Stock bin control system

A control system and silo technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems that the detection probe is easily covered, the material level detection is distorted, and the interface of the material forms a pile angle, etc. Achieve the effect of solving easy damage failure and measurement result distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

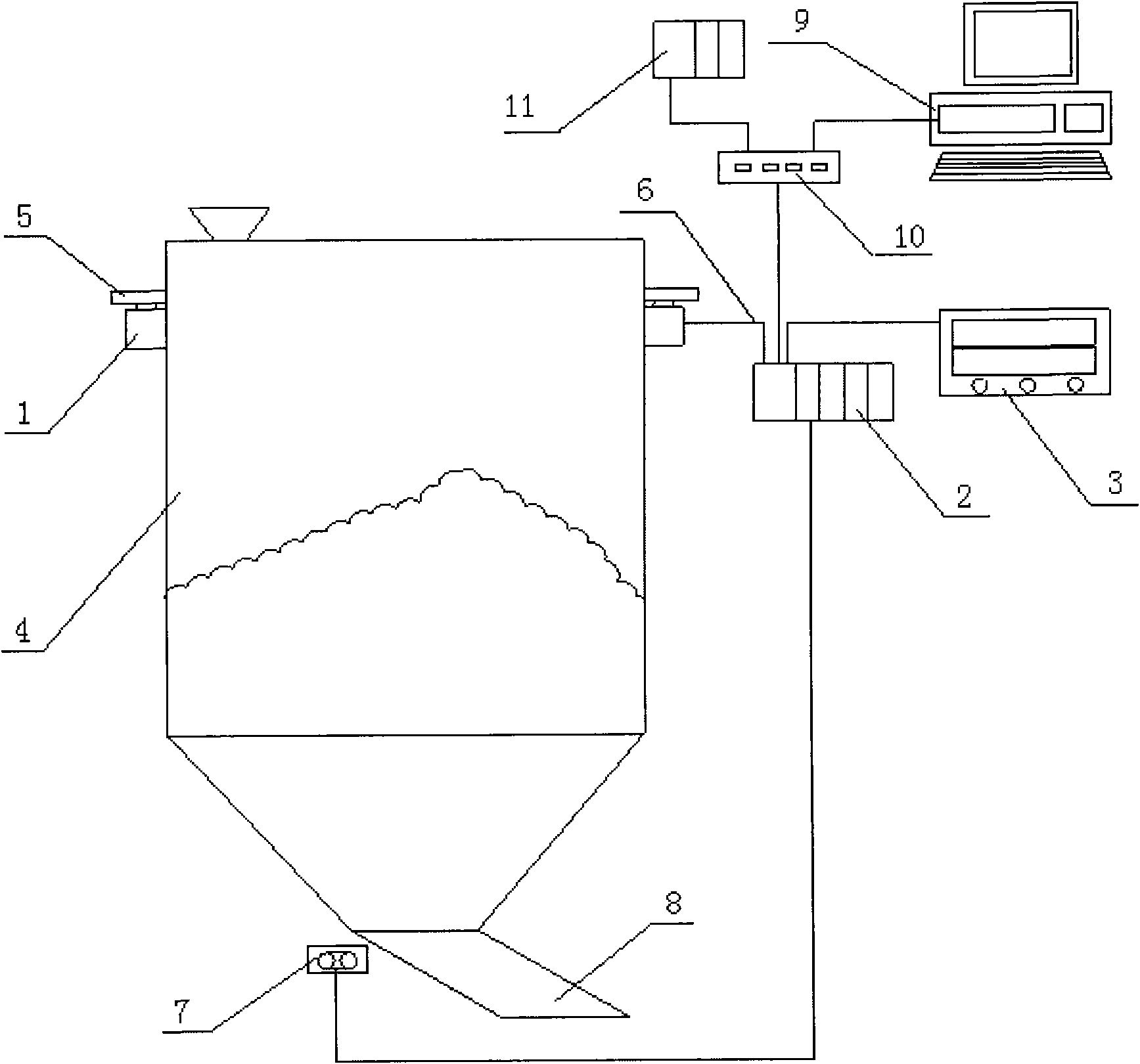

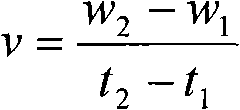

[0022] See figure 1 , a silo control system, comprising a load cell 1, a programmable controller 2, and a display instrument 3, the load cell 1 is arranged under the support 5 of the silo 4, and the unloading mechanism 7 is arranged at the discharge port 8 of the silo In order to prevent electromagnetic interference, the programmable controller 2 is respectively connected to the load cell 1 and the display instrument 3 through a two-core shielded cable 6. The standard 4~ 20mA signal transmission, the input and output of all signals are relative to the programmable controller 2, that is, the load cell 1 transmits the input signal to the programmable controller 3, and the programmable controller 2 sends the display instrument 3 as an output signal. Load cell 1 generally has 3 to 4 points. The programmable controller 2 is equipped with a communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com