Preparation device and method of amorphous alloy component, amorphous alloy component and electronic equipment

A technology for amorphous alloys and preparation devices, which is applied in the preparation of amorphous alloys and its application fields, can solve problems such as high cost and low yield, and achieve the effects of reducing production costs, improving yield, and improving surface quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] The preparation device of the amorphous alloy component uses the centrifugal effect of the centrifugal casting arm and the forming mold to rotate at a high speed and the pressure of the high-pressure inert gas chamber to release the high-speed flowing gas to quickly inject the melt into the forming mold, and finally obtain the amorphous alloy product , such as amorphous Cato. The preparation device combines the pressure effect of high-pressure inert gas with centrifugal casting technology to realize the molding of castings. Compared with traditional amorphous alloy forming equipment, it improves the filling capacity and feeding capacity of metal melt on the one hand, and improves the The surface quality of the casting, the performance of the product is better, the structure is more compact, and the yield rate of the product is improved. On the other hand, the clever use of centrifugal force and pressure difference to achieve rapid cooling ensures that the product is an a...

Embodiment 1

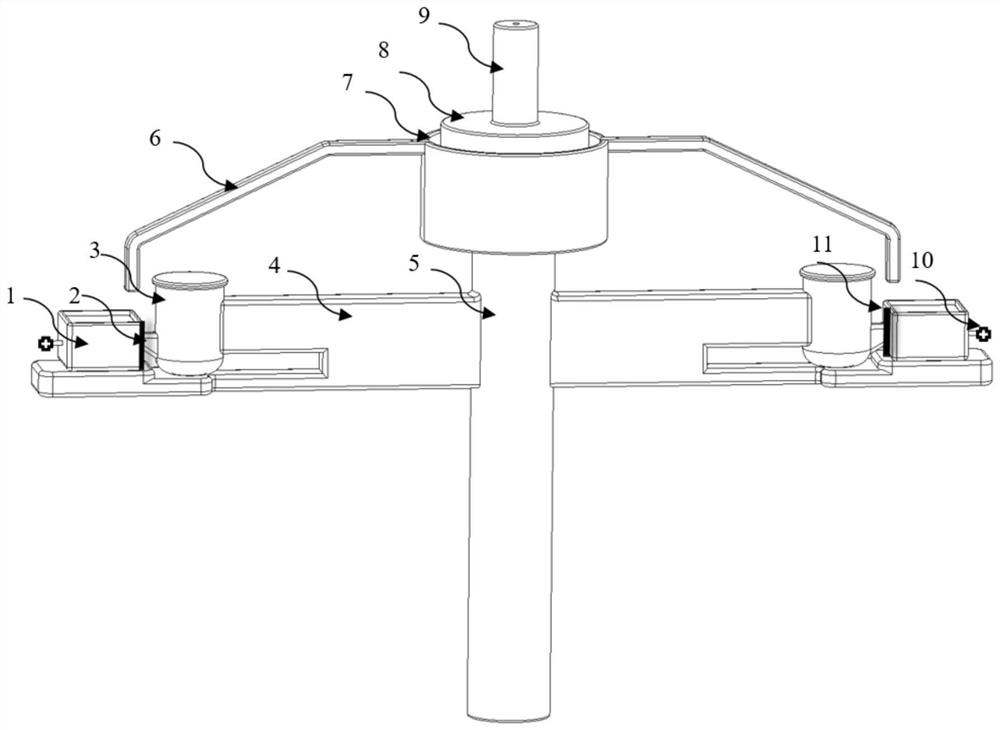

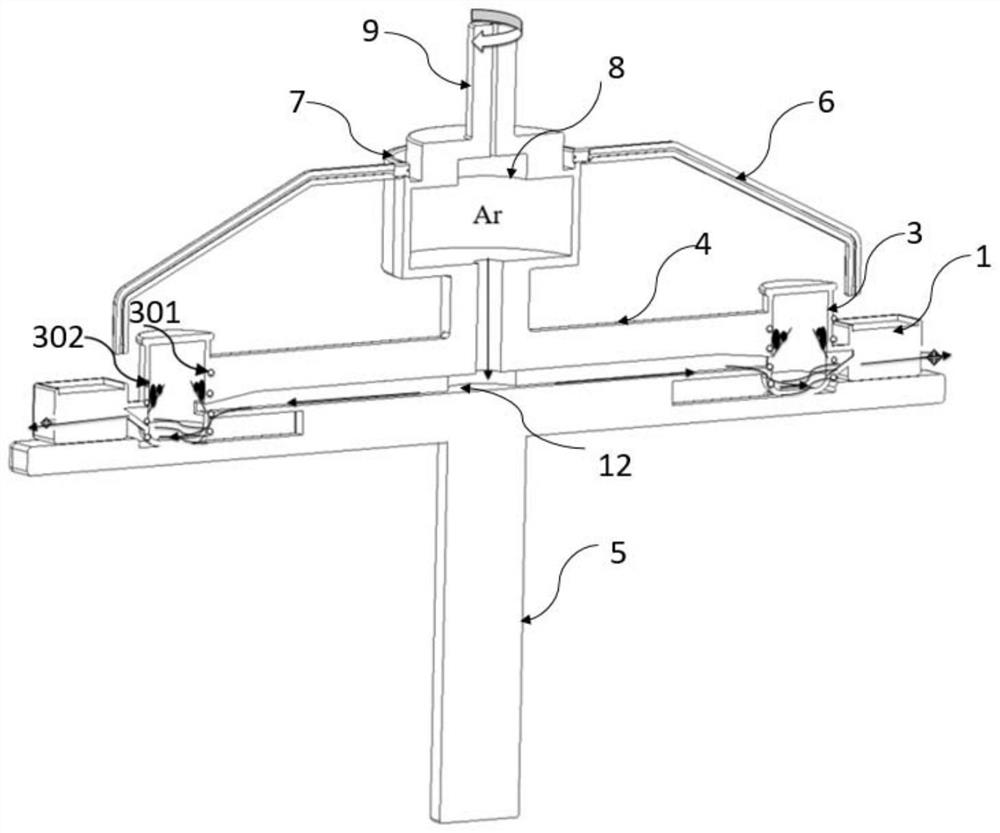

[0161] Such as figure 1 and figure 2 As shown, a preparation device for an amorphous alloy component includes a centrifugal mechanism, a melting and forming mechanism, an inert gas mechanism and a cooling mechanism.

[0162]Among them, the centrifugal mechanism includes a centrifugal casting arm 4 and a centrifugal shaft 5. The bottom end of the centrifugal shaft 5 is connected to the centrifugal casting machine, and the centrifugal casting machine is used to drive the centrifugal shaft 5 to rotate. The top of the centrifugal shaft 5 is connected to the inert gas chamber 8. The centrifugal casting The arm 4 is connected to the middle and upper part of the centrifugal shaft 5, and both the centrifugal casting arm 4 and the centrifugal shaft 5 have an inert gas channel 12 for the inert gas to flow through.

[0163] The inert gas mechanism includes a high-pressure inert gas chamber 8, an inert gas pipe 9, a one-way gas stop valve 10, and an inert gas supply device; the inert ga...

Embodiment 2

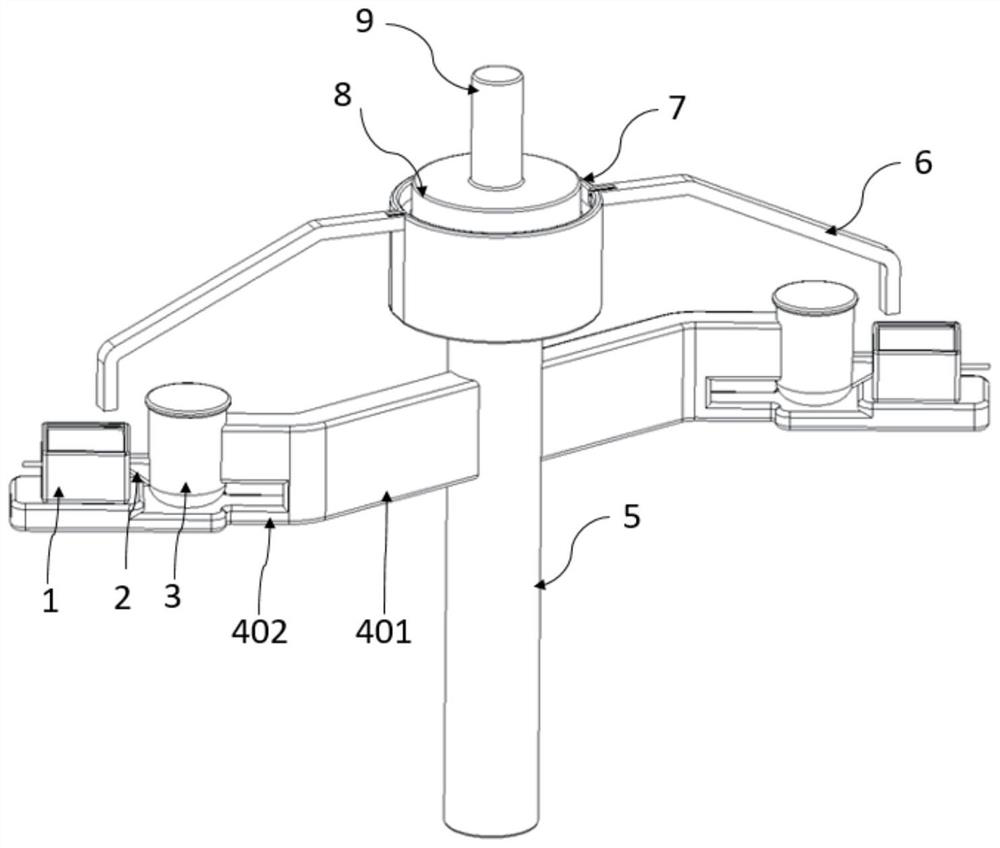

[0167] Such as image 3 As shown, a preparation device for an amorphous alloy component differs from Example 1 in the centrifugal casting arm.

[0168] In this embodiment, the main body of the centrifugal casting arm 4 is bent, including a first bent portion 401 and a second bent portion 402 connected to each other, wherein one end of the first bent portion 401 can be connected to the centrifugal shaft 5, The crucible 3 and the forming mold 1 are arranged on the second bending part 402 , and the bending angle between the first bending part 401 and the second bending part 402 may be 45°.

[0169] During the centrifugal casting process, the pouring direction of the metal molten liquid is 45° to the centrifugal shaft. After a lot of experiments, it is found that when the pouring angle is adjusted to 45°, the amorphous alloy structural parts can obtain better surface quality and forming accuracy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com