Patents

Literature

1259 results about "Car manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Car manufacturer - a business engaged in the manufacture of automobiles. auto maker, auto manufacturer, automaker, car maker, carmaker. manufacturer, manufacturing business, maker - a business engaged in manufacturing some product. automobile industry - the manufacturers of automobiles considered collectively.

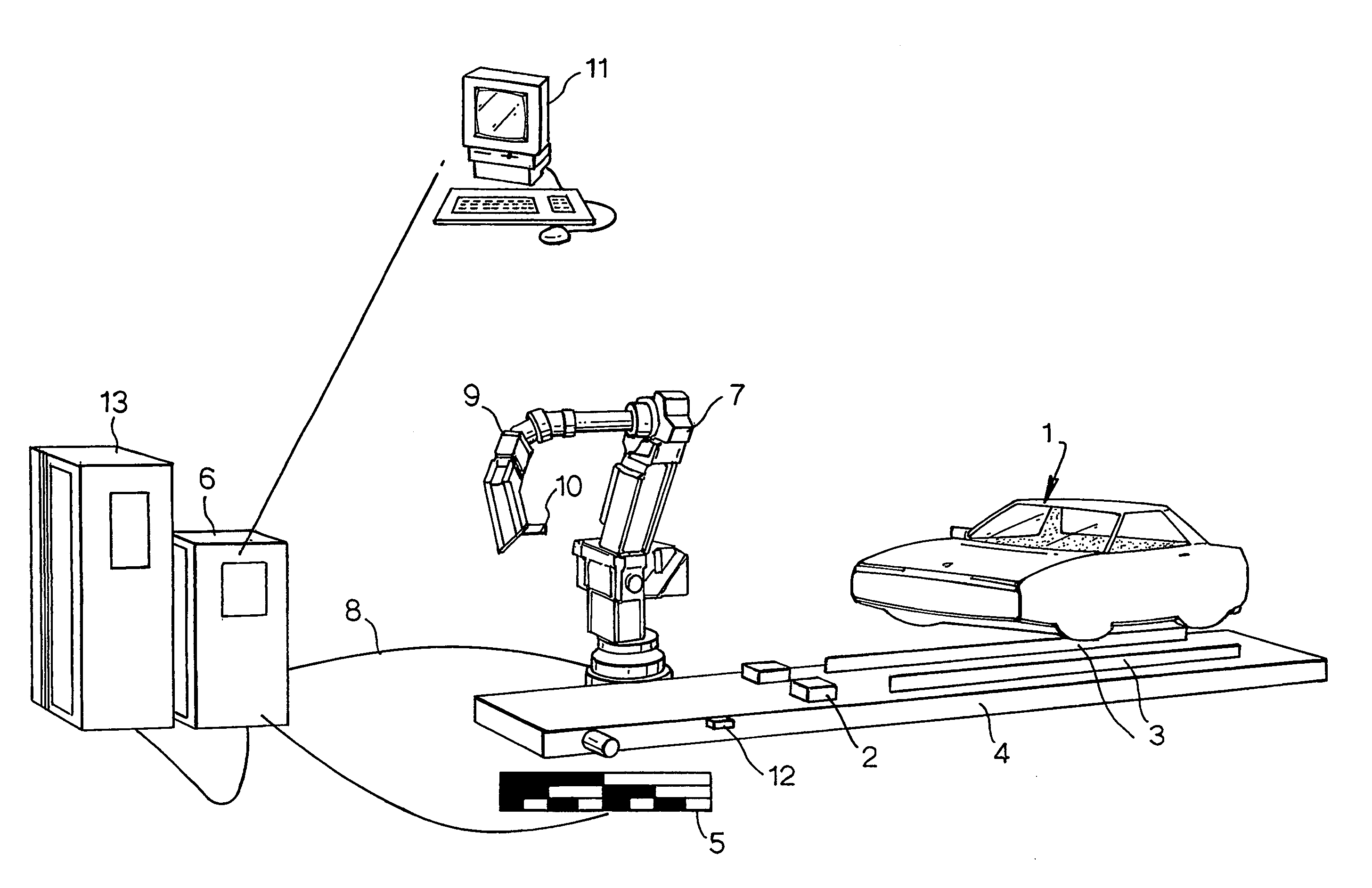

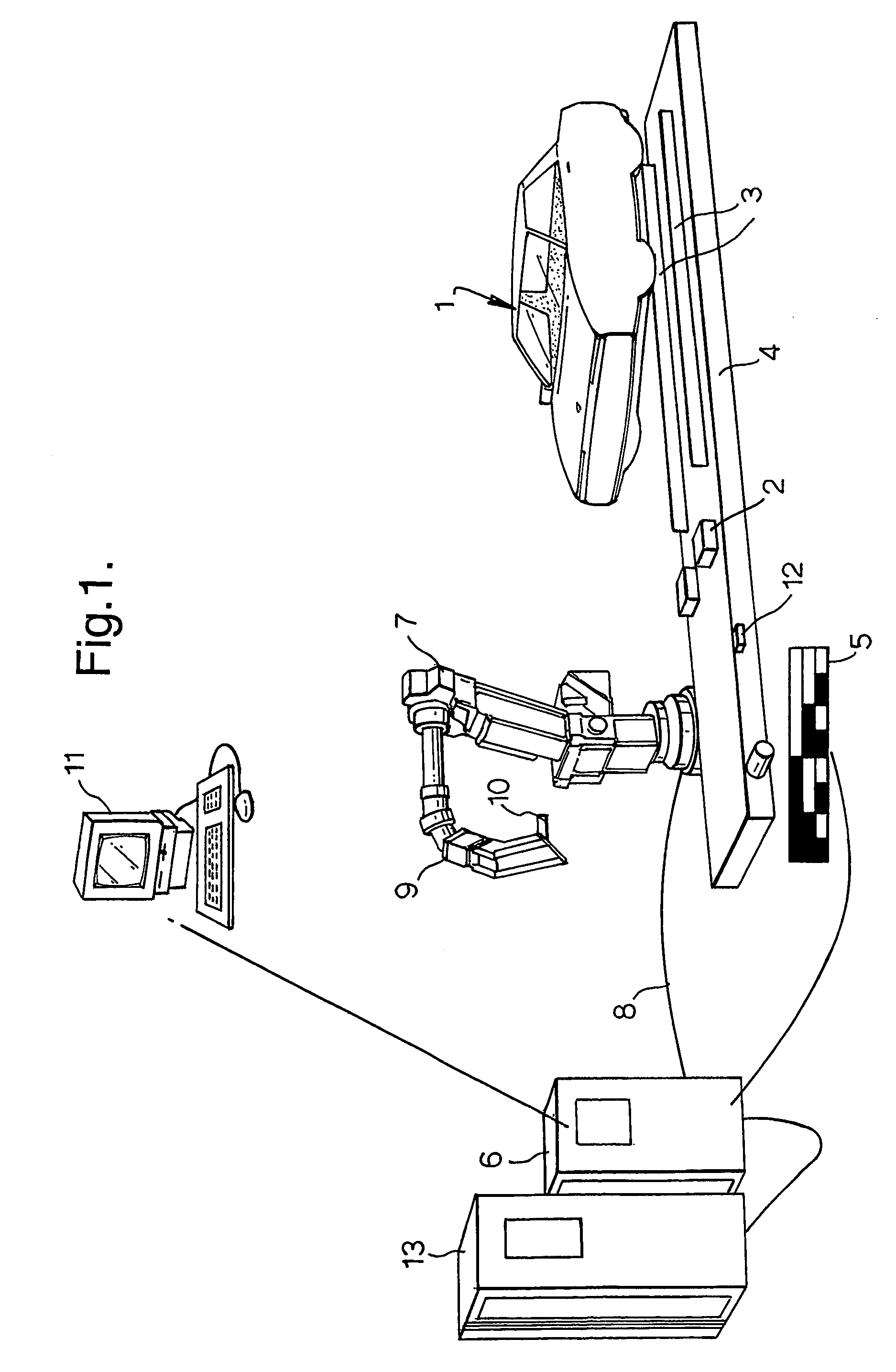

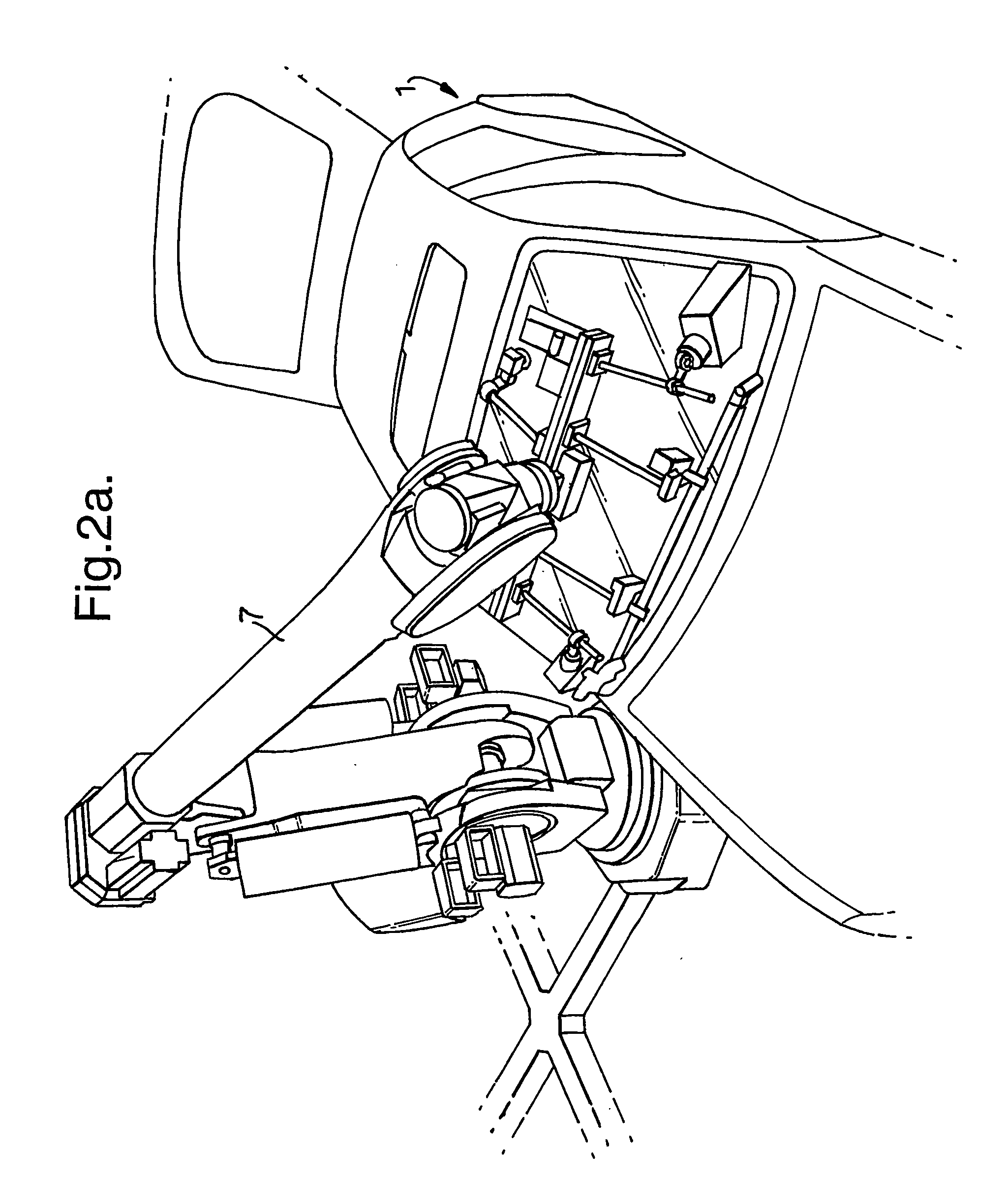

Auto Motion: Robot Guidance for Manufacturing

A robot manufacturing facility, for example for use in automobile manufacture, includes at least one robot for acting on a workpiece or intermediate product of a pre-calculated shape and dimensions at a pre-calculated position and orientation relative to a reference frame. The robot includes a body or base structure, at least one end effector movable with respect to the body or base structure for acting on workpieces, means for moving the end effector and sensing means for sensing the position of the each effector. The sensing means preferably includes a laser light source carried by the robot and means for detecting laser light, from said source, reflected from the workpiece. The movement of the end effector is controlled according to a predetermined program, modified in accordance with signals from the sending means, so that the robot is able to compensate for departures from pre-calculated values of the position and orientation and / or shape and / or dimensions of the workpiece.

Owner:READ DALE

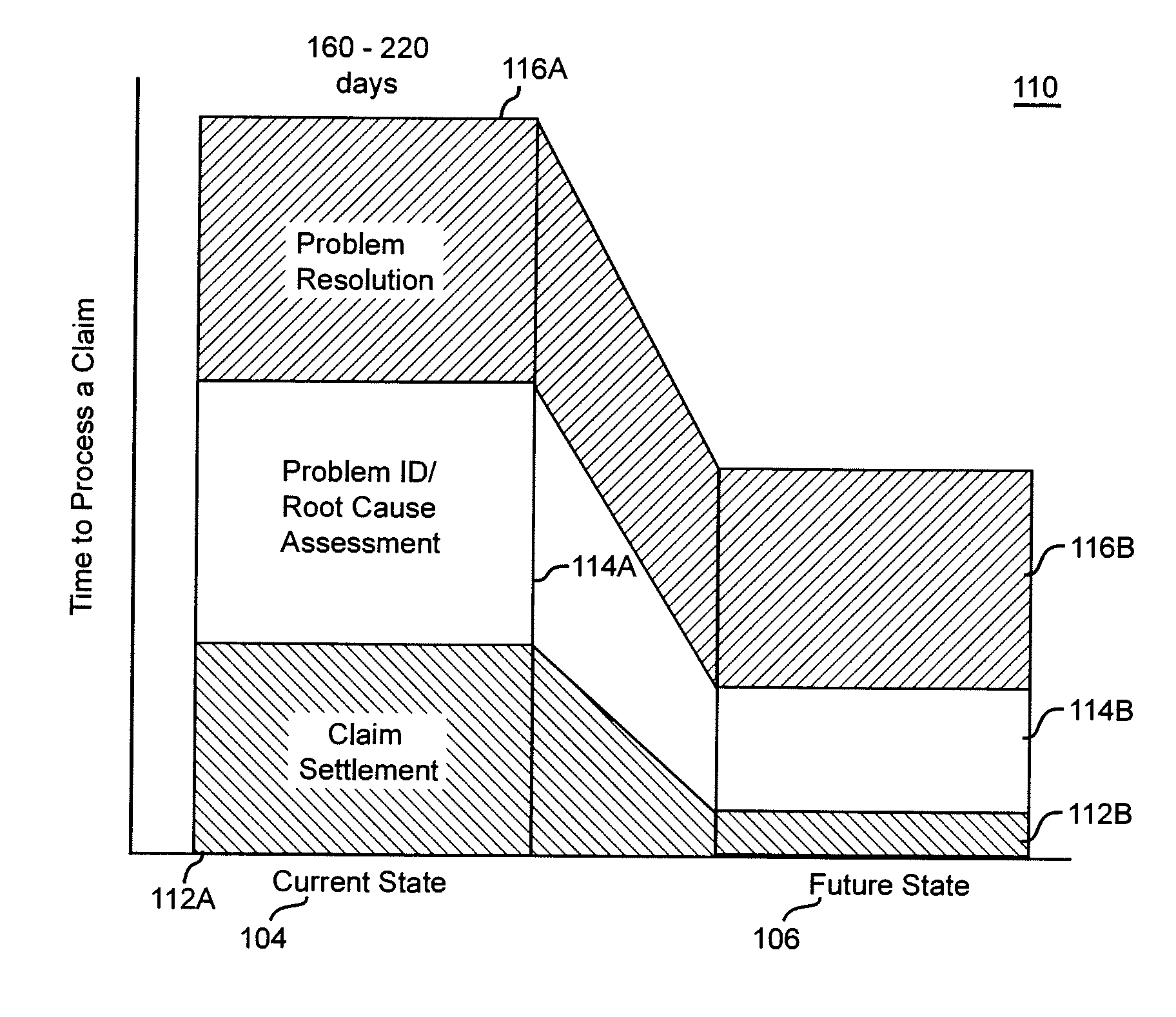

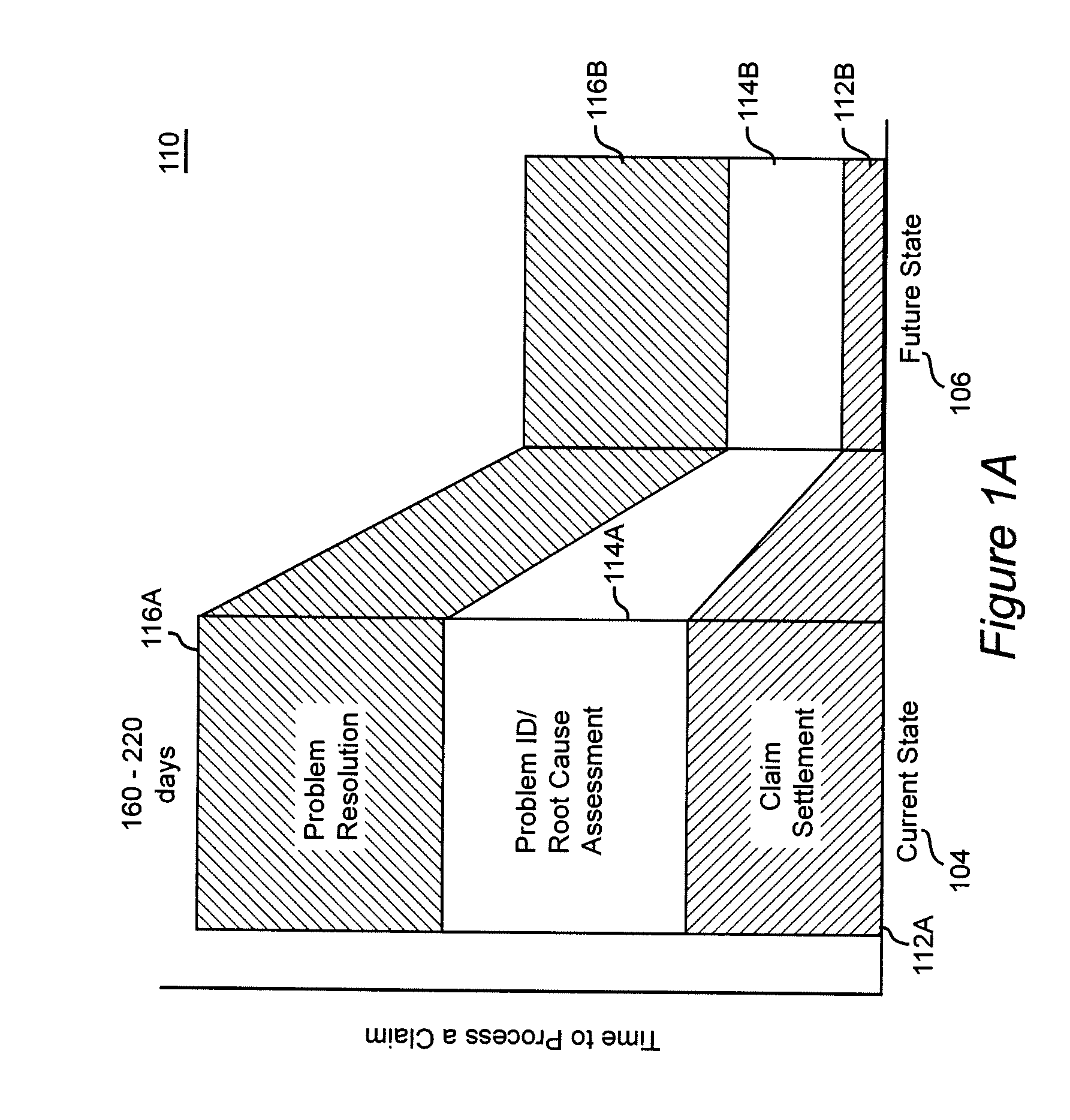

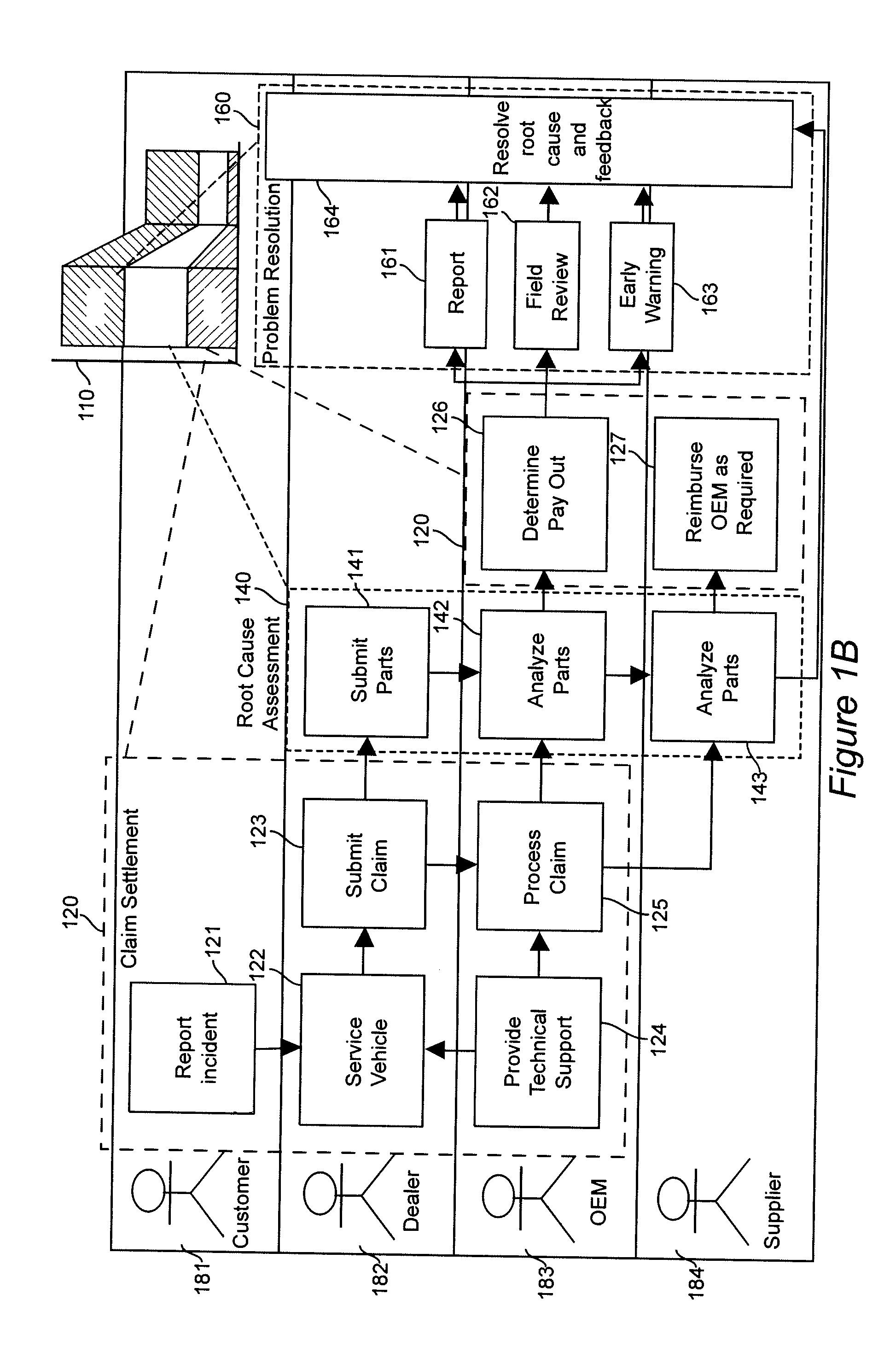

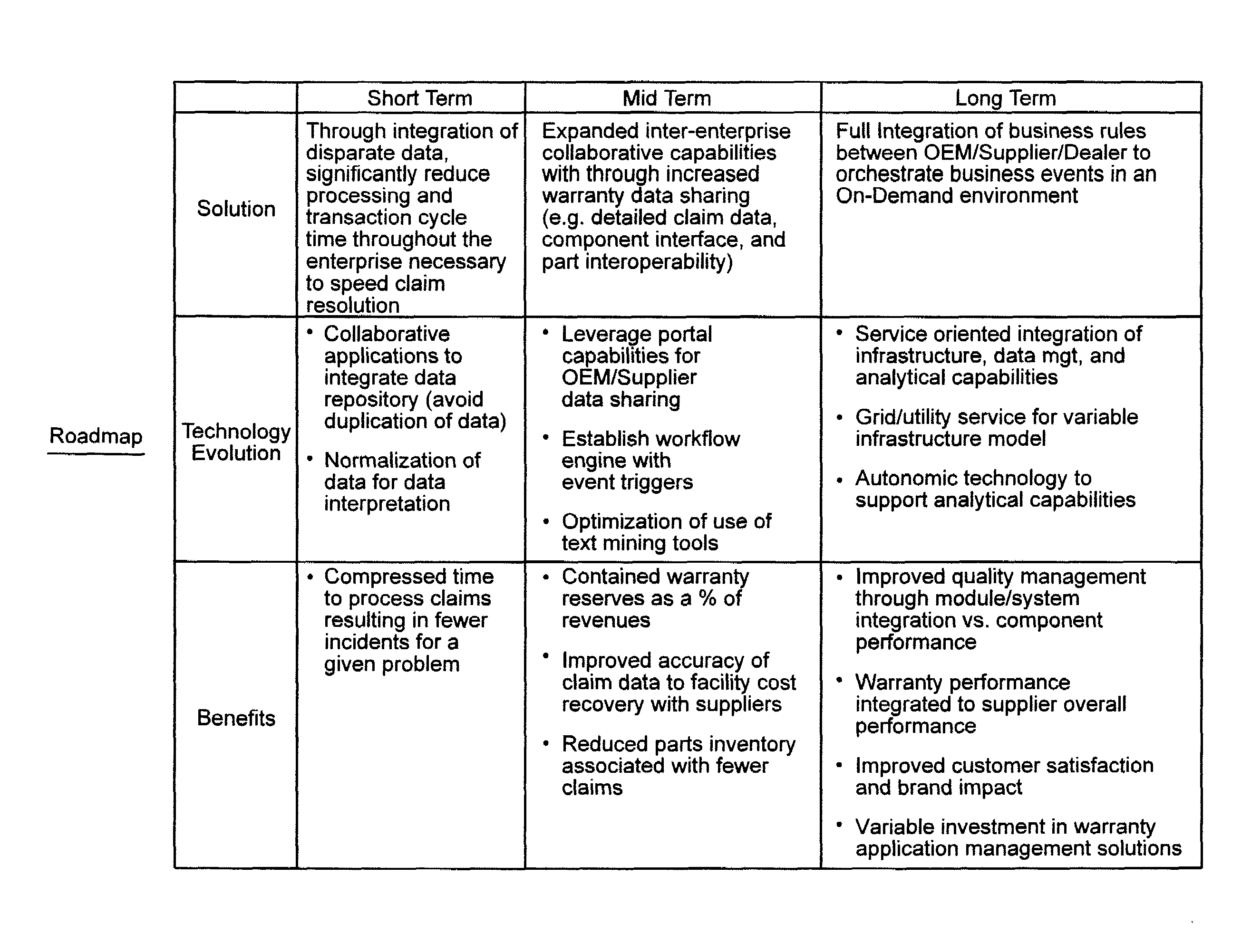

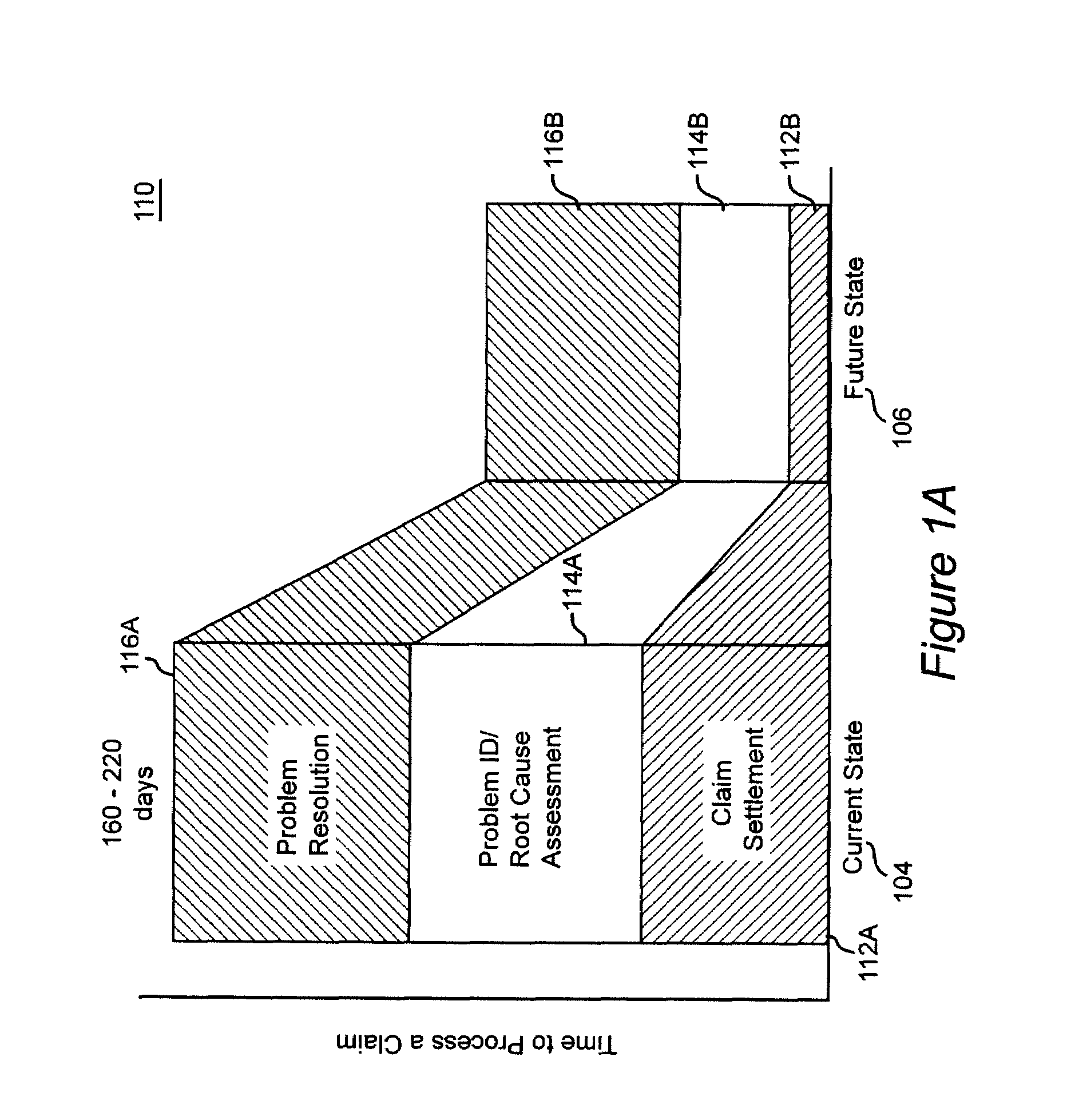

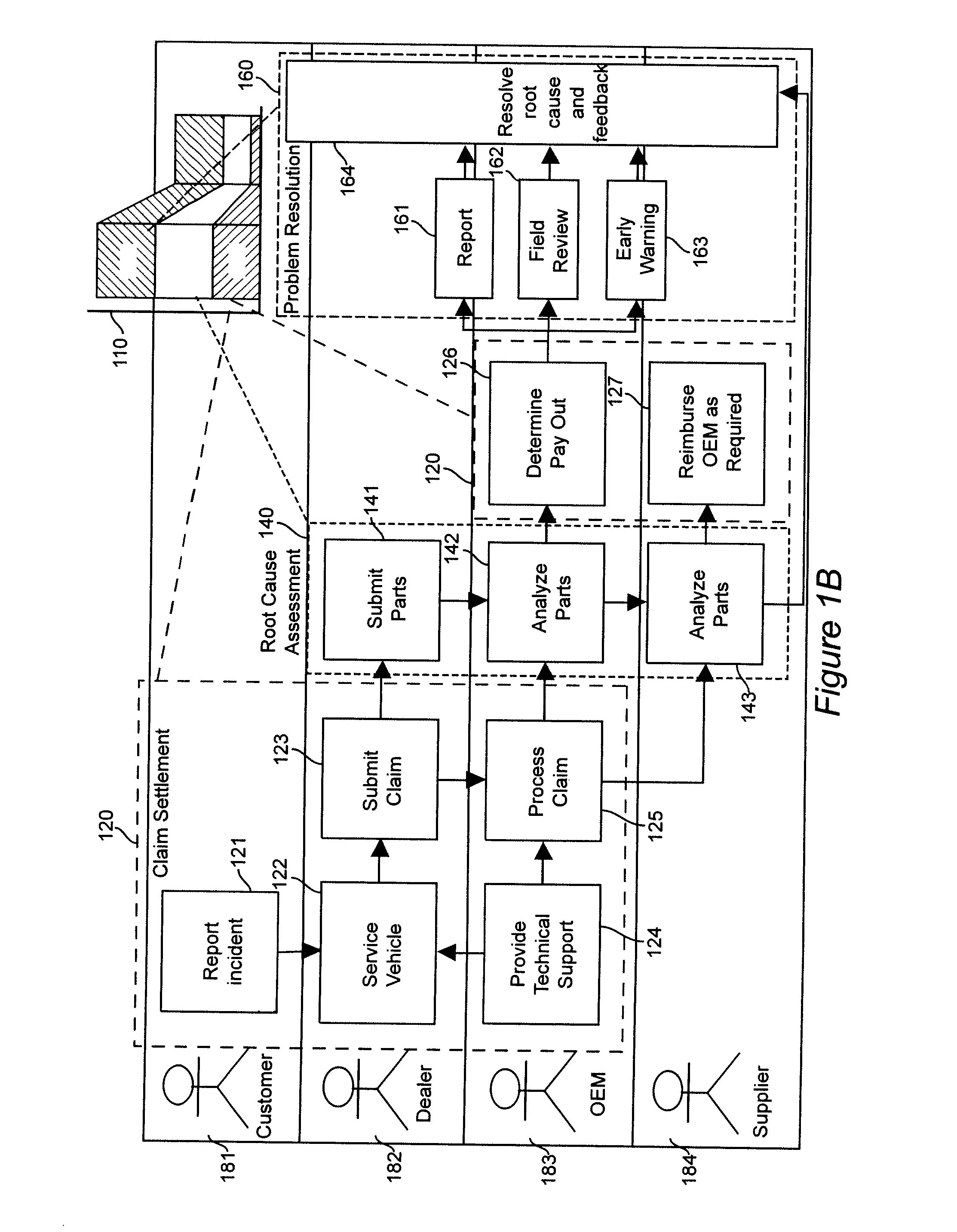

Method and system for using a component business model to transform warranty claims processing in the automotive industry

InactiveUS20070022410A1Optimize business processesResourcesSpecific program execution arrangementsAutomotive industryComponent business model

A method, system and service for using a component business model to transform a business process. The invention uses a component business model of a business to prioritize business changes affecting key performance indicators for the business process, defines an information technology architecture to support the business changes, and specifies a roadmap for implementing the supporting information technology architecture. In a particular application of the invention to the automobile manufacturing business, the business process is the warranty claims process, and a length of time to process a warranty claim is a key performance indicator.

Owner:IBM CORP

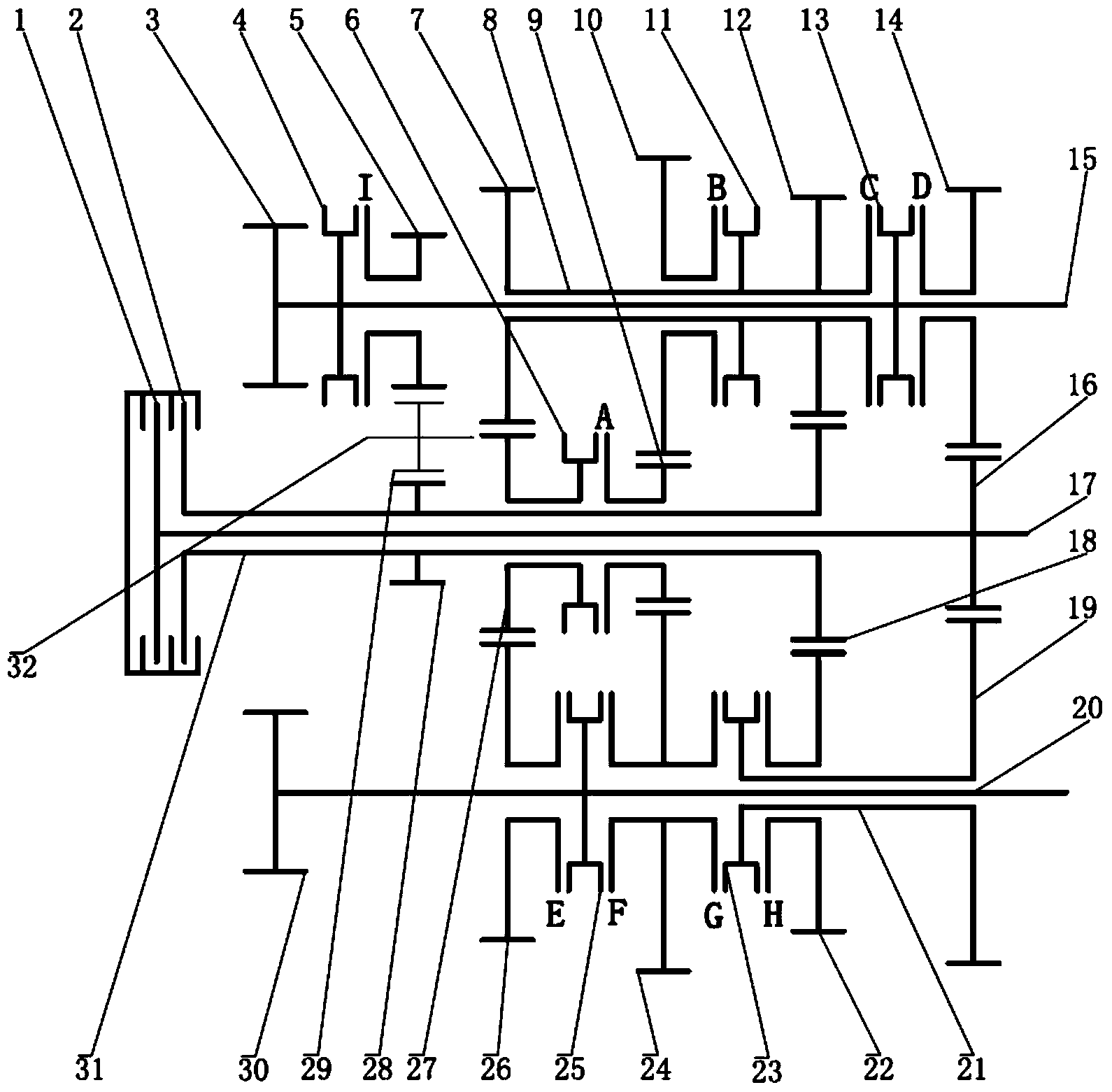

Multi-gear dual-clutch transmission and car

ActiveCN103711845ASimple structureCompact structureToothed gearingsTransmission elementsCar manufacturingControl theory

The invention relates to the technical field of car manufacturing, and particularly discloses a multi-gear dual-clutch transmission and a car. The multi-gear dual-clutch transmission comprises an outer input shaft, an inner output shaft, a first outer output shaft, a first inner output shaft, a second outer output shaft, a second inner output shaft and a switching element, wherein the outer input shaft and the inner input shaft are nested together, the first outer output shaft and the first inner output shaft are nested together, the second outer output shaft and the second inner output shaft are nested together, the inner input shaft is connected with a power source through a first clutch, the outer input shaft is connected with the power source through a second clutch, each input shaft is provided with at least one driving gear, the first inner output shaft and the second inner output shaft are provided with a first output gear and a second output gear respectively, each output shaft is provided with at least one driven gear, and the switching element can control the driving gears to be combined and control the driven gears to be combined so that the transmission can output speed ratios with a plurality of gears. The car comprises the multi-gear dual-clutch transmission. Seventeen advancing gears and one reverse gear can be achieved by the multi-gear dual-clutch transmission at most, and therefore the multi-gear dual-clutch transmission can be matched with high-gear cars.

Owner:HYCET TRANSMISSION TECH HEBEI CO LTD

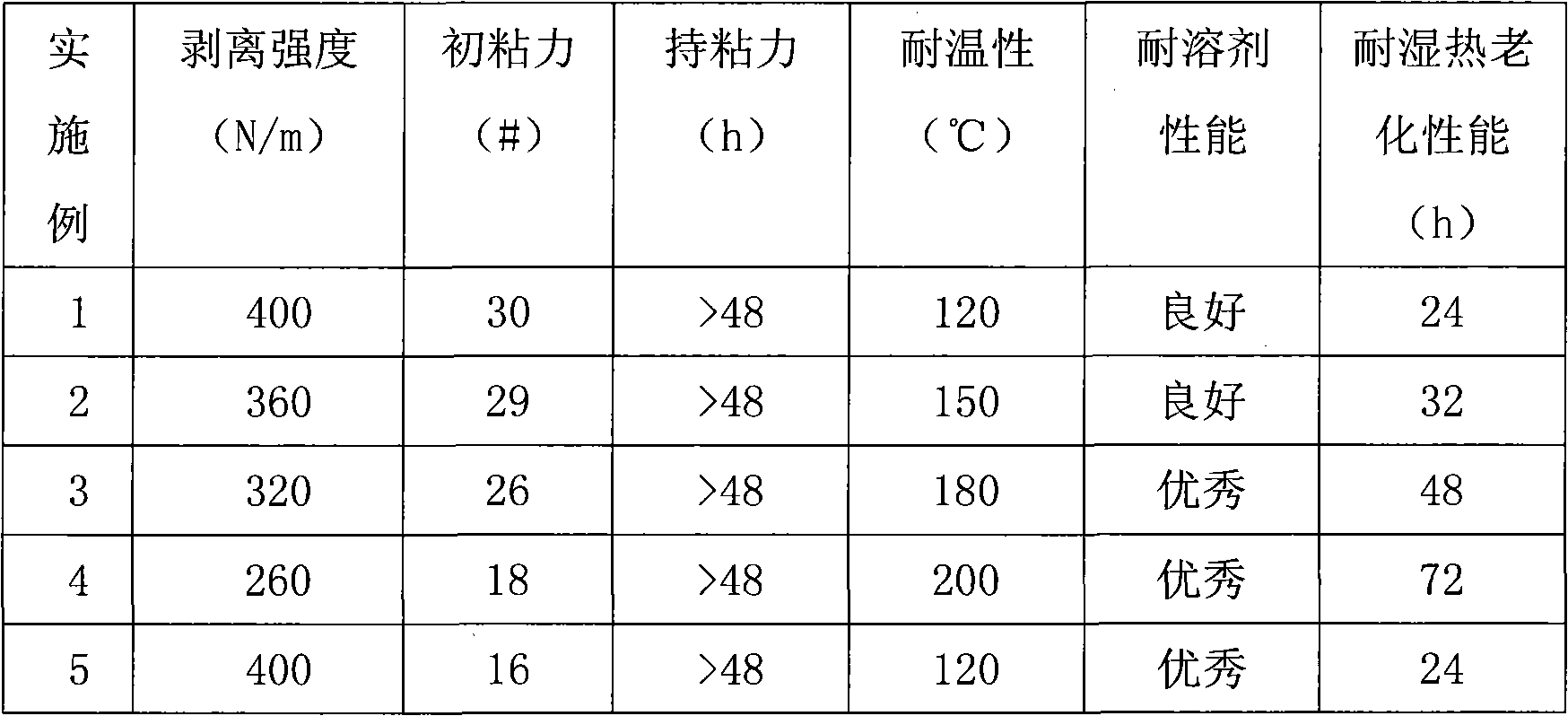

High temperature-resistant polyacrylate pressure-sensitive adhesive emulsion and preparation method and application thereof

InactiveCN101974299AEnsure mechanical stabilityConducive to environmental protectionEster polymer adhesivesRosin adhesivesFunctional monomerPressure sensitive

The invention relates to high temperature-resistant polyacrylate pressure-sensitive adhesive emulsion and a preparation method and application thereof. The emulsion mainly consists of a hard monomer, a soft monomer, a functional monomer, reactive tackifying resin, a reactive emulsifier, an initiator and a curing agent. The preparation method comprises the following steps of: adding a monomer dissolved with the tackifying resin into the aqueous solution of the reactive emulsifier for pre-emulsification by adopting the pre-emulsification semi-continuous seeding polymerization process, performing polymerization on the pre-emulsified liquid through the initiator, and adding the curing agent to prepare the high temperature-resistant polyacrylate pressure-sensitive adhesive emulsion. The pressure-sensitive adhesive of the invention has heat resistance of 200 DEG C, has excellent water resistance, aging resistance and mechanical property, and can be widely applied to the fields of electronics, electrical appliances, automobile manufacturing and the like.

Owner:新丰杰力电工材料有限公司 +1

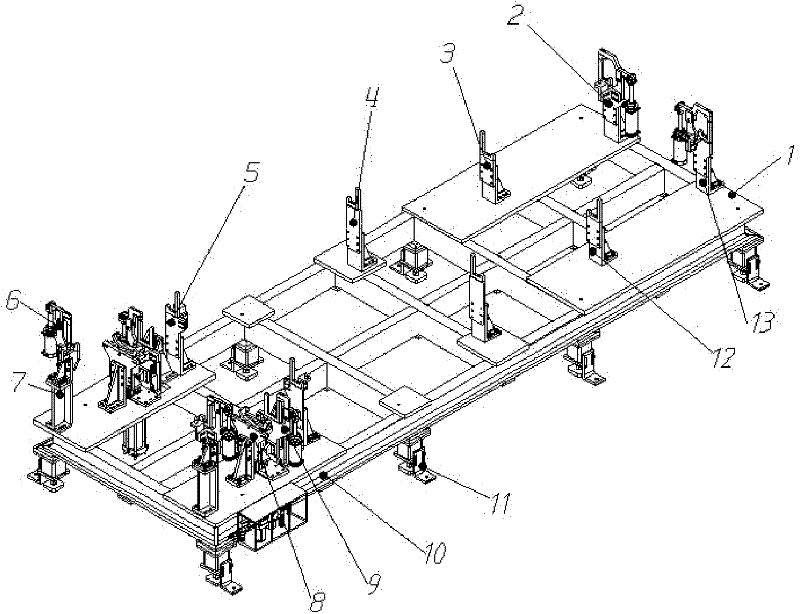

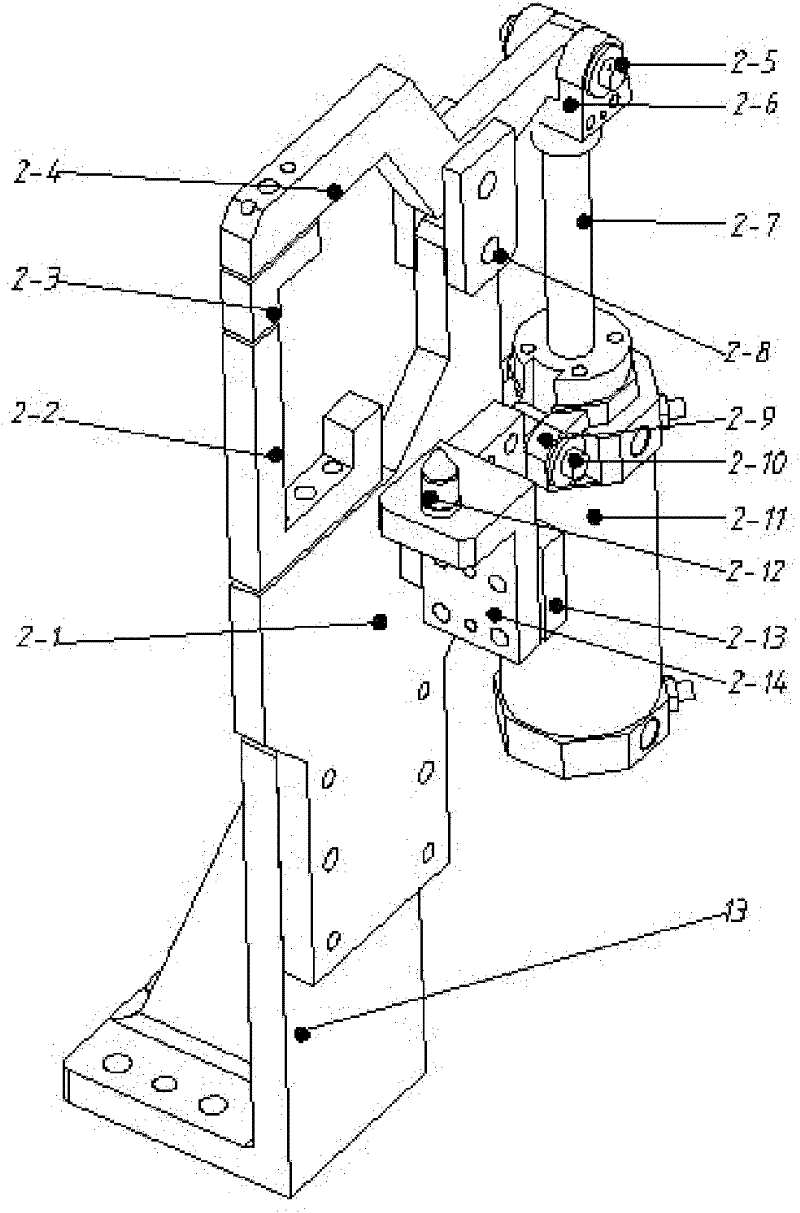

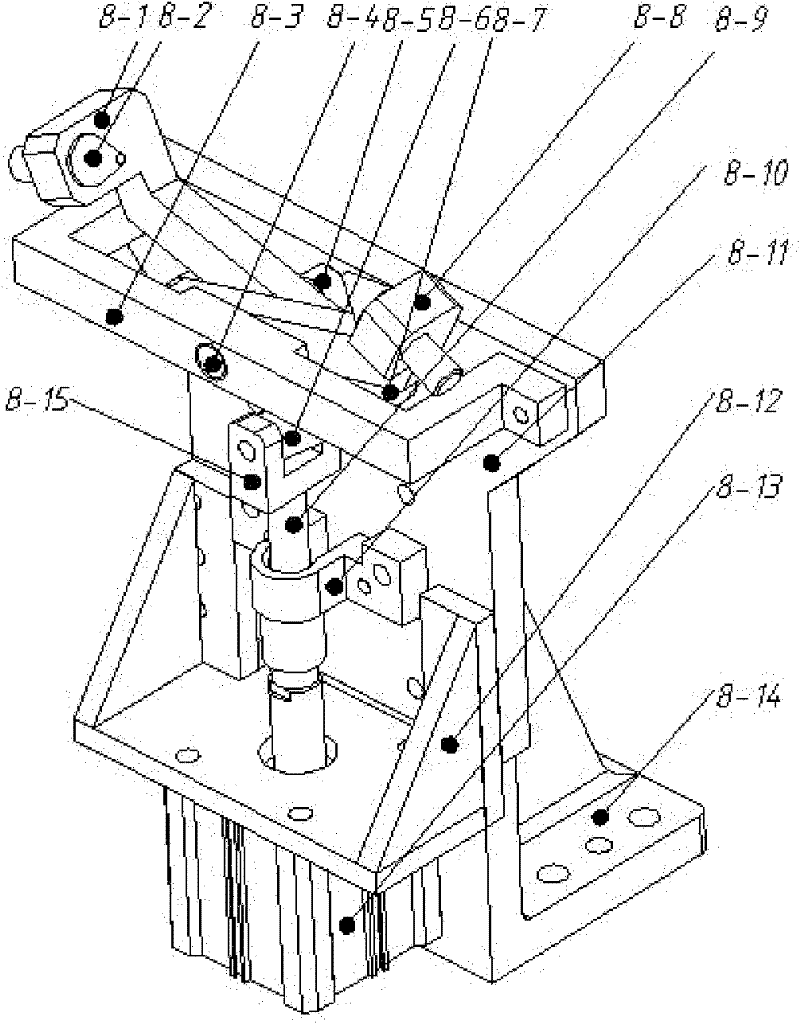

Repair welding clamp for lower body of light weight vehicle

InactiveCN102689125AGuarantee product qualityPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesCar manufacturingEngineering

The invention relates to a repair welding clamp for lower body of light weight vehicles. The invention belongs to the automobile manufacturing industry field. The repair welding clamp for lower body of light weight vehicles is provided based on disadvantages that conventional welding device adopts mainly manual operation or is low in automation, so that the welding efficiency is low or the welding quality is low and cost is high. The repair welding clamp includes mainly an adjustable bracing frame, an I-shaped bracing body, an operation platform, positioning devices, locking devices, an electrical system or the like. The operation platform has six sets of positioning devices, eight sets of positioning clamping devices and can be latched dynamically and randomly by latching devices. The positioning locking devices are arranged in a symmetric manner, bear balanced force and have a linkage function. The positioning and locking devices can be adjusted dynamically according to different types of light weight cars and different positioning positions different lengths of vehicles and changes of different structures of vehicles. The repair welding clamp is used for four vehicle types such as single-row cars, double-row cars, vans and half-row cars. The repair welding clamp not only has a simple structure, is economical and practical, reduces labor intensity of operation and improves production efficiency, but also has the characteristic of being suitable for lower bodies of vehicles of various kinds. The repair welding clamp serves as one machine used for various vehicles and helps to realize flexible production.

Owner:哈尔滨新科锐工艺装备制造有限公司

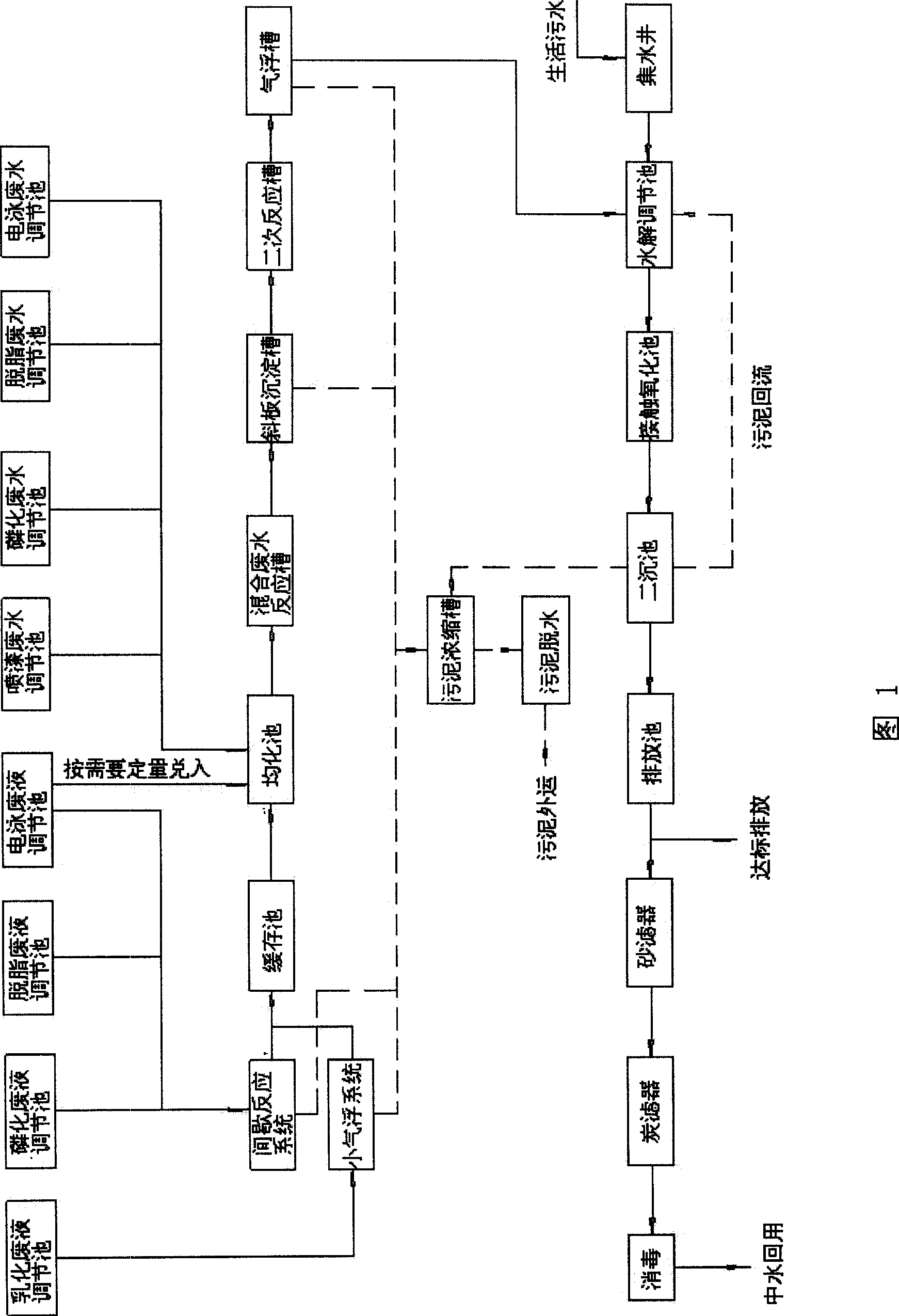

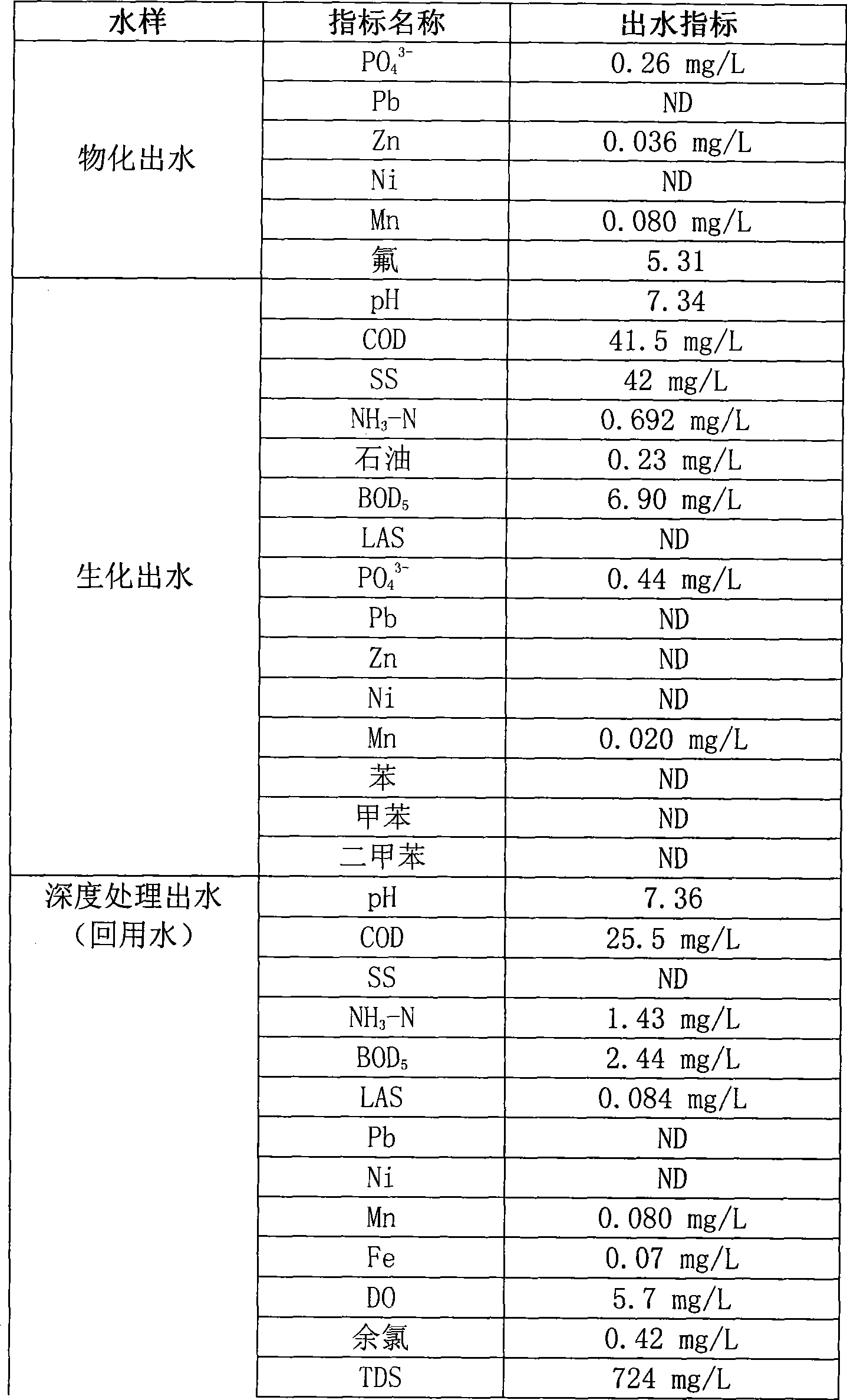

Automobile manufacturer wastewater treatment method

ActiveCN101456647AEasy to handleHigh activityTreatment using aerobic processesDispersed particle separationOperational costsIndustrial waste water

The invention relates to a method for treating wastewater and discloses a method for treating wastewater in an automobile manufacturing plant. A method of pretreatment, two-stage physicochemical treatment, biochemical treatment and advanced treatment is adopted to treat wastewater. The method for treating wastewater in the automobile manufacturing plant has little investment, small occupied area and low operating cost and has good integrated treatment effect on industrial wastewater and domestic sewage discharged from the automobile manufacturing plant.

Owner:SHANGHAI YIKE GREEN ENG

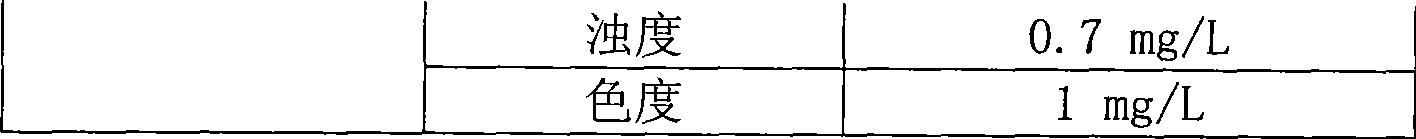

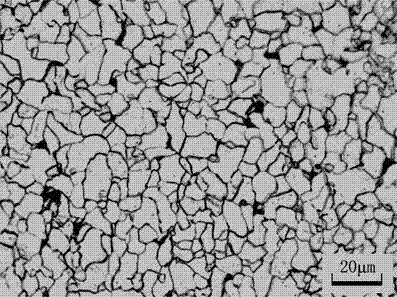

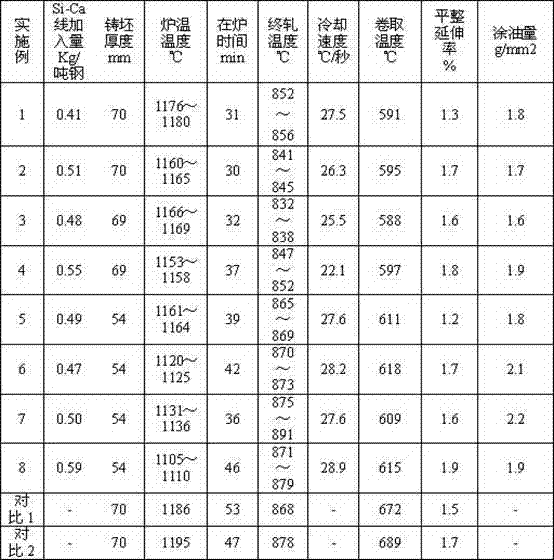

Sheet-billet produced hot-rolled pickled steel with thickness of 1.8mm or lower for automobile and production method thereof

InactiveCN102787273ALow yield ratioImprove surface qualityWork treatment devicesMetal rolling arrangementsCar manufacturingHigh pressure water

The invention relates to a sheet-billet produced hot-rolled pickled steel with thickness of 1.8mm or lower for an automobile, which comprises the following chemical components by weight: 0.04-0.07% of C, 0.10-0.30% of Si, 0.60-1.30% of Mn, 0.025% of P or less, 0.012% of S, 0.02-0.04% of Ti and 0.010-0.030% of Als. The preparation method of the sheet-billet produced hot-rolled pickled steel with thickness of 1.8mm or lower comprises the following steps: desulphurizing molten iron, smelting by a converter, alloying, treating by a ladle furnace, casting and rolling continuously, dephosphorizing high-pressure water by controlling the pressure at 25-35Mpa, controlling rolling, cooling by laminar flow, curling, pickling by acid, levelling by controlling the extension rate at 2% or lower, and finishing by adopting static oil removal. The produced thin hot-rolled pickled steel for the automobile, which has the tensile strength of 400MPa or higher and the thickness of 1.8 mm or lower, has the characteristics of low yield ratio, high surface quality, short production cycle and low cost, achieve the match of high strength and good stamping performance and can replace the cold-rolled high-strength steel to manufacture the automobile.

Owner:武钢集团有限公司

Method and system for using a component business model to transform warranty claims processing in the automotive industry

ActiveUS20080215400A1Optimize business processesResourcesMarket data gatheringCar manufacturingComponent business model

A method, system and service for using a component business model to transform a business process. The invention uses a component business model of a business to prioritize business changes affecting key performance indicators for the business process, defines an information technology architecture to support the business changes, and specifies a roadmap for implementing the supporting information technology architecture. In a particular application of the invention to the automobile manufacturing business, the business process is the warranty claims process, and a length of time to process a warranty claim is a key performance indicator.

Owner:IBM CORP

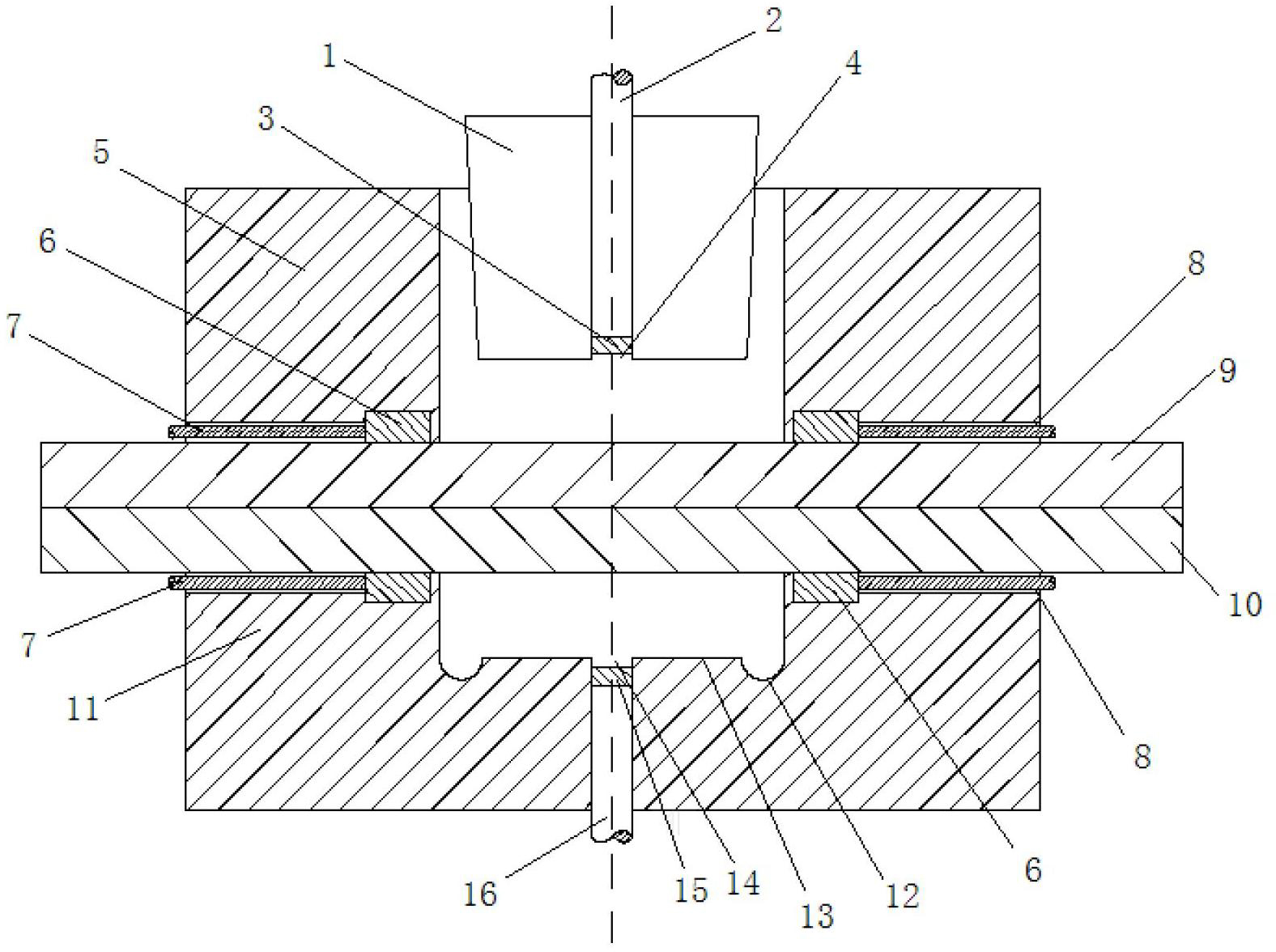

Laser heating rivetless riveting device

InactiveCN102672062AGood formabilityImprove ductilityShaping toolsElectrical resistance and conductanceControl system

The invention relates to a laser heating rivetless riveting device in the technical field of automobile manufacturing. The laser heating rivetless riveting device comprises a compound punch pin, a compound blank holder, a compound lower die and a laser control system, wherein, the compound punch pin is sheathed with the compound blank holder, and the compound punch pin, a workpiece and the lower die are arranged coaxially from top to bottom; hollow circular holes are formed at the center parts of the compound punch pin and the compound lower die; optical fiber tubes and concave lenses are arranged in the hollow circular holes; grooves are formed in the surfaces of the compound blank holder and the compound lower die in contact with a panel veneer, and are used for laying out thermistors that are lead wires; and the lead wires are connected with a laser control system. The laser heating rivetless riveting device heats a forming area of riveting material through laser before riveting forming so as to improve the forming performance of material, prevents fragile material from being easy to crack and fracture during the riveting process, reduces the plastic deformation resistance of material at the same time, enables the panel veneer to deform fully during the forming process, is easy to get a rivet joint with better quality, and reduces the requirements on riveting force and rigidity of riveting equipment at the same time along with the reduction of plastic deformation resistance of material.

Owner:JILIN UNIV

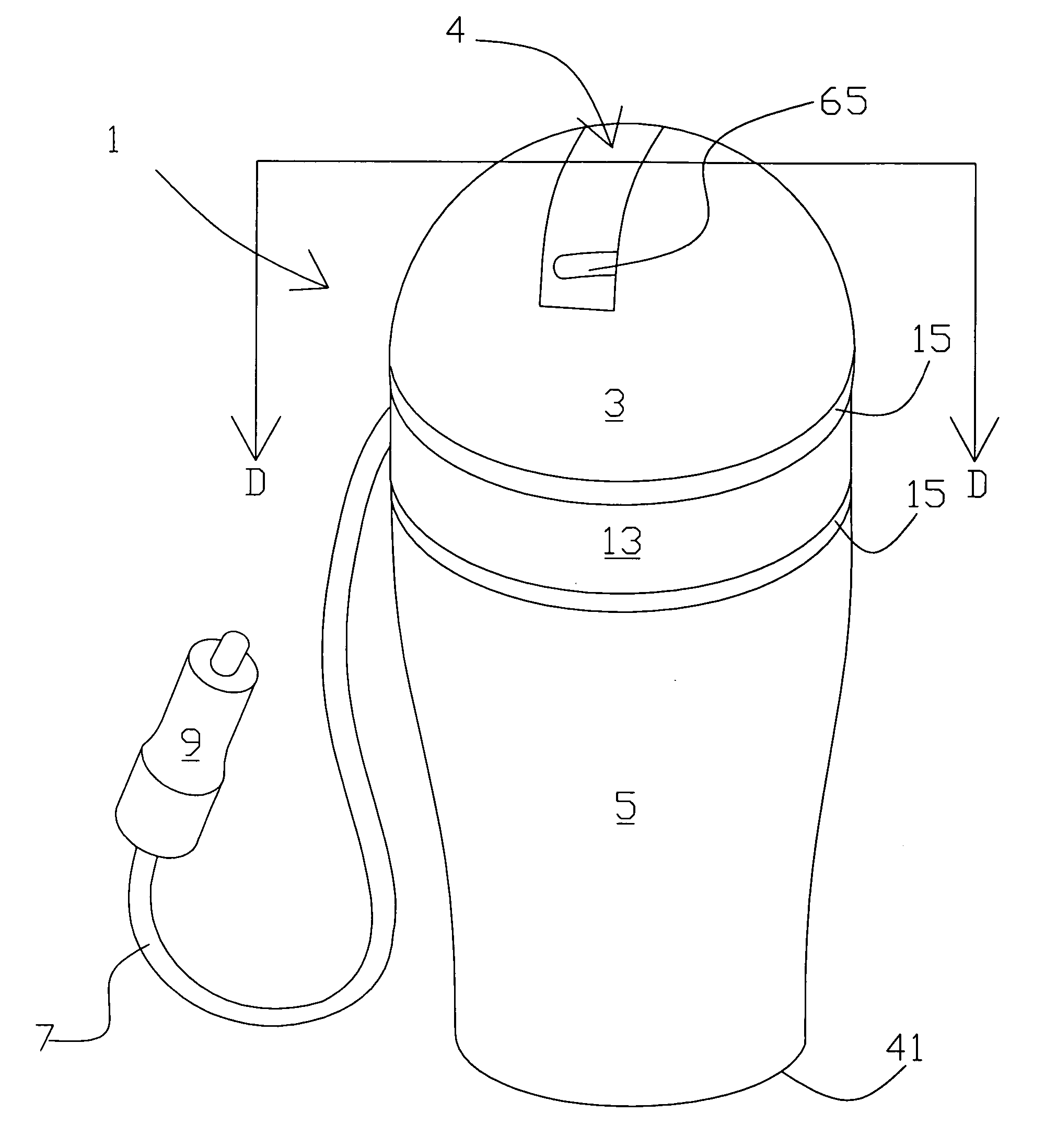

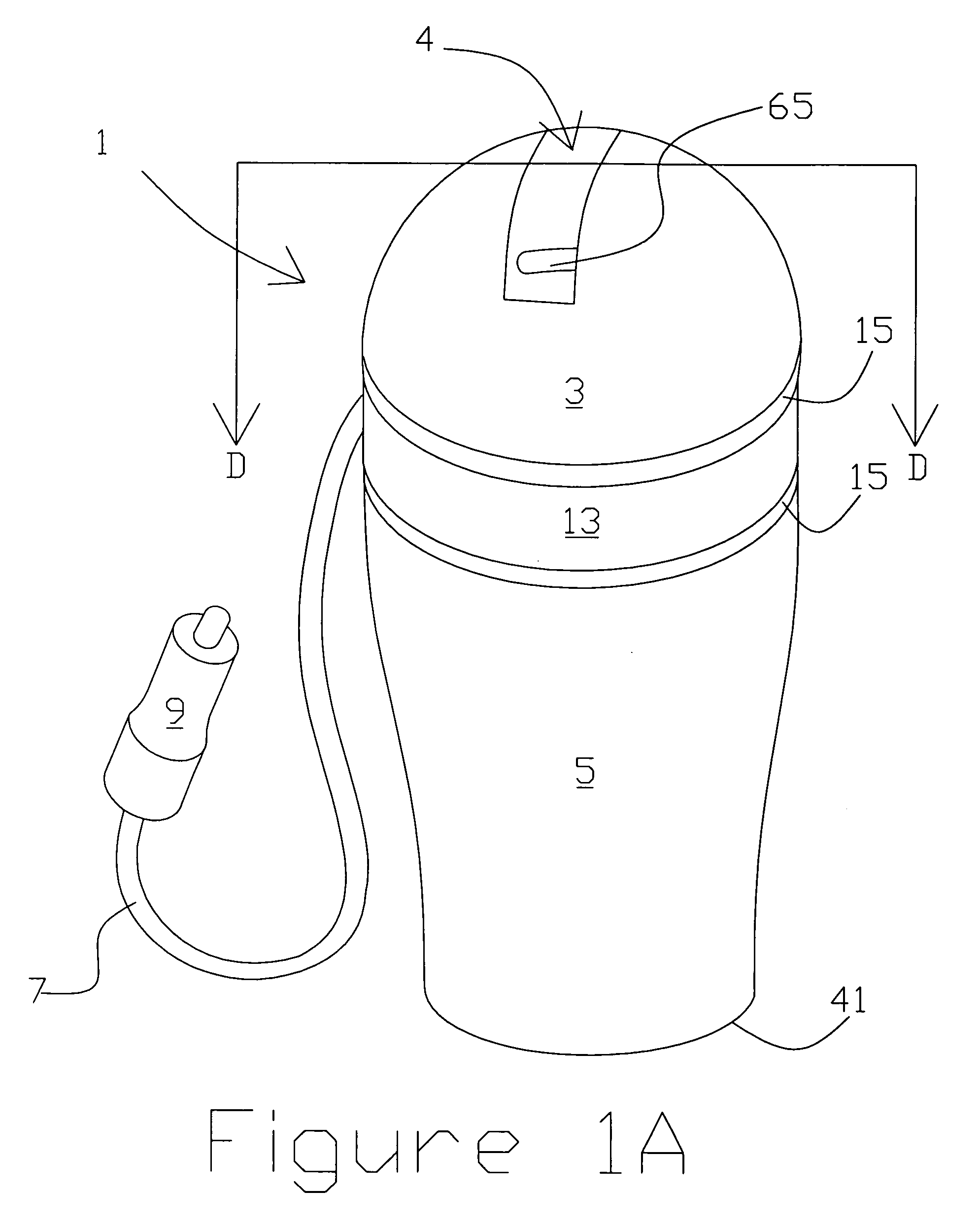

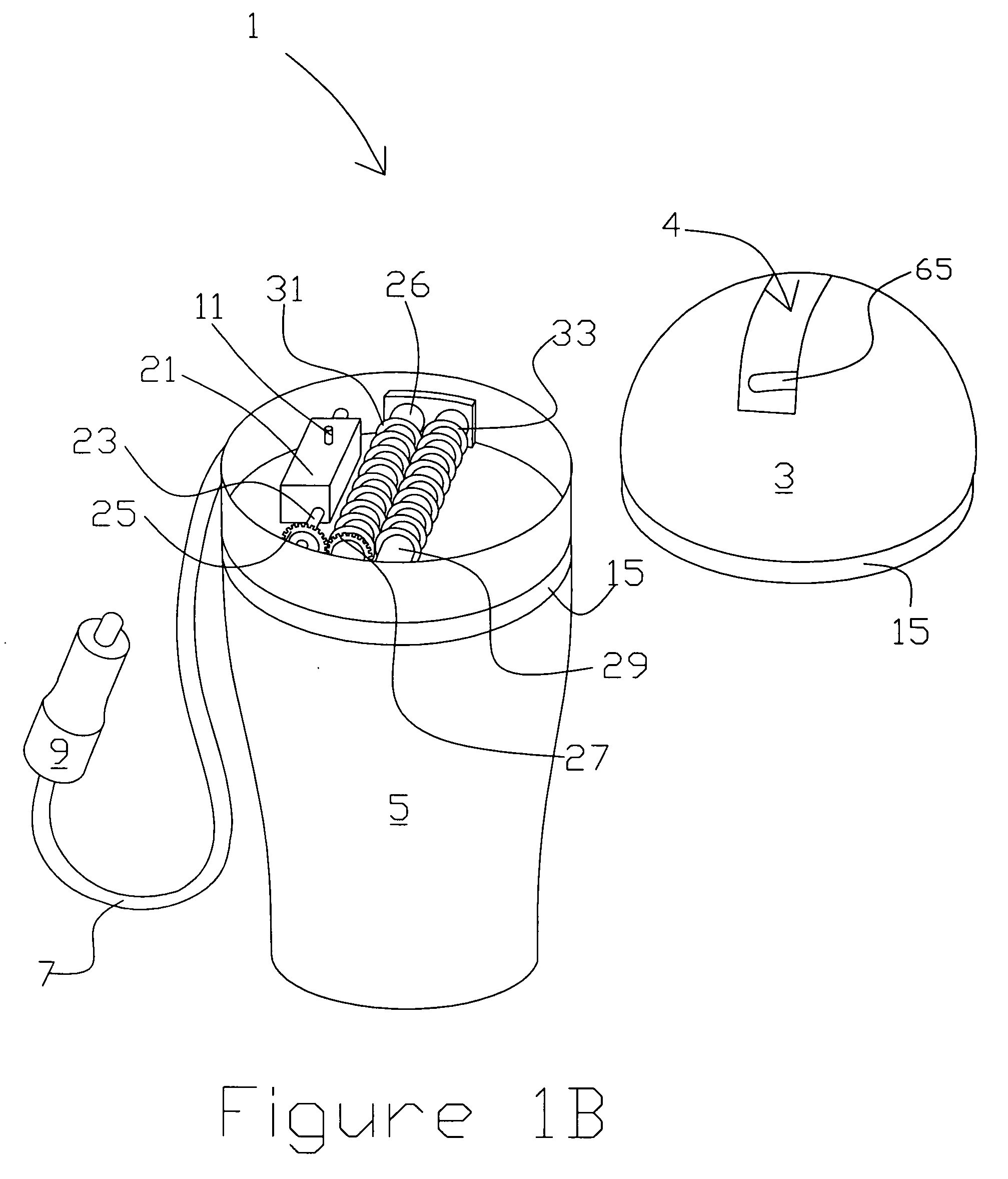

Portable shredder

The invention includes a plurality of parts or elements including at least a cap removably coupled with a container formed in the shape of a cup to provide a portable shredder that may be employed mounted in an automobile for destroying receipts and the like to prevent identity theft. The portable shredder comprises at least one rotating shaft having a first plurality of circular blades that engage a second set of blades to shred a receipt as it passes between the first and second sets of blades. The exterior shredder may be formed in the shape of a cup to be easily accommodated by a cup holder in an automobile. Otherwise, the shredder may be incorporated into an automobile part such as a door, console, dash or the like and installed during manufacture of the automobile.

Owner:BARKLAGE KEVIN

High-strength high-tensile ratio cold-rolled steel sheet and manufacturing method thereof

ActiveCN101376944AAdd lessReduce the impactRoll mill control devicesMetal rolling arrangementsChemical compositionSheet steel

The invention provides a high-strength and high-yield ratio cold-rolled steel sheet and a manufacturing method thereof. The high-strength and high-yield ratio cold-rolled steel sheet comprises the following chemical components by the weight percentage: C: 0.08 percent to 0.14 percent, Si: 0.4 percent to 1.0 percent, Mn: 1.2 percent to 2.0 percent, P: less than or equal to 0.03 percent, S: less than or equal to 0.02 percent, N: less than or equal to 0.008 percent, Al: 0.02 percent to 0.06 percent, Nb: 0.01 percent to 0.03 percent, and the rest are Fe and inevitable impurities. The high-strength and high-yield ratio cold-rolled steel sheet is manufactured through processes, such as final rolling at normal temperature, coiling at low temperature, heating and heat preservation at quite high temperature, quick cooling and the like. The yield strength of the cold-rolled steel sheet is more than or equal to 500Mpa, the tensile strength is more than or equal to 600Mpa and the yield ratio is more than or equal to 0.80; therefore, the steel sheet can meet the requirements of the automobile manufacturing industry for high-yield ratio steel sheets with higher strength.

Owner:BAOSHAN IRON & STEEL CO LTD

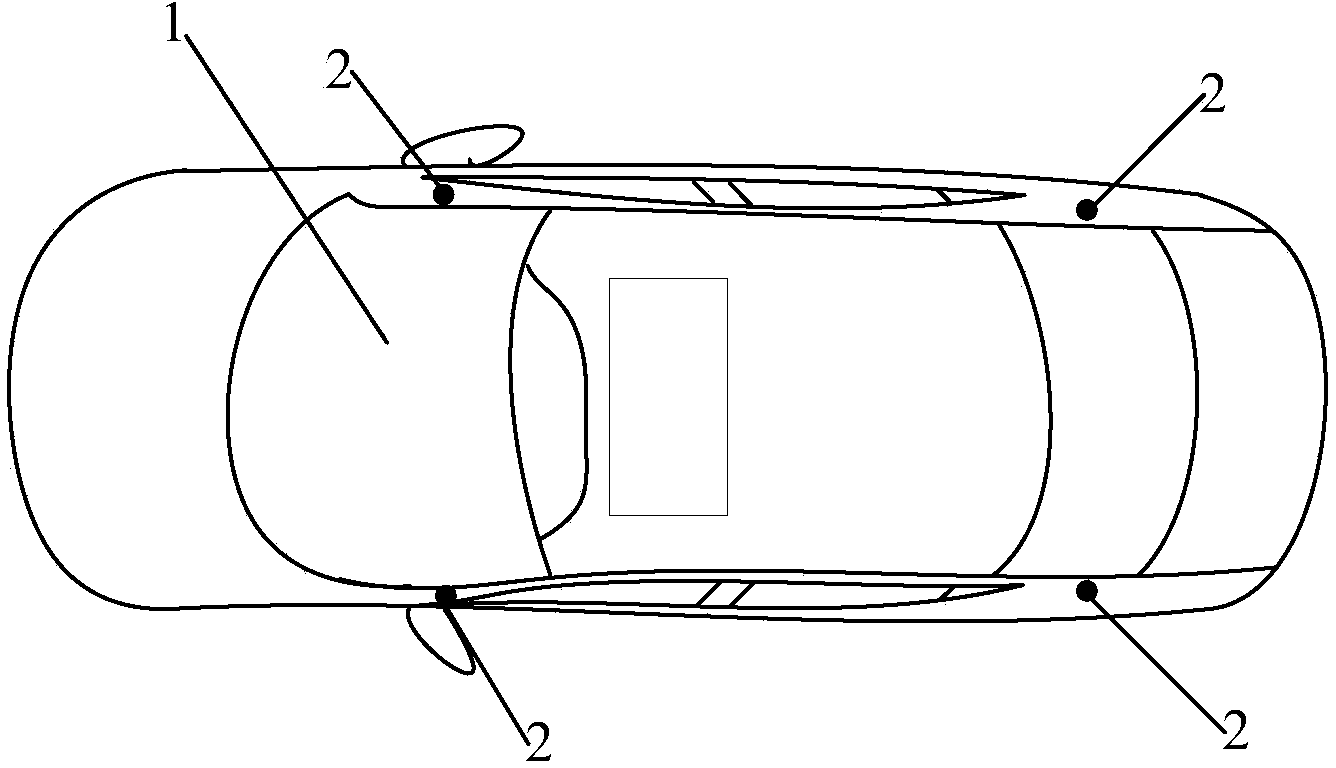

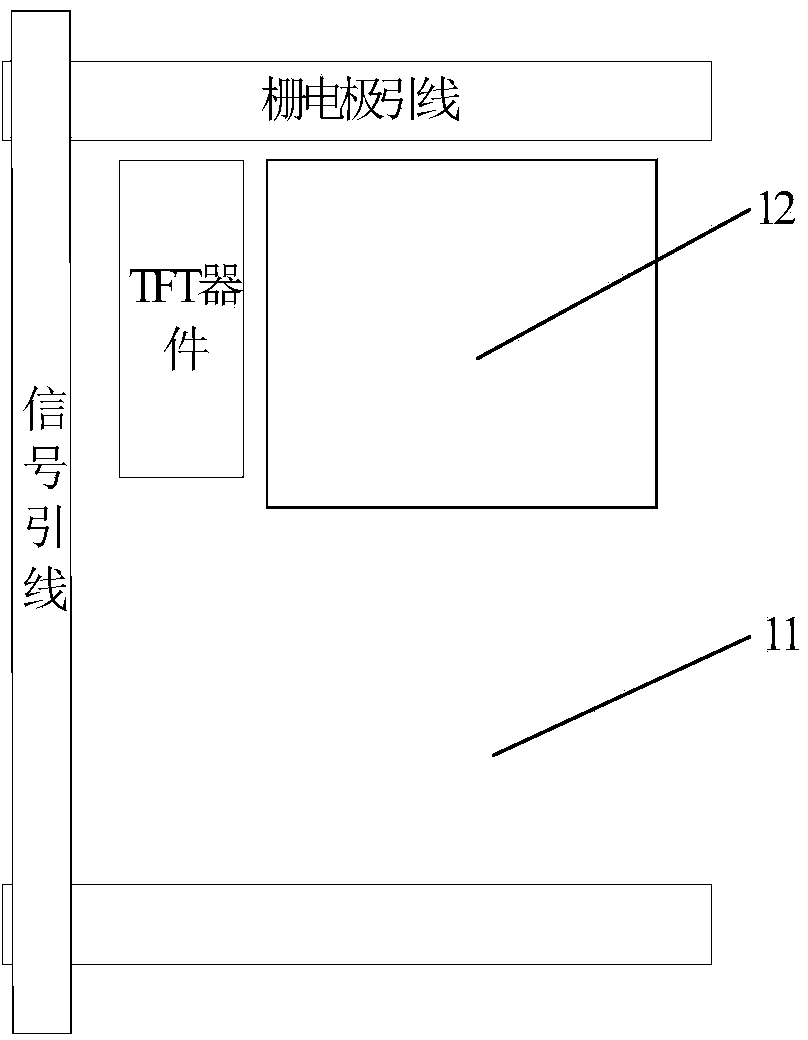

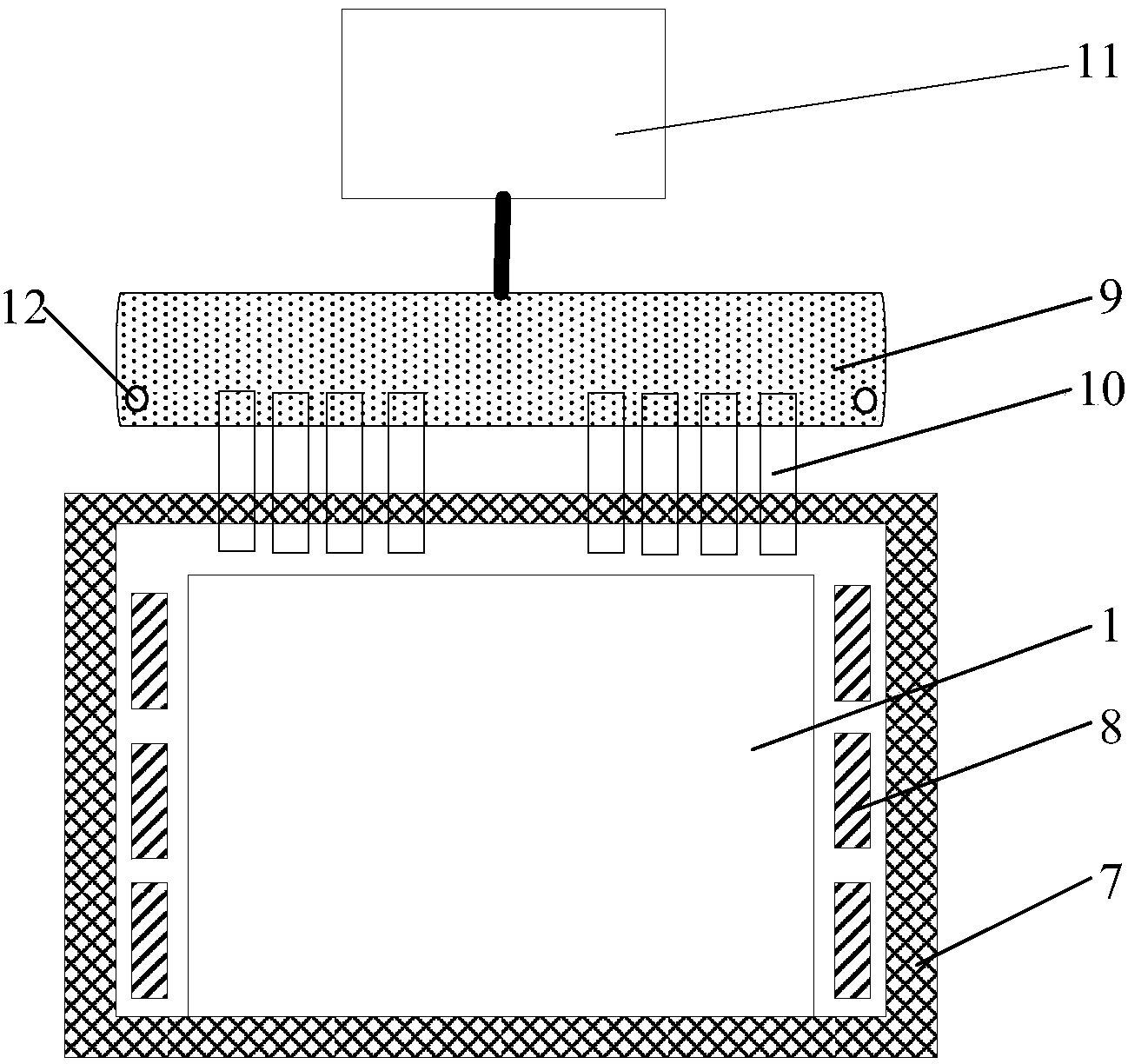

System for achieving real scene simulation by means of vehicle front windshield

ActiveCN104163134AFix security issuesEnsure driving safetyElectric/fluid circuitOptical viewingControl systemCar manufacturing

The embodiment of the invention provides a system for achieving real scene simulation by means of a vehicle front windshield, and relates to the field of display. The system solves the problem that according to an existing vehicle structure, a driver can not see clearly environment outside a vehicle in dark or on foggy days, and accordingly traffic safety is not guaranteed or the driver goes a wrong way, guarantees driving safety of the driver, increases driving speed and improves efficiency. The system comprises a flexible transparent OLED display screen attached to a front windshield glass of the vehicle, the flexible transparent OLED display screen and at least two infrared cameras are connected with a center control system in the vehicle, the at least two infrared cameras are arranged on the two sides of a vehicle body, an array substrate of the flexible transparent OLED display screen and a substrate body of an encapsulation substrate are made of flexible materials, an ITO pixel electrode layer in the array substrate comprises a light-pervious area and a pixel area, and the flexible transparent OLED display screen displays vehicle outside environment information obtained by the at least two infrared cameras through the center control system. The system is applied to vehicle manufacturing.

Owner:BOE TECH GRP CO LTD +1

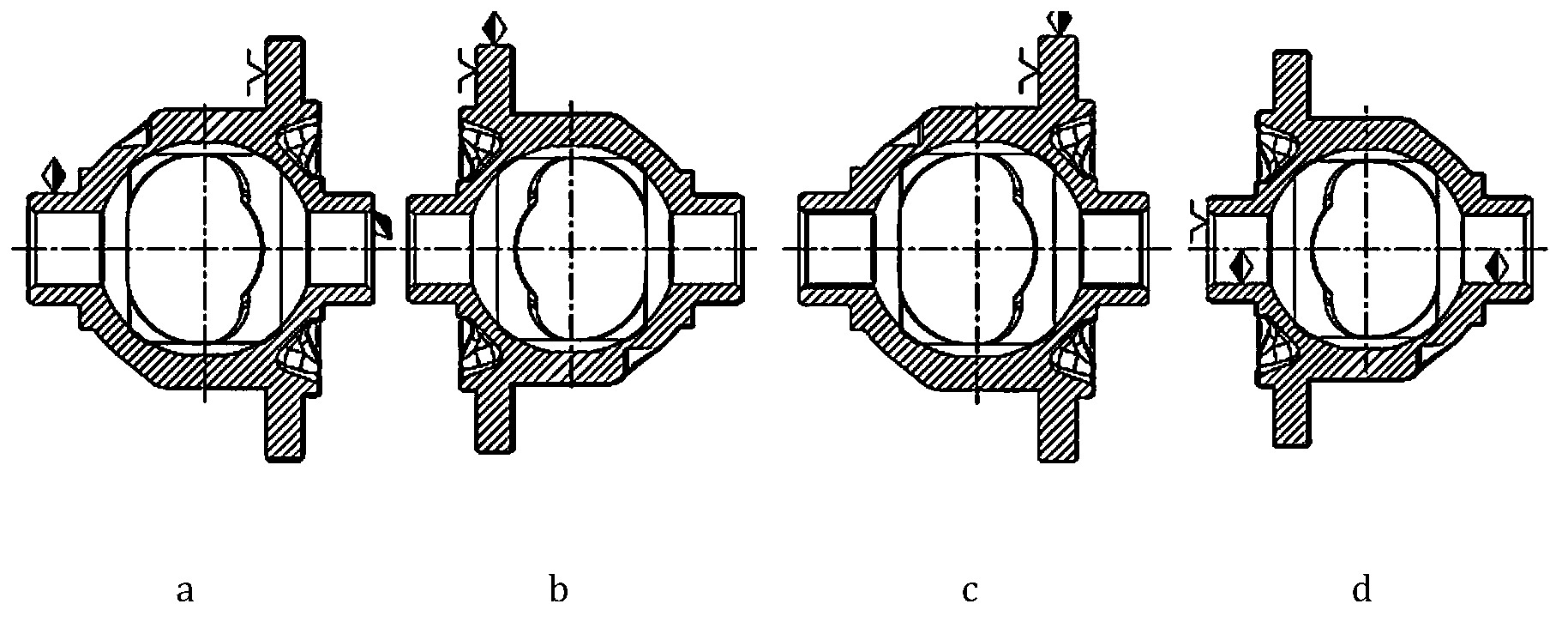

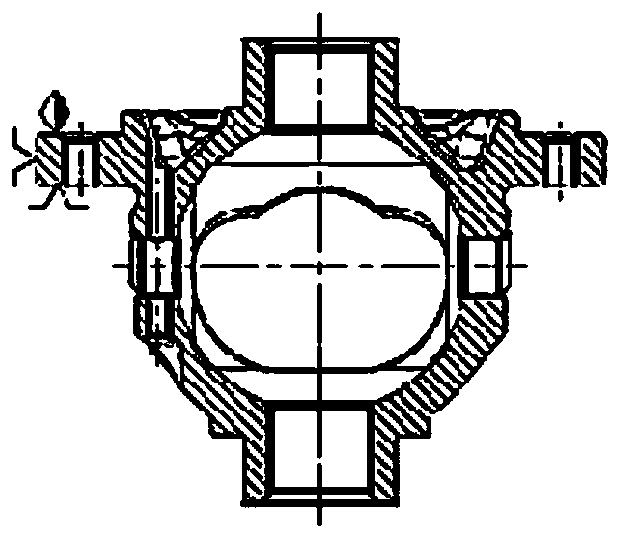

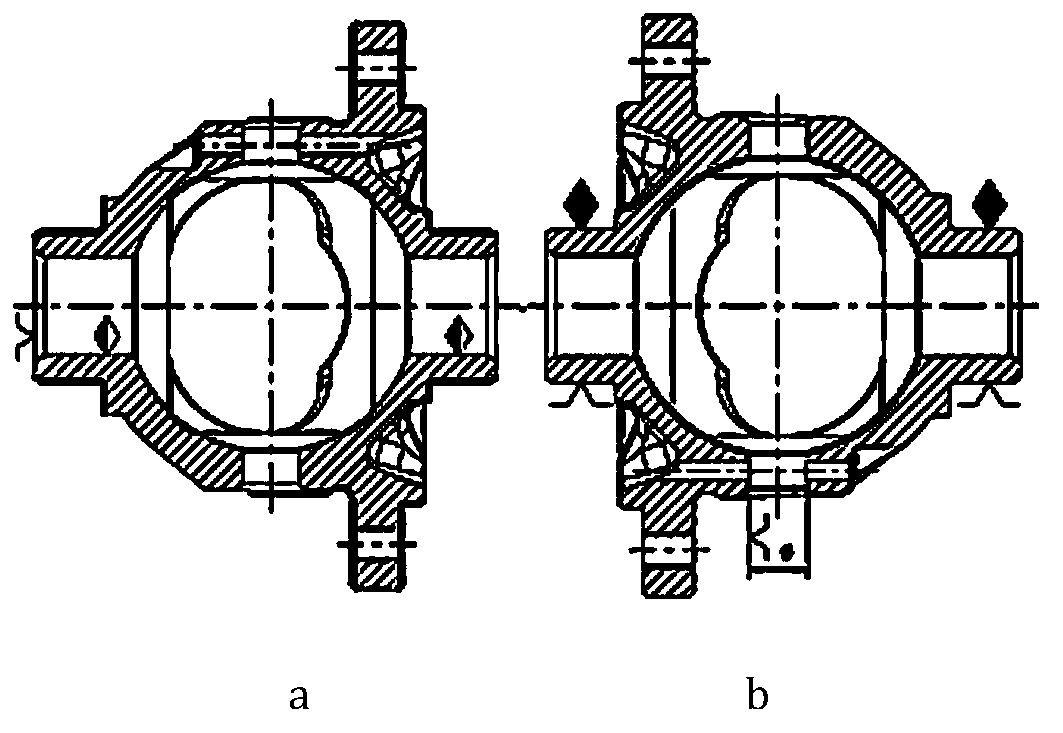

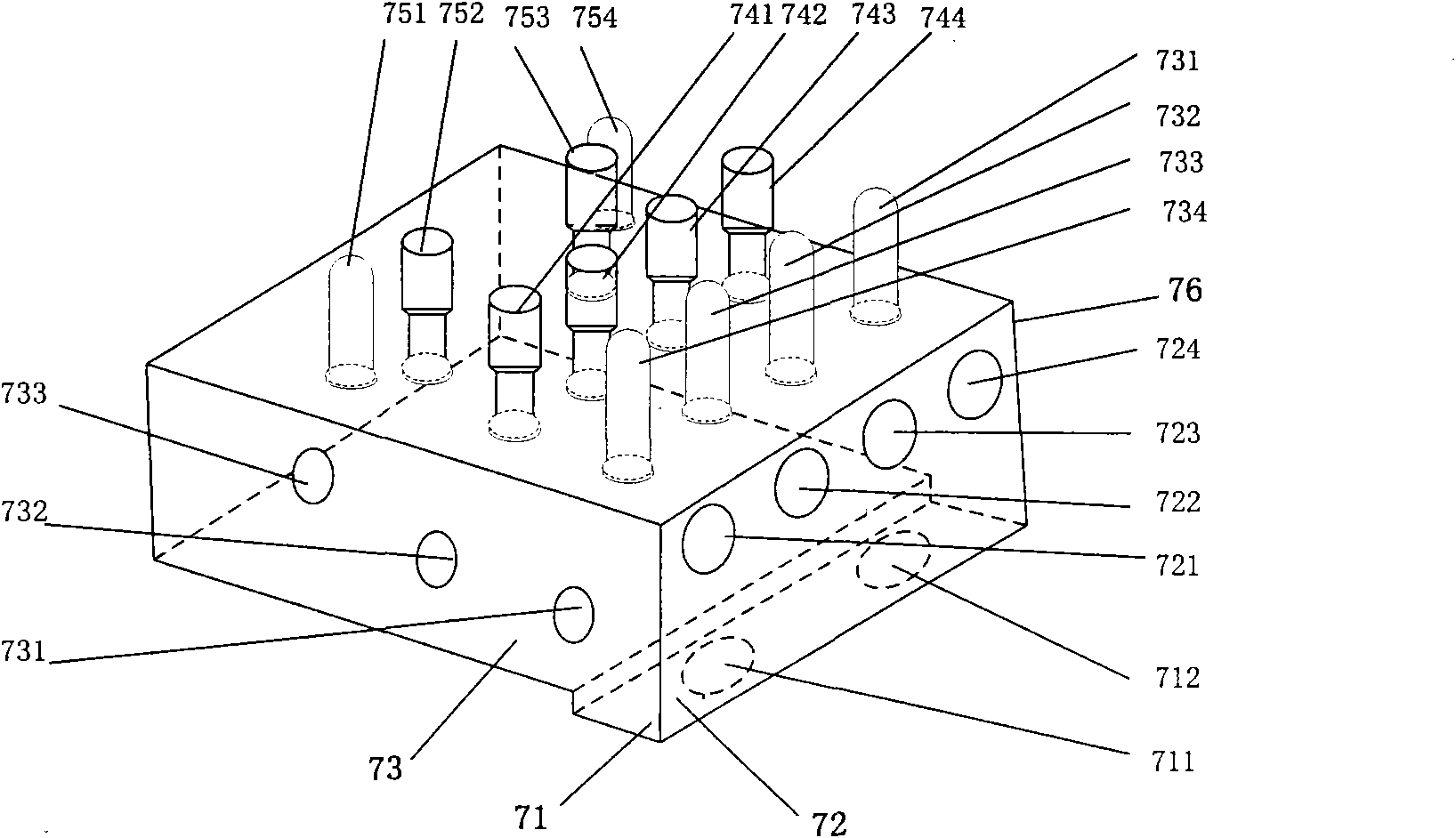

Device and process for machining differential housing

ActiveCN103753322ARealize batch production processingRealize inputWork clamping meansExpansion mandrelsNumerical controlCar manufacturing

The invention belongs to the technical field of automobile manufacturing and discloses a device and process for machining a differential housing. The device is composed of a rotary jig, an internally-expanding lathing jig and a spherical surface lathing jig, wherein the rotary jig is arranged on a machining center and comprises an operation part with the two ends arranged on the machining center through rotating assemblies, and the internally-expanding lathing jig and the spherical surface lathing jig are arranged on a common numerically-controlled lathe. Synchronous machining of two parts can be achieved through the high-precision rotary jig when the machining center is used for machining various axial inner holes, and therefore efficiency is higher; a high-precision numerically-controlled indexing table is applied to the jigs, rotating accuracy is as high as 20'' or higher, and precision of the critical size of a product is better guaranteed; the parts can be automatically clamped and dismounted by the jigs through numerical control programs, and therefore labor can be saved.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

Single-sided self-piercing friction stub rivet welding device and connection method thereof

InactiveCN101829903ARealization of mechanical-solid phase double connectionAchieving a one-sided connectionOther manufacturing equipments/toolsNon-electric welding apparatusCar manufacturingAlloy

The invention discloses a single-sided self-piercing friction stub rivet welding device in the technical field of automobile manufacture, which comprises a drive loop bar, a positioning guide sleeve, a positioning mechanism and a semi-hollow self-piercing stub rivet, wherein the drive loop bar and the semi-hollow self-piercing stub rivet are sequentially sleeved in the positioning guide sleeve from top to bottom; the positioning mechanism is horizontally distributed in the positioning guide sleeve along a circumferential direction; the semi-hollow self-piercing stub rivet is arranged over against the drive loop bar; and a workpiece to be connected is fixed below the semi-hollow self-piercing stub rivet through a far-end clamping mechanism. In the invention, the semi-hollow self-piercing stub rivet is enabled to move in an axial direction and simultaneously rotate at a high speed in the circumferential direction. In the invention, by adopting friction heat generated by the high-speed rotation of the semi-hollow self-piercing stub rivet to soften the materials of non-ferrous alloys or dead-hard steel and the like, the plasticity of a riveted material is improved, the riveting force in the process of riveting the dead-hard steel is greatly decreased, an upper workpiece and a lower workpiece are cut off through the stub rivet to form mechanical self-locking connection, and the solid phase connection between the rivet and the riveted material is formed through the friction heat generated by the high-speed rotation of the rivet.

Owner:SHANGHAI JIAO TONG UNIV

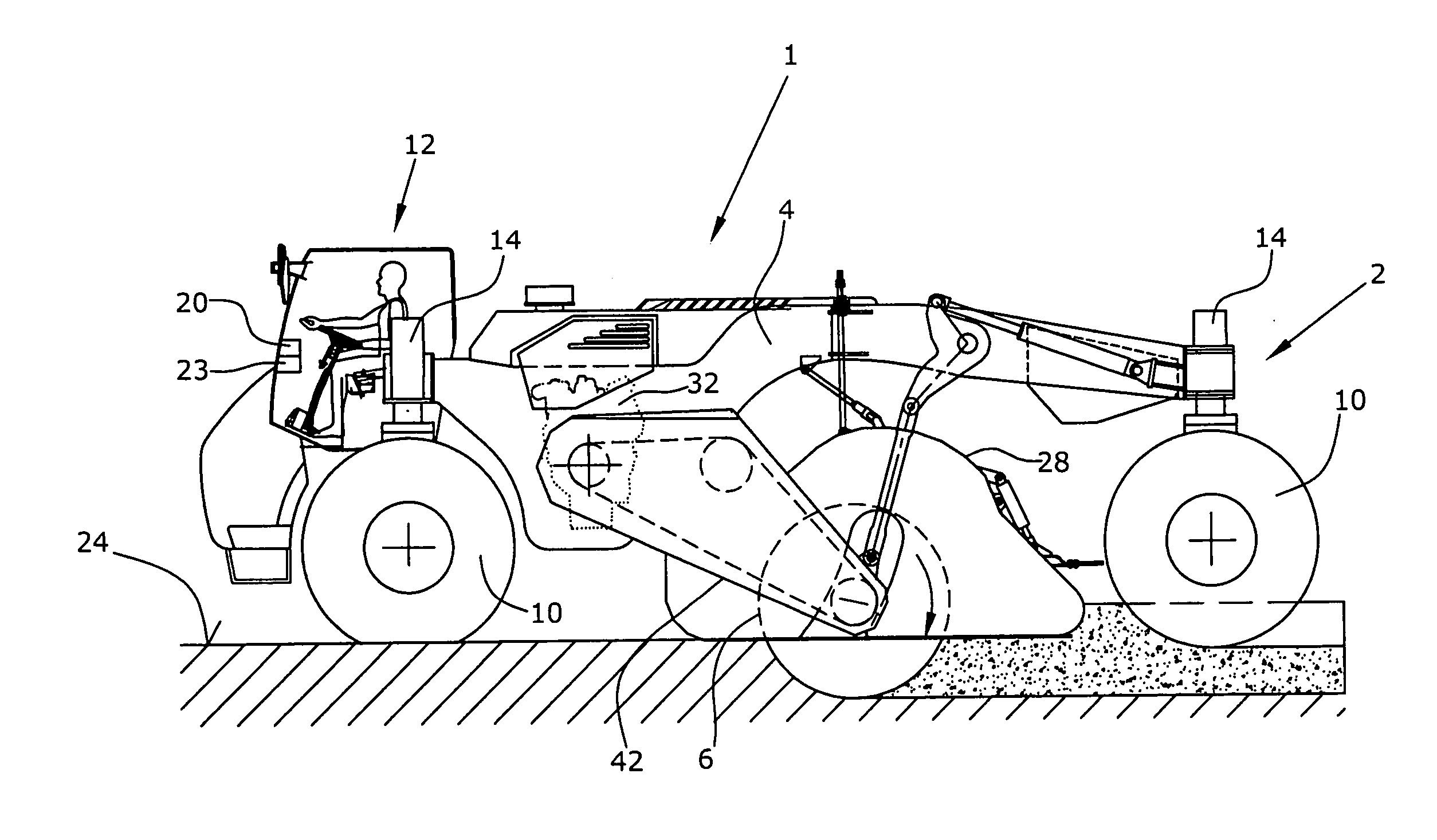

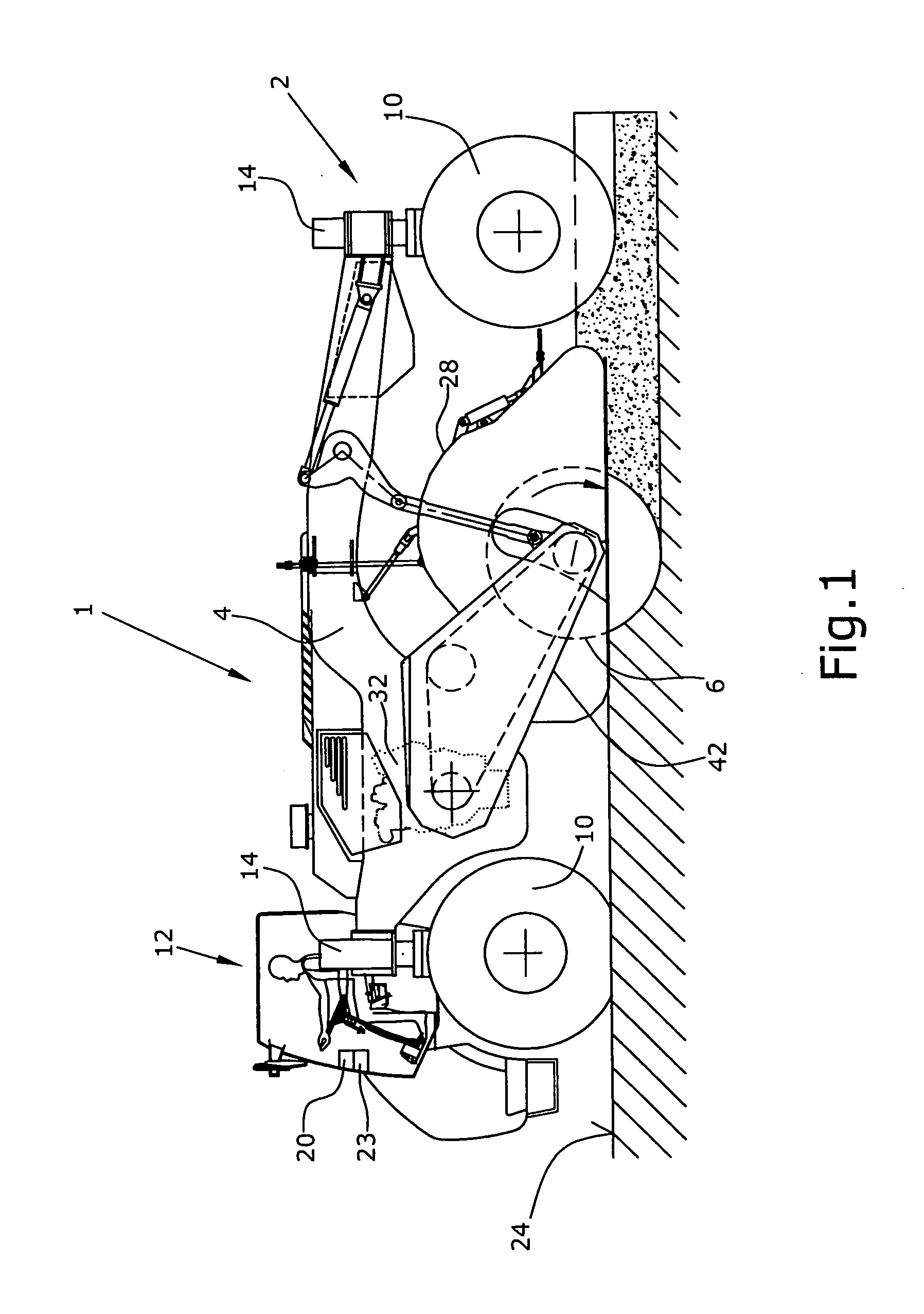

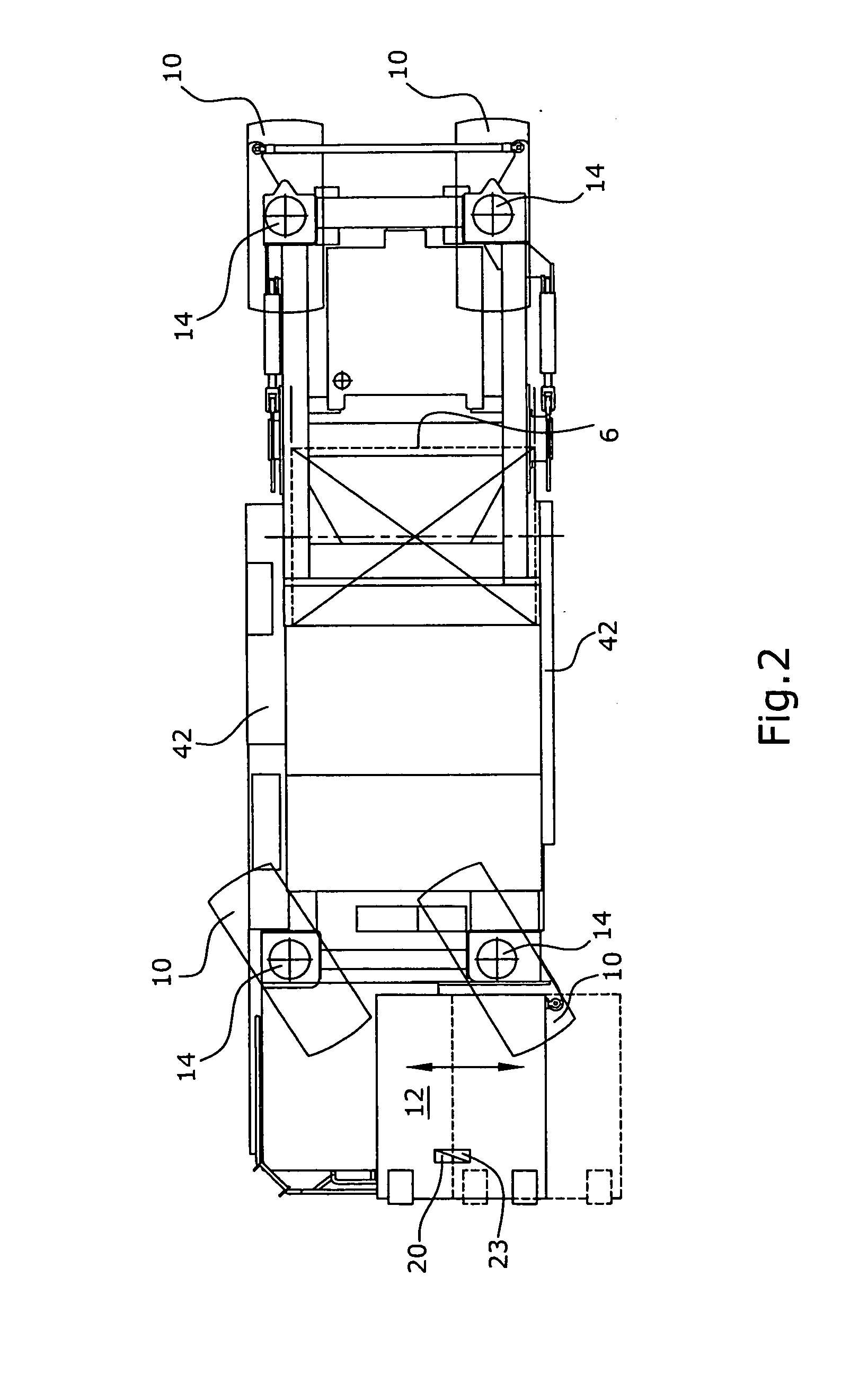

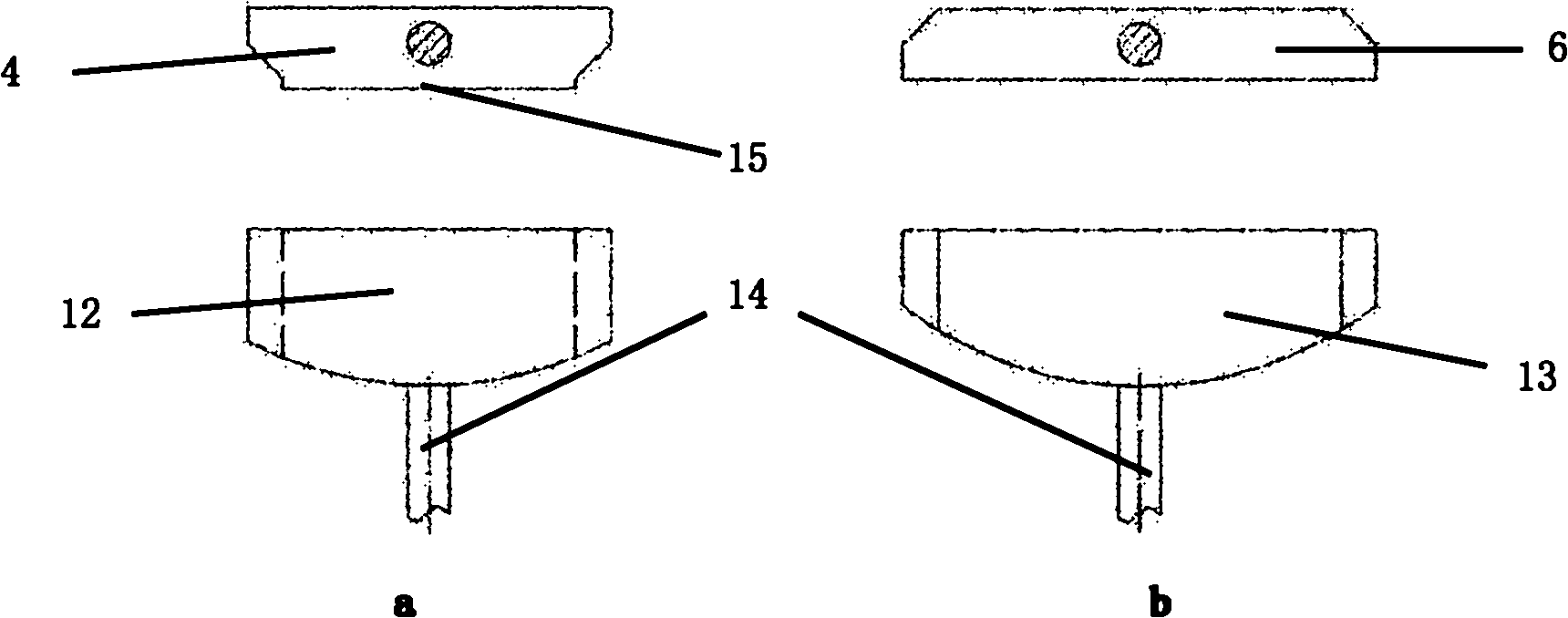

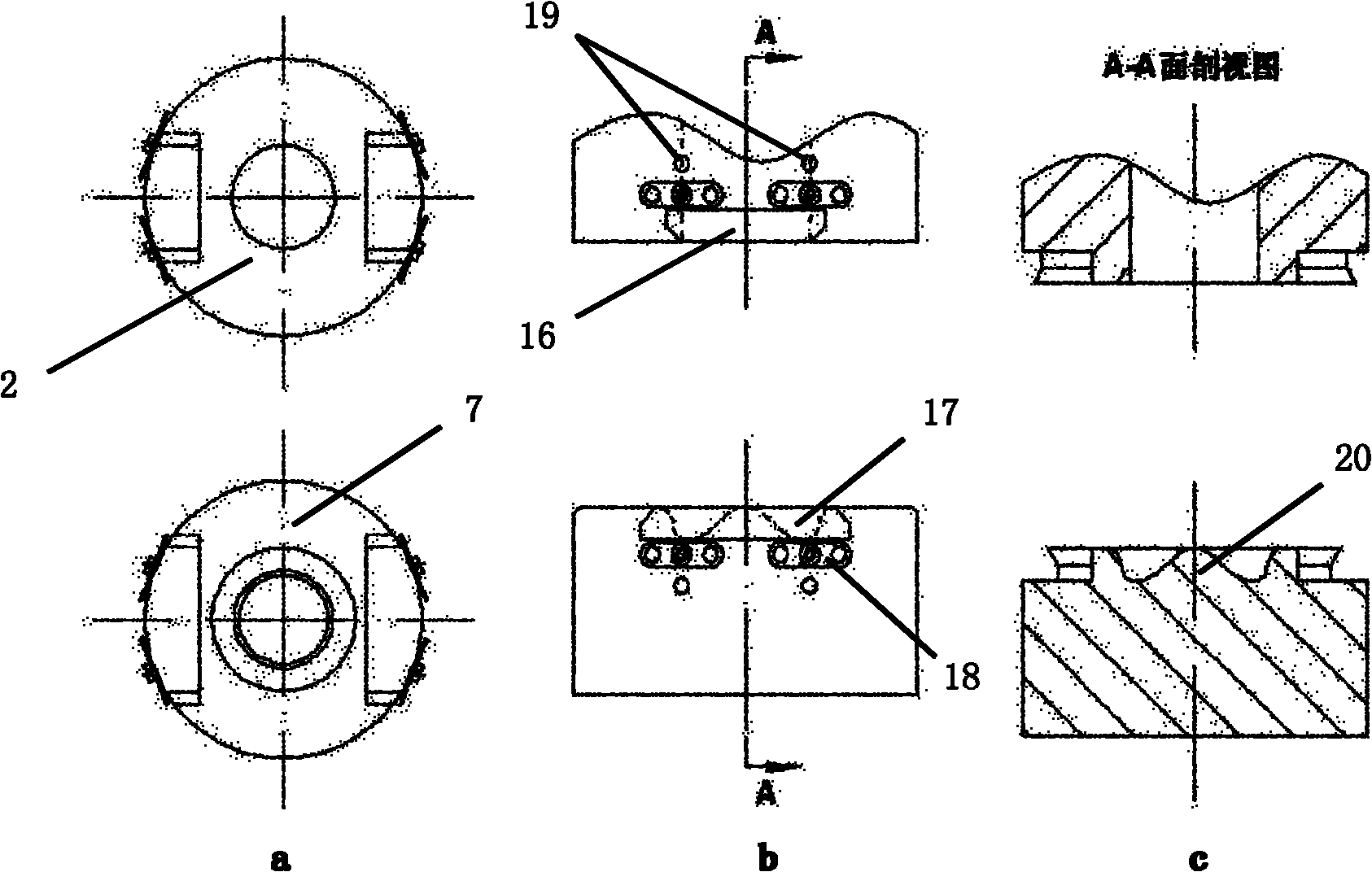

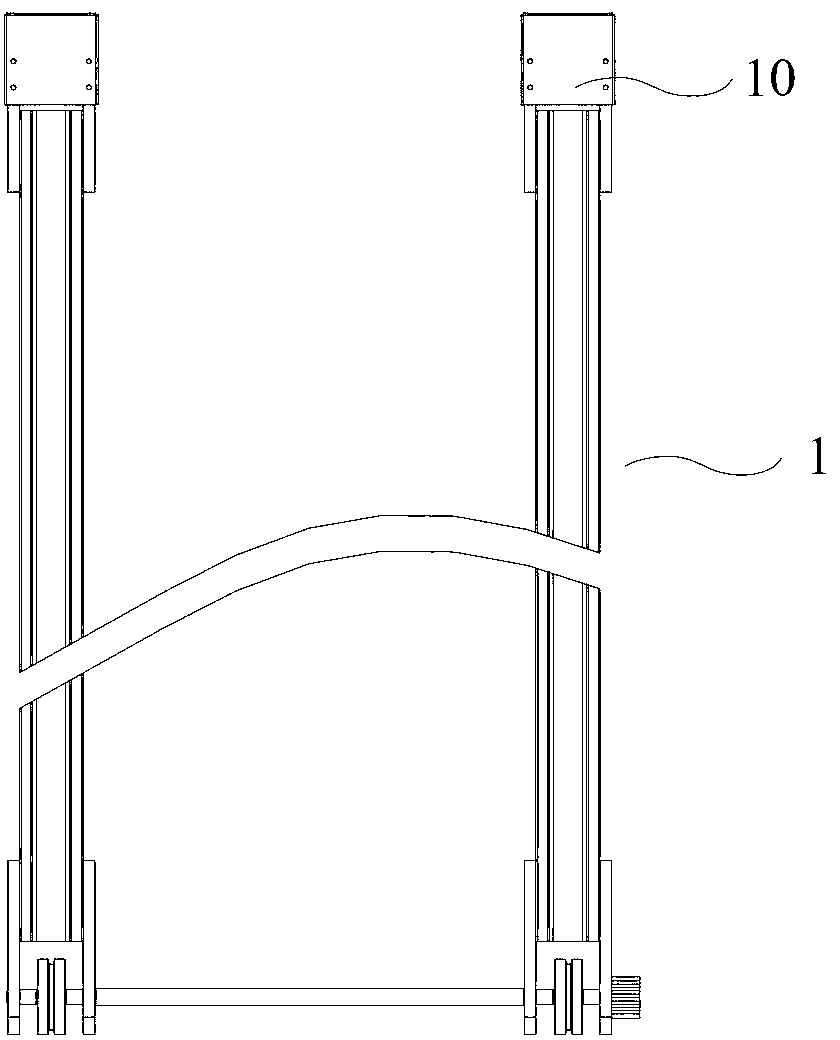

Automotive Construction Engine and Lifting Column for a Contruction Engine

ActiveUS20100109422A1Small possible displacementDigital data processing detailsVehicle body-frame connectionsCar manufacturingRoad surface

Disclosed is an automotive road construction engine (1), particularly a recycler or a cold stripping machine, comprising an engine frame (4) that is supported by a chassis (2), a working roller (6) which is stationarily or pivotally mounted on the engine frame (4) and is used for machining a ground surface or road surface (24). The chassis (2) is provided with wheels (10) or tracked running gears which are connected to the engine frame (4) via lifting column (14) and are vertically adjustable relative to the engine frame (4). The lifting columns (14) are composed of two hollow cylinders (13, 15) that can be inserted into each other, are used as a guiding unit, and preferably coaxially accommodate at least one piston-cylinder unit (16) therein for vertical adjustment purposes. Each individually vertically adjustable lifting column (14) is equipped with a device (18) for measuring the actual vertical state of the lifting column (14). Said measuring device (18) is coupled to lifting column (14) elements that can be adjusted relative to each other according to the vertical position in such a way that the measuring device (18) can continuously detect a path signal regarding the vertical position of each lifting column (14). A controller (23) which receives the measured path signals of the measuring devices (18) of all lifting columns (14) regulates the vertical state of the lifting columns (14) in accordance with the measured path signals of the measuring devices (18) and / or the changes thereof over time.

Owner:WIRTGEN AMERICA

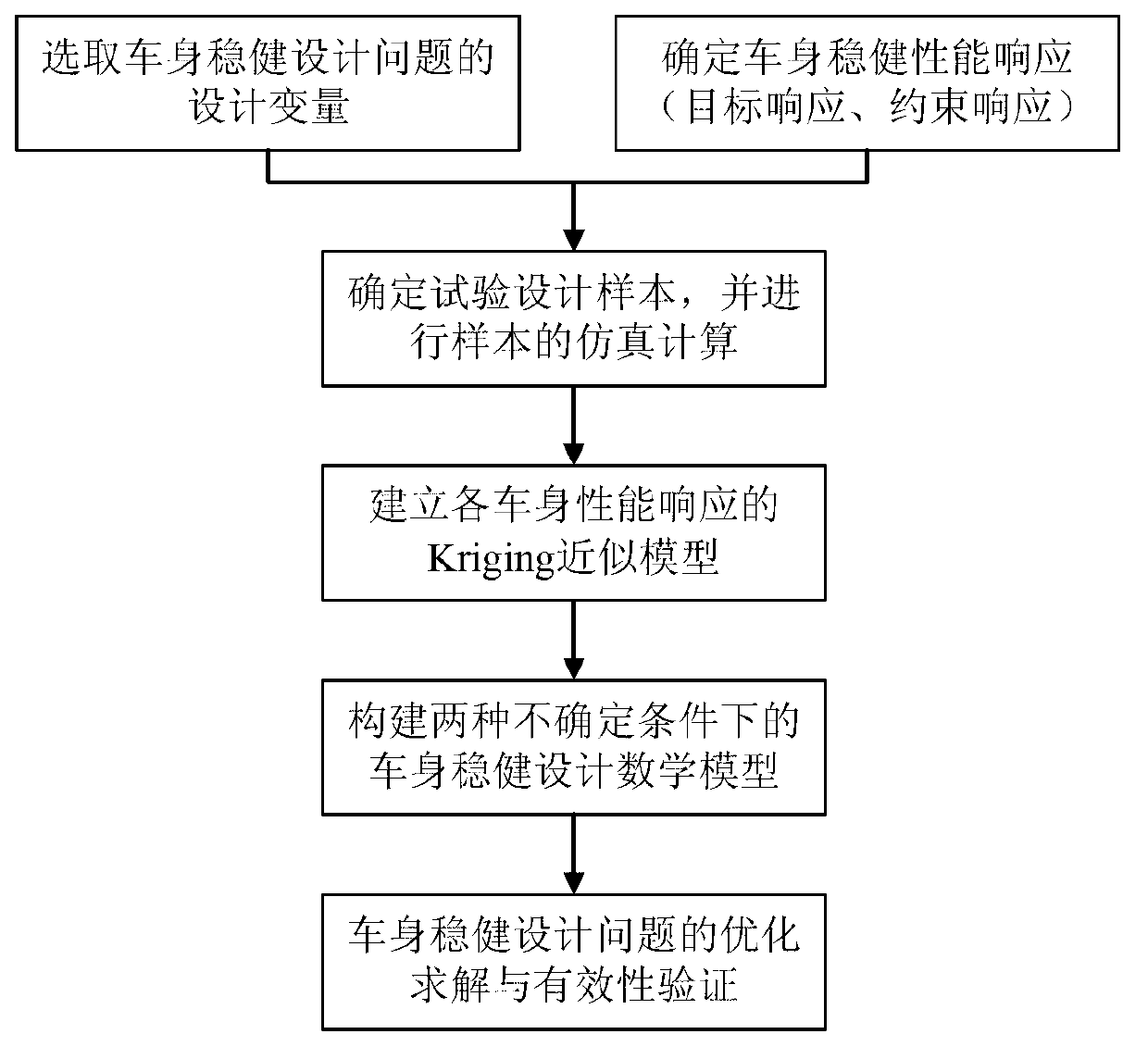

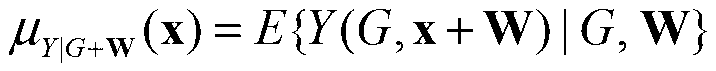

Vehicle body structure steady design method based two uncertain saloon cars

InactiveCN103136428AImprove effectivenessImprove accuracySpecial data processing applicationsCar manufacturingDesign methods

The invention discloses an approximation model uncertainty state salon car body structure steady design method in the technical field of automobile manufacturing, based on parameter uncertainty of vehicle body design variable, and taking vehicle body performance to respond a Kriging model. The salon car body structure steady design method aims at overcoming the defects that at present, a vehicle steady design method just considers parameter uncertainty to obtain steady solving which easily generates big forecast error, and even generates failure constraints, vehicle body parameter uncertainty can be reduced, and approximation model uncertainty affects vehicle body structural performance. The salon car body structure steady design method improves accuracy of design scheme target performance of a vehicle body structure and effectiveness of restraint performance.

Owner:SHANGHAI JIAO TONG UNIV

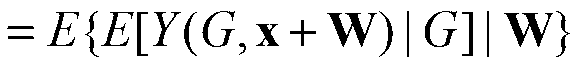

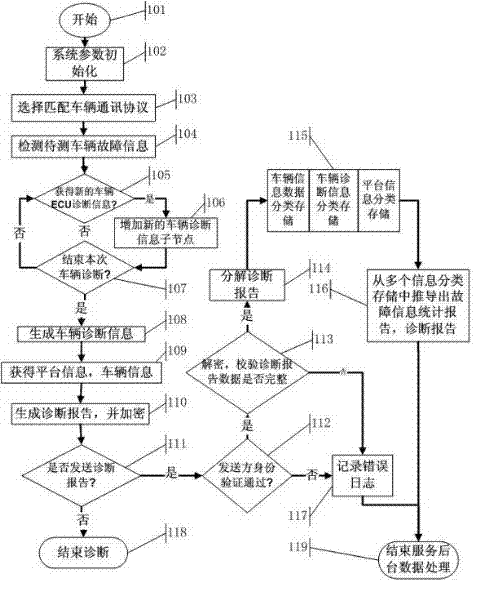

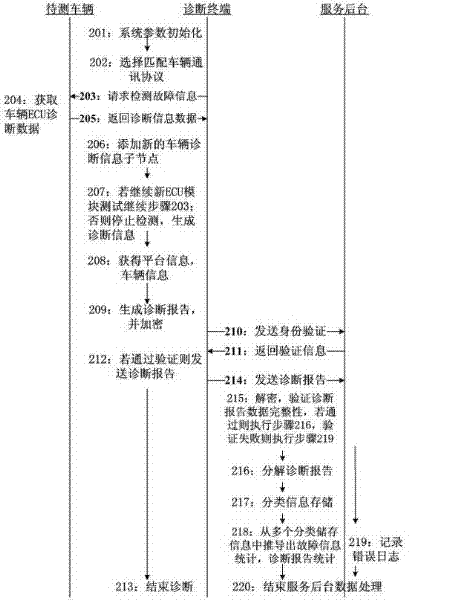

Method and system for realizing real-time interaction of automobile fault diagnosis information

InactiveCN102455700AEnable real-time interactionReal-time acquisitionElectric testing/monitoringSimulationCar manufacturing

The invention discloses a method for realizing real-time interaction of automobile fault diagnosis information, which comprises real-time acquisition, analysis, statistics and share of diagnosis information, and classification and authorization of diagnosis functions. The invention additionally discloses a system for realizing real-time interaction of automobile fault diagnosis information, which comprises a diagnosis terminal which is installed at an automobile maintenance service station and a service background which is installed at an automobile manufacturer. By using the method and the system for realizing real-time interaction of automobile fault diagnosis information, the real-time interaction of the automobile fault diagnosis information between the automobile maintenance service station and the automobile manufacturer, wherein the real-time interaction includes the real-time acquisition, analysis, statistics and share of the diagnosis information, and the classification and authorization of the diagnosis functions.

Owner:BOSCH AUTOMOTIVE SERVICE SOLUTIONS SUZHOU

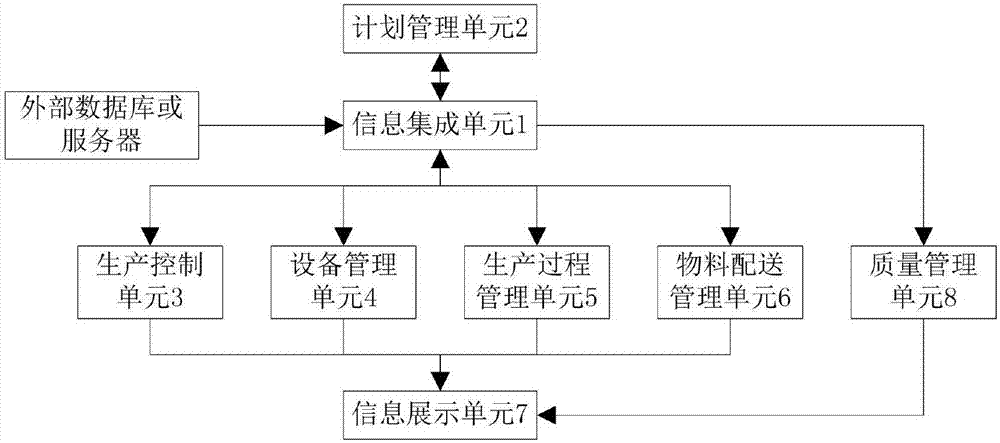

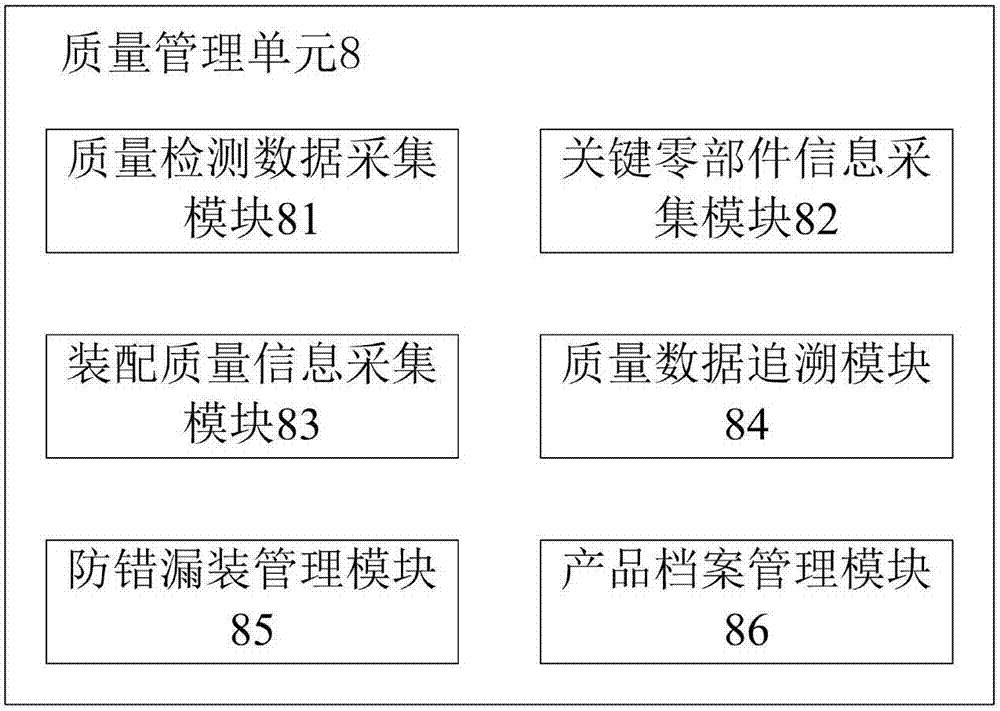

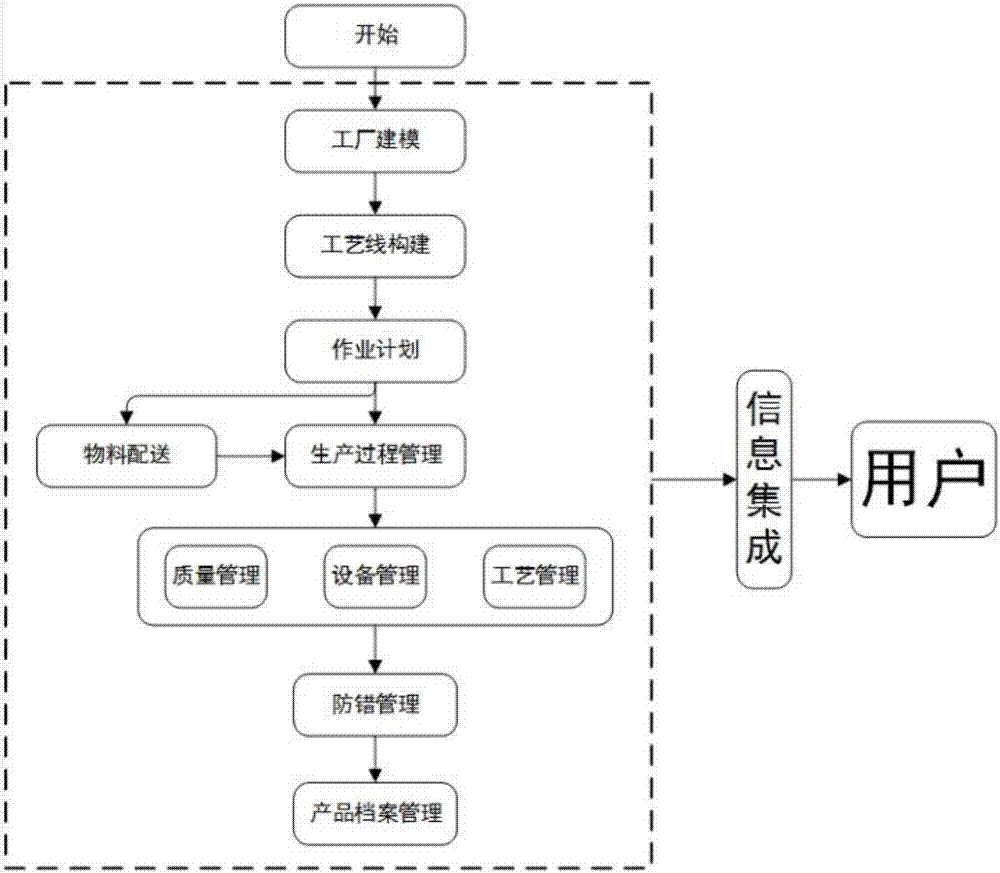

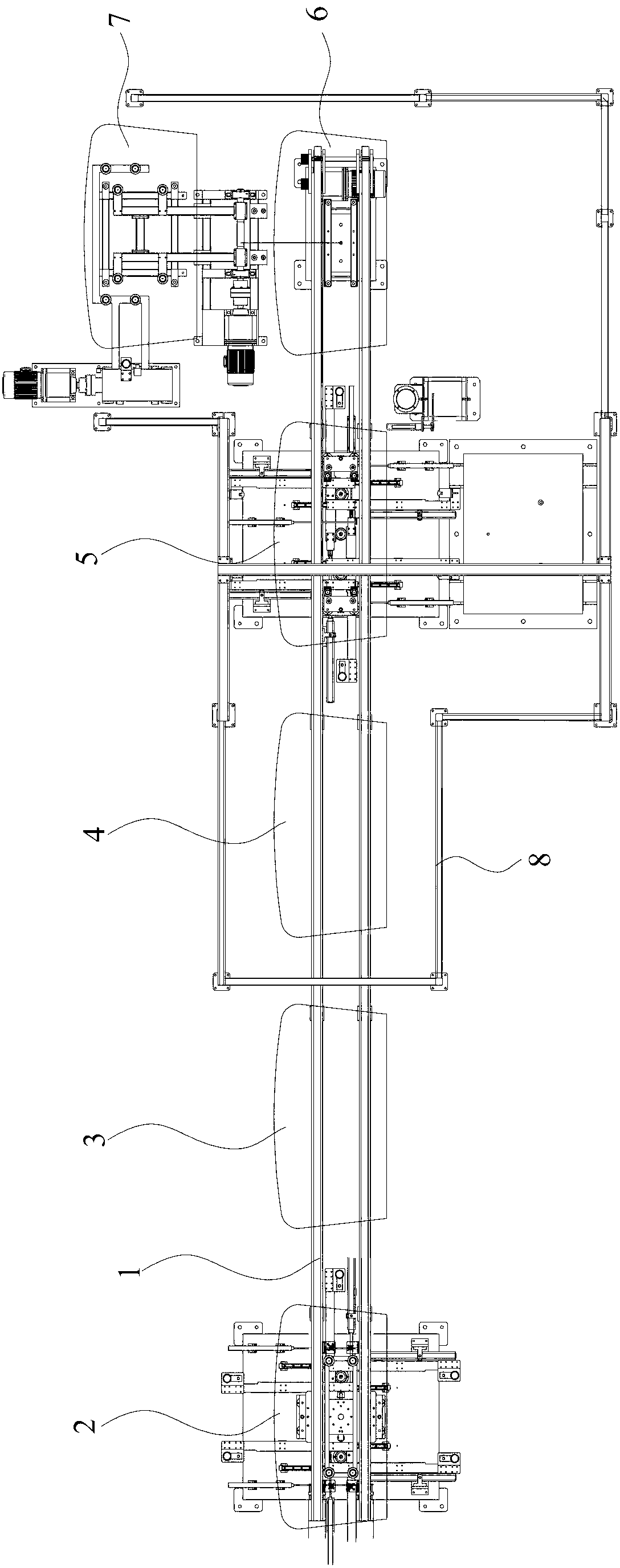

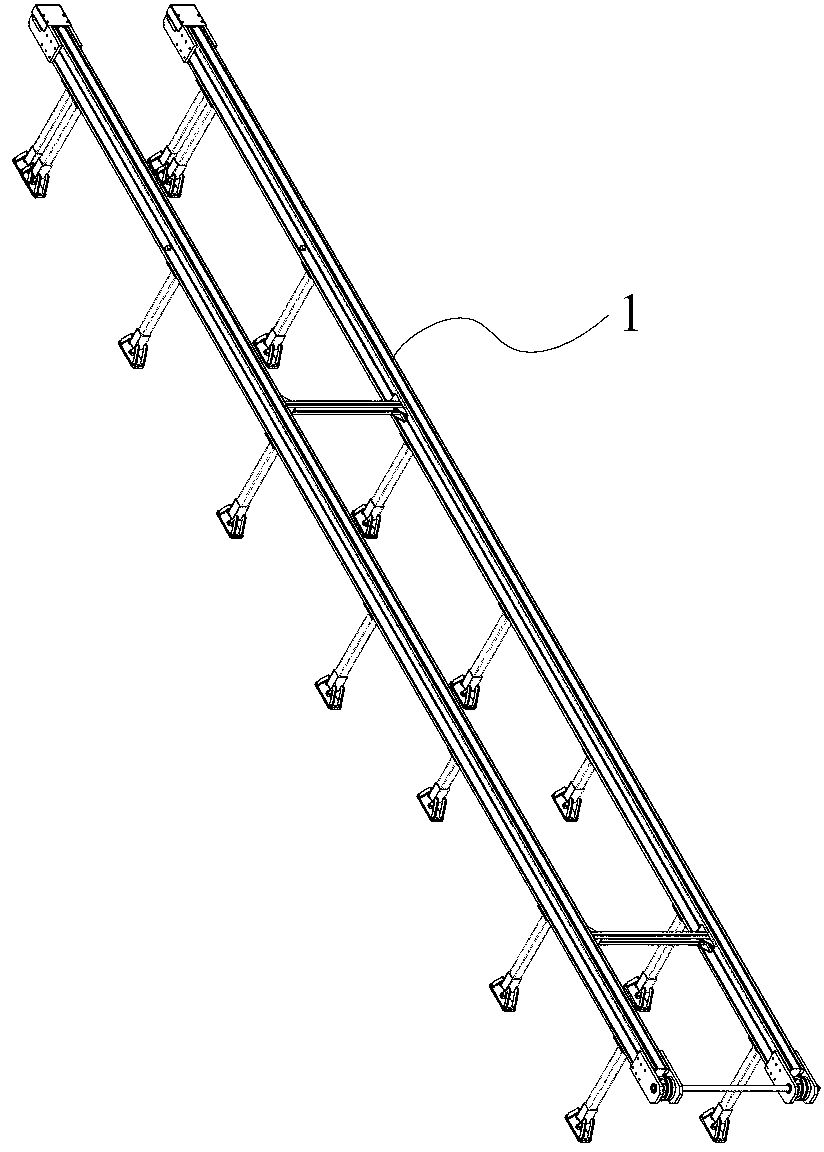

Digitalized flexible system and management method used for automobile manufacturing

ActiveCN107168258ASee clearlyProgramme total factory controlData connectionThree dimensional simulation

The invention discloses a digitalized flexible system and a management method used for automobile manufacturing. The system comprises an information integrating unit (1), a plan management unit (2), a production control unit (3), an equipment management unit (4), a production process management unit (5), a material distribution management unit (6), an information displaying unit (7) and a quality management unit (8). According to the invention, users are enabled to see all kinds of data in production quite clearly through a visualization interface; the whole production processes can be displayed to the users through a simulation mode; through interconnection of production and manufacturing onsite control data, a three-dimensional simulation model and onsite data acquisition, and data connection with an external management system, complete availability of information flows of enterprises is achieved; production and manufacturing preparation time of a general assembly shop is effectively shortened; and efficiency and quality of technology planning of the general assembly shop are improved.

Owner:大唐互联科技(武汉)有限公司

Manufacturing method of aluminum magnesium alloy

The invention relates to a manufacturing method of plates and particularly relates to a manufacturing method of an aluminum magnesium alloy thick plate, which can be used for solving the problems that a process for processing a plate made of aluminum alloy 5083 which is in the H321 state and is 12.5-75mm in thickness, and the aluminum alloy 5083 being in the H321 state and being 12.5-75mm in thickness, which is prepared by the existing casting method, is poor in strength and percentage elongation. The method comprises the steps of firstly, melting; secondly, casting; thirdly, evening fire; fourthly, rolling and fifthly, annealing. According to the method disclosed by the invention, the blank of the manufacturing method of an alloy thick plate 5083H321 being 12.5-75mm in thickness is filled; and according to the method, a reasonable technological process is selected, so that the yield strength of the plate is 275-293MPa, the tensile strength of the plate is 350-365MPa, and the percentage elongation of the plate is 10.8-11.9%. The aluminum magnesium alloy thick plate manufactured by the method can be used for the industrial fields of armored vehicles, ships, automobile industries, and canning.

Owner:NORTHEAST LIGHT ALLOY CO LTD

One-component silicyl polyether sealing adhesive and preparation method thereof

The invention relates to a one-component silicyl polyether sealing adhesive and a preparation method thereof, belonging to the technical field of one-component silicyl polyether sealing adhesive; the one-component silicyl polyether sealing adhesive mainly solves the problems that the existing silicyl-terminated polyether sealing adhesive has low tensile strength, and the tensile strength is only 0.5-3.5MPa and affects the application range; the one-component silicyl polyether sealing adhesive comprises the following ingredients: 20-40 parts of silicyl-terminated polyether, 5-20 parts of plasticizers, 30-50 parts of incremental fillers, 4-10 parts of reinforcing fillers, 0-20 parts of coloring agents, 0.1-5 parts of thixotropic agent, 0.01-1 part of ultraviolet absorber, 0.01-1 part of radical scavenger, 0.1-3 parts of moisture content scavenger, 0.1-5 parts of adhering accelerator and 0.1-3 parts of catalysts; the one-component silicyl polyether sealing adhesive has high tensile strength, the tensile strength can reach 5.12MPa, and the one-component silicyl polyether sealing adhesive is used for sealing adhesive of various materials and splicing, thereby having wide application on automobile making industry, railway transportation industry, container manufacturing industry, metal and nonmetallic processing industry, equipment manufacturing, air conditioner and ventilator devices.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

Silencing film for automobile

InactiveCN101497768AEasy to break awayGood workmanshipMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesElectrophoresisCar manufacturing

The invention relates to a binding material, in particular to an automobile sound deadening film which is used on metal plates for locally reinforcing the metal plates and particularly on automobile doors to reduce noises generated by the vibration of a running automobile. The automobile sound deadening film is prepared by mixing and extruding 10-25 percent of synthetic rubber, 5-15 percent of thermoplastic resin, 5-20 percent of thickening resin, 10-25 percent of plasticizing agent, 25-50 percent of vibration damping and sound deadening agent, 10-20 percent of oil absorbing and filling agent and 5-10 percent of reinforcing filling material. The automobile sound deadening film can be used for the large-area sound deadening and vibration damping of the metal plates during the automobile manufacturing process. When being used, the automobile sound deadening film can be operated by hands, is innoxious and odorless, is easy to separate from release paper, has good manufacturability, can not shift after being pasted, is less susceptible to oil washing, phosphating process, electrophoresis, paint spraying and drying, and other subsequent automobile body manufacturing processes and is convenient to use.

Owner:广州市东明扬汽车部件有限公司

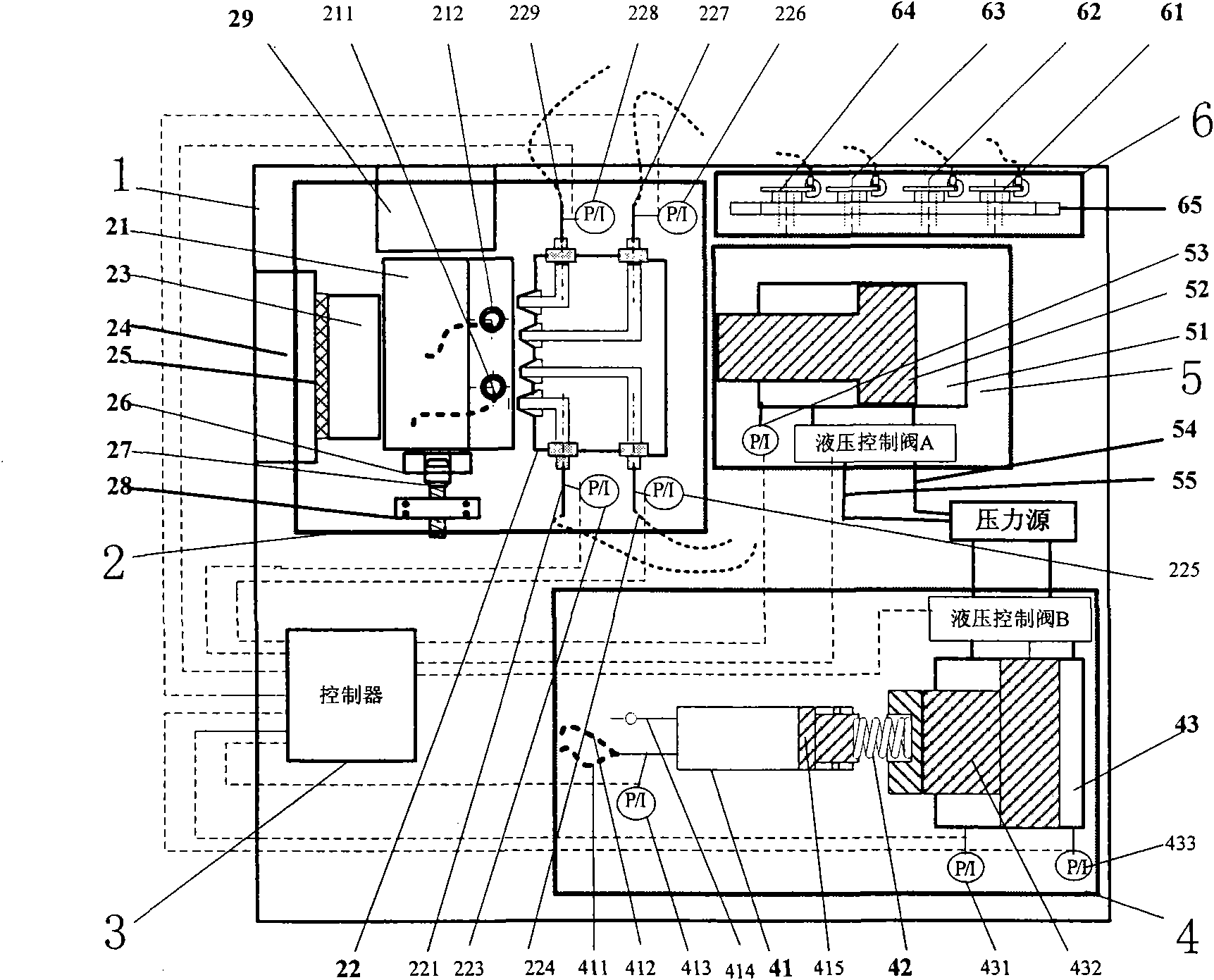

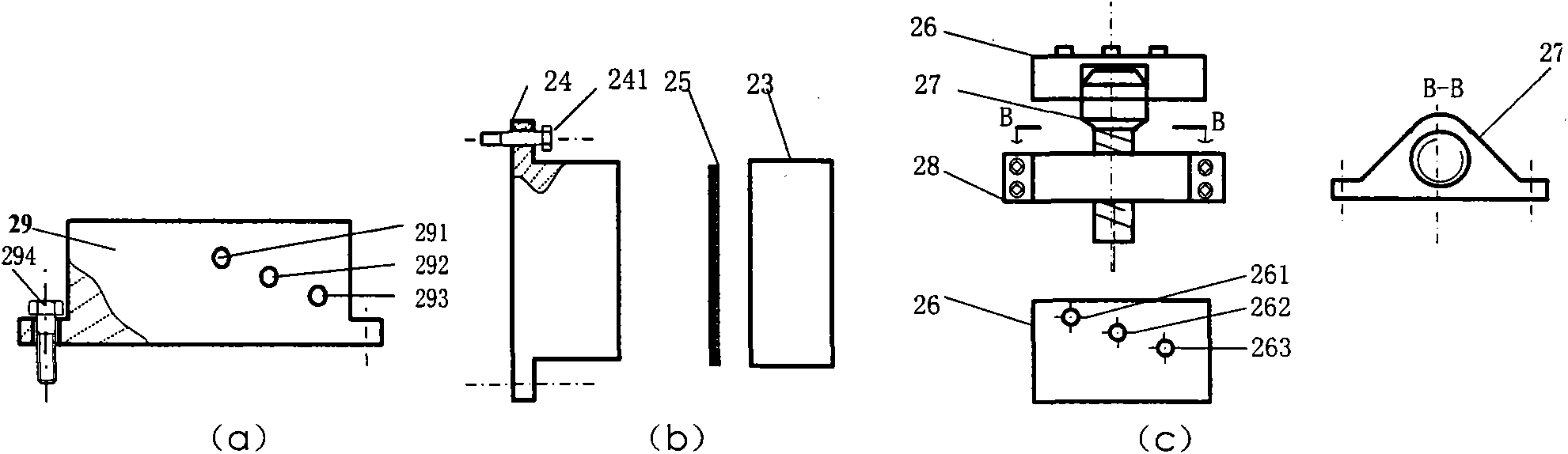

Hydraulic control unit performance test station for stability control system in vehicle dynamics

ActiveCN101566527ARapid positioningQuick dockingVehicle testingFluid-tightness measurementHydraulic cylinderHydraulic control unit

The invention relates to a hydraulic control unit performance test station for a stability control system in vehicle dynamics and belongs to the technical field of automobile manufacturing. The test station comprises a flat workbench, an HCU fast limiting and oil circuit sealing platform which is arranged on the workbench, a controller, a sealing feeding differential hydraulic cylinder, a hydraulic test system, a vehicle braking system, and a pressure source; the controller is respectively connencted with the HCU fast limiting and oil circuit sealing platform, the differential hydraulic cylinder and the hydraulic test system by a circuit; the differential hydraulic cylinder contacts the HCU fast limiting and oil circuit sealing platform; the hydraulic test system is connencted with the HCU fast limiting and oil circuit sealing platform by a test oil circuit; the vehicle braking system is connencted with the HCU fast limiting and oil circuit sealing platform by a braking fluid interface pipeline; and the hydraulic test system and the oil circuit sealing differential hydraulic cylinder are connencted with the pressure source by a hydraulic pipeline. The invention meets the delivery inspection needs of HCU, has easy and quick operation, and achieves low cost.

Owner:TSINGHUA UNIV

Heat-cured high-intensity flaky adhesive for automobile and preparation method thereof

ActiveCN102181238AReduce noiseComfortable and safeNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyAdhesive

The invention provides a heat-cured high-intensity flaky adhesive for an automobile and a preparation method thereof. The heat-cured high-intensity flaky adhesive for the automobile comprises three layers, wherein the upper layer is made of glass fiber cloth, the middle layer is made of a high-intensity adhesive, and the bottom layer is made of barrier paper. The high-intensity adhesive is prepared from synthetic rubber, a plasticizer, epoxy resin, thermoplastic resin, tackifying resin, a curing agent, a vulcanizing agent, an accelerating agent, an anti-aging agent and calcium carbonate. Due to the adoption of the flaky adhesive, the rigidity of a metal sheet can be increased greatly in the automobile manufacturing process, the running noise of the automobile can be reduced, and the comfort and the safety of the automobile are ensured. The heat-cured high-intensity flaky adhesive has high adhesion to an oil surface metal material, can be operated manually and directly in the construction process, is non-sticky, nontoxic and tasteless, has high manufacturability, is prevented from moving, and is convenient to use. The flaky adhesive can be cut according to different requirements onpositions, sizes and shapes and can be stored for over 3 months at the temperature of 25 DEG C.

Owner:三友(天津)高分子技术有限公司

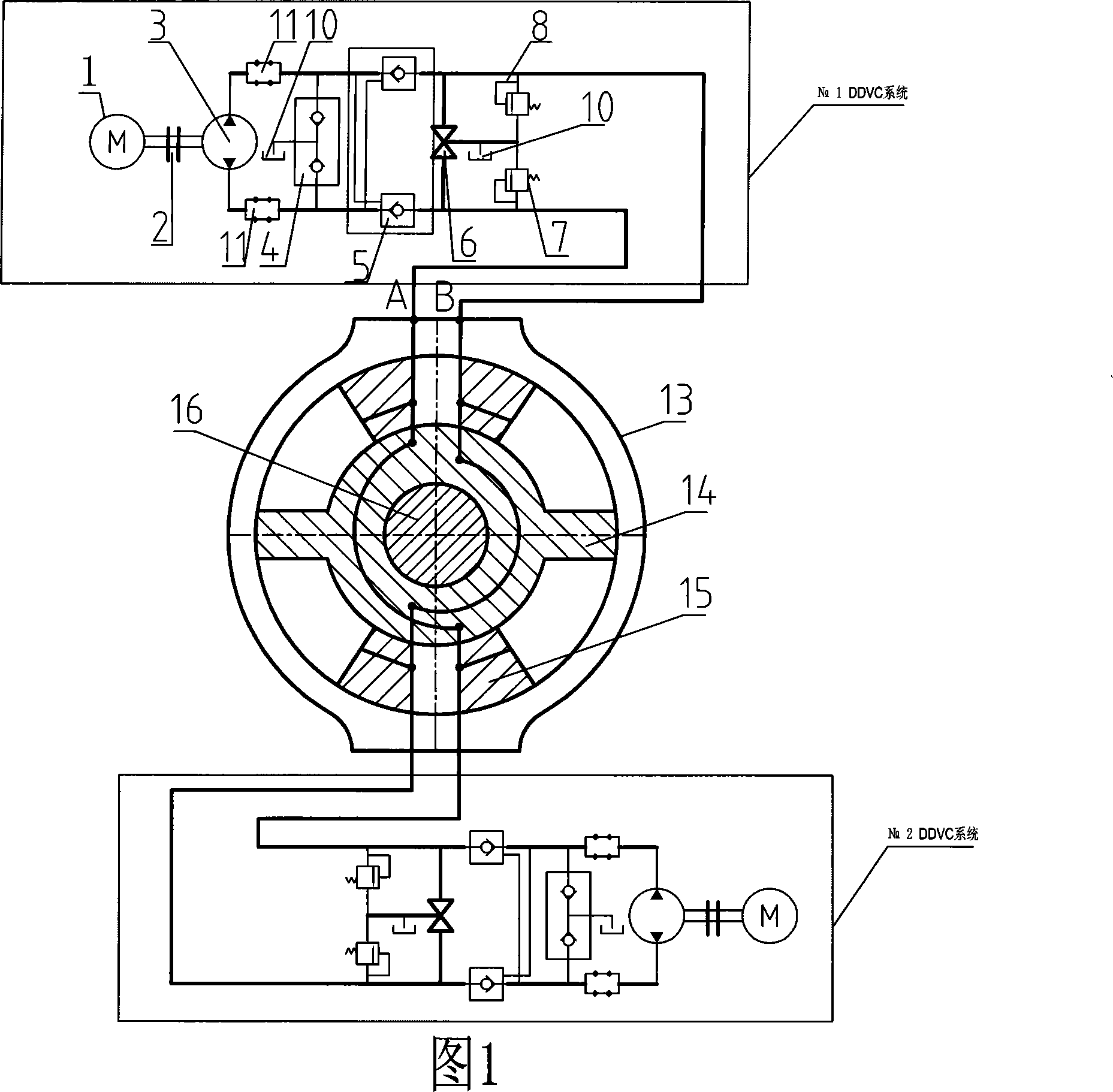

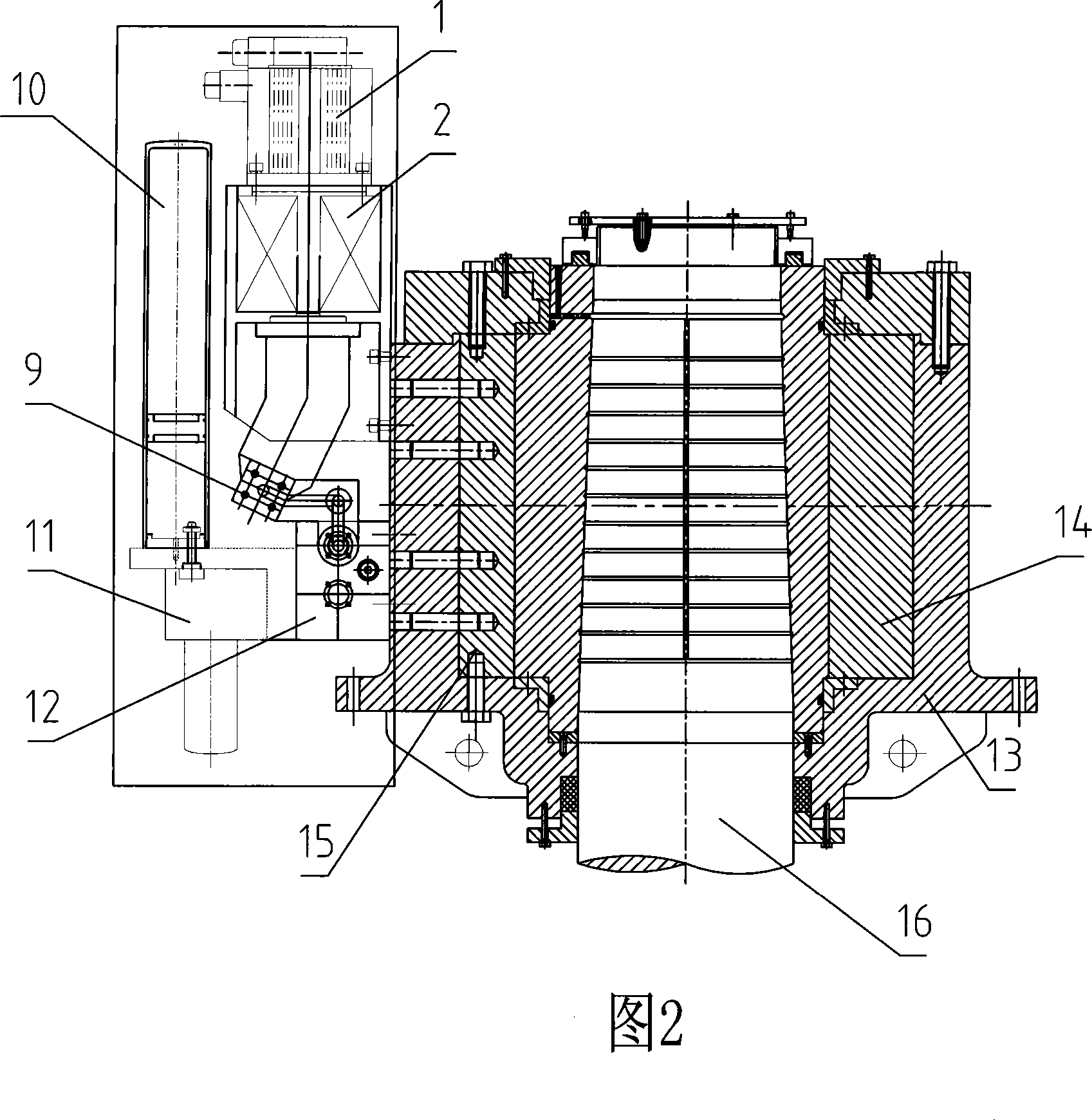

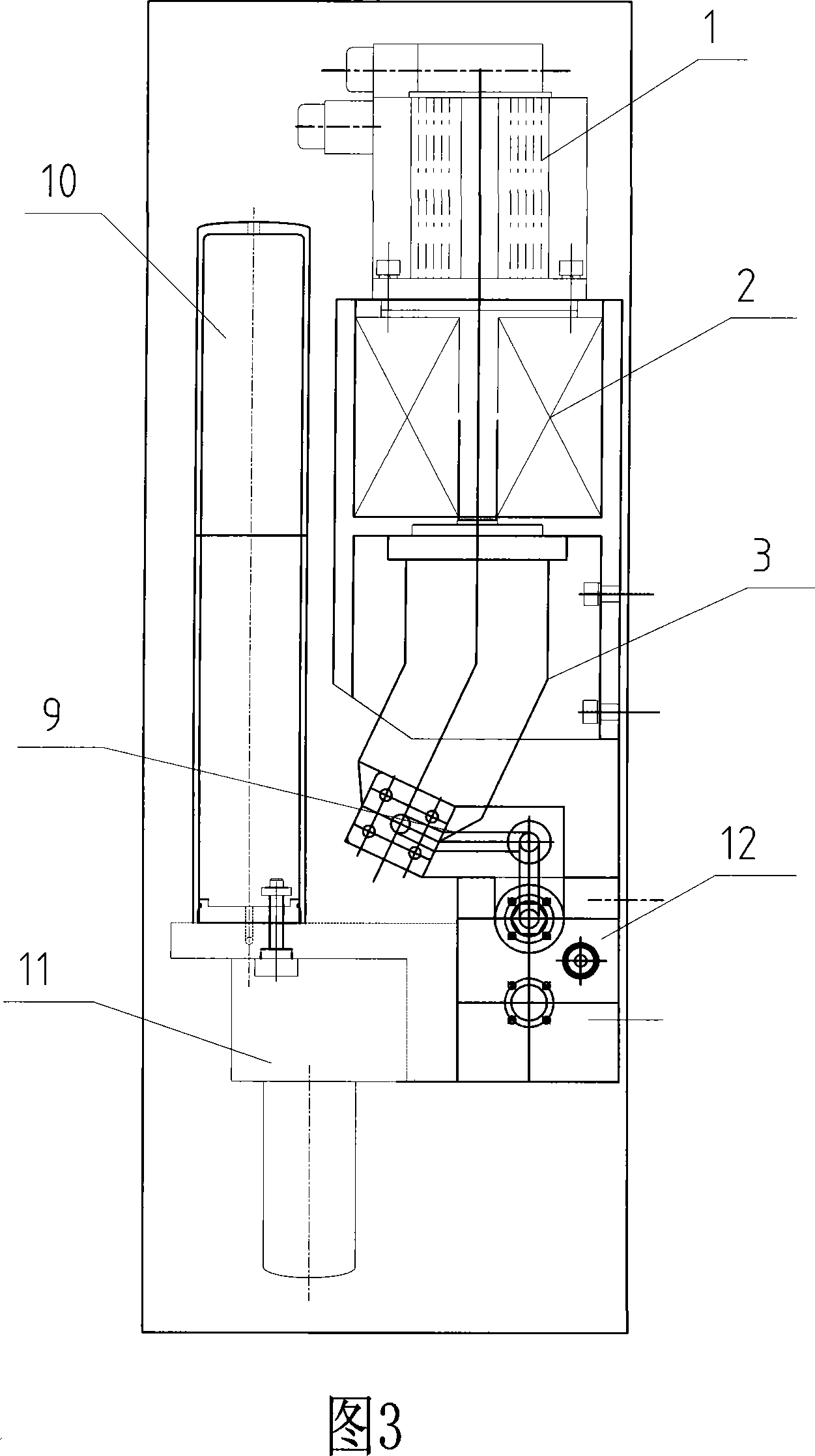

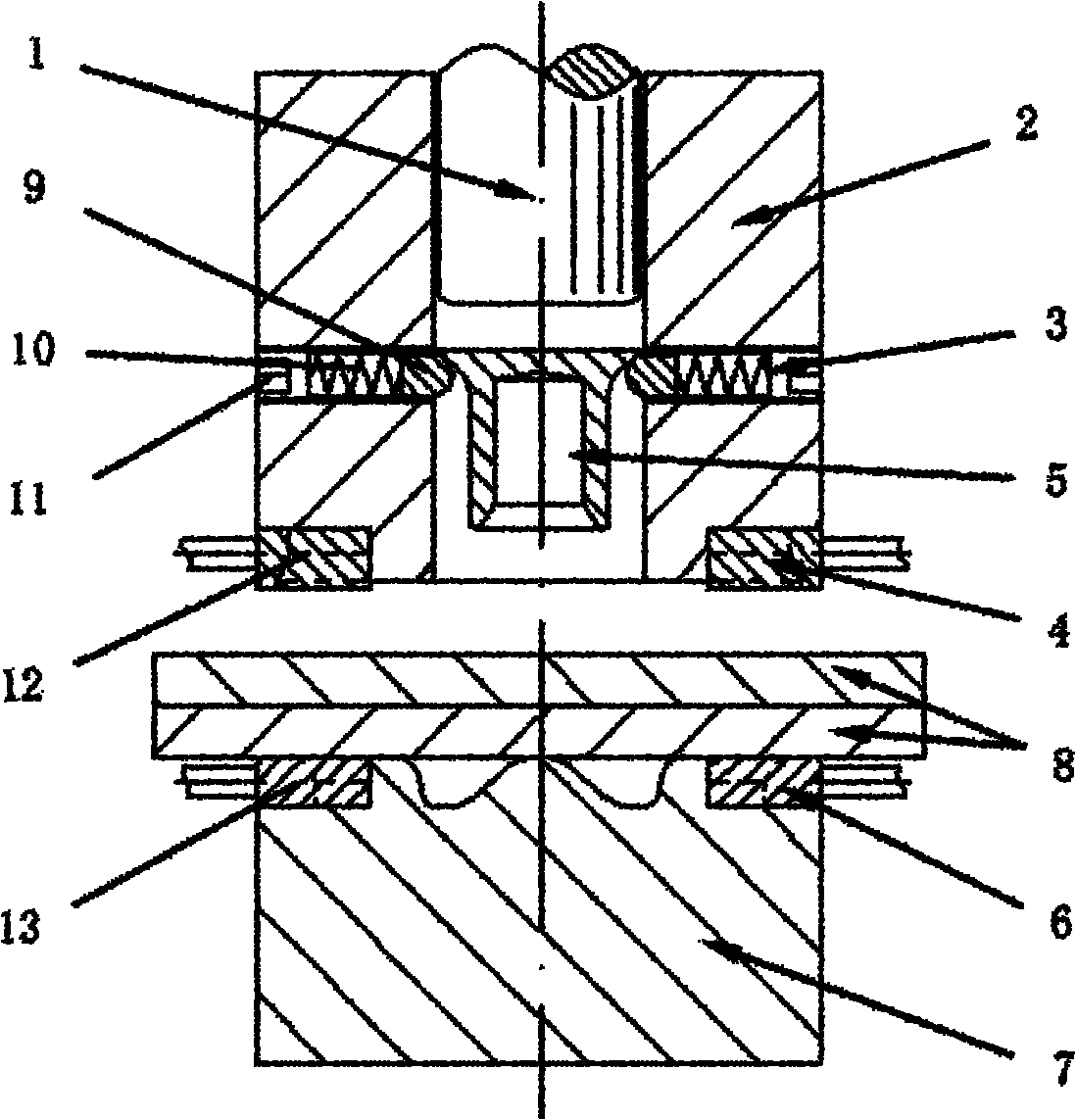

Direct driving type volume servo control power installation

The invention belongs to a direct driving volume servo control power device which controls a rotary vane actuator system in an electro-hydraulic servo technical field. The invention consists of a servo motor, a bidirectional valve, a shuttle valve, a lock valve, a safety valve, an oil storage tank and a connecting oil path; two output terminals A and B of the oil path are connected with a hydraulic execution mechanism in positive or reversed rotation direction or steering; the servo motor receives the electric instruments to implement the flux control, steering control, pressure control, program control and position control of the hydraulic system; the invention is a fully novel electro-hydraulic servo control technology implementing the automatic control and integrating the machine, electricity and liquids into a whole. The invention can be widely applied to the fields such as ship marine engineering, mechanics, mines, metallurgy, nuclear power, pressure processing and automobile manufacture, etc.

Owner:LIAONING XINYU EQUIP AUTOMATION

Al-mg-zn Alloy With Scandium For The Integral Construction Of Alm Structures

InactiveCN107058825AOmit levelingGood reproducibilityAdditive manufacturing apparatusCar manufacturingScandium

The present invention relates to an Al-Mg-Zn alloy with scandium for the integral construction of alm structures, an aluminum alloy, a method for producing a lightweight metal workpiece, a lightweight metal workpiece including the aluminum alloy, as well as the use of the aluminum alloy for producing high-strength lightweight metal workpieces by additive layer manufacturing (ALM) and / or spraying methods for load-optimized components, in particular in automobile manufacturing or in aviation and aerospace applications, plant engineering, medical technology, or as coating material for structural components.

Owner:AIRBUS DEFENCE & SPACE

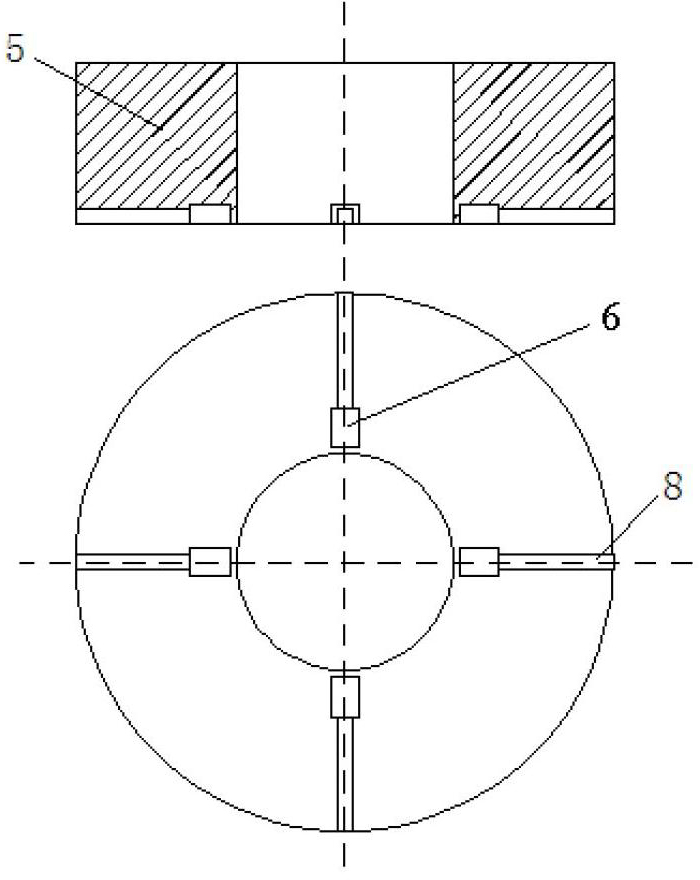

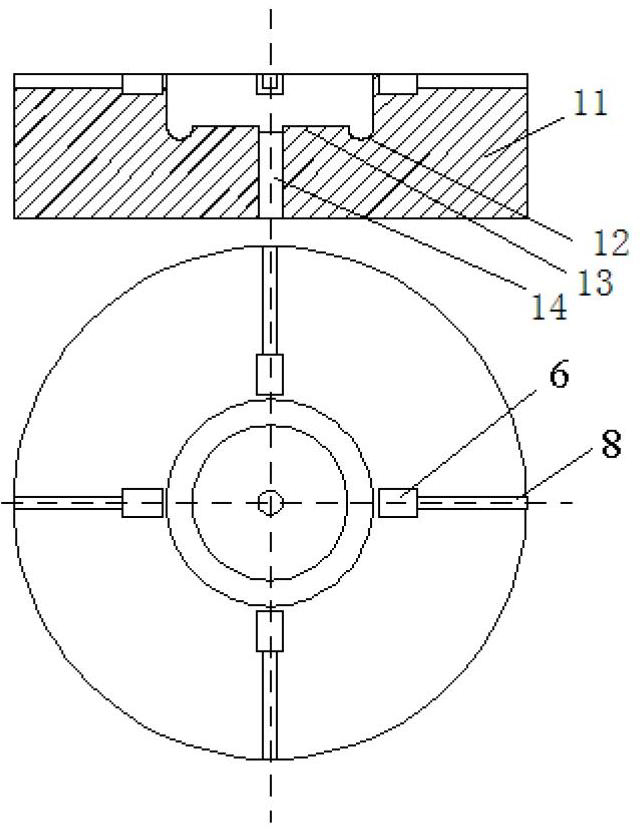

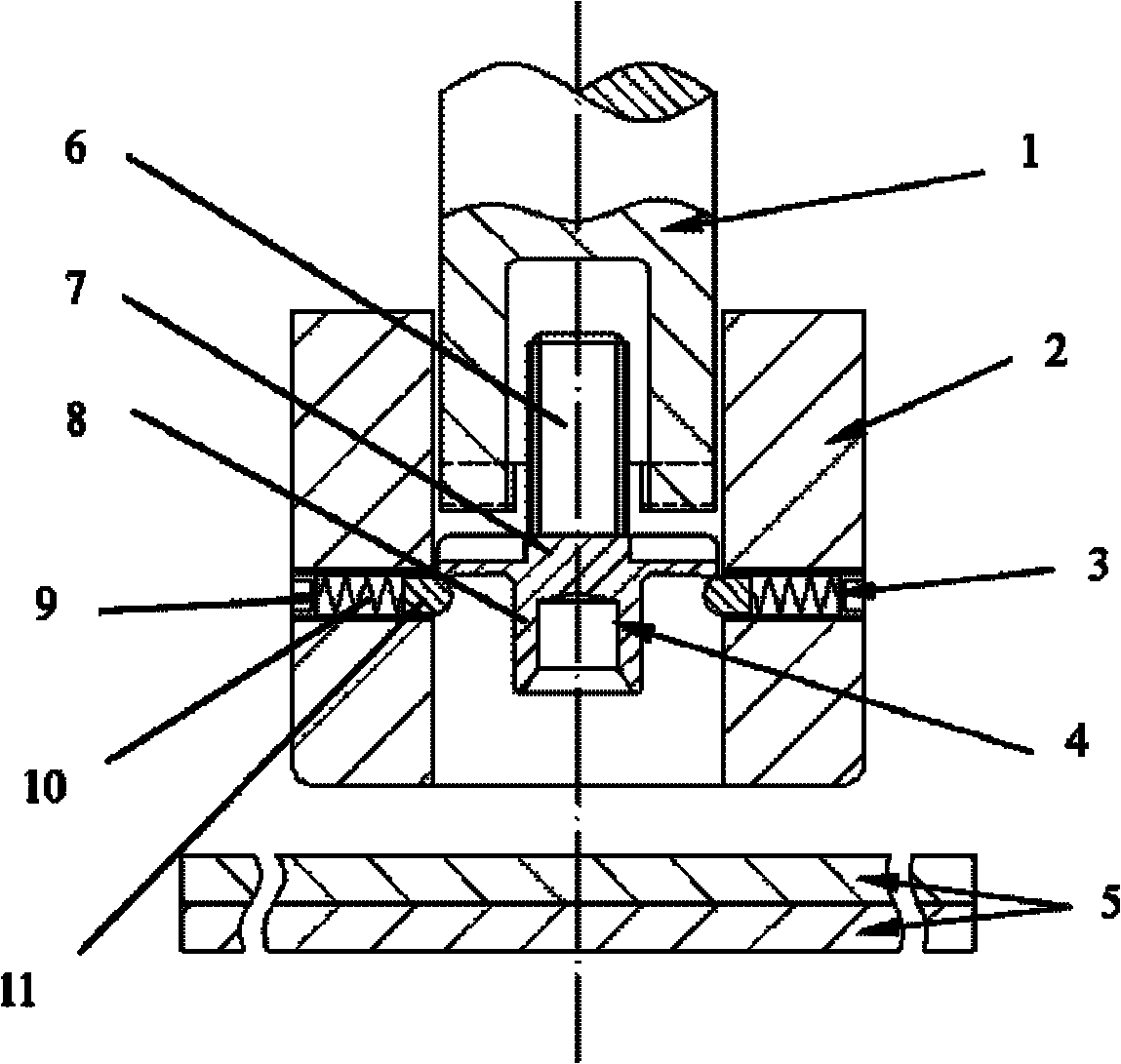

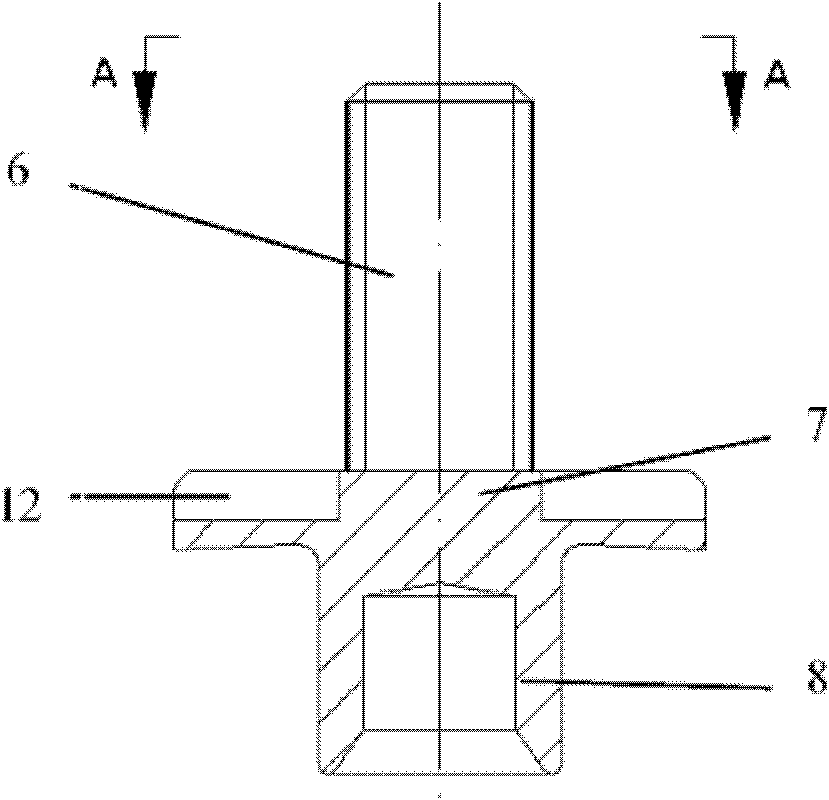

Electroplastic self-piercing riveting device

The invention relates to an electroplastic self-piercing riveting device belonging to the technical field of automobile manufacture. The device comprises a driving rod, a blank holder, a plurality of spring bead positioning mechanisms, four electric brushes in two groups, semitubular rivets and a female die, wherein the blank holder, a plate to be connected and the female die are sequentially arranged from top to bottom; the driving rod is sleeved in the blank holder; the plurality of spring bead positioning mechanisms are horizontally distributed in the blank holder along the radial direction; the semitubular rivets are vertically arranged in the blank holder and are in contact with the spring bead positioning mechanisms; the driving rod, the blank holder, the semitubular rivets and the female die are coaxially arranged; two upper electric brushes are respectively arranged at the bottom of the blank holder; and two lower electric brushes are oppositely arranged at the top of the female die. The invention solves the problem that when an alloy plate is riveted, the bottom of a joint generates radial cracks easily and even generates brittle rupture; and the invention reduces the plastic deformation resistance when the advanced high strength steel is riveted, and improves the comprehensive connection quality of joints.

Owner:SHANGHAI JIAO TONG UNIV +1

Automobile windshield glass rubber coating device

ActiveCN102847667AImprove drying effectImprove production taktPretreated surfacesCoatingsCar manufacturingIdentification device

The invention discloses an automobile windshield glass rubber coating device, which relates to the technical field of an automatic manufacturing technique device, and aims at better improving the rubber coating speed of the windshield glass. The automobile windshield glass rubber coating device comprises a platform for transporting the windshield glass, wherein the platform is sequentially provided with a primary rubber coating station, a secondary rubber coating station and a grabbing overturning station according to a sequence; the primary rubber coating station is correspondently provided with a first aligning identification device for primary rubber coating; the second rubber coating station is correspondently provided with a second aligning identification device for the secondary rubber coating; and the grabbing overturning station is correspondently provided with a grabbing overturning device for grabbing the windshield glass and overturning the windshield glass, a drying station is arranged between the primary rubber coating station and the secondary rubber coating station, the drying station is correspondently provided with a drying device, and the drying device is used for drying the windshield after the primary rubber coating. The automobile windshield glass rubber coating device is mainly applicable to the automobile manufacturing process.

Owner:GREAT WALL MOTOR CO LTD

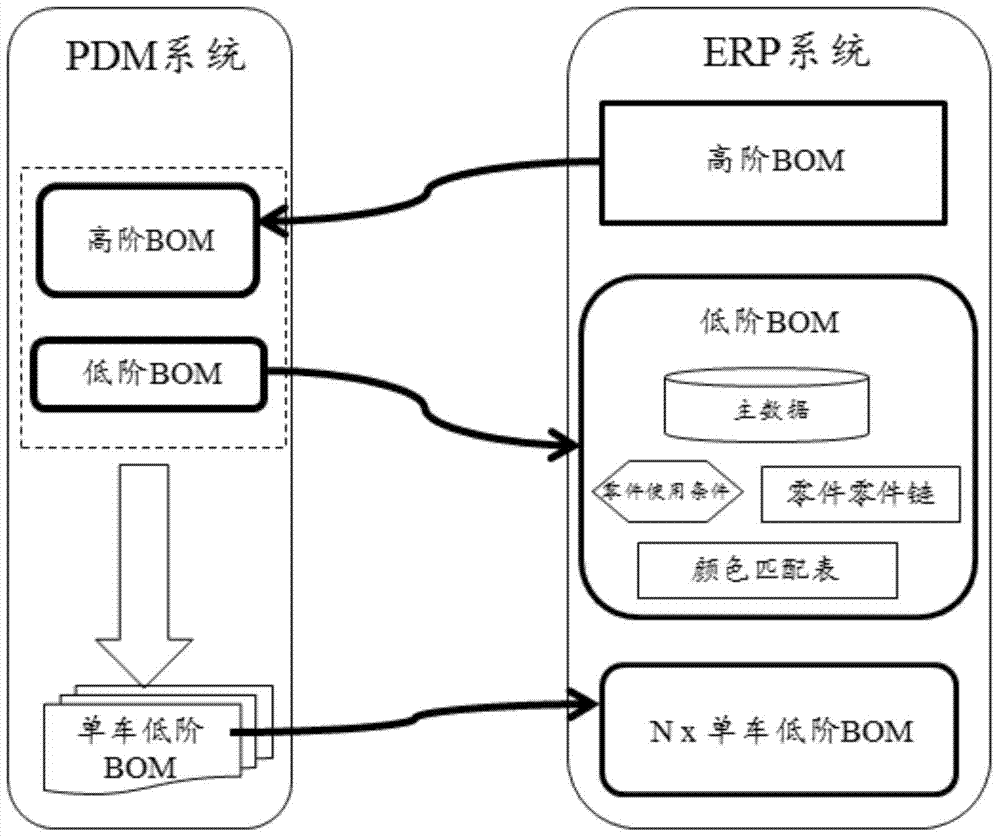

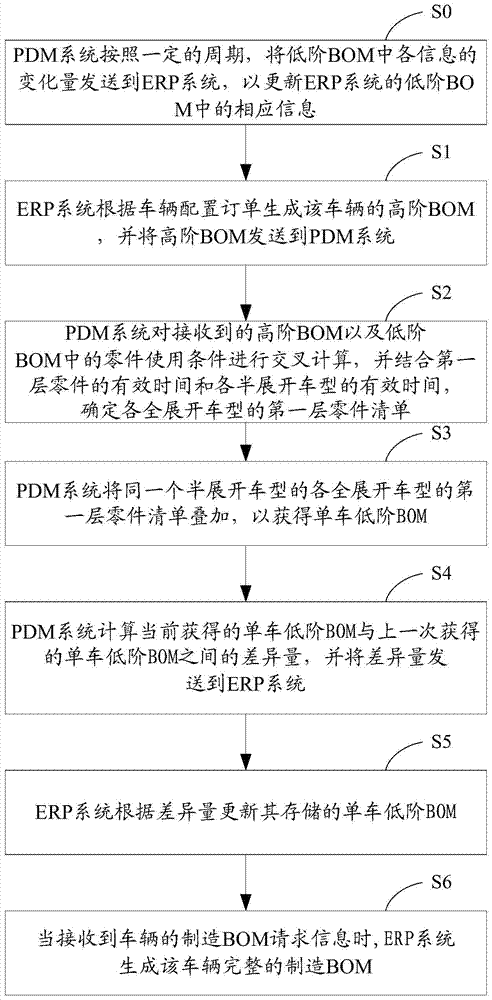

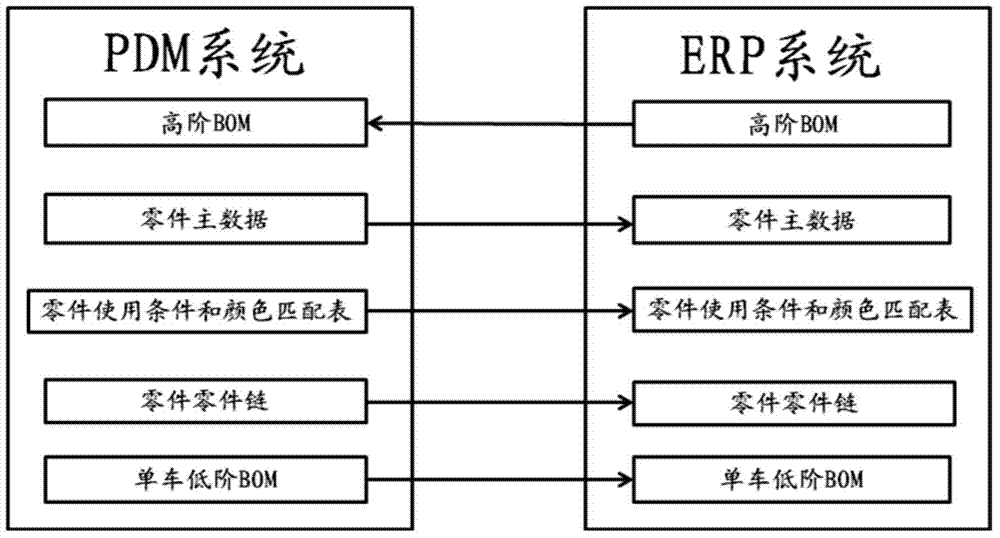

Car manufacturing BOM management method and management system

ActiveCN103593727AReduce repetitive workEfficient configurationResourcesManufacturing computing systemsCar manufacturingSingle vehicle

The invention discloses a car manufacturing BOM management method and management system. The management system comprises a low-order BOM updating unit, a high-order BOM generation unit, a first layer part list calculation unit and superposition unit, a difference quantity calculation unit, a single car low-order BOM updating unit and a car manufacturing BOM generation unit. The method includes the steps that a PDM system sends variable quantity of information of a low-order BOM to an ERP system; the ERP system generates a high-order BOM and sends the high-order BOM to the PDM system; the PDM system determines first layer part lists of all unfolding vehicle models; the PDM system determines a single car lower-order BOM; the PDM system calculates difference quantity between the last single car lower-order BOM and the current single car lower-order BOM and sends the difference quantity to the ERP system; the ERP system updates single car lower-order BOMs stored in the ERP system according to the difference quantity; when car manufacturing BOM request information is received, the ERP system generates a car complete manufacturing BOM. The BOM is managed and manufactured on the basis of a platform, and repeated operation is reduced.

Owner:CHANGAN PSA AUTOMOBILES

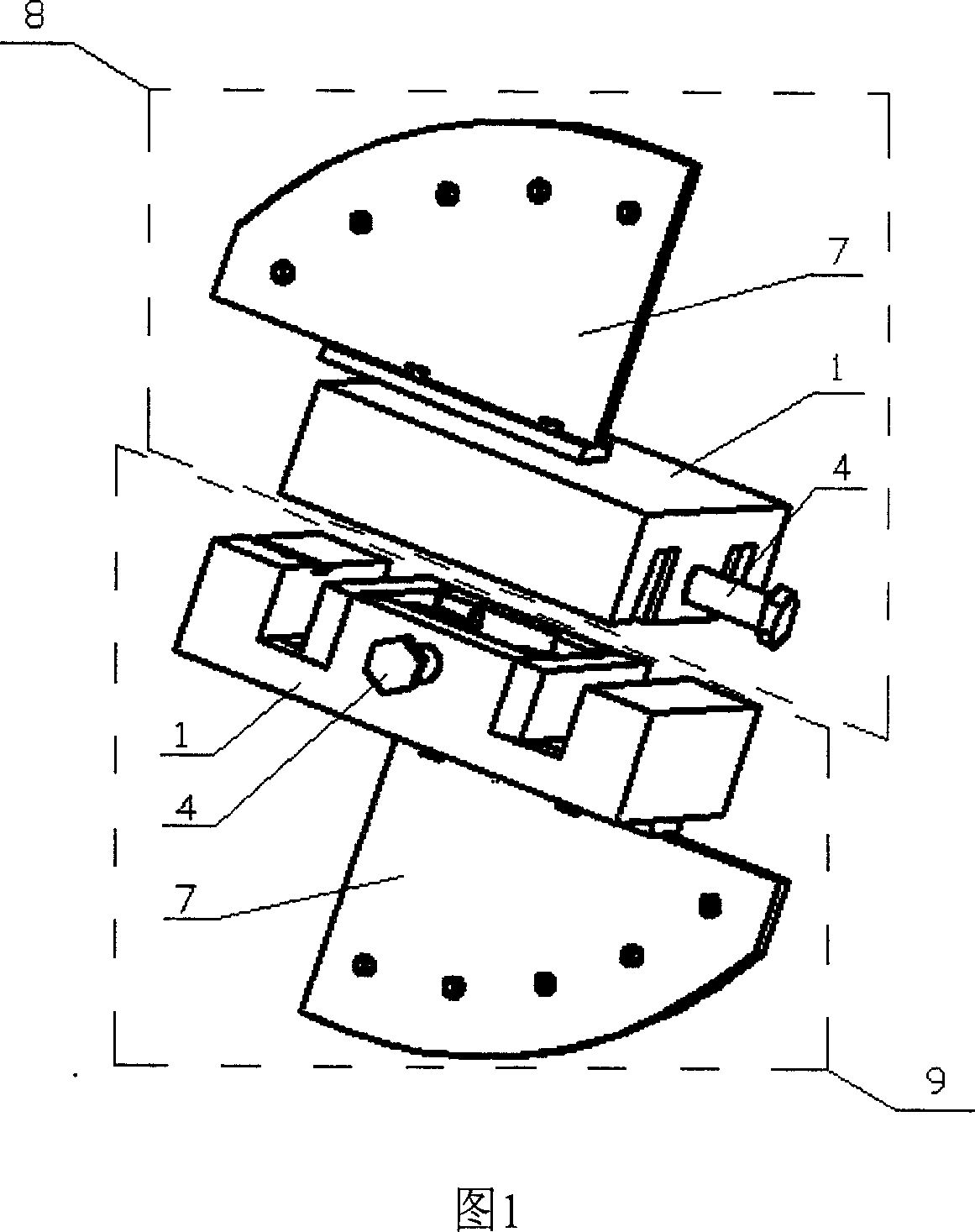

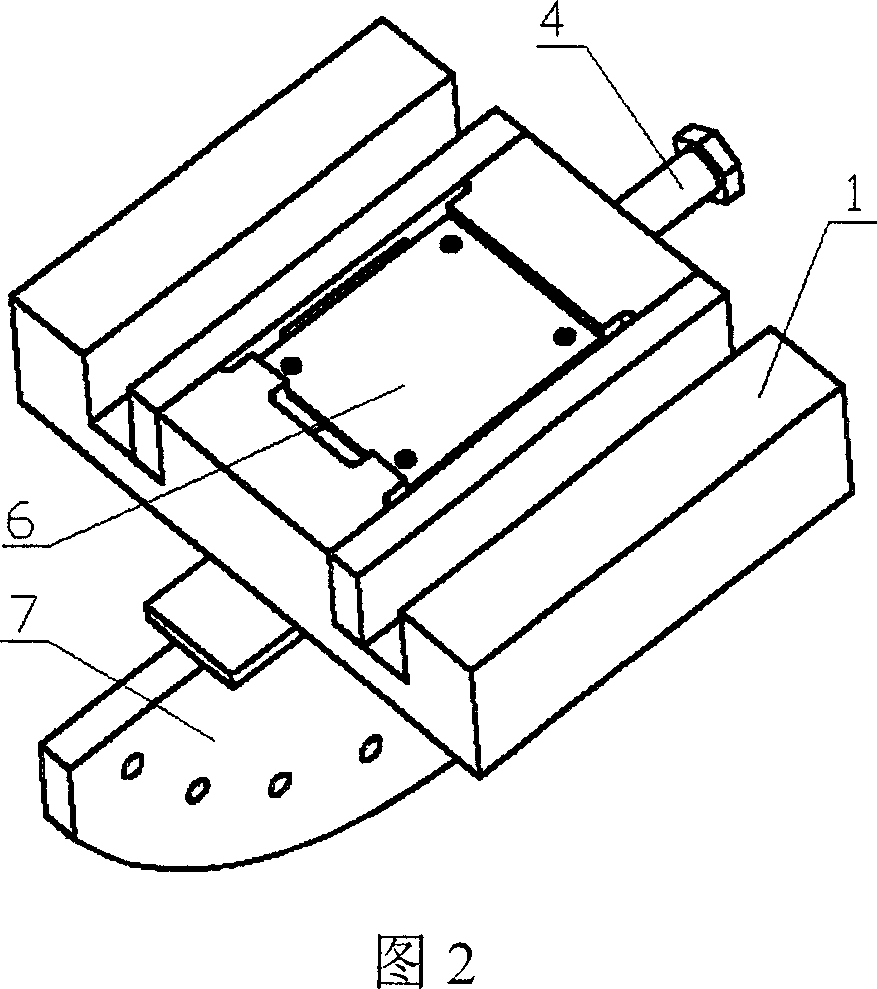

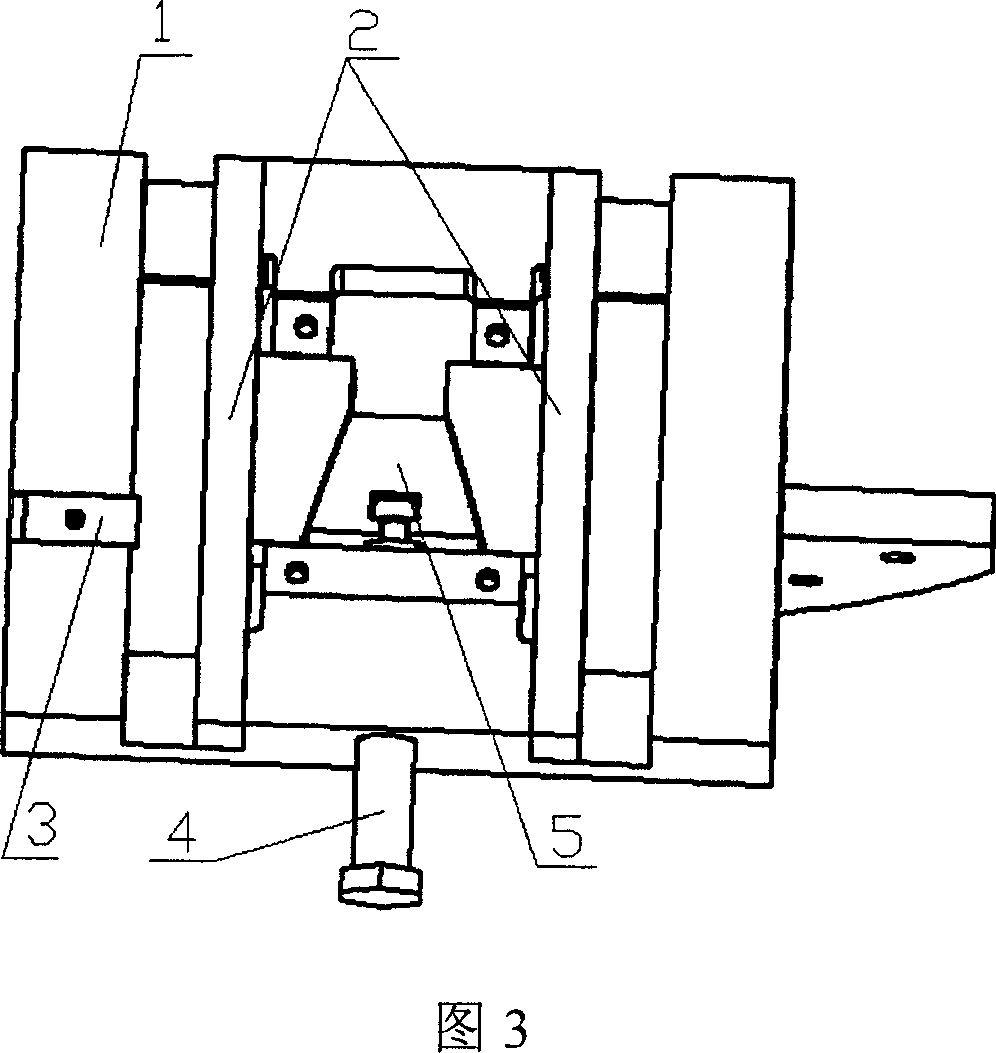

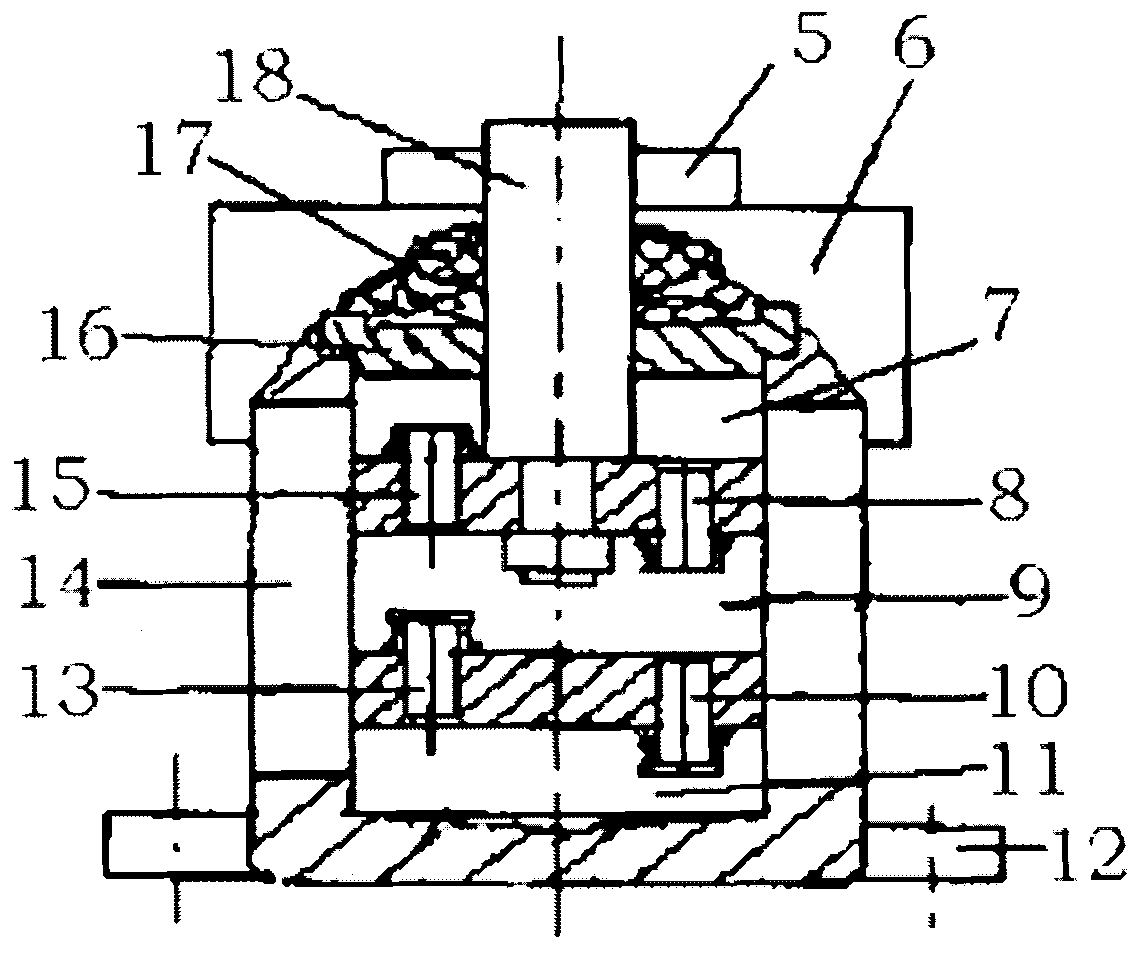

Cross point welding sample multidirectional fatigue loading fixture

InactiveCN1924546AGuaranteed clamping degreeGuaranteed neutralityStrength propertiesFatigue loadingCar manufacturing

This invention provides one crossing weld specimen multi-fatigue loading clamper device in the mechanic, auto process technique filed, which comprises the following parts: down clamper part 9 and upper clamper 8, wherein, the clamper 9 and the basic socket upper surface is set with gradient block sliding along the surface; the gradient block both sides are set with wedge clamping block sliding along the slope of the gradient block; the other surface of the wedge clamping block to take weld specimen; the down clamper 9 above part is similar to the upper clamper 8 and their difference lies in the following: the down clamper 9 lock panel 7 is located on the basic socket down surface and the upper clamper 8 lock panel 7 is located on the upper surface with loading holes.

Owner:BEIJING UNIV OF TECH

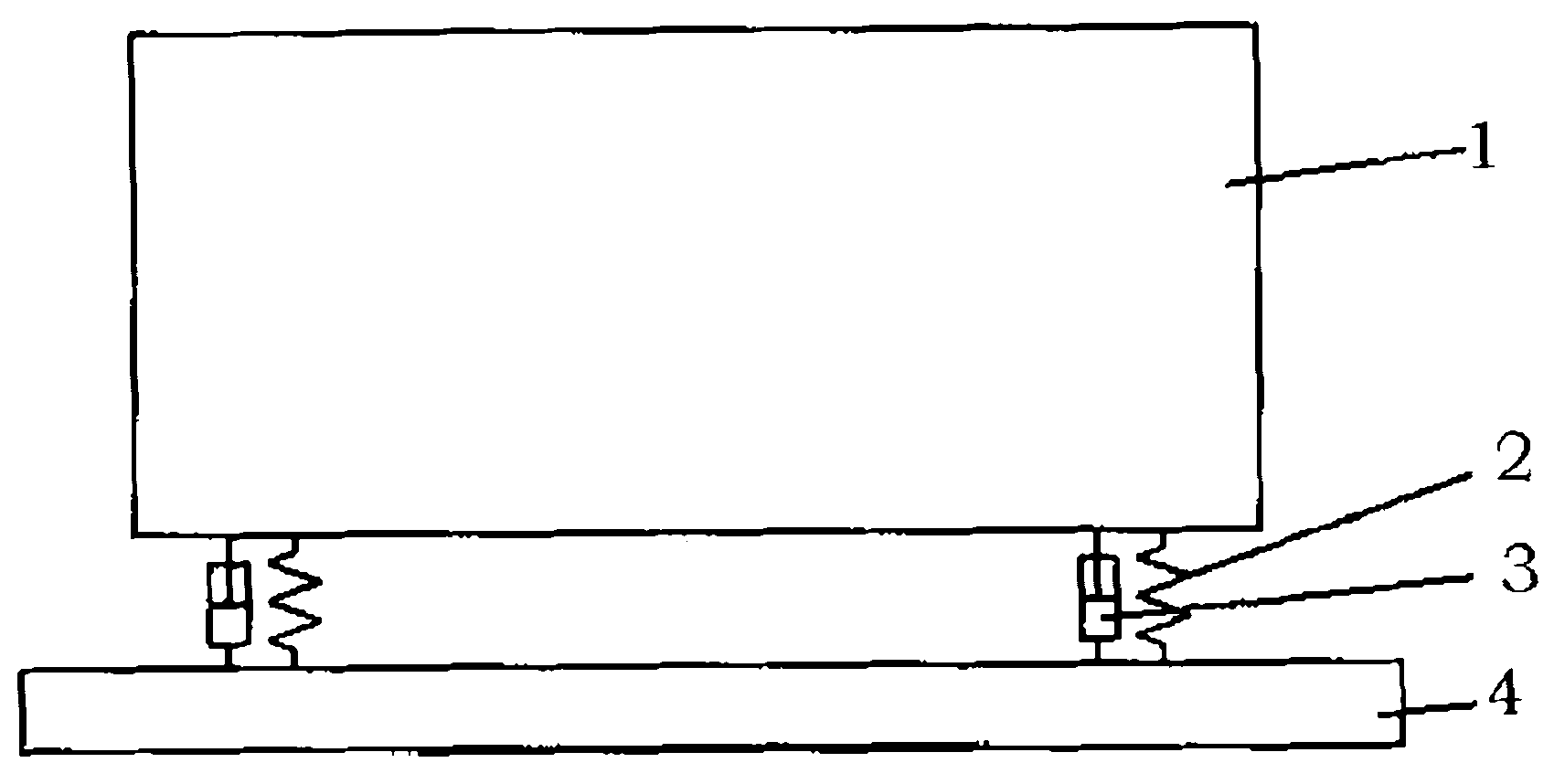

Supporting device for battery pack of electric automobile

InactiveCN102320234AReduce shockReduce vibrationElectric propulsion mountingVehicle frameAutomotive battery

The invention discloses a supporting device for a battery pack of an electric automobile, belonging to the electric automobile manufacturing technical field. The battery pack of the supporting device is connected to a frame through four sets of parallelly connected springs and dampers, wherein the dampers are used for damping vibration. The purpose of using a rubber type or dual-action cylinder type shock absorber battery pack to be connected with the frame through the springs and the dampers, instead of adopting a bolt fixing type to implement hard connection, is to reduce the impact and the vibration which are transferred to the battery pack when the automobile is in motion, so that the load-carrying situation of the battery pack is improved, and the service life is prolonged.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com