Nail-free all-purpose adhesive and preparation method thereof

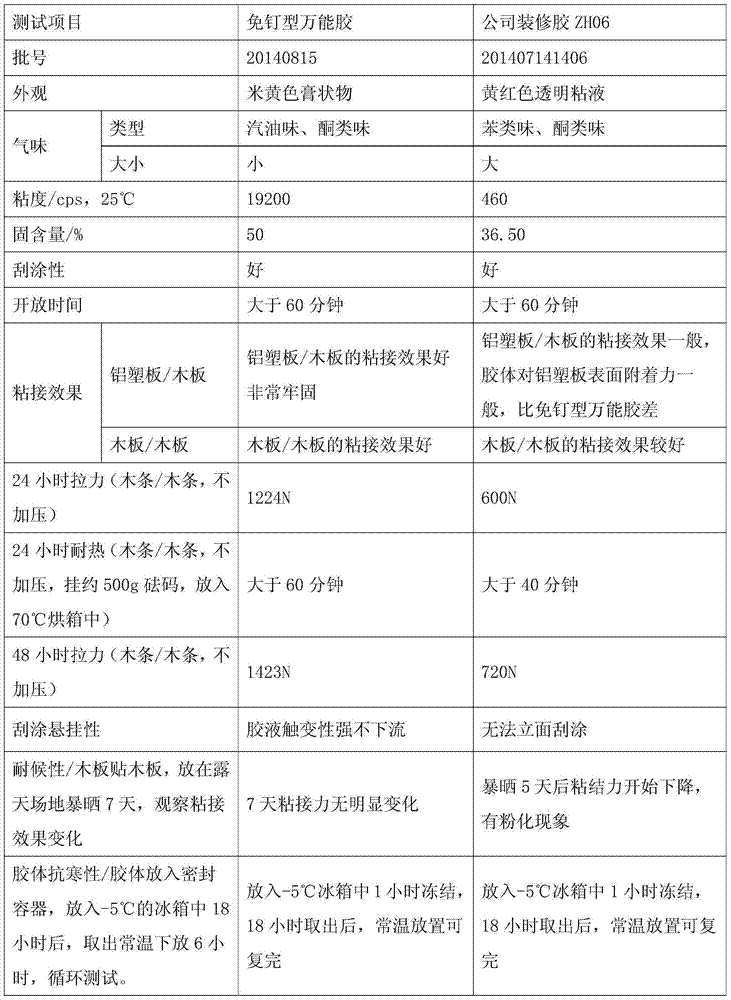

An all-purpose adhesive and rubber technology, applied in the polymer field, can solve the problems of imperfect polar surface adhesion, high cost of neoprene special effect all-purpose adhesive, not resistant to aging and easy to pulverize, etc., and achieve short construction waiting time. , The effect of excellent anti-slip performance and high post-strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A nail-free universal glue provided by the present invention is made of the following components: rubber SBSYH-792 60kg; rubber SBSYH-796 20kg; rubber LGSBS411 20kg; polar EVA R5011 5kg; methyl acetate 170kg; ExxsoL DSP 440kg; Dichloromethane 50kg; cold poly C9 petroleum resin 40kg; hot poly C9 petroleum resin 50kg; activated magnesium oxide 4kg; water 0.125kg; p-tert-butylphenolic resin 10kg; terpene resin 90kg; 5kg; antioxidant CIBA IRGANOX 1010 5kg; fumed silica 20kg; γ-aminopropyltriethoxysilane 0.25kg, γ-(2,3-glycidoxy)propyltrimethoxysilane 0.25kg; Zhejiang Hongyu HY-778 40kg; zinc stearate 5kg; titanium dioxide 5kg.

[0048] 1) take each component by weight parts described in the foregoing examples;

[0049] 2) Add the rubber SBSYH-792 weighed in step 1), rubber SBSYH-796, rubber LGSBS411 and polar EVA into 160kg methyl acetate, dissolve in 440kgExxsoL DSP, and mix for 40 minutes;

[0050] 3) Add cold poly C9, hot poly C9, p-tert-butylphenolic resin, terpene re...

Embodiment 2

[0055] A nail-free universal glue provided by the present invention is made of the following components: rubber SBSYH-792 50kg; rubber SBSYH-796 20kg; rubber LGSBS411 20kg; polar EVAR5011 5kg; methyl acetate 170kg; ExxsoL DSP 445kg; Chloromethane 50kg; cold poly C9 petroleum resin 70kg; heat poly C9 petroleum resin 20kg, p-tert-butylphenolic resin 10kg; active magnesium oxide 4kg; water 0.125kg; terpene resin 90kg; modified rosin resin 35kg; vinyl chloride resin 5kg ; Antioxidant CIBA IRGANOX 1010 5kg; Fumed silica 15kg; Huate Group Organic Bentonite BP-186C 50kg; Zinc Stearate 5kg; Titanium Dioxide 5kg.

[0056] 1) take each component by weight parts described in the foregoing examples;

[0057] 2) Add the rubber SBSYH-792 weighed in step 1), rubber SBSYH-796, rubber LGSBS411 and polar EVA into 150kg methyl acetate, 250kgExxsoL DSP and 50kgMC, dissolve and mix for 40 minutes;

[0058] 3) Add cold poly C9, hot poly C9, p-tert-butylphenolic resin, terpene resin, modified rosi...

Embodiment 3

[0063] A nail-free universal glue provided by the present invention is made of the following components: rubber SBSYH-792 100kg; rubber SBSYH-796 50kg; rubber SBSLG411 20kg; polar EVAR5011 5kg; methyl acetate 170kg; ExxsoL DSP350kg; Methane 30kg; cold poly C9 petroleum resin 90kg; hot poly C9 petroleum resin 20kg; activated magnesium oxide 4kg; p-tert-butylphenolic resin 10kg; terpene resin 90kg; modified rosin resin 35kg; IRGANOX 1010 5kg; fumed silica 20kg; γ-aminopropyltriethoxysilane 0.25kg, γ-(2,3-epoxypropoxy)propyltrimethoxysilane 0.25kg; Zhejiang Huate Group organic bentonite BP-186C 50kg; zinc stearate 5kg; water 0.125kg; titanium dioxide 5kg.

[0064] 1) take each component by weight parts described in the foregoing examples;

[0065] 2) The rubber SBSYH-792, rubber SBSYH-796, rubber LGSBS411 and polar EVA weighed in step 1) were added to 160kg methyl acetate, dissolved in 250kgExxsoL DSP, and mixed for 40 minutes;

[0066] 3) Add cold poly C9 to the mixture of ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com