Patents

Literature

126results about How to "Improve initial viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

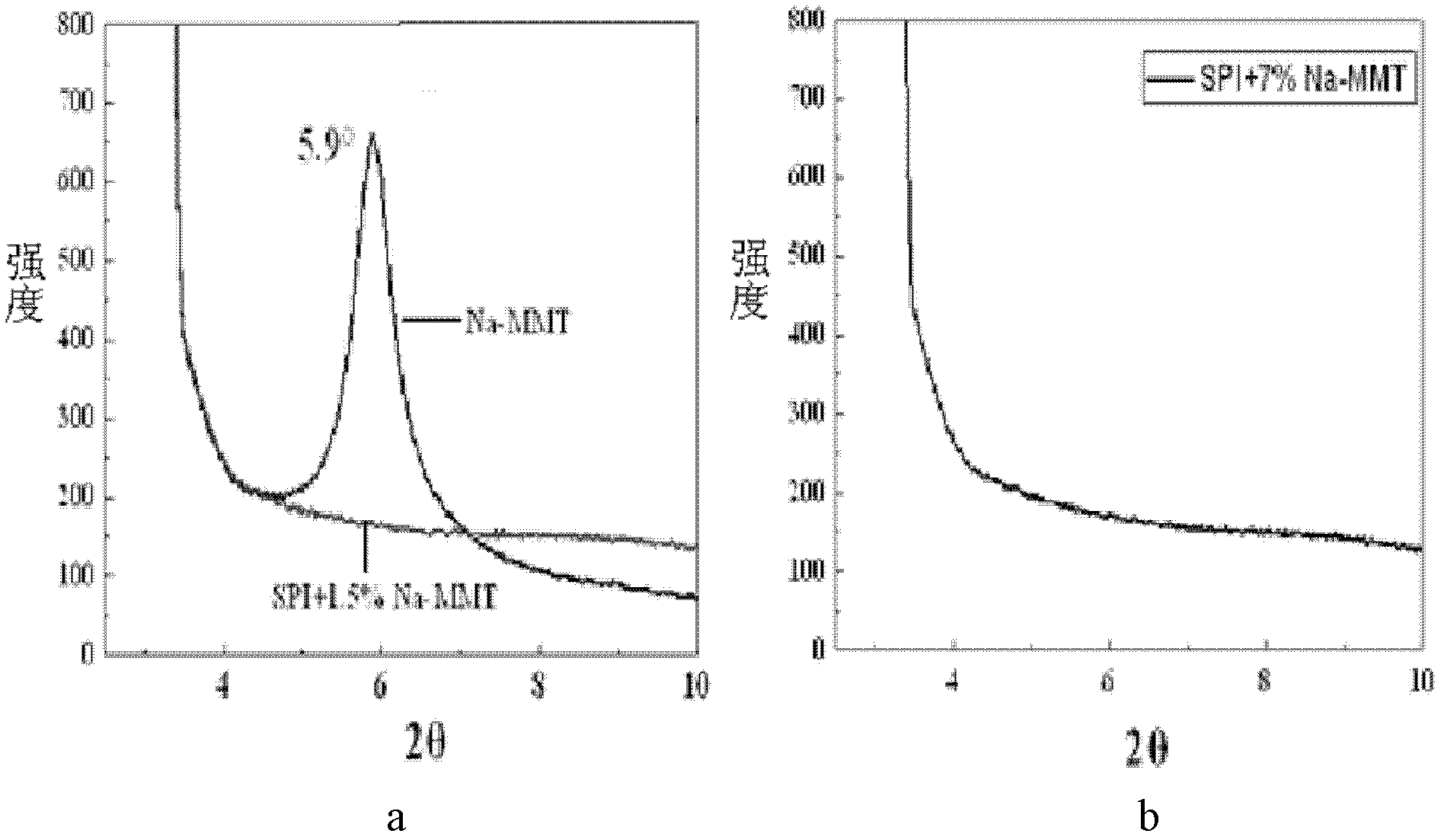

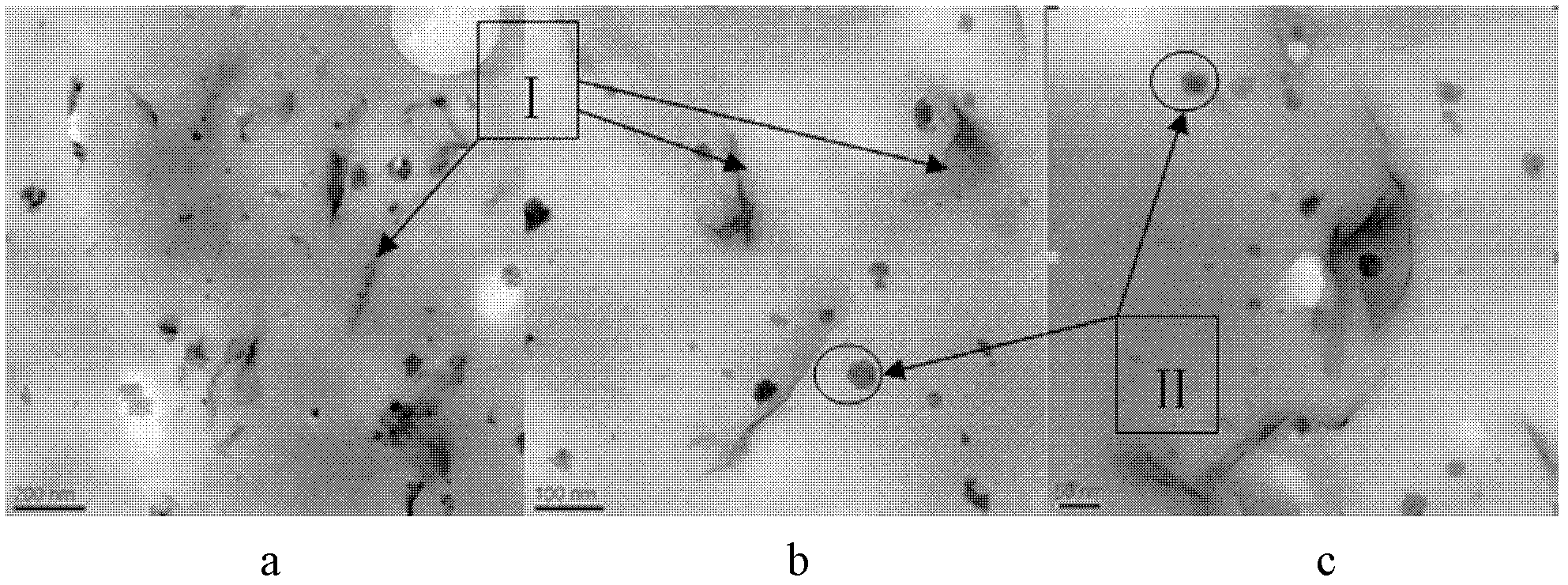

Layered silicate reinforced soybean adhesive, its preparation method and application

ActiveCN102516933AHigh bonding strengthImprove water resistanceNon-macromolecular adhesive additivesProtein adhesivesAdhesiveEconomic benefits

The invention discloses a layered silicate reinforced soybean adhesive, comprising 100 weight parts of water, 10-50 weight parts of soybean derivative, 0.1-10 weight parts of modifier, and 0.1-10 weight parts of layered silicate. The soybean adhesive disclosed herein comprises no formaldehyde as a raw material, thus the soybean adhesive belongs to an environmentally friendly adhesive. By using the modifier and layered silicate to modify soybean protein in the soybean derivative, the initial adhesion is raised, and simultaneously the bonding intensity and water resistance of the soybean adhesive are raised. The soybean adhesive is especially suitable for being used as a timber adhesive. The invention further provides a preparation method of the layered silicate reinforced soybean adhesive.The method has the advantages of simple preparation, good controllability, and low production cost, is easy to operate and is easy to industrialize, has good economic benefits, is beneficial for popularization and application, and has a wide application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

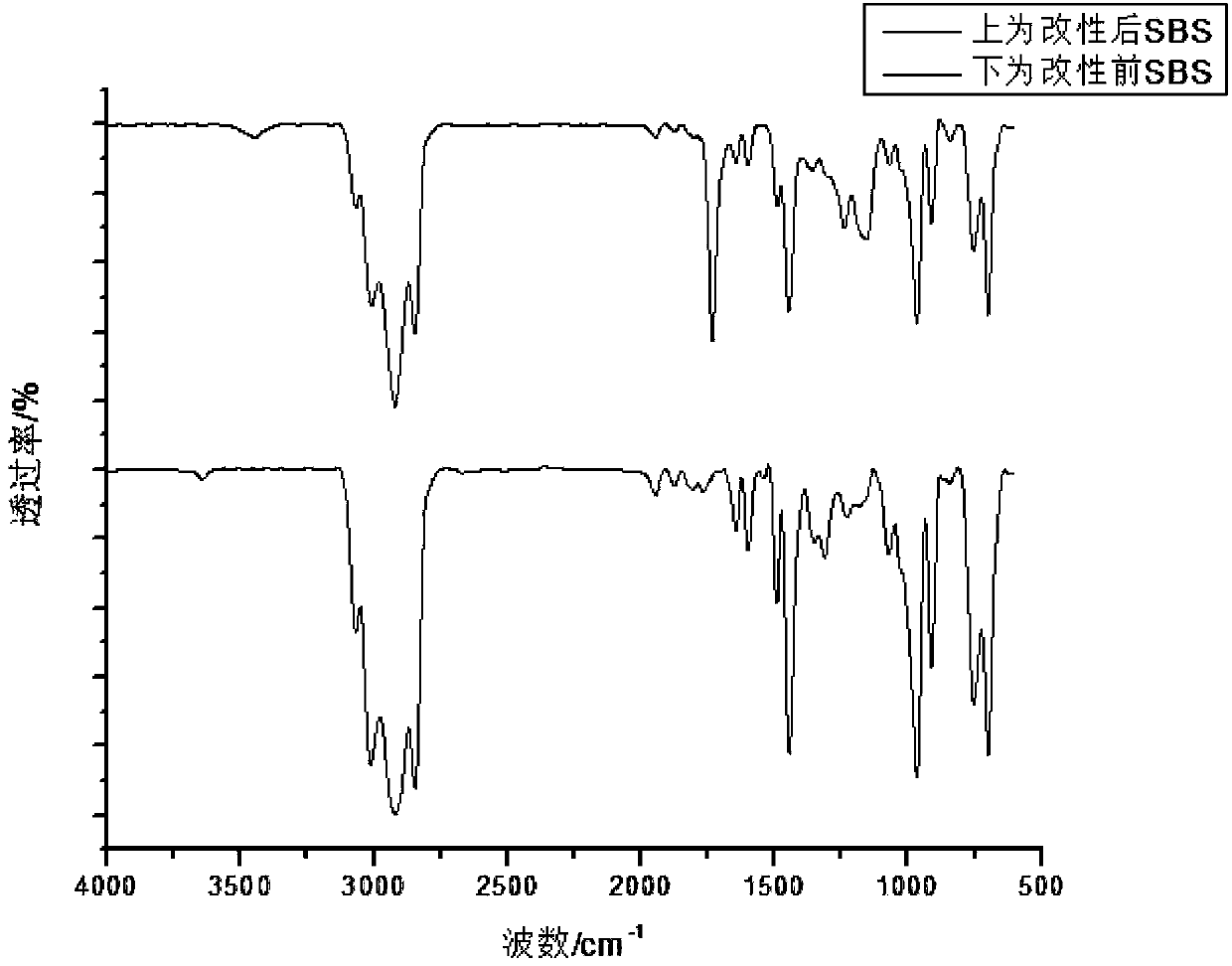

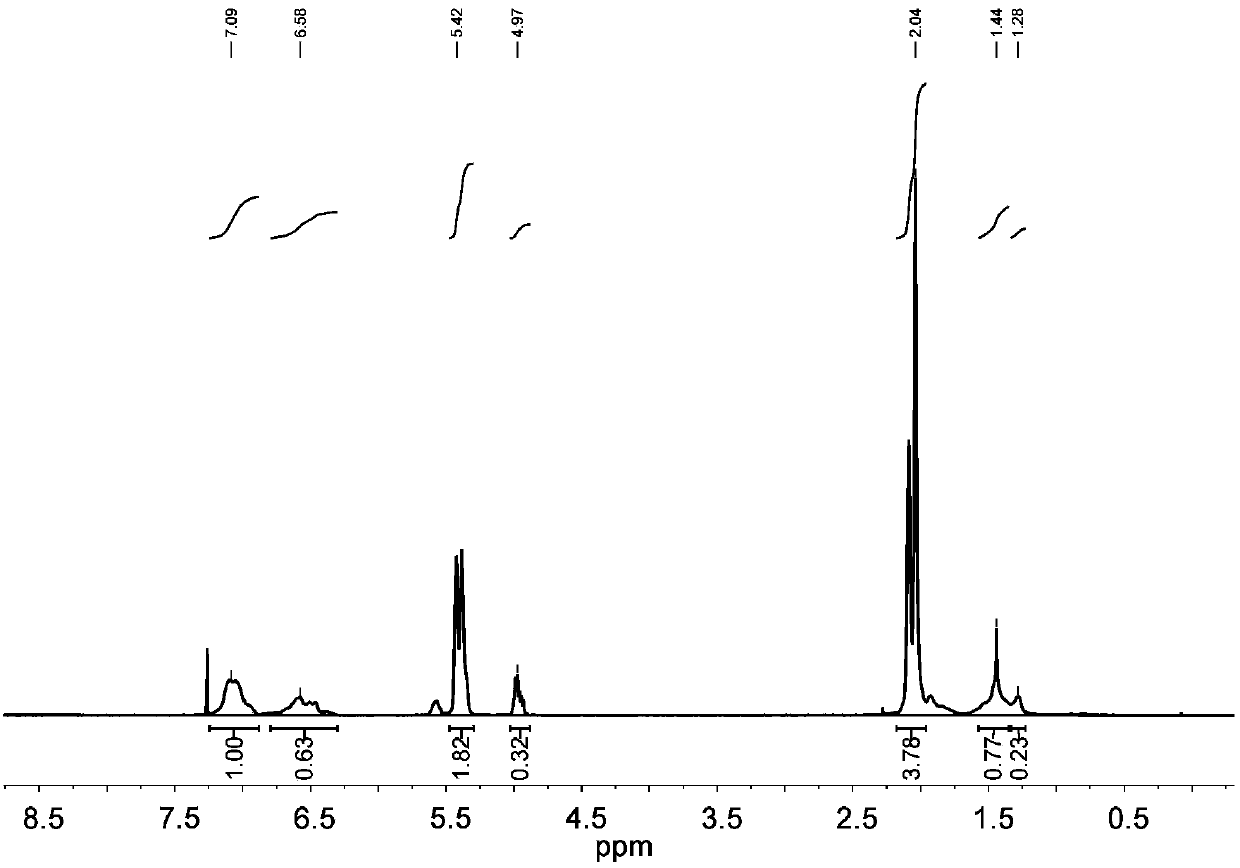

Benzene compound-free and halide-free environment-friendly SBS (Styrene Butadiene Styrene) graft modification adhesive and preparation method thereof

ActiveCN103396748AIncrease polarityHigh molecular weightMineral oil hydrocarbon copolymer adhesivesRosin adhesivesChemistryDouble bond

The invention discloses a benzene compound-free and halide-free environment-friendly SBS (Styrene Butadiene Styrene) graft modification adhesive and a preparation method thereof. The adhesive comprises SBS, an environment-friendly solvent, a grafting monomer, an initiator, a molecular weight regulator, a terminator and thickening resin. The preparation method comprises the following steps of: initiating double bonds on the SBS by using a free radical initiator, adding the monomers to carry out an addition reaction; with the reaction product as a seed, dropwise adding the subsequent monomers to continuously react to realize graft modification on the SBS; and finally adding the thickening resin, so as to obtain the final adhesive product. The preparation method has the advantage that since the SBS is dissolved by utilizing the environment-friendly solvent, the use of toxic solvents such as toluene and chlorohydrocarbon is effectively avoided. The adhesive utilizing the formula is environment-friendly and has low toxicity, high bonding strength, light color, good water tolerance and high solid content; and the general disadvantages that the SBS type adhesives containing benzene compounds and halides are high in toxicity, lower in viscosity and low in bonding strength, are easy to permeate and are difficult to roll up are overcome; and the color does not change after the adhesive provided by the invention is stored for a long time.

Owner:BEIJING UNIV OF CHEM TECH

Environment-friendly high-strength water-resisting and mildew-resisting adhesive for plywood and preparation method of environment-friendly high-strength water-resisting and mildew-resisting adhesive

InactiveCN105542683AReduced effectReduce hydrogen bondingNon-macromolecular adhesive additivesStarch adhesivesBond ForceP-hydroxybenzoic acid

The invention discloses an environment-friendly high-strength water-resisting and mildew-resisting adhesive for a plywood and a preparation method of the environment-friendly high-strength water-resisting and mildew-resisting adhesive. The environment-friendly high-strength water-resisting and mildew-resisting adhesive is prepared from the following raw materials including polyvinyl alcohol, cassava starch, dibutyl phthalate, sodium pyrosulfite, tannic acid, jade powder, calcium silicate hydrate, asbestos powder, p-hydroxybenzoic acid hydrazide, diammonium hydrogen phosphate, hydroquinone, sodium diethylhexyl sulfosuccinate, triethyltin chloride, phenyl mercury oleate, borax and the like. The polyvinyl alcohol and the cassava starch are subjected to a cross-linking reaction so that crystallization degrees of the polyvinyl alcohol and the cassava starch are reduced and a new cross-linking structure is formed, and furthermore, the thermal stability of the adhesive is improved; the borax is added and the polyvinyl alcohol and the starch can be subjected to further cross linking, so that the cross-linking degree and the initial viscosity of the adhesive are improved, and furthermore, the water resistance and the bonding force of the adhesive can be improved; the triethyltin chloride, the phenyl mercury oleate, the p-hydroxybenzoic acid hydrazide and the like are added so that the mildew-resisting capability of the plywood can be improved.

Owner:倪协照

Protein adhesive, preparation method and application thereof

InactiveCN103709989AImprove initial viscosityLow viscosityNon-macromolecular adhesive additivesProtein adhesivesDiluentUltimate tensile strength

The invention relates to a protein adhesive, a preparation method and application thereof. The protein adhesive consists of the following raw materials by weight: 10-30 parts of a protein substrate, 30-70 parts of water, 10-30 parts of a formaldehyde-free crosslinking agent, and 10-30 parts of a diluent. The protein adhesive prepared by the invention has the advantages of high initial adhesion, low viscosity, and high solid content that can be adjustable according to the actual production status. An artificial board made by the protein adhesive prepared by the invention not only has good bonding strength and water resistance, but also has no release of formaldehyde, and all indicators reach and exceed the standards of national Class II artificial boards.

Owner:张成栋 +2

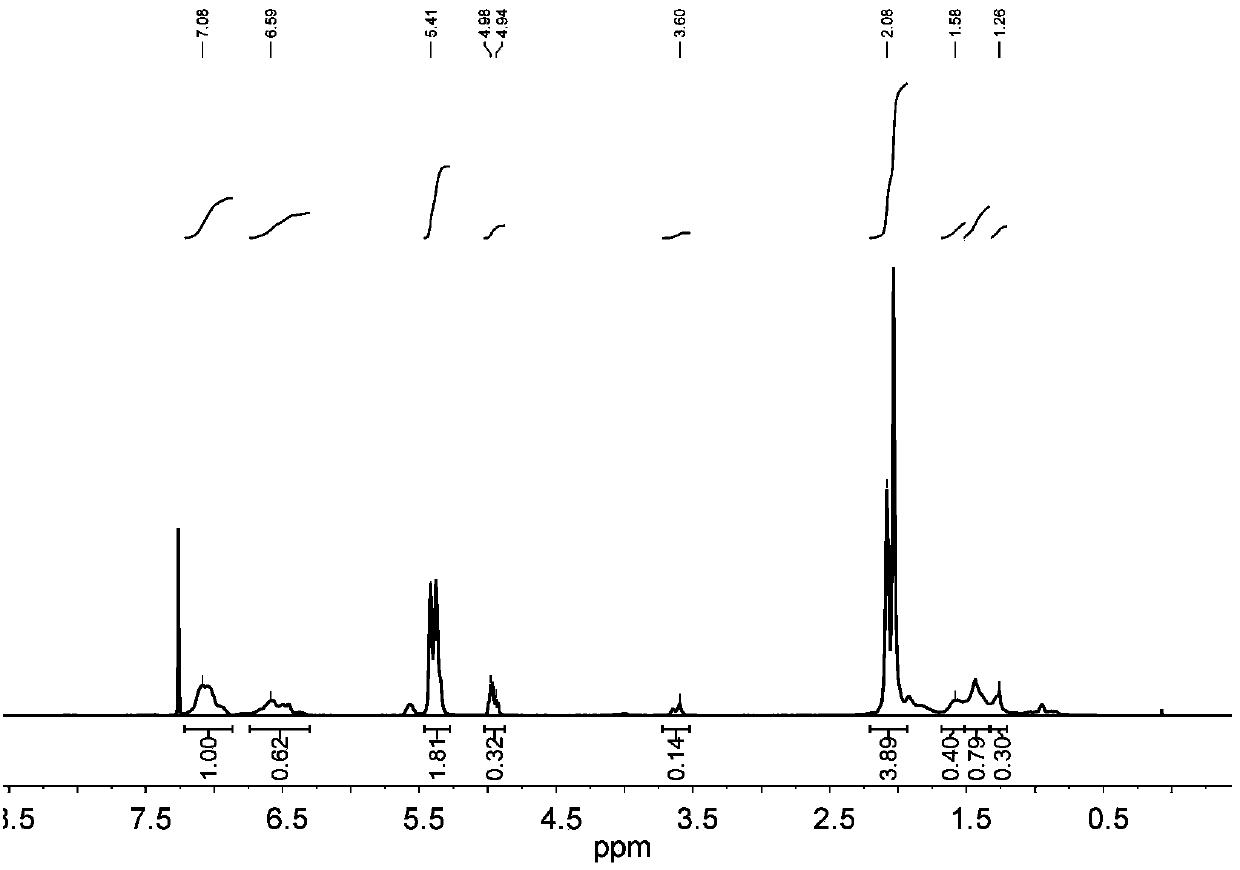

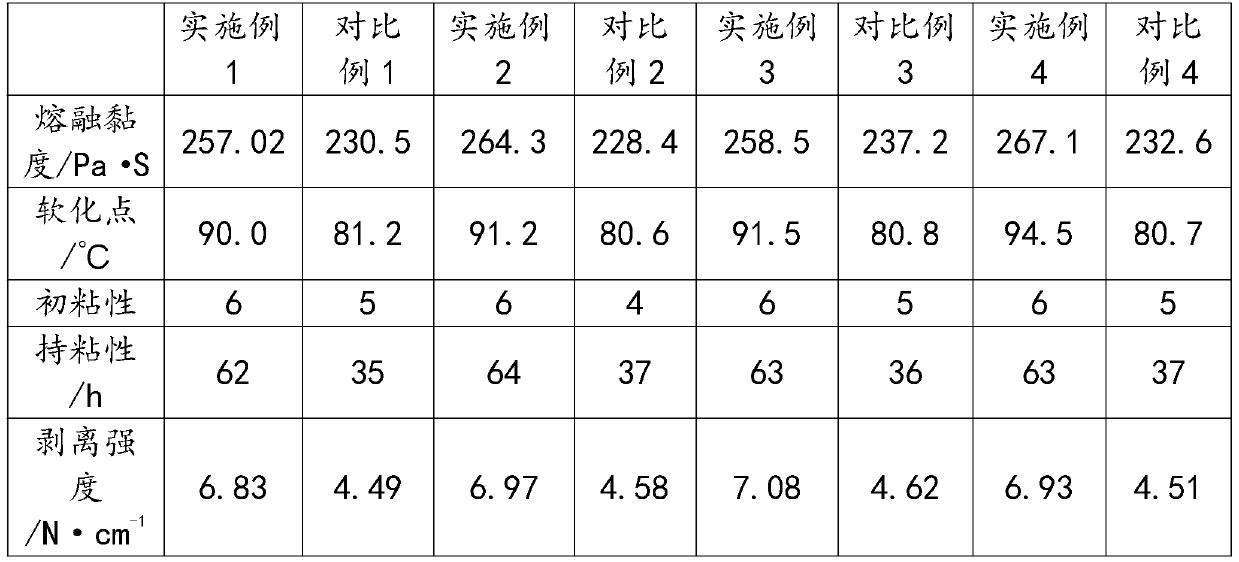

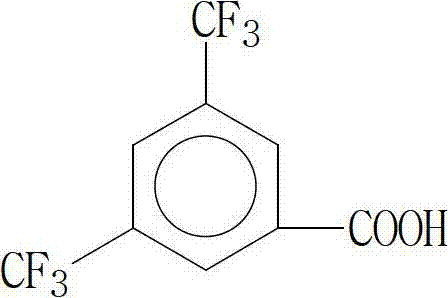

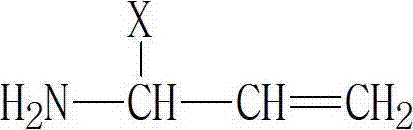

Environmentally-friendly hot-melt pressure sensitive adhesive and preparation method thereof

PendingCN110093128AUniform molecular weightGood solubilityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesEnvironmental resistanceAntioxidant

The invention discloses an environmentally-friendly hot-melt pressure sensitive adhesive. The environmentally-friendly hot-melt pressure sensitive adhesive is prepared from, by weight, 25-35 parts ofa thermoplastic elastomer, 28-36 parts of modified petroleum resin, 6-10 parts of natural tackifying resin, 12-20 parts of a plasticizer, 2-3 parts of a modifying filler, 0.2-0.3 part of a coupling agent and 0.2-0.3 part of an antioxidant. The present invention also discloses preparation method of the hot-melt pressure sensitive adhesive. The thermoplastic elastomer is used as a matrix for the hot-melt pressure sensitive adhesive, the modified petroleum resin and the natural tackifying resin are used as tackifying resins, and no organic solvent is needed, so the raw materials are safe and environmentally friendly; the petroleum resin is modified, so the compatibility of the petroleum resin and the thermoplastic elastomer is improved, and the thermal stability of the hot-melt pressure sensitive adhesive is improved; and the reinforcing effect of the modifying filler improves the initial viscosity, the glass strength and the thermal stability of the hot-melt pressure sensitive adhesive are improved, so the environmentally-friendly hot-melt pressure sensitive adhesive with excellent performances is prepared.

Owner:黄敏

Fluoroacrylate pressure sensitive adhesive, and preparation method thereof

ActiveCN102775942AImprove cohesion and bond strengthCarbon-fluorine bond energyOrganic compound preparationPretreated surfacesPressure sensitiveSolvent

The invention provides a fluoroacrylate pressure sensitive adhesive and a preparation method of the adhesive. The fluoroacrylate pressure sensitive adhesive is characterized by containing at least 2.5% of fluoric hard monomer in percentage by weight. The number-average molecular weight of the prepared fluoroacrylate pressure sensitive adhesive is 9000-300000; and the pressure sensitive adhesive has low surface property, so the silicon transfer in the separation process of adhesive and the release paper is reduced and the adhering strength between the adhesive and the adhered object is enhanced. The invention further provides a coating and drying technique of the fluoroacrylate pressure sensitive adhesive. The coating and drying technique comprises two steps of coating and drying, and is characterized by evenly coating the fluoroacrylate pressure sensitive adhesive on a substrate, performing thermal insulation treatment before drying, and then drying to remove solvent. The fluoroacrylate pressure sensitive adhesive has the following characteristics of simple production technique, easy operation, solvent resistance, good cohesion, and high adhering strength.

Owner:滁州云林数码影像耗材有限公司

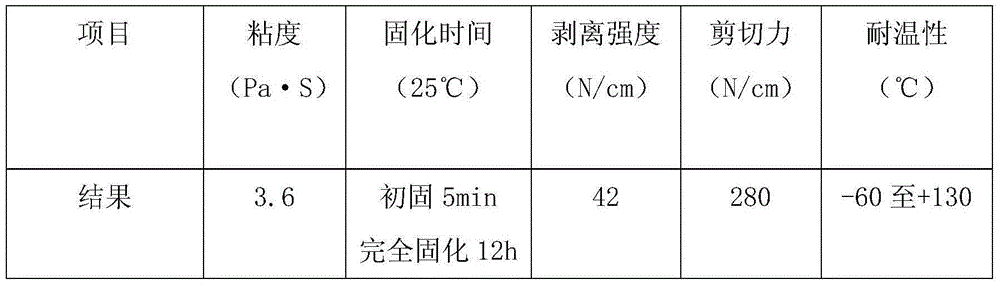

An addition type silicone pressure-sensitive adhesive used for medicines and a preparing method thereof

ActiveCN107338020ALow shrinkageReduce pollutionNon-macromolecular adhesive additivesFilm/foil adhesivesHydrogenSilicone oil

An addition type silicone pressure-sensitive adhesive used for medicines and a preparing method thereof are disclosed. Raw materials of the addition type silicone pressure-sensitive adhesive include, by weight, 100 parts of vinyl silicone oil, 5-10 parts of hydrogen-containing silicone oil, 3-5 parts of a filler, 0.03-0.3 part of an inhibitor and 0.03-0.3 part of a catalyst. The pressure-sensitive adhesive is nontoxic, nonirritant, waterproof and breathable, has good initial adhesive force, holding power and peel strength, can be uncovered and adhered repeatedly, and is a pressure-sensitive adhesive material having ideal properties for medicines.

Owner:南宁市六分仪生物科技有限责任公司

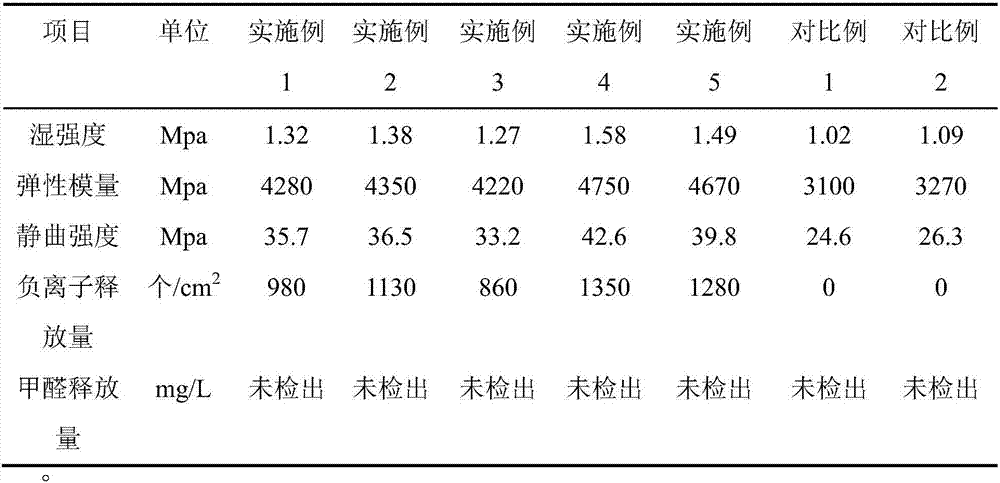

Negative ion soybean formaldehyde-free adhesive

ActiveCN107011857AInhibition releaseImprove initial viscosityNon-macromolecular adhesive additivesProtein adhesivesUltimate tensile strengthBonding strength

The invention discloses a negative ion soybean formaldehyde-free adhesive. The negative ion soybean formaldehyde-free adhesive is prepared from the following raw materials in parts by weight: 10 to 100 parts of soybean derivative, 0.1 to 10 parts of modifier, 30 to 100 parts of crosslinking agent, 100 parts of water and 0.1 to 10 parts of negative ion additive. An artificial board made of the negative ion soybean formaldehyde-free adhesive prepared by the invention has the advantages that the formaldehyde is completely not released, and the air negative ion which is beneficial for a human body can be released; by adding the negative ion, the initial adhering property and bonding strength of the soybean adhesive are improved.

Owner:宁波朝露新材料科技有限公司

Thermosetting reaction type EVA hot-melt adhesive

InactiveCN101070455AImprove heat resistanceImprove cohesive strengthNon-macromolecular adhesive additivesHeat resistanceCohesive strength

The present invention relates to a hot-set reactive EVA thermo sol. The weight proportion of this material: EVA gum (55-85 shares), increase dimension agent (25-45 shares), crummy peroxide (0.01-0.6 shares), benzoic peroxide (0.01-0.5 shares), 1, 2-divinylbenzene (0.01-0.5 shares). Comparing to normal EVA thermo sol, the present invention obviously increases heat endurance, cohesive strength, bonding action and refractoriness of the EVA thermo sol. The technical level of the EVA thermo sol is increased, and in some aspects, it can replace the PA, PUR, PET thermo sols.

Owner:杭州仁和热熔胶有限公司

Plastic label adhesive and preparation method thereof

InactiveCN105647441AImprove pass rateHigh viscosityNon-macromolecular adhesive additivesStarch derivtive adhesivesAmmonium sulfateSolvent

The invention discloses a plastic label adhesive which comprises water, hydroxypropyl distarch phosphate, polyvinyl alcohol, vinyl acetate, butyl acrylate, vinyl versatate, dibutyl maleate, ethylene glycol, tributyl citrate, polyisobutylene, alkyl phenol polyoxypropylene, sodium dodecyl benzene sulfonate and ammonium persulfate. The invention also discloses a preparation method of the plastic label adhesive. The preparation method mainly comprises a solvent technique and polymerization reaction. The preparation method is simple and easy to implement, is nontoxic and environment-friendly in the preparation process, and has the advantage of low preparation cost. The label adhesive has higher adhesive force for plastics under the condition that no solvent is allowed, has certain pressure sensitiveness, and is suitable for both manual and mechanical bonding.

Owner:苏州市丛岭胶粘剂有限公司

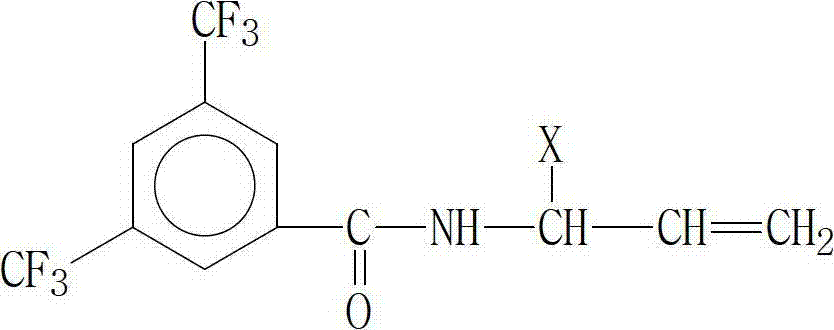

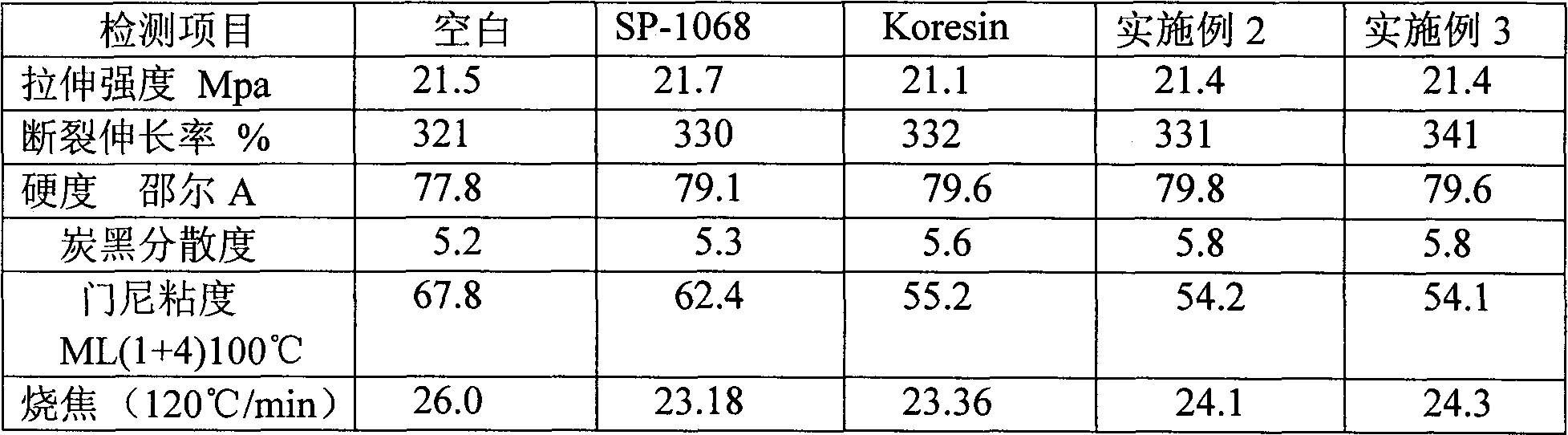

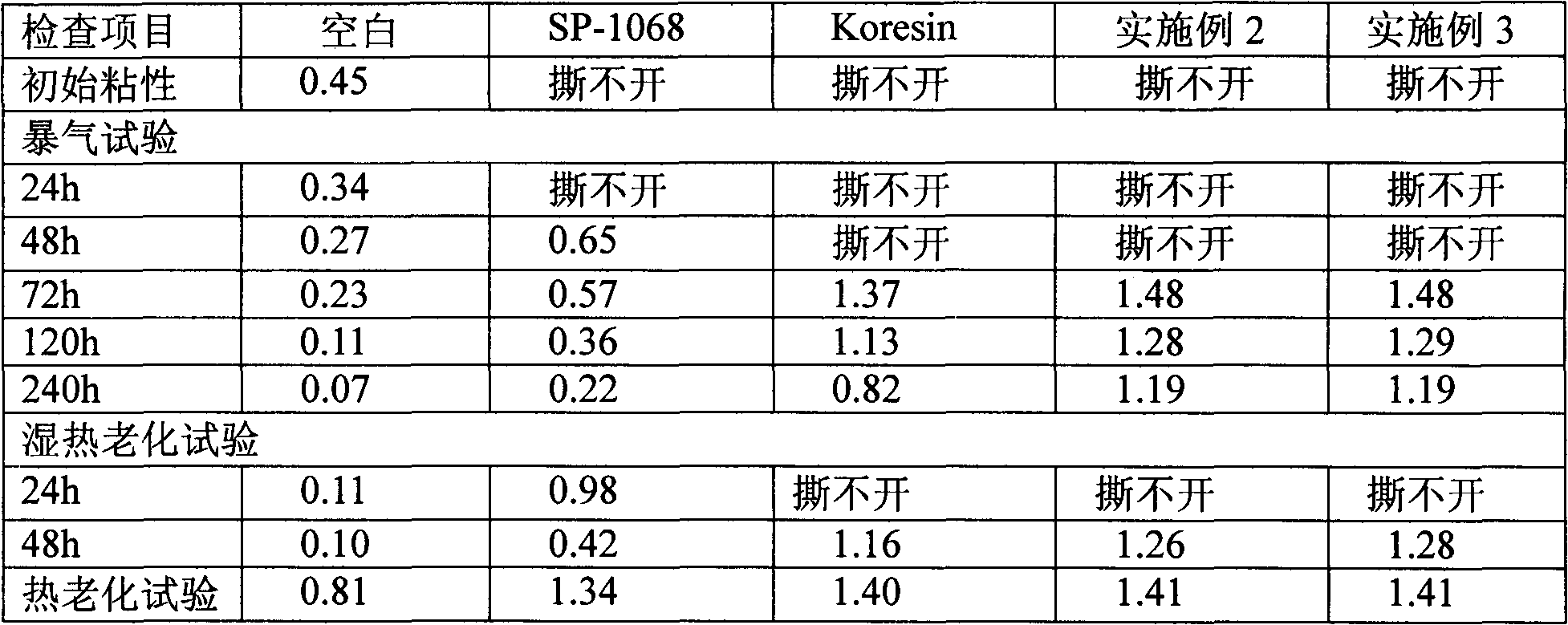

Alkyl phenolic resin rubber tackifier and preparation method

ActiveCN103183799AImprove adhesionImprove performanceSpecial tyresAldehyde/ketone condensation polymer adhesivesRubber materialPolymer science

An alkyl phenolic resin rubber tackifier of the invention has a molecular structure containing benzoxazole heterocyclic groups, and the benzoxazole heterocyclic groups are bonded into the molecules by forming ether bonds through etherification reactions between benzoxazole heterocyclic compounds with monoetherification reaction functional groups and alkylphenol. The tackifier can provide good viscosity for unvulcanized rubber materials. In addition, the alkyl phenolic resin rubber tackifier of the invention can also significantly improve the adhesive force between rubber materials and steel cord materials.

Owner:JIANGSU GUOLI CHEM TECH

Preparation method of modified starch adhesive

The invention provides a preparation method of a modified starch adhesive, which comprises the following steps: (1) adding deionized water as a solvent into a three-neck flask, adding corn starch into the deionized water, and stirring and heating until the corn starch is sufficiently swollen; (2) adding hydrochloric acid, heating, adding an oxidizer, and keeping the temperature to sufficiently react the oxidizer with the corn starch; (3) adding polyvinyl alcohol, and heating; (4) adding a boric acid solution, heating, and keeping the temperature to sufficiently perform coupling reaction on the boric acid and polyvinyl alcohol; (5) adding a formaldehyde solution, and continuing keeping the temperature; (6) adding sodium hydroxide to terminate the reaction; and (7) adding a surfactant, a drier and a preservative, cooling and discharging to obtain the modified starch adhesive. The preparation method has the advantages of simple technique, accessible raw materials and low cost, and can obtain the modified starch adhesive, which has the advantages of favorable initial viscosity, high drying rate, high viscosity, high mounting performance and stable performance and is convenient for sizing.

Owner:TANGSHAN NORMAL UNIV

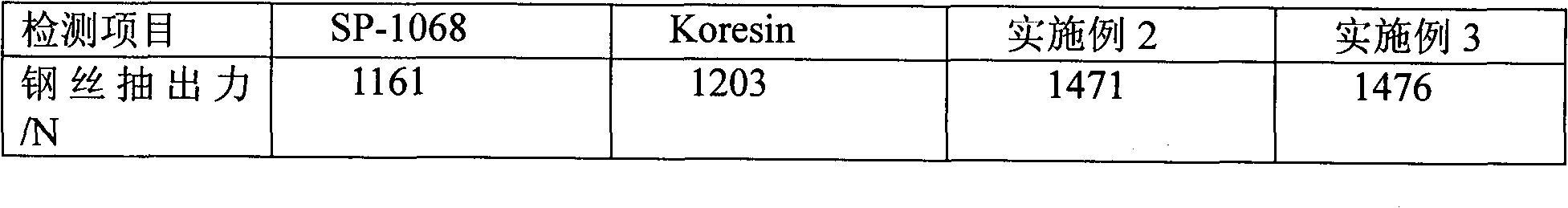

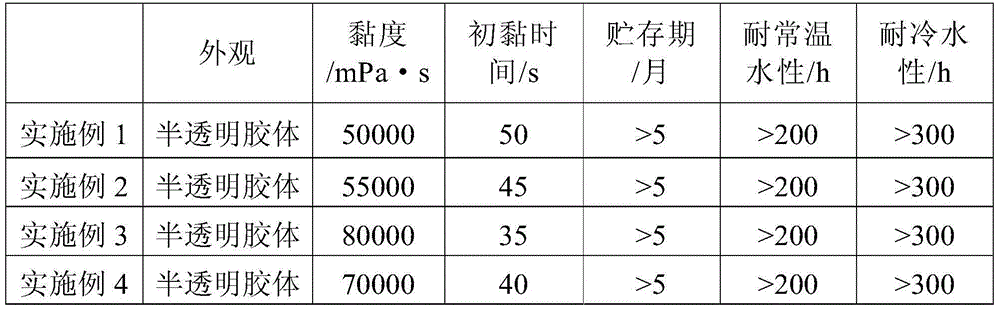

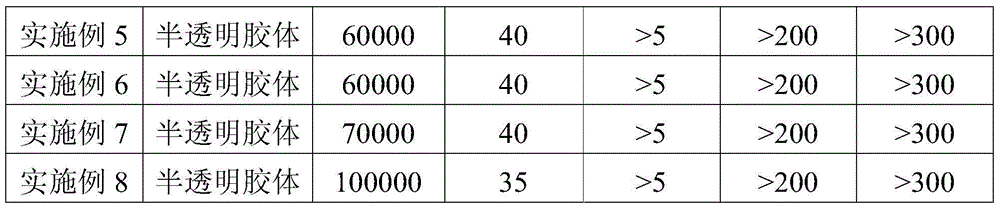

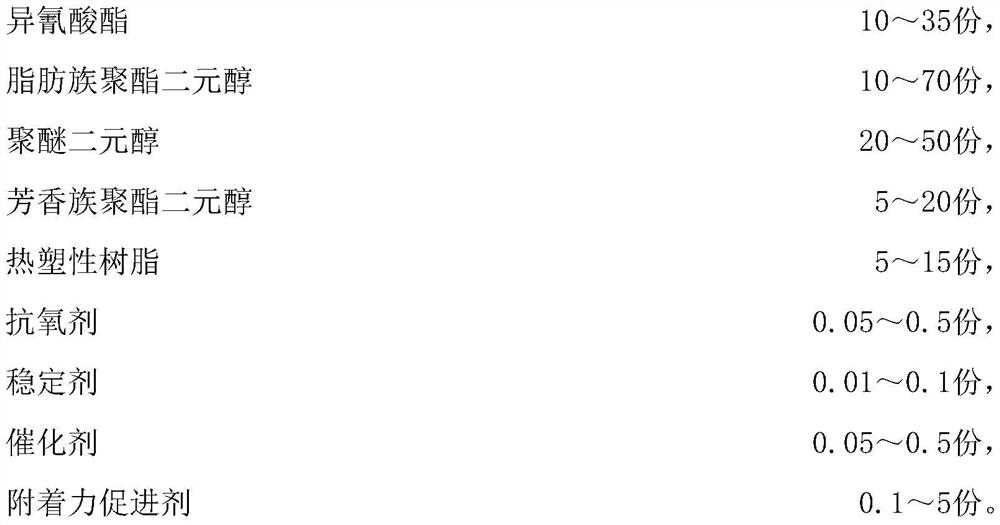

Reactive polyurethane hot melt adhesive for bonding aluminum plate and wood veneer and preparation method of reactive polyurethane hot melt adhesive

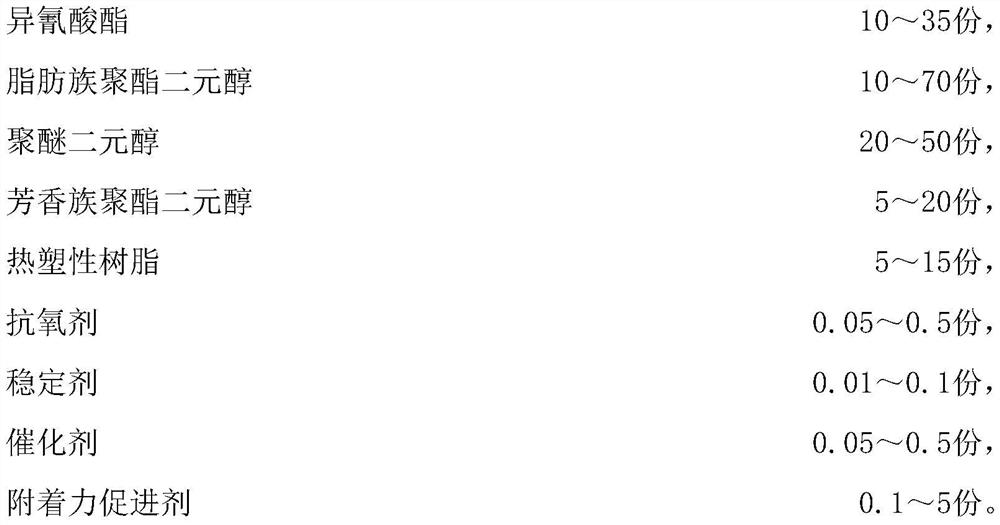

InactiveCN111662671AMeet bonding needsReduce dosageNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterWood veneer

The invention discloses a reactive polyurethane hot melt adhesive for bonding an aluminum plate and a wood veneer and a preparation method of the reactive polyurethane hot melt adhesive. The reactivepolyurethane hot melt adhesive is prepared from the following raw materials in parts by weight: 10-35 parts of isocyanate, 10-70 parts of aliphatic polyester diol, 20-50 parts of polyether diol, 5-20parts of aromatic polyester diol, 5-15 parts of thermoplastic resin, 0.05-0.5 part of an antioxidant, 0.01-0.1 part of a stabilizer, 0.05-0.5 part of a catalyst and 0.1-5 parts of an adhesion promoter. The adhesive has high initial adhesion and good later adhesion, can meet the adhesion requirement of an aluminum plate and a wood veneer, and can improve the working efficiency in the adhesion process.

Owner:BEIJING COMENS NEW MATERIALS

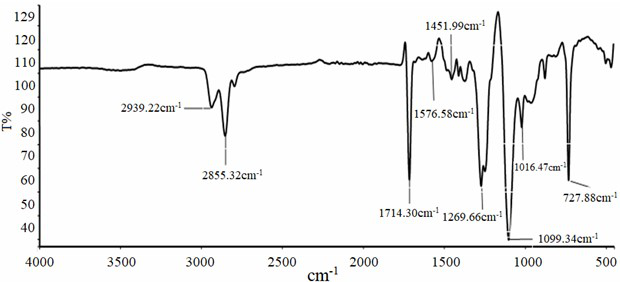

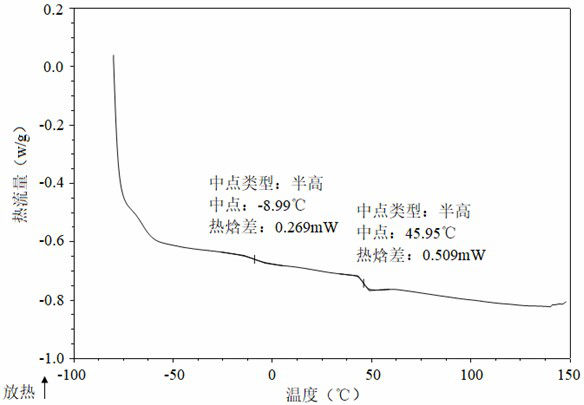

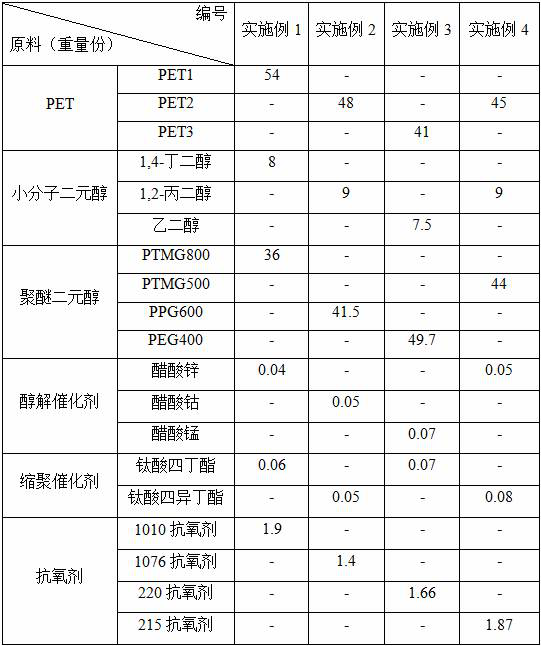

Polyether ester multi-block copolymerized dihydric alcohol, synthetic method and application of reactive hot melt adhesive

ActiveCN111875785AGood compatibilityExtended opening hoursPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses polyether ester multi-block copolymerized dihydric alcohol, a synthesis method and application of a reactive hot melt adhesive. The polyether ester multi-block copolymerized dihydric alcohol is mainly prepared from the following raw materials: polyethylene glycol terephthalate, small molecular dihydric alcohol, polyether dihydric alcohol, an alcoholysis catalyst, a polycondensation catalyst and an antioxidant. The synthesis method comprises the following steps: adding polyethylene glycol terephthalate, small molecular diol, polyether diol and an alcoholysis catalyst into a reactor, carrying out alcoholysis reaction under the protection of nitrogen, adding a polycondensation catalyst and an antioxidant, heating the reactants, carrying out vacuum polycondensation reaction, and cooling a reaction product. The invention also discloses an application of the polyether ester multi-block copolymerized dihydric alcohol in preparation of the reactive hot melt adhesive. The polyether ester multi-block copolymerized dihydric alcohol has a micro-phase separation structure and-lower and-zero glass transition temperatures, and has good intermiscibility with polyester and polyether polyol. The method is short in reaction time, simple, low in cost and suitable for industrial production. The obtained hot melt adhesive has high initial adhesion and long opening time.

Owner:湖南恒旺新材料科技有限公司

Non-substrate easy-to-pull removable adhesive tape as well as preparation and use method thereof

ActiveCN108570293AConvenient after-sales maintenanceConvenience for other needsMacromolecular adhesive additivesFilm/foil adhesives without carriersTolueneElectronic component

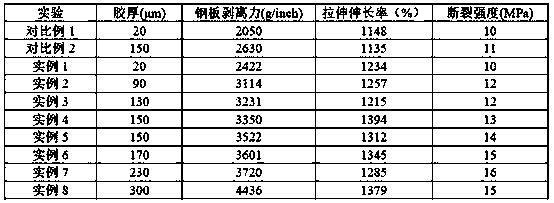

The invention discloses a non-substrate easy-to-pull removable adhesive tape. The adhesive tape has a thickness of 20 to 300 mu m, is prepared from the following components in parts by mass: 80 to 150parts of thermoplastic rubber, 60 to 150 parts of tackifying resin, 100 to 330 parts of toluene, 1 to 30 parts of softener, 1 to 10 parts of color paste, and 0.1 to 1 part of leveling agent. The non-substrate adhesive tape is a double-sided fixing tape with high bonding strength, can be used without pretreatment, and can be used after just peeling off the release paper or the release film. When the adhesive tape needs to be removed, the adhesive tape is only stretched to remove. The adhesive tape can bring great convenience to the staff during the maintenance of the electronic components.

Owner:SUZHOU SHIHUA NEW MATERIAL TECH

Preparation method of waterborne polyurethane leather glue

InactiveCN103031732AHigh solid contentStrong environmental protectionFibre treatmentPolymer sciencePropanoic acid

The invention discloses a preparation method of waterborne polyurethane leather glue. The waterborne polyurethane leather glue is prepared by preparing a prepolymer based on isophorone diisocyanate (IPDI), polycrylactone 1000 (PCL1000), propylene glycol (PG) and dimethylol propionic acid (DMPA) as raw materials; modifying the prepolymer by adding a proper amount of carboxyl butadiene-styrene rubber water emulsion; adding triethylamine and carrying out a neutralization reaction to produce salt; and adding a proper amount of de-ionized water. The waterborne polyurethane leather glue disclosed by the invention has the advantages of high solid content, good binding power, strong environmental protection property and the like.

Owner:QINGDAO WINCHANCE TECH

Aqueous acrylic acid adhesive and preparation method thereof

InactiveCN108084927AReduce pollution indexHigh water resistance and temperature resistanceAcid polymer adhesivesChemical industryAdhesive

The invention belongs to the field of a chemical industry, and especially relates to an aqueous acrylic acid adhesive and a preparation method thereof. The aqueous acrylic acid adhesive comprises thefollowing components in parts by weight: 15-20 parts of acrylic acid, 10-15 parts of methyl acrylate, 10-15 parts of ethyl acrylate, 10-15 parts of acrylic acid-2-ethylhexyl acrylate, 10-15 parts of methyl methacrylate, 10-15 parts of butyl acrylate, 5-10 parts of dimethylolpropionic acid, 5-10 parts of an emulsifier, 5-8 parts of triethylamine, 3-5 parts of a silane coupling agent, 3-5 parts of ablocking agent, 3-5 parts of an adhesion agent, 3-5 parts of aqueous silicone oil, and 300-500 parts of deionized water. The technology is simple and easy to control, and a polymerization system is stable; the obtained adhesive has the advantages of good mechanical stability, storage stability, and compatibility with a general auxiliary agent, and is suitable for industrial production.

Owner:辽宁东夫材料科技有限公司

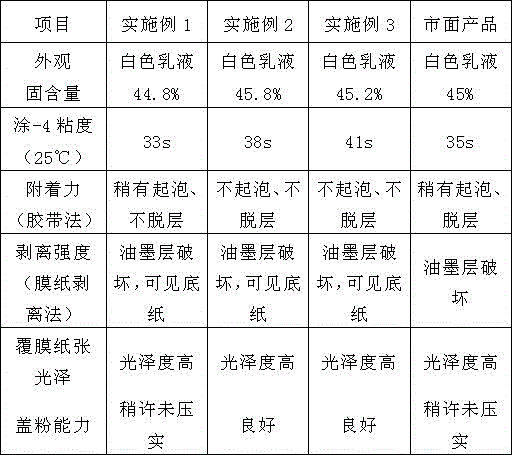

Aqueous dry lamination adhesive and preparation method thereof

ActiveCN105482745AFully bondedImprove adhesionEster polymer adhesivesRosin adhesivesSodium bicarbonateIsooctyl acrylate

The invention discloses an aqueous dry lamination adhesive and a preparation method thereof. Raw materials of the aqueous dry lamination adhesive comprise styrene, butyl acrylate, isooctyl acrylate, acrylonitrile, N-methylolacrylamide, hydroxyethyl acrylate, acrylic acid, rosin, potassium persulfate, sodium dodecylbenzene sulfonate, isooctyl phenol polyoxyethylene ether, sodium bicarbonate, deionized water, ammonia water, a wetting agent and antifoaming agent. Aqueous latex with a core-shell structure is prepared through a segmented polymerization technology, so functional groups make a substrate and a plastic film be fully bonded, and polymer molecular chains are self-crosslinked, thereby the adhesion and the peeling strength of the substrate are improved, the adhesive has excellent initial adhesion, pressure sensitivity and covering ability, the excellent leveling property and the dynamic wetability of the adhesive make a laminated product have brilliant gloss, and the adhesive can be widely used in paper plastic lamination.

Owner:常德市雄鹰科技有限责任公司

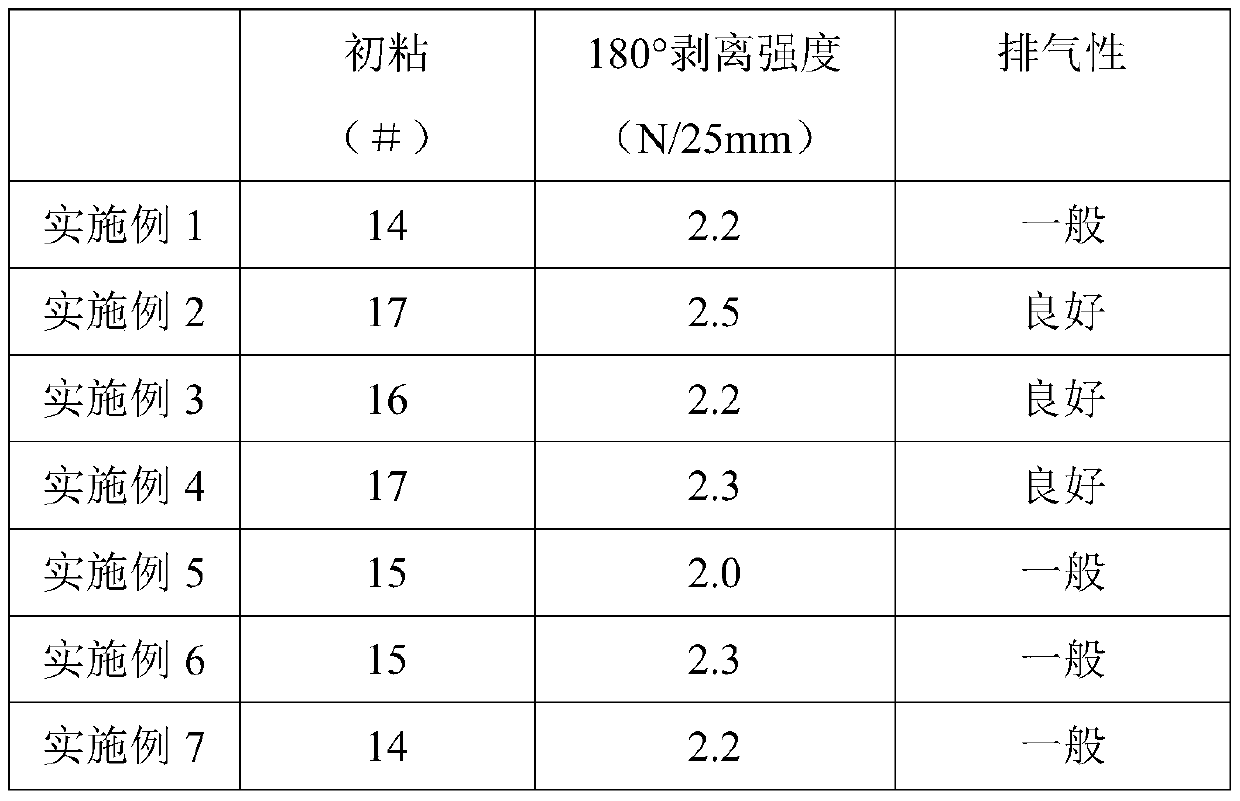

Pressure-sensitive adhesive for intelligent touch screen protective film and preparation method thereof

ActiveCN110607147ALow peel strengthExcellent adhesionEster polymer adhesivesPressure sensitive film/foil adhesivesTectorial membraneUltimate tensile strength

The invention discloses a pressure-sensitive adhesive for an intelligent touch screen protective film, and belongs to the technical field of pressure-sensitive adhesives, wherein the pressure-sensitive adhesive for the intelligent touch screen protective film is prepared from the following raw materials in percentage by mass: 96-98% of polyacrylate resin and 2-4% of a curing agent. According to the invention, the formula of the pressure-sensitive adhesive is preferably selected on the basis of the research on the surface property of the touch screen and an acrylic pressure-sensitive adhesive,so that the adhesive has the advantages of high initial adhesion, good exhaust property and the like; the prepared electronic protective film has low peel strength and good adhesion, the electronic protective film can be easily adhered to cover plate glass and easily torn, the adhesive layer polymer of the electronic protective film has excellent stability, and the problem that the cleanliness ofthe cover plate glass is affected due to the fact that an additive is transferred to an adhesion object can be prevented.

Owner:GUANGDONG DONGLI NEW MATERIALS SCI & TECH CO LTD

Bright silver reflective fabric complex adhesive and preparation method thereof

InactiveCN105001814AImprove initial viscosityHigh bonding strengthNon-macromolecular adhesive additivesHydrocarbon polymer adhesivesAdhesiveTitanium carbide

The invention discloses a bright silver reflective fabric complex adhesive and a preparation method thereof. The bright silver reflective fabric complex adhesive comprises, by weight, 20-30 parts of acrylate resin, 2-4 parts of diphenyl-methane-diisocyanate, 1-3 parts of tetraisopropyl titanate, 8-14 parts of polymethylphenyl silicone, 5-10 parts of poly-alpha-methylstyrene resin, 12-16 parts of ethyl acetate, 0.4-0.6 part of modified aluminum silver powder, 0.2-0.4 part of pearl powder, 0.5-1 part of polymer ferrophosphorus powder, 1-2 parts of aluminum dihydrogen tripolyphosphate and 2-3 parts of nano-titanium carbide. The polymethylphenyl silicone, the poly-alpha-methylstyrene resin, the polymer ferrophosphorus powder, the aluminum dihydrogen tripolyphosphate and the nano-titanium carbide are used in a compounding mode, so the primary viscosity and the bonding strength of the complex adhesive are improved, and the weather resistance, the corrosion resistance and the heat resistance of the complex adhesive can also be improved. The complex adhesive prepared through the method is excellent in combination performance, has the advantages of high bonding strength, good weather resistance, good corrosion resistance and good heat resistance, is long in service life and has broad market prospects.

Owner:ANHUI SHUOMING SAFETY TECH CO LTD

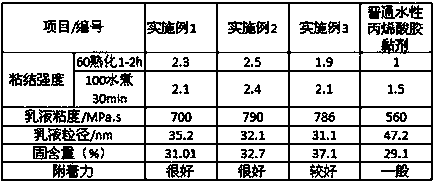

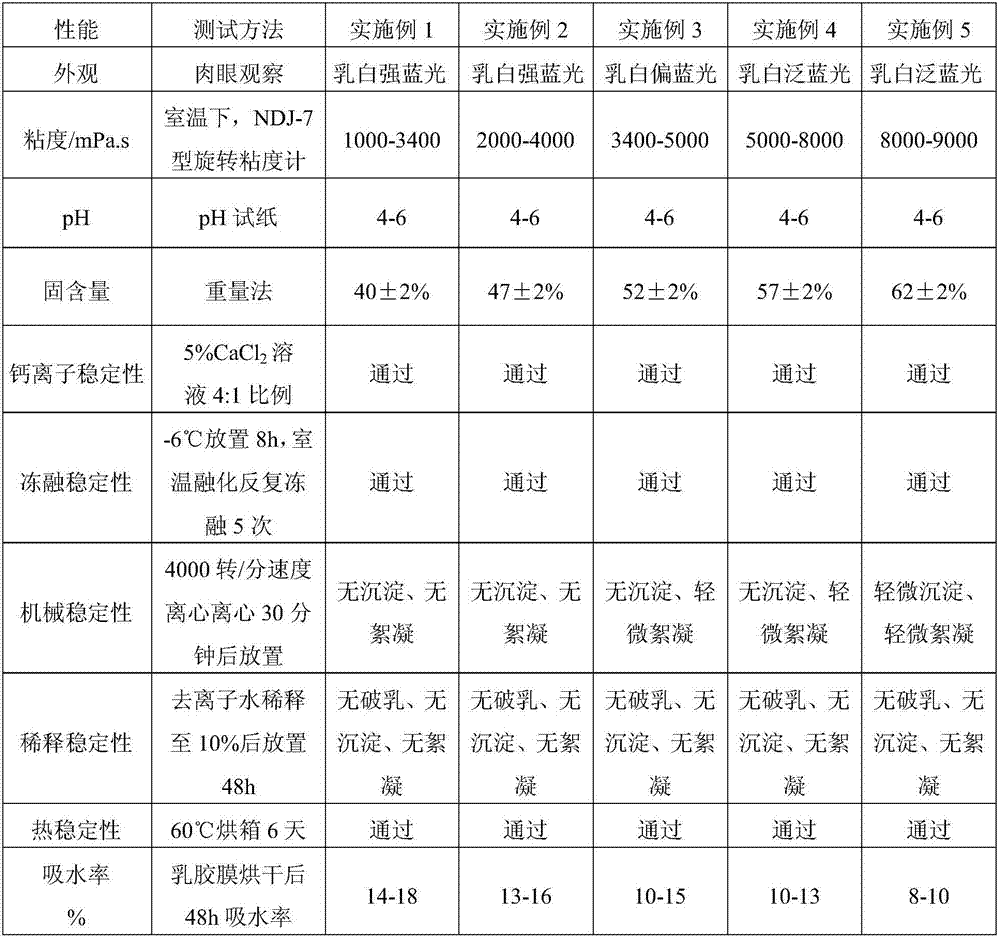

Self-crosslinking vinyl acetate-acrylic emulsion modified with waterborne neoprene latex and cured at room temperature and preparation method of vinyl acetate-acrylic emulsion

The invention belongs to the technical field of emulsion preparation and discloses a self-crosslinking vinyl acetate-acrylic emulsion modified with waterborne neoprene latex and cured at room temperature and preparation method of vinyl acetate-acrylic emulsion. The emulsion is prepared from the following components in parts by mass through a reaction: 39.43-55.93 parts of water, 12.66-15.88 parts of aqueous neoprene latex, 8.12-15.72 parts of butyl acrylate, 12.12-19.72 parts of vinyl acetate, 9.86-12.12 parts of isooctyl acrylate, 1.4-1.5 parts of a functional monomer, 0.2-0.3 parts of polyvinyl alcohol, 2.33-3.7 parts of an emulsifier, 0.07-0.093 parts of a buffer agent, 0.14-0.2 parts of an initiator, 0.42-0.64 parts of diacetone acrylamide, 0.21-0.32 parts of a crosslinking agent, 0.025-0.035 parts of tert-butyl hydroperoxide and 0.015-0.025 parts of sodium formaldehyde sulfoxylate. With introduction of the water-based neoprene latex, initial viscosity and cohesion strength are significantly improved, and waterproof, anti-fouling and anti-corrosion properties as well as peel strength are greatly improved after film forming.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

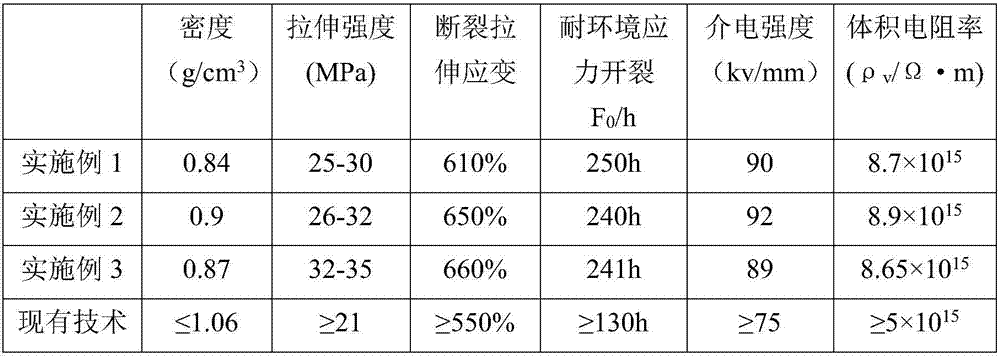

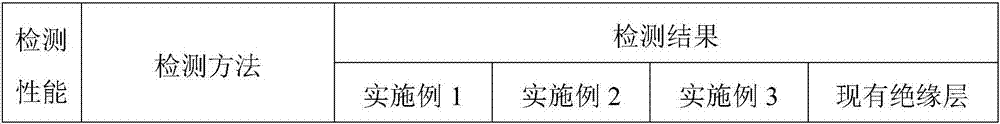

Insulating layer for power transmission and transformation lines

InactiveCN107216631AImprove insulation performanceIncrease flame retardancyPlastic/resin/waxes insulatorsBuilding insulationsChemistryRosin

The invention discloses an insulating layer for power transmission and transformation lines, which consists of the following materials in parts by weight: 5 to 15 parts of silicone rubber; 6 to 15 parts of isoprene rubber; 15 to 20 parts of mineral colloid; 2 to 5 parts of chlorinated polyether; 15 to 40 parts of polycarbonate; 1 to 3 parts of ethylene-vinyl acetate copolymer; 15 to 20 parts of ABS plastic; 4 to 10 parts of dioctyl sodium sulfosuccinate; 2 to 4 parts of lead monoxide; 1 to 3 parts of graphite powder; 1 to 3 parts of rosin; 2 to 5 parts of epoxy fatty acid octyl ester; 2 to 4 parts of poly diallyldimethylammonium chloride; 10 to 15 parts of hexamethylenetetramine; 5 to 15 parts of fire retardant; 1 to 4 parts of cross-linking agent; and 5 to 10 part of filler. The insulating layer for power transmission and transformation lines provided by the invention has excellent properties, such as mechanical property, breakdown resistance and heat resistance.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

Epipastic mineral surface solidifying agent

InactiveCN101492597AReduce churnDo not change the original performanceOther chemical processesLoading/unloadingNon toxicitySodium Bentonite

The invention discloses a powdered mineral surface curing agent which comprises swelling starch, alum, anhydrous calcium chloride, bentonite of calcium, borax and other accessory ingredients. The powdered mineral surface curing agent has the advantage that a 'liquid tarpaulin' is used in a way of spraying in the process of transporting coal or powdered ore by utilizing swelling adhesive technology. As the coal layer or the powdered ore layer is effectively sprayed and covered, the loss, the environmental pollution and potential safety hazard which are caused in the transportation of coal or powdered ore can be reduced. Being different from the original method for oxidizing and pasting by using other formulation under the condition of liquidoid, the invention reduces a great deal of equipment and complicated working procedures. For the transportation of coal or powdered ore, the powdered mineral surface curing agent does not change the original properties of coal or powdered ore and has the advantages of lower cost, non-toxicity, no corrosion, no pollution, light weight, good fluidity, rapid dryness, fine toughness, high primary adhesive force, stable viscocity, high intensity, strong curing force, high stability, simple and convenient use, etc.

Owner:王耀权 +1

Hot-melt type environment-friendly pressure-sensitive adhesive for double sticky tape and preparation method of pressure-sensitive adhesive

InactiveCN103305166AReasonable preparation processSimple implementationMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesPlasticizerHot melt

The invention provides a hot-melt type environment-friendly pressure-sensitive adhesive for a double sticky tape and a preparation method of the pressure-sensitive adhesive. The hot-melt type environment-friendly pressure-sensitive adhesive is prepared from a tackifier, a flexibilizer, a plasticizer, an antioxidant and an antiager. The preparation method comprises the following steps of: (a) proportioning raw materials; (b) melting the tackifier; (c) preparing the adhesive; and (d) carrying out post treatment. The hot-melt type environment-friendly pressure-sensitive adhesive has a reasonable preparation process and simple implementation links, the prepared hot-melt type environment-friendly pressure-sensitive adhesive is not only transparent in color and luster, good in appearance and initial stickness, but also non-poisonous and pollution-free, and when the hot-melt type environment-friendly pressure-sensitive adhesive is stripped, a surface to be covered cannot be stuck with dirt.

Owner:KUNSHAN HANBAO TAPE TECH

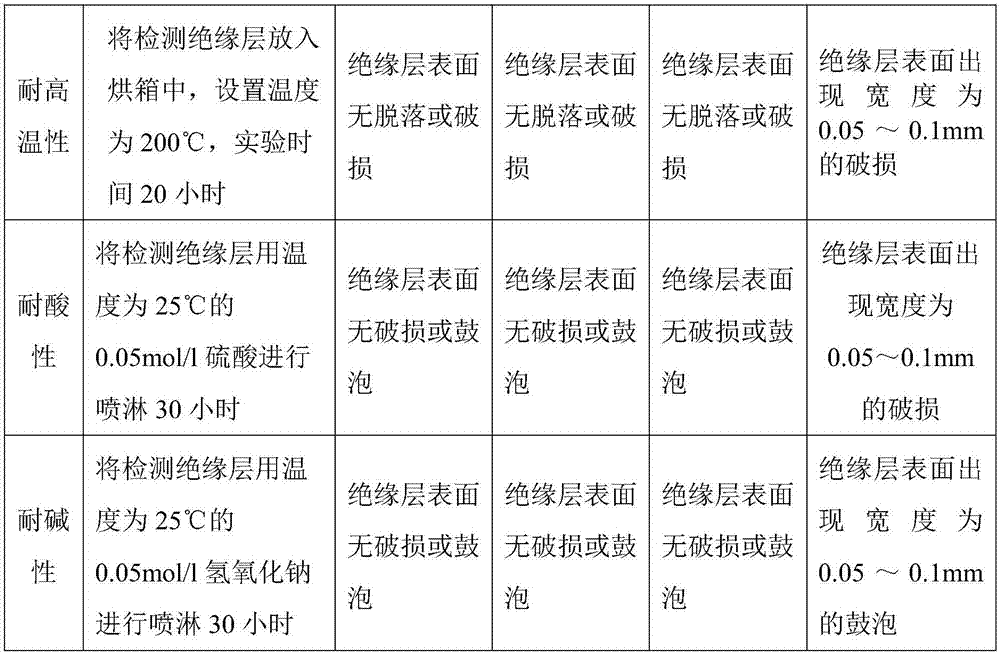

Nail-free all-purpose adhesive and preparation method thereof

InactiveCN104710954AHigh strengthEasy to useMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesTert butyl phenolAntioxidant

The invention discloses a nail-free all-purpose adhesive and a preparation method thereof, and aims to provide a nail-free all-purpose adhesive which has the advantages of high viscosity, high safety and environment friendliness and is convenient to use. The technical scheme is as follows: the nail-free all-purpose adhesive is composed of 50-100 parts of rubber SBSYH-792, 20-50 parts of rubber SBSYH-796, 20 parts of rubber LGSBS411, 5 parts of polar EVA (ethylene-vinyl acetate), 170 parts of methyl acetate, 350-445 parts of ExxsoL DSP, 30-50 parts of dichloromethane, 40-90 parts of cold-polymerized C9 petroleum resin, 20-50 parts of hot-polymerized C9 petroleum resin, 10 parts of p-tert-butyl phenol formaldehyde resin, 4 parts of active magnesium oxide, 0.125 part of water, 90 parts of terpene resin, 35 parts of modified rosin resin, 5 parts of vinyl chloride-vinyl acetate resin, 5 parts of antioxidant, 15-20 parts of vapor-phase silicon dioxide, 5 parts of titanium white, 0.5 part of coupling agent, 40-50 parts of modified bentonite and 5 parts of zinc stearate. The nail-free all-purpose adhesive belongs to the technical field of high polymers.

Owner:GUANGDONG ORIENT RESIN

Pressure-sensitive adhesive protection film for mobile phone screen and preparation method of pressure-sensitive adhesive protection film

InactiveCN109593483AImprove hydrophobicityImprove initial viscosityEster polymer adhesivesPressure sensitive film/foil adhesivesTectorial membraneFunctional monomer

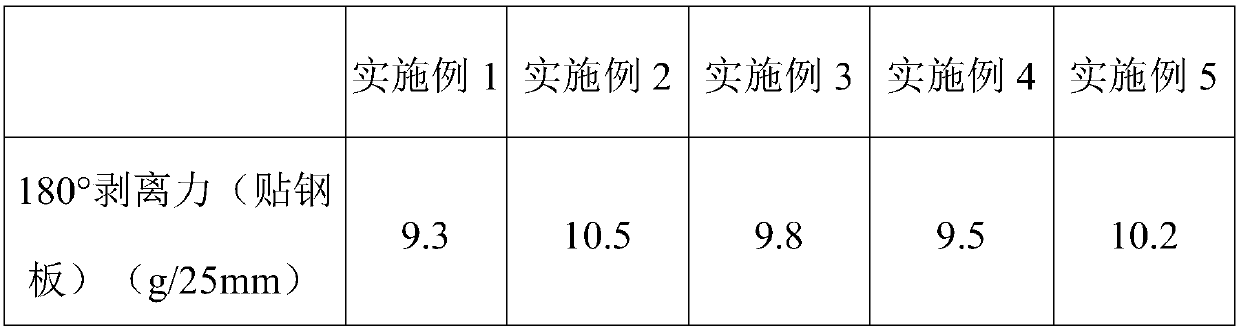

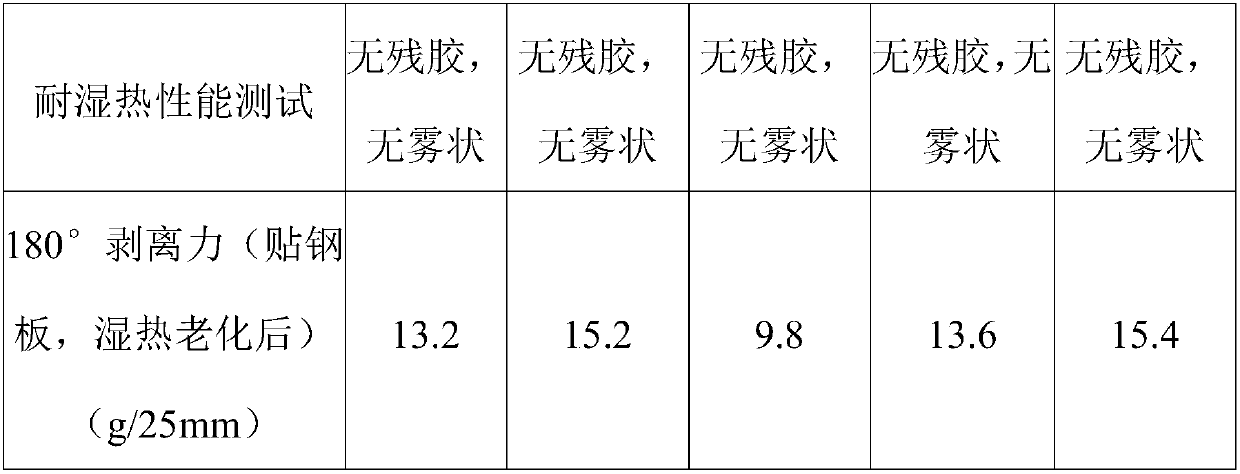

The invention discloses a pressure-sensitive adhesive protection film for a mobile phone screen and a preparation method of the pressure-sensitive adhesive protection film. Raw materials of the pressure-sensitive adhesive protection film for the mobile phone screen, disclosed by the invention, comprise two components A and B; the component A comprises the components in percentage by weight: 4-10%of hard monomer, 18-29.5% of soft monomer, 1-5% of functional monomer, 0.5-2% of silicon monomer, 65% of solvent and an initiator accounting for 0.1-0.5% of the total weight of the hard monomer, the soft monomer, the functional monomer and the silicon monomer; and the component B is a curing agent accounting for 0.5-3% of the total weight of the component A. The pressure-sensitive adhesive protection film for the mobile phone screen, disclosed by the invention, is very good in initial adhesion and wet-heat resistance, incapable of remaining fog-shaped adhesive marks on the surface of a glass screen of a mobile phone under a wet-heat condition, stable in performance and capable of use for a long time.

Owner:无锡市上都新材料科技有限公司 +1

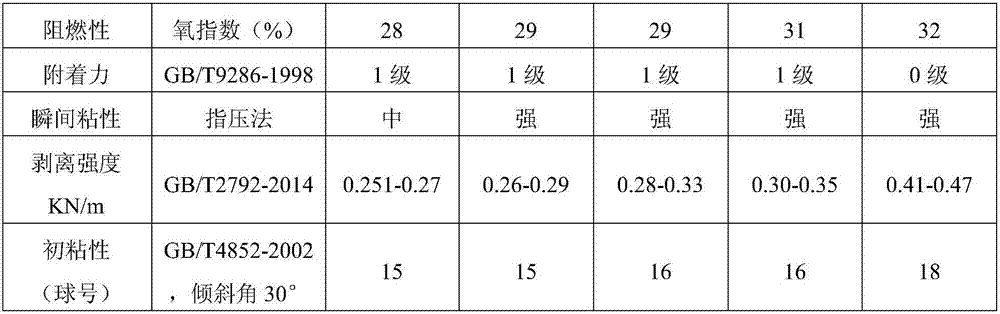

Acrylate emulsion pressure-sensitive adhesive for beautiful textured paper masking tapes, preparation method and applications thereof

ActiveCN104371608AHigh temperature resistantImprove initial viscosityFilm/foil adhesivesEster polymer adhesivesFunctional monomerEmulsion

The invention relates to an acrylate emulsion pressure-sensitive adhesive for beautiful textured paper masking tapes, and a preparation method thereof. The provided acrylate emulsion pressure-sensitive adhesive is prepared from the following components through a pre-emulsification semi-continuous polymerization technology: 2-ethylhexyl acrylate, butyl acrylate, methylbutyl acrylate, 2-hydroxypropyl acrylate, carboxyl-containing functional monomers, internally-crosslinked polyacrylate monomers, and a chain transfer agent. The prepared acrylate emulsion pressure-sensitive adhesive has the advantages of high solid content, low gel content, and good stability, and can be used as a single-component adhesive directly.

Owner:XIANGYANG SUNVALOR AEROSPACE FILMS CO LTD

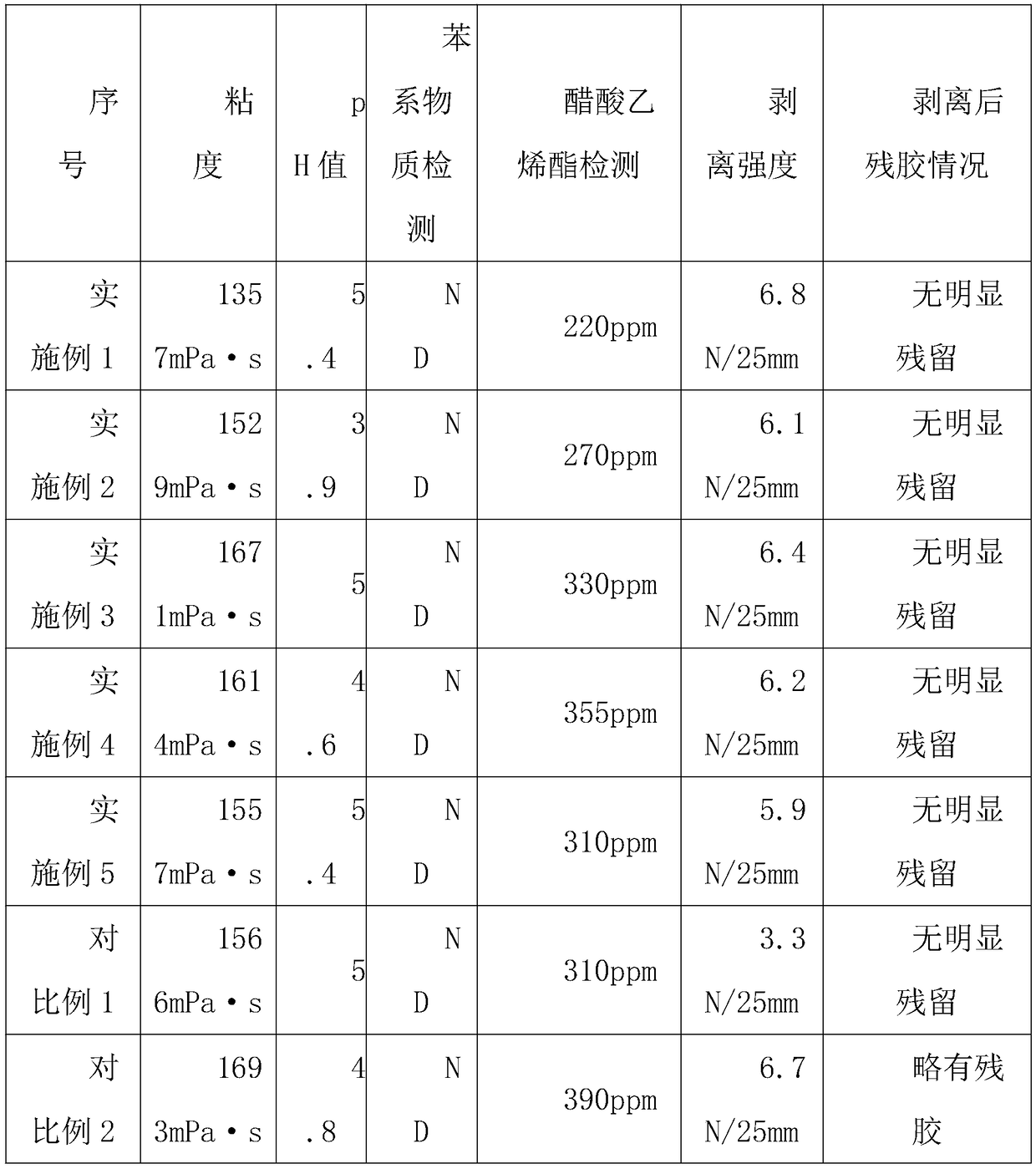

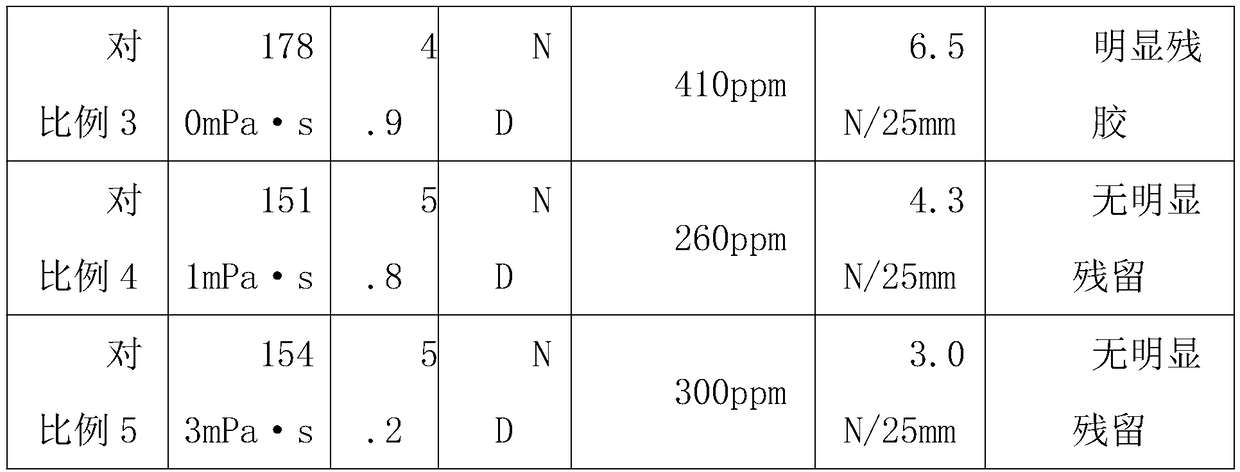

Water-based laser packaging glue used for cigarettes and preparation method thereof

ActiveCN109294488AFast dryingStrong adhesionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesChemistryCalcium

The invention relates to a water-based laser packaging glue used for cigarettes and a preparation method thereof. The water-based laser packaging glue consists of the following components: a VAE emulsion, nano alumina / crystal alumina, calcium chloride, polyvinyl alcohol, alcohol, a nonionic emulsifier, an environmental protection agent, a preservative, and water. Compared with the prior art, the water-based laser packaging glue has the characteristics of fast drying speed, strong cohesive force, good fluidity, no toxicity, no odor, no corrosion, no burning, and storage resistance. The productquality and various technical performance indicators are superior to similar products, especially in terms of drying speed, bond strength and fluidity, which can be increased by 60% based on the past.The water-based laser packaging glue strictly implements the requirements of the People's Republic of China tobacco industry standard-Volatile and semi-volatile components of tobacco water-based glue, formaldehyde is less than 20ppm, ethyl acetate is less than 400ppm, and the water-based laser packaging glue is inspected by the National Tobacco Quality Supervision and Inspection Center.

Owner:湖北恒阳科技发展有限公司

Moisture-curable polyurethane hot melt adhesive for automobile roof pendants and preparation method of the moisture-curable polyurethane hot melt adhesive

PendingCN110607160AImprove wettabilityGood flexibilityPolyureas/polyurethane adhesivesPolymer scienceMoisture cure polyurethane

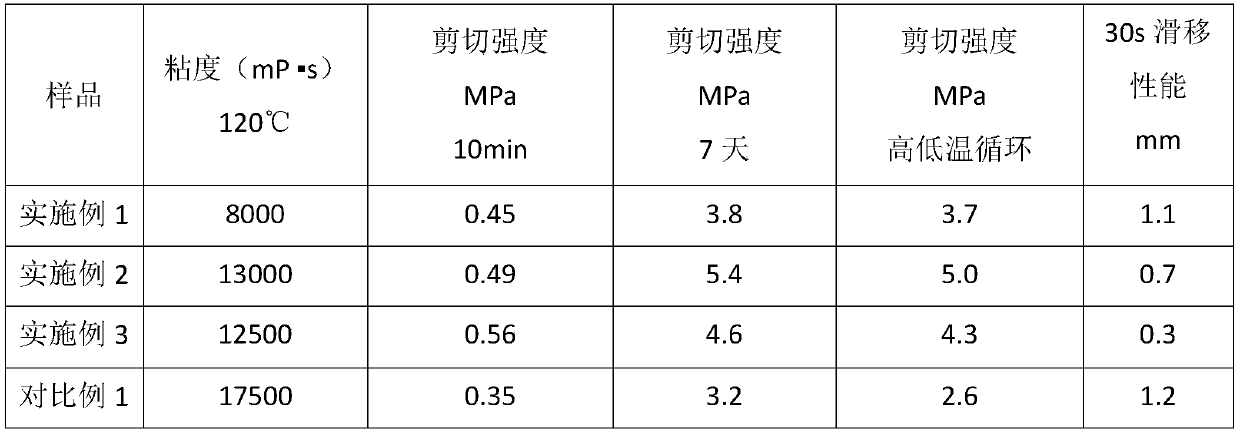

The invention discloses a moisture-curable polyurethane hot melt adhesive for automobile roof pendants. The moisture-curable polyurethane hot melt adhesive comprises the following raw materials in parts by weight: 10-40 parts of polyester polyol, 10-50 parts of polyether polyol, 5-15 parts of high-molecular-weight saturated polyester resin, 5-40 parts of terpene resin, 8-25 parts of isocyanate and0.1-1 part of an antioxidant. The embodiment of the invention further provides a preparation method of the moisture-curable polyurethane hot melt adhesive for the automobile ceiling pendants. The polyester polyol, the polyether polyol, the high-molecular-weight saturated polyester resin, the terpene resin, the isocyanate and the like are used as reaction raw materials to prepare the moisture-curable polyurethane hot melt adhesive for the automobile roof pendants. The polyurethane hot melt adhesive prepared by the invention has relatively high initial bonding strength and final bonding strength, adjustable opening time, relatively low construction temperature and excellent high-temperature and low-temperature cyclic resistance. The raw materials for preparing the polyurethane hot melt adhesive are simple, easy to obtain and low in cost.

Owner:上海汉司实业有限公司

Method for preparing artificial plate adhesive

InactiveCN108424734AImprove adsorption capacityImprove qualityNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesivePhenol

The invention discloses a method for preparing an artificial plate adhesive and belongs to the field of adhesives. According to the artificial plate adhesive, an extract of ginkgo seed coat and nano zinc borate are used; due to substances such as ginkgolic acid and phenol in the ginkgo seed coat, the security and environment protection properties of a wooden product can be improved, and the livingenvironment can be protected; due to addition of the nano zinc borate, the decomposition reaction process and directions of wood can be changed, and pyrolytic reactions of the wood can be developed to generate relatively rich charcoal; meanwhile, a substrate is covered by generated molten boric oxide, so that the flame retardancy of the wooden product can be improved, and the body security can befurther improved. By adopting the method, the problems that a great amount of an adhesive is used in conventional artificial plate production, most adhesives are good in combination property, but poor in function and thus the formaldehyde release amount of an artificial plate is kept at a high level and the living environment can be deteriorated, can be solved.

Owner:翟琳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com