Car manufacturing BOM management method and management system

A management method and vehicle technology, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve problems such as the increase in the number of BOMs, large workloads, and increased errors, and achieve the effect of reducing repetitive work and effective product configuration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

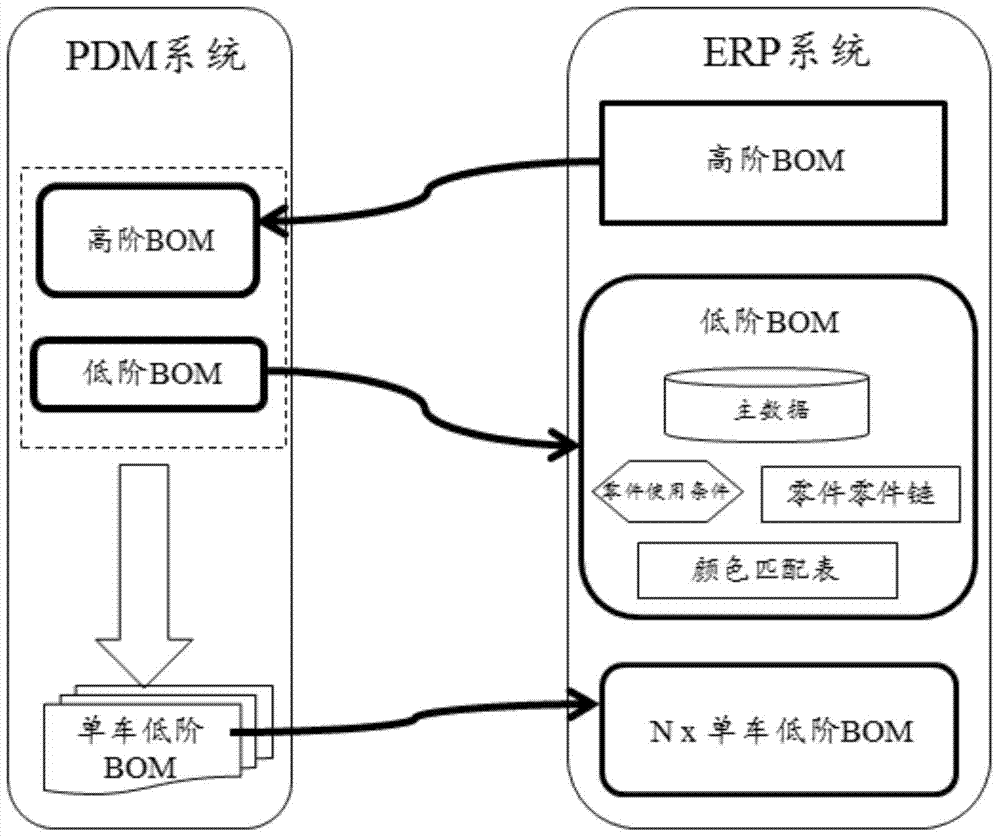

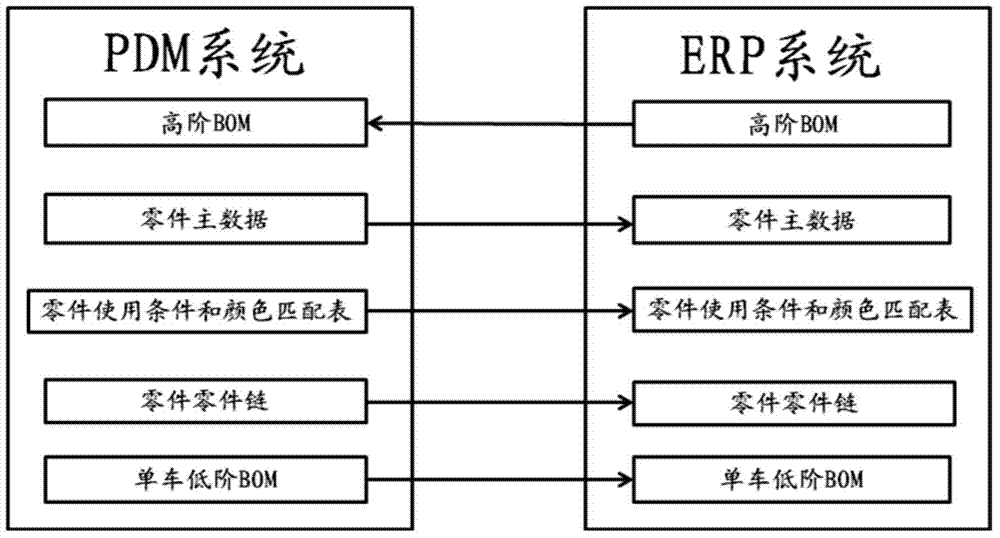

[0062] The data interaction between PDM system and ERP system is as follows: figure 1 As shown, the PDM system and the ERP system include a low-level BOM, which includes part master data, part usage conditions, color matching tables, and part part chains. Among them, the part use condition is a Boolean logic expression, which determines the applicable vehicle configuration of the part, and the first layer of parts has part use conditions. The color matching table indicates the coloring rules for each part. A part part chain indicates the parent-child link relationship of parts.

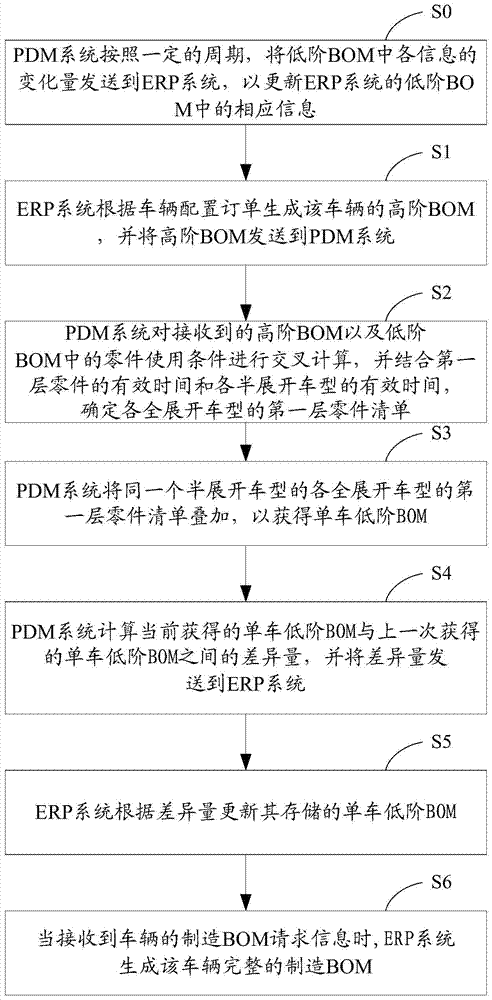

[0063] figure 2 For the flowchart of the first embodiment of the management method of manufacturing BOM for the vehicle of the present invention, see Figure 1-2 , in this embodiment, the management method includes the following steps:

[0064] S0. The PDM system sends th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com