Method for preparing suede surface of single crystal silicon wafer

A monocrystalline silicon wafer and suede technology, applied in the field of solar cells, can solve problems such as unsuitable for industrial applications and unfavorable battery yields, and achieve the effect of simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

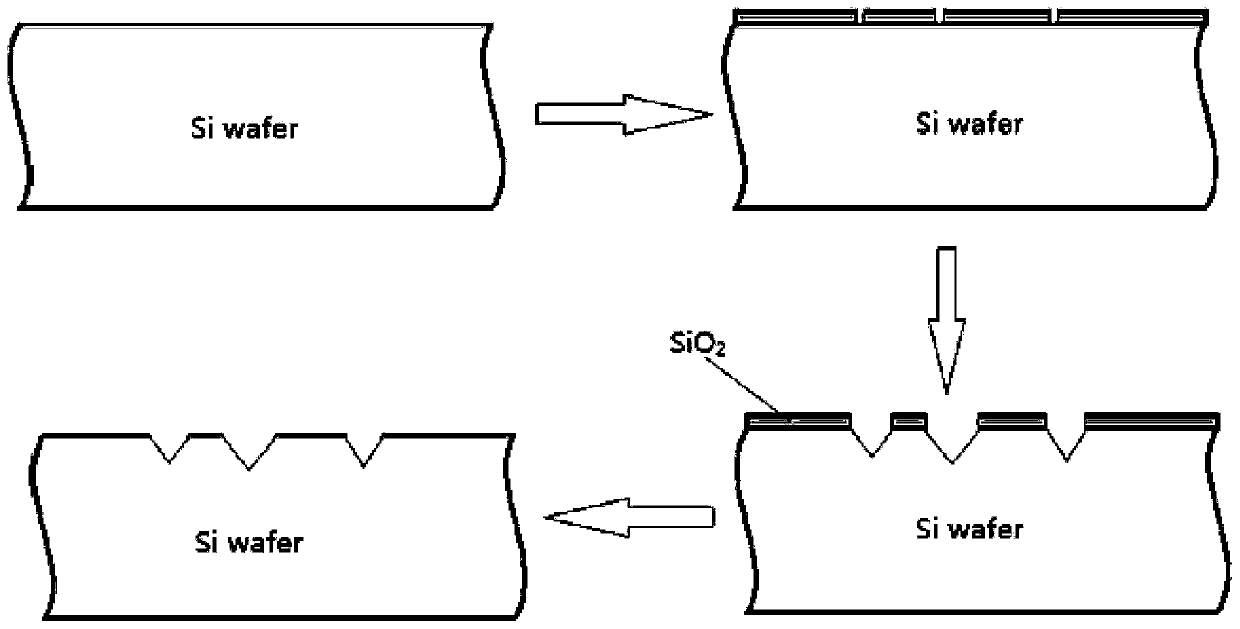

[0037] As shown in the figure, a method for preparing a textured surface of a single crystal silicon wafer includes the following steps:

[0038] (1) After pre-cleaning the monocrystalline silicon wafer with a cleaning solution to remove organic dirt on the surface, dry it;

[0039] (2) Carry out surface oxidation to the monocrystalline silicon slice obtained in step (1), produce oxide layer;

[0040] (3) performing high-temperature annealing on the monocrystalline silicon wafer obtained in step (2); the silicon oxide mask produces high-density pinholes after annealing, forming a channel for the direct contact reaction between the alkali solution and the silicon wafer;

[0041] (4) the monocrystalline silicon chip obtained in the step (3) is subjected to texturing; finally an inverted pyramid structure is formed at the pinhole position of the silicon oxide mask;

[0042] (5) removing the silicon oxide mask layer from the monocrystalline silicon wafer obtained in step (4), to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com