Patents

Literature

69 results about "Stock control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stock control is defined as "the activity of checking a shop’s stock". Many shops now use stock control systems. The term "stock control system" can be used to include various aspects of controlling the amount of stock on the shelves and in the stockroom and how reordering happens. Typical features of stock control software include: Ensuring that the products are on the shelf in shops in just the right quantity. Recognizing when a customer has bought a product. Automatically signaling when more products need to be put on the shelf from the stockroom. Automatically reordering stock at the appropriate time from the main warehouse. Automatically producing management information reports that could be used both by local managers and at head office. These might detail what has sold, how quickly and at what price, for example. Reports could be used to predict when to stock up on extra products, for example, at Christmas or to make decisions about special offers, discontinuing products and so on. Sending reordering information not only to the warehouse but also directly to the factory producing the products to enable them to optimize production.

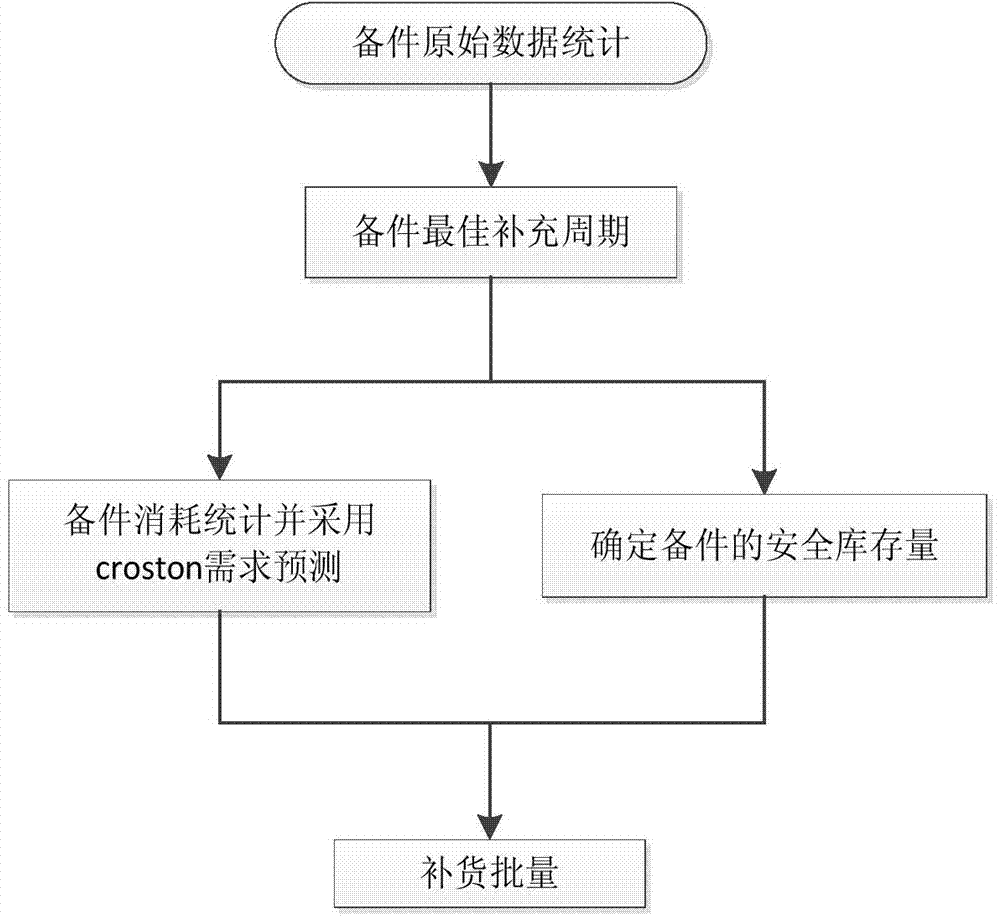

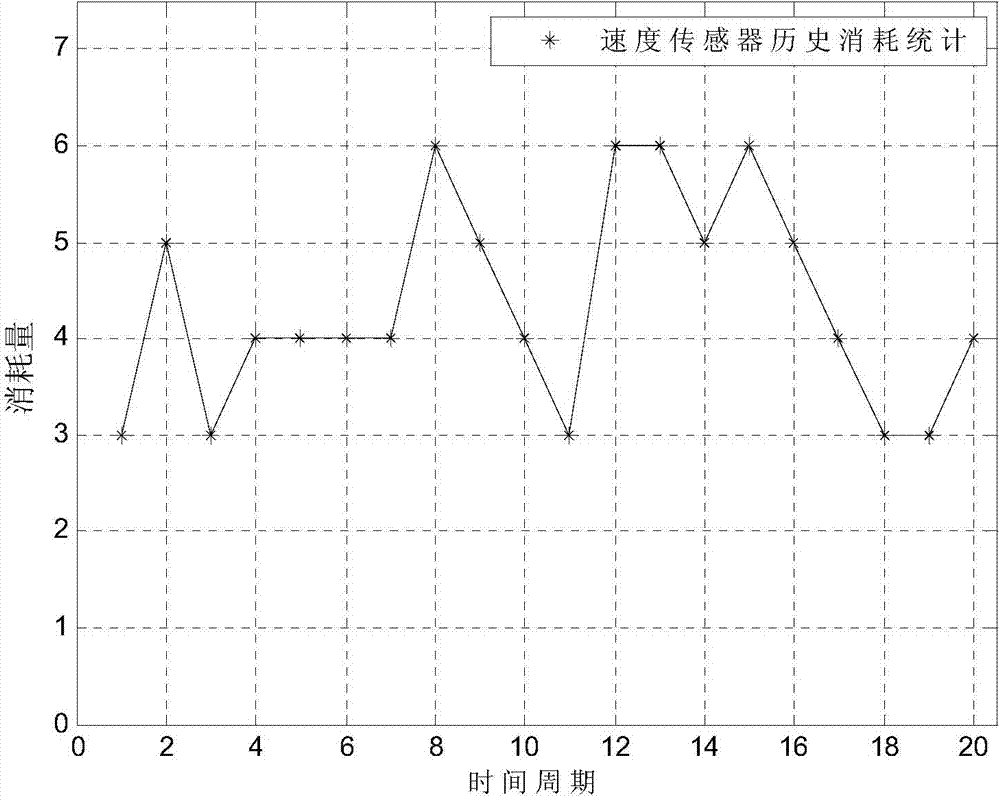

Stock control method based on optimum replenishment period of spare part

ActiveCN104732287AControl the average inventoryAchieve reasonable controlForecastingLogisticsStock levelEngineering

The invention provides a stock control method based on an optimum replenishment period of a spare part, and aims at lowering the cost of spare part stock of a company. By means of the influence of a replenishment period of the spare part on the stock level, a complete stock control module based on the optimum replenishment period of the spare part is provided, and the stock of the spare part of the company is optimized. By means of the history requirement characteristic of the spare part and costs such as spare part purchasing and storing, a spare part optimum replenishment time and the safety stock of the spare part storing of the spare part in one replenishment period are judged, and the replenishment sending time and the replenishment batch of the spare part are judged by combining the requirement predicted value of the spare part.

Owner:GUANGZHOU METRO GRP CO LTD

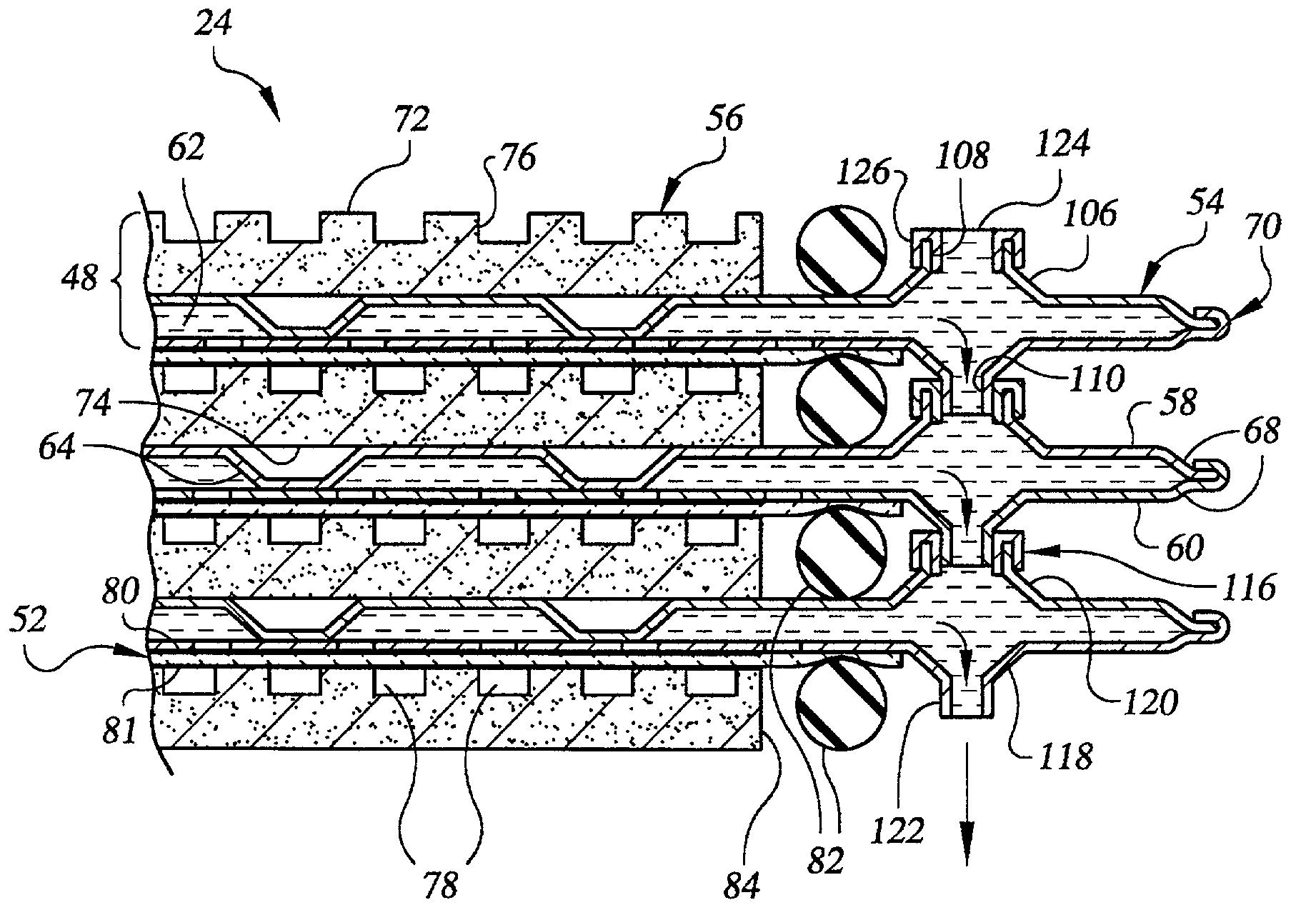

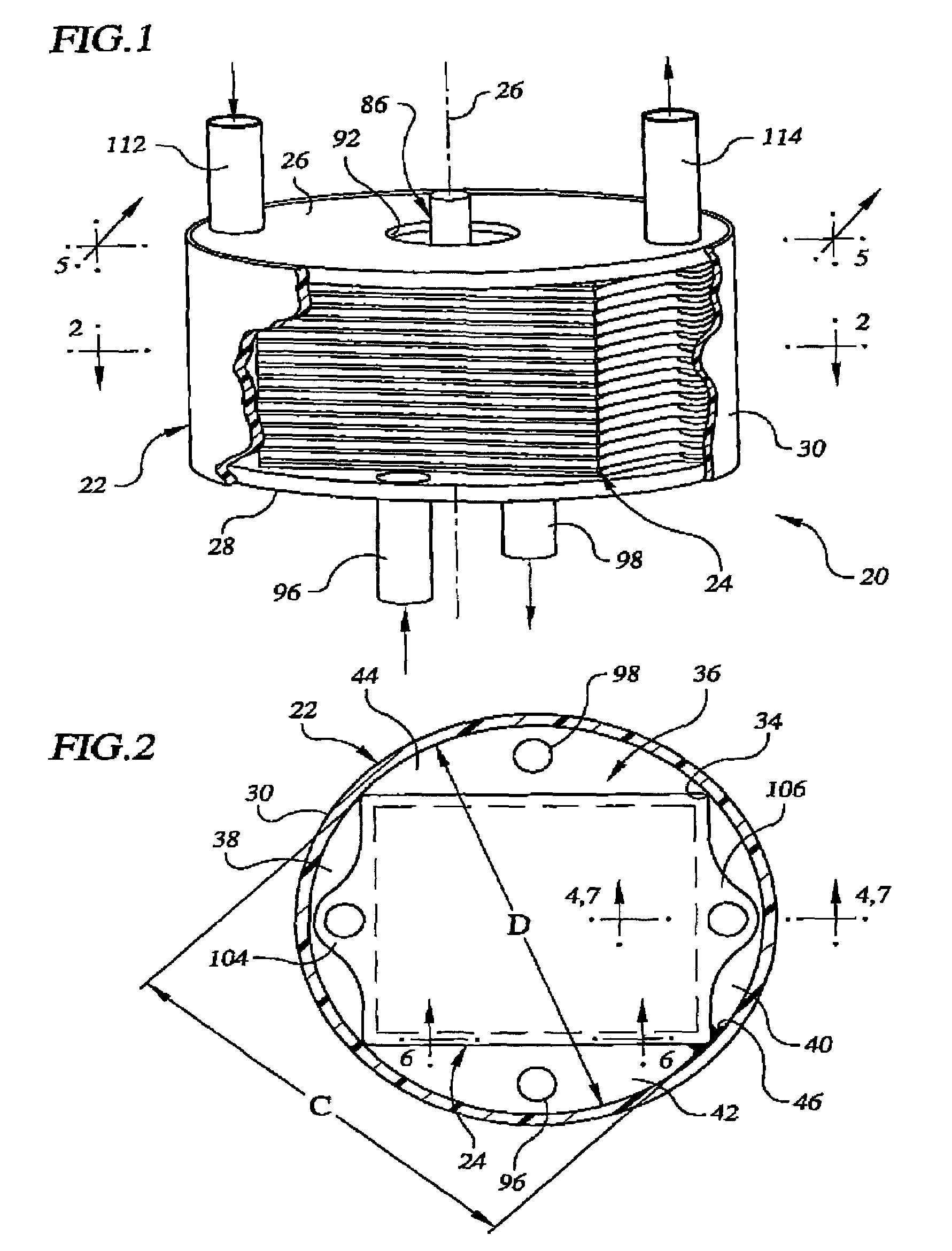

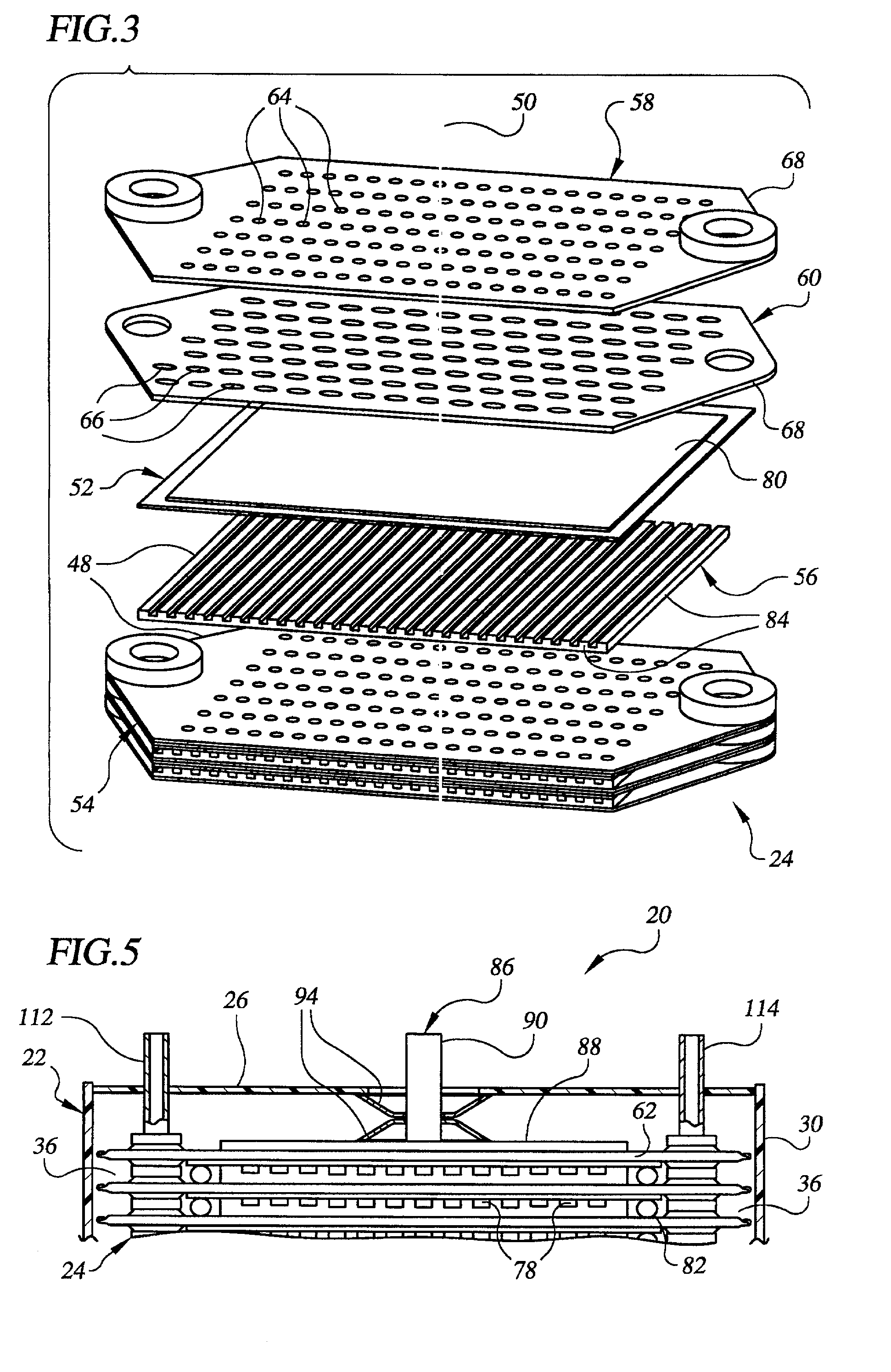

Lightweight direct methanol fuel cell

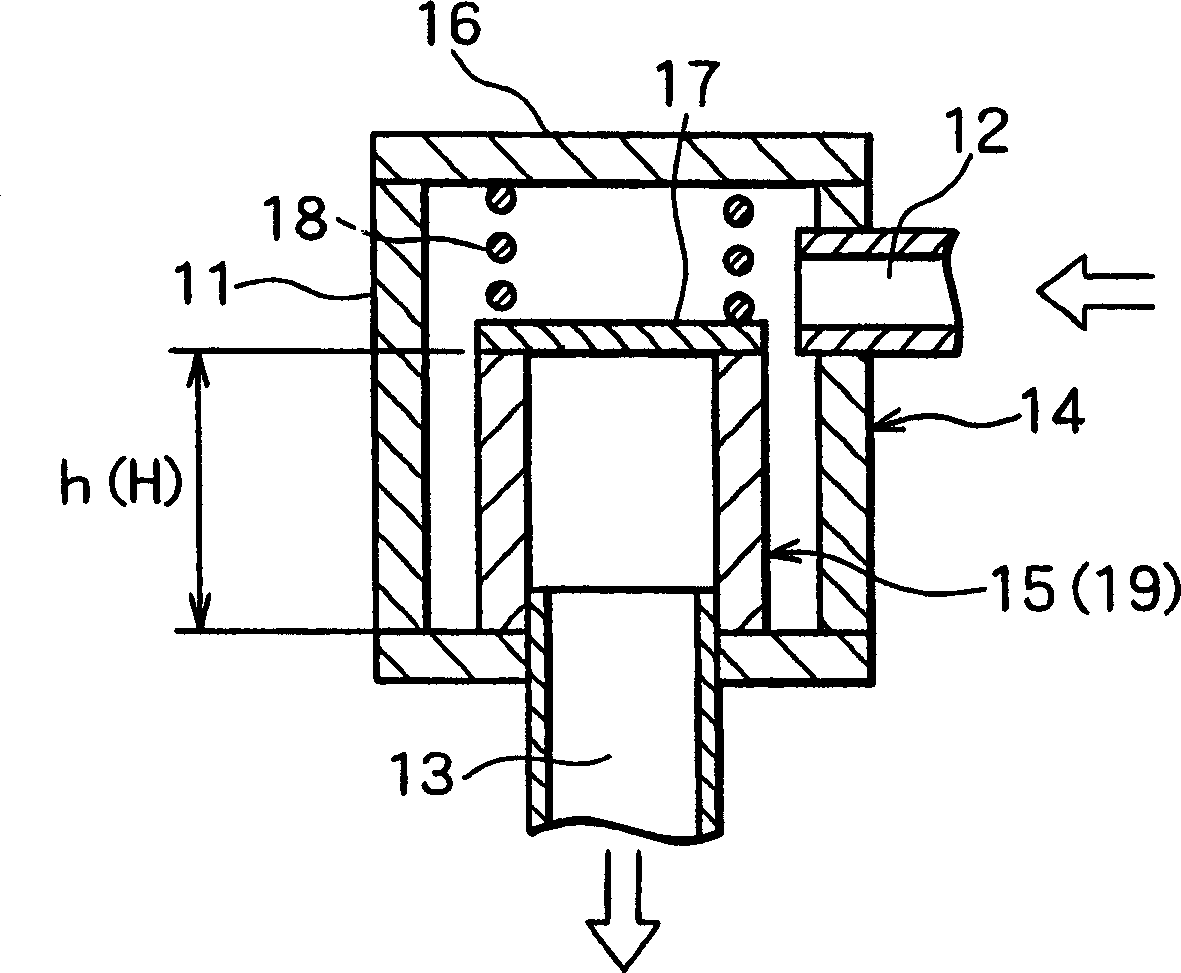

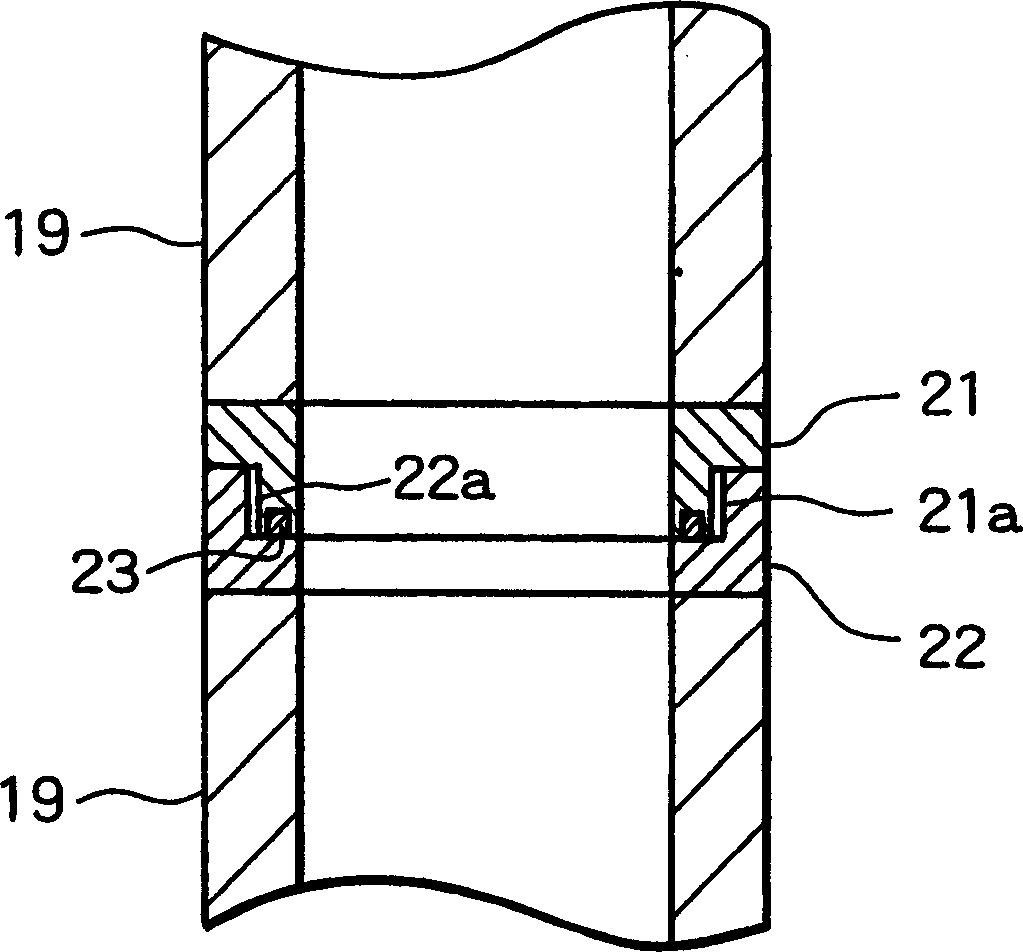

InactiveUS7189468B2Fuel cell heat exchangeReactant parameters controlHandling systemCompression member

A lightweight direct methanol fuel cell unit (20) comprising a fuel cell stack (24) enclosed within a housing (22). In one embodiment the fuel cell stack includes a plurality of polymer electrolyte membrane electrode assemblies (52) stacked alternatingly with a plurality of bipolar plates (48). Each bipolar plate includes a cathode flow field (78) defined by a porous cathode flow field structure (56) and an anode flow field (62) defined by an upper plate (58) and a lower plate (60) separated from one another by a plurality of spacers (64). The anode flow fields are manifolded with one another via manifold embossments (118, 120) that are hermetically sealed with one another with a gasket (126). The fuel cell stack and housing are shaped so as to form four manifold regions (36) in the spaces between the fuel cell stack and housing. The fuel cell stack is compressed within the housing by compression members (94) located between the fuel cell stack and housing so as to place the sidewall (30) of the housing into tension. Supporting systems for the fuel cell unit include a fuel handling system (502), an oxidant handling system (600), and a liquid inventory control system (700).

Owner:CREARE INC

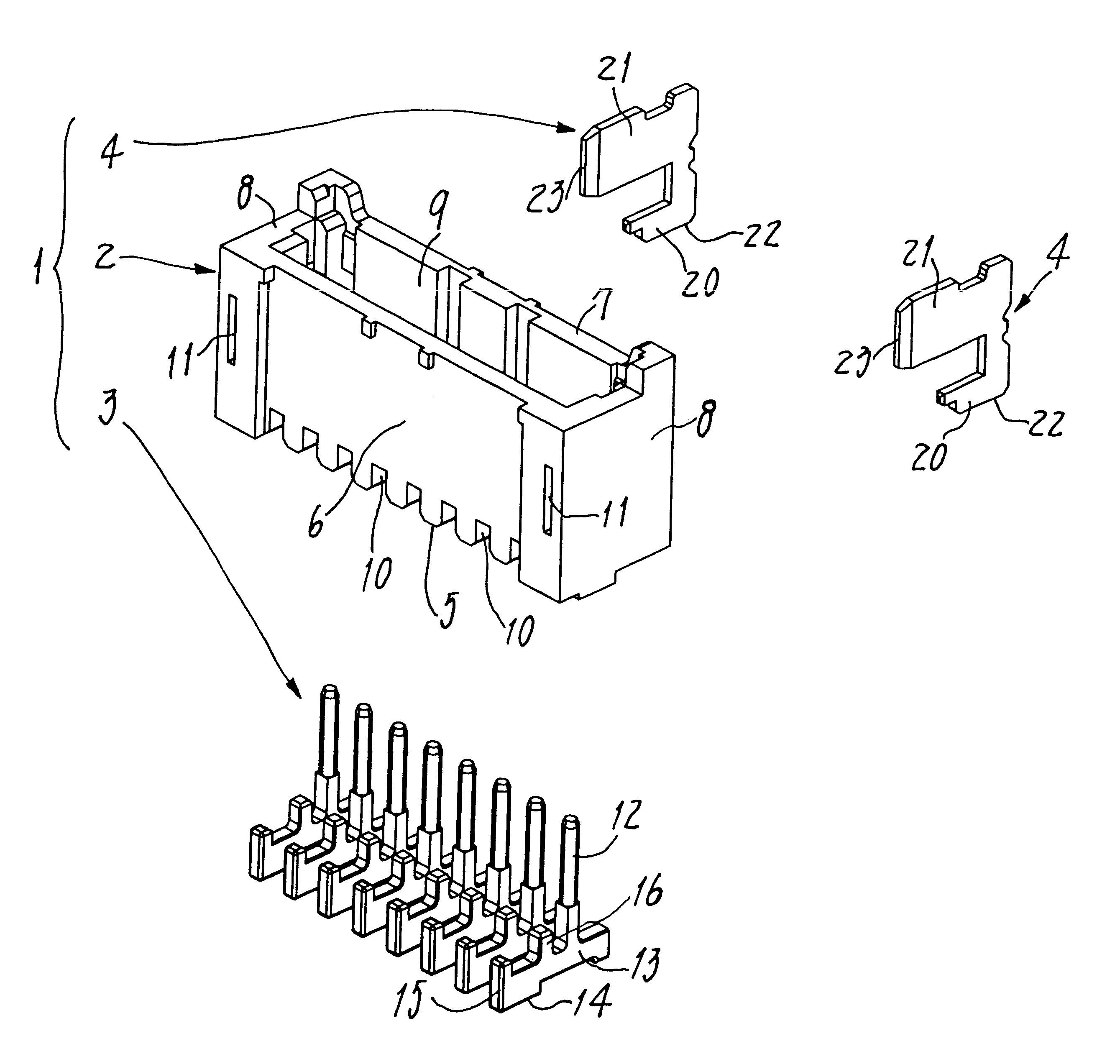

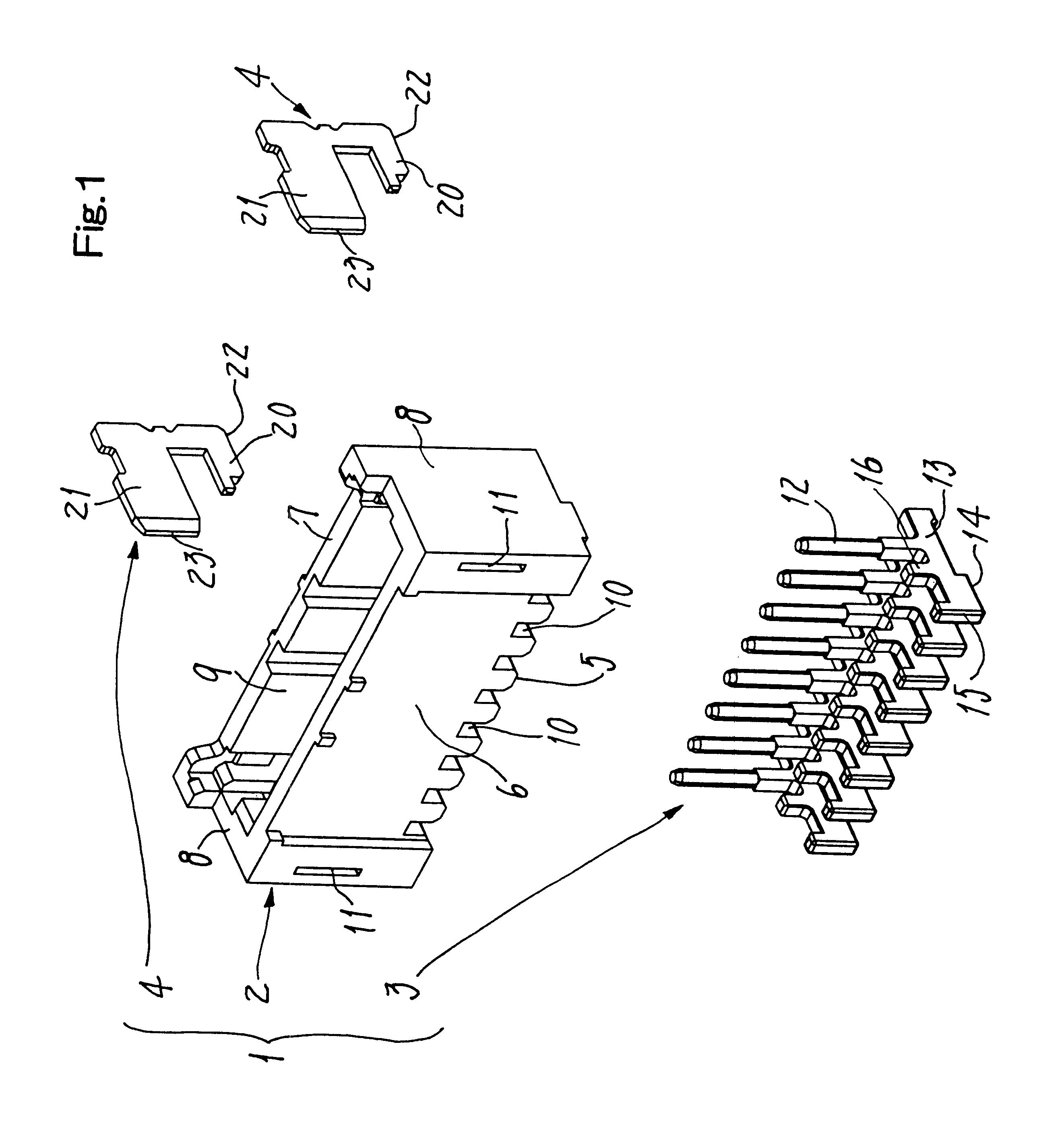

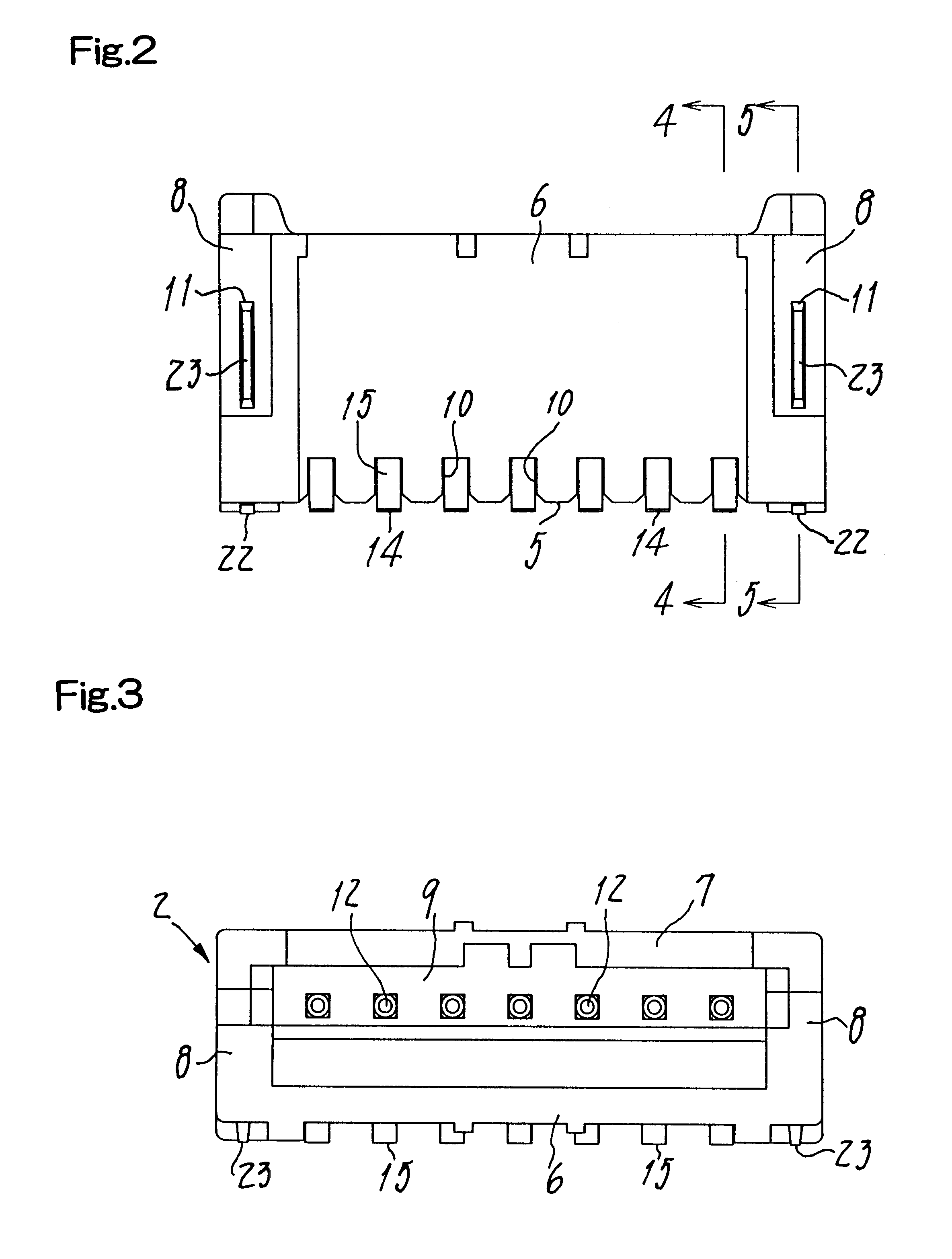

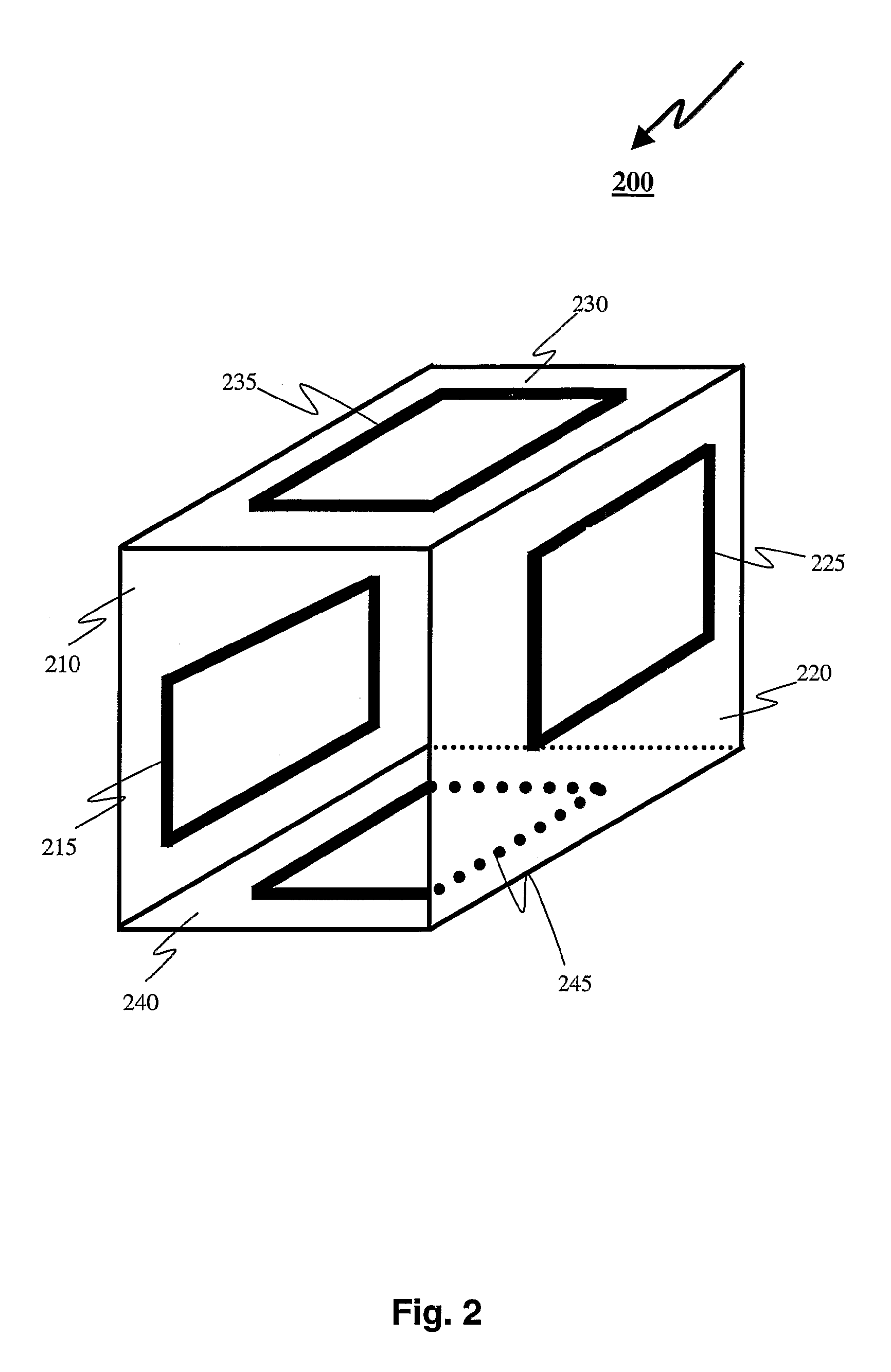

Horizontally and vertically convertible connector for printed circuit boards

InactiveUS6328600B1High densityImprove reliabilityWater closetsLighting and heating apparatusManufacturing cost reductionEngineering

A connector (1) for printed circuit boards (25) has an insulated housing (2), contacts (3) each with a lead (13) protruding from the contact to be soldered to a circuit pattern (26), and reinforcement metals (4) fixed in both sides of the housing and capable of soldering to a fixation pattern (27) on a board. These housing (2), contacts (3) and metals (4) are useful as they are, whether the connector takes a top type or a side type position. Each lead (13) and metal (4) respectively have first solderable portion (14) and zone (22) for top type position, and second solderable portion (15) and zone (23) for the side type position. The first portions and zones extend along the housing's bottom (5), the second portions and zones extending along the housing's front wall (6) or rear wall (7), such that the housing, contacts and metals need no change in shape between the top type and side type position so that the connector is made efficiently with reduced facility investment and with reduced sorts of its parts, lowering manufacture cost and facilitating stock control of parts.

Owner:JST MFG CO LTD

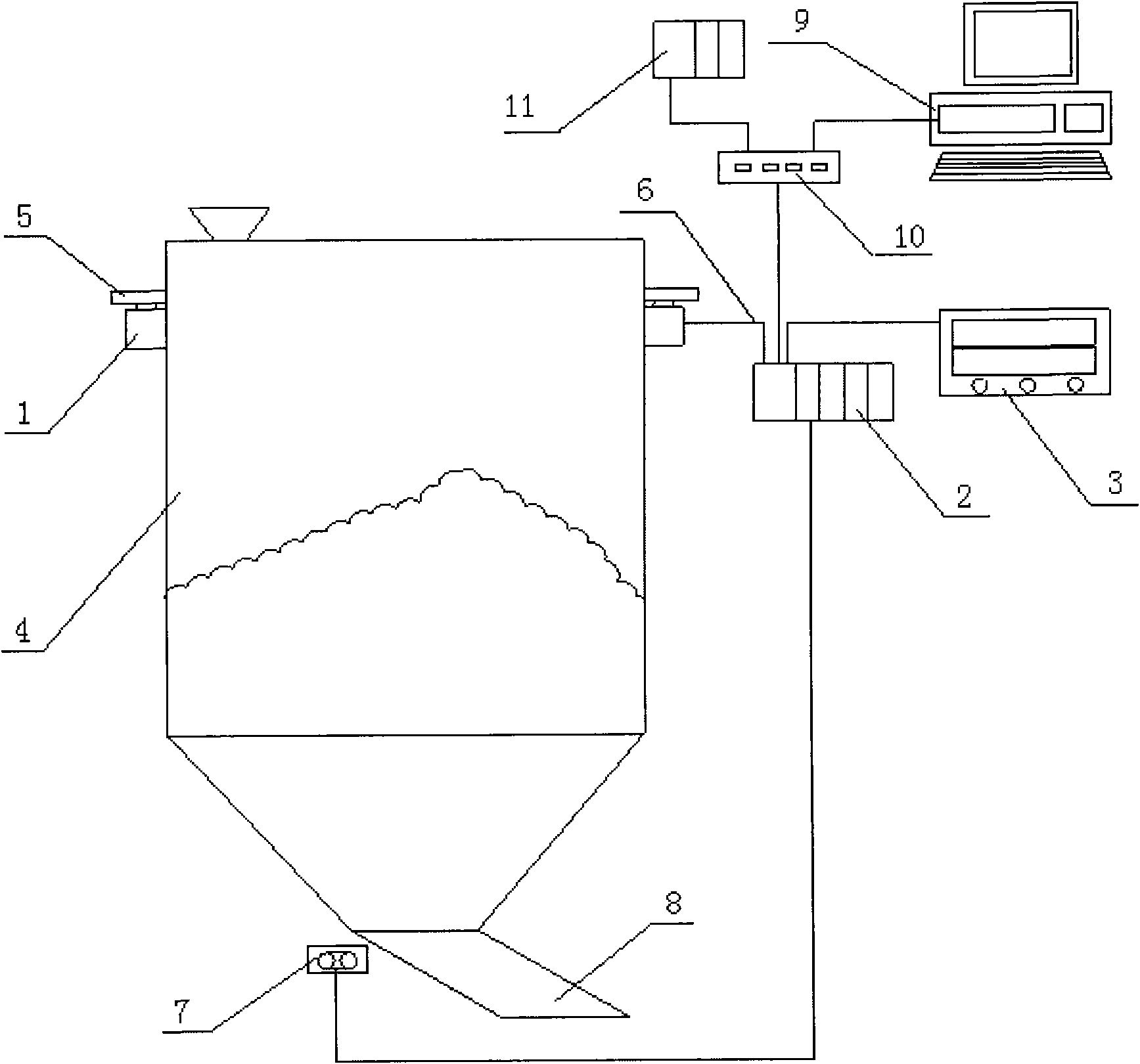

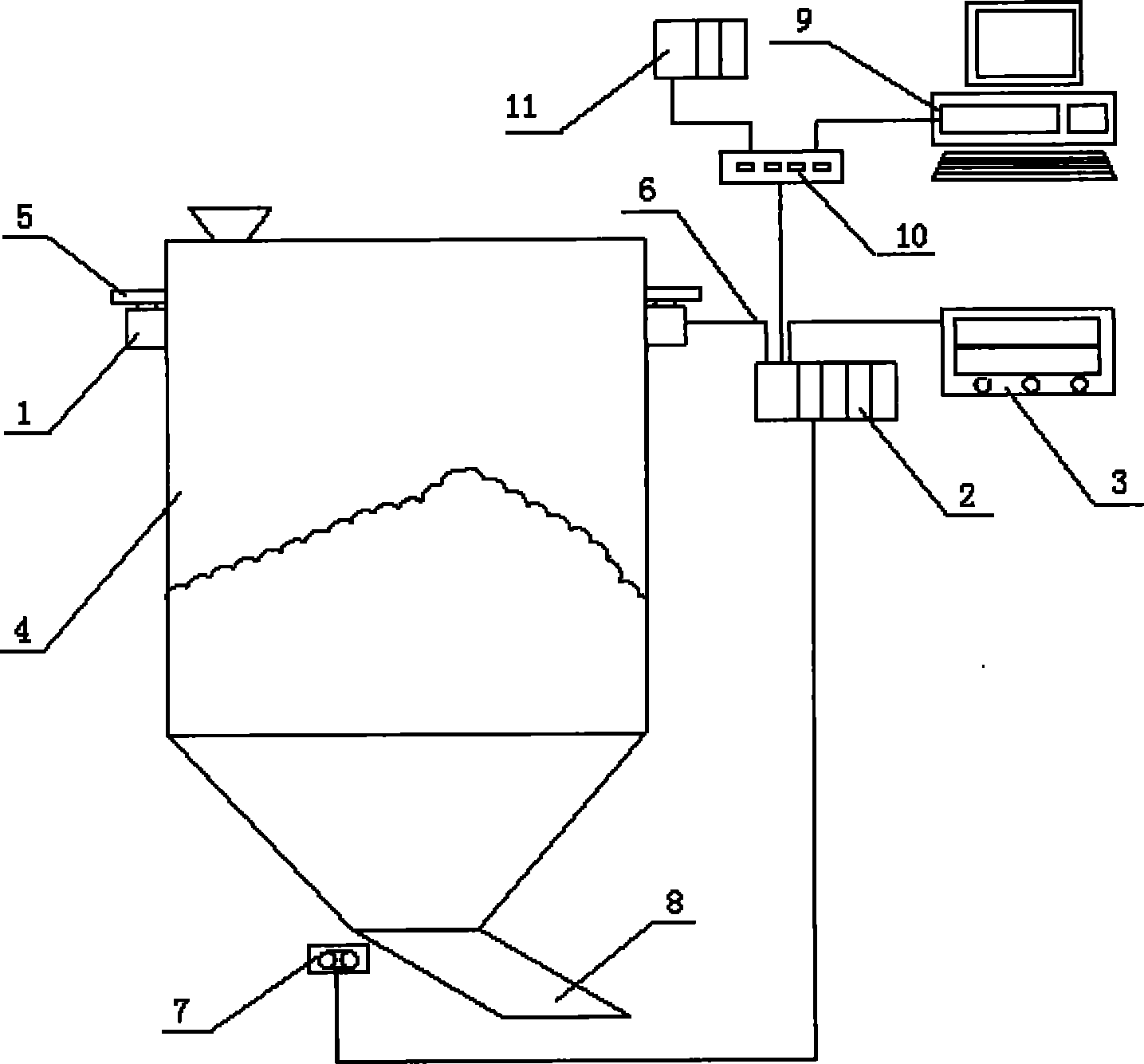

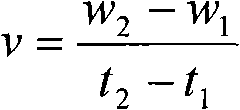

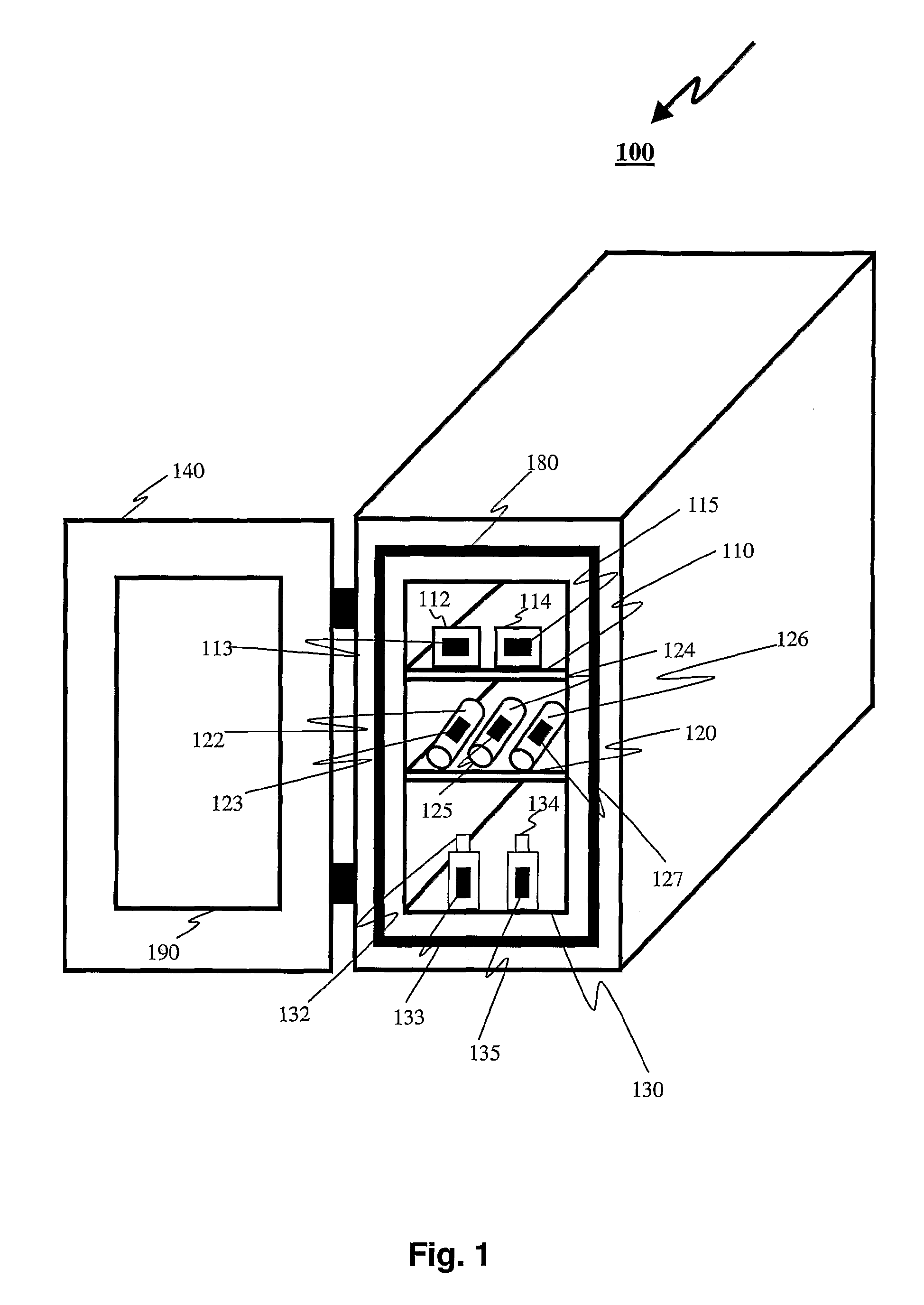

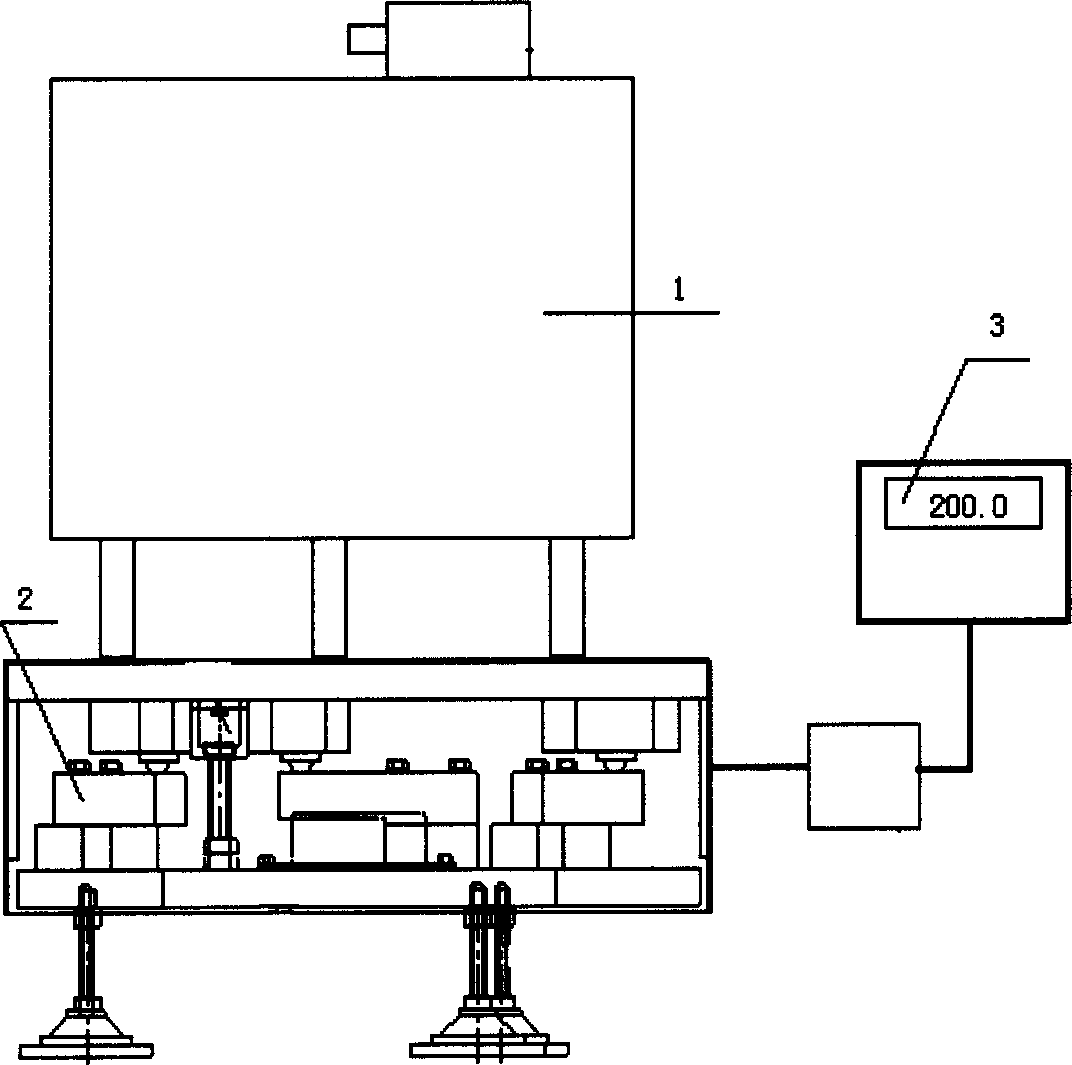

Stock bin control system

InactiveCN101807062ASolve fragile failureSolve the resultProgramme control in sequence/logic controllersShielded cableControl system

The invention relates to a stock bin control system, which comprises a weighting sensor, a programmable controller and a display instrument. The weighting sensor is arranged under a supporting seat of the stock bin, the programmable controller is respectively connected with the weighting sensor and the display instrument through a shielded cable, and a standard 4-20mA signal transmission is adopted for the weighting sensor, the programmable controller and the display instrument. The weighting sensor is generally set with 3-4 points. The stock bin control system is characterized by indirectly measuring the material level of the material stock in the stock bin by means of weighing, and calculating the material flow rate through the weight change to accurately determine the condition of the material discharge and jamming. The invention has the advantages that: the method of weighing is adopted to directly measure the material level of the material stock in the stock bin and the material flow rate is calculated through the weight change to accurately determine the condition of the material discharge and jamming, thereby solving the problems of easy damage and failure of the contact charge level indicator and the non-contact charge level indicator and the infidelity of the measured result, and particularly solving the problem of detection of jamming in the discharge port.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

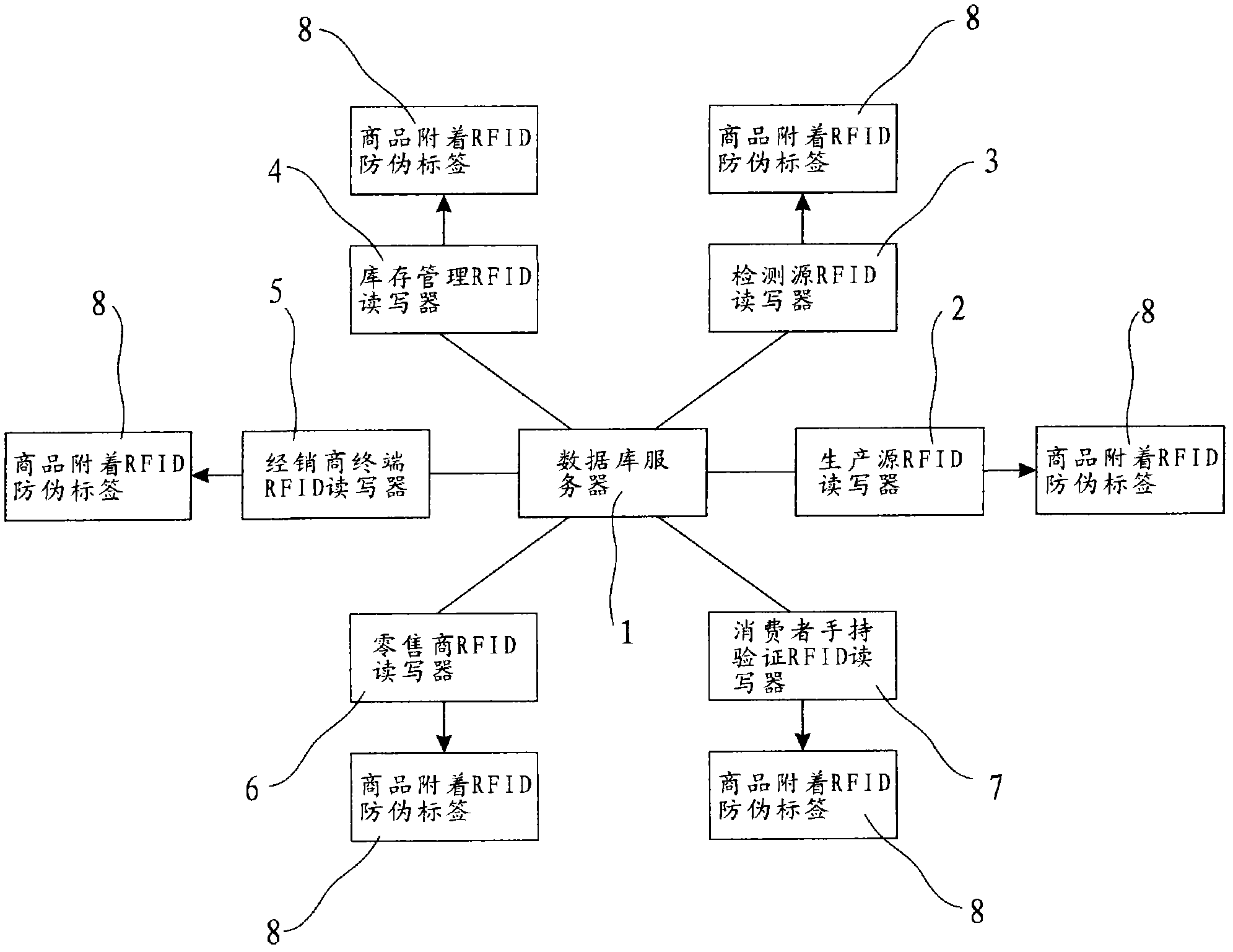

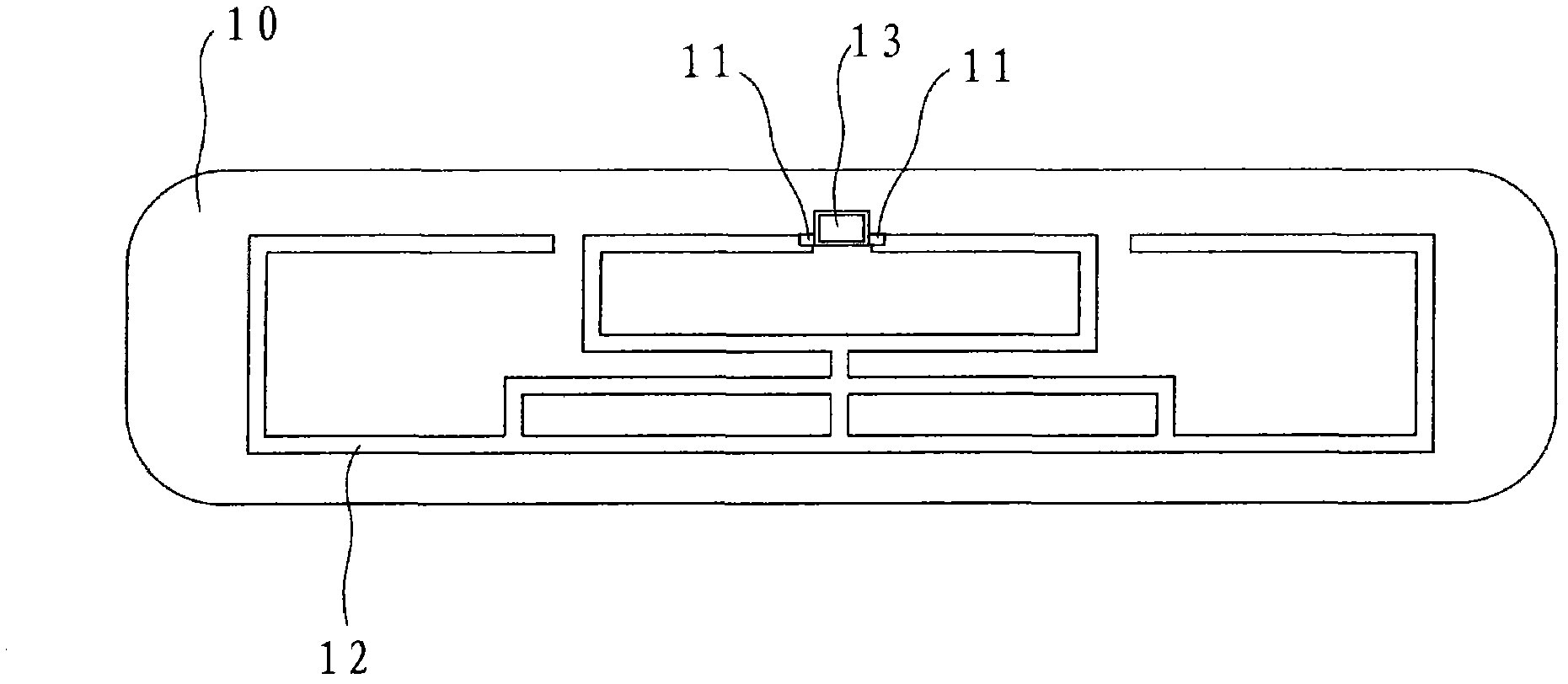

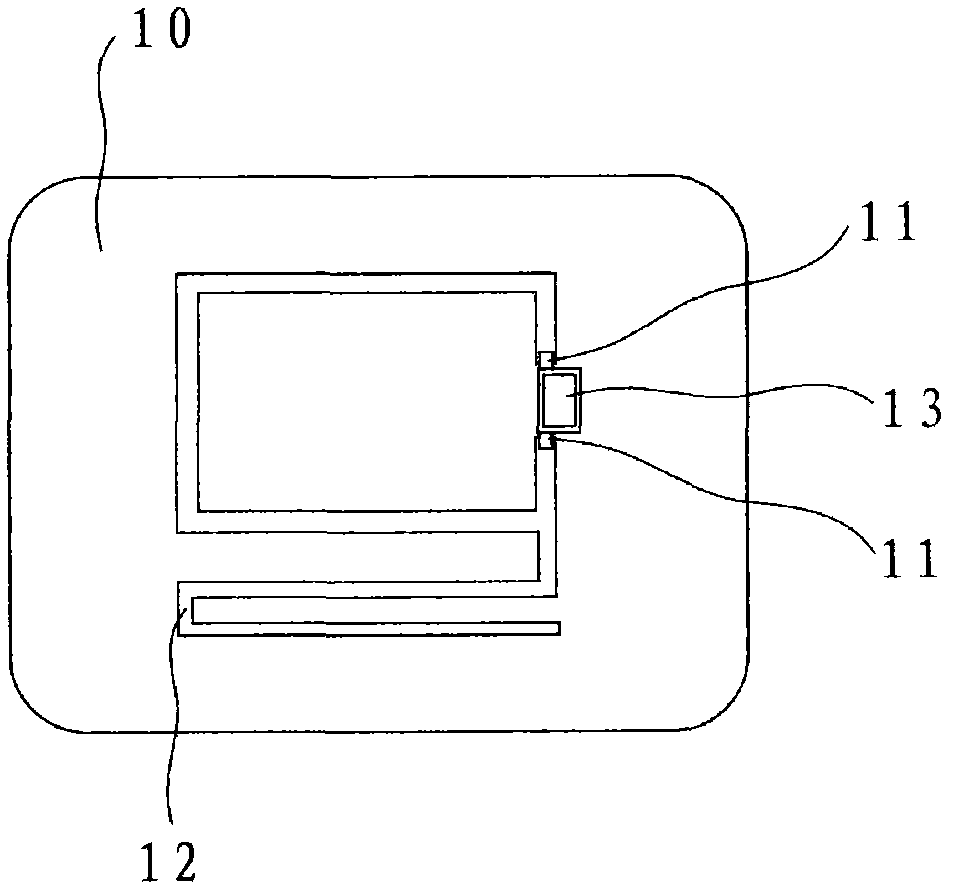

Source-tracing anti-counterfeiting system for radio frequency identification (RFID)

InactiveCN102968724AConvenient anti-counterfeiting queryImprove anti-counterfeiting effectCo-operative working arrangementsCommerceDatabase serverRadio frequency

The invention discloses a source-tracing anti-counterfeiting system for RFID. The system comprises a database server, a production source RFID reader, a detection source RFID reader, a stock control RFID reader, a dealer terminal RFID reader, a retainer RFID reader, a consumer handheld verification RFID reader and a commodity-attached RFID anti-counterfeit label, wherein each RFID reader is in a communication connection with the database server through a network and in a wireless read-write communication connection with the commodity-attached RFID anti-counterfeit label. According to the system, electronic read-write operation is performed on the RFID anti-counterfeit label adhered to the opening of a product package through the RFID readers, the place of origin, processing information, detection information and detailer information of a product are written in or read out, anti-counterfeiting inquiry for the product attached with the RFID anti-counterfeit label is facilitated for a manufacturer, a detailer or a terminal user, the overall situation of production of the product can be known, and the anti-counterfeiting effect is good.

Owner:周朝成

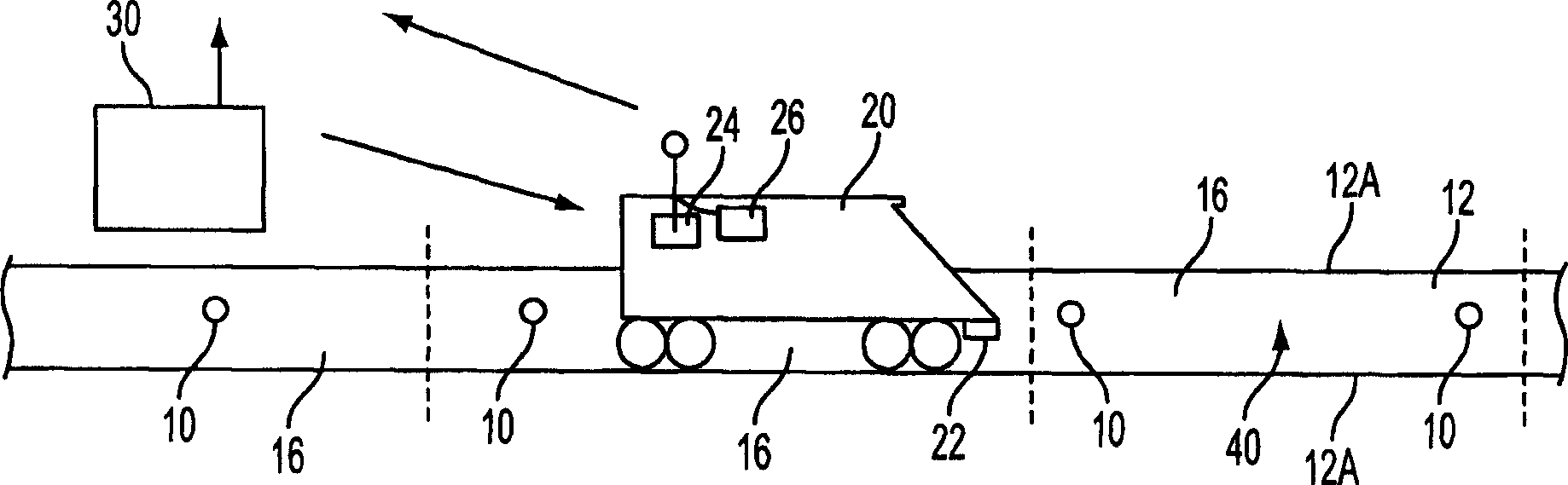

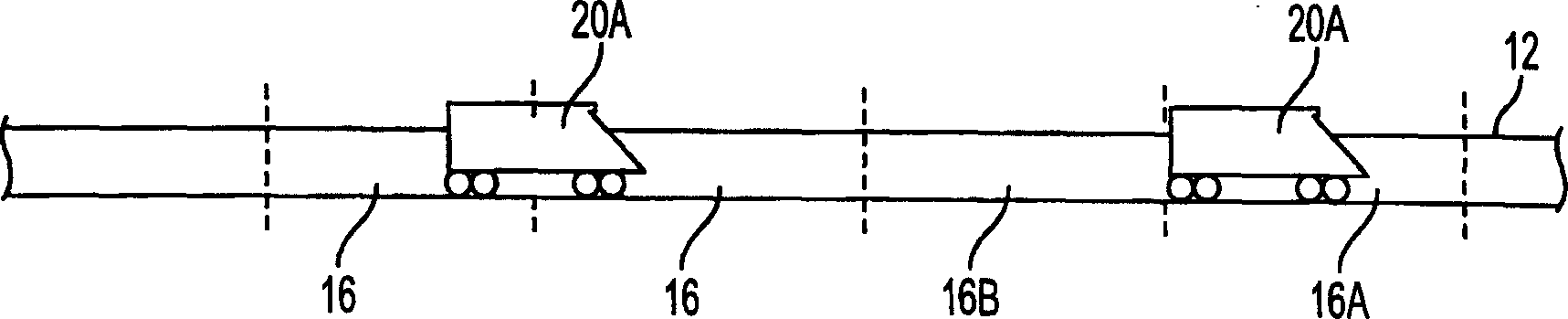

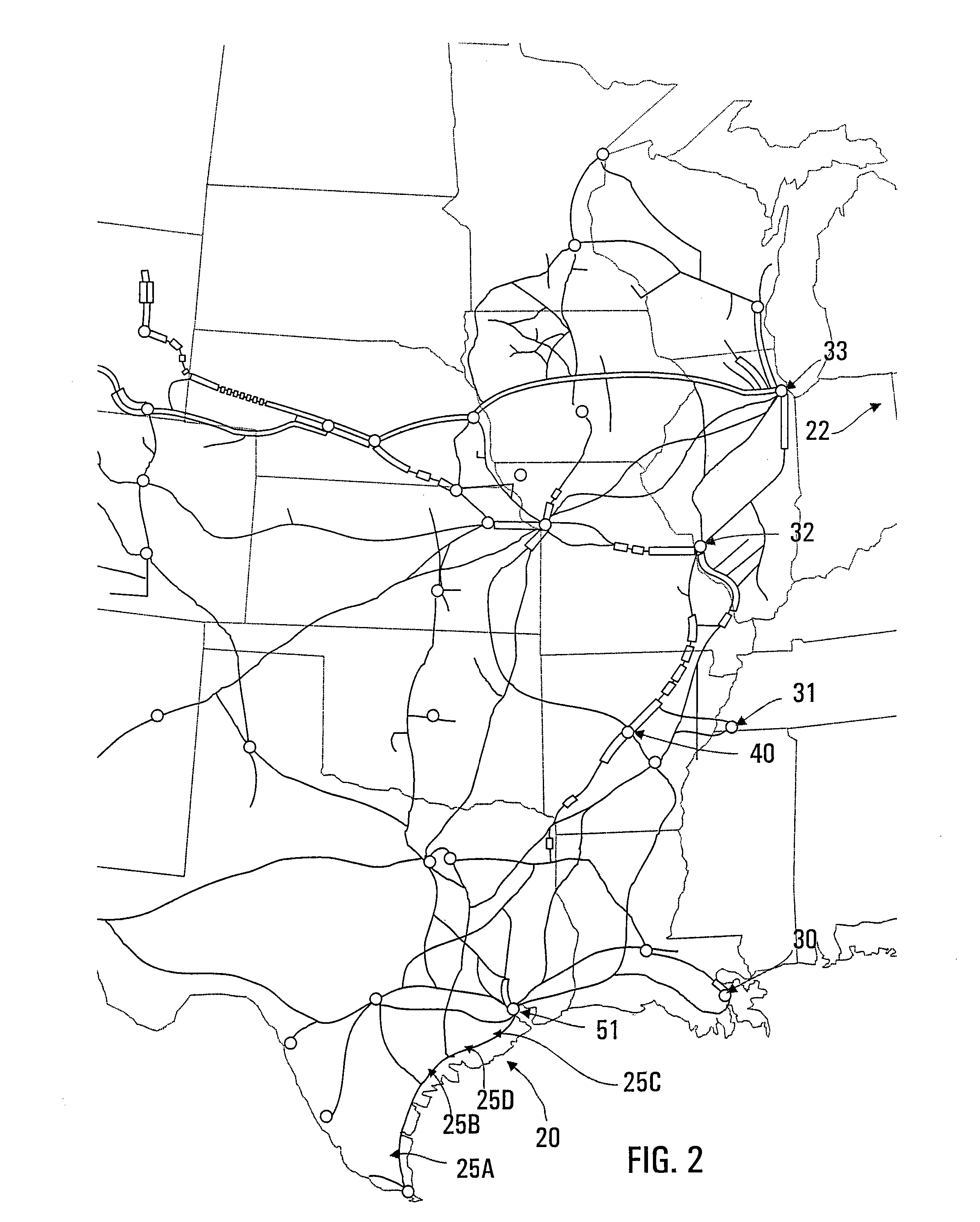

Rolling stock control system and method by device along route

InactiveCN1461719ARailway traffic control systemsRoute devices for controlling vehiclesControl systemEngineering

A vehicle control system and method in which a plurality of beacon tags are disposed along a length of a track for a predetermine number of blocks. The beacon tags each provide information pertaining its location. Each vehicle that passes along the track has a tag reader that solicits information from the beacon tags and a transmitter that transmits the solicited information, as well as vehicle identification information for the transmitting vehicle, to a wayside control unit. The wayside control unit receives the transmitted position information and vehicle identification information and in turn transmits a single broadcast of information pertaining to each of the blocks of the predetermined number of blocks. This signal is received by all of the vehicles, which use only the information about immediately approaching blocks. In addition, dynamic tags located at positions along the length of the predetermine number of blocks can be used as a backup system for providing the same information that is provided by the wayside control unit.

Owner:ALCATEL LUCENT SAS

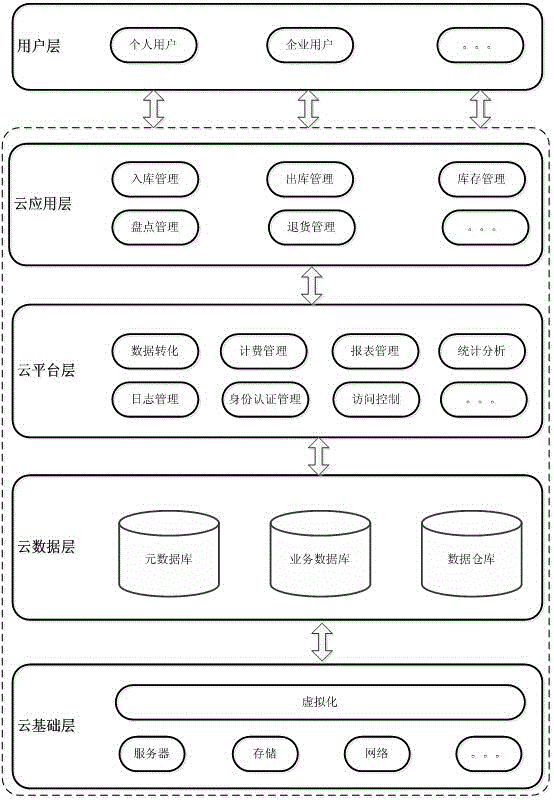

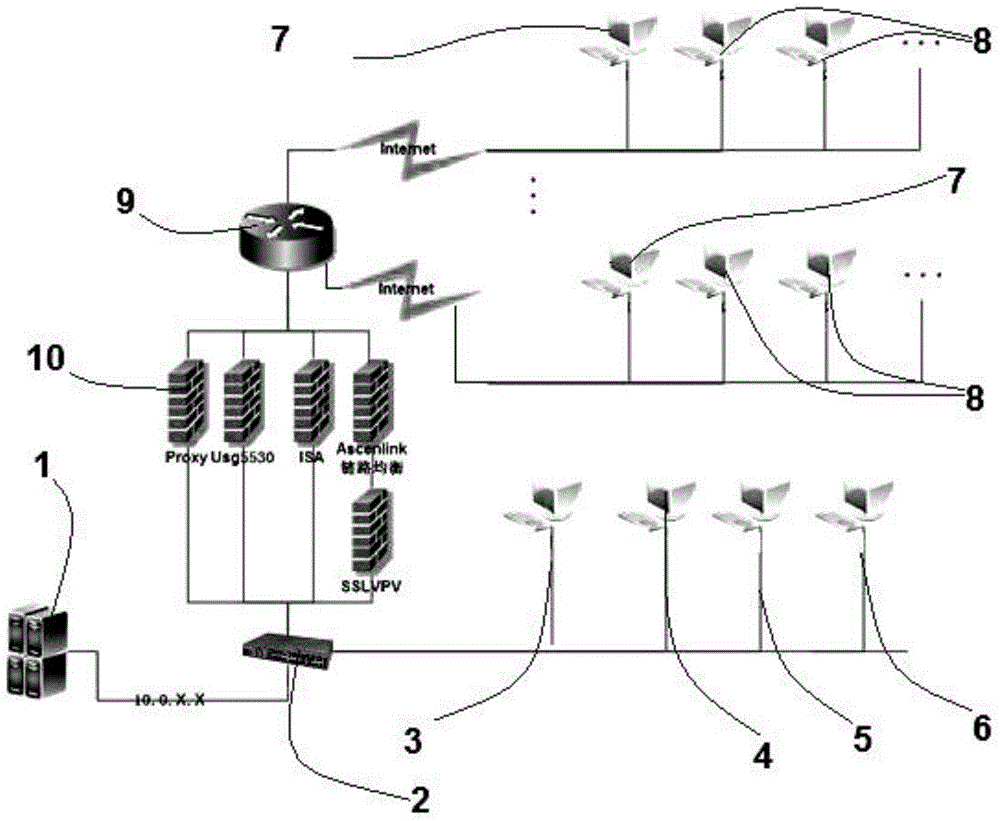

Third-party logistics cloud warehousing system

InactiveCN104463537AShorten the construction periodReasonable structureLogisticsData warehouseCloud base

The invention relates to a third-party logistics cloud warehousing system. The third-party logistics cloud warehousing system at least comprises a cloud application layer providing stock management, delivery management, stock control, check management, return management and other main services, a cloud platform layer providing a basic application and function assembly for the cloud application layer, a cloud data layer and a cloud base layer. The cloud platform layer mainly comprises data conversion, accounting management, report management, statistical analysis, log management, identity authentication management, access control and the like. The cloud data layer comprises a metadatabase, a service database and a data warehouse, and is used for storing various service data of the system. The cloud base layer is mainly constructed by a virtual system, a network, a memorizer, a server and the like. By means of the construction of the third-party logistics cloud warehousing system, the stability, flexibility and expandability of the system are improved, and the operation is more convenient for a user.

Owner:江苏中科今朝科技有限公司 +1

Steel coil stock control method based on crane positioning system

InactiveCN105427064AAutomate jobsImprove turnover rateUsing optical meansLogisticsEngineeringManagement system

Disclosed is a steel coil stock control method based on a crane positioning system. The method comprises the following steps: installing a conveying chain tracking and positioning system of a crane laser positioning system grade, conducting coordinate positioning on stock sites and rolling line conveying chains in a steel coil warehouse, establishing stock site tracking for each steel coil, detecting the operating coordinate of a crane through a laser measuring technology, combining coordinate information with crane work commands, and tracking the steel coil according to the operating position of the steel coil in one conveying chain till the steel coil is off line to be placed in the steel coil warehouse. The stacking principle in the steel coil warehouse is determined, a mathematic model and an algorithm are established, and optimized control over the stock of the steel coil warehouse is conducted through a crane positioning system, so the status of steel coil stock can be analyzed in an accurate and systemic manner, the functions of a steel coil warehouse management system are improved, crane positioning and steel coil warehouse management highly fit each other, automated operation of the steel coil warehouse is achieved, and the stock is increased. Moreover, the turnover rate of the steel coil warehouse and the work efficiency of workers are improved, the labor cost is reduced, and the production efficiency is increased.

Owner:ANGANG STEEL CO LTD

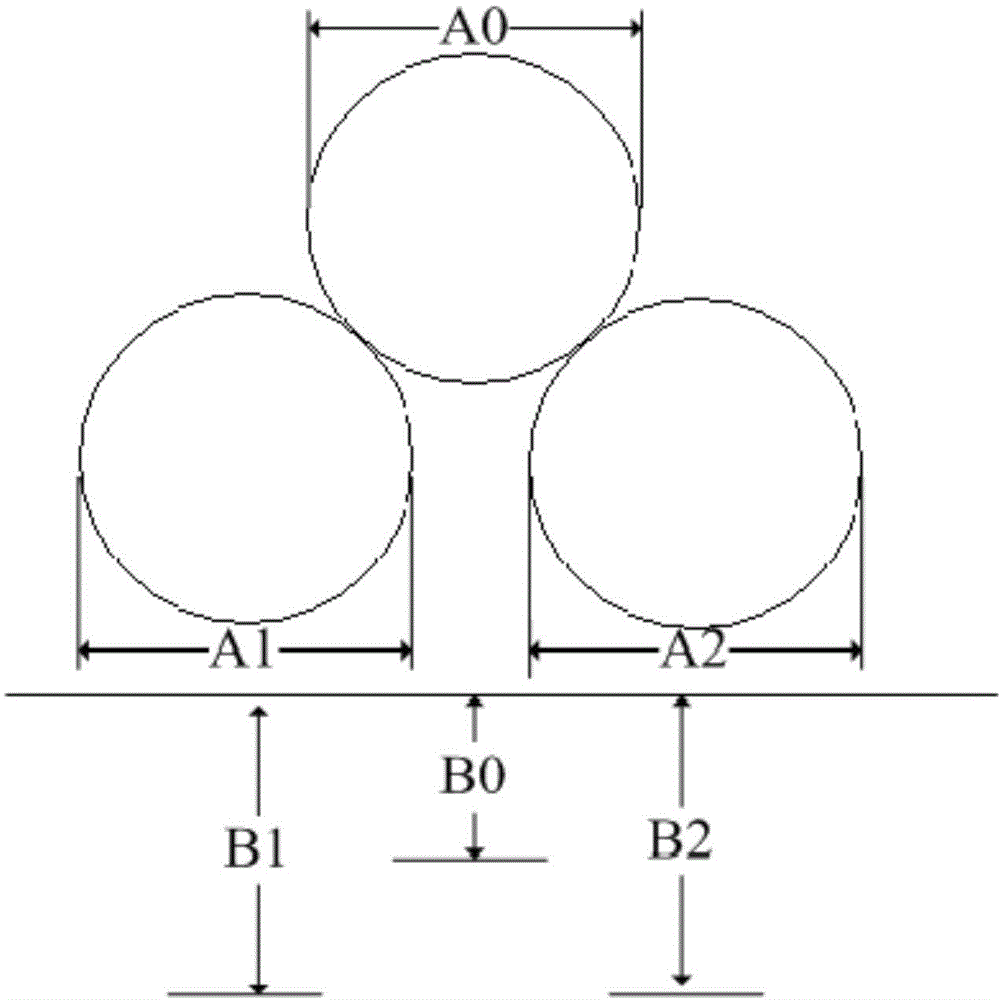

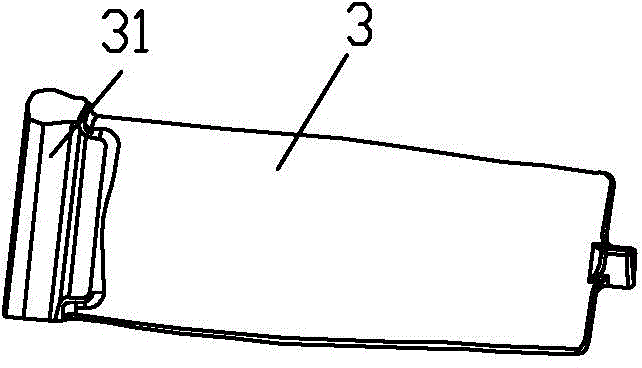

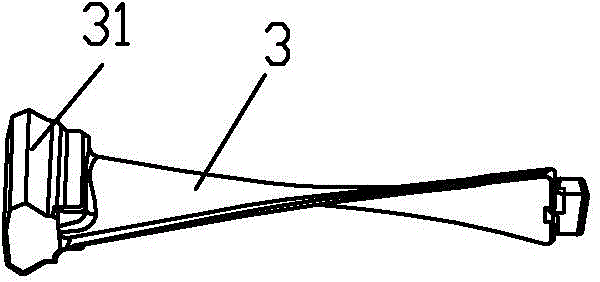

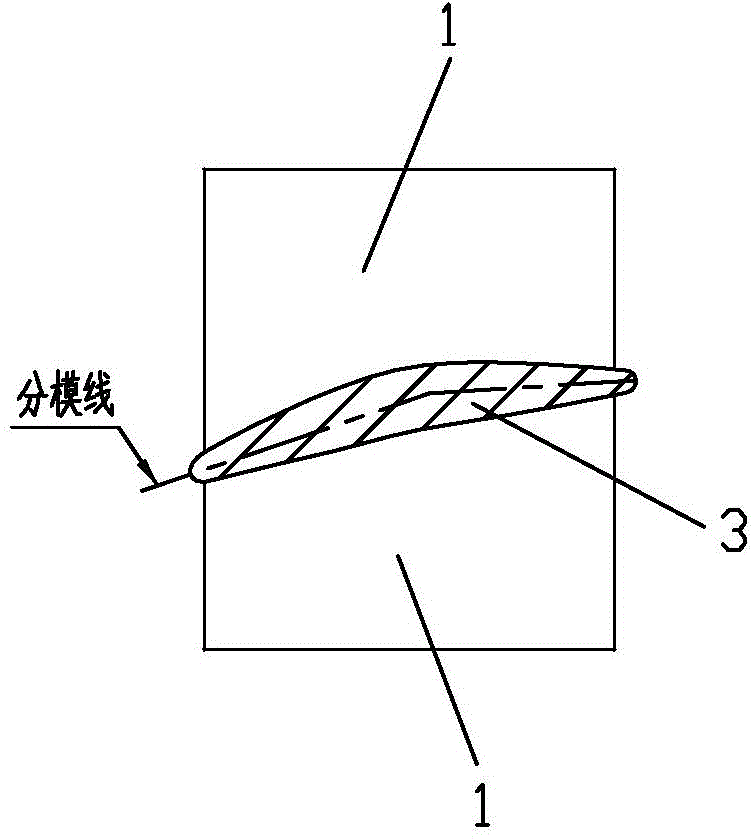

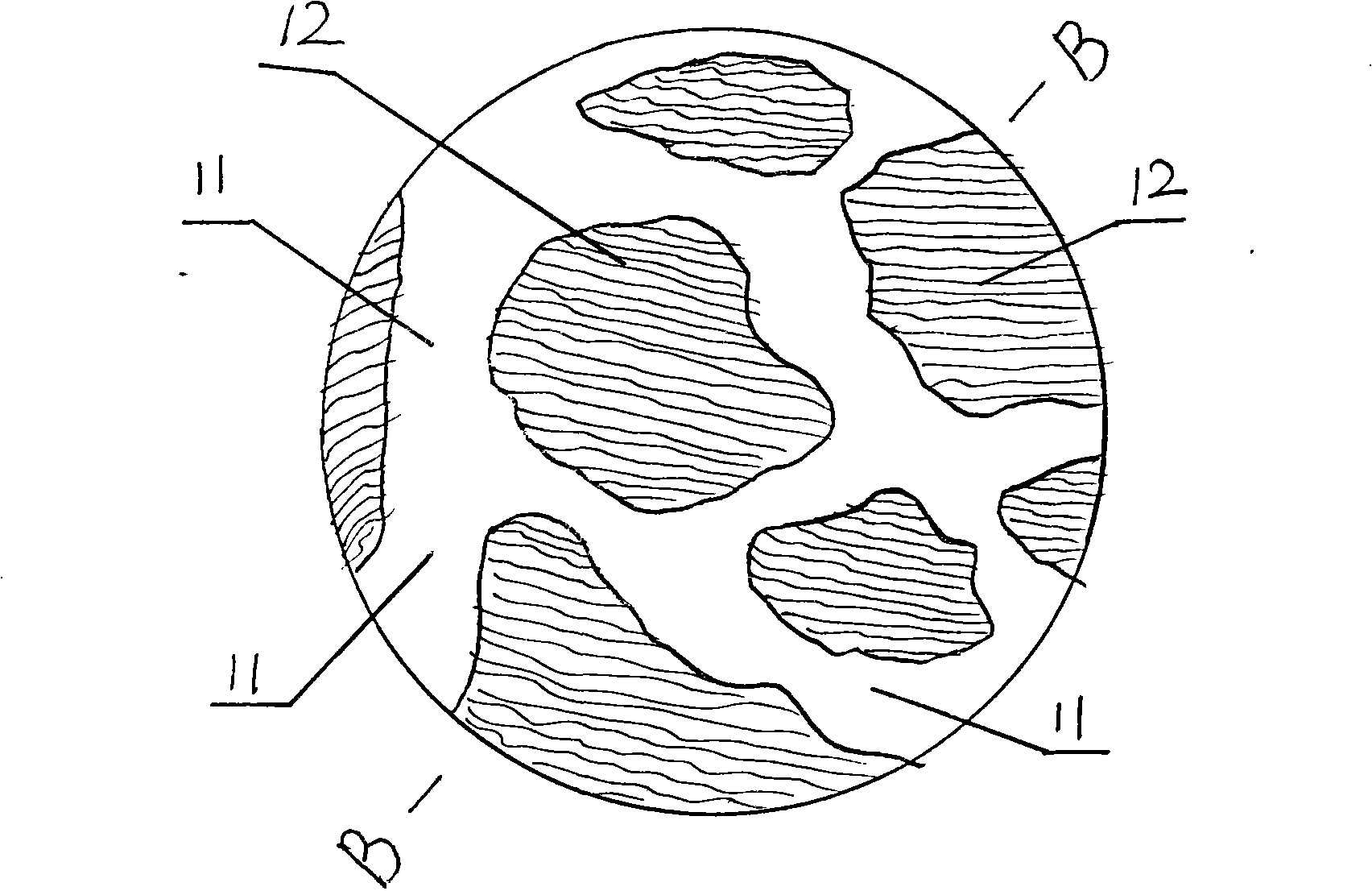

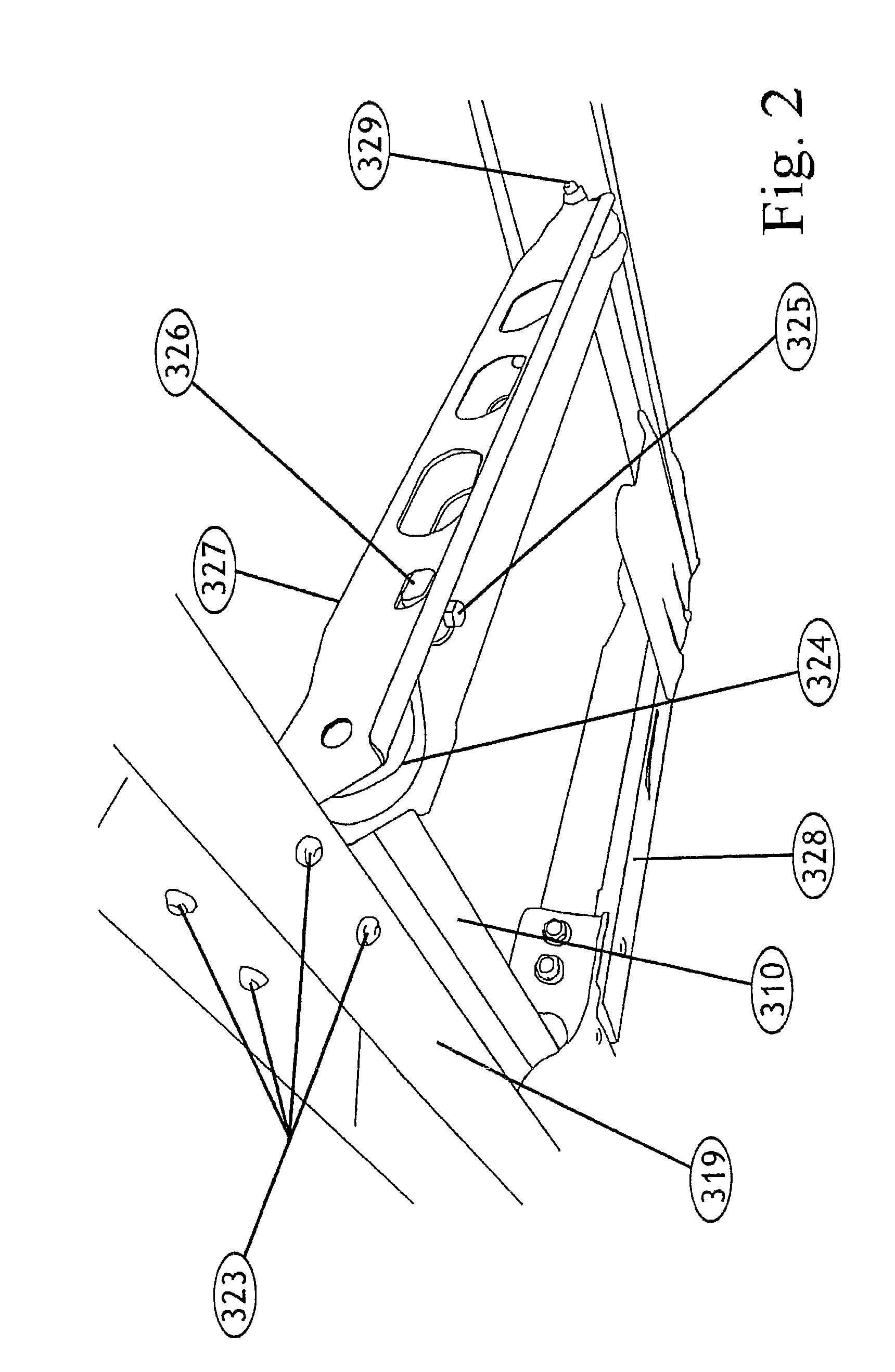

Control method for a gas turbine blade forging stock geometry and testing model

ActiveCN104406502ASimple structureReduce weightMechanical counters/curvatures measurementsProduction modelGraphics

The invention discloses a gas turbine blade geometry forging stock control methods and a testing model. The method includes the model of production and specific inspection, the model produced by the cross-sectional model making, model making and model axis combinations, axial cross-sectional model making production model are by cutaway model of the blade-shaped three-dimensional model of two-dimensional graphics, the graphics were produced by two-dimensional cross-sectional axis model and model both inside and outside the arc, and then combined to form inside and outside the arc than the fixed model with a model than by combining visual and feeler the methods were inside and outside the arc blades comparison checks. Model by a number of cross-section than the production model by forming an axis model fishbone-shaped cross-section and the axis of the model than the model on the side blade-shaped formation. The beneficial effect of the invention is a method which can detect the test results obtained in several parts of the blade, simple operation, high accuracy and high detection efficiency; check the model structure is simple, low labor intensity is detected, the detection of low skill requirements.

Owner:CHONGQING CHANGZHENG HEAVY IND

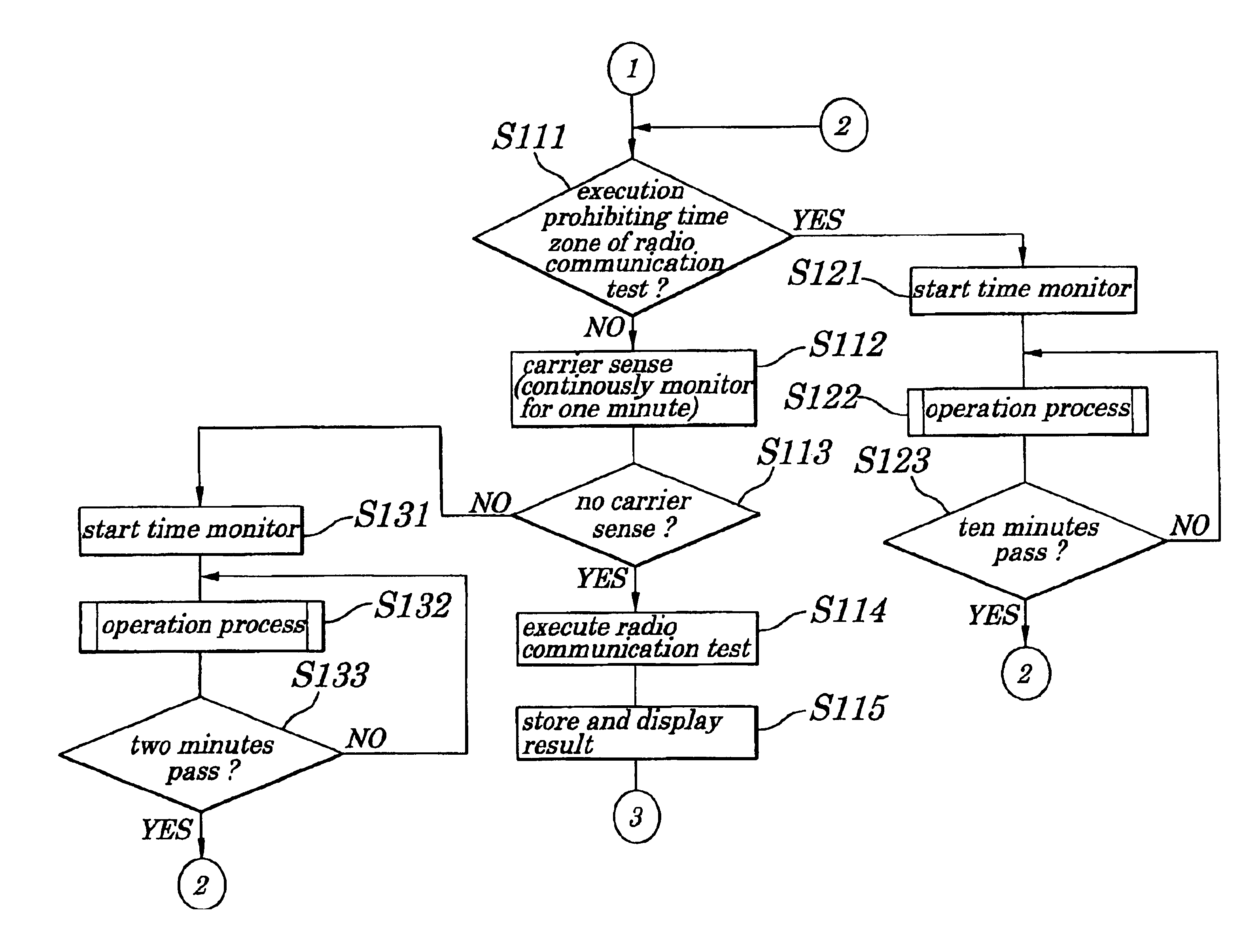

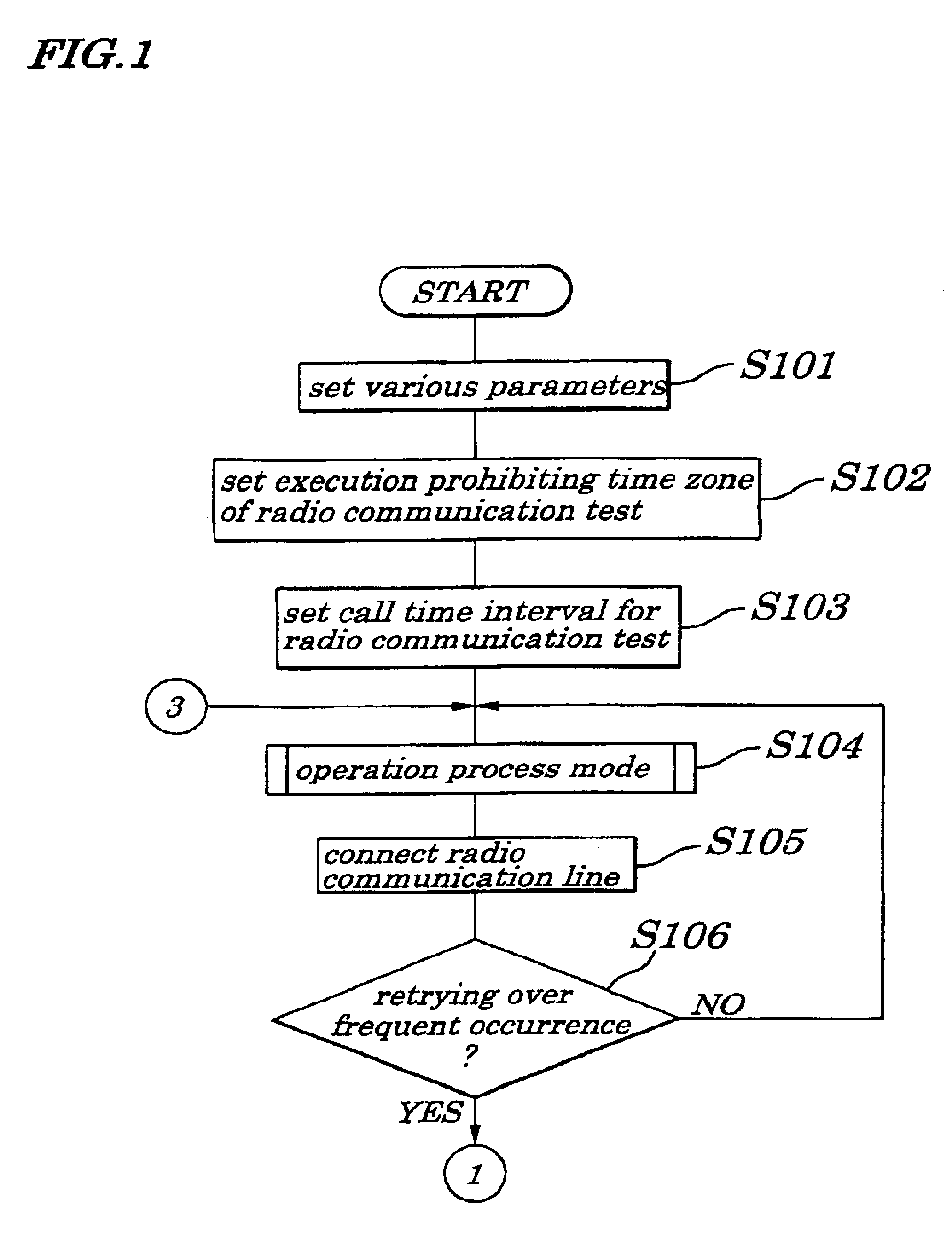

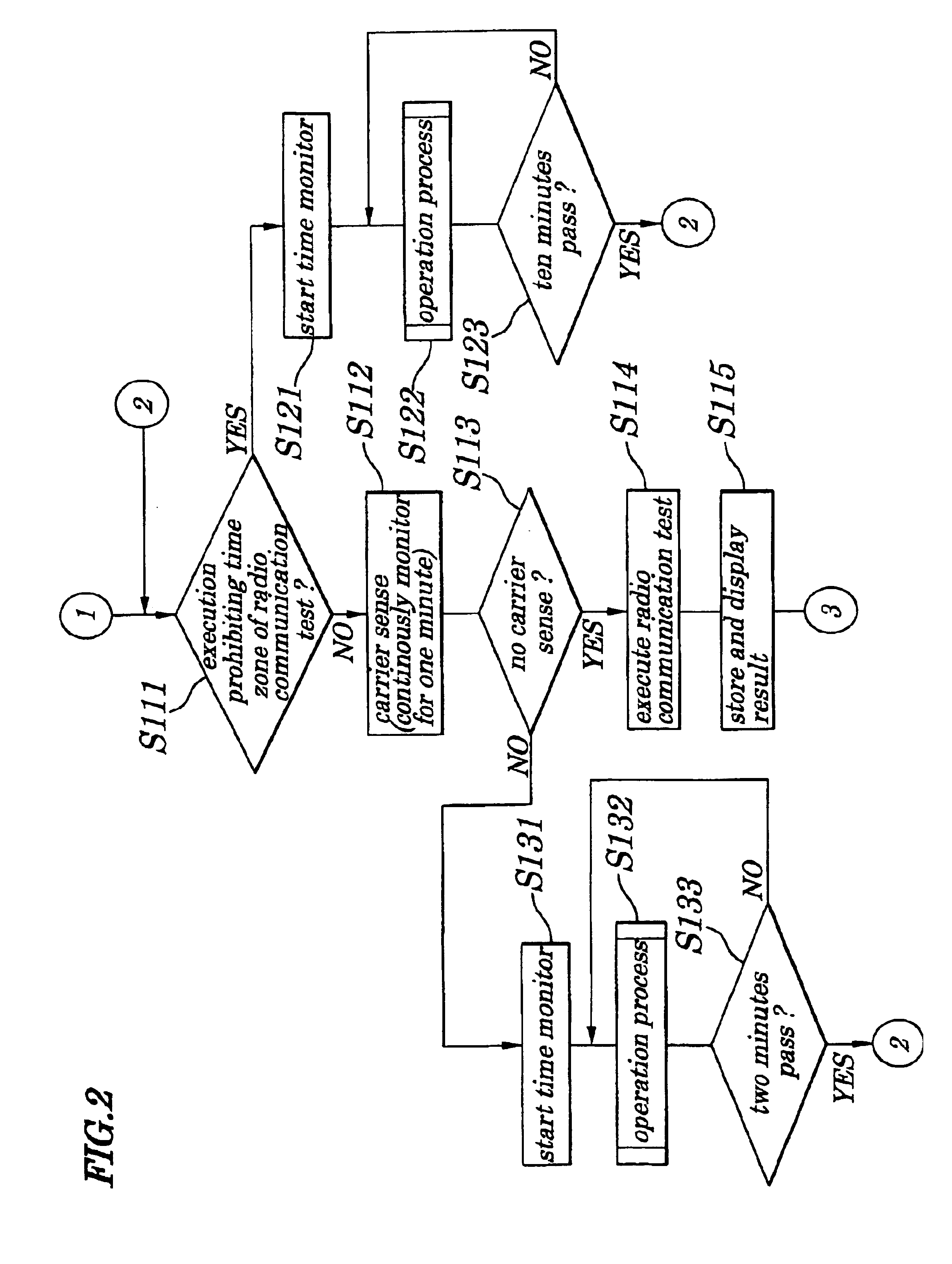

Fault monitoring method for commodity management radio communicating apparatus, storage medium for storing fault monitoring program for commodity management radio apparatus and fault monitoring program

In a fault monitoring method for a portable radio communication terminal, plural portable radio communication terminals communicate with an inventory controller via a radio communication base station. In the portable radio communication terminal in a commodity management system, when the number of retrying times of radio communication between the portable radio communication terminal and the radio communication base station exceeds a predetermined number of times, the portable radio communication terminal automatically executes a test of a radio communication section and displays a fault on a display section of the portable radio communication terminal when a fault occurs.

Owner:NEC PLATFORMS LTD

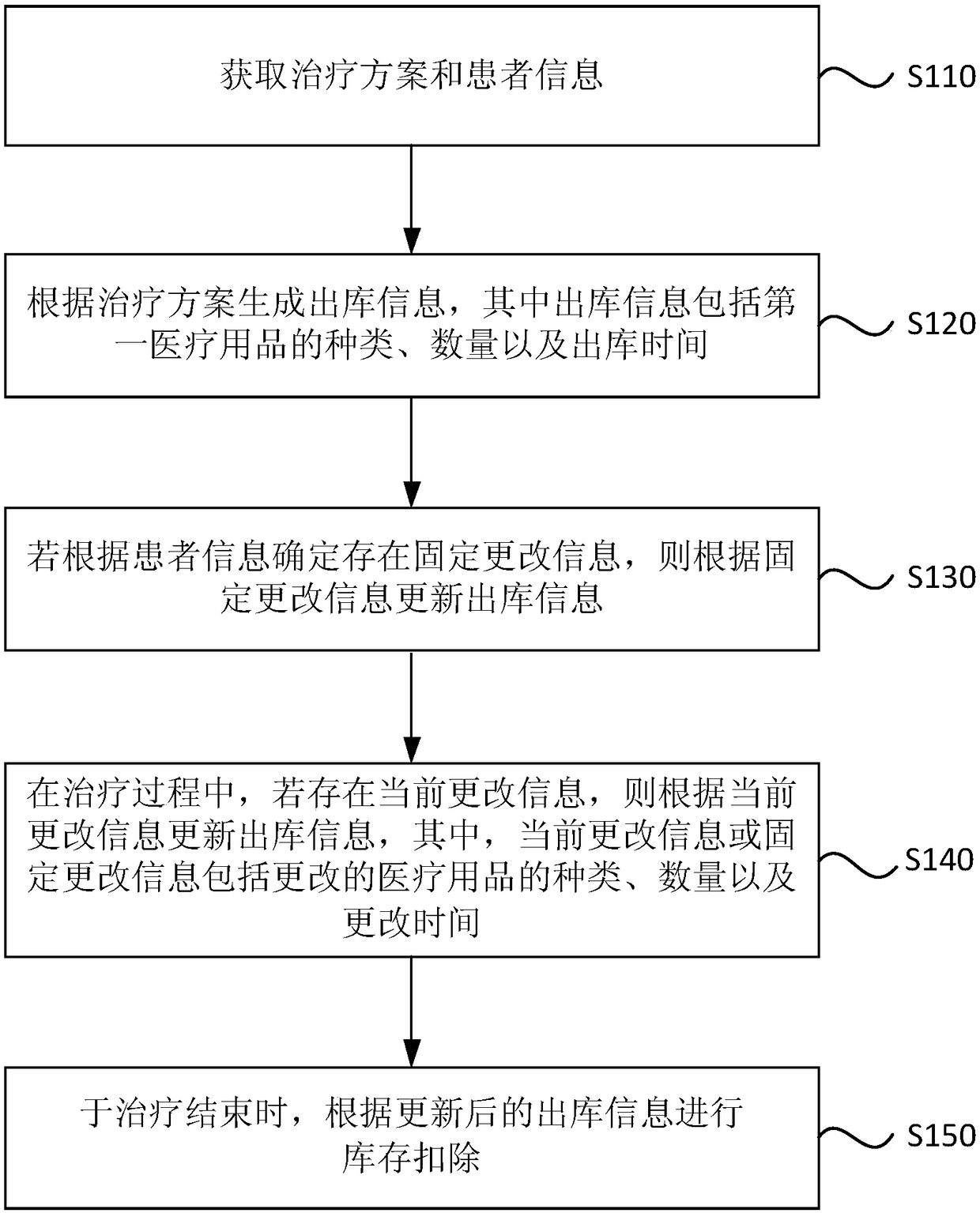

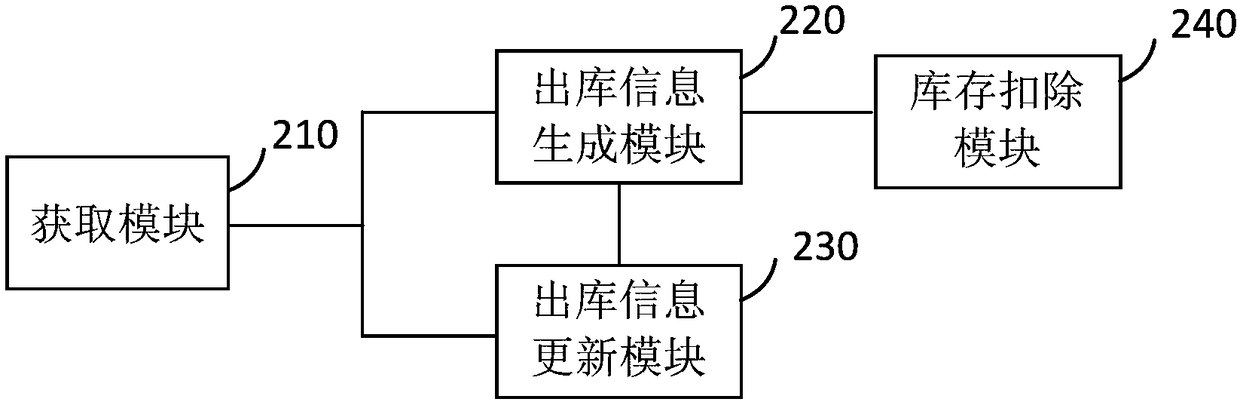

Stock removal method and device for medical supplies, terminal and computer readable medium

ActiveCN108133747ASolve real-timeResolve accuracyHealthcare resources and facilitiesLogisticsComputer terminalInventory management

An embodiment of the invention discloses a stock removal method and device for medical supplies, a terminal and a computer readable medium. The method includes acquiring a treatment scheme and patientinformation; generating stock removal information according to the treatment scheme; updating stock removal information according to fixed change information if the presence of fixed change information is determined according to the patient information; updating stock removal information according to current change information in the presence of current change information in a treatment process;performing stock removal according to the updated stock removal information when the treatment is completed. According to the invention, the stock removal information and the fixed change informationare generated through acquiring the treatment scheme and the patient information and the stock removal information is updated according to the fixed change information and the current change information, so that a problem that incapability of real time recording and low accuracy in stock removal of the medical can be effectively solved. Therefore, resource waste is avoided and stock control of themedical supplies is facilitated.

Owner:SUZHOU MEHDI HOUSTTON MEDICALSYST TECH

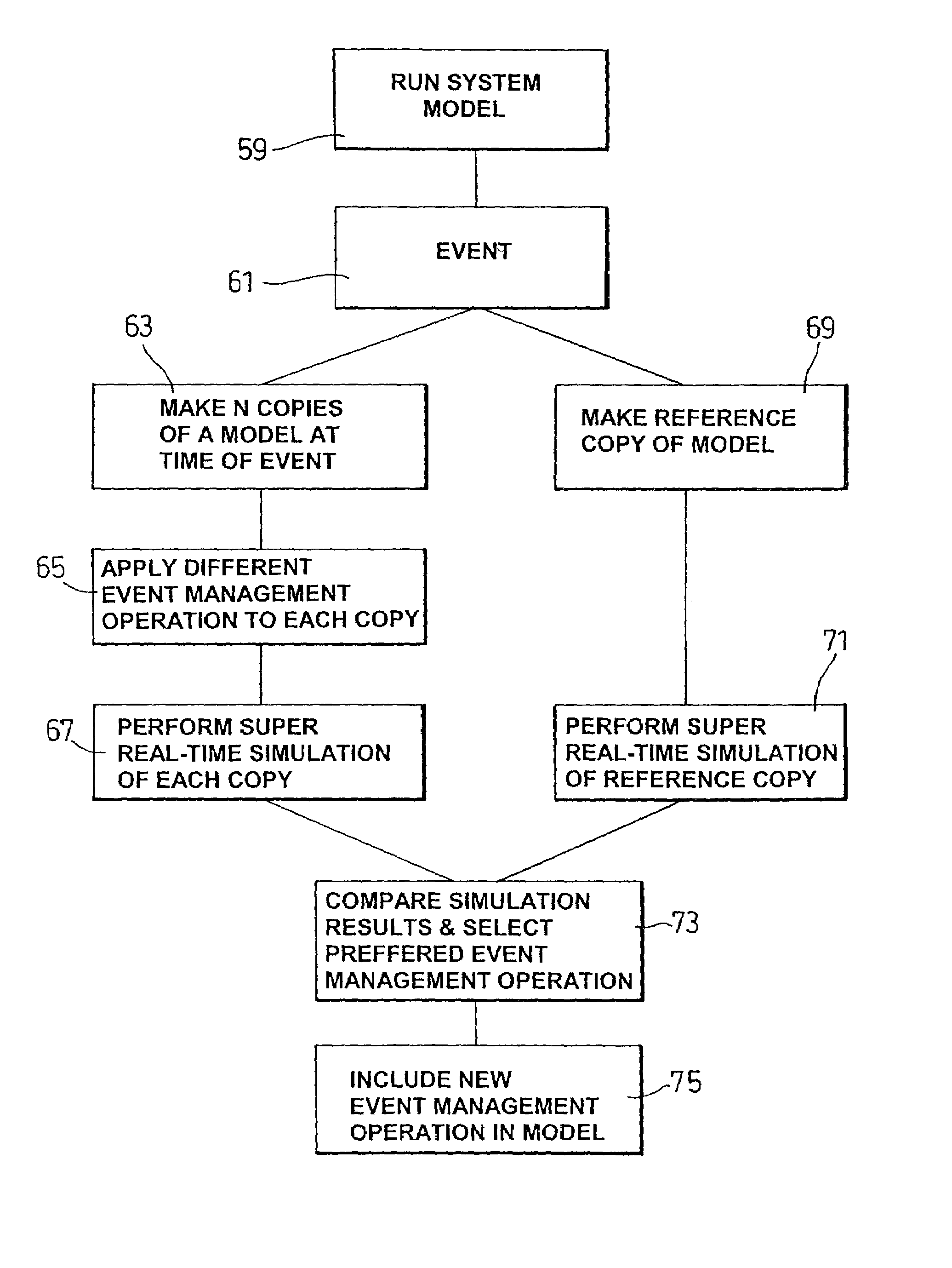

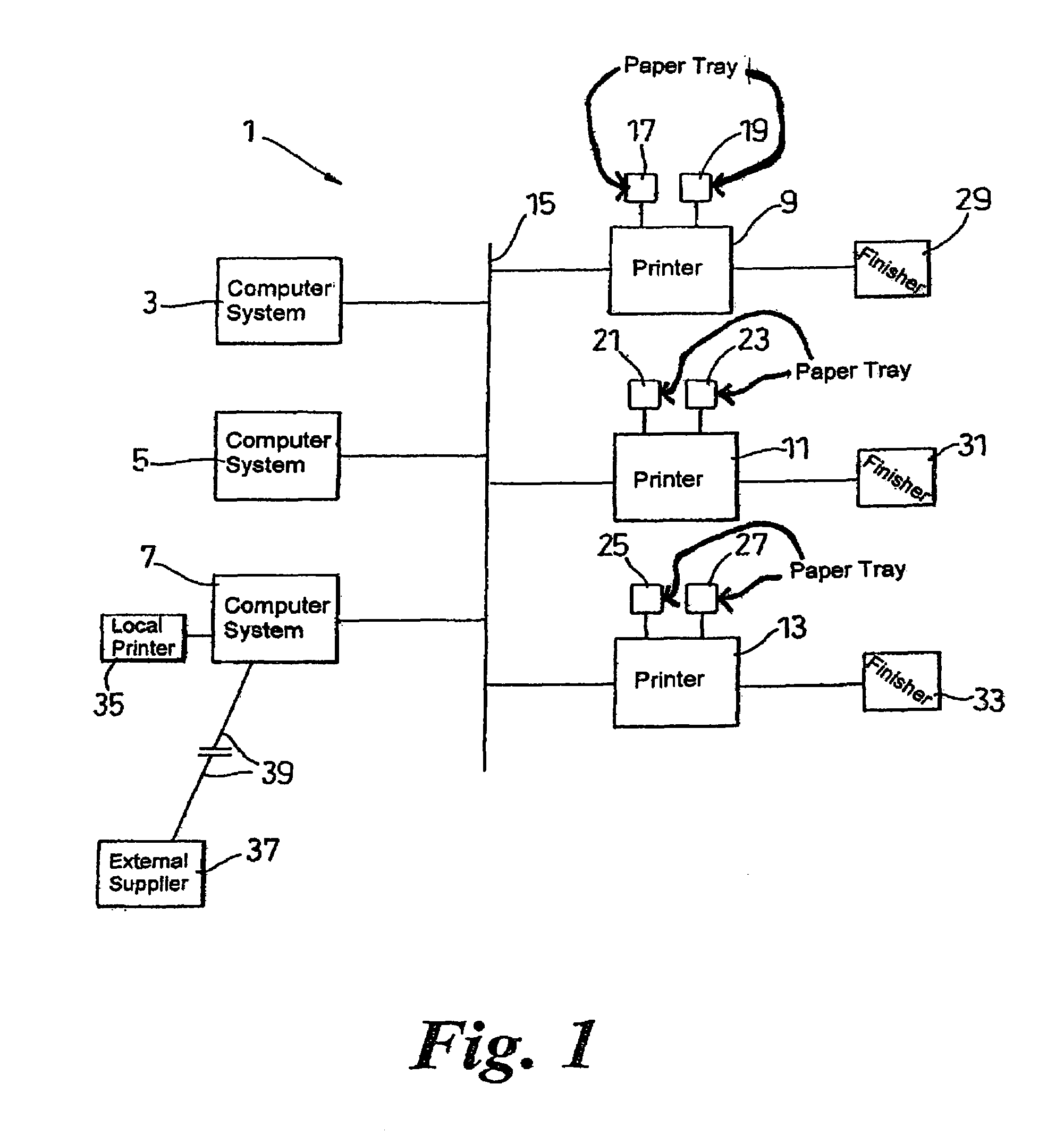

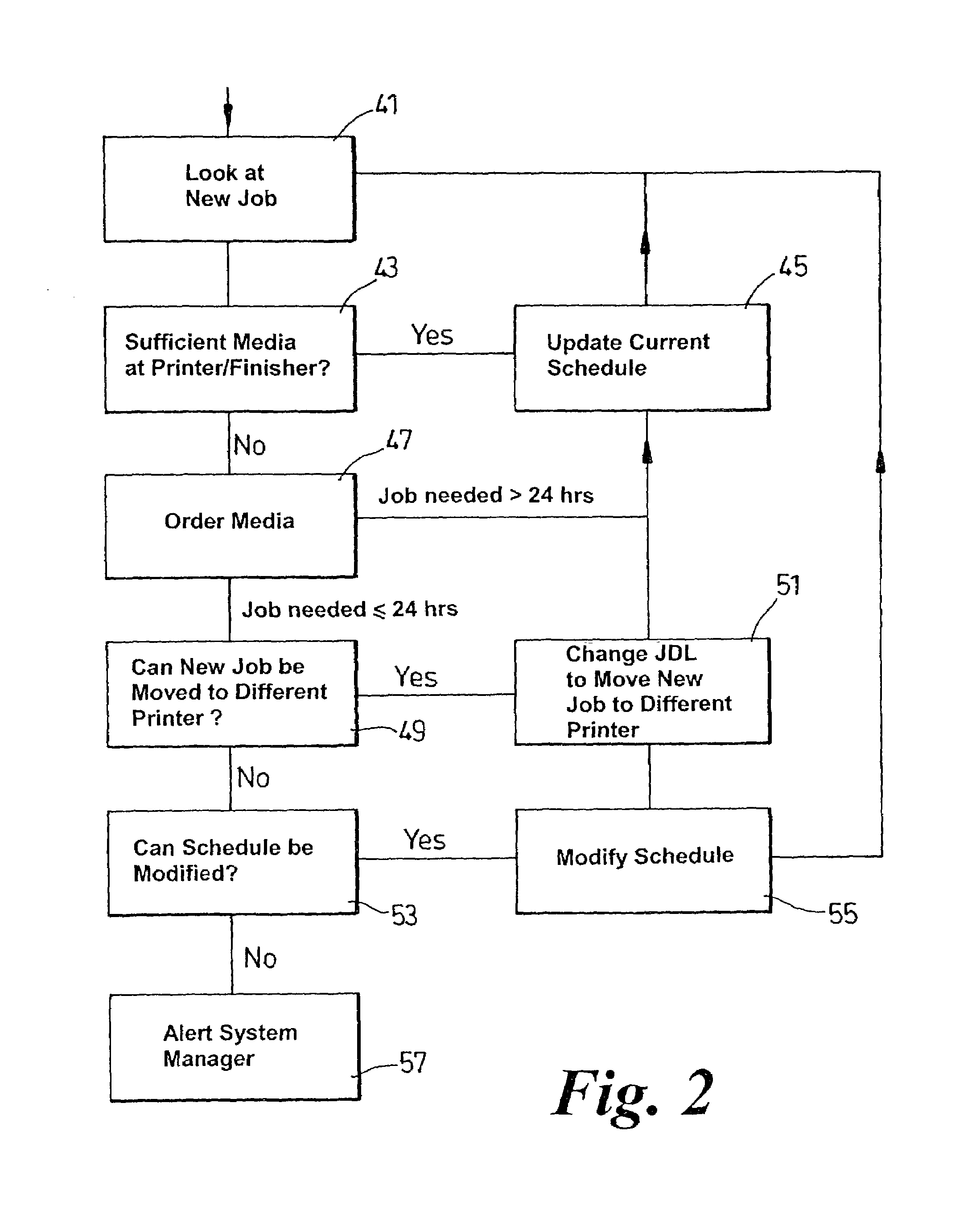

Method of, computer program for, and system for maintaining print system media resources

ActiveUS7298501B2No delayDigitally marking record carriersData processing applicationsComputerized systemApplication software

Owner:HEWLETT PACKARD DEV CO LP

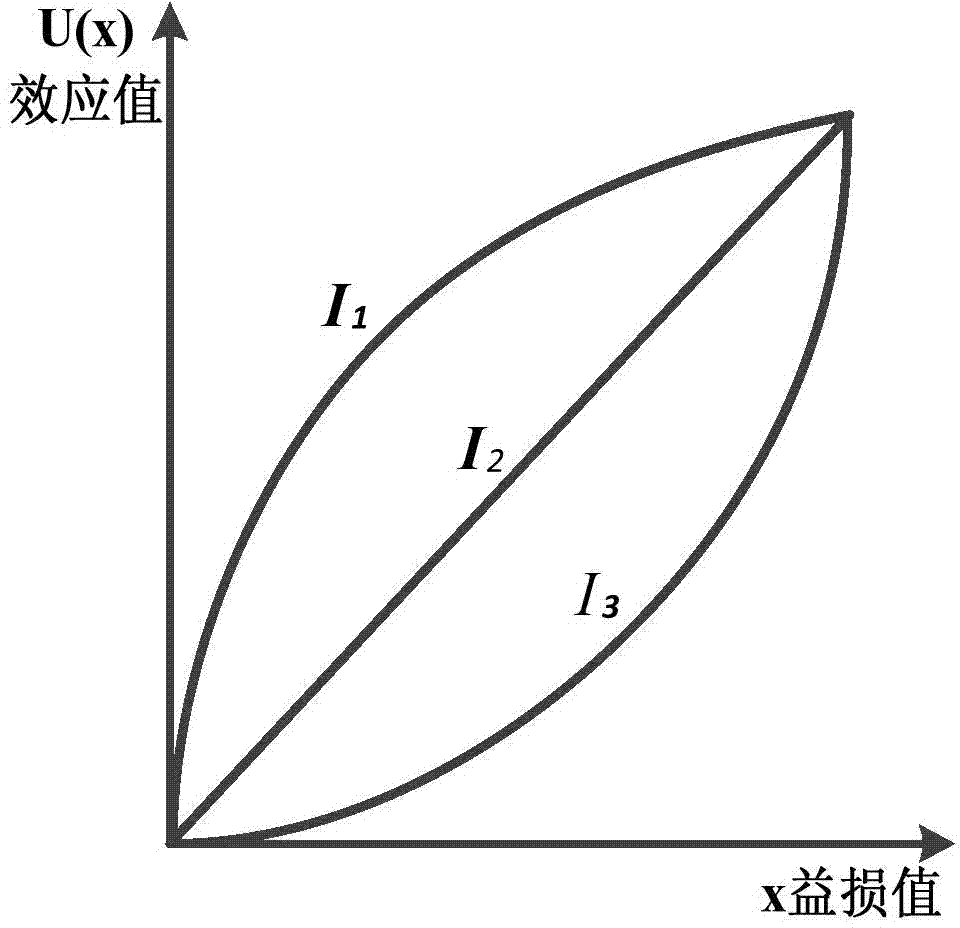

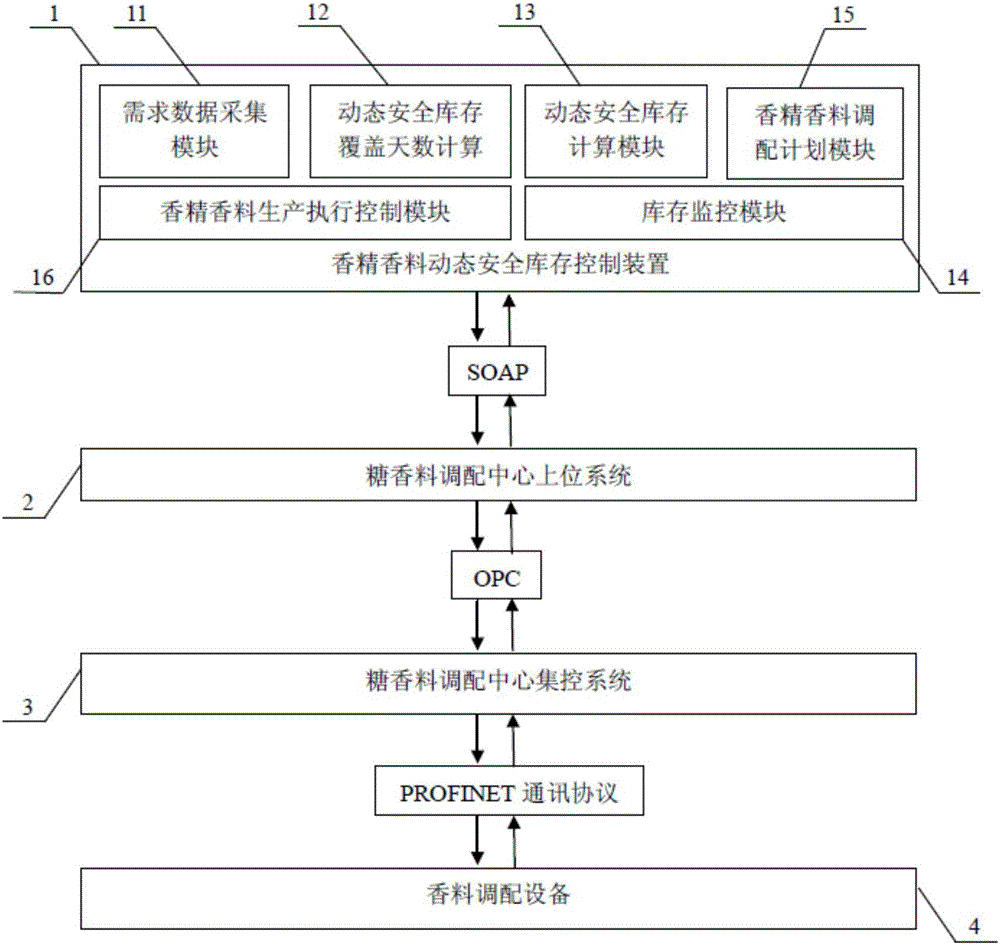

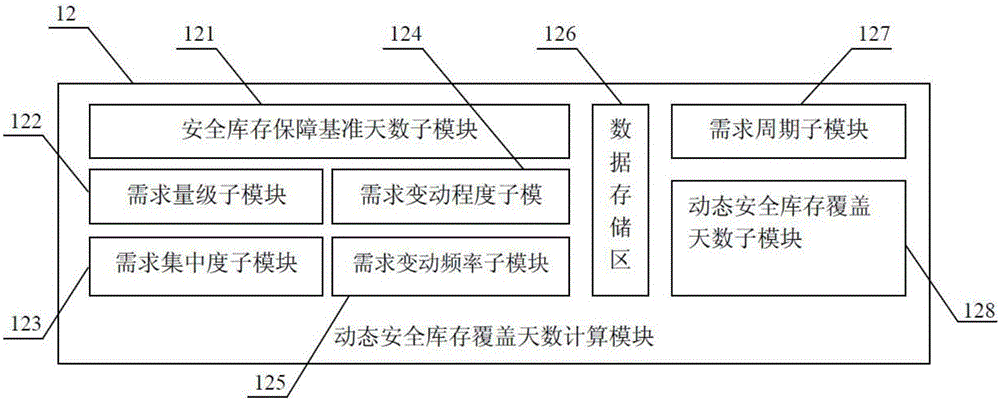

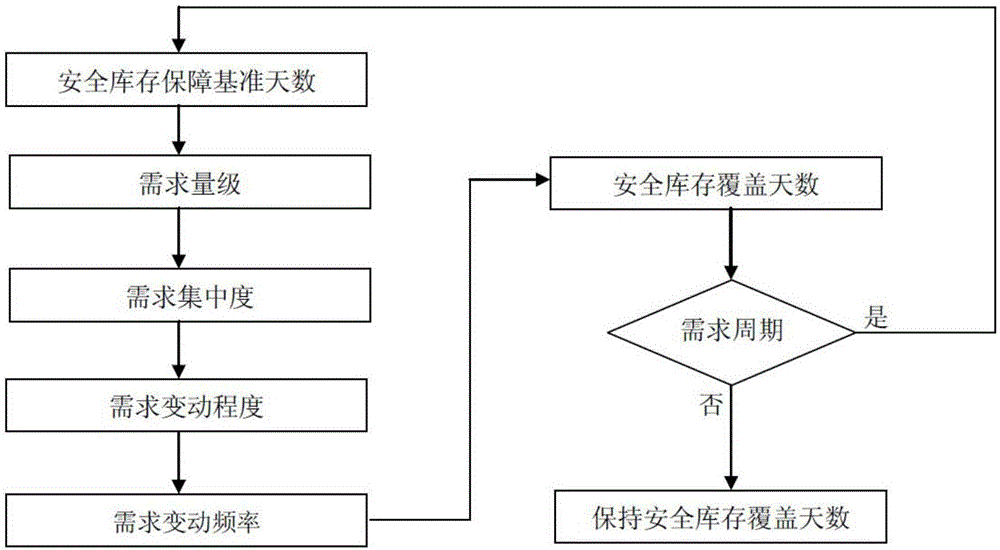

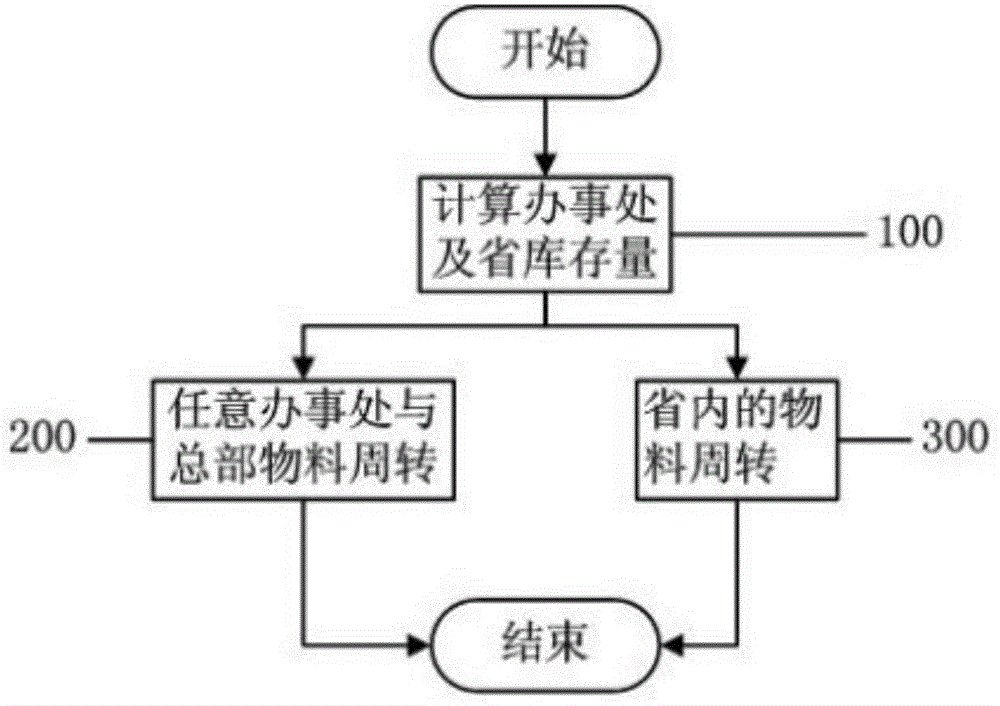

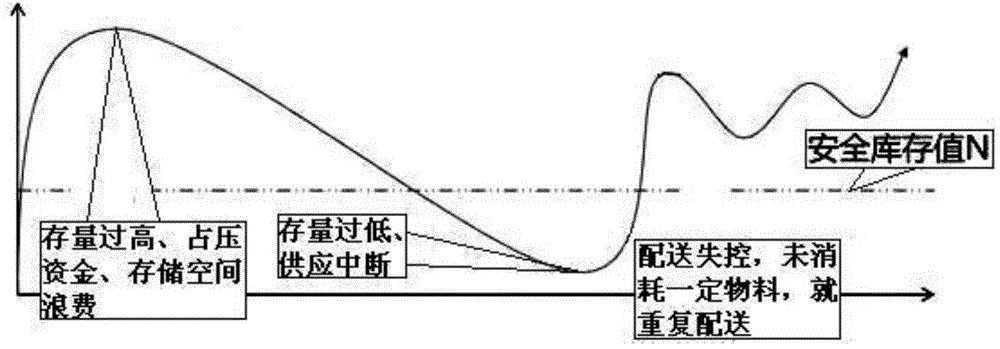

Control device of dynamic safety stock, and regulation and control method of safety stock

InactiveCN106529859AReduce sluggishnessOptimize inventory structureLogisticsData acquisitionExecution control

The invention discloses a control device of dynamic safety stock. The control device of dynamic safety stock includes a demand data acquisition module, a dynamic safety stock duration of dressing calculating module, a dynamic safety stock calculating module, a stock monitoring module, an allocation plan module and a production execution control module. The invention also discloses a dynamic regulation and control method of the control apparatus. The dynamic regulation and control method of the control apparatus can realize real-time control of allocation equipment and control the safety stock to maintain at a reasonably level, and can effectively reduce the stock maintenance cost and improve the stock turnover rate when stock can be supplied continuously.

Owner:CHINA TOBACCO ZHEJIANG IND

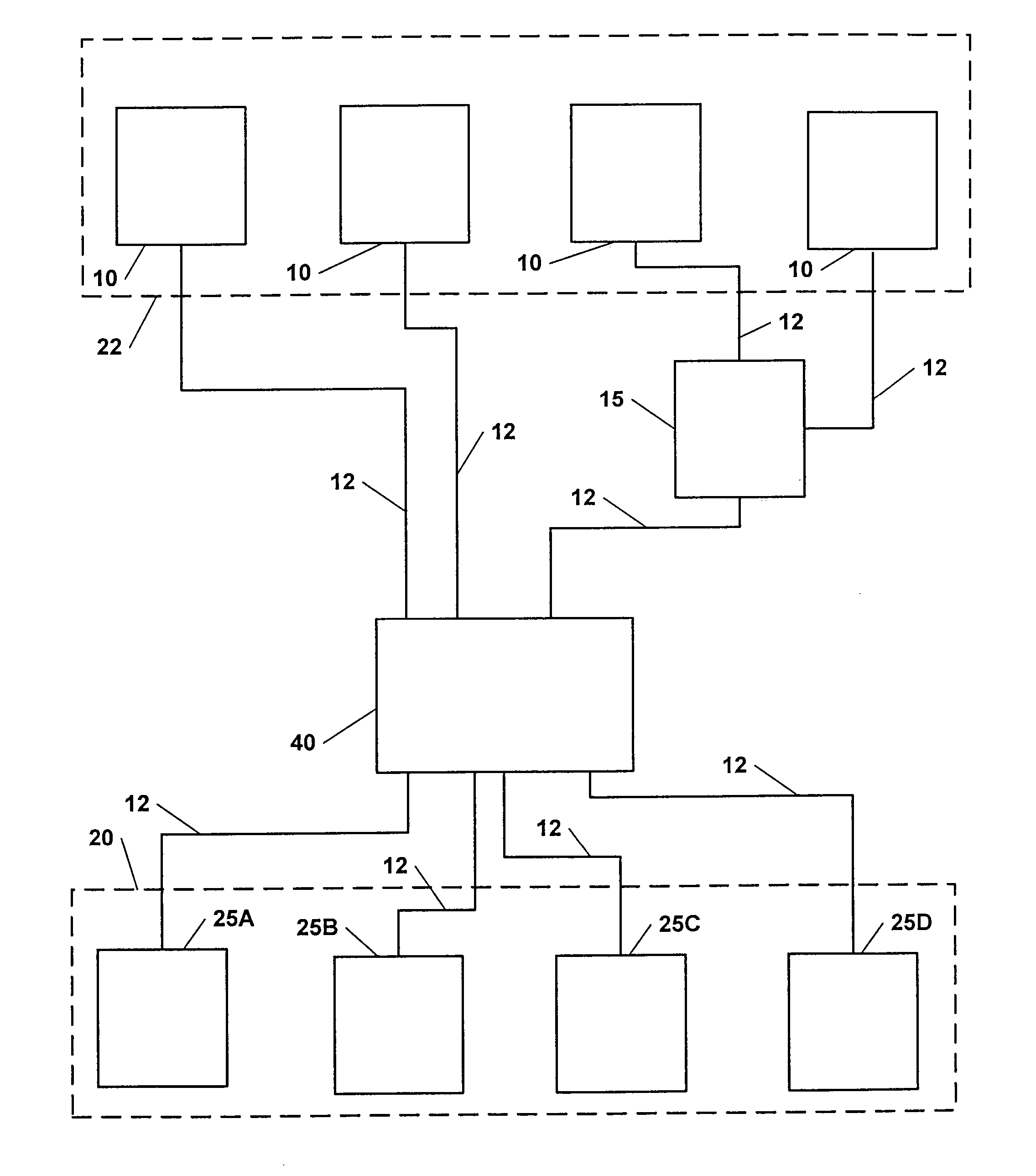

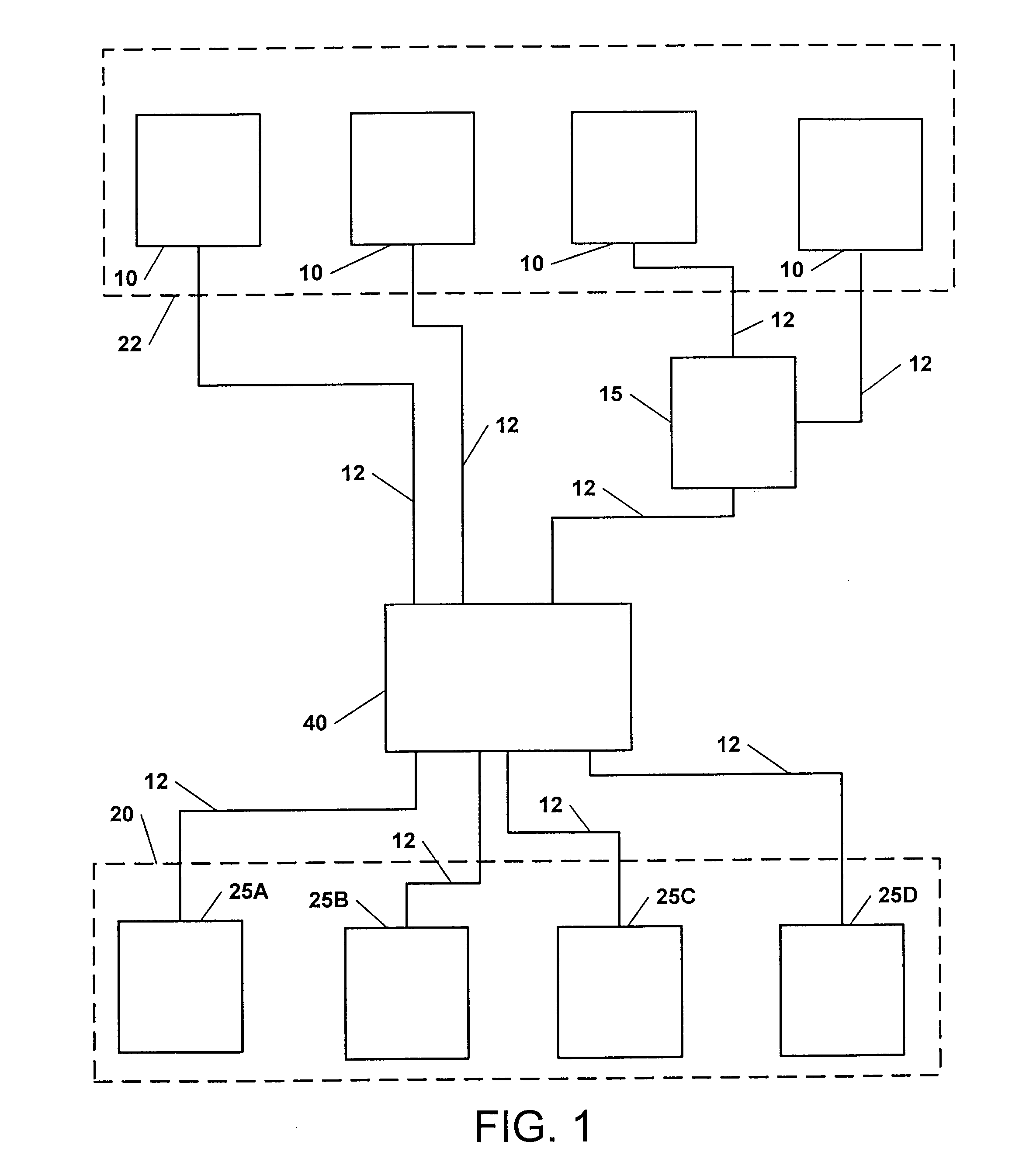

Control method of safe stock control system

The invention discloses a control method of a safe stock control system. The control system comprises a server, a switch, a dispatching computer, a spare part planning computer, a warehouse computer, a director computer, province material management computers and office computers, wherein the server, the switch, the dispatching computer, the spare part planning computer, the warehouse computer and the director computer are arranged in headquarters; the province material management computers are arranged in each province; the office computers are arranged in each office in the provinces; the switch is electrically connected with the server, the dispatching computer, the spare part planning computer, the warehouse computer and the director computer; and the switch is respectively connected with each province material management computer and each office computer through Internet. The control method provided by the invention has the characteristics that the stock is always in a reasonable range; overstocked products are effectively reduced; the stock turnover is accelerated; and the stock occupation cost is further reduced.

Owner:EASTERN COMM

Apparatus and system for stock control

InactiveUS7737855B2Hand manipulated computer devicesLighting and heating apparatusRadio frequencyComputer science

Owner:MINIBAR SOLUTIONS

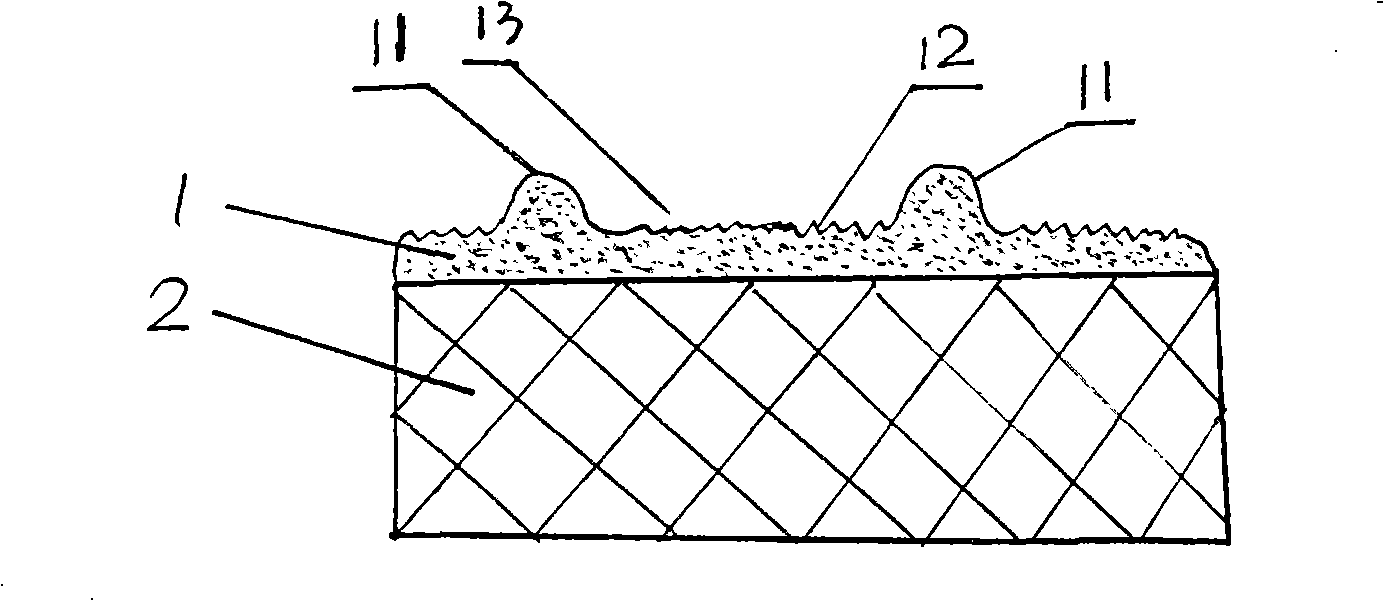

UV printing ink printing art of forming texture

InactiveCN101342829ALarge embossment widthIncrease heightPattern printingPrinting after-treatmentUltraviolet lightsPrinting ink

The invention provides a veining UV ink printing technology which sequentially includes the main steps as follows: a. printing UV ink on a sheet printing stock by a silk screen of 150 to 250 mesh; b. UV radiating the sheet printing stock under low temperature for the first time; c. after 2 to 8 seconds of the first UV radiation, UV radiating the sheet printing stock under low temperature for the second time; d. after 1 to 5 seconds of the second UV radiation, UV radiating the sheet printing stock under high temperature, and radiating the sheet printing stock with an ultraviolet light with the power of ranging from 10000W to 16000W, with the transmitted speed of the printing sheet stock controlled within 20 to 30m / min, and completely solidifying the UV ink. The UV ink printing technology of the invention is distinct in visual effect, rich in level, and strong in stereoscopic veins. Besides, the invention can prevent the printing stock from deforming.

Owner:SHANTOU GUOXING PRINTING

Method, device and equipment for determining actual controller of share company

PendingCN110807697ADetermine the actual controllerIdentify holdingsFinanceBusiness enterpriseComputer science

The embodiment of the invention discloses a method, device and equipment for determining an actual controller of a share company. According to the scheme, the method comprises the steps of obtaining first stock right structure distribution information of a target enterprise based on a stock right query request of the target enterprise submitted by a user; determining a direct shareholder of the target enterprise and a stock holding proportion of the direct shareholder according to the first shareright structure distribution information; judging whether a non-personal shareholder in the directshareholders is detachable or not to obtain a first judgment result; when the first judgment result shows that the non-personal shareholders in the direct shareholders are detachable, obtaining secondshareholder right structure distribution information of the direct shareholders; splitting the direct shareholders according to the second shareholder structure distribution information to obtain allnon-detachable shareholders corresponding to the direct shareholders; calculating a stock control rate of each non-detachable shareholder for the target enterprise; and determining an actual controller of the target enterprise according to the control rate of each non-detachable shareholder.

Owner:ALIPAY (HANGZHOU) INFORMATION TECH CO LTD

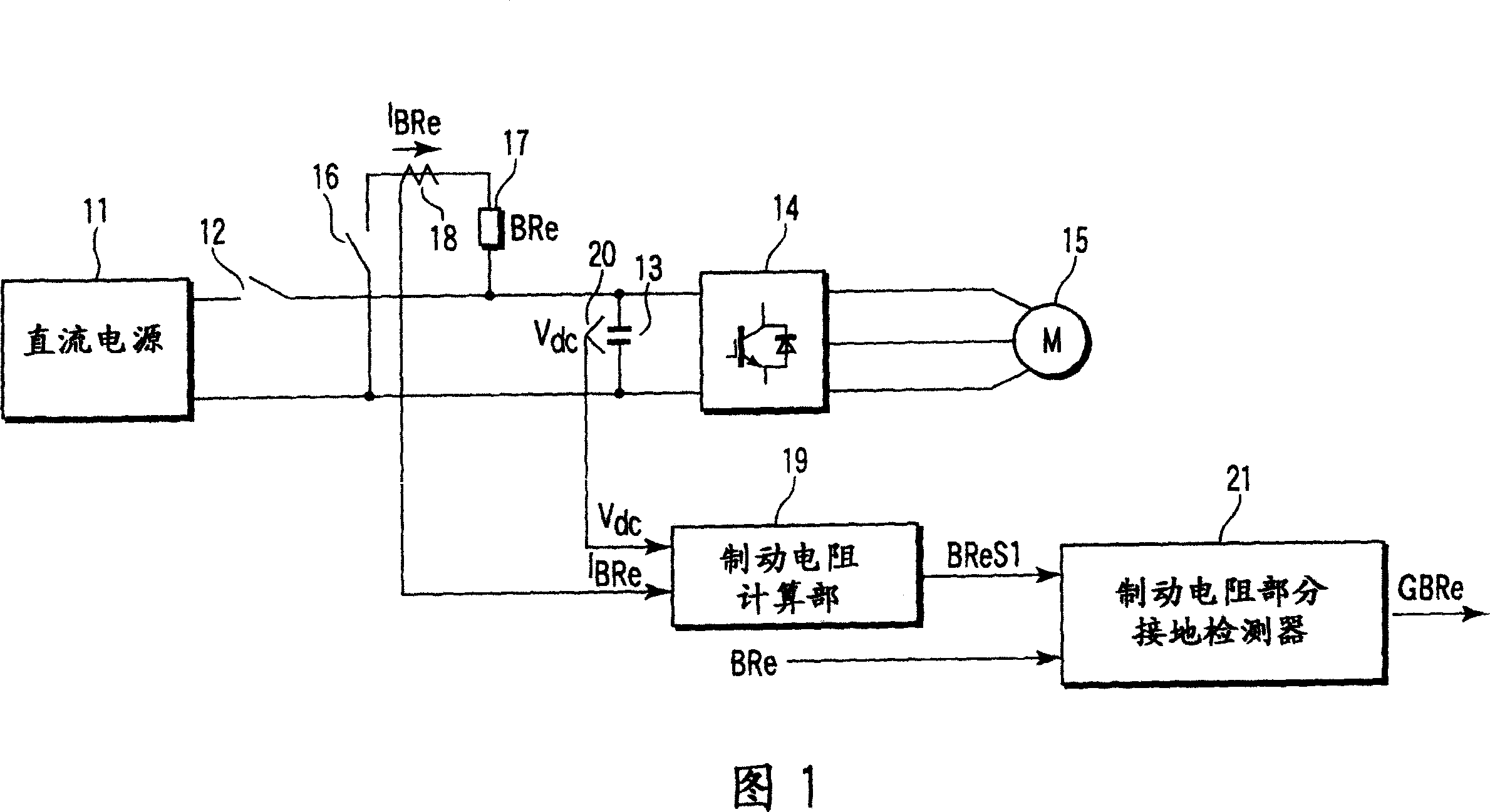

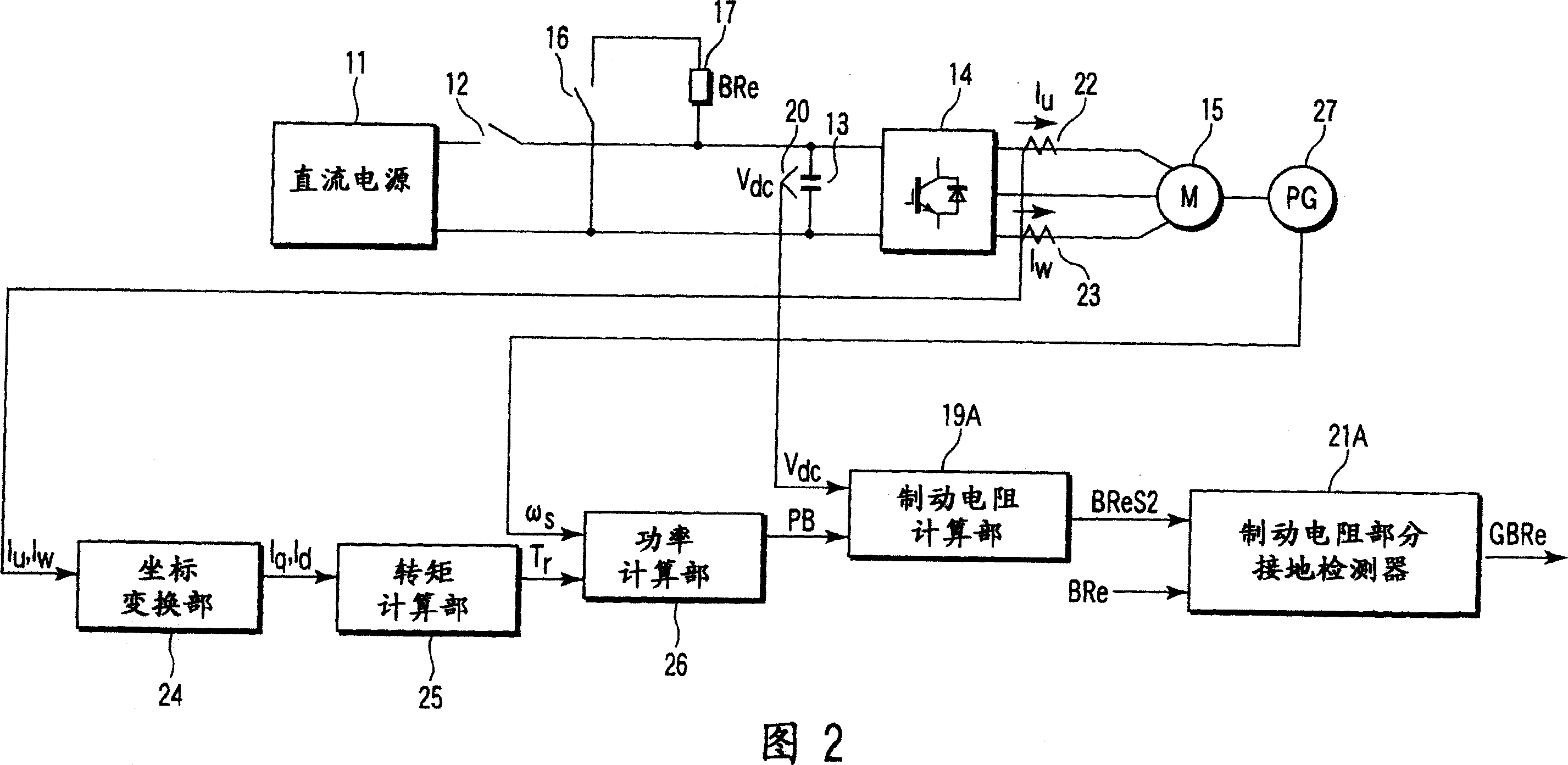

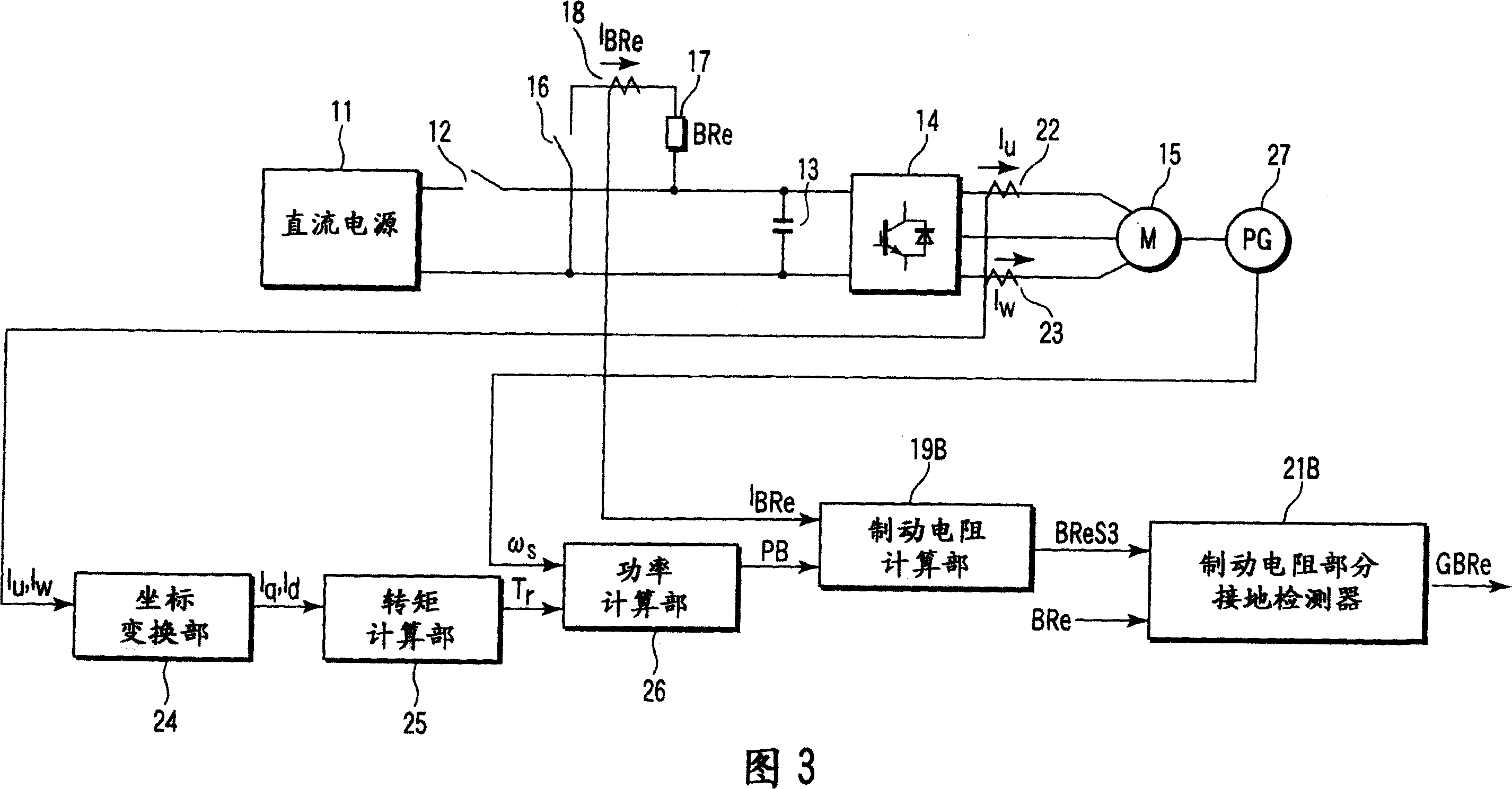

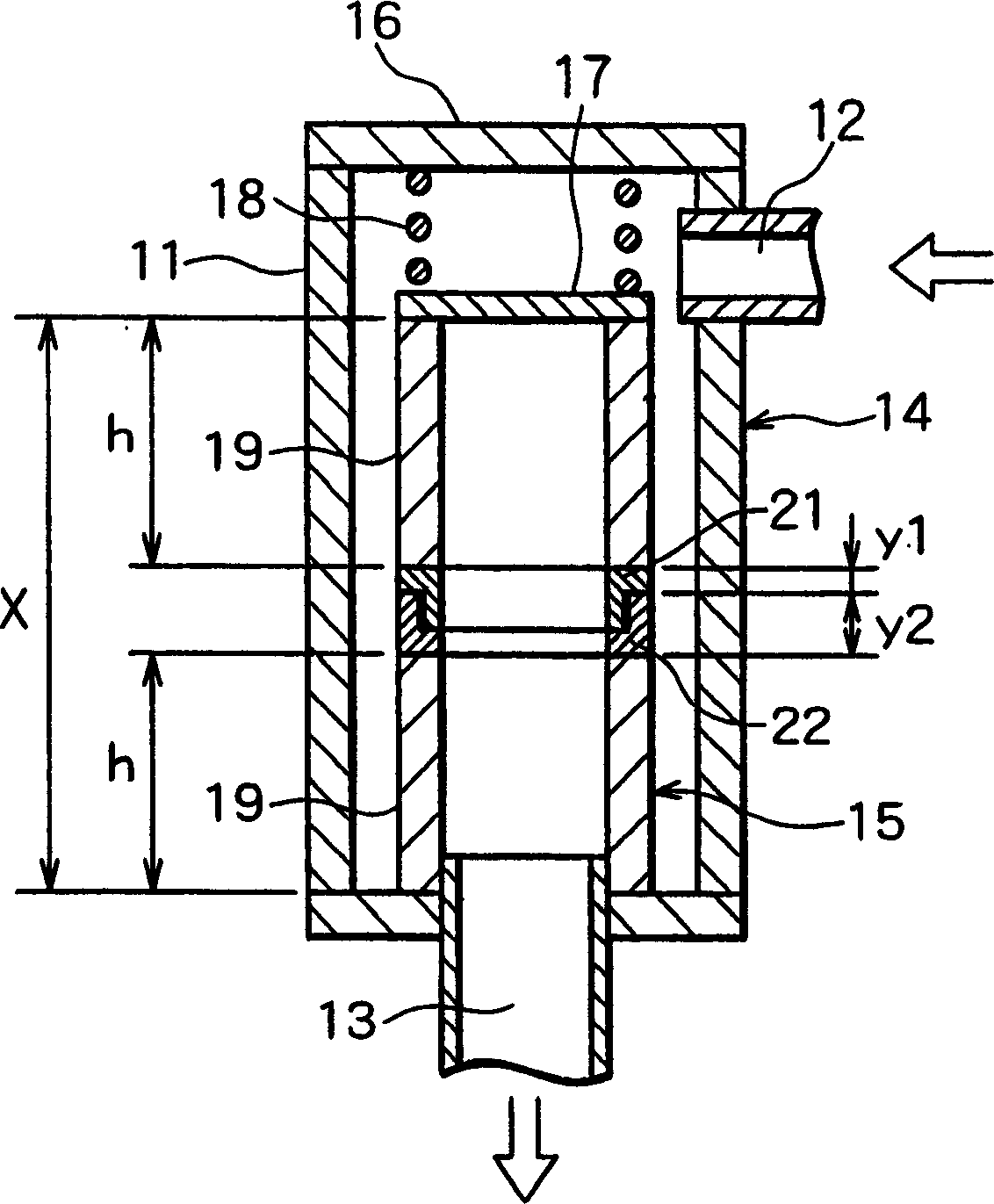

Electric car control apparatus

InactiveCN101024378AElectric devicesElectrodynamic brake systemsElectrical resistance and conductanceElectric power system

An electric rolling stock control apparatus includes, an alternating-current motor (15) for making an electric rolling stock run, and for carrying out brake control of the electric rolling stock, a dynamic braking resistor (17) for consuming electric power generated by the brake control, electric current detector (18) for detecting a value of current flowing in the dynamic braking resistor (17), voltage detector (20) for detecting a value of voltage between both terminals of the dynamic braking resistor (17), dynamic braking resistance calculating unit (19) for calculating a value of resistance of the dynamic braking resistor (17) on the basis of the value of current and the value of voltage, and a dynamic braking resistance partial ground fault detector (21) for detecting a partial ground fault in the dynamic braking resistor (17) when the value of resistance is less than a predetermined value.

Owner:KK TOSHIBA

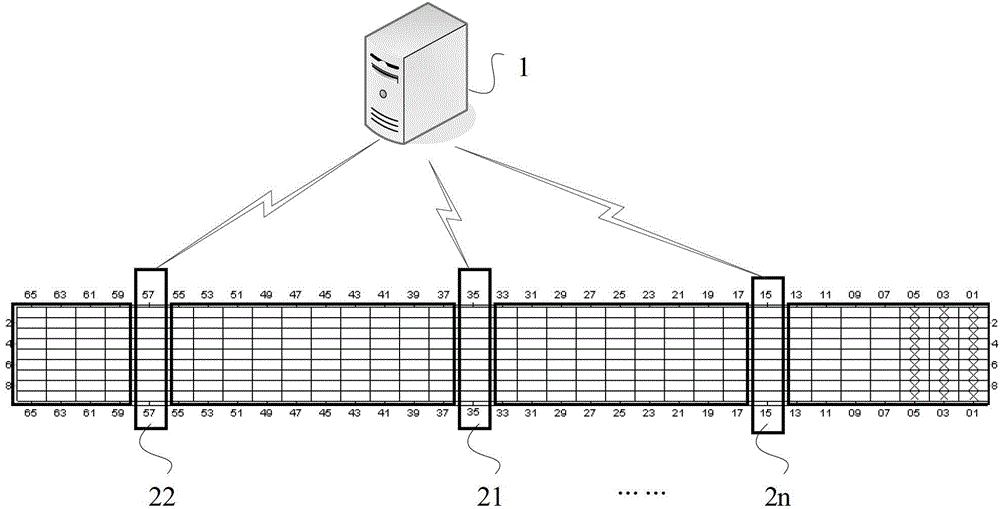

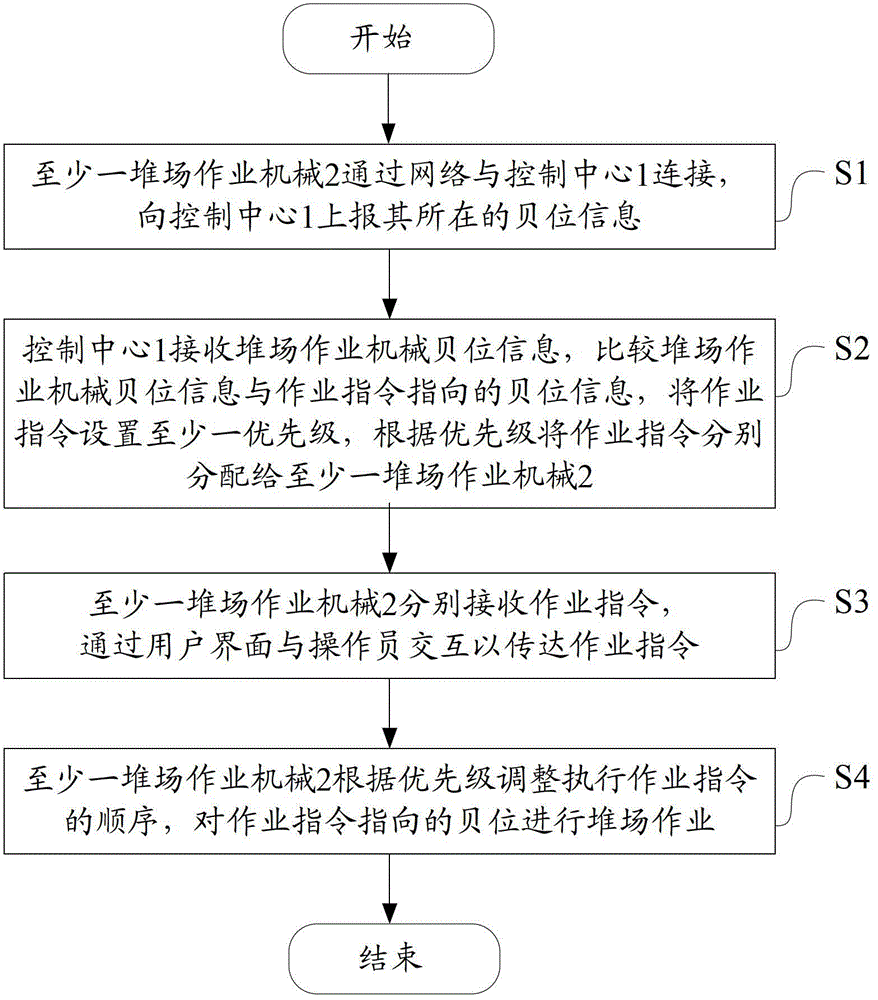

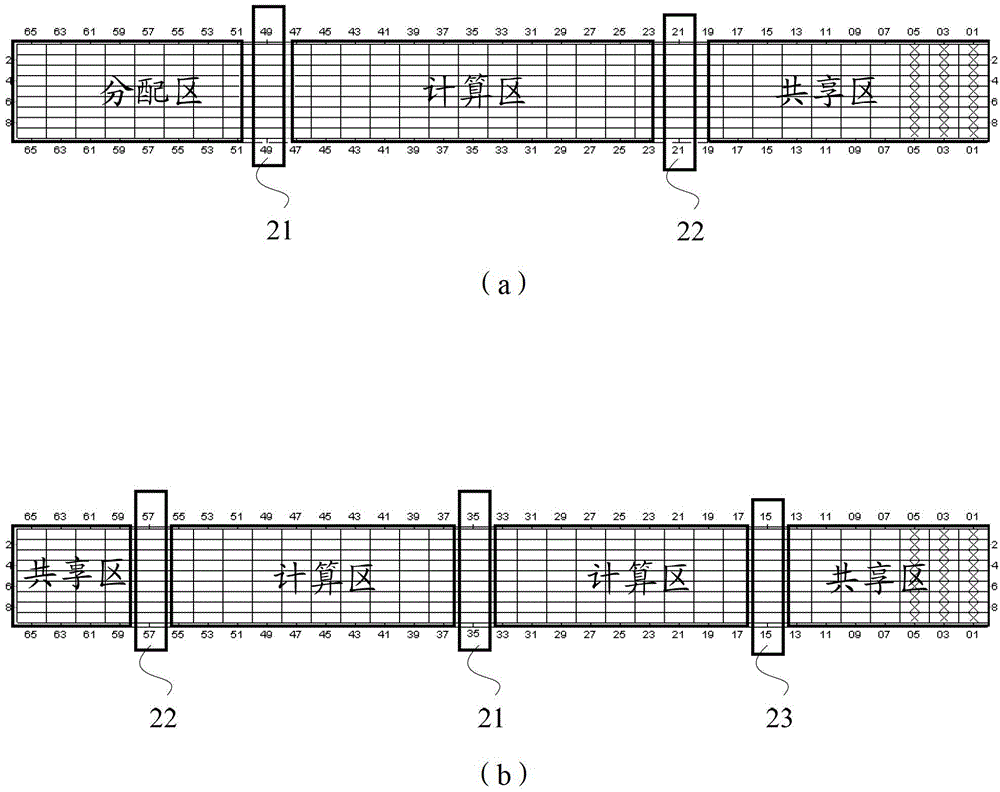

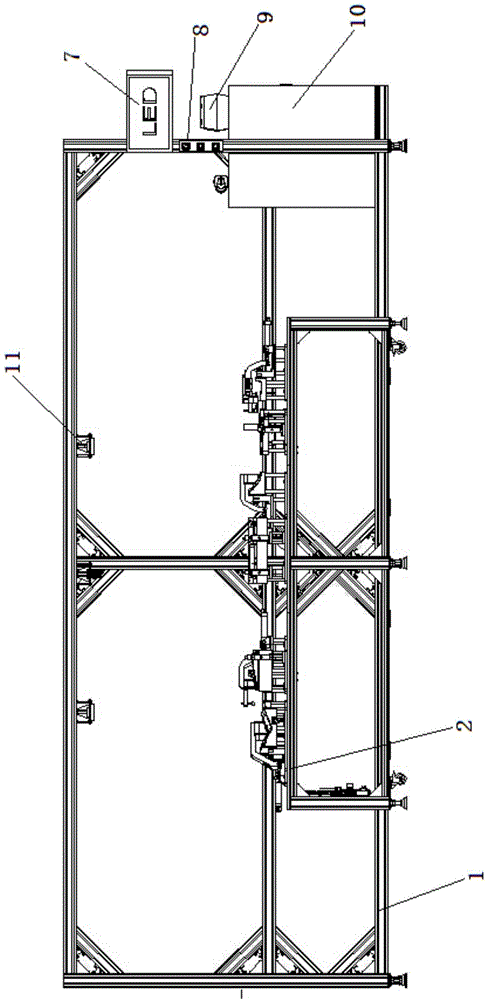

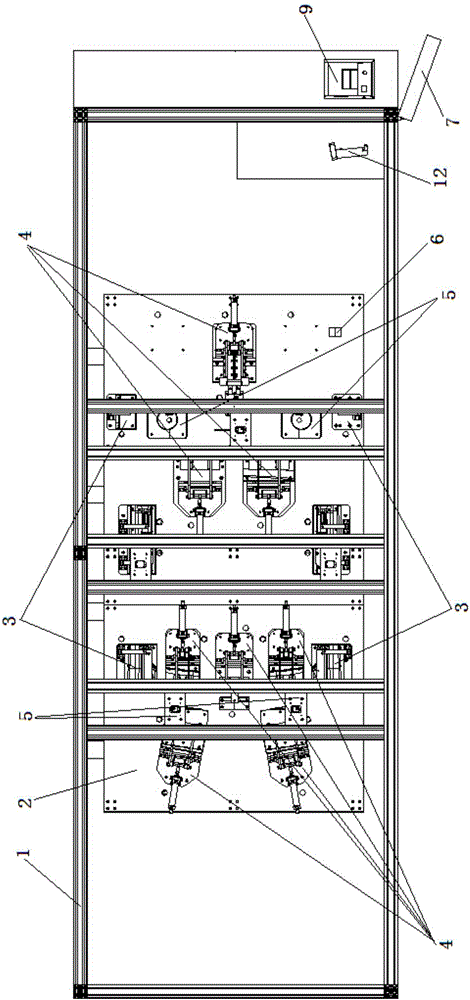

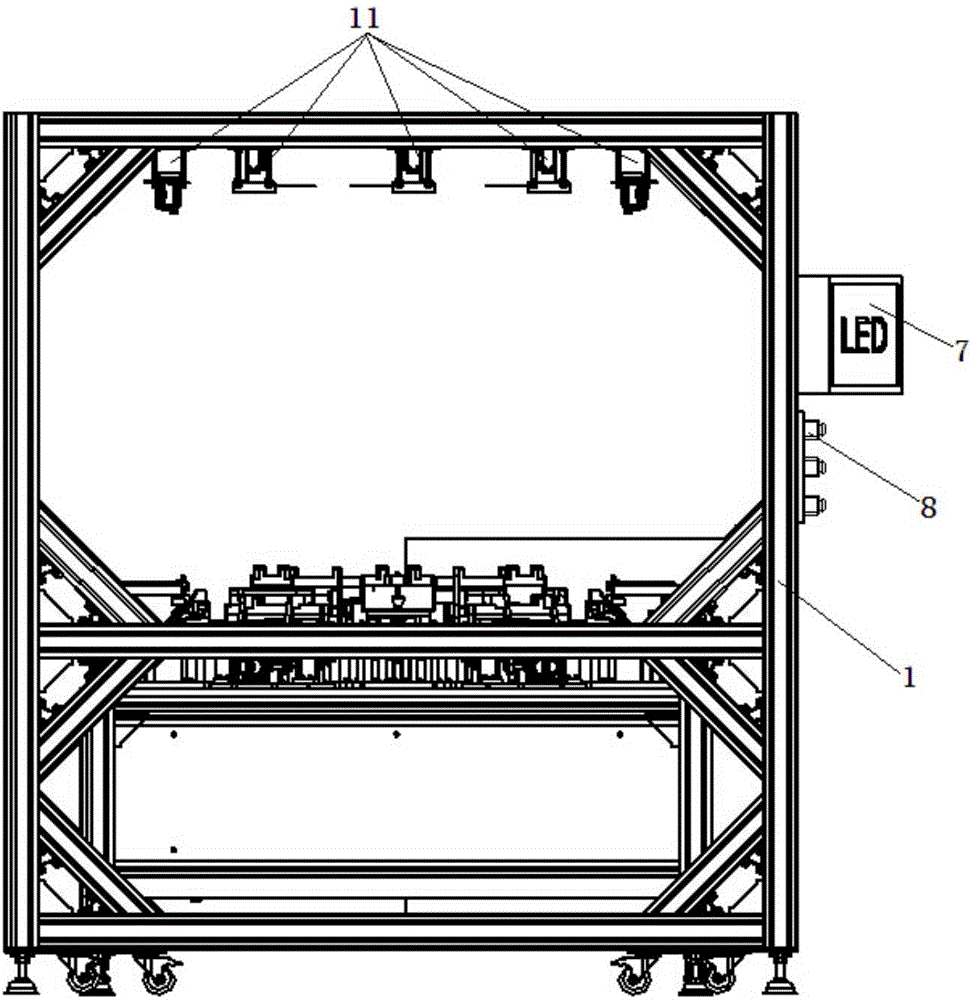

Stock dump control system and stock dump control method

ActiveCN103064386AImprove work efficiencyRealize intelligent managementTotal factory controlProgramme total factory controlControl systemUser interface

The invention provides a stock dump control system which comprises a control center and at least one stock dump working machine, at least one stock dump working machine is connected with the control center through a network, and reports stowage location information of where the working machine is to the control center. The control center receives the stowage location information of the stock dump working machine, compares the stowage location information of the stock dump working machine and the stowage location information indicated by working instructions, at least one priority level is set to the working instructions, and the control center distributes the working instructions to stock dump working machines respectively according to the priority level. The stock dump working machines receive working instructions respectively, and convey the working instructions through the interaction of a user interface and an operator. The stock dump working machines adjust the orders of exacting the working instructions according to the priority level, and carry out stock dump working to the stowage location indicated by the instructions. The invention further provides a stock dump control method. The stock dump control system and the stock dump control method can carry out flexible adjustment according to changeable data at any time, adopt a proximity principle to adjust the priority levels of the working instructions, and send the working instructions to corresponding stock dump equipment flexibly.

Owner:CHINA MERCHANTS HLDG INT INFORMATION TECH COMPANY

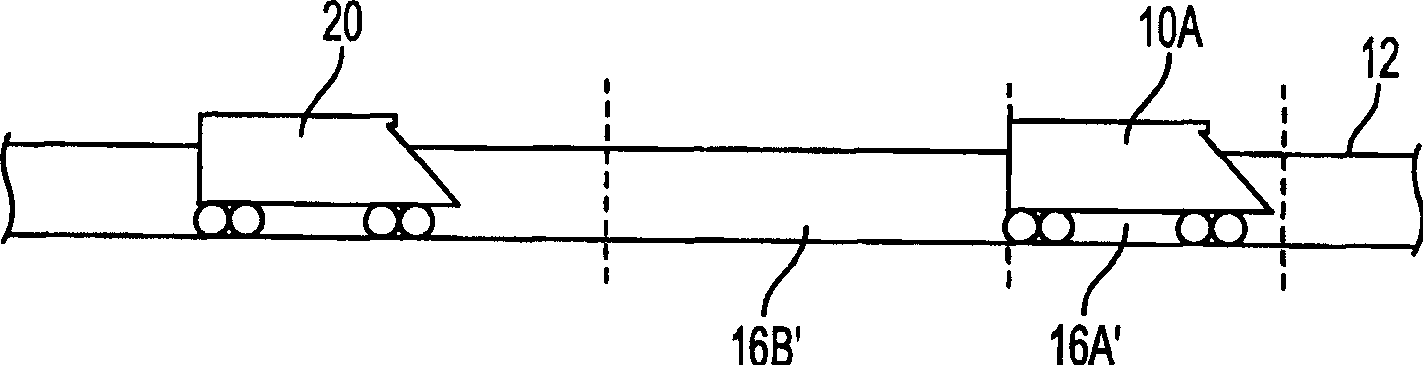

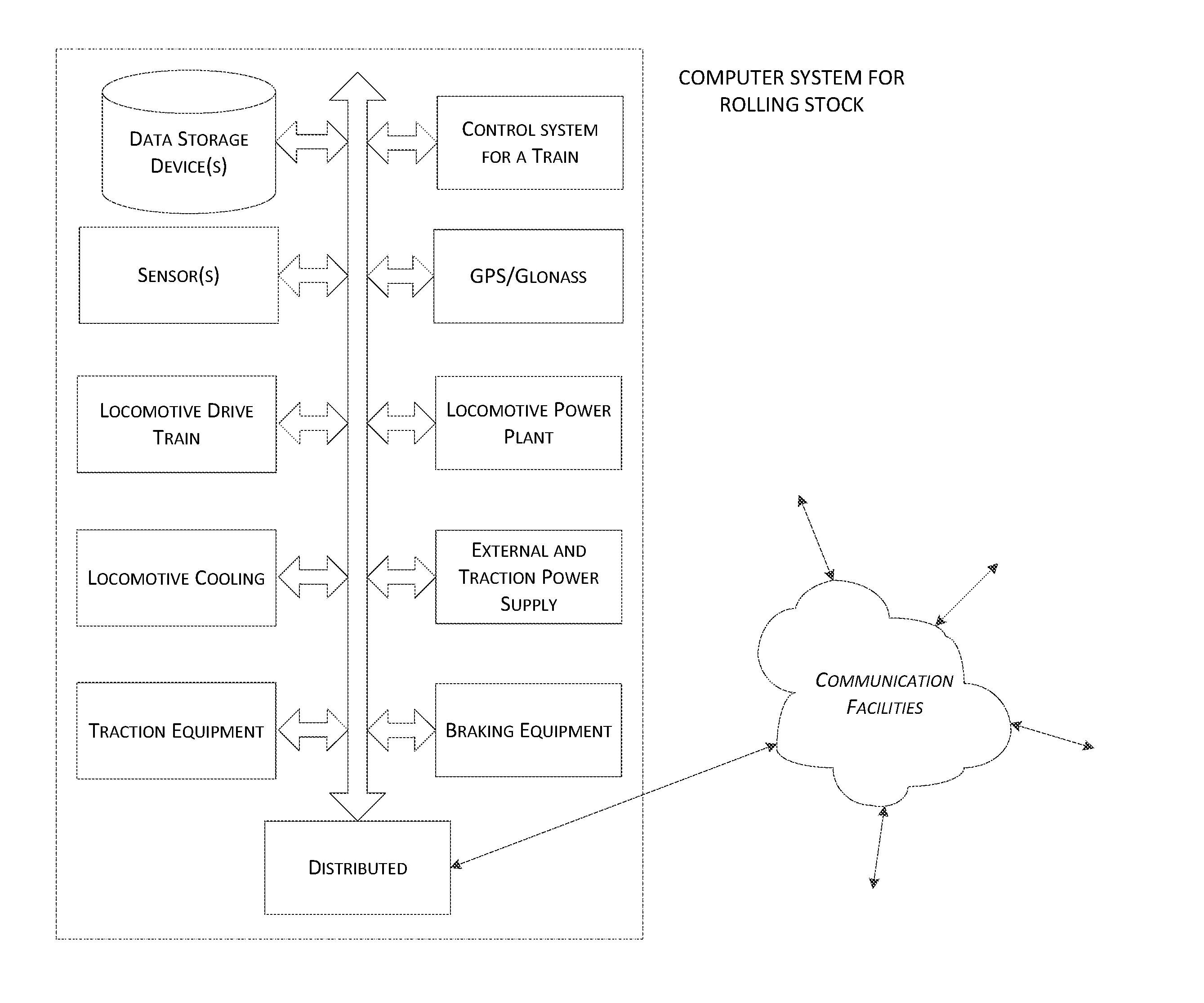

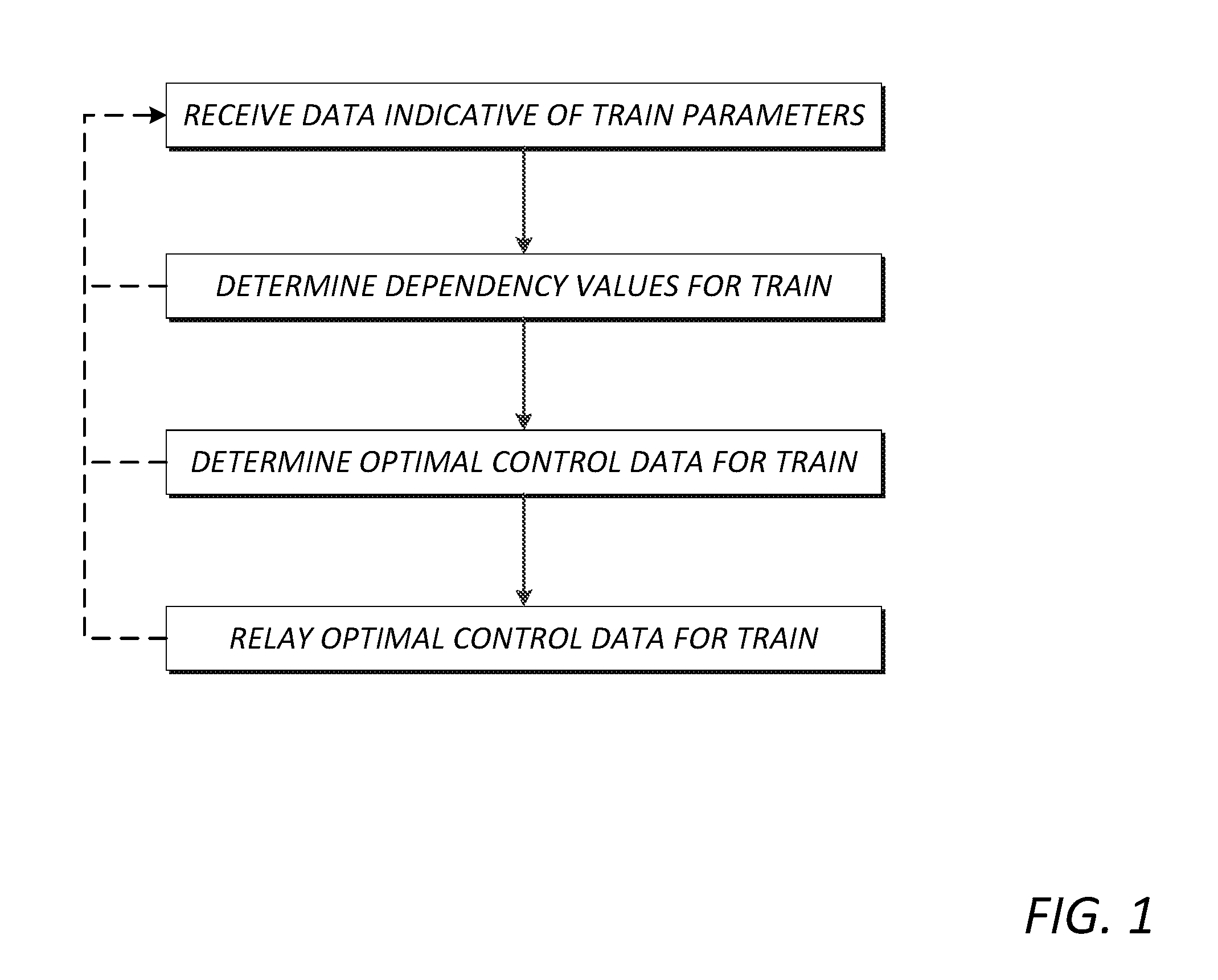

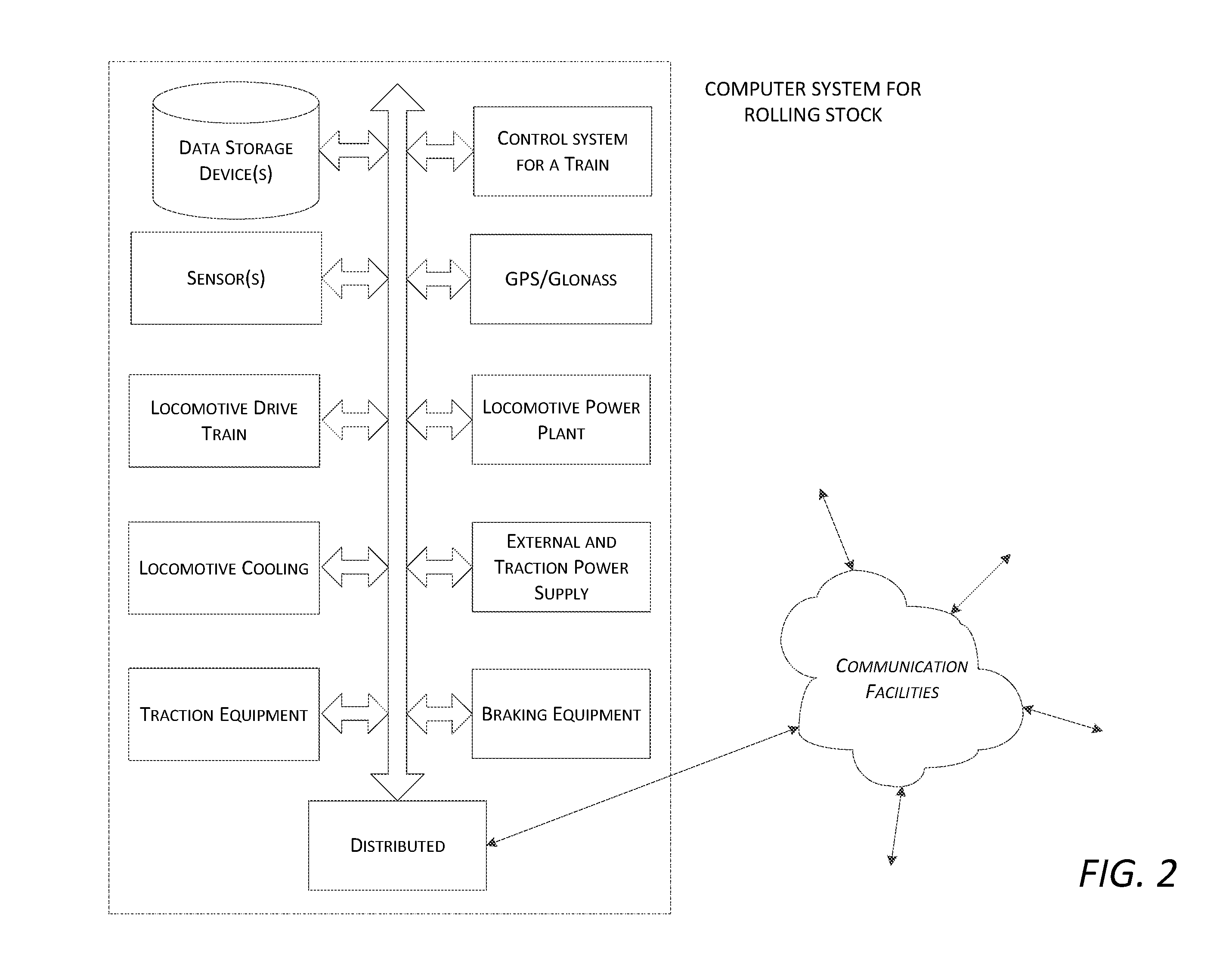

Method and system for increasing efficiency of rolling stock

ActiveUS20170021845A1Drawback can be obviatedReduce consumptionPower supply linesSignalling indicators on vehicleControl systemOptimal control

The invention is intended for conserving energy expended by railway rolling stock, for instance by a locomotive when carrying out train operations and shunting, when trains are run in an automatic mode or in a train operator assistance mode. A method for increasing the efficiency of rolling stock includes the following steps: obtaining the parameters of the rolling stock, including at least the following: speed, coordinates, overhead system voltage, traction engine current voltage, brake line discharging; in addition, determining at least the dependence parameters of an active traction force, braking force, motion resistance force, force of wheel adherence to the rails, and the mass of the rolling stock; then, determining the optimal control to be carried out by traction and braking equipment of railway rolling stock based on the dependence parameters obtained during the previous step; then, transmitting the optimal control, determined during the previous step, to a rolling stock control system for implementation or for displaying to the train operator.

Owner:OBSCHESTVO S OGRANICHENNOY OTVETSTVENNOSTYU SMARTWIZ

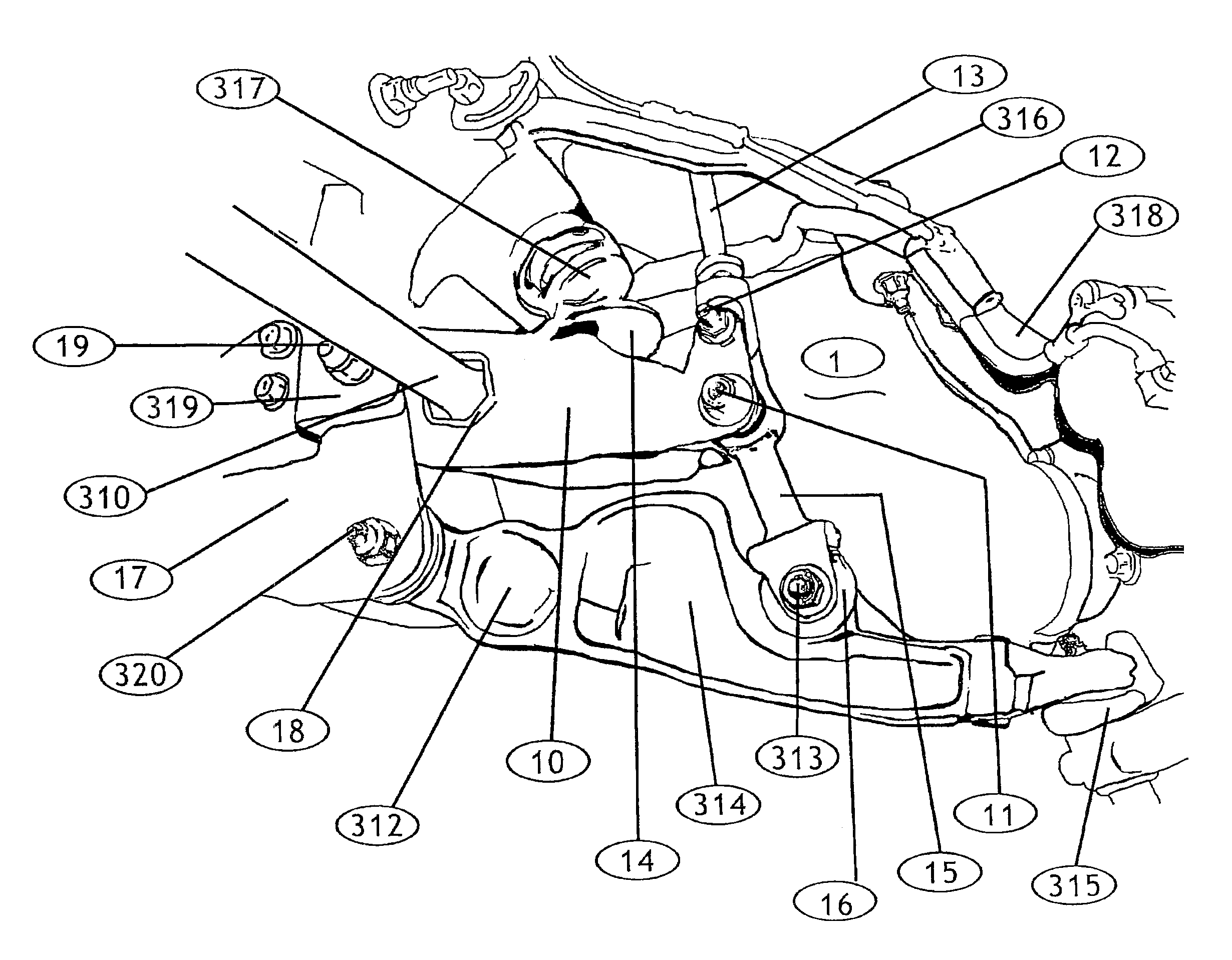

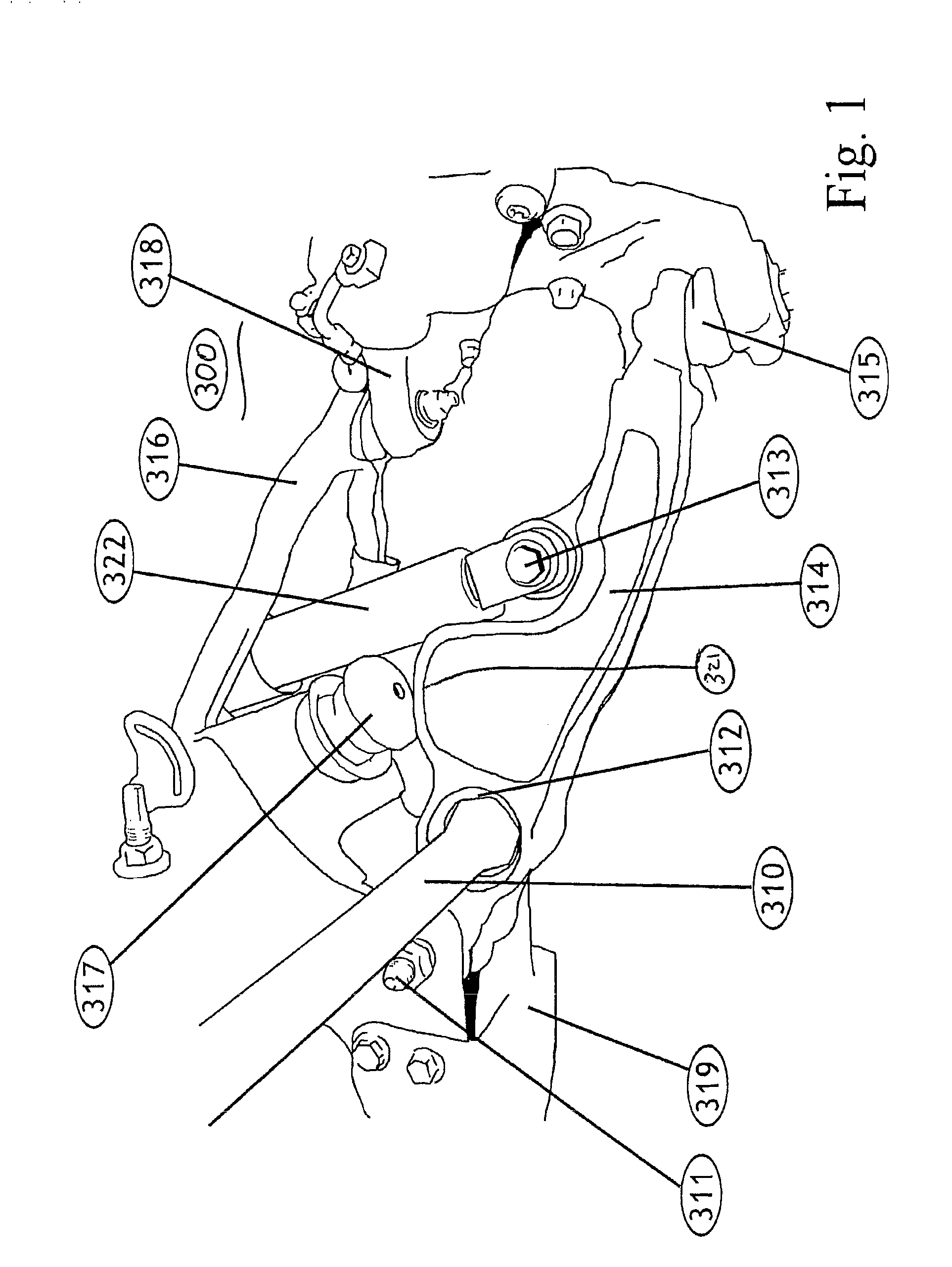

Non-drop torsion bar bracket and assembly

InactiveUS7429054B1Easy to installKeep distanceInterconnection systemsResilient suspensionsShock mountControl arm

The present invention discloses a vehicle lift kit that allows a vehicle to be lifted or raised from the ground without moving the stock torsion bar bracket and assembly. The present lift kit has a drop bracket having a front pivot point, a rear pivot point, and a torsion bar socket for receiving a torsion bar of the vehicle. The lift kit also provides a link attached to the front pivot point of the drop bracket and a stock control arm and a bracket attachable to the rear pivot point of the drop bracket and the stock control arm. The drop bracket may have a bump stop pad. The link attaches to a shock mount of the stock control arm. The bracket is attaches to a pivot point of the stock control arm. The link has a body joining an upper hole and a lower hole.

Owner:HECKETHORN PRODS

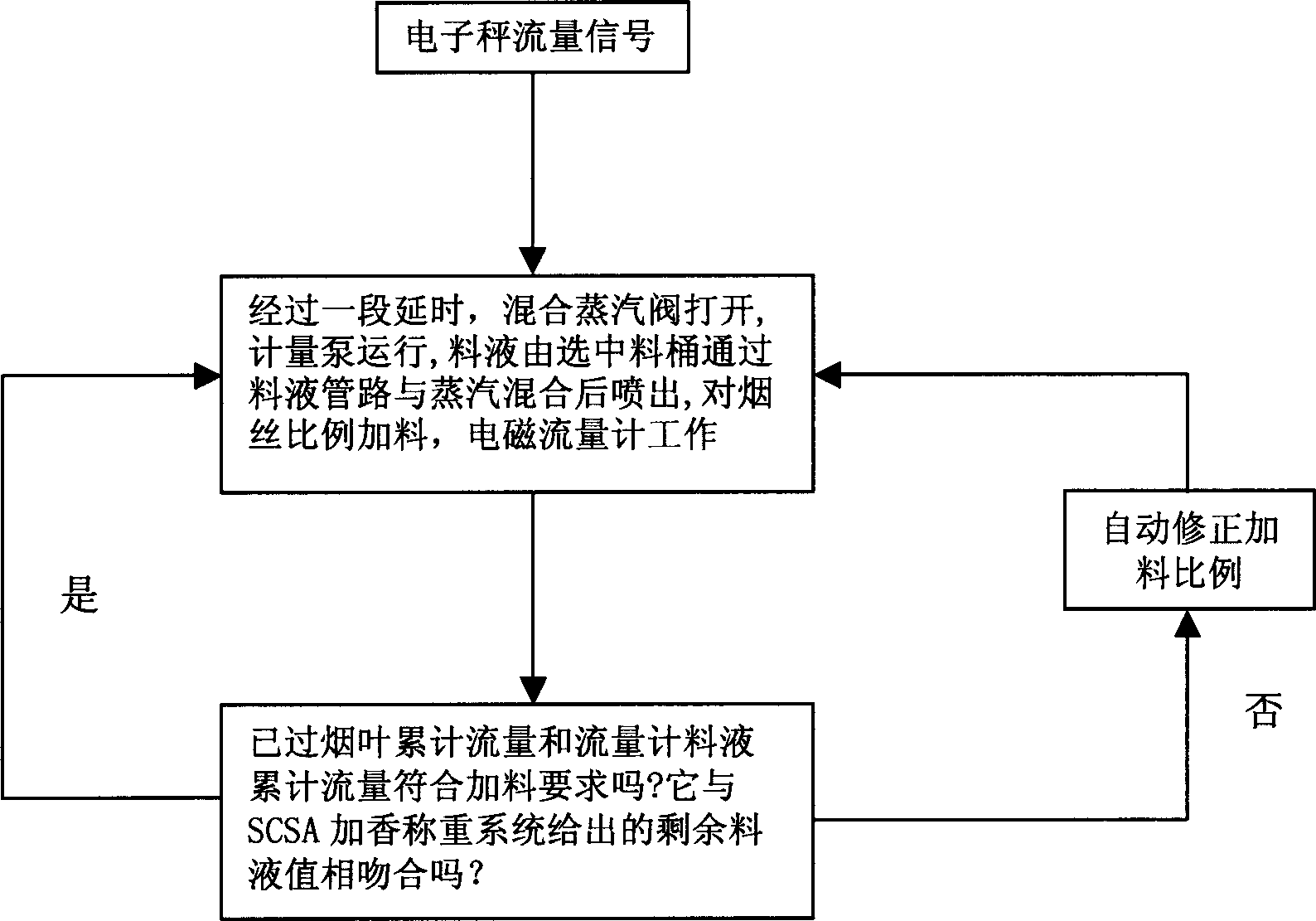

Perfuming/charging method for tobacco scrap prodn. line

InactiveCN1785074AReduced precision requirementsConducive to production process controlTobacco preparationProduction lineAutomatic control

A method for adding perfume or raw material on the production line to prepare tobacco shreds from tobacco leaves includes such steps as putting the liquid material drum on sensor connected to a weighting instrument, displaying the weight of material via conversion, and automatically controlling the addition of perfume or material by the upper-layer machine connected with said weighting instrument. Its advantage is high control accuracy.

Owner:云南昆船电子设备有限公司

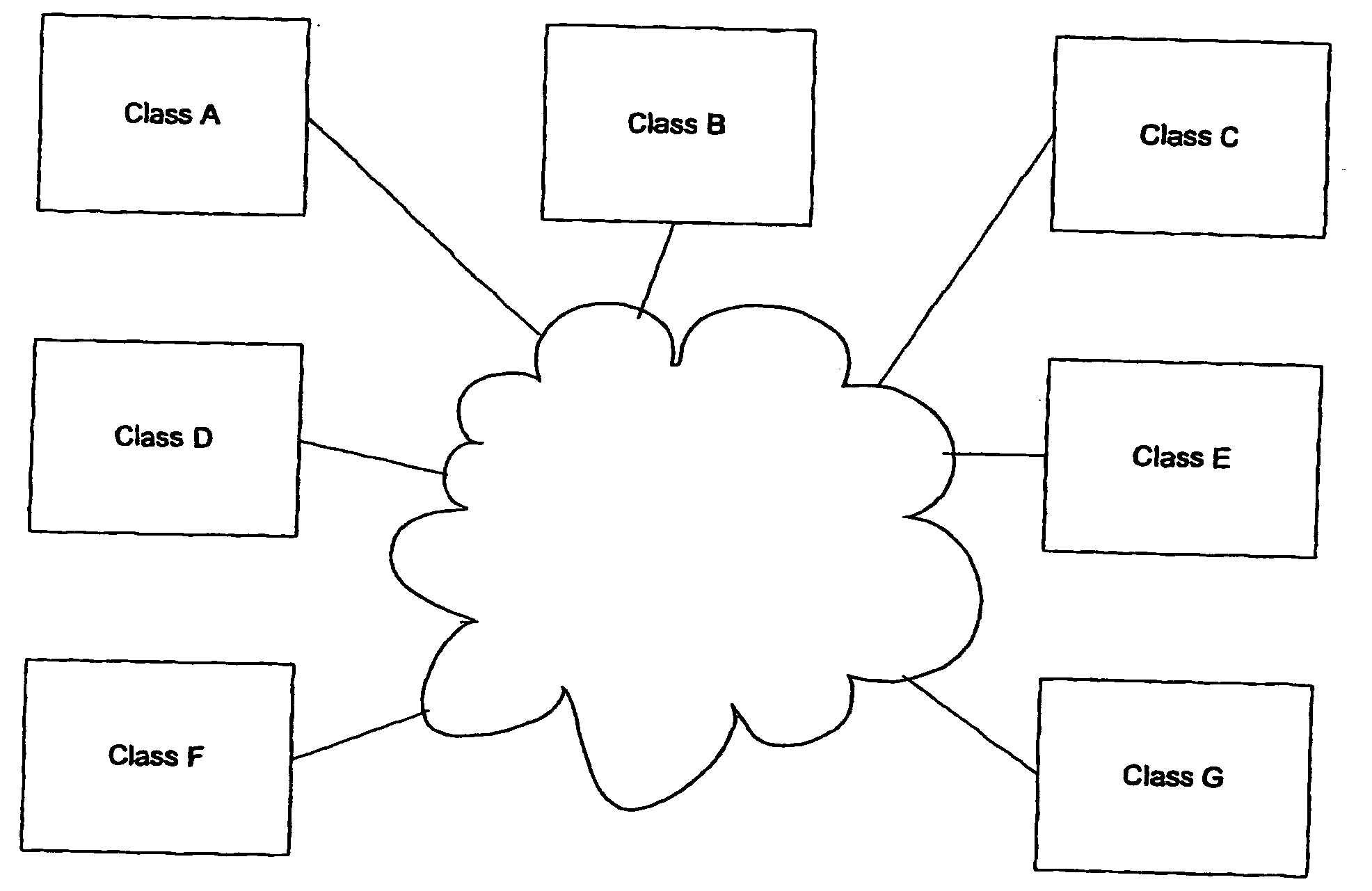

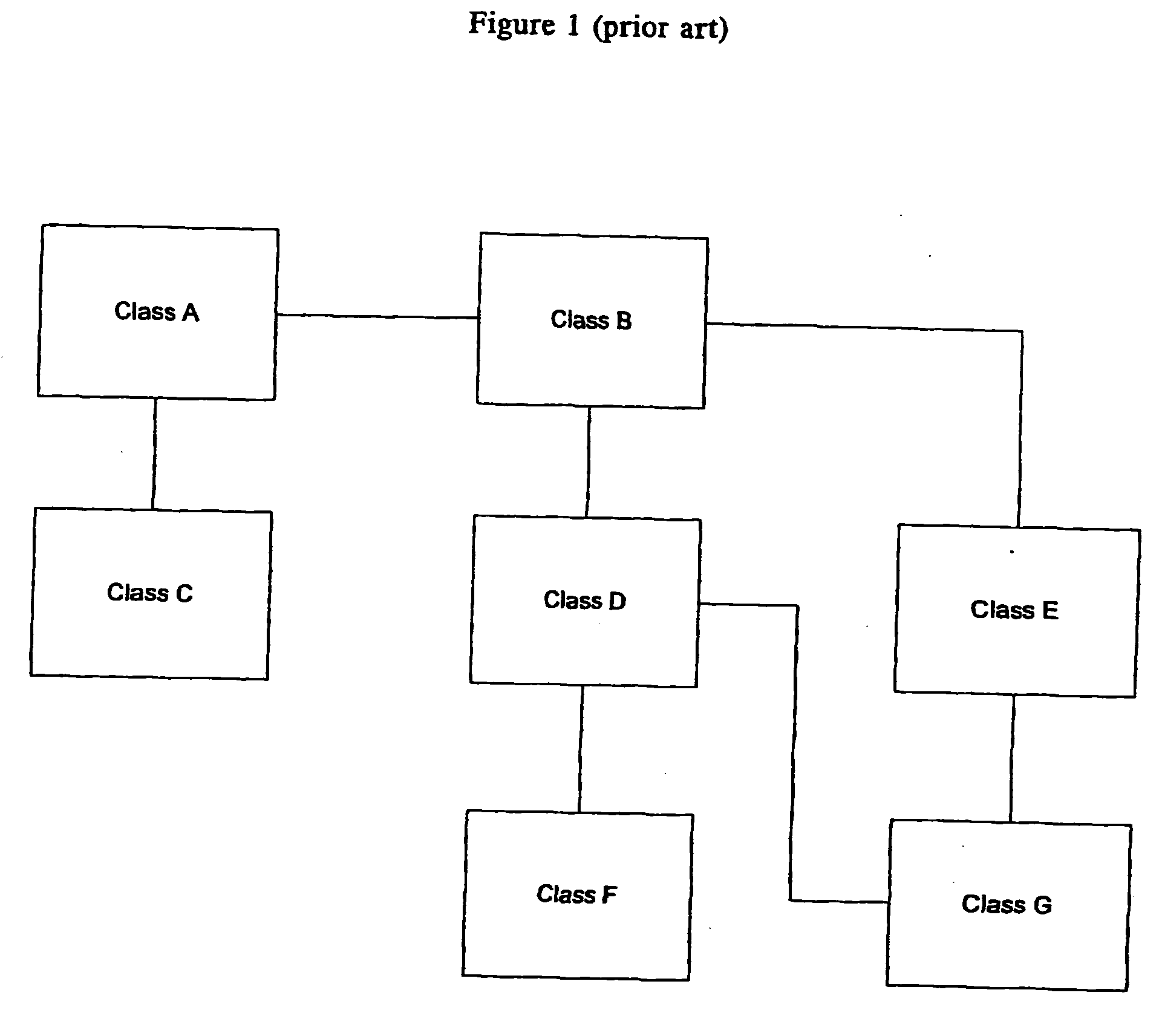

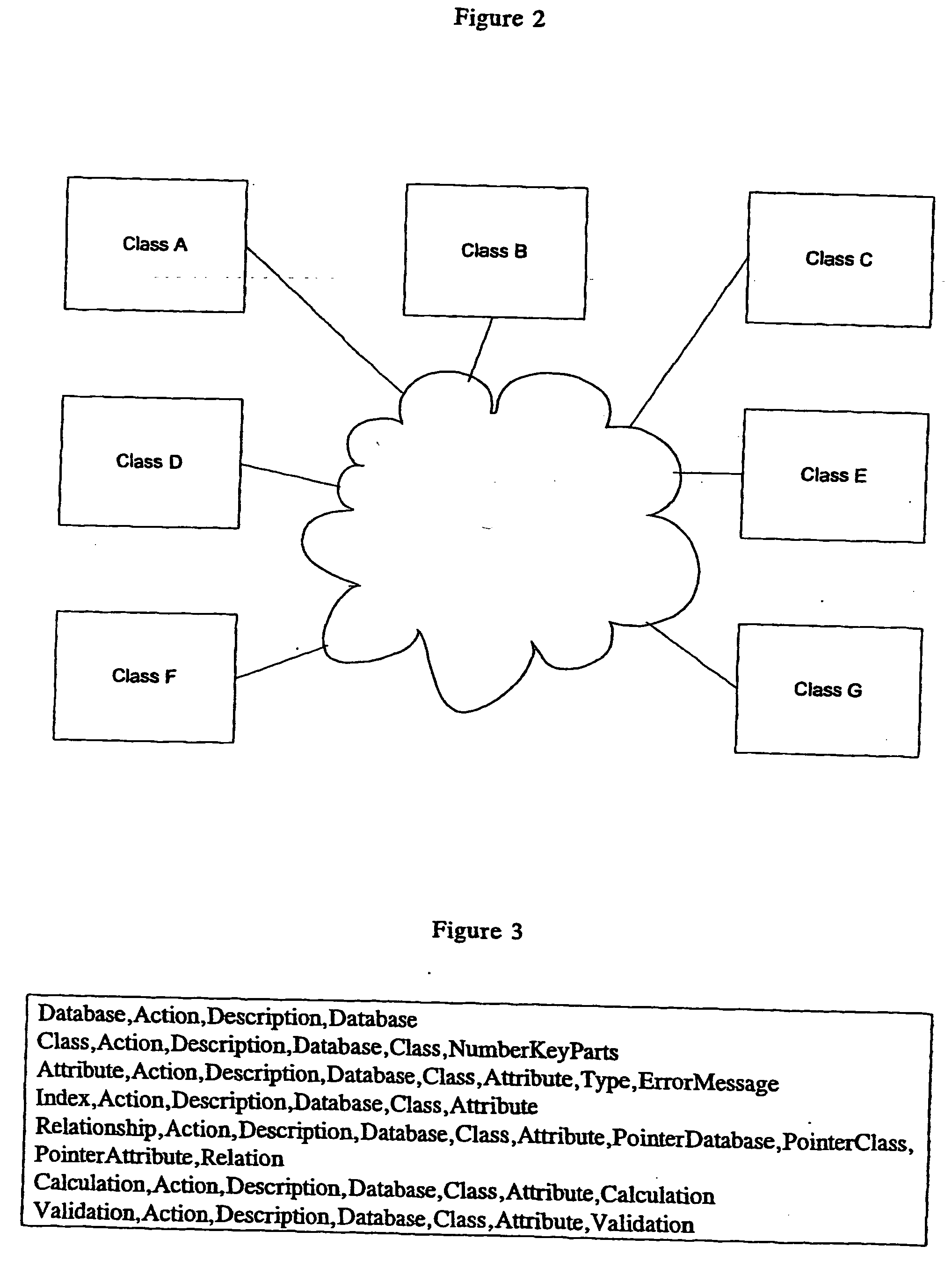

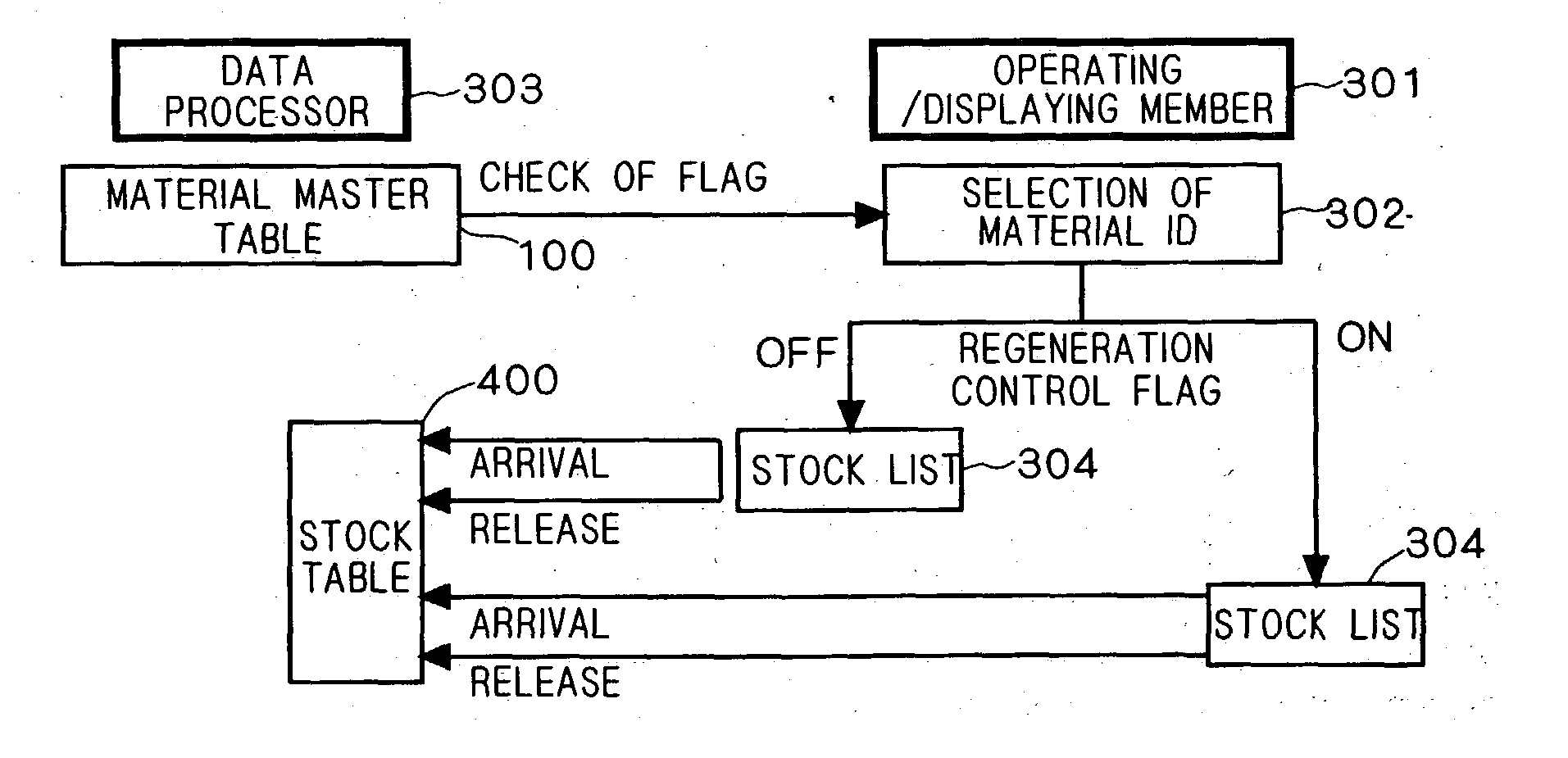

Developing and maintaining customised computer information systems

InactiveUS20040153464A1Less timeEliminate requirementsData processing applicationsObject oriented databasesSoftware development processKnowledge management

In one embodiment, a method or software development tools are provided which allow customised information systems, for example accounts receivable or stock control software, to be designed, implemented and maintained in less time than is generally presently required, whilst still providing a customised information system which conforms to the requirements of an industry, individual or an organisation. The invention also provides a customised information system in which the existing development steps of Analysis, Design, and Coding are transformed into a single Definition step.

Owner:THE FUTURE IS FREEDOM

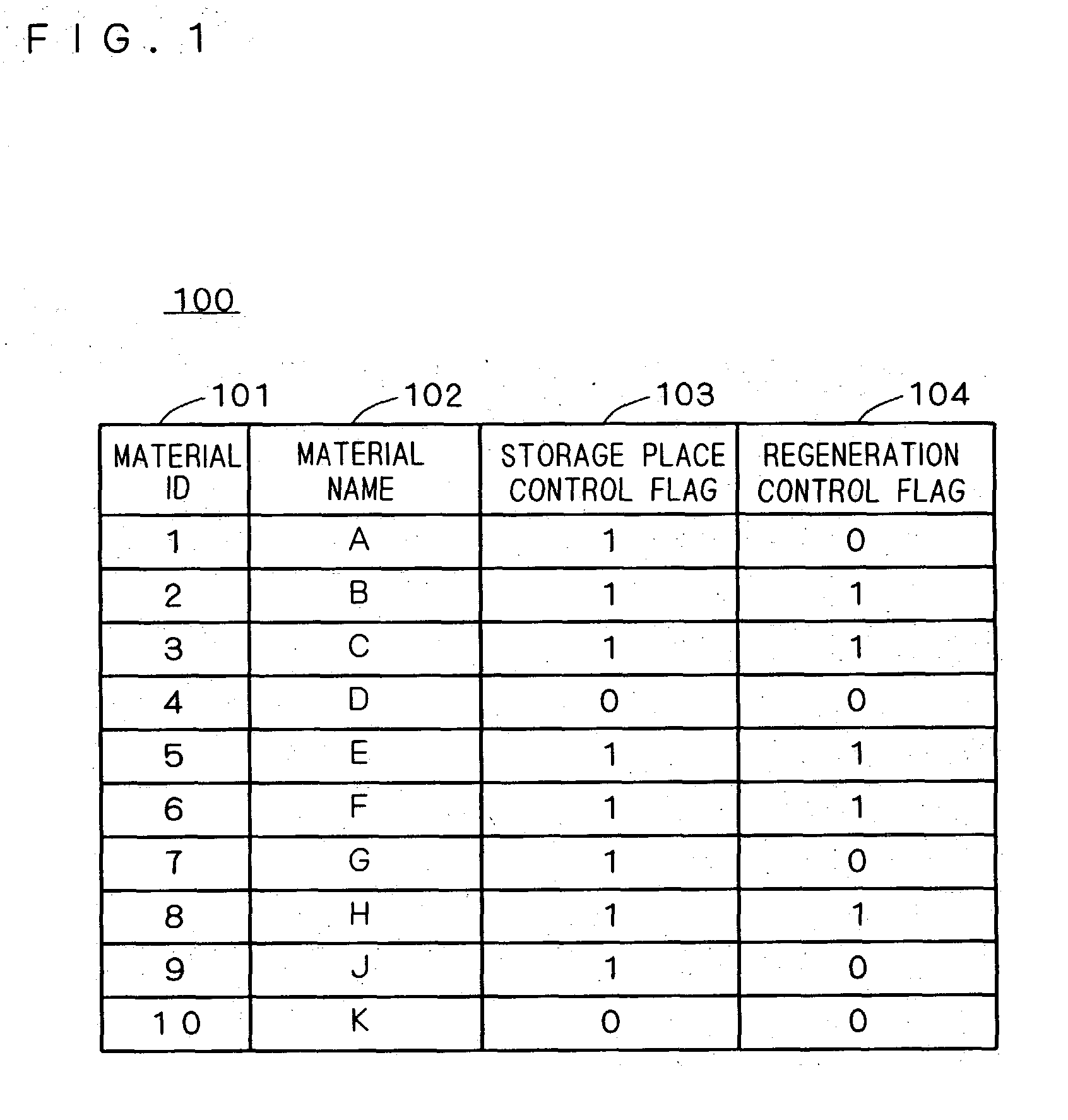

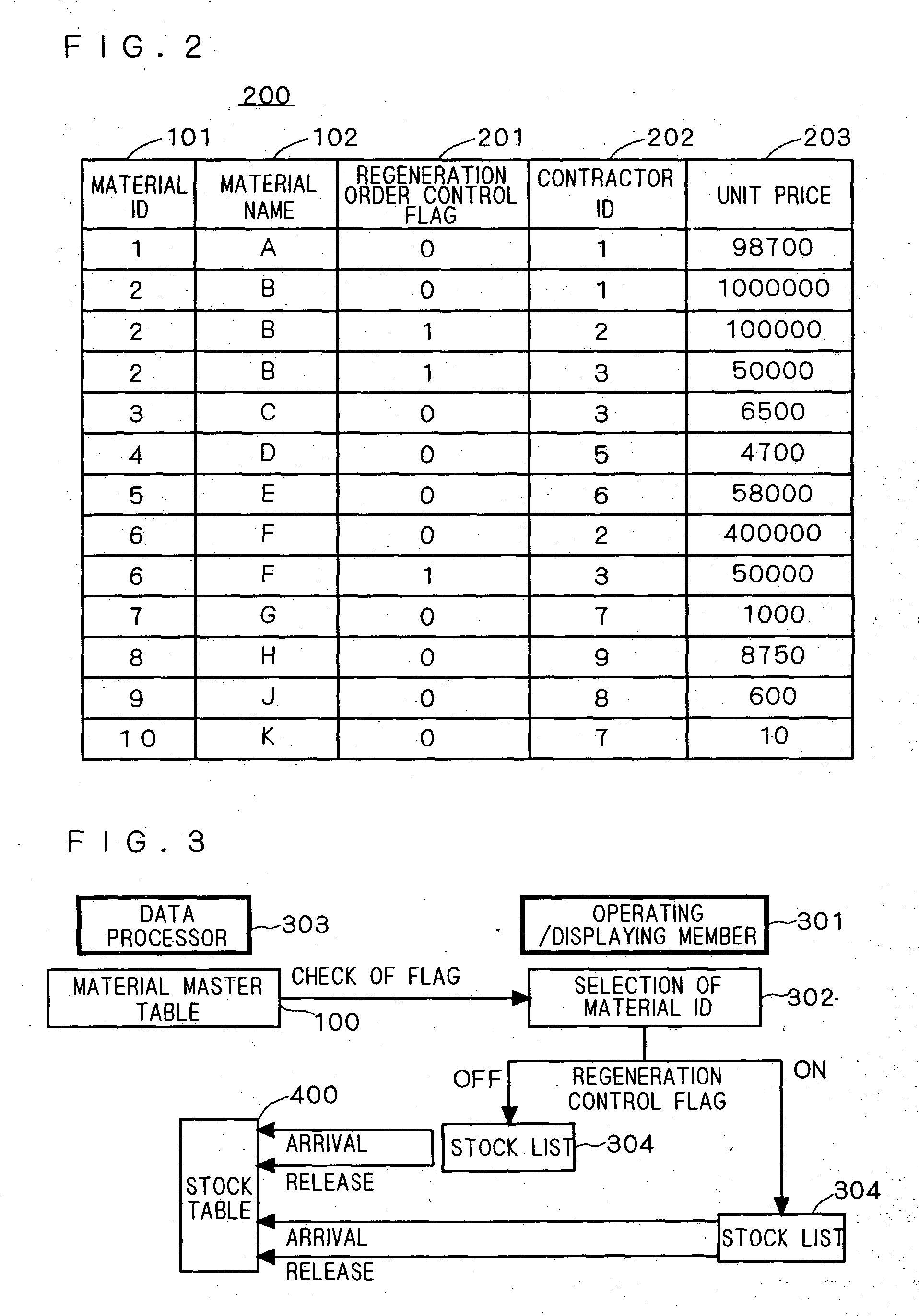

Material control system

A material control system which provides for centralized control of a stock and an order so as to keep an appropriate control of materials in stock without differentiating a material which requires a regenerating process and a material which does not require a regenerating process. The material control system includes a master table storing information for controlling each of materials. The information is provided in an entry field of a regeneration control flag (104) indicating whether or not each of materials to be used in a manufacturing apparatus is regeneratable and an entry field of a regeneration order control flag (201) indicating whether or not a registered contractor is a seller or a regeneration contractor. The material control system further includes an order control section for making a purchase order for the materials and an order for a regenerating process, using the regeneration order control flag (201), and a stock control section for controlling a stock of the materials. The order control section and the stock control section are controlled in a centralized manner.

Owner:RENESAS TECH CORP

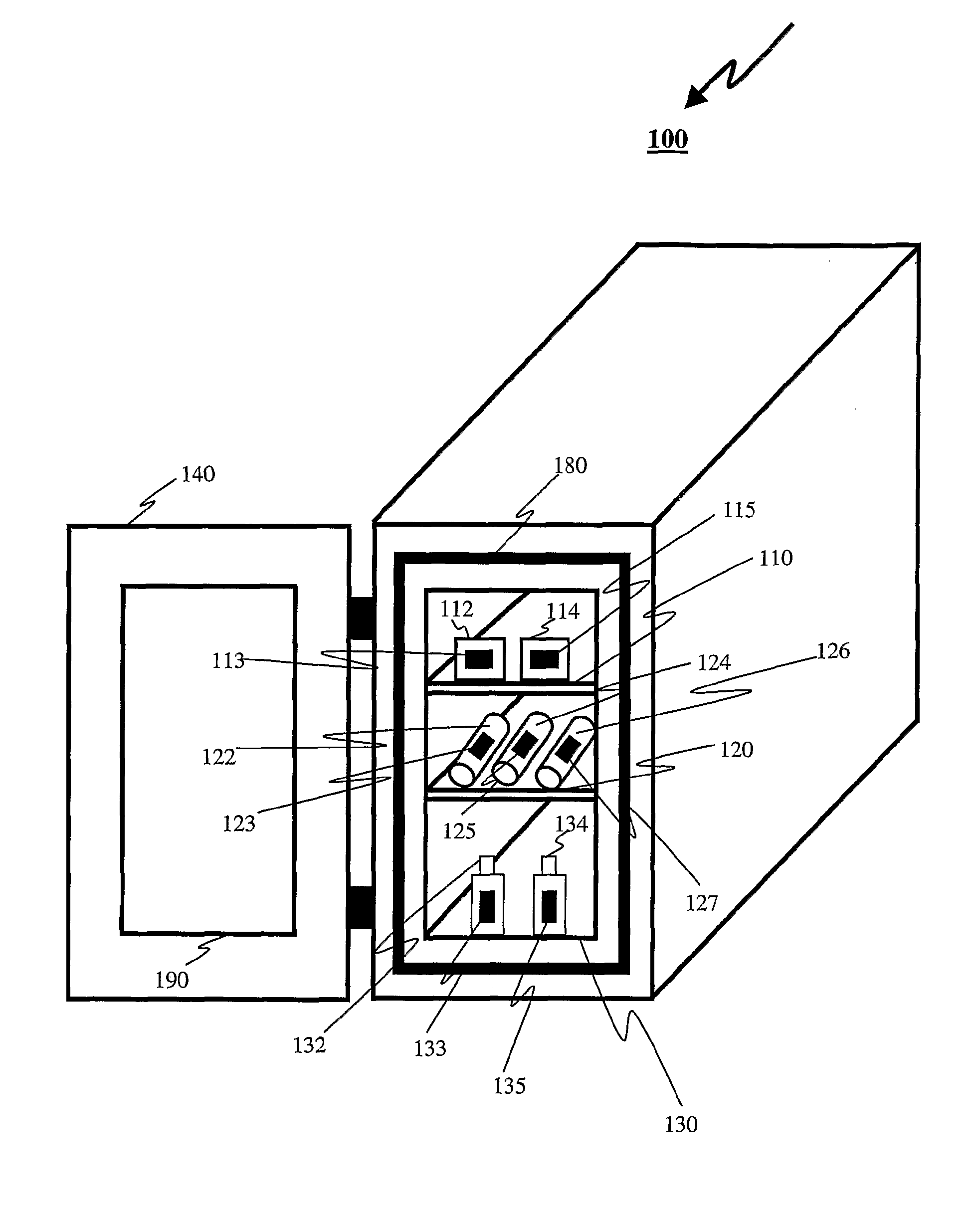

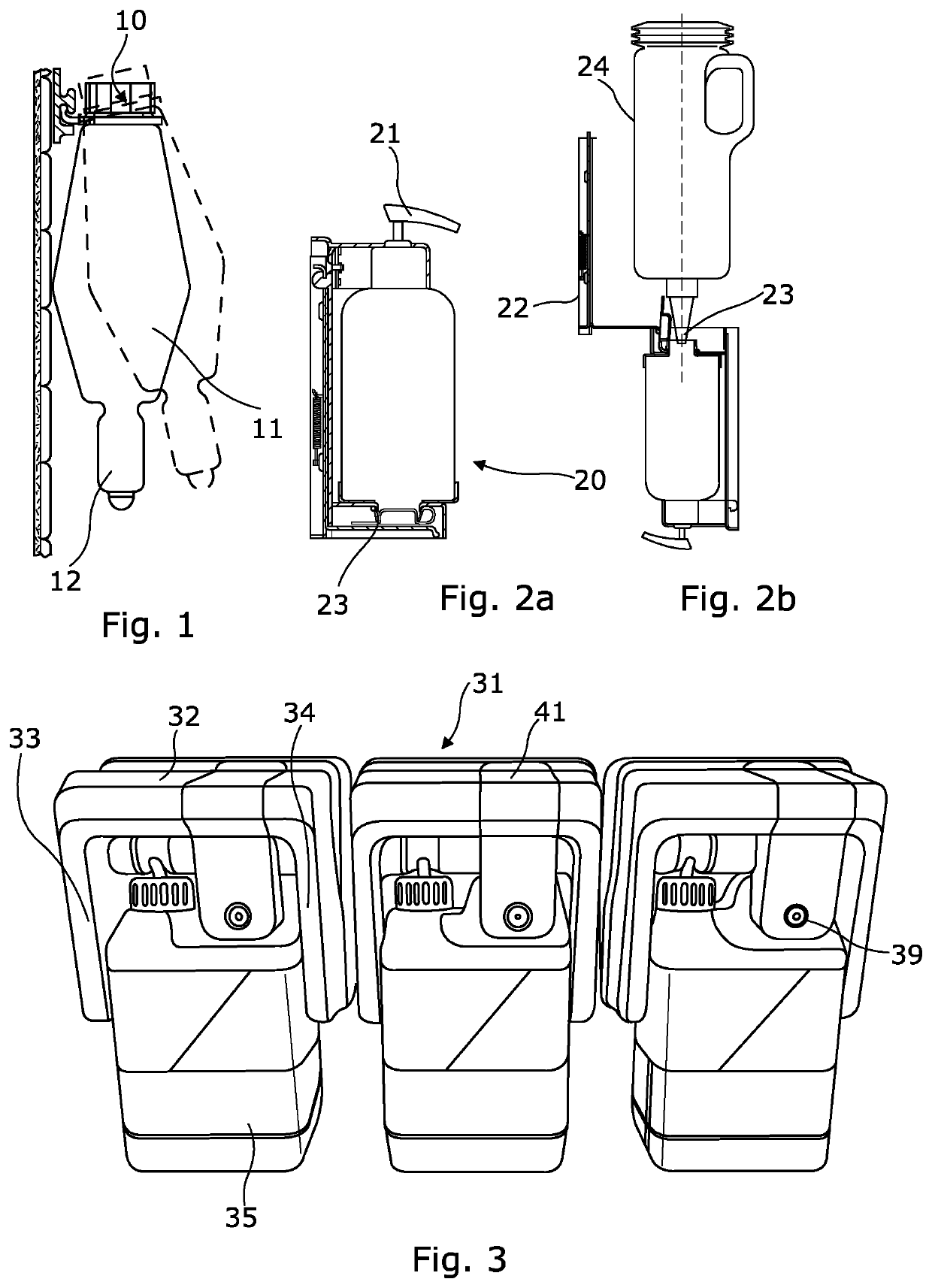

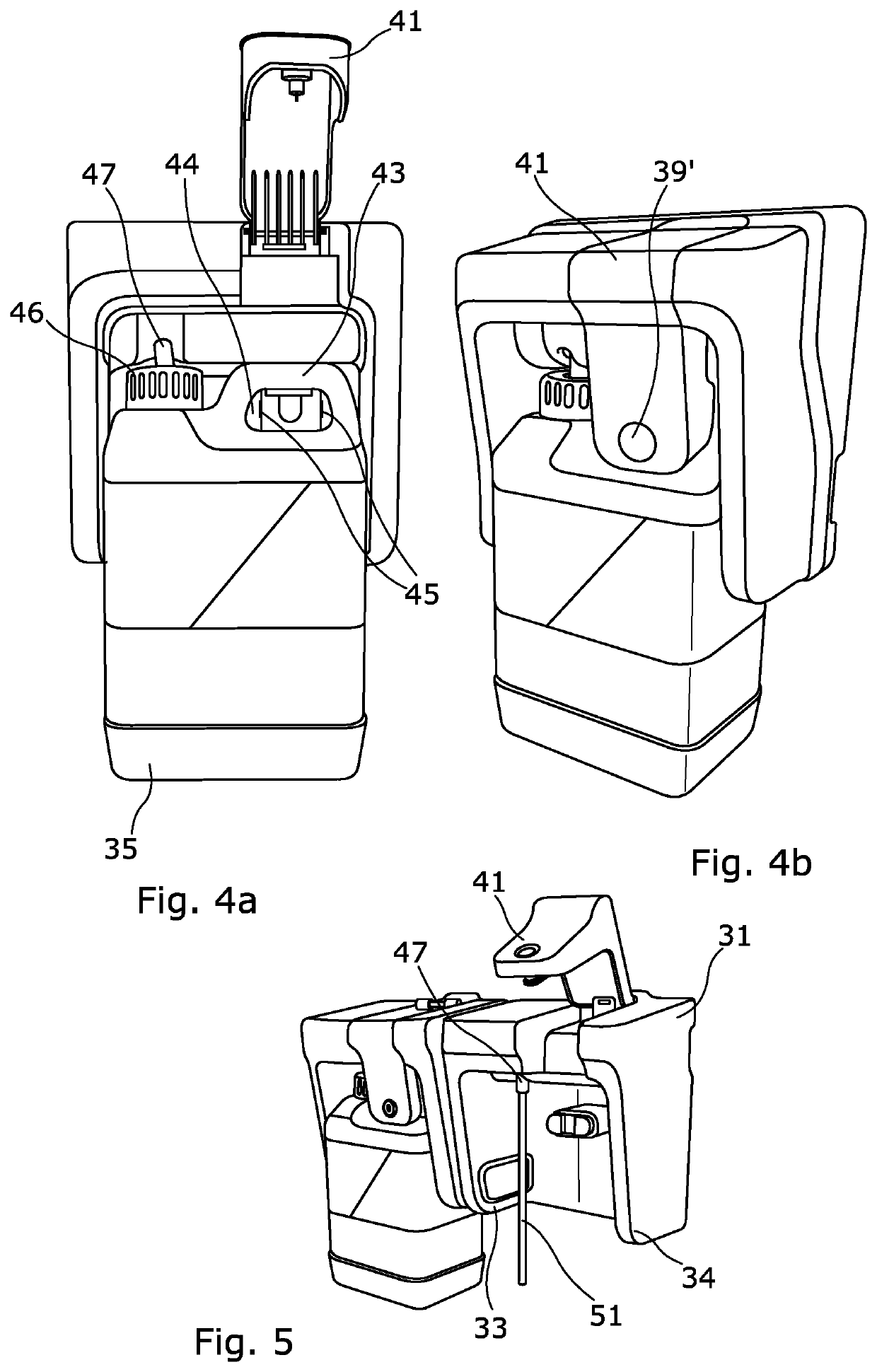

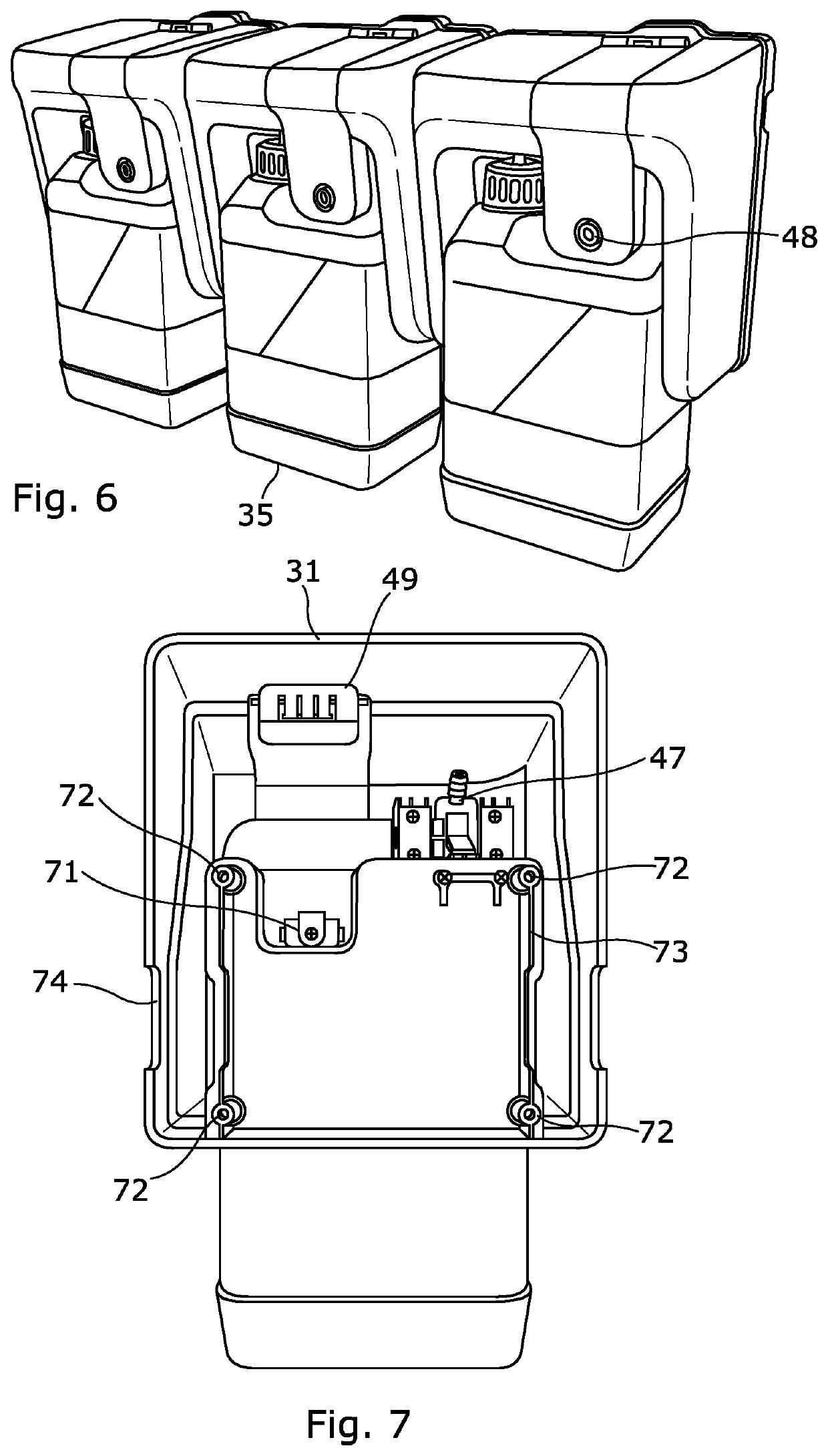

Dispensing System

ActiveUS20200029748A1Easy to cleanForm evenlyBottlesHolders and dispensersMachine shopProcess engineering

The present invention relates to dispensing systems that include containers used to contain fluids that need to be dispensed in controlled quantities. In particular, the present invention relates to a dispensing system which can be readily and securely fastened to the walls and other operating surfaces associated with bathrooms, changing rooms, machine shops and the like. In water closets at places of work, hospitals, laboratories, workshops and similar places, there are many individuals who require access to liquids such as liquid soap, oils and production process chemicals etc. usually have a reservoir that must be filled from a larger supply container. The filling operation tends to be complicated and thus time-consuming and with the likelihood of the creation of a mess. It is often difficult to feed the product directly into the dispenser container by pouring the liquid from a big supply tank. It is important that the fluids—whether for lubricating, cleaning or production processes—are managed such that only the correct fluids are. In the installation of a liquid dispensing system, factors of convenience in ensuring that the dispensers are maintained at a suitable level must be weighed against security of product. Many “universal” systems relinquish security and stock control and / or are complex to utilise. The present invention seeks to provide a solution to the problems addressed above. The present invention seeks to provide a dispensing system and a container that enables simple checking of fluid levels and simple re-filling thereof.

Owner:BRADLEY MARK ANTHONY

System and method for processing and distributing freight containers

InactiveUS8250989B1Improve utilization efficiencyTrain hauling devicesRailway stationPolymer resinYard

Owner:HOWELL BRADLEY N

Green organic honey peach planting method

InactiveCN106489640APromote natural growthImprove orderCultivating equipmentsHorticulture methodsDiseaseFruit tree

The invention discloses a green organic honey peach planting method. The green organic honey peach planting method includes the following steps: nursery stock selection; orchard establishment and planting; fertilizing; shaping and pruning; fruit management; disease and pest control; and harvesting. The green organic honey peach planting method is beneficial to ecological environmental protection, can reduce water and soil pollution, and can enhance environment protection; stable manure is used as a main fertilizer, and then chemical fertilizers are reduced, damage to water and soil is reduced, and natural growth of peach fruits is facilitated; shaping and pruning is timely performed on the peach fruits, the uniformity of the orchard is facilitated, and the utilization value of nutriments can be improved; diseases and pest control can increase the yield of the peach fruits; and fruit management can improve the quality of fruits and is beneficial to the sustainable development of the orchard.

Owner:淮南市农康生态农业有限公司

Oil-filter of building machine and its assembling method

InactiveCN1470718AExtend your lifeAverage congestionSoil-shifting machines/dredgersMembrane filtersEngineeringInventory management

The prevent invention provides an oil filter comprising a filter element housed in a casing, the filter element being formed of two or more cylindrical element pieces piled on top of another in the height direction and attachably and detachably connected through connecting members. Accordingly, the efficiency in each of manufacture, stock control and storage of the filter element can be improved, and the cost can be also reduced.

Owner:KOBELCO CONSTR MASCH CO LTD

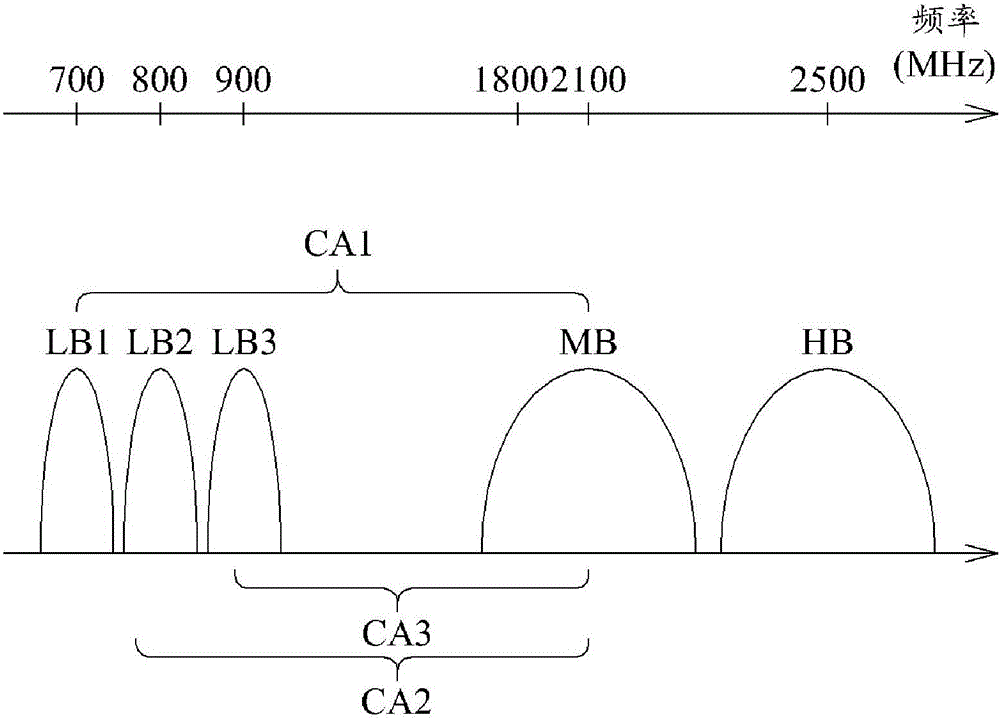

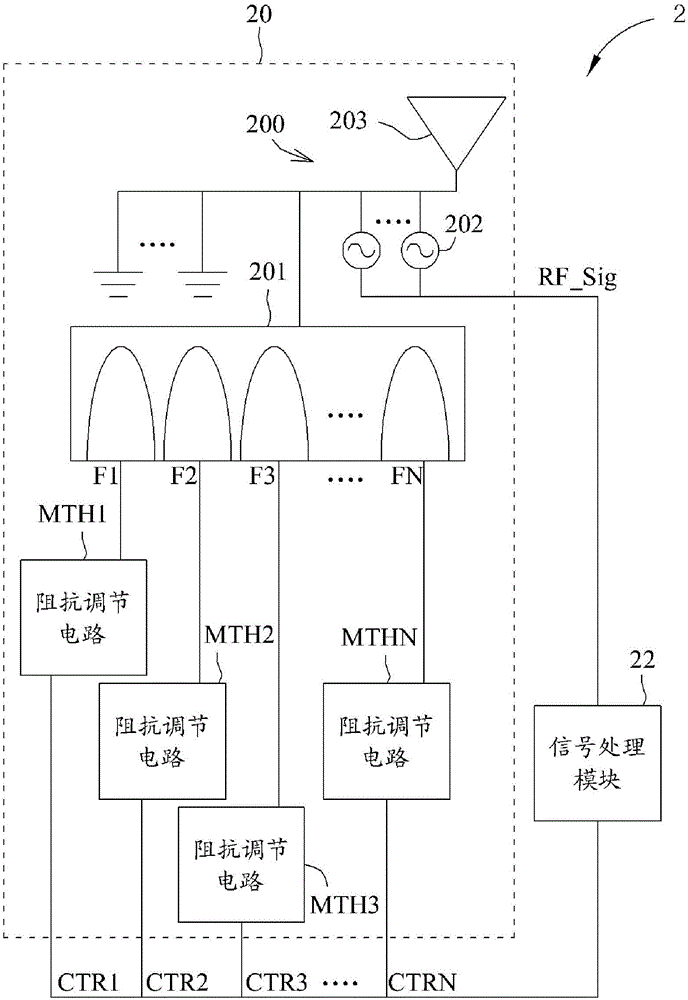

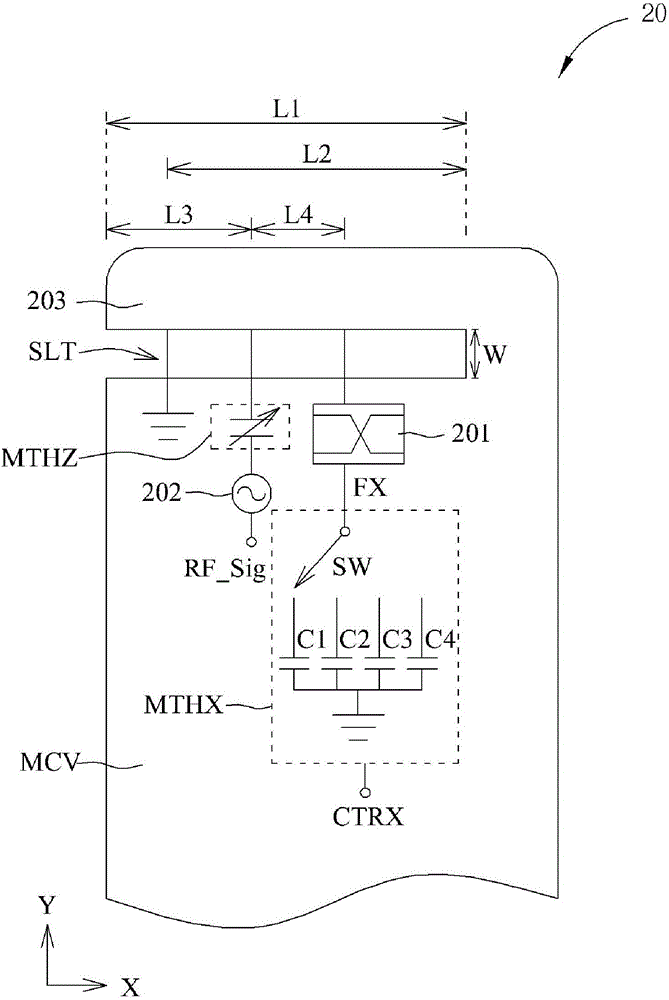

Tunable antenna module and mobile device

InactiveCN106329133ASimultaneous aerial operationsAntenna supports/mountingsRadio frequency signalInventory management

A tunable antenna module for a mobile device includes an antenna, a radiator, a frequency-division circuit and one or more impedance-tuning circuits. The antenna comprises a feed point for feeding in a radio frequency signal. The radiator is coupled to the feed point to resonate the radio frequency signal. The frequency-division circuit is coupled to the radiator of the antenna for forming one or more signal paths for one or more of component frequencies of a radio-frequency signal of the antenna. One or more the impedance-tuning circuits are coupled to the frequency-division circuit for tuning an impedance of the antenna at one or more of the component frequencies of the radio-frequency signal. The radiator, an open slot and a ground are formed in a metal housing of the mobile device. The production cost is saved and the stock control work is reduced.

Owner:MEDIATEK INC

Detection device

InactiveCN105137259ADecrease stockImprove work efficiencyColor measuring devicesElectrical testingDisplay deviceEngineering

The invention relates to the technical field of machinery, and specifically relates to a detection device. The detection device comprises a frame and is characterized in that a deck plate is arranged at the middle part of the frame; horizontal pen-shaped cylinders are respectively arranged at the left and right sides on the deck plate; rotation compaction cylinders are respectively arranged at the front side and the back side of each horizontal pen-shaped cylinder; a color sensor is arranged between each horizontal pen-shaped cylinder and each rotation compaction cylinder; cameras are arranged on the frame above the deck plate; and an electric detection plug is arranged at the corner at the front side of the deck plate. Compared with the prior art, the detection device can use a program to control cameras to take pictures for a ceiling and starts detecting configured colors and on-off of wire harness, and is provided with functions for preventing mis-assembling of assembly and detecting neglected assembling, and can display the result on a display after determination on the device; and the detection device can completely eradicate an automobile ceiling configuration determination, neglected assembling and mis-assembling, and can be communicated with a host of a factory to reduce the stock so that the working efficiency can be improved greatly and the beat of the factory and the requirement for stock control for the factory can be satisfied.

Owner:SHANGHAI MJ INTELLIGENT SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com