Patents

Literature

175 results about "Production model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

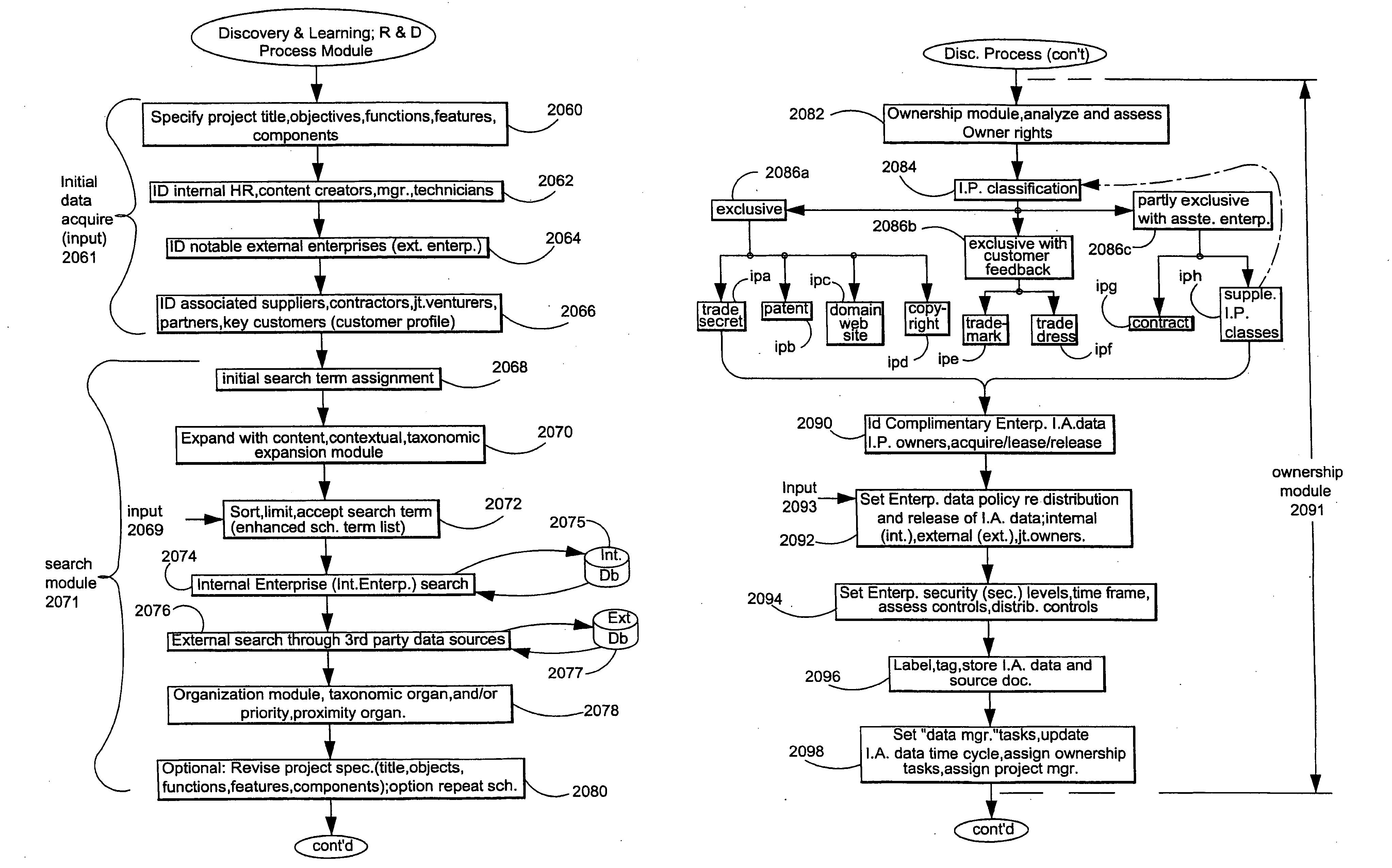

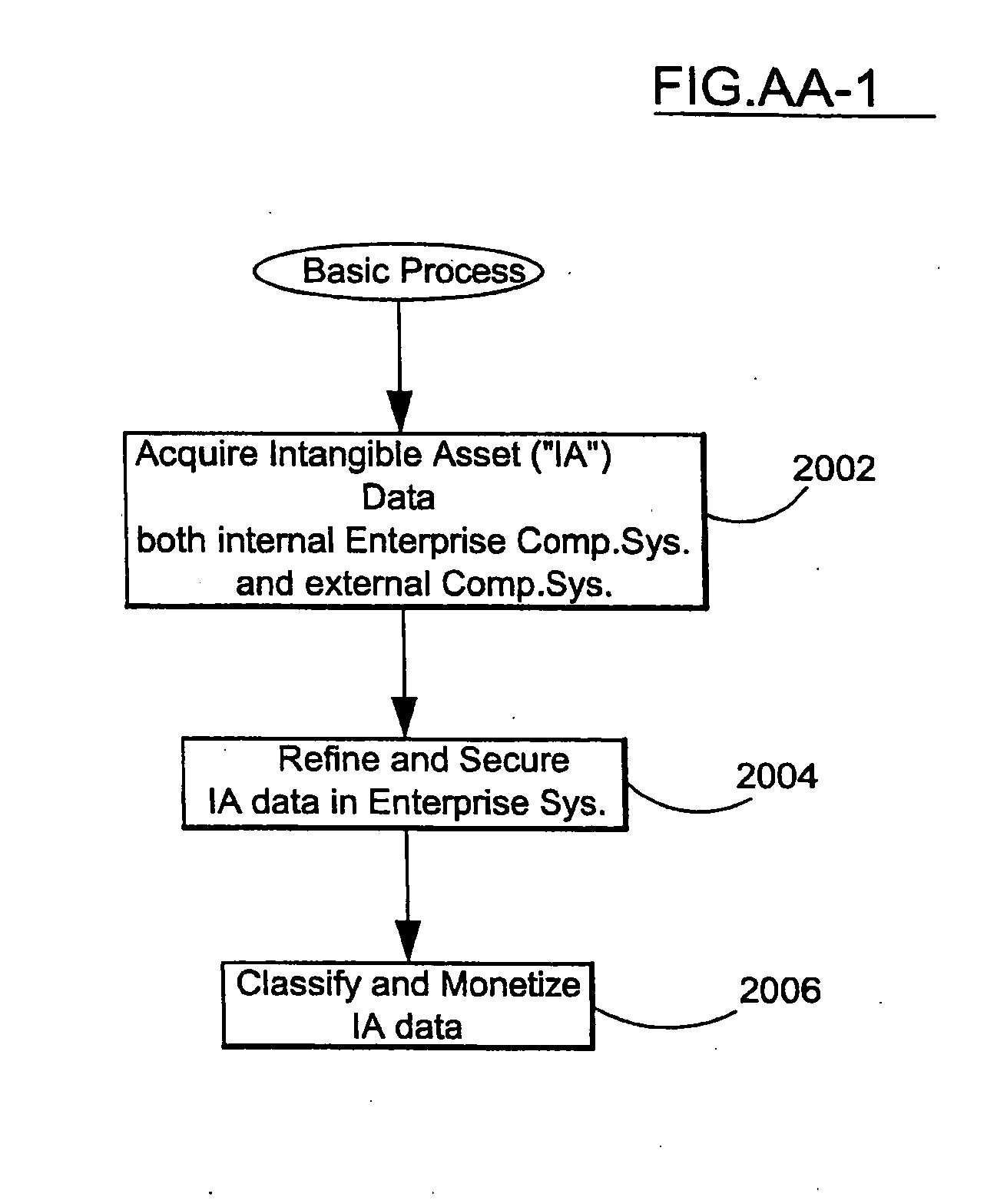

System and method to identify, classify and monetize information as an intangible asset and a production model based thereon

ActiveUS20100010968A1Digital data information retrievalDigital data processing detailsProduction modelDigital data

The method and system identifies and classifies and monetizes intangible asset (I.A.) unstructured digital data in a computer system by ownership characterizations and intellectual property (I.P.) classifications. Enterprise and non-enterprise data collections are searched based upon an expanded project specification (of descriptive functions, characteristics and objectives). Primary search terms from the project are expanded by content, contextual and taxonomic analysis to generate a plurality of search string parameters employed to search the data collections. The search engine returns data and documents, ownership characteristics are ascertained by comparison of the returns and I.P. classifications are made based upon the returns. This process also handles unstructured enterprise specific data not otherwise located in the data collections or unstructured data from other I.A. programs such as H.R. performance modules, supply chain modules or CRM modules. Unstructured data matching an organized data set from project and the search returns is integrated into the organized data set.

Owner:DIGITAL DOORS

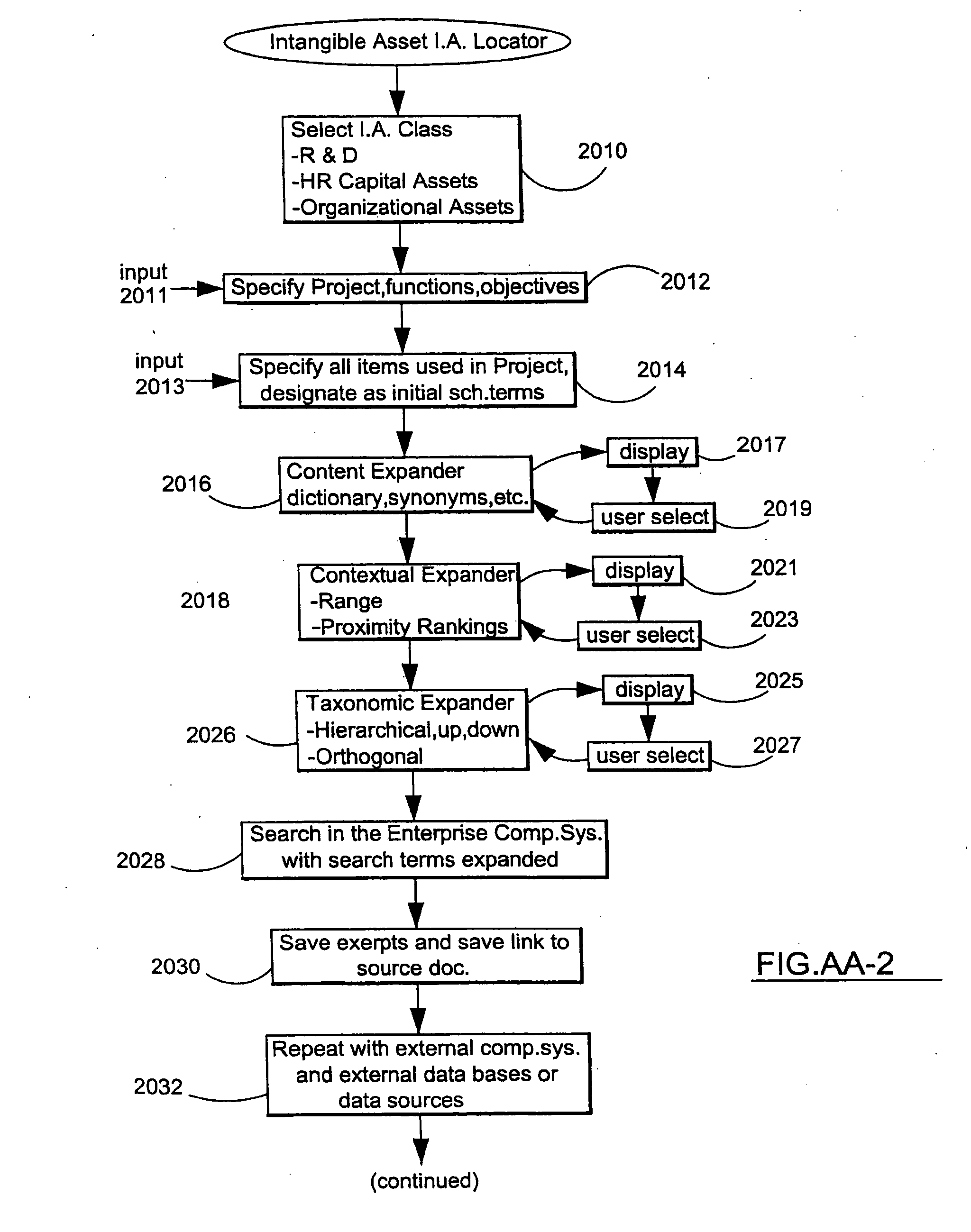

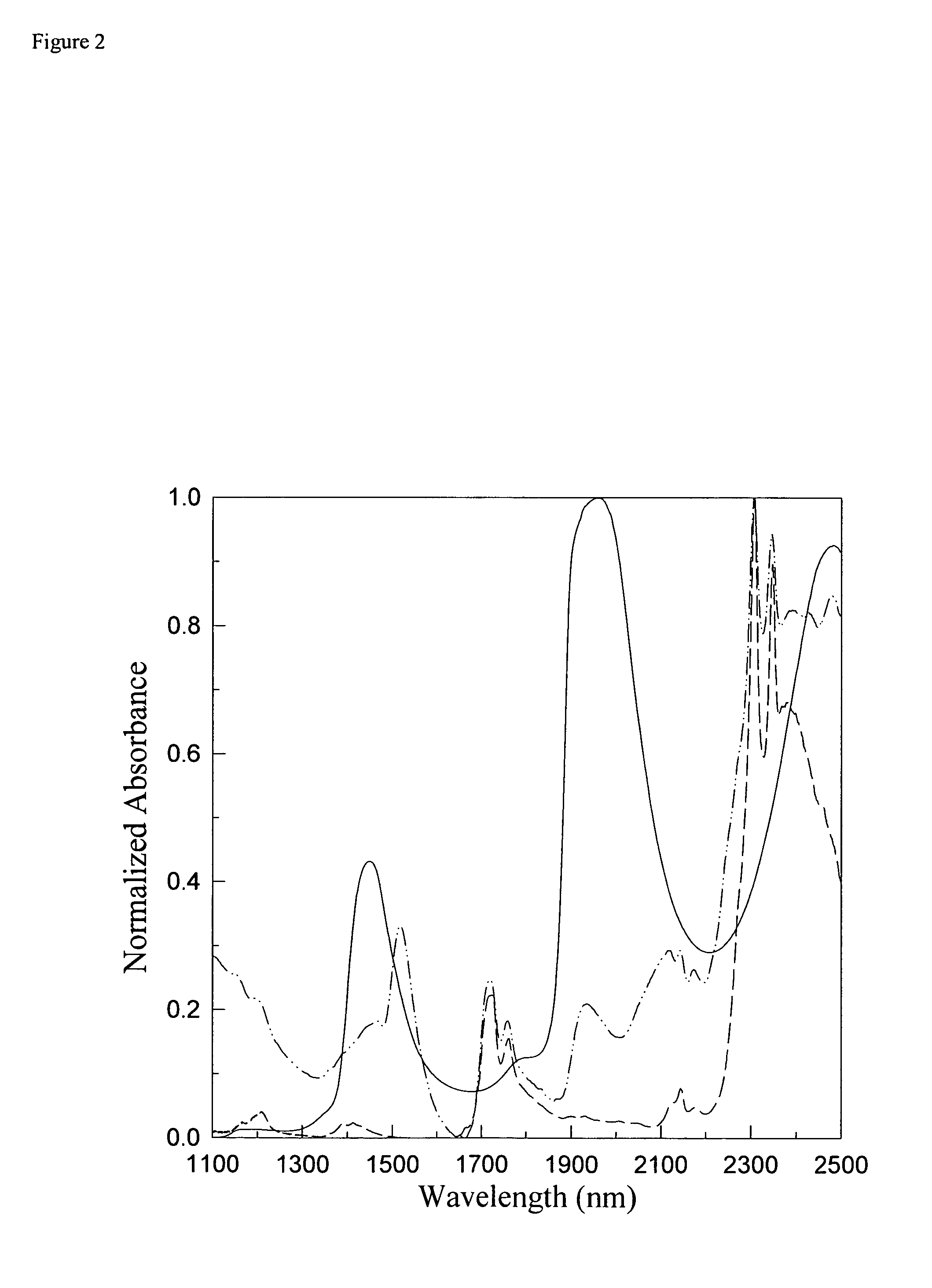

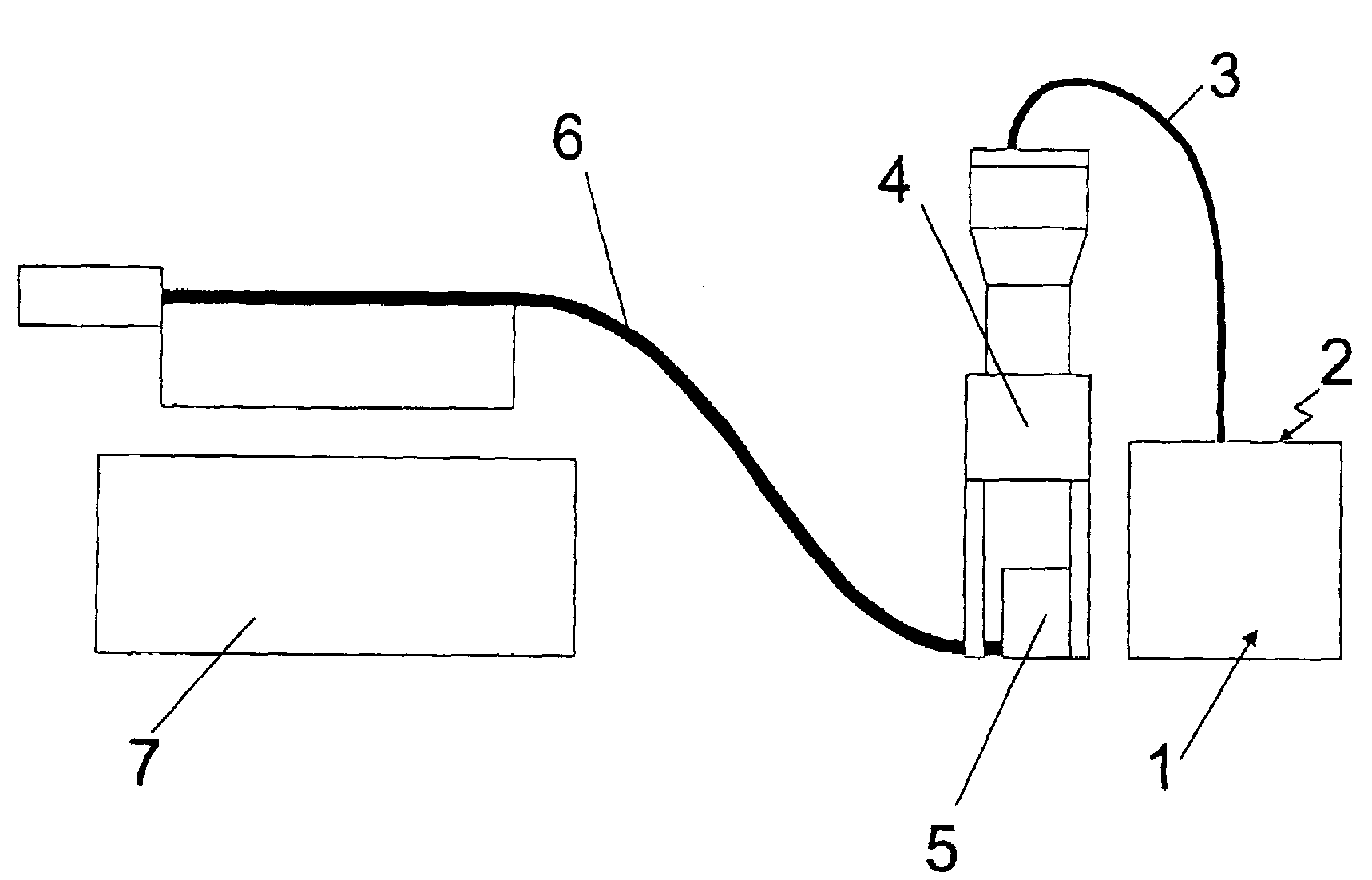

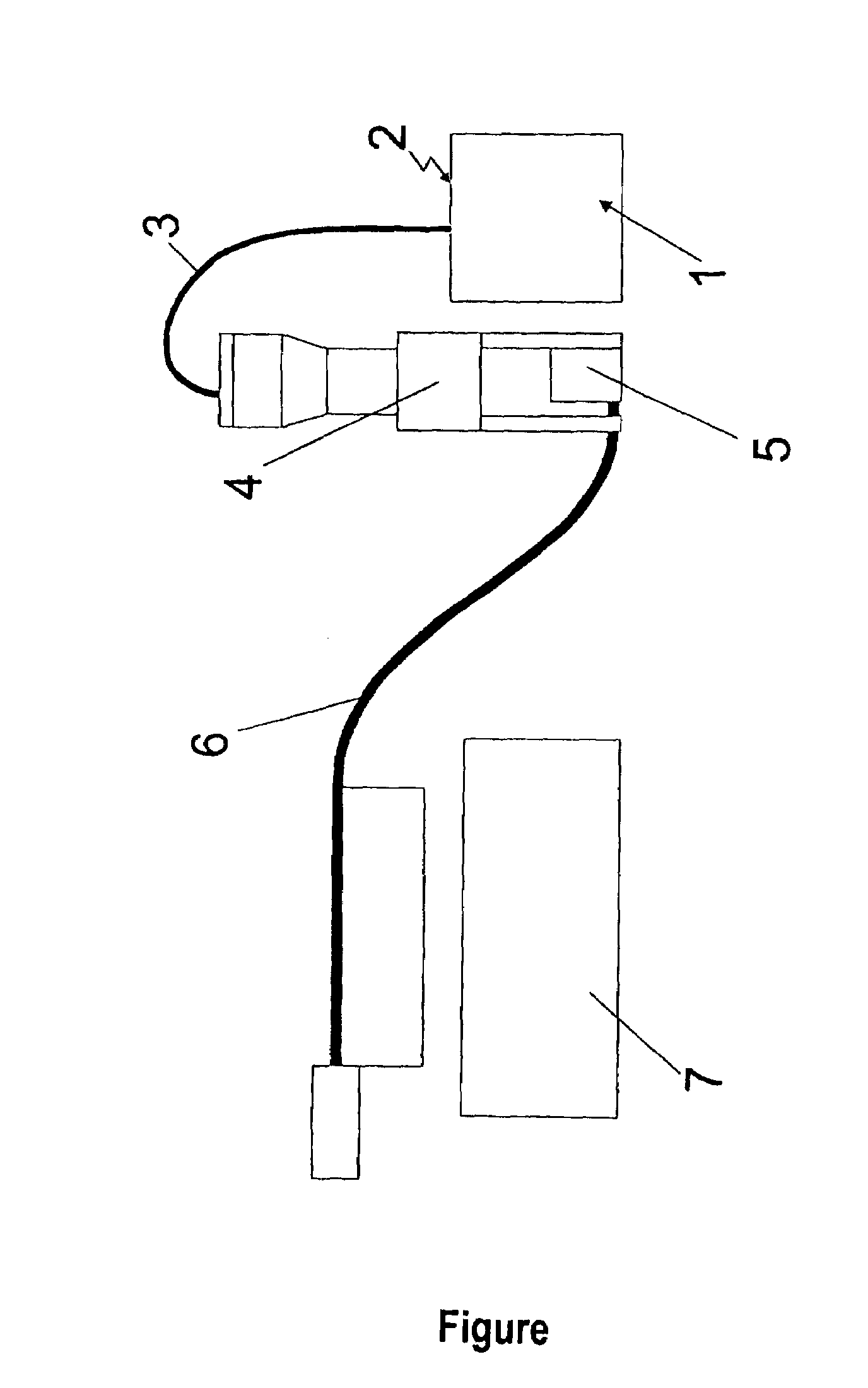

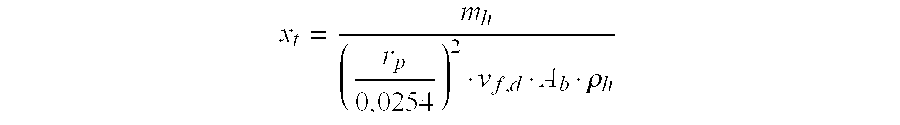

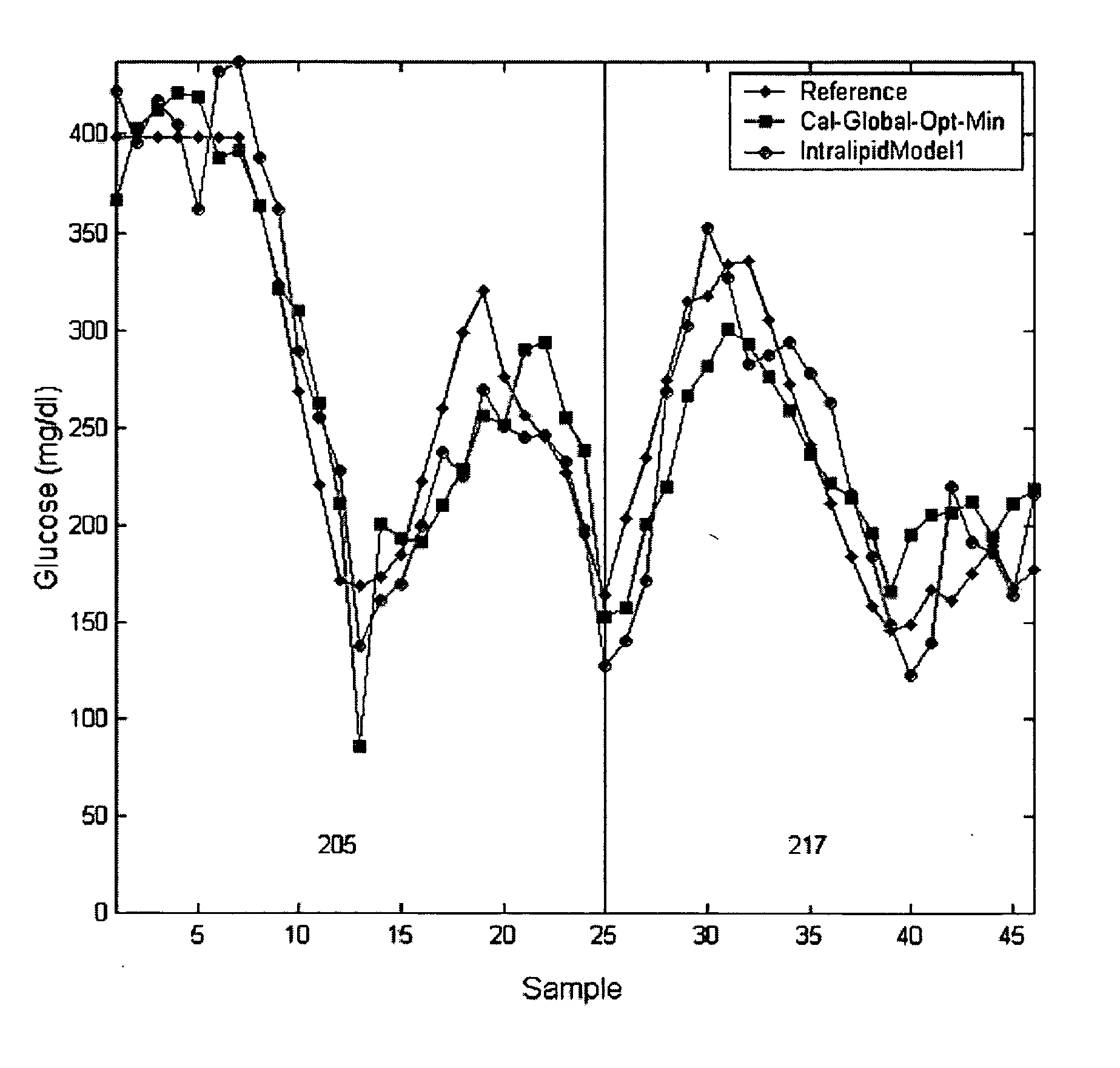

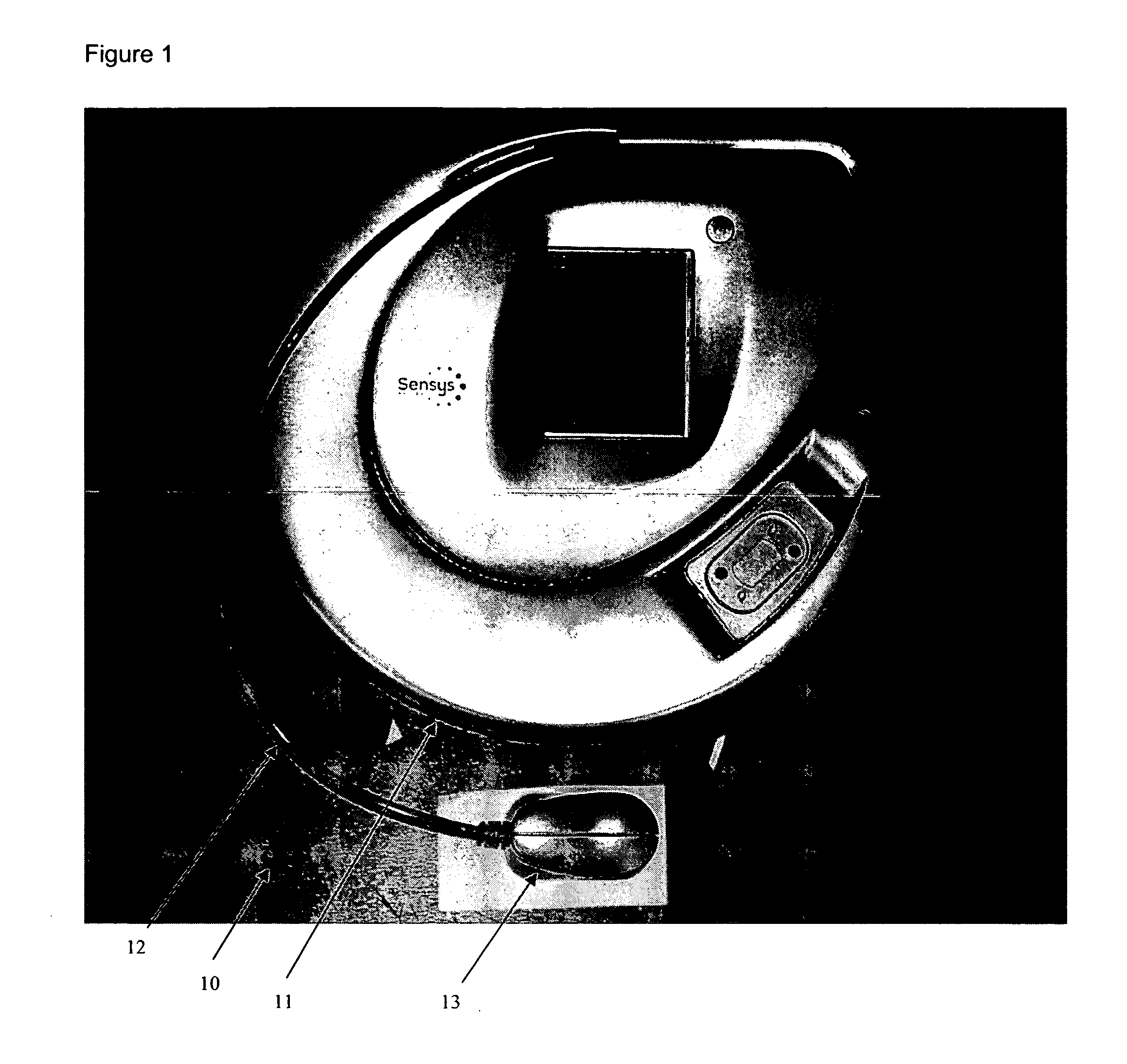

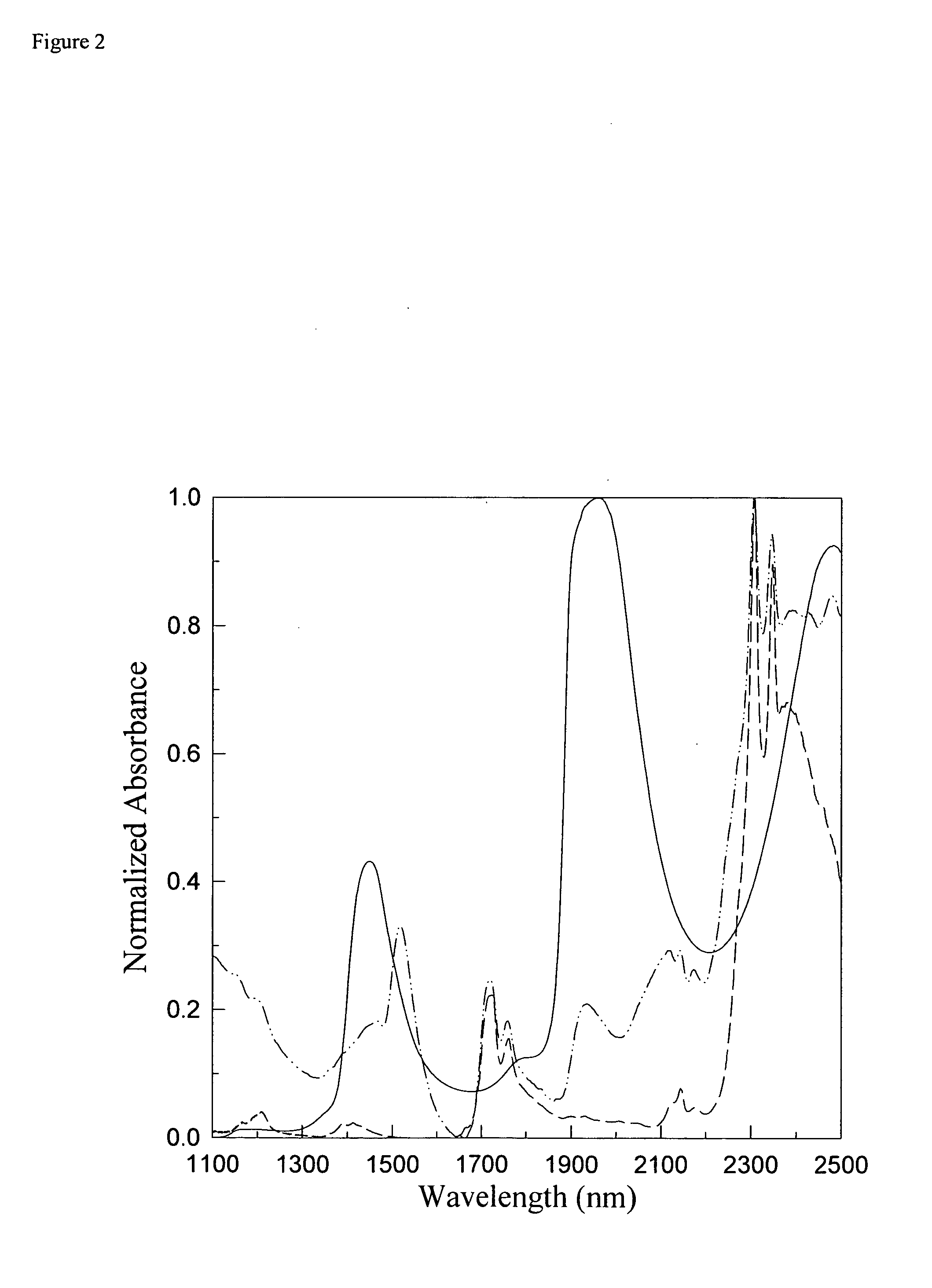

Method of adapting in-vitro models to aid in noninvasive glucose determination

InactiveUS7317938B2Easy to controlStrict controlDiagnostic recording/measuringSensorsConcentrations glucoseNon invasive

Owner:GLT ACQUISITION

Method for constructing patterns in a layered manner

A process to produce models in layers is described, whereby a first material and then selectively a second material is applied in layers on a building platform and these two application stages are repeated until a desired pattern is achieved. The two materials form a solid if a suitable mixture ratio is used and the first material is a material mixture. The material mixture is at least partially prepared prior to each application stage.

Owner:EXONE

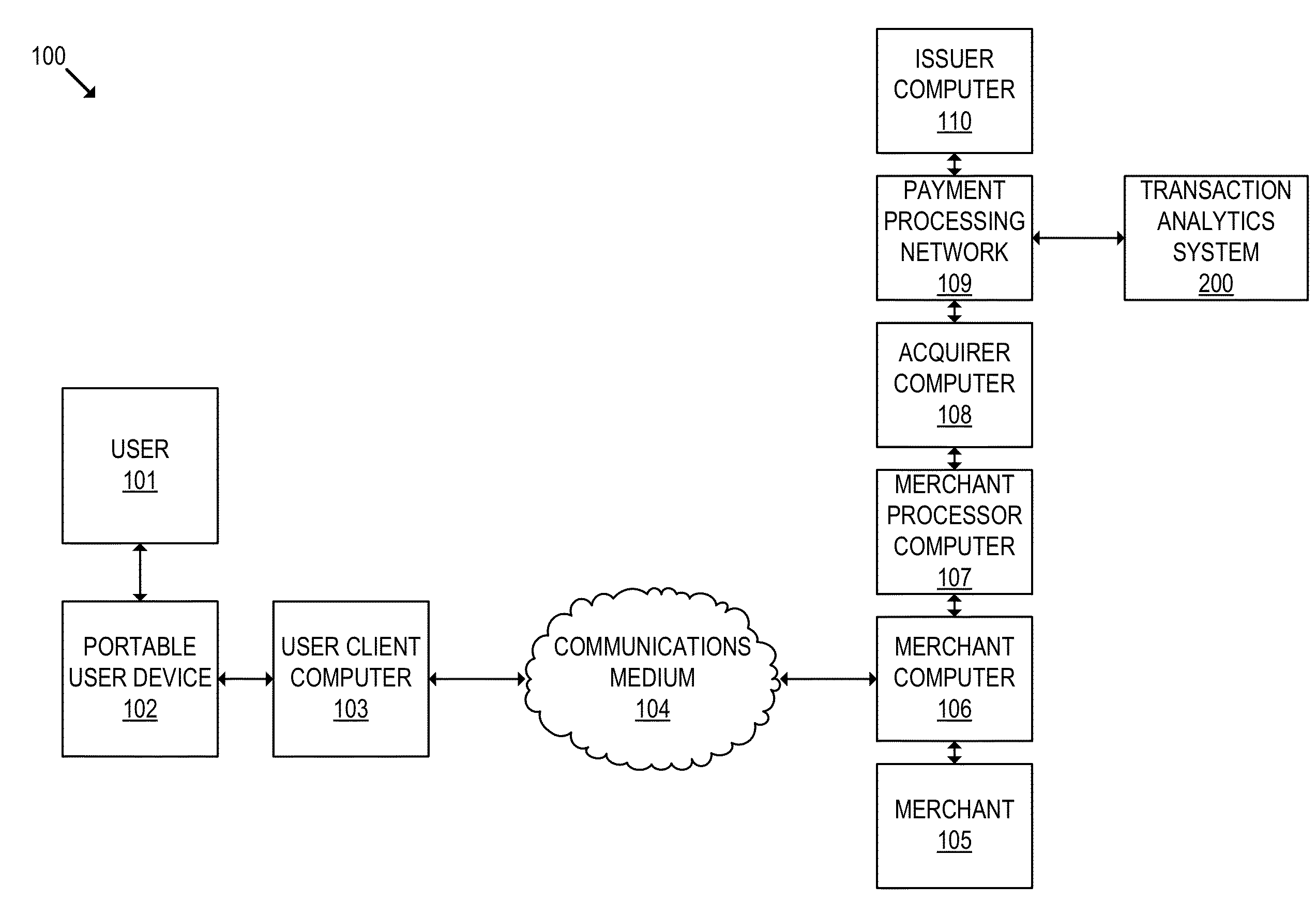

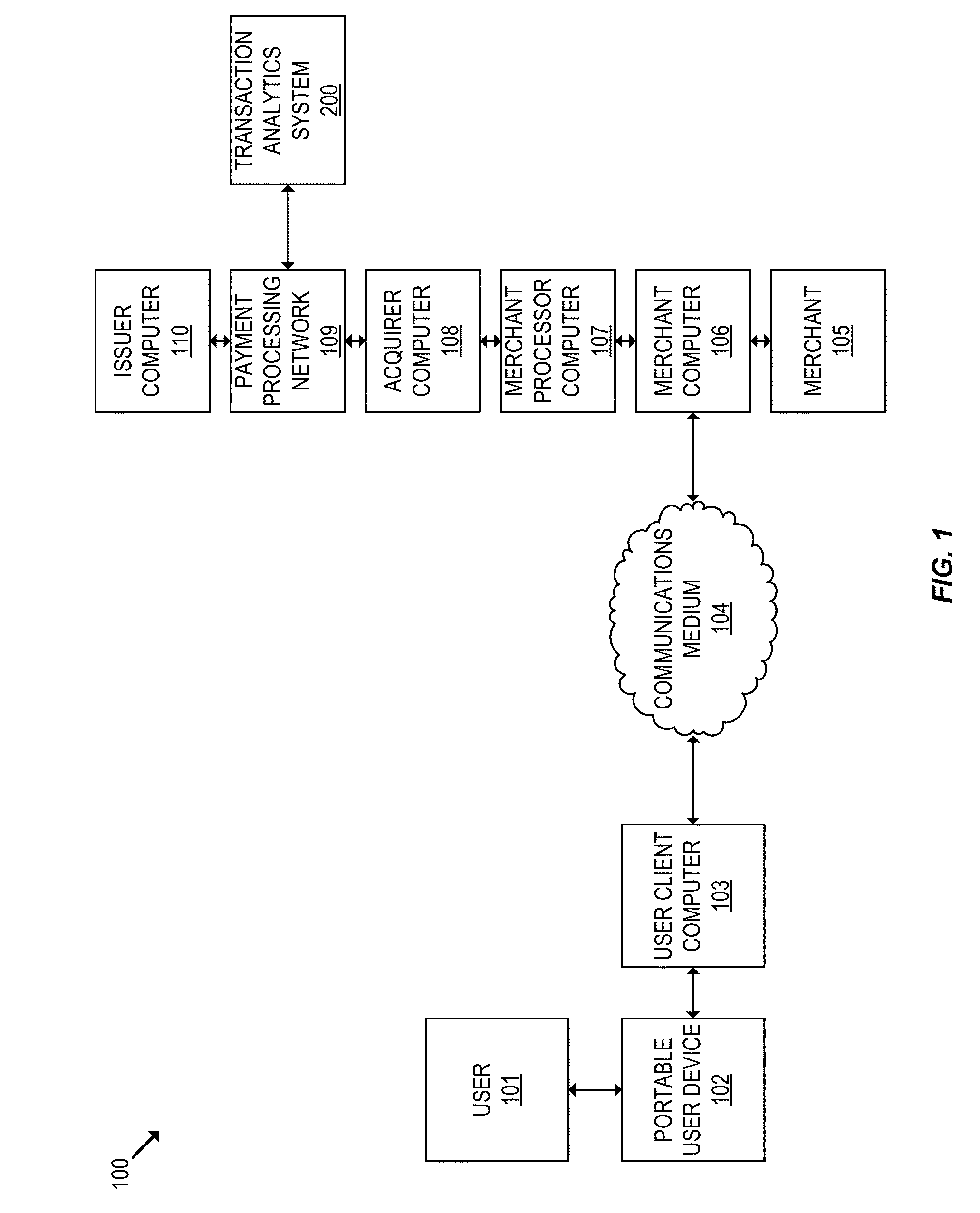

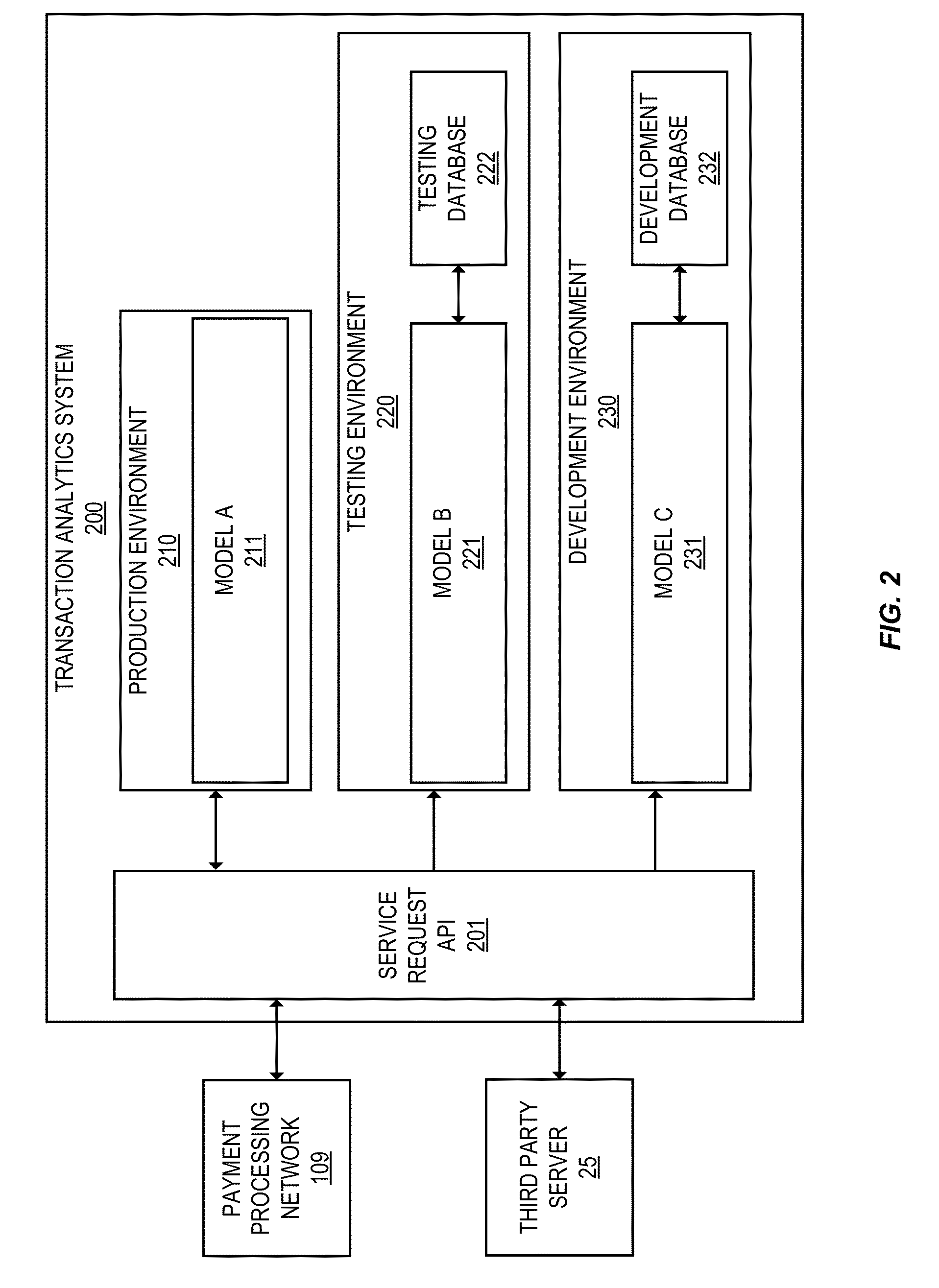

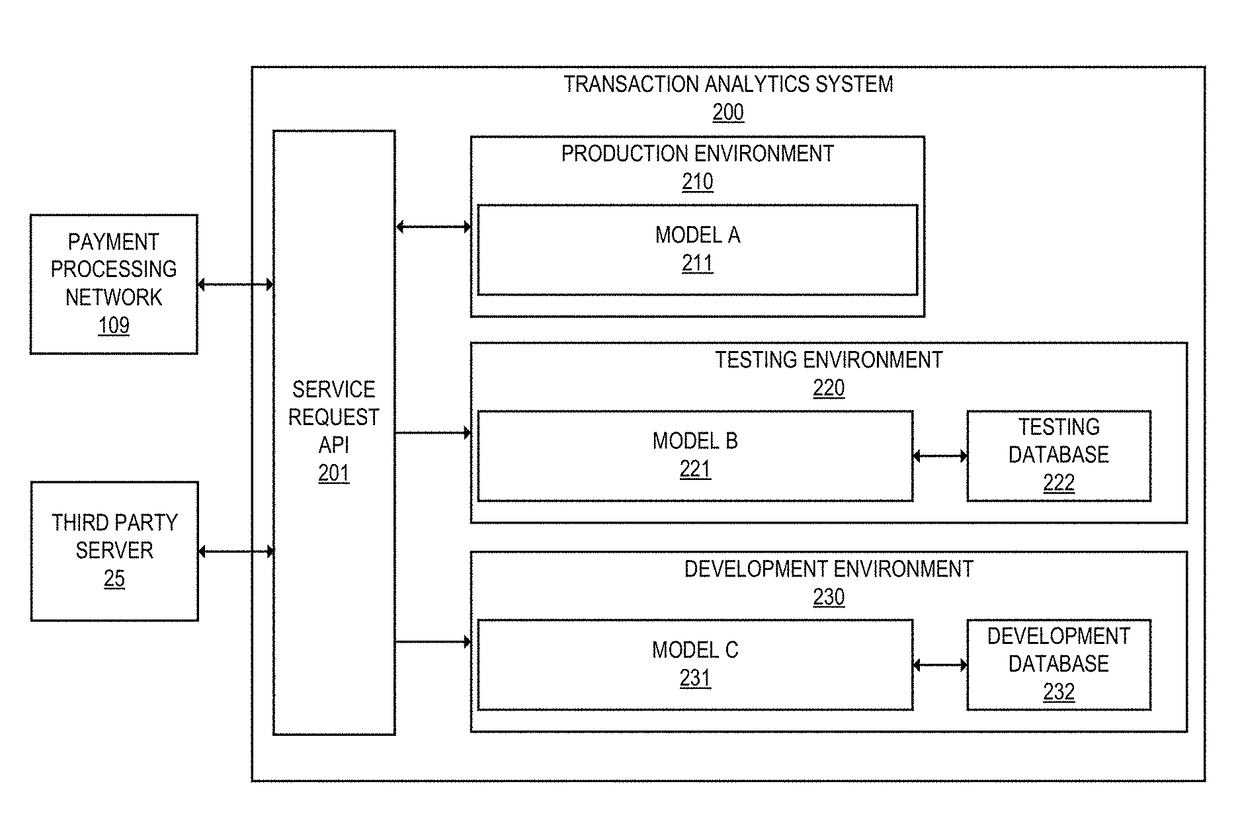

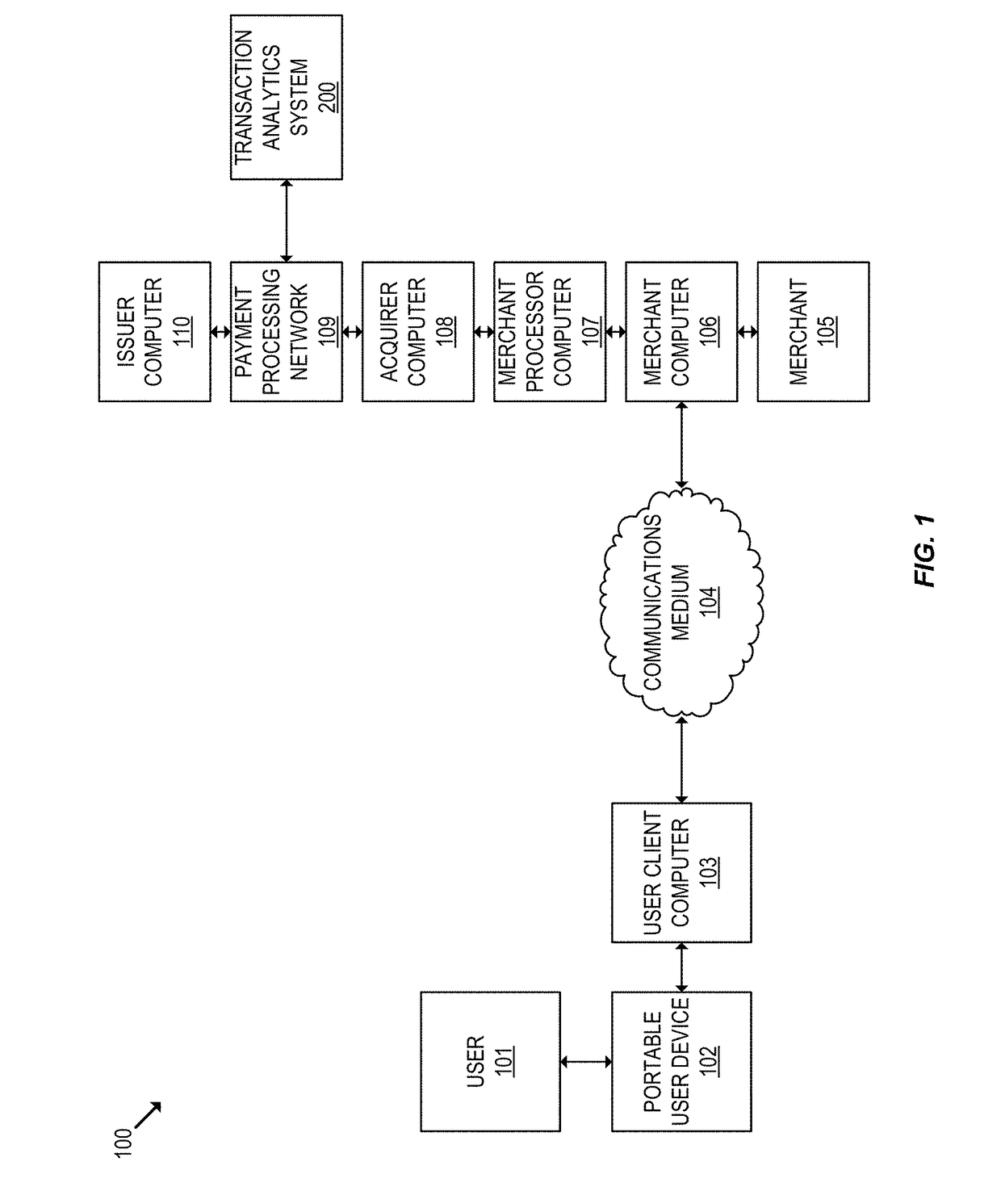

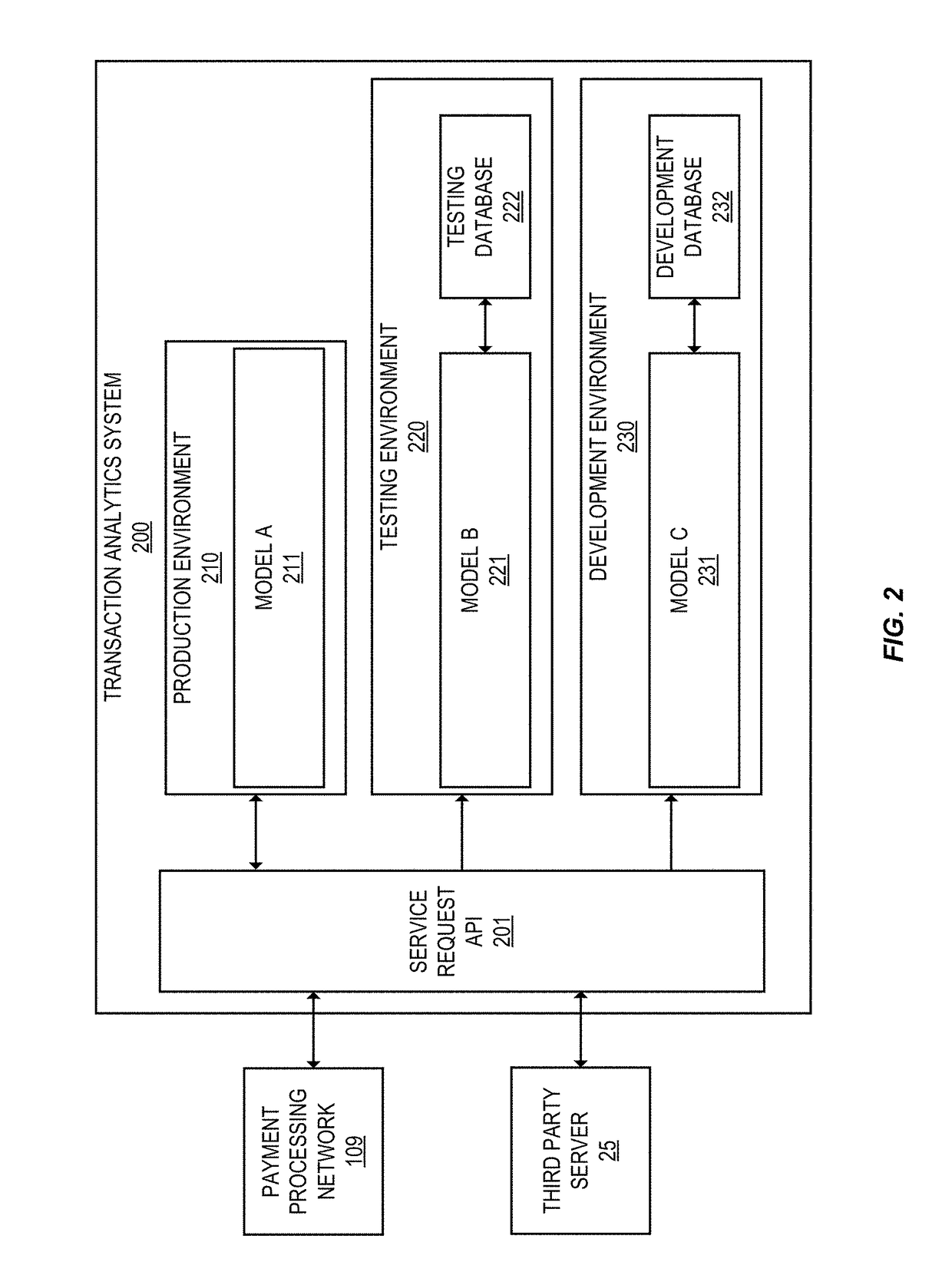

Real time analytics system

ActiveUS20150026061A1Improved real-time analytics systemFinanceProtocol authorisationProduction modelReal time analytics

Improved real-time analytics systems are provided. An analytics system may be used to generate transaction scores for transactions. A method may comprise receiving a scoring request associated with a transaction, sending the scoring request to a plurality of scoring models including a production model, wherein each scoring model is operable to generate a transaction score in response to the scoring request, and wherein each scoring model may be implemented using a virtual machine, receiving a transaction score generated by the production model, and sending the transaction score to a server for approval or denial the transaction.

Owner:VISA INT SERVICE ASSOC

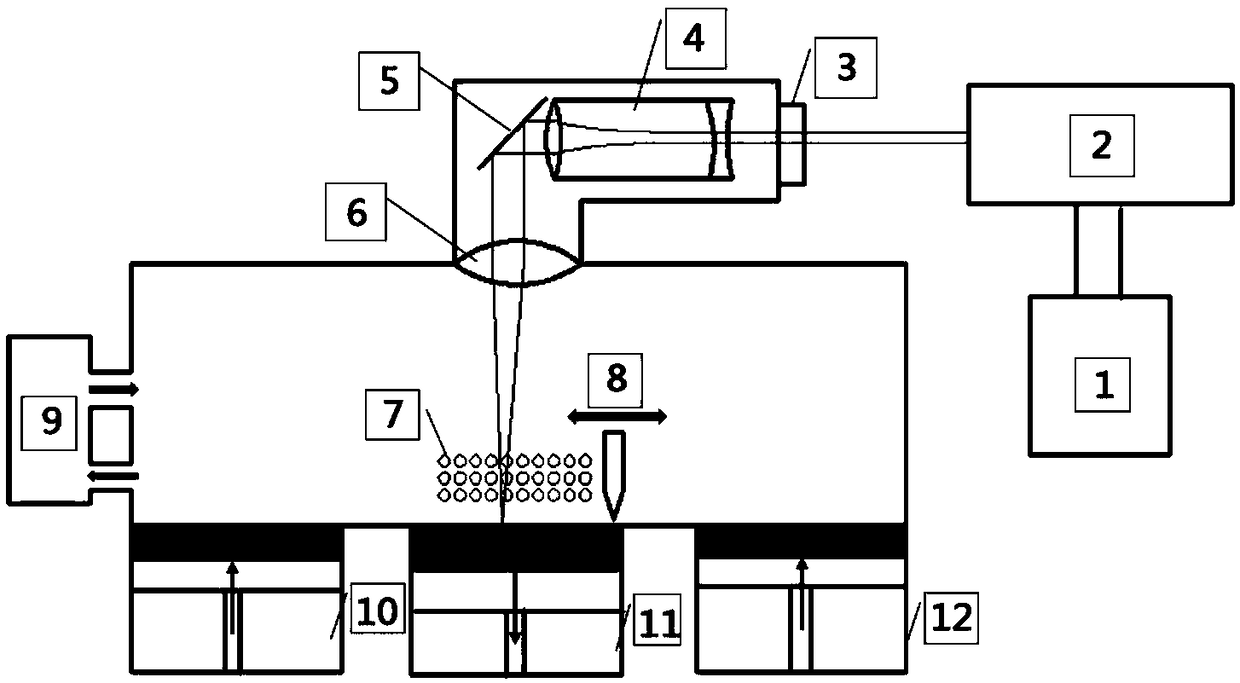

Method of adapting in-vitro models to aid in noninvasive glucose determination

InactiveUS20050119541A1Easy to controlStrict controlDiagnostic recording/measuringSensorsConcentrations glucoseNon invasive

The invention relates to a noninvasive analyzer and a method of using information determined at least in part from in-vitro spectra of tissue phantoms or analyte solutions to aid in the development of a noninvasive glucose concentration analyzer and / or in the analysis of noninvasive spectra resulting in glucose concentration estimations in the body. The preferred apparatus is a spectrometer that includes a base module and a sample module that is semi-continuously in contact with a human subject and that collects spectral measurements which are used to determine a biological parameter in the sampled tissue, such as glucose concentration. Collection of in-vitro samples is, optionally, performed on a separate instrument from the production model allowing the measurement technology to be developed on a research grade instrument and used or transferred to a target product platform or production analyzer for noninvasive glucose concentration estimation.

Owner:GLT ACQUISITION

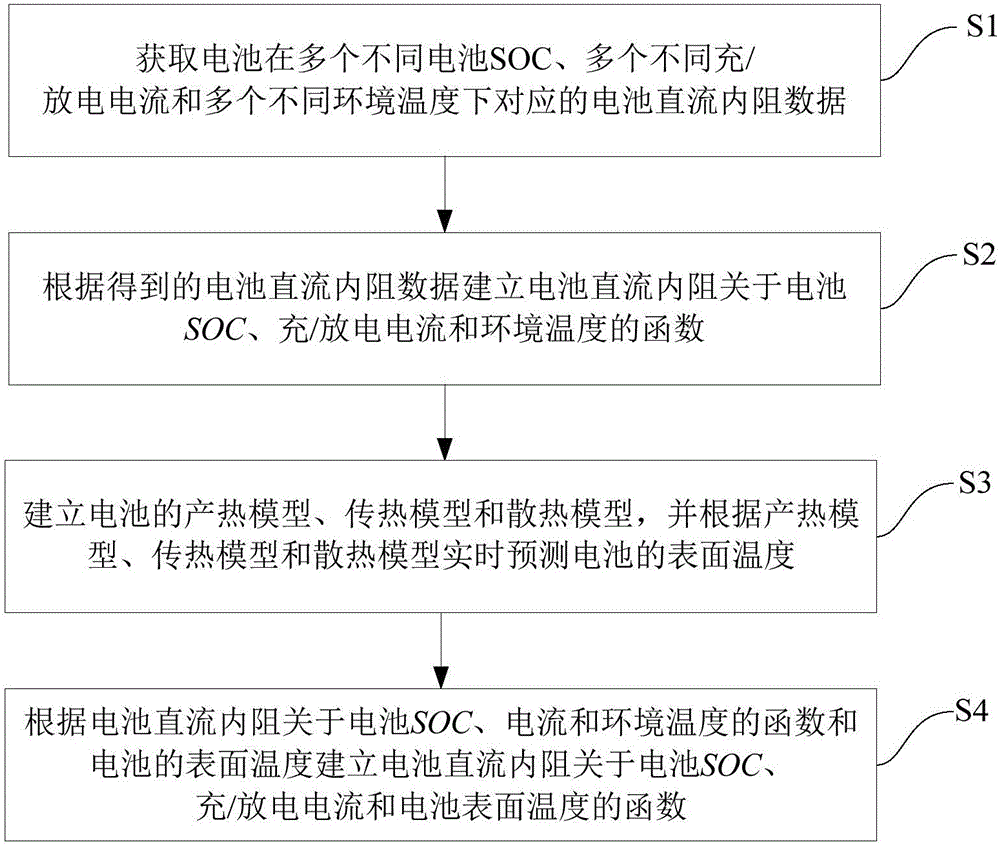

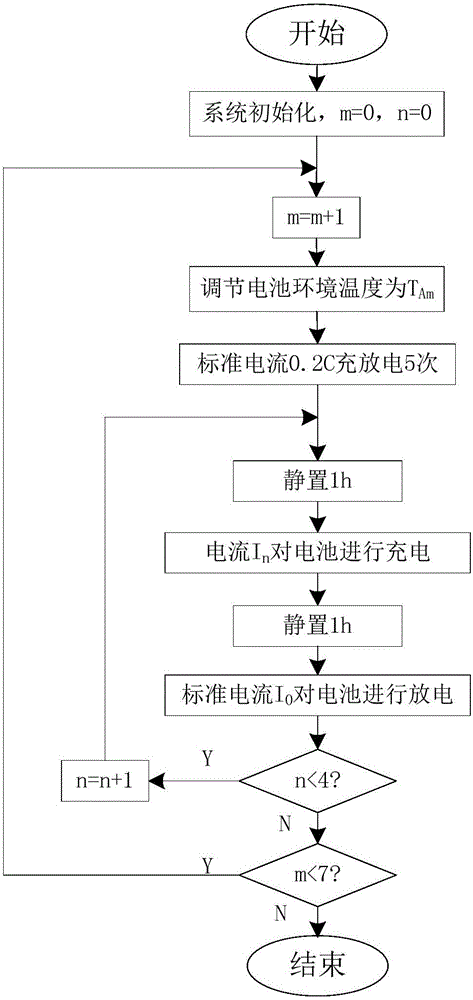

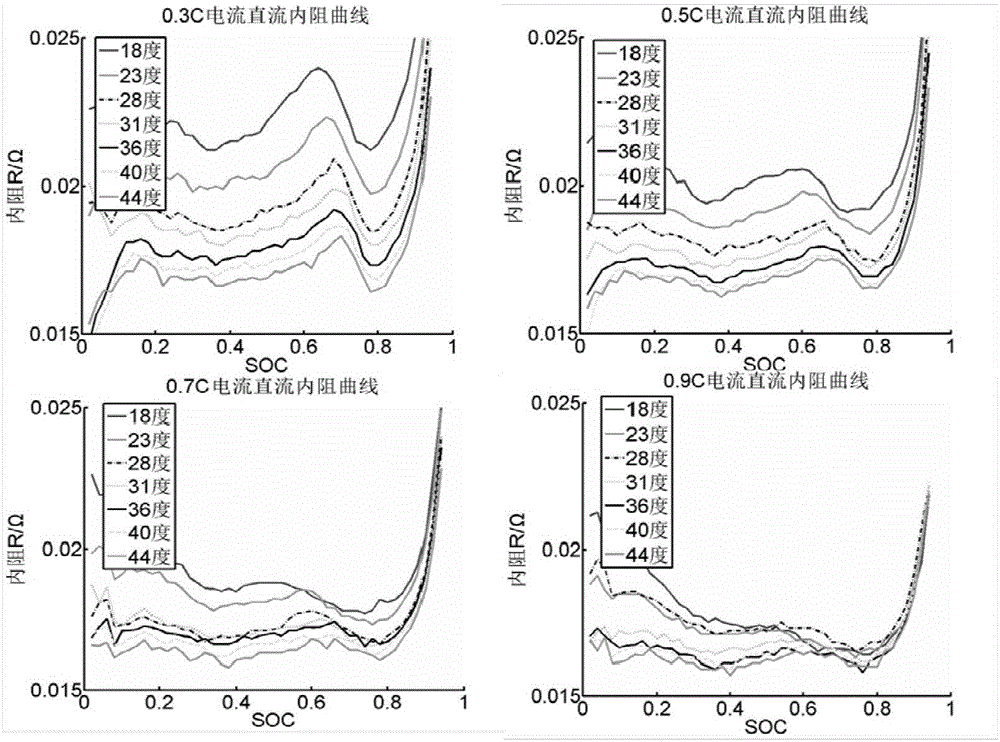

Method of building battery DC inner resistance function

The invention provides a method of building a battery DC inner resistance function. The method comprises the following steps: corresponding battery DC inner resistance data of a battery under different battery SOCs (State of Charge), multiple different charging / discharging currents and multiple different ambient temperatures are acquired; according to the acquired battery DC inner resistance data, a function of the battery DC inner resistance relative to the battery SOCs, the charging / discharging currents and the ambient temperatures is built; a heat production model, a heat transfer model and a heat dissipation model for the battery are built, and according to the heat production model, the heat transfer model and the heat dissipation model, the surface temperature of the battery is predicted in real time; and according to the function of the battery DC inner resistance relative to the battery SOCs, the currents and the ambient temperatures and the surface temperature of the battery, a function of the battery DC inner resistance relative to the battery SOCs, the charging / discharging currents and the surface temperature of the battery is built. The function relationship between the battery SOCs, the current and the surface temperature of the battery and the battery DC inner resistance can be described simply, comprehensively, accurately and in real time, realization is easy, and engineering applications are facilitated.

Owner:TSINGHUA UNIV

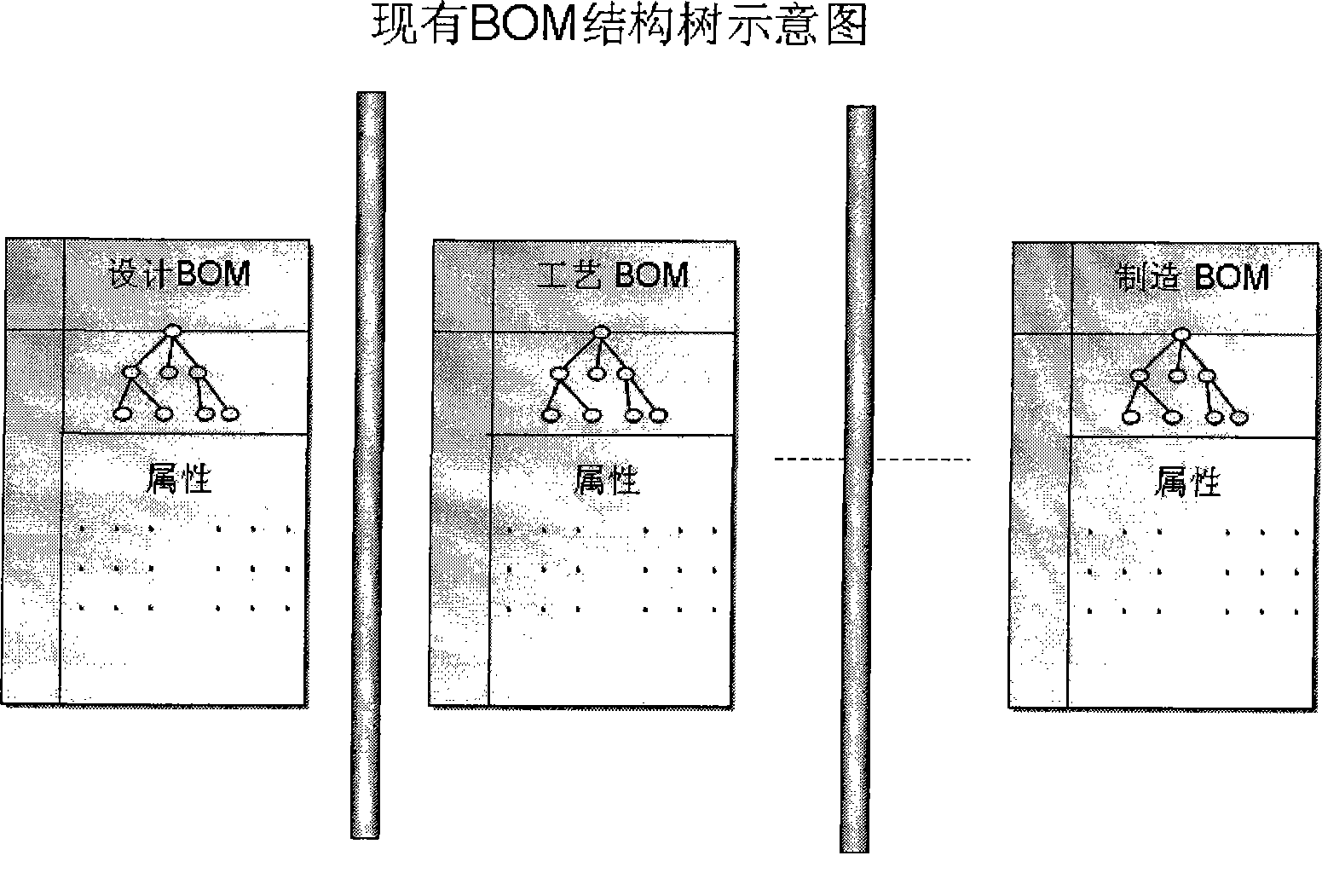

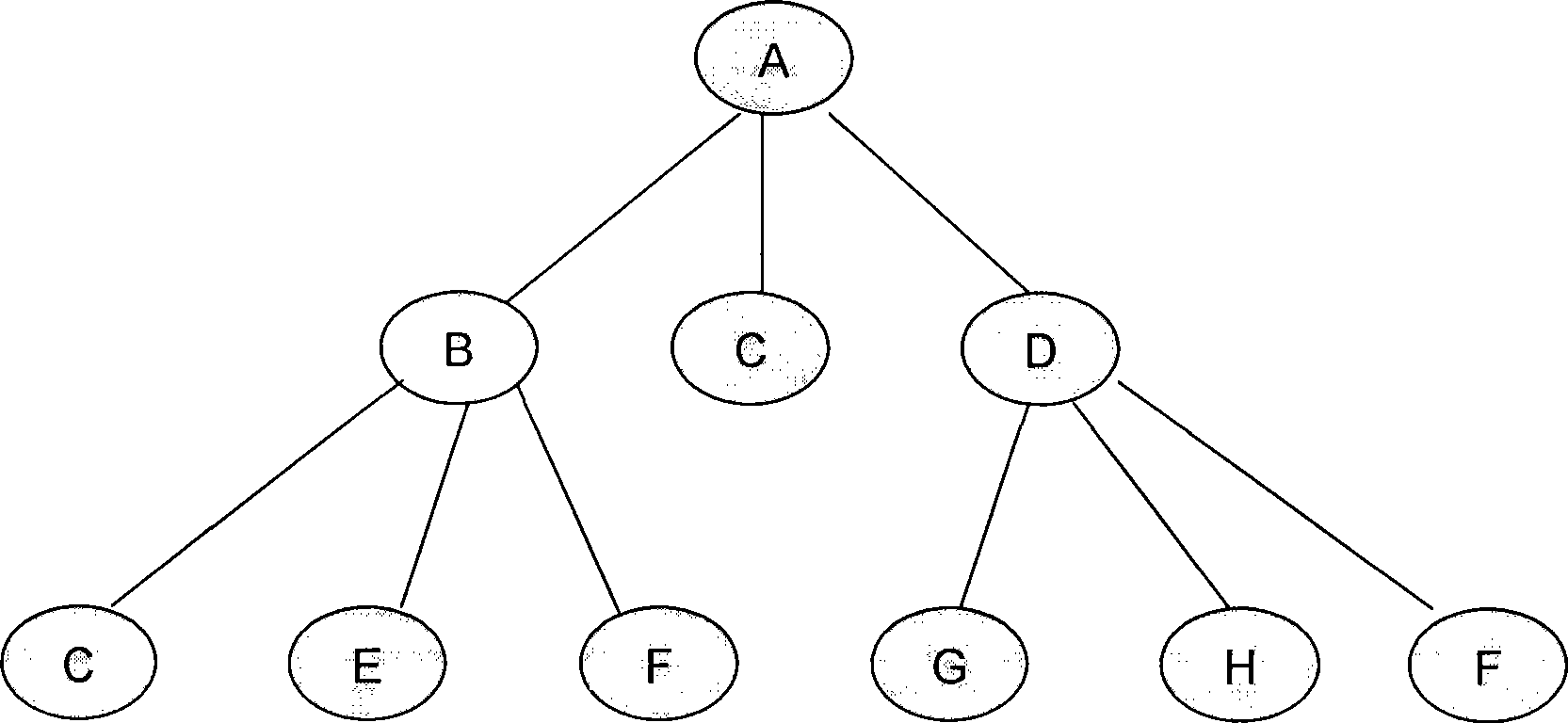

Method for constructing BOM container based on SOA architecture

InactiveCN101364288AImprove good performanceEasy to modifySpecial data processing applicationsProduction modelLoose coupling

The invention provides a BOM container constructing method based on an SOA architecture. A BOM generating rule set and a BOM calculating rule set are built up to form a certain BOM generating rule and calculating rule; the generating rule is utilized to build a specific instantiated BOM structure object; communication is established among the instantiated BOM objects which have different classes and are mutually independent so as to form a BOM object relation set, and the built BOM object relation set is processed through encapsulation and normalization; the BOM generating rule, the BOM calculating rule, the BOM object relation and a BOM attribute set form a loose coupling relation mutually, thereby forming a virtual BOM structure that is a BOM container. The BOM container constructing method can build and manage the needed specific BOM structure in a dynamic manner according to the BOM rule so as to show the production process which is a motive and changing process, and the BOM can be adjusted limberly to adapt to the variable production model.

Owner:于万钦

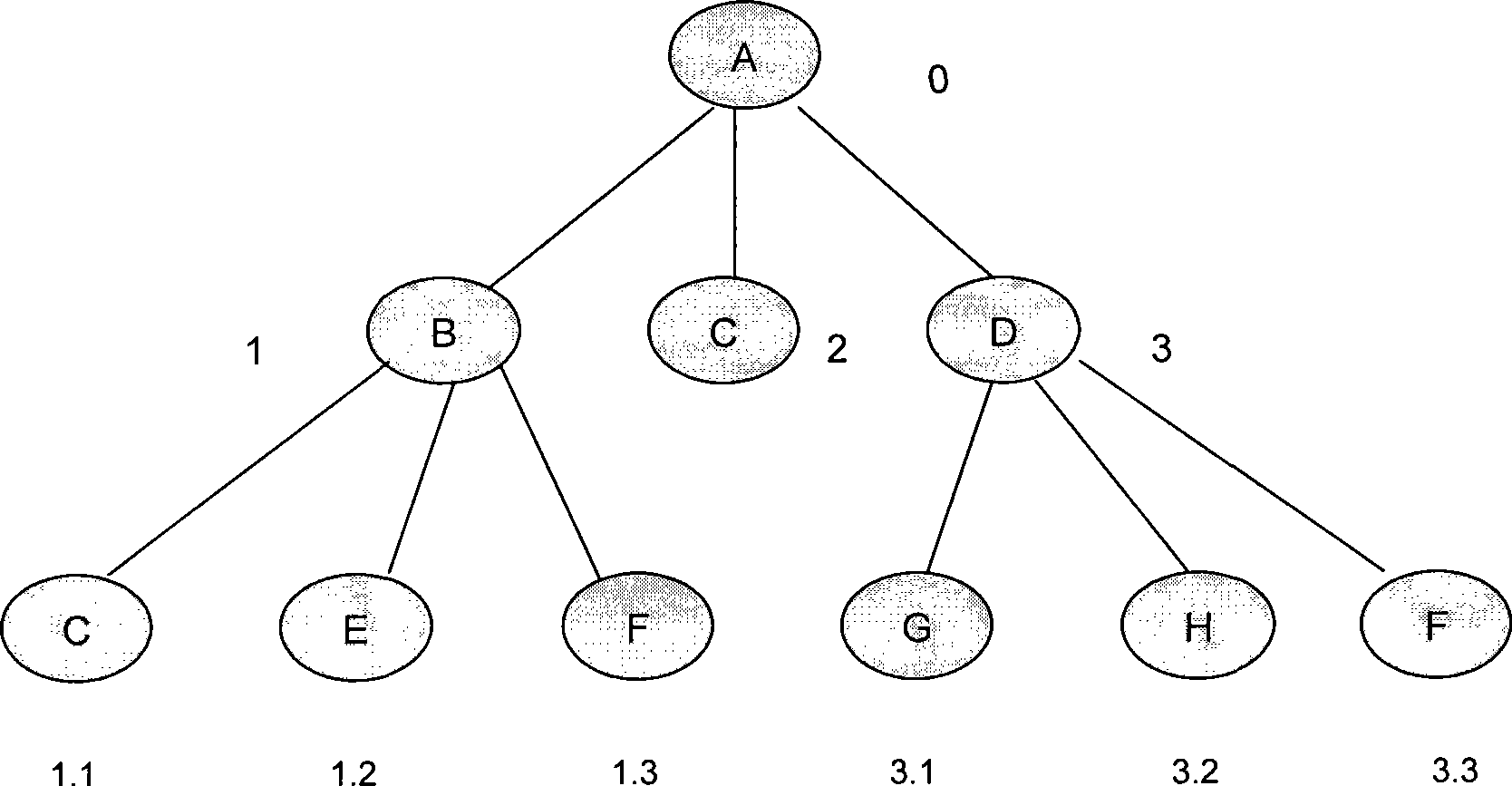

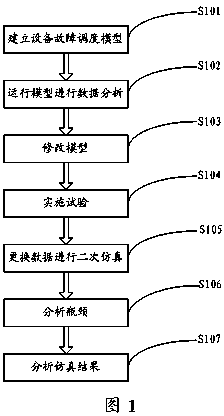

Workshop scheduling simulation method based on equipment failure scheduling model

InactiveCN103823455AReduce complexityReduce lossesTotal factory controlProgramme total factory controlProduction modelHolding cost

The invention discloses a workshop scheduling simulation method based on an equipment failure scheduling model. The workshop scheduling simulation method comprises the following steps: establishing an equipment failure scheduling model and an operation model for performing data analysis, modifying the models, implementing tests, replacing data for performing the secondary simulation, analyzing the bottle neck, and analyzing the simulation result. According to the workshop scheduling simulation method based on the equipment failure scheduling model, provided by the invention, the possibility of successfully designing a workshop production system is increased, and the design cost and risks are reduced; the simulation result is verified by using an genetic algorithm, the design period of a traditional design is shortened from the aspect of time, the probability of the equipment failure is reduced, the defect produced by re-processing the product replacing equipment is lowered. The actual production model is applied to eM-Plant software and is converted into a model recognizable by the software, the time wasting for re-clamping is avoided, the stock-holding cost caused by the overstock waste of to-be-processed products is reduced, and liquidated damages and the reputation loss caused by delayed delivery are reduced.

Owner:XIAN TECH UNIV

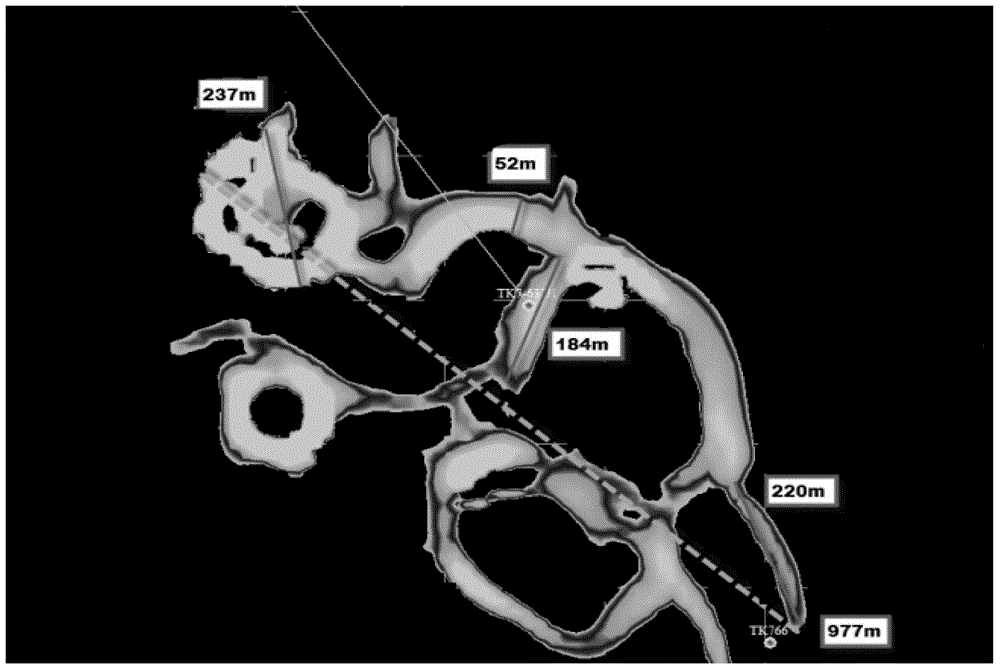

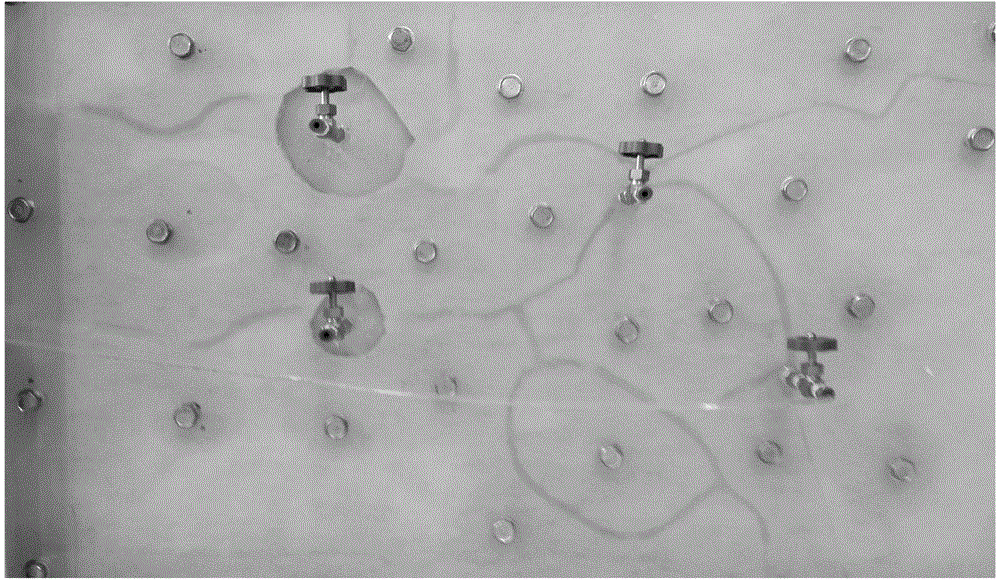

Rock seam hole type oil deposit tracer-agent-injection injection-production model and manufacturing method and application thereof

InactiveCN104153766AReduce lossesIndoor detection method is simple and easyConstructionsBorehole/well accessoriesProduction modelAdhesive

The invention provides a rock seam hole type oil deposit tracer-agent-injection injection-production model and a manufacturing method and application of the rock seam hole type oil deposit tracer-agent-injection injection-production model. A carbonate rock is cut into a square plate, on the surface of the plate, the sizes of seam holes in the model are calculated according to a set proportional scale on the basis of the distribution condition of the seam holes on an actual oil deposit earthquake curvature graph, and the rock plate is etched to obtain cracks or caves. The two sides of the etched rock plate are respectively coated with adhesives and are then respectively covered with transparent organic glass, pressed and sealed, set screws are arranged on related portions, and the joints are coated with glue and sealed. Holes are drilled in different portions of the model according to the requirement for setting simulation well positions, valves are installed, different types of well position distribution of seam hole oil deposit is simulated, and then the rock seam hole type oil deposit tracer-agent-injection injection-production model is obtained. By means of the model, the test process of real seam hole oil deposit injection-production well network tracer agent injection can be well simulated, and guidance is provided for the research on the oil-water relation of seam hole oil deposit.

Owner:SOUTHWEST PETROLEUM UNIV

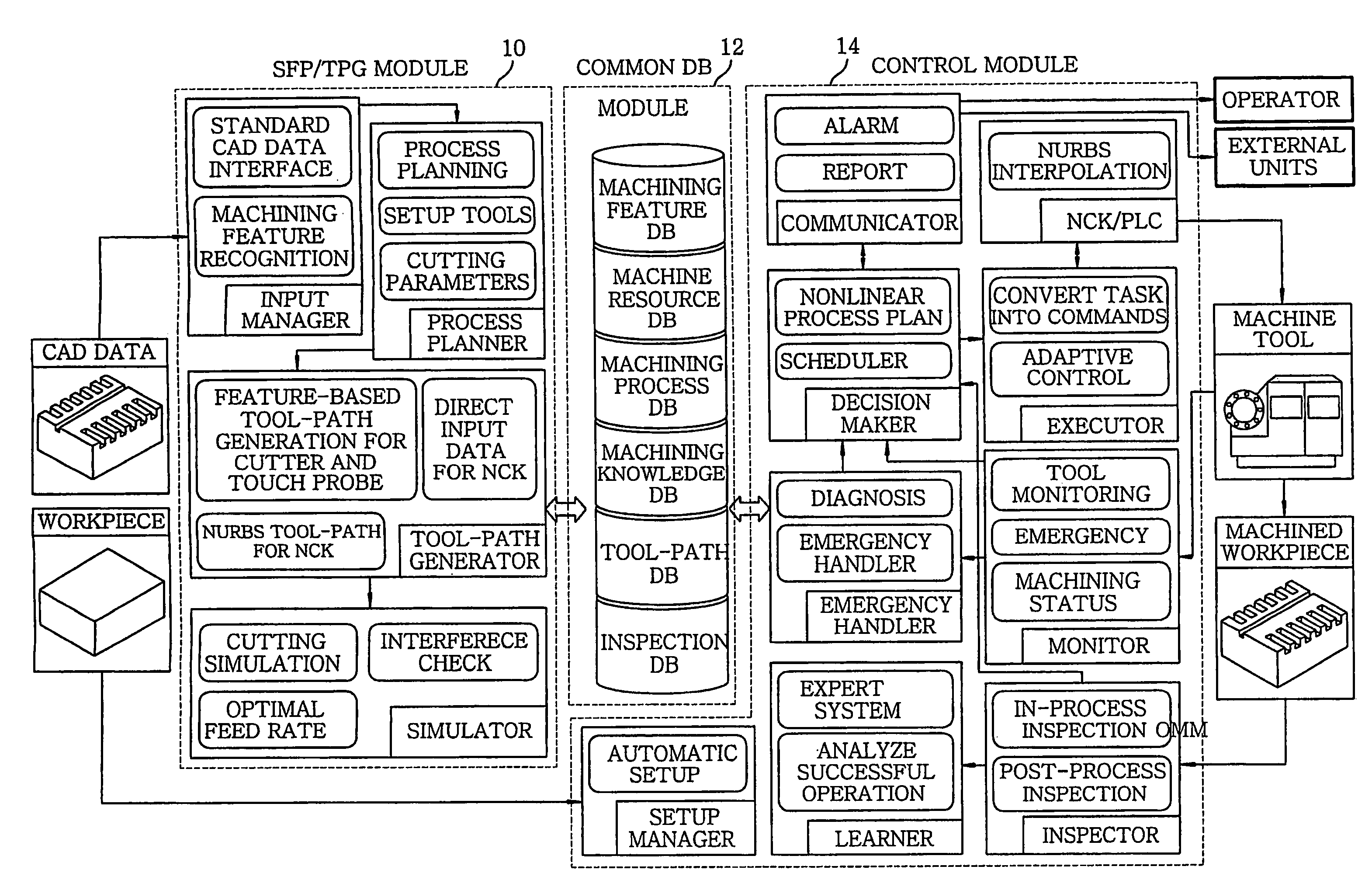

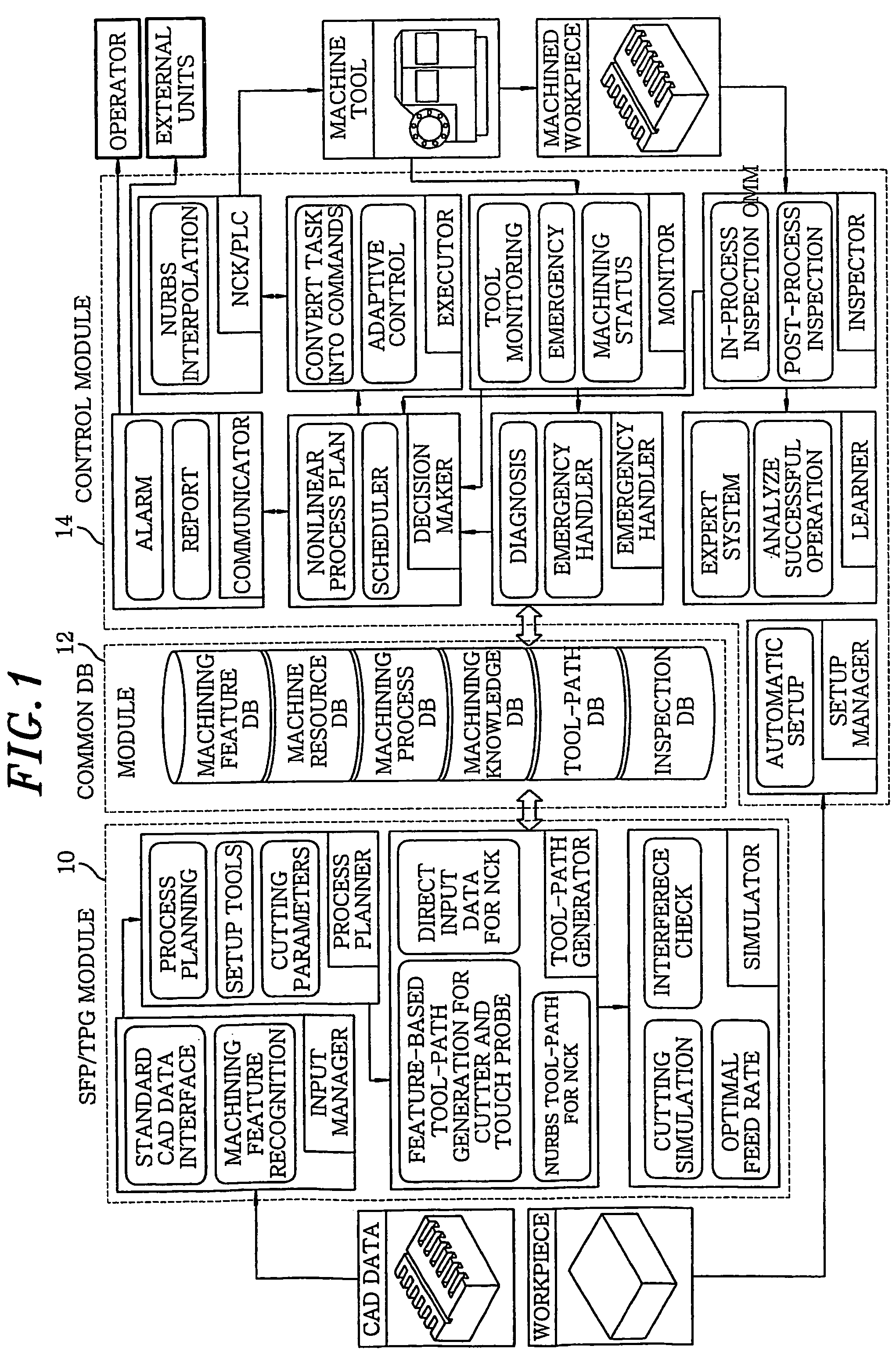

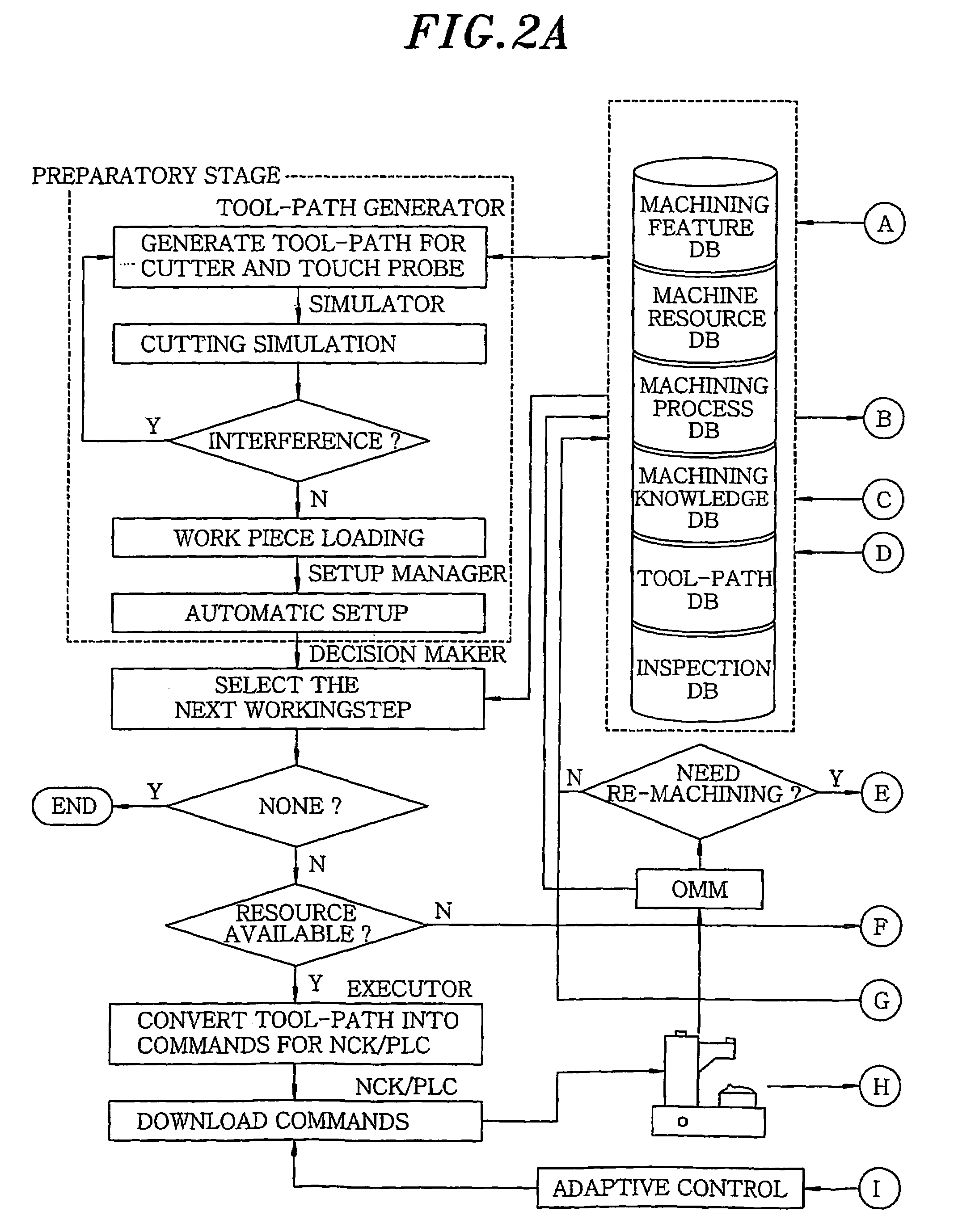

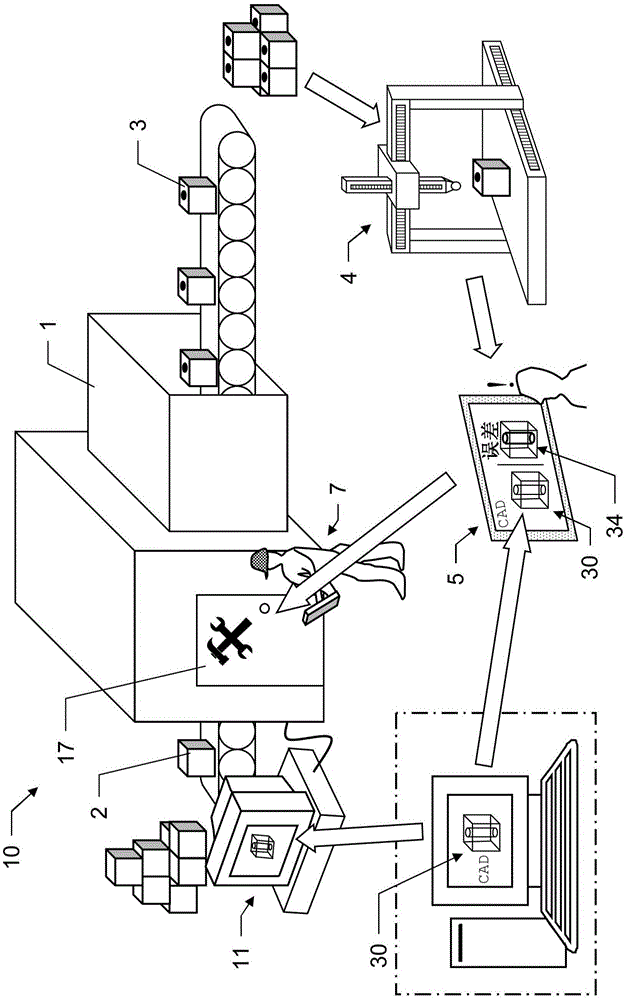

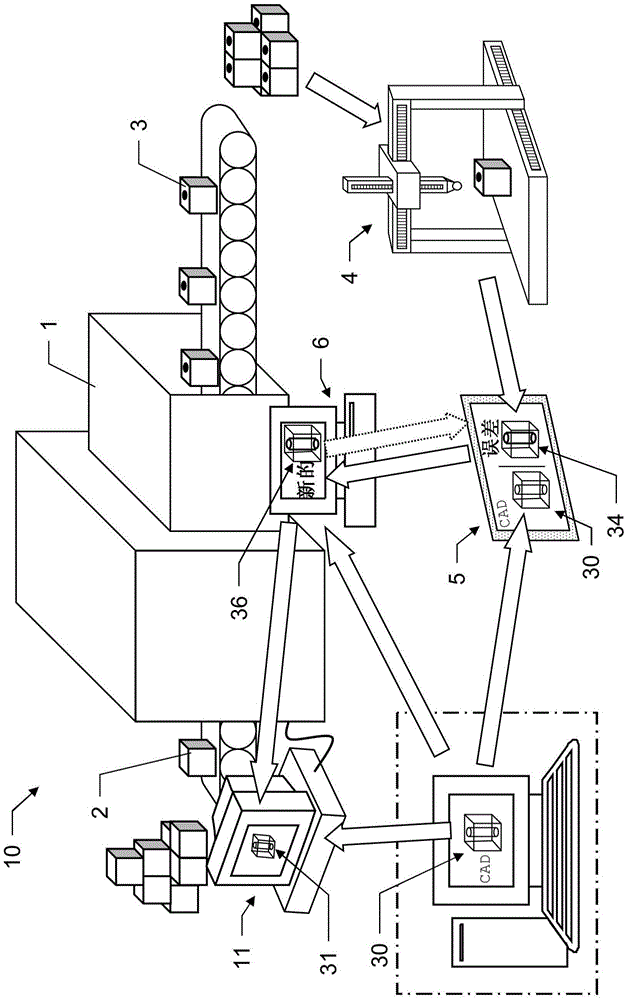

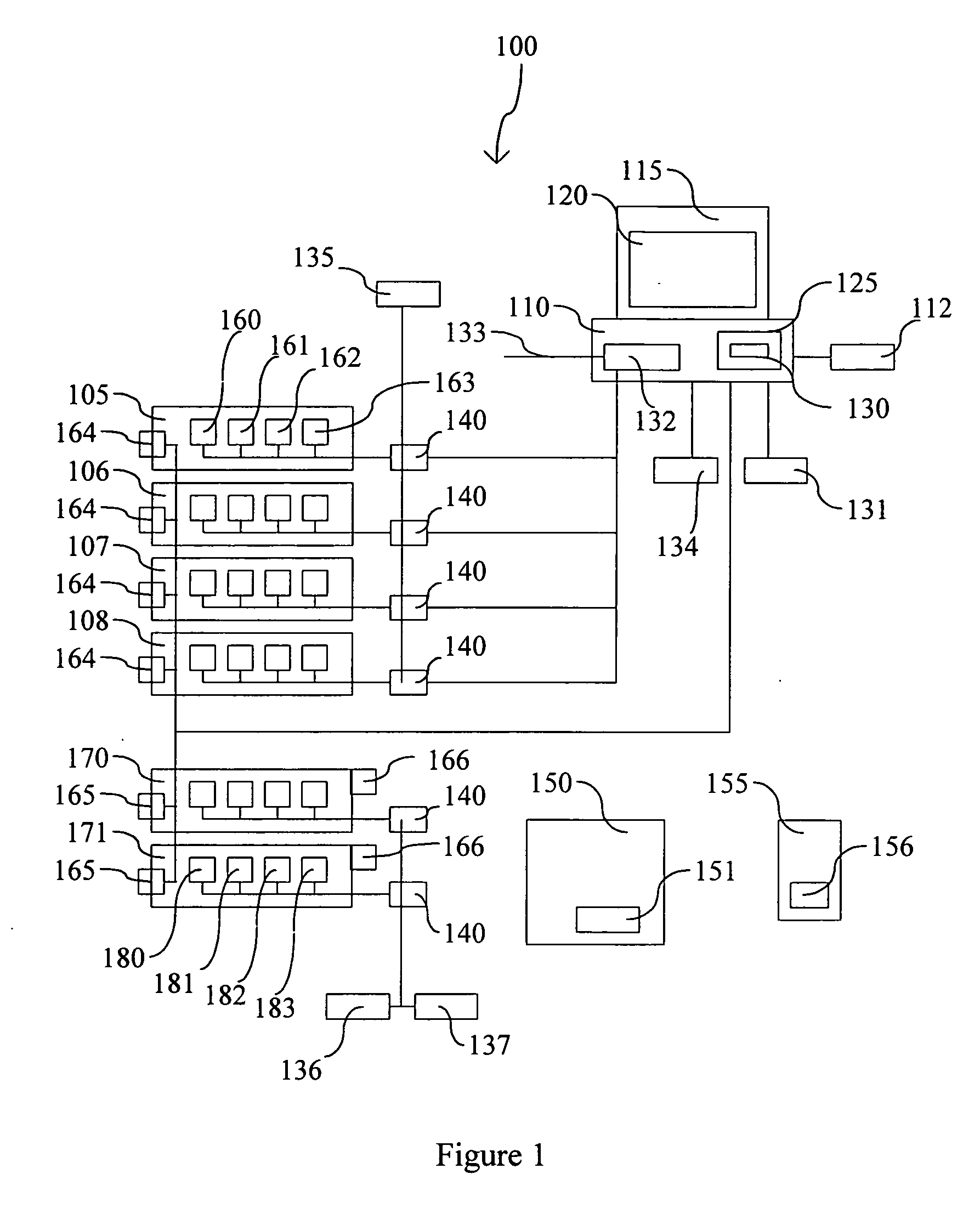

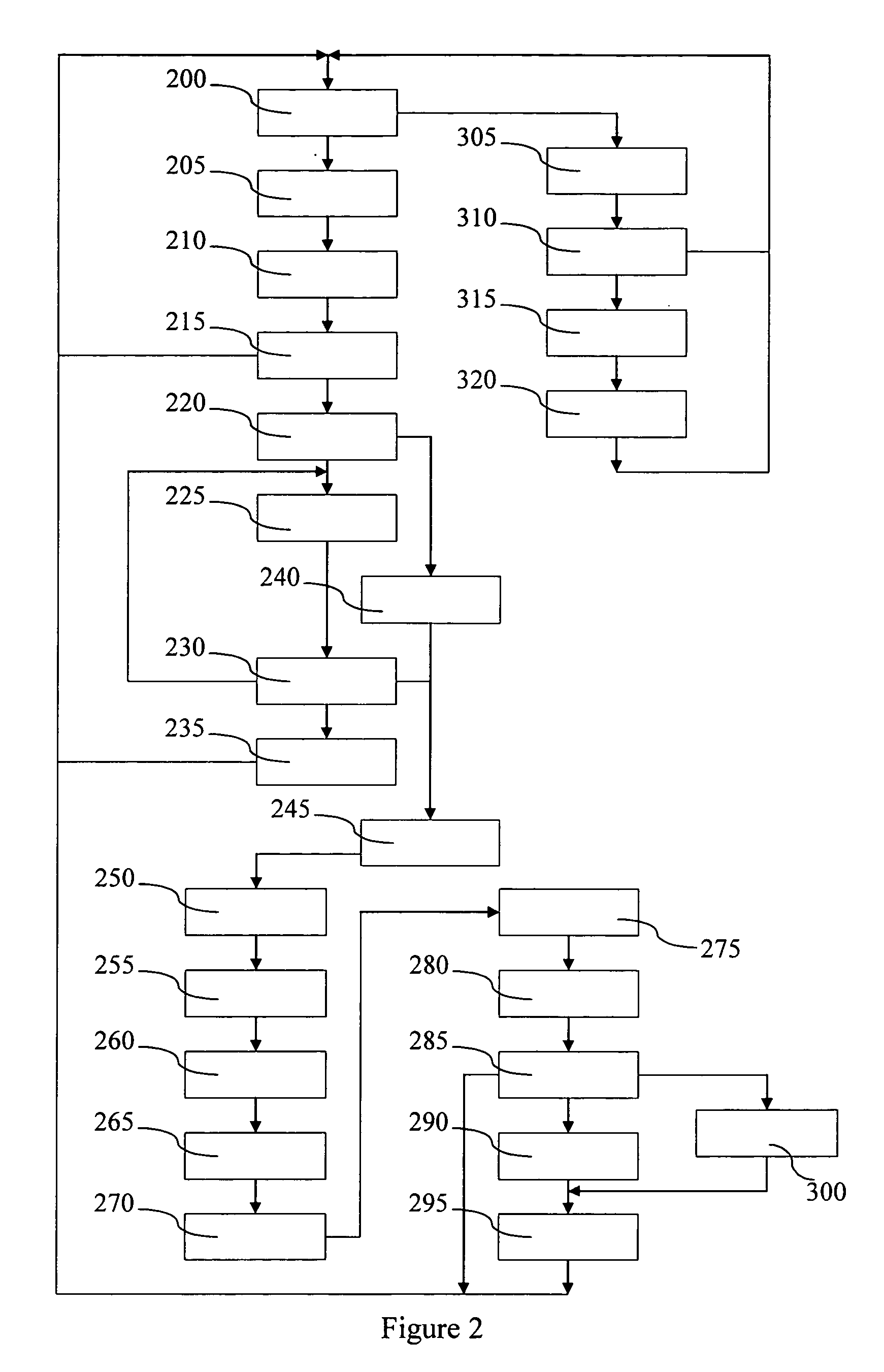

Intelligent STEP-NC controller

InactiveUS7099737B2Improve efficiencyMinimize directionProgramme controlAutomatic control devicesProduction modelEngineering

An intelligent STEP-NC (Standard for the Exchange of Produce model-Numerical Controller) overcomes short-comings of conventional NCs with a closed structure The intelligent STEP-NC intelligently performs a machining process based on ISO 14649 data while autonomously coping with an emergency at a shop-floor. Thus, the discontinuity of information in a CAD-CAM-CNC chain where the current NCs are operated can be overcome and the concept of “design-to-manufacture” can be realized.

Owner:POSTECH ACAD IND FOUND

Real time analytics system

Improved real-time analytics systems are provided. An analytics system may be used to generate transaction scores for transactions. A method may comprise receiving a scoring request associated with a transaction, sending the scoring request to a plurality of scoring models including a production model, wherein each scoring model is operable to generate a transaction score in response to the scoring request, and wherein each scoring model may be implemented using a virtual machine, receiving a transaction score generated by the production model, and sending the transaction score to a server for approval or denial the transaction.

Owner:VISA INT SERVICE ASSOC

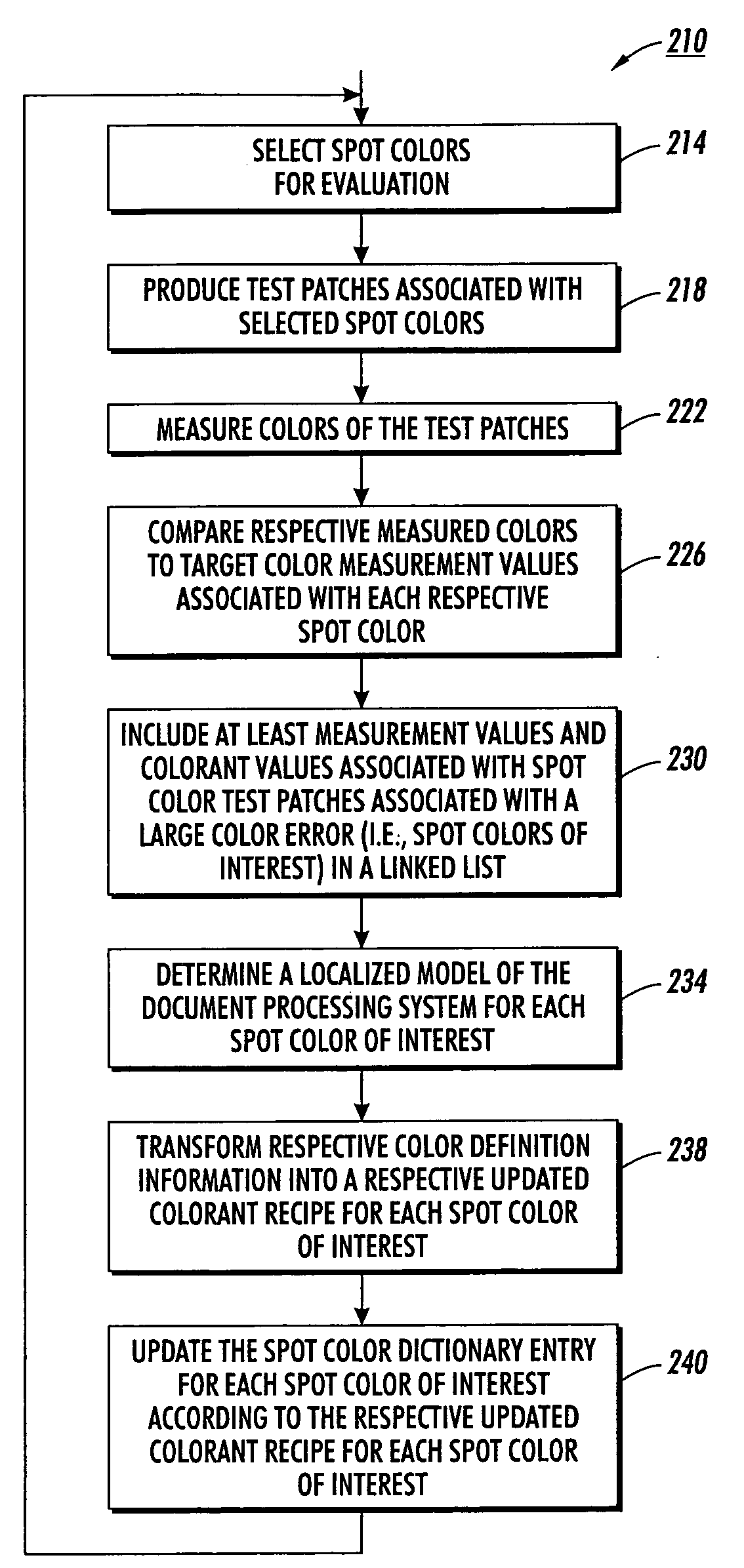

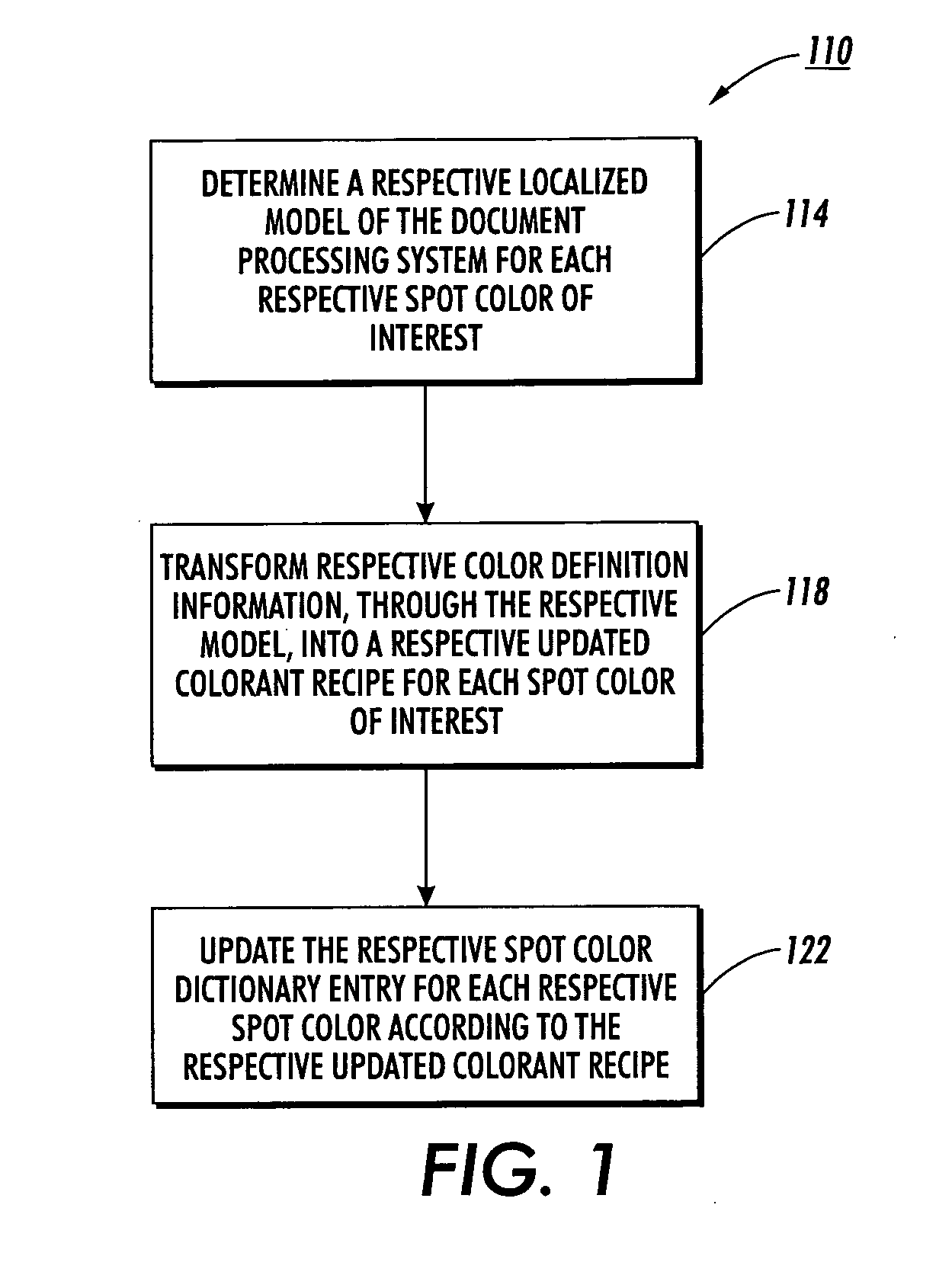

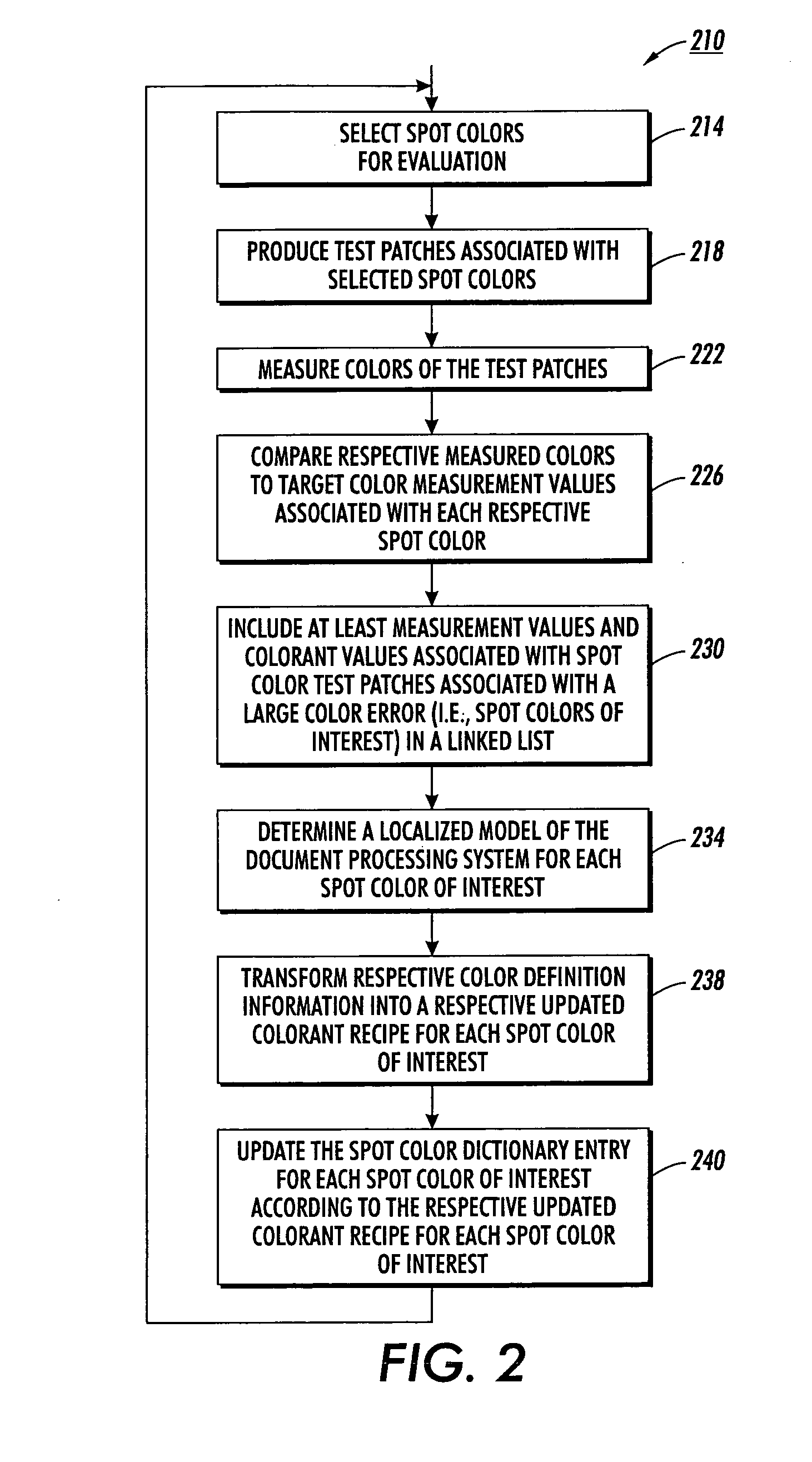

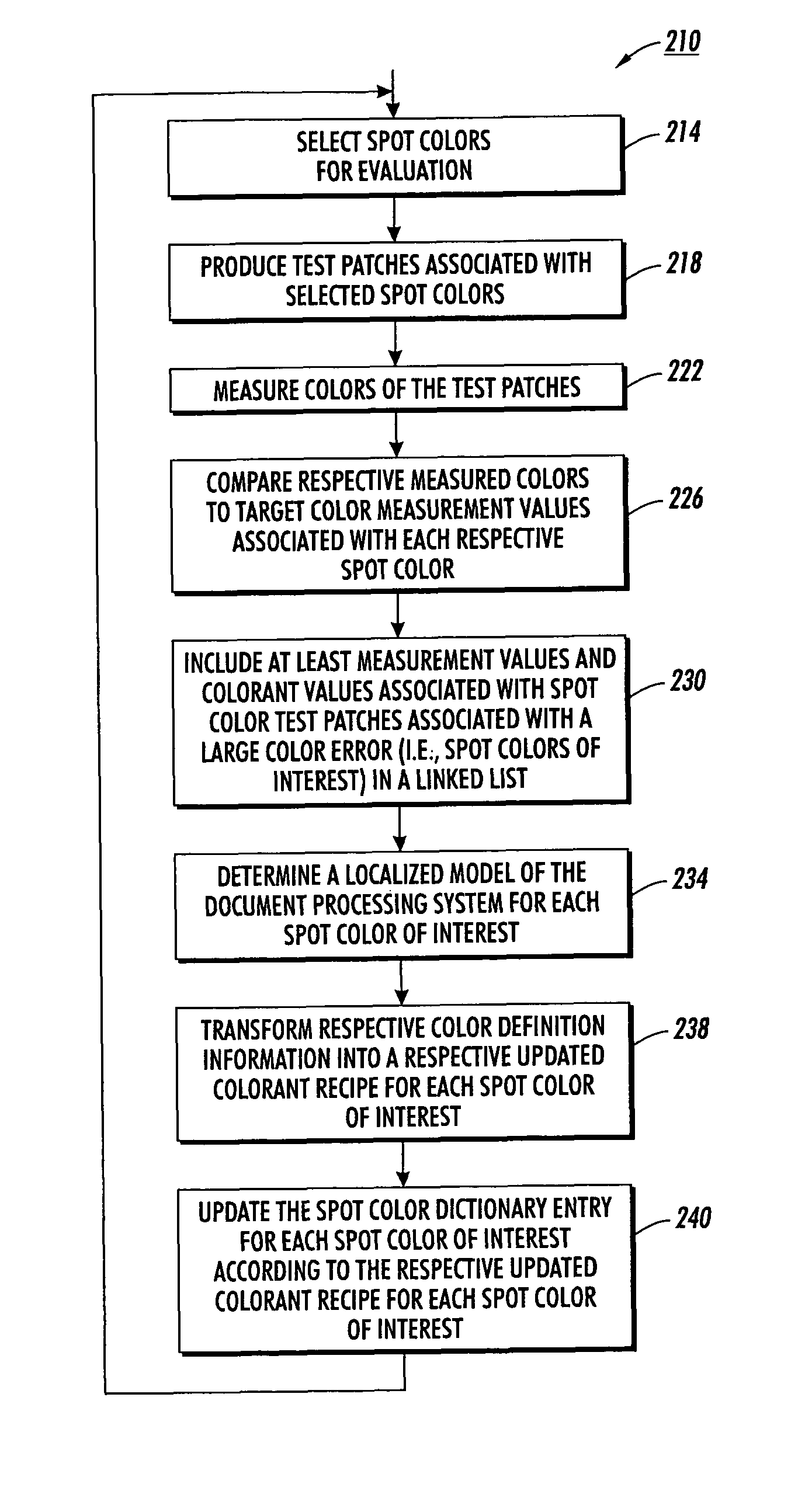

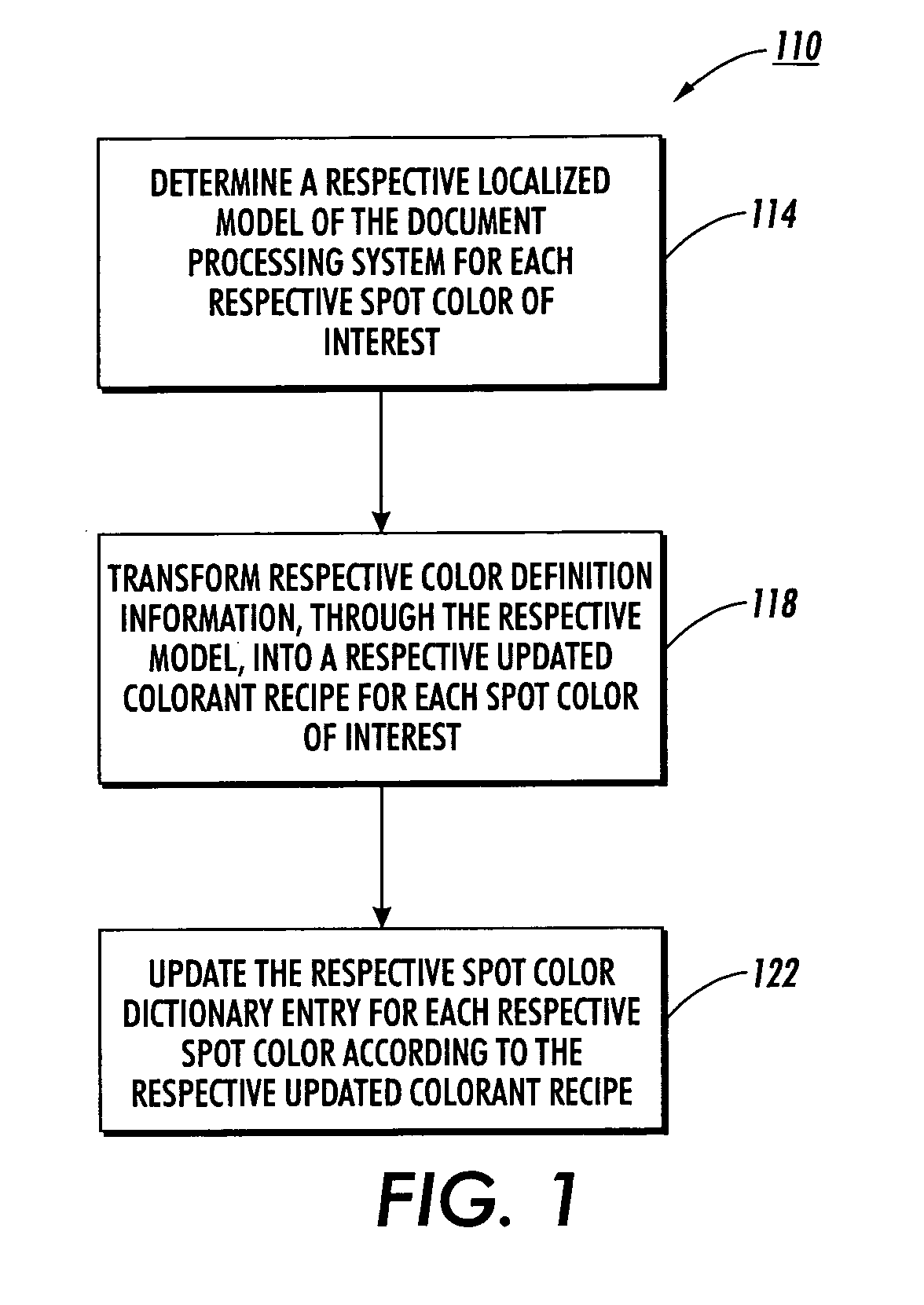

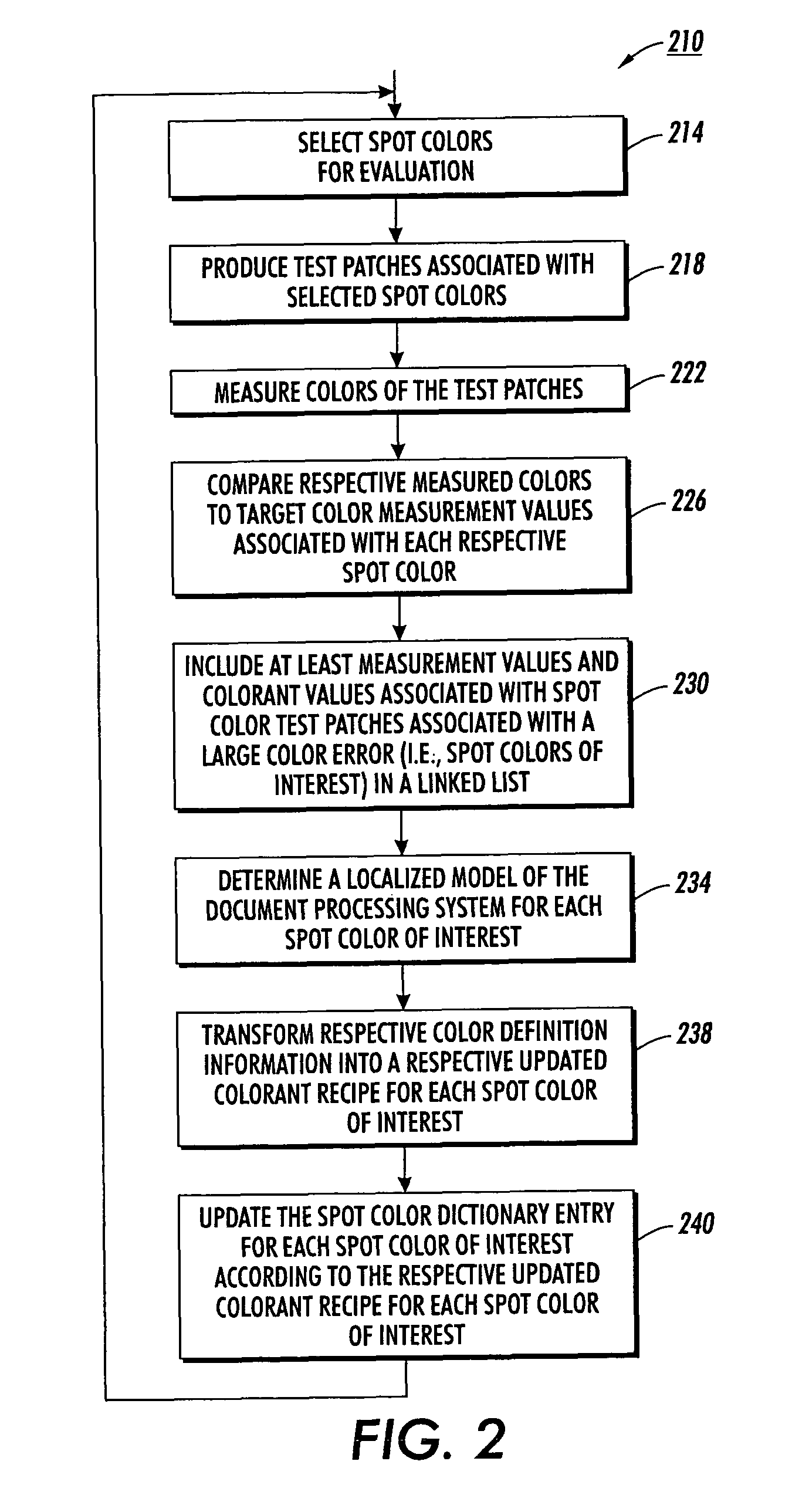

Fine tuning color dictionaries

InactiveUS20080130022A1Increase weightReduce weightDigitally marking record carriersDigital computer detailsProduction modelPattern recognition

A spot color dictionary is fine tuned or updated. Localized color production models are determined for spot colors of interest to be produced by an associated document processing system or printer. Measurements are made of colors of produced spot colors. Optionally, measurements are made of colors of test patches that are based on perturbations from the colors of the spot colors. In determining a model for the production of a target spot color, measurement data related to colors that are closer in color space to a given target color is given a higher weight than is measurement data related to colors that are further in color space from the target color. Accordingly, the model is localized to the region of color space about the target color and therefore, more accurately predicts a colorant recipe for the target color than would interpolation based on a full gamut, or more general model.

Owner:XEROX CORP

Method for compensating errors occurring in a production process

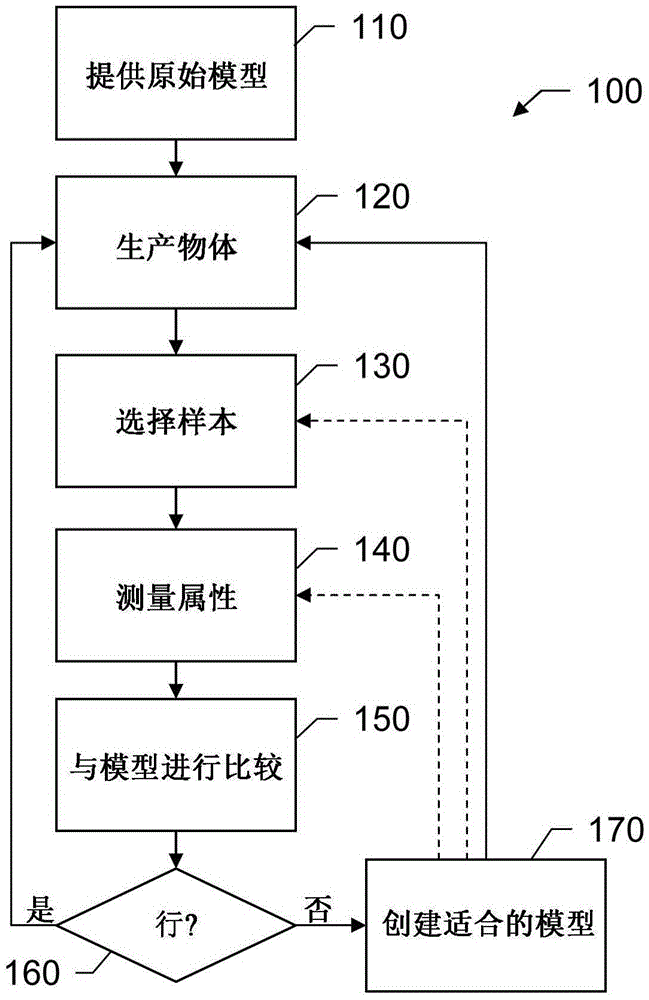

The invention pertains to a method for controlling a production process of an object in a production assembly and for compensating errors occurring in the production process, the method (100) comprising generating actual property data comprising obtained values of properties of at least one sample object produced in the production assembly according to a production model; performing a nominal-actual value comparison (150) with the obtained values of properties of the actual property data and set values of corresponding properties of nominal property data of the object, thereby generating deviation data, and automatically creating (170) an adapted production model based on the nominal property data and on the deviation data, wherein the adapted production model is useable in an adapted production process for producing an adapted object in the production assembly, and differs from the nominal property data so that the errors occurring in the production process are at least partially compensated in the adapted production process. The invention furthermore pertains to a self-compensating manufacturing system, a measurement unit and an error compensation unit for execution of said method (100).

Owner:HEXAGON TECH CENT GMBH

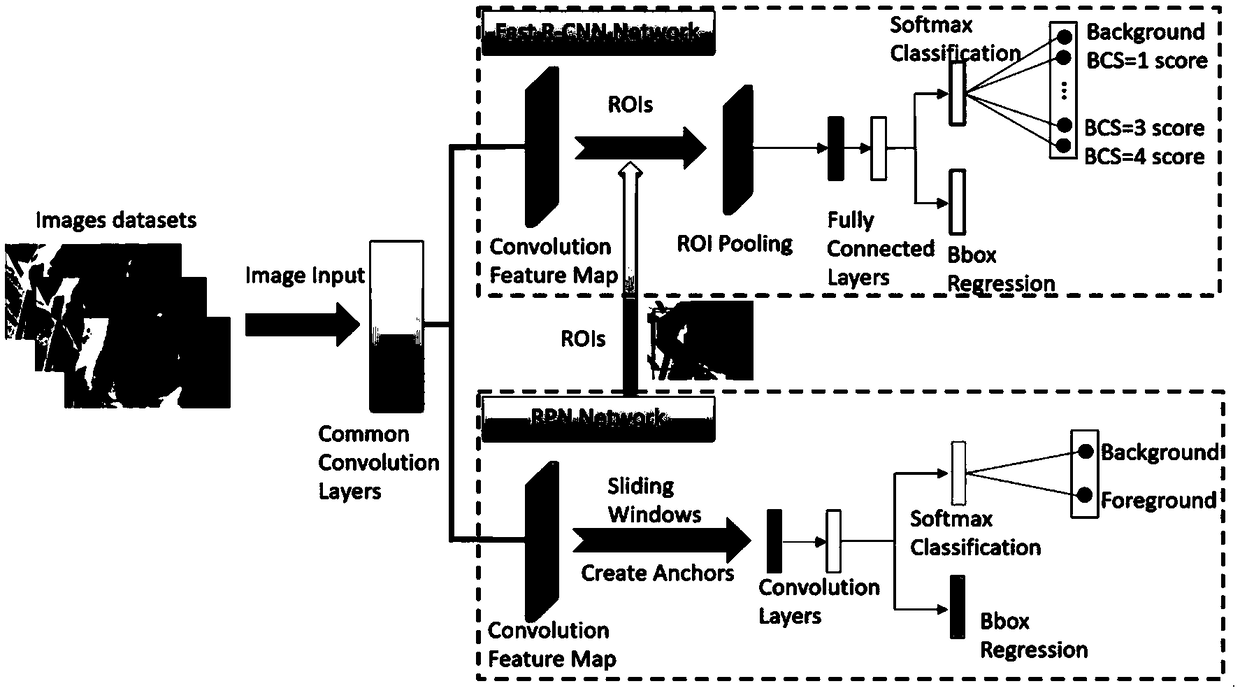

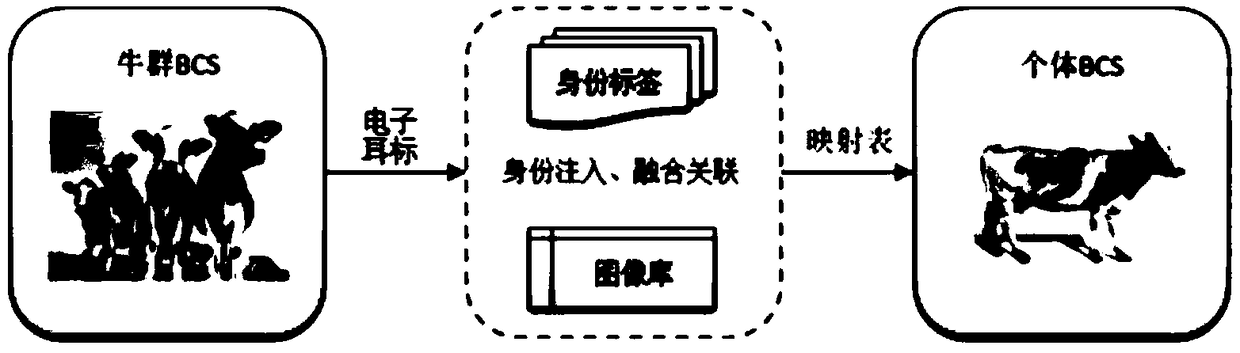

Intelligent scoring system for dairy cow body condition based on deep learning and long-distance video

InactiveCN109508907ARapid positioningRapid diagnosis of the causeCo-operative working arrangementsResourcesProduction modelEar tag

The invention particularly relates to an intelligent scoring system for dairy cow body condition based on depth learning and remote video, comprises a cow walking channel, an ear tag reader, a 3D camera and a processing module, wherein the ear tag reader is used for reading cow ear tag information, the 3D camera is used for shooting a 3D image of the cow, and the processing module adopts a depth learning algorithm Faster R-CNN processes the received cow 3D image to obtain cow scoring data, associates the cow scoring data with cow ear tag information, and outputs and / or stores the cow ear tag information. The original 3D images of cow body were obtained by 3D camera and the feature database of cow BCS images was constructed. The sample set was trained by depth learning algorithm and the classification accuracy of BCS was 0.1 point. Then, 3D infrared camera and electronic ear tag are used to construct a model that can continuously track the healthy growth and production of dairy cows inthe life cycle, so that the system can identify and early warn the abnormal condition of dairy cows in advance.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

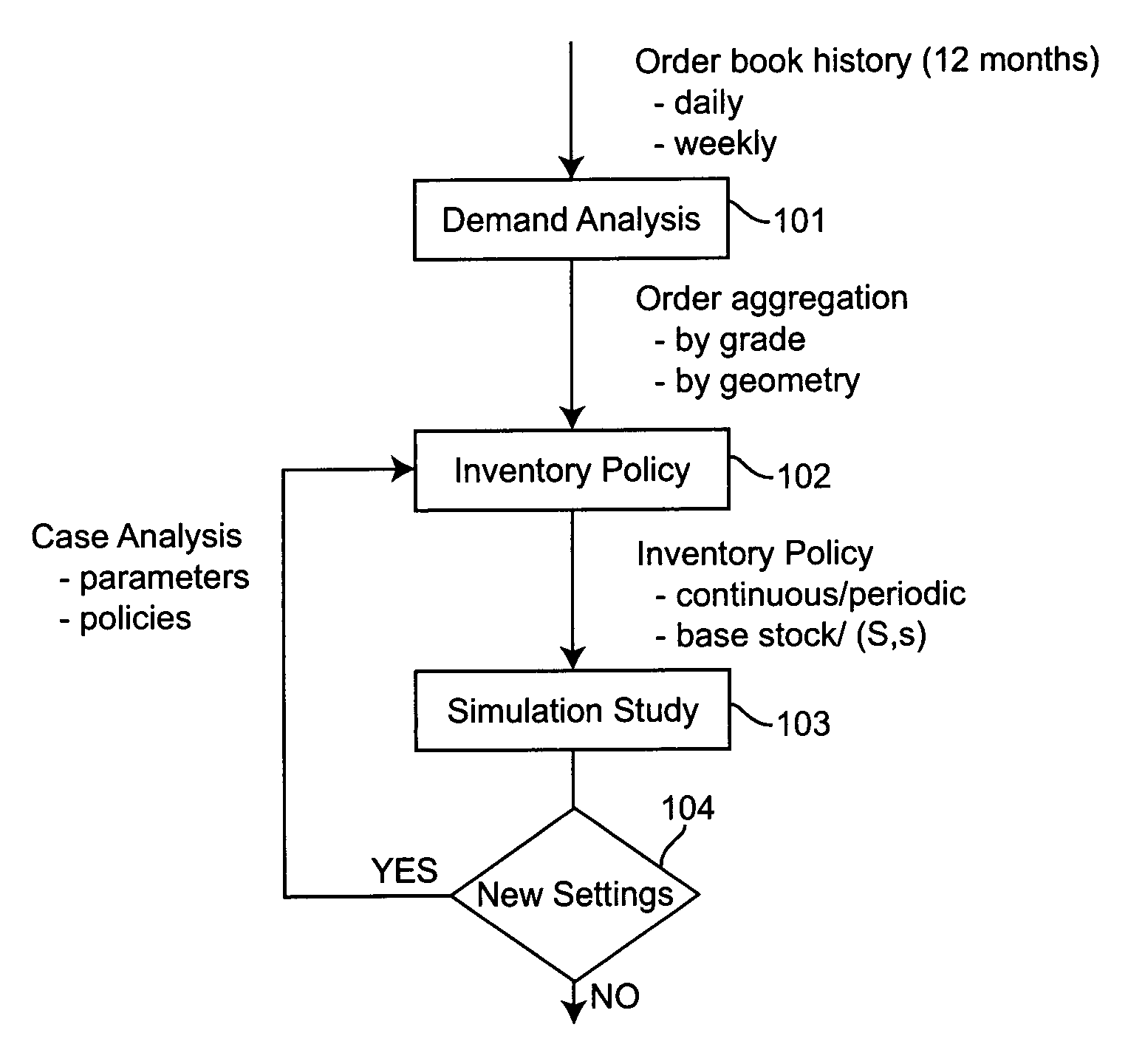

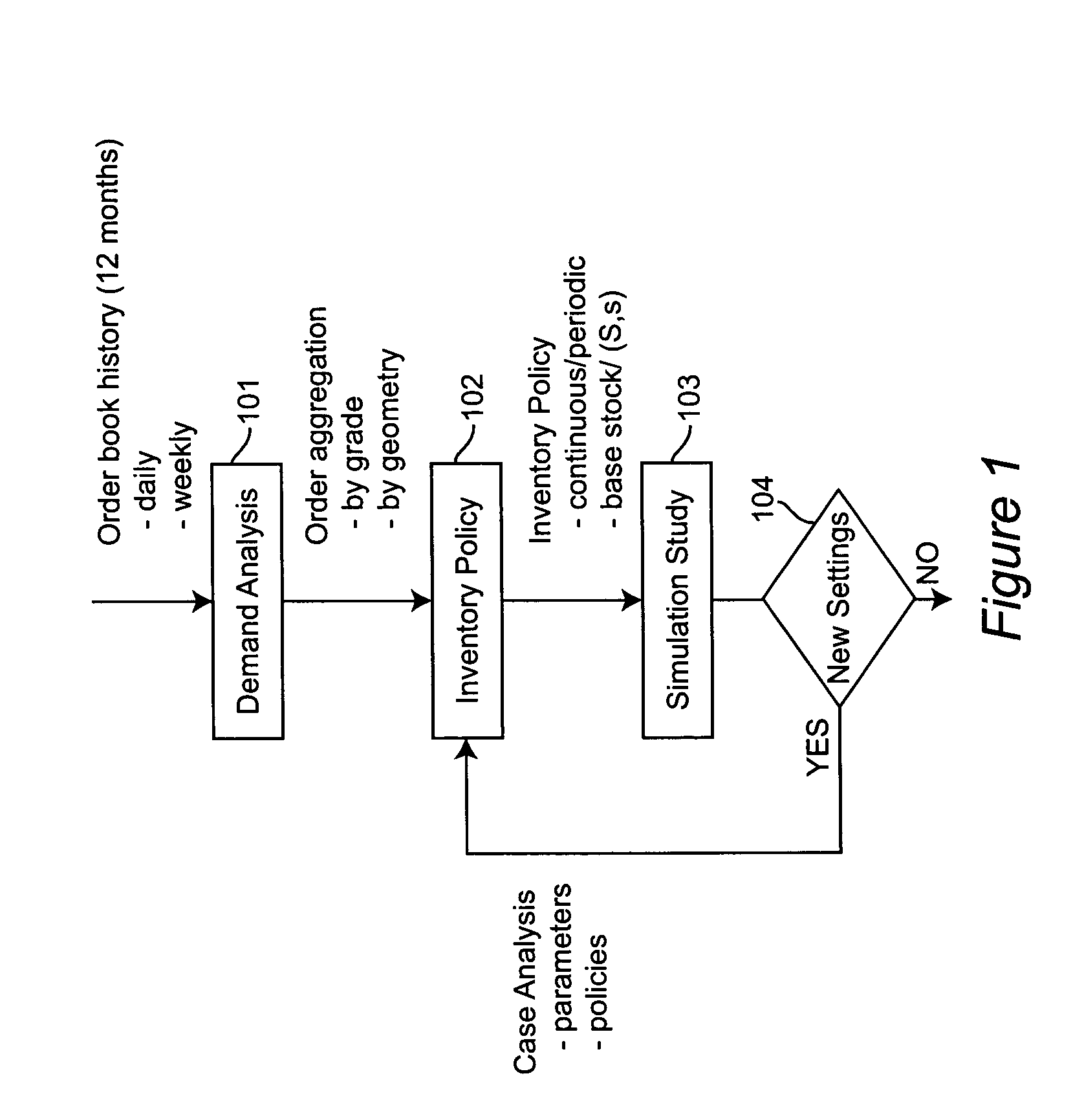

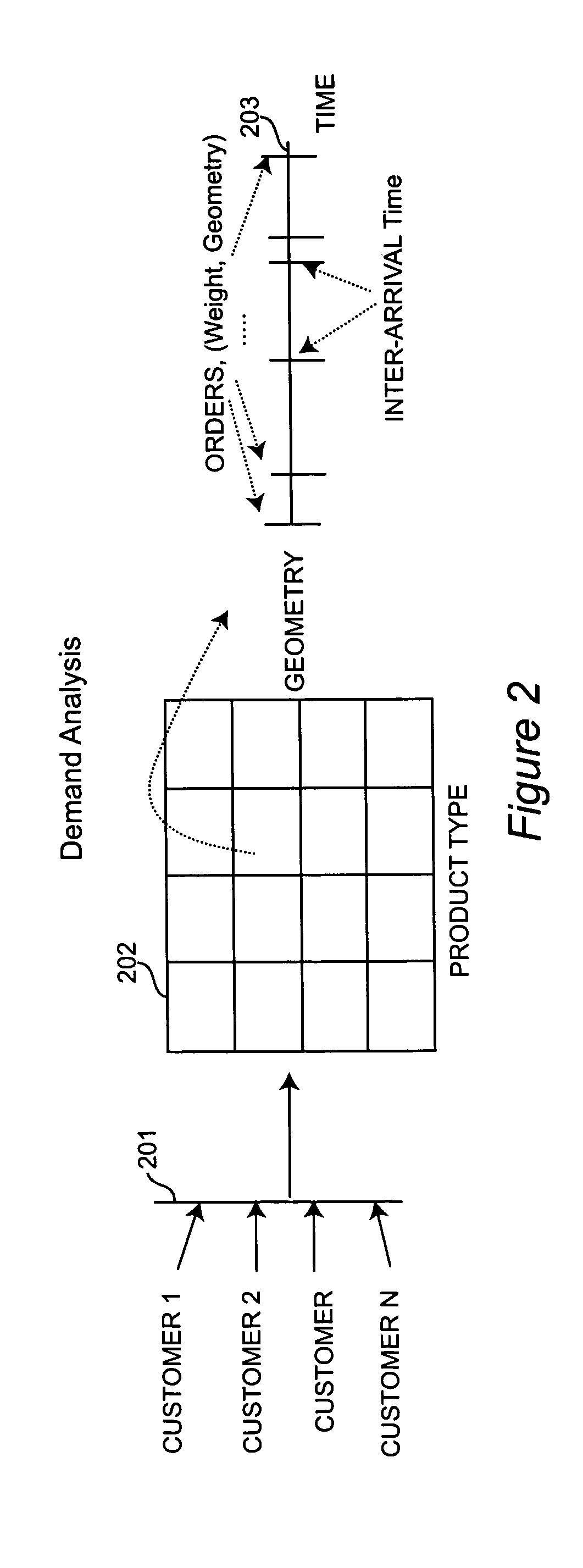

Method and system for small-lot orders to optimize production runs in the steel industry

InactiveUS7130712B1Maximizing numberIncrease productivityRoll mill control devicesSpecial data processing applicationsProduction modelDowntime

Steel making is a batch production process in which batches of 250 tons, called charges or heats, are grouped together in a single production run, called a cast. Because of fixed costs and downtime associated with cleanup and setup between casts, a cast of less than three charges is likely to be inefficient. As a result, short-run orders (such as, for example, orders of less than 750 tons) may present efficiency problems. The present invention transforms the operation from a make-to-order model to a make-to-stock model, enabling orders to be clustered based on considerations such as grade and geometry to maximize the number of clusters that satisfy the cast-size constraint.

Owner:IBM CORP

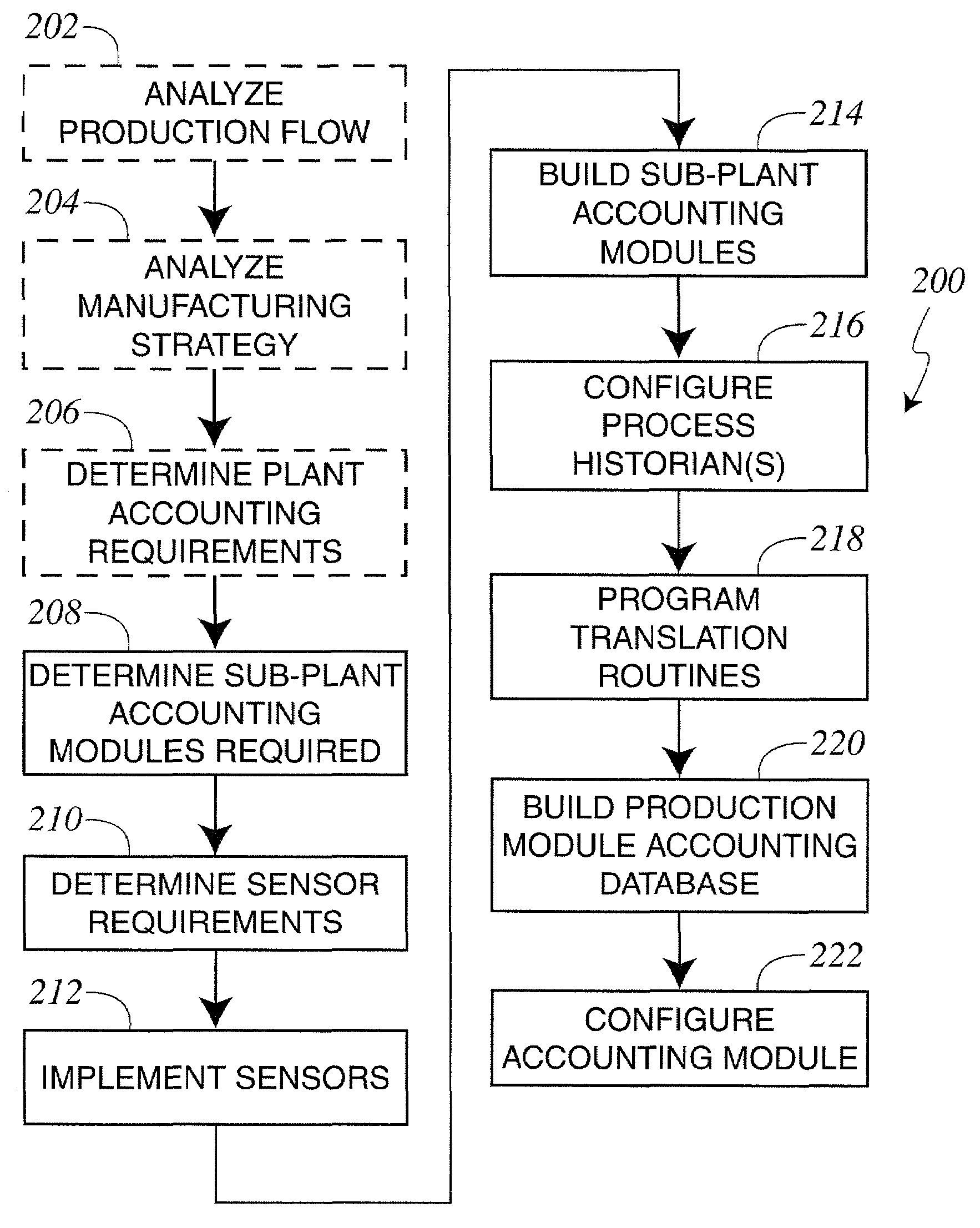

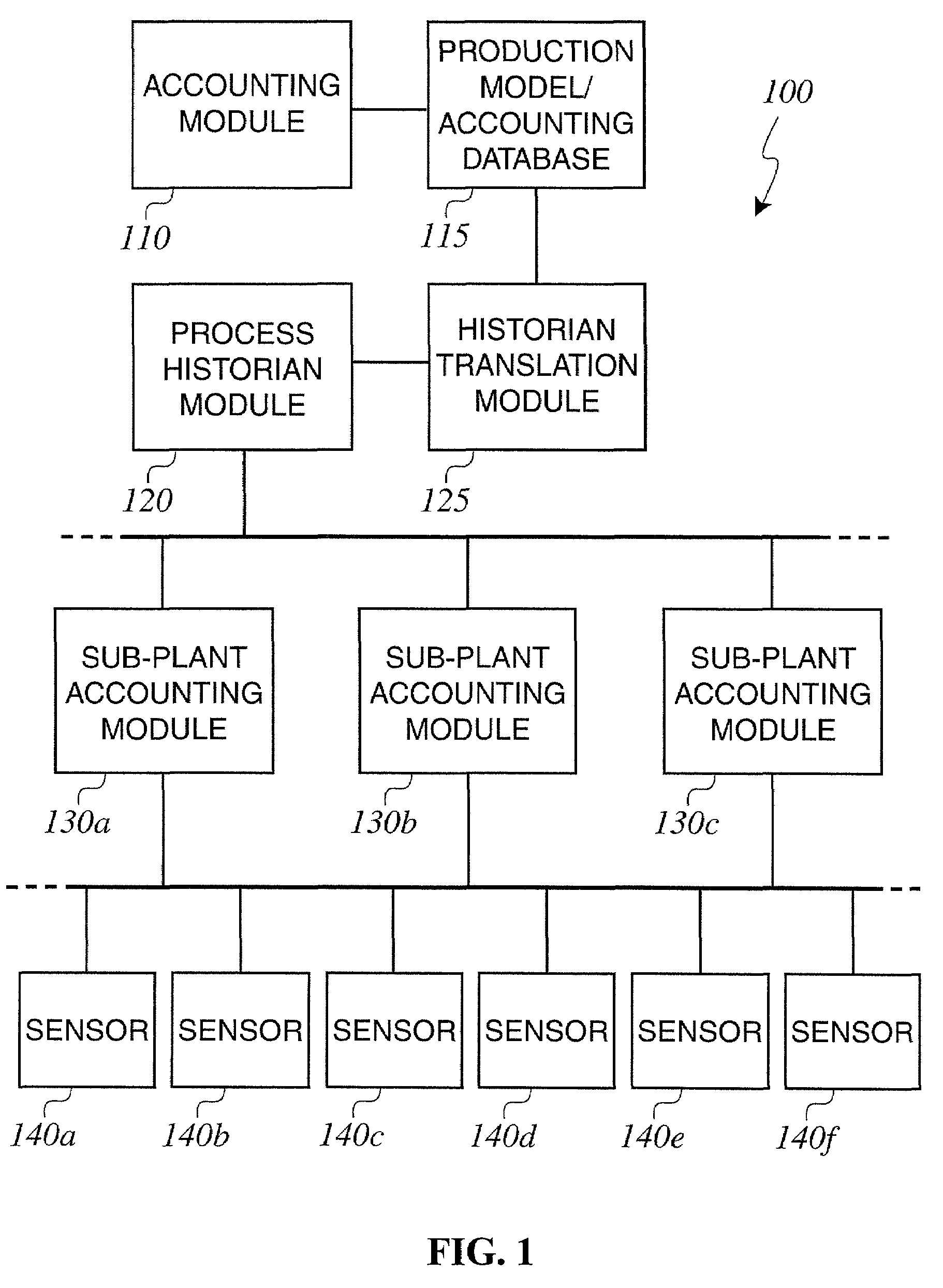

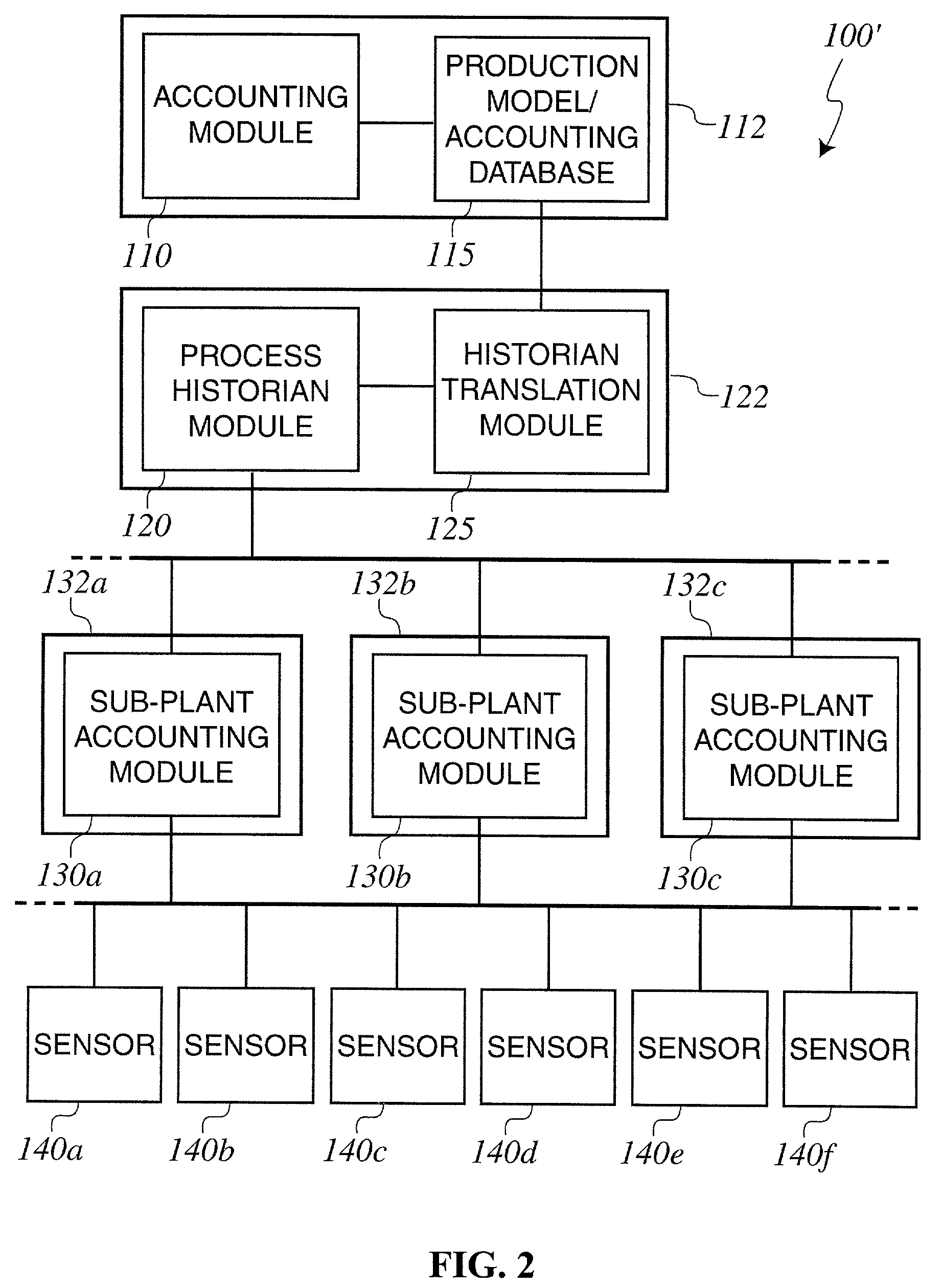

System and method for real-time activity-based accounting

ActiveUS7685029B2Complete banking machinesRegistering/indicating time of eventsProduction modelProcess equipment

An accounting method and system is disclosed that provides for real time financial accounting of plant performance at a sub-plant level. A multiplicity of process variable transmitters is utilized to sense, in real time, the current state of the processes and process equipment used in a manufacturing plant. Sub-plant accounting modules utilize the sensed process data to calculate a plurality of sub-plant accounting measures, which are stored in one or more real time plant historian. The accounting measures are typically converted to a suitable format and subsequently stored in a production model accounting database where they are accessible to an accounting module.

Owner:SCHNEIDER ELECTRIC SYST USA INC

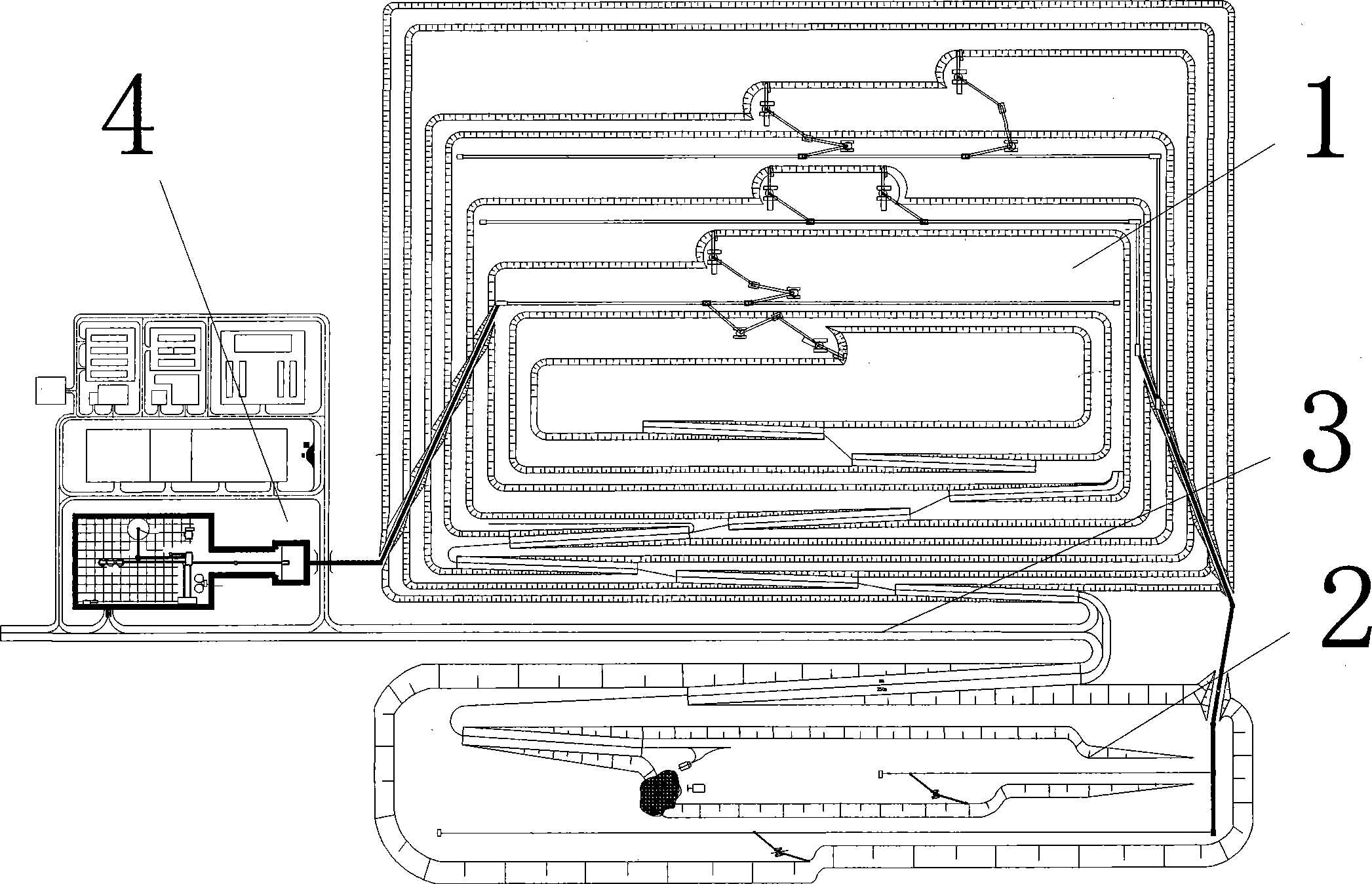

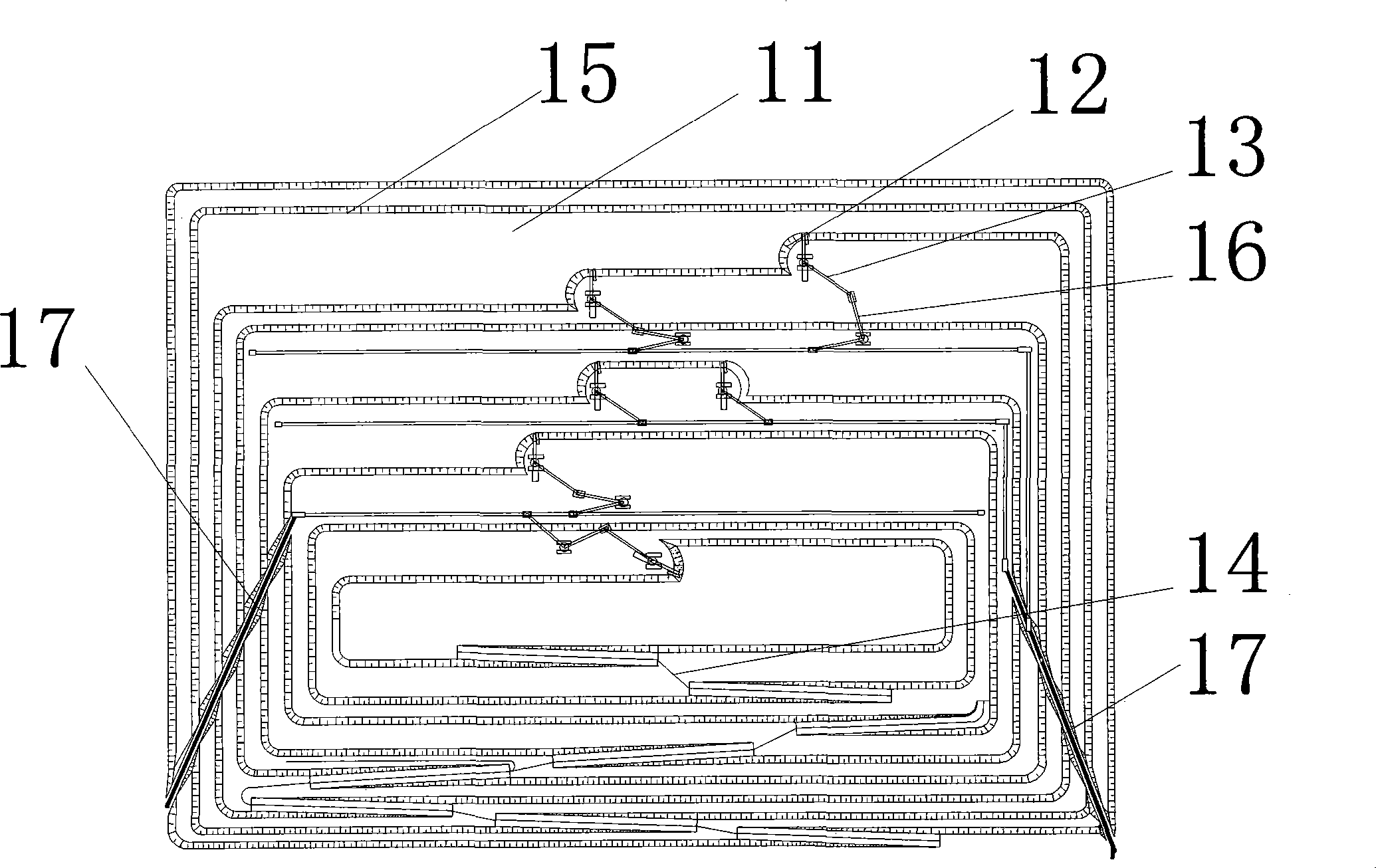

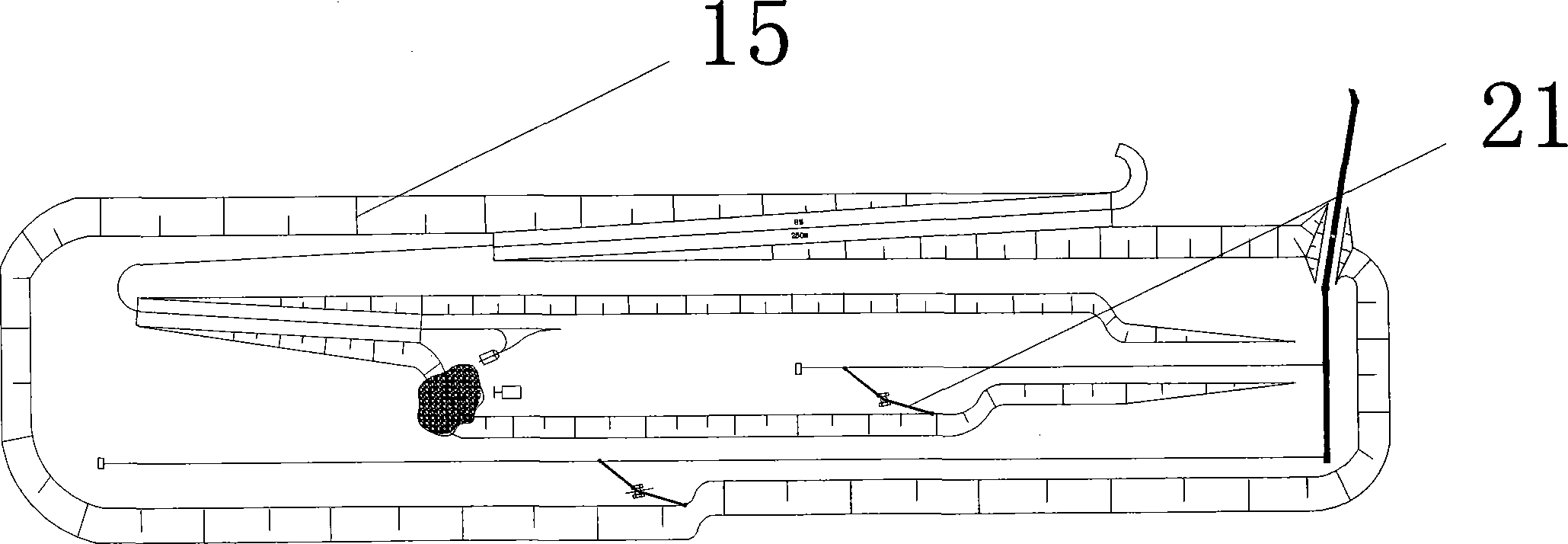

Deep-concave strip mine production model system

The invention relates to a deep-concave strip mine production model system which comprises a deep-concave excavating plant, a refuse dump, ground transportation roads and a raw coal washing field. The deep-concave excavating plant is a coal excavating plant arranged on a coal seam in a simulating mode; as simulation, multiple bucket wheel excavators conduct continuous stripping work on the north working pit edge and conduct coal production work in a deep place, stripped objects in the excavating plant are conveyed to the refuse dump on the south part of the ground through a belt conveyor arranged on the east end pit edge to be discharged through a dumping plough, and run-of-mine coal in the excavating plant is conveyed to the raw coal washing field on the west side of the ground surface boundary through a belt conveyor arranged on the west end pit edge to be processed. By means of the deep-concave strip mine production model system, tests under various construction process conditions can be simulated, the improvement can be carried out in real time according to the mining requirements, and overall adjustment can be conducted on a mining site.

Owner:XINJIANG INST OF ENG

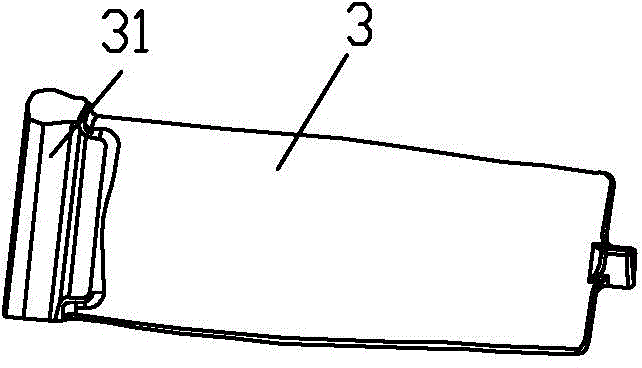

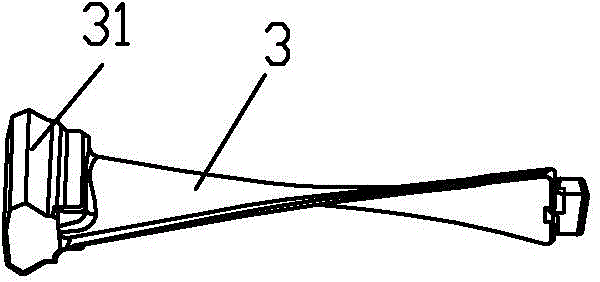

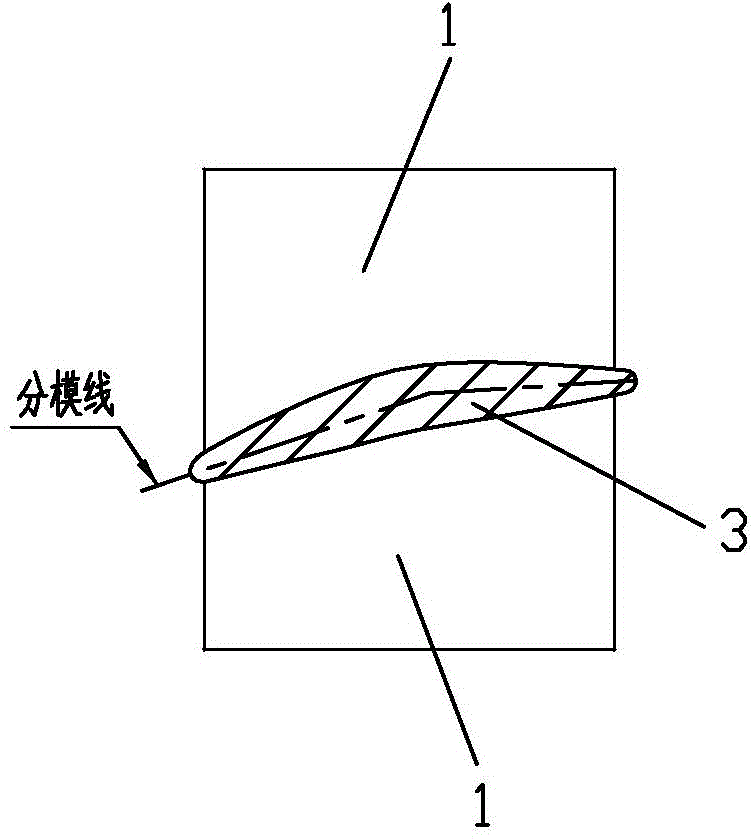

Control method for a gas turbine blade forging stock geometry and testing model

ActiveCN104406502ASimple structureReduce weightMechanical counters/curvatures measurementsProduction modelGraphics

The invention discloses a gas turbine blade geometry forging stock control methods and a testing model. The method includes the model of production and specific inspection, the model produced by the cross-sectional model making, model making and model axis combinations, axial cross-sectional model making production model are by cutaway model of the blade-shaped three-dimensional model of two-dimensional graphics, the graphics were produced by two-dimensional cross-sectional axis model and model both inside and outside the arc, and then combined to form inside and outside the arc than the fixed model with a model than by combining visual and feeler the methods were inside and outside the arc blades comparison checks. Model by a number of cross-section than the production model by forming an axis model fishbone-shaped cross-section and the axis of the model than the model on the side blade-shaped formation. The beneficial effect of the invention is a method which can detect the test results obtained in several parts of the blade, simple operation, high accuracy and high detection efficiency; check the model structure is simple, low labor intensity is detected, the detection of low skill requirements.

Owner:CHONGQING CHANGZHENG HEAVY IND

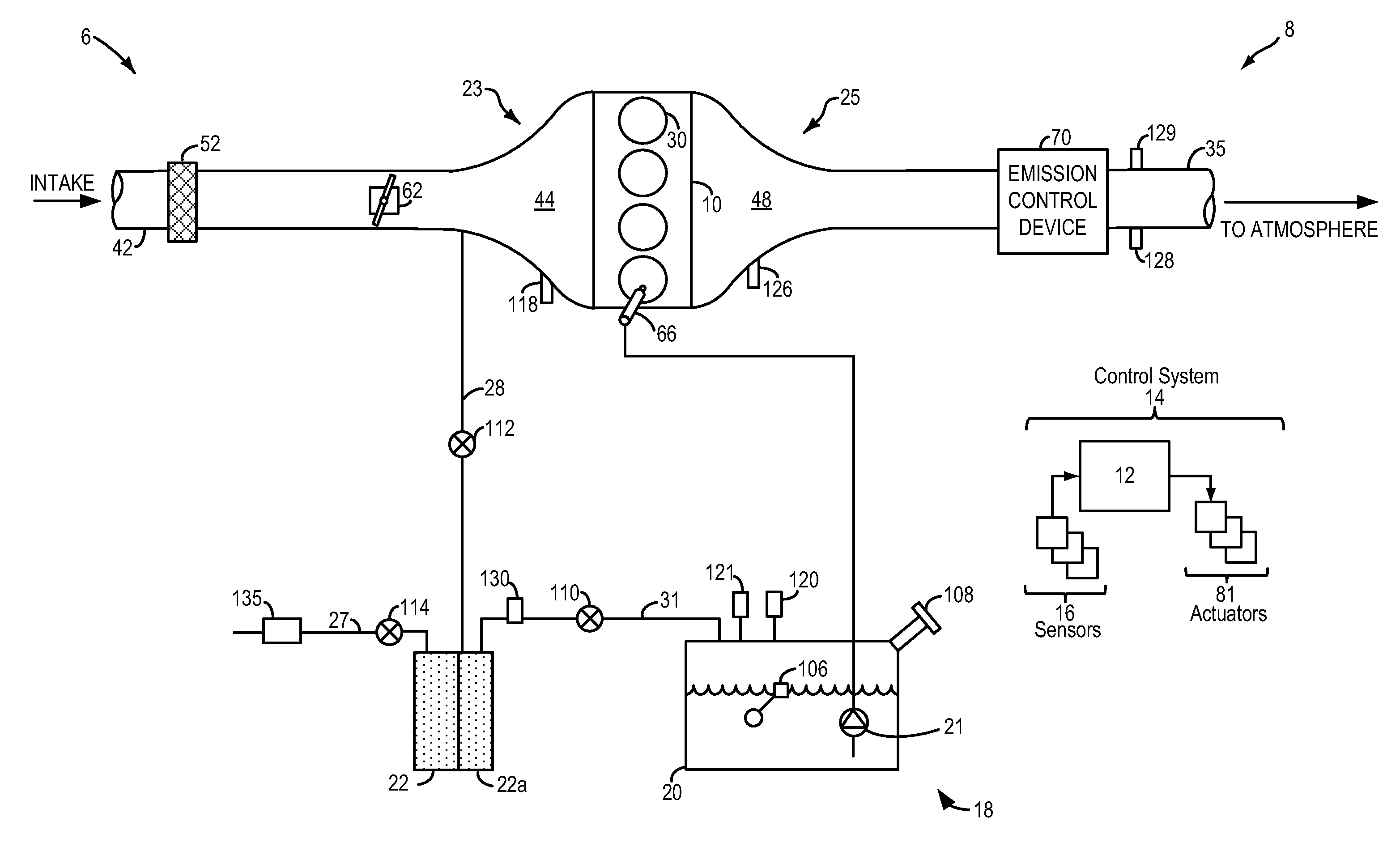

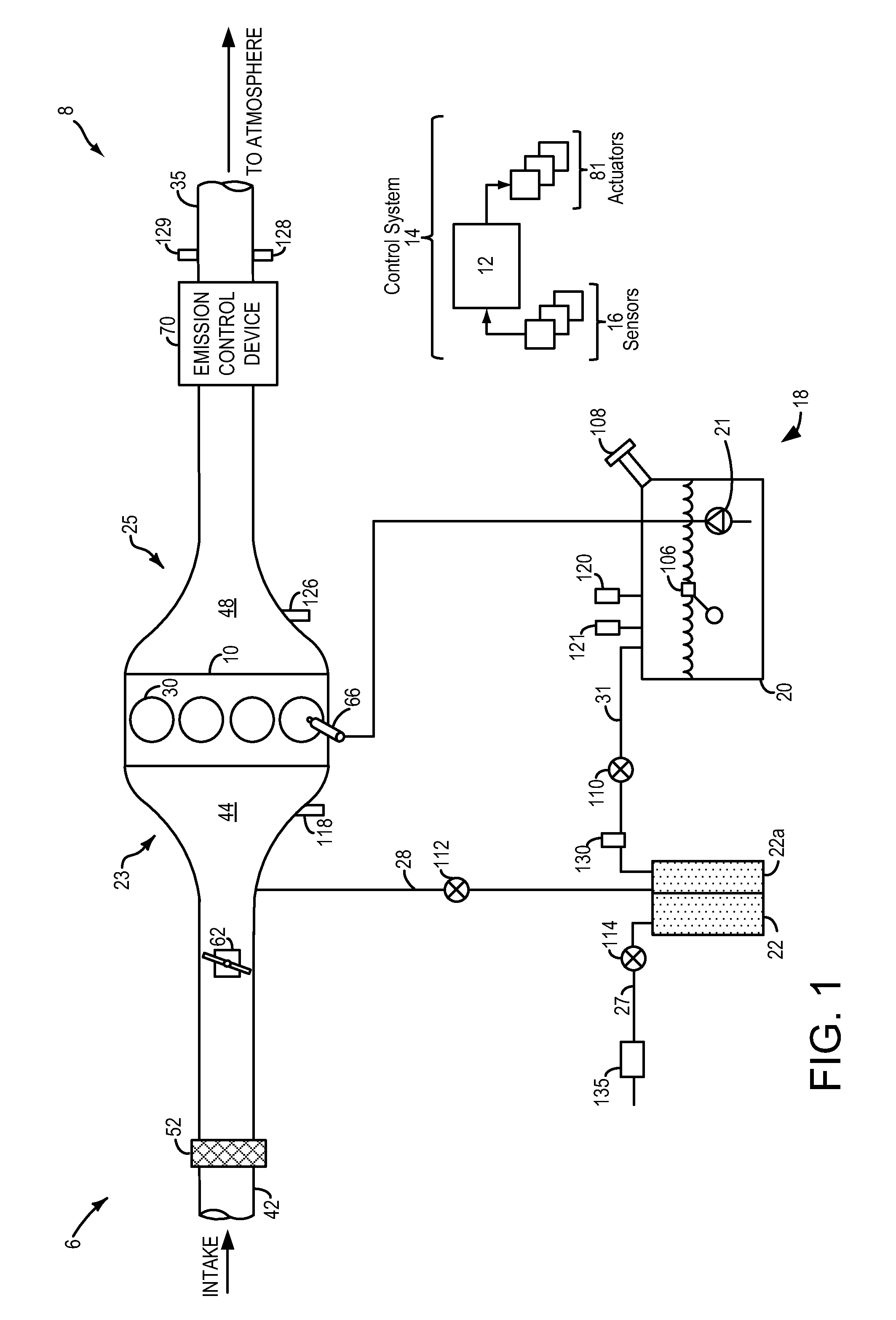

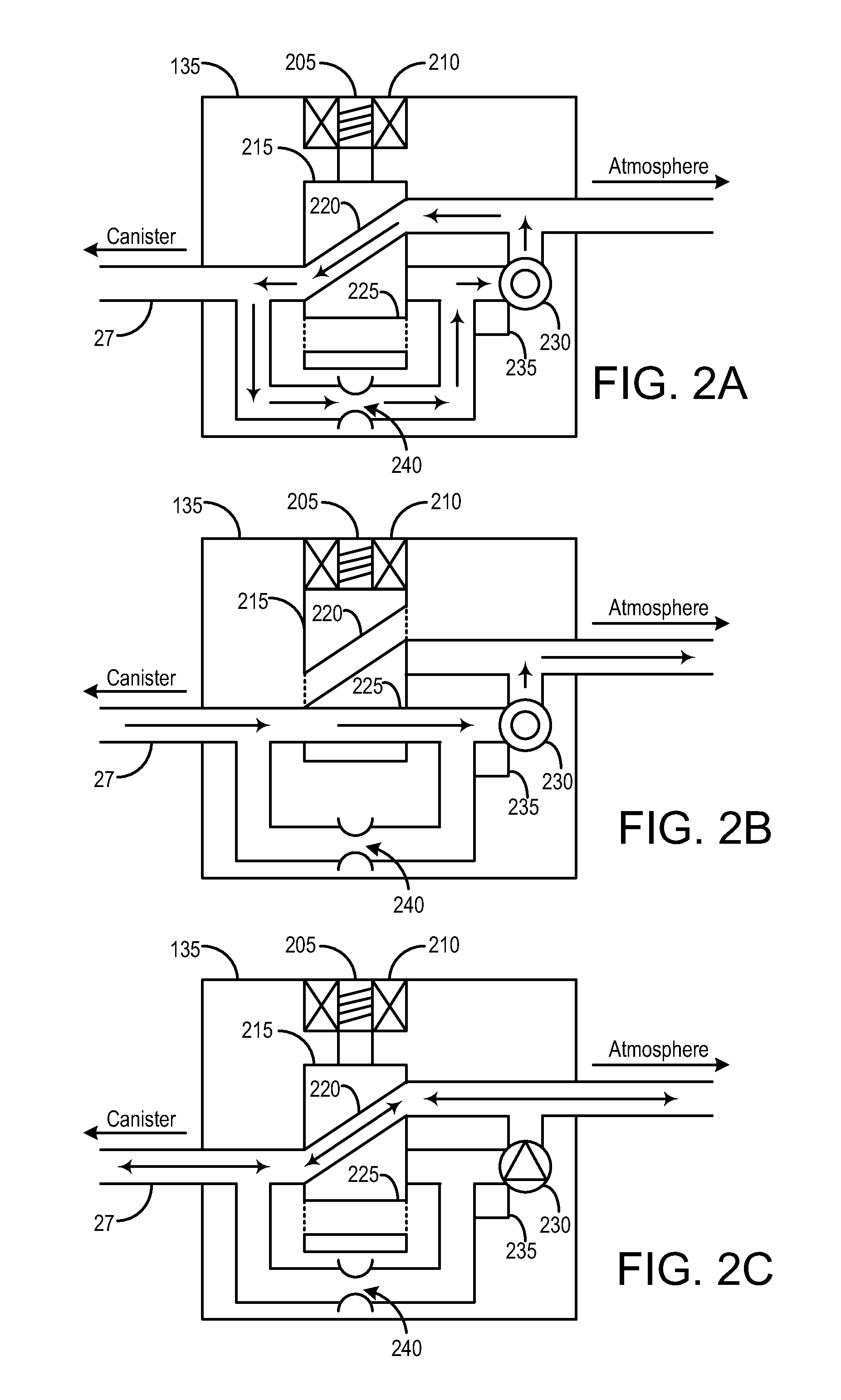

Systems and methods for determining the integrity of a vehicle fuel system

ActiveUS20150198103A1Low costMaintaining and improving vehicle fuel economy benefitAnalogue computers for vehiclesElectrical controlProduction modelIsolation valve

A method, comprising: indicating a leak of a first diameter on a canister side of a fuel system following applying a vacuum to the fuel system with a fuel tank isolation valve closed; and indicating a leak of a second diameter on a fuel tank side of the fuel system, based on a vacuum decay in an isolated fuel tank following applying a vacuum to the fuel system with the fuel tank isolation valve open. In this way, an evaporative leak check module with a single reference orifice may be used to determine leaks of multiple sizes in multiple sectors of a fuel system. This may allow current production models to meet more stringent emissions regulations in the future.

Owner:FORD GLOBAL TECH LLC

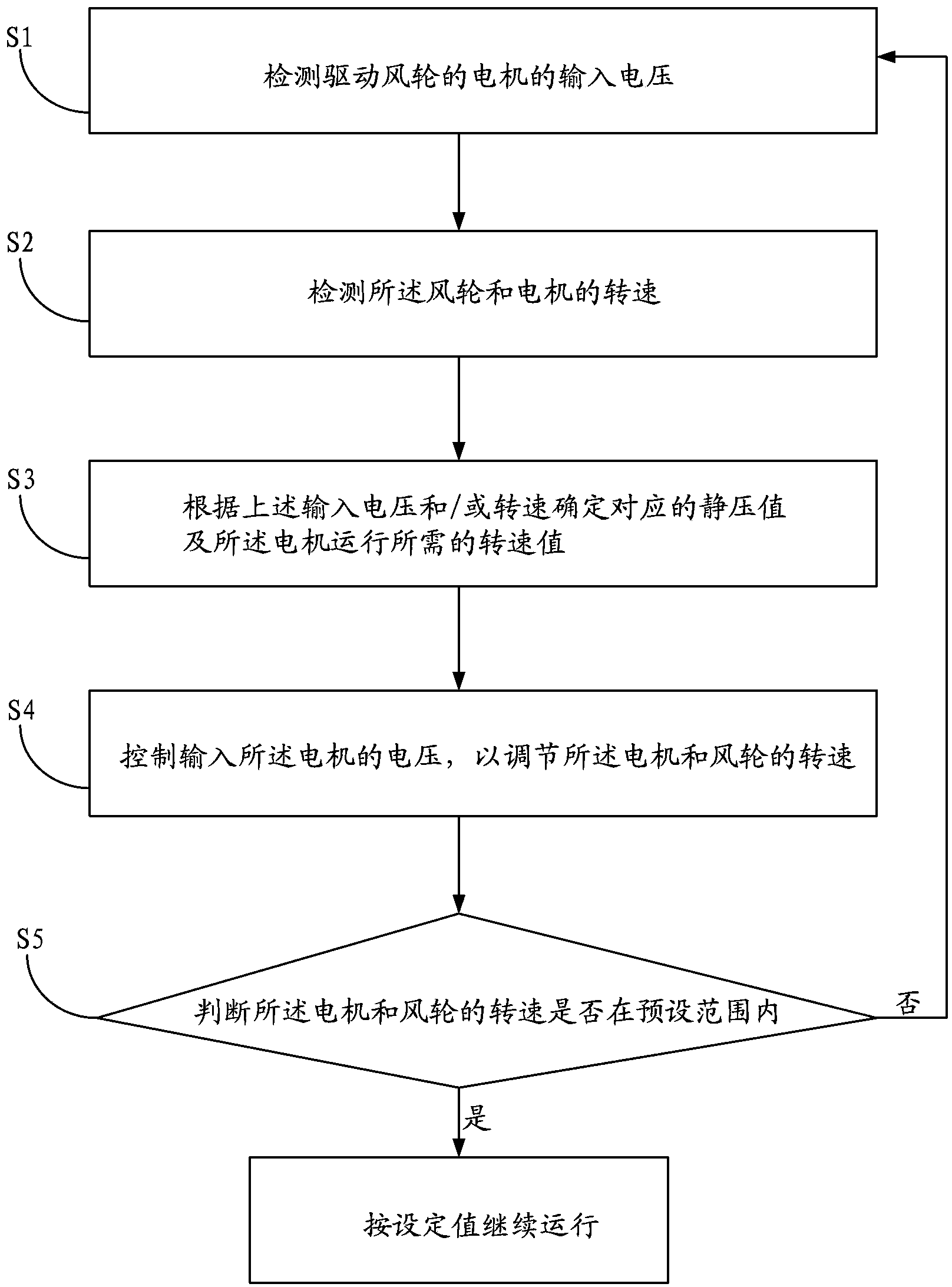

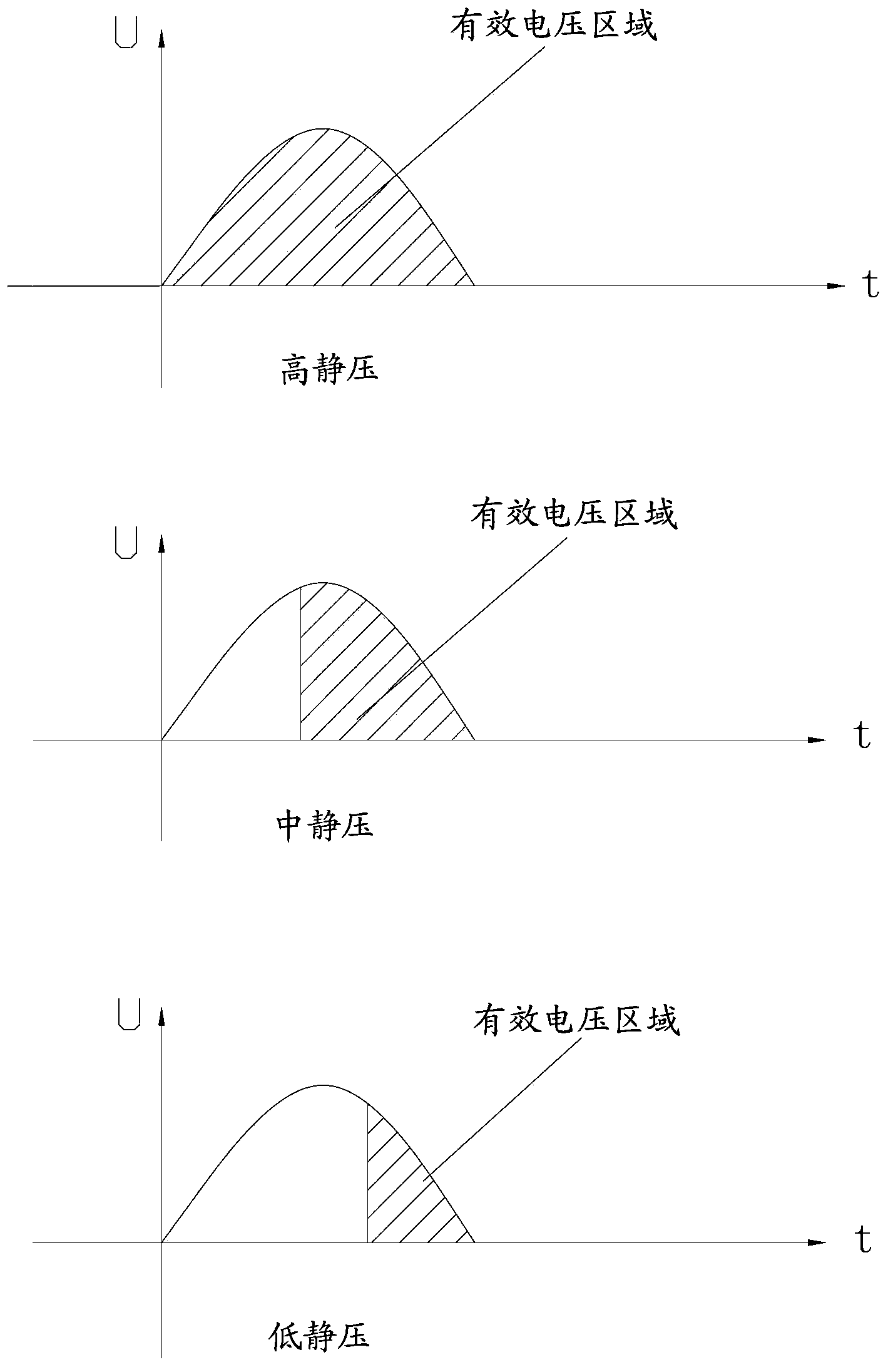

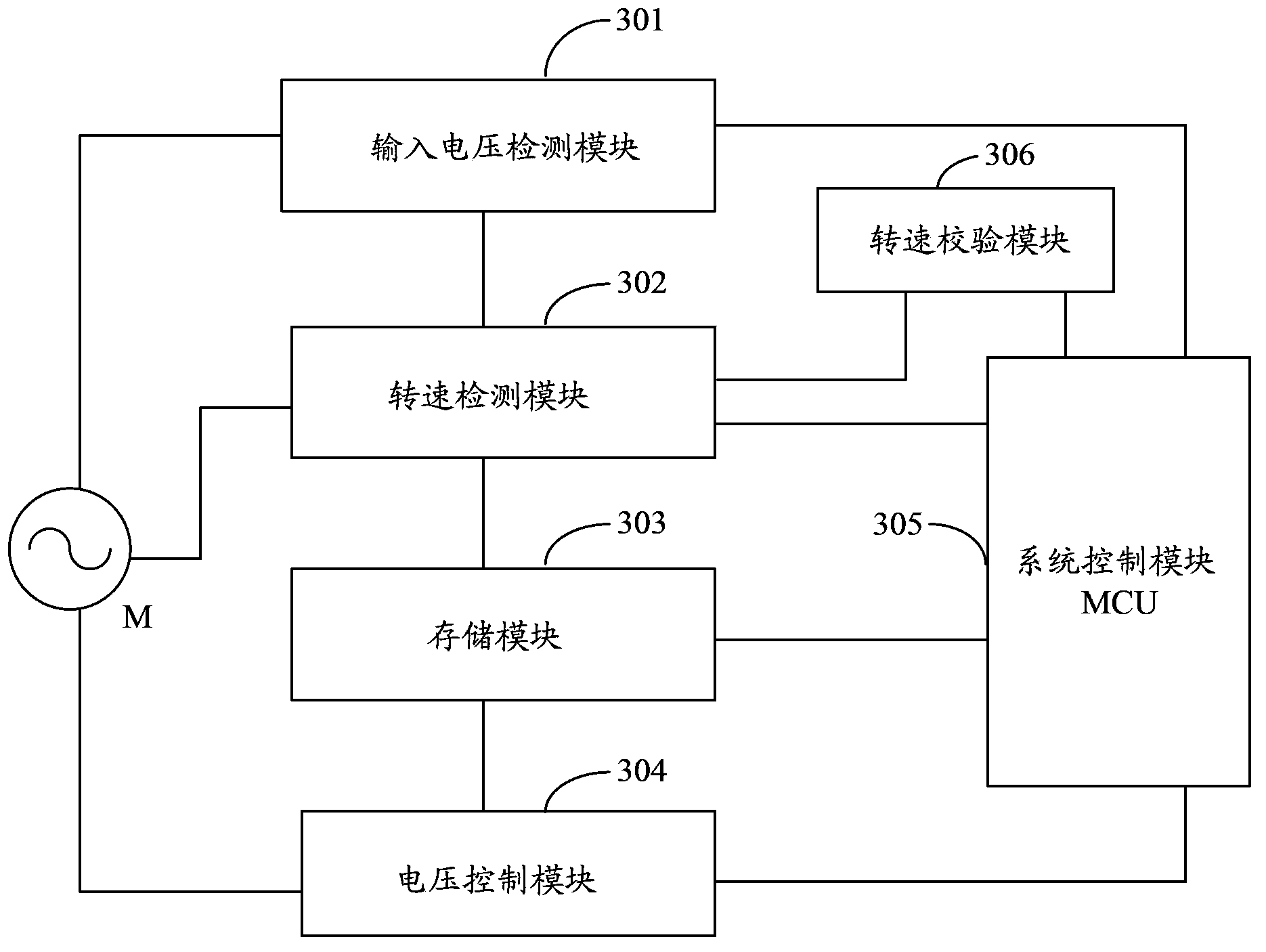

Air conditioner indoor unit and automatic static pressure regulating method and device thereof

InactiveCN103836766ASolve abnormal operation problemsEliminate abnormal operation problemsSpace heating and ventilation safety systemsLighting and heating apparatusProduction modelAir volume

The invention belongs to the field of air conditioners, and particularly relates to an air conditioner indoor unit and an automatic static pressure regulating method and device thereof. According to the air conditioner indoor unit and the automatic static pressure regulating method and device of the air conditioner indoor unit, after the input voltage of a motor driving a wind wheel and the rotation speed of a fan are detected, the corresponding static pressure value and the rotation speed value which is needed by the motor during working are determined according to the input voltage and / or the rotation speed so as to control the input voltage of the alternating-current motor to enable the motor to reach ideal rotation speed; whether the rotation speed is within a set range or not can be further detected, if yes, automatic regulation is completed, and if not, the prior step is returned and reregulation is conducted until the rotation speed meets the requirement so that the rotation speed, the air volume and the like can be controlled to enable the indoor unit to be capable of working under various working conditions including low static pressure, medium static pressure and high static pressure. Through the design, the static pressure adjustable purpose is achieved, therefore, integrated design of the low-static-pressure, medium-static-pressure and high-static-pressure air-duct-type air conditioner indoor unit is realized, the production models of air conditioners are reduced, and the manufacturing cost is lowered.

Owner:MIDEA GRP CO LTD

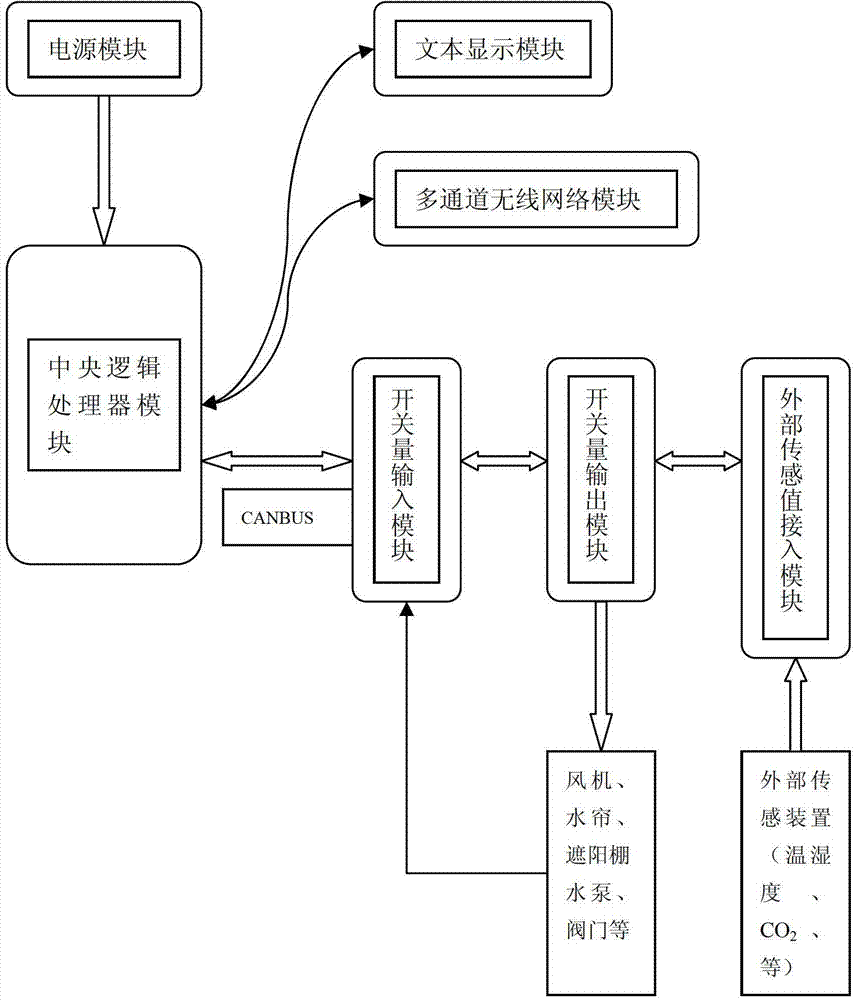

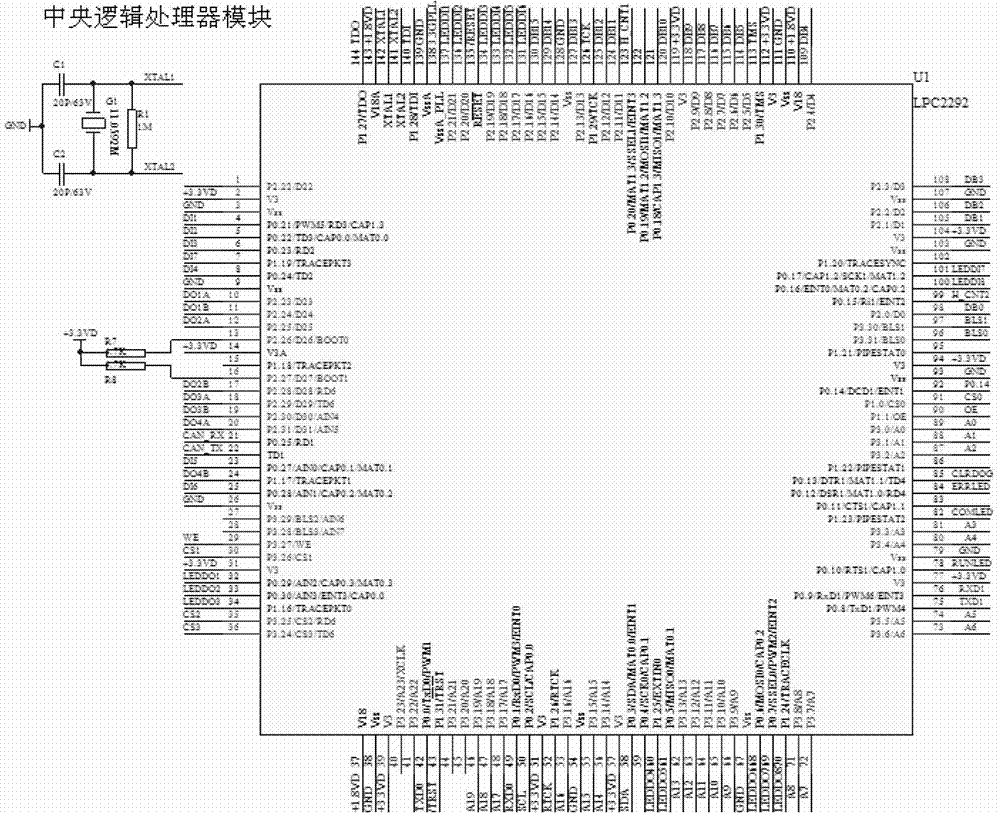

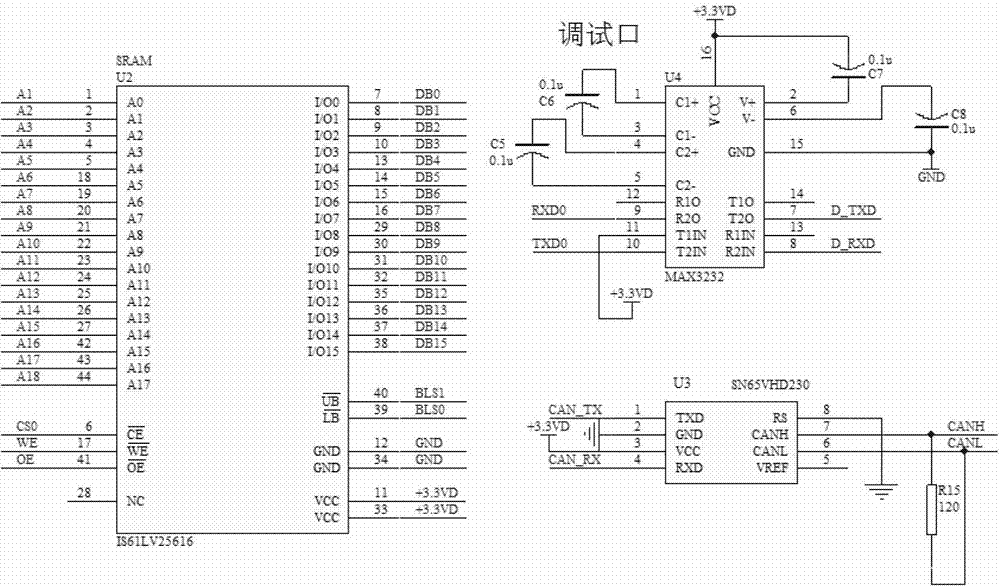

Internet-of-Things-based intelligent production monitoring terminal of agricultural greenhouse

The invention relates to an Internet-of-Things-based intelligent production monitoring terminal of an agricultural greenhouse. The Internet-of-Things-based terminal comprises a central logic processor module, a text display module, a sensing device, a sensing device accessing module, control equipment, a switching value input module, a relay type switching value output module, a multi-channel wireless network interface module and a power supply module. The Internet-of-Things-based intelligent production monitoring terminal disclosed by the invention can carry out online monitoring on environmental factors which influence the production of the agricultural greenhouse, including temperatures, humidity, illumination intensity, CO2 concentration, soil moisture content and the like; environmental factor measured parameters are linked with corresponding movement equipment according to a pre-set production model to intelligent adjust the production process of the agricultural greenhouse; and the intelligent production and the unattended operation of the agricultural greenhouse are realized, and the intelligent production monitoring terminal can be arranged on various wireless network platforms, thus realizing remote data sharing and command remote control.

Owner:江苏宏瑞通信科技股份有限公司

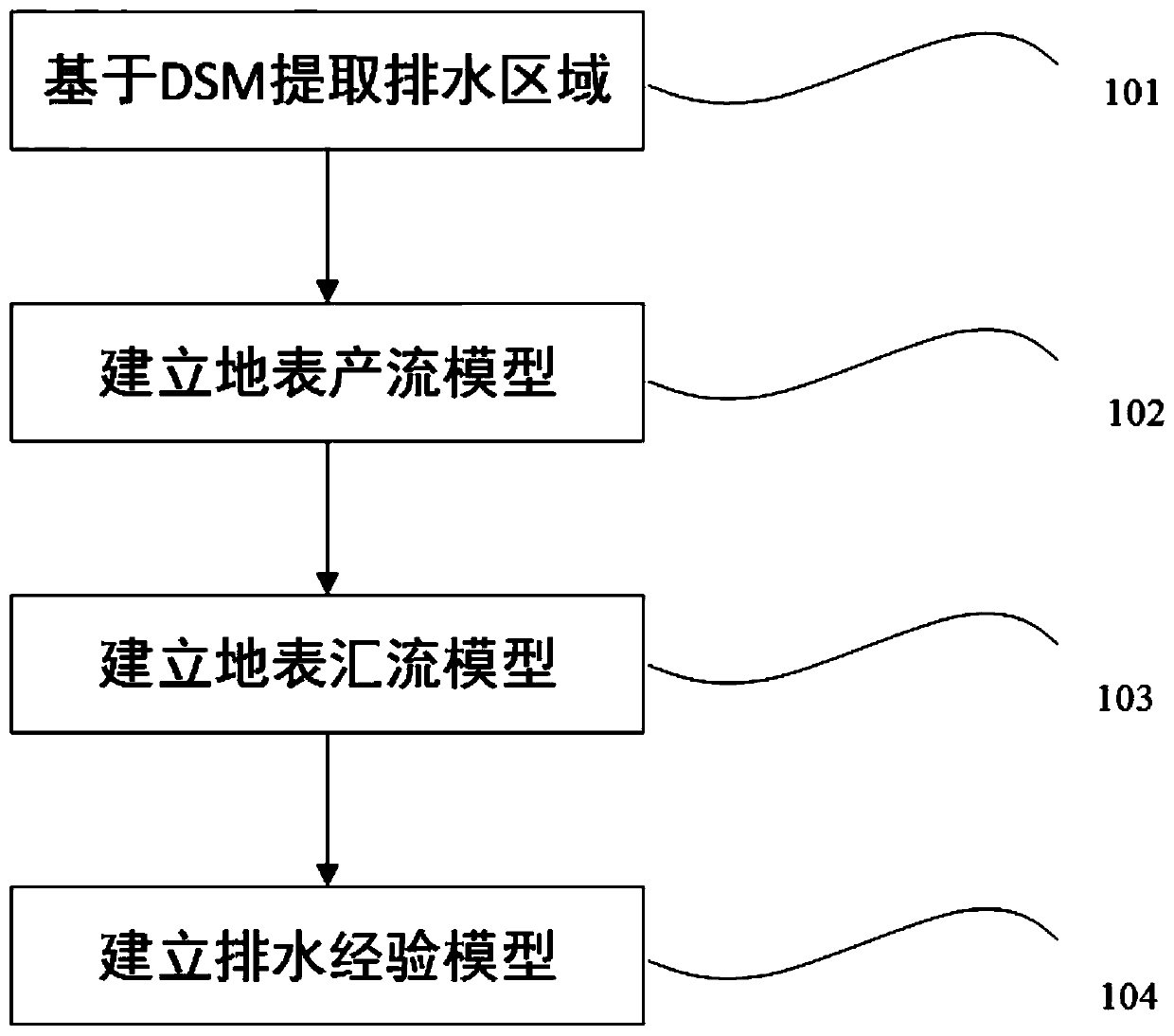

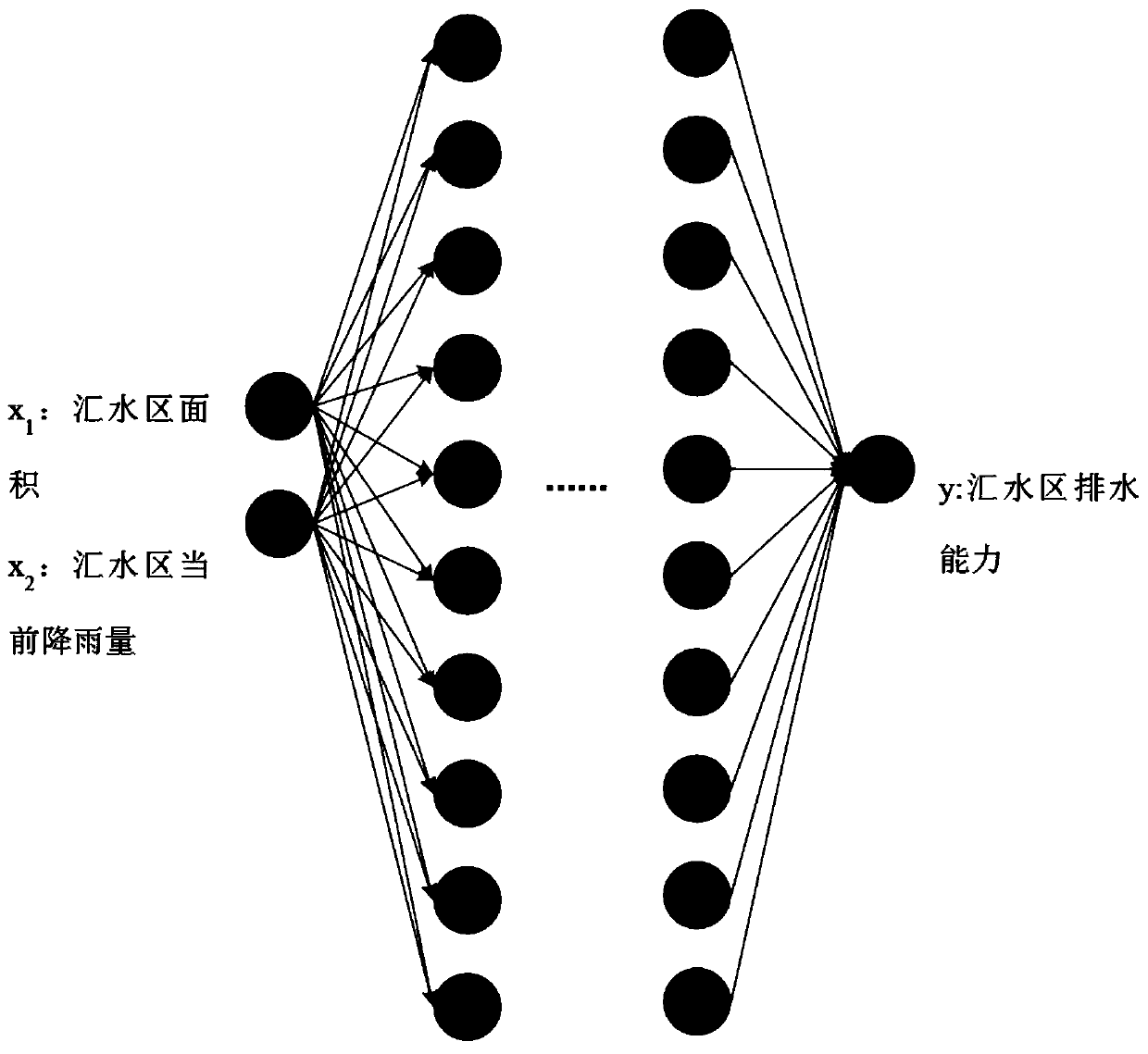

An urban rainstorm water accumulation assessment modeling method based on full space-time

PendingCN109919372AReflect retrofit impactShorten operation timeForecastingNeural learning methodsPondingProduction model

The invention discloses an urban rainstorm water accumulation assessment modeling method based on full space-time, and the method comprises the following steps: 1, obtaining DSM data containing surface information, employing a D8 algorithm to divide a water catchment area, and modifying the boundary of the water catchment area according to the connection and distribution conditions of a real pipenetwork, so as to obtain the divided water catchment area; 2, establishing a surface runoff production model, and calculating runoff production of each catchment area; Step 3, establishing a surface confluence model, and calculating confluence of each catchment area; And step 4, establishing a drainage experience model to carry out drainage calculation, and calculating the drainage capacity of each catchment area through the drainage experience model so as to obtain an urban inland inundation assessment result. The DSM is adopted to divide the urban catchment area, the influence of urban planning and construction on urban topography reconstruction can be well reflected, and the method is more practical; The problem that drainage calculation cannot be carried out due to lack of structural data of a drainage pipeline is solved, and the operation time of the model is remarkably shortened.

Owner:WUHAN UNIV

Process and device for recharging portable electronic devices

InactiveUS20070063683A1Digital data processing detailsMobile unit charging stationsProduction modelElectrical battery

The recharging device for portable electronic devices includes at least one protective case for a portable electronic device in the process of being recharged, at least one electrical power supply for a battery of a portable electronic device in the case, a case management device capable of controlling on the one hand the power supply for the battery of a portable electronic device placed inside a case and, on the other hand, the access to each case. In production models, at least one protective case includes recharge connectors of different shapes that fit the recharge connectors of portable electronic devices. In production models, the management device includes a user interface which includes a user identification device.

Owner:TENSINGTON TECH

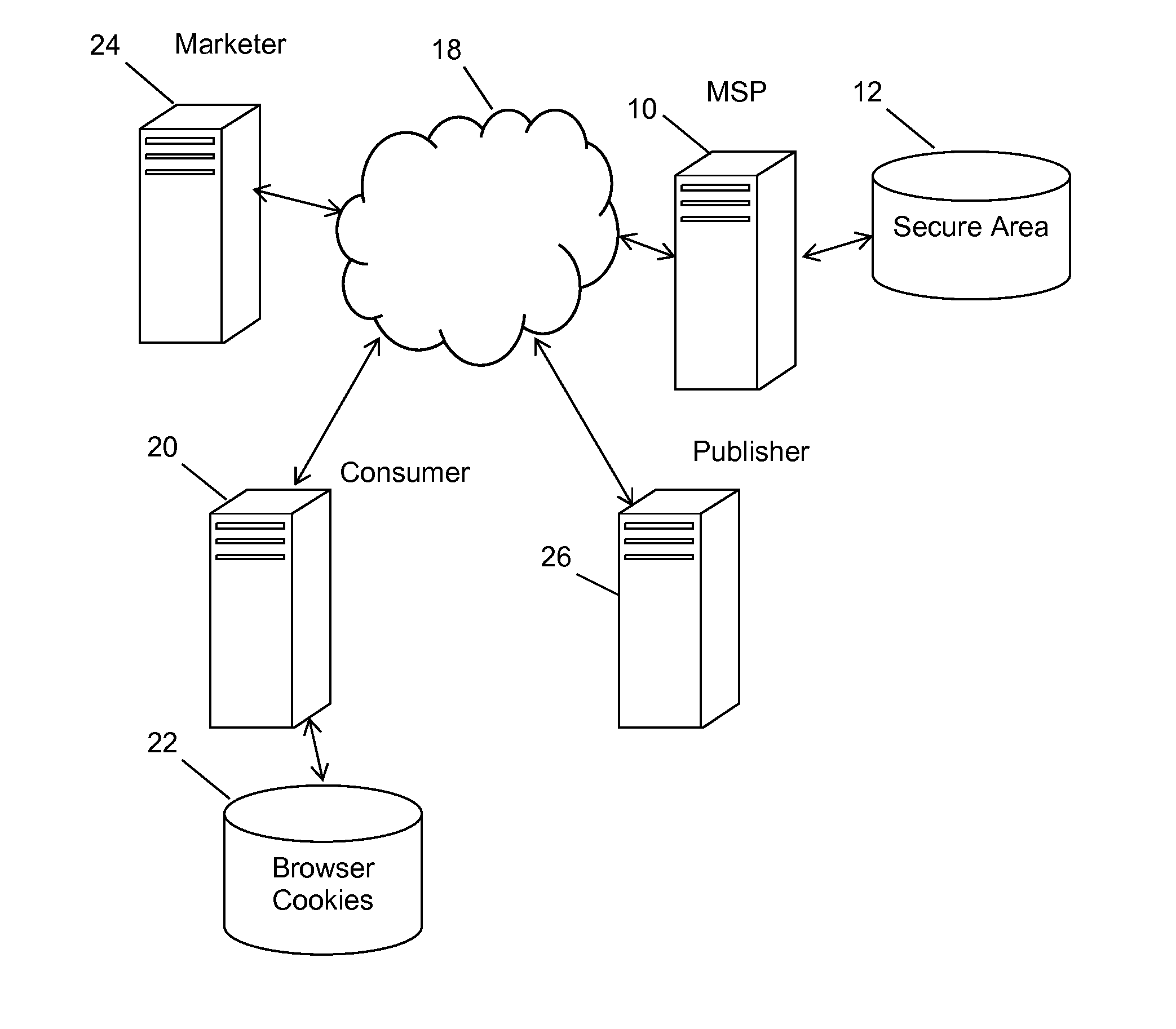

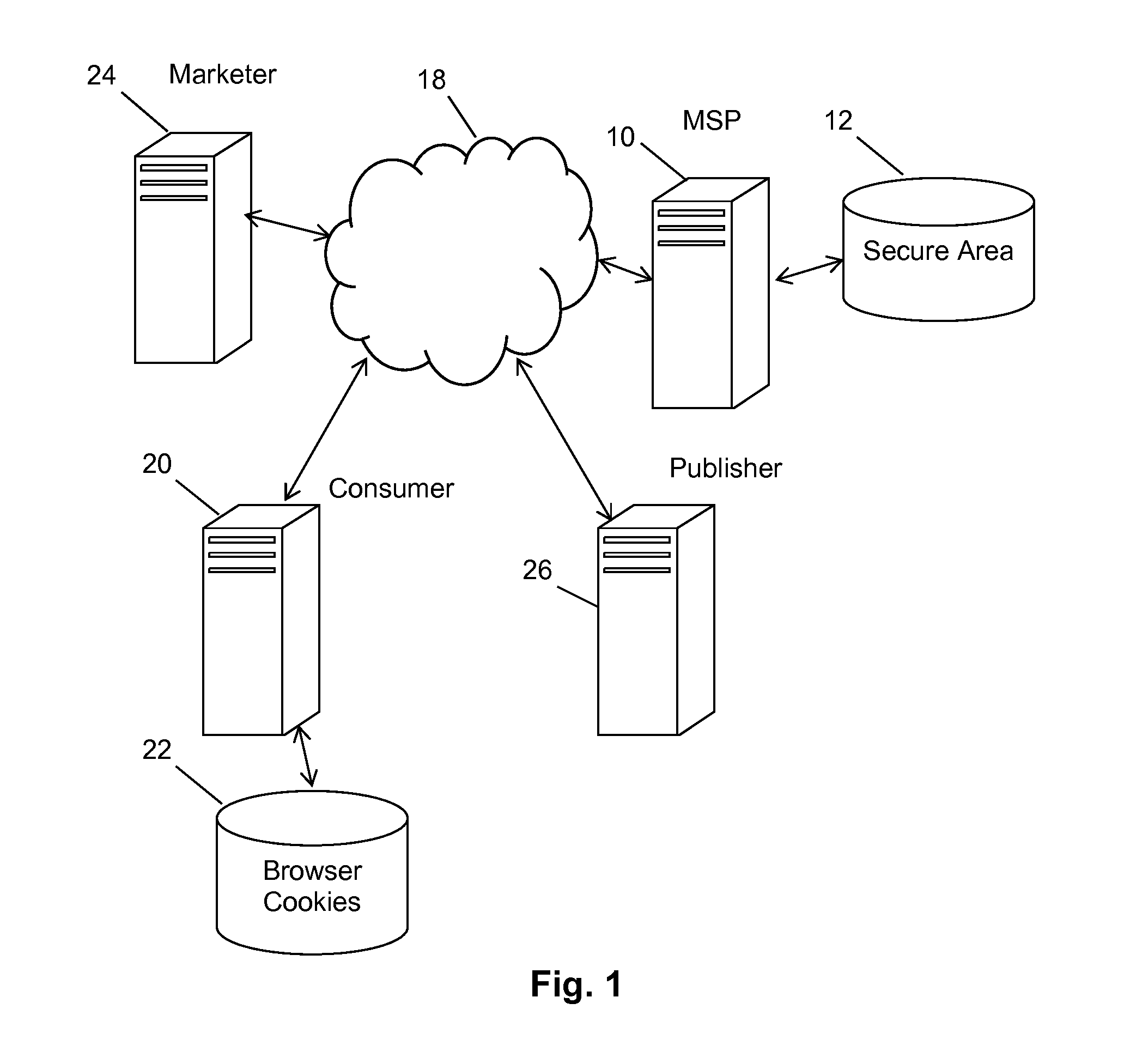

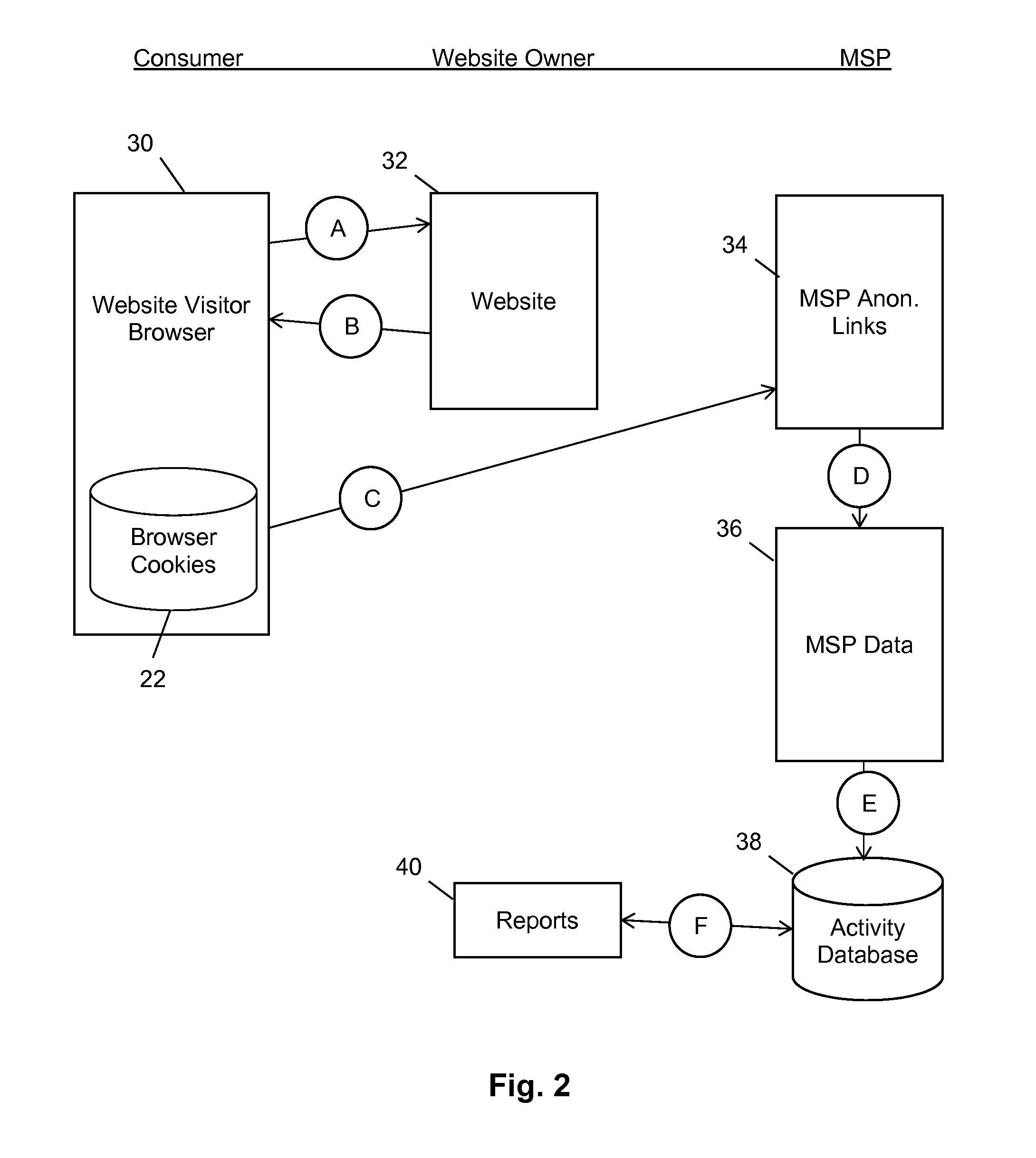

Method for Analyzing Website Visitors Using Anonymized Behavioral Prediction Models

A method for analyzing web visitors using anonymized behavior production models begins with a website visitor accessing a website. The website includes a web beacon, which redirects the website visitor's browser to the server of a marketing services provider (MSP). The MSP server reads a cookie previously set by the MSP that includes an anonymous link. The anonymous link may be used to match data related to the website visitor that is maintained by the MSP, and browsing activity for that visitor is stored in an activity database from which periodic reports may be constructed for the website owner. The anonymous link is not associated with any personally identifiable information (PII), and thus privacy for the visitor is maintained.

Owner:LIVERAMP

Optimized arrangement method of annealing production for bell-type furnace

InactiveCN1422964AReduce labor intensityImprove accuracyHeat treatment process controlBell type furnacesProduction modelTube furnace

There is a cover annealing production and optimized excluding method in a computer. The method belongs to information technology field, refers to the application of genetic arithmetic and computer simulation in mantle quenched production. The character lies in that the method is made up of genetic arithmetic model and computer simulation quenched production model. The simulation model is used in simulating the whole quenche production process, the genetic arithmetic model optimizes the work scheme, the best scheme can be achieved through the interaction of the two models.

Owner:DALIAN UNIV OF TECH +1

Fine tuning color dictionaries

InactiveUS7933053B2Increase weightReduce weightDigitally marking record carriersDigital computer detailsPattern recognitionProduction model

A spot color dictionary is fine tuned or updated. Localized color production models are determined for spot colors of interest to be produced by an associated document processing system or printer. Measurements are made of colors of produced spot colors. Optionally, measurements are made of colors of test patches that are based on perturbations from the colors of the spot colors. In determining a model for the production of a target spot color, measurement data related to colors that are closer in color space to a given target color is given a higher weight than is measurement data related to colors that are further in color space from the target color. Accordingly, the model is localized to the region of color space about the target color and therefore, more accurately predicts a colorant recipe for the target color than would interpolation based on a full gamut, or more general model.

Owner:XEROX CORP

Metal part grafting printing method

ActiveCN108907197ALow cost efficiencyReduce production efficiencyAdditive manufacturing apparatusProduction modelSelective laser melting

The invention discloses a metal part grafting printing method. The method comprises the following steps that CAD software is utilized to plan an area to be machined and an area to be subjected to selective laser melting machining on product production models, after a machining model adopts a traditional method to machine a finished product, a special method is adopted to carry out accurate positioning on the upper surface of the finished product and the area to be subjected to selective laser melting, and then grafting printing forming is carried out. The method belongs to composite manufacturing, the metal part grafting printing method based on the selective laser melting technology can fully play the advantages of 3D printing, the printing cost of a large-scale part including a part of complex structures is greatly reduced while the production efficiency is greatly improved, the cost can be reduced to be 30% or below of the original printing cost to the maximum, and the efficiency can be improved by 70% or above to the maximum; and the method is suitable for grafting and printing of any metal powder capable of being printed, so that the application field of metal 3D printing is expanded.

Owner:GUANGDONG INST OF NEW MATERIALS

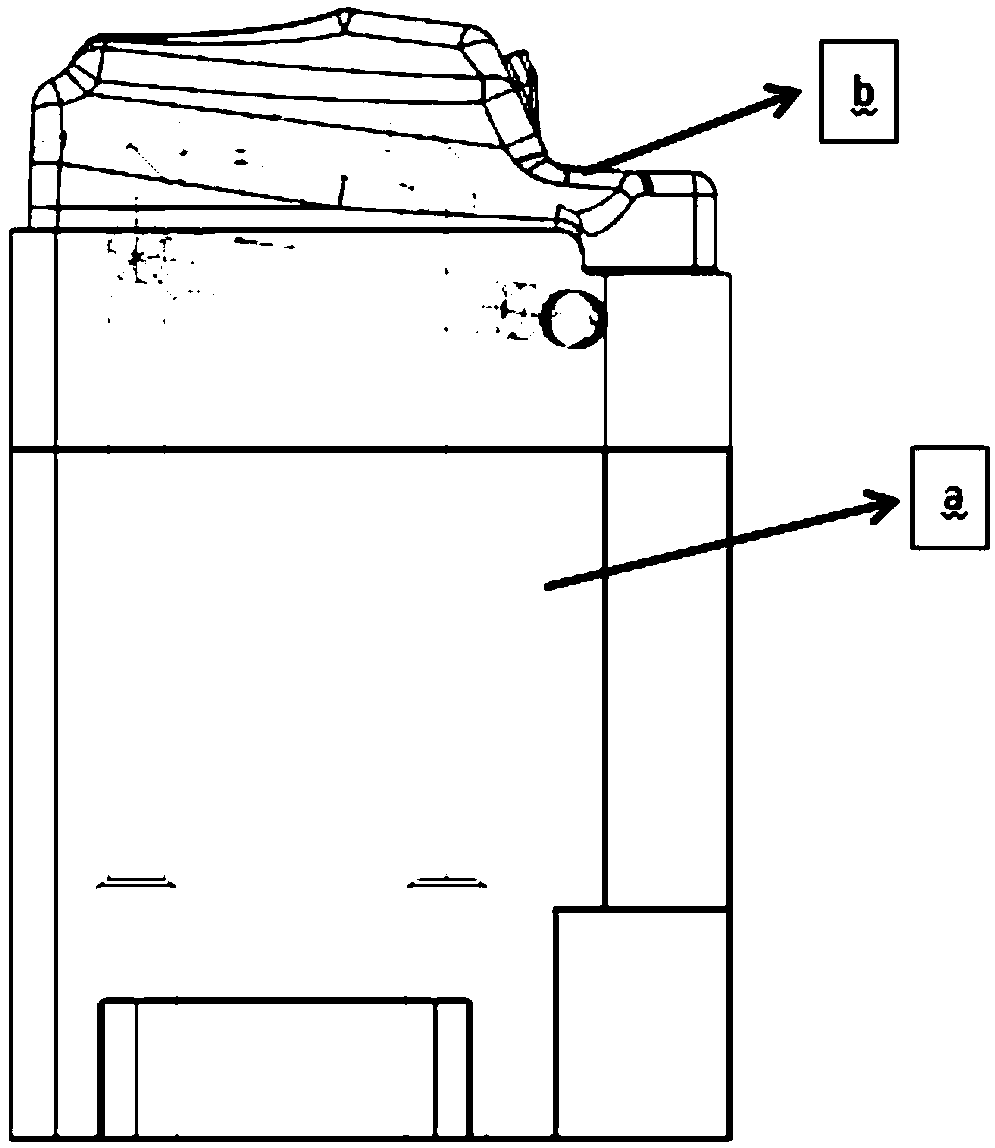

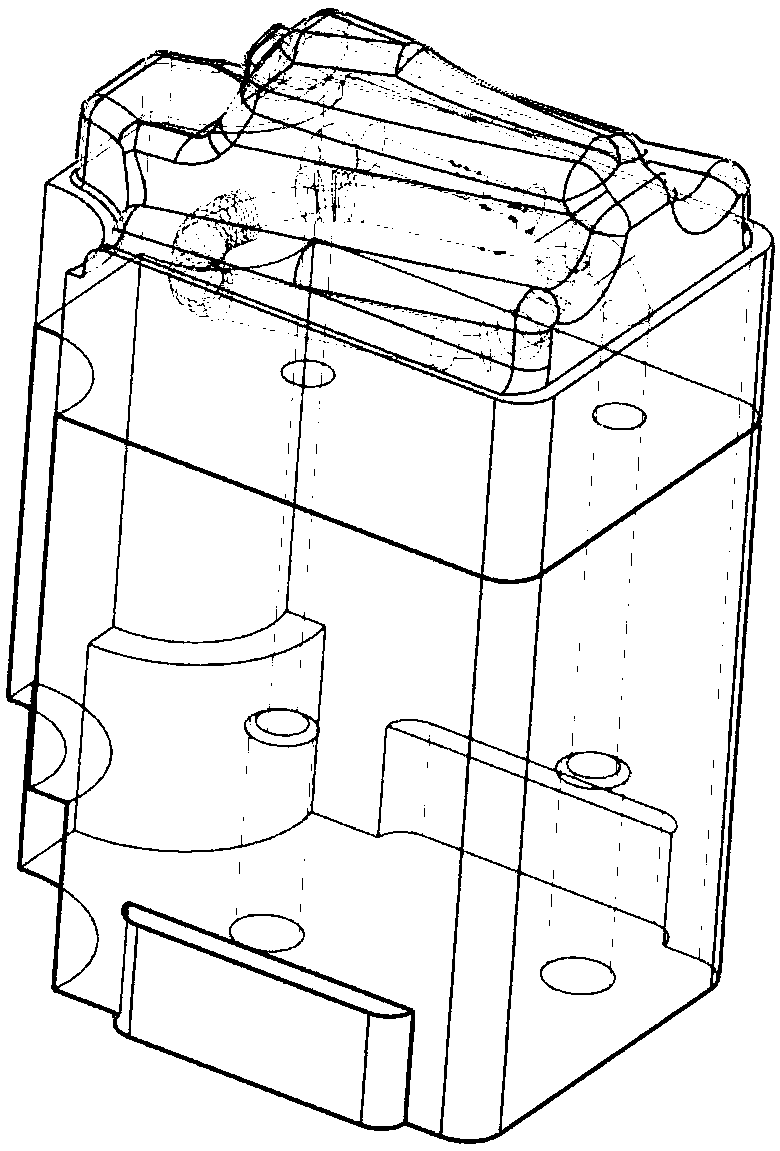

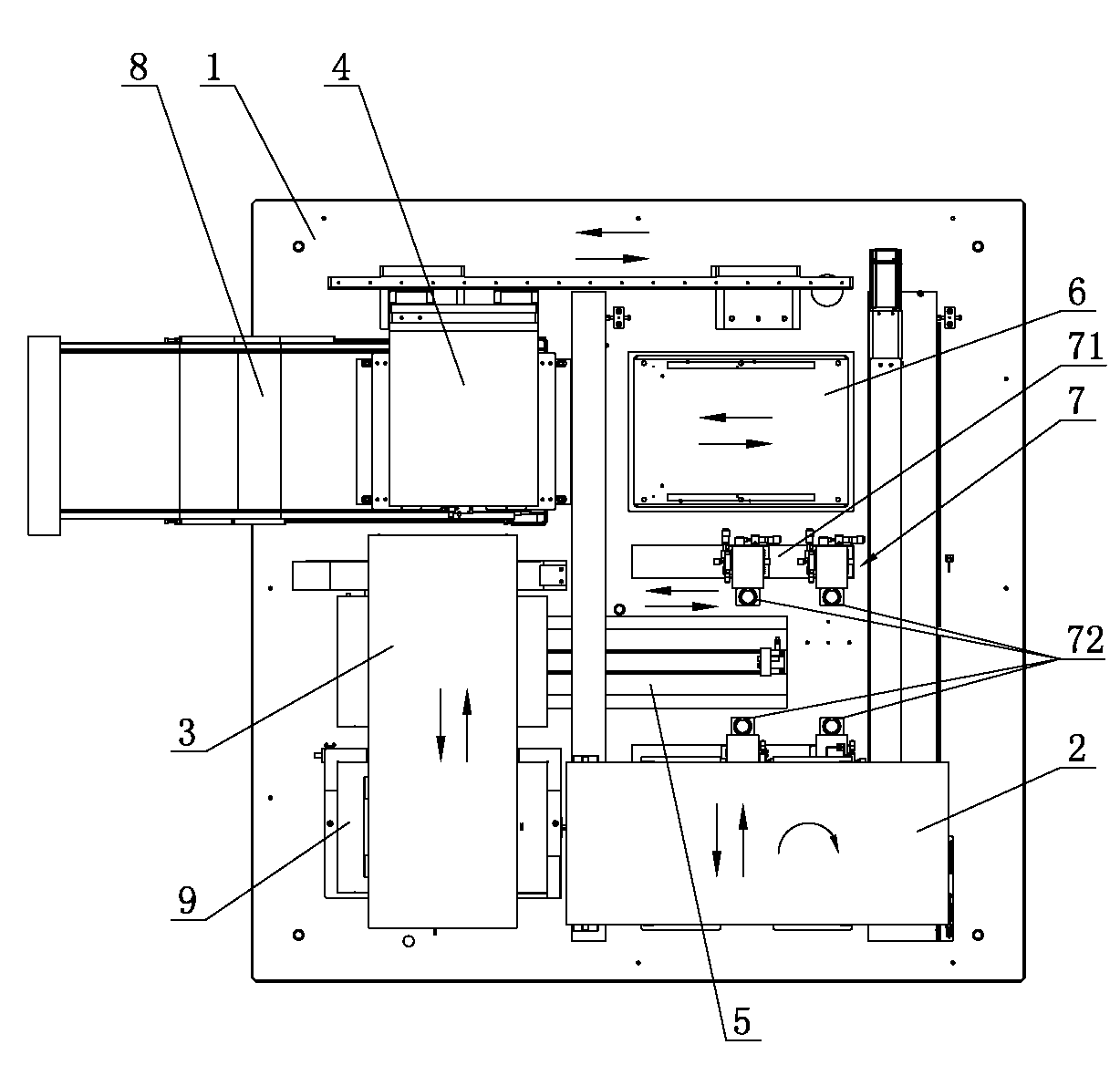

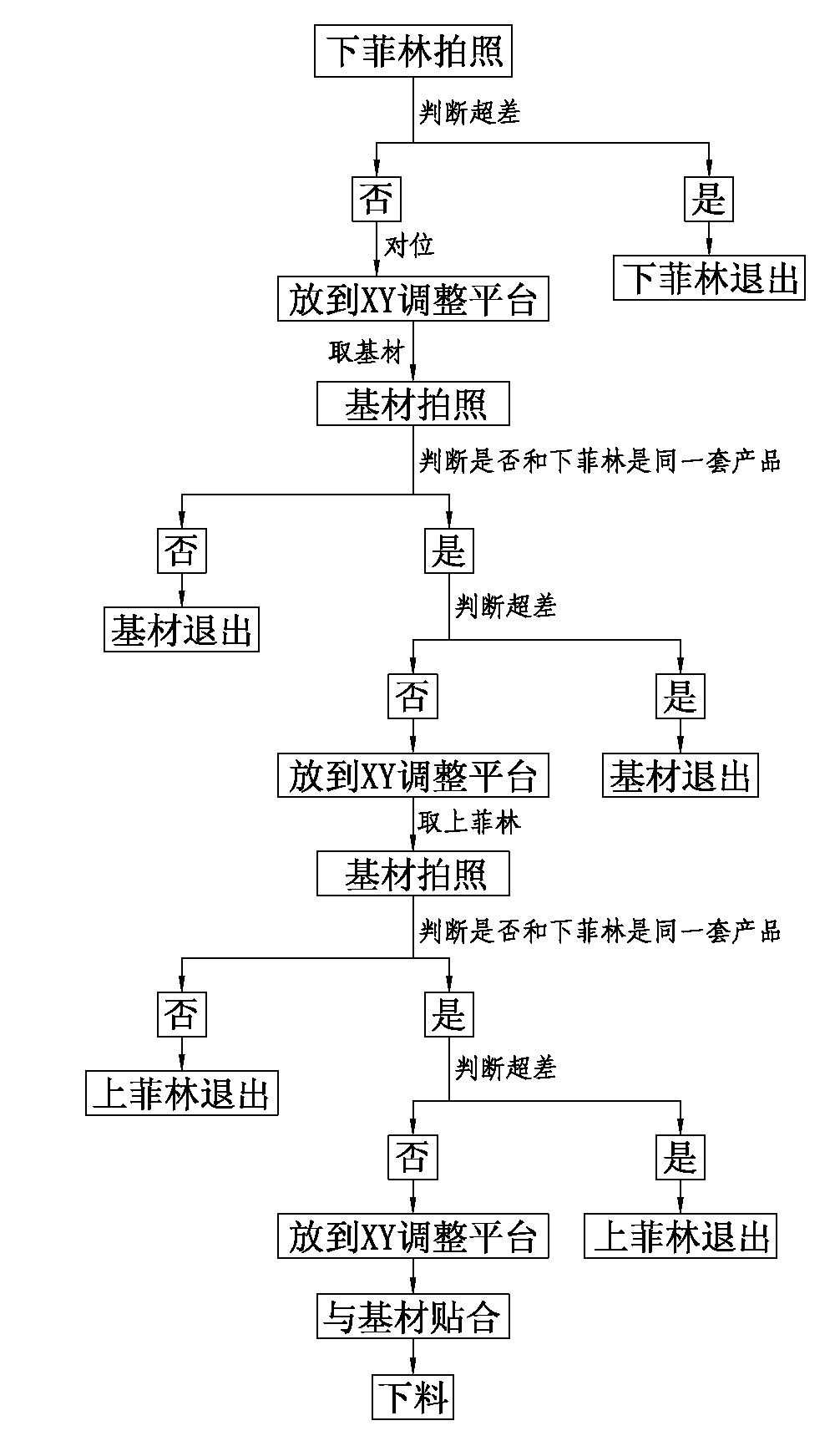

Automatic film alignment machine

ActiveCN103645616AGuaranteed accuracyEasy to trainPhotomechanical treatmentProduction modelManipulator

The invention relates to the field of production processes of flexible printed circuit (FPC) boards, and in particular relates to an automatic film alignment machine. The automatic film alignment machine comprises a rack, and a film feeding manipulator, a base material feeding manipulator, a finished product blanking manipulator and a base material conveying unit which are installed on the rack, wherein an XY adjusting platform and an alignment device are also installed on the rack, the film feeding manipulator longitudinally moves back and forth between the right upper part of the XY adjusting platform and the right upper part of the alignment device, the finished product blanking manipulator is transversely and movably installed on the rack, and when the finished product blanking manipulator transversely moves to the right end, the finished product blanking manipulator is positioned right above the XY adjusting platform. The automatic film alignment machine provided by the invention can produce various materials simultaneously, and automatically identify good products, operators can be trained easily to mount guard, the production efficiency is high, the conversion of production models and material number is fast, the equipment is compact in structure and small in occupied space, the efficient high-quality production of the FPC boards is realized, and the production cost of the exquisite mechanism is reduced.

Owner:GUANGDONG HUAHENG INTELLIGENT TECH CO LTD

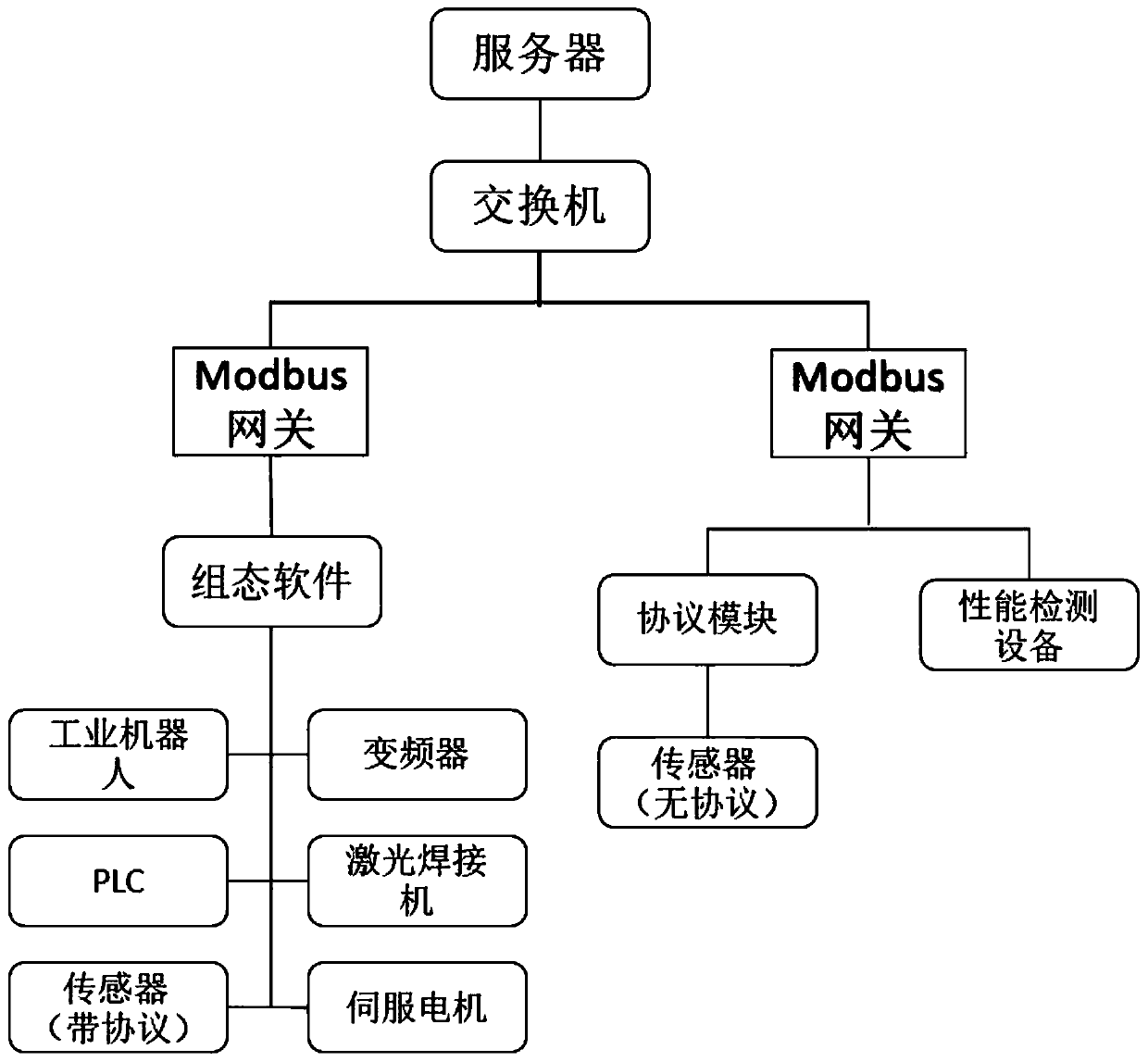

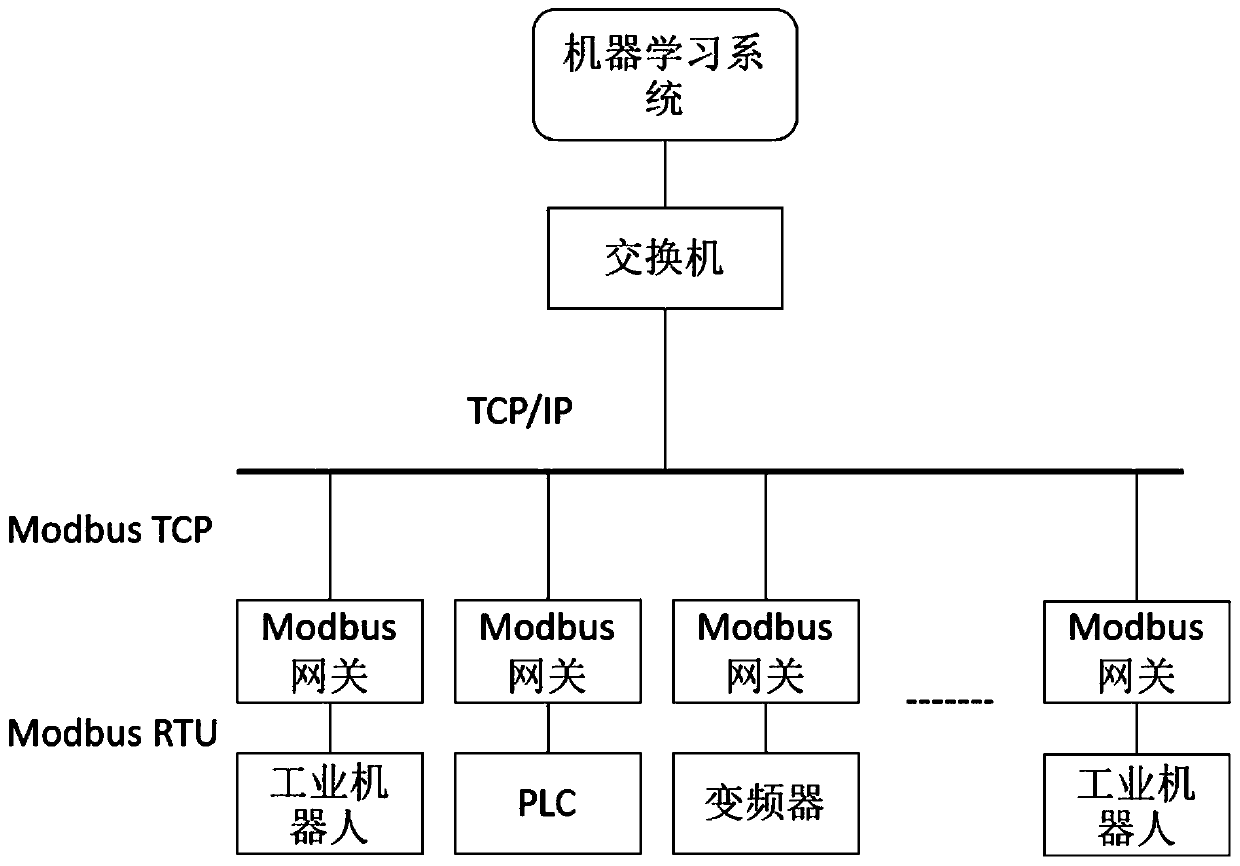

Intelligent manufacturing industry parameter optimization method based on machine learning and industrial Internet of Things

PendingCN111580479AImprove performanceImprove flexibilityProgramme total factory controlAnalytic modelProduction model

The invention discloses an intelligent manufacturing industry parameter optimization method based on machine learning and industrial Internet of Things, and the method comprises the following steps: S1, building an industrial Internet of Things system, bottom-layer equipment being connected into the industrial Internet of Things system, and extracting the operation data of the bottom-layer equipment; S2, analyzing process steps of the intelligent production line, building a digital production model of the intelligent production line, and the collected data corresponding to variables in the model and storing at different positions in a database; S3, building an association analysis model; S4, building a sequence model, and quantifying relevance rules; and S5, obtaining the relationship between different sections of the production line, and then building a gray model to calculate the change trend of the data between different sections. By importing the industrial Internet of Things system, centralized collection, centralized cleaning and centralized processing of production data are achieved, data support is provided for subsequent work, the optimal value of each part is calculated through a machine learning model, an engineer adjusts with the optimal value as the reference value, and a large amount of debugging workloads are reduced.

Owner:刘金涛

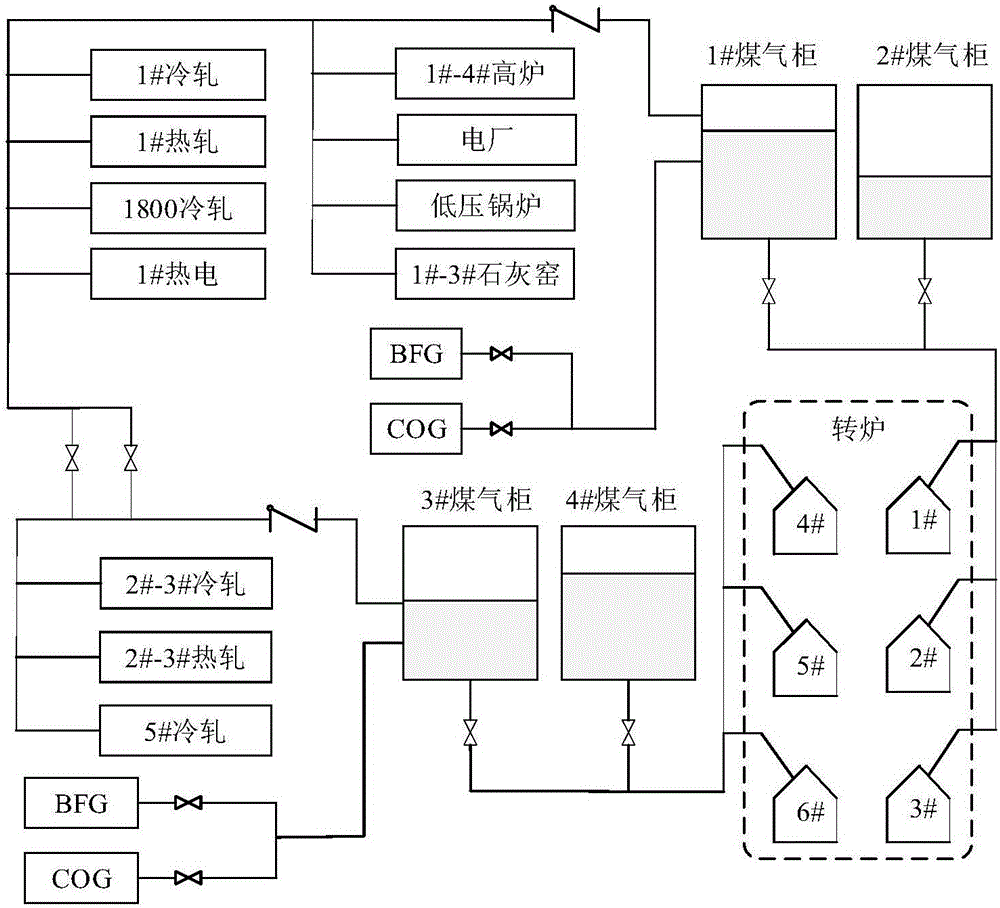

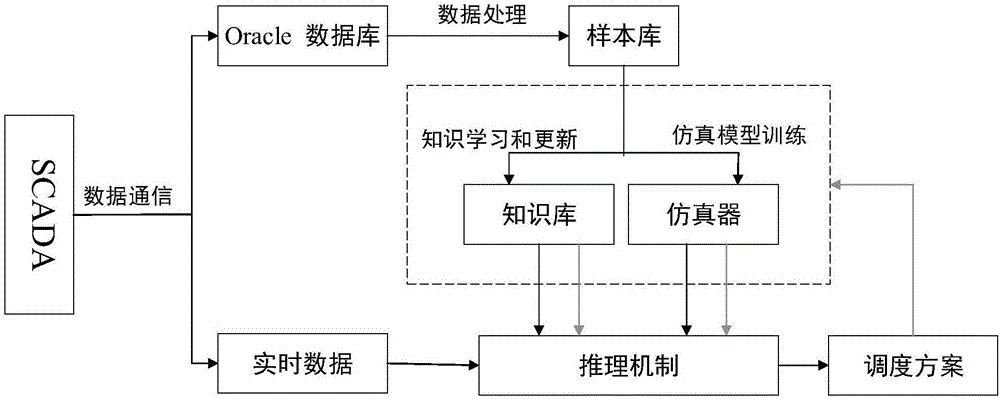

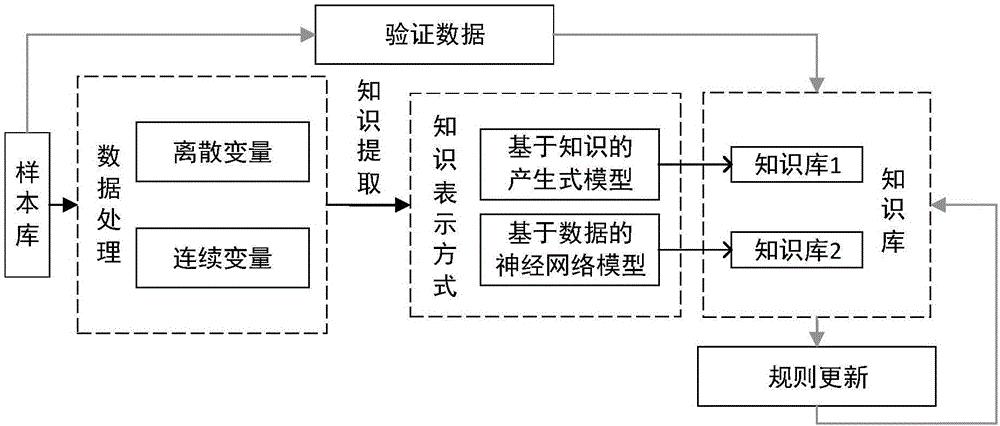

Metallurgical enterprise converter gas scheduling method based on knowledge

ActiveCN106650944AReduce the influence of high noiseDesign optimisation/simulationInference methodsProduction modelNetwork model

The invention provides a metallurgical enterprise converter gas scheduling method based on knowledge. The method comprises steps: firstly, as for a procedure variable which is needed in a scheduling decision process but can not be acquired directly, a neural network model is adopted for modeling analysis, and a neural network model based on data is formed; secondly, a production rule model based on fuzzy clustering is designed, through carrying out clustering analysis and association rule mining on historical data, knowledge information contained in the data is mined, fusion with expert prior knowledge is further carried out, and a production model based on knowledge is built; and finally, an online updating strategy for the production rule model is designed, if large deviation exists between a reasoning result and a practical solution, the output parameters of the production rule are updated. By using the method of the invention, the balance state of a converter gas system can be dynamically analyzed, a corresponding scheduling scheme can be obtained, and decision by the scheduling person can be reasonably guided.

Owner:DALIAN UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com