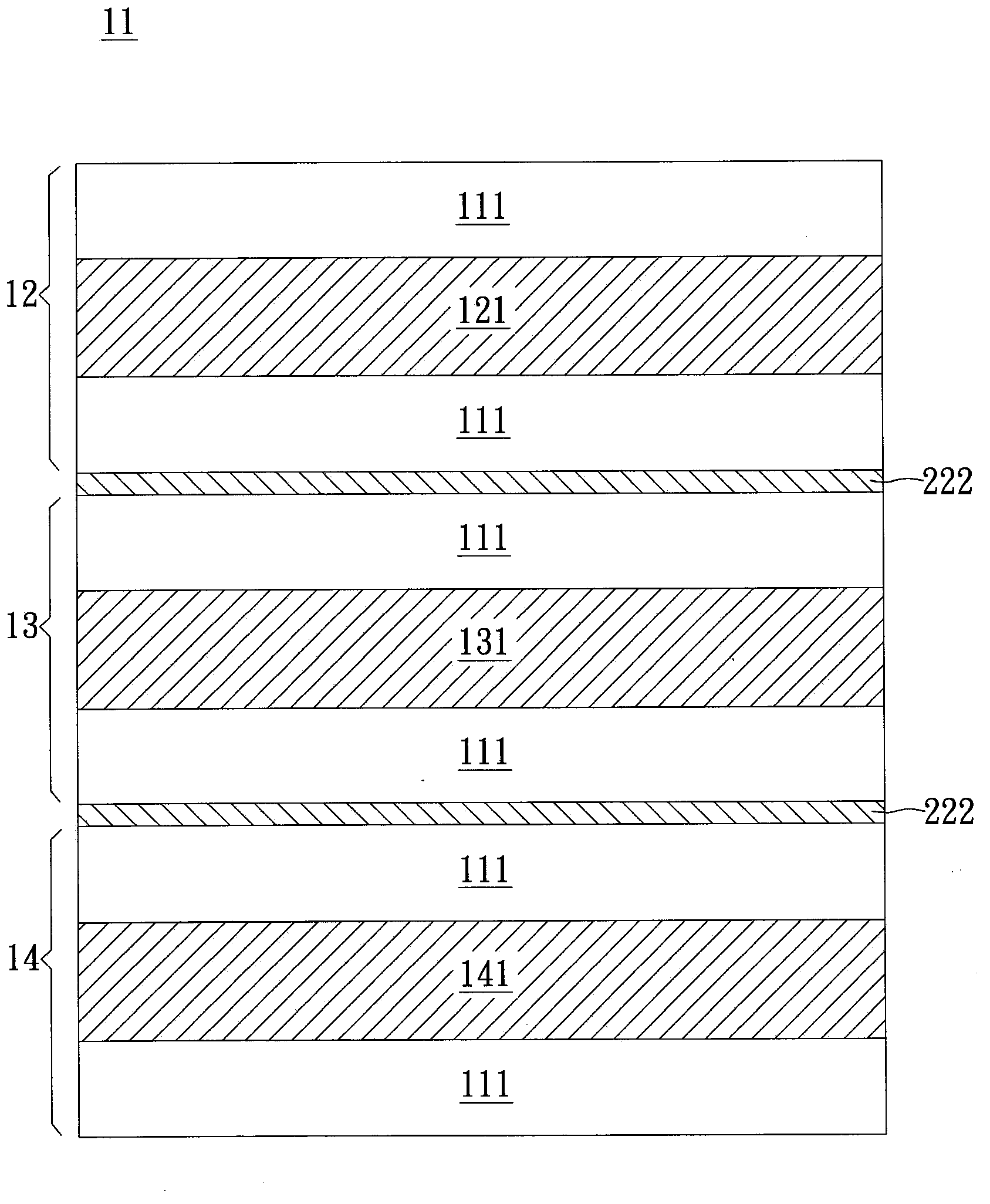

Touch control type stereoscopic image control module and touch control type stereo display device

InactiveCN103529975AReduce in quantityReduce usageNon-linear opticsInput/output processes for data processingGratingComputer module

A stereoscopic image control module that can be disposed on a display module to form a stereoscopic image display module is provided. The stereoscopic image control module includes a first substrate, a touch composite layer, and a grating composite layer. The first substrate has a first surface and a second surface opposite to the first surface, and the touch composite layer is disposed on at least one of the first surface and the second surface and includes a plurality of touch electrodes. The grating composite layer is disposed on the second surface and includes a plurality of grating control electrodes and a grating layer, wherein the grating control electrodes change a polarity of the grating layer to determine a display mode.

Owner:HANNSTAR DISPLAY CORPORATION

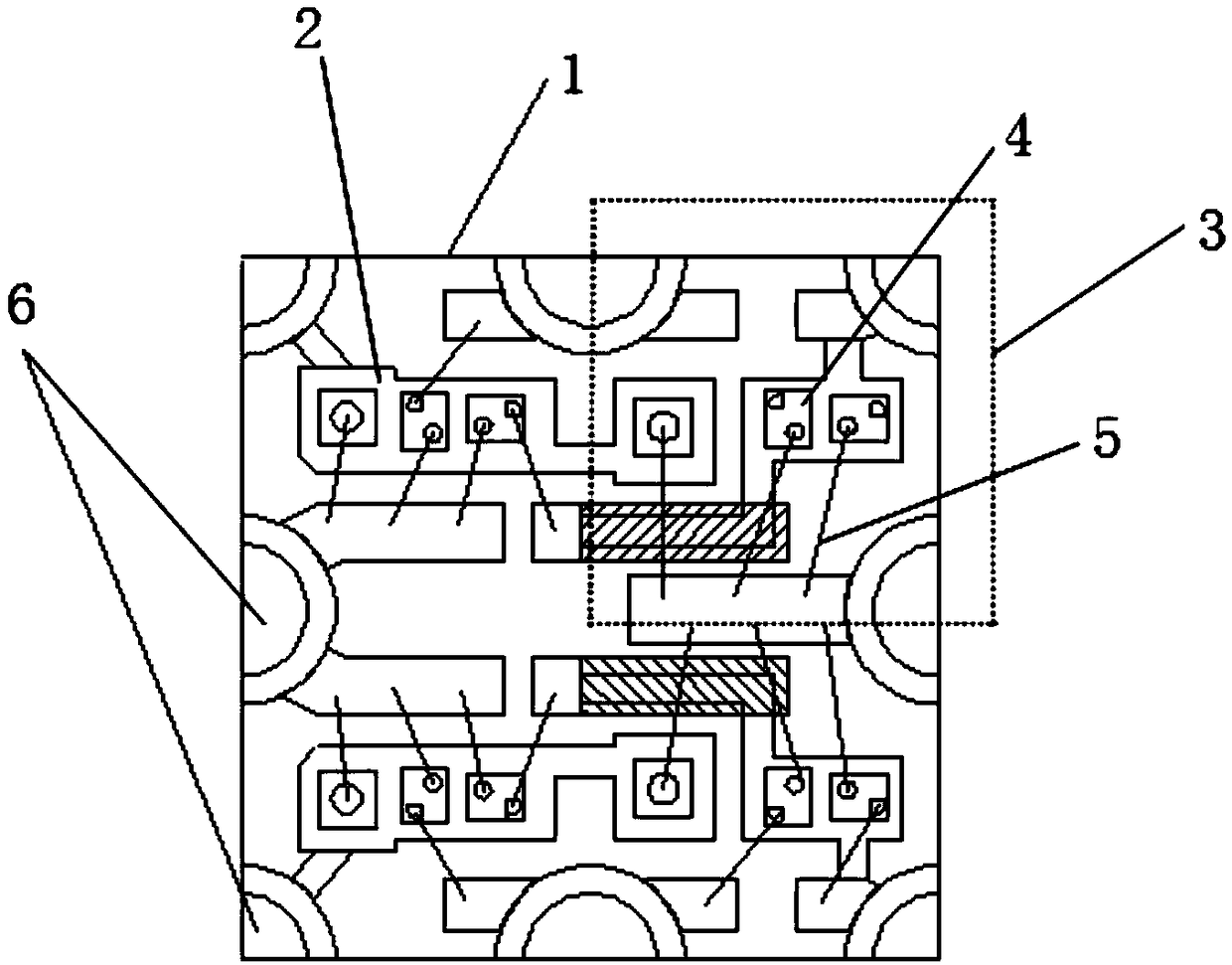

Chip structure and circuit structure

ActiveCN103531552ASolve the cooling problemSolve the yield problemCross-talk/noise/interference reductionSemiconductor/solid-state device detailsCapacitanceEngineering

The invention provides a chip structure and a circuit structure. The chip structure is arranged on a printed circuit board provided with a part layer and a copper foil ground layer, and comprises a chip main body, a power supply line, power supply input lines and bypass capacitors, wherein the chip main body is arranged on the part layer and comprises a plurality of power supply pins; the power supply line is arranged on the part layer and used for supplying power to the chip main body; main bodies of the power supply input lines are arranged on the copper foil ground layer; two ends of the power supply input lines are arranged on the part layer; the main bodies of the power supply input lines are connected with the two ends of the power supply input lines by through holes in the printed circuit board; one end of each bypass capacitor is connected with the power supply pins of the chip main body by the part layer; and the other end of each bypass capacitor is connected with the power supply line by the power supply input lines. The invention further provides the circuit structure. The power supply line of the chip structure and a power supply line of the circuit structure are arranged on the part layer, so that a heat-dissipation effect of the copper foil ground layer is good, and production yields of a corresponding chip and a corresponding circuit are high.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

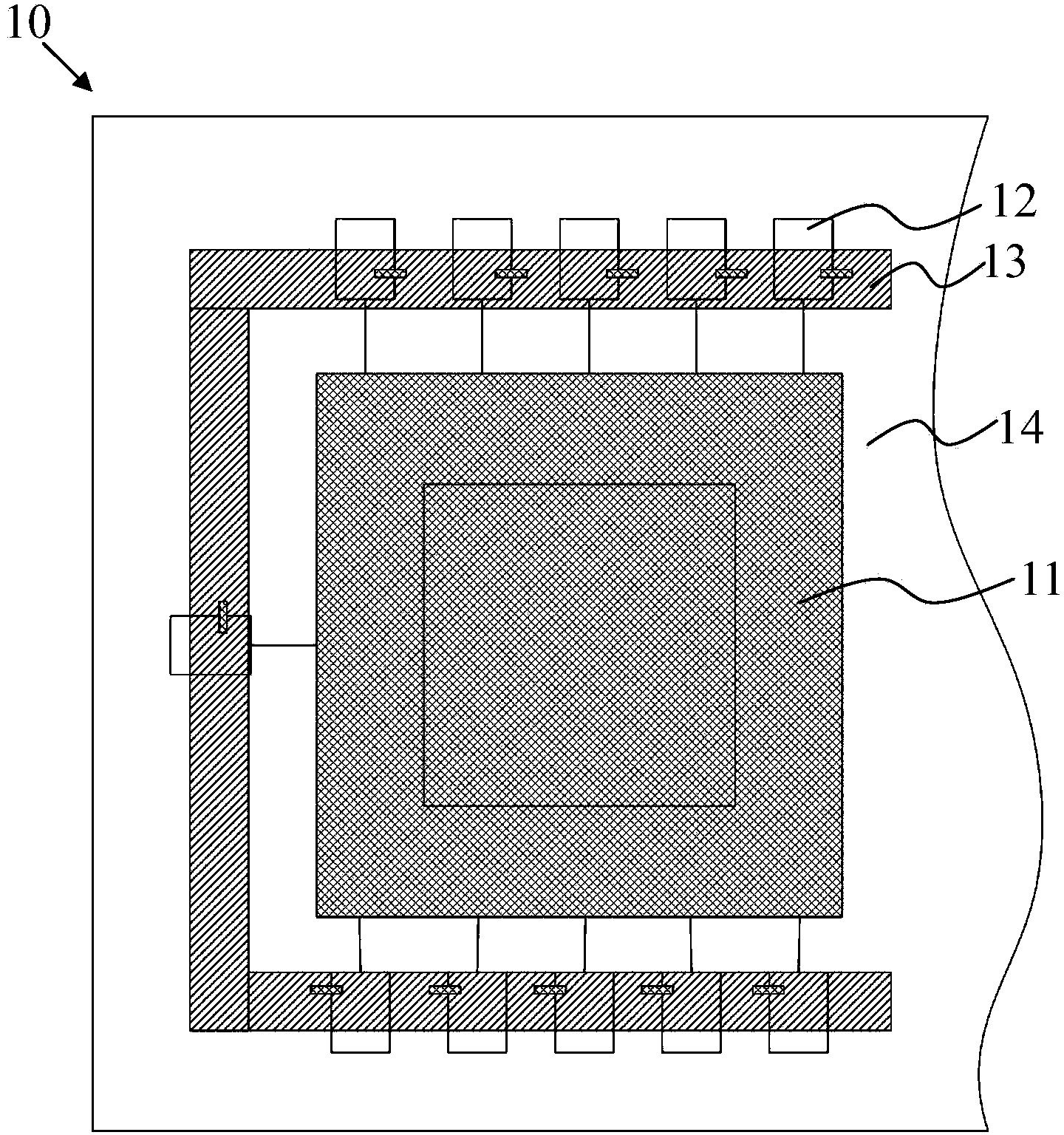

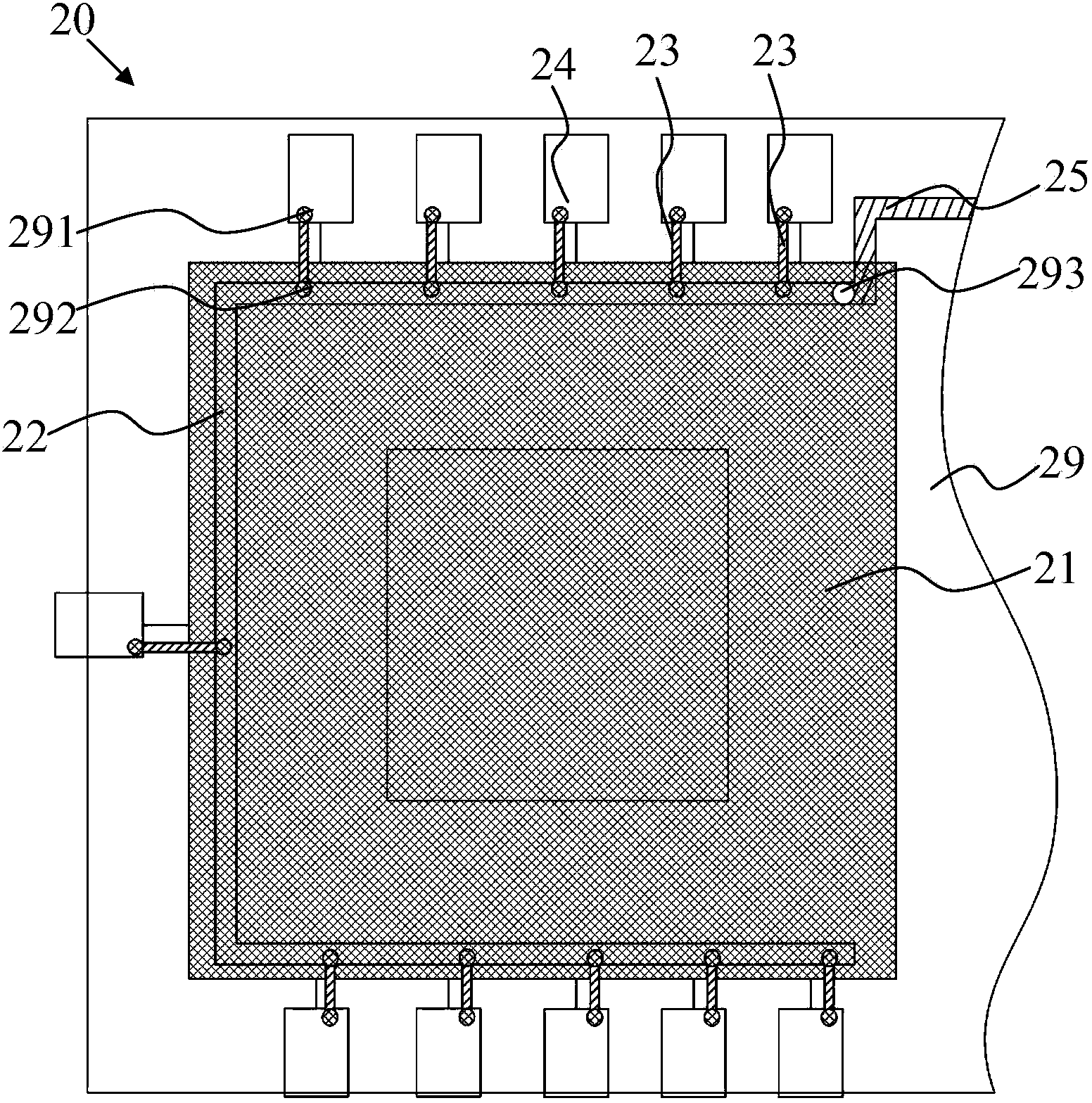

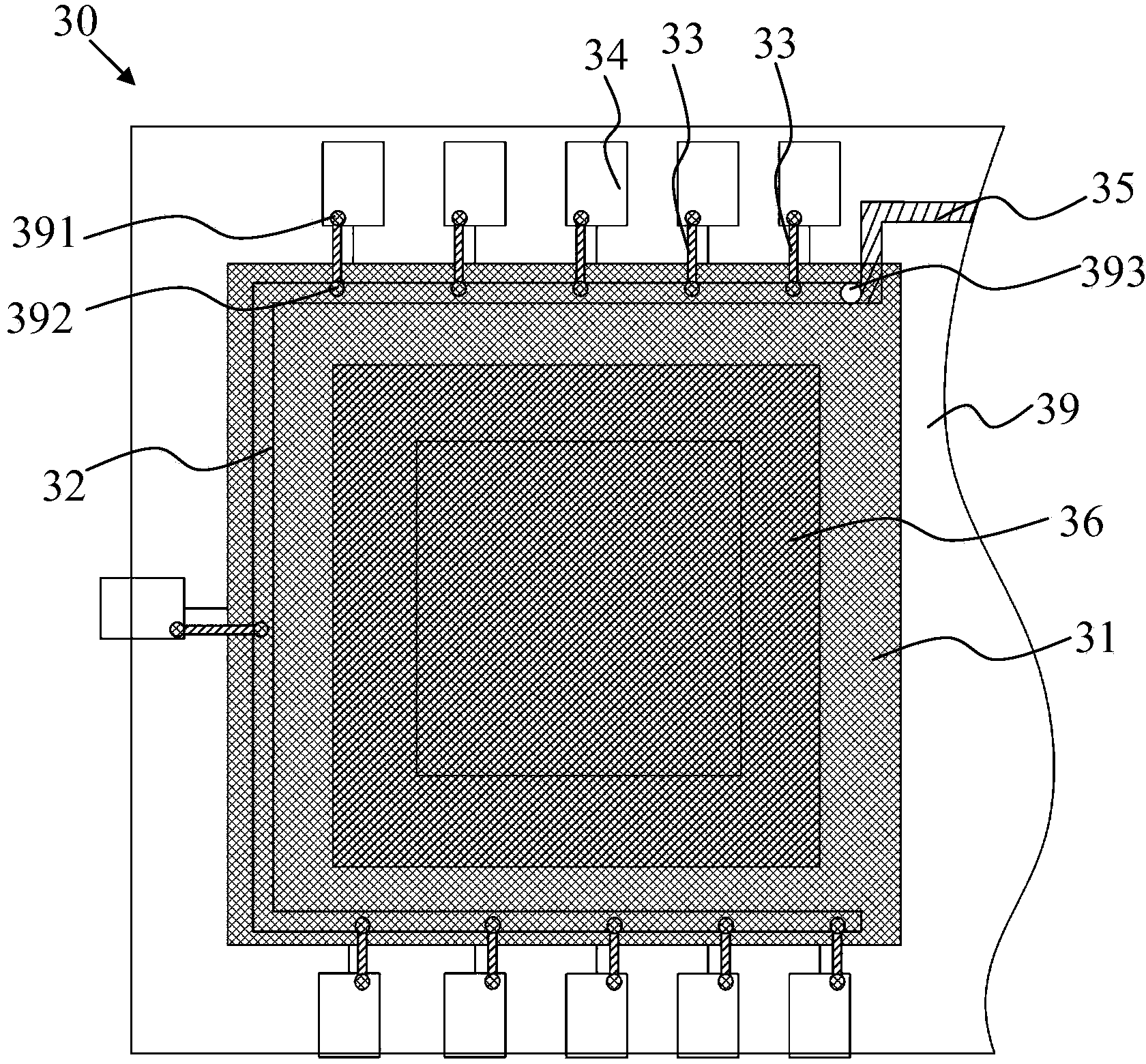

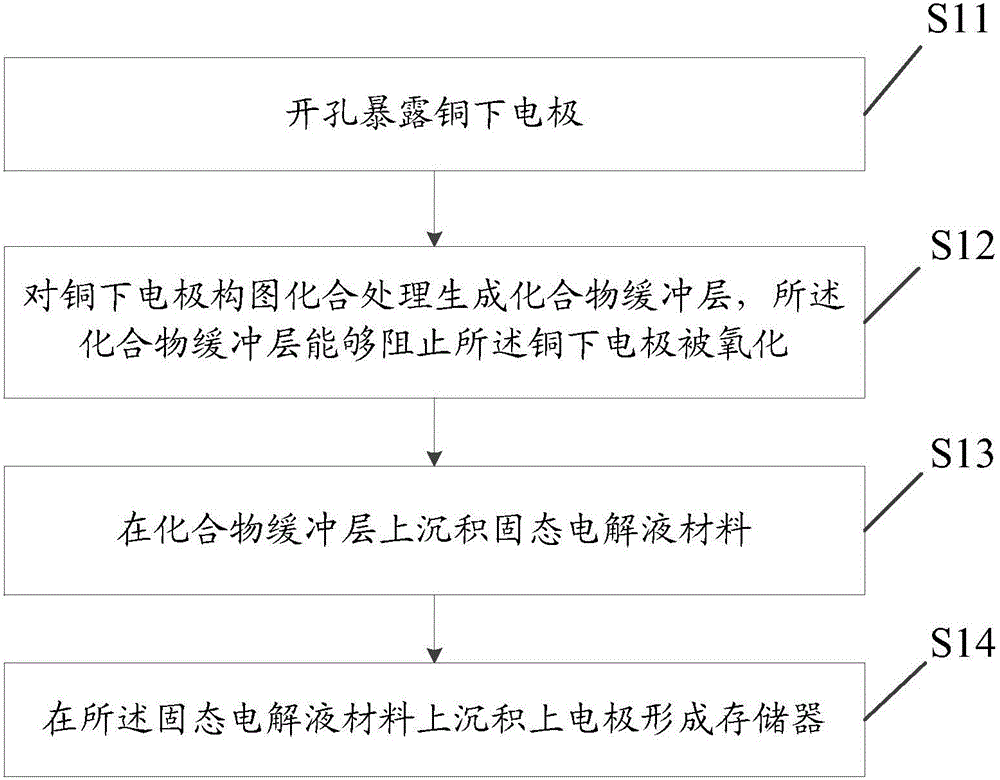

Cu-based resistive random access memory manufacturing method and memory

ActiveCN105789439ASolve the problem of low device reliability and yieldImprove yield and reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingElectrode interfaceOptoelectronics

The invention discloses a Cu-based resistive random access memory manufacturing method and a memory. The manufacturing method comprises steps: combination processing is carried out on the composition of a Cu lower electrode to generate a compound buffer layer, wherein the compound buffer layer can prevent the Cu lower electrode from being oxidized; a solid electrolyte material is deposited on the compound buffer layer; and an upper electrode is deposited on the solid electrolyte material to form a memory. In the technical scheme of the invention, through inserting the compound buffer layer capable of preventing the Cu lower electrode from being oxidized between the Cu lower electrode and the solid electrolyte material, the Cu lower electrode can be effectively prevented from being oxidized during growth of the solid electrolyte material, and an electrode interface does not become rough due to oxidation, and thus, the technical problems of low device reliability and low yield of the Cu-based resistive random access memory caused as the electrode interface is rough in the prior art can be solved, and the reliability and the yield of the device are further improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Packaging structure of high-density display light source device of LED

InactiveCN108091644ARealize ultra-dense display functionSolve efficiency problemsSolid-state devicesIdentification meansStructural reliabilityHigh density

The invention discloses a packaging structure of a high-density display light source device of an LED. The packaging structure is composed of a substrate, a circuit arranged on the substrate and a packaging adhesive. The circuit includes a front-side circuit part arranged at the front side of the substrate and a back circuit part arranged at the back of the substrate. Conduction holes for connecting the front-side circuit part and the back circuit part are formed in the substrate; the walls of the conduction holes are plated with conductive materials; the conduction holes are filled with conductive materials or non-conductive materials. The front-side circuit part includes at least two light-emitting units; a light-emitting chip is arranged in each light-emitting unit; and the light-emitting chips and the substrate are in conduction through bonding wires. The disclosed packaging structure has advantages of high reliability and low cost; and the high-density display function with the pixel interval of 0.5 to 1.3mm can be realized.

Owner:SHENZHEN JINGTAI

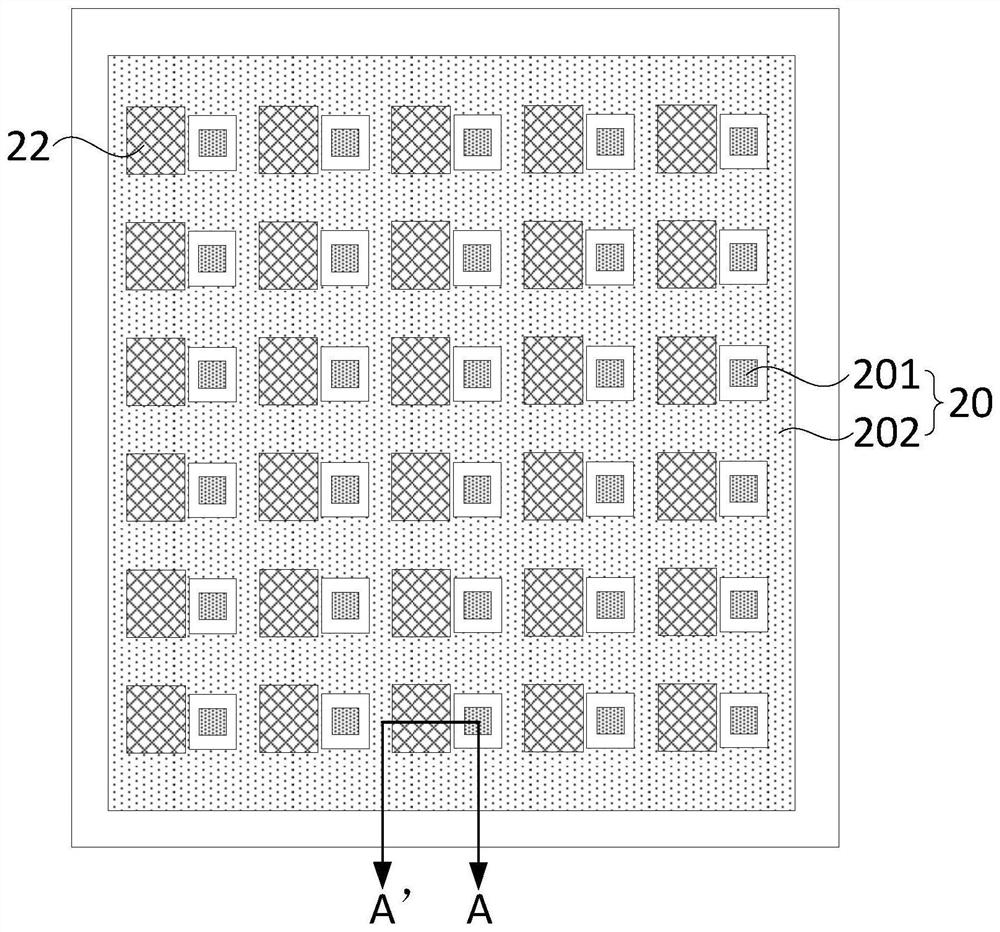

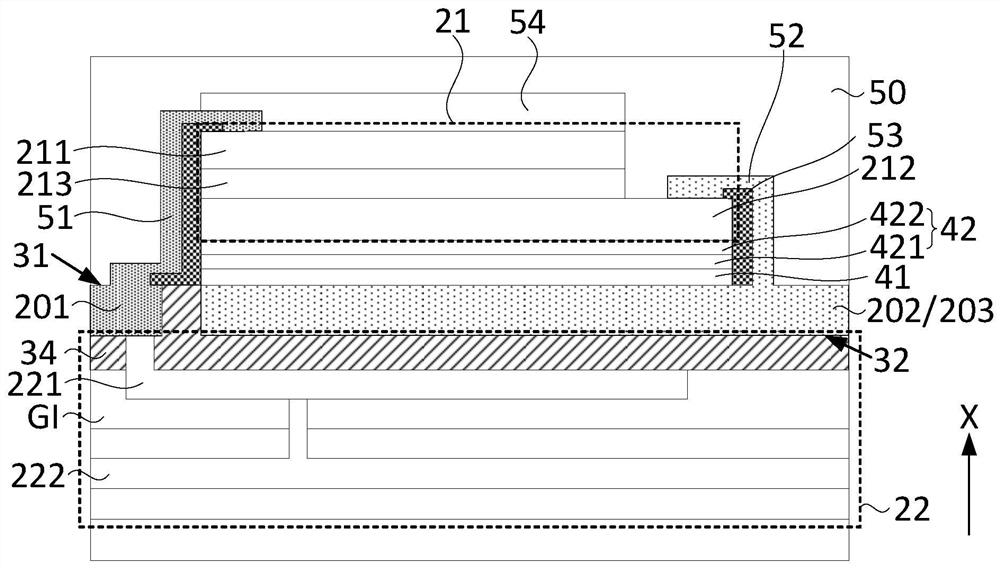

Light emitting diode display panel, preparation method thereof and display device

ActiveCN112447785AIncrease the number of pixelsSimple preparation processSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLight-emitting diode

The invention discloses a light emitting diode display panel, a preparation method thereof and a display device. The light emitting diode display panel comprises a metal substrate, a plurality of inorganic light-emitting diodes located on the first side of the metal substrate and a plurality of driving units located on the second side of the metal substrate, and the first side and the second sideare oppositely arranged. The inorganic light emitting diode comprises a first semiconductor layer and a second semiconductor layer, the metal substrate at least comprises a first electrode part and asecond electrode part which are insulated from each other, the first electrode part is electrically connected with the first semiconductor layer, and the second electrode part is electrically connected with the second semiconductor layer; the driving unit is electrically connected with the first electrode part, or the driving unit is electrically connected with the second electrode part. Accordingto the light emitting diode display panel, the preparation method thereof and the display device, inorganic light-emitting diodes prepared on other native substrates do not need to be transferred through a huge transfer technology, and the problems of low efficiency and yield caused by the adoption of the huge transfer technology in the prior art are solved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

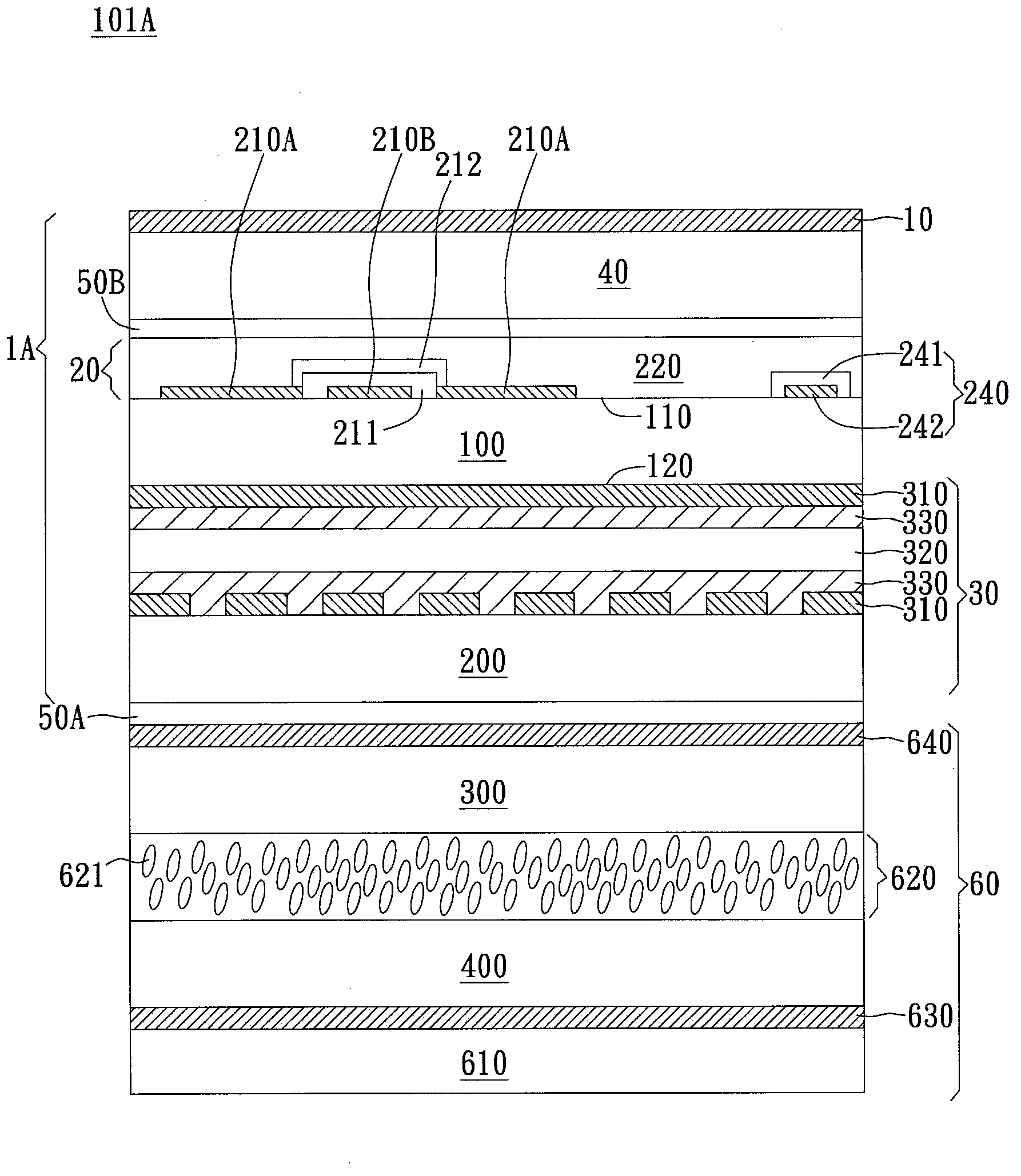

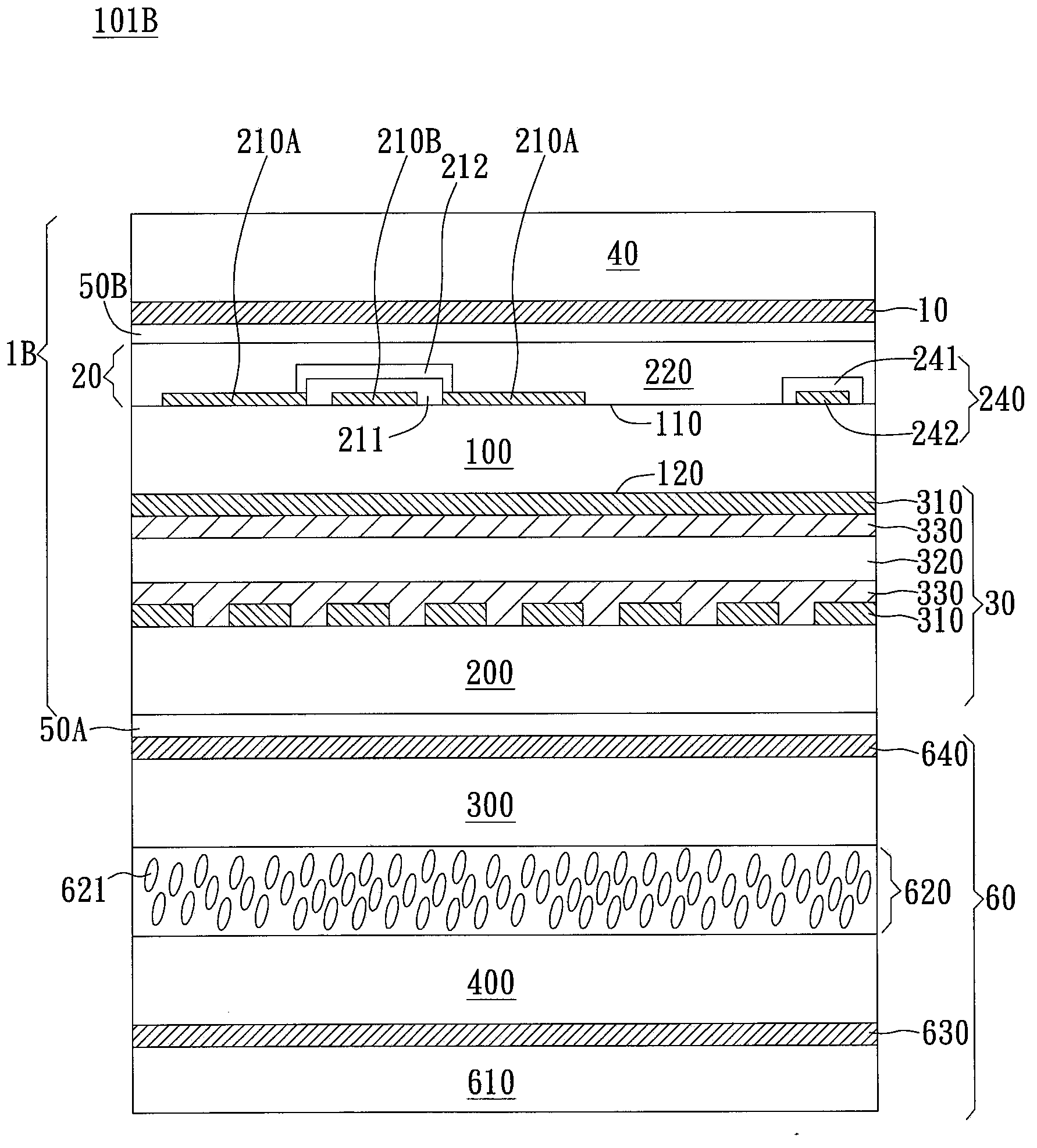

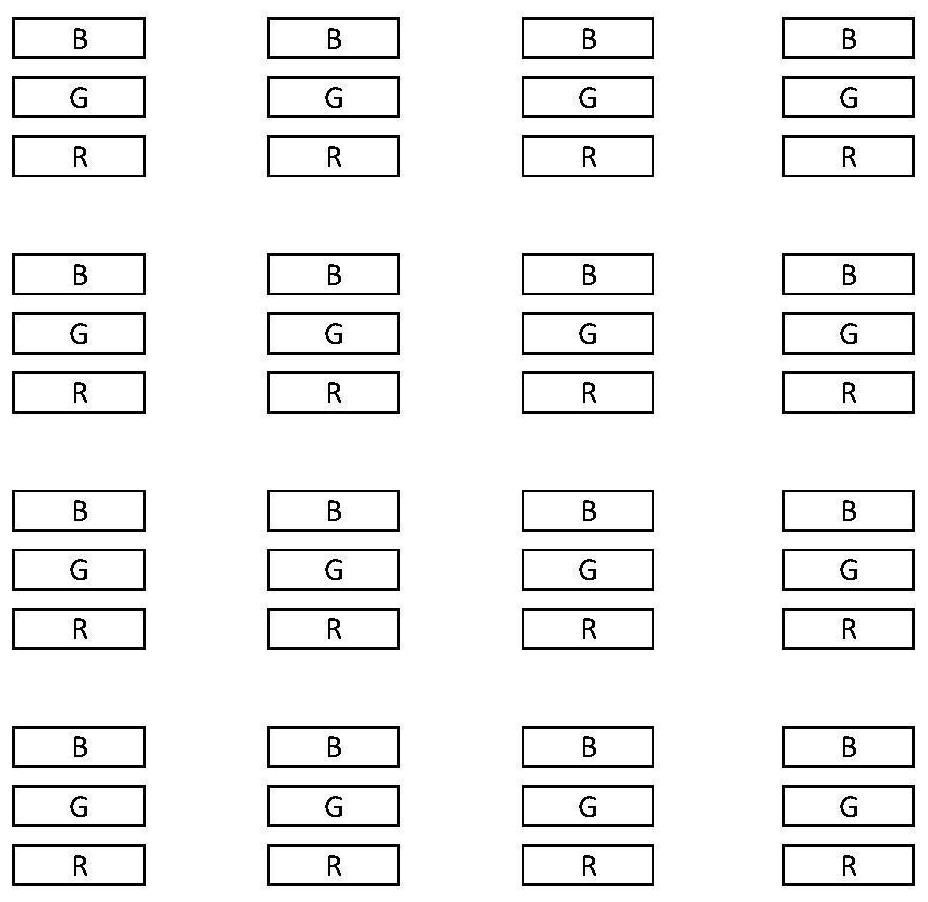

Display module and manufacturing method and driving method thereof, and display device

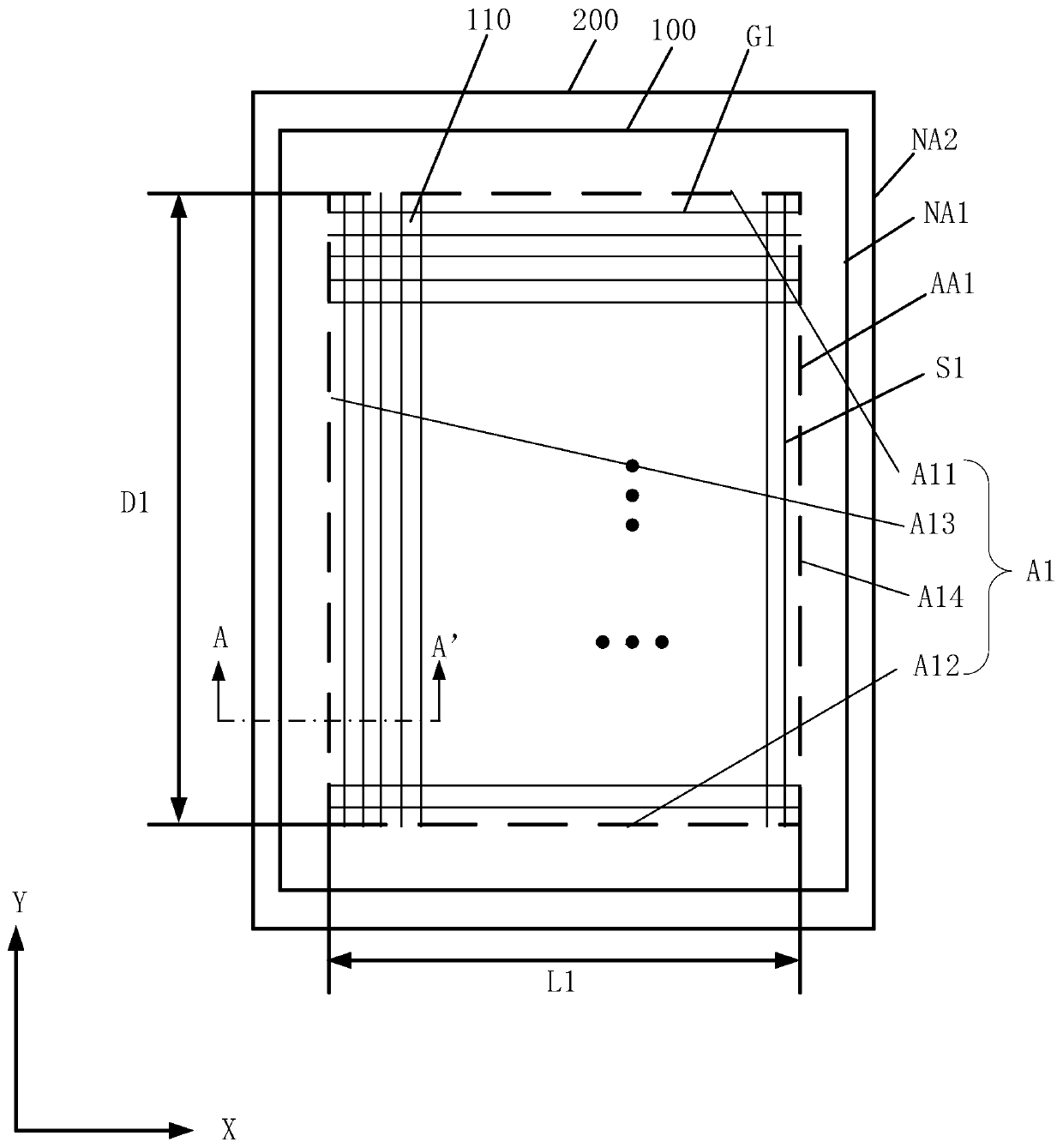

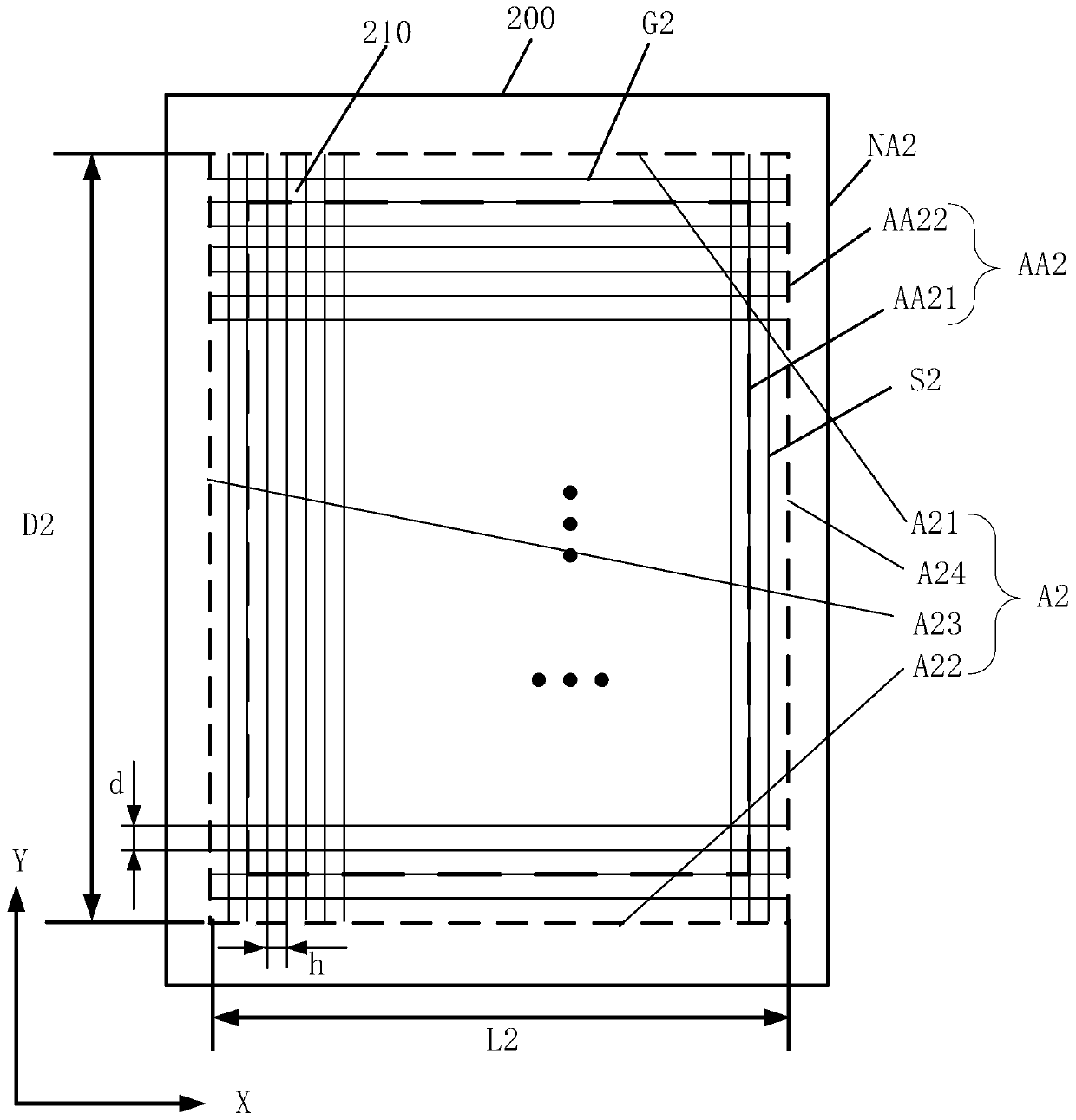

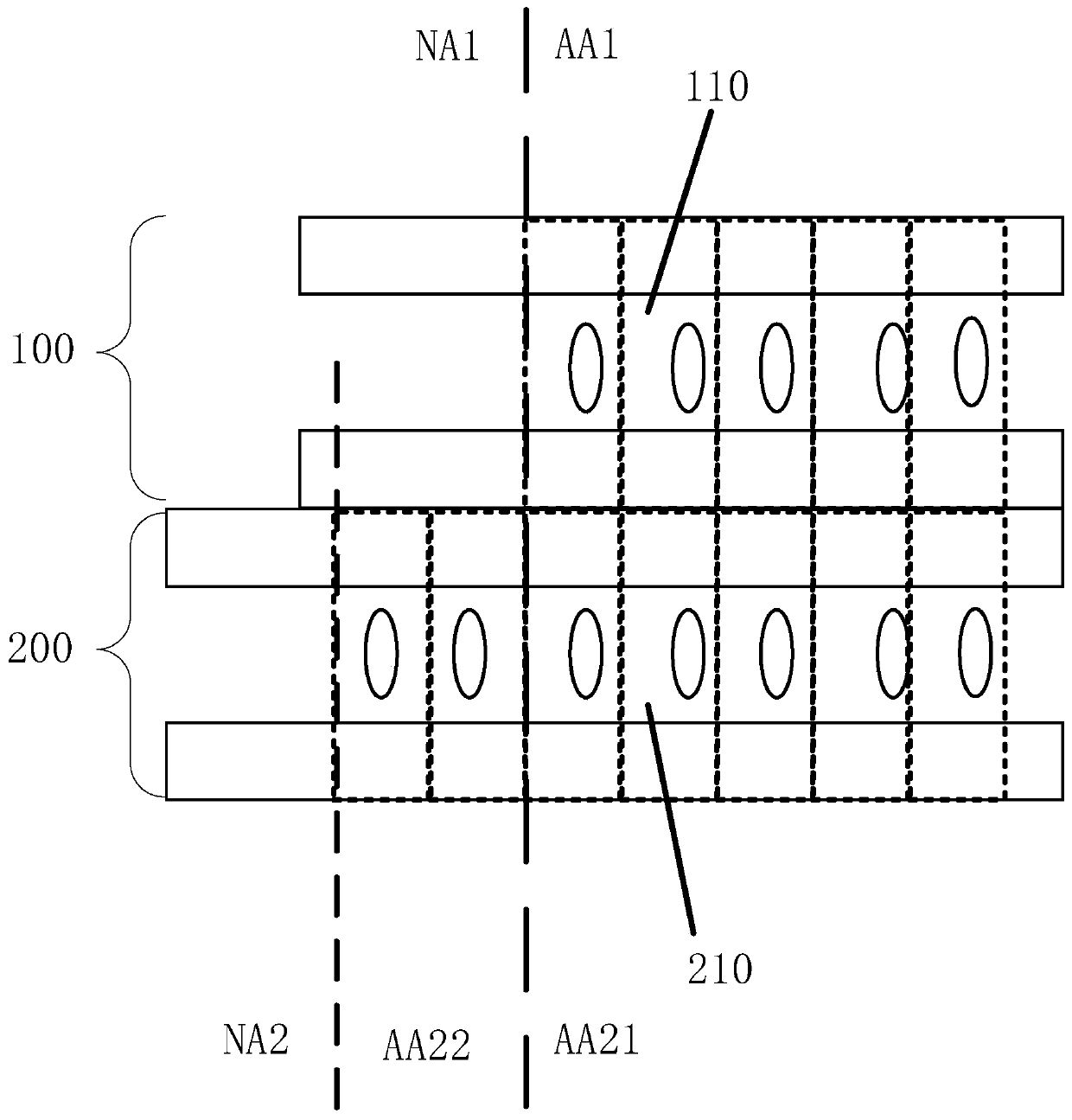

ActiveCN110441967AThe display effect is consistentImprove the display effectStatic indicating devicesNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a display module and a manufacturing method and a driving method thereof, and a display device, and relates to the technical field of display. The display module comprises a first display panel and a second display panel, wherein in a direction perpendicular to a light emitting surface of the first display panel, a first sub-display area and a first display area overlap, asecond sub-display area and the first display area do not overlap; a second sub-pixel in the first sub-display area and a first sub-pixel in the first sub-display area are arranged one by one; the length of the first display area along a first direction is L1, the width of the first display area along a second direction is D1, the length of the second display area along the first direction is L2,and the width of the second display area along the second direction is D2; L1 is less than L2 and greater than 0, and D1 is less than D2 and greater than 0; and in the display phase, the second sub-pixel in the second sub-display area remains normally black displayed or not displayed. The invention solves the problems existing in the double-box liquid crystal display module in the prior art that the image display quality and the process yield are both not high.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Low-sensitivity and high-quality fidelity camera assembly

The invention discloses a low-sensitivity and high-quality fidelity camera assembly. The camera assembly sequentially comprises a first lens having positive focal power, a crescent-shaped second lens having positive focal power and bending towards an object space, a third lens having negative focal power, an imaging face, an optical filter and a diaphragm in the direction from the object side to the image side along an optical axis of the camera assembly, wherein the first lens is provided with a convex face towards the object side and a convex face towards the image side; the second lens is provided with a concave face towards the object side; the optical filter is located between the third lens and the imaging face; the diaphragm is located between the object space and the first lens. In addition, the camera assembly meets the following conditions that (1) 0.7<F / F1<1.2, -0.7<F3 / F2<-1.5; (2) 0.6<F12 / Y<1.4; (3) 4<T12 / T23<11; (4) 0.2<BL / TTL<0.6. The camera assembly is designed aiming at a current high-pixel photographing digital product, has the characteristics of being low in sensitivity and high in fidelity, and can guarantee high imaging quality on the premise of meeting miniaturization.

Owner:GUANGDONG XUYE OPTOELECTRONICS TECH

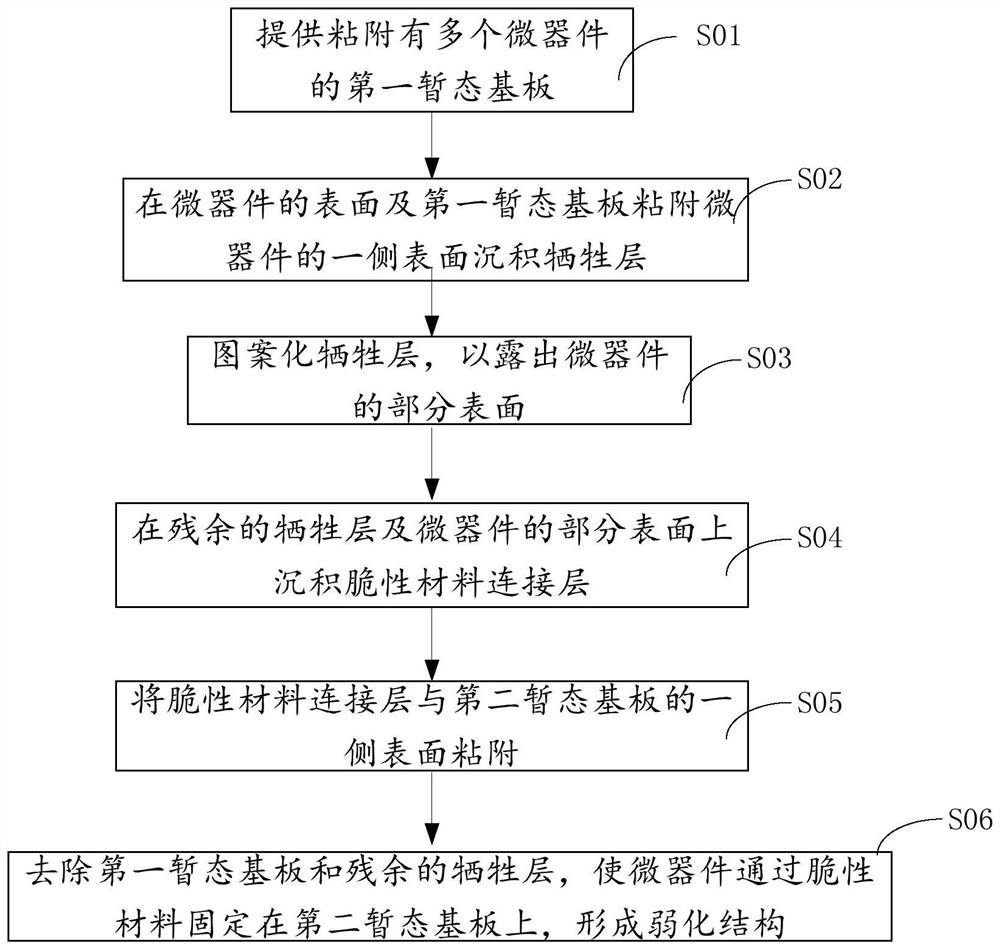

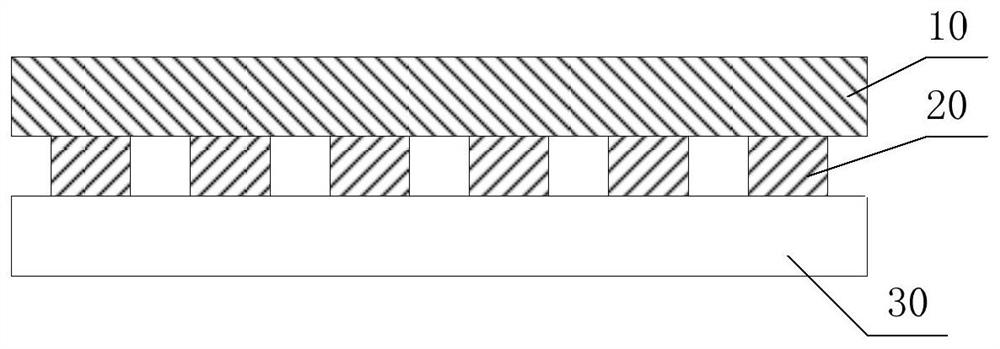

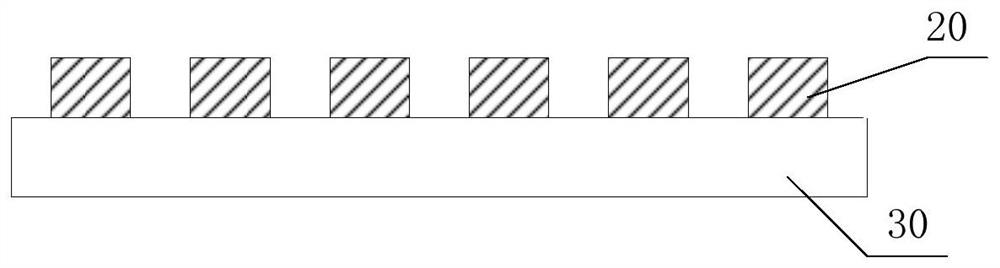

Manufacturing method of weakening structure and transfer method of micro device

ActiveCN112968107AAvoid damageReduce difficultySolid-state devicesSemiconductor/solid-state device manufacturingMicro devicesMaterials science

The invention relates to a manufacturing method of a weakening structure and a transfer method of micro devices. The manufacturing method of the weakening structure comprises the following steps of: providing a first transient substrate adhered with a plurality of micro devices; depositing sacrificial layers on the surfaces of the micro devices and the surface of one side, adhered with the micro devices, of the first transient substrate; patterning the sacrificial layers to expose part of the surfaces of the micro devices; depositing brittle material connecting layers on the residual sacrificial layers and the partial surfaces of the micro devices; adhering the brittle material connecting layers to the surface of one side of a second transient substrate; and removing the first transient substrate and the residual sacrificial layers, so that the micro devices are fixed on the second transient substrate through the brittle material to form the weakening structure. According to the manufacturing method of the weakening structure and the transfer method of the micro devices of the invention, the problems of high transfer difficulty and low yield in the mass transfer process are effectively solved.

Owner:CHONGQING KONKA PHOTOELECTRIC TECH RES INST CO LTD

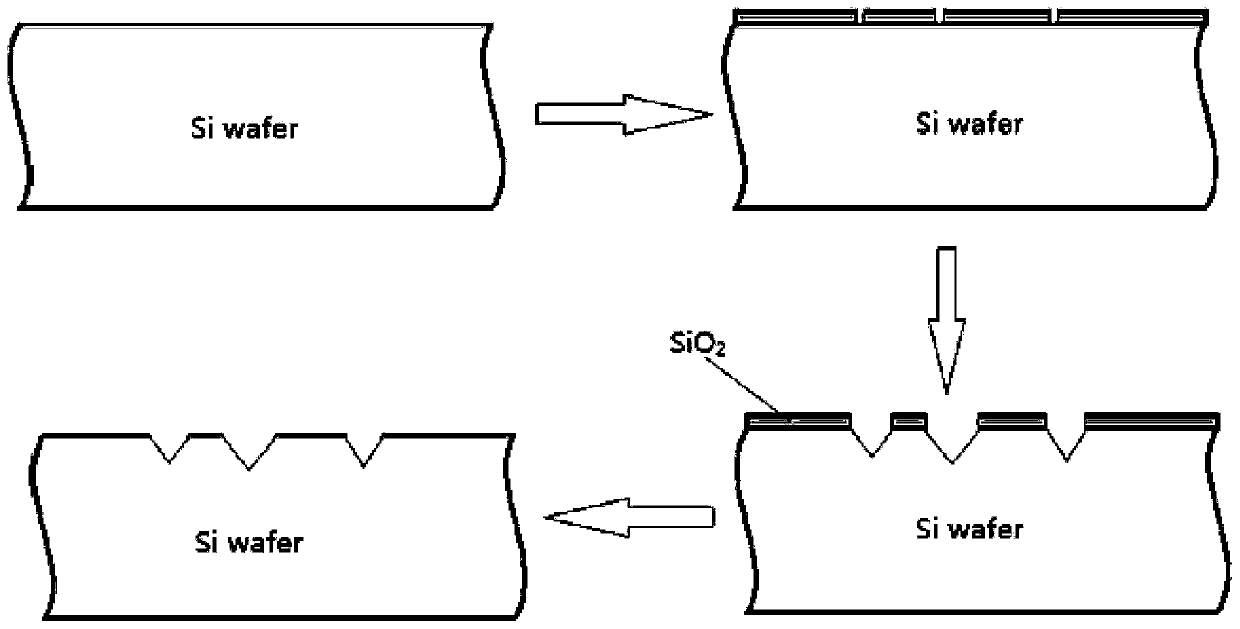

Method for preparing suede surface of single crystal silicon wafer

ActiveCN110391317ASolve the yield problemSolve problems that are not suitable for industrial applicationsFinal product manufactureSemiconductor/solid-state device manufacturingHigh densitySurface oxidation

The invention discloses a method for preparing the suede surface of a single crystal silicon wafer. A novel method for preparing an inverted pyramidal suede structure by using a SiO2 mask is provided.According to the technical scheme, (1) organic smudge on the surface of the single crystal silicon wafer is removed; (2) surface oxidation is carried out on the single crystal silicon wafer acquiredin the step (1) to produce an oxide layer; (3) high temperature annealing is carried out on the single crystal silicon wafer acquired in the step (2); the silicon oxide mask generates a high-density pinhole after annealing, forming a channel in which an alkali solution directly contacts the silicon wafer; (4) the single crystal silicon wafer acquired in the step (3) is subjected to texturing, andfinally the inverted pyramidal structure is formed in the pinhole of the silicon oxide mask; and (5) the silicon oxide mask layer is removed from the single crystal silicon wafer acquired in the step(4) to acquire the desired inverted pyramidal suede. According to the invention, the inverted pyramidal suede is simply prepared based on the existing industrial manufacturing equipment without addingadditional consumption and introducing additional contaminating products.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID

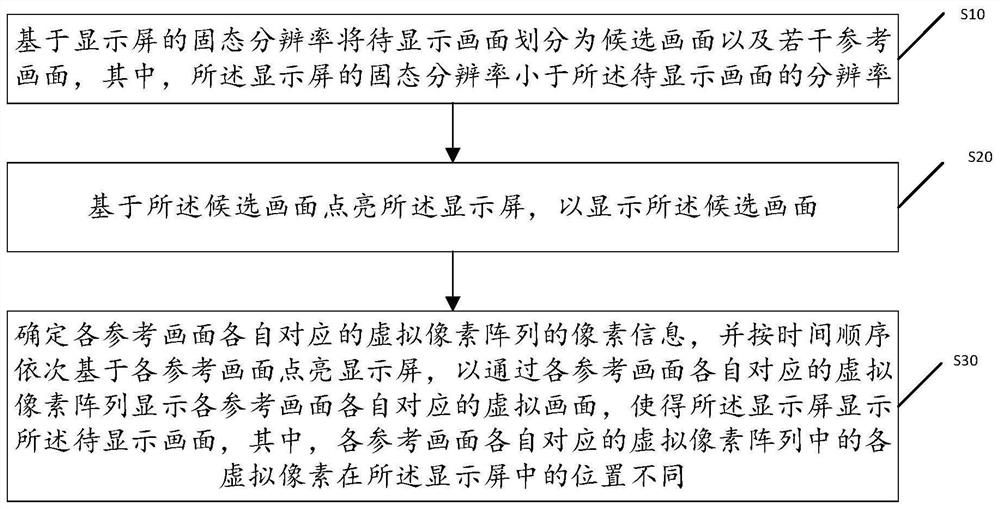

Pixel multiplexing display method and device, storage medium and terminal equipment

ActiveCN113362760ASolve the display effectSolve complexityStatic indicating devicesComputer hardwareComputer graphics (images)

The invention discloses a pixel multiplexing display method and device, a storage medium and terminal equipment. The method comprises the steps: dividing a to-be-displayed picture into candidate pictures and a plurality of reference pictures based on the solid-state resolution of a display screen; lightening a display screen based on the candidate picture to display the candidate picture; determining pixel information of the virtual pixel array of each reference picture, and sequentially lightening the display screen based on each reference picture according to a time sequence so as to display a virtual picture corresponding to each reference picture through the virtual pixel array of each reference picture, so that the display screen displays a picture to be displayed. The virtual pixel array is formed on the display screen, and the virtual picture corresponding to the reference picture is displayed through the virtual pixel array, so that the display screen displays the to-be-displayed picture with the resolution higher than the resolution of the display screen, and the high-resolution display picture can be displayed on the basis of the solid resolution, so the problem that the manufacturing and mass transfer process of high-resolution display products is complex is solved, and the product cost is reduced.

Owner:KONKA GROUP

Deep pad wafer-level preparation method for reducing wafer-level glue bonding bubbles

PendingCN114566436AReduce the risk of glue overflowReduce defective rateFinal product manufactureSemiconductor/solid-state device manufacturingWaferComposite material

The invention provides a deep pad wafer-level preparation method capable of reducing wafer-level glue bonding bubbles, which is characterized in that the generation of the Pad bubbles is controlled by controlling the flow rate of glue through temperature and coating reasonable glue amount, and particularly, a wafer is repeatedly pre-vacuumized in a bonding chamber for many times to finish the bubble discharging process of the wafer, so that the production efficiency of the wafer is improved. Meanwhile, a low-temperature preheating method is combined, so that the flowing speed of the bonding glue is slowed down under the condition of low viscosity, the risk of residual glue overflowing is reduced, low-rate stepped heating is matched, a traditional one-step heating bonding mode is changed, and the bubble reject ratio is basically controlled and is basically about five thousandths.

Owner:珠海天成先进半导体科技有限公司

Touch screen and manufacturing method thereof

InactiveCN105630245AAdd varietyReduce defective rateInput/output processes for data processingAdhesiveEngineering

The invention discloses a touch screen and a manufacturing method thereof. The manufacturing method comprises the following steps of forming a film, on which any patterns can be printed, on a transparent PET / PC sheet, and forming a viewing window or other patterns on the PET / PC sheet through the film; performing hot pressing and forming on the PET / PC sheet; blanking the PET / PC sheet subjected to hot pressing and forming to form a PET / PC front panel; performing hot pressing and forming on a film circuit or an ITO circuit and then blanking; performing injection molding between the PET / PC front panel and the film circuit / ITO circuit to form a plastic main body. According to the manufacturing method disclosed by the invention, the problems that a glass curved surface or an irregular special-shaped surface is difficult to laminate and is high in rejection ratio are effectively solved; meanwhile, the manufacturing cost of glass is avoided, OCA (Optical Clear Adhesive) laminating working procedures are omitted, and a multi-person operation working procedure is omitted; the PET / PC sheet replaces a glass lenses, so that the subsequent laminating procedure of glass is solved; the glass is subjected to injection molding by an injection molding process to obtain a finished product which can be assembled on a required product.

Owner:深圳市恒维川电子科技有限公司

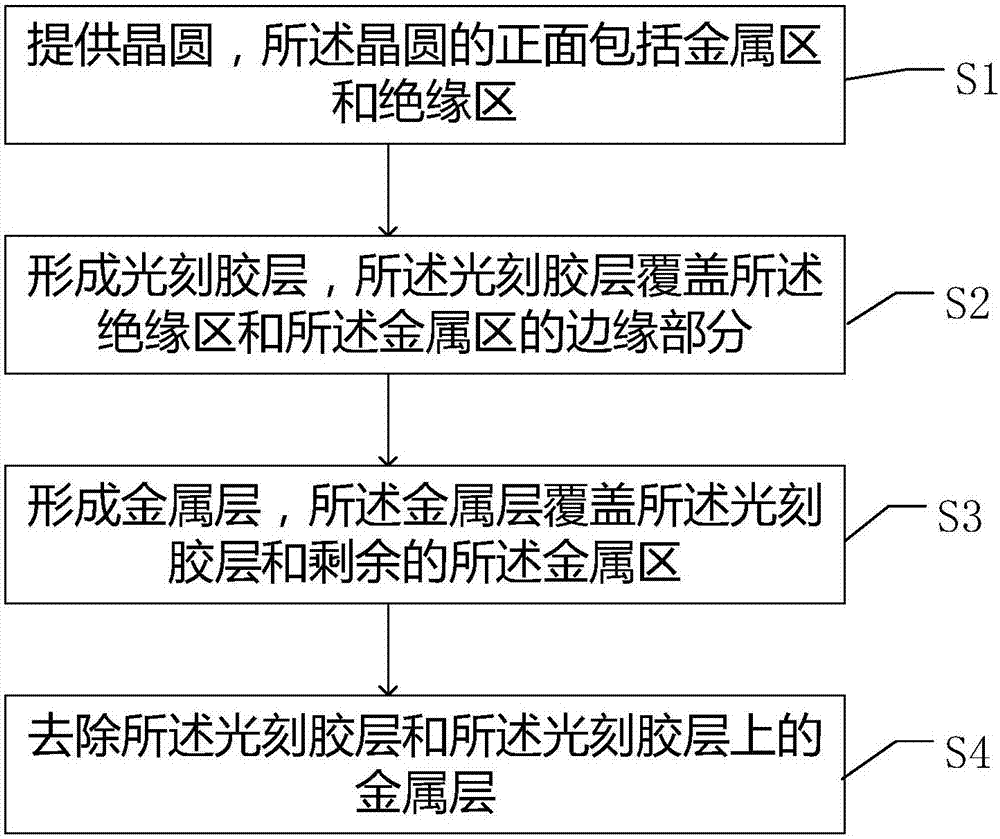

Method for evaporating gold on front surface of wafer

InactiveCN107887257ASolve the yield problemAddress reliabilitySemiconductor/solid-state device manufacturingMetallic materialsPhotoresist

The invention provides a method for evaporating gold on a front surface of a wafer. The method comprises the steps of forming a metal region and an insulation region on the front surface of the wafer,covering an edge part of the insulation region and the metal region with a photoresist layer, forming a metal layer on the photoresist layer and the remaining metal region, and removing the photoresist layer and the metal layer on the photoresist layer. According to the method for evaporating gold on the front surface of the wafer, the photoresist layer covers the edge part of the metal region, the metal layer is covered on the remaining metal region and the photoresist layer, the adhesive force between a metal material of front-surface metal and a metal region is larger than the adhesive force between the front-surface metal and the photoresist layer, the photoresist layer and the metal layer on the photoresist layer can be subsequently and easily removed according to the difference between the adhesive forces of the metal material on the photoresist layer and the metal, and the front-surface metal cannot be stripped or upwarped.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

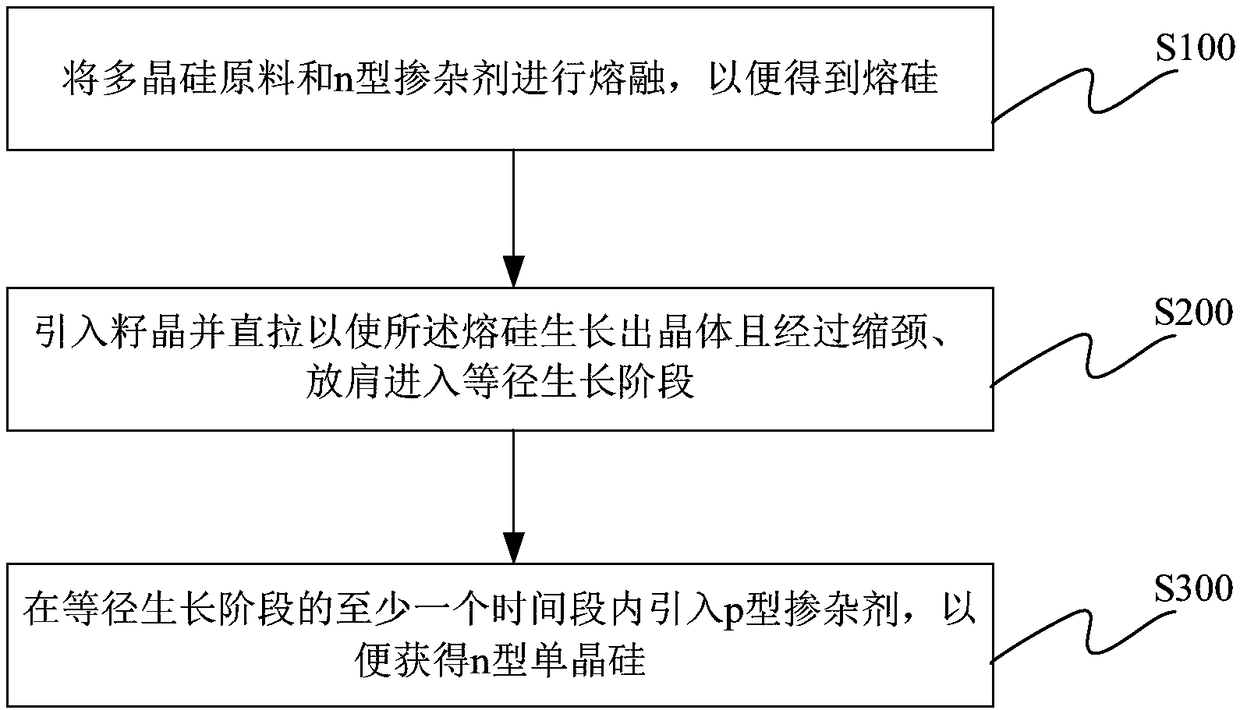

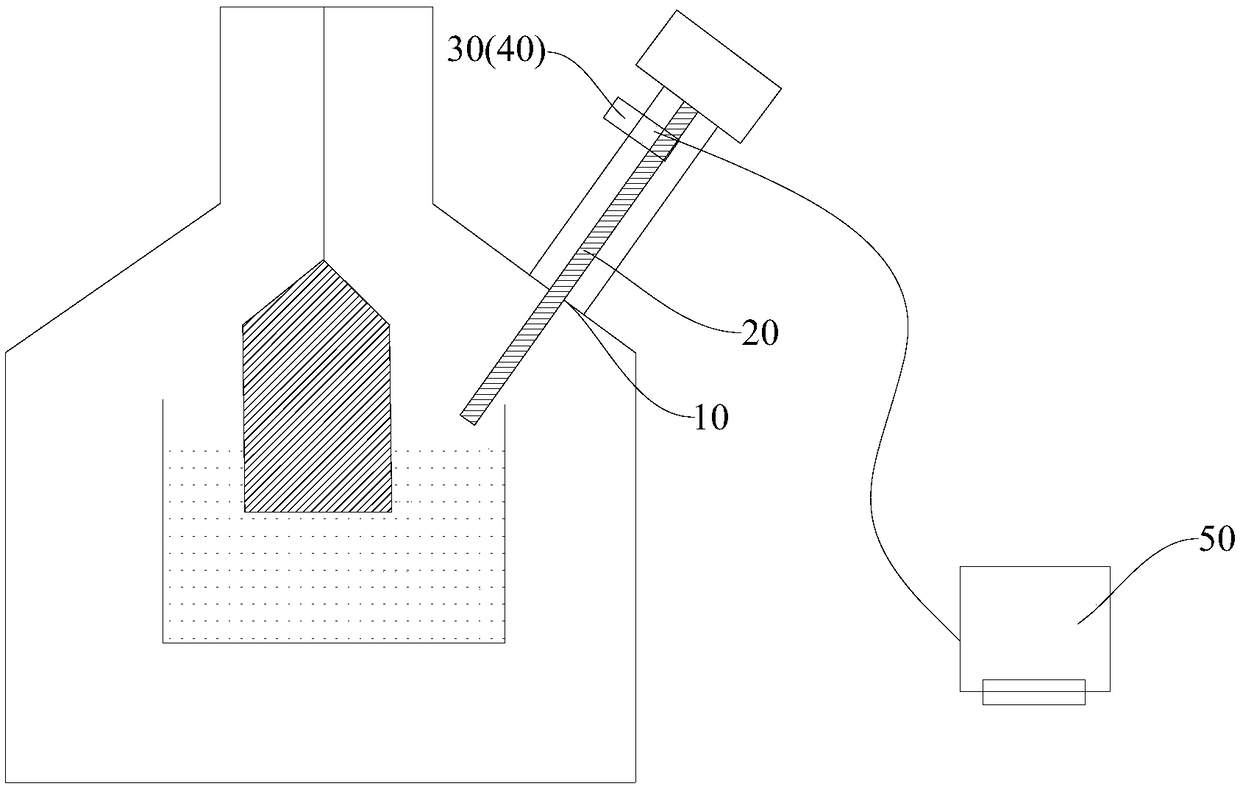

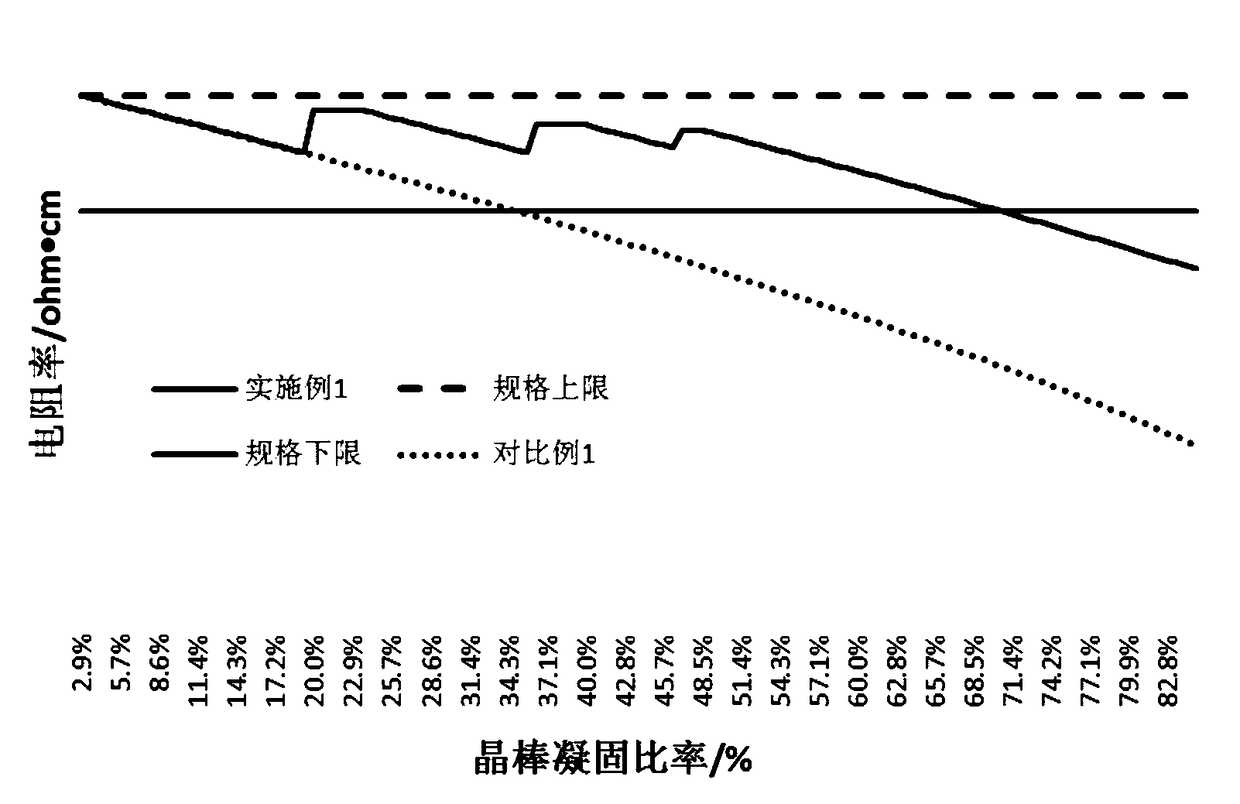

Method for preparing n-type single crystal silicon and single crystal furnace

ActiveCN109505005ASolve the yield problemChange the resistivityPolycrystalline material growthBy pulling from meltDopantSeed crystal

The invention discloses a method for preparing n-type single crystal silicon and a single crystal furnace, wherein the method for preparing the n-type single crystal silicon comprises the following steps: melting a polycrystalline silicon raw material and an n-type dopant to obtain molten silicon; introducing a seed crystal and straightening to enable crystals to grow out of the molten silicon, and subjecting the crystals to necking and shouldering so as to enter an equal diameter growth stage; and introducing a p-type dopant in at least one period of the equal diameter growth stage to obtainthe n-type single crystal silicon. By adopting the method, the crystal resistivity can be effectively changed, and the usable length can be increased for compliance, so that the problems that the light-doped n-type single crystal silicon having the resistivity greater than 50 ohm.cm is too short in usable length and too poor in yield can be effectively solved.

Owner:XUZHOU XINJING SEMICON TECH CO LTD +1

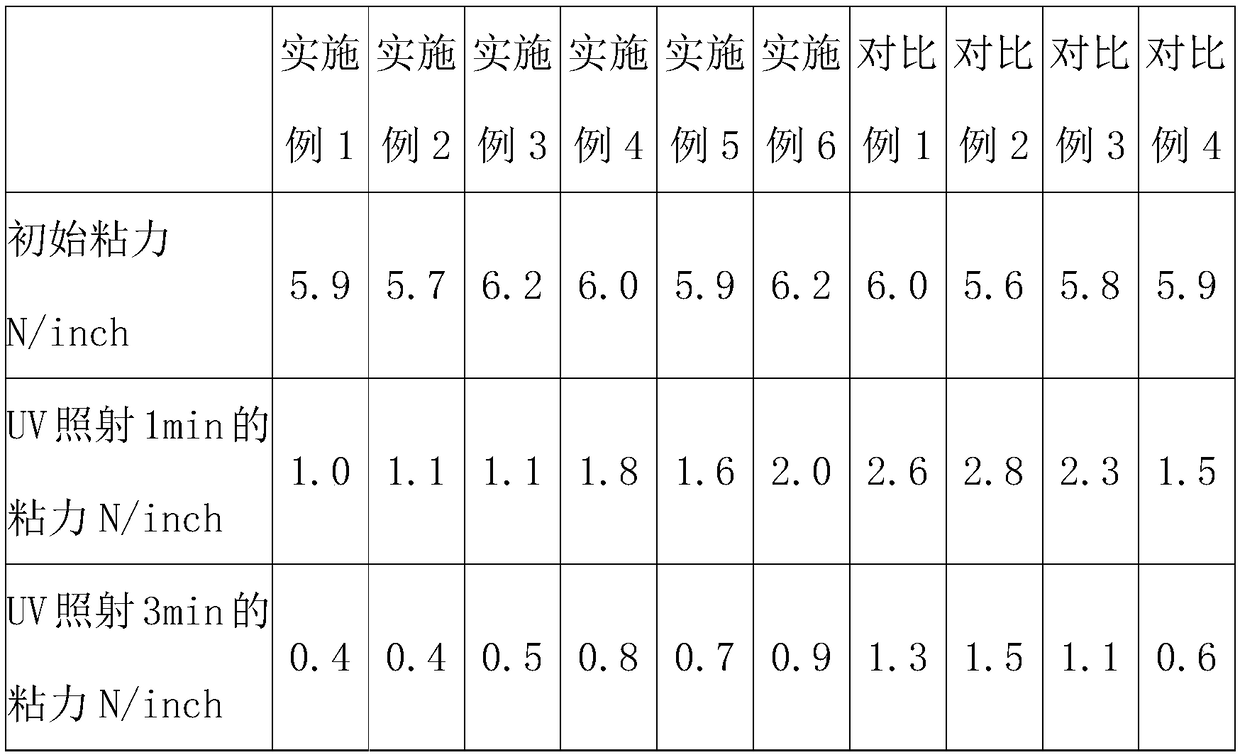

Novel adhesive sticker with viscous force reduced after UV illumination and preparation method thereof

ActiveCN109181571AImprove initial viscositySolve the yield problemNon-macromolecular adhesive additivesEster polymer adhesivesIsocyanateChemistry

The invention relates to a novel adhesive sticker which comprises release body paper and an outer adhesive layer, wherein the outer side adhesive layer comprises an acrylic sensitive adhesive having amolecular weight of 500-600 thousand, a free radical photoinitiator with an ultraviolet region in a range of 250-420 nm, and isocyanate. The outer side adhesive layer is 18-25 [mu]m thick; the mass ratio of the acrylic sensitive adhesive to isocyanate to the free radical photoinitiator is 100: (1.5-3): (12-20); and the release body paper is coated by 80 g glassine body paper with a releasing function. The adhesive sticker prepared by the method has a relatively high initial viscous force, the viscous force can be quickly reduced after UV illumination to achieve a natural falling extent, and the adhesive sticker is not left on a wafer body.

Owner:深圳深汕特别合作区昌茂粘胶新材料有限公司

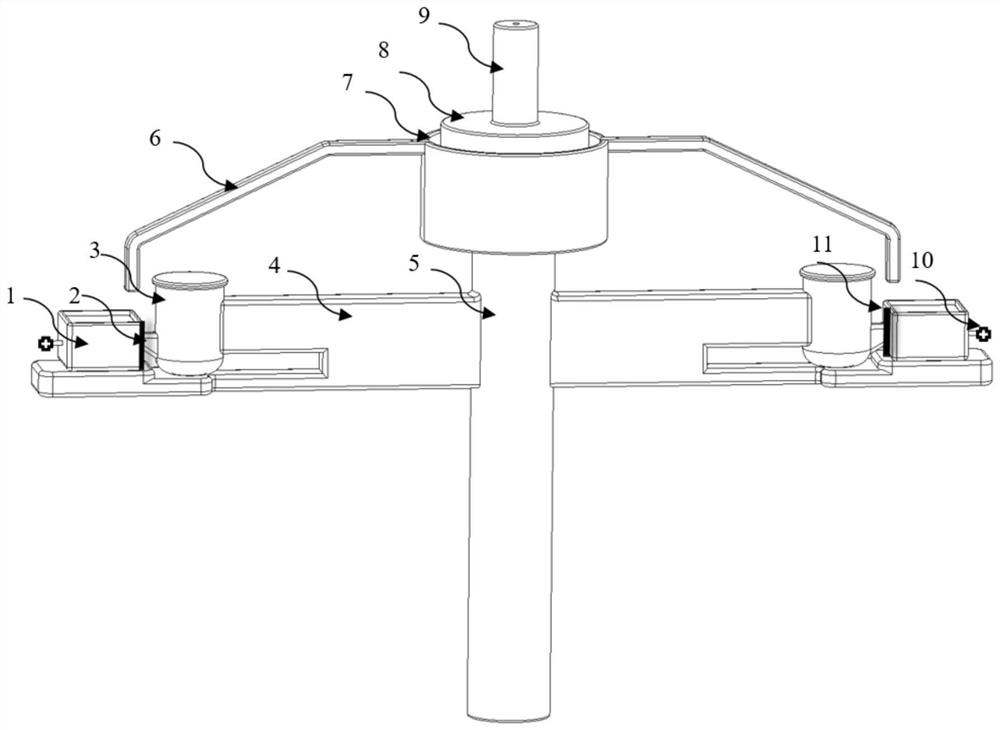

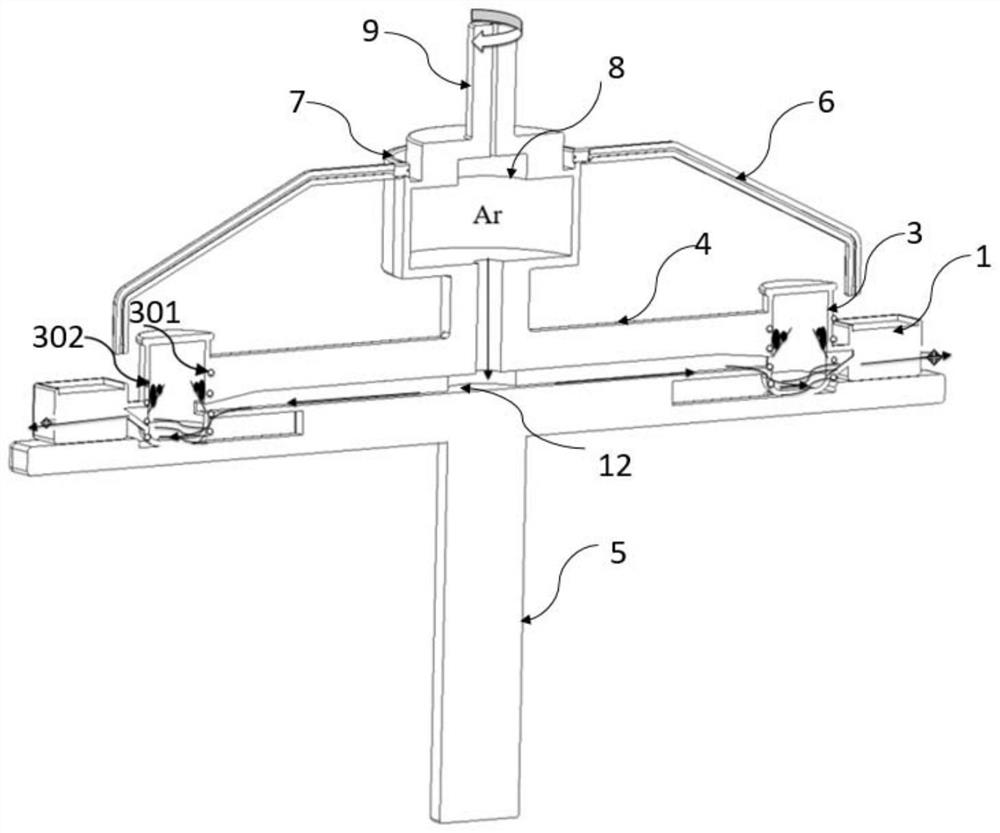

Preparation device and method of amorphous alloy component, amorphous alloy component and electronic equipment

The invention relates to the technical field of preparation and application of amorphous alloy, and particularly relates to a preparation device and method of an amorphous alloy component, the amorphous alloy component and electronic equipment. The preparation device of the amorphous alloy component comprises a centrifugal mechanism, a smelting forming mechanism, an inert gas mechanism and a cooling mechanism, the centrifugal mechanism comprises a centrifugal rotating shaft and a centrifugal casting arm, and each of the centrifugal casting arm and the centrifugal rotating shaft is provided with an inert gas channel allowing inert gas to circulate; the smelting forming mechanism comprises a crucible and a forming mold, the crucible and the forming mold are arranged on the centrifugal casting arm, and the centrifugal casting arm, the crucible and the forming mold can be driven to rotate synchronously by driving the centrifugal rotating shaft to rotate; the inert gas mechanism is in communication with the inert gas channel of the centrifugal rotating shaft, and the inert gas released from the inert gas mechanism can sequentially pass through the inert gas channel of the centrifugal rotating shaft and the inert gas channel of the centrifugal casting arm to enter the crucible; and the cooling mechanism is used for cooling the forming mold. The problems of high cost and low yield in the existing amorphous alloy preparation process are solved.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com