Perfuming/charging method for tobacco scrap prodn. line

A material feeding method and silk threading technology, which are applied in the field of adding spices/materials, can solve the problems of long distance between the spice room and the flavoring (material) machine, the influence of material types, material pollution and corrosion, etc., so as to facilitate the production process control , Strengthen the production process control, maintain the effect of safety and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

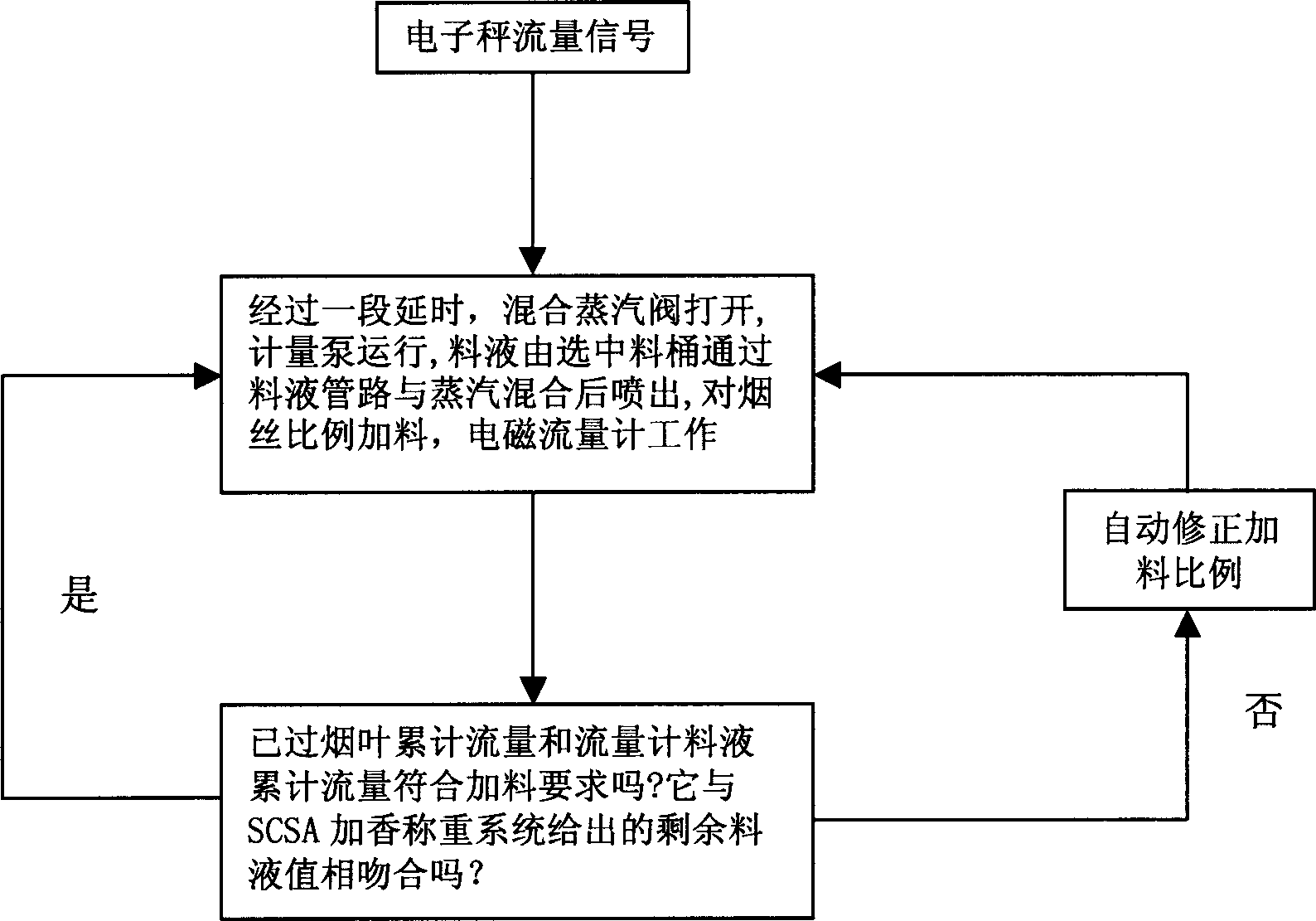

Method used

Image

Examples

Embodiment Construction

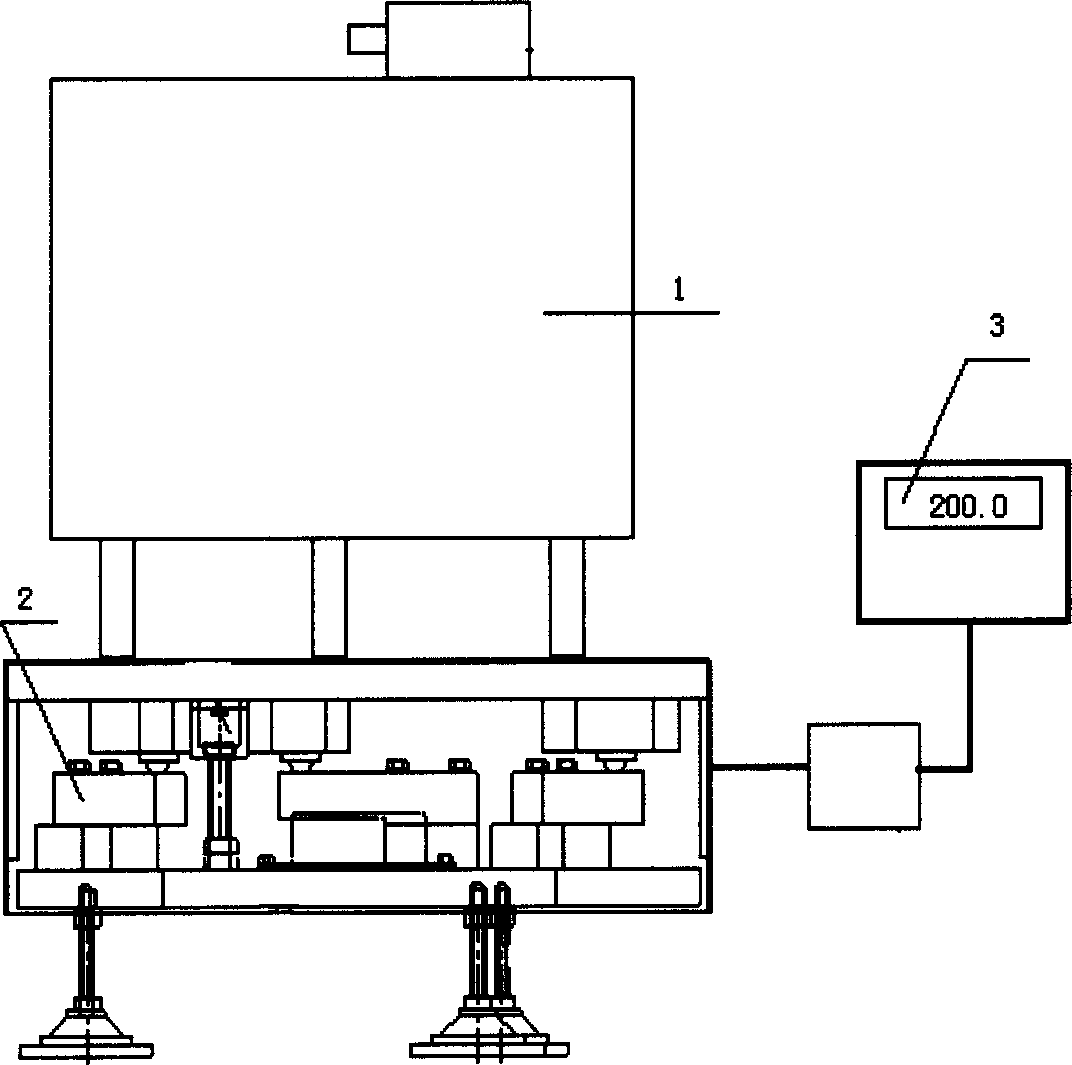

[0014] The material barrel 1 that feed liquid is housed according to the present invention is placed on the weighing platform, and under the action of gravity, the elastic body of the load cell 2 is deformed, so that the resistance strain gauge bridge pasted on the elastic body loses balance, and the output and weight The data is proportional to the millivolt voltage signal. The signal enters the display instrument 3 and becomes a digital signal after linear amplification and A / D conversion. The microprocessor processes the weight signal and directly displays the weight data of spices / materials on the instrument. . The weighing signal of the material tank directly enters the host computer control system, and the direct weighing data can judge whether the material in the material tank is empty, how much material is left, and can promptly indicate the abnormal condition in the material tank, so it is accurate in detection and easy to maintain specialty. The weight signal has no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com